Page 1

‘ii

hobbylock

4762

_i

L

Instruction

manual

Page 2

/

For

please

I

j

easier

\

understanding

thisorthe

fold

Safety

For

The

the

three

The

ding

last

the

leads

safety

pins.

wires

to

of

rules

United

in

the

this

page

must

lead

the

followg

instruction

out

Kingdom

definitely

terminal

mains

when

lead

code:

only

not

I

nortoa

manual

reading.

be

coloured

are

connected

plug

-J

to

with

accor

Brown.

the

As

this

appliance

colour

es

ceed

wire

The

to

ted

N

ter

or

wire

The

nected

letter

L

Cut-off

disposed

but

leads

Only3A

ASTA

by

cover

colour

ding

plug

The

Spare

suppliers

Please

2.

page

colours

coding

follows:

which

the

coloured

which

to

or

mains

must

must

fuse

also

of

may

of

terminal

terminal

the

coloured

plugs

of

replaced

be

spare

according

marked

be

code.

neverbeused

must

covers

or

the

observe

Live

wires

the

correspond

not

terminals

the

coloured

is

whichismarked

black.

coloured

is

which

red.

definitely

are

immediately.

fuses

to

are

PFAFF

the

completely.

must

BS

A

3

available

agencies.

general

in

blue

brown

be

1362

or

mains

the

in

your

must

must

marked

is

nottobe

Defective

used

and

with

without

from

safety

with

plug,

be

with

es

the

the

fuse

electrical

lead

the

pro

connec

the

be

con

the

with

used,

mains

approved

fuse

correspon

cover.

notes

of

let

on

I

and

5

You

will

find

the

Contents

on

pages

4

Page 3

appliance,

to

sewing

instructions

es

follows:

machine.

basic

safety

Read

precau

all

States

an

electrical

safety

only

adhered

be

using

this

Important

United

the

For

you

should

use

always

before

When

I

tions

instructions

reduce

from

unplug

reach

place

in

or

sewing

it

has

the

use

operate

unplug

needle.

use

use

pull

the

unplug

when

when

observe

To

machine

the

before

a

for

or

store

drop

or

To

usedasa

to

be

children.

near

machine

recommended

sewing

this

been

authorized

sewing

the

sewing

or

insert

outdoors.

where

turn

pulling

by

awey

proper

the

or

bent

or

push

sewing

sewing

making

rewinding

the

DANGER

sewing

The

1.

appliance

Always

2.

not

Do

3.

Do

not

4.

place

not

V(ARNlNG

allow

not

Do

1.

used

by

this

Use

2.

attachments

3.

4,

5.

6.

7.

8.

9.

10.

11.

1

2.

1

3.

14.

1

5.

6.

1

17.

Please

operate

Nover

if

perly,

nearest

the

adjustment.

nical

operate

Never

of

nings

loose

cloth.

drop

Never

not

Do

not

Do

administered.

To

disconnect,

operateona

Never

blocked.

not

Do

fingers

Keep

machine

Always

not

Do

not

Do

Switch

suchasthreading

etc.

Always

or

ting,

manual.

plug

Hold

also

should

electric

relamping.

sewing

sewing

a

into

reduce

dropped

dealer

machine

any

aerosol

controls

all

soft

from

blunt

fabric

machine

needle,

any

general

risk

the

never

outlet

machine

machine

water

the

toy.

for

only

by

machineifit

or

or

machine

and

object

(spray)

surface

cord.

on

moving

all

plate.

needle

needles.

while

off

changing

machine

other

into

safety

electric

of

left

be

immediately

Replace

that

other

or

risk

of

attention

Close

intended

its

manufacturer

the

has

damaged,

service

with

control

foot

any

into

products

off

to

(“0”)

as

such

unplug,

To

parts.

The

Use

stitching.

when

(“0”)

needle,

the

from

servicing

user

reel.

cord

notesonpage

shock:

unattended

bulb

fallen

has

where

liquid.

burns,

damaged

a

dropped

or

centerfor

air

any

free

opening.

position,

a

bed

Special

wrong

needles

It

may

making

threading

electric

Do

when

using

after

with

same

into

fall

can

it

electric

fire,

necessary

is

describedinthis

use

as

containedinthis

as

cord

into

examination,

openings

from

being

are

then

couch

or

the

grasp

care

can

plate

recommended

deflect

any

outlet

adjustments

allow

not

2.

plugged

before

and

rated

type

Unplug

water.

pulled

or

be

shock,

when

plug,

or

water.

repair,

blocked.

accumulation

the

or

used

remove

the

where

not

plug,

required

is

cause

by

needle,

the

adjustments

bobbin,

or

removing

when

mentioned

plugtowhip

Alweys

in.

cleaning

1

into

injury

or

sewing

this

manual.

is

if

it

Return

electrical

Keep

where

plug

air

cord.

the

around

needle

the

manufacturer

the

causingitto

in

changing

when

unplug

it.

Watts.

5

immediately.

or

sink.

tub

a

persons:

to

machine

working

appliance

the

or

ventilation

lint,

of

oxygen

outlet.

the

to

needle

the

presser

covers,

instruction

the

rewinding.

Use

dust

is

break.

manual.

not

from

openings

in

this

only

pro

mecha

ope

and

being

may

sewing

only.

break.

area,

foot,

lubrica

Do

is

to

be

Keep

sewing

This

these

machine

instructions

manufactured

designed

is

and

in

for

safe

a

HOUSEHOLD

place

only.

use

Page 4

Page 5

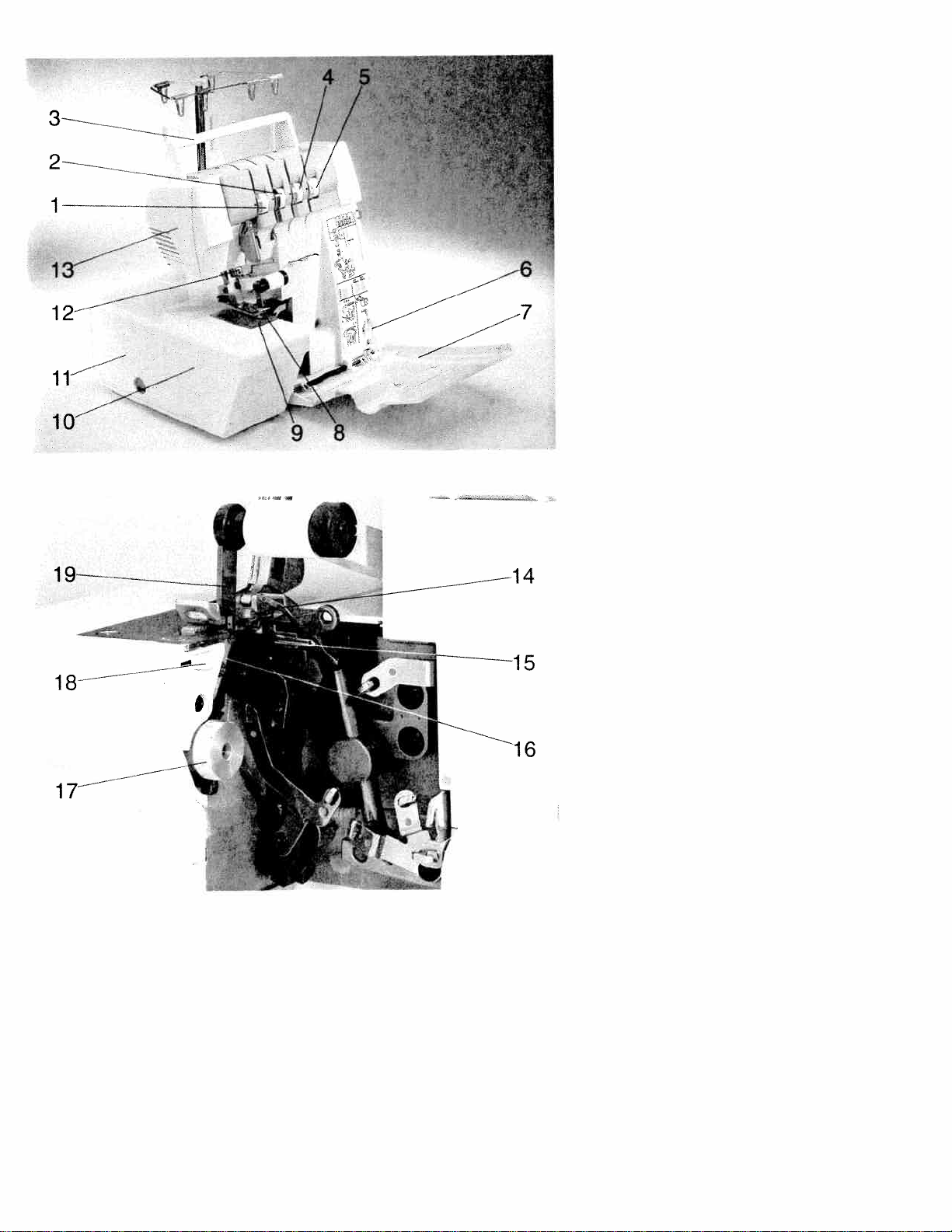

Parts

of

the

hobbylock

4762

Thread

1

Thread

2

3

Carrying

Thread

4

5

Thread

Converter

6

7

Looper

8

Sewing

Needle

9

Detachable

0

1

Accessory

11

Needle

2

1

Lamp

13

tension

tension

handle

tension

tension

cover

foot

plate

holder

cover

work

box

dial/left

dial/right

dial/right

dial/left

support

needle

needle

looper

looper

Right

14

Left

1

5

Fixed

1

6

17Seam

Bed

1

8

Movable

1

9

overedge

overedge

lower

width

slide

for

upper

looper

looper

knife

adjustment

stitch

knife

width

knob

chaining

land

Page 6

Notes

Notes

machines

60335-2-28

EN

The

1.

tion

movement

stantly

sewing.

When

2.

ded,

when

accessories,

machine

out

3.

The

the

The

4.

be

5.

The

tion

tion

Do

6.

on

7.

Do

—

—

—

which

is

8.

Do

socket

If

9.

than

it

accept

caused,

To

10.

not

parts

user

responsibility

vice

Be

11.

parts.

11.

Be

parts.

on

safety

on

accordance

user

with

during

replacing

the

maximum

sewing

tension

adjusted

machine

in

plate.

not

the

not

there

its

function

wet,

is

it

brought

not

this

that

wrongly

is

avoid

open

inside

can

staff.

sure

sure

Safety

for

and

must

regard

the

of

observe

leaving

maintenance

always

from

mains

lamp

of

by

must

accordance

any

insert

machine.

the

use

visible

is

e.g.

occur

can

into

pull

the

its

by

appliance

which

for

operated,

liability

any

risk

the

the

the

repair.

to

use

use

to

domestic

with

IEC

exercise

the

to

needle

sewing

the

machine

the

mechanical

mains

the

plug.

permissible

15

is

drive

the

PFAFF

a

be

with

objects

sewing

damage.

disturbed

is

condensation

with

when

warm

a

mains

cord.

is

used

it

electric

of

machine.

machine

This

our

of

only

only

sewing

60335-2-28.

adequate

and

up

con

and

area

unatten

work

parts

disconnect

pulling

by

wattage

Watts.

may

belt

mechanic.

into

put

indica

the

openings

in

machine

cold

a

room.

out

plug

for

a

intended

is

cannot

we

is

any

There

which

solely

damage

shock,

for

qualified

original

original

cau

down

while

or

the

only

opera

if:

machine

the

of

purpose

or

no

are

the

the

ser

PFAFF

PFAFF

1

2.

