Pitney Bowes DI350 Operator Guide

DI350 OfficeRightTM

Inserting System

Operator Guide

SV40190-OG Rev. A

Contents

NOTE: This equipment has been tested and found to comply with the limits for a Class A device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with the instruction manual, may cause interference to radio communications. Operation of this equipment in a residential area is likely to cause interference, in which case the user, at their own expense, will be required to correct the interference.

Trademark Notice

OfficeRight™ and EZ Seal® are trademarks of Pitney Bowes Inc.

First Edition, September 2002 ©2002 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion or stored in a retrieval system of any type or transmitted by any means, electronically or mechanically, without the express written permission of Pitney Bowes.

We have made every reasonable effort to assure the accuracy and usefulness of this manual, however we cannot assume responsibility for errors or omissions or liability for the misuse or misapplication of our products.

ii

Contents

ABOUT THIS GUIDE

This guide explains how to setup and use the DI350 OfficeRight™ Inserting System . Please spend a few moments reading through it. Understanding what the inserter does, and how it does it, will keep problems to a minimum and help you get the best performance possible.

This Guide is organized into seven sections:

1. |

INTRODUCTION |

|

|

|

|

|

|

To the Operator |

1-5 |

||

|

Three-Station Model .................................................... |

1-5 |

|

|

Two-Station Model ...................................................... |

1-6 |

|

|

One-Station Model ...................................................... |

1-6 |

|

Safety ................................................................................ |

1-7 |

||

Machine Identification ....................................................... |

1-8 |

||

Control Panel .................................................................. |

1-10 |

||

|

Control Panel Buttons ............................................... |

1-10 |

|

|

Display Symbols ........................................................ |

1-12 |

|

|

|

|

|

2. |

OPERATION |

|

|

|

|

|

|

Connecting Power ............................................................. |

2-1 |

||

Selecting and Running a Job ............................................ |

2-1 |

||

|

Select the Job .............................................................. |

2-1 |

|

|

Run a Trial Piece ......................................................... |

2-2 |

|

|

Start Machine Operation ............................................. |

2-3 |

|

Setting the Sheet Feeders ................................................ |

2-3 |

||

Setting the Envelope Feeder ............................................. |

2-4 |

||

Setting the Insert Feeder ................................................... |

2-5 |

||

Filling the Sealer ............................................................... |

2-6 |

||

Programming Options By Model |

....................................... 2-7 |

||

iii

Contents

3.CREATE A NEW NON-OMR JOB

Create New Non-OMR Job ............................................... |

3-1 |

Entering the Setup Mode............................................. |

3-1 |

Choosing the New Job Number .................................. |

3-2 |

Selecting Non-OMR Option ......................................... |

3-2 |

Flowchart for Non-OMR Job ........................................ |

3-3 |

Setting the Accumulation Function .............................. |

3-5 |

Fold Type .................................................................... |

3-6 |

Setting Sheet Feeder 1 ............................................... |

3-7 |

Setting Sheet Feeder 2 ............................................... |

3-8 |

Setting Insert Feeder ................................................... |

3-9 |

Mode ........................................................................... |

3-9 |

Sealer ........................................................................ |

3-10 |

Paper Length ............................................................. |

3-10 |

Fold A ........................................................................ |

3-11 |

Fold B ........................................................................ |

3-11 |

Envelope Depth ......................................................... |

3-12 |

Envelope Stop ........................................................... |

3-12 |

Batch Mode ............................................................... |

3-13 |

Confirming the Job Setup .......................................... |

3-13 |

Testing the Job .......................................................... |

3-14 |

Changing an Existing Job ............................................... |

3-15 |

Deleting a Job ................................................................. |

3-15 |

iv

Contents

4.WHAT IS OMR (OPTICAL MARK RECOGNITION)?

What is OMR? ................................................................... |

4-1 |

What Do OMR Marks Look Like on Paper? ...................... |

4-2 |

How are OMR Marks Read on the DI350? ....................... |

4-3 |

How are OMR Marks Generated? ..................................... |

4-4 |

What OMR Marks are Used on the DI350? ...................... |

4-5 |

OMR Group Combinations ................................................ |

4-9 |

Details of Basic Level OMR ............................................ |

4-10 |

Group 1 Marks (“OMR”) ............................................. |

4-10 |

Details of Enhanced Level OMR ..................................... |

4-14 |

Group 2 Marks (“Select Feed”) ................................... |

4-14 |

Group 3 Marks (“Sequence”) ...................................... |

4-17 |

Considerations When Implementing OMR ...................... |

4-20 |

v

Contents

5. |

CREATE A NEW OMR JOB |

|

|

|

|

|

Creating a New OMR job .................................................. |

5-1 |

|

What Is OMR? ............................................................. |

5-1 |

|

Entering the Setup Mode............................................. |

5-1 |

|

Choosing the New Job Number .................................. |

5-2 |

|

Selecting OMR Option ................................................. |

5-3 |

|

Flowchart for OMR Job ............................................... |

5-4 |

|

Fold Type .................................................................... |

5-6 |

|

Setting Main (Scanning) Sheet Feeder ....................... |

5-7 |

|

Setting Other Sheet Feeder ........................................ |

5-7 |

|

Setting Insert Feeder ................................................... |

5-9 |

|

Sealer ........................................................................ |

