Page 1

Installation Instructions

POINT I/O

Use this document to install and wire the following components of your POINT™ I/O system:

Interface: 1734-ADN, -PDN Bases: 1734-TB, -TBS, -TB3, -TB3S

POINT I/O modules have no switches to set. You set module parameters with a software configuration tool. To obtain EDS files for use in

configuration, go to: http://www.ab.com/networks/eds

(RTB usage covered)

This product installation information is also available at: http://www.ab.com/manuals/io/

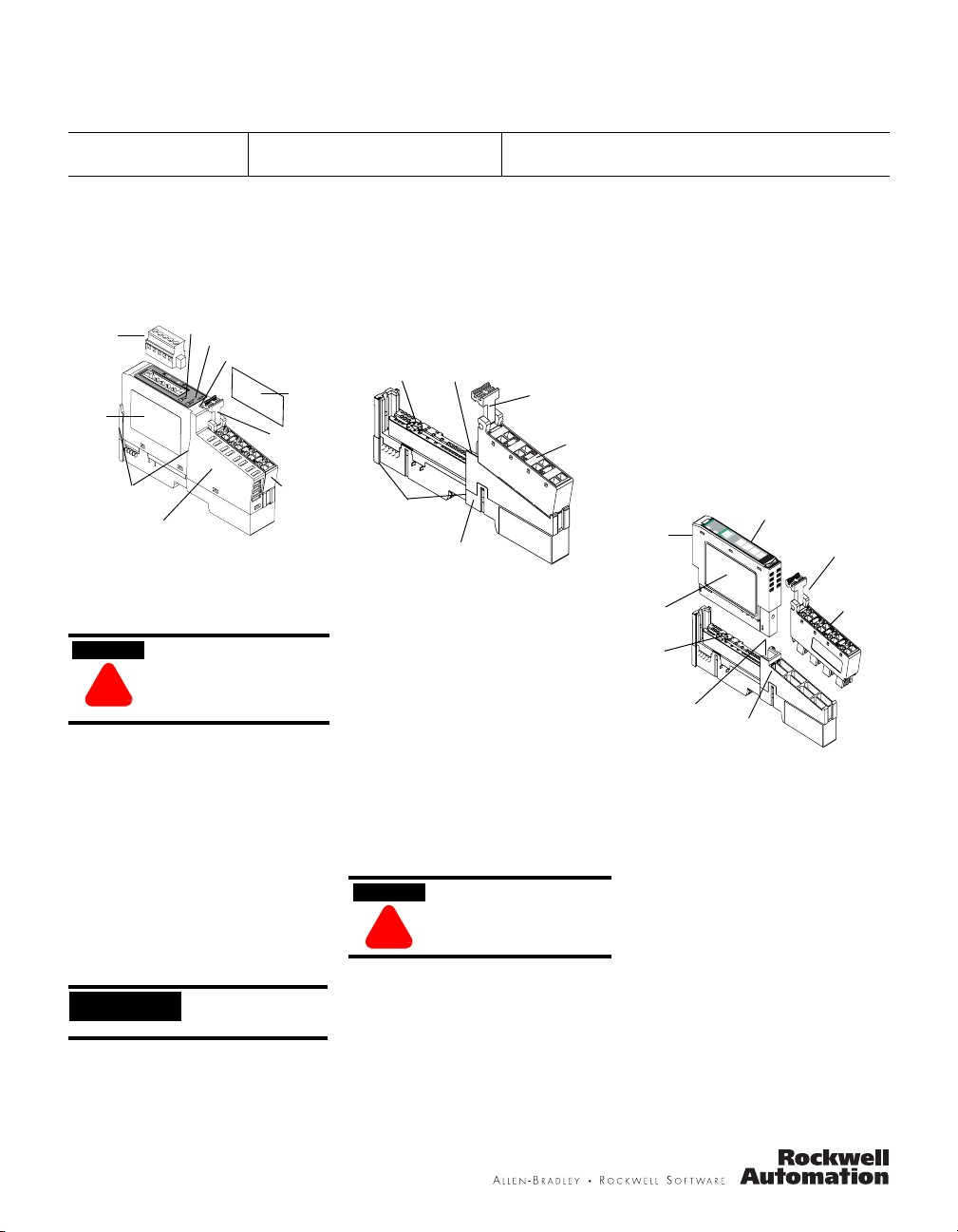

Installing the POINT I/O Adapter or Communication Interface

The 1734-ADN DeviceNet adapter and

1734-PDN communication interface install

onto a DeviceNet network.

DeviceNet

connector

Module

label

Interlocking

side pieces

1. Position the interface above the DIN rail.

2. Press down firmly to install the interface

3. The locking mechanism will lock the

4. Remove safety end cap. Slide it up to

1734-PDN Adaptor

on the DIN rail.

interface to the DIN rail.

expose backplane and power connections.

ATTENTION

!

If installing a replacement interface to an

existing system:

1. Position the interface above the DIN rail.

2. Slide the interface down allowing the

interlocking side pieces to engage the

adjacent module.

3. Press firmly to seat the interface on the

DIN rail. The interface locking mechanism

will snap into place.

4. To remove the interface from the DIN rail,

pull up on the RTB removal handle to

remove the terminal block.

5. Use a small bladed screwdriver to rotate

the DIN rail locking screw to a vertical

position.

6. This releases the locking mechanism.

Then lift straight up to remove.

System Power Indicator

Module Power Indicator

DIN Rail Locking Screw

Do not discard end cap. Use

end cap to cover exposed

connections on the last terminal

base in the chassis. Failure to

do so could result in injury or

equipment damage.

(orange)

Safety

End Cap

RTB Removal

Handle

Removable

Ter mi na l

Block

Installing the Field Potential Dist.

IMPORTANT

The 1734-FPD installs onto a DeviceNet

network using the same steps as the

1734-PDN communication interface with one

additional step included.

The 1734-FPD looks

like the 1734-PDN but

has no indicators.

After positioning the 1734-FPD above the

DIN rail, engage the interlocking side pieces

with the unit on the left.

Installing the POINT I/O Wiring Base

The wiring base consists of a base and a

removable terminal block (RTB). The

1734-TB uses screw-clamp terminations; the

1734-TBS uses spring-clamp terminations.

Mech. Keying

Interlocking

Side Pieces

Installing the Wiring Base

1. Position wiring base vertically above

installed units (interface, power supply or

existing module.

2. Slide the wiring base down allowing the

interlocking side pieces to engage the

adjacent module or interface.

3. Press firmly to seat the wiring base on the

DIN rail. The wiring base will snap into

place.

4. To remove the wiring base from the DIN

rail, remove the module, and use a small

bladed screwdriver to rotate the base

locking screw to a vertical position. This

releases the locking mechanism. Then lift

straight up to remove.

