Page 1

Supplementary Instructions for

ProSYS Version 8.xx

Page 2

Table of Contents

Introduction ............................................................................................................................ 3

New BUS Accessories...........................................................................................................3

Touchscreen Keypad ........................................................................................................3

BUS Zone Expanders ........................................................................................................3

Fast PSTN Modem - 2400 BPS..........................................................................................3

iWISE Grade 2 and 3 BUS Zone Detectors......................................................................4

BUS Zone Parameters: iWISE DT Grade 2................................................................ 6

BUS Zone Parameters: iWISE DT Grade 3................................................................ 7

BUS Zone Parameters: iWISE QUAD Grade 2 .......................................................... 8

BUS Zone Parameters: iWISE QUAD Grade 3 .......................................................... 9

BUS Detector Naming Conventions...............................................................................10

New Firmware Capabilities.................................................................................................. 10

WatchOUT Proximity Anti Mask.....................................................................................10

Programming Output Operation Using Proximity Tag.................................................11

PCB Labeling Modification.................................................................................................. 11

2 ProSYS Version 8.xx - Supplementary Instructions

Page 3

Introduction

This document describes the following improvements and changes in the ProSYS version 8.XX

due to market requirements and quality improvements:

x ProSYS Touchscreen keypad

x Fast PSTN modem – 2400 BPS

x iWISE BUS detectors (Grade 2, Grade 3)

x BUS detector naming conventions

x Proximity Anti-Mask setting for WatchOUT DT Version B

x Output activation using a Proximity Tag

x PCB labeling modification

Please follow the instructions below and refer to the indicated documents for a detailed

description of all the software changes.

New BUS Accessories

The information in this section describes new accessories that have been added to the ProSYS

BUS and modifications that have been implemented in parameters under the Engineer

programming menu.

Touchscreen Keypad

There is a new 7" Touchscreen keypad with a slim and contemporary design. The Touchscreen

Keypad is compatible with any ProSYS version and is available with or without a proximity

reader.

Adding/deleting the Touchscreen keypad is identical to the procedure for the adding/deleting of

current ProSYS keypads.

BUS Zone Expanders

There are new wired BUS Zone Expanders that enable to expand the number of BUS zone

detectors in the ProSYS.

When adding/deleting a BUS Zone Expander there are four new types to choose from:

x BZE08 (8 BUS zone expander)

x BZE16 (16 BUS zone expander)

x BZE24 (24 BUS zone expander)

x BZE32 (32 BUS zone expander)

For detailed information refer to the instructions supplied with the product.

Fast PSTN Modem - 2400 BPS

The Fast PSTN Modem enables PSTN communication at 2400 Bps between a remote PC and

the ProSYS security panel when programming the system using the Upload/Download software.

Important:

Communication with the fast modem is supported by ProSYS Version 8 and above and by

Upload/Download software version 3.2.4.8 and above.

Adding the Fast PSTN Modem to ProSYS:

1. Access the Engineer menu and select [7] Install > [1] Add Delete Module > [9] More.. > [6]

XMODEM.

Set the Type field to XModem.

ProSYS Version 8.xx - Supplementary Instructions 3

Page 4

2. Enable communication with the external fast modem:

Select [5] Digicom > [5] Control > [15] X. Modem Enable.

Set the parameter to Yes.

3. Ensure that the Upload/Download GSM parameter is set to No:

Select [5] Digicom > [5] Control > [14] Upload Download GSM Enable.

Verify that the parameter is set to No.

Note that when using the Upload/Download software in the Client Screen, the Fast PSTN

Modem option needs to be selected.

iWISE Grade 2 and 3 BUS Zone Detectors

There are two iWISE BUS zone detectors:

x iWISE DT AM Grade 2 15m and 25m

x iWISE QUAD AM Grade 2 15m

x iWISE DT AM Grade3 15m and 25m

x iWISE QUAD AM Grade 3 15m

All iWISE BUS detectors include an additional on-board wired zone defined in the software as

an “input”. This zone can be used and defined as any wired zone in the system.

Programming:

The iWISE BUS detectors are part of the BUS zones category. Therefore, adding/deleting an

iWISE BUS is identical to adding/deleting any BUS zone in the system.

The iWISE BUS detectors can be assigned to a physical wired zone or to a virtual zone or to a

BUS Zone Expander.

Physical zone: Any zone on the ProSYS PCB (zones 1-8) or on a wired zone expander

(G3Z08, G3Z16

Virtual zone: Any zone on a virtual zone expander defined as VBZ08 or VBZ16.

Notes:

Virtual BUS zones are cost effective. They enable to expand your system zones without adding

physical zone expanders.

