Page 1

Allen-Bradley

Direct

Communication

User

Module

(Cat. No. 1747-DCM)

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC, PLC-2, PLC-3, and PLC-5 are registered trademarks of Allen-Bradley Company, Inc.

SLC, SLC 500, Dataliner, PanelView, RediPANEL, PLC-5/11, PLC-5/15, PLC-5/20, PLC-5/12,

PLC-5/25, PLC-5/30, PLC-5/40, PLC-5/60 are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Page 3

Summary of Changes

Summary of Changes

The information below summarizes the changes to this manual since the last

printing as 1747-NM007–September 1993.

To help you find new information and updated information in this release of

the manual, we have included change bars as shown to the right of this

paragraph.

New Information

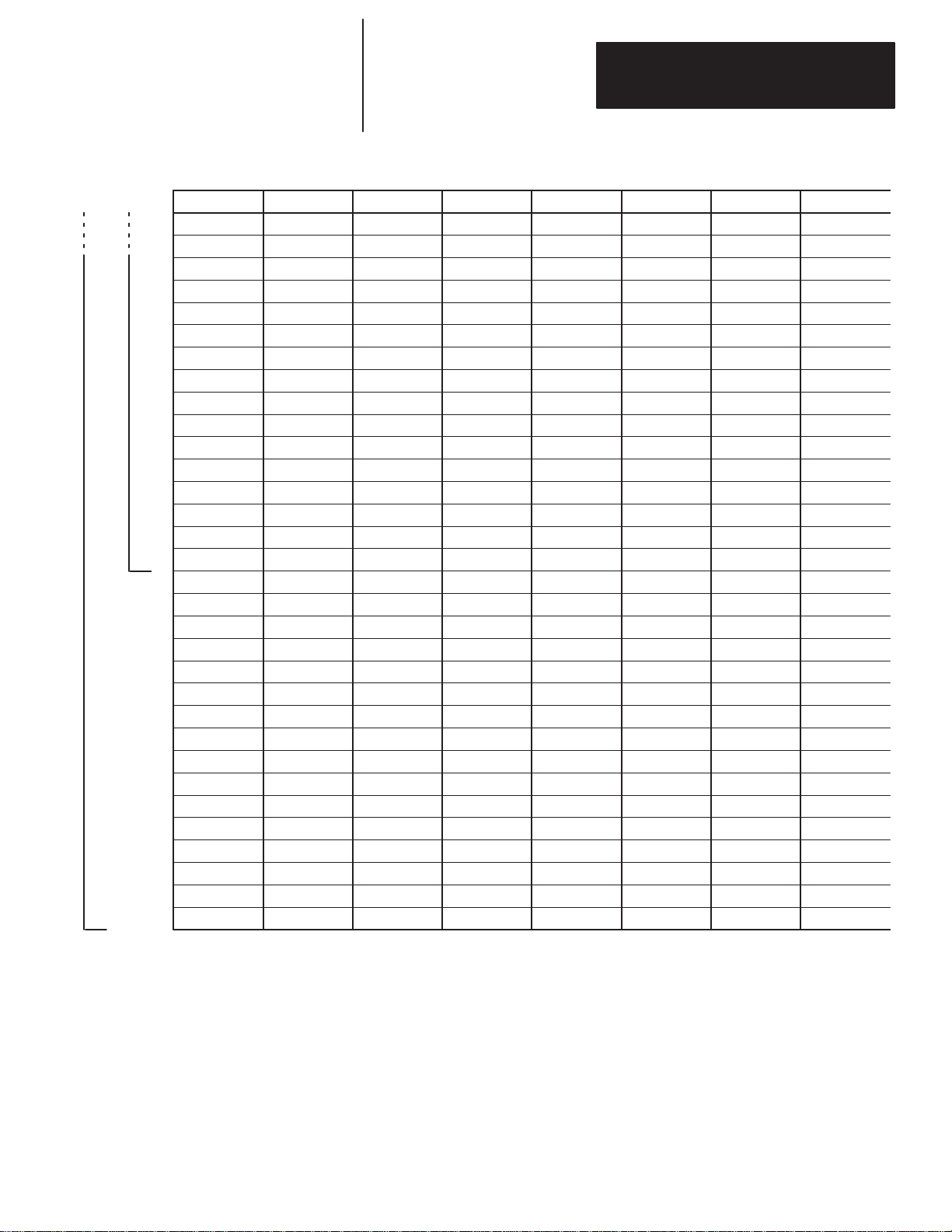

The table below lists sections that document new features and additional

information about existing features, and shows where to find this new

information.

For This New Information See

Related documentation updated preface

Quick Start for Experienced Users chapter 2

Default DIP switch settings chapter 4

CE certification chapter 5, appendix A

DCM clear on fault DIP switch chapter 6

Page 4

Page 5

T

able of Contents

Direct Communication Module

User Manual

Preface

Who

Should Use this Manual

Purpose

Terms

Common

Allen-Bradley

of this Manual

Contents

Related

Local

Technical Product Assistance P–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Your Questions or Comments on this Manual P–5. . . . . . . . . . . . . . . . . . . . .

of this Manual

Documentation

and Abbreviations

Techniques Used in this Manual

Support

Product Support

P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–5. . . . . . . . . . . . . . . . . . . . . . . . . .

P–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

Quick Start

for Experienced Users

Addressing

Chapter 1

Hardware Overview 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Overview 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What

Is a Remote I/O Adapter?

Extended

Scanner Image Division 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scanner

Data Exchange Between RIO Scanners and the DCM 1–6. . . . . . . . . . . . . . . . .

What

Node Capability

Image Division Configuration Example

Is the Status W

ord? 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Required Tools and Equipment

Procedures 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Addressing

PLC/Scanner Addresses 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Addresses 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O

Image

Ladder Logic Instructions

Image T

PLC to DCM/SLC 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCM/SLC

Mapping

ables 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to PLC

1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5. . . . . . . . . . . . . . . . . . .

2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Configuration

Chapter 4

DIP Switches 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP

Switch 1 Settings

Starting

Rack

DIP

Rack

Last Rack (SW2-4) 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear

Data

I/O Group Number (SW1-7 and SW1-8)

Address (SW1-1 through SW1-6)

Switch 2 Settings

Size (SW2-5 and SW2-6))

On Fault (SW2-3)

Rate (SW2-1 and SW2-2)

4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2. . . . . . . . . . . . . . . . . . .

4–3. . . . . . . . . . . . . . . . . . . . . . . . .

4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 6

T

able of Contents

Direct Communication Module

User Manual

Installation and Wiring

Programming

Chapter 5

Compliance

EMC Directive 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCM

Installation 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network

to European Union Directives

Installation

Wiring

Chapter 6

Overview 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Examples 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical

Physical

Physical

Physical

Status Words 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RIO

DCM/SLC

Applications Using I/O Status W

RIO

DCM/SLC

RIO

Input into PLC – Physical Output from SLC

Input into SLC – Physical Output from PLC

Input into Both PLC and SLC (Logical AND) –

Physical Output from SLC 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input into First SLC – Physical Output from Second SLC

Scanner Input Status W

Output Status W

Scanner Status W

Using

the Program/T

Output Status W

Using

the Data Invalid Bit

Using

the User Status Flag Bit

Scanner Input Status and DCM/SLC Output Status

Using

the Logical OR Bit

ord Examination (Decimal) 6–5. . . . . . . . . . . . .

ord Examination (Octal) 6–6. . . . . . . . . . . . . . . .

ord Bits

ord 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est/Fault Mode Bit

ord 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–1. . . . . . . . . . . . . . . . . . . . . . . . . .

5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–2. . . . . . . . . . . . . . . .

6–3. . . . . . . . . . . . . . . .

6–4. . . . . .

6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–7. . . . . . . . . . . . . . . . . . . . . . .

6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–10. . . . . . . . . . . . .

6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Application Examples

ii

Chapter 7

DCM

Status Indicators

Troubleshooting

Troubleshooting Using the COMM LED (Green) 7–2. . . . . . . . . . . . . . . . . . . . . .

Using the F

AULT LED (Red) 7–1. . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8

Basic Example 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1747-SN

DIP

System

System

Image

Program

Supplementary Example 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module

DIP

System

Image

Module Configuration

Switch Settings

Configuration for Rack 1

Configuration for Rack 2

T

able Configuration

Listing

Configuration

Switch Settings

Configuration

T

able Configuration

7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

T

able of Contents

Direct Communication Module

User Manual

Specifications

DCM Addressing

Worksheet

Program

Program

Listing for 5/01

Listing for PLC5/15

Appendix A

Electrical

Environmental

Network

Throughput

Specifications

Specifications

Specifications

T

iming A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Directions B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing Review B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Addresses B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Addresses B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 8

Page 9

Preface

Preface

Read this preface to familiarize yourself with the rest of the manual. This

preface covers the following topics:

• who should use this manual

• the purpose of this manual

• terms and abbreviations

• conventions used in this manual

• Allen–Bradley support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use Allen–Bradley

small logic controllers.

You should have a basic understanding of SLC 500t products. You should

understand programmable controllers and be able to interpret the ladder logic

instructions required to control your application. If you do not, contact your

local Allen–Bradley representative for information on available training

courses before using this product. If using Advanced Programming

Software (APS), we recommend that you review The APS Quick Start for

New Users, Publication 9399-APSQS.

This manual is a reference guide for the Direct Communication Module

(DCM). It describes the procedures you use to address, configure and

program the DCM for application with PLCs and SLCs.

P–1

Page 10

Preface

Contents of this Manual

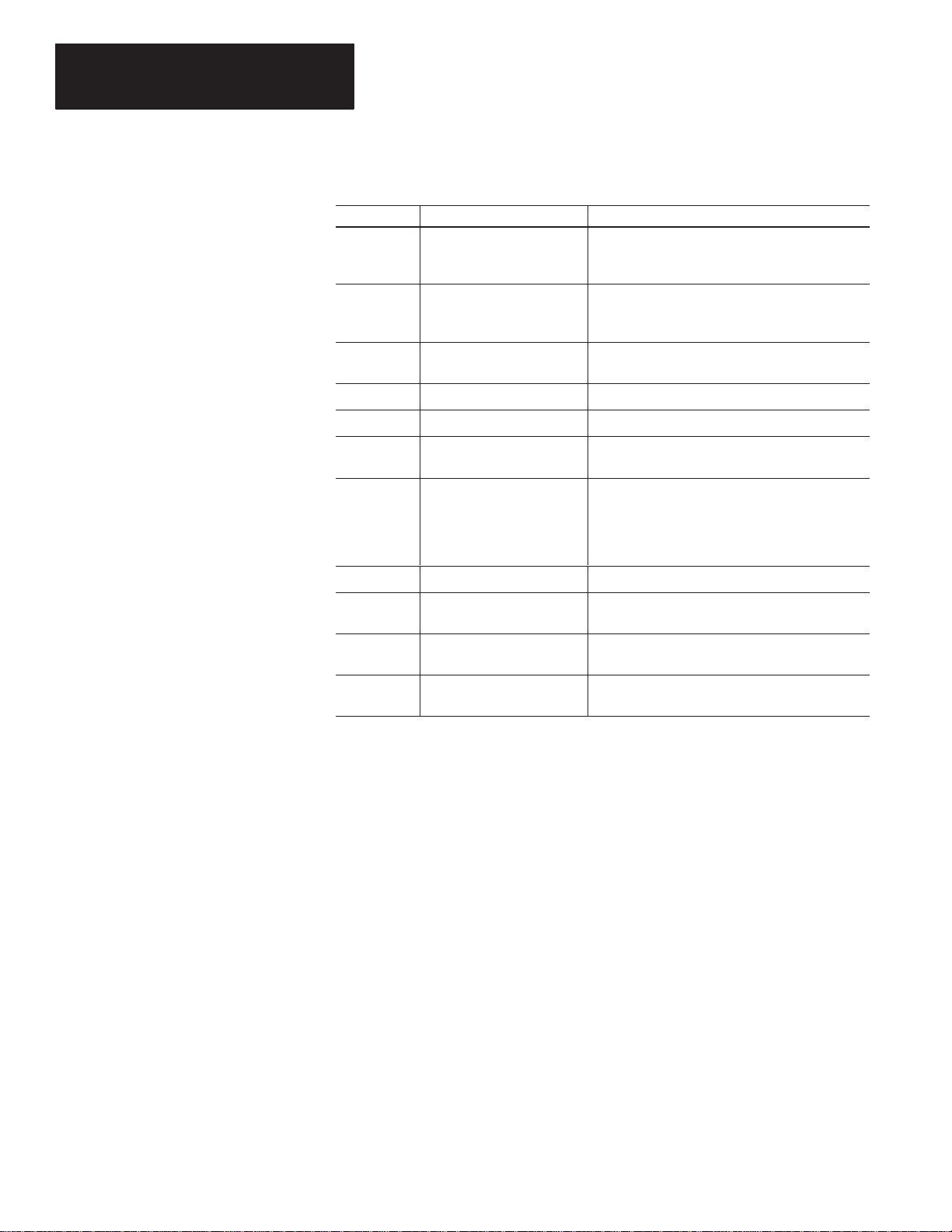

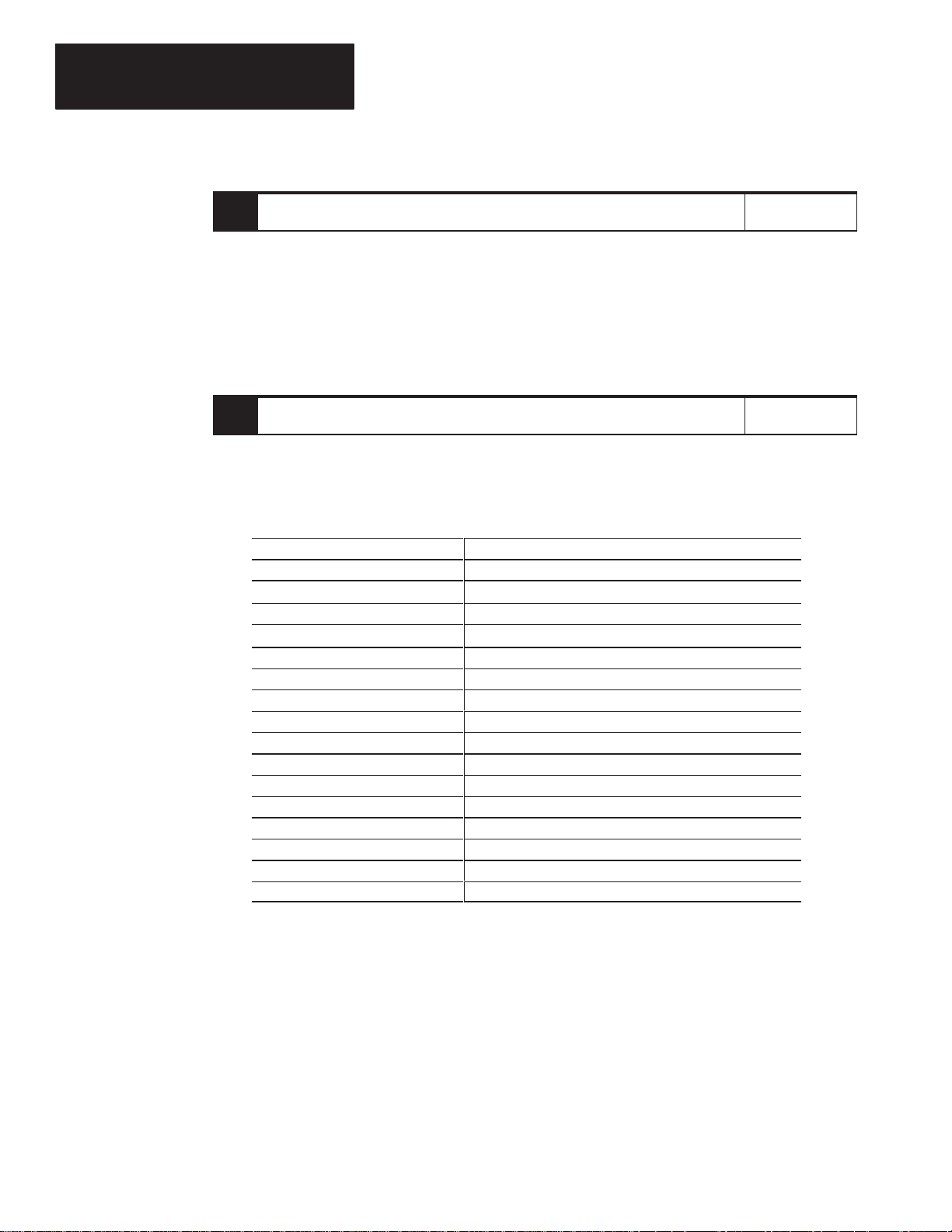

Chapter Title Content

Describes the purpose, background, and scope of

Preface

1 Overview

this manual. Also specifies the audience for whom

this manual is intended.

