Page 1

___

-D

0

z

9

z

—I

Cl)

C

n

z

Page 2

z

C)

t)

U)

Ct)

H

0

ni

z

H

C’)

-

-

0)

(ii

CX)

—

CX)

(C)

-

-

-O

U>

Z

-

C)

CD

r-

C

U)

Q

(0

3

Q

5-

-

—

3

—

C)

--1

1

0

>

N)

>

0)

I

CU

0

CU

Cl)

CU

a

a

—

U>

0

—.

3

CD

3

CD

-

0

3

-.

0

—.

3

CU

:

U)

a

U)

•-

-o

:

3

(0

C)

3:

a

co

3

—

C”

-

C)

U>

CU

C)

-

CU

ct

:)

-

-

CU

U>

-

-

U>

o

-o

:

-

:

CU

c

:

I

:

:

:

CU

0

:

:

:

:

-

:

:

:

:

-‘

:

:

:

3

:

4Mm

:

:

:

-

:

:

tO

N)

:

:

:

-

:

:

:

:

-

:

:

-

:

:

-

:

:

-

:

-

:

:

:

:

0)

0)

0)

C))

Co

CO

O

CC)

3;

3

CD

o

C)

n

—J

o

I

ç)

—4

0

(1)

-

CO

]J

>

N)

CJ

0

U)

CU

0

3

0

C)

5-

U)

>

C)

C)

3

U)

a

(0

C)

Q

S

-.

CU

0

CD

j

CU

C)

U)

CU

x_3

3

0

C)

—

°

CU

S

:

CU

C’)

:

:

CD

:

:

:

:

:

:

a

CU

()

:

:

:

:

3

-‘

3

0

CU

3.

5-

a

C”

:

:

:

:

:

:

.

•

:

.

:

:

c’o

:

C))

ci

3;

3;

3;

3;

.

.

Page 3

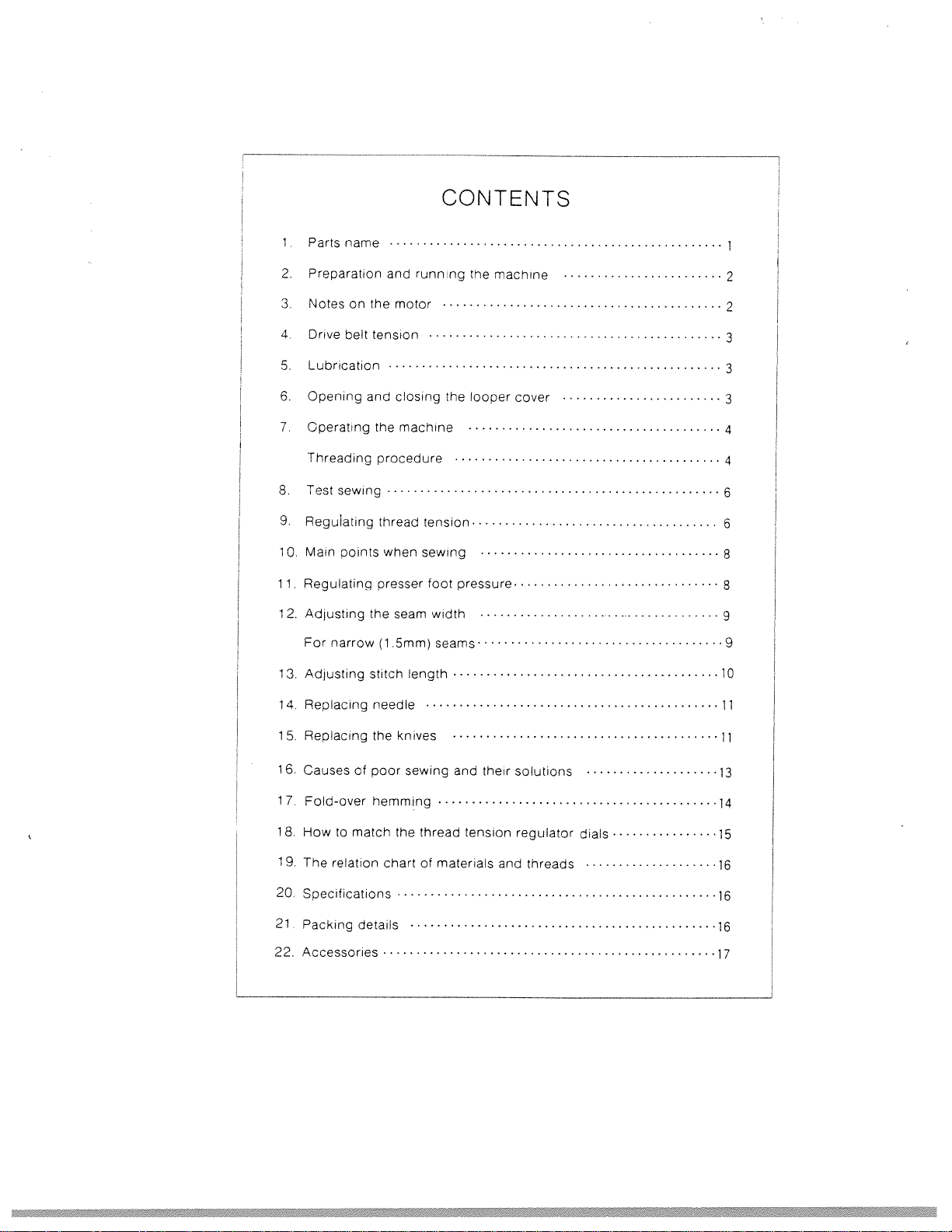

1.

