Page 1

74

0

Instruction

manual

I

Page 2

Notes

on

safety

and

A)

Duetothe

the

needle,

sufficient

observe

while

B)

When

changing partsoraccessories,

machine

from

The maximum

C)

the

D)

The

by

agent.

sewing.

leaving

the

light

drive

anyone

caretoavoid

the

must

power

bulbis15

belt

down

up

user

the

area

sewing

machine,

the

disconnected

be

source.

approved

watts.

must

butanauthorized

neverbeadjusted

movement

must

injury

continuously

wattage

take

of

and

the

of

Pfaff

Page 3

Contents

controls

The

Accessory

Electrical

Foot

control

Preparing

Threading,

Threading

Threading

Threading

Inserting

Sewing

Points

Securing

Checking

3-thread

Thread

Adjusting

Adjusting

Adjusting

Regulating

Adjusting

Changing

Sewing

Changing

Changing

Changing

Changing

Cleaning

Oiling

Sewing

Accessories

Specifications

test

to

chart

rolled

the

problems

the

of

box

connection

threading

for

4-thread

right

looper

left

needles

the

lint

the

observe

seam

the

adjusting

and

overedge

stitch

the

stitch

the

differential

the

sewing

the

seam

the

sewing

the

hems

needles

lower

upper

bulb

light

the

thread

machine

sewing

double-overedge

looper

box

during

seam

length

length

foot

width

feet

knife

knife

tensions

solutions

and

machine

sewing

thread

on

on

feed

tension

794

796

on

pressure

796

seam

7—11

15,

20,21

24,

26,

3

2,

4

4,

5

5

6,

7

8

9

10

11

12

13

14

16

17

18

18

19

18

22

23

25

26

27

28

29

29

30

31

32

32

Page 4

C,’

