Raypak H3-302B Installation Manual

INSTALLATION & OPERATING

INSTRUCTIONS

Models 302B–902B

Types H, WH & P

® LLC

® LLC

WARNING: If these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids or other combustible materials in the vicinity of this or any other appliance. To do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in another safe place for future reference.

CATALOG NO. 1000.501M |

Effective: 07-01-16 |

Replaces: 04-30-14 |

P/N 240757 Rev. 14 |

Rev. 14 reflects the following:

Changes to: “Gas supply pressure” on page 22, wiring diagram on page 46

Additions: None

Deletions: Type “P” warranty on page 57

2

CONTENTS

WARNINGS |

4 |

BEFORE INSTALLATION |

5 |

Product Receipt |

5 |

Model Identification |

5 |

Ratings and Certifications |

5 |

Installations at Elevation |

5 |

Component Locations |

6 |

General Information |

7 |

GENERAL SAFETY |

8 |

Time/Temperature Relationships in |

|

Scalds |

8 |

INSTALLATION |

9 |

Installation Codes |

9 |

Equipment Base |

9 |

Stacking |

9 |

Clearances |

10 |

Combustion and Ventilation Air |

12 |

Conventional Combustion Air Supply |

13 |

Water Piping |

14 |

Hydronic Heating |

16 |

Gas Supply |

21 |

Electrical Power Connections |

23 |

Field Wiring Connection |

24 |

Venting |

25 |

Changing the Flue Outlet |

28 |

Venting Installation Tips |

28 |

Venting Configurations |

28 |

Outdoor Installation

Controls

Heater Sequence of Operations

Wiring Diagram

START-UP

Pre Start-up

Start-Up

OPERATION

Lighting Instructions

To Turn Off Gas To Appliance

TROUBLESHOOTING

MAINTENANCE

Suggested Minimum

Maintenance Schedule

Preventative Maintenance Schedule

APPENDIX

Inside Air Contamination

WARRANTIES

Type H and WH

Start-Up Checklist

Important Instructions for the Commonwealth of Massachusetts

34

34

35

41

42

42

43

46

46

46

47

48

48

48

50

50

52

52

54

55

3

WARNINGS

Pay Attention to These Terms

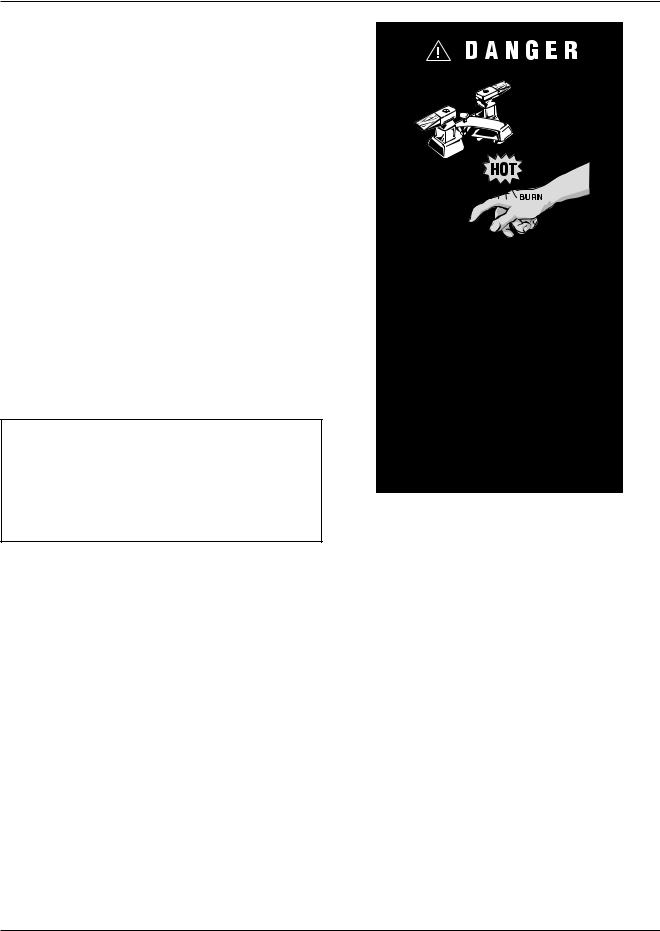

DANGER: Indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored.

WARNING: Indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial property damage if ignored.

CAUTION: Indicates the presence of hazards or unsafe practices which could cause minor personal injury or product or property damage if ignored.

NOTE: Indicates special instructions on installation, operation, or maintenance which are important but not related to personal injury hazards.

