Page 1

MVI69-PDPMV1

CompactLogix or MicroLogix

Platform

PROFIBUS DPV1 Master

July 8, 2011

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

MVI69-PDPMV1 User Manual

July 8, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided o n the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Warning: This module is not hot-swappable! Always remove power from the rack before inserting or removing this

module, or damage may result to the module, the processor, or other connected devices.

Page 4

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Markings

Electrical Ratings

Backplane Current Load: 800 mA @ 5.1 Vdc

Power Supply Distance Rating: 2

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Relative Humidity: 5% to 95% (with no condensation)

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Label Markings

<cULus>

E193122

Class I Div 2

Groups A,B,C,D T6

-30°C <= Ta <= 60°C

<Ex>

II 3 G

Ex nA IIc T6 X

0°C <= Tamb <= 60°C

II - Equipment intended for above ground use (not for use in mines).

3 - Category 3 equipment, investigated for normal operation only.

G - Equipment protected against explosive gasses.

Agency Approvals and Certifications

Agency Applicable Standard(s)

ATEX EN 60079-0:2006, EN 60079-15:2005

DNV DET NORSKE VERITAS Test 2.4

CE EN61000-6-4:2007

CB Safety

GOST-R EN 61010

CSA 61010

cULus UL508, UL1604, CSA 22.2 No 142 & 213

Lloyds Lloyds Register Test Specification Number 1,200 2

CA/10533/CSA, IEC 61010-1 Ed. 2, CB 243333-2056722

(2090408)

ME06

E193122

Page 5

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS DPV1 Master User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 4

Markings .............................................................................................................................................. 4

Guide to the MVI69-PDPMV1 User Manual 9

1 Start Here 11

1.1 System Requirements ............................................................................................. 12

1.2 Package Contents ................................................................................................... 13

1.3 Installing ProSoft Configuration Builder Software ................................................... 14

1.4 Setting Jumpers ...................................................................................................... 15

1.5 Installing the Module ............................................................................................... 16

2 Ladder Logic 19

2.1 MVI69-PDPMV1 Sample Add-On Instruction Import Procedure............................. 20

2.1.1 Creating a New RSLogix5000 Project ..................................................................... 21

2.1.2 Creating the Module ................................................................................................ 21

2.1.3 Importing the Ladder Rung ..................................................................................... 24

2.1.4 Adding Multiple Modules (Optional) ........................................................................ 28

2.1.5 Connecting Your PC to the Processor .................................................................... 35

2.1.6 Downloading the Sample Program to the Processor .............................................. 36

2.2 Adding the Module to an Existing CompactLogix Project ....................................... 39

2.3 Adding the Module to an Existing MicroLogix Project ............................................. 43

3 Module Setup 45

3.1 Connecting Your PC to the Module ......................................................................... 46

3.2 Configuring the Module ........................................................................................... 47

3.2.1 Setting Up the Project ............................................................................................. 47

3.2.2 Setting Module Parameters ..................................................................................... 49

3.2.3 Configuring the PROFIBUS Master ........................................................................ 51

3.2.4 Installing the GSD Files ........................................................................................... 53

3.2.5 Configuring the PROFIBUS Slaves ......................................................................... 53

3.2.6 Calculating the Checksums ..................................................................................... 66

3.2.7 Printing the Processor Network Memory Map ........................................................ 66

3.3 Backing Up the Project ............................................................................................ 68

3.4 Downloading the Project to the Module Using a Serial COM Port .......................... 70

3.4.1 Disabling the RSLinx Driver for the Com Port on the PC ........................................ 71

3.5 Downloading the Project to the Module Using CIPconnect .................................... 73

3.5.1 Example................................................................................................................... 75

ProSoft Technology, Inc. Page 5 of 225

July 8, 2011

Page 6

Contents MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

4 Mailbox Messaging 81

4.1 Mailbox Message Queuing ..................................................................................... 82

4.1.1 Queue Timeouts ..................................................................................................... 82

4.2 Sending a Mailbox Message in RSLogix 5000 ....................................................... 83

4.3 Receiving Mailbox Message Responses from the Module ..................................... 84

4.4 Special Function Mailbox Messaging Commands .................................................. 85

4.4.1 Mailbox Message: Set Operating Mode ................................................................. 88

4.4.2 Mailbox Message: Set Slave Mode ........................................................................ 90

4.4.3 Mailbox Message: Get Slave Diagnostics .............................................................. 94

4.4.4 Mailbox Message: Get Slave Configuration ........................................................... 96

4.4.5 Mailbox Message: Set Slave Address .................................................................... 98

4.4.6 Mailbox Message: Get Live List ............................................................................ 100

4.4.7 Mailbox Message: Start Slave .............................................................................. 102

4.4.8 Mailbox Message: Stop Slave .............................................................................. 104

4.4.9 Mailbox Message: Class 1 Acyclic Data Read ..................................................... 106

4.4.10 Mailbox Message: Class 1 Acyclic Data Write ..................................................... 108

4.4.11 Mailbox Message: Initiate Class 2 Connection ..................................................... 110

4.4.12 Mailbox Message: Class 2 Acyclic Data Read ..................................................... 116

4.4.13 Mailbox Message: Class 2 Acyclic Data Write ..................................................... 118

4.4.14 Mailbox Message: Abort Class 2 Connection ....................................................... 120

4.4.15 Mailbox Message: Class 2 Connection Abort Indication ...................................... 122

4.4.16 Mailbox Message: Alarm Indication ...................................................................... 126

4.5 Mailbox Messaging Error Codes ........................................................................... 128

4.5.1 Acyclic Message Status Word .............................................................................. 128

4.5.2 Return Codes ........................................................................................................ 129

4.5.3 Error Codes ........................................................................................................... 130

4.5.4 DPV1 Class 1-Related Error Codes ..................................................................... 131

4.5.5 DPV1 Class 2-Related Error Codes ..................................................................... 132

5 Diagnostics and Troubleshooting 133

5.1 Verifying Correct Operation .................................................................................. 134

5.1.1 Checking the PROFIBUS LEDs on the MVI69-PDPMV1 ..................................... 134

5.1.2 Viewing the Online Status of the PROFIBUS Network ......................................... 135

5.1.3 Viewing the Fieldbus Data from the MVI69-PDPMV1’s Configuration/Debug Menu137

5.1.4 Viewing the Controller Tags in RSLogix 5000 ...................................................... 141

5.2 Basic Troubleshooting Steps ................................................................................ 143

5.3 LED Indicators: Front of MVI69 Module ............................................................... 144

5.3.1 Module Status Indicators ...................................................................................... 144

5.3.2 PROFIBUS Master Indicators ............................................................................... 145

5.4 Using ProSoft Configuration Builder (PCB) for Diagnostics ................................. 147

5.4.1 Using the Diagnostic Window in ProSoft Configuration Builder ........................... 147

5.4.2 Navigation ............................................................................................................. 150

5.4.3 Main Menu ............................................................................................................ 151

5.5 Reading Status Data from the Module ................................................................. 154

5.6 Standard PROFIBUS Slave Diagnostic Bytes ...................................................... 155

5.6.1 Byte 0 - Station Status 1 Bits ................................................................................ 155

5.6.2 Byte 1 - Station Status 2 Bits ................................................................................ 155

5.6.3 Byte 2 - Station Status 3 Bits ................................................................................ 156

5.6.4 Byte 3 - Master Address ....................................................................................... 156

5.6.5 Byte 4 - Ident Number High .................................................................................. 156

5.6.6 Byte 5 - Ident Number Low ................................................................................... 156

Page 6 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 7

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS DPV1 Master User Manual

6 Reference 157

6.1 Product Specifications ........................................................................................... 157

6.1.1 General Specifications .......................................................................................... 158

6.1.2 Hardware Specifications ........................................................................................ 158

6.1.3 Functional Specifications ....................................................................................... 159

6.2 PROFIBUS DP Architecture .................................................................................. 160

6.2.1 Bus Access ............................................................................................................ 161

6.2.2 Token Passing ....................................................................................................... 161

6.2.3 Master/Slave Communication Phases .................................................................. 161

6.2.4 Communication Types ........................................................................................... 161

6.2.5 Master/Slave Polling .............................................................................................. 162

6.3 Functional Overview .............................................................................................. 163

6.3.1 About the PROFIBUS Protocol ............................................................................. 163

6.3.2 General Overview .................................................................................................. 163

6.3.3 Block Numbers for Transfer .................................................................................. 165

6.3.4 MVI69 Input and Output Data Blocks .................................................................... 167

6.4 PROFIBUS comDTM ............................................................................................ 184

6.4.1 ProSoft Technology Product Availability ............................................................... 185

6.4.2 Introduction to PROFIBUS comDTM .................................................................... 185

6.4.3 Installation ............................................................................................................. 189

6.4.4 Quick Start ............................................................................................................. 190

6.4.5 Verifying the comDTM Version and comDTM Install Version ............................... 199

6.5 RS-232 Configuration/Debug Port ........................................................................ 205

6.6 DB9 to RJ45 Adaptor (Cable 14) .......................................................................... 205

6.7 PROFIBUS Master Port ........................................................................................ 206

6.8 Supported PROFIBUS Services ........................................................................... 207

6.9 Constructing a Bus Cable for PROFIBUS DP ....................................................... 208

7 Support, Service & Warranty 213

Contacting Technical Support ......................................................................................................... 213

7.1 Return Material Authorization (RMA) Policies and Conditions .............................. 215

7.1.1 Returning Any Product .......................................................................................... 215

7.1.2 Returning Units Under Warranty ........................................................................... 216

7.1.3 Returning Units Out of Warranty ........................................................................... 216

7.2 LIMITED WARRANTY ........................................................................................... 217

7.2.1 What Is Covered By This Warranty ....................................................................... 217

7.2.2 What Is Not Covered By This Warranty ................................................................ 218

7.2.3 Disclaimer Regarding High Risk Activities ............................................................ 218

7.2.4 Intellectual Property Indemnity .............................................................................. 219

7.2.5 Disclaimer of all Other Warranties ........................................................................ 219

7.2.6 Limitation of Remedies ** ...................................................................................... 220

7.2.7 Time Limit for Bringing Suit ................................................................................... 220

7.2.8 No Other Warranties ............................................................................................. 220

7.2.9 Allocation of Risks ................................................................................................. 220

7.2.10 Controlling Law and Severability ........................................................................... 221

Index 223

ProSoft Technology, Inc. Page 7 of 225

July 8, 2011

Page 8

Contents MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

Page 8 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 9

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Guide to the MVI69-PDPMV1 User Manual

PROFIBUS DPV1 Master User Manual

Guide to the MVI69-PDPMV1 User Manual

Function

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Support, Service, and

Warranty

Index

Section to Read Details

Start Here (page 11)

Diagnostics and

Troubleshooting

(page 133)

Reference (page

157)

Product

Specifications (page

157)

Support, Service

and Warranty (page

213)

Index

This section introduces the customer to the

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

This section describes Diagnostic and

Troubleshooting procedures.

These sections contain general references

associated with this product and its

Specifications..

