Page 1

MVI69E-MBTCP

CompactLogix Platform

Modbus TCP/IP Enhanced

Communication Module

May 20, 2015

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

MVI69E-MBTCP User Manual

May 20, 2015

ProSoft Technology®, is a registered copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD and are

available at no charge from our web site: http://www.prosoft-technology.com

Content Disclaimer

This documentation is not intended as a substitute for and is not to be used for determining suitability or reliability of

these products for specific user applications. It is the duty of any such user or integrator to perform the appropriate

and complete risk analysis, evaluation and testing of the products with respect to the relevant specific application or

use thereof. Neither ProSoft Technology nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. Information in this document including illustrations, specifications and

dimensions may contain technical inaccuracies or typographical errors. ProSoft Technology makes no warranty or

representation as to its accuracy and assumes no liability for and reserves the right to correct such inaccuracies or

errors at any time without notice. If you have any suggestions for improvements or amendments or have found errors

in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of ProSoft Technology. All pertinent state, regional, and local safety

regulations must be observed when installing and using this product. For reasons of safety and to help ensure

compliance with documented system data, only the manufacturer should perform repairs to components. When

devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use ProSoft Technology software or approved software with our hardware products may result in injury,

harm, or improper operating results. Failure to observe this information can result in injury or equipment damage.

Copyright © 2015 ProSoft Technology, Inc. All Rights Reserved.

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1 (661) 716-5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Agency

ATEX; Category 3, Zone 2

CE Mark

CSA; CB Safety

Environmental

KCC

RoHS Compliant

UL/cUL; Class 1, Div. 2 Groups A, B, C, D

Important Safety Information

North America Warnings

A This Equipment is Suitable For Use in Class I, Division 2, Groups A, B, C, D or Non-Hazardous Locations Only.

B Warning – Explosion Hazard – Substitution of Any Components May Impair Suitability for Class I, Division 2.

C Warning – Explosion Hazard – Do Not Disconnect Equipment Unless Power Has Been Switched Off Or The

Area is Known To Be Non-Hazardous.

D The subject devices are powered by a Switch Model Power Supply (SMPS) that has regulated output voltage of

5 VDC.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Agency Approvals and Certifications

Page 4

Page 5

MVI69E-MBTCP ♦ CompactLogix Platform Contents

Modbus TCP/IP Enhanced Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

Content Disclaimer .............................................................................................................................. 2

Important Safety Information ............................................................................................................... 3

1 Start Here 9

1.1 System Requirements ............................................................................................. 10

1.2 Deployment Checklist .............................................................................................. 11

1.3 Setting Jumpers ...................................................................................................... 11

1.4 Installing the Module in the Rack ............................................................................ 12

1.5 DVD Contents ......................................................................................................... 15

1.6 Package Contents ................................................................................................... 15

2 Adding the Module to RSLogix 17

2.1 Creating the Module in an RSLogix 5000 Project ................................................... 17

2.1.1 Creating a Module in the Project Using an Add-On Profile ..................................... 18

2.1.2 Creating a Module in the Project Using a Generic 1769 Module Profile ................. 21

2.2 Installing ProSoft Configuration Builder .................................................................. 24

2.3 Generating the AOI (.L5X File) in ProSoft Configuration Builder ............................ 25

2.3.1 Setting Up the Project in PCB ................................................................................. 25

2.3.2 Creating and Exporting the .L5X File ...................................................................... 27

2.4 Creating a New RSLogix 5000 Project .................................................................... 30

2.5 Importing the Add-On Instruction ............................................................................ 31

2.6 Adding Multiple Modules in the Rack (Optional) ..................................................... 34

2.6.1 Adding an Additional Module in PCB ...................................................................... 34

2.6.2 Adding an Additional Module in RSLogix 5000 ....................................................... 36

3 Configuring the MVI69E-MBTCP Using PCB 43

3.1 Basic PCB Functions ............................................................................................... 44

3.1.1 Creating a New PCB Project and Exporting an .L5X File ....................................... 44

3.1.2 Renaming PCB Objects .......................................................................................... 44

3.1.3 Editing Configuraiton Parameters ........................................................................... 44

3.1.4 Printing a Configuration File .................................................................................... 46

3.2 Module Configuration Parameters .......................................................................... 47

3.2.1 Module ..................................................................................................................... 47

3.2.2 MBTCP Servers ...................................................................................................... 48

3.2.3 MBTCP Client x ....................................................................................................... 50

3.2.4 MBTCP Client x Commands ................................................................................... 51

3.2.5 Ethernet 1 ................................................................................................................ 54

3.2.6 Static ARP Table ..................................................................................................... 55

3.3 Downloading the Configuration File to the Processor ............................................. 56

3.4 Uploading the Configuration File from the Processor ............................................. 59

4 MVI69E-MBTCP Backplane Data Exchange 63

4.1 General Concepts of the MVI69E-MBTCP Data Transfer ...................................... 63

ProSoft Technology, Inc. Page 5 of 150

May 20, 2015

Page 6

Contents MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

4.2 Backplane Data Transfer ........................................................................................ 64

4.3 Normal Data Transfer ............................................................................................. 65

4.3.1 Write Block: Request from the Processor to the Module ........................................ 65

4.3.2 Read Block: Response from the Module to the Processor ..................................... 65

4.3.3 Read and Write Block Transfer Sequences ........................................................... 66

4.4 Data Flow Between the Module and Processor ..................................................... 70

4.4.1 Server Mode ........................................................................................................... 70

4.4.2 Master Mode ........................................................................................................... 72

5 Using Controller Tags 75

5.1 Controller Tags ....................................................................................................... 75

5.1.1 MVI69E-MBTCP Controller Tags ............................................................................ 76

5.2 User-Defined Data Types (UDTs)........................................................................... 76

5.2.1 MVI69E-MBTCP User-Defined Data Types ........................................................... 77

5.3 MBTCP Controller Tag Overview ........................................................................... 79

5.3.1 MBTCP.CONFIG .................................................................................................... 79

5.3.2 MBTCP.DATA ......................................................................................................... 80

5.3.3 MBTCP.CONTROL ................................................................................................. 80

5.3.4 MBTCP.STATUS .................................................................................................... 86

5.3.5 MBTCP.UTIL ........................................................................................................... 89

6 Diagnostics and Troubleshooting 93

6.1 Ethernet LED Indicators .......................................................................................... 93

6.2 LED Status Indicators ............................................................................................. 94

6.2.1 Clearing a Fault Condition ...................................................................................... 94

6.2.2 Troubleshooting ...................................................................................................... 95

6.3 Connecting the PC to the Module's Ethernet Port .................................................. 96

6.3.1 Setting Up a Temporary IP Address ....................................................................... 96

6.4 Using the Diagnostics Menu in ProSoft Configuration Builder ............................... 98

6.4.1 Diagnostics Menu ................................................................................................. 100

6.4.2 Monitoring General Information ............................................................................ 101

6.4.3 Monitoring Backplane Information ........................................................................ 101

6.4.4 Modbus Server Driver Information ........................................................................ 102

6.4.5 Monitoring Data Values in the Module’s Database............................................... 103

6.4.6 Modbus Client Driver Information ......................................................................... 103

6.5 Communication Error Codes ................................................................................ 104

6.5.1 Standard MODBUS Protocol Exception Code Errors ........................................... 104

6.5.2 Module Communication Error Codes ................................................................... 104

6.5.3 Command List Entry Errors .................................................................................. 104

6.5.4 MBTCP Client-Specific Errors .............................................................................. 105

6.6 Connecting to the Module’s Webpage .................................................................. 105

7 Reference 107

7.1 Product Specifications .......................................................................................... 107

7.1.1 General Specifications - Modbus Client/Server .................................................... 108

7.1.2 Hardware Specifications ....................................................................................... 108

7.2 About the Modbus TCP/IP Protocol ...................................................................... 109

7.2.1 Modbus Client ....................................................................................................... 109

7.2.2 Modbus Server...................................................................................................... 110

7.2.3 Function Codes Supported by the Module ........................................................... 110

Page 6 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 7

MVI69E-MBTCP ♦ CompactLogix Platform Contents

Modbus TCP/IP Enhanced Communication Module User Manual

7.2.4 Read Coil Status (Function Code 01) ................................................................... 111

7.2.5 Read Input Status (Function Code 02) .................................................................. 112

7.2.6 Read Holding Registers (Function Code 03) ........................................................ 113

7.2.7 Read Input Registers (Function Code 04) ............................................................. 114

7.2.8 Force Single Coil (Function Code 05) ................................................................... 115

7.2.9 Preset Single Register (Function Code 06) ........................................................... 116

7.2.10 Diagnostics (Function Code 08) ............................................................................ 117

7.2.11 Force Multiple Coils (Function Code 15) ............................................................... 119

7.2.12 Preset Multiple Registers (Function Code 16) ...................................................... 120

7.3 Floating-Point Support ........................................................................................... 121

7.3.1 ENRON Floating Point Support ............................................................................. 122

7.3.2 Configuring the Floating Point Data Transfer ........................................................ 122

7.4 Function Blocks ..................................................................................................... 127

7.4.1 Event Command Blocks (2000 to 2019) ............................................................... 128

7.4.2 Client Status Request/Response Blocks (3000 to 3019) ...................................... 129

7.4.3 Event Sequence Request Blocks (4000 to 4019) ................................................. 130

7.4.4 Event Sequence Command Error Status Blocks (4100 to 4119) .......................... 131

7.4.5 Get Queue and Event Sequence Block Counts Block (4200)............................... 132

7.4.6 Command Control Blocks (5001 to 5016) ............................................................. 132

7.4.7 Add Event with Data for Client Blocks (8000) ....................................................... 133

7.4.8 Get Event with Data Status Block (8100) .............................................................. 134

7.4.9 Get General Module Status Data Block (9250) ..................................................... 135

7.4.10 Set Driver and Command Active Bits Block (9500) .............................................. 136

7.4.11 Get Driver and Command Active Bits Block (9501) .............................................. 137

7.4.12 Pass-Through Formatted Block for Functions 6 and 16 with Word Data Block

(9956) 138

7.4.13 Pass-Through Formatted Block for Functions 6 and 16 with Float Data Block

(9957) 139

7.4.14 Pass-Through Formatted Block for Function 5 (9958) .......................................... 139

7.4.15 Pass-Through Formatted Block for Function 15 (9959) ........................................ 140

7.4.16 Pass-Through Formatted Block for Function 23 (9961) ........................................ 141

7.4.17 Pass-Through Block for Function 99 (9970) ......................................................... 141

7.4.18 Set Module Time Using Received Time Block (9972) .......................................... 142

7.4.19 Pass Module Time to Processor Block (9973) ...................................................... 143

7.4.20 Reset Status Block (9997)..................................................................................... 143

7.4.21 Warm-boot Control Block (9998) ........................................................................... 144

7.4.22 Cold-boot Control Block (9999) ............................................................................. 144

7.5 Ethernet Port Connection ...................................................................................... 145

7.5.1 Ethernet Cable Specifications ............................................................................... 145

8 Support, Service & Warranty 147

8.1 Contacting Technical Support ............................................................................... 147

8.2 Warranty Information ............................................................................................. 148

Index 149

ProSoft Technology, Inc. Page 7 of 150

May 20, 2015

Page 8

MVI69E-MBTCP ♦ CompactLogix Platform

Modbus TCP/IP Enhanced Communication Module User Manual

ProSoft Technology, Inc. Page 8 of 150

May 20, 2015

Page 9

MVI69E-MBTCP ♦ CompactLogix Platform Start Here

In This Chapter

System Requirements ........................................................................... 10

Deployment Checklist ............................................................................ 10

Setting Jumpers .................................................................................... 11

Installing the Module in the Rack ........................................................... 12

DVD Contents ....................................................................................... 15

Package Contents ................................................................................. 15

Modbus TCP/IP Enhanced Communication Module User Manual

1 Start Here

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

Modbus and CompactLogix devices to a power source and to the MVI69EMBTCP module’s Ethernet port

ProSoft Technology, Inc. Page 9 of 150

May 20, 2015

Page 10

Start Here MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

1.1 System Requirements

The MVI69E-MBTCP module requires the following minimum hardware and

software components:

Rockwell Automation CompactLogix® processor (firmware version 10 or

higher), with compatible power supply and one free slot in the rack, for the

MVI69E-MBTCP module.

Important: The MVI69E-MBTCP module has a power supply distance rating of 2 (L43 and L45

installations on first 2 slots of 1769 bus). It consumes 500 mA at 5 Vdc.

Important: For 1769-L23x processors, please make note of the following limitation:

1769-L23E-QBFC1B = 450 mA at 5 Vdc (No MVI69E module can be used with this processor.)

The module requires 500 mA of available 5 Vdc power

Rockwell Automation RSLogix 5000 programming software version 16 or

higher

Rockwell Automation RSLinx® communication software version 2.51 or higher

ProSoft Configuration Builder (PCB) (included)

ProSoft Discovery Service (PDS) (included in PCB)

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o Microsoft Windows

o Microsoft Windows Vista

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 x 768 recommended)

DVD drive

®

7

Note: The Hardware and Operating System requirements in this list are the minimum

recommended to install and run software provided by ProSoft Technology®. Other third party

applications may have different minimum requirements. Refer to the documentation for any third

party applications for system requirements.

Page 10 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 11

MVI69E-MBTCP ♦ CompactLogix Platform Start Here

Modbus TCP/IP Enhanced Communication Module User Manual

1.2 Deployment Checklist

Before you begin to configure the module, consider the following questions. Your

answers will help you determine the scope of your project, and the configuration

requirements for a successful deployment.

