Colour Television Chassis

EM1A

AA

CL 06532111_000.eps

171000

Contents Page Contents Page

1. Technical specifications, connection facilities &

chassis overview 2

2. Safety- and maintenance instructions, 4

warnings and notes.

3. Directions for use 6

4. Mechanical instructions 11

5. Faultfinding and repair tips 15

Block-, wiring diagrams and testpoint overviews

6.

Blockdiagram video processing 27

Blockdiagram audio & control 28

Blockdiagram Large Signal Panel: supply 29

Powerlines overview 30

Wiring diagram 31

2

C overview 32

I

Testpoint overview LSP 33

Testpoint overview SSB / DW / CRT panel 34

Electrical diagram’s en PWB’s Diagram PWB

7.

Main supply (Diagram A1) 35 43-48

Standby supply (Diagram A2) 36 43-48

Line deflection (Diagram A3) 37 43-48

Frame deflection (Diagram A4) 38 43-48

Audio amplifier (Diagram A5) 39 43-48

Headphone amplifier (Diagram A6) 40 43-48

Tuner, I/O, SIMM-connector (Diagram A7) 41 43-48

Front control (Diagram A8) 42 43-48

SSB: SIMM-connector (Diagram B1) 49 55-60

IF, I/O, videoprocessing (Diagram B2) 50 55-60

Feature box (Diagram B3) 51 55-60

HOP (Diagram B4) 52 55-60

Audio demodulator (Diagram B6) 53 55-60

Painter (Diagram B7) 54 55-60

Multi PIP controller (Diagram C1) 61 65/66

Tuner (Diagram C2) 62 65/66

I/O processing (Diagram C3) 63 65/66

©

Copyright 2000 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

IF video sync (Diagram C4) 64 65/66

Side I/O panel (Diagram D) 67 67

Top control panel (Diagram E) 69 69

CRT panel (Diagram F) 70 71

DC-shift panel (Diagram G) 71 71

Horizontal DAF panel (Diagram I1) 72 74

Vertical DAF panel (Diagram I2) 73 74

Mains switch panel (Diagram J) 75 75

Mains harmonic panel (Diagram Y) 76 76

8. Alignments 77

9. Circuit description and 82

list of abbreviations 96

10. Spareparts list 98

Published by CO 0070 Service PaCE Printed in the Netherlands Subject to modification 5 3122 785 10850

GB 2 EM1A1.

Technical specifications, connection facilities & chassis overview

1. Technical specifications, connection facilities & chassis

overview

1.1 Technical specifications

1.1.1 Reception

Tuning system : PLL

Colour systems (off-air) : NTSC M (3.58 &

4.43 MHz),

: PAL B/G/D/K/I/M/N,

: SECAM B/G/D/K/L

Sound systems : FM/FM,

: 2SC B/G,

: NICAM B/G/D/K/I/L

A/V connections : PAL B/G,

:SECAM,

: NTSC M (3.58 &

4.43 MHz).

Channel selections : 100 channels,

: UVSH-channels

Frequency range : 44.25 - 855.25 MHz

Aerial input : 75 Ω, Coax

1.1.2 Miscellaneous

Set stroke numbers : /56, /57, /69, /79,

/93

Mains voltage : 160 - 276 V

(± 10 %),

: 50 / 60 Hz (± 5 %)

Ambient temperature : + 5 to + 45 deg. C.

Standby Power consumption : < 1 W.

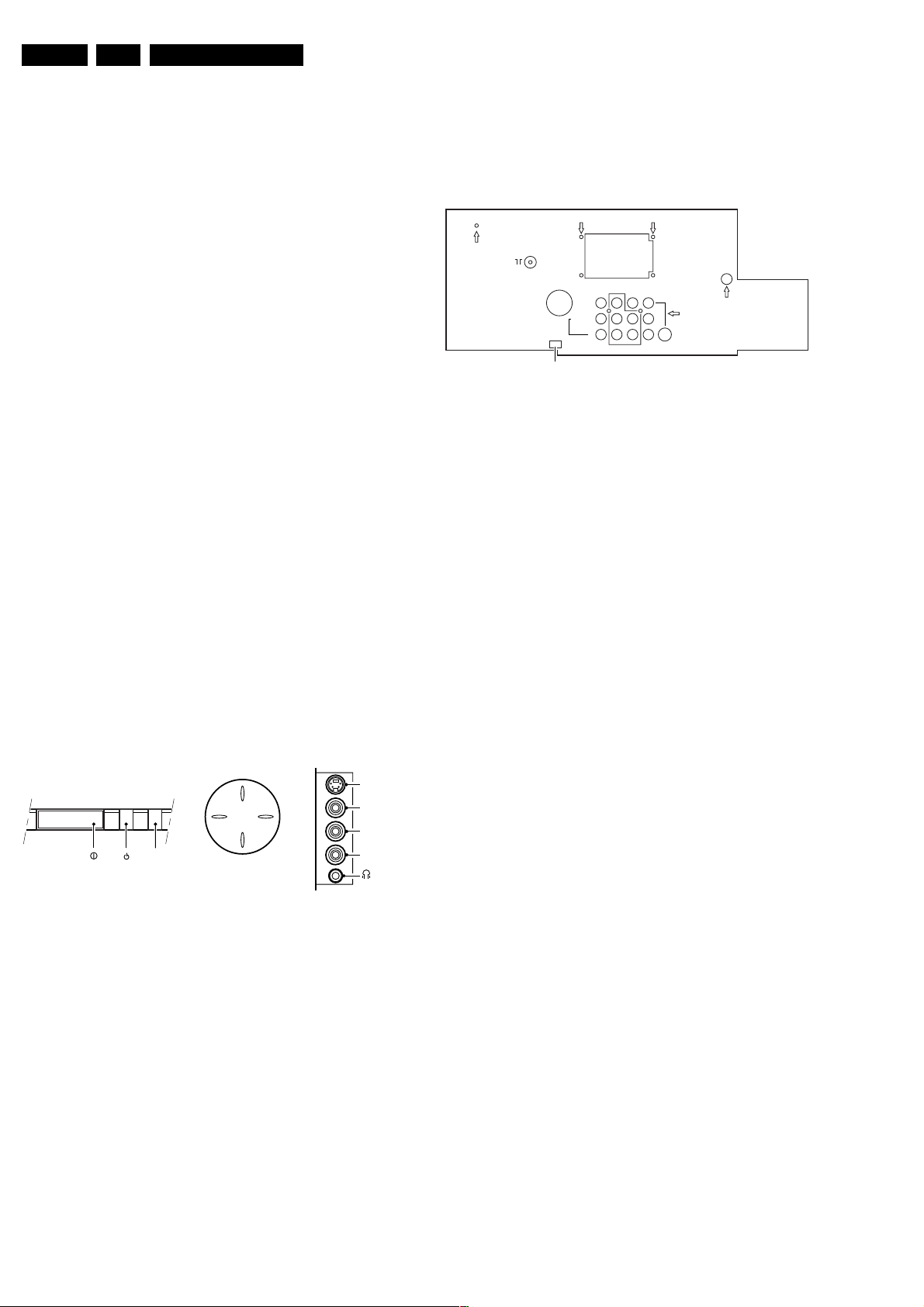

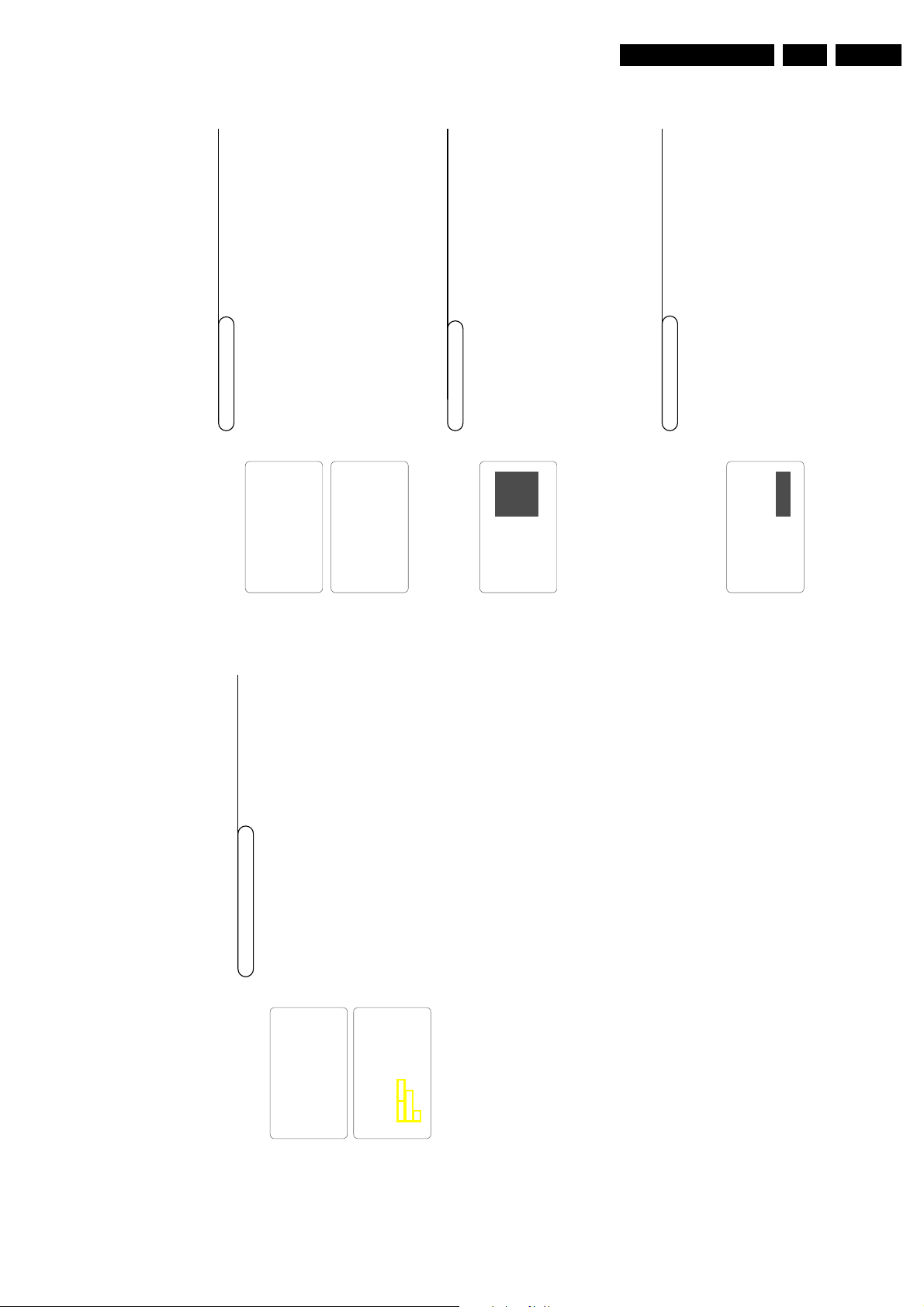

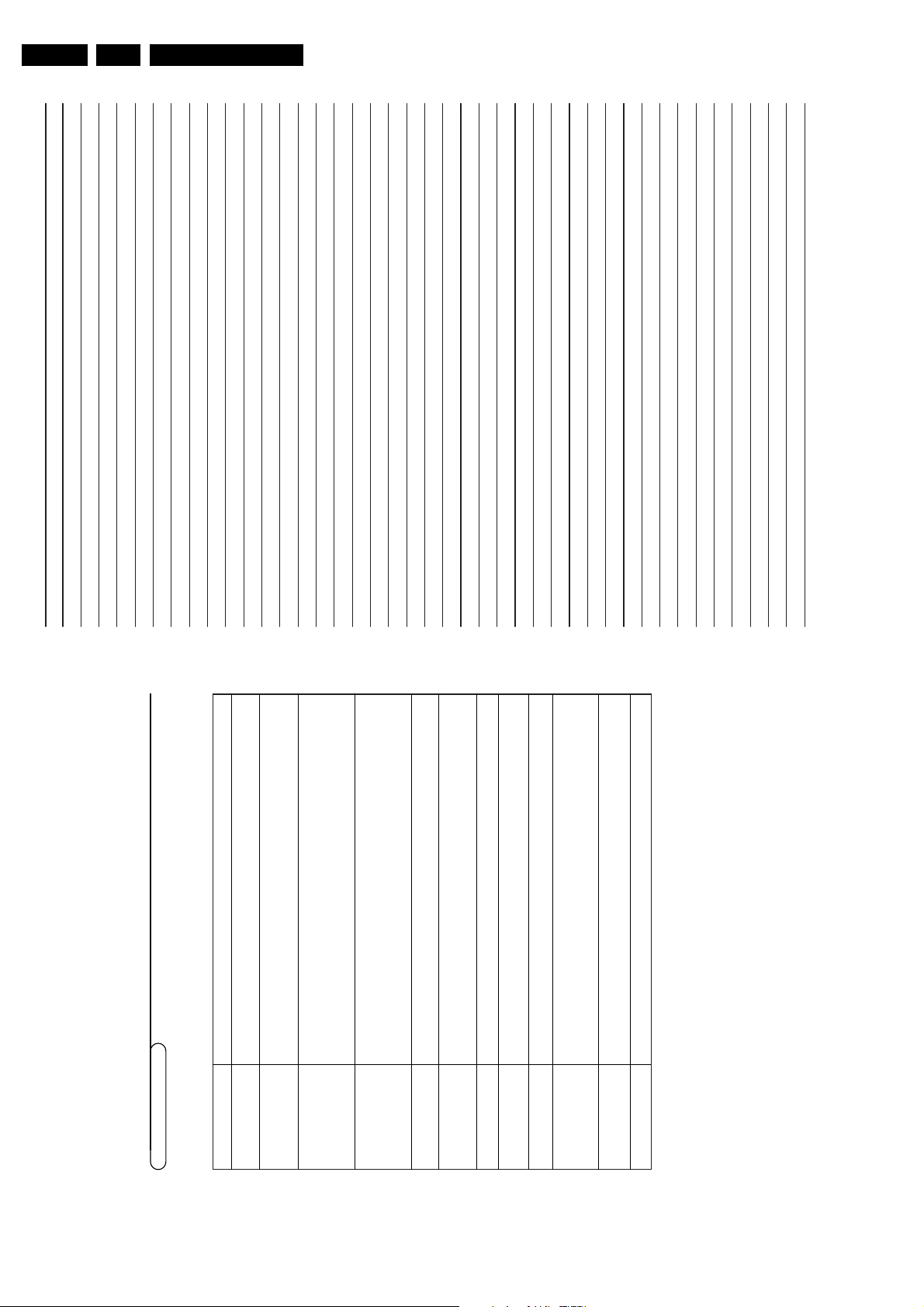

1.2.2 Rear connections

75Ω

MONITOR

OUT

VIDEO

L/MONO

AUDIO

R

COMPONENT VIDEO INPUT

SERVICE

CONNECTOR

Figure 1-2

Monitor out

1 - Video 1 Vpp / 75 Ω

2 - Audio L (0.5 Vrms / 10 kΩ)