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 9 of 225

July 8, 2011

Page 10

Guide to the MVI69-PDPMV1 User Manual MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

Page 10 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 11

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

1 Start Here

In This Chapter

System Requirements ........................................................................... 12

Package Contents ................................................................................. 13

Installing ProSoft Configuration Builder Software .................................. 14

Setting Jumpers .................................................................................... 15

Installing the Module ............................................................................. 16

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

PROFIBUS DPV1 and CompactLogix or MicroLogix devices to a power

source and to the MVI69-PDPMV1 module’s application port(s)

®

RSLogix™ software: launch the program, configure

ProSoft Technology, Inc. Page 11 of 225

July 8, 2011

Page 12

Start Here MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

1.1 System Requirements

The MVI69-PDPMV1 module requires the following minimum hardware and

software components:

Rockwell Automation CompactLogix processors or MicroLogix 1500 LRP

processor, with compatible power supply and one free slot in the rack, for the

MVI69-PDPMV1 module. The module requires 800 mA of available power.

Important: The MVI69-PDPMV1 module has a power supply distance rating of 2 (L43 and L45

installations on first 2 slots of 1769 bus).

Important: For 1769-L23x processors, please make note of the following limitations.

1769-L23-QBFC1B = 800 mA at 5 Vdc (One MVI69-PDPMV1 will use all 800 mA of available

power. No other modules can be used with an MVI69 module connected to this processor.)

1769-L23E-QB1B = 1000 mA at 5 Vdc (One MVI69-PDPMV1 will use 800 mA of available

power. One other module can be used on this rack provided it consumes less than 200 mA at

5 Vdc.)

1769-L23E-QBFC1B = 450 mA at 5 Vdc (No MVI69 module can be used with this processor.)

Rockwell Automation RSLogix 5000 (CompactLogix) or RSLogix 500

(MicroLogix) programming software

Rockwell Automation RSLinx communication software

Pentium

recommended

Supported operating systems:

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 768 recommended)

CD-ROM drive

HyperTerminal or other terminal emulator program capable of file transfers

using Ymodem protocol.

®

II 450 MHz minimum. Pentium III 733 MHz (or better)

NOTE: MVI69/PS69 modules will not work with CompactLogix L4x processors using RSLogix 5000

v17. All other processor combinations and RSLogix versions will work correctly.

Page 12 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 13

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

1.2 Package Contents

The following components are included with your MVI69-PDPMV1 module, and

are all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

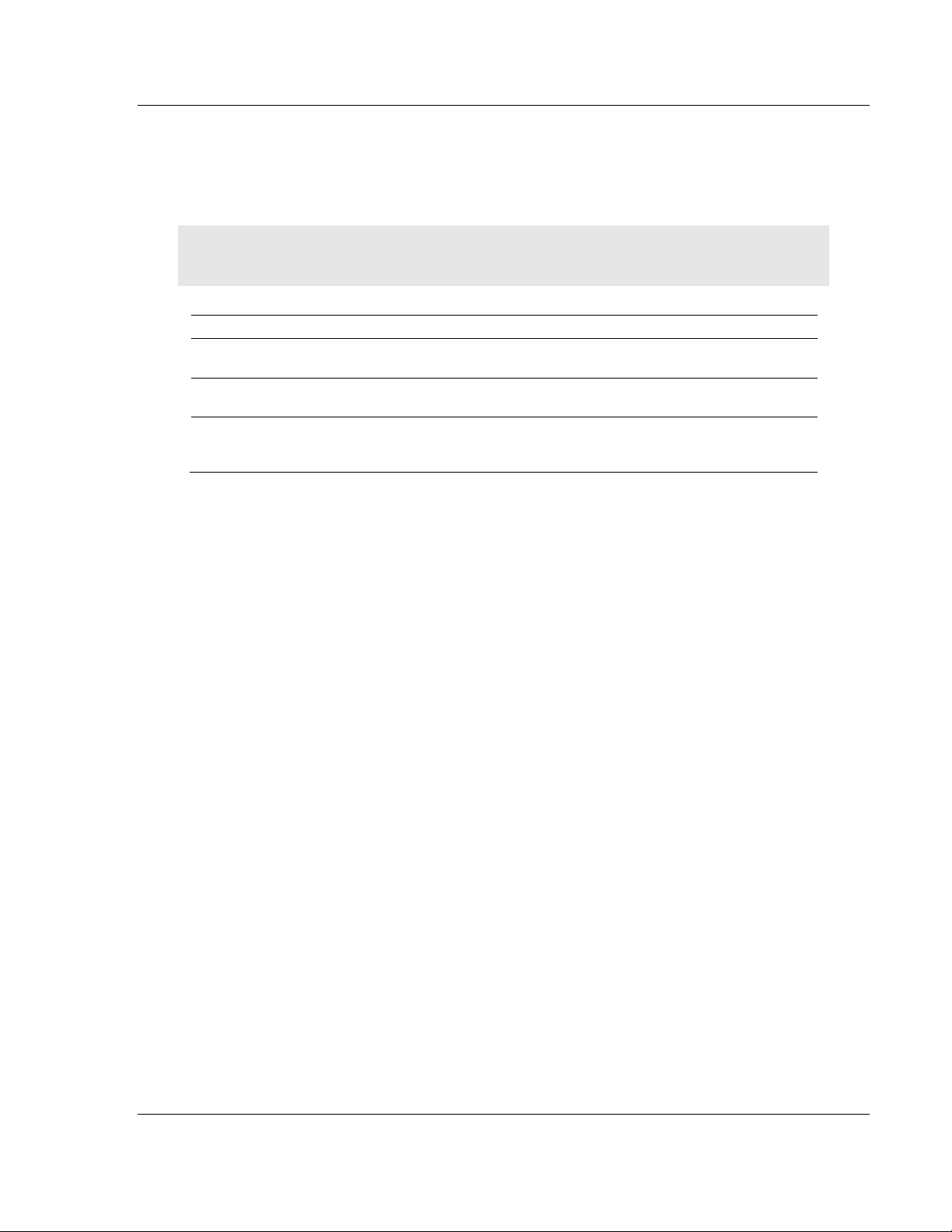

Qty. Part Name Part Number Part Description

1

1 Cable

1 Cable

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

MVI69-PDPMV1

Module

MVI69-PDPMV1 PROFIBUS DPV1 Master

Cable #15, RS232

Null Modem

Cable #14, RJ45 to

DB9 Male Adapter

cable

For RS232 Connection to the CFG Port

For DB9 Connection to Module’s Port

ProSoft Technology, Inc. Page 13 of 225

July 8, 2011

Page 14

Start Here MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

1.3 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the module. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

To install ProSoft Configuration Builder from the ProSoft Technology website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your module.

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

Windows Explorer file tree window.

3 Click to open the U

and files you will need to set up and configure your module.

4 Double-click the S

PCB_*.

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

OWNLOAD HERE link to download the latest version of ProSoft

AVE or SAVE FILE when prompted.

RODUCT DOCUMENTATION. This action opens a

TILITIES folder. This folder contains all of the applications

ETUP CONFIGURATION TOOL folder, double-click the

EXE file and follow the instructions on your screen to install the

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

Page 14 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 15

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

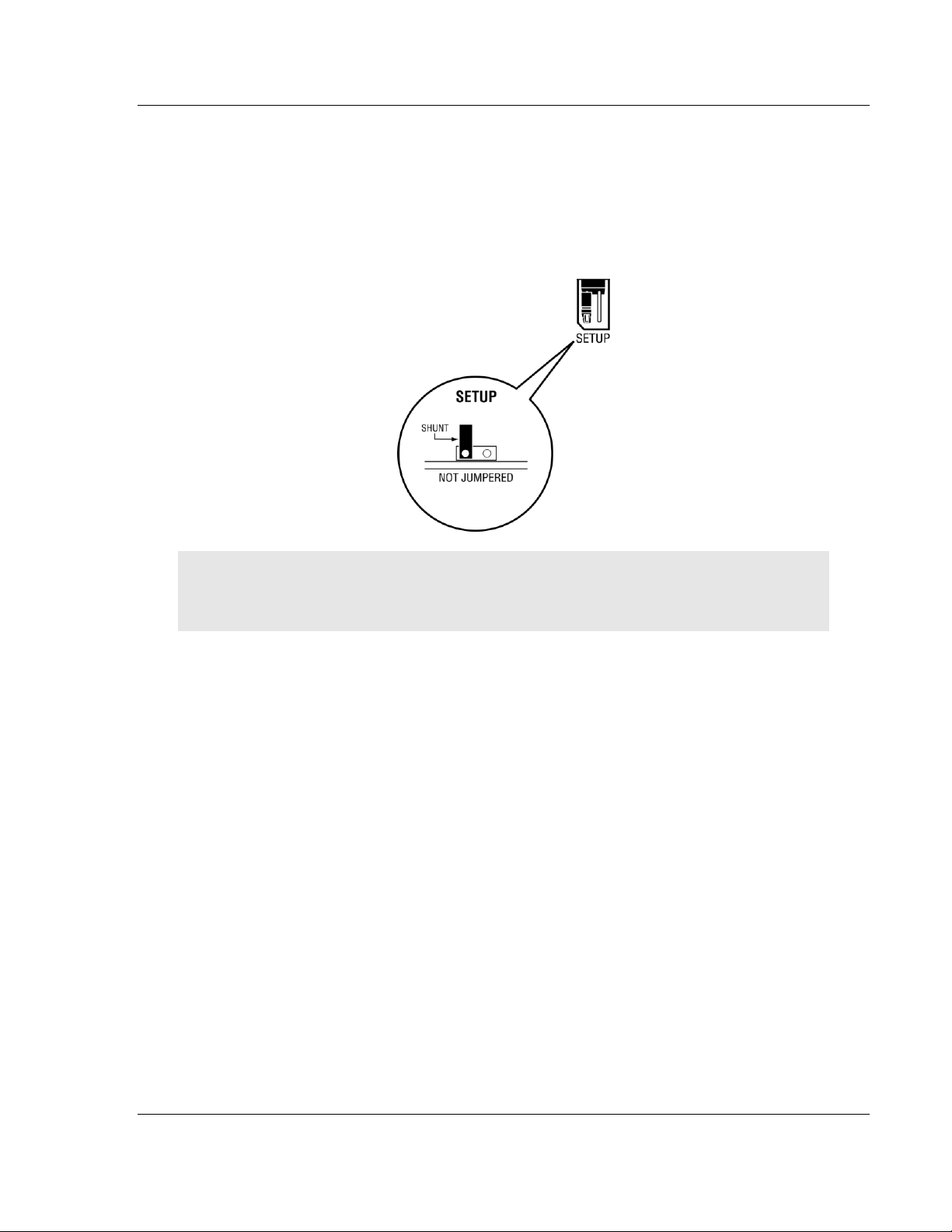

1.4 Setting Jumpers

The Setup Jumper acts as "write protection" for the module’s flash memory. In

"write protected" mode, the Setup pins are not connected, and the module’s

firmware cannot be overwritten. Do not jumper the Setup pins together unless

you are directed to do so by ProSoft Technical Support.

The following illustration shows the MVI69-PDPMV1 jumper configuration.

Note: If you are installing the module in a remote rack, you may prefer to leave the Setup pins

jumpered. That way, you can update the module’s firmware without requiring physical access to

the module.

ProSoft Technology, Inc. Page 15 of 225

July 8, 2011

Page 16

Start Here MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

1.5 Installing the Module

Before you attempt to install the module, make sure that the bus lever of the

adjacent module is in the unlocked (fully right) position.

Warning: This module is not hot-swappable! Always remove power from the rack before

inserting or removing this module, or damage may result to the module, the processor, or other

connected devices.