5-10 |

|

Paper Length ............................................................. |

5-10 |

|

Fold A ........................................................................ |

5-11 |

|

Fold B ........................................................................ |

5-11 |

|

Envelope Depth ......................................................... |

5-12 |

|

Envelope Stop ........................................................... |

5-12 |

|

Batch Mode ............................................................... |

5-13 |

|

Confirming the Job Setup .......................................... |

5-13 |

|

Adjustment of OMR Scanner ..................................... |

5-14 |

|

Loading the Material .................................................. |

5-17 |

|

Testing the Job .......................................................... |

5-18 |

|

Changing an Existing Job ............................................... |

5-19 |

|

Deleting a job .................................................................. |

5-19 |

vi

Contents

6. |

REFERENCE |

|

|

|

|

|

|

|

Changing the Display Language ....................................... |

6-1 |

|

|

Clearing Material ............................................................... |

6-1 |

|

|

Hand Crank ................................................................. |

6-1 |

|

|

Removal & Replacement of Sheet Feeder and |

|

|

|

Envelope Trays ........................................................ |

6-2 |

|

|

Removal & Replacement of the Fold Plates ................ |

6-2 |

|

|

Removal & Replacement of the Insert Tray ................ |

6-3 |

|

|

Access to Carriage Assembly ..................................... |

6-3 |

|

|

Access to Envelope Feeder Area ................................ |

6-3 |

|

|

Access to the Envelope Exit Area ............................... |

6-4 |

|

|

Access to the Envelope Inserting Area ....................... |

6-4 |

|

|

Access to the Sheet Feed Area ................................... |

6-4 |

|

|

Troubleshooting ................................................................ |

6-5 |

|

|

Error Messages ............................................................... |

6-11 |

|

|

Paper Handling .......................................................... |

6-11 |

|

|

OMR Errors ............................................................... |

6-15 |

|

|

Material Specifications .................................................... |

6-17 |

|

|

Sheet Feeders ........................................................... |

6-17 |

|

|

Insert Feeder ............................................................. |

6-17 |

|

|

Sealer ........................................................................ |

6-18 |

|

|

Stacker ...................................................................... |

6-18 |

|

|

Envelope Feeder ....................................................... |

6-18 |

|

|

Material Requirements .............................................. |

6-19 |

|

|

OMR Specifications (General) ........................................ |

6-19 |

|

|

Machine Specifications ................................................... |

6-20 |

|

|

Physical Dimensions: ................................................ |

6-20 |

|

|

Noise Level ................................................................ |

6-20 |

|

|

Electrical/BTU Rating ................................................ |

6-20 |

|

|

Speed ........................................................................ |

6-20 |

|

|

Fold Modes ................................................................ |

6-20 |

|

|

Compliance ............................................................... |

6-20 |

|

|

Usage ........................................................................ |

6-21 |

|

|

Machine Life .............................................................. |

6-21 |

|

|

Service ............................................................................ |

6-21 |

|

vii

Contents

APPENDIX A – TRAINING CHECKLIST

Operator Training Checklist .............................................. |

A-1 |

Introduction .................................................................. |

A-1 |

Operation ..................................................................... |

A-1 |

Create (Program) Non-OMR Job ................................ |

A-1 |

What Is OMR? ............................................................. |

A-2 |

Create (Program) OMR Job ........................................ |

A-2 |

Reference .................................................................... |

A-2 |

INDEX

viii

Introduction

1.INTRODUCTION

To the Operator

Your Pitney Bowes DI350 Inserting System is a compact, desk top unit, which is simple to set up and run while offering the following features:

•Envelope seal/no seal option

•Semi-automatic single insert operation (not on single station model)

•Fully automatic material separation on sheet feeder(s)

•Fully automatic settings on fold plates

•Fully automatic envelope separation

•Fully automatic double document detection when selected

•Fold only option (fold without insertion)

•Semi-automatic insertion of single and multiple sheet Inserts

•Option of single fold, letter (C) fold, accordion (Z) fold or double fold

•Job recall, operator programmable (up to 20, depending on model)

•Switchable feeding

•Optical Mark Recognition (OMR) scanning for greater collation integrity and additional feeding flexibility (3-station model only)

This guide covers all three models of the DI350 inserter system.

