Page 1

77”

OPERATiNG

iNSTRUCTION

Page 2

CONTENTS

Parts

A.

Preparation

B.

Preparation

a.

Fitting

b.

How

c.

Turning

d.

Labrication

e.

f.

Opening

Threading

g.

Operating

C.

Test

a.

Thread

b.

Dial

c.

Relation

d.

e.

Correct

1.

Incorrect

Roll

g.

h.

Points

i.

3-thread

Some

D.

Adjusting

a.

Adjusting

b.

Replacing

c.

Replacing

d.

Replacing

e.

f.

Replacing

E.

Sewing

names

for

foot

the

adjust

to

on

and

the

sewing

tension

chart

for

chart

thread

thread

hemming

to

obseave

overedge

adjustments

the

the

needle

the

the

the

problems

the

sewing

controller

the

the

/

off

closing

procedure

machine

adjustment

thread

for

tension

tension

/

seam

stitch

upper

lower

light

and

foot

controller

lamp

looper

tension

fabrics

during

seam

Maintenance

(s)

solutions

and

and

sewing

width

length

knife

knife

bulb

cover

(Normal

adjustment

thread

how

and

hemming)

stitch

to

adjust

side

cover

length

2

4

4

4

4

4

5

6

6

9

9

9

9

10

10

11

12

13

14

15

15

15

16

17

18

19

20

Page 3

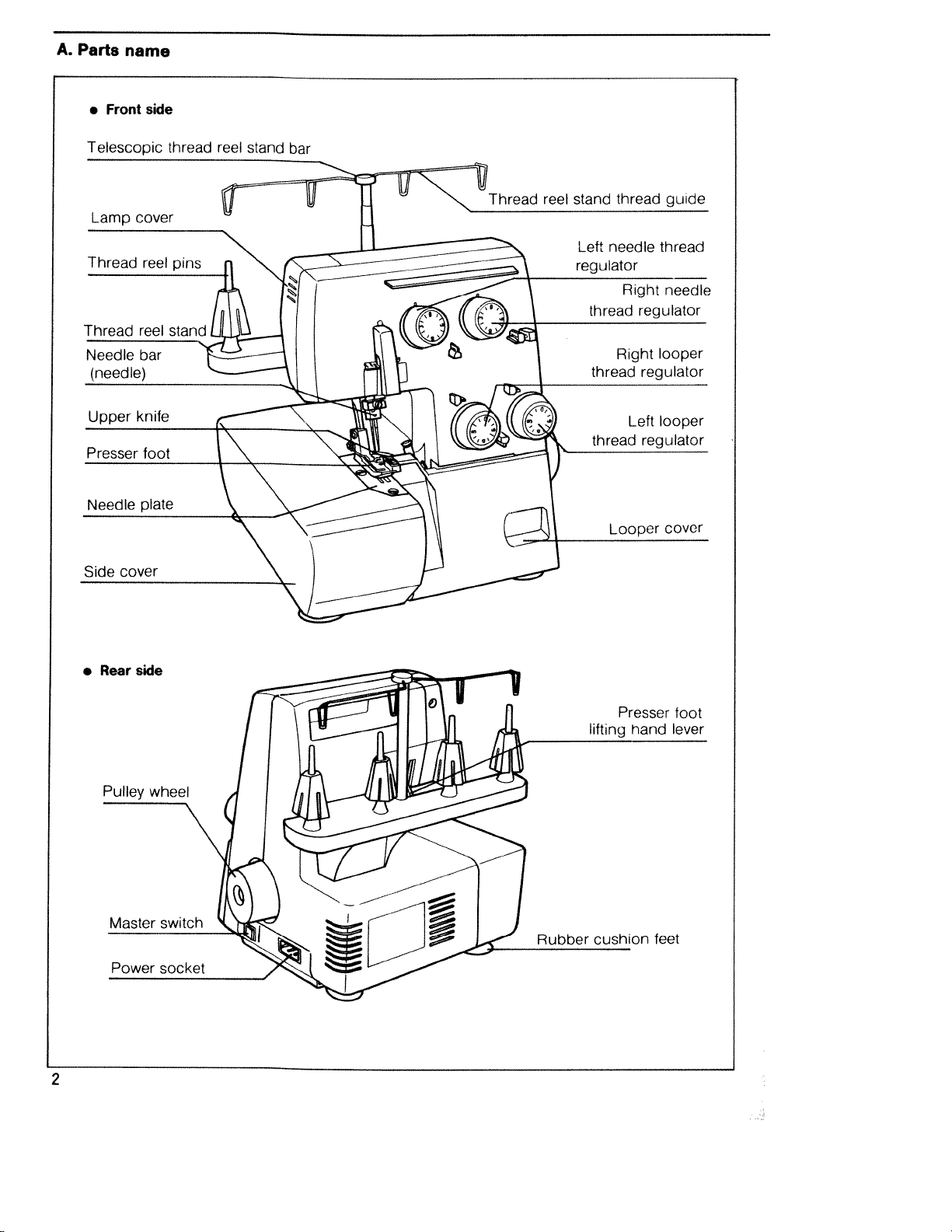

A.