|

|

|

|

|

DANGER: Make sure the gas on which the heater |

|

WARNING: Both natural gas and propane have an |

||

will operate is the same type as that specified on the |

|

odorant added to aid in detecting a gas leak. Some |

||

heater rating plate. |

|

people may not physically be able to smell or |

||

|

|

recognize this odorant. If you are unsure or |

||

|

||||

|

|

unfamiliar with the smell of natural gas or propane, |

||

WARNING: Should overheating occur or the gas |

||||

|

ask your local gas supplier. Other conditions, such |

|||

supply valve fail to shut, do not turn off or disconnect |

|

|||

|

as "odorant fade," which causes the odorant to |

|||

the electrical supply to the heater. Instead, shut off |

|

|||

|

diminish in intensity, can also hide, camouflage, or |

|||

the gas supply at a location external to the heater. |

|

|||

|

otherwise make detecting a gas leak by smell more |

|||

|

|

|||

|

|

difficult. |

||

WARNING - CALIFORNIA PROPOSITION |

||||

|

|

|

||

|

|

|

||

65: This product contains chemicals known to the |

|

|

|

|

|

WARNING: UL recognized fuel gas detectors are |

|||

State of California to cause cancer, birth defects or |

|

|||

|

recommended in all enclosed propane and natural |

|||

other reproductive harm. |

|

|||

|

gas applications wherein there is a potential for an |

|||

|

|

|||

|

|

explosive mixture of fuel gas to accumulate and their |

||

WARNING: To minimize the possibility of improper |

|

installation should be in accordance with the |

||

operation, serious personal injury, fire, or damage to |

|

detector manufacturer's recommendations and/or |

||

the heater: |

|

local laws, rules, regulations, or customs. |

||

• Always keep the area around the heater free of |

|

|

|

|

|

WARNING: Risk of electrical shock. More than one |

|||

combustible materials, gasoline, and other flam- |

|

disconnect switch may be required to deenergize the |

||

mable liquids and vapors. |

|

equipment before servicing. |

||

• Heater should never be covered or have any |

|

|

|

|

|

|

|

||

|

CAUTION: Operation of this heater in low- |

|||

blockage to the flow of fresh air to the heater. |

|

|||

|

|

temperature systems requires special piping. |

||

|

||||

|

|

Harmful internal condensation will occur if the inlet |

||

WARNING: Do not use this heater if any part has |

||||

been under water. Immediately call a qualified |

|

water temperature does not exceed 105°F. Warranty |

||

|

claims will be denied when condensation occurs. |

|||

service technician to inspect the heater and to |

|

|||

replace any part of the control system and any gas |

|

|

|

|

control which has been under water. |

|

CAUTION: If this heater is to be installed above |

||

|

|

radiation level, it must be provided with a low water |

||

WARNING: All venting types must be of the same |

|

cut-off device at the time of heater installation. |

||

material or product throughout the entire exhaust |

|

|

|

|

installation to ensure proper securing and sealing. |

|

CAUTION: If this heater is to be installed in a |

||

|

|

negative or positive pressure equipment room, there |

||

|

|

are special installation requirements. Consult factory |

||

|

|

for details. |

||

|

|

|

|

|

|

4 |

|

|

|

BEFORE INSTALLATION

Raypak strongly recommends that this manual be reviewed thoroughly before installing your Hi Delta® heater. Please review the General Safety information before installing the heater. Factory warranty does not apply to heaters that have been improperly installed or operated. (Refer to the warranty at the back of this manual.) Installation and service must be performed by a qualified installer, service agency or gas supplier. If, after reviewing this manual, you still have questions which this manual does not answer, please contact the manufacturer or your local Raypak representative.

Thank you for purchasing a Raypak product. We hope you will be satisfied with the high quality and durability of our equipment.

Product Receipt

On receipt of your heater it is suggested that you visually check for external damage to the shipping crate. If the crate is damaged, make a note to that effect on the Bill of Lading when signing for the shipment. Remove the heater from the shipping packaging. Report any damage to the carrier immediately.

On occasion, items are shipped loose. Be sure that you receive the correct number of packages as indicated on the Bill of Lading.

Claims for shortages and damages must be filed with the carrier by consignee. Permission to return goods must be received from the factory prior to shipping. Goods returned to the factory without an authorized Returned Goods Receipt number will not be accepted. All returned goods are subject to a restocking charge.

When ordering parts, you must specify the model and serial number of the heater. When ordering under warranty conditions, you must also specify the date of installation.

Purchased parts are subject to replacement only under the manufacturer’s warranty. Debits for defective replacement parts will not be accepted and will be replaced in kind only per Raypak’s standard warranties.

Model Identification

The model identification number and heater serial number are found on the heater rating plate located on the lower right outside jacket of the heater. The model

number will have the form H9 1262B or similar depending on the heater size and configuration. The letter(s) in the first group of characters identifies the application (H = Hydronic Heating, WH = Domestic Hot Water (DHW), P = Pool). The number which follows identifies the firing mode (1 or 4 = on-off, 3 = 2-stage, 8 = 3-stage and 9 = 4-stage). The second group of characters identifies the size of the heater (four numbers representing the approximate MBTUH input), and, where applicable, a letter, indicating the manufacturing series.

Ratings and Certifications

Standards:

•ANSI Z21.13 · CSA 4.9 - latest edition, Gas-Fired Hot Water Boilers

•CAN 3.1 - latest edition, Industrial and Commercial Gas-Fired Package Boilers

•ANSI Z21.56 · CSA 4.7 - latest edition Gas-Fired Pool Heaters

•ANSI Z21.10.3 · CSA 4.3 - latest edition Gas Water Heaters

•Low-lead content (<.25%) CSA-certified

All Raypak heaters are National Board Approved, and design-certified and tested by the Canadian Standards Association (CSA) for the U.S. and Canada. Each heater is constructed in accordance with Section IV of the American Society of Mechanical Engineers (ASME) Heater Pressure Vessel Code and bears the ASME stamp. The heater also complies with the latest edition of ASHRAE 90.1 Standard.

WARNING: Altering any Raypak pressure vessel by installing replacement heat exchangers, tube bundle headers, or any ASME parts not manufactured and/or approved by Raypak will instantly void the ASME and CSA ratings of the vessel and any Raypak warranty on the vessel. Altering the ASME or CSA ratings of the vessel also violates national, state, and local approval codes.

Installations at Elevation

Rated inputs are suitable for up to 4,500 ft elevation without de-rating. Consult the factory for installations at altitudes over 4,500 ft above sea level.