The virtual BUS Zone expander can be used only for BUS zone detectors. To add a virtual BUS

zone expander select type VBZ08 or VBZ16 when adding a zone expander.

1. Add/delete an iWISE BUS detector:

, BZE08, BZE16, BZE24, BZE32).

a. Access the Engineer menu and select [7] Install > [1] Add Delete Module > [9]

More.. > [5] BUS Zone. The display will show:

BUS Zone:

(0:yy) TYPE=None

In the 0:yy designation, the 0 represents that the Bus detector is not assigned to a

Bus Zone Expander and the yy represents the BUS detector ID number as set by

the detector's DIP switches

b. Use the

to which you want to assign (or delete) a detector. Make sure that the detector’s

physical ID dipswitch setting is identical to the ID number you select during

programming.

c. Place the cursor on the TYPE field and use the

iDTG2 for an iWISE DT grade 2 detector

iQDG2 for an iWISE QUAD grade 2 detector

iDTG3 for an iWISE DT grade 3 detector

iQDG3 for an iWISE QUAD grade 3 detector

and

keys to position the cursor over the BUS Zone ID number

key to select:

4 ProSYS Version 8.xx - Supplementary Instructions

Page 5

d. Press to confirm.

e. Repeat the above steps for other BUS detectors.

2. Assign the iWISE BUS detectors to a Zone:

a. From the main Engineer menu select [2] Zones > [1] One by One.

b. Select the zone number that you want to assign the BUS detector.

Note:

If you defined a virtual BUS Zone Expander, select a zone number from the virtual zones (defined

by the BUS Zone expander).

c. Define Partitions, Groups, Zone Type and Zone Sound.

d. In the Termination category, select [5] BUS Zone followed by

e. Select the BUS zone number to assign to the programmed zone. The type field

will be updated automatically when selecting the zone.

f. Press

g. Press

3. If you want to us e the extra wired zone input on the iWISE BUS detector:

a. Repeat steps a. – c. in step 2 above.

b. In the Termination category, select the relevant BUS Zone input termination:

[07] BUS Zone Input N/C

[08] BUS Zone Input EOL

[09] BUS Zone Input DEOL

[10] BUS Zone Input N/O

[11] BUS Zone Input TEOL

c. Press

will be updated automatically when selecting the zone.

d. Press

e. Press

4. Configure the iWISE BUS detector parameters:

a. From the main Engineer menu select [2] Zones > [0] Miscellaneous > [3] BUS

Zone Parameters.

b. Select the zone that the BUS Zone was assigned to and press

c. Use the following tables to configure the parameters for the relevant iWISE BUS

detector.

. The loop response category is not applicable to a BUS zone.

, assign a label and press .

. Select the BUS zone that the input zone belongs to. The Type field

. Define the loop response time.

, assign a label and press .

.

.