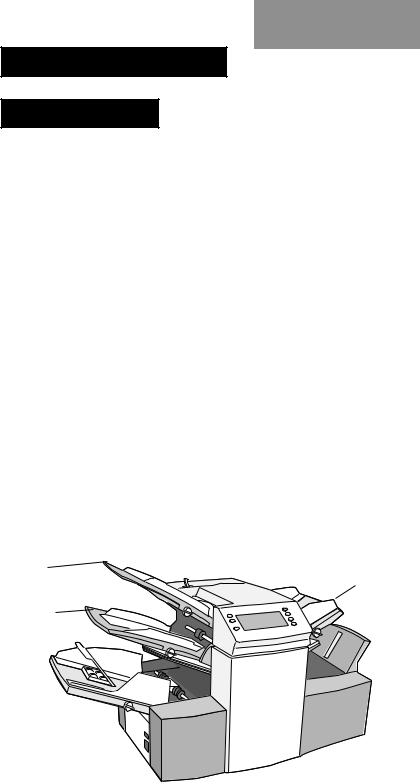

Three-Station Model

This model incorporates two sheet feeders and an insert feeder.

It is the only model that has OMR and has the most setup options. For this reason, all illustrations in this guide show this model.

Sheet |

Insert Feeder |

Feeder 1 |

Sheet

Feeder 2

1-1

Introduction

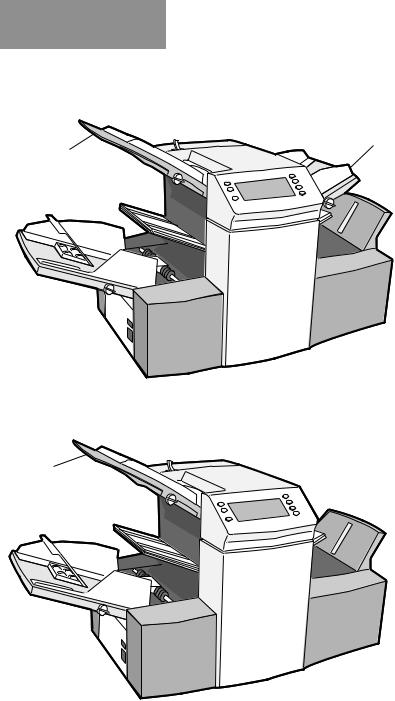

Two-Station Model

This model incorporates a single sheet feeder and an insert feeder.

Insert Feeder

Sheet Feeder 1

One-Station Model

This model incorporates a single sheet feeder.

Sheet Feeder 1

All models are set up and operated in a very similar way. Procedures in this guide cover all models. If a function is model dependent, the accompanying text will explain this.

1-2

Introduction

Safety

Safety Precautions:

When using this machine, follow the normal safety precautions for all office equipment:

Keep loose clothing, jewelry and long hair away from all moving parts.

Avoid touching moving parts or materials while the machine is in use.

Before clearing a jam, be sure machine mechanisms come to a stop.

When removing jammed material, avoid using too much force to protect against minor personal injury and damaging equipment.

Use the power cord supplied with the machine and plug it into a properly grounded wall outlet located near the machine and easily accessible. Failure to properly ground the machine can result in severe personal injury and/or fire.

The power cord wall plug is the primary means of disconnecting the machine from AC supply.

DO NOT use an adapter plug on the line cord or wall outlet.

DO NOT remove the ground pin from the line cord.

Avoid using wall outlets that are controlled by wall switches, or shared with other equipment.

DO NOT route the power cord over sharp edges or trapped between furniture.

Insure there is no strain on the power cord where it becomes jammed between the equipment, walls or furniture.

Be certain the area in front of the wall receptacle into which the machine is plugged is free from obstruction.

Do not remove covers. Covers enclose hazardous parts that should only be accessed by Pitney Bowes Customer Service. Report any damage of covers to a Pitney Bowes Customer Service Representative.

To prevent overheating, do not cover the vent openings.

Read all instructions before attempting to operate the equipment.

Use this equipment only for its intended purpose.

In addition, follow any specific occupational safety and health standards for your workplace or area.

