Page 1

D

Cl)

©

-‘

C

C-)

0

SD

D

©

D

C

c)

4

I

Page 2

Notes

A)

B)

C)

0)

on

Owing

the

of

user

the

avoid

continuously

area

When

changing

machine

from

maximum

The

light

the

drive

The

anyone

by

agent.

safety

to

needle

must

injury

leaving

the

the

and

parts

must

power

bulb

belt

but

and

up

and

take

observe

the

or

be

source.

approved

15

is

must

an

down

upper

the

sufficient

the

sewing.

while

machine,

accessories,

disconnected

wattage

watts.

be

never

authorized

movement

knife,

care

sewing

the

adjusted

Pfaff

to

of

Page 3

Contents

V

Parts

of

Electrical

Master

switch

Foot

control

Notes

on

Installing

Opening

Threading

Threading

Threading

Threading

Thread

reel

Inserting

Seam

allowance

Sewing

Points

test

to

Securing

Axial

blocking

Setting

the

Correcting

Thread

Setting

chart

the

Disengaging

Adjusting

Changing

Rolled

hems

Changing

Changing

Changing

Changing

Changing

Cleaning

Oiling

the

Sewing

problems

Accessories

Thread

spool

Specifications

Contents

the

sewing

connection

.

safety

the

thread

the

looper

guide

the

the

the

change

the

lint

observe

the

seam

standard

the

for

stitch

the

the

seam

the

sewing

the

needle

the

knives

the

upper

the

lower

the

light

the

thread

machine

net/thread

of

the

and

sewing

.

.

wires

right

left

looper

needle

box

during

of

the

thread

3-thread

length

upper

bulb

and

cardboard

machine

spool

cover

and

looper

on

threaded

upper

thread

tensions

knife

width

foot

knife

knife

. .

tensions

their

light

stand

.

the

sewing

knife

tensions

overedge

.

removal

unreeling

box

.

thread

machine

. .

.

disc

guides

seam

V

behind

the

carrying

.

V

V V

.

.

V

.

.

. .

handle

.

.

.

