Page 1

-F’

0

N

I

-‘I

11

7

C,

c)

0

0

C)

Page 2

For

please

easier

understanding

told

this

The

be

nor

The

according

As

of

colour

proceed

The

connected

with

The

connected

with

Under

mains

disposed

leads

Only

approved

and

with

The

covers.

electrical

Please

notes

or

Safety

the

For

connected

the

this

wire

the

plug

the

rules

United

leads

to

a

plug

wires

Blue:

Brown

colours

appliance

coding

as

wire

which

the

letter

which

the

letter

no

circumstances

plugs

of

must

3

A

spare

by

fuse

corresponding

the

must

Spare

suppliers

also

on

pate

of

this

last

page

Kingdom

must

to

with

in

the

the

to

Neutral

Live

of

of

follows:

is

to

the

N

is

to

the

L

or

used.

be

immediately.

be

completely

fuses

ASTA

cover

never

fuse

observe

2

instruction

out

under

the

safety-lead

three

mains

following

the

wires

may

not

terminals

the

coloured

terminal

or

coloured

coloured

terminal

coloured

They

must

according

must

be

covers

or

the

the

reading.

when

only.

no

circumstances

pins.

lead

are

coloured

code:

mains

in

the

correspond

in

your

blue

must

which

is

black

must

brown

whichismarked

red.

should

cut-off

should

used

to

marked

code.

without

available

safety

be

BS

agencies.

Defective

replaced.