1-3

Introduction

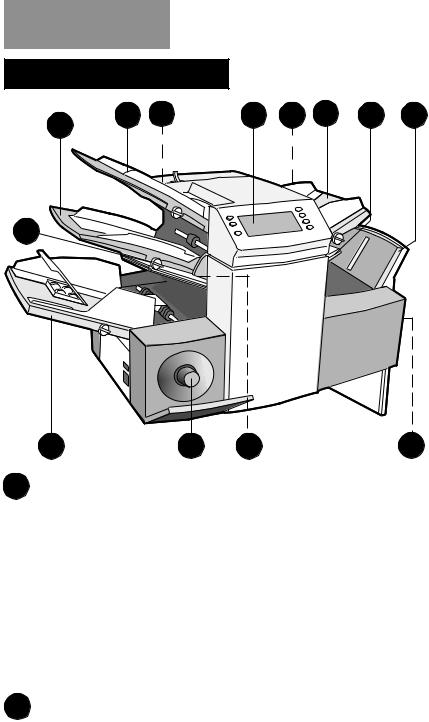

Machine Identification |

|

|

|

|

|

||

2 |

1 |

12 |

6 |

11 |

3 |

4 |

10 |

|

|

|

|

|

|

|

|

5

9 |

8 |

13 |

7 |

1Sheet Feeder 1

This feeder is intended for feeding material that requires folding. If you are running addressed documents for insertion into window envelopes, feed them from this feeder.

In addition, sheet feeder 1 can be set to ‘manual feed’. In this mode, stapled sets of up to 5 sheets may be run. The machine waits for each set to be manually fed into sheet feeder 1 before folding and inserting the set automatically. See the specifications section of Chapter 6 (Reference) for full details of the sets possible.

2Sheet Feeder 2 (three-station machine only)

For feeding material that requires folding. Its functions are similar to sheet feeder 1 but ‘manual feed’ is NOT available from this feeder.

1-4

Introduction

3Insert Feeder (two and three-station machines only)

Use this feeder to add additional inserts to your envelope. Material fed from this feeder cannot be folded by the inserter. However, this feeder is especially suited to feeding pre-folded or thicker inserts.

4Fold Plate 2

5Fold Plate 1

These units are used to create the desired fold in material fed from the sheet feeder(s). The fold plates are automatically set from the control panel.

6Display/Control Panel

This is where you enter commands and where the machine informs you of its status with the use of symbols and icons. Full details of each button function are given on the following page.

7Stacker and Measuring Scale

Located at the right end, is the fold-down stacker. This unit can be latched against the right side of the machine when not in use to save space.

A scale is located along the front edge of the stacker to aid measurement of material and envelopes.

8Hand Crank

The hand crank is located behind a drop down cover at the left front. It can be used to manually turn the machine mechanisms to free a material stoppage.

9Envelope Feeder

This feeder feeds envelopes into the inserting area where they are filled with the sheets requested from the other feeders.

10Envelope Inverter Unit

This unit exits the envelope into the stacker face up.

1-5

Introduction

11Sealer Water Bottle

The sealer water bottle is located behind a drop down cover at the right rear of the machine. It provides water or EZ Seal® solution to the envelope sealer unit.

12Upper OMR Scanner (three-station machine only)

Scanner used to read OMR marks on sheet feeder 1 from above the sheet.

13Lower OMR Scanner (three-station machine only)

Scanner used to read OMR marks on sheet feeder 2 from under sheet.

