Page 1

User Manual

1732E ArmorBlock EtherNet/IP Dual Port 8-Point

Sequence of Events Input and Scheduled Output

Modules

Catalog Numbers

1732E-IB8M8SOER, 1732E-OB8M8SR

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, ArmorBlock, RSLogix, R SLinx, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this

Manual

Purpose of this Manual

Resource Description

ArmorBlock Dual-Port EtherNet/IP 8-Point Digital Modules

1732E-WD002

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that 1732E ArmorBlock EtherNet/IP Dual Port

8-Point Sequence of Events Input and Scheduled Output Modules.

You should have a basic understanding of electrical circuitry and familiarity with

relay logic. If you do not, obtain the proper training before using this product.

This manual is a reference guide for the 1732E-IB8M8SOER,

1732E-OB8M8SR modules. It describes the procedures you use to install, wire,

troubleshoot, and use your module.

Related Documentation

The following documents contain additional information concerning Rockwell

Automation products. To obtain a copy, contact your local Rockwell Automation

office or distributor.

Information on wiring the ArmorBlock Dual-Port EtherNet/IP 8-Point Digital

Modules.

1732E ArmorBlock 2 Port Ethernet Module Installation

Instructions, publication 1732E-IN007

1732E ArmorBlock 2 Port Ethernet Module Release Notes,

publication 1732E-RN001

ControlLogix Sequence of Events Module User Manual,

publication 1756-UM528

EtherNet/IP Embedded Switch Technology Application Guide,

publication ENET-AP005

EtherNet/IP Modules in Logix5000 Control Systems User

Manual, publication ENET-UM001

Integrated Architecture and CIP Sync Configuration Application

Techniques, publication IA-AT003

Getting Results with RSLogix 5000, publication

9399-RLD300GR

Allen-Bradley Industrial Automation Glossary, AG-7.1

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 iii

Information on installing the ArmorBlock EtherNet/IP module.

Release notes to supplement the existing documentation supplied with the

ArmorBlock EtherNet/IP module.

A manual on how to install, configure and troubleshoot the ControlLogix

Sequence of Events module in your ControlLogix application.

A manual on how to install, configure and maintain linear and Device-level

Ring (DLR) networks using Rockwell Automation EtherNet/IP devices with

embedded switch technology.

A manual on how to use EtherNet/IP modules with Logix5000 controllers and

communicate with various devices on the Ethernet network.

A manual on how to configure CIP Sync with Intergrated Architecture products.

and applications.

Information on how to install and navigate RSLogix 5000. The guide includes

troubleshooting information and tips on how to use RSLogix 5000 effectively.

A glossary of industrial automation terms and abbreviations.

Page 4

Common Techniques Used

in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

iv Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 5

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated

Information

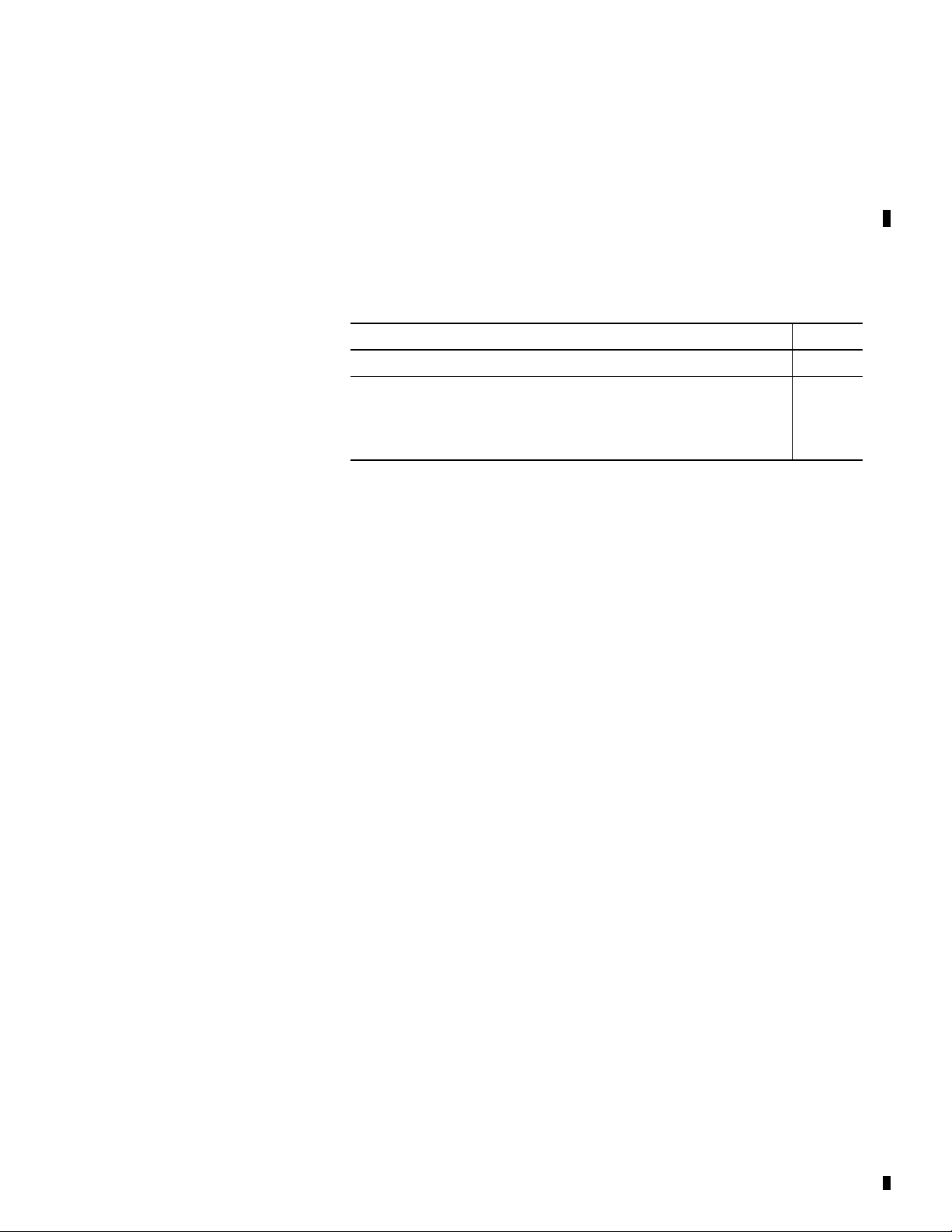

This table contains the changes made to this revision.

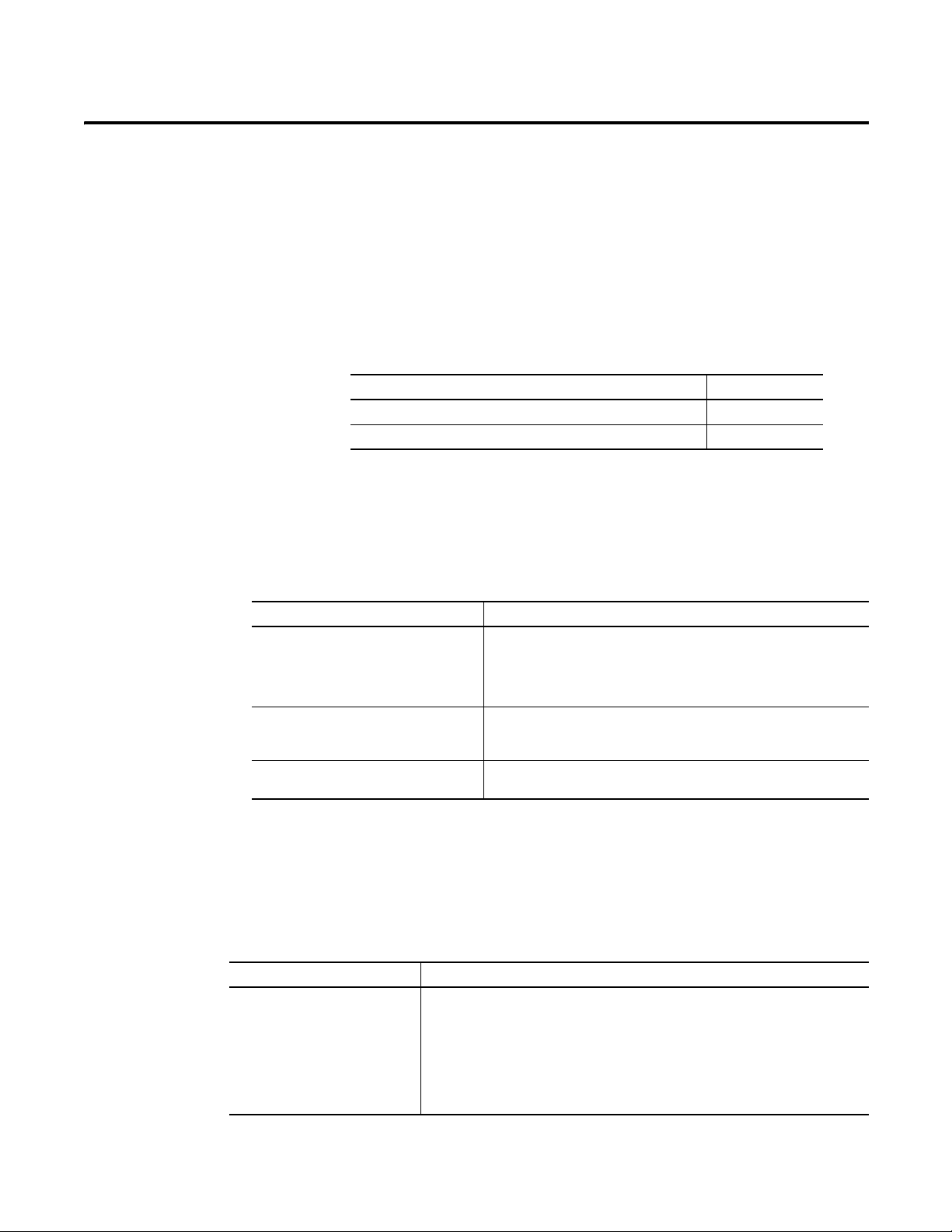

Topic Page

Additional warning for I/O connectors 20

Updated values of the following input specifications:

•On-state current, min

•Off-state current, max

93

Publication 1732E-UM003B-EN-E - March 2014

Page 6

vi Summary of Changes

Notes:

Publication 1732E-UM003B-EN-E - March 2014

Page 7

Table of Contents

Preface

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Common Techniques Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Chapter 1

About ArmorBlock Modules Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hardware/Software Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Use of the Common Industrial Protocol (CIP) . . . . . . . . . . . . . . . . . . . . . . 2

Understand the Producer/Consumer Model. . . . . . . . . . . . . . . . . . . . . . . . . 2

Specify the Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2

Module Overview and Features

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EtherNet/IP Network Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Introduction to CIP Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What is IEEE 1588 PTP (Precision Time Protocol)? . . . . . . . . . . . . . 7

