Page 1

DH-485/RS-232C

Interface Module

Catalog Number 1747-KE

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls, publication SGI-1.1,

available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com, describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard.

• avoid a hazard.

• recognize the consequences.

Labels may be located on or inside the equipment (for

example, drive or motor) to alert people that dangerous

voltage may be present.

Labels may be located on or inside the equipment (for

example, drive or motor) to alert people that surfaces may

be dangerous temperatures.

Page 3

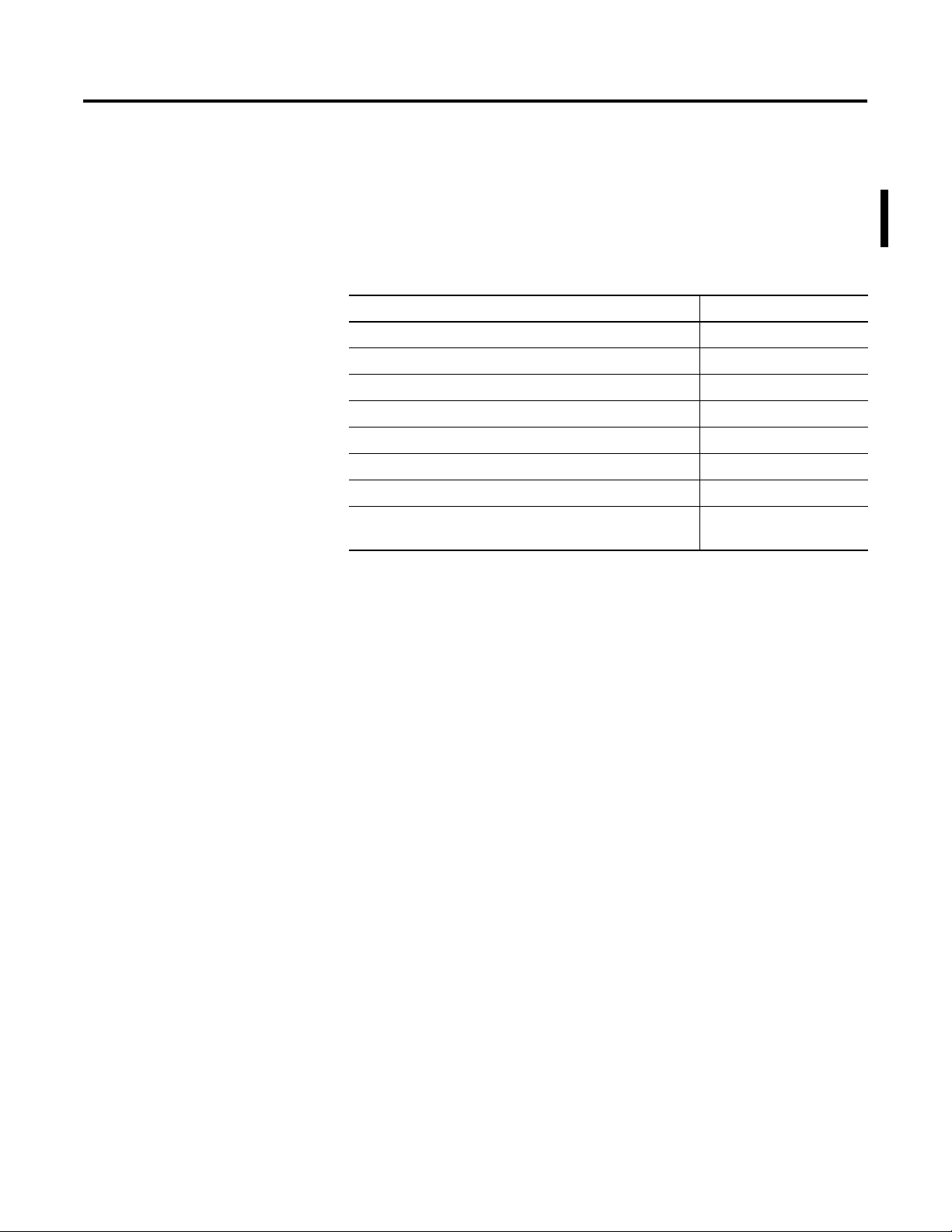

Summary of Changes

The information below summarizes the changes to this manual since

the last printing.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

For See page

Updated method of ordering publications P-2

Updated battery location on circuit board 1-2, C-2

Revised JW1 jumper illustration 1-2, 1-4

Revised JW2 jumper illustration 1-2, 1-4

Revised JW4 jumper illustration 1-2, 1-4

Replaced APS with RSLinx software throughout

Updated information on configuring your SLC chassis 4-13

Updated information on configuring your DF1 driver with

RSLinx software

4-14

Publication 1747-UM005B-EN-P - March 2006

Page 4

2 Summary of Changes

Notes:

Publication 1747-UM005B-EN-P - March 2006

Page 5

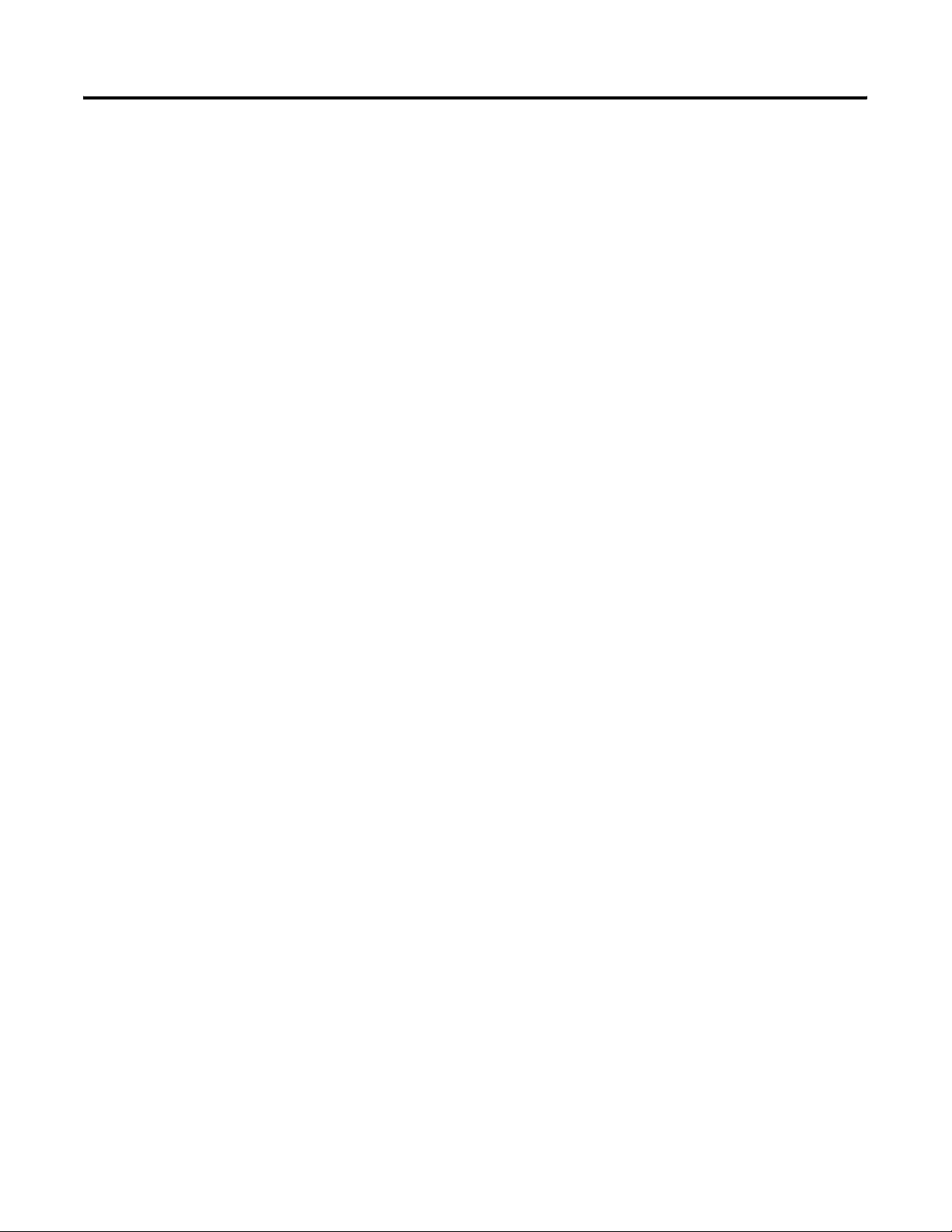

Overview

Table of Contents

Preface

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . P-2

Terms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . P-3

Chapter 1

Interface Module Overview . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Jumper JW1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Jumper JW2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Jumper JW4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Use a Modem with Your Interface Module . . . . . . . . . . . . . 1-5

Use DF1 Protocol and Your Module. . . . . . . . . . . . . . . . . . 1-5

Typical Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Full-duplex (Point-to-point) . . . . . . . . . . . . . . . . . . . . . 1-6

Full-duplex (Network, Example 1) . . . . . . . . . . . . . . . . 1-6

Full-duplex (Network, Example 2) . . . . . . . . . . . . . . . . 1-7

Half-duplex (Local Mode). . . . . . . . . . . . . . . . . . . . . . . 1-8

Half-duplex (Remote Mode) . . . . . . . . . . . . . . . . . . . . . 1-9

Half-duplex (Slave-to-slave Communication) . . . . . . . . . 1-10

Quick Start

Communicate with the Interface

Module

Installation and System

Configuration

Chapter 2

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . 2-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpack the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Install the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Configure the Module . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Start-up the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter 3

DF1 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Full-duplex DF1 Protocol . . . . . . . . . . . . . . . . . . . . . . . 3-1

Half-duplex DF1 Protocol. . . . . . . . . . . . . . . . . . . . . . . 3-2

Communicate with DH-485 Devices. . . . . . . . . . . . . . . . . . 3-10

DH-485 Token Passing Devices . . . . . . . . . . . . . . . . . . 3-10

DH-485 Non-Token Passing Devices. . . . . . . . . . . . . . . 3-11

Communicate with a Modem. . . . . . . . . . . . . . . . . . . . . . . 3-11

Chapter 4

European Union Directives Compliance . . . . . . . . . . . . . . . 4-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Choose the Module’s Functionality. . . . . . . . . . . . . . . . . . . 4-2

i Publication 1747-UM005B-EN-P - March 2006

Page 6

ii Table of Contents

Module Configuration Using an

ASCII Terminal

Add an Interface Module to Your System . . . . . . . . . . . 4-2

Replace a Series A Interface Module in Your System . . . 4-2

Set the Module’s Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Configure with an ASCII Terminal . . . . . . . . . . . . . . . . 4-4

Configure Through the Backplane . . . . . . . . . . . . . . . . 4-4

Verify CONFIG Port Configuration . . . . . . . . . . . . . . . . . . . 4-5

Verify DF1 Port Configuration . . . . . . . . . . . . . . . . . . . . . . 4-6

Install Your Module in an Open Slot . . . . . . . . . . . . . . . . . 4-7

Connect Cable to CONFIG or DF1 Ports. . . . . . . . . . . . . . . 4-8

Connect Cable to the DH-485 Port . . . . . . . . . . . . . . . . . . . 4-11

Configure Your SLC Chassis. . . . . . . . . . . . . . . . . . . . . . . . 4-13

Configure the DF1 Driver within RSLinx Software. . . . . . . . 4-14

Configure Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Complete the Installation of Your Module . . . . . . . . . . . . . 4-15

Chapter 5

ASCII Terminal Configuration . . . . . . . . . . . . . . . . . . . . . . 5-2

Module Configuration with a Terminal Overview . . . . . . . . 5-3

Top Level Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Change Parameters for Menus 1 through 4 . . . . . . . . . . 5-4

CONFIG Port Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

CONFIG PORT Setup Parameters . . . . . . . . . . . . . . . . . 5-5

DF1 Port Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

DF1 Port Setup Parameters. . . . . . . . . . . . . . . . . . . . . . 5-6

DH-485 Port Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

DH-485 Port Setup Parameters . . . . . . . . . . . . . . . . . . . 5-7

DF1 Protocol Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

DF1 Full-duplex Setup Menu . . . . . . . . . . . . . . . . . . . . 5-8

DF1 Full-duplex Setup Parameters . . . . . . . . . . . . . . . . 5-9

DF1 Half-duplex Setup Menu . . . . . . . . . . . . . . . . . . . . 5-10

DF1 Half-duplex Setup Parameters . . . . . . . . . . . . . . . . 5-10

Display Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Module Configuration Using the

Backplane

Publication 1747-UM005B-EN-P - March 2006

Chapter 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Configure the Interface Module from the SLC Processor . . . 6-2

Place the Module into Software Run Mode from

SLC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Read the Module’s Configuration from the SLC Processor . . 6-5

Examine the SLC Processor’s Status Word. . . . . . . . . . . . . . 6-6

SLC Output Status Word to the Interface Module. . . . . . 6-6

SLC Input Status Word from the Interface Module . . . . . 6-6

Status Codes from the Module to the Processor. . . . . . . 6-7

Build the DF1 Configuration Packet . . . . . . . . . . . . . . . . . . 6-8

DF1 Port Setup Parameters. . . . . . . . . . . . . . . . . . . . . . 6-9

Page 7

Interpret the LED Indicators

Table of Contents iii

DF1 Full-duplex Setup Parameters . . . . . . . . . . . . . . . . 6-10

DF1 Half-duplex Setup Parameters . . . . . . . . . . . . . . . . 6-11

Build the DH-485 Configuration Packet . . . . . . . . . . . . . . . 6-12

DH-485 Port Setup Parameters . . . . . . . . . . . . . . . . . . . 6-12

Build the Modem Init String Configuration Packets . . . . . . . 6-13

Modem Init String for Characters 1 Through 14 . . . . . . . 6-14

Modem Init String for Characters 15 Through 28 . . . . . . 6-15

Use the Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Establish a Data Echo Between the Interface Module and

the SLC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Reset the Interface Module from the SLC Processor. . . . . . . 6-18

Chapter 7

Interface Module Status Indicators . . . . . . . . . . . . . . . . . . . 7-1

Input Image Description . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Status Codes from the Module to the Processor . . . . . . . . . 7-3

SLC Fault Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Application Examples

Specifications

Chapter 8

Basic Configuration Example Using the Backplane . . . . . . . 8-1

Parameter Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Configuration Results . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Backplane Configuration User Program. . . . . . . . . . . . . 8-4

Configuration Data Table . . . . . . . . . . . . . . . . . . . . . . . 8-8

Supplementary Example Using the Backplane . . . . . . . . . . 8-9

Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Data Echo Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

RSLogix Software to SLC Network via Modem Example . . . 8-14

Configure the Module’s Serial Port . . . . . . . . . . . . . . . . 8-15

Configure the DF1 Modem Driver Using RSLinx 2.x or

Later. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Go Online using RSLogix 500 Software and RSLinx

Version 2.x and Later . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Appendix A

Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Port Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Maximum Communication Distances . . . . . . . . . . . . . . A-3

Publication 1747-UM005B-EN-P - March 2006

Page 8

iv Table of Contents

PLC-5 to SLC 500 Communications

Lithium Battery Replacement,

Handling, and Disposal

Interface Module Configuration

Worksheets

Appendix B

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

PLC-5 Message Instruction . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Use the SLC 500 CIF File . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Use the PLC-5 Message Instruction with Word . . . . . . . . . . B-3

Use the PLC-5 Message Instruction with Byte . . . . . . . . . . . B-4

Appendix C

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Battery Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Appendix D

DF1 Full-duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

DF1 Half-duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Index

Publication 1747-UM005B-EN-P - March 2006

Page 9

Preface

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics.