be

be

colour

used

are

PFAFF

general

terminal

to

plug,

be

marked

mains

as

1362

3

A

fuse

from

I

lead

the

be

or

Zlfinhecontentsonnd>

Page 3

Page 4

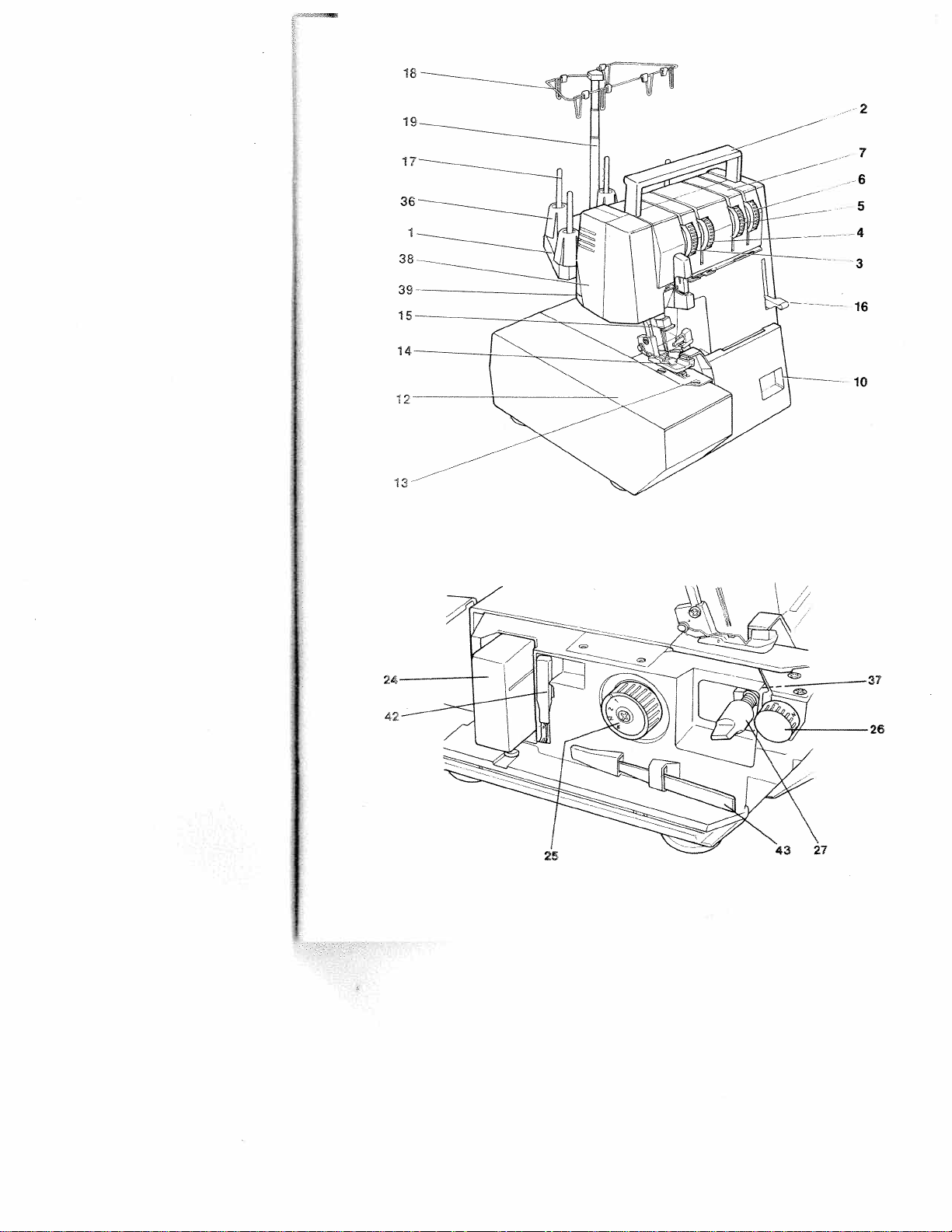

Parts

(10)

(12)Swivel-type

(13)

(14)

(15)

(16)

(1

(18)

(19)

(24)

(25)

(26)

(27)

(36)

(37)

(38)

(39)

(42)

(43)

of

(1)

Thread

Carrying

(2)

(3)

Left

(4)

Right

Right

(5)

Left

(6)

Thread

(7)

Looper

Needle

Sewing

Needle

Sewing

Thread

7)

Color-coded

Telescopic

Accessory

Stitch

Seam

Rotary

Thread

Upper

Lamp

Thread

Needle

Tweezers

the

needle

needle

looper

looper

spooler

length

width

lever

spool

knife

cover

cutter

threader

hobbylock

spool

stand

handle

thread

thread

thread

thread

tension

cover

with

work

plate

foot

holder

foot

lifting

thread

thread

box

adjustment

adjustment

for

centering

arresting

tension

tension

cover

recess

support

lever

holder

guide

upper

tension

tension

guides

knife

piece

screw

4760

dial

dial

dial

dial

bar

knob

knob

disengagement

Page 5

Important

For

United

use

always

using

States

an

electrical

be

this

the

When

you

ons should

before

tions

safety

only

appliance,

sewing

to

machine.

adhered

instructions

as

basic

follows:

safety

Read

precauti

all

instruc

DANGER

The

1.

sewing

appliance

Always

2.

3.

4.

Do

Do

not

not

not

place

unplug

reach

place

VVARNING

1.Donot

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12. Always

13.

14.

15.Switch

16.

1

7.

Please

allow

used

byornear

this

Use

attachments

Never

operate

perly,

ifithas

nearest

authorized

adjustment.

Never

operate

of

the

sewing

cloth.

Never

drop

Do

not

use

operate

Do

not

administered.

disconnect,

To

Never

operate

blocked.

not

unplug

Do

fingers

Keep

machine

use

Do

not

use

not

pull

Do

the

as

threading

Always

unplug

when

making

plug

Hold

also

observe

reduce

To

machine

from

in

or

sewing machine

recommended

or

outdoors.

away

needle.

the

bent

or

sewing

needle,

when

should

the

electric

before

forasewing

store

or

drop

into

To

reduce

be

to

used as

children.

this

sewing

been

dropped

dealer

the

sewing

machine

insert

any

where

turn

all

on

a

soft

pulling

by

from

proper

or

blunt

push fabric

machine

changing

sewing

any

other

rewinding

the

general

a

the

risk

never be

outlet

relamping.

machine

sewing

water

the

a

only

by

machine

or

or

service

machine

and foot

object

aerosol

controls

surface

cord.

on

moving

all

needle

needles.

while

off

machine

user

servicing

into

safety

of

machine

or

risk

toy.

for

the

damaged,

control

into

(spray)

to

such as

plate.

stitching.