Parts

•

name

Front

side

Rear

•

side

Presser

toot

feet

2

Page 4

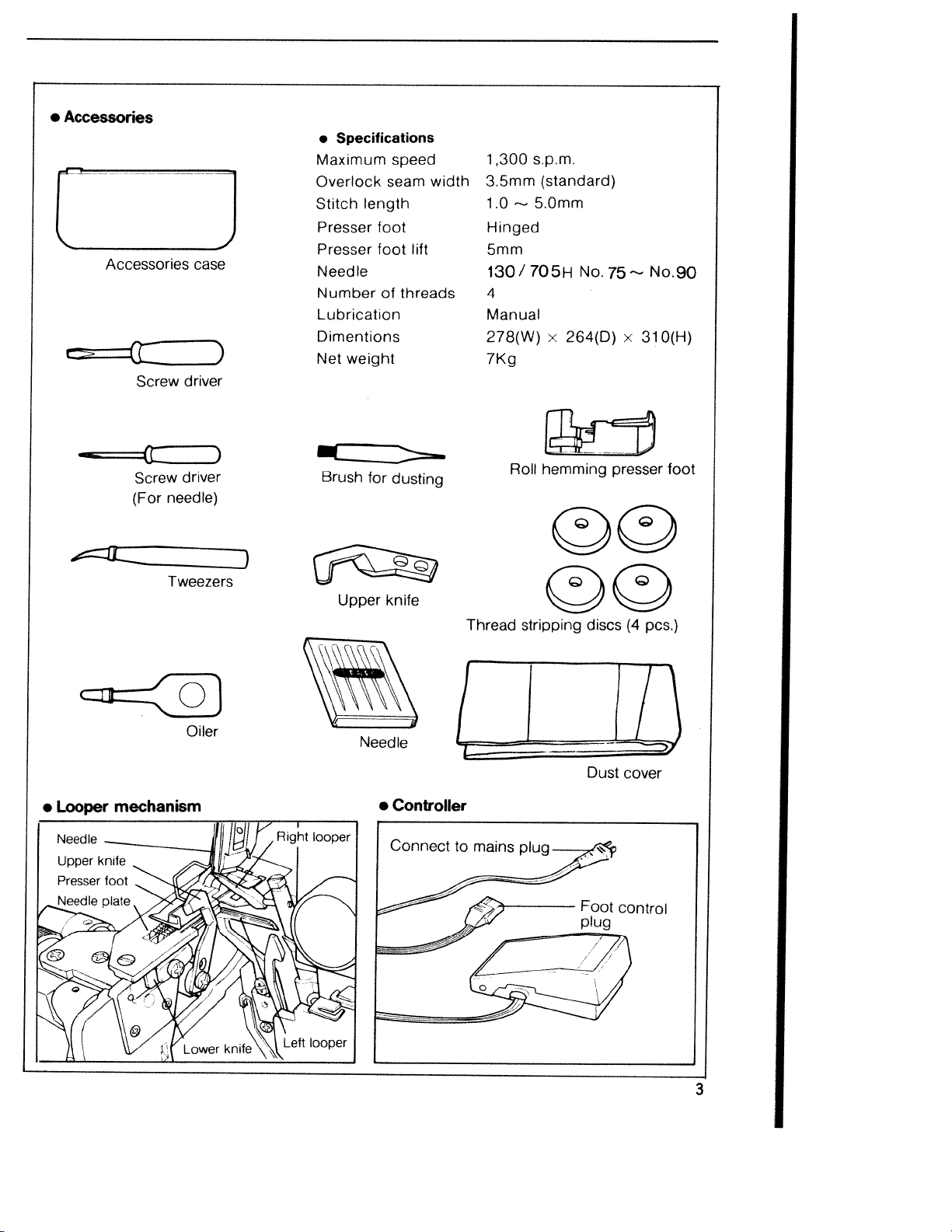

•

Accessories

Accessories

Screw

Screw

needle)

(For

case

driver

driver

•

Specifications

Maximum

Overlock

Brush

length

weight

for

Stitch

Presser

Presser

Needle

Number

Lubrication

Dimentions

Net

speed

seam

foot

foot

of

dusting

width

lift

threads

300

1

35mm

1.0

Hinged

5mm

130/705H

4

Manual

278(W)

7Kg

Roll

s.p.m.

(standard)

5.0mm

x

264(D)

hemming

No.75—

presser

><

No.90

310(H)

foot

•

Looper

Tweezers

mechanism

Oiler

Upper

Needle

knife

•

Controller

Thread

stripping

discs

Dust

(4

pcs.)

cover

3

Page 5

Preparation

B

Preparation

a.

