Page 1

747!

instruction

manual

ii;

II.

I

V

Page 2

Notes

A)

B)

C)

D)

on

Owing

of

the

the

user

avoid

area

When

changing

machine

from

The

maximum

the

light

The

drive

by

anyone

agent.

safety

to

the

up

needles

must

injury

and

continuously

leaving

the

the

parts

must

power

approved

bulb

is

belt

must

but

an

and

and

the

take

sufficient

observe

while

machine,

or

accessories,

be

disconnected

source.

15

watts.

never

authorized

down

upper

sewing.

wattage

movement

care

the

sewing

be

adjusted

Pfaff

knife,

to

the

of

Page 3

-

()

-

0)

C

(V

p..)

*

t)

Page 4

&

Contents

2.

19,20

24,

3

4

4

5

6

7

7

8

8

9

10

10

11

11

12

13

14

14

15

16

17

18

18

21

21

22

23

23

25

26

26

27

28

29

30

31

31

32

32

Controls

Electrical

Master

switch

Foot

control

Notes

on

Installing

Opening

Threading

4-thread

Threading

Threading

Threading

reel

Thread

Inserting

Seam

allowance

Sewing

Points

test

to

Securing

blocking

Axial

the

Setting

Correcting

3-thread

Thread

overedge

chart

Adjusting

Adjusting

Disengaging

Adjusting

Changing

Changing

Cleaning

Rolled

hems

Changing

Changing

Changing

Changing

the

Oiling

Sewing

problems

Accessories

spool

Thread

Specifications

Contents

of

the

connection

and

safety

the

thread

the

looper

guide

overedge

the

right

the

left

the

left

change

the

lint

observe

the

seam

of

standard

the

thread

the

stitch

the

differential

the

the

seam

the

sewing foot

the

light

the

thread

the

needles

the

knives

the

upper

the

lower

machine

net/thread

the

of

sewing

sewing

spool stand

cover

wires

seam

looper

looper

and

on

box

during

upper

the

thread

seam

length

upper

width

bulb

tensions

knife

knife

and

cardboard

machine

18

and

right

threaded

sewing

tensions

feed

knife

their

unreeling

light

the

needle

knite

tensions

on

hobbylock

(hobbyfock

removal

box

thread

machine

disc

guides

784

786)

and

behind

786

.

.

the

carrying

handle

.

Page 5

I

Controls

Thread

1

Carrying

2

3

Left

Right

4

Right

5

Left

6

Thread

7

Lint

8

Handwheel

9

10

Looper

11

Upper

Work

12

Needle

13

14

Sewing

Needle

15

Sewing

16

Thread

17

Thread

18

Thread

19

Machine

20

Master

21

Rear

22

Differential

23

Accessory

24

Stitch

25

Seam

26

27

Rotary

disengagement

Foot

28

Foot

29

Mains

30

Right

31

Left

32

Lower knife

33

Lower

34

Retaining

35

Thread

36

Accessories

37

Retaining

38

upper

of

spool

needle

needle

looper

looper

tension

box

cover

knife

support

plate

bar

spool

guides

guide

switch

thread

length

width

lever

control

control

plug

looper

looper

knife

spool

knife

the

handle

thread

thread

foot

foot

socket

feed

box

screw

screw

screw

sewing

stand

tension

thread

tension

thread

tension

cover

recess

with

(swivel-type)

lifting

lever

holder

bar

guide(4x)

adjustment

adjustment

adjustment

for

upper

plug

for

of

upper

centering

retainer

for

blocking

machine

tension

knob

knob

knife

machine

piece

dial

dial

dial

dial

knob

socket

knife

the

3

Page 6

Electrical

Use

this

on

or

a

Connecting

Insert

the

machine

plug

toapower

Caution:

switch

disconnect

source.

foot

control.

connection

machine

special

plug

socket.

When

it

off

Do

the

not

the

at

sewing

foot

of

Then

source.

the

the

plug

place

only

control:

the

machine

master

from

on

table.

control

connect

any

flat

a

in

is

switch

the

objects

surface

the

the

not

power

and

on

mains

in

the

use,

Switching

Power

and

off

switch

Switching

Press

switch.

are

switched

Switching

Press

switch

light

are

the

machine

and

sewing

simultaneously

12.

on:

Machine

on.

off:

again.

switched

light

Machine

off.

with

and

ON

are

and

switched

master

sewing

and

OFF

on

light

sewing

4

Page 7

Foot

The

as

The

down,

control

speed

follows:

more

the

of

you

faster

the

press

Hobbylock

the

the

machine

foot

is

regulated

control

will

sew.

Notes

A)

Owing

must

while

B)

When

disconnected

The

C)

The

D)

on

safety

to

take

sewing.

leaving

maximum

drive

the

up

sufficient

the

from

belt

must

and

machine,

the

approved

never

down

care

movement

to

power

wattage

be

avoid

changing

source.

of

adjusted

injury

the

of

parts

by

the

and

light

anyone

Electronic

Maximum

two

control.