Page 5

_______________________________________

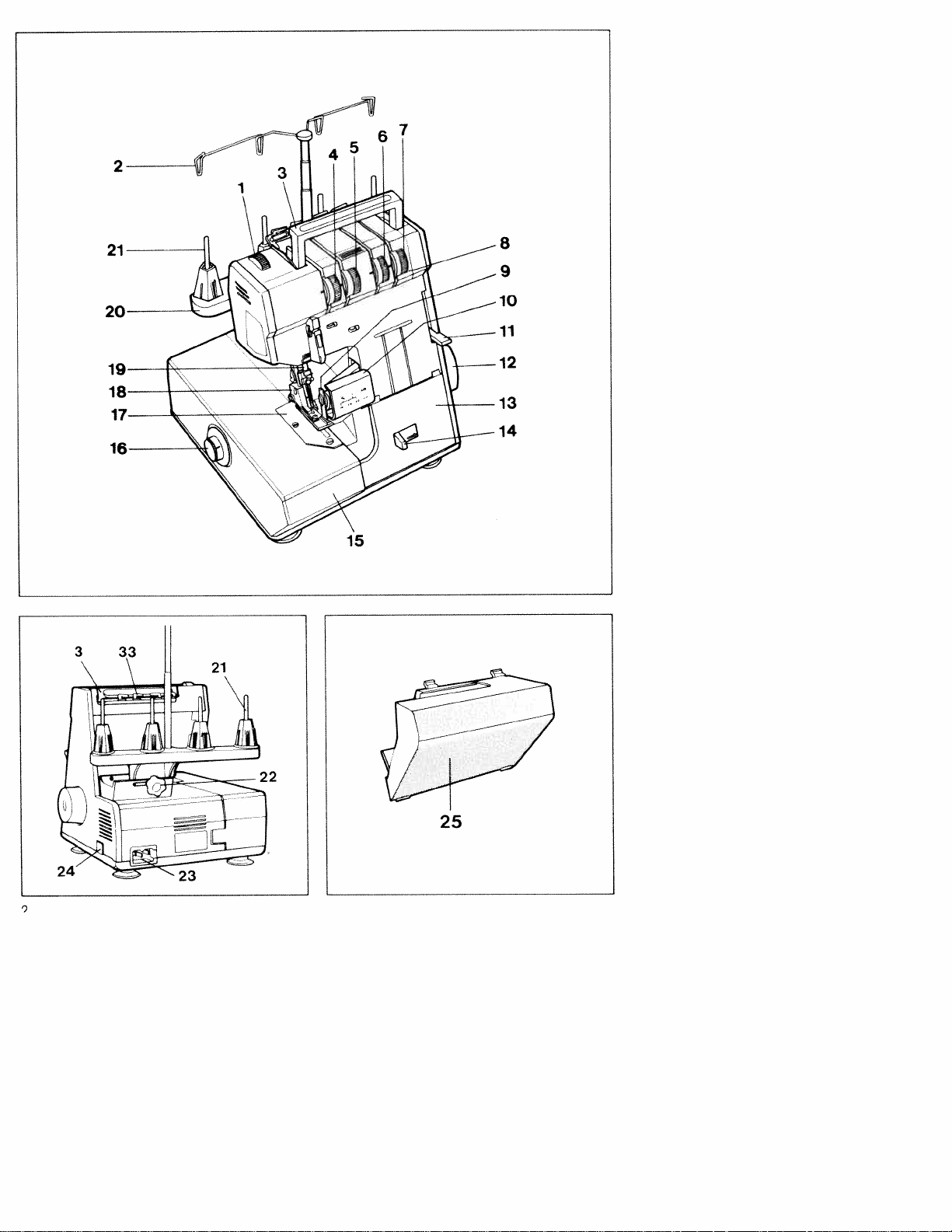

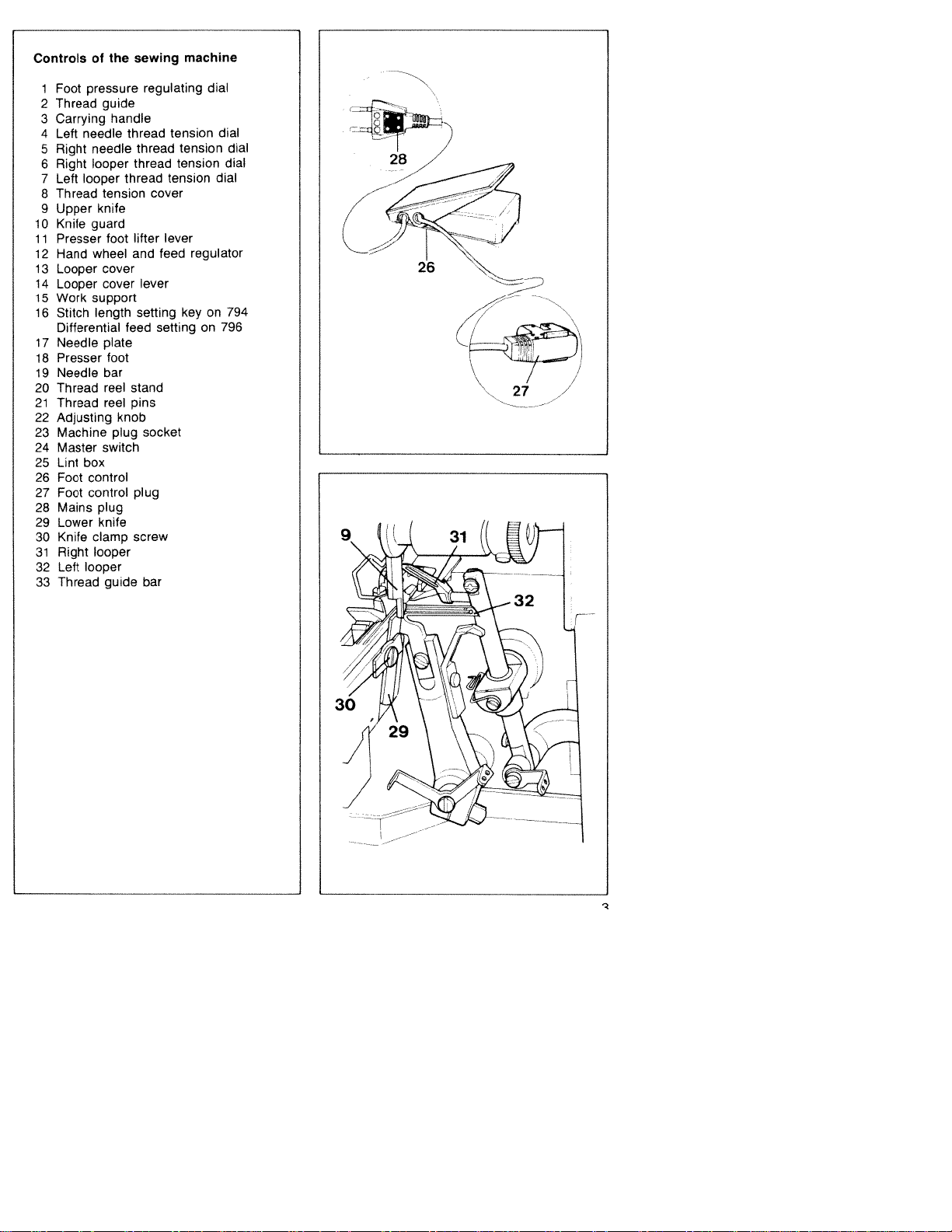

Controlsofthe

pressure

1

Foot

2

3

4

5

6

7

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Thread

Carrying

Left

Right

Right

Left

Work

guide

needle

needle

looper

looper

Presser

wheel

Hand

cover

Looper

cover

Looper

support

length

Stitch

Differential

Needle

Presser

Needle

Thread

Thread

Adjusting

Machine

Master

Lint

Foot

Foot

Thread

Mains

Lower

Knife

Right

Left

plate

bar

reel

reel

switch

box

control

control

plug

knife

clamp

looper

looper

handle

foot

foot

plug

guide

sewing

regulating

thread

thread

thread

thread

lifter

and feed

lever

setting

feed

stand

pins

knob

socket

plug

screw

bar

machine

dial

tension

tension

tension

tension

cover

lever

regulator

key

settingon796

on

dial

dial

dial

dial

794

28

‘N

2

--

/

///

26

27

9

31

32

30

29

if

I

Page 6

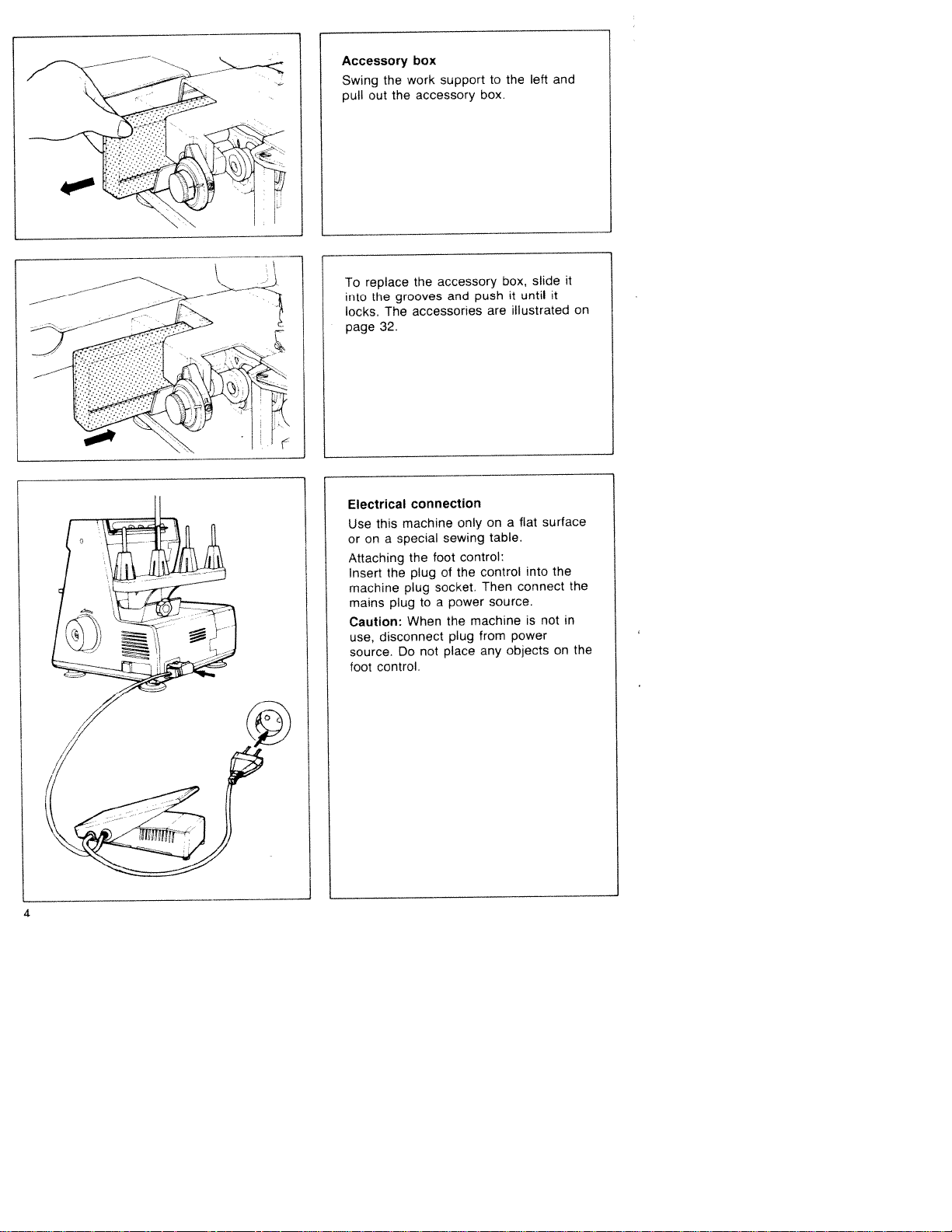

Accessory

the

Swing

pull

out

To

replace

the

into

The

locks.

