Page 1

MVI46-103M

SLC Platform

IEC 60870-5-103 Master Communication

Module

User Manual

September 12, 2006

Page 2

Please Read This Notice

Successful application of this module requires a reasonable working knowledge of the Rockwell

Automation SLC hardware, the MVI46-103M Module and the application in which the combination

is to be used. For this reason, it is important that those responsible for implementation satisfy

themselves that the combination will meet the needs of the application without exposing personnel

or equipment to unsafe or inappropriate working conditions.

This manual is provided to assist the user. Every attempt has been made to assure that the

information provided is accurate and a true reflection of the product's installation requirements. In

order to assure a complete understanding of the operation of the product, the user should read all

applicable Rockwell Automation documentation on the operation of the Rockwell Automation

hardware.

Under no conditions will ProSoft Technology, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of the product.

Reproduction of the contents of this manual, in whole or in part, without written permission from

ProSoft Technology, Inc. is prohibited.

Information in this manual is subject to change without notice and does not represent a

commitment on the part of ProSoft Technology, Inc. Improvements and/or changes in this manual

or the product may be made at any time. These changes will be made periodically to correct

technical inaccuracies or typographical errors.

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have

suggestions, comments, compliments or complaints about the product, documentation or support,

please write or call us.

ProSoft Technology, Inc.

1675 Chester Avenue, Fourth Floor

Bakersfield, CA 93301

(661) 716-5100

(661) 716-5101 (Fax)

http://www.prosoft-technology.com

Copyright © ProSoft Technology, Inc. 2000 - 2006. All Rights Reserved.

MVI46-103M User Manual

September 12, 2006

Page 3

Contents MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

Contents

PLEASE READ THIS NOTICE...........................................................................................................2

Your Feedback Please ..................................................................................................................2

1 PRODUCT SPECIFICATIONS....................................................................................................7

1.1 General Specifications..................................................................................................7

1.1.1 Physical..........................................................................................................................7

1.1.2 SLC Interface .................................................................................................................8

1.2 Hardware Specifications...............................................................................................8

2 QUICK START ............................................................................................................................9

3 FUNCTIONAL OVERVIEW.......................................................................................................15

3.1 General Concepts........................................................................................................15

3.1.1 Module Power Up ........................................................................................................15

3.1.2 Main Logic Loop...........................................................................................................16

3.1.3 SLC Processor Not in Run...........................................................................................16

3.1.4 Backplane Data Transfer .............................................................................................17

3.1.5 Data Types and Mapping.............................................................................................17

3.1.6 Command Control Blocks ............................................................................................20

3.2 Master Driver................................................................................................................27

4 MODULE CONFIGURATION....................................................................................................29

4.1 Installing and Configuring the Module......................................................................29

4.2 Module Data .................................................................................................................31

4.3 Configuration File........................................................................................................31

4.4 Uploading and Downloading the Configuration File................................................35

4.4.1 Transferring the Configuration File to Your PC............................................................35

4.4.2 Transferring the Configuration File to the Module .......................................................37

5 LADDER LOGIC........................................................................................................................41

ProSoft Technology, Inc. Page 3 of 187

September 12, 2006

Page 4

MVI46-103M ♦ SLC Platform Contents

IEC 60870-5-103 Master Communication Module

5.1 Main Routine................................................................................................................ 41

5.2 Data Transfer (U:3)...................................................................................................... 42

5.3 Control Routine (U:4).................................................................................................. 43

