Page 1

POINT I/O

PROFIBUS Adapter

Module

Cat. No. 1734-APB

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley, RSNetworx and POINT I/O are trademarks of Rockwell Automation

PROFIBUS is a trademark of PROFIBUS Trade Organization

Identifies information that is critical for successful

application and understanding of the product.

Page 3

About This User Manual

Preface

Purpose of This Manual

Who Should Use This Manual

This manual describes how to install, configure and troubleshoot your

PROFIBUS Adapter module.

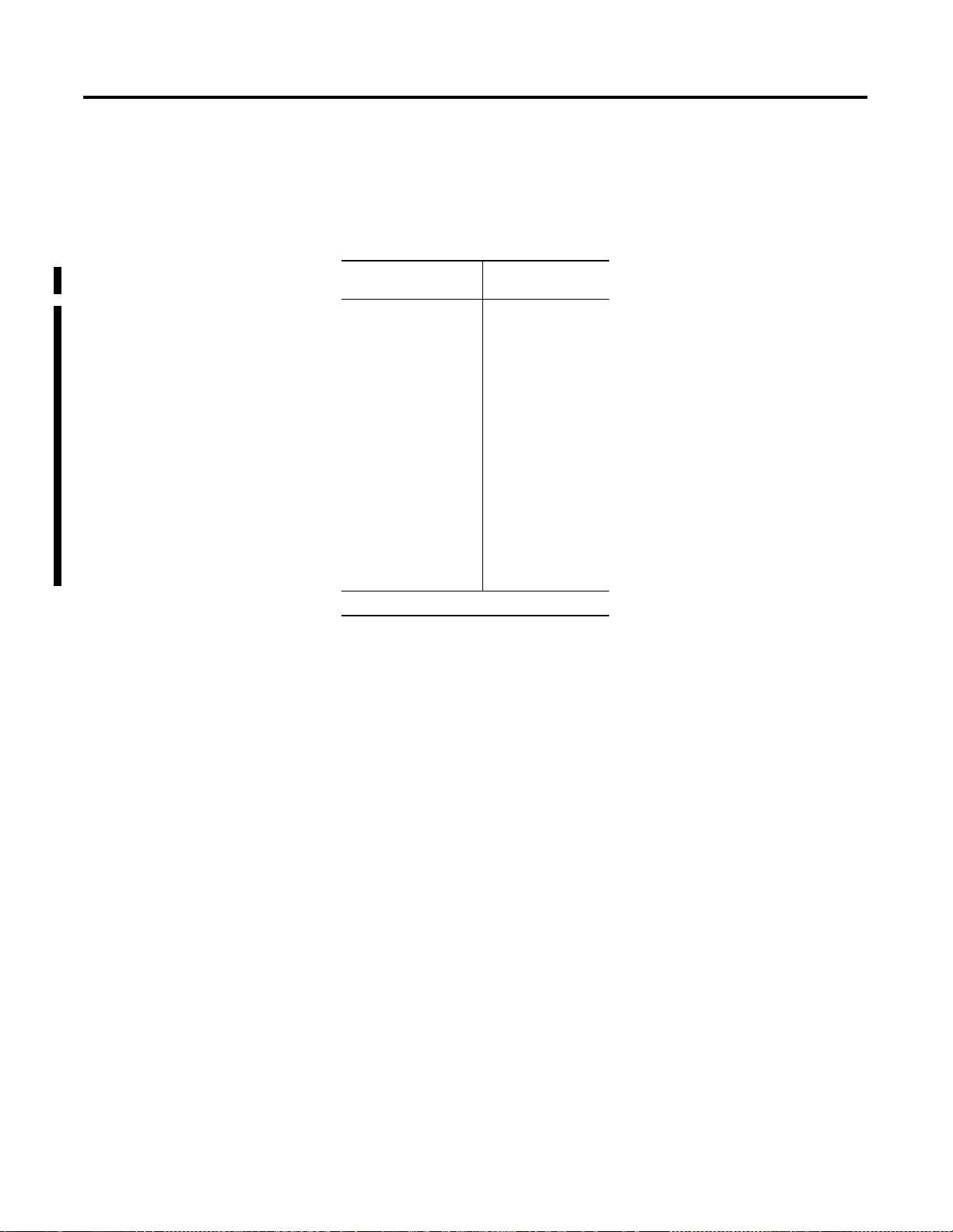

For information about: See:

What is the PROFIBUS Adapter Chapter 1

Installing the PROFIBUS Adapter Chapter 2

Configuring the POINT I/O System Chapter 3

Communication and I/O Table Mapping Chapter 4

Grouped Modules Chapter 5

Troubleshooting the PROFIBUS Adapter Chapter 6

Specifications Appendix A

Default Data Maps Appendix B

You must be able to use your selected configuration software to set up

and calibrate these modules. You must have the capability to

download and use files.

Related Products and Documentation

Description Cat. No. Publication

POINT I/O Technical Data 1734-Series 1734-2.1

Sink Input Module Installation Instructions 1734-IB2, -IB4 1734-IN051

Source Output Module Installation Instructions 1734-IV2, -IV4 1734-IN052

220V ac Input Module Installation Instructions 1734-IM 1734-IN008

120V ac Input Module Installation Instructions 1734-IA2 1734-IN010

120/220V ac Output Module Installation Instructions 1734-OA2 1734-IN009

Analog Current Input Module Installation Instructions 1734-IE2C 1734-IN053

We assume you know how to do this in this manual. If you do not,

refer to your software user manuals or online help before attempting

to use these modules.

The following table lists related 1734 products and documentation.

1 Publication 1734-UM005B-EN-P - June 2001

Page 4

Preface 2

Description Cat. No. Publication

Analog Current Output Module Installation Instructions 1734-OE2C 1734-IN054

Analog Voltage Input Module Installation Instructions 1734-IE2V 1734-IN001

Analog Voltage Output Module Installation Instructions 1734-OE2V 1734-IN002

Very High Speed Counter Module Installation Instructions 1734-VHSC24 1734-IN003

Very High Speed Counter Module Installation Instructions 1734-VHSC5 1734-IN004

5V Encoder/Counter Module Installation Instructions 1734-IJ 1734-IN005

24V Encoder/Counter Module Installation Instructions 1734-IK 1734-IN006

Relay Output Module Installation Instructions 1734-OW2 1734-IN055

Protected Output Module Installation Instructions 1734-OB2E, -OB4E 1734-IN056

DeviceNet Communication Interface Installation Instructions 1734-PDN 1734-IN057

POINT I/O 24V dc Expansion Power Supply Installation Instructions 1734-EP24DC 1734-IN058

Field Potential Distributor Installation Instructions 1734-FPD 1734-IN059

General Installation Instructions All 1734 1734-IN510

Wiring Base Assembly Installation Instructions 1734-TB, -TBS 1734-5.11

Wiring Base Assembly Installation Instructions 1734-TB3, -TB3S 1734-IN013A

Cold Junction Wiring Base Assembly Installation Instruction 1734-TBCJC 1734-IN583

8 dc Input/8 Output Module Installation Instructions 1734D-IB8XOB8 1734-5.20

8 dc Input/8 Relay Output Module Installation Instructions 1734D-IB8XOW8 1734-5.21

8 ac Input/8 OutputModule Installation Instructions 1734D-IA8XOA8 1734-5.22

8 ac Input/8 Relay Output Module Installation Instructions 1734D-IA8XOW8 1734-5.23

16 ac Input Module Installation Instructions 1734D-IA16 1734D-IN001

16 dc Input Module Installation Instructions 1734D-IB16 1734D-IN002

Publication 1734-UM005B-EN-P - June 2001

Page 5

Preface 3

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial

Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Environmental/Safety Protection

Open style devices must be provided with environmental and safety

protection by proper mounting in enclosures designed for specific

application conditions. See NEMA Standards publication 250 and IEC

publication 529, as applicable, for explanations of the degrees of

protection provided by different types of enclosures. Refer to

Allen-Bradley publication 1770-4.1, Industrial Automation Wiring and

Grounding Guidelines for more information.

Publication 1734-UM005B-EN-P - June 2001

Page 6

Preface 4

Publication 1734-UM005B-EN-P - June 2001

Page 7

Preface

What is the PROFIBUS Adapter

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . P-1

Related Products and Documentation. . . . . . . . . . . . . . . . . P-1

European Communities (EC) Directive Compliance . . . . . . P-3

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Environmental/Safety Protection . . . . . . . . . . . . . . . . . . P-3

Chapter 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

PROFIBUS Adapter Overview . . . . . . . . . . . . . . . . . . . . . . 1-1

Communicating through the Adapter . . . . . . . . . . . . . . 1-2

I/O Module Removal and Insertion Under Power . . . . . 1-2

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Set the Adapter Node Address . . . . . . . . . . . . . . . . . . . 1-2

Configure the Adapter for PROFIBUS Communication . . 1-3

Configure the I/O Modules for PointBus Communication 1-3

Diagnostic Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Network Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 1-4

Installing the PROFIBUS Adapter

Configuring the POINT I/O System

Chapter 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installing the PROFIBUS Adapter . . . . . . . . . . . . . . . . . . . . 2-2

Installing a Replacement PROFIBUS Adapter to an

Existing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Wiring the PROFIBUS Adapter. . . . . . . . . . . . . . . . . . . . . . 2-6

Module Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

PROFIBUS Connection Plug Wiring . . . . . . . . . . . . . . . 2-9

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 2-9

Chapter 3

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installing the GSD File. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Adding the Master to the Network . . . . . . . . . . . . . . . . . . . 3-3

Adding the Adapter to the Network . . . . . . . . . . . . . . . . . . 3-5

Adding I/O Modules to the Adapter. . . . . . . . . . . . . . . . . . 3-6

Configuring I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Enable/Disable Diagnostic Functionality for

your Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Configure Fault Action/Value for your Output Modules . 3-10

Configure Idle Action Value for your Output Modules . . 3-11

Download to Master System . . . . . . . . . . . . . . . . . . . . . . . 3-13

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 3-14

i Publication 1734-UM005B-EN-P - June 2001

Page 8

Table of Contents ii

Communication and I/O Table Mapping

Grouped Mode

Chapter 4

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Image Table Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

How Data Communication Takes Place . . . . . . . . . . . . . . . 4-2

Set_Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check_Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Get_Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Global_Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Data_Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Slave_Diag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Grouping Modules for Memory Management . . . . . . . . . . . 4-16

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 4-16

Chapter 5

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

How to Configure the Adapter for Grouped Mode . . . . . . . 5-2

Configuration Example. . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 5-4

Troubleshooting the PROFIBUS Adapter

Specifications

Default Data Maps

Chapter 6

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Using the Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Using PROFIBUS Diagnostics. . . . . . . . . . . . . . . . . . . . . . . 6-3

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 6-3

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

1734-IB2 Sink Input Module . . . . . . . . . . . . . . . . . . . . . . . B-2

Product Code: 0081h . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

1734-IB4 Sink Input Module . . . . . . . . . . . . . . . . . . . . . . . B-3

Product Code: 0082h . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Publication 1734-UM005B-EN-P - June 2001

Page 9

Table of Contents iii

1734-IV2 Source Input Module. . . . . . . . . . . . . . . . . . . . . . B-4

Product Code: 0083h . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

1734-IV4 Source Input Module. . . . . . . . . . . . . . . . . . . . . . B-5

Product Code: 0084h . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

1734-OB2E Electronically Protected Output Module . . . . . . B-6

Product Code: 0085h . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

1734-OB4E Electronically Protected Output Module . . . . . . B-7

Product Code: 0086h . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

1734-OW2 Relay Sink/Source Output Module. . . . . . . . . . . B-8

Product Code: 0087h . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

1734-IE2C Analog Current Input Module . . . . . . . . . . . . . . B-9

Product Code: 0018h . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

1734-OE2C Analog Current Output Module . . . . . . . . . . . B-11

Product Code: 0019h . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

1734-IE2V Analog Voltage Input Module . . . . . . . . . . . . . B-12

Product Code: 0018h . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

1734-OE2V Analog Voltage Output Module . . . . . . . . . . . B-14

Product Code: 0019h . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Publication 1734-UM005B-EN-P - June 2001

Page 10

Table of Contents iv

Publication Problem Report

Index

Back Cover

1734-IA2 120V ac Input Module. . . . . . . . . . . . . . . . . . . . B-15

Product Code: 1111h . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

1734-IM2 220V ac Input Module . . . . . . . . . . . . . . . . . . . B-16

Product Code: 1112h . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

1734-OA2 120/220V ac Output Module . . . . . . . . . . . . . . B-17

Product Code: 1113h . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Data Map: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Configuration Data: . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Publication 1734-UM005B-EN-P - June 2001

Page 11

What is the PROFIBUS Adapter

Chapter

1

General

PROFIBUS Adapter Overview

This chapter describes the purpose of the POINT I/O PROFIBUS

adapter, and what tasks have to be performed after installing the

adapter.

