Page 1

Backup Scanner Module

Catalog Number 1747-BSN

Installation Instructions

Publication 1747-5.38

Page 2

2 Backup Scanner Module

Important User Information

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of this control equipment must satisfy

themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including any

applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid-State Control (available from your local

Allen-Bradley office), describes some important differences between solid-state

equipment and electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or in part,

without written permission of Allen-Bradley Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTEN T I O N :

that can lead to personal injury or death, property damage or economic

!

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

Publication 1747-5.38

loss.

application and understanding of the product.

Identifies information about practices or circumstances

Page 3

Backup Scanner Module 3

For More Information

As part of our effort to preserve, protect, and improve our environment,

Allen-Bradley is reducing the amount of paper we use. Less paper means more

options for you. In addition to traditional printed publications and CD-ROM

versions, we now offer on-line materials with the most up-to-date information

you can get. We recommend that you read the related publications listed below

before starting up your control system.

Related Publications

For Refer to this Document Pub. No.

A more detailed description on how to install,

configure, and operate your Backup Scanner.

A more detailed description on how to install

and use your modular SLC 500™ system

A reference manual that contains status file

data and instruction set information for SLC

500 processors.

Backup Scanner

User Manual

SLC 500 Modular Hardware

Style Installation and Operation

Manual

SLC 500™ and MicroLogix™

1000 Instruction Set Reference

Manual

1747-6.22

1747-6.2

1747-6.15

How to Get More Information

If you would like a manual, you can:

• download a free electronic version from the internet at

www.theautomationbookstore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell Automation representative

– visiting www.theautomationbookstore.com and placing your order

– calling 1.800.963.9548 (USA/Canada) or 001.330.725.1574 (Outside

USA/Canada)

Publication 1747-5.38

Page 4

4 Backup Scanner Module

Safety Considerations

This equipment is UL certified for ordinary locations only. The module is

C-UL certified for use in Class I, Division 2, Groups A, B, C, D, or nonhazardous locations only. The following attention statement applies to use in

hazardous locations.

Explosion Hazard

Class I, Division 2.

power has been switched off, and the area is known to be

non-hazardous.

while circuit is live unless the area is known to be nonhazardous.

Note:

ATTENTION:

• Substitution of components may impair suitability for

!

• Do not replace components or disconnect equipment unless

• Do not connect or disconnect connectors or operate switches

The temperature code rating is marked on the product

label.

Environnements dangereux

Cet équipement est certifié UL pour une utilisation en environnements ordinaires

seulement. Le module est certifié UL Canada pour une utilisation en

environnements de Classe 1, Division 2, Groupes A, B, C, D, ou non dangereux.

La mise en garde suivante s’applique à une utilisation dans des environnements

dangereux.

ATTEN T I O N :

• La substitution de composants peut rendre cet équipement

!

DANGER D’EXPLOSION

impropre à une utilisation en environnement de Classe 1,

Division 2.

Remarque :

Publication 1747-5.38

• Couper le courant ou s’assurer que l’emplacement est

désigné non dangereux avant de remplacer les composants.

• Couper l’alimentation ou s’assurer que l’environnement est

classé non dangereux avant de brancher ou débrancher des

connecteurs ou de faire fonctionner des commutateurs.

Le taux du code de température est indiqué sur l’étiquette

du produit.

Page 5

Backup Scanner Module 5

Overview

The 1747-BSN Backup Scanner Module provides a high-speed communication

channel between two modular SLC 500™ (5/02 or higher) processors. The 1747BSN backup system uses a set of modules, with one or more 1747-BSN modules

residing in the primary system and one or more complementary modules in the

secondary or backup system. The primary system controls the operation of

remote I/O, while the secondary system monitors communications via the highspeed serial link (HSSL) and is available to take over control in the event of a

fault in the primary system.

The backup scanner has the capability to switch between two communication

channels. The first channel is configurable as Remote I/O (RIO) or Data

Highway Plus™ (DH+). The second channel is used to switch one RS232/485

channel in order to provide connection for electronic operator interfaces.

A backup system using the 1747-BSN modules supports up to eight BSN

modules in each processor chassis, connected by a local status link (LSL). Only I/

O residing in remote chassis is backed up. Local I/O is not backed up. Examples

of RIO and DH+ system configurations are shown in Figures 1 and 2 on page 6.

Note: During the transfer of control from one processor to

another (switchover), the output modules in the remote

chassis maintain their last state until the secondary

processor program takes control. The secondary

processor program is not synchronized with the primary

program.

