Page 1

Allen-Bradley

SLC500 ControlNet

RS-232 Interface

User

(Cat. No. 1747-KFC15)

Manual

Page 2

Important User Information

Because of t he vari ety of us es for the pro duc ts de scribed in t his p ubli cati on, tho se

responsible for the application and use of this control equipment must satisfy

themselves that all necessary steps have been taken to assure that each application

and use meets all performance and safety requirements, includi ng any applicable

laws, regulations , codes and standards.

The illustrat ions, charts, sample program s and layout examples shown in this guide

are intende d sol ely for purposes of example. Since there are many variables and

requirements as sociated with any partic ular installation, Allen-Brad ley does not

assume responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradle y publication SGI-1. 1, Safety Guidelines for the Applicati on,

Installation, and Maintenance of Solid State Control (available from your local

Allen-Bradle y office), describes some important differences betwee n solid-state

equipment and ele ctrom echan ical devices that shoul d be ta ken into co nside rat ion

when applying products such as those des cribed in this publication.

Due to the r apid change in techno logy and par t availabi lity , Allen-Bra dley reser ves

the right to cha nge the a ppeara nce of c er tain pr oduc ts whic h may not ma tch th ose

shown in this manual.

Reproduction of the conten ts of this copyrighted publication, in whole or in part,

without written permission of Allen-Bradley Company, Inc., is prohibited.

Throughout thi s manual we use notes to make yo u aware o f s afety cons id erati ons:

ATTENTION: Identifies information about practice s or

circumstances that can lead to personal injury or death, property

!

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful application and

understanding of the product.

damage or economic loss.

Page 3

Preface

The 1747-KFC15 allows an SLC500 modular process or to

communicate with the ControlNet™ network via the processor’s

RS-232 serial port.

Purpose of the Manual

Throughout this manua l we refe r to the 1747-KFC15 Communic ation

Interface as the KFC15 module. Use this manual to:

• install and configure the KFC15 module

• understand how the KFC15 module communicates on the

network (procedure s and protocols)

• troub le shoot for problems

1747-5.34 - June 1998

Page 4

P-2

Related Publications

The following publicat ions co ntain information related to the KFC15

module:

Publication Publication Number

Allen-Bradley ControlNet Cable System

Planning and Installation Manual

Allen-Bradley ControlNet Cable System

Component List

Allen-Bradley Industrial Automation Wiring

and Grounding Guidelines

SLC 5/03 and 5/04 Modular Processors

Installation Instructions

1786-6.21

AG-2.2

1770-4.1

1747-5.27

Related Products

The KFC15 module creates an interface between the ControlNet network

and an SLC500 processor. It has been veri fied to work with t he following

products:

• Allen-Bradley ControlNet taps (1786-TPR, 1786-TPS, 1786-TPYR

and 1786-TPYS)

• Allen-B radle y high voltage ac and dc type repeaters (1786-RPT and

1786-RPTD)

• Allen-B radle y PLC-5

®

processors (1785-L20C15, -L40C15,

-L60C15, and -L80C15)

• Allen-B radle y computer interface cards (1784- KTC15 and

1784-KTCX15)

• Allen-B radle y 1794 FLEX I/O Adapters (1794-ACN15 and

1794-ACRN15)

• Allen-B radle y 1771 I/O Adapters (1771-ACN15 and 1771-ACNR15)

1747-5.34 - June 1998

Page 5

P-3

• Rockwell Software’s RSLogix500™, and RSLinx™

• Network Acce ss cable (1786-CP)

Other ContolNet devices and softwar e that comply with the ControlNet

Network specifications can also be used with the KFC15 module.

Glossary of Terms and Abbreviations

This manual may use the following terms as defined below:

ControlNet

The communication archite ct ure that allows the exchange of messages

between devices t hat follow the ControlNet spe cifications. ControlNet is

a real-time, control-layer network that provides high-spee d transport for

both time-critic al I/O and message data. A ControlNet network can be

either single or redunda nt media.

DF1

Allen-Bradley’s RS-232 proprietary protocol.

Full Duplex

The ability to simultaneously send/receive data between devices,

point-to-point.

Half Duplex

The data transmission in one dir ection at a time, usually

point-to-multipoint.

1747-5.34 - June 1998

Page 6

P-4

NAP (Network Access Port)

An input/output (RJ-45 style) connector for a programming terminal to

gain full access to the network.

Network

A collection of connected nodes (end devices). The connection paths

between any pair of nodes can include repeate rs, routers, bridges, and

gateways.

Network Addr e ss

The network address of a node on the ControlNet network. This addre ss

must be in the range of 1 to 99 (decimal) and be unique to that subnet. A

subnet can contain a maximum of 99 nodes.

Node

Any physical device connect ing to the Control Net network tha t requires a

network address in order to funct ion on the network.

NUT (Network Update Time)

The rate at which access to the network is granted.

PCCC (Programmable Controller Communications

Commands)

An application-leve l command set that Allen-Bradley programmable

controllers use to communicate across networks.

Repeater

A two-port active physical la yer component that reconstructs all traffic it

hears on one network segment side and retransmits it to another network

segment side. Repeaters allow for extensions in network distance,

conversion to altern ate media (coaxial cable, fiber, etc.) and altering the

topology of the network.

1747-5.34 - June 1998

Page 7

RS-232C Port

A serial port that complies with accepte d industry standards for seria l

communications connections.

Segment

Trunkline sections connected via taps with term inators at each end, and

with no repeat ers.

Serial Port

Input/output connec tor for a device that transmits data and controls bits

sequentially over a sin gle transmission line. (See RS-232C port.)

Subnet

Network segments connected by repe at s to make up on ControlNet

network.

P-5

Tap

The connection device betwee n any devic e and the trunkline. A tap is

required for each node and for both sides of each repeater.

Terminator

A special c ircuit that pre vents signal reflections form occurring at the e nd

of the cable.

Trunkline

The bus or central part of a cable system

Trunkline Section

A length of trunkline cable between any two taps.

1747-5.34 - June 1998

Page 8

P-6

1747-5.34 - June 1998

Page 9

Table of Contents

Chapter 1 Introducing the 1747-KFC15 Module

Overview of the 1747-KFC15 Module .................................... 1-1

Compatibility .........................................................................1-5

European Union Directive Compliance ................................... 1-6

CSA Hazardous Location Approval ......................................... 1-7

Approbation d’utilisation dans des emplacements

dangereux par la CSA ...........................................................1-8

Chapter 2 Configuring the KFC15 Module

Overview of Configuration Procedures ................................... 2-1

DIP Switches ........................................................................2-2

Configuring the KFC15 Module Using Rotary Switches ..........2-5

Chapter 3 Installing the KFC15 Module

Electrostatic Damage ............................................................ 3-2

Overview of the Installation Procedure .................................. 3-2

Connecting a Device to the Network Access Port ..................3-3

Connecting to the ControlNet Cable System ..........................3-4

Chapter 4 Communicating with the KFC15 Module

RSLinx and RSLogix500 ........................................................ 4-1

Setting the Correct Options ...................................................4-2

Verifying the KFC and SLC Processor Communication

Parameters ...........................................................................4-3

Related Publications .............................................................4-4

Chapter 5 Troubleshooting the KFC15 Module

Interpreting the Status LEDs .................................................5-1

Interpreting the Dot Matrix Displays ...................................... 5-3

Page 10

toc-ii

Appendix A Product Specifications

RS–232C Interface ................................................................A-1

ControlNet Interface ..............................................................A-2

Network Access Port (NAP) Interface .....................................A-2

Physical ................................................................................A-2

Environmental .......................................................................A-2

Agency Safety Certification ....................................................A-3

Appendix B Cabling and Pinouts

Cabling and Pinouts for RS–232C Connection ........................B-1

Appendix C DF1 Diagnostic Command Support

Diagnostic Loop ....................................................................C-2

Diagnostic Read Counters .....................................................C-2

Diagnostic Status ..................................................................C-3

Diagnostic Counter Reset ......................................................C-4