For more information about: See page:

PROFIBUS Adapter Overview 1-1

Startup Procedure 1-2

Chapter Summary and What’s Next 1-4

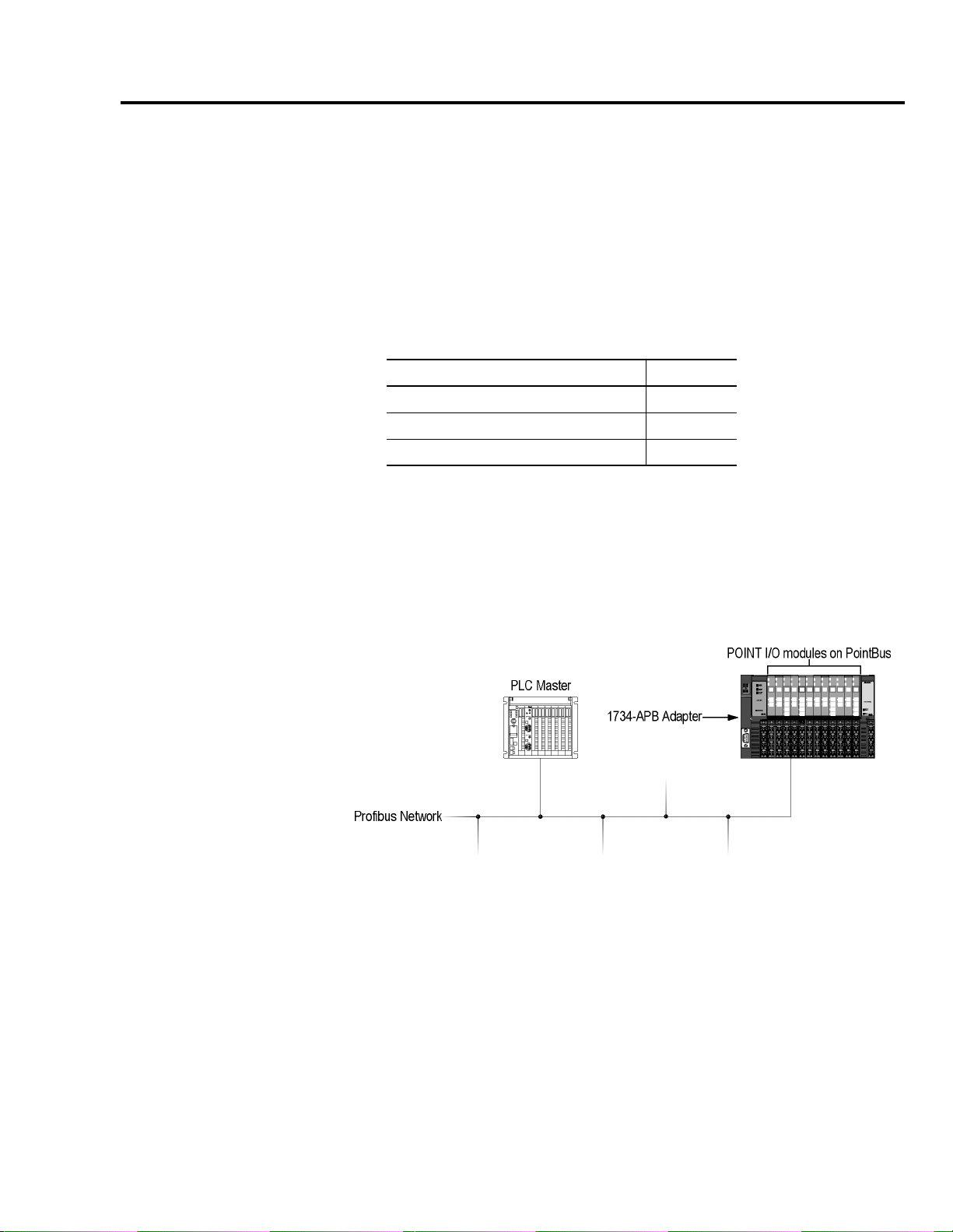

The POINT I/O 1734-APB adapter resides on the PROFIBUS network

and the POINT I/O backplane (PointBus) simultaneously. From this

position, the adapter interfaces between the PROFIBUS network and

the POINT I/O modules. The illustration below shows the adapter on

the PROFIBUS network and the PointBus.

The adapter functions are:

• PROFIBUS - adapter serves as a slave that exchanges I/O data

with a PROFIBUS master.

• PointBus - the adapter serves as a master that communicates

with up to 63 POINT I/O modules

1 Publication 1734-UM005B-EN-P - June 2001

Page 12

1-2 What is the PROFIBUS Adapter

Communicating through the Adapter

Output data is sent from the master across the PROFIBUS network to

the 1734-APB adapter. The adapter automatically transfers the data

across the PointBus backplane to the output modules.

Inputs from the input modules are collected by the PROFIBUS adapter

via the backplane and sent across the PROFIBUS network to the

master.

I/O Module Removal and Insertion Under Power

I/O modules can be removed under power from their positions in the

backplane without interfering with the communication with the other

modules. When reinserting the removed module, communication is

automatically started up again if the following criteria is fulfilled:

1. The inserted module is the same type as the one removed.

Startup Procedure

2. If more than one module is removed, communication will not be

regained until all modules are inserted in their correct positions

again.

Starting the adapter module consists of:

• Installing the adapter in the system

• setting the adapter node address

• configuring the adapter for PROFIBUS communication

• configuring the I/O modules for PointBus communication

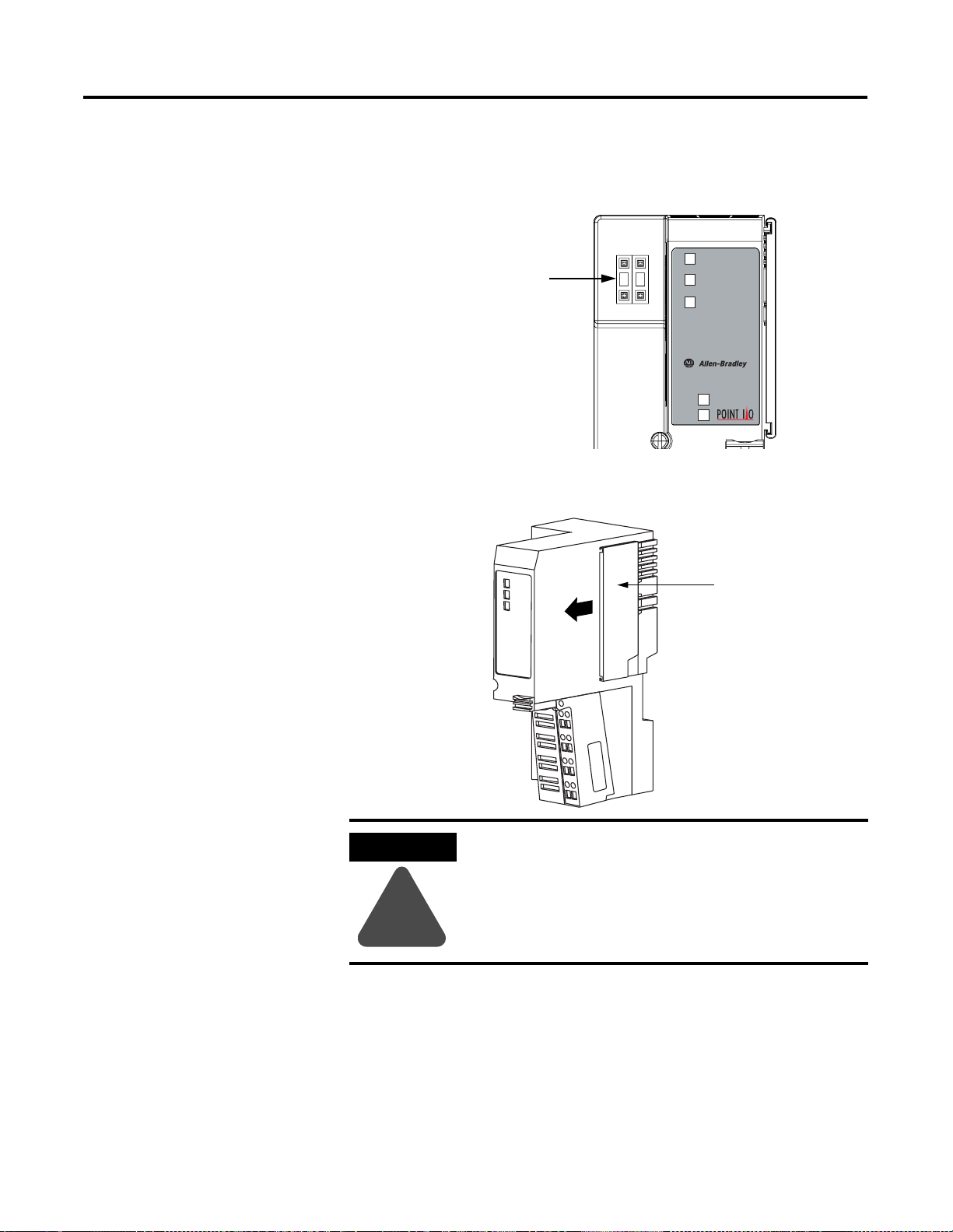

Set the Adapter Node Address

Set the node address using the 2-position thumbwheel switch. Valid

settings range from 01 to 99. Use a pen to press either the + or –

buttons to change the number.

Publication 1734-UM005B-EN-P - June 2001

01

Page 13

What is the PROFIBUS Adapter 1-3

Configure the Adapter for PROFIBUS Communication

• Install the GSD file you received into your configuration tool

• add the adapter to your configuration

• select the node address and baud rate

• add I/O modules to the configuration

For more information, refer to Chapter 3 - Configuring the POINT I/O

System.

Configure the I/O Modules for PointBus Communication

You must configure each I/O module to establish its actions on the

PointBus. Each module has a set of parameters that can be set (i.e.

Idle value, Fault value, etc.).

For more information, refer to Chapter 3 - Configuring the POINT I/O

System.