Provides a hardware and system overview including

physical features, system communication, scanner

image division and communications flow.

2

3 Addressing Explains slot numbering and image mapping.

4 Module Configuration Provides DIP switch setting information.

5 Installation and Wiring

6 Programming

7 Troubleshooting Describes troubleshooting using front panel LEDs.

8 Application Examples

Appendix A Specifications

Appendix B DCM Addressing Worksheet

Quick Start

for Experienced Users

Serves as a Quick Start Guide for using the DCM.

Provides installation procedures and a wiring

diagram.

Shows how to program ladder logic in the PLCr

and the SLC 500, including an examination of

special programming instructions that affect system

response. Also examines the status word and its

applications.

Provides and examines both basic and

supplementary applications.

Provides module and system specifications and

discusses throughput.

Helps you to work out the image table configuration

for DCMs in your system.

P–2

Page 11

Preface

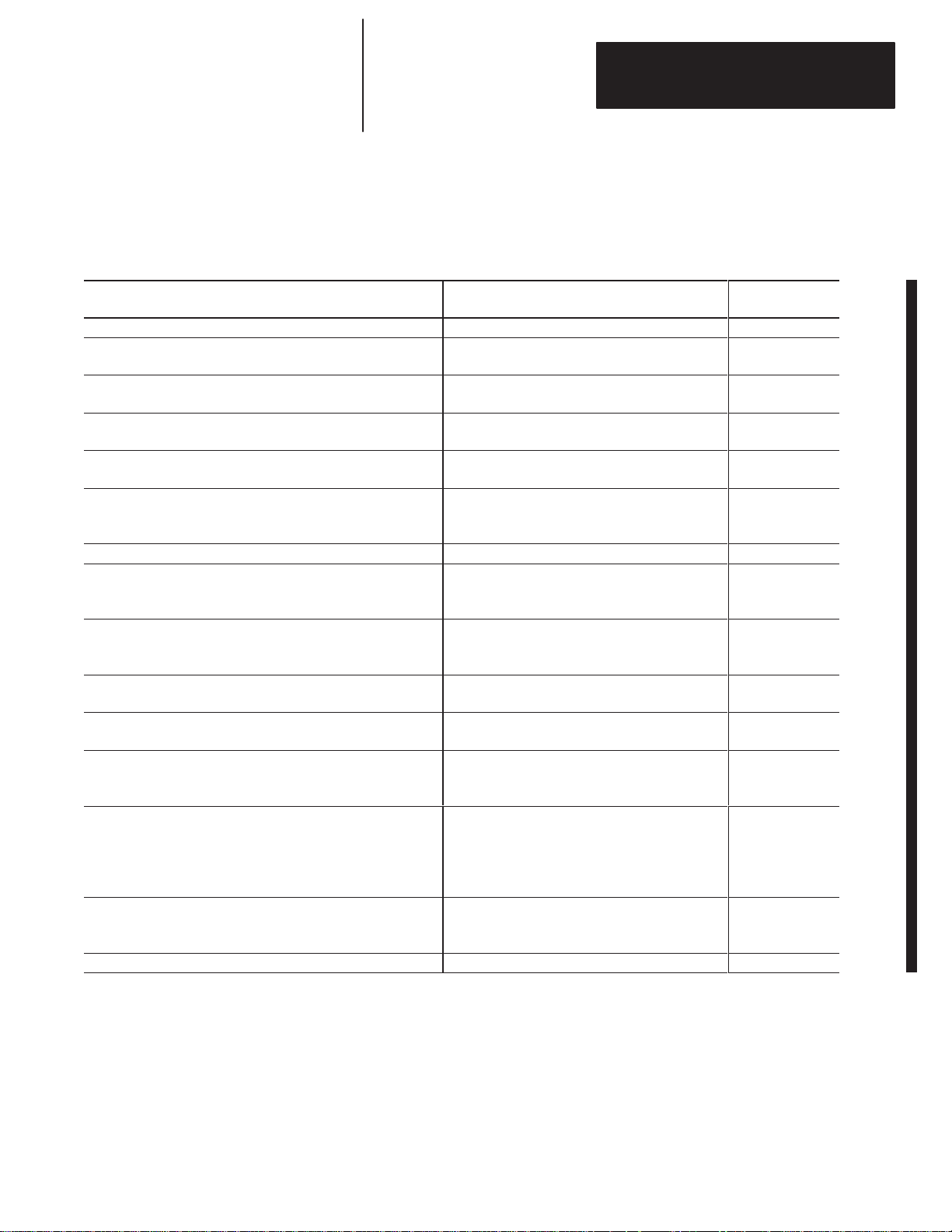

Related Documentation

The following documents contain additional information concerning

Allen–Bradley SLCt and PLC products. To obtain a copy, contact your

local Allen–Bradley office or distributor.

For Read This Document

An overview of the SLC 500 family of products SLC 500 System Overview 1747-2.30

A description on how to install and use your Fixed SLC 500

programmable controller

A description on how to install and use your Modular SLC 500

programmable controller

A reference manual that contains information regarding the use of

the PLC–5r programmable controller

A procedural manual for technical personnel who use APS to

develop control applications

A reference manual that contains status file data, and instruction

set information for the SLC 500 processors and MicroLogix 1000

controllers.

Information regarding the use of the 1747–SN SLC RIO scanner Remote I/O Scanner User Manual 1747-6.6

An introduction to APS for first–time users, containing basic

concepts but focusing on simple tasks and exercises, and allowing

the reader to begin programming in the shortest time possible

A training and quick reference guide to APS

A common procedures guide to APS.

A procedural and reference manual for technical personnel who

use an HHT to develop control applications

An introduction to HHT for first–time users, containing basic

concepts but focusing on simple tasks and exercises, and allowing

the reader to begin programming in the shortest time possible

An article on wire sizes and types for grounding electrical

equipment

A complete listing of current Allen–Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD–ROM or in multi–languages.

A glossary of industrial automation terms and abbreviations Allen–Bradley Industrial Automation Glossary AG-7.1

Installation & Operation Manual for Fixed Hardware

Style Programmable Controllers

Installation & Operation Manual for Modular

Hardware Style Programmable Controllers

PLC–5 Reference Instruction Set 1785-6.1

Rockwell Software Advanced Programming

Software (APS) User Manual

SLC 500t and MicroLogix 1000t Instruction Set

Reference Manual

Quick Start for New Users 9399-APSQS

SLC 500 Software Programmer’s Quick Reference

Guideavailable on PASSPORT at a list price of

$50.00

SLC 500 Common Procedures Guideavailable on

PASSPORT at a list price of $50.00

Allen–Bradley Hand–Held Terminal User Manual 1747-NP002

Getting Started Guide for HHT 1747-NM009

National Electrical Code

Allen–Bradley Publication Index SD499

Document

Number

1747-6.21

1747-6.2

9399-APSUM

1747-6.15

ABT-1747-TSG001

ABT-1747-TSJ50

Published by the

National Fire

Protection

Association of

Boston, MA.

P–3

Page 12

Preface

Terms and Abbreviations

The following terms and abbreviations are specific to this product. For a

complete listing of Allen–Bradley terminology, refer to the Allen–Bradley

Industrial Automation Glossary, Publication Number ICCG–7.1.

Adapter – Any physical device that is a slave on the RIO link.

Adapter Image – The portion of scanner image assigned to an individual

adapter. You configure the adapter image by assigning it a starting logical

rack number, starting logical group number and the number of logical groups

it uses. In the case of the DCM, this is referred to as the DCM image.

DCM – Refers to the Direct Communication Module.

Distributed Control/Controller – Refers to a control system that employs a

number of different hardware controllers/processors, each designed to

perform a different subtask on behalf of an overall program or process. In a

single processor (non–distributed) system, each task would be done by the

single processor controlling the process. In a distributed system, each task is

targeted to the specific processor required to perform its needs. Since all

processors run simultaneously and independently, the time required to

perform each task of the overall process is reduced in comparison to a single

processor system. Therefore, overall program or process performance is

typically better.

Inhibit – A function by which the scanner stops communicating with a

logical device. The logical device will consider itself inhibited if it does not

receive communications from the scanner within a certain period of time.

Logical Device

Logical Group – A logical group consists of one input and one output word

within a logical rack. A word consists of 16 bits, each bit represents one

terminal on a discrete I/O module. Also referred to as an I/O Group.

Logical Rack – A fixed section of the scanner image comprised of eight

input words and eight output words. Also referred to as a rack.

Logical Slot – A logical slot consists of one input and one output byte within

a logical group. A byte consists of 8 bits, each bit represents one terminal on

a discrete I/O module.

Physical Device – The number of devices that the supervisory processor/

scanner will support.

PLC Chassis – A physical PLC (Programmable Logic Controller) rack that

houses PLC processors and 1771 I/O modules.

– Any portion of a logical rack assigned to a single adapter.

P–4

Page 13

Preface

Rack Size – The logical rack size of the DCM image.

RIO Link – (Remote Input/Output) Refers to an Allen–Bradley

communication system supporting high–speed serial transfer of Remote I/O

(RIO) control information.

Scanner – The communication master on the RIO link.

Scanner Image – The data table area within the scanner, used to exchange

I/O information between the scanner and all the adapters on the RIO link.

The scanner image is a portion of the SLC or PLC processor image.

Slave – In a communication link, a station that cannot initiate

communication.

SLC Chassis – A physical SLC (Small Logic Controller) rack that houses

SLC processors and 1746 and 1747 I/O modules.

Slot – The physical location in any chassis used to insert I/O (or specialty)

modules.

Common Techniques Used in this Manual

Supervisory Control/Controller – A control system whereby a host

(supervisory) controller/processor monitors and intermittently adjusts control

parameters, as necessary, of one or several lower level processors while the

lower level processor(s) performs the control task continuously in real time.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

P–5

Page 14

Preface

Allen–Bradley Support

Allen–Bradley offers support services worldwide, with over 75 Sales/Support

Offices, 512 authorized Distributors and 260 authorized Systems Integrators

located throughout the United States alone, plus Allen–Bradley

representatives in every major country in the world.

Local Product Support

Contact your local Allen–Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen–Bradley for technical assistance, please review

the information in the Troubleshooting chapter first. Then call your local

Allen–Bradley representative.

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the enclosed

Publication Problem Report.

If you have any suggestions for how this manual could be made more useful

to you, please contact us at the address below:

Allen–Bradley Company, Inc.

Automation Group

Technical Communication, Dept. 602V, T122

P.O. Box 2086

Milwaukee, WI 53201–2086

P–6

Page 15

Chapter

are Overvie

1

Overview

This chapter provides a hardware and system overview including physical

features and connectivity illustrations. It also explains data exchange

between processors and discusses rack size. Topics include:

