Page 1

_Name_Bookmark2_

_Name_Bookmark2_

PNOZ m0p

PNOZmulti Modular Safety System

Operating Manual — No. 1002053-EN-03

Page 2

_Name_Bookmark2_

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Page 3

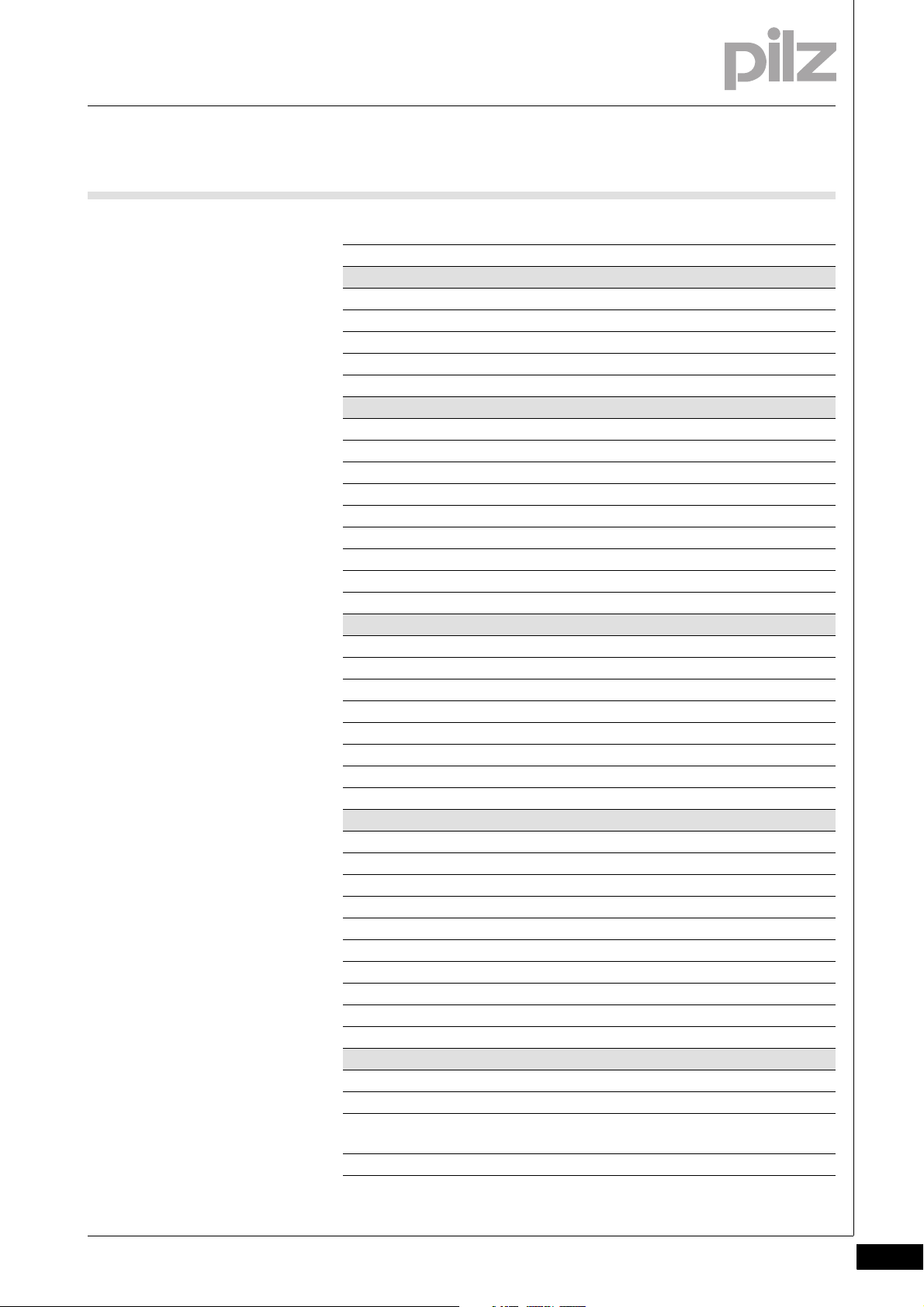

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Unit structure 2-1

2.1.1 Scope of delivery 2-1

2.1.2 Unit features 2-1

2.1.3 Chip card 2-2

2.2 Front view 2-3

2.2.1 PNOZ m0p 2-3

2.2.2 PNOZ m0p ETH 2-3

2.2.3 Key 2-4

Chapter 3 Safety

3.1 Intended use 3-1

3.1.1 System requirements 3-1

3.2 Safety regulations 3-2

3.2.1 Use of qualified personnel 3-2

3.2.2 Warranty and liability 3-2

3.2.3 Disposal 3-2

3.2.4 For your safety 3-3

Chapter 4 Function description

4.1 Unit properties 4-1

4.1.1 Integrated protection mechanisms 4-1

4.1.2 Function description 4-1

4.1.2.1 Operation 4-1

4.1.2.2 Block diagram 4-2

4.1.2.3 Diagnostics 4-2

4.1.2.4 Cascading 4-2

4.1.2.5 Safety mat, muting 4-3

4.1.3 Interfaces 4-3

Chapter 5 Installation

5.1 General installation guidelines 5-1

5.1.1 Dimensions 5-2

5.2 Connecting the base unit and expansion

modules

5-3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

Chapter 6 Commissioning

6.1 General wiring guidelines 6-1

6.2 Ethernet interfaces (only PNOZ m0p ETH) 6-2

6.2.1 RJ45 interfaces ("Ethernet") 6-2

6.2.2 Requirements of the connection cable and

connector

6.2.3 Interface configuration 6-2

6.2.4 RJ45 connection cable 6-3

6.2.5 Process data exchange 6-3

6.3 Preparing for operation 6-5

6.3.1 Function test during commissioning 6-5

6.3.2 Commissioning the PNOZmulti safety system for the first time

6.3.2.1 Load project from chip card 6-5

6.3.2.2 Load project via integrated interface 6-6

6.3.3 Download modified project to the

PNOZmulti safety system

6.3.3.1 Load modified project from chip card 6-6

6.3.3.2 Load modified project via integrated interface

6.3.4 Connection 6-7

6.4 Connection example 6-9

6-2

6-5

6-6

6-6

Chapter 7 Operation

7.1 Messages 7-1

7.1.1 Display elements for device diagnostics 7-1

7.1.2 Display elements for the Ethernet connection (only PNOZ m0p ETH)

7.2 Reset Ethernet connection settings 7-3

Chapter 8 Technical details

8.1 Technical details 8-1

8.2 Service life graph of output relays 8-5

8.3 Maximum capacitive load C (μF) with load

current I (mA) at the semiconductor outputs

8.4 Order reference 8-7

7-2

8-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-Einf Gltigkeit der Dokumentation

This documentation is valid for the product PNOZ m0p. It is valid until

Einf Einleitung

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

new documentation is published.

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product .

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 6

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-Einf_Uebersicht_über_die_Doku_6_Inbetriebnahme

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on intended use.

4 Function Description

This chapter describes the product's mode of operation.

5 Installation

This chapter explains how to install the product.

6 Commissioning

This chapter describes the product's commissioning and wiring.

7 Operation

This chapter describes how to operate the product and gives tips in the

case of a fault.