1

3.

Environment

or

The

temperature

to

for

The

interference;

rated

radios,

etc.

This

tronic-mechanical

for

operated

ted

light,

objects,

For

be

both

Care

Always

if

damage

dropping.

Cleaning

do

Housing

To

and

removed

paraffin.

Please

Do

products

fluid

machine

The

with

supply

+1-10%

+1-4%.

used

When

outer

the

of

tronically

reach

up

low

speed

order

to

recommended

80%.

machine

electronic

near

TVs,

sewing

supervised

in

to:

dust,

static

corrosive

ventilation

free-standing,

and

firm

the

of

protect

which

the

clean

lint-free

withasoft

Notel

not

use

such

chemicals

designed

is

nominal

a

rated

a

and

properly,

components

controlled

85°C.

to

therefore

is

damage.

avoid

environment

10°Cto

suppressed

is

however,

broadcasting

PCs,

machine

appliance;

in

use

suchaway

severe

electricity,

chemicals

purposes

on

even.

machine

machine

the

occur

may

housing

Any

cloth.

insecticides

any

benzine

as

cleaning

for

voltage

frequency

the

foot

Constant

not

40°

C,

and

should

it

devices

high-quality

is

a

home.

the

that

dampness,

heat-producing

the

surface

a

by

dry,

a

use

stubborn

cloth

and

(petroleum)

mains

for

a

of

of

temperature

non-elec

of

a

control

use

permitted

Ambient

is:

Humidity

immune

notbeope

such

as

transmitters

a

is

it

should

It

not

is

it

direct

liquids.

or

machine

which

against

knocking

clean,

dirt

alcohol

chemical

or

housing.

the

can

at

a

20%

elec

machine

subjec

sun

must

is

or

soft

can

or

or

in

to

be

be

2

Page 7

Simple,

up-to-date

sewing

Congratulations!

hobbylock

and

operation.

PFAFF

this

as

now

you

manual,

certainly

is

to

put

have

you

dealer.

help

now

that

and

find

it

will

take

to

or

let’s

hours

hobbylock

technology,

instruction

out

any

advice.

product

new

stride

one

Your

design

use

If

tion

It

way

and

If

PFAFF

any

So,

enjoyable

ideas.

You

provides

4760

sew,

little

a

nothing

well

time

just

full

use.

further

He

is

get

started!

creating

have

unique

can

trim

manual

time

can

what

happy

bought

take

and

neaten

features

anditis

to

amiss.

go

spent,

your

questions

to

We

your

high-quality

a

advantages.

material

any

for

up

the

very

just

as

to

follow.

is

the

study

itisthe

since

machine

just

—

beofservice

you

wish

very

many

own

Your

in

you

latest

easy

instruc

only

do

can

ask

your

with

fashion

its

in

in

to

3

Page 8

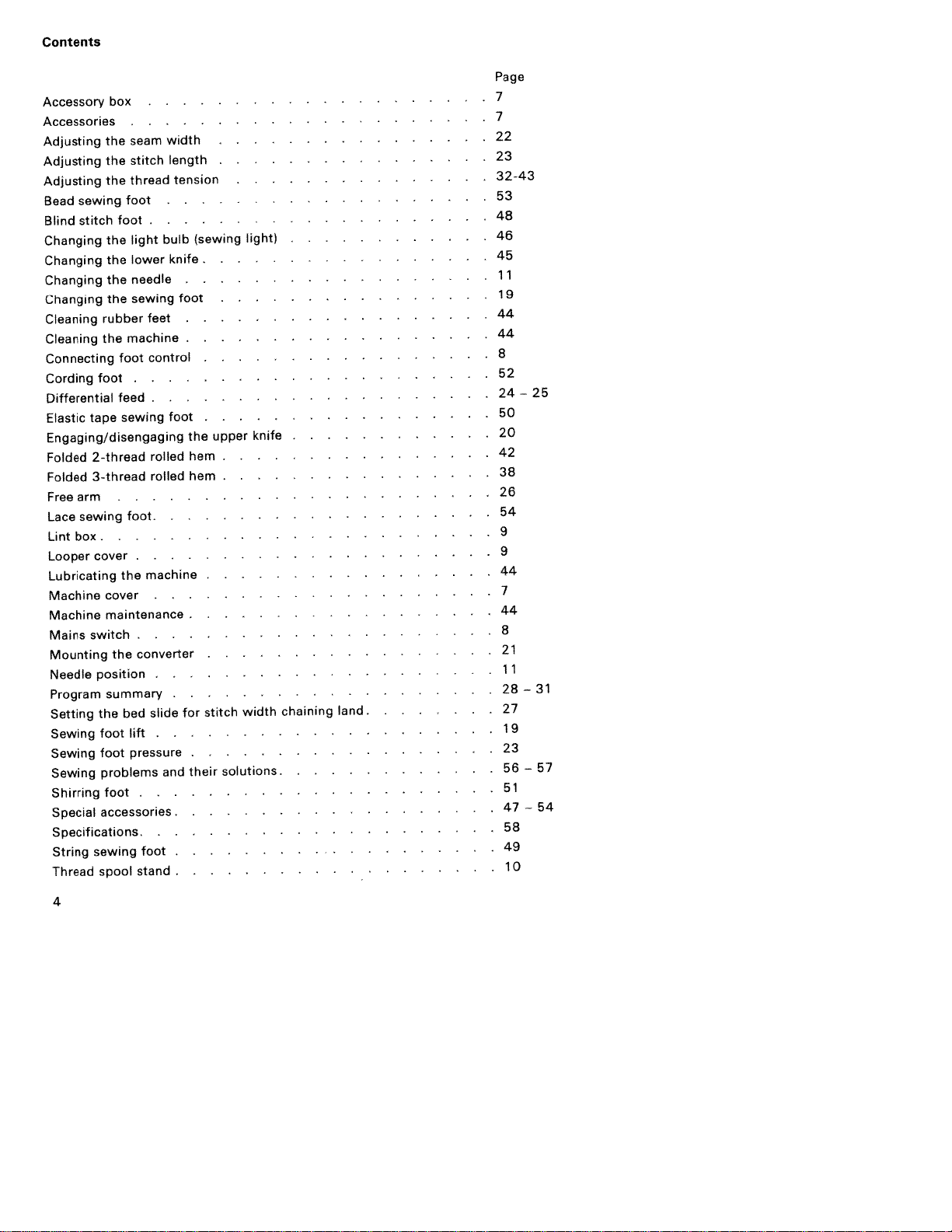

Contents

sewing

stitch

the

foot

tape

box

the

the

the

foot

the

the

the

the

rubber

foot

feed

sewing

.

seam

stitch

thread

foot

light

lower

needle

sewing

machine

Accessory

Accessories

Adjusting

Adjusting

Adjusting

Bead

Blind

Changing

Changing

Changing

Changing

Cleaning

Cleaning

Connecting

Cording

Differential

Elastic

Engaging/disengaging

2-thread

Folded

3-thread

Folded

arm

Free

cover

the

cover

maintenance

switch

the

position

summary

bed

the

foot

foot

problems

foot

accessories

foot

converter

lift

pressure

sewing

Lace

Lint

box

Looper

Lubricating

Machine

Machine

Mains

Mounting

Needle

Program

Setting

Sewing

Sewing

Sewing

Shirring

Special

Specifications

sewing

String

stand

Thread

spool

width

bulb

feet

control

rolled

rolled

machine

slide

and

foot

length

tension

knife

foot

foot

the

for

(sewing

hem

hem

stitch

their

upper

solutions.

light)

knife

width

chaining

.

land

Page

7

7

22

23

32-43

53

48

46

45

11

19

44

44

8

52

24—25

50

20

42

38

26

54

9

9

44

7

44

8

21

11

28—31

27

19

23

56—57

51

47-54

58

49

10

4

Page 9

Telescopic

Thread

Thread

thread

spool

unreeling

Threading/guide

Threading

Threading

Threading

Threading

Thread

Thread

Thread

2-needle,

2-thread

2-thread

2-thread

3-thread

3-thread

3-thread

3-thread

4-thread

right

left

right

left

reel

chain

table

3-thread

overedge

serging

rolled

overedge

serging

decorative

rolled

overedge

net

overedge

needle

change

cutter

for

guide

disc

wires

overedge

needle

on

3-

2-,

overedge

seam

seam

hem

seam

seam

seam

hem

seam

.

looper

looper

(green)

A

B

(blue)

threaded

and

FLATLOCK

(wide,

(wide,

(wide,

serging

(red)

(yellow)

machine

4-thread

closing

narrow)

narrow)

narrow)

overedge

seam.

(wide,

seam

.

narrow).

FLATLOCK/wide,

narrow

Page

10

10

12

13

14—15

16

17

18

19

55

43

39

40

41

34

35

36

37

32—33

5

Page 10

I

I

I?

A

W;e4Wtj

I

i

Page 11

44,

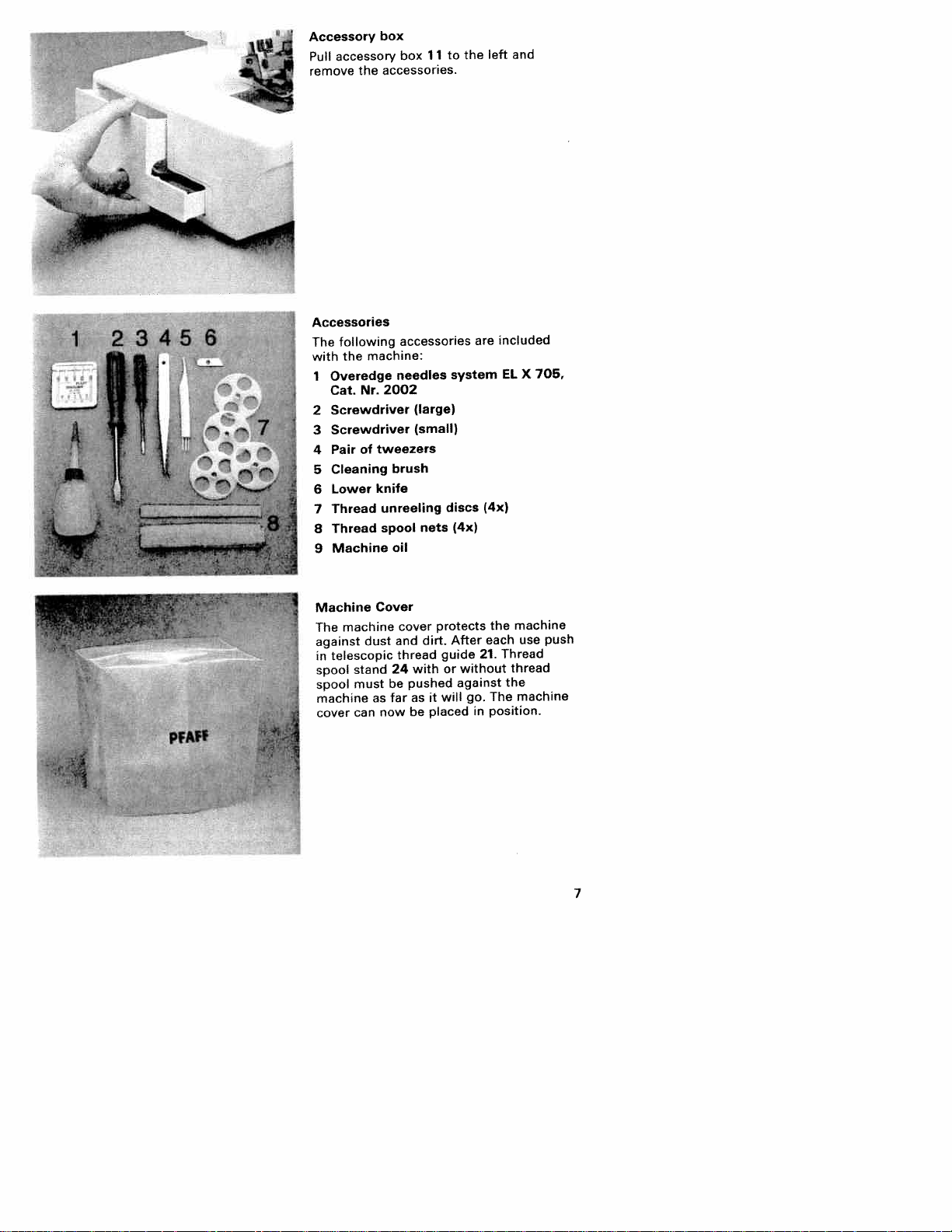

Accessory

accessory

Pull

remove

Accessories

following

The

the

with

Overedge

1

Cat

Screwdriver

2

Screwdriver

3

Pair

4

Cleaning

5

Lower

8

Thread

7

Thread

8

Machine

9

box

accessories.