This

horizontal

machine

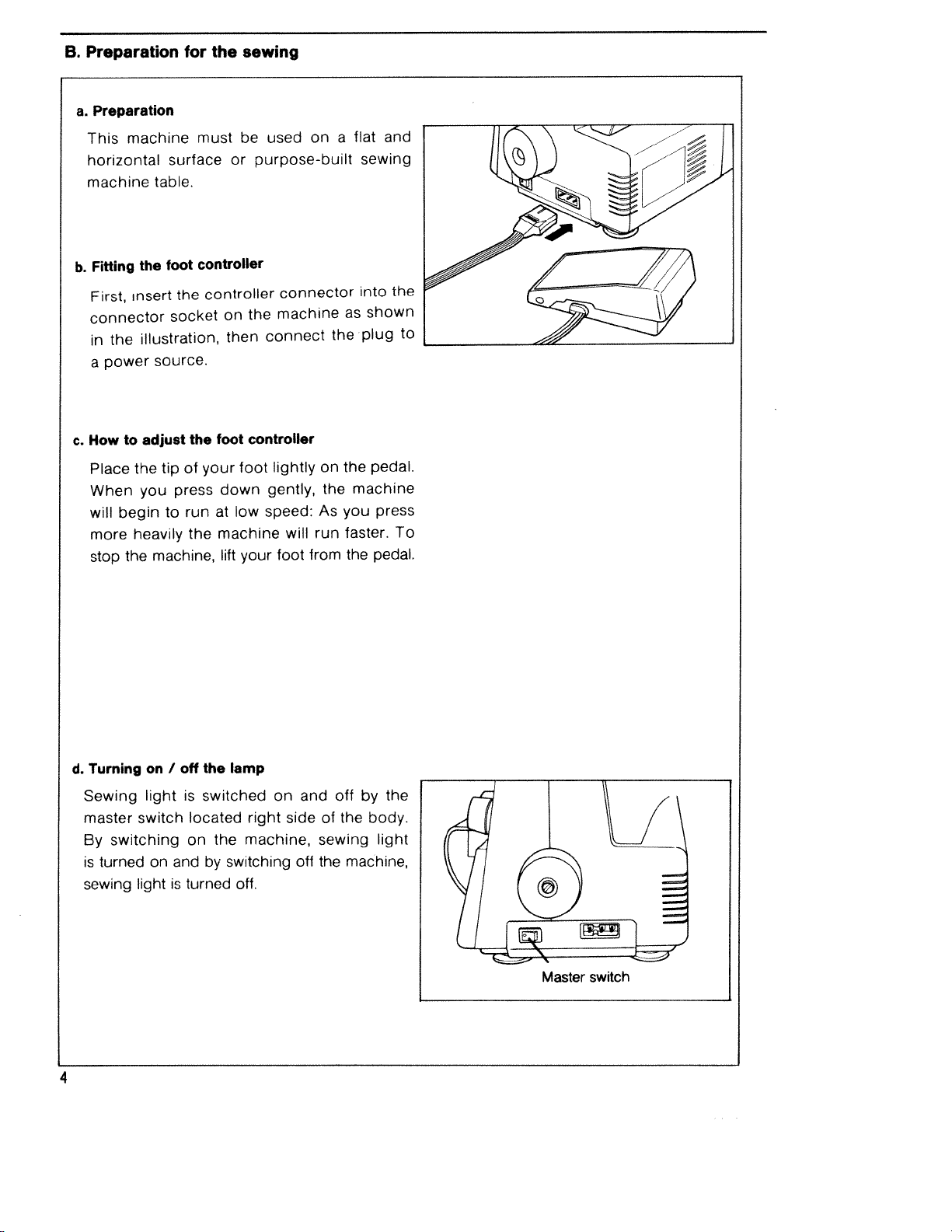

Fitting

b.

First,

connector

in

a

How

c.

Place

When

will

more

stop

machine

the

power

to

begin

the

surface

table.

foot

the

the

insert

socket

illustration,

source.

adjust

the

tip

press

you

to

heavily

machine,

the

for

must

controller

controller

foot

the

your

of

at

run

the

sewing

be

or

purpose-built

the

on

then

controller

foot

down

low

machine

lift

your

used

connector

machine

connect

lightly

gently,

speed:

will

foot

on

on

the

As

run

from

a

as

the

the

you

faster.

the

and

flat

sewing

the

into

shown

plug

pedal.

machine

press

pedal.

