Page 1

PNOZ e8.1p

} Safety relays

Operating Manual-1002226-EN-06

Page 2

Preface

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes. Suggestions and comments for improving this documentation will be

gratefully received.

Source code from third-party manufacturers or open source software has been used for

some components. The relevant licence information is available on the Internet on the Pilz

homepage.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®,

SafetyEYE®, SafetyNET p®, the spirit of safety® are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries.

SD means Secure Digital

Page 3

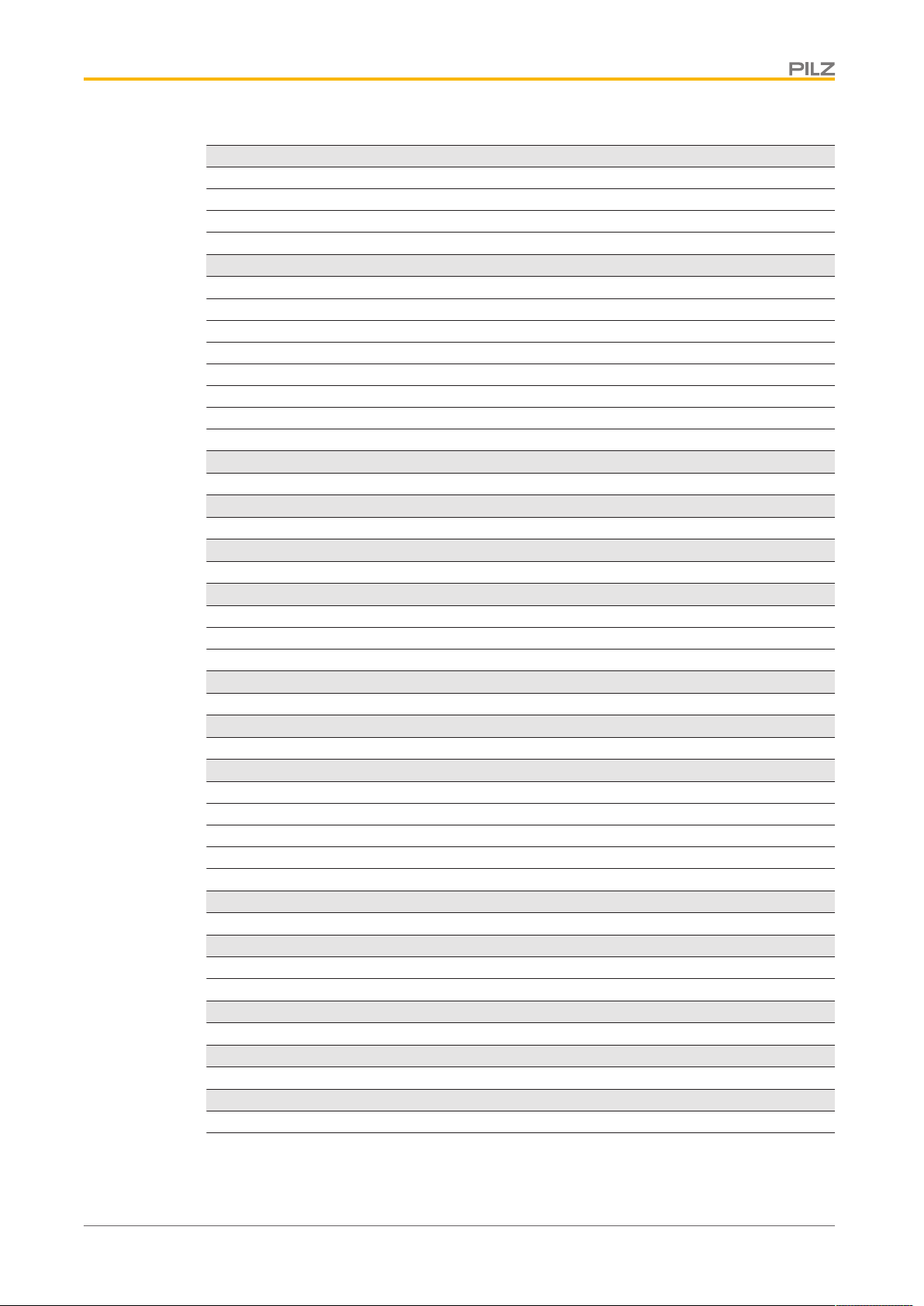

Contents

Introduction 5

Validity of documentation 5

Using the documentation 5

Definition of symbols 5

Safety 6

Intended use 6

Safety regulations 6

Safety assessment 6

Use of qualified personnel 7

Warranty and liability 7

Disposal 7

For your safety 7

Unit features 8

Safety features 8

Block diagram/terminal configuration 8

Function description 9

Operating modes 10

Selecting sensors 10

Installation 10

Wiring 11

Preparing for operation 12

Supply voltage 12

Input circuit 12

Start circuit/feedback loop 13

Application example 14

Logic connection between several units 15

Operation 16

Status indicators 16

Faults – Interference 17

Dimensions in mm 22

Technical details 22

Safety characteristic data 25

Operating Manual PNOZ e8.1p

1002226-EN-06

3

Page 4

Contents

Remove plug-in terminals 26

Order reference 26

Product 26

Accessories 26

Operating Manual PNOZ e8.1p

1002226-EN-06

4

Page 5

PNOZ e8.1p

Introduction

Validity of documentation

This documentation is valid for the product PNOZ e8.1p. It is valid until new documentation

is published.

