Page 1

fr:

p

\

hobbylock

787

•

788

Instruction

manual

Page 2

IMPORTANT

-This

sewing

When

including

Read

D

AI\IG

1.

The

unplug

cleaning.

2.

Always

3.

Do

4.

Do

sink.

all

using

the

instructions

sewing

this

unplug

not

reach

not

place

Do

not

rrachine

an

electric

following:

ER

machine

appliance

before

for

or

place

is

before

sewing

a

store

in

VV

1.

Do

not

2.

only

Never

3.

working

Return

nation,

4.

Never

openings

lint,

Never

5.

6.

Do

7.

Do

bein-g

8.

To

Never

9.

may

10.

Do

11.

Keep

sewing

12.

Always

13.

Do

only.

14.

Do

15.

Switch

area,

presser

16.

Always

lubricating,

the

17.

Hold

machine

this

Use

attachments

dust,

not

not

disconnect,

be

not

not

not

such

instruction

plug

allow

is

sewing

operate

properly,

the

repair,

operate

of

and

drop

use

operate

administered.

operate

blocked.

unplug

fingers

machine

use

use

pull

the

foot,

unplug

to

used

this

appliance

electrical

the

the

loose

or

insert

outdoors.

where

turn

on

by

away

the

proper

bent

or

push

sewing

threading

as

etc.

sewing

when

or

manual.

when

be

by

machine

recommended

sewing

sewing

a

pulling

needle.

or

blunt

fabric

machine

rewinding

winding.

SAVE

designed

appliance,

To

should

from

relamping.

sewing

or

drop

To

to

used

or

near

sewing

if

it

has

the

to

or

machine

cloth.

any

object

aerosol

all

controls

soft

from

needle

needles.

while

needle,

machine

making

SAFETY

and

manufactured

basic

safety

using

this

sewing

reduce

only

surface

on

the

never

the

electric

machine

machine

into

reduce

persons:

as

a

toy.

children.

for

machine

been

nearest

mechanical

machine

into

(spray)

to

cord.

all

moving

plate.

stitching.

off

(“Os)

changing

from

any

into

risk

Replace

that

water

the

Close

its

the

by

dropped

authorized

with

and

any

off

(“0”)

such

To

unplug,

The

Use

when

other

cord

be

intended

if

foot

products

parts.

needles

the

THESE

precautions

machine.

of

electric

left

unattended

outlet

immediately

with

bulb

fallen

has

where

it

or

other

risk

of

burns,

attention

use

manufacturer

it

hasadamaged

or

damaged,

adjustment.

any

air

controller

opening.

are

position,

bed

as

a

grasp

Special

wrong

plate

recommended

It

may

deflect

making

needle,

electrical

user

servicing

reel.

Do

INSTRUCTIONS

INSTRUCTIONS

for

HOUSEHOLD

schock:

same

water.

into

can

fall

liquid.

fire,

is

necessary

described

as

as

or

dealer

openings

free

being

then

or

couáh

the

plug,

careisrequired

can

the

any

threading

outlet

adjustments

not

allow

should

when

after

type

Unplug

or

be

electric

contained

cord

or

dropped

service

blocked.

from

the

or

used

remove

where

not

cause

the

by

needle

adjustments

bobbin,

when

plugtowhip

always

plugged

rated15Watts.

pulled

in

or

the

causingitto

removing

only.

use

be

using

immediately.

into

schock,

this

when

this

manual.

this

in

plug,

into

center

ventilation.

Keep

accumulation

where

from

plug

air

the

cord.

around

needle

manufacturer

the

in

the

or

mentioned

followed,

in.

Always

and

before

a

tub

or

injury

sewing

manual.

if

it

is

water.

for

exami

oxygen

-

outlet.

openings

to

break.

break.

needle

changing

covers,

when

or

Use

not

of

is

the

in

re

Page 3

Contents

Controls

Accessory

Electrical

switch

Master

control

Foot

on

Notes

How

to

handle

Opening

Threading

Threading

Threading

Threading

Needle

Thread

threader

reel

Inserting

allowance

Seam

Sewing

to

Points

Thread

cutter

Securing

Setting

Possibilities

3-thread

Engaging

Thread

Thread

tension

chart

Adjusting

Adjusting

Disengaging

Adjusting

Changing

Changing

Cleaning

hem

Rolled

hem

Rolled

Changing

Changing

Changing

Changing

knife

Upper

Cleaning

the

Oiling

selection

Stitch

Sewing

Accessories

Thread

Mounting

Special

Specifications

the

of

box

connection

and

safety

looper

the

guide

right

the

left

the

left

the

change

lint

the

test

observe

the

seam

the

standard

requiring

overecige

disengaging

and

stitch

the

differential

the

the

seam

the

sewing

the

light

the

thread

the

with

with

needles

the

knives

the

the

the

arresting

knives

the

machine

problems

net/thread

spool

the

of

accessories

sewing

sewing

thread

the

cover

wires

looper

looper

and

on

box

during

seam

adjustment

length

upper

width

bulb

threads

3

threads

2

upper

lower

table

and

Converter

contents

/

machine

18

/

right

threaded

sewing

thread

thread

knife

foot

tensions

knife

knife

their

light

spool

and

the

22

and

threading

needle

tensions

tension

the

sewing

for

(Hobbylock

feed

removal

unreeling

the

of

stand

swivel-type

slide

machine

converter

disc

cardboard

corrections

(Hobbylock

1

with

788)

box

work

needle

-

support.

.

•

788)

and

•

2.3

•

.6

.8

10

.

•

11

.

.

2

.

threads

•

•

•

•

•

•

•

•

•

11

•

12

.

.

12

.

•

13

•

•

14

.

14

.

.

14

-

.

15

.

.

16

.

.

17

.

18

.

.

19

21,22

26,27

32

42

43

.

1

Page 4

(0

Page 5

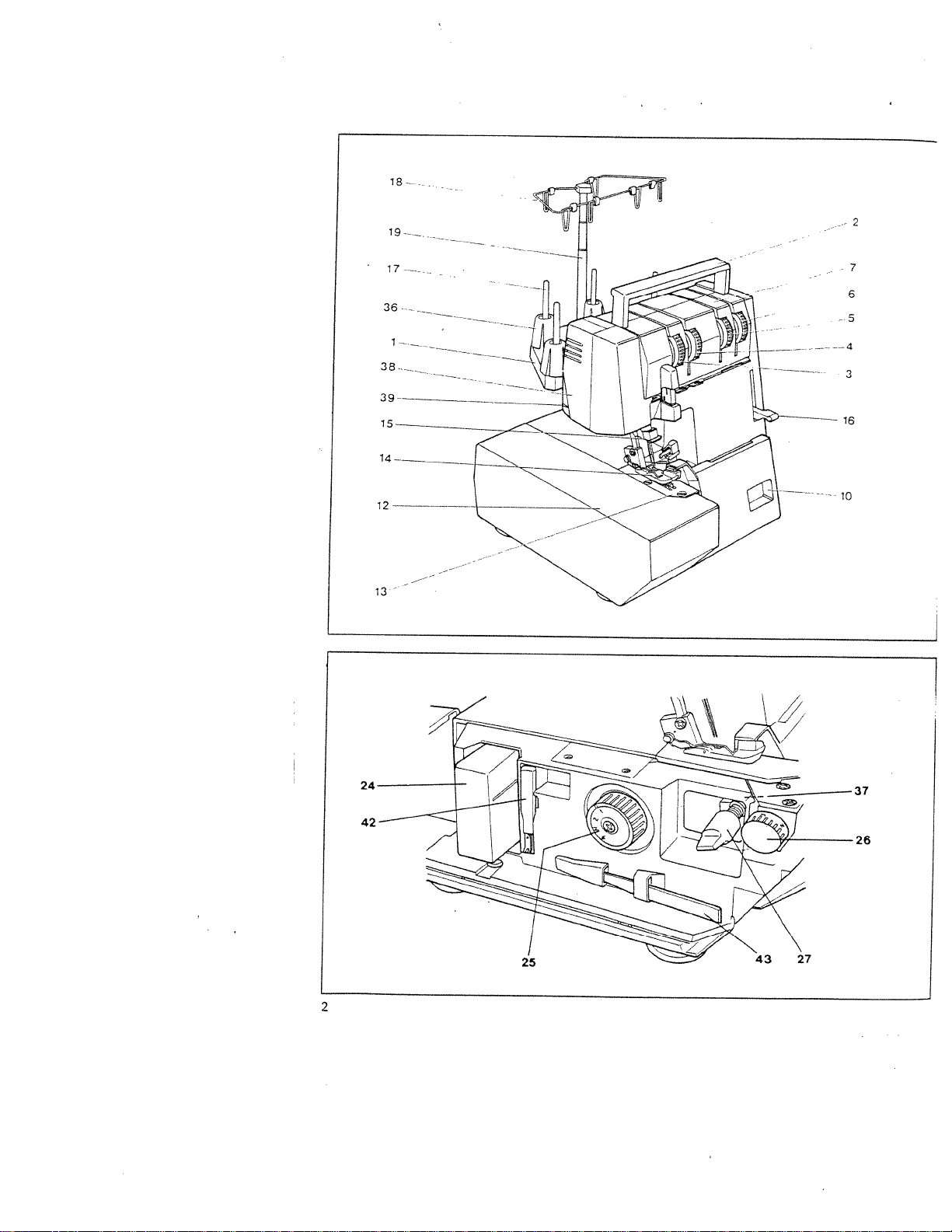

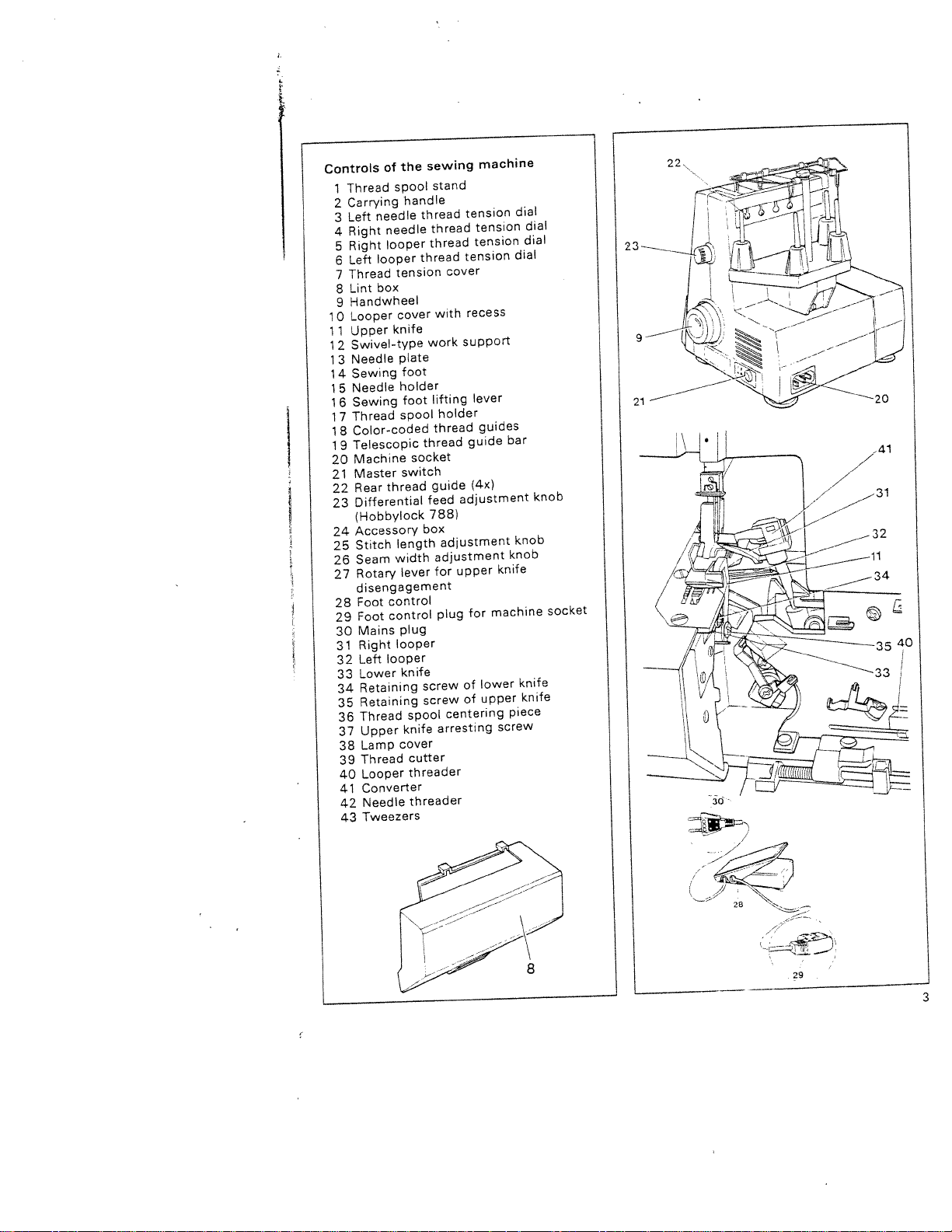

Controls

Thread

1

Carrying

2

Left

3

Right

4

Right

5

Left

6

Thread

7

Lint

8

Handwheel

9

Looper

0

1

Upper

11

Swivel-type

1

2

Needle

3

1

Sewing

14

Needle

1

5

Sewing

1

6

Thread

7

1

Color-coded

18

Telescopic

1

9

Machine

20

Master

21

Rear

22

Differential

23

(Hobbylock

Accessory

24

Stitch

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

the

of

spool

handle

thread

needle

needle

looper

thread

looper

tension

box

cover

knife

plate

foot

holder

foot

spool

socket

switch

thread

length

width

Seam

lever

Rotary

disengagement

control

Foot

control

Foot

plug

Mains

looper

Right

looper

Left

knife

Lower

Retaining

Retaining

Looper

spool

knife

cover

cutter

threader

Thread

Upper

Lamp

Thread

Converter

Needle

threader

Tweezers

sewing

stand

thread

thread

cover

with

work

lifting

holder

thread

thread

guide

feed

788)

box

adjustment

adjustment

for

plug

screw

screw

centering

arresting

machine

tension

tension

tension

tension

recess

support

lever

guides

guide

(4x)

adjustment

upper

machine

for

lower

of

upper

of

dial

dial

dial

dial

bar

knob

knob

knob

knife

socket

knife

knife

piece

screw

29

Page 6

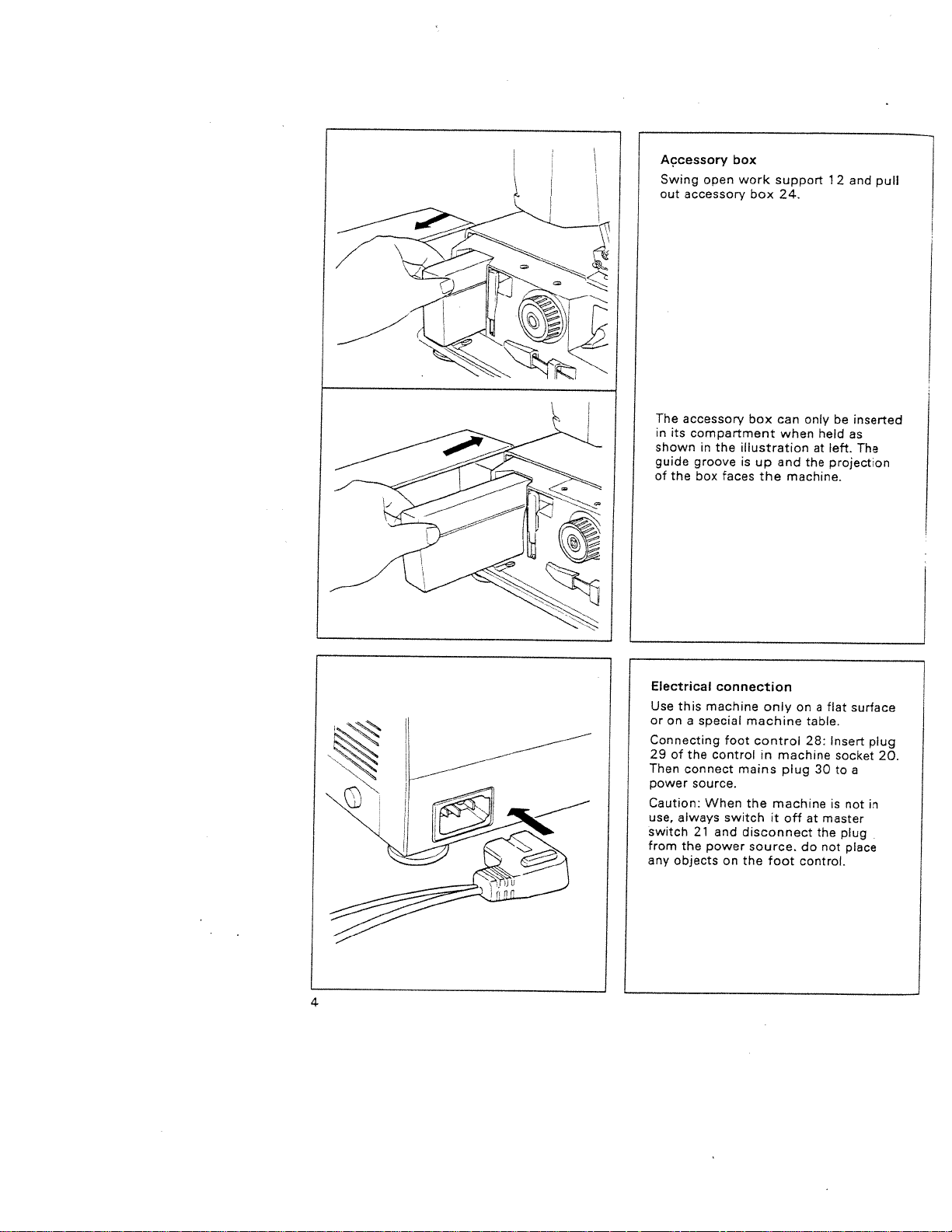

Accessory

Swing

out

accessory

The

accessory

its

in

shown

guide

of

the

box

work

open

compartment

the

in

illustration

groove

is

box

faces

box

box

up

the

support

24.