Installing the Removable Terminal Block

A removable terminal block is supplied with

your terminal base. To remove, pull up on

the RTB removal handle.

ATTENTION

!

This allows the base to be removed and

replaced as necessary without removing any

of the wiring. To reinsert the removable

terminal block:

1. Insert the end opposite the handle into the

base unit. This end has a curved section

that engages the wiring base.

2. Rotate the terminal block into the wiring

base until it locks itself in place.

DIN Rail Locking Screw (orange)

Wiring Base

Do not pull on the installed

wiring to remove a terminal

block. A shock hazard exists if

power is applied to the

terminal block.

Modules:1734-IA2, IB2, -IB4, -IJ, -IK, -IM2, -IV2, -IV4, -IE2C, -OA2,

-OE2C, -OW2, -OB2E, -OB4E, -VHSC24, -VHSC5

3. If an I/O module is installed, snap the RTB

handle into place on the module.

4. Insert module straight down into wiring

base and press to secure. Module locks

into place.

Removing a Wiring Base

To remove a wiring base, you must remove

any installed module, and remove the

removable terminal block (if wired). Then

follow these steps:

RTB

6

Removal

Handle

RTB

1. Remove the RTB (if wired).

2. Turn the wiring base locking screw to a

vertical position to unlock the base from

the DIN rail.

3. Slide base up to release it from its mating

units.

Installing the I/O Module

I/O Module

le

u

s

d

o

tu

M

ta

S

Network

Status

Module

Locking

Mechanism

Module

Wiring

Diagram

Mech.

Keying

DIN Rail

Locking Screw

(orange)

The module can be installed before, or after

base installation. Make sure that the wiring

base is correctly keyed before installing the

module into the wiring base. In addition,

make sure the wiring base locking screw is

positioned horizontal according to the base.

1. Using a bladed screwdriver, rotate the

keyswitch on the wiring base clockwise to

until the number required for the type of

module being installed aligns with the

notch in the base.

2. Make certain the DIN rail locking screw is

in the horizontal position. (You cannot

insert the module if the locking

mechanism is unlocked.)

3. Insert the module straight down into the

wiring base and press to secure. The

module will lock into place.

NODE:

24VDC

Source

Output

0

1

Wiring Base

2

3

1734

B4E

O

RTB

Removal

Handle

RTB

30880-MB

Page 2

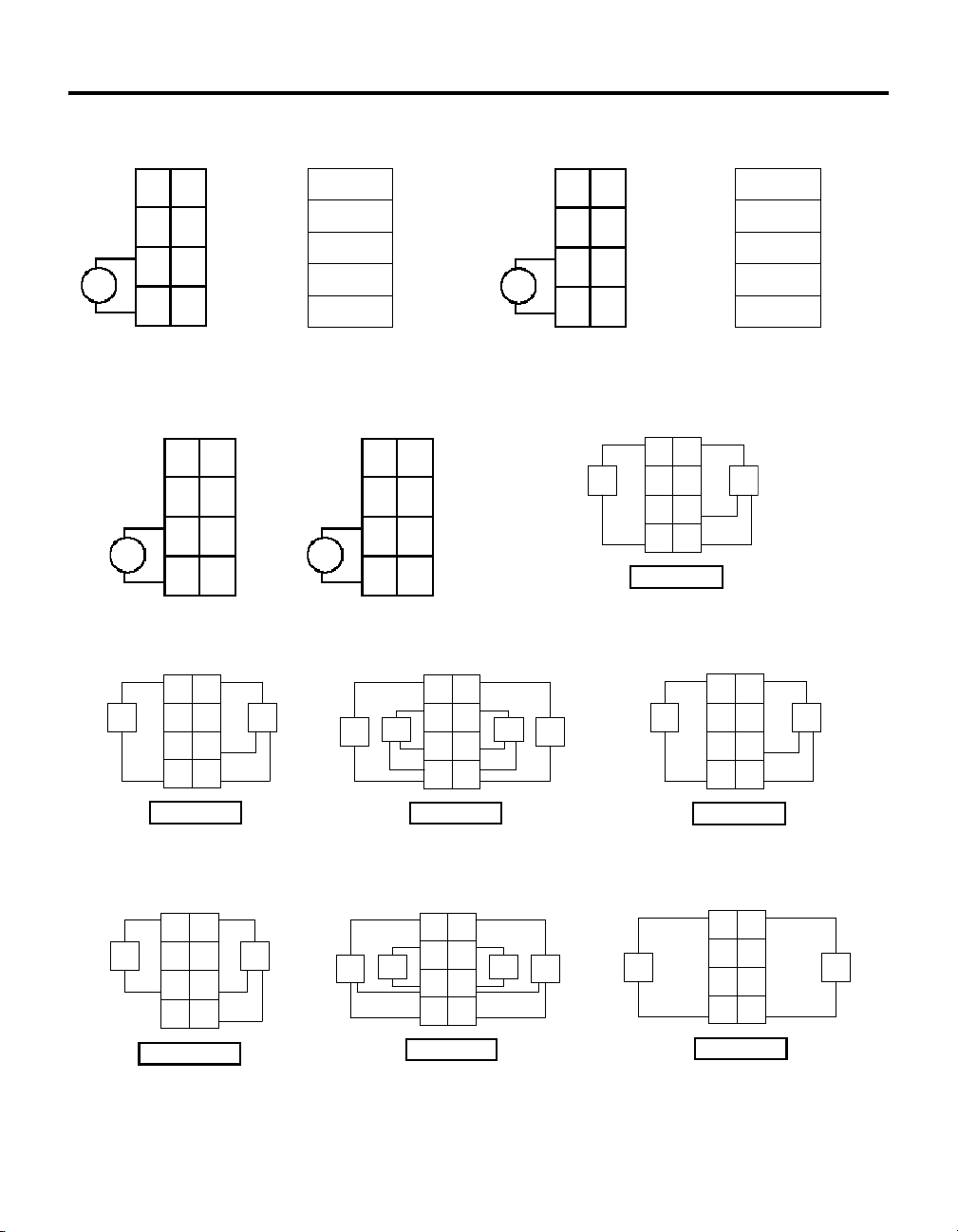

2 POINT I/O

Wiring Diagrams

1734-ADN

0

V dc

12/24V dc

Power

2

1

4

6

12/24V dc

Power

NC = No Connection Chass GND = Chassis Ground

C = Common V = Supply

1

Do not connect 120/240V ac power to this supply. This dc

supply will be connected to the internal pow er bus.

V dc

V = 12/24V dc, C = Common Chass GND = Chassis Ground

This supply will be connected to the internal power b us.