6 DIAGNOSTICS AND TROUBLESHOOTING........................................................................... 47

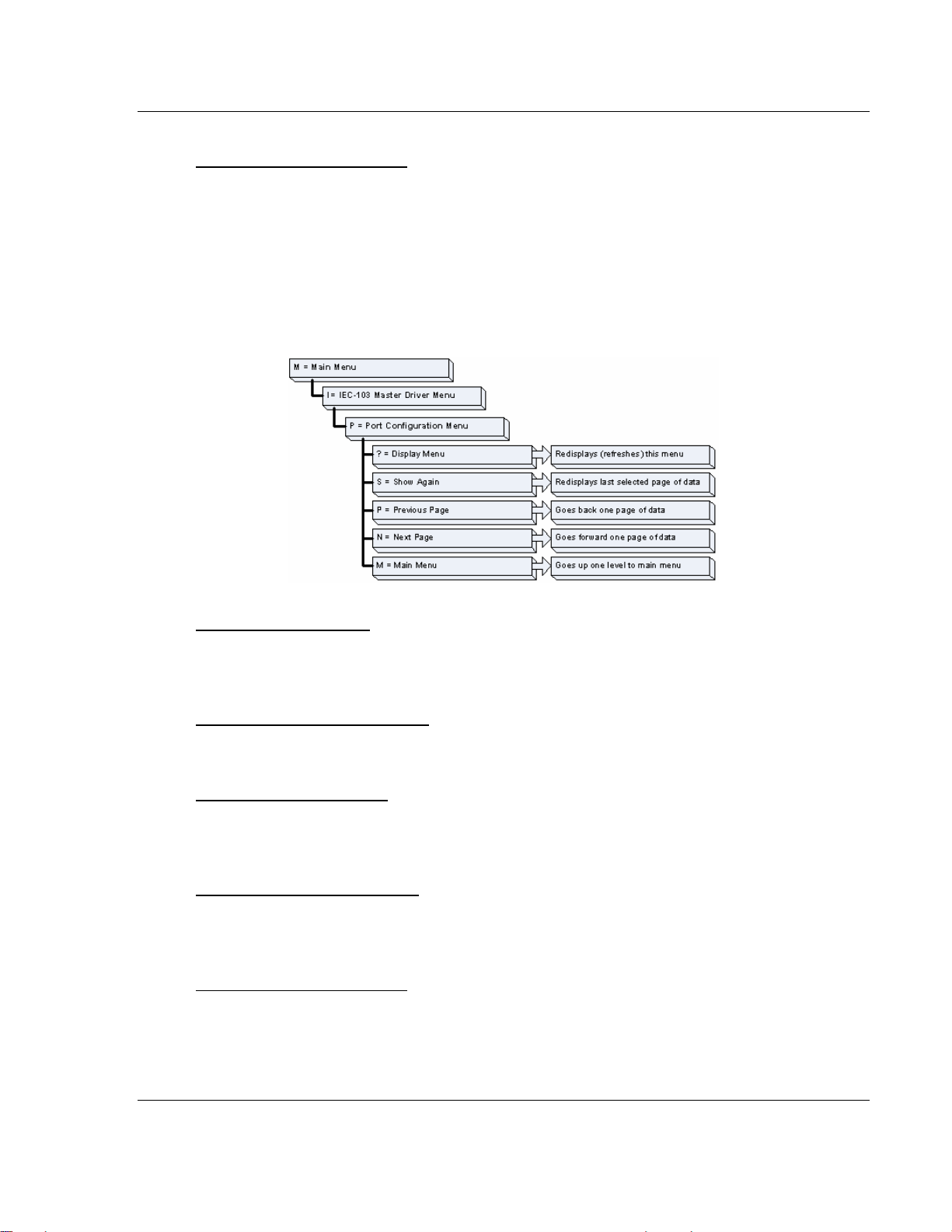

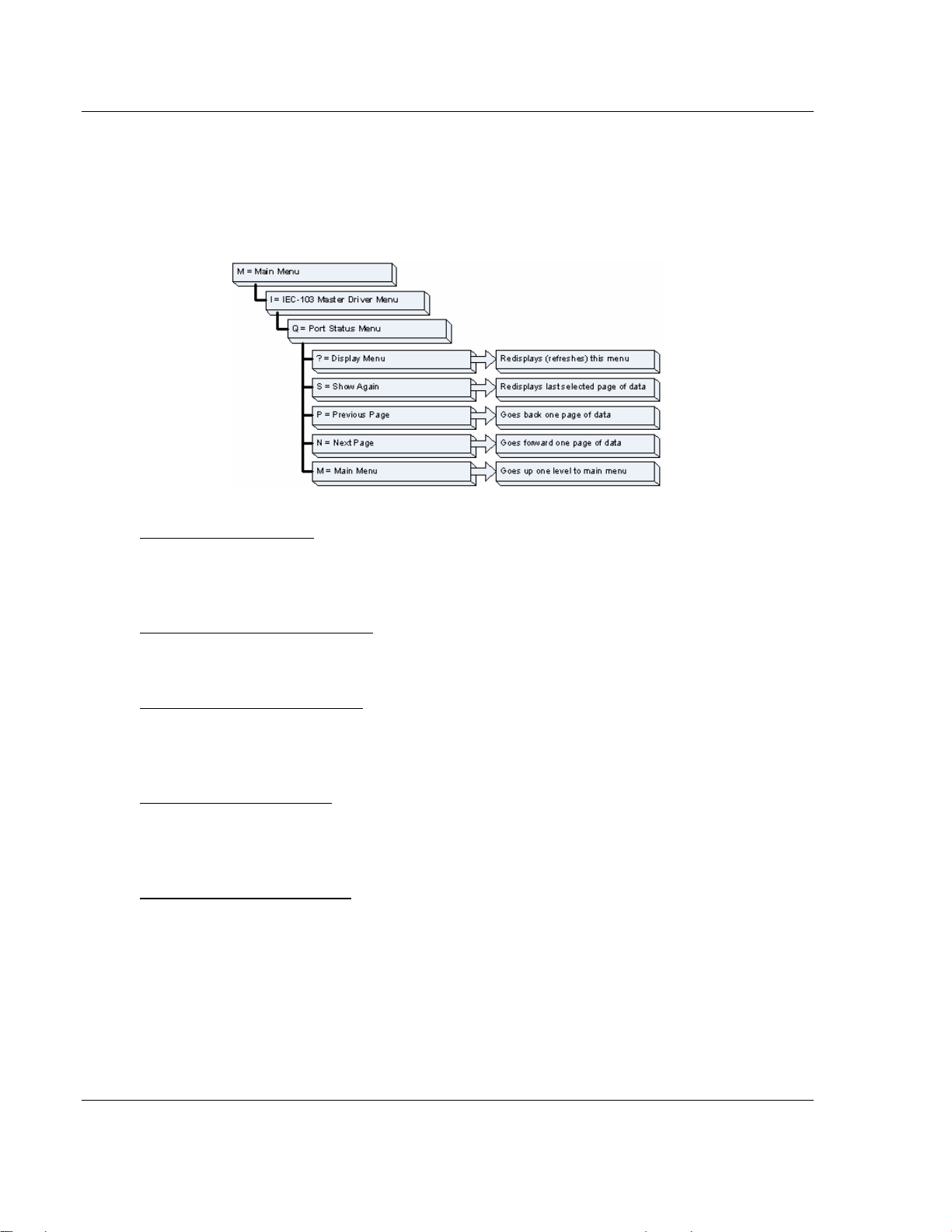

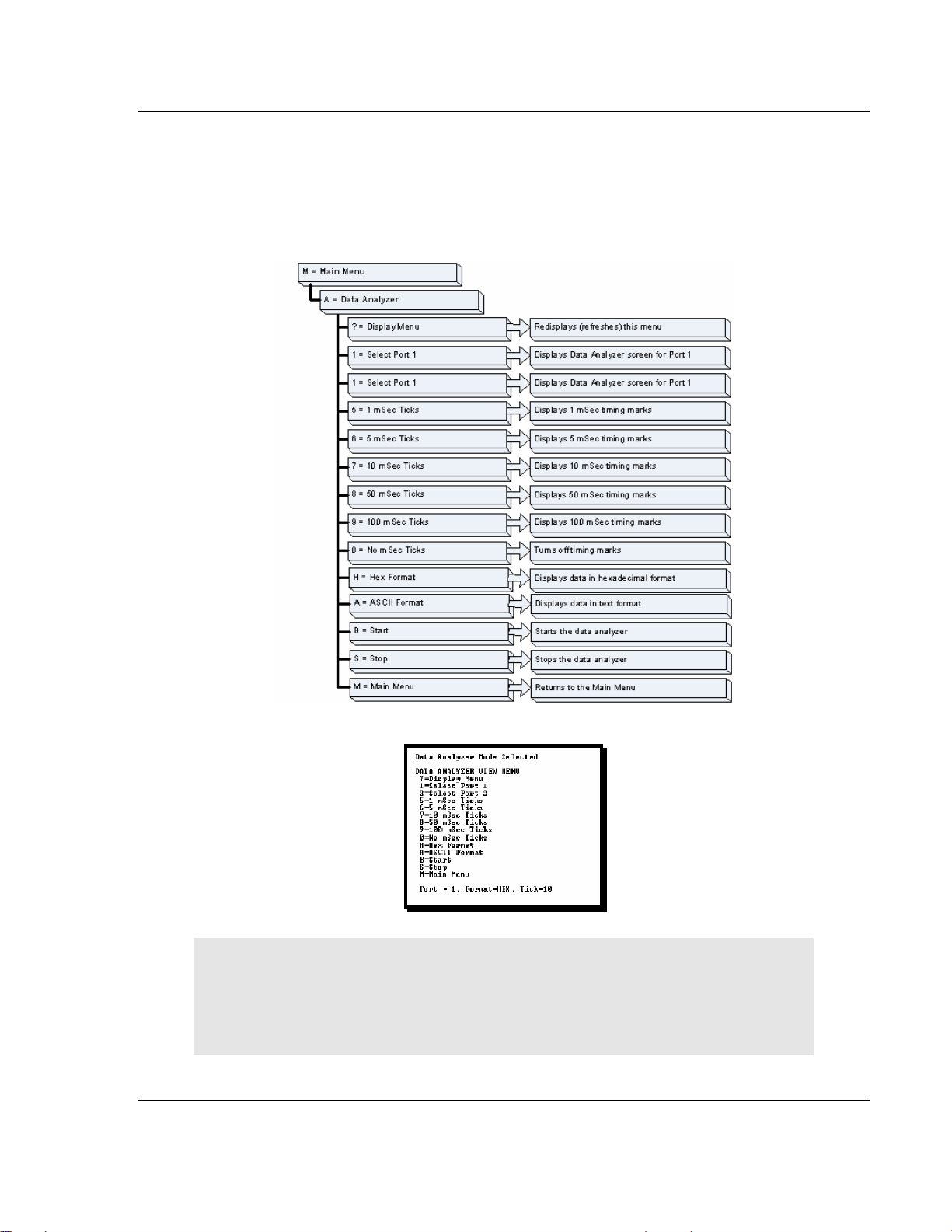

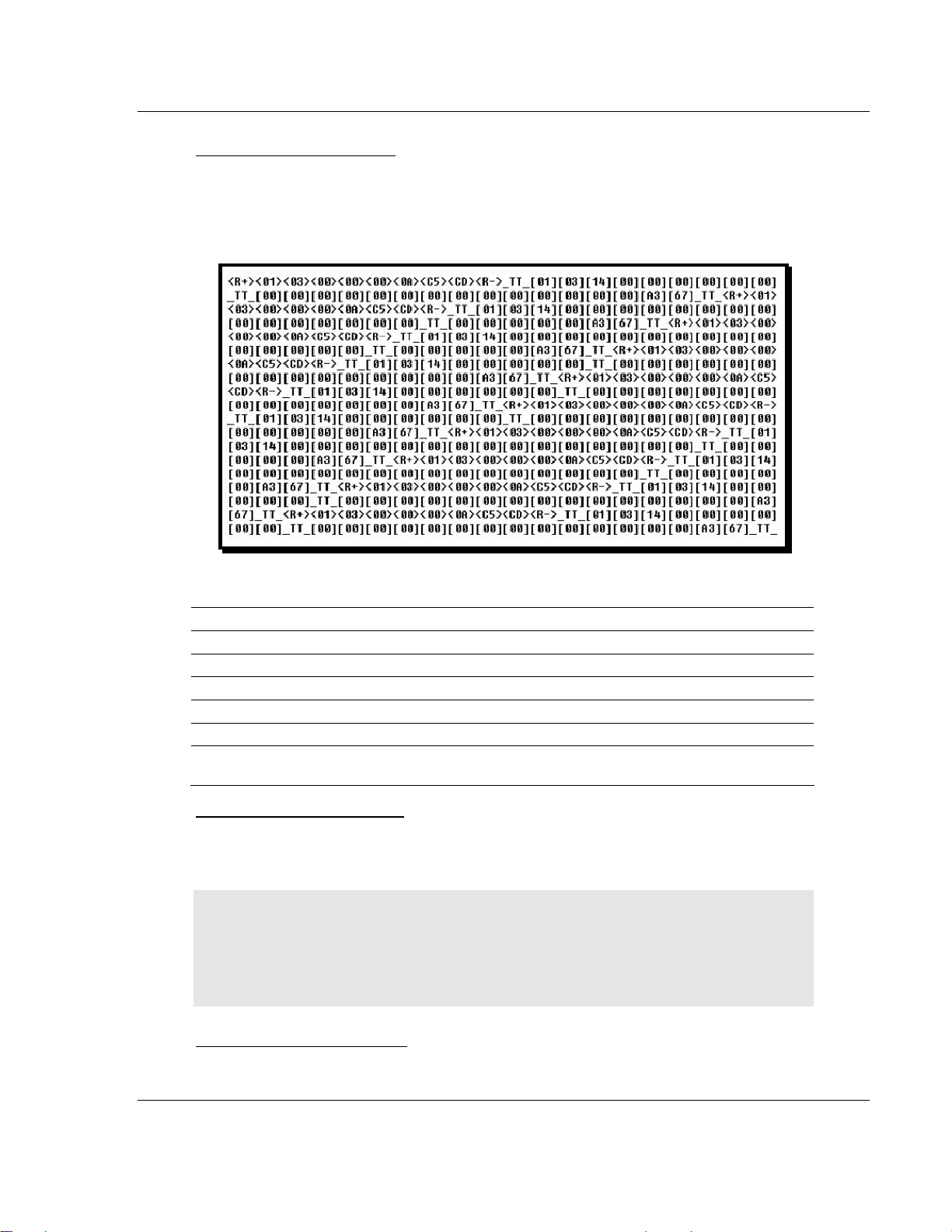

6.1 The Configuration/Debug Menu ................................................................................ 47

6.1.1 Navigation.................................................................................................................... 47

6.2 Required Hardware.....................................................................................................48

6.3 Required Software ......................................................................................................49

6.4 Using the Configuration/Debug Port.........................................................................49

6.4.1 Main Menu................................................................................................................... 50

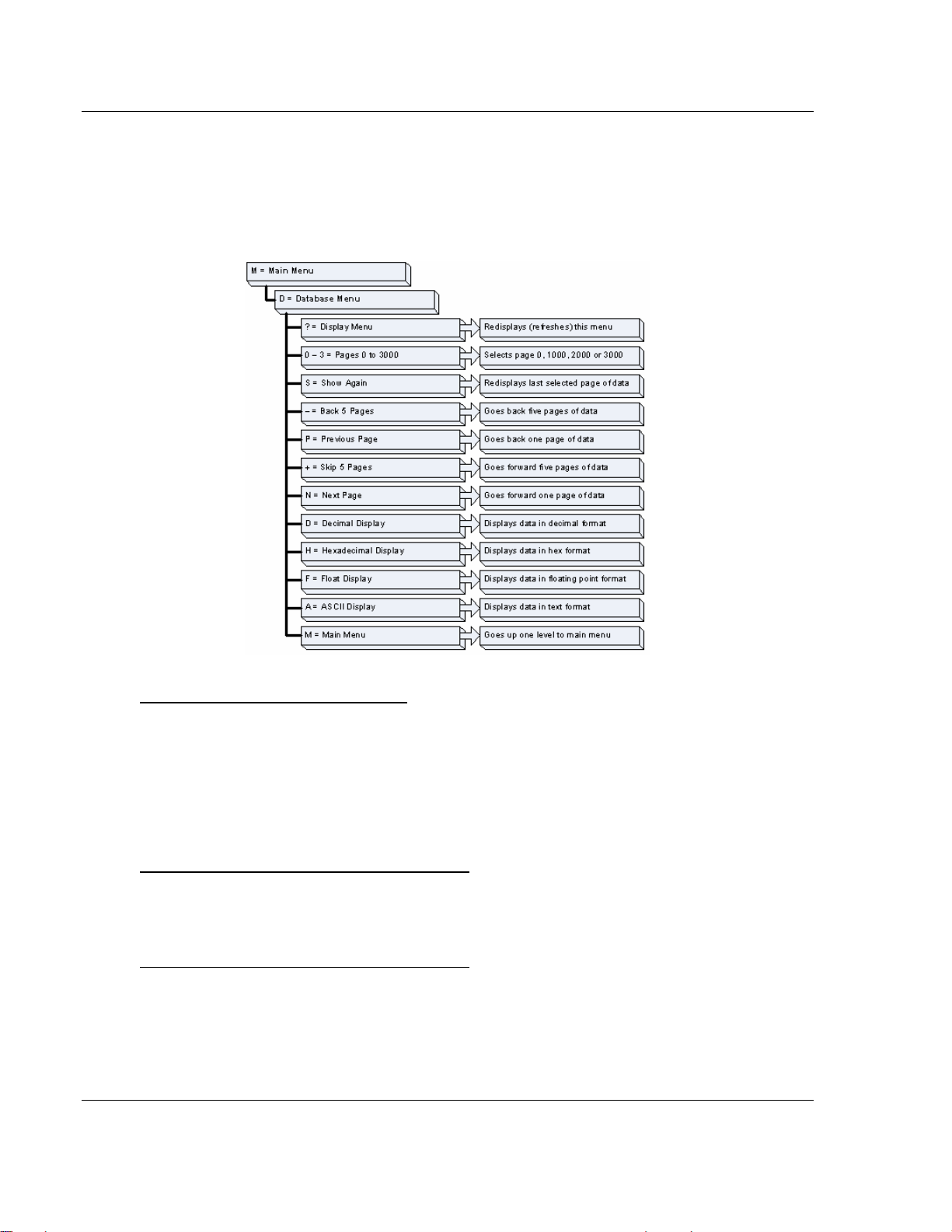

6.4.2 Database View Menu .................................................................................................. 54

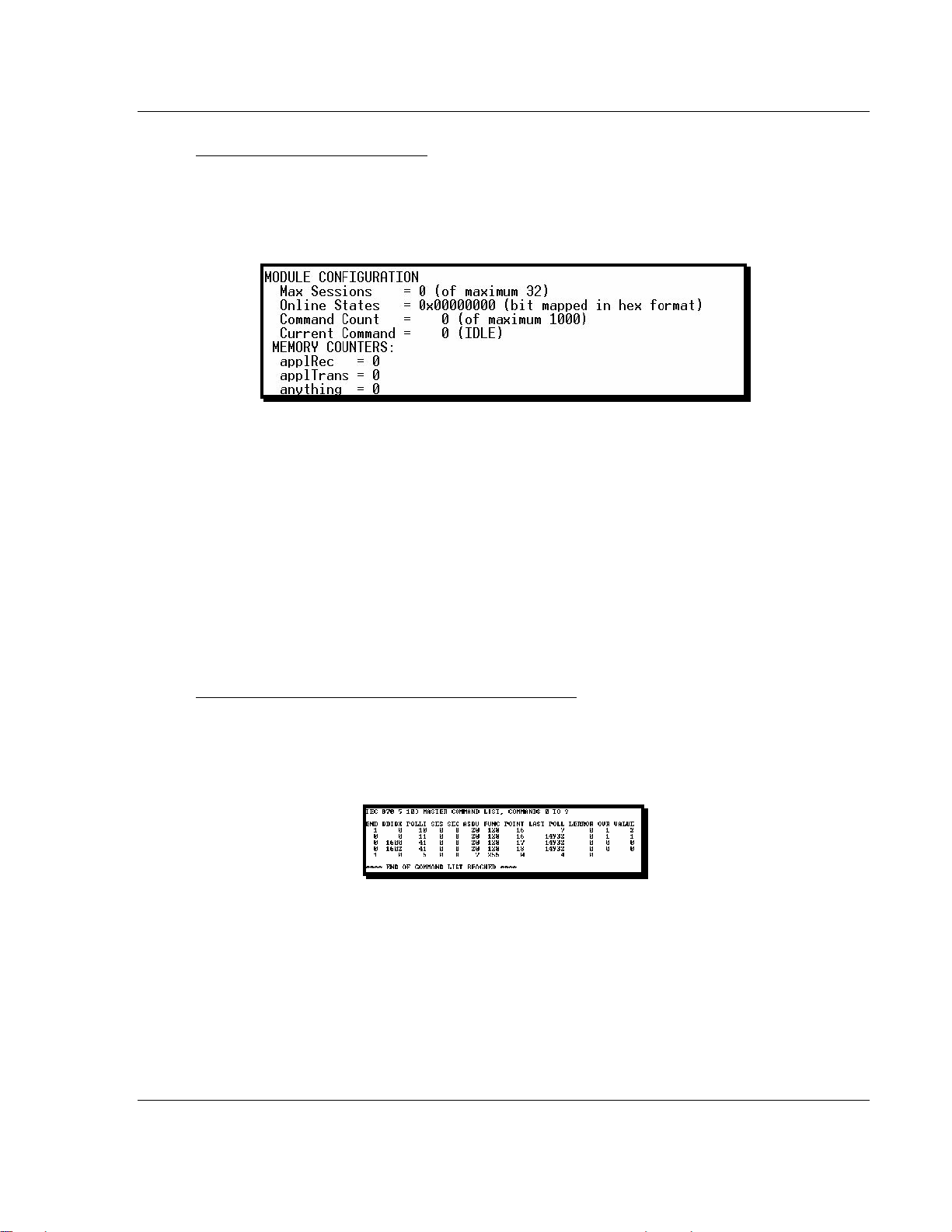

6.4.3 IEC-103 Master Driver Menu....................................................................................... 56

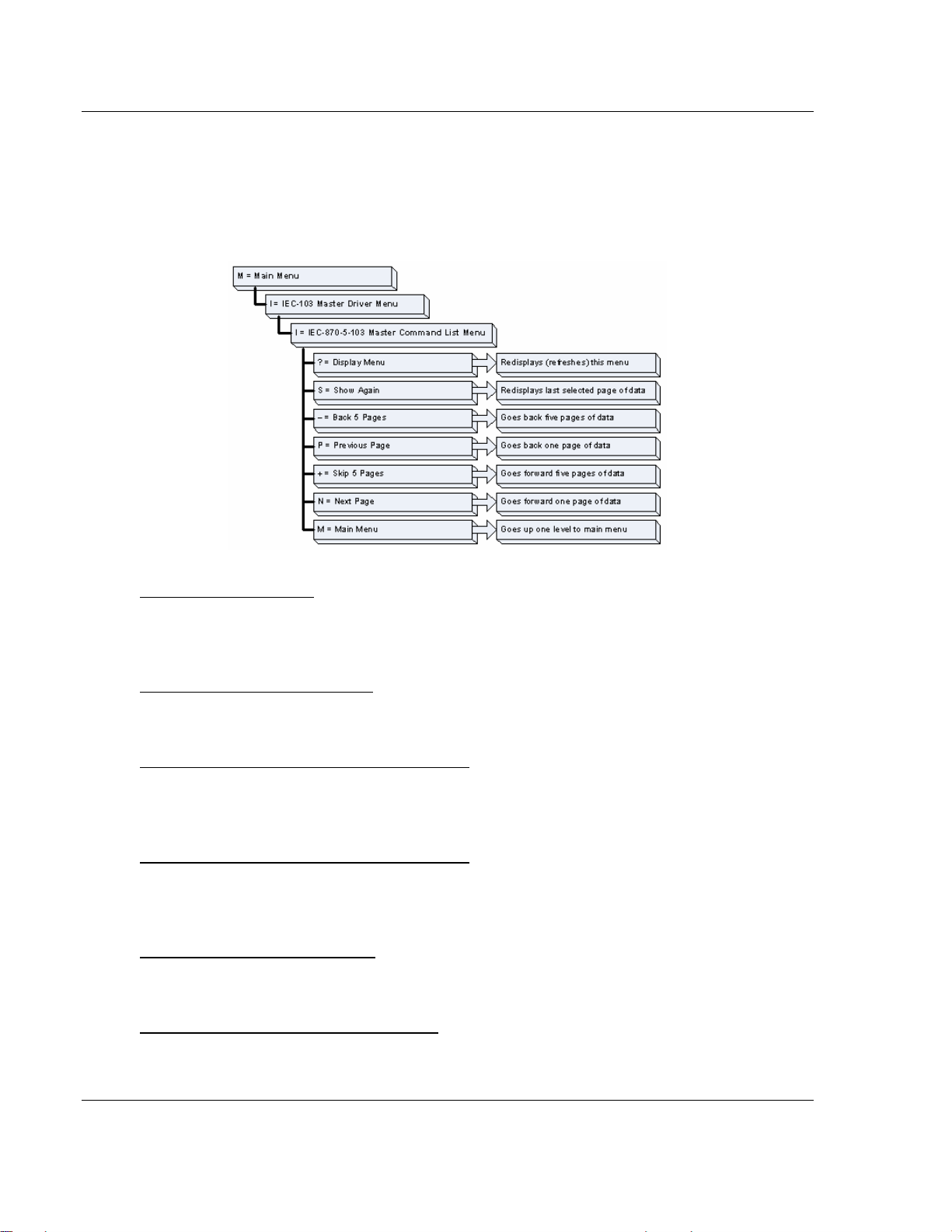

6.4.4 IEC-870-Master Command List Menu......................................................................... 60

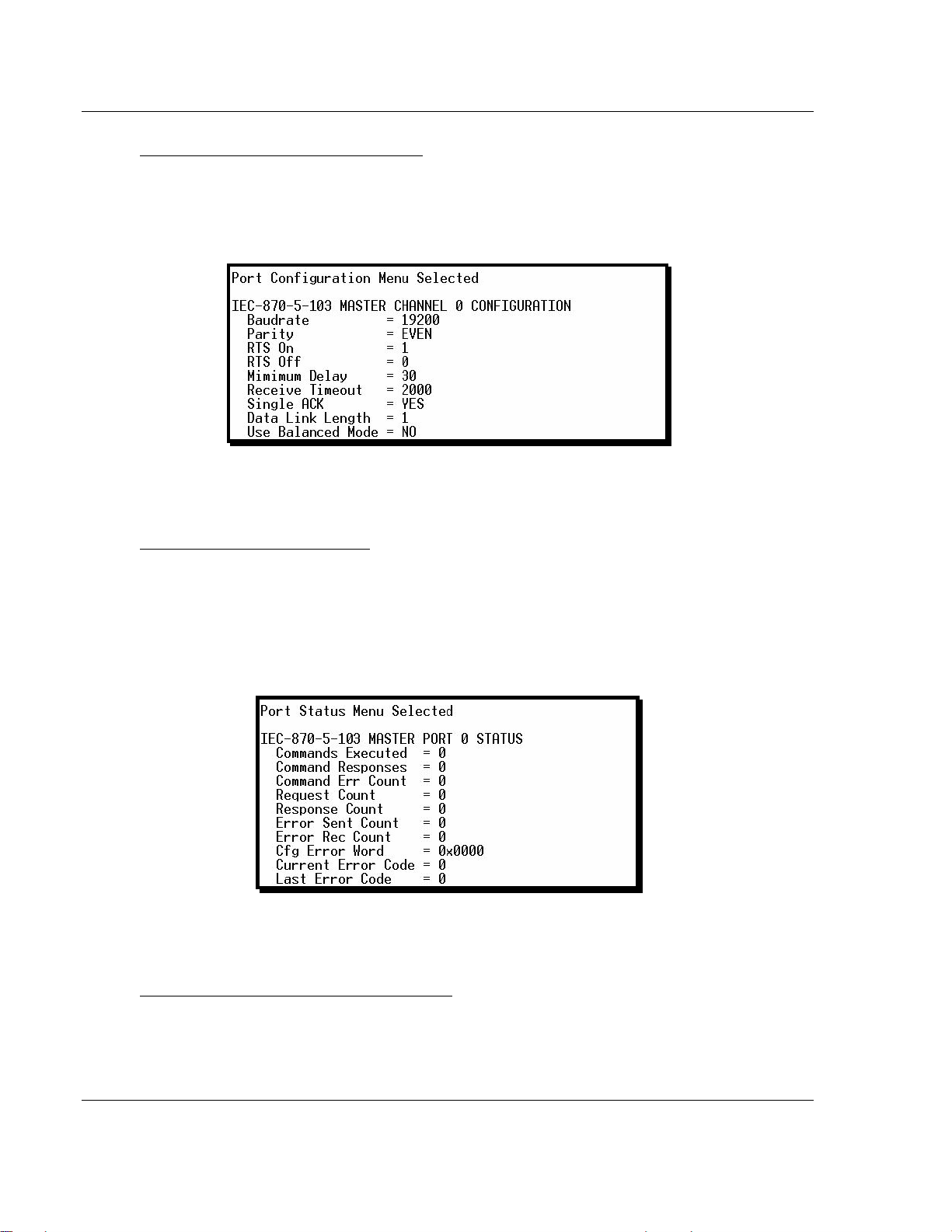

6.4.5 Port Configuration Menu ............................................................................................. 61