Position

Position

needles

observe

or

accessories,

bulb

is

but

steps

15

+4

and

the

watts.

an

authorized

foot

speed

the

by

=

=

the

sewing

the

control

can

switch

Half

Full

upper

area

machine

pre-selected

be

on

speed

speed

knife,

continuously

Pfaff

the

the

must

agent.

in

foot

user

be

5

Page 8

Installing

Loosen

/

washer

thread

clamp

up

spool

the

to

thread

screw

the

stand

screw

1

spool

A

from

a

head.

little

the

stand

and

Insert

top.

pull

A

4

Tighten

Insert

centering

the

thread

four

clamp

thread

pieces

spool

screw

spool

36

stand.

A

fully

securely.

holders

in

the

17

holes

with

of

/

-

Push

thread

bar

19.

Pull

I

up

thread

spool

guiding

guide

guides

holders.

bar

part

18

into

guide

and

align

it

that

18

are

exactly

so

above

the

6

Page 9

I

n

H

E1

Opening

work

and

Push

hold

close

To

until

open

To

To

left.

the

to

A

threacing

machine

diagram

paths

looper

it,

and

locks.

it

close

right

by

and

support

cover

swing

the

work

until

diagram

behind

shows

different

closing

looper

support

the

the

it

work

it

the

colors

looper

fully

down.

cover,

locks.

is

looper

different

the

to

pushitup

pushitto

12,

support,

fixed

(see

cover

right.

push

to

the

cover.

threading

Fig.

the

it

This

A).

Threading

spool

behind

The

First

their

and

Then

sequence:

right

1.

2.

left

right

3.

4.

left

C

Figure

individual

For

handle

(Fig.

After

be

the

stand

the

machine

the

pull

corresponding

C).

thread

looper

looper

needle

needle

shows

B

threads

threading

the

2,

C).

threading,

pushed

and

carrying

must

respective

the

(red)

(yellow)

(green)

(blue)

the

handle

down

the

handle

be

guides

tensions

threading

the

for

guides

carrying

again.

thread

threaded

threads

thread

must

guides

(Figs.

in

the

oehind

be

handle

correctly.

following

path

guides

pulled

through

B

of

18.

carrying

must

2

thread

the

of

wire

guide

1

the

up

7

Page 10

4-thread

This

1

2

-

3

4

7

5

-

-

-

threads

The

described

Threading

Thread

1

to

of

thread

Important:

In

the

tension

tensions.

seam

3-thread

9

thread

order

thread

the

and

path

to

discs

overedge

is

and

two

on

the

right

pull

through

is

obtain

must

when

seam

sewn

with

looper

overedge

page

17.

right

looper:

looper

approximately

the

looper

marked

perfect

be

pulled

threading

two

threads.

seam

in

red).

needle

is

sequence

10

eye

sewing

between

the

cm

(4”)

(the

results,

the

If’

5,

/2

/

1

H

8

8

5

6

Page 11

—

—

0

0

‘°

-

CD

x—

0—’

o-

CD

a_

<

C

Cd)