the

machine:

2002

Nr.

tweezers

of

knife

unreeling

spool

11

box

accessories

needles

(large)

(small)

brush

nets

oil

the

to

system

discs

(4x)

are

(4x)

left

included

EL

and

X

705,

Machine

machine

The

against

telescopic

in

spool

spool

machine

cover

dust

stand

must

can

Cover

be

far

as

now

cover

and

thread

24

dirt.

with

pushed

it

as

placed

be

protects

After

guide

or

without

against

will

go.

in

the

each

21.

Thread

The

position.

machine

use

thread

the

machine

push

7

Page 12

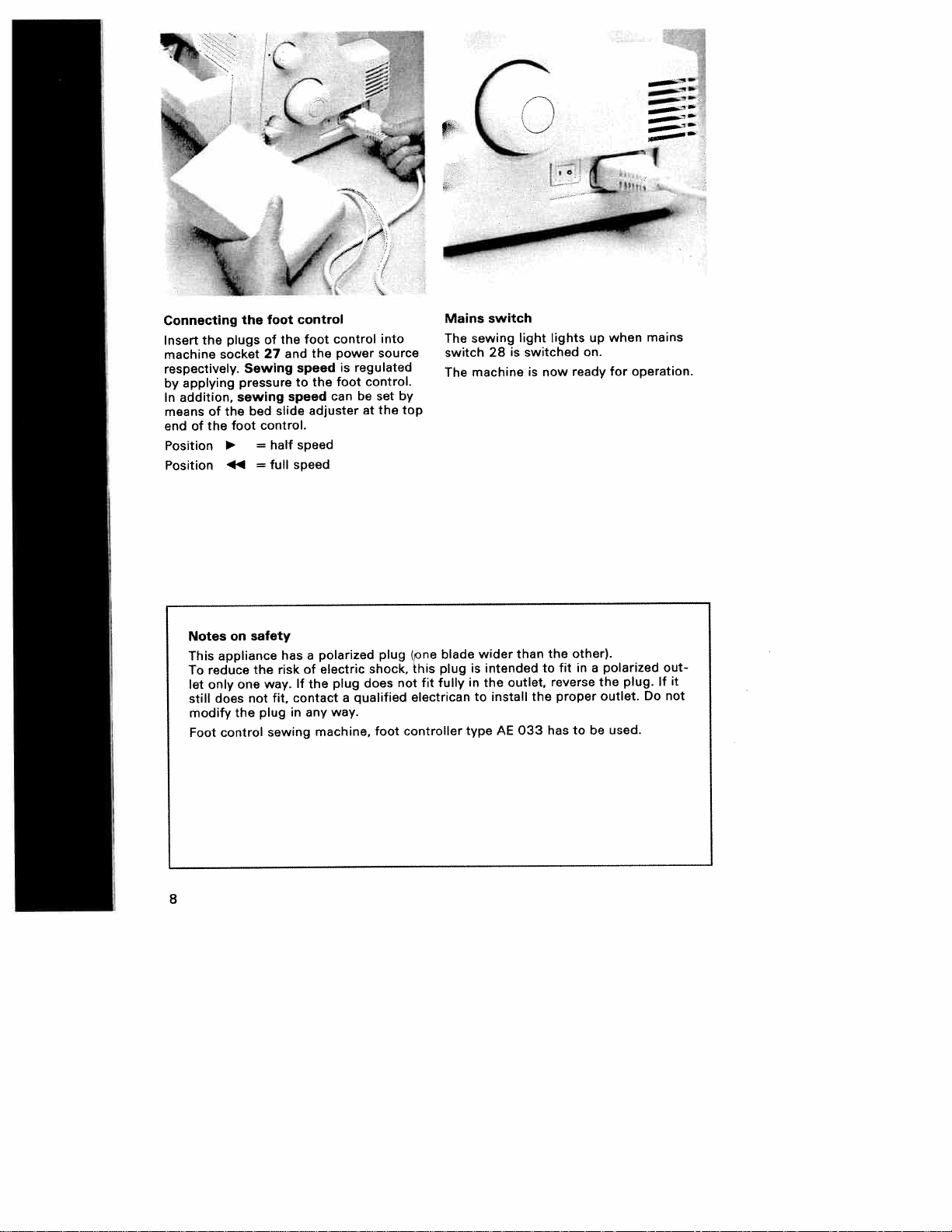

Connecting

Insert

the

machine

respectively.

applying

by

addition,

In

of

means

the

of

end

Position

Position

Notes

This

To

reduce

only

let

does

still

modify

Foot

the

plugs

socket

Sewing

pressure

sewing

bed slide

the

foot

44

safety

on

appliance

the

one

not

the

control

foot

of

27

control.

half

=

full

=

way.

fit,

plug

sewing

the

and

speed

has

risk

in

control

foot

the

speed

to

the

adjuster

speed

speed

a

of

If

the

contact

any

machine,

control

power

is

foot

can

polarized

electric

plug

qualified

a

way.

into

source

regulated

control.

be

set

at

the

plug

shock,

does

foot

Mains

The

switch

The

by

top

blade

(one

plug

this

fully

fit

not

electrican

controller type

switch

sewing

28

machine

wider

is

intended to

outlet,

the

in

install

to

AE

light

switched

is

is

than

the proper

033

lights

now

the

reverse

has to

fit

up

on.

ready

other).

in

a

be

when

for

polarized

plug.

the

outlet.

used.

mains

operation.

out

If

not

Do

it

8

Page 13

Lint

Insert

the

box

the

upper

4

upper

of

slots

PFAcF

tabs

looper

of

hobbYkk

4l62

lint

cover

box

part

snap

box,

cover.

use

4762

of

into

the

contai

the

the

hobbYkCk

the

lower

the

of

of

sequence.

PIAFF

the

the

lower

tabs

looper

lint

I

4

against

Press

until

into

34

7.

ner

lower

For

reverse

slots

removal

Looper

Slide

the

dual

colour

well

cover

looper

right

threading

on

the

as

looper.

edge

procedure

common

most

symbolically.

cover

and

the

threading

for

swing

paths

inside

addition,

In

the

stitch

as

far

7

downwards.

it

are

the

of

method

converter

types

it

as

displayed

machine,

of

mounting

the

and

are

will

the

the

shown

go

Indivi

in

over-

three

soon

power

as

i.e.

sup

the

9

is

interrupted,

as

the

Note:

cover

looper

to

as

to

ply

machine

the

machine

will

is

not

opened,

operate.

reasons,

safety

For

the

Page 14

Thread

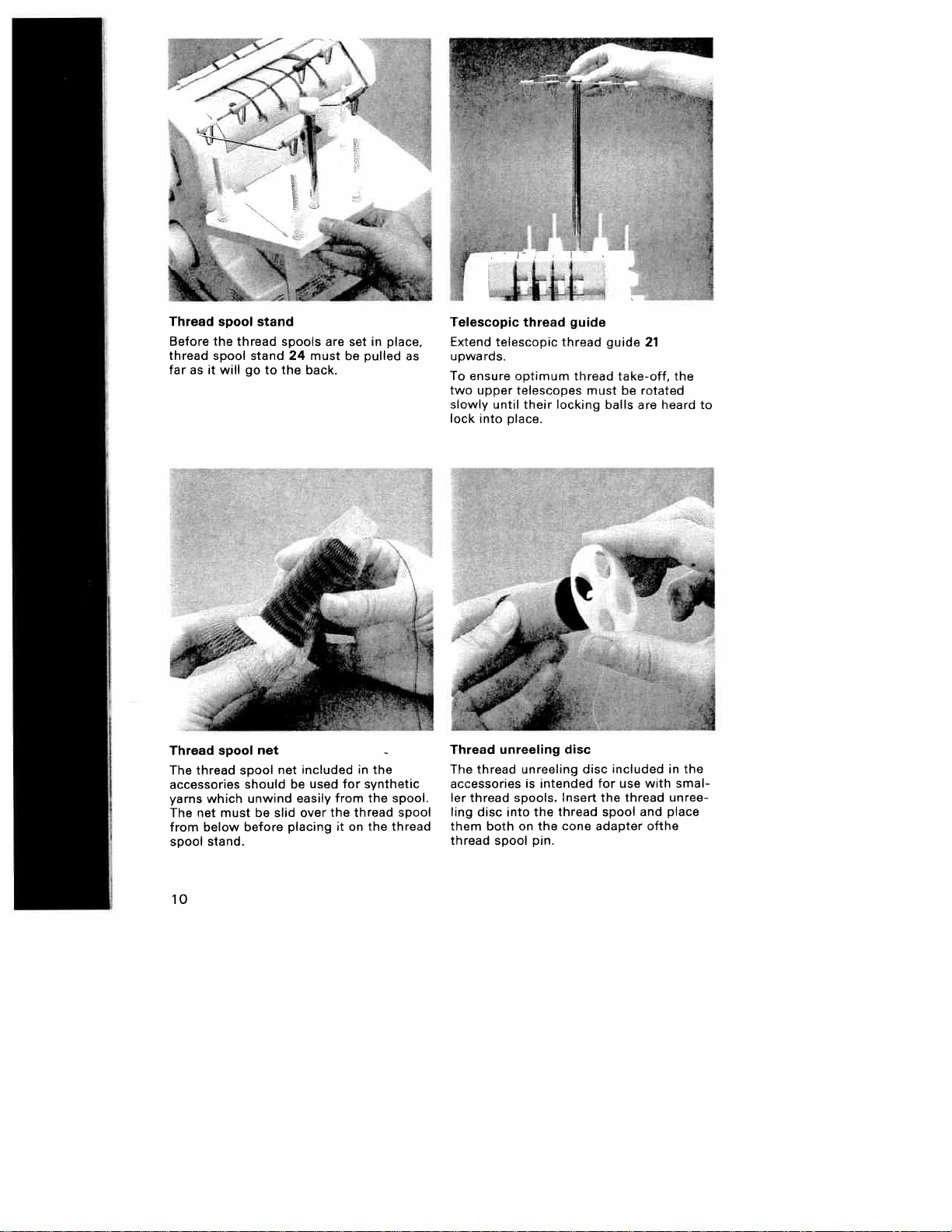

Before

thread

as

far

the

spool

it

spool

will

stand

thread

stand 24

gotothe

spools

are

mustbepulled

back.

