Page 1

0

(0

C)

(0

C)

p

0

C

C)

D

C)

3

D

0

0

-‘

C

D

C’)

‘I

p

•

I

I,

P

Page 2

IMPORTANT

designed

electric

is

appliance,

before

sewing

This

When

including

all

Read

using

the

instructions

machine

an

following

SAFETY

manufactured

and

safety

basic

sewing

this

using

INSTRUCTIONS

only.

for

precautions

machine

HOUSEHOLD

should

use

always

be

followed,

DANGER

sewing

The

1

unplug

cleaning.

Always

2.

not

Do

3

Do

not

4

Do

sink.

ARNING

W

not

Do

1

machine

this

Use

2.

attachments

only

Never

3.

working

Return

nation

Never

4

openings

dust,

lint,

Never

5

not

Do

6

not

7.

Do

being

disconnect

To

8

Never

9

may

not

10.

Do

Keep

11

sewing

Always

12.

not

Do

13.

only.

not

Do

14

Switch

15.

area,

presser

Always

16

lubricating,

instruction

the

Hold

17.

machine

appliance

this

unplug

for

reach

or

place

place

not

allow

used

is

sewing

operate

properly,

appliance

the

repair

operate

the

of

and

or

drop

outdoors

use

operate

administered.

operate

blocked.

be

unplug

fingers

machine

the

use

bent

use

pull

or

sewing

the

such

as

etc.

foot,

unplug

or

when

plug

to

winding

risk

never

the

machine

machine

into

reduce

persons

toy

a

as

children.

for

only

machine

been

nearest

mechanical

machine

object

(spray)

surface

cord.

on

moving

all

plate.

needles.

stitching

while

off

needle,

any

into

the

electric

Replace

that

water

the

Close

its

the

by

dropped

with

and

into

off(0

to

such

To

Use

(0)

changing

from

other

cord

before

sewing

a

store

or

in

used

be

or

by

machine

recommended

sewing

this

if

electrical

sewing

the

sewing

cloth.

loose

any

insert

where

all

turn

on

a

pulling

by

from

away

needle

proper

blunt

or

fabric

push

machine

threading

sewing

when

manual.

rewinding

reduce

To

should

from

relamping.

sewing

drop

To

to

near

has

it

the

to

or

machine

aerosol

controls

soft

needle

machine

making

SAVETHESE

electric

of

left

be

outlet

bulb

has

where

other

or

risk

attention

intended

manufacturer

has

if

it

authorized

adjustment

any

controller

foot

opening

any

products

)

a

as

unplug,

parts

wrong

The

needles

It

may

when

the

user

reel.

schock:

plugged

same

into

is

as

being

then

couch

or

the

can

any

threading

not

when

type

water

orbepulled

fall

electric

fire,

necessary

described

contained

as

cord

service

or

blocked

from

free

used

remove

plug,

care

cause

needle

the

adjustments

outlet

adjustments

allow

after

Unplug

or

where

is

when

plug

using

rated

schock,

when

this

in

or

dropped

center

the

where

or

plug

the

the

not

required

needle

the

the

by

causing

bobbin,

removing

to

15

immediately

into

this

in

plug,

Keep

accumulation

cord.

manufacturer

in

mentioned

whip

unattended

immediately

with

fallen

can

it

liquid.

burns,

of

use

damaged

a

damaged,

or

dealer

air

openings

are

position

bed

grasp

Special

plate

recommended

deflect

making

needle,

electrical

servicing

Do

INSTRUCTIONS

Always

in

and

Watts.

a

or

this

manual.

manual

it

if

into

for

ventilation

oxygen

from

openings

air

around

to

it

to

the

changing

or

when

before

tub

injury

sewing

Use

not

is

water.

exami

outlet

break.

break

needle

covers

or

of

is

the

in

re

Page 3

Contents

Controls

of

Accessory

Electrical

switch

Main

control

Foot

on

Notes

Handling

Thread

Opening

guides

the

Threading

Threading

Needle

combinations

Threading

Threading

Threading

Threading

Needle

Thread

Fitting

Thread

Sewing

Points

threader

reel

the waste

regulator

test

to

Securing

or

the

chainstitch,

4-thread

safety

Setting

2-thread

24-thread

Correcting

3-thread

Engaging

Correcting

Thread

Thread

chart

chart

Pushlock

Setting

Setting

the

the

Disengaging

Disengaging

Converting

Inserting

the

Adjusting

Thread

regulator

Changing

Changing

Changing

Changing

Changing

Cleaning

Stitch

Sewing

Oiling

the

selection

problems

the

Accessories

Thread

Special

spool

accessories

Specifications

sewing

the

box

connection

and

safety

thread

the

behind

looper

diagram

thread

right

the

left

the

chainstitch

the

needles

the

change

observe

seam/sewing

the

standard

overedge

stitch,

the

thread

overedge

disengaging

and

thread

the

for

for

stitchlength

for

stitch

differential

the

the

machine

the

workpiece

seam

the

sewing

the

needles

the

lower

the

the

upper

the

light

thread

table

machine

net

sewing

spool

cover

on

guides

looper

looper

with

box

during

thread

4-thread

tensions

stitch

tensions

5-thread

4-thread

length

upper

everedge

width

foot

knife

knife

bulb

tensions

and

thread

and

machine

light

stand

carrying

the

and

waste

and

2

looper

machine

sewing/thread

foot

tensions

stitch

2-thread

the

overedge

overedge

settings

feed

knife

looper

to

2-thread

guide

remedies

their

unreeling

.

handle

the

swingout

box

34

threaded

pressure/upper

safety

4-thread

/

chainstitch

converter

of

the

stitch

stitch

chainstitch

plate

trimmer

stitch.

safety

with

twothread

disc

work

knife

3-thread

(stitch

support

lock

stitch

overedge

seam

overedge

stitch

type

. .

1)

stitch

.

2,3

4

4,5

5

5

5

6

6

7

7

8

8

9

2

22-24

.29,30

31,32

.33.34

44-51

52-53

56-62

Page 4

LL

z

Page 5

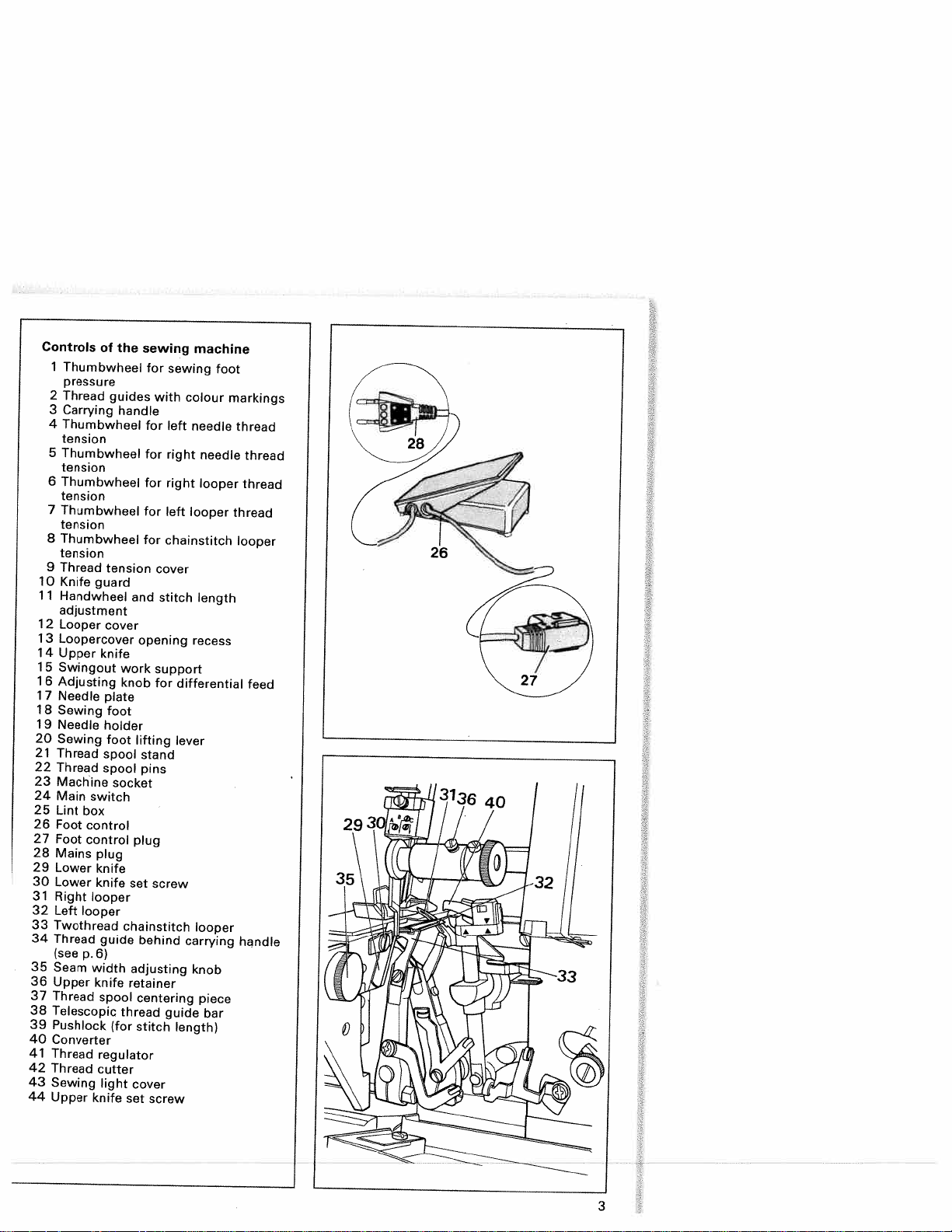

Controls

Thumbwheel

1

pressure

2

Thread

Carrying

3

Thumbwheel

4

tension

Thumbwheel

5

tension

Thumbwheel

6

tension

7

Thumbwheel

tension

8

Thumbwheel

tension

9

Thread

10

Knife

11

Handwheel

adjustment

12Looper

13

Loopercover

14

Upper

15Swingout

16

Adjusting

17

Needle

18

Sewing

19

Needle

20

Sewing

21

Thread

22

Thread

23

Machine

24

Main

25

Lint

26

Foot

27

Foot

28

Mains

29

Lower

30

Lower

31

Right

32

Left

33

Twothread

34

Thread

(see

35

Seam

36

Upper

37

Thread

38

Telescopic

39

Pushlock

40

Converter

41

Thread

42

Thread

43

Sewing

44

Upper

of

guard

knife

switch

box

control

control

plug

knife

knife

looper

looper

guide

p.6)

width

knife

spool

regulator

cutter

light

knife

the

guides

handle

tension

cover

work

knob

plate

foot

holder

foot

spool

spool

socket

chainstitch

thread

(for

set

sewing

for

with

for

for

for

for

for

cover

and

stitch

opening

support

for

lifting

stand

pins

plug

set

screw

behind

adjusting

retainer

centering

stitch

cover

screw

machine

sewing

colour

left

needle

right

needle

right

looper

left

looper

chainstitch

length

recess

differential

lever

looper

carrying

knob

piece

guide

bar

length)