can

when

and

machine.

only

at

the

1

2

be

held

left.

projection

and

inserted

as

The

pull

Electrical

Use

or

on

Connecting

29

Then

power

Caution:

use,

switch

from

any

4

this

a

of

the

connect

always

the

objects

connection

machine

special

control

source.

When

21

and

power

foot

mains

switch

disconnect

on

the

only

machine

control

in

the

machine

it

source.

foot

onaflat

table.

28:

machine

plug

off

at

do

control.

30

master

the

not

Insert

socket

to

is

not

plug

place

surface

plug

20.

a

in

Page 7

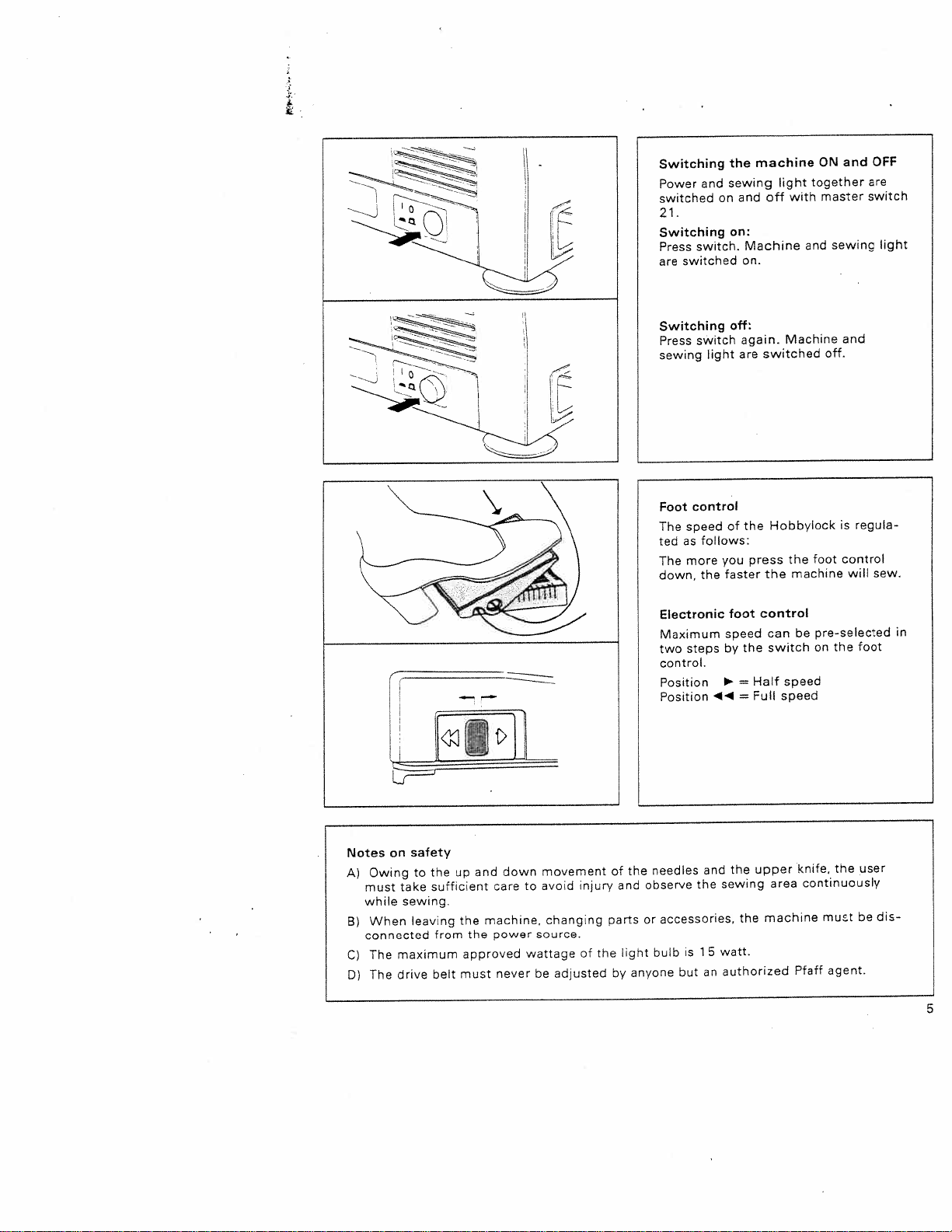

Switching

Power

switched

21.

Switching

switch.

Press

switched

are

and

the

sewing

on

on:

machine

and

Machine

on.

off

light

with

ON

together

master

and

and

sewing

OFF

are

switch

light

Switching

switch

Press

sewing

contro’

Foot

speed

The

as

ted

more

The

down,

Electronic

Maximum

steps

two

control.

Position

Position

off:

light

of

follows:

you

faster

the

foot

speed

by

44

again.

are

the

press

the

Half

=

=

Full

Machine

switched

Hobbylock

the

the

control

can

switch

speed

speed

foot

machine

pre-selected

be

on

off.

and

is

control

will

the

regula

sew.

in

foot

Notes

A)

must

while

B)

connected

C)

D)

on

Owing

When

The

The

safety

the

to

sufficient

take

sewing.

leaving

maximum

belt

drive

from

and

up

the

the

approved

must

down

care

machine,

power

never

movement

avoid

to

changing

source.

wattage

be

injury

of

adjusted

the

of

and

parts

by

the

light

anyone

needles

observe

accessories,

or

bulb

but

is

the

and

1

an

5

upper

the

sewing

the

watt.

authorized

area

machine

Pfaff

the

knife,

continuously

muzt

agent.

user

be

dis

5

Page 8

e3-O

————

to

thread

go

handle

in

I

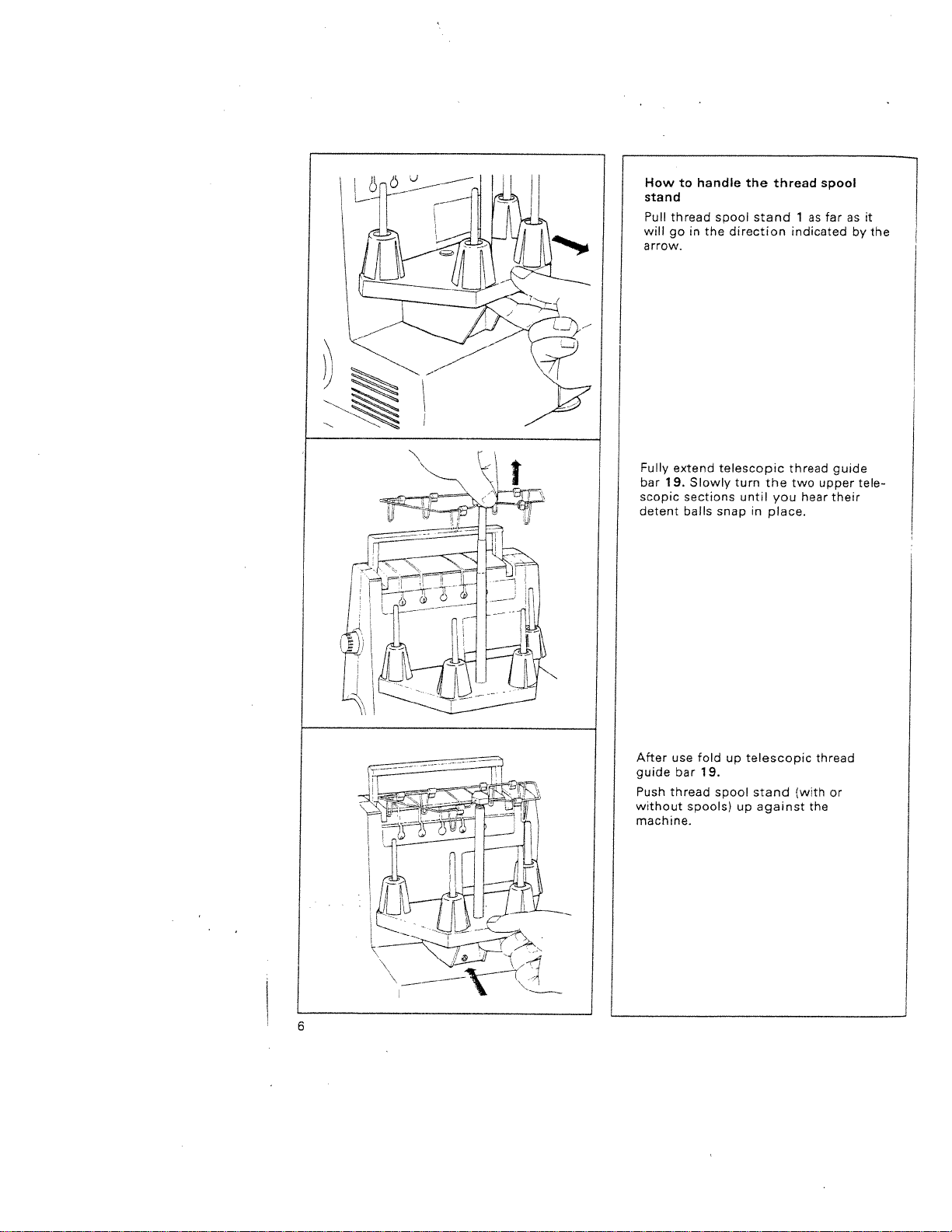

How

stand

Pull

will

the

spool

direction

the

thread

stand1as

spool

far

indicated

it

as

the

by

arrow.

Fully

extend

telescopic

Slowly

bar

\

—

scopic

detent

19.

sections

balls

turn

until

snap

thread

two

hear

guide

upper

their

tele

the

you

in

place.

After

guide

fold

use

bar

19.

read spool

up

telescopic

stand

(with

thread

or

machine.

6

Page 9

____

1

—‘

—

support

10

it

cover

is

the

cover

supply

pull

and

2

Set

(yellowl

(green)

looper

fully

down.

cover,

12.

by

push

converter

illustrated

respective

the

of

paths

or

to

wires

on

thread

must

threads

the

colors.

to

place

the

the

down

2

to

the

push

push

the

it

looper

work

machine

the

18

be

the

thread

machine

right,

it

up

in

it

arrow.

lightly

with

stitch

cover

are

support

and

spoo

1

threaded

through

Then

thread

tensi

in

again.

To

41

its

is

19

lift

the

closing

and

looper

it,

close

it

open

direction

the

it

settings

On

individual

the

open,

thread

rear

at

right

left

right

left

carrying

and

and

the

locks.

work

work

locks.

the

the

power

The

18

handle

guides

and

N

looper

looper

needle

needle

work

cover

swing

looper

support

indicated

support,

looper

788)

for

inside

threading

colors.

in

ooøer

of

guide

spools

machine

First

according

22.

thread

sequence:

(redl

(blue)

handle

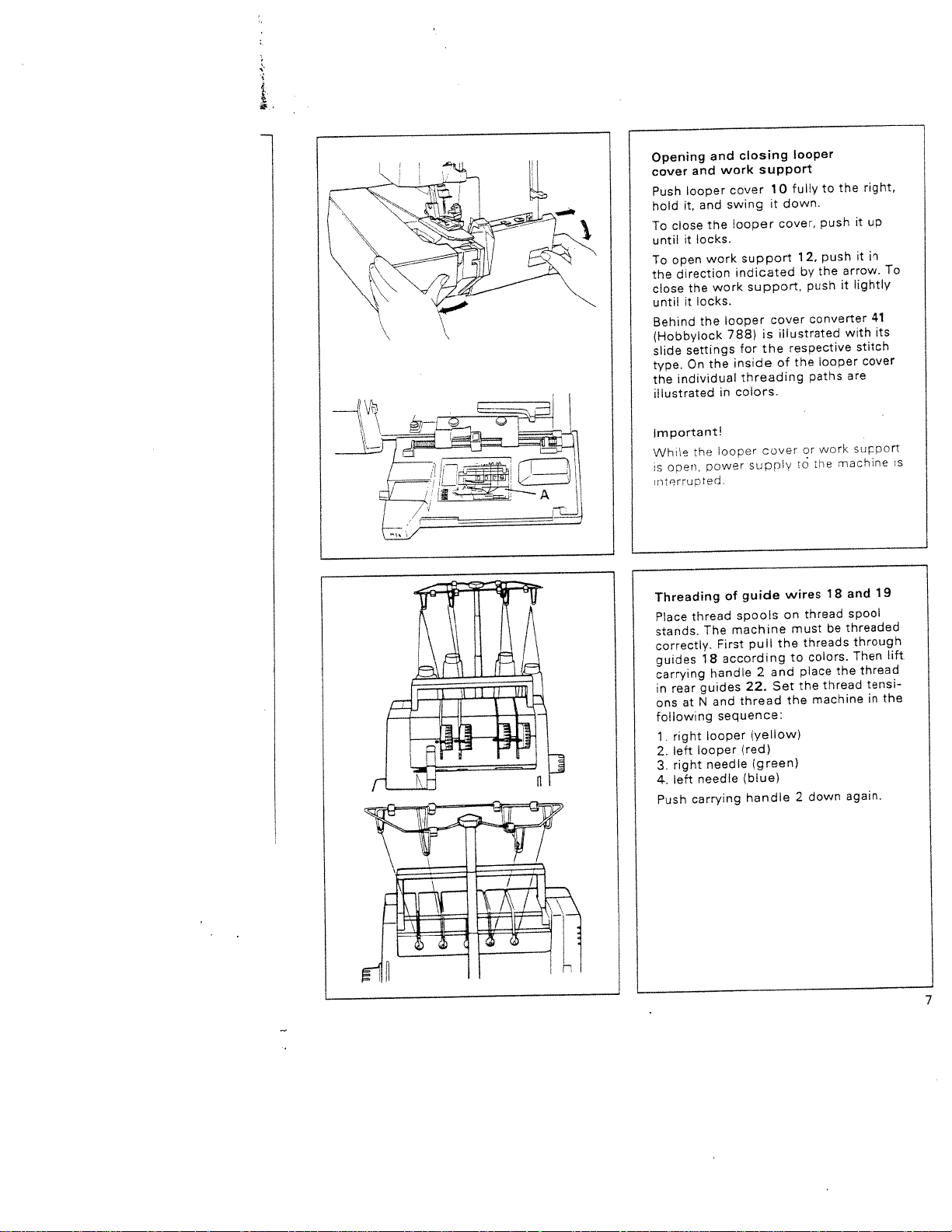

Opening

cover

Push

hold

To

until

To

the

close

until

Behind

(Hobbylock

slide

type.

the

f1\

____

/

/—

‘-==

—

/_____________

-D-

i’)

I

A

—

illustrated

lmportantl

While

s

inrorrupted.