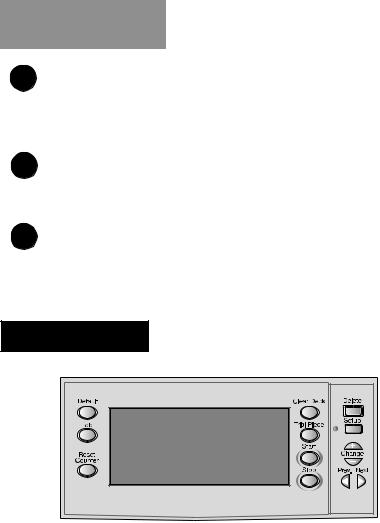

Control Panel

Control Panel Buttons

Default |

Press this button to return the system to its |

|

‘standard’ settings. These settings come pre- |

|

configured from the factory but can be modified to |

|

suit your needs by a Pitney Bowes Customer Service |

|

Representative. |

Job |

Press to step through the jobs you have programmed |

|

into the machine’s memory. Up to twenty (20) jobs can |

|

be held, depending on model (see page 2-9). See |

|

Chapters 3 or 5 for details on programming jobs. |

1-6

|

|

Introduction |

Reset Counter |

|

|

Press this button to reset the item counter. |

||

Clear Deck |

Pressing this button will jog material through and out |

|

|

of the machine. It can be used to clear the machine |

|

|

ready for automatic operation after a stoppage has |

|

|

occurred etc. |

|

Trial Piece |

This button is used to run a single test piece so that |

|

|

you can check machine setup. A trial piece must be |

|

|

run before automatic operation can be commenced |

|

|

using the Start button. If double detection is in use, |

|

|

the machine sets itself automatically as it runs the |

|

|

trial piece. This envelope will be unsealed and |

|

|

counted as one item. |

|

Start |

Starts automatic operation. |

|

Stop |

Stops automatic operation at the end of the next |

|

|

cycle. |

|

Delete |

Used in setup mode to delete a programmed job |

|

|

from memory. |

|

Setup |

When pressed, the machine enters setup mode. This |

|

|

mode allows you to program jobs into memory for |

|

|

instant recall using the Job button. |

|

Change + – |

In setup mode, used to select options or set values |

|

|

of machine settings. |

|

Prev. |

In setup mode, used to step backwards/forwards |

|

Next |

through the various machine settings. |

|

1-7

Introduction

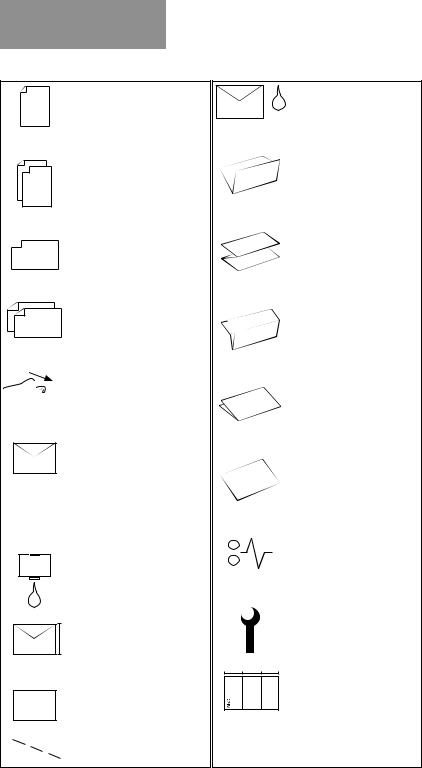

Display Symbols

Used on sheet feeders to signify that the feeder is on without double detection.

Used on sheet feeders to signify that the feeder is on with double detection.

Used on insert feeder to signify that the feeder is on without double detection.

Used on insert feeder to signify that the feeder is on with double detection.

Used on sheet feeder 1 to

Used on sheet feeder 1 to

signify that the feeder is set for manual feed.

signify that the feeder is set for manual feed.

Used on envelope feeder to signify that the feeder is on.

Indicates the setting (from

. . 3 . . 1 to 5) of the envelope stop.

Indicates that the sealer water bottle needs refilling.

Indicates the envelope depth.

Indicates that the sealer unit is off (envelopes not sealed).

Used on any feeder to indicate feeder is not in use.

1-8

Indicates that the sealer unit is on (automatic envelope sealing).

Indicates a ‘C’ - Letter fold is selected.

Indicates a ‘Z’ - Accordion fold is selected.

Indicates a double fold is selected.

Indicates a single fold is selected.

Indicates a no-fold insert operation.

Indicates a material stoppage. The position of this symbol in the display indicates where the stoppage has occurred.

Call Pitney Bowes

Service.

Indicates the paper size, address orientation and fold(s) set for sheet feeder.

Operation

2. OPERATION

This section explains operation of the DI350 inserter, assuming the job to be run is already programmed into the machine.

If the job has not been programmed, refer to “Create NonOMR Job” on page 3-1 or “Create OMR Job” on page 5-1.

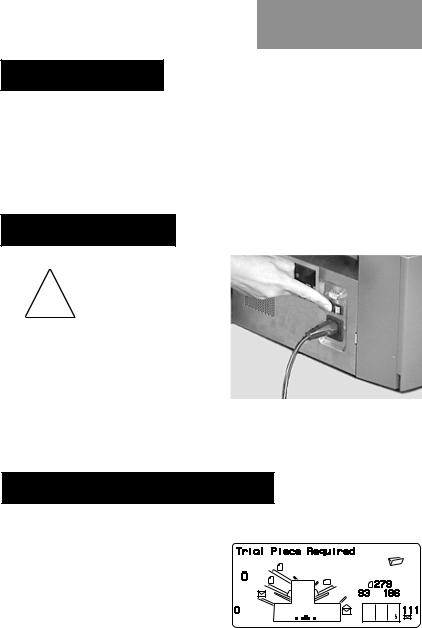

Connecting Power

Read the safety information on ! page 1-3 before connecting the

machine.

Connect the power cord to the socket on the left side of the machine. Plug the power cord into a suitable power

outlet. Make sure the power outlet is near the machine and is easily accessible. Turn the machine power switch ON.

Selecting and Running a Job

Select the Job

When the machine is turned ON, the display will show the last job run and ‘Trial Piece Required’.

Press the Job button until the job you require is displayed,

or press Default if you want to run the machine with your ‘standard’ settings.

Note: The default job can be altered only by a Pitney Bowes Customer Service Representative.

2-1

Operation

If you have material loaded, press Trial Piece. The machine will set itself and run a test piece for you to check.