1747-5.34 - June 1998

Page 11

Chapter

1

Introducing the 1747-KFC15 Module

Overview of the 1747-KFC15 Module

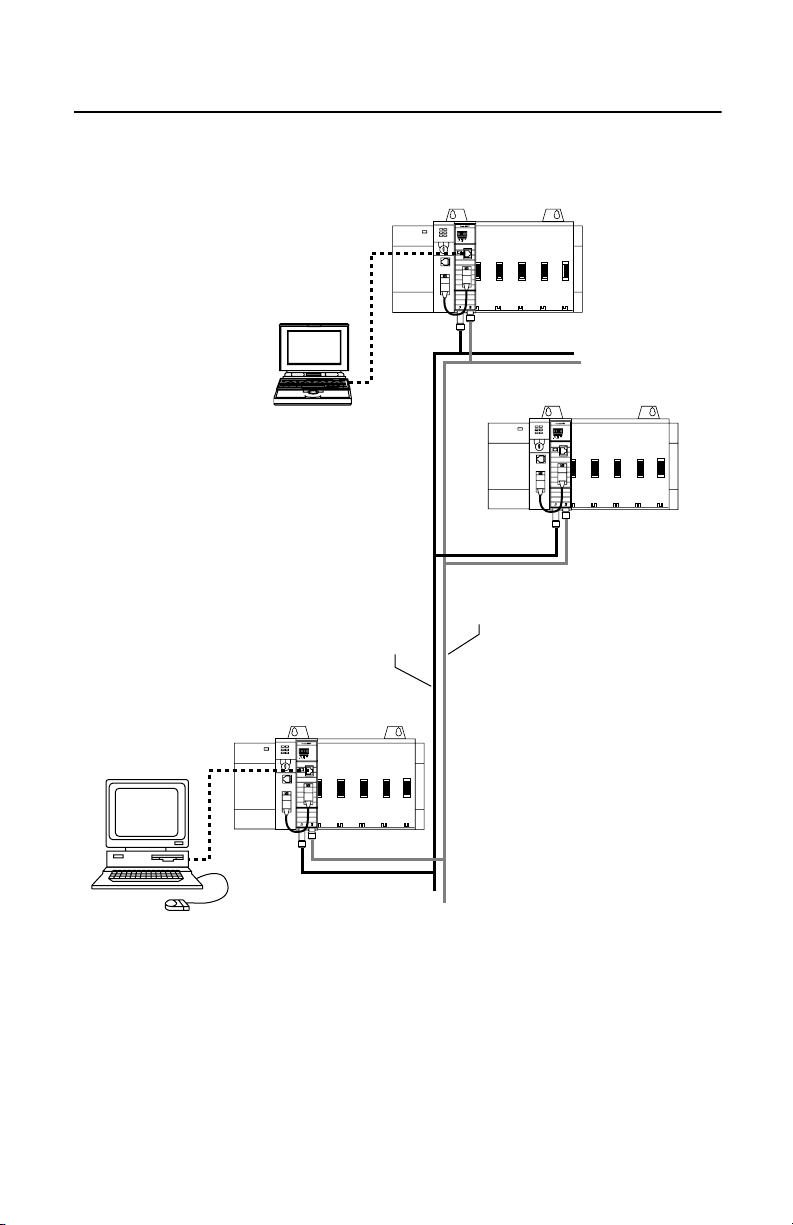

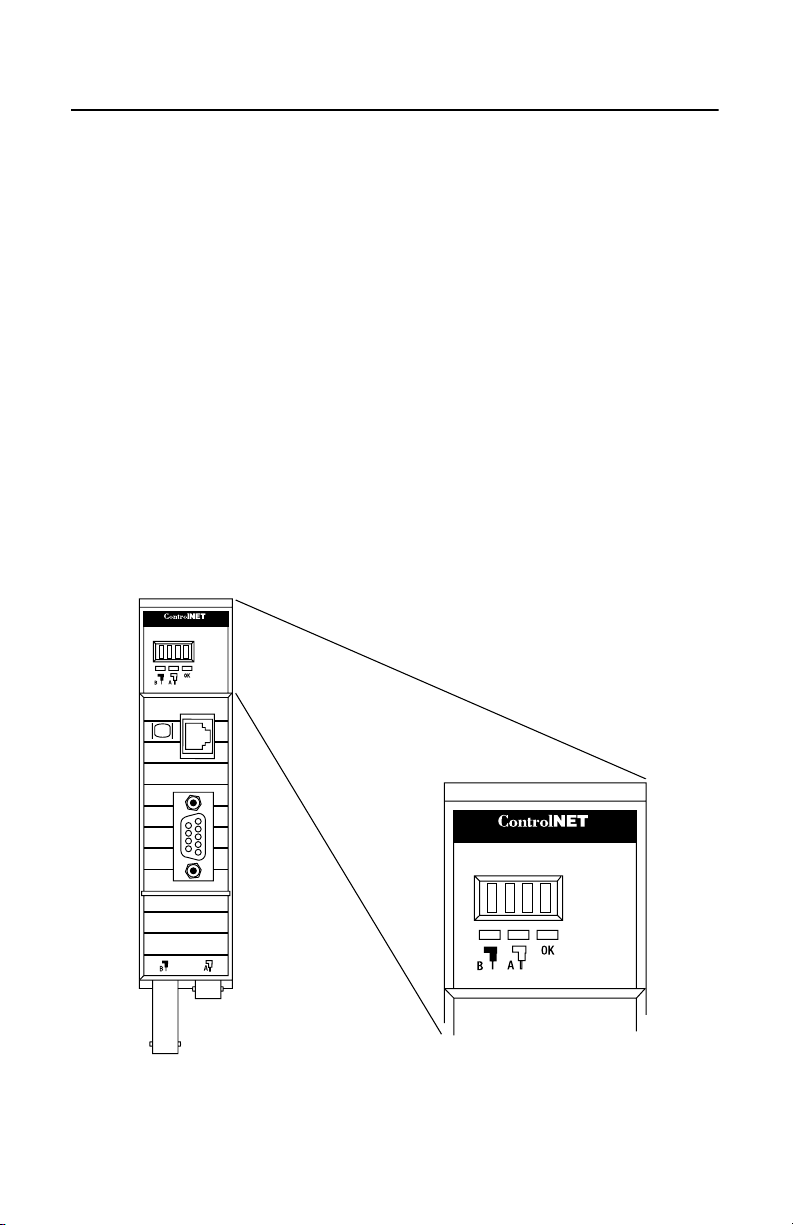

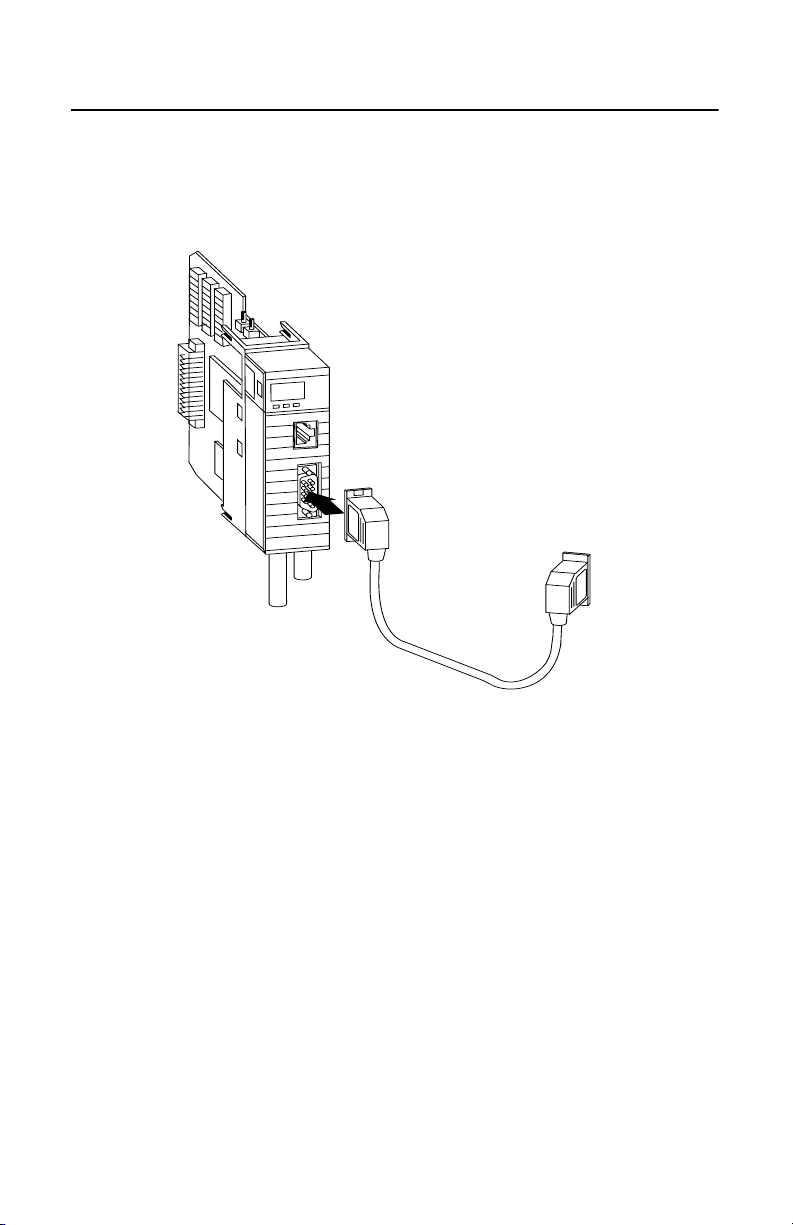

The KFC15 module enables you to communicate with your SLC500

processor using a ControlNe t network. You can examine the

processor’s ladder program, monitor program operation, and make

program changes. The KFC15 module acts as a bridge between a

ControlNet network and your SLC500 processor’s RS-232C serial

port.

SLC500 Processor

30667-M

1747-5.34 - June 1998

Page 12

1-2 Introducing the 1747-KFC15 Module

RS-232C

Laptop PC

ControlNet

Network B

ControlNet

Network A

Desktop PC

30668-M

The KFC15 module connects to the ControlNet network from one

(channel A) or both o f it s two BNC connectors via a standar d, one-meter,

ControlNet coaxial tap. For redundant media, both connectors are used.

1747-5.34 - June 1998

Page 13

Introducing the 1747-KFC15 Module 1-3

RS-232C

The KFC15 module has two ports for device connections:

RS-232C serial por t—provides half- or full -duplex communication wi th

a serial port on your SLC500 processor.

network access port—lets you connect a ControlNet programming

terminal or other device to the KFC15 module for full network access

without disrupting the cable wiring

The serial port uses DF1 protocol while the network access port handles

ControlNet packets directly .

Status LEDs and the dot matr ix disp lay on the fr ont of the KFC15 indica te

current operating co nditions of the unit and communication activities

taking place through the ports.

RS-232C

Display on the

1747-KFC15

module

30662-M

30665-M

1747-5.34 - June 1998

Page 14

1-4 Introducing the 1747-KFC15 Module