CD

CD

0

CD

CD

Page 12

H—

rrc

5

.1

•f?3111.3

2

—3

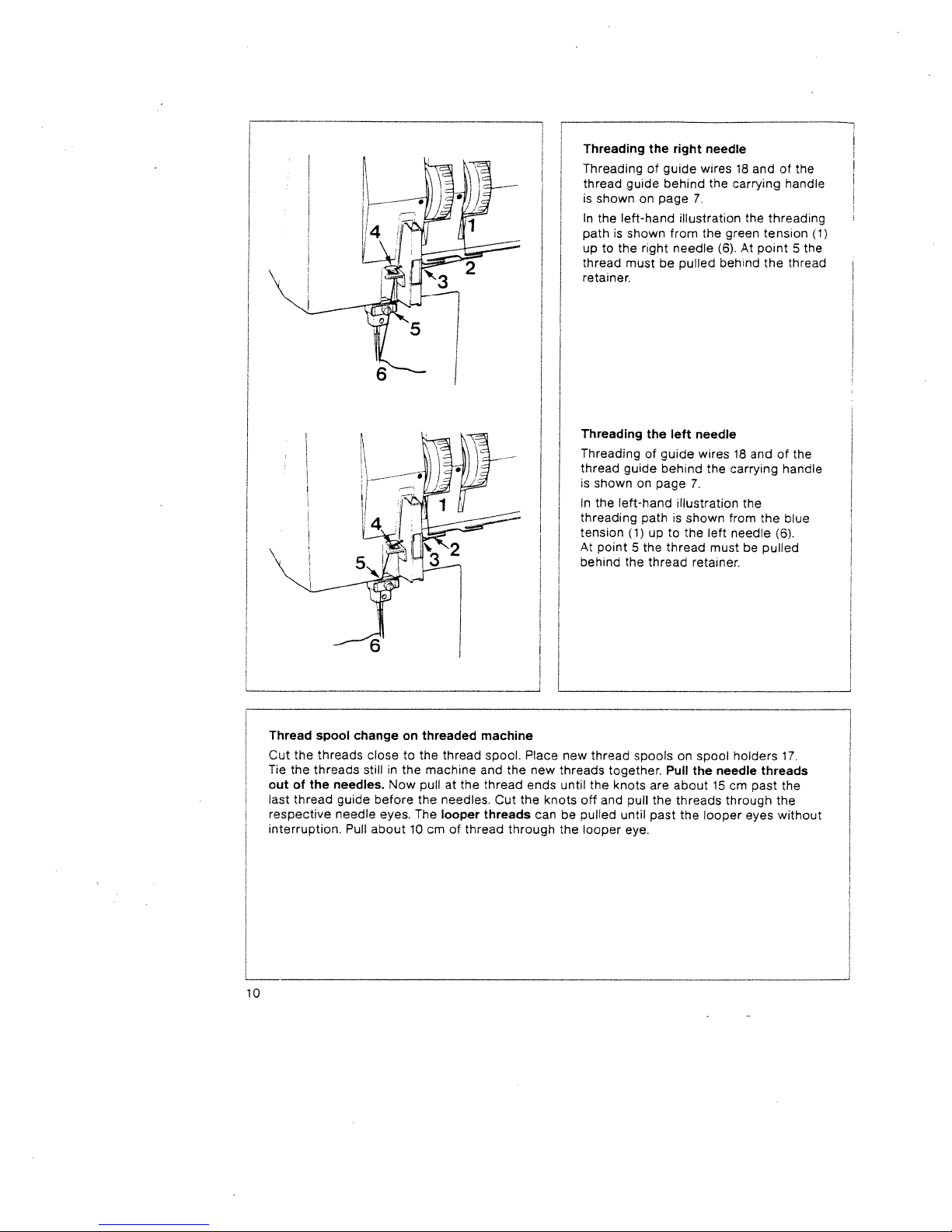

Threading

Threading

guide

thread

is

shown

on

In

the

left-hand

pathisshown

up to

the

thread

retainer.

right

mustbepulled

the

of

right

guide

behind

page

from

needle

needle

wires

the

7.

illustration

the green

(6>.

behind

18

andofthe

carrying

the

At

point5the

handle

threading

tension

the

thread

(1>

Thread

Cut

Tie

out

last

respective

interruption.

the

the

of

thread

spool

threads

threads

the

:‘1i

Ll

change

needles.

guide

needle

Pull

on

closetothe

still

in

the

Now

before

eyes.

about10cmofthread

•L!J

:

rk

threaded

machine

pullatthe

the

The

thread

needles.

looper

machine

spool.

and

thread

threads

the

Cut

through

the

Threading

Threading

thread

is

In

threading

tension

At

behind

Place

new

new

threads

ends

until

knots

off

canbepulled

the looper

guide

shown

the

left-hand

(1)

point5the

the

thread

together.

the

knots

and

pull

until

eye.

the

left

needle

of

guide

wires

behind the

on

page

7.

illustration

path

is

shown

up to

the

left

thread

thread

spoolsonspool

are

the

past

mustbepulled

retainer.

Pull

the

about15cm

threads

the

looper

18

carrying

from

needle

holders

needle

through

the

eyes

and

the

threads

past

of

the

handle

blue

(6>.

17.

the

the

without

10

Page 13

I

After

threading

down,

-

I-J

2

looper

cover

and

close

10.

the

machine,

work

support

push

12

handle

and

Inserting

downwards

cover.

/

/

I

against

Seam

If

the

the

Then

the

allowance

cutting

lint

the

push

machine.

the

is

guided

box:

the

lint

bottom

box,

along

use

below

of

the

box

the

1

Page 14

Sewing

-

-

‘I

—-

-

.

.

After

be

Raise

the

test

threading,

made.

sewing

illustration.

foot

sewing

a

lever

16,

test

as

test

shown

should

in

/

/

/

.

knife

upper

the

to

up

test

lower

fabric

the

sewing

foot.

Insert

and

Hold

I

I

‘N

\

12

I

I

\

while

hand

arrow

back

that

in

under

threads

turning

the

the

on

hand

direction

wheel.

sewing

the

have

wheel

indicated

the

Lay

foot.

interlocked

with

your

by

threads

Make

correctly.

right

the

sure

hand

left

your

with

ends

thread

Page 15

sewing

when

push

completely

stitches

is

the

only.

during

starting

been

has

slowly.

automatically,

fed

fabric.

cm

5

scissors

a

under

sew.

to

rethreaded.)