8 Technical Details

This chapter contains the product's technical details and order reference.

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the product or devices could

be damaged and also provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on

special features, as well as highlighting areas within the text that

are of particular importance.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 8

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

2 Overview

2.1 Unit structure

22000OverviewOverview2-2.1Unit structure2100Unit structure2-

2.1.1 Scope of delivery

Scope of delivery2-Lieferumfang_Abschl_77 9 110_Basis_BA

2.1.2 Unit features

Unit features2-Gerätemerkmale_Verwendung

` Base unit PNOZ m0p

` Terminator 779 110

Verwendung/Bildunterschrift_multi_Basis

Geraetemerkmale_Zusatz BA Einleitung

Gertemerkmale PNOZ m0p

Using the product PNOZ m0p:

Base units from the PNOZmulti modular safety system

The product has the following features:

` Can be configured in the PNOZmulti Configurator

` Positive-guided relay outputs:

– 2 safety outputs

Depending on the application, up to PL e of EN ISO 13849-1 and

up to SIL CL 3 of EN IEC 62061

` Semiconductor outputs:

– 4 safety outputs

Depending on the application, up to PL e of EN ISO 13849-1 and

up to SIL CL 3 of EN IEC 62061

– 1 auxiliary output

` 4 test pulse outputs

` 1 cascading input and output; can also be used as a standard output

` 20 inputs for connecting:

– E-STOP pushbuttons

– Two-hand buttons

– Safety gate limit switches

– Reset buttons

– Light beam devices

– Scanners

– Enabling switches

– PSEN

– Operating mode selector switches

– Pressure sensitive mats

` Integrated interface:

– PNOZ m0p: Serial interface RS 232

– PNOZ m0p ETH: Ethernet interface

` Muting function

` Connectable:

– 1 fieldbus module on the left

– 4 expansion modules on the left

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 10

2 Overview

2.1 Unit structure

2.1.3 Chip card

Chip card2-Bestimmung/Gertebeschreibung_multi_Chipkarte

` LED for:

– Diagnostics

– Supply voltage

– Output circuits

– Input circuits

` Monitors shorts across the inputs through test pulse outputs

` Monitoring of shorts between the safety outputs

` Plug-in connection terminals (either cage clamp terminal or screw ter-

minal)

To be able to use the product you will need a chip card.

Chip cards are available with memories of 8 kByte and 32 kByte. For

large-scale projects we recommend the 32 kByte chip card (see Technical Catalogue). Accessories chapter).

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

2 Overview

2.2 Front view

2.2Front view2200Front view2-

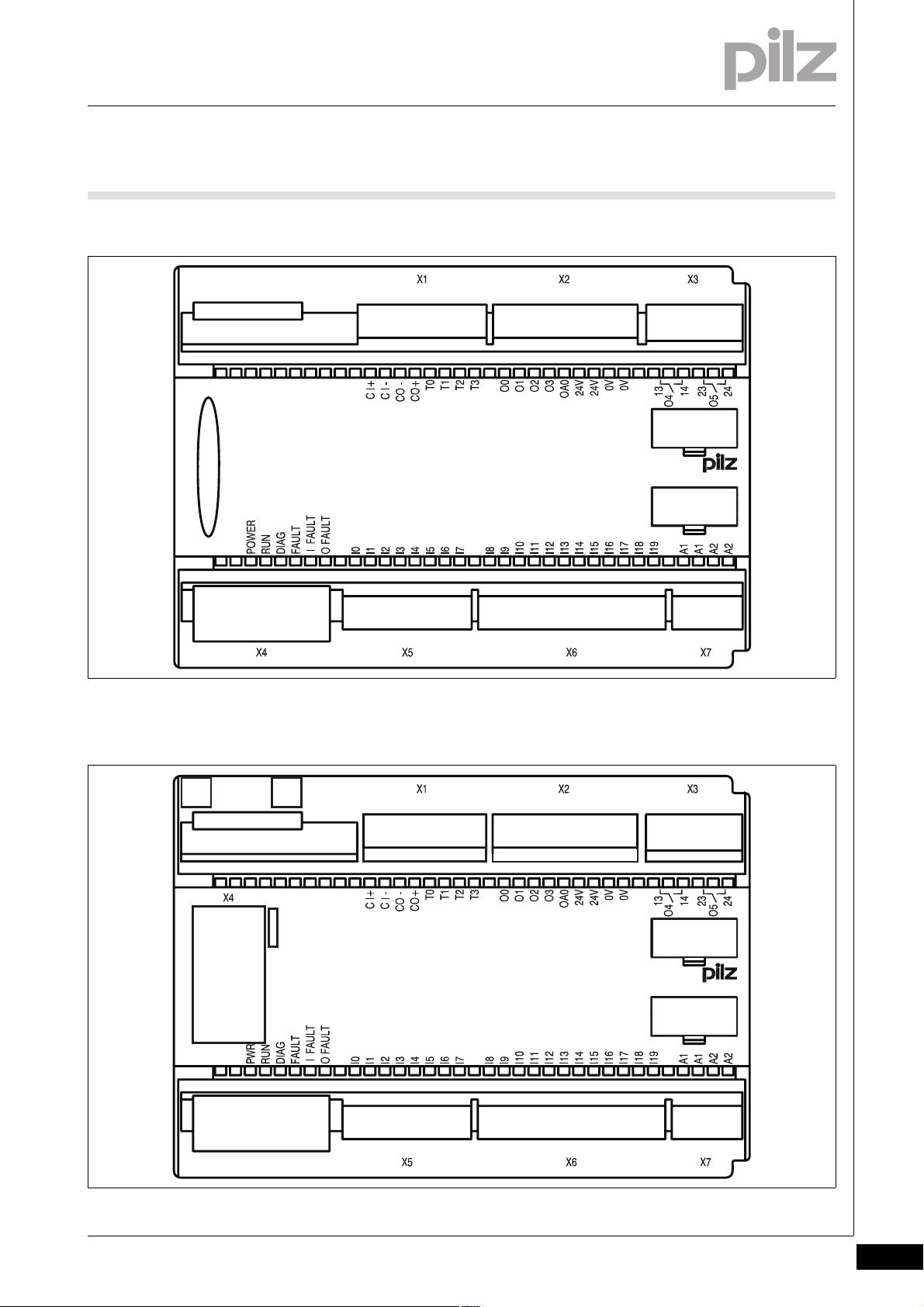

2.2.1 PNOZ m0p

PNOZ m0p2-Z-PNOZmulti-Basis-RS232-front-x.EPS

CHIP-Card

2.2.2 PNOZ m0p ETH

PNOZ m0p ETH2-Z-PNOZmulti-Basis-ETH-front-x.EPS

CHIP-Card

LNK

TRF

LNK

TRF

MAC ADD_00-02-47-MAC-VAR

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

Page 12

2 Overview

2.2 Front view

2.2.3 Key

Key2-Legende_Klemmenbelegung_multi_Basis_ETH+RS232_BA

Key:

` CHIP card:

– Interface chip card

` X1:

– Cascading inputs and outputs CI and CO,

– Test pulse outputs T0 … T3

` X2:

– Semiconductor outputs O0 ... O3,

– Auxiliary output OA0,

– Supply connections

` X3:

– Relay outputs O4 and O5

` X4:

– RJ 232 interface / Ethernet interface

` X5, X6:

– Inputs I0 ... I19

` X7:

– Power supply

` LEDs:

–PWR

–RUN

– DIAG

–FAULT

–I FAULT

–O FAULT

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-Bestimmung/Gertebeschreibung_multi_System

Bestimmung/Gertebeschreibung_multi_Zusatz_Achtung_Standard-Ausgaenge_BA

Bestimmung/Gertebeschreibung_Ausschluss

The modular safety system PNOZmulti is used for the safety-related interruption of safety circuits and is designed for use on:

` E-STOP equipment

` Safety circuits in accordance with VDE 0113 Part 1 and EN 60204-1

CAUTION!