• Who should use this manual

• The purpose of this manual

• Contents of this manual

• Terms and abbreviations

• Conventions used in this manual

Who Should Use This Manual

Purpose of This Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use

Allen-Bradley small logic controllers.

You should have a basic understanding of SLC 500 products, DF1

communications protocol, and DH-485 network communications. If

you do not, contact your local Allen-Bradley representative for

information on available training courses before using this product.

This manual is a reference guide for the DH-485/RS-232C Interface

Module. It describes the procedures you use to install and configure

your interface module for application with PLC and SLC controllers.

1 Publication 1747-UM005B-EN-P - March 2006

Page 10

2 Preface

Related Documentation

The following documents contain additional information regarding

Rockwell Automation products.

Related Documentation

For Read This Document Document

Number

A guide to understanding and selecting SLC 500 products SLC 500 System Selection Guide 1747-SG001

A description on how to install and use your modular SLC 500

programmable controller

A reference manual that contains status file data, instruction set, and

troubleshooting information

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

If you would like a manual, you can:

• download a free electronic version from the Internet at

www.literature.rockwellautomation.com.

• purchase a printed manual by contacting your local distributor

or Rockwell Automation representative.

User Manual for Modular Hardware Style

Programmable Controllers

SLC 500 Instruction Set Reference Manual 1747-RM001

1747-UM011

Terms and Abbreviations

The following terms and abbreviations are specific to this product. For

a complete listing of Allen-Bradley terminology, refer to the

Allen-Bradley Industrial Automation Glossary, publication AG-7.1.

ASCII Terminal - an industrial terminal, workstation, or personal

computer with terminal mode software (such as PBASE or Windows

HyperTerminal) that communicates in alphanumeric mode.

Backplane - a printed circuit board, at the back of a chassis, that

provides electrical interconnection between the modules inserted into

the chassis.

DF1 - a serial communication protocol capable of

delimiting-messages, controlling message flow, detecting and

signalling errors, and retrying after errors are detected. See half- and

full-duplex.

DH-485 Link - Data Highway-485 link. An Allen-Bradley token-passing

baseband link for a local area network based on the RS-485 standard.

Full-duplex - a mode of operation for a point-to-point link with two

physical circuits, in which messages or transmission blocks can be

sent in both directions at the same time.

Publication 1747-UM005B-EN-P - March 2006

Page 11

Preface 3

Half-duplex - a mode of operation for a point-to-point or multi-point

baseband link with two physical circuits, in which messages or

transmission blocks can be sent in one direction or the other, but not

both at the same time.

Modem - Modulator/demodulator. Equipment that connects data

terminal equipment to a communication line.

RAM - random access memory. The type of memory in which each

storage location is by X/Y coordinates, as in core or semiconductor

memory. (Tape or bubble memory cannot be random access.) Thus,

the data access time is independent of the location of the data. Unless

stated otherwise, RAM usually implies read/write and volatile.

RS-232-C - an EIA standard that specifies electrical, mechanical, and

functional characteristics for serial-binary communication circuits in a

point-to-point link.

RS-422 - an EIA standard that specifies electrical characteristics of

balanced-voltage digital interface circuits in a point-to-point link.

Conventions Used in This Manual

RS-423 - an EIA standard that specifies electrical characteristics of

unbalanced voltage digital interface circuits in a point-to-point link.

RS-485 - an EIA standard that specifies mechanical and functional

characteristics for digital interface circuits. This standard is used in

combination with either RS-422 or RS-423.

SLC 500 controller - the SLC 500 family of fixed and modular

controllers.

The following conventions are used throughout this manual.

• Bulleted lists such as this one provide information, not

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Bold type is used for emphasis

Publication 1747-UM005B-EN-P - March 2006

Page 12

4 Preface

Publication 1747-UM005B-EN-P - March 2006

Page 13

Chapter

Overview

This chapter provides:

• an overview of the interface module.

• features (communication ports, LED indicators, and jumpers).

• guidelines outlining the type of modems you can use with the

module.

• a brief discussion on using RSLinx software with your module.

• typical configurations.

1

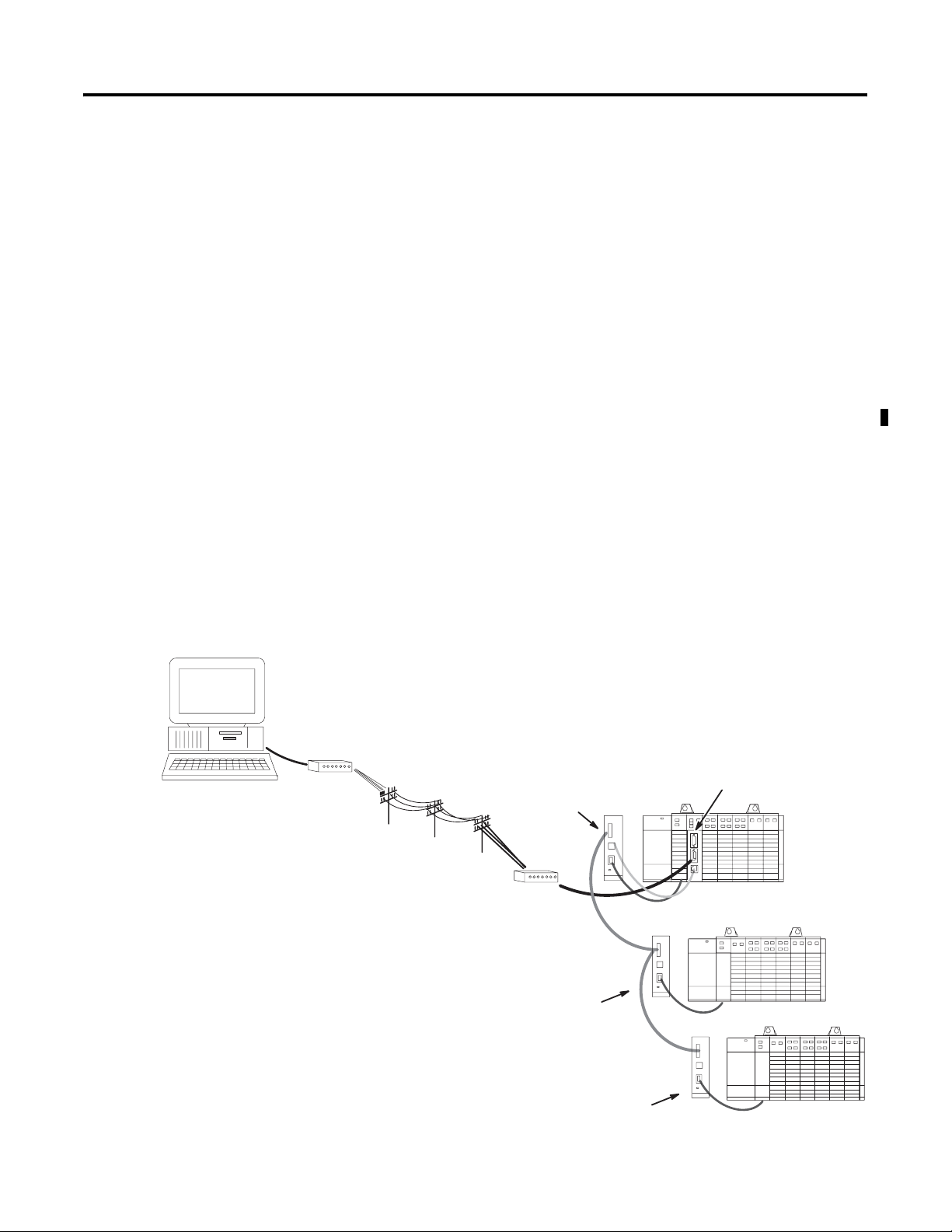

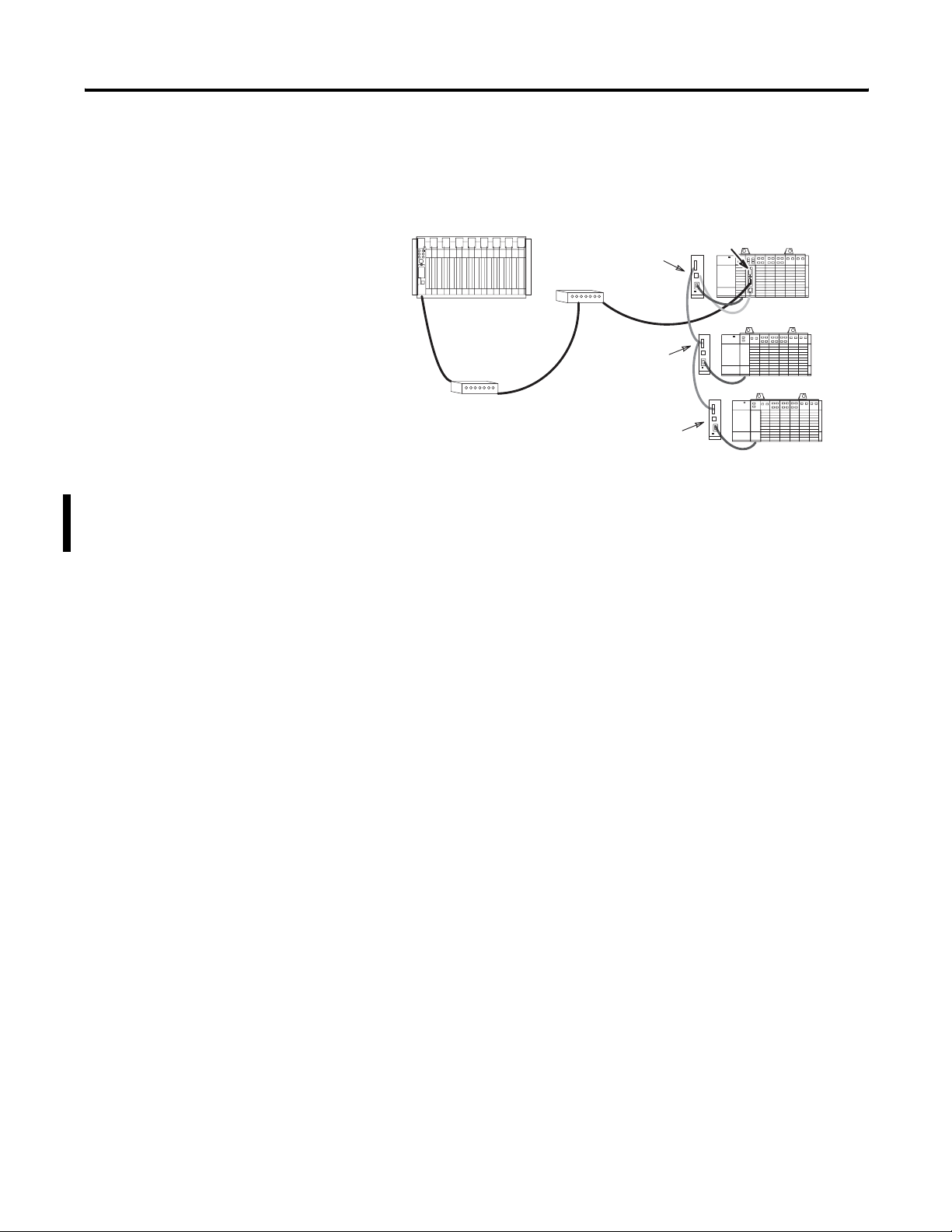

Interface Module Overview

Local Host

Modem

The DH-485/RS-232C Interface Module, catalog number 1747-KE, is a

communications interface module that acts as a bridge between

DH-485 networks and devices requiring DF1 protocol. The DF1 port

on the interface module can be configured for RS-232/423, RS-422, or

RS-485 devices. Residing in an SLC 500 chassis, the module is ideally

used as an interface module, linking remote DH-485 networks via a

modem to a central host.