setinplace,

Telescopic

Extend

upwards.

as

ensure

To

two

slowly

lock

telescopic

upper

until

into

thread

optimum

telescopes

their

place.

guide

thread

thread

locking

must

guide

take-off,

be

balls

21

rotated

are

the

heard

to

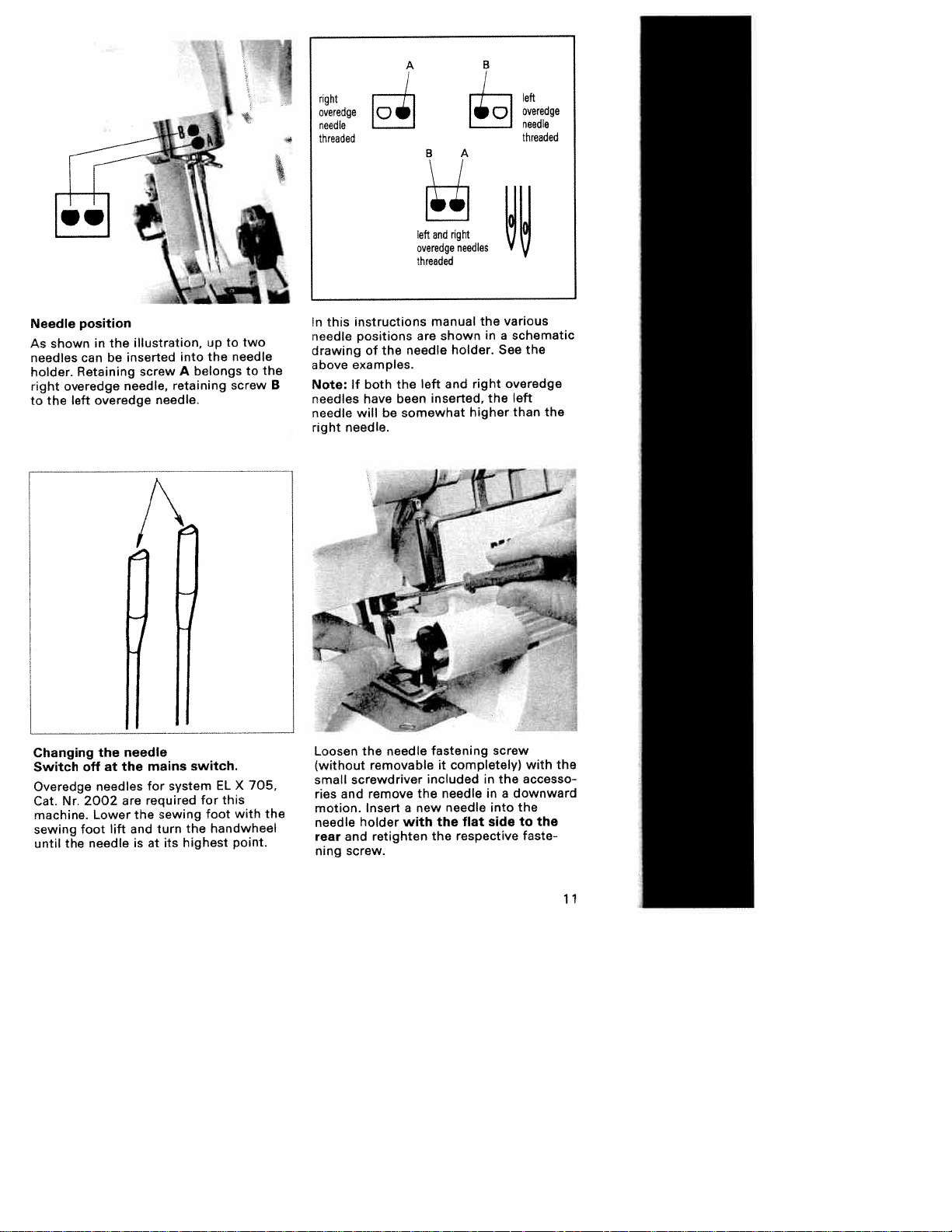

Thread

The

thread

accessories

yarns

which

net

The

below

from

spool

stand.

10

spool

net

spool

shouldbeused

unwind

must

be

before

includedinthe

net

easily

over

slid

placing

from

the

for

it

synthetic

the

thread

the

on

spool.

spool

thread

Thread

The

thread

accessories

ler

thread

ling

disc

them

both

thread

unreeling

unreeling

is

spools.

into

on

spool

intended

the

thread

the

pin.

disc

disc included

for

Insert

the

cone

adapter

spool

use

thread

with

and

ofthe

in

smal

unree

place

the

Page 15

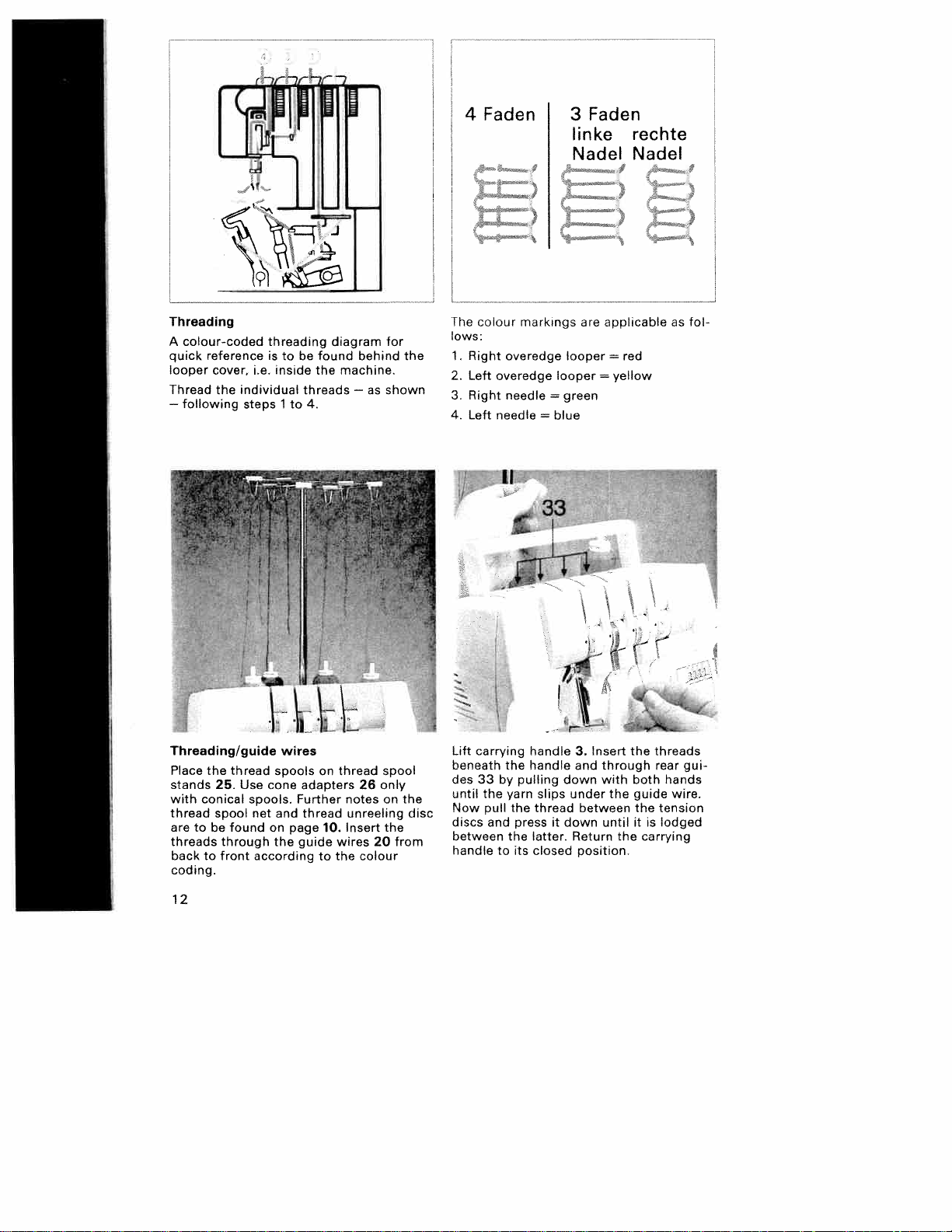

Needle

shown

As

needles

holder.

right

the

to

position

in

can

Retaining

overedge

left

overedge

the

be

needle,

illustration,

inserted

screw

needle.

into

A

belongs

retaining

up

the

to two

needle

to

screw

the

B

I

right

overedge

needle

threaded

In

this

needle

drawing

above

Note:

needles

needle

right

o

instructions

positions

of

the

examples.

If

both

have

will

be

needle.

A

left

overedge

threaded

are

needle

left

the

been

somewhat

right

and

needles

manual

shown

holder.

and

inserted,

B

the

in

right

the

higher

Q

various

schematic

a

See

overedge

left

overedge

needle

threaded

the

left

than

the

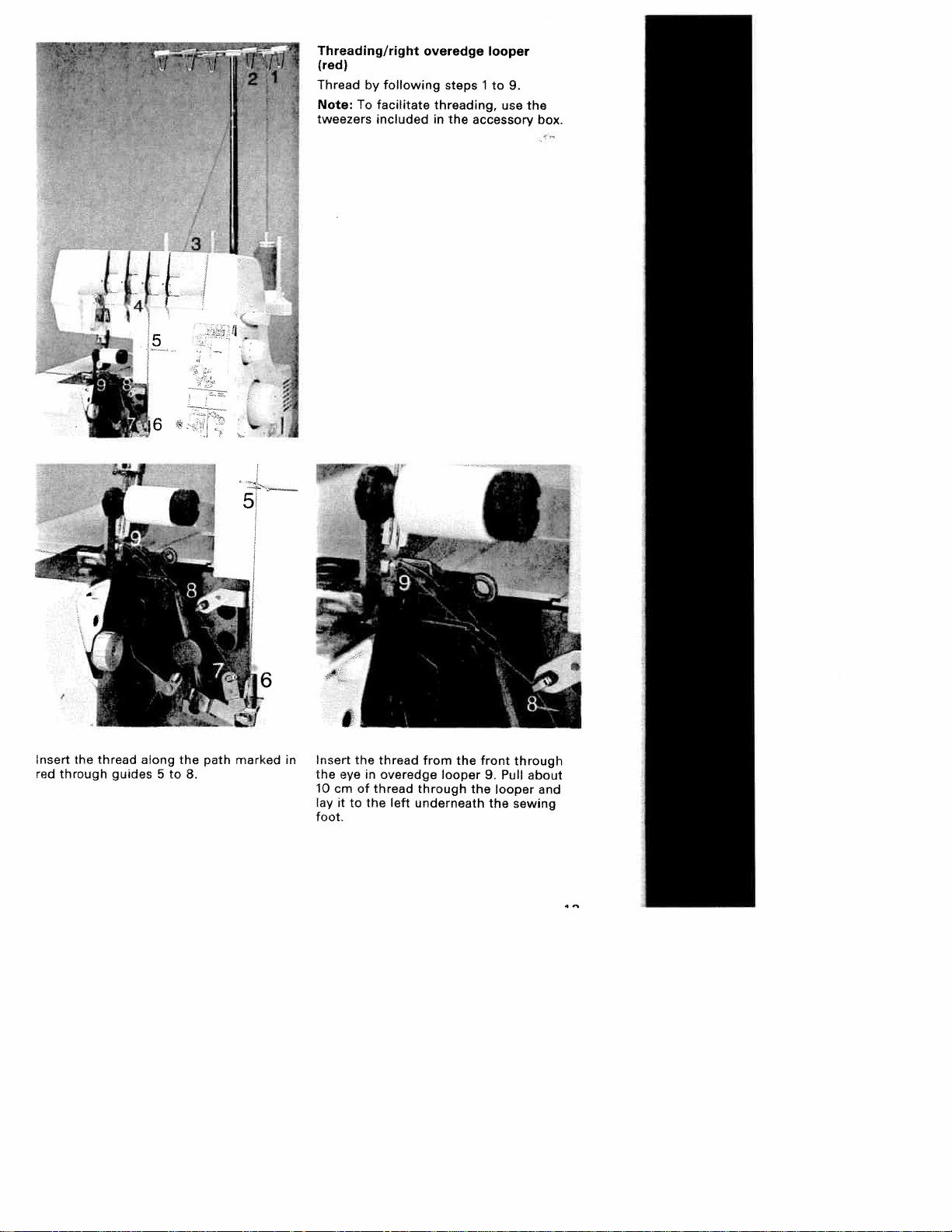

Changing

Switch

Overedge

Cat.

