Page 1

C

Cs’

C,

C-)

C

C)

Cl)

C)

D

3

0

a)

D

C

a)

C

Page 2

ion.

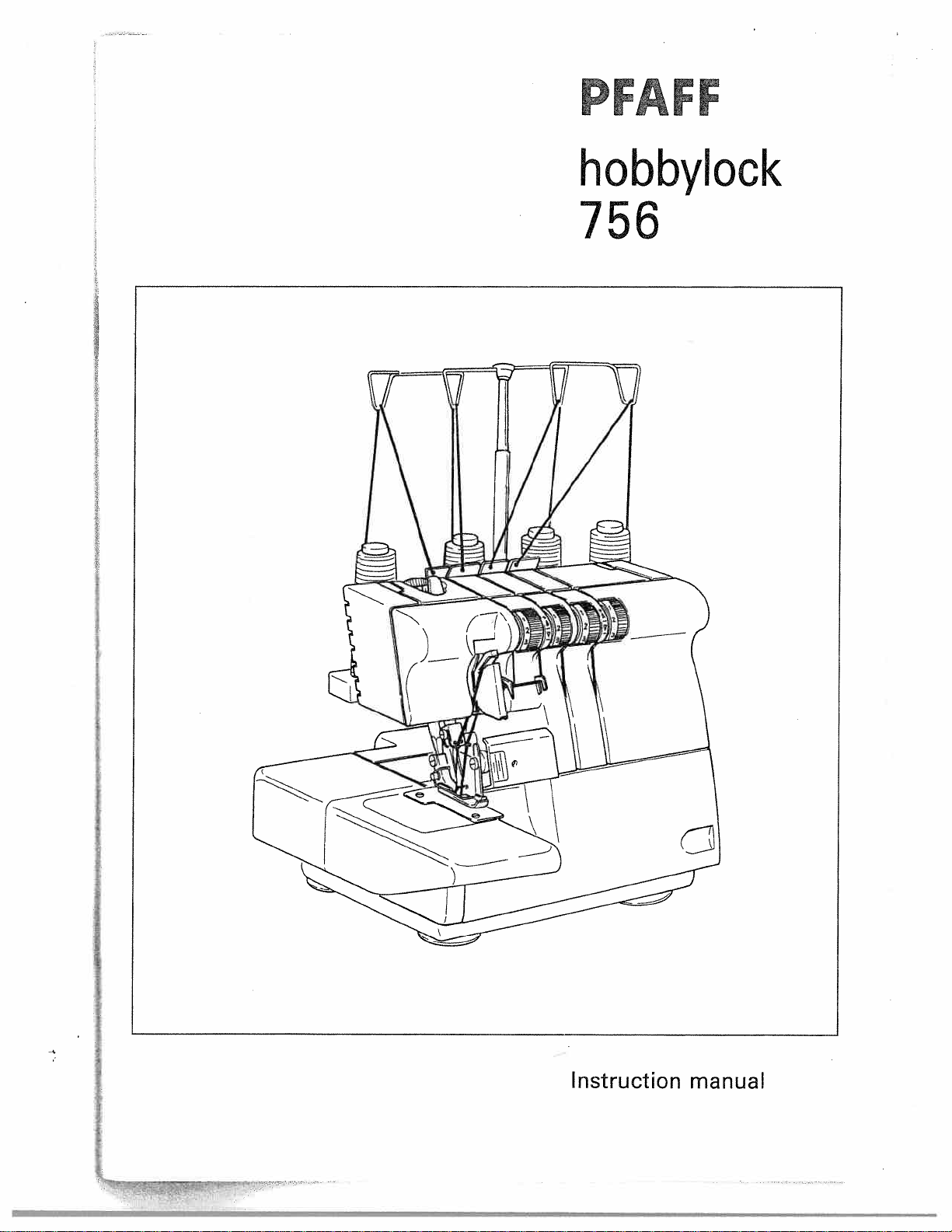

PFAFF

instruction

now

certainly

to

it

have

advice.

or

let’s

now

up-to-date

756

hobbylock

take

full

use.

any

Simple,

Congratulations!

hobbylock

ope

Your

this

as

you

If

It

is

put

you

If

help

So

time

get

You

can

manual

a

bit

well

further

started!

sewing

have

take

features

time

of

spent,

questions

bought

any

is

We

material

the

follow.

to

study

to

since

wish

high-quality

a

in

very

the

it

is

just

ask

many

you

stride

its

latest

instruction

only

the

your

enjoyable

product

and

design

in

way

PFAFF

will

and

manual

find

to

dealer.

hours

provides

that

sew,

technology,

nothing

out

He

creating

trim

just

is

and

can

what

happy

your

unique

neaten

and

go

your

to

very

advantages.

up

just

is

it

amiss.

machine

service

of

be

own

for

you

easy

as

can

fashion

Your

with

one

in

to

do

any

ideas.

new

use

and

Safety

the

For

leads

The

with

wires

The

the

As

coding

wire

The

coloured

or

wire

The

coloured

or

L

Under

tely.

Only

must

The

pliers

Please

ru’es

United

must

three

in

Blue:

Brown:

colours

the

of

which

which

circumstances

no

Defective

spare

A

3

marked

be

must

plug

the

or

also

Kingdom

pins.

the

Neutral

of

terminals

black.

red.

mains

fuses

never

PFAFF

observe

under

mains

Live

the

coloured

is

coloured

is

A

3

only

no

lead

wires

your

in

should

leads

must

with

or

used

be

agencies.

general

the

circumstances

coloured

are

mains

the

in

proceed

plug,

must

blue

brown

must

be

must

cut-off

be

as

used

corresponding

the

without

safety

completetly

be

according

lead

connected

be

connected

be

mains

approved

covers.

fuse

notes

connected

to

this

of

follows:

as

plugs

replaced.

ASTA

by

colour

Spare

page

on

to

following

the

appliance

the

to

the

to

used.

be

according

code.

fuse

2.

the

may

terminal

terminal

They

covers

safety-lead

code:

correspond

not

which

which

should

BS

to

are

terminal

marked

is

marked

is

disposed

be

362

1

available

and

from

to

I

the

with

with

of

the

to

nor

colour

lettter

the

the

immedia

fuse

electrical

plug

a

letter

cover

N

sup

:

Page 3

___________________

DANGER

sewing

The

1.

electric

the

not

not

unplug

reach

place

into

water

Always

2.

Do

3.

Do

4.

:

drop

WARNING

allow

not

Do

1.

1:

children.

this

2.

3.

4.

5.

6.

7

8.

9

10.

11.

12.

13.Donot

14.

15

16.

17.

:

use

Only

commended

operate

Never

dropped

been

service

Never

machine

Never

Do

Do

To

Never

Do

Keep

Always

Do

Switch

needle,

Always

any

Hold

center

operate

and

drop

use

not

operate

not

disconnect,

operateona

unplug

not

fingers

use

use

pull

not

the

changing

unplug

other

plug

user

when

machine

outlet

before

a

for

store

or

or

be

to

sewing

by

the

this

or

for

the

foot

insert

or

out

of

where

turn

by

away

proper

the

or

bent

push

or

sewing

sewing

servicing

rewinding

IMPORTANT

For

This

you

be

reduce

To

should

immediately

relamping.

sewing

other

used

damaged,

examination

sewing

control

doors.

pulling

needle,

machine

sewing

a

liquid.

reduce

To

as

machine

manufacturer

sewing

machine

free

anything

aerosol

controls

all

surface

soft

on

all

from

needle

needles,

blunt

while

fabric

machine

threading

machine

adjustments

United

the

sewing

an

use

adhered

risk

the

never

after

machine

risk

toy.

a

for

machine

dropped

or

repair,

from

into

(spray)

to

such

cord.

moving

plate.

stitching.

off

0’)

(

from

cord

into

States

machine

electric

to:

of

electric

left

be

using

Replace

that

of

burns

Great

intended

its

as

contained

if

it

electrical

with

the

opening.

any

products

(,,O’)

off

as

To

unplug,

parts.

The

Only

when

bobbin,

the

mentioned

reel.

only

designed

is

appliance,

instructions

all

Read

shock:

unattended

before

and

with

bulb

fallen

has

whereitcan

electric

fire

necessary

care

is

purpose

this

in

has

damaged

a

water.

into

or

openings

air

any

accumulation

are

position,

couch

or

bed

a

hold

plate

needles

may

making

or

changing

not

care

deflect

outlet

in

allow

Special

wrong

use

It

electric

Do

SAFETY

and

following

the

before

plugged

when

cleaning.

type

same

water.

into

be

or

fall

shocks

when

described

as

manual

cord

the

Return

mechanical

blocked.

dust

of lint

used

being

remove

then

where

not

plug,

the

is

required

cause

can

recommended

needle,

the

adjustments

any

presser

when

instruction

the

to

plug

manufactured

basic

using

Always

in.

15

rated

Unplug

or

removing

immediately.

into

pulled

injury

or

sewing

this

in

if

plug,

appliance

adjustment

Keep

loose

and

where

or

from

plug

air

the

cord.

the

around

needle

the

by

causing

in

etc.

foot,

manual

when

whip

this

it

openings

the

the

covers,

INSTRUCTIONS

HOUSHOLD

for

precautions

safety

sewing

this

Watts.

tub

a

persons

to

machine

manual.

not

is

to

the

ventilation

cloth

oxygen

socket.

sewing

the

to

manufacturer.

itto

needle

rewinding.

machine.

or

sink.

openings

is

being

may

break.

area

this

is

Only

authorized

be

machine

such

unplug

working

nearest

break.

lubricating,

Do

used

properly,

only.

use

should

appliance

place

not

or

by

attachments

use

if

dealer

the

of

administered

blocked

needle.

threading

as

when

or

When

always

from

in

or

near

has

it

sewing

making

re

or

I

Please

KEEP

4

observe

also

THESE

the

general

safety

page

on

notes

INSTRUCTIONS

2

IN

SAFE

A

PLACE.

Page 4

Notes

on

safety

.1

Notes

according

nes

335-2-28.

The

1.

with

ment

area

working.

2.

When

maintenance

mechanical

disconnect

by

The

3.

sewing

The

4.

be

The

5.

as

Do

6.

the

Do

7.

—

—

—

8.

Do

ket

If

9.

pose

operated,

for

To

0.

1

open

side

pair.

our

Be

11.

safety

on

user

regard

under

pulling

maximum

tension

adjusted

machine

indicated

not

machine.

not

there

its

function

is

it

not

by

this

any

avoid

the

This

qualified

sure

to

must

the

of

constant

leaving

out

lamp

place

use

visible

is

e.g.

wet,

pull

cord.

its

appliance

that

than

we

damage

the

machine.

the

machine

the

to

domestic

for

60335-2-28

EN

exercise

the

to

needle

the

work

parts

machine

the

the

permissible

15

is

the

of

a

by

should

the

on

any

sewing

the

defective,

is

with

mains

the

intended

cannot

caused.

risk

exclusive

service

only

use

adequate

and

up

and

observation

machine,

when

or

accessories,

or

mains

Watts.

drive

Ptaff

be

specification

objects

damage,

condensation.

plug

used

is

accept

electric

of

There

which

staff.

original

sewing

bzw.

down

the

keep

during

changing

the

from

plug.

wattage

should

belt

mechanic.

into

put

in

openings

machine

of

out

another

for

is

it

or

if

any

shock,

no

are

user

the

responsibility

PFAFF

machi

IEC

caution

move

sewing

while

always

mains

the

for

only

operation

plate.

on

if:

sok

the

pur

wrongly

liability

not

do

in

parts

re

can

parts.

of

Environment

recommended

The

Ambient

Humidity

This

mechanical

supervised

rated

dust,

tic

sive

To

must

and

Treatment

Always

by

Cleaning

Housing

To

cloth

born

fin.

Please

Never

such

the

temperature

sewing

in

such

severe

electricity,

chemicals

permit

kept

be

even

make

knocking

clean

which

dirt,

Note!

use

as

housing.

