Page 1

API Software for 1746 I/O PCI Interface and 1747-OC Open Controller

1747-OCF, -PCIS

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 3

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical

construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be

mounted in an enclosure during operation to provide safety

protection.

Page 4

Page 5

Preface

Who Should Use this Manual

Terminology

Reference Material

Use this manual if you are responsible for developing control

applications using the 1746 I/O PCI Interface API (application

programming interface) software or Open Controller API software in

an MS-DOS or Windows NT environment.

This manual documents the 1746 I/O PCI Interface API and Open

Controller API software packages for DOS and Windows NT. The APIs

use most of the same calls. Differences are noted as appropriate.

Throughout the language of this document, we refer to the 1746 I/O

PCI Interface card (1747-PCIS) as the scanner and the 1747-PCIL

chassis interface module as the adapter. We also refer to the open

controller (1747-OCF) as a scanner.

There are two versions of the PCI Bus Interface Card. 1747-PCIS has a

256k memory capacity and the 1747-PCIS2 has a 1M capacity.

The following books might be useful as you develop your 1746 I/O

PCI Interface applications:

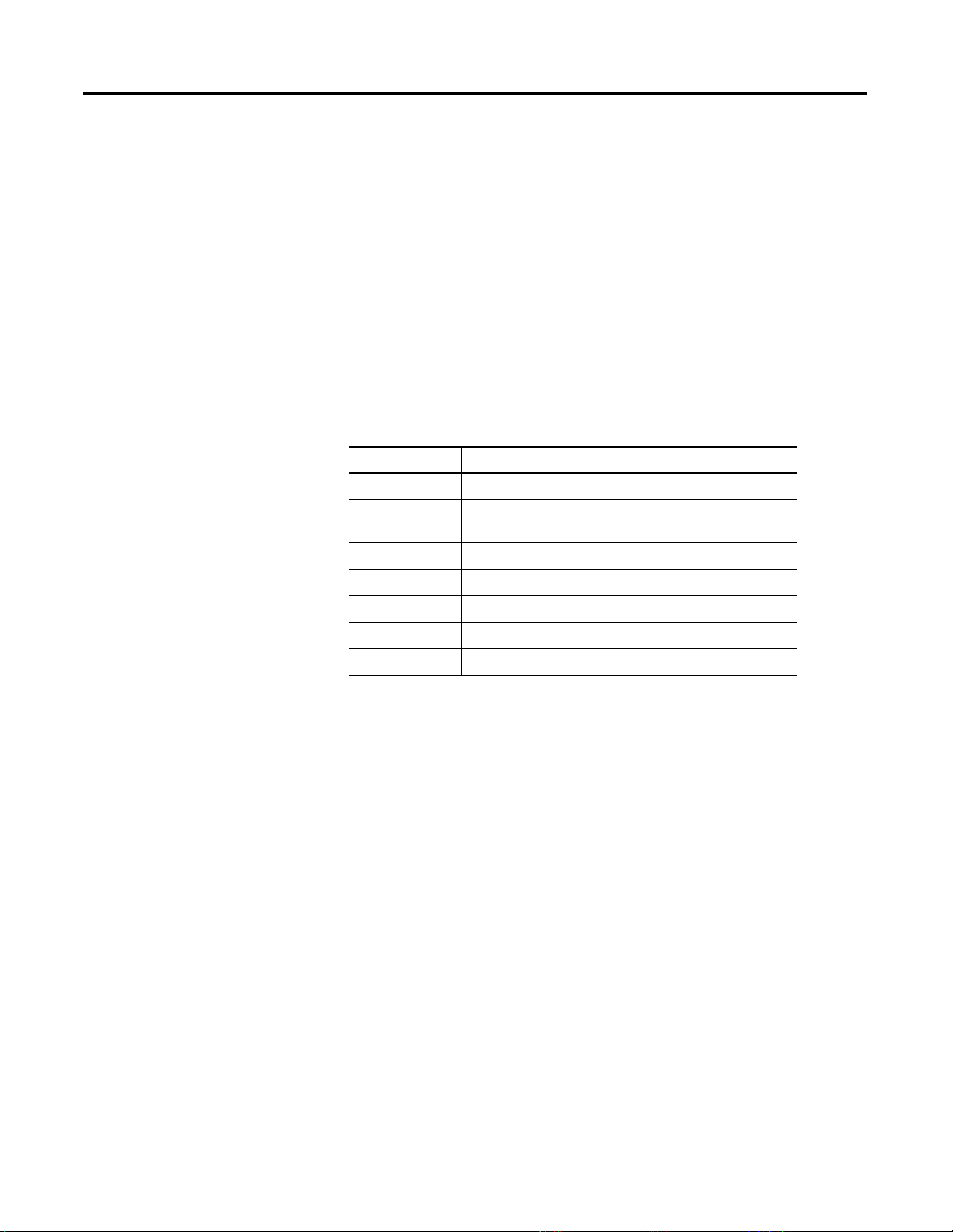

This document: Written by: Has this ISBN number:

PC System Architecture Series

PCI System Architecture

PCI Hardware and Software Architecture and Design Edward Solari and George Willse ISBN: 0-929392-28-0

In addition to the books listed above, the following books might be

useful as you develop your 1746 I/O PCI Interface applications:

This document: By: Has this ISBN number:

PC System Architecture Series

ISA System Architecture

PC System Architecture Series

ISA System Architecture

The PCMCIA Developerÿs Guide Michael T. Mori and W. Dean Welder ISBN: 0-9640342-1-2

MindShare, Inc.

Addison-Wesley Publishing Company

MindShare, Inc.

Addison-Wesley Publishing Company

MindShare, Inc.

Addison-Wesley Publishing Company

ISBN: 0-201-40993-3

ISBN: 0-201-40996-8

ISBN: 0-201-40991-7

1 Publication 1747-UM002A-US-P - June 2000

Page 6

Preface 2

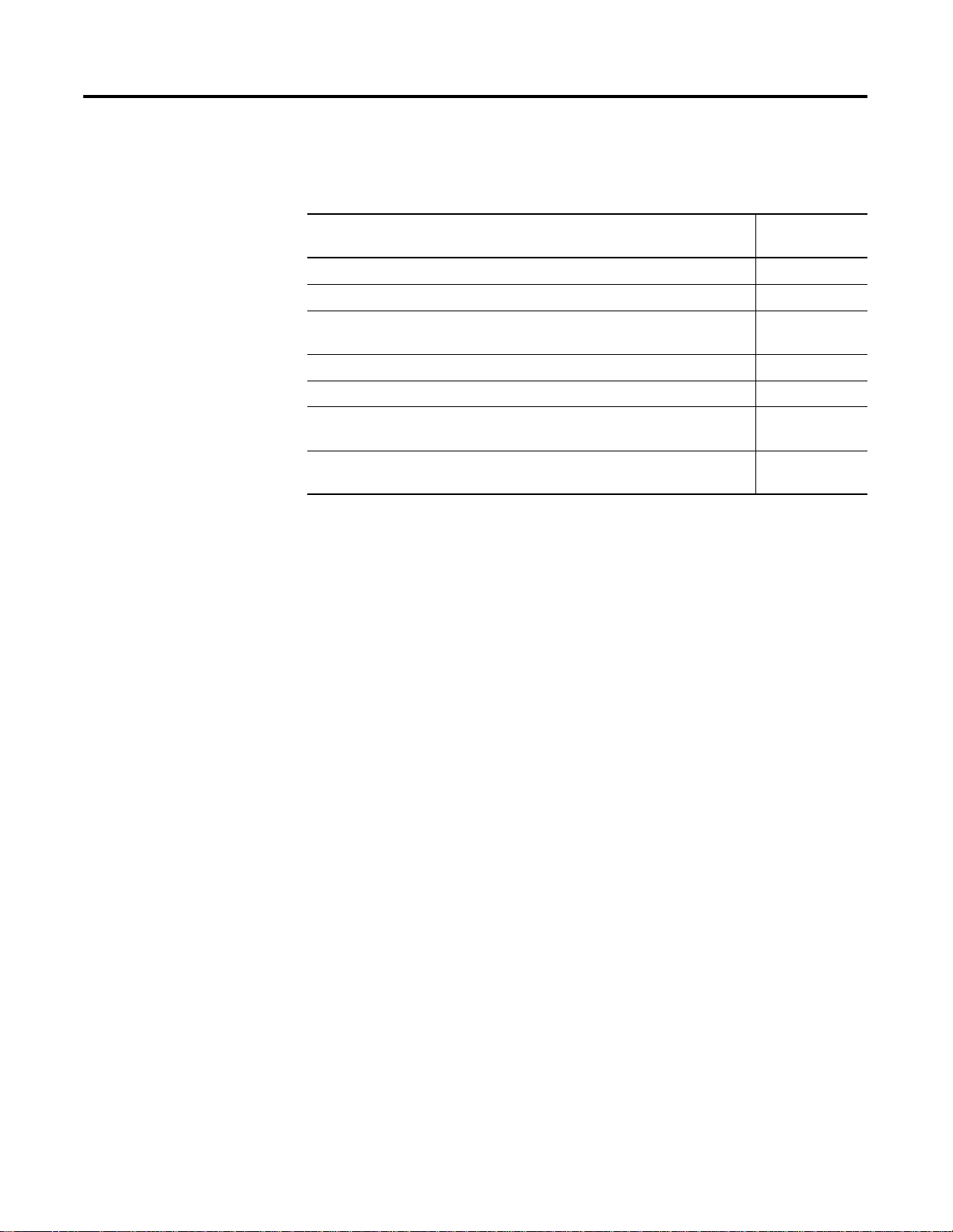

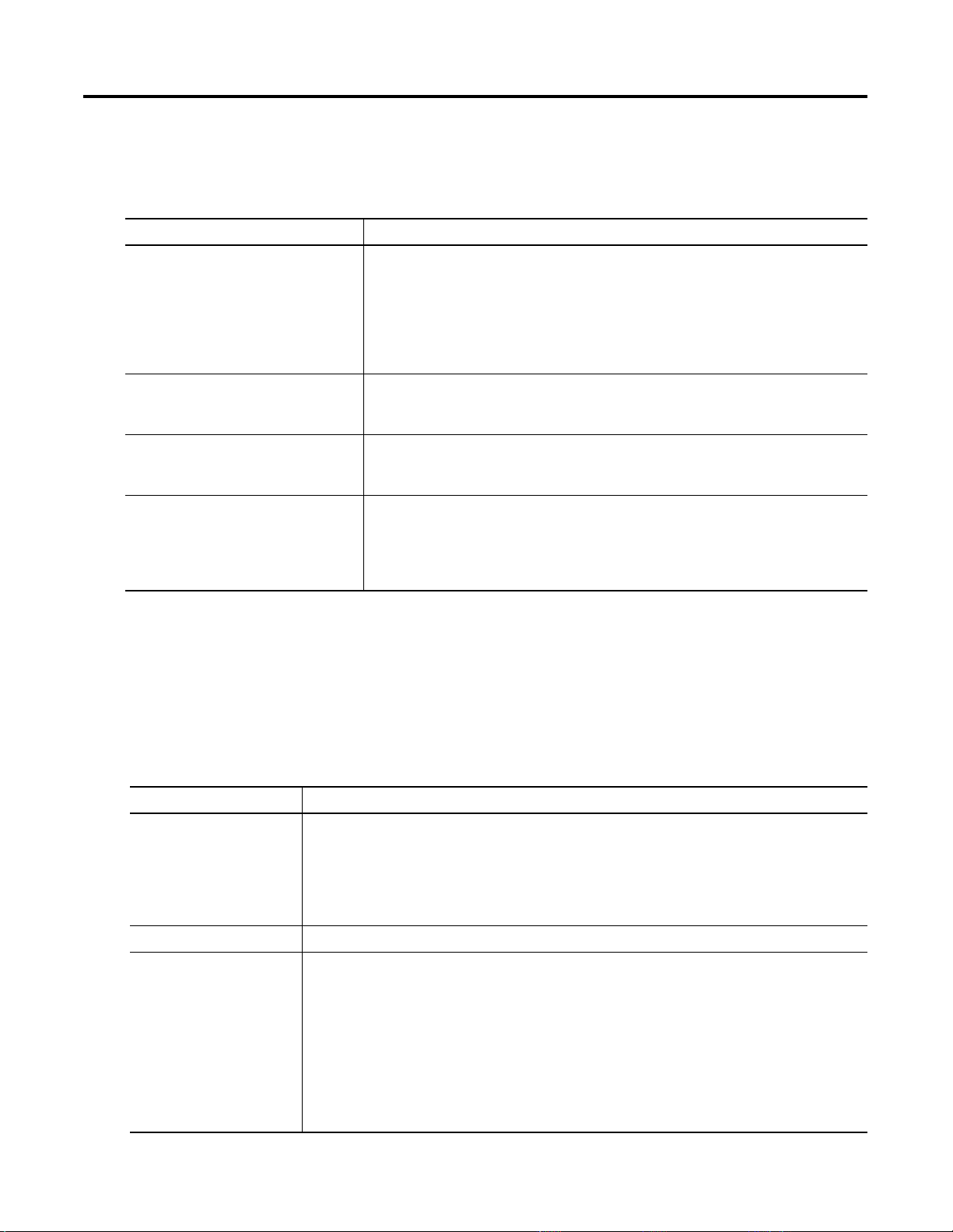

Additional Open Controller Documentation

This document: Has this

1747 Open Controller PCI Expansion Bus Installation Instructions 1747-5.16

1747 Open Controller PCMCIA Interface Module Installation Instructions 1747-5.13

1747 Open Controller A-B Communication Interface Module Installation

Instructions

1747 Open Controller Video Interface Module Installation Instructions 1747-5.15

1747 Open Controller A-B Communication Interface Module User Manual 1747-6.18

1747 Open Controller IDE Interface Module for IDE-Compatible ATA Devices

(PCCards) Installation Instructions

1747 Open Controller IDE Interface Module for an Internally-Mounted 2.5" IDE

Drive Installation Instructions

The following documents are available for additional information

about the open controller and its options.

publication:

1747-5.14

1747-5.29

1747-5.30

Each open controller component ships with installation instructions.

The user manuals are part of the open controller documentation set

(catalog number 1747-OCDOC1) so you can order as many copies as

you need. The documentation set includes one copy of each open

controller document (as listed above).