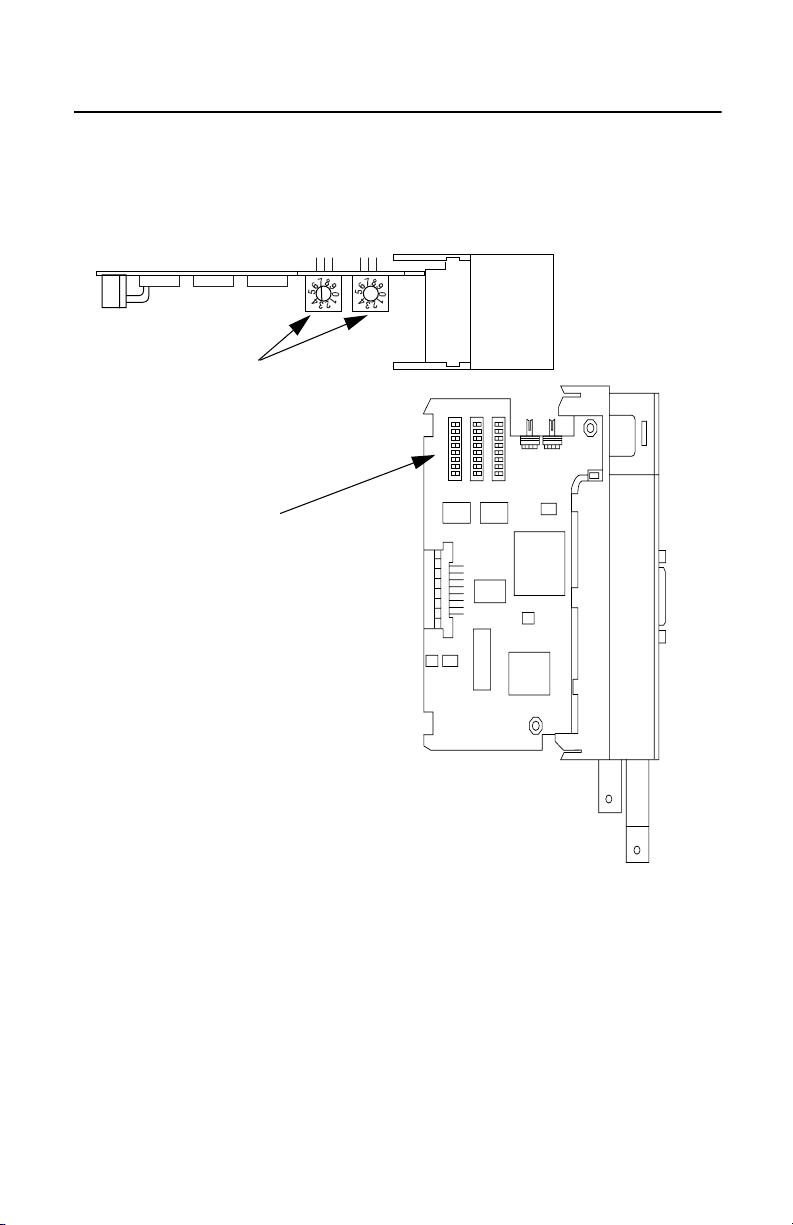

Top View of Module

Rotary Switches

3 Banks of

DIP Switches

30663-M

30666-M

You use the three banks of DIP switches to configure the RS-232C serial

communication parameter s. Two rotary switches are available to set the

ControlNet network ad dress. To verify your settings, you can use the dot

matrix displa y located on the front of the module. Refer to Chapter 2 and

Chapter 4 for more information.

1747-5.34 - June 1998

Page 15

Introducing the 1747-KFC15 Module 1-5

Compatibility

The KFC15 is compatible with the following interfaces:

• RS-232C serial ports that comply with DF1 protocol

• ControlNet devices that comply with the ControlNet specification

• Progr amming ter minal products that comply with ControlNet

specifications for the Network Access Port

Contents of Your Order

Make sure that you have these items before you discar d any packing

material. If an item is missing or incorrect, contact your local

Allen-Bradley office.

• 1747-KFC15 module

• RS-232 cabl e

• SLC500 ControlNet RS-232 Interface User Manual

(pub. no. 1747-5.34)

1747-5.34 - June 1998

Page 16

1-6 Introducing the 1747-KFC15 Module

European Union Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed a nd tested to

meet the following direct ives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compat ibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2 EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requir eme nts of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publica tion, as well as the Allen-Bradley Industr ial

Automation W iring and Grounding Guidelines For Noise Immunit y,

publication 1770-4.1.

This equipment is classif ied as open equipment and must be mounted in

an enclosure during operation to provide safety protection .