• hardware overview

• system overview

• scanner image division

• communications flow

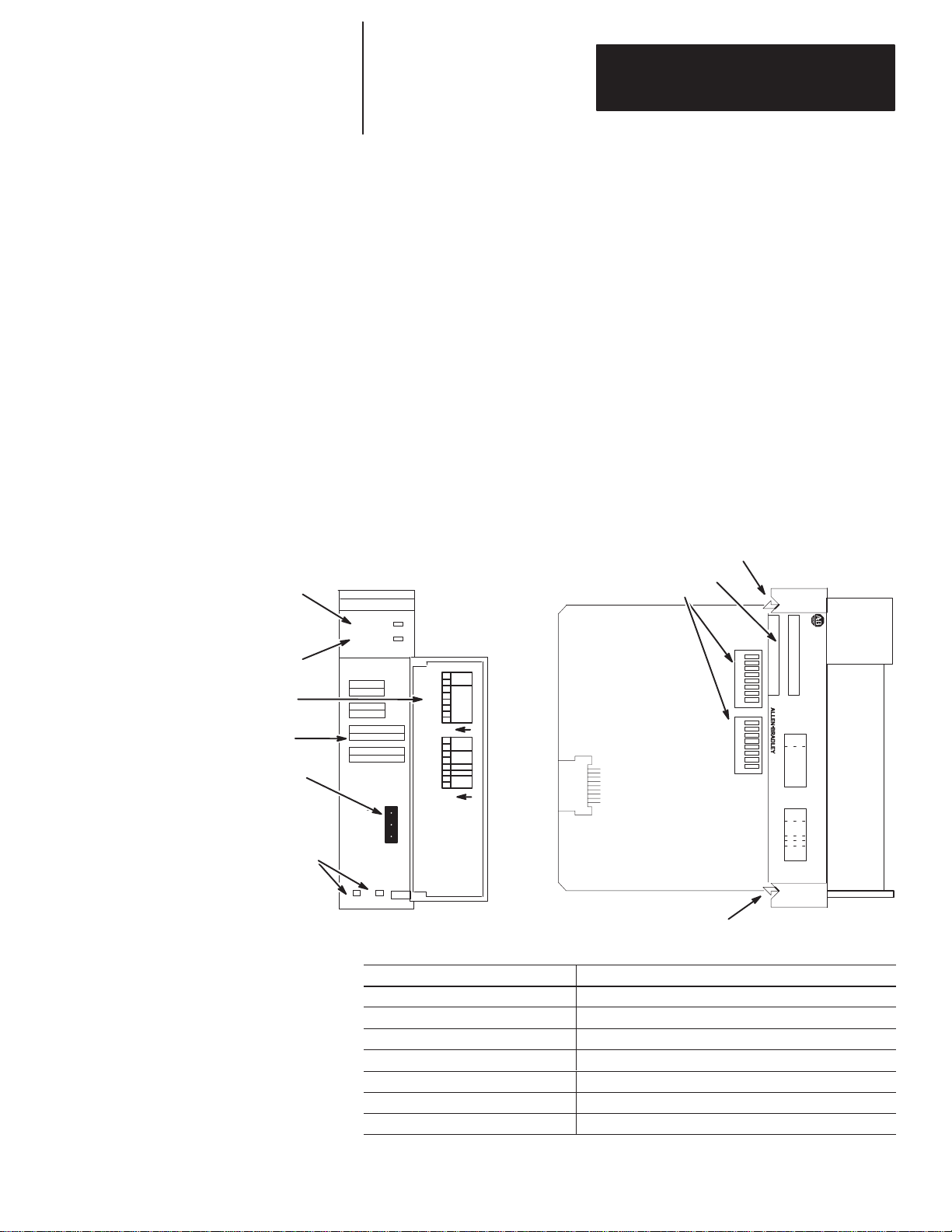

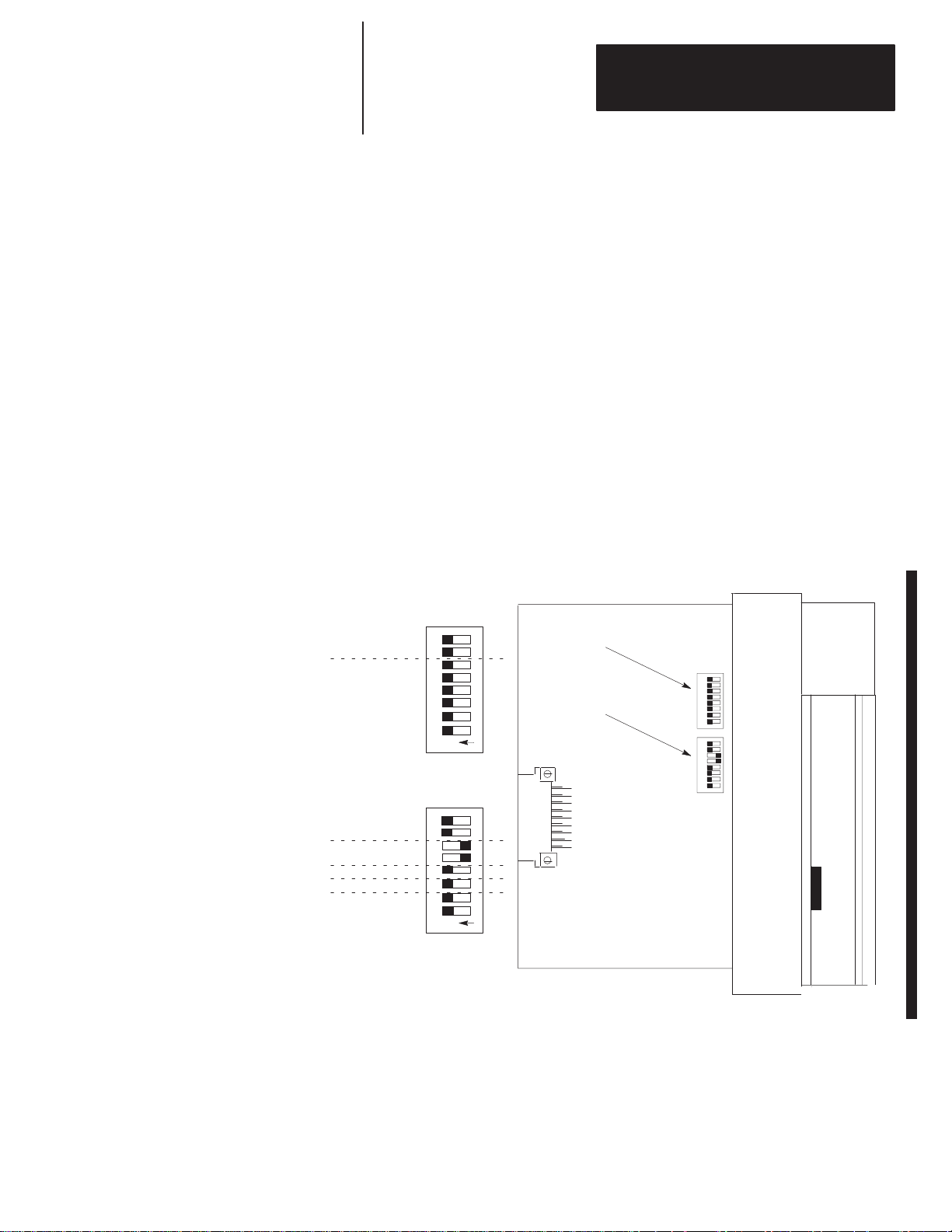

Hardw

w

FAULT LED

(Red)

COMM LED

(Green)

Door Label

Front Label

RIO Link Connector

Cable Tie Slots

The Direct Communication Module, Catalog Number 1747–DCM, is used to

connect an SLC 500 Fixed Programmable Controller with expansion chassis

or any SLC 500 Modular Programmable Controller to a supervisory

Allen–Bradley Programmable Controller via the RIO Link, thereby

providing a distributed processing system. The DCM occupies one slot in

any SLC 500 chassis.

Self–Locking Tab

Side Label

DIP Switches

DCM

FAULT

COMM

CONFIGURATION

RACK ADDR

RACK SIZE

1/4 1/2 3/4 1

FIRST I/O GROUP

0 2 4 6

DATA RATE (K B/S)

57.6 115.2 230.4

LINE 1 _______

SHIELD ______

LINE 2 _______

SW1

SW2

1747–DCM

I/O

GROUP

(LSB)

RACK

ADDRESS

2345678

(MSB)

1

O

N

X

X

RACK

SIZE

LAST

RACK

CLR ON FL

T

2345678

DATA

RATE

1

O

N

2345678

1

2345678

1

SW1 SW2

SERIAL NO.

SW 1

I/O

GROUP

(LSB)

RACK

ADDR

(MSB)

SW 2

RACK

SIZE

LAST

CLR ON FL

MADE IN USA

DATA

RATE

CAT

MODULE

X

X

RACK

T

DIRECT COMMUNICATION

SLC 500

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

Self–Locking Tab

Hardware Features

Hardware

Function

FAULT LED Displays operating status

COMM LED Displays communication status

Front, Side and Door Labels Provide module configuration information

RIO Link Connector Provides physical connection to RIO network

Cable Tie Slots Secure and route wiring from module

DIP Switches Establish configuration parameters for the module

Self–Locking Tabs Secure module in chassis slot

1–1

Page 16

Chapter 1

stem Overvie

Overview

Sy

w

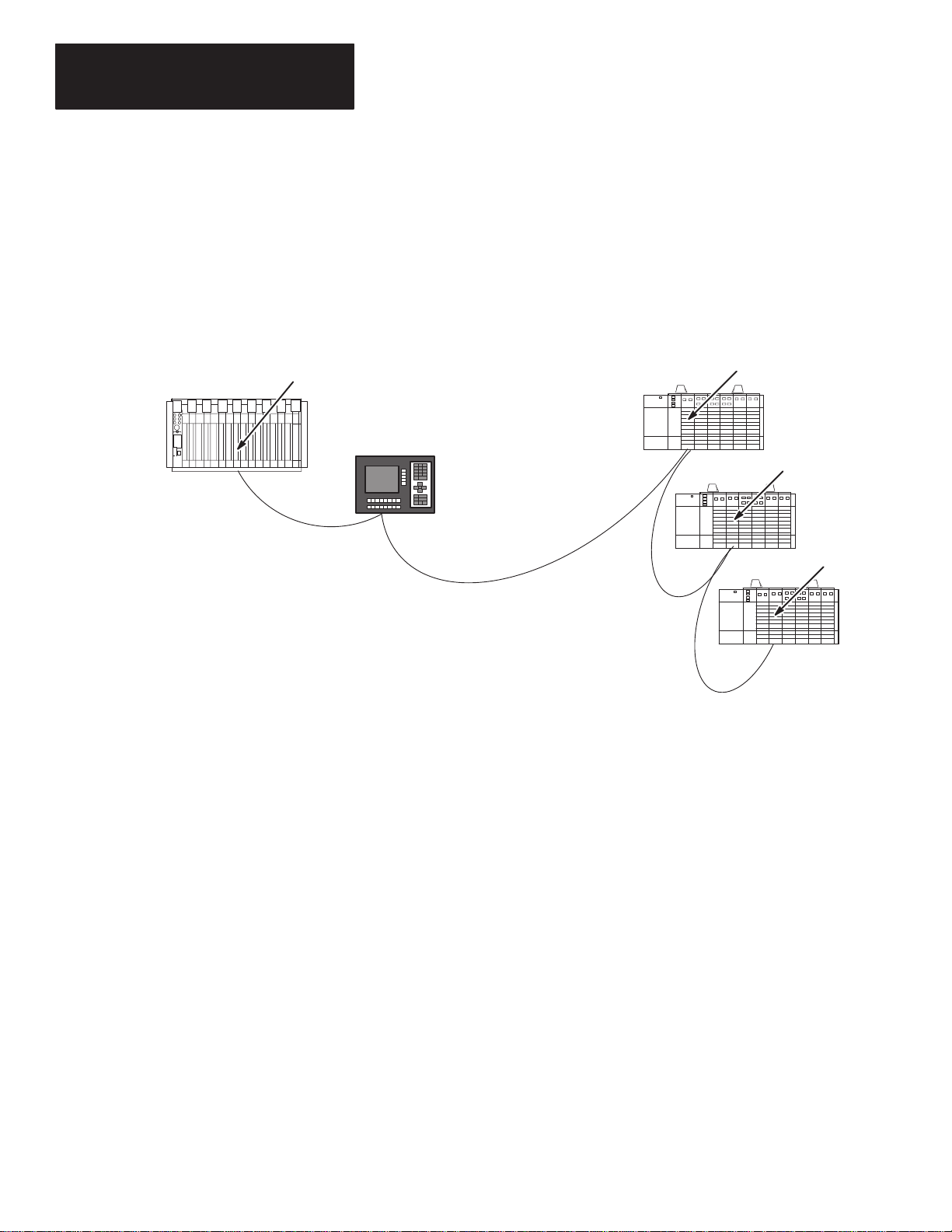

Supervisory PLC or SLC

The Direct Communication Module is an SLC 500 family Remote I/O (RIO)

adapter. It allows supervisory processors, such as PLC–5s, and distributed

SLC–500 processors residing on an Allen–Bradley RIO Communication

Link to transfer data between each other. The DCM appears as an RIO

adapter to:

• a PLC processor with integral RIO scanner on the RIO Communication

Link

• an RIO scanner, Catalog Number 1771–SN or 1747–SN, on the RIO

Communication Link

RIO

Scanner

PanelViewt

(adapter)

Distributed SLCs with

DCMs (adapters)

RIO Communication Link

DCM 1

DCM 2

DCM 3

DCM modules are connected in a daisy–chain configuration using Belden

9463 cable.

What Is a Remote I/O Adapter?

A remote I/O adapter (RIO adapter) is any module that acts as a slave to an

RIO scanner, the master on the RIO link. The DCM is an RIO adapter.

All RIO scanners have defined physical and logical specifications. Physical

specifications are the maximum number of adapters that can be connected to

the scanner. (See Extended Node Capability on page 1–4.) Logical

specifications are the maximum number of logical racks the scanner can

address, the ways logical racks can be assigned, and the ability of the scanner

to perform block transfers. Refer to the appropriate scanner manual for

details concerning physical and logical specifications.

The DCM can physically reside on the RIO link with any other adapter. The

following table lists the adapters available for use with an RIO link.

1–2

Page 17

Chapter 1

Overview

Compatible

Number

1785-LT/x PLC-5/15 Yes In adapter mode

1785-LT2 PLC-5/25 Yes In adapter mode

1785-LT3 PLC-5/12 Yes In adapter mode

1785-L30x PLC-5/30 Yes In adapter mode

1785-L40x PLC-5/40 Yes In adapter mode

1785-L60x PLC-5/60 Yes In adapter mode

1771-ASC Remote I/O Adapter Module No

1771-ASB Remote I/O Adapter Module

1771-AM1

1771-AM2

1784-F30D

1771-RIO Remote I/O Interface Module No

Catalog

Adapters

Device

1-Slot I/O Chassis with Integral

Power Supply and Adapter

2-Slot I/O Chassis with Integral

Power Supply and Adapter

Plant Floor Terminal Remote I/O

Expansion Module

Extended

Node

Capability

Series B and

C only

Yes

Yes

Yes

Comments

Series A, B, and C

1771-JAB Single Point I/O Adapter Module Yes

1771-DCM Direct Communication Module No

1778-ASB Remote I/O Adapter Module Yes

1747-ASB Remote I/O Adapter Module Yes

2706-xxxx

2705-xxx

2711-xx PanelView Terminal Yes

1336-RIO

1395-NA

1747-ASB

DL40 Datalinert

RediPANELt

Remote I/O Adapter for 1336 AC

Industrial Drives

Remote I/O Adapter for 1395 DC

Industrial Drives

SLC 500 Remote I/O Adapter

Module

Yes

Yes

Yes

Yes

Yes

Must be catalog number

2706-ExxxxxB1.

1–3

Page 18

Chapter 1

canner Image

on

Overview

Extended Node Capability

Both scanners and adapters can have extended node capability. Extended

node capability allows you to have up to 32 adapters on the RIO link using

an 82 Ohm termination resistor at both ends of the RIO link for all baud

rates.

Extended node capability can only be used if the scanner and all adapters on

the RIO link have extended node capability. The DCM has extended node

capability.