Are you creating a new application or integrating the module into an existing

application?

Most applications can use the Sample Add-On Instruction or Sample Ladder

Logic without any modification.

Which slot number in the chassis does the MVI69E-MBTCP module occupy?

For communication to occur, you must enter the correct slot number in the

sample program.

Are the RSLogix 5000 and RSLinx software installed?

RSLogix and RSLinx are required to communicate to the CompactLogix

processor.

How many words of data do you need to transfer in your application (from

CompactLogix to Module / to CompactLogix from Module)?

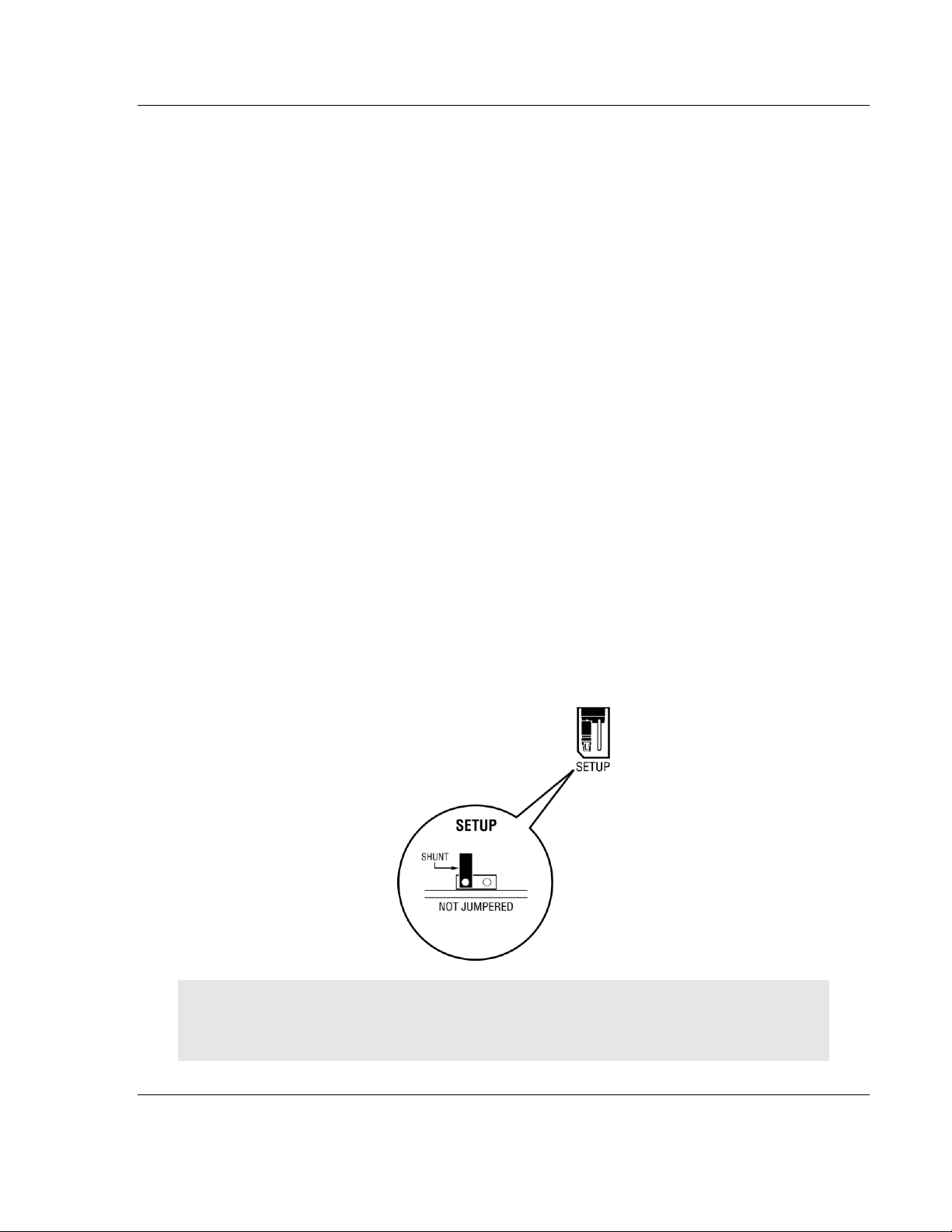

1.3 Setting Jumpers

The Setup Jumper acts as "write protection" for the module’s firmware. In "write

protected" mode, the Setup pins are not connected, and the module’s firmware

cannot be overwritten. The module is shipped with the Setup jumper OFF. Do not

jumper the Setup pins together unless you are directed to do so by ProSoft

Technical Support (or you want to update the module firmware).

The following illustration shows the MVI69E-MBTCP jumper configuration with

the Setup Jumper OFF.

Note: If you are installing the module in a remote rack, you may prefer to leave the Setup pins

jumpered. That way, you can update the module’s firmware without requiring physical access to

the module.

ProSoft Technology, Inc. Page 11 of 150

May 20, 2015

Page 12

Start Here MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

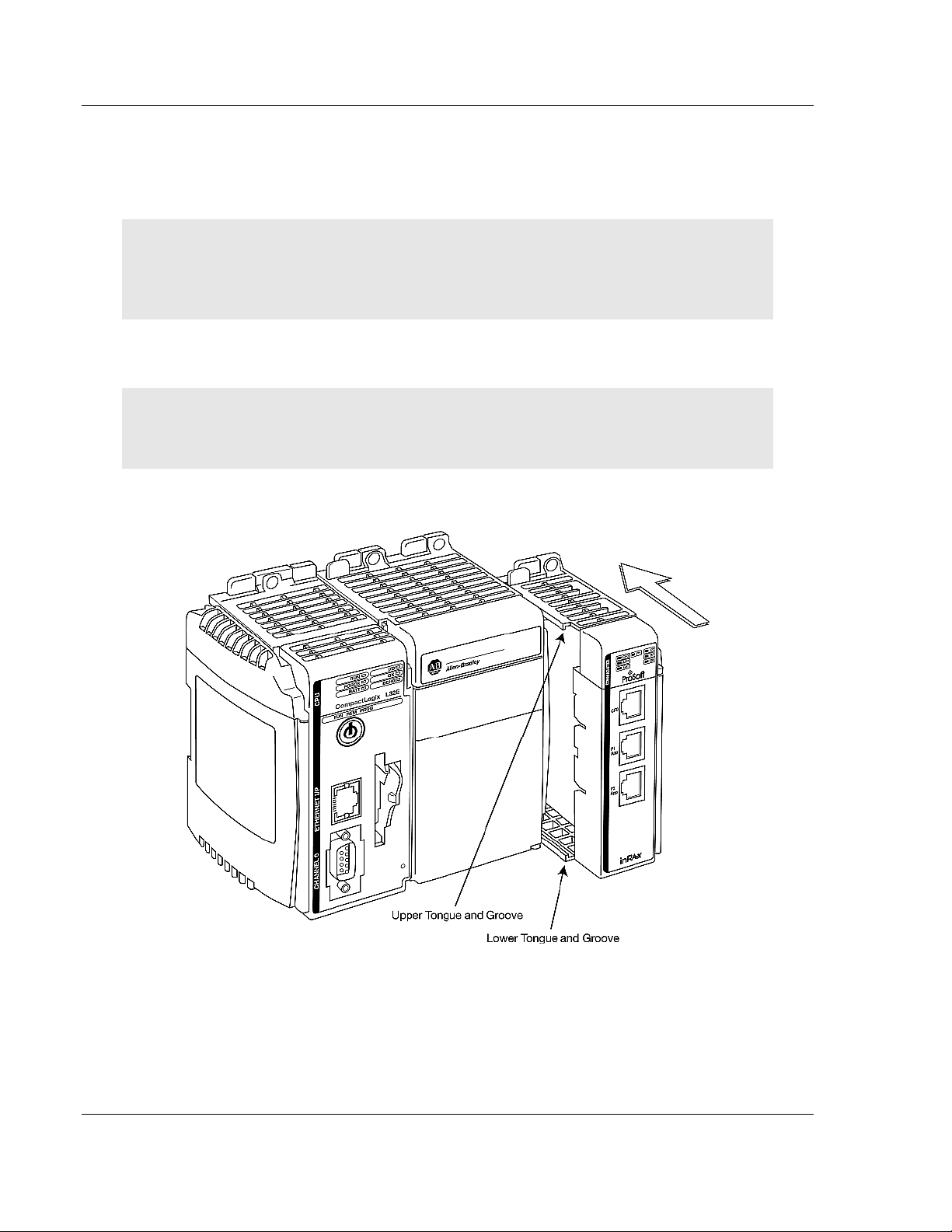

1.4 Installing the Module in the Rack

Make sure the processor and power supply are installed and configured before

installing the MVI69E-MBTCP module. Refer to the Rockwell Automation product

documentation for installation instructions.

Warning: Please follow all safety instructions when installing this or any other electronic devices.

Failure to follow safety procedures could result in damage to hardware or data, or even serious

injury or death to personnel. Refer to the documentation for each device to be connected to verify

that suitable safety procedures are in place before installing or servicing the device.

After you verify the jumper placements, insert the MVI69E-MBTCP into the rack.

Use the same technique recommended by Rockwell Automation to remove and

install CompactLogix modules.

Warning: This module is not hot-swappable! Always remove power from the rack before

inserting or removing this module, or damage may result to the module, the processor, or other

connected devices.

1 Align the module using the upper and lower tongue-and-groove slots with the

adjacent module and slide forward in the direction of the arrow.

2 Move the module back along the tongue-and-groove slots until the bus

connectors on the MVI69 module and the adjacent module line up with each

other.

Page 12 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 13

MVI69E-MBTCP ♦ CompactLogix Platform Start Here

Modbus TCP/IP Enhanced Communication Module User Manual

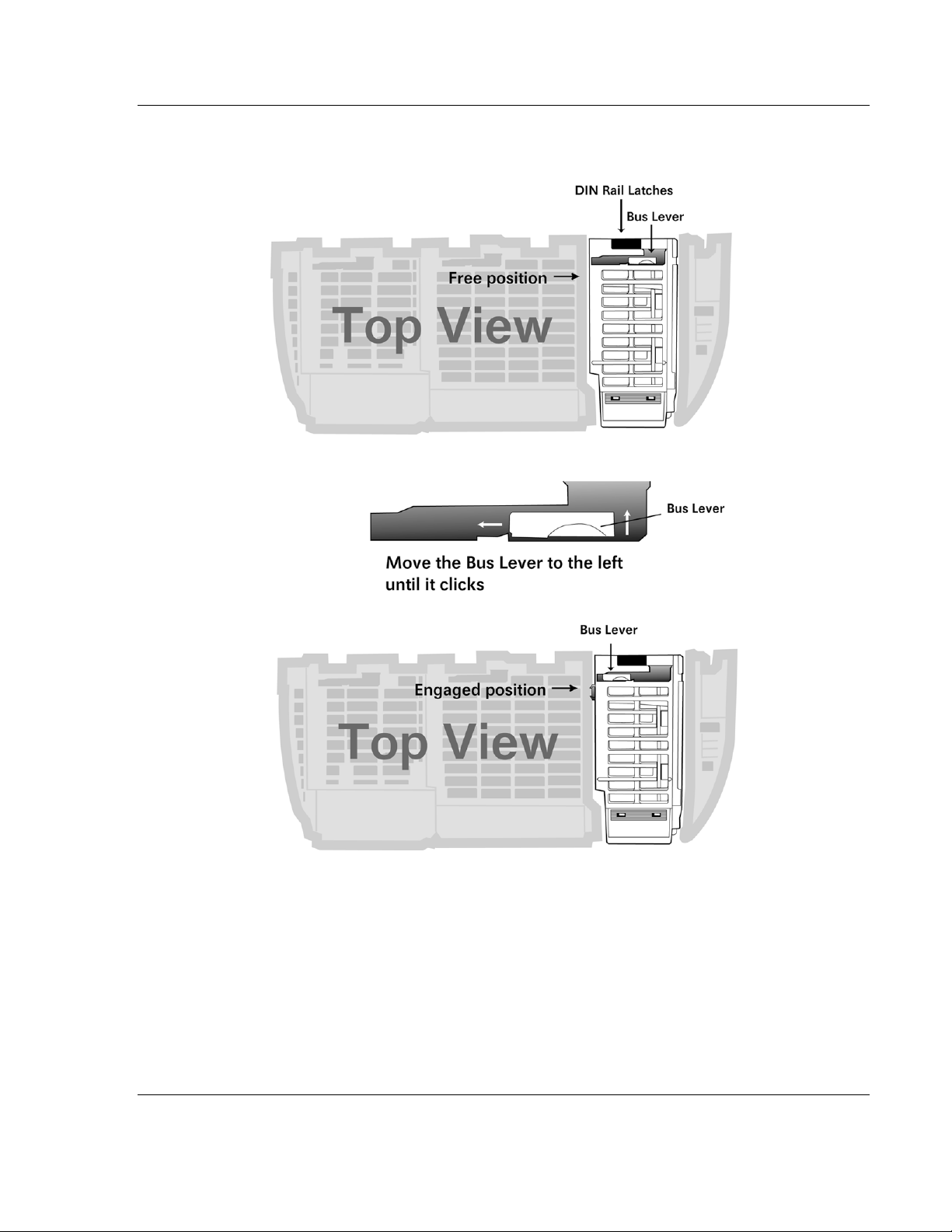

3 Push the module’s bus lever back slightly to clear the positioning tab and

move it firmly to the left until it clicks. Ensure that it is locked firmly in place.