In addition to the above documentation, the:

• 1747-OCVGA1 video interface module and the 1747-OCVGAE

video and Ethernet interface module include a disk with

documentation for the video drivers

• 1747-OCPCM2 PCMCIA interface module kit (1747-OCPCM1

interface module plus CardSoft™ for DOS) includes a disk with

CardSoft documentation.

Publication 1747-UM002A-US-P - June 2000

Page 7

Preface 3

Support

Due to the PC-based architecture of the 1746 I/O PCI Interface and

open controller, the telephone support provided with the purchase

price of either product consists primarily of determining if the system

software and hardware is operating within documented specifications.

The tools for this support are:

• diagnostic utility disks that ship with the 1746 I/O PCI Interface

and open controller

• system diagnostic LEDs for 1746 I/O PCI Interface and

open controller

The diagnostic utility disk uses the DOS API as its programming

interface, which provides examples of how to use the API. The

diagnostic utility disk is a good tool to help diagnose your API

application software. See appendix B for more information.

When you purchase either product (1746 I/O PCI Interface system or

open controller system), you also receive firmware upgrades during

the 12-month warranty period.

You can purchase extended support in blocks of 5 hours by ordering

support contracts (1747-OCTS).

Publication 1747-UM002A-US-P - June 2000

Page 8

Preface 4

Publication 1747-UM002A-US-P - June 2000

Page 9

Overview

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Relationship to the Open Controller. . . . . . . . . . . . . . . . . . 1-1

Interface API to the Scanner . . . . . . . . . . . . . . . . . . . . . . . 1-2

API Software for DOS . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

API Software for Windows NT . . . . . . . . . . . . . . . . . . . 1-3

Understanding the 1746 I/O PCI Interface Architecture . . . . 1-4

Understanding the Open Controller Architecture . . . . . . . . 1-4

Common Attributes of the 1746 I/O PCI Interface and 1747

Open Controller Architectures . . . . . . . . . . . . . . . . . . . 1-5

Scanner Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Checking LED Indicators . . . . . . . . . . . . . . . . . . . . . . . 1-7

STATUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Installing the DOS API . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Installing the Windows NT API . . . . . . . . . . . . . . . . . . . . . 1-8

Installation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Uninstalling the Windows NT API. . . . . . . . . . . . . . . . . 1-10

Using the API

Developing Applications

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Programming Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2-2

DOS Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Windows NT Considerations . . . . . . . . . . . . . . . . . . . . 2-3

Tools to Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Sample DOS MAKE file for Borland compilers. . . . . . . . 2-4

Sample DOS MAKE file for Microsoft compilers. . . . . . . 2-5

Sample Windows NT MAKE file for Microsoft compilers 2-6

Sample Windows NT MAKE file for Borland compilers . 2-8

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

How the API Functions Are Organized. . . . . . . . . . . . . . . . 3-1

Programming Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Access the scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Initialize the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Configure the scanner . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Control scanner operation . . . . . . . . . . . . . . . . . . . . . . 3-4

Scan I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Programming Example for DOS. . . . . . . . . . . . . . . . . . . . . 3-5

Programming Example for Windows NT . . . . . . . . . . . . . . 3-11

Handling Interrupt Messages . . . . . . . . . . . . . . . . . . . . . . . 3-17

Handling Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Determining Partition Sizes for Shared Memory . . . . . . . . . 3-18

i Publication 1747-UM002A-US-P - June 2000

Page 10

Table of Contents ii

Using the API Structures

Configuring I/O Modules

Library of Routines

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

API Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Configuring I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Using M0-M1 Files and G Files. . . . . . . . . . . . . . . . . . . . . . 5-3

M0-M1 files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

G files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Supported I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

OC_CalculateCRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

OC_ClearFault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

OC_CloseScanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

OC_ConfigureDII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

OC_CreateIOConfiguration . . . . . . . . . . . . . . . . . . . . . . . . 6-6

OC_DemandInputScan . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

OC_DemandOutputScan . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

OC_DownloadIOConfiguration . . . . . . . . . . . . . . . . . . . . . 6-9

OC_EnableEOSNotify . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

OC_EnableForces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

OC_EnableSlot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

OC_ErrorMsg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

OC_ExtendedErrorMsg . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

OC_GetBatteryStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

OC_GetDeviceInfo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

OC_GetExtendedError. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

OC_GetInputImageUpdateCounter. . . . . . . . . . . . . . . . . . . 6-20

OC_GetIOConfiguration . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

OC_GetLastFaultCause . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

OC_GetMeasuredScan Time. . . . . . . . . . . . . . . . . . . . . . . . 6-24

OC_GetResetCause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

OC_GetScannerInitInfo . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

OC_GetScannerStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

OC_GetScannerWatchdogCount. . . . . . . . . . . . . . . . . . . . . 6-29

OC_GetStatusFile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

OC_GetSwitchPosition. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

OC_GetTemperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

OC_GetUserJumperState . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

OC_GetUserLEDState . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

OC_GetVersionInfo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

OC_InitScanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Publication 1747-UM002A-US-P - June 2000

Page 11

Table of Contents iii

OC_OpenScanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

OC_PetHostWatchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

OC_PollScanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

OC_ReadHostRetentiveData. . . . . . . . . . . . . . . . . . . . . . . . 6-46

OC_ReadInputImage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

OC_ReadIOConfigFile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

OC_ReadModuleFile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-50

OC_ReadOutputImage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

OC_ReadSRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

OC_ResetScanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

OC_SetForces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

OC_SetHostWatchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

OC_SetInputUpdateMode . . . . . . . . . . . . . . . . . . . . . . . . . 6-58

OC_SetIOIdleState. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

OC_SetModuleInterrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-60

OC_SetOutputUpdateMode . . . . . . . . . . . . . . . . . . . . . . . . 6-61

OC_SetScanMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63

OC_SetScanTime. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

OC_SetUserLEDState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-65

OC_SetupPowerFailAction. . . . . . . . . . . . . . . . . . . . . . . . . 6-66

OC_WaitForDII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-68

OC_WaitForEos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-69

OC_WaitForEosDmdIn . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-70

OC_WaitForEosDmdOut . . . . . . . . . . . . . . . . . . . . . . . . . . 6-71

OC_WaitForExtError . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-73

OC_WaitForIoInt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-74

OC_WriteHostRetentiveData . . . . . . . . . . . . . . . . . . . . . . . 6-75

OC_WriteIOConfigFile. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-76

OC_WriteModuleFile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-77

OC_WriteOutputImage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-78

OC_WriteSRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-80

Error Codes

Testing Function Calls

Header File

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Error Code Returned by API Functions. . . . . . . . . . . . . . . . A-1

Extended Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

DOS Header File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Windows NT Header File . . . . . . . . . . . . . . . . . . . . . . . . C-10

Publication 1747-UM002A-US-P - June 2000

Page 12

Table of Contents iv

Publication 1747-UM002A-US-P - June 2000

Page 13

Overview

Chapter

1

Introduction

Relationship to the Open Controller

This chapter provides an overview of the 1746 I/O PCI Interface and

the API software. This chapter also describes how to install the API.

You should have one of the following APIs:

• API for DOS (catalog number 1747-PCIDOS or 1747-OCAPID)

• API for Windows NT (catalog number 1747-PCINT or

1747-OCAPINT)

The API software license agreement allows you to freely distribute the

executable.

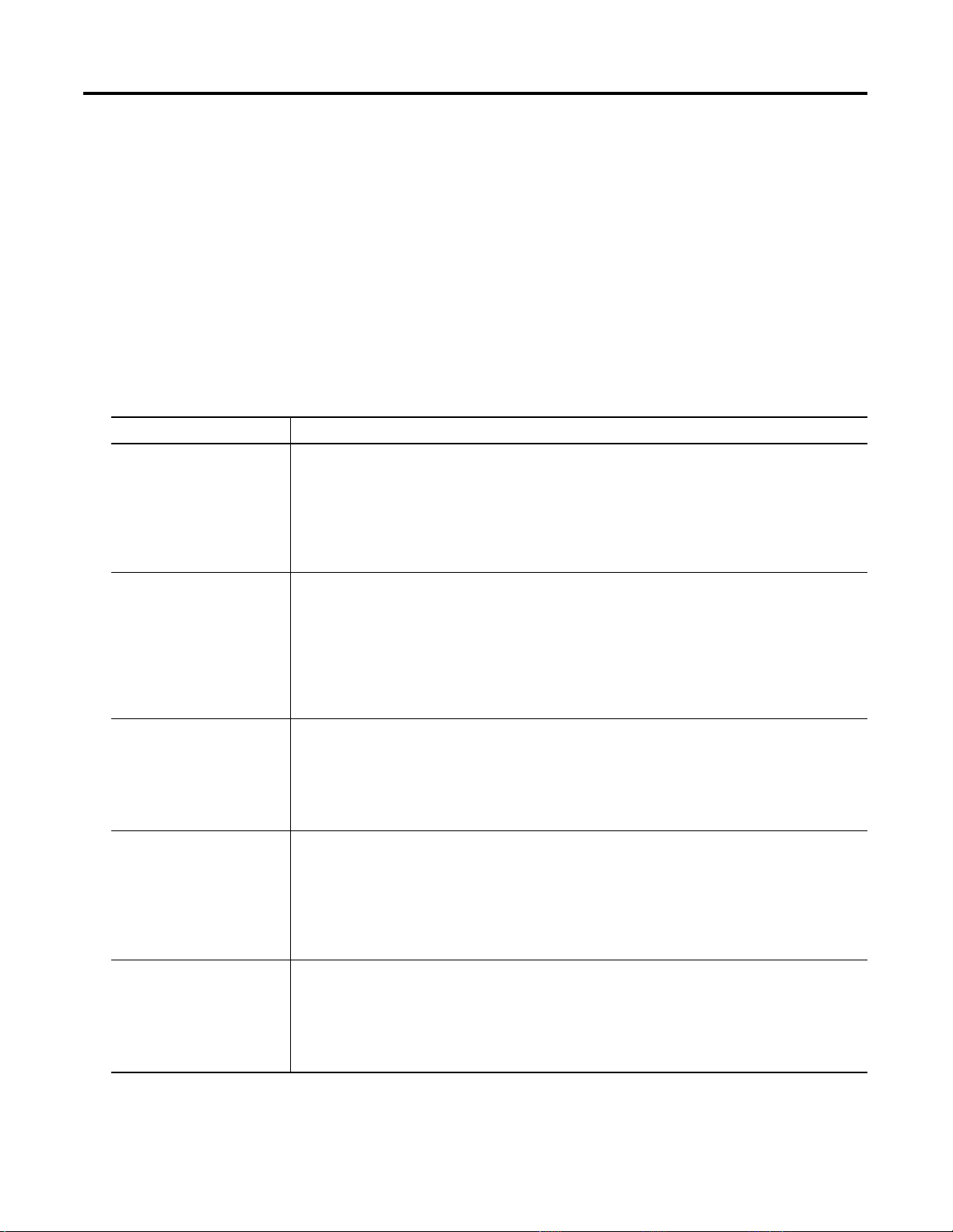

The API software for the 1746 I/O PCI Interface is compatible with the

API for the 1747 Open Controller. The sample code and header files

contain comments and functions that are supported by the Open

Controller but not supported by the 1746 I/O PCI Interface. The

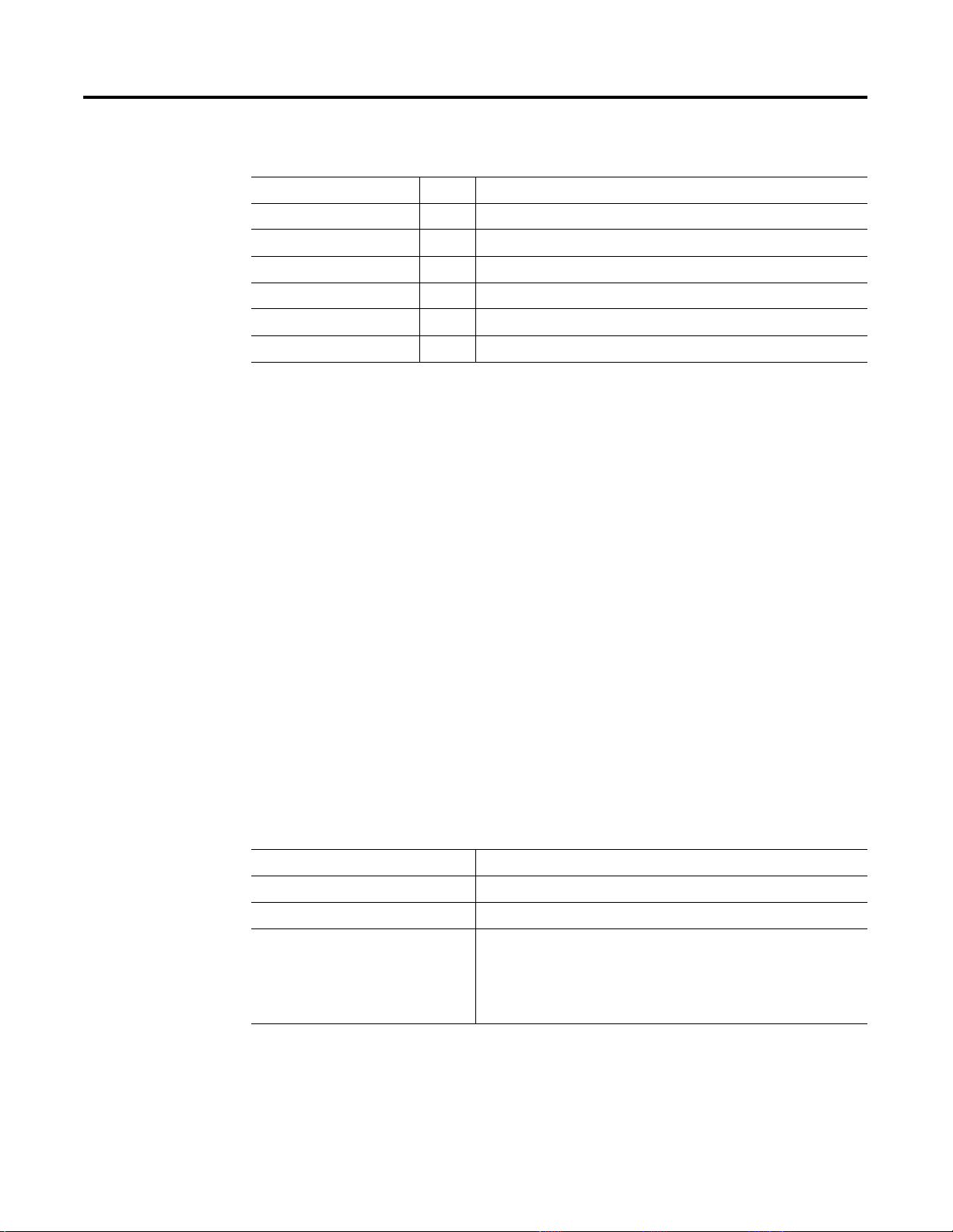

following table lists the differences between the 1747-OCF Open

Controller and the 1746 I/O PCI Interface.