32.

page

box

work

accessory

the

the

grooves

accessories

support

accessory

push

and

to

box.

are

the

left

slide

box,

until

it

illustrated

and

it

it

on

Electrical

this

Use

orona

Attaching

Insert

machine

mains

Caution:

disconnect

use,

source.

control.

foot

machine

special

the

plug

plug

When

Do

connection

sewing

toot

the

of

plug

socket.

power

a

to

the

plug

place

not

only

control:

control

the

Then

machine

from

any

a

on

table.

source.

objects

flat

into

connect

is

power

surface

the

not

on

the

in

the

Page 7

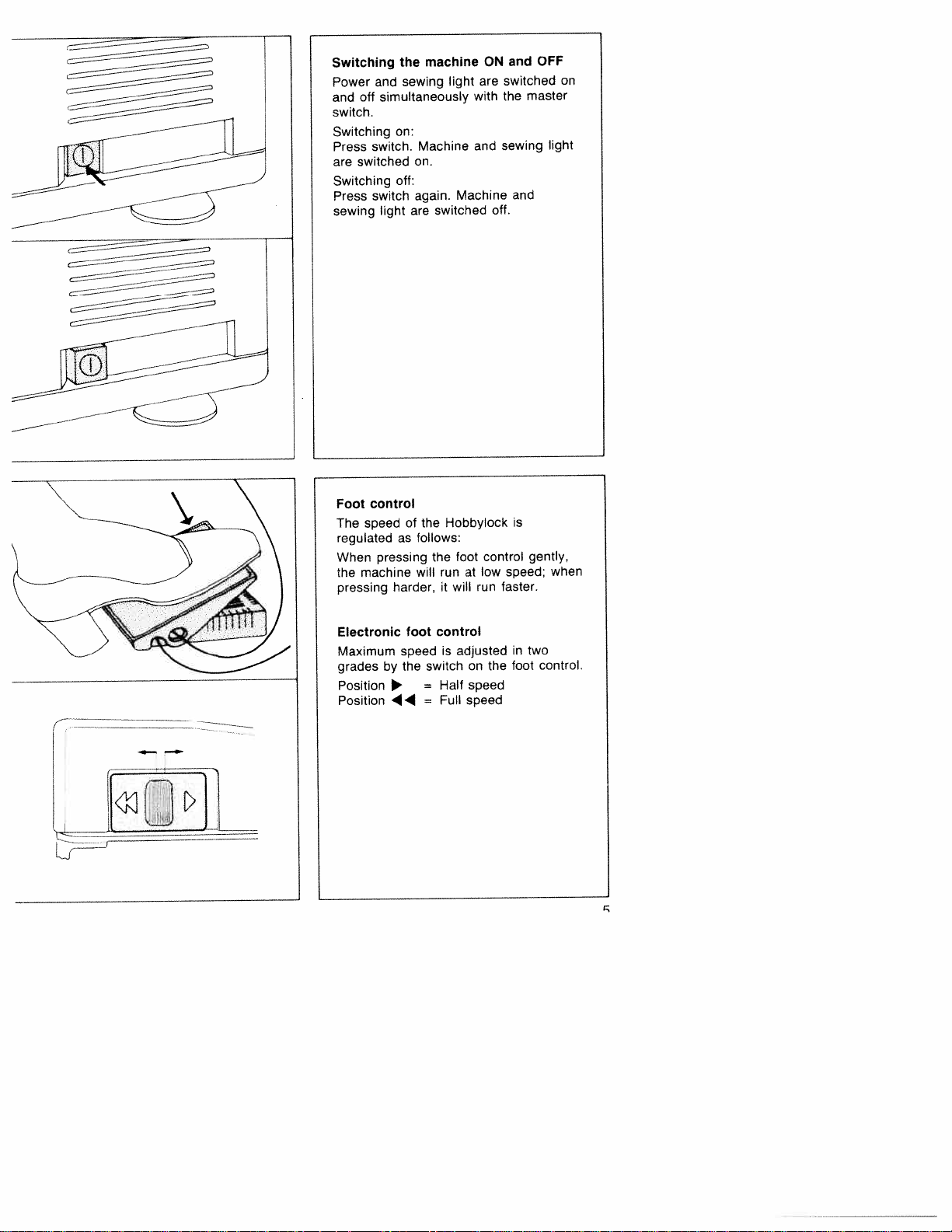

Switching

Power

off

and

Switch

S

Witching

Press

switch.

are

switched

Switching

Press

switch

sewing

Foot

Control

The

speed

regula

When

the

machine

Pressing

the

machine

and

sewing

simultaneously

on:

Machine

on.

off:

again.

are

light

press,g

of

as

harder

switched

the

follows:

the

will

light

Machine

HObbyIo

foot

run

at

it

will

ON

are

with

and

Control

low

run

and

switched

the

sewing

and

off.

Speed.

faster.

