Raypak MVB 504 User Manual

Models 504 thru 2004

Category I with vertical vent

Models 503 thru 2003

Category IV Venting

Up to 88.4% thermal efficiency!

CSA Certified Lead Content

Less Than .25 Pb

Category I*-up to 85% efficiency Category IV-up to 88.4% efficiency

Raypak’s Next Generation

Modulating Boiler

Time-honored technologies unite with cutting-edge advancements in Raypak’s MVB modulating vertical boiler. Never before has a vertical boiler provided both the installer and building owner such installation flexibility, ease-of-commissioning, reliability and long-term performance. Small space, not a problem. The MVB has the smallest installed footprint of any vertical boiler, only 5.4 square feet. Raypak’s MVB is built with commercial-grade components and materials. From our steel channel base to our stainless steel flue wrapper, you can tell the MVB is built to last. It’s easy to handle and install, but still user friendly to service. Our compact design fits through a 30” door opening making it the perfect choice for those hard to reach retrofit projects. Now is the perfect time to take a closer look at Raypak.

True Modulation

Modulation is nothing new to Raypak, we have honed our gas modulation experience for over 50 years. The Raypak MVB will infinitely track the heating load precisely with it’s built in TempTracker Mod control, eliminating costly overshooting. Utilizing the latest European technology for the blower-gas valve package, the optimum fuel-air ratio is maintained throughout the entire range of the load-tracking operation. Our smooth 4:1 turndown (503 thru 2003) ensures efficiency is maintained through out the firing rate and actually increases during part load, right when you want it! The MVB automatically selftunes to accommodate the widest range of gas supply pressures. The high quality integrated blower-gas valve is self-correcting and allows smooth operation with fluctuating gas supply pressures. The Raypak MVB is cutting edge technology with atmospheric simplicity.

Flexibility

Small diameter vents and industry-leading vent length allowances afford greater vent location options, thus reducing wasted space. Vent versatility is further enhanced by the self-tuning combustion system which compensates for unusual chimney and vent configurations.

Category I* -CSA-certified 84% boiler and up to 85% water heater models available. Our category I solution is the perfect replacement for your retro-fit applications. This reduces the installed cost by using existing category I venting or chimney. Installation couldn’t be easier; all connections are on the back of the unit. Start-up is a snap, it’s as close to plug-n-play as a boiler can get.

Category IV -CSA-certified 87% efficiency at full fire–the highest possible for non-condensing boilers (Up to 88.4% at part load!) When the job requires high efficiency, our category IV solution meets your needs.

At the heart of every Raypak MVB is a unique integral evaporator system - the first defense against harmful condensation. Raypak’s evaporator system collects and re-evaporates condensate which may form during initial start-up or brief periods of cold-water operation, eliminating the need for a boiler condensate drain. This saves you money on installation costs as well as the headache of dealing with multiple condensate drains.

Key Features

•12 models from 500,000 to 2,000,000 BTUH

•Up to 85% efficiency (Cat. I*);

•Up to 88.4% efficiency (Cat. IV)

•No boiler condensate drain required (proprietary design)

•Lowest minimum required inlet water temperature (120F)

•Modulating gas valve and burner, up to 4:1 (503 thru 2003) turndown

•Engineered with precisely matched system components

•Smallest installed footprint (5.4 square feet) design fits tight spaces and easily replaces larger boilers

•Advanced diagnostics center, real English fault codes

•All models indoor/outdoor certified

•Complete cabinet protects all controls and wiring

•Meets all current Low NOx regulations

•Suitable for altitudes up to 10,000 ft. (derate above 5,000 ft.)

•With all copper and optional bronze waterways, the MVB is available in boiler and water heater configurations

•Inline combustion air filter (MERVB)

*Category I with vertical vent, category III with horizontal venting and no extractor.

