Page 1

MANUALE STAZIONE DI SERVIZIO

677276 - 677281 (IT-EN-FR-DE-ES-EL)

MSS APE 50

Page 2

MANUALE

STAZIONE DI

SERVIZIO

MSS APE 50

© Copyright 2010 - PIAGGIO & C. S.p.A. Pontedera.

All rights reserved. No part of this publication may be reproduced.

This publication has been edited by:

After sales - PIAGGIO & C. S.p.A.

V.le Rinaldo Piaggio, 23 - 56025 PONTEDERA (Pi)

ITALY

www.piaggio.com

Page 3

MANUALE STAZIONE DI

SERVIZIO

MSS APE 50

N.B. Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle. Refers to

specific procedures to carry out for preventing damages to the vehicle. Refers to specific procedures to

carry out for preventing damages to the vehicle. Refers to specific procedures to carry out for preventing

damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle

to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

Page 4

Page 5

INDEX OF TOPICS

GENERAL GUIDELINES GEN

CHARACTERISTICS CH

SPECIAL TOOLS ST

MAINTENANCE MA

EMISSION CONTROLO SYSTEM CO EM

TROUBLESHOOTING TROUBL

ELECTRICAL SYSTEM ES

ENGINE FROM VEHICLE EV

ENGINE EN

BRAKING SYSTEM BS

STEERING COLUMN SC

SUSPENSIONS SS

CHASSIS CH

PRE-DELIVERY PD

TIME-SHEET TEMP

Page 6

Page 7

INDEX OF TOPICS

GENERAL GUIDELINES GEN

Page 8

Safety guidelines

- If work can only be done on the vehicle with the engine running, make sure that the premises are well

ventilated, using special extractor fans if necessary; never let the engine run in an enclosed area.

Exhaust gasses are toxic.

The battery electrolyte contains sulphuric acid. Protect your eyes, clothes and skin. Sulphuric acid is

highly corrosive; in the event of contact with your eyes or skin, rinse thoroughly with abundant water

and seek immediate medical attention.

The battery produces hydrogen, a gas that can be highly explosive. Do not smoke and avoid sparks or

flames near the battery, especially when charging it.

Petrol is highly flammable and it can be explosive given some conditions. Do not smoke in the working

area, and avoid open flames or sparks.

- Clean the blocks, the drums, and pads in a well ventilated area, directing the jet of compressed air in

such a way that you do not breathe in the dust produced by the wear of the blocks. Dust caused by

shoe wear is toxic since it contains asbestos.

Maintenance guidelines

Use original PIAGGIO spare parts and lubricants recommended by the Manufacturer. Non-original or

non-conforming spares may damage the vehicle.

Use only the appropriate tools designed for this vehicle. Always use new gaskets, sealing rings and

split pins upon refitting.

After removing these components, clean them using a non-flammable or high flash-point solvent. Lubricate all the work surfaces except the tapered couplings before refitting.

After refitting, make sure that all the components have been installed correctly and work properly.

For disassembly, overhaul and refit operations use only tools with metric measures. Metric bolts, nuts

and screws are not interchangeable with coupling members with English measurement. Using unsuitable coupling members and tools may damage the scooter.

When carrying out maintenance operations on the vehicle that involve the electrical system, make sure

the electrical connections have been made properly, particularly the ground connections.

General guidelines MSS APE 50

GEN - 8

Page 9

INDEX OF TOPICS

CHARACTERISTICS CH

Page 10

Identification

VEHICLE IDENTIFICATION

Vehicle Chassis prefix Engine prefix

APE 50 TL6T TL3T

APE 50 EUROPA TL5T TL3T

APE 50 mix ZAPC80000 C801M

APE 50 EUROPE (EURO 2) ZAPC80000 C801M

Characteristics

SIZES

Sizes (mm) Deck Van

(1) Length 2670 2560

(2) Width 1250

(3) Height 1530 1560

(4) Wheelbase 1590

(5) Track 1100

(6) Turning spokes 2400 2400

(7) Rear cantilever 760 660

SIZES - LOAD COMPARTMENT

Sizes (mm)

Deck Van

(8) Length 1420 (9) Width 1200 -

WEIGHTS

(*) = besides the driver.

Characteristics MSS APE 50

CH - 10

Page 11

Kilograms (kg) Deck Van

Kerb vehicle weight 270 300

Useful load capacity (*) 200 170

SIZES - APE 50 EUROPA

Sizes (mm) Deck Short deck Van Cross

(1) Length 2660 2520 2560 2580

(2) Width 1250 1250 1250 1270

(3) Height 1530 1530 1560 1580

(4) Wheelbase 1590 1590 1590 1590

(5) Turning spokes 2400 2400 2400 2400

SIZES - LOAD COMPARTMENT - APE 50 EUROPA

Sizes (mm)

Deck Short deck Van Cross

(8) Length 1420 1270 1260 1270

(9) Width 1200 1200 1200 1200

(10) Height - - 960 Top box size - - - 900x460x300

WEIGHTS - APE 50 EUROPA

(*) = besides the driver.

Kilograms (kg)

Deck Short deck Van

Total dry weight 220 215 250

Useful load capacity (*) 200 205 170

SIZES - APE 50 EUROPE 2 - APE 50 MIX

Sizes (mm)

Long deck

base

Short deck

base

Van Cross Top long deck

(1) Length 2660 2490 2500 2700 2660

(2) Width 1260 1260 1260 1260 1260

(3) Height 1550 1550 1590 1610 1550

(4) Wheelbase 1590 1590 1590 1590 1590

MSS APE 50 Characteristics

CH - 11

Page 12

SIZES - LOAD COMPARTMENT - APE 50 EUROPE 2 - APE 50 MIX

Sizes (mm)

Long deck

base

Short deck

base

Van Cross Top long deck

(8) Length 1427 1257 1257 1427 1422

(9) Width 1211 1211 1211 1211 1262

WEIGHTS - APE 50 EUROPE 2 - APE 50 MIX

(*) = besides the driver.

Kilograms (kg)

Long Deck Short deck Van Cross Top

Total dry weight 230 230 260 245 230

Useful load capacity (*) 205 205 175 190 205

TECHNICAL DATA - CHASSIS

Specification

Desc./Quantity

Chassis stamped plate unitised body and a single central longitudinal

arm (integrated structure).

Seats in driving cab One.

TECHNICAL DATA - ENGINE

Specification

Desc./Quantity

Engine Single-cylinder, 2-stroke with rotating timing and with three

transfer ducts, with transmission and differential grouped on

the axis of the rear wheels.

Engine capacity 49.8 cm³

Bore x Stroke 38.4 mm x 43 mm

Compression ratio (10÷10.5):1

Ignition advance 15°±2° before TDC

Carburettor Dell'orto SHBC 18/16A.

Fuel 2% petrol-oil mixture (20 c.c. of oil per litre of regular petrol for

cars). Recommended oil: see "recommended products" table

Spark plug PIAGGIO P82M; BOSCHW5AC; CHAMPIONL82C;

LODGE2HN; AC430Z.

Characteristics MSS APE 50

CH - 12

Page 13

Specification Desc./Quantity

Consumption (CUNA) ~2.7 litres per 100 km.

Km range Around 370 Km.

GEAR RATIO

Specification Desc./Quantity

Gear ratio First 1/54.17

Gear ratio Second 1/29.75

Gear ratio Third 1/19.28

Gear ratio Fourth 1/13.35

Gear ratio Reverse 1/76.47

STEERING

Specification Desc./Quantity

Steering Steering tube pivoted on the arm with front wheel-holder oscil-

lating clamp.

SUSPENSION

Specification Desc./Quantity

Front - rear suspension Made using integrated helicoidal springs and hydraulic shock

absorber.

TYRES

Specification Desc./Quantity

Wheel rim 2.10"

Front tyre pressure 1.5 bar.

Rear tyre pressure 2.5 bar.

TYRES - APE 50 - APE 50 EUROPA - APE 50 EUROPE EURO 2 - APE 50 MIX

Specification

Desc./Quantity

Wheel rim 10-2.50"

Tyre 100/90x10"

Front tyre pressure 2 bar.

Rear tyres - inflation pressure 3 bar.

Tightening torques

ENGINE - DIFFERENTIAL UNIT

Name

Torque in Nm

Crankcase halves coupling nuts 13 to 15 Nm

Coil support fixing screw 3 to 5 Nm

Spark plug 14 to 18 Nm

Engine gear locking nut 50 to 55 Nm

Clutch assembly locking nut 40 ÷ 45 Nm

Fan flywheel locking nut 45 to 50 Nm

Filler joint fixing nuts 5 to 7 Nm

Nuts fixing the exhaust pipe to the cylinder 5 to 7 Nm

Clutch cover fixing bolts 6 to 8 Nm

Big end fixing bolts 13 to 18 Nm

Nuts fixing the cylinder to the crankcase 13 to 15 Nm

Nuts fixing the differential unit to the engine 32 to 35 Nm

Differential crankcase halves coupling nuts 8 to 10 Nm

Engine - chassis anchoring plate fixing nuts 20 to 24 Nm

Differential oil drain plug 20 ÷ 25 Nm

Gear control guide bushing 60 to 65 Nm

Nuts fixing the silencer to the engine support 23 to 25 Nm

Nuts fixing the elastic connection to the engine support 25 to 30 Nm

Engine front fixing bolt 25 to 30 Nm

MSS APE 50 Characteristics

CH - 13

Page 14

FRONT SUSPENSION UNIT

Name Torque in Nm

Wheel locking centre nut 75 to 90 Nm

Nuts fixing the wheel rim to the drum 20 to 28 Nm

Shock absorber lower anchoring nut 100 to 130 Nm

Shock absorber upper fixing nut 30 to 40 Nm

Steering upper seat 30 to 40 Nm

Steering upper bearing ring nut 50 to 60 Nm

REAR SUSPENSION UNIT

Name Torque in Nm

Nuts fixing the shoe support to the wheel hub 22 to 28 Nm

Nut fixing the wheel hub to the swinging arm 50 to 70 Nm

Nut for shock absorber lower and upper anchorage 30 to 40 Nm

Nut for anchoring the swinging arm to the chassis 40-50 Nm

Wheel locking centre nut 80 to 100 Nm

Nuts fixing the wheel rim to the drum 20 to 28 Nm

GENERAL PART

Name Torque in Nm

Brake pump to the chassis 12 to 20 Nm

Handlebar fixing bolt 35 to 60 Nm

Assembly clearances

FITTING CLEARANCES

Name

Description Dimensions Initials Quantity

Distance between the

ends of seal rings within

the upper and lower cyl-

inder-ring (mm)

0.2 to 0.3

Gearbox fitting clear-

ance (mm)

0.15 to 0.40

CAUTION

THE GEARBOX SHAFT FITTING CLEARANCE MUST BE VERIFIED WITH THE FEELER GAUGE.