foot

markings

thread

thread

thread

thread

looper

feed

handle

3

Page 6

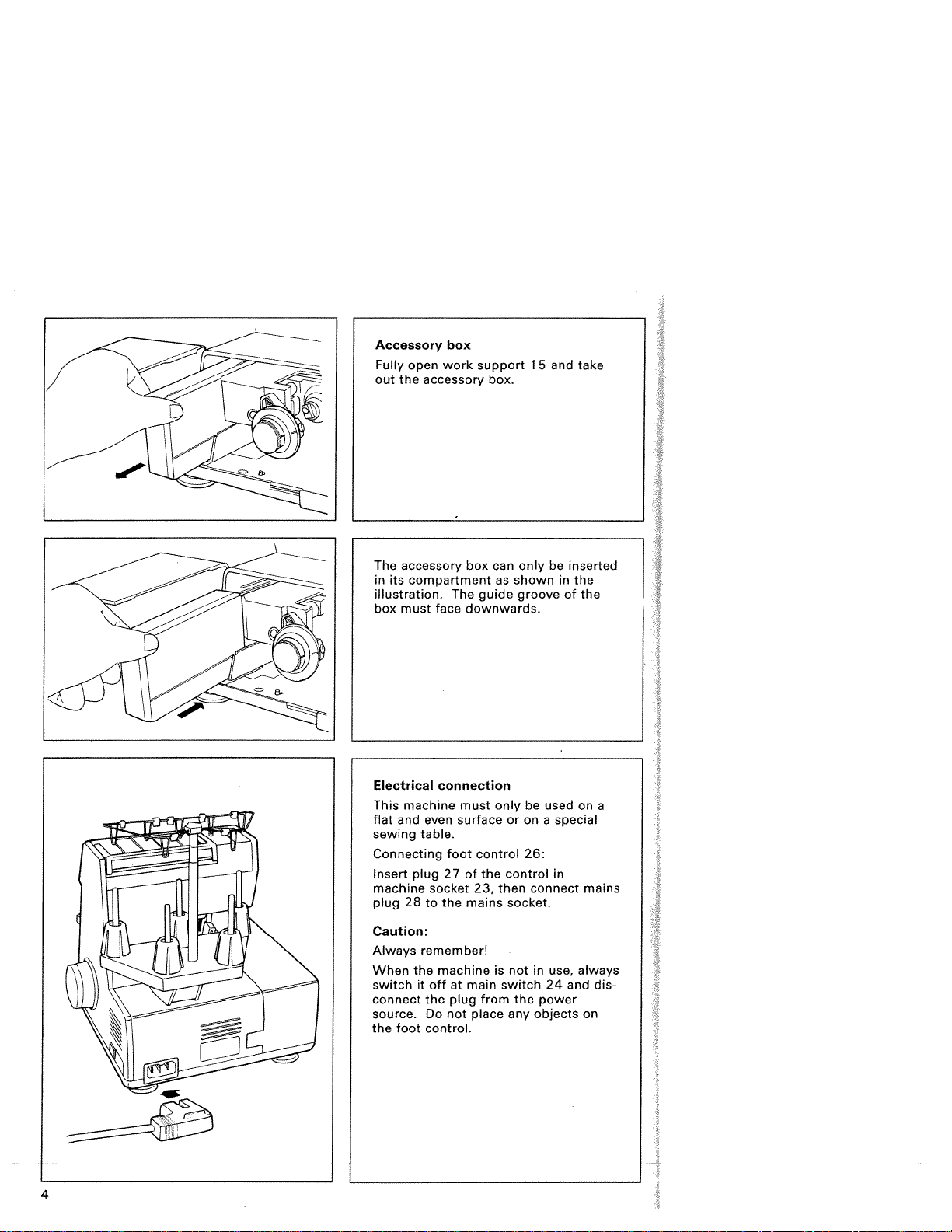

Accessory

Fully

open

out

the accessory

The

accessory

in

compartment

its

illustration.

box

must face

box

work

box

The

downwards.

support

box.

can

as

guide

15

and take

onlybeinserted

shown

in

groove

the

of

the

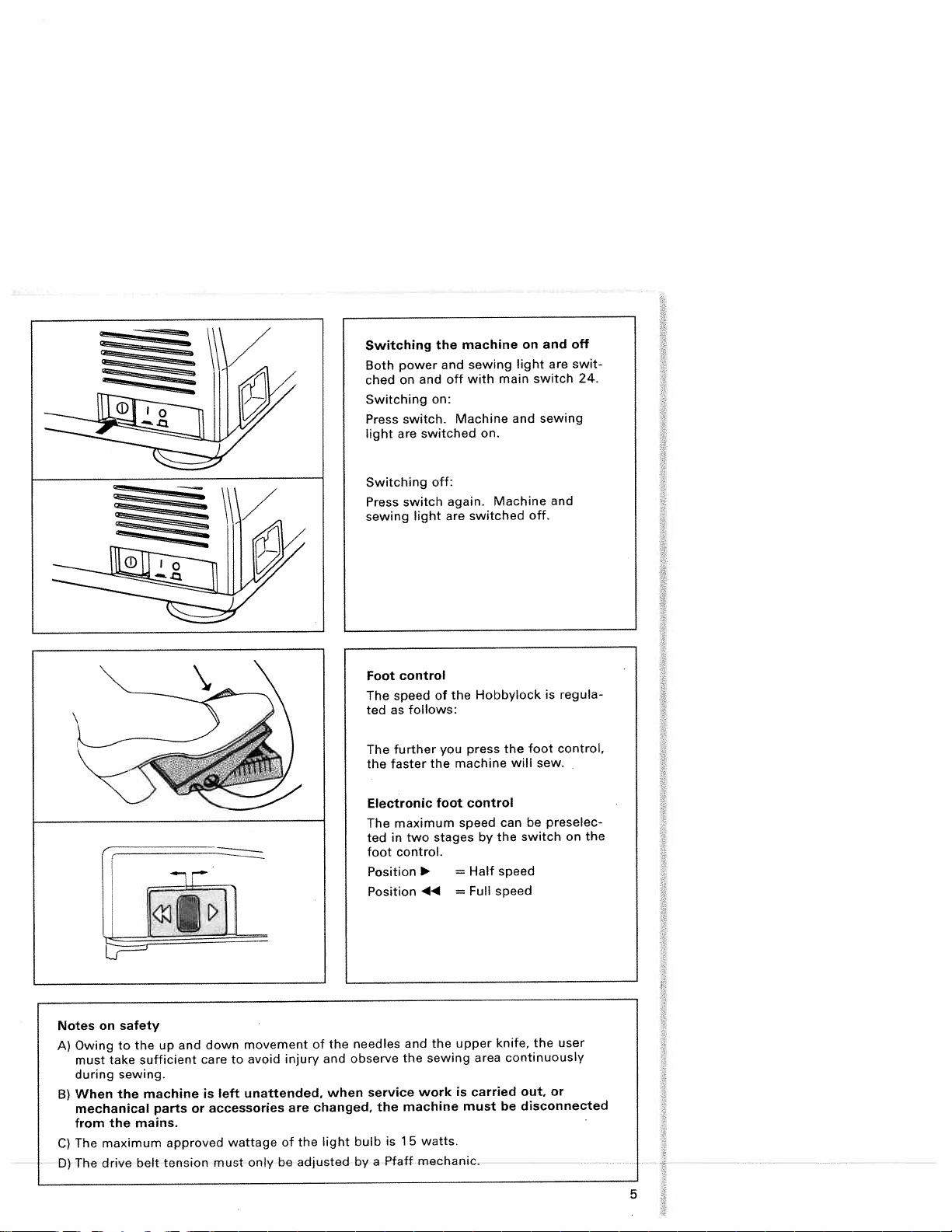

Electrical

This

flat

sewing

Connecting foot control

Insert

machine

plug28to

connection

machine must

even

and

surface

table.

plug

27ofthe

socket

the

23,

mains

only be

or

on

26:

control

then

socket.

used

special

a

in

connect

on

mains

a

Caution:

Always

When

switchitoffatmain

connect

source.

the

remember!

the

machineisnotinuse,

plug

the

not

Do

control.

foot

from

place

switch

the

any

24

power

objects

always

and

dis

on

4

Page 7

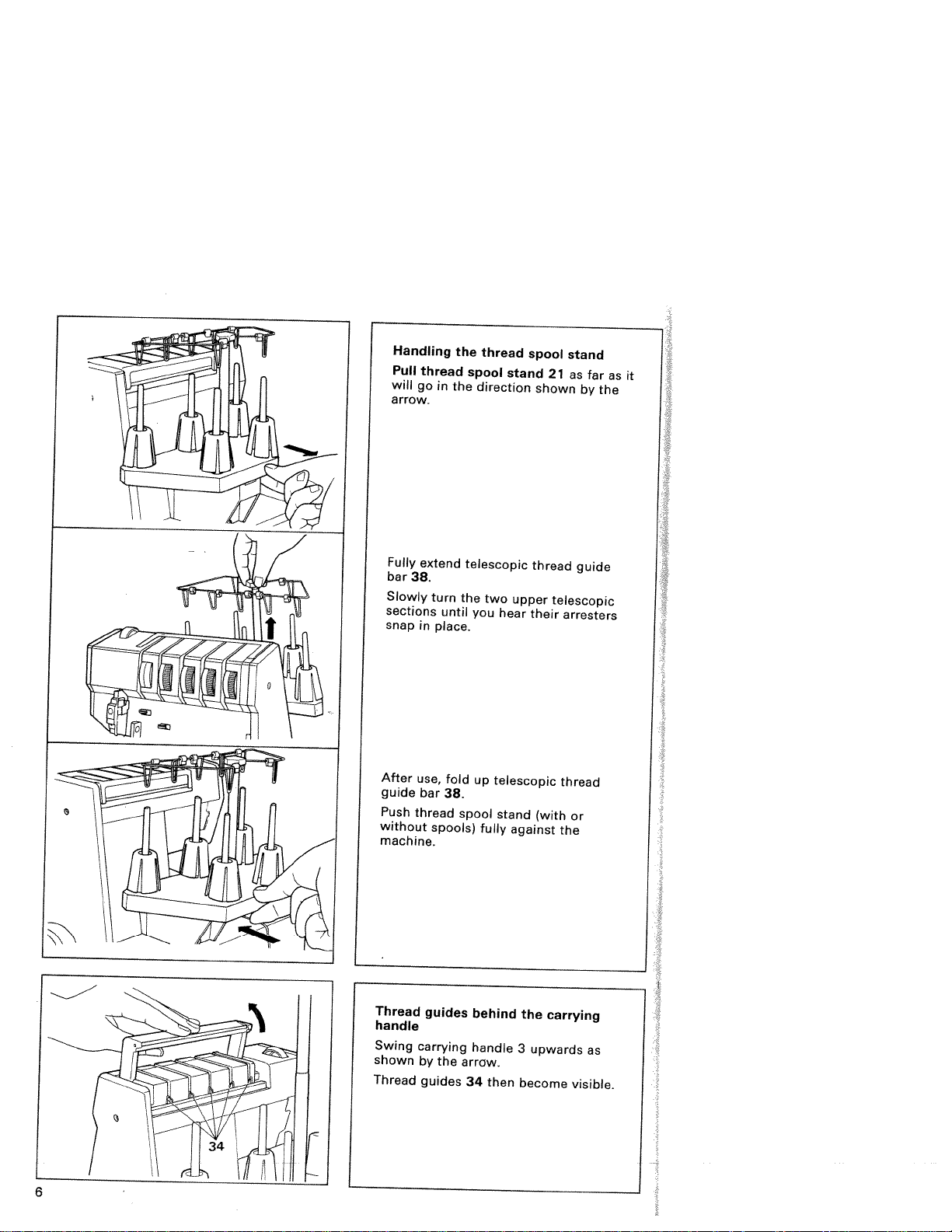

Switching

power

Both

on

ched

Switching

switch.

Press

are

light

the

and

off

and

on:

switched

machine

sewing

with

Machine

on.

main

light

and

on

and

are

switch

sewing

off

swit

24.