1747-5.34 - June 1998

Page 17

Introducing the 1747-KFC15 Module 1-7

CL I, DIV 2

GP A,B,C,D

TEMP

CSA Hazardous Location Approval

CSA certifies products fo r general use as well a s for use in hazardous locations. Actual CSA

certification is indicated by the product label as shown below, and not by statements in any user

documentation.

Example of the CSA certification produc t label :

To comply with CSA certification for use in hazardous lo cati ons, the

following information becomes a part of the product literature for this

CSA-certi fied industrial contro l product.

• This equipment is suitable for use in Class I, Divisio n 2, Groups A, B, C, D, or non-hazardous

locations only.

• The produ cts having the appropriate CSA markings (that is, Class I , Division 2, Groups A, B, C,

D) are certified for use in other equipment where the suitability of combination (that is, application

or use) is determined by the CSA or the local inspection office having jurisdiction.

Important: Due to the modular nature of a pro gr a mmable control s ys tem, the product with the

Temperature code rating:

highest te mperature rati ng determines the overall temper ature code rati ng of a

programmabl e con trol sy stem i n a C lass I, Divi sion 2, l ocatio n. The temperat ure co de

rating is mar ked on the product label as shown.

CL I, DIV 2

GP A,B,C,D

TEMP

Look for temperature

code rating here.

The followi ng warnings app ly to products ha ving CSA certification for use in hazar dous locations.

WARNING: Explosion hazard--

• Substitution of components may impair suitability for Class I, Division 2.

• Do not re place co m ponents unless po w er ha s be e n s w it c h ed off or the are a is know n to be non-

hazardous.

• Do not disconnect equipment unless po w e r has been switched off or the area is known t o be non-

hazardous.

• Do not d isconnect connectors unl es s power has been switched off or the area is known to be non-

hazardous. Secure any user-suppli ed connectors that mate to external circuits on this equipment

by using scre ws, sli ding latches , thread ed connec tors, or oth er means suc h that any co nnectio n can

withstand a 15 Newton (3.4 lb.) separating force applied for a minimum of one minute.

• Batteries m ust only be changed in an area known to be non-hazardou s .

CSA logo is a registered trademark of the Canadian Standards Association.

1747-5.34 - June 1998

Page 18

1-8 Introducing the 1747-KFC15 Module

C

Approbation d’utilisation dans des emplacements dangereux par la CSA

La CSA certifie les produits d'utilisation générale aussi bien que ceux qui s'utilisent dans des

emplacement s dangereux . La cer tificati on CSA en vi gueur est indiquée p ar l'ét iquette du produ it et non

par des affirmations dans la documentation à l'usage des utilisateurs.

Exemple d'étiquette de certif ica tion d'un produit par la CSA:

Pour satisfaire à la certification de la CSA dans des endroits

dangereux, les informations suivantes font partie intégrante de la

documentation ce produit industriel de contrôle certi fié par la CSA.

L I, DIV 2

GP A,B,C,D

TEMP

• Cet équipement convient à l'utilisation dans des emplacements de Classe 1, Division 2, Groupes

A, B, C, D, ou ne convient qu'à l' utilisation dans des endroits non dangereux.

• Les produi ts por tant le marqu age app ropri é de la CSA (c'est à dir e, Clas se 1, Divisi on 2, Gro upe s

A, B, C, D) sont cert ifies a l'utili sation pour d'aut res équipement s où la convenance de comb inaison

(application ou utilisation) est déterminée par la CSA ou le bureau local d'inspection qualifié.

Important: Par suite de la nature modulaire du système de contrôle programmable, le produit

Taux du code de température:

Les avertissements suivants s’appliquent aux produits ayant la certification CSA pour leur utilisation

dans des emplacements dange reux.

AVERTISSEMENT: R isque d’explosion --

ayant le taux le plus élevé de temperature déterm ine le taux d'ense mble du code de

températur e du s ys tème de contrôle d' un programmable dans un emplacement de

Classe 1, Division 2. Le taux du code de température est indiqué sur l'étiquett e du

produit.

CL I, DIV 2

GP A,B,C,D

TEMP

Le taux du code de

température est indiqué ici.

• La substitution de composants peut rendre ce matériel inacceptable pour lesemplacements de

Classe I,

Division 2.

• Couper le courant ou s'assurer quel'emplacem ent est désigné non dangereux avant de remplacer

lescomposants.

• Avant de débrancher l'équipement, couper le courant ou s'assurer que l'emplacement est dési gné

non dangereux.

• A vant de d ébrancher les con necteu rs, coup er le c ourant ou s'assur er que l'emplaceme nt est r econn u

non dang ereux . Att acher tou s co nne cteur s fo urni s p ar l' uti lisat eur et rel iés a ux ci rcui ts ext ern es d e

cet appareil à l 'aide de vis, lo quets coulissants, connecteurs filetés ou autres moyens per m ettant

aux connexions de résister à une force de séparation de 15 Newtons ( 3,4 lb. - 1,5 kg) ap pliquée

pendant au moins une minute.

• Afin d'éviter tout risq ue d'expl osion, s'as surer que l'emplace ment est dési gné non danger eux avant

de cha n ge r la ba t t erie.

Le sigle CSA est la marque déposée de l'Ass oc iation des Standards pour le Canada .

1747-5.34 - June 1998

Page 19

Chapter

2

Configuring the KFC15 Module

Use this chapter to configur e the KFC15 communica tion parameters

via the DIP switches and rotary switches on the module.

Overview of Configuration Procedures

The KFC15 module is configured by using the DIP and rotary

switches located on the module. These two types of switches

configure the RS-232 seri al communic ation parameters, and the

network address. During configuration, the module must not be

powered. Once the switches are set, the module can then be i nstalled

in the SLC chassis. Located on the front of the KFC module is a dot

matrix display, which you can use to verify your settings. Refer to

Chapter 5 for more information on the dot matrix display.

Refer to Chapter 4 for information on configuring the communicat ion

between the SLC500 and the KFC15 modules.

1747-5.34 - June 1998

Page 20

2-2 Configuring the KFC15 Module

DIP Switches

ON

1 2 3 4 5 6 7 8

The white area

indicates the position

of the switch specified

as on.

S2

S1

S3

30663-M

Located within the body of the 1747-KFC15 module are three banks (S1,

S2, and S3) of eight DIP switches. These switches are used to conf igure

the RS-232 serial communicat ion por t.

Important: The communicat ion paramet ers betwee n the SLC500 a nd the

KFC15 must be identical. Refer to Chapter 4 for more information.

Use a ball-poi nt pen to set a ny of the s witc hes withi n the th ree ba nks to on

or off.

Important: Do not use a pencil because the tip can bre ak off and short the

switch.

1747-5.34 - June 1998

Page 21

Configuring the KFC15 Module 2-3

Documented in the tables below are the DIP switches, the bank in which

they are located, and the paramete rs controlled by each switch.

Table 2-1: Bank S1 DIP Switches

DIP Switch Parameter Description

Upper digit of

Switches 1-3

Switches 4-6

Switches 7-8 Leave off

the DF1 station

addre ss

Lower digit of

DF1 station

address

SW 1/4

on

off

on

off

on

off

on

off

Table 2-2: Bank S2 DIP Switches

DIP Switch Parameters Description

Switch 1

off

off

Switches 1-3

Switch 4

Switch 5 Parity

Switch 6

Switch 7 Handshake

Switch 8

Serial Port

Baud Rate

Full/Half

duplex

Odd/Even

parity (when

used with

Switch 5)

Diagnostic

Command

Execution

off

off

on

on

on

on

off = Full duplex (default)

on = Half duplex

off = No parity (default)

on = See switch 6

off = Odd parity

on = Even parity

off = No handshake (default)

on = Hardware handshake enable

off = Disabled (default)

on = Enabled

SW 2/5

on

on

off

off

on

on

off

off

Switch 2

off

off

on

on

off

off

on

on

SW 3/6

on

on

on

on

off

off

off

off

Switch 3

off

on

off

on

off

on

off

on

Digit

0

1

2

3

4

5

6

7 (default)

Baud Rate

1200 (default)

2400

4800

9600

19200

38400

57600

Reserved

1747-5.34 - June 1998

Page 22

2-4 Configuring the KFC15 Module

Table 2-3: Bank S3 DIP Switches

DIP

Switch

Switch 1

Switch 2 Error detect

Switch

3-4

Switch

5-8

Parameter Description

Duplicate

detect

off = Duplicate detect off (default)

on = Duplicate detect on

off = CRC error check (default)

on = BCC error check

Number of

allowable

Number of

retries

retries per

attempt on the

RS-232C link:

00 - 07

The time to wait

DF1 ACK

time-out

for an ACK from

the host

computer.