Inputs and outputs for standard functions must not be used for

safety-related applications.

Intended use includes making the electrical installation EMC-compliant.

The product is designed for use in an industrial environment. It is not

suitable for use in a domestic environment, as this can lead to interference.

3.1.1 System requirements

System requirements3-Systemvoraussetzungen

The following is deemed improper use in particular:

` Any component, technical or electrical modification to the product

` Use of the product outside the areas described in this manual

` Use of the product outside the technical details (see chapter entitled

“Technical Details”)

` PNOZmulti Configurator from Version:

– 4.0.0 (PNOZ m0p)

– 7.1.0 (PNOZ m0p ETH)

Please contact Pilz if you have an older version.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 14

3 Safety

3.2 Safety regulations

3.2Safety regulations3200Safety regulat ions3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

` Are familiar with the basic regulations concerning health and safety /

accident prevention

` Have read and understood the safety guidelines given in this descrip-

tion

` Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

3.2.3 Disposal

Disposal3-Si ch Entsorgung

All claims to warranty and liability will be rendered invalid if:

` The product was used contrary to the purpose for which it is intended

` Damage can be attributed to not having followed the guidelines in the

manual

` Operating personnel are not suitably qualified

` Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

` In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

` When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

3 Safety

3.2 Safety regulations

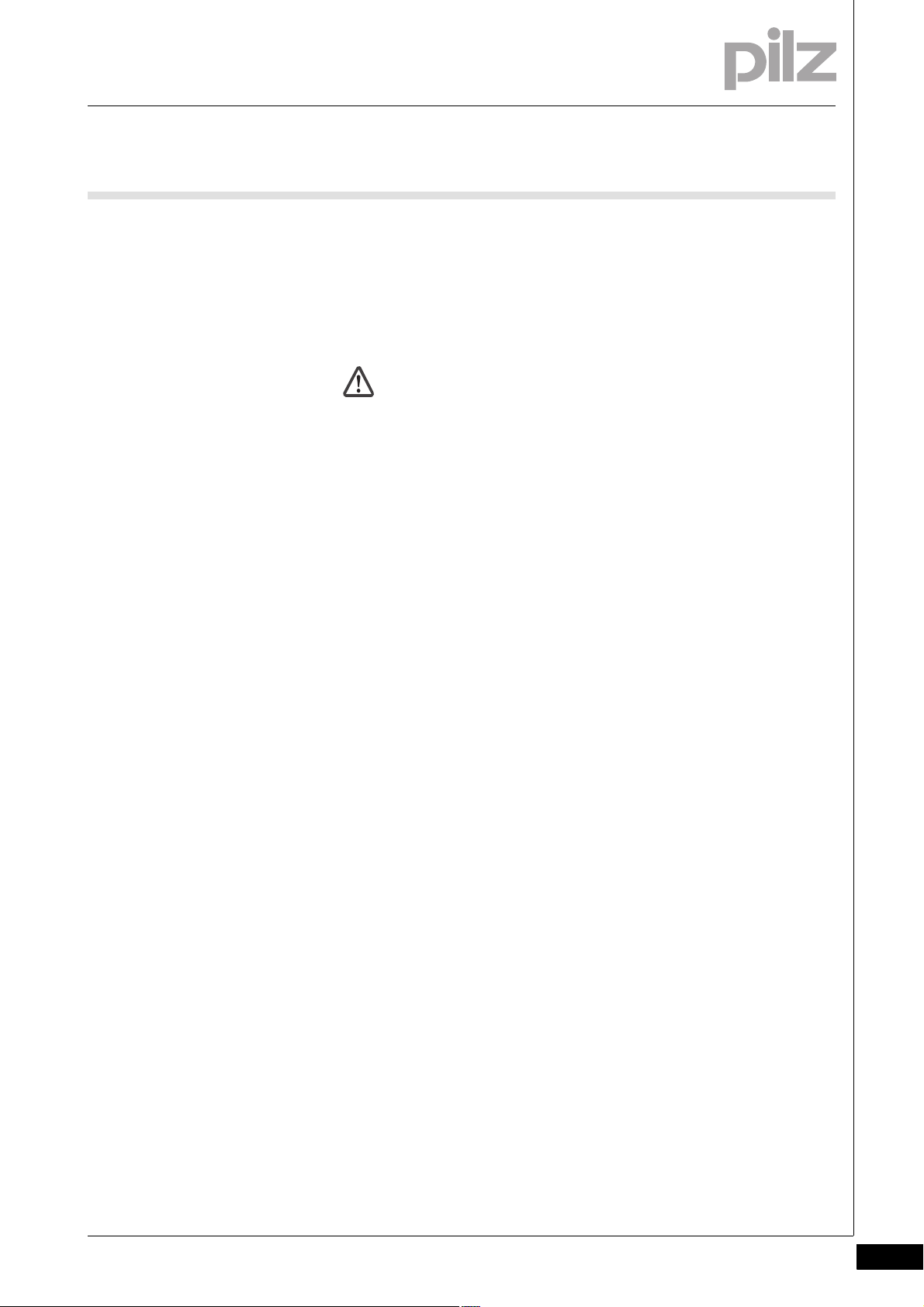

3.2.4 For your safety

For your safety3-Zu Ihrer Sicherheit_multi_Basis

The unit meets all necessary conditions for safe operation. However,

you should always ensure that the following safety requirements are

met:

` This operating manual only describes the basic functions of the unit.

Information on the expanded functions such as cascading can be

found in the online help for the PNOZmulti Configurator and in the

PNOZmulti technical catalogue. Only use these functions after you

have read and understood the documentation. All necessary documentation can be found on the PNOZmulti Configurator CD.

` Adequate protection must be provided for all inductive consumers.

` Do not open the housing or make any unauthorised modifications.

` Please make sure you shut down the supply voltage when performing

maintenance work (e.g. exchanging contactors).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 16

3 Safety

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

4 Function description

4.1 Unit properties

44000Function descriptionFunction description4-4.1Unit properties4100Unit properties4-

4.1.1 Integrated protection mechanisms

Integrated protection mechanisms4-Sicherheitseigenschaften_multi_allgemein

The relay conforms to the following safety criteria:

` The circuit is redundant with built-in self-monitoring.

` The safety function remains effective in the case of a component fail-

Sicherheitseigenschaften_Relais

Sicherheitseigenschaften_Halbleiter

4.1.2 Function description

Function description4-

ure.

` The relay contacts meet the requirements for safe separation through

increased insulation compared with all other circuits in the safety system.

` The safety outputs are tested periodically using a disconnection test.