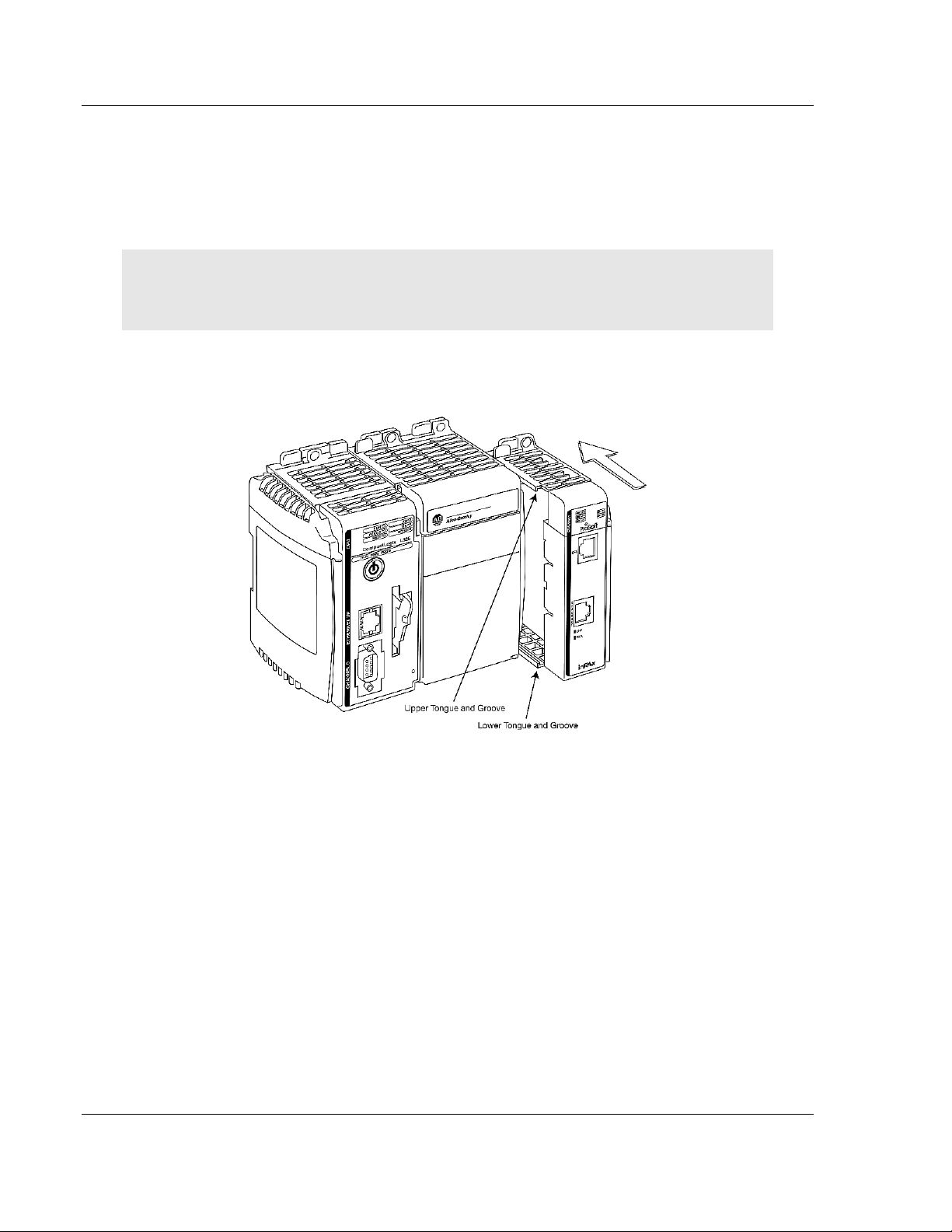

1 Align the module using the upper and lower tongue-and-groove slots with the

adjacent module and slide forward in the direction of the arrow.

2 Move the module back along the tongue-and-groove slots until the bus

connectors on the MVI69 module and the adjacent module line up with each

other.

Page 16 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 17

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

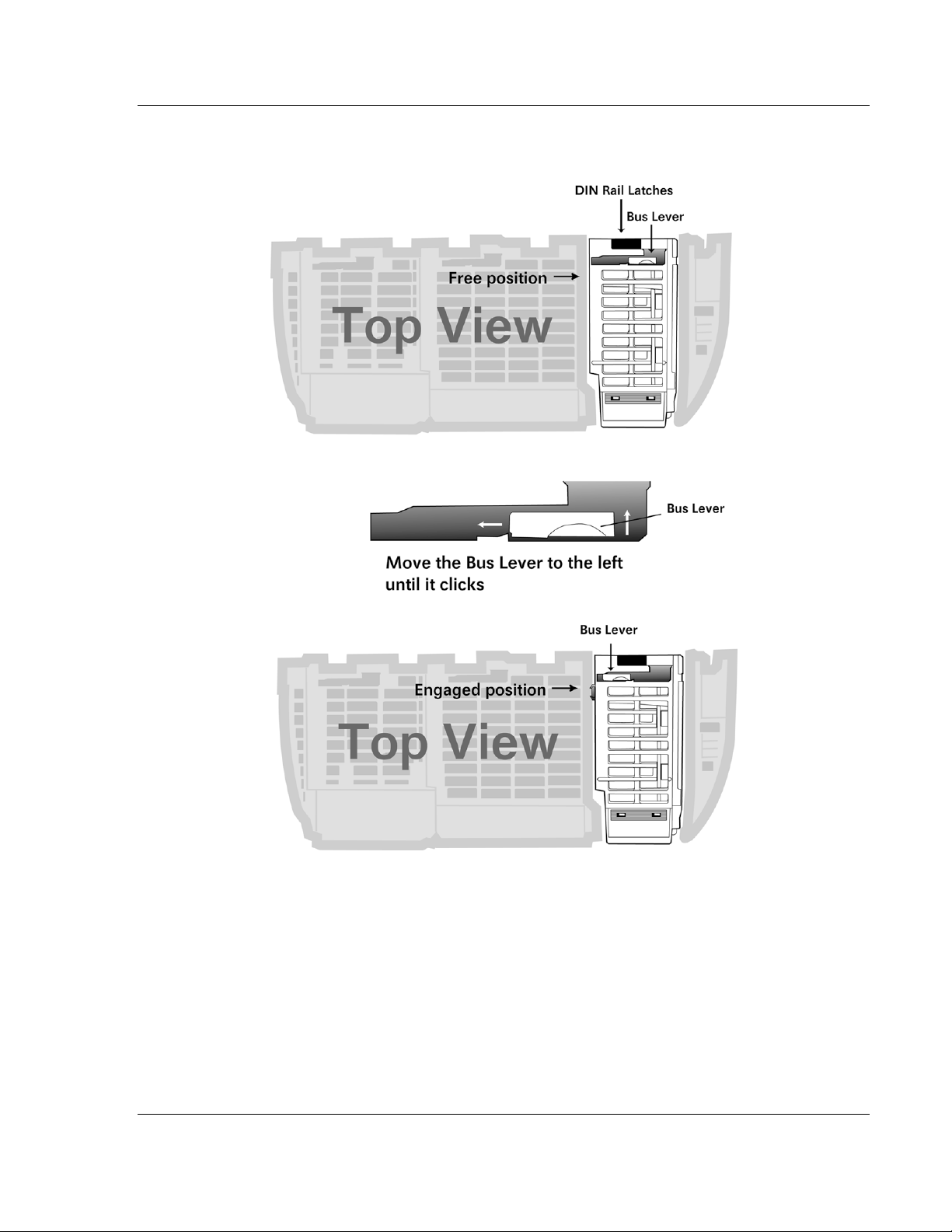

3 Push the module’s bus lever back slightly to clear the positioning tab and

move it firmly to the left until it clicks. Ensure that it is locked firmly in place.

4 Close all DIN-rail latches.

ProSoft Technology, Inc. Page 17 of 225

July 8, 2011

Page 18

Start Here MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

5 Press the DIN-rail mounting area of the controller against the DIN-rail. The

latches will momentarily open and lock into place.

Page 18 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 19

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

2 Ladder Logic

In This Chapter

MVI69-PDPMV1 Sample Add-On Instruction Import Procedure ............ 20

Adding the Module to an Existing CompactLogix Project ...................... 39

Adding the Module to an Existing MicroLogix Project ............................ 43

Ladder logic is required for the MVI69-PDPMV1 module to work. Tasks that must

be handled by the ladder logic are module data transfer, special block handling,

and status data receipt. Additionally, a power-up handler may be needed to

handle the initialization of the module’s data and to clear any processor fault

conditions.

The sample ladder logic, on the inRAx CD-ROM, is extensively commented, to

provide information on the purpose and function of each rung. For most

applications, the sample ladder will work without modification.

ProSoft Technology, Inc. Page 19 of 225

July 8, 2011

Page 20

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

2.1 MVI69-PDPMV1 Sample Add-On Instruction Import Procedure

Note: This section only applies if you are using a CompactLogix processor running RSLogix 5000

version 16 or higher. If you are configuring the MVI69-PDPMV1 module with an earlier version of

RSLogix 5000, please refer to Adding the Module to an Existing CompactLogix Project (page 39). If

you are using a MicroLogix processor, please see Adding the Module to an Existing MicroLogix

Project (page 43).

The following file is required before you start this procedure. Copy the file from

the ProSoft Solutions CD-ROM, or download it from

www.prosoft-technology.com.

File Name Description

MVI69PDPMV1(60)_AddOn_Rung_v1_3.L5X

MVI69PDPMV1(120)_AddOn_Rung_v1_3.L5X

MVI69PDPMV1(240)_AddOn_Rung_v1_3.L5X

MVI69PDPMV1(240)_AddOn_Rung_v1_4.L5X

L5X file contains the Add-On instruction, the

User-defined Data Types, data objects and ladder

logic required to set up the MVI69-PDPMV1

module.

Choose the file with the block size (60, 120 or

240) to match your application.

L5X file contains all of the standard items

(above), plus additional items for the Add-On

instruction, the User-defined Data Types, data

objects and ladder logic required to set up the

MVI69-PDPMV1 module to act as a PROFIBUS

Acyclic Class 2 Master.

Class 2 sample ladder currently available only for

Backplane Transfer Size of 240.