7

Page 4

Page 5

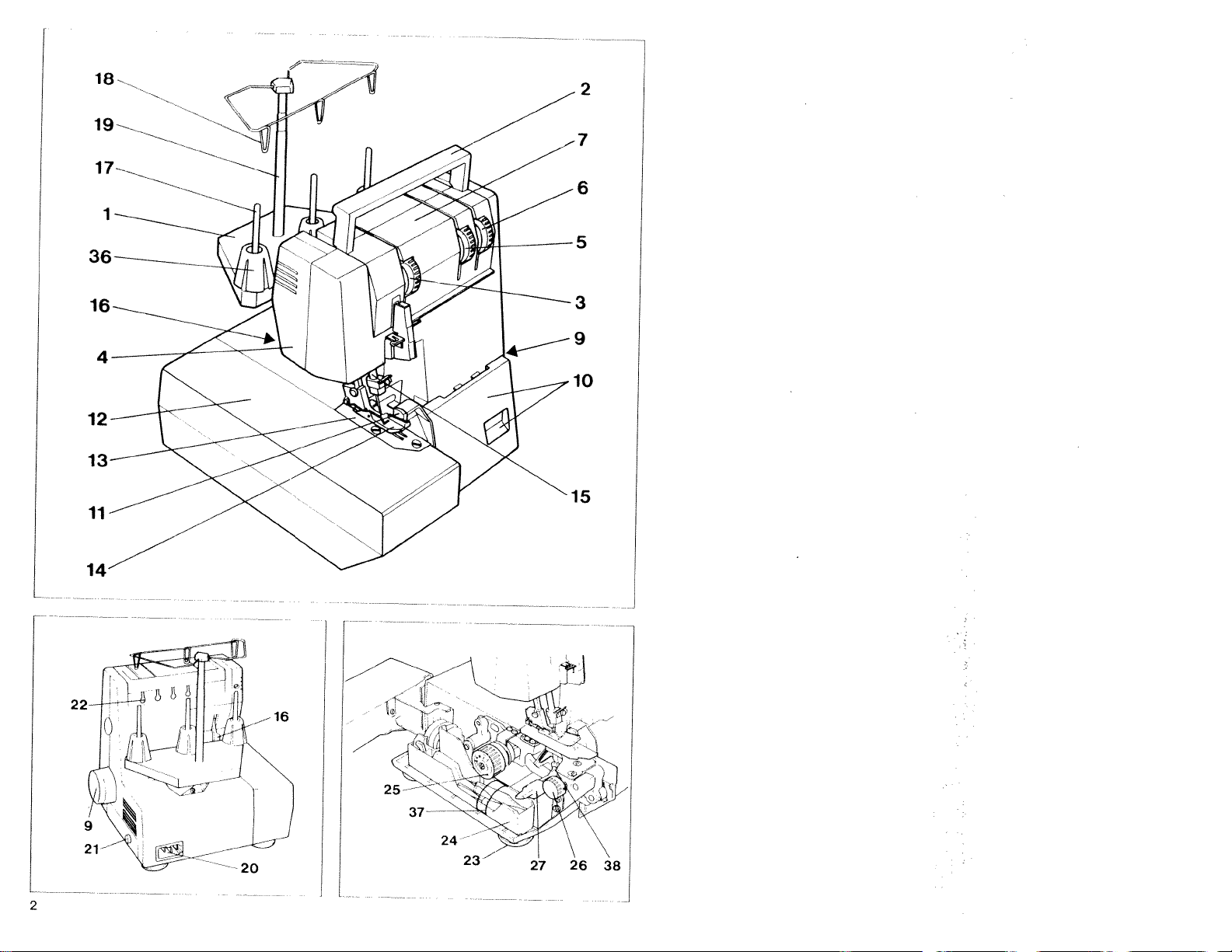

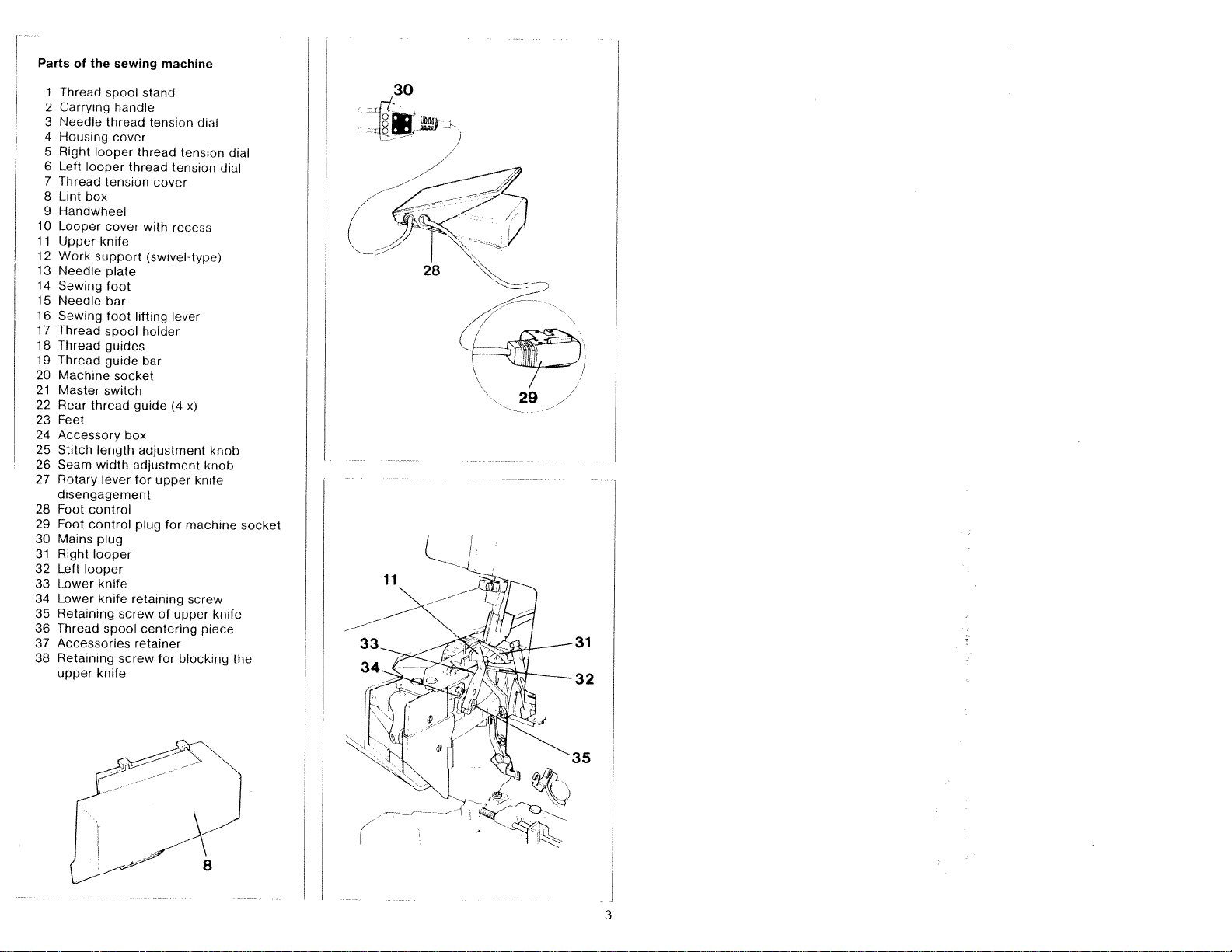

Parts

sewing

of

the

machine

Thread

Carrying

2

Needle

3

4

Housing

Right

5

Left

6

Thread

7

Lint

8

Handwheel

9

Looper

10

11

Upper

12

Work

13

Needle

Sewing

14

15

Needle

16

Sewing

Thread

17

Thread

18

Thread

19

Machine

20

Master

21

Rear

22

Feet

23

Accessory

24

Stitch

25

26

Seam

Rotary

27

disengagement

28

Foot

Foot

29

Mains

30

Right

31

Left

32

Lower

33

Lower

34

Retaining

35

Thread

36

37

Accessories

Retaining

38

upper

looper

looper

box

knife

support

thread

length

width

lever

control

control

plug

looper

looper

knife

knife

knife

spool

handle

thread

cover

tension

cover

plate

foot

bar

foot

spool

guides

guide

socket

switch

box

screw

spool

screw

stand

tension

thread

thread

cover

with

(swiveLtype)

lifting

holder

bar

guide

adjustment

adjustment

for

upper

plug

for

retaining

of

centering

retainer

for

tension

tension

recess

lever

x)

(4

machine

screw

upper

blocking

30

dial

dial

dial

28

knob

knob

knife

socket

knife

piece

31

the

32

.35

3.

Page 6

this

a

on

to

control

off

switched

are

the

it

and

switch.

switch

connection

machine

sewing

special

the

foot

of

plug

Then

socket

source.

power

a

the

When

the

off

at

plug

the

place

Do

not

machine

the

sewing

simultaneously

12

On:

Machine

on.

off:

again.

switched

only

the

machine

master

light

Machine

off.

on

table.

control:

control

connect

from

any

ON

are

with

and

fiat

a

is

switch

the

objects

and

switched

master

sewing

surface

in

the

the

not

power

and

in

and

on

OFF

tight

sewing

mains

use,

the

on

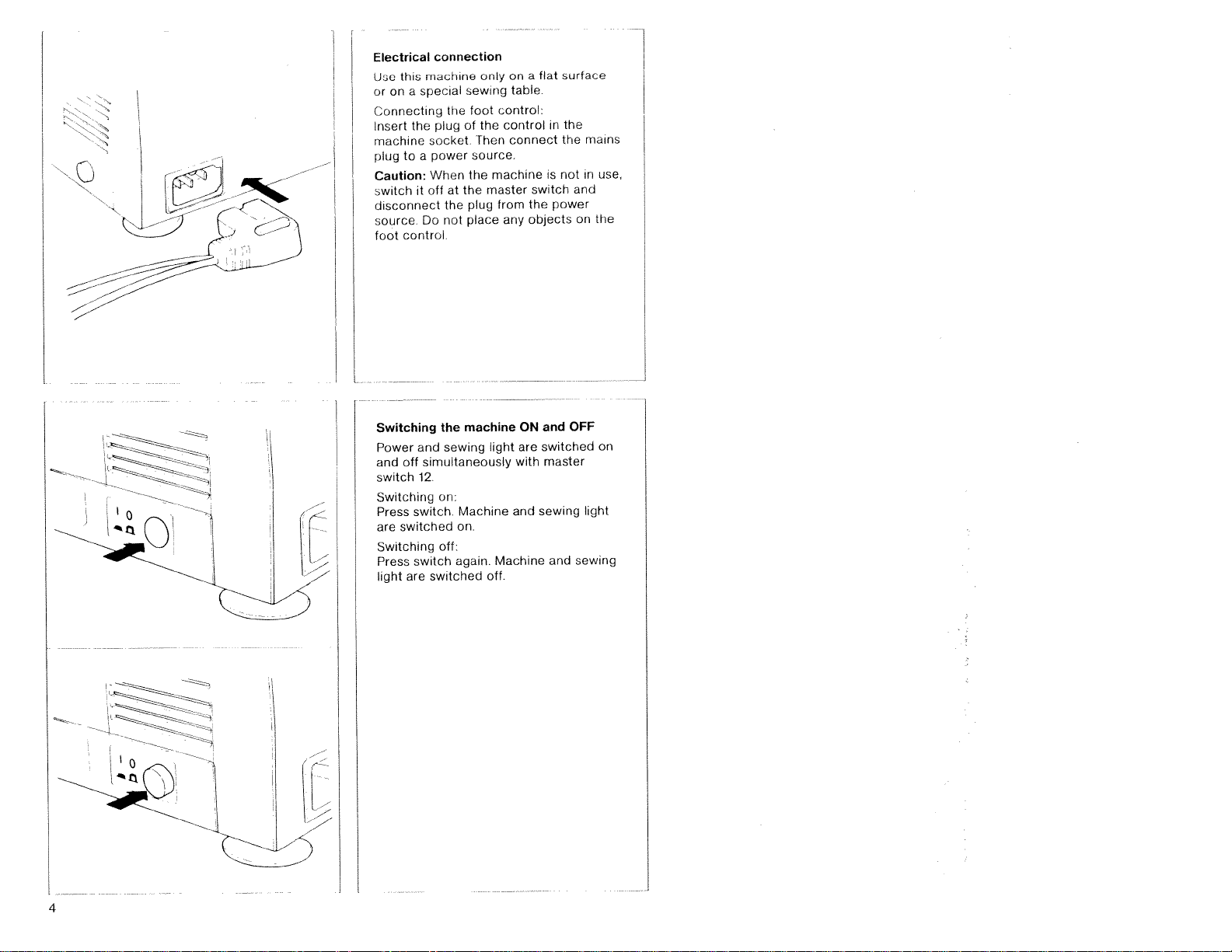

Electrical

Use

or

Connecting

Insert

machine

plug

Caution:

switch

disconnect

source

foot

Switching

Power

and

switch

Switching

0

Press

are

Switching

Press

tight

4

Page 7

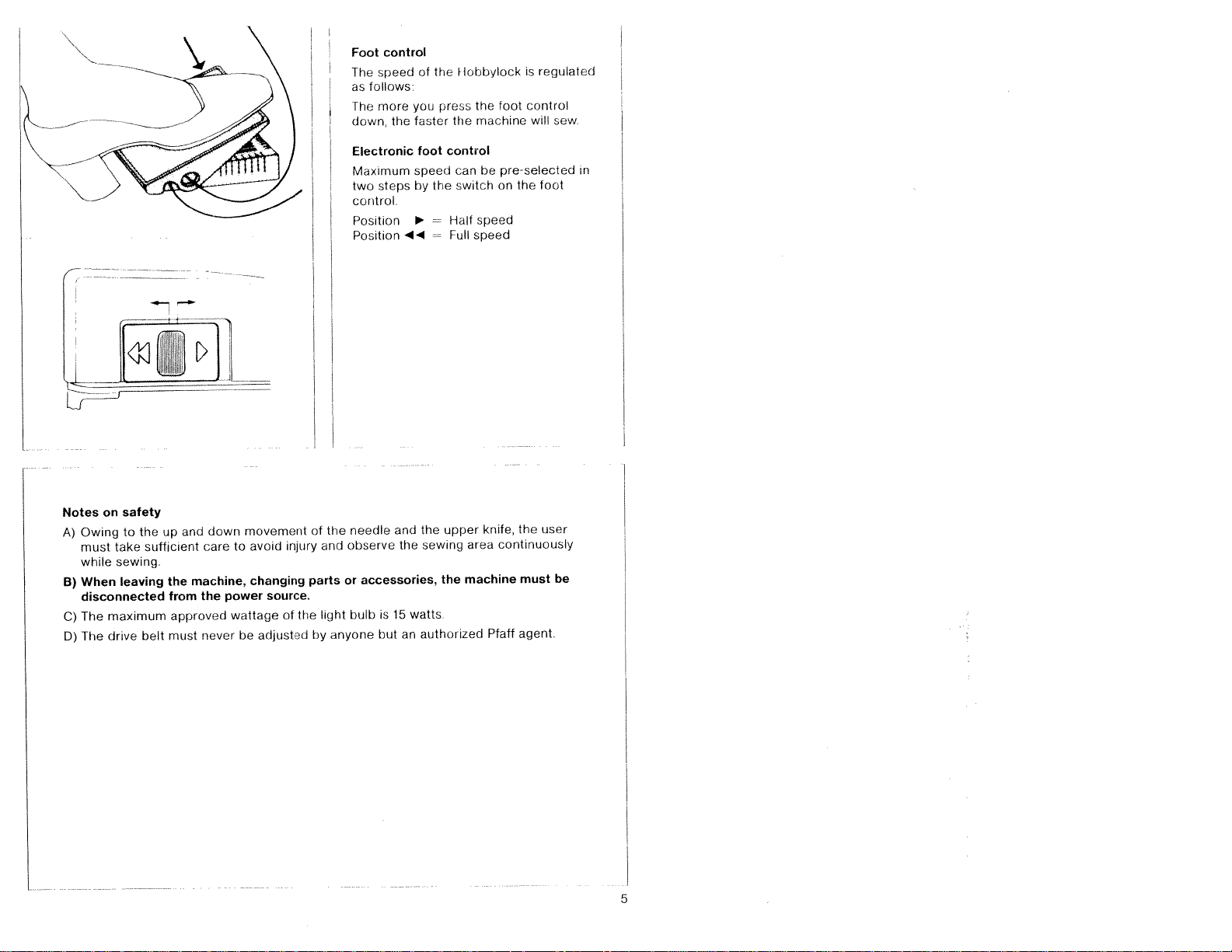

control

Foot

speed

The

follows

as

more

The

the

down,

Electronic

Maximum

steps

two

control

Position

Position

4

of

you

faster

toot

speed

by

the

press

control

the

[lobbylock

the

machine

the

be

can

switch

Half

speed

speed

Full

is

regulated

control

foot

will

pre-selected

foot

the

on

sew.

in

Notes

A)

Owing

must

while

When

B)

disconnected

The

C)

The

D)

safety

on

to

take

sewing.