%

20

machine

appliance;

use

a

dampness,

adequate

unblocked

surface.

sure

or

display:

and

housing,

the

is

use

insecticides

petrol

environment

100

C

%

80

to

is

a

is

it

the

home.

in

it

that

way

direct

heat-producing

liquids.

or

ventilation

and

damage

not

to

of

cloth

or

it.

use

fluff.

or

thin

dropping

free

soft

a

(gas)

is:

C

40°

to

high-quality

machine

a

It

should

exposed

is

not

sunlight,

objects,

the

on

used

your

clean

dry,

a

remove

To

alcohol

with

chemical

chemicals

electro

for

be

machine

firm

a

machine

and

any

or

products

to

ope

to:

sta

corro

soft

stub

paraf

clean

I

I

I

I

I

2

Ir

Page 5

CONTENTS

4

J

Accessories

1

2.

Needle

Principal

3.

Howtoopen

4.

Principal

5.

Preparation prior

6.

7.

Setting

Howtoremove

8.

•

•

Howtoremove

9.

10.

How

Threading

11.

•

•

•

a

•

12.

Chaining

13.

Basic

•

•

a

Howtoadjust

14.

•

a

a

•

•

•

15.

How

16.

How

17.

How

•

To

•

To

information

parts

looper

behind

parts

up the

thread

and insert

To

To

remove

insert

needle

needle

and

cloth

plate

remove

to

cylinder

Threading

cover

the

and

machine

diagram

Understanding

diagram

Stitch

To

thread

the

Important

stitch

thread

4

mock

off

and

types

overlock

safety

threading

Wide3thread

Narrow

3

thread

thread

Suggested

overlock

Correct

overlock

tension

mock

balanceofthe

mock

Howtobalance

thread

balance

to

balance

change

adjust

disengage

movable

mock

tension

overlock

stitch

stitch

threads/tie

the

overlock

Suggested

3

Correct

overlock

How

overlock

to

to

to

place

nonworking

place movable

position

cover

looper

to

sewing

guide

needle

(s)

(s)

replace

replace

color

the

machine

correctly

information

sewing

test

stitch

overlock

stitch

overlock

tension

settings

stitch

safety

4

safety

stitch

the4thread

safety

stitch

setting

stitch

of

the

3

the3thread

on

stitch length

movable

knife

upper

in

position

knifeinworking

cover

holder

code

stitch

for4thread

thread

for

the

thread

method

knife

Page

4

4

5

6

6

6

7

8

8

8

9

9

10

10

10

10

10

17

18

19

19

19

19

19

20

20

20

21

21

21

. .

.

.22

23

.

.

.

.23

18.

Seam guide

How

19.

seam

How

20.

•

•

•

•

•

•

21.

Stitch

•

•

•

•

•

•

•

•

•

•

How

22.

23.

Free

24.

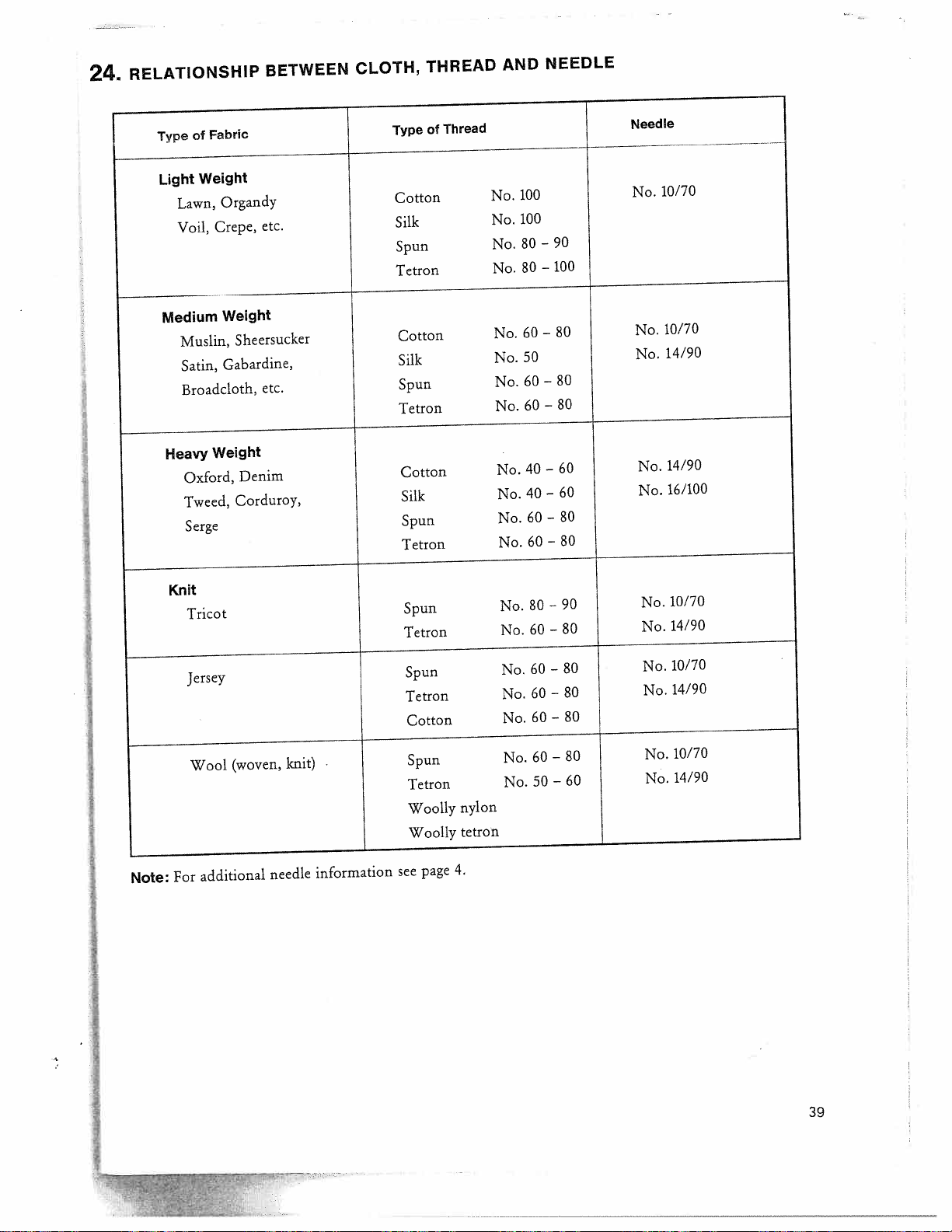

Relationship

25.

Machine

•

•

•

•

26.

Troubleshooting

27.

Optional

28.

Specification

lines

to

adjust

the

overedge

width

to

sewarolled

Machine

set up

Suggested

standard rolled

Suggested

thread

looper

How

to balance

thread

wrapped

Additional

rolled

hemming

To

secure

hem

tension

settings

hem

tension

settings

wrapped

the

rolled

information

rolled

the

chain

variations

and

sewing

techniques

Howtosewaflatlock

seam

How

to

sewanoverlock

How

to

sew

Turning

Pin

square

placement

Securing

Applying

How

to

reinforceaseam

Braiding

Differential

feed

machine

to

adjust

arm

sewing

the

elastic

by

chaining

feed

the

pin

corners

thread

only)

presser

tucks

(with

between cloth,

and

needle

maintenance

Cleaning

Oiling

How

How

the

machine

the machine

to

replace

to

exchange

the

light

chart

accessories

and

for

for

rolled

looper

upper

hem

about

hem

thread

decorative

blind

chain

off

differential

foot

thread

stationary

bulb

attachments

upper

hem

hem

pressure.

knife

Page

24

25

26

26

27

. .

.

.27

27

28

28

29

29

31

31

32

33

33

34

35

35

36

.

.

.38

38

39

40

40

40

.

.

.

.41

42

43

44

45

23

24

3

Page 6

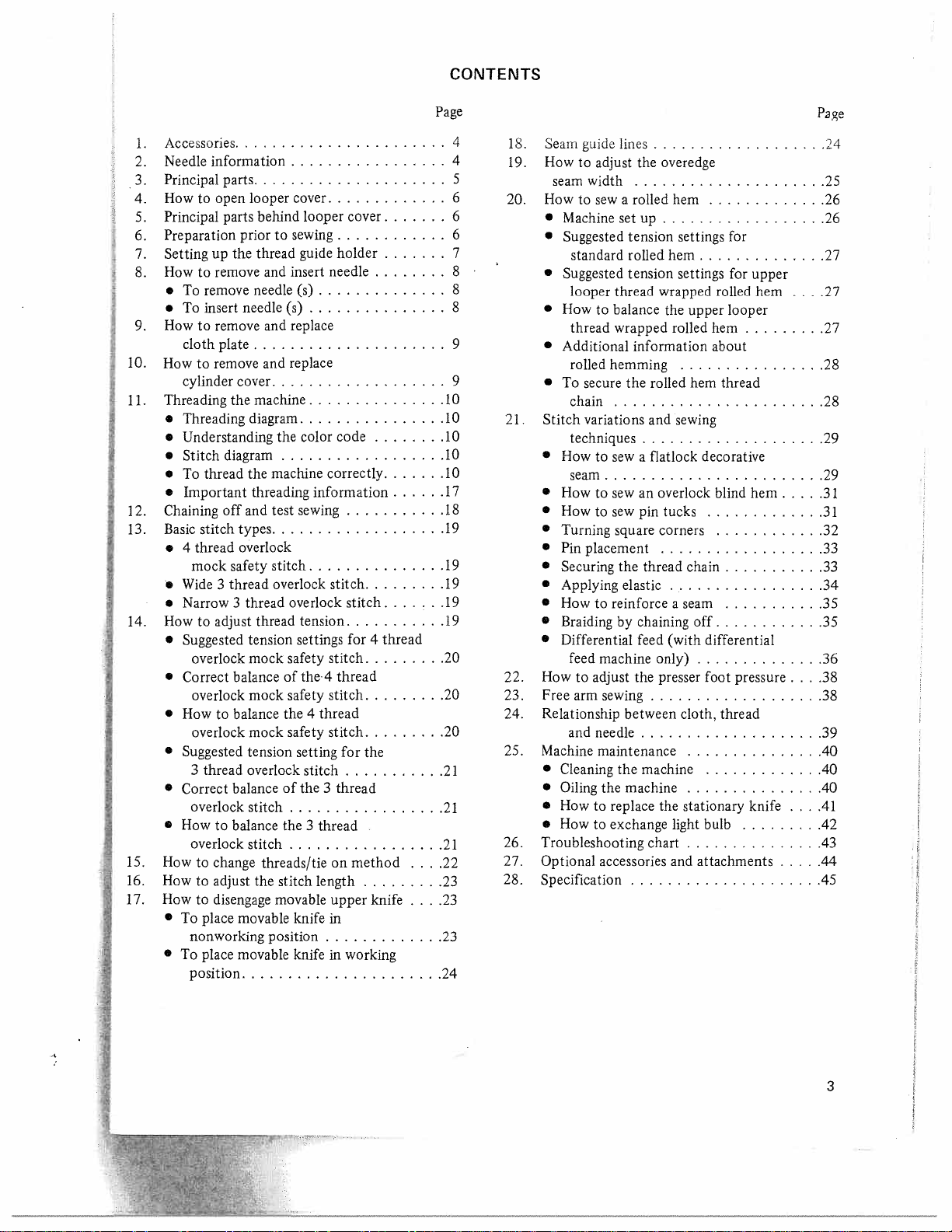

ACCESSORIES

1.

(

(

®

©

©

See

2.