Use

beyond

your

to

the

(Also

the

cut

do

end

observe

to

Points

fabric

the

Place

foot

sewing

after

Sew

Since

4

not

hand

Sew

machine

the

first

the

fabric

the

or

pull

guiding

for

approximately

Page 16

Securing

Knot

a

crochet

thread

Or:

Sew

seam.

sew

and

just

sewn

chain.

the

about

Then

thread

chain

a

the

seam:

needle

into

cm

5

turn

few

without

chain.

can

the

(2”)

the

stitches

cutting

For

be

used

seam.

beyond

workpiece

over

the

knit

the

the

thread

fabrics,

to

pull

end

around

seam

the

of

Blocking

Sewing

with

different

On

this

extremely

processed.

fabrics

thicknesses,

must

be

illustration.

tightening

By

of

the

upper

Note:

When

sewing

screw

of

loosened

upper

knife

the

very

machine,

thin

When

or

workpieces

tightened,

the

by

can

upper

thick

fabrics

thicknesses:

all

extremely

to

sewing

the

screwofthe

screw,

the

knife

is

thin

or

upper

about

move

knife

kinds

with

shown

as

inhibited.

medium

knife

turns,

2

axially.

and

of

fabric

thick

extremely

different

axial

holder

so

workpieces

from

can

upper

in

the

movement

fabrics,

must

that

the

be

thick

knife

the

be

14

Page 17

do±

SP!S

BUIBaS

aLp

sq

uo

pBsJq

eq

D1JqB4

N

Lfl

UO

ePSOddO

uoiBi

(Mojaq

a

UOIBU!WBXB

SBOJLfl

Bd

pauoD

9

aifl)

ssq

IBflPIA!PUI

B

eq

,to

(wBas

Uoisua

dA

L44

puno

DaLiOD

aq

pBeJq

piepues

sq

PUB

pBeJlfl

oqwAs

UOflBJ4SflflI

UC

sedwBxe

io

EOiL4

as

pBeJq

4UWSflpB

6UDjDOIJeU!

eq

SuO!SUe

ezs

UOiSU

es)

J83B

LO

4j

N

UO!SUa4

spud&p

psn

seip

-snip

SMOqS

O

UOD8JJOD

S

Page 18

Top

side

Correcting

When

(+)

direction,

When

decreased.

The

(blue

left

thread

the

turned

needle

the

thread

the

in

tension).

thread

tensions

tension

tension

direction

(—)

threadAis

turned

is

is

increased.

it

too

in

is

loose

J

The

right

needle

(green

thread

thread

tension).

D

C

Reverse

side

The

thread

D

too

right

loose

looper

tension>

(yellow

thread

or

the

left

thread

B

C

is

too

is

too

looper

tension).

loose

tight

thread

(red

16

—

The

(yellow

looper

left

looper

thread

thread

thread

tension)

C

too

D

loose

is

too

tight

or

the

right

(red

thread

tension).

Page 19

I

3-thread

overedge

seam:

The

with

thread.

The

3-thread

looper

two

or

left

overedge

right

threads

needle

seam

and

must

is

one

be

sewn

needle

removed.

fl

needle

Left

3-thread

overedge

seam

Right

needle

!J

N

width

Standard

seam

width

N

Standard

seam

*

Max.

seam

5,7

width

mm

7.2

mm

Max.

seam

width

3.5

5

mm

mm

17

Page 20

Thread

chart

for

4-thread

overedge seam

Material

Light

materials:

Organdy,

fabric,

Taffeta,

lining

materials

Medium-heavy

materials:

Cotton,

linen,

Heavy

Tweed,

denim,

Knit

Rolled

tricot,

dress

materials:

suit

heavy

fabrics:

hem

light-knit

silk,

materials

materials,

cloth

,J

I

Thread

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Polyester

Mercerized

(bulk

-

-

-

i....

)

.

thread

thread

thread

thread

thread

thread

thread)

No.

80—100

No.

80—100

No.

70—140

No.

60—100

No.

50—100

No.

70—140

No.

40—60

No.

40—60

No.

70—140

No.

40—60

No.

40—60

No.

70—140

No.

120—140

Setting

hobbylock

Open

work

fast

and

knob

25

between

is3mm.

the

set

at

1

stitch

784

support

the

and

length

without

stitch-length

stitch

mm.

5

2.0

2.0

2.0

2.0

12.

Hold

length

Standard

Stitch

2.0

to

to

2.0

to

5.0

to

4.0

to

5.0

to

4.0

1.0

to

on

the

differential

hand

adjustment

desired

length

4.0

4.0

mm

mm

mm

mm

2.0

wheel

setting

mm

mm

(784)

(786)

(784)

(786)

mm

feed

9

N

c\

L-_

.i,___c(

Setting

hobbylock

Open

fast

knob

between

/7

/

/

A

.