Open Controller (1747-OCF) 1746 I/O PCI Interface (1746-PCIS)

Watchdog can reset the entire system. Watchdog cannot reset entire system.

API function call OC_GetResetCause returns

reason scanner was reset

Dual-port memory not battery-backed Jumper to enable battery-backup for the

IMPORTANT

1 Publication 1747-UM002A-US-P - June 2000

All references to Open Controller in the example

code or header files apply to the 1746 I/O PCI

Interface.

No function call OC_GetResetCause because

the watchdog cannot reset the entire system

dual-port memory

Page 14

1-2 Overview

Interface API to the Scanner

You must develop a software interface between your application and

a scanner to control local I/O and to control remote I/O via the

1747-SN or 1747-SDN scanners. Develop a software interface in one of

the following methods:

• Use the 1746 I/O PCI Interface API to develop the interface

between your application and the 1746 I/O PCI

Interface scanner.

• Use the API for 1747 Open Controller to develop the interface

between your application and the 1747 Open Controller.

In either application type (1746 I/O PCI Interface or 1747 Open

Controller), the API provides calls for typical control functions,

such as:

• configuring I/O files

• initializing the scanner

• accessing the user LEDs, user jumper, and 3-position switch

• reading 1746 I/O PCI Interface status

• enabling/disabling forces

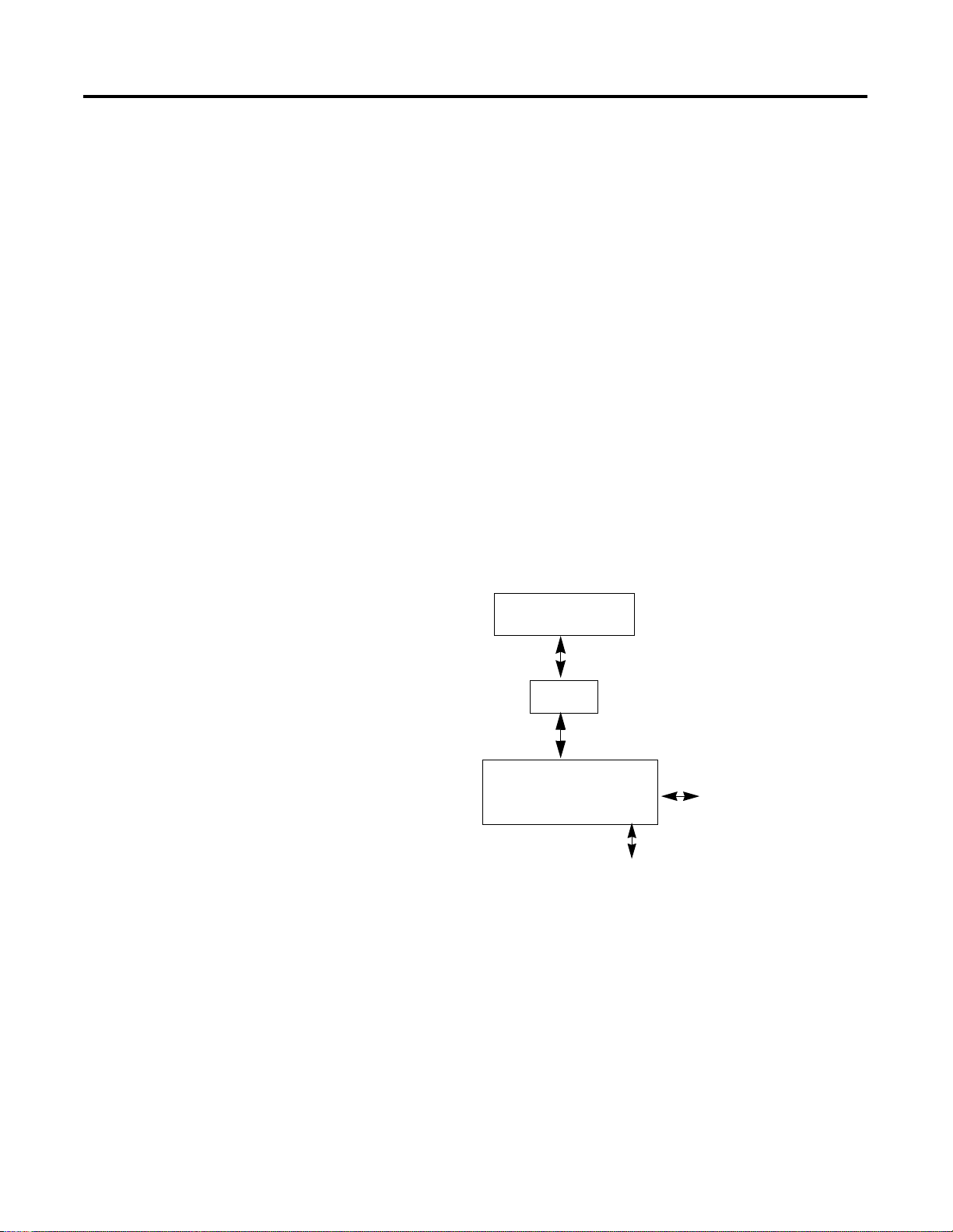

Application

API

1746 I/O PCI

Interface/Open Controller

dual port memory

remote I/O via

1747-SN or 1747-SDN

local I/O

API Software for DOS

The DOS API software provides a library of C function calls for DOS

application programs to interface with the dual port memory. The

DOS API supports any language compiler that uses the Pascal calling

convention.

Publication 1747-UM002A-US-P - June 2000

Page 15

Overview 1-3

API Software for Windows NT

The Windows NT API supports any programming languages that use

the Win32 _stdcall calling convention for application interface

functions. The Windows NT API function names are exported from a

DLL in undecorated format to simplify access from other

programming languages.

The Windows NT API software consists of two main components:

• the OCdriver (depending on your application, either 1746 I/O

PCI Interface device driver or Open Controller device driver)

• the API library, which is a DLL (dynamically-linked library)

The Windows NT API library is a DLL and must be installed on the

system in order to run an application which uses it. The Windows NT

API accesses the scanner via the driver created for the bus interface

The driver:

• allocates resources (interrupt and memory window)

• initializes scanner hardware

• provides access to the scanner’s dual port RAM

• services interrupts from the scanner (priority messages)

• provides access to SRAM

IMPORTANT

Only access the OCdriver through the API library

functions.

When the OCdriver is loaded it tries to allocate an interrupt and a

memory window for the memory and interrupt that were allocated

using the settings by the PCI bus at power-up for the dual port RAM.

If IRQ 11 and address oxC8000 are not available (i.e., another device

already allocated the resource), OCdriver tries to allocate any resource

for which the scanner hardware can be configured (IRQ 10, 12, and

15; memory address 0xCA000 - 0xDE000). OCdriver fails to load if an

interrupt and memory window cannot be allocated.

Once an interrupt and memory window are allocated, OCdriver

initializes the scanner hardware to match the allocated resources.

Publication 1747-UM002A-US-P - June 2000

Page 16

1-4 Overview

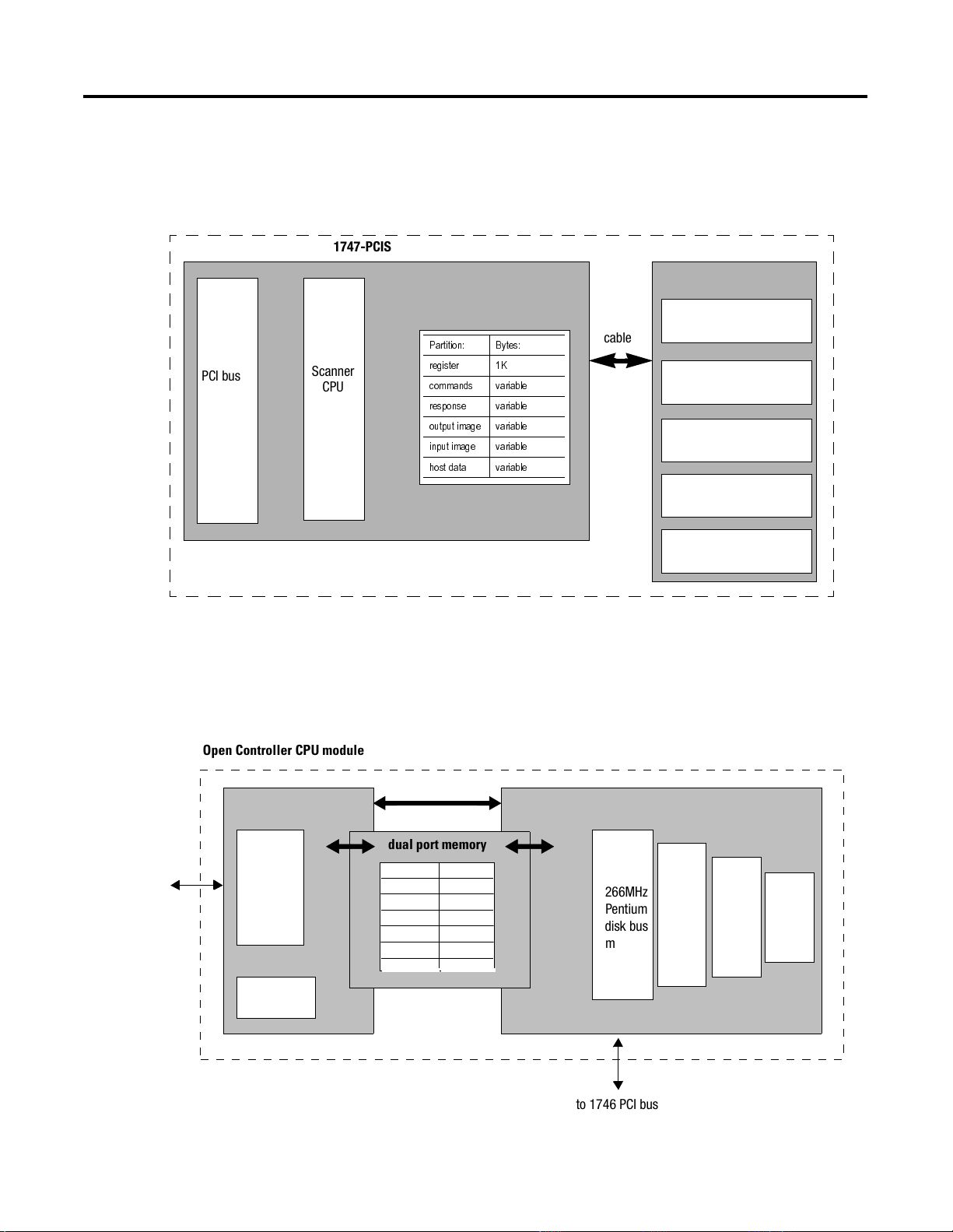

Understanding the 1746 I/O PCI Interface Architecture

PCI bus

Scanner

The 1746 I/O PCI Interface architecture consists of a PCI card that

plugs into a PC and cables to a 1746 I/O chassis. The scanner scans

the 1746 local I/O bus and reads/writes inputs and outputs to/from

the dual port registers.

1747-PCIS

CPU

dual port memory

3DUWLWLRQ %\WHV

UHJLVWHU .

FRPPDQGV YDULDEOH

UHVSRQVH YDULDEOH

RXWSXWLPDJH YDULDEOH

LQSXWLPDJH YDULDEOH

KRVWGDWD YDULDEOH

cable

1747-PCIL

1746 backplane interface

status and user LEDs

3-position switch

user jumper

watchdog contact

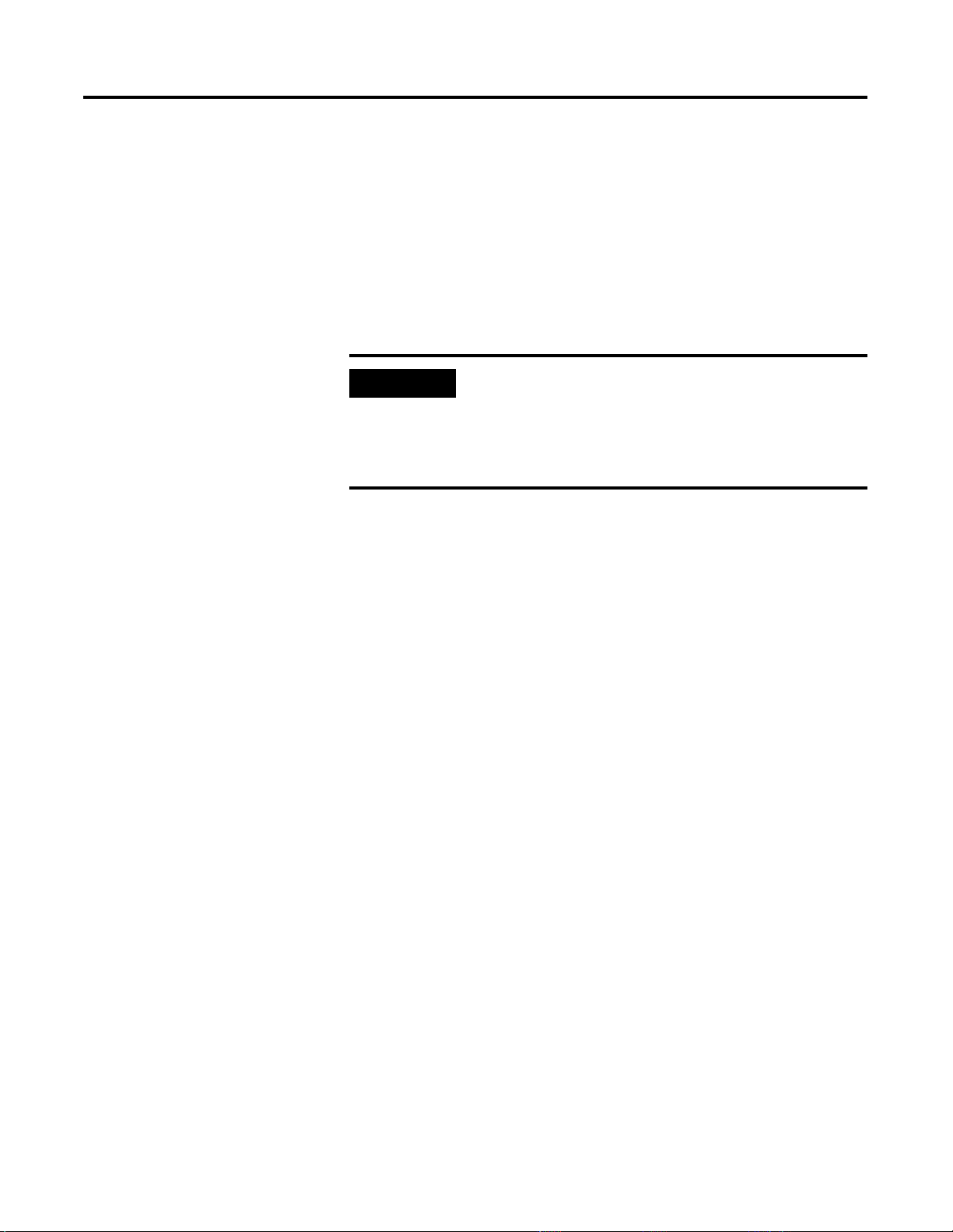

Understanding the Open Controller Architecture

Open Controller CPU module

scanner

80188

to 1746 local

I/O bus

CPU

bus

memory

scanner

firmware

The open controller architecture consists of two CPUs (scanner and

controller) that share dual-port memory. The scanner scans the 1746

local I/O bus and reads/writes inputs and outputs to/from the

dual-port registers. The controller has a PC-based architecture with a

266Mhz Pentium to run your application software.