4 Close all DIN-rail latches.

ProSoft Technology, Inc. Page 13 of 150

May 20, 2015

Page 14

Start Here MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

5 Press the DIN-rail mounting area of the controller against the DIN-rail. The

latches momentarily open and lock into place.

Page 14 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 15

MVI69E-MBTCP ♦ CompactLogix Platform Start Here

Qty.

Part Name

Part Number

Part Description

1

MVI69E-MBTCP Module

MVI69E-MBTCP

Modbus TCP/IP Enhanced

Communication Module

1

Ethernet Cable

RL-CBL025

Straight-through Ethernet cable

1

ProSoft Solutions DVD

DVD-001

Contains sample programs, ProSoft

Configuration Builder (PCB), and

documentation.

Modbus TCP/IP Enhanced Communication Module User Manual

1.5 DVD Contents

The DVD contains all the necessary files for the module including the User

Manual and the ProSoft Configuration Builder (PCB) software. It also may

contain module-specific configuration files such as the RSLogix 5000 Add-On

Profile and sample Add-On Instruction (where applicable to the module).

If the DVD is not present, please visit http://www.prosoft-technology.com for the

latest files.

1.6 Package Contents

The following components are included with your MVI69E-MBTCP module, and

are all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

If any of these components are missing, please contact ProSoft Technology

Technical Support for replacement parts. For the latest files, or if the DVD is not

present, please visit http://www.prosoft-technology.com.

ProSoft Technology, Inc. Page 15 of 150

May 20, 2015

Page 16

MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

Page 16 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 17

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

In This Chapter

Creating the Module in an RSLogix 5000 Project .................................. 17

Installing ProSoft Configuration Builder ................................................. 24

Generating the AOI (.L5X File) in ProSoft Configuration Builder ........... 25

Creating a New RSLogix 5000 Project .................................................. 30

Importing the Add-On Instruction ........................................................... 31

Adding Multiple Modules in the Rack (Optional) .................................... 34

Modbus TCP/IP Enhanced Communication Module User Manual

2 Adding the Module to RSLogix

To add the MVI69E-MBTCP module in RSLogix 5000, you must:

1 Create a new project in RSLogix 5000.

2 Add the module to the RSLogix 5000 project. There are two ways to do this:

o You can use the Add-On Profile from ProSoft Technology. This is the

preferred way, but requires RSLogix version 15 or later.

o You can manually create the module using a generic 1769 profile, and

then manually configure the module parameters. Use this method if you

have RSLogix version 14 or earlier.

3 Create an Add-On Instruction file using ProSoft Configuration Builder (PCB)

and export the Add-On Instruction to an RSLogix 5000 compatible file (.L5X

file).

4 Import the Add-On Instruction (the .L5X file) into RSLogix 5000.

The .L5X file contains the Add-On Instruction, user-defined data types, controller

tags and ladder logic required to configure the MVI69E-MBTCP module.

2.1 Creating the Module in an RSLogix 5000 Project

In an RSLogix 5000 project, there are two ways you can add the MVI69EMBTCP module to the project.

You can use an Add-On Profile (AOP) from ProSoft Technology. The AOP

contains all the configuration information needed to add the module to the

project. This is the preferred way, but requires RSLogix version 15 or later.

Refer to Creating a Module in the Project Using an Add-On Profile (page 18).

If using an AOP is not an option, you can manually create and configure the

module using a generic 1769 profile. Use this method if you have RSLogix

version 14 or earlier. Refer to Creating a Module in the Project Using a

Generic 1769 Module Profile (page 21).

ProSoft Technology, Inc. Page 17 of 150

May 20, 2015

Page 18

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

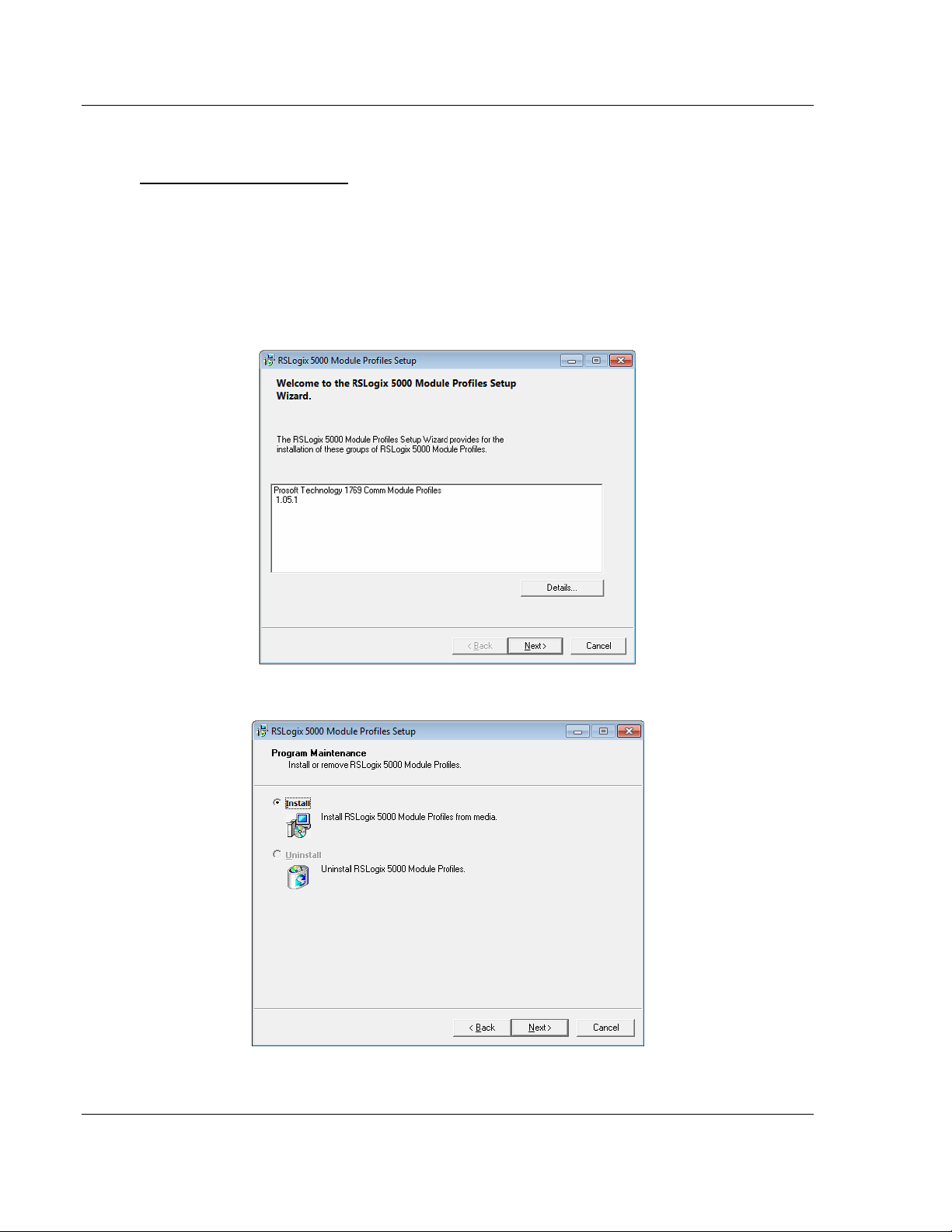

2.1.1 Creating a Module in the Project Using an Add-On Profile

Installing an Add-On Profile

Download the AOP file (MVI69x_RevX.X_AOP.zip) from the product webpage

(found at http://www.prosoft-technology.com) or from the ProSoft Solutions DVD

onto your local hard drive and then extract the files from the zip archive. Make

sure you have shut down RSLogix 5000 and RSLinx before you install the AddOn Profile (AOP).

Run the MPSetup.exe file to start the Setup Wizard. Follow the Setup Wizard to

install the AOP.

Continue to follow the steps in the wizard to complete the installation.

Page 18 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 19

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

Click FINISH when complete. The AOP is now installed in RSLogix 5000. You do

not need to reboot the PC.

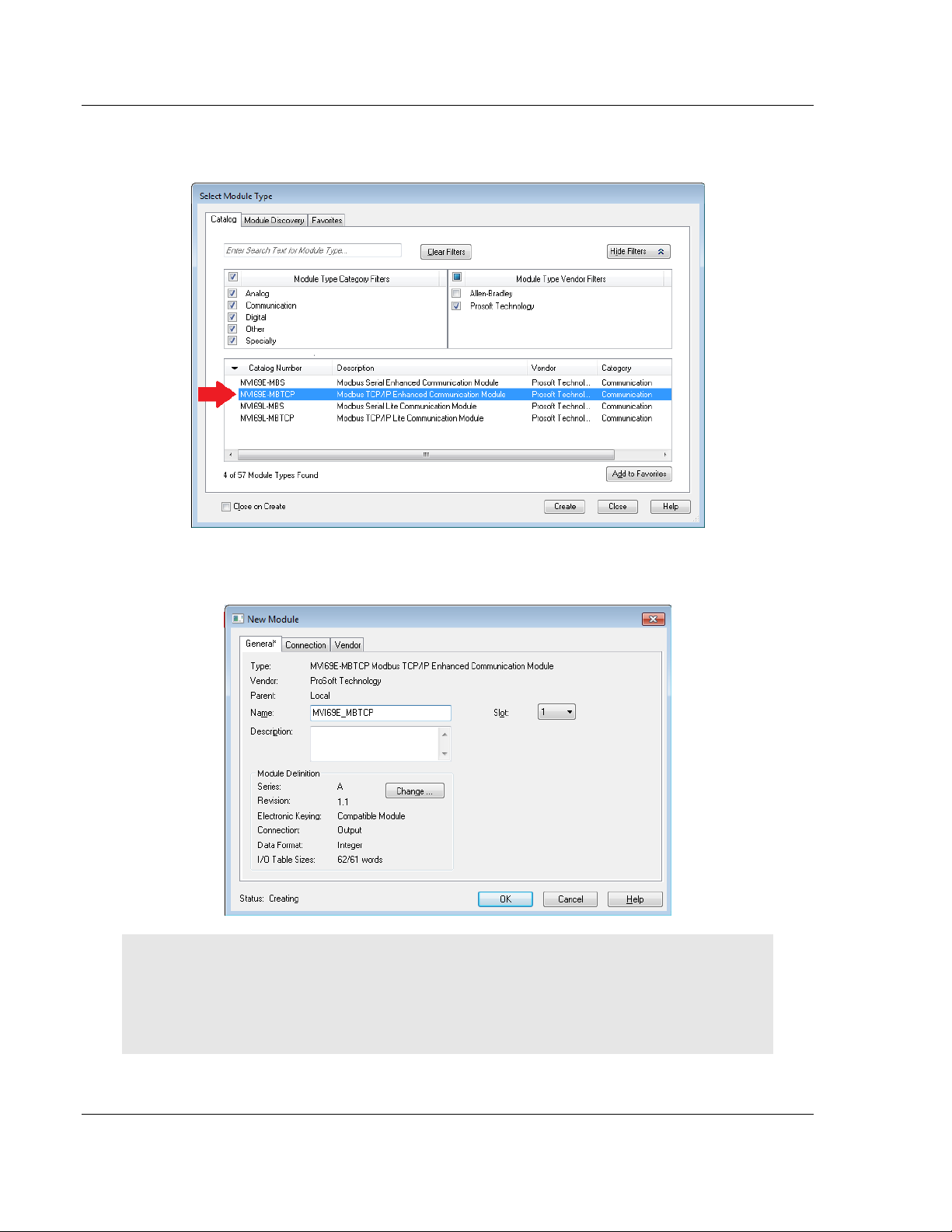

Using an Add-On Profile

1 In RSLogix 5000, expand the I/O CONFIGURATION folder in the Project tree.

Right-click the appropriate communications bus and choose NEW MODULE.

This opens the Select Module Type dialog box.

ProSoft Technology, Inc. Page 19 of 150

May 20, 2015

Page 20

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

2 In the Module Type Vendor Filters area, uncheck all boxes except the

PROSOFT TECHNOLOGY box. A list of ProSoft Technology modules appears.

3 Select the MVI69E-MBTCP module in the list and click CREATE.

4 In the New Module dialog box, edit the NAME and SLOT. Click OK.

Note : The I/O TABLE SIZES above should reflect the Block Transfer Size parameter set in ProSoft

Configuration Builder (see Module Configuration Parameters (page 47)).

A Block Transfer Size of 60 uses an I/O TABLE SIZE of 62/61 words.

A Block Transfer Size of 120 uses an I/O TABLE SIZE of 122/121 words.

A Block Transfer Size of 240 uses an I/O TABLE SIZE of 242/241 words.