If you don’t have material loaded, do this now, then return to this section. Loading feeders etc. is covered on the following pages.

Note:

You may have selected a ‘manual feed’ job where sheet feeder 1 is set for

manual feed of collated sets. If this is the case, the sheet

feeder should not be loaded, as the collated sets are fed one at a time as required by the machine. However, the

lever shown in the illustration should be pulled back to open the feed mechanism to ready the manual feed operation. Remember to return this lever to its normal position when you use the feeder for automatic operation.

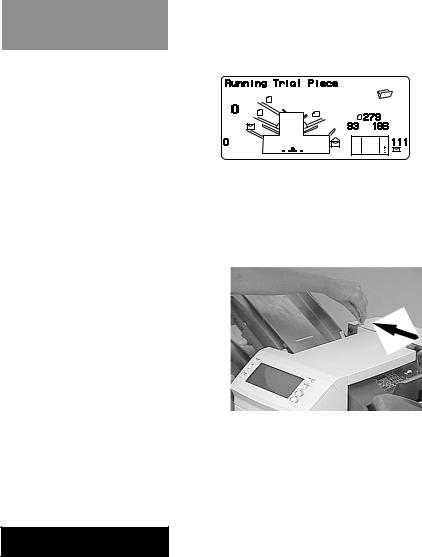

Run a Trial Piece

Once material is in place, press Trial Piece so you can check that the setup is correct.

Note: In switchable mode both sheet feeders must be loaded. A trial piece will be run for both feeders.

Minor changes to the job settings can be made at this stage if the trial piece needs ‘fine tuning’. Press Setup, then use the Prev (  ), Next (

), Next (  ) and Change (+/-) buttons as required to modify job settings. When you have made the necessary changes, press Setup again to return to run mode. The job will be saved with the new settings.

) and Change (+/-) buttons as required to modify job settings. When you have made the necessary changes, press Setup again to return to run mode. The job will be saved with the new settings.

2-2

Operation

Start Machine Operation

Press Start to begin automatic operation. The machine will operate until either material runs out or the Stop button is pressed.

Note: If the three station machine is set for switchable feeding, the display will show:

Ready: 1 > 2 > 1

This confirms that feeding will automatically switch between sheet feeders. See page 3-8 or 5-7 for more details.

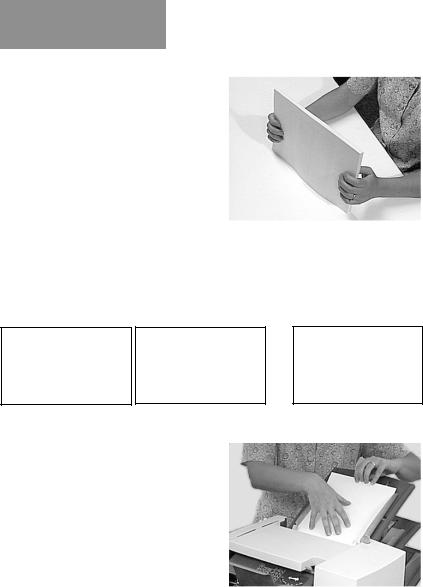

Setting the Sheet Feeders

1.Adjust the side guides to the width of the material being fed, then back-off a quarter turn on the side guide control. This will set the correct clearance between the guides and the material.

2.Take the stack of paper and aerate it to ensure the individual sheets are not stuck together.

2-3

Operation

3.Jog the stack back into alignment. The sheet feeders take the paper stack aligned in a similar way to a photocopier paper cassette.

4.The three possible

choices for loading you documents with addresses are listed below. NOTE: The display will indicate the correct orientation of the paper in the first two cases only.

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

ABC

FACE UP FEET FIRST

5.Place the paper stack onto the feed deck. Allow the deck to move down and the top of the paper stack to slide under the feed roller.

Note: When using both sheet feeders with accordion fold, sheet feeder 2 must be used for the prime (address bearing) document.

6.You can pull out the sliding supports from the end of the deck to help support long material.

2-4

Operation

Setting the Envelope Feeder

1.Adjust the side guides to the width of the envelopes being fed, then back-off half a turn on the side guide control. This will set the correct clearance between the guides and the envelopes.

2.Aerate the stack of envelopes to be run.

3.Place them on the feed deck with the flaps up and trailing. The lead edge of the first envelope should be under the front feed roller.

Let the ‘wedge’ slide down behind the stack so that the envelopes are supported.

2-5

Operation

Setting the Insert Feeder

1.Adjust the side guides to the width of the material being fed, then back-off a quarter turn on the side guide control. This will set the correct clearance between the guides and the material.