(“0”)

needle,

from

cord

electric

left

unattended

immediately

Replace

that

has

where

other

liquid.

burns,

of

Close

attention

its

intended

manufacturer

ifithas

or

center

with

any

free

opening.

any

products

(“0”)

off

a

bed

unplug,

To

parts.

Special

wrong

The

Use

needles

It

when making

threading

electric

the

adjustments

reel.

Do

notes

on

shock:

after

bulb

with

fallen

it

fire,

use

a

damaged

dropped

for

examination,

air

openings

from

are

position,

or

grasp

plate

recommended

may

bobbin,

not

page

using

same

into

can

fallorbe

electric

is

necessary

as

described

contained

as

the

accumulation

being

then

couch

the

care

can

deflect

any

outlet

mentioned

allow

2.

plugged

when

and

type

water.

shock,

or

cord

water.

into

repair,

blocked.

used

remove

where

plug,

is

required

cause

needle,

the

adjustments

changing

or

removing

when

plug

to

before

rated

Unplug

pulled

when

in

in

this

plug,

or

the

not

the

by

in

the

whip

in.

cleaning

15

into

injury

or

this

this

manual.

if

Return

electrical

Keep

of

lint,

where

from

plug

openings

air

the

cord.

around

needle

the

manufacturer

causing

in

the

presser

instruction

when

unplug

Always

it.

Watts.

immediately.

tub

or

a

persons:

to

sewing

manual.

itisnot

covers,

the

appliance

or

ventilation

dust,

oxygen

outlet.

the

sewing

break.

to

ittobreak.

needle

foot,

rewinding.

Use

working

mechanical

and

is

may

lubricating,

manual.

sink.

machine

only

openings

loose

being

be

only.

area,

etc.

this

pro

to

such

Do

is

the

or

Keep

sewing

This

these

machine

instructions

is

designed

and

manufactured

in

safe

a

for

place

HOUSEHOLD

use

only.

Page 6

Notes

Notes

on

machines

28

or

IEC

1.

The

user

with

of

the

sewing

When

2.

maintenance

mechanical

always

the

mains

plug.

The

3.

maximum

sewing

4. The

tension

be

adjusted

5.

The

machine

according

specification

Do

6.

not

the

machine.

7.

Do

not use

—

there

—

its

function

—

it

is

8.

Do

not

socket

If

9.

this

than

pose

rated,

any

damage

To

10.

avoid

open

the

inside

repair.

of

our

11.

Be

sure

parts.

on

safety

according

335,

must

regard

needle

area

leaving

disconnect

lamp

place

is

visible

wet,

pull

by its

appliance

intended

we

will

the

machine.

machine

the

This

qualified

to

safety

for

domestic

to

Section

exercise

to

the

up

and

constantly

during

the

work

parts

or

by

pulling

permissible

is

15

Watts.

of

the

drive

by

a Piaff

must

be

the

indications

to

plate.

any

objects

the

sewing

damage,

is

disturbed,

e.g.

with

mains

the

cord.

is

used

or

not

accept

caused.

risk

of

electric

There

which

is

solely

service

only

use

sewing

57

DIN

adequate

and

down

or

when

accessories,

the

machine

out

the

wattage

belt

mechanic.

into

put

in

machine

plug

out

for

another

ifitis

any

shock,

are

the

the

responsibility

700,

must

openings

wrongly

no

user

28.

work.

machine,

condensation.

staff.

original

PFAFF

Section

caution

moving

observe

during

changing

from

mains

for

only

operation

on

the

if:

of

the

pur

liability

do

parts

can

on

ope

not

the

the

for

Environment

The

recommended

temperature

80%.

This

sewing

nic-mechanical

supervised

rated

in

such

dust,

severe

tic

electricity,

rosive

chemicals

For

ventilation

used

on

protect

night

clean

which

Note!

not

use

such

cleaning

a

the

dirt,

even.

Treatment

Always

which

Cleaning

Housing:

To

cloth

stubborn

paraffin.