Page 20 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 21

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

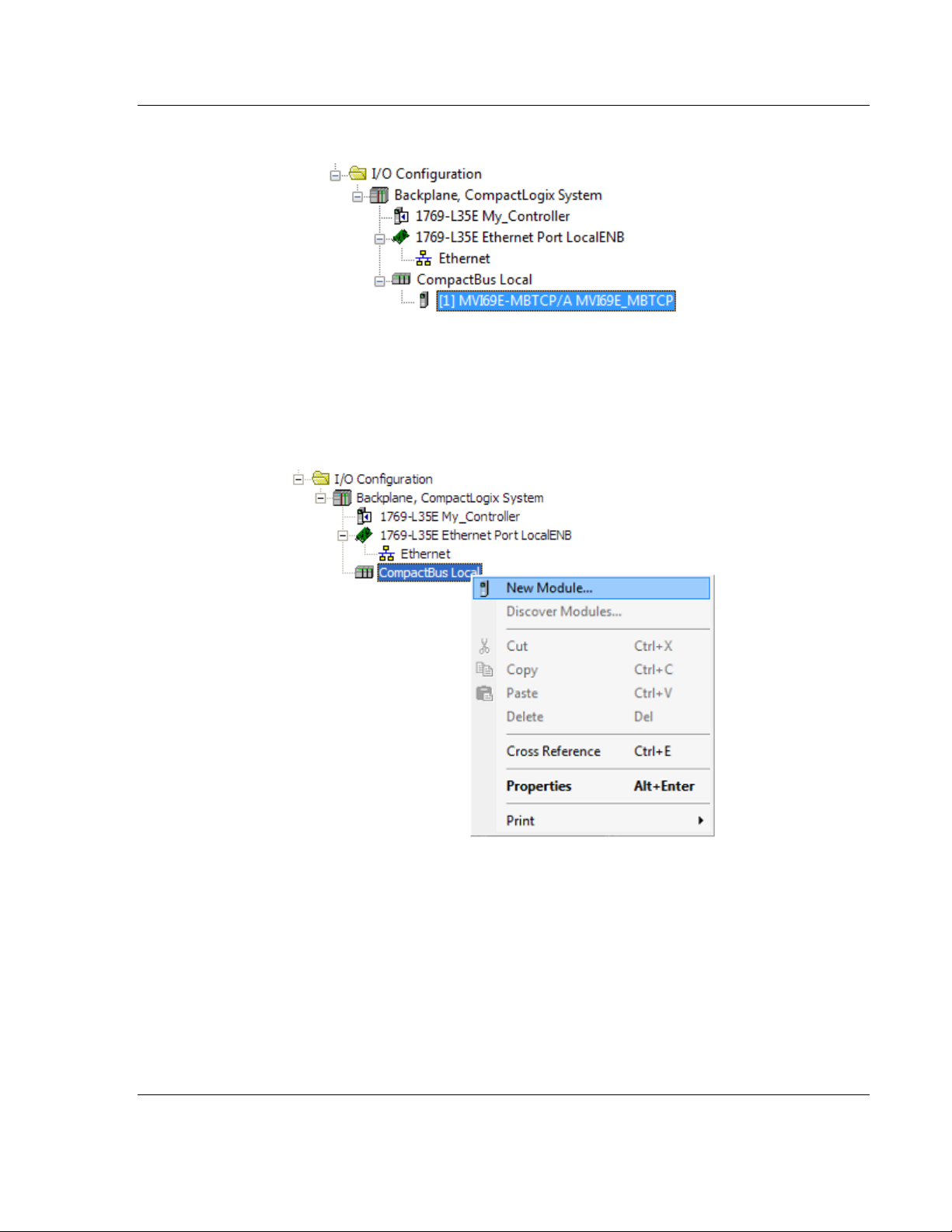

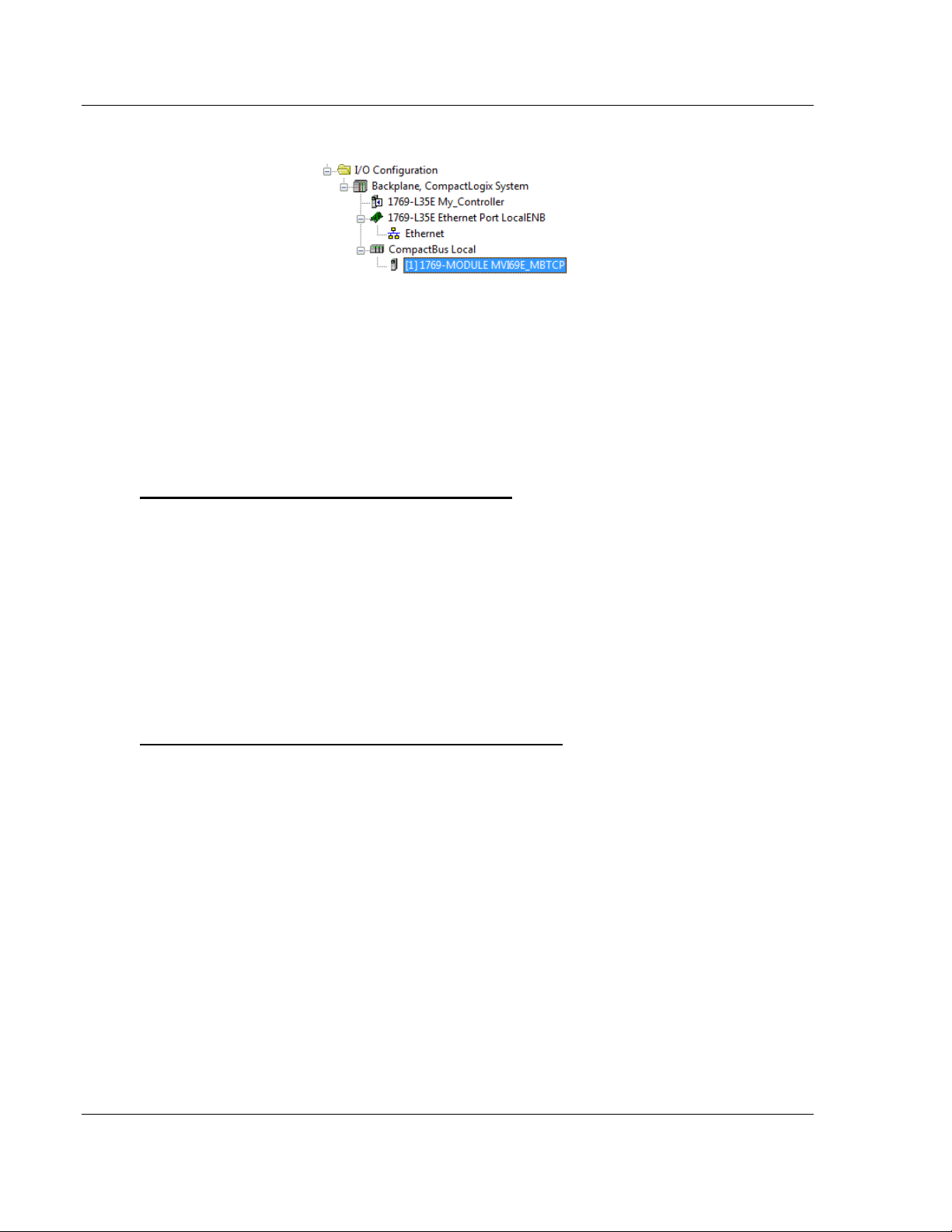

The MVI69E-MBTCP module is now visible in the I/O Configuration tree.

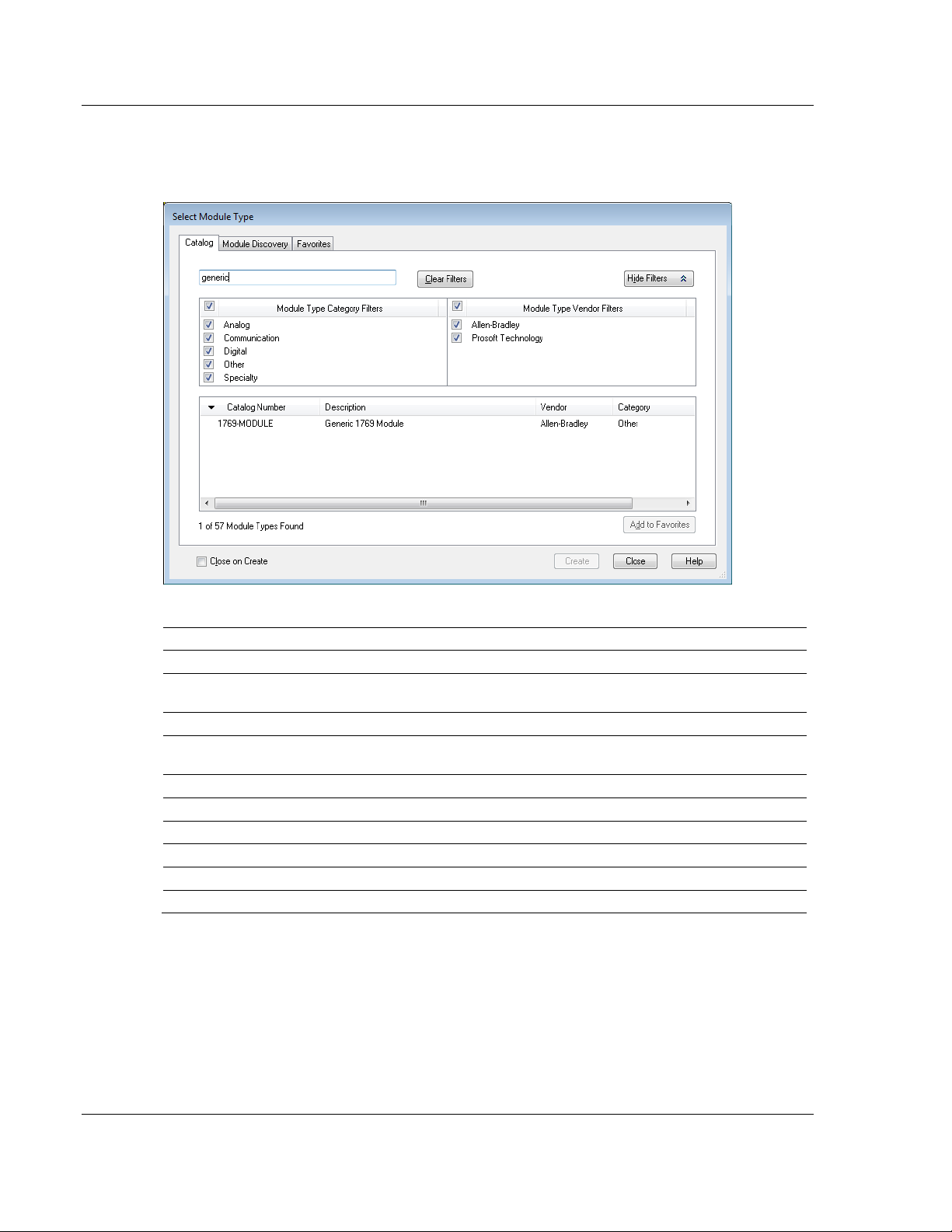

2.1.2 Creating a Module in the Project Using a Generic 1769 Module

Profile

1 Expand the I/O CONFIGURATION folder in the Project tree. Right-click the

appropriate communications bus and choose NEW MODULE.

This opens the Select Module Type dialog box.

ProSoft Technology, Inc. Page 21 of 150

May 20, 2015

Page 22

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

Parameter

Value

Name

Enter a module identification string. Example: MVI69E_MBTCP

Description

Enter a description for the module. Example: ProSoft

communication module for Serial Modbus communications.

Comm Format

Select DATA-INT

Slot

Enter the slot number in the rack where the MVI69E-MBTCP

module is installed.

Input Assembly Instance

101

Input Size

62 / 122 / 242

Output Assembly Instance

100

Output Size

61 / 121 / 241

Configuration Assembly Instance

102

Configuration Size

0

User Manual Modbus TCP/IP Enhanced Communication Module

2 Enter GENERIC in the search text box and select the GENERIC 1769 MODULE. If

you're using an earlier version of RSLogix, expand OTHER in the Select

Module dialog box, and then select the GENERIC 1769 MODULE.

3 Set the Module Properties values as follows:

Page 22 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 23

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Block Transfer Size

Input Block Size

Output Block Size

60

62

61

120

122

121

240

242

241

Modbus TCP/IP Enhanced Communication Module User Manual

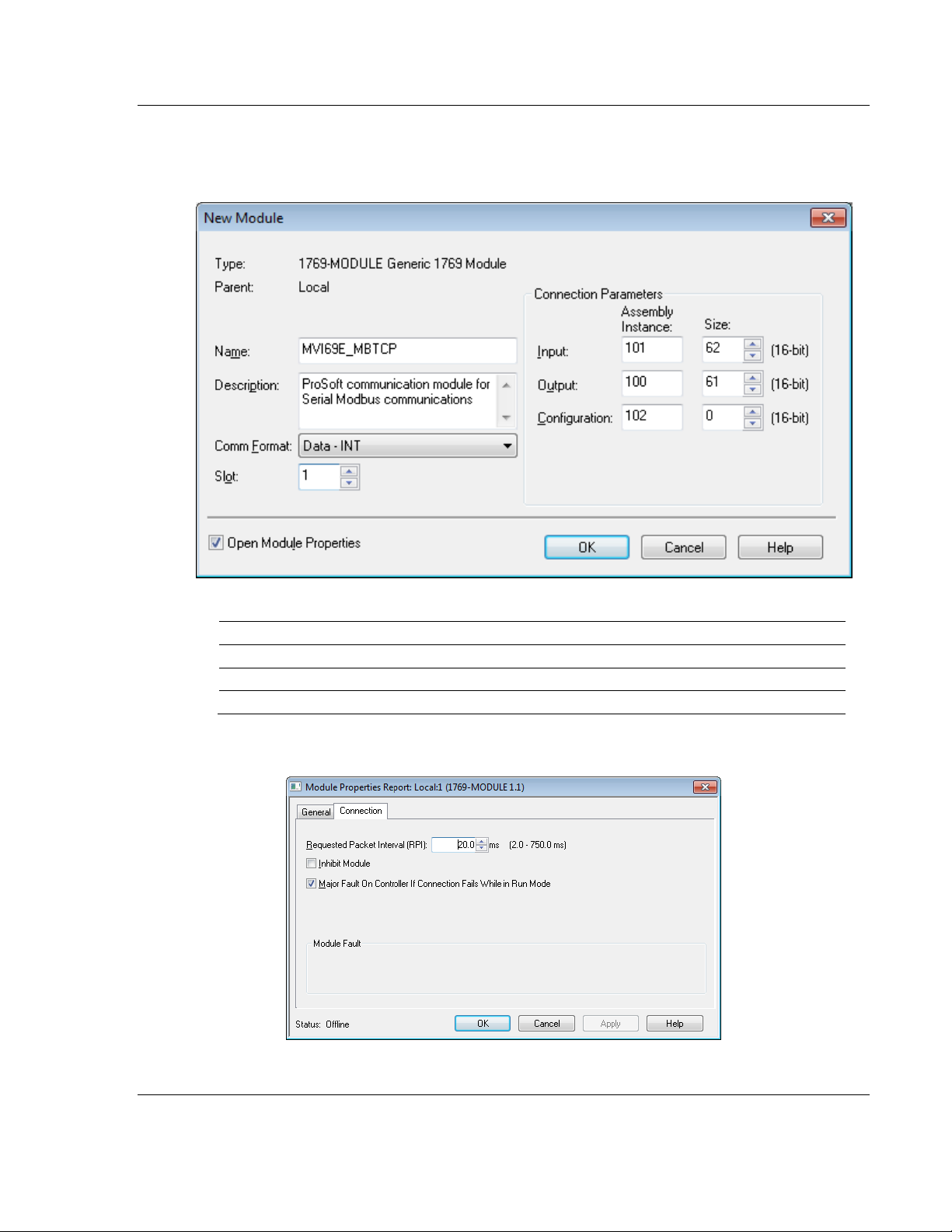

The following illustration shows an example where the module was

configured for a block transfer size of 60 words (input block size = 62 words,

output block size = 61 words):

The following options are available:

4 On the Connection tab, set the REQUESTED PACKET INTERVAL value for your

project and click OK.