CIP Sync Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What is CIP Sync?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

What is Time Stamping? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Introduction to the Sequence of Events Input Module. . . . . . . . . . . . . . . . 8

High Performance Sequence of Events Applications in the Logix

Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

First Fault Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Time Stamped I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

High Speed Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Global Position Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction to Scheduled Output Module. . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

High Speed Product Reject . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3

Use the Modules in an

ArmorBlock System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Differences Between Module and Standard I/O. . . . . . . . . . . . . . . . . . . . . 15

Similar Functionality to Standard ArmorBlock . . . . . . . . . . . . . . . . . . . . . 15

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 4

Install Your Module

vii Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page 8

viii Table of Contents

Configure the Module for Your

EtherNet/IP Network

Set the Network Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mount the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wire the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configuration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Set the Network Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Use the Rockwell Automation BootP/DHCP Utility . . . . . . . . . . . . . . . 27

Save the Relation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Use DHCP Software to Configure Your Module . . . . . . . . . . . . . . . . . . . 30

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configure the Module Using

RSLogix 5000 Software

Common Features of the

1732E-IB8M8SOER and

1732E-OB8M8SR Modules

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Create the

Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Configure Your I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

RSLogix 5000 Configuration Software . . . . . . . . . . . . . . . . . . . . . . . . . 36

Overview of the Configuration Process through RSLogix 5000. . . . . . . 36

Add a New Bridge and Module to Your RSLogix 5000 Project . . . . . . . 36

Add the Local EtherNet/IP Bridge to the I/O Configuration . . . . 37

Add the I/O module as a child of the 1756-EN2T module . . . . . . . 38

Use the Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Change the Default Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Download Your Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Edit Your Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Access Module Data in RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . 45

Configure RSLogix 5000 and the 1756-EN2T Communication Module

for CIP Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Communications Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Module Inhibiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Module Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fully Configurable via Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 9

Producer/Consumer Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Status Indicator Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Agency Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 8

Specific Features of the

1732E-IB8M8SOER Sequence of

Events Input Module

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Determine Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operational Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Timestamp Latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Software Configurable Input Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Sync to Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 9

Specific Features of the

1732E-OB8M8SR Scheduled

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operational Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Output Module

Configurable Point-Level Output Fault States . . . . . . . . . . . . . . . . . . . . . . 61

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table of Contents ix

Time-Scheduled Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Output State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Use the Sequence of Events

Input and Scheduled Output

Modules

Chapter 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Use the Sequence of Events Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . 65

How Does 1732E-IB8M8SOER Store Timestamp Data?. . . . . . . . 65

Use Timestamp Latching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Use Timestamp Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Operational Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Manage the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Module Sends Data to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Copy Relevant Input Data to a Separate Data Structure. . . . . . . . . . 74

Acknowledge Timestamp Latching Timestamp Data . . . . . . . . . . . . 76

Sort the Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Clear All Data From the Module Buffer At Once. . . . . . . . . . . . . . . . 78

Propagate a Signal From Input Pin to EtherNet . . . . . . . . . . . . . . . . . 78

Per Point Mode of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Use the Scheduled Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Usage with MAOC Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Schedule Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 11

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 10

x Table of Contents

Troubleshoot the Module

Interpret Status Indicators

Specifications

Module Tags

Data Tables

Troubleshoot the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Determine Fault Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 12

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Appendix B

Fault and Status Reporting Between the Module and Controllers. . . . . 97

Module Tag Names and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Tags Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix C

Communicate with Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Connection Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Connect to Networks via

Ethernet Interface

1732E ArmorBlock Embedded

Web Server

Appendix D

ArmorBlock Module and Ethernet Communication . . . . . . . . . . . . . . . 119

ArmorBlock module and PC Connections to the Ethernet Network. 119

Ethernet Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Connecting to an Ethernet Network . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

EtherNet/IP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Duplicate IP Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Configure Ethernet Communications on the ArmorBlock module . . 121

Configure Using

RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Configure Using Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Appendix E

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Typical Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Browser Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Access the Home Page of the Web Server. . . . . . . . . . . . . . . . . . . . . . . . . . 124

Log On to the Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Navigate the 1732E ArmorBlock I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Access Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Index

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 11

About ArmorBlock Modules

Chapter

1

Overview

Module Features

This chapter is an overview of the ArmorBlock family of modules. You will need

to understand the concepts discussed in this chapter to configure your module

and use it in an EtherNet/IP control system. The following table guides you

where to find specific information in this chapter.

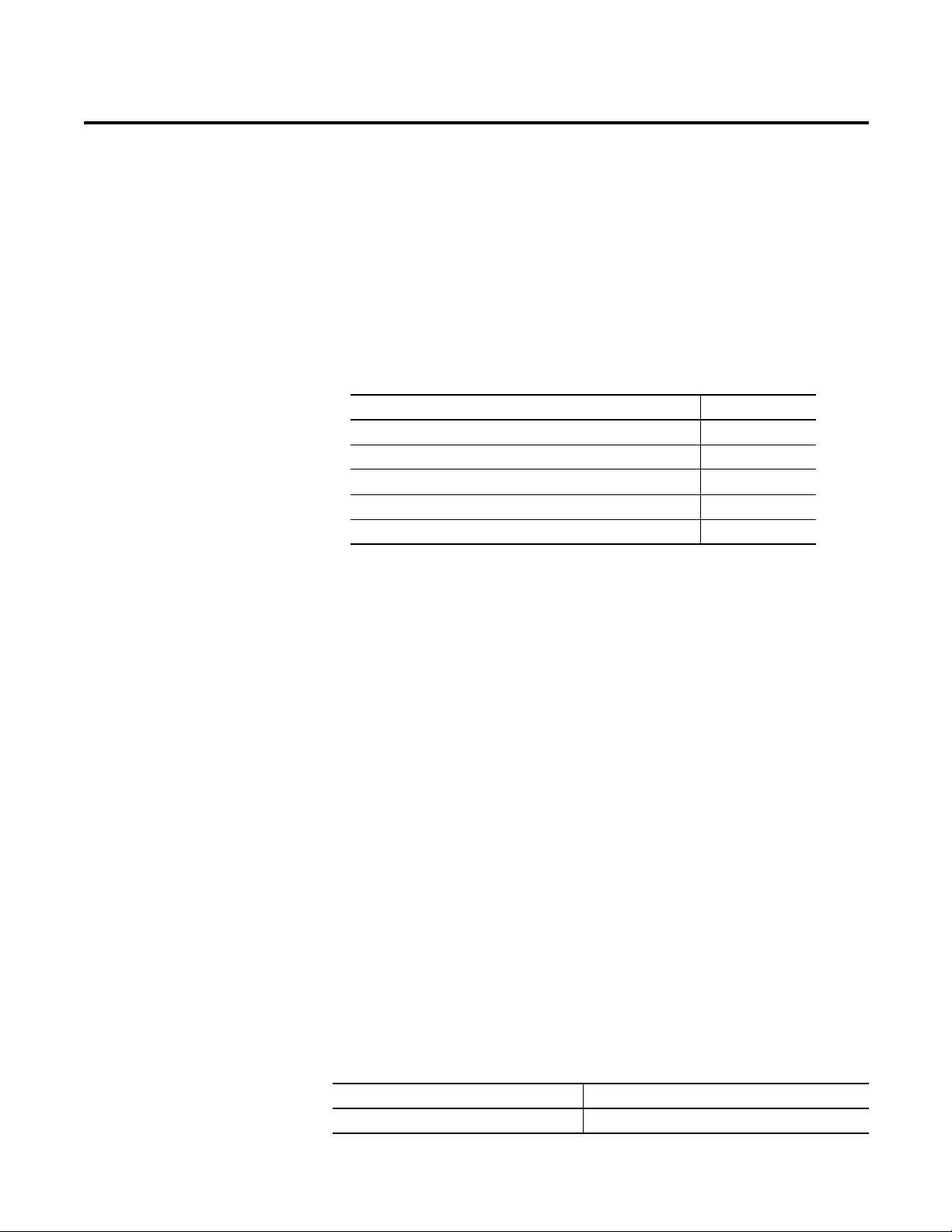

Topic Page

Module Features 1

Hardware/Software Compatibility 1

Use of the Common Industrial Protocol (CIP) 2

Understand the Producer/Consumer Model 2

Specify the Requested Packet Interval (RPI) 2

The module features include:

• use of EtherNet/IP messages encapsulated within standard TCP/UDP/IP

protocol

• common application layer with ControlNet and DeviceNet

• interfacing via Category 5 rated twisted pair cable

• half/full duplex 10 Mbit or 100 Mbit operation

• mounting on a wall or panel

• communication supported by RSLinx software

• IP address assigned via standard DHCP tools

• I/O configuration via RSLogix 5000 software

• no network scheduling required

• no routing tables required

• supports connections from multiple controllers simultaneously

Hardware/Software Compatibility

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 1

The module and the applications described in this manual are compatible with

the following firmware versions and software releases.

Contact Rockwell Automation if you need software or firmware upgrades to use

this equipment.

Product Firmware Version / Software Release

1732E-IB8M8SOER and 1732E-OB8M8SR Firmware rev. 1.1 or later

Page 12

Chapter 1 About ArmorBlock Modules

Product Firmware Version / Software Release

1756-EN2T, 1756-EN2TR, 1756-EN3TR 3.x version when using RSLogix 5000 v18 or later

RSLogix 5000 software 18 or later

RSLinx software 2.56 or later

For a complete ControlLogix compatibility matrix, see publication IA-AT003.

Use of the Common Industrial Protocol (CIP)

Understand the Producer/ Consumer Model

The 1732E-IB8M8SOER and 1732E-OB8M8SR modules use the Common

Industrial Protocol (CIP). CIP is the application layer protocol specified for

EtherNet/IP, the Ethernet Industrial Protocol. It is a message-based protocol that

implements a relative path to send a message from the “producing” device in a

system to the “consuming” devices.

The producing device contains the path information that steers the message along

the proper route to reach its consumers. Because the producing device holds this

information, other devices along the path simply pass this information; they do

not need to store it.

This has two significant benefits:

• You do not need to configure routing tables in the bridging modules,

which greatly simplifies maintenance and module replacement.

• You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end device.

The CIP “producer/consumer” networking model replaces the old source/

destination (“master/slave”) model. The producer/consumer model reduces

network traffic and increases speed of transmission. In traditional I/O systems,

controllers poll input modules to obtain their input status. In the CIP system,

input modules are not polled by a controller. Instead, they produce their data

either upon a change of state (CoS) or periodically. The frequency of update

depends upon the options chosen during configuration and where on the

network the input module resides. The input module, therefore, is a producer of

input data and the controller is a consumer of the data.

The controller can also produce data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers and other

devices over the EtherNet/IP network. This data exchange conforms to the

producer/consumer model.