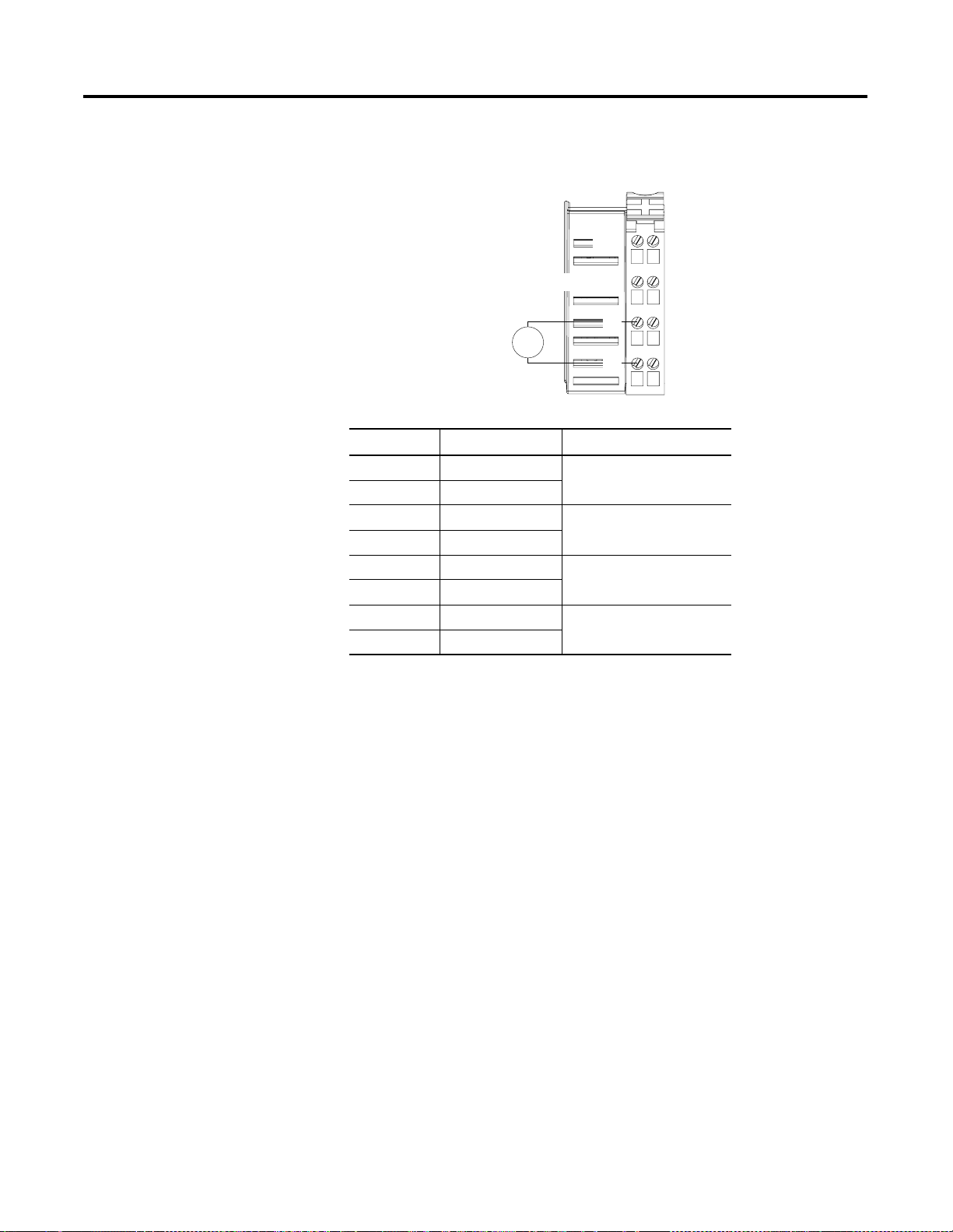

Adapter

Node Address

Thumbweel

Profibus

Connector

System

Power

Field

Power

Status

PROFIBUS

Status

PointBus

Status

1734-APB

01

NC

CHAS GND

Adapter Status

PROFIBUS Status

PointBus Status

System Power

Field Power

NC

CHAS GND

NC = No Connection

CHAS GND = Chassis Ground

C = Common

V = Supply

C

V

C

V

Publication 1734-UM005B-EN-P - June 2001

Page 14

1-4 What is the PROFIBUS Adapter

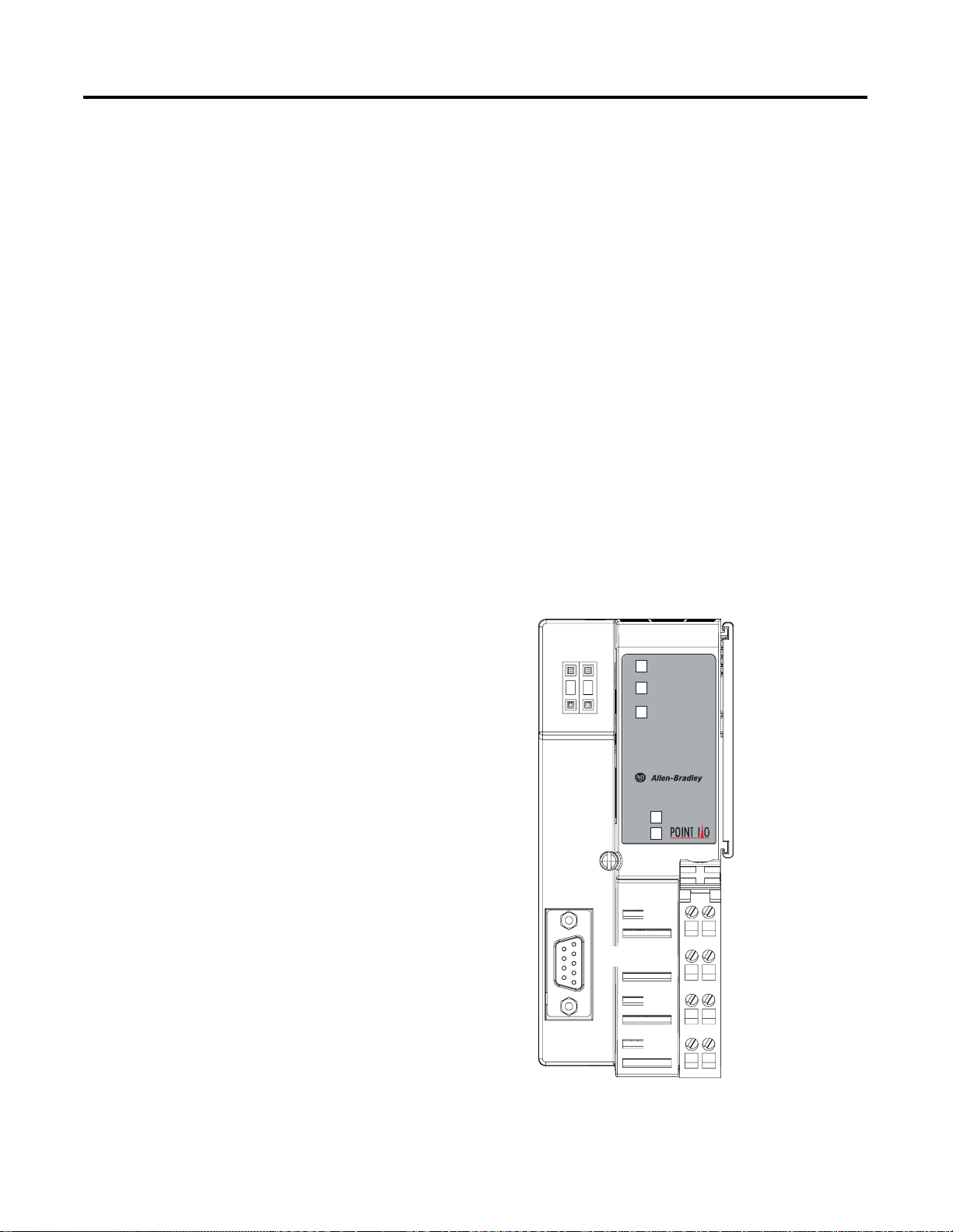

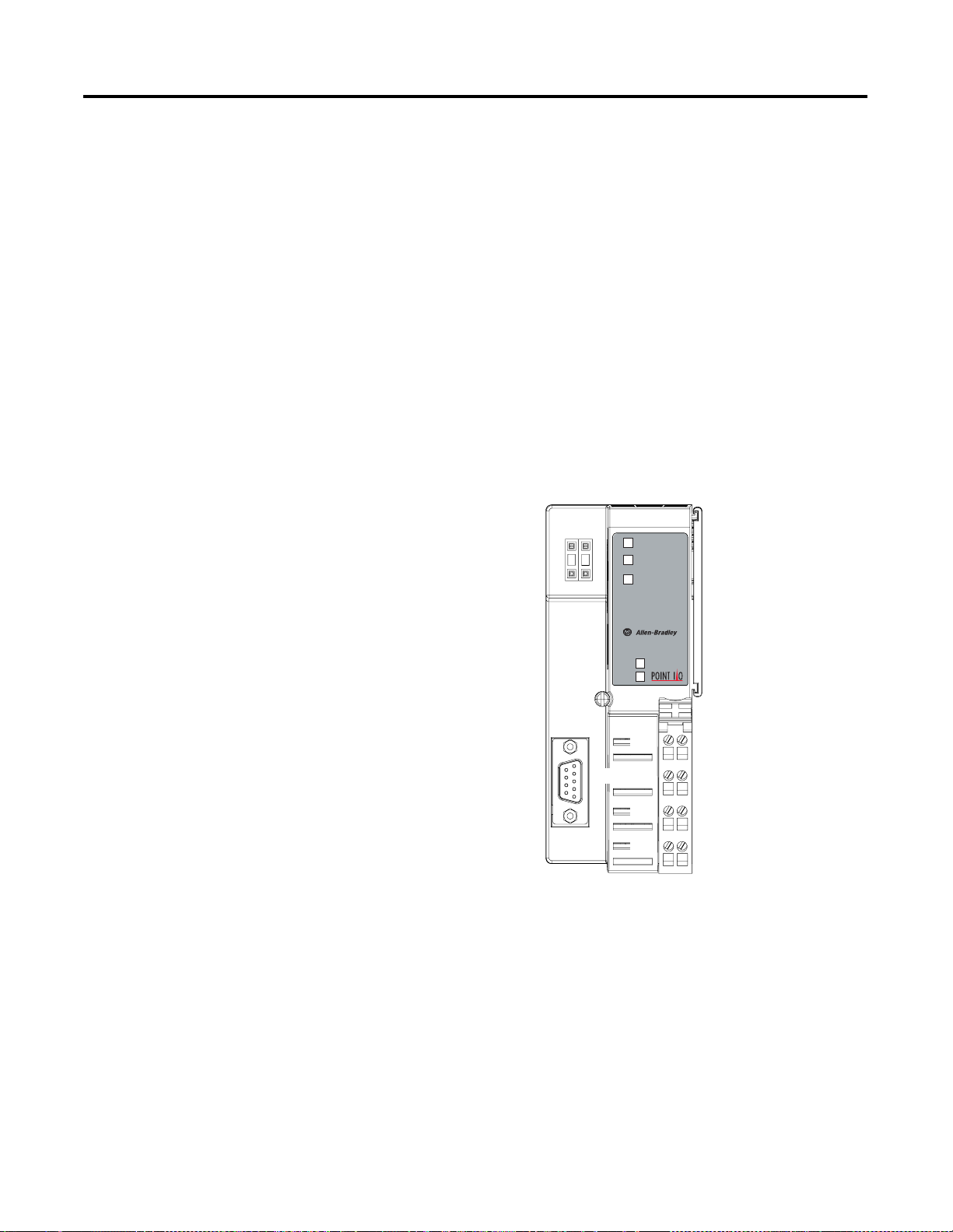

Diagnostic Indicators

Diagnostic indicators are located on the front panel of the adapter

module. They show both normal operation and error conditions in

your POINT I/O system. The indicators are:

• Adapter status

• PROFIBUS status

• PointBus status

• System power

• Field power

Upon power-up, the adapter goes to an initialization state and

performs a self-test (memory check, data memory clear, firmware

integrity). The indicators also go through a self-test sequence. If a

failure occurs, the adapter transitions to a faulted state and waits for

reset (cycle power). Otherwise, the adapter begins monitoring the

network (run state) for messages. Chapter 6 describes the diagnostic

indicators and how to use them for troubleshooting.

Chapter Summary and

What’s Next

Network Connector

Use the 9-pin D-shell connector (shown below) to connect your

adapter to the PROFIBUS network.

Connections are provided for connecting the required 24V dc power

to the front of the module.

Refer to Chapter 2 or the Installation Instructions (pub. no.

1734-IN014) you received with your adapter to learn how to install

and wire the adapter.

This chapter provided a brief overview of the 1734-APB PROFIBUS

adapter. Go to chapter 2 to learn how to install and wire your adapter.

Publication 1734-UM005B-EN-P - June 2001

Page 15

Installing the PROFIBUS Adapter

Chapter

2

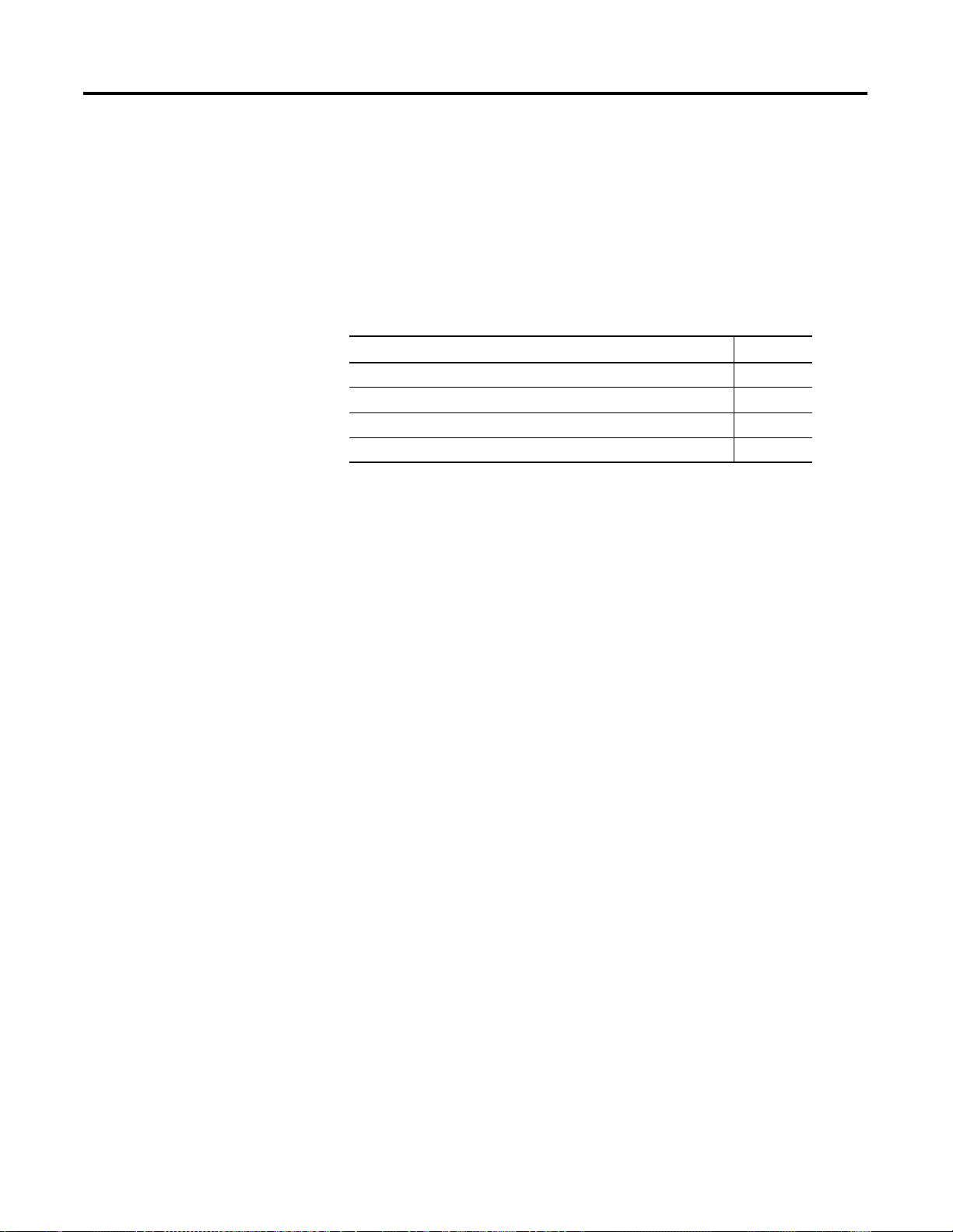

General

This chapter describes how to install and wire your adapter.

For information about: See page:

Installing the PROFIBUS Adapter 2-2

Installing a Replacement PROFIBUS Adapter to an Existing System 2-4

Wiring the PROFIBUS Adapter 2-6

Chapter Summary and What’s Next 2-9

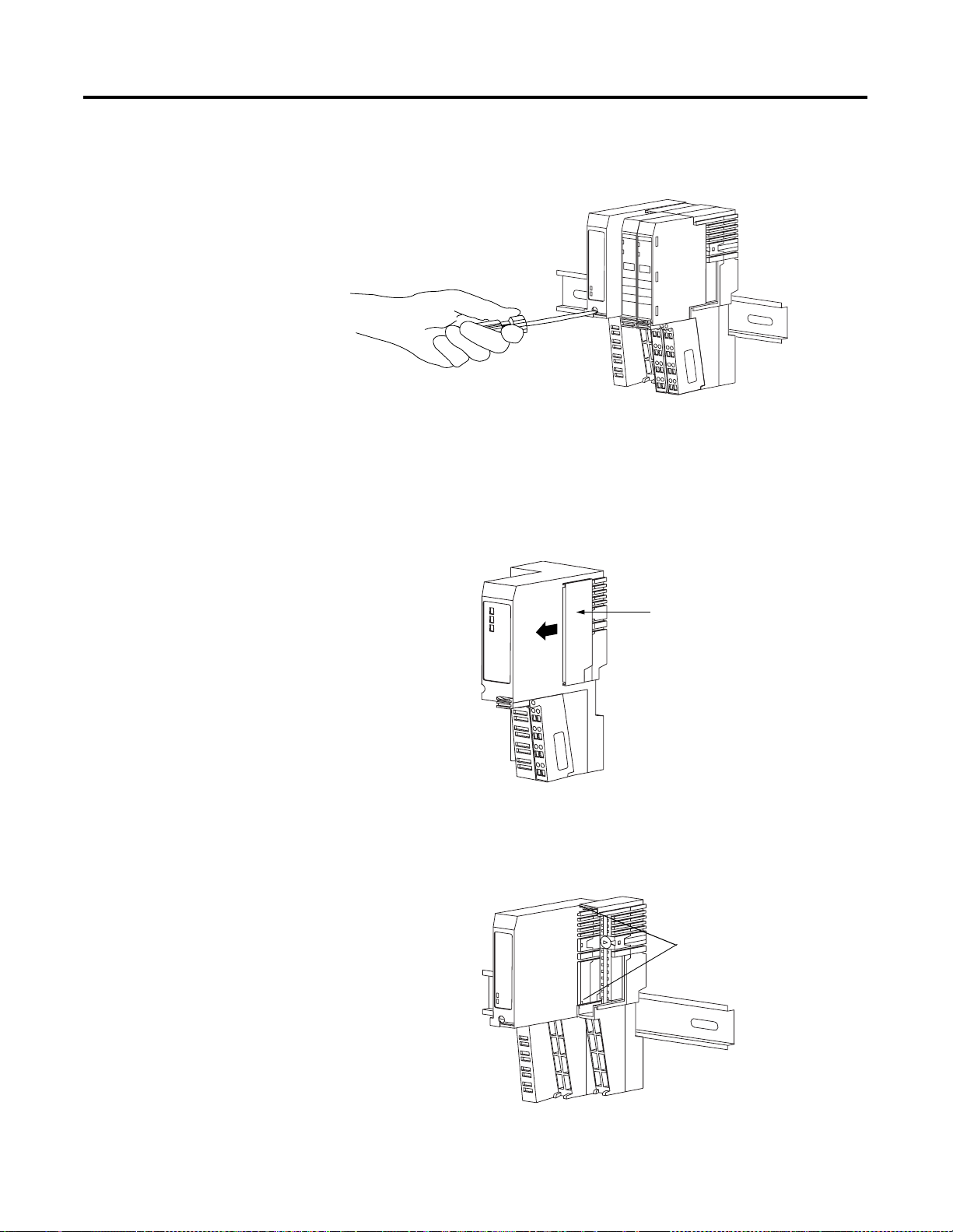

When properly installed, POINT I/O is grounded through the DIN rail

to chassis ground. Use zinc plated, yellow chromated steel DIN rail to

assure proper grounding.