-

/

t>

and

work

25

the

set

at

1

and

stitch

786

support

the

length

with

differential

12.

stitch-length

stitch

mm.

4

on

Hold

adjustment

length

Standard

the

hand

desired

setting

feed

wheel

9

N

Page 21

Adjusting

on

the

The

shift.

arranged

both

the

The

be

set

the

feed

versa.

results

rential

you

page

button

Setting

Setting

Setting

Setting

The

differential

from

hobbylock

differential

It

consists

one

pick

up

same

time.

feed

amount

separately.

workpiece

than

dog

Owing

are

feed

wish

to

The

20).

are

23

0.5

—

N

1.5

2

to

0.5

differential

the

786

feed

of

two

behind

and

move

of

It

moved

the

by

that

to

accomplished.

according

process

following

possible:

=

Short

dog,

long

feed

=

dog

Same

dogs

=

Long

stroke

short

dog,

feed

=

dog

Front

longest

rear

feed

shortest

feed

also

2,

during

prevents

feed

the

the

either

is

possible

more

rear

very

to

(see

settings

stroke

stroke

feed

possible

dog

possible

can

feed

other,

workpiece

feed

one

good

Set

the

table

of

stroke

of

of

stroke

dog

be

set

sewing.

inter-ply

dogs,

which

to

by

the

and

sewing

the

material

on

front

of

both

front

of

set

stroke,

for

set

stroke

infinitely

dog

at

at

can

have

front

vice

diffe

feed

rear

feed

feed

rear

for

Note:

The

following

to

obtain

garments:

The

gather

rential

fabrics

wave

The

rential

heavy

to

fashionable

feed

are

processed.

effect

feed

elastic

variants

effect

setting

setting

is

of

is

obtained

of

fabrics

can

effects

obtained

1.5—2

when

0.5

are

be

employed

on

at

when

at

a

medium

processed.

a

diffe

diffe

light

19

Page 22

table indicates

This

required

differential

The

for

the

fabric

feed

possible

you

can

also

settings

wish

order

feed.

of

the

differential

to

process,

be

set

during

sewing

a

sewing.

test

has

In

to

to

be made.

make

sure

about

the

setting

Setting

ferential

0.5

—

1.5

to

1.5

dif-

N

of

—

feed

N

Illustration

1

2

3

—

2

4

Correct

seam

a

d

tricot,

Nylon,

and

poplin,

Light

(normal

Jersey,

nicki

silk

cotton,

fabrics)

medium

fabrics,

Heavy knitwear,

rib

stitch

goods

lining

jeans

light

Fabric

fabrics,

cotton,

knittings

ve

elastic

satin,

fabrics,

I

C

Fig.

Fig.

Fig.

1

3

2

Fig. 4

20

Page 23

*

0

cA

Disengaging

Remove

and

looper

loosen

blocking.

Push rotary

knife

guide

turnitforwards

the

hole

knifeisdisengaged.

the

box

lint

cover

screw38for

lever

fullytothe

of

the

upper

knife

Open

8.

10.Ifnecessary,

axial

of

the

27

right,

pin

until

knife. Now

A

work

upper

axial

engages

the

hold

upper

support

knife

upper

it,

12

and

in

—

fl\

Adjusting

The

standard

marked

Disengage

the

above

The

desired

adjusting

width

adjustment

2.5to5.

the

Set

and

again

When

tighten

knife,

see

Sew

a

Note:

After

adjusting

necessary

be

tension.

the seam

N

with

the

description.

seam

knob

upper

close

processing

screw

page

test

seam.

width

width

seam

mm).

(3.5

upper

width

The

26.

knob

knifeatits

the

looper

thick

for

38

14,

the

seam

to

re-adjust

setting

knife

according

is

set

scale

ranges

basic

fabrics,

blocking

width,itmay

the

on

cover.

the

thread

is

with

the

from

position

securely

upper

c

to

seam-

21

Page 24

‘.—...,

H

Changing

Raise

Engage

Place

holder

foot

sewing

the

of

sewing

sewing

the

the

foot

foot

foot

the

the

sewing

sewing

so

engages

sewing

foot

sewing

that

lifting

holder.

lifting

foot.

foot

when

lever,

foot

foot

in

under

groove

16.

lever

by

the

you

crosspiece

pressing

sewing

lower

of

H

r

the

G

the

illustration

The

correctly

engaged

on

the

sewing

left

shows

foot.

a

Page 25

I

‘\

H

Changing

Pull

out

Loosen

screw.