Switching

switch

Press

sewing

control

Foot

speed

The

as

ted

further

The

faster

the

Electronic

maximum

The

in

ted

control.

foot

Position

Position

off:

light

follows:

the

stages

two

44

are

of

you

foot

again.

switched

the

press

machine

control

speed

=

Half

=

Full

Machine

Hobbylock

the

will

can

the

by

speed

speed

off.

foot

sew.

be

switch

and

regula

is

control,

preselec

on

the

Notes

Owing

A)

must

during

B)

When

mechanical

from

The

C)

The

0)

safety

on

to

the

take

sewing.

the

the

maximum

drive

up

sufficient

machine

parts

mains.

tension

belt

and

or

approved

down

care

to

left

is

accessories

wattage

must

movement

injury

avoid

unattended,

are

of

only

be

of

and

when

changed,

light

the

adjusted

the

needles

observe

service

the

bulb

a

by

is

Pfaff

the

and

the

sewing

work

machine

1

5

watts.

mechanic.

upper

is

carried

must

knife,

area

be

the

continuously

or

out,

disconnected

user

5

Page 8

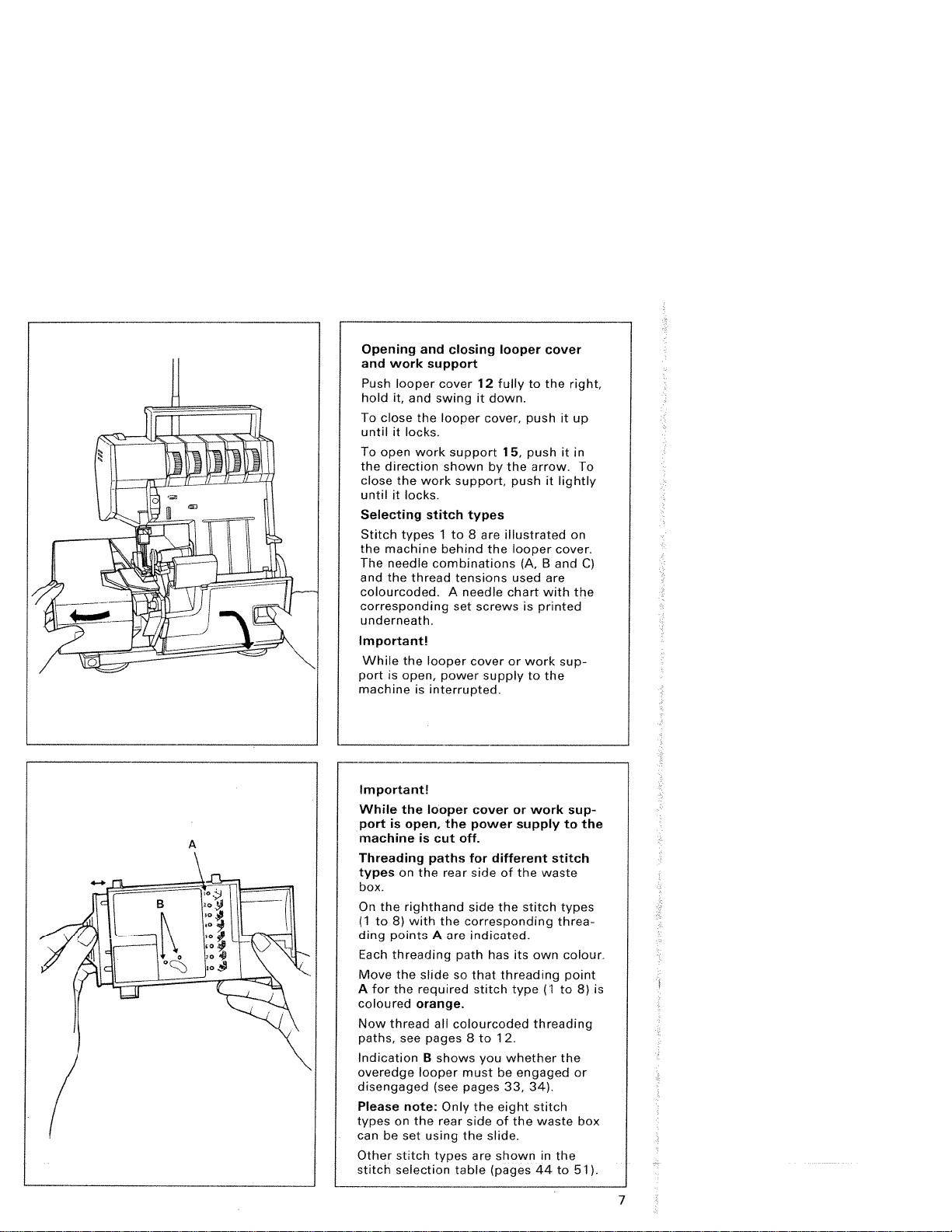

Handling

Pull

will

arrow.

Fully

bar

38.

Slowly

sections

snap

After

guide

Push

thread

without

machine.

thread

go

extend

turn

in

use,

bar

spools)

in

the

until

place.

fold

38.

the

thread

spool

direction

telescopic

the

two

you

up

spool

fully

spool

stand

thread

upper

hear

their

telescopic

stand

against

21

shown

telescopic

(with

stand

as

by

guide

arresters

thread

or

the

far

the

as

it

Thread

handle

Swing

shown

Thread

6

guides

carrying

by

the

guides

behind

handle

arrow.

34

then

the

3

upwards

become

carrying

as

visible.

Page 9

Opening

and

Push

hold

To

until

To

the

close

until

Selecting

Stitch

the machine

The

and

colourcoded.

corresponding

underneath.

Important!

While

port

machine

Important!

While

portisopen,

A

machine

Threading

types

box.

On

(1to8)

ding

Each

Move

A

for

coloured

Now

paths,

Indication

overedge

disengaged

Please

typesonthe

can

Other

stitch

and

work

looper

it,

close

it

open

direction shown

the

it

types1to8are

needle

the

is

the

on

the

points

threading

the

the

thread

see

be

sttch

selection

closing

support

cover12fullytothe

and swing

the

looper

locks.

work

support

work

locks.

stitch

behind

combinations

thread

A

set

the

looper

open, power supplytothe

is

interrupted.

looper

the

is

cut

paths

the

rear

righthand

with

the corresponding

A

are

slide

so

required

orange.

all

colourcoded

pages8to12.

B

shows

looper

(see

note

Only

rear

set

using

types

looper

it

down.

cover,

by

support,

types

the

tensions

needle

screwsisprinted

coverorwork

coverorwork

power

off.

for

different

sideofthe

side

the

indicated.

path

has

threading

that

stitch

you

mustbeengaged

pages

the

eight

side

of

the

slide.

showninthe

are

table

(pages

pushitup

15,

pushitin

the

arrow.

push

illustrated

looper

(A,Band

used

chart

supply to

stitch types

its

own

type

threading

whether

33, 34).

stitch

the

waste

44to51).

cover

it

cover.

are

with

stitch

waste

threa

(1

right,

To

lightly

on

the

sup

sup

colour.

point

to

8)

the

or

box

C)

the

is

7

Page 10

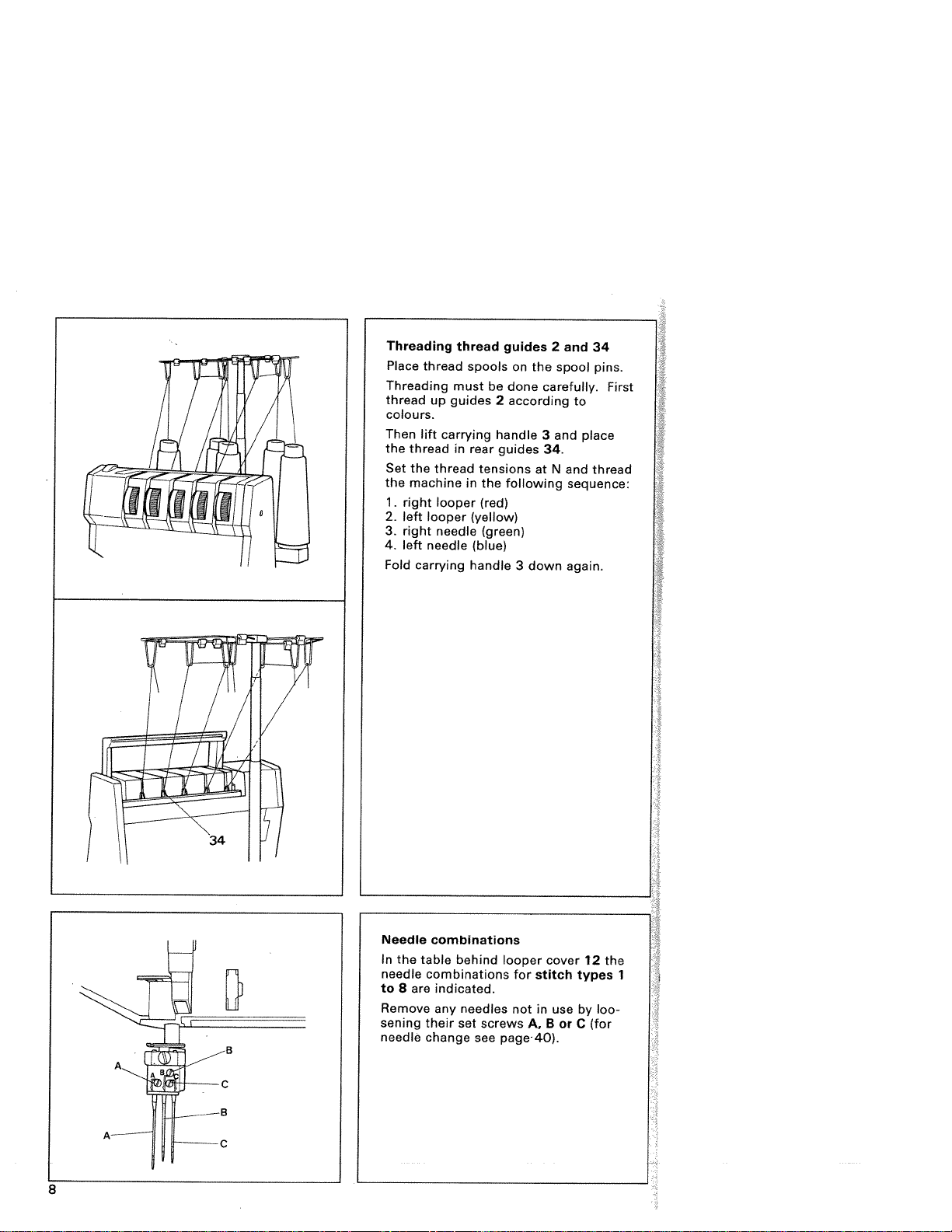

Threading

Place

thread

Threading

thread

colours.

Then

lift

the

thread

Set

the

the

machine

1.

right

2.

left

looper

3.

right

4.

left

needle

Fold

carrying

guides

up

carrying

thread

looper

needle

thread

spools

must

rear

in

in

(yellow)

handle

be

2

handle

tensions

the

(red)

(green)

(blue)

guides

on

done

according

guides

following

3

down

2

the

spool

carefully.

3

and

34.

at

N

and

34

pins.

to

place

and

thread

sequence:

again.

First

Needle

In

needle

to8are

Remove

sening

needle

8

combinations

the table

combinations

their

change

behind

indicated.

any

needles

set

screws

see

looper

for

not

page-

stitch

A,

40).

cover

in

B

12

types

usebyloo

or

C

(for

the

1

Page 11

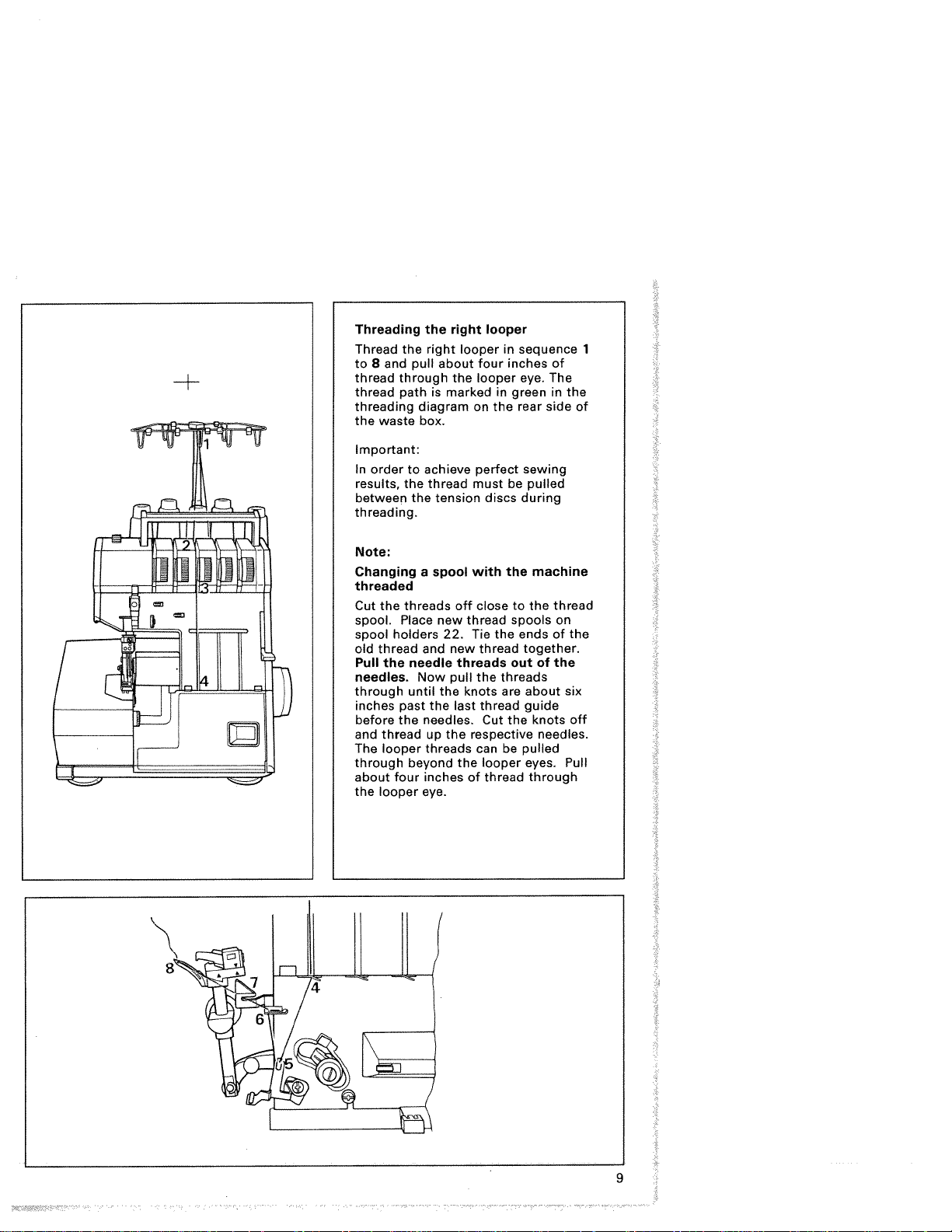

Threading

Thread

B

and

to

thread

thread

threading

waste

the

Important:

In

order

results,

between

threading.