leaving

maximum

drive

the

up

sufficient

belt

and

machine,

the

from

approved

must

down

care

the

never

to

power

wattage

be

movement

avoid

changing

source.

of

adjusted

injury

the

of

and

parts

light

by

the

or

anyone

needle

observe

accessories,

is 15

bulb

but

and

the

an

the

sewing

watts

authuiized

upper

the

knife,

area

machine

Pfaff

user

the

continuously

must

agent.

be

5

Page 8

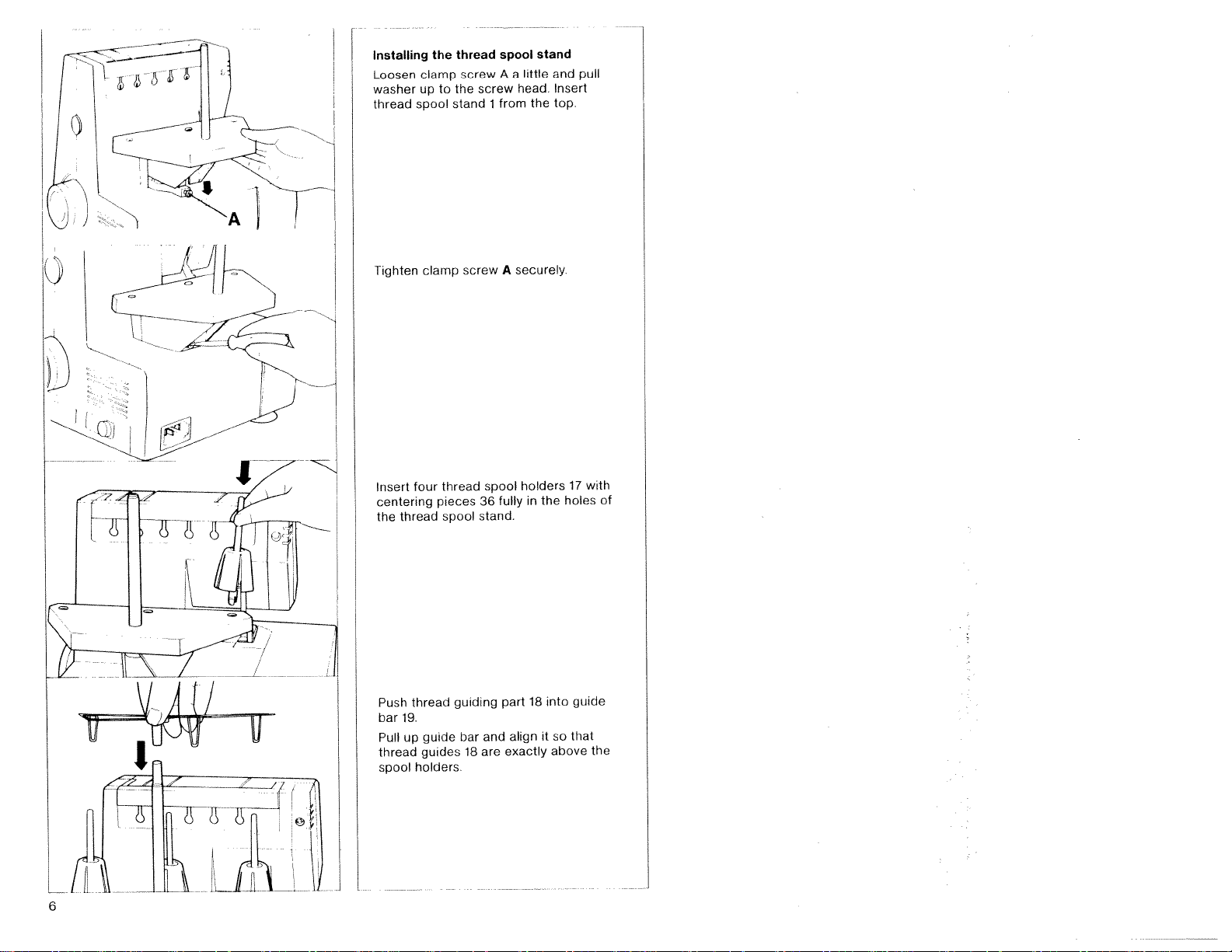

Installing

Loosen

washer

thread

clamp

up

spool

the

to

thread

screw

the

stand

screw

1

spool

A

a

from

little

head.

stand

the

and

Insert

top.

pull

Tighten

Insert

centering

thread

the

Push

19.

bar

Pull

up

thread

spool

clamp

four

thread

guide

guides

holders.

thread

pieces

spool

guiding

screw

bar

18

spool

36

stand.

and

are

securely

A

fully

part

align

exactly

holders

the

in

18

it

into

so

above

17

holes

guide

that

with

of

the

6

Page 9

cover

it

support

work

it

the

the

looper

fullytothe

down

cover,

push

12.

support,

locks.

fixed

is

looper

different

(see

colors

push

to

cover

threading

right,

it

it

push

the

Fig.

up

to

the

it

This

A)