This operating manual explains the function and operation, describes the installation and

provides guidelines on how to connect the product.

Using the documentation

This document is intended for instruction. Only install and commission the product if you

have read and understood this document. The document should be retained for future reference.

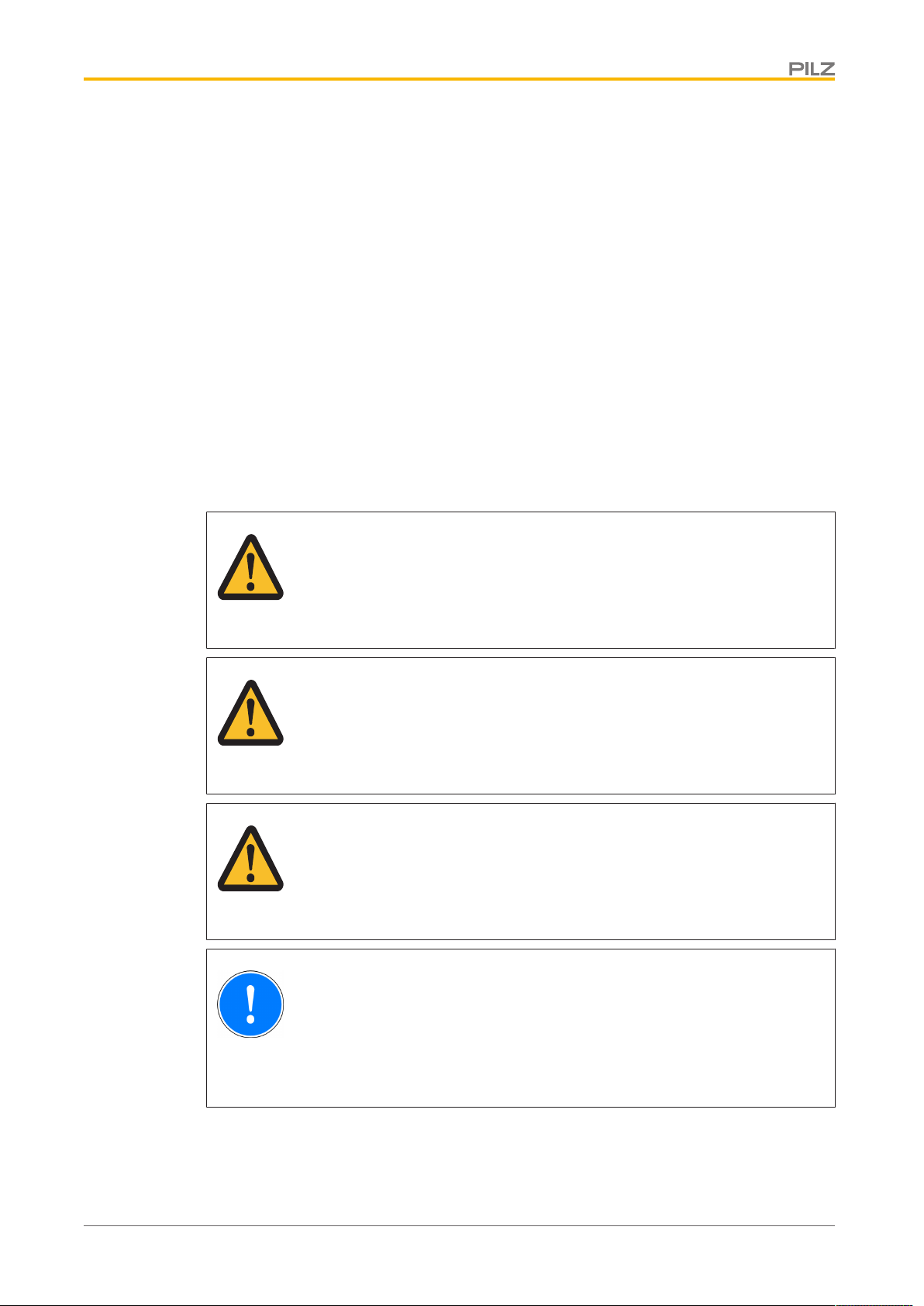

Definition of symbols

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses

an immediate threat of serious injury and death and indicates preventive

measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that could

lead to serious injury and death and indicates preventive measures that can

be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

Operating Manual PNOZ e8.1p

1002226-EN-06

This describes a situation in which the product or devices could be damaged and also provides information on preventive measures that can be

taken. It also highlights areas within the text that are of particular importance.

5

Page 6

PNOZ e8.1p

INFORMATION

This gives advice on applications and provides information on special features.

Safety

Intended use

The PNOZ e8.1p is the evaluation device for safe line inspection with PLID d1. As the evaluation device for PLID d1, the PNOZ e8.1p achieves PL d (Cat. 2) in accordance with EN

ISO 13849-1 and SIL CL 2 in accordance with EN IEC 62061.

The safety relay PNOZ e8.1p provides a safety-related interruption of two safety circuits.

It may be used in conjunction with PLID d1

} In emergency stop equipment

} In safety circuits in accordance with VDE0113 Part 1 and EN60204-1

} As an evaluation device for position switches with N/C / N/C combination

The following is deemed improper use in particular:

} Any component, technical or electrical modification to the product

} Use of the product outside the areas described in this manual

} Use of the product outside the technical details (see Technical details [ 22]).