SW3

on

off

on

off

SW5

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

SW4

on

on

off

off

SW6

on

on

off

off

on

on

off

off

on

on

off

off

on

on

off

off

Number of retries

3 (default)

SW7

SW8

on

on

on

on

on

on

on

on

off

on

off

on

off

on

off

on

on

off

on

off

on

off

on

off

off

off

off

off

off

off

off

off

0

1

2

Time

Out

.2

.4

.6

.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2 (default)

1747-5.34 - June 1998

Page 23

Configuring the KFC15 Module 2-5

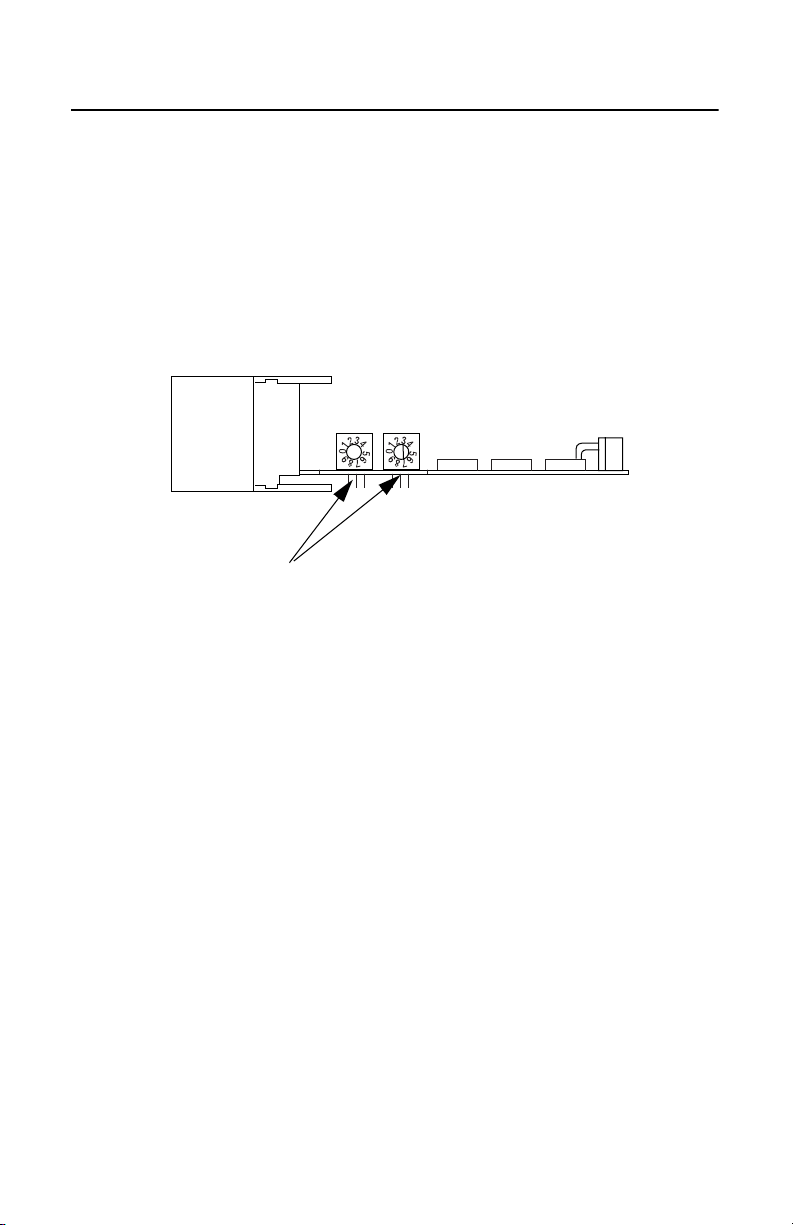

Configuring the KFC15 Module Using Rotary Switches

The KFC15’ s Control Net networ k addres s is set by the rotar y switches S4

and S5. Switch S5 sets the upper digit of the address and S4 the lower.

These switches ca n be turne d manually by hand while hol ding the module

in the orientation il lustrated below.

S5 S4

Rotary Switches S5

and S4 respectively

1747-5.34 - June 1998

Page 24

2-6 Configuring the KFC15 Module

1747-5.34 - June 1998

Page 25

Chapter

3

Installing the KFC15 Module

Use this chapter to instal l the KFC15 module. This chapter describes:

• an overvi ew of the genera l installation procedure

• how to connect the KFC15 module to your SLC500 proce ssor

through the RS-232C serial port

• how to connect the KFC15 module to a host throug h the isol ated

network access port (NAP)

• how to connect the KFC15 module to the ControlNe t network

Pinout and wiring details are provided in Appendix B, Cabling and

Pinouts. Read this if you need to construc t cables. If a tap is not

available on the ControlNe t net work for the KFC15 module, refer to

the ControlNet Cable System Planning and Installation Manual

(pub. no. 1786-6.2.1) to det ermine if your cable system can

accommodate another node and to plan where to mount the tap, then

follow the mounting instr uctions at the end of this chapter.

If you have attempted to install the KFC15 module and still have

questions, please call Rockwell Automation Technical Support at

(440) 646-6800.

1784-5.34 - June 1998

Page 26

3-2 Installing the KFC15 Module

Electrostatic Damage

ATTENTION: Electrostati c discharge can damage

semiconductor devices inside the KFC15 module. To

!

guard against electr ostatic damage wear an approved

wrist strap gr ounding devi ce, or to uch a grounded obj ect

to rid yourself of electrostatic cha rge before handli ng the

products.