work

looper

and

it

close

locks

it

open

close

To

right

the

threading

by

and

support

cover

swing

looper

the

work

until

diagram

behind

shows

different

the

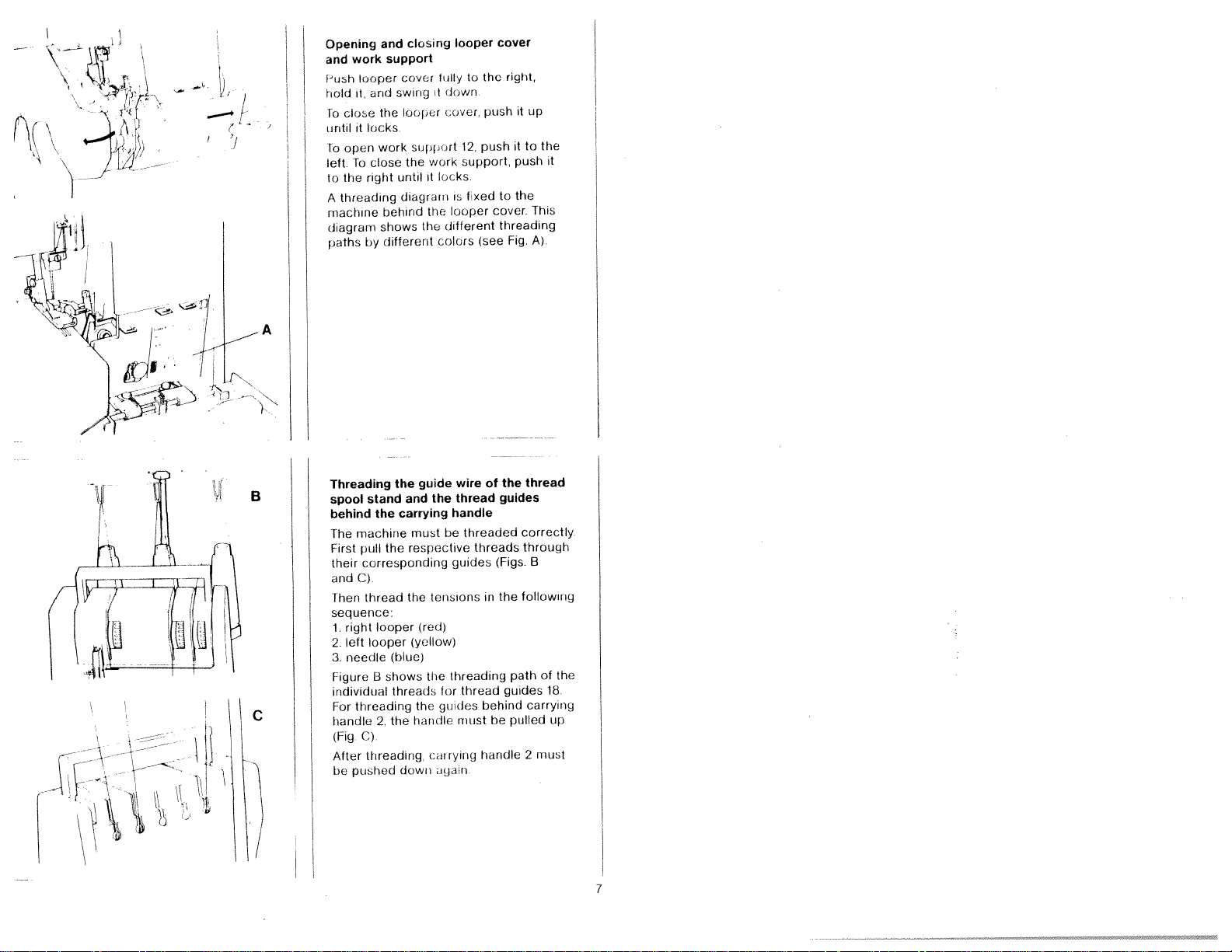

Opening

and

2

A

Push

hold

Fo

until

lo

left

to

A

machine

diagram

paths

closing

B

)

Threading

stand

spool

behind

machine

The

First

pull

corresponding

their

C)

and

thread

Fhen

sequence:

right

1.

left

2.

3.

needle

Figure

individual

threading

For

handle

C)

(Fig

Aftei

threading.

pushed

be

the

the

looper

looper

shows

H

2.

the

and

carrying

the

(blue)

threads

the

dowii

wireofthe

guide

thread

the

handle

mustbethreaded

respective

(red)

(yellow)

the

the

handle

guides

tensions

threading

for

guides

cm

rying

igdin

threads

in

thread

behind

must

handle

guides

(Figs

the

be

correctly

following

path

guides

pulled

thread

through

B

of

18

carrying

up

2

must

the

7

Page 10

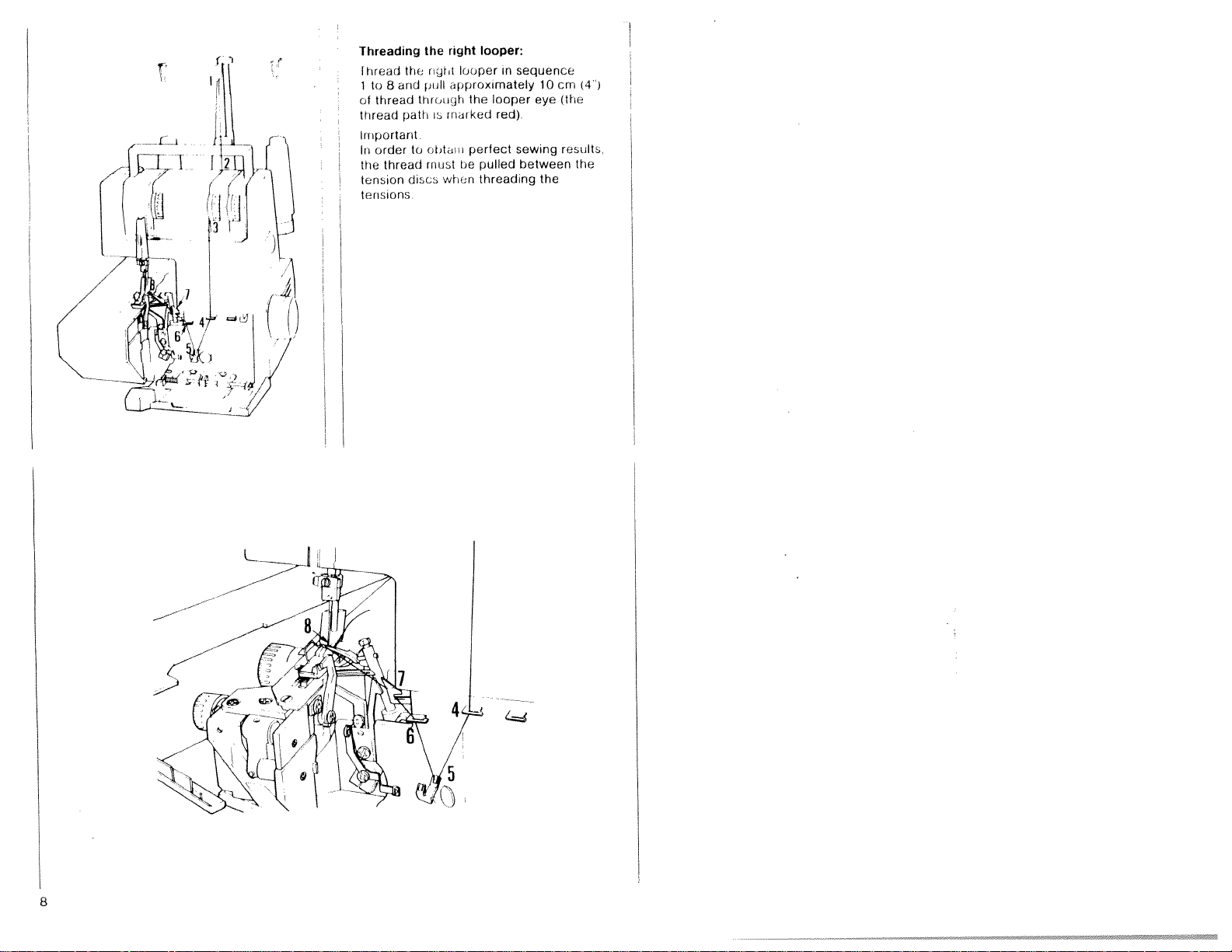

Threading

thread

Band

1

to

thread

of

thread

Important

order

In

thread

the

tension

nsmns

te

right

the

the

rtt

tiull

through

murked

path

s

obtdln

to

mustbepulled

disco

when

looper:

looper

in

opproximately

looper

the

red)

perfect

threading the

sequence

10

eye

sewing

between

cm

(the

results

(4)

the

8

Page 11

I

Threading

1

Insert

to

1

thread

of

thread

the

yellow)

sequence

in

10

eye

cm

(the

(4

the

and

9

path

pull

through

is

approximately

looper

the

marked

thread

looper

left

looper:

left

9

Page 12

Threading

Threadingofguide

thread

is

shown

In

the

pathisshoiiri

up

thread

retainer

the

guide

on

hand

left

to

the

right

mustbepulled

needle

behind

page

from

needle

wires18and

the

7

illustration

the

blue

(6).Atpoint5the

behind

carrying

the

tension

of

the

handle

threading

the

thread

(1)

Thread

Cut

the

Tie

the

threads

outofthe

last

thread

respective

interruption

spool

threads

needle.

needle

change

guide

Pull

on

closetothe

stillinthe

Now

pullatthe

before

eyes.

about

10

threaded

thread

machine

the

needles.

looper

The

cmofthread

machine

spool.

and

thread

Cut

threads

Place

the

new

ends

the

through

threads

until

knots

can be

the

new

After

down,

2

looper

thread

the

off

pulled

looper

threading

together

knots

and

until

and

cover

spools

pull

eye

the

close

10

Pull

are

about15cm

the

threads

past

machine, push handle

work

support

on

spool

holders

the

needle thread

past

through

the

looper

eyes

12

and

17.

the

the

without

Page 13

Inserting

Insert

downwards

_\

cover

against

For

reverse

removal

the

Then

the

the

two

order

lint

tubs

in

the

push

machine

of

the

box:

of

recess

the

lint

the

bottom

box,

lint

of

the

use

box

of

looper

the

the

box

/

/

Seam

allowance

If

the

cutting

marking

allowance

consideration

guided

is

on

N

the

of

16

when

looper

mm

along

must

cutting

cover,

be

below

taken

the

a

seam

fabric.

into

11

Page 14

Sewing

After

he

Raise

the

test

threadingasewing

made

sewing

illustration

foot

lever

16,

test

as

test

shown

should

in

5thN

.1

Insert

test

and

lower the

Hold

thread

while

turning hand wheel

hand

arrowonthe

back under

that

the

in

threads

fabricupto

sewing

with

ends

direction

wheel.

the

sewing

have

interlocked

the

foot.

your

indicated

Lay

the

foot.

upper

with

left

your

threads

Make

correctly.

hand

by

knife

right

the

sure

Page 15

Points

Place

sewing

after

Sew

Since

not

hand

Sew

of

the

the

pull

observe

to

fabric

the

when

foot

machine

the

stitches

first

the

fdbricisfed

the

push

or

guiding

for

approxirriately

thread

seam

and

chain.

during

completely

starting

has

been

slowly

automatically,

fabric

the

only

cm

5

a

use

sewing

under

to

rethreaded)

Use

beyond

scissors

sew

your

to

the

(Also

the

cut

do

end

13

Page 16

Securing

Knot

a

crochet

thread

Or:

about5cm

Sew

scam

and

sew

sewn

just

chain

the

chain

Then

the

thread

needle

few

a

without

into

turn

seam:

stitches

chdin

can

the

(2

the

cutting

be

eani

beyoi

work

For

ovei

knit

ued

piece

the

d

to

the

the

thread

fabrics,

pull

end

around

seam

the

knife

upper

very

different

this

or

be

the

thick

machine,

thin

Plheni

wonkpieces

the

tightened,

fabrics

thicknesses:

kinds

all

extremely

to

sewing

screw

as

workpieces

and

of

fabric

thick

extremely

different

with

the

of

upper

showninthe

can

from

be

thick

knife

Blocking

Sewing

with

On

extremely

processed

of

fabrics

thicknesses

must

illustration

tightening

By

the

of

upper

ft

knife

ie

screw,

is

inhibited

axial

movement

Note:

that

must

the

be

the

When

screw

loosened

upper

sewing

the

of

by

knife

medium

or

thin

knife

upper

about2turns,

move

can

fabrics,

holder

so

axially.

14

Page 17

thread

fabric

7

the

16

the

N

(see

(the

lists

standard

tension

on

the

correct

seam)

type

and

thread

the

edgeofthread

front

Hustration

adjustment

of

the

Hustrator

examples

thread

thread

tobeset

thread

tension

below>

interlocking

on

the

for

correction

tensions

tension

depends

size

dials

after

of

left

N

used

tension

shows

of

Setting

Heverse

Left

0

/

;

i/

.1

//

;;1

/

t

i

Iou

thread

Right

looper

thread

Needle

Top

per

side

side

The

on

the

the

Set

opposite

cover

Make

examination

threads

a

correct

Page

individual

the

i•’

Wj\

Page 18

Feerse

k)J

0

C

side

side

Correcting

When

(+)

direction

When

decreased

The

needle

(blue

The

right

(red

thread

thread

tension>.

the

turned

thread

D

too

the

thread

thread

looper

tension)

thread

the

iii

(

tcniori)

thread

tight

tension

tension

direction

>

A

or

(yellow

tensions

is

too

Cistoo

the

is

turned

is

increased

loose

left

thread

it

is

looper

in

loose

The

left

looper

thread

0

is

too

(yellow

looper

thread

thread

tension)

too

C

tight

loose

or

the

right

(red

thread

tension>.

D

C

Page 19

Material

Light

materials

Organdy,

fabric,

Taffeta,

lining

materials

Medium-heavy

materials.

Cotton,

linen,

Heavy

Tweed,

denim,

Knit

Rolled

tricot,

dress

materials:

suit

heavy

fabrics:

hem

light-knit

silk,

materials

materials,

cloth

Thread

chart

Cotton

Silk

Synthetic

Cotton

Silk

Synthete

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Polyester

Mercerized

(bulk

thread)

for

3-thread

thread

thread

thread

ttiread

thread

thread

hread

overedge

No

No

No.