Specific tooling

060824Y Probe

Cylinder-piston oversizes

CYLINDER - PISTON

Specification

Desc./Quantity

Normal cylinder nominal sizes Ø=38.40 +0.025 - 0.005

Normal piston nominal sizes Ø=38.265 ±0.015

CYLINDER COUPLING - PISTON

Name

Initials Cylinder Piston Play on fitting

Coupling 1st Oversize 38.600 to 38.620 38.455 to 38.475 0.145

Coupling 2nd Oversize 38.800 to 38.820 38.655 to 38.675 0.145

Coupling 3rd Oversize 39.000 to 39.020 38.855 to 38.875 0.145

Characteristics MSS APE 50

CH - 14

Page 15

Piston ring oversizes

SEALING RINGS

Specification Desc./Quantity

Upper seal ring (Nominal sizes) Diameter=38.40 mm

Lower seal ring (Nominal sizes) Diameter=38.40 mm

CLEARANCE UPON FITTING

Name Description Dimensions Initials Quantity

Upper sealing ring 1st Oversize 38.60 0.20 to 0.60

Lower sealing ring 1st Oversize 38.60 0.20 to 0.60

Upper sealing ring 2nd Oversize 38.80 0.20 to 0.60

Lower sealing ring 2nd Oversize 38.80 0.20 to 0.60

Upper sealing ring 3rd Oversize 39.00 0.20 to 0.60

Lower sealing ring 3rd Oversize 39.00 0.20 to 0.60

Connecting rod - roller cage fitting

CONNECTING ROD - ROLLER CAGE

Connecting rod Roller cage

1.a category 4.a category

2.a category 3.a category

3.a category 2.a category

4.a category 1.a category

CAUTION

IN CASE OF NOISE, USE CAGE OF THE CATEGORY IMMEDIATELY BELOW.

Crankshaft alignment check

With the proper equipment, check that the eccentricity of the surface of Ø "3"and "1" are contained

within 0.003 mm. (the maximum reading limit on the dial gauge clock); Also check the eccentricity of Ø

"2", which are allowed for a maximum reading of 0.02 mm. In the case of eccentricities not much greater

than that prescribed, perform the straightening of the shaft by means of counterweights with a wedge,

or tightening it in a vice (equipped with aluminium bushings) as needed, for much greater eccentricities

replace the crankshaft.

Specific tooling

020074Y Crankshaft Alignment Check Tool

MSS APE 50 Characteristics

CH - 15

Page 16

Piston - Pin

PISTON - PIN ASSEMBLY CLEARANCE

Name

Description Dimensions Initials Quantity

Piston - pin assembly

clearance (mm)

0

Characteristics MSS APE 50

CH - 16

Page 17

INDEX OF TOPICS

SPECIAL TOOLS ST

Page 18

Tooling

SPECIAL TOOLS

Stores code Description

014499Y Bearing extractor

016029Y Lower Steering Bearing Fitting Tool on

the steering tube

017104Y Pliers for circlips

018119Y Axle Fitting Tool

020004Y Steering seats extraction punch

020042Y Steering tube bearing extractor

Special tools MSS APE 50

ST - 18

Page 19

Stores code Description

020043Y Rear Wheel Hub Roller Bearing Fitting

Punch

020044Y Front Wheel Hub Roller Bearing Fitting

Punch

020055Y Steering Ring Nut Key

020057Y Tool for Starter Motor Bushing Calking

020074Y Crankshaft Alignment Check Tool

020119Y Flywheel extractor

020120Y Punch for Clutch Side Secondary Shaft

Roller Bearing

MSS APE 50 Special tools

ST - 19

Page 20

Stores code Description

020121Y Punch for Flywheel Side Secondary

Shaft Roller Bearing

020123Y Valves Sealing Rings Punch

020125Y Punch to Fit Sealing Rings

020126Y Clutch Stop Key

020127Y Transmission Spider Calking Punch

020128Y Tool to Fit Sealing Rings

020129Y Engine Clearance Gear Check Tool

Special tools MSS APE 50

ST - 20

Page 21

Stores code Description

020130Y Punch to Fit Roller Casing of Main Shaft,

Flywheel Side Crankcase Half

020131Y Flywheel lock tool

020132Y Gearbox Shaft Shimming Gauge

020133Y Tappet plates replacement tool

020144Y Primary Sprocket Lock

020147Y Flywheel Cone Extractor

020150Y Support

MSS APE 50 Special tools

ST - 21

Page 22

Stores code Description

020151Y Heat gun

020156Y Clutch puller

020161Y Differential Box Extractor

020322Y Clutch Removal

020781Y Bearings Fitting Punch

020842Y Upper Steering Bearing Removal Punch

021071Y punch to fit bearings and sealing rings

Special tools MSS APE 50

ST - 22

Page 23

Stores code Description

021330Y Steering seats fitting tool

021467Y Bearing extractor

022465Y Pliers for circlips

023638Y Pliers for circlips

029551Y Clutch puller

029569Y Gear Engagement Fitting Tool

030250Y Clutch Stop Key

MSS APE 50 Special tools

ST - 23

Page 24

Stores code Description

032975Y Punches for Roller Casings

033970Y Punches for Roller Casings

038077Y Engine support

038137Y Rear Hub Extractor

038138Y Roller Casings Punch

048564Y Flywheel extractor

060824Y Probe

Special tools MSS APE 50

ST - 24

Page 25

Stores code Description

020095Y Flywheel Lock

020332Y Digital rev counter

494929 Exhaust fumes analyzer

021330Y003 Steering seats fitting

021330Y004 Steering seats fitting

020114Y Pane positioning band

018119Y007 Axle fitting

018119Y009 Axle fitting

018119Y014 Axle fitting

018119Y015 Axle fitting

021467Y009 extractor

021467Y013 extractor

MSS APE 50 Special tools

ST - 25

Page 26

INDEX OF TOPICS

MAINTENANCE MA

Page 27

WINDSCREEN WASHER FLUID TOP-UP - APE

50

Inside the passenger compartment in the front left

part, there is a container for windscreen washer

fluid. If the fluid does not escape when pressing

the button, remove the pipe that goes from the

container to the and blow inside with compressed

air. Do the same for the pipe that goes from the

pump to the external nozzle. Refit everything and

try pressing the button several times to recharge

the system. If despite the above operations, the

fluid does not come out, clean the external nozzle

with iron wire of a suitable diameter.

WINDSCREEN WASHER FLUID TOP-UP- APE

50 EUROPA

The windscreen washer fluid tank is located inside

the passenger compartment, in the front right part.

To fill the tank, unscrew the cover (1), restore the

fluid level and recharge the system by using the

pump on the left side of the passenger compartment several times, until the liquid comes out of

the sprayer.

WINDSCREEN WASHER FLUID TOP-UP APE

50 MIX - APE 50 EUROPE

The windscreen washer fluid tank is located inside

the cab on the front right panel.

To fill the tank, unscrew cover(1), and top up.

Use a specific detergent.

Scheduled maintenance chart

The following table must be regarded as a general guide for periodic inspections and lubrication interventions. It is necessary to also consider the weather, terrain, geographic location and variety of special

use. This interventions table must therefore be changed to reflect the particular needs of the owner.

For example, if a vehicle is exposed to sea salt, all parts should be lubricated more frequently than

shown in the table to prevent damage caused by corrosion to metal parts.

MSS APE 50 Maintenance

MA - 27

Page 28

MAINTENANCE OPERATIONS

In the event of prolonged vehicle inactivity, adhere to the following standards:

1) Clean the vehicle.

2) Remove the fuel from the vehicle.

3) Remove the air filter and with the engine is running at low rpm and input 30 cc. of specific oil through the diffuser of the

carburettor.

4) Spread antirust grease on the unpainted metallic parts.

5) Lift the wheels off the ground.

A) Operation to be carried out when the engine is warm. Amount of new oil: about 600 gr. for the engine unit (until touching the

load hole) and about 300 gr. for the differential unit (maximum level on the check rod).

B) For the oil level in the tank and to replace, use specific oil.

Unit Operations After the

first 1000

Km

Every

4000 Km

Every

8000 Km

In the

event of a

review

Notes

MOTOR

Carburettor locking • See locking torque ta-

ble:

Piston - big end - cylin-

der lights descaling

• See locking torque table:

Cleaning and descaling

of the still usable engine

parts

• See locking torque table:

TRANSMISSION AND

DIFFERENTIAL

Oil replacement •(A) •(A) •

Check and restore oil

level

•

air filter

Cleaning • Clean with pure petrol

and dry with com-

pressed air

SPARK PLUG

Electrode gap and des-

caling check

• • Bosch W54C; Lodge

2HN; Champion L82C;

NGK B6HS;

Replacement • Bosch W54C; Lodge

2HN; Champion L82C;

NGK B6HS;

BEARINGS

Grease •

ARTICULATIONS AND

CONTROL LEVERS

(ENGINE SIDE)

Grease • •

HYDRAULIC BRAKE

Check and restore oil

level

•(B)

FLEXIBLE TRANSMISSIONS

Adjust •

Lubricate • •

MAIN NUTS AND

BOLTS OF THE VEHICLE

Locking check • • See locking torque ta-

ble:

SCHEDULED MAINTENANCE - APE 50 EUROPA

KEY: (*)= Every 2 years.