Prox

V = 12/24V dc, C = Common

Field power is supplied from power bus

NC

Chass

Gnd

C

V

1734-IB2

1

NC

3

Chass

Gnd

5

C

7

V

0

NC

2

Chass

Gnd

4

C

6

V

0

In 0 In 1

2

NC

NC

4

C

C

6

VV

IB2 Sink Input

30880

NC

Chass

Gnd

C

V

1

3

5

7

DeviceNet

connection

1734-FPD

1

3

5

Daisy

chain

power

7

out to

modules

Prox

41966

Black

Blue

Bare

White

Red

0

NC

2

120/240V ac

Power

Chass

Gnd

4

L2/

V ac

N

6

L1

L2/N = Neutral, L1 = 120/240V ac

This supply will be connected to

the internal power bus.

Prox

V = 12/24V dc, C = Common

Field power is supplied from power bus

-V

CAN - Low

Shield

CAN - High

+V

1

NC

3

Chass

Gnd

5

L2/

N

7

L1

1734-IB4

0

In 0 In 1

2

In 2

4

6

IB4 Sink Input

Daisy

chain

power

out to

modules

1

3

In 3

5

C

C

7

VV

1734-PDN

0

1

NC

NC

2

3

Chass

V dc

Chass

Gnd

4

C

6

V

Gnd

C

V

5

Daisy chain

7

power out to

modules

DeviceNet

connection

12/24V dc

Power

NC = No Connection Chass GND = Chassis Ground

C = Common V = Supply

1734-IA2

0

1

Ch 0 Ch 1

2

Prox

2-Wire 3-Wire

Ch 0 = Channel 0 Ch 1 = Channel 1 NC = No Connection

L2/N = 120V ac Neutral L1 = 120V ac

Prox

ProxProx

41967

Ch 0 = Channel 0 Ch 1 = Channel 1 NC = No Connection

L2/N = 220V ac Neutral L1 = 220V ac

3

NC

NC

4

5

L2/N

L2/N

6

7

L1 L1

IA2 Input

Prox

2-Wire 3-Wire

Prox

1734-IM2

0

Ch 0 Ch 1

2

NC

NC

4

L2/N

L2/N

6

L1 L1

IM2 Input

Black

Blue

Bare

White

Red

41960

1

3

5

7

-V

CAN - Low

Shield

CAN - High

+V

Prox

41968

1734-IV2

1

0

In 0 In 1

3

2

NC

Prox

V = 12/24V dc, C = Common

Field power is supplied from power bus

NC

4

C

C

6

VV

IV2 Source Input

Prox

5

7

41968

Publication 1734-IN510B-EN-P - August 2000

1734-IV4

0

In 0 In 1

2

In 2

Prox

V = 12/24V dc, C = Common

Field power is supplied from power bus

In 3

4

C

C

6

VV

IV4 Source Input

1734-OA2

1

1

3

Prox

5

7

ProxProx

41969

Load

Ch 0 = Channel 0 Ch 1 = Channel 1 NC = No Connection

L2/N = 120/220V ac Return L1 = 120/220V ac Supply

Field power is supplied from the internal power bus.

0

Ch 0 Ch 1

2

NC

4

L2/N

L2/N

6

L1 L1

OA2 Output

3

NC

5

7

Load

42014

Page 3

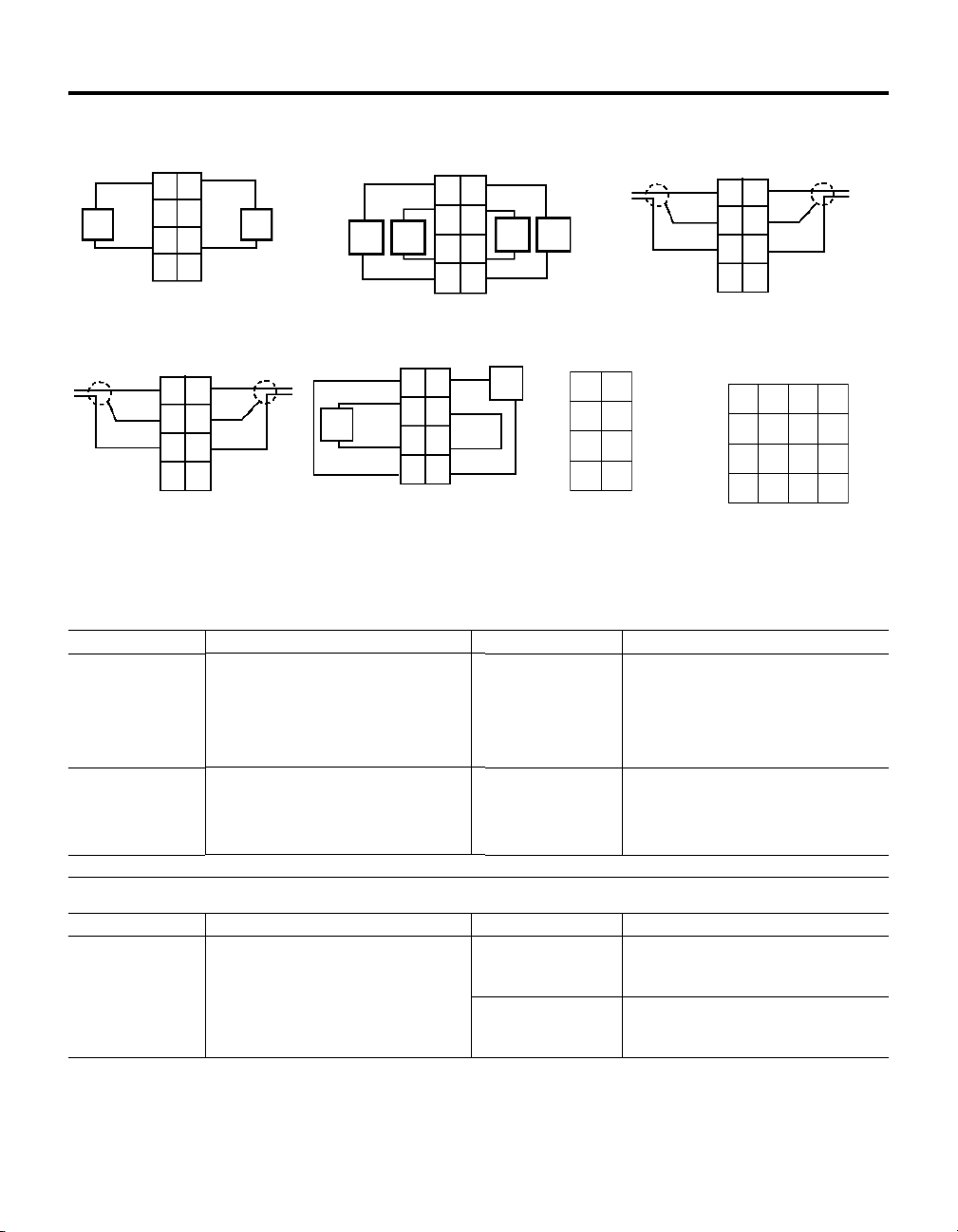

Wiring Diagrams

1734-OB2E

1

0

Out 0Out

1

3

2

Out

Out

1

Load Load

V = 12/24V dc, C = Common

Field power is supplied from power bus

0

4

CC

6

5

7

VV

42014

1734-OE2C

Out 0 Out 1

0

1

Out 0Out

1

2

3

Chass

Chass

Gnd

Gnd

4

5

CC

6

7

VV

V = 12/24V dc, C = Common

Chass GND = Chassis Ground

This supply will be connected to

the internal power bus.