3 - Audio R (0.5 Vrms / 10 kΩ)

AV1 in

1 - Y 0.7 Vpp / 75 Ω

2 - Pb 0.7 Vpp / 75 Ω

3 - Pr 0.7 Vpp / 75 Ω

AV1 in

4 - Video 1 Vpp / 75 Ω

5 - Audio L (0.5 Vrms / 10 kΩ)

6 - Audio R (0.5 Vrms / 10 kΩ)

AV1

AV2

IN

IN

Y

Pb

Pc

S-VIDEO

CL 06532130_001.eps

021000

kq

kq

q

jq

jq

jq

jq

jq

jq

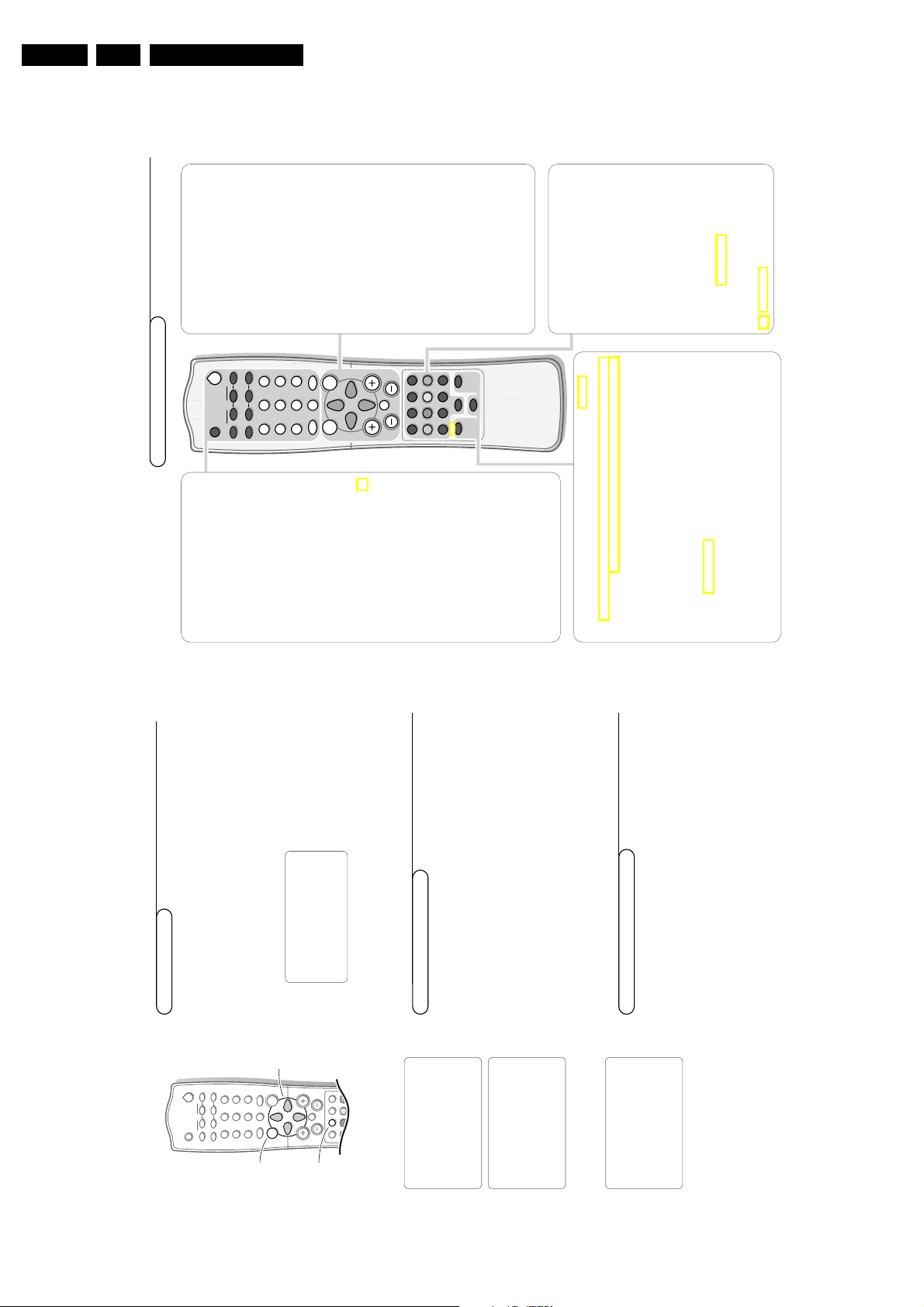

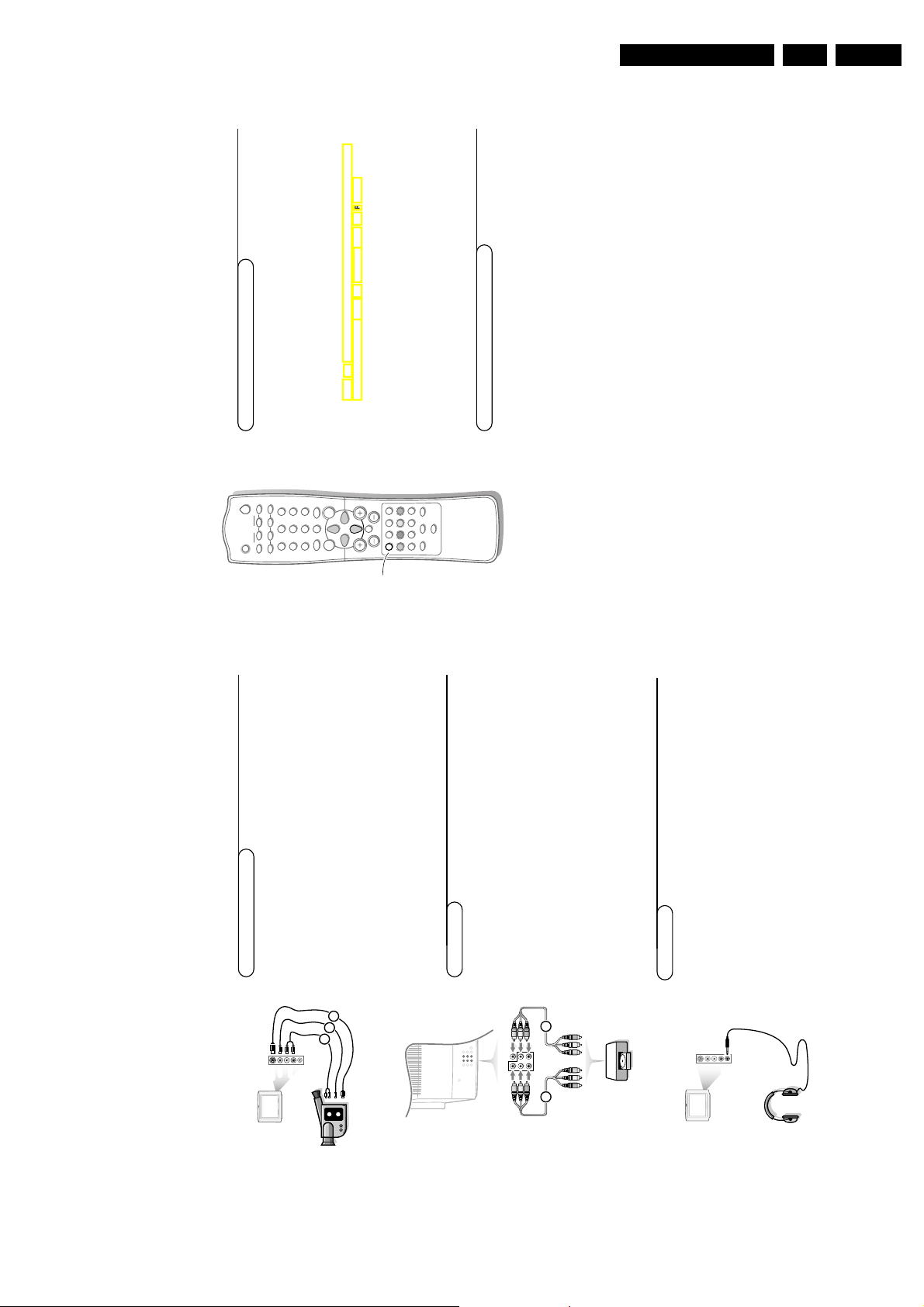

1.2 Connection facilities

1.2.1 Control buttons & Side I/O connections

TOP CONTROL

P+

V+V-

IR

RED

Figure 1-1

SVHS

1 - gnd

2 - gnd

3 - Y 1 Vpp / 75 Ω

4 - C 0.3 Vpp / 75 Ω

Audio / video

1 - Video 1 Vpp / 75 Ω

2 - Audio L (0.2 Vrms / 10 kΩ)

3 - Audio R (0.2 Vrms / 10 kΩ)

4 - Headphone 32 - 2000 Ω / 10 mW

P-

SIDE I/OFRONT CONTROL

S-Video

Video

L

Audio

R

CL 06532130_002.eps

031000

j

j

jq

jq

jq

rt

v

v

AV2 in

1 - Video 1 Vpp / 75 Ω

2 - Audio L (0.5 Vrms / 10 kΩ)

3 - Audio R (0.5 Vrms / 10 kΩ)

AV2 in (SVHS)