Open

Behind

is

light

Removing

the

Push

to

fully

Inserting

Insert

pins

the

fully

it

Close

the

the

the

housing

the

the

it,

situated.

light

the

the

the

in

the

to

and

mains

housing

the

left.

new

the

right.

fasten

light

light

light

bulb

light

bulb

slots,

bulb:

plug.

cover

cover.

bulb

bulb:

upwards

bulb:

(15

push

housing

of

Watt

retaining

sewing

the

and

max.)

it

up

cover.

and

turn

it

with

turn

Cleaning

Pull

thread

to

hands

remove

and

the

Use

accessories

between

from

Replace

engageing

retainers

the

the

brush

the

A

thread

tension

front

it.

provided

to

the

thread

the

the

of

(direction

remove

tensions.

tabs

housing.

tensions:

cover

tension

the

of

with

dust

7

cover

with

of

the

and

cover

both

arrow)

lint

by

in

23

Page 26

aoo

apis

esja,e

ep!s

waL’

pejo

—o

jojj

110

iq

1lS!U4

ov

J04

noA

eEo!ep

ueo

)j39U

SpEJ1i

8!

we

110

9!

‘saöp

JBu0!sSaJOJd

SIML4S

Weq

9!

‘(

ieseAiod

J0

pesn

noqi

U9

UMS

pooiq

N6!I

8Ai3EJB8

Auu

swq

SOupEA

IfliM

!M

y

pejjoi

pu

souqe

uado

M9

‘SeAJE,s

j}OJ

y

s)

5ed

j7

Page 27

I

hem

Rolled

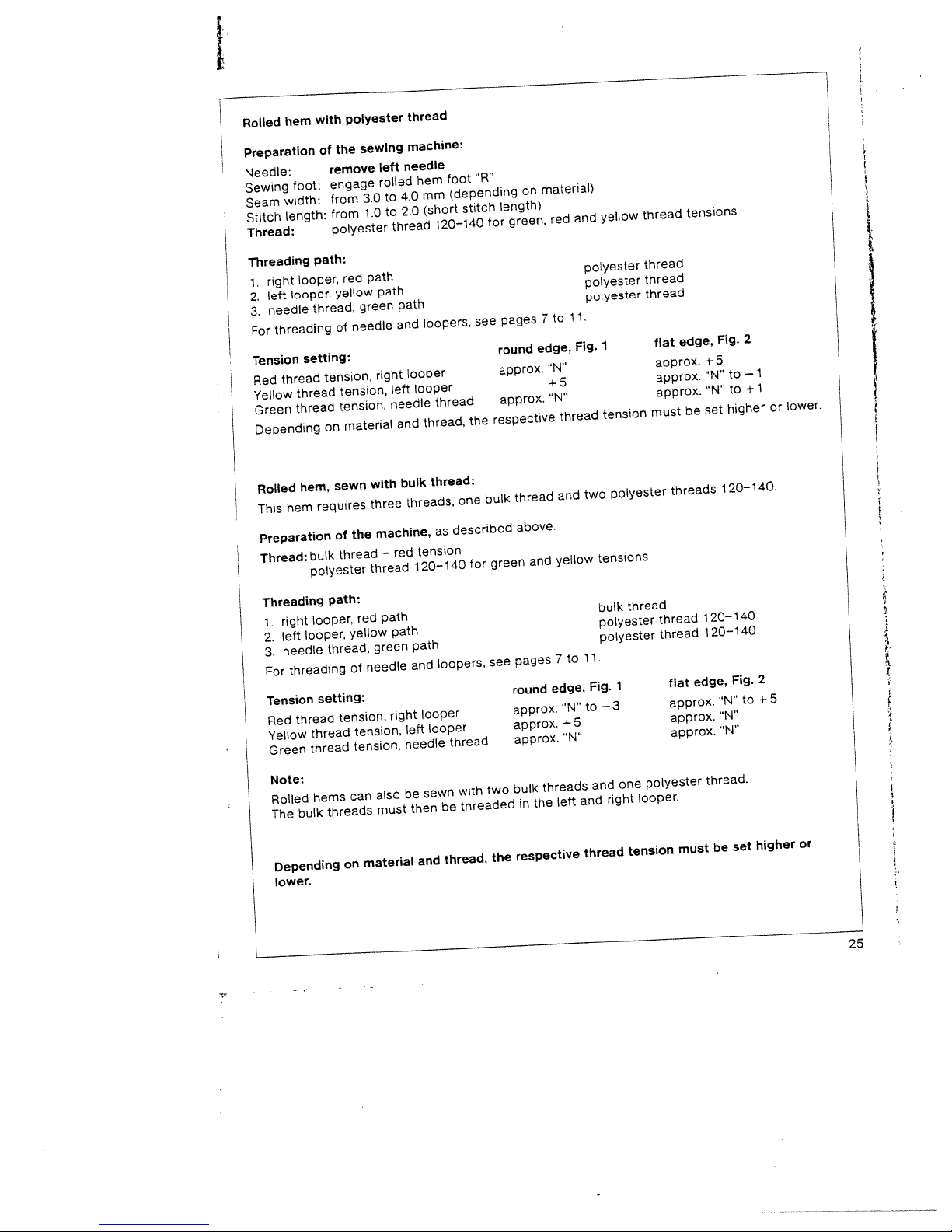

Preparation

Needle:

Sewing

width:

Seam

length:

Stitch

Thread:

Threading

right

1.

left

2.

needle

3.

threading

For

Tension

thread

Red

Yellow

Green

Depending

Rolled

This

Preparation

Thread:

foot:

looper,

looper,

setting:

thread

thread

hem,

hem

with

the

of

remove

engage

from

from

polyester

path:

red

yellow

thread,

of

tension,

tension,

tension,

on

sewn

requires

of

thread

bulk

polyester

polyester

sewing

3.0

1.0

path

path

green

needle

right

material

with

three

machine,

the

thread

left

rolled

to

to

thread

and

left

needle

and

red

—

thread

machine:

needle

hem

4.0

2.0

path

looper

looper

bulk

threads,

tension

120—140

foot

(depending

mm

(short

120—140

loopers,

thread

thread,

thread:

as

“R”

stitch

for

see

the

bulk

one

described

for

on

length)

green,

pages

round

approx.

approx.

respective

thread

above.

green

material)

7

edge,

“N”

+

“N”

and

red

to

5

thread

and

yellow

and

polyester

polyester

polyester

11.

Fig.

two

yellow

1

tension

polyester

tensions

thread

thread

thread

thread

flat

approx.

approx.

approx.

must

tensions

edge,

be

threads

Fig.

+5

“N”

‘N”

higher

set

120—140.

2

1

—

to

1

+

to

lower.

or

Threading

right

1.

left

2.

needle

3,

threading

For

Tension

thread

Red

Yellow

Green

Note:

Rolled

bulk

The

Depending

lower.

looper,

looper,

thread,

setting:

thread

thread

hems

threads

path:

tension,

red

yellow

of

tension,

tension,

can

on

path

green

needle

right

also

must

material

path

path

and

looper

left

needle

be

then

and

looper

sewn

loopers,

thread

with

threaded

be

thread,

see

two

the

pages

round

approx.

approx.

approx.

threads

bulk

the

in

respective

7

edge,

“N”

+

“N”

left

to

5

and

thread

bulk

polyester

polyester

11.

Fig.

—3

to

and

1

right

thread

one

tension

thread

thread

polyester

looper.

edge,

flat

approx.

approx.

approx.

must

120—140

120—140

Fig.

“N”

“N”

“N”

thread.

set

be

to

2

+5

higher

or

25

Page 28

Changing

Pull

out

sewing

direction

bar

is

needle

(see

p.

needle

tool.

Loosen

with

the

by

pulling

the

foot.

at

its

change

31,

in

screw

the

needles

mains

Turn

of

the

highest

tern

hole

Mofthe

the

driver.

downwards.

it

plug.

Lower

the

hand

arrow

until

position.

tool

from

11)asfollows:

set

the

needle

screw

Remove

the

wheel

the

Use

accessories

Insert

change

of

the

the

in

needle

the

needle

the

the

needle

Inserting

Insert

change

of

the

the

needle

needle

as

will

it

Tighten

K

I

Remove

needle.

the

tool

needle

up

go.

needle

needle

the

needle

change

into

needle

in

shank

such

the

set

change

in

tool.

needle

screw

hole

way

a

faces

M

of

that

surface

Then

holder

securely.

tool

the

push

from

flat

needle

side

L

the

as

the

K

of

far

Notes:

The

L

M

\\

I

following

machines:

System

Although

on

the

used,

An

incorrectly

cause

stitches.

we

thread

Changing

are

Pull

out

Knives

-,/y

—

___;_

.

Disengage

130/705

the

material

recommend

the

available

the

mains

the

needles

H

correct

and

inserted

breakage

knives

plug.

upper

are

(75—90)

needle

the

thread

needle

needle

and

as

spare

knife,

used

size

size

skipped

parts.

see

on

size

will

page

these

depends

75—90.

21.

26

\c;;—r-

I

Page 29

__

I

__

-

-

/

knife:

upper

the

out

upper

the

retaining

the

the

new

mains

knife

knife.

screw

upper

plug.

retaining

knife

securely.

screw

and

and

tighten

Changing

Pull

Unscrew

remove

[

1

Insert

its

I—

L_—--

N’

.

up

27

guide

knife

with

knife

upper

Set

(cutting

/

until

the

position).

upper

Turn

knife

is

the

at

its

handwheel

lowest

27

Page 30

:;;:

-ZL--1

/(

Changing

Pull

I

Disengage

Remove

knife.