5

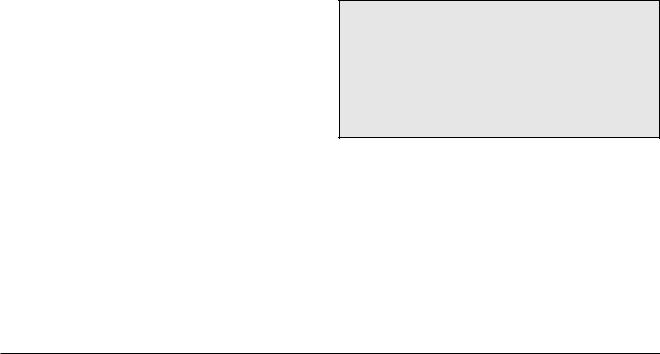

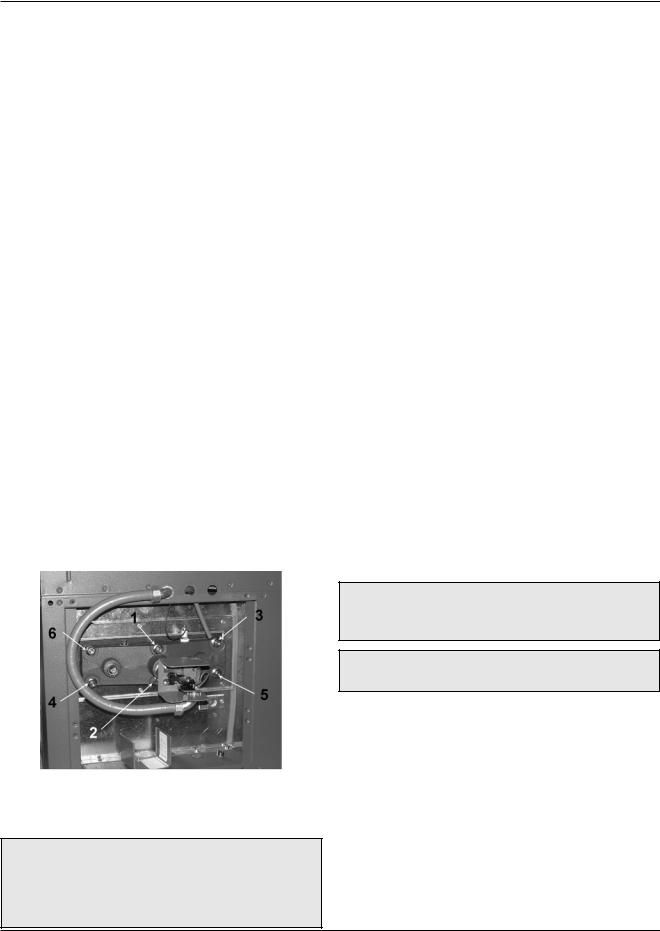

Component Locations

Fig. 1: Component Locations – Back

Fig. 2: Component Locations – Left Side

Panels removed for clarity

Fig. 3: Component Locations – Front

6

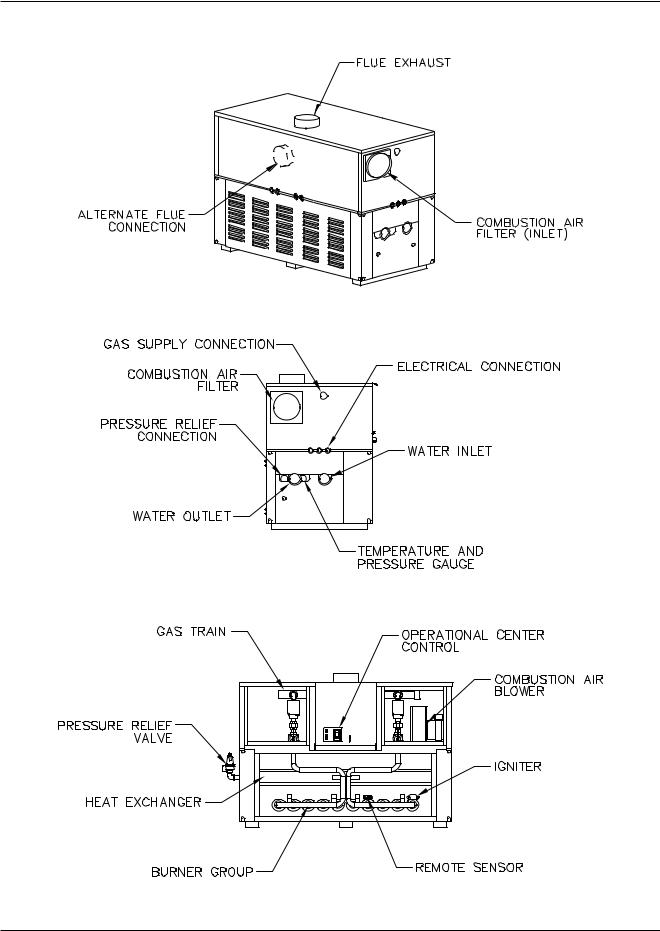

General Information

|

|

Quantity of |

|

Vent Size |

|

Model |

|

|

(in.) |

||

|

|

|

|||

No. |

Burners |

Gas |

Blowers |

Flue |

Intake |

|

|||||

|

Valves |

||||

|

|

|

|

|

|

|

|

|

|

|

|

302B |

6 |

1 |

1 |

5 |

6 |

|

|

|

|

|

|

402B |

8 |

1 |

1 |

6 |

6 |

|

|

|

|

|

|

502B |

10 |

2 |

1 |

6 |

6 |

|

|

|

|

|

|

652B |

13 |

2 |

1 |

8 |

6 |

|

|

|

|

|

|

752B |

15 |

2 |

1 |

8 |

6 |

|

|

|

|

|

|

902B |

18 |

3 |

1 |

8 |

6 |

Table A: Basic Data

Model |

# Burners per |

|

Stages |

|

|

% Fire at |

||||||||||

|

Valve |

|

|

|

|

|

Stage |

|||||||||

No. |

|

|

|

|

|

|

|

|

|

|

|

|||||

1 |

2 |

|

3 |

|

1 |

|

2 |

|

|

1 |

|

2 |

||||

|

|

|

|

|

|

|

||||||||||

302B |

6 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

100 |

|

402B |

8 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

100 |

|

502B |

5 |

5 |

|

|

|

|

1 |

|

1, 2 |

|

50 |

|

100 |

|||

652B |

7 |

6 |

|

|

|

|

1 |

|

1, 2 |

|

54 |

|

100 |

|||

752B |

8 |

7 |

|

|

|

|

1 |

|

1, 2 |

|

53 |

|

100 |

|||

902B |

6 |

6 |

|

6 |

|

1, 2 |

|

1, 2, 3 |

|

66 |

|

100 |

||||

|

|

Table B: Manifold Data |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Model |

# Burners |

|

|

|

Valve |

|

|

% Firing |

||||||||

per Valve |

|

|

Staging |

|

|

at Stage |

||||||||||

No. |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2* |

|

|

1 |

|

|

2 |

|

1 |

|

2 |

|||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

302B |

4 |

2 |

|

|

|

1 |

|

|

1, 2 |

|

66 |

|

100 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

402B |

5 |

3 |

|

|

|

1 |

|

|

1, 2 |

|

63 |

|

100 |

|||

|

|

|

|

|

|

|

||||||||||

* Valve 2 is inside the air plenum on H3/WH3 302B-402B |

||||||||||||||||

|

Table C: 2-Stage Design Option |

|

||||||||||||||

7

GENERAL SAFETY

To meet commercial hot water use needs, the high limit safety control on this water heater is adjustable up to 210°F. However, water temperatures over 125°F can cause instant severe burns or death from scalds. When supplying general purpose hot water, the recommended initial setting for the temperature control is 125°F.

Safety and energy conservation are factors to be considered when setting the water temperature on the thermostat. The most energy-efficient operation will result when the temperature setting is the lowest that satisfies the needs of the application.

Water temperature over 125°F can cause instant severe burns or death from scalds. Children, disabled and elderly are at highest risk of being scalded.

•Feel water before bathing or showering.

•Temperature limiting valves are available.

NOTE: When this water heater is supplying general purpose hot water for use by individuals, a thermostatically controlled mixing valve for reducing point of use water temperature is recommended to reduce the risk of scald injury. Contact a licensed plumber or the local plumbing authority for further information.

Maximum water temperatures occur just after the heater’s burner has shut off. To determine the water temperature being delivered, turn on a hot water faucet and place a thermometer in the hot water stream and read the thermometer.

Water temperature over 125°F can cause instant severe burns or death from scalds.

Children, disabled, and elderly are at highest risk of being scalded.