1 - gnd

2 - gnd

3 - Y 1 Vpp / 75 Ω

4 - C 0.3 Vpp / 75 Ω

jq

jq

jq

v

v

j

j

Technical specifications, connection facilities & chassis overview

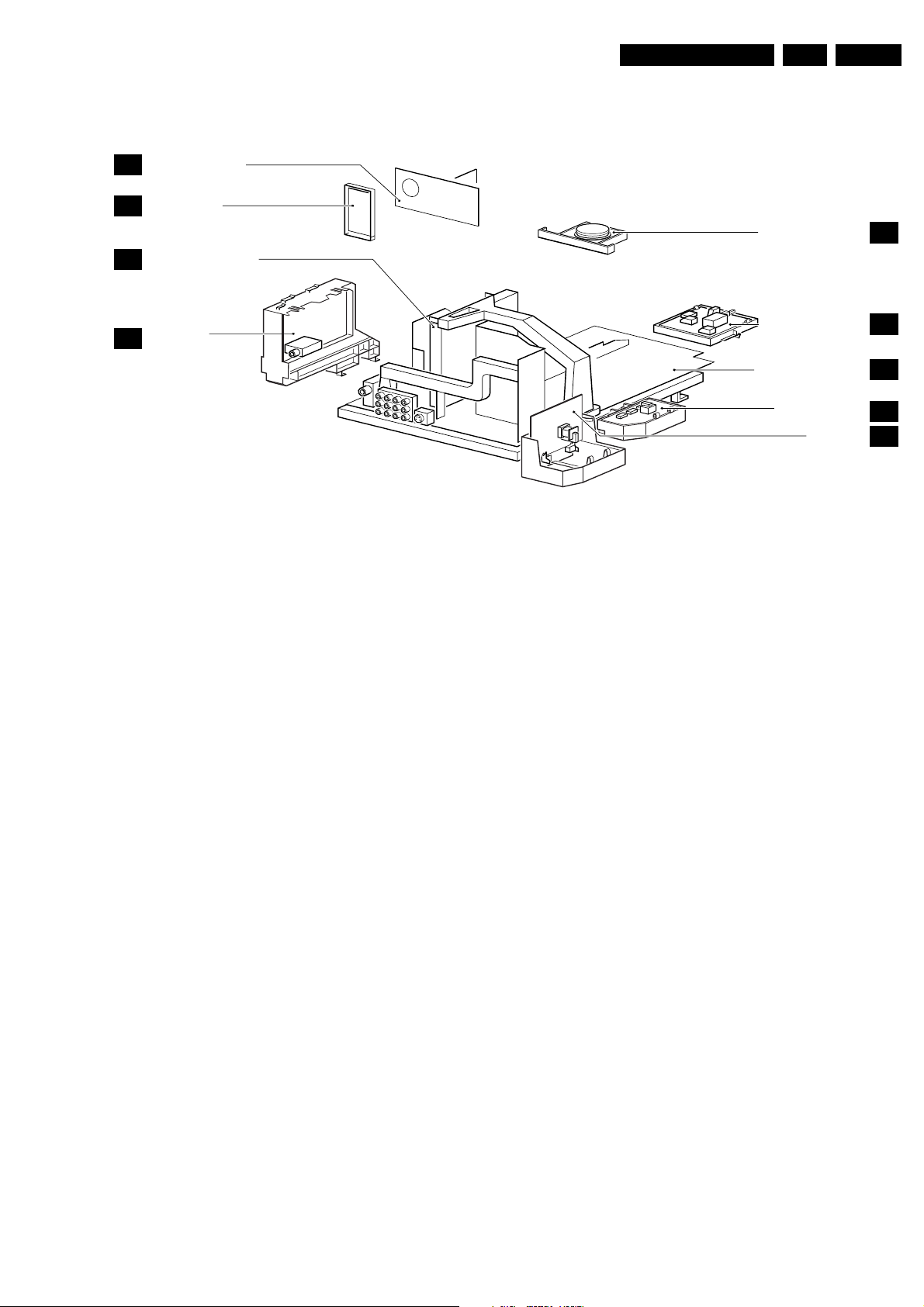

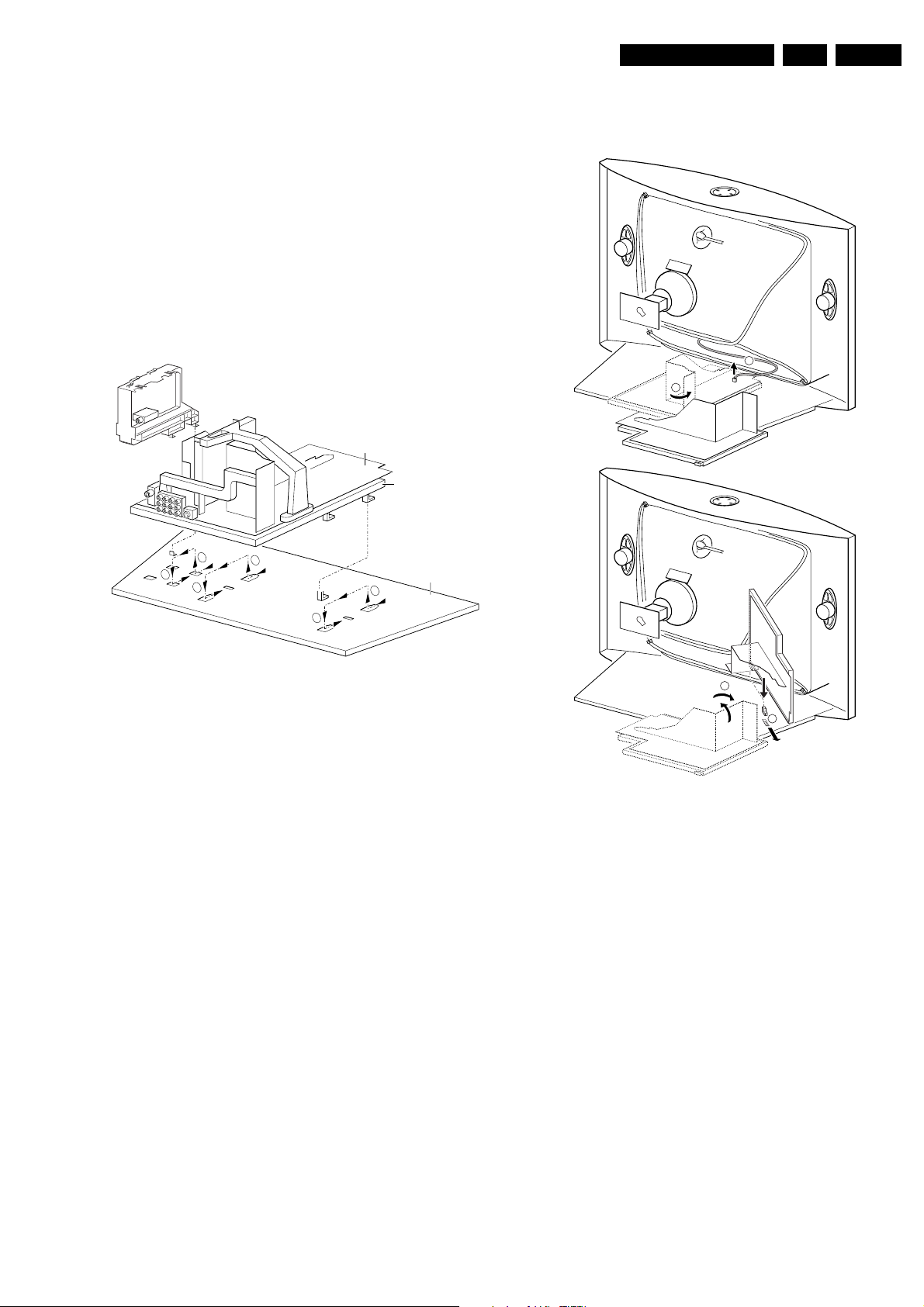

1.3 Chassis overview

CRT/SCAVEM PANEL

F

SIDE I/O PANEL

D

SMALL SIGNAL BOARD

B

TOP CONTROL PANEL

GB 3EM1A 1.

E

PIP/DOUBLE

C

WINDOW PANEL

Figure 1-3

MAINS SWITCH PANEL

LARGE SIGNAL PANEL

MAINS HARMONIC

PANEL

DAF PANEL

CL 06532130_003.eps

J

A

Y

I

181000

GB 4 EM1A2.

Safety & maintenance instructions, warnings and notes

2. Safety & maintenance instructions, warnings and notes

2.1 Safety instructions for repairs

Safety regulations require that during a repair:

• Safety components, indicated by the symbol ∆, should be

replaced by components identical to the original ones;

• When replacing the CRT, safety goggles must be worn.

Safety regulations require that after a repair, the set must be

returned in its original condition. In particular attention should

be paid to the following points:

• General repair instruction: as a strict precaution, we

advise you to resolder the solder joints, through which

the horizontal deflection current is flowing, in particular:

– All pins of the line output transformer (LOT);

– Fly-back capacitor(s);

– S-correction capacitor(s);

– Line output transistor;

– Pins of the connector with wires to the deflection coil;

– Other components through which the deflection

current flows.

Note: This resoldering is advised to prevent bad connections

due to metal fatigue in solder joints and is therefore only

necessary for television sets older than 2 years.

• The wire trees and EHT cable should be routed correctly

and fixed with the mounted cable clamps.

• The insulation of the mains lead should be checked for

external damage.

• The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

• The electrical DC resistance between the mains plug and

the secondary side should be checked (only for sets

which have a mains isolated power supply). This check

can be done as follows:

– Unplug the mains cord and connect a wire between

the two pins of the mains plug;

– Set the mains switch to the 'ON' position (keep the

mains cord unplugged!);

– Measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner or

the aerial connection on the set. The reading should

be between 4.5 MΩ and 12 MΩ.

– Switch off the TV and remove the wire between the

two pins of the mains plug.

• The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

2.2 Maintenance instructions

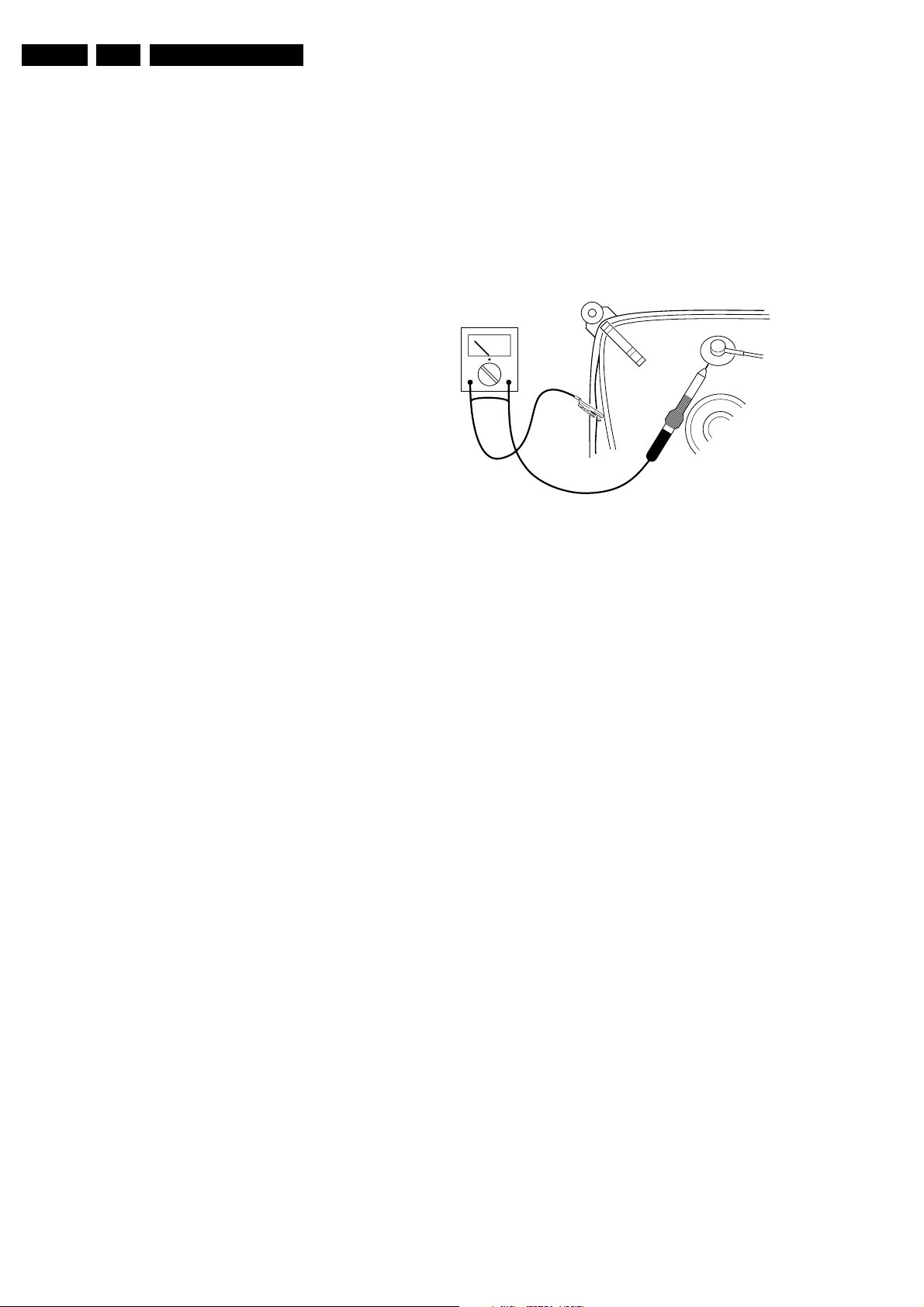

2.3 Warnings

• In order to prevent damage to IC's and transistors, all

high-voltage flashovers must be avoided. In order to

prevent damage to the picture tube, the method shown in

Fig. 2-1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position

VDC). Discharge until the meter reading is 0 V (after

approx. 30 s).

V

Figure 2-1

• All IC's and many other semiconductors are susceptible

to electrostatic discharges (ESD). Careless handling

during repair can reduce life drastically. When repairing,

make sure that you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this same

potential. Available ESD protection equipment:

– Complete kit ESD3 (small table mat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Together with the deflection unit and any multipole unit,

the used flat square picture tubes form an integrated unit.

The deflection and the multipole units are set optimally at

the factory. Adjustment of this unit during repair is

therefore not recommended.

• Be careful during measurements in the high-voltage

section and on the picture tube.

• Never replace modules or other components while the

unit is switched ON.

• When making settings, use plastic rather than metal

tools. This will prevent any short circuits and the danger

of a circuit becoming unstable.

CL 26532098/042

140792

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

• When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3

to 5 years.

• When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

• The maintenance inspection contains the following

actions:

– Execute the above-mentioned 'general repair

instruction'.

– Clean the power supply and deflection circuitry on

the chassis.

– Clean the picture tube panel and the neck of the

picture tube.

2.4 Notes

Safety & maintenance instructions, warnings and notes

GB 5EM1A 2.

• The direct voltages and oscillograms should be

measured with regard to the tuner earth (

(

) as this is called.

I

• The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

• Where necessary, the oscillograms and direct voltages

are measured with (

Voltages in the power supply section are measured both

for normal operation (

values are indicated by means of the appropriate

symbols.

• The picture tube PWB has printed spark gaps. Each

spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

• The semiconductors indicated in the circuit diagram and

in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

• DOLBY, the double D symbol and PRO LOGIC are

trademarks of Dolby Laboratories Licensing Corporation.

Manufactured under license from Dolby Laboratories

Licensing Corporation.

) and without (E) aerial signal.

D

) and in Standby (F). These

G

), or hot earth

H

GB 6 EM1A3.

2

A/CH

MENU SURF

SMARTSMART

CH

V

¬

i

bh

f◊

h

î

gU

XC

5

1

3

2

4

6

7

9

8

0

AV

PIP

PIP CH

UP DN

ACTIVE CONTROL

PROGRAM LIST

DOLBY V.

D

æ

q©

ßê

S

M

a

B

Sleep

D

Allows you to select a time period after which

the set will switch to standby mode

automatically.

Standby

B

• Switch set off temporarily to standby mode.

(The red light indicator lights up when set is

on standby mode).

• To switch on set from standby mode, press

button again.

(Alternate Channel)

A/CH

Allows you to alternate between the last

viewed channel and the present channel.

PIP (Picture in Picture)/Dual Window On/Off

æ

ßê©

PIP CH UP/DOWN

(if provided) See p. 12

Freeze

S

Allows you to freeze the main picture.

Screen format

q

Press this key repeatedly to select another

screen format:Auto, 4:3, Expand 4:3 and

Compress 16:9. See also p. 11.

Digit

(0-9)

Allows you to select a channel.

Note: For a 2-digit number,the second digit

must be entered before the “-”sign disappears.

Smart Sound

M

Allows you to select your desired sound setting

from 4 types of sound settings.

Press the key repeatedly to select the different

settings.

Smart Picture

a

Allows you to select 5 types of picture settings.

Press the key repeatedly to select the different

settings.

Preparation

Your remote control

DOLBY V

◊

Dolby Virtual (with Dolby Surround signals)

Dolby Virtual (Virtual Dolby Surround) enables you to experience the effect

of Dolby Pro Logic Surround,reproducing a rear sound effect.

Incredible Surround

In

Stereo

sound mode, when

Incredible Surround

is selected, it seems as

though the loudspeakers are spread further apart from one another.

In

Mono

sound mode, this feature,when switched on, enables you to hear

a spatial effect of sound.

Active Control On/Off

h

Measures and corrects all incoming signals in order to provide the best picture

quality settings. Press to select the Active Control values On or Off.

ON: Sharpness and Noise Reduction are controlled automatically.The Picture

settings are being adapted continuously and automatically. The menu items cannot

be selected.

PROGRAM LIST

î

Allows you to navigate through a list of installed programmes for a quick overview

of the channels and activate the channel you have selected.

MENU

Displays main menu.

Also exits the menu from the screen or returns

to a higher menu level.

SURF

Allows you to select up to a maximum of 10

favourite channels or sources and view quickly

the selected channels or sources.

To add a new channel or source:

• Select the channel number or source you

want to add to the surf list.

• Press the SURF key.

The request ADD? appears next to the

selected channel number or source.

• Press the cursor right to add.

To delete a channel or source:

• Select the channel number or source you

want to remove from the surf list.

• Press the SURF key.

The request DELETE? appears next to the

selected channel number or source.

• Press the cursor right to delete.

Press the SURF key repeatedly to scroll

through the selected channels or sources.

Cursor

Up/Down: allows you to select the next or

previous item on the menu and to

select another picture format

Left/Right:

allows you to access the sub-menus

and adjust the settings.

V

Volume

+/-

Increases or decreases volume.

¬

Mute

Mutes the sound.To restore the sound,press

the button again.

CH +/-

Selects channels in ascending or

descending order.

AV

Allows you to select the AV channels.

i

On Screen Display

• Displays the channel number, sound

transmission mode, the clock and the status

of the sleeptimer.

• Also allows you to exit menu from screen.XAllows you to switch from Stereo to Mono

sound during stereo transmission or to choose

between Language Y or Language Z during

dual sound transmission.

C

Timer

Allows you to set the clock to switch to

another channel at a specified time while you

are watching another channel or when the

set is on standby mode.

Colour keys,

bhUf

Teletext

(if provided) See p. 13

Allows you to access teletext information.

g

for future use

A/CH

MENU

SURF

SMARTSMART

CH

V

¬

i

i

bhgU

XC

5

1

3

2

4

6

7

9

8

0

AV

VIDEO MOVIES

PIP

PIP CH

UP DN

D

æ

q©

ßê

S

M

a

B

3. Directions for use

Directions for use

Installation

MENU

Press the

&

Use the cursor in the up/down directions to select a menu item.