Interface Module Overview

Interface Module

Link Coupler

(1747-AIC)

Modem

DH-485

(1747-KE)

Link Coupler

(1747-AIC)

DH-485

Link Coupler

(1747-AIC)

1 Publication 1747-UM005B-EN-P - March 2006

Remote Network

Page 14

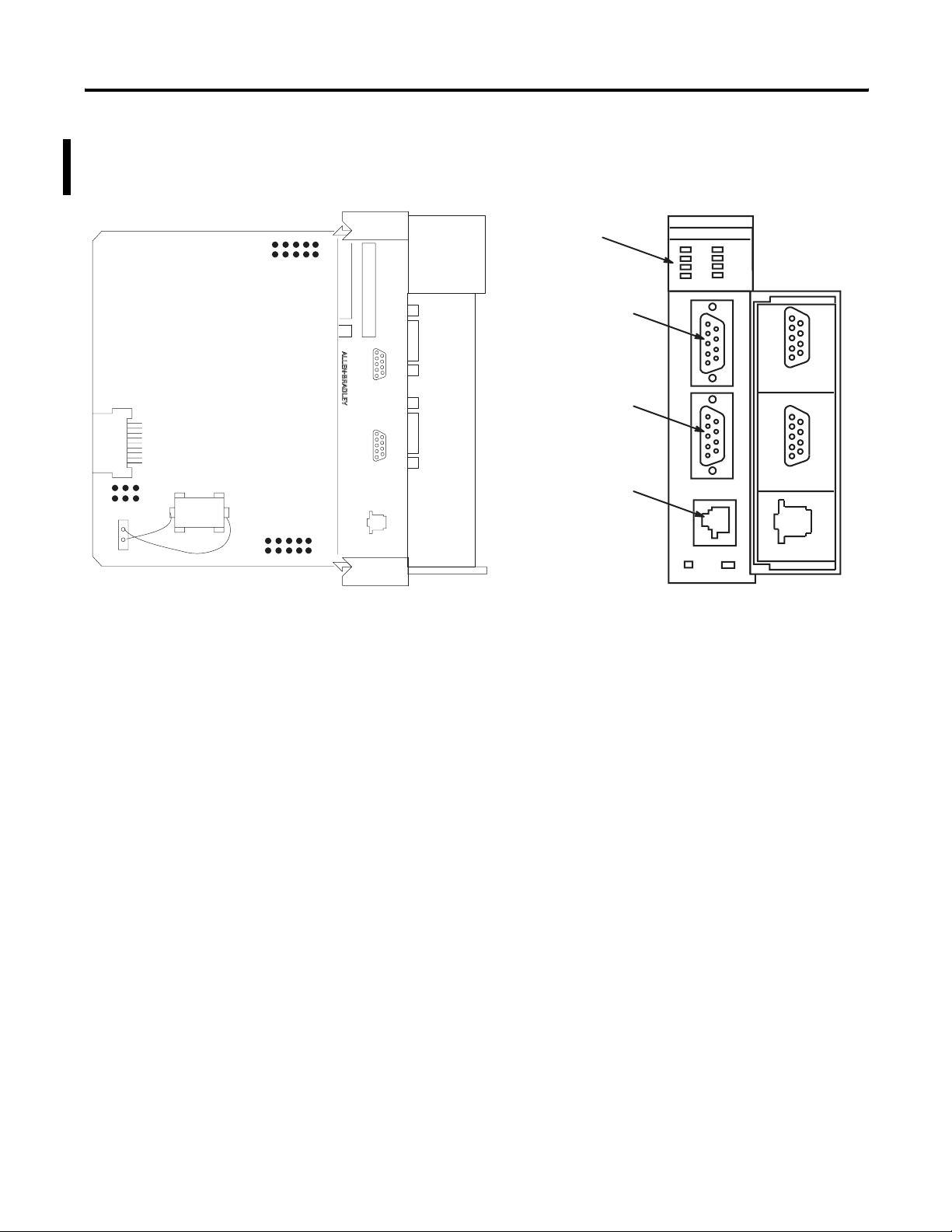

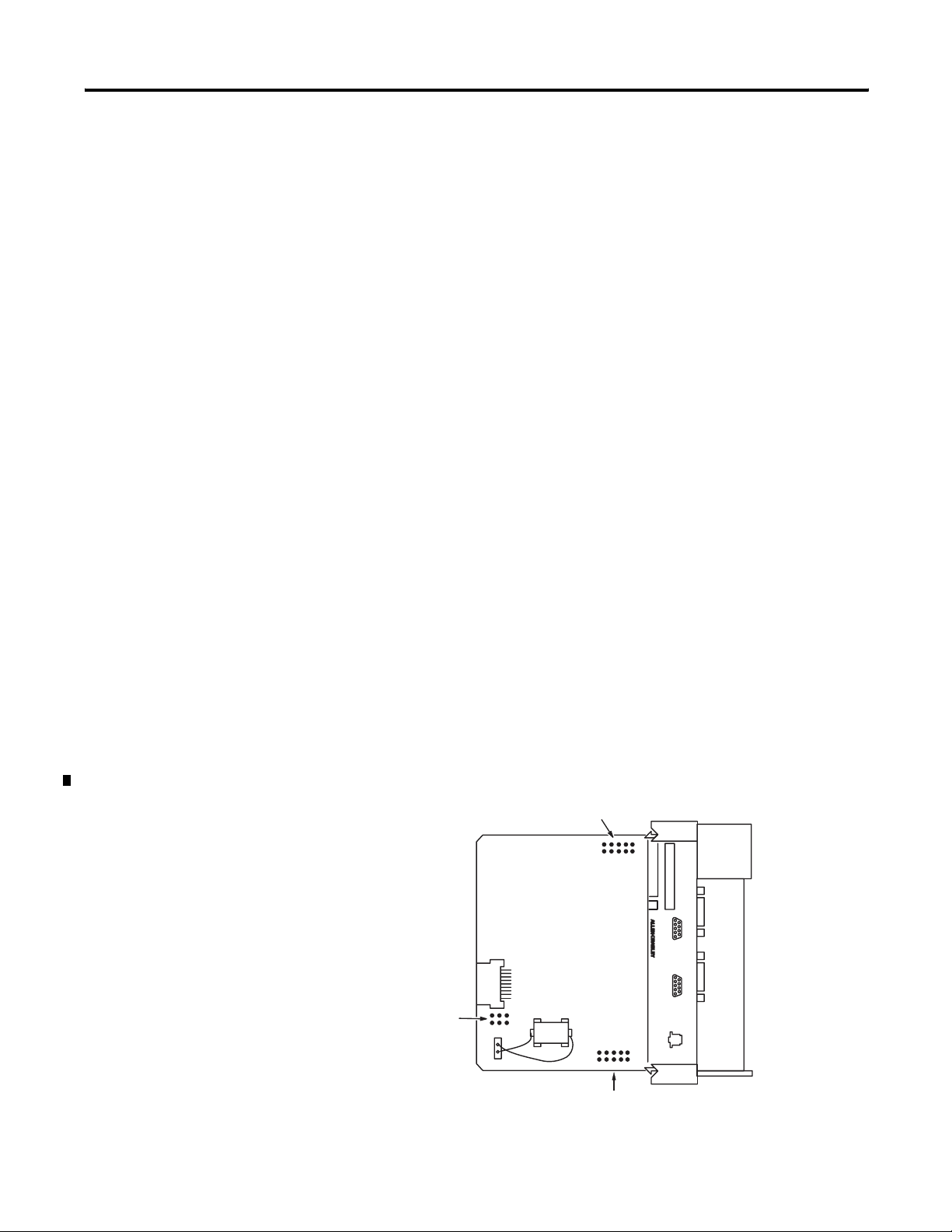

1-2 Overview

Features

JW4

Battery

JW1

JW2

The features of the module are shown below.

1747-KE Module Features

SERIAL NO.

FRN

CONFIG

12345

DF1

12345

DH485

CAT SER

SLC 500

INTERACE MODULE

6789

6789

LEDs

CONFIG

Port

DF1

Port

DH-485

Port

DH-485/RS-232C

5

4

3

2

1

CONFIG

5

4

3

2

1

DF1

DH485

Door Label

9

8

7

6

9

8

7

6

There are three communication ports on the front of the module.

They are:

• CONFIG - used to configure the module with an ASCII terminal.

This serial port accommodates RS-232/423, RS-422, and RS-485

communication interfaces. The CONFIG port is capable of

operating at 300, 600, 1200, 2400, 4800, 9600, and 19200 Kbps. It

is electrically isolated to 500V dc.

• DF1 - used to interface the module to a modem or other user

devices using DF1 protocol. This serial port accommodates

RS-232/423, RS-422, and RS-485 communication interfaces. The

DF1 port is capable of operating at 300, 600, 1200, 2400, 4800,

9600, and 19200 Kbps. It is electrically isolated to 500V dc.

• DH485 - used to interface the module with the DH-485 network.

This port is not isolated and cannot directly drive a multi-node

DH-485 network. You must use a 1747-AIC link coupler to

connect this port to a DH-485 network that includes multiple

SLC 500 processors.

The 1747-C11 or 1747-C13 cables can connect the interface module’s

DH-485 port to a 1747-AIC link coupler. The 1747-C13 cable can also

connect the module’s DH-485 port directly to a single SLC processor.

Publication 1747-UM005B-EN-P - March 2006

See page 4-11 for cable connections.

Page 15

LED Indicators

DH

485/RS-

232

C

There are eight LED indicators on the front of the module. These LED

indicators are used for module diagnostics and operator interface. The

LED indicators and their descriptions are provided below.

LED Indicators

LED Indicator Status

LED Color Status Indication

ACT Green

ON

(1)

The module is receiving power from the backplane, is configured properly, and

is placed in Run mode.

Flashing The module requires configuration or is being configured.

DH

485/RS-

AC

485

C

FG

DF1

INTERFACE

Overview 1-3

232

C

T

FAULT

BA

LO W

H/D

F/

D

OFF The module is not receiving power from the backplane. A fault condition

exists.

485 Green ON The DH485 port is active on the network.

OFF The DH485 port is not active on the network or the module is in Configuration

mode.

CFG Green Flashing The CONFIG port is transmitting or receiving signals.

OFF The CONFIG port is not transmitting or receiving signals.

DF1 Green Flashing The DF1 port is transmitting or receiving signals. (The flashing may occur so

rapidly that the LED indicator appears to be on.)

OFF The DF1 port is not transmitting or receiving signals or the module is in

Configuration mode.

FAULT Red ON A system problem was detected during diagnostics. Cycle power to reset. If it

remains on, contact your Allen-Bradley representative.

OFF No system problems are detected during diagnostics.

BA LOW Red ON The voltage of the battery that backs up configuration RAM is low. A new

battery is needed.

OFF The voltage of the battery that backs up configuration RAM is at an

acceptable level.

H/D Amber ON The module is configured for half-duplex DF1 protocol (local or remote).

OFF The module is not configured for half-duplex DF1 protocol.

F/D Amber ON The module is configured for full-duplex DF1 protocol.

OFF The module is not configured for full-duplex DF1 protocol.

(1)

Indicates normal operation after the module has been configured.

Publication 1747-UM005B-EN-P - March 2006

Page 16

1-4 Overview

Jumper JW1

JW1 lets you to select the communication interface for the CONFIG

port.

Refer to page 4-5.

Jumper JW2

JW2 lets you to select the communication interface for the DF1 port.

Refer to page 4-6.

Jumper JW4

JW4 lets you to select the functionality and mode of the interface

module. The orientation of the jumper determines the module’s

functionality. A horizontal orientation gives the module functionality

equivalent to a series A module (module configuration ID=4209),

while a vertical orientation of the jumper accesses the added

functionality of a series B module (module configuration ID=3509).

The position of the jumper determines the module’s mode

(Configuration or Run), and thus, which method is used to configure

the module (ASCII terminal or backplane communications).

Refer to Chapter 4.

Jumper Placement

JW1

CAT SER

SERIAL NO.

SLC 500

INTERACE MODULE

FRN

CONFIG

6789

12345

DF1

6789

12345

JW4

DH485

Publication 1747-UM005B-EN-P - March 2006

JW2

Page 17

Overview 1-5

Use a Modem with Your Interface Module

The module can be connected to most types of dial-up network or

direct connect modems.

IMPORTANT

The type of modems you can use are:

• Manual - typically acoustically-coupled modems. A person on

each end of the phone line establishes the connection. They

then insert the handsets into an acoustic coupler to complete the

connection.

• DTE controlled answer - these unattended modems are attached

directly to the phone lines. The interface module acts as the

Data Terminal Equipment (DTE), which controls the modem via

the DTR, DSR, and DCD signals. The module incorporates

timeouts and tests to properly operate these types of modems.

• Auto answer - these modems have self-contained timeouts and

tests. They can answer and hang up the phone automatically.

The module has no means of controlling an auto-dial modem,

but it can be used in conjunction with a separate auto-dialer.

• Direct connect - these modems connect to a dedicated, leased

phone line and remain active at all times.

Some modems are designed to respond to the DTR

signal by answering the phone whether it is ringing

or not. Since the module asserts DTR at all times

(except during the hang-up sequence), the phone

appears to be busy at all times. Do not use the

interface module with any type of modem that

answers the phone as soon as DTR is asserted.