No

No

No.

No.

No.

No

No.

No.

No.

No.

80-

1

80-100

70—

140

60--lOU

50-100

70—140

40—60

40-60

70—140

40-60

40-60

70—140

120—140

(JO

seam

2.0

20

2.0

2.0

1.0

Stitch

to

to

to

to

to

5.0

20mm

length

4

40

50

0

mm

mm

mm

mm

Setting

Open

fast

and

knob

between

is

3

mm.

work

25

the

set

at

1

arid

stitch

support

the

length

12.

stitch-length

stitch

5

mm

Hold

adjustment

length

Standard

hand

desired

setting

wheel

9

N

17

Page 20

L

1

kf[J)

\

N,

Disengaging

Remove

arid

looper

loosen

screw

hi

ock

ng

Push

rotary

knife

guide

turn

forwards

it

the

hole

knife

disengiged

is

lint

nf

the

bn

cover

lenr

full,’

the

‘38

until

knife

upper

Open

8

10

If

for

axial

27ofthe

to

the

pin

Now

knife

work

necessary,

upper

axial

rrght,

hold

engages

A

the

support

knife

upper

it,

upper

12

and

in

A

2

(

Adjusting

The

standard

marked

Disengage

the

above

The

desired

adjusting

width

to

3

5.

Set

the

again

When

tighten

knife,

Sew

a

Note,

Atler

adjusting

be

necessary

tension.

the

with

the

description

seam

knob

adjustment

upper

and

close

processing

screw

see

page

test

sewn

scorn

N

knife

38

to

seam

(3

upper

2b

the

14

the

re

5

width

The

knob

thick

for

seam

width

width

mm).

knife

at

its

looper

blocking

aillust

setting

is

scale

ranges

basic

fabrics,

width,

the

according

set

with

on

the

from

position

cover.

securely

the

it

thread

is

to

seam

upper

may

Page 21

Changing

Raise

Disengage

ever

sewing

F

the

the

sewing

fuot

sewing

lifting

foot

foot

ever

by

1

16

pressing

F

G

Engage

Place

foot

sewing

of

the

sewing

The

illustration

correctly

the

holder

foot

foot

foot

the

sewing

sewing

so

lifting

engages

holder

engaged

on

that

foot.

foot

when

lever

in

the

sewing

under

crosspjece

groove

left

you

shows

foot.

the

lower

H

sewing

of

a

the

G

the

19

Page 22

lop

101)

side

side

Reverse

Reverse

side

side

Rolled

sewn

A

roWed

fabrics

open

sew

scarves

(see

hem

with

polyester

hem

and

is

edges

professioriat

shawL,

page

21)

is

used

an

uttractive

Witfiout

rolled

and

thread

for

light

any

hems

valances

120--140

finish

effort

delicate

for

you

on

neck

cdn

Page 23

Rolled

hem

with

polyester

thread

Preparation

I

Jcedk

Sewing

Seam

width,

Stitch

length:

Thread:

Threading

right

I

left

looper,

2

3

needle

For

ttireading

Tension

Red

thread

Yellow

Blue

thread

3epending

Rolled

bern

This

Preparation

Thread:

of

engage

foot.

from10

polyester

path:

looper, red

yellow

thread,

of

setting:

tension,

thread

tension,

on

hem,

sewn

requires

of

thread--red

bulk

polyester

the

insert

from

blue

needle

tension

material

the

sewing

needle

rulkit

30

patti

putt

right

needle

with

three

machine,

thread

to4Ii

to

20

threud

pat

1

rind

looper

loft

and

bulk

threads,

tension

120

machine:

tern

mm

(short

120

loopers,

limper

thread

thread,

thread:

as

140

tout

(depending

stitch

-140

see

the

one

descnit,ed

for

‘‘0

length)

for

pages1to

round

upprox.

appi

respective

bulk

tilne

blue

thread

above

id

ai

on

ox

matenal)

red

edge,

“N”

+

5

“N”

thread

and

yellow

and

11

Fig.

two

tensions

yellow

polyester

polyester

polyester

1

tension

polyester

threud

tensions

thread

tire

t

ad

thread

flat

edge,

approx

approx

upprox

mustbeset

threads

+ 5

“N”

“N”

Fig.

to—1

to+1

higher

120—

2

140

or

lower.

Threading

1

rigfrt

left

2.

needle

3

threading

For

Tension

Red

thread

Yellow

thread

Blue

Note:

Rolled

bulk

The

Depending

lower.

lonper,

looper,

setting:

thread

hems

threads

path:

thread,

tension,

tension,

can

on

red

yellow

of

needle

tension,

also

must

mateiial

putt

patti

blue

path

and

right

looper

left

needle

be

sewn

Uteribethreaded

and

loopers,

looper

thread

thread,

with

see

two

the

pages7to

round

edge,

appnox

appiox.

upirox.

bulk

threads

ri

the

respective

left

“N”

-t

“N”

5

and

thread

thread

bulk

polyester thread

polyester

ii.

Fig.

1

3

to

and one

right

polyester

looper

tension

ttrread

flat

dpfiroX

approx

upprox.

must be

120—140

120—140

edge,

thread

“N”

“N”

“N”

set

Fig.

to

higher

2

4

5

or

21

Page 24

Changing

Pull

out

sewing

direction

bar

is

needle

(see

needle

tool

with

the

by

pulling

the

toot

at

change

31.

p

in

Loosen

screw

the

ii

[urn

of

the

its

highest

tern

hole

tnic

it

downwards.

needle

ii.

arrow

tool

llj

M

of

set

driver

plug

the

position

from

as

the

screw

Lower

hand

until

the

follows:

needle

Remove

the

wheel

the

needle

Use

accessories

Insert

change

of

the

the

in

the

the

needle

needle

the

(

Inserting

Insert

change

of

the

the

needle

needle

as

it

will

Tighten

Remove

needle

Notes:

ihe

following

machines.

System

Although

on

the

used,

An

incorrectly

cause

s

ti

let

res.