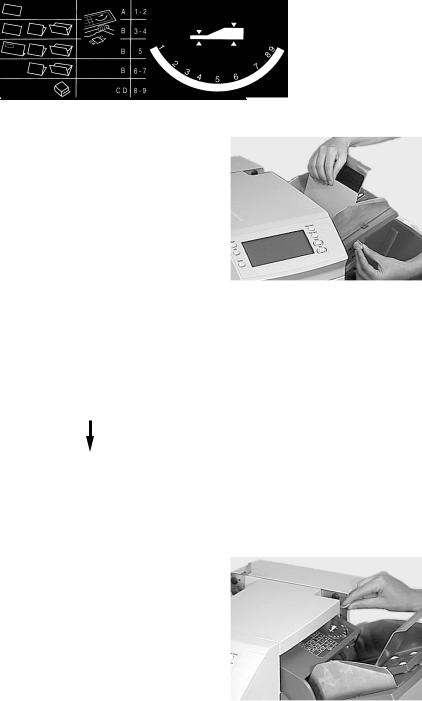

2.Refer to the ‘label’ located on the insert

feeder. Compare your insert with the diagram. Read off the settings for the insert feeder blue lever (numbers 1 to 9) and the separator shield (letters A to D).

Thin Material

Thicker Material

Thick Inserts/

Booklets etc.

3.Set the blue lever to the number required.

2-6

Operation

4.Set the separator shield to the letter required.

5.Fan the inserts to be run and place them onto the feed deck face up with their bottom edge feeding first.

Let the ‘wedge’ slide down behind the stack so that the inserts are supported.

2-7

Operation

Filling the Sealer

When the sealer unit needs refilling, the Add Fluid symbol will flash in the display.

Add Pitney Bowes EZ Seal® solution or water in the following way:

Note: EZ Seal® solution is recommended to minimize growth of algae and scale build-up.

Hinge open the Water Bottle

Cover located at the rear right hand side of the machine. Remove the bottle

Fill the bottle up to the level indicated.

Replace the water bottle and close the cover.

If the sealer unit has been allowed to completely empty, you should allow time for water to soak through the sealer mechanism.

2-8

Operation

Programming Options By Model

The DI350 has the ability to be programmed by the operator with up to 20 jobs (depending on model) which can be recalled at the touch of a button. The following table shows which functions are available on a machine by the number of stations it has ( = present on machine):

Function |

# of Stations |

Possible Settings |

|||

1 |

2 |

3 |

|||

|

|

||||

|

|

|

|

|

|

Sheet Feeder 1 |

|

|

|

On (with double detect), On (without |

|

|

|

|

|

double detect), Off, or Manual Feed |

|

|

|

|

|

In addition to above: Select Feed (with |

|

|

|

|

|

double detect), or Select Feed (without |

|

|

|

|

|

double detect) |

|

|

|

|

|

|

|

Insert Feeder |

|

|

|

On (with double detect), On (without |

|

|

|

|

|

double detect), Off |

|

|

|

|

|

|

|

|

|

|

|

In addition to above: Select Feed (with |

|

|

|

|

|

double detect), or Select Feed (without |

|

|

|

|

|

double detect) |

|

Sheet Feeder 2 |

|

|

|

On (with double detect), On (without |

|

|

|

|

|

double detect), Off, Select Feed (with |

|

|

|

|

|

double detect), or Select Feed (without |

|

|

|

|

|

double detect) |

|

|

|

|

|

|

|

Accumul Mode |

|

|

|

Off or On (with 2, 3,4, or 5 pages) |

|

|

|

|

|

|

|

OMR Mode |

|

|

|

Off, On, OMR + Sequence, OMR + |

|

|

|

|

|

Select Feed and Sequence, OMR + |

|

|

|

|

|

Select Feed |

|

|

|

|

|

|

|

Mode |

|

|

|

Insertion Mode, Fold Only Mode |

|

|

|

|

|

|

|

Number of Jobs |

10 |

10 |

20 |

Each job can be programmed by operator |

|

Fold Type |

|

|

|

C - Letter, Z - Accordion, Double or |

|

|

|

|

|

Single |

|

|

|

|

|

|

|

Paper Length |

|

|

|

any within machine specification limits |

|

|

|

|

|

|

|

Fold A |

|

|

|

any within machine/fold specification |

|

|

|

|

|

limits |

|

|

|

|

|

|

|

Fold B |

|

|

|

any within machine/fold specification |

|

|

|

|

|

limits |

|

Envelope Depth |

|

|

|

any within machine specification limits |

|

Envelope Stop |

|

|

|

1 to 5 |

|

|

|

|

|

|

|

Batch Mode |

|

|

|

Off or On (from 50 to 99) |

|

2-9

Operation

2-10

Create Non-OMR Job

3. CREATE NON-OMR JOB

This section takes you step-by-step through the process of setting up a new (non-OMR) job and saving it in the memory.