Note:

Changing

threaded

Cut

the

spool.

spool

holders

old

thread

Pull

the

needles.

through

inches

before

and

thread

looper

The

through

about

four

looper

the

the

right

the

right

about

diagram

box.

achieve

tension

spool

a

new

22.

and

Now

the

the

needles.

up

threads

inches

eye.

the

off

new

threads

pull

last

the

the

looper

thread

knots

respective

of

pull

through

pathismarked

to

the thread

the

threads

Place

needle

until

past

the

beyond

looper

in

sequence

four

inches

looper

eye.

greeninthe

in

on

the

rear

perfect

must

be

discs

during

with

the

closetothe

spools

Tie

the

ends

thread

outofthe

threads

the

are

thread

the

Cut

pulled

can

be

looper

thread

of

The

side

sewing

pulled

machine

thread

of

together.

about

guide

knots

needles.

eyes.

through

1

of

on

the

six

off

Pull

I

9

Page 12

Threading

Thread

10

and

through

The

threading

low

in

rear

side

Important:

In

order

results

ween

ding.

Note

Changing

threaded

Cut

the

spool.

spool

old

thread

Pull

the

needlesS

until

the

past

the

needles.

up

the

threads

the

looper

of

thread

the

pull

the

the

threading

of

to

the

the

tension

a

threads

Place

holders

and

needle

Now

knots

last

Cut

respective

can

eyes.

through

the

left

about

looper

path

the

achieve

thread

spool

new

22

new

pull

are

thread

the

be

pulled

left

looper

four

waste

perfect

must

discs

with

off

close

thread

Tie

thread

threads

the

about

guide

knots

needles.

Pull

the

looper

in

eye.

is

indicated

diagram

box.

the

threads

off

through

about

looper

sequence

inches

be

during

the

to

spools

ends

together.

out

six

before

and

The

of

on

sewing

pulled

threa

machine

the

of

inches

thread

beyond

four

eye.

thread

in

yel

the

bet

thread

on

of

the

the

through

the

looper

inches

1

to

L

t

10

-..

Page 13

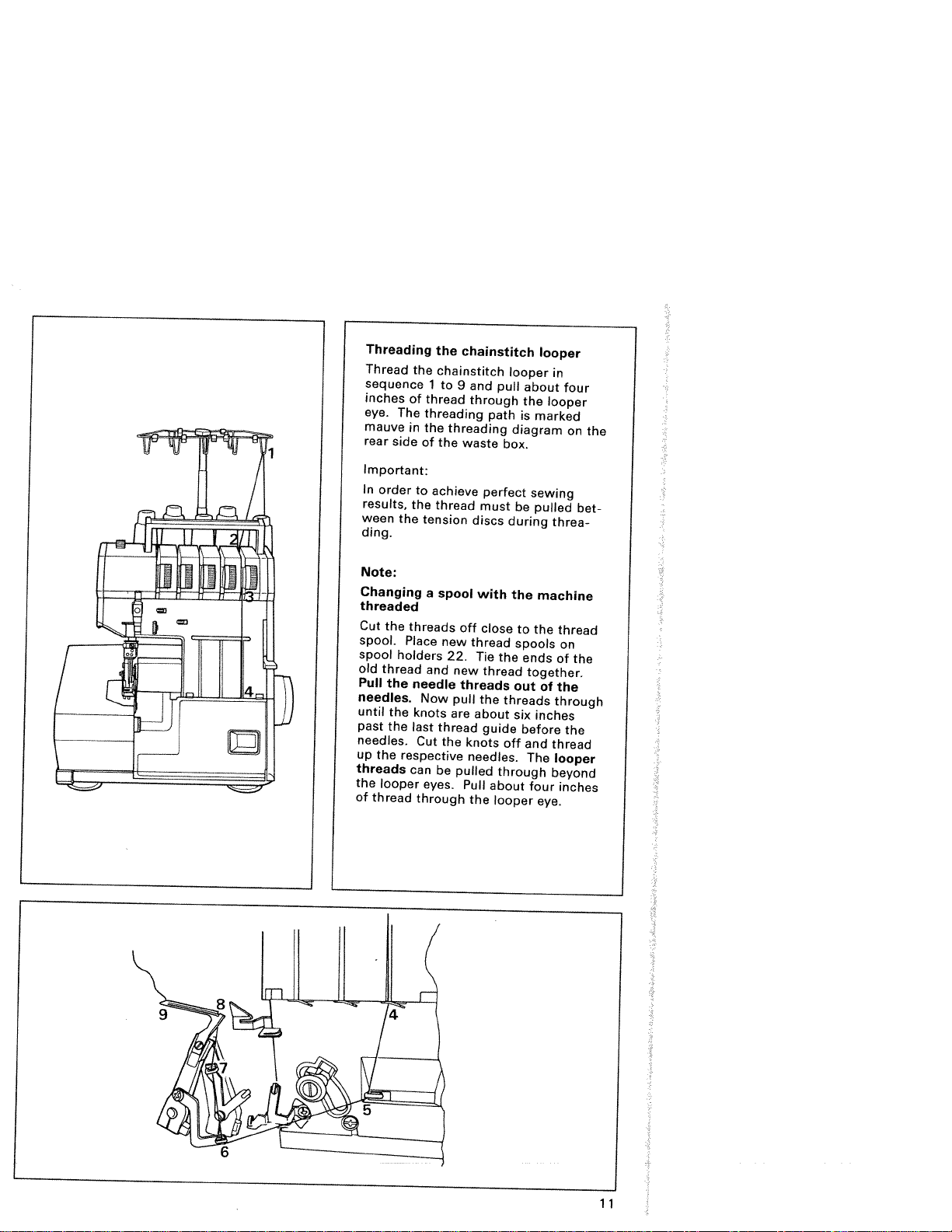

Threading

Thread

sequence

inches

eye.

mauve

rear

Important:

In

order

results,

ween

ding.

Note:

Changing

threaded

Cut

the

spool.

spool

old

thread

Pull

the

needles.

until

the

past

the

needles.

up

the

threads

the

looper

of

thread

the

of

The

in

side

of

to

the

the

tension

threads

Place

holders

needle

Now

knots

last

Cut

respective

can

eyes.

through

the

chainstitch

1

to

9

thread

threading

the

threading

the

achieve

thread

a

spool

off

new

22.

and

new

threads

pull

are

thread

the

be

pulled

chainstitch

and

pull

through

path

waste

perfect

must

discs

with

close

thread

Tie

the

thread

the

about

guide

knots

needles,

through

Pull

about

the

looper

looper

about

the

is

diagram

box.

be

during

the

to

spools

ends

together.

out

threads

six

before

off

and

The

looper

looper

marked

sewing

pulled

machine

the

of

inches

beyond

four

eye.

in

four

on

bet

threa

thread

on

the

of

the

through

the

thread

looper

inches

the

11

Page 14

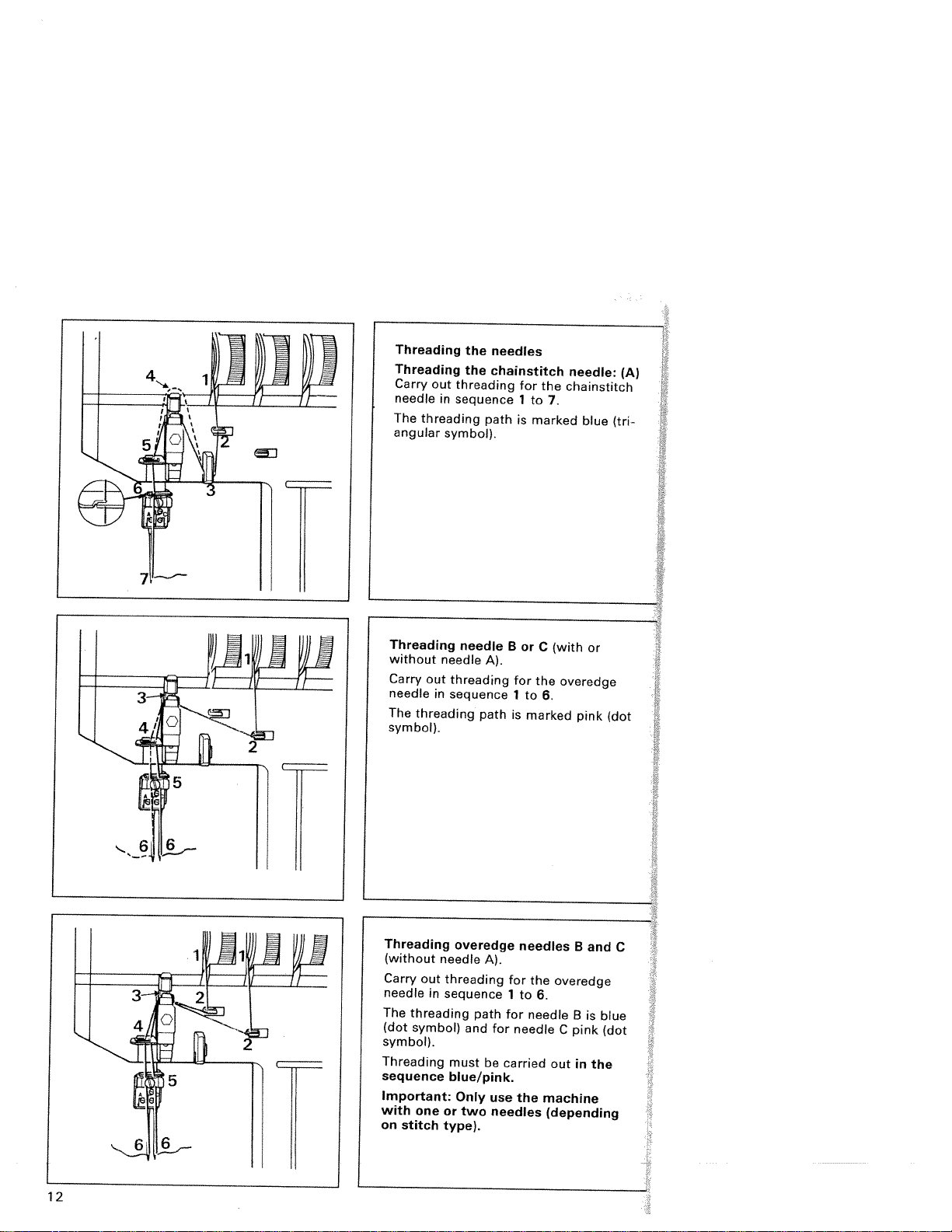

Threading

Threading

Carry

out

needle

The

threading

angular

the

the

threading

in

sequence

symbol).

needles

chainstitch

for

1

path

is

the

to

7.

marked

needle

chainstitch

blue

(A>

(tri

Threading

without

Carry

needle

The

threading

symbol).