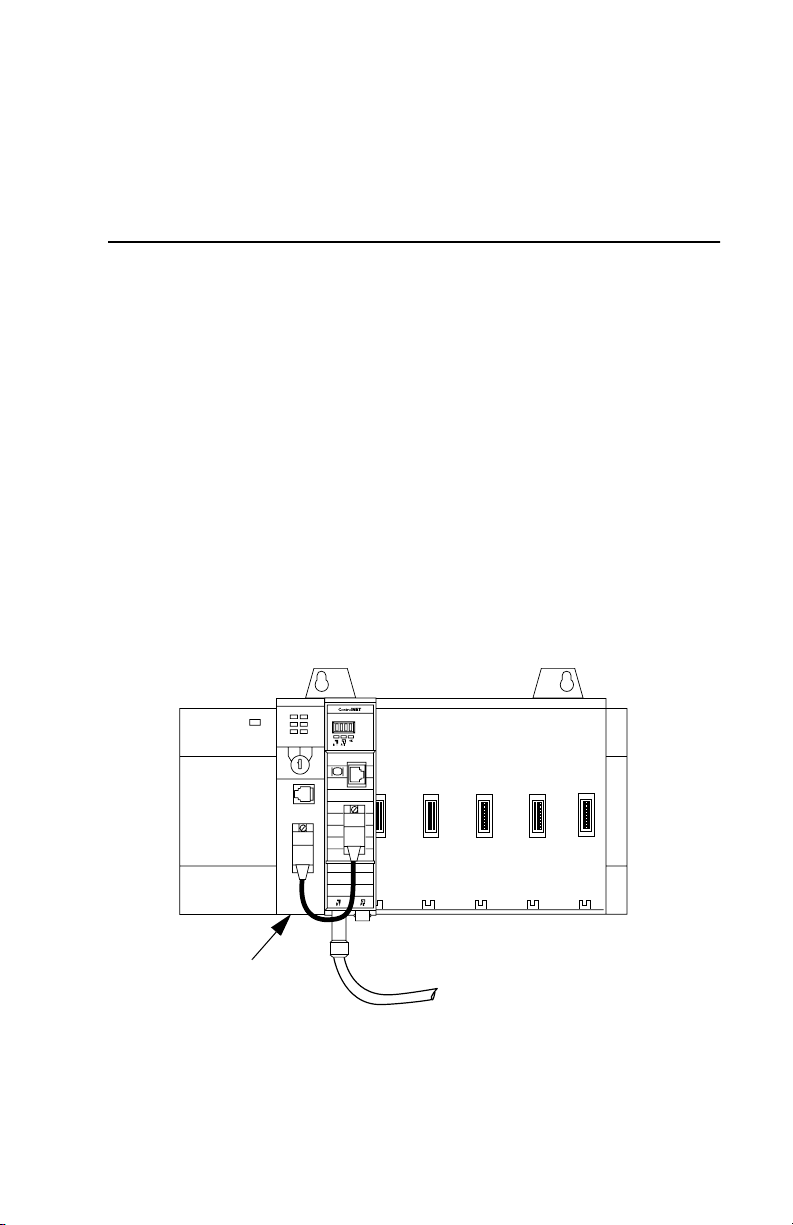

Overview of the Installation Procedure

1. Configure t he communications parameters by setting the rotary and DIP

switches on the KFC15 a s detailed in Chapter 2, Configurin g the KFC15

Module. Remember tha t the R S-232 seria l communi catio n parameter s

must be the same b etween the KFC15 and the SLC500. Refer to Chapter

4 for more information.

2. Make sure that the ControlNet cabl e syst em can accommodate

additional nodes (one per KFC15 module bei ng insta lled).

3. Remove power from your SLC500 chassis.

4. Install the KFC15 module into an empty I/O slot. The 1747-KFC15

module must be placed near the SLC processor. In a large chassis, any

empty slot will not work.

5. Connect the KFC15 to the ControlNet network using taps.

1747-5.34 - June 1998

Page 27

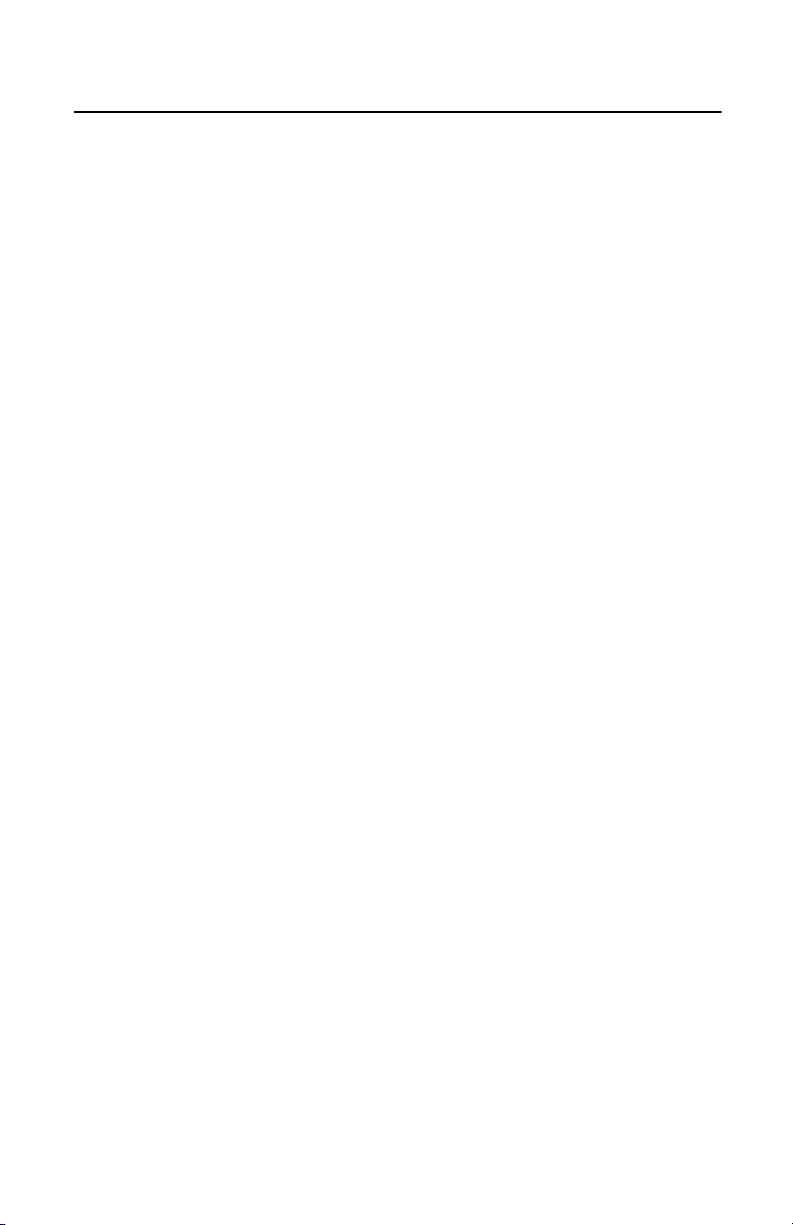

Installing the KFC15 Module 3-3

30664-M

RS-232 cable

6. Connect the KFC15 module to your SLC500 processor with the supplied

RS-232 cable.

7. Apply power to your SLC500 chassis.

Connecting a Device to the Network Access Port

Use the isolated network access port to connect a transitory device, such

as a programming device, to the KFC15 module.

Cables

You must use the Allen-Bradley Network Access cable

(cat. no. 1786-CP).

1784-5.34 - June 1998

Page 28

3-4 Installing the KFC15 Module

Connecting to the ControlNet Cable System

T o connect the KFC15 to the ControlNet cable system use an approved

ControlNet tap. Refer to the ControlNet Cable Syste m Planning and

Installation Manual (pub. no. 1786-6.2.1) for complete instructions on

connecting the tap to the cable syste m.

ATTENTION: If the KF C15 module is conne cted to a

cable system tha t does not s upport re dundant media, t he

!

tap dropline should be connecte d to the BNC connector

labeled channel A. The channel B connector should be

unused. If the cable system is redund ant, the KFC15

module should be c onnecte d su ch that a ll devices on the

network use the same cable for the same channel. The

channel A connector on all produc ts should be connected

to the same cable. The same applies for the channel B

connectors.

T o connect the KFC15 module to the tap do the following:

1. If the KFC15 module is not the last device in the segment:

• Connect the tap to the coaxial trunkli ne .

• Connect the dropline BNC to the channel A BNC of the KFC15

module.

2. If the KFC15 module is t he last device in the segment, ins tall a terminator

at the end of the cable segment, then follo w the instructions in step 1.

3. If using redundant media, repeat e ither step 1 or step 2 for channel B of

the KFC15 module.

1747-5.34 - June 1998

Page 29

Chapter

4

Communicating with the KFC15 Module

This chapter explains how to use your 1747-KFC15 module to

communicate with your SLC500 processor.

RSLinx and RSLogix500

To use your KFC15 module to communicate with your SLC500

processor, you must have RSLinx and RSLogix500 installed on your

personal computer, along with an add-on module or communica tion

card to communication between your PC and the ControlNet networ k.

Examples of add-on modules for this type of configuration are the

1784-KTCX15, 1770-KFC15, and the 1784-PCC.

1747-5.34 - June 1998

Page 30

4-2 Communicating with the KFC15 Module

Setting the Correct Options

T o communicate with your SLC500 processor, using RSLogix500,

perform the following:

1. Start RSLogix500 and choose Comms from the menu.

2. Select System Comms from the pop-up menu. A dialog box is

displayed.

1747-5.34 - June 1998

Page 31

Communicating with the KFC15 Module 4-3

3. Select the System Communications tab.

4. From the Driver field, choose the appropriate driver for the add-on

module you are using from the drop-down list that was used to co nfigure

RSLinx for communications on the ControlNet network.