Other DIN rail material (such as aluminum, plastic, etc.) can corrode

or oxidize and are poor conductors that may result in improper or

intermittent platform grounding.

If you choose not to use zinc plated, yellow chromated steel DIN rail

for your POINT I/O, periodically clean the DIN rail to prevent or

lessen the effects of oxidation and corrosion.

1 Publication 1734-UM005B-EN-P - June 2001

Page 16

2-2 Installing the PROFIBUS Adapter

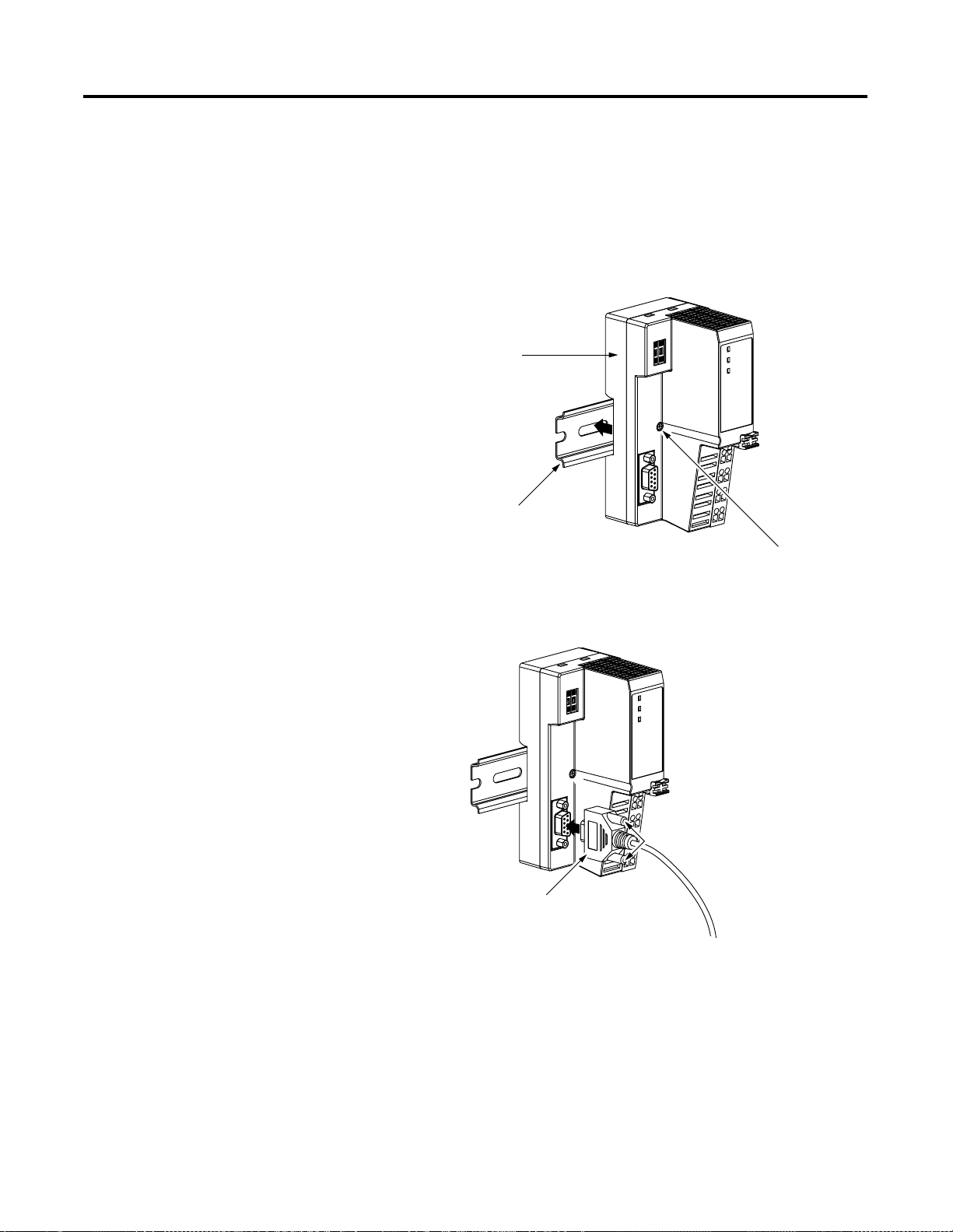

Installing the PROFIBUS Adapter

To install the adapter on the DIN rail prior to installing other base

units, proceed as follows.

1. Position the adapter vertically above the DIN rail.

2. Press down firmly to install the adapter on the DIN rail. (The

locking mechanism will lock the adapter to the DIN rail.)

1734-APB communication interface

DIN rail

Orange screw slot

3. Insert the PROFIBUS network plug and tighten the holding

screws.

Publication 1734-UM005B-EN-P - June 2001

Holding screws

Profibus network plug

Page 17

Installing the PROFIBUS Adapter 2-3

4. Set the node address using the 2-position thumbwheel switch.

Valid settings range from 01 to 99. Press the + or - buttons to

change the numbers.

System

Power

Field

Power

Adapter

Status

PROFIBUS

Status

PointBus

Status

1734-APB

Network Node

Address Thumbwheel

Press either the + or buttons to change the

number

01

5. Slide the safety end cap (9) up to remove. This exposes the

backplane and power interconnections.

Safety end cap

ATTENTION

!

Do not discard the safety end cap. Use this end cap

to cover the exposed interconnections on the last

mounting base on the DIN rail. Failure to do so

could result in equipment damage or injury from

electric shock.

Publication 1734-UM005B-EN-P - June 2001

Page 18

2-4 Installing the PROFIBUS Adapter

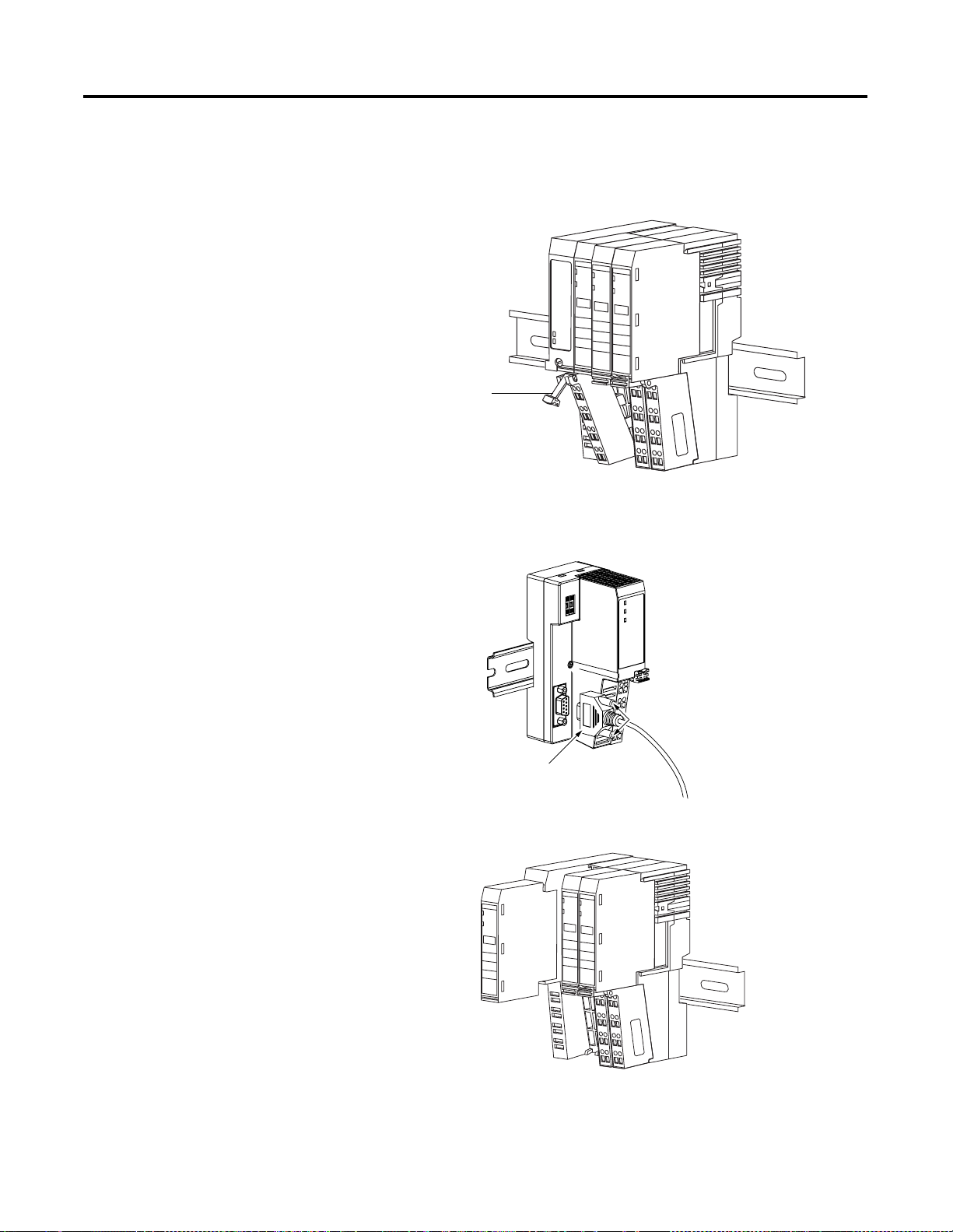

Installing a Replacement PROFIBUS Adapter to an Existing System

1. Remove the existing adapter from the DIN rail as follows:

A. Pull up on the removable terminal base (RTB) removal

handle (7) to remove the terminal block.

RTB removal handle

B. Loosen the screws holding the PROFIBUS network plug and

pull up to remove.

Loosen holding screws

PROFIBUS network plug

C. Remove the adjacent module from its base.

Remove adjacent

module.

Publication 1734-UM005B-EN-P - June 2001

Page 19

Installing the PROFIBUS Adapter 2-5

D. Use a small bladed screwdriver to rotate the DIN rail locking

screw (5) to a vertical position. This releases the locking

mechanism.

E. Pull straight out to remove.

2. Set the desired node address on the replacement adapter.

3. Slide the safety end cap up and remove it from the replacement

adapter. This exposes the backplane and power connections.

Safety end cap

4. Position the replacement adapter vertically above the DIN rail.

(Make certain the DIN rail lock is in the horizontal position.)

Slide the adapter down, allowing the interlocking side pieces to

engage the adjacent module.

Align the

interlocking side

pieces and slide

adapter into place

on the DIN rail.

Publication 1734-UM005B-EN-P - June 2001

Page 20

2-6 Installing the PROFIBUS Adapter

5. Press firmly to seat the adapter (1) on the DIN rail. The adapter

locking mechanism will snap into place.

6. Insert the PROFIBUS network plug and tighten the holding

screws.

7. Insert the end opposite the handle into the base unit. This end

has a curved section that engages with the wiring base.

8. Rotate the terminal block into the wiring base until it locks itself

in place.

9. Replace the adjacent module in its base.

Wiring the PROFIBUS Adapter

Refer to the figure below when wiring the PROFIBUS adapter.

Adapter

Node Address

Thumbweel

Profibus

Connector

NC = No Connection

CHAS GND = Chassis Ground

C = Common

V = Supply

01

Status

PROFIBUS

Status

PointBus

Status

1734-APB

System

Power

Field

Power

NC

CHAS GND

C

V

Adapter Status

PROFIBUS Status

PointBus Status

System Power

Field Power

NC

CHAS GND

C

V

Publication 1734-UM005B-EN-P - June 2001

Module Power

The adapter supplies 5V logic power to POINT I/O modules by

converting the applied 12/24V dc field power to PointBus 5V power.