*

Needle

set

Screwdriver

Sciewdiver

Tweezers

hemming

Rolled

Hex-head

44

page

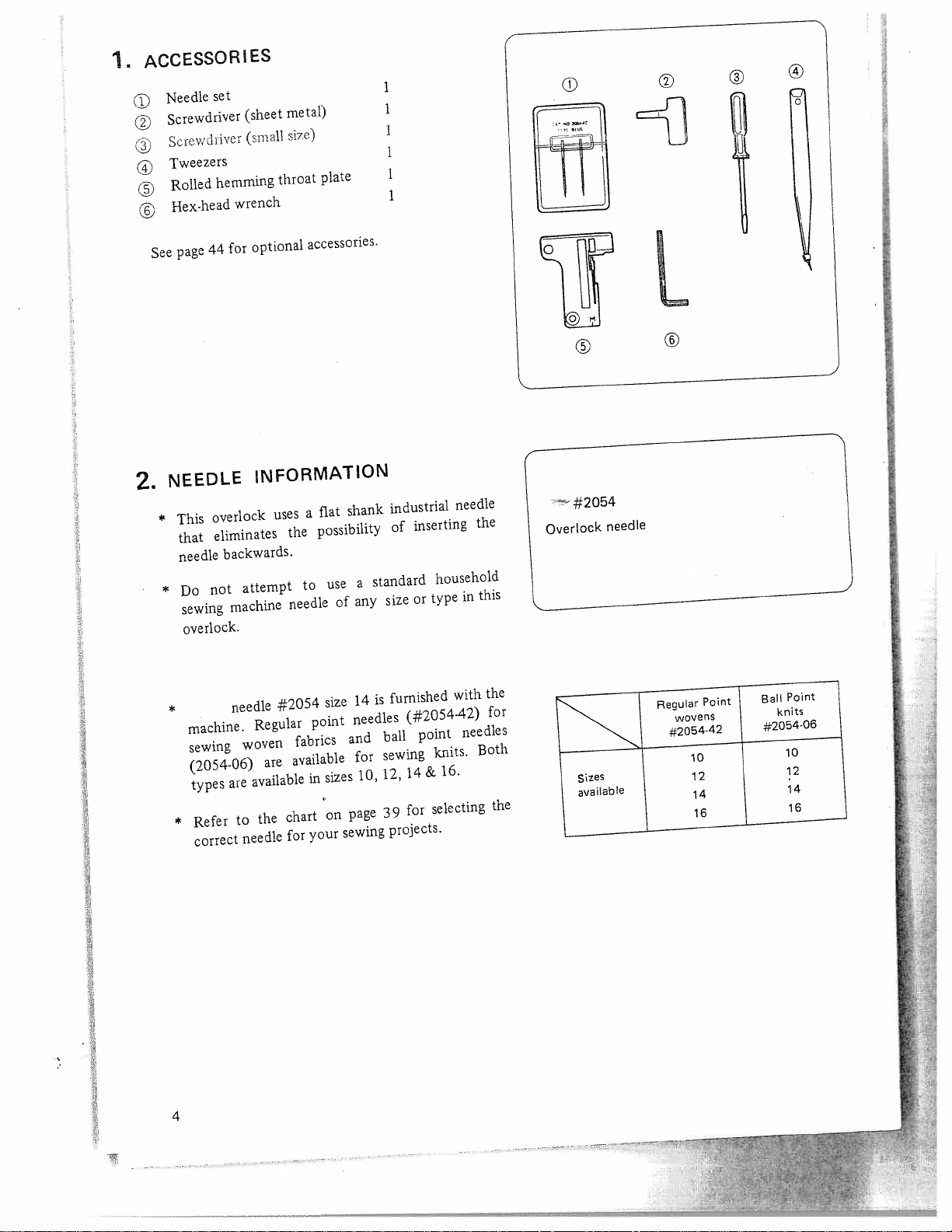

NEEDLE

overlock

This

eliminates

that

needle

*

not

Do

sewing

overlock.

metal)

(sheet

si7e)

(small

throat

wrench

optional

for

INFORMATION

uses

the

backwards.

attempt

machine

to

needle

plate

accessories.

shank

flat

a

possibility

a

use

any

of

1

1

I

industrial

of

standard

size

inserting

household

type

or

needle

the

this

in

#2054

Overlock

needle

L

fl

U

J

-

0

V

*

machine.

sewing

(2054-06)

types

*

Refer

correct

4

needle

woven

are

to

needle

#2054

Regular

available

are

available

chart

the

for

point

fabrics

in

your

size

sizes

on

14

needles

and

for

10,

page

sewing

furnished

is

ball

sewing

12,

39

projects.

with

(#2054-42)

14

for

point

knits.

16.

&

selecting

needles

the

for

Both

the

Ball

Sizes

available

Regular

wovens

#2054-42

Point

10

12

I__________

Point

knits

#2054-06

10

12

Page 7

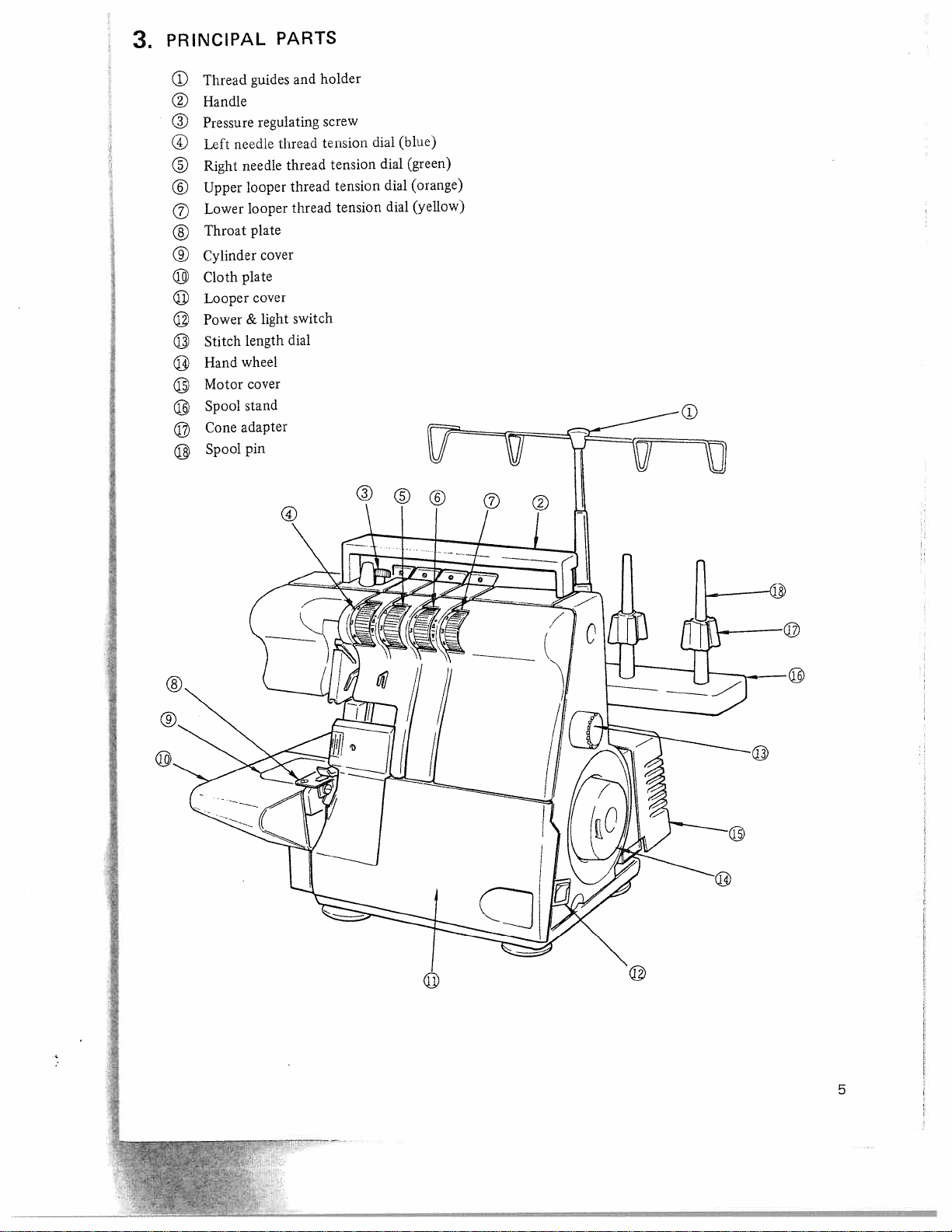

PRINCIPAL

3.

©

®

©

©

®

®

©

©

©

©

©

®

©

®

Thread

Handle

Pressure

Left

needle

needle

Right

Upper

Lower

Throat

Cylinder

plate

Cloth

Looper

Power

Stitch

wheel

Hand

Motor

Spool

adapter

Cone

Spool

PARTS

guides

regulating

thread

looper

looper

plate

cover

cover

light

&

length

cover

stand

pin

and

thread

thread

thread

switch

dial

holder

screw

tension

tension

tension

tension

dial

dial

dial

dial

(blue)

(green)

(orange)

(yellow)

5

Page 8

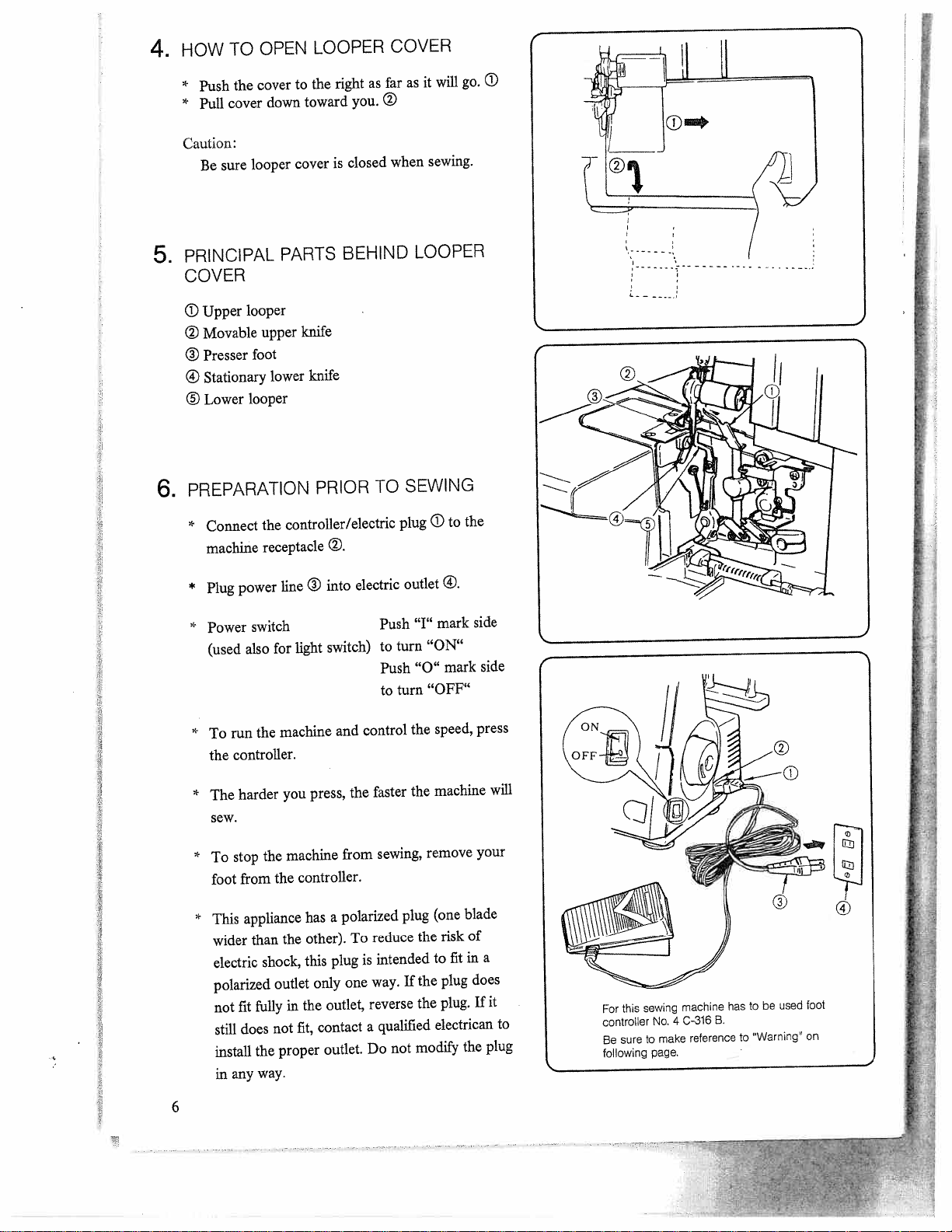

4.