to

To

4

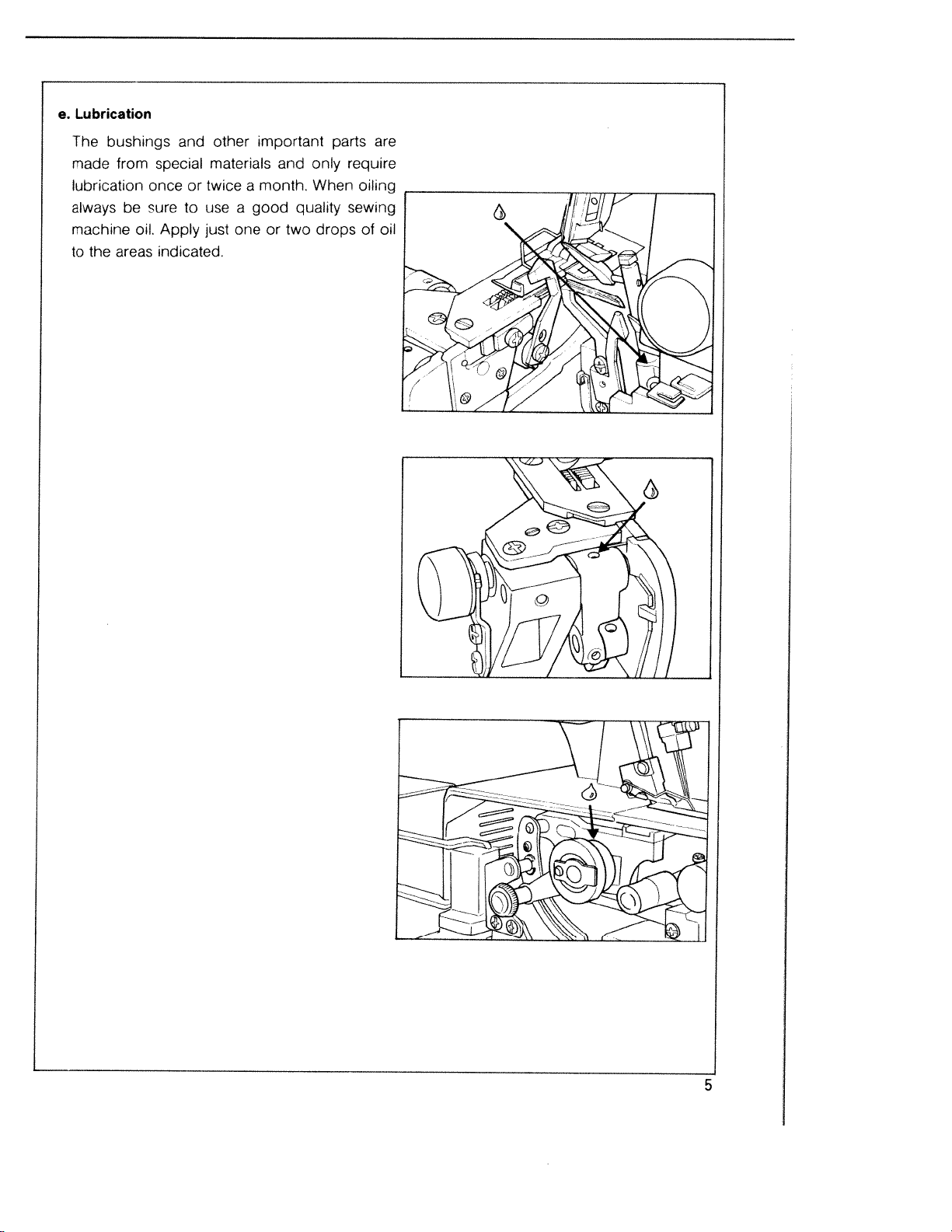

d.

Turning

Sewing

master

By

is

sewing

switching

turned

on

light

switch

on

light

/

and

is

off

the

is

switched

located

on

turned

the

by

switching

lamp

right

machine,

off.

on

side

off

and

off

of

the

sewing

the

machine,

by

body.

the

light

Page 6

Lubrication

e.

The

made

lubrication

always

machine

to

the

bushings

from

be

oil.

areas

and

special

once

sure

to

Apply

indicated.

or

twice

use

just

other

materials

a

good

a

oneortwo

important

and

month.

quality

parts

only

When

drops

are

require

oiling

sewing

of

oil

5

Page 7

f.

Opening

and

side

and

cover

closing

looper

cover

1.

To

tion

To

it

To

2.

cover

To

3.