See instruction manual before setting temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are available, see manual.

Time/Temperature Relationships in Scalds

The following chart details the relationship of water temperature and time with regard to scald injury and may be used as a guide in determining the safest water temperature for your applications.

Water |

Time to Produce Serious |

Temp. |

Burn |

120°F |

More than 5 minutes |

|

|

125°F |

1-1/2 to 2 minutes |

|

|

130°F |

About 30 seconds |

135°F |

About 10 seconds |

140°F |

Less than 5 seconds |

|

|

145°F |

Less than 3 seconds |

150°F |

About 1-1/2 seconds |

|

|

155°F |

About 1 second |

Table courtesy of The Shriners Burn Institute

Table D: Time to Produce Serious Burn

8

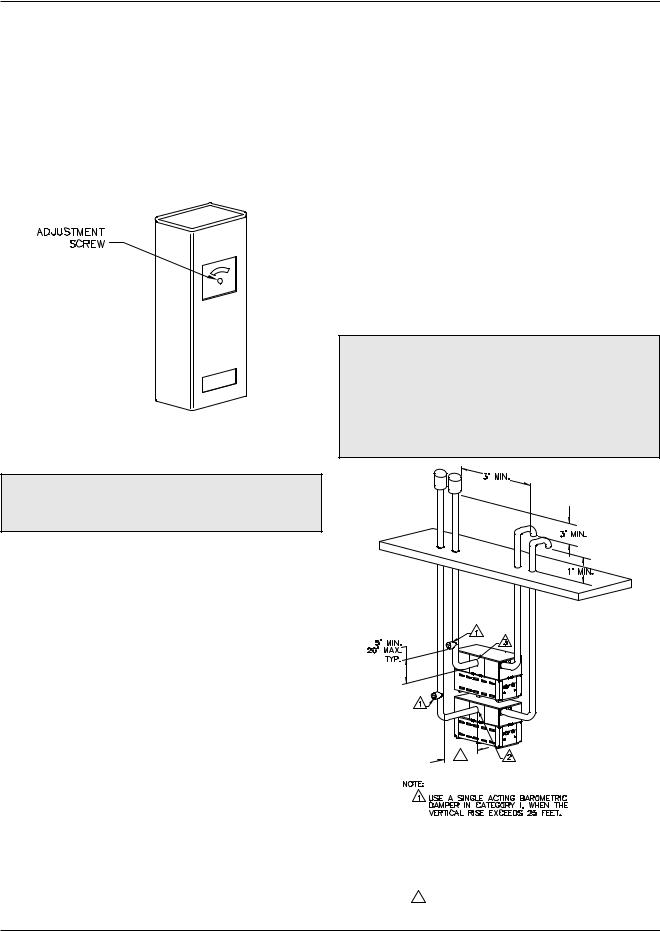

The temperature of the water in the heater can be regulated by using the temperature controller. To comply with safety regulations, the temperature controller is set at the lowest setting when shipped from the factory.

To adjust the water temperature, insert a small straight screwdriver into the adjustment screw on the front of temperature controller and turn the wheel to the desired setting (See Fig. 4.).

Fig. 4: Temperature Controller

INSTALLATIONCAUTION: Hotter water increases the risk of scalding! There is a hot water scald potential if the thermostat is set too high.

INSTALLATION

Installation Codes

Installations must follow these codes:

•Local, state, provincial, and national codes, laws, regulations and ordinances

•National Fuel Gas Code, ANSI Z223.1/NFPA 54 – latest edition (NFGC)

•National Electrical Code, ANSI/NFPA 70 - latest edition (NEC)

•Standard for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1, when required (CSD-1)

•For Canada only: CAN/CSA B149 Installation Code (B149) and CSA C22.1 C.E.C. Part 1 (C22.1)

Equipment Base

The heater should be mounted on a level, structurally sound surface. The heater is approved for installation on a combustible surface but must NEVER be installed on carpeting. Gas-fueled equipment installed in enclosed parking garages must be located at least 18 in. above the floor.

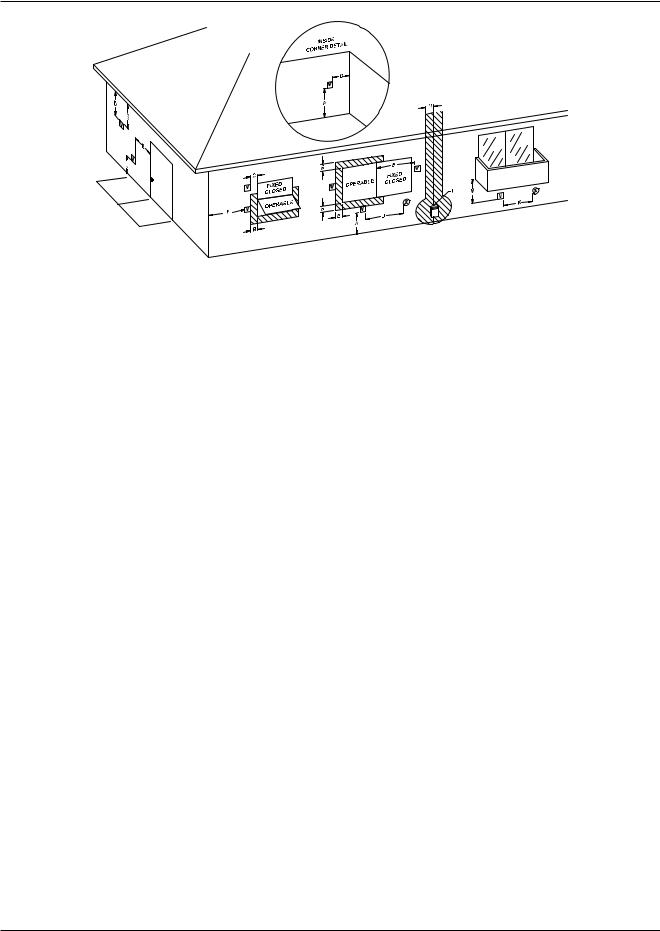

Stacking

Hi Delta units can be stacked two units high with an optional stacking rack. A stacking kit (sales order option X-1) is available from Raypak for this type of installation.

For installations above grade, a reinforcing kit (sales order option X-2) may also be required.

CAUTION: The heaters should be located in an area where water leakage will not result in damage to the area adjacent to the appliances or to the structure. When such locations cannot be avoided, it is recommended that a suitable catch pan, adequately drained, be installed under the appliance. The pan must not restrict air flow.

4

REQUIRES OPTIONAL VENT TEE.

REQUIRES OPTIONAL VENT TEE.