Specify the Requested Packet Interval (RPI)

2 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

The Requested Packet Interval (RPI) is the update rate specified for a particular

piece of data on the network. This value specifies how often to produce the data

for that device. For example, if you specify an RPI of 50 ms, it means that every

Page 13

About ArmorBlock Modules Chapter 1

50 ms the device sends its data to the controller or the controller sends its data to

the device.

RPIs are only used for devices that exchange data. For example, a ControlLogix

EtherNet/IP bridge module in the same chassis as the controller does not require

an RPI because it is not a data-producing member of the system; it is used only as

a bridge to remote modules.

Chapter Summary and What’s Next

In this chapter you were given an overview of the 1732E ArmorBlock family of

modules.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 3

Page 14

Chapter 1 About ArmorBlock Modules

Notes:

4 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 15

Module Overview and Features

Chapter

2

Overview

This chapter provides an overview of the 1732E ArmorBlock EtherNet/IP Dual

Port 8-Point Sequence of Events Input and Scheduled Output Modules,

1732E-IB8M8SOER and 1732E-OB8M8SR. The modules provide

timestamping functionality when an input event occurs and allow for scheduling

of outputs.

Although primarily described in this manual as having CIP Sync functionality,

both modules can be configured to function as standard I/O modules.

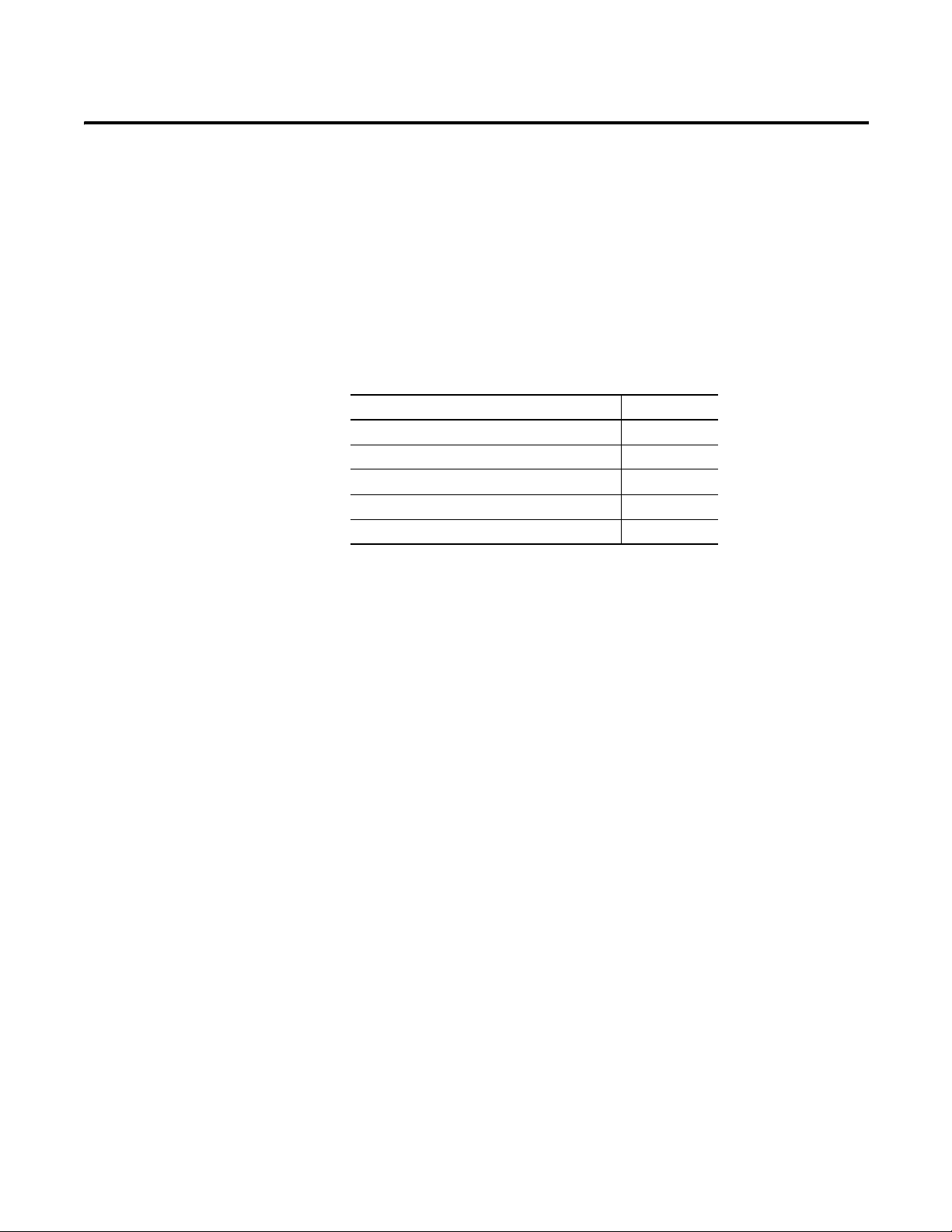

The following table indicates where you can information on this chapter:

Topic Page

EtherNet/IP Network Overview 6

Introduction to CIP Sync 7

What is IEEE 1588 PTP (Precision Time Protocol)? 7

CIP Sync Support 7

What is CIP Sync? 8

What is Time Stamping? 8

Introduction to the Sequence of Events Input Module 8

High Performance Sequence of Events Applications in the Logix Architecture 9

First Fault Detection 10

High Speed Applications 10

Motion Control 11

Global Position Registration 11

Introduction to Scheduled Output Module 11

Operation 11

High Speed Product Reject 12

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 5

Page 16

Chapter 2 Module Overview and Features

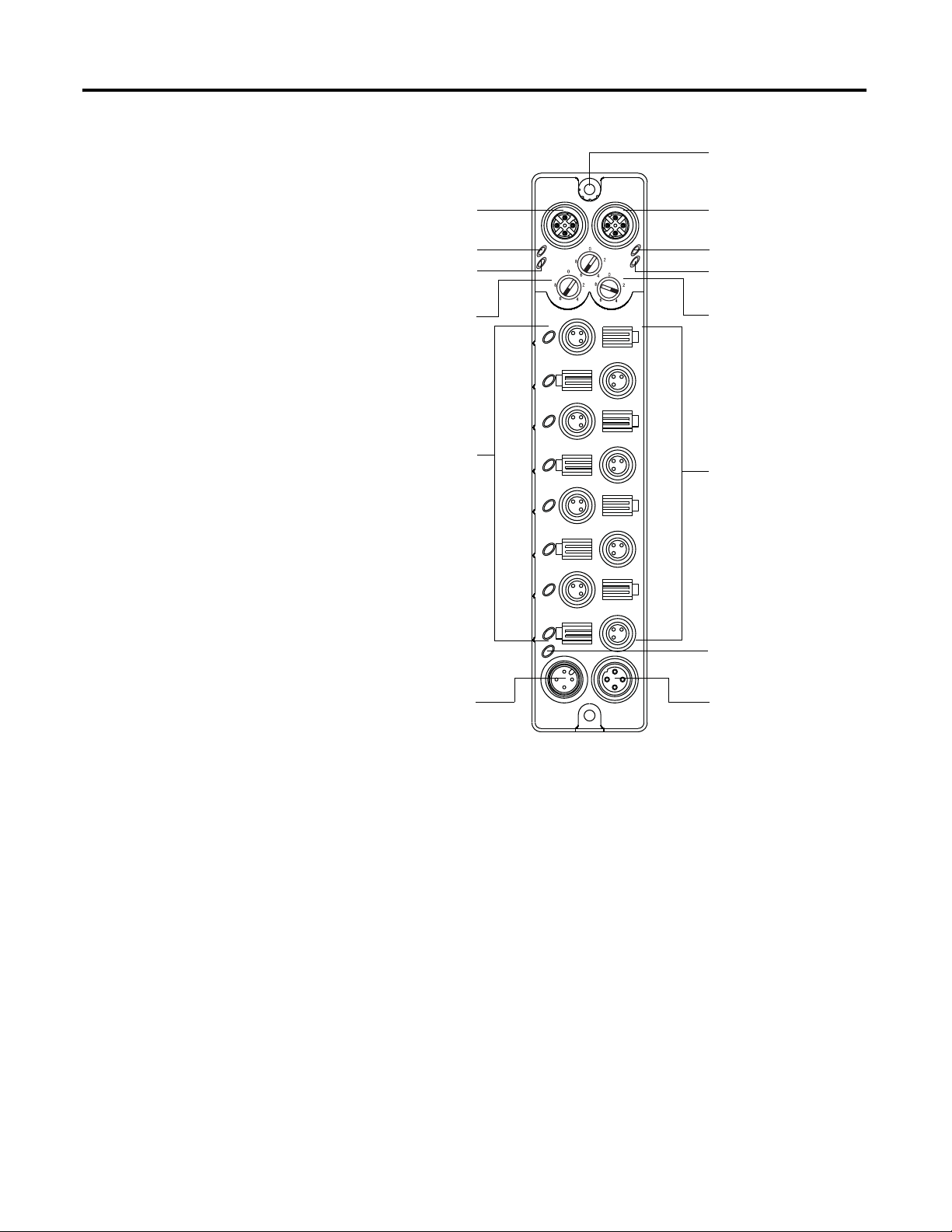

LINK1

NET

MOD

X10

X100

X1

LINK2

45766

Functional Earth ground

(1)

M8 I/O connectors

Node address switches

EtherNet/IP D-Code

M12 connector

EtherNet/IP D-Code

M12 connector

M8 I/O connectors/

status indicators

Power status

indicator

Network status LED

Link 1 status LED

Link 2 status LED

Module status LED

Node address switches

Power connector

Power connector

(1)

Functional Earth grounds the I/O block’s EtherNet/IP communication circuitry which is designed to

mitigate the effect of noise on the network. It requires a solid earth ground connection, either through a

metal screw to a grounded metal panel or through a wire.

EtherNet/IP Network Overview

The modules incorporate embedded switch technology. They support Star, Tree,

Daisychain or Linear, and Ring network topologies.

• Star or Tree topologies can connect to either Port 1 or Port 2.

• Daisy Chain/Linear topologies will pass communications from Port 1 to 2,

or Port 2 to 1.

• Ring topology will pass communications from Port 1 to 2, or Port 2 to 1.

The 1732E-IB8M8SOER and 1732E-OB8M8SR modules support the

management of network traffic to ensure timely delivery of critical data, Quality

of Service (QoS) and Internet Group Management Protocol (IGMP) protocols

6 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

are supported.

Page 17

Module Overview and Features Chapter 2

If the ring topology is used, the Ring Master (not the 1732E ArmorBlock

EtherNet/IP Dual Port 8-Point Sequence of Events Input or Scheduled Output)

must be designated in the system, and determines the beacon rate and the timeout

period. For more information on topologies, refer to publication ENET-AP005

The 1732E-IB8M8SOER and 1732E-OB8M8SR modules are CIP Sync slave

only devices. There must be another module on the network that functions as a

master clock.