cover

until

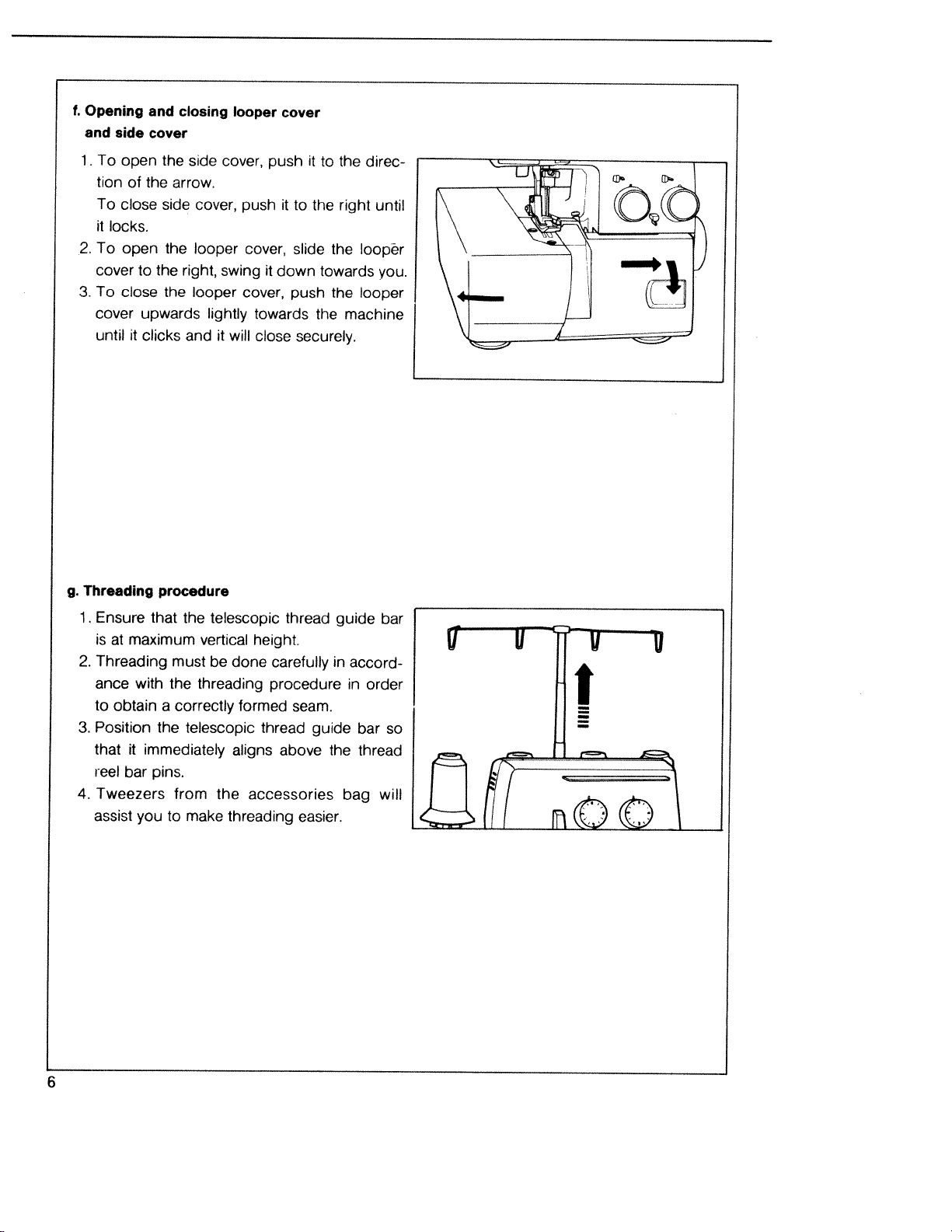

Threading

g.

open

of

close

locks.

open

close

it

the

the

arrow.

side

the

to

the

the

upwards

clicks

procedure

side

cover,

looper

right,

looper

and

cover,

swing

lightly

it

will

push

cover,

cover,

towards

close

push

it

down

it

it

to

slide

push

securely.

to

the

the

right

the

towards

the

the

direc

until

looper

you.

looper

machine

maximum

at

with

obtain

bar

you

that

must

the

a

the

pins.

to

1.

Ensure

is

Threading

2.

ance

to

Position

3.

thatitimmediately

reel

Tweezers

4.

assist

the

telescopic

vertical

be

threading

correctly

telescopic

from

make

done

formed

aligns

the

accessories

threading

height.

carefully

procedure

thread

above

thread

seam.

easier.

in

guide

the

guide

accord

in

bag

bar

order

bar

thread

will

so

ff7

\

6

Page 8

0

0

e

0

0.

-I

C

C

•0

•0

-I

8

g.

r

OCD

‘<

oc

CD

CD

CD

0

00C

3

0

0

0

C,

C

Page 9

Next

thread

the

right

neecile

3.

4.

Lastly

thread

the

left

needle

Leave

beyond

surplus

needle

surplus

needle

thread

eyes.

thread

eyes.

about

about

cm

5

(about

cm

5

(about

2”)

2”)

It

would

coloured

this

(4),

Once

threads

careful

Be

breakage

Then

are

achieved.

8

be

threads

will

are

you

that

of

proceed

helpful

identify

satisfied

are

when

thread

to

are

the

to

be used.

passing

that

sew

in

used.

the

threads

that

these

may

with

initial

Similar

the

occur

caution

stage,

to

being

tension

threads

if

those

used

due

until

(before

illustrated

with

balance

through

care

you

commencing

on

respective

is

correct

the

machine,

is

not

taken.

are

satisfied

the

needle

that

to

Tension

(page

so

sew)

the

and

10)

as

correct

that

Dial

looper.

tie

avoid

to

different

Diagram

on

those

results

any

Page 10

OPerating

C.

a.