Parts

name

Thread

Presser

Thread

Presser

Needle

Presser

Needle

Sidebox

Cushion

je

car

gu

foot

ree’

Denter

toot

itt

ever

bar

foot

plate

rutber______________________

Carr

/

Neule

reguatDr

Right

oocer

0

N

ri

=

N

-.

regulator

Loft

egulator

ooper

Upper

trad

thread

rhread

Puley

Looper

g

Knife

a

tsion

ktiif

tension

tension

guard

cover

Upper

Right

Lower

kni

looper

knife

I,,

e

Thread

reel

Thread

guide

bar

center

%\

\N

,1

Motor

Page 4

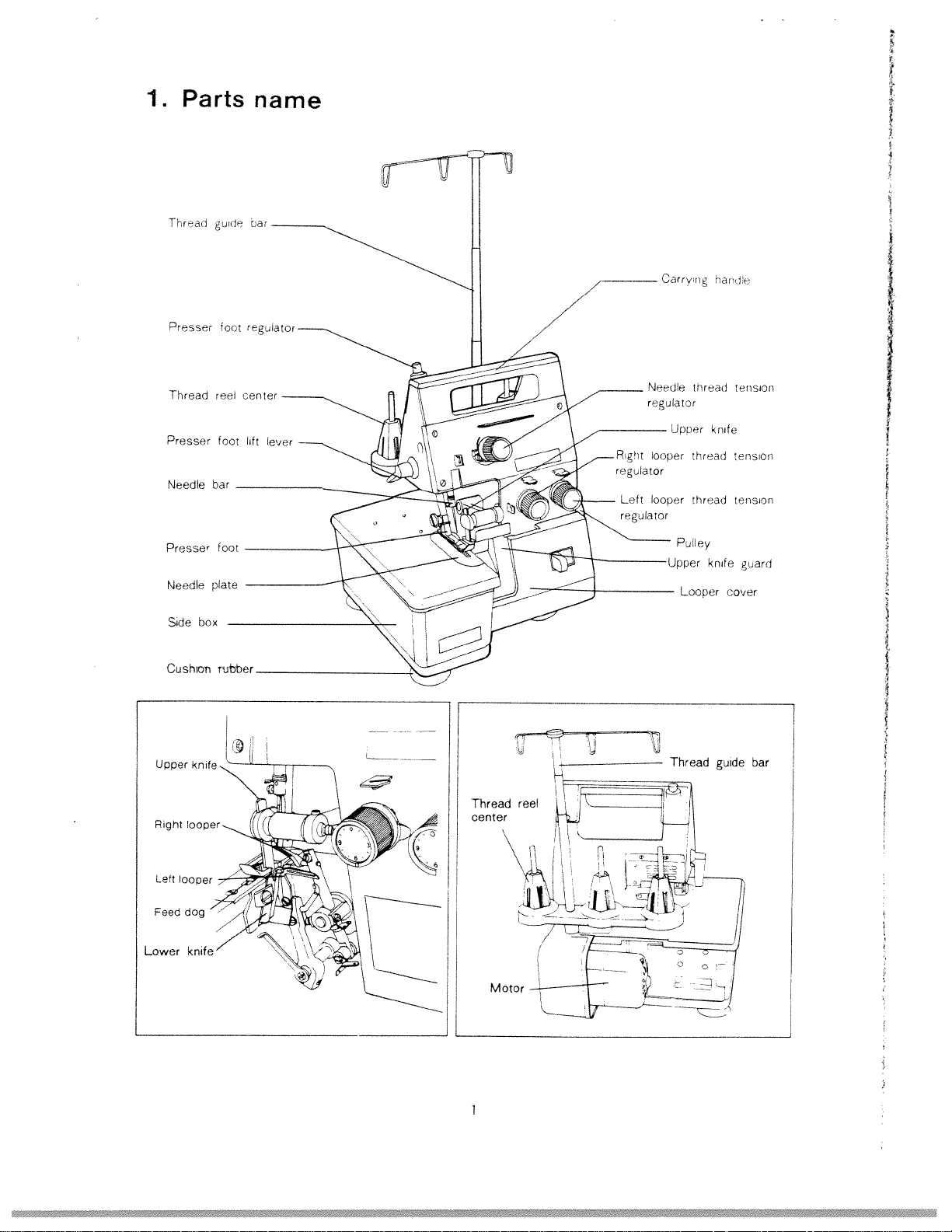

Preparation

2.

Preparation

I.

macnine

This

honzontai

and

flat

macnne

sewing

must

tab.

onis

surface

the

or

a

running

and

jseJ

te

Ort)urDOse.tiruit

machine

Fitting

2.

First,

connector

srrown

power

a

to

Disconnect

when

not

Do

pedal.

3.