42018

Load Load

Load

V = 12/24V dc, C = Common

This supply will be connected to

the internal power bus.

1734-OB4E

0

1

Out 0Out

1

2

3

Out

Out

3

2

5

7

CC

Load Load

4

CC

6

V = 12/24V dc, C = Common

Field power is supplied from powe r bus

1734-OW2

0

1

Out

Out

0A

2

Out

Out

0B

4

C

6

VV

1A

1B

C

Load

3

5

7

42019

42015

V = 12/24V dc, C = Common Chass GND = Chassis Ground

This supply will be connected to the internal pow er bus.

1734-IJ, & 1734-IK

1

0

AAnot

3

2

B

Bnot

5

4

Z

Znot

7

6

FE FE

A, B, Z, Anot, Bnot,

and Znot = inputs

FE = Functional Earth

41975

1734-IE2C

In 0 In 1

0

2

Chass

Gnd

4

6

Specifications

General specifications - These specifications are shared by all components of the 1734 POINT I/O system.

Specification: Value: Specification: Value:

Environ. Conditions

Operating Temp.

Storage Temp.

Relative Humidity

Shock Operating

Non-operating

Vibration

Terminal Base Screw

Torque

1

Use this conductor category information for planning conductor routing as described in the system level installation manual.

30g peak acceleration, 11(±1)ms pulse width

50g peak acceleration, 11(±1)ms pulse width

Tested 5g @ 10-500Hz per IEC 68-2-6

o

-20 to 55

C (-4 to 131oF)

o

C (-40 to 185oF)

-40 to 85

5 to 95% noncondensing

7 inch-pounds max Agency Certification

Conductors

Wire Size

Category

(When Product or

Packaging is Marked)

14 AWG (2.5mm

(18 AWG max if connecting 2 wires to same terminal)

CE marked for all applicable directives

C-Tick marked for all applicable acts

CUL listed – Class I, Division 2

CUL recognized

DeviceNet conformance tested

solid or stranded max

3/64 inch (1.2mm) insulation max

Groups A, B, C and D certified

POINT I/O 3

1

In 0In

1

3

Chass

Gnd

5

CC

7

VV

42017

1734-VHSC24, &

1734-VHSC5

0

1

0

FE FE

2

RET 0

RET 1

4

-Vaux -Vaux

6

+Vaux +Vaux

1

3

5

7

42444

A Anot

2

3

B

Bnot

4

5

Z

Znot

6

7

Out 0 Out 1

A, B, Z, Anot, Bnot, and Znot = inputs

FE = Functional Earth

-Vaux = Auxiliary Supply

+Vaux = Auxiliary Supply

2

) - 22 AWG (0.25mm2)

1

2

1734-TB, -TBS, -TB3 and -TB3S Specifications

Specification: 1734-TB, -TBS, -TB3, -TB3S Specification: 1734-TB, -TBS, -TB3, -TB3S

Field Power Bus

Voltage 240V ac (1734-TB, -TBS)

28.8V dc, 120/240V ac (1734-TB3, -TB3S)

Current 10A max Mass 2.94 oz/83.35 grams (1734-TB)

Dimensions

(HxWxL)

65mm x 12mm x 133.4mm

(2.560in x 0.472in x 5.250in) (1734-TB, -TBS)

65mm x 12mm x 160mm

(2.560in x 0.472in x 6.25in) (1734-TB3, -TB3S)

2.57 oz/73.86 grams (1734-TBS)

3.44 oz/97.5 grams (1734-TB3)

3.07 oz/87 grams (1734-TB3S)

Publication 1734-IN510B-EN-P - August 2000

Page 4

4 POINT I/O

1734-ADN Specifications

Specification Value Specification Value

Expansion I/O Capacity 12 modules (Note: Total expansion up to 63 modules

DeviceNet Communication

Rate

Module Location Starter module - left side of 1734 system Input Voltage Rating 24V dc nominal

Power Supply Note: In order to comply with CE Low Voltage

DeviceNet Input Voltage

Range

Power Consumption 8.1W maximum @ 28.8V dc Isolation Voltage 1250V rms/V ac

Power Dissipation 2.8W maximum @ 28.8V Thermal Dissipation 9.5 BTU/hr maximum @ 28.8V dc

Field Power Bus

Nominal Voltage

Supply Voltage Range

Supply Current 10A maximum Mass 9.0 oz/255 grams

Field Wiring Terminations

DeviceNet 1 - Black Wire V

with 1734-EP24DC)

125K bit/s (500m maximum)

250K bit/s (250m maximum)

500K bit/s (100m maximum)

Directives (LVD), you must use a Safety Extra Low

Voltage (SELV) or a Protected Extra Low Voltage (PELV)

power supply to power this adapter.

11-25V dc DeviceNet specification DeviceNet Power

24V dc

10-28.8V dc range,

2 - Blue Wire CAN Low

3 - Bare Wire Shield

4 - White Wire CAN High

5 - Red Wire +V

Power Supply Specifications

Power Supply Note: In order to comply with CE Low Voltage

Input Voltage Rating 24V dc nominal

Inrush Current 6A maximum for 10ms PointBus Output Current 1A maximum @ 5V dc ±5% (4.75 - 5.25)

Input Overvoltage Protection

Directives (LVD), you must use a Safety Extra Low

Voltage (SELV) or a Protected Extra Low Voltage (PELV)

power supply to power this adapter.