HOW

TO

OPEN

LOOPER

COVER

*

*

Push

Pull

the

cover

Caution:

sure

Be

PRINCIPAL

5.

COVER

Upper

()

()

Movable

Presser

®

Stationary

®

Lower

®

PREPARATION

6.

*

Connect

machine

to

cover

down

cover

looper

PARTS

looper

knife

upper

foot

lower

looper

controller/electric

the

receptacle

the

toward

knife

PRIOR

().

as

right

you.

closed

is

BEHIND

TO

as

far

()

when

LOOPER

SEWING

plug

will

it

sewing.

tD

to

go.

the

*

*

*

*

*

*

Plug

Power

(used

power

switch

also

run

To

controller.

the

harder

The

sew.

stop

To

from

foot

appliance

This

wider

electric

polarized

fit

not

does

still

install

any

in

the

the

than

shock,

fully

the

way.

line

light

for

machine

you

machine

controller.

the

has

other).

the

this

outlet

the

in

fit,

not

proper

into

©

switch)

press,

only

outlet,

contact

outlet.

electric

control

and

the

from

polarized

a

To

is

plug

one

Push

to

Push

to

faster

sewing,

reduce

intended

way.

reverse

qualified

a

not

Do

outlet

turn

turn

the

the

plug

If

®.

mark

“I”

“ON”

mark

“0”

“OFF”

speed,

machine

remove

(one

risk

the

to

plug

the

plug.

the

electrican

modify

fit

side

side

press

your

blade

of

in

does

If

the

will

a

it

plug

B.

to

“Warning”

to

on

For

to

controWe

sure

Be

foflowing

to

page.

No.

make

4

C-316

reference

machine

sewing

this

foot

used

be

has

6

Page 9

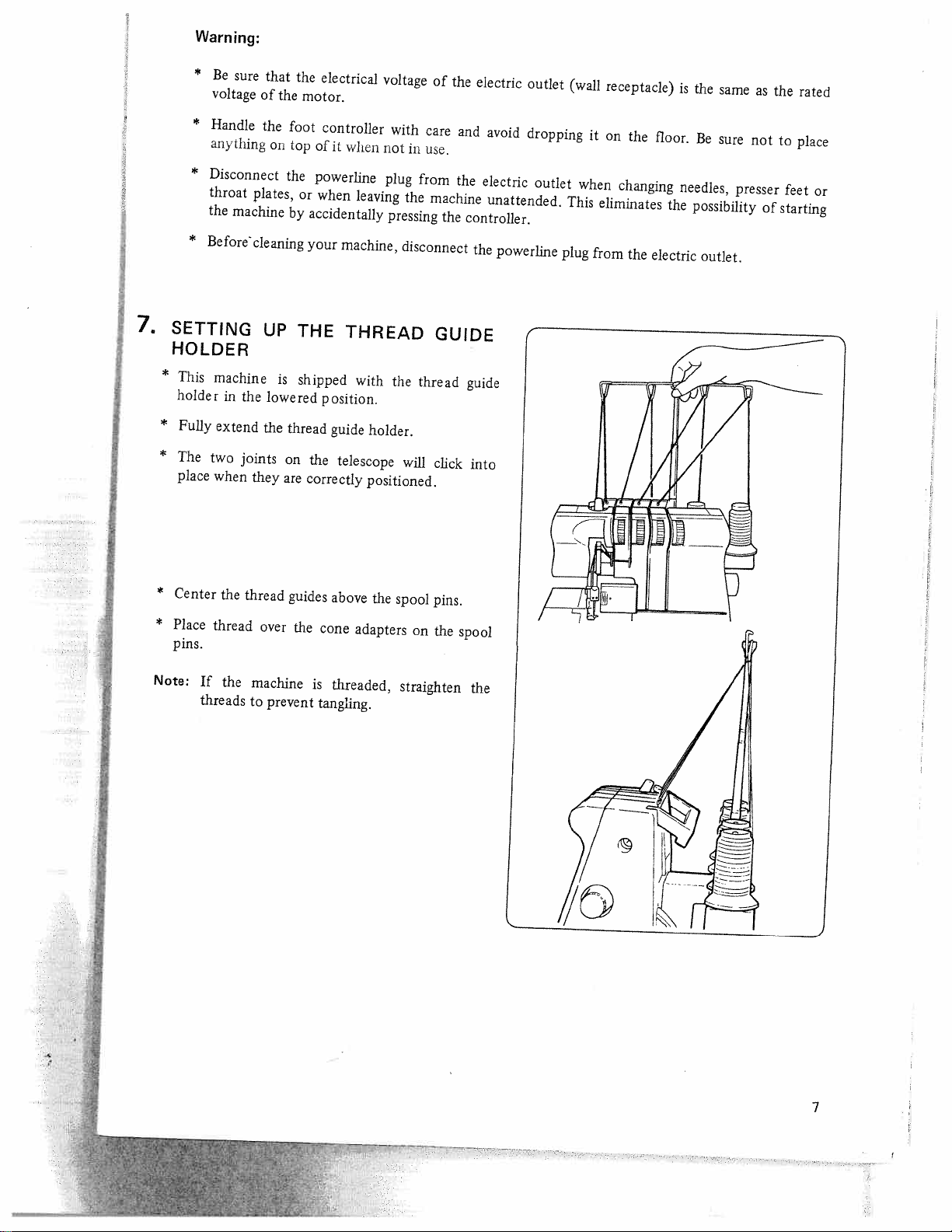

7.

*

*

*

Warning:

*

Be

sure

voltage

*

Handle

anything

*

Disconnect

throat

the

machine

*

Befor&cleaning

SETTING

HOLDER

This

machine

holder

The

place

Fully

in

extend

two

when

of

plates,

the

joints

they

that

the

the

the

foot

on

top

the

by

UP

is

lowered

the

thread

on

are

electrical

motor.

controller

of

it

when

powerline

or

when

accidentally

your

machine,

THE

THREAD

shipped

position.

guide

the

telescope

correctly

voltage

with

not

plug

leaving

pressing

with

the

holder.

positioned.

of

the

care

in

use.

from

the

machine

the

disconnect

GUIDE

thread

will

click

electric

and

avoid

the

electric

unattended.

controller.

the

guide

into

outlet

dropping

outlet

powerline

(wall

This

plug

it

on

when

eliminates

from

receptacle)

the

floor.

changing

the

electric

is

the

needles,

the

possibility

Be

outlet.

same

sure

presser

as

not

the

of

rated

to

place

feet

starting

or

*

*

Place

pins.

Note:

Center

If

threads

the

thread

the

thread

over

machine

to

prevent

guides

the

is

above

cone

adapters

threaded,

tangling.

the

spool

pins.

on

the

straighten

spool

the

7

Page 10

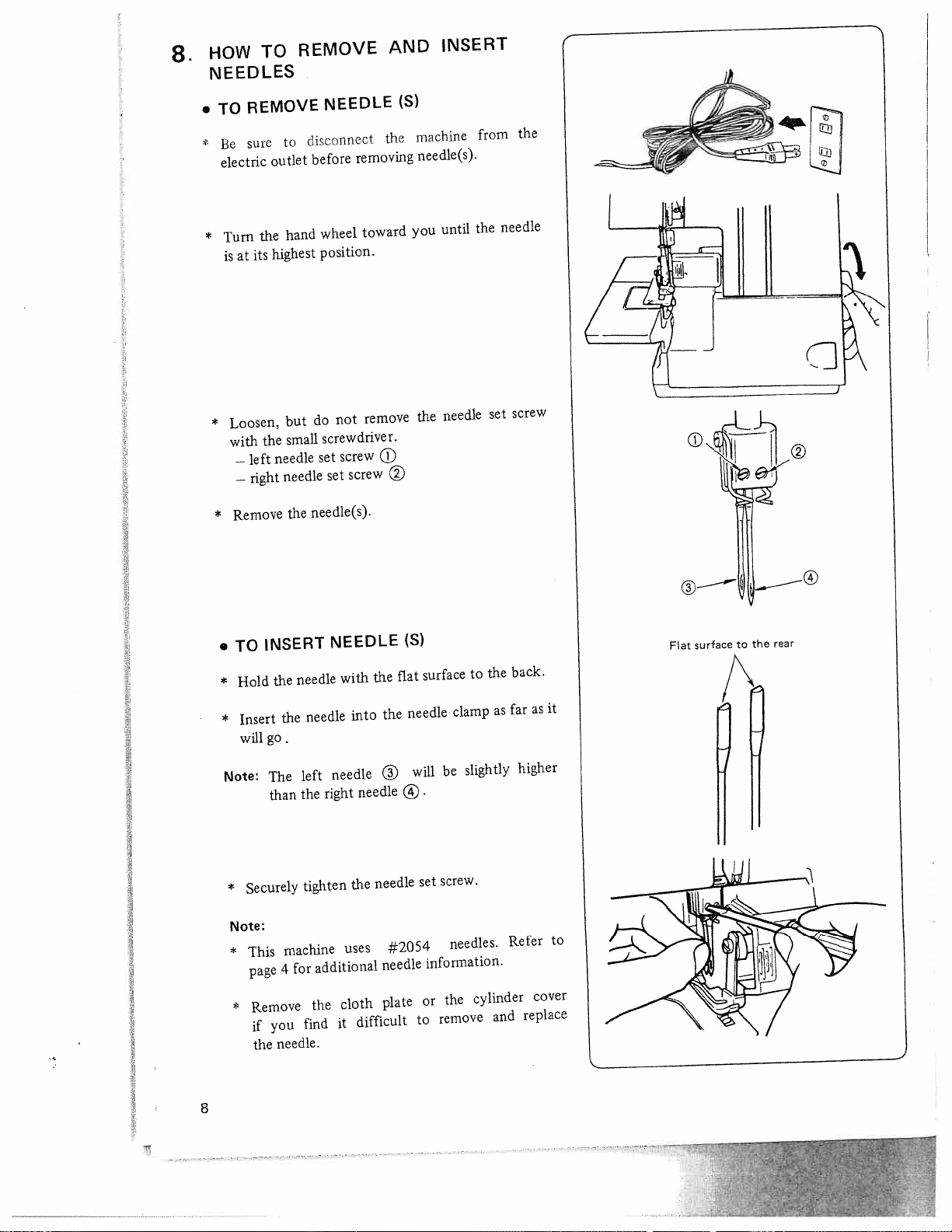

8.

HOW

TO

NEEDLES

REMOVE

AND

INSERT

•

*

*

*

*

REMOVE

TO

sure

Be

electric

Turn

at

is

Loosen,

with

—

—

Remove

the

its

the

left

right

to

outlet

hand

highest

but

small

needle

needle

the

NEEDLE

disconnect

removing

before

wheel

position.

not

do

screwdriver.

screw

set

screw

set

needle(s).

the

toward

remove

©

(S)

machine

needle(s).

you

the

until

needle

from

the

needle

set

the

screw

•

*

*

Note:

*

Note:

*

*

INSERT

TO

Hold

Insert

will

Securely

This

page

Remove

if

the

the

the

go.

The

than

machine

4

you

needle.

needle

needle

left

the

tighten

additional

for

the

find

NEEDLE

with

into

needle

needle

right

the

uses

cloth

difficult

it

flat

the

the

®

needle

#2054

needle

plate

(S)

surface

needle

will

®.

screw.

set

information.

or

remove

to

to

clamp

slightly

be

needles.

cylinder

the

the

as

and

back.

far

higher

Refer

replace

it

as

to

cover

Rat

rear

the

to

surface

1?