Place

When

begio

heavily

the

insert

socket

the

in

source.

the

not

is

it

place

Running

tip

the

press

you

run

to

the

machine,

motor

the

controfler

the

on

illustration,

macPine

use.

in

ob1ects

the

your

of

down

low

at

machine

lift

the

on

machine

foot

speed

will

your

controller

connector

of

side

then

from

top

iightiy

gently.

As

run

toot

the

connect

the

of

faster.

from

power

the

the

you

machine

on

machine

press

the

nto

plug

the

source

controller

pedal.

toe

To

pedal.

the

as

will

more

stop

Controller

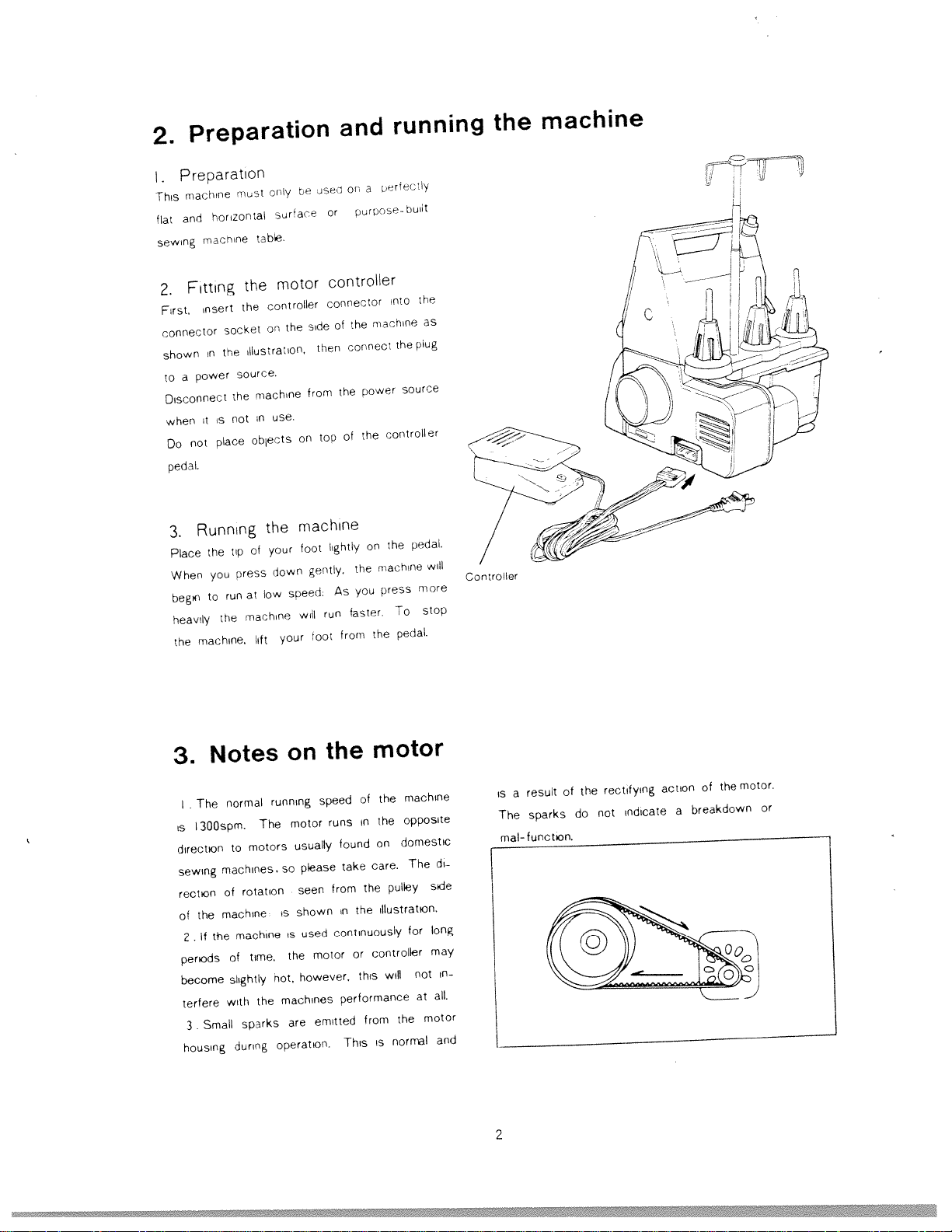

3.

The

•

I

is

direction

sewing

rection

the

of

2.

periods

become

terfere

3

housing

Notes

normal

300spm.

to

machines.

of

machine

machine

If

the

of

slightly

with

Small

during

The

motors

rotation

time,

the

sparks

on

running

motor

usually

so

seen

shown

s

is

the

however,

hot,

machines

are

operation.

please

used

motor

emtted

the

speed

runs

found

take

from

in

continuously

performance

This

motor

the

of

the

in

on

care.

the

illustration.

the

controller

or

this

from

is

pulley

will

the

norrriol

machine

opposite

domestic

The

side

for

may

not

at

motor

di

long

in

all.

and

is

The

2

mal-

a

result

sparks

functlen.

motor.