Please

Do

ducts

for

10°

machine

appliance;

use

in

a

way

dampness,

heat-producing

purposes

free

surface,

the

occur

housing,

is

free

use

any

insecticides

as

petrol

the

housing.

environment

to

40°

C

is

the

home.

that

or liquids.

machine

hitting

by

use

of

fluff.

soft

a

(gas)orthin

C,

Humidity

high-quality

a

it

isamachine

it

is

direct

the

machine

which

against

a

dry,

To

cloth

or

It

should

not

sunlight,

objects,

is

both

or

dropping

clean

remove

with

chemical

is:

Ambient

20%

electro

be

subjected

must

firm

damage

and

any

alcohol

chemicals

to

for

ope

to:

sta

cor

be

and

it.

soft

or

pro

2

Page 7

Simple,

up-to-date

sewing

Congratulations!

product

that

hobbylock

and

will

sew,

operation.

Your

PFAFF

design

as

If

manual

It

to

to

If

dealer.

help

So

able

this

you

is

certainly

find

full

you

or

now

hours

and

instruction

now

take

nothing

out

just

use.

have

any

He

is

advice.

let’s

creating

You

provides

4760

can

trim

and

hobbylock

technology,

manual

a

bit

can

time

well

what

further

happy

get

to

started!

your

have

unique

take

neaten

features

and

of

time

go

amiss.

spent,

your

questions

be

bought

any

it

is

machine

of

service

We

very

a

advantages.

material

for

up

the

very

is

just

to

follow.

to

study

since

it

can

just

with

wish

you

own

fashion

high-quality

Your

in

its

you

in

one

latest

as

easy

to

the

instruction

is

the

only

and

do

ask

your

any

many

enjoy

ideas.

new

stride

in

use

way

put

PFAFF

it

3

Page 8

Contents

Accessory

Electrical

Master

Foot

control

Notes

on

How

to

Opening

Threading

Threading

Threading

Threading

Needle

Thread

Inserting

Seam

allowance

Sewing

Points

to

Thread

cutter

Securing

Setting

Possibilities

3-thread

Engaging

Thread

tension

Thread

chart

Adjusting

Adjusting

Disengaging

Adjusting

box

connection

switch

safety

handle

the

guide

the

the

the

threader

reel

change

the

test

observe

the

the

standard

requiring

overedge

and

the

the

the

and

the thread

looper

wires

right

left

left

and

lint

box

during

seam

disengaging

adjustment

stitch

differential

the

upper

seam

sewing

cover and

18

looper

looper

right

on

threaded

thread

thread

seam

length

knife

width

light

spool

and

threading

/

needle

sewing

tensions

the

for

feed

stand

the

22

machine

tension

converter

sewing

swivel-type

slide

corrections.

with1needle

work

support.

.

and2threads

4

Page 9

Changing

Changing

Cleaning

Rolled

Rolled

Changing

Changing

Changing

Changing

Upper

Cleaning

Oiling

Stitch

Sewing

the

the

the

hem

with

with2threads

hem

the

the

the

the

arresting

knife

the

machine

the

selection

problems

thread tensions

knives

Accessories

Thread

spool

Mountingofthe

Special

accessories

Specifications

sewing

bulb

light

3

threads

needles

knives

upper

knife

lower

table

and

net/thread

Converter

contents

/

foot

knife

their

removal

unreeling

of

the

.

disc

cardboard

box

•

• •

•

28,

•

26

27

29

30

31

.