Nr.

machine.

sewing

the

until

off

2002

foot

needle

the

at

needles

Lower

lift

needle

the

are

the

and

is

mains

system

for

required

sewing

turn

its

at

switch.

for

foot

the

highest

705,

X

EL

this

with

handwheel

point.

the

Loosen

(without

small

ries

motion. Insert

needle

rear

ning

the

removable

screwdriver

remove

and

holder

and

retighten

screw.

needle

a

with

fastening

included

the

new

the

completely>

it

needle

needle

the

flat

respective

screw

with

in

the

accesso

inadownward

the

into

the

to

side

faste

the

11

Page 16

Threading

A

colour-coded

quick

reference

looper

Thread

—

following

cover,

the

threading

is

inside

i.e.

individual

steps

tobefound

the

threads—as

ito

4.

diagram

behind

machine.

for

the

shown

4

Faden

The

colour

lows:

1.

2.

3.

4.

Right

Left

Right

Left

markings

overedge

overedge looper=yellow

needle

needle=blue

H

Faden

3

linke

Nadel Nadel

are

applicable

looper=red

=

green

rechte

fol

as

Threading/guide

Place

the

25.

conical

spool

through

to front

thread

Use

stands

with

thread

are tobefound

threads

back

coding.

12

I

wires

spoolsonthread

cone

on

and

the

adapters

thread

page

guide

to

spools. Further

net

according

10.

the

26

notes

unreeling

Insert

wires

colour

20

spool

only

on

the

the

from

disc

Lift

carrying

beneath

des33by

until

Now

discs

between the

handle

the handle

the

pull

and

to

yarn

handle3.Insert

pulling

the thread

pressitdown

its

slips

latter.

closed

down

under

and

between

Return

position.

the

through

with

both

the

guide

the

untilitis

the

threads

rear

hands

tension

lodged

carrying

gui

wire.

Page 17

J1

3

I

Threading/right

(red)

Thread

tweezers

by

following

Note:Tofacilitate

included

overedge

steps

threading,

in

the accessory

looper

ito

use

9.

the

box.

tnsert

red

the thread

through

along

guides5to

the

5—

path

8.

marked

in

Insert

the

the

eyeinoveredge

10cmof

layitto

foot.

the

thread

thread

left

from

the

looper

through

underneath

the

front

9.

the

through

Pull

looper

sewing

about

and

Page 18

the

direction

looper15is

right.

loopers

of

the

left

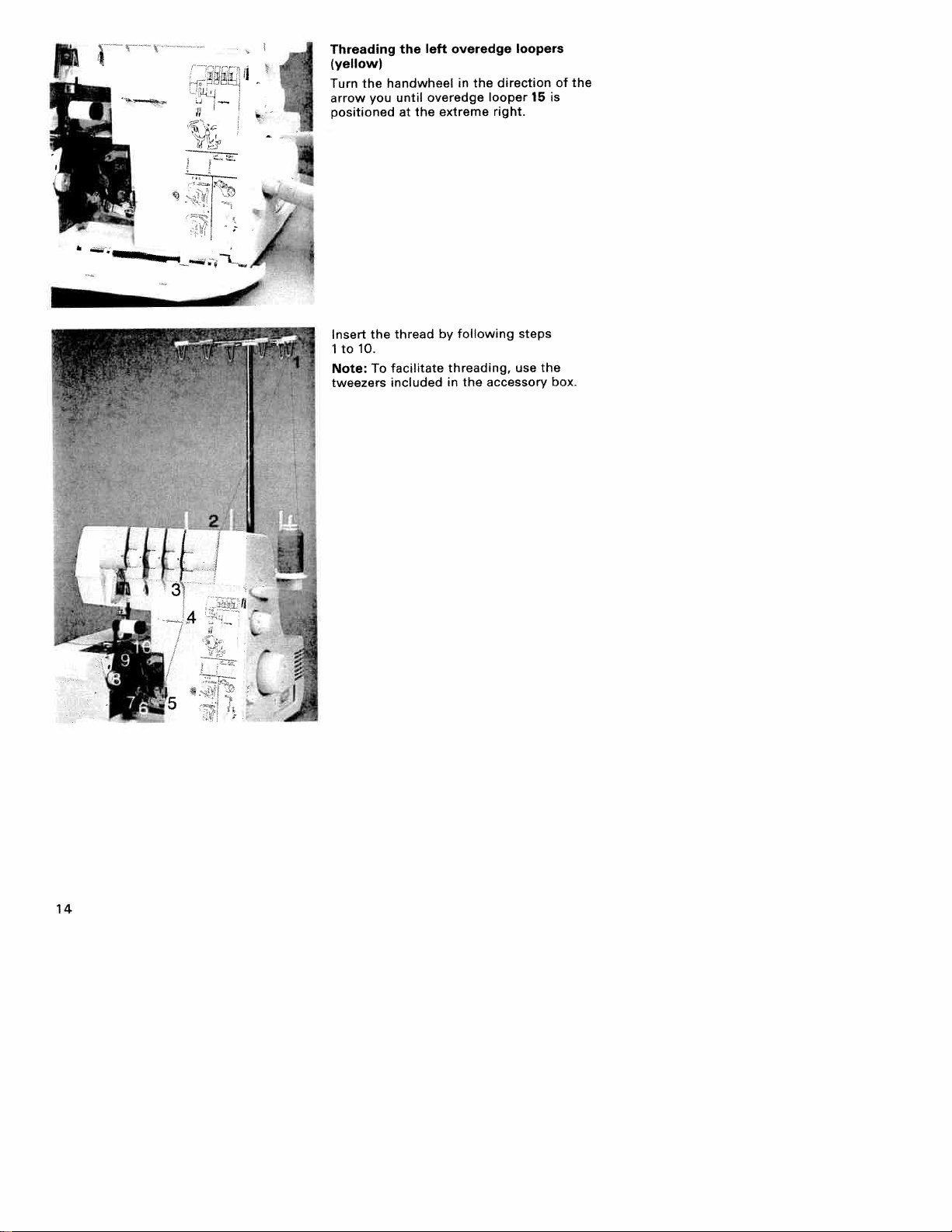

Threading

:J

‘:

(yellow)

Turn

arrow

positionedatthe

the

you

the

handwheel

until

overedge

in

overedge

extreme

I

‘I

Insert

ito

10.

Note:

tweezers

the

To

thread

facilitate

included

following

by

threading,

in

the

steps

use

accessory

the

box.

14

Page 19

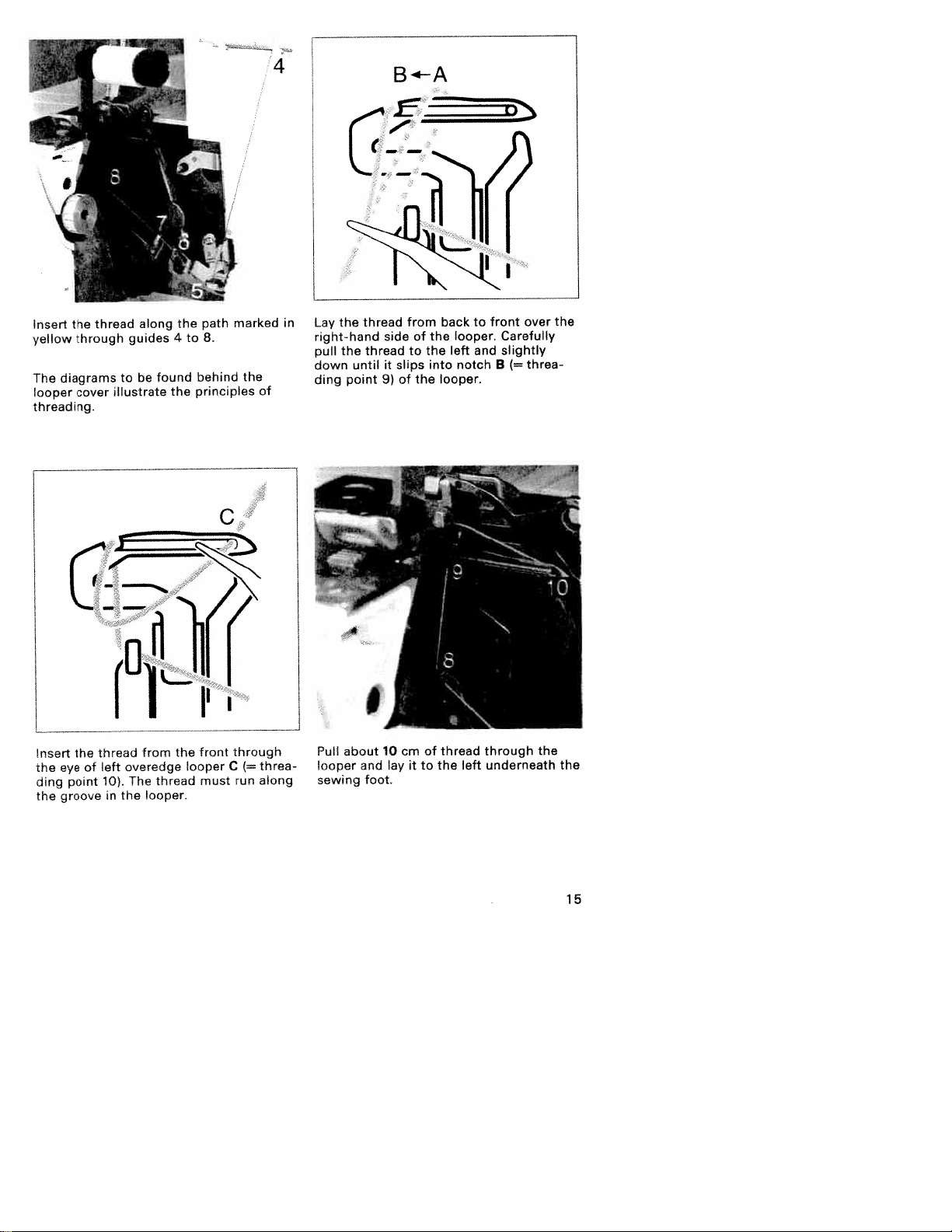

4

the

Insert

yellow

diagrams

The

looper

threading.