6.4.6 Port Status Menu......................................................................................................... 62

6.4.7 Data Analyzer .............................................................................................................. 63

6.4.8 Session Configuration Menu ....................................................................................... 66

6.4.9 Sector Configuration Menu.......................................................................................... 67

6.4.10 Sector Database Menu................................................................................................ 68

6.5 LED Status Indicators................................................................................................. 69

6.5.1 Clearing a Fault Condition........................................................................................... 70

6.5.2 Troubleshooting........................................................................................................... 70

7 REFERENCE ............................................................................................................................73

7.1 Cable Connections......................................................................................................73

7.1.1 RS-232 ........................................................................................................................ 74

7.1.2 RS-232 Configuration/Debug Port............................................................................... 76

7.1.3 RS-485 ........................................................................................................................ 76

7.1.4 RS-422 ........................................................................................................................ 77

7.2 Setting Jumpers.......................................................................................................... 77

7.3 MVI46-103M Status Data Area.................................................................................... 78

7.3.1 MVI46-IEC 60870-5-103 Master Communication Module Error/Status Data Format. 78

Page 4 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 5

Contents MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

7.3.2 MVI46-IEC 60870-5-103 Master Communication Module Error Codes ......................80

7.4 MVI46-103M Configuration Data Definition...............................................................82

7.4.1 MVI46 IEC 60870-5-103 Master Communication Module Configuration ....................82

7.5 MVI46-103M Configuration File Example ..................................................................86

7.6 Database Form...........................................................................................................158

7.7 Command List Form..................................................................................................160

7.8 Protocol Support .......................................................................................................162

7.8.1 List of Type Identification Codes................................................................................162

7.8.2 List of Cause of Transmission Codes ........................................................................163

7.8.3 List of Function Types................................................................................................164

7.8.4 Information Numbers Used In Monitor Direction........................................................164

7.8.5 Information Numbers Used In Control Direction ........................................................167

7.8.6 Definition and Presentation of ASDU'S In Monitor Direction .....................................168

7.8.7 Definition and Presentation Of ASDU'S In Control Direction.....................................171

7.9 Protocol Interoperability Documentation................................................................172

7.9.1 Physical Layer............................................................................................................173

7.9.2 Electrical Interface .....................................................................................................173

7.9.3 Optical Interface.........................................................................................................173

7.9.4 Transmission speed...................................................................................................174

7.9.5 Link Layer...................................................................................................................174

7.9.6 Application Layer .......................................................................................................174

7.9.7 Transmission mode for application data....................................................................174

7.9.8 Common address of ASDU........................................................................................174

7.9.9 Selection of standard information numbers in monitor direction................................174

7.9.10 System functions in monitor direction ........................................................................174

7.9.11 Status indications in monitor direction .......................................................................174

7.9.12 Supervision indications in monitor direction...............................................................175

7.9.13 Earth fault indications in monitor direction .................................................................176

7.9.14 Fault indications in monitor direction .........................................................................176

7.9.15 Auto-reclosure indications in monitor direction ..........................................................177

7.9.16 Measurands in monitor direction................................................................................177

ProSoft Technology, Inc. Page 5 of 187

September 12, 2006

Page 6

MVI46-103M ♦ SLC Platform Contents

IEC 60870-5-103 Master Communication Module

7.9.17 Generic functions in monitor direction ....................................................................... 177

7.9.18 Selection of standard information numbers in control direction ................................ 178

7.9.19 System functions in control direction......................................................................... 178

7.9.20 General commands in control direction..................................................................... 178

7.9.21 Generic functions in control direction ........................................................................ 178

7.9.22 Basic application functions ........................................................................................ 179

7.9.23 Miscellaneous............................................................................................................ 179

SUPPORT, SERVICE & WARRANTY........................................................................................... 181

Module Service and Repair...................................................................................................... 181

General Warranty Policy – Terms and Conditions................................................................ 182

Limitation of Liability................................................................................................................183

RMA Procedures.......................................................................................................................183

INDEX.............................................................................................................................................185

Page 6 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 7

Product Specifications MVI46-103M ♦ SLC Platform IEC 60870-5-103 Master Communication Module

1 Product Specifications

In This Chapter

General Specifications .............................................................7

Hardware Specifications .......................................................... 8

The MVI46-103M ("IEC 60870-5-103 Master Communication Module") allows

Rockwell Automation SLC I/O compatible processors to interface easily with IEC

60870-5-103 slave (controlled unit) protection devices. Compatible devices

include relays, breakers, sub-station communication modules and other serial

communication devices.

1.1 General Specifications

The MVI46-103M module interfaces up to 32 serial communication devices with

the Rockwell Automation SLC processor. Two communication ports on the

module act as controlling devices (masters) to interface with controlled devices

on their own networks. Each port is individually configurable. Data is exchanged

between the serial network and the Rockwell Automation processor using the

internal database contained in the module and direct control by the controller's

ladder logic.

Some of the general specifications include:

Built in accordance to the approved international specification

Two independent master ports completely user configurable

Up to 32 sessions (controlled devices)

Up to five sectors (separate databases) for each session

Individual database definition for each sector

1000 commands to control stations

SLC processor can issue control commands directly to the module or a

controlled device

Pass-through of event messages from controlled device to processor for

logging of time-tagged events

1.1.1 Physical

This module is designed by ProSoft Technology and incorporates licensed

technology from Rockwell Automation (SLC backplane technology).

SLC Form Factor - Single Slot

ProSoft Technology, Inc. Page 7 of 187

September 12, 2006

Page 8

MVI46-103M ♦ SLC Platform Product Specifications

IEC 60870-5-103 Master Communication Module

Connections:

1 - RJ45 RS-232 Configuration Tool Connector

2 - RJ45 RS-232/422/485 Application ports

1.1.2 SLC Interface

Operation via simple ladder logic

Complete set up and monitoring of module through RSLogix 500 software

and user constructed configuration file (IEC103M.CFG)

SLC backplane interface via M-File access

All data related to the module is contained in user data files to ease in the

monitoring and interfacing with the module

Control of module and controlled devices on serial network available from

ladder logic

1.2 Hardware Specifications

The MVI46-103M module is designed by ProSoft Technology and incorporates

licensed technology from Rockwell Automation (SLC backplane technology).

Current Loads: 800 ma @ 5V (from backplane)

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: –40 to 85°C (–40 to 185°F)

Relative Humidity: 5 to 95% (non-condensing)

Configuration Connector: RJ45 RS-232 Connector (RJ45 to DB-9 cable

shipped with unit)

Application Port Connector: RJ45-RS-232/422/485 Connector (RJ45 to DB-9

cables shipped with unit)

Page 8 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 9

Quick Start MVI46-103M ♦ SLC Platform IEC 60870-5-103 Master Communication Module

2 Quick Start

This section provides the steps required to configure the module. After you

download the sample configuration file, please perform the following steps:

Step 1 - Configure the Number of Slaves (Sessions)

The IEC 60870-5-103 protocol is a master-slave protocol where the slaves are

typically protection equipments for substations. The MVI46-103M module

supports up to 32 slaves (total) connected to its ports. Each slave has to be

configured as a session. Refer to the configuration file to enter the number of

slaves that will be connected to the MVI46-103M module:

[IEC-870-5-103 Master]

Session Count : 5 #1 to 32 - maximum number of slaves on all channels

In the example above, the module will only poll sessions 0 to 4. The module

would not poll sessions 5 to 15.

In the Step 3, the user will configure each session as an actual slave in the

network.

Step 2 - Configure the Port Communication Parameters

The user should configure the port communication parameters in order to enable

data transfer between the master and the slave(s). The port communication

parameters include: baud rate, parity, RTS ON, RTS OFF and Minimum Delay.

The IEC 60870-5-103 protocol uses two baud rates: 19200 or 9600 kb/s and

even parity.

Refer to the [IEC-870-5-103 Master Port 0] section in the configuration file in

order to configure the communication parameters for the 103M port:

[IEC-870-5-103 Master Port 0]

# Communication Parameters

Baud Rate : 19200 #Baud rate for port 9600-19200

Parity : E #N=None, O=Odd, E=Even, M=Mark, S=Space

RTS On : 0 #0-65536 mSec before message

RTS Off : 1 #0-65536 mSec after message

Minimum Delay : 10 #Minimum # of mSec before response sent

Receive Timeout : 2000 #Maximum mSec from first char to last to wait

# These parameters are protocol specific

Single char ACK F0,1 or 3 : Y #Single E5 resp to ACK func 0, 1 & 3 req (Y/N)

The user should also configure the jumpers located at the back at the module in

order to select the correct communication mode: RS-232, RS-422 or RS-485.

ProSoft Technology, Inc. Page 9 of 187

September 12, 2006

Page 10

MVI46-103M ♦ SLC Platform Quick Start

IEC 60870-5-103 Master Communication Module

Step 3 - Configure the Session (Slave) Poll Parameters

According to the IEC 60870-5-103 protocol, the master cyclically polls data from

the slaves. The data is classified into two classes; Class 1 and Class 2. Events

belong to Class 1 and analog data to Class 2. The module can request data

through Class 1 or Class 2 requests. Responses to control command and

general interrogation commands are also sent as Class 1 data.

Please refer to the [IEC-103 Master Session x] section in the configuration file in

order to configure how each slave will be polled.

Initially, the user should enter the MVI46-103M port number that will be

connected to the session (slave) using the "Communication Port" parameter.

Valid values are 0 or 1.

These parameters include the Data Link Address, which is the slave address that

identifies all protection equipment on the network. There should be a unique

number for each slave on the network. There are also certain parameters that

pertain to how the Class 1 and Class 2 polls will be used for data transfer.

You must enter the number of sectors for each session using the Sector Count

parameter. The module accepts up to 3 sectors per session.

[IEC-103 Master Session 0]

Communication Port : 0 #Index of COM port for session (0 or 1)

Sector Count : 5 #5 is max for this version of app

Data Link Address : 0 #Range is 0 to 65535 DL address of slave

Failure Delay : 3 #Min Sec to delay before poll of offline slave

#(0 to 2000 seconds)

Confirm Timeout : 20000 #0 to 2^32-1 mSec to wait for DL confirm

Retry Count : 5 #0 to 255 retries for if no confirm

Response Timeout : 5000 #Timeout for confirm of req (0 to 2^32-1)

C1/C2 Poll Count Pend : 6 #class 1 or 2 polls before next slave tried (0-

65535)

Class 1 Polls : 10 #Max class 1 polls to this session

Class 1 Pend delay : 1000 #Min mSec delay between call (0 to 2^32-1)

Class 2 Pend delay : 1000 #Min mSec delay between call (0 to 2^32-1)

Class 1 Poll delay : 1000 #Min mSec delay between call (0 to 2^32-1)

Class 2 Poll delay : 1000 #Min mSec delay between call (0 to 2^32-1)

This step should be repeated for each session to be used. For example, if the

user selected 8 sessions during Step 1, he or she should configure sessions 0 to

7:

[IEC-103 Master Session 0]

[IEC-103 Master Session 1]

[IEC-103 Master Session 2]

[IEC-103 Master Session 3]

[IEC-103 Master Session 4]

[IEC-103 Master Session 5]

[IEC-103 Master Session 6]

[IEC-103 Master Session 7]

Page 10 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 11

Quick Start MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

Step 4 - Sector (Data Set) Configuration

For each session (slave), you must configure one or more sectors (maximum of

5). A sector is a data set defined by the vendor. Each sector is identified by the

Common ASDU Address parameter in the [IEC-103 Master Session x Sector 0]

area in the configuration file. This area also contains some parameters that will

affect the module initialization procedure.

[IEC-103 Master Session 0 Sector 0]

Common ASDU Address : 0 #Range 0 to 255 Sector address

#Req init requests when session first online (not req if slave sends

# EOI sequence)

Online Time sync : Y #Send time sync message when first online

Online General Int : Y #Send general interrogation

#Req init requests when EOI (end of initialization) received from slave

EOI Time sync : Y #Send time sync message when first online

EOI General Int : Y #Send general interrogation

# ASDU Database Function Point

# Type Index Code Index

START

1 0 128 16

1 16 128 18

1 32 128 19

1 48 128 20

1 64 128 21

1 80 128 22

1 96 128 23

1 112 128 24

1 128 128 25

1 144 128 26

END

This step should be repeated for each sector used by the application. The

module will only use the sectors configured in the previous step.

Step 5 - Monitor Point Configuration (Monitor Direction)

After the slave receives a Class 1 or Class 2 request from the master, it responds

with a message containing data. Each piece of equipment is normally configured

to respond with specific points when it is being polled with a Class 2 request.

During a Class 2 response, the slave may set a control bit (ACD) to inform the

master that there are new events to be transmitted. Then, the master will send a

Class 1 poll to read the events from the slave.

The IEC 60870-5-103 protocol states that the data is transferred between the

master and slave using an ASDU (Application Service Data Unit) format. Each

format is given by:

Type Identification

Variable Structure Qualifier

ProSoft Technology, Inc. Page 11 of 187

September 12, 2006

Page 12

MVI46-103M ♦ SLC Platform Quick Start

IEC 60870-5-103 Master Communication Module

Type Identification

Cause Of Transmission

Common Address of ASDU

Function Type

Information Number

Data…

Data…

…

The user should refer to the protection equipment specification for the following

information about each point:

Type: Type of the message

Function Type: Type of protection function

Information Number: Point Identification

This information will identify each point in the MVI46-103M configuration file. The

user has to configure the points that will be updated in the MVI46-103M database

when a Class 2 or Class 1 response containing data is sent from the slave. The

user can refer to [IEC-103 Master Session x Sector y] section in the configuration

file in order to configure each point:

# ASDU Database Function Point

# Type Index Code Index

START

1 0 128 16

1 16 128 17

1 32 160 18

1 48 176 19

1 64 192 20

1 80 128 21

END

Where the user should enter:

ASDU Type: ASDU type for the point

Function Type: Function type for the point

Point Index: Information number for the point

Database Index: The MVI46-103M database location where the value will be

copied. Special attention should be considered since the type of addressing will

depend on the ASDU type:

ASDU Type DB Addressing

1 Bit address with each point occupying 2 bits

2 Bit address with each point occupying 2 bits

3 Word address with each point occupying 4 words

4 Double-word address for the single float value

Page 12 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 13

Quick Start MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

ASDU Type DB Addressing

5 Byte address with each point occupying 12 bytes

9 Word address with each point occupying 9 words

For example, in order to configure the following points:

Time-tagged message point with information number 17 (teleprotection

active) and distance protection function (128). The value will be copied to bits

0 and 1 in word 1 (second word) in the module's database.