PCI

dual port memory

Partition: Bytes:

register 1K

commands

responses

output image

input image variable

host data variable

variable

variable

variable

controller (PC-based architecture)

266MHz

Pentium

disk bus

memory

BIOS

OS

application

software

Publication 1747-UM002A-US-P - June 2000

to 1746 PCI bus

Page 17

Overview 1-5

Common Attributes of the 1746 I/O PCI Interface and 1747 Open

Controller Architectures

The functionality described in the rest of this chapter is shared by

both architectures, 1746 I/O PCI Interface and 1747 Open Controller.

The dual port is an 8K byte memory partition (optionally

battery-backed) that provides an interface between the integrated

scanner and your application software that resides on the host.

IMPORTANT

Your application (the code you develop using the API) uses the dual

port memory to communicate with the scanner to handle control

functions on the 1746 backplane, such as:

• scanner commands and responses

• battery and scanner status

• scan rate frequency and timing

• I/O image counters

• priority messages and interrupts

• semaphores to ensure data integrity

• software-generated watchdogs

• control of the 4 user-definable LEDs, the 2-position jumper, and

the 3-position switch

On the 1747-PCIS only, the jumper for the

battery-backup dual-port memory is disabled by

default. You must switch the jumper to enable the

battery-backup feature.

The 1747-OCF dual port is NOT battery-backed.

The scanner functionality of the dual port supports I/O control

functions, such as:

• synchronizing scans to the application

• forcing I/O

• defining discrete-input interrupts

• defining I/O module-driven interrupts (such as for the 1746-BAS

module)

• enabling and disabling I/O slots

• resetting I/O

Publication 1747-UM002A-US-P - June 2000

Page 18

1-6 Overview

In addition to providing access to the control scanner, the dual port

memory also provides non-volatile (optional battery-backed) storage

for:

• I/O values

• application parameters (timers, counters, presets)

Scanner Modes

In both application types, the scanner CPU operates in six

basic modes:

• performing POST (power-on self test)

• waiting for host initialization

• Idle

• Scan

• Faulted

• non-recoverable fault

After the scanner successfully completes the POST, the scanner waits

for an initialization complete command from the application. Once the

scanner receives this command, the scanner enters Idle mode.

Before the scanner can enter Scan mode, the application must

download a valid I/O configuration to the scanner.

If a recoverable fault occurs, the scanner enters Faulted mode. Use the

OC_ClearFault API function to clear the fault before the scanner can

resume operating in Scan mode.

If a non-recoverable fault occurs, reset the scanner (cycle power).

Some possible non-recoverable faults include:

Publication 1747-UM002A-US-P - June 2000

• POST failure

• background diagnostic failure

• internal watchdog timeout

Page 19

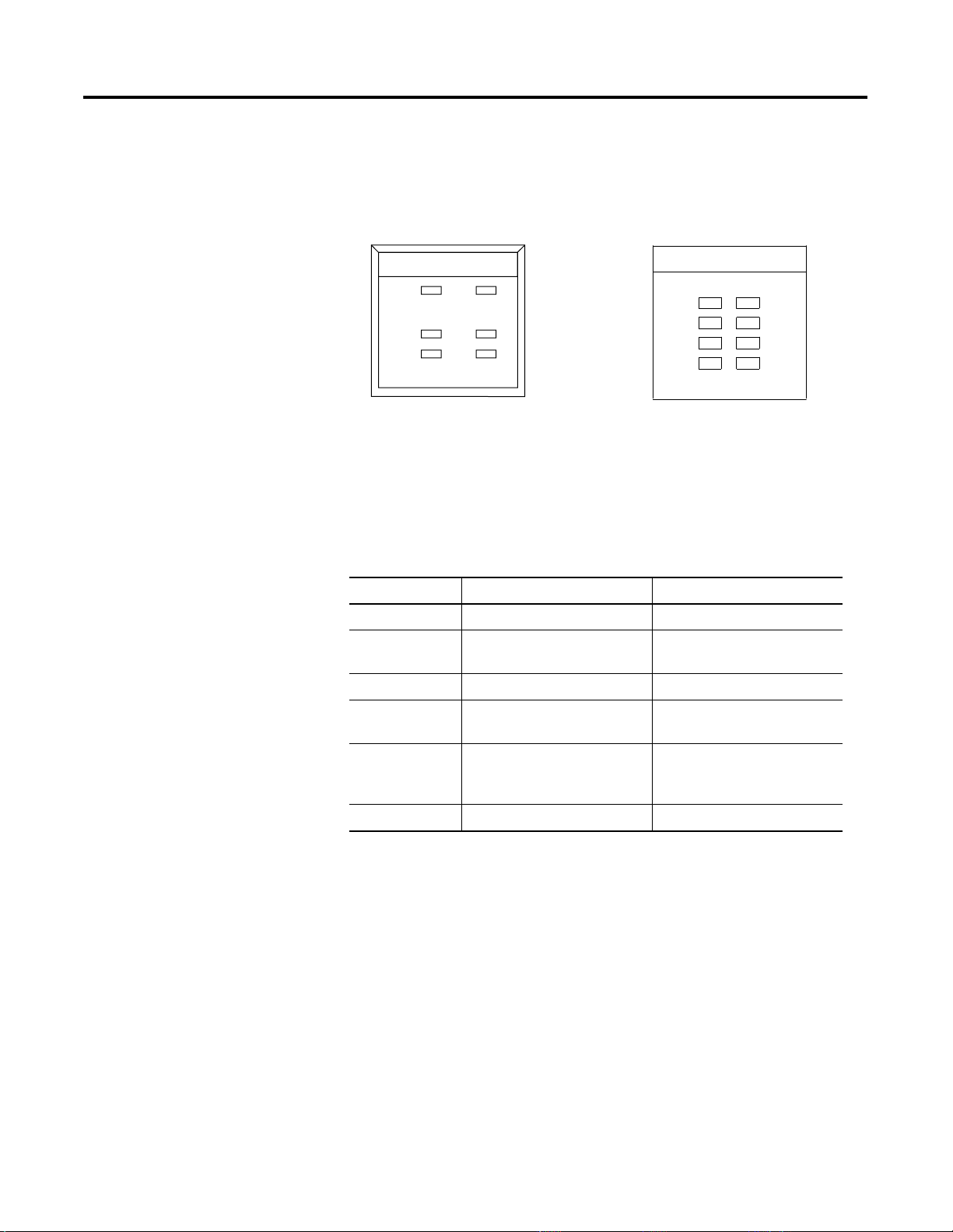

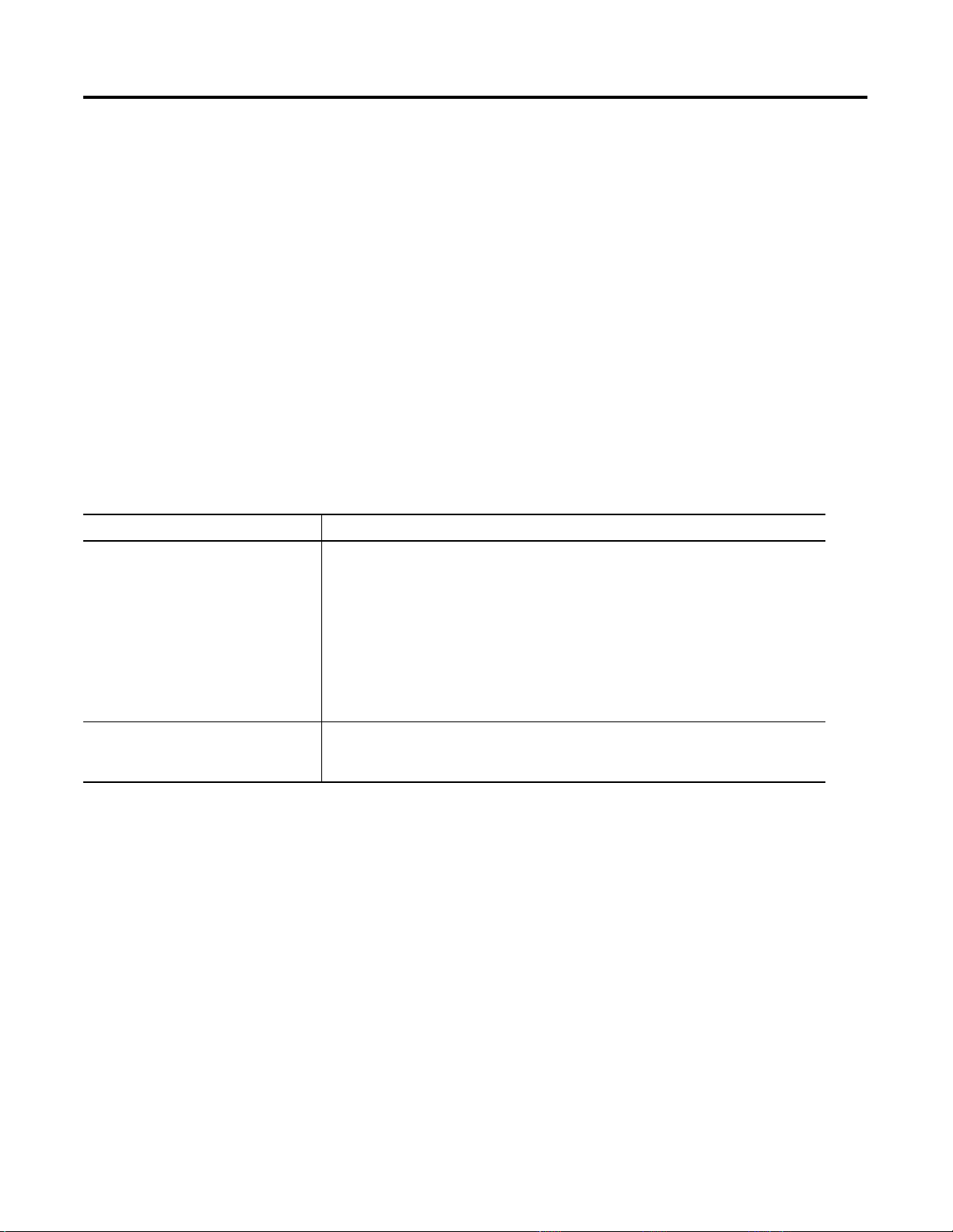

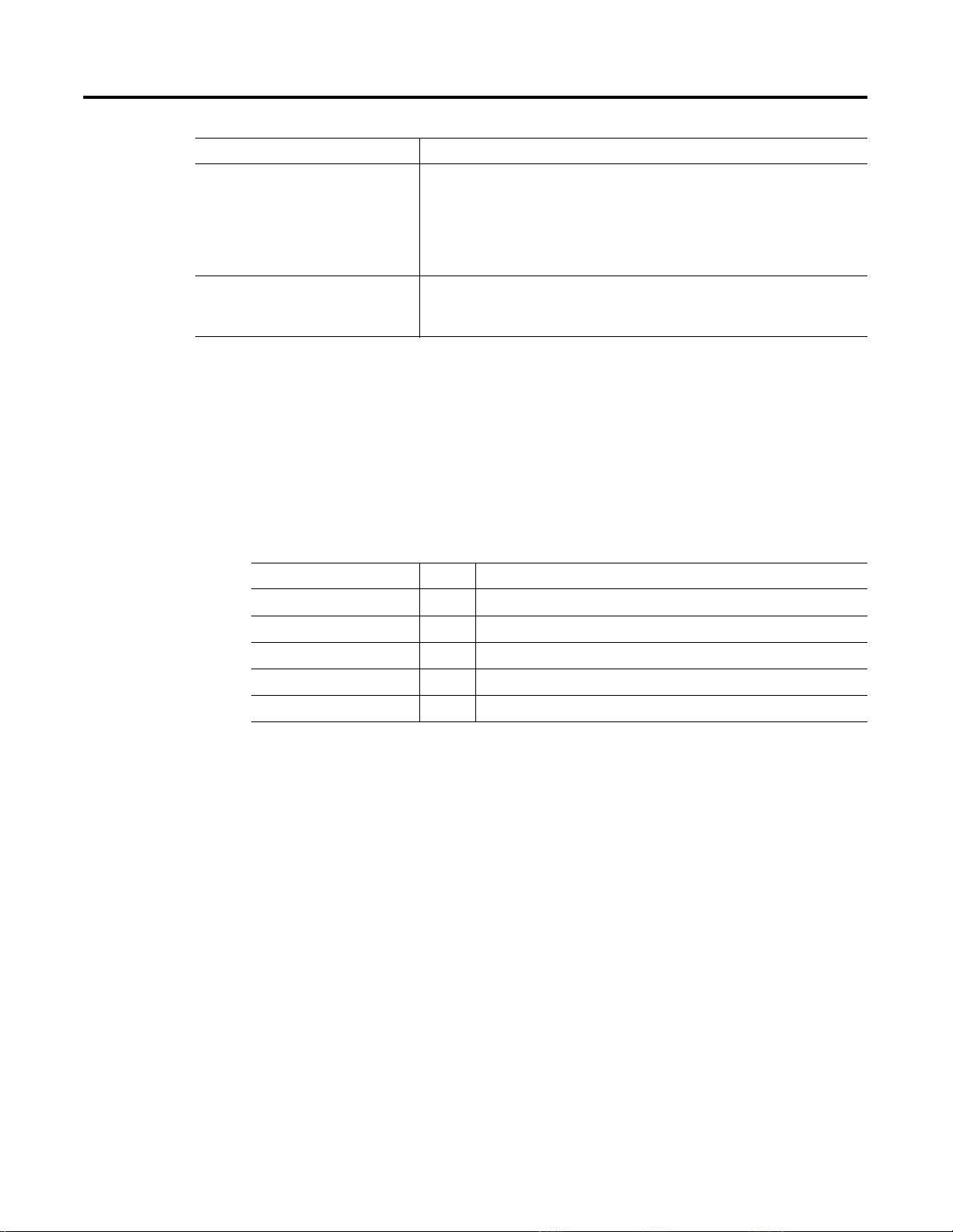

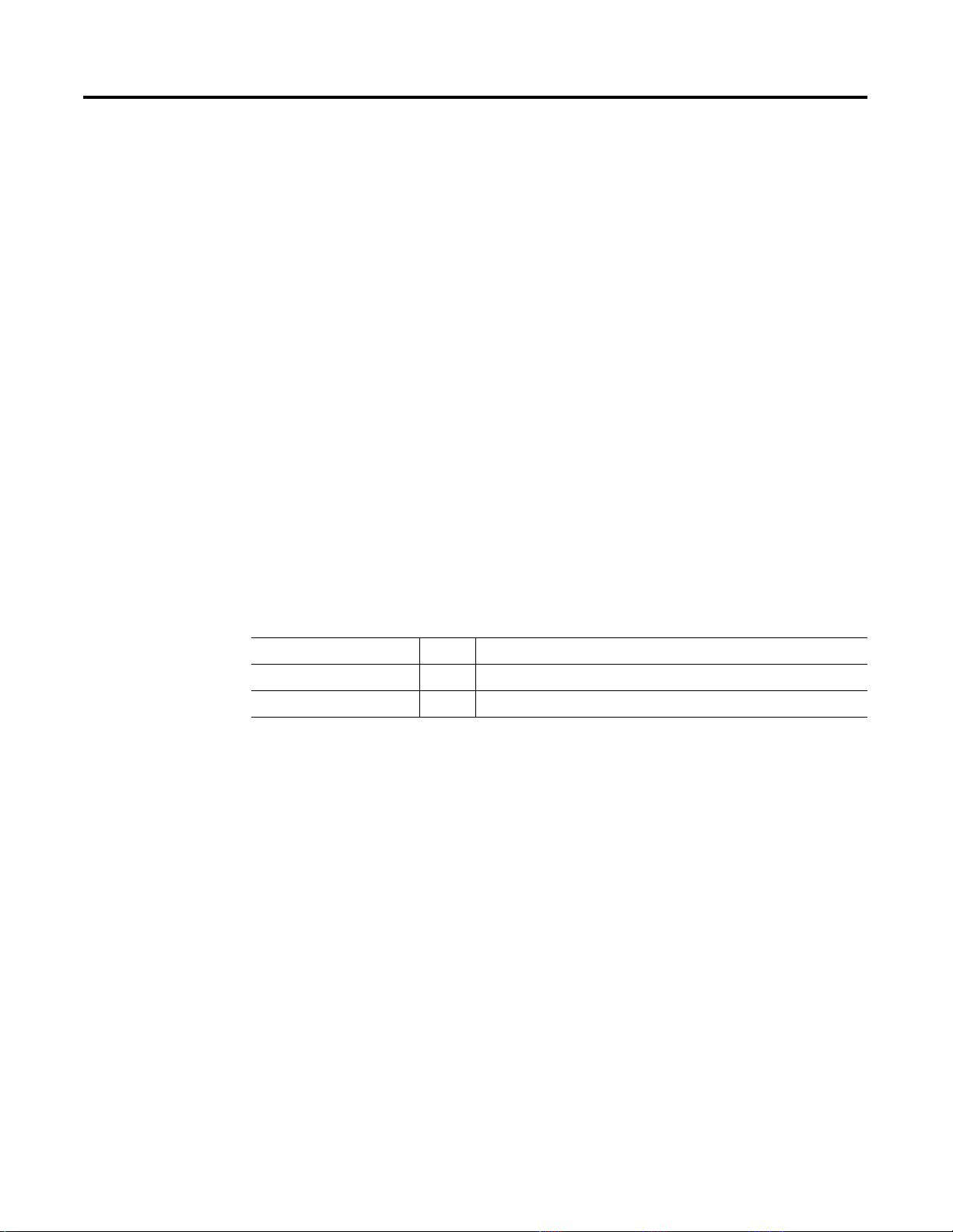

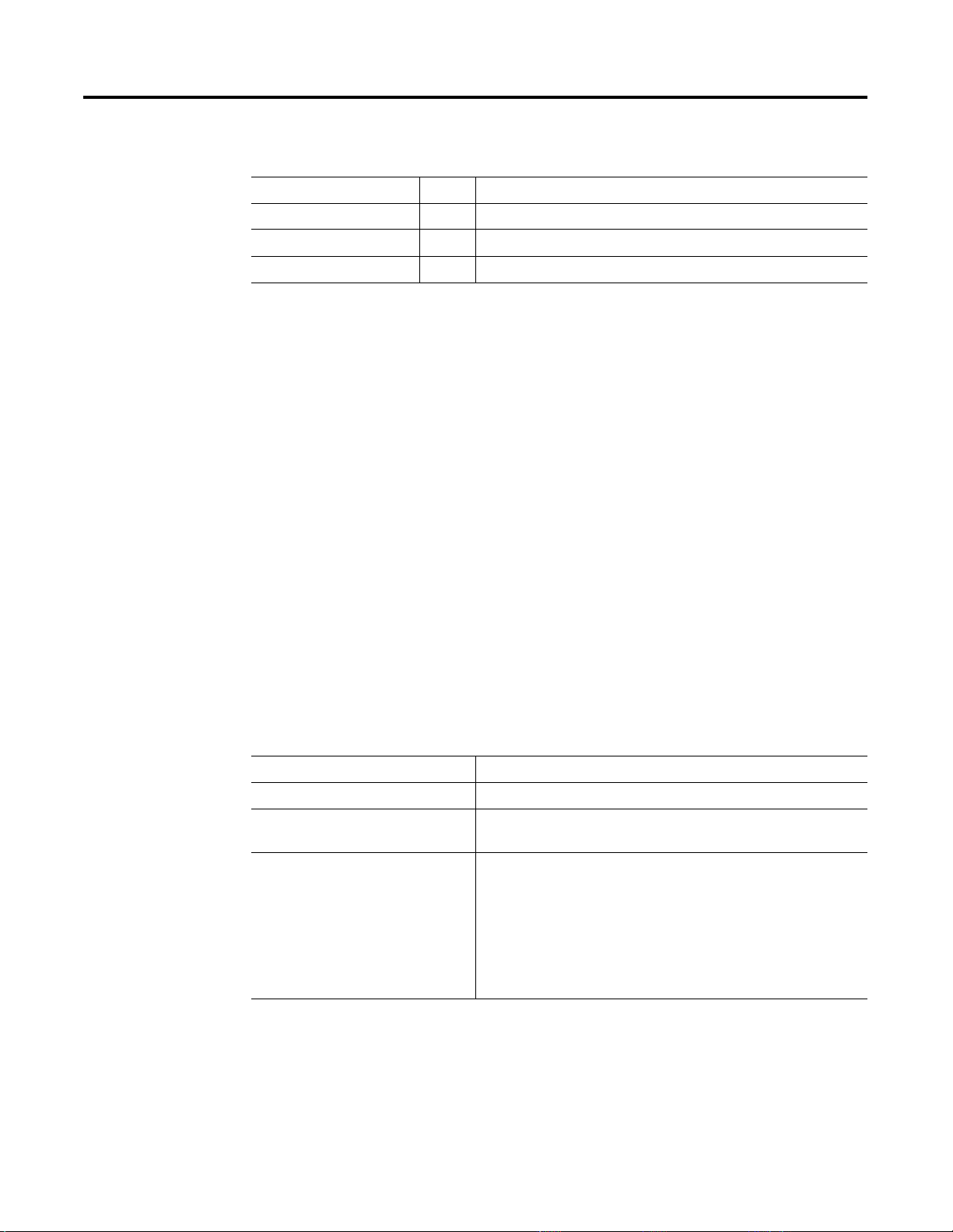

Checking LED Indicators

The graphics below show LED displays.

1746 PCI I/O Interface 1747 Open Controller

Overview 1-7

PCI INTERFACE

STATUS BATT

LED 1 LED 2

LED 3 LED 4

OC 266 PENTIUM

STATUS BATT

COM 1 COM 2

LED 1 LED 2

LED 3 LED 4

STATUS

The STATUS indicator reports the status of the scanner. The following

table lists the LED states for STATUS:

This state: Means: Take this action:

Yellow The scanner is running POST. None

Flashing green The scanner is in idle mode and

is not scanning I/O.

Solid green The scanner is scanning I/O. None

None

Flashing red An I/O fault has occurred. Check software to identify

fault condition.

Solid red A scanner internal fault has

occurred.

Power system off and back on.

If the problem persists, service

may be required.

Off The adapter is not powered up. Turn on power.

Publication 1747-UM002A-US-P - June 2000

Page 20

1-8 Overview

Installing the DOS API

Installing the Windows NT API

To install the DOS API, copy the following files to a directory you

create. The sample code files are optional, but they show how to use

the API functions.

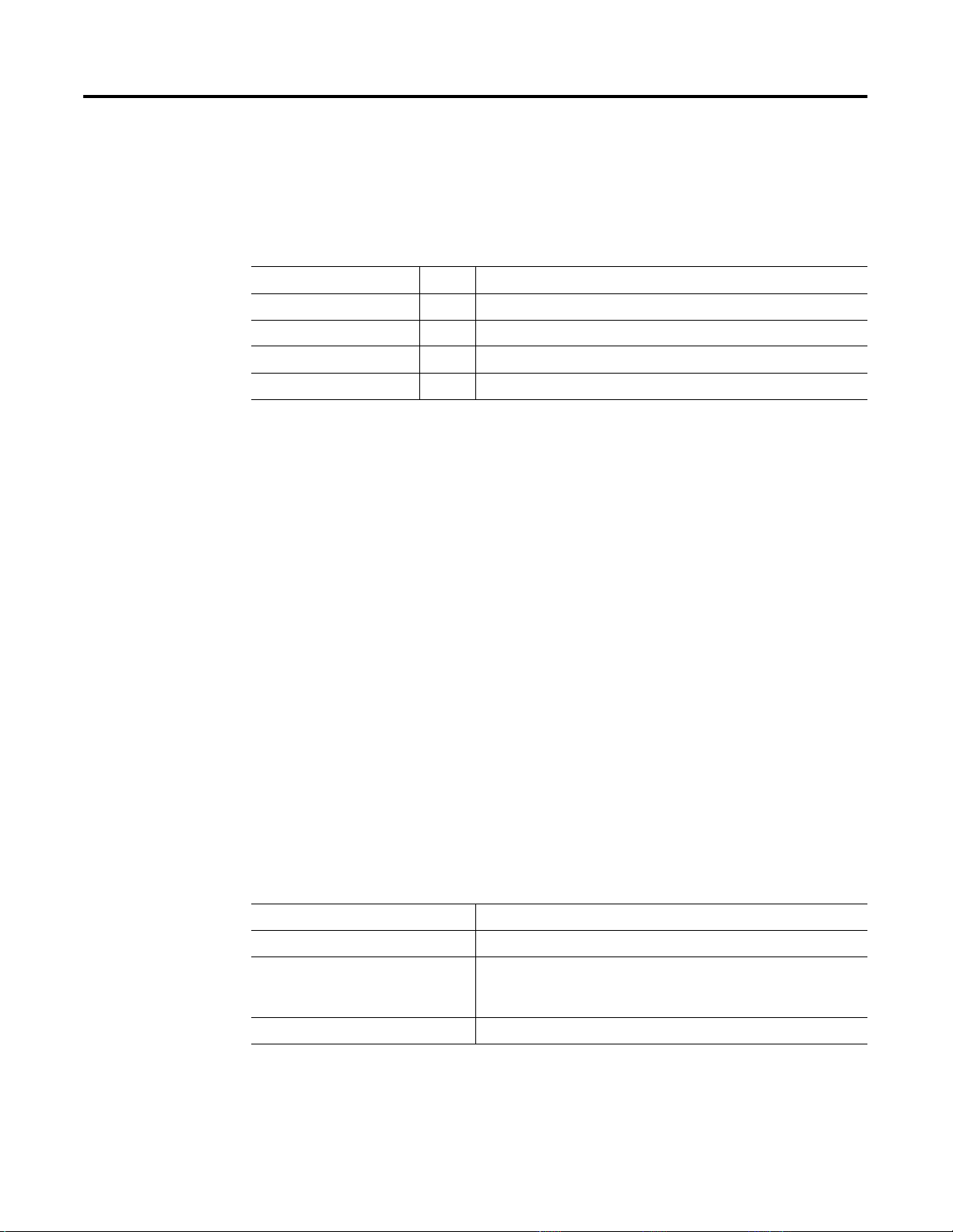

This file: Contains:

ocapil.lib API functions that you link to your application

ocapi.h API header file that contains API-referenced structures

sample.c Sample application program calling the API functions

sampleb.mak Sample make file for the Borland C compiler

samplem.mak Sample make file for the Microsoft C compiler

To install the Windows NT API, use the setup utility:

TIP

It is recommended that you exit all applications

before starting the setup process.