.

Introduction to CIP Sync

CIP is the Common Industrial Protocol that we use to let all

Rockwell Automation products communicate with each other whether it be on a

DeviceNet, ControlNet, and/or an EtherNet network. Since it is an ODVA

standard, other industrial product manufacturers develop products to

communicate via the CIP protocol.

CIP Sync is a CIP implementation of the IEEE 1588 PTP (Precision Time

Protocol) in which devices can bridge the PTP time across backplanes and on to

other networks via EtherNet/IP ports.

What is IEEE 1588 PTP (Precision Time Protocol)?

The IEEE 1588 standard specifies a protocol to synchronize independent clocks

running on separate nodes of a distributed measurement and control system to a

high degree of accuracy and precision. The clocks communicate with each other

over a communication network. In its basic form, the protocol is intended to be

administration free. The protocol generates a master slave relationship among the

clocks in the system. Within a given subnet of a network there will be a single

master clock. All clocks ultimately derive their time from a clock known as the

grandmaster clock. This is called Precision Time Protocol (PTP).

The PTP is a time-transfer protocol defined in the IEEE 1588-2008 standard

that allows precise synchronization of networks, for example, Ethernet. Accuracy

within the nanosecond range can be achieved with this protocol when using

hardware generated synchronization.

IEEE 1588 is designed for local systems requiring very high accuracies beyond

those attainable using Network Time Protocol (NTP). NTP is used to

synchronize the time of a computer client or server to another server or reference

time source, such as a GPS.

CIP Sync Support

CIP Sync supports the IEEE 1588-2008 synchronization standard. In this

architecture, a grandmaster clock provides a master time reference for the system

time. The 1732E-IB8M8SOER, 1732E-OB8M8SR modules are CIP Sync slave

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 7

Page 18

Chapter 2 Module Overview and Features

only devices. There must be another module on the network that will function as

a master clock. The grandmaster could be:

• a 1756 ControlLogix L6 or L7 controller when using RSLogix 5000

software v18 or later.

• an Ethernet bridge that supports IEEE 1588 V2, or

• a Symmetricom Grand Master GPS or equivalent.

What is CIP Sync?

CIP Sync is a CIP implementation of the IEEE 1588 PTP (Precision Time

Protocol). CIP Sync provides accurate real-time (Real-World Time) or Universal

Coordinated Time (UTC) synchronization of controllers and devices connected

over CIP networks. This technology supports highly distributed applications

that require time stamping, sequence of events recording, distributed motion

control, and increased control coordination.

What is Time Stamping?

Each input has its own individual timestamp recorded for both ON and OFF

transitions. The offset from the timestamp to the local clock is also recorded so

that steps in time can be detected and resolved.

Timestamping uses the 64-bit system time whose time base is determined by the

modules master clock resolved in microseconds. Each timestamp is updated as

soon as an input transition is detected, before input filtering occurs. When

filtering is enabled, the transition is only recorded if the transition passes the

filter.

The module starts timestamping as soon as it powers up, even if it is not

synchronized to a master clock. If it is synchronized to a master clock and then

becomes unsynchronized it continues to time stamp. All time stamps and offsets

have a value of zero at power-up.

For more information on how to use CIP Sync technology, see the Integrated

Architecture and CIP Sync Configuration Application Technique publication

IA-AT003

.

Introduction to the Sequence of Events Input Module

8 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

The 1732E-IB8M8SOER is an input module that offers sub-millisecond

timestamping on a per point basis in addition to providing the basic ON/OFF

detection. It supports two modes of operation: Per Point Mode and FIFO (First

In First Out) Mode. To learn more about using the modules in these modes of

operation, see Operational Modes on page 68.

Page 19

Module Overview and Features Chapter 2

All input point event times are recorded and returned in a single buffer. The

module returns two 64-bit timestamps for each input, thus allowing:

• ON and OFF events for each point to be displayed simultaneously in the

input data.

• ladder logic not being explicitly required to see events, although needed to

archive events.

• events to be kept in the controller memory during remote power loss thus

eliminating data loss.

All inputs on the module can be filtered for both ON to OFF and OFF to ON

transitions. The timestamp for a filtered input will be the time of the initial

transition to the new state and not the time that the filter validates the event as

real.

Selective Event Capturing allows particular events to be disabled per input and

per transition, ON to OFF or OFF to ON.

Event latching ensures that events are not overwritten. A single transition in each

direction is recorded per point. Any new event, which occurs after the point has

captured a timestamp, is dropped until the stored events have been

acknowledged.

If latching is not enabled in point mode, new events will overwrite old events

when they are received. In FIFO mode, up to 256 events per input will be

buffered before events are overwritten. Thus, if inputs are changing rapidly it may

be possible that events will be lost either in the module or the controller prior to

an event being operated on by ladder logic.

When events are lost, either old ones being overwritten or new ones being

ignored due to latching, an EventOverflow bit will be set for each point that loses

an event. The EventOverflow bit will clear when the blocking events for that

point are acknowledged.

Timestamping is a feature that registers a time reference to a change in input

data. For the 1732E-IB8M8SOER, the time mechanism used for timestamping is

(PTP) system time. The 1732E-IB8M8SOER module is a PTP slave-only device.

There must be another module on the network that functions as a master clock.

High Performance Sequence of Events Applications in the Logix Architecture

Sequence of Events (SOE) applications span a wide range of industry

applications. Typically any event that needs to be compared against a second

event can be classified as SOE.

• Used on discrete machines to identify failure points

• Used in Power Substations or power plants to indicate first fault

conditions

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 9

Page 20

Chapter 2 Module Overview and Features

• Used in SCADA applications to indicate pump failures or other discrete

events

• Used in motion control applications to increase control coordination.

• Used in high speed applications

• Used in Global Position Registration

In today's environment, specifications for SOE applications typically require 1 ms

or better resolution on timestamps. There are two types of SOE applications.

• First Fault – measures the time between events with no correlation to

events outside of that system.

• Real Time – captures the time of an event occurrence as it relates to some

master clock. Typically this is a GPS, NTP server or some other very

accurate clock source. This method allows distributed systems to capture

events and build a history of these events. These events are almost always

digital, however some are analog for which lower performance

requirements can be configured.

First Fault Detection

An example of first fault detection would be intermittent failure from a sensor on

a safety system faults a machine and halts production cascading a flood of other

interrelated machine faults. Traditional fault detection or alarms may not appear

in the correct timed order of actual failure making root cause of the down time

difficult or impossible.

Time Stamped I/O

High precision timestamps on I/O allows very accurate first fault detection

making it easy to identify the initial fault that caused machine down time.

Common Time base for Alarming System logs user interaction as well as alarm

events using common time reference.

The power industry requires sub 1 ms accuracy on first fault across geographically

dispersed architecture.

High Speed Applications

Packaging machines or sorters that have fast part cycles are often bottlenecked by

controller scan times. By switching to a time-based solution, you can remove

many scan time critical components of the system. This programming technique

allows you to do predictive events and schedule outputs to run things like

diverters without having a scan time to match the part cycle time.

10 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 21

Module Overview and Features Chapter 2

IMPORTANT

Motion Control

CIP Sync also provides a common time reference for distributed VFD drives,

servos, and controllers throughout the system. This allows controllers to request

axes, reach a pre-defined position at a known time reference, or run at a set speed

using the same reference. Since all drives and controllers in the system have the

same reference to time, the controller can issue simple requests for axes to reach

target positions in a synchronized fashion.

Global Position Registration

Registration refers to a function usually performed by the drive where a physical

input is triggered causing the drive to precisely capture the actual axis position

when the input event occurred. Rather than wiring inputs to the registration

input on all of the drives, this time-based system lets you wire an input to only

one time based SOE input module. The timestamp returned for that input, can

be used by the motion planner to calculate the actual axis position at the time the

input triggered. This simplifies system installation, reduces wiring costs, and

provides a global machine registration for all the axes in the system thru one SOE

input.

Introduction to Scheduled Output Module

The 1732E-OB8M8SR Scheduled Output module is designed to work in

conjunction with the MAOC motion instruction to provide position-based

output control (also known as PLS). The MAOC instruction by itself allows

position-based output control using the position of any motion axis in

ControlLogix as the position reference and any output or boolean as the output.

The MAOC updates the outputs based on motion axis position at the motion

group coarse update rate (typically 2…10 ms). While this is adequate for some

applications, it is too slow for many high speed applications typically found in

converting and packaging segments. The 1732E-OB8M8SR module improves

performance by supporting the ability to schedule the output turn-on/turnoff time of its 8 outputs (outputs 0…7) in 1 µs increments. Outputs are

scheduled by entering data into one or more of the 16 schedules provided by the

output connection data store.

When using the 1732E-OB8M8SR module with the MAOC instruction,

make sure you use the default Communication Format for the module,

that is, Schedule Output Data Per Point. If you change the

Communication Format when the module is used with an MAOC

instruction, an error may result.

Operation

This scheduled output implementation schedules outputs on a per point basis

and each individual output point is controlled by its own timestamp.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 11

Page 22

Chapter 2 Module Overview and Features

Individual schedules are created in the controller, stored in the output image table

for the module, and sent over the backplane to the Scheduled Output module.

The schedule specifies a sequence count, the output point to be associated with

the schedule, the time at which an output value should be applied to the physical

output point, and the value to be applied at the scheduled time. The I/O module

receives and stores the schedule. The CIPSync time of each schedule is monitored

by the module. When a schedule has expired, that is the current time, matches the

scheduled timestamp, the output value is then applied to the corresponding

output bit. Timer hardware in the ASIC is used to optimize the scheduling

algorithm. This hardware also reduces the latency and jitter performance. Status

of each schedule is reported in the output echo connection and reflected in the

input image for the module.

The scheduled output functionality relies on CIPSync time. Unused outputs may

be used as normal outputs and are applied immediately rather than waiting for

the CIPSync time to expire. A mask is sent to the module to indicate which

outputs are to function as normal outputs. The scheduled output module

supports up to 8 outputs that can be individually scheduled. The scheduled

outputs must be between output points 0 and 7. The 1732E-OB8M8SR module

supports up to 16 schedules with two schedules per output. Outputs that are not

“scheduled” are used as normal output points. A mask is used to indicate which

points are scheduled and which points are unscheduled. Jitter performance is less

than 25 µs. All of the scheduling configuration is done through the MAOC

instruction.

If a new schedule as indicated by a change in the sequence count is received by the

I/O module before the current schedule has expired, the current schedule is

overwritten. This mechanism can be used to cancel currently active schedule.

Status bits returned in the output echo connection may be used to determine the

current state of each schedule and to trigger corresponding event tasks.

If a new schedule is sent by the controller and the CIPSync time has already past,

the output is asserted until the CIPSync time has completely wrapped around.

The module does not check for an expired CIPSync time.