ProSoft Technology, Inc. Page 23 of 150

May 20, 2015

Page 24

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

The MVI69E-MBTCP module is now visible in the I/O Configuration tree.

2.2 Installing ProSoft Configuration Builder

Use the ProSoft Configuration Builder (PCB) software to configure the module.

You can find the latest version of the ProSoft Configuration Builder (PCB) on our

web site: http://www.prosoft-technology.com, or you can install it from the ProSoft

Solutions DVD. The installation filename contains the PCB version number. For

example, PCB_4.3.4.5.0238.EXE.

If you are installing PCB from the ProSoft website:

1 Open a browser window and navigate to

http://www.prosoft-technology.com/pcb.

2 Click the download link for ProSoft Configuration Builder, and save the file to

your Windows desktop.

3 After the download completes, double-click the file to install. If you are using

Windows 7, right-click the PCB installation file and then choose RUN AS

ADMINISTRATOR. Follow the instructions that appear on the screen.

4 If you want to find additional software specific to your MVI69E-MBTCP, enter

the model number into the ProSoft website search box and press the Enter

key.

If you are installing PCB from the ProSoft Solutions DVD:

1 Insert the ProSoft Solutions DVD into your computer's DVD drive and wait for

the ProSoft Installation program to start.

2 If the ProSoft Installation program does not start, open the Windows file

Explorer, navigate to the DVD, and double-click the ProSoft_DVD.exe file.

3 Navigate to the MVI69E-MBTCP selection using the PLATFORM and PRODUCT

selections.

4 Click PROSOFT CONFIGURATION BUILDER.

5 Follow the instructions that appear on the screen.

Page 24 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 25

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

2.3 Generating the AOI (.L5X File) in ProSoft Configuration Builder

The following sections describe the steps required to set up a new configuration

project in ProSoft Configuration Builder (PCB), and to export the .L5X file for the

project.

2.3.1 Setting Up the Project in PCB

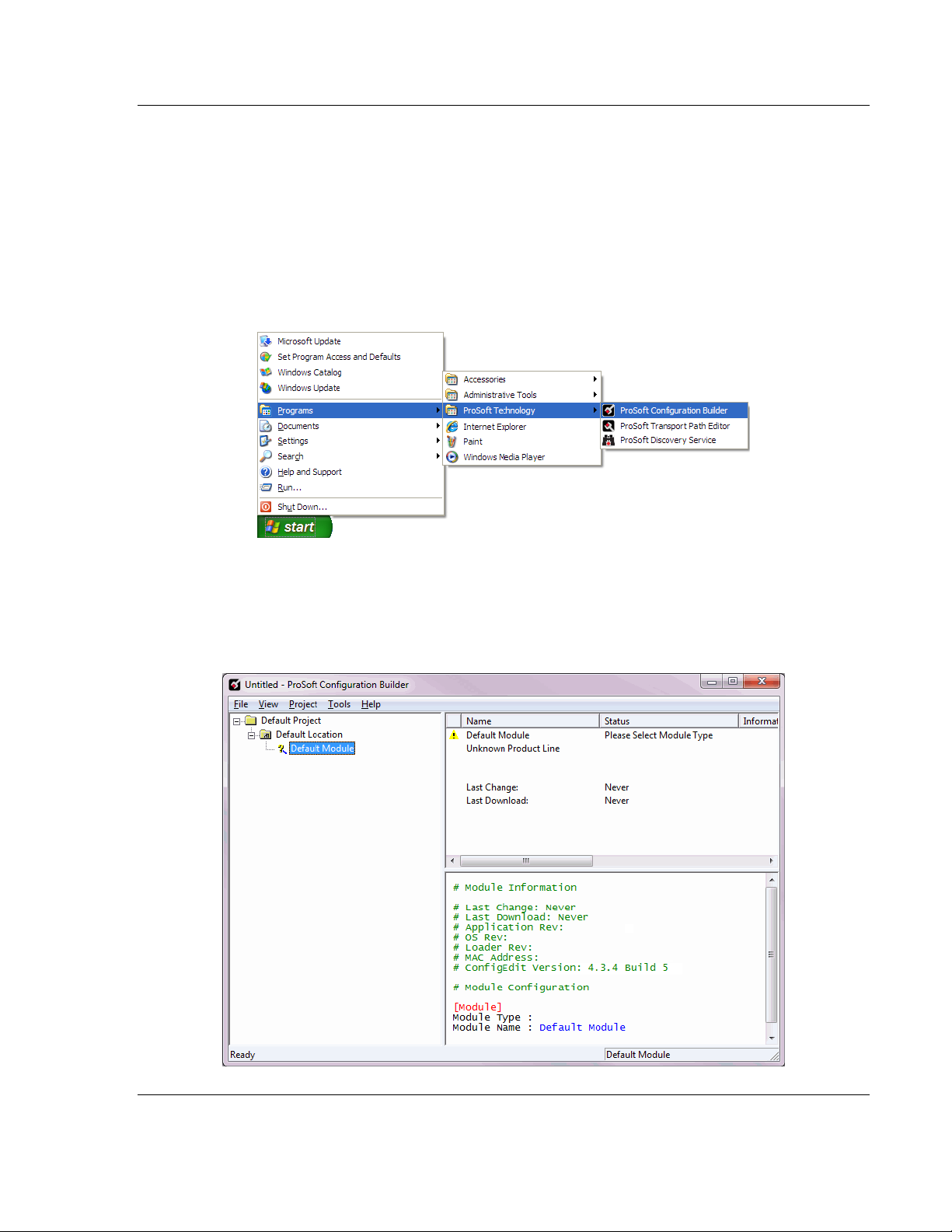

To begin, start PROSOFT CONFIGURATION BUILDER (PCB).

The PCB window consists of a tree view on the left, and an information pane and

a configuration pane on the right side of the window. The tree view consists of

folders for Default Project and Default Location, with a Default Module in the

Default Location folder. The following illustration shows the PCB window with a

new project.

ProSoft Technology, Inc. Page 25 of 150

May 20, 2015

Page 26

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

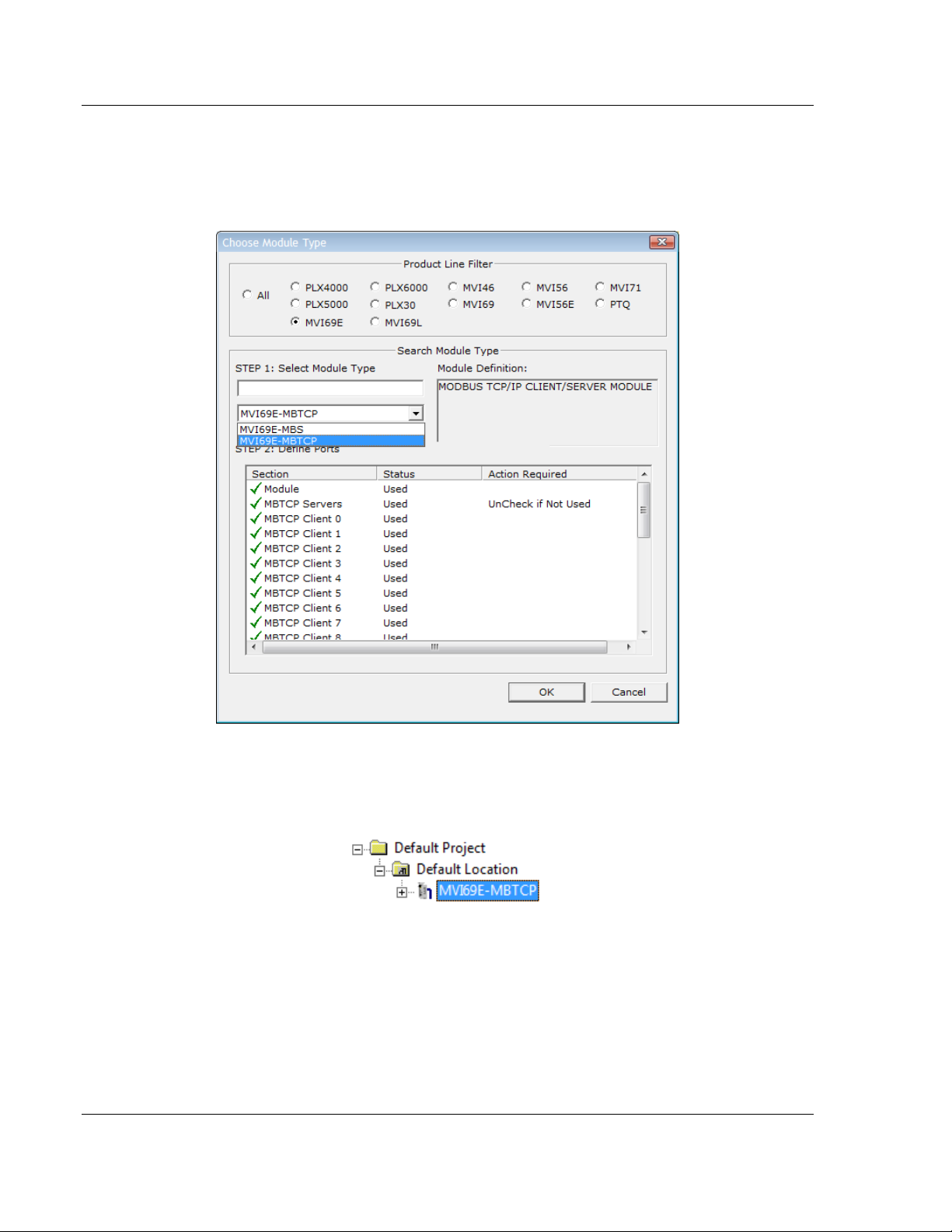

Your first task is to add the MVI69E-MBTCP module to the project.

1 In the Tree view, right-click DEFAULT MODULE, and then choose CHOOSE

MODULE TYPE. This opens the Choose Module Type dialog box.

2 In the Product Line Filter area of the dialog box, click MVI69. In the Select

Module Type dropdown list, click MVI69E-MBTCP, and then click OK to save

your settings and return to the ProSoft Configuration Builder window. The

MVI69E-MBTCP icon is now visible in the tree view.