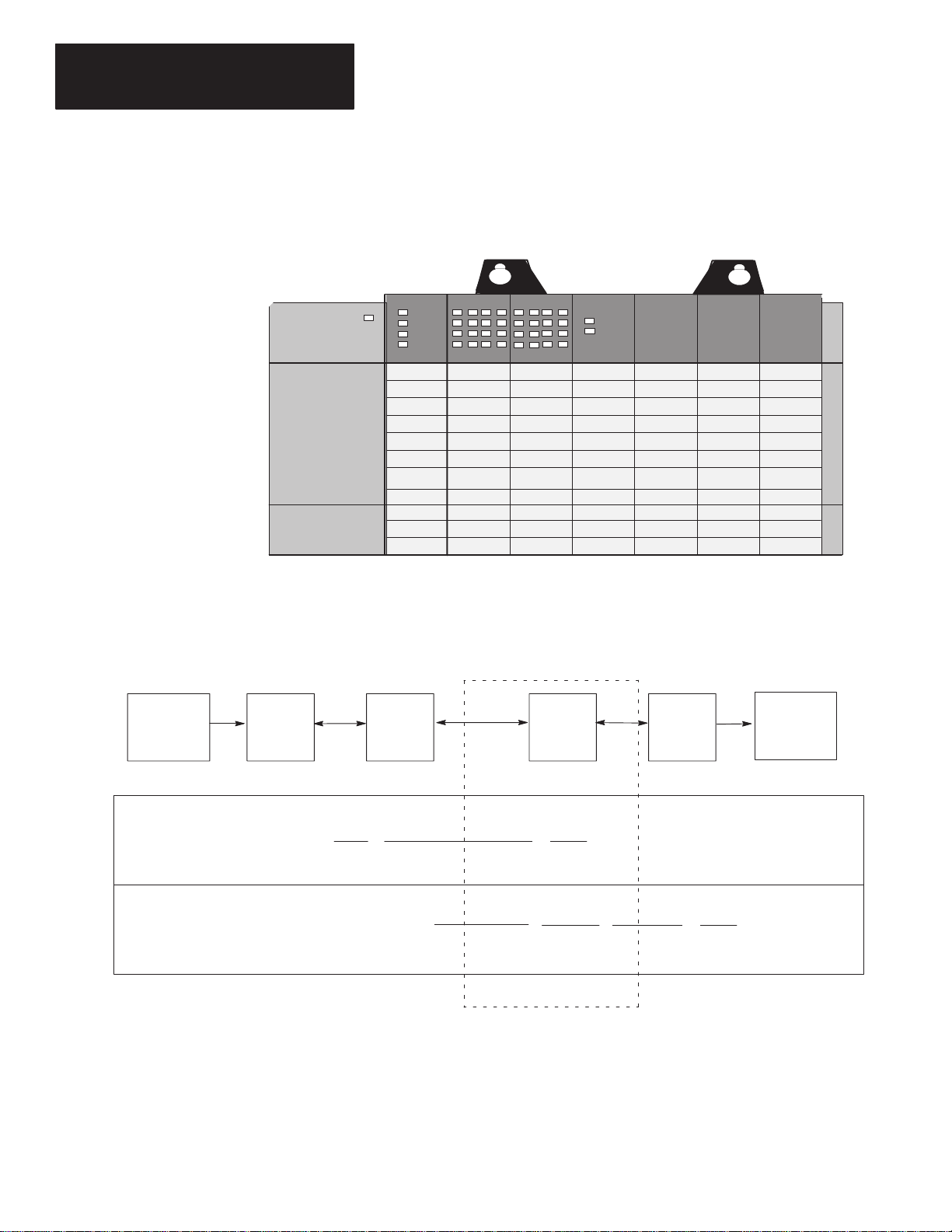

S

Divisi

The scanner allows each adapter to use a fixed amount (user defined) of its

input and output image.

The scanner image is divided into logical racks and further divided into

logical groups. A full logical rack consists of eight input and eight output

image words. A logical group consists of one input and one output word in a

logical rack. Each logical group is assigned a number from 0–7. The

number of racks available for data and I/O transfer depends on the scanner

you are using.

Local I/O

Logical Rack 0

Remote I/O

(Scanner

Image)

Processor I/O Image Scanner I/O Image Adapter

Logical Rack 1

Logical

Rack 2

Logical Rack 3

Logical Group 0

Logical

Group 7

Image

1–4

The scanner image also contains the image of each adapter on the RIO link.

The adapter is assigned a portion of the scanner image, which is referred to

as the adapter image.

Page 19

Chapter 1

Overview

Scanner Image Division Configuration Example

The example presented here can help you configure your RIO architecture.

Refer to it as necessary.

The following figure shows how a portion of a scanner’s input image table

might be configured. An output image table would be identically configured.

Logical

0

Rack

Logical

1

Rack

Logical

Rack 2

Decimal Bit Number

Octal Bit Number

Rack 0 Group 0

Rack 0 Group 1

Rack 0 Group 2

Rack 0 Group 3

Rack 0 Group 4

Rack 0 Group 5

Rack 0 Group 6

Rack 0 Group 7

Rack 1 Group 0

Rack 1 Group 1

Rack 1 Group 2

Rack 1 Group 3

Rack 1 Group 4

Rack 1 Group 5

Rack 1 Group 6

Rack 1 Group 7

Rack 2 Group 0

Rack 2 Group 1

Rack 2 Group 2

Rack 2 Group 3

Rack 2 Group 4

Rack 2 Group 5

Rack 2 Group 6

Rack 2 Group 7

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Word 10

Word 11

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Word 23

0123456789101112131415

012345671011121314151617

Device

(Full logical rack)

1

Device 2

(3/4 logical rack)

Device 3

(1/4 logical rack)

Device

Device

4

5

(1/2 logical rack)

(1/2 logical rack)

Important: The configured image size of a DCM cannot cross logical rack

boundaries; it cannot use a portion of rack 0 and a portion of

rack 1.

1–5

Page 20

Chapter 1

Overview

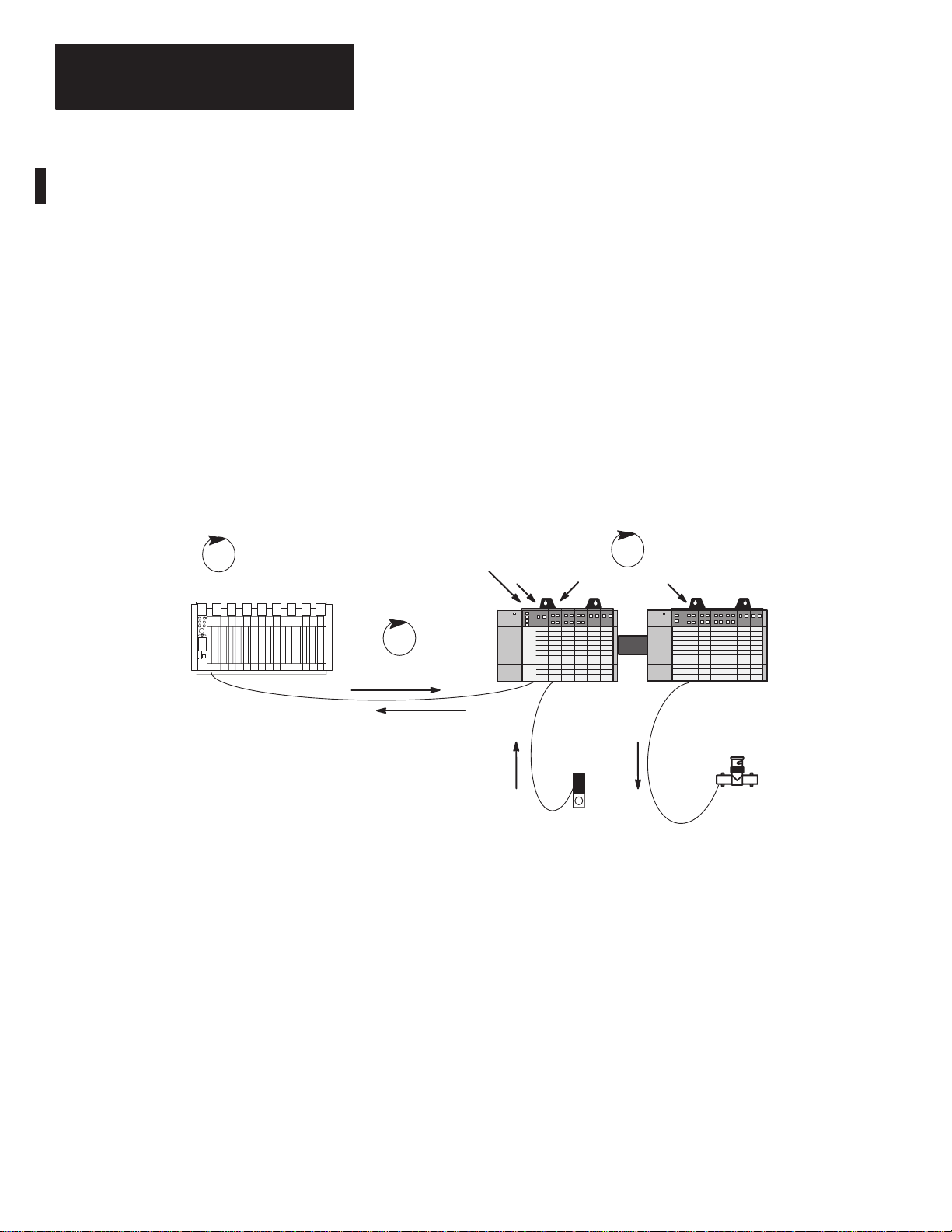

Data Exchange Between RIO Scanners and the DCM

Processor Scan

Supervisory PLC or SLC

Information is transferred between the RIO scanner and the DCM every RIO

scan. RIO transmissions are asynchronous to the processor scans.

Important: The DCM provides word integrity on all words transferred via

the SLC backplane.

The DCM communicates with supervisory PLC or SLC controllers through

RIO scanners, as if they were addressing a logical rack. However, the DCM

does not scan the I/O in its local I/O chassis, rather it passes the supervisory

data to the distributed SLC processor.

In the DCM, outputs from the SLC output image table are inputs to the

supervisory processor input image table. Likewise, outputs from the

supervisory processor output image table are inputs to the SLC input image

table.

The diagram that follows depicts the communications flow between an RIO

scanner and the DCM.

Distributed Processor Scan

SLC Distributed

Scanner

RIO Scan

Processor

DCM

I/O Module

I/O Module

Outputs from PLC,

Input Data to DCM

SLC Expansion

Chassis

Outputs from

Modules

Output Device

Inputs to PLC, Output

Data from DCM

SLC Chassis

Inputs to Modules

Input Device

What Is the Status Word?

The first word of the DCM input and output image is the status word. The

status word indicates the status of communication and data between the RIO

scanner and the DCM. For more information on status words and their

applications, see chapter 6, Programming.

1–6

Page 21

Chapter

2

Quick Start for Experienced Users

This chapter helps you to get started using the Direct Communication

Module (DCM). We base the procedures here on the assumption that you

have a basic understanding of SLC 500 products.

You must:

• understand electronic process control

• be able to interpret the ladder logic instructions for generating the

electronic signals that control your application

Because it is a start-up guide for experienced users, this chapter does not

contain detailed explanations about the procedures listed. It does, however,

reference other chapters in this book where you can get more detailed

information. It also references other documentation that may be helpful if

you are unfamiliar with programming techniques or system installation

requirements.

Required Tools and Equipment

If you have any questions, or are unfamiliar with the terms used or concepts

presented in the procedural steps, always read the referenced chapters and

other recommended documentation before trying to apply the information.

This chapter:

• tells you what tools and equipment you need

• lists preliminary considerations

• describes when to address, configure and program the module

• explains how to install and wire the module

• discusses system power-up procedures

Have the following tools and equipment ready:

• medium blade screwdriver

• (2) 1/2 watt terminating resistors (See chapter 5, Installation and Wiring,

for correct size.)

• programming equipment (All programming examples shown in this

manual demonstrate the use of Allen-Bradley’s Advanced Programming

Software [APS] for personal computers.)

2–1

Page 22

Chapter 2

Quick Start for Experienced Users

Procedures

Check

1.

the contents of the shipping box.

Unpack the module making sure that the contents include:

• Direct Communication Module (Catalog Number 1747-DCM)

• removable connector (factory-installed on module)

• cable tie

• user manual (Catalog Number 1747-NM007)

If the contents are incomplete, call your local Allen-Bradley representative for assistance.

2.

2.

Select

a scanner

.

To begin configuration of your RIO system, you should know three things:

• which scanner is compatible with your PLC/SLC controller. Use the table below to select a

scanner that is compatible with your processor. The DCM is compatible with all RIO

scanners.

Catalog Number

➀

1747-SN

➁

1771-SN

1772-SD, -SD2

➂➃

1775-S4A, -S4B, -S5

1775-SR, -SR5

1785-L11B

1785-LT/x

1785-L20B

1785-LT2

1785-L30x

1785-L40x

1785-L60x

5250-RS

6008-SI

6008-SV

➀

➀

➀➄

➀

➀➄

➀

➀

➀

➀

➀

➀

➀

SLC Remote I/O Scanner

Sub I/O scanner for Mini–PLC-2r and PLC-5 families

Remote scanner/distribution panel for PLC-2 family

I/O scanner-programmer interface module for PLC-3r family

Remote scanner/distribution panel for PLC-3/10 family

PLC 5/11t (in scanner mode)

PLC 5/15 (in scanner mode)

PLC 5/20t (in scanner mode)

PLC 5/25 (in scanner mode)

PLC 5/30t (in scanner mode)

PLC 5/40t (in scanner mode)

PLC 5/60t (in scanner mode)

Remote scanner for PLC 5/250

IBMr PC I/O Scanner Module

VMEbus I/O Scanner Module

6008-SQH1, -SQH2 Q-bus I/O Scanner Module

Description

Reference

–

Reference

The manual for

the scanner you

select

2–2

➀

Extended

➁

Revision D or later

➂

Rev

➃

Extended node capability not available with Series A.

➄

node capability

. 3 or later

.

Rev.

3 or later

PLC 5/25 Series A Revision D or later have partial rack addressing. Earlier versions are limited to 7 devices.

.PLC 5/15 Series B Revision H or later have partial rack addressing. Earlier versions are limited to 3 devices.

.

.

Page 23

Chapter 2

Quick Start for Experienced Users

• the maximum number of physical devices and logical racks your scanner supports.

• the logical rack size of each DCM. This depends on how many I/O data words you need to transfer. The first word

is always the status word. The table below shows the number of data words transferred relative to the rack size.

If you configure the DCM as:

1/4 Rack

1/2 Rack

3/4 Rack

Full Rack

3.

Select DCM addressing. (A configuration worksheet is included in appendix B to assist you in DCM

image table addressing.)

Choose

4.

Configure your system by setting the DIP switches.

5.

the type of slot addressing you will use.

Configure

Insert

the 1747-DCM module into the chassis.

1 data word (16 bits of I/O

3 data words (48 bits of I/O

5 data words (80 bits of I/O

7 data words (112 bits of I/O

the module using the DIP switches.

Then: Including the Status Word

data) are transferred.

data) are transferred.

data) are transferred.

data) are transferred.