1. Copy the contents of the API diskette to a temporary directory

on the open controllerÿs disk drive. (This step is not necessary if

a local diskette drive is connected.) The device driver file is

OCdriver.sys.

2. Select Run from the startup menu, then select the setup.exe

program from the temporary directory.

3. Click on OK to execute the setup utility. Follow the displayed

instructions. Click on Continue.

4. The next dialog lets you choose whether to install the API

executable alone (Runtime) or the API executable and the

development files (Runtime and & Development). To develop

applications with the API, you need the development files. To

only run applications, the development files are not necessary.

The development files consist of an include file, import library,

and sample code.

IMPORTANT

Runtime files may only be installed on a Windows

NT system. However, the development files may be

installed on either Windows NT or Windows 95

systems.

Publication 1747-UM002A-US-P - June 2000

Choose the appropriate installation option and click on Next.

Page 21

Overview 1-9

5. Click on Continue.

6. If the development files were selected in the last dialog, the next

dialog allows a destination directory to be specified. Click on

Continue after you select the directory.

7. The necessary files are copied to the disk, and the system

registry is updated to include the OCdriver information.

8. Press OK to exit the setup utility. The contents of the

temporary directory can now be deleted.

IMPORTANT

You must shutdown and reboot the scanner before

using the API. (The setup utility sets the registry Start

parameter for OCdriver to Automatic; therefore, the

service manager starts the OCdriver when the system

is booted.)

The Windows NT API uses these files:

This file: Contains:

ocapi.lib Import library in Microsoft COFF format

ocapi.h API header file that contains API-referenced structures

ocapi.dll API DLL

sample.c Sample application program calling the API functions

sampleb.mak Sample make file for the Borland C compiler

samplem.mak Sample make file for the Microsoft C compiler

Installation Details

This section describes the actions the setup utility performs to install

the API and OCdriver.

If you select Runtime (Complete), the setup utility:

1. copies the device driver file,

driver directory (

%SystemRoot%\system32\drivers).

OCdriver, to the system device

Publication 1747-UM002A-US-P - June 2000

Page 22

1-10 Overview

2. adds this key and these values to the system registry:

HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Services

OCdriver

ErrorControl: REG_DWORD 0x1

Group: REG_SZ Extended base

Start: REG_DWORD 0x2

Type: REG_DWORD 0x1

HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Services

Drivers\ OCdriver

EventMessageFile=

REG_EXPAND_SZ%SystemRoot%\System32\Drivers\OCdriver.sys

TypesSupported= REG_DWORD 0X00000007

3. copies the library file,

OCapi.dll, to the %SystemRoot%\system32

directory.

If you select Runtime & Development, the setup utility performs the

same steps as for Runtime only and the setup utility copies

ocapi.h, and the sample source files to a development directory.

,

ocapi.lib

If you want to develop your application on a computer other than the

open controller, copy the ocapi.lib and ocapi.h files to the

development computer (do not run the setup utility on the

development computer). You won’t be able to run your application

on the development computer. The runtime API only works on an

open controller.

Uninstalling the Windows NT API

To uninstall Windows NT API, use the following instructions.

1. From the Control Panel, select Add/Remove Programs.

2. From the list of installed programs, select Open Control API.

Publication 1747-UM002A-US-P - June 2000

3. Click on Add/Remove.

4. Click on Yes.

All of the API files and registry keys will be deleted.

Page 23

Using the API

Chapter

2

Introduction

Getting Started

This chapter describes the API and how to use its components. For

more information about developing applications using the API, see

chapter 3.

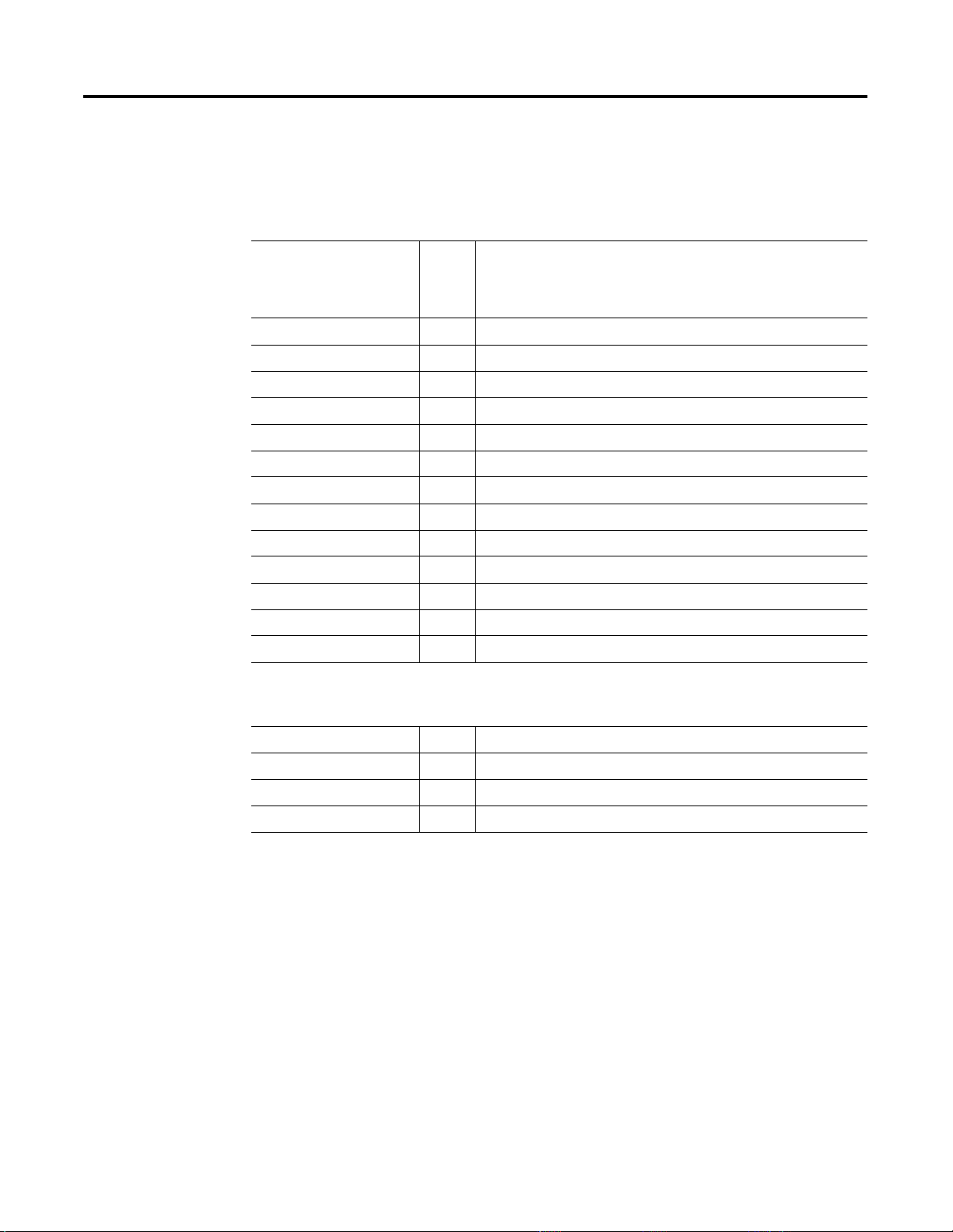

To use the API, make sure you have copied the following files to your

development directories. The sample files are optional.

This file: Contains:

ocapil.lib API functions that you link to your application (DOS only)

ocapi.lib Import library in Microsoft COFF format (Windows NT

only)

ocapi.h API header file that contains API-referenced structures

ocapi.dll API DLL (Windows NT only)

sample.c Sample application program calling the API functions

sampleb.mak Sample MAKE file for the Borland C compiler

samplem.mak Sample MAKE file for the Microsoft C compiler

Your application must link to the appropriate library (

DOS or

copy the sample files and adapt them for your application.

ocapi.lib for Windows NT) and include ocapi.h. You can

ocapil.lib for

1 Publication 1747-UM002A-US-P - June 2000

Page 24

2-2 Using the API

Programming Conventions

This convention: Considerations:

calling convention The DOS API functions are specified using the C programming language syntax. To

header files The API includes a header file (ocapi.h) that contains API function declarations,

sample code The API comes with sample files to provide an example application that communicates

compiler support The DOS API is supplied in the large memory model, compatible with both Microsoft

The API is supplied as an object code library file [DOS (ocapil.lib)]

or a DLL [NT (

ocapi.dll)] that you link with the host application’s

object code using commercially-available tools.

allow you to develop control applications in other programming languages, the API

functions use the standard Pascal calling convention.

The Windows NT API supports any programming languages that use the Win32 _stdcall

calling convention for application interface functions. The Windows NT API function

names are exported from the DLL in undecorated format to simplify access from other

programming languages.

data structure definitions, and other constant definitions. The header file is in standard

C format.

with the scanner. The sample files include all source files and MAKE files required to

build the sample application.

and Borland compilers. The DOS library (ocapil.lib) is compiled as a 16-bit

MS-DOS library using the 80386 instruction set.

The Windows NT library (ocapi.dll) is compiled for use with Microsoft Visual C++

or Borland C++.

DOS Considerations

The DOS API is as consistent as possible with APIs for other operating

system platforms. This makes it easier for you to migrate applications

and it simplifies support. To create a consistent API, careful

consideration was given to these requirements:

This requirement: Considerations:

memory mapping The dual port RAM, or shared memory, is mapped automatically at power-up by the PCI bus in the

host processor’s memory address space on any even 8K boundary between 0xC0000 and 0xDFFFF.

For MS-DOS, it is important that any installed memory managers (such as EMM386) or other TSR

software avoid accessing the 8K dual port memory window.

Place the base memory select jumper in 1M position to allow the PCI BIOS to assign a base

memory address.

DOS interrupts An interrupt is automatically assigned to the scanner by the PCI bus at power-up.

control-break handler Because communication with the scanner requires memory and interrupt resources (as described

above), improper termination of the host application can leave these resources allocated by the

scanner and unusable by other applications. For this reason the API includes a default

control-break handler.

The default control-break handler is installed by OC_OpenScanner. If you press a [Ctrl-C] or

[Ctrl-Break] key sequence, the following prompt is displayed:

Terminate Application? (Y/N) _

A response of Y properly exits the application; a response of N causes the application to continue.

If you need a different control-break handler, you must install it after calling the OC_OpenScanner

function. Always call the OC_CloseScanner function before exiting an application.

Publication 1747-UM002A-US-P - June 2000

Page 25

Windows NT Considerations

During development, the application must be linked with an import

library that provides information about the functions contained within

the DLL. The API import library is compatible with the Microsoft

linker. You can generate import libraries for other programming

languages from the DLL.

The Windows NT API can only be accessed by one process at a time.

The API is designed to be multi-thread safe, so that multi-threaded

control applications can be developed. Where necessary, the API

functions acquire a mutex before accessing the scanner interface. In

this way, access to the scanner device is serialized. If the mutex is in

use by another thread, a thread will be blocked until it is freed.

To create a consistent API, careful consideration was given to these

requirements::

This requirement: Considerations:

Using the API 2-3

memory mapping The NT API device driver detects the Scanner Adapter and automatically configures the

memory window address and interrupt assignment. The base memory address jumper

must be positioned to choose 32 bit addressing. The API and device driver must be

installed on the system.

Place the base memory select jumper in 32-bit position to allow the PCI BIOS to assign a

base memory address anywhere in 32-bit memory for protected-mode applications

(WinNT). NT device drivers (1747-PCINT) use the PCI BIOS or OS services to determine

the memory window base address and provide access to the dual port memory.

• To determine the allocated memory base address and interrupt, run the

Windows NT diagnostic found in Administrative Tools.

NT interrupts An interrupt is automatically assigned to the scanner by the PCI bus at power-up

• To determine the allocated memory base address and interrupt, run the

Windows NT diagnostic found in Administrative Tools.

A group of thread-blocking functions are provided to aid

multi-threaded application development. The functions are:

• OC_WaitForDII

• OC_WaitForEos

• OC_WaitForEosDmdOut

• OC_WaitForIoInt

• OC_WaitForDmdIn

• OC_WaitForExtError

For more information, see chapter 6.

Publication 1747-UM002A-US-P - June 2000

Page 26

2-4 Using the API

Tools to Use

The API functions support both Microsoft and Borland C compilers.

The API disk includes sample MAKE files for each compiler.

When you use the DOS API and link to

ocapil.lib, use the

appropriate command-line switch to select the large memory model.

For more information, see your user manual for your compiler.

If you plan to use a programming language other than C, make sure

the programming language follows the appropriate calling convention

(Pascal for the DOS API; Win32 _stdcall for Windows NT). After you

write your application, use your compiler to link to

(DOS) or

ocapi.lib (Windows NT).

ocapil.lib

The follow pages offer sample MAKE files for DOS and Windows NT

systems on Microsoft and Borland compilers.

Sample DOS MAKE file for Borland compilers

The following sample file shows how to use a Borland MAKE file. The

bold headings indicate the statements you need to modify for your

environment.

#************************************************************************

#

# Title: Makefile for Open Controller API Sample

#

# Abstract:

# This file is used by the Borland MAKE utility to build the

# sample application.

#

# Environment:

# 1747-OCE Open Controller

# MS-DOS

# Borland C/C++ Compiler (16-bit)#

#************************************************************************

#

# Paths to Tools

#

# Note: Modify the following paths to

# correspond to your environment.

#

#---------------------------------------------CPATH = D:\BC5 # Location of Borland tools

CC = $(CPATH)\bin\Bcc # compiler

LINK = $(CPATH)\bin\TLink # linker

MAKE = $(CPATH)\bin\Make # make utility

#---------------------------------------------# Path to API Library and Include file

#

# Note: Modify the following path to

# correspond to your environment.

#

#---------------------------------------------APILIB = ..\ocapil.lib # Path to Open Controller API library

Publication 1747-UM002A-US-P - June 2000

Page 27

APIINC = .. # Path to Open Controller API include file

#---------------------------------------------# Options

#---------------------------------------------CFLAGS = -c -v- -w -ml -I$(APIINC)

LFLAGS = -v- -Tde -d -c

sample.exe : sample.obj $(APILIB) sampleb.mak

$(LINK) $(LFLAGS) c0l sample.obj, $*.exe, $*.map, $(APILIB) cl

clean:

del *.exe

del *.obj

del *.map

rebuild:

$(MAKE) clean

$(MAKE)

.c.obj:

$(CC) $(CFLAGS) $*.c

sample.obj: sample.c $(APIINC)\ocapi.h

sampleb.mak

Using the API 2-5

Sample DOS MAKE file for Microsoft compilers

The following sample file shows how to use a Microsoft MAKE file.