WARNING: If the time between two schedules is less than the

minimum schedule interval (for example, 100 µs), then deviation occurs.

This means that even though two outputs are scheduled at different

times (for example, time 90 and time 110), they both activate at the

same time (for example, time 90). The minimum schedule interval should

not be set to faster than 100 µs.

High Speed Product Reject

In a control system you can program a scheduled output module, which can

trigger multiple outputs simultaneously or trigger a reject at the precise point a

product is at the reject station.

12 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 23

Module Overview and Features Chapter 2

By using time to schedule the output in advance,and identifying when the

product will be at a known position, hitting the exact point when a part is in front

of a reject station on a high speed packaging machine, can be controlled.

Chapter Summary and What’s Next

In this chapter, you were given an overview of the 1732E ArmorBlock EtherNet/

IP Dual Port 8-Point Sequence of Events Input and Scheduled Output Modules

modules. The next chapter describes how the modules operate in an ArmorBlock

system.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 13

Page 24

Chapter 2 Module Overview and Features

Notes:

14 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 25

Chapter

3

Use the Modules in an ArmorBlock System

Introduction

Differences Between Module and Standard I/O

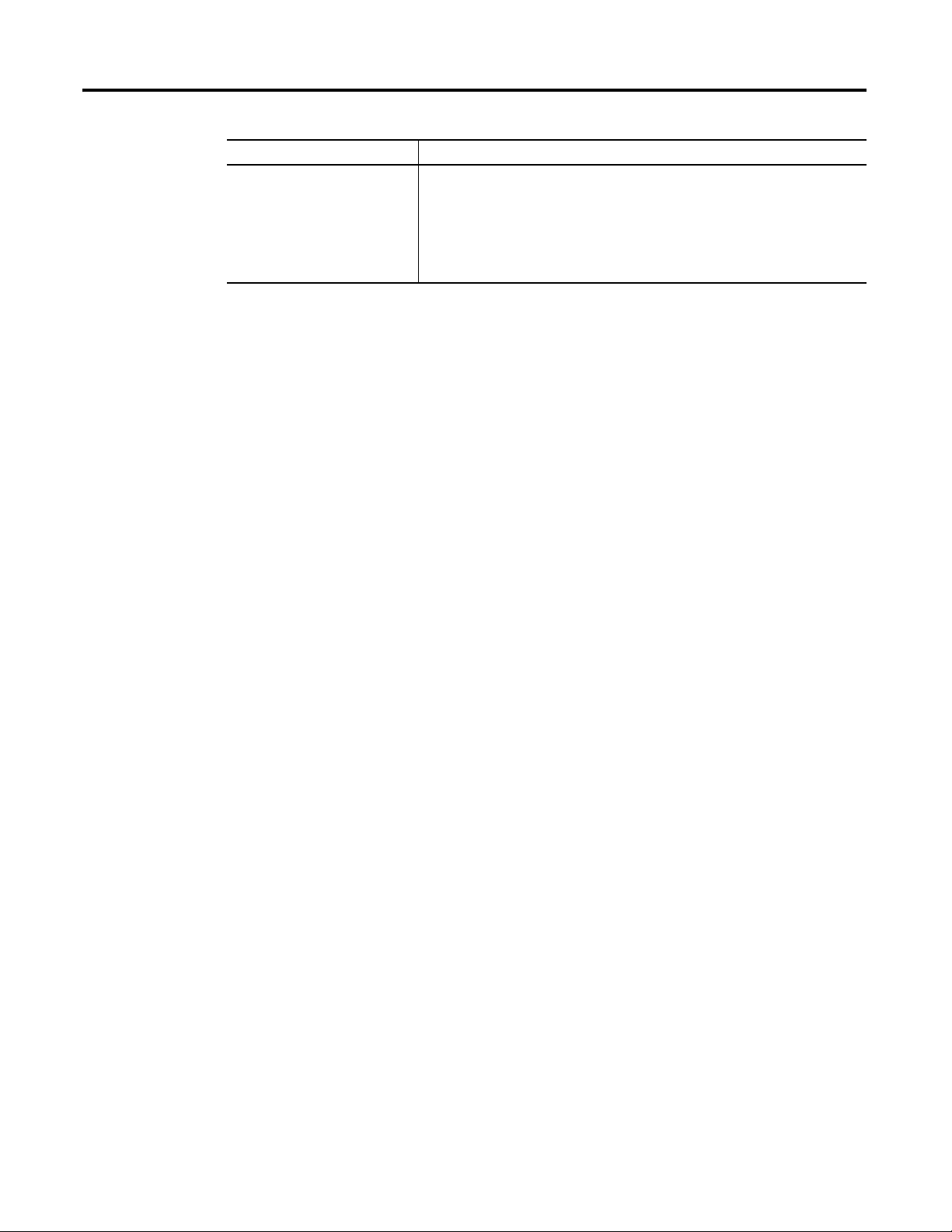

Difference Description

Additional data produced for controller The modules produce significantly more data for its owner-controller than

CIP Sync These modules have an internal clock that is synchronized with a master

Only one owner-controller per module While multiple controllers can simultaneously own other digital input

This chapter describes how the 1732E ArmorBlock EtherNet/IP Dual Port 8Point Sequence of Events Input and Scheduled Output Modules modules operate

in an ArmorBlock system.

Topic Page

Differences Between Module and Standard I/O 15

Similar Functionality to Standard ArmorBlock 15

In many aspects, the modules behave the same as any other ArmorBlock digital

module. However, the modules offer several significant differences from other

EtherNet/IP ArmorBlock digital input modules, including those described in the

following table.

standard ArmorBlock digital input modules. While other input modules only

produce ON/OFF and fault status, the modules produce data such as ON/

OFF and fault status, timestamp data, indication of whether new data was

produced for specific input points or if transitions were not timestamped.

clock using CIP Sync. This clock is used for time stamping inputs and

outputs.

modules, the module only supports a single owner-controller.

Similar Functionality to Standard ArmorBlock

Concept Description

Ownership Every module in an ArmorBlock system must be owned by a Logix5000 controller. This

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 15

This chapter focuses on how the module behavior differs from that of other

ArmorBlock modules. However, you should be aware of aspects in which the

module is similar to standard EtherNet/IP ArmorBlock modules. The following

table describes the similarities.

owner-controller:

• stores configuration data for every module that it owns.

• sends the module configuration data to define the module behavior and begin

operation with the control system.

This module does not support multiple owner-controllers.

Page 26

Chapter 3 Use the Modules in an ArmorBlock System

Concept Description

Using RSLogix 5000 software The I/O configuration portion of RSLogix 5000 software, v18 or greater, generates the

configuration data for each module.

Configuration data is transferred to the controller during the program download and

subsequently transferred to the appropriate modules.

Modules are ready to run as soon as the configuration data has been downloaded.

Configure all modules for a given controller using RSLogix 5000 software and download

that information to the controller.

Chapter Summary and What’s Next

In this chapter, you learned about the differences between this module and other

EtherNet/IP ArmorBlock I/O modules. The next chapter describes how to

install and wire your module.

16 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 27

Install Your Module

Chapter

4

Overview

Install the Module

This chapter shows you how to install and wire the 1732E ArmorBlock

EtherNet/IP Dual Port 8-Point Sequence of Events Input and Scheduled Output

Modules modules. The only tools you require are a flat or Phillips head

screwdriver and drill. This chapter includes the following topics:

Topic Page

Install the Module 17

Set the Network Address 17

Mount the Module 18

Wire the Module 19

Power Connectors 20

To install the module:

• Set the network address

• Mount the module

• Connect the I/O, Network, and Auxiliary cables to the module.

Set the Network Address

The I/O block ships with the rotary switches set to 999 and DHCP enabled. To

change the network address, you can do one of the following:

• adjust the node address switches on the front of the module.

• use a Dynamic Host Configuration Protocol (DHCP) server, such as

Rockwell Automation BootP/DHCP.

• retrieve the IP address from nonvolatile memory.

The I/O block reads the switches first to determine if the switches are set to a

valid number. To set the network address:

1. Remove power.

2. Remove the switch dust caps.

3. Rotate the three (3) switches on the front of the module using a small

blade screwdriver.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 17

Page 28

Chapter 4 Install Your Module

45765

Millimeters

(Inches)

Functional Earth

Grounds the I/O block

EtherNet/IP communication

circuitry which is designed to

mitigate the effect of noise on

the network. It requires a solid

earth ground connection,

either through a metal screw

to a grounded metal panel or

through a wire.

4. Line up the small notch on the switch with the number setting you wish to

use.

Valid settings range from 001…254.

5. Replace switch dust caps. Make sure not to over tighten.

6. Reapply power.

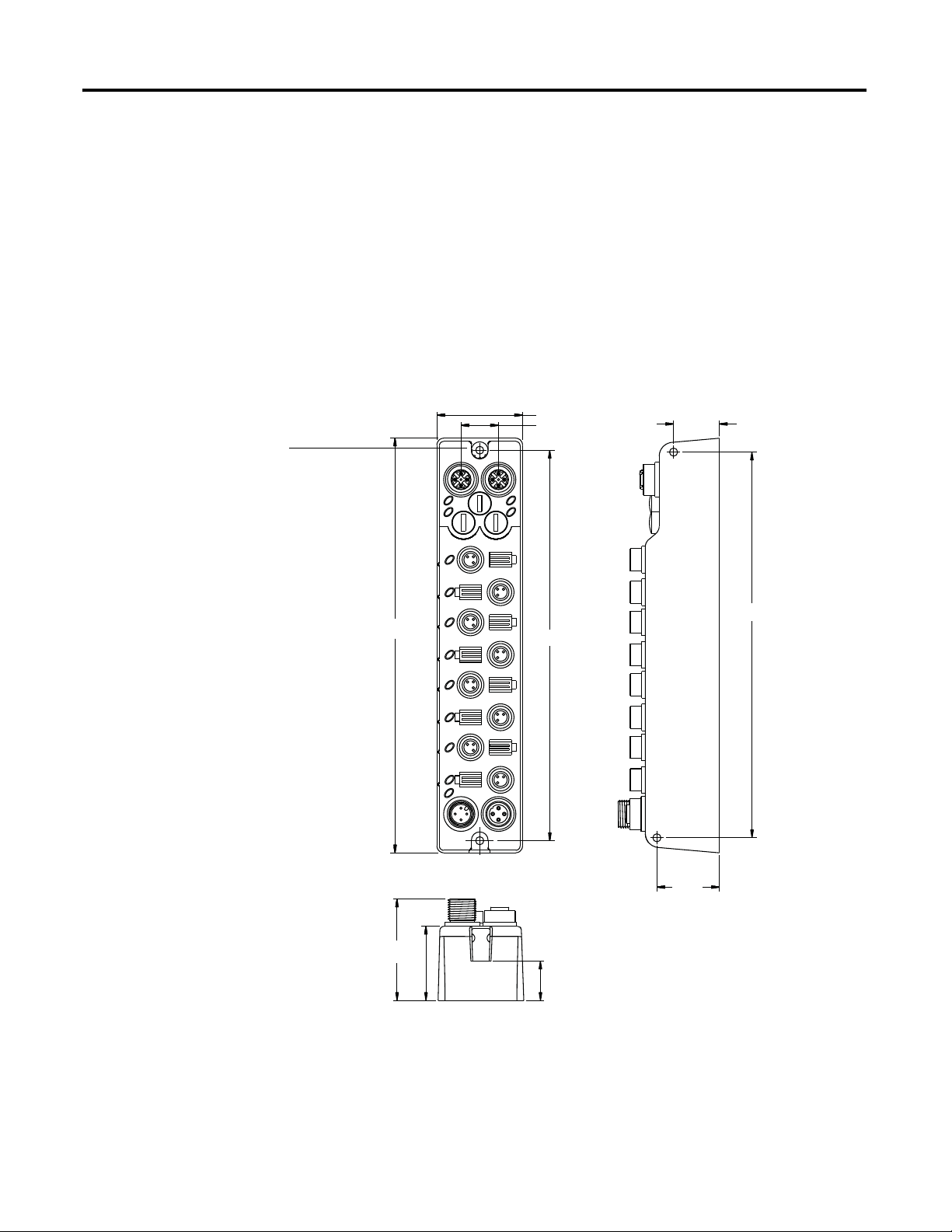

Mount the Module

To mount the module on a wall or panel, use the screw holes provided in the

module. Refer to the drilling dimensions illustration to guide you in mounting

the module.