OFF

on

master

light

is

gently

when

Electronic

Maximum

grad

5

Pos,ho,,

Posillon

by

4

foot

speed

the

control

switch

Half

=

Full

=

is

adjusted

on

Speed

speed

the

in

foot

two

control

Page 8

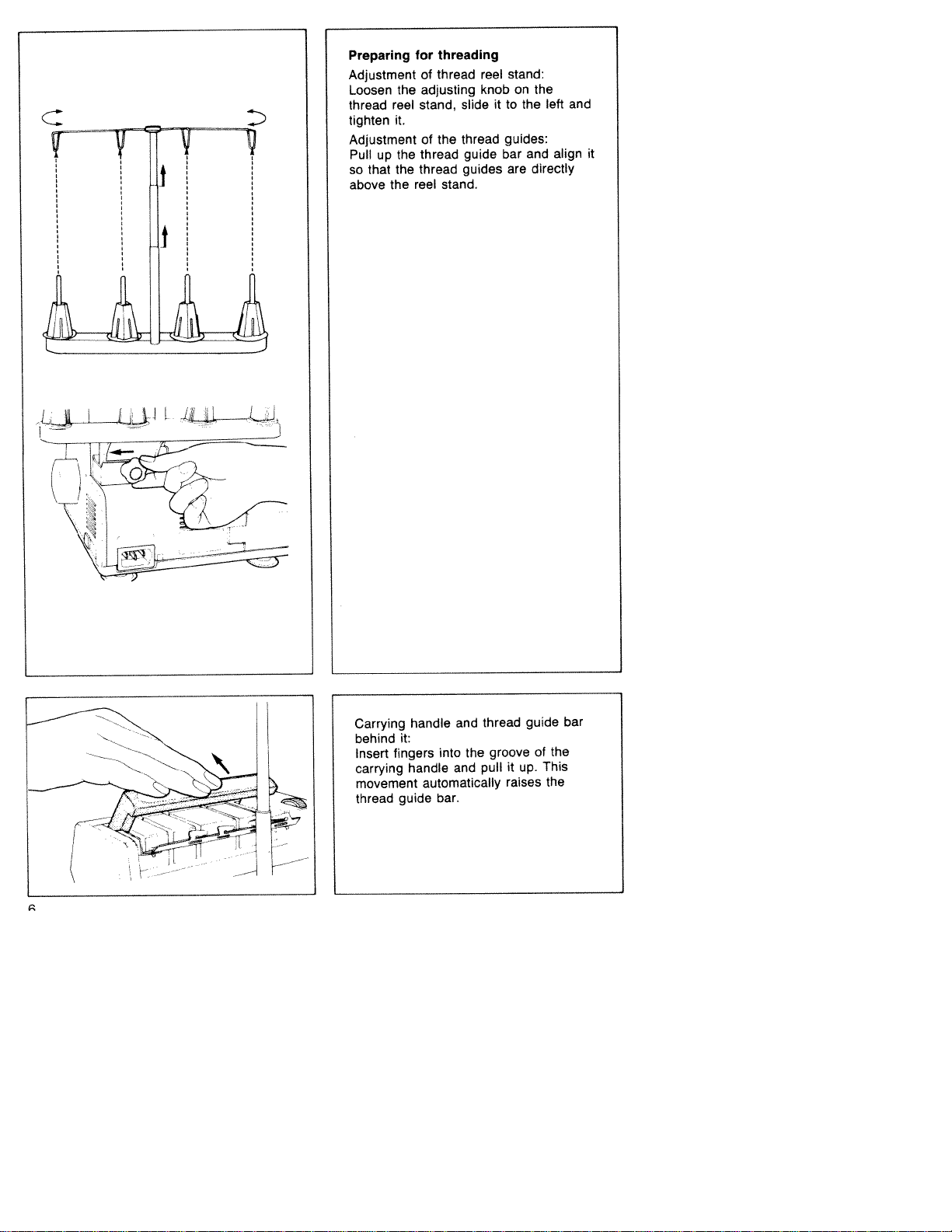

threading

reel

it.

the

the

the

for

of

thread

adjusting

stand,

the

of

thread

thread

reel

stand.

reel

knobonthe

it

slide

thread

guide

guides

stand:

to

the

guides:

bar

are

left

and

directly

align

and

it

Preparing

Adjustment

Loosen

thread

tighten

Adjustment

Pullupthe

that

j

so

above

JL_L_LjjJ

N

zr’

L

bar

guide

into

bar

and

and

the

thread

groove

pull

it

up.

raises

of

the

This

the

Carrying

behind

\

Insert

carrying

movement

thread

handle

it:

fingers

handle

automatically

guide

Page 9

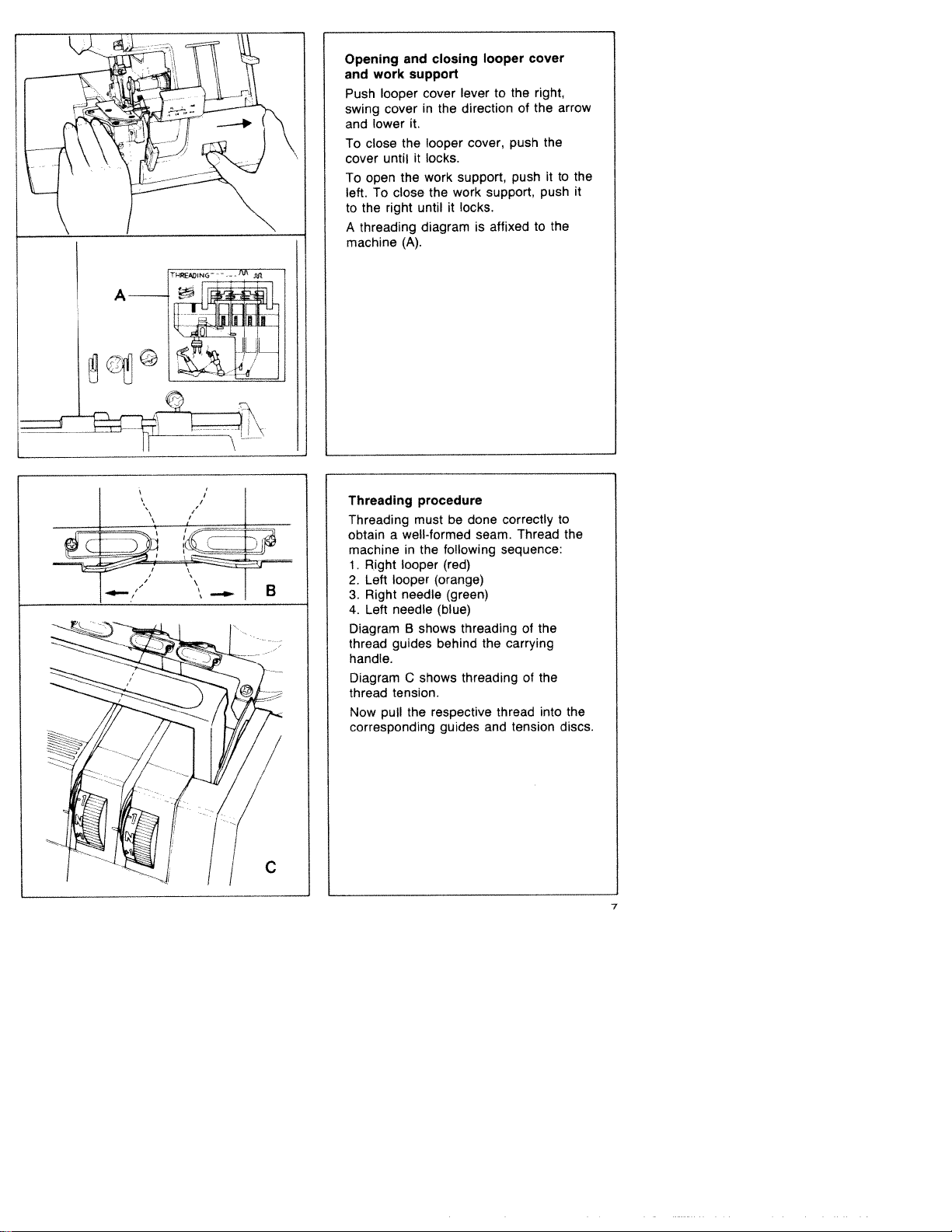

Opening

work

and

Push

swing

lower

and

close

To

cover

To

open

To

left.

the

to

A

threading

machine

looper

cover

the

until

the

close

right

and

support

cover

in

it.

it

until

diagram

(A).

closing

the

looper

locks.

work

the

lever

direction

support,

work

it

locks.

looper

cover,

is

the

to

push

push

support,

affixed

of

cover

right,

the

the

push

to

it

the

arrow

to

the

it

a

well-formed

looper

looper

needle

needle

B

guides

C

tension.

pull

the

procedure

must

be

following

(red)

(orange)

(green)

(blue)

shows

behind

shows

respective

Threading

Threading

obtain

machineinthe

1.

Right

2.

Left

Right

3.

Left

4.

Diagram

thread

handle.

Diagram

thread

Now

corresponding guides

correctly

done

threadingofthe

threadingofthe

seam.

the

and

Thread

sequence:

carrying

thread

tension

into

to

the

the

discs.