the

of

indicate

action

a

breakdown

or

rectifying

the

of

not

do

j

Page 5

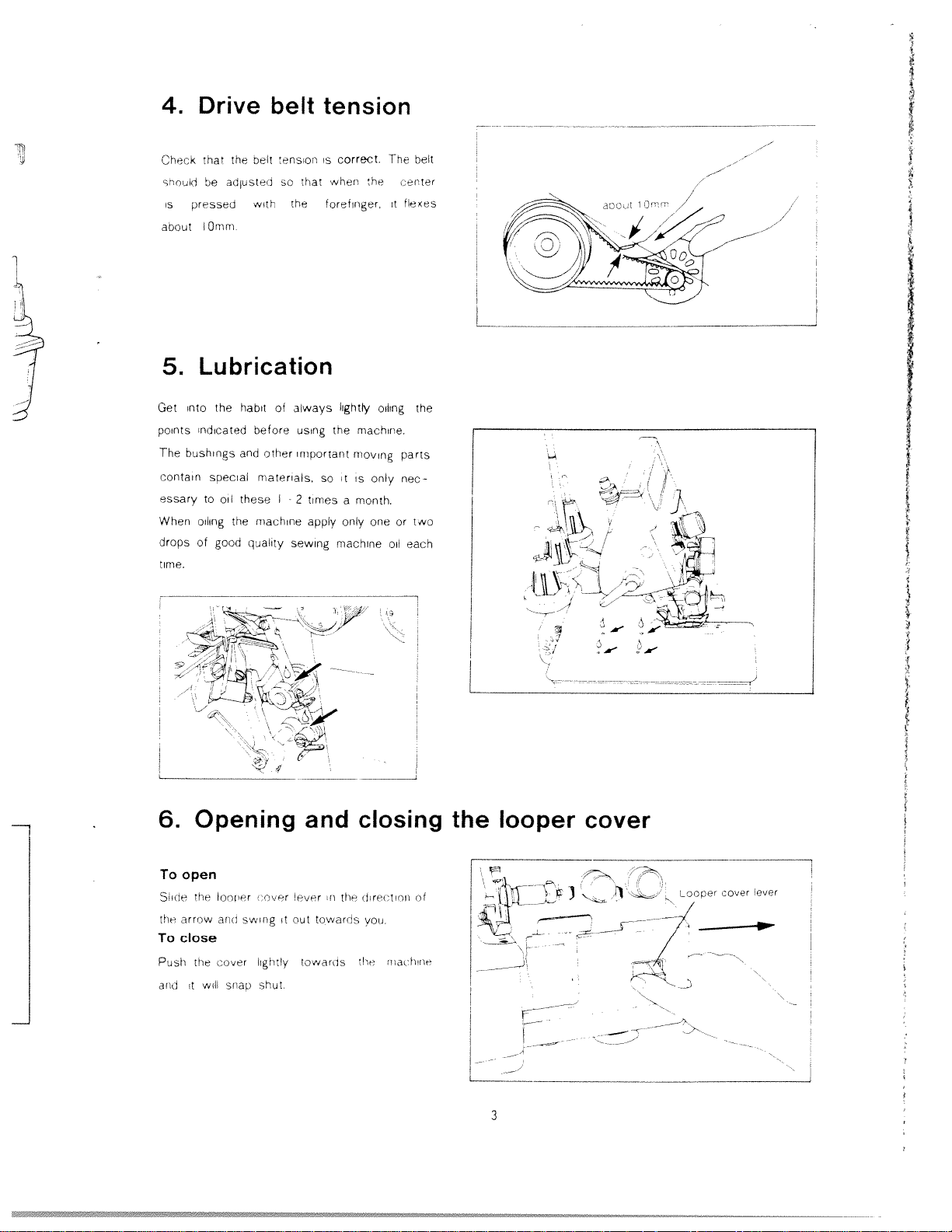

4.

Drive

belt

tension

nat

oin

te

5

Omssed

0mm

300ut

Lubrication

5

nto

Get

points

The

contain

essarv

When

oroos

hrue.

the

ndicated

bushings

special

to

oiling

of

good

a

cmv

moving

month.

•h

oiling

machine.

only

one

TO

bt

r

‘

hexs

the

parts

nec

-

1

or

tso

oil

each

ma

always

using

important

soitis

2

times

apply

correct.

s

nei

forennger,

hghtly

the

macnne

the

net

ust-]

w

habit

before

and

these

quality

‘nsicr

s

tb

of

other

materials,

-

machine

the

sewing

the

Si]

oil

6.

To

S

To

Push

am]

p

open

t-

rr)

close

t

Opening

rh

the

cocr

I

i

snap

‘‘‘r

g’y

srmt.

ir

u

towartu

and

t

1.war

closing

up

dir

vu..