You can connect up to 63 I/O modules to each adapter, and you can

power up to 14 I/O modules from the adapter (with a maximum of

10A of field power). Add up the current requirements of the modules

you want to use, and determine that they do not exceed the amperage

limit of the 1734-APB. (Note: Total expansion up to 63 modules - 14

modules (with 75mA current draw) maximum with 1734-APB - add

1734-EP24DC modules for additional 14 modules (or less based on

current requirements), up to 63 module maximum)

Page 21

Installing the PROFIBUS Adapter 2-7

After the 14th (or last) module, you must insert an expansion

power supply (cat. no. 1734-EP24DC) to power additional I/O

modules.

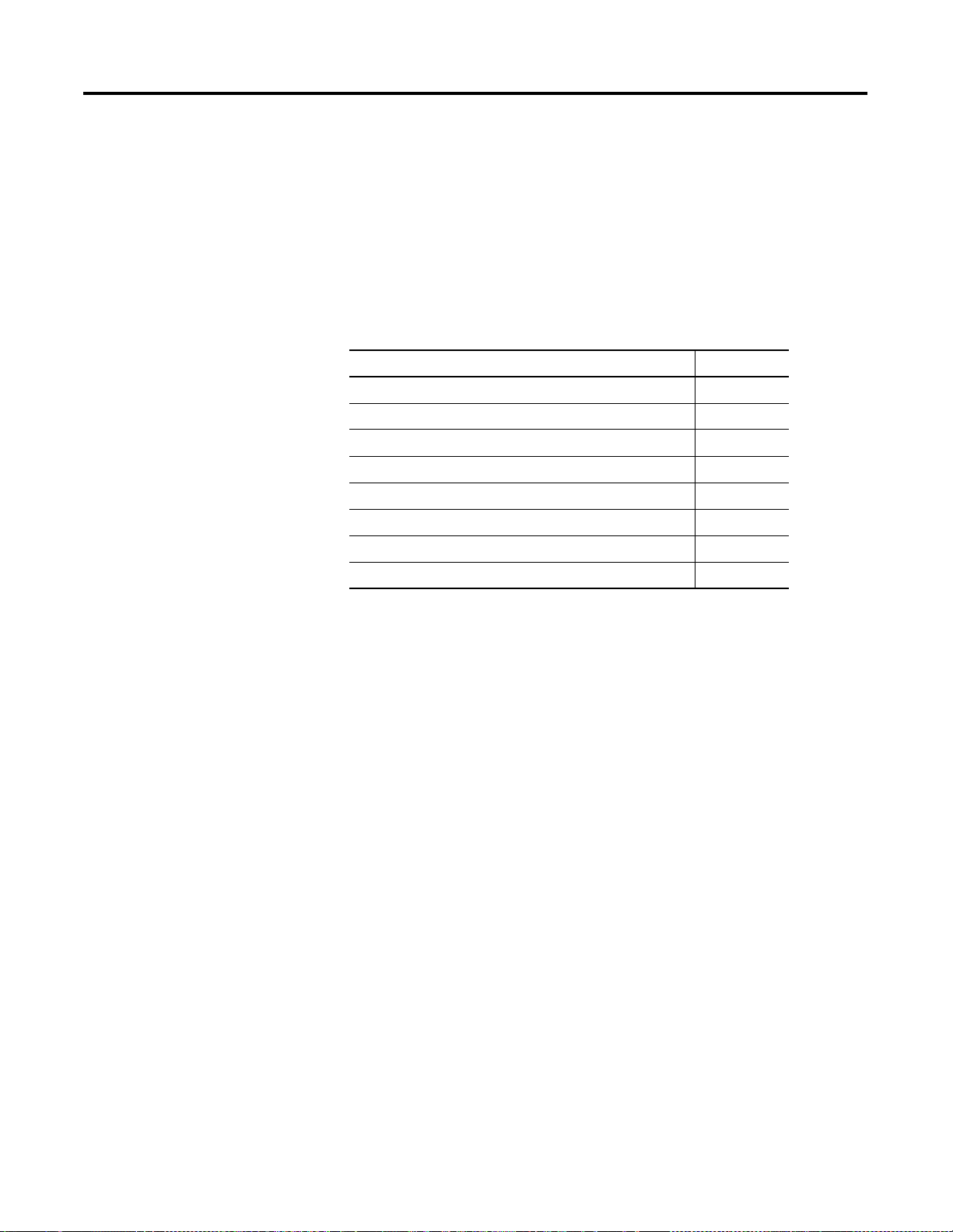

Refer to the table below for various POINT I/O modules current

requirements.

POINT I/O Cat. No. PointBus Current

1734-IB2

1734-IB4

1734-IV2

1734-IV4

1734-OB2E

1734-OB4E

1734-OW2

1734-IE2C

1734-OE2C

1734-IE2V

1734-OE2V

1734-IA2

1734-IM2

1734-OA2

1734-IJ2

1734-IK2

1734-IR2

1734-IT2

1734-VHSC5

1734-VHSC24

Requirements

75mA

75mA

75mA

75mA

75mA

75mA

80mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

160mA

160mA

220mA

175mA

180mA

180mA

For more information on the Expansion Power Supply, cat. no.

1734-EP24DC, refer to:

• POINT I/O Technical Data, publication 1734-TD001A

• POINT I/O Expansion Power Supply Installation Instructions,

publication 1734-IN058A

Publication 1734-UM005B-EN-P - June 2001

Page 22

2-8 Installing the PROFIBUS Adapter

Wiring Connections

12/24V dc

Do not connect 120/240V ac

power to this supply.

NC = No Connection

CHAS GND = Chassis Ground

C = Common

V = Supply

V dc

NC

CHAS GND

NC

1

0

CHAS GND

3

2

C

V

C

5

4

V

7

6

This dc supply will be

connected to the

internal power bus.

Terminal Description Notes

0 No connection Reserved

1 No connection

2 Chassis Ground

3 Chassis Ground

4 Common

5 Common

6 Voltage Input Apply 12/24V dc. Connects to

7 Voltage Input

the internal power bus.

Proceed as follows. Make all connections to the removable terminal

block (RTB).

Publication 1734-UM005B-EN-P - June 2001

1. Connect chassis ground to terminal 2.

2. Connect 12/24V supply positive lead to terminal 6.

3. Connect 12/24V negative lead to terminal 4.

External power applied across terminal 6 (+) and 5 (-) connects

to the internal power bus.

Do not connect anything to terminals 0 and 1. These are

reserved terminals.

4. Connect the PROFIBUS connector plug to the D-shell on the

adapter. Tighten the screws to secure.

Page 23

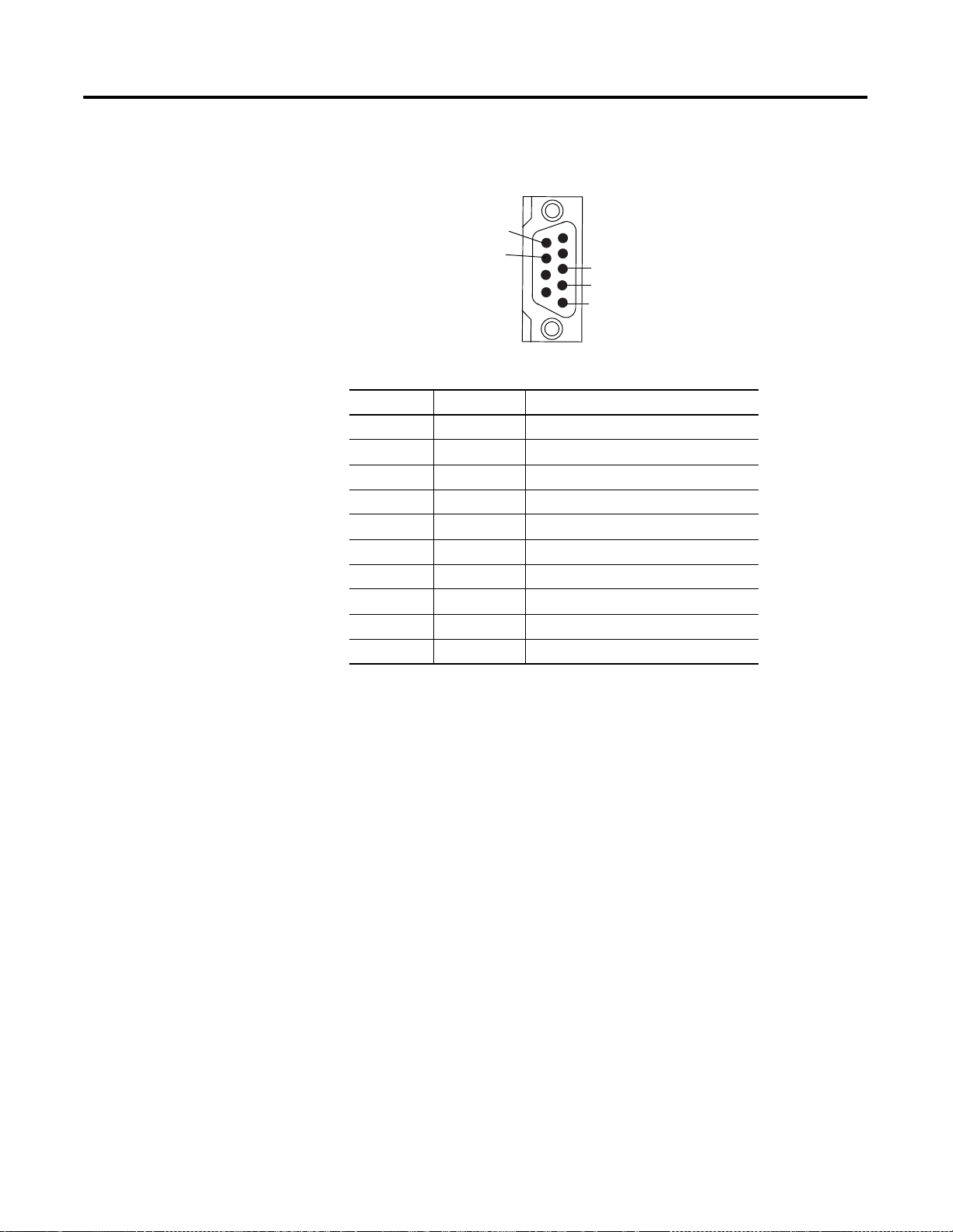

PROFIBUS Connection Plug Wiring

T

PROFIBUS connection

Pin 6 - +5V

Pin 8 - RX/TX Data -

Pin 3 - RX/TX Data +

Pin 4 - Request to send (R

Pin 5 - Data Ground

Pin Number Name Description

Housing Shield Connected to Chassis Ground

1 Not connected

2 Not connected

3 RX/TX Data + Positive RX/TX data line

4 RTS Request to send

5 Data Ground Isolated ground

6 +5V BUS Isolated +5V from RS485 side

7 Not connected

8 RX/TX Data - Negative RX/TX data line

9 Not connected

Installing the PROFIBUS Adapter 2-9

Chapter Summary and

What’s Next

In this chapter, you learned how to install and wire your adapter.

Move to chapter 3 for information on configuring the POINT I/O

system.

Publication 1734-UM005B-EN-P - June 2001

Page 24

2-10 Installing the PROFIBUS Adapter

Publication 1734-UM005B-EN-P - June 2001

Page 25

Configuring the POINT I/O System

Chapter

3

In This Chapter

Configuration Overview

This chapter describes how to configure your adapter for PROFIBUS

communication and how to configure the POINT I/O modules.

For more information about: See page

Configuration Overview 3-1

Installing the GSD File 3-2

Adding the Master to the Network 3-3

Adding the Adapter to the Network 3-5

Adding I/O Modules to the Adapter 3-6

Configuring I/O Modules 3-8

Download to Master System 3-13

Chapter Summary and What’s Next 3-14

Since the POINT I/O adapter is compatible with any master system,

you can use any configuration tool available on the market. Just

import the GSD file included on the diskette you received with your

shipment of the adapter into your configuration tool. The

configuration tool uses the GSD file to help you set up the system.

The file is in raw ASCII format and you can view it with any text

editor.

Throughout this chapter, we use the Sycon configuration software

from HMS Industrial Networks as an example of how to configure the

adapter. For information on how to configure your system, refer to the

documentation associated with your master and configuration tool.