Measurands I point with information number 144 (measurands I) and

overcurrent protection function (160). The value will be copied to word 50 in

the module's database.

The following configuration information should be entered:

# ASDU Database Function Point

# Type Index Code Index

START

1 16 128 17

1 50 160 144

END

Every time the module responds with a Class 1 or Class 2 poll with these points,

the module will update its value to the database.

All the points configured in this section are sent from the slave to the master. The

protocol specification refers to this data flow as the Monitor Direction.

This step should be repeated for each sector.

Step 6 - Command Configuration (Control Direction)

The user might also configure the master to send commands to slaves. The IEC

60870-5-103 protocol specification refers to this data flow as Control Direction.

The commands include general commands, interrogation requests, and time

synchronization requests. In order to configure a command, the user should refer

to the [IEC-103 Master Commands] section:

[IEC-103 Master Commands]

# Enable Database Poll Session Sector Data Func Point Ovrd Ovrd

# Code Index Interval Index Index Type Code Index Flag Val

START

1 0 0 0 0 6 255 0 0 0

1 10 0 0 0 7 255 0 0 0

END

When sending a General Command, the user might associate the source data

with a register in the MVI46-103M database to be sent to the remote slave. The

following example will send 8 commands to the slave configured as Session

0/Sector 0. When using a General Command, the bit addressing should be used:

# Enable DB Poll Session Sector Data Func Point Ovrd Ovrd

# Code Index Interval Index Index Type Code Index Flag Val

START

ProSoft Technology, Inc. Page 13 of 187

September 12, 2006

Page 14

MVI46-103M ♦ SLC Platform Quick Start

IEC 60870-5-103 Master Communication Module

1 16000 0 0 0 20 128 16 0 0

1 16016 0 0 0 20 128 17 0 0

1 16032 0 0 0 20 128 18 0 0

1 16048 0 0 0 20 128 19 0 0

1 16064 0 0 0 20 128 23 0 0

1 16080 0 0 0 20 128 24 0 0

1 16096 0 0 0 20 128 25 0 0

1 16112 0 0 0 20 128 26 0 0

END

The user should refer to the device specification for the Point Index (Information

Number) listing available for control direction.

The module can also send a periodic General Interrogation command in order to

initialize and refresh the event-updated points in its database. The slave keeps a

list of all data subject to General Interrogation.

Step 7 - Transfer the Configuration (on page 37) from the Computer to

the module.

Page 14 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 15

Functional Overview MVI46-103M ♦ SLC Platform IEC 60870-5-103 Master Communication Module

3 Functional Overview

In This Chapter

General Concepts .................................................................. 15

Master Driver.......................................................................... 27

This chapter provides an overview of how the MVI46-103M module transfers

data using the 103M protocol. You should understand the important concepts in

this chapter before you begin installing and configuring the module.

The standards used to build the module are listed in the following table:

PUBLICATION TITLE

IEC 60870-5-103 Companion Standard for the informative interface of protection equipment.

IEC 60870-5-103

Annex A

IEC 60870-5-1 Transmission Frame Formats

IEC 60870-5-2 Link Transmission Procedures

IEC 60870-5-3 General Structure of Application Data

IEC 60870-5-4 Definition and Coding of Application Information Elements

IEC 60870-5-5 Basic Application Functions

Generic functions --Examples of constructing a directory

These documents should be obtained, reviewed, and understood in order to fully

appreciate the protocol implementation. Most of the complexity of the protocol is

hidden from the user and simplified in the application of the module. Detailed

questions of about the protocol can be answered by reading these documents. In

addition to calling our technical support group, there is also help available for the

protocol using the following mail list Web Site:

www.TriangleMicroWorks.com/iec870-5

(http://www.trianglemicroworks.com/iec870-5). Go to this site to join the mail list

and to review questions and answers from mail list users.

3.1 General Concepts

The following discussion explains several concepts that are important for

understanding the operation of the MVI46-103M module.

3.1.1 Module Power Up

On power up the module begins performing the following logical functions:

ProSoft Technology, Inc. Page 15 of 187

September 12, 2006

Page 16

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

1 Initialize hardware components

o Initialize SLC backplane driver

o Test and clear all RAM

o Initialize the serial communication ports

2 Read configuration for module from IEC103M.CFG file on Compact Flash

Disk

3 Initialize the databases and ports

4 Set up the serial communication interface for the debug/configuration port

After the module has received the configuration, the module will begin receiving

and transmitting messages with devices on the serial networks.

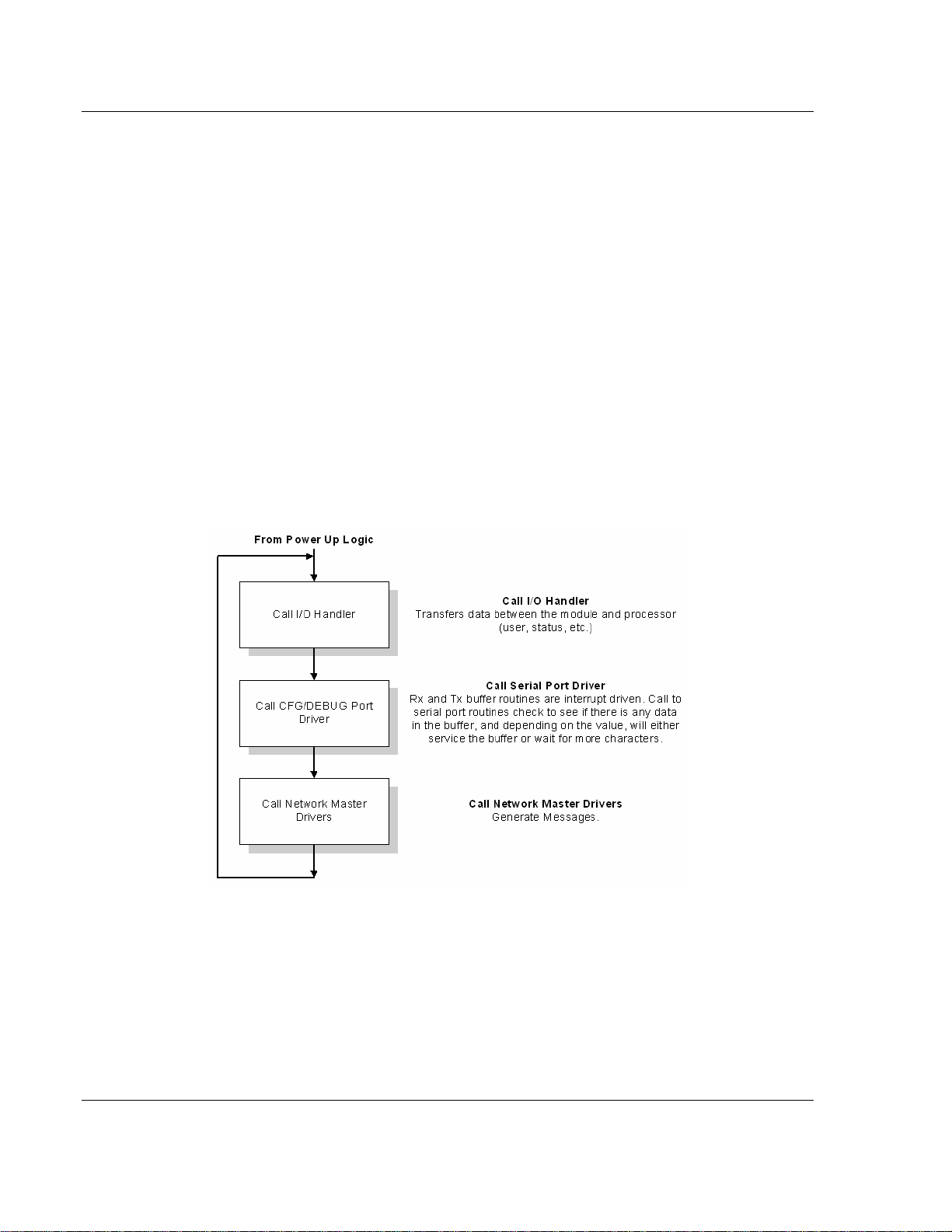

3.1.2 Main Logic Loop

Upon completing the power up configuration process, the module enters an

infinite loop that performs the following functions:

3.1.3 SLC Processor Not in Run

Whenever the module detects that the processor has gone out of the Run mode

(that is, Fault or PGM), the protocol ports can be shut down as prescribed in the

user configuration. When the processor is returned to a running state, the module

will resume communications on the network.

Page 16 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 17

Functional Overview MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

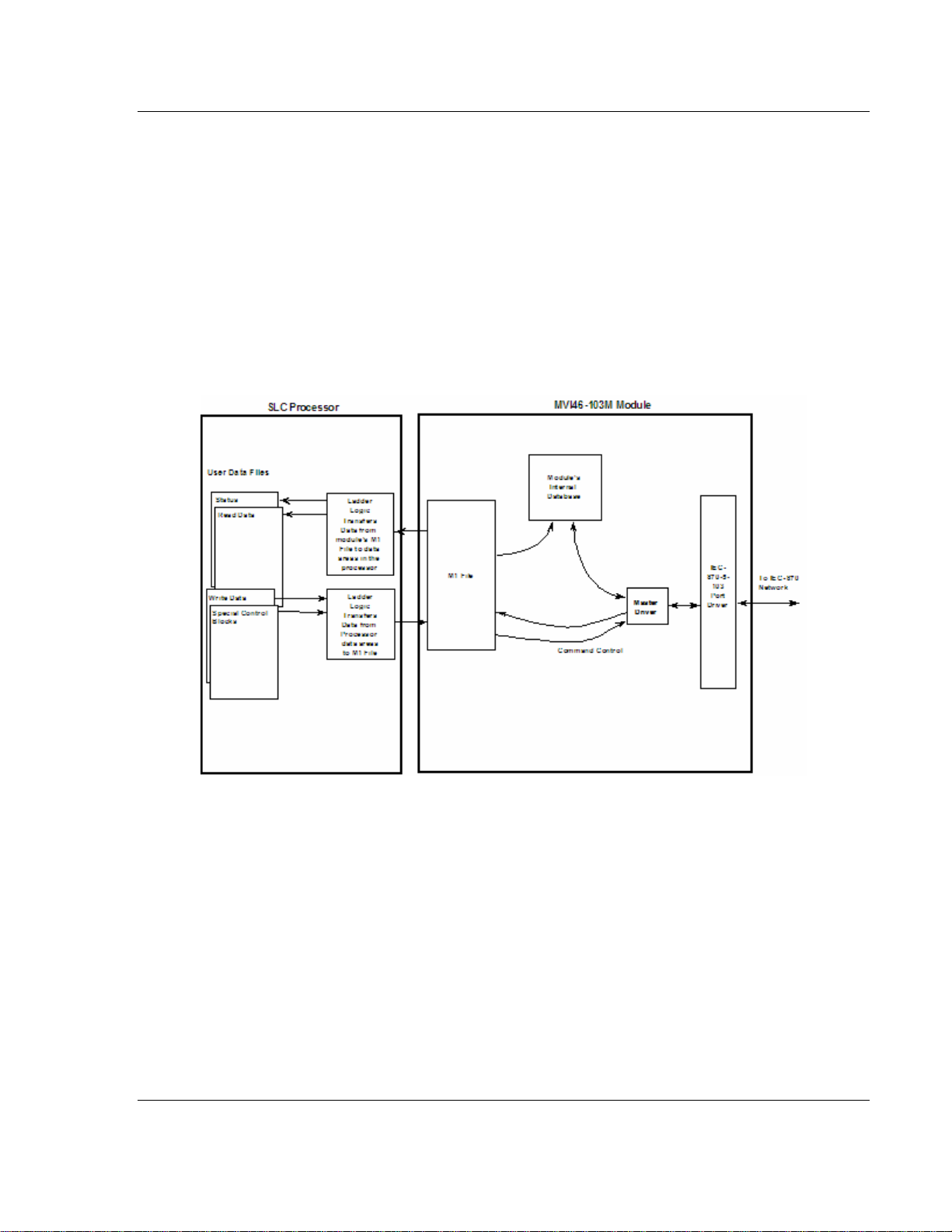

3.1.4 Backplane Data Transfer

The MVI46-103M module is unique in the way it utilizes the SLC backplane. All

data for the module is contained in the module's M1 file. Data is moved between

the module and the SLC processor across the backplane using the module's M1

file. The SLC scan rate and the communication load on the module determine the

update frequency of the M1 file. The COP instruction can be used to move data

between user data files and the module's M1 file.

The following illustration shows the data transfer method used to move data

between the SLC processor, the MVI46-103M module and the IEC 60870-5-103

network.

As shown in the previous diagram, all data transferred between the module and

the processor over the backplane is through the M1 file. Ladder logic must be

written in the SLC processor to interface the M-file data with data defined in the

user-defined data files in the SLC. All data used by the module is stored in its

internal database. Data contained in this database is constantly updated with the

M1 file data by the module and requires no SLC ladder logic to implement. The

user database resides in the M1 file at addresses 0 to 3999. Addresses above

3999 are used for special block control of the module.

3.1.5 Data Types and Mapping

When interfacing data in the processor to that of the IEC 60870-5-103 protocol, it

is important that the user understand the mapping of the data types to their

corresponding representation in the modules database. The table that follows

ProSoft Technology, Inc. Page 17 of 187

September 12, 2006

Page 18

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

lists the data types supported by the module and their associated storage

representation:

Type

ID

1

2

3

4

5

9

20

* The words should be swapped in the ladder logic.

Description Data Representation

Time-tagged messages with each data

point represented by two bits.

Time-tagged messages with relative time

with each point represented by two bits.

Measurands with quality descriptor. The

lower 3 bits of the values represented in

this data type contain status information.

The upper 13 bits of the value contained a

signed, 12-bit number. This data type will

return from 1 to 4 values. The number of

words received is dependant on the

information object number and the slave

device.

Time-tagged measurands with relative time

with the value in the packet represented by

a single floating point number.*

Identification data composed of 12

characters of data. Each point in defined of

this data type should reserve 12 bytes (6word addresses) in the database for the

data received.

Measurands with quality descriptor. The

lower 3 bits of the values represented in

this data type contain status information.

The upper 13 bits of the value contained a

signed, 12-bit number. This data type will

return from 1 to 9 values (some slaves

may return up to 16 values). The number

of words received is dependant on the

information object number and the slave

device.

General command to control a dual-point

object. Each command issued by the

module uses the values of two adjacent

bits in the database or an override value

specified by the user command.

Dual-bit status (7.2.6.5 with 00b

(0 decimal) = not used

01b (1 decimal) = Off,

10b (2 decimal) = On and

11b (3 decimal) = not used

Dual-bit status (7.2.6.5 with 00b

(0 decimal) = not used

01b (1 decimal) = Off,

10b (2 decimal) = On and

11b (3 decimal) = not used

Measurand with quality descriptor (7.2.6.8)

Bit 0: 0 = No overflow, 1 = Overflow

Bit 1: 0 = Valid, 1 = Invalid

Bit 2: Reserved

Bits 3-25: Value from –1..+1-2

Short floating-point number stored in IEEE

STD 754 format (Fraction, Exponent, Sign)

(7.2.6.20)

Byte data as defined in 7.2.6.2. First 8

bytes are characters 1 to 8 and last 4

bytes are manufacture bytes either

decimal (0-255) or as ASCII characters.