7

Page 10

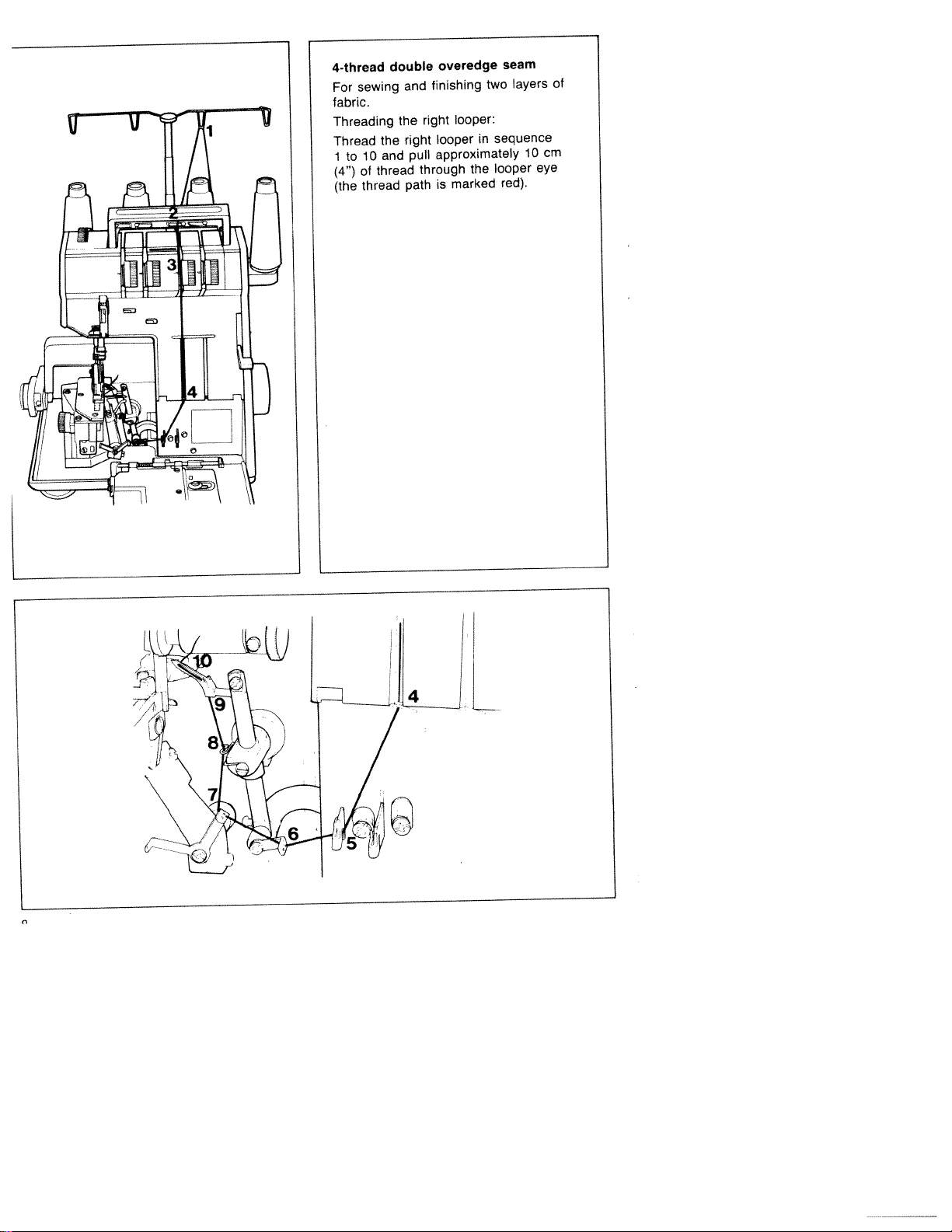

Jo

o

()

eip,)

pea-

Duqe

pEeJqJ

o

to

pu

bU1MeS

eq

6uipeaiqj

eq

pu

pEeJig

peiqi

aqnop

q6i

jjnd

qed

q6ii

si

6uiqsui

iedooi

ut

6noJ1B

ei.g

e6paJaAo

OMI

:iedooi

AIeew!xoJddE

iadooj

(pai

pajiew

was

SeAej

eouenbes

oi.

LO

wo

eAs

Page 11

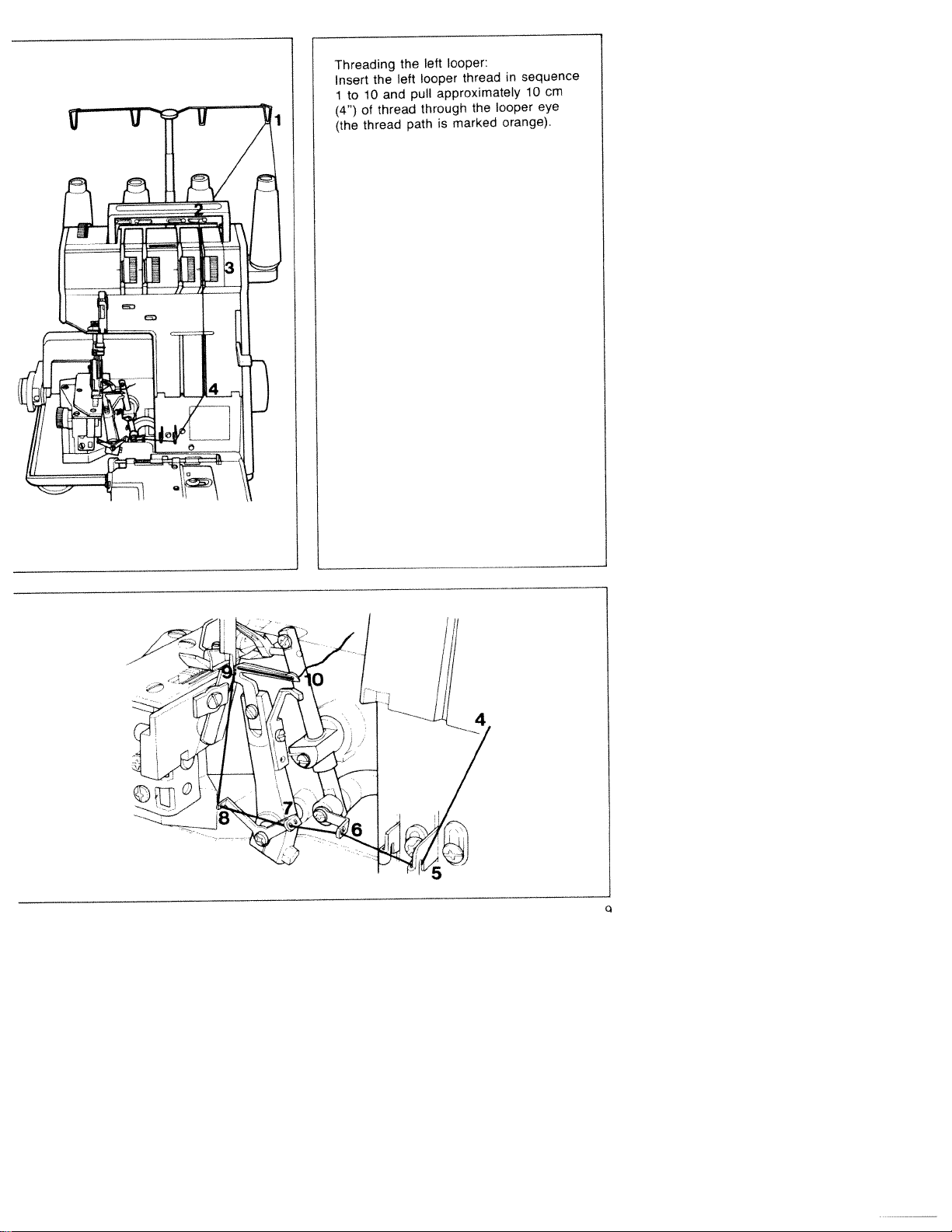

Threading

the

Insert

10

to

1

of

(4)

thread

(the

and

thread

the

left

pull

path

looper:

left

thread

looper

approximately

through

marked

is

the

in

looper

orange).