The bold headings indicate the statements you need to modify for

your environment.

#************************************************************************

#

Title: Makefile for Open Controller API Sample

#

# Abstract:

# This file is used by the Microsoft NMake utility to build the

# sample application.

#

# Environment:

# 1747-OCE Open Controller

# MS-DOS

# Microsoft C/C++ Compiler (16-bit)

#************************************************************************

#---------------------------------------------# Note: The environment variables LIB and

# INCLUDE must be set to the path to the

# Microsoft C library and include files.

# For example:

#

# set LIB=D:\MSVC15\LIB

# set INCLUDE=D:\MSVC15\INCLUDE

#

#---------------------------------------------# Paths to Tools

#

# Note: Modify the following paths to

# correspond to your environment.

#

#---------------------------------------------CPATH = D:\MSVC15 # Location of Microsoft tools

CC = $(CPATH)\bin\cl # compiler

LINK = $(CPATH)\bin\link # linker

MAKE = $(CPATH)\bin\nmake # make utility

#---------------------------------------------# Path to API Library and Include file

Publication 1747-UM002A-US-P - June 2000

Page 28

2-6 Using the API

#

# Note: Modify the following path to

# correspond to your environment.

#

#---------------------------------------------APILIB = ..ocapil.lib # Path to Open Controller API library

APIINC = .. # Path to Open Controller API include file

#---------------------------------------------# Options

#------------ -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -CFLAGS = /c /nologo /G3 /W3 /AL /Oi /D /Gx- /I $(APIINC)

LFLAGS = /MAP:A /NOI /PACKC

sample.exe : sample.obj $(APILIB) samplem.mak

$(LINK) $(LFLAGS) sample.obj, $*.exe, $*.map, $(APILIB), nul.def

clean:

del *.exe

del *.obj

del *.map

rebuild:

$(MAKE) -f samplem.mak clean

$(MAKE) -f samplem.mak

.c.obj:

$(CC) $(CFLAGS) $*.c

sample.obj: sample.c $(APIINC)\ocapi.h

samplem.mak

Sample Windows NT MAKE file for Microsoft compilers

The following sample file shows how to use a Microsoft MAKE file.

The bold headings indicate the statements you need to modify for

your environment.

#************************************************************************

# Title: Makefile for Open Controller NT API Sample

#

# Abstract:

# This file is used by the Microsoft NMake utility to build the

# sample application.

#

# Environment:

# 1747-OCE Open Controller

# Microsoft Windows NT 4.0

# Microsoft Visual C++

#

# (c)Copyright Allen-Bradley

#

#************************************************************************

#---------------------------------------------# Note: The environment variable LIB

# must be set to the path to the

# Microsoft C library files.

# For example:

#

# set LIB=D:\MSDEV\LIB

#

#----------------------------------------------

Publication 1747-UM002A-US-P - June 2000

Page 29

Using the API 2-7

# Paths to Tools

#

# Note: Modify the following paths to

# correspond to your environment.

#

#---------------------------------------------CPATH = D:\MSDEV # Location of Microsoft tools

CC = $(CPATH)\bin\cl # compiler

LINK = $(CPATH)\bin\link # linker

MAKE = $(CPATH)\bin\nmake # make utility

#---------------------------------------------# Path to API Library and Include file

#

# Note: Modify the following paths to

# correspond to your environment.

#

#---------------------------------------------APILIB = ..\api\lib\ocapi.lib # Path to Open Controller API library

APIINC = ..\api\include # Path to Open Controller API include file

#---------------------------------# Compiler/Linker Debugging Options

# (Define DEBUG for debugging.)

#---------------------------------!ifdef DEBUG

CDEBUG = -Zi -Od

LDEBUG = -debug:full -debugtype:cv

!else

CDEBUG = -Ox

LDEBUG = /RELEASE

!endif

#------------------------------------------# Compiler Options

#

# -W3 Turn on warnings

# -GB Optimize code for 80486/Pentium

# -MT Use Multithreaded runtime lib

#

#------------------------------------------CFLAGS = -W3 -GB -MT \

-I$(APIINC) -I$(CPATH)\include

#---------------------------------# Linker Options

#

#---------------------------------LFLAGS = /NODEFAULTLIB /SUBSYSTEM:CONSOLE \

/INCREMENTAL:NO /PDB:NONE

#-----------------------------------# Libraries

#

# libcmt Multithreaded C runtime

# kernel32 Base system lib

#

#-----------------------------------LIBS = libcmt.lib kernel32.lib

#--------------------------------# Final target

Publication 1747-UM002A-US-P - June 2000

Page 30

2-8 Using the API

#--------------------------------sample.exe : sample.obj $(APILIB)

$(LINK) @<<

$(LDEBUG) $(LFLAGS) $(LIBS) $**

<<

@echo Finished

clean:

del *.exe

del *.obj

del *.map

rebuild:

$(MAKE) -f samplem.mak clean

$(MAKE) -f samplem.mak

#-------------------------# Intermediate target rules

#-------------------------.c.obj:

$(CC) @<<

/c $(CDEBUG) $(CFLAGS) $*.c

<<

#--------------------------------# Intermediate target dependancies

#---------------------------------

sample.obj: sample.c $(APIINC)\ocapi.h

samplem.mak

Sample Windows NT MAKE file for Borland compilers

The following sample file shows how to use a Borland MAKE file. The

bold headings indicate the statements you need to modify for your

environment.

#************************************************************************

#

# Title: Makefile for Open Controller API Sample

#

# Abstract:

# This file is used by the Borland MAKE utility to build the

# sample application.

#

# Environment:

# 1747-OCE Open Controller

# Microsoft Windows NT 4.0

# Borland C++ Compiler

#

# (c)Copyright Allen-Bradley

#

#************************************************************************

#---------------------------------------------# Paths to Tools

#

# Note: Modify the following paths to

Publication 1747-UM002A-US-P - June 2000

Page 31

Using the API 2-9

# correspond to your environment.

#

#---------------------------------------------CPATH = D:\BC5 # Location of Borland tools

CC = $(CPATH)\bin\Bcc32 # compiler

LINK = $(CPATH)\bin\TLink32 # linker

MAKE = $(CPATH)\bin\Make # make utility

#---------------------------------------------# Path to API Library and Include file

#

# Note: Modify the following path to

# correspond to your environment.

#

#---------------------------------------------APIDLL = ..\api\lib\ocapi.dll # Path to Open Controller API library

APIINC = ..\api\include # Path to Open Controller API include file

APILIB = .\ocapi.lib # Borland compatible import library

#---------------------------------------------# Options

#---------------------------------------------CFLAGS = -c -v -4 -tWM -w -I$(APIINC)

LFLAGS = -v -Tpe -d -c -ap -r

#---------------------------------------------# Final Target

#---------------------------------------------sample.exe : sample.obj $(APILIB) sampleb.mak

$(LINK) @&&|

$(LFLAGS) +

D:\BC5\LIB\c0x32.obj +

$*.obj, $*.exe, $*.map

D:\BC5\LIB\import32.lib +

D:\BC5\LIB\cw32mt.lib +

$(APILIB)

|

clean:

del *.exe

del *.obj

del *.map

del *.lib

rebuild:

$(MAKE) -f sampleb.mak clean

$(MAKE) -f sampleb.mak

.c.obj:

$(CC) $(CFLAGS) $*.c

#---------------------------------------------# Create a Borland-compatible import library

#---------------------------------------------$(APILIB): $(APIDLL)

implib $(APILIB) $(APIDLL)

sample.obj: sample.c $(APIINC)\ocapi.h sampleb.mak

Publication 1747-UM002A-US-P - June 2000

Page 32

2-10 Using the API

Notes:

Publication 1747-UM002A-US-P - June 2000

Page 33

Developing Applications

Chapter

3

Introduction

How the API Functions Are Organized

Programming Sequence

This chapter describes the proper programming sequence for your

application. This chapter also describes how to partition the dual port

memory in the 1746 I/O PCI Interface.

Each of the API functions falls into one of these four categories:

• scanner initialization

• scanner I/O configuration

• data input/output

• user interface/miscellaneous

Chapter 6 describes each API function and identifies its functionality

group.

Follow this programming sequence when you develop your

application.

1

Access the scanner

2

2

Initialize the scanner

Initialize the scanner

3

Configure the scanner

4

Control scanner

operation

5

Scan I/O

1 Publication 1747-UM002A-US-P - June 2000

Page 34

3-2 Developing Applications

Access the scanner

The host application must first call OC_OpenScanner to gain access to

the scanner. Once an application has access, no other application can

gain access to the scanner. When the application no longer requires

access to the scanner, it must call OC_CloseScanner to release access

of the scanner to other applications.

Once the scanner is opened, you must call OC_CloseScanner before

exiting the application.

Initialize the scanner

After the scanner is reset and performs its POST, the scanner waits for

initialization. In this state, the scanner can’t be configured or control I/

O. The only operational function is that which controls the LEDs. Any

call to a function that requires the scanner to be initialized returns an

error. You must initialize the scanner by sending it partitioning

information before the host application can communicate with the

scanner.

Initialize the scanner by calling the OC_InitScanner function to send

the scanner partitioning information, which defines in bytes the size of

the output image, the input image, and the host retentive data. Each

of these memory segments must be at least large enough to hold their

respective data, and must be an even number. If the input or output

partition is initialized smaller than the actual size of the input or

output image for a configuration, the OC_DownloadIOConfiguration

function returns an error. The host retentive data size is optional and

can be 0.

To determine the input image and output image sizes, use the

OC_CreateIOConfiguration function to create an I/O configuration.

OC_CreateIOConfiguration returns an I/O configuration with the

number of bytes of inputs and outputs for each module. If a

configuration already exists, you can use OC_GetIOConfig to return

the current I/O configuration. The application can then calculate the

minimum size of the segments required to hold the input and output

images. For more information, see page 3-18.

Publication 1747-UM002A-US-P - June 2000

Page 35

Developing Applications 3-3

The API has a defined constant specifying the total number of bytes

available for the three segmenters This constant is specified as:

OCSEGMENTSIZELIMIT

Once the scanner has been initialized properly it cannot be

re-initialized unless it is reset with the OC_ResetScanner function.

Once the scanner is reset, scanner communications are disabled again

until the scanner is initialized. The host application can call

OC_GetScannerStatus to determine if the scanner has been initialized.

If the scanner was previously initialized, the host application can

retrieve the initialization partition information with the

OC_GetScannerInitInfo function instead of resetting and re-initializing

the scanner.

Configure the scanner

To access I/O modules in a rack, you must define the rack sizes and

installed module types for the scanner. You can either create a specific

configuration or read the current configuration. The scanner cannot

be set to Scan mode until it has been configured (received a valid

scanner configuration).

If the scanner is in Scan mode and the host application has not

downloaded a scanner configuration, the scanner has already been

configured. To control I/O, use OC_GetIOConfiguration to retrieve

the current scanner configuration.

The application can read the current I/O configuration with the

OC_GetIOConfiguration function. If the scanner is not in Scan mode,

this function returns the current scanner configuration which can be

downloaded to the scanner using OC_DownloadIOConfiguration.

If the application requires a specific I/O configuration, the application

can define the I/O configuration structure with the rack sizes and

module types installed in each slot. The application passes this

configuration structure to OC_CreateIOConfiguration.

OC_CreateIOConfiguration returns a scanner configuration that can be

downloaded to the scanner. For more information, see chapter 5.

Once a valid scanner configuration is successfully downloaded to the

scanner via OC_DownloadIOConfiguration, the application can set the

scanner to Scan mode and control I/O.

Both OC_CreateIOConfiguration and OC_GetIOConfiguration build

the configuration data from an internal database of supported I/O

modules.

Publication 1747-UM002A-US-P - June 2000

Page 36

3-4 Developing Applications

Control scanner operation

Once the scanner has been configured, the application can control

scanner operation. The host application can:

• set the scanner to Idle or Scan mode

• control the scan time

• control I/O

• read or write module files

• clear faults

• enable/disable slots

• set I/O Idle state

• install/remove forces

• handle module interrupts and discrete input interrupts

The API uses messages to communicate with the scanner. The scan

time settings affect the time allowed by the scanner to process a

message. OC_SetScanTime adjusts the scan time of the application.

The scanner processes messages during any available time that it is

not scanning I/O. If the scan time is set too small, some API functions

might take a relatively long time to complete. If some functions seem

to be taking too long to complete, increase the scan time to provide

more time for the scanner to process messages. If the scan time is set

too large, I/O won’t update fast enough.

From the end of post until entering scan mode, the scanner holds the

I/O reset line high.

For information about estimating scan time, see PCIS Bus Card for

1746 Local I/O Installation Instructions, publication 1747-5.31.

Scan I/O

The scanner provides two basic methods for scanning I/O: timed

scans and on-demand scans. The host application can use either, or a

combination of both.

Typically, the scanner reads inputs from modules and writes outputs

to modules once every scan time. To read inputs and write outputs,

the application calls OC_ReadInputImage and OC_WriteOutputImage

independently from the scanner’s scan sequence.

Publication 1747-UM002A-US-P - June 2000

Page 37

Developing Applications 3-5

The application can change the behavior of the input and output

scans by allowing the application to have more control over I/O

scanning. The application can prevent the scanner from doing any

output scans and allow the application to read inputs and initialize

outputs before the scanner begins to write outputs. This mode allows

the application to pre-scan the inputs before the outputs are written.

The application can set the scanner to a conditional scan mode where

the scanner writes outputs at the next scan time after the application

writes data to the output image. In this mode, the scanner only writes

outputs each time the application writes data to the output image.

The application can also prevent output scans by the scanner and

have the scanner send a message after every input scan. The

application can detect an end-of-scan message and then read the

input image, perform logic, and write outputs using

OC_DemandOutputScan to force the scanner to write outputs

immediately. This lets the application synchronize its control loop

with the input and output scans.

The application can also disable both input and output scans. In this

mode, the scanner is a slave and input or output scans only take place

when requested by the host application.