Insert

ihe

eye

point

ding

groove

the

thread

through

cover

thread

the

left

of

guides

tobefound

illustrate

overedge

The

10).

the

in

along

from

looper.

4to8.

the

the

thread

the

behind

principles

looper

path

front

must

C

C

marked

the

of

through

(=

run

threa

along

in

the

Lay

right-hand

the

pull

untilitslips

down

ding

point9)of

Pull

about

looper

sewing

thread

sideofthe

thread

10cmof

and

foot.

from

to

the

layitto

the

into

back

looper.

left

looper.

thread

the

notch

left

front

to

Carefully

slightly

and

B

through

underneath

(=

over

threa

the

the

the

15

Page 20

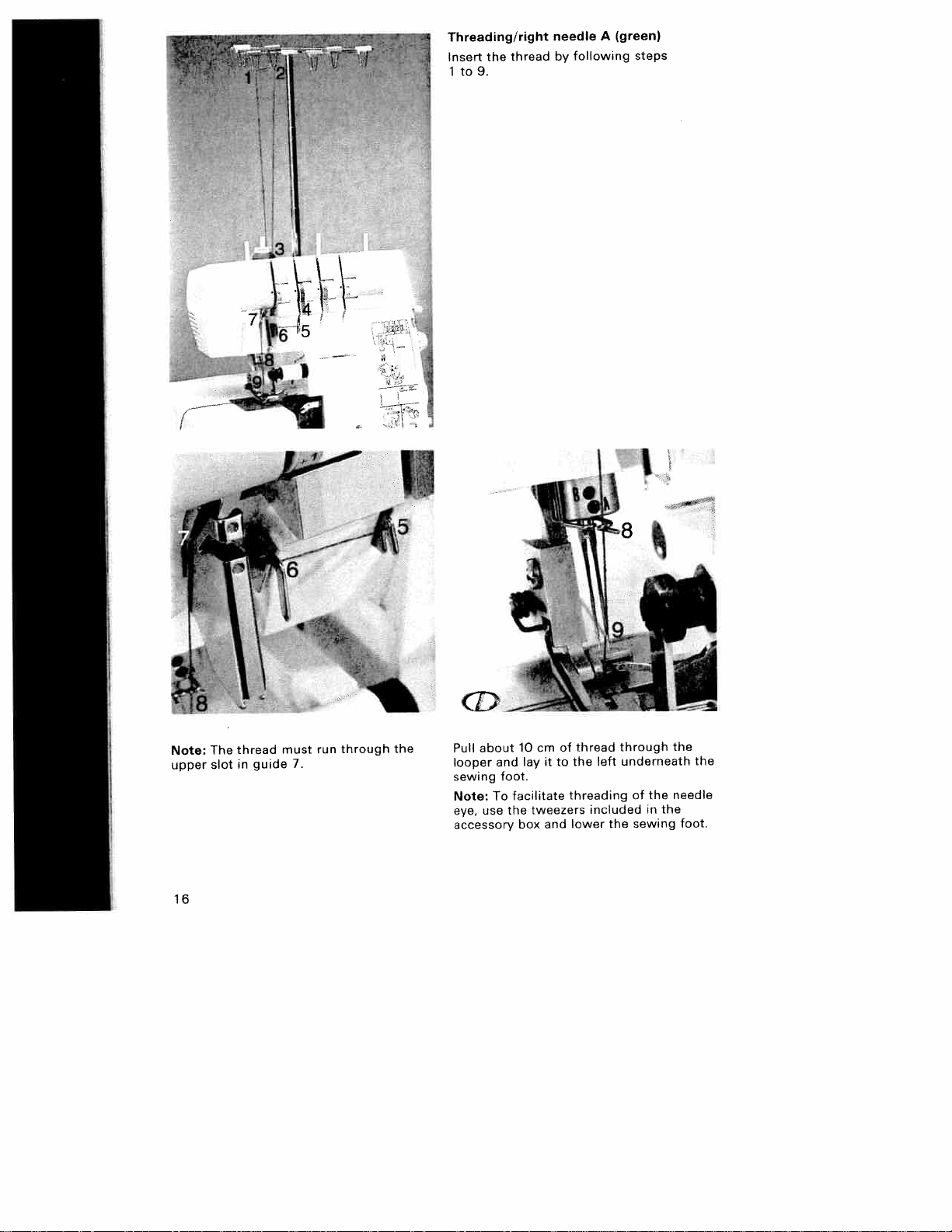

Threading/right

thread

the

Insert

1

9.

to

needleA(green)

following

by

steps

Note:

upper

16

The

slot

thread

guide

in

must

7.

run

through

the

Pull

about

looper

sewing

Note:

use

eye,

accessory

and

foot.

To

10

lay

facilitate

tweezers

the

box

cm

it

and

thread

of

to

the

threading

lower

through

underneath

left

included

the

the

of

in

sewing

I

the

the

needle

the

foot.

Page 21

Hi

Threading/left

steps

the

ito

Thread

B

B

(blue>

by

following

needle

needle

left

7.

Note:

lower

The

slot

thread

in

guide

must

5.

run

through

the

Pull

about

needle

neath

Note:

use

eye,

accessory

eye

the

To

10

and

sewing

facilitate

tweezers

the

box

cm

lay

and

thread

of

it

to

foot.

threading

lower

through

the

included

the

left

of

sewing

under

the

the

in

the

needle

foot.

17

Page 22

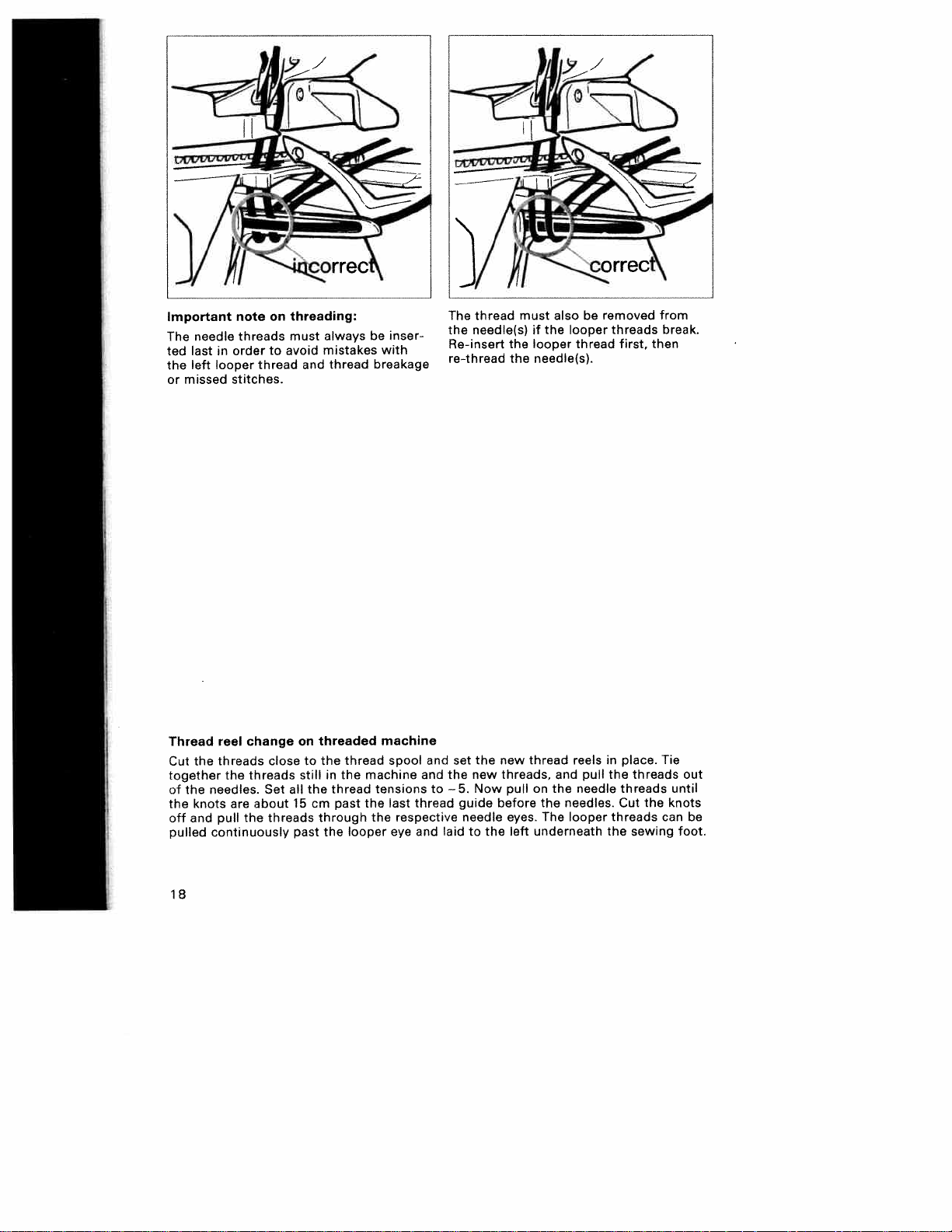

Important

The

needle

lastinorder

ted

left

the

or

missed

note

looper

stitches.

threads

thread

on

to

threading:

must

avoid

and

always

mistakes

thread

be

inser

with

breakage

The

thread

the

needle(s)

Re-insert

re-thread

the

the

must

if

looper

needle(s).

the

also

be

looper

thread

removed

threads

first,

from

break.

then

Thread

Cut

the

together

of

the

knots

the

off

and

pulled

18

reel

change

threads

threads

the

needles.

about

are

pull

the

continuously

on

closetothe

stillinthe

Set

all

the

15

cm

threads

past

threaded

thread

thread

past

through

looper

the

machine

spool

machine

tensions

the

last

the

eye

and

and

to

thread

respective

and

the

—5.

laid

set

guide

needle

new

to

the

Now

the

new

threads,

pull

before

eyes.

left

thread

and

the

on

needles.

the

The

looper

underneath

reels

pull

needle

in

place.

the

threads

Cut

threads

the

threads

the

sewing

Tie

knots

can

out

until

be

foot.

Page 23

Sewing

The

red

mum

foot

achievedbyalso

foot

foot

sewing

with

foot canberaised

sewing

vertical

for

particularly thick

lift

towards

lift

liftof6

lift

foot

mm

depressing

the

back.

32.

for

fabrics

The

the

the

and

maxi

can

sewing

lowe

sewing

be

Thread chain

After

finishingaseam, continuetosew

thread

thread

chain

cutter

be

cut.

cutter

chainof15—20

chain

towards

23.

The

thread

the

cm.

front

Pull

chain

the

over

wilt

a

thread

thus

Changing

Switch

To

highest

Press

sewing foot

be

and

lift

To

insert

that

red,

sewing

Check:

ensure

locked into

the

sewing foot

off

at the

remove:

released

canberemovedtothe

the

insert:

when

the

Raise

position and

the

white

holder.

automatically

spring

Lift

the

sewing

the

pinofthe

foot

holder.