8

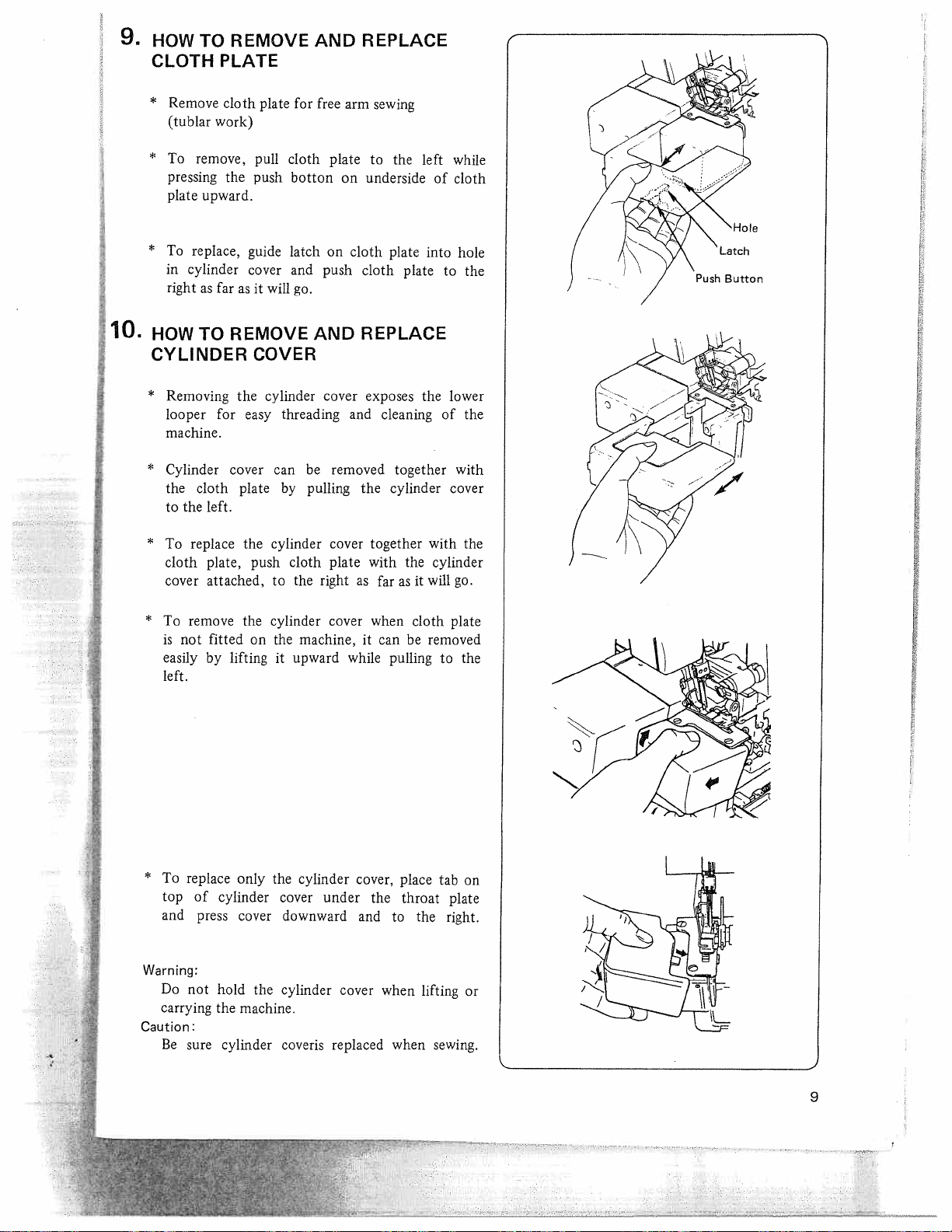

Page 11

9

HOW

CLOTH

*

Remove

(tublar

*

To

pressing

plate

*

To

replace,

in

cylinder

right

REMOVE

TO

PLATE

cloth

work)

remove,

the

upward.

as

far

as

plate

pull

push

guide

cover

will

it

for

cloth

botton

latch

and

go.

AND

free

plate

on

push

REPLACE

arm

sewing

to

on

underside

cloth

plate

cloth

the left

into

plate to

of

while

cloth

hole

the

:10.

HOWTO

CYLINDER

*

Removing

looper

machine.

*

Cylinder

the

to

*

To

cloth

cover

*

To

is

easily

left.

cloth

the

replace

remove

not

for

left.

plate,

attached,

fitted

by

REMOVEAND

COVER

the

easy

cover

plate

the

push

the

on

lifting

cylinder

can

cylinder

to

cylinder

the

it

cover

threading

be

pulling

by

cloth

the right

machine,

upward

removed

cover

plate

cover

REPLACE

exposes the

and

cleaningofthe

together

cylinder

the

together

with

the

as

far

as

when

it

canberemoved

while

pulling

with

will

it

cloth

lower

with

cover

the

cylinder

go.

plate

the

to

•1

4

*

To

top

and

Warning:

Do

carrying

Caution:

Be

replace

of

press

not

hold

the

sure

only

cylinder

cover

the cylinder

machine.

cylinder

the

cylinder

cover

downward

coveris

under

cover

replaced

cover,

the

and

when

place

throat

to the

lifting

when

tab

on

plate

right.

or

sewing.

9

Page 12

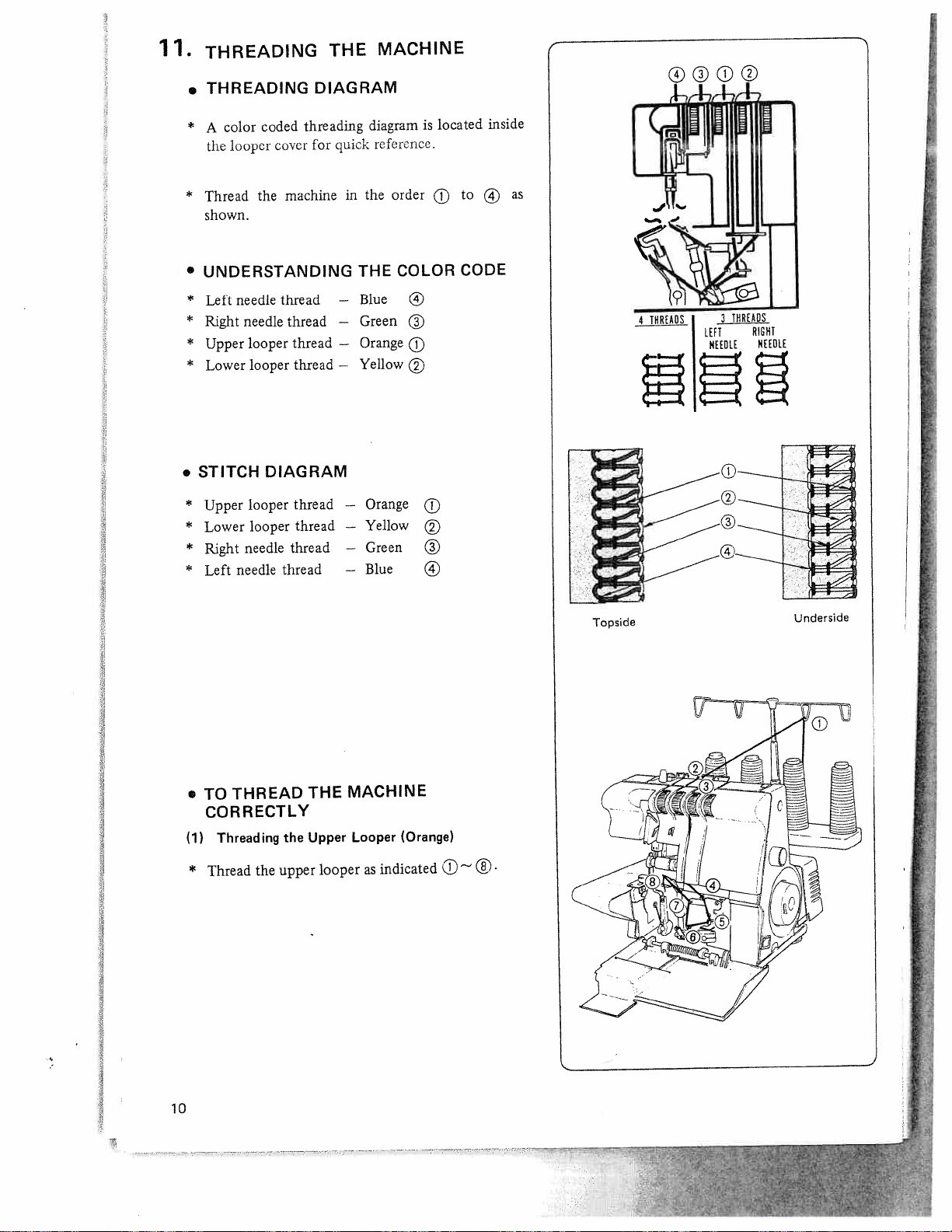

11.

THREADING

THE

MACHINE

r

THREADING

•

*

*

A

the

Thread

color

loopei

coded

cover

the

machine

shown.

UNDERSTANDING

•

*

Left

*

Right

*

Upper

*

Lower

STITCH

•

*

Upper

*

Lower

*

Right

*

Left

needle

needle

looper

looper

DIAGRAM

looper

looper

needle

needle

thread

thread

thread

thread

thread

DIAGRAM

threading

quick

for

—

—

—

thread

thread

thread

in

THE

Blue

Green

Orange

Yellow

—

—

—

—

diagram

refcrcnce.

the

order

COLOR

Orange

Yellow

Green

Blue

®

®

®

©

located

is

®

©

inside

to

CODE

as

THREAD

TO

•

CORRECTLY

Threading

(1)

*

Thread

the

the

upper

THE

Upper

looper

MACHINE

indicated

as

(Orange)