Page 20 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 21

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

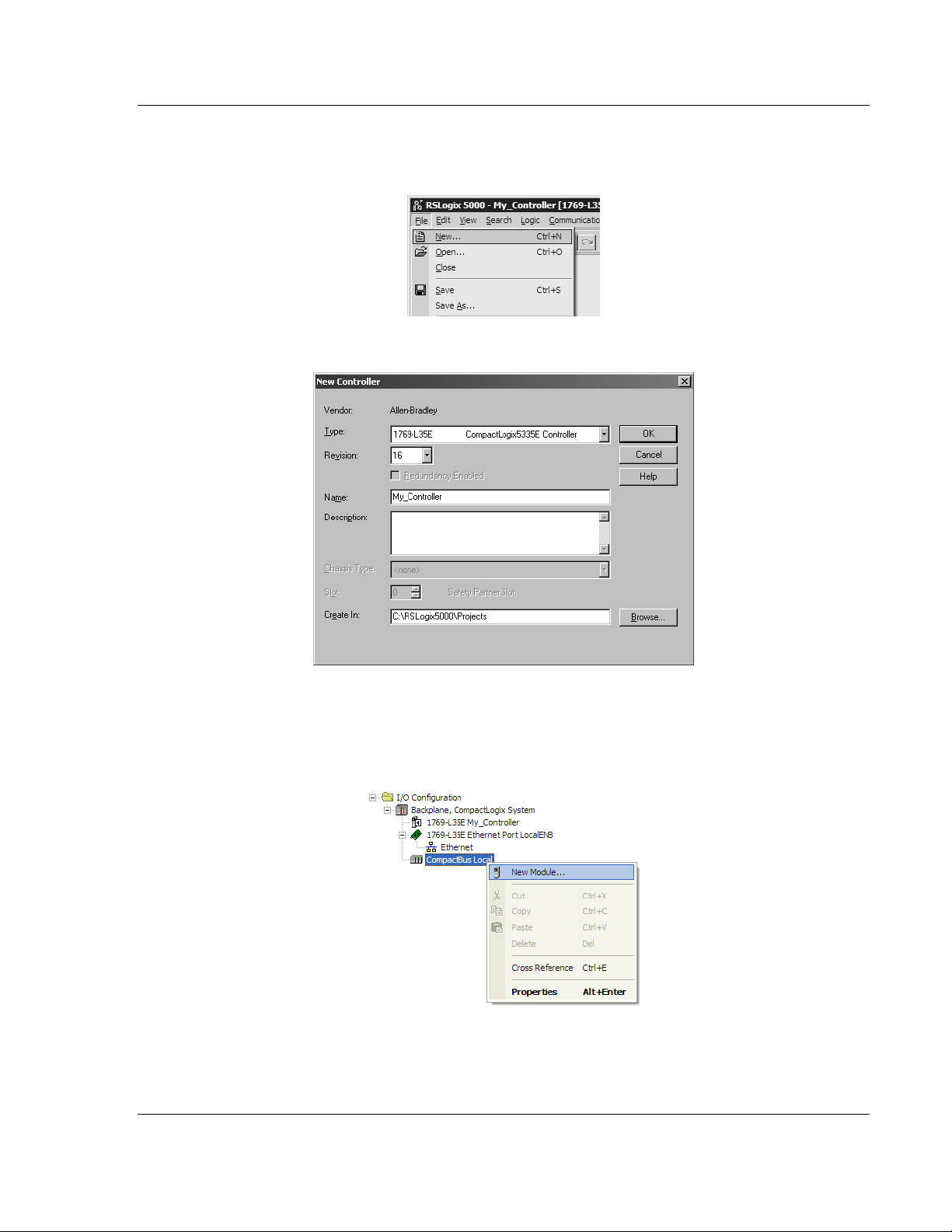

2.1.1 Creating a New RSLogix5000 Project

1 Open the FILE menu, and then choose NEW.

2 Select Revision 16.

2.1.2 Creating the Module

1 Right-click I/O CONFIGURATION and choose NEW MODULE.

ProSoft Technology, Inc. Page 21 of 225

July 8, 2011

Page 22

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

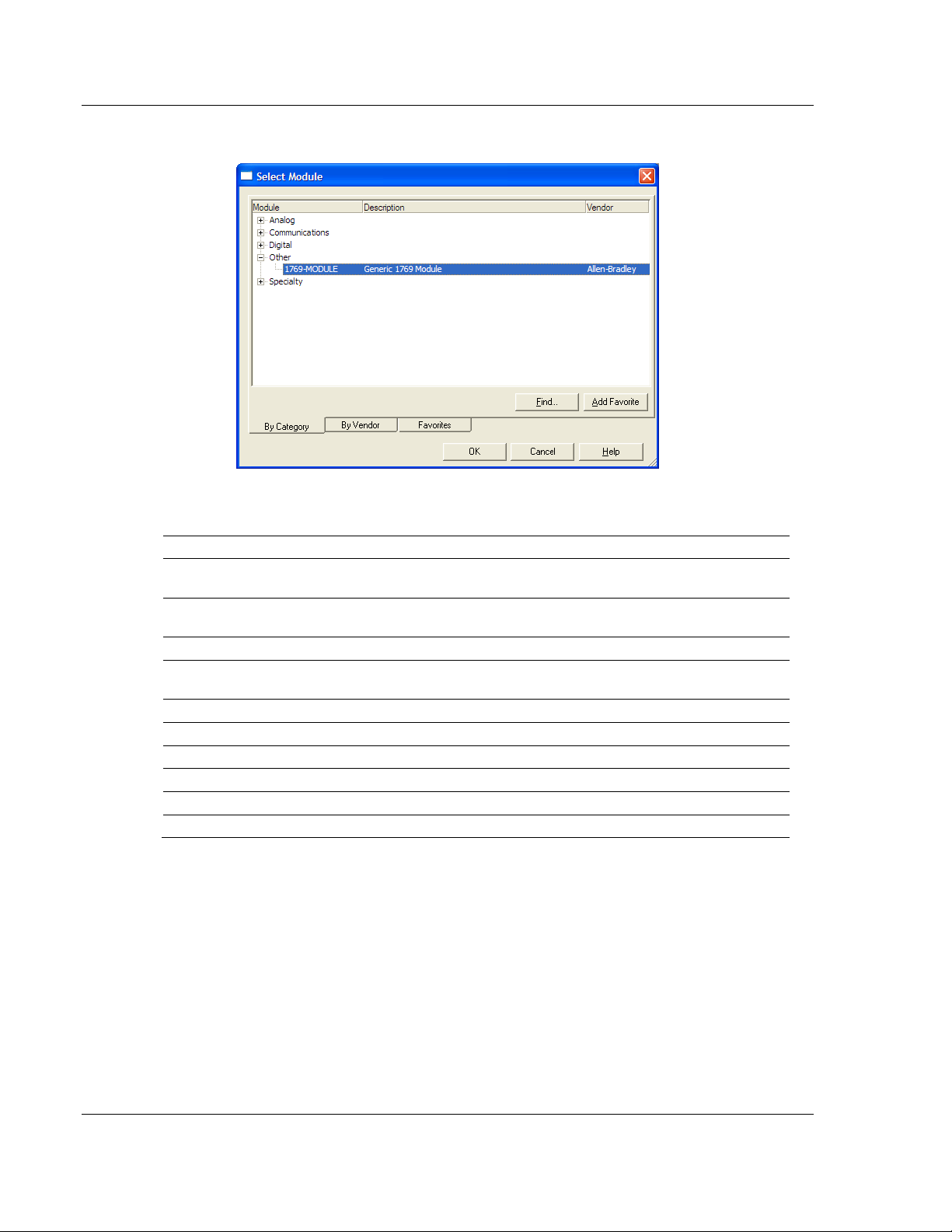

2 Select 1769-MODULE.

3 Set the Module Properties values as follows:

Parameter Value

Name

Description

Comm Format

Slot

Input Assembly Instance

Input Size

Output Assembly Instance

Output Size

Configuration Assembly Instance

Configuration Size

Enter a module identification string. Example:

MVI69PDPMV1

Enter a description for the module. Example: PROFIBUS

DPV1 MASTER

Select D

Enter the slot number in the rack where the MVI69-

PDPMV1 module will be installed.

101

62 / 122 / 242

100

61 / 121 / 241

102

0

ATA-INT

Page 22 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 23

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

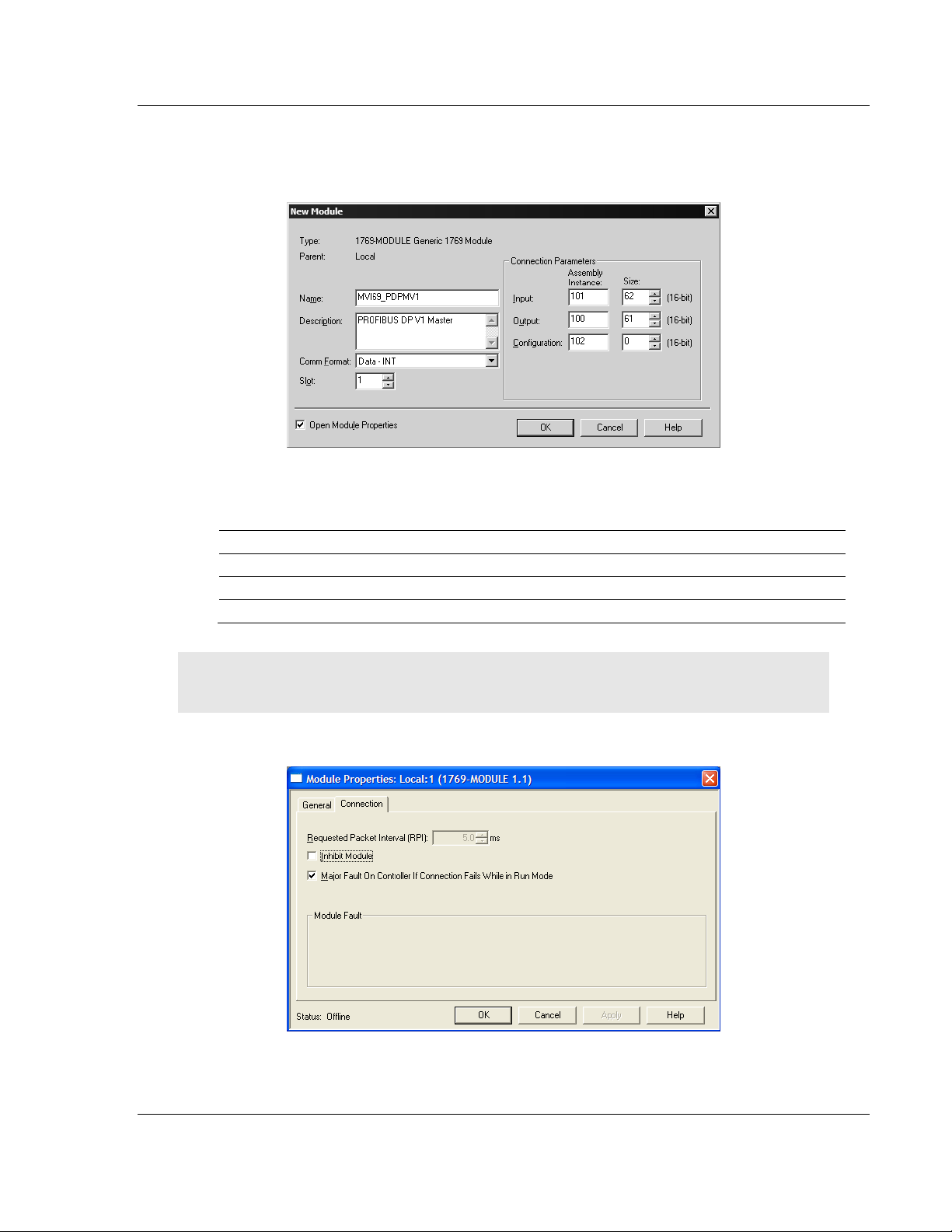

4 The following illustration shows an example where the module was

configured for a block transfer size of 60 words (input block size = 62 words,

output block size = 61 words):

Enter the Input Block Size and Output Block Size parameters according to

the Block Transfer Size to use:

Block Transfer Size Input Block Size Output Block Size

60 62 61

120 122 121

240 242 241

Important: You must set the Block Transfer Size in ProSoft Configuration Builder to match the

block size for the Add-On Instruction, otherwise the module may not function correctly.

5 On the C

ONNECTION tab, check or un-check, as desired the Major fault option.