(I) = Check and clean, adjust, lubricate or replace if necessary.

(R)=Replace

In the event of prolonged vehicle inactivity, adhere to the following standards:

1) Clean the vehicle.

2) Remove the fuel from the vehicle.

Maintenance MSS APE 50

MA - 28

Page 29

3) Remove the spark plug, enter from its hole 10/15 cc of oil recommended for the mixer, and then operate the starter lever 2-3

times and refit the spark plug.

4) Spread antirust grease on the unpainted metallic parts.

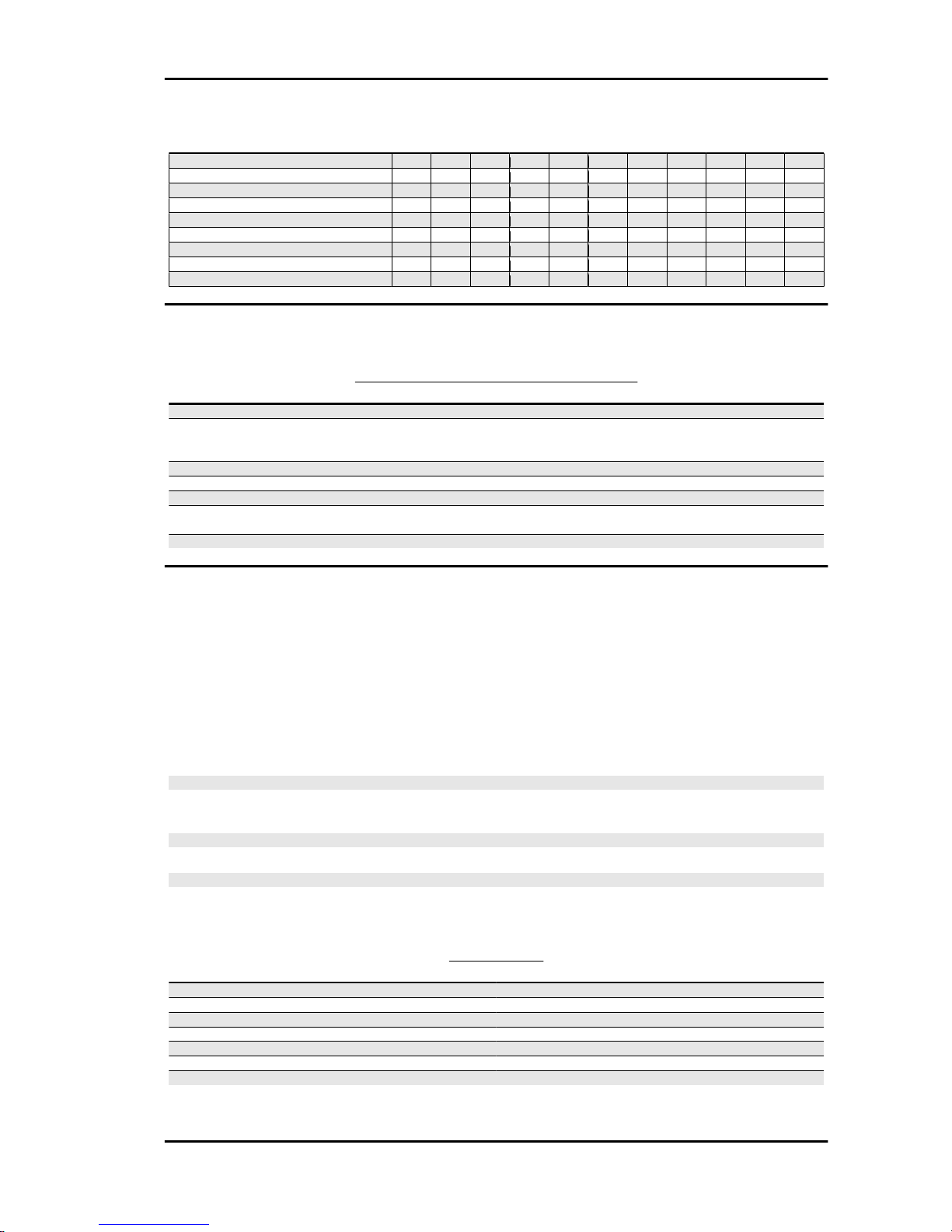

km x 1,000

(months)

1

(4)6(12

)

10

(24

)

15

(36

)

20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Locks - Inspection (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Spark plug - Replacement

(R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R)

Carburettor Check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Carburetion check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Controls - Inspection/Adjustment

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Condition and tyres

use - Check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Air filter - Cleaning (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Steering clearance

- Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Electrical system

and battery - Check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Cylinder fan system - Inspection

(I) (I) (I) (I)

Brake and clutch

lever - Grease

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Battery level - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Differential oil level

- Inspection

(I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R)

Brake fluid level Check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Gearbox oil - replacement

(R) (R) (R) (R) (R) (R) (R) (R) (R) (R)

Brake fluid - Replacement

(*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*)

Tyre pressure - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Headlights - check/

adjust

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Vehicle and brake

test - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Suspension - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Flexible transmissions - Lubrication

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Pressure flexible

brakes pipes

(R) (R) (R)

SCHEDULED MAINTENANCE - APE 50 MIX

KEY: (*)= Every 2000 Km or 2 years.

(I) = Check and clean, adjust, lubricate or replace if necessary.

(R)=Replace

In the event of prolonged vehicle inactivity, we recommend doing the following:

1) Clean the vehicle.

2) With the engine off and the piston at bottom dead center, remove the spark plug, enter from the corresponding hole 10 to 15

cc of specific oil. Then press the engine start-up button 3-4 times, making the engine and the spark plug slowly turn.

3) Drain the fuel tank, cover the unpainted metal parts with rustproof grease;

4) For the battery, follow the instructions set out in the specifications section.

km x 1,000

(months)

1

(4)6(12

)

10

(24

)

15

(36

)

20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Safety locks

(wheels,brakes,ste

ering,suspensions)

- Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

MSS APE 50 Maintenance

MA - 29

Page 30

km x 1,000

(months)

1

(4)6(12

)

10

(24

)

15

(36

)

20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Spark plug - Replacement

(R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R) (R)

Carburettor Cleaning

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Carburetion -

Check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Throttle grip/mixer

control - Adjustment

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Condition and tyres

use - Check

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Tyre pressure - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Air filter - Cleaning (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Steering clearance

- Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Brake and clutch

lever - Grease

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Braking system fluid level

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Braking system fluid level - Replacement

(*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*)

Gearbox oil - Replacement/Inspection

(I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R)

Differential oil - Replacement/Inspection

(I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R) (I) (R)

Battery fluid level Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Headlights - check/

adjust

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Suspension - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Flexible transmis-

sions - Lubrication

(I) (I) (I) (I) (I) (I) (I) (I) (I)

Rear brake disc

piping - Replacement

(R) (R) (R)

Vehicle and brake

test

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Drive shaft nut mix

- Inspection

(I) (I) (I) (I) (I) (I)

SCHEDULED MAINTENANCE - APE 50 EUROPE

KEY: (*)= Every 2000 Km or 2 years.

(I) = Check and clean, adjust, lubricate or replace if necessary.

(R)=Replace

km x 1,000 (months)

1 (4) 5 (12) 10

(24)15(36)

20 25 30 35 40 45 50

Safety locks (wheels,brakes,steering,suspensions) - Inspection

(I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Spark plug - Replacement (R) (R) (R) (R) (R) (R) (R) (R) (R) (R)

Carburettor - Cleaning (I) (I) (I) (I) (I)

Carburetion - Check (I) (I) (I) (I) (I) (I)

Throttle grip/mixer control - Adjustment (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Condition and tyres use - Check (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Tyre pressure - Inspection (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Air filter - Cleaning (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Steering clearance - Inspection (I) (I) (I) (I) (I)

Clutch brake lever - Grease (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Fluid level and braking system - Check (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Braking system fluid level - Replacement (*) (*) (*) (*) (*) (*) (*) (*) (*) (*) (*)

Maintenance MSS APE 50

MA - 30

Page 31

km x 1,000 (months) 1 (4) 5 (12) 10

(24)15(36)

20 25 30 35 40 45 50

Gearbox oil - Replacement/Inspection (I) (R) (I) (R) (I) (R) (I) (R) (I) (R)

Differential oil - Replacement/Inspection (I) (R) (I) (R) (I) (R) (I) (R) (I) (R)

Battery fluid level - Inspection (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Headlights - check/adjust (I) (I) (I) (I) (I) (I)

Suspension - Inspection (I) (I) (I) (I) (I)

Flexible transmissions - Lubrication (I) (I) (I) (I) (I)

Rear brake disc piping - Replacement (R)

Vehicle and brake test (I) (I) (I) (I) (I) (I) (I) (I) (I) (I) (I)

Air filter and SAS box (sponge) cleaning (R) (R) (R) (R) (R)

Suggested products chart

RECOMMENDED PRODUCTS TABLE

Product Description Specifications

AGIP CITY TEC 2T Oil mixer for 2-stroke engines JASO FC, ISO-L-EGD Specifications

AGIP CITY HI TEC 4T Oil for lubricating the flexible transmission

lines (brakes, throttle grip, odometer,

etc.).

Specifications: SAE 5W-40, API SL,

ACEA A3, JASO MA

AGIP GEAR Differential Oil Specifications: SAE 80W-90; API GL-4

AGIP GEAR Gearbox oil SAE 80W-90; API GL-4

AGIP GREASE PV 2 Grease for brake control levers Specifications: NLGI 2 ; ISO-LXBIB2

AGIP GREASE MU3 Grease for odometer transmission gear

case

Specifications: NLGI 3; ISO-L-XBCHA3,

DIN K3K-20

AGIP BRAKE 4 Brake fluid FMVSS DOT 4

Carburettor

The carburettor is completely decomposed, check all calibrated parts (main jets, idle jets, emulsifiers

tubes, etc.). The value of these calibrated parts must correspond to the adjustment data prescribed for

the type of carburettor. For a thorough cleaning of all components of the carburettor, use a bath of

suitable solvent and blow with compressed air. To clean the calibrated jets, avoid using metallic spikes

or wires.