Measurand with quality descriptor (7.2.6.8)

Bit 0: 0 = No overflow, 1 = Overflow

Bit 1: 0 = Valid, 1 = Invalid

Bit 2: Reserved

Bits 3-25: Value from –1..+1-2

Dual-bit status (7.2.6.4 with 00b

(0 decimal) = not used

01b (1 decimal) = Off,

10b (2 decimal) = On and

11b (3 decimal) = not used

12

12

Page 18 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 19

Functional Overview MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

As shown in the table above, all bit types are addressed as bits in the modules

database.

Addressing the Data Types

The following table shows an example of how to address the data types in the

MVI46-103M:

Data Type Address Type Length Example

1 Bit 2 bits

2 Bit 2 bits

3 Word 4 words Address 50 refers to word 50, 51, 52, and 53.

4 Double-word 2 words

5 Bit 12 bits

9 Word 5 words

20 Bit 2 bits

Address 160 refers to first and second bits from

word 10.

Address 160 refers to first and second bits from

word 10.

Address 40 refers to two consecutive words

starting at word 80.

Address 180 refers to 12 consecutive bits

starting at the LSB of word 90.

Address 100 refers to 9 consecutive words

starting at word 100.

Address 160 refers to the first and second bits

from word 10.

Therefore, address 16000 represents bit zero in word 1000 of the module's

database. Short floating-point, 32-bit strings and integrated total values each

occupy a double-word space in the database. Therefore, short float database

address of 100 represents the two words, 200 and 201, in the modules database.

Identification objects are stored as byte values in the modules database.

Identification object address 1000 is stored in the module's database in word

addresses 500 to 505.

When setting the monitored data and commands, each point is defined by its

ASDU type, function code, and information number. Valid function codes are

listed in the following table:

Function Code Symbol Number

Distance Protection T(z) 128

Over-current Protection I>> 160

Transformer Differential

Protection

Line Differential Protection rIl 192

Global Function Type GLB 255

rIt 176

Refer to Protocol Interoperability Documentation for a full listing of the protocol

support offered by the module.

Ladder logic in the SLC can control the module or devices on the serial network

using special control blocks. The following table lists the special control codes

(block numbers) used by the module:

ProSoft Technology, Inc. Page 19 of 187

September 12, 2006

Page 20

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

Block Code Descriptions

9901 User Constructed Command

9902 Command Control Block (Add command to Command List Queue)

9903 Event Messages from Master port

9950 Command List Error data

9970 Set SLC time using module's time

9971 Set module's time using SLC time

9998 Warm Boot Request from SLC (Block contains no data)

9999 Cold Boot Request from SLC (Block contains no data)

Registers 4000 to 4099 report module status data. This data area should be

copied to a user file for use in the SLC. MVI46-103M Status Data Area (on page

77) contains a listing of the contents of this data area.

Registers 4200 to 4299 are utilized for the transfer of event messages from the

master driver to the SLC. These data are passed to the module when a value of

9903 is placed in register 4200. The ladder logic should copy the information

contained in the block of data and then set register 4200 to 0 to inform the

module that the messages have been accepted.

Registers 4100 to 4199 are used control of the module by the ladder logic. For

example,

if the processor places a value of 9998 in register 4100, the module will perform

a warm-boot operation. If the processor places a value of 9999 in this register,

the module will perform a cold-boot operation. In this application module, both of

these operations perform the same function. They exit the program and then

restart the program. Many of the program parameters set in the user

configuration must be set at program initialization and cannot be set while the

program is running. Therefore, both functions operate the same.

The command functions supported by the module and there data formats are

discussed in the following section.

3.1.6 Command Control Blocks

Block identification codes greater than 9900 are utilized to perform special

functions in the module when placed in the M-file's 4100 register. Each control

block recognized and used by the module is defined in the following sections:

User Constructed Command Block (9901)

Block identification code 9901 issues one or more user constructed commands.

When the module receives a block 9901 identification code, it will place the

included commands into the command queue.

Page 20 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 21

Functional Overview MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

Word Offset in

Block

4100 Block ID

4101 Command Count

4102 to 4111 Command #1

4112 to 4121 Command #2

4122 to 4131 Command #3

4132 to 4141 Command #4

4142 to 4151 Command #5

4152 to 4161 Command #6

4161 to 4171 Command #7

4172 to 4181 Command #8

Data Field(s) Description

This field contains the block identification code of 9901

for the block.

This field defines the number of user commands

contained in the block. The valid range for the field is 1

to 8.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

Data required to build the user defined command in the

command queue.

The following fields are used for each 10-word record in the command list:

Word Offset Definitions Description

0 Database Index Address in module to associate with the command.

1 Session Index

2 Sector Index Sector index for session as defined in the module.

3 Data Type ASDU data type associated with the command.

4 Function Code Function Code for the command.

5

6 Override Flag Override flag for general command.

7 Override Value Override value for general command.

8 Reserved Reserved for future use.

9 Reserved Reserved for future use.

Point Index *

*Information

Number

Session index defined in the module to associate with

the command.

Information object address for the point on which the

command operates.

Refer to the command list section of this documentation for a detailed definition

of the fields contained in this block. They are the same as those used in

constructed the commands in the command list.

There is no response block built by the module to send back to the processor

after the block is processed. The module will set register 4100 to a value of zero

after the commands have been processed. The commands are placed in the

command queue and issued at a high priority.

ProSoft Technology, Inc. Page 21 of 187

September 12, 2006

Page 22

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

This block and block 9902 should be used when controlling double-point data

points in remote units using general commands. This provides complete control

of the slave devices under ladder logic control. Alternatively, the slaves can be

controlled by changing data in the database and having the data be transferred

using pre-constructed commands in the user's command list. Some points only

accept value of on for control (that is, LED reset or activate characteristic). For

these points, block 9901 and 9902 should only be utilized.

Command Control Block (9902)

The block 9902 identification code is used by the processor to send a list of

commands to be placed in the command queue from the user configured

command list. Commands placed in the queue with this method need not have

their enable bit set in the command list.

Word Offset

in Block

4100 Block ID

4101 Command count

4102 to 4161

Data Field(s) Description

This field contains the value of 9902 identifying the enable

command to the module.

This field contains the number of commands to enable in the

command list. Valid values for this field are 1 to 60.

Command

Numbers to

enable

These 60 words of data contain the command numbers in

the command list to enable. The commands in the list will be

placed in the command queue for immediate processing by

the module. The first command in the list has an index of 0.

There is no response to this block by the module. The module will place the

selected commands into the command queue and set register 4100 to a value of

0. If the command references a unit that is not defined, the command will not be

placed in the command queue. Normal processing of the command list will

continue after the commands specified in this block are processed.

For digital output control, the use of block 9901 and 9902 is preferred to the use

of the command list. The exact state of the output can be specified in the

command list and then the command can be enabled through the use of block

9902. When the user wishes to execute this command (knowing the state of the

command), can enable the command with the block 9902 request.

Event Message Block (9903)

Block identification code 9903 sends event messages received on the master

port to the processor.

Note: Events are recognized when using a COT=SPONTANEOUS.

Page 22 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 23

Functional Overview MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

Block Format for Read

Word Offset in

Block

4200 Block ID

4201 Event Count

4202-4211 Event 1 Event message

4212-4221 Event 2 Event message

4222-4231 Event 3 Event message

4232-4241 Event 4 Event message

4242-4251 Event 5 Event message

4252-4261 Event 6 Event message

4262-4271 Event 7 Event message

4272-4281 Event 8 Event message

4282-4291 Event 9 Event message

Data Field(s) Description

This field contains the block identification code of 9903 for the

block.

This field contains the number of events present in the block.

Values of 1 to 20 are valid.

The format of each 10-word data region in the block is as follows:

Word Offset Definitions Description

0

1 ASDU Type

2

3 Fault Number

4 Sec/mSec

5 Hr/Min.

6 Invalid/DST

7 Relative Time

Session Index/Sector

Index

Function Code/Point

Index*

This field contains the session and sector indices

used to define the controlled unit in the module from

which the event was generated. The MSB contains

the session index and the LSB contains the sector

index.

This field contains the ASDU type code for the data

contained in the message.

This field contains the function code and the point

index associated with the event message. The MSB

contains the function code and the LSB contains the

point index.

This is the fault number for the event if applicable.

Only valid for ASDU types 2 and 4.

This word contains the seconds and millisecond

values with a range of 0 to 59999 time at which the

message was generated by the slave device.

This word contains the hour and minutes the

message was generated by the slave. The MSB

contains the hour and the LSB contains the minute

value.

This word contains two bits that relate to the time

value recorded in the slave device for the message.

Bit 0 corresponds to the validity of the time (0=valid,

1=invalid) and Bit 1 defines if daylight savings time is

used in the time (0=no, 1=yes).

This field contains the relative time value if

applicable to the object. Only valid for ASDU types 2

and 4.

ProSoft Technology, Inc. Page 23 of 187

September 12, 2006

Page 24

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

Word Offset Definitions Description

8 to 9 Value

*

Point Index refers to the Data Information Number

This double-word value contains the value for the

point index/function code in the event message. For

ASDU types 1 and 2, this value is only 2 bits wide.

For ASDU type 4, this double-word value contains

the floating-point number (short circuit location).

In order for this feature to be activated, the event pass-through parameter must

be set. When a master driver receives an event message from a controlled

station, it will build an event message corresponding to the event in the event

buffer of the module. This buffer is then sent to the processor when any

messages are present. Therefore, these blocks are sent to the processor on a

high priority. After the block is sent, the event message is removed from the

module's event buffer. The ladder logic should set register 4200 to a value of

zero after processing the event message data.

If too many events are present in the buffer (>200), the module will set the event

message overflow flag in the error/status data area of the normal read data

block. There is no response block to be received by the module from the

processor.

Command List Error Data Block (9950)

Block 9950 identification code requests the Command List Error Table from the

module for the 1000 user configurable commands. The format for the block is

shown in the following table:

Word Offset

in Block

4100 Block ID

4101

4102

Data Field(s) Description

This field contains the value of 9950 identifying the block

type to the module.

Number of

Commands to

report

Start Index of

First Command

This field contains the number of commands to report in the

response message. The value has a range of 1 to 60.

This parameter sets the index in the command list where to

start. The first command in the list has a value of 0. The last

index in the list has a value of MaxCommands –1.

The module will respond to a valid request with a block containing the requested

error information. The format for the block is shown in the following table:

Word Offset

in Block

4100 Done Flag

4101 Block ID

4102

Data Field(s) Description

A value of zero will be placed in this register to indicate the

function is complete and the data is ready.

This field contains the value of 9950 identifying the block

type to the PLC.

Number of

Commands

reported

This field contains the number of commands contained in

the block that must be processed by the PLC. This field will

have a value of 1 to 60.

Page 24 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 25

Functional Overview MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

Word Offset

Data Field(s) Description

in Block

4103

Start Index of

First Command

This field contains the index in the command list for the first

value in the file. This field will have a value of 0 to

MaxCommands–1.

4104 to 4163

Command List

Errors

Each word of this area contains the last error value recorded

for the command. The command index of the first value

(offset 4) is specified in word 3 of the block. The number of

valid command errors in the block is set in word 2 of the

block. Refer to the command error list to interpret the error

codes reported.

Set SLC Time Block (9970)

Block 9970 identification code requests the module's date and time. Use this data

to set the PLC clock.

Word Offset in

Block

4100 Block ID

Data Field(s) Description

This field contains the value of 9970 identifying the block

type to the module.

The module will respond to a valid block 9970 request with a block containing the

requested date and time. The format for the block is shown in the following table:

Word Offset in

Block

4100 Done Flag

4101 Block ID

4102 Year

4103 Month

4104 Day

4105 Hour

4106 Minute

4107 Seconds

4108 Milliseconds

Data Field(s) Description

A value of zero will be placed in this register to indicate the

function is complete and the data is ready.

This field contains the identification code of 9970 for the

block block.

This field contains the four-digit year to be used with the

new time value.

This field contains the month value for the new time. Valid

entry for this field is in the range of 1 to 12.

This field contains the day value for the new time. Valid

entry for this field is in the range of 1 to 31.

This field contains the hour value for the new time. Valid

entry for this field is in the range of 0 to 23.

This field contains the minute value for the new time. Valid

entry for this field is in the range of 0 to 59.

This field contains the second value for the new time. Valid

entry for this field is in the range of 0 to 59.

This field contains the millisecond value for the new time.

Valid entry for this field is in the range of 0 to 999.

Set Module Time Block (9971)

Block identification code 9971 passes the clock time in the SLC to the module.

The date and time provided will be used to set the module's clock.

ProSoft Technology, Inc. Page 25 of 187

September 12, 2006

Page 26

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

Word Offset in

Block

4100 Block ID

4101 Year

4102 Month

4103 Day

4104 Hour

4105 Minute

4106 Seconds

4107 Milliseconds

Data Field(s) Description

This field contains the block identification code of 9971 for

the block.

This field contains the four-digit year to be used with the

new time value.

This field contains the month value for the new time. Valid

entry for this field is in the range of 1 to 12.

This field contains the day value for the new time. Valid

entry for this field is in the range of 1 to 31.

This field contains the hour value for the new time.Valid

entry for this field is in the range of 0 to 23.

This field contains the minute value for the new time. Valid

entry for this field is in the range of 0 to 59.

This field contains the second value for the new time. Valid

entry for this field is in the range of 0 to 59.

This field contains the millisecond value for the new time.

Valid entry for this field is in the range of 0 to 999.

The module does not send a response block to the processor after receiving this

block. The module will set register 4100 to zero after processing the data.

Warm Boot Block (9998)

Block 9998 performs a warm-boot operation on the module. The format of the

block constructed by the processor is as follows:

Offset Description Length

4100 9998 1

In this version of the module, the warm and cold boot processes perform the

same operation as many of the variables that must be initialized are fixed when

the module first boots and cannot be changed after the application starts.

Cold Boot Block (9999)

Block 9999 performs a cold-boot operation on the module. The format of the

block constructed by the processor is as follows:

Offset Description Length

4100 9999 1

In this version of the module, the warm and cold boot processes perform the

same operation as many of the variables that must be initialized are fixed when

the module first boots and cannot be changed after the application starts.