Threading

Place

stands.

correctly.

guides

carrying

in

ons

following

1.

2.

3.

4.

Push

7

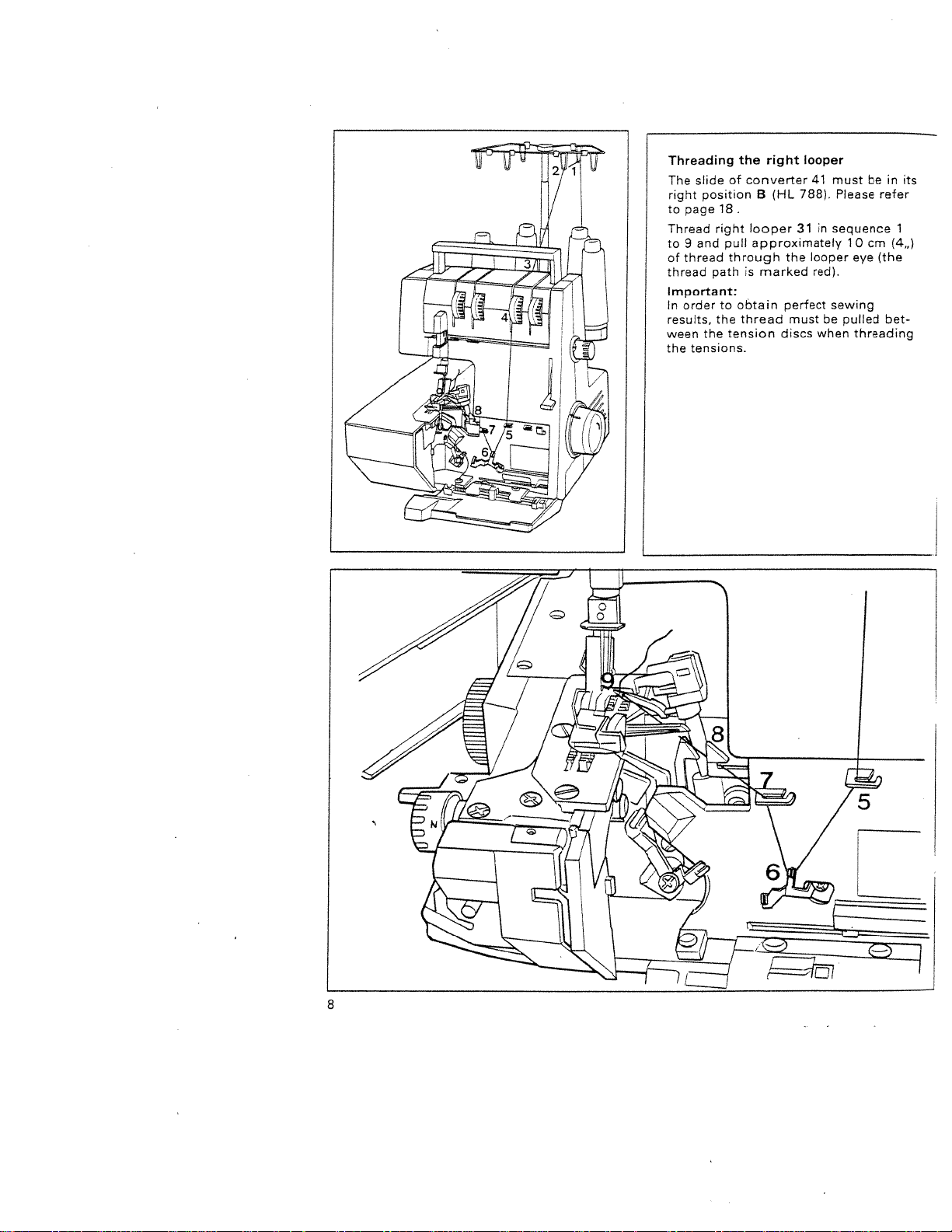

Page 10

-1

-l

0

CDZT

CD

CD

ao

D

CD

O

0

3CD

O(DCD

—

0

•0

C

co0co

lCD

__<

3

CT

U)

CD

-.

CD

CD—.

CD

U)

(IC

C)

CD

o

CD<CD

•c

“U)CD

••‘

•

CDm

CD

ciCD

CD

CD

a

U)3CD

D

CD-

CDOD

•

CDCDa

cT

-CD

-,

DC

a

CD

—

Z

—.

•-“

C)

ci

O

o

.CflCD

CD

CO

ci

CD

C

D

D

T

CD

1

U)

o

-

CD

U)

7

U)

Page 11

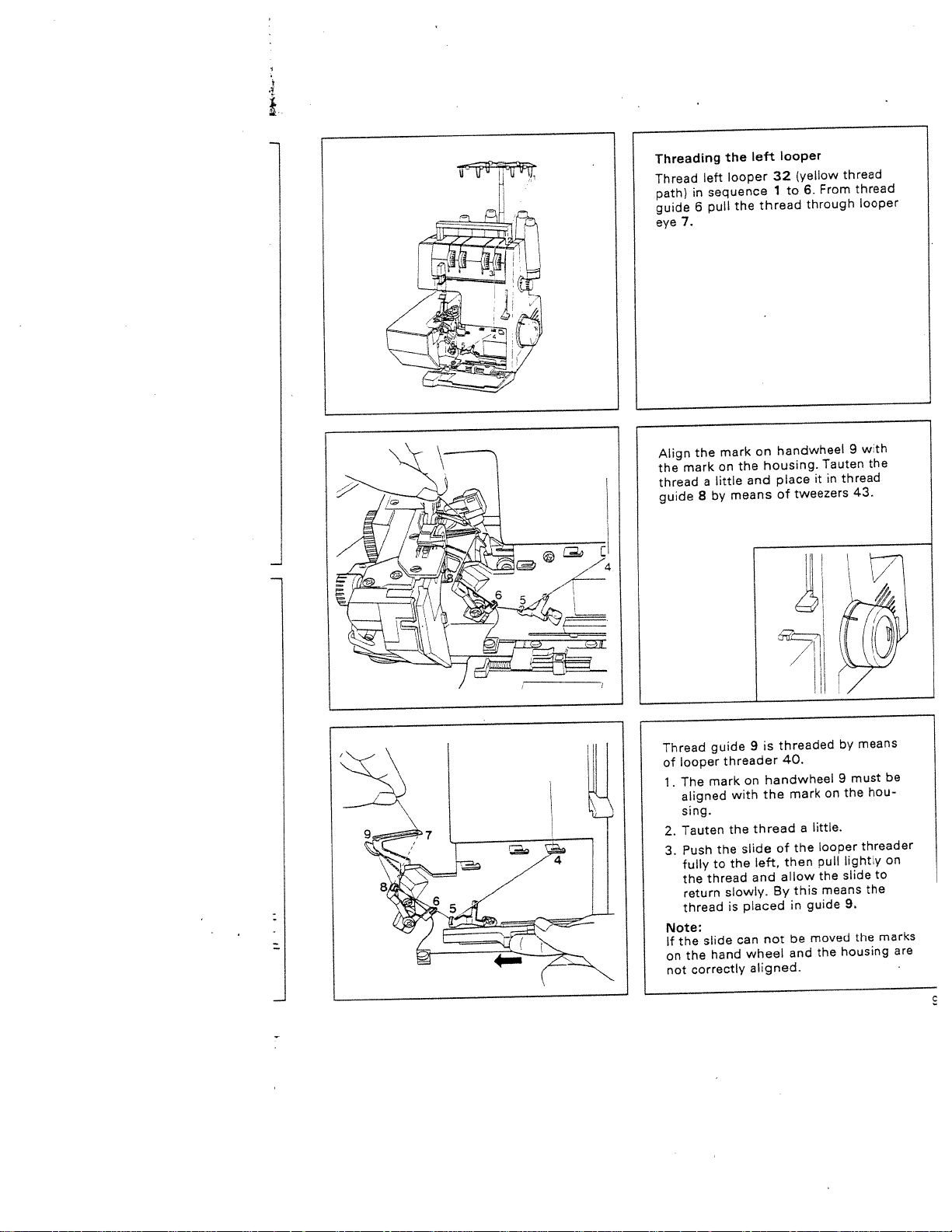

/

z/__w__J

looper

left

in

7.

mark

left

sequence

pull

6

the

a

by

B

the

mark

on

little

looper

the

the

and

means

32

1

thread

handwheel

on

housing.

place

of

(yellow

to

6.

through

tweezers

From

Tauten

in

it

thread

thread

looper

9

thread

43.

with

the

Threadng

j

1

Thread

path)

guide

eye

Align

the

thread

guide

Thread

looper

of

1

The

aligned

sing.

Tauten

2.

Push

3.

fully

the

return

thread

Note:

If

the

the

on

not

guide

threader

mark

the

to

thread

slide

hand

correctly

on

with

the

slide

the

slowly.

placed

is

can

wheel

is

9

handwheel

the

thread

of

left,

and

By

not

aligned.

threaded

40.

mark

a

the

then

allow

this

guide

in

moved

be

and

on

little.

looper

pull

the

means

the

means

by

must

9

the

threader

lightly

slide

9.

the

housing

be

hou

on

to

the

marks

are

C

Page 12

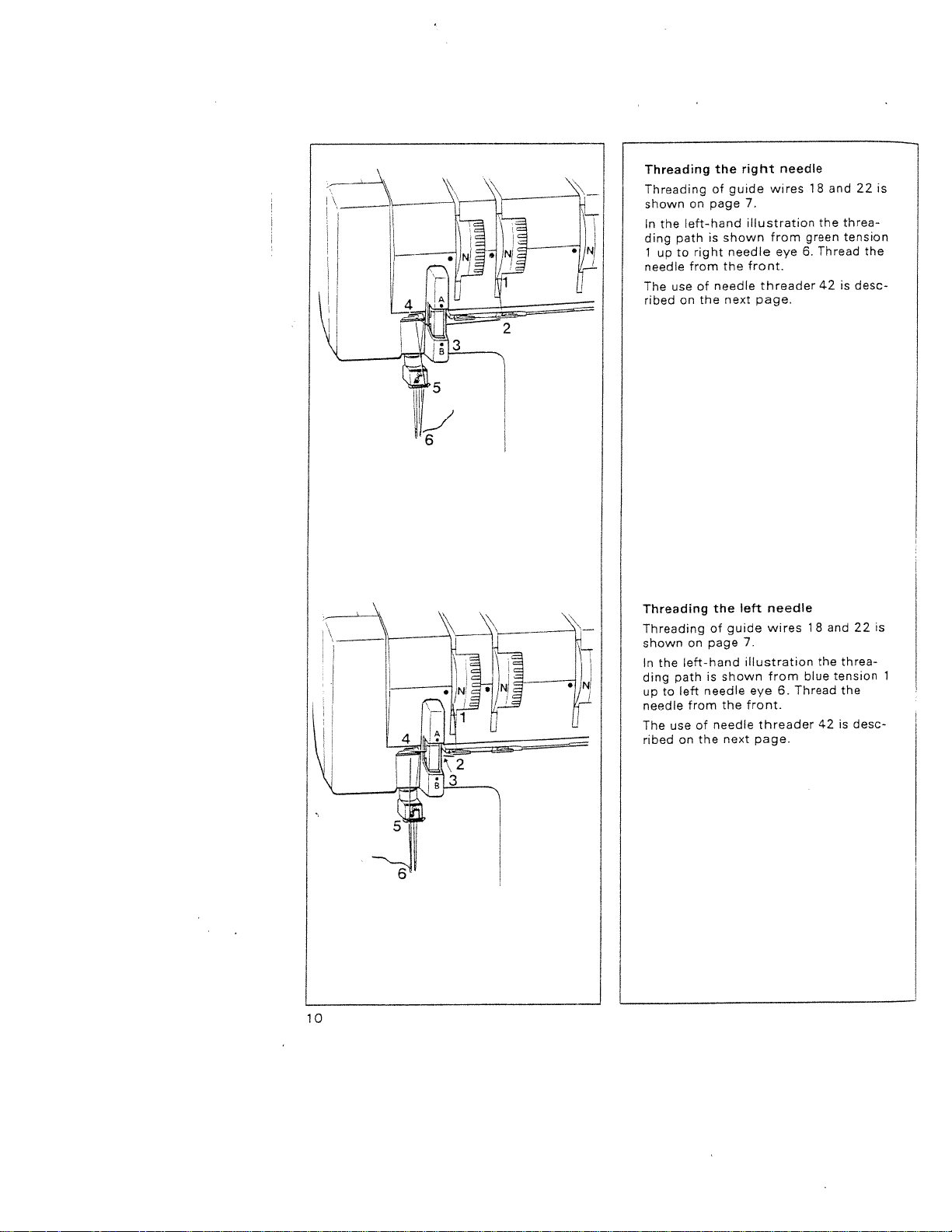

Threading

Threading

shown

In

the

path

ding

to

1

up

needle

use

The

on

ribed

Threading

Threading

shown

In

the

ding

path

left

up

to

needle

The

use

on

ribed

the

of

page

on

left-hand

is

right

from

needle

of

the

the

of

on

page

left-hand

is

needle

from

needle

of

the

right

guide

shown

needle

the

next

left

guide

shown

the

next

needle

wires

7.

illustration

from

eye

front.

threader

page.

needle

wires

7.

illustration

from

6.

eye

front.

threader

page.

18

green

6.

18

blue

Thread

and

the

Thread

is

42

and

the

tension

42

is

22

threa

tension

desc

22

threa

the

desc

is

the

is

1

10

Page 13

is

Needle

Lower

ting

Turn

31

(see

in

tauten

threaderalittle

With

two

threader

side

engages

Hold

hookD;it

placed

threader

the

lever

the

positioned

is

topofpage

slot

A

italittle,

the

guide

slowly

of

the

in

the

in

sewing

16.

wheel

hand

of

needle

thread

rightofthe

18).

needle

holding

turnedtothe

located

move

lugs

B

downwards

needle

the

needle

taut

then

will

hookC,too.

foot

until

meansoflif

by

until

right

Place

threader

automatically

the

the

between

the

needle

small

eye.

and placeitin

needle

42

needle

front.

the

at

hook

looper

thread

and

the

rear

C

be

Thread

the

Cut

Tie

the

threads

past

through

looper

spool

threads

threads

the

eyes

change

outofthe

last

thread

respective

the

without

on

close

to

stillinthe

needles.

guide

interruption.

threaded

the

machine

before

needle

thread

Now

eyes.

machine

spool.

and

pullatthe

the

needles.