10-28.8V dc range

Reverse polarity protected

Input Overvoltage

Protection

DeviceNet Cable Allen-Bradley part number 1485C-P1-Cxxx

Indicators 3 red/green status indicators

Requirements

Dimensions Inches

(Millimeters)

Field Wiring Terminations

Power Supply

Interruption Output voltage will stay within specifications when

Field Side Power

Requirements

Reverse polarity protected

Refer to publication DN-2.5 for more information

Adapter status

DeviceNet status

PointBus status

2 green power supply status indicators:

System Power (PointBus 5V power)

Field Power (24V from field supply)

24V dc (+4% = 25V dc max) @ 30mA maximum

3.0H x 2.16W x 5.25L

(76.2H x 54.9W x 133.4L)

0 - No Connection 1 - No Connection

2 - Chassis Ground 3 - Chassis Ground

4 - Common 5 - Common

6 - Supply 7 - Supply

input drops out for 10ms at 10V with maximum load.

24V dc (+20% = 28.8V dc maximum) @ 400mA

maximum

1734-PDN Specifications

Specification Value: Specification Value:

Expansion I/O Capacity 12 modules Module Location Starter module - left side of 1734 system

Communication Rate 125K bits/s (500m max)

DeviceNet Power Req. 24V dc (+4% = 25V dc max @ 400mA max Dimensions (HxWxL) 76.2mm x 25.4mm x 133.4mm (3.0in x 1.0in x 5.25in)

DeviceNet Cable Allen-Bradley PN 1485C-P1-Cxxx

Power Supply Note: In order to comply with CE Low Voltage

Field Wiring

Power Supply

Input Voltage Rating 24V dc nominal Power Dissipation 1.2W max @ 25V

Input Voltage Range 11-25V dc DeviceNet specification Thermal Dissipation 4.1 BTU/hr max @ 25V dc

250K bits/s (250m max)

512K bits/s (100m max)

Refer to publication DN-2.5

Directives (LVD), you must use a Safety Extra Low

Voltage (SELV) or a Protected Extra Low Voltage (PELV)

power supply to power this interface.

0 - No connection 4 - Common

1 - No connection 5 - Common

2 - Ground 6 - Supply

3 - Ground 7 - Supply

Indicators 2 green power supply status indicators

Input Overvoltage

Protection

Field Power Bus

Voltage

Current

Field Wiring Terminations

DeviceNet

System power (PointBus 5V power)

DeviceNet power (24V from DeviceNet)

Reverse polarity protected

10V to 28.8V dc,

120V ac or 240V ac

10A max

1 - Black -V 4 - White CAN High

2 - Blue CAN Low 5 - Red +V

3 - Bare Drain

Publication 1734-IN510B-EN-P - August 2000

Page 5

Specification Value: Specification Value:

Inrush Current 6A for 5ms Power Consumption 7.0W max @ 25V dc

Pointbus Output Current 1A maximum @ 5V dc +

Isolation Voltage 1528V rms/V ac

5% (4.75-5.25) Mass 4.56 oz/129.28 grams

POINT I/O 5

1734-FPD Specifications

Specification Value: Specification Value:

Pointbus Output Current Pass through Indicators None

Input Current 10A max Inrush Current 10A max

Module Location Between I/O modules in 1734 system

Field Power Bus

Volt age

Current

Input Voltage Rating 12V dc, 24V dc, 120V ac, 240V ac nominal Mass 4.38 oz/124.17 grams

Breaks power bus

264V ac max

12V dc, 24V dc/120V ac or 240V ac

10A max

Dimensions

(HxWxL)

Power Supply 0 - No connection 4 - Common

76.2mm x 25.4mm x 133.4mm

(3.00in x 1.00in x 5.25in)

1 - No connection 5 - Common

2 - Ground 6 - Supply

3 - Ground 7 - Supply

1734-AC Input Modules (1734-IA21, -IM22)

Specification Value Specification Value

Module Location 1734-TB, -TBS, -TB3 or -TB3S wiring base assembly Pointbus Current 75mA maximum @ 5V dc

Power Dissipation 0.7W maximum @ 28.8V dc Thermal Dissipation 2.4 BTU/hr maximum @ 28.8V dc

Isolation Voltage Tested at 1250V rms/V for 1s (1734-IA2)

External AC Power Supply

Volt age

Field Wiring Terminations 0 - Input 0 1 - Input 1

Tested at 1500V rms/V for 1s (1734-IM2)

120V ac, 60Hz nominal (1734-IA2)

220V ac, 60Hz nominal (1734-IM2)

2 - No Connection 3 - No Connection

4 - L2N 5 - L2/N

6 - L1 7 - L1

Input Specifications (1734-IA2, -IM2)

Number of Inputs 2 (1 group of 2) non-isolated, sinking OFF-State Voltage 43V ac maximum

ON-State Voltage 1734-IA2

OFF-State Current 2.5mA maximum (1734-IA2)

3

Delay Time

OFF to ON and

ON to OFF

Keyswitch Position 8

65V ac minimum 159V ac minimum

120V ac nominal 220V ac nominal

2.9mA maximum (1734-IM2)

20ms hardware filter plus 1ms - 64ms digital filter

programmable in increments of 1ms

1734-IM2

Dimensions Inches

(Millimeters)

External AC Power Supply

Voltage Range

Mass 1.09 oz/30.90 grams

ON-State Current 1734-IA2

Nominal Input Impedance 10.6kΩ (1734-IA2)

Indicators 2 yellow input status, logic side

1

This module is IEC3 120V ac input compliant.

2

This module is IEC3 220V ac input compliant.

3

Off/on delay is time from a valid out put “on” signal to output energization. On/off delay is time

from a valid output “off” signal to ou tput deenergization.

2.21H x 0.47W x 2.97L

(56.0H x 12.0W x 75.5L)

85-132V ac, 47-63Hz (1734-IA2)

159-264V ac, 47-63Hz (1734-IM2)

3.7mA minimum 5.7mA minimum

6.9mA nominal @ 120V ac, 60Hz 8.0mA nominal

22.3kΩ (1734-IM2)

1 green/red network status, logic side

1 green/red module status, logic side

1734-IM2

Publication 1734-IN510B-EN-P - August 2000

Page 6

6 POINT I/O

1734-AC Output Modules1 (1734-OA2)

Specification Value Specification Value

Module Location 1734-TB, TBS, TB3 or -TB3S wiring base assembly Pointbus Current 75mA maximum @ 5V dc

Power Dissipation 0.8W maximum @ 28.8V dc Thermal Dissipation 2.7 BTU/hr maximum @ 28.8V dc

Isolation Voltage Tested at 1500V rms/V ac dc for 1s Mass 1.09 oz/30.9 grams

External AC Power Supply

Volt age

Dimensions Inches

(Millimeters)

Output Specifications

Outputs per Module 2 non-isolated, sourcing ON-State Voltage Drop 1.0V maximum @ 0.75A

ON-State Voltage Range 74V ac minimum

ON-State Current 10mA minimum per channel

OFF-State Leakage 2.7mA max Output Current Rating 1.5A (2 channels @ 0.75A each)

Surge Current 16A for 100ms, repeatable every 10s Keyswitch Position 8

1

This module is IEC3 120V/220V ac Output Compliant

1

Off/on delay is time from a valid output “on” signal to output energization. On/off delay is time from a valid output “off” signa l to output deenergization.