sequence

cm

10

eye

0

Page 12

Threading

Thread

1

7

to

thread

thread

(The

sure

Make

insert

care;

the

thread

sides.

Threading

Thread

to7and

1

thread

thread

(The

sure

Make

insert

care;

thread

the

sides.

the

and

through

the

through

needle:

right

the

right

needleinsequence

pull

approximately

eye

the

is

marked

path

thread

to

thread

the

guide

plates

needle:

left

the

needle

left

approximately

pull

to

guide

path

the

the

thread

thread

eye

marked

is

plates

point

behind

in

point

behind

the needle.

of

green.)

4

with

fitted

sequence

of

the

blue.)

4

fitted

5

hook

on

5

needle.

with

hook

on

cm

special

both

cm

special

both

of

of

A

of

A

of

The

diagram

threaded

shows

machine.

the

correctly

Page 13

Now

the

looper

close

handle

cover

the

down

(3).

work

(2)

support

and

close

(1),

push

the

Inserting

Insert

slots

(4)

Push

cover

Use

the

box.

the

the

until

the

tabs

of

the

lint

it

reverse

lint

of

front

box

snaps

box:

the

up

order

lint

cover.

against

in

place.

to

box

the

remove

into

the

front

lint

11

Page 14

Sewing

threading,

After

sewn.

presser

Raise

illustration.

sample

test

a

be

foot

sample

test

a

lever,

as

should

shown

in

Insert

Hold

while

clockwise

the

so,

rear,

that

test

thread

turning

threads

under

threads

fabric

ends

with

the

hand

have

and

with

your

must

presser

interlocked

lower

wheel

right

be

your

foot.

presser

left

counter

hand.

guided

hand

In

to

Make

correctly.

foot.

doing

the

sure

Page 15

Points

Place

the

presser

the

after

threaded).

the

Sew

the

Since

pull

not

for

hand

observe

to

fabric

foot

machine

first

fabric

or

guiding

when

stitches

push

during

completely

starting

been

has

slowly.

automatically,

fed

is

fabric.

the

only.

sewing

under

sew.

to

re

Use

the

(Also

do

your

Finishing

Sew

approximately

the

end

cutter

thread

the

(1)

seam

of

behind

the

chain.

seam

the

cm

5

and

presser

beyond

use

foot

the

thread

cut

to

Page 16

Securing

Knot

the

crochet

a

the

thread

the

thread

needle

chain

seam:

chain.

into

can

knit

For

be

usedtopull

the

seam.

fabrics,

To

prevent

approximately

seam.

Raise

over.

Lower

the

seam

without

Sewing

cutting

very

thicknesses

This

machine

very

to

very

knife

heavy

heavy

screw.

Note:

When

sewing

upper

knife

fabrics.

(See

ravelling

of

3cm(1”)

presser

presser

foot

approximately

the

chain.

heavy

fabrics

of

fabric:

will

sew

fabrics.

fabrics,

screw

thin

tighten

fabrics,

after

illustration).

seams,

beyond

foot.

2

through

When

sewing

Flip

and

cm

and

the

loosen

sew

the

fabric

sew

(1/2’)

different

very

sewing

upper

on

over

thin

the

heavy

Page 17

Top

side

Right

looper

thread

Setting

The

thread

according

Examine

necessary

thread

to

the

tension

tensions:

tension

fabric

seam

should

be

and

type

make

and

adjustments.

adjusted

thread

the

size.

-

Reverse

I

side

-

Left

needle

Right

needle

thread

Left

looper

thread

thread

Adjusting

all

Set

(standard

below.

Sew

test

a

correct

illustration

thread

thread

setting).

tension

tension

sample

above.

tension:

has

See

to

been

dials

illustration

sure

be

obtained.

“N”

to

that

the

See

1

Page 18

When

direction,

(+)

When

decreased.

Incorrect

left

The

thread

right

The

(green

right

The

thread

loose

too

thread

the

turned

thread

needle

tension).

needle

thread

tension)

the

in

tension).

looper

(orange

tension

tension

direction

(—)

tension;

thread

thread

thread

or

thread

the

is

left

turned

is

is

increased.

too

too

is

too

is

looper

tension).

it

loose

is

loose

tight

in

(blue

(red

thread

Top

side

Reverse

1

tight

is

loose

too

or

(red

the

right

thread

side

The

(orange

looper

left

looper

thread

thread

thread

tension)

too

tension).

-

Page 19

3-thread

overedge

seam

convert

to

How

sewing:

thread

Three-thread

either

using

10).

page

Remove

page

(see

the

26).

sewing

right

needle

from

or

_____

four-thread

is

possible

left

needles

is

that

riot

to

by

(see

used

three-

Needle

Thread

Thread

clamp

thread

tension

in

guides

needle

3-thread

Left

Marked

needle

blue

0

overedge

seam

Rht

Marked

needle

green

0

Standard

seam

maxim

seam

width

urn

width

6.5

mm

4.5

mm

Page 20

Material

materials:

Light

Organdy,

light-knit

fabric,

Taffeta,

lining

silk,

materials.

Medium-heavy

materials:

Cotton,

linen,

Heavy

Tweed,

tricot,

dress

materials:

suit

materials,

denim,

heavy

fabrics:

Knit

materials

cloth

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Thread

thread

thread

thread

thread

chart

Thread

No.

No.

No.

No.

No.

No.

No.

No.

No.

No,

No.

No.

80—100

80—100

70—140

60—100

50—100

70—140

40-60

40—60

70—140

40—60

40—60

70—140

Stitch

2.0

2.0

2.0

2,0

length

4.0

mm

to

to

4,0

mm

to

4.5

mm

to

4.5

mm

Rolled

hem

Polyester

Mercerized

thread

thread

No.

(bulk

Sewing

Position

the

normally

heavy

Thin

Reduce

setting

Heavy

Increase

setting

Stitch

The

feed

the

is

A

120/2

(180)

thread)

foot

standard

reset

fabrics.

fabrics:

the

to

fabrics:

the

to

Ienght

stitch

regulator

stitch

N(3mm).