Total transfer = 2 words

Total transfer = 4 words

Total transfer = 6 words

Total transfer = 8 words

Reference

Chapter 3

(Addressing)

Appendix B

(DCM Worksheet)

Reference

Chapter 4

(Module

Configuration)

Reference

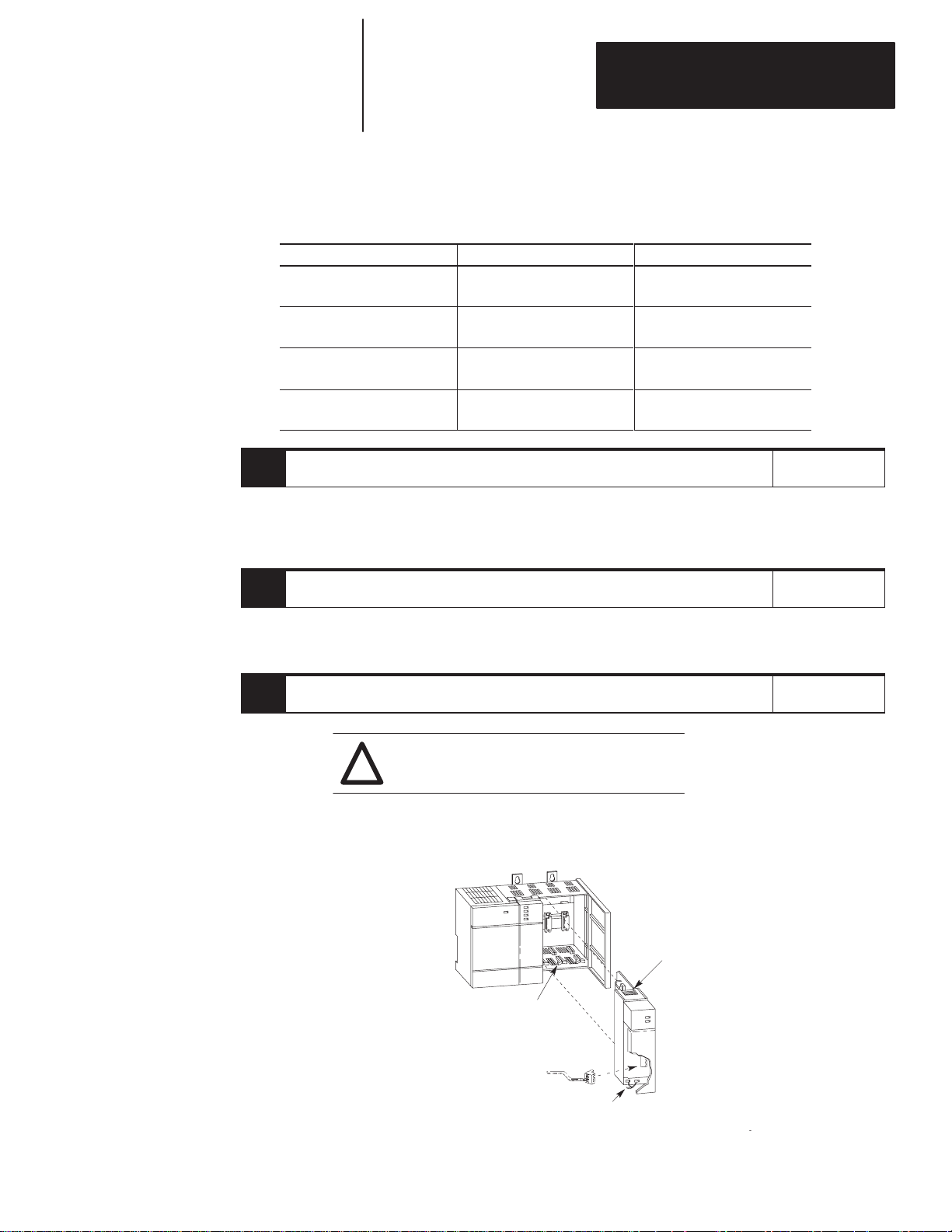

ATTENTION: Never install, remove, or wire

modules with power applied to the chassis or

!

devices wired to the module.

SLC/DCM power requirements to ensure your SLC power supply has adequate reserve power

Review

Make sure system power is off; then insert the DCM into your 1746 chassis. In this example

procedure, local slot 1 is selected.

Module Release

Card Guide

.

.

.

Cable Tie

Chapter 5

(Installation and

Wiring)

.

2–3

Page 24

Chapter 2

Usin

xtende

8

apabilit

1

1

xtende

e

Quick Start for Experienced Users

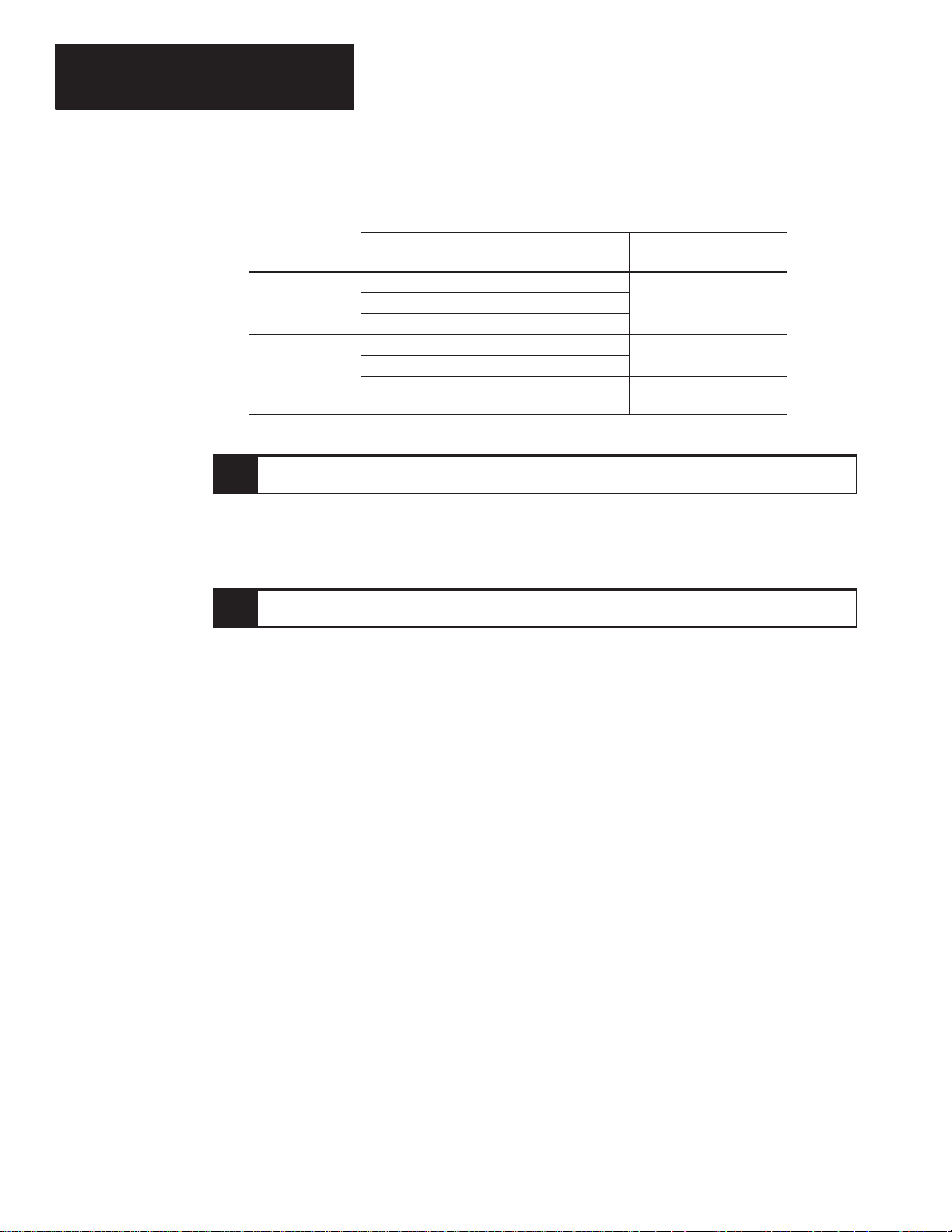

To wire the network, a 1/2 watt terminating resistor must be attached across line 1 and line 2 of the connectors at each

end (scanner and last physical device) of the network. The size of the resistor depends on the baud rate and extended

node capability, as shown below:

Baud Rate

g E

Node C

Not Using

E

d Nod

Capability

6.

Define the application requirements. Write and enter the ladder logic program.

7.

Power up your system by performing standard start-up procedures as indicated in your processor

manual. No special start-up procedures are required when using the DCM module.

57.6K baud 3048 meters (10,000 feet)

d

115.2K baud 1524 meters (5,000 feet)

y

230.4K baud

57.6K baud 3048 meters (10,000 feet)

115.2K baud 1524 meters (5,000 feet)

230.4K baud 762 meters (2,500 feet)

Enter

Go

through the system start-up procedure.

Maximum Cable Distance

(Belden 9463)

762 meters (2,500 feet)

your ladder program.

Resistor Size

2W 1/2 Watt

Brown–Green–Brown–Gold

50W 1/2 Watt

50W 1/2 Watt

Brown–Green–Brown–Gold

82W 1/2 Watt

Gray–Red–Black–Gold

Reference

Chapter 6

(Programming)

Chapter 8

(Application

Examples)

Reference

–

2–4

Page 25

Chapter

l

3

Addressing

This chapter provides general information about how to address supervisory

PLC and distributed SLC ladder logic instructions. It also illustrates image

mapping and provides an example of how a PLC output image is mapped

into an SLC input image.

Addressing Ladder Logic Instructions

All PLC and SLC processors use 3-part addresses. These three parts include:

• logical rack or physical slot address

• logical group or word address

• bit address

PLC processors use the octal number system for bit addressing. SLC

processors use the decimal number system for bit addressing.

PLC Processors/Scanners Address By: SLC Processors Address By:

Logical Rack: PLC/scanner input and output

images are organized in logical

racks, which consist of eight

groups.

The rack address does not need to

match the SLC slot address.

Logical Group: There are eight logical groups per

logical rack, numbered 0–7. One

group consists of one input and one

output word. Each word is made

up of 16 bits.

The group number does not need

to match the SLC word address.

Bit: PLC bits are numbered octally, from

0 to 7 and 10 to 17.

Physical Slot: The slot address is determined

by what slot number you place

your DCM. SLC slots are

numbered 0–30.

The slot address does not need

to match the PLC rack address.

Word: One word is 16 bits in size. The

number of words used in input

and output images varies

according to how many you

specify in your setup. Words are

numbered consecutively

beginning with 0.

The word number does not need

to match the PLC group number.

Bit: SLC bits are numbered

decimally, from 0–15.

The bit number does not need to

match the SLC bit number

(because SLCs use decimal);

however, the position of the bit in

the word must be the same.

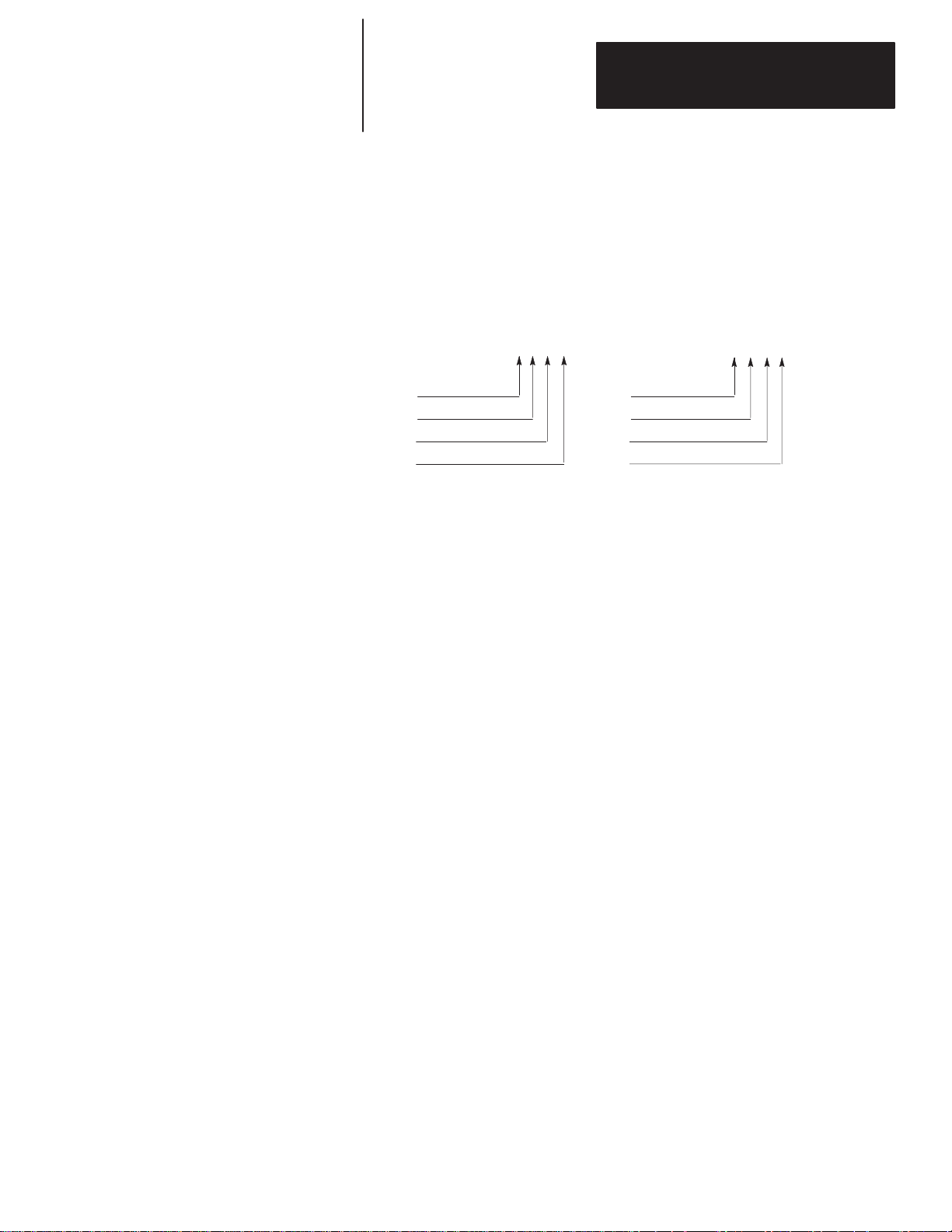

Octal

171615141312111076543210

Bit Number

Group 0

Group 1

Group 2

Rack

#x

Group 3

Group 4

Group 5

Group 6

Group 7

Logical

Decimal

Bit Number

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

The bit number does not need to

match the PLC bit number

(because PLCs use octal);

however, the position of the bit in

the word must be the same.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Physica

Slot

#x

3–1

Page 26

Chapter 3

Addressing

PLC/Scanner Addresses

The three parts of the PLC address include the:

• logical rack

• logical group (I/O group)

• bit

PLC Input

Address

PLC Output

Address

O:017/10I:023/10

I = Input

02 = Logical Rack

3 = I/O Group

10 = Bit (octal)

The rack address refers to the logical rack assigned to the DCM in the PLC/

scanner I/O image table. It is selected using switches 1 through 6 of SW1 on

the DCM. This address does not need to match the physical slot address of

the DCM. Complete information about DIP switch selection is in chapter 4,

Module Configuration.

The I/O group address refers to the word in the PLC/scanner image table

that contains the referenced I/O data bit. The I/O group address does not

need to match the word address of the SLC I/O instruction.

The bit address is the bit within the word being addressed. Bits are

numbered 0–17 (octal) for the PLC and 0–15 (decimal) for the SLC. The

physical position of the bit in the PLC word must match the position of the

bit in the SLC word to address the correct bit.

O = Output

01 = Logical Rack

7 = I/O Group

10 = Bit (octal)

3–2

Page 27

Chapter 3

Addressing

SLC Addresses

The three parts of the SLC address include the:

• physical slot

• word

• bit

SLC Input

Address

SLC Output

Address

O:1.7/8I:2.3/8

I = Input

2 = Physical Slot

3 = Word

8 = Bit (decimal)

The slot address refers to the physical slot (1–30) in the modular SLC chassis

or fixed SLC expansion chassis where the DCM is installed. This address

does not need to match the logical rack address of the PLC I/O instruction.

The word address refers to the word number (0–7) of the slot being

addressed. The maximum number of SLC I/O words that a DCM can be

assigned is 8.

The bit address is the bit within the word being addressed. Bits are

numbered 0–15 (decimal) for the SLC and 0–17 (octal) for the PLC. Outputs

from the SLC output image are inputs to the supervisory processor input

image table. Likewise, outputs from the supervisory processor output image

table are inputs to the SLC image table.