4.1.2.1 Operation

Operation4-Funktionen_multi_Basis

The function of the safety system's inputs and outputs depends on the

safety circuit created using the PNOZmulti Configurator. A chip card is

used to download the safety circuit to the base unit. The base unit has

2 microcontrollers that monitor each other. They evaluate the input circuits on the base unit and expansion modules and switch the outputs on

the base unit and expansion modules accordingly.

The LEDs on the base unit and expansion modules indicate the status

of the PNOZmulti safety system.

The online help on the PNOZmulti Configurator contains descriptions of

the operating modes and all the functions of the PNOZmulti safety system, plus connection examples.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 18

4 Function description

4.1 Unit properties

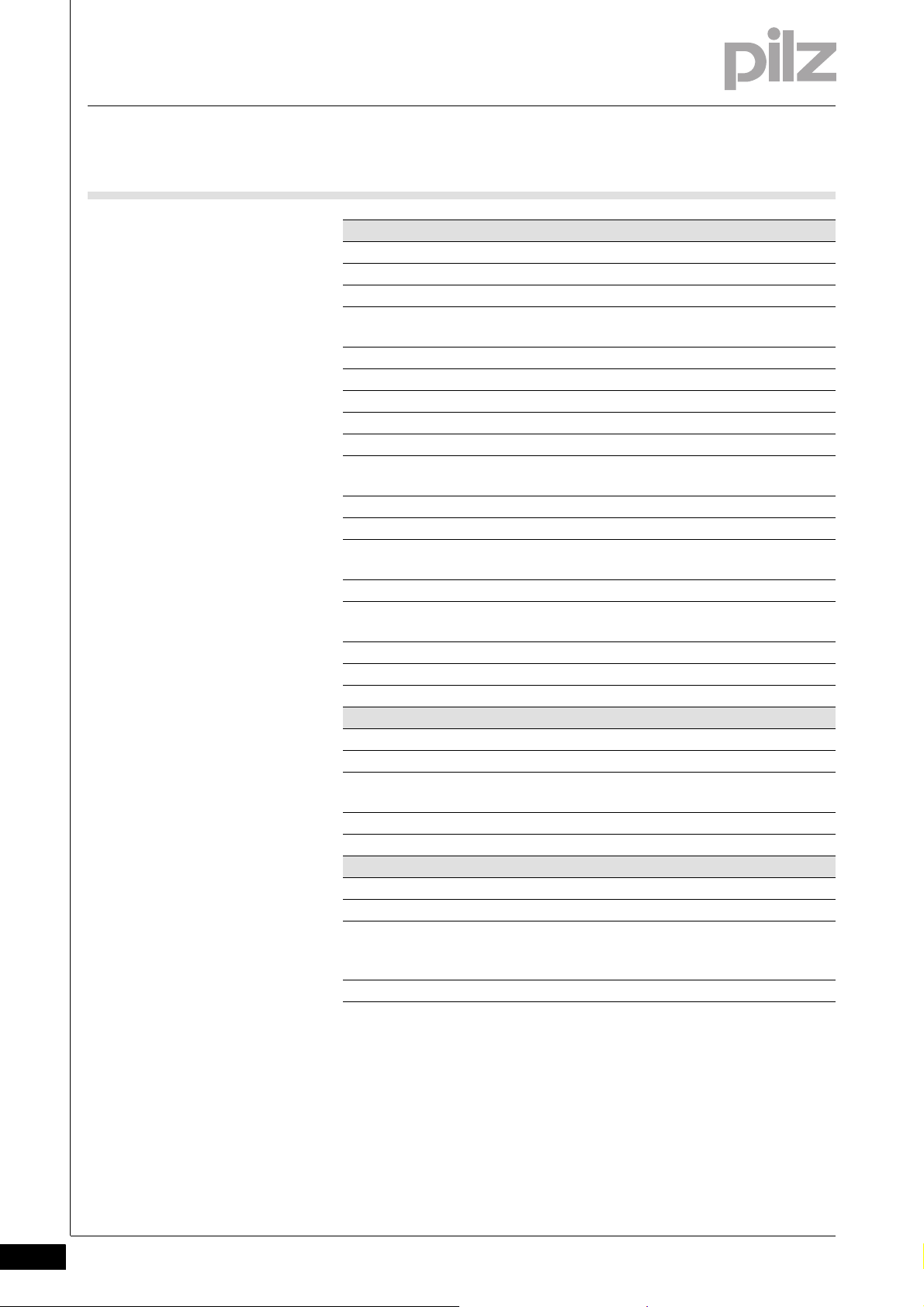

4.1.2.2 Block diagram

Block diagram4-Blockschaltbild_Basis_RS232+ETH

Interface

chip card

module

fieldbus,

Interface

extension

A1 A2

=

Power

I0 I19I1 I2 I3 I8I5

=

I4 I9 I12 I13 I14 I15 I16 I17I7 I18I6

Input

I10

I11

13 23

O4 O5

module

Interface

expansion

RS 232

Ethernet/

4.1.2.3 Diagnostics

Diagnostics4-Funktionen_multi_Basis_Diagnose_ETH und RS232

4.1.2.4 Cascading

Cascading4-Funktionen_multi_Basis_Kaskadierung

Cascading

CI+ CI- CO+

Test pulse

CO-

output

O1

O3

O0

O2

OA0

T3T0

T2T1

24 V 0 V

24 V 0 V

14 24

The status and error messages displayed by the LEDs are saved in an

error stack. This error stack can be read from the PNOZmulti Configurator via the interfaces (RS 232 or Ethernet). More comprehensive diagnostics are possible via the interfaces or one of the fieldbus modules,

e.g. the PROFIBUS module.

The cascading inputs and outputs enable several PNOZmulti and

PNOZelog units to be connected in series or as a tree structure.

4-2

INFORMATION

Detailed information on these functions and connection examples can be found in the online help for the PNOZmulti Configurator and in the PNOZmulti technical catalogue.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

4 Function description

4.1 Unit properties

4.1.2.5 Safety mat, muting

Safety mat, muting4-Funktionen_multi_Basis_Schaltmatte_Muting

INFORMATION

Detailed information on these functions and connection examples can be found in the online help for the PNOZmulti Configurator and in the supplement to the "PNOZmulti - special

applications" technical catalogue.

4.1.3 Interfaces

Interfaces 4-Funktionen_Schnittstelle_multi_ETH und RS232

The product PNOZ m0pETH has two Ethernet interfaces, the product

PNOZ m0p has one serial interface to

` Download the project

` Read the diagnostic data

` Set virtual inputs for standard functions

` Read virtual outputs for standard functions.

Information on diagnostics via the interfaces can be found in the Special

Applications Technical Catalogue.

The connection to Ethernet is made via the two 8-pin RJ45 sockets.

The Ethernet interface is configured in the PNOZmulti Configurator and

is described in the online help for the PNOZmulti Configurator.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 20

4 Function description

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

5 Installation

5.1 General installation guidelines

55000InstallationInstallation5-5.1General installation guidelines5100General installation guidelines5-Montage_multi_allgemein

Montage_multi_Bild_BA

` The safety system should be installed in a control cabinet with a pro-

tection type of at least IP54. Fit the safety system to a horizontal DIN

rail. The venting slots must face upward and downward. Other mounting positions could destroy the safety system.

` Use the notches on the back of the unit to attach it to a DIN rail. Con-

nect the safety system to the DIN rail in an upright position so that the

earthing springs on the safety system are pressed on to the DIN rail.