‘m-

the

looper

:-J

—

cover

:oer

-F

ejpr

3

Page 6

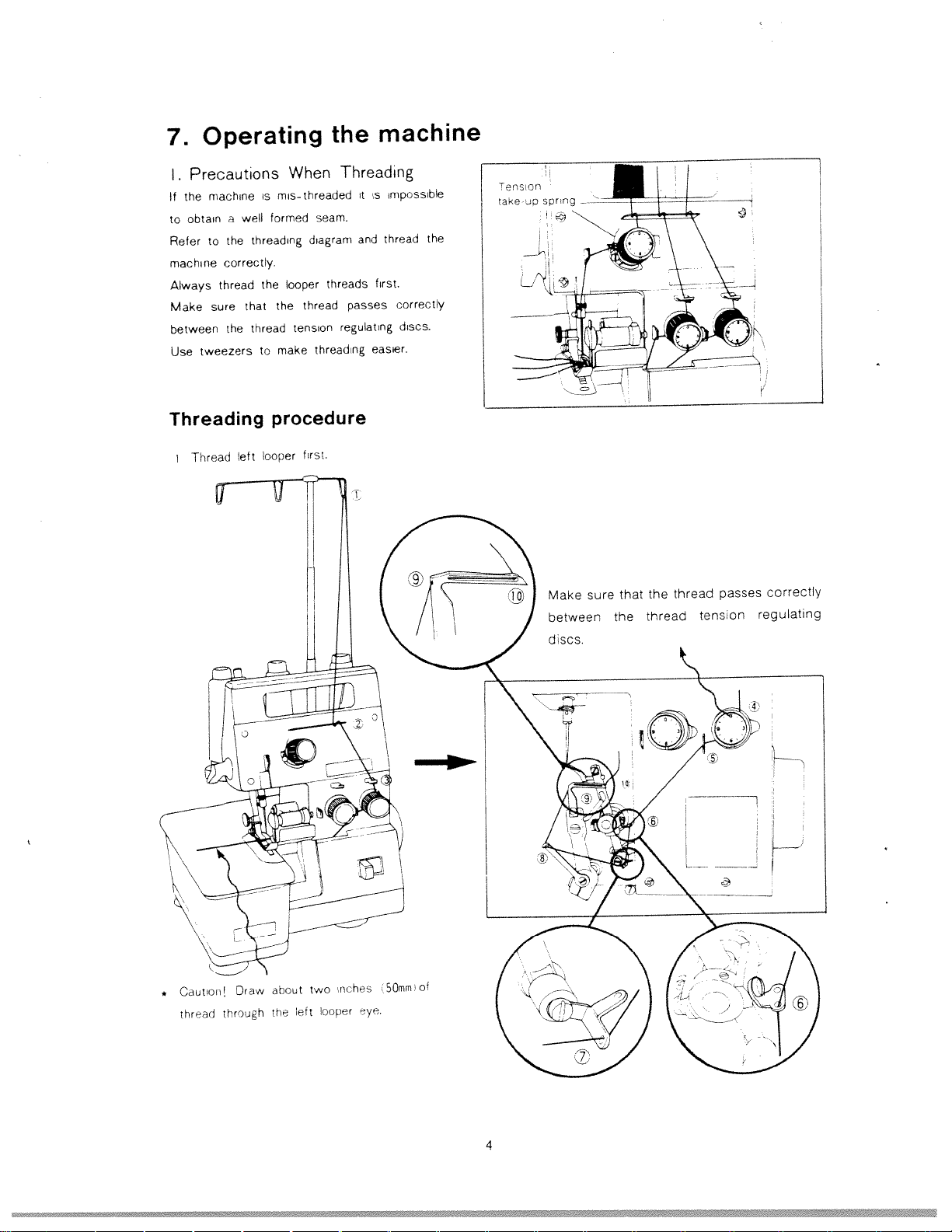

Operating

7.

the

machine

Precautions

I.

machine

if

the

obtain

to

Refer

machine

Always

Make

between

Use

a

the

to

correctly.

thread

sure

the

tweezers

Threading

Thread

1

rfl,

well

threading

that

thread

left

is

the

to

looper

When

threaded

mis

seam.

formed

diagram

threads

looper

thread

the

tension

threading

make

procedure

first.

Threading

it

impossible

is

threan

and

first.

passes

regulating

easier.

correctly

discs.

the

ng

spr

Make

between

discs.

—

sure

the

that

the

thread

thread

passes

tension

correctly

regulating

*

\

Ca.it’on

thread

Draw

trough

zz

aoujt

rh.

\f_

\

)K)

/

\

v_,

.

of

50mm

he

r’

two

ocuer

ye.

4

Ott

/

/

\L

—

Page 7

2

Thread

rght

ooper

secona.

*

Caution!

m

of

50mm)

Draw

thread

about

through

two

the

nches

right

ooier

eye.

—c;

-

9_

8

‘4

I,,,,,

-

6

7

/

3

Thread

need!e

*

Caution!

thread

ast

—

through

I

2

Draw

I

I

about

the

H

two

needle

,nches

eye

50mm

;1’i

4

5

6

-

of

ii

3

k

Page 8

8.

Test

sewing

After

oni[s

sew

a

rg

mach

ne.

Cr

Hoid

2.

the

your

right

direct

on

turns.

Check

tnat

rectFy

and

Regulating

9.

Toe

correct

on

the

type

thread.

of

obtained

be

the

appronriate

:es

hand

of

then

The

ig

3

threacs

the

toe

thread

of

cfoth

correct

cxaiin

Dy

adfustrrents.

bior

mat—raF

turn

ar-ew

threads

start

and

rnaliPg.

actua

in

your

the

to

tension

the

setting

ig

e

hv

eft

Fey

pu

‘FocKwise

nave

slowFy.

sew

thread

varies

type

the

seam

s_r-

C-at

haiiil

smooth

‘or

nterioceed

depending

and

thickness

shouLd

and

r

-

and

y

2

always

makng

f

w

n

or

cor

iie

the

3

tension

Sktcb

Correct

shows

thread

a

proijerSttch

tension

formation.