The

Pull

about

Place new

the

new

looper

10cmof

Pull

the

the

of

pulled

be

Pull

the

needle

thread

threads to-gether.

thread

ends

Cut

the

knots

threads

thread

needle

needle

through

thread

eye.

until

can

eye,

spools

the

off

and

pulled

be

through

threader

and

the

completey

on

spool

Pull

knots

pull

until

the

to

the

the

thread

eye.

through

holders17.

the

needle

are

about15

the threads

past

looper

rear,

the

eye.

out

will

the

cm

11

Page 14

After

handle

12

threading

and

down,

2

looper

the

and

cover

machine,

close

1

0.

work

push

support

Inserting

Insert

the

wardsinthe

Then

push

against

For

revese

Seam

If

the

removal

order.

allowance

the

cuttingisguided

markNon

allowance

consideration

into

fabric.

the

two

recess

the

machine.

of

looper

of 16

lint

tabs

bottom

the

box:

of

of

lint

cover

mm

when

lint

box8down

looper cover

of

the

box

box,

use

along

below

10,aseam

must

be

cutting

10.

the

taken

the

12

Page 15

Sewing

After

made.

be

Raise

illustration.

the

test

threading,

sewing

foot

a

sewing

lever

16,

test

as

should

shown

in

Hold

hand

your

ted

Hold

back

sure

during

Insert

11

by

and

the

while

right

the

under

the

the

thread

the

threads

threads

sewing

lower

turning

hand

arrow

sewing

test

ends

in

on

(thread

fabric

sewing

with

the

direction

the

the

taut

foot

interlock

up

foot

hand

wheel.

and

14.

chain).

to

your

wheel

lay

Make

correctly

upper

lever

left

indica

them

knife

1

6.

with

13

Page 16

to

Points

Sew

the

machine

fabric

the

pushitup

sew.

to

Since

the

pullorpush

not

for

hands

observe

first

has

under

to

fabric

guiding

stitches

been

sewing

the

needle

is

the

during

slowly.Ifthe

rethreaded,

fed

automatically,

fabric.

only.

sewing

foot

before

Use

place

14

and

starting

do

your

Thread

order

In

itisnecessary

39

end

of

thread

from

the

left).

Securing

Knot

the

crochet

a

thread

the

Or:

Sew

about

Turn

seam.

few

sew

a

sewn

without

cutter

to

be

the

seam.

through

chain

rear

the

thread

needle

chain

cm

5

the workpiece

stitches

abletouse

sew

to

Draw the

illustration

(see

seam:

chain.

can

into

(2”)

over

cutting

the

thread

beyond

resulting

the thread

For

knit

be

used

the

seam.

beyond

around

the

seam

thread

below

fabrics,

to

the

cutter

the

cutter

pull

end

and

just

chain.

of

14

Page 17

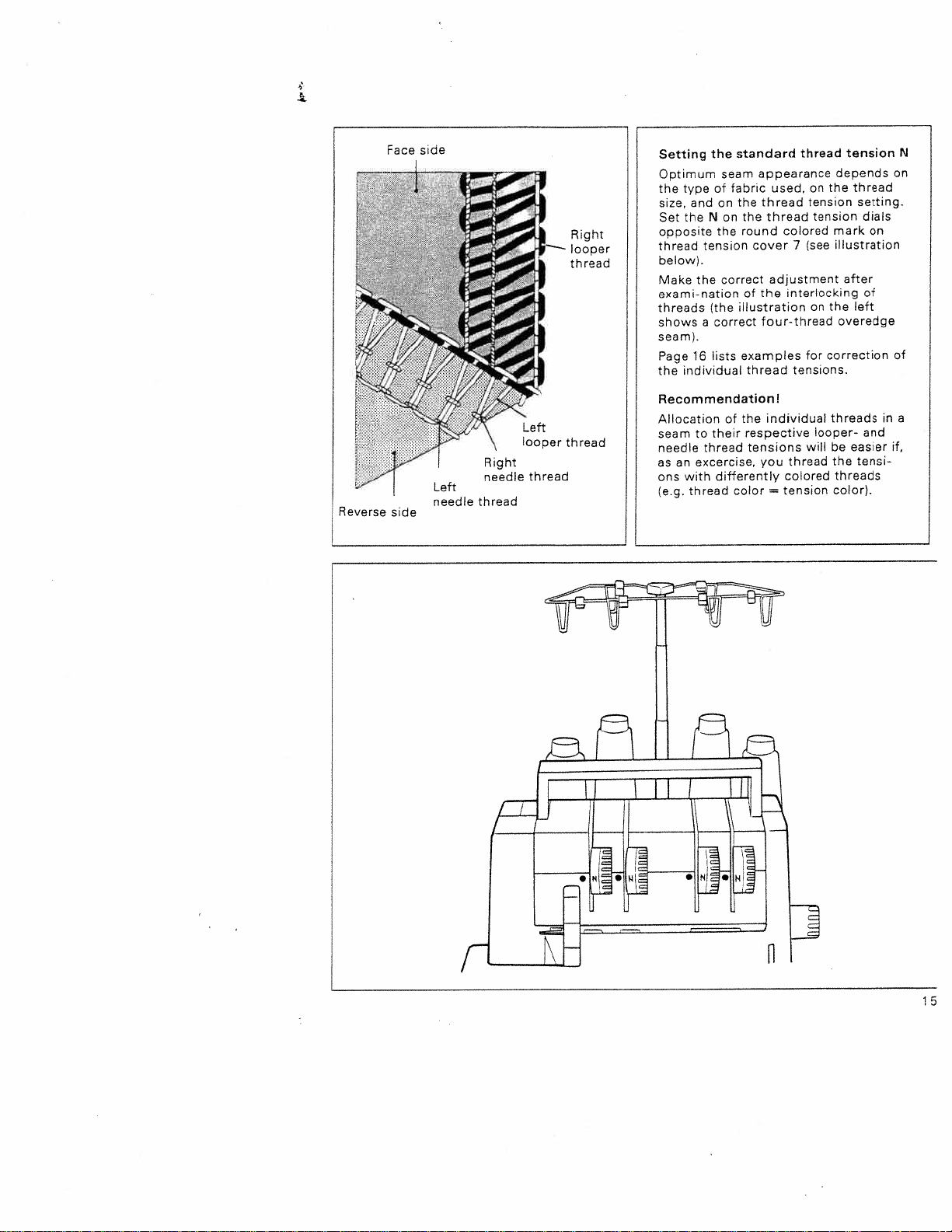

Reverse

Face

.:.•

side

side

Left

needle

;1

\

Right

needle

thread

Left

looper

thread

thread

thread

standard

type

and

the

tension

the correct

a

16

individual

to

thread

excercise.

an

with

thread

the

seam

fabric

of

on

the

on

N

the

illustration

(the

correct

lists

of

their

differently

color

Setting

Optimum

the

size,

Set

opposite

thread

below).

Make

exami-nation

threads

shows

seam).

Page

the

Recommendation!

Allocation

seam

needle

as

ons

(e.g.

appearance

used,

thread

thread

the

round

cover

adjustment

the

of

four-thread

examples

thread

individual

the

respective

tensions

you

=

thread

on

tension

tension

colored

7

(see

interlocking

on

for

tensions.

looper-

will

thread

colored

tension

tension

depends

thread

the

setting.

dials

mark

illustration

after

of

left

the

overedge

correction

threads

and

easier

be

the

tensi

threads

color).

N

on

on

of

in

a

if,

HI!

zijE.

Li

15

Page 18

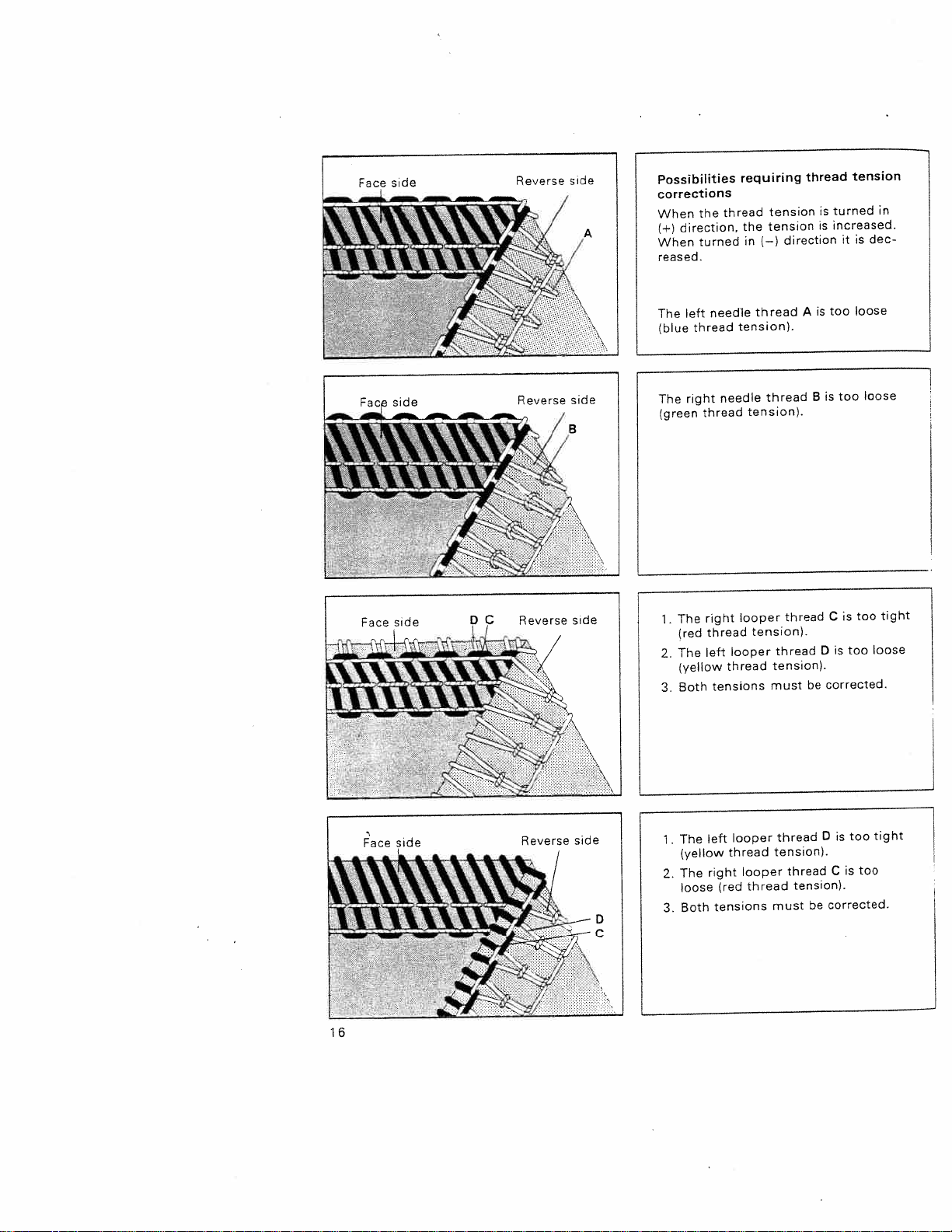

Possibilities

corrections

the

When

direction,

(+)

turned

When

reased.

left

The

thread

(blue

right

The

thread

(green

right

The

1.

thread

(red

left

The

2.

(yellow

Both

3.

thread

needle

needle

looper

thread

tensions

requiring

tension

tension

the

in

(—(

thread

tension).

thread

tension).

looper

tension).

must

direction

A

thread

thread

tension(.

thread

is

is

is

B

0

be

tension

turned

increased.

it

is

loose

too

is

too

too

is

C

too

is

corrected.

in

dec

loose

tight

loose

16

1.

2.

3.

The left

(yellow

right

The

loose

Both

looper

thread

(red

tensions

looper

thread

thread

tension).

thread

tension).

must

0

be

too

is

is

too

C

corrected.

tight

Page 19

i

3-thread

Threading

described

of

converter

position

overedge

of

on

41

B

(see

the

pages

Left

right

must

p.

seam:

8

18).

needle

ih

one

adjustment

at

refer

mm

sewn

is

to

the

(seam

needle

the

set

mm)

mm).

by

needle

only

is

2.2

seam

and

used,

looper

width

(3

the

increased

5.2

overedge

adjustments

to

5

left

needle

7.2

to

Right

threads

3-thread

The

with

left

and

The

9.

and

set

at

be

looper

slide

its

3-thread

is

right

overedge

thread.

Seam

knob

right

When

value

width

seam

two

26

needle.

is

UJL

rn

width

seam

seam

width

57mm

7.2

mm

Standard

Max.

width

3,5m

5

N

mm

17

seam

seam

--

width

N

Standard

Max.

Page 20

Engaging

the

For

available

(see

p.

Turn

the

positioned

is

31

sewing

For

looper

out

led

seams

All

sewn

only

one

with

left

The

looper

of

point

the

of

illustration.

the

Hobbylock

a

as

and

42

hand

with

thread

the

of

sewn

with

two

or

looper

must

31

right

the

arrow,

converter

special

46).

wheel

right

converter

must

looper

with

left

needle

thread

be

looper

shown

as

787

accessory

until

of

be

eye.

converter

looper

pulled

(HL

the

the

cut

threads.

placed

in

in

788)

converter

right

needle.

41

the

off

32

over

over

the

the

part

looper

right

pul

and

are

41

and

right

the

direction

left-hand

is

symbols

As

must

see

position

position

from

(position

41

Fig.

until

the

see

you

engage

A

B

point

the

B).

are

do

A.

Con

the

conver

For

8.

p.

so

in

left

of

slide

the

with

of

triangular

each

the

of

the

engaged

the

wheel

drops

31.

position

the

of

&ide

looper,

converter

9

Disengage

right

other.

=

=

slowly

looper,

the

Push

until

left

aligned

point

the

the

eye

Converter

disengages

verter

A

+—.B

18

Disengaging

hand

Turn

thread

looper

looper

right

this

in

ter

threading

converter

the

to

Page 21

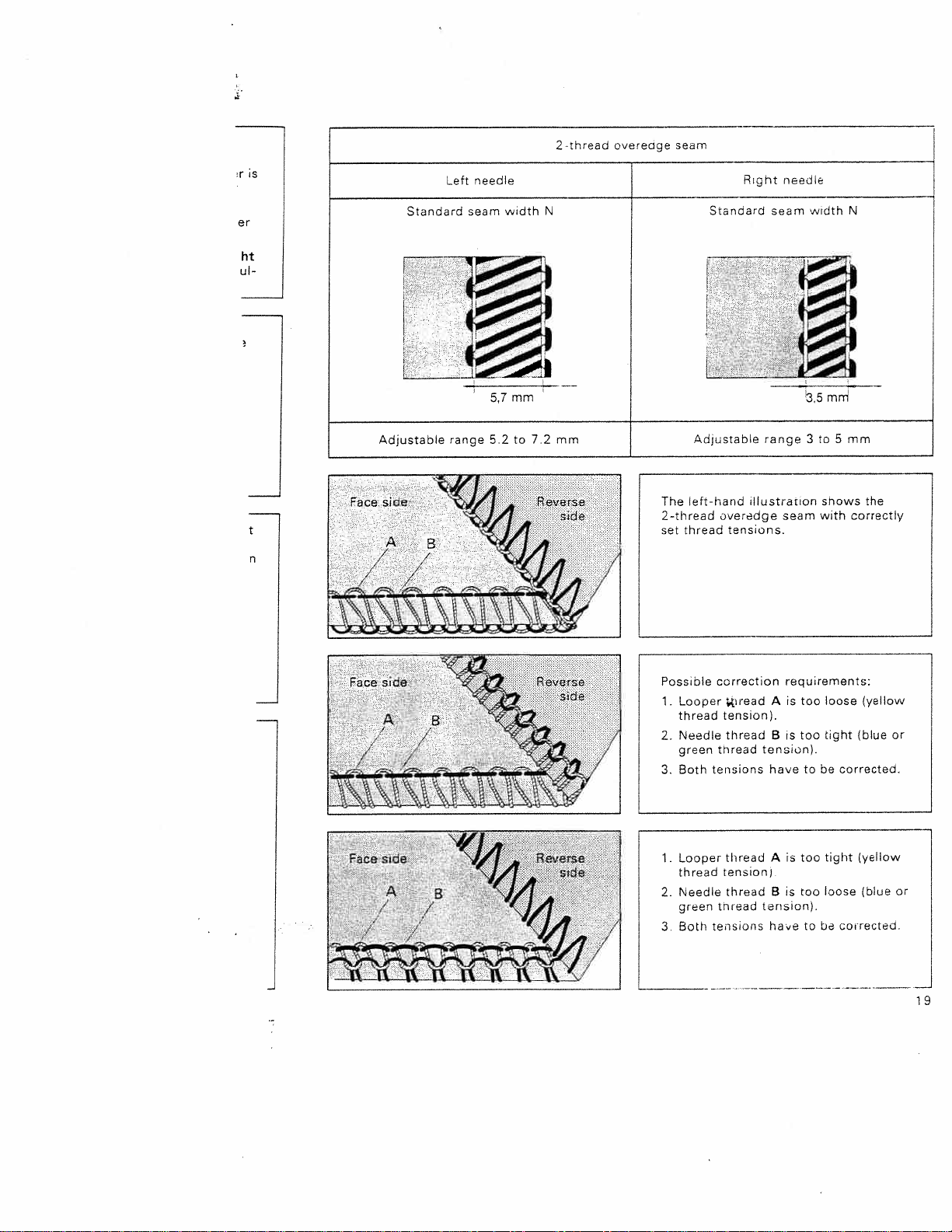

2-thread

is

r

Left

needle

overeoge

seam

Rght

needle

N

width

range

seam

5.2

mm

7.2

to

er

Standard

Adjustable

The

2-thread

set

B

n

/

/

/1

‘

/

/,

/

Standard

Adjustable

left-hand

thread

llustration

oeredge

tensions.

seam

range

seam

width

3

to

shows

with

N

5

mm

correctly

the

Possible

1.