1734 DC Input Sink Modules

Specification: Value: Specification: Value:

Module Location 1734-TB or -TBS terminal base unit Pointbus Current 75mA max @ 5V dc

Inputs/Module 2 (1 group of 2) non-isolated, sinking (1734-IB2)

ON-State Voltage 10V dc min

OFF-State Voltage 5V dc max OFF-State Current 1.5mA min

Input Impedance 5.3K Ω max Keyswitch Position 1

Indicators 2 yellow input status, logic side (1734-IB2)

Power Dissipation 0.7W max @ 28.8V dc (1734-IB2)

Field Power

Supply Voltage

Voltage Range

Dimensions (HxWxL) 56mm x 12mm x 75.5mm (2.206in x 0.472in x 2.97in) Mass 1.09 oz/30.90 grams - (1734-IB2)

1

1734-IB2 and -IB4 specifications are IEC 1+ 24V dc input compliant

2

Input OFF to ON, and ON to OFF, filter time is the time from a valid input signal to recognition by the module.

120/220V ac, 60Hz nominal External AC Power Supply

2.21H x 0.47W x 2.97L

(56.0H x 12.0W x 75.5L)

120/220V ac nominal

264V ac maximum

750mA maximum per channel

1

(1734-IB2, -IB4)

4 (1 group of 4) non-isolated, sinking (1734-IB4)

24V dc nominal

28.8 V dc max

4 yellow input status, logic side (1734-IB4)

1 green/red network status, logic side

1 green/red module status, logic side

0.9W max @ 28.8V dc (1734-IB4)

24V dc nominal

10-28.8V dc

Voltage Range

Field Wiring Terminations 0 - Output 0 1 - Output 1

2

Delay Time

OFF to ON

ON to OFF

Indicators (field side

indication, logic driven)

Input Filter Time

ON-State Current 2mA min

Power Supply 0 - Input 0 6 - Supply

Thermal Dissipation 2.4 BTU/hr max @ 28.8V dc (1734-IB2)

Isolation Voltage 1250V rms/V ac

2

85-264V ac, 47-63Hz

2 - No Connection 3 - No Connection

4 - L2N Return 5 - L2/N Return

6 - L1 7 - L1

1/2 cycle maximum

1/2 cycle maximum

2 yellow status

2 green/red status

OFF to ON: 0-65ms (1ms default)

ON to OFF: 0-65ms (1ms default)

4mA nominal @ 24V dc

5mA max

1 - Input 1 7 - Supply

2 - No Conn. (1734-IB2) - Input 2 1734-IB4)

3 - No Conn. (1734-IB2) - Input 3 (1734-IB4)

4 - Common (1734-IB2) - User Supply (1734-IB4)

5 - Common (1734-IB2) - User Supply (1734-IB4)

3.1 BTU/hr max @ 28.8V dc (1734-IB2)

1.12 oz/31.75 grams - (1734-IB4)

Publication 1734-IN510B-EN-P - August 2000

Page 7

POINT I/O 7

1734 DC Input Source Modules1 (1734-IV2, -IV4,)

Specification: Value: Specification: Value:

Module Location 1734-TB or -TBS terminal base unit Pointbus Current 75mA max @ 5V dc

Inputs/Module 2 (1 group of 2) non-isolated, sourcing (1734-IV2)

ON-State Voltage 10V dc min

OFF-State Voltage 5V dc max OFF-State Current 1.5mA min

Input Impedance 5.3K Ω max Keyswitch Position 1

Power Dissipation 0.7W max @ 28.8V dc (1734-IV2)

Field Power

Supply Voltage

Voltage Range

Indicators 2 yellow input status, logic side (1734-IV2)

Dimensions (HxWxL) 56mm x 12mm x 75.5mm (2.206in x 0.472in x 2.97in) Mass 1.10 oz/31.19 grams - (1734-IV2)

1

1734-IV2 and -IV4 specifications are IEC 1+ 24V dc input compliant.

2

Input OFF to ON, and ON to OFF, filter time is the time from a valid input signal to recognition by the module.

4 (1 group of 4) non-isolated, sourcing (1734-IV4)

24V dc nominal

28.8 V dc max

0.9W max @ 28.8V dc (1734-IV4)

24V dc nominal

10-28.8V dc

4 yellow input status, logic side (1734-IV4)

1 green/red network status, logic side

1 green/red module status, logic side

Input Filter Time

ON-State Current 2mA min

Thermal Dissipation 2.4 BTU/hr max @ 28.8V dc (1734-IV2)

Isolation Voltage 1250V rms/V ac

Power Supply 0 - Input 0 4 - Common

2

OFF to ON: 0-65ms (1ms default)

ON to OFF: 0-65ms (1ms default)

4mA nominal @ 24V dc

5mA max

3.1 BTU/hr max @ 28.8V dc (1734-IV4)

1 - Input 1 5 - Common

2 - No Conn. (1734-IV2) 6 - Supply (1734-IV2)

Input 2 (1734-IV4) Common (1734-IV4)

3 - No Conn. (1734-IV2) 7 - Supply (1734-IV2)

Input 3 (1734-IV4) Common (1734-IV4)

1.12 oz/31.75 grams - (1734-IV4)

1734 DC Electronically Protected Output Modules (1734-OB2E, -OB4E)

Specification: Value: Specification: Value:

Module Location 1734-TB or -TBS terminal base unit Pointbus Current 75mA max @ 5V dc

Number of Outputs 2 (1734-OB2E) - 4 (1734-OB4E) nonisolated, sourcing Keyswitch Position 1

ON-State Current 1.0mA min/channel OFF-State Voltage 28.8V dc max

ON-State

Voltage Range

ON-State Voltage Drop 0.2V dc max OFF-State Leakage 0.5mA max

Output Current Rating Max 1.0A/output

Surge Current 2A for 10ms, repeatable every 3s Isolation Voltage 1250V rms/V ac

Power Dissipation 0.8W max @ 28.8V dc - (1734-OB2E)

Field Wiring Terminations 0 - Output 0

1

OFF to ON delay is time from a valid output ON signal to output energization. ON to OFF delay is time from a valid output OFF signal to output deenergization.