Proper

stitch

formation

Right

pave-se

ioooer

5:

e

thread

/

Page 9

Adjusting

2.

Thread

ensicn

reduces

thread

tension

regulator

the

tension.

thread

is

tension.

adjusted

diais

tension

clockwise

greater

The

thread

the

counterclockwise

greater

the

toe

the

vnile

regulators.

turrnng

front

of

1

thread

3

the

of

means

by

figure

thread

shown

vceases

the

enson

tension

on

the

Turning

them

dial,

Toe

tension

‘oooer

increase

decrease

tensions.

The

2

thread

ooper

lncrease

decrease

or

sketch

s

thread

the

the

sketcn

tension

thread

the

cc

needle

right

tension

right

the

shows

oose,

tensions

shows

is

left

and

too

looper

looper

the

or

thread

left

the

loose,

too

s

needle

oght

are

looper

tignt.

thread

tnread

too

tension,

right

or

thread

and

threac

the

tension.

tenscn.

left

tight.

or

ooper

elf

The

3

tension

thread

Increase

or

decrease

sKetch

is

tension

the

too

the

shows

cose,

is

too

left

rignt

the

tight.

looper

looper

thread

looper

left

looper

right

the

or

thread

tension,

tension.

7

thread

Page 10

10.

•

toot

wr

iPRur

stt

puH

maticafly

When

nor

of

the

chainisleft.

2.

Tie

knit

chain

3.

At

chain and

the

little

Main

Always

‘c

i

r05

r

re

‘f

s

Uemach

hes.

Use

your

t

forwards

sothssnot

•

Removing

you

the

machine

thread

chain.

fabricsothat

At

the

the end

fabrics

into

Prevention

the endofthe

fabric

way.

r

se’t

stir’

1!

a

rca

Ie

I

ham

or

have

Then

end

of

the

usealatch

the

seam.

den,

without

over

and

see

points

rre

r

t’

U

se

r

f

rOt

thread

ftnr

re

cw

y

only

to

guste

tug

t.

The

necossary.

the

sewn

sewntoInc

slowly

and

the

cut

.there

s

of

the

thread

needle

of

seam

seam

run off

cutting

sew

back

illustration

when

fu

.r

Ocr

y

r

T

s

g

threado

for

sew

about

chain,Inthe

at

1

hmakages

te

drst

ooth

.Joth

s

arucle

endofthe

off

about

thread

cnannear

3cmofthread

seam

to

pull

unravelhng

5cm

a

the

chain,

along

the

‘

C

cs

iiIwi

Do

fed

case

the

thread

thread

seam

rsSCr

utr

few

not

outo

seam

5cm

of

turn

a

sewing

L

Reverse

see

lop

side

11.

The

presser

medium

set

for

pressure

extra

light

Decrease

and

increase

increase

To

center

the

decrease

The

center

its

original

canbedecreased.

ssure

Regulating

foot

pressure

weight

fabrics.

needs

only

the

button. Conversely,

pressure,

position

or

pressure

it

the

button

extra

for

presser

to

be

heavy

for

heavy

press

will

and the

presser

on

this

The

adlusted

weight

light

weight

weight

fabrics.

foot

pressure,

if

you

the

outer

automatically

presser

machine

presser

when

rim.

foot

sewing

fabrics.

fabrics

want

return

push

pre

foot

to

to

is

foot

S

pressure

Increase

Decrease

Page 11

1

2.

Loosen

2.

sbcwn

as

sole

hoc

‘IiOvngroe

3.

To

narrow

Knife

cart

wdth.

siide

4.

Fasten

as

shown

Knite

to

Adjusting

r

Kt

ort-r,

the

er

the

n

the

Thc.

ower

to

t

tb

normal

:oe

to

ower

o,<u-

owr

he

he

the

Ke:cb,

srolh

ad1sSt

KnOe

scan

ef.

r

knife

uoSt0n

f

ki

ght.

i

a

i

caner

soc

and

Ss

at

:e

‘to.

‘

atr

o

arrier

nstore

the

ar

sac

ngnt

s

sion

L

Cr

la

set

seam

a

set

r-nirrg

dth

s

cf.

r

tie

the

screw

toe

Jper

owor

sear

ala

row

V

_______________

width

/

-no——-———

I

;

Knfe

aDer

I

For

charging

By

,oo

narrow

can

sew

needle

narrow

a

(15mm)

date

seam.

lBS

shown

seams.

on

page

1

14)

1’

Narrow

9

Page 12

13.

To

bo

to

prevent

regu’ator

Align

2

on

the

ngth

To

make

number.

.

After

3

feed

Adjusting

change

and.