All gaskets, seal rings and springs of the carburettor, should be replaced with each revision.

WARNING

THE CARBURETTOR IS VERY EXPLOSIVE; BE VERY CAREFUL NOT TO SPILL FUEL DURING

THE REMOVAL OF THE CARBURETTOR

WARNING

USE EXTREME CAUTION WHEN WORKING ON COMPONENTS CONTAINING PETROL.

WARNING

PETROL IS HIGHLY EXPLOSIVE

ALWAYS REPLACE THE GASKETS TO AVOID PETROL LEAKS

SPECIFICATIONS

Specification

Desc./Quantity

Dell'Orto type SHBC 18/16 A.

Diffuser mm. 16.

Max. jet 60/100.

Minimum jet 42/100 long.

Minimum fixed air 110/100.

Maximum fixed air 150/100.

Starter jet 50/100.

MSS APE 50 Maintenance

MA - 31

Page 32

KEY:

1. Fuel adjustment screw at idle.

2. Minimum adjustment screw.

3. Minimum jet.

4. Starter valve.

5. Minimum air calibrator.

6. Maximum air calibrator.

7. Starter jet.

8. Float.

9. Max. jet

10. Throttle valve.

Air filter

CLEANING:

- Clean with a solvent with high flash point.

- Dry with compressed air.

CAUTION

NEVER RUN THE ENGINE WITHOUT THE AIR FILTER,

THIS WOULD RESULT IN AN EXCESSIVE WEAR OF THE

PISTON AND CYLINDER.

Maintenance MSS APE 50

MA - 32

Page 33

Engine oil replacement

ENGINE OIL AND DIFFERENTIAL REPLACEMENT

- The oil change must be performed with the engine warm.

- Remove the oil filler cap.

- Unscrew the oil drainage plug and drain out all

the oil.

- Retighten the drainage plug and fill with oil (about

0.600 litres for the engine and about 0.300 litres

for the differential).

- Start the engine and stop it after having run it for

about 1 minute in idle.

- Restore, if necessary, the oil level and check for

leaks.

- Use appropriate oils.

WARNING

DO NOT REMOVE THE OIL COVER IMMEDIATELY AFTER

AN ACTIVITY WITH THE ENGINE AT FULL SPEED AND/OR

WITH THE ENGINE RUNNING. THE HEATED OIL MAY

LEAK, WITH THE RISK OF BURNING

Recommended products

AGIP GEAR Differential Oil

Specifications: SAE 80W-90; API GL-4

AGIP CITY TEC 2T Oil mixer for 2-stroke engines

JASO FC, ISO-L-EGD Specifications

Spark plug

- Disconnect the spark plug pipe and remove it.

- Examine it carefully and if the insulators are chipped or damaged replace them.

- Measure the distance between the electrodes

using a feeler gauge and adjust if necessary by

carefully bending the outer electrode.

- Make sure that the seal washer is in good condition.

MSS APE 50 Maintenance

MA - 33

Page 34

Fit the spark plug, screw by hand and then tighten

with a key for the spark plug to the prescribed torque.

Characteristic

Electrode gap

0.6 to 0.7 mm

Recommended spark plugs

PIAGGIO P82M; Champion L82C; Bosch W54C;

Lodge 2HN; Ac 430Z.

Locking torques (N*m)

Spark plug 14 to 18 Nm

Mixer timing

To adjust the timing, operate on the transmission

adjuster screw so that the reference stamped on

the mobile control coincides with that made on the

mixer body.

N.B.

CHECK FOR THE PROPER TIMING OF THE MIXER, IT IS

NECESSARY TO FIRST REMOVE THE METAL COVER

FIXED WITH THREE SCREWS ON THE CLUTCH COVER.

DUE TO THE PASSAGE OF AN EXHAUST PIPE ON ONE OF

THE SCREWS, THE LATTER'S HOUSING HOLE HAS BEEN

MADE OPEN TO REMOVE THE LID BY LOOSENING ONLY

ONE OF THE SCREWS IN QUESTION.

N.B.

WHENEVER REMOVING THE MIXER FROM THE CLUTCH

COVER, THE SEALING O-RING LOCATED ON THE COLLAR OF THE MIXER MUST BE REPLACED.

CAUTION

IN THE EVENT OF REMOVAL OR EXHAUSTION OF THE

OIL IN THE TANK, PROCEED TO BLEED THE MIXER AS

FOLLOWS: WITH THE MIXER FITTED ON THE VEHICLE

WITH THE ENGINE TURNED OFF, PULL OFF THE MIXER

TUBE FROM THE CARBURETTOR AND LOOSEN THE

BLEED SCREW UNTIL OIL STARTS TO FLOW. TIGHTEN

THE SCREW, START THE ENGINE AND WAIT UNTIL OIL

COMES OUT OF THE DELIVERY LINE TO THE CARBURETTOR (PREVIOUSLY DISCONNECTED). RECONNECT

THE PIPE TO THE CARBURETTOR FIXING IT WITH A

BAND.

In carrying out this operation, the engine must be fed with a mixture of 2% of appropriate oil (at least

0.5 litres if the tank is empty).

Recommended products

AGIP CITY TEC 2T Oil mixer for 2-stroke engines

JASO FC, ISO-L-EGD Specifications

Maintenance MSS APE 50

MA - 34

Page 35

Secondary air system

FILTER CLEANING AND INTEGRITY CHECK

To clean the sponge filters of the secondary air

system, proceed as follows:

1) Unscrew the fixing screws «1» from the aluminium lid of the secondary air box to access the

polyurethane sponge contained inside the same

box.

2) Clean the polyurethane sponge by washing with

soap and water, then dry everything with compressed air and reposition everything back in the

corresponding seats, after checking at the same

time that the blade is not warped, cracked and/or

does not guarantee its seal on its contact surface;

replace if necessary.

N.B.

WHEN REASSEMBLING, TAKE CARE TO PROPERLY RE-

POSITION THE BLADE IN ITS SEAT ON THE TWO PLASTIC

AND ALUMINIUM COVERS.

CAUTION

DURING THE OPERATION 1) ALWAYS CHECK THE IN-

TEGRITY AND THE SEAL OF THE RUBBER SLEEVE LOCATED ON THE END OF THE SECONDARY AIR TUBE; IF

NECESSARY, REPLACE THE FIXING CLAMPS.

Headlight alignment check

APE 50 - APE 50 EUROPA

Position the unloaded vehicle on a flat surface and at 10 m away from a white screen located in the

dark. Make sure that the vehicle axis is perpendicular to the screen.

Draw a horizontal line on the screen with a height corresponding to 58-60 cm.; Check that the tyres are

inflated to the pressure required, start the engine and lock the throttle twist grip at approximately 1/3 of

its travel, turn on the headlight, insert the low beam and aim it so that the horizontal demarcation line

between the dark and the lighted area does not fall above the horizontal line marked on the screen.

WARNING

THE HEADLIGHT IS FITTED WITH TWO ADJUSTMENT SCREWS, LOCATED AT THE TOP TO

ALLOW CORRECTION OF ANY ALTERATION OF THE LIGHT BEAMS. TO ACCESS THESE

SCREWS AND, IT IS NECESSARY TO REMOVE THE PROTECTIVE FRONT COWL OF THE HEADLIGHT UNIT BY TURNING THE TWO SCREWS THAT FIX THE SHIELD OF THE FRAME.

MSS APE 50 Maintenance

MA - 35

Page 36

HEADLIGHTS AIMING INSPECTION

N.B.

BEFORE CARRYING OUT THE OPERATION FOR HEADLIGHTS AIMING, CHECK THAT THE

TYRES ARE INFLATED TO THE PRESSURES INDICATED IN THE SPECIFIC SECTION.

Proceed as follows:

1. Place the vehicle in conditions of use, without

load, with the tyres inflated to the prescribed pressure on flat grounds at 10 m from a white screen

placed in the shade. Make sure the vehicle axis is

perpendicular to the screen;

2.Draw two vertical lines «a-a» at a distance «1»

corresponding to the distance between headlight

axes. Draw a horizontal line «b-b» at height «2»

from ground corresponding to the headlight centre

height from ground multiplied by 0.9;

3.Start the engine and lock the throttle twist grip at

approximately 1/3 of its travel. Switch the dipped

beam headlight on. Direct the beam so that the

horizontal line between the light and the shade

falls above the horizontal line «b-b» drawn on the

screen;

Maintenance MSS APE 50

MA - 36

Page 37

4.If this is not so, adjust the headlight by means of

the two screws (1) to correct any beam alterations.

Cables adjustment

SPLITTER_ADJUSTMENT CONTROL CABLE

Splitter control cable «1»: adjust so that clearance

is felt on the throttle grip.

Mixer cable «2»: see section "Mixer timing".

Throttle grip cable «3»: adjust so that the sheath

does not have clearance.

TRANSMISSIONS ADJUSTMENTS

Adjust the control cables: Cable mix: see "mixer timing" specification section.

Gas cable: adjust so that the sheath does not have clearance.

Splitter control cable: adjust so that clearance is felt on the throttle grip. All transmissions must be

adjusted so that the sheaves have no clearances.

MSS APE 50 Maintenance

MA - 37

Page 38

INDEX OF TOPICS

EMISSION CONTROLO SYSTEM CO EM

Page 39

CO check

The test must be done after a thorough cleaning

of all parts of the carburettor, with the air filter clean

and spark plug in good condition.

1) Heat the vehicle for the time necessary to activate the catalytic converter.

2) Turn off the vehicle for the time necessary to

perform the operations of 3) and 4).

3) Insert an extension pipe of ~ 50 cm at the exhaust fumes socket on the silencer.

4) With the utmost care, check the seal between

silencer and tube. Insert the probe of the exhaust

fumes analyser into the tube.

5) Start the engine.

6) Wait for a minute for the minimum to stabilise.

7) Without ever operating the accelerator and using the appropriate screw (1), bring the engine

speed to 1350 ± 100g/min.