Please

that

the

place.

slightly.

the

sewing

mains

needle(s)

the

lift

leveratthe

The

spring

foot

under

foot

foot

lift

the

sewing

sewing foot

switch

the

sewing

rearofthe

sewing foot

from

the

left.

slightly

the

leverislowe

locks into

foot

properly

is

to

the

foot.

will

holder

Todothis,

and

holder

the

lever

so

to

19

Page 24

Disengaging

Switch

Raise

position

Detach

cover.

ble

off

upper

by

the

Now

upper

Engaging

Slide

the

towards

knife

knife

back

position.

attach

the

at

knife

rotating

lint

slide

knife

the

holder

until

Close

lint

the

the

box

fully

upper

the

it

the

box.

upper

mains

19

to

its

the

and

holder

the

towards

knife

movable

of

the

right

and swing

locks

looper cover

knife

switch

upppermost

handwheel.

open

the

of

the

the

into

its

looper

mova

right.

upper

the

working

and

Turn

from

horizontal

re

the

you

head

until

position.

of

the

the

upper

upper

knife

knife

away

locks

into

a

20

Page 25

Mounting

Switch

converter

The

2-thread

3-thread

lint

the

Converter

machine

Insert hub

aperture

the

at

off

seams

overedge

box

and

6

housing.

A

of

converter

the

must

located

is

of

the

and

open

the

right

mains

be

the

closing

the

Pull

converter

overedge

switch

mounted

2-needle,

seam.

looper

in

the

it

out.

front

into

for

Detach

cover.

of

the

looper.

all

the

Rotate

edge

movable

the

Rotate

press the

the

that

of

eye

converter

The

ing

these

the

looper

the

the

handwheel

is

upper

converter

upper

of

tip

looper.

directions

positioned

knife.

part

converter

the

be

can

in

until

to

towards

slightly

removed

reverse

the

the

the

to

locks

right

right

the

by

order.

over-

left

rear

into

follow

of

and

so

the

21

Page 26

Adjusting

Switch

Detach

continuously

be

3.0

mm

adjustment

can

be

holderispushed

knife

off

the

to

more

seam

at

mt

4.5

knob

the

box.

mm

easily

width

mains

The

adjusted

by

The

17.

adjusted

switch

seam

as

turning

seam

slightly

width

desired

seam

width

the

if

to

upper

the

can

from

width

is

right.

The

needle

ment

adjustments

plate.

for

rolled

R

are

is

the

seams.

5,2rnm

marked

seam

11

the

on

width

adjust

Note:

needle

width

22

The

only.

can

seam

For

continuously

be

width

the

adjustments

needle,

left

adjusted

the

between

value

set

from

5.2

3.0

increased

is

mm

mm

to

6.7

and

4.5

by

mm.

2.3

O24)

mm

apply

mm,

i.e.

the

right

to

seam

the

Page 27

3

Adjusting

The

from

stitch

For

adjustment

I

When

the

Sewing

The

pressure

fabrics.

The

to

or

ever

sure.

In

from

for

The

set

weight

the

fabrics:

set

Note:

it

strikes

screw

Now

set.

the

length

stitch

1

F

(

length

sewing

most

working

adjustment

toot

machine’s

is

sewing

changed

be

heavier

this

fabrics

become

event,

accessory

the

adjusting

pressure

screwtothe

fabrics:

screw

set

increase

to

screw

Turn

against

back

standard

the

can

to

mm>

adjustment

work,

shouldbeset

knob

with

knob

pressure

factory-set

suitable

pressure

foot

for

necessary

insert

sewing

the

is

adjusted

left

reduce

to

the

pressure

right.

the

set

the

the

the

to

be

4

mm

close-knit

to

for

most

sewn,

are

the

box

or

left.

screw

top

left,

sewing

the

pressure

rotating

desired

set

as

turning

by

31.

knob

length

stitch

at

3

fabrics,

4

mm.

sewing

medium-heavy

does

fabrics.

to

reset

small

into

foot

by

right.

For

by

to

lid.

foot

foot

not

lighter

If

it

may

the

screwdriver

screw

set

pressure.

turning

light

For

by

heavyweight

turning

right

the

turn

Then

it

6

pressure

mm.

set

need

how

pres

22

the

turning

the

until

the

times.

is

length

stitch

23

Page 28

Differential

The

differential

(A

dogs

which

other,

lever

ment

the

front

amount

be

adjusted

The

standard

the

which

chronously

front

the

same

the

The

Note:

also

feed

selected

A

feed

arranged

+

B),

move

30

feed

fabric

of

within

front

with

rear

and

amount

effectiveness

depends

the

and

consists

feed

the

regulates

(A),

dog

tobefed

the

adjustment

dog

feed

the

rear

feed

fabric.

of

on

type

of

one

behind

workpiece,

movement

the

thus

and

through.Itcan

0.5

range

is

1

moves

(A)

feed

dogs

both

the

of

stitch

the

fabric

of

two

the

Adjust

the

and

by

.0,

dog

(B),

move

differential

lenght

used.

feed

of

2.0.

syn

i.e.

If

differential

to

set

fast

as

dog

feed

fabric

a

As

24

0.5,

as

as

result,

the

the

feeds

the

the

feed

front

rear

rear

adjustment

feed

through

feed

fabric

feed

dog

dog.

only

dog.

is

stretched,

lever

moves

i.e.

half

the

is

30

half

front

much

as

prevents

This

gathered

fabrics

such

smooth

a

is

Fashionable

in

duced

using

when

when

this

the

sewing

as

silk

seam

touches

way,

rib

knit

seam

and

(A).

such

(B).

can

very

taffeta.

also

as

delicate

be

the

The

intro

wave

result

effect

becoming

from

Page 29

4

Set

differential

to

10

so

twiceasfastasthe

front

feed

fabricasthe

much

Asaresult,

The

following

should

you

Fabric

very

thin

normal

fine

cord,

thin

knitted

fine

knitwear

thick knitted

knitwear.

Stretch—wave

fabrics,

openings,

feed

that

the

feeds

dog

fabric

the

table

always

type/Effects

fabrics:

fabrics:

thermal

fabrics:

and

fabrics:

Jersey,

skirt

adjustment

front

feed

dog

feed

rear

through

rear

indicates

performasewing

silk,

lightweight cotton,

fabrics.

cuffs,

effect:

knitwear,

hems,

feed

is

gathered.

satin,

Jersey,

sweatshirt

medium-

frilled

set

dog,

twice

dog.

possible

poplin,

polo

tight

lever

moves

i.e.

edges

stitch

30

the

as

testonyour

taffeta,

medium

fabric,

fabric,

and

lightweight

on

length.

This

stretched

suchasJersey

result

Fashionable

ducedinthis

effect

(D).

settings

lining

cotton,

nicki,

thick

cuffs,

sleeves

prevents

isasmooth seam

when

for

fabrics.

frotté,

knitted

and neck

the

when

touches

way,

using

the

differential

fabric before

•

sewing

and

knitted

rib

stitch

(C).

can alsobeintro

suchasthe gather

very

delicate

feed.

starting

Differential

gather

2,O

from

seam

becoming

fabrics

goods.

fabrics

However,

work.

feed

normal

)1,O(

The

setting

stretch

O,5

Crimping:

seam

shirts,

slightly

or

sewing

Frills

allowancesincircular

skirts,

crimping sleeve

sleeves

made

from

round

pockets,

onto

cuffsorwristbands.

fabrics

thin

cut-outs,

flaps

(shoulder) curves,

and

curvesonblouses,

lapels,

and

lace,

gathering

25

Page 30

pcAFF

Sewing with

Detach

Remove

work

Reattach

The

sewing

and

arm.

the

the

support

free

tubular

sleeves.

the

arm

the

work

lint

10

lint

is

particularly

items

Insert

free

arm

support

box

and

towards

box.

suchastrouser

article

the

pull

detachable

the

useful for

left.

over

the

legs

free

26

Reattaching

Position

that

it

is

then

slide

position.

the

level

it

the

work

detachable

with

to

the

support

work

the

machine

right

untilitlocks into

support

cover,

so

Page 31

Setting

width

For

standard

the

Set

position

I

the

chaining

slide

bed

S.

bed

slide

land

overlock

for

for

the

seams:

chaining

stitch

land

18

N

.-

Chaining

All

with

to

standard

this

landAwill

overlock

adjustment.

be

seams

pushed

can

forward

be

sewn

4

For

rolled

Set

the

position

hems

bed slide

R.

for

chaining

land

18

to

Chaining

All

rolled

adjustment.

land

hems

A

will

pushed

can

be

sewn

be

backward.

with

this

27

Page 32

Program

Program

4-thread

summary

overedge

position

Application

material,

elastic

any

fabrics,

serging.

with

seam

-

Sewing

especially

simultaneous

together

Needle

=

=

links

rechts

3-thread

3-thread-overedge

3-thread

3-thread

overedge

serging

serging

tsLsLt;\

3-thread

decorative

seam

seam

seam

seam

\

seam

(wide)

(narrow)

(wide)

(narrow)

Serging

flatlock

As

together

a

as

tightly-woven

frayed)

lightweight

tightly-woven

lightweight

medium-heavy

decorative

Serging

(easily

Serging

(easily-frayed)

Serging

(non-fraying)

Serging

(easily-frayed)

seam

stretch

fabrics

fabrics

fabrics

fabrics

finished

for

fabrics

fabrics.

sewing

and

edge

[.oj

3-thread

3-thread

28

decorative

rolled

hem

seam

Serging

flatlock

As

together

decorative

a

as

Serging

Decorative

medium-heavy

stretch

medium-heavy

seam

finished

finished

for

fabrics

sewing

edges.

fabrics.

and

edge

fabrics.

I

10

o.J

Page 33

Needle

The

fabrics

thread

settings

and

tension

are

normal

medium-heavy

for

polyester

yarn

Stitch

length

Stitchwidth

Position

of

bed

chaining

for

land

slide

Converter

=

with

S

=

with-

D

out

blue

green

N

—2

N

N

N

N

red

—2

—2

—2

-5

-5

yellow

-1

—1

—1

+35

+4

3

3

3

3

3

3.5

3.5

3.5

35

3,5

S

S

S

S

S

D

D

D

D

C

—4.5

—4.5

-1

+2

N

N

+2

+2

-1

3

3

F

3.5

3.5

R

5

S

R

C

C

C

29

Page 34

Program

Programs

summary

Application

Needle

2!J

position

=Ieft

right

=

Folded

2-thread

FLATLOCK

2-thread

FLATLOCK

2-thread

2-thread

2-thread

3-thread

oeredge

o

serging

.<<

<

serging

:-

-...

‘

rolled

rolled

•je

seam

seam

seam

hem

(wide>

(wide)

(narrow>

Serging

medium-heavy

Decorative

Serging

flatlock

As

together

Serging

flatlock

As

together

Serging

lightweight

finished

medium-heavy

seam

stretch

lightweight

seam

stretch

lightweight

fabrics.

for

fabncs

for

fabrics.

to

edges.

fabrics.

sewing

fabrics.

sewing

fabrics.

i•°I

(narrow>

—

Serging

lightweight

fabrics.

r

seam

osi

lightweight

hem

Serging

fabrics.

Decorative

very

finished

edges.

Folded

2-needle,

ciosing

30

2-thread

3-thread

seam

‘

V_

‘

:

.

.

4_

rolled

\

s..\

hem

overedge

Serging

fabrics.