` The ambient temperature of the PNOZmulti units in the control cabi-

net must not exceed the figure stated in the technical details, otherwise air conditioning will be required.

` To comply with EMC requirements, the DIN rail must have a low im-

pedance connection to the control cabinet housing.

Montage_EMV ESD

CAUTION!

Damage due to electrostatic discharge!

Electrostatic discharge can damage components. Ensure

against discharge before touching the product, e.g. by touching

an earthed, conductive surface or by wearing an earthed armband.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 22

5 Installation

5.1 General installation guidelines

5.1.1 Dimensions

Dimensions5-Abmessungen

121 (4.76")

94 (3.70")

135 (5.31")

5-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

5 Installation

5.2 Connecting the base unit and expansion modules

5.2Connecting the base unit and expansion modules5200Connecting the base unit and expansion modules5-Montage_multi_Basis_verbind_mit_Modul_links-PNOZ m0p_BA

Jumpers are used to connect the modules.

There are 2 pin connectors on the rear of the base unit.

A max. of 4 expansion modules plus one fieldbus module may be connected to one base unit.

` Connect the base unit, the expansion modules and the fieldbus mod-

ule using the jumpers supplied.

Fieldbus module

Expansion module 1 ... 4

Power supply

Base unit

Jumper

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-3

Page 24

5 Installation

5-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

6 Commissioning

6.1 General wiring guidelines

66000CommissioningCommissioning6-6.1General w iring guidelines6100General wiring guidelines6-Verdrahtung_multi_Basis

The wiring is defined in the circuit diagram in the Configurator. There you

can select the inputs that are to perform a particular safety function and

the outputs that will switch this safety function.

Please note:

CAUTION!

DThe plug-in connection terminals on the relay outputs that

carry mains voltage should only be connected and disconnected

when the voltage is switched off.

` Information given in the “Technical details” must be followed.

` Outputs:

– O0 to O5 are safety outputs

– O4 and O5 are relay outputs

– O0 to O3 are semiconductor outputs

– OA0 is an auxiliary output.

` To prevent contact welding, a fuse should be connected before the

output contacts (see technical details).

` Use copper wire that can withstand 75 °C.

` Sufficient fuse protection must be provided on all output contacts

with inductive loads.

` Power for the safety system and input circuits must always be provid-

ed from a single power supply. The power supply must meet the regulations for extra low voltages with safe separation.

` Two connection terminals are available for each of the supply con-

nections 24 V and 0 V (semiconductor outputs), plus A1 and A2 (power supply). This means that the supply voltage can be looped through

several connections. The current at each terminal may not exceed 3

A.

` Test pulse outputs must exclusively be used to test the inputs. They

must not be used to drive loads.

Do not route the test pulse lines together with actuator cables within

Verdrahtung_multi_Basis_Schaltmatte

an unprotected multicore cable.

` Test pulse outputs are also used to supply safety mats that trigger a

short circuit.

Test pulses that are used for the safety mat may not be reused for

other purposes.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 26

6 Commissioning

6.2 Ethernet interfaces (only PNOZ m0p ETH)

6.2Ethernet interfaces (only PNOZ m0p ETH)6200Ethernet interfaces (only PNOZ m0p ETH)6-

6.2.1 RJ45 interfaces ("Ethernet")

RJ45 interfaces ("Ethernet")6-ETH_RJ45-Schnittstellen ("Ethernet")_Switch

Two free switch ports are provided as Ethernet interfaces via an internal

autosensing switch. The autosensing switch automatically detects

whether data transfer is occurring at 10 Mbit/s or 100 Mbit/s.

The switch's automatic crossover function means there is no need to

distinguish on the connection cable between patch cable (uncrossed

data line connection) and crossover cable (crossover data line connection). The switch automatically creates the correct data line connection

internally. It is therefore possible to use patch cable as the connection

cable for both end devices and cascading.

Both Ethernet interfaces use RJ45 technology.

6.2.2 Requirements of the connection cable and connector

Requirements of the connection cable and connector6-ETH_Anforderungen an das Verbindungskabel und den Stecker

The following minimum requirements must be met:

` Ethernet standards (min. Category 5) 10BaseT or 100BaseTX

` Double-shielded twisted pair cable for industrial Ethernet use

` Shielded RJ45 connectors (industrial connectors)

6.2.3 Interface configuration

Interface configuration6-ETH_Schnittstellenbelegung_Switch-8-polig

RJ45 socket

8-pin

8 1

PIN Standard Crossover

1 TD+ (Transmit+) RD+ (Receive+)

2 TD- (Transmit-) RD- (Receive-)

3 RD+ (Receive+) TD+ (Transmit+)

4n.c. n.c.

5n.c. n.c.

6 RD- (Receive-) TD- (Transmit-)

7n.c. n.c.

8n.c. n.c.

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

6 Commissioning

6.2 Ethernet interfaces (only PNOZ m0p ETH)

6.2.4 RJ45 connection cable

RJ45 connection cable6-ETH_RJ45 Ve rbindungskabel-8-pol ig

RJ45 connector

8-pin

10BaseT cable or 100BaseTX cable

max. 100 m

8

1

ETH_Wichtig_bedingte_Belastbarkeit_Datenkabel

6.2.5 Process data exchange

Process data exchange6-ETH_Prozessdatenaustausch_Switch

The RJ45 interfaces on the internal autosensing switch enable process

data to be exchanged with other Ethernet subscribers within a network.

The product PNOZ m0pETH can also be connected to Ethernet via a

hub (hub or switch).

ETH_Prozessdatenaustausch_Switch_Grafik_multi

NOTICE

With the plug-in connection please note that the data cable and

connector have a limited mechanical load capacity. Appropriate

design measures should be used to ensure that the plug-in connection is insensitive to increased mechanical stress (e.g.

through shock, vibration). Such measures include fixed routing

with strain relief, for example.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-3

Page 28

6 Commissioning

6.2 Ethernet interfaces (only PNOZ m0p ETH)

Ethernet

Hub/Switch Hub/Switch

Ethernet subscriber

PNOZmulti base unit

with Ethernet interface

Ethernet subscriber

PC with PNOZmulti

Configurator

PNOZmulti base unit

with Ethernet interface

Fig. 6-1: PNOZmulti as Ethernet subscriber - possible topologies

6-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

6 Commissioning

6.3 Preparing for operation

6.3Preparing for operation6300Preparing for operation6-

6.3.1 Function test during commissioning

Function test during commissioning6-Verdrahtung_multi_Basis_Betr_Funktionstest_BA

CAUTION!

It is essential to check that the safety devices operate correctly

` after the chip card has been exchanged

` after a project has been downloaded

` when the project has been deleted from the base unit's mem-

ory ("Reset Project" menu)

6.3.2 Commissioning the PNOZmulti safety system for the first time

Commissioning the PNOZmulti safety system for the first time6-Verdrahtung_multi_Basis_Betr_erstes_Mal_BA

Procedure:

` Wire the inputs and outputs on the base unit and expansion modules

in accordance with the circuit diagram.

` Cascading output as auxiliary output: Connect the load to CO+ and

A2, see connection example.