After

before

Procedure

1.

2.

sewing

Test

threading,

Hold

turn

you

Checking

Insert

the

sewing

actual

the

the

with

the

edge

the

operation.

4

pulley

your

the

cloth

of

slowly.

machine

be

threads

2

right

threads

under

the

sure

or

hand.

upper

to

by

3

being

the

make

your

turns

a

left

slowly

interlocked.

presser

cutter

test

hand

foot

and

sewing

and

towards

up

start

to

b.

Thread

The

thread

you

c.

Dial

Broad

Denim

Georgette

•

Narrow

Broad

Georgette

correct

and

in

achieving

chart

Thread

Fabrics

iply

2plies

lply

tension

thread

must

for

2plies

hemming

ply

1

adjustment

tension

therefore

the

best

thread

L.needle

Spun

*80

Spun

*80

be

results.

tension

Rneedle

Spun

*80

Spun

*80

•

(Normal

varies

adjusted

adjustment

Thread

R.looper

.

hemming)

depending

accordingly.

Spun

*80

•

Spun

*80

Lkioper

Spun

*80

•

Spun

*80

on

the

fabric

By

Dial

for

L.needle

3

4

2

—

—

refering

Dial

Rneedle

and

type

and

3

for

thickness

the

to

chart

below

Dial

R.looper

Dial

for

L.looper

3

of

the

will

it

assist

for

Presser

toot

3

toi

4

2

3

2

3

3

6

6

NOrmal

3

hemming

3

3

for

Roll

3

hemming

•

Fold-over

Broad

Georgette

iply

hemming

i

Spun

*80

•

Spun

*80

•

Spun

*80

•

Spun

*80

—

—

3

2

3

3

10

10

for

Roll

hemming

9

Page 11

d.

Relation

chart

for

fadrica

and

thread

stitch

length

Normal

h.nimlng

Roll

m

Fabrics

Cotton,

dress

Light

light-knit

silk,lining

Mdlum

tricot,

materials

H.avy

suit

heavy

tadrica

KnIt

george

c

fabric,

materials

linen,

materials,

cloth

tte

Organdy,

Taffeta,

Tweed,

denim,

g

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Polyester

Polyester

Synthetic

Woolly_nylon

Polyester

Synthetic

Woolly

thread

thread

thread

thread

thread

thread

thread

nylon

Thr.ad

No.80—100

No.80—100

No.80

No.60—100

No.50—100

No.60—80

No.40—60

No.40—60

No.30—SO

No.50—80

No.60—80

No.80—100

No.80—100

Stitch

to4.0mm

3.0

to

3.0

to

3.0

2.0to4.

to

1.0

l.ngth

4.0mm

4.0mm

0mm

1.5mm

10

e.

Correct

Top

thread

side

tension

Left

Right

needle

needle

thread

thread

Page 12

f.

Incorrect

1.

The

tension

thread

sketch

is

too

tension

shows

loose.

the

and

left

how

needle

to

adjust

thread

The

2.

tensionistoo

3.

The

sketch

tension

sketch

is

too

shows

loose.

shows

loose.

the

the

right

right

needle

looper

thread

thread

4.

The

tension

sketch

is

too

shows

loose.

the

left

looper

thread

11

Page 13

g.

Roll

•

Normal

hemming

hemming

foot

•

Roll

hemming

foot

Remove

ing

normal

N

By

results

•

How

to

replace

the

presser

foot

.

1

2.

(narrow

stitch

following

can

Raice

small

then

be

With

roll

hemming

lower

in

contact,

the

new

the

the

lever.

taken

the

the

foot

left

/

foldover

foot

this

be

achieved.

presser

The

presser

shank

then

needle

by

instruction,

foot

foot

off.

foot

foot

until

lower

will

then

first.

For

hemming)

the

roll

very

and

for

normal

still

under

connecting

the

be

engaged.

the

hemming

good

then

raised,

the

presser

roll

replace

push

sewing

place

shank

points

foot

hemm

the

foot.

sewing

up

can

the

and

are

and

the

12

•

Correct

thread

Top

Narrow

side

tension

hemming

of

roll

hemming

Top

side

Fold-over

hemming

Page 14

h.