179 (7.05)

37 (1.46)

16.2 (0.64)

168.6 (6.64)

19.8

(0.78)

166.5 (6.56)

27 (1.06)

Side Mounting

43.3 (1.70)

32 (1.26 )

Front Mounting

18 (0.71)

Install the mounting base as follows:

1. Lay out the required points as shown above in the drilling dimension

drawing.

18 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 29

Install Your Module Chapter 4

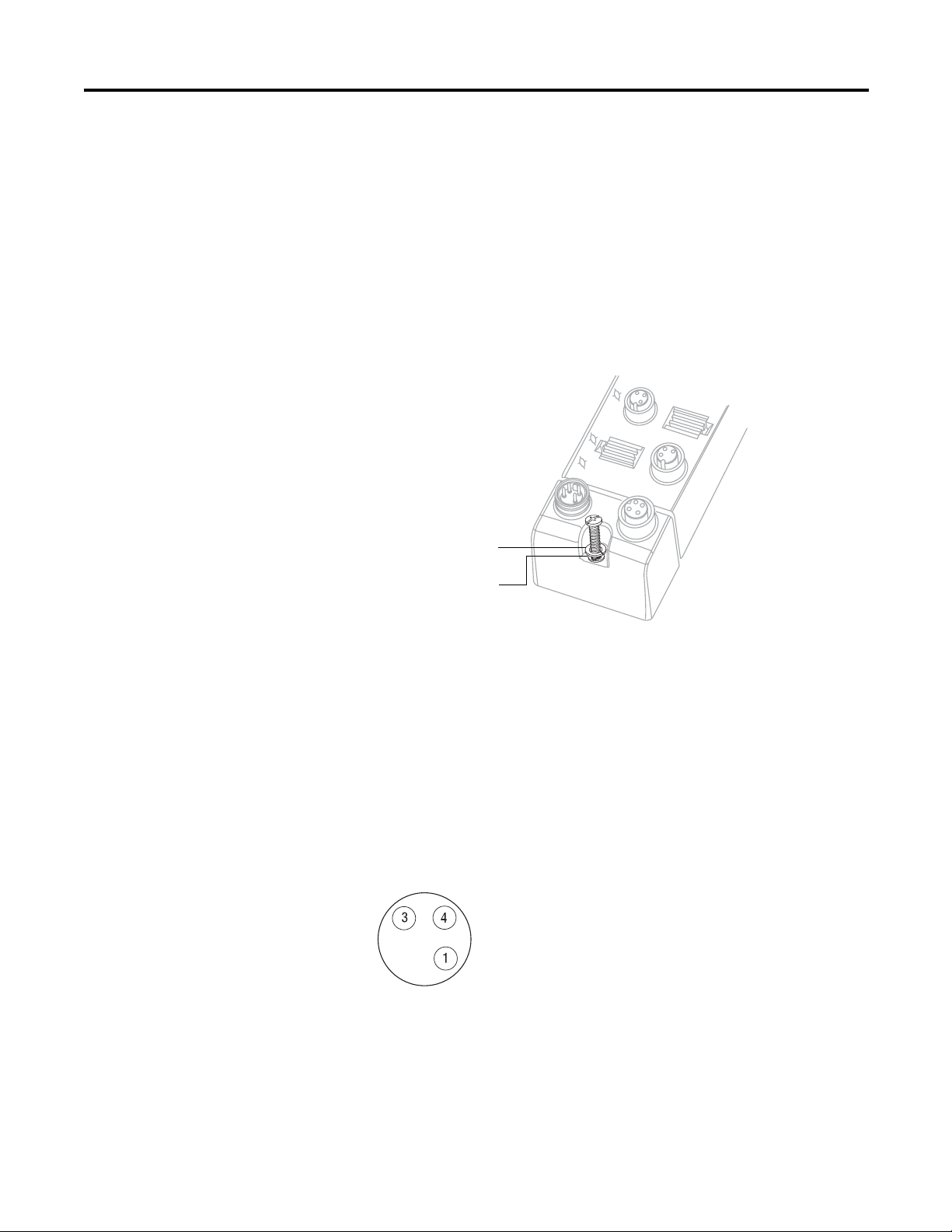

45768

Lock washer

Flat washer

(View into connector)

Pin 1 Sensor source voltage

Pin 3 Return

Pin 4 Input

43583

2. Drill the necessary holes for #6 (M3) pan head screws.

3. Mount the module using #6 (M3) screws.

Mount the Module in High Vibration Areas

If you mount the module in an area that is subject to shock or vibration, we

recommend you use a flat and a lock washer to mount the module. Mount the flat

and the lock washer as shown in the mounting illustration. Torque the mounting

screws to 0.68 Nm (6 lb-in.).

High Vibration Area Mounting

Wire the Module

The 1732E-OB8M8SR and 1732E-IB8M8SOER ArmorBlock EtherNet/IP

modules have 3-pin pico-style I/O connectors. We provide caps to cover the

unused connectors on your module. Connect the quick-disconnect cord sets you

selected for your module to the appropriate ports.

I/O Connectors

Refer to the pinout diagrams for the I/O connectors.

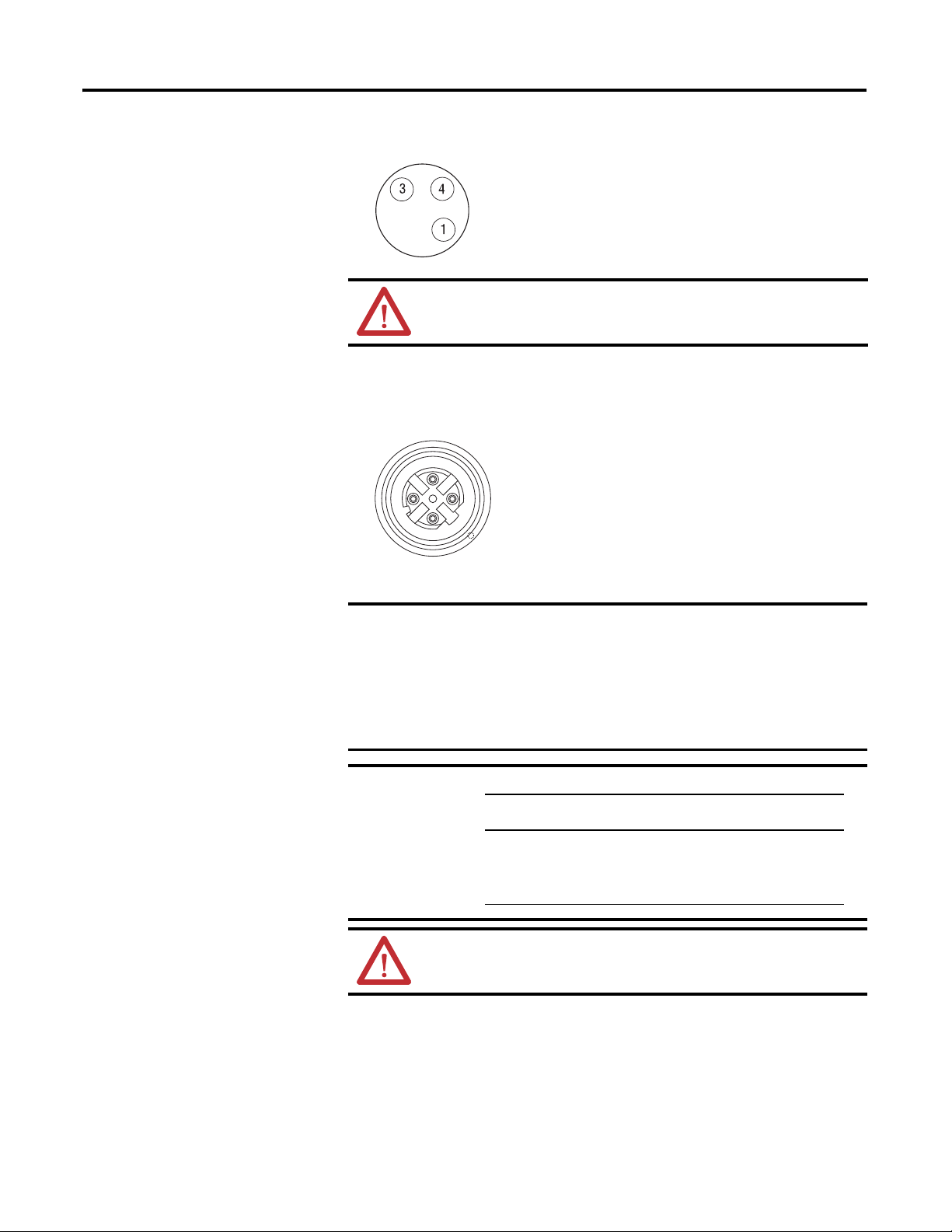

Pico-style 3-Pin Input Female Connector

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 19

Page 30

Chapter 4 Install Your Module

IMPORTANT

IMPORTANT

43583

(View into connector)

Pin 1 Sensor Source Voltage

Pin 3 Return

Pin 4 Output

(View into connector)

Pin 1Tx+

Pin 2 Rx+

Pin 3 TxPin 4 RxPin 5 Shell

44808

D-Code

M12 Pin

Wire Color Signal 8-way Modular

RJ45 Pin

1 White-Orange TX+ 1

2 White-Green RX+ 3

3 Orange TX- 2

4 Green RX- 6

Pico-style 3-Pin Output Female Connector

ATTENTION: Sensors/actuators power should not be

supplied externally.