Note: Sometimes not all the menu items are visible on the screen;press the cursor

é

down until all the items are displayed.“Use the cursor in the left/right directions to access the sub-menu and to

To use the menus

key to display/cancel the main menu.

adjust the settings.

Press the menu key to return.(Press the i key to switch the menu off.

‘

select menu

return

PICTURE

SOUND

item

switch

menu off

FEATURES

INSTALL

Note: If no action is executed, the menu automatically disappears after about 12

seconds.

key.

MENU

Press the

First, select your language.

&

Select the menu language

Store TV channels

PICTURE

SOUND

FEATURES

INSTALL

.

LANGUAGE

with the cursor down.

INSTALL

Select

é

key to return to the main menu.

MENU

Press the cursor right to select

Press the cursor right again.

Select your language with the cursor up/down.§Press the

“

‘

(

LANGUAGE

AUTO STORE

MANUAL STORE

SORT

CHANNEL EDIT

INSTALL

NAME

From now onwards, all on-screen displays will appear in the language that you

have chosen.

You can now search for and store the TV channels in two different ways: using

Auto store or Manual store (tuning in channel by channel).

key to return to the

MENU

menu.

INSTALL

in the

menu or press the i key to switch the menu off.

AUTO STORE

Select

&

Automatic tuning of channels

Press the cursor right to start the searching.

All TV channels are searched for and stored automatically.“When the tuning is completed, press the

é

INSTALL

SORT

CHANNEL EDIT

NAME

LANGUAGE

AUTO STORE

MANUAL STORE

INSTALL

Note: Channel numbers will always be written in Latin characters, even when a

language has been selected which uses other characters.

Installation

4

Directions for use

6

Installation

Sorting of channels

According to your preference you can change the order of the stored TV

channels.

&

Select

SORT

in the

INSTALL

menu.

é

Press the cursor right to enter the menu.“Key in the channel number in the

FROM

column you want to swap from. Use

the digit keys or the cursor left/right.

‘

Press the cursor down and select

TO

.

(

Key in the channel number in the

TO

column you want to swap to.

§

Press the cursor down and select

EXCHANGE

.

è

Press the cursor right.

The message

EXCHANGED

appears and the selected channels are exchanged.

!

Repeat steps

“

to

è

until all TV channel are allocated as you like.

ç

Press the

MENU

key to return to the

INSTALL

menu or press the i key to

switch menu off.

This feature allows you to edit or skip channels from the channel list which

have bad or weak signals or channels which you do not watch often.

Note: Once a channel is skipped, you cannot select it with the

CH -

or

+

key.

You can only access the channel with the digit keys.

&

Select

CHANNEL EDIT

in the

INSTALL

menu.

é

Press the cursor right to enter the channel list.

“

Select the channel you want to skip with the cursor up/down.‘Press the cursor right to skip the selected channel.

The message

SKIPPED

is displayed.

(

Press the cursor up/down to select another channel and repeat step

‘

.

§

Press the cursor left or the

MENU

key to return to the install menu or the

i key to switch menu off.

Note: to add back channels to the list, repeat steps

&

to

‘

and press the

i key to switch menu off.

Editing of channels

It is possible to assign a name to a TV channel.This feature allows you to

enter a new name or modify an existing name of a channel, including

peripherals.

Note: Even when you have selected another language in the language menu, only

the English language character set is offered to enter names to the TV channels

stored.

&

Select a TV channel or peripheral you want to assign a name or modify the

existing name.éSelect

NAME

in the

INSTALL

menu.

“

Press the cursor right to enter the menu.‘Key in the selected character with the cursor up/down.(Move to the next character with the cursor right and key in the next

character.You can key up to a maximum of 5 characters.

§

Press the

MENU

key to store the named channel.

Naming of channels

INSTALL

LANGUAGE

AUTO STORE

MANUAL STORE

SORT

CHANNEL EDIT

NAME

INSTALL

LANGUAGE

AUTO STORE

MANUAL STORE

SORT

CHANNEL EDIT ƒ

NAME

SORT

FROMTOEXCHANGE/EXCHANGED

34567 SKIPPED

INSTALL

LANGUAGE

AUTO STORE

MANUAL STORE

SORT

CHANNEL EDIT

NAME

CNN

GB 7EM1A 3.

Manual tuning of channels

menu.

INSTALL

in the

MANUAL STORE

Manual tuning allows you to store channel by channel.

You must go through every step of the manual store menu.&Select

LANGUAGE

AUTO STORE

MANUAL STORE

SORT

INSTALL

and press the cursor right.

is selected, the respective colour system will be automatically

COLOUR SYSTEM

AUTO

If

selected according to the transmission system.

Press the cursor right to enter the menu.“Select

é

If the reception is poor, select another colour system with the cursor up/down.

CHANNEL EDIT

NAME

COLOUR SYSTEM

SOUND SYSTEM

MANUAL STORE

and press the cursor right.

key or the cursor left.

MENU

is selected, the respective sound system will be automatically

SOUND SYSTEM

AUTO

selected according to the transmission system.

If

Press the

Select

‘

(

SEARCH

CHANNEL

STORE/STORED

FINE TUNE

PLL

key or the cursor left.

and press the cursor left or right to start the searching.

MENU

SEARCH

Note: If the reception is poor,select another sound system with the cursor up/down.

Searching stops once a transmitting channel is found.

Note: If the reception is poor, select another colour and/or sound system.

Press the

Select

§

è

.

CHANNEL

Select

Key in the desired channel number with the digit keys or with the cursor

!

ç

left/right.0Press the cursor down.

and press the cursor left/right to adjust.

FINE TUNE

In case of poor reception, you can improve the reception by adjusting the

frequency.1Select

In rare cases certain TV channels may reproduce distorted or unstable

pictures.

2

menu or press the i key to

.

STORE

(Phase Locked Loop) to switch to the setting 2 with the cursor

PLL

left/right to restore the picture for the respective transmission.

Select

Press the cursor down to select

Press the cursor right.

3

4

INSTALL

to continue searching for another transmitting

4

to

appears and the search menu item is highlighted again.

è

key to return to the

STORED

MENU

switch menu off.

channel.

The message

Now repeat steps

Press the

5

6

5

Installation

GB 8 EM1A3.

16

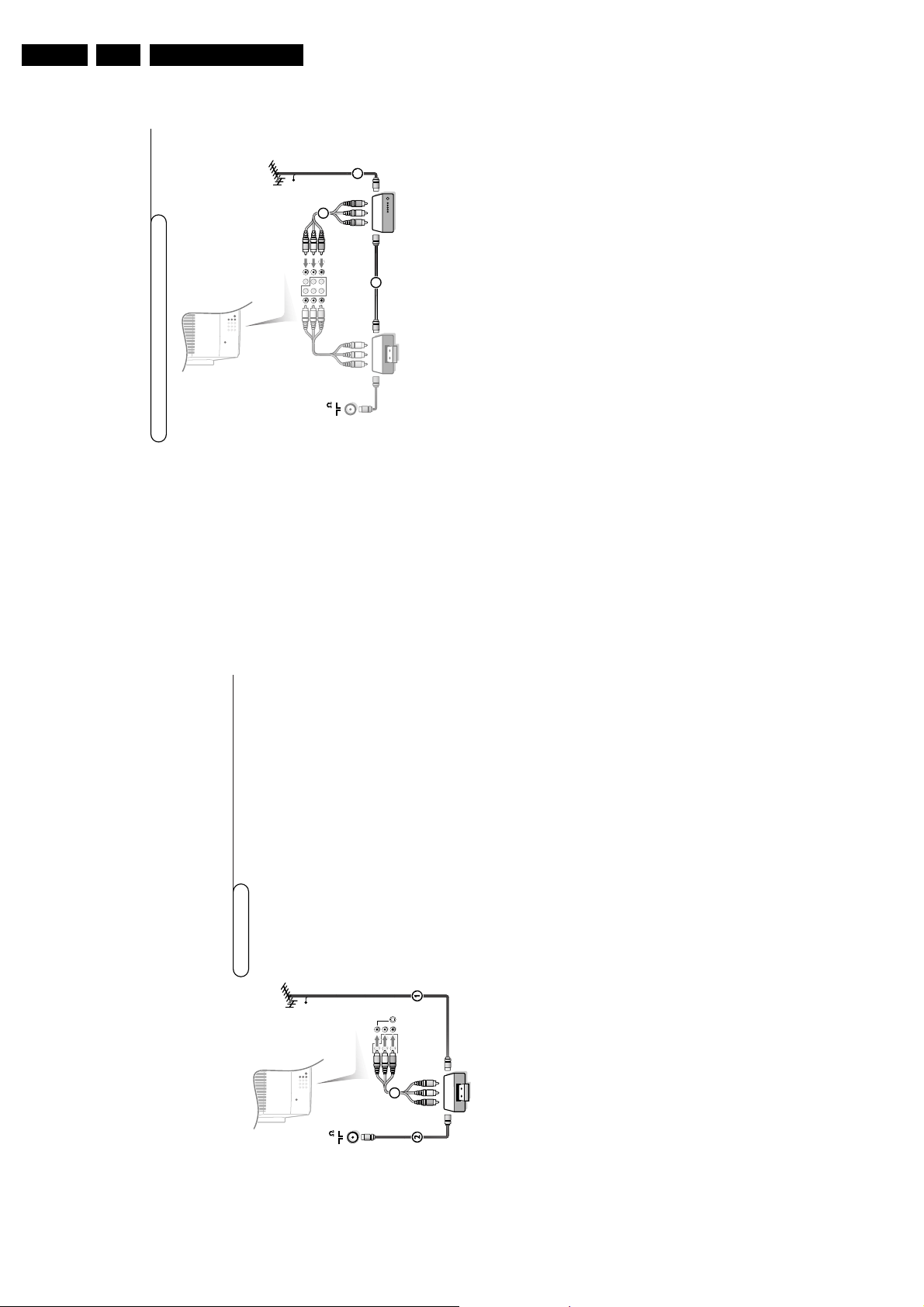

Connect Peripheral Equipment

75

CABLE

VCR

AV 2

in

AV 1

in

Monitor

out

COMPONENT VIDEO INPUT

VIDEO

L/Mono

R

Y

Pb

Pr

AUDIO

S-VIDEO

OUT

OUT

OUT IN

j x

4

1

3

Video recorder and other A/V peripherals

&

Interconnect your video recorder with extra RF cables 3.éTo obtain better picture quality, also connect the Video,Audio left and Audio

right (only for stereo equipment) cables to the

VIDEO

,

AUDIO L/

Mono and

AUDIO R

input of

AV2 IN

sockets 4.

Note: in case of mono equipment, only the left loudspeaker reproduces sound.

Use a mono to stereo adaptor (not supplied) for sound reproduction via all

internal loudspeakers.

When a video recorder is not connected to

MONITOROUT

you can only record a

programme from the aerial or from the cable system.

Only when a video recorder is connected to

MONITOROUT

it is possible to record a

programme from other equipment connected to the TV. See Record with your video

recorder, p.18.

CABLE

VCR

75

OUT

j x

AV 2

in

AV 1

in

Monitor

out

COMPONENT VIDEO INPUT

VIDEO

L/Mono

R

Y

Pb

Pr

AUDIO

S-VIDEO

3

Directions for use

There is a wide range of audio and video equipment that can be connected

to your TV.The following connection diagrams show you how to connect

them.

Video recorder

Connect Peripheral Equipment

Connect the RF cable 1 to the RF socket x of your video recorder.éConnect another RF cable 2 from the output j of your video recorder to

&

15

,

VIDEO

input instead of connecting the video

.

AV2 IN

input

R

Mono and

Use a mono to stereo adaptor (not supplied) for sound reproduction via all

internal loudspeakers.

Better playback quality can be obtained if you also connect the Video,Audio

Left and Right (only for stereo equipment) cables 3 to the

Note: in case of mono equipment, only the left loudspeaker reproduces sound.

AUDIO L/

the input x of your TV.

connectors can be used for daisy chaining or to record

MONITOR OUT

The

programmes from your TV. See Record with your video recorder, p. 18.

S-VIDEO

input. (See the instructions of your video recorder.)

cable with the

VIDEO

quality with a S-VHS video recorder is obtained by connecting

S-VHS-Video

recorder to the

the

S-VHS-Video

If the cables 3 are not used the following steps are required:

Search for and store the test signal of the video recorder

Unplug the RF cable 1 from the RF socket x of your video recorder.éSwitch on your TV and put the video recorder on the test signal or play a

&

prerecorded tape (See the handbook for your video recorder.).“Search for the test signal of your video recorder in the same way as you

searched for and stored the TV signals. See Installation, Store TV Channels,

Manual Tuning, p. 5.‘Store the test signal under programme number 0 or between 90 and 99.

Replace the RF cable in the RF socket x of your video recorder after

(

Connect Peripheral Equipment

you have stored the test signal.

Directions for use

18

Record

Equipment connected with an aerial cable only :

Select the channel number under which you have stored the test signal with

the digit keys.

Equipment connected to the back or to the right side of the TV

Press the

AV

key repeatedly to select

AV1

,

CVI

,

AV2

or

FRONT

, according to

where you connected your equipment at the back or the right side of your

TV.

Select

CVI

to view the playback of DVD discs if you used the Component

Video Input sockets (

Y-Pb-Pr

and

AUDIO L

/

Mono

and

R

inputs).

If you want to change to TV channels?

Enter the channel number of the TV channel which you want to watch with

the digit keys.

To select connected equipment

A/CH

AV

MENU

SURF

SMARTSMART

CH

V

¬

i

bh

f◊

h

gU

XC

5

1

3

2

4

6

7

9

8

0

AV

PIP

PIP CH

UP DN

DOLBY V.

ACTIVE CONTROL

PROGRAM LIST

D

æ

q©

ßê

M

a

B

S

To record S-VHS quality, connect an S-VHS peripheral directly to the video

recorder.

Record a TV programme&Select the channel number on your video recorder.éSet your video recorder to record.

See the handbook for your video recorder.

Switching channel numbers on your TV does not disturb recording !

Record a programme on your video recorder connected to

MONITOR OUT

from Audio/Video equipment connected to

AV1,AV2

or to sockets on the right side of the TV

&

Switch on the equipment.

é

Select the correct external on your TV and on your video recorder.“Set your video recorder to record.

You record what you are watching on the screen.

Do not switch channel numbers or do not switch off your TV when you are recording !