Points

•

Place

the

•

Then

fabric

guide

•

Do

avoid

to

foot

not

observe

the

before

slowly

will

by

push

the

during

fabric

commencing

sew

feed

hand.

or

possibility

sewing

under

the

the

first

automatically

pull

the

of

breaking

cutter

to

sew.

few

material

and

stitches,

and

so

the

needles.

lower

the

genUy

as

to

Caution

in

needle

to

needle

•

For

cm

beyond

thread

•

Securing

Tie

crochet

chain

•

To

prevent

proximately

flip

fabric

proximately

•

This

machine

fabrics.

tighten

pushing

breakage

plate,

finishing

chain.

the

the

thread

needle

into

over

When

the

and

a

the

seam:

can

the

seam.

unravelling

cm

5

and

2

cm.

will

sewing

upper

or

and

seam,

end

chain.

beyond

sew

knife

pulling

looper

of

be

used

sew

from

screw.

of

cause

mechanism.

approximately

sew

the

seam

For

to

of

seams,

the

over

fine

very

heavy

(see

fabric

further

then

knit

pull

the

seam.

the

seam

to

very

illustration).

can

damage

cut

fabric,

thread

sew

Then,

heavy

fabrics,

result

5

the

a

ap

ap

•

Caution:

When

loosen

have

sewing

the

been

upper

sewing

fine

fabrics,

knife

on

screw

heavy

remember

again

fabrics.

to

if

you

13

Page 15

i.

3

thread

overedge

seam

Three-thread

either

right

Threading

For

wide

Remove

1.

the

Use

2.

looper

left

width

Seam

3.

mm.

7

For

narrow

1.

Remove

2.

Use

the

left

&

looper

Seam

3.

5

width

mm.(Standard

Wide

left

Use

sewing

or

left

procedure

seam

the

left

hand

thread.

can

(Standard

seam

the

left

right

thread.

can

seam

hand

sewing.

right

hand

hand

needle

hand

hand

needle

be

seam

sewing.

needle

be

changed

seam

is

possible

needles.

is

as

needle.

thread

changed

width

needle.

width

only.

usuaJ.

is

thread

is

from

5.5

from

3.5

and

by

5

mm).

and

3

mm).

using

right

mm

right

mm

&

to

to

14

Narrow

right

Use

seam

hand

needle

El

Iii

Ii

only.

Page 16

D.

a.

Some

Adjusting

Standard

adjusted

the

different

1.

Open

the

right

the

releasing

To

ations

2.

Adjust

the

adjustments

the

seam

from

materials.

the

side

upper

knob

raise

dial.

and,

above.

the

knife

whilst

and

the

the

required

seam

width

3.0mm

cover

knife

pressure

knife,

/

Maintenance

width

is

3.5

to

5.0mm

and

looper

control

maintaining

towards

as

simply

seam

knob

the

mm.

pressure,

you

knife

reverse

width

It

can

when

using

cover.

firmly

downwards,

is

the

by

Push

to

lowered.

oper

turning

be

the

turn

After

necessary

Adjusting

b.

1.

2.

Align

3.

on

length

number.

select

4.

After

feed

Wide

seam

To

change

cover.

Loosen

the

width

adjusting

to

the

the

the

feed

feed

longer

To

a

lower

making

regulator

Narrow

the

reset

stitch

the

stitch

feed

regulator

regulator

regulator.

move

make

number.

the

nut

seam

the

thread

length

length,

nut

To

the

the

stitch

adjustment,

and

close

seam

width,

tension.

nut.

and

make

nut

length

the

open

the

to

tighten

width

it

may

the

the

a

side

be

side

number

stitch

higher

shorter

the

cover.

15

Page 17

c.Replacing

needle

(S)

DURING

MAINS

1

Removing

Turn

the

(in

the

to

the

(s)

loosen

needle(s).

Fitting

2.

Whilst

fully

upwards

sure

that

towards

the

needle

The

recommended

705H,

and

No.90.

Depending

Needle

used.

a

finer

needle,

weights.

Ensure

to

not

as

breakage

THIS

PLUG

pulley

direction

highest

the

needle

If

necessary,

new

in

this

the

Then

you.

clamp

the

on

sizes

Light

you

carry

so

do

and

OPERATION

FROM

needle

wheel

of

the

position.

clamp

needle(s)

position,

into

the

long

groove

using

screw

needle

normal

the

weight

from

No.

weight

with

a

out

could

also

skipped

DISCONNECT

THE

POWER

(s)

towards

arrow),

Using

screw

use

the

insert

needle

in

the

a

screwdriver,

securely.

system

recommended

of

fabric

75toNo.

materials

thicker

result

this

needle

procedure

in

stitches.

SOURCE.

you

raising

a

and

tweezers

new

holder(s)

needle(s)

you

90

thread

THE

by

hand,

the

needle

screwdriver,

remove

supplied.

needle(s)

making

face

re-tighten

are:

130

size

are

using

may

needing

for

heavier

correctly

or

needle

the

/

is

be

Fitting

the

left

needle

screw

16

ATTENTION

When

of

The

crosses

erly

Take

the

slant

replacing

the

illustrations

needle

insert

special

screw

and

the

the

straight

do

clamp

other.

screws

care

not

needles,

below:

screw

It

is

when

not

but

force

please

for

each

important

refitting

to

try

to

rather

the

screw.

take

to

needles.

put

follow

note

needle

prop

back

the

F.ftng

the

right

needle

Needle

screw

cramp

clamp

Page 18

d.

Replacing

the

upper

knife

DURING

PLUG

1.