Publication 1747-5.38

Page 6

6 Backup Scanner Module

Figure 1 RIO System Configuration

Processor Processor

RS232

1747-BSN

HSSL

Remote I/O

1747-ASB

Remote I/O

Figure 2 DH+ System Configuration

1747-BSN

RS232/DH485 to Operator

Interface Device

1747-ASB

Processor Processor

RS232

Publication 1747-5.38

DH+

1747-BSN

HSSL

DH+

1747-BSN

To DH+ Network

RS232/DH485 to Operator

Interface Device

Page 7

Backup Scanner Module 7

The 1747-BSN module provides backup functionality for the following:

• DH+ or RIO on a single pair of modules - Both may be backed up when two

or more pairs of modules are used.

• RS232 - Any RS232 device communicating with channel 0 of the SLC

controller may be backed up provided hardware-handshake lines are not

required. These ports only allow switchover of the transmit, receive and

ground wires for RS232.

Features

Figure 3 Hardware Features

Local Status

Link (LSL)

BACKUP SCANNER

PRI

SEC

ERR

RIO

FLT

HSSL

Status LEDs

High Speed Serial

Link (HSSL)

Publication 1747-5.38

Page 8

8 Backup Scanner Module

Status LEDs

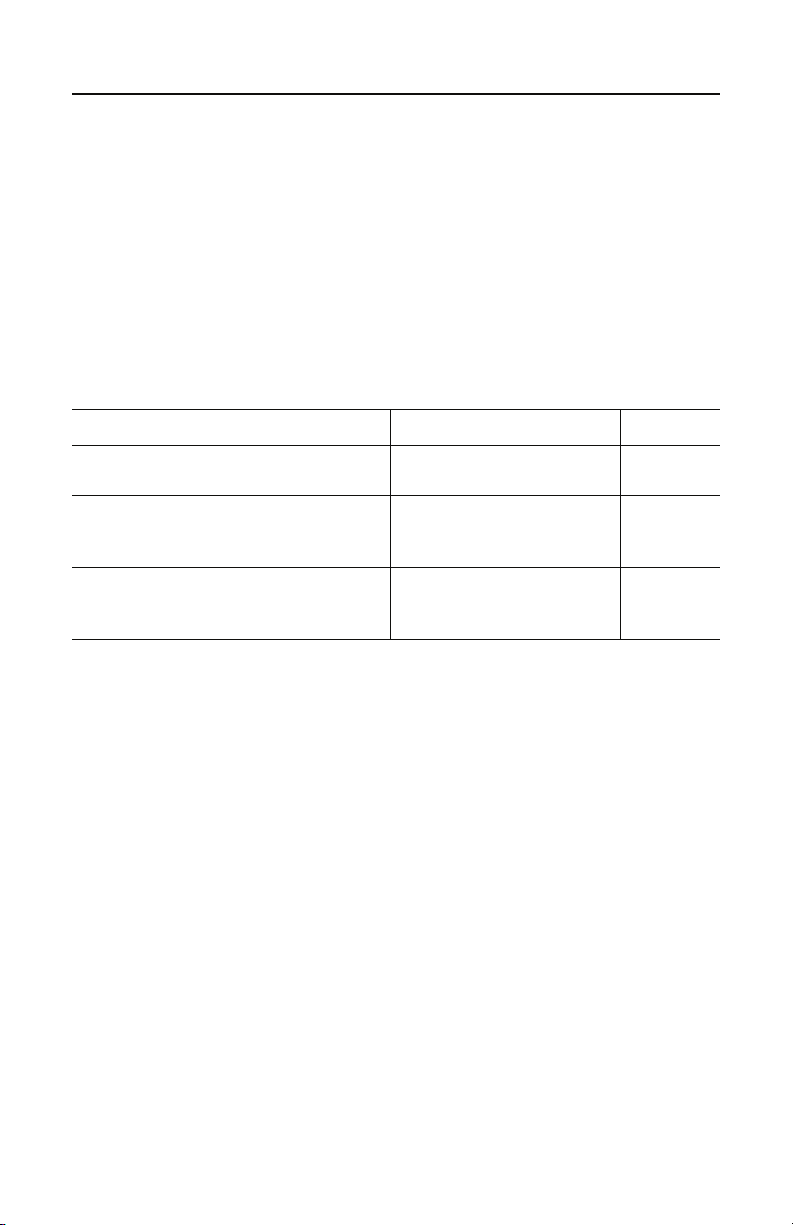

The table below describes the six LEDs located on the module’s front panel.

To

ensure that they are operating correctly, all LEDs are illuminated during power-up.

LED Definition Status and Color Indication

PRI Primary Steady Green The module is in the primary mode.

SEC Secondary Steady Amber The module is in the secondary mode.

Steady Green The RIO link is working properly.

A remote device is not configured or

connected correctly, or is faulted.

The RIO link has a fault. The scanner is

connected incorrectly, or all devices are

configured improperly, have no power,

or are faulted.

The communication channel is not

configured as RIO.