ProSoft Technology, Inc. Page 23 of 225

July 8, 2011

Page 24

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

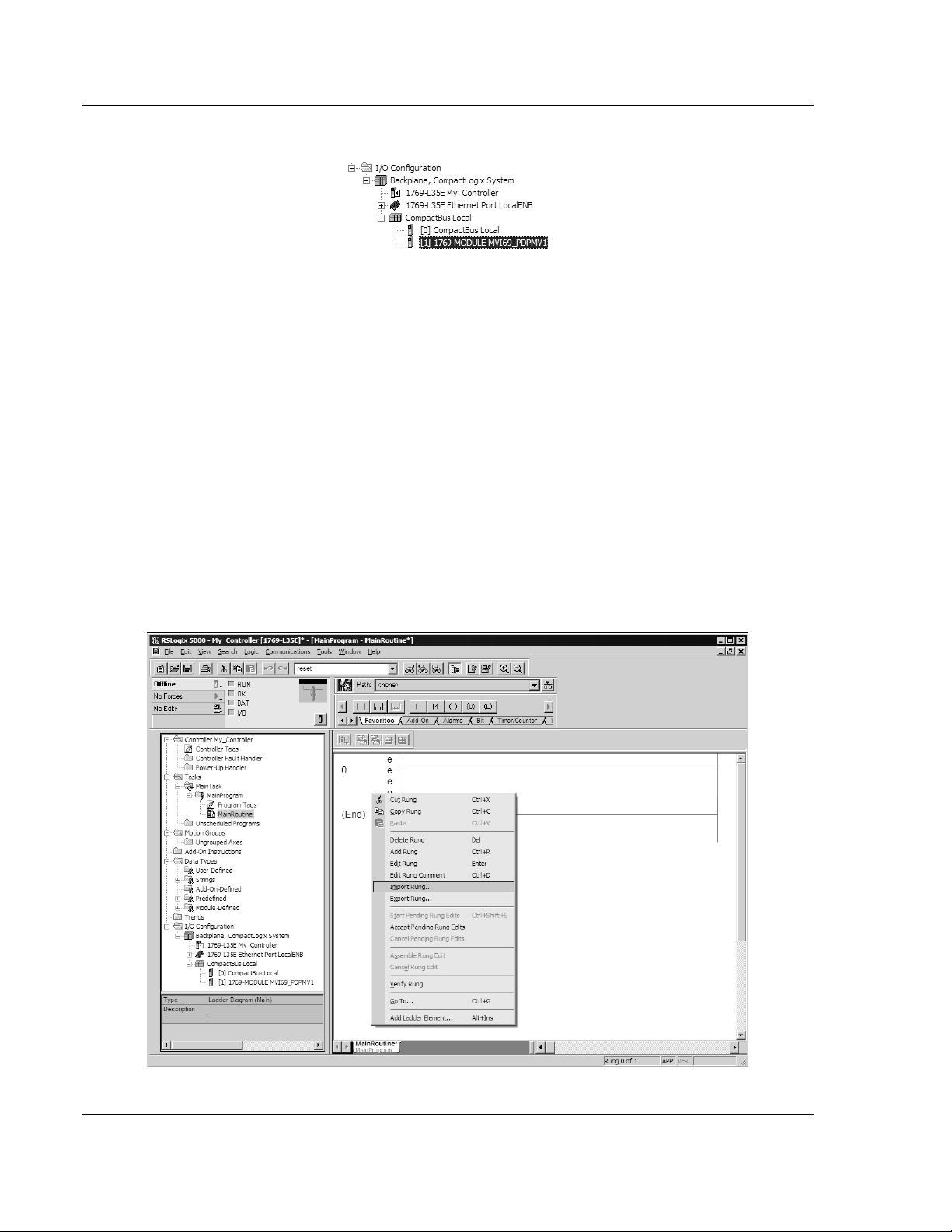

Now the MVI69-PDPMV1 module will be visible at the I/O Configuration section.

2.1.3 Importing the Ladder Rung

1 Open your application in RSLogix 5000.

2 To create a new routine, expand the T

TASK folder.

3 On the M

AIN PROGRAM folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose N

4 In the New Routine dialog box, enter the name and description of your

routine, and then click OK. In this example we are demonstrating the

importing of the ladder rung using the default MainRoutine. In the case where

you create a routine by an other name for placing the Add-On Instruction,

then in your original routine where your other ladder logic is located you need

to add a rung with a jump instruction to the new routine holding the Add-On

Instruction.

5 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose I

ASKS folder, and then expand the MAIN

EW ROUTINE.

MPORT RUNG.

Page 24 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 25

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

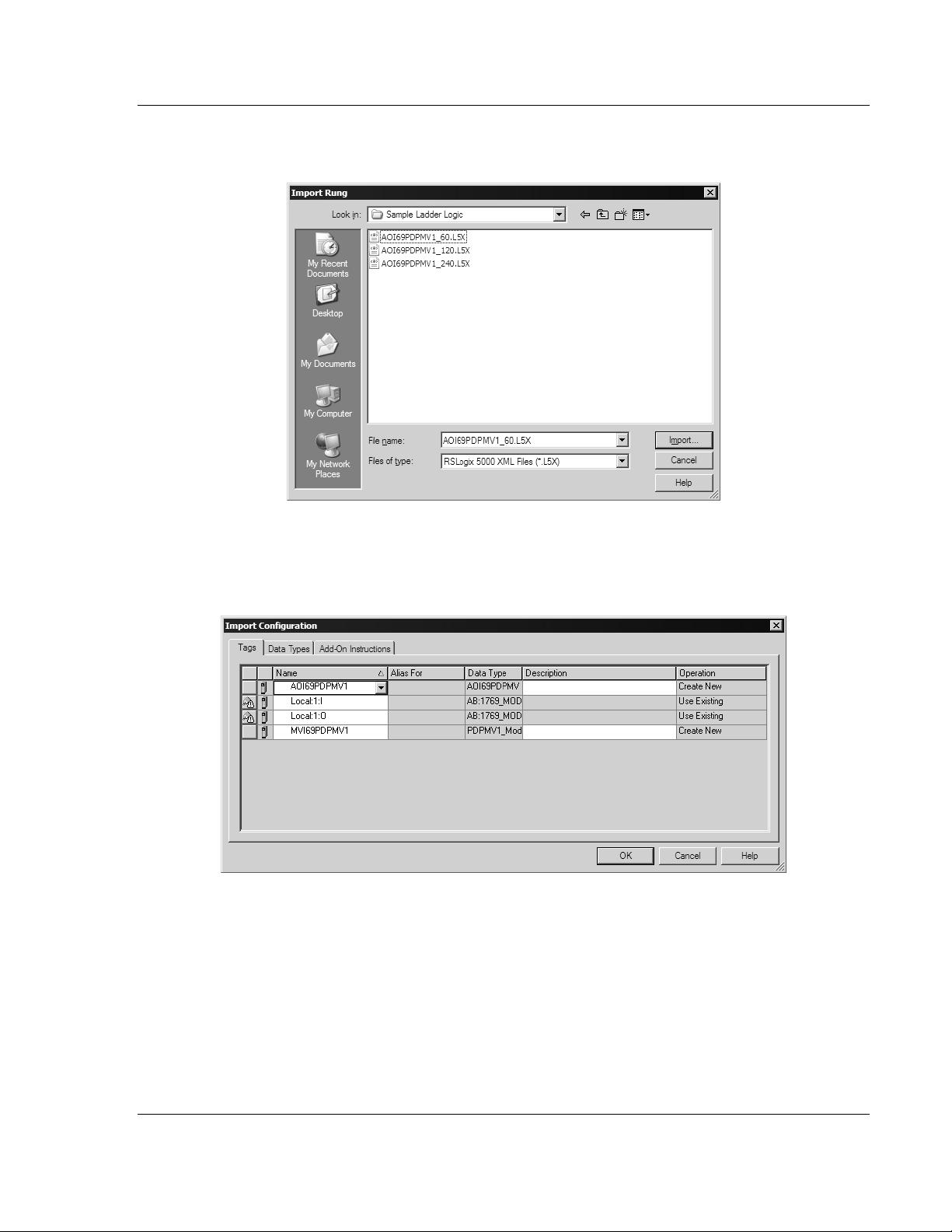

6 Select the AOI69PDPMV1_60.L5X file for the block size you selected for the

module (60, 120 or 240).

7 The following window will be displayed showing the controller tags to be

created during the import procedure: If desired, the description, "MVI69PDPMV1 Interface AOI" may be typed into the description field for

AOI69PDPMV1_60.L5X file.

ProSoft Technology, Inc. Page 25 of 225

July 8, 2011

Page 26

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

8 If you are using the module in a different slot (or remote rack), select the

correct connection input and output variables associated to the module. If

your module is located in slot 1 of the local rack, this step is not required.

Click OK to confirm the import. RSLogix will indicate that the import is in

progress:

Page 26 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 27

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

The imported rung will contain the Add-On Instruction as shown in the

following illustration. Notice that the block size is determined by the Add-On

Instruction that you imported.

Important: You must set the Block Transfer Size in ProSoft Configuration Builder to match the

block size for the Add-On Instruction, otherwise the module may not function correctly.

The procedure has also imported new user-defined data types, data objects

and the Add-On Instruction to be used at your project.

ProSoft Technology, Inc. Page 27 of 225

July 8, 2011

Page 28

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

2.1.4 Adding Multiple Modules (Optional)

Important: If your application requires more than one MVI69-PDPMV1 module into the same

project, follow the steps below and make certain that both modules are assigned identical Block

Transfer Sizes.