As noted, if the supervisory processor is a PLC the I/O image bits are octal

and SLC bits are decimal. While the addresses are different, the position of

the bit in the SLC word must match the position of the bit in the PLC word.

The following diagrams show this relationship.

O = Output

1 = Physical Slot

7 = Word

8 = Bit (decimal)

3–3

Page 28

Chapter 3

Addressing

I/O Image Tables

PLC to DCM/SLC

DCM/SLC configuration: Logical Rack Address = 1

Physical Slot Number = 1

Logical I/O Group = 0

Full Logical Rack

Decimal

15 14 13 12 11 10 7 6 5 4 3 2 1 098

17 16 15 14 13 12 7 6 5 4 3 2 1 011 10Octal

PLC Output Image T

Reserved for Status W

Reserved for Status W

O:011/10

O = Output

01 = Logical Rack

1 = Logical I/O Group

10 = Bit (octal)

able

ord

ord

DCM Input Image T

Decimal 15 14 13 12 11 10 7 6 5 4 3 2 1 098 Decimal 15 14 13 12 11 10 7 6 5 4 3 2 1 098

Status W

Word 0

Word 1

Word

Word 3

Word 4

Word 5

Word 6

Word 7

2

Reserved for Status W

ord

able

ord

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

SLC Input Image T

Status W

Reserved for Status W

I = Input

1 = Physical DCM Slot

1 = Word

8 = Bit (decimal)

DCM/SLC to PLC

DCM/SLC configuration: Logical Rack Address = 1

Physical Slot Number = 1

Logical I/O Group = 0

Full Logical Rack

ord

able

ord

I:1.1/8

Decimal

15 14 13 12 11 10 7 6 5 4 3 2 1 098

17 16 15 14 13 12 7 6 5 4 3 2 1 011 10Octal

3–4

PLC Input Image T

Status W

Reserved for Status W

I = Input

01 = Logical Rack

6 = Logical I/O Group

2 = Bit (octal)

ord

able

ord

I:016/2

DCM Output Image T

Decimal 15 14 13 12 11 10 7 6 5 4 3 2 1 098 Decimal 15 14 13 12 11 10 7 6 5 4 3 2 1 098

Status W

Word 0

Word 1

Word

Word 3

Word 4

Word 5

Word 6

Word 7

2

Reserved for Status W

ord

able

ord

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

SLC Output Image T

Reserved Status W

Reserved for Status W

O = Output

1 = Physical DCM Slot

6 = Word

2 = Bit (decimal)

able

ord

ord

O:1.6/2

Page 29

Chapter 3

Addressing

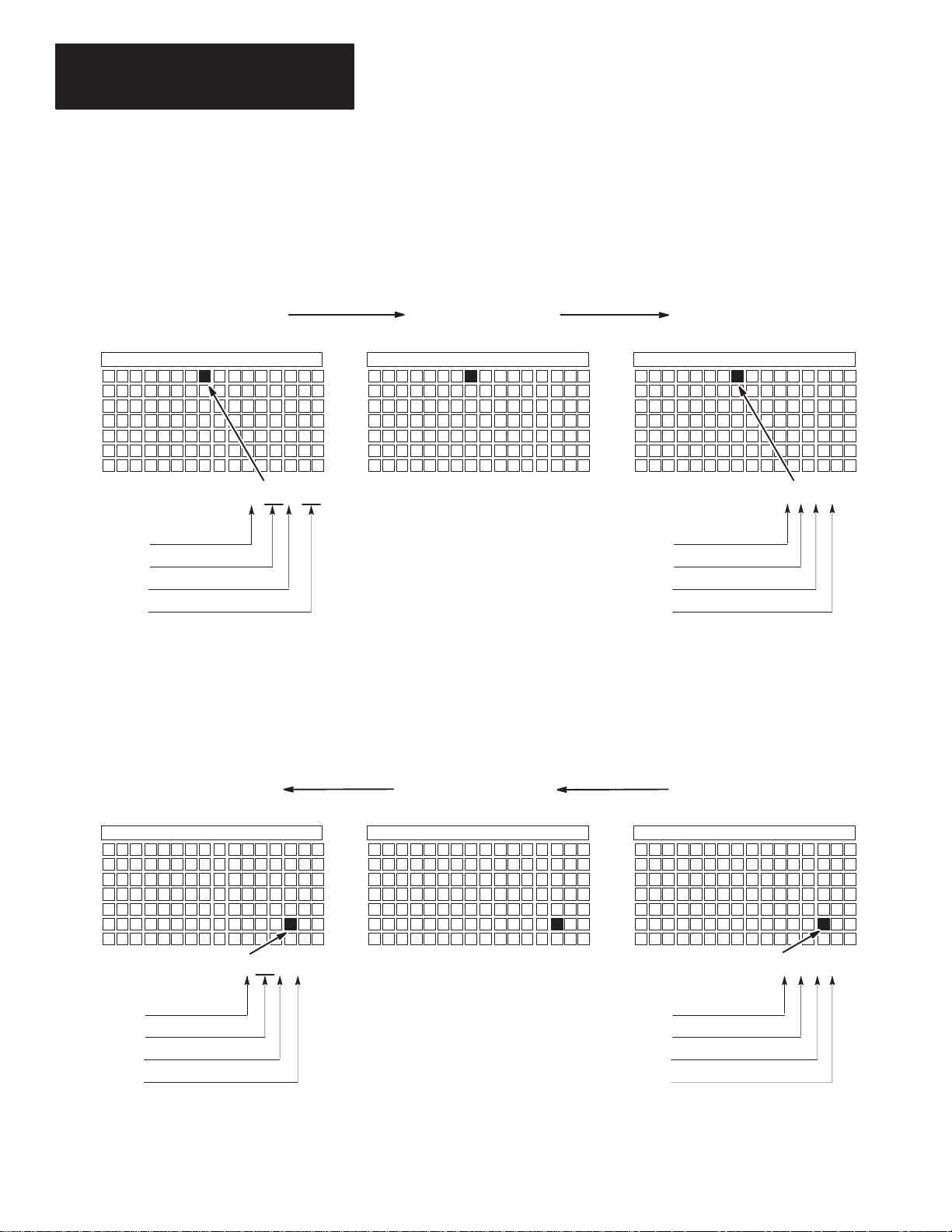

Image Mapping

An image map is a diagram showing how the scanner image is mapped into

the image of multiple adapters. The following table and illustration show

how an example PLC output image is mapped into the image of multiple

SLC processors through the DCM.

PLC Scanner Output Image To: DCM SLC Input Image

O:011/10 Starting Group 0

(Rack 01, Group 1, Bit 10 octal)

O:021/3 Starting Group 0

(Rack 02, Group 1, Bit 3 octal)

O:025/13 Starting Group 2

(Rack 02, Group 5, Bit 13 octal)

→

→

→

I:1.1/8

1

(Slot 1, Word 1, Bit 8 decimal)

I:1.1/3

2

(Slot 1, Word 1, Bit 3 decimal)

I:2.3/11

3

(Slot 2, Word 3, Bit 11 decimal)

Each row in the table represents the address of a data bit being transferred

from the PLC scanner output image to the SLC input image via three

different DCMs. The figure on the next page illustrates this data transfer.

Appendix B contains a worksheet designed to help you work out your DCM

system addressing. Use it if necessary to record I/O addresses.

3–5

Page 30

Chapter 3

Addressing

Scanner Output Image

Bit

Number:

DCM

DCM 2

DCM 3

Octal 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Group 0

Group 1

Group 2

Group 3

1

Group 4

Group 5

Group 6

Group 7

Group 0

Group 1

Group 2

Group 3

Group 4

Group 5

Group

6

Group 7

17 16

10 9

13 12 11 8 7 6 5 4 3 2 1 015 14Decimal

Reserved for Status W

Reserved for Status W

Reserved for Status W

ord

ord

ord

Supervisory SLC or

PLC Processor

O:011/10

(Rack 1, Group 1, Bit 10 Octal)

O:021/2

(Rack 2, Group 1, Bit 3 Octal)

O:025/13

(Rack 2, Group 5, Bit 13 Octal)

RIO Link

Supervisory SLC or PLC

Remote I/O Scanner

SLC 1 Input Image for DCM 1

Bit

Number: Decimal

15 14 13 12 11 10 7 6 5 4 3 2 1 098

Word 0

Word 1

Word

2

Word 3

Word 4

Word 5

Word 6

Word 7

Reserved for Status W

Reserved for Status W

SLC 2 Input Image for DCM 2

Bit

Number: Decimal

15 14 13 12 11 10 7 6 5 4 3 2 1 098

Word

0

Word 1

Reserved for Status W

SLC 3 Input Image for DCM 3

Bit

Number: Decimal

15 14 13 12 11 10 7 6 5 4 3 2 1 098

Word 0

Word 1

Word 2

Word 3

Reserved for Status W

ord

ord

ord

ord

I:1.1/8

(Slot

1, Word 1, Bit 8 Decimal)

I:1.1/3

(Slot 1, Word 1, Bit 3 Decimal)

I:1.3/11

(Slot 2, W

ord 3, Bit 1

1 Decimal)

Distributed SLC

Processor 1

Distributed SLC

Processor 2

Distributed SLC

Processor 3

DCM 1

Module 1 Configured As:

Rack Address 1

Slot Number 1

DCM 2

Module 2 Configured As:

Rack Address 2

Slot Number 1

DCM 3

Module 3 Configured As:

Rack Address 2

Slot Number 2

I/O Group

Rack Size Full

I/O Group

Rack Size 1/4

I/O Group

Rack Size 1/2

0

0

2

3–6

Page 31

Chapter

4

Module Configuration

This chapter provides DIP switch setting information for the DCM. Topics

include:

• DIP switches

• DIP switch 1 settings

• DIP switch 2 settings

DIP Switches

To configure the DCM for your application, you must set the DIP switches.

These switches enable the DCM to properly interpret the RIO system

addressing. The DCM has two banks of DIP switches mounted on its circuit

board. Each bank contains eight switches. The default settings are shown

below.

DIP

Starting I/O Group Number

Rack Address

Reserved

Rack

Size

Last Rack

Clear On Fault

Data Rate

8

1234567

O

N

SW1

8

1234567

O

N

SW2

Switch 1

(SW1)

DIP Switch 2

(SW2)

SW1

2345678

1

234567 8

1

SW2

4–1

Page 32

Chapter 4

Module Configuration

DIP Switch 1 Settings

Starting I/O Group Number (SW1-7 and SW1-8)

The starting I/O group number is the first word assigned to the DCM from

the scanner’s image table. The starting I/O group number must be an even

number from 0 to 6 and is dependent upon whether the DCM has been

configured as a full, 3/4, 1/2, or 1/4 rack. The first word transferred is

always the status word for the DCM.

Rack Size Number of RIO Words Transferred Total Words

1/4 Logical Rack 1 Status and 1 Data 2

1/2 Logical Rack 1 Status and 3 Data 4

3/4 Logical Rack 1 Status and 5 Data 6

Full Logical Rack 1 Status and 7 Data 8

Reference the table below to set the starting I/O group number.

Starting I/O Group Number SW1-7 SW1-8 Valid Rack Configuration

0 ON ON All

2 ON OFF 3/4, 1/2, 1/4

4 OFF ON 1/2, 1/4

6 OFF OFF 1/4

Starting Group 0

Starting Group 2

Starting Group 6

Example of different starting groups:

Octal

Bit Number:

Group

Group 1, Word 1

Group 2, Word 2

Group 3, Word 3

Group 4, Word 4

Group 5, Word 5

Group 6, Word 6

Group 7, Word 7

Decimal 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0, W

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

ord 0

RR

A SS T T U W O R D

A SS T T U W O R D

A SS T T U W O R D

In the above image map example, selecting I/O Group Number 2 instructs the scanner

to address Word 2 as the beginning of DCM 2 image. In this example, a half rack is

selected for DCM 2 (using SW2 switches 5 and 6). Since Word 2 is the first word

assigned, it becomes the Status Word.

DCM 1 Rack Size

= 1/4 Rack

DCM 2 Rack Size

= 1/2 Rack

DCM 3 Rack Size

= 1/4 Rack

4–2

Page 33

Chapter 4

Module Configuration

Rack Address (SW1-1 through SW1-6)

The rack address refers to the logical rack number from the scanner image

that contains a particular DCMs image.

The table on page 4–4 gives the switch settings that define possible rack

address choices for all scanners. To use this table, first determine which of

the following categories applies to your scanner:

• PLC-2, mini PLCs, PLC-2/30 with 1772-SD, SD2 remote scanner

• PLC-3 and PLC-5/250 processors. (This category includes those with

built-in scanners, as well as the following without built-in scanners:

catalog numbers 1775-54A, -54B, -S5, -SR, -SR5 and 5250-RS.)

• PLC-5/11, PLC-5/15, PLC-5/20, PLC-5/25, PLC-5/30, PLC-5/40, or

PLC-5/60 and 1771-SN. (This category includes all smaller in-rack

processors and standalone scanners that have local and remote I/O and

begin rack addressing at rack 1.)

• SLC-5/02 (or above) with 1747-SN scanner

After determining which category applies to your DCM application:

1. Find the column for the scanner used in your application.

2. Go down the column to the rack address that you assigned to the DCM.

3. Use the switch settings in the right-most columns of the table that

correspond to your rack address.