Looper

thread

Needle

2.

green

Both

3.

Looper

1.

thread

Needle

2.

green

3.

Both

correction

read

tension>.

thread

thread

tensions

thread

tensIOnl

thread

tnread

tensions

requirements:

Aistoo

is

B

tension>.

have

is

A

Bistoo

tension).

have

(yellow

loose

tight

too

to

too

be

tight

loose

(blue

corrected.

(yellow

blue

tobecorrected.

or

or

19

Page 22

materials:

Light

Organdy,

fabric.

lining

Material

light-knit

Taffeta,

materials

silk,

Thread

chart

Cotton

Silk

Synthetic

for

thread

2-,

4-thread

3-,

Thread

No.

No.

No.

808070-

100

100

140

overedge

seam

2.0

Stitch

to

4.0

length

mm

Medium-heavy

materials:

Knit

Rolled

or

2

(bulk

tricot,

dress

materials:

suit

heavy

fabrics:

hem

threads

3

thread)

Cotton,

linen,

Heavy

Tweed,

denim,

materials

materials,

cloth

with

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Polyester

Mercerized

thread

thread

thread

thread

thread

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

60-100

50-100

70-140

404070-140

40-60

40-60

70-140

20-140

1

60

60

Setting

Hobbylock

work

Open

hand

Hold

length

length

Standard

stitch

the

788

support

wheel

adjustment

desired

setting

2.0

2.0

2.0

2.0

2.0

length

with

fast

9

knob

between

N

to

to

to

to

to

to

1

.0

differential

2.

1

3

is

and

25

1

mm.

4.0mm

5.0

4.0

5.0

4.0

2.0

the

on

set

at

and

mm

mm

mm

mm

mm

the

4

(787)

(788)

(787)

(788)

feed

stitch-

stitch

mm.

20

Setting

Hobbylock

feed

work

Open

hand

Hold

length

length

Standard

stitch

the

787

support

wheel

adjustment

desired

setting

length

without

fast

9

knob

between

N

1

is

2.

3

on

differential

set

and

at

25

and

1

mm.

the

the

5

stitch

stitch

mm.

Page 23

Adjusting

the

on

differential

The

It

shift.

arranged

pick

both

the

at

feed

The

set

be

workpiece

the

dog

feed

versa.

results

rential

wish

you

The

22).

button

at

Setting

Setting

Setting

to

2

differential

The

from

tely

the

Hobbylock

consists

one

up

time.

same

amount

separately.

than

Owing

accomplished.

are

according

feed

process

to

following

23:

0.5

N

1.5

0.5

differential

feed

of

behind

move

and

of

moved

the

by

that

to

Short

=

feed

rear

Same

=

feed

Long

=

feed

of

feed

to

2,

788

prevents

two

either

is

It

very

(see

settings

dog,

feed

dogs

dog,

rear

can

also

feed

feed

other,

the

the

workpiece

feed

possible

more

one

rear

good

Set

the

to

tableonpage

are

stroke

long

dog

stroke

stroke

short

feed

be

during

inter-ply

dogs,

the

by

and

sewing

the

material

of

stroke

of

front

of

dog

set

sewing.

which

dog

have

to

front

vice

diffe

possible

front

both

stroke

infini

can

of

Note:

following

The

obtain

to

t

s:

men

gather

The

ferential

fabrics

light

wave

The

ferential

medium

processed.

variants

fashionable

effect

setting

feed

are

effect

setting

feed

heavy

to

effects

obtained

is

of

processed.

obtained

is

of

elastic

can

1.5

0.5

fabrics

be

on

—

at

when

employed

gar

dif

at

a

when

2

dif

a

are

21

Page 24

This

table

make

sure

made.—The

indicates

about

differential

the

possible

setting

feed

settings

required

can

also

of

for

be

the

the

set

differential

fabric

during

Hobbylock

of

feed

wishtoprocess,asewing

you

sewing.

the

788.

test

In

order

to

has

to

be

Setting

ferential

a

0.5

1.5

1.5

of

dif-

feed

to

N

N

to

2

Illustration

1

2

3

4

Correct

seam

a

c

d

f

Fabric

Nylon,

satin,

Light

(normal

Jersey,

fabrics,

Heavy

fabrics,

tricot,

poplin,

cotton,

fabrics)

medium

light

knitwear,

rib

lining

and

jeans

knittings

stitch

silk

cotton,

very

goods

fabrics,

nicki

elastic

22

Fig,1

Fig.

c

3

Fig,

4

Page 25

I

knife

upper

lint

looper

upper

the

knife

the

box

knife

lever

fully

hole

disengaged.

is

8.

cover

to

of

Open

arresting

27

the

the

0.

1

of

until

knife.

work

If

the

right,

the

support

necessary,

screw

upper

axial

hold

pin

Now

37.

it,

enga

the

Disengaging

Remove

and

1

2

loosen

rotary

Push

guide

knife

turnitforwards

and

in

ges

upper

Adjusting

standard

The

marked

Disengage

above

the

desired

The

adjusting

seam-width

3

from

the

Set

and

again

sewing

When

37

screw

system

test

a

Sew

Note:

seam

The

adjustment

to

refer

needle

by

sed

mm).

7.2

the

with

upper

description.

knob

5

to

upper

close

of

securely

seam,

width

knob

right

the

used

is

mm

2.2

seam

seam

N

(3.5

knife

width

seam

26.

adjustment

mm.

knife

the

thick

upper

the

(see

adjustments

26

needle.

the

(seam

width

width

mm).

11

scale

The

its

at

looper

materials,

knife

p.

to

(3

value

width

setting

according

set

is

knob

basic

cover.

32).

5

When

set

is

with

the

on

ranges

position

tighten

arresting

made

only

mm)

the

increa

is

to

5.2

to

at

left

23

Page 26

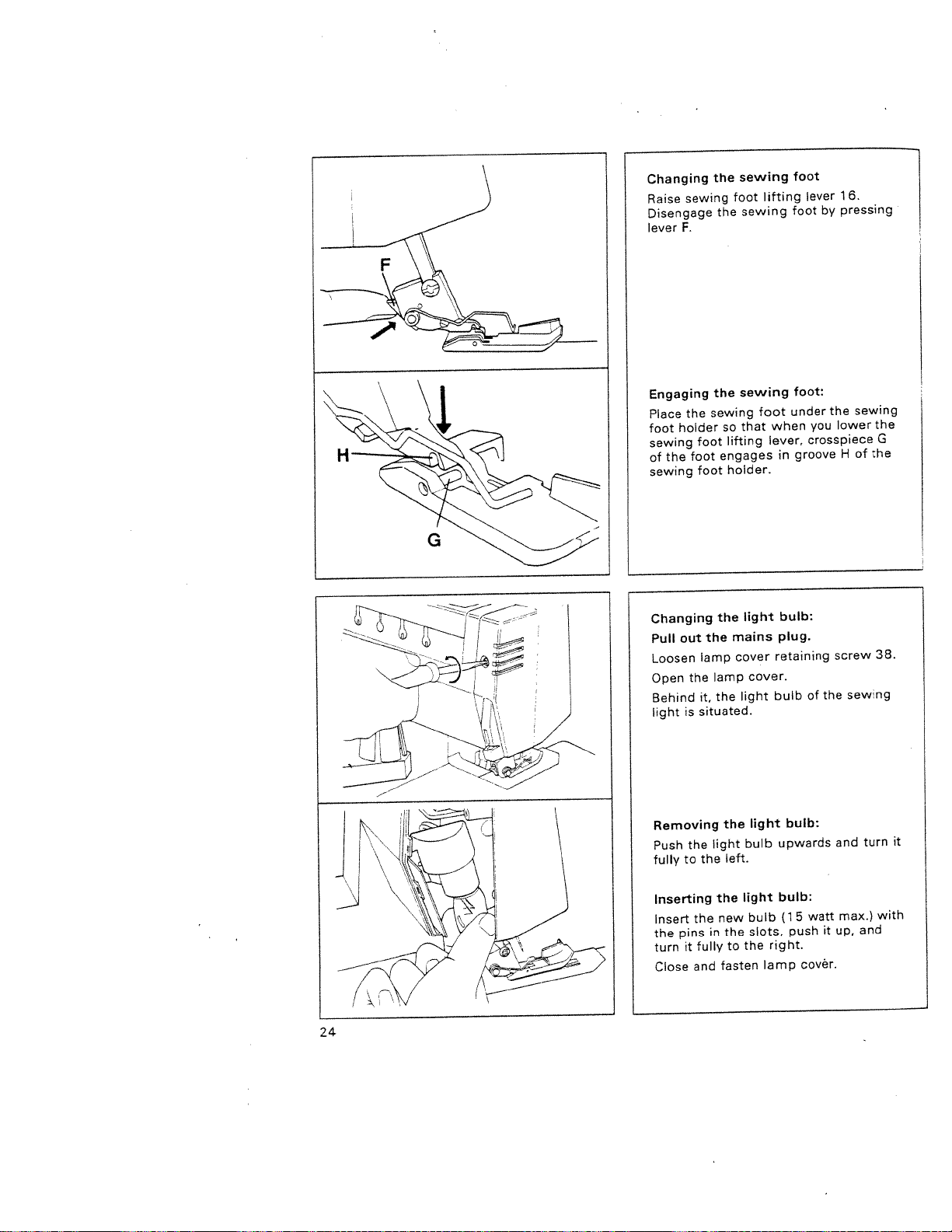

Changing

sewing

Raise

Disengage

F.

lever

the

the

sewing

foot

sewing

lifting

foot

lever16.

foot

by

pressing

Engaging

the

Place

holder

foot

sewing

the

of

sewing

Changing

out

Pull

Loosen

Open

Behind

is

light

Removing

Push

to

fully

foot

foot

foot

lamp

the

it,

situated.

the

the

the

sewing

so

engages

the

the

lamp

the

the

light

left.

sewing

that

lifting

holder.

light

mains

cover

cover.

light

light

bulb

foot

when

lever,

bulb

foot:

under

crosspiece

groove

in

bulb:

plug.

retaining

of

bulb:

upwards

you

the

the

lower

H

screw

and

sewing

of

sewing

turn

the

G

the

38.

it

24

Inserting

Insert

pins

the

it

turn

Close

the

fully

and

in

the

new

the

to

fasten

light

bulb

slots,

the

right.

lamp

bulb:

(15

push

watt

cover.

it

max.)

up.

with

and

Page 27

/

z.

in

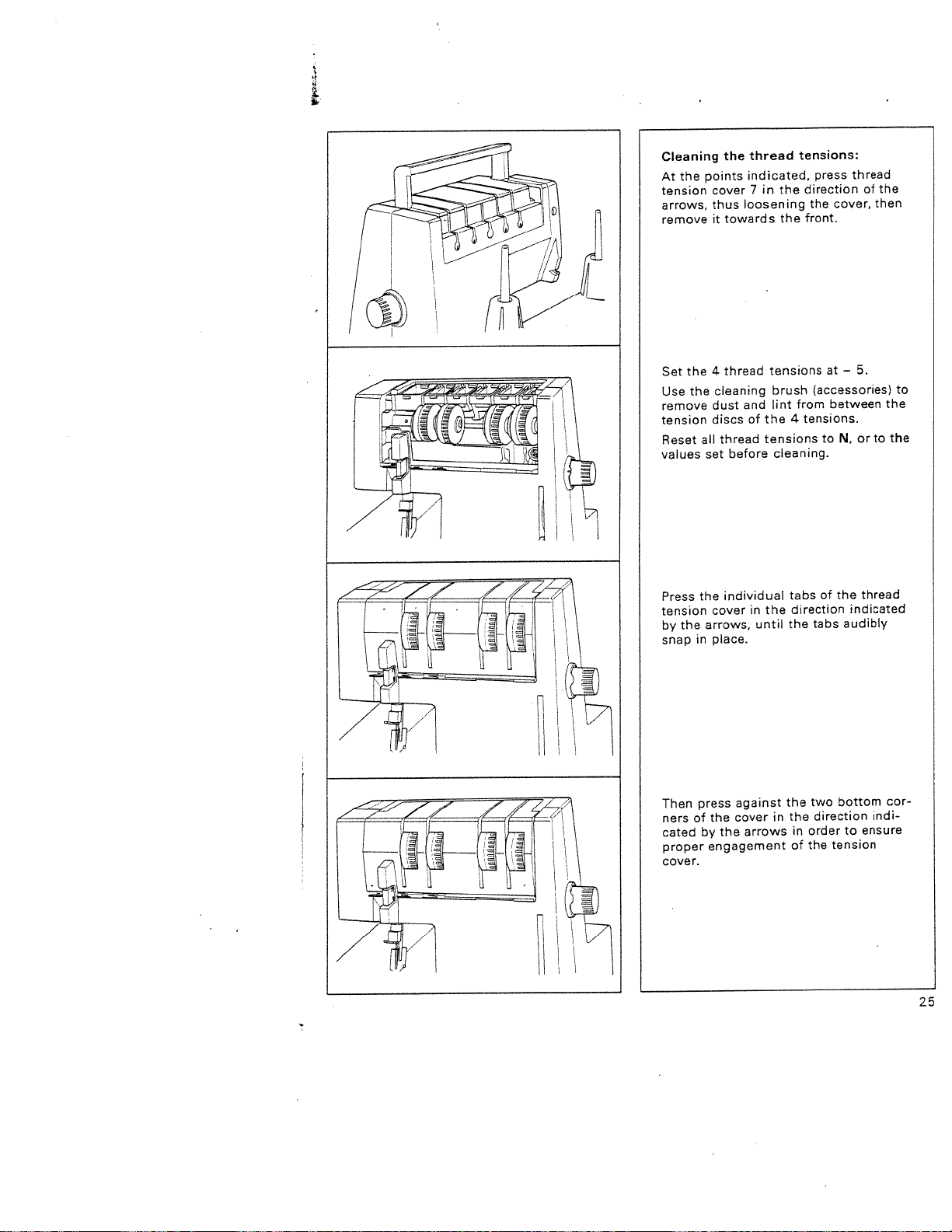

tensions

brush

lint

the

tensions

cleaning.

the

until

tensions;

the

the

from

4

tabs

direction

the

press

direction

cover,

the

front.

at

—

(accessories)

between

tensions.