You must follow these steps during configuration:

1. Install the GSD file

2. Add the adapter to your PROFIBUS network

3. Add I/O modules to the adapter

4. Configure the modules

5. Download to master system

1 Publication 1734-UM005B-EN-P - June 2001

Page 26

3-2 Configuring the POINT I/O System

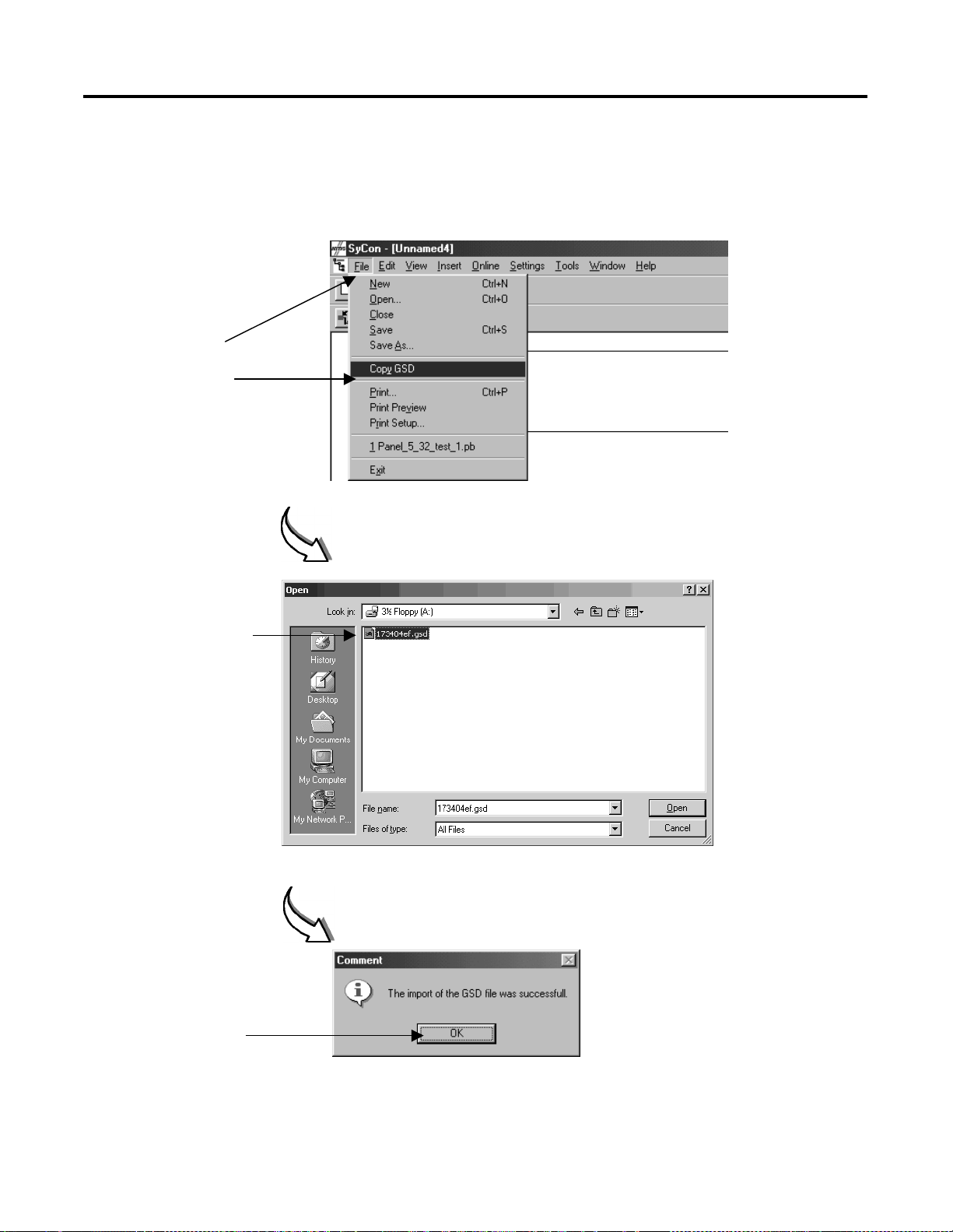

Installing the GSD File

1. Open

the

file.

Select the GSD file

(173404EF.GSD) included

on the diskette you received

with your shipment of the

adapter.

This dialog indicates that the GSD

file was successfully imported into

the configuration tool.

(Click “Okay” to

continue.)

Publication 1734-UM005B-EN-P - June 2001

Page 27

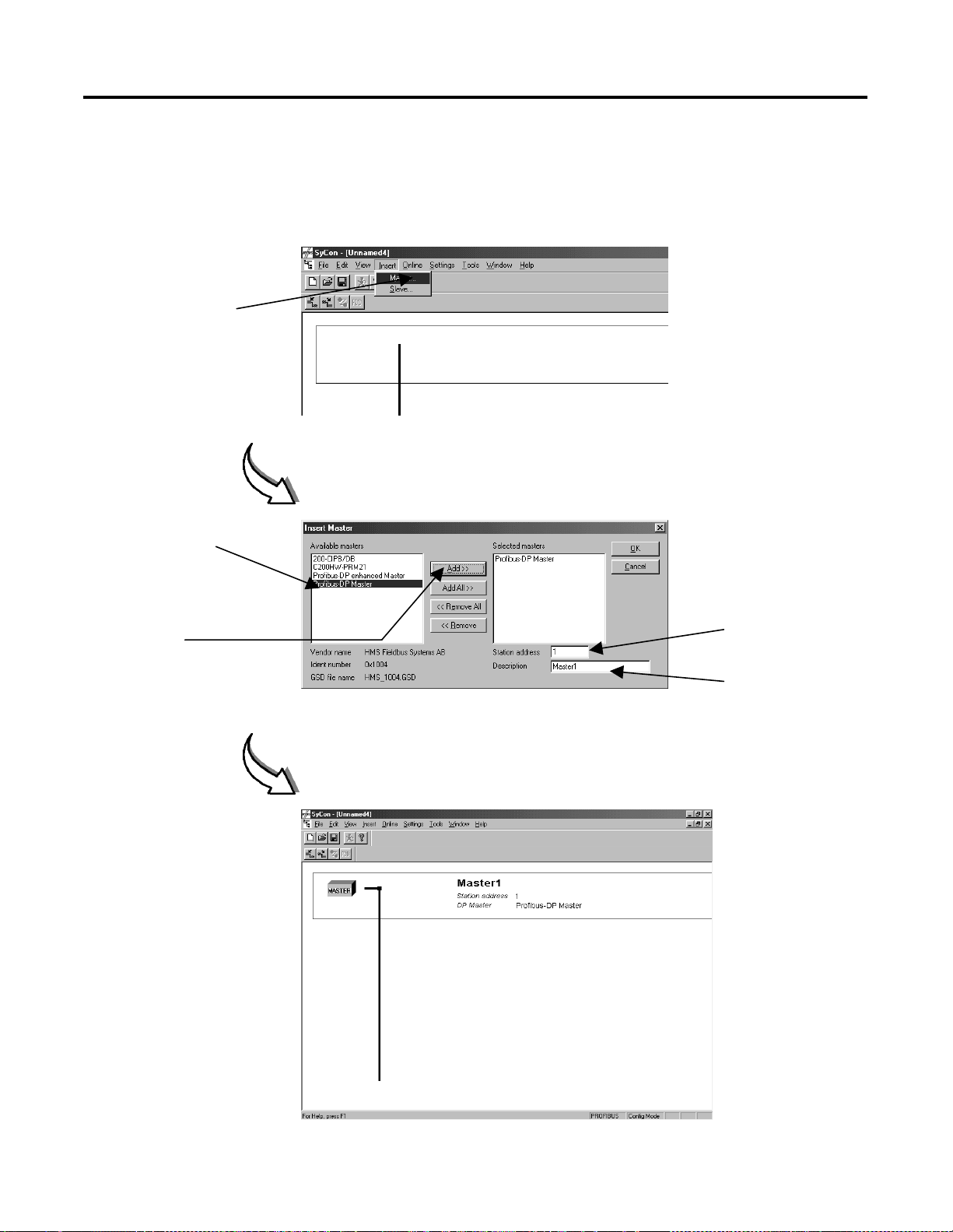

Adding the Master to the

.

Network

Select the “Master” entry in

the “Insert” menu.

Configuring the POINT I/O System 3-3

1. Select “PROFIBUS-DP

Master” in the list

called “Available

Masters.”

2. Click “Add>>”.

The master appears on the

network.

Select station address here

Type a description here.

Publication 1734-UM005B-EN-P - June 2001

Page 28

3-4 Configuring the POINT I/O System

Select the master icon

Select the “Bus Parameters”

entry in the “Settings” menu.

lSelect the required baud rate

from the list.

(Click “OK” to continue.)

Publication 1734-UM005B-EN-P - June 2001

Page 29

Adding the Adapter to the Network

Select the “Slave” entry in the

“Insert” menu.

Configuring the POINT I/O System 3-5

1. Select “1734-APB” in

the “Available Slaves”

list.

2. Click “Add>>”.

(Click “OK” to continue.)

The slave appears on the

network.

Select station address here.

Type a description here.

Publication 1734-UM005B-EN-P - June 2001

Page 30

3-6 Configuring the POINT I/O System

Adding I/O Modules to the Adapter

After you add the adapter, you must add the POINT I/O modules

connected to the adapter in the backplane.

You can select any of 5 different types:

1. Modules with Configuration Data

If you select modules with configuration data (i.e. 1734-IB2), the

configuration data would be available for you to manually

modify. Refer to “Configuring I/O Modules” later in this chapter.

2. Modules without Configuration Data

If you select modules without configuration data (i.e.1734-IB2/

No config data), you will not be able to change the

configuration data. This data would be set to a default setting.

However, you can still disable the diagnostic functionality for

the module.

3. Empty Slot Modules

If you have a gap in the backplane, you should use an empty

slot module (i.e. 1734-IB2/Empty slot). The empty slot module

reserves memory space in your master for addition of a module

at a later date.

4. Grouped Modules

In order to use memory more efficiently, modules can be

grouped together in a single byte. The modules must be inserted

next to each other and be of the same module family. Each

module will have the same configuration as the first module in

the group. Eight channels (1 byte) is the maximum allowed.

Refer to chapters 4 and 5 for “Grouped Mode” information.

When configured for grouped mode, you can save user

parameter data and I/O data.

5. Grouped Empty Slot Modules

If you have a gap in the backplane where the missing modules

belong to a group, use a grouped empty slot module. Refer to

chapter 4 for more information.

NOTE: In the following example, only modules with configuration

data are used.

The modules you select are transferred to the adapter with the

PROFIBUS Check_Config service. For a detailed description of the

Check_Config service, refer to Chapter 4.

Publication 1734-UM005B-EN-P - June 2001

Page 31

Double click on the slave icon to

add modules to your adapter.

Configuring the POINT I/O System 3-7

To add modules, double-click on the slave icon.

1. Double click on the

module you wish to add.

2. The module appears in

the list below.

Publication 1734-UM005B-EN-P - June 2001

Page 32

3-8 Configuring the POINT I/O System

Configuring I/O Modules

Most I/O modules have configuration data associated with them. This

configuration data can be set manually. For a detailed description of

the configuration data supported for different modules, refer to

Appendix B.

The configuration you select is transferred to the adapter with the

PROFIBUS Set_parameter service. (Set_parameter service is described

in chapter 4.)

Note: Download of new configuration data is only possible in the

offline mode.

Note: If you added modules without configuration data, the only

parameter you can edit is Extended diagnostics. All other parameters

retain their default settings. (Refer to Appendix B for default settings.)

To configure I/O modules, click on the Parameter Data button in the

Slave Configuration window.

Click on the “Parameter Data”

button to open the Parameter

Data window.

Publication 1734-UM005B-EN-P - June 2001

Page 33

Parameter Data in hexadecimal.

Select the module you wish to

configure.

(Click “OK” to continue.)

Configuring the POINT I/O System 3-9

To configure a module, click

on the “Module” button.

Module Parameters

Select the value you wish to

use, and click “OK.”

From the list, select the

parameter you wish to

change.

(Click “OK” to continue.)

Example: To change the

“Range” parameter, select

“Range” in the list and click

“OK.”

Available parameters are module dependant. However, some

parameters are common for all module types. These parameters are:

Extended Diagnostics, Fault Action and Idle Action.

Publication 1734-UM005B-EN-P - June 2001

Page 34

3-10 Configuring the POINT I/O System

Module parameters

Enable/Disable Diagnostic Functionality for your Modules

The diagnostic functionality is enabled at default, but may be turned

off (disabled) at the module level. When the diagnostic is disabled,

the module will not report any diagnostic information to the adapter.

Refer to chapter 4 for more information on module diagnostics.

Select the “Extended

Diagnostics” parameter.

(Click on “OK” to

continue.)

Select “Enable” to enable

and “Disable” to disable

the diagnostic

functionality of an I/O

module.

(Click on “OK” to

continue.)

Module parameters

Configure Fault Action/Value for your Output Modules

When communication between master and adapter is lost, the adapter

puts all connected I/O modules in their Fault state.

Select the “Fault Action”

parameter.

(Click on “OK” to continue.)

Select the desired state.

Possible settings are “Fault

Value,” and “Hold Last State

(HLS).

(Click on “OK” to continue.)

Publication 1734-UM005B-EN-P - June 2001

Page 35

Module parameters

Configuring the POINT I/O System 3-11

If you select “Hold Last State,” the module outputs are frozen in their

current state. If you select “Fault Value,” you need to define the Fault

Value parameter. Possible settings are: digital modules - ON/OFF;

analog modules - any value within a predefined range.

Select the “Fault Value” parameter.

(Click on “OK” to continue.)

Enter the value you wish to use.

(Click on “OK” to continue.)

Module parameters

Configure Idle Action Value for your Output Modules

When the adapter receives a clear command from the master, the

adapter puts all connected I/O modules into their Idle state.

Select the “Idle Value”

parameter.

(Click on “OK” to continue.)

Select the desired state.

Possible settings are “Idle

Value,” and “Hold Last State

(HLS).

(Click on “OK” to continue.)

Publication 1734-UM005B-EN-P - June 2001

Page 36

3-12 Configuring the POINT I/O System

Module parameters

If you select “Hold Last State,” the module outputs are frozen in their

current state if power to the module is lost. If you select “Idle Value,”

you need to define the Idle Value parameter. Possible settings are:

digital modules - ON/OFF; analog modules - any value within a

predefined range.

Select the “Idle Value”

parameter.

(Click on “OK” to continue.)

Enter the value you wish to

use.

(Click on “OK” to continue.)

Publication 1734-UM005B-EN-P - June 2001

Page 37

Configuring the POINT I/O System 3-13

Download to Master System

Select the “Download” entry in

the “Online” menu.

Select the “CIF Serial Driver.”

(Click “OK” to continue.)

When you are finished setting parameters, you must download the

configuration data into the master

Select port “COM 2.

(Click “OK” to continue.)

If the download is done during

bus operation, the

communication between master

and slave is stopped.

Confirm the download by clicking

“Yes.”

Downloading...

Publication 1734-UM005B-EN-P - June 2001

Page 38

3-14 Configuring the POINT I/O System

Chapter Summary and

What’s Next

In this chapter, you learned how to configure the POINT I/O system.

Go to chapter 4 for information about communication and I/O table

mapping.

Publication 1734-UM005B-EN-P - June 2001

Page 39

Chapter

Communication and I/O Table Mapping

This chapter describes the communication process and I/O image

table mapping as they occur through the 1734-APB adapter.

For more information about: See page:

Image Table Mapping 4-1

How Data Communication Takes Place 4-2

Grouping Modules for Memory Management 4-16

Chapter Summary and What’s Next 4-16

4

Image Table Mapping

The adapter must map the data it receives to its internal memory

before passing it to the appropriate module. The image table map for

a module is divided into:

• Read bytes - input and status bytes

• Write bytes - output and configuration bytes

The length of each module’s read bytes and write bytes vary in size

depending on module complexity. The following illustration shows

how the adapter maps information. Refer to appendix B for the data

maps of the different POINT I/O modules.