Ho

the

it

nut

the

feed

feed

regutor.

longer

move

the

stitch

making

regu’ator

puly

from

with

nut

he

sutch

firmly

moving

the

regutor

the

length

the

and

length.

w

and

screwdriver.

nut

To

nut

to

shorter

ad1ustments,

close

stitch

th

your

loosen

anul

make

highur

a

select

the

open

side

right

the

the

a

tighten

length

the

hand

the

number

stitch

nun

n&r.

siT

aller

box.

svi

feed

the

I

ed

‘cpu

ator

‘Ut

—

Eee

‘eg.

-

ator

10

Page 13

14.

Replacing

needle

•

“‘-

•

nprrdahC

jry

Tjrr

tt’e

highest

oosen

neede

2

Turn

h

ghest

Wily

ong

the

At

‘inn

5rp

o

P’uo

arrow

°tting

into

groove

need’e

ugi

:ne

the

toosition

the

Jut

‘hr

DoSitiOn.

up,

size

rig

pulley

ny

needle

needle

nuiley

the

‘CS

‘n

.1

.-‘ptr-s

usng

rreedle

faces

honer

sr’r

uand

iur

5rfr

Lsing

tweezers

and

Pusn

screw

‘••‘

rrr’

‘

5nJ

se-

9

bc

Kwise

and

cmo

‘rioStr

the

holdr.

forwards,

‘[

p

---l6

roe

p

es-,

,

tne

shank

mace

hrmiy

i’

‘‘‘

n

‘cc

screw

rw

p

z—

‘‘rr-at

3’

-

65’—iCO

‘Pc

am

ceoie

ad

needle

f

the

5ure

and

then

ret

“owevr.

lriv&r.

tjl(

bar

needkll

that

wh

‘i

“av

ton

tO

‘o

tghterr

the

/

/

—

Ii

-

--

•ot

Long

groove

to

the

1

ront

its

th

15.

If

‘oflows.

Always

power

Pemovrg

*

Loosen

-rove

Replacing

toe

knives

disconnect

source

before

Replacing

knife

the

upper

the

knie

become

the

knife

upward.

hiunt

the

repacing

upper

gue

the

rePace

machine

the

knife

screw

knives

them

from

knives.

and

re-

the

as

-

u

i

/

/

t

-•-

--

-

-<N

-s

,

jJ,

‘-c

‘\/

c

)

7

L

11

Page 14

Replacing

*

Push

the

knife

the

cutting

Next,

position

overlap

and

the

upper

2.

Replacing

*Removing

Loosen

move

the

the

turn

knife

the

upper

into

edge

the

and

between

lower

gurie

knife

lower

lower

knife

knife

t

from

faces

pulloy,move

adiust

the

knife

screw

the

knife

knife

holder

above.

to

the

the

upper

front

is

I

0

securely.

lower

clamp

downward.

the

to

loft,

of

mm.

the

1aktng

tighten

knife

knife

the

knife

screw

right

to

so

upper

Tighten

sure

and

and

it

lightly.

ts

that

that

lowest

knife

the

re

nsert

the

0mm

U

ff.,.,.

Replacing

*

Insert

below

2.Next,

with

the

clamp

toes

the

not

with

the

the

line

surface

screw

move.

knife

up

lower

cutting

the

of

knife

blade

the

securely

edge

needle

into

facing

of

so

the

the

plate

that

hokier

to

lower

and

the

the

from

right.

knife

tighten

Knife

--,

Surface

ni

wle

Ctung

ot

ola

lower

th

edge

i.;::::;-..

knite

/

r//ç/

1

-t:

I

of

.

12

Page 15

16.

Th

ad,jstments

Tney

Cloth

not

Needle

Thread

Skip

occurs

Poor

formation

s

macrune

can

PROBLEM

does

feed

breaks

stitching

seam

Causes

has

RreaKdow”s

be

cured

breaks

oeen

simpiy

The

needle

Needle

Cloth

excessively

The

ed

Thread

or

Tension

Needles

Wrong

The

i

needle

Needles

The

Tnreading

Presser

Incorrect

Thread

of

Presser

a1<

machine

ncorrectly

caught.

needle

wrong

des

smilar

by

needle

is

has

fitted

needle

point

are

foot

threads

tension

poor

gued

mak

foot

point

fitted

been

has

is

too

damaged

not

needle

is

incorrect.

pressure

fo

ce

to

me

ng

tne

CAUSE

pressure

IS

Dent

is

incorrectly

pulled

has

been

become

tight.

incorrectly

has

been

is

bent

fitted

is

are

incorrect.

sewing

as

asv

ones

correct

perfectly.

being

s

being

s

or

damaged

thread-

tangled

used

or

used

too

weaK.

used.

ad(ustments

the

to

oeiow

100

1he

and

use

occur

°-ess

the

1he

Reølace

Fit

Avoid

during

Re-thread

Check

on

See

See

Always

Replace

Re-fit

Always

Re-thread

0

usn

and

Use

See

p

as

presser

presser

needles

the

p

p

needles

me

increase

correct

6

their

possiole

because

as

descr

n

pushing

sewing.

that

thread

6

‘1

use

needles

use

center

the

foot

1

oot

neecle

correctly

correctly

the

stand

DC

correctly

DC

correctly.

ot

the

threads

so’utions

There

of

simole

bed

oelow

ADJUSTMENT

control

thread

‘he

regulating

pressure(see

for

a

or

pulling

(see

I

needles

(see

p.111

1

needles.

presser

presser

and

Outton

new

(see

has

(see

toot

needle

s

p.4)

toot

no

one

p

the

not

need

ad1ustment

n

button

p.8)

(see

11)

fabr

become

p.11)

regulating

pressure

size.

for

he

center

to

0

excessively

c

(see

difficult

errors

increase

11)

tangled

button

o

of

81

Fabric

occurs

puckering

Thread

Threading

Thread

tension

is

has

incorrect

become

is

too

strong.

tangled.