ProSYS Version 8.xx - Supplementary Instructions 5

Page 6

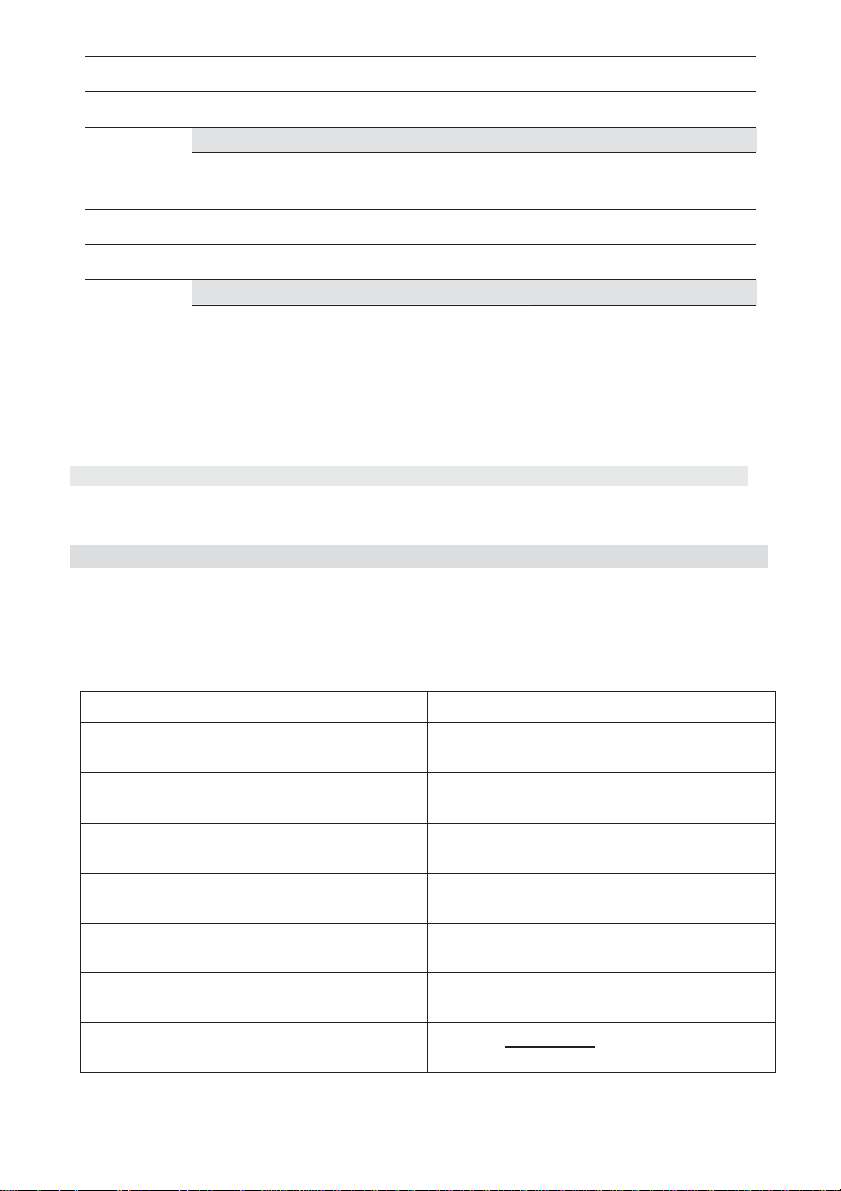

BUS Zone Parameters: iWISE DT Grade 2

Quick Keys Parameter Default Range

[2][0][3][zz]

[1]

[2][0][3][zz]

[1] [1] to [2]

[2][0][3][zz]

[2]

[2][0][3][zz]

[2] [1] to [7]

[2][0][3][zz]

[3]

[2][0][3][zz]

[3] [1] to [2]

[2][0][3][zz]

[4]

[2][0][3][zz]

[4] [1] to [2]

[2][0][3][zz]

[5]

[2][0][3][zz]

[5] [1] to [2]

[2][0][3][zz]

[6]

[2][0][3][zz]

[6][1]

LEDS

Defines the LEDS operation mode.

LEDS Options

1) Off - Disables the LEDS operation.

2) On – Enables the LEDS operation.

MW (Microwave) Range Trimmer

Defines the microwave channel range.

MW Range Options

1) Minimum 2) 25% 3) 50% 4) 65% 5) 85% 6) Maximum 7) Trimmer (MW is

defined by the trimmer setting on the PCB)

ACT No

Defines the Anti-Cloak™ Technology (ACT) operation mode.

ACT Options

1) No - Disables the ACT mode.

2) Yes – Enables the ACT mode.

Automatic Microwave Omit No

Defines whether the MW channel will be bypassed or not while the detector

identifies trouble in the MW channel.

Automatic Microwave Omit Options

1) No - While detecting a problem in the MW channel it is not omitted. Alarm

condition cannot be established until the MW channel is fixed.

2) Yes - Switches the detector to operate only in PIR mode in case of MW

trouble.

Green Line No

A feature that follows environmental guidelines by avoiding surplus emission.

This feature defines the activation of the microwave channel while the system

is disarmed.

Green Line Options

1) No - Green Line feature is disabled. MW is constantly activated.

2) Yes – Green Line feature is activated.

Self Test Remote

Used to test the detection technologies. In the event of a failed test, a Self

Test Trouble is created.

Remote (manual)

The remote self test is performed by the system when a user manually

selects the Diagnostics option from the Maintenance menu via the ProSYS

User Functions menu.

On

6 ProSYS Version 8.xx - Supplementary Instructions

Page 7

BUS Zone Parameters: iWISE DT Grade 2

Quick Keys Parameter Default Range

[2][0][3][zz]

Local (automatic)

[6][2]

Once an hour, the detector automatically checks that the detector’s channels

are functioning properly.

BUS Zone Parameters: iWISE DT Grade 3

Quick Keys Parameter Default Range

[2][0][3][zz][1] LEDS

On

Defines the LEDS operation mode.

[2][0][3][zz][1]

LEDS Options

[1] to [2]

1) Off - Disables the LEDS operation.

2) On – Enables the LEDS operation.

[2][0][3][zz][2] MW (Microwave) Range Trimmer

Defines the microwave channel range.