Ethernet Connectors

Refer to the pinout diagrams for the network connectors.

4

31

2

5

.

Use the 1585D–M4DC–H: Polyamide small body unshielded mating

connectors for the D-Code M12 female network connector.

Note that the distance between the center of each Ethernet

connector is 16.2 mm (see dimensions on page 18).

Rockwell Automation recommends the use of suitable cable based

on this measurement. Some of the recommended cables are 1585DM4TBJM-x and 1585D-M4TBDM-x for daisychains.

Use two twisted pair CAT5E UTP or STP cable.

ATT ENTI ON: Make sure all connectors and caps are securely

tightened to properly seal the connections against leaks and maintain

IP enclosure type requirements.

Power Connectors

20 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Attach the mini-style 4-pin connector to the mini-style 4-pin receptacle as shown

below.

Page 31

Micro-style 4-Pin Input Male Receptacle

IMPORTANT

3

4

1

2

45764

(View into receptacle)

Pin 1 Auxiliary power+

Pin 2 Module power+

Pin 3 Module powerPin 4 Auxiliary power-

45763

Male Input

Female Output

2

Install Your Module Chapter 4

3

1

4

The maximum current that any pin on the power connectors can

carry is 4 A.

The power required by the module is based on a 4-pin micro-style connector

system. The module receives its required power through the male connector on

the left. A female connector on the right is also provided so that power can be

daisy-chained from module to module.

Both modules require two 24V DC (nominal) supplies. These supplies are called

the Module Power and the Auxiliary Power. The Module Power powers the

microprocessor and Ethernet portions of the module. The Auxiliary Power

provides power for the Digital Outputs, the Digital Inputs, and the Sensor

Vo l t a g e .

Internally, the Module Power and Auxiliary Power are isolated from each other.

The Module Power current required for a module can be estimated as 2.4W/

(Module Power Voltage). For example, if the Module Power Voltage is 24V DC,

then the Module Power current (Imp) would be,

Imp ~ 2.4W/24VDC = 100 mA DC

If the power for four modules were daisy-chained together and the voltage is 24V

DC, then the Module Power current through the first connector in the daisychain would be 4 x Im ~ 400 mA which is less than 4 A, so Module Power current

is within acceptable limits.

The Auxiliary Power current is more complicated. The equation is below:

Iap ~ Iapm + Isp0 + Isp1+ Isp2+ Isp3 + Isp5+ Isp5 + Isp6 + Isp7 + IDO0

+ IDO1 + IDO2 + IDO3 + IDO4 + IDO5 + IDO6 + IDO7 +

IAPDC

Where:

Iap i s t h e A u x i l i a r y P o w e r c u r r e nt t h r o u g h t h e f i r s t c o n n e c t o r i n t h e d a i s y - c h a i n .

Iapm is the Auxiliary Power current required by the module itself.

IspN is the Sensor Power current for Digital Input N (0…7).

I

DON is the Digital Output current for Digital Output N (0…7).

I

APDC is the Auxiliary Power current requirement for the remaining modules in

the daisy-chain.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 21

Iapm can be approximated by 0.5W/(Auxiliary Power Voltage).

Page 32

Chapter 4 Install Your Module

The table Auxiliary Power Calculation shows the resulting Auxiliary Power

current calculation for a system of four modules. The Auxiliary Power voltage is

24V DC in this example. As can be seen in the cell with value set in bold, the

Auxiliary Power current through the first connector in the daisy-chain is 3.898A

which is less than 4A, so this system is adequate.

Auxiliary Power Calculation

Module 1 Module 2 Module 3 Module 4

APDC 3.108A 2.772A 1.301A 0.000A

I

Iapm 0.021A 0.021A 0.021A 0.021A

Isp0 0.000A 0.000A 0.300A 0.050A

Isp1 0.000A 0.000A 0.000A 0.000A

Isp2 0.000A 0.000A 0.000A 0.250A

Isp3 0.000A 0.000A 0.000A 0.000A

Isp4 0.000A 0.000A 0.000A 0.000A

Isp5 0.000A 0.000A 0.000A 0.000A

Isp6 0.000A 0.000A 0.000A 0.000A

Isp7 0.000A 0.000A 0.000A 0.000A

I

DO0 0.270A 0.025A 0.500A 0.025A

I

DO1 0.200A 0.290A 0.300A 0.500A

IDO2 0.300A 0.000A 0.250A 0.300A

IDO3 0.000A 0.000A 0.100A 0.125A

I

DO4 0.000A 0.000A 0.000A 0.030A

IDO5 0.000A 0.000A 0.000A 0.000A

IDO6 0.000A 0.000A 0.000A 0.000A

I

DO7 0.000A 0.000A 0.000A 0.000A

Iapm 3.898A 3.108A 2.772A 1.301A

ATTENTION: To comply with the CE Low Voltage Directive (LVD), this

equipment and all connected I/O must be powered from a source

compliant with the following:

Safety Extra Low Voltage (SELV) or Protected Extra Low Voltage (PELV).

ATTENTION: To comply with UL restrictions, this equipment must be

powered from a source compliant with the following: Limited Voltage.

ATTENTION: The device meets UL Type 1 Enclosure rating.

Chapter Summary and What’s Next

In this chapter, you learned how to install and wire your module. The following

chapter describes how to configure your module to communicate on the

EtherNet/IP network by providing an IP address, gateway address, and Subnet

mask.

22 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 33

Configure the Module for Your EtherNet/IP Network

Chapter

5

Introduction

Before using the modules in an EtherNet/IP network, you need to configure

them with an IP address, subnet mask, and optional Gateway address. This

chapter describes these configuration requirements and the procedures for

providing them. Here are the ways you can do this:

• Use the Rockwell Automation BootP/DHCP utility, version 2.3 or

greater, that ships with RSLogix 5000 or RSLinx software. You can also

use this utility to reconfigure a device whose IP address must be changed.

• Use a third party DHCP (Dynamic Host Configuration Protocol) server.

• Use the Network Address switches.

• Have your network administrator configure the module via the network

server.

See the table for a list of where to find specific information in this chapter.

Topic Page

Configuration Requirements 23

IP Address 24

Gateway Address 25

Subnet Mask 26

Set the Network Address 27

Use the Rockwell Automation BootP/DHCP Utility 27

Save the Relation List 30

Use DHCP Software to Configure Your Module 30

Configuration Requirements

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 23

Before you can use your module, you must configure its IP address, its subnet

mask, and optionally, gateway address. You have the option to use the Rockwell

Automation BootP/DHCP utility, version 2.3 or greater, to perform the

configuration. You also have the option to use a DHCP server or the network

address switches to configure these parameters.

Page 34

Chapter 5 Configure the Module for Your EtherNet/IP Network

IMPORTANT

Class C

Net ID

Host ID

Class B

Net ID

Host ID

Class A

Net ID

Host ID

0

0

0

1 0

1 1 0

0

78

31

15 16

31

233124

If the module needs to be reset to factory defaults, set the switches on the module

to the value 888 and then cycle power to the module.

IP Address

The IP address identifies each node on the IP network (or system of connected

networks). Each TCP/IP node on a network (including your module) must have

a unique IP address.

If using the BootP/DHCP utility, you will need to know the

Ethernet hardware address of your module.

Rockwell Automation assigns each module a unique 48-bit

hardware address at the factory. The address is printed on a

label on the side of your module. It consists of six

hexadecimal digits separated by colons. This address is fixed

by the hardware and cannot be changed.

If you change or replace the module, you must enter the

new Ethernet hardware address of the module when you

configure the new module.

The IP address is 32 bits long and has a net ID part and a Host ID part. Networks

are classified A, B, C, (or other). The class of the network determines how an IP

address is formatted.

You can distinguish the class of the IP address from the first integer in its dotteddecimal IP address as follows:

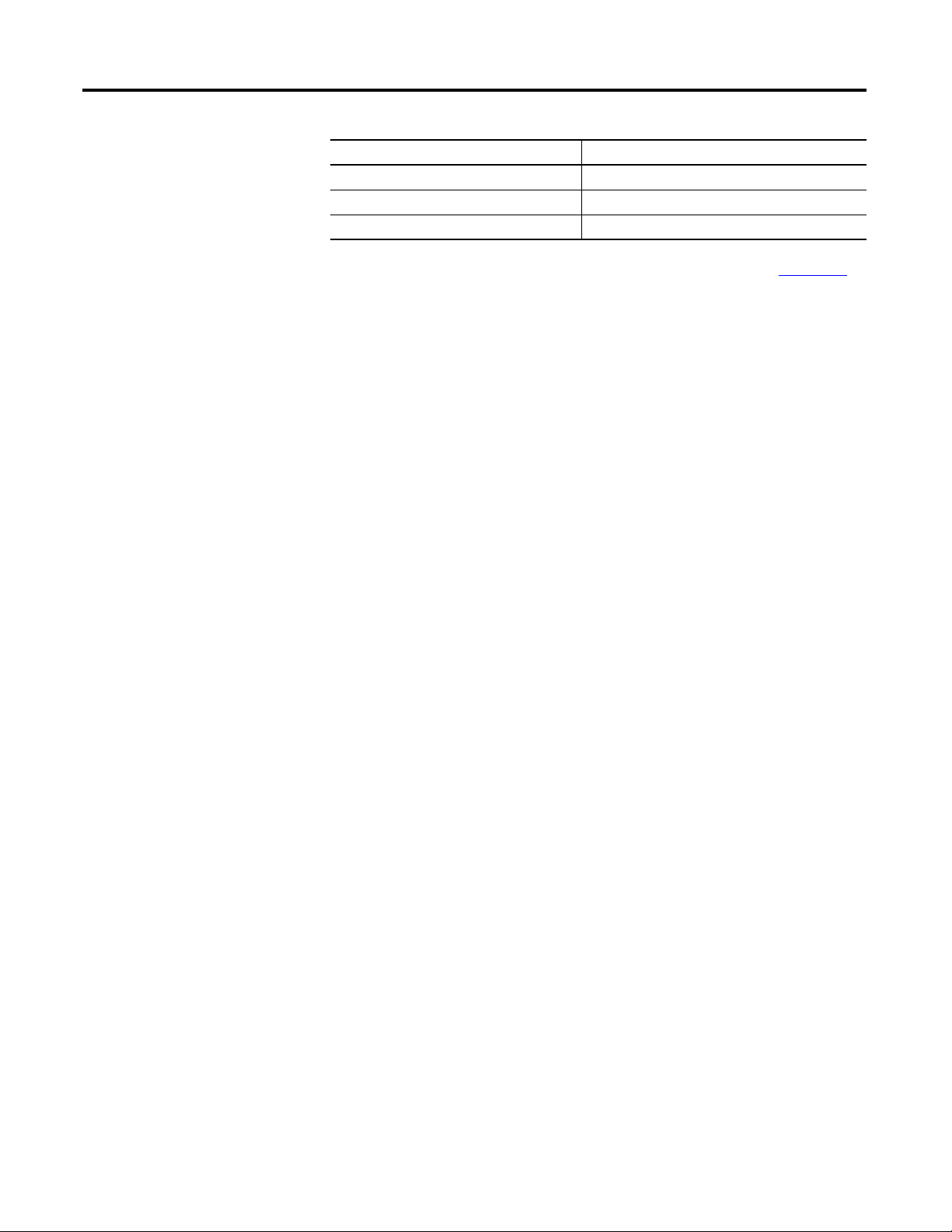

Classes of IP Addresses

Range of first integer Class Range of first integer Class

0…127 A 192…223 C

128...191 B 224…255 other

Each node on the same logical network must have an IP address of the same class

and must have the same net ID. Each node on the same network must have a

different Host ID thus giving it a unique IP address.