Looper

Topside

©

10

Page 13

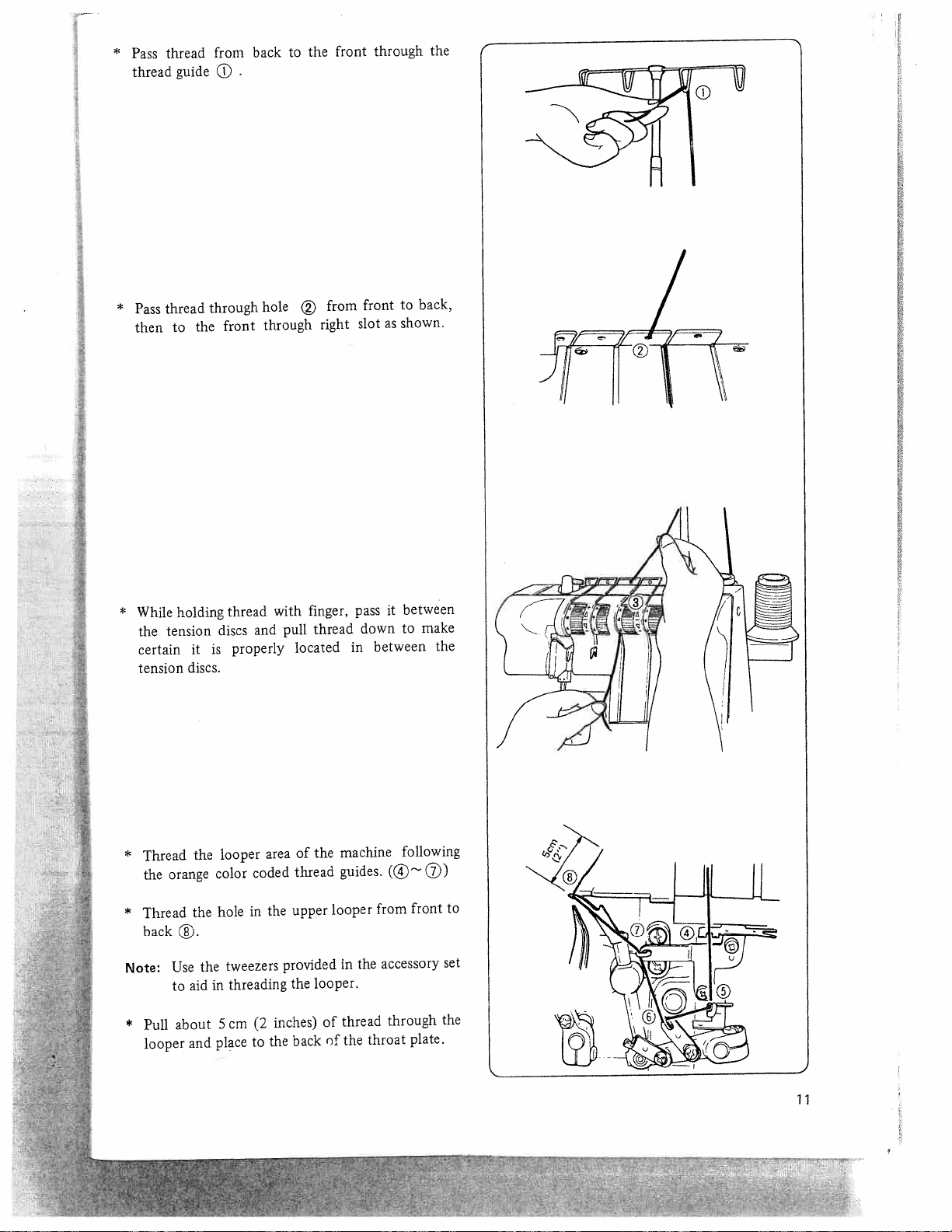

*

Pass

thread

thread

guide

from

D

back

front

through

the

to

the

F

F

*

*

Pass

then

While

the

certain

tension

thread

the

to

holding

tension

it

discs.

through

front

thread

discs

properly

is

hole

through

with

and

@

pull

located

from

right

finger,

thread

front

slot

pass

down

in

to

shown.

as

between

it

to

between

back,

F

make

the

I

I

:4

*

*

Note:

*

Thread

orange

the

Thread

back

Use

to

Pull

looper

the

the

®.

aid

about

and

color

the

in

place

looper

in

hole

tweezers

threading

cm

5

area

coded

the

inches)

(2

the

to

the

of

thread

upper

provided

looper.

the

of

back

machine

guides.

looper

in

thread

the

of

from

the

throat

following

®)

(®-

front

accessory

through

plate.

to

set

the

11

.-

-

--

.-

-

Page 14

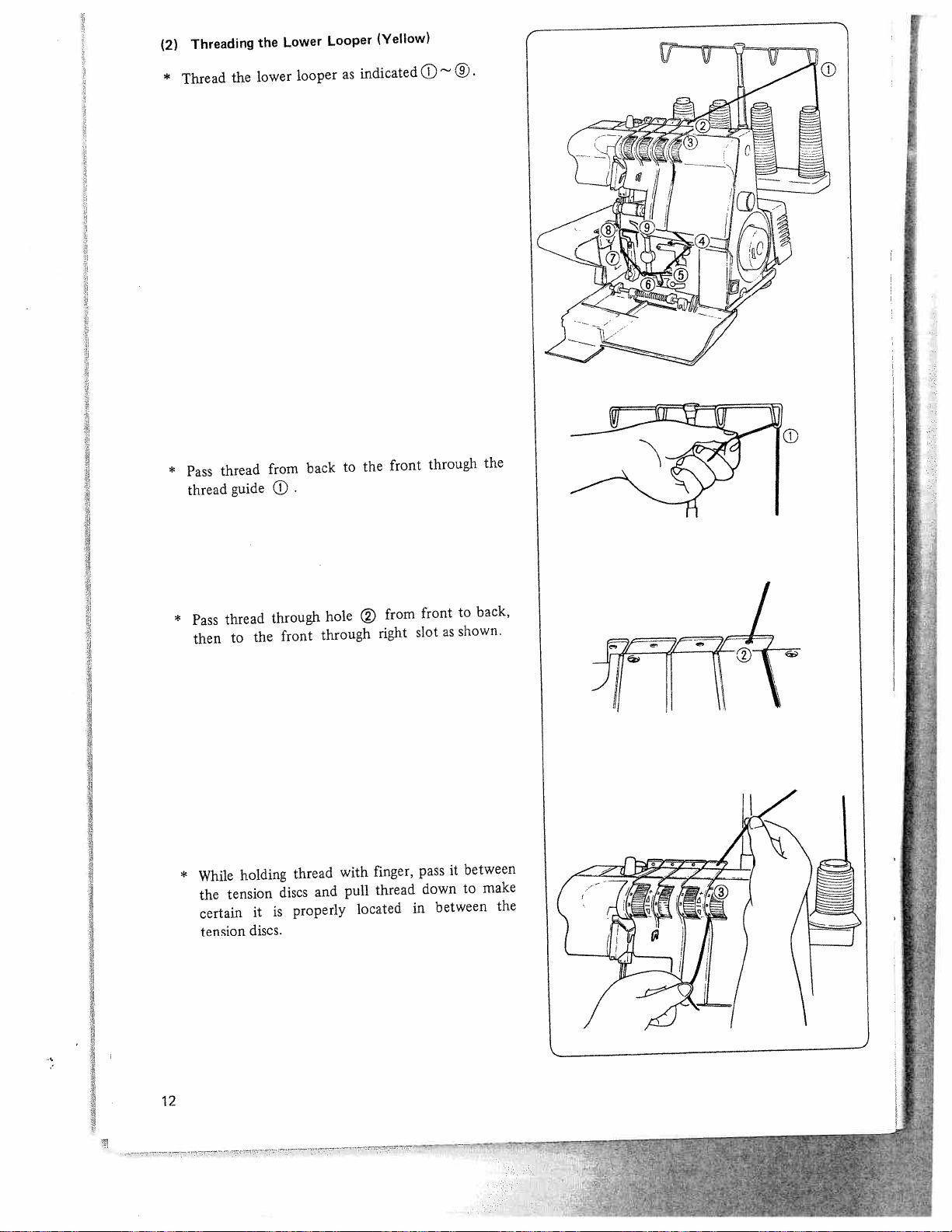

(2)

*

Threading

Thread

the

the

lower

Lower

looper

Looper

as

(Yellow)

indicated

D

*

*

Pass

thread

Pass

then

*

While

the

certain

tension

thread

guide

thread

to

holding

tension

from

through

the

it

discs.

front

discs

is

back

hole

through

thread

and

properly

to

with

pull

the

from

J

right

finger,

thread

located

front

through

front

slot

pass

down

in

to

shown.

as

between

it

to

between

the

back,

make

the

12

Page 15

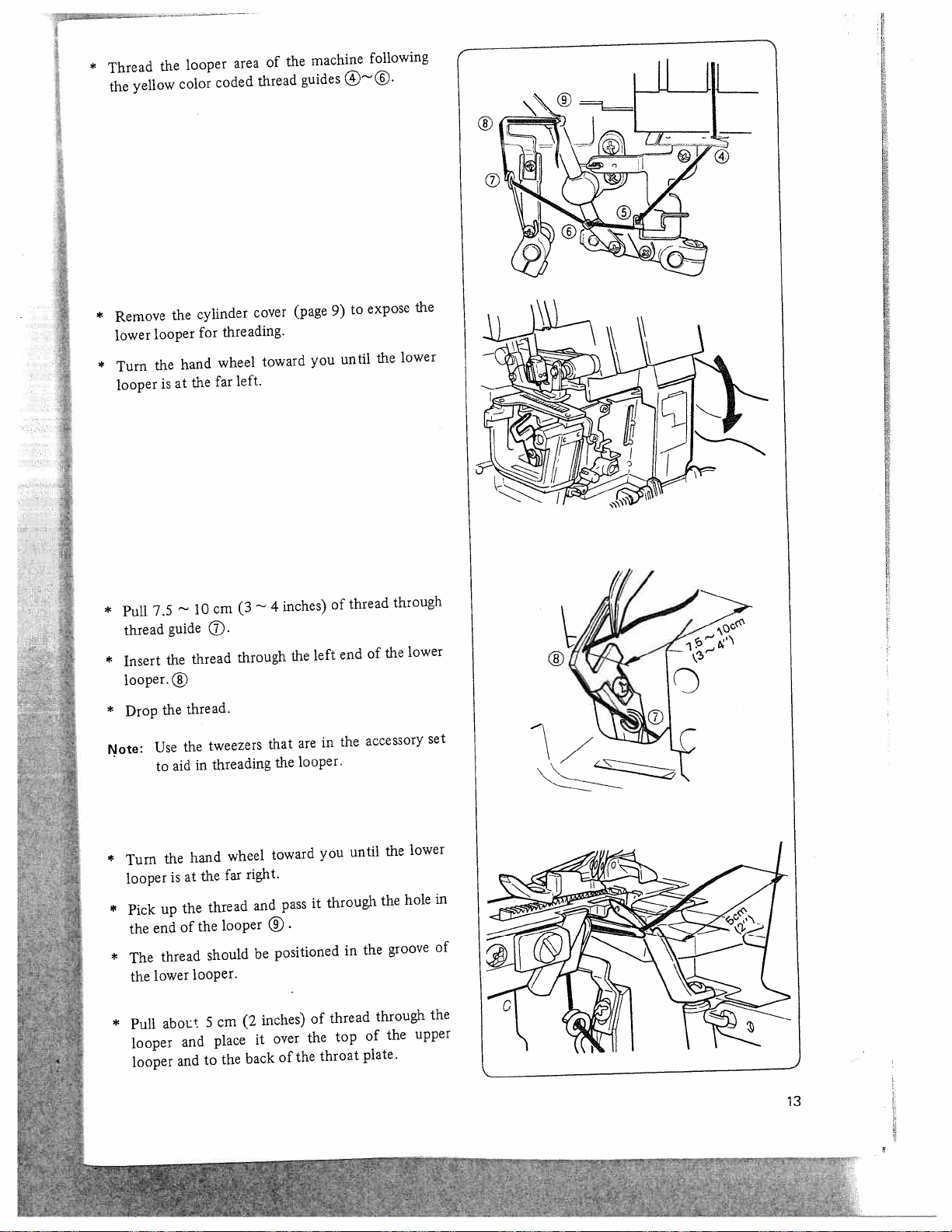

*

*

*

Thread

yellow

the

Remove

lower

Turn

looper

the

color

the

looper

hand

the

at

is

looper

cylinder

for

the

area

coded

cover

threading.

wheel

left.

far

of

thread

toward

the

(page

machine

guides

you

9)

until

following

®®.

expose

to

the

I:

I

the

lower

I

through

thread

the

are

looper.

it

of

left

in

you

through

end

the

until

in

the

of

accessory

the

hole

the

groove

the

lower

set

lower

in

of

*

j

*

Pull

thread

Insert

looper.®

*

Drop

Note:

*

Turn

looper

*

Pick

the

*

The

the

7.5

guide

the

the

Use

aid

to

the

is

up

end

thread

lower

thread.

the

hand

at

the

of

cm

10

(ij.

thread

tweezers

threading

in

the

thread

the

should

looper.

(3

through

wheel

right.

far

looper

that

the

toward

pass

and

®.

positioned

be

4

inches)

*

Pull

looper

looper

about

and

and

5

place

to

cm

the

(2

it

back

inches)

over

of

the

of

the

thread

top

throat

through

of

plate.

the

the

upper

13

rr

:

t

Page 16

(3)

*

Threading

Thread

the

the

right

Right

needle

Needle

indicated

as

(Green)

(iJ--®.

I

—

.