Page 26 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 27

Functional Overview MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

3.2 Master Driver

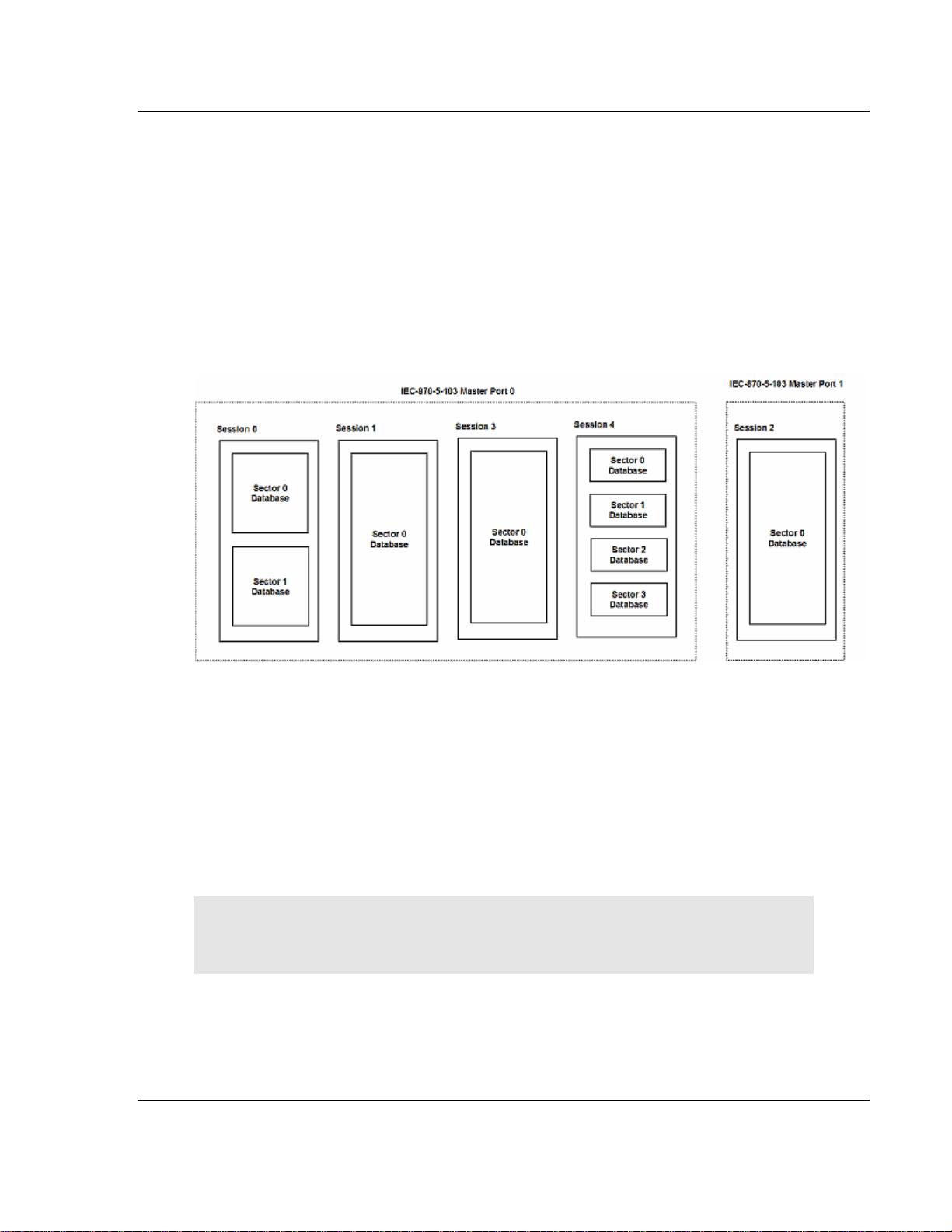

The master driver supported on each application port of the module emulates an

IEC 60870-5-103 Master device. Configuration of each port is independent and

should be connected to different serial networks.

Each port on the module communicates with one or more controlled stations on

what are referred to as sessions. A session represents a controlled device with a

unique data link layer address. Each session (controlled device) contains one or

more data sets (sectors) that are defined by the vendor of the device. The

following illustration shows these relationships.

Port 0 on the module communicates with 4 sessions (0, 1, 3 and 4) each of which

has their own data set(s). Session 1 only has one sector (all data for device

contained in a single database). This sector is addressed by the master using the

Common address of ASDU value set for the sector in the configuration file.

Session 0 contains two sectors each with their own unique Common address of

ASDU value to identify the sector.

Port 1 is connected to one device on the network. This device is defined in the

Session 2 section of the configuration file. In this example, all data of the device

is stored in a single sector.

Note: The IEC 60870-5-103 specification only supports the unbalanced mode.

No support is given in the protocol for the balanced mode and the module

does not support this mode.

The module supports two application ports. Thirty-two sessions can be defined

on the module with each session being assigned to an application port. Within

each session, up to five sectors can be defined. This system permits a very

flexible assignment of resources in the module. The definition of the data

ProSoft Technology, Inc. Page 27 of 187

September 12, 2006

Page 28

MVI46-103M ♦ SLC Platform Functional Overview

IEC 60870-5-103 Master Communication Module

associated with each sector in the system is defined by the user in the

configuration file.

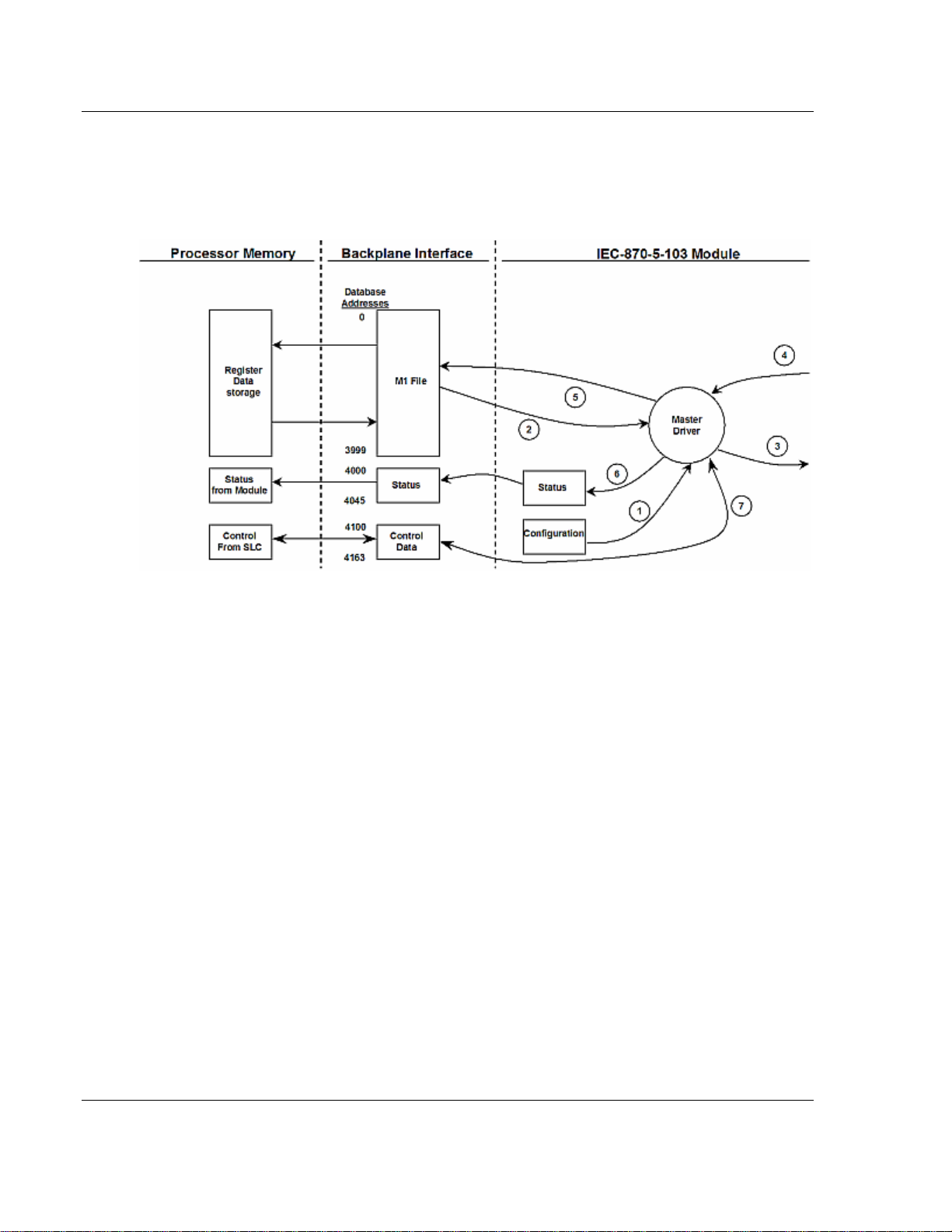

The following diagram illustrates the functionality of the master driver:

1 The master driver is configured as specified by the IEC103M.CFG file

2 The master will construct control commands using the data in the database

3 The master will send these commands and class polls out on the serial

network

4 Response messages or spontaneous messages generated by controlled

devices on the serial network are received by the master driver

5 Monitor data received by the master is passed to the module's database and

passed to the processor

6 Additionally, status data for the module is passed to the processor

Page 28 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 29

Module Configuration MVI46-103M ♦ SLC Platform IEC 60870-5-103 Master Communication Module

4 Module Configuration

In This Chapter

Installing and Configuring the Module .................................... 29

Module Data........................................................................... 31

Configuration File ................................................................... 31

Uploading and Downloading the Configuration File ............... 35

This section contains the setup procedure, data, and ladder logic for successful

application of the MVI46-103M module. Each step in the setup procedure is

defined in order to simplify the use of the module.

4.1 Installing and Configuring the Module

This chapter describes how to install and configure the module to work with your

application. The configuration process consists of the following steps.

1 Use RSLogix to identify the module to the processor and add the module to a

project.

NOTE: The RSLogix software must be in "offline" mode to add the module to a

project.

2 Modify the module's configuration files to meet the needs of your application,

and copy the updated configuration to the module. Example configuration

files are provided on the CD-ROM.

3 Modify the example ladder logic to meet the needs of your application, and

copy the ladder logic to the processor. Example ladder logic files are provided

on the CD-ROM.

Note: If you are installing this module in an existing application, you can copy

the necessary elements from the example ladder logic into your application.

The rest of this chapter describes these steps in more detail.

ProSoft Technology, Inc. Page 29 of 187

September 12, 2006

Page 30

MVI46-103M ♦ SLC Platform Module Configuration

IEC 60870-5-103 Master Communication Module

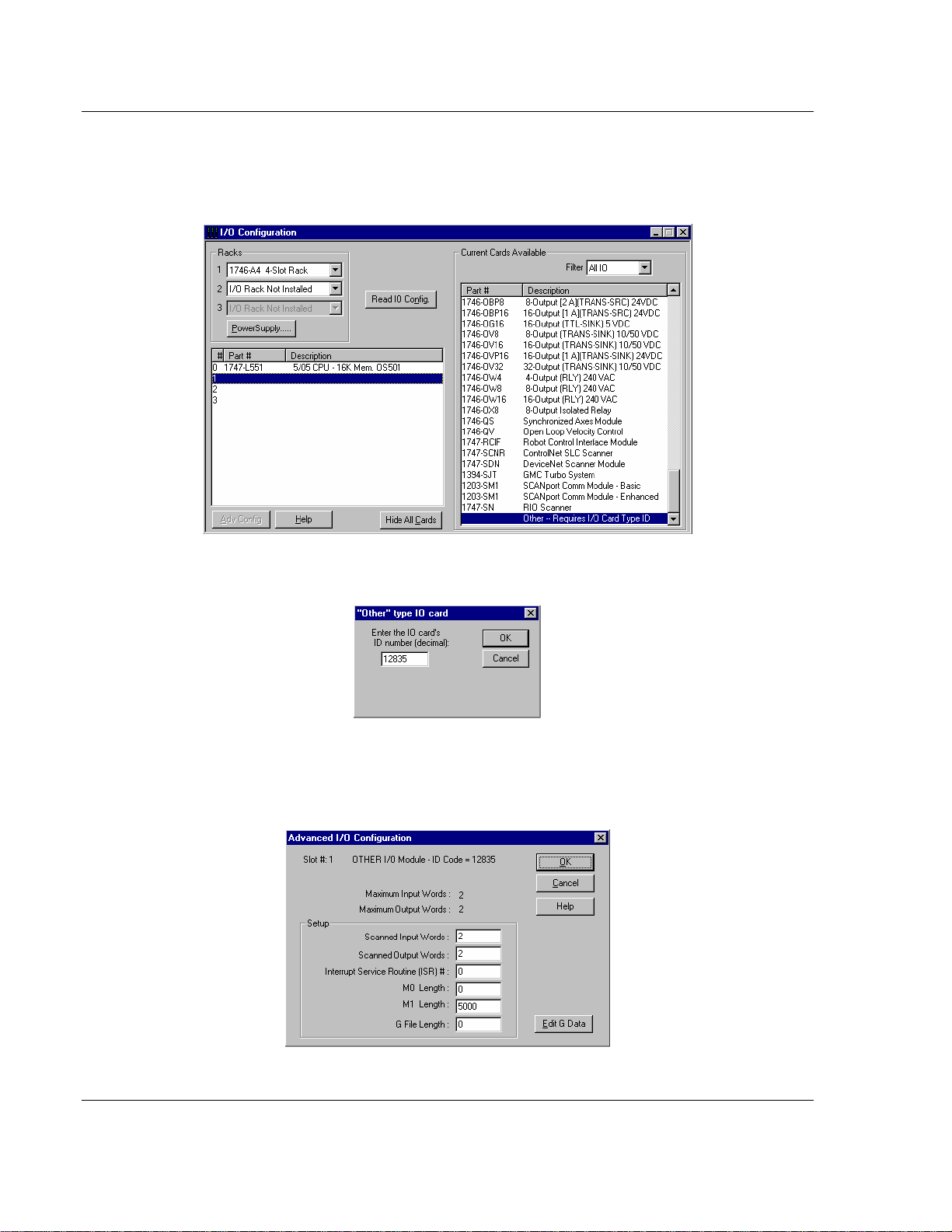

The first step in installing and configuring the module is to define the module to

the system. Select the I/O Configuration option from the program screen. This

displays the following dialog box:

Select the Other module from the list. This action opens the following dialog box.

Enter the module I/O card ID number as 12835, and then select the OK

command button. Double-click the mouse on the module just added to the rack.

Fill in the dialog box presented as shown in the following screen shot:

Page 30 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 31

Module Configuration MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

Select the OK command button to apply these settings to the module. Then,

close the I/O Configuration dialog box.

The next step in the module's setup is to define the user defined data areas to

hold the status and read and write database areas. Edit the IEC103M.CFG file

now for the application to implement. Use any text editor to set the values in the

file. You must retain the file name, IEC103M.CFG.

The last step in the module setup is to add the ladder logic. If the example ladder

logic is used, adjust the ladder to fit the application. When the ladder example is

not used, copy the example ladder logic to your application and alter as

necessary.

The module is now set up and ready to be used with your application. Insert the

module in the rack and attach the serial communication cables. Download the

IEC103M.CFG file to the module. Download the new application to the controller

and place the processor in run mode. If all the configuration parameters are set

correctly and the module is attached to a network, the module's Application LED

(APP LED) should remain off and the backplane activity LED (BP ACT) should

blink very rapidly. Refer to the Troubleshooting section if you encounter errors.

Attach a computer or terminal to Debug/Configuration port on the module and

check the status of the module using the resident debugger in the module.

4.2 Module Data

All data related to the MVI46-103M module is stored in a user defined data files

and the module's M1 file. Files should be defined for each data type to be used

with the module. Additionally, a file should be defined to hold the module status

data. The status data should be copied from the M1 file and placed in the

assigned status file. Input (monitor) data should be copied from the user file to

the M1 file and output (command) data should be copied from the user files to

the M1 file.

4.3 Configuration File

The module requires a configuration file (IEC103M.CFG) to operate. This

configuration file configures the module's master drivers, sets up the databases

for the controlled devices and establishes a command list. Each parameter in the

file must be set carefully in order for the application to be implemented

successfully.

The configuration file contains at least the following seven sections with topic

header names enclosed in [ ] characters.:

[Backplane Configuration] Backplane tran sfer p arameter section

[IEC-870-5-103 Master] General Configuration for driver

[IEC-870-5-103 Master Port 0] Configuration for first application port

ProSoft Technology, Inc. Page 31 of 187

September 12, 2006

Page 32

MVI46-103M ♦ SLC Platform Module Configuration

IEC 60870-5-103 Master Communication Module

[Backplane Configuration] Backplane tran sfer p arameter section

[IEC-870-5-103 Master Port 1] Configuration for second application port

[IEC-103 Master Session x] Definition for each control unit

[IEC-103 Master Session x Sector y] Definition for each sector in each controlled unit

[IEC-103 Master Commands] Command list to control slave units

A set of parameters follows each each section header. Use unique labels under

each section to specify a parameter. Each label in the file must be entered

exactly as shown in the file for the parameter to be identified by the program. If

the module is not considering a parameter, check the label for the data item.