Page 26 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 27

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

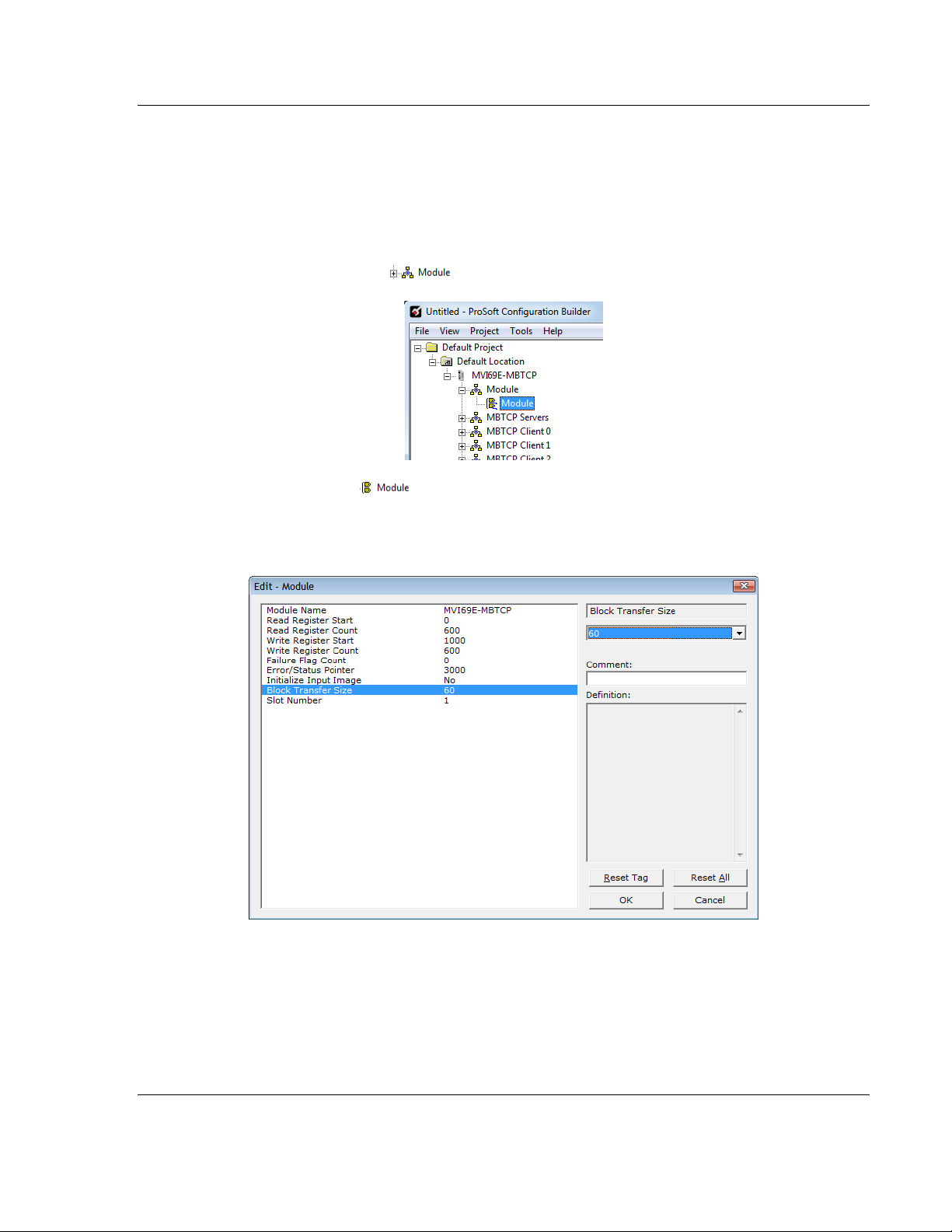

2.3.2 Creating and Exporting the .L5X File

There are two parameters in the PCB configuration that affect the format of the

.L5X file that is exported. Before exporting the .L5X file to the PC/Laptop, check

the Block Transfer Size and Slot Number parameters.

1 Expand the MVI69E-MBTCP icon by clicking the [+] symbol beside it.

Similarly, expand the icon.

2 Double-click the icon to open the Edit - Module dialog box.

3 Set the Block Transfer Size to the desired size of the data blocks transferred

between the module and processor (60, 120 or 240 words). You can find

block transfer size information starting in Normal Data Transfer (page 65).

ProSoft Technology, Inc. Page 27 of 150

May 20, 2015

Page 28

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

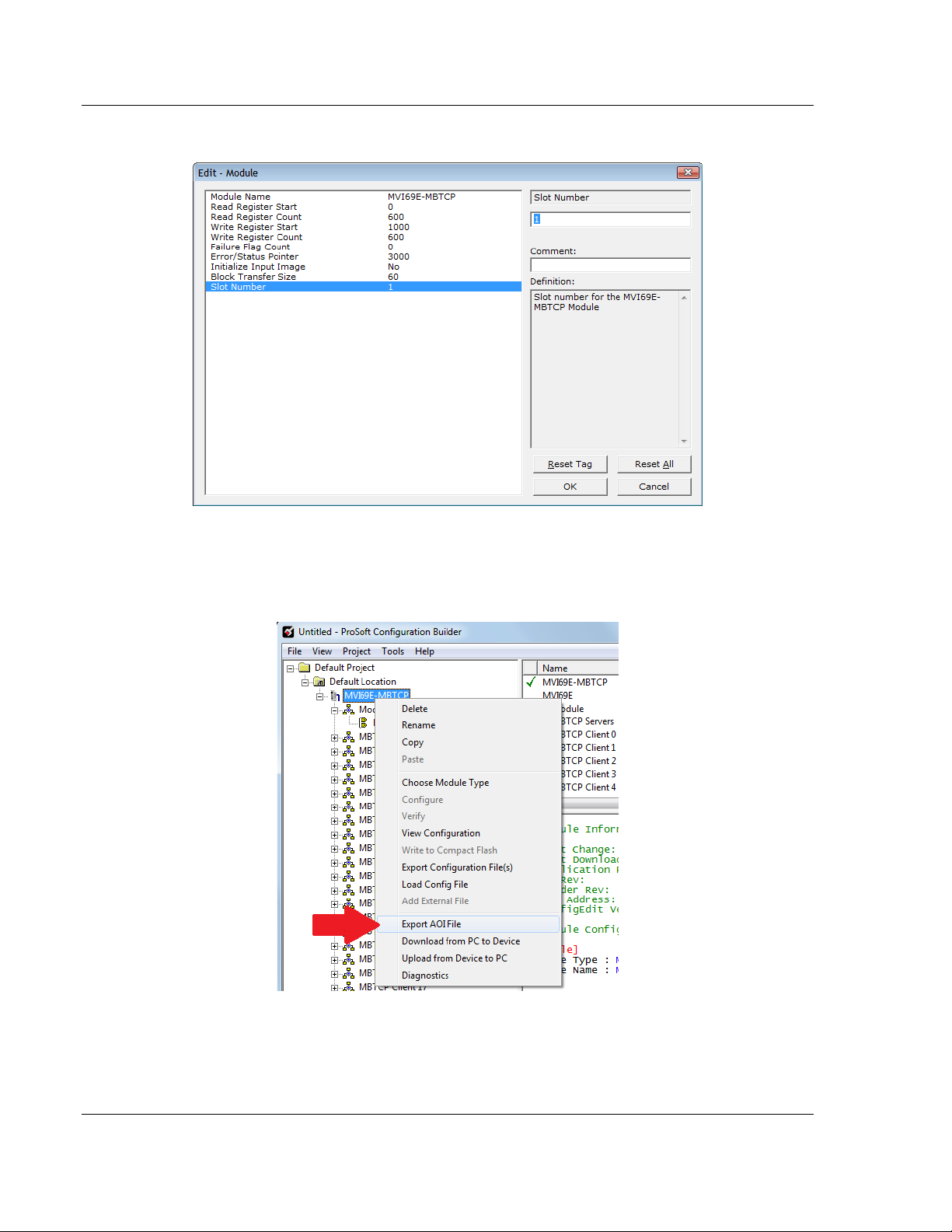

User Manual Modbus TCP/IP Enhanced Communication Module

4 Edit the Slot Number indicating where the module is located in the 1769 bus.

5 Click OK to close the Edit – Module dialog box. The .L5X file is now ready to

export to the PC/Laptop.

6 Right-click the MVI69E-MBTCP icon in the project tree and choose EXPORT

AOI FILE.

Page 28 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 29

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

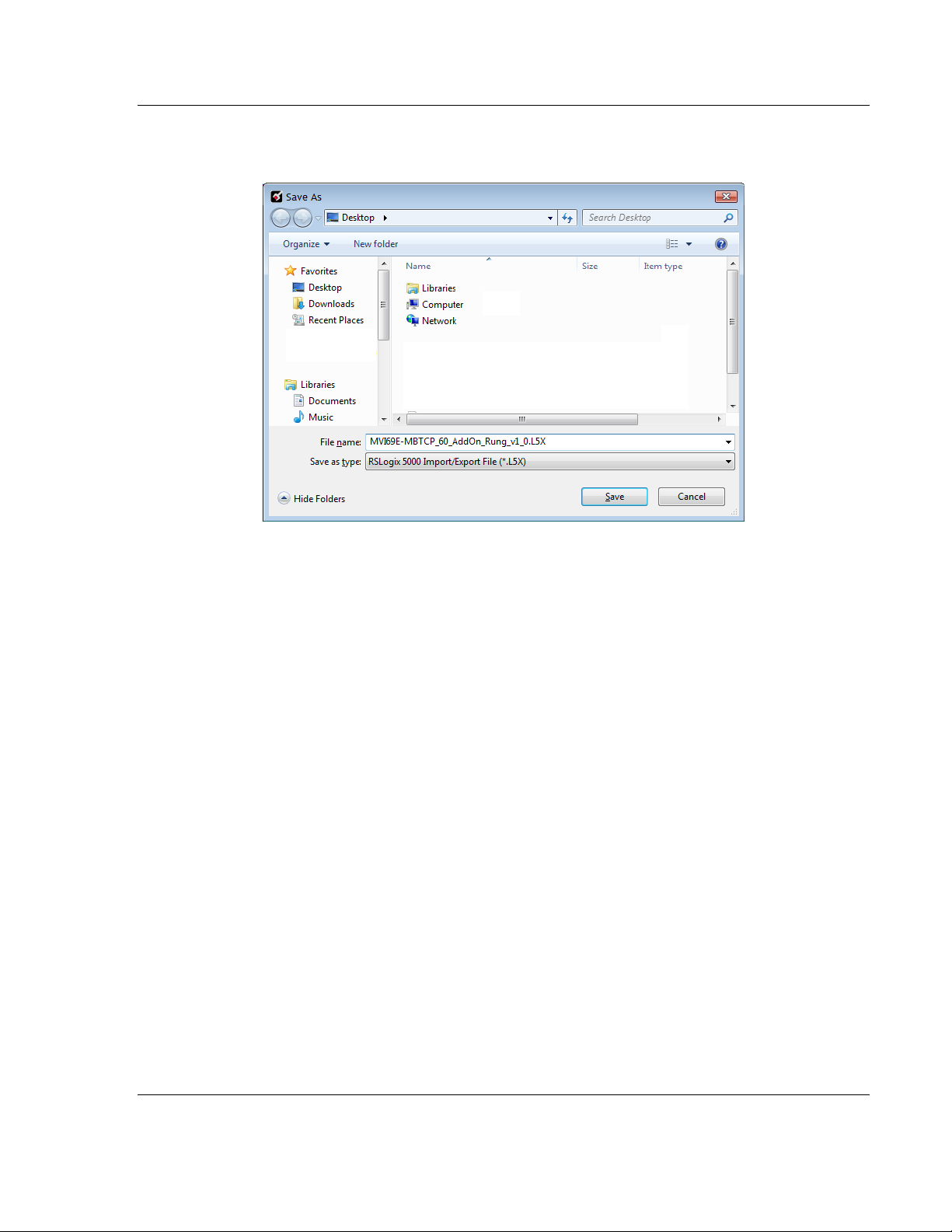

7 Save the .L5X file to the PC/Laptop in an easily found location, such as the

Windows Desktop.

ProSoft Technology, Inc. Page 29 of 150

May 20, 2015

Page 30

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

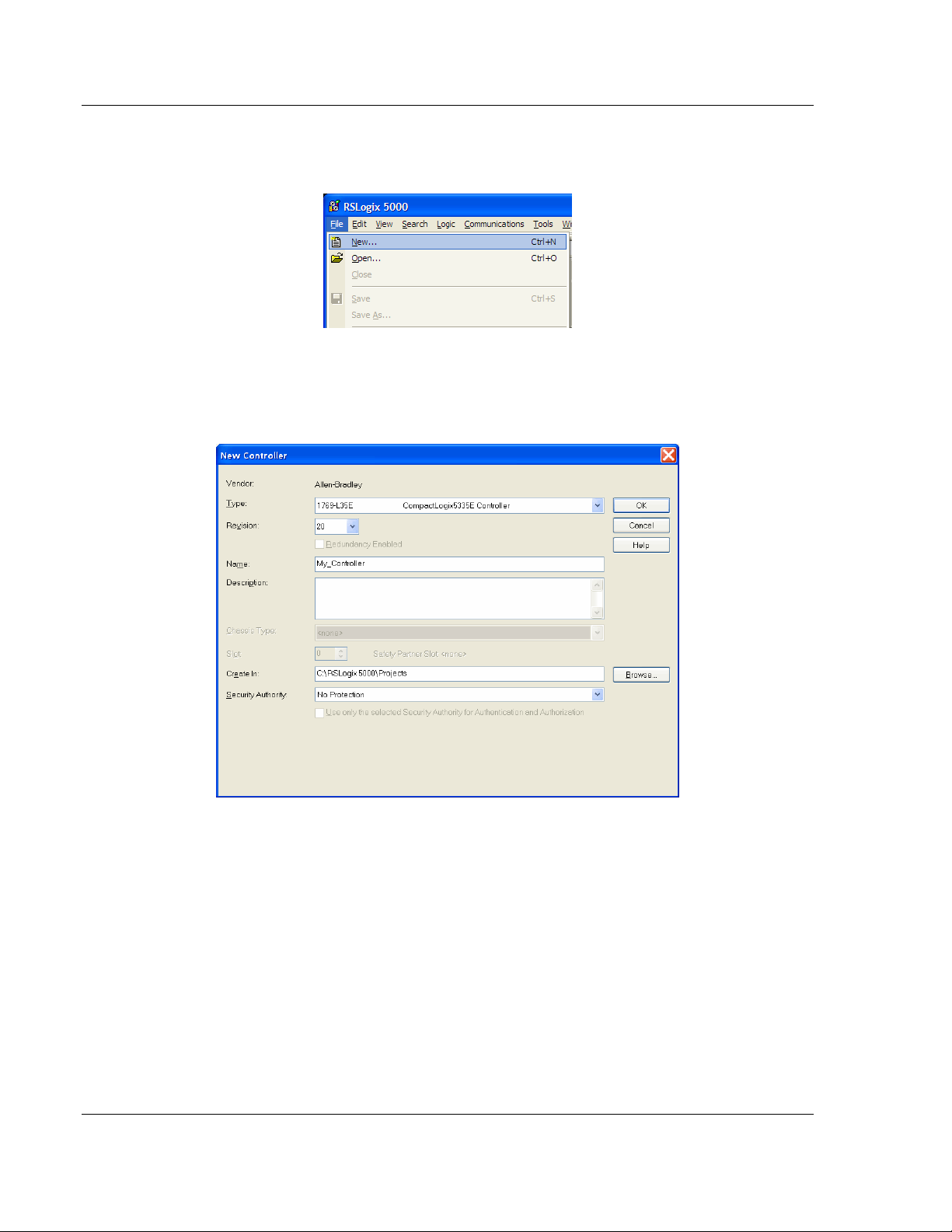

2.4 Creating a New RSLogix 5000 Project

1 Click the FILE menu and then choose NEW.

2 Select your CompactLogix controller model.

3 Select REVISION 16 or newer.

4 Enter a name for your controller, such as My_Controller.

5 Select your CompactLogix chassis type.

Page 30 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 31

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

2.5 Importing the Add-On Instruction

1 Open the application in RSLogix 5000.

2 Expand the TASKS folder, and expand the MAINTASK folder.

3 Expand the MAINPROGRAM folder and then double-click the MAINROUTINE

icon to display the Routine Editor. The MainRoutine contains rungs of logic.