5. Within the Processor Node field, enter the 1747-KFC15 ControlNet

network address displa ying on the KFC15 module. If you are unsure,

remember the network address is se t by the rota ry switches on the

KFC15 mo dule. Refer t o Cha p te r 2 for more i n form at ion .

At this point you should be able to go on-line with your SLC500

processor.

Verifying the KFC and SLC Processor Communication Parameters

Both the SLC500 and the 1747-KFC15 RS-232 serial communication

parameters need to be identical for proper communication. The default

DIP switch settings for the KFC15 are the same defaul t settings used for

the SLC500. Only if you have changed the SLC500 se ttings do you need

to modify the settings for the KFC15. Below are the steps, perfor me d in

RSLinx, to verify the parameter s between the two modules.

Determine the Serial Parameters for the SLC Processor

1. Connect a serial cable from one of the communicat ion ports on your

computer to the SLC500 processor’s serial port.

2. Start RSLinx .

3. From the menu bar choose Communications, then Configure Drivers.

4. When the dialog box appears, choose RS232 DF1 Devices from the

Available Drivers list. Click on the Add New pushbutton.

5. When the di alog box appears , select SLC-CH0/Micr o/Panelview fr om

the Device Type list.

1747-5.34 - June 1998

Page 32

4-4 Communicating with the KFC15 Module

6. Select the Auto-Configure pushbutton to obtain the serial parameters.

Once you have confirmed the communication se ttings for the SLC500,

you can use the dot matrix display on the KFC15 to verify the settings are

the same. Refer to Chapter 5 for infor mation on interpreting the display.

If you are unsure, you can check the three DIP switch banks on the

KFC15 module for the particular settings.

Related Publications

Listed below are publications you can reference for information about

RSLogix500 and RSLinx.

• Getting Results with RSNetworks for ControlNet -

pub. no. 9399-CNETGR

• Getting Resul ts with RSLogix500 with RSNetworks for ControlNet -

pub. no. 9399-RWCNPGR

• Getting Results with RSLogix500 - pub. no. 9399-RL50GR

• Getting Results with RSLinx - pub. no. 9399-WAB32GR

1747-5.34 - June 1998

Page 33

Chapter

RS-232C

5

Troubleshooting the KFC15 Module

Use this chapter to interpr et the indicators (status LEDs and dot

matrix display) on the KFC15 module to help you troubleshoot

problems.

Interpreting the Status LEDs

There are three, bi-col or (red/green) status LEDs on the top of the

KFC15 module. Two are for ControlNet, showing the physical layer

status of channels A (primary connection) and B (redundant media

connection), and one is for the KFC15 (STATUS). These indicators

can help you diagnose problems with the modul e’s installation and

operation.

RS-232C

Display on the

1747-KFC15

module

30662-M

30665-M

1747-5.34 - June 1998

Page 34

5-2 Troubleshooting the KFC15 Module

The following terms are used to describe the state of the LEDs:

solid - on continuously in the defined state

flashing - each LED alternates betwee n the two defined states (or with

OFF if only one state is defined). This only appl ies to a single LED

viewed independently of the other. If both ControlNet LEDs are flashing,

they flash together (in pha se).

railroad - both LEDs alter nate between the two de fined sta tes a t the same

time. This only applies to both ControlNet LEDs when viewed together.

The two LEDs are always in opposite states (out-of-phase).

flickering - intermittent on/off between the two states, often in an erra tic

pattern

LED State Probable Cause Recommended Action

Channels A

and B

(viewed

together)

OFF No power or reset

SOLID RED Failed unit Check network setup then cycle

power to the KFC15 module. If

the fault persists, contact your

authorized Allen-Bradley

representative or distributor.

RAILROAD RED GREEN

RAILROAD RED OFF

Self test None

Incorrect node

configuration

(duplicate node, ID,

etc.)

Check network address and

other ControlNet configuration

parameters.

1747-5.34 - June 1998

Page 35

Troubleshooting the KFC15 Module 5-3

LED State Probable Cause Recommended Action

Channel A or

B (viewed

separately)

STATUS OFF No power is applied to

OFF Channel disabled or

unused

SOLID GREEN Channel good—data is

being received and

transmitted on this

channel

FLASHING

GREEN - OFF

FLASHING RED GREEN

FLASHING RED OFF

SOLID GREEN Normal operation—the

FLASHING

GREEN

SOLID RED Critical fault—the

FLASHING RED Non-critical fault—the

Temporary errors or

device is not on-line

Bad network

configuration

Media fault or no other

nodes present on the

network

the KFC15 module

module is OK

The KFC15 is not

properly configured

KFC15 has detected an

unrecoverable fault and

must be replaced

KFC15 has detected a

recoverable fault

Program network for redundant

media if required.

None

None. Unit will correct itself.

Check network setup then cycle

power to the KFC15 module.

Check media for broken cables,

loose connector, missing

terminators, etc.

None

None

Check and change parameter

settings.

Contact your authorized AllenBradley representative or

distributor.

Reconfigure or reset the KFC15.

Interpreting the Dot Matrix Displays

Under normal conditions, the dot matrix display should be displaying the

ControlNet network addre ss as well as the ControlNet network status.

During operation , the dot matrix dis play is use d to indic ate hardware fa ult

conditions. When the STA TUS LED is solid or flashing red, the display

shows a number indicatin g the type of ha rdware f ault. The fol lowing table

gives a description of the faults.

1747-5.34 - June 1998

Page 36

5-4 Troubleshooting the KFC15 Module

This

number

1 Processor Fault A hardware fault was detected in the processor.

2 Invalid Firmware The Flash EPROM does not contain valid firmware. New

3 Firmware Checksum

4 RAM Fault The static RAM cannot be written to reliably or a parity

5 Flash EPROM Write

9 Invalid Network

10 Duplicate Network

11 Unrecoverable

Indicates this fault Meaning

This is a major fault. Return the KFC15 for servicing.

firmware must be downloaded to the unit.

A checksum error was detected in the main application

Fault

Fault

Address

Address

Firmware Error

code of the Flash EPROM.

error has occurred. Cycle power to the KFC15.

If the problem persists, return the KFC15 for servicing.

The Flash EPROM could not be programmed correctly

during download of new firmware.

This is a major fault. Return the KFC15 for servicing.

The chosen network address is greater than the highest

network address ControlNet is configured for.

There is a device on the ControlNet network with the

same address.

Failed to re-program the boot block of the Flash EPROM.

Return the KFC15 module for servicing.

If the displays show symbols other than those shown in this chapter, this

also indicate s that th e module is malfunc tioni ng. In t his case , contac t your

Allen-Bradley repre sentative.

During the power-up of the KFC15, the display shows the serial port

parameters based on the DIP switch settings. Refer to Chapter 2 for

details on these parameters.

1747-5.34 - June 1998

Page 37

Appendix

Product Specifications

RS-232C Interface

• Start Bits 1

• Data Bits 8

• Parity None, Even, Odd

• Stop Bits 1

• Baud Rates 1200, 2400, 4800,

9600,19200, 38400, 57600

• Connect or DB-9P (male)

A

• Output RS-232C

• Protoc ol Allen-Bradley DF1

• Cable Length Recommended maximum of

7.5 m (25 ft) at 57600

baud, or 15 m (50 ft) at

lower baud rates

• Cable Type Shielde d

• Ground Isola tion Opto-coupled

1747-5.34 - June 1998

Page 38

A-2 Product Specifications

ControlNet Interface

• Connect ors Standa rd BNC Connector s

• Cable RG-6 75-ohm coaxial cable

• Media Redundanc y Connection for 2 independent

coaxial cables

• Ground Isola tion Dual transformers

Network Access Port (NAP) Interface

• Connector RJ-45 8-pin, phone jack

with shield

• Ground Isola tion Opto-coupled

Physical

• Dimensions 140 cm wide x 145 cm long x

35 cm high

• W eight 217.6 g

• Mounting SLC500 chassis

Environmental

• Operating Temperature 0°C to 60°C (32°F to 140°F)

• Storage Temperature –40°C to 85°C (–40° to 1 85°F)

• Operating Humidity 5% to 95% (non-condensing)

1747-5.34 - June 1998

Page 39

Product Specifications A-3

Agency Safety Certification

• CSA Approved. Class 1, Group A, B, C or D

Division 2

• UL Listed

• C E Compliant for all application directives

1747-5.34 - June 1998

Page 40

A-4 Product Specifications

1747-5.34 - June 1998

Page 41

Appendix

B

Cabling and Pinouts

This appendix contains the pinout and wiring information required if

you need to construct cables before installing the KFC15 to a host

device.