Record with your video recorder

L

A

U

D

IO

V

ID

E

O

S

•V

ID

E

O

3

2

1

AV 2

in

AV 1

in

Monitor

out

COMPONENT VIDEO INPUT

VIDEO

L/Mono

R

Y

Pb

Pr

AUDIO

S-VIDEO

1 2

DVD

GB 9EM1A 3.

1 for mono

AUDIO L

2 and

VIDEO

equipment.

Connect your camera or camcorder to sockets at the right side of your TV.éConnect the equipment to

&

Camera & camcorder

AUDIO

2) and

VIDEO

1.

AUDIO R

input 3 (instead of

S-VIDEO

S-VHS quality with an S-VHS camcorder is obtained by connecting the S-VHS

cables with the

For stereo equipment also connect

inputs 1.

“

DVD-player

input

Y-Pb-Pr

.

VIDEO

input.

R

Mono and

in sockets on the TV.

(See the handbook of your DVD player.)

For correct picture reproduction also connect to

Connect the cables of your Y-Pb-Pr DVD player 1 to the

AV1

Connect the Audio left and right (only for stereo equipment) cables to the

AUDIO L/

&

é

Insert the plug into the headphone socket L at the right side of the TV.éPress ¬ on the remote control to switch off the internal loudspeakers

&

Headphone

17

to adjust the headphone volume and

Headphone

Connect Peripheral Equipment

menu select

SOUND

of the TV.

balance.

The headphone impedance must be between 8 and 4000 Ohm.

The headphone socket has a 3.5 mm jack.

In the

GB 10 EM1A3.

Directions for use

Personal notes:

Using a highly directional antenna may improve the picture .

Then re-insert the plug into the mains socket and turn on the television again.

Items to Check and Actions to follow

• This may be caused by obstruction to the antenna due to high rise buildings or hills.

• Check that the television's AC power cord is plugged into the mains socket.

• Unplug the television, wait for 60 seconds.

• Check the antenna connection at the rear of the television to see if it is properly connected to the

television input terminal.

• Possible broadcast station trouble. Try another channel.

• Adjust the contrast and brightness settings or select another picture setting with the smart picture key.

• Increase the VOLUME.

• Check that the television is not muted, press the ¬ button on the remote control.

• When no signal is detected, the television automatically switches off the sound.

This is proper operation and does not indicate a malfunction.

• Check the transmission system’s sound settings of this set.

connected to the right side of of your TV and another peripheral is connected to AV1 or AV2 at the

• Adjust the contrast and brightness setting or select another picture setting with the smart picture key.

same time. In this case, switch off one of the other peripherals.

• Check the transmission system’s colour settings of this set.

• Sometimes, poor picture quality occurs when having activated an S-VHS camera or camcorder

• Check the antenna connection.

• This may be caused by electrical interference (e.g. hairdryer, nearby neon lights,etc.)

• Turn off the equipment.

• Turn off the television immediately and consult a qualified service personnel.

• Check whether the batteries are working. Replace if necessar y.

• Clean the remote control sensor lens on the television.

• Operating range between television and the remote control should not be more than 6 meters.

• You can still use the keys at the top of your TV.

• This could be due to antenna siting or reflected signal.

• Switch over to “MONO” mode by pressing the X key.

• Press the i key again to exit from the menu.

19

Before Calling Service

Before Calling Service

Please make these simple checks before calling service.These tips may save you time and money since charges for television installation and

adjustments of customer controls are not covered under your warranty.

Symptoms

“Ghost” or double images

No power

No picture

Good picture but no sound

Good sound but poor

colour or no picture

Poor picture

Snowish picture and noise

Horizontal dotted line

One white line across the

screen

Television not responding to

remote control

NICAM sound distortion

(crackling noise)

Wrong menu

If your problem is not solved

Turn your TV off and then on again once.

Never attempt to repair a defective TV yourself.

Check with your dealer or call a TV technician.

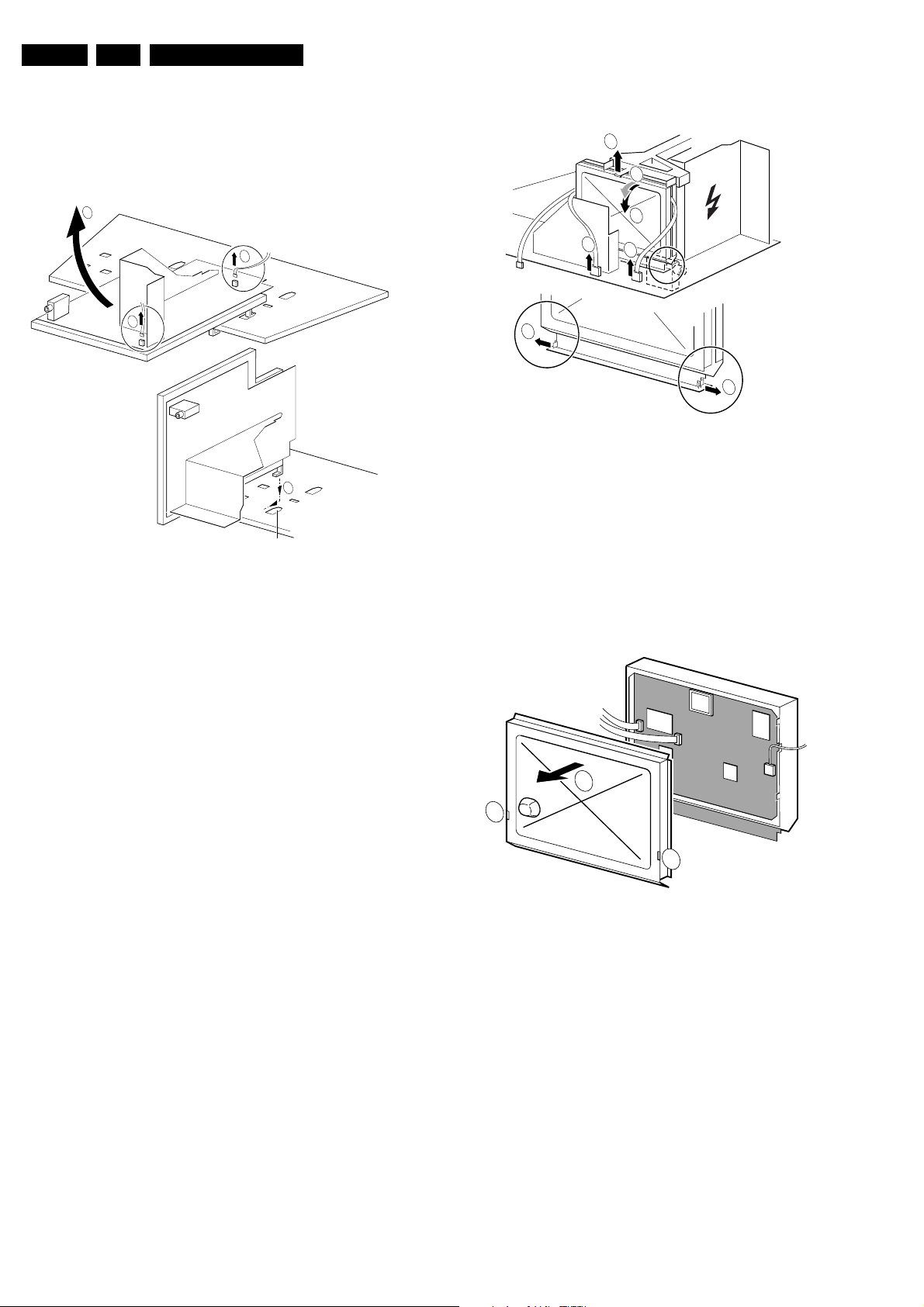

4. Mechanical instructions

4.1 Removing the Rear Cover

1. Remove all the fixation screws of the rear cover.

2. Now the rear cover can be removed by pulling it

backward.

4.2 Service positions

4.2.1 Service position LSP

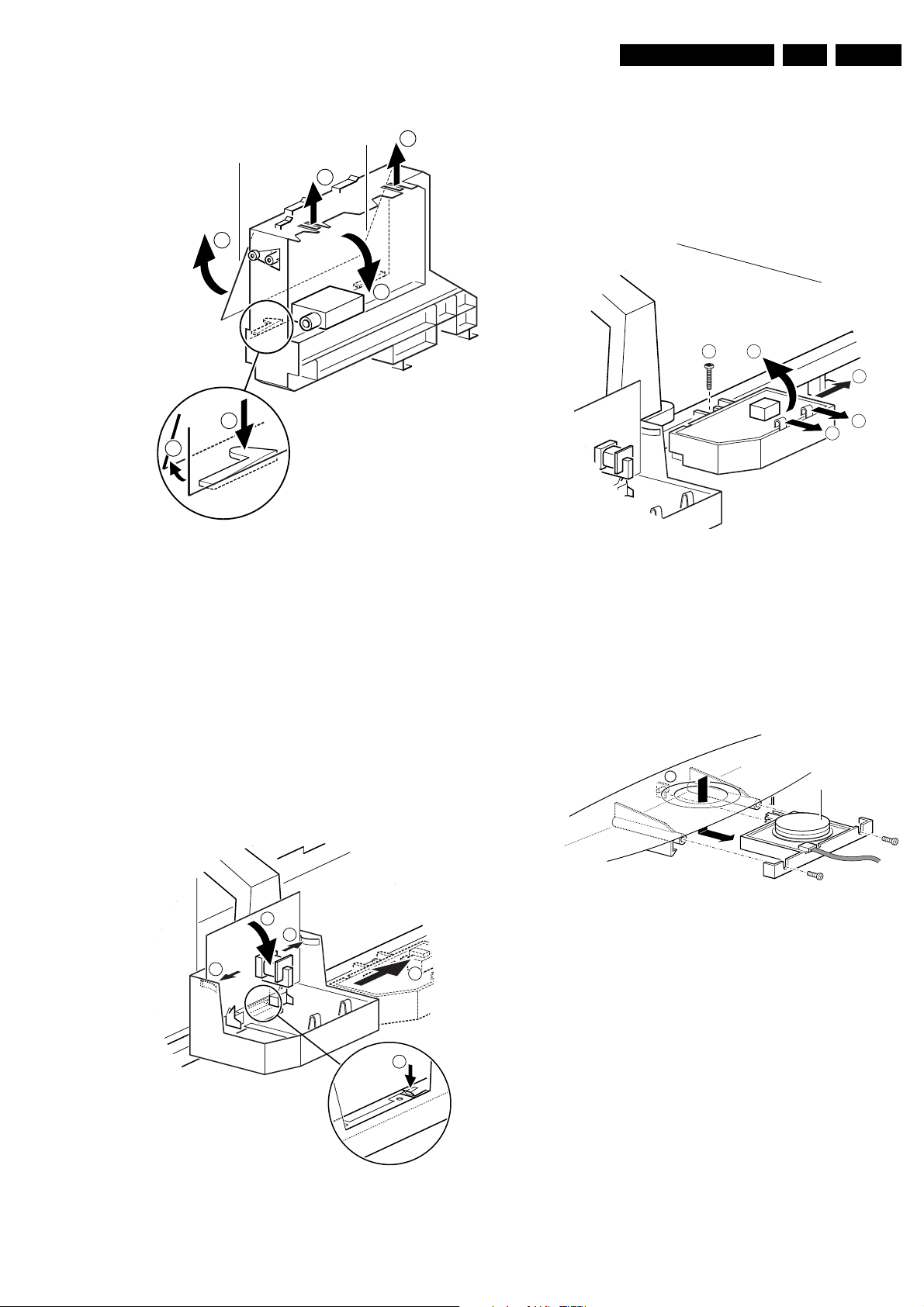

Position 1: For better accessibility of the LSP, do the

following:

SSB

LSP

LSP - bracket

Mechanical instructions

GB 11EM1A 4.

1

2

A

3

4

2

1

1

2

Bottom tray

CL 06532130_004.eps

031000

Figure 4-1

1. Remove the LSP-module from the bottom tray by pulling

the complete module back- and then upward.

2. Hook the bracket in the first row of fixation holes of the

cabinet bottom. In other words reposition the bracket

from [1] to [2].

3. The same can be done with the DW-module (position [3]

to [4]).

Position 2: This service position is comparable to that of the

A10A. To get access to the bottom side (solder side) of the

LSP, do the following:

3

4

CL 06532130_006.eps

B

121000

Figure 4-2

1. Disconnect the CRT/SCAVEM panel from the CRTsocket.

2. Release LSP and DW-module, and pull backward.

3. Remove Mains switch module from bottomplate (see

description below).

4. Free the necessary wiring from their fixation clamps, for

the ease of handling.

5. Sometimes a cable must be disconnected for the ease of

handling, like the degaussing coil (0020) and

loudspeaker (1735, 1736 & 1737) cables.

6. Now reposition following modules, in order to cope with

the LSP service position:

– DAF-module from the LSP-bracket by pressing lever

while pushing the module forward in the direction of

the CRT (see also description below).

– Mains Harmonic module from the LSP-bracket by

removing 1 screw and then slide the module

backward, away from the CRT (see also description

below).

7. Turn the chassis tray 90 degrees counter clockwise (see

figure 4.2 - [2]).

8. Flip the chassis tray with the rear I/O panel towards the

CRT [3].

9. Place the hook of the tray in the fixation hole at the right

side of the cabinet bottom and pull the chassis tray

backward [4].

GB 12 EM1A4.

Mechanical instructions

10. Reconnect cables (except degaussing cable 0020),

panels and modules.

Alternative position 2: A somewhat easier way to access the

bottom side (solder side) of the LSP is the following (only

possible when the high tension cable is long enough):

2

1

1

3

A

Figure 4-3

1. Disconnect the CRT/SCAVEM panel from the CRTsocket.

2. Release LSP and DW-module, and pull backward.

3. Remove Mains switch module from bottomplate (see

description below).

4. Free the necessary wiring from their fixation clamps, for

the ease of handling.

5. Sometimes a cable must be disconnected for the ease of

handling, like the degaussing coil (0020), loudspeaker

(1735, 1736 & 1737) cables and 0325 (frame deflection).

6. Now reposition following modules, in order to cope with

the LSP service position:

– DAF-module from the LSP-bracket by pressing lever

while pushing the module forward in the direction of

the CRT (see also description below).

– Mains Harmonic module from the LSP-bracket by

removing 1 screw and then slide the module

backward, away from the CRT (see also description

below).

7. Flip the chassis tray 90 degrees clockwise [2].

8. Place the hook of the tray in fixation hole [A] of the

cabinet bottom and pull the chassis tray backward [3].

9. Reconnect the cables (except degaussing cable 0020),

panels and modules.