REQUIRES OPTIONAL VENT TEE IF VENTED OUT BACK

REQUIRES OPTIONAL VENT TEE IF VENTED OUT BACK

OF HEATER.

4 PER NATIONAL FUEL GAS CODE (NFGC).

9

Fig. 5: Typical Stacked Installation

In addition, the heater shall be installed such that the gas ignition system components are protected from water (dripping, spraying, rain, etc.) during appliance operation or service (circulator replacement, control replacement, etc.).

Clearances

Indoor Installations

Heater |

Minimum Clearance |

Recommended |

|

from Combustible |

Service |

||

Side |

|||

Surfaces |

Clearance |

||

|

|||

|

|

|

|

Floor* |

0” |

0” |

|

|

|

|

|

Rear |

1” |

6” |

|

|

|

|

|

Water Side |

12” |

24” |

|

|

|

|

|

Other Side |

1” |

24” |

|

|

|

|

|

Top |

1” |

6” |

|

|

|

|

|

Front |

Open |

24” |

|

|

|

|

|

Vent |

2” |

2” |

|

|

|

|

|

* DO NOT install on carpeting. |

|

||

Table E: Clearances – Indoor Installations

TOP VIEW

FRONT VIEW

Venting not shown for clarity. Heater must be vented

per instructions in this manual

Fig. 6: Minimum Clearances from Combustible Surfaces – Indoor Installations

When installed according to the listed minimum clearances from combustible construction, these heaters can still be serviced without removing permanent structural construction around the heater. However, for ease of servicing, we recommend a clearance of at least 24 in. in front, and at least 12 in. on the water connection side. This will allow the heater to be serviced in its installed location without movement or removal of the heater.

Service clearances less than the minimums may require removal of the heater to service either the heat exchanger or the burner tray. In either case, the heater must be installed in a manner that will enable the heater to be serviced without removing any structure around the heater.

Outdoor Installations

These heaters are design-certified for outdoor installation. Heaters must not be installed under an overhang that is less than 3 ft from the top of the heater. Three sides must be open in the area under the overhang. Roof water drainage must be diverted away from heaters installed under overhangs.

Heater |

Min. Clearance |

Recommended |

|

from Combustible |

Service |

||

Side |

|||

Surfaces |

Clearance |

||

|

|||

|

|

|

|

Front |

Open |

24” |

|

|

|

|

|

Rear |

12” |

24” |

|

|

|

|

|

Water Side |

36” |

36” |

|

|

|

|

|

Other Side |

36” |

36” |

|

|

|

|

|

Top |

Unobstructed |

Unobstructed |

|

|

|

|

|

Vent |

N/A |

N/A |

Table F: Clearances – Outdoor Installations

These clearances are required when the outdoor vent cap is used. If installing the heater outdoors with a vent stack, the indoor clearances may be utilized.

The combustion air intake hood MUST be used for outdoor installations. The hood is shipped loose and installed on the side of the heater over the filter box at the jobsite.

10

Fig. 7: Minimum Clearances from Vent/Air Inlet Terminations – Indoor and Outdoor Installations

|

|

U.S. Installations1 |

Canadian Installations2 |

|

A |

Clearance above grade, veranda, porch, |

1 ft (30 cm) |

1 ft (30 cm) |

|

deck, or balcony |

||||

|

|

|

||

|

Clearance to window or door that may be |

4 ft (1.2m) below or to side |

|

|

B |

of opening; 1 foot (30 cm) |

3 ft (91 cm) |

||

opened |

||||

|

above opening |

|

||

|

|

|

||

C |

Clearance to permanently closed window |

* |

* |

|

|

Vertical clearance to ventilated soffit located |

|

|

|

D |

above the terminal within a horizontal dis- |

5 ft (1.5m) |

* |

|

tance of 2 ft (61cm) from the centerline of the |

||||

|

|

|

||

|

terminal |

|

|

|

E |

Clearance to unventilated soffit |

* |

* |

|

F |

Clearance to outside corner |

* |

* |

|

G |

Clearance to inside corner |

6 ft (1.83m) |

* |

|

|

Clearance to each side of center line ex- |

* |

3 ft (91 cm) within a height |

|

H |

15 ft above the me- |

|||

tended above meter/regulator assembly |

||||

|

|

ter/regulator assembly |

||

|

|

|

||

I |

Clearance to service regulator vent outlet |

* |

6 ft (1.83m) |

|

|

Clearance to non-mechanical air supply inlet |

4 ft (1.2m) below or to side |

|

|

J |

to building or the combustion air inlet to any |

of opening; 1 ft (30 cm) |

3 ft (91 cm) |

|

|

other appliance |

above opening |

|

|

K |

Clearance to mechanical air supply inlet |

3 ft (91 cm) above if within |

6 ft (1.83m) |

|

10 ft (3m) horizontally |

||||

|

|

|

||

L |

Clearance above paved sidewalk or paved |

7 ft (2.13m) |

7 ft (2.13m) t |

|

driveway located on public property |

||||

|

|

|

||

M |

Clearance under veranda, porch, deck or |

* |

12 in. (30 cm) TT |

|

balcony |

||||

|

|

|

1In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Code

2In accordance with the current CAN/CSA-B149 Installation Codes

tVent terminal shall not terminate directly above sidewalk or paved driveway located between 2 single family dwellings that serves both dwellings

TT Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor and top of terminal and underside of veranda, porch, deck or balcony is greater than 1 ft (30cm)

* Clearances in accordance with local installation codes and the requirements of the gas supplier