8) Record the flow screw (2) in order to have a

value of «CO» at a minimum of 2.0 ± 1.0.

9) Operate the throttle grip by slowly speeding up

the engine to a speed of 4000 rpm. and return to

the closed position; check that the idle speed remains at the previously established value, otherwise repeat the procedure starting from point 3).

Specific tooling

020332Y Digital rev counter

494929 Exhaust fumes analyzer

MSS APE 50 Emission Controlo System

CO EM - 39

Page 40

INDEX OF TOPICS

TROUBLESHOOTING TROUBL

Page 41

Probable cause and troubleshooting

DETONATIONS TO THE EXHAUST

Possible Cause Operation

Detonations in the silencer to the gas release Check the ducts and the membrane of the choke device on the

carburettor.

NOISE - KNOCKS

Possible Cause Operation

Worn or leaking shock absorbers Replace.

Flexible buffers of the swinging arms Replace.

Insufficient lubrication of the hubs Remove the hubs and fill the appropriate chamber with special

grease.

RUBBER JOINT FAILURE OF THE SECONDARY PIPE ON THE AIR SILENCER

Possible Cause Operation

Secondary air reed locking Replace.

Secondary air filter clogging Clean the filter and the box.

Clogging of the secondary air joint on the silencer Descale the joint taking care to not let the residues fall into the

silencer.

THE VEHICLE PULLS TO ONE SIDE

Possible Cause

Operation

The pressure of one of the tyres is not right Check and set to the prescribed pressure

Rear swinging arms Straighten out if possible, or replace.

Worn rubber buffers Replace.

Engine

ENGINE STOP

Possible Cause

Operation

Idle speed too low Work on the appropriate adjuster screw del of the carburettor.

Dirt or water in the mixture of the ducts Clean thoroughly.

Inefficient spark plug Clean and adjust the gap between the electrodes or replace.

Cock obstruction Clean.

H.V. cable or spark plug hood damaged Check or replace.

Fuel tank cap breather obstruction (defective fuel system) Clean properly.

CRANKSHAFT KNOCKS

Possible Cause

Operation

Excessive clearance of the main bearings Replace.

Big end failure Replace the crankshaft.

Crankshaft unbalanced Check the alignment

Piston pin worn Replace.

RINGING OF THE PISTON

Possible Cause

Operation

Excessive clearance between the piston and cylinder Replace the piston and correct the cylinder.

Excessive clearance of the roller pin-connecting rod small end

or piston pin

Review (for any replacement of the rollers of the connecting rod

small end, see the section "Specifications").

MSS APE 50 Troubleshooting

TROUBL - 41

Page 42

Poor performance

LOW POWER

Possible Cause Operation

Timing incorrect Perform the foreseen checks.

Cylinder head or spark plug not fitted correctly Correct the locking and the fitting.

Leakage of current of the ignition system Locate the dispersion and act accordingly.

Excessive incrustation on the lights of the cylinder Descale.

Silencer blocked Descale with iron wire bent into a hook or with compressed air

introduced into the cylinder nozzle fixed to the cylinder after the

external exhaust pipe.

Starting difficulties

PROBLEMS WITH STARTING

Possible Cause

Operation

Battery terminals oxidised or not properly locked Clean, tighten and protect with neutral petroleum jelly

Discharged battery The battery is the electrical device in the system that requires

the most frequent inspections and thorough maintenance. Frequently check that the fluid level fully covers the plates; if not,

restore the level adding distilled water (never use natural water,

even if it is drinking water) and check fluid density at the same

time.

If the vehicle is not used for some time (1 month or longer) the

battery needs to be recharged periodically. The battery runs

down completely in the course of three months. When the battery is being placed on the vehicle, make sure that the connections are not misplaced, keeping in mind that the black ground

cable with the terminal attached to the frame is to be connected

to the negative terminal whereas, the other cable, must be con-

nected to the terminal marked +.

Carburettor body nozzles Remove and clean in petrol; dry with a compressed air jet.

Inefficient spark plug Replace.

Troubleshooting MSS APE 50

TROUBL - 42

Page 43

Clutch slipping

CLUTCH SLIPPAGE

Possible Cause Operation

Insufficient idle stroke Adjust the stroke.

Weak return spring Replace.

Worn or burned driven disc gasket Replace the disc.

Insufficient oil in the differential transmission or unsuitable oil Restore the oil level or replace.

Gearbox

OIL LOSS FROM THE TRANSMISSION - DIFFERENTIAL UNIT

Possible Cause Operation

Excessive filling Bring back to level.

Loosening of the crankcase halves locking nuts and the differ-

ential cover

Check the locks, replace the gaskets if necessary.

Axle shaft oil seal hood worn or broken Replace.

Cracked crankcase Replace.

Loose oil drain plug Lock and replace if damaged

Gears disengage abruptly or are difficult to engage

SPONTANEOUS GEARS DISENGAGEMENT

Possible Cause

Operation

Gearbox housing worn or damaged Verify and replace if necessary

Badly adjusted control cable Adjust.

Trasmission gears or spiders not properly assembled or worn Review.

Noisy gears

NOISY TRANSMISSION

Possible Cause

Operation

Excessive clearance between the gears of the transmission Review and replace the worn components.

Insufficient oil in the differential transmission Restore the oil level or replace.

Bearings of the gear shaft are noisy Replace.

Locked brakes

BRAKES LOCKED EVEN WHEN YOU CEASE TO PRESS THE PEDAL

Possible Cause

Operation

Return springs stretched Replace.

Compensation hole on the pump clogged Clean and bleed the air out of the system.

Rubber gasket swollen or sized Check the system, replace all the rubber parts and the fluid,

bleed air from the system: use the recommended oil

Noisy suspension

NOISY FRONT SUSPENSION

Possible Cause

Operation

Hub bearings worn or with excessive clearance Replace.

The wheel hub chamber needs to be greased Disassemble and apply grease.

MSS APE 50 Troubleshooting

TROUBL - 43

Page 44

Possible Cause Operation

Hydraulic absorber inefficient or discharged Replace.

Roller casings of swinging arm worn Replace.

Difficult riding

GUIDE IRREGULARITIES

Possible Cause Operation

The vehicle "pulls" to one side due to deformation of the steer-

ing tube

Check the steering unit and replace if necessary.

Steering is hard or knocks Check the steering fifth wheels: if they are loose they must be

properly tightened; if marked with pricks, they must be re-

placed.

Troubleshooting MSS APE 50

TROUBL - 44

Page 45

INDEX OF TOPICS

ELECTRICAL SYSTEM ES

Page 46

Dispositivi e accessori

ELECTRICAL SYSTEM DEVICES - APE 50

1. FRONT HEADLIGHTS, 12V-15W AND FROM 12V-5W BULBS

2. HORN

3. FRONT TURN INDICATORS, 12V-10W BULBS

4. WINDSCREEN WIPER

5. INDICATOR UNIT, 12V-1.2 W BULBS

6. WINDSCREEN WIPER SWITCH

7. START-UP BUTTON

8. LIGHT SWITCH

9. TURN INDICATOR SWITCH

10.HORN BUTTON

11. IGNITION SWITCH

12. STOP BUTTON

13.TURN INDICATOR CONTROL DEVICE

14. LOW FUEL WARNING LIGHT INDICATOR

15. START-UP MOTOR

16. 7.5A FUSE

17. START-UP REMOTE CONTROL SWITCH

18. REGULATOR

19.12V-32Ah BATTERY

20. ELECTRONIC CONTROL UNIT

21. SPARK PLUG

22.MAGNETO FLYWHEEL

23.REAR DAYLIGHT RUNNING LIGHTS, 12V- 4W BULBS

24. STOPLIGHTS, 12V-10W BULBS

25. REAR TURN INDICATORS, 12-10W BULBS

Electrical system MSS APE 50

ES - 46

Page 47

ELECTRICAL CABLES COLOUR CODING - APE 50

B = White

Bl = Blue

G = Yellow

M = Brown

N = Black

BV = White-Green

GN = Yellow-Black

RN = Red-Black

Gr = Grey

Rs = Pink

R = Red

Vi = Purple

V = Green

A = Orange

VN = Green-Black

BN = White-Black

BBI = White-Blue

BR = White-Red

CAUTION

MSS APE 50 Electrical system

ES - 47

Page 48

WHEN INTERVENING ON THE ELECTRICAL SYSTEM, MAKE ESPECIALLY SURE THAT THE

WIRES LEADING TO THE ELECTRONIC CONTROL UNIT ARE CORRECTLY CONNECTED AND

RESPECT THE COLOUR CODING GIVEN ON THE CONTROL UNIT.