2

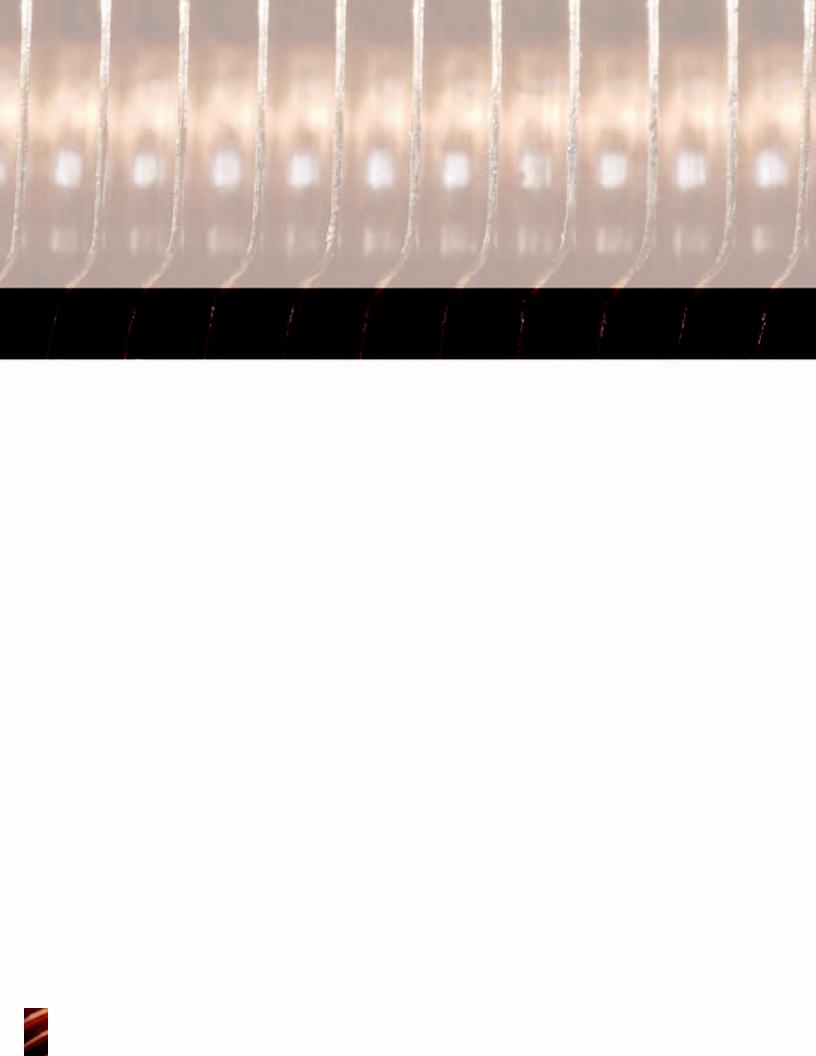

2 1

3

12

6

10

4

9

7

8

13

11

State of the art European combustion technology

1. Control Panel

Fully enclosed controls and wiring protect against damage or vandalism. Cabinet design affords easy access to controls for installation and service.

2. Temp-Tracker Mod Control

This factory-mounted multi-function control delivers precise load-tracking with selectable mode displays that are easy to access and read.

3. On Board Diagnostic Center

Factory-mounted standard equipment. Gives relevant service feedback as well as possible solutions to clear the fault. All in plain English, no cryptic codes to decipher. The control also stores up to 16 fault codes in its history file for the service technician to review.

4. Weather-Proof Jacket

Heavy gauge galvanized steel with a UV-resistant Polytuf powder coat finish is impervious to weather and corrosion.

5. Combustion Air Fan

Cast aluminum, non-sparking construction.

6. Vent Pressure Switch

Monitors vent pressure and provides safe shut down if back pressure is excessive.

7. Minimum Clearance Requirements

Only one inch of side clearance is required from combustible surfaces.

8. Vertical Heat Exchanger

Cylindrical, multi-pass heat exchanger captures all radiant energy, eliminating the need for heavy refractory.

9. Rugged Cast Headers

Bronze headers standard on water heater models. Castiron standard on boiler models, with bronze headers optional.

10. Tube Sheet Construction

Eliminates the repair & maintenance problems associated with rolled-tube construction. Easy, cost-effective component replacement.

11. Viewing Port

Allows easy burner inspection.

12. Low Voltage Wiring Connections

Up front and easy to get to. Makes sensor wiring and external control wiring simple and clean.

13. Drain Valves

Two drain valves located at the bottom of the heat exchanger. This allows for complete winterizing and drainage of the heater.

Optional Equipment

Cold Water Solutions

Cold Water Start – For applications that require reliable protection against harmful condensation caused by frequent, extended, cold water start-ups. Raypak’s Cold Water Start protection system utilizes a proportional threeway valve to bypass water from the boiler outlet to the inlet during start-up, when the sys-

tem return water temperature is below the minimum acceptable level. (See Cat. #1000.19)

Cold Water Run – For applications requiring constant condensation protection. Raypak’s Cold Water Run system utilizes a variablespeed pump to inject just the right amount of water from the main system loop into the boiler to maintain the optimum inlet temperature. This approach allows the full capacity of the boiler to be utilized to meet the system load,

while at the same time continuously maintaining the optimum inlet water temperature to prevent condensation. (See Cat. #1000.19)

Multi Boiler Solutions

TempTracker Mod+ Hybrid– Controls up to 16 Raypak boilers with PID logic. Automatic or manually selectable lead-lag boiler operation. TempTracker Mod+ Hybrid monitors and displays supply water temperatures on all applications including outdoor temperature

when outdoor reset mode is selected. Can Hybrid Control also be used to control a mix of condensing

and non condensing boilers using our Hybrid control algorithm. Now available with optional BACnet® BMS link.

(See Cat. # 5100.22)

BACnet BMS Link

3

Loading...

Loading...