4.2.2 Service position SSB

All relevant test points can be accessed with the SSB in

original position, but for ease of use a 'SSB extension board'

is available under number 9965 000 05769.

Before usage of this board, the 'LSP top-bracket' has to be

taken out. This can be done by:

1. Remove the DAF panel (see 4.2.5).

2. Remove the 2 screws which hold the bracket at the right

side.

3. Lift the bracket at the same side. It hinges at the cooling

plate.

Note: For some type numbers, the LSP has to be moved

slightly to the right side in order to create enough space for

the SSB extension board.

CL 06532130_007.eps

131000

To get access to the test points of the SSB, the shielding has

to be removed:

2

3

5

11

1

FROM

PIP/DW MODULE (0205)

4

0948

0946

4

CL 06532130_008.eps

131000

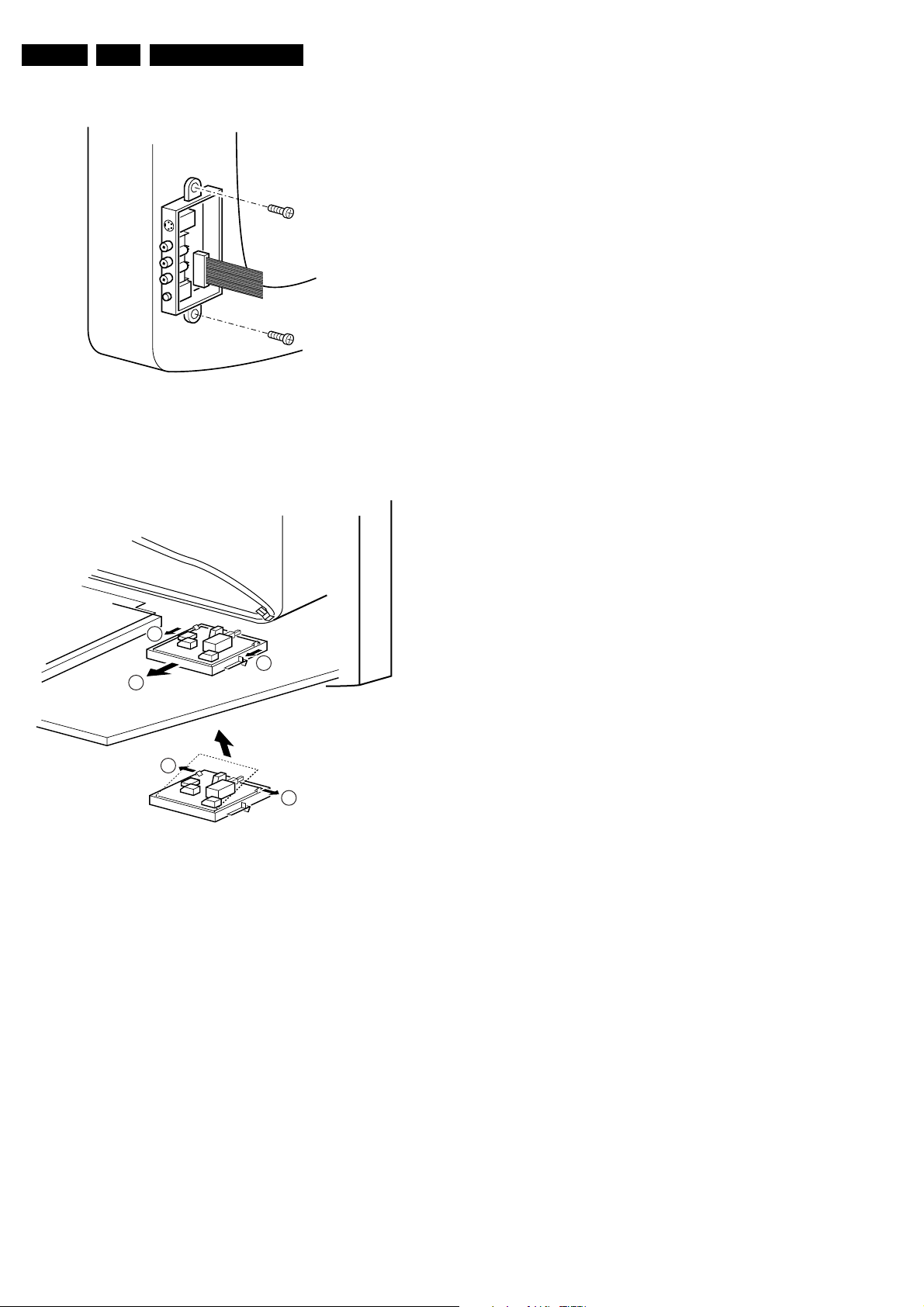

Figure 4-4

1. Put the LSP in service position 1 (as described above).

2. If a PIP/DW module is present, then disconnect the IFcable from connector 1946, flatcable from connector

1948 and flatfoil on DW-module connector 0205 [1].

3. Release the 'top fixation clamp' which holds the SSB [2]

and pull the SSB slightly towards the Tuner [3]. At the

same time, the 2 metal clamps at both sides of the SIMMconnector must be released [4] . The complete SSB can

be taken out now by pulling the topside of the SSB

towards the Tuner [5]. It 'hinges' in the SIM-connector.

2

1

1

CL 06532130_009.eps

Figure 4-5

1. Once the SSB has been taken out of the connector, the

shielding can be removed.

2. After removal of the shielding, the panel can be replaced

in its connector in reverse order. Don't forget to

reconnect the cables.

3. If necessary for the measurement, the LSP can be put in

'service position 2' (as described above).

031000

Mechanical instructions

GB 13EM1A 4.

4.2.3 Accessing the Double Window (DW) panel

PIP/Double Window

1

Multi Voltage

1

4

2

3

4

CL 06532130_015.eps

Figure 4-6

1. Remove the DW bracket from the bottom tray by pulling

it backward (after pressing the fixation clamp).

2. The board can easily be lifted out of the bracket [2] after

releasing the 2 fixation clamps [1].

4.2.4 Accessing the Multi Voltage panel (if present)

031000

1. The complete module can be removed from the LSPbracket by pressing its fixation clamp [1] (located behind

the PWB), while sliding the module in the direction of the

CRT [2].

2. The board can easily be lifted from its bracket after

releasing the 2 fixation clamps [3].

4.2.6 Accessing the Mains Harmonic panel

31

CL 06532130_017.eps

Figure 4-8

1. The complete module can be removed from the LSPbracket (after removal of the DAF-panel) by removing

screw [1] and then slide the module in the opposite

direction of the CRT [2].

2. The board can easily be lifted from its bracket after

releasing the 2 fixation clamps [3].

3

2

3

131000

1. Remove the DW bracket from the bottom tray by pulling

it backward.

2. Press the 2 fixation clamps downward [3] (see figure 4-

7).

3. The board can easily be lifted out of the bracket after

releasing the 2 fixation clamps [4].

4.2.5 Accessing the Double Astigmatic Focus (DAF) panel

3

3

3

2

1

4.2.7 Accessing the Top Control panel

M

Figure 4-9

1. Remove the two fixation screws, which hold the panel.

2. Pull the board backward (w.o.w. release it from its front

hinge [M]).

3. The board can easily be lifted from its bracket after

releasing the 2 fixation clamps at the connector side.

Top control board

CL 06532012_003.eps

030200

Figure 4-7

CL 06532130_016.eps

031000

GB 14 EM1A4.

Mechanical instructions

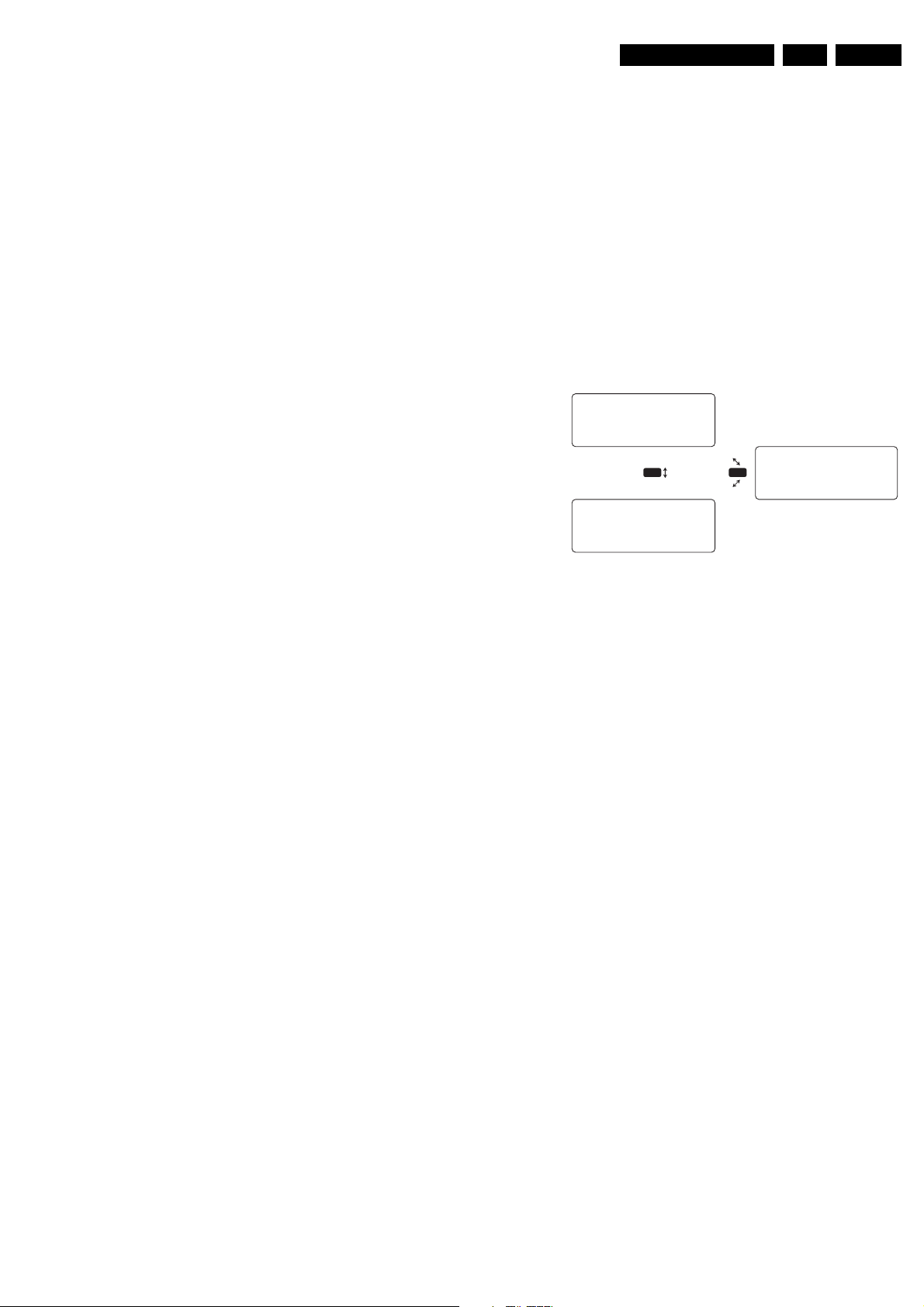

4.2.8 Accessing the Side I/O panel

CL 06532012_004.eps

Figure 4-10

4.2.9 Accessing the Mains Switch panel

1. The complete Side I/O-assembly can easily be removed

by unscrewing the 2 fixation screws.

2. The board can easily be lifted out of the bracket after

releasing the 2 fixation clamps.

030200

1

1

2

3

3

Figure 4-11

The easiest way to access this module is with the LSP in

service position 2.

1. Release the two fixation clamps by pulling them

backward [1].

2. At the same time, the complete assy must be pulled

backward [2].

3. If the board has to be removed, release the 2 clamps at

the bracket sides and lift panel up [3].

4.3 Mounting the Rear Cover

Before mounting the Rear Cover, some checks has to be

performed:

• Check whether the Mains Cord is mounted correctly in

the guiding brackets.

• Check whether all cables are replaced in their original

position. This is very important due to the large 'hot' area

of the set.

CL 06532130_018.eps

021000

Fault finding and repair tips

5. Fault finding and repair tips

GB 15EM1A 5.

In this chapter the following paragraphs are included:

1. Test points.

2. Service Modes.

3. Problems and solving tips (related to CSM).

4. ComPair.

5. Error codes.

6. The 'blinking LED' procedure.

7. Protections.

8. Repair tips.

5.1 Test points

The EM1A chassis is equipped with test points in the service

printing. These test points are referring to the functional

blocks:

• A1-A2-A3, etc.: Test points for the audio processing

circuitry [A5, A6, and B6].

• C1-C2-C3, etc.: Test points for the control circuitry [B7].

• F1-F2-F3, etc.: Test points for the frame drive and frame

output circuitry [A4, B4] and Double Window [C].

• F1F-F2F, etc.: Test points for the RGB-signals on the

CRT panel [F].

• I1-I2-I3, etc.: Test points for the intermediate frequency

circuitry [A7, B2].

• L1-L2-L3, etc.: Test points for the line drive and line

output circuitry [A3, B4].

• P1-P2-P3, etc.: Test points for the power supply [A1, A2].

• SC1-SC2, etc.: Test points for the synchronisation

circuitry on the CRT panel [F].

• V1-V2-V3, etc.: Test points for the video processing

circuitry [B].

• Via grounding the 'Front Detect'-line on the Side I/O

panel during switch ON (pins 1 and 7 of connector

0936).

• By the 'DEFAULT' button on the DST while the set is in

the normal operation mode.

CAUTION: Entering SDM by grounding the 'Front Detect'line will override the 5V-protection. This should only be

done for a short period of time. In case of SW-protections

(errors 1 - 4), the set will shutdown in 15 s.

When doing this, the service-engineer must know what

he is doing as it could lead to damaging the set.