To

Push

towards

the

remove

into

knife

THIS

FROM

the

you,

is

(approximately

Then

loosen

the

knife,

2.

Fitting

a

Place

the

the

(in

a

opposite

screwdriver,

securely.

Turn

the

release

the

knife

to

pressure

firmly

guard

normal

3.

To

Place

and,

you,

the

lower

re-tighten

against

on

set

the

by

lower

tip

knife

on the

the

operation.

the

turning

it

of

the

the

driver.

If

it

is

necessary

knife

screw

Only

very

tiny

OPERATION

THE

the

right,

the

held

horizontal

the

taking

new

upper

new

retighten

a

vertical

the

presser

cutting

upper

the

to

its

upper

by

1.0mm.

screw

(A)

and

movements

MAINS

upper

and

upper

in

position

retaining

care

knife

manner

knob

knob,

lower

position:

knife

pulley

bottom

(A)

to

adjust,

raise

OUTLET.

knife.

turn

down

knife

by

to

screw

not

to

knife

onto

the

as

abnve),

the retaining

away

position,

the

knife

knife

foot.

It

in

the

wheel

position

knife

should

When

securely,

loosen

or

lower

shouki

DISCONNECT

anti-clockwise

release

the

knob,

carrier

stopper

you).

and

take

touch

carrier

the

stopper

and,

screw

from

you,

then,

by

releasing

will

be

brought

and

behind

is

now

ready

cutting

by

hand

at

position

towards

which

overlap

in

this

position,

using

a

the

upper

as

required.

be

necessary.

THE

until

blade.

using

(A)

raising

the

for

point

the

screw

off

1.0mm

Surface

of

needle

plate

17

Page 19

e.

Replacing

the

lower

knife

DURING

PLUG

FROM

To

remove the

1.

push

First

knob

turning

upper

Loosen

lower

knife,

Fitting

2.

Insert

holder

knife

set

right,

the

blade

and

plate

using

a

Replace

means

by

1

7).

THIS OPERATION

ThE

MAINS

lower

the

into

knife

the

taking

new

a

knife

the

the

aligns

then

screwdriver.

the

of

right

it

anti-clockwise

described

(as

knife

lower

care

lower

into

with

and,

knife

with

re-tighten

upper

the

release

so

knife

DISCONNECT

OUTLET

knife.

upper

the

on

screw

nottotouch

knife

groove

the

cutting

the

the

that

the

surface

fixing

the

in

its

knob

knile

to

release

page

remove

and

of

edge

cutting

of

screw

working

(see

release

1

7)

the

the

edge

the

securely.

position

also

THE

the

the

blade.

lower

facing

of

needle

page

18

Page 20

f.

Replacing

FIRST

THE

the

DISCONNECT

POWER

SOURCE

light

bulb

THE

MAINS

PLUG

FROM

•

Loosen

and

body

•

Turn

the

Insert

turningitin

Replace

Caution:

screwofthe

the

remove

the

bulbindirection

new

the

bulb

direction

the

cover.

maximum15

Use

a

rearofthe

lamp

(1)

pushing

by

(2).

cover.

and

watt

machine

remove

upward,

bulb

it.

only.

19

Page 21

Sewing

E.

Used

from

various

Listed

overcome

problems

correctly,

time

to

adjustments

below

most

time

are

your

encounter

the

these

of

and

machine

in

the

more

difficulties.

solutions

should

the

occasional

recommended

common

problems,

operate

efficiently

problem

manner.

together

and

which

with

without

usually

their

difficulty.

results

simple

However

from

solution

not

carrying

which

you

shouki

my

uiit

Problem

Needle

Thread

Skipped

Incorrect

formation

breakage

breakage

stitches

stitch

Needle

Needle

Material

Incorrectly

Thread

Thread

Needle

Incorrect

Needle

Needle

Incorrect

Incorrectly

Incorrect

tensions

is

not

not

bent

not

bent

correctly

pulled

threaded

caught

has

tension

correctly

needle

correctly

needle

threaded

setting

Cause

or

too

or

damaged

point

used

used

of

inserted

tight

inserted

inserted

thread

damaged

Insert

Insert

Do

not

sewing.

Thread

Check

reel

stand,

Regulate

Insert

Use

needle

Insert

Insert

needle

Use

Thread

thread

Set

new

new

pull

correctly.

whether

tension.

needle

new

needle

correctly.

tensions

needle.

needle

or

push

etc.

correctly.

system

needle.

correctly.

system

Solution

correctly.

material

thread

130/705

130

correctly.

is

/70

caught

during

at

only.

H

5H

the

only.

20

Puckered

Material

correctly

is

seams

not

fed

Thread

Thread

incorrect

Sewing

position

tension

has

caught

threading

is

foot

too

not

tight

due

in

the

to

working

Reduce

Thread

Push

thread

correctly

the

presser

tension

foot

lever

down.

Loading...

Loading...