[2][0][3][zz][2]

MW Range Options

[1] to [7]

1) Minimum 2) 25% 3) 50% 4) 65% 5) 85% 6) Maximum 7) Trimmer (MW is

defined by the trimmer setting on the PCB)

[2][0][3][zz][3] ACT No

Defines the Anti-Cloak™ Technology (ACT) operation mode.

[2][0][3][zz][3]

ACT Options

[1] to [2]

1) No - Disables the ACT mode.

2) Yes – Enables the ACT mode.

[2][0][3][zz][4] Automatic Microwave Omit No

Defines whether the MW channel will be omitted or not while the detector

identifies a fault in the MW channel.

[2][0][3][zz][4]

Automatic Microwave Bypass Options

[1] to [2]

1) No - While detecting a problem in the MW channel it is not omitted. Alarm

condition cannot be established until the MW channel is fixed.

2) Yes - Switches the detector to operate only in PIR mode in case of MW

fault.

[2][0][3][zz][5] Green Line No

A feature that follows environmental guidelines by avoiding surplus emission.

This feature defines the activation of the microwave channel while the system

is disarmed.

[2][0][3][zz][5]

Green Line Options

[1] to [2]

1) No - Green Line feature is disabled. MW is constantly activated.

2) Yes – Green Line feature is enabled.

[2][0][3][zz][6] Anti-Mask Enable

Defines the operation of Anti Masking detection.

ProSYS Version 8.xx - Supplementary Instructions 7

Page 8

BUS Zone Parameters: iWISE DT Grade 3

Quick Keys Parameter Default Range

[2][0][3][zz][6]

Anti-Mask Options

[1] to [2]

1) Disable 2) Enable and behaves according to the settings defined in quick

keys [2][0][3][zz][7].

[2][0][3][zz][7] Set/Unset No

Defines the operation of the anti masking feature while the detector is set or

unset.

[2][0][3][zz][7]

Set/Unset Options

[1]

1) No – When detector is set or unset Anti-mask behaves according to the

settings defined in quick keys [2][0][3][zz][6] above.

2) Yes – when detector is set Anti-mask is disabled. When detector is unset

Anti-mask behaves according to the settings defined in quick keys

[2][0][3][zz][6]

[2][0][3][zz][8] Self Test Remote

Used to test the detection technologies. In the event of a failed test, a Self

Test Fault is created.

[2][0][3][zz][8]

Remote (manual)

[1]

The remote self test is performed by the system when a user manually

selects the Diagnostics option from the Maintenance menu via the ProSYS

User Functions menu.

[2][0][3][zz][8]

Local (automatic)

[2]

Once an hour, the detector automatically checks that the detector’s channels

are functioning properly.

BUS Zone Parameters: iWISE QUAD Grade 2

Quick Keys Parameter Default Range

[2][0][3][zz]

LEDS

On

[1]

Defines the LEDS operation mode.

[2][0][3][zz]

LEDS Options

[1] [1] to [2]

1) Off - Disables the LEDS operation.

2) On – Enables the LEDS operation.

[2][0][3][zz]

Sensitivity Normal

[2]

Defines the sensitivity of the detector (PIR).

[2][0][3][zz]

Sensitivity Options

[2] [1]to[4]

1) Low 2) High

[2][0][3][zz]

Self Test Remote

[3]

Used to test the detection technologies. In the event of a failed test, a Self

Test Trouble is created.

8 ProSYS Version 8.xx - Supplementary Instructions

Page 9

BUS Zone Parameters: iWISE QUAD Grade 2

Quick Keys Parameter Default Range

[2][0][3][zz]

Remote (manual)

[3][1]

The remote self test is performed by the system when a user manually

selects the Diagnostics option from the Maintenance menu via the ProSYS

User Functions menu.

[2][0][3][zz]

Local (automatic)

[3][2]

Once an hour, the detector automatically checks that the it's channels are

functioning properly.

BUS Zone Parameters: iWISE QUAD Grade 3

Quick Keys Parameter Default Range

[2][0][3][zz][1] LEDS

On

Defines the LEDS operation mode.

[2][0][3][zz][1]

LEDS Options

[1] to [2]

1) Off - Disables the LEDS operation.

2) On – Enables the LEDS operation.

[2][0][3][zz][2] Sensitivity Normal

Defines the sensitivity of the detector (PIR).

[2][0][3][zz][2]

Sensitivity Options

[1]to[4]

1) Low 2) High

[2][0][3][zz][3] Anti-Mask Enable

Defines the operation of Anti Masking detection.

[2][0][3][zz][3]

Anti-Mask Options

[1]to[2]

1) Disable 2) Enable and behaves according to the settings defined in quick

keys [2][0][3][zz][4].