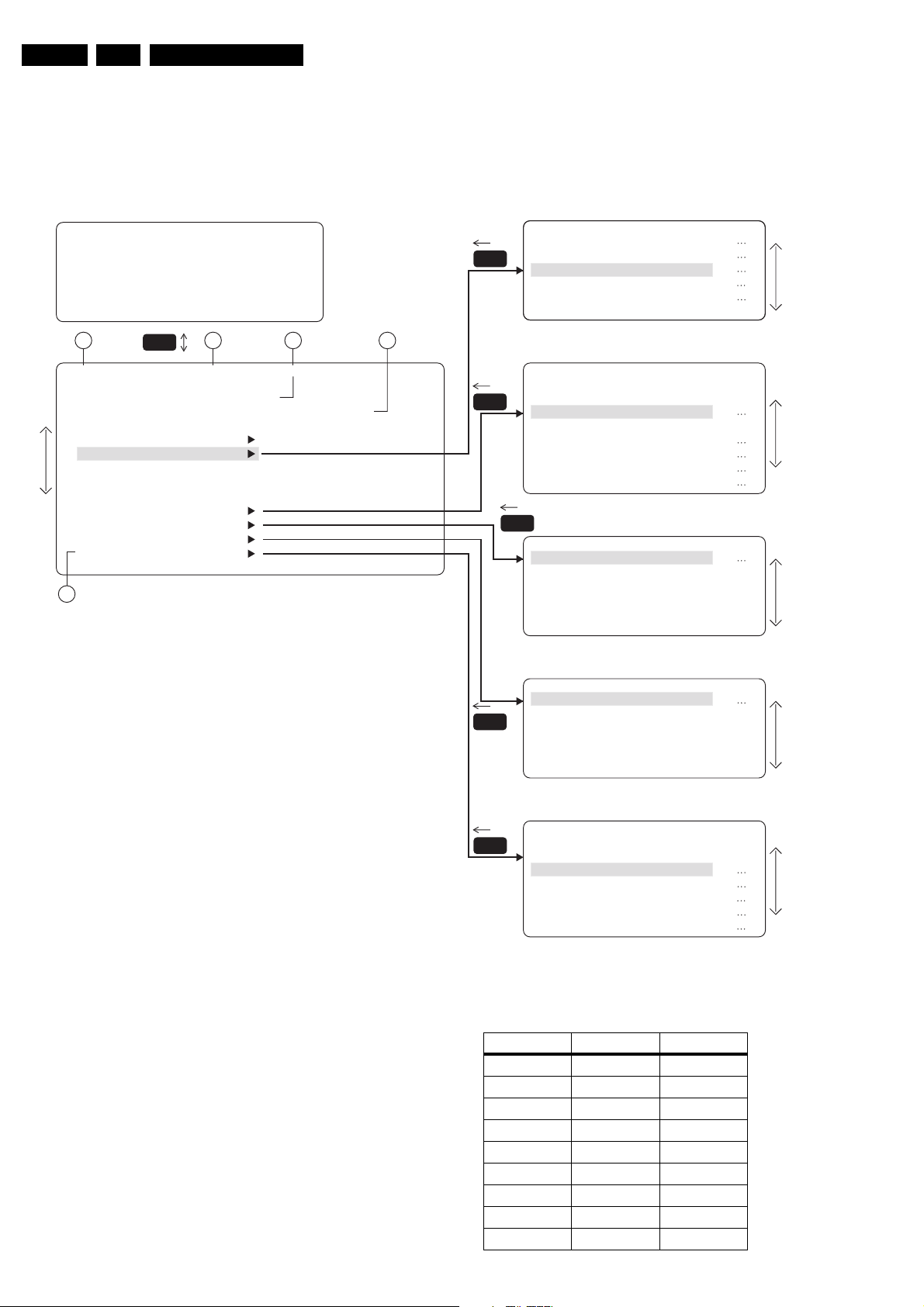

After entering SDM, the following screen will be shown with

'SDM' at the upper right side for recognition.

SDM Menu

HRS: 0001 SWID: EM11A1-1.0

ERR: 0 0 0 0 0 0 0

SDM

PICTURE BRIGHTNESS

+

i

SDM

SOUND COLOUR

MENU

FEATURES CONTRAST

INSTALL SHARPNESS

COLOUR TEMP

CL 06532130_010.eps

SDM

031000

Figure 5-1

Explanation

The numbering is done, in a for diagnostics logical sequence;

always start diagnosing within a functional block in the

sequence of the relevant test points for that functional block.

Measurements are performed under the following conditions:

• Service mode: SDM.

• Video: colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service modes

5.2.1 Service Default Mode (SDM)

Purpose

• To provide a situation with predefined settings to get the

same measurement results as given in this manual.

• Start the 'Blinking LED' procedure.

• Have the possibility to override the 5V-protection.

Specification

• Tuning frequency 475.25 MHz for PAL/SECAM sets and

at channel 3 (61.25 MHz) for NTSC-sets.

• All picture settings at 50 % (brightness, colour, contrast,

hue).

• All sound settings at 50 % except volume at 25 % (so

bass, treble, balance at 50 %, volume at 25 %).

• All service-unfriendly modes are disabled, like timer,

sleep timer, parental lock, blue mute, hospitality mode

and no-ident timer (normally the set is automatically

switched off when no video signal - IDENT - was received

for 15 minutes).

Entering

• Via a standard RC-handset by entering the code

'062596' followed by the 'MENU' button.

• Via ComPair.

Access to normal user menu

Pressing the 'MENU' button on the remote control, switches

between the SDM and the normal user menus (with the SDM

mode still active in the background).

Error buffer

Pressing the 'OSD' button [i+] of the remote control, shows /

hides the error buffer. OSD can be hidden to prevent

interference with oscillogram measurements.

Access to SAM

By pressing the 'VOLUME +' and 'VOLUME -' buttons on the

local keyboard simultaneously for a few seconds, the set

toggles from SDM to SAM.

Exiting

There are 2 ways to exit this mode:

• Switch the set to 'STANDBY', the error buffer will also be

cleared (by switching the set OFF-ON with the mains

switch, the set will come up again in the SDM).

• By pressing the 'EXIT' button on the DST.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform alignments.

• To change option settings.

• To display / clear the error code buffer.

Specification

• Software alignments (see chapter 8).

• Option settings (see chapter 8).

• Error buffer reading and erasing. The most recent error

code is displayed on the left side.

• Operation counter.

• Software version.

GB 16 EM1A5.

Fault finding and repair tips

Entering

• Via a standard RC-handset by entering the code

'062596' followed by the 'OSD' button [i+].

• Via ComPair.

SAM Menu

PICTURE BRIGHTNESS

SOUND COLOUR

FEATURES CONTRAST

INSTALL SHARPNESS

1

HRS: 0003 SWID: EM11A1-1.0

ERR: 0 0 0 0 0 0 0

OPT: 254 100 128 0 0 0 0 0

CLEAR ERRORS

OPTIONS

AKB ON/OFF

OPC ON/OFF

VSD ON/OFF

TUNER

WHITE TONE

GEOMETRY

SOUND

COLOUR TEMP

MENU

2 3 4

SAM

SAM

• By the 'ALIGN' button on the DST while the set is in the

normal operation mode.

The following screen will be shown, with 'SAM' at the upper

right side for recognition.

SAM

SAM

SAM

MENU

MENU

NPRG

WSSB

SYSTEM

OB1

OB2

TUNER

IF-PLL OFFSET

AGC

2ND

AFA

AFB

MENU

NORMAL RED

5

Explanation

The Service Alignment Mode menu will now appear on the

screen. The following information is displayed:

1. Operation hours timer (hexadecimal).

2. Software identification of the main micro controller

(AAABBB-X.Y).

• AAA is the chassis name (EM1= Painter processor,

EM2= OTC processor).

• B = Software code belonging to a certain stroke

number (see table below).

• X = (main version number).

• Y = (subversion number).

3. Error buffer (7 errors possible).

4. Option bytes (8 codes possible), summary of options are

explained below.

Figure 5-2

VER-SLOPE

MENU

MENU

SOUND

NIC-FMAM

2CS-FM

PS-FM

PS-NIC-BGDK

PS-NIC-I

CL 06532130_011.eps

5. Sub menus are listed in a scroll-menu.

Country Strokenumber Software

Singapore /69 2A1

Thailand

Malaysia

Indonesia

Middle East /56 2A2

China /93 1A1

Hong Kong /57 2A1

Australia /79

New Zealand

SAM

SAM

021000

Fault finding and repair tips

GB 17EM1A 5.

Menu control

Menu items can be selected with the 'CURSOR UP/DOWN'

key. The selected item will be highlighted. When not all menu

items fit on the screen, moving the 'CURSOR UP/DOWN' will

display the next/previous menu items.

With the 'CURSOR LEFT/RIGHT' keys, it is possible to:

• (De)activate the selected menu item (e.g. GEOMETRY).

• Change the value of the selected menu item (e.g. VER-

SLOPE).

• Activate the selected submenu (e.g. SERV-BLK).

Access to normal user menu

Pressing the 'MENU' button on the remote control switches

between the SDM and the normal user menus (with the SAM

mode still active in the background). Pressing the 'MENU'

key in a submenu will go to the previous menu.

The menus and submenus

• CLEAR ERRORS. Erasing the contents of the error

buffer. Select the CLEAR ERRORS menu item and press

the 'CURSOR RIGHT' key. The content of the error

buffer is cleared.

• The functionality of the OPTIONS and ALIGNMENTS

(TUNER, WHITE TONE, SOUND, GEOMETRY and

SMART SETTING) sub menus is described in chapter 8.

Exiting

There are 2 ways to exit this mode:

• Switch the set to 'STANDBY', the error buffer will also be

cleared (by switching the set OFF-ON with the mains

switch, the set will come up again in the SAM).

• By pressing the 'EXIT' button on the DST.

5.2.3 Customer Service Mode (CSM)

Purpose

The 'Customer Service Mode' is a special service mode,

which can be activated and deactivated by the customer

upon request of the service technician/dealer during a

telephone conversation, in order to identify the status of the

set. This CSM is a 'read only' mode, therefore modifications

in this mode are not possible.

Entering

The Customer Service Mode will switch ON after pressing

the 'MUTE' key on the remote control handset and any of the

top control buttons on the TV for at least 4 seconds

simultaneously. This activation only works if there is no menu

on the screen.

HRS:

Hexadecimal

counter of operating hours (example: 1B

(hex) = 0001 1011 (bin) = 27 (dec)). Standby hours are not

counted as operating hours.

SWID: Software identification of the main micro controller

(see paragraph 5.2.2). Details on available software versions

can be found in the chapter 'Software Survey' of the

publication 'Product Survey - Colour Television'.

Line 2:

Error code buffer (for more details see paragraph 5.3).

Displays the last 7 errors of the error code buffer.

Line 3:

Software and hardware functionality of the EM1A is

controlled by option bits. An option byte or option number

represents 8 of those bits. Each option number is displayed

as a decimal number between 0 and 255. The set may not

work correctly when an incorrect option code is set. See

chapter 8 for more information on correct option settings

Line 4:

Indicates which colour and sound system is installed for the

selected pre-set:

Line 5:

Indicates that the set is not receiving an 'ident' signal on the

selected source.

Note: On some models, BLUE MUTE is displayed (if the BM

option is ON) when no signal is received.

Line 6:

Indicates whether the SLEEPTIMER function is ON/OFF.

Line 7:

Indicates whether the CHILD LOCK function is ON/OFF.

Line 8:

Indicates whether the current pre-set is defined as SKIPPED

or NON-PREFERRED.

Line 9:

Indicates whether the HOTEL MODE is activated.

Line 10:

Indicates which SOURCE is installed for this pre-set: EXT1,

SVHS2, EXT2, and Tuner.

Line 11:

Indicates which sound mode is installed for this pre-set:

Mono, NICAM, Stereo, L1, L2, SAP or Virtual

Line 12 to 17:

Value indicates parameter levels at CSM entry.

Explanation

After switching on the Customer Service Menu the following

screen will appear:

CSM Menu

1 HRS: 0005 SWID: EM11A1-1.0

2 CODES: 0 0 0 0 0 0 0

3 OPT: 254 100 128 0 0 0 0 0

4 SYSTEM: AUTO 11 SOUND: MONO

5 NO SIGNAL 12 VOLUME:

6 TIMER ON 13 BALANCE: +/7 CHANNEL BLOCKED 14 HUE: +/8 NOT PREFERRED 15 COLOUR:

9 HOTELMODE ON 16 BRIGHTNESS:

10 SOURCE: 1 17 CONTRAST:

CL 06532130_012.eps

CSM

131000

Figure 5-3

Line 1:

Exiting

The Customer Service Mode will switch OFF after pressing

any key of the remote control handset (with exception of the

'P+' and 'P-' keys) and switching OFF the TV set with the

mains switch.

5.3 Problems and solving tips (related to CSM)

5.3.1 Picture problems

No colours / noise in picture

Check CSM line 4. Wrong colour system installed. To change

the setting:

1. Press the 'MENU' button on the remote control.

2. Select the INSTALL sub menu.

3. Select the MANUAL STORE sub menu.

4. Select and change the COLOUR SYSTEM setting until

picture and sound are correct.

5. Select the STORE menu item.

GB 18 EM1A5.

Fault finding and repair tips

Colours not correct / unstable picture

Check CSM line 4. Wrong colour system installed. To change

the setting:

1. Press the 'MENU' button on the remote control.

2. Select the INSTALL sub menu.

3. Select the MANUAL STORE sub menu.

4. Select and change the COLOUR SYSTEM setting until

picture and sound are correct.

5. Select the STORE menu item.

TV switches off or changes channel without any user

action

The TV-set switches off after 'TV SWITCHING OFF' was

displayed.

Auto standby switched the set off because:

• There was no ident signal for more than 15 minutes.

• There was no remote control signal received or local key

pressed for > 2 hours.

See chapter 8 for a description on the options to enable/

disable auto standby

Picture too dark or too bright

• Press 'Smart Picture' button on the remote control. In

case the picture improves, increase / decrease the

brightness value or increase / decrease the contrast

value. The new 'Personal Preference' value is

automatically stored after 3 minutes.

• After switching on the Customer Service Mode the

picture is OK. Increase / decrease the brightness value

or increase / decrease the contrast value. The new

'Personal Preference' value is automatically stored after

3 minutes.

White line around picture elements and text

• Press 'Smart Picture' button on the remote control. In

case the picture improves, decrease the sharpness

value. The new 'Personal Preference' value is

automatically stored after 3 minutes.

• After switching on the Customer Service Mode the

picture is OK. Decrease the sharpness value. The new

'Personal Preference' value is automatically stored after

3 minutes.

Snowy picture

Check CSM line 5. If this line indicates NO SIGNAL, check

following:

• no or bad antenna signal; connect a proper antenna

signal

• antenna not connected; connect the antenna

• no channel / pre-set is stored at this program number; go

to the INSTALL menu and store a proper channel at this

program number

• the tuner is faulty (in this case the CODES line will

contain number 13 or 16); check the tuner and replace/

repair if necessary

Snowy picture and/or unstable picture

• A scrambled or decoded signal is received.

Black and white picture

• Press 'Smart Picture' button on the remote control. In

case picture improves, increase the COLOUR value. The

new 'Personal Preference' value is automatically stored

after 3 minutes.

• After switching on the Customer Service Mode the

picture is OK. Increase the COLOUR value. The new

'Personal Preference' value is automatically stored after

3 minutes.