10V dc min

24V dc nominal

28.8V dc max

2.0 max/module (1734-OB2E)

4.0 max/module (1734-OB4E)

1.2W max @ 28.8V dc - (1734-OB4E)

1 - Output 1

2 - Output 0 (1734-OB2E) - Output 2 (1734-OB4E)

3 - Output 1 (1734-OB2E) - Output 3 (1734-OB4E)

4 - Common

5 - Common

6 - Supply (1734-OB2E) - Common (1734-OB4E)

7 - Supply (1734-OB2E) - Common (1734-OB4E) Mass 1.15 oz/32.60 grams (1734-OB2E)

Output Signal Delay

OFF to ON

ON to OFF

Dimensions

(HxWxL)

Thermal Dissipation 2.7 BTU/hr max @ 28.8V dc - (1734-OB2E)

External dc Power

Supply Voltage

Voltage Range

Indicators (Field side

indication, logic driven)

1

0.1ms max

0.1ms max

56mm x 12mm x 75.5mm

(2.206in x 0.472in x 2.97in)

4.1 BTU/hr max @ 28.8V dc - (1734-OB4E)

24V dc nominal

10 - 28.8V dc

2 yellow status (1734-OB2E) - 4 yellow status (1734-OB4E)

2 red fault (1734-OB2E) - 4 red fault (1734-OB4E)

2 green/red status

1.17 oz/33.43 grams (1734-OB4E)

Publication 1734-IN510B-EN-P - August 2000

Page 8

8 POINT I/O

1734 Analog Modules (1734-IE2C, -OE2C)

Specification: 1734-IE2C Value: 1734-OE2C Value: Specification: 1734-IE2C Value: 1734-OE2C Value:

Module Location 1734-TB or -TBS terminal base unit Pointbus Current 75mA max @ 5V dc

Inputs/Module 2 single-ended,

Input Current Terminal 4-20mA

Output Current Terminal 0mA Output until module

non-isolated

0-20mA

is configured

4-20mA user configurable

0-20mA user configurable

Number of Outputs 2 single-ended,

non-isolated

Keyswitch Position 3 4

Resolution

Current

16 bits - over 21mA

1.28μA/cnt, 0.32μA/cnt

13 bits over 21mA

2.56μA/cnt

Data Format Signed Integer Calibration Factory Calibrated

Conversion Type Delta Sigma Digital to Analog

Conversion Rate

External dc Power

Supply Voltage

Voltage Range

Supply Current

Field Wiring Terminations 0 - Input 0 4 - Common

Absolute Accuracy

60ms/channel @ Notch = 50Hz

50ms/channel @ Notch = 60Hz

12ms/channel @ Notch = 250Hz

6ms/channel @ Notch = 500Hz

24V dc nominal

10-28.8V dc

10mA @ 24V dc

1 - Input 1 5 - Common

2 - Ground 6 - Supply

3 - Ground 7 - Supply

1

0.1% of Full Scale @ 25°C 0.3% of Full Scale @ 25°C Accuracy Drift w/Temp. 30ppm/°C

convertor

Digital to Analog

convertor

24V dc nominal

10-28.8V dc (includes 5%

ac ripple)

50mA @ 24V dc (including

outputs @ 20mA)

0 - Output 0 4 - Common

1 - Output 1 5 - Common

2 - Ground 6 - Supply

3 - Ground 7 - Supply

Common Mode Rejection

Ration

Step Response to 63% of

Full Scale

Step Response to Current

Ter mi na l

Normal Mode Rejection

Ration

120dB

Notch Filter

60Hz 70ms

50Hz 80ms

250Hz 16ms

500Hz 8ms

-60dB

-3dB

Notch filter

13.1Hz @ Notch = 50Hz

15.7Hz @ Notch = 60Hz

65.5Hz @ Notch = 250Hz

131Hz @ Notch = 500Hz

24μs

Maximum Overload Fault protected to 28.8V dc Resist. Load on mA Output 0-330Ω

Indicators 4 green/red indicators Mass 1.22 oz/34.59 grams 1.26 oz/25.72 grams

Power Dissipation 0.5W max @ 28.8V dc 1.0W max @ 28.8V dc Thermal Dissipation

Isolation Voltage 1250V rms/V ac

1

Includes offset, gain, non-linearity and repeatability error terms.

No isolation between individual channels

Dimensions

(HxWxL)

1.7 BTU/hr max @ 28.8V dc 3.4 BTU/hr max @ 28.8V dc

56mm x 12mm x 75.5mm

(2.206in x 0.472in x 2.97in)

1734 Relay Module (1734-OW2)

Specification: Value: Specification: Value:

Module Location 1734-TB or -TBS terminal base unit Pointbus Current 80mA max @ 5V dc

1

Number of Outputs

OFF-State Leakage 1.2mA (max @ 240V ac)

Output Voltage Range

(load dependent)

Output Current Rating (at

rated power)

2 Form A isolated (normally open) electromechanical relays

Bleed resistor through snubber circuit

5-28.8V dc @ 2.0A resistive

48V dc @ 0.5A resistive

125V dc @ 0.25A resistive

125V ac @ 2.0A resistive

240V ac @ 2.0A resistive

Resistive

2A @ 5-28.8V dc 2A @ 125V ac

0.5A @ 48V dc 2A @ 240V ac

0.25A @ 125V dc

Inductive

2A steady state @ 5-30V dc, L/R = 7ms

0.5A steady state @ 48V dc, L/R = 7ms

0.25A steady state @ 125V dc, L/R = 7ms

2A steady state, 15A make @ 125V ac, PF = cos θ = 0.4

2A steady state, 15A make @ 240V ac, PF = cos θ = 0.4

Keyswitch Position 7

Output Signal Delay OFF to ON - 8ms max

Power Supply 0 - Output 0A 4 - Common

Power Rating (steady

state)

ON to OFF - 26ms max

1 - Output 1A 5 - Common

2 - Output 0B 6 - Supply

3 - Output 1B 7 - Supply

250W max for 125V ac resistive output

480W max for 240V ac resistive output

60W max for 28.8V dc resistive output

24W max for 48V dc resistive output

31W max for 125V dc resistive output

250VA max for 125V ac inductive output

480VA max for 240V ac inductive output

60VA max for 30V dc inductive output

24VA max for 48V dc inductive output

31VA max for 125V dc inductive output

Publication 1734-IN510B-EN-P - August 2000

Page 9

Specification: Value: Specification: Value:

Isolation Voltage

Between any 2 sets

of contacts

Customer load to logic

Initial Contact Resistance 30mΩ Operate/Release Time 10ms max

Switching Frequency 1 operation/3s (0.3Hz at rated load) max Bounce Time 1.2ms (mean)

Min. Contact Load 100μA at 100mV dc Mass 1.30 oz/36.86 grams

Expected Life of Electrical

Contacts

Power Dissipation 0.5W max @ 28.8V dc Thermal Dissipation 1.7 BTU/hr max @ 28.8V dc

Dimensions (HxWxL) 56mm x 12mm x 75.5mm (2.206in x 0.472in x 2.97in)

1

Module outputs are not fused. If external fusing is desired, you must provide external fusing.