Table G: Vent/Air Inlet Termination Clearances

11

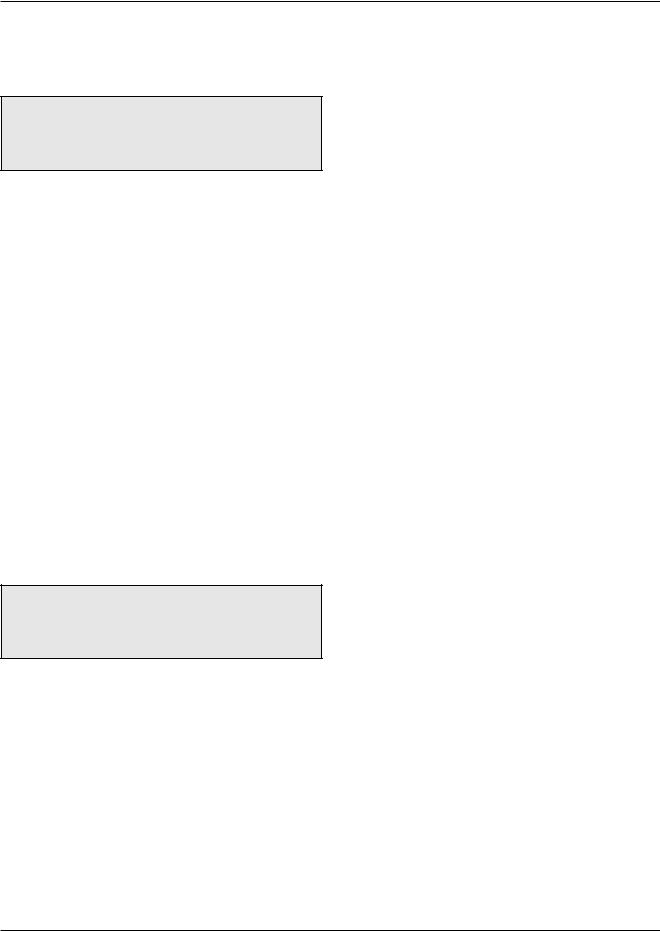

Fig. 8: Minimum Clearances from Combustible Surfaces – Outdoor Installations

Combustion and Ventilation Air

NOTE: Use of the heater in construction areas where fine particulate matter, such as concrete or drywall dust, is present may result in damage to the heater that is not covered by the warranty. If operated in a construction environment, a clean source of combustion air must be provided directly to the heater.

Indoor Units

The heater must be supplied with sufficient quantities of non-contaminated air to support proper combustion and equipment ventilation. Combustion air can be supplied via conventional means where combustion air is drawn from the area immediately surrounding the heater, or via direct vent, where combustion air is drawn directly from outside. All installations must comply with the requirements of the NFGC (U.S.) and B149 (Canada), and all local codes.

CAUTION: Combustion air must not be contaminated by corrosive chemical fumes which can damage the heater and void the warranty. (See the Appendix.)

NOTE: It is recommended that the intake vent be insulated to minimize sweating.

Reversing Air Filter

Follow these instructions to change the air duct connection from the left-hand side (standard) to the right-hand side:

1. Remove the four screws and the dust cover from the right-hand side of the heater.

2. Remove the four screws and the air filter bracket from the left-hand side of the heater.

3. Reverse the components and reattach in the new location, making sure that the air filter locking bracket is on the bottom. (The air filter locking bracket is reversible.)

Direct Vent

If outside air is drawn through the intake pipe directly to the unit for combustion:

1. Install combustion air direct vent in accordance with Fig. 27 (horizontal) or Fig. 28 (vertical) of this manual (pages 31 and 32, respectively).

2. Ventilation of the space occupied by the heater(s) is recommended and can be provided by an opening(s) for ventilation air at the highest practical point communicating with the outdoors. The total cross-sectional area should be at least 1 in.2 of free area per 20,000 BTUH (111 mm2 per kW) of total input rating of all equipment in the room when the opening is communicating directly with the outdoors or through vertical duct(s). The total cross-sectional area should be at least 1 in.2 of free area per 10,000 BTUH (222 mm2 per kW) of total input rating of all equipment in the room when the opening is communicating with the outdoors through horizontal duct(s). Damage to the equipment due to inadequate ventilation of the space is not a warrantable failure.

3. In cold climates, and to mitigate potential freezeup, Raypak highly recommends the installation of a motorized sealed damper to prevent the circulation of cold air through the heater during the non-operating hours.

Direct-Ducted Combustion Air

In certain applications it may be desirable to duct the combustion air directly to the heater. This should be done with PVC, CPVC or single-wall galvanized ducting. The duct will attach directly to the collar on the air filter housing located on the side of the heater. The ducting is attached to the air filter housing collar using

12

three or four sheet metal screws (not supplied) equally distributed around the circumference of the duct. All ducting should be self-supported. The filter housing is not designed to support the air duct.

CAUTION: Use TrueSeal combustion air if damaging airborne contaminants are or will be present in the heater area. See the Appendix regarding air contamination.

TruSeal® Combustion Air

In certain applications it may be necessary to utilize the TruSeal option (sales order option D-21 or D-22) and duct the combustion air directly to the blower. Combustion air may be ducted directly to the heater by using PVC, CPVC or sealed single-wall galvanized ducting. The duct will attach directly to the air collar located on the side of the heater, using three or four sheet metal screws (not supplied) equally positioned around the circumference of the duct. The screws and duct connection point must be sealed with RTV (not supplied). An in-line intake air filter kit (sales order option D-17) must be installed in the combustion air duct. TruSeal is generally used when damaging contaminants are present in the mechanical room.

TruSeal heater connection points are available as follows:

302B & 402B

502B to 902B

CAUTION: This type of installation is recommended if damaging airborne contaminants are or will be present in the heater area. See the Appendix regarding air contamination.

Conventional Combustion Air Supply

U.S. Installations

All Air from Inside the Building

The confined space shall be provided with TWO permanent openings communicating directly with an additional room(s) of sufficient volume so that the combined volume of all spaces meets the criteria for a room large in comparison (NFGC). The total input of all gas utilization equipment installed in the combined

space shall be considered in making this determination. Each opening shall have a minimum free area of 1 in.2 per 1,000 BTUH (2,225 mm2 per kW) of the total input rating of all gas utilization equipment in the confined space, but not less than 100 in.2 (645 cm2). One opening shall commence within 12 in. (305 mm) of the top, and one opening shall commence within 12 in. (305 mm) of the bottom of the enclosure. The minimum dimension of air openings shall be not less than 3 in. (76 mm) in any direction.

All Air from Outdoors

The confined space shall communicate with the outdoors in accordance with one of the methods below. The minimum dimension of air openings shall not be less than 3 in. (76 mm) in any direction. Where ducts are used, they shall be of the same cross-sectional area as the net free area of the openings to which they connect.

1.Two permanent openings, one commencing within 12 in. (305 mm) of the top, and one commencing within 12 in. (305 mm) of the bottom of the enclosure, shall be provided. The openings shall communicate directly, or by ducts, with the outdoors or spaces (crawl or attic) that freely communicate with the outdoors.

a.Where directly communicating with the outdoors or where communicating to the outdoors through vertical ducts, each opening shall have a minimum free area of 1 in.2 per 4,000 BTUH (550 mm2 per kW) of total input rating of all equipment in the enclosure.

b.Where communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 in.2 per 2,000 BTUH (1,100 mm2 per kW) of total input rating of all equipment in the enclosure.