Menu text not sharp enough

• Press 'Smart Picture' button on the remote control. In

case the picture improves, decrease the CONTRAST

value. The new 'Personal Preference' value is

automatically stored after 3 minutes.

• After switching on the Customer Service Mode the

picture is OK. Decrease the CONTRAST value. The new

'Personal Preference' value is automatically stored after

3 minutes.

5.3.2 Sound problems

No sound or sound too loud (after channel change /

switching on)

• After switching on the Customer Service Mode the

volume is OK. Increase / decrease the volume level. The

new 'Personal Preference' value is automatically stored

after 3 minutes.

5.4 ComPair

5.4.1 Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the DST service remote control allowing

faster and more accurate diagnostics. ComPair has three big

advantages:

1. ComPair helps you to quickly get an understanding how

to repair the EM1A in short time by guiding you step by

step through the repair procedures.

2. ComPair allows very detailed diagnostics (on I2C level)

and is therefore capable of accurately indicating problem

areas. You do not have to know anything about I2C

commands yourself; ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the EM1A (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together

with the SearchMan EM1A electronic manual,

schematics and PWBs are only a mouse-click away.

ComPair consists of a Windows based faultfinding program

and an interface box between PC and the (defective)

product. The ComPair interface box is connected to the PC

via a serial or RS232 cable. In case of the EM1A chassis, the

ComPair interface box and the TV communicate via a bidirectional service cable via the service connector at the rear

side of the set (located at the left side of the rear cinch

connectors, see also figure 1-2).

The ComPair faultfinding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in 2 ways:

1. Communication to the television (automatic)

2. Asking questions to you (manually)

ComPair combines this information with the repair

information in its database to find out how to repair the TVset.

Automatic information gathering

Reading out the error buffer, ComPair can automatically read

out the contents of the entire error buffer.

Diagnosis is done on I2C level. ComPair can access the I2C

bus of the television. ComPair can send and receive I2C

commands to the micro controller of the television. In this

way it is possible for ComPair to communicate (read and

write) to devices on the I2C busses of the TV-set.

Manual information gathering

Automatic diagnosis is only possible if the micro controller of

the television is working correctly and only to a certain

extend. When this is not the case, ComPair will guide you

through the faultfinding tree by asking you questions and

showing you examples. You can answer by clicking on a link

(e.g. text or a waveform picture) that will bring you to the next

step in the faultfinding process.

Fault finding and repair tips

A question could be: Does the screen give a picture? (Click

on the correct answer)

YES / NO

An example can be: Measure test-point I7 and click on the

correct oscillogram you see on the oscilloscope

GB 19EM1A 5.

I7 B7502

1V / div DC

10µs / div

Figure 5-4

By a combination of automatic diagnostics and an interactive

question/answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

Additional features

Beside fault finding, ComPair provides some additional

features like:

• Uploading/downloading of pre-sets.

• Managing of pre-set lists.

• Emulation of the Dealer Service Tool.

5.4.2 SearchMan (Electronic Service Manual)

If both ComPair and SearchMan are installed, all the

schematics and the PWBs of the faulty set are available

when clicking on the hyper-link of a schematic or a PWB in

ComPair. Example: Measure the DC-voltage on capacitor

C2568 (Schematic/Panel) at the Monocarrier.

Clicking on the PWB hyper-link automatically shows the

PWB with a highlighted capacitor C2568. Clicking on the

schematic hyper-link automatically shows the position of a

highlighted capacitor at the schematic.

5.4.3 Connecting the ComPair interface

The ComPair Browser software should be installed and setup before connecting the ComPair interface to the TV-set

(see the ComPair Browser Quick Reference Card for

installation instructions).

1. Connect the RS232 interface cable to a free serial (COM)

port on the PC and the ComPair interface PC connector

(connector marked with 'PC').

2. Connect the mains adapter to the connector marked

'POWER 9V DC' on the ComPair interface.

3. Switch the ComPair interface 'OFF'.

4. Switch the television set 'OFF' with the mains switch.

5. Connect the interface cable to the connector on the rear

side of the ComPair interface that is marked 'I

figure 5-6).

6. Connect the other end of the interface cable to the

ComPair connector on the monocarrier (left to the rear

cinch connectors).

7. Plug the mains adapter in the mains outlet and switch

'ON' the interface. The green and red LEDs light up

together. The red LED extinguishes after approx. 1

second (the green LED remains lit).

8. Start-up ComPair and select 'File' menu, 'Open...:; select

'EM1A Fault finding' and click 'OK'.

9. Click on the icon to switch 'ON' the communication mode

(the red LED on the ComPair interface will light up).

10. Switch 'ON' the TV-set with the mains switch.

11. When the set is in standby, click on 'Start-up in ComPair

mode from standby' in the ComPair EM1A faultfinding

tree, otherwise continue.

2

C' (see

EXTERNAL 2

L

R

AUDIO EXTERNAL 1

SERVICE

CONNECTOR

PC VCR I2CPower

9V DC

Figure 5-5

The set has now started up in ComPair mode. Follow the

instruction in the EM1A faultfinding tree to diagnose the set.

Note that the OSD works but that the actual user control is

disabled

5.4.4 Pre-set installation

Pre-sets can be installed via the service cable:

• sending TO the television and reading FROM the

television

• the rear cover does NOT have to be removed

Click on 'File', 'Open' and select 'EM1A fault finding' to use

the cable.

Pre-sets can be installed via menu 'Tools', 'Installation' and

'Pre-sets'.

5.4.5 Ordering ComPair

ComPair order codes:

• Starter kit ComPair + SearchMan software + ComPair

interface (excluding transformer): 4822 727 21629

• ComPair interface (excluding transformer): 4822 727

21631

• Starter kit ComPair software: 4822 727 21634

• Starter kit SearchMan software: 4822 727 21635

• Starter kit ComPair + SearchMan software: 4822 727

21636

• ComPair CD (update): 4822 727 21637

• SearchMan CD (update): 4822 727 21638

• ComPair interface cable (for EM1A): 4822 727 21641

5.5 Error codes

5.5.1 Error buffer

The error code buffer contains all errors detected since the

last time the buffer was erased. The buffer is written from left

to right. When an error occurs that is not yet in the error code

buffer, the error is written at the left side and all other errors

shift one position to the right.

The error code buffer will be cleared in the following cases:

• By activating 'CLEAR ERRORS' in the SAM menu:

– Exiting SDM or SAM with the 'Standby' command on

the remote control (by leaving SDM or SAM with the

mains switch, the error buffer is not reset).

– Transmitting the commands 'DIAGNOSE 99 OK' with

the DST (RC7150) or with ComPair

• Automatically reset if the content of the error buffer has

not changed for 50 hours

Examples:

ERROR: 0 0 0 0 0 0 0 : No errors detected

ERROR: 6 0 0 0 0 0 0 : Error code 6 is the last and only

detected error

CL96532160_029.eps

110100

GB 20 EM1A5.

Fault finding and repair tips

ERROR: 9 6 0 0 0 0 0 : Error code 6 was first detected and

error code 9 is the last detected (newest) error

The contents of the error buffer can also be made visible

through the 'blinking LED' procedure. This is especially

useful when there is no picture. See paragraph 5.6 'The

blinking LED procedure '.

5.5.2 Error codes

In case of non-intermittent faults, clear the error buffer before

starting the repair. This is to prevent that 'old' error codes are

still present.

If possible, check the entire content of the error buffer. In

some situations an error code is only the result of another

Error Device Description Def. item Diagram

0

1 FBX 3V3 prot FBX 3V3 protection 5703 B3

2 No HFB No Horizontal Flyback 0325 A4

3 X-Ray protection X-Ray protection

4 5 V protection 5 V protection 1200/7651 A7/B6

5 No HOP POR Startup failure B4

6 General I

7 Mains Dip error HW-error

10 MC24C32 NVM communication error 7012 B7

11 MC24C32 NVM identification error 7012

12 SAA5667 Main µP, int. RAM test failure 7001 B7

13 TEDE9 Main Tuner 1200 A7

14 MSP3415D MSP34xx 7651 B6

15 CY7C1019 SRAM test failure 7011 B7

16 TELE9 PIP/DW Tuner 7201 C2

17 SAB9081H Multi PIP-IC 7801 C1

18 M62320P PIP/DW IO-expander 7403 C3

23 TDA888xx PIP/DW BOCMA-IC 7301 C4

27 Virtual Dolby Virtual Dolby error

30 TDA9320 HIP I/O-video processing 7323 B2

31 SAA4978 PICNIC 7709 B3

32 TDA9330 HOP video control/geometry 7301 B4

2

C bus error General I2C bus error

error code (and not the actual cause). E.g. a fault in the

protection detection circuitry can also lead to a protection.

Explanation of error codes:

Error 0

No errors.

Error 1

This protection is activated, when the PICNIC (pos. 7709 on

diagram B3) can not communicate via I2C for a certain time.

This could mean that stabiliser 7713 is defective. When e.g.

2704 makes a short circuit to ground, 7713 will become very

hot. For safety reasons the set will be switched to protection

mode.

Error 2

The absence of an HFB-pulse (pin 4 of connector 0324 on

LSP, diagram A3) is detected by the HOP (pos. 7301 on

diagram B4). A bit will be set in the HOP. After filtering by the

software, the set will switch to protection mode.

Error 3

Reserved.

Error 4

When the +5 V protection is active, the set is switched to

protection and error code 4 is placed in the error buffer. The

LED will blink 4 times (repeatedly). A 5 V failure can cause

a drop in the 5 V supply output, resulting in an undefined

behaviour of the set. Therefore, some I2C devices (Tuner

and MSP) connected to the 5 V supply are constantly

monitored. When none of these devices responds to the

micro controller for a prolonged time, the micro controller

assumes that there is a failure in the 5 V supply. By starting

up the set via grounding of the FRONT_DETECT-line (on the

side I/O), the +5 V protection will be overruled and it will be

easier to determine the cause. The +5V protection will be

activated when these I2C devices fail (no I2C

communication):

– Main Tuner (pos. 1200 on the LSP),

– MSP34xx sound processor (pos. 7651 on the SSB).

The following tips are useful to isolate the problem area, after

overriding the +5 V protection. Determine whether:

– The MSP sound processor is loading the +5 V; isolate

3650 and/or 4604 (see diagram B6).

– The main Tuner is loading the +5 V source; isolate coil

5200.

Caution! Overriding the +5 V protection when there is a 5 V

failure can increase the temperature in the set and may

cause permanent damage to components. Do not override

the +5V-protection for a prolonged time.

Error 5

Fault finding and repair tips

GB 21EM1A 5.

This error is covered by the Flash/Main routine described at

error 7. When during restart the 8 V remains absent, error 5

will be generated.

Error 6

This will occur in the following cases:

– SCL or SDA is shorted to ground.

– SCL is shorted to SDA.

– SDA or SCL connection at the micro controller is open

circuit.

Error 7

Flash detection: From the EHT-info, via D6303 and T7303 a

flash will stop the H-drive and line output stage immediately.

The FLS-bit in the status register of the HOP is set to ‘high’.

As the duration of a flash is very short the FLS-bit will be reset

to ‘low’ again after the flash refresh, so via a slow start the set

will be started again. If this interrupt occurs 5 times within an

interval of 10 seconds (indicating a mains interruption), the

set will go into protection and will generate error 7.

Error 10

Non Volatile Memory (EEPROM - pos. 7012) does not

respond to the micro controller.

Error 11

During the last start-up, the NVM and the micro controller did

not recognise each other (e.g. one of them was replaced or

the NVM memory has been changed/adapted or lost),

therefore the NVM was loaded with default values.

Error 12

Microprocessor (Painter - pos. 7001) internal RAM test

failure.

Error 13

Tuner (pos. 1200) is corrupted, the I

2

C line to the tuner is low,

or there is no supply voltage at pins 7, 4 and 5 of the tuner.

Error 14

Sound controller MSP34xx (pos. 7651) does not respond to

the micro controller.

Error 15

SRAM test failure (pos. 7011).

Error 16

The Tuner (pos. 7201) on the PIP/DW-panel does not

respond to the micro controller.

Error 17

Multi PIP IC SAB9081 I

2

C communication failure (pos. 7801

on the PIP/DW-panel).

Error 18

I/O expander IC M62320P I

2

C communication failure (pos.

7403 on the PIP/DW-panel).

Error 23

BOCMA IC TDA888xx I

2

C communication failure (pos. 7301

on the PIP/DW-panel).

Error 27

Virtual Dolby IC error.

Error 30

TDA 9320 HIP I/O-video processing (pos. 7323 on the SSB).

Error 31

SAA4978 PICNIC error (pos. 7709 on the SSB).

Error 32

TDA 9330 HOP video control/geometry error (pos. 7301 on

the SSB).

Note:

Error codes 1, 2 and 4 are protection codes and in this case

supplies of some circuits will be switched off. Also in

protection, the LED will blink the number of times equivalent

to the most recent error code.

5.6 The 'blinking LED' procedure

The contents of the error buffer can also be made visible

through the 'blinking LED' procedure. This is especially

useful when there is no picture.

When the SDM is entered, the LED will blink the contents of

the error-buffer. Error-codes ≥ 10 are shown as follows. A

long blink of 750 msec. which is an indication of the decimal

digit, followed by a pause of 1500 msec, followed by n short

blinks. When all the error-codes are displayed, the sequence

is finished with a LED display of 3 seconds. Then the

sequence starts again.

Example:

Error code position 1 2 3 4 5

Error buffer: 12 9 6 0 0

After entering SDM: 1 long blink (750 ms.) - pause (1500 ms.)

- 2 short blinks - pause (3 s.) - 9 short blinks - pause (3 s.) -

6 short blinks - pause (3 s.) - long blink (3 s.) - etc.

Note: If errors 1, 2 or 4 occur, the LED

always

occurred error, even if the set is NOT in service mode.

5.7 Protections

5.7.1 General

The EM1A has only one microprocessor (Painter) which

remains active during Standby. This because power of the

microprocessor and the memories is coming from the 3V3

supply, which is derived from the 5V Standby-circuitry. So in

both Power-on as in Standby-mode the microprocessor is

connected to this power supply.

If a fault situation is detected an error code will be generated

and if necessary the set will be put in the protection-mode.

The protection-mode is indicated by blinking of the red LED

at a frequency of 3 Hz. In some error cases the

microprocessor does not put the set in the protection-mode.

The error codes of the error buffer can be read via the

service-menu (SAM), the blinking LED procedure or via DST/

ComPair. The DST diagnose functionality will force the set

into the Service-standby, which is alike the usual Standby,

however the microprocessor has to remain in normal

operation completely.

To get a quick diagnosis the EM1A has 3 service-modes

implemented:

• The Customer Service Mode (CSM).