A communications error has been

detected on the HSSL.

RIO RIO Communication

Backup Module

ERR

Error

HSSL

High Speed Serial

Link Communication

FLT Fault

Flashing Green

Flashing Red

Steady Red There is a configuration error.

Off

Flashing Red The module is not ready for switchover.

Off The module is ready for switchover.

Flashing Green The link is operating with no errors.

Off

Steady Red A hardware fault has occurred.

Flashing Red The module is not configured properly.

High-Speed Serial Link (HSSL)

The high-speed serial link supports communication between the primary and

secondary backup scanner modules. The baud rate is 2M baud, and the link

supports a distance of up to 4.5 m (15 feet).

The HSSL also transfers a limited number of SLC 500 data table files from the

primary to the secondary processor. The data table transfer is controlled by an

application program in the processor.

Publication 1747-5.38

Page 9

Backup Scanner Module 9

Local Status Link (LSL)

The local status link is a 57.6K baud serial link used to exchange status between

up to eight 1747-BSN modules residing in the same chassis. The illustration

below shows the LSL and HSSL connections between primary and secondary

chassis with more than one 1747-BSN module.

Figure 4 LSL and HSSL Connections

Processor

LSL

1747-BSN #1

1747-BSN #2

Processor

1747-BSN #3

HSSL#1

HSSL#2

HSSL#3

1747-BSN #1

1747-BSN #2

1747-BSN #3

LSL

DIP Switches

The locations of the six-position configuration DIP switch and the four-position

module address DIP switch are shown on page 10.

Publication 1747-5.38

Page 10

10 Backup Scanner Module

Figure 5 DIP Switch Locations

Configuration Switch

Module Address Switch

O

N

12 3456

12 34

O

N

123456

123

4

Configuration Switch

The six-position Configuration DIP Switch is used to select the baud rate,

configure the communication channel, and identify each individual BSN module

and the last BSN module. The tables below define the DIP switch configuration

settings.

DIP Switch

Posit ion

1 and 2 Set the communication channel baud rate.

3 Channel configuration.

This user identification switch differentiates between BSN

4

modules in the primary system and BSN modules in the

secondary system, helping determine if switchover has

occurred.

5 Reserved.

6 Identifies the last module in the local status link.

Definition Setting

see the table on

page 11

DH+ = ON

RIO = OFF

User selectable

Last module = ON

All others = OFF

Publication 1747-5.38

Page 11

Backup Scanner Module 11

Baud Rate Settings

Position 1 Position 2 Baud Rate

ON ON 57.6K

ON OFF 115.2K

OFF ON 230.4K

OFF OFF Disabled

Module Address Switch

The four-position Module Address DIP switch configures the BSN address in the

LSL. The table below shows the address that corresponds to each setting.

Note:

Switch Position

123

OFF OFF OFF 1

ON OFF OFF 2

OFF ON OFF 3

ON ON OFF 4

OFF OFF ON 5

ON OFF ON 6

OFF ON ON 7

ON ON ON 8

Switch position 4 is not used.

1747-BSN Address

Configuration Errors

The module reports the following configuration errors by flashing the fault LED:

• two 1747-BSN modules are configured with the same address

• LSL addresses are not consecutive (addresses must be numbered 0, 1, 2,

etc.)

• last LSL switch is not set in the last module in the link

• last LSL switch is set in a module that is not the last in the link, or

• primary and secondary modules do not have the same configuration settings

(secondary module shows the configuration error)

Publication 1747-5.38

Page 12

12 Backup Scanner Module

Switchover Conditions

The 1747-BSN module transfers control from the primary to the secondary

processor (switchover) if one of the following fault conditions occurs in the

primary system:

• power failure

• major fault in the processor

• 1747-BSN module fault

• primary processor mode change from Run to Program

Note:

In order for switchover to occur, both primary and

secondary modules must be working without faults prior

to the event that triggers the switchover.

Installation

ATTENTION:

!

wire the module.

Determining Power Requirements

The BSN module is powered through the backplane of the I/O chassis. Before

installation, make sure that your modular SLC power supply has adequate reserve

capacity. The BSN module requires 800 mA at 5V.

Important: Use separate power sources for the primary and secondary

processors to protect against interruptions and incoming power

failures.

Disconnect system power before attempting to install, remove, or

Publication 1747-5.38

Page 13

Backup Scanner Module 13

Inserting the Module into the Chassis

1.

Disconnect power.

2.

Align the full-sized circuit board with the chassis card guides of the leftmost slot of the first I/O module group in the I/O chassis. The first slot of

the chassis is reserved for the processor.

3.

Slide the module into the chassis until the top and bottom latches catch.

Figure 6 Inserting the Module

Wiring

Terminal Wiring

ATTENTION:

!