NOTICE

EMC-compliant electrical installation

The product is designed for use in an industrial environment. The product

may cause interference if installed in other environments. If installed in other

environments, measures should be taken to comply with the applicable

standards and directives for the respective installation site with regard to interference.

Safety regulations

Safety assessment

Before using a unit it is necessary to perform a safety assessment in accordance with the

Machinery Directive.

Functional safety is guaranteed for the product as a single component. However, this does

not guarantee the functional safety of the overall plant/machine. In order to achieve the required safety level for the overall plant/machine, define the safety requirements for the

plant/machine and then define how these must be implemented from a technical and organisational standpoint.

Operating Manual PNOZ e8.1p

1002226-EN-06

6

Page 7

PNOZ e8.1p

Use of qualified personnel

The products may only be assembled, installed, programmed, commissioned, operated,

maintained and decommissioned by competent persons.

A competent person is a qualified and knowledgeable person who, because of their training, experience and current professional activity, has the specialist knowledge required. To

be able to inspect, assess and operate devices, systems and machines, the person has to

be informed of the state of the art and the applicable national, European and international

laws, directives and standards.

It is the company’s responsibility only to employ personnel who

} Are familiar with the basic regulations concerning health and safety / accident preven-

tion,

} Have read and understood the information provided in this description under "Safety"

} Have a good knowledge of the generic and specialist standards applicable to the spe-

cific application.

Warranty and liability

All claims to warranty and liability will be rendered invalid if

} The product was used contrary to the purpose for which it is intended

} Damage can be attributed to not having followed the guidelines in the manual

} Operating personnel are not suitably qualified

} Any type of modification has been made (e.g. exchanging components on the PCB

boards, soldering work etc.).

Disposal

} In safety-related applications, please comply with the mission time TM in the safety-re-

lated characteristic data.

} When decommissioning, please comply with local regulations regarding the disposal of

electronic devices (e.g. Electrical and Electronic Equipment Act).

For your safety

The unit meets all the necessary conditions for safe operation. However, please note the

following:

} Please make sure you shut down the supply voltage or open the input circuit (e.g. oper-

ate the E-STOP pushbutton) when performing maintenance work (e.g. when replacing

contactors), otherwise the unit might switch on unexpectedly in the case of a wiring error.

Operating Manual PNOZ e8.1p

1002226-EN-06

7

Page 8

PNOZ e8.1p

Input

PLIDdys

Input

Feedback

Diagnostic

Power

Test

Pulse

Output

S12

S36

Y6

Y5

14 24Y32

A1 A2

S22

Start

S34

Input

S32

S42

Y33Y37

Y7

&

PNOZ e8.1p

Unit features

} Outputs using semiconductor technology:

– 2 safety outputs

– 2 auxiliary outputs

– 1 test pulse output

} Connection options:

– PLID d1

– E-STOP pushbuttons

– Safety gate limit switches

– Start button

– Proximity switch

– Position switch with N/C / N/C combination

} To process signals from output signal switching devices (OSSDs) on light grids

} LED display for:

– Supply voltage

– Switch state of safety outputs

} Feedback loops for monitoring external contactors

Safety features

The relay meets the following safety requirements:

} The circuit is redundant with built-in self-monitoring.

} The safety device remains effective in the case of a component failure.

} The safety outputs are tested periodically using an off-test.