Programming Example

The following DOS example (sample.c on your API disk) shows

how to program the above steps. Callouts on the right margin identify

for DOS

/************************************************************************

*

* FILE: sample.c

*

* PURPOSE:Sample application code for 1746 I/O PCI Interface API

*

* SUMMARY:This program,

* - Resets and initializes the scanner.

* - Displays the scanner firmware and hardware versions.

* - Autconfigures the I/O in chassis.

* - Reads the front panel switch position and lights LED 1.

* - Reads first discrete input module data word.

* - Writes incremental data to first output module data word.

* - Closes connection to scanner and exits.

*

* ENVIRONMENT: 1747-PCIS 1746 I/O PCI Interface

* MS-DOS

* Borland/Microsoft C/C++ Compiler (16-bit)

*

************************************************************************/

the code for each step.

Publication 1747-UM002A-US-P - June 2000

Page 38

3-6 Developing Applications

/*=======================================================================

= INCLUDE FILES =

=========================================================================*/

#include ”ocapi.h”

#include <stdio.h>

#include <dos.h>

#include <time.h>

#include <conio.h>

#include <string.h>

/*=======================================================================

= MODULE WIDE GLOBAL VARIABLES =

=========================================================================*/

HANDLE Handle; /* Software ID to scanner device */

OCIOCFG OCcfg; /* Chassis I/O config. data structure */

/*=======================================================================

= FUNCTION PROTOTYPES =

=========================================================================*/

void Ioexit( int );

/*=======================================================================

= MAIN PROGRAM =

=========================================================================*/

void main()

{

int retcode; /* Return code from API calls */

int i;

int slots;

int input_slot, input_found = 0;

int output_slot, output_found = 0;

OCINIT ocpart;

BYTE status;

OCVERSIONINFO verinfo;

BYTE swpos;

WORD wData;

/*

** Open the scanner

*/

retcode = OC_OpenScanner( &Handle, 0, 0);

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_OpenScanner failed: %d\n”, retcode );

Ioexit( 1 );

}

Access the

scanner.

Publication 1747-UM002A-US-P - June 2000

Page 39

Developing Applications 3-7

/*

** Reset the scanner

*/

printf( ”\n\n Going to reset OC, takes 6 seconds to complete...\n” );

table

retcode = OC_ResetScanner( Handle, OCWAIT );

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_ResetScanner failed: %d\n”, retcode );

Ioexit( 1 );

}

/*

** Check scanner status register

*/

retcode = OC_GetScannerStatus( Handle, &status );

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_GetScannerStatus failed: %d\n”, retcode );

Ioexit( 1 );

}

if ( status != SCANSTS_INIT)

{

printf(”\nERROR: POST failure detected: %d\n”, status);

Ioexit(1);

}

/*

** Initialize the DPR partitions

** You can use OC_CreateIOConfiguration to determine the I/O image

** sizes before paritioning the DPR

*/

ocpart.OutputImageSize = 0x800;

ocpart.InputImageSize = 0x800;

ocpart.HostRetentiveDataSize = 0;

retcode = OC_InitScanner( Handle, &ocpart );

if ( retcode != SUCCESS )

{

printf(” \nERROR: OC_InitScanner failed: %d\n”, retcode );

Ioexit( 1 );

}

/*

** Display software/hardware versions

*/

retcode = OC_GetVersionInfo( Handle, &verinfo );

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_GetVersionInfo failed: %d\n”, retcode );

Ioexit( 1 );

}

printf( ”\n\n Scanner Firmware Series: %02d Revision: %02d ”,

verinfo.ScannerFirmwareSeries, verinfo.ScannerFirmwareRevision );

printf( ”\n Hardware Series: %02d Revision: %02d”,

verinfo.OCHardwareSeries, verinfo.OCHardwareRevision );

delay( 3000 );

/*

** Read switch position

*/

retcode = OC_GetSwitchPosition( Handle, &swpos );

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_GetSwitchPosition failed: %d\n”, retcode );

Ioexit( 1 );

Initialize the

scanner

Publication 1747-UM002A-US-P - June 2000

Page 40

3-8 Developing Applications

}

printf( ”\n\n Switch position: ” );

switch( swpos )

{

case SWITCH_TOP:

case SWITCH_BOTTOM:

case SWITCH_MIDDLE:

}

delay( 3000 );

/*

** Read auto-config

*/

retcode = OC_GetIOConfiguration( Handle, &OCcfg );

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_GetIOConfiguration failed: %d\n”, retcode );

Ioexit( 1 );

}

/*

** Display rack configuration

*/

slots = OCcfg.Rack1Size + OCcfg.Rack2Size + OCcfg.Rack3Size;

if ( slots > 31 )

slots = 31;

printf( ”\n\n Chassis configuration ” );

for ( i=1; i < slots; i++ )

{

if ( OCcfg.SlotCfg[i].type != 0xff )

else

/* Find digital input card */

if ( OCcfg.SlotCfg[i].mix < 8 && !input_found )

{

}

/* Find digital output card */

if ( (OCcfg.SlotCfg[i].mix > 7) && (OCcfg.SlotCfg[i].mix < 32) && !output_found

)

{

}

}

delay( 3000 );

printf( ”Top \n” );

break;

printf( ”Bottom \n” );

break;

printf( ”Middle \n” );

break;

printf( ”\n Slot %2d: Type %2d, Mix %3d %s”,

i, OCcfg.SlotCfg[i].type, OCcfg.SlotCfg[i].mix,

OCcfg.SlotCfg[i].Name );

printf( ”\n Slot %2d: %s”, i, OCcfg.SlotCfg[i].Name );

input_found = 1;

input_slot = i;

output_found = 1;

output_slot = i;

Publication 1747-UM002A-US-P - June 2000

Page 41

/*

** Download the configuration to the scanner

*/

retcode = OC_DownloadIOConfiguration( Handle, &OCcfg );

if ( retcode != SUCCESS )

{

retcode );

}

/*

** Set output update mode to always

*/

retcode = OC_SetOutputUpdateMode( Handle, OUTUPD_ALWAYS );

if ( retcode != SUCCESS )

{

retcode );

}

/*

** Set scan time to 5ms, periodic scan mode

*/

retcode = OC_SetScanTime( Handle, SCAN_PERIODIC, 20 );

if ( retcode != SUCCESS )

{

}

/*

** Goto Scan Mode

*/

retcode = OC_SetScanMode( Handle, SCAN_RUN );

if ( retcode != SUCCESS )

{

}

/*

** Turn on User LED 1

*/

retcode = OC_SetUserLEDState( Handle, 1, LED_GREEN_SOLID );

if ( retcode != SUCCESS )

{

}

printf( ”\n\n LED1 is on solid green now. \n” );

delay( 3000 );

Developing Applications 3-9

printf( ”\nERROR: OC_DownloadIOConfiguration failed: %d\n”,

Ioexit( 1 );

printf( ”\nERROR: OC_SetOutputUpdateMode failed: %d\n”,

Ioexit( 1 );

printf( ”\nERROR: OC_SetScanTime failed: %d\n”, retcode );

Ioexit( 1 );

printf( ”\nERROR: OC_SetScanMode failed: %d\n”, retcode );

Ioexit( 1 );

printf( ”\nERROR: OC_SetUserLEDState failed: %d\n”, retcode );

Ioexit( 1 );

Configure

the

scanner.

Control scanner

operation

Publication 1747-UM002A-US-P - June 2000

Page 42

3-10 Developing Applications

/*

** Read first Input word

*/

retcode = OC_ReadInputImage( Handle, NULL, input_slot, 0, 1, &wData );

if ( retcode != SUCCESS )

{

printf( ”\nERROR: OC_ReadInputImage failed: %d\n”, retcode );

Ioexit( 1 );

}

printf( ”\n\n First input image data word --> 0x%04x \n”, wData );

delay( 3000 );

/*

** Write to the first Output word

*/

printf( ”\n\n Incrementing first discrete output word. \n” );

for ( wData=0; wData < 256; wData++)

{

retcode = OC_WriteOutputImage( Handle, NULL, output_slot, 0, 1,

&wData );

if ( retcode != SUCCESS )

{

printf(”\nERROR: OC_WriteOutputImage failed: %d\n”,

retcode);

Ioexit(1);

}

delay ( 10 );

}

/*

** Must always close the scanner before exiting

*/

OC_CloseScanner( Handle );

printf( ”\n\n Program is done! \n\n” );

} /* end main() */

/************************************************************************

*

* Name: Ioexit

*

* Description:

*

* Common error handling routine. This routine displays any

* extended error and exits the program.

*

* Arguments:

* retcode : int ( input )

* This error code is passed to the exit() routine.

*

* External effects:

* The program is terminated.

*

* Return value:

* none

*

************************************************************************/

void Ioexit( int retcode )

{

OCEXTERR exterr;

char *msg;

if (OC_GetExtendedError(Handle, &exterr) == SUCCESS)

{

if ( exterr.ErrorCode != 0 )

{

Scan I/O

Publication 1747-UM002A-US-P - June 2000

Page 43

OC_ExtendedErrorMsg(Handle, &exterr, &msg);

printf(”\nERROR: %s\n”, msg);

}

}

OC_CloseScanner(Handle);

exit(retcode);

} /* end Ioexit() */

Developing Applications 3-11

Programming Example for

The following Windows NT example (sample.c on your Windows

NT API disk) shows how to program the above steps. Callouts on the

Windows NT

/********************************************************************

* Title: Simple application sample code for 1746 I/O PCI Interface API

*

* Abstract:

*

* This file contains a simple application using the PCI

* bus interface API.

*

* Environment:

* 1747-PCIS 1746 I/O PCI Interface

* Microsoft Windows NT 4.0

* Microsoft Visual C++ / Borland C++

* (c)Copyright Allen-Bradley *

************************************************************************/

/*=======================================================================

= INCLUDE FILES =

=======================================================================*/

#include <windows.h>

#include <process.h>

#include <stdio.h>

#include <stdlib.h>

#include <time.h>

#include <conio.h>

#include <string.h>

#include "ocapi.h"

/*=======================================================================

= MODULE WIDE GLOBAL VARIABLES =

=======================================================================*/

HANDLE OChandle;

OCIOCFG OCcfg;

/************************************************************************

* Entry point:

* Ioexit

*

* Description:

* Common error handling routine. This routine displays any

* extended error and exits the program.

*

* Arguments:

* rc : int ( input )

* This error code is passed to the exit() routine.

right margin identify the code for each step.

Publication 1747-UM002A-US-P - June 2000

Page 44

3-12 Developing Applications

*

* External effects:

* The program is terminated.

*

* Return value:

* none

*

* Access: Public

* ----------------------------------------------------------------------* Notes:

*

*************************************************************************/

void Ioexit

int rc

) {

OCEXTERR exterr;

char *msg;

if (OC_GetExtendedError(OChandle, &exterr) == SUCCESS)

{

if ( exterr.ErrorCode != 0 )

{

OC_ExtendedErrorMsg(OChandle, &exterr, &msg);

printf("\n\nERROR: %d %s\n", msg, exterr.ErrorCode);

}

}

OC_CloseScanner(OChandle);

exit(rc);

} /* end Ioexit() */

/*************************************************************************

* Entry point:

* tErrorEvent

*

* Description:

* Thread to handle errors.

*

* Arguments:

* none

*

* External effects:

* none

*

* Return value:

* none

*

* Access: Public

*

*----------------------------------------------------------------------* Notes:

*

************************************************************************/

void tErrorEvent( void *dummy )

{

while(1)

{

/* Sleep until the scanner reports an error */

OC_WaitForExtError(OChandle, INFINITE);

/* An error has occurred. Perform whatever error handling */

/* that is necessary. In this case, we just print a message */

/* and exit the process. */

Ioexit(1);

}

} /* end tErrorEvent() */

Publication 1747-UM002A-US-P - June 2000

Page 45

Developing Applications 3-13

/************************************************************************ *

* Entry point:

* main

*

* Description:

* Entry point of the PCI I/O bus interface API sample application.

*

* This program resets, initializes, and autoconfigures the scanner.

* It displays the scanner firmware and hardware versions, and

* the front panel switch position.

* It lights User LED 1, reads inputs from a 32 pt discrete

* input module, and writes data to the M0 file on a BAS module.

*

* Arguments:

* none

*

* External effects:

* none

*

* Return value:

* 0 if no errors were encountered

* 1 if errors

*

* Access: Public

*

*----------------------------------------------------------------------* Notes:

*

************************************************************************/

main()

{

int rc;

int i;

int slots;

int BASslot;

int IB32slot;

int fRecreateIOcfg;

OCINIT ocpart;

BYTE status;

OCVERSIONINFO verinfo;

BYTE swpos;

WORD wData,wLen;

BYTE temp;

BASslot = IB32slot = 0;

fRecreateIOcfg = 0;

/* Open the scanner */

if (SUCCESS != (rc = OC_OpenScanner(&OChandle)))

{

Access the

scanner.

printf("\nERROR: OC_OpenScanner failed: %d\n", rc);

Ioexit(1);

}

/* Create an error-handling thread */

if (-1 == (long) _beginthread(tErrorEvent, 0, NULL))

printf("\nERROR: _beginthread tErrorEvent failed.\n");

Publication 1747-UM002A-US-P - June 2000

Page 46

3-14 Developing Applications

/* Reset the scanner */

printf("\nResetting the scanner...");

if (SUCCESS != (rc = OC_ResetScanner(OChandle, OCWAIT)))

{

printf("\nERROR: OC_ResetScanner failed: %d\n", rc);

Ioexit(1);

}

/* Check scanner status register */

if (SUCCESS != (rc = OC_GetScannerStatus(OChandle, &status)))

{

printf("\nERROR: OC_GetScannerStatus failed: %d\n", rc);

Ioexit(1);

}

if ( status != SCANSTS_INIT)

{

printf("\nERROR: POST failure detected: %d\n", status);

Ioexit(1);

}

/* Initialize the DPR partitions */

ocpart.OutputImageSize = 0x800;

ocpart.InputImageSize = 0x800;

ocpart.HostRetentiveDataSize = 0;

if (SUCCESS != (rc = OC_InitScanner(OChandle, &ocpart)))

{

printf("\nERROR: OC_InitScanner failed: %d\n", rc);

Ioexit(1);

}

/* Display software/hardware versions */

if (SUCCESS != (rc = OC_GetVersionInfo(OChandle, &verinfo)))

{