Changing

Knives

Pull

out

Disengage

the

tool

needle

up

go

needle

needle

130/705

the

material

we

recommend

thread

the

are

the

the

needle

needle

in

such

shank

change

info

the

needles

correct

and

inserted

breakage

knives

avuilulile

mains

the

upper

in

set

change

H

plug.

hole

a

faces

tool.

needle

screw

(75-

needle

the

needle

as

knife,

way

Then

tool

are

90)

thread

needle

and

spare

M

of

that

surface

push

holder

securely.

from

used

size

size

will

skipped

parts

see

page

the

flat

on

depends

size

needle

side

L

the

as

the

these

75

K

of

far

90

18

Page 25

1;

c

I

I

/

Changing

Pull

Unscrew

rerr1cje

Insert

its

retaining

out

the

the

knife

upper

new

the

mains

screw

upper

rctdriring

knife

upper

knife:

plug.

knife

Securely

screw

and

35

tighten

arid

Set

upper

knife

with

knife

guide

27

lowest

of

mm

up

the

below

1

I

(cutting

until

position

In

upper

the

this

needle

the

position

knife

position)

upper

must

plate

Turn

knife

the

be

surface.

is

front

0.5

at

the

its

edge

to

handwheel

1

/

23

Page 26

Changing

Pull

Disengage

Remove retaining

knfe

Place

guide

it

up,asshown

Replace

plate.

out the

the

of

the

the

the

mains

the

new

lower

screw

lower

upper

lower

in

knife

plug!

screw

knife

knife

the

with

knife

(see

34

of

against

holder

illustration.

the

pressure

the

and

page

the

18)

lower

left

push

Align

the

cutting

edge

of

the

lower

so

that

itisflush

surface

Before

tightening

align

the

upper

knife

24

pressure

to

with

the

cutting

plate.

the

needle

retaining

Reset

position

knife

plate

screw,

the

Page 27

)

Changing

Pull

ousen

screw

)

/

Open

Behind

light

out

4

the

is

the

the

housing

hoicei

it,

the

situated

hght

mains

lijhl

g

plug.

cer

cover

bulb

bulb:

retaining

of

the

sewing

H

Removing

I

‘

/

(

Push

fully

Inserting

Insert

the

it

fully

Close

Cleaning

Pull

hands

and

Use

the

accessories

from

Replace

engageing

retainers

the

to

the

the

pins

to

and

thread

to

remove

brush

between

the

A

light

the

new

in

the

the

the

the

of

the

left

light

the

right

fasten

thread

tension

front

it

provided

to

remove

the

thread

tubs

the

light

bulb

bulb

slots,

housing

tensions.

housing

bulb:

upwards

bulb:

(15

Watt

push

tensions:

cover

(direction

with

dust

tension

of

the

it

cover.

7

with

and

cover

cover

up

of

the

and

max.)

arrow)

in

and

both

lint

by

turn

it

with

turn

25

Page 28

Oiling

the

machine:

F

very

rio

oil

and

rriade

oiled

two

oil

operation

to

the

other

of

only

drops

are

time

before

places

important

special

once

of

sufficient

high

you

Jou

should

indicated.

material

or

twice

quality

for

oiling.

take

moving

apply

The

and

a

month.

sewing

the

parts

need

machine

a

little

bushings

are

to

One

machine

be

to

26

Page 29

iese

made

e

peratiori

machines

Sewing

errors

have

problems

Ihey

been

can

of

easily

veliped

ftc

be

tind

corrected

for

easy

described

operation.

by

follnwing

below

and

may

the

there

ucr;ur

rnstruchoi

etc

(1(10

tO

10

.

difhcult

minOr

below.

adlustments

adjust

rnent

fri

and

Needle

Thread

Skipped

Prohlerri

breakage

breakage

stitches

F

teedle

ni

Intl

lUL(Jk(

F

Metered

Ii

icnr

tread

1

1

fired

Needle

Incur

Needle

damn

aged

Needle

Incorrect

Incur

redly

reef

redly

bet

damaged

riot

pulled

has

tension

not

needle

bent

not

needle

it

fully

threaded

caught

fully

or

pond

fully

threaded

ii

iSe

too

inserted

used

inset

used

led

fight.

led

Insert

Insert

(see

Do

sew

Thread

(see

Check

the

at

Regulate

(pages

Insert

use

Insert

Insert

Use

Thread

new

page

riot

i

rig

pages

reel

needle

needle

new

needle

needle

new

pull

correctly

whether

tension,

15,

needle

cnr

r

SO

i

cedle

needle

22)

n

aterial

7—10)

stamrd,

16)

correctly

system

correctly

system

ectly

it)

(01

thread

etc.

(pageS

fl

correctly

during

catches

(page

130/705

(page

130/705

22>

H

221

H

7—10).

Incorrect

formation

Puckered

stitch

seams

Incorrect

tensto

Thread

Incorrect

differential

hreid

1

incur

reef

setting

rs.

tension

setting

has

threading

teed.

caught

too

of

thread

tight

of

doe

In

Set

thread

(pages

Reduce

cially

(pages

Re-adjust

Thread

15,

thread

for

15,

correctly

tensions

16)

light

materials)

161

differential

tension

pages

correctly

(espe

feed.

7—

10>

27

Page 30

60

zz

77

2

3

8

H

)Y’i’

11

(115i]

Accessories

I

Screwcii

2

Screwdriver

3

nt

4

Tweezer,

5

Upper

6

Thread

7

Needles

8

Sewing

9

Rolled

10

Thread

11

Needle

bru

vol

h

kniif

uereehng

rTldchine

hem

spool

change

(big)

(small)

sewing

net

disc

oil

foot

tool

Thread

Very

tend

clown

Thread

Fhe

item

smaller

Remove

from

Put

pin

on

facing

28

the

and

top

useful

to

(Fig.

thread

6

of

the

of

down,

spool

for

become

A)

unreeling

unreeling

the

thread

thread

thread

thread

place

it,

with

net

synthetic

loose

disc

accessories

spools.

spool

reel

spool

the

thread

rounded-off

as

shown

unravel

disc

centering

pin.

on

the

in

threads

shown

is

used

thread

unreeling

section

Fig.

B

and

piece

Which

slip

as

for

36

reel

disc

C

Page 31

Specifications;

Maximum

Seam

width

Stitch

length

Sewing

I

Sewing

Needle

Number

foot

uhricatuori

foot

system

of

Dimensions

Weight

‘ewing

height

threads

speed

.

1300

1

3

ches’inin

mn

5

15inn

Hinged

Manual

5

mm

130/705

1

(rio

75

-

no.

90)

4

.

.

315x280

approx

x

330

80

mm

kg

Contents

1

umiachune

1

foot

1

instruction

lint

1

1

thread

4

thread

1

thread

1

machine

of

control

box

spool

spool

guide

cardboard

with

motor

manual/gu000ltee

stand

stand

cover

box

certificate

bars

29

Page 32

Loading...

Loading...