Threading

(without

Carry

out

needle

The

threading

symbol)

(dot

symbol).

Threading

sequence

Important:

with

one

on

stitch

needle

out

in

needle

in

or

type).

needle

threading

sequence

overedge

threading

sequence

path

and

must

blue/pink.

Only

two

A).

path

A).

for

be

use

needles

B

or

for

1

to

is

marked

needles

for

1

to

for

needle

carried

the

C

(with

the

6.

the

6.

needle

out

machine

(depending

or

overedge

pink

B

and

overedge

B

is

C

pink

in

(dot

C

blue

(dot

the

12

Page 15

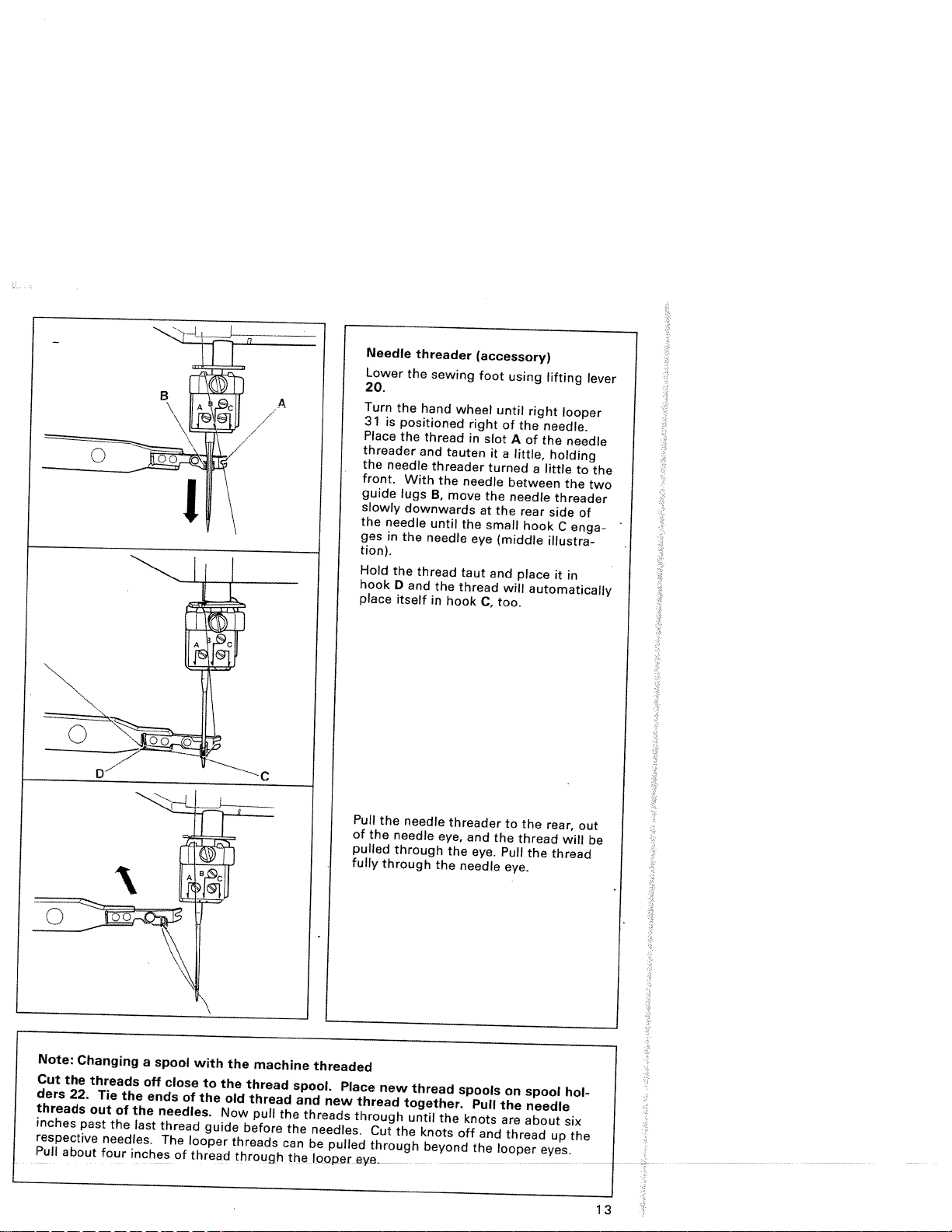

Needle

Lower

20.

Turn

31

Place

threader

the

front.

guide

slowly

the

ges

tion>.

Hold

hook

place

the

the

is

positioned

the

needle

With

lugs

downwards

needle

in

the

the

0

and

itself

threader

sewing

hand

thread

and

threader

the

B,

until

needle

thread

the

in

wheel

tauten

needle

move

the

taut

thread

hook

(accessory)

foot

using

until

right

of

in

slot

it

a

turned

between

the

needle

at

the

small

eye

(middle

and

will

C,

too.

lifting

right

the

needle.

A

of

the

little,

holding

a

little

rear

side

hook

illustra

place

automatically

looper

needle

to

the

threader

of

C

enga

it

in

lever

the

two

Note:

Cut

the

ders

22.

threads

inches

respective

Pull

about

Changing

threads

Tie

out

of

past

the

needles.

four

the

the

inches

last

a

off

ends

spool

close

of

needles.

thread

The

of

with

to

the

guide

looper

thread

the

the

old

Now

threads

machine

thread

thread

pull

before

through

the

can

spool.

and

the

the

threaded

new

threads

needles.

be

pulled

looper

Pull

of

pulled

fully

Place

thread

through

eye.

the

the

needle

through

through

new

Cut

the

through

needle

the

thread

together.

until

knots

beyond

threader

eye,

the

the

off

and

eye.

needle

spools

Pull

knots

and

the

to

the

Pull

eye.

on

the

are

thread

looper

the

thread

the

spool

needle

about

rear,

thread

up

eyes.

will

hol

six

the

out

be

13

Page 16

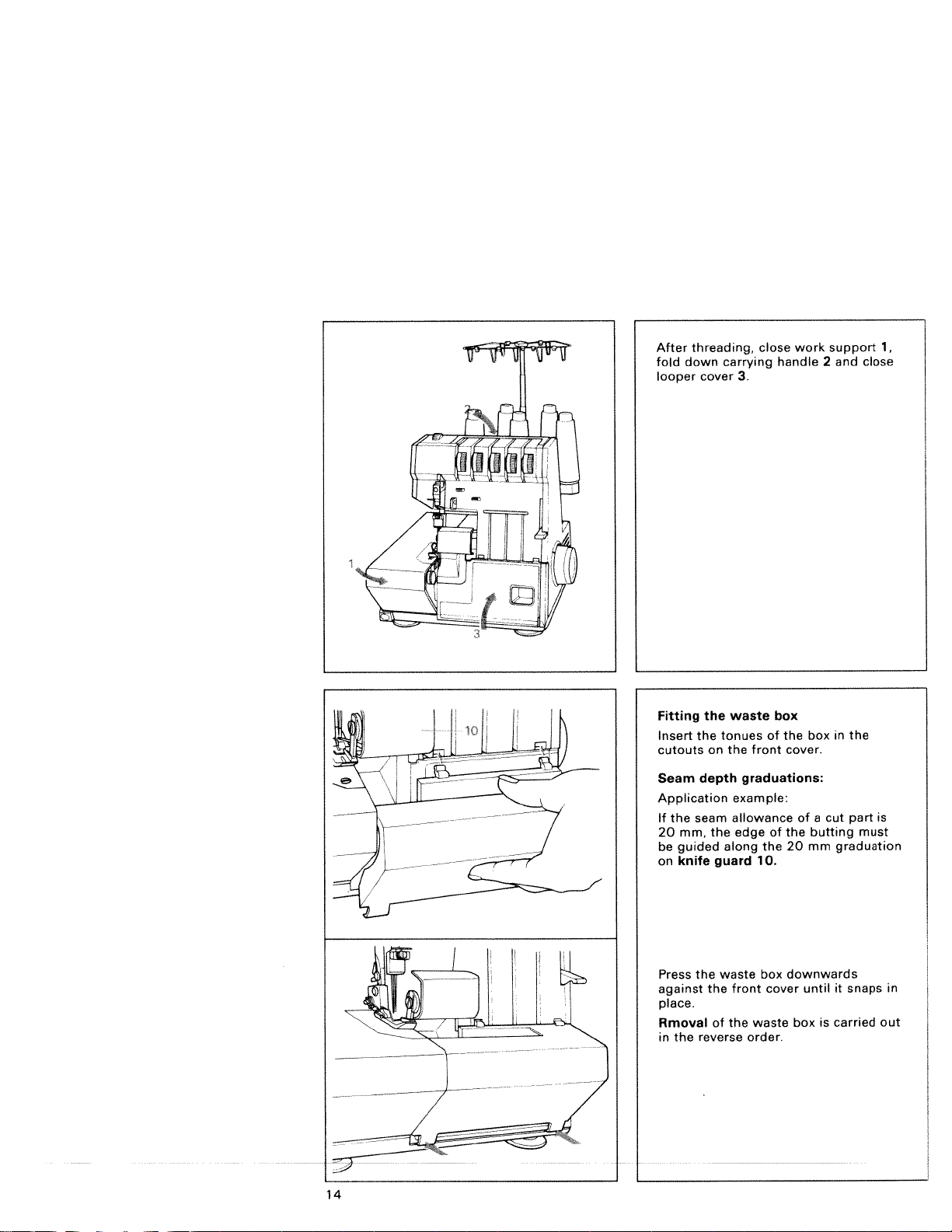

After

fold

looper

threading,

down

cover

carrying

3.

close

work

handle

support

2

and

1,

close

the

Fitting

the

Insert

cutouts

depth

Seam

Application

If

the

seam

mm,

20

guided along

be

on

knife

the

Press

against

place.

Rmoval

reverse

in

the

on

the

guard

the

of

tonues

the

waste

the

waste

of

front

graduations:

example:

allowance

edge

of

the

10.

box

cover

front

waste

order.

box

box

the

cover.