The backup scanner module contains a green removable terminal block. The

terminal pinout is shown on page 14.

or wire the removable terminal wiring block.

Disconnect power to the SLC before attempting to install, remove

Publication 1747-5.38

Page 14

14 Backup Scanner Module

Figure 7 Terminal Pinout

LSL (Line 1 – Blue)

LSL (Shield)

LSL (Line 2 – Clear)

232 / 485 (A) to CPU

232 / 485 (B) to CPU

232 / 485 (COM) to CPU

DH+ (Line 1) to CPU

DH+ (Shield) to CPU

DH+ (Line 2) to CPU

Release Screw

Release Screw

HSSL (Line 1 – Blue)

HSSL (Shield)

HSSL (Line 2 – Clear)

232 / 485 (A) to Link

232 / 485 (B) to Link

232 / 485 (COM) to Link

RIO / DH+ (Line 1) to Link

RIO / DH+ (Shield) to Link

RIO / DH+ (Line 2) to Link

Use Belden™ 9463 cable when wiring the module.

2

Terminal screws accept a maximum of two #14 AWG (2mm

) wires. Tighten

terminal screws only tight enough to immobilize wires. Maximum torque on

terminal screws is 0.9 Nm (8 in-lbs.).

ATTENTION:

tightening of the slotted release screws. Maximum torque on the release screws

!

is 0.6 Nm (5.3 in-lbs.).

To avoid cracking the terminal block, alternate the removal and

For Remote I/O Installations

1. To ensure a proper earth ground of the cable shield, follow these steps:

2. Strip back enough of the RIO cable to expose enough shield drain wire to

reach a chassis mounting bracket.

3. Attach the ring terminal lug to the end of the shield drain wire.

4. Attach the ring terminal lug to the SLC chassis mounting bracket.

Important: The RIO cable shield must be grounded at the backup scanner end

only.

Publication 1747-5.38

Page 15

Backup Scanner Module 15

HSSL Wiring

Connect the HSSL to establish communication between the primary and

secondary systems. Maximum cable length for the HSSL is 4.5 m (15 ft.).

Local Status Link Wiring

If you have more than one 1747-BSN module in the chassis, connect the LSL in

series between modules in the same chassis. This enables BSN modules in the

same chassis to exchange status information in order to perform switchovers in

unison.

RIO Link Wiring

The backup scanner module is connected to other devices on the RIO link in a

daisy-chain (serial) configuration. There are no restrictions governing the space

between devices, provided the maximum cable distance is not exceeded.

A ½ watt terminating resistor must be attached across lines one and two at each

end of the RIO link. The value of the resistor depends on the baud rate and

extended node capability, as shown in the table that follows.

Note:

To use extended node, all devices on the RIO link must support it. Refer

to each device’s user manual.

Using

Extended Node

Capability

Not Using

Extended Node

Capability

Baud Rate

57.6K baud 3048 m (10,000 ft.)

115.2K baud 1524 m (5,000 ft.)

230.4K baud 762 m (2,500 ft.)

57.6K baud 3048 m (10,000 ft.)

115.2K baud 1524 m (5,000 ft.)

230.4K baud 762 m (2,500 ft.)

Max. Cable Distance

(Belden™ 9463)

Resistor Size

1/2 Watt

82

Ω

Gray-Red-Black-Gold

1/2 Watt

150

Brown-Green-Brown-Gold

Ω

82

1/2 Watt

Ω

Gray-Red-Black-Gold

Publication 1747-5.38

Page 16

Specifications

Operating Specifications

Backplane Current Consumption

Operating Temperature

Storage Temperature

Humidity

Noise Immunity

Agency Certification

(when product or packaging is marked)

800 mA at 5V

+32°F to +140°F (0°C to +60°C)

-40°F to +185°F (-40C to +85°C)

5 to 95% without condensation

NEMA Standard ICS 2-230

UL listed

C-UL listed – Class I, Division 2, Groups A, B, C, D

Temp. Code T3C

CE compliant for all applicable directives

Network Specifications

Baud Rate Determination of Maximum Cable Length and Terminating

Resistor Size

Baud Rate Maximum Cable Distance Terminating Resistor Size

1/2 Watt

150

57.6K baud 3048 meters (10,000 feet)

115.2K baud 1525 meters (5,000 feet)

230.4K baud 750 meters (2,500 feet)

Ω

Brown-Green-Brown-Gold

1/2 Watt

150

Ω

Brown-Green-Brown-Gold

82

1/2 Watt

Ω

Gray-Red-Black-Gold

DIP switch configuration settings are shown on page 10.

Publication 1747-5.38 – September 1999 40071-040-01 (A)

1999 Rockwell International. All Rights Reserved. Printed in USA

©

Loading...

Loading...