Each parameter's value is separated from the label with the ':' character. This

character is used by the program to delimit the position in the data record where

to start reading data. All data for a parameter must follow the ':' character. There

must be at least one space character between the end of the parameter value

and the following text. An example of a parameter entry is given below:

Baud Rate : 19200 #Baud rate for master port

The parameter label is "Baud Rate" and the parameter value is 19200. The

characters after a numeric parameter value are ignored and can be used to

document the configuration file.

Any record that begins with the '#' character is considered to be a comment.

Comments can be placed anywhere in the file so long as the '#' character is the

first column of the line. Liberal use of comments within the file can ease the use

and interpretation of the data in the file.

Use any text editor to alter the supplied IEC103M.CFG file for the specific

application. You must enter each parameter correctly for successful application

of the module. MVI46-103M Configuration Data Definition (on page 82)

contains a complete listing and definition of all parameters utilized by the module.

The session sections of the configuration file are determined by the number of

sessions set in the configuration file. The sessions are referenced by a zero

based index value. For example, if the module is configured for four sessions, the

configuration file should contain sections for sessions 0 to 3 (that is, [IEC-103

Master Session 0] to [IEC-103 Master Session 3]. Each of these sections will

define the characteristics of the specific controlled device to be interfaced. Within

each session definition, is a parameter that specifies the number of sectors for

the session. For each sector defined for a session, there must exist a [IEC-103

Master Session x Sector y] section. Where the x value represents the session

index and the y value represents sector index. For example if session 0 contains

1 sector, there must be a section with the following name in the configuration file:

[IEC-103 Master Session 0 Sector 0]. The specific sector parameter set and

database is defined in this section.

The last section of the configuration file is the command list definition ([IEC-103

Master Commands]). This section can contain up to 1000 user defined

commands to be executed by the module and sent to the controlled devices.

There is no need to place Class 1 or Class 2 polls in the this list for the controlled

Page 32 of 187 ProSoft Technology, Inc.

September 12, 2006

Page 33

Module Configuration MVI46-103M ♦ SLC Platform

IEC 60870-5-103 Master Communication Module

devices as the master driver for each port will execute these automatically when

the port is idle. In order for the port to be idle, make sure that there is idle time

available and that the commands do not constantly utilize the ports. The

command list section starts with a reserved label START and ends with the label

END. Each row in the file corresponds to an individual command with the first

character position in each row left blank (white space). The contents of each

command record is outlined in the following table:

Col Field Description

1

2

3

4 Session

5 Sector

Enable

Code

Database

Index

Poll

Interval

This field determines when the command will be executed according to the

following codes:

0=Command is disabled and will only execute if enabled from PLC

processor

1=Command will execute no more frequently than the time set in the Poll

interval

2=Command will execute when the last value read in the database differs

from the current value

This field specifies the location in the module's internal database to

associate with the command. The data type used in the command

determines addressing of the index as follows:

Type Description DB Index type

0 Special command *Word address

6 Time synchronization *Word address

7 General interrogation *Word address

20

*Word address = Value only used to signal when to send event (Enable

Code = 2)

This parameter is used if the Enable Code field is set to a value of 1. It

sets the minimum number of seconds to delay between successive

execution of the command.

This parameter is utilized to associate the command with one of the

sessions defined for the module.

This parameter associates the command with the proper sector of the

selected session.

General command (2

bit control)

Bit address

ProSoft Technology, Inc. Page 33 of 187

September 12, 2006

Page 34

MVI46-103M ♦ SLC Platform Module Configuration

IEC 60870-5-103 Master Communication Module

Col Field Description

1

6 Data Type

7

8

9

10

* The Point Index is the Data Information Number.

Enable

Code

Function

Code

Point

Index

Override

Flag

Override

Value

This field determines when the command will be executed according to the

following codes:

0=Command is disabled and will only execute if enabled from PLC

processor

1=Command will execute no more frequently than the time set in the Poll

interval

2=Command will execute when the last value read in the database differs

from the current value

This parameter sets the ASDU data type to be used with the message.

The codes specified are those defined for the IEC-870-5-103 protocol. The

following is a listing of command control data types supported in this

module:

Type Description

0 Special command

6 Time synchronization

7 General interrogation

20 General command (2 bit control)

The type 0 is not defined in the protocol specification but is added to the

module application to perform special commands. The command to be

issued is determined by the value of the function field. If the function is set

to 1, the module will issue a reset process command to the session

specified. If the function is set to 2, the module will a class 2 poll to the

selected session.

This parameter specifies the function code as specified in the protocol

specification except when Data Type code 0 is used. For the general

commands, this field is used in conjunction with the Point Index to

determine the point to control in the remote slave device. For the special

commands, a value of 1 performs a reset process and 2 to issue a class 2

poll.

This parameter along with the Function Code determines the point to

control in the remote device when the general command is utilized. For all

other commands this field is ignored.

This field is used with general commands to determine if the override or

database value should be used with the command. If the flag is set to 0,

the value in the module's database will be sent when the command is

issued. If the flag is set to 1 (or non-zero value), the value set in the

Override Value will be sent with the command. When the override flag and

value are utilized, the Enable Code 2 and Database Index can be used to

trigger the execution of the command.

This parameter specifies the override value to use with the command if the

Override Flag is set. This value should have one of the following values:

1=Off and 2=On. Other values maybe valid for certain controlled

As an alternative to using a command list, blocks with an identification code of

9901 can be used to issue commands from the ladder logic.

Page 34 of 187 ProSoft Technology, Inc.