of

the butting

mm

20

downwards

until

box

a

cut

is

in

carried

the

part

must

graduation

snaps

it

is

in

out

14

Page 17

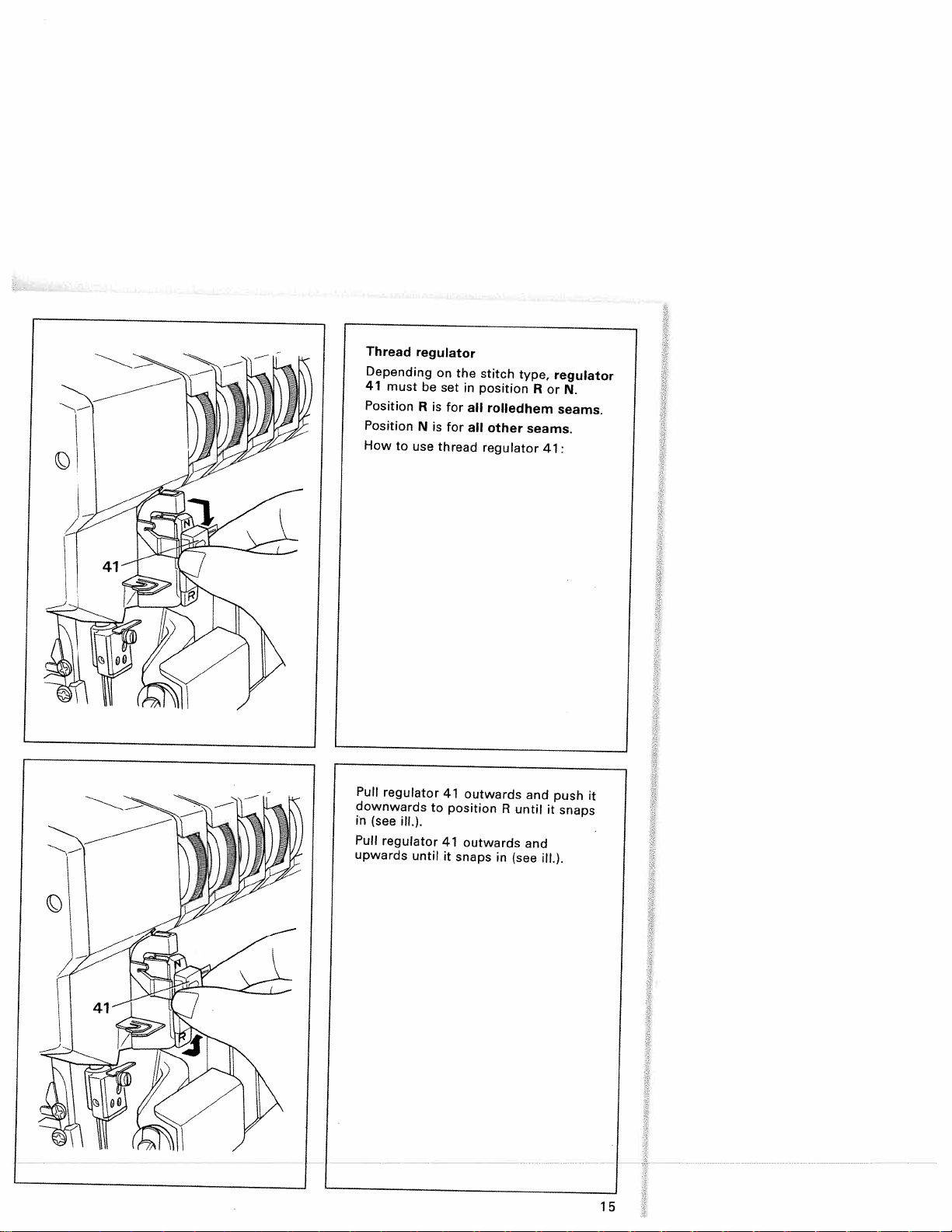

Thread

Depending

41

must

Position

Position

How

to

Pull

regulator

downwards

n

(see

ill.).

Pull

regulator

upwards

regulator

on

be

set

R

is

is

N

use

thread

41

to

41

until

it

the

in

for

all

for

all

outwards

position

outwards

snaps

stitch

position

rolledhem

other

regulator

R

in

type,

until

(see

R

seams.

41:

and

and

ill.).

regulator

or

N.

seams.

push

it

snaps

it

15

Page 18

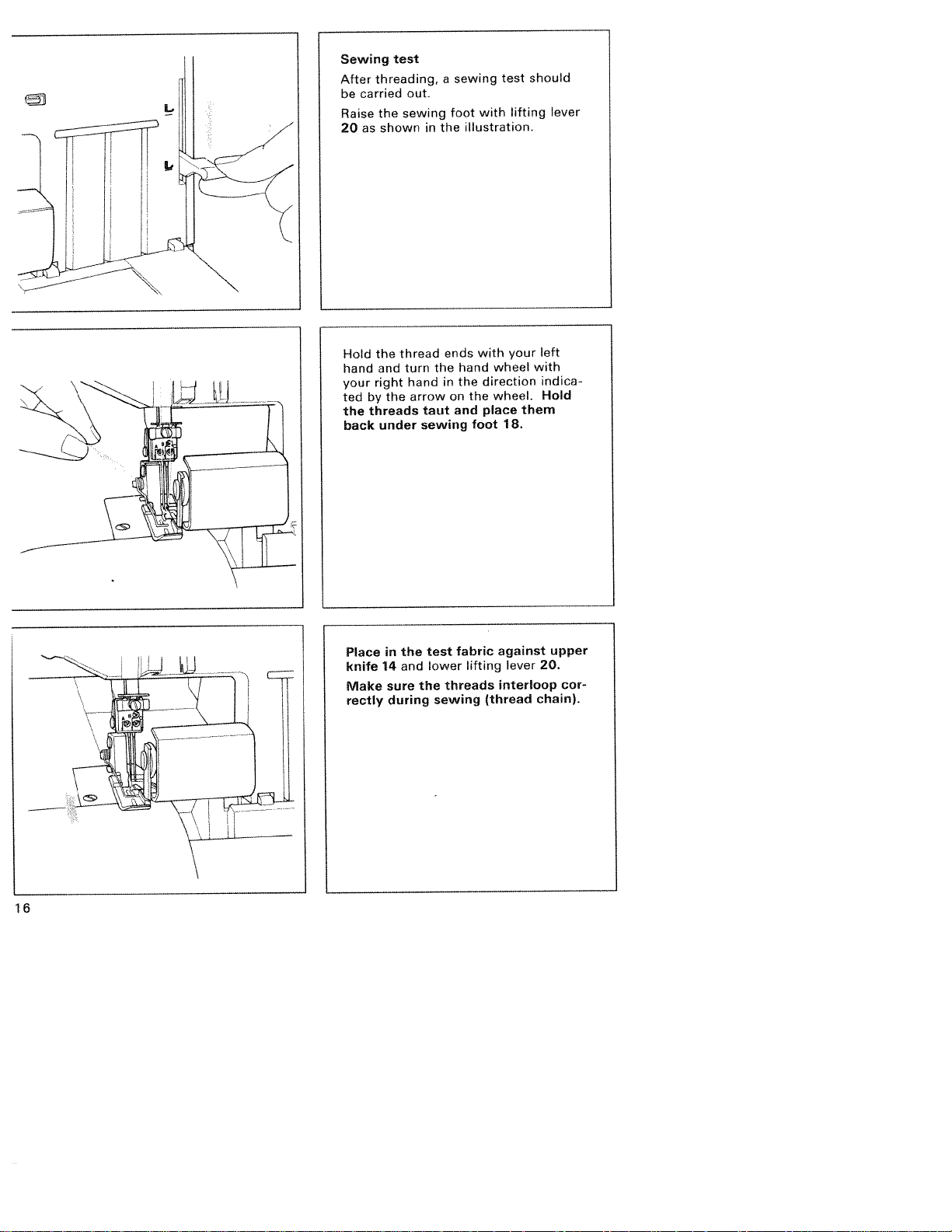

Sewing

After

carried

be

Raise

20

as

Hold

hand

your

ted

the

back

test

threading,

the

shown

the

and

right

the

by

threads

under

out.

sewing

thread

turn

hand

arrow

a

the

in

ends

the

in

taut

sewing

sewing

with

foot

illustration.

with

hand

the

the

on

and

foot

test

lifting

your

wheel

direction

wheel.

place

18.

should

lever

left

with

indica

Hold

them

Place

knife

Make

rectly

in

14

sure

during

the

and

test

the

lower

threads

sewing

fabric

lifting

against

lever

interloop

(thread

upper

20.

cor

chain).

Page 19

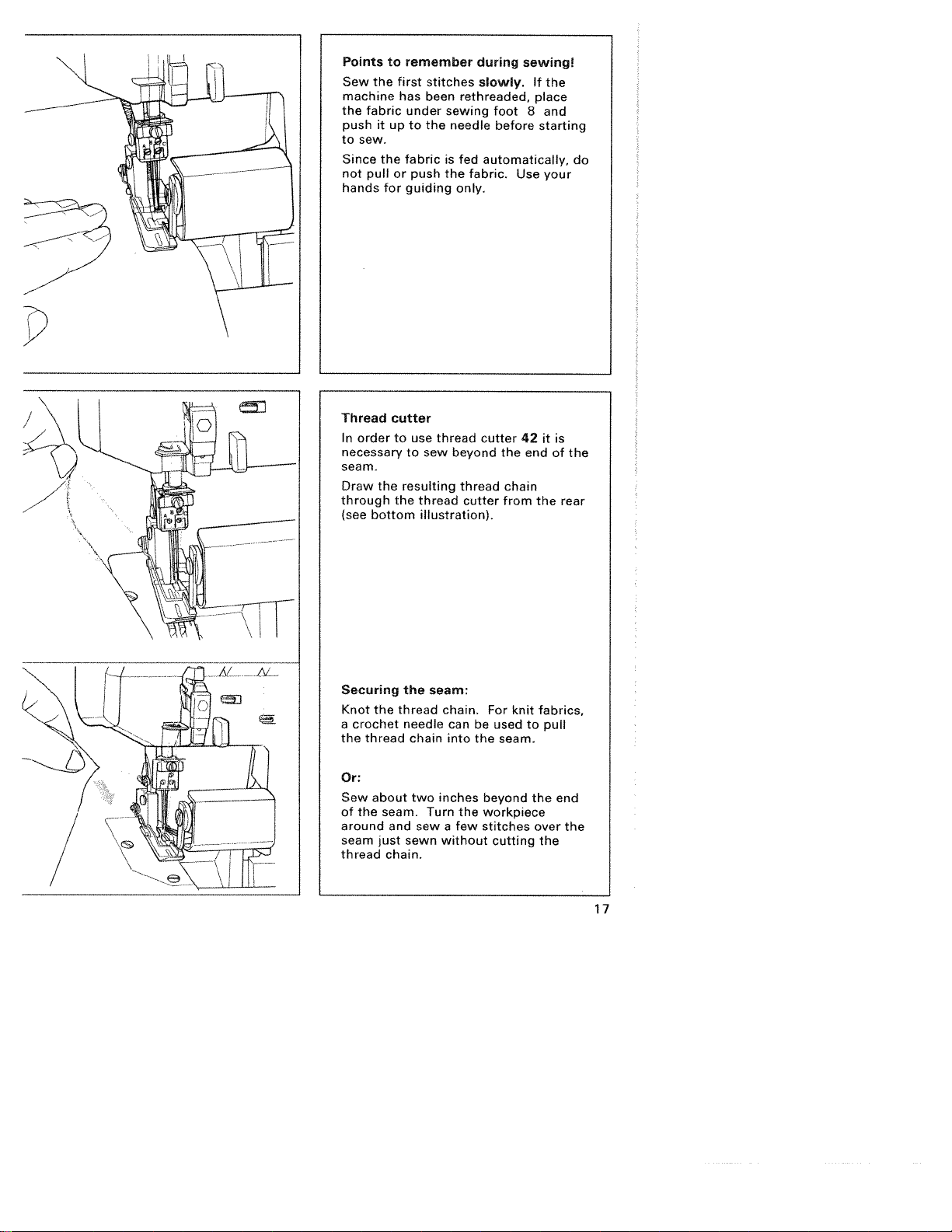

Points

to remember

Sew

the

machine

fabric

the

pushitup

sew.

to

Since

the

pull

not

for

hands

first

has

under

fabric

or

guiding

to

push

stitches

been

the

during

sIowy.

rethreaded,

sewing foot

needle

before

is

fed

automatically,

the

fabric.

only

sewing!

If

place

8

Use

the

and

starting

do

your

Thread

In

necessary

seam.

Draw

through the

(see

order

bottom

cutter

to

the

Securing

Knot

the

crochet

a

thread

the

Or:

Sew

about

the seam.

of

around

thread

seam

and

just

chain.

use

to

sew

resulting

thread

illustration).

the

thread

needle

chain

two

Turn

sewafew

sewn

thread

cutter

beyond

thread

cutter

seam

chain.

For

can

be

usedtopull

into

the

inches

beyond

the

workpiece

stitches

without cutting

the

chain

from

knit

seam.

42itis

endofthe

the

rear

fabrics,

the

end

over

the

the

17

Page 20

Adjusting

Setting

standard

If

the

For

heel

Upper

Sewing

ply

thicknesses:

This

fabric

For

pieces

of

the

ned

screw

is

locked

very

thick

thumbwheel

very

at

,,1”.

knife

very

machine

from

extremely

of

different

upper

as

shown

36

is

axially.

the

,,N”

of

sewing

fabrics

thin

lock

thick

can

very

heavy

knife

in

tightened,

sewing

thumbwheel

foot

at

fabrics

fabrics

sew

light

fabrics,

thickness,

must

the

illustration.

pressure.

are

,,4’.

set

all

to

be

the

foot

to

kinds

very

be

the

in

different

or

fully

upper

pressure:

1

is

sewn,

thumbw

of

heavy.

work-

the

screw

tighte

When

knife

the

set

18

Please

To

sew

loosen

lock

by

upper

direction.

note:

light

screw

about

knife

or

mediumheavy

36

for

two

can

move

the

turns,

in

upper

so

the

that

axial

fabrics,

knife

the

Page 21

Setting

Optimum

correct

The

,,N”

Set

needle

If

mauve

The

the

on

seam

A

standard

tension

thread

the

(only

tension

thread

appearance

set

is

tension

for

chainstitch)

setting

tension

depends

after

is

on

checking

thumbwheels

use,

is

in

used

only

the

the

type

thread

at

,,N”

for

fabric

of

interloop

corresponding

the

be

must

chainstitch

used

set

(triangular

size.

thread

the

on

and

to

20

pages

see

colour

triangular

blue

at

the

symbol).