4–3

Page 34

Chapter 4

Module Configuration

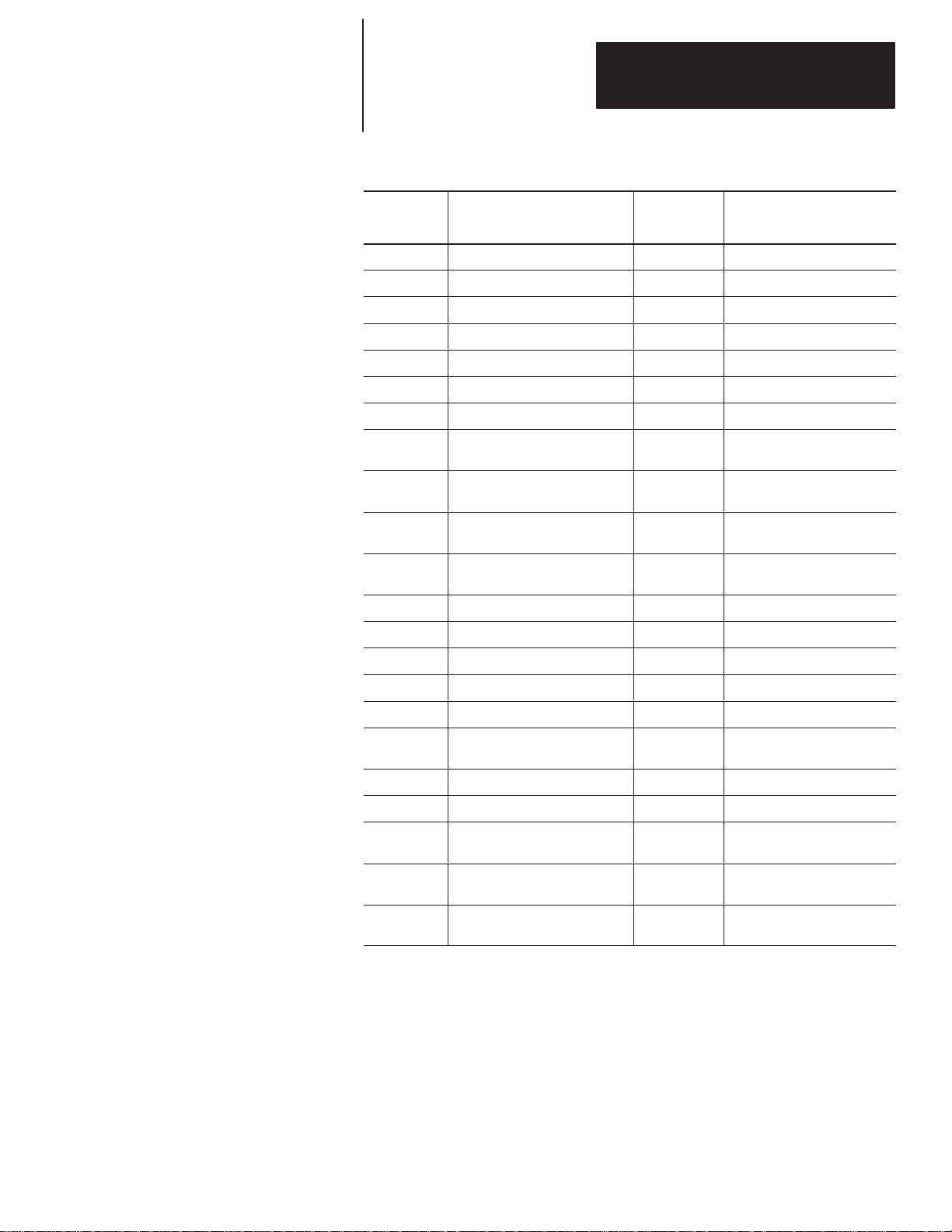

Use this table to set SW1 – switches 1 through 6.

1747-SNPLC-2PLC-3PLC-

0 1 0 – – – – 0 ON ON ON ON ON ON

1 2 1 1 1 1 1 1 ON ON ON ON ON OFF

2 3 2 2 2 2 2 2 ON ON ON ON OFF ON

3 4 3 3 3 3 3 3 ON ON ON ON OFF OFF

5 4 4 4 4 4 ON ON ON OFF ON ON

6 5 5 5 5 5 ON ON ON OFF ON OFF

7 6 6 6 6 6 ON ON ON OFF OFF ON

Logical Rack Number (Octal) Switch Number (SW1)

7 7 7 7 7 ON ON ON OFF OFF OFF

10 10 10 10 ON ON OFF ON ON ON

11 11 11 11 ON ON OFF ON ON OFF

12 12 12 12 ON ON OFF ON OFF ON

13 13 13 13 ON ON OFF ON OFF OFF

14 14 14 14 ON ON OFF OFF ON ON

15 15 15 15 ON ON OFF OFF ON OFF

16 16 16 16 ON ON OFF OFF OFF ON

17 17 17 17 ON ON OFF OFF OFF OFF

20 20 20 ON OFF ON ON ON ON

21 21 21 ON OFF ON ON ON OFF

22 22 22 ON OFF ON ON OFF ON

23 23 23 ON OFF ON ON OFF OFF

24 24 24 ON OFF ON OFF ON ON

25 25 25 ON OFF ON OFF ON OFF

26 26 26 ON OFF ON OFF OFF ON

27 27 27 ON OFF ON OFF OFF OFF

30 30 ON OFF OFF ON ON ON

31 31 ON OFF OFF ON ON OFF

32 32 ON OFF OFF ON OFF ON

33 33 ON OFF OFF ON OFF OFF

34 34 ON OFF OFF OFF ON ON

35 35 ON OFF OFF OFF ON OFF

36 36 ON OFF OFF OFF OFF ON

37 37 ON OFF OFF OFF OFF OFF

40 OFF ON ON ON ON ON

41 OFF ON ON ON ON OFF

42 OFF ON ON ON OFF ON

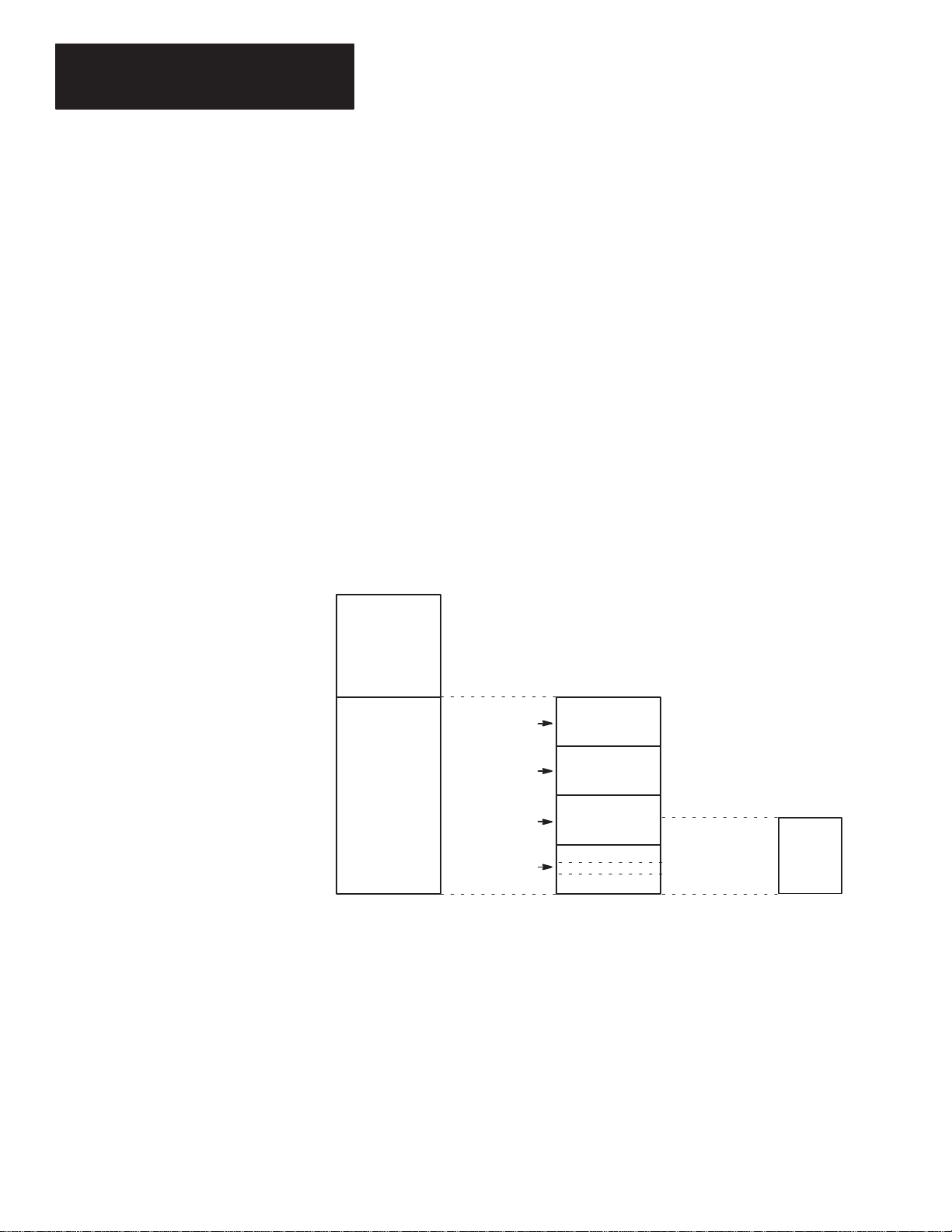

43 OFF ON ON ON OFF OFF

44 OFF ON ON OFF ON ON

5/15

PLC-

5/25

PLC-

5/40

PLC-

5/60

PLC-

1 2 3 4 5 6

5/250

4–4

Continued on next page.

Page 35

Chapter 4

Module Configuration

1747-SNPLC-2PLC-3PLC-

45 OFF ON ON OFF ON OFF

46 OFF ON ON OFF OFF ON

47 OFF ON ON OFF OFF OFF

50 OFF ON OFF ON ON ON

51 OFF ON OFF ON ON OFF

52 OFF ON OFF ON OFF ON

53 OFF ON OFF ON OFF OFF

54 OFF ON OFF OFF ON ON

55 OFF ON OFF OFF ON OFF

56 OFF ON OFF OFF OFF ON

57 OFF ON OFF OFF OFF OFF

60 OFF OFF ON ON ON ON

61 OFF OFF ON ON ON OFF

62 OFF OFF ON ON OFF ON

63 OFF OFF ON ON OFF OFF

64 OFF OFF ON OFF ON ON

65 OFF OFF ON OFF ON OFF

66 OFF OFF ON OFF OFF ON

67 OFF OFF ON OFF OFF OFF

70 OFF OFF OFF ON ON ON

71 OFF OFF OFF ON ON OFF

72 OFF OFF OFF ON OFF ON

73 OFF OFF OFF ON OFF OFF

74 OFF OFF OFF OFF ON ON

75 OFF OFF OFF OFF ON OFF

76 OFF OFF OFF OFF OFF ON

77 77 77 77 77 77 77 77 Reserved

5/15

PLC-

5/25

PLC-

5/40

PLC-

5/60

PLC-

1 2 3 4 5 6

5/250

4–5

Page 36

Chapter 4

Module Configuration

DIP Switch 2 Settings

Rack Size (SW2-5 and SW2-6)

The logical rack size allocates image space in the scanner for each DCMs I/O

data. The DCM allows 1/4, 1/2, 3/4, and full rack addressing. SW2 switches

5 and 6 define the rack size.

Rack Size SW2-5 SW2-6

1/4 Logical Rack ON ON

1/2 Logical Rack ON OFF

3/4 Logical Rack OFF ON

Full Logical Rack OFF OFF

Important: The DCM image cannot cross logical rack boundaries.

Therefore, as an example, configuring the module for 1/2

logical rack with starting group 6 will cause a configuration

error. Refer to Starting I/O Group Number on page 4–2.

Last Rack (SW2-4)

Switch 4 of SW2 must be set to the OFF position if the DCM shares its

logical rack with at least one other adapter and has been assigned the highest

I/O group number in that logical rack.

Last Rack SW2-4

Yes OFF

Logical

Rack

1

SLC

Bit Number:

Module

Module 2

Module 3

Module 4

1

Octal 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Group

0, W

Group 1, Word 1

Group 2, Word 2

Group 3, Word 3

Group 4, Word 4

Group 5, Word 5

Group 6, Word 6

Group 7, Word 7

ord 0

Module 4 is the last device in the logical rack.

13 12 11 10 9 8 7 6 5 4 3 2 1 015 14Decimal

17 16

No ON

Remote I/O Scanner

Output Image (to the PLC)

Because Module 4 is the last RIO adapter

in a logical rack shared by other adapter(s),

SW2 switch 4 must be in the OFF position.

Direct Communications Module 1

Module 1 Configured As:

Logical Rack Address 1

I/O Group 0

Module Rack Size 1/4

Module 2 Configured As:

Logical Rack Address 1

I/O Group 2

Module Rack Size 1/4

Module 3 Configured As:

Logical Rack Address 1

I/O Group 4

Module Rack Size 1/4

Module 4 Configured As:

Logical Rack Address 1

I/O Group 6

Module Rack Size 1/4

4–6

Page 37

Chapter 4

7

Module Configuration

Clear On Fault (SW2-3)

ATTENTION: Before setting SW2-3 to ON, make sure that

holding all DCM input bits in their last state, in the event a

communication error occurs, does not create an unsafe condition

!

in the distributed SLC processor.

Clear On Fault SW2-3

Yes OFF

No ON

Turn switch to OFF position if you want the DCM to clear and hold clear all

data bits in its input image table, in the event of an RIO communication

failure or when the supervisory processor enters Program/Test/Fault Mode.

Status bits will not be cleared.

Turn switch to ON position if you want the DCM to hold all input data bits in

their last state when an RIO communication failure occurs or when the

supervisory processor enters Program/Test/Fault Mode.

Data Rate (SW2-1 and SW2-2)

Data Rate SW2-1 SW2-2 Cable Length (Belden 9463)

57.6K baud ON ON 3048 meters (10,000 feet)

115.2K baud ON OFF 1524 meters (5,000 feet)

230.4K baud

OFF ON

62 meters (2,500 feet)

OFF OFF

4–7

Page 38

Page 39

Chapter

5

Installation and Wiring

This chapter explains how to install the DCM into the SLC chassis and

provides information about terminal wiring. Topics include:

• DCM installation

• network wiring

Compliance to European Union Directives

DCM Installation

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in whole

or in part, documented in a technical construction file:

• EN 50081-2

EMC – Generic Emission Standard, Part 2 – Industrial Environment

• EN 50082-2

EMC – Generic Immunity Standard, Part 2 – Industrial Environment

This product is intended for use in an industrial environment.

Installation procedures for this module are the same as for any other discrete

I/O or specialty module. Refer to the illustration on page 5–2 to identify

chassis and module components listed in the procedures below.

ATTENTION: Disconnect power before attempting to install,

remove, or wire the DCM.

!

Important: Make sure you have set the DIP switches properly before

installing the DCM.

Before installation make sure your modular SLC power supply

has adequate reserve current capacity. The DCM requires

360mA @ 5 volts. Each Fixed SLC 500 controller can support

up to one DCM in a 2-slot expansion chassis, depending on

which I/O module is in the second slot. Refer to the Discrete

I/O Modules Product Data, Publication Number 1746-2.35.

5–1

Page 40

Chapter 5

Installation and Wiring

Installation

1. Disconnect power.

2. Align the full-sized circuit board with the chassis card guides. The first

slot (slot 0) of the first rack is reserved for the CPU.

3. Slide the module into the chassis until the top and bottom latches are

latched.

4. Attach the RIO link cable to the connector on the front of the module

behind the door.

5. Insert the cable tie in the slots.

6. Route the cable down and away from module, securing it with the cable tie.

7. Cover all unused slots with the Card Slot Filler, Catalog Number 1746-N2.

Module Release

Card Guide

.

.

.

Cable Tie

19627

Removal

1. Disconnect power.

2. Press the releases at the top and bottom of the module and slide the

module out of the chassis slot.

3. Cover all unused slots with the Card Slot Filler, Catalog Number

1746-N2.

5–2

Page 41

Chapter 5

xten e o e

Installation and Wiring

Network Wiring

CONFIGURATION

RACK ADDR

1/4 1/2 3/4 1

RIO Link

Connector

LINE 1 _______

SHIELD ______

LINE 2 _______

Using Extended

Node Capability

Not Using

Not Using

Extended Node

Capability

DCM

FAULT

COMM

RACK SIZE

FIRST I/O GROUP

0 2 4 6

DATA RATE (K B/S)

57.6 115.2 230.4

A 1/2 watt terminating resistor must be attached across line 1 and line 2 of

the connectors at each end (scanner and last physical device) of the network.