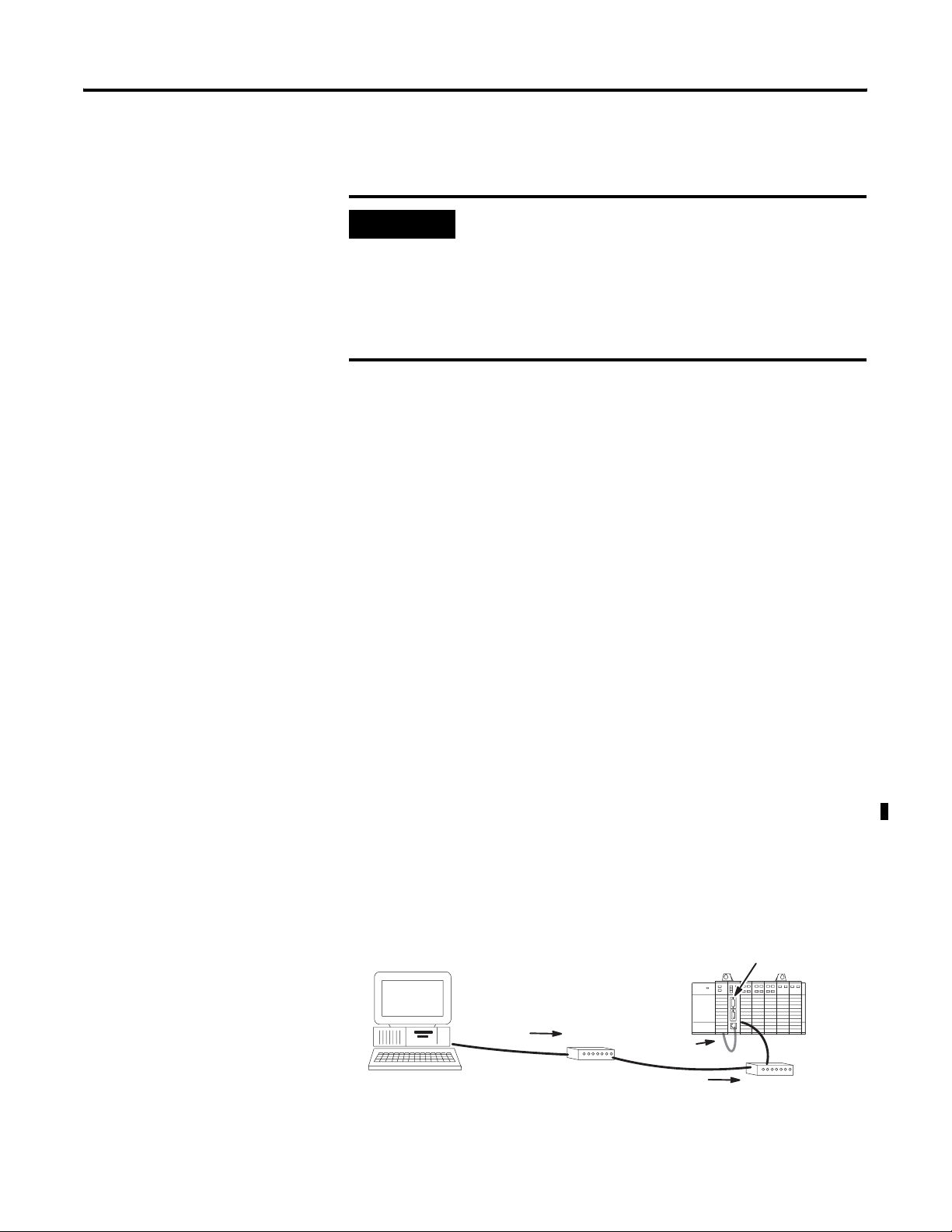

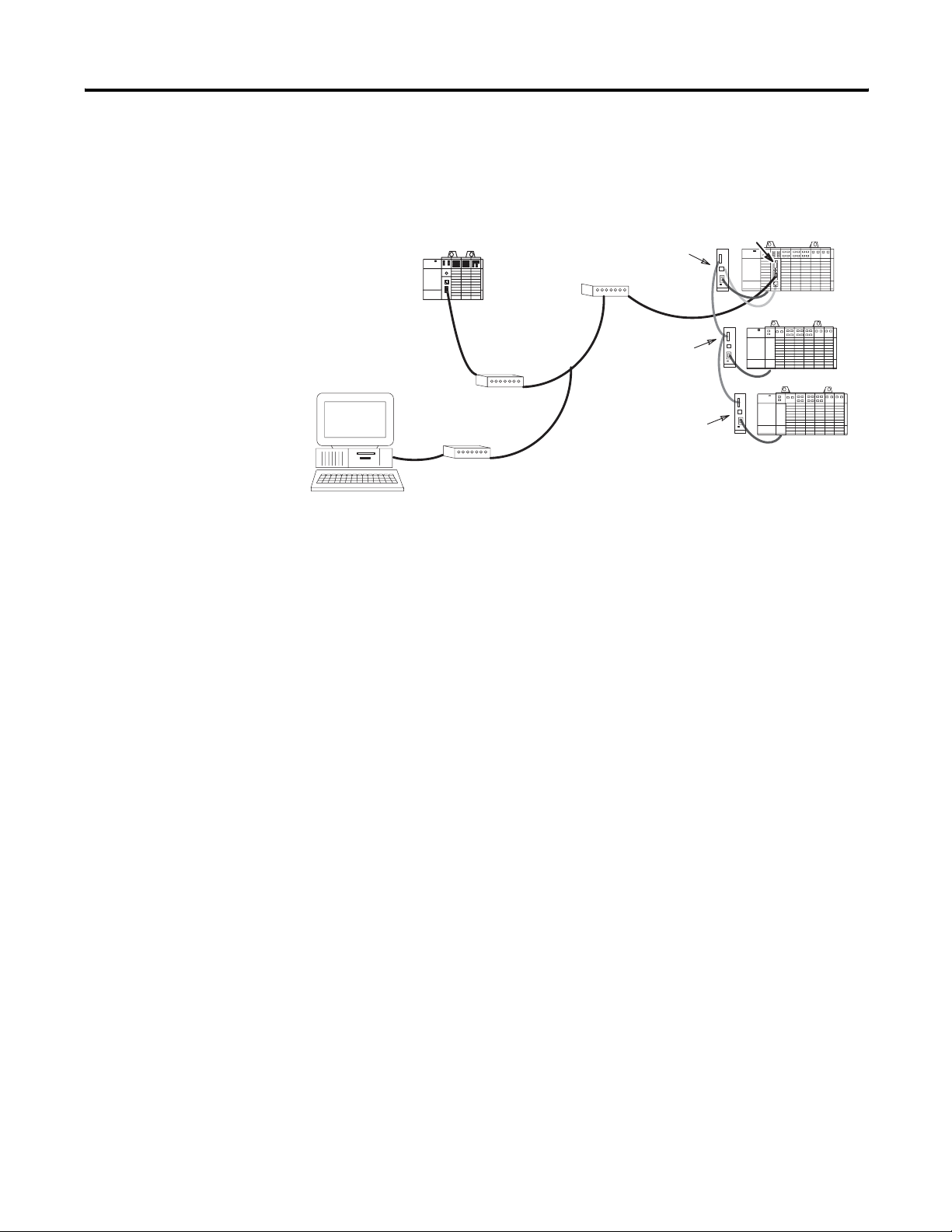

Use DF1 Protocol and Your Module

RSLinx software supports DF1 communications directly from your

computer’s serial communication port. Connecting a modem to this

port lets you to call remote networks and control them as if you were

connected locally.

DF1 Protocol

Interface Module

(1747-KE)

DF1

DF1 Protocol

1747-C13 Cable

Modem

DF1 Protocol

Publication 1747-UM005B-EN-P - March 2006

Modem

Page 18

1-6 Overview

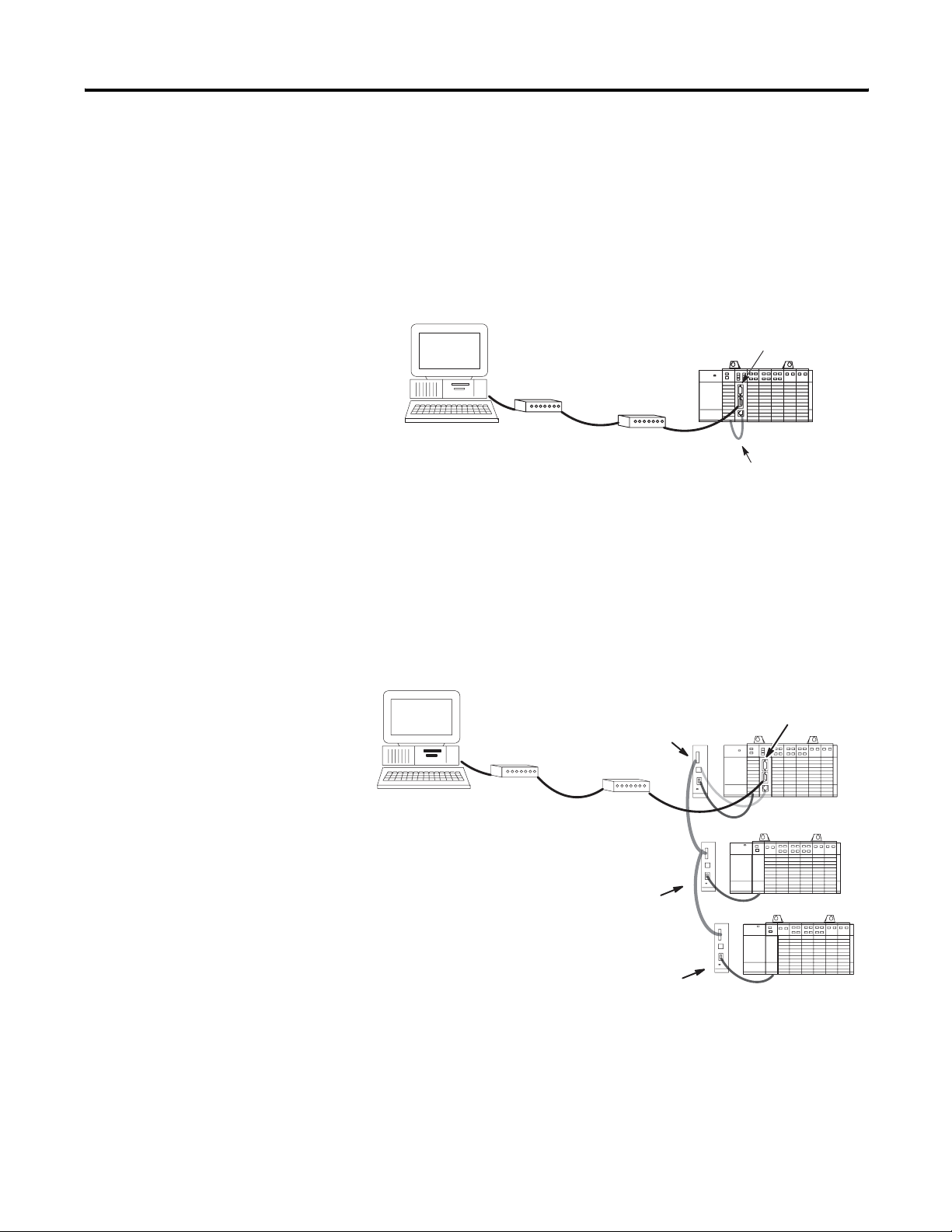

Typical Configurations

The following configurations illustrate some of the possible uses for

the module.

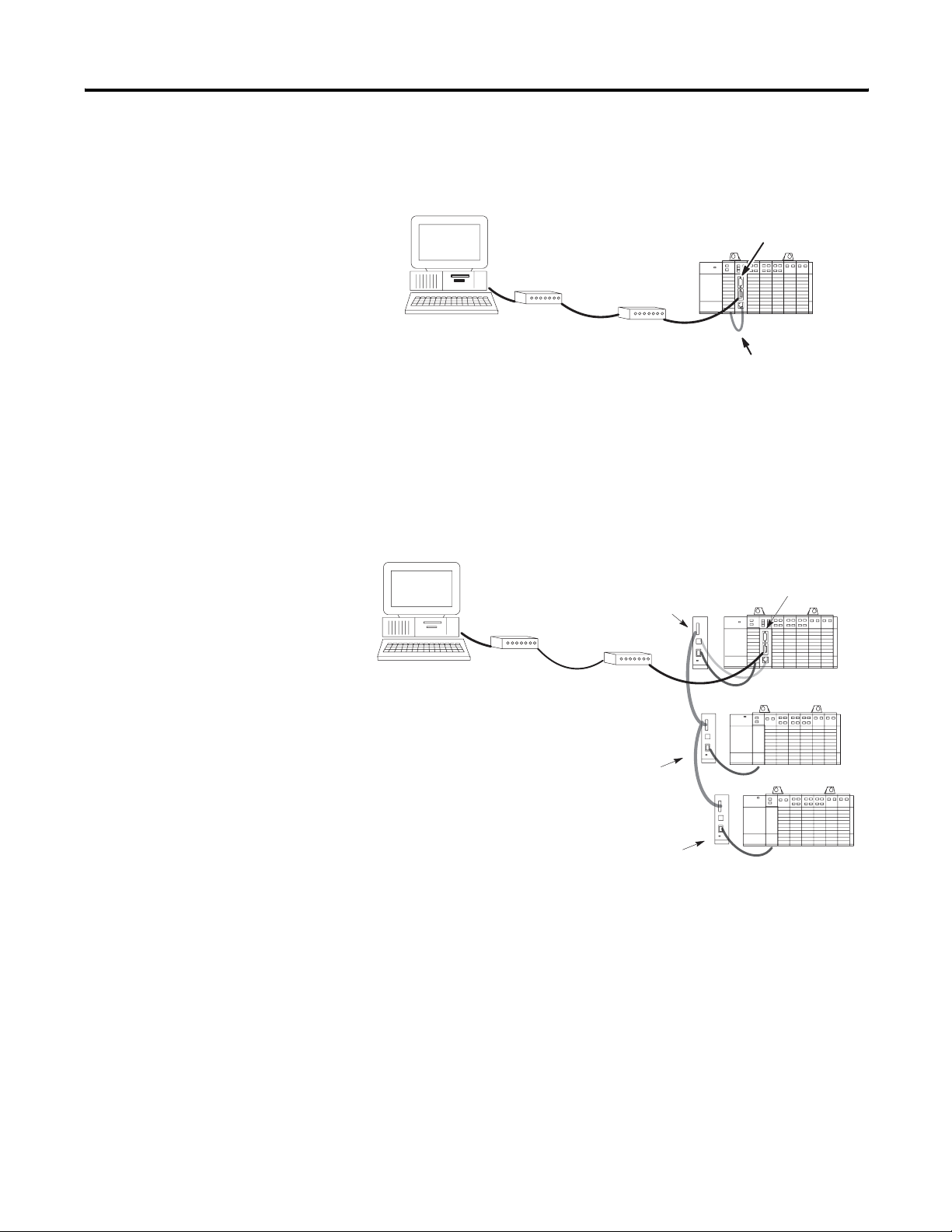

Full-duplex (Point-to-point)

Full-duplex (Point-to-point)

Interface Module

DF1

Modem

Modem

This illustration shows a connection to a single remote SLC node. The

1747-C13 cable eliminates the need for a 1747-AIC link coupler.

(1747-KE)

1747-C13 Cable

Full-duplex (Network, Example 1)

Full-duplex (Network, Example 1)

Interface Module

RSLInx

Link Coupler

(1747-AIC)

Modem

Modem

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

This illustration shows a connection to a remote DH-485 network of

up to 31 SLC nodes.