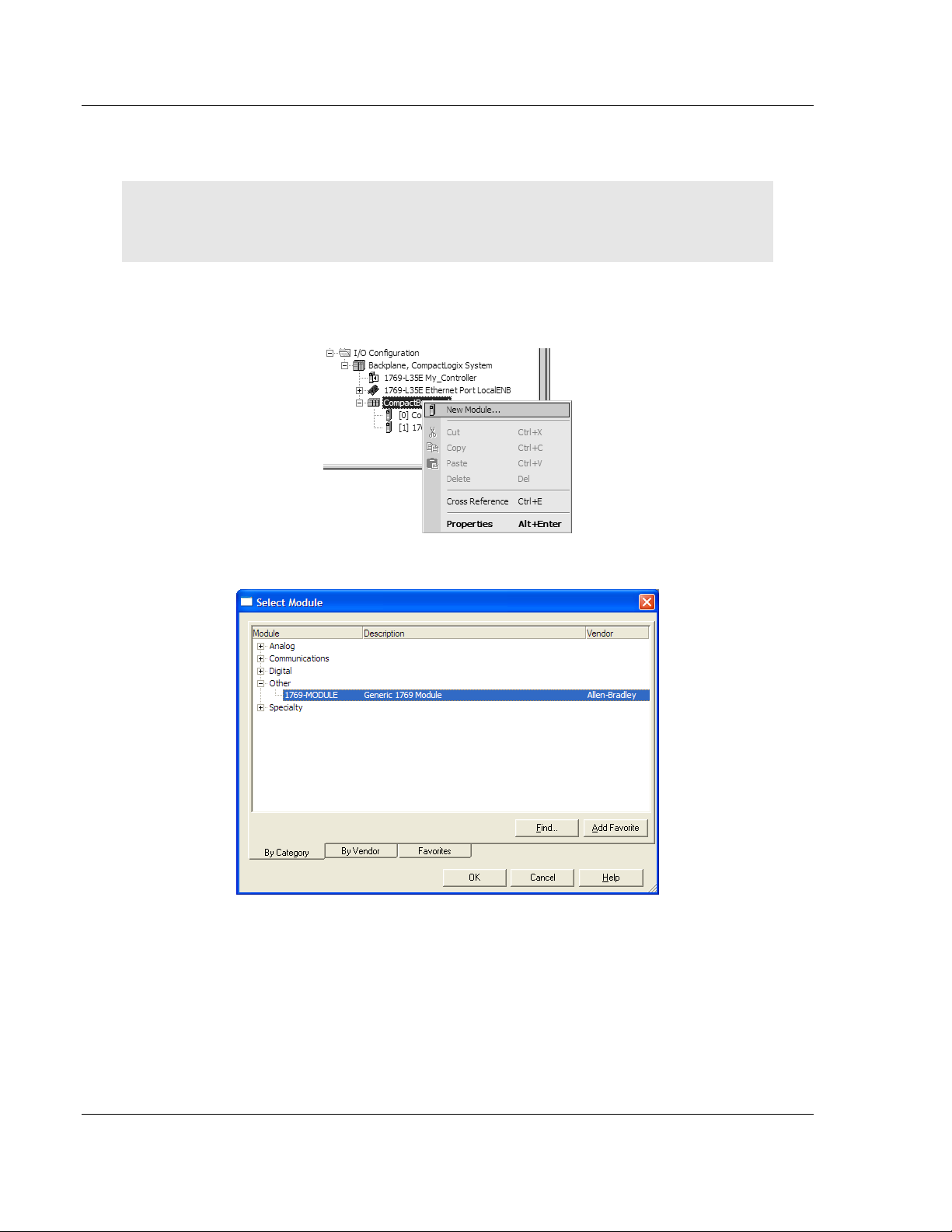

1 In the I/O

shortcut menu, and then choose N

2 Select 1769-MODULE.

CONFIGURATION folder, click the right mouse button to open a

EW MODULE.

Page 28 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 29

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

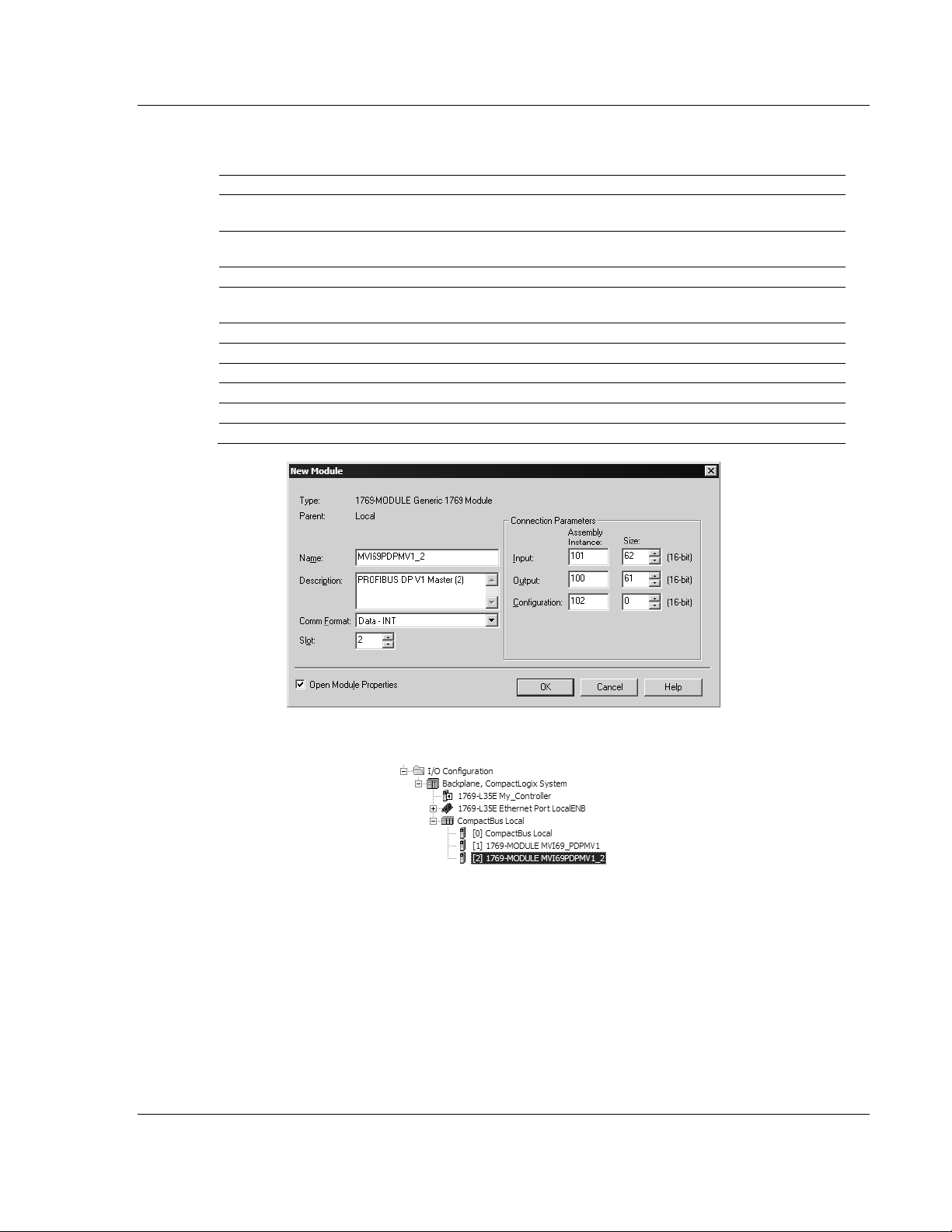

3 Fill the module properties as follows:

Parameter Value

Name

Description Enter a description for the module. Example: PROFIBUS

Comm Format

Slot

Input Assembly Instance

Input Size

Output Assembly Instance

Output Size

Configuration Assembly Instance

Configuration Size

Enter a module identification string. Example:

MVI69PDPMV1_2

DPV1 MASTER

Select D

Enter the slot number in the rack where the MVI69-

PDPMV1 module will be located.

101

62 / 122 / 242

100

61 / 121 / 241

102

0

ATA-INT

4 Click OK to confirm. The new module is now visible:

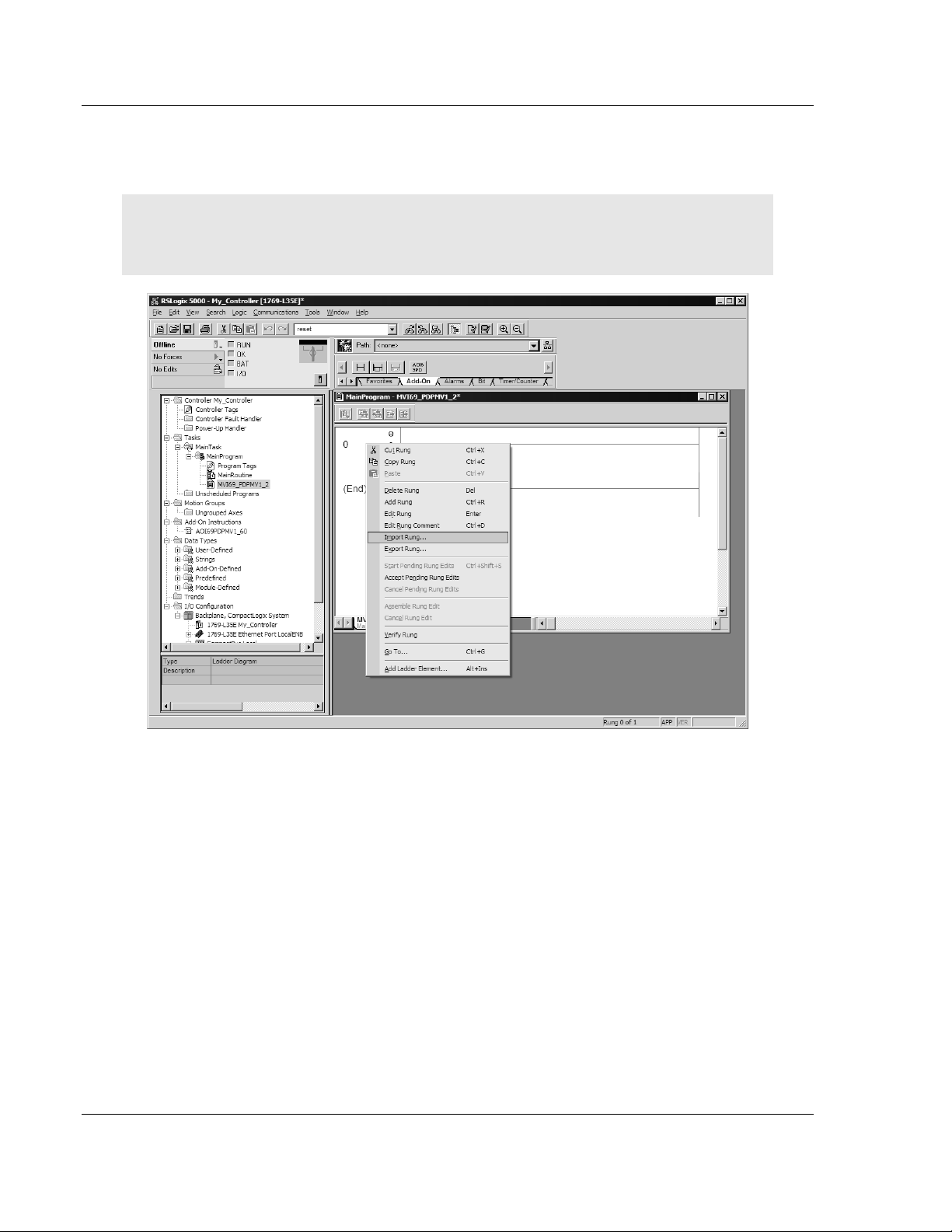

5 Expand the T

6 On the M

menu. On the shortcut menu, choose N

ASKS folder, and then expand the MAINTASK folder.

AINPROGRAM folder, click the right mouse button to open a shortcut

EW ROUTINE.

7 In the New Routine dialog box, enter the name and description of your

routine, and then click OK.

ProSoft Technology, Inc. Page 29 of 225

July 8, 2011

Page 30

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

8 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose I

MPORT RUNG.

Note: It is not necessary to create a completely new routine. It is possible to add the MVI69-

PDPMV1_2 module in the previously created routine. If you need to create a new routine, insert a

jump instruction in the previous routine to the new routine.

Page 30 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 31

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

9 Select the AOI69PDPMV1_60.L5X file for the block size you selected for the

module (60, 120 or 240).

10 The following window will be displayed showing the tags to be imported:

ProSoft Technology, Inc. Page 31 of 225

July 8, 2011

Page 32

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

11 Associate the I/O connection variables to the correct module. The default

values are Local:1:I and Local:1:O. These require re-assignment to the new

module's location.

12 Change the default tags AOI69PDPMV1 and MVI69PDPMV1 to avoid conflict

with existing tags. In this step, you should append a string to the default tag

names, such as "_2", as shown in the following illustration.

Page 32 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 33

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

13 You will be prompted to confirm your change. Click OK to continue.

ProSoft Technology, Inc. Page 33 of 225

July 8, 2011

Page 34

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

If the second module's logic was created in a new routine, enter a rung in the

Main routine with a JSR instruction to the new routine to enable the PLC logic to

communicate with both modules.