` Connect the supply voltage:

– Supply voltage for the units (connector X7):

– Terminal A1: + 24 VDC

–Terminal A2: 0 V

– Supply voltage for the semiconductor outputs (connector X2):

– Terminal 24 V: + 24 VDC

– 0V terminal: 0 V

Note: Supply voltage must always be applied to X2 and X7, even if you

are not using the semiconductor outputs.

6.3.2.1 Load project from chip card

Load project from chip card6-Verdrahtung_multi_Basis_Betr_erstes_Mal_von_Chipkarte_BA_alt

Procedure:

` Insert the chip card containing the current project into the card slot on

` Switch on the supply voltage.

NOTICE

Chip contacting is only guaranteed if the contact surface is

clean and undamaged. The chip's contact surface should therefore be protected from contamination, contact and mechanical

impact such as scratches.

the base unit.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-5

Page 30

6 Commissioning

6.3 Preparing for operation

6.3.2.2 Load project via integrated interface

Load project via integrated interface6-Verdrahtung_multi_Basis_Betr_erstes_Mal_Schnittstelle_BA

Procedure:

` Insert a chip card into the chip card slot on the base unit.

` Connect the computer containing the PNOZmulti Configurator to the

base unit via the interface.

` Switch on the supply voltage.

ETH_Info_PC_mit_Ethernet-Karte

` Download the project (see PNOZmulti Configurator's online help).

INFORMATION

You will need a PC with an Ethernet card in order to establish an

Ethernet connection.

6.3.3 Download modified project to the PNOZmulti safety system

Download modified project to the PNOZmulti safety system6-

6.3.3.1 Load modified project from chip card

Load modified project from chip card6-Verdrahtung_multi_Basis_Betr_geaend_Projekt_von_Chipkarte_BA

To download data via chip card, the existing configuration data must

first be deleted (general reset of device).

Procedure:

` Switch off the supply voltage.

` Disconnect all the output terminals.

` Jumper OA0-I19 on the base unit.

` Switch on the supply voltage.

When the "DIAG" LED on the base unit flashes, the memory has been

cleared. The project data can now be downloaded:

` Switch off the supply voltage.

` Remove the old chip card from the chip card slot on the base unit.

` Remove the link from OA0-I19 on the base unit.

` Insert the chip card containing the current project into the card slot.

` Switch on the supply voltage.

6-6

6.3.3.2 Load modified project via integrated interface

Load modified project via integrated interface6-Verdrahtung_multi_Basis_Betr_geaend_Projekt_Schnittstelle_BA

Proceed as described for the initial commissioning

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

6 Commissioning

6.3 Preparing for operation

6.3.4 Connection

Connection6-Betriebsbereitschaft he rstellen multi Basige rät

` Supply voltage

Supply voltage AC DC

For the safety system

(connector X7)

A1

+ 24 V DC

For the semiconductor outputs

(connector X2)

Must always be present, even if the

semiconductor outputs are not used

` Connection examples for the input circuit

Input circuit Single-channel Dual-channel

E-STOP

without detection of shorts across

S1

I0

L+

contacts

E-STOP

with detection of shorts across con-

S1

I0

tacts

T0

A2

24 V

0 V

I0

I1

T1

T0

0 V

+ 24 V DC

0 V

S1

I0

I1

L+

L+

S1

` Connection examples for reset circuit

Reset circuit Input circuit without detection of

shorts across contacts

S3

I5

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Input circuit with detection of shorts

across contacts

S3

I5

L+

T0

6-7

Page 32

6 Commissioning

6.3 Preparing for operation

` Connection examples for semiconductor outputs

Redundant output

Single output

` Connection examples for relay outputs

Redundant output

O0 (O2)

O1 (O3)

O0 (O2)

O1 ( O3)

13

O4

14

23

O5

24

K1

K2

K1

K2

K3

K4

K1

K2

L-

L-

L-

L-

L1

N

Single output

O4

O5

` Connection examples for feedback loop

Feedback loop Redundant output

Contacts from external contactors

O0 (O2, O4)

O1 (O3, O5)

13

14

23

24

K2

I0

K2

K1

K1

L1

N

L-

L-

L+

6-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

6 Commissioning

6.4 Connection example

6.4Connection example6400Connection example6-Anschlussbeispiel_Basisgeräte_BA

Dual-channel E-STOP and safety gate wiring, monitored reset (I17),

feedback loop (I14), cascading output as auxiliary output (CO+/A2)

L+

L-

CI+

CI-

CO-

CO+T0T1T2T3O0O1O2O3

OA0

24V

24V0V0V13142324

K1

K2

I0I1I2I3I4I5I6I7I8I9I10

S1

I11

I12

I13

I14

I15

I16

I17

I18

I19A1A1A2A2

K2

S2

S3

K1

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-9

Page 34

6 Commissioning

6-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

7 Operation

7.1 Messages

77000OperationOperation7-7.1Messages71 00Messages7-Betr ieb_Meldungen_Basi s_BA

The PNOZmulti safety system is ready for operation when the "POWER"

and "RUN" LEDs on the base unit are lit continuously.

7.1.1 Display elements for device diagnostics

Display elements for device diagnostics 7-Anzeige Legende 3x

Key:

LED on

LED flashes

LED off

Betrieb_Anzeige_multi_Bas is_ETH_BA

Basic Exp. Errors

Input Ix

RUN

DIAG

FAULT

IFAULT

OFAULTCICO

FAULT

IN/OUT

The existing user program has been deleted.

External error on the base unit, leading to a safe condition, e.g.

terminator not connected.

External error, leading to a safe condition, e.g. short across the

contacts or error on safety mat input.

External error on the outputs of the base unit, e.g. short across

the contacts, leading to a safe condition.

External error, leading to a safe condition, e.g. short across the

contacts.

External error on the output

Internal error on the base unit

Internal error on the base unit

Internal error on the base unit

Internal error on the expansion module

Base unit in a STOP condition

External error on the inputs of the base unit, which does not

lead to a safe condition, e.g. partially operated.

External error on the outputs of the base unit, which does not

lead to a safe condition, e.g. feedback input defective.

External error on the inputs, which does not lead to a safe condition, e.g. partially operated; feedback input defective.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-1

Page 36

7 Operation

7.1 Messages

The fieldbus module has not been recognised.

Or

The base unit was identified via the PNOZmulti Configurator.

Error on cascading input; unit remains in a RUN condition.

Error on cascading output; unit remains in a RUN condition.

7.1.2 Display elements for the Ethernet connection (only PNOZ m0p ETH)

Display elements for the Ethernet connection (only PNOZ m0p ETH)7-ETH_Anzeigeelemente_fuer_Ethernet_LNK_TRF

The operating statuses and fault conditions of the Ethernet connection

are shown via the LEDs LNK (link) and TRF (traffic) at the Ethernet interfaces.

LED Signal Meaning

LNK

(green)

No network connection

Network connection present

TRF (yellow)

No data traffic

Data traffic present

7-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

7 Operation

7.2 Reset Ethernet connection settings

7.2Reset Ethernet connection settings7200Reset Ethernet connection settings7-ETH_Verbindungseinstellungen_zuruecksetzen_multi

The Ethernet connection settings of the base unit can be configured in

the PNOZmulti Configurator.

You can reset the base unit's Ethernet connection settings to the default

settings.

Proceed as follows:

` Switch off the supply voltage

` Remove the chip card

` Restart the base unit without the chip card inserted.