Reduce

possible

Re-thread

the

when

correctly

thread

sewing

tension

lightweight

tsee

p.4)

as

much

fabrics

as

13

Page 16

17.

F

DO

re

as

snon

1

Excnange

Procedure

\\

L1t

Turn

:

its

3

Loosen

side

Fold-over

r

‘atD

c.

-he

ft

ever

te

nighest

tne

with

nrnr

C!

the

presser

puSey

position

the

r

ag

neeo

needle

screw

j

toot

c

hemming

e

olaa

by

the

move

plate

ver

dr

--

1he

screw

nan

or

presser

neeole

o

iB

re

0

need

v

cr0

F

t

he

neeoe

nerming

Normal

*

E

*

and

sewing

dover

ioot

on

this

Set

2

the

regulator

teed

to

No

e

c

fasten

hemming

:

L

regulator

I

ac

anct

pui

t

c

tor

ate

p

-

it

B

tOiD

ro

Os

screw

A

B

ncuded)

-

nut

on

the

teed

1Q

See

Fold

over

hemming

14

Page 17

18.

How

to

match

the

thread

tension

regulator

dials

*

Set

alaofthe

1

Norma’

Mse

Broad

cob

Pool

n)

m

Den

nng

2

Narrow

:be

a

s

orooer

toHowlng

seNing

Need

Syn!netc

Polyester

Codon

Synthet

Polyester

:80

Cotton

Syntt7etc

Po!yester

:80

sewIng

80

:bread

chart

e

c

Rn

O

Synoret

Polyester

Cotton

Syronetic

P0

otton.

SnIhetc

Polyester

1enstcs

ocoe

POP

:80

yeste

:80

:80

N

the

ZL

D

‘Or

Needle

oert

coDer

7otcn

C

Syntrrerc

Polyester

:80

Cotto-’

S

,nthehc

yester

Po

:80

Cotton,

Syntrreuc

Polyester

0

80

rread

/

0

ngn.i

a!

or

ocoe

Djal

et:

t

0

oooe

Needle

75

:14

05

75

NeeO!e

A

Georget’e

Tricot

Foidover

3.

Georgette

hnng

Sot

Polyester

:80

Polyester

:80

hernmtng

Polyester

Polyester

:80

Polyester

:80

yester

o

:80

Wooly

nylon

Polyester

:80

Polyester

:80

Noo

ny

on

“\

0

77\\

15

7

Ljc±

0

/4

\‘!

B

:9

65

Page 18

19.

The

relation

chart

of

materials

and

threads

Normal

sewing

Fold-over

hemming

20.

Maximum

Overlock

Stitch

length

Presser

Presser

Needle..

Number

Oiling

Dimensions

Net

weight

Material

Light

weight

Organd

S

K.

Medium

Cotton.

Genera

Heavy

Tweed,

Heavy

Knit

fabrics

Knit

faorics

Georgette

Tricots

Suit

lining

e

weight

Tricot,

dress

weight

Coat

Neight

materials

Fine

ning

cloth,

Specifications

speed

seam

width

foot

foot

lift

oi

threads

tr

cots,

materials

Linen,

mater

materials

cloth

ais

Denim,

taffeta,

•

Cotton

Sntheic

Silk

Cotton

Synthetic

Silk

Cotton

SIk

Polyester

Polyester

Synthetic

Wooly

nylon

Polyester

Wooly

nylon

l300s.p

3.

5mm

1.0mm

Hinged

Upto4.Omm

Type

DC

9

(65)—

3

Manual

263mm

263mm275mm

8

kg

(complete

Thread

60

m

(standard),l.

4.0mm,

.

I

size

16(100’

Stitch

length

80

100

80

-

100

too

80

too

60

60

60

80

80

100

(Fold-over

(75

also

motor>

3.0mm

3.0mm

3.0mm

2.0mm

1

.0mm

standard.

available

80

60

—

60

50

40

4

30

50

80

—

5mm

11

set

with

4

.Cmm

‘

4.0mm

4.0mm

4.0mm

1

.5mm

hemming>

Needle

—

—

14

t1

75—90

9

55—

5

11

14

—11

5

21.

Machine

2.

Controlr

,

3

Operating

4,

Accessones.,,.

Packing

(with

motor

inStruCtn

details

I

set

Iset

I

PC.

Iset

16

Page 19

C,

CD

Co

0

0

-‘

-.

CD

C’)

I

—

—

.J”

I

-

C)

I

—

(0

H

H

CD

CD

N

CD

—

If

m

IHI

cj

11

——C)

—

n-

fi

-

(DC)

(0

IL

?1

w

0

0

0

3

(1)

00

0

t30

z

CD

1

0

p

j

HI

ii

If

3

0

0

Loading...

Loading...