L_—4

\

1-

—

•

—-

*

*

*

Pass

thread

Pass

then

While

the

certain

tension

thread

guide

thread

the

to

holding

tension

it

discs.

from

D

through

front

thread

discs

properly

is

back

hole

through

with

and

to

®

pull

located

front

the

from

right

finger,

thread

slot

pass

down

in

through

front

as

it

between

the

back,

to

shown.

between

make

to

the

I

I

A

14

Page 17

*

Continue

to

thread

points®

—®.

Note:

*

*

*

Be

thread

Thread

needle

The

upper

operating

Be

—

Place

foot.

sure

the

knife

sure

the

to

of

path

of

eye

may

is

position.

engage

to

thread

the

pass

thread

the

right

the

easier

be

disengaged

page

(see

knife

the

to

thread

guide().

needle

to

and

23).

before

back,

through

®.

thread

placed

sewing.

under

when

in

the

upper

the

presser

the

non

15

L

Page 18

(4)

*

Threading

Thread

the

the

left

Left

needle

Needle

indicated

as

(Blue)

I

*

*

Pass

*

thread

Pass

then

While

the

certain

tension

thread

guide

thread

to

holding

tension

it

discs.

the

from

through

front

thread

discs

properly

is

back

hole

through

with

and

to

pull

located

front

the

from

right

finger,

thread

front

slot

pass

down

in

through

to

shown.

as

between

it

to

between

the

back,

°Tfl

make

the

16

J

(.

Page 19

*

Continue

to

thread

points

®—®.

Note:

*

Thread

*

The

upper

operating

—

*

Place

foot.

Be

thread

Be

sure

the

needle

knife

sure

the

to

path

of

eye

may

disengaged

is

position

engage

to

thread

of

pass

the

the

be

(see

to

the

thread

left

easier

page

knife

the

thread

guideC.

needle.

to

and

17).

before

back,

through

®

thread

placed

sewing.

under

when

in

the

lower

the

presser

the

non

I

.1

1

*1

IMPORTANT

•

*

Always

threading

*

the

If

1)

2)

3)

lower

Unthread

Thread

Thread

thread

the

looper

the

the

THREADiNG

needle(s)

the

looper.

lower

should

needle(s)

the

looper

lower

needle(s)

INFORMATION

to

last

unthreaded.

come

prevent

mis

Correct

view

Wrong

view

17

Page 20

12.

*

*

*

*

CHAINING

SEWING

When

the

machine

all

of

the

threads

to

the

Hold

Turn

turnstostart

Lower

left

the

the

presser

under

threads

hand

wheel

the

foot.

OFF

over

the

and

thread

AND

is

completely

the

throat

presser

apply

toward

chain.

foot.

a

slight

TEST

plate

you

threaded,

and

tension.

2

or

3

bring

slightly

complete

*

Continue

control

in

*

Place

sew

Note:

length.

fabric

test

a

Do

may

holding

until

under

sample.

not

pullonthe

deflect

the

chainis5

the

the

the

needle,

chain

front

fabric

pressonthe

and

7.5

cm

the

of

while

causing

(2

presser

sewing

it

to

inches)

3

foot

as

break.

foot

and

this

18

*

At

machine

chain

*

Clip

Note:

the

end

with

reaches

thread

the

Anytime

always

tensions

of

5

you

chain

and

the

the

7.5

chain.

off

make

sample,

presser

cm

(2

have

and

adjustments

continue

foot

3

inches)

rethreaded

sew

a

test

down

the

sample

as

necessary.

to

run

until

in

length.

machine

the

the

to

test

Page 21

13.

BASIC

4

•

SAFETY

*

This

two

(7/32

STITCH

THREAD

STITCH

machine

needles

inch)

OVERLOCK

four-thread

a

is

two

and

four-thread

wide

TYPES

loopers

mock

MOCK

overlock

create

to

safety

that

5.7mm

a

stitch.

uses

LOCK

removed

is

stitch

OVERLOCK

removed

is

be

can

25).

stitch

5.7mm

stitch

3.5mm

needle

THREAD

3

needle

three-thread

wide

width

(page

knife

needle

left

from

2inch),

right

from

OVER

needle

THREAD

WIDE

•

*

4

•

*

3

the

When

inch)

(7/32

NARROW

When

(9/64

The

Note:

ing

—

—

right

three-thread

left

the

inch)

stitch

the

The

creased

(9/3

The

creased

3/64inch).

(1

STITCH

wide

a

sewn.

is

narrow

a

is

stitch

increased

width

(7/32inch)

width

(9/64inch)

5.7mm

sewn.

by

can

to

can

to

STITCH

3.5mm

adjust

in

be

7.2mm

in

be

5.0mm

114.

I

*1

.4

S

HOW

TENSION

*

The

turn

*

As

tension

=

0

=

9

*

Be

wise

*

When

is

it

1)

2)

ADJUST

TO

tensiod

thread

system.

number

the

becomes

tension

lowest

highest

sure

tension

machine

the

thread

proper

making

recommended

Adjustments

number

a

test

a

Sew

on

dials

increases

tighter.

is

tension

adjustments

that

made

be

time.

a

at

after

sample

THREAD

machine

this

the

on

correctly

cannot

balance

to

no

in

each

are

the

dial

threaded

obtained.

be

tensions,

the

greater

adjustment.

than

one-

a

thread

other

half

Current

Adjustment

turn

for

Y

2

Setting

would

adjustment.

is

1’.

1

or

be

to

2

19

Page 22

SUGGESTED

•

4

FOR

SAFETY

Note:

*

*

CORRECT

•

•

These

Tension

1)

2)

3)

OVER

HOW

are

Type

Needle

Size,

LOCK

TO

OVER

*

*

When

side

Turn

—

(orange)

Or

—

low)

When

the

of

Turn

—

toward

Or

(orange)

the

of

TENSION

THREAD

STITCH

suggested

settings

thickness

and

size

and

type

BALANCE

MOCK

BALANCE

LOCK

upper

fabric

the

upper

the

toahigher

lower

turn

lower

a

to

lower

the

fabric

lower

higher

a

the

turn

toward

OVERLOCK

tension

effected

are

fiber

SAFETY

MOCK

looper

looper

number

looper

number.

looper

number

upper

a

thread

lower

looper

SETTINGS

settings

by

fabric

of

content

OF

THE

4

THE

SAFETY

thread

thread

thread

appears

thread

tension

looper

thread

number.

MOCK

only.

thread

of

THREAD

4

STITCH

THREAD

STITCH

lies

on

tension

tension

on

dial

tension

under

the

dial

the

(yellow)

dial

(yel

top

dial

Light

weight

Right

thread

needl’\

needle

thread

Upper

J’

Tension

looper

hread

ierXooper

L

Dial

thread

\

Underside

*

*

20

When

Turn

—

toward

When

Turn

—

(green)

the

the

left

the

a

right

the

toward

needle

left

higher

needle

right

thread

needle

number.

needle

a

higher

thread

thread

tension

tension

tension

thread

number.

too

is

is

loose

dial

too

tension

(blue)

loose

dial

Page 23

SUGGESTED

•

THREAD

3

THE

Note:

*

*

These

Tension

Type

1)

Needle

2)

Size,

3)

are

suggested

settings

thickness

and

size

type

TENSION

OVER

tension

effected

are

fiber

and

SETTINGS

LOCK

settings

by

fabric

of

content

STITCH

only.

thread.

of

FOR

Left

Light

Medium

Heavy

Needle/Wide

Fabric

weight

weight

weight

Blue

3

5

3

Thread

Overlock

Tension

Green

:

Dial

Orange

1

1

1.5

Stitch

Yellow

2

2

2.5

1

Dial

Orange

1.5

1,5

2

Stitch

Yellow

2

2

2.5

Overlock

Thread

Blue

3

Tension

Green

3

4

:

5

Needle/Narrow

Right

Fabric

Lightweight

weight

Medium

Heavyweight

THREAD

3

THE

OF

Needle

LOCK

BALANCE

STITCH

CORRECT

•

OVER

I

1

Topside

THREAD

3

looper

lower

a

upper

lower

THE

thread

looper

number.

looper

number.

thread

looper

higher

looper

number.

lies

thread

thread

appears

thread

number.

thread

the

on

tension

tension

on

tension

tension

the

under

dial

dial

top

dial

dial

Topside

Topside

Needle

b00

Lower

Upper

thread

thread

looper

looper

Needle

thread

thread

L9Werloper

-

Underside

Underside

BALANCE

TO

HOW

•

the

turn

upper

fabric

to

the

to

lower

the

toward

the

to

STITCH

upper

higher

a

lower

a

looper

lower

a

of

Turn

LOCK

the

the

OVER

*

1,

When

side

—

(orange)

I

I

I

*

Or

—

(yellow)

When

Turn

—

turn

the

(yellow)

Or,

—

(orange)

the

Turn

loose,

too

(blue

is

higher

a

or

green)

to

*

When

needle

the

tension

needle

thread

dial

number.

1.

Topside

Underside

21

Page 24

15.

HOW

ON

TO

CHANGE

METHOD

THREADS/TIE

*

change

To

spool.

the

*

Place

*

Tie

new

new

thread

thread

thread

and

type

on

stand.

old

or

thread

color,

ends

clip

together.

thread

near

*

*

*

*

thread

Clip

clipped

Firmly

Note

Turn

too

pull

tension

the

tails

short,

both

dial

tension

to

2

threads

thread

settings.

dials

cm

3

may

to

down

(1

come

test

until

inch)

untied.

knot

the

length.

security.

dial

If

stops.

22

Page 25

*

*

Pull

time.

threads

If

thread

the

guides

threads

not

do

or

through

pull

looping

the

easily,

under

machine

check

thread

for

stand.

one

tangles

a

at

1’

on

16.

17.

*

When

when

*

Cut

*

Return

HOW

LENGTH

*

The

(7/64

*

Adjust

sewing

*

pulling

the

the

stitch

inch)

Adjust

sewing

seams

HOW

UPPER

knot

thread,

tension

TO

length

the

heavy

the

light

without

TO

in

and

dials

through

front

insert

to

thread

is

ADJUST

dial

for

setting

length

stitch

fabrics.

weight

length

stitch

weight

puckering.

DISENGAGE

KNIFE

the

of

through

it

previous

THE

should

sewing

most

4mm

to

2mm

to

fabrics

needle,

the

needle.

the

settings.

STITCH

on

set

be

conditions.

(5/32

(5/64

obtain

to

MOVABLE

STOP

needle.

the

inch)

inch)

excellent

3mm

when

when

J

to

you

up

IN

right

the

until

position

until

you

the

to

the

from

far

as

knife

the

knife

the

horizontal

as

KNIFE

disconnected

is

6).

holder

from

position.

the

in

toward

machine.

knife

the

the

Source.

looper

movable

go.

the

into

the

the hand

the

MOVABLE

POSITION

machine

(page

cover

knife

away

knob

horizontal

a

stops

knife

wheel

the

of

top

rotate

to

9

PLACE

TO

WORKING

NON

*

sure

Be

I

I

power

*

Open

*

*

I

Push

it

Turn

clicks

Note:

*

the

will

If

Turn

clears

*

Continue

position.

23

Page 26

PLACE

TO

•

WORKING

MOVABLE

POSITION

KNIFE

IN

18.

*

Open

holder

*

Turn

clicks

Caution:

SEAM

*

When

the

looper

to

the

into

Always

machine.

the

left

the

knob

the

GUIDE

left

the

of

cover

as

right

and

up

operating

close

needle

looper

and

as

far

toward

position.

looper

LINES

inserted,

is

cover

push

it

is

the

will

you

cover

16.0mm

movable

go.

until

before

the

the

operating

thick

(5/8

knife

knife

line

inch).

[

on

24

*

When

Note:

on

inch).

the

All

sewing

left

lines

of

with

are

the

2.0mm

the

looper

right

cover

(5/64

needle,

is

inch)

the

14.0mm

apart.

thick

(35/64

line

Page 27

9.