The Ethernet connection settings are now reset to the default settings.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-3

Page 38

7 Operation

7-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

8 Technical details

8.1 Technical details

88000Technical detailsTechnical details8-8.1Technical details8100Technical details8-][Technische Daten_multi_Basis

Technical details

Electrical data

Supply voltage UB DC 24 V

Voltage tolerance -15 %/+20 %

Power consumption at U

without load 8.0 W No. 773110

per expansion module 2.50 W

Residual ripple DC 5 %

Status display LED

Times

Switch-on delay 5.00 s

Simultaneity channel 1/2/3 3 s

Two-hand circuit 0.5 s

Supply interruption before de-energisation 20 ms

Inputs

Number 20

Max. number of live inputs in the area of max. permitted

ambient temperature (see "Environmental data")

Voltage and current at input, reset and feedback circuit 24.0 V, 8.0 mA

Galvanic isolation no

Signal level at "0" -3 - +5 V DC

Signal level at "1" 15 - 30 V DC

Min. pulse duration 18 ms

Pulse suppression 0.6 ms

Test pulse outputs

Number of test pulse outputs 4

Voltage and current, 24 V 0.5 A

Off time during self test 5 ms

Galvanic isolation no

Short circuit-proof yes

Semiconductor outputs

Number 4

Switching capability

voltage 24 V

current 2 A

power 48 W

Max. capacitive load 1 µF

External supply voltage 24.0 V

Voltage tolerance -15 %/+20 %

Max. duration of off time during self test 300 µs

Galvanic isolation yes

Short circuit-proof yes

Switch-off delay 30 ms

Residual current at "0" 0.5 mA

Signal level at "1" UB - 0.5 V DC bei 2 A

Relay outputs

Number 2

DC

B

9.0 W No. 773113

U_B > 26.4 V : 15, U_B <= 26.4 V : 20

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-1

Page 40

8 Technical details

8.1 Technical details

Relay outputs

Utilisation category in accordance with EN 60947-4-1

Safety contacts: AC1 at 240 V 6.0 A, 1440 VA

Safety contacts: DC1 at 24 V 6.0 A, 144 W

Utilisation category in accordance with EN 60947-5-1

Safety contacts: AC15 at 230 V 3.0 A, 690 W

Safety contacts: DC13 at 24 V (6 cycles/min) 3.0 A, 72 W

Airgap creepage between

relay contacts 3 mm

relay contacts and other safe circuits 5.5 mm

External contact fuse protection (I

EN 60947-5-1

Blow-out fuse, quick 6 A

Blow-out fuse, slow 6 A

Circuit breaker 24 VAC/DC, characteristic B/C 6 A

Switch-off delay 50 ms

Auxiliary outputs

Number 1

Switching capability

voltage 24 V

current 0.5 A

power 12.0 W

Galvanic isolation yes

Short circuit-proof yes

Residual current at "0" 0.5 mA

Signal level at "1" UB - 0.5 V DC bei 0.5 A

Cascading output as auxiliary output

Number 1

Switching capability

voltage 24 V

current 0.2 A

power 4.8 W

Galvanic isolation no

Short circuit-proof yes

Residual current at "0" 0.5 mA

Environmental data

EMC EN 60947-5-1

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Amplitude 0.35 mm

Climatic suitability EN 60068-2-78

Airgap creepage in accordance with EN 60664-1

Ambient temperature 0 - 60 °C

Storage temperature -25 - 70 °C

Mechanical data

Protection type

Mounting (e.g. cabinet) IP54

Housing IP20

Terminals IP20

DIN rail

Top hat rail 35 x 7.5 EN 50022

Recess width 27 mm

= 1 kA) to

K

8-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

8 Technical details

8.1 Technical details

Mechanical data

Maximum cable runs

per input 1 km

Sum of individual cable runs at the test pulse output 40 km

Housing material

Housing PPO UL 94 V0

Front ABS UL 94 V0

Cross section of external conductors with screw terminals

Power supply, inputs, auxiliary output, semiconductor out-

puts, test pulse outputs, cascading outputs:

1 core flexible 0.50 - 1.50 mm² , 22 - 14 AWG No. 773113

0.50 - 2.50 mm² , 22 - 14 AWG No. 773110

2 core, same cross section, flexible:

with crimp connectors, without insulating sleeve 0.50 - 0.75 mm² , 22 - 20 AWG

without crimp connectors or with TWIN crimp connectors 0.50 - 0.75 mm² , 22 - 20 AWG

Relay outputs:

1 core flexible 0.5 - 1.5 mm² No. 773110

0.5 - 2.5 mm² No. 773113, 22 - 12 AWG

2 core, same cross section, flexible:

with crimp connectors, without insulating sleeve 0.50 - 1.25 mm², 22 - 16 AWG

without crimp connectors or with TWIN crimp connectors 0.50 - 1.25 mm², 22 - 16 AWG

Torque setting with screw terminals 0.25 Nm

Cross section of external conductors with spring-loaded

terminals: Flexible with/without crimp connectors

Spring-loaded terminals: Terminal points per connection 1

Stripping length 9 mm

Dimensions

Height 94.0 mm

Width 135.0 mm

Depth 121.0 mm

Weight 490 g No. 773110

Technische Daten_Satz No .

0.50 - 1.50 mm² , 26 - 14 AWG

520 g No. 773113

Si-Kennzahlen_alle

Safety characteristic data

Unit Operating mode

Logic

CPU PL e (Cat. 4) Cat. 4 SIL CL 3 4.90E-09 20

Input

SC inputs single-channel PL d (Cat. 2) Cat. 2 SIL CL 2 2.50E-09 20

SC inputs dual-channel PL e (Cat. 4) Cat. 4 SIL CL 3 2.90E-10 20

SC inputs light beam device PL e (Cat. 4) Cat. 4 SIL CL 3 2.50E-10 20

SC inputs dual-channel pres-

sure sensitive mat

cascading inputs PL e (Cat. 4) Cat. 4 SIL CL 3 3.10E-10 20

Output

SC outputs single-channel PL d (Cat. 2) Cat. 3 SIL CL 2 7.00E-09 20

SC outputs dual-channel PL e (Cat. 4) Cat. 4 SIL CL 3 8.60E-10 20

cascading outputs PL e (Cat. 4) Cat. 4 SIL CL 3 4.91E-10 20

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

No. stands for order number.

EN ISO 13849-1PLEN 954-1

Category

PL d (Cat. 3) Cat. 3 SIL CL 2 1.81E-09 20

EN IEC 62061

SIL CL PFH [1/h] tM [year]

8-3

Page 42

8 Technical details

8.1 Technical details

Output

relay outputs single-channel PL c (Cat. 1) Cat. 2 - 2.90E-08 20

relay outputs dual-channel PL e (Cat. 4) Cat. 4 SIL CL 3 3.00E-10 20

Si-Kennzahlen_Zusatz_Relais_1kan_EN954_Cat2

Requirement on 1-channel relay outputs for Cat. 2 in accordance with

EN 954-1: An additional output switches to a safe condition in the event

Si_Kennzahlen_Erläuterung

Technische Daten_Satz No rmen

of an error or, if that is impossible, signals a hazardous condition.

All the units used within a safety function must be considered when calculating the safety characteristic data.