The size of the resistor depends upon the baud rate and extended node

capability, as shown below:

Baud Rate Terminating Resistor Size

All Baud Rates

57.6K baud

115.2K baud

230.4K baud

RIO

I/O

GROUP

(LSB)

SW1

RACK

ADDRESS

2345678

(MSB)

1

O

N

X

X

RACK

SIZE

SW2

LAST

RACK

CLR ON FL

T

2345678

DATA

RATE

1

O

N

1747-DCM

Direct Communication Module

82W 1/2 Watt

150W 1/2 Watt

150W 1/2 Watt

82W 1/2 Watt

Scanner

Maximum Cable Distance

(Belden 9463)

10,000 feet at 57.6K baud

5,000 feet at 115.2K baud

2,500 feet at 230.4K baud

3048 meters (10,000 feet)

1524 meters (5,000 feet)

762 meters (2,500 feet)

Terminating

Resistor

Line 1 – Blue

Shield – Shield

Line 2 – Clear

Line 1 – Blue

Shield – Shield

Line 2 – Clear

1747–DCM

1747-DCM

Direct Communication Module

Line 1 – Blue

Shield – Shield

Line 2 – Clear

Terminating

Resistor

5–3

Page 42

Page 43

Chapter

6

Programming

This chapter shows you how to program ladder logic in the supervisory

processor/scanner and the distributed SLC to transfer data via the DCM.

Topics include:

• overview

• programming examples

• status words

• applications using status word bits

Overview

Both the supervisory processor/scanner and the distributed SLC transfer data

to and from the DCM automatically via their I/O and the RIO scan. The

DCM, as a common memory site for both supervisory and distributed

processors, has two addresses; one for the supervisory processor/

scanner and one for the SLC. The supervisory processor/scanner address is

the DCM logical rack address as set by DCM SW-1 switches 1 through 6.

The distributed SLC address is determined by the slot where the DCM is

physically installed.

The supervisory processor/scanner and distributed SLC addresses can be

different; however, the bit position part in each word must be the same.

In the programming examples on the following page, an Examine If Open

contact similar to the one shown below is used in each output rung:

I:4.0

]/[

08

This instruction checks that the Logical OR bit of the status word is false.

Whenever any of the status word bits (except the User Status Flag bit) is set,

it is indication that a condition has occurred in your logic program that may

require inspection. If this happens you would normally want to inhibit some

outputs by using a ladder logic instruction. Using an Examine If Open (XIO)

instruction examining the Logical OR bit (word 0, bit 8 for SLC; word 0, bit

10 for PLC) is the easiest way of doing this.

6–1

Page 44

Chapter 6

Programming

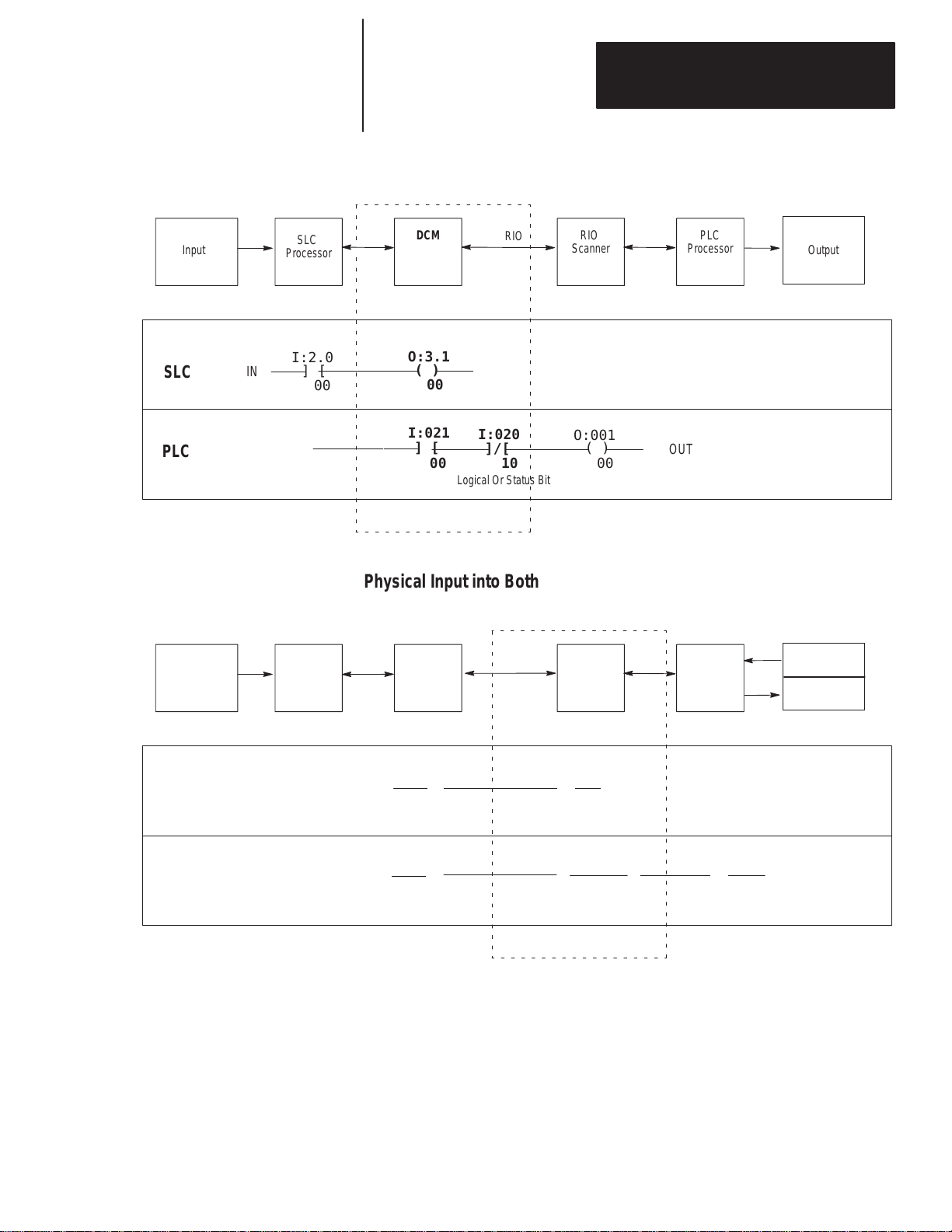

Programming Examples

The following programming examples are typical of applications using the

DCM. In each example the portion of the scanner image assigned to the

DCM is logical rack 2, starting group 0, 1 full rack, and is located in SLC

physical slot 3.

Power Supply

Physical Slot #

Output

SLC Processor

0123456

Input

DCM 1

Physical Input into PLC – Physical Output from SLC

PLC

Input Output

PLC

Processor

IN

SLC

In the example above, PLC output O:021/00 controls the (on/off) status of

DCM input I:3.1/00.

I:3.1/00 is used as a conditional ladder logic along with the Logical OR input

status bit to control SLC output O:1.0/00.

Scanner

I:000

] [

00

RIO

RIO

O:021

( )

00

I:3.1

] [

00

DCM

I:3.0

]/[

08

Logical Or Status Bit

SLC

Processor

O:1.0

( )

00

OUT

6–2

Page 45

Chapter 6

Programming

Physical Input into SLC – Physical Output from PLC

RIO

Input Output

SLC

Processor

I:2.0

SLC

IN

] [

00

DCM

O:3.1

( )

00

I:021

PLC

] [

00

Logical Or Status Bit

RIO

I:020

]/[

10

Scanner

O:001

( )

00

PLC

Processor

OUT

Physical Input into Both PLC and SLC (Logical AND) – Physical Output

from SLC

Input

PLC

Processor

RIO

Scanner

RIO

DCM

SLC

Processor

Input

Output

PLC

SLC

IN

I:000

] [

00

I:2.0

] [

00

O:021

( )

00

I:3.1

] [

00

I:3.0

]/[

08

Logical Or Status Bit

O:1.0

( )

00

OUTIN

6–3

Page 46

Chapter 6

Programming

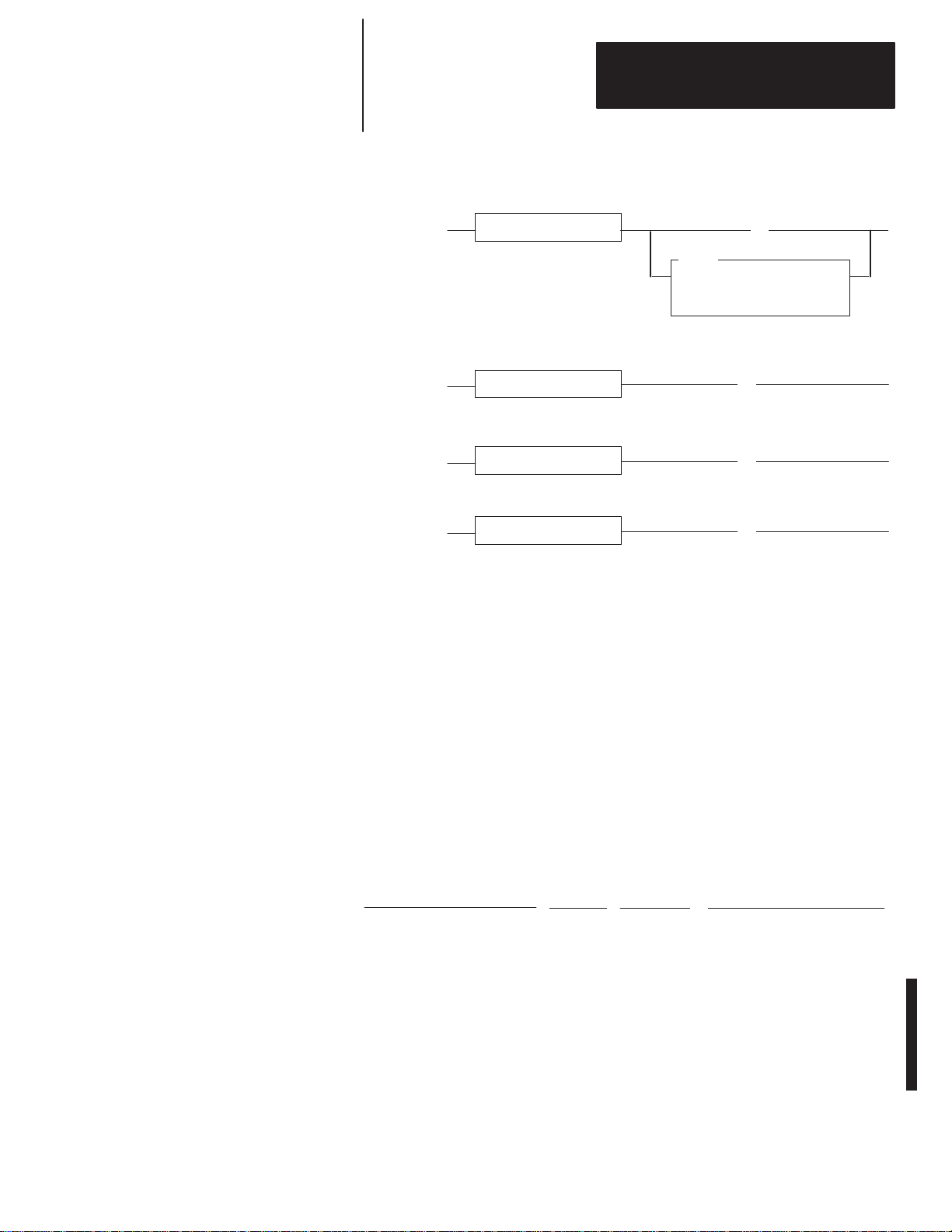

Input

First

SLC

Processor

Physical Input into First SLC – Physical Output from Second SLC

For this example the second SLC has a logical PLC rack address of 3 and an

SLC slot address of 4.

PLC with

RIO

scanner

DCM

RIO

DCM

Second

SLC

Processor

Output

I:2.0

SLC

IN

] [

00

PLC

(No physical input into the PLC)

O:3.1

( )

00

I:021

] [

00

I:020

]/[

10

Logical Or Status Bit

I:4.1

] [

00

O:031

( )

00

I:4.0

]/[

08

Logical Or Status Bit

O:1.0

( )

00

OUT

When transmitting data from a PLC to an SLC, if the Clear On Fault (CLR

ON FLT) is active (switch is OFF), the instruction to examine the Logical

OR bit of the status word can be omitted as long as clearing the DCM input

image table puts SLC outputs into a safe state for the specific application.

6–4

Page 47

Chapter 6

Í

Í

Programming

Status Words

Bit Number: Decimal

Status Word:

Data Words:

Status Word:

Data Words:

The first word of the DCM I/O image is the status word. The status word

indicates the status of communication and data between the RIO scanner and

the DCM. Depending on what logical rack size the DCM is configured for, it

will transfer the following number of I/O words:

Rack Size Number of RIO Words Transferred Total Words

1/4 Logical Rack One (plus one Status Word) 2

1/2 Logical Rack Three (plus one Status Word) 4

3/4 Logical Rack Five (plus one Status Word) 6

Full Logical Rack Seven (plus one Status Word) 8

The figure below shows how I/O bits are transferred from the scanner to two

DCMs, each configured as a 1/2 logical rack device.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0

R

RR

R

RR

RR

RR

RRRRRRRR

DCM 1

1/2 Rack Device

RR

RRRRRRRR

DCM 2

1/2 Rack Device

Word

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

DCM

Reserved Bits

Status Bits

R

= Reserved for future use

RIO Scanner Input Status Word Examination (Decimal)

This is the input status word sent in a data transfer from a supervisory

processor/RIO scanner to a DCM. These bits can be used as conditional

logic in your SLC program to flag DCM, RIO, or supervisory processor

system errors and/or status. Scanner status bits not defined below are

reserved for future use.

14

15

13

0

12

5

10

11

897

6

342

1

Logical OR of other Status Word bits. It is set when any

other bit is set. It is cleared when all other bits are cleared.

Program/Test/Fault Mode bit. This bit is set whenever the

supervisory processor is in the Program, Test, or Fault Mode.

DCM Initialization bit. This bit is set when the DCM is in its power-up initialization.

It will be cleared when valid data is received from the supervisory processor output

image table.

Communication Error bit. This bit is set whenever the DCM detects an RIO communication

error. It is cleared when the Communication error is cleared.

6–5

Page 48

Chapter 6

Programming

SLC

PLC

17

15

DCM/SLC Output Status Word Examination (Octal)

This is the output image status word sent in a data transfer from a DCM to a

supervisory processor/scanner. These bits can be used as conditional logic in

your supervisory processor program to flag DCM or SLC system errors

and/or status. DCM/SLC status bits not defined below are reserved for

future use.

Both the decimal and octal bit addresses are shown below to assist you in

programming your supervisory (PLC) processor and distributed SLC

processor.

0

1

0

1

16

14

15

13

14

12

11

13

10

12

897

10117

5

6

5

6

342

342

Reserved Bits

Status Bits

Logical OR of Status Word bits 11 and 12 (9 and 10 for

SLC). It is set when either 11 or 12 (9 or 10) is set. It is

cleared when 11 or 12 (9 or 10) is cleared.

Program/Test/Fault Mode bit. This bit is set whenever

the SLC controlling the DCM is in the Program, Test, or

Fault Mode.

DCM Output Data Invalid bit.➀ This bit is set when DCM output image data

could be invalid.