Place

guide

it

up,

Replace

plate.

out

as

the

of

the

the

the

new

the

shown

the

lower

mains

the

retaining

lower

lower

in

screw

upper

knife

the

with

knife

plug’

knife

screw

knife

holder

illustration.

the

(see

of

against

pressure

and

page

the

the

21).

lower

left

push

p

28

Align

so

that

surface.

Before

align

upper

the

it

tightening

the

pressure

knife

cutting

is

flush

to

edge

with

the

cutting

plate.

of

the

the

needle

retaining

Reset

position.

lower

screw,

the

knife

plate

Page 31

•1

*

bU!I!O

sjd

peu

qWOw

EUiMS

eje

o

euiqw

ejwj

s6uiqsnq

eq

0

eU)L0W

eq

eo

noA

eJo,eq

ewq

io

P0

ou

o

pue

P91!°

o

ISJOA3

,o

apow

e

ieqo

Auo

sdoip

uoqiedo

seojd

eds

DU0

40

Ue!D!4flS

noA

JO

uodwi

nb-q8iq

JO

pjnoqs

peipui

ueew

9DIM

W

8u!!o

cdd

eqj

5uIAOw

pu

aq

.UiLpew

7

Page 32

Sewing

These

made.

be

operation

problems

machines

Sewing

errors.

and

have

problems

They

solutions

been

easily

can

developed

the

of

be

for

kind

corrected

easy operation,

described

by

below

following

and

may

the

there

are

due

occur

instructions

no

to

difficult

minor

below.

adjustments

adjustment-

to

and

______

Needle

Thread

Skipped

Problem

breakage

breakage

stitches

Needle

point

or

Needle

Material

Incorrectly

Thread

Thread

Needle

Incorrect

Needle

damaged.

Needle

Incorrect

Incorrectly

Cause

bent

damaged.

not

fully

pulled.

threaded.

caught.

has

tension

fully

not

needle

bent

fully

not

needle

threaded.

or

inserted.

too

inserted.

used.

point

inserted.

used.

tight,

Insert

Insert

page

(see

not

Do

sewing.

Thread

pages

(see

Check

the

at

Regulate

(pages

Insert

needle

Use

Insert

Insert

needle

Use

Thread

new

new

pull

correctly

whether

reel

tension.

15,16).

needle

new

needle

correctly

Solution

needle.

needle

26).

material

7—10).

stand,

correctly

system

needle.

correctly

system

correctly

thread

etc.

(pages

during

catches

(page

130/705

(page

130/705

26).

H

26).

H

7—10).

Incorrect

formation

Puckered

30

stitch

seams

Incorrect

tensions.

Thread

Incorrect

differential

Thread

incorrect

setting

tension

setting

feed.

has

threading.

caught

too

of

of

thread

tight.

due

Set

(pages

Reduce

cially

(pages

Re-adjust

to

Thread

15,

thread

for

15,

correctly

16).

light

16).

differential

tensions

thread

correctly

tension

materials)

(pages

(espe

feed.

7—10).

Page 33

I

Accessories

knife

unreeling

machine

hem

spool

change

(big)

(small)

sewing

net

tool

disc

oil

foot

t

I

Screwdriver

1

Screwdriver

2

Lint

3

Tweezers

4

Upper

5

Thread

6

Needles

7

Sewing

8

Rolled

9

Thread

10

Needle

11

brush

5o

6Q

I

II#ICIIIII*IIIiIlI,

•11

Bfl

net

Thread

thread

The

item

smaller

Remove

from

Put

the

pin

and

top

on

facing

spool

useful

become

to

(Fig.

unreeling

of

6

thread

the

of

down,

1).

the

thread

thread

thread

place

it,

synthetic

for

loose,

unreeling

accessories

spools.

spool

reel

spooi

the

rounded-off

with

shown

as

disc

thread

threads

unravel

disc

centering

pin.

the

on

in

and

shown

used

is

thread

unreeling

section

B.

Fig.

which

as

for

piece

1

slip

I

36

/

reel

disc

C

Thread

Very

tend

down

E

‘1

31

Page 34

Specifications:

Maximum

Seam

Stitch

Sewing

Lubrication

Sewing

Needle

Numberofthreads

Dimensions

Weight

width

length

foot

foot

system

sewing

height

speed

1.300

3-7.2mm

1

—4

1

-5

Hinged

Manual

5mm

130/705

4

x

315

approx.

stitches/mm.

mm

(HL-786)

(HL-784)

mm

H

(no.

x

330mm

280

kg

8.0

75—

no.

90)

Contents

machine

1

foot

1

1

instruction

1

lint

thread

1

4

thread

1

thread

machine

1

of

control

box

spool

spool

guide

cardboard

with

motor

manual/guarantee

stand

stand

cover

box

certificate

bars

32

Loading...

Loading...