(1747-KE)

Publication 1747-UM005B-EN-P - March 2006

Page 19

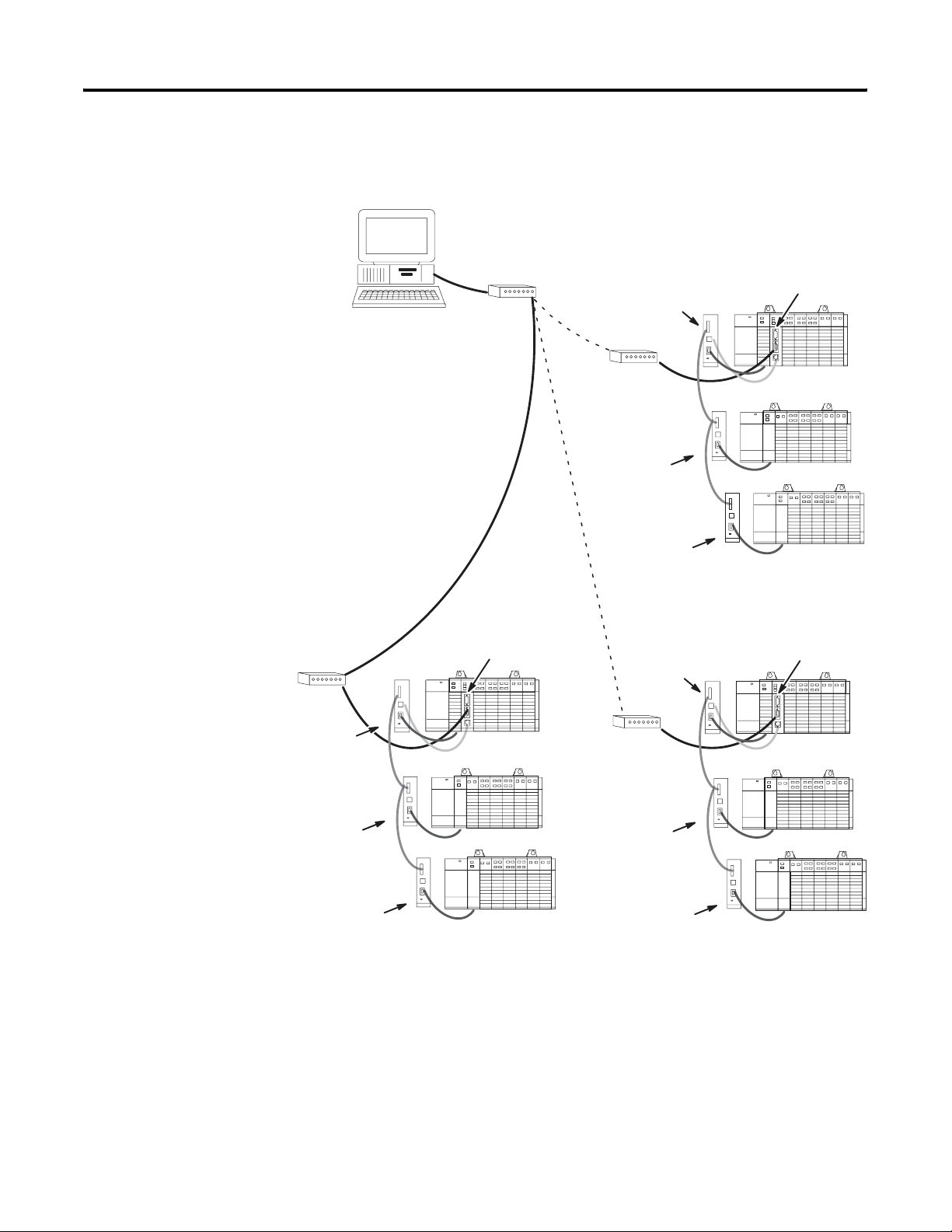

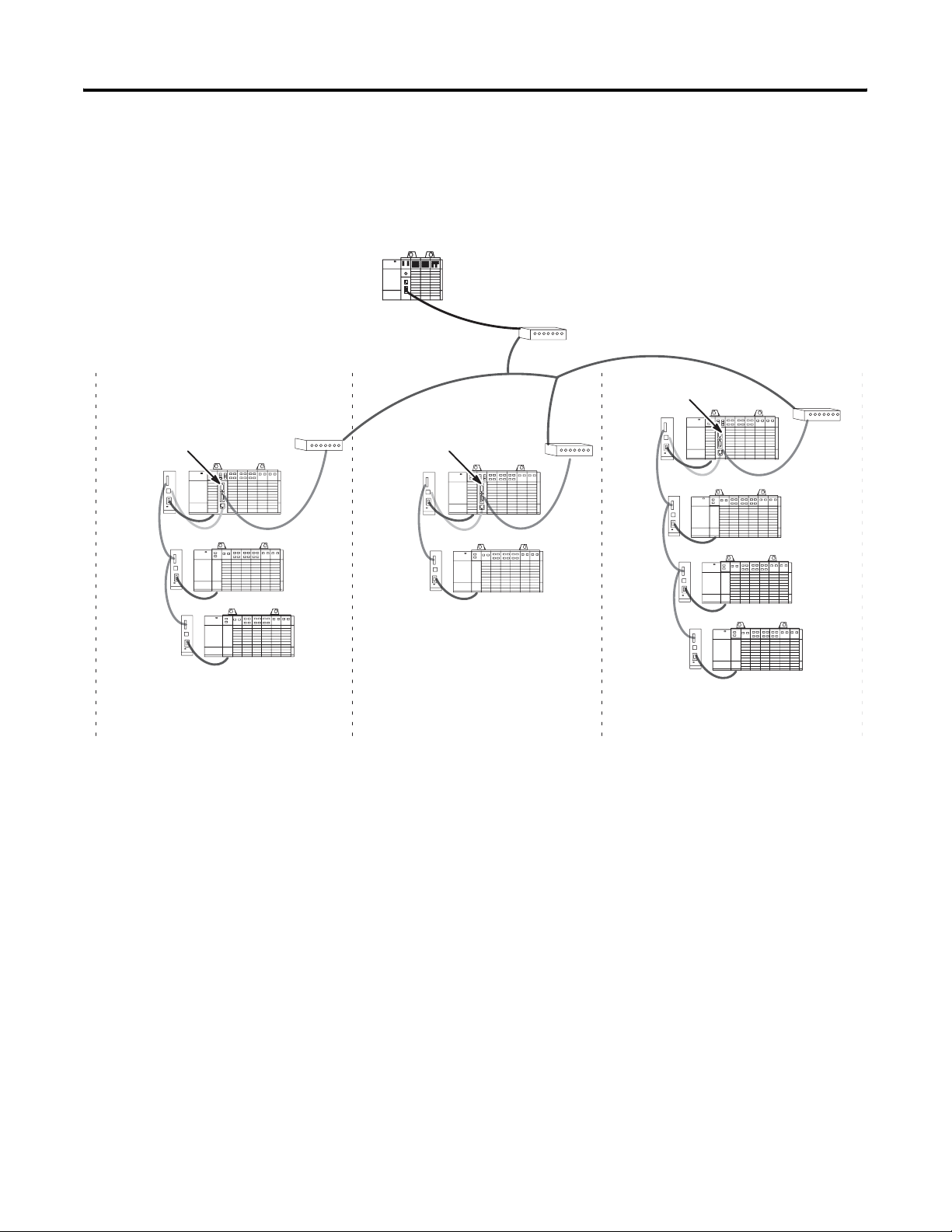

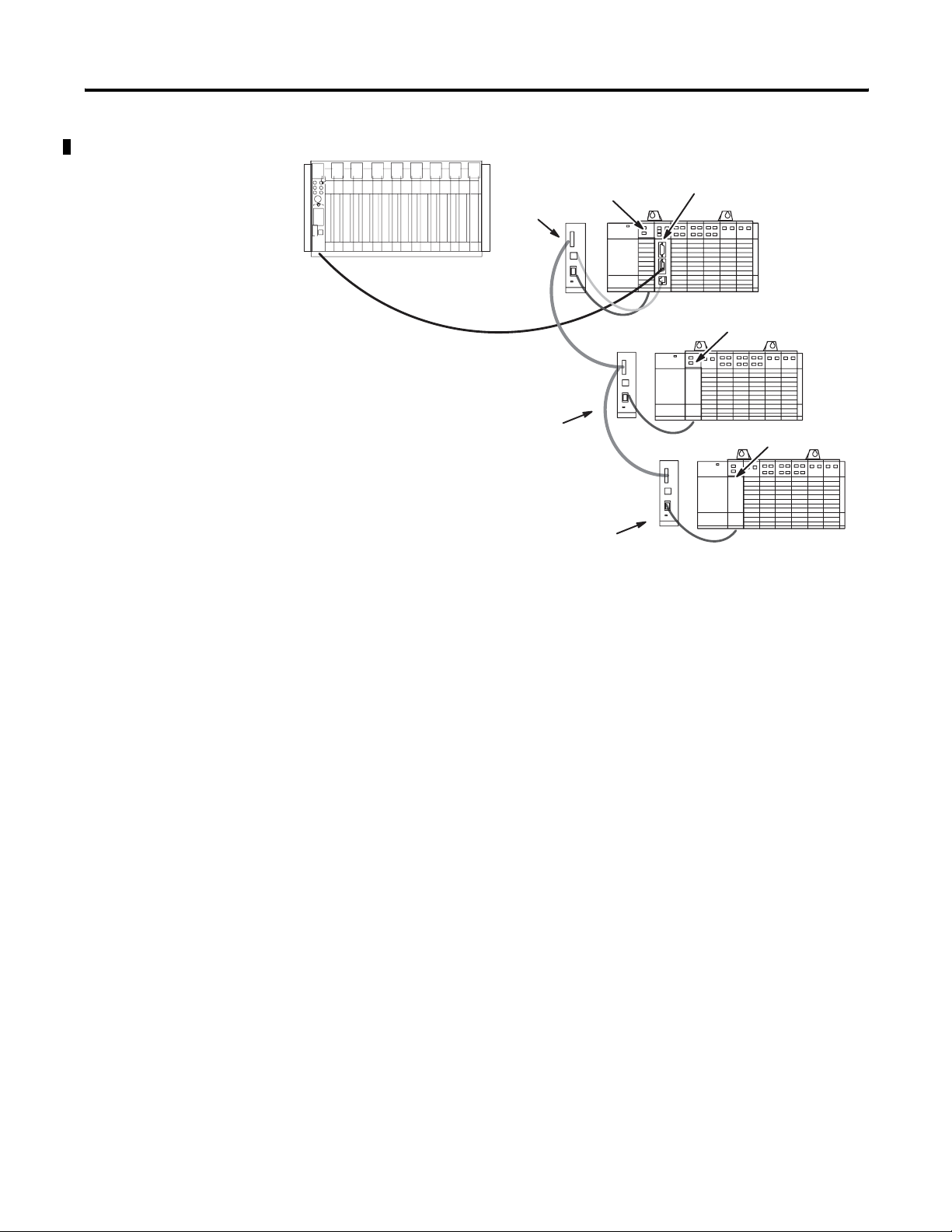

Full-duplex (Network, Example 2)

Full-duplex (Network, Example 2)

RSLinx

Modem

Host computer is capable of

calling and interfacing with

one network at a time.

Overview 1-7

Interface Module

(1747-KE)

Link Coupler

(1747-AIC)

Modem

Link Coupler

(1747-AIC)

Modem

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

Interface Module

(1747-KE)

Link Coupler

(1747-AIC)

Modem

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

Interface Module

(1747-KE)

This configuration allows the host to call more than one remote

network (one network connected at a time). Each remote network can

consist of up to 31 SLC nodes.

Publication 1747-UM005B-EN-P - March 2006

Page 20

1-8 Overview

Half-duplex (Local Mode)

Half-duplex (Local Mode) Master

Interface Module

PLC-5

processor

Modem

Link Coupler

(1747-AIC)

Modem

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

This configuration allows the host controller to interface on a remote

DH-485 network of up to 31 SLC nodes using the half-duplex

protocol.

(1747-KE)

Publication 1747-UM005B-EN-P - March 2006

Page 21

Half-duplex (Remote Mode)

Half-duplex (Remote Mode) Master

SLC 5/05

processor

Overview 1-9

Dedicated Line

Modem

Interface Module

(1747-KE)

Dedicated Line

Modem

Dedicated

Line Modem

Interface Module

(1747-KE)

Group 01Group 00

Dedicated Line

Modem

Interface Module

(1747-KE)

Group

02

This illustration shows a host connect up to eight groups of DH-485

networks, connecting up to a total of 254 SLC nodes.

Publication 1747-UM005B-EN-P - March 2006

Page 22

1-10 Overview

Half-duplex (Slave-to-slave Communication)

Half-duplex (Slave-to-slave Communication)

Link Coupler

Link Coupler

(1747-AIC)

SLC 5/05

processor

Dedicated Line

Modem

(1747-AIC)

Interface Module

(1747-KE)

(DF1 Slave)

RSLinx

(DF1 Slave)

Dedicated Line

Modem

Dedicated Line

Modem

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

This configuration allows a DF1 slave device send a message to

another DF1 slave device. In this example, RSLinx can communicate

to an SLC slave.

Publication 1747-UM005B-EN-P - March 2006

Page 23

Chapter

2

Quick Start

This chapter can help you to get started using the DH-485/RS-232C

Interface Module (catalog number 1747-KE). The procedures included

here assume that you have a basic understanding of SLC 500 products.

You should understand electronic process control and be able to

interpret the ladder logic instructions required to generate the

electronic signals that control your application.

Because it is a start-up guide, this chapter does not contain detailed

explanations about the procedures listed. It does, however, reference

other chapters in this book where you can get more information about

applying the procedures described in each step.

Required Tools and Equipment

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended documentation before

trying to apply the information.

This chapter:

• tells you what tools and equipment you need.

• lists preliminary considerations.

• explains how to install the module.

• describes when to configure the module.

• discusses system start-up procedures.

Have the following tools and equipment ready.

• Medium blade screwdriver

• Programming equipment (RSLogix 500 software)

1 Publication 1747-UM005B-EN-P - March 2006

Page 24

2-2 Quick Start

Procedures

Unpack the Module

Remove the items from the package making sure that the contents

include:

• DH-485/RS-232C Interface Module (catalog number 1747-KE).