2.One permanent opening, commencing within 12 in. (305 mm) of the top of the enclosure, shall be permitted where the equipment has clearances of at least 1 in. (25 mm) from the sides and back and 6 in. (152 mm) from the front of the appliance. The opening shall directly communicate with the outdoors or shall communicate through a vertical or horizontal duct to the outdoors or spaces that freely communicate with the outdoors, and shall have a minimum free area of:

a.1 in.2 per 3,000 BTUH (740 mm2 per kW) of the total input rating of all equipment located in the enclosure, and

13

b.Not less than the sum of the areas of all vent connectors in the confined space.

WARNING: Do not use one permanent opening method if the equipment room is under negative pressure conditions or the equipment is common vented with other gas-fired appliances.

Canadian Installations

CAUTION: All combustion air must be drawn from the air outside of the building; the mechanical equipment room must communicate directly with the outdoors.

1.Ventilation of the space occupied by the heater shall be provided by an opening(s) for ventilation air at the highest practical point communicating with the outdoors. The total cross-sectional area of such an opening(s) shall be at least 10% of the area required in 2. and 3. (below), but in no case shall the cross-sectional area be less than 10 in.2 (65 cm2).

2.For heaters using a barometric damper in the vent system there shall be a permanent air supply opening(s) having a cross section area of not less than 1 in.2 per 7,000 BTUH (320 mm2 per kW) up to and including 1 million BTUH, plus 1 in.2 per 14,000 BTUH (160 mm2 per kW) in excess of 1 million BTUH. This opening(s) shall be either located at or ducted to a point not more than 18 in. (450 mm) nor less than 6 in. (152 mm) above the floor level. The duct can also “goose neck” through the roof. The duct is preferred to be straight down and terminated 18 in. (450 mm) from the floor, but not near piping. This air supply opening requirement shall be in addition to the air opening for ventilation air required in 1. (above).

WARNING: Care must be taken to ensure that the equipment room is not under negative pressure conditions or that the equipment is not commonvented with other gas-fired appliances.

3.For heaters not using a barometric damper in the vent system, and when air supply is provided by natural air flow from outdoors for a power burner and there is no draft regulator, drafthood or similar flue gas dilution device installed in the same space, in addition to the opening for ventilation air required in 1., there shall be a permanent air supply opening(s) having a total cross-sectional area

14

of not less than 1 in.2 for each 30,000 BTUH mm2 per kW) of total rated input of the burner(s), and the location of the opening(s) shall not interfere with the intended purpose of the opening(s) for ventilation air referred to in (1). This opening(s) can be ducted to a point not more than 18 in. (450 mm) nor less than 6 in. (152 mm) above the floor level. The duct can also “goose neck” through the roof. The duct is preferred to be straight down 18 in. (450 mm) from the floor, but not near piping.

4. Refer to the B149 Installation code for additional information.

Water Piping

General

The heater should be located so that any water leaks will not cause damage to the adjacent area or structures.

CAUTION: This heater requires forced water circulation when the burner is operating. See Table H and Table I for minimum and maximum flow rates and water pump selection. The pump must be interlocked with the heater to prevent heater operation without water circulation.

NOTE: Minimum pipe size for in/out connections is 2 in. Verify proper flow rates and ∆T as instructed in this manual.

Reversing Water Connections

Follow these instructions to change the water connections from the left-hand side (standard) to the right-hand side.

1.Disconnect all electrical power from the heater (if applicable).

2.Label all electrical connections and conduit lines. This may include the flow switch, low water cut-off probe and/or pump.

3.Disconnect or isolate the main gas pipe from the heater (if applicable).

4.Remove both in/out and return header access panels by removing all sheet metal screws.

5.Remove all plumbing fittings to the header. This will include both inlet and outlet water pipe unions and the pressure relief valve and drain piping.

6.Remove limits, control bulbs and/or thermocouples.

7.Remove the six flange nuts and the in/out header from the left-hand side.

8.Remove the six flange nuts and the return header from the right-hand side.

9.Remove the header stud bolts from each tube sheet.

10.Reverse the headers and stud bolts to the new location.

11.Install NEW red beveled O-rings flush against both tube sheets with the bevel facing outward.

12.Push the header firmly against the O-rings. Install and tighten the flange nuts onto the stud bolts until finger tight.

13.Slowly tighten the flange nuts, starting from the center nut (number 1) in Fig. 9 and working sequentially around the header as indicated. Torque all nuts to 25 ft/lb. DO NOT OVER-TIGHTEN.

14.Re-route the capillary(s), wiring etc. to the new location, adding thermal paste and shim to the capillary well.

Fig. 9: Torque Sequence

Relief Valve Piping

WARNING: Pressure relief valve discharge piping must be piped near the floor and close to a drain to eliminate the potential of severe burns. Do not pipe to any area where freezing could occur. Refer to local codes.

Hydrostatic Test

Unlike many types of heaters, this heater does not require hydrostatic testing prior to being placed in operation. The heat exchanger has already been fac- tory-tested and is rated for 160 psi operating pressure. However, Raypak does recommend hydrostatic testing of the piping connections to the heater and the rest of the system prior to operation. This is particularly true for hydronic systems using expensive glycolbased anti-freeze. Raypak recommends conducting the hydrostatic test before connecting gas piping or electrical supply.

Leaks must be repaired at once to prevent damage to the heater. NEVER use petroleum-based stop-leak compounds.

To perform hydrostatic test:

1.Connect fill water supply. With bleed valve open, fill heater with water. When water flows from bleed valve, shut off water. Close bleed valve. Carefully fill the rest of the system, making sure to eliminate any entrapped air by using high-point vents. Close feed valve. Test at standard operating pressure for at least 24 hours.

2.Make sure constant gauge pressure has been maintained throughout test.

3.Check for leaks. Repair if found.

Cold Water Operation

CAUTION: Damaging internal condensation may occur if the heater inlet water temperature does not exceed 105ºF (41ºC) within 7 minutes of start-up.

NOTE: See Raypak Catalog No. 1000.57 for information on Cold Water Protection.

A heater operated with an inlet temperature of less than 105ºF (41ºC) must have a manual bypass or an approved low-temperature operation system to prevent problems with condensation. A manual bypass, shown in Fig. 15, must be piped into the system at the time of installation. This piping is like a primary/secondary boiler installation with a bypass acting as the secondary boiler piping. Raypak strongly recommends that thermometer(s) be placed into the heater piping next to the in/out header to facilitate temperature adjustment. Inlet water temperatures below 105ºF (41ºC) can excessively cool the products of combustion, resulting in condensation on the heat exchanger

15 and in the flue.