1 Publication 1734-UM005B-EN-P - June 2001

Page 40

4-2 Communication and I/O Table Mapping

How Data Communication Takes Place

Publication 1734-UM005B-EN-P - June 2001

Before any data transfer can take place, the adapter has to verify and

accept the PROFIBUS services Set_Parameter and

Check_Configuration that are sent from the master at startup. If the

adapter accepts these services, data transmission is executed

automatically in a cyclic manner with the Data_Exchange service. In

addition to these 3 services, the adapter may notify the master of its

current status by means of the Slave_Diagnostic service.

The master can read the actual configuration with the

Get_Configuration service and send control commands to the adapter

by means of the Global_Command service.

Page 41

Communication and I/O Table Mapping 4-3

This section describes how the adapter handles the following services:

• Set_Parameter

• Check_Configuration

• Get_Configuration

• Data_Exchange

• Global_Command

• Slave_Diagnostic

Set_Parameter

The master uses this service to identify itself with the adapter and to

specify how the adapter is to operate. Set_parameter data is

comprised of a series of octets (maximum of 244). Octet 0-6 is defined

in the DIN 19245-3 standard, while octet 7-243 contain specific

information for the adapter itself (referred to as User Parameter Data).

The module configuration you previously selected is passed on to the

adapter and I/O modules via the User Parameter data.

Octet Value Description

0 - Station Status (see DIN 19245-3)

1 1-255 Watchdog Factor 1

2 1-255 Watchdog Factor 2

3 0-255 Minimum Station Delay (TSDR)

4 4 Vendor (High byte)

5 239 Vendor (Low byte)

6 - Group Identification (see DIN 19245-3)

7-243 See below User Parameter Data

User Parameter Data

Octet 7 in the parameter data is reserved for the Profibus-DP ASIC

onboard and must equal 00h.

Beginning at octet 8, each configured module allocates a minimum of

three bytes of user parameter data as shown in the following table.

The first two bytes define the product code for the installed module,

the third byte defines the control byte followed by configuration data

(if used).

Publication 1734-UM005B-EN-P - June 2001

Page 42

4-4 Communication and I/O Table Mapping

Octet Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

7 Reserved

8 Product Code High Byte of First Module

9 Product Code Low Byte of First Module

10 Control Byte for First Module

11 Configuration Data for First Module*

... ...

X Product Code High Byte for last Module

X + 1 Product Code Low Byte for last Module

X + 2 Control Byte for Last Module

X + 3 Configuration Data for Last Module*

* Present only if selected module has configuration data. Refer to “Adding I/O Modules to your Configuration.”

Product Code

The product code is used to determine the identity of the module

installed in each slot. The code is defined in the GSD file and is

automatically extracted by the configuration tool when you add the

modules to your configuration. (Refer to appendix B for module

product codes.) If an installed module does not match the product

code for that slot, the slot is considered faulty and the adapter will

respond to the Set_Parameter service with a negative

acknowledgement. This will cause the master to set the Parameter

fault bit in the Slave_Diagnostic service.

Note: Data exchange is not possible if the product code and installed

module do not match.

Control Byte

The control byte is used to determine how the module should

operate. The control byte is included in the GSD file.

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Diagnostic

ON/OFF

Module

Type

Configuration data size (bytes); or number of bits allocated

to the opened byte (in bit-stuffing)

Publication 1734-UM005B-EN-P - June 2001

Bit 7 - This bit is used to enable/disable the diagnostic function for the

module.

Bit Value Description

0 Disable diagnostics

1 Enable diagnostics

Page 43

Communication and I/O Table Mapping 4-5

Bit 6 - This bit is used to enable/disable the module grouping feature

for the module.

Bit Value Description

0 Grouped module disabled

1 Grouped module enabled

Bit 0-5 - Without grouped modules - Defines the number of

configuration data bytes for the module. With grouped modules -

Defines the number of bits the module should allocate in the opened

byte.

Configuration Data

Configuration data is passed on to each I/O module using User

Parameter Data. The data is module dependant (see Appendix B).

IMPORTANT

Using your PROFIBUS configuration tool, it is

possible to select modules with no configuration

data. If you use this type of module, the

configuration data for that module will be a default

value. (See Appendix B.)

The following table is an example of how User Parameter Data might

look with a 1734-OB2E in slot 1, 1734-IB4 in slot 2, and 1734-OE2C in

slot 3. All modules in this example use Configuration Data.

Octet Value Description

700hReserved

8 00h 1734-OB2E Product Code High Byte

9 85h 1734-OB2E Product Code Low Byte

10 81h 1734-OB2E Control Byte

11 10h 1734-OB2E Configuration Data

12 00h 1734-IB4 Product Code High Byte

13 82h 1734-IB4 Product Code Low Byte

14 81h 1734-IB4 Control Byte

15 00h 1734-IB4 Configuration Data

16 00h 1734-OE2C Product Code High Byte

17 19h 1734-OE2C Product Code Low Byte

18 C9h 1734-OE2C Control Byte

19 03h 1734-OE2C Configuration Data byte 1

20 06h 1734-OE2C Configuration Data byte 2

Publication 1734-UM005B-EN-P - June 2001

Page 44

4-6 Communication and I/O Table Mapping

Octet Value Description

21 66h 1734-OE2C Configuration Data byte 3

22 1Fh 1734-OE2C Configuration Data byte 4

23 FFh 1734-OE2C Configuration Data byte 5

24 00h 1734-OE2C Configuration Data byte 6

25 00h 1734-OE2C Configuration Data byte 7

26 00h 1734-OE2C Configuration Data byte 8

27 00h 1734-OE2C Configuration Data byte 9

Check_Configuration

After the set_parameter service, the master sends a

check_configuration service to the adapter. This service causes the

adapter to check its default configuration (determined at powerup),

against the actual configuration specified in the master configuration.

If the actual configuration does not match the default configuration,

the master will respond to the Check_configuration service with a

negative acknowledgement, which causes the master to set the

Configuration fault bit in the Slave_diagnostic service.

Note: Data exchange is not possible as long as the actual

configuration does not match the default configuration.

The POINT I/O PROFIBUS adapter is a modular slave, which means

that the size of the I/O block is flexible and not tied to a specific block

length. Each I/O module is represented by an identifier byte. This

byte defines the input- and/or output data length as well as the data

consistency of the I/O data.

The identifier bytes for all POINT I/O modules are contained in the

GSD file and are automatically extracted by the configuration tool

when you add the modules to your configuration.

The identifier byte is described below. More information is contained

in the PROFIBUS-DP standard (DIN 19245-3).

Bit 7

0 = Consistency of byte/word

1 = Consistency of entire length

0 = Byte

1 = Word

Bit 0

Length of Data

0 = 1 byte/word

15 = 16 bytes/words

Input/Output

00 = Special Format

01 = Input

10 = Output

11 = Input and Output

Publication 1734-UM005B-EN-P - June 2001

Page 45

Communication and I/O Table Mapping 4-7

Without Grouped Modules

The table below shows an example of how the identifier bytes would

look for a configuration with a 1734-OB2E in slot 1; a 1734-IE2C in

slot 2; a 1734-OE2C in slot 3; and a 1734-IA2 in slot 4.

Identifier Byte Value Description

0 20h 1734-OB2E; 1 byte out, consistency over byte

1 51h 1734-IB4; 1 byte in, consistency over byte

2 61h 1734-OE2C; 2 words out, consistency over word

3 10h 1734-IA2, 2 byte in, consistency over byte

With Grouped Modules

If using grouped modules, the following table shows an example of

how the identifier bytes would look for a configuration with four

1734-OB2E modules.

Slot

Number

1 1734-OB2E Byte 1 = 0x20; 1

2 1734-OB2E/grouped Byte 2 = 0x00; 0

3 1734-OB2E/grouped Byte 3 = 0x00; 0

4 1734-OB2E/grouped Byte 4 = 0x00; 0

Description Identifier Byte

Buffer

byte output

bytes of I/O

data

bytes of I/O

data

bytes of I/O

data

User Parameter Data Buffer

Byte 1 = 0x00; product code (high byte)

Byte 2 = 0x85; product code (low byte)

Byte 3 = 0x81; control byte (diagnostics enabled, no bit

stuffing, 1 byte of configuration data follows)

Byte 4 = 0x10; configuration data

Byte 5 = 0x00; product code (high byte)

Byte 6 = 0x85; product code (low byte)

Byte 7 = 0xC2; control byte (diagnostics enabled, bit

stuffing module, 2 bits (channels) to store in the opened

byte.

Byte 8 = 0x00; product code (high byte)

Byte 9 = 0x85; product code (low byte)

Byte 10 = 0xC2; control byte (diagnostics enabled, bit

stuffing module, 2 bits (channels) to store in the opened

byte.

Byte 11 = 0x00; product code (high byte)

Byte 12 = 0x85; product code (low byte)

Byte 13 = 0xC2; control byte (diagnostics enabled, bit

stuffing module, 2 bits (channels) to store in the opened

byte.

Publication 1734-UM005B-EN-P - June 2001

Page 46

4-8 Communication and I/O Table Mapping

Get_Configuration

This service permits the master to read out the Identifier bytes for the

actual adapter configuration. (Refer to the previous section for the

format of the identifier byte.)

The table below shows an example of how the identifier bytes from a

Get_configuration response would look like when you have the

following modules in the backplane: slot 1 = 1734-OB4E; slot 2 =

1734-IE2C; slot 3 = 1734-OE2C; and slot 4 = 1734-IA2.

Identifier Byte Value Description

0 20h 1734-OB4E; 1 byte out, consistency over byte

1 51h 1734-IE2C; 2 words in, consistency over word

2 61h 1734-OE2C; 2 words out, consistency over word

3 10h 1734-IA2; 1 byte in, consistency over byte

Global_Command

Sync/Freeze

In addition to the cyclic data exchange, which is executed

automatically by the master, the master can send control commands to

a single slave, a group of slaves or all slaves simultaneously. These

control commands are transmitted as multicast commands and permit

use of sync and freeze modes for event-controlled synchronization of

the slaves.

The POINT I/O adapter begins sync mode when it receives a sync

command from the assigned master. The output channels of all I/O

modules are then frozen in their current state. During subsequent user

data transmissions, the output data are stored at the adapter, but the

output states remain unchanged. The stored output data is not sent to

the outputs until the sync command is receivied. Sync mode is

concluded with the unsync command.

Similarly, a freeze control command causes the adapter to assume

freeze mode. In this operating mode, the states of the input channels

of all I/O modules are frozen at the current value. Input data is not

updated again until the master sends the next freeze command.

Freeze is concluded with the unfreeze command.

Publication 1734-UM005B-EN-P - June 2001

Page 47

Communication and I/O Table Mapping 4-9

Operating States

The general system behavior is determined by the operating status of

the master. The 3 main states are:

• Stop - No data transmission occurs between the master and the

slaves.

• Operate - The master is in the data transfer phase. In cyclic data

communication , inputs of the slaves are read, and output

information is written to the slaves.

• Clear - The master reads the information of the slaves and sets

the outputs to an idle state. (Refer to “Configure Idle Action

Value for Your Output Modules,” page 3-11.)

Data_Exchange

After correct set_parameter and check_configuration services, the

master automatically starts exchanging data with the adapter by means

of the data_exchange service.

Slave_Diag

The adapter may notify the master of its current state by means of the

slave_diag service. The information received from this service request

can be divided into 3 parts:

• Standard diagnostic information according to the PROFIBUS

standard DIN 19245-3

• Module related diagnostics indicates which I/O module has

diagnostic events pending.

• Channel related diagnostics, give more detailed information of

the actual cause of the event (wire-break, overcurrent, etc.).

Publication 1734-UM005B-EN-P - June 2001

Page 48

4-10 Communication and I/O Table Mapping

Structure of Slave_Diagnosis

Octet Description

0 Station Status 1

1 Station Status 2

2 Station Status 3

3 Master PROFIBUS address

4 Identifier number (high byte)

5 Identifier number (low byte)

6 Module-related header byte

7-14 Module-related diagnostic block

15-17 1st channel-related diagnostic message

18-20 2nd channel-related diagnostic message

..

..

42-44 10th channel-related diagnostic message

IMPORTANT

The length of the diagnostic frame varies between 15

and 45 bytes since the length of the channel-related

part is dynamic in its structure.

Publication 1734-UM005B-EN-P - June 2001

Page 49

Communication and I/O Table Mapping 4-11

Station Status 1, 2 and 3

Station status 1, 2 and 3 provide an overview of the status of the slave.

Station Status 1

Bit Description Cause

0 - Station nonexistent The master cannot be

addressed by the master

• Correct node address set on the

• Bus connector connected?

• Bus cable pin configuration

• Power to the slave switched on?

• Is the RS485 repeater set

adapter?

correct (Pin 3 to 3 and pin 8 to 8)?

correctly?

1 - Station not ready Adapter not yet ready for

data exchange

2 - Configuration fault Configuration data sent by

the master to the adapter

does not match the

backplane configuration.

3 - Extended diagnostic Diagnostics available for the

master

4 - Function not supported The requested function is

not supported by the module

5 - Invalid slave response The master has received an

invalid response

6 - Parameter fault Parameters sent by the

master are containing

wrong or insufficient data.

7 - Master lock The adapter has already

been parameterized by

another master and is

locked in its access.

Wait for the adapter to start up.

Do the modules installed in the

backplane match the modules entered

in the master configuration?

Evaluate the module-related and/or

channel-related diagnostics.

This bit is cleared (0) when there are no

diagnostic messages available.

Trying to set PROFIBUS address over

the network?

Check the bus setup.

Do the modules installed in the

backplane match the modules entered

in the master configuration?

Check if another master is present on

the network, and delete its

assignments to the adapter or remove

the other assigned master from the

network to get the communication with

the adapter run.