Cabling and Pinouts for RS-232C Connection

The KFC15 RS-232C connector is a DB-9 male with the following

EIA standard pinout:

Signal I/O Pin

GND Chassis ground . Housing

TXD Transmitted data O 3

RXD Received data I 2

RTS Request to send O 7

CTS Clear to send I 8

DSR Data set ready I 6

COM Signal common . 5

DCD Data carrier detect I 1

DTR Data terminal ready O 4

1747-5.34 - June 1998

Page 42

B-2 Cabling and Pinouts

The following diagram illustrates wiring for a DB-9 cable.

9P R/A D-Shell

I

3

2

6

5

4

8

7

9

Shield

9P R/A D-Shell

I

2

3

4

5

6

7

8

9

Shield

The following diagram illustrates the handshake wiring between the

SLC500 and the KFC15.

SLC500

KFC15

TXD 3

RXD 2

RTS 7

CTS 8

GND 5

DSR 6

DCD 1

DTR 4

1747-5.34 - June 1998

Shield

2 RXD

3 TXD

8 CTS

7 RTS

5 GND

4 DTR

6 DSR

1 DCD

Page 43

Appendix

C

DF1 Diagnostic Command Support

The information in this appendix deals with DF1 communications

between the host processor and KFC15 module. The KFC15 module

interprets and responds to the following diagnostic commands from

its DF1 RS-232 serial port:

Description Command Byte Function Code (hex)

Diagnostic Loop 06 00

Diagnostic Read Counters 06 01

Diagnostic Status 06 03

Reset Diagnostic Counters 06 07

In the Comman d and Reply Format tables below, all values are in hex

and the following abbrevi ations are used:

ADDR - address of data to be read

CMD - command code

FNC - function code

STS - status code

TNS - transaction number

1747-5.34 - June 1998

Page 44

C-2 DF1 Diagnostic Command Support

Diagnostic Loop

You ca n use th is comma nd to chec k the integr ity of the tr ansmissi ons ove r

the communicati on link. The c ommand m essage transmits up to 243 by tes

of data to a node interface module. The receiving module should reply to

this command by tra nsmitting the same data back to the originating node.

Table C.1: Command Format

1 byte 1 byte 2 bytes 1 byte

CMD

06

STS TNS

FNC

00

243 bytes

max

DATA

Table C.2: Reply Format

1 byte 1 byte 2 bytes 243 bytes max

CMD

46

STS TNS DATA

Diagnostic Read Counters

This command reads the diagnostic counters from the KFC15 module.

The format of these counters is given below. The address and size fields

can have any value (but they must be included).

Table C.3: Command Format

1 byte 1 byte 2 bytes 1 byte 2 bytes 1 byte

CMD

06

STS TNS

FNC

01

ADDR

0000

SIZE

00

Table C.4: Reply Format

1 byte 1 byte 2 bytes 16 bytes

CMD

46

1747-5.34 - June 1998

STS TNS DATA

Page 45

DF1 Diagnostic Command Support C-3

Table C.5: Reply Values

1 Total DF1 packets received, low byte

2 Total DF1 packets received, high byte

3 Total DF1 packets transmitted, low byte

4 Total DF1 packets transmitted, high byte

5 Number of DF1 retries

6 Number of DF1 packets where the retry limit was exceeded

7 Number of DF1 NAKs sent

8 Number of DF1 NAKs received

9 Number of DF1 bad messages received

10 Number of RS–232C line errors

11 Total good ControlNet packets received, low byte

12 Total good ControlNet packets received, high byte

13 Total bad ControlNet packets received, low byte

14 Total bad ControlNet packets received, high byte

15 Total ControlNet packets transmitted, low byte

16 Total ControlNet packets transmitted, high byte

Diagnostic Status

This command requests a block of status information from an RS-232C

device. The reply contains the information in its DATA field. The status

information varies f rom devi ce to devi ce. The status block is shown

below.

Table C.6: Command Format

1 byte 1 byte 2 bytes 1 byte

CMD

06

STS TNS

Table C.7: Reply Format

1 byte 1 byte 2 bytes 24 bytes

CMD

46

STS TNS DATA

FNC

03

1784-5.34 - June 1998

Page 46

C-4 DF1 Diagnostic Command Support

Table C.8: Reply Values

Data Byte Description Status Reply

1 Mode/Status Byte 00 (No Modes)

Interface/Processor Type

Bits 0 – 3: Interface type

2

3 Extended Interface Type 5F (KFC15) 60 (KFCD15)

4 On-line/Off-line Mode 0 = on-line; 1 = off-line

5

6 – 16

17 – 24 Reserved for factory use only Values may vary

(E = Extended)

Bits 4 – 7: Processor type

(F = Computer)

Series/Revision

Bits 0–4:

Bits 5–7:

Bulletin Name =

ASCII

FE (Extended)

0 = Revision A

1 = Revision B, etc.

0 = Series A

1 = Series B, etc.

“1770-KFC15 ”

“1770-KFCD15 ”

Diagnostic Counter Reset

This command resets the diagnostic counters listed above.

Table C.9: Command Format

1 byte 1 byte 2 bytes 1 byte

CMD

06

1747-5.34 - June 1998

STS TNS

FNC

07

Page 47

DF1 Diagnostic Command Support C-5

Table C.10: Reply Format

1 byte 1 byte 2 bytes

CMD

46

STS TNS

1784-5.34 - June 1998

Page 48

C-6 DF1 Diagnostic Command Support

1747-5.34 - June 1998

Page 49

Index-1

A

agency safety certification A-3

C

Cabling and Pinouts B-1

Compatibility 1-5

Connecting to the ControlNet

Cable System 3-4

ControlNet interface A-2

D

DF1 1-3

commands from host C-1

DF1 diagnostic command support

C-1

diagnostic counter reset C-4

diagnostic loop C-2

diagnostic read counters C-2

diagnostic status C-3

DIP switches

Bank S1 DIP Switches 2-3

Bank S2 DIP Switches 2-3

Bank S3 DIP Switches 2-4

S1, S2, S3 2-2

dot matrix display

interpretation table 5-4

I

Installation Procedure 3-2

L

LEDs 1-3

flashing 5-2

flickering 5-2

interpreting 5-1

railroad 5-2

solid 5-2

table of 5-2

N

network access cable 3-3

network access port 1-3, 1-5, 3-

1, A-2

1786-CP 3-3

P

product specifications A-1

R

rotary switch settings 2-5

Rotary Switches

S4, S5 2-5

RS-232C serial port 1-1, 1-3, 1-4,

1-5, 3-1, A-1, B-1

connecting to host B-1

RSLinx 4-1

RSLogix500 4-1

S

SLC500 1-1, 4-1

1747-5.34-June 1998

Page 50

Index-2

1747-5.34 - June 1998

Page 51

Page 52

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration,

and troubleshooting, we offer TechConnect Support programs. For more

information, contact your local distributor or Rockwell Automation representative,

or visit http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can

also contact a special Customer Support number for initial help in getting your

module up and running.

, you can find

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning, it may need to be returned.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Publication 1747-5.34 - June 1998 PN 955132-68

Supersedes Pub lication 1747-IN006A- US-P - February 2000 C opyright © 2007 Rockw ell Automation, Inc. A ll rights reserved. Prin ted in Singapore.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Loading...

Loading...