IGNITION SECTION

KEY:

1.Alternator

2. Electronic control unit

3. Spark plug

4. Engine stop

STARTER AND RECHARGE SECTION

KEY:

1.Alternator

2.Voltage regulator

3.Starter motor

4.Starter button

5. Key switch

6. 7.5A Fuse

7.Remote control

8. 12V-32Ah battery

Electrical system MSS APE 50

ES - 48

Page 49

TURN INDICATORS - STOP - WINDSCREEN WIPER

KEY:

1. Windscreen wiper switch

2. Windscreen wiper

3. 12V-1.2W turn indicator warning light

4. No. 4 12V-10W turn indicator bulbs

5. Turn indicator command

6. Turn indicator switch

7. No.2 12V-10W stop bulbs

8. Stop switch

9. From B+ of the regulator

MSS APE 50 Electrical system

ES - 49

Page 50

HORN SECTION - LEVEL TRANSMITTER

KEY:

1. Turn indicators

2.Horn button

3. Horn

4. 12V-1.2W Low fuel warning light

5.Fuel warning light transmitter

6. From B+ of the regulator

Electrical system MSS APE 50

ES - 50

Page 51

LIGHTS SECTION

KEY:

1.Alternator

2. 12V-15W Headlight light

3. 12V-5W City lights

4. 12V-4W Rear daylight running light

5. 12V-1.2W headlight warning light

6. Light switch

7. Voltage regulator

MSS APE 50 Electrical system

ES - 51

Page 52

ELECTRICAL SYSTEM DEVICES - APE 50 EUROPA

1. FRONT HEADLIGHTS, 12V-3W, 12V- 15W AND 12V-10W BULBS

2. HORN

3. REAR HEADLIGHTS, 12V-4W, 12V-10W AND 12V-10W BULBS

4. WINDSCREEN WIPER

5. INSTRUMENT PANEL, 12V- 1.2W BULBS

6. WINDSCREEN WIPER SWITCH

7. STARTER BUTTON

8. LIGHT SWITCH

9. TURN INDICATOR SWITCH

10. HORN BUTTON

11. IGNITION SWITCH

12. STOP BUTTON

13. TURN INDICATOR CONTROL DEVICE

14. LOW FUEL WARNING LIGHT CONTROL

15. START-UP MOTOR

16. 8A FUSE

17. START-UP REMOTE CONTROL SWITCH

18. VOLTAGE REGULATOR

19. 12V-9Ah BATTERY

20. ELECTRONIC CONTROL UNIT

Electrical system MSS APE 50

ES - 52

Page 53

21. SPARK PLUG

22.MAGNETO FLYWHEEL

23. INTERNAL LIGHT FITTING, 12V-5W BULB

24. ALTERNATOR LIGHT, 12V-1.2W BULB

25. STOP SWITCH

ELECTRICAL CABLES COLOUR CODING - APE 50 EUROPA

B = White

Bl = Blue

G = Yellow

M = Brown

N = Black

BV = White-Green

GN = Yellow-Black

RN = Red-Black

Gr = Grey

Rs = Red

Vi = Purple

V = Green

VN = Green-Black

BN = White-Black

BBI = White-Blue

MSS APE 50 Electrical system

ES - 53

Page 54

BR = White-Red

A = Blue

Ar = Orange

CAUTION

WHEN INTERVENING ON THE ELECTRICAL SYSTEM, MAKE ESPECIALLY SURE THAT THE

WIRES LEADING TO THE ELECTRONIC CONTROL UNIT ARE CORRECTLY CONNECTED AND

RESPECT THE COLOUR CODING GIVEN ON THE CONTROL UNIT.

LIGHTS SECTION - APE 50 EUROPA

KEY:

1.Alternator

2. 12V-15W Headlights

3. 12V-5W City lights

4. 12V-4W Rear daylight running light

5. Headlight warning light

6. Light switch

7. Voltage regulator

ELECTRICAL SYSTEM DEVICES (TOP AND BASE) - APE 50 mix

1. FRONT HEADLIGHTS AND TURN INDICATORS, 12V-3W, 12V- 15W AND 12V-10W BULBS

2. HORN

3. REAR LIGHTS, 12V-4W, 12V-10W AND 12V-10W BULBS

Electrical system MSS APE 50

ES - 54

Page 55

4. WINDSCREEN WIPER

5. INSTRUMENT PANEL, 12V- 1.2W BULBS

6. WINDSCREEN WIPER SWITCH

7. STARTER BUTTON

8. LIGHT SWITCH

9. TURN INDICATOR SWITCH

10. HORN BUTTON

11. IGNITION SWITCH

12. STOP BUTTON ON THE REAR BRAKE

13. CIGARETTE LIGHTER

14. LOW FUEL WARNING LIGHT CONTROL

15. OIL RESERVE WARNING LIGHT CONTROL

16. START-UP MOTOR

17. CIGARETTE LIGHTER LIGHTING, 12V-1.2W BULB

18. STOP BUTTON ON THE FRONT BRAKE

19. STARTER RELAY

20. Voltage regulator

21. 12V-9AH BATTERY

22.ELECTRONIC CONTROL UNIT

23.SPARK PLUG

24. MAGNETO FLYWHEEL

25. INTERNAL LIGHT FITTING, 12V-5W BULB

26. 7.5A (GENERAL) FUSE

27. (CIGARETTE LIGHTER AND LIGHT FITTING) 10A FUSE

28. DIGITAL CLOCK LIGHTING, 12V-1.2W BULBS (TOP VERSION ONLY)

29. DIGITAL CLOCK (TOP VERSION ONLY)

MSS APE 50 Electrical system

ES - 55

Page 56

ELECTRICAL CABLES COLOUR CODING - APE 50 mix

Ar = Orange

B = White

BBI = White-Blue

BIN = Blue-Black

BIR = Blue-Red

BN = White-Black

BVi = White-Purple

GN = Yellow-Black

Gr = Grey

GrR = Grey-Red

GV = Yellow-Green

M = Brown

N = Black

Rs = Pink

V = Green

R = Red

Vi = Purple

VN = Green-Black

CAUTION

Electrical system MSS APE 50

ES - 56

Page 57

WHEN INTERVENING ON THE ELECTRICAL SYSTEM, MAKE ESPECIALLY SURE THAT THE

WIRES LEADING TO THE ELECTRONIC CONTROL UNIT ARE CORRECTLY CONNECTED AND

RESPECT THE COLOUR CODING GIVEN ON THE CONTROL UNIT.

ELECTRICAL SYSTEM DEVICES - APE 50 mix (CROSS VERSION)

1. FRONT HEADLIGHTS AND TURN INDICATORS, 12V-3W, 12V- 15W AND 12V-10W BULBS

2. HORN

3. REAR LIGHTS, 12V-4W, 12V-10W AND 12V-10W BULBS

4. WINDSCREEN WIPER

5. INSTRUMENT PANEL, 12V- 1.2W BULBS

6. WINDSCREEN WIPER SWITCH

7. STARTER BUTTON

8. LIGHT SWITCH

9. TURN INDICATOR SWITCH

10. HORN BUTTON

11. IGNITION SWITCH

12. STOP BUTTON ON THE REAR BRAKE

13. CIGARETTE LIGHTER

14. LOW FUEL WARNING LIGHT CONTROL

15. OIL RESERVE WARNING LIGHT CONTROL

16. START-UP MOTOR

17. CIGARETTE LIGHTER LIGHTING, 12V-1.2W BULB

18. STOP BUTTON ON THE FRONT BRAKE

19. STARTER RELAY

20. Voltage regulator

21. 12V-9AH BATTERY

22.ELECTRONIC CONTROL UNIT

23.SPARK PLUG

24. MAGNETO FLYWHEEL

25. INTERNAL LIGHT FITTING, 12V-5W BULB

26. 20A (GENERAL) FUSE

27.(CIGARETTE LIGHTER AND LIGHT FITTING) 10A FUSE

28. 7.5A (SERVICE) FUSE

29. 4A FUSE (DAYLIGHT RUNNING LIGHT)

30. 4A FUSE (LOW-BEAM LIGHTS)

31. DIGITAL CLOCK LIGHTING, 12V-1.2W BULBS

32. DIGITAL CLOCK

33. TURN INDICATOR CONTROL DEVICE

MSS APE 50 Electrical system

ES - 57

Page 58

ELECTRICAL CABLES COLOUR CODING - APE 50 mix (CROSS VERSION)

Ar = Orange

B = White

BBI = White-Blue

BIN = Blue-Black

BIR = Blue-Red

BN = White-Black

BVi = White-Purple

G = Yellow

GN = Yellow-Black

Gr = Grey

GrN = Grey-Black

GV = Yellow-Green

M = Brown

N = Black

R = Red

RB = Red-White

Rs = Pink

V = Green

Vi = Purple

ViN = Purple-Black

Electrical system MSS APE 50

ES - 58

Page 59

VN = Green-Black

CAUTION

WHEN INTERVENING ON THE ELECTRICAL SYSTEM, MAKE ESPECIALLY SURE THAT THE

WIRES LEADING TO THE ELECTRONIC CONTROL UNIT ARE CORRECTLY CONNECTED AND

RESPECT THE COLOUR CODING GIVEN ON THE CONTROL UNIT.

ELECTRICAL SYSTEM DEVICES - APE 50 EUROPE

1. HORN

2. NO.2 BULBS FOR FRONT TURN INDICATORS

3. CABLE ASSEMBLY

4. COMPLETE WINDSCREEN WIPER

5. CIGARETTE LIGHTER

6. COMPLETE FRONT COWL

7. COMPLETE BULB HOLDER

8. CLOCK

9. No.2 BULBS FOR HEADLIGHTS

10. No.2 BULBS FOR DAYLIGHT RUNNING LIGHT

11. No.2 BULBS FOR FRONT TURN INDICATORS

12. CABLE ASSEMBLY OF THE CHASSIS

13. STOP BUTTON ON THE FRONT BRAKE

14. LIGHT SWITCH

15. WINDSCREEN WASHER SWITCH

16. START-UP BUTTON

17. IGNITION SWITCH

18. INSTRUMENT PANEL BULB

19. INSTRUMENT PANEL WITH No.6 BULBS

20. MIX OIL WARNING LIGHT

21. TURN INDICATOR WARNING LIGHT

22. CARB. RESERVE WARNING LIGHT

23. HEADLIGHT WARNING LIGHT

24. CABLE HARNESS

25. LIGHT FITTING

26. HORN BUTTON

27. TURN INDICATOR SWITCH

28. VOLTAGE REGULATOR

29. FUSE HOLDER WITH FUSE

30. FUSE HOLDER WITH FUSE

31. Battery

MSS APE 50 Electrical system

ES - 59

Page 60

32. NEGATIVE BATTERY CABLE

33. STARTER RELAY

34. LOW FUEL WARNING LIGHT CONTROL

35. No.2 BULBS FOR STOP LIGHT

36. No.2 BULBS FOR REAR TURN INDICATORS

37. No.2 BULBS FOR DAYLIGHT RUNNING LIGHT

38. No.2 REAR LIGHTS

39. LIGHT FOR LICENCE PLATE WITH BULB

40. MIX OIL WARNING LIGHT CONTROL

41. CHASSIS-ENGINE GROUND CABLE

42. STARTER MOTOR

43. ELECTRONIC IGNITION DEVICE

44. MAGNETO FLYWHEEL

45. GROUND ON THE CHASSIS

46. Electric screen washer pump

47. STOP BUTTON ON THE REAR BRAKE

ELECTRICAL CABLES COLOUR CODING - APE 50 EUROPE

B = White

Bl = Blue

G = Yellow

M = Brown

Electrical system MSS APE 50

ES - 60

Page 61

N = Black

BV = White-Green

GN = Yellow-Black

RN = Red-Black

Gr = Grey

Rs = Pink

R = Red

Vi = Purple

V = Green

A = Orange

VN = Green-Black

BN = White-Black

BBI = White-Blue

BR = White-Red

RGr = Red-Grey

BIN = Blue-Black

BVi = White-Purple

RBI = Red-Blue

CAUTION

WHEN INTERVENING ON THE ELECTRICAL SYSTEM, MAKE ESPECIALLY SURE THAT THE

WIRES LEADING TO THE ELECTRONIC CONTROL UNIT ARE CORRECTLY CONNECTED AND

RESPECT THE COLOUR CODING GIVEN ON THE CONTROL UNIT.