The very last rung in this routine is blank. This is where you can import the

Add-On Instruction (AOI).

Note: You can place the Add-On Instruction in a different routine than the MainRoutine. Make sure

to add a rung with a jump instruction (JSR) in the MainRoutine to jump to the routine containing the

Add-On Instruction.

4 Right-click an empty rung in the routine and choose IMPORT RUNGS.

ProSoft Technology, Inc. Page 31 of 150

May 20, 2015

Page 32

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

5 Select the .L5X file that you exported from ProSoft Configuration Builder. See

Creating and Exporting the .L5X File (page 27).

This opens the Import Configuration dialog box. Click TAGS under

MAINROUTINE to display the controller tags in the Add-On Instruction.

Note: If you are using RSLogix version 16 or earlier, the Import Configuration dialog box does not

contain the Import Content tree.

Page 32 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 33

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

6 If the module is not located in the default slot (or is in a remote rack), edit the

connection input and output variables that define the path to the module in

the FINAL NAME column (NAME column for RSLogix version 16 or less). For

example, if your module is located in slot 3, change Local:1:I in the FINAL

NAME column to Local:3:I. Do the same for Local:1:O.

Note: If your module is located in Slot 1 of the local rack, this step is not required.

7 Click OK to confirm the import. RSLogix indicates that the import is in

progress:

When the import is completed, the new rung with the Add-On Instruction is

visible as shown in the following image.

The procedure has also imported new user-defined data types, data objects

and the Add-On instruction to be used in the project with the MVI69E-MBTCP

module.

ProSoft Technology, Inc. Page 33 of 150

May 20, 2015

Page 34

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

2.6 Adding Multiple Modules in the Rack (Optional)

Important: This procedure is for multiple MVI69E-MBTCP modules running in the same

CompactLogix rack

You can add additional modules of the same type to the rack.

1 Add a new MVI69E-MBTCP module to the ProSoft Configuration Builder

(PCB) project.

2 Export the module configuration as an L5X file.

3 Add a new MVI69E-MBTCP to the RSLogix 5000 project.

4 Import the .L5X file into RSLogix 5000 for the new module as an Add-On

Instruction.

2.6.1 Adding an Additional Module in PCB

1 Start ProSoft Configuration Builder (PCB).

2 Right click DEFAULT LOCATION (which you can rename) and choose ADD

MODULE.

3 Right-click NEW MODULE and choose CHOOSE MODULE TYPE.

4 In the Choose Module Type dialog box, select MVI69E in the PRODUCT LINE

FILTER area, and then select MVI69E-MBTCP as the MODULE TYPE. Click

OK.

Page 34 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 35

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

5 Select the MVI69E-MBTCP module in the tree and repeat the above steps to

add a second (or more) module in the PCB project.

Note: You must give each MVI69E-MBTCP module a unique name. The default name on a

duplicate module appends a number to the end such as MVI69E-MBTCP_000, MVI69E-

MBTCP_001, etc.

6 You can rename the module by right clicking the module and selecting

Rename.

7 Configure the module parameters. See Module Configuration Parameters

(page 47), and then export the AOI .L5X file for the new module (right-click

the module and then choose EXPORT AOI FILE). See Creating and Exporting

the .L5X File (page 27).

ProSoft Technology, Inc. Page 35 of 150

May 20, 2015

Page 36

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

2.6.2 Adding an Additional Module in RSLogix 5000

You can place multiple MVI69E-MBTCP modules in the same rack provided it

does not exceed the power distance rating of the CompactLogix rack (see

System Requirements (page 10)). Adding an additional module is similar to

installing a new module; however, the name of the module must be unique.

1 Start RSLogix 5000 and open the project.

2 In RSLogix 5000, locate the I/O CONFIGURATION folder. Right click

COMPACTBUS LOCAL and choose NEW MODULE.

3 In the Select Module Type dialog box, select theMVI69E-MBTCP module.

o If you are using an Add-On Profile (AOP), this adds the MVI69E-MBTCP

module and configures the relevant parameters. You must be using

RSLogix version 15 or later to to use an AOP.

o If using an AOP is not an option, select GENERIC 1769 MODULE and click

CREATE.

4 The New Module dialog box appears. Enter a unique name for the new

module, and confirm the slot number of the new module.

Page 36 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 37

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

5 Click OK. The new module is now visible.

6 You must also import the Add-On Instruction(AOI) for the new module (see

Adding another module in PCB). In the Controller Organizer pane, doubleclick MAINROUTINE to open the ladder for the routine.

ProSoft Technology, Inc. Page 37 of 150

May 20, 2015

Page 38

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

7 Right-click an empty rung in the routine and then choose IMPORT RUNGS…

8 Select the .L5X file you created and exported for the new module, and click

IMPORT. Recall that the new .L5X file has a unique filename that is specific to

the new module.

Page 38 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 39

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

9 This opens the Import Configuration dialog box. Click TAGS to show the

controller tags in the AddOn Instruction. You must edit the FINAL NAME

column of the tags for the second module to make them unique.

ProSoft Technology, Inc. Page 39 of 150

May 20, 2015

Page 40

Adding the Module to RSLogix MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

10 Associate the I/O connection variables to the correct module in the

corresponding slot number. The default values are Local:1:I and Local:1:O.

You must edit these values if the card is placed in a slot location other than

slot 1 (Local:1:x means the card is located in slot 1). Since the second card is

placed in slot 2, change the FINAL NAME to Local:2:I and Local:2:O. Also,

you can append a ‘_2’ at the end of the FINAL NAME of ‘AOI69_MBTCP’ and

‘MBTCP’ arrays as shown below.

Page 40 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 41

MVI69E-MBTCP ♦ CompactLogix Platform Adding the Module to RSLogix

Modbus TCP/IP Enhanced Communication Module User Manual

11 Click OK.

The setup procedure is now complete. Save the project. It is ready to download

to the CompactLogix processor.

ProSoft Technology, Inc. Page 41 of 150

May 20, 2015

Page 42

MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

Page 42 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 43

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Modbus TCP/IP Enhanced Communication Module User Manual

3 Configuring the MVI69E-MBTCP Using PCB

In This Chapter

Basic PCB Functions ............................................................................. 44

Module Configuration Parameters ......................................................... 47

Downloading the Configuration File to the Processor ............................ 56

Uploading the Configuration File from the Processor ............................ 59

ProSoft Configuration Builder (PCB) provides a quick and easy way to manage

module configuration files customized to meet your application needs.

You build and edit the module’s configuration in ProSoft Configuration Builder.

You use PCB to download the configuration file to the CompactLogix processor,

where it is stored in the MBTCP.CONFIG controller tag generated by the

previously exported AOI. See Creating and Exporting the .L5X File (page 27).

When the MVI69E-MBTCP module boots up, it requests the processor to send

the configuration over the backplane in special Configuration Blocks.

See the chapter Adding the Module to RSLogix (page 16) for the procedures to

create a new PCB project and export a .L5X file for the processor. This chapter

describes the module configuration parameters in detail, as well as how to

download the configuration to the processor using PCB.

ProSoft Technology, Inc. Page 43 of 150

May 20, 2015

Page 44

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

3.1 Basic PCB Functions

3.1.1 Creating a New PCB Project and Exporting an .L5X File

Please see the chapter Adding the Module to RSLogix (page 16).

3.1.2 Renaming PCB Objects

You can rename objects such as the Default Project and Default Location folders

in the tree view. You can also rename the Module icon to customize the project.

1 Right-click the object you want to rename and then hoose RENAME.

2 Type the new name for the object and press Enter.

3.1.3 Editing Configuraiton Parameters

1 Click the [+] sign next to the MVI69E-MBTCP icon to expand module

information.

2 Click the [+] sign next to any icon to view module information and

configuration options.

3 Double-click any icon to open an Edit dialog box.

To edit a parameter, click the parameter in the left pane and then make your

changes in the right pane.

Note: Depending on the parameter, you must enter text, or a valid number, or select from a list of

options.

4 Click OK to save your changes.

Page 44 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 45

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Modbus TCP/IP Enhanced Communication Module User Manual

5 Double-click any icon to open an Edit dialog box with a table. Use this

dialog box to build and edit Modbus Client commands.

6 To add a row to the table, click ADD ROW.

ProSoft Technology, Inc. Page 45 of 150

May 20, 2015

Page 46

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

7 To edit the row, click EDIT ROW. This opens an Edit dialog box.

3.1.4 Printing a Configuration File

1 In the main PCB window, right-click the MVI69E-MBTCP icon and then

choose VIEW CONFIGURATION.

2 In the View Configuration dialog box, click the FILE menu and then click

PRINT.

3 In the Print dialog box, choose the printer to use from the drop-down list,

select the printing options, and then click OK.

Page 46 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 47

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Parameter

Value

Description

Module Name

ASCII

characters

(max. 80)

Assigns a name to the module that can be viewed using the

configuration/debug port. Use this parameter to identify the module

and the configuration file.

Read Register Start

0 to 9999

Specifies the starting address of the module's Read Data area.

Data in this area is transferred from the module to the processor.

Read Register Count

0 to 10,000

Specifies the size of the Read Data area.

Write Register Start

0 to 9999

Specifies the start of the Write Data area in module memory. Data

in this area is transferred in from the processor.

Write Register Count

0 to 10,000

Specifies the size of the Write Data area.

Failure Flag Count

0 to 65535

Specifies the number of consecutive backplane transfer failures

that can occur before Modbus communications are halted.

Error/Status Block Pointer

-1 to 9939

Starting register location in the module’s database for the

error/status table. This data must be placed in the read data range

of module memory. If a value of -1 is entered, the error/status data

is not placed in the database. All other valid values determine the

starting location of the data.

This data area includes the module version information and all

server error/status data. Refer to MBTCP.STATUS.GeneralStatus

(page 88) for more information.

Initialize Input Image

Yes or No

This parameter determines if the input image data and the

module’s Read Register Data values are initialized with Read

Register Data values from the processor. If you set the parameter

to No, the Read Register Data values in the module are set to 0

upon initialization. If you set the parameter to Yes, the data is

initialized with Read Register Data values from the processor.

Using this option requires associated ladder logic to pass the data

from the processor to the module.

Block Transfer Size

60, 120 or 240

Specifies the number of words in each block transferred between

the module and processor.

Slot Number

1 to x

Specifies the slot in the CompactLogix rack for the module.

Modbus TCP/IP Enhanced Communication Module User Manual

3.2 Module Configuration Parameters

3.2.1 Module

This section contains general module configuration parameters. In the ProSoft

Configuration Builder (PCB) tree view, expand the MVI69E-MBTCP icon, then

expand MODULE, and then double-click the MODULE icon.

Important: The sum of the Read Register Count and Write Register Count cannot exceed 10,000

total registers. Furthermore, neither the Read Data nor the Write Data area may extend above

module register 9999. The Read Data and Write Data areas must have separate address ranges in

the module database and must not overlap.

ProSoft Technology, Inc. Page 47 of 150

May 20, 2015

Page 48

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

Parameter

Value

Description

Start Active

Yes or No

Specifies whether or not the port and commands are active

upon module boot-up.

Pass-Through

Mode

Client, Server,

or Server with

Pass-Through

Specifies which device type the port emulates. Refer to the

section Data Flow Between the Module and Processor (page

70) for more information on the server with Pass-Through

option.

Float Flag

Yes or No

Specifies how the Server driver responds to Function Code 3,

6, and 16 commands (read and write Holding Registers) from a

remote client when it is moving 32-bit floating-point data.

If the remote client expects to receive or send one complete

32-bit floating-point value for each count of one (1), then set

this parameter to YES. When set to YES, the Server driver

returns values from two consecutive 16-bit internal memory

registers (32 total bits) for each count in the read command, or

receive 32-bits per count from the client for write commands.

Example: Count = 10, Server driver sends 20 16-bit registers

for 10 total 32-bit floating-point values.

If, however, the remote client sends a count of two (2) for each

32-bit floating-point value it expects to receive or send, or if

you do not plan to use floating-point data in your application,

then set this parameter to NO (the default setting).

You also must set the Float Start and Float Offset parameters

to appropriate values whenever the Float Flag parameter is set

to YES.

Float Start

0 to 32767

Defines the first register of floating-point data. All requests with

register values greater-than or equal to this value are

considered floating-point data requests. This parameter is only

used if the Float Flag is enabled. For example, if you enter a

value of 7000, all requests for registers 7000 and above are

considered as floating-point data.