24).

symbol.

symbol.

19

Page 22

Chainstitch

Set

regulator

(see

page

Stitch

type

Thread

blue

mauve

Application

Joining

serging.

1

5).

1

tensions:

=

=

example:

linen-

41

at

sewn

triangular

triangular

or

jeans

N

with

needle

symbol

symbol

parts

A

without

5-thread

Set

regulator

Stitch

and

C

Stitch

and

B

Thread

blue

pink

green

yellow

mauve

Application

on

blouses,

with

serging

3-thread

Set

regulator

Stitch

type

(narrow)

Stitch

type

(wide>

Thread

pink

green

yellow

Application

fabric

types.

safetystitch

type

type

3

(wide>

tensions:

=

=

=

=

=

examples:

shirts,

overedge

4

5

tensions:

=dotsymbol

=

dot

=

dot

example:

41

2

sewn

sewn

triangular

dot

symbol

dot

symbol

dot

symbol

triangular

seam.

41

sewn

sewn

symbol

symbol

at

at

with

with

jeans

seam

N

with

with

For

N

symbol

symbol

Joining

(see

seam

(see

needles

needles

and

needle

needle

serging

(narrow)

page

bed

page

A

A

seams

linen

1

C

B

all

15).

5).

20

Page 23

4-thread

Set

regulator

Stitch

type6sewn

and

C

Thread

tensions:

blue

pink

green

yellow

Application

serging

suitable

overedge

=

=

=

=

examples:

all

types

for

stretch

dot

dot

dot

dot

41

symbol

symbol

symbol

symbol

at

of

seam

N

(see

with

For

fabric,

fabrics.

page

needles

sewing

especially

15>

B

and

underside

overedge

chainstitch,

side

top

chainstitch,

top

side

overedge

side

top

stitch,

underside

stitch,

underside

2-thread

Set

regulator

Stitch

type

Thread

pink

yellow

Application

serging

suitable

4-thread

Set

regulator

Stitch

type

Thread

tensions:

blue

pink

yellow

mauve

Application

serging

suitable

overedge

41

7

(with

tensions:

=

dot

=

dot

examples:

all

types

for

stretch

safetystitch

41

(with

8

=

triangular

=

dot

symbol

=

dot

symbol

=

triangular

examples:

all

typesoffabric,

for

stretch

seam

at

N

converter>

symbol

symbol

of

fabric,

fabrics.

at

N

converter)

fabrics.

(see

For

seam

(see

symbol

symbol

For

especially

page

sewing

especially

page

sewing

1

5).

and

1

5).

and

21

Page 24

Correcting

The

thread

to

+5.

or

range

appearance.

seam

Towards

Towards

Chainstitch

thread

The

weak.

The

towards

Note:

2-thread

For

page

see

3-thread

The

thread

The

weak.

turned

3-thread

The

thread

weak.

The

towards

turned

the

tensions

tensionisset

The

plus

=

+

=

—

tension

blue

+.

27.

overedge

tension

pink

towards

overedge

tension

pink

Thread

range

stronger

weaker

tension

overedge

thread

+.

thread

+.

tensions:

can

be

according

tension

tension

needleAis

of

must

seams

seam

needleBis

of

tension

seam

needleCis

of

tension must

set

at

the

be

(wide)

(narrow)

from

minus

to

turned

please

must

—5

the

too

too

be

too

be

22

3-thread

right

The

(green

thread

sion).

possible

It

is

incorrectly

Adjust

overedge

looper

thread

too loose

is

set.

tensions

thread

tension)

both

that

accordingly.

seam

or

(yellow

tensions

tight

is

too

looper

left

the

thread

ten

are

Page 25

3-thread

left

The

low

tension)

(green

loose

possible

It

is

incorrectly

Adjust

overedge

looper

set.

tensions

seam

threadistoo

the

right

or

tension).

that

both

accordingly.

looper

tensions

tight

(yel

too

is

are

right

thread

looper

4-thread

The

left

low

tension)

loose (green

is

too

possible

It

is

incorrectly

Adjust

4-thread

The

left

low

tension)

is

too

tight

is

possible

It

incorrectly

Adjust

overedge

looper

set.

tensions

overedge

looper

(green

set.

tensions

seam

threadistoo

right

or

the

tension).

both

that

accordingly.

seam

thread

right

or

the

tension).

that

both

accordingly.

looper

tensions

is

too

looper

tensions

tight

loose

(yel

thread

are

(yel

thread

are

23

Page 26

4-thread

The

thread

weak.

towards

The

+.

overedge

tension

pink

seam

of

tension

needle

must

too

is

C

turned

be

5-thread

Since

consists

3-thread

of

tion

again

safetystitch

5-thread

the

of

overedge

this

(see

chainstitch

a

seam

pages

is

22

safety

seam,

not

and

seam

stitch

seam

the

described

23>.

seam

and

correc

seam

of

tension

safety

chainstitch

seam,

described

not

is

27>.

needle

must

seam

seam

stitch

the

too

is

B

turned

be

seam

a

and

correction

again

(see

thread

this

overedge

The

+.

safetystitch

the

of

overedge

seam

20

tension

blue

4-thread

a

and

4-thread

The

weak.

towards

4-thread

Since

a

consists

2-thread

of

pages

24

Page 27

3-thread

regulator

Set

(see

page

overedge

41at,,N”

1

5)

seam

The

3-thread

with

two

needle

page

Changes

sting

apply

If

needle

increased

to

7.2

thread

40).

knob

to

mm).

looper

of

seam

35

needle

B

is

by

overedge

threads

(needle

width

(2.5

C.

used,

2.2

mm

seam

and

change

made

to5mm)

the

setting

(seam

is

one

see

on

only

width

sewn

adju

is

4.7

Needle

Standard

i__•

seam

B

width

3-thread

N

overedge

seam

Standard

Needle

seam

C

width

1i

N

Li

Max.

seam

width

5,7

mm

7,2

mm

LI

-

Maximum

seam

width

5

mm

25

Page 28

Engaging

verter

Hand

wheel

in

the

Set2at

sing.

and

11

illustration.

the

marking

disengaging

mustbesetasshown

the

lineonthe

con

hou

Before

you

right

looper

unthreaded

All

seams

sewn

with

two

needles

The

left

looper

31

pointofthe

arrow

of

the

tion.

Push

the

left until

aligned

the

the

with

pointofthe

eye

Converter

Converter

work

with

thread

from

with

left

(see

looper

mustbepulled

right

as showninthe

slideofconverter

the

triangular

each

the

of

converter

must

the

looper

converter

looper

page

thread

looperinthe

other.

slide

looper,

placed

must engage

engaged=position

disengaged

be

40

32

and

27).

over

40tothe

symbols

As

Fig.

see

=

position

40

the

cut

and

eye.

are

only

one

right

over

the

direction

illustra

are

youdoso

A.

A

B

or

in

26

Disengaging

Turn

hand

left

looper

of

right

looper

In

this

position,

ter

(position

For

threading

see

page

wheel

thread

9.

the

B).

the

converter

11

drops

31.

disengage

right

slowly

from

looper,

the

until

the

the

point

conver

Page 29

2-thread

overedge

seam

top

Setting

side

Standard

range

B

Needle

seam

4,7

B

width

to

7,2

underside

N

mm

This

illustration

redge

tensions.

Regulator

page

15).

Needle

Standard

seam

C

width

El

,5

Setting

seam

41

with

must

range

shows

2,5

correctly

be

to

a

set

2-thread

set

at

N

m

5

mm

ove

thread

N

(see

top

top

side

side

//

B

,/

underside

underside

/

i

i(

‘P

i

.(

14,

r

.V,

Possible

1.

2.

3.

Both

1.

Looper

thread

1

Needle

green

3.

Both

Looper

thread

Needle

green

correction

thread

tension).

thread

thread

tensions

thread

tension>.

thread

thread

tensions

of

A

is

B

is

tension>.

have

A

is

B

is

tension>.

have

too

too

to

too

too

to

thread

loose

tight

be

tight

loose

be

tenions:

(yellow

(blue

corrected.

(yellow

(blue

corrected.

or

or

27

Page 30

Fabric

weight

Thread

Fabric

chart

for

5-thread

Stitch

safetystitch

type

seam

Thread

Stitch

length

Light

fabrics

Medium

heavy

fabrics

Heavy

fabrics

Organdy,

silk,

knis,

lining

Cotton,

knits,

fabrics

fress

Tweed,

materials,

denim,

cloth

light-

fabrics

light,

linen,

jacket

heavy

Chaindtitch

Overedge

stitch

Chainstitch

Overedge

stitch

Chainstitch

stich

Overedge

stitch

Cotton:

80

Size

Synthetic

70

Size

Cotton:

80

Size

Silk

80

Size

Synthetic

70

Size

Cotton:

60

Size

Silk

50

Size

Synthetic

70

Size

Cotton

60

Size

Silk

50

Size

Synthetic

70—

Size

Cotton:

40

Size

Silk

40

Size

Synthetic

70

Size

Cotton:

Size

Synthetic

Size

40

70

100

—

140

—

100

—

100

—

140

—

100

—

100

—

140

—

100

-

100

—

to

2

3

to

2to3

to

3

mm

3

4

mm

mm

mm

4

140

60

—

mm

4

to

2

60

—

140

—

60

—

140

—

28

Knitwear

Chainstitch

stich

Overedge

stitch

Cotton:

40

Size

Silk

50

Size

Synthetic

70—

Size

Synthetic:

70

Size

50

—

mm

3

to

2

100

—

140

140

—

Page 31

Lighth

Organdy,

knits,

lining

fabrics:

silk,

fabrics

Fabric

light-

Thread

chart

for

2-,

Cotton

Silk

Synthetic

and

4-thread

3-

overedge

Thread

80

Size

80—100

Size

Size

70

seams

length

Stitch

—

100

—

140

2,0

mm

4,0

to

Medium-heavy

Cotton,

linen,

Heavy

Tweed,

denim,

light-knits,

dress

fabrics:

jacket

heavy

Knitwear:

3-thread

2-

or

rolled

hem

fabrics:

fabrics

fabrics,

cloth

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Polyester

Texturized

(bulk

thread)

Size

Size

Size

Size

Size

Size

Size

Size

Size

Size

Pushlock

To

set

pushlock

port)

turn

Now

the

pushlock

Continue

and

set

page

on

—

100

60

50—100

—

140

70

40—60

—

60

40

140

70

—

—

60

40

-

60

40

140

70

—

—

120

for

stitch

the

39

and

hold

the

holding

the

30.

140

stitch

(at

hand

snap

stitch

it

left

there.

length

length,

under

wheel

in.

the

length

2,0

2.0

2,0

1

,0

fully

work

until

pushlock

as

4,0

to

4,0

to

4,0

to

to

2,0

setting

press

sup

you

pressed

described

mm

mm

mm

mm

feel

29

Page 32

30

Setting

Still

stitch

The

The

When

Please

The

the

holding

length

stitch

numbers

you

note:

hand

stitch

pushlock

length

have

wheel

at

on

mark

settings

the

set

cannot

length

39

A.

hand

the

(see

page

from

range

wheel indicate

required

be

turned

stitch

beyond

29), now

mm

1

the

length,

stitch

turn

to

stitch

4

mm.

release

length

hand

length

wheel

in

pushlock

1

or

mm.