2550V dc for 1s

2550V dc for 1s

Min 100,000 operations @ rated loads Indicators 2 green/red module/network status

Field Power

Supply Voltage

Voltage Range

Supply Current

None required

240V ac max

2A/channel max 4A/module

2 yellow output status

1734-Counter Modules (1734-IJ, -IK)

Specification Value Specification Value

Number of Inputs 1 - 1 group of A/Areturn, B/Breturn and Z/Zreturn Input Voltage 5V (1734-IJ)

Input Current 19.1mA @ 5V dc (1734-IJ); 6.1mA @ 15V dc (1734-IK)

Input OFF-State Current <

Input OFF-State Voltage <

Input Filter Selections (per

A/B/Z group)

Module Location 1734-TB, -TBS, -TB3, -TB3S wiring base assembly Pointbus Current 160mA maximum

Keyswitch Position 2 Mass 1.15 oz/32.60 grams

Thermal Dissipation 3.75 BTU/hr maximum @ rated load (1734-IJ)

Isolation Voltage

(minimum)

External dc Power No additional external power required to power

25.7mA @ 6V dc (1734-IJ);10.2mA @ 24V dc (1734-IK)

0.250mA max Input ON-State Current >5mA

1.25V dc (1734-IJ) / <1.8V dc (1734-IK) Input ON-State Voltage >2.6V dc (1734-IJ); >12.5V dc (1734-IK)

Off

10μs

100μs

1.0ms

10.0ms

5.1 BTU/hr maximum @ rated load (1734-IK)

Prequalified at 1250V ac/rms between:

System side

Chassis ground

A/B/Z inputs

module.

Maximum ON-State

Voltage

Maximum Input Frequency 1.0MHz counter and encoder X1 configurations

Power Dissipation 1.1W maximum @ rated load (1734-IJ)

Field Wiring Terminations 0 - A 1 - Aret

DimensionsInches

(Millimeters)

15-24V dc (1734-IK)

+

6V (1734-IJ)

For 1734-IK, see pub. 1734-TD002A-EN-P

500kHz encoder X2 configuration (no filter)

250kHz encoder X4 configuration (no filter)

1.5W maximum @ rated load (1734-IK)

2 - B 3 - Bret

4 - Z 5 - Zret

6 - Chassis ground 7 - Chassis ground

2.21H x 0.47W x 2.97L

(56.0H x 12.0W x 75.5L)

POINT I/O 9

1734-Very High Speed Counter Modules (1734-VHSC24, -VHSC5)

Specification Value Specification Value

Module Location 1734-TB, -TBS, -TB3, -TB3S wiring base assembly Keyswitch Position 2

Pointbus Current 180mA maximum Field Power Bus 24V dc nominal; range 10-28.8V dc

Power Dissipation 1.9W maximum @ rated load (1734-VHSC24)

Isolation Voltage

(minimum)

External dc Power (does

not represent power

required to supply outputs)

1.5W maximum @ rated load (1734-VHSC5)

Prequalified for 1250V ac/rms between:

Module 1

System side (PointBus)

Chassis ground

A/B/Z inputs

O0/O1 and user power supply

Module 2

System side

Chassis ground

Vaux +

User power supply common

No additional external power required to

power module

Thermal Dissipation 6.5 BTU/hr maximum @ rated load (1734-VHSC24)

Field Wiring Terminations Module 1

Dimensions Inches

(Millimeters)

5.1 BTU/hr maximum @ rated load (1734-VHSC5)

0 - A 1 - Aret

2 - B 3 - Bret

4 - Z 5 - Zret

6 - Output 0 7 - Output 1

Module 2

0 - Chassis ground 1 - Chassis ground

2 - Return 0 3 - Return 1

4 - -V 5 - -V

6 - +V 7 - +V

2.21H x 0.47W x 2.97L

(56.0H x 12.0W x 75.5L)

Publication 1734-IN510B-EN-P - August 2000

Page 10

10 POINT I/O

Mass 1.15 oz/32.60 grams

Input Specifications

Number of Inputs 1 - 1 group of A/Areturn, B/Breturn and Z/Zreturn Maximum Input Frequency 1.0MHz counter and encoder X1 configurations

Input Voltage 15-24V dc(1734-VHSC24)

Input Current 6.1mA @ 15V dc (1734-VHSC24)

Input OFF-State Current <

Input ON-State Current >

5V dc (1734-VHSC5)

10.2mA @ 24V dc (1734-VHSC24)

19.1mA @ 5V dc (1734-VHSC5)

25.7mA @ 6V dc (1734-VHSC5)

0.250mA max Input OFF-State Voltage <1.8V dc (1734-VHSC24); <1.25V dc (1734-VHSC5)

5mA Input ON-State Voltage >12.5V dc (1734-VHSC24); >2.6V dc (1734-VHSC5)

Maximum ON-State

Voltage

Input Filter Selections Off

Output Specifications (1734-VHSC24, -VHSC4)

Number of Outputs 1 isolated group of 2 capable of 0.5A @ 24V dc Output Control Outputs can be tied to any of 4 compare windows

Output Supply Volt. Range 10-28.8V dc ON-State Current 0.5A maximum

OFF-State Leakage Current <

Short Circuit Current 6A - Outputs are short circuit protected and either

ON-State Voltage Drop <

0.5mA Open Wire Detection Open wire detected when output is turned off

1

cycle until the fault is corrected, or latch off

(depending upon programming)

Short circuit detected when output is turned on.

0.3V dc @ 0.5A

Delay Time

OFF to ON

ON to OFF

1 Off/on delay is time from a valid output “on” signa l to output energization. On/off delay is time

from a valid output “off” signal to ou tput deenergization.

500kHz encoder X2 configuration (no filter)

250kHz encoder X4 configuration (no filter)

For 1734-VHSC24, see pub. 1734-TD002A-EN-P

+

6V (1734-VHSC5)

10μs

100μs

1.0ms

10.0ms

25μs (load dependent)

150μs (load dependent)

Publication 1734-IN510B-EN-P - August 2000

Page 11

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic Compatibility (EMC) by applying the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted

in an enclosure during operation to provide safety protection.

POINT I/O 11

Publication 1734-IN510B-EN-P - August 2000

Page 12

Publication 1734-IN510B-EN-P - August 2000 PN 957395-13

Supersedes Publication 1734-5.10 - September 1999 © 2000 Rockwell International Corporation. Printed in Singapore.

Loading...

Loading...