=

setting

N”

sewing

lower

a

higher

a

length

length

pressure:

of

the

sewing

only

sewing

setting

is

16.

in

mark.

foot

foot

for

very

foot

number.

foot

number.

on

regulated

The

mm

1.5

to

pressure

pressure.

thin

pressure

pressure

794

numbers

which

2.5

mm

dial

or

by

by

turning

indicate

normally

by

is

It

is

Page 21

length

stitch

main

the arrow

the

continuing

numbers

in

mm

stitch

as

you

feeddog.

the

lateral

feed

required

or

(point

which

lengthisset

release

swivel

dog

(see

and

hold

in

the

12

until

stitch

turn

to

backwards,

of

indicate

normally

the

table

it

direction

snaps

it

handwheel

arrow).

stop

Setting

Open

of

downwards

handwheel

by

Set

by

forwards

required

di

if

If

I!

II

Ii

II

I

I

I

/

The

The

15.

arrow)

there.

length

as

the

is

N

firmly

of

on

into

may

stitch

=

the

796

Press

fully

Turn

indicated

place.

mark

at

12

be

length

mm.

3

soon

as

main

stop

A

5:

19

Page 22

prevents

teed

the

the

either

is

possible

more

rear

very

process

stroke

stroke

long

dog

stroke

feed

dogs,

other,

workpiece

feed

by

one

good

Set

to

the

(see

settings

of

of

interpIy

which

dog

have

to

the

and

sewing

the

table

front

of

rear

both

at

can

front

vice

at

teed

feed

differential

differential

consists

It

one

up

pick

same

amount

feed

separately.

set

workpiece

than

dog

Owing

are

you

21).

page

16

0.5

the

feed

two

of

behind

and

move

time.

of

It

moved

the

by

that

to

accomplished.

according

feed

to

wish

following

The

are

possible:

Short

=

U

WLfl

Adjusting

The

shift.

arranged

both

the

The

be

the

teed

versa.

results

differential

material

on

button

Setting

dog,

/cF

Setting

feed

Same

—

=

dogs

feed

front

ot

stroke

Long

=

The

from

1.5

=

2

differential

2,

to

0.5

dog,

feed

Front

longest

rear

shortest

feed

also

short

dog

feed

possible

feed

can

during

stroke

dog

dog

possible

be

sewing.

set

set

set

rear

of

for

stroke,

for

stroke

infinitely

Setting

Setting

Page 23

ms

table

quired

differential

r1e

indicates

for

the

fabric

feed

possible

you

can

also

settings

wish

the

about

sure

make

to

order

In

differential

the

of

process

to

during

set

be

sewing

a

sewing.

test

feed.

has

made.

be

to

setting

Setting

ferential

0.5

1.5

dif-

of

feed

Illustration

1

—

2

3

Correct

seam

a

c

d

Nylon,

popelin

Light

(normal

Jersey,

nicki

tricot,

cotton.

fabrics,

Heavy

2

very

elastic

lining

Jeans

fabrics)

medium

silk,

knitwear,

fabrics

Fabric

light

fabrics,

cotton.

knittings

0’

Gathering

differential

can

feed

be

setting

1

Ill.

III.

employed

2).

2

III

g

Ill.

3

garments

on

to

obtain

fashionable

effects

4

21

Page 24

Adjusting

Standard

width

can

6.5

mm.

seam

Note:

Before

disengage

To

disengage

cover.

the

far

clockwise

Choose

turning

Normal

upper

position

Sew

a

Note:

After

necessary

be

tension.

width:

seam

settingis3.5

changed

be

accordingtofabric

requirements.

adjusting the

the

upper

upper

upper

Turn

knife

knurled

Push

right.

untilitclicks.

required

the

the

stitch

knifetothe

and

test

adjusting

stitch

width

close

sample.

the

to

width

lower

the

reset

stitch

knife.

knife,

seam

is

seam

mm.

from

holder

button

“N”.

(cutting)

looper

the

The

2.5

type

width,

open

knob

width

Reset

width,

thread

seam

to

looper

(1)

(2)

(3).

cover.

it

and

always

to

by

the

may

22

Page 25

Changing

lever

Push

presser

the

the

Place

holder

foot

hem

holder

down

lever

gently

snaps

so

(Fig.

push

on.

the

A

up

foot

foot

that

engages

2).

and

lever

sewing

slightly

snap

will

the

under

crosspiece

groove

in

the

Push

the

with

up

A

feet

(Fig.

presser

other

until

out.

of

B

C

presser

the

1),

the

of

hand

and

foot

rolled

the

foot

foot

23

Page 26

Page 27

hem

Rolled

rolled

a

Use

rolled

for

a

Hobbylock

Remove

1.

Snap

2.

Use

3.

Thread

4.

satin

a

Set

5.

Set

6.

Set

7.

red

Set

8.

Set

9.

used.

hem

Flat

flat

a

Use

this

for

Remove

1.

Snap

2.

Use

3.

Thread

4.

satin

Set

5.

Set

6.

wider

a

Set

7.

Set

8.

the

of

Set

9.

the

of

on

green,

the

finish.

stitch

stitch

green

orange

hem

type

on

green,

finish.

stitch

stitch

green

red

fabric.

orange

hem

hem

quickly

will

needle.

left

rolled

red,

above

Or

length

width

threading

threading

threading

on

hem.

of

needle.

left

rolled

red,

above

the

Or

length

width

hem.

threading

threading

threading

fabric.

on

is

hem

and

use

at

heavier

hem

use

fine

to

three

at

2.5.

path

and

at

at

path

and

roll

produce

foot,

orange

threading

regular

the

path

(upper

path

fabrics

foot,

orange

three

regular

the

for

2.5

path

(upper

path

delicate

fabric

the

marked

shortest

(needle

(lower

marked

threading

shortest

a

(needle

(lower

fabrics.

professional

a

with

threading

paths

sewing

setting

tension)

looper

looper

cannot

that

threading

sewing

setting

narrow

looper

looper

between

the

paths

with

thread,

tension)

the

with

paths

thread,

flat

tension)

tension)

A

letter

1.

at

tension)

be

paths

with

I.

hem.

tension)

quick

thumb

rolled

only.

Mez

woolly

N.

at

rolled.

letter

only.

Mez

woolly

Or

N.

at

at

test

and

hem.

R”,

Alcazar

nylon

4

+

at

The

“R”,

Alcazar

nylon

set

3,

+

at

to

from

or

+

from

the

+

+

determine

index

accessory

rayon

any

or

5,

+

or

3

Pfaff

the

rayon

any

or

stitch

or

4,

more,

or

2

finger.

thread

other

depending

depending

5,

+

Hobbylock

accessory

thread

other

width

depending

5,

+

depending

if

the

If

box.

for

good

good

at

it

on

794

a

fabric

rolls,

rolled

a

quality

the

box.

for

higher

is

fabric

on

also

is

hem

a

quality

on

on

suitable

the

hem

thread.

the

perfect

thread.

setting

the

the

Pfaff

with

used.

fabric

with

weight

weight

a

for

25

Page 28

Changing

Removing

Unplug

the

Turn

raise

to

position.

with

screw

needle

Inserting

When

position,

needle

the

of

(centre

side.

the

will

go

screw.