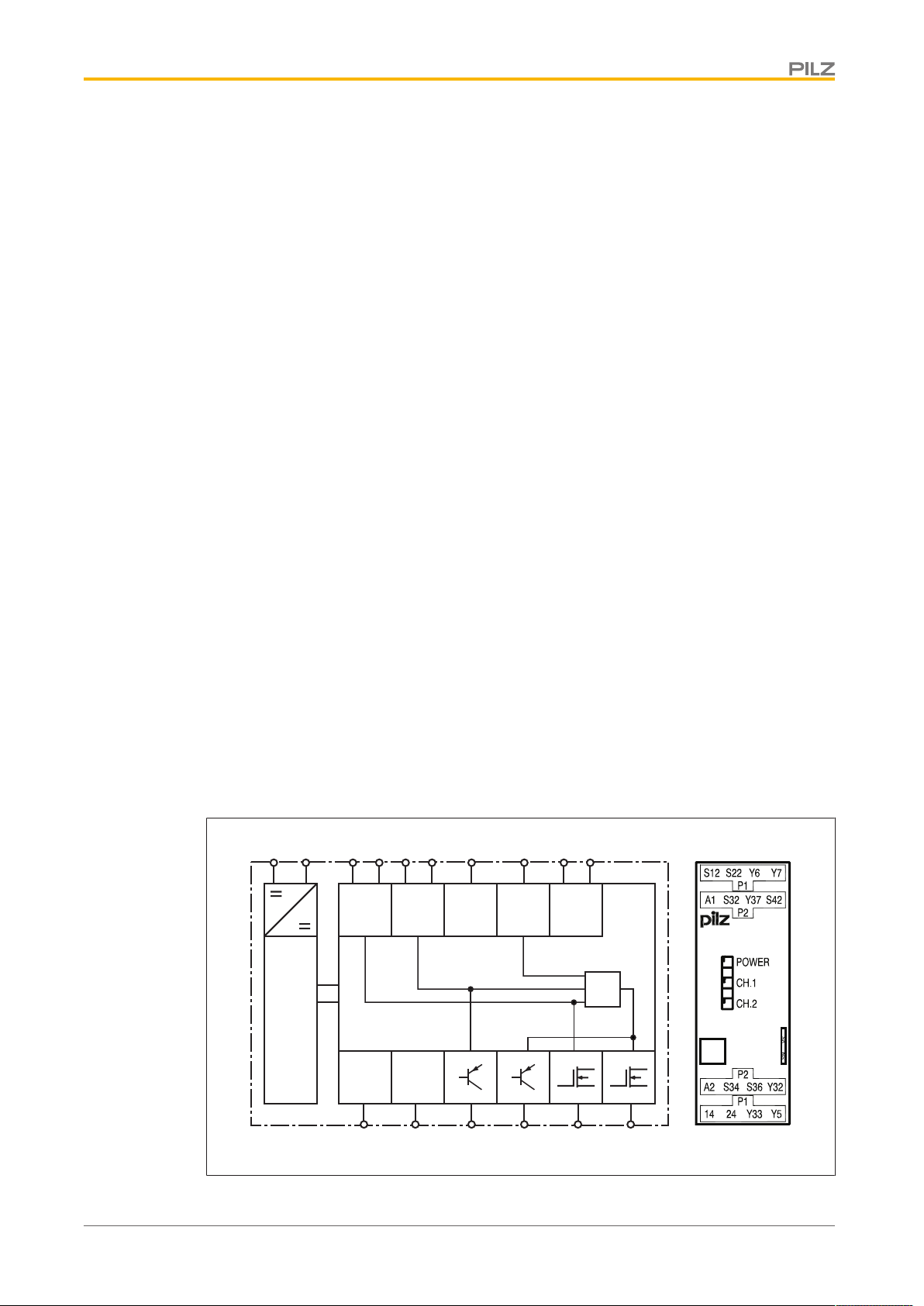

Block diagram/terminal configuration

Operating Manual PNOZ e8.1p

1002226-EN-06

8

Page 9

PNOZ e8.1p

Function description

When supply voltage is applied and the set operating mode is detected (initialisation

phase), the "POWER" LED is lit. The unit is ready for operation when the feedback loops

are closed.

} Input circuit S12, S22 is closed (e.g. E-STOP pushbutton not operated):

– The LED "CH.1" is lit.

– There is a high signal at safety output 14, the unit is active.

} Input circuit S12, S22 is opened (e.g. E-STOP pushbutton operated):

– The LEDs "CH.1" and "CH.2" go out.

– There is a low signal at safety outputs 14 and 24 and auxiliary output Y32.

Input circuit S32, S42 is AND-linked with input circuit S12, S22 and PLIDdys input S36. The

result of the logic operation can be viewed through safety output 24 and auxiliary output

Y32. If

} Input circuit S12, S22 is closed (e.g. E-STOP pushbutton not operated)

and

} Input circuit S32, S42 is closed (e.g. safety gate closed)

and

} PLID d1 is connected to PLIDsys input S36, the input circuit and the contact (E-STOP

pushbutton or start button) are closed and the cable routing is error-free, then

– The LED "CH.2" is lit and

– There is a high signal at safety outputs 14 and 24 and auxiliary output Y32. The unit

is active.

} Input circuit S32, S42 is opened (e.g. safety gate opened), then

– The LED "CH.2" goes out and

– There is a low signal at safety output 24 and auxiliary output Y32.

Auxiliary output Y33 indicates the status of input circuit S32, S42. There is a high signal at

the auxiliary output if the input circuit S32, S42 is closed (e.g. safety gate closed).

Feedback loop

Before a safety output is switched on, a test is run to establish whether the contacts at

feedback loop inputs Y6 and Y7 are closed. If a contact is open, an error is detected and

LEDs CH.1 and CH.2 will flash alternately. It will not be possible to switch the unit back on

until the feedback loops are closed and the safety function has been reset.

The feedback loop contacts are also checked when the signal at the output changes from

high to low. After this signal change, the contacts at the feedback loop inputs must close

within 150 ms. If a contact is still open after 150 ms has elapsed, an error is detected and is

displayed as a flashing code 1,8 (see Faults – Interference [ 17]). It will not be possible

to switch the unit back on until the error has been rectified and the supply voltage has been

switched off and then on again.

Operating Manual PNOZ e8.1p

1002226-EN-06

9

Page 10

PNOZ e8.1p

Operating modes

} Single-channel operation: Input wiring in accordance with EN 60204, no redundancy in

the input circuit; earth faults in the input circuit and start circuit are detected.

} Dual-channel operation: Redundant input circuit; earth faults in the input circuit and

start circuit are detected.

} Automatic start: Unit is active once the input circuit has been closed.

} Monitored start: Unit is not active until the start button has been operated and then re-

leased.

} Increase in the number of available contacts by connecting contact expander modules

or external contactors/relays.

Selecting sensors

When selecting sensors, you must comply with the technical details of the input circuits on

the PNOZelog units.

Installation

CAUTION!

Electrostatic discharge can damage components on the safety system!

Ensure against discharge before touching the safety system, e.g. by touching an earthed, conductive surface or by wearing an earthed armband.

} The unit should be installed in a control cabinet with a protection type of at least IP54.

} Use the notch on the rear of the unit to attach it to a DIN rail (35 mm).