• cable (1747-C13).

• installation instructions, publication 1747-IN006.

If the contents are incomplete, call your local Rockwell Automation

representative for assistance.

Install the Module

ATTENTION

Do not install or remove the 1747-KE module from

the SLC chassis until all power dissipates from the

SLC 500 power supply (approximately 10 seconds).

Install the module and configure the SLC chassis. The following steps

summarize these procedures.

1. Choose the module’s functionality.

2. Select the configuration method you want to use and place your

module in the corresponding mode using JW4.

3. Set your CONFIG and DF1 ports using JW1 and JW2.

4. Configure your SLC chassis using RSLogix 500 software.

5. Configure the module.

6. If your module is still in Configuration mode, place it in Run

mode using the JW4 jumper.

7. Connect your DH-485 and DF1 cabling.

8. Turn on power and verify module status.

For more information refer to Chapter 4 (Installation and System

Configuration).

Publication 1747-UM005B-EN-P - March 2006

Page 25

Quick Start 2-3

Configure the Module

Configure the module by either connecting to an ASCII terminal or

communicating through the backplane.

For more information, see Chapter 5 (Module Configuration Using an

ASCII Terminal) and Chapter 6 (Module Configuration Using the

Backplane).

Start-up the Module

Power up your system by performing standard start-up procedures as

indicated in your processor manual. No special start-up procedures

are required when using the module.

Before applying power to the module, make sure:

• the module is installed in the SLC chassis.

• all communication devices are connected.

• your SLC processor is configured to operate with the interface

module.

Refer to Chapter 4 for more information.

• your interface module is configured properly.

Refer to Chapters 5 and 6 for more information.

When power is applied to the SLC system, the SLC processor and

module run through a power cycle diagnostic sequence. After the

diagnostics are successfully completed, the SLC processor enters Run

mode and normal operation begins.

ATTENTION

This module is a device used for communications.

Improper configuration or module failure may cause

communications to stop. Be careful to avoid system

designs that would cause potential safety concerns

within the system in the event of a communications

failure.

Publication 1747-UM005B-EN-P - March 2006

Page 26

2-4 Quick Start

Publication 1747-UM005B-EN-P - March 2006

Page 27

Chapter

Communicate with the Interface Module

This chapter explains:

• full- and half-duplex DF1 communication.

• local and remote half-duplex operation.

• communicating with master and slave DH-485 devices.

• communicating with a modem.

3

DF1 Communication

The module supports full-duplex DF1 protocol and half-duplex DF1

slave protocol on its RS-232 connection to the host computer (using

the DF1 Port). The details of these protocols can be found in the DF1

Protocol and Command Set Reference Manual, publication

1770-RM516.

Full-duplex DF1 Protocol

Full-duplex DF1 protocol is provided for applications where high

performance peer-to-peer communication is needed.

In full-duplex mode, the module can send embedded responses. If the

embedded response detect option is set to auto-detect embedded

response, the module will not send embedded responses until it

receives one from the host. The module makes an assumption that if a

host computer sends embedded responses, it can also receive them.

In full-duplex mode, the destination address in a packet sent from the

host computer to the module is the address of the DH-485 node for

which the packet is intended. The source address in packets received

by the host computer from the module is the node address of the

sender.

1 Publication 1747-UM005B-EN-P - March 2006

Page 28

3-2 Communicate with the Interface Module

Full-duplex (Point-to-point)

Full-duplex (Point-to-point)

Interface Module

RSLinx

Modem

Modem

(1747-KE)

1747-C13 Cable

This illustration shows a connection to a single remote SLC node. The

1747-C13 cable eliminates the need for a 1747-AIC link coupler for

connections to one node.

Full-duplex (Network Example)

Full-duplex (Network Example)

Interface Module

RSLinx

Link Coupler

((1747-AIC)

Modem

Modem

Link Coupler

((1747-AIC)

Link Coupler

((1747-AIC)

(1747-KE)

This illustration shows a connection to a remote DH-485 network of

up to 31 SLC nodes.

Publication 1747-UM005B-EN-P - March 2006

Half-duplex DF1 Protocol

The module provides two modes of half-duplex addressing: local and

remote. Local mode is provided for compatibility with earlier DF1

products, such as the Data Highway/Data Highway Plus

Asynchronous Interface Module (catalog number 1770-KF2) and when

only one interface module is used in the system.

Page 29

Communicate with the Interface Module 3-3

You may prefer local mode for use in applications where the RS-232C

link is not networked, since it simplifies the polling algorithm.

Remote mode should be used when more than 31 SLC nodes are

required on the DH-485 network. Because the interface module is

transparent to the master device, existing drivers can be used without

rewriting.

Local Mode

Local mode requires an intelligent master device, capable of

specifying both a station address and a destination address. Because

the interface module acts as a slave on a half-duplex network, the

half-duplex master’s access to the DH-485 node is indirect. The

destination address and the station address are generally different.

In local mode, the polling algorithm used by the half-duplex master is

simplified so that the master only needs to poll the single interface

module. The module will respond to messages from the half-duplex

master only if the station address contained in these messages is the

node address of the interface module. The module then forwards the

packet to the appropriate DH-485 node, as defined by the destination

address.

Responses from remote nodes on the DH-485 network contain a

destination address equal to that of the interface module, and not that

of the half-duplex master device. The module responds to poll

packets from the half-duplex master by returning whatever data has

been forwarded to it by the remote nodes under its jurisdiction.

In the Local Mode illustration on page 3-4, the half-duplex master only

polls the interface module at station address 01.

Messages from the half-duplex master to the SLC 500 controllers are

sent using a master message containing both the station address of the

interface module (node 01) and the destination address of the SLC 500

controller (node 03 for example). Responses from the SLC 500

controllers to the half-duplex master contain the destination address

of the interface module (node 01), which then returns all responses to

the half-duplex master station upon being polled.

During configuration of the interface module, the module’s

destination address, or slave address, is selected if Local mode has

been selected.

Publication 1747-UM005B-EN-P - March 2006

Page 30

3-4 Communicate with the Interface Module

Local Mode

PLC 5

controller

DF1 Master

Remote Mode

Link Coupler

((1747-AIC)

RS-232C DF1

Link Coupler

((1747-AIC)

DH-485

SLC 500

Node 02

DH-485

Link Coupler

((1747-AIC)

SLC 500

Node 01

SLC 500

Node 03

SLC 500

Node 00

The valid range of slave addresses on a half-duplex network is 000

through 376 octal (000 through 254 decimal) accommodating a total of

255 devices. The valid range of addresses on a DH-485 network is 00

through 37 octal (00 through 31 decimal).

To let addressing of up to 255 DH-485 nodes, eight groups (group

numbers 00 through 07) of DH-485 networks are established. Each

group number defines a DH-485 network, which can consist of up to

32 nodes each (except for group 07 which is limited to 31 nodes).

Refer to the table on page 3-6.

During configuration of the interface module, the module’s group

number is selected if Remote mode has been selected.

In remote mode, the module appears transparent to the half-duplex

master, so that remote SLC 500 controllers can be polled directly as

individual slaves on the half-duplex network. The interface module

responds to the half-duplex master if the station address specified

corresponds to the node address of any (token-passing) station on

the DH-485 network connected to that interface module.

Publication 1747-UM005B-EN-P - March 2006

Page 31

Communicate with the Interface Module 3-5

Messages from the remote nodes on the DH-485 network (such as the

SLC nodes) use the destination address of the module. Normally the

module responds to a message from the DF1 master by swapping the

source and destination addresses in the received message, assuring

that the reply message is sent to the proper DF1 master station.

If a DH-485 node initiates a message to the DF1 master, the module

overwrites the destination address with the master station value

configured in the Remote mode submenu. The message received by

the half-duplex master will contain a source address equal to the

station address specified in the poll packet, and a destination address

equal to the address of the half-duplex master device.

Remember that half-duplex DF1 (group) addresses are in octal and

DH-485 node addresses are in decimal.

The table on page 3-6 provides the conversion using the group

number.

Publication 1747-UM005B-EN-P - March 2006

Page 32

3-6 Communicate with the Interface Module

Half-duplex Remote Address Conversion Table

DH-485

Node

Address

(decimal)

Group 00 Group 01 Group 02 Group 03 Group 04 Group 05 Group 06 Group 07

Half–duplex DF1 Address (octal)

00 000 040 100 140 200 240 300 340

01 001 041 101 141 201 241 301 341

02 002 042 102 142 202 242 302 342

03 003 043 103 143 203 243 303 343

04 004 044 104 144 204 244 304 344

05 005 045 105 145 205 245 305 345

06 006 046 106 146 206 246 306 346

07 007 047 107 147 207 247 307 347

08 010 050 110 150 210 250 310 350

09 011 051 111 151 211 251 311 351

10 012 052 112 152 222 252 322 352

11 013 053 113 153 213 253 313 353

12 014 054 114 154 214 254 314 354

13 015 055 115 155 215 255 315 355

14 016 056 116 156 216 256 316 356

15 017 057 117 157 217 257 317 357

16 020 060 120 160 220 260 320 360

17 021 061 121 161 221 261 321 361

18 022 062 122 162 222 262 322 362

19 023 063 123 163 223 263 323 363

20 024 064 124 164 224 264 324 364

21 025 065 125 165 225 265 325 365

22 026 066 126 166 226 266 326 366

23 027 067 127 167 227 267 327 367

24 030 070 130 170 230 270 330 370

25 031 071 131 171 231 271 331 371

26 032 072 132 172 232 272 332 372

27 033 073 133 173 233 273 333 373

28 034 074 134 174 234 274 334 374

29 035 075 135 175 235 275 335 375

30 036 076 136 176 236 276 336 376

31 037 077 137 177 237 277 337 Illegal

Publication 1747-UM005B-EN-P - March 2006

Page 33

Remote Mode Addressing on a Multi-drop Network Example

This example shows a PLC-5 controller as the half-duplex master in a

multi-drop configuration. Each interface module has been configured

after Remote mode has been selected. The half-duplex master address

of the PLC-5 controller has been set to 010 (octal).

Remote Mode Addressing on a Multi-drop Network

PLC-5 processor

010

8

Communicate with the Interface Module 3-7

Dedicated Line

Modem

SLC 500

005

8

05

SLC 500

002

02

SLC 500

011

09

Interface Module

010

8

01

8

8

Dedicated Line

Modem

Interface Module

040

8

Dedicated Line

Modem

00

SLC 500

044

8

04

SLC 500

043

8

03

XXX

= DF1 Multi-drop Address (octal)

8

XX = DH-485 Local (decimal) Network Address

Group 01Group 00

SLC 500

100

8

00

SLC 500

131

8

25

SLC 500

120

16

Interface Module

0101

8

01

8

SLC 500

104

8

04

Group

Dedicated Line

Modem

02

IMPORTANT

Each interface module must be set up for a unique

group number.

Publication 1747-UM005B-EN-P - March 2006

Page 34

3-8 Communicate with the Interface Module

The group number is used by the interface module to create a

half-duplex DF1 address for each node on the DH-485 network. The

DF1 addresses are the octal equivalent of an eight bit binary word

with the three most significant bits corresponding to the group

number and the five least significant bits corresponding to the local

network address.

Addresses

Group Number

(3 in this example)

and

DH-485 Local Network Address

(29 in this example)

011 11101

combine to make

this binary word

which has this octal value.

(DF1 Multi-drop Address)

The following table lists the devices from the above network along

with their DH-485 local network address and their DF1 multi-drop

address.

Devices and Corresponding Addresses

Group Device DH-485 Address

00 1747–KE 01 00|000|001 001

SLC 500 02 00|000|010 002

SLC 500 05 00|000|101 005

SLC 500 09 00|001|001 011

01 1747–KE 00 00|100|000 040

SLC 500 04 00|100|100 044

SLC 500 03 00|100|011 043

1747–KE 01 01|000|001 101

02 SLC 500 00 01|000|000 100

SLC 500 25 01|011|001 131

SLC 500 16 01|010|000 120

SLC 500 04 01|000|100 104

01

(decimal)

111 101

17

DF1 Address

(binary)

5

DF1 Address

(octal equivalent)

Publication 1747-UM005B-EN-P - March 2006

Page 35

Communicate with the Interface Module 3-9

Slave-to-slave Communication

The interface module lets communication from a DH-485 network

device to a single DF1 slave device, regardless of which mode of

half-duplex addressing is selected (local or remote). To achieve this,

the interface module’s Master Station Address must be configured as

that DF1 slave address.

For example, if the RSLinx terminal in the illustration below is DF1

node 3, the interface module’s Master Station Address must be

configured as node 3.

Slave-to-slave Communication

PLC-5

processor

(DF1 Master)

(DF1 Slave)

DF1 Slave

Dedicated Line

Modem

Dedicated Line

Modem

Dedicated Line

Modem

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

Link Coupler

(1747-AIC)

Interface Module

(1747-KE)

In this illustration, a packet from the RSLinx computer, intended for an

SLC node, is first transferred to the PLC-5 controller (DF1 master). The

PLC-5 controller then transfers the packet to the interface module,

which converts it to a DH-485 packet and sends it to the specified SLC

node. The SLC node’s response goes through the interface module to

the PLC-5 controller. The PLC-5 controller then transfers the response

to the RSLinx computer.

The operation of slave-to-slave communication differs slightly

depending on whether the interface module is in local or remote

mode.

Publication 1747-UM005B-EN-P - March 2006

Page 36

3-10 Communicate with the Interface Module

Slave-to-slave communication

When the interface module is in Slave-to-slave communication occurs

Local mode Only if the module’s DF1 node is the same as the

DH-485 node for which the message is destined.

In this mode the RSLinx computer can only

communicate with one SLC node.

For example, if you want a DF1 slave terminal in

the illustration above to communicate with an

SLC processor in node 2 of the DH-485 network,

then the interface module’s DF1 slave address

must be set to 2.

Remote mode Between the DF1 slave and any of the DH-485

devices connected to the interface module. The

addresses for the DH-485 devices are

determined by the group number in the interface

module.

Refer to the Half-duplex Remote Address

Conversion Table in Chapter 3.