Programming is carried out in the ‘Setup Mode’…

Entering the Setup Mode

Open the hinged cover to the right of the display. This will expose the setup buttons.

Press Setup. The indicator will light and the machine will ask for an access code. This code prevents the machine’s settings being changed by unauthorized personnel.

The Prev (  ) and Next (

) and Next (  ) buttons are used to step forward or backwards through the settings available. Once the item is displayed, the Change (+/-) buttons are used to select the option or value you want.

) buttons are used to step forward or backwards through the settings available. Once the item is displayed, the Change (+/-) buttons are used to select the option or value you want.

Use the Change (+/-) buttons to select the access code 71.

Press Next (  ) to advance to the next setting….

) to advance to the next setting….

3-1

Create Non-OMR Job

Choosing the new job number

The machine will ask for the job number you wish the new

settings to be stored under (the default job number is 1). Use the Change (+/-) buttons

to display the job number you want.

Notes:

•If you use an existing job

number, the old settings will be overwritten by the new settings you are about to make.

•If you want to find a

currently unused job number, press Change (+/-)until you see a job where the display shows no symbols alongside the feeders or in the fold setup area. This means the job is currently empty.

Press Next (  ) to advance to the next setting…

) to advance to the next setting…

Selecting Non-OMR Option

Press Change (+/-) until you see this option:

OMR off OMR is turned off for this job.

Press Next ( ) to advance to the next setting... (see page 3-5)

) to advance to the next setting... (see page 3-5)

The flowchart on the following pages describe the setup for a non-OMR job.

3-2

Create Non-OMR Job

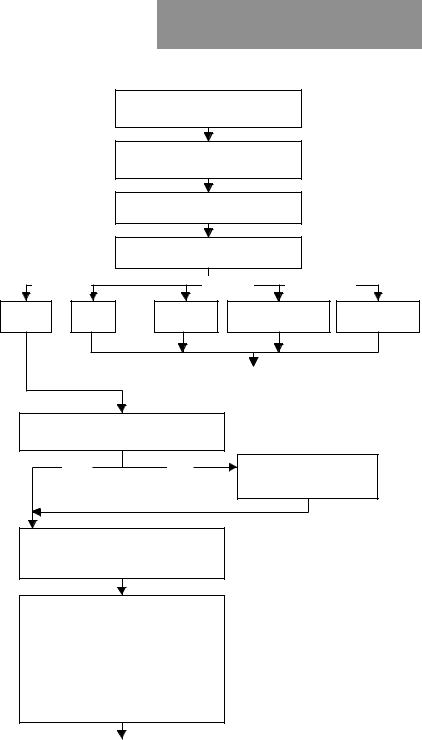

Flowchart for Non-OMR Job Setup

Open hinged cover on right side of control panel and press Setup k e y

Use + / - keys to enter 7 1 for access code, then press > key

Use + / - keys to enter job number, then press > key

Use + / - keys to select OMR function, then press > key

Base Level |

OMR off |

OMR on |

Enhanced |

Level Only |

OMR + |

OMR + Select |

OMR + Select |

Sequence |

Feed + Sequence |

Feed |

See Separate

Flowchart for

OMR Job

Use + / - keys to select accumulation

Off or On, then press > key

O f f |

On |

Use + / - enter keys to |

|

select 2, 3, 4 or 5 pages, |

|||

|

|

||

|

|

then press > key |

Use + / - keys to select fold type (c-letter, z-accordion, double, single), then press > key

Use + / - keys to select whether the main sheet feeder is:

•On Double Detect

•Manual Feed

•On

•Off

•Switchable - On Double Detect

•Switchable - On

then press > key

continued on next page

3-3

Create Non-OMR Job

Flowchart for Non-OMR Job Setup

continued from previous page

Use +/ - keys to select whether other sheet feeder is Off, On with

double detect or On with no double detect, then press > key

Use + /- keys to select whether insert feeder is Off, On with

double detect or On with no double detect, then press > key

|

|

|

|

|

|

|

|

|

|

Insert Feeder On |

|

|

Insert Feeder Off |

|

|

|

|

|

|

|

|||

Use +/ - keys to select whether insert feeder is in insertion mode or fold only mode, then press > key

Use +/ - keys to select whether sealer is Off or On, then press > key

Use +/ - keys to change paper length of your sheets, then press > key

Use + /- keys to change Fold A setting (if neccesary), then press > key to continue

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single Fold |

|

|

|

|

C, Z, Double Folds |

|

|

|

Use + /- keys to change Fold B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

setting (if neccesary), then |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

press > key to continue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use +/ - keys to change envelope depth, then press > key

continued on next page

3-4

Loading...

Loading...