} When installed vertically: Secure the unit by using a fixing element (e.g. retaining

bracket or end angle).

NOTICE

If you are connecting several units logically, please note the guidelines in

the section entitled Logic connection between several units [ 15].

Operating Manual PNOZ e8.1p

1002226-EN-06

10

Page 11

PNOZ e8.1p

R

lmax

Rl / km

I

max

=

Wiring

Please note:

} Information given in the "Technical details [ 22]" must be followed.

} Use copper wire that can withstand 60/75°C.

} Calculation of the max. cable length l

R

= max. overall cable resistance (see Technical details [ 22])

lmax

Rl/km = cable resistance/km

} Cables that have to be laid outside the control cabinet must be protected from mechan-

ical damage, e.g. by installing them in a conduit.

} The unit and the input circuits must always be supplied by a single power supply.

} Safety outputs 14 and 24 should exclusively be used for safe applications.

} The safety outputs must not be connected to control inputs.

} To suppress the pulse on switching off at safety outputs 14 and 24, use the terminal

block with filter (see Order reference [ 26]).

} You must comply with the idling capacity at safety outputs 14 and 24 (see Technical

details [ 22]).

} Only contactors with positive-guided contacts should be used for safety functions.

} Outputs Y32 and Y33 are auxiliary outputs, e.g. for communication with a PLC or text

display.

} Do not use auxiliary outputs Y32 and Y33 for safety circuits!

} Use freewheel diodes to drive inductive loads (e.g. contactors or relays) with the safety/

auxiliary outputs.

} When connecting magnetically operated, reed proximity switches, ensure that the max.

peak inrush current (on the input circuit) does not overload the proximity switch.

} The power supply must comply with the regulations for extra low voltages with protect-

ive electrical separation (SELV, PELV) in accordance with VDE 0100, Part 410.

} Ensure the wiring and EMC requirements of EN 60204-1 are met.

} Terminal Y5 is provided for Pilz-internal diagnostic purposes.

} Where one line is to be monitored, only use one PNOZ e8.1p and one PLID d1. Route

the line so that it is protected.

in the input circuit:

max

Operating Manual PNOZ e8.1p

1002226-EN-06

11

Page 12

PNOZ e8.1p

A1

F1

A2

L+

L-

A1

A2 S12

S22

24 V DC

GND

A1

A2 S32

S42

24 V DC

GND

Preparing for operation

Supply voltage

Supply voltage AC DC

Input circuit

Evaluation device for PLID d1:

The PLID d1 should be wired as described in the operating manual for PLID d1.

Input circuit Input circuit S12, S22 Input circuit S32, S42

Single-channel

Dual-channel (without detection of shorts across contacts)

Light guard or safety switch,

detection of shorts across

contacts via ESPE

The E-STOP pushbutton and safety gate switch symbolise a trigger element with N/C / N/C

combination.

Input circuit Input circuit S36, A2

PLID d1

Connection example with

N/C contact (continuous

test)

PLID d1

Connection example with

N/O contact (manual test)

Operating Manual PNOZ e8.1p

1002226-EN-06

12

Page 13

PNOZ e8.1p

CAUTION!

A short circuit on the pushbutton or on the supply line to the pushbutton is

not monitored!

Use appropriate measures to prevent a short circuit on the pushbutton.

Start circuit/feedback loop

Terminals Y6 and Y7 are used to connect the feedback loops and also to define the start

behaviour.

} The Y6 terminal is used to

– Determine the start behaviour for input circuit S12, S22 and

– To connect the feedback loop for safety output 14.

} The Y7 terminal is used to

– Determine the start behaviour for input circuit S32, S42 and

– Connect the feedback loop for safety output 24.

Start behaviour Input circuit S12, S22 Input circuit S32, S42

Automatic start

Monitored start

Feedback loop unconnected:

If you do not wish to connect any contacts to the feedback loop, replace the contacts at Y6 /

Y7 with a bridge, depending on the required start behaviour.

NOTICE

With automatic start

The unit starts up automatically when the safeguard is reset, e.g. when the

E-STOP pushbutton is released. Use external circuit measures to prevent

an unexpected restart.

Operating Manual PNOZ e8.1p

1002226-EN-06

13

Page 14

PNOZ e8.1p

Application example

Fig.: Safe line inspection with PLID d1 and AND-link with PNOZ e3.1p

Operating Manual PNOZ e8.1p

1002226-EN-06

14

Page 15

PNOZ e8.1p

Logic connection between several units

Units from the PNOZelog product range can be logically connected to each other and to

units from the PNOZmulti product range. On the PNOZelog, input S35 is intended for the

logic OR connection and input S36 for the logic AND connection. Safety outputs 14 and 24

on the PNOZelog are suitable for logic connections.

When linking several units logically, please note:

} When PNOZelog units are linked logically to each other, a safety output from a

PNOZelog unit may be connected to logic inputs from one or more PNOZelog units.

} When linking PNOZelog units logically to PNOZmulti units

– a cascading output from PNOZmulti units may be connected to logic inputs on

PNOZelog units

or

– a safety output from PNOZelog units may be connected to cascading inputs on

PNOZmulti units.

} The unit with the lowest SIL/PL value determines the SIL/PL value of the entire circuit.

} PNOZ e1p, PNOZ e8.1p: These units do not have logic inputs. Their safety outputs can

be used to logically link the units to the logic inputs of other PNOZelog units or to the

cascading inputs from PNOZmulti units.