24 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 35

Configure the Module for Your EtherNet/IP Network Chapter 5

EXAMPLE

Network 1

Network 2

128.2.0.3

128.1.0.2

128.1.0.1

128.2.0.1

128.2.0.2

A

B

C

G

IP addresses are written as four decimal integers (0...255) separated by periods

where each integer gives the value of one byte of the IP address.

For example, the 32-bit IP address:

10000000 00000001 00000000 00000001 is written as

128.1.0.1.

Gateway Address

This section applies to multi-network systems. If you have a single network

system, go to the next section.

The gateway address is the default address of a network. It provides a single

domain name and point of entry to the site. Gateways connect individual

networks into a system of networks. When a node needs to communicate with a

node on another network, a gateway transfers the data between the two

networks. The following figure shows gateway G connecting Network 1 with

Network 2.

When host B with IP address 128.2.0.1 communicates with host C, it knows

from C’s IP address that C is on the same network. In an Ethernet environment,

B then resolves C’s IP address into a hardware address (MAC address) and

communicates with C directly.

When host B communicates with host A, it knows from A’s IP address that A is

on another network (the net IDs are different). In order to send data to A, B must

have the IP address of the gateway connecting the two networks. In this example,

the gateway’s IP address on Network 2 is 128.2.0.3.

The gateway has two IP addresses (128.1.0.2 and 128.2.0.3). The first must be

used by hosts on Network 1 and the second must be used by hosts on Network 2.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 25

To be usable, a host’s gateway must be addressed using a net ID matching its own.

Page 36

Chapter 5 Configure the Module for Your EtherNet/IP Network

EXAMPLE

1111111 11111111 11000000 00000001 = 255.255.192.0

These two bits of the host ID used to

extend the net ID

Network 1

Network 2.1

Network 2.2

128.1.0.1

128.1.0.2

128.2.128.3

A

B

C

G

DE

G2

128.2.64.3

128.2.128.2

128.2.128.1

128.2.64.1

Subnet Mask

The subnet mask is used for splitting IP networks into a series of subgroups, or

subnets. The mask is a binary pattern that is matched up with the IP address to

turn part of the Host ID address field into a field for subnets.

Two bits of the Class B host ID have been used to extend the net ID. Each unique

combination of bits in the part of the Host ID where subnet mask bits are 1

specifies a different logical network.

Take Network 2 (a Class B network) in the previous

example and add another network. Selecting the following

subnet mask would add two additional net ID bits, allowing

for four logical networks:

The new configuration is:

A second network with Hosts D and E was added. Gateway G2 connects

Network 2.1 with Network 2.2.

Hosts D and E use Gateway G2 to communicate with hosts not on Network 2.2.

Hosts B and C use Gateway G to communicate with hosts not on Network 2.1.

When B is communicating with D, G (the configured gateway for B) routes the

data from B to D through G2.

26 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 37

Configure the Module for Your EtherNet/IP Network Chapter 5

This example

shows the network

address set at 163

44233

Note: You need to remove the

protective switch dust caps

before you can adjust the

address settings.

Set the Network Address

The I/O block ships with the rotary switches set to 999 and DHCP enabled. To

change the network address, you can do one of the following:

1. Adjust the switches on the front of the module.

2. Use a Dynamic Host Configuration Protocol (DHCP) server, such as

Rockwell Automation BootP/DHCP.

3. Retrieve the IP address from nonvolatile memory.

The I/O block reads the switches first to determine if the switches are set to a

valid number. Set the network address by adjusting the 3 switches on the front of

the module. Use a small blade screwdriver to rotate the switches. Line up the

small notch on the switch with the number setting you wish to use. Valid settings

range from 001…254.

Network Address Example

2

0

2

4

0

6

8

4

8

6

2

0

4

6

8

Use the Rockwell Automation BootP/DHCP Utility

When the switches are set to a valid number, the I/O block’s IP address is

192.168.1.xxx (where xxx represents the number set on the switches). The I/O

block’s subnet mask is 255.255.255.0 and the gateway address is set to 0.0.0.0.

When the I/O block uses the network address set on the switches, the I/O block

does not have a host name assigned to it or use any Domain Name Server.

If the switches are set to an invalid number (for example, 000 or a value greater

than 254, excluding 888), the I/O block checks to see if DHCP is enabled. If

DHCP is enabled, the I/O block asks for an address from a DHCP server. The

DHCP server also assigns other Transport Control Protocol (TCP) parameters.

If DHCP is not enabled, and the switches are set to an invalid number, the I/O

block uses the IP address (along with other TCP configurable parameters) stored

in nonvolatile memory.

The Rockwell Automation BootP/DHCP utility is a standalone program that

incorporates the functionality of standard BootP/DHCP software with a userfriendly graphical interface. It is located in the Utils directory on the

RSLogix 5000 installation CD. The module must have DHCP enabled (factory

default and the network address switches set to an illegal value) to use the utility.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 27

To configure your module using the BootP/DHCP utility, perform the following

steps:

Page 38

Chapter 5 Configure the Module for Your EtherNet/IP Network

1. Run the BootP/DHCP software.

The BOOTP/DHCP Request History dialog appears showing the

hardware addresses of devices issuing BootP/DHCP requests.

2. Double-click the hardware address of the device you want to configure.

The New Entry dialog appears showing the device’s Ethernet

Address (MAC).

3. Enter the IP Address you want to assign to the device and click OK.

28 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 39

Configure the Module for Your EtherNet/IP Network Chapter 5

TIP

The device is added to the Relation List, displaying the Ethernet Address

(MAC) and corresponding IP Address, Hostname and Description (if

applicable).

When the IP address assignment is made, the address displays in the IP

Address column in the Request History section.

4. To assign this configuration to the device, highlight the device in the

Relation List panel and click Disable BOOTP/DHCP. When power is

cycled to the device, it uses the configuration you assigned and does not

issue a DHCP request.

To enable DHCP for a device that has had DHCP disabled,

highlight the device in the Relation List and click Enable

DHCP. You must have an entry for the device in the

Relation List panel to re-enable DHCP.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 29

Page 40

Chapter 5 Configure the Module for Your EtherNet/IP Network

Save the Relation List

You can save the Relation List to use later. To save the Relation List do the

following:

1. Select Save As... from the File menu.

Use DHCP Software to Configure Your Module

The Save As dialog box appears.

2. Select the folder you want to save the list to.

3. Enter a file name for the Relation List (for example, control system

configuration) and click Save.

If you want to see your saved file names in the Open dialog box, save your

files using the default file type (*.bpc).

Dynamic Host Configuration Protocol (DHCP) software automatically assigns

IP addresses to client stations logging onto a TCP/IP network. DHCP is based

on BootP and maintains some backward compatibility. The main difference is

that BootP was designed for manual configuration, while DHCP allows for

30 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 41

Configure the Module for Your EtherNet/IP Network Chapter 5

dynamic allocation of network addresses and configurations to newly attached

devices.

Be aware that a DHCP server typically assigns a finite lease time to the offered IP

address. When 50 percent of the leased time has expired, the module will attempt

to renew its IP address with the DHCP server. The module could be assigned a

different IP address, which would cause communicating with the ControlLogix

controller to cease.

ATTENTION: To avoid unintentional control, the module must be

assigned a fixed IP address. The IP address of this module should not be

dynamically provided. If a DHCP server is used, it must be configured to

assign a fixed IP address for your module.

ATTENTION: Failure to observe this precaution may result in unintended

machine motion or loss of process control.

Chapter Summary and What’s Next

In this chapter, you learned how to configure the module to communicate on

your EtherNet/IP network by providing an IP address, gateway address, and

Subnet mask. The next chapter describes an example application in which you

configure discrete I/O.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 31

Page 42

Chapter 5 Configure the Module for Your EtherNet/IP Network

Notes:

32 Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014

Page 43

Configure the Module Using RSLogix 5000 Software

Chapter

6

Introduction

This chapter guides you through the steps required to configure your 1732E

ArmorBlock EtherNet/IP Dual Port 8-Point Sequence of Events Input and

Scheduled Output Modules modules using the RSLogix 5000 software. Note

that the modules presented in this chapter are configured using RSLogix 5000

software, version 18 or later.

Topic Page

Set Up the Hardware 34

Create the Example Application 35

Configure Your I/O Module 35

Overview of the Configuration Process through RSLogix 5000 36

Add a New Bridge and Module to Your RSLogix 5000 Project 36

Use the Default Configuration 41

Change the Default Configuration 41

Download Your Configuration 43

Edit Your Configuration 43

Access Module Data in RSLogix 5000 Software 45

Configure RSLogix 5000 and the 1756-EN2T Communication Module for CIP Sync 46

The configuration of the two modules through the RSLogix 5000 software

involve the same procedure. Note, however, that the two modules have different

Module Definition properties and Configuration tabs. Both are distinctly

covered in this chapter.

Rockwell Automation Publication 1732E-UM003B-EN-E - March 2014 33

Page 44

Chapter 6 Configure the Module Using RSLogix 5000 Software

Local

Chassis

1732E

ArmorBlock

Logix5565

Controller (slot 1)

1756-EN2T

192.168.1.1 (slot 3)

Data

Switch

192.168.1.100

Programming

Terminal

0

1732E ArmorBlock

Ethernet Module

192.168.1.20

44971

32Slot 1

Embedded

Tec hn ol og y

Set Up the Hardware

In this example, a ControlLogix chassis contains the Logix5565 processor in slot

1 and a 1756-EN2T bridge module in slot 3. The 1732E ArmorBlock module is

mounted remotely.

LINK2LINK1

X10

NET

Logix5565

EtherNet/IP

Logix5565

1756-EN2T

MOD

X1

X100

AUX POWER

To work along with this example set up your system as shown.

• Note that in the example application, the Logix5565 controller and

1756-EN2T module (firmware version 2.3 or higher) are assumed to be in

the slots shown.