Notes:

System

with

used

Although

depends

size

a

incorrectly

An

thread

Always

changing

needles

needle:

the

hand

the

Loosen

Out.

needle:

needle

the

insert

holder,

needle

of

illustration)

Push

and

D8

this

the

on

needle

14

breakage

turn

needles.

machine.

wheel

needle

the

allen

a

making

faces

the

tighten

or

1,

x

machine.

correct

the

fabric

inserted

the

counter-clockwise

bar

to

needle

the

wrench

is

at

bar

needleinthe

new

sure

and

you

can

needle

needle

the

1738

needles

needle

and

recommended.

is

needle

and

skipped

machine

OFF

its

the

the

be

up

thread

highest

clamp

and

highest

scarf

seen

as

clamp

size

will

stitches.

when

pull

groove

A

from

far

are

used,

cause

the

it

as

Changing

Knives

should

Removing

Unplug

the

Raise

holder

knife

clockwise

knob

are

be

the

knives

available

replaced

lower

machine.

needle

to

the

until

knife:

bar.

far

as

when

Push

it

spare

right

clicks.

they

the

and

parts

are

upper

turn

and

blunt.

the

Page 29

_________

_____

t:z

clamp

lower

knife

knife

-

Loosen

the

down.

screw

(1)

and

pull

I

Inserting

Insertanew

knife

lower

right.

facing

the

Set

aligns

with

knife:

lower

knife

holder

knifesothat

the

surfaceofthe

into

with

the

the

the

groove

cutting

cutting

edge

needle

of

edge

the

screw.

clamp

knife

lower

the

the

upper

front

knife

until

position).

it

to

snaps

the

right

into

and

place

turn

—

Tighten

Push

to

(operative

-

I

1

27

Page 30

Changing

upper

The

will

not

It

use.

cutting

Unplug

Push

and

right

clicks.

Unscrew

remove

replace

To

retaining

knife.

knife

the

upper

the

Turn

until

lowest

upper

lower

needle

the

screw

need

has

edge

the

the

upper

Screw

the

the

position.

knife

in

securely.

upper

knife

to

machine.

upper

turn

the

the

screw

holder.

knife

hand

upper

this

be

to

be

has

the

knife

knife.

into

it

should

position

plate.

knife:

carbide

is

replaced

replaced

been

knife

knob

retaining

upper

through

Tighten

the

in

wheel

knife

The

Tighten

holder

threaded

arm

front

be

and

tipped

normal

with

when

only

damaged.

the

to

is

edge

to

the

the

screw

insert

hole

position.

in

1.0

retaining

until

and

(1)

(2)

and

the

of

mm

surface

clockwise

knife,

cutout

slightly

cutting

counterclockwise

0.5

than

far

the

of

the

it

the

of

set

the

of

Page 31

Changing

Unplug

Remove

cover

light

the

Turn

remove

into

slots

direction

in

Replace

Caution:

Cleaning

Flip

the

the

the

bulb

it.

(3).

cover.

Use

tension

the

machine.

retaining

and

in

Insert

Push

(2).

a

thread

light

swing

direction

the

15

cover

bulb:

screw

cover

new

bulb

watt

tensions:

down.

bulb

up

bulb

(1)

from

to

and

only.

and

the

with

the

turn

left.

pins

it

the

Use

accesories

discs.

the

the

Close

brush

to

tension

provided

remove

cover.

dust

with

and

the

lint

from

29

Page 32

6uipo

eq

:aulLpew

sAo’

6u!IiO

o

ioud

snp

esn

Ajuo

4!Ienb

PoeoiPu!

eouis

eq

peeu

Aeq

e

quow

euo

buiMes

&j)

o

O!d)

o

(i.

eq

o,q

aulLpew

8J

s5uiqsnq

Peilo

O

eUiq3eW

o

sdoip

e

jio

110

Aiuo

U!

euo

aIB

p006

io

ptie

seDeld

peeueJdw!

e3!M

eqi

ueep

OE

Page 33

ewing

hs

the

the

problems

machine

ones

solutions

is

easy

described

offered.

and

solutions

operate

to

below,

occur

and

because

there

are

of

difficult

no

simple

adjustments

adjustment

errors.

tobemade.

can

They

Problems,

easily

be

similar

corrected

Material

correctly

Needle

Thread

Skipped

Problem

is

breakage

breakage

stitches

not

fed

Sewing

weak

Needle

point

or

Needle

Material

Incorrectly

Thread

Thread

Needle

Incorrect

Needle

Needle

Incorrect

Incorrectly

Sewing

weak

Cause

foot

pressure

bent

damaged.

correctly

not

pulled

threaded

caught

has

tension

correctly

not

needle

bent

correctly

not

needle

threaded

foot

too

used

damaged

or

used

pressure

too

inserted.

tight

inserted

inserted

too

sewing

Turn

clockwise

Insert

Insert

page

(see

not

Do

during

Thread

(see

pages

Check

the

at

Regulate

(page

Insert

needle

Use

1738).

(or

Insert

Insert

needle

Use

1738

or

Thread

Increase

to

new

new

pull

sewing.

correctly

whether

reel

tension,

15,

needle

new

needle

correctly

sewing

foot

increase

needle.

needle

26).

or

7—11).

stand,

16).

system

needle.

system

Solution

pressure

correctly

push

thread

etc.

correctly

correctly

(pages

foot

pressure.

material

catches

(page

x

DB

(page

DBx1,

7—11).

pressure.

screw

26).

1

26).

Incorrect

formation

Puckered

stitch

seams

Incorrect

tensions

Thread

Thread

incorrect

setting

tension

caught

has

threading

too

of

thread

tight

due

Set

(pages

Reduce

cially

pages

to

Thread

15,

thread

for

15,

correctly

16).

light

16.

tensions

thread

correctly

tension

materials)

(pages

(espe

7—11).

31

Page 34

3

4

/__•

60

Specifications

Highest

Overedge

Stitch

Sewing

Lubrication

Needle

Dimensions

Weight

sewing

length

foot

system

seam

5

.

speed

width

Accessories

1

Screwdriver

AlIen

2

Lint

brush

3

Tweezers

4

Lower

5

Thread

6

Needles

7

Oil

8

Rolled

9

Optional

(not

Blindhem

Elastic

accessories

illustrated):

foot

•

•

•

.

wrench

knife

unreeling

presser

hem

foot

30—6.5

1—5mm

Snap-on

Manual

x

DB

.

24x22x18.5cm

lbs.)

(19

disc

foot

stitches/mm,

mm

or

1738

1

kg

8.5

(size

9—14)

Page 35

Page 36

PFAFF-HANDELSGESELLSCHAFT

H

m

Haushaltnäh

für

7500

Karlsruhe

maschinen

West

41

b.

Germany

Sube

No.

30068

to

aftratons

0288

design

in

.

Loading...

Loading...