N.

to

the

of

audibly

tabs

thread

of

the

then

5.

or

to

thread

indicated

to

the

the

thread

the

the

the

the

points

cover

thus

it

4

dust

discs

all

set

the

cover

arrows,

place.

in

the

indicated,

7

loosening

towards

thread

cleaning

and

of

thread

before

individual

in

Cleaning

—

I

-

-

-

1

At

tension

arrows,

remove

Set

Use

remove

‘

1

‘

_•

J

—

tension

Reset

values

/

,--

‘—

(9

-

I

,—

Press

tension

by

snap

..“

__Th

--EZEE

1

j7

to

cor

mdi

ensure

25

bottom

two

arrows

the

direction

the

in

order

in

tension

the

of

7__

(

/

/

‘

y’

-—

.-

‘?

I

Then

ners

cated

proper

cover.

the

of

the

by

engagement

cover

against

press

Page 28

Face

MW

ece

side

side

Reverse

Reverse

side

side

roiled

Fold-over

sewn

rolled

A

fabrics

open

sew

professional

scarves,

This

rolled

threads

with

and

edges.

(see

3-thread

polyester

hem

is

shawls

hem

used

is

an

Without

and

is

page

attractive

rolled

sewn

27).

thread

light,

for

any

effort

hems

valances.

with

hem

finish

three

120

delicate

you

on

neck

-140.

for

can

\

3-thread

rolledhem

—

2

26

Page 29

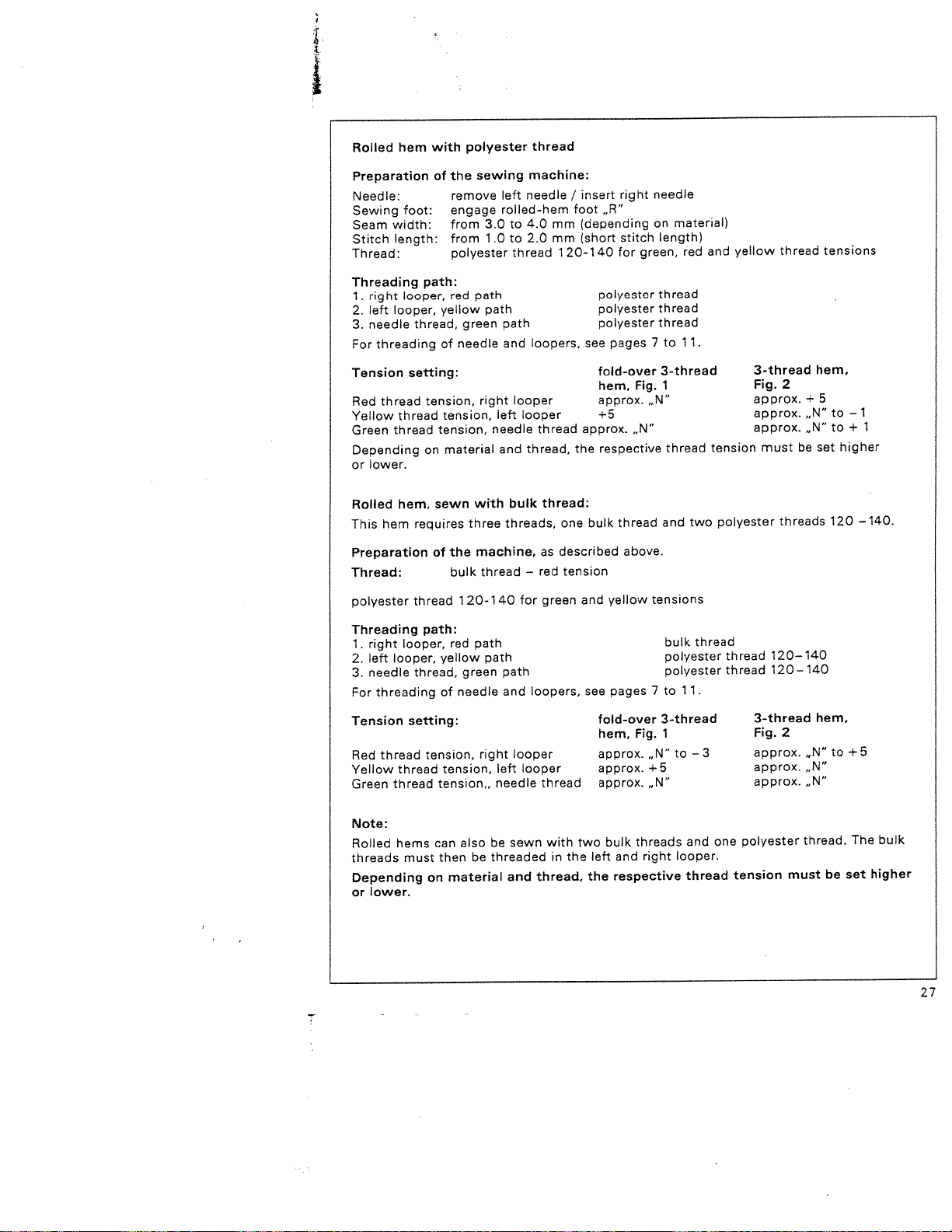

Rolled

hem

with

polyester

thread

Preparation

Needle:

Sewing

width:

Seam

length:

Stitch

Thread:

Threading

right

1

looper,

left

2.

needle

3.

threading

For

Tension

Red

thread

Yellow

thread

Green

Depending

lower.

or

Rolled

This

hem

Preparation

Thread:

polyester

foot:

looper,

thread,

setting:

thread

hem,

requires

thread

of

path:

yellow

of

tension,

tension,

tension,

material

on

sewn

of

sewing

the

remove

engage

3.0

from

from1.0

polyester

path

red

path

green

needle

right

with

three

machine,

the

thread

bulk

120-140

machine:

left

needle

rolled-hem

4.0

to

to

2.0

thread

path

and

looper

looper

left

needle

and

thread,

bulk

threads,

—

for

mm

mm

120-140

loopers,

thread

thread:

described

as

red

green

insert

/

foot

(depending

(short

see

approx.

the

one

tension

and

,,R”

polyester

polyester

polyester

pages

fold-over

hem.

approx.

÷5

respective

thread

bulk

yellow

right

stitch

for

Fig.

,,N”

above.

needle

on

length)

green,

thread

thread

thread

7

3-thread

,,N”

tensions

material)

red

11.

to

1

thread

and

two

and

tension

polyester

yellow

3-thread

Fig.

approx.

approx.

approx.

must

thread

2

be

threads

hem,

+

,,N”

,,N”

set

tensions

5

to

to

higher

120

1

—

+

—140.

1

Threading

right

1.

looper,

left

2.

needle

3.

threading

For

Tension

thread

Red

Yellow

Green

thread

Note:

Rolled

threads

Depending

lower.

or

looper,

setting:

thread

hems

must

path:

thread,

tension,

can

on

red

yellow

green

needle

of

tension,

tension,,

also

then

material

path

right

be

path

path

and

left

needle

sewn

be

threaded

and

loopers,

looper

looper

thread

with

in

thread,

the

see

two

left

the

pages7to

fold-over

Fig.

hem,

approx.

approx.

approx.

threads

bulk

and

respective

,,N”

+

N”

right

bulk

polyester

polyester

11.

3-thread

1

to

5

and

looper.

thread

thread

—3

one

thread

thread

polyester

tension

120—140

120—140

3-thread

Fig.

2

approx.

approx.

approx.

must

hem,

,,N”

,,N”

..N”

thread.

be

+5

to

bulk

The

higher

set

27

Page 30

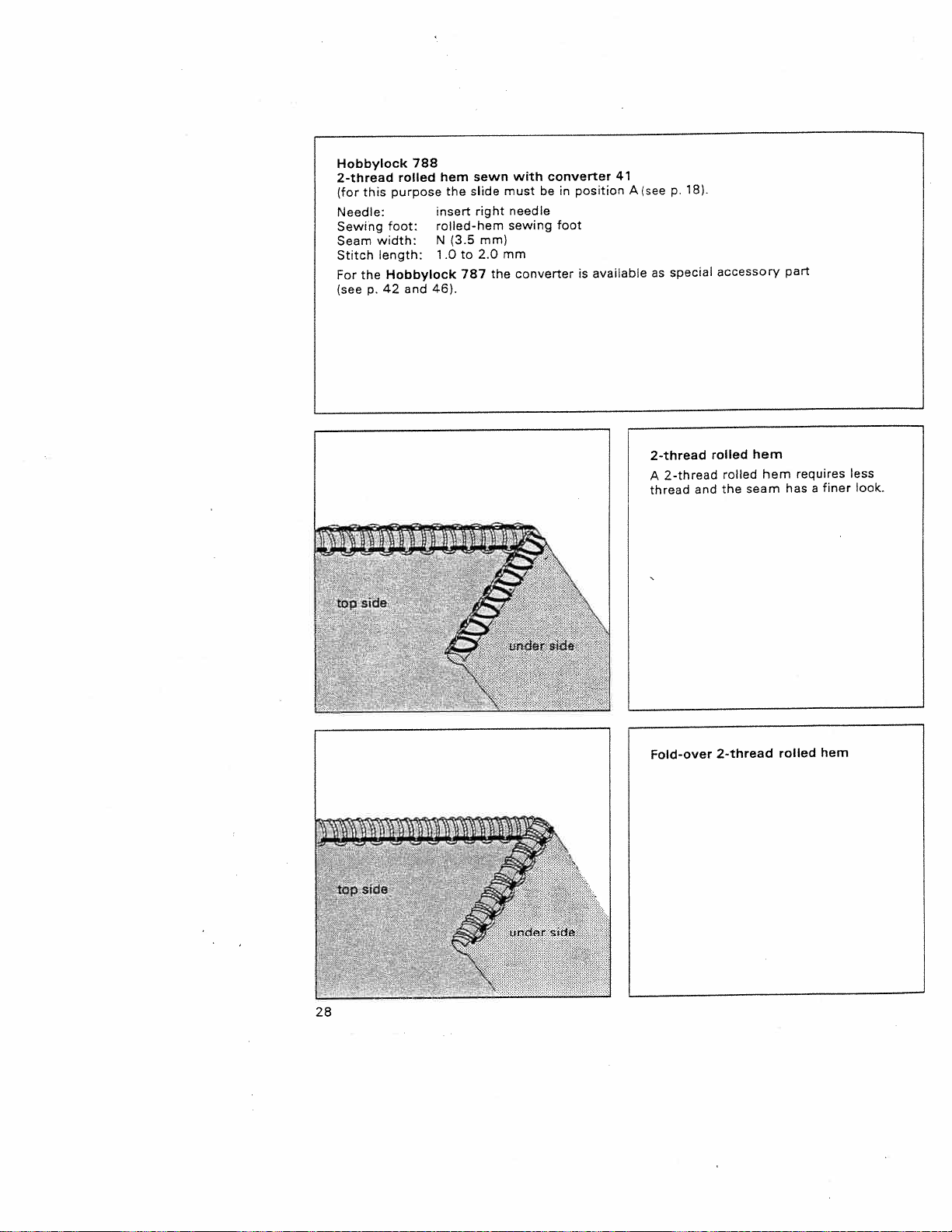

Hobbylock

2-thread

this

(for

Needle:

Sewing

width:

Seam

Stitch

the

For

(see

p.

788

rolled

purpose

foot:

length:

Hobbylock

and

42

hem

the

insert

rolled-hem

(3.5

N

to

1

.0

787

46>.

sewn

slide

right

mm>

2.0

mm

the

with

must

needle

sewing

converter

converter

in

be

foot

position

available

is

41

Asee

p.

special

as

2-thread

2-thread

A

thread

181.

and

accessory

rolled

rolled

the

hem

seam

hem

part

requires

has

less

look.

a

finer

28

top

side

wtder

side

Fold-over

2-thread

rolled

hem

Page 31

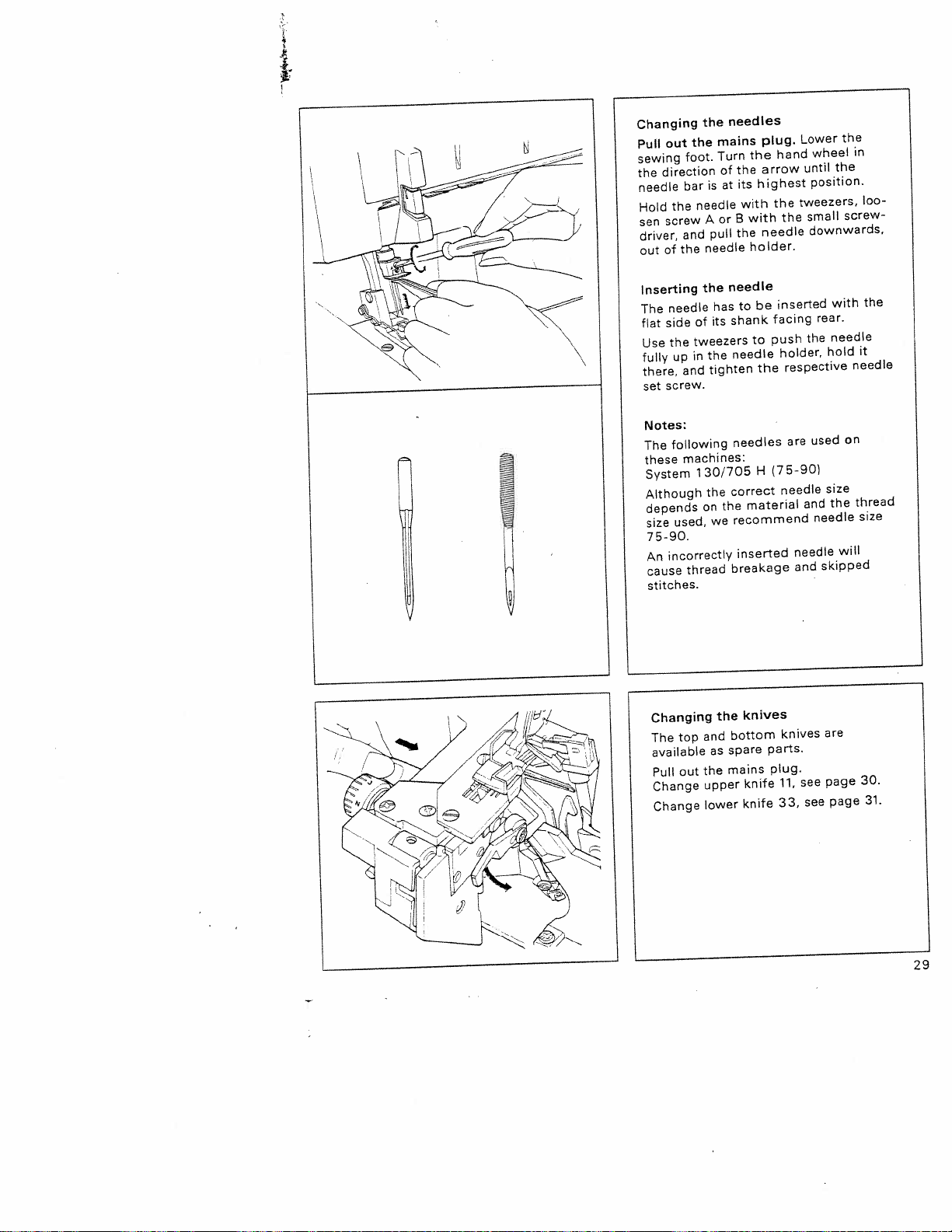

Changing

out

Pull

sewing

direction

the

needle

the

Hold

screw

sen

driver,

of

out

Inserting

needle

The

side

flat

the

Use

fully

there,

screw.

set

the

the

foot.

bar

needle with

and

the

the

of

tweezers

in

up

and

mains

Turn

of

at

is

or

A

pull

needle

has

its

the

tighten

needles

the

the

its

with

B

the

holder.

needle

to

shank

to

needle

plug.

hand

arrow

highest

the

needle

inserted

be

facing

push

the

Lower

wheel

until

position.

tweezers,

small

the

downwards.

the

holder,

respective

rear.

hold

the

the

screw

with

needle

in

loo

the

it

needle

Notes:

following

The

these

System

Although

depends

used,

size

75-90.

incorrectly

An

cause

stitches.