} Safety outputs from the PNOZ e1p are suitable for logic connections from unit version

3.0.

} Each safety output on a PNOZelog unit that is connected to the load may also be con-

nected to the logic inputs of a maximum of four PNOZelog units.

} Up to 50 logic inputs from PNOZelog units can be connected to safety outputs with no

load.

} Logically linking the units leads to delays when switching on and off (see on-delay and

response time in the Technical details [ 22]). These are added up with each unit

that is logically linked.

} Install all the logically linked units in the same control cabinet or ensure that faults re-

garding the units' connection are excluded, e.g. via protected installation of the connection cables.

} All linked units must be connected to the same supply voltage.

Operating Manual PNOZ e8.1p

1002226-EN-06

15

Page 16

PNOZ e8.1p

Operation

NOTICE

The safety function should be checked after initial commissioning and each

time the plant/machine is changed. The safety functions may only be

checked by qualified personnel.

INFORMATION

The safety outputs are constantly checked via test pulses. This may generate a humming noise on the connected contactors, which does not affect

the function. The test pulses also mean that, when measured with a multimeter, the voltage at the safety outputs is displayed to be less than it actually is.

The unit detects the set operating mode once supply voltage is applied. During this time

(initialisation phase) the "POWER" LED will flash. The unit is ready for operation when the

"POWER" LED is lit continuously.

LEDs indicate the status and errors during operation:

LED on

LED flashes

Status indicators

POWER

Supply voltage is present, operating mode is detected.

POWER

Initialisation phase

CH.1

There is a high signal at safety output 14.

CH.2

There is a high signal at safety output 24.

Operating Manual PNOZ e8.1p

1002226-EN-06

16

Page 17

PNOZ e8.1p

Faults – Interference

INFORMATION

Supply interruptions lasting longer than 20 ms are detected as an error. The

LEDs indicate an error and the safety outputs carry a low signal. The plant

or machinery driven via the safety outputs will be shut down. The unit can

only be restarted when the supply voltage is switched off for at least 1 s and

then switched on again.

Fault

Fault conditions are indicated by flashing the LEDs. There are faults that are displayed via

periodic flashing (see table "Display of fault conditions") and faults where an error code can

be determined via the number of flashes (see table "Relationship between the number of

flashes and the decimal error code"). These faults are always indicated by three short

flashes at LED CH.1 or CH.2. After a longer pause, the LED will then flash at one second

intervals. The number of LED flashes corresponds to a digit in the error code. The error

code can consist of up to 4 digits. The digits are separated by a longer period without flashing. The entire sequence is constantly repeated.

INFORMATION

Error code 0: 16 flashes

Operating Manual PNOZ e8.1p

1002226-EN-06

17

Page 18

PNOZ e8.1p

I

IV

II

Display of fault conditions

LED Fault Remedy

LEDs unlit Supply voltage is missing,

too low, wrongly connected

POWER flashes Unknown operating mode,

initialisation phase, start not

executed

CH.1 or CH.2 flash a code Error coding, see table "Er-

ror code [ 20]"

CH.1 and CH.2 flash alternately

1.) Feedback loop open on

start-up

2.) Only one channel of the

input circuit is open or is partially operated

Examples

Error code 1, 3:

LED CH.1 or CH.2 flashes

} 3 times, short

} Pause

} Once for one second

} Pause

} 3 times, for one second each

Connect supply voltage: A1 +24 VDC and A2 - 0 VDC

Permitted voltage range:

19.2 ... 30VDC

Depending on operating

mode: Press start button or

perform start-up test

See table "Error

code [ 20]"

1.) Close feedback loop,

open input circuit, start unit

again

2.) Open both input circuit

channels or activate and

then clear the safety mat

Error code 1:

LED CH.1 or CH.2 flashes

} 3 times, short

} Pause

} Once for one second

Operating Manual PNOZ e8.1p

1002226-EN-06

18

Page 19

PNOZ e8.1p

I

IV

III

II

Error code 1, 0:

LED CH.1 or CH.2 flashes

} 3 times, short

} Pause

} Once for one second

} Pause

} 16 times, for one second each

I Code for error message

II Code for 1st digit

III Code for 2nd digit

IV Code for error message repeated

The table below shows the relationship between the number of flashes and the error code.

The key to the error codes is described in the Error coding table.

Number of

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

flashes

Decimal er-

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 0

ror code

Operating Manual PNOZ e8.1p

1002226-EN-06

19

Page 20

PNOZ e8.1p

Error coding

INFORMATION

Each time a fault is rectified, switch the supply voltage off for at least 1 s

and then switch it back on.