Failure to exceed 105ºF (41ºC) within 7 minutes may result in the premature failure of the hot surface igniter, remote flame sensor, burners and heat exchanger. It can cause operational problems, bad combustion, sooting, flue gas spillage and reduced service life of the vent system. The bypass allows part of the heater discharge water to be mixed with the cooler heater return water to increase the heater inlet temperature above 105ºF (41ºC). This precautionary measure should prevent the products of combustion from condensing in most installations. Warranty claims will be denied when condensation occurs.

Cold water operation issues are applicable to both cold water start and cold water run applications. Cold water operation for 7 minutes or less on start-up is acceptable. Where cold water starts will last longer than 7 minutes or where cold water operation is continuous, provisions must be made to mix higher temperature outlet water with the colder inlet water and thereby raise the inlet temperature to at least 105ºF (41ºC) within the 7-minute time limit.

Cold Water Starts

Frequent (more than once a week) cold water starts, wherein the inlet water temperature remains below 105ºF (41ºC) for more than 7 minutes, must have cold water start protection. Known protection methods consist of mixing heated outlet water with the inlet water with a bypass to raise the inlet to 105ºF (41ºC) or higher. Once the system is heated up and has return water temperatures of 105ºF (41ºC) or higher, the mixing of outlet water with inlet water is no longer needed and the bypass can be shut off. If the bypass is not shut off as the system heats up, the outlet temperature may continue to climb and actuate the high limit, thereby shutting down the heater. Thus an automatic valve system, such as a three-way proportional valve or a modulating two-way valve to control the bypass, should be utilized.

NOTE: Individual and multi-boiler Cold Water Start systems require the use of a 20°F ∆T boiler pump.

Cold Water Run

Cold water run differs from cold water start in that the system water entering the heater remains below 105ºF (41ºC) continuously. Typically, this is the case in swimming pool heating and water source heat pump applications as well as some others. If the system water is kept in a narrow temperature range, a permanent manual bypass can be employed and manually adjusted to achieve an inlet temperature of 105ºF (41ºC) or higher. An injector pump arrangement may also be utilized to keep the heater loop at or above 105ºF (41ºC). An injector pump approach has the added value of being able to adjust to changes in the system water coming back to the heater take-off.

NOTE: To ensure proper operation, use 20°F ∆T boiler flow rates when designing the heating system loop pump.

Temperature & Pressure Gauge

The temperature and pressure gauge is factorymounted in the in/out header.

Hydronic Heating

System Design

How water heating systems all have unique levels of operating diversity. Raypak equipment design utilizes as little water mass as possible to ensure maximum operating efficiency. Primary / Secondary piping arrangement is the method recommended and the only method supported by Raypak for installtion of Raypak heating equipment. Proper system design should always include system flow in excess of the connected boiler flow for proper operation (Boiler Flow + 15% = Min. System Flow). When appropriate, a Buffer/De-coupler Tank can be used where system flow may be reduced below the connected boiler flow. Failure to design for adequate system flow (i.e. bypasses, 3-way control valves, flow limiting balance devices, buffer tanks, etc.) will result in boiler short cycling and poor system performance. Always contact your local Raypak representative for sytem design assistance to avoid these issues.

16

|

Model |

10°F |

T |

20°F |

T |

30°F |

T |

40°F |

T |

Min. Flow |

|

Max Flow |

|

|

||||||

|

No. |

gpm |

|

P (ft) |

gpm |

|

P (ft) |

gpm |

|

P (ft) |

gpm |

|

P (ft) |

gpm |

P (ft) |

T |

gpm |

P (ft) |

T |

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

302B |

50 |

|

3.3 |

25 |

|

0.8 |

N/A |

|

N/A |

N/A |

|

N/A |

20 |

0.5 |

25 |

90 |

9.8 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

402B |

67 |

|

5.8 |

34 |

|

1.4 |

22 |

|

0.6 |

N/A |

|

N/A |

20 |

0.5 |

34 |

90 |

10.0 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

502B |

84 |

|

9.1 |

42 |

|

2.3 |

28 |

|

1.1 |

21 |

|

0.6 |

21 |

0.6 |

40 |

90 |

10.4 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

652B |

N/A |

|

N/A |

55 |

|

4.1 |

36 |

|

1.8 |

27 |

|

1.1 |

27 |

1.1 |

40 |

90 |

10.8 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

752B |

N/A |

|

N/A |

63 |

|

5.7 |

42 |

|

2.6 |

32 |

|

1.5 |

32 |

1.5 |

40 |

90 |

11.3 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

902B |

N/A |

|

N/A |

76 |

|

8.3 |

50 |

|

3.8 |

38 |

|

2.2 |

38 |

2.2 |

40 |

90 |

11.7 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Notes: 1. Basis for minimum flow is 20 gpm or 40°F ∆T. Basis for maximum flow is 90 gpm. Flow switch will not operate if flow is less |

||||||||||||||||||||

|

than 20 gpm. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

2. Rear-mounted pumps may provide higher flow rates on smaller models than the system requirements. |

|

|

|

||||||||||||||||

|

|

|

|

|

Table H: Heater Rates of Flow and Pressure Drops |

|

|

|

|

|

||||||||||

In order to ensure proper performance of your heater system, you must install a correctly sized pump. Raypak recommends using a 20°F ∆T as design ∆T. (∆T is the temperature difference between the inlet and outlet water when the heater is firing at full rate). If a ∆T of larger than 20°F is necessary, see Table H and Table I for flow rate requirements.

Pressure Drop in Feet of Head Feedwater Regulator

Raypak recommends that a feedwater regulator be installed and set at 12 psi minimum pressure at the highest point of the system. Install a check valve or back flow device upstream of the regulator, with a manual shut-off valve as required by local codes.

Piping

All high points should be vented. Purge valves and a bypass valve should be installed. A heater installed above radiation level must be provided with a low water cut-off device (sales order option F-10). The heater, when used in connection with a refrigeration system, must be installed so that the chilled medium is piped in parallel with the heater with appropriate valves to prevent the chilled medium from entering the heater.

The piping system of a hot water heater connected to heating coils located in air handling units where they may be exposed to circulating refrigerated air, must be equipped with flow control valves or other automatic means to prevent gravity circulation of the heater water during the cooling cycle. It is highly recommended that the piping be insulated.

Fig. 10: Air-Separation/Expansion Tank

Air-Separation/Expansion Tank

All heaters should be equipped with a properly sized expansion tank and air separator fitting as shown in Fig. 10.

Three-Way Valves

Valves designed to blend water temperatures or reduce water circulation through the heater should not be used. Raypak heaters are high-recovery, low-mass heaters which are not subject to thermal shock. Raypak offers a full line of electronic sequencers that produce direct reset of heater water temperature. (Refer to the Controls section of the Raypak Catalog.)

17

Loading...

Loading...