Publication 1734-UM005B-EN-P - June 2001

Page 50

4-12 Communication and I/O Table Mapping

Bit Description Cause

Station Status 2

0 - Parameterization

requested

1 - Static diagnostic The adapter cannot provide

2 - Not used Always set to 1.

3 - Watchdog on Watchdog control is the

4 - Freeze mode The adapter has received a

5 - Sync mode The adapter has received a

6 - Reserved Always set to 0.

7 - Slave deactivated The adapter has been

The slave has forced the

master system to do a new

parameterization.

valid I/O data.

adapter is active to

supervise its corresponding

master connection.

freeze command.

sync command.

marked inactive in its

parameter set and has been

removed from cyclic I/O

processing.

This bit is set as long as new

parameterization must be performed.

The backplane bus communication is

terminated. This bit will not be cleared

(0) until the power to the adapter is

cycled.

Check bus settings in the configuration

tool.

Station Status 3

Bit Description Cause

0 to 6 - Not used These bits are always 0.

7 - Diagnostic overflow There are more diagnostic

messages than the adapter

can store.

More than 10 channel-related

messages present at the same time.

Note: New messages are queued in

the adapter and are passed on to the

master as soon as ther is space in the

diagnostic buffer.

Publication 1734-UM005B-EN-P - June 2001

Page 51

Communication and I/O Table Mapping 4-13

Master PROFIBUS Address

In this octet (byte 3), the address of the master that has done the

parameterization of the adapter is entered. If the adapter is not

parameterized from any master, the adapter writes the address 255

(decimal) here.

Identity Number

The identity number (byte 4-5) is a unique code that describes the

type of DP-slave. The identity number for the 1734-APB adapter is

04EF (hexidecimal).

Module-related Diagnostics

The module-related diagnostics indicates if any of the connected I/O

modules reports errors. More detailed information of the error can be

found by further evaluation of the channel-related diagnostic message.

Bit Value Module Status

0 Module is OK

1 Module reports error

Octet Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

601001001

...

7 Module 8 Module 7 Module 6 Module 5 Module 4 Module 3 Module 2 Module 1

8 Module 16 Module 15 Module 14 Module 13 Module 12 Module 11 Module 10 Module 9

9 Module 24 Module 23 Module 22 Module 21 Module 20 Module 19 Module 18 Module 17

10 Module 32 Module 31 Module 30 Module 29 Module 28 Module 27 Module 26 Module 25

11 Module 40 Module 39 Module 38 Module 37 Module 36 Module 35 Module34 Module 33

12 Module 48 Module 47 Module 46 Module 46 Module 44 Module 43 Module 42 Module 41

13 Module 56 Module 55 Module 54 Module 53 Module 52 Module 51 Module 50 Module 49

14 Not used Module 63 Module 62 Module 61 Module 60 Module 59 Module 58 Module 57

Channel Related Diagnostics

These diagnostics give information on channel errors of the I/O

modules and expand on the module related diagnostics. The message

entry length is 3 bytes.

Publication 1734-UM005B-EN-P - June 2001

Page 52

4-14 Communication and I/O Table Mapping

Byte 15 1 0 Slot number of the module that reports diagnostics (1-63)

A maximum of 10 channel related diagnostic messages are possible. If

you exceed the limit, the diagnostic overflow bit in station status 3 will

be set.

Note: If the diagnostic buffer is full and the adapter receives an

additional error message, this new message will be queued in the

adapter internally and passed on to the master as soon as space is

available in the diagnostic buffer (i.e. when older messages are

deleted).

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Channel Direction

Byte 16

Byte 17 Channel Type:

Byte 18-20 2nd channel specific message (same assignments as bytes 15-17)

Byte 42-44 10th channel specific message (same assignments as bytes 15-17)

01 - Input

10 - Output

11 - Input/Output

001 = Bit

010 - 2 bits

011 - 4 bits

100 - Byte

101 - Word

110 - Double word

Type of channel that reports diagnostics

Error codes (see Appendix B)

Publication 1734-UM005B-EN-P - June 2001

Page 53

Select the “Start Debug Mode”

entry in the “Online” menu.

Double click on the slave icon.

Communication and I/O Table Mapping 4-15

Viewing Diagnostic Data within the Configuration Tool

Station status 1 - 3

Interpreted view of diagnostic

messages

Error details

Complete diagnostic message

in hexadecimal.

Station status 1 - 3

1. Select error message

2. A detailed description

appears

(Click on “OK” to exit.)

Publication 1734-UM005B-EN-P - June 2001

Page 54

4-16 Communication and I/O Table Mapping

Grouping Modules for Memory Management

You can install up to 8 of the same type of module (identical product

code) next to each other and use only one word of input or output

memory. The module requirements are:

• the modules must be next to each other

• the modules must be members of the same module family

• must total 8 channels or less

• the modules will share the same configuration data.

You select the option 4, bit stuffing module, in the hardware catalog

in the configuration tool.

1. Select the 1734-OB2E (hardware type 1) from the hardware catalog.

The adapter will open a byte and store the first 1734-OB2E module there.

2. Select the 1734-OB2E (hardware type 4 - grouped) from the hardware catalog.

The adapter will store the second 1734-OB2E in the opened byte.

Chapter Summary and

What’s Next

3. Select the 1734-OB2E (hardware type 4 - grouped) from the hardware catalog.

The adapter will store the third 1734-OB2E in the opened byte.

4. Select the 1734-OB2E (hardware type 4 - grouped) from the hardware catalog.

The adapter will store the fourth 1734-OB2E in the opened byte.

Note that the grouped modules will share the same configuration data

as the first module in the group. If the first module has no

configuration data, the other three modules will have no configuration

data.

In this chapter, you learned about communication and I/O table

mapping. Move to chapter 5 for troubleshooting.

Publication 1734-UM005B-EN-P - June 2001

Page 55

Grouped Mode

Chapter

5

In This Chapter

General

In this chapter, you will learn about:

For more information about: See page:

General 5-1

How to Configure the Adapter for Grouped Mode 5-2

Configuration Example 5-3

Chapter Summary and What’s Next 5-4

In order to use master memory most effectively, and reduce data

transfer between the POINT I/O adapter and the master, you can

group several modules in a single byte.

To configure the adapter for grouped mode you must:

1. insert modules adjacent to each other

2. Modules must be in the same module family

Groups may exist as follows:

• 1734-IB2, 1734-IV2, 1734-IM2 and 1734-IA2 can be grouped

together

• 1734-IB4 and 1734-IV4 can be grouped together

• 1734-OW2, 1734-OA2 and 1734-OX2 can be grouped together

The following modules cannot be grouped with any other

module type:

• 1734-OB2E can only be grouped with 1734-OB2E modules

• 1734-OB4E can only be grouped with 1734-OB4E modules

3. A maximum of 8 channels (1 byte) per group

4. Modules in a single byte will have the configuration of the first

module in the group. (Exception: Extended diagnostics can be

enabled/disabled on a per module basis.)

1 Publication 1734-UM005B-EN-P - June 2001

Page 56

5-2 Grouped Mode

How to Configure the Adapter for Grouped Mode

You can select the following modules in the configuration tool:

1. Module without configuration data (e.g. 1734-OB2E/no config)

2. Module with configuration data (e.g. 1734-OB2E/with config)

3. Empty slot module (e.g. 1734-OB2E/empty slot)

4. Grouped module (e.g. 1734-OB2E/grouped)

5. Grouped empty slot module (e.g. 1734-OB2E/grouped empty

slot)

By combining these modules, groups can be created in 3 different

ways:

1. A group of modules with configuration data

2. A group of modules without configuration data (default

configuration will be used for all modules in the group)

3. A group of empty slot modules

The following example illustrates how to group modules in a single

byte.

1. Select the 1734-OB2E (hardware type 1) from the hardware catalog.

The adapter will open a byte and store the first 1734-OB2E module there.

Bit

Output Byte

2. Select the 1734-OB2E (hardware type 4 - grouped) from the hardware catalog.

The adapter will store the second 1734-OB2E in the opened byte.

Bit

Output Byte

3. Select the 1734-OB2E (hardware type 4 - grouped) from the hardware catalog.

The adapter will store the third 1734-OB2E in the opened byte.

Bit

Output Byte

4. Select the 1734-OB2E (hardware type 4 - grouped) from the hardware catalog.

The adapter will store the fourth 1734-OB2E in the opened byte.

Bit

Output Byte

5

5

5

5

0123467

0123467

0123467

0123467

Publication 1734-UM005B-EN-P - June 2001

If more modules are to be grouped, a new byte has to be opened (repeat steps 1 through 4).

Page 57

Grouped Mode 5-3

Note that the grouped modules will share the same configuration data

as the first module in the group. If the first module has no

configuration data, the other modules in the group will have no

configuration data.

The configuration for the above example will look like the following

in the configuration tool.

Slot

Configuration Example

The following example shows how modules can be grouped together,

and how the I/O data is mapped in the PROFIBUS adapter.

12 3 4 5 6 7 8 91011121314

PROFIBUS Adapter

1734-OB2E Output Module

1734-OB2E Output Module/Grouped

1734-OB2E Output Module/Grouped

1734-OB2E Output Module/Grouped

1734-IB2 Input Module/Grouped

1734-OB4E/Empty slot

1734-OB4E/Grouped Empty slot

1734-IB2 Input Module

1734-IV2 Input Module/Grouped

1734-IE2C Input Module

1734-OE2C Output Module

1734-IB4 Input Module/No config

1734-IB4 Input Module/Grouped

1734-IB4 Input Module

Publication 1734-UM005B-EN-P - June 2001

Page 58

5-4 Grouped Mode

Configuration table and memory map

Note the following module groups:

• slots 1, 2, 3 and 4 - A group of modules with configuration data

• Slots 7, 8 and 9 - A group of modules with configuration data

• Slots 5 and 6 - A group of empty slots

• Slots 12 and 13 - A group of modules without configuration data

(default configuration data)

In this example, the input/output addresses start at byte 0.

Slot Module

1 1734-OB2E 0.0 to 0.1

2 1734-OB2E/grouped 0.2 to 0.3 Same configuration data as first

3 1734-OB2E/grouped 0.4 to 0.5

4 1734-OB2E/grouped 0.6 to 0.7

5 1734-OB4E/empty slot 1.0 to 1.3

6 1734-OB4E/grouped empty slot 1.4 to 1.7

7 1734-IB2E 0.0 to 0.1

8 1734-IB2E/grouped 0.2 to 0.3 Same configuration data as first

9 1734-IV2E/grouped 0.4 to 0.5

10 1734-OE2C 2 to 5

11 1734-IE2C 1 to 4

12 1734-IB4/no configuration 5.0 to 5.3 Default configuration data

13 1734-IB4/grouped 5.4 to 5.7

14 1734-IB4 6.0 to 6.3

I/O Address

Notes

Input Output

module in group (slot 1).

module in group (slot 7).

Chapter Summary and

What’s Next

Publication 1734-UM005B-EN-P - June 2001

In this chapter, you learned how to group modules for reduced

memory space. Move to chapter 6 for information on troubleshooting

your adapter.

Page 59

Chapter

Troubleshooting the PROFIBUS Adapter

6

In This Chapter

Using the Status Indicators

In this chapter, you will learn about:

For more information about: See page:

Using the Status Indicators 6-1

Using PROFIBUS Diagnostics 6-3

Chapter Summary and What’s Next 6-3

You can use the status indicators to troubleshoot your adapter. These

indicators consist of:

Adapter

System

Power

Field

Power

Status

PROFIBUS

Status

PointBus

Status

1734-APB

Adapter Status

PROFIBUS Status

PointBus Status

System Power

Field Power

1734apbfrt

Use the following table to troubleshoot your adapter.

1 Publication 1734-UM005B-EN-P - June 2001

Page 60

6-2 Troubleshooting the PROFIBUS Adapter

Indicator Indication Probable Cause

System Power Off Not active.

Field power is off; or dc-dc converter problem.

Green System power on.

Dc-dc converter active (5V).

Field Power Off Not active.

Field power not applied.

Green Power on, 24V present.

Adapter Status Off No power supplied.

Hardware check in progress.

Initialization in progress.

Green Adapter operating normally

Red Hardware check fault.

PROFIBUS Status Off No power supplied.

Adapter is off-line (no data exchange with the

PROFIBUS master).

Green Adapter is online (data exchange with the PROFIBUS

master).

Flashing Green Adapter is in CLEAR mode and has set the connected

I/O modules into an idle state.

Red No POINT I/O modules installed in the backplane.

Flashing Red Set_Parameter telegram rejected.

Maximum number of user parameter bytes overridden.

PointBus Status Off No power applied to adapter

PointBus initialization in progress.

Green Normal operation.

Flashing Red Incorrect POINT I/O module installed or

POINT I/O module removed from backplane.

Red Critical link failure. Adapter detected error that

prevents its communication on the PointBus.

Publication 1734-UM005B-EN-P - June 2001

Page 61

Troubleshooting the PROFIBUS Adapter 6-3

Using PROFIBUS Diagnostics

PROFIBUS diagnostics provides detailed information about the

adapter and the I/O modules. (Refer to Slave_Diag in chapter 4 for

detailed information about diagnostic capabilities of the adapter.)

Pay special attention to the following indications in the diagnostic

response.

Station Bit Response Reason

Station Status 1 0 Station nonexistent Wrong node address.

Bus cable problem.

Incorrect pin configuration.

2 Configuration fault Wrong module installed.

Identifier bytes for one or more

modules does not match master

configuration identifier bytes.

3 Extended diagnostic One or more modules report errors.

(To find out reasons for the error

indication, evaluate the module and

channel related diagnostic.)

6 Parameter fault Wrong module installed.

Product code for one or more

modules does not match master

configuration product code.

Chapter Summary and

What’s Next

Station Status 2 1 Static diagnostic PointBus communication

terminated. Adapter cannot provide

valid data.

Station Status 3 7 Diagnostic overflow More than 10 channel related

messages present at the same time.