Decim

al error

code Number of flashes Description Remedy

1

3x short – 1x long

– 3x short

2

3x short – 2x long

– 3x short

3 3x short – 3x long

– 3x short

4

3x short – 4x long

– 3x short

…

9

…

3x short – 9x long

– 3x short

10

3x short – 10x long

– 3x short

…

1, 0

…

3x short – 1x long

– 16x long – 3x short

1, 1

3x short – 1x long

– 1x long – 3x short

1, 9

3x short – 1x long

– 9x long – 3x short

Faulty wiring, short circuit Wiring error at start input, input cir-

cuits, feedback loop or programming

input

Operating mode changed during

operation

In the initialisation phase, short

Check wiring for the operating mode

and rectify fault

Rectify wiring error at terminals 14, 24

circuit between the safety outputs and +24 VDC

During operation, short circuit

Rectify wiring error at terminals 14, 24

between the safety outputs and

+24 VDC

10.1

3x short – 10x long

– 1x long – 3x short

14.5

3x short – 14x long

– 5x long – 3x short

1, 2

3x short – 1x long

– 2x long – 3x short

1, 3

3x short – 1x long

– 3x long – 3x short

1, 12

3x short – 1x long

– 12x long – 3x short

1, 13

3x short – 1x long

– 13x long – 3x short

1, 4 3x short – 1x long

– 4x long – 3x short

Operating Manual PNOZ e8.1p

1002226-EN-06

During operation, short circuit

between the safety outputs and

0 VDC or UB<19.2 VDC

Operating mode changed during

operation

Rectify wiring error at terminals 14, 24;

Keep within the supply voltage range

of 19.2 ... 30 VDC

Check wiring for the operating mode

and rectify fault

20

Page 21

PNOZ e8.1p

Decim

al error

code Number of flashes Description Remedy

1, 5 3x short – 1x long

– 5x long – 3x short

1, 6

3x short – 1x long

– 6x long – 3x short

1, 7

3x short – 1x long

– 7x long – 3x short

1, 8

3x short – 1x long

– 8x long – 3x short

1, 11

3x short – 1x long

– 11x long – 3x short

1, 10 3x short – 1x long

– 10x long – 3x short

5, 10 3x short – 5x long

– 10x long – 3x short

8, 1 3x short – 8x long

– 1x long – 3x short

8, 2

3x short – 8x long

– 2x long – 3x short

8, 3

3x short – 8x long

– 3x long – 3x short

Unexpected status at S36 Check wiring at terminal S36

Wiring of operating mode “with

Rectify wiring error at input circuits

detection of shorts across contacts” faulty

1. Maximum time of feedback

loop monitoring exceeded

2. PNOZe6.1p, PNOZe6vp:

External feedback loop

1. Check contactor for contact welding

2. No user remedy possible. Change

the unit.