The setup procedure is now complete. Save the project and download the

application to your CompactLogix processor.

Page 34 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 35

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

2.1.5 Connecting Your PC to the Processor

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

ProSoft Technology, Inc. Page 35 of 225

July 8, 2011

Page 36

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

2.1.6 Downloading the Sample Program to the Processor

Note: The key switch on the front of the CompactLogix processor must be in the REM or PROG

position.

1 If you are not already online to the processor, open the C

menu, and then choose DOWNLOAD. RSLogix will establish communication

with the processor.

2 When communication is established, RSLogix will open a confirmation dialog

box. Click the D

OWNLOAD button to transfer the sample program to the

processor.

OMMUNICATIONS

3 RSLogix will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix will open another confirmation

dialog box. Click OK

to switch the processor from PROGRAM mode to RUN

mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

Page 36 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 37

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

Configuring the RSLinx Driver for the PC COM Port

If RSLogix is unable to establish communication with the processor, follow these

steps.

1 Open RSLinx.

2 Open the C

OMMUNICATIONS menu, and choose CONFIGURE DRIVERS.

This action opens the Configure Drivers dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the

Available Driver Types list. The recommended driver type to choose for serial communication with

the processor is RS-232 DF1 Devices.

ProSoft Technology, Inc. Page 37 of 225

July 8, 2011

Page 38

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

3 Click to select the driver, and then click CONFIGURE. This action opens the

Configure RS-232 DF1 Devices dialog box.

4 Click the A

UTO-CONFIGURE button. RSLinx will attempt to configure your

serial port to work with the selected driver.

5 When you see the message Auto Configuration Successful, click the OK

button to dismiss the dialog box.

Note: If the auto-configuration procedure fails, verify that the cables are connected correctly

between the processor and the serial port on your computer, and then try again. If you are still

unable to auto-configure the port, refer to your RSLinx documentation for further troubleshooting

steps.

Page 38 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 39

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

2.2 Adding the Module to an Existing CompactLogix Project

Important: The MVI69-PDPMV1 module has a power supply distance rating of 2 (L43 and L45

installations on first 2 slots of 1769 bus).

If you are installing and configuring the module with a CompactLogix controller,

follow these steps. If you are using a MicroLogix controller, refer to the next

section.

1 Add the MVI69-PDPMV1 module to the project. Right-click the mouse button

on the I/O

display a pop-up menu. Select the N

CONFIGURATION menu.

CONFIGURATION option in the Controller Organization window to

EW MODULE option from the I/O

This action opens the Select Module dialog box:

ProSoft Technology, Inc. Page 39 of 225

July 8, 2011

Page 40

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

2 Select the 1769-Module (Generic 1769 Module) from the list and click OK.

3 Enter the Name, Description and Slot options for your application, using the

values in the illustration above. You must select the Comm Format as D

ATA -

INT in the dialog box, otherwise the module will not communicate over the

backplane of the CompactLogix rack.

4 Configure the Connection Parameters to match to the Block Transfer Size

parameter in the configuration file. Use the values in the table corresponding

with the block transfer size you configured.

Block Transfer Size = 60

Field Recommended Value

Type 1769-MODULE Generic 1769 Module

Parent Local

Name MVI69

Description MVI69 Application Module

Comm Format Data - INT

Slot The slot number in the rack where the module is installed

Input Assembly Instance 101

Input Size

Output Assembly Instance 100

Output Size

Configuration Assembly Instance 102

Configuration Size

62

61

0

Page 40 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 41

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

Block Transfer Size = 120

Field Recommended Value

Type 1769-MODULE Generic 1769 Module

Parent Local

Name MVI69

Description MVI69 Application Module

Comm Format Data - INT

Slot The slot number in the rack where the module is installed

Input Assembly Instance 101

Input Size

Output Assembly Instance 100

Output Size

Configuration Assembly Instance 102

Configuration Size

122

121

0

Block Transfer Size = 240

Field Recommended Value

Type 1769-MODULE Generic 1769 Module

Parent Local

Name MVI69

Description MVI69 Application Module

Comm Format Data - INT

Slot The slot number in the rack where the module is installed

Input Assembly Instance 101

Input Size

Output Assembly Instance 100

Output Size

Configuration Assembly Instance 102

Configuration Size

242

241

0

ProSoft Technology, Inc. Page 41 of 225

July 8, 2011

Page 42

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

5 Click NEXT to continue.

6 Select the Requested Packet Interval value for scanning the I/O on the

module. This value represents the minimum frequency at which the module

will handle scheduled events. It should not be set to less than 1 millisecond.

Values between 5 and 10 milliseconds should work with most applications.

AVE the module. Click OK to dismiss the dialog box. The Controller

7 S

Organization window now displays the module's presence. The following

illustration shows the Controller Organization window:

8 Copy the user-defined data types from the sample program.

9 Copy the controller tags from the sample program.

10 Copy the ladder rungs from the sample program.

11 Save and download (page 36) the new application to the controller and place

it in RUN mode.

Page 42 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 43

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Ladder Logic

PROFIBUS DPV1 Master User Manual

2.3 Adding the Module to an Existing MicroLogix Project

If you are installing and configuring the module with a MicroLogix controller,

follow these steps. If you are using a CompactLogix controller, refer to the

previous section.

The first step in setting up the processor ladder file is to define the I/O type

module to the system. Start RSLogix 500, and follow these steps:

1 In RSLogix, open your existing application, or start a new application,

depending on your requirements.

2 Double-click the

project tree. This action opens the

I/O CONFIGURATION icon located in the Controller folder in the

I/O Configuration dialog box.

3 In the

I/O Configuration dialog box, select "OTHER - REQUIRES I/O CARD TYPE

ID" at the bottom of the list in the right pane, and then double-click to open

the "Other" type IO card dialog box.

4 Enter the values shown in the following illustration to define the module

correctly for the MicroLogix processor, and then click OK

to save your

configuration.

ProSoft Technology, Inc. Page 43 of 225

July 8, 2011

Page 44

Ladder Logic MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

The Input Words and Output Words parameters will depend on the Block

Transfer Size parameter you specify in the configuration file. Use the values

from the following table.

Block Transfer Size Input Words Output Words

60

120

240

62 61

122 121

242 241

5 Click OK

to continue.

6 After completing the module setup, the I/O Configuration dialog box will

display the module's presence.

The last step is to add the ladder logic. If you are using the example ladder logic,

adjust the ladder to fit your application.

Download the new application to the controller and place the processor in RUN

mode. If you encounter errors, refer to Diagnostics and Troubleshooting (page

133) for information on how to connect to the module's Config/Debug port to use

its troubleshooting features.

Page 44 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 45

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

3 Module Setup

In This Chapter

Connecting Your PC to the Module ....................................................... 46

Configuring the Module ......................................................................... 47

Backing Up the Project .......................................................................... 68

Downloading the Project to the Module Using a Serial COM Port ......... 70

Downloading the Project to the Module Using CIPconnect ................... 73

This section contains the setup procedure, data, and ladder logic for successful

application of the MVI69-PDPMV1 module. Each step in the setup procedure is

defined in order to simplify the use of the module.

Important: Before connecting the cables, please insert the supplied PROFIBUS adaptor in the

PROFIBUS port on the MVI69 module. This adaptor provides additional space between the front of

the module and the shell of the PROFIBUS cable, allowing the PROFIBUS cable to connect

without interfering with cables connected to the Configuration/Debug port on the module. Refer to

the following illustration for the correct cabling configuration.

ProSoft Technology, Inc. Page 45 of 225

July 8, 2011

Page 46

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

3.1 Connecting Your PC to the Module

With the module securely mounted, connect your PC to the Configuration/Debug

port using the RJ45-DB-9 Serial Adapter Cable and the Null Modem Cable

included in the package with the MVI69-PDPMV1 module.

1 Connect the RJ45-DB-9 Serial Adapter Cable to the Null Modem Cable.

2 Insert the RJ45 cable connector from the RJ45-DB-9 cable into the

Configuration/Debug port of the module.

3 Attach the other end to the serial port on your PC.

Page 46 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 47

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

3.2 Configuring the Module

ProSoft Technology has provided a configuration tool called ProSoft

Configuration Builder (PCB) that will help you with the following tasks:

Creating a configuration project

Setting module parameters

Configuring the PROFIBUS network (Master and slaves)

Calculating checksums

Copying the project to the module.

The following topics of this chapter explain each task step-by-step.

3.2.1 Setting Up the Project

To begin, start ProSoft Configuration Builder (PCB). If you have used other

Windows configuration tools before, you will find the screen layout familiar.

PCB’s window consists of a tree view on the left, an information pane and a

configuration pane on the right side of the window. When you first start PCB, the

tree view consists of folders for Default Project and Default Location, with a

Default Module in the Default Location folder. The illustration below shows the

PCB window with a new project.

ProSoft Technology, Inc. Page 47 of 225

July 8, 2011

Page 48

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

First, add the MVI69-PDPMV1 module to the project.

1 Use the mouse to select D

EFAULT MODULE in the tree view, and then click the

right mouse button to open a shortcut menu.

2 On the shortcut menu, select C

HOOSE MODULE TYPE. This action opens the

Choose Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select MVI69. In the Select

Module Type dropdown list, select MVI69-PDPMV1, and then click OK to

save your settings and return to the ProSoft Configuration Builder window.

Page 48 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 49

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

3.2.2 Setting Module Parameters

Notice that the contents of the information pane and the configuration pane

changed when you added the MVI69-PDPMV1 module to the project. The red X

icon indicates that the module’s configuration is incomplete.

In the following steps, you will provide the missing information to begin

configuring the module.

1 Click the plus sign

then expand the MVI69

2 Double-click the MVI

[+] next to the module to expand the module tree, and

PDPM-V1 tree.

PROFIBUS MASTER DPV1 object. This action opens the

Edit dialog box.

ProSoft Technology, Inc. Page 49 of 225

July 8, 2011

Page 50

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

3 In the Edit dialog box, configure the values for Input Data Size and Output

Data Size (PROFIBUS input and output point words) to match the values

required by your application. To change a value, select the parameter to

modify in the left pane, and then type the new value in the edit field in the

right pane.

4 When you have finished updating the values, click OK to save your settings

and return to the ProSoft Configuration Builder window.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view.

To rename an object

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose R

ENAME.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

Page 50 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 51

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

3.2.3 Configuring the PROFIBUS Master

In this task, you will configure the PROFIBUS Master, and then add PROFIBUS

slaves to the network. When this step is complete, you will download the

configuration information to the MVI69 module. You will also export the I/O maps

for the processor.

1 In ProSoft Configuration Builder tree view, click [+]

PDPMV1 tree, and then double-click the PROFIBUS

opens the PDPMV1 PROFIBUS Master Setup dialog box.

2 On the Master Setup dialog box, click the C

ONFIGURE PROFIBUS button.

This action opens the ProSoft Configuration Builder for PROFIBUS

application.

3 Click [+] to expand the PROFIBUS Master tree.

4 Drag the PROFIBUS Master icon into the Bus Configuration window. This is

automatically done by the software for new applications.

to expand the MVI69-

DP icon. This action

ProSoft Technology, Inc. Page 51 of 225

July 8, 2011

Page 52

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

5 Double-click the PROFIBUS MASTER icon in the Bus Configuration window.

This action opens the Master Properties dialog box.