September 12, 2006

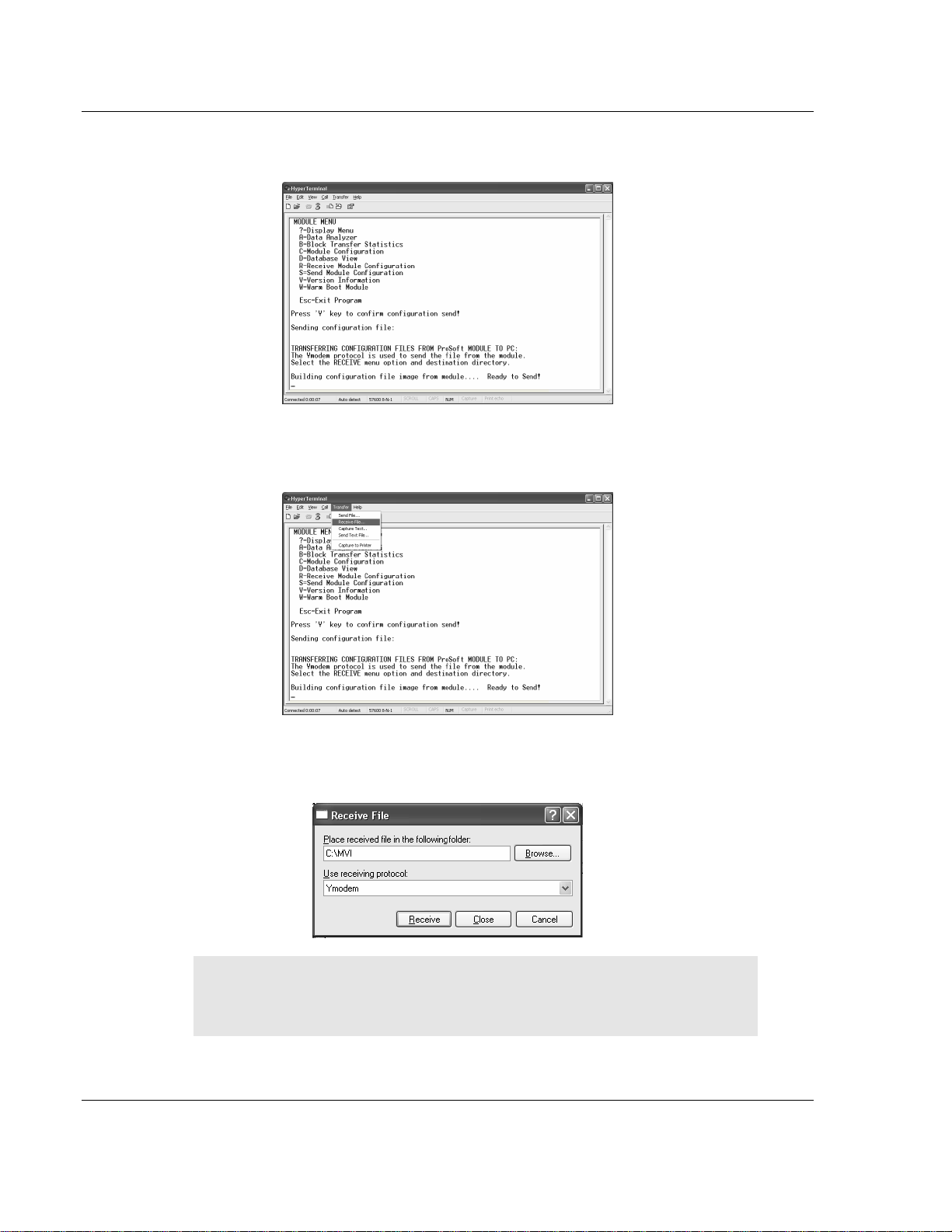

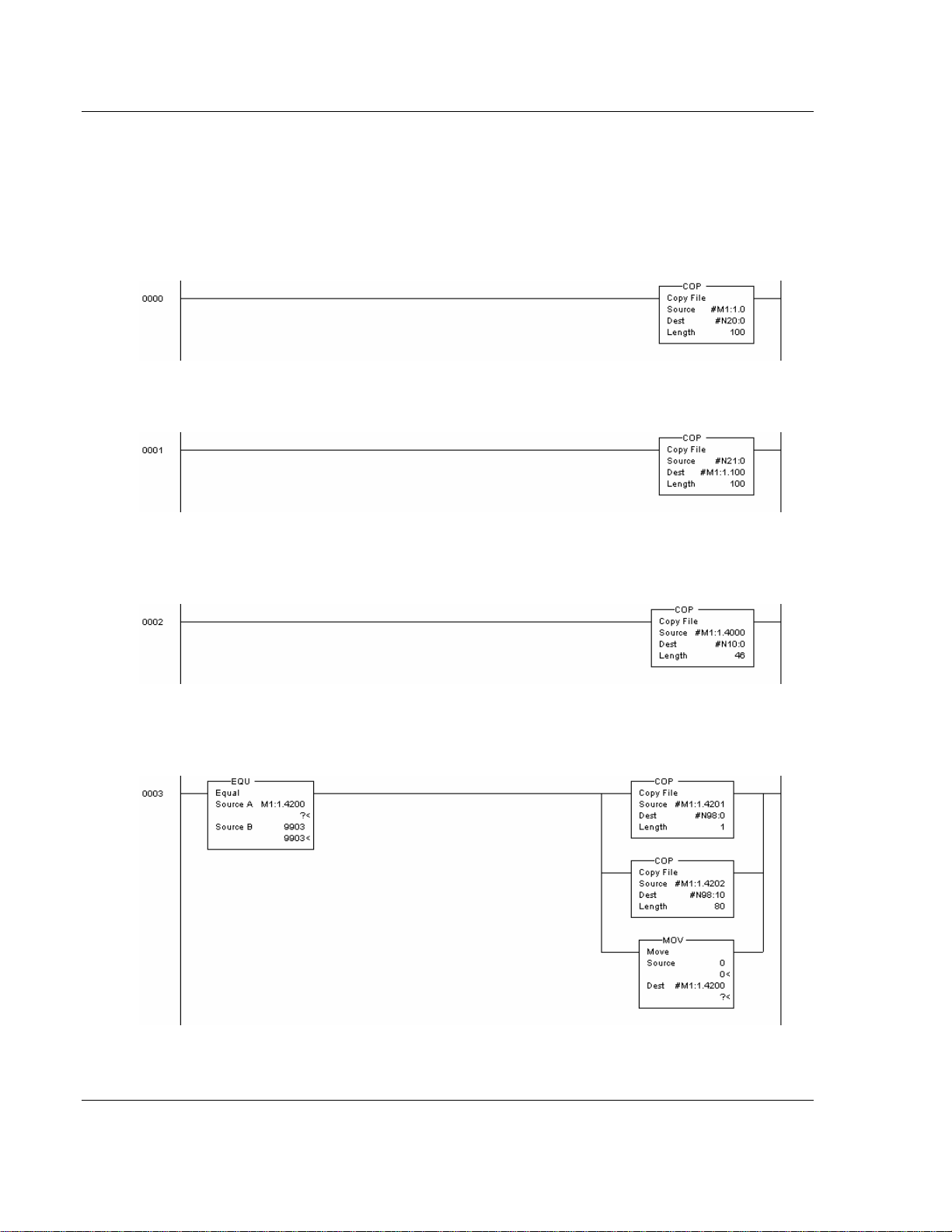

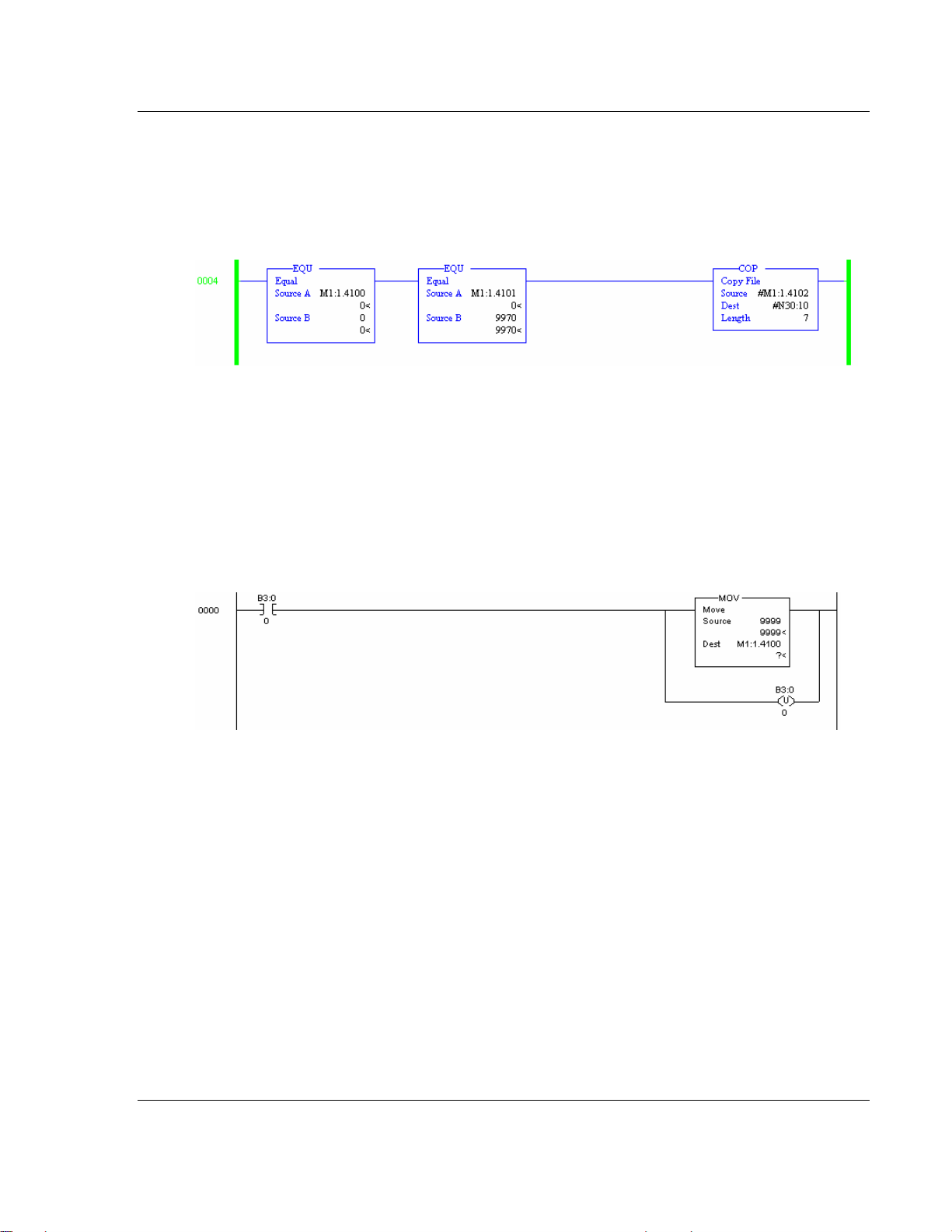

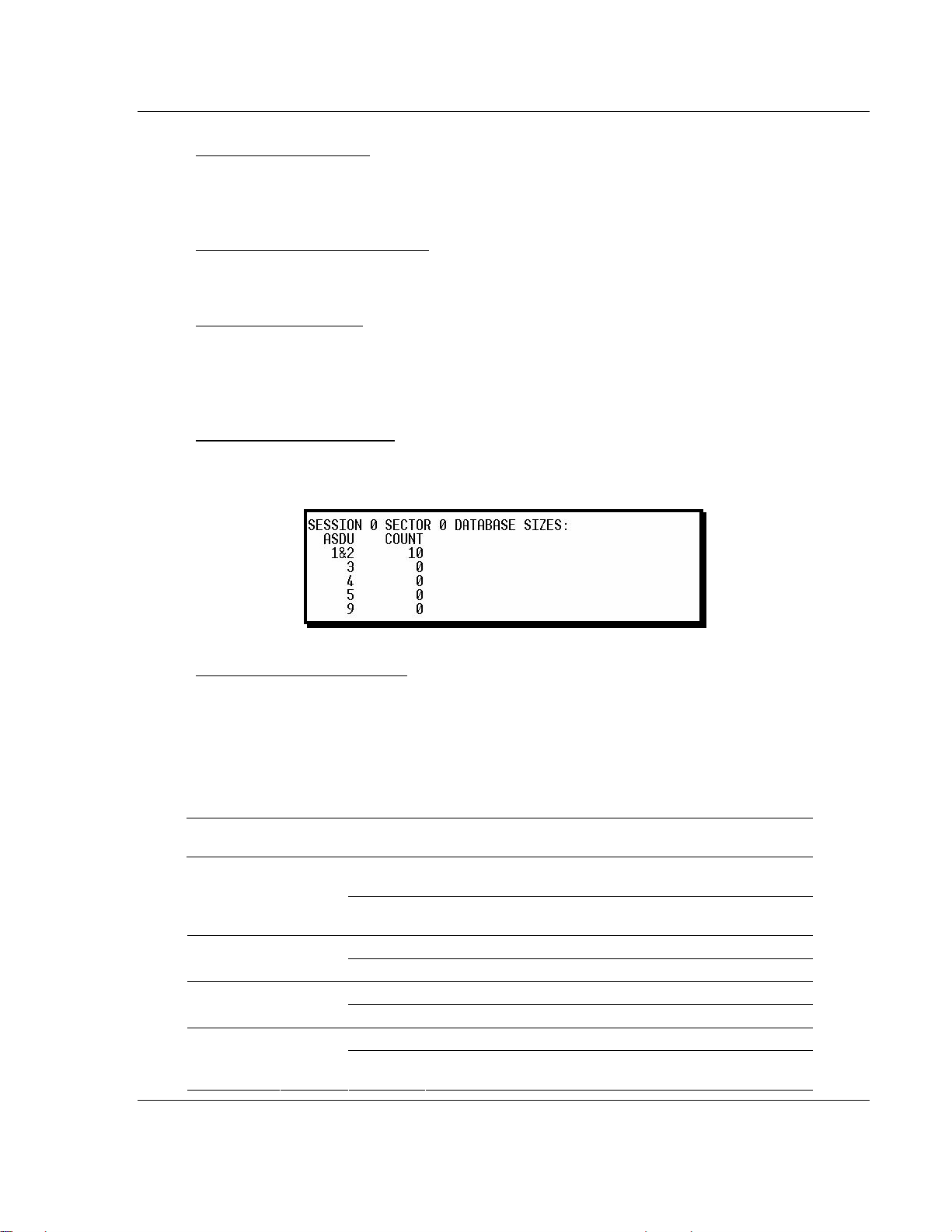

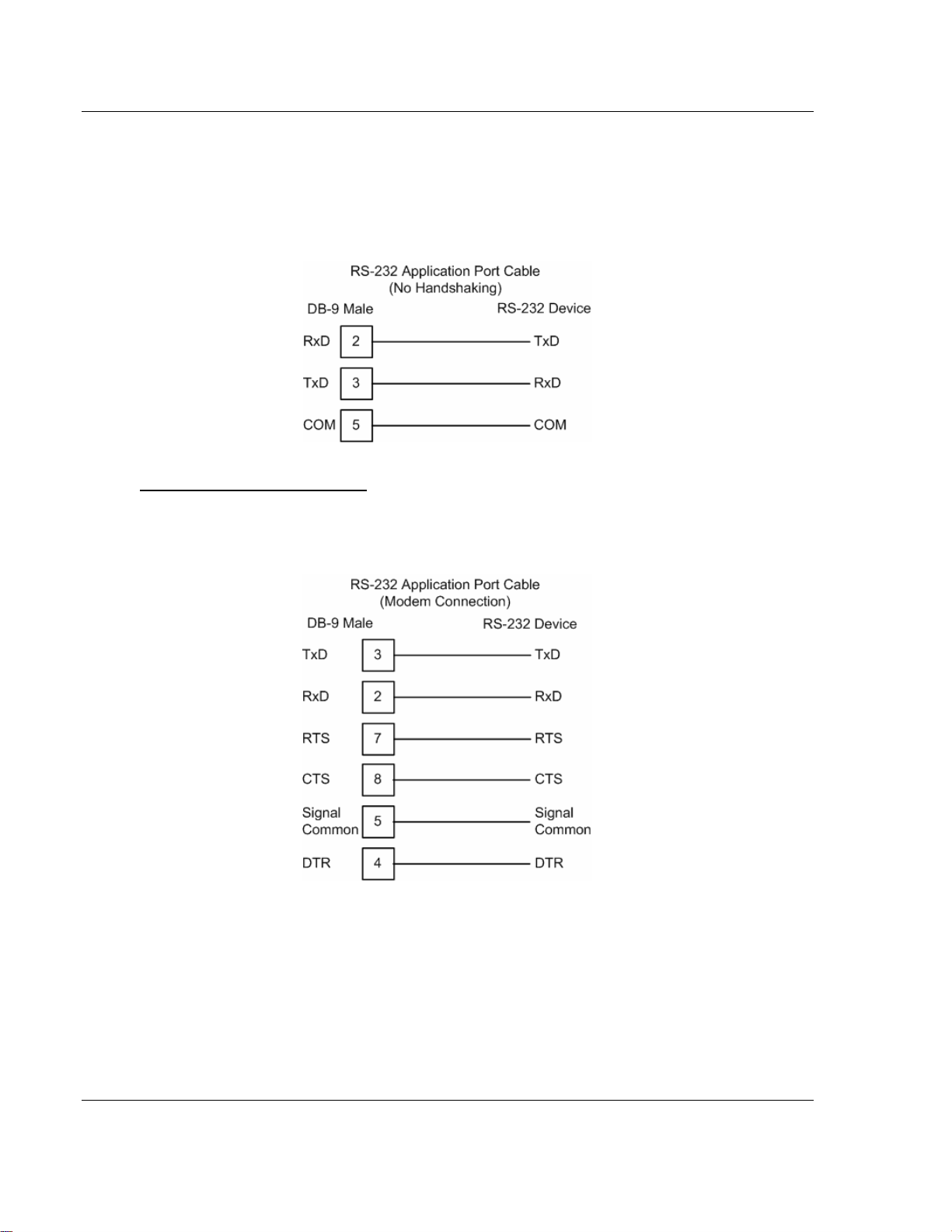

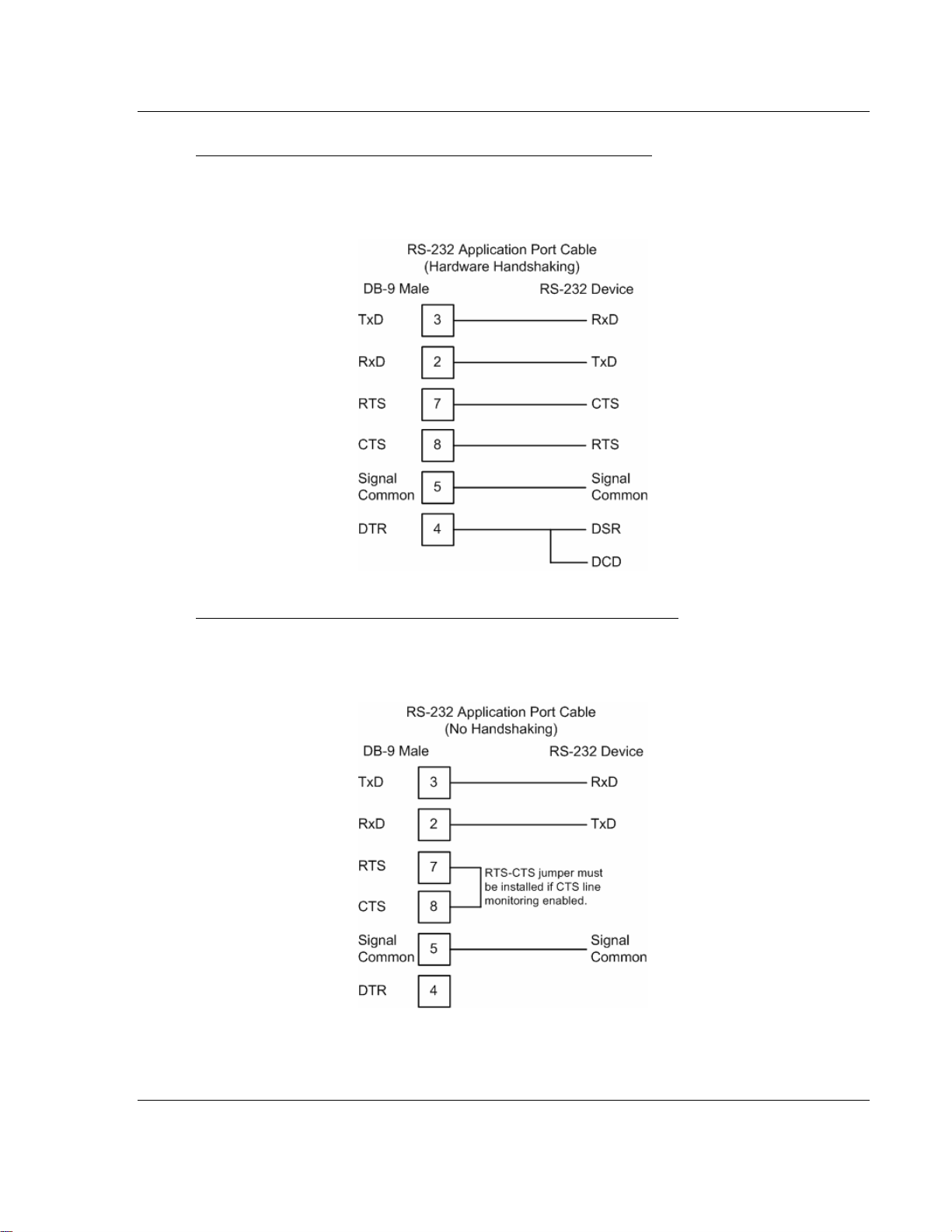

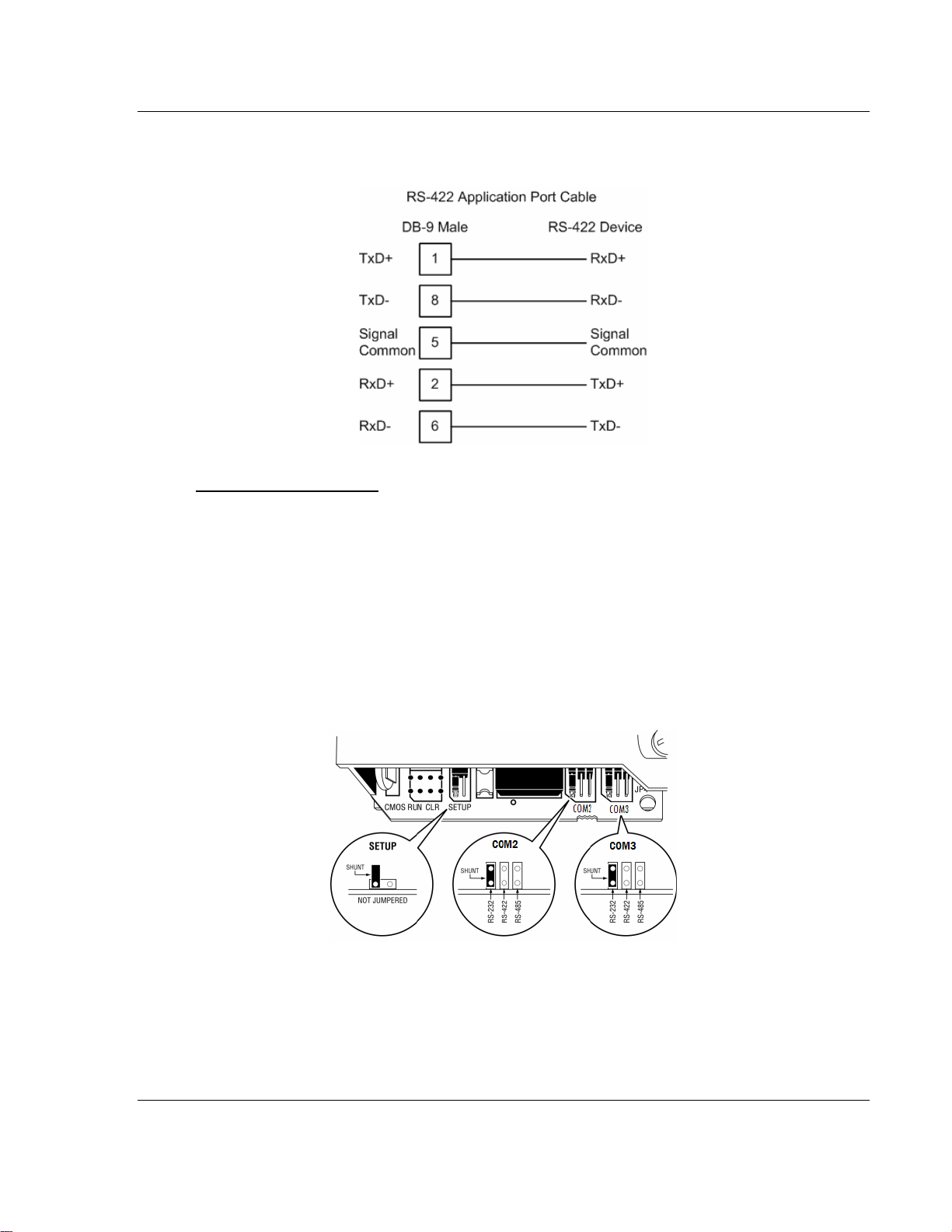

Page 35