Changing

top

The

available

out

Pull

Change

Change

machines:

130/705

the

on

we

thread

the

and

as

the

upper

lower

needles

H

correct

material

the

recommend

inserted

breakage

knives

bottom

spare

mains

knife

knife

are

(75-90)

needle

knives

parts.

plug.

11,

33,

used

and

needle

needle

and

see

see

on

size

the

will

skipped

are

page

page

thread

size

30.

31.

29

Page 32

Changing

out

Pull

Unscrew

remove

Disengage

page

see

Insert

retaining

its

upper

upper

the

knife

the

knife

23.

the

the

new

mains

screw

to

upper

retaining

knife

upper

upper

cutting

its

knife:

plugl

11.

knife,

knife

securely.

screw

and

position.

35

Reset

and

tighten

27

lowest

of

lower

up

the

Set

(cutting

until

position.

In

upper

below

knife.

30

this

the

position,

knife

the

position>.

upper

cutting

must

Turn

knife

the

be

edge

is

front

0.5

handwheel

the

its

at

edge

to1mm

of

the

guide

knife

with

knife

upper

Page 33

1:

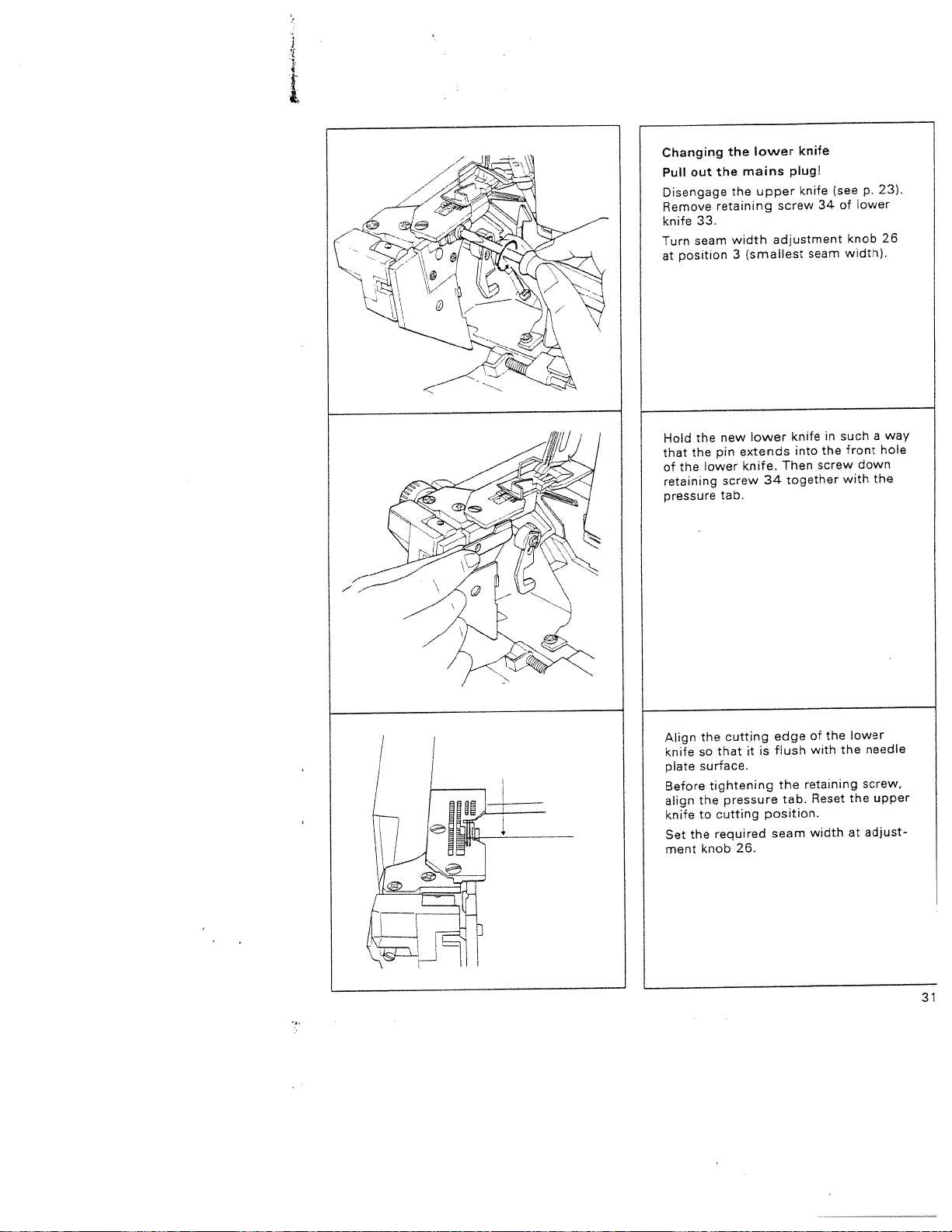

Changing

out

Pull

Disengage

Remove

33.

knife

seam

Turn

position

at

the

Hold

the

that

of

the

retaining

pressure

the

retaining

new

pin

lower

screw

tab.

the

mains

the

width

3

extends

knife.

lower

upper

screw

adjustment

(smallest

lower

34

knife

plug!

knife

knife

into

Then

together

(seep.23).

34

seam

in

the

screw

lower

of

knob

width).

such

front

with

down

a

the

26

way

hole

Align

knife

plate

Before

align

knife

Set

ment

the

so

surface.

the

to

the

knob

cutting

it

that

tightening

pressure

cutting

required

26.

edge

is

flush

the

tab.

position.

seam

the

of

with

retaining

Reset

width

the

lower

the

at

needle

screw,

upper

adjust

31

Page 34

Upper

Sewing

with

ces

this

On

extremely

from

be

can

thick

mely

different

upper

shown

tightening

By

is

knife

Note:

When

screw

system

turns,

axially.

Cleaning

Disengage

23).

p.

the

Use

remove

knife

very

different

machine,

processed.

fabrics

thicknesses,

knife

in

the

arrested

sewing

of

37

must

that

so

the

the

lint

lint

arresting

thick

thin

must

illustration.

screw

thin

the

upper

be

loosened

the

knives

upper

brush

from

fabrics

thicknesses:

ply

kinds

all

extremely

to

When

workpieces

or

the

tightened,

be

37,

axially.

medium

or

knife

upper

knife

(accessories)

upper

and

workpie

of

fabric

sewing

screwofthe

upper

the

fabrics,

arresting

by

about

can

knife

(see

lower

and

as

top

to

thick

extre

with

2

move

of

knife.

32

Page 35

Oiling

the

machine:

Every

into

to

oil

hings

parts

need

month.

sewing

time

operation,

places

the

other

and

made

are

be

to

One

machine

before

oiled

to

you

you

indicated.

important

special

of

only

two

oil

take

should

once

drops

are

the

apply

The

moving

material

twice

or

of

PFAFF

sufficient.

machine

little

a

bus

and

a

33

Page 36

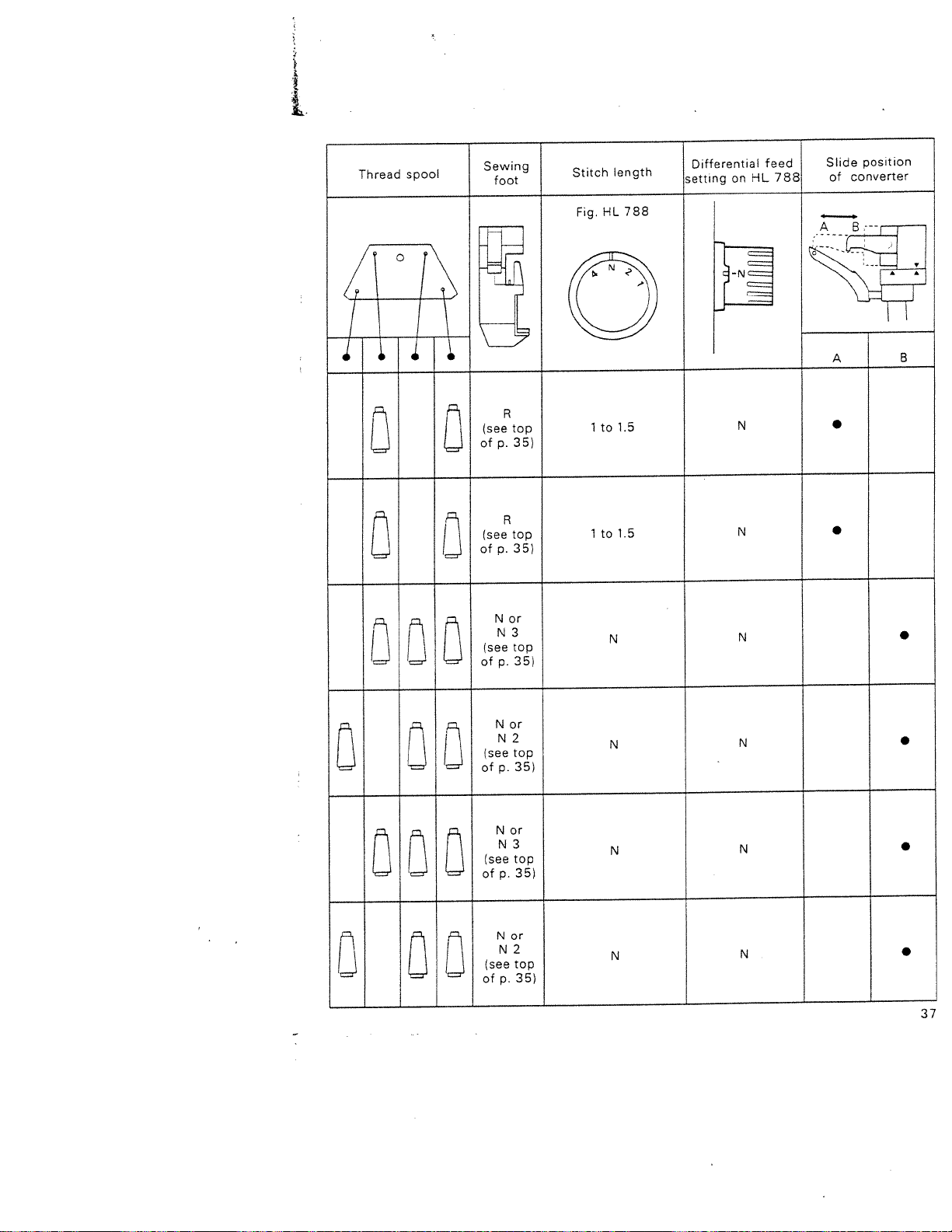

Stitch

values

The

(788)

fabric,

of

sewing

The

differential

The

all

For

converter

HL

For

selection

only

are

the

2-thread

787

41

set

fabric

foot

the

table

thread

for

basic

must

feed

seams

(HL

converter

settings

thickness,

setting

788)

tension,

be

and

must

is

that

and

selected

depends

for

be

available

stitch

have

the

set

thread

the

according

on

2-needle

at

as

length,

be

to

the

position

special

a

varied

used.

to

type

3-thread

needle

the

of

A.

accessory

size,

according

seam

fabric

overedge

and

sewn

to

width

part

the

the

(see

closing

(see

differential

application,

ill,

(see

22).

p.

42

p.

at

seam

and

feed

i.e.

right).

the

46).

setting

to

the

slide

type

of

2-thread

narrow

5earni

2-ihread

wide

seam

2-thread

without

narrow)

e=a.wsw=

Stitch

overedge

2-thread

-K

2-thread

edge

overede

serging

type

flahock

thread

seam.

fiatock

seam,

seam

Q

Fabric

(see

on

p

light

medium

heavy

light

medium

heavy

light

medium

heavy

table

20)

Needle

biue

—

—5

-4

tension

5

thread

green

2

2

1

Needle-System

130705

H

1

x

15

A

H

B

thread

Looper

tension

red

2

—

2

—

N

I

yellow

--

-i-

+3

+

Size

+1

2

+

+

2

N

Size

2

+

+3

N

N

90

14

2-thread

without

wide)

34

sergirig

edge

thread

seam

£:,.

light

medium

heavy

-

—

—1

1

2

—

Size

1

2

—

90

4

1

—1

Page 37

O

JO

E

6U!MES

WEeS

9

O

004

EN

sqpiM

ww

N

‘J

SLflP!M

JO

JO

99

N

JOJ

OOJ

6U!M89

WS

9

ww

o

Sqp!M

17

JO

6U1MS

WS

ZL

O

WW

po

6uiws

weq

oo

Page 38

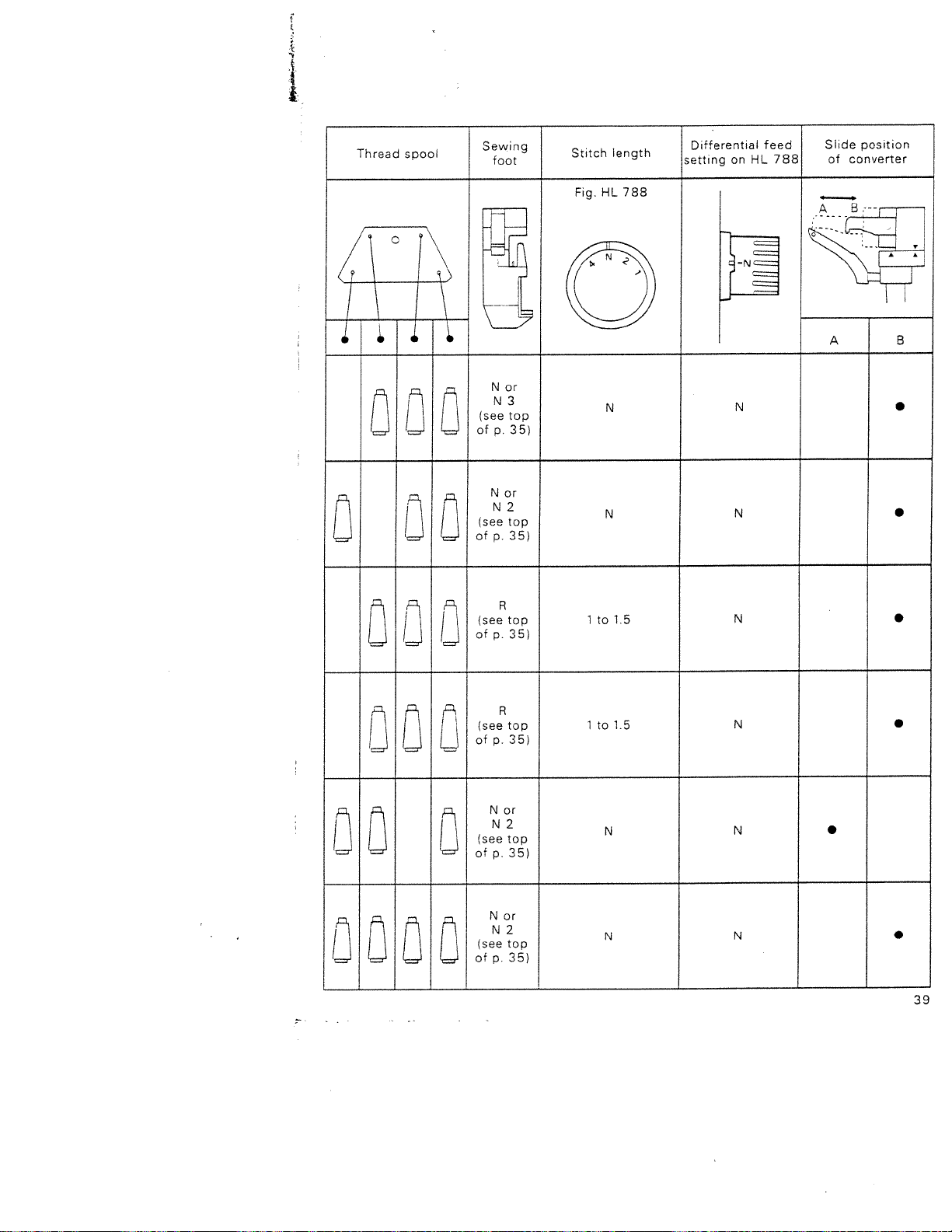

Stitch

type

(see

on

p.