Float Offset

0 to 9999

Defines the start register for floating-point data in the internal

database. This parameter is used only if the Float Flag is

enabled. For example, if you set the Float Offset value to 3000

and set the float start parameter to 7000, data requests for

register 7000 use the internal Modbus register 3000.

User Manual Modbus TCP/IP Enhanced Communication Module

3.2.2 MBTCP Servers

This section applies to configuring the MVI69E-MBTCP Server (Slave) Driver.

In the ProSoft Configuration Builder tree view, double-click the MBTCP SERVERS

icon.

Page 48 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 49

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Output Offset

0 to 9998

Specifies the offset address into the internal Modbus database

for network requests for Modbus function 1, 5 or 15

commands. For example, if you set the value to 100, an

address request of 0 corresponds to register 100 in the

database.

Bit Input Offset

0 to 9998

Specifies the offset address into the internal Modbus database

for network requests for Modbus function 2 commands. For

example, if you set the value to 150, an address request of 0

returns the value at register 150 in the database.

Holding Register

Offset

0 to 9998

Specifies the offset address in the internal Modbus database

for network requests for Modbus function 3, 6, or 16

commands. For example, if you enter a value of 50, a request

for address 0 corresponds to the register 50 in the database.

Word Input Offset

0 to 9998

Specifies the offset address into the internal Modbus database

for network requests for Modbus function 4 commands. For

example, if you set the value to 150, an address request of 0

returns the value at register 150 in the database.

Connection

Timeout

0 to 1200

Specifies the server’s timeout period if it is not receiving any

new data in the amount of seconds preset.

Modbus TCP/IP Enhanced Communication Module User Manual

ProSoft Technology, Inc. Page 49 of 150

May 20, 2015

Page 50

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

Parameter

Value

Description

Enabled

Yes or No

Enables this client

Start Active

Yes or No

Specifies whether to start with commands active on boot up

Error/Status Pointer

-1 to 9990

Specifies the starting register location in the module’s database for

the error/status table for this client. If you enter a value of -1, the

error/status data is not placed in the database.

All other valid values determine the starting location of the data. This

data should be placed within the read data range of module memory.

Command Error Pointer

-1 to 9999

Specifies the address in the module’s database where the command

error data is placed. If you set the value to -1, the data is not

transferred to the database. This data should be placed within the

read data range of module memory.

Minimum Command

Delay

0 to 65535

milliseconds

Specifies the number of milliseconds to wait between receiving the

end of a server's response to the most recently transmitted command

and the issuance of the next command.

You can use this parameter to place a delay after each command to

avoid sending commands on the network faster than the servers can

be ready to receive them. It does not affect retries of a command, as

retries are issued when a command failure is recognized.

Response Timeout

1 to 65535

milliseconds

Specifies the command response timeout period in 1 millisecond

increments. The client waits for a response from the addressed

server within the timeout period before re-transmitting the command

(Retries) or skipping to the next command in the Command List.

The value depends on the communication network used and the

expected response time (plus or minus) of the slowest device on the

network.

Retry Count

0 to 10

Specifies the number of times a command is retried if it fails.

Float Flag

Yes or No

Specifies if the Daniel/ENRON-specific floating-point data access

functionality is to be implemented. If you set the Float Flag to Y,

Modbus functions 3, 6 and 16 interpret floating point values for

registers as specified by the two following parameters (Float Start,

Float Offset).

Note: You do not need to enable this parameter for most

applications using floating-point data.

Float Start

0 to 65535

Specifies the first register of floating-point data. All requests with

register values greater-than or equal to this value are considered

floating-point data requests. This parameter is only used if the Float

Flag is enabled.

User Manual Modbus TCP/IP Enhanced Communication Module

3.2.3 MBTCP Client x

This section defines the general configuration for MBTCP Client x. You can

configure up to 20 MBTCP clients, each using the parameters below. In the

ProSoft Configuration Builder tree view, double-click the MBTCP CLIENT X icon.

Page 50 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 51

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Float Offset

0 to 9999

Specifies the start register for floating-point data in the internal

database. This parameter is used only if the Float Flag is enabled.

ARP Timeout

1 to 60 seconds

Specifies the number of seconds to wait for an ARP reply after a

request is issued. If the value is out of range, the module uses the

default value of 5.

Command Error Delay

0 to 300

Specifies the number of 100 millisecond intervals to turn off a

command in the error list after an error is recognized for the

command. If you set this parameter to 0, there is no delay.

MBAP Port Override

Yes or No

Override default port settings.

NO = Use standard server Port 502 with MBAP format messages. All

other server Port values use encapsulated Modbus message format

(RTU via TCP).

YES = Use MBAP format messages for all server Port values. RTU

via TCP is not used.

Modbus TCP/IP Enhanced Communication Module User Manual

3.2.4 MBTCP Client x Commands

In order to interface the MVI69E-MBTCP module with Modbus server devices,

you must create a command list. The commands in the list specify the server

device to be addressed, the function to be performed (read or write), the data

area in the device to interface with, and the registers in the internal database to

be associated with the device data.

Each of the 20 Client Command Lists supports up to 16 commands each. The

command list is processed from top (Command #0) to bottom.

Read commands are executed without condition. You can set write commands to

execute only if the data in the write command changes (Conditional Enable). If

the register data values in the command have not changed since the command

was last issued, the command is not executed. You can use this feature to

optimize network performance.

The MBTCP Modbus client (and server) communication drivers support several

data read and write commands. When you configure a command, you need to

consider the type of data (bit, 16-bit integer, 32-bit float, etc), and the level of

Modbus support in the server equipment. For information on floating-point

support, please see Floating-Point Support.

In the ProSoft Configuration Builder tree view, double-click the MBTCP CLIENT X

COMMANDS icon.

ProSoft Technology, Inc. Page 51 of 150

May 20, 2015

Page 52

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

Parameter

Value

Description

Enable

Disable, Enable,

Conditional,

Bit/Word Override,

Float Override

Specifies whether the command is executed and under what

conditions.

DISABLE (0) = The command is disabled and is not executed in the

normal polling sequence.

ENABLE (1) = The command is executed each scan of the command

list if the Poll Interval (see below) is set to zero. If the Poll Interval is

set to a nonzero value, the command is executed when the interval

timer expires.

CONDITIONAL (2) = For write commands only. The command executes

only if the internal data associated with the command changes.

BIT/WORD OVERRIDE (3) = For read commands only. If a command

error occurs, the module overrides the associated database area with

the Override Value Upon Error parameter value.

FLOAT OVERRIDE (4) = For read commands only. If a command error

occurs, the module overrides the associated database area (2x word

count) with the Override Value Upon Error parameter value.

Internal Address

0 to 9999 (wordlevel)

or

0 to 65535 (bit-level)

Specifies the module’s internal database register to be associated

with the command. Allowable range is 0 to 9999 for Modbus Function

Codes 3, 4, 6, or 16, and 0 to 65535 for Modbus Function Codes 1, 2,

5, or 15.

If the command is a read function, the data read from the server

device is stored beginning at the module’s internal database register

value entered in this field. This register value must be in the Read

Data area of the module’s memory, defined by the Read Register

Start and Read Register Count parameters in the Module section.

If the command is a write function, the data to be written to the server

device is sourced beginning from the module’s internal database

register specified. This register value must come from the Write Data

area of the module’s memory, defined by the Write Register Start and

Write Register Count parameters in the Module section.

Poll Interval

0 to 65535 seconds

Specifies the minimum interval between executions of continuous

commands (Enable code = 1).

Example: If you set the value to 10, the command executes no more

frequently than once every 10 seconds. When the command reaches

the top of the command queue and 10 seconds has not elapsed, it is

skipped until the poll interval has expired.

Register Count

1 to 125 (words) or

1 to 800 (coils)

Specifies the number of registers or digital points to be associated

with the command. Modbus Function Codes 5 and 6 ignore this field

as they only apply to a single data point.

For Modbus Function Codes 1, 2, and 15, this parameter sets the

number of single bit digital points (inputs or coils) to be associated

with the command.

For Modbus Function Codes 3, 4, and 16, this parameter sets the

number of 16-bit registers to be associated with the command.

Swap Code

No Change,

Word Swap,

Word and Byte

Swap,

Byte Swap

Defines if the data received from the Modbus server is to be ordered

differently than received from the server device. This parameter is

helpful when dealing with floating-point or other multi-register values,

as there is no standard method of storing these data types in server

devices. You can set this parameter to order the register data

received in an order useful by other applications.

NO CHANGE = No change is made in the byte ordering (ABCD =

ABCD)

WORD SWAP = The words are swapped (ABCD= CDAB)

WORD AND BYTE SWAP = The words are swapped, then the bytes in

each word are swapped (ABCD=DCBA)

BYTE SWAP = The bytes in each word are swapped (ABCD=BADC)

Note: Each pair of characters is a byte (example: AB and CD). Two

pairs of characters is a 16-bit register (example: ABCD).

User Manual Modbus TCP/IP Enhanced Communication Module

Page 52 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 53

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Node IP Address

xxx.xxx.xxx.xxx

Specifies the IP address of the target device being addressed by the

command.

Service Port

1 to 9999

Use a value of 502 when addressing Modbus TCP/IP servers which

are compatible with the Schneider Electric MBAP specifications (most

devices).

If a server implementation supports another service port, enter the

value here. Service Port 2000 is common for encapsulated format

messages.

Slave Address

0 to 255

Mainly used for Modbus TCP/IP to serial conversion. This specifies

the Modbus slave node address on the serial network to be

considered.

If a Modbus TCP/IP server device does not have or need a slave

address, use a value of ‘1’.

If you set the value to zero, the command is a broadcast message on

the network. The Modbus protocol permits broadcast commands for

write operations. Do not use this node address for read operations.

Modbus Function

1, 2, 3, 4, 5, 6, 15,

16

Specifies the Modbus function to be executed by the command.

These function codes are defined in the Modbus protocol.

1 = Read Coil Status (0xxxx)

2 = Read Input Status (1xxxx)

3 = Read Holding Registers (4xxxx)

4 = Read Input Registers (3xxxx)

5 = Force (Write Single) Coil (0xxxx)

6 = Force (Write Single) Holding Register (4xxxx)

15 = Preset (Write) Multiple Coils (0xxxx)

16 = Preset (Write) Multiple Registers (4xxxx)

MB Address in

Device

0 to 9999

Specifies the register or digital point address offset within the Modbus

server device. The MBTCP client reads or writes from/to this address

within the server.

Refer to the documentation of each Modbus server device for their

register and digital point address assignments.

Note: The value you enter here does not need to include the "Modbus

Prefix" addressing scheme. Also, this value is an offset of the zerobased Modbus addressing scheme.

Example: When using a Modbus Function Code 3 to read from

address 40010 in the server, enter a value of ‘9’ for this parameter.

The firmware (internally) adds a ‘40001’ offset to the value entered.

This is the same for all Modbus addresses (0x, 1x, 3x, 4x).

Override Value

Upon Error

This parameter is only applicable when the Enable parameter is 3

(Bit/Word Override) or 4 (Float Override).

If an error occurs associated with a read command, the module

automatically populates the associated database area with this

override value.

Modbus TCP/IP Enhanced Communication Module User Manual

ProSoft Technology, Inc. Page 53 of 150

May 20, 2015

Page 54

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

Parameter

Description

IP Address

Unique IP address assigned to the module

Netmask

Subnet mask of module

Gateway

Gateway (if used)

User Manual Modbus TCP/IP Enhanced Communication Module

3.2.5 Ethernet 1

This section defines the permanent IP address, Subnet Mask, and Gateway of

the module.

In the ProSoft Configuration Builder tree view, double-click the ETHERNET 1 icon.

Page 54 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 55

MVI69E-MBTCP ♦ CompactLogix Platform Configuring the MVI69E-MBTCP Using PCB

Parameter

Value

Description

IP Address

xxx.xxx.xxx.xxx

This table contains a list of static IP addresses that the module

uses when an ARP is required. The module accepts up to 40

static IP/MAC address data sets.

Important: If the device in the field is changed, this table must be

updated to contain the new MAC address for the device and

downloaded to the module. If the MAC is not changed, there is no

communication with the module.

Hardware MAC

Address

FF.FF.FF.FF.FF.FF

This table contains a list of static MAC addresses that the module

uses when an ARP is required. The module accepts up to 40

static IP/MAC address data sets.

Important: If the device in the field is changed, this table must be

updated to contain the new MAC address for the device and

downloaded to the module. If the MAC is not changed, there is no

communication with the module.

Modbus TCP/IP Enhanced Communication Module User Manual

3.2.6 Static ARP Table

This section defines a list of static IP addresses that the module uses when an

ARP (Address Resolution Protocol) is required. The module accepts up to 40

static IP/MAC Address data sets.

Use the Static ARP table to reduce the amount of network traffic by specifying IP

addresses and their associated MAC (hardware) addresses that the MVI69EMBTCP module communicates with regularly.

In ProSoft Configuration Builder tree view, double-click the STATIC ARP TABLE

icon.

ProSoft Technology, Inc. Page 55 of 150

May 20, 2015

Page 56

Configuring the MVI69E-MBTCP Using PCB MVI69E-MBTCP ♦ CompactLogix Platform

User Manual Modbus TCP/IP Enhanced Communication Module

3.3 Downloading the Configuration File to the Processor

1 In the ProSoft Configuration Builder tree view, right-click the module icon and

then click DOWNLOAD FROM PC TO DEVICE.

2 In the Download Configuration File dialog box, click RSWHO.

Page 56 of 150 ProSoft Technology, Inc.

May 20, 2015

Page 57