Communicate with DH-485 Devices

For example, if the interface module in the

illustration above is configured as group 03, and

the DH-485 node to be accessed has a DH-485

address of 01, then the DF1 slave device will use

address 141 (octal) when accessing this device.

ATTENTION

Do not force outputs to a remote SLC system through

the interface module. Phone line disturbances,

interface module failure, or other system failure

could disrupt remote communications and cause the

outputs to remain active.

DH-485 Token Passing Devices

The interface module operates as a token passing master on the

DH-485 network. It can communicate with other DH-485 master

stations (such as an SLC 5/02 processor) and with DH-485 token

passing slave devices (such as an SLC 5/01 processor).

Publication 1747-UM005B-EN-P - March 2006

The module communicates with other master stations using the

Allen-Bradley programmable controller command set. For details,

refer to the DF1 Protocol and Command Set Reference Manual,

publication 1770-RM516.

Page 37

Communicate with the Interface Module 3-11

DH-485 Non-Token Passing Devices

The DH-485 network also supports non-token passing slave devices.

The module communicates with these slaves using a special PLC

command (CMD) byte.

Application programs communicate with non-token passing slaves via

Send and Receive Data (SRD) messages on DH-485. The SRD message

is a link layer service provided on DH-485. The Programmable

Controller Communications Command Set (PCCC) has been extended

to provide SRD messages by setting the PCCC CMD byte to 09. The

SRD message cannot be used in slave-to-slave communication.

A detailed description of the packet is found in the DF1 Protocol and

Command Set Reference Manual, publication 1770-RM516.

The format of the application layer data within the packet is

completely dependent on how the destination device is implemented.

Refer to the destination device’s user manual for this information.

Communicate with a Modem

The hardware handshaking option must be enabled for the module to

properly control a modem.

The module continually asserts DTR while it is waiting for a call.

Under this condition, the modem answers a call and asserts DCD

upon connection. When the module detects DCD, communications

can start.

After detecting DCD, the module continues to monitor the DCD line.

If DCD goes off, the module restarts the 10-second timeout. If DCD is

not restored within 10 seconds, the module initiates the hang-up

sequence. This feature lets the remote node to redial in case the

connection was lost due to a fault in the phone system.

This handshaking is necessary to guarantee access to the phone line.

If the handshaking protocol is defeated by improper selection of

modem options or wiring of communication cables, the modem may

still answer a call. But if the connection is lost, the modem will not

hang up. It will then be impossible for the remote node to reestablish

the connection because it will get a busy signal.

Publication 1747-UM005B-EN-P - March 2006

Page 38

3-12 Communicate with the Interface Module

For successful modem communication be sure that:

• RSLinx software and the interface module agree on

communication rate and error checking.

• both modems have the echo disabled.

• both modems have Carrier Detect set to normal (unforced).

• both modems have DTR Dialing disabled.

• the modem to receive the call has auto answer enabled.

Publication 1747-UM005B-EN-P - March 2006

Page 39

Chapter

Installation and System Configuration

This chapter provides the following installation and system

configuration information.

• European Union directives compliance

• Module functionality

• Mode selection

• Port configuration verification

• Module installation

• Cable connection

•

SLC chassis, DF1 driver, and module configuration

4

European Union Directives Compliance

ATTENTION

If this product has the CE mark, it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

Do not install or remove the 1747-KE module from

the SLC chassis until all power dissipates from the

SLC 500 power supply (approximately 10 seconds).

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2

EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

1 Publication 1747-UM005B-EN-P - March 2006

Page 40

4-2 Installation and System Configuration

Choose the Module’s Functionality

Your series B interface module has the ability to function as a series A

interface module. This feature may be important to you if you are

replacing a series A module with a series B module.

Refer to page 4-2 for more information.

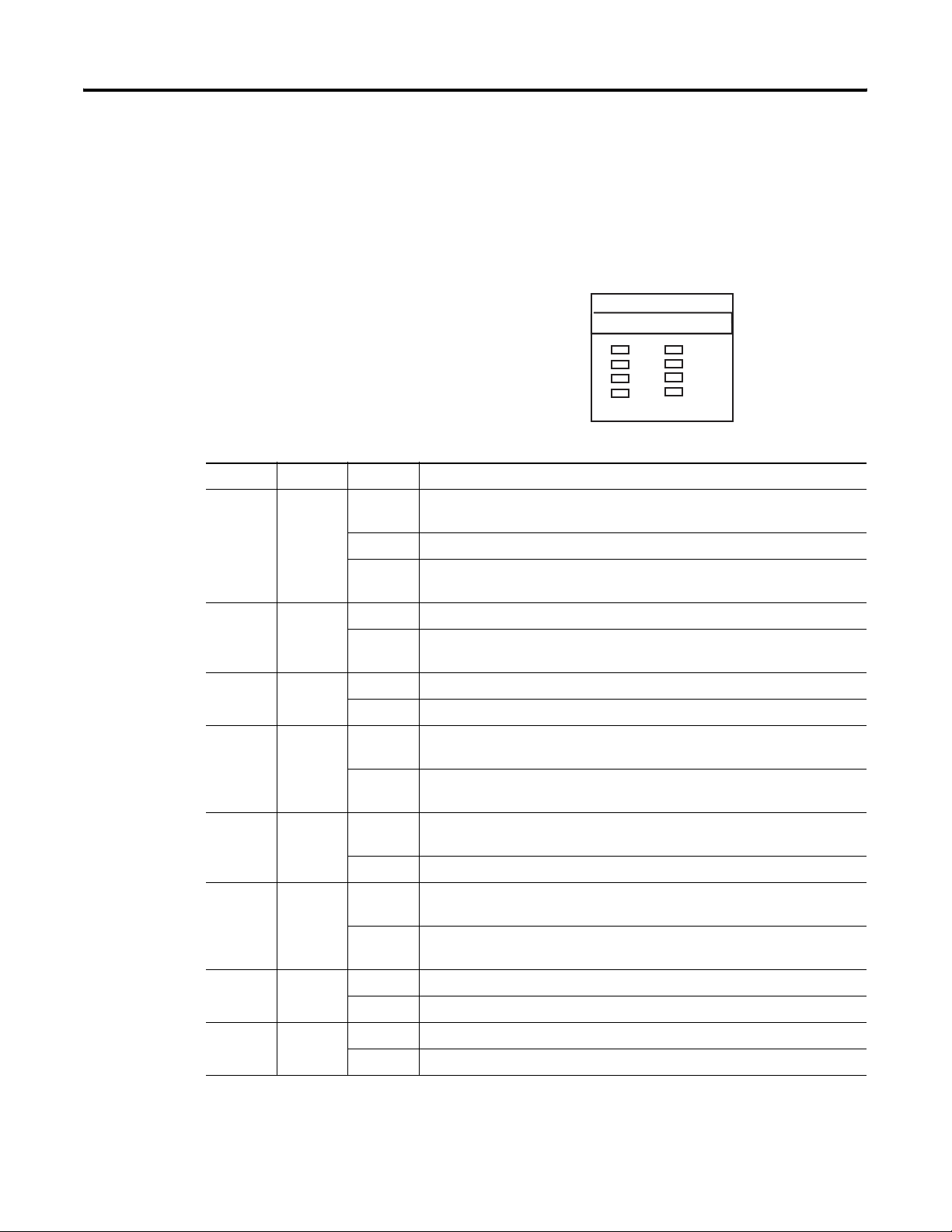

The module’s functionality depends on the placement of the JW4

jumper. Horizontal placement of the jumper gives the module

functionality equivalent to a series A interface module, while vertical

placement of the jumper accesses the added functionality of a series B

interface module.

Module Functionality Settings

Series A Functionality

(mod. config. ID=4209)

Horizontal

Configuration

Mode

Horizontal Run

Mode

Series B Functionality

(mod. config. ID=3509)

Vertical

Configuration

Mode

Vertical Run

Mode

Add an Interface Module to Your System

If you are not replacing a series A module, you will want to access the

full functionality of the series B module. Therefore, as you work

through the remainder of this manual, follow the instructions for

series B functionality (vertical placement of the JW4 jumper).

Skip the next section and move on to Set the Module’s Mode.

Replace a Series A Interface Module in Your System

IMPORTANT

Series A Functionality

If you do not want to alter the existing configuration in your user

program in any way, choose the series A functionality for your new

module. The horizontal placement of JW4 gives the series B module a

Choosing series B functionality requires you to

change the module configuration ID assigned in

your processor.

Publication 1747-UM005B-EN-P - March 2006

Page 41

Installation and System Configuration 4-3

module configuration ID equivalent to the module configuration ID of

the series A module you are replacing (4209).

As you work through the remainder of this manual, follow the

instructions for series A functionality (horizontal placement of the JW4

jumper).

IMPORTANT

The increased functionality of the series B interface

module (for example, the Real Time Clock,

backplane configuration, and SLC processor reset of

the interface module) is not available with the series

A functionality.

Series B Functionality

The series B module functions identical to the series A module, but

has these additional features.

• Real Time Clock (RTC)

• Backplane configuration

• SLC processor reset of the interface module

If you want to use the added features of the series B interface module,

follow the directions given for series B functionality (vertical

placement of the JW4 jumper) as you work through the remainder of

this manual.

IMPORTANT

You will be required to change the module

configuration ID assigned in your processor. The

vertical placement of the JW4 jumper gives your

module a configuration ID that differs from the

configuration ID of your series A interface module.

The procedure for changing the module

configuration ID is explained later in this chapter.

See page 4-13 for more information.

Publication 1747-UM005B-EN-P - March 2006

Page 42

4-4 Installation and System Configuration

Set the Module’s Mode

Setting the module’s mode depends on which method you want to

use to configure the module. You can configure the module using:

• an ASCII terminal.

• backplane communications.

IMPORTANT

You can only use backplane communications if you

selected series B functionality for the module.

Decide which method you want to use and then place the JW4 jumper

according to the directions given below.

Configure with an ASCII Terminal

Configuration of the interface module with an ASCII terminal is

allowed only when the JW4 jumper is in Configuration mode. Place

the module in the Configuration mode that corresponds to the

functionality you chose for the interface module.

JW4 in Configuration Mode

Series A Functionality Series B Functionality

Horizontal

Configuration

Mode

Vertical

Configuration

Mode

Configure Through the Backplane

Reading and writing configuration data through the backplane is

allowed only for series B interface modules, and then only when the

JW4 jumper is in the vertical Run mode position. Place the module in

vertical Run mode.

JW4 in Vertical Run Mode

JW4

Publication 1747-UM005B-EN-P - March 2006

Vertical Run Mode

Page 43

Installation and System Configuration 4-5

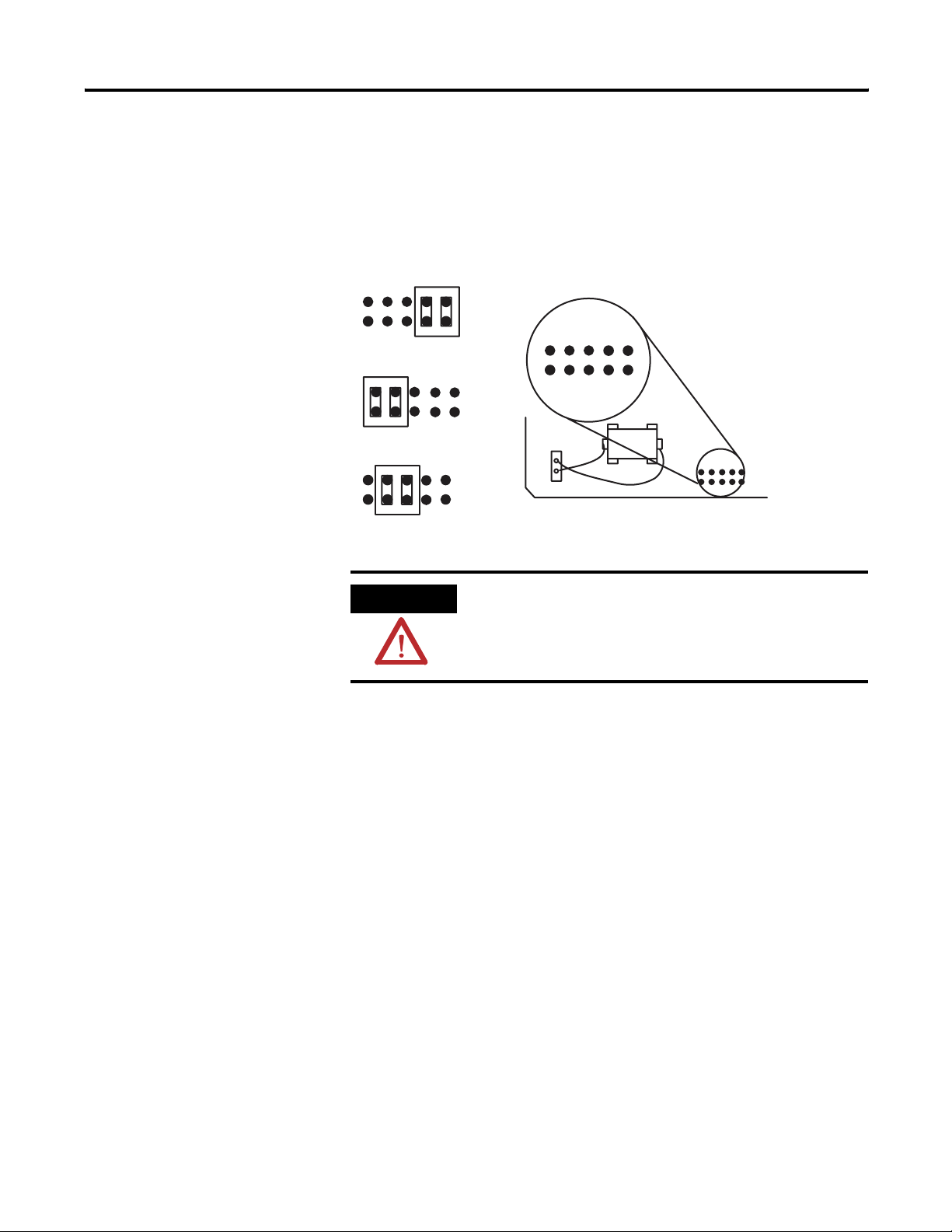

Verify CONFIG Port Configuration

RS-423/232

RS-422

RS-485

Jumper JW1, located at the top of the module, selects the following

electrical interface for the CONFIG port.