6 On the Common tab, name your PROFIBUS drop.

Note: The PROFIBUS tab contains the address setting and advanced configuration settings for the

Master. The default settings on this tab work best in most applications.

7 Click OK to save your changes and return to the Bus Configuration window.

Page 52 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 53

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

3.2.4 Installing the GSD Files

The GSD configuration files contain information on PROFIBUS slaves that you

can configure as part of your PROFIBUS network. In order for this configuration

information to be available in ProSoft Configuration Builder, you must install the

GSD files.

To install GSD files manually

1 In ProSoft Configuration Builder tree view, click [+] to expand the MVI69-

PDPMV1 tree, and then double-click the PROFIBUS

opens the PDPMV1 PROFIBUS Master Setup dialog box.

2 Click the C

ONFIGURE PROFIBUS button. This action opens the ProSoft

Configuration Builder for PROFIBUS application.

3 Open the T

OOLS menu, and then choose INSTALL NEW GS* FILE. This action

opens a dialog box that allows you to browse for the location of the GSD

configuration files to install.

4 Choose the file to install, and then click O

PEN. If the file already exists in the

configuration file path, you will be prompted to overwrite the file.

5 You will be prompted to associate the GSD configuration file with a bitmap

image of the slave device. Use the File / Open dialog box to browse for the

location of the image file to use.

DP icon. This action

Tip: GSD configuration files for popular PROFIBUS slaves and ProSoft Technology modules are

included with the installation. If you have other GSD files for your PROFIBUS slaves, copy them

into C:\Documents and Settings\All Users\Application Data\ProSoft\GSD (Windows XP / 2000) or

C:\My Documents\ (Windows 98) and ProSoft Configuration Builder will load them automatically.

3.2.5 Configuring the PROFIBUS Slaves

There are two essential steps to configuring a slave:

1 Add the slave in ProSoft Configuration Builder (PCB) as a device connected

to the PROFIBUS Master, specifying the slave address and any necessary

input and output configuration. Download the PROFIBUS Master

configuration to the MVI69-PDPMV1 module.

2 Configure the slave (using PCB or the configuration tool supplied by the

manufacturer, for some PROFIBUS slaves). Verify that the slave address

configured in the slave module matches the slave address configured in PCB.

Download the PROFIBUS Slave configuration to the slave module.

Using The Autoscan Feature

The concept of Automatic network scanning means that the user can instruct the

Bus Configuration window to automatically gather information about slaves that

are connected to the network. When the scan is completed the user can adopt

the detected slaves to the bus configuration and download to the Master.

ProSoft Technology, Inc. Page 53 of 225

July 8, 2011

Page 54

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

This is a quick way to get a network up and running. However, one should be

aware that it is not guaranteed that any particular slave will enter data exchange

since the user parameter data might not match. This is especially obvious if no

associated GSD-file is found during the network scan, this means that no user

parameter data would be sent to the slave.

N

ETWORK SCAN is selectable from the Online menu as well as from the drop-

down menu for the M

ASTER icon.

The only prerequisite for scanning the network is that the project consists of a

Master with no slaves assigned to it. If a network scan is initiated and the project

already contains slaves, a message window similar to the one below will appear.

When the window is closed the network scan will be omitted.

When a network scan is initiated, the PROFIBUS Master Configuration window

will download the Master bus parameters (baudrate etc.).

Page 54 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 55

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

When the download is completed, the PROFIBUS Master Configuration window

will initialize the Master to operate as a Class1/Class 2 Master. In this mode it is

possible to initialize the Master even if the database does not contain any slaves.

After successful initialization, the PROFIBUS Master Configuration window will

issue the following mailboxes in order to gather information about the connected

slaves:

1 1. Send FB_APPL_GET_LIVE_LIST in order to detect connected slaves,

2 2. Send FB_APPL_GET_SLAVE_DIAG (external request) to all devices

identified as slaves according to the Live list.

3 3. Send FB_APPL_GET_SLAVE_CONFIG to all devices identified as slaves

according to the Live list.

ProSoft Technology, Inc. Page 55 of 225

July 8, 2011

Page 56

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

When the information is collected the PROFIBUS Master Configuration window

will find a matching GSD-file and extract information from it. Refer to the

flowchart below for this sequence:

GSD Selection Algorithm

If two or more matching GSD-files are found, the first one found should be

selected. The other compatible files should be stored so that the user can select

one of them instead. If the user selects another GSD-file, the PROFIBUS Master

Configuration window will run through the Module Selection Algorithm (described

below) again.

Page 56 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 57

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

Module Selection Algorithm

The algorithm used to find modules in the GSD based on the Identifier byte(s) is

as follows:

Select the module that matches the largest number of Identifier bytes. If the GSD

contains two or more modules with the exact set of Identifier bytes, use the first

module found.

Example:

If a slave responds with identifier bytes: 0x11, 0x21, 0x31 and that the associated

GSD-file contains five modules: “A” = 0x11, “B” = 0x21, “C” = 0x31, “AB” = 0x11,

0x21 and “BC” = 0x21, 0x31. The PROFIBUS Master Configuration window will

then select modules "AB" and "C".

Note: If no matching module is found in the GSD, The PROFIBUS Master Configuration window

will display the identifier byte(s) instead.

Network scan window

The information extracted from the GSD-file(s) will be displayed in the Network

scan window.

Note: Only slaves are shown here, possible Masters connected to the network will not be listed

here!

Select

In this column all found slaves will be marked as selected by default, except for

slaves with the special address 126 (refer to the next section that describes the

Address column). Only selected slaves will be added to the PROFIBUS Master

Configuration when the A

DOPT SELECTED SLAVES button is clicked.

Address

In this column the node address of the slaves will be displayed. Found slaves

should be listed in ascending order according to their node addresses.

ProSoft Technology, Inc. Page 57 of 225

July 8, 2011

Page 58

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

Special address 126 -Set Slave address

If a slave with node address 126 is detected during the network scan, the

PROFIBUS Master Configuration window will display the address in red color. It

will not be possible for the user to adopt the slave to the configuration since it is

not allowed to exchange data with devices having this address. The check box in

the Select column will be grayed out.

Page 58 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 59

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

To be able to adopt a slave with address 126 the user must first assign a valid

address by clicking the icon next to the node address. By doing so the Set Slave

Address dialog box is started.

Note: The Old slave address is preset to a value of 126 that is not editable (grayed out).

The PROFIBUS Master Configuration window will prevent the user from selecting

a New slave address that is already occupied by another device; this includes

detected Master stations as well. If the user selects an occupied address, a

message similar to the one shown here will open.

When an address has been successfully assigned, the PROFIBUS Master

Configuration window will update the Network scan window as shown here. The

node address will be updated to the one that the user selected in the Set Slave

dialog box. The check box in the Select column will be marked allowing the user

to adopt the slave to the configuration.

ProSoft Technology, Inc. Page 59 of 225

July 8, 2011

Page 60

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

Slave

In this column the name of the slave as stated in the assigned GSD-file will be

displayed. If no matching GSD-file is found the Ident number will be displayed in

red color in the drop-down list.

Module

This column shows the name of the module(s) as stated in the assigned GSDfile, which matches the Identifier byte(s) derived from the GetCfg mailbox

message. If no GSD-file or no matching module is found the Identifier byte(s) will

be displayed in red color. If the configuration for a slave is constructed of several

modules, the modules will be listed under each other.

If there is more than one module in the GSD-file that matches the Identifer bytes,

the first matching module will be displayed in blue color in a drop-down list. The

drop-down list will contain all other matching modules so that the user can select

the desired one.

Note: Only modules that have the exact same Identifer bytes as the first matching module will be

displayed in the drop-down list.

GSD-file

This column shows the name of the GSD-file that matches the Ident number

derived from the SlaveDiag mailbox message. If there are more files with the

same Ident number in the device catalog, the first matching GSD-file will be

displayed in blue color in a drop-down list.

Page 60 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 61

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

This could be the case if the device catalog contains two or more brand labeled

devices, or GSD-files for two or more languages (for example NICEDEV.GSD

and NICEDEV.GSE) exist.

Note: If the user selects another GSD-file, The PROFIBUS Master Configuration window will

update the modules for that slave accordingly.

If no GSD-file is found the user will be able to copy the expected GSD to the

device catalog by clicking the icon next to the text No GSD found. This will start

the Install new GS*-file dialog box. When the file is installed, the PROFIBUS

Master Configuration window will verify that the installed file matches the slave

and update the modules for the slave accordingly.

Rescan

Pressing the Y

ES button will trigger a new network scan. Before proceeding with

the scan a message similar to the one below will appear. If a new scan is

accepted, detected slaves found during the previous scan will be lost.

If no slaves are found a message similar to the one below will appear. The same

message will also show up if no slaves are found during the initial scan (for

example when selecting S

CAN NETWORK from the Online menu).

ProSoft Technology, Inc. Page 61 of 225

July 8, 2011

Page 62

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

Adopt selected slaves

Pressing this button will cause all selected slaves to be adopted to the

PROFIBUS Master Configuration window. Before carrying on with this action a

message similar to the one below will appear.

If accepted, the network scan window will close and the PROFIBUS Master

Configuration window will be populated with the slaves that were found during

the network scan.

Note: The icon for slave 104 displays the Ident number since no GSD-file exists for this device.

Also observe the configuration for the very same slave at the bottom of the screen.

Note: Slave is equal to the Ident number and that the Device path and Order number/designation

fields are left empty.

Page 62 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 63

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

Cancel and Help

If the C

ANCEL button is pressed a message similar to the one below will appear.

If the H

ELP button is pressed the online help will start.

Scanning for Slaves Manually

In this part of the procedure, you will add and configure the PROFIBUS slaves. In

the following steps, you will add and configure a ProLinx PROFIBUS slave

module. The configuration information (.GSD file) for this module is provided on

the inRAx Solutions CD-ROM.

1 In ProSoft Configuration Builder for PROFIBUS, click the plus sign [+] to

expand the PROFIBUS DP tree.

2 Navigate to the folder containing the type of slave device to add, and then

click the plus sign [+] to expand the folder.

3 Drag the slave icon into the Bus Configuration window. The slave device

appears in the Bus Configuration window as a network location to the Master.

ProSoft Technology, Inc. Page 63 of 225

July 8, 2011

Page 64

Module Setup MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

4 In the tree view, click the plus sign [+] to expand the slave device you added.

This action opens a list of device configuration values. The following

illustration shows the device configuration values for a ProLinx PROFIBUS

Slave. The values for other devices may be different, so you should review

the specifications for the product you are installing in order to determine the

correct values to use.

5 Drag the input and output parameters to the slot location grid below the Bus

Configuration window. This view displays the configuration data, order

number, and starting input and output addresses.

Page 64 of 225 ProSoft Technology, Inc.

July 8, 2011

Page 65

MVI69-PDPMV1 ♦ CompactLogix or MicroLogix Platform Module Setup

PROFIBUS DPV1 Master User Manual

6 Double click the slave icon to view the Slave Device properties.

In particular, note the following settings:

o Automatic PROFIBUS Address Assignment:

ProSoft Configuration Builder automatically assigns a PROFIBUS address

to each new slave. The address assignment begins at address 3, and is

incremented by 1 for each new slave added to the network. You can

change the address in the Common tab of the Slave Properties dialog

box.

o Automatic Input/Output Address Assignment:

For each new slave added to the PROFIBUS network, ProSoft

Configuration Builder automatically converts the input/output byte

addresses to word input/output addresses for the State RAM in the

processor.