Si-Kennzahlen_Zusatz_Relais_Lebensdauer_BA

The standards current on 2009-03 apply.

CAUTION!

It is essential to consider the relay's service life graphs. The relay

outputs' safety-related characteristic data is only valid if the values in the service life graphs are met.

The PFH value depends on the switching frequency and the load on the

relay output. If the service life graphs are not accessible, the stated PFH

value can be used irrespective of the switching frequency and the load,

as the PFH value already considers the relay's B10d value as well as the

failure rates of the other components.

8-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

8 Technical details

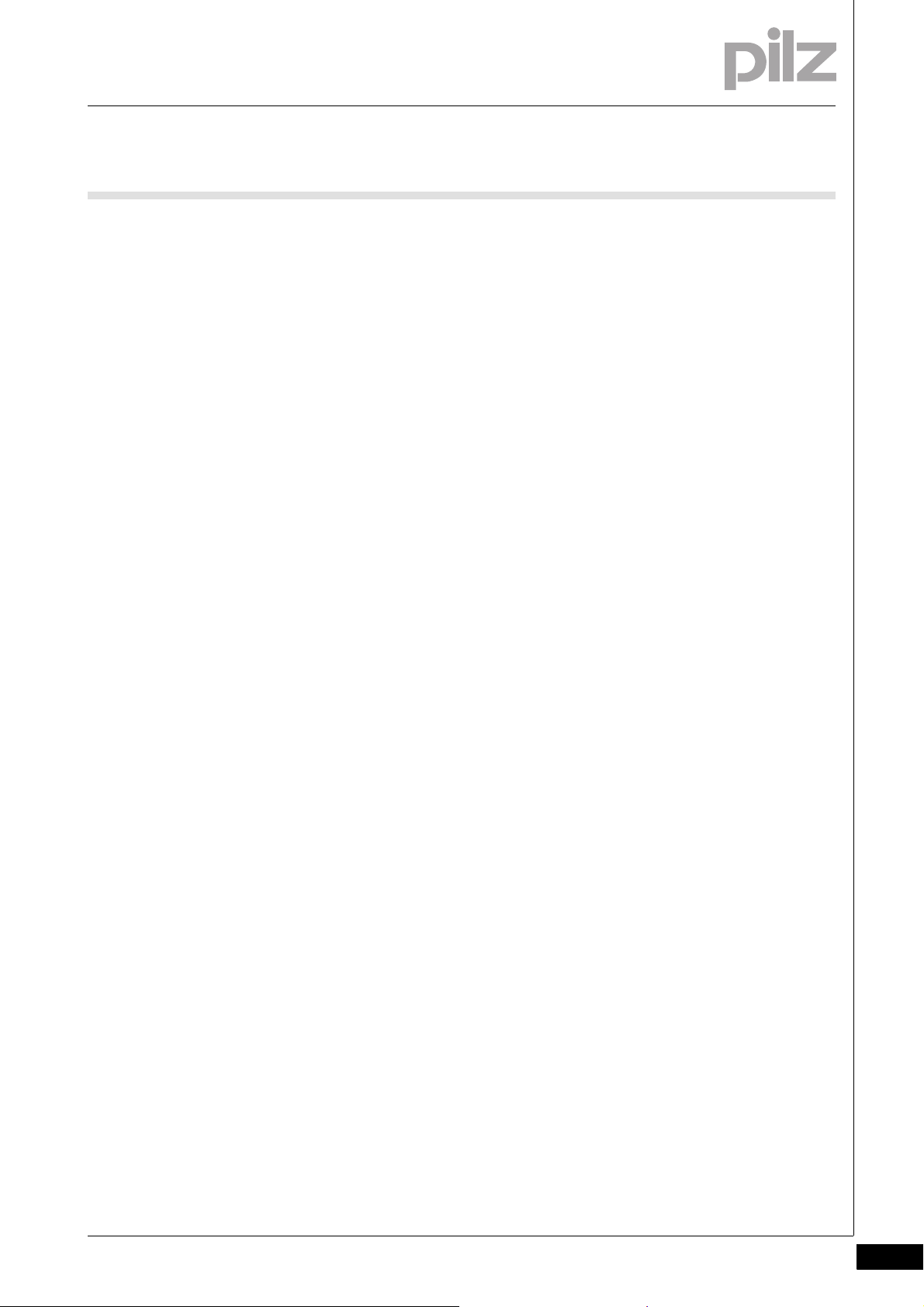

8.2 Service life graph of output relays

8.2Service life graph of output relays8200Service life graph of output relays8-Lebensda uerkurve_Relais_T ext vor Kurve

The service life graphs indicate the number of cycles from which failures

due to wear must be expected. The wear is mainly caused by the elec-

Lebensdauerkurve SIS_212

trical load; the mechanical load is negligible.

Lebensdauerkurve_Relai s_Text nach Kurv e_SIS212_SIR-SLR B sp

10

1

D Nennbetriebstrom (A)

GB Nominal operating current (A)

F Courant coupé (A)

0.1

E Corriente nominal de servicio (A)

I Corrente di esercizio nominale (A)

NL Nominale bedrijfsstroom (A)

10 100 1000 10000

D Schaltspielzahl x 10

GB Cycles x 10

F Nombre de manuvres x 10

AC15: 230 V

DC13: 24 V

3

AC1: 230 V

3

DC1: 24 V

E Número de ciclos x 10

I Numero dei cicli di commutazione x 10

3

NL Aantal schakelingen x 10

3

3

Example

` Inductive load: 0.2 A

` Utilisation category: AC15

` Contact service life: 1 000 000 cycles

Provided the application requires fewer than 1 000 000 cycles, the PFH

value (see technical details) can be used in the calculation.

3

To increase the service life, sufficient spark suppression must be provided on all output contacts. With capacitive loads, any power surges that

occur must be noted. With contactors, use freewheel diodes for spark

suppression.

Lebensdauerkurve_Relais_Text nach Kurve-2_ Empfehlung Halbleiterausgänge

We recommend you use semiconductor outputs to switch 24 VDC

loads.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-5

Page 44

8 Technical details

8.3 Maximum capacitive load C (mF) with load current I (mA) at the semiconductor outputs

8.3Maximum capacitive load C (μF) with load current I (mA) at the semiconductor outputs8300Maximum capacitive load C (μF) with load current I (mA) at the semiconductor outputs8-Kapazitaet

C (µF)

6

4

2

0

0 10 50 100 200 400 600 800

1000

1400 1600 1800 2000

1200 I (mA)

8-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 45

8 Technical details

8.4 Order reference

8.4Order reference8400Order reference8-Bes telldaten

Order reference

Type Features Order no.

PNOZ m0p Base unit 773 110

PNOZ m0p ETH Base unit 773 113

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-7

Page 46

8 Technical details

8-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 47

© Pilz GmbH & Co. KG, 2010

1002053-EN-03, 2010-10 Printed in Germany

... www

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

www.pilz.com

Technical support

+49 711 3409-444

support@pilz.com

are registered and protected trademarks

®

, the spirit of safety

®

, SafetyNET p

®

, SafetyEYE

®

, SafetyBUS p

®

, PVIS

®

, PSS

®

, PSEN

®

, Primo

®

, PNOZ

®

, PMI

®

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

, PMCprotego

®

, PIT

®

, Pilz

®

InduraNET p

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Loading...

Loading...