• RS-423/232 (default)

• RS-422

• RS-485

CONFIG Port Configuration

246810

13579

JW1 CONFIG Port

ATTENTION

All other jumper settings are illegal and may cause

damage to the module.

Publication 1747-UM005B-EN-P - March 2006

Page 44

4-6 Installation and System Configuration

Verify DF1 Port Configuration

RS-423/232

RS-485

RS-422

Jumper JW2 selects the following electrical interface for the DF1 port.

• RS-423/232 (default)

• RS-422

• RS-485

DF1 Port Configuration

13579

246810

JW2 DF1 Port

ATTENTION

All other jumper settings are illegal and may cause

damage to the module.

Publication 1747-UM005B-EN-P - March 2006

Page 45

Installation and System Configuration 4-7

Install Your Module in an Open Slot

Installation procedures for this module are the same as any other

digital I/O or specialty module.

IMPORTANT

ATTENTION

Make sure you have JW1, JW2, and JW4 configured.

Do not install or remove the 1747-KE module from

the SLC 500 chassis until all power dissipates from

the SLC 500 power supply (approximately 10

seconds).

To install the module:

1. Align the full-size module circuit board with the chassis card

guide.

The first slot (slot 0) of the first chassis is reserved for the CPU.

2. Slide the module into the chassis until the top and bottom

latches are latched.

To remove the module, press the releases at the top and bottom

of the module and slide it out.

Module Release

Card Guide

Publication 1747-UM005B-EN-P - March 2006

Page 46

4-8 Installation and System Configuration

Connect Cable to CONFIG or DF1 Ports

The CONFIG and DF1 ports communicate to user devices through

RS-423/232, RS-422, and RS-485 Communication modes.

The Communication mode is selected by setting jumpers JW1 and JW2

as described on pages 4-5 and 4-6.

IMPORTANT

The following table and cable drawings assume the

peripheral devices have conventional pin

assignments. Check the documentation for your

device to verify signals conform to those shown.

Use these pin assignments to construct communication cables for the

CONFIG and DF1 ports. These connectors must be wired to

correspond to the selected communication mode.

Pin Assignments for CONFIG and DF1 Ports

Pin for

Interface

Module

1

RS-423/232

Signal

(1)

RS-422

Signal

RS-485

Signal

IBM AT Standard

RS-423/232

Signal 25-pin

Pin

9-pin

Pin

TXD- TRXD- DCD or CD81

2 RXD RXD-

3TXD

4DTR

(2)

(2) (2)

(3)

(2)

RXD 3 2

TXD 2 3

DTR 20 4

5 COM COM COM COM 7 5

6 DSR RXD+

7RTS

8CTS

9

(1)

(2)

(3)

(1)

In RS-423 mode, these pins are still connected to their RS-422 loads. Do not use these pins in RS-423

mode.

In RS-422 and RS-485 modes these pins are connected to their RS-423 drivers and receivers. Do not

use these pins in either RS-422 or RS-485 modes.

In RS-485 mode, these pins are still connected to their RS-422 receivers. Do not use these pins in

RS-485 mode.

IMPORTANT

(2) (2)

(2) (2)

TXD+ TRXD+ RI 22 9

The signal names on a DCE device are viewed from

(3)

DSR 6 6

RTS 4 7

CTS 5 8

a DTE perspective. For example, TXD is a DTE

output and also a DCE input.

Publication 1747-UM005B-EN-P - March 2006

Page 47

Installation and System Configuration 4-9

These illustrations show wiring diagrams for the RS-423/232, RS-422,

and RS-485 communications.

RS-423/232 DTE to DCE (Non-modem Hardware Handshake to DCE)

Interface Module

NC

1

RXD

TXD

DTR

COM

DSR

RTS

CTS

NC

2

3

4

5

6

7

8

9

DTE DCE

RS-423/232 DTE to DCE (Modem Hardware Handshake to DCE)

NC

RXD

TXD

DTR

COM

DSR

RTS

CTS

NC

1

2

3

4

5

6

7

8

9

CD

RXD

TXD

DTR

COM

DSR

RTS

CTS

PeripheralInterface Module

CD

RXD

TXD

DTR

COM

DSR

RTS

CTS

RI

Peripheral

RI

9-pin 25-pin

1

2

3

4

5

6

7

8

9

9-pin 25-pin

1

8

2

3

3

2

4

20

5

7

6

6

7

4

8

5

9

22

8

3

2

20

7

6

4

5

22

DTE DCE

Publication 1747-UM005B-EN-P - March 2006

Page 48

4-10 Installation and System Configuration

1)

1)

1)

1)

RS-423/232 DTE to DCE (No Handshake to DCE)

PeripheralInterface Module

9-pin 25-pin

NC

RXD

TXD

DTR

COM

DSR

RTS

CTS

NC

1

2

3

4

5

6

7

8

9

CD

RXD

TXD

DTR

COM

DSR

RTS

CTS

RI

1

8

2

3

3

2

4

20

5

7

6

6

7

4

8

5

9

22

(

(

DTE DCE

(1)

Connect DSR to DTR and CTS to RTS when using devices that cannot disable their hardware handshaking.

RS-423/232 DTE to DTE (Soft or No Handshake to DTE

Interface Module

NC

RXD

TXD

DTR

COM

DSR

RTS

CTS

NC

1

2

3

4

5

6

7

8

9

COM

Peripheral

CD

RXD

TXD

DTR

DSR

RTS

CTS

RI

9-pin 25-pin

1

8

2

3

3

2

4

20

5

7

6

6

7

4

8

5

9

22

(

(

(1)

Publication 1747-UM005B-EN-P - March 2006

DTE DTE

Connect DSR to DTR and CD, and CTS to RTS when using devices that cannot disable their handshaking.

RS-422

PeripheralInterface Module

TXDRXD-

COM

RXD+

TXD+

DTE

1

2

3

RXDTXD-

4

5

6

7

COM

TXD+

8

9

RXD+

Page 49

RS-485

Installation and System Configuration 4-11

PeripheralInterface Module

Connect Cable to the DH-485 Port

TRXD-

COM

TRXD+

1

2

3

4

5

6

7

8

9

DTE

TRXD-

COM

TRXD+

The DH485 port can communicate to user devices through the

DH-485 Communication mode. Use a 1747-C11, 1747-C10, or

1747-C13 interface cable to connect the module to a link coupler

interfaced with the DH-485 network.

If you use the 1747-C11 or 1747-C10 cable, it connects between the

DH-485 port on the module and the J1 (CPU) connector on the link

coupler. Power for the link coupler will come from the interface

module.

Refer to page A-1 for more information.

Connect to the DH-485 Port via the 1747-C11 Cable

Link Coupler (1747-AIC)

J1 (CPU)

Cable

(1747-C11)

Interface Module (1747-KE)

CONFIG Port

DF1 Port

DH-485 Port

If you use the 1747-C13 cable, it connects between the DH-485 port

on the module and the J2 (Peripheral) connector on the link coupler.

Power for the link coupler must be provided from some other source.

See page A-1 for more information.

Publication 1747-UM005B-EN-P - March 2006

Page 50

4-12 Installation and System Configuration

Connect to the DH-485 Port via the 1747-C11 Cable

Link Coupler (1747-AIC)

Cable

(1747-C11)

Power is supplied to link coupler through the

DH-485 port on the SLC 500 processor.

OR

Power is supplied to link coupler by an

eternal power source.

J2 (Peripheral)

J1 (CPU)

The 1747-C13 cable can also connect the module’s DH-485 port

directly to a single SLC processor. It connects between the DH-485

port on the module and the DH-485 port on the SLC 500 processor.

Connect to the DH-485 Port via the 1747-C13 Cable

SLC 500 Processor

Interface Module (1747-KE)

Cable

(1747-C11)

Interface Module

(1747-KE)

CONFIG Port

DF1 Port

DH-485 Port

Publication 1747-UM005B-EN-P - March 2006

Module is connected directly to the

DH-485 port on the SLC processor.

Cable

(1747-C13)

Page 51

Installation and System Configuration 4-13

Configure Your SLC Chassis

The slot containing the interface module must be assigned within the

SLC program. Using RSLogix 500 software, you can either manually

insert the KE module into the chassis configuration in I/O

Configuration or select Read I/O Config to read the current I/O

configuration out of the processor and insert the module

automatically. Enter the module ID code 4209. The ID code for

interface modules with series A functionality is 4209, while the ID

code for the interface modules with series B functionality is 3509.

Entering the module ID code will automatically create the correct

input and output words.

Publication 1747-UM005B-EN-P - March 2006

Page 52

4-14 Installation and System Configuration

Configure the DF1 Driver within RSLinx Software

To configure the DF1 driver within RSLinx software:

1. Open RSLinx Classic.

2. Select Configure Drivers.

3. Click Add New.

4. Click Auto-Configure.

If RSLinx software successfully communicates with the 1747-KE

module, the following dialog appears.

Publication 1747-UM005B-EN-P - March 2006

Page 53

Installation and System Configuration 4-15

Configure Your Module

Complete the Installation of Your Module

Configuration instructions are in Chapter 5, Module Configuration

Using an ASCII Terminal, and Chapter 6, Module Configuration Using

the Backplane.

Proceed to the chapter that corresponds to the configuration method

you have chosen.

ATTENTION

This module is a device used for communications.

Improper configuration or module failure may cause

communications to stop. Be careful to avoid system

designs that would cause probable safety concerns

within the system in the event of a communication

failure.

Once your interface module has been configured, complete the

module’s installation.

ATTENTION

Do not install or remove the 1747-KE module from

the SLC 500 chassis until all power dissipates from

the SLC 500 power supply (approximately 10

seconds).

1. If you configured your module using an ASCII terminal, place

the module into Run mode.

a. Remove the module from the chassis.

The removal is reverse of the installation directions found on

page 4-7.

b. Place your module in Run mode using JW4

Series A Functionality

(mod. config. ID=4209)

Horizontal Run

Mode

Series B Functionality

(mod. config. ID=3509)

Vertical Run

Mode

Publication 1747-UM005B-EN-P - March 2006

Page 54

4-16 Installation and System Configuration

c. Re-insert the module into the chassis.

IMPORTANT

Make sure you have JW4 positioned for the Run

mode that corresponds to the functionality you’ve

chosen for your module.

2. Connect the DF1 cable to the DF1 port.

3. Connect the DH-485 cable to the DH-485 port.

4. Insert the cable tie in the slots and secure the cable.

5. Cover all unused slots with the Card Slot Filler (catalog number

1746-N2).

Publication 1747-UM005B-EN-P - March 2006

DF1 Port

DH-485 Port

6. Apply power to the SLC 500 chassis.

7. Verify that the LED indicators on the module indicate normal

operation per the LED indicator table on page 1-3.

Page 55

Chapter

5

Module Configuration Using an ASCII Terminal

This chapter guides you through the configuration of your interface

module using an ASCII terminal.

If you prefer to configure your module using backplane

communication, proceed to Chapter 6.

Once you complete the configuration, return to page 4-15 for

instructions on completing the installation of your module.

This chapter includes:

• configuration of the ASCII terminal.

• overview of module configuration with a terminal.

• top level setup menu.

• CONFIG port menu.

• DF1 port menu.

• DH-485 port menu.

• DF1 protocol menu.

• display parameters menu.

IMPORTANT

Configuration with an ASCII terminal is an alternate

configuration method than that presented in Chapter

6, Module Configuration Using the Backplane.

1 Publication 1747-UM005B-EN-P - March 2006

Page 56

5-2 Module Configuration Using an ASCII Terminal

ASCII Terminal Configuration

To communicate with the interface module through an ASCII terminal,

connect the terminal to the CONFIG port.

ASCII Terminal Configuration

Interface Module

(1747-KE)

ASCII Terminal

Cable

(1747-C13)

The ASCII terminal can be any industrial terminal, workstation, or

personal computer with terminal mode software that communicates in

alphanumeric mode.

Allen-Bradley has a development software package (catalog number

1747-PBASE) for the SLC 500 BASIC module that is capable of ASCII

terminal emulation on an IBM compatible computer.

HyperTerminal is a terminal emulation program included with all

versions of MicroSoft Windows.

Configure the ASCII terminal’s communication parameters for:

• 1200 Kbps.

• 8 bits per character.

• no parity.

• 1 stop bit.

• software handshaking enabled (

XON/XOFF).

Publication 1747-UM005B-EN-P - March 2006

Page 57

Module Configuration Using an ASCII Terminal 5-3

Module Configuration with a Terminal Overview

Configuration of the module with an ASCII terminal requires:

• an ASCII terminal connected to the CONFIG port.

• jumper JW4 to be in the configuration position.

See page 4-4 for more information.

• knowledge of the communication parameters of the devices you

will be connecting to each of the module ports.

• knowledge of what types of cables will be used to connect

devices to the module ports.

Refer to the cable information beginning on page 4-8.

When you power up the module and your ASCII terminal, a Top Level

Setup menu appears. The menu structure is three levels deep.

Menu Structure

Top Level

Setup

Menu

CONFIG

Setup

Port

DF1 Port

Setup

DH-485 Port

Setup

Half-duplex

Setup

DF1

Protocol

Setup

Display

Parameters

Full-duplex

Setup

Publication 1747-UM005B-EN-P - March 2006

Page 58

5-4 Module Configuration Using an ASCII Terminal

Top Level Setup Menu

The Top Level Setup Menu provides six selections.

Top Level Setup Menu

1747 KE Module, FRN #

T

op Level Setup Menu.

1.

CONFIG PORT

2. DF1 PORT

3. DH 485 PORT

4. DF1 PROTOCOL

5. DISPLA

X. SA

Enter Selection. . . . .

Y P

ARAMETERS

VE AND EXIT

• To redisplay the above menu, press [ENTER].

• To access the corresponding menus (described on the following

pages), press [1] through [5].

• To save changes and exit, press [X]. This enables the DH-485

and DF1 ports.

IMPORTANT

After configuration is complete, place the module in

Run mode as described on page 4-15.

If you operate the module in Configuration mode,