[2][0][3][zz][4] Set/Unset No

Defines the operation of the anti masking feature while the detector is set or

unset.

[2][0][3][zz][4]

Set/Unset Options

[1]to[2]

1) No – When detector is set or unset Anti-mask behaves according to the

settings defined in quick keys [2][0][3][zz][6] above.

2) Yes – when detector is set Anti-mask is disabled. When detector is unset

Anti-mask behaves according to the settings defined in quick keys

[2][0][3][zz][3]

[2][0][3][zz][5] Self Test Remote

Used to test the detection technologies. In the event of a failed test, a Self

Test Fault is created.

ProSYS Version 8.xx - Supplementary Instructions 9

Page 10

BUS Zone Parameters: iWISE QUAD Grade 3

Quick Keys Parameter Default Range

[2][0][3][zz][5]

Remote (manual)

[1]

The remote self test is performed by the system when a user manually

selects the Diagnostics option from the Maintenance menu via the ProSYS

User Functions menu.

[2][0][3][zz][5]

Local (automatic)

[2]

Once an hour, the detector automatically checks that the detector’s channels

are functioning properly.

BUS Detector Naming Conventions

The following table contains the names of the various BUS detectors and their corresponding

Engineer programming menu codes under the Type field, when adding a new BUS zone to the

system.

BUS Detector TYPE Field Option

in Previous Versions

TYPE Field Option

in Version 7 and above

WatchOUT DT ODT15 ODT15

WatchOUT PIR OPR12 OPR12

Industrial LuNAR LUNR Cannot be selected,

Replaced by Industrial

LuNAR Grade 3.

Industrial LuNAR Grade 3 LUNG3 ILun3

WatchIN IDT25 WatIN

iWISE DT G2 BUS 15m, 25m N/A iDTG2

iWISE QUAD G2 BUS N/A IQUG2

iWISE DT G3 BUS 15m, 25m N/A iDTG3

iWISE QUAD G3 BUS N/A IQUG3

New Firmware Capabilities

The information in this section describes new capabilities in the ProSYS firmware and new

parameters under the Engineer programming menu.

WatchOUT Proximity Anti Mask

WatchOUT DT version B (P/N RK325DT00UKB) has a new proximity anti masking capability in

addition to its regular IR anti masking capability.

When the WatchOUT DT is installed as a BUS zone, in order to enable Proximity Anti-Mask the

following parameters must be programmed:

10 ProSYS Version 8.xx - Supplementary Instructions

Page 11

Zones Miscellaneous: BUS Zone - WatchOUT

Quick Keys Parameter Default Range

[2][0][3][zz][8] Prox Anti Mask Enable

Defines the operation of proximity anti masking detection.

[1] Disable [2] Enable

System: Controls

Quick Keys Parameter Default Range

[1][2][57] Prox AM=Tamper No

Used to determine the operation of the proximity anti masking detection.

Yes: Proximity anti mask detection will activate the tamper alarm.

No: Proximity anti mask detection will be regarded as a fault.

Note that this parameter is new and replaces the VBR=Tamper parameter

that once used the same quick key sequence.

Note that Proximity AM operates for approximately 2.2 seconds when the

detector is approached in close proximity.

Programming Output Operation Using Proximity Tag

A Programming Output that is defined as “Follow Code” can now also be activated when a

proximity tag is presented to a proximity key reader, a proximity keypad or a G-Tag reader.

PCB Labeling Modification

Some of the labels on the ProSYS PCB will be modified with the following textual changes.

Labels that do not appear in the table below will remain the same.

Note that these modifications a re purely textual and have no impact on the functionality of the

PCB which will remain the same.

New PCB Label Current PCB Label

Phone A1

Phone A

-

Terminal HO SPK

+ Terminal TR

-

Terminal LID

TMP

Terminal OUTPUT 1

TRG C N.O

ProSYS Version 8.xx - Supplementary Instructions 11

Phone SET Phone B1

Phone LINE Phone B

Terminal COM Terminal HO

Terminal BELL/LS

+ -

Terminal BELL

TMP

Terminal BOX

TMP

Terminal N.C C N.O

UO1

Page 12

RISCO Group UK Ltd

Tel: 0161 655 5500

Fax: 0161 655 5501

Internet: www.riscogroup.co.uk

Technical Support Tel: 0161 655 5600

Technical Support Fax: 0161 655 5610

Technical e-mail: technical@riscogroup.co.uk

RISCO Group UK Ltd reserve the right to amend the software and features without prior notice.

© RISCO Group 08/09 5IN1182 B

Loading...

Loading...