4.

to

again.

the

‘Ii

39

required

set

Page 33

Adjusting

differential

The

behind

feed

The

workpiece

to

this,

material

following

The

Setting

Setting

Setting

to

2

differential

The

Note:

following

The

gather

The

fabrics

waved

The

heavy

the

amount

very

you

0.5

—

1.5

are

elastic

the

other,

moved

good

wish

effect

sewn.

effect

differential

prevents

feed

which

of

either

more

sewing

to

sew

settings

=

Short

=

Same

=

Long

is

feed

variants

is

is

fabrics

feed

simultaneously

feed

the

by

results

(see

possible

are

stroke

stroke

stroke

infinitely

can

obtained

obtained

are

sewn.

interply

dog

front

table

of

of

front

of

variable

be

employed

at

at

can

feed

achieved.

are

on

using

front

both

feed

a

differential

a

differential

shift.

take

page

feed

feed

be

dog

button

from

It

hold

set

32).

dog,

dogs

dog,

to

consists

of

separately.

than

Set

16:

long

short

0.5

to

obtain

feed

feed

of

two

the

workpiece

It

the

rear

by

the

differential

strokeofrear

stroke

2,

also

fashionable

setting

settingof0.5

feed

is

one,

of

ear

during

of

dogs,

and

possible

and

feed

feed

feed

sewing.

effects

1.5

—

when

arranged

move

to

vice

according

dog

dog

on

when

2

it.

have

versa.

garments:

light

medium

the

one

to

Due

the

to

31

Page 34

This

the

The

table

correct

differential

indicates

setting

feed

possible

for

can

your

also

settings

fabric.

be

set

of

during

the

differential

sewing.

feed.

Carry

out

a

sewing

test

find

out

to

Differentialfeed

setting

0,5

to

—

1,5

1,5

to

a

Illustration

N

2

1

2

3

4

Correct

seam

a

C

d

Nylon,

satin,

Light

(normal

Jersey,

nicki

Heavy

fabrics,

tricot,

popelin,

cotton,

fabrics)

medium

fabrics,

knitwear,

rib-knit

Fabric

lining

and

jeans

light

fabrics

fabrics,

silk

cotton,

knittings

very

elastic

32

b

Abb.

1

C

Abb.

2

-..

IIiI

Abb.3

Abb.

4

Page 35

Converting

stitch,

Remove

Open

looper

off

knife

Insert

Note:

For

sewing

width

14

and

gaged.

(see

page

stitch

waste

guard

needle

greater

right

Insert

34).

the

cover

with

looper

the

machine

type

box

10

upwards.

A

(see

chainstitch

than

fabric

1

1

25,

31

2

page

9

see

a

mm.

must

guide

little

to

40).

chain

page

and

at

upper

be

plate

a

14.

pull

hem

knife

disen

Disengaging

Set

the

position

Press

against

the

upper

holder

fully

first

loosen

lock

(see

In

this

position,

clockwise

in.

Disengaging

The

looper

ted

behind

Turn

the

bar

its

at

disengaging

in

this

position.

gaging

lever

turn

the

setting

into

redge

looper,

ged.

upper

by

knife

to

screw

page

until

disengaging

the

hand

highest

lever

fully

lever

cutout

the

knife

turning

retaining

to

the

18).

turn

the

the

looper

wheel

Pull

away

right

upper

at

the

push

right.

36

of

the

knife

overedge

cover.

to

position,

can

only

the

to

the

from

1.

Now

looper

knife

its

hand

screws

the

To

the

knurled

holder

lever

set

be

looper

front.

the

the

31

highest

wheel.

upper

do

upper

looper

is

the

needle

because

operated

Now

standard

ove

is

44

this,

knob

snaps

loca

disen

disena

of

knife

knife

the

33

Page 36

Inserting

Open

When

plate,

needle

the

and

stitch

the

Set

width.

Note:

the

If

overedge

must

31)

the

work

inserting

make

plate.

work

seam

edge

fabric

workpiece

support

sureitis

Close

support.

can

guide

guide

looper

disengaged.

be

1

workpiece

the

the

sewn!

be

to

plate

(righthand

5

a

level

the

guide

little.

looper

Now

is

guide

with

cover

the

required

use,

in

looper

plate

the

chain-

hem

the

After

sewing

the

out

machine:

the

Open

support

work

workpiece

left).

at

is

needle

disengaging

back

it

turn

8.

to

the

Now

again.

Engage

10

guard

latter.

the

replace

and

sewing

For

correct

chainstitch

following

looper

guide

the

Turn

fully

lever

to

overedge

upper

the

the

in

Then

waste

the

needles.

instructions

cover.

little

a

plate

hand

down.

the

looper

close

next

and

(see

wheel

Pull

forward

fully

standard

looper

knife,

the

box.

seam,

seams,

Then

remove

the

is

insert

cover

work

carry

the

on

open

the

illustration

until

looper

and

position

engaged

knife

close

and

support

the

insert

the

the

2

34

Page 37

Adjusting

standard

The

different

the

mm

3.5

mm

5.7

mm

7.5

Disengage

33.

page

Remove

required

The

adjusting

seamwidth

the

from

the

Set

again

2.5

and

for

for

for

the

upper

the

needle

needle

needle

upper

knob

to

close

seam

seam

needles

waste

seam

35.

adjusting

5.

knife

width

C

B

A

knife

box

the

width

are:

width

The

at

looper

settings

described

as

page

(see

is

graduations

knob

basic

its

cover.

set

N

14>.

with

range

position

for

on

on

Note:

The

knob

when

is

B

2.2

the

A

to

seamwidth

35

needle

used,

mm

set

to

6.5

(2.5

the

to

setting

9

4.7

mm

settings

to

is

C

setting

to

5

7.2

is

hem

mm)

used.

on

only

When

increased

is

mm.

increased

width.

adjusting

apply

needle

needle

For

4

by

by

mm

35

Page 38

Twothread

page

(see

Needle:

Sewing

width:

Seam

length:

Stitch

Set

slide

rolled

A

Without

valances.

rolled

26).

foot:

R

41

at

hemisused

effort

any

hems

Use

Rolledhem

N

1,0

(see

for

you

top

can

(3,5

light,

sewn

right

to

of

sew

with

needle

mm)

2.0

mm

page

delicate

professional

sewing

37)

converter

foot

fabrics

40:

R

and

rolled

slide

the

attractive

an

is

on

hems

2-thread

thread

The

hems

rolled

appearance

Application

hems

Rolled

must

be

finish

scarves,

head

hem

rolled

consumption

is

lower,

finer.

is

example:

very

on

set

for

and

thin

in

position

raw

shawls

for

the

materials.

A

edges.

and

2-thread

seam

36

d6

under

side

2-thread

Folded

Application

hems

Rolled

rolled

example:

thin

on

hems

materials.

Page 39

Thread

Depending

regulator

Position

How

to

Pull

regulator

down

to

ill.).

(see

regulator

on

41

R

is

regulator

set

position

for

is

41

the

set

stitch

in

all

rolled

forward

so

R

position

41:

that

type,

hems.

and

it

thread

R

push

snaps

or

N.

it

in

3-thread

Sewn

140.

rolled

A

fabrics

raw

sew

scarves,

A

rolled

ster

Set

rolled

with

hem

and

edges.

professional

shawls

hem

threads

regulator

hem

polyester

is

used

is

an

Without

and

is

sewn

(see

41

thread

for

attractive

any

rolled

valances.

with

page

at

R

(see

hems

38).

light,

finish

effort

three

100

delicate

you

on

above>.

to

for

can

head

polye

2

37

Page 40

Rolled

hem

with

polyester

thread

(Figs.

page

37,

2,

and

1

bottom)

Preparation

Needle:

Sewing

Seam

Stitch

foot:

width:

length:

Thread:

Threading

Right

1.

looper,

Left

2.

Needle

3.

Forthreading

Tension

thread

Green

thread

Yellow

thread

Pink

Depending

lower.

hem

Rolled

hem

This

120—140.

Preparation

Thread:

the

of

path:

looper,

green

yellow

thread,

pink

needles

setting:Fólded

tension,

tension,

tension,

material

on

sewn

requires

the

of

bulk

thread

sewing

Remove

Fit

From

From

Polyester

path

path

path

and

right

needle

with

three

machine,

thread

1

20/2,

rolled

3-thread

left

and

bulk

threads,

machine:

2.5

1

.5

loopers,

looper

looper

thread

thread,

thread:

as

—

green

for

needles

hem

3.0

to

to

2.5

00

1

one

described

tension

pink

foot

mm

(short

to

see

the

bulk

and

and

A

,,R”

(depending

stitch

for

140,

polyester

polyester

polyester

pages

3-thread

rolled

approx.

+5

approx.

respective

thread

above.

polyester

yellow

B

8

hem.

+2

length)

pink,

thread

thread

thread

1

to

rolled

to

,,N”

thread

and

tensions

green,

3.

Fig.2

on

+4

two

material)

and

tension

polyester

yellow

hem,

approx.

approx.

approx.

must

threads

thread

Fig.

be

+5

+2.5

,,N”

1

set

tensions

to

higher

—3

or

Threading

1.

2.

3,

For

Tension

Green

Yellow

Pink

Depending

lower.

Note:

38

right

looper,

left

needle

threading

thread

thread

looper,

thread,

setting:

thread

path:

yellow

needles

tension,

tension,

on

Rolled

thread.

green

pink

tension,

material

hems

Bulk

path

path

path

and

right

left

needle

and

can

threads

loopers,

looper

looper

thread

thread,

also

be

must

see

the

sewn

then

thread

bulk

polyester

polyester

pages

Folded

rolled

approx.

+5

approx.

respective

with

be

thread

thread

8

to

3-thread

hem.

,,N”

,,N”

thread

two

threaded

13.

Fig.2

to

bulk

120-140

1

—1

threads

in

20-140

tension

the

left

3-thread

hem,

approx.

approx.

approx.

must

one

and

and

Fig.

,,N”

+2.5

,,N”

be

right

rolled

1

to

to

higher

set

polyester

looper.

+2

—3

or

Page 41

on

the

foot

foot.

sewing

the

illustration.

foot

hol

The

Changing

Disengage

in

Push

as

der

sewing

lever

shown

foot

sewing

the

sewing

the

F

in

disengages.

F

H

Engaging

Place

holder

foot

lifting

groove

This

engaged

the

sewing

the

so

lever,

of

H

illustration

sewing

sewing

foot

that

crosspiece

sewing

the

shows

foot.

foot.

when

under

G

foot

a

the

you

engages

holder.

correctly

sewing

lower

the

in

39

Page 42

Changing

out

Pull

sewing

shown

bar

in

needle

zers.

the

small

needle

it

ling

the

mains

the

foot.

Turn

by

the

its

highest

to

changed

be

Loosen

screwdriver.

the

from

downwards.

needles

arrow

set

needle

plug.

the

to

position.

with

screws

Lower

hand

the

set

the

A,

Remove

holder

wheel

Hold

or

B

the

needle

the

twee

C

the

pul

by

as

with

Inserting

The flat

face

the

far

ten

side

the

rear.

needle

asitwill

the corresponding

screw.

Notes:

following

The

machines:

these

to

(75

90)

used,

to

90,

wrongly

the

on

breakage

Though

depends

size

75

A

thread

Changing

are

Knives

needles

the

of

up

go,

needles

correct

the

we

recommend

inserted

the

available

needle

the

the

Using

into

the

holditthere

System

needle

material

needle

skipped

and

knives

as

shank

tweezers,

needle

needle

are used

130/705

size

and

needle

causes

spare

holder

and

set

on

the

thread

stitches.

parts.

must

push

as

tigh

H

sizes

40

Pull

Change

Change

out

the

lower

upper

mains

knife

knife

plug.

29,

14,

see

see

page

page

41.

42.

Page 43

Changing

out

Pull

Disengage

33).

out

Take

29.

knife

seamwidth

Set

2,5

(smallest

Inserting

the

Push

the

into

cutting

retaining

pressure

Position

knife

the

of

edge

so

needle

the

mains

the

the

retaining

the

new

groove

screw

plate.

cutting

the

that

lower

upper

adjusting

seam

lower

lower

of

must

30

is

it

plate.

plug

screws

width).

knife

the

face

together

edge

flush

knife

knife

knife

knife

with

30

knob

from

right.

of

(see

holder.

with

the

the

page

lower

of

35

below

Tighten

lower

surface

at

The

the

Before

the

of

Turn

ter.

working

the

Set

width

tightening

pressure

the

position.

required

adjusting

plate,

upper

knob

the

seam

retaining

position

knife

width

35.

back

on

screw

the

to

seam

lat

its

41

Page 44

Changing

Pull

out

Disengage

see

page

the