closed, but internal feedback

loop faulty

Open circuit Check safety mat wiring

UB<19.2VDC Keep within the supply voltage range

of 19.2 ... 30 VDC

Invalid operating mode Check wiring for the operating mode

and rectify fault

Supply interrupted, possibly

caused by a short to earth

Rectify wiring error at terminal A1 or

check supply voltage

14, 13

3x short – 14x long

– 13x long – 3x short

2, 0, 0

3x short – 2x long

– 16x long – 16x long

– 3x short

2, 0, 1

3x short – 2x long

– 16x long – 1x long

– 3x short

2, 0, 2 3x short – 2x long

– 16x long – 2x long

– 3x short

2, 0, 3 3x short – 2x long

– 16x long – 3x long

– 3x short

UB<19.2VDC Keep within the supply voltage range

of 19.2 ... 30 VDC

In the initialisation phase, short

Rectify wiring error at terminals 14, 24

circuit between the safety outputs and +24 VDC

UB<19.2VDC Keep within the supply voltage range

of 19.2 ... 30 VDC

Operating Manual PNOZ e8.1p

1002226-EN-06

21

Page 22

PNOZ e8.1p

Dimensions in mm

* With spring-loaded terminals

Technical details

General 774198 784198

CE, EAC (Eurasian), TÜV, cULus

Approvals

Electrical data 774198 784198

Supply voltage

Voltage 24 V 24 V

Kind DC DC

Voltage tolerance -15 %/+10 % -15 %/+10 %

Output of external power supply

(DC) at no load 3 W 3 W

Residual ripple DC 20 % 20 %

Duty cycle 100 % 100 %

External unit fuse protection F1

max. 6 A slow/10 A quick 6 A slow/10 A quick

Inputs 774198 784198

Voltage at

Input circuit DC 24 V 24 V

Start circuit DC 24 V 24 V

Feedback loop DC 24 V 24 V

Logic input 24 V 24 V

Current at

Input circuit DC 5 mA 5 mA

Start circuit DC 5 mA 5 mA

Feedback loop DC 5 mA 5 mA

Logic input 5 mA 5 mA

Listed

CE, EAC (Eurasian), TÜV, cULus

Listed

Operating Manual PNOZ e8.1p

1002226-EN-06

22

Page 23

PNOZ e8.1p

Inputs 774198 784198

Max. overall cable resistance Rlmax

Start circuit and feedback loop 1.000 Ohm 1.000 Ohm

Input circuit, single-channel 1.000 Ohm 1.000 Ohm

Input circuit, dual-channel 2.000 Ohm 2.000 Ohm

Max. line capacitance 450 nF 450 nF

Semiconductor outputs 774198 784198

Overall performance ext. loading,

semiconductor 80 W 80 W

Number of safety outputs

Instantaneous 2 2

Number of auxiliary outputs 2 2

Number of test pulse outputs 1 1

Switching capability, 2 safety outputs under load

Current at UB ≤ 26.5 V 1,5 A 1,5 A

Power at UB ≤ 26.5 V 40 W 40 W

Switching capability, 1 safety output under load

Current at UB ≤ 26.5 V 2 A 2 A

Power at UB ≤ 26.5 V 50 W 50 W

Max. line capacitance at the outputs without load 2 nF 2 nF

Voltage auxiliary and test pulse

outputs 24 V 24 V

Current auxiliary and test pulse

outputs 0,5 A 0,5 A

Times 774198 784198

Switch-on delay

After power on 3 s 3 s

With automatic start typ. 60 ms 60 ms

With automatic start max. 210 ms 210 ms

With monitored start typ. 120 ms 120 ms

With monitored start max. 260 ms 260 ms

Logic inputs typ. 150 ms 150 ms

Logic inputs max. 200 ms 200 ms

Response time tr semiconductor

outputs

Via input circuit max. 35 ms 35 ms

Via logic input max. 50 ms 50 ms

Maximum time of feedback loop

monitoring 150 ms 150 ms

Supply interruption before de-energisation 20 ms 20 ms

Simultaneity, channel 1 and 2 max. ∞ ∞

Operating Manual PNOZ e8.1p

1002226-EN-06

23

Page 24

PNOZ e8.1p

Environmental data 774198 784198

Climatic suitability EN 60068-2-78 EN 60068-2-78

Ambient temperature

Temperature range -10 - 55 °C -10 - 55 °C

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C

Climatic suitability

Humidity 93 % r. h. at 40 °C 93 % r. h. at 40 °C

Condensation during operation Not permitted Not permitted

EMC EN 60947-5-1, EN 61000-6-2, EN

61000-6-4, EN 61326-3-1

EN 60947-5-1, EN 61000-6-2, EN

61000-6-4, EN 61326-3-1

Vibration

In accordance with the standard EN 60068-2-6 EN 60068-2-6

Frequency 10 - 55 Hz 10 - 55 Hz

Amplitude 0,35 mm 0,35 mm

Airgap creepage

In accordance with the standard EN 60947-1 EN 60947-1

Overvoltage category III III

Pollution degree 2 2

Rated insulation voltage 30 V 30 V

Rated impulse withstand voltage 0,8 kV 0,8 kV

Protection type

Housing IP40 IP40

Terminals IP20 IP20

Mounting area (e.g. control cab-

inet) IP54 IP54

Mechanical data 774198 784198

Mounting position Any Any

Material

Bottom PPO UL 94 V0 PPO UL 94 V0

Front ABS UL 94 V0 ABS UL 94 V0

Top PPO UL 94 V0 PPO UL 94 V0

Connection type Screw terminal Spring-loaded terminal

Mounting type plug-in –

Conductor cross section with screw

terminals

1 core flexible 0,25 - 2,5 mm², 24 - 12 AWG –

2 core with the same cross sec-

tion, flexible with crimp connect-

ors, no plastic sleeve 0,25 - 1 mm², 24 - 16 AWG –

2 core with the same cross sec-

tion, flexible without crimp con-

nectors or with TWIN crimp con-

nectors 0,2 - 1,5 mm², 24 - 16 AWG –

Torque setting with screw terminals 0,5 Nm –

Conductor cross section with

spring-loaded terminals: Flexible

with/without crimp connector – 0,2 - 1,5 mm², 24 - 16 AWG

Operating Manual PNOZ e8.1p

1002226-EN-06

24

Page 25

PNOZ e8.1p

Mechanical data 774198 784198

Spring-loaded terminals: Terminal

points per connection – 2

Stripping length with spring-loaded

terminals – 8 mm

Dimensions

Height 94 mm 101 mm

Width 22,5 mm 22,5 mm

Depth 121 mm 121 mm

Weight 130 g 125 g

Where standards are undated, the 2017-01 latest editions shall apply.

Safety characteristic data

NOTICE

You must comply with the safety-related characteristic data in order to

achieve the required safety level for your plant/machine.

Operating

Mode

EN ISO

13849-1:

2015

PL

EN ISO

13849-1:

2015

Category

EN 62061

SIL CL

EN 62061

PFHD [1/h]

IEC 61511

SIL

IEC 61511

PFD

EN ISO

13849-1:

2015

TM [year]

SC output

via PLIDdys PL d Cat. 2 SIL CL 2 8,02E-09 SIL 2 4,55E-04 20

SC output

via 2-ch. input circuit PL e Cat. 4 SIL CL 3 3,44E-09 SIL 3 4,53E-05 20

All the units used within a safety function must be considered when calculating the safety

characteristic data.

INFORMATION

A safety function's SIL/PL values are not identical to the SIL/PL values of

the units that are used and may be different. We recommend that you use

the PAScal software tool to calculate the safety function's SIL/PL values.

Operating Manual PNOZ e8.1p

1002226-EN-06

25

Page 26

PNOZ e8.1p

Remove plug-in terminals

Procedure: Insert the screwdriver into the housing recess behind the terminal and lever the

terminal out.

Do not remove the terminals by pulling the cables!

Order reference

Product

Product type Features Connection type Order no.

PNOZ e8.1p 24 VDC Screw terminals 774 198

PNOZ e8.1p C 24 VDC Spring-loaded terminal 784 198

PLID d1 24 VDC Screw terminals 774 260

PLID d1 C 24 VDC Spring-loaded terminal 784 260

Accessories

Product type Features Order no.

Terminal block filter 1 Terminal block with filter for 3-10 kOhm load range 774 195

Terminal block filter 2 Terminal block with filter for 10-30 kOhm load range 774 196

Operating Manual PNOZ e8.1p

1002226-EN-06

26

Loading...

Loading...