HOW

SEAM

*

The

and

width

ADJUST

TO

WIDTH

machine

three-thread

of

is

5.7mm

set

left

(7/32

to

THE

sew

needle

inch).

OVEREDGE

four-thread

the

position

stitch

stitch

at

a

*

*

The

needle

*

*

*

*

*

*

machine

inch).

5.7mm

The

7.2mm

setting

adjusting

sure

Be

power

Open

Disengage

Remove

Loosen

with

ries.

Move

increase

the

*

sure

Be

knife

(2)

position

(9/32

can

the

the

source.

the

the

the

the

(1)

the

the

stitch

to

level

set

is

stitch

(7/32

inch)

increased

be

stationary

machine

looper

movable

the

cylinder

stationary

2

hex-head

stationary

stitch

width.

align

with

to

inch)

and

cover

wrench

width,

the

the

sew

a

at

setting

to

knife.

is

(page

upper

cover

knife

cutting

top

width

the

surface

three-thread

the

3.5mm

of

increased

be

can

3.5mm

(13/64

5mm

disconnected

6).

(page

knife

9).

(page

holder

knife

to

edge

the

of

in

to

left

of

the

provided

holder

or

(9/64

inch)

set

the

the

to

the

throat

right

(9/64

to

inch)

by

the

from

23).

screws

accesso

right

decrease

stationary

plate.

need’e

Left

need’e

Left

Right

needle

to

(2)

I

*

Tighten

*

Replace

*

Return

(page

*

Test

pensate

‘

width.

Note:

24).

sew

Do

set

the

the

for

not

screws.

and

3.5mm

cylinder

movable

adjust

the

the

set

(9/64

(3)

cover

knife

tensions

increase

overedge

inch).

(page

to

as

or

9).

original

its

necessary

decrease

seam

in

width

position

corn

to

stitch

below

(31

25

Page 28

20.

HOW

*

Rolled

the

*

Light

crepe,

*

Rolled

fabrics.

0

MACHINE

*

Be

power

*

Remove

*

Insert

needle

*

Turn

is

*

Unscrew

hemming

fabric

weight

etc.

sure

at

TO

edge.

perform

hemming

the

source.

the

a

#2054

position.

hand

the

highest

its

the

SEW

is

fabrics

is

SET

machine

left

wheel

position.

throat

A

done

such

the

not

UP

needle.

#10

size

plate

ROLLED

rolling and

by

lawn,

as

best.

suited

disconnected

is

or

toward

3crew.

#14

for

you

you,

heavy

needle

until

HEM

overedging

organdy,

stiff

or

from

right

the

in

needle

the

1F

the

26

*

Install

careful

and

*

Replace

*

Open

*

Disengage

*

Remove

*

Align

“M”

*

See

Note:

*

the

looper

the

mark

page

Be

with

plate.

Replace

the

close

rolled

the

to

not

machine.

throat

cover

upper

cylinder

the

left

on

25

sure

the

the

looper

catch

plate

(page

knife

edge

rolled

the

adjustment.

for

stationary

the

edge

cylinder

cover.

hemming

threads

the

screw.

6).

(page

cover

stationary

the

of

hemming

the

of

cover,

throat

23).

(page

knife

rolled

engage

plate

between

9).

knife

throat

not

is

hemming

upper

the

with

plate.

contact

in

knife

being

plate

the

throat

and

Stationary

holder

knife

Page 29

fine

a

of

and

rolled

hems.

*

Set

seam

*

This

stitch

the

will

machine

be

sewn.

can

length

sew

dial

two

to

types

“2—F”

SUGGESTED

•

FOR

*

Always

balance

*

Adjust

three—thread

SUGGESTED

UPPER

ROLLED

*

medium

For

difficult

Always

adjust

TENSION

STANDARD

test

a

sew

neccessary.

if

tension

balance

overlock

TENSION

LOOPER

HEM

and

roll.

to

test

a

sew

tension

balance

ROLLED

sample

the

stitch

THREAD

heavy

sample,

instructed

as

SETTINGS

and

same

(page

SETTINGS

WRAPPED

weight

and

HEM

adjust

for

as

21).

fabrics

if

below.

tension

narrow

a

FOR

are

that

neccessary,

Topside

Blue

Topside

Green

3.5

Tension

Dial

Orange

3.5

Underside

Yellow

2.5

1

I

i

•

*

beautiful

a

For

looper

loopet

lower

TO

HOW

THREAD

the

When

Turn

—

(orange)

wooly

with

BALANCE

WRAPPED

upper

the

to

with

looper

upper

a

higher

rolled

nylon

lightweight

looper

hem

and

THE

ROLLED

thread

number.

thread

the

regular

UPPER

loose

too

is

thread

the

needle

LOOPER

HEM

tension

upper

and

thread.

dial

Blue

Needle

Topside

thread

Upper

thread

Green

3.5

looper

Tension

:

Dial

Orange

1

Low

Yellow

5.5

looper

Underside

27

Page 30

*

When

—

—

*

Turn

(yellow)

Or,

(orange)

When

Turn

—

a

lower

the

the

turn

the

higher

toward

the

to

needle

the

number.

looper

lower

upper

lower

a

thread

needle

looper

higher

a

thread

thread

number.

looper

number.

too

is

too

is

thread

thread

loose

tension

loose

tension

tension

dial

(green)

dial

dial

I

Topside

to

Topside

Uppee\

thread

Lower

Neidle

\

looper

thread

Underside

ADDITIONAL

•

ROLLED

*

Hold

keep

*

Place

direction

*

The

obtained

mm

set

the

from

it

a

minimum

(1/16

below

INFORMATION

HEMMING

curling

and

rolled

for

inch)

3.5mm

chain

tension

finer

a

overedge

thread

slight

when

into

on

seam

hemming

since

(9/64

the

the

stitch

the

inch).

you

seam.

material

finish

is

cutting

begin

can

width

ABOUT

sewing

sewing

the

in

obtained.

be

can

that

approximately

cannot

width

to

be

1.5

be

28

TO

•

CHAIN

*

Apply

end

close

Note:

SECURE

small

a

the

of

the

to

the

Test

before

THE

drop

seam.

stitches.

liquid

use.

ROLLED

of

Allow

seam

liquid

dry,

to

sealant

HEM

seam

then

sealant

for

THREAD

the

cut

fastness

color

to

chain

the

Page 31

21.

STITCH

SEWING

•

HOW

SEAM

VARIATIONS

TECHNIQUES

TO

SEW

A

FLATLOCK

AND

DECORATIVE

*

flatlock

A

tensionofthe

the

seam

seam.

*

The

flatlock

decorative

and

MachineSetUp

(1)

*

Remove

*

Begin

balanced

21).

*

Loosen

generously.

*

Loosen

slightly.

*

Tighten

generously.

stitch

and

pulling

stitch

the left

the

with

the

for

the needle

upper

the

lower

the

achieved

is

three-thread

the

canbeusedasa

stitchorfor

right

or

needle.

machine

three-thread

thread

looper

looper

by

overlock

fabric

apart

ornamentation

threaded

overlock

tension

thread

thread

adjusting

stitch,

flatten

to

construction

and

stitch

(green or

tension

tension

the

sewing

the

only.

tension

(page

blue)

(orange)

(yellow)

FatIocking

(2)

*

Place

the

decorative

*

Sew

*

The

the

*

The

lineatthe

stitch

the

seam,

needle

undersideofthe fabric.

lower

fabric

a

Seam

fabric

trimming

thread

looper

the

sides

right

wrong

on

the

(greenorblue)

thread

will

edge.

together

side

excess

pull

of

fabric.

will

into

to

garment.

the

formaV

a

sew

on

straight

a

29

Page 32

*

Pull

stitches

on

opposite

flat.

sides

of

the

seam

the

pull

to

(3)

*

*

*

*

Place

position

this

Fold

Position

of

Pull

Decorative

the

stitch.

fabric

stitch

the

opposite

on

Flatlocking

movable

(page

wrong

fabric

the

extending

23).

sides

uper

The

sides

so

knife

fabric

together.

seam

the

the

off

the

of

in

is

fabric.

stitch

is

the

not

sewn

to

nonworking

trimmed

part

with

flatten.

on

30

(4)

*

*

*

Note:

The

fabric

The

in

the

lower

Additional

tensions

to

upper

fiatlock

the

upper

looper

a

For

together.

that

thread

An

44)

Information

pull

looper

looper

ladder

The

creates

optional

aid

to

must

flat.

stitch.

and

stitch,

needle

in

correctly

be

thread

Place

inconspicuous

and

needle.

sew

thread

ladder

the

Edge

sewing

about

is

Guide

flatlock

a

Flatlocking

adjusted

prominent

the

decorative

a

with

seam

be

will

(A).

is

thread

threads

right

prominent

the

available

stitch.

for

thread

in

(page

the

in

the

sides

Underside

(A

Topside

Page 33

HOW

•

excess

The

the

and

overlock

The

wear.

invisible.

*

Remove

narrow

Note:

*

Set

TO

fabric

edges

raw

provides

It

the

three-thread

The

used.

stitch

the

AN

SEW

trimmed

is

overlocked

are

hem

blind

durable

a

needle

left

three-thread

length

OVER

best

is

and

overlock

flatlock

at

dial

LOCK

and

in

suited

finish

adjust

stitch.

4

the

one

stitch

5.

BLIND

hem

operation.

sewing

for

is

that

machine

can

sewn

is

almost

for

also

HEM

knit

a

be

I

g

*

*

Note:

HOW

•

Sew

out

*

Note

*

*

the

Fold

to

back

fold.

the

Stitch

machine

fold

An

FOOT)

decorative

garment

the

Remove

narrow

The

technique.

Place

position

ing

Mark

tucks

hem

right

the

the

on

needle

optional

is

SEW

TO

pin

left

the

three-thread

rolled

movable

the

(page

fabric

the

water

a

using

the

to

side

extended

to

blind

available

PIN

tucks

needle

hem

upper

23)

with

soluble

wrong

with

hem

barely

hem

(page

TUCKS

the

on

and

overlock

can

stitch

knife

the

side

6mm

edge,

catch

foot

45)

fabric

adjust

stitch.

also

desired

fabric

the

of

the

(ULTR

be

ir

marker

fabric,

(1/4”)

allowing

edge

before

machine

used

nonoperat

the

number

then

beyond

the

the

of

HEM

cutting

for

this

for

pin

of

a

I

ii

31

Page 34

*

Fold

the

fabric

with

the

wrong

sides

together

and

sew.

*

Press

TURNING

•

Outside

(1)

*

Cut

the

*

Sew

*

Raise

*

Pull

enough

the

of

Note:

the

pin

Corner

approximately

out

corner,

stitch

one

needle

fabric

the

release

to

throat

Presser

in

tucks

SQUARE

with

line

in

beyond

presser

and

the

to

the

plate.

has

foot

same

the

CORNERS

2

cm

the

point

foot.

rear

thread

removed

been

direction.

(51/64

overedge

and

(A)

the

of

caught

inch)

seam

stop.

machine

the

on

show

to

from

edge.

just

finger

detail.

32

foot

edge.

cut

the

sew.

to

line

the

start

presser

with

*

Turn

the

*

Pull

(2)

*

Cut

the

knife

slack

Inside

fabric

fabric

positioned

is

threads

Corner

at

and

seam

up,

lower

in

then

edge.

that

so

Page 35

*

Place

tion

movable

(page

23).

knifeinnonoperating

upper

posi

I..

*

Stitch

*

Stop

the

*

Continue

straight

a

PIN

•

*

Insert

will

ting

Caution:

edge

cut

on

to

to

line

before

the

sew

moving

sewing

fabric

PLACEMENT

the

to

pins

to

easy

be

the

of

action

Sewing

the

stroy

fabric.

of

you

to

left

slowly

left

remove

knives.

over

cutting

reach

straighten

holding

fold

the

the

of

and

will

pins

edge

the

as

presser

away

are

damage

of

corner

the

the

you

the

corner.

fabric

sew.