Key-switch

LOCK Position: contacts 7-8, ground ignition, ex-

tractable key, locked steering.

OFF: contacts 7-8, ground ignition. Key may be

removed.

ON Position: contacts 1 -3 (c.c. to the services)

and 5-6 (Provision to the ignition of the daylight

running light in c.a.). Key may not be removed.

Position 1: contacts 7-8 (ground ignition) and 3-5

(c.c. to the daylight running light). Parking extractable key.

MSS APE 50 Electrical system

ES - 61

Page 62

Turn signal switch

Position 0: no contact.

Position 1: contact between the Blue and White Blue cables.

Position 2: contact between the Blue and Brown

cables.

Horn button

Button in working position, contact between the

White and Grey Black cables.

Headlight switch

Position O: no contact.

Position 1: contact between the Pink and Grey cables.

Position 2: contact between the Pink and Grey and

Purple cables.

Electrical system MSS APE 50

ES - 62

Page 63

Wiper switch

In working position, contact between the White

and White Black cables.

POSITIONS OF THE WINDSCREEN WIPER

SWITCH - APE 50 MIX - APE 50 EUROPE

0 = Windscreen wiper turned off

1 = Windscreen wiper turned on

2 = Windscreen washer enabling

Pulsante avviamento

In working position, contact between the White

and Green Black cables.

MSS APE 50 Electrical system

ES - 63

Page 64

Interventions

The failure of the alternate current section of the

voltage regulator can cause, depending on the

type of fault, the following problems:

1) Burning of the bulbs (regulator stopped).

2) Operation failure of the lighting (short circuit in

the regulator).

FAILURE 1

Replace the regulator because it is securely inefficient.

FAILURE 2

a) Check the correct current output of the alternator: disconnect the grey regulator cable, place a

voltmeter between the cable and ground to detect

the alternate current voltages and to check that the

output voltage at 3000 rpm is greater than or equal

to 20V.

b) If the checks carried out disclose no failures,

replace the regulator.

c) If replacing the regulator does not restore proper

operation, proceed to the checks of the electrical

system connections.

interventions

The failure of the direct current section of the voltage regulator can cause, depending on the type of

fault, the following problems:

3) Burning of the protective fuse (short circuit in the regulator) and subsequent battery recharge failure.

4) Battery recharge failure(regulator stopped).

FAILURE 3

Replace the regulator, because it is securely inefficient and replace the protective fuse.

FAILURE 4

a) Insert an ammeter between the regulator and the battery and verify that the current ouput at 3000

rpm is greater than 1 amp, with the battery maintained at 13V. If the values are lower than required,

replace the regulator.

Electrical system MSS APE 50

ES - 64

Page 65

b) If replacing the regulator does not restore proper operation, check the voltage output from the alternator, as in point 2a. Checking the output voltage at 3000 rpm on the c.c. section is greater than or

equal to 25V.

Characteristics

STARTER MOTOR

Specification Desc./Quantity

Rated voltage 12V.

rated power 0.25 Kw.

Rotation Left.

Bench tests

TESTS TO BE PERFORMED AT THE BENCH WHEN THE STARTER MOTOR HAS TO BE OVERHAULED.

1) No-load test: the starter motor, under no-load, must draw a maximum of 30 Amp. with a supply voltage

of 11.5 to 12V and must rotate at rpm 11,000.

2) Load test: braking the starter motor so that it draws 60 Amp, and with a supply voltage of 10 to 10.5

V a torque 0.06 kgm must be obtained, for no lower than 4,600 rpm.

3) Pickup test: with rotor locked and a supply voltage 8 to 8.5V the current drawn must not be higher

than 160 Amp and the torque must be no lower than 0.3 kgm.

N.B.

THE VALUES SHOWN ABOVE MUST BE TAKEN WITH A CHARGED BATTERY AND AFTER THE

STARTER MOTOR HAS BEEN ROTATING FOR 30" UNDER CONDITIONS OF POINT 1.

MSS APE 50 Electrical system

ES - 65

Page 66

KEY:

1 = Starter button

2 = Remote control

Starter motor removal

Safety cap removal

Coupling pin removal

Remove the retainer ring and remove the pinion.

CAUTION

ALWAYS REPLACE THE INDICATED GASKET GIVEN TO-

GETHER WITH THE SPECIFIC RECOMMENDED PRODUCT.

Electrical system MSS APE 50

ES - 66

Page 67

Safety cap calkin

- Position the hood.

- Chamfer, as shown, the hood with the appropriate tool.

CAUTION

REPLACING THE BRUSHES, AND REMOVE THE REAR LID

AND REPLACE.

Specific tooling

020057Y Tool for Starter Motor Bushing Calking

Controllo impianto di accensione

All system check operations involving disconnection of the cables (inspections of connections and

devices that are part of the ignition circuit) must be

made with the engine turned off: otherwise the

control unit could be irreparably damaged.

It is therefore important and necessary that in case

of removal of the cables, when refitting attention is

paid to correctly reconnecting each cable to the

corresponding coupling respecting the distinct colour codings.

KEY:

1 = Red

2 = White

3 = Green

INSPECTIONS TO BE PERFORMED IN THE EVENT OF IGNITION IRREGULARITIES

In the event of failure and abnormal operation of the ignition, whose causes are not detectable by a

visual inspection, it is necessary first to replace the control unit with a corresponding, safely functional

replacement.

Remember that the disconnections and connections to replace the control unit must be performed when

the engine stopped.

If replacing it restores the ignition operation, the fault lies in the control unit, which obviously needs to

be replaced.

In the event that the failure persists, it is necessary to carry out checks on the alternator and on the

stator parts as follows:

After a visual inspection of the electrical connections, measurements are carried out on the loading coil

and on the pick-up using an Ohm meter, capable of detecting the resistance from 1 to 1000 ohms.

MSS APE 50 Electrical system

ES - 67

Page 68

Connect the instrument between the green cable

and the white one, there must be continuity and an

ohmic value of 500± 20 ohm.

KEY:

1 = Red

2 = White

3 = Green

4 = Black

5 = Blue

Connect the instrument between the red and white

cables, there must be continuity and an ohmic value of 110± ±5 ohm.

KEY:

1 = Red

2 = White

3 = Green

4 = Black

5 = Blue

If there are failures on the checks on the loading coil and on the pick-up, proceed to the replacement.

Electrical system MSS APE 50

ES - 68

Page 69

INDEX OF TOPICS

ENGINE FROM VEHICLE EV

Page 70

Remove the oil from the engine.

Disconnect the negative cable from the battery and the starter motor cables.

Remove the fuel delivery line.

Remove the throttle grips, starter, etc.

Remove the axle shaft complete with hubs.

Remove the three fixing bolts (due at the front, and one at the rear) and remove the differential engine

unit of the chassis.

WARNING

WE RECOMMEND THE USE OF EYE PROTECTION WHEN USING CONTACT TOOLS.

WARNING

DO NOT REMOVE THE OIL COVER IMMEDIATELY AFTER AN ACTIVITY WITH THE ENGINE AT

FULL SPEED AND/OR WITH THE ENGINE RUNNING. THE HEATED OIL MAY LEAK, WITH THE

RISK OF BURNING

CAUTION

WHEN INSTALLING THE BATTERY, ATTACH THE POSITIVE LEAD FIRST AND THEN THE NEGATIVE LEAD.

Engine from vehicle MSS APE 50

EV - 70

Page 71

INDEX OF TOPICS

ENGINE EN

Page 72

Engine type 1

Flywheel

Remove the scroll cover.

Using the special tool to block the flywheel.

Specific tooling

020095Y Flywheel Lock

Using the appropriate tool, unscrew the lock-nut of

the flywheel.

Specific tooling

048564Y Flywheel extractor

Engine MSS APE 50

EN - 72

Page 73

Stator

For refit operations, operate in the opposite direction to the removal, bearing in mind the following:

position the stator as shown, correctly position the

key, and lock the flywheel nut to the prescribed

torque.

Locking torques (N*m)

Fan flywheel locking nut 45 to 50 Nm

Crankcase splitting

Fitting:

Clean the mating surfaces thoroughly.

Position a new gasket on the flywheel side crankcase halves.

Join the two crankcase halves.

Insert the flywheel side seal ring.

MSS APE 50 Engine

EN - 73

Page 74

Half-crankcase splitting

Removal:

Undo the screws and disassemble the crankcase

halves.

Crankcase bearings

Removal:

Remove the circlips and with punches of a suitable

diameter to eject the bearings.

Specific tooling

022465Y Pliers for circlips

Fitting:

Heat the crankcase to around 80° C.

Position the bearings.

Fit the retainer ring.

Fit the bench seal ring.

Specific tooling

020150Y Support

020151Y Heat gun

022465Y Pliers for circlips

Engine MSS APE 50

EN - 74

Page 75

Fly-wheel side half-crankcase

Removal:

Remove the bench bearing, operate with a punch

of an adequate diameter.

Specific tooling

021467Y Bearing extractor

021467Y013 extractor

021467Y009 extractor

After warming the crankcase, remove it with light

taps of the hammer.