table

20)

Needle

tension

thread

Looper

tension

thread

Needle-System

1

15

H

2-thread

hem

Folded

roiled

3-thread

seam

3-thread

seam

3-thread

seam

(narrow)

‘fl7\

3-thread

without

(wide)

36

narrow)

2-thread

hem

(narrow)

(widet

without

edge

rolled

overedge

overedge

serging

sergirig

thread

edge

F

)j’

47

3

team

?

thread

Q

y’

light

medium

light

medium

light

medium

heavy

light

medium

heavy

light

medium

heavy

light

medium

heavy

blue

—

—

—

-2

N

green

red

yellow

A

B

[

N

—

1

—

—

—

to

1toN

1

to

1toN

N

N

N

—

1

—

1

N

+

2

2

±

+2

+

2

+2

+4

Size

N

Size

75

11

Size

Size

90

14

-

Size

90

14

Size

90

14

—

2

—

2

N

N

—

1

N

-i-i

4

3

N

N

N

N

3

N

N

N

—

—

N

—

-

—3

—

2

2

3

3

4

-4

-4

Page 39

c)

Page 40

Stitch

type

(se:tle

on

Looper

Needle

20)

p

thread

tension

thread

tension

Ntm

x

I

15

H

Decoratme

sergng

fiatioce

Decoratme

sergrng

3thread

3-thread

hem

——--------=—

Oided

roiled

2-needie

overedge

without

seam

Seam)

seam

narrow)

3-thread

hem

edge

3-thread

3-thread

fiatiock

rofled

3-thread

ciosirtg

3-thread

wide

thread

seam)

seam

-

tight

medium

heavy

tight

medium

heavy

light

medium

-

light

medium

tight

medium

heavy

blue

—

-5

—5

—

—2

N

green

—

red

2

+

yellow

±

2

4

A

B

Size

+

+5

+4

+

+3

4

3

90

N

—

-4-2

+

2

1

—

2

—2

5

+1

+1

1

—

1

—

90

14

Size

N

—

I

1

1

+

N

N

75

Size

+

N

—

3

2

N

5

3

to

+

—

2

Size

—1

N

—2

—1

75

Size

4-thread

seam

38

overedge

7’

7\

light

medium

heavy

—

—1

N

1

Size

90

14

Size

90

14

2

—

—

3

—

2

N

2

—

1

N

—

2

—

N

Page 41

-

CD

Co

I

I

I

0

I

iI

U_—LtJ

\ij

HL_

.

1

C9

/;::::::z\

7/’

—‘

\-->/

CD

3

C,)

c

co

I-

,I

z

:

r

—

zz

Zzm

Ezzi

ZZD

aZzzi

tZZ

Cj

CJzj

z

z

—

-

Ui

z

z

z

z

z z

.

•

zz

UZz

czD

z

2

t3

z

•

cc,

Page 42

Sewing

These

to

be

and

problems

machines

made.

operation

Sewing

errors.

have

and

been

problems

They

solutions

developed

can

of

easily

the

for

kind

be

easy

described

corrected

operation,

below

by

and

may

following

there

occur

the

no

are

to

due

instructions

difficult

minor

adjustments

adjustment.

below.

Problem

Needle

Thread

Skipped

breakage

breakage

stitches

Cause

Needle

point

or

Needle

Material

incorrectly

Thread

Thread

Needle

Incorrect

Needle

damaged

Needle

Incorrect

Incorrectly

bent

damaged

fully

not

pulled

threaded

has

tension

not

fully

needle

bent

fully

not

needle

threaded

caught

or

inserted

too

inserted

used

point

inserted

used

tight

Solution

new

Insert

new

Insert

29>

(see

p.

pull

not

Do

sewing

during

(see

pp.

29>

needle

Insert

Insert

29>

(p.

needle

Use

(pp.7-li)

corrcetly

whether

needle

new

needle

correctly

Thread

Check

catches

Regulate

(pp.15—16)

Insert

(p.

Use

Thread

needle

needle

7-1

the

at

tension,

needle

material

1

thread

reel

correctly

system

correctly

system

correctly

stand,

1

30/705

1

30/705

etc.

H

H

Incorrect

corformation

The

overedge

an

pearance,

right

has

in

40

3-

irregular

looper

not

seam

the

stitch

4-thread

or

seam

ap-

and

thread

interlocked

the

has

incorrect

thread

converter

The

left

position

(see

p.

setting

tensions

18>

of

its

is

in

A

Set

rectly

converter

Set

position

(pp.15—iS)

8

(see

right

its

in

18>

p.

tensions

thread

Page 43

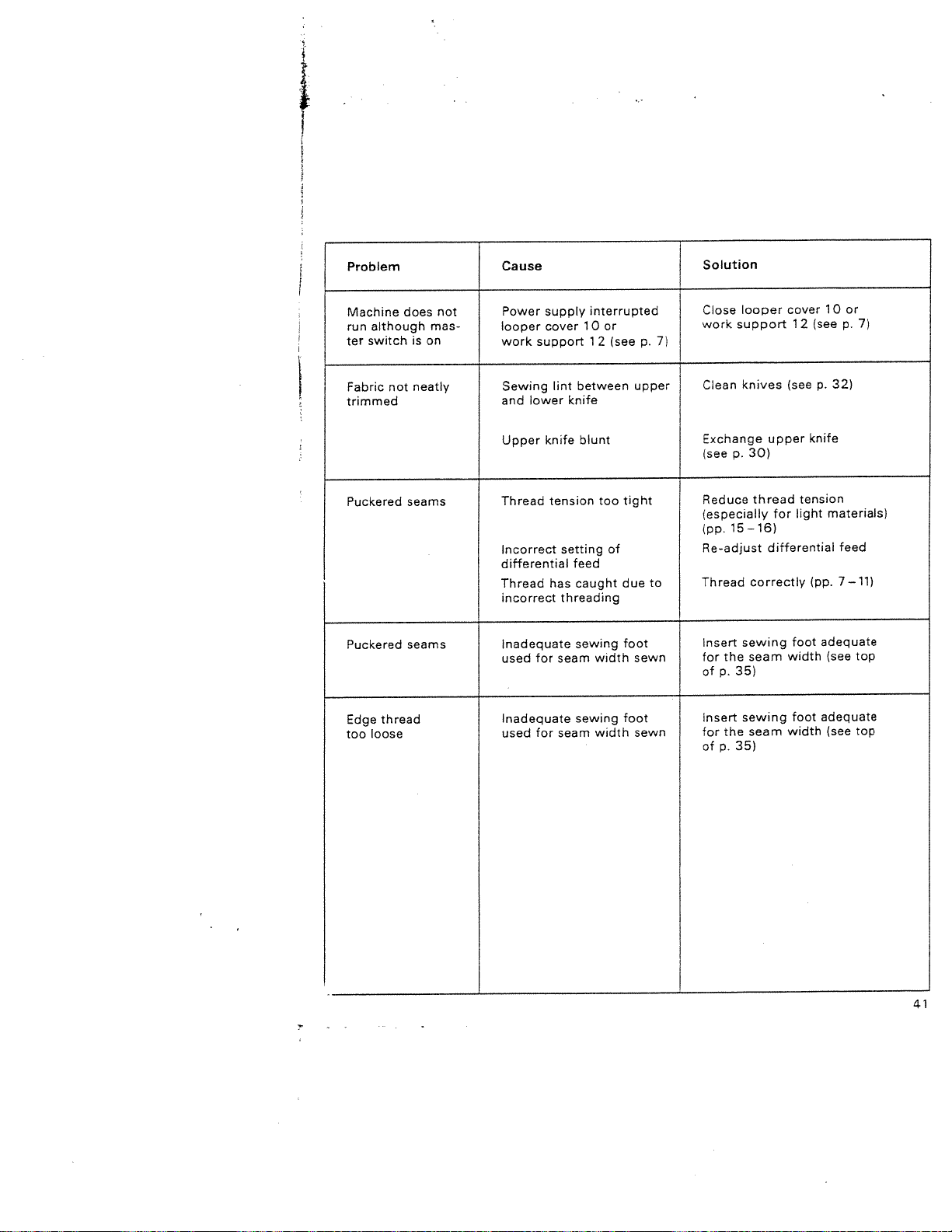

Prob’em

Cause

So’ution

Machine

although

run

switchison

ter

Fabric

trimmed

Puckered

Puckered

thread

Edge

too

loose

not

does

neatly

seams

seams

not

mas-

Power

looper

support

work

Sewing

lower

and

Upper

Thread

Incorrect

differential

Thread

incorrect

Inadequate

for

used

Inadequate

for

used

supply

cover

lint

knife

tension

setting

has

threading

seam

seam

interrupted

10or

1

between

knife

blunt

feed

caught

sewing

sewing

2

(see

too

of

width

width

tight

due

foot

foot

p.

upper

to

sewn

sewn

cover

looper

Close

support12

work

7(

knives

Clean

Exchange

(see

p.

Reduce

(especially

15—16)

(pp.

Re-adjust

Thread

Insert

the

for

of

35>

p.

insert

the

for

35)

of

p.

upper

30)

thread

differential

correctly

sewing

seam

sewing

seam

for

(see

tension

light

foot

width

foot

width

10

(see

p.

knife

materials)

(pp.

adequate

(see

adequate

(see

or

p.

32)

feed

7—11)

7(

top

top

41

Page 44

Accessories

knife

unreeling

machine

hem

foot

foot

spool

threader

(big)

(small)

sewing

N2

N3

net

disc

oii

foot

(R)

Screwdriver

1

Screwdriver

2

brush

Lint

3

Tweezers

4

Upper

5

Thread

6

Needles

7

Sewing

8

Rolled

9

Sewing

10

Sewing

11

Thread

1

2

Needle

2

13

specia’

tape

29-924

foot

29-924

29-924

sewing

29-924

foot

29-924

foot

29-924

29-924

thread

29-924

spool

29-924

46)

29-924

of

sewing

sewing

foot

foot

sewing

(HL

support

787)

Description

pp.43—50

on

Elastic

No.

Part

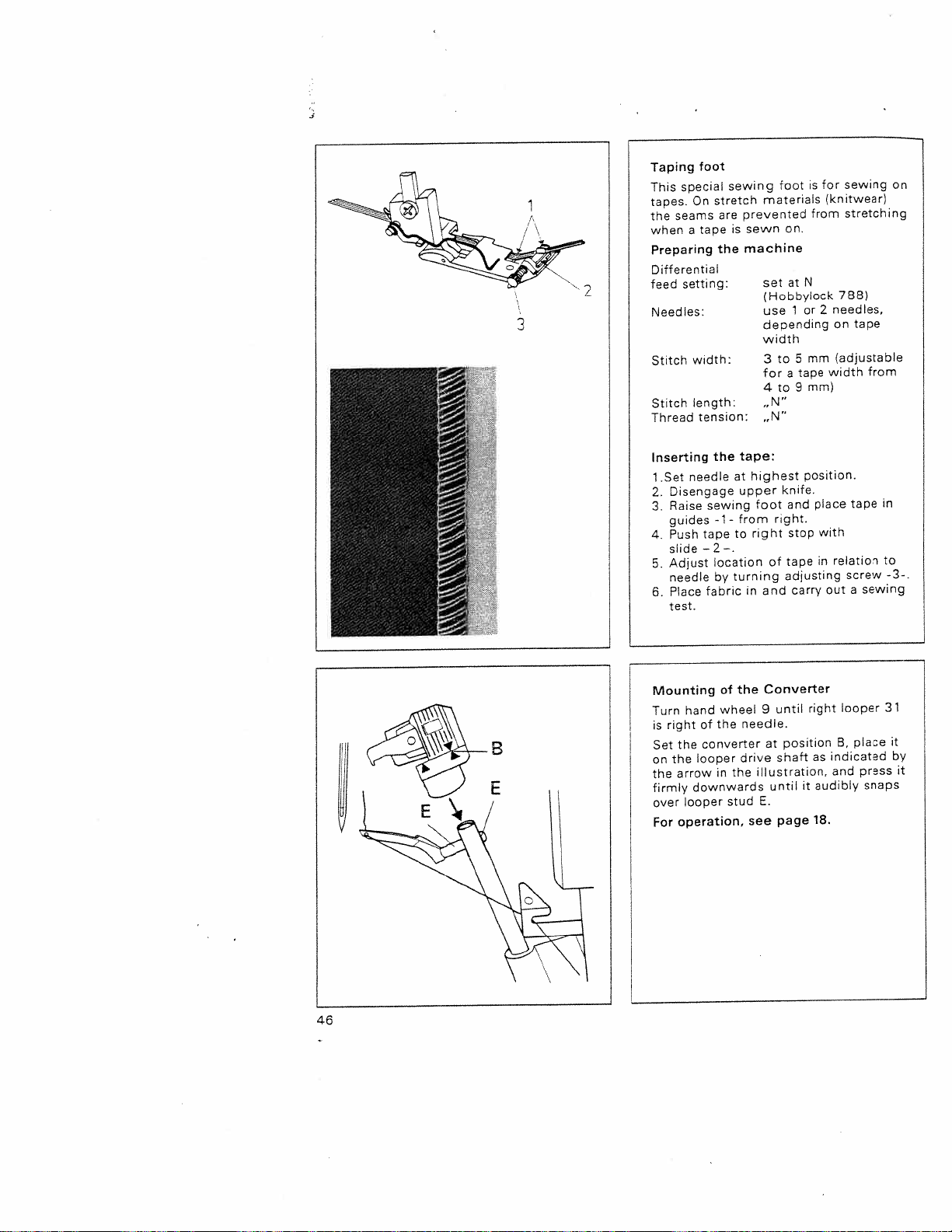

Taping

No.

Part

Blindstitch

No.

Part

6

O

9

8

7

10

11

Bead

No.

Part

Cording

No.

Part

Shirring

No.

Part

sewing

Lace

No.

Part

Gimp

No.

Part

Thread

No.

Part

Converter

(see

p.

No.

Part

accessories

foot

993-80/000

993-82/000

foot

993-81/000

993-83/000

993-70/900

993-70/901

997-70/906

foot

924-70/908

997-70/936

997-70/937

42

13

Page 45

Thread

Very

tend

down

useful

to

become

(Fig.

spool

for

A>.

net

synthetic

loose,

threads

unravel

and

which

slip

B

The

item6of

smaller

Remove

36

Put

Thread

C

pin

on

facing

TE

Bfindstitch

43

Preparing

Differential

feed

Needle:

Sewing

Stitch

Stitch

Thread

The

in

Before

2

This

Place

sewing

is

of

edgeofguide

Regulating

needle

Loosen

adjust

one

by

unreeling

thread

the

thread

thread

from

the

the

thread

place

and

top

of

it,

down,

the

setting:

foot:

width:

length:

tension:

hemistrimmed,

one

operation.

sewing,

cm.

avoids

the

prepared

foot

under

edge

the

outer

the

in

the

adjusting

edge

threadofthe

the

needle.

unreeling

accessories

spools.

thread

spool

the

with

as

sewing

machine

cut

shifting

that

so

guide

fabric

—2—.

penetration

outer

guide

disc

disc

centering

spool

reel

on

thread

rounded-off

shown

foot

set

at

(Hobbylock

insert

insert

longest

N”

(red,

serged

hem

of

the

hem

folded

-2-.

must

fabric

screw

—2—

outer

shown

is

used

pin.

the

thread

unreeling

Fig.

in

N

788)

the

right

blindstitch

stitch

yellow,

and

part

—3—

hem.

under

hem

Crease

run

along

of

the

—