Decorative

Sewing

simultaneous

lightweight,

of

fabrics.

very

together

lightweight

finished

serging

high-stretch

edges.

and

Page 35

Needle

The

fabrics

blue

thread

settings

and

tension

are

normal

green

meddium-heavy

for

polyester

red

yarn

yellow

Stitch

length

Stitch

width

Position

of

bed

slide

for

chaining

land

Converter

=

with

1

=

with-

D

out

—4

N

-2

—4

N

N

+3

+25

+2

—3.5

—3.5

F

3

3

3

3

R

35

3.5

3.5

3.5

R

S

S

S

S

D

I

S

S

S

—1

—4

-1

—2

+1

-2

—4

F

F

3

R

R

3.5

R

R

S

I

S

S

31

Page 36

Adjusting

following

The

setting

Adjust

wheel

rnng

desired

thread

the

setting.

the

pages

tension

until

thread

tensions

by

the

tension

contain

for

turning

dot

all

marker

directions

programs.

tensio

the

is

at

for

the

The

and

test

tension

Tip:

dual

redge

Note:

length,

settrngs

needle

seam

settings.

When

thread

looper

All

stitch

for

gsuc’

cnc

to

testrig,

tensions,

with

further

PFAFF

adjusting

will

the

it

yellow

settings

etc.)

width,

hobbylock

thread

influence

interlocking

a

good

is

thread

e.g.

yarn.

required

are

to

seam

idea

etc.

be

tension

of

to

right

the

for

found

are

results.

threads.

thread

use

overedge

individual

in

recommendations,

this

It

may

colours

programs

program

blue

N

all

edge

reason

be

looper

overedge

tensions

threads

of

For

the

4-thread

If

looper

‘ery

Fabric

always

is

it

necessary

corresponding

red

with

(needle

summary

seam

green

—2

optimally

are

be

will

fabric

the

type,

correct

to

yarn,

position,

pages

on

red

—2

interlocked

best

to

the

set,

yarn

the

stitch

28

to

the

left

the

quality

sew

thread

indivi

ove

to

yeIIowj

—1

two

the

at

a

31.

32

Page 37

left

The

Increase

The

reverse

the

ncrease

and/or

thread.

right

needle

the

looper

the

reduce

tension

side

tension

the

thread

thread

of

tension

the

of

of

(blue)

the

(red)

fabric.

the

blue

red

of

is

is

the

too

thread,

visible

thread

yellow

loose.

on

The

right

loose.

Increase

The

the

on

Increase

and/or

thread.

left

needle

the

looper

face

the

reduce

tension

side

tension

the

thread

thread

of

tension

the

of

of

(green)

green

the

(yellow)

fabric.

the

of

yellow

the

is

thread.

visible

is

red

too

thread

33

Page 38

3-thread

wide

[

overedge

blue

N

J

seam

green

red

-2

yellow

—1

needle

The

Increase

needle

the

thread.

thread

tension

loose.

too

is

respective

the

of

[narrow

The

the

Increase

and,’or

thread,

right

reverse

reduce

blue

tooper

the

side

tension

the

I

green

thread

of

N

the

of

tension

T

(red)

fabric,

the

I

yellow

red

the

visible

s

thread

yellow

-1

visible

yellow

the

of

is

thread

red

of

tension

the

of

(yellow)

fabric.

the

the

left

looper

face

the

reduce

side

tension

the

The

on

on

Increase

and/or

thread.

thread

-2

red

of

34

Page 39

3-thread

wide

serging

blue

N

seam

green

red

—5

yellow

1

needle

The

Increase

needle

the

thread.

thread

tension

loose.

is

too

of

respective

the

narrow

The

partly

fabric.

Reduce

increase

or

thread.

right

looper

looped

the

blue

tension

the

thread

around

tension

green

N

of

the

<red)

edge

the

of

redjyellow

—5

only

is

the

of

thread

red

yellow

the

+4

and!

left

The

the

on

Increase

and/or

thread.

looper

face

the

reduce

side

tension

the

thread

of

tension

the

of

(yellow)

fabric.

yellow

the

of

the

is

red

visible

thread

35

Page 40

_______________________________________

3-thread

FLATL.OCK

wide

narrow

decorative

blue

-4,5

blue

I

I

green

green

seam

I

1

serging,

red

N

red

N

yellow

j

yellow

I

j

+2

+2

j

The

Reduce

needle

needle

thread.

the

thread

tension

tight.

too

is

respective

the

of

right

The

reverse

the

Increase

looper

the

side

tension

thread

of

the

of

(red)

fabric,

the

red

visible

is

thread.

on

left

The

loose.

Increase

looper

the

thread

tension

(yellow)

of

the

yellow

is

too

thread.

Page 41

3-thread

—

blue

The

the

Increase

and/or

thread.

right

reverse

reduce

rolled

looper

the

—

green

side

tension

hem

the

thread

the

of

tension

of

red

+2

(red>

fabric.

the

too

The

right

needle

thread

(green)

is

loose.

yellow

Increase

the

tension

the

of

green

thread.

-1

visible

yellow

the

of

is

thread

red

of

tension

the

fabric.

of

(yellow)

the

is

thread

red

yellow

the

of

the

on

Increase

and/or

thread.

face

the

reduce

side

tension

the

thread

looper

left

The

on

visible

37

Page 42

Folded

blue

[

3-thread

green

-2

rolled

tension

thread

is

(green)

of

green

the

too

thread.

The

right

hem

red

N

j

yellow

÷3

oose.

Increase

needle

the

The

loops

Reduce

or

increase

thread.

38

right

around

the tension

looper

the

thread

the edge

tension

partly

only

(red)

fabric.

the

of

red

of

the

thread

and/

yellow

of

the

The

left

on

the

Increase

and/or

thread.

looper

face

the

reduce

thread

sideofthe

tension

the

tension

fabric.

of

(yellow)

yellow

the

of

the

s

visible

thread

red

Page 43

24hread

overedge

seams

FLATLOCK

yellow

red

[

+

narrow

)-

I

Attach

Note:

sewrng

for

1

FLATLOCK).

needle

The

thread

looper

the

the

thread

yellow

Increase

needle

of

blue

the

2thread

thread

tension

thread.

green

converter

is

(yellow)

and/or

-4

overedge

too

is

of

the

reduce

red

(see

loose

too

respective

seams

or

tight.

the

yellow

page

the

tension

+2

21)

left

left

The

on

the

Increase

and/or

thread

looper

reverse

the

reduce

tension.

thread

side

tension

the

(yellow)

the

of

of

the

respective

fabric.

yellow

needle

is

visible

thread

39

Page 44

Attach

sewing

needle

the

serging

thread

yellow

2-thread

wide

narrow

Note:

for

(FLATLOCK).

The

Increase

needle

of

blue

N

blue

2-thread

thread

the

seam

I

I

I

the

tension

and/or

thread.

green

green

N

converter

serging

too

is

of

reduce

the

I

I

I

loose.

I

red

I

red

I

I

j_3,5J

page

(see

seams

respective

tension

the

yellowl

yellow

21)

I

I

40

left

The

loose.

Increase

looper

the

thread

tension

(yellow)

the

of

yellow

is

too

thread.

Page 45

2-thread

Note:

sewing

for

The

tight.

Reduce

and/or

thread

Attach

right

rolled

2-thread

needle

tension

the

increase

the

hem

converter

thread

the

rolled

the

of

tension

(see

hems

(green)

green

of

page

the

too

is

thread

yellow

21)

The

tight

Reduce

and/or

thread

left

looper

tension

the

increase

thread

the

(yellow)

the

of

tension

yellow

of

the

is

too

thread

green

41

Page 46

Folded

blue

[

Note:

for

Attach

sewing

2-thread

2-thread

green

the

rolled

converter

rolled

hem

red

(see

hems.

elloj

page

21)

The

loose.

Increase

and/or

thread.

The

tight.

Reduce

and/or

thread.

right

left

needle

the

reduce

looper

the

increase

tension

the

thread

tension

thread

tension

the

of

the

(yellow)

the

of

tension

(green)

green

of

the

yellow

of

is

yellow

is

the

too

thread

too

thread

green

42

Page 47

2-needle,

seam

blue

(

[-i

Note:

sewing

for

closing

Attach

seams.

3-thread

green

-2

the

2-needle,

reverse

overedge

converter

3-thread

side

red

(see

side

face

closing

yeiiowj

page

overedge

face

-

side

21)

left

The

Increase

needle

the

thread

tension

reverse

of

side

(blue)

the

blue

is

face

too

thread.

face

side

loose.

side

right

The

loose,

Increase

needle

the

tension

reverse

thread

side

thread

tension

reverse

of

(yellow)

yellow

the

is

thread.

too

43

side

looper

left

too

green

is

thread.

(green)

the

of

The

tight.

Reduce

the

Page 48

Machine

Cleaning

Switch

Detach

cover.

remove

Lubricating

Switch

point

The

with

ted

time

drops

sufficient.

from

red

require

maintenance

the

at

off

lint

the

Disengage

sewing

the

off

shown

the

machine

the

PFAFF

of

All

special

lubrication.

machine

the

box

the

the

at

oil

other

mains

and

the

foot.

machine

mains

above

from

is

sewing

material

switch

open

upper

should

the

cleaned.

machine

parts

looper

the

and

knife

switch

be

accessories

One

manufactu

are

do

and

lubrica

or

oil

not

every

two

are

Use

remove

upper

Cleaning

Clean

to

good

the

time

lint

lint

lower

and

the

with

stability.

brush

from

rubber

the

machines

rubbing

from

the

knives

the

needle

and

feet

rubber

alcohol.

accessories

the

plate,

looper

from

feet

This

to

area.

time

ensures

44

Page 49

W11

Changing

Switch

Removal:

looper

the

and

knife

uppermost

driver

lower

screw

Insertion:

recess

the

ning

close

off

from

knife

and

screw.

the

the

at

Detach

cover.

move

position.

the

retaining

the

Insert

provided

Engage

looper

lower

mains

the

the

Disengage

needle(s)

the

accessories

lower

new

a

cover.

knife

lint

Use

screw

knife.

and

the

switch

box

the

lower

tighten

upper

the

to

arge

to

A.

open

and

upper

the

screw

loosen

Remove

knife

the

knife

the

into

retai

and

45

Page 50

Changing

Switch

the

Use

sories

sewing

removed.

be

Push

half-turn

remove

and

to

the

off

large

loosen

light

the

at

bulb

in

cover

a

it.

the

screwdriver

light

mains

switch

(sewing

bulb

from

retaining

the

into

1

the

3

until

socket,

the

counter-clockwise

the

screw

latter

give

light)

acces

of

can

a

it

direction

Insert

socket

bulb

the

socket,

direction

sewing

the

retaining

new

a

and

lock

thereby

rotate

until

lamp

screw.

bulb

in.

(max.

it

Push

rotating

it

is

cover

until

firmly

the

1

and

the

it

5

bulb

in

in

Watt)

two

a

place.

tighten

into

cams

the

into

clockwise

Replace

the

the

of

Page 51

Special

the

On

accessories

sewing

perfect

ring

special

The

Special

Blindstitch

String

Elastic

Shirring

Cording

Bead

Lace

accessories

following

to

feet,

you

sewing

accessories

accessory

sewing

thread

tape

foot

foot

sewing

sewing

pages

help

can

sewing

sewing

foot

foot

you

perform

results.

foot

foot

you

to

can

foot