Remove the bearing from the shaft, by leveraging

it with 2 screwdrivers.

Fitting:

Heat the crankcase to around 80° C.

Fit the bench ball bearing.

Fit main shaft of the transmission complete with

bearing.

Specific tooling

020150Y Support

020151Y Heat gun

Fitting:

Let the crankcase cool and fit the roller bearing.

Specific tooling

032975Y Punches for Roller Casings

MSS APE 50 Engine

EN - 75

Page 76

Gear-box coupling replacement

Removal:

Using the special tool remove the gear retaining

seeger.

Specific tooling

023638Y Pliers for circlips

Removal.

Fitting.

Fitting:

Reposition the transmission secondary shaft in its

seat.

Engine MSS APE 50

EN - 76

Page 77

Overhaul

Using the appropriate tool, disassemble the gear

engagement.

Inspect the components and replace those that are

damaged.

Specific tooling

023638Y Pliers for circlips

Coupling refitting

Using the appropriate tool, reassemble the gear

engagement.

Specific tooling

029569Y Gear Engagement Fitting Tool

Clutch drum

Removal:

After removing the circlips (for the piston pin), using a hard plastic mallet, remove the clutch housing

Specific tooling

023638Y Pliers for circlips

MSS APE 50 Engine

EN - 77

Page 78

Fitting:

Position the clutch housing with light taps with the

hard plastic mallet.

Fit the locking circlip.

Specific tooling

023638Y Pliers for circlips

Differential assembly

WARNING

REFIT THE PARTS IN REVERSE ORDER OF THE REMOVAL, TAKING CARE TO CORRECTLY

INSERT THE REVERSE GEAR CONTROL FORK INTO THE SLIDING GEAR.

WARNING

AFTER INSTALLING THE AXLE SHAFT IN THE CROWN WHEEL, CHECK THE PROPER SWING

OF THE AXLE SHAFT IN RELATION TO THE CROWN WHEEL.

Engine MSS APE 50

EN - 78

Page 79

Cover removal

Undo the indicated screws.

Differential box and transmission gears

Remove the gears

Differential case

Undo the indicated screws.

MSS APE 50 Engine

EN - 79

Page 80

Remove the bearing using a section of tube.

Refit the bearing as shown in figure.

Specific tooling

038138Y Roller Casings Punch

Differential box overhaul

Inspect all components and replace damaged

parts

Clutch cover and thrust plate

Removal:

Undo the indicated screws.

Fitting:

In order to correctly position the thrust plate actuating pad, follow these steps: hold the clutch

lever full stroke, insert the actuating pad into its

housing and holding the actuating pad, slowly release the clutch lever, check that the references

on the clutch lever and on the cover are the same

as shown in the figure.

Engine MSS APE 50

EN - 80

Page 81

Clutch and engine gear

Using the special tool to block the clutch assembly.

Specific tooling

030250Y Clutch Stop Key

Using the special tool, undo the fixing nut of the

clutch assembly

Specific tooling

029551Y Clutch puller

Fitting:

Reposition the clutch assembly and the engine

gear in their seat.

Tighten to the specified torque.

CAUTION

REFIT ALL PARTS, COMPONENTS, THE UNIT IN REVERSE ORDER TO THE REMOVAL, PAYING ATTENTION

TO REPOSITION THE CLUTCH KEY AND ENGINE GEAR

MOTOR.

Specific tooling

030250Y Clutch Stop Key

Locking torques (N*m)

Engine gear locking nut 50 to 55 Nm Clutch assembly locking nut 40 ÷ 45 Nm

MSS APE 50 Engine

EN - 81

Page 82

Clutch overhaul

Using the special tool to disassemble the clutch

assembly.

Specific tooling

020322Y Clutch Removal

Inspect the components and replace damaged

parts.

Cylinder head

Undo the fixing screws and remove the cylinder

hood

Undo the fixing screws of the cylinder head.

Engine MSS APE 50

EN - 82

Page 83

Piston

Remove the seal ring of the pin.

Remove the seal ring by removing the pin.

CAUTION

REFIT THE PARTS IN REVERSE ORDER TO THE DISASSEMBLY, TAKING CARE TO POSITION THE PISTON WITH

THE ARROW STAMPED ON THE SKY IN THE SAME DIRECTION AS THE EXHAUST.

Crankshaft

Removal:

To remove the crankshaft, separate the crankcase

halves and using gentle taps with a rubber mallet

to remove it.

CAUTION

SUPPORT THE CRANKSHAFT TO PREVENT DAMAGE BY

FALLING.

Fitting:

Using the appropriate tools necessary, position

the crankshaft in its seat.

Specific tooling

018119Y Axle Fitting Tool

018119Y009 Axle fitting

018119Y007 Axle fitting

MSS APE 50 Engine

EN - 83

Page 84

Engine timing

Coil support operation check.

ENGINER TIMING CHECK

Check to be carried with the Tecno- test 130/P

strobe gun (or a similar one that is able to function

properly up to at least 11,000 times per minute).

CAUTION

BEFORE PERFORMING THE TESTS ABOVE, CHECK THE

CORRECT JOINING OF THE FLYWHEEL ON THE CRANKSHAFT.

Engine MSS APE 50

EN - 84

Page 85

INDEX OF TOPICS

B

RAKING SYSTEM BS

Page 86

Brake pump

Key pump section:

1) Lug

Braking system MSS APE 50

BS - 86

Page 87

2) Gasket

3) Seeger ring

4) Washer

5) Gasket

6) Buffer

7) Plug

8) Pump body

9) Piston

10) Ring

11) Toric gasket

12) Spring

13) Cup

14) Spring

Brake pump overhaul specifications

After washing all the parts with a specific solvent, never use oil, petrol or solvents that have a corrosive

effect on the rubber, check that:

The pump body does not show signs of internal damage or corrosion as this may result in sealing ring

or piston failure; the latter must also be replaced if worn or scratched.

The rubber parts in the piston and the valve are not dilated or damaged as this most likely leads to poor

braking.

The piston return spring is in good condition.

The passages connecting the pump tank to the pump body are not clogged or dirty.

Removing brake fluid reservoir and pump from chassis

Removal:

After removing the brake fluid, remove the tank.

CAUTION

•

BRAKE FLUID IS HARMFUL TO THE EYES. IF

IT COMES INTO CONTACT WITH THE EYES

WASH THE AFFECTED PART CAREFULLY

AND CONSULT A DOCTOR.

•

FOR CORRECT OPERATION OF THE

BRAKES, USE ONLY THE RECOMMENDED

BRAKE FLUID.

•

FOLLOW THE INSTRUCTIONS PROVIDED BY

THE BRAKE FLUID MANUFACTURER.

•

NEVER MIX LIQUIDS WITH DIFFERENT

TECHNICAL SPECIFICATIONS.

•

USE ONLY BRAKE FLUID KEPT IN SEALED

CONTAINERS. IF THE LIQUID IS EXPOSED

TO THE AIR FOR TOO LONG IT ABSORBS

HUMIDITY AND LOSES ITS EFFICIENCY.

•

KEEP THE BRAKE FLUID FREE OF LITTER,

SAND OR DUST.

MSS APE 50 Braking system

BS - 87

Page 88

•

IF THE BRAKE FLUID LEVEL FALLS CONSIDERABLY, HAVE THE BRAKING SYSTEM

CHECKED BY AN AUTHORISED PIAGGIO

SERVICE CENTRE.

Refitting brake fluid reservoir and pump from chassis

Fitting:

Reposition the brake fluid tank appropriately.

Restore the correct level and bleed the system.

Air bleed of brake hydraulic circuit

Push down the pedal to the end of its travel and

slowly let it return to its starting position, repeating

the operation until the pedal feels a back pressure.

As this operation is carried out add fluid to the

tank to prevent the pump from discharging.

Lower the pedal, keeping it pressed, undo the

bleed screw on a rear wheel, let the air out, after

this bleed point has been connected through a

small rubber pipe to a tray full of brake fluid.

Screw the bleed screw.

Repeat the above operations until the escape of air bubbles from the that tube does not stop.

Repeat the above operations for the other wheel.

CAUTION

THE AIR COMING OUT OF THE TUBE MAY ENTER DURING THE CONTINUOUS BLEEDING OPERATION; IN SUCH A CASE INSPECT ALL FITTINGS AND THE CORRECT TIGHTENING OF THE

GASKETS OF THE PUMP AND OF THE CYLINDERS OF THE WHEEL.

In performing the circuit filling operation shown above, ensure that the liquid level in the tank never falls

below the minimum, and top up continuously with the recommended product.

Braking system MSS APE 50

BS - 88

Page 89

CAUTION

BRAKE FLUID IS HYGROSCOPIC; IT TENDS TO ABSORB MOISTURE FROM THE SURROUNDING AIR.

IF THE HUMIDITY IN THE BRAKE FLUID IS ABOVE A GIVEN VALUE, BRAKING IS POOR.

UNDER NORMAL DRIVING AND CLIMATIC CONDITIONS YOU SHOULD CHANGE THE FLUID

EVERY TWO YEARS.

IF THE BRAKES UNDERGO SEVERE OPERATING CONDITIONS THE LIQUID SHOULD BE REPLACED MORE FREQUENTLY.

CAUTION

WHEN REFILLING TO LEVEL USE ONLY THE TYPE OF LIQUID THAT HAD BEEN USED PREVIOUSLY.

Recommended products

AGIP BRAKE 4 Brake fluid

FMVSS DOT 4

Drum removal

In the filling operations, a maximum oversize of 0.4

mm on the regular drum diameter is allowed.

Shoe and drum clearance adjustment

Before performing the adjustment between the

shoe and the drums, it is necessary to set the

brakes in motion, in a way that ensures the centring of said shoe.

Then act as follows for each wheel:

Lift the wheel off the ground, lower of the brake

pedal to the bottom until it brings the shoe against

the drum.

Holding down the pedal, rotate the nuts of the adjustment eccentricities outwards until they stop,

then rotate them in the opposite direction by about

45°.

MSS APE 50 Braking system

BS - 89

Page 90

Then release the pedal and check that the wheel