31

44

45

48

53

5

Page 10

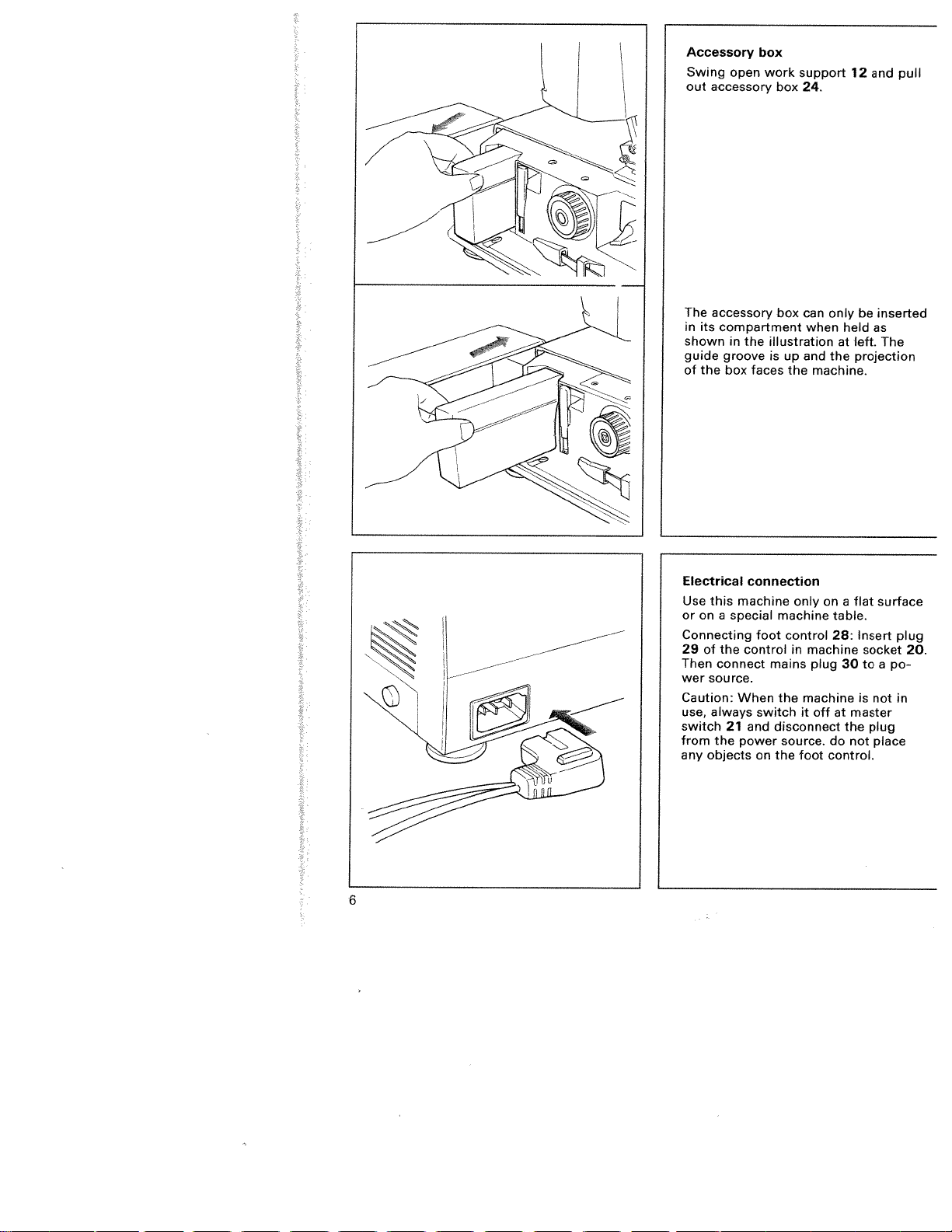

Accessory

Swing

accessory

out

accessory

The

compartment

in

its

shown

guide

groove

of

the

open

in

box

box

the

faces

work

support

box

box

illustration

is

up

the

24.

12

can

onlybeinserted

when

held

at

and

the

machine.

and

as

left.

The

projection

pull

Electrical

Use

or

on

Connecting

29

Then

wer

Caution:

use,

switch

from

any

C

this

a

the

of

connect

source.

always

the

objects

connection

machine

special

foot

control

When

switch

21

and

power

on

only

machine

control

in

mains

machine

the

it

disconnect

source.

foot

the

on

table.

28:

machine

plug

off

at

do

control.

flat

a

30

master

the

not

Insert

socket

to

is

not

plug

place

surface

plug

a

po

in

20.

Page 11

Switching

and

Power

switched

21.

Switching

switch.

Press

switched

are

the

sewing

on

on:

machine

and

off

Machine

on.

light

with

ON

together

master

and

and

sewing

OFF

are

switch

light

Switching

switch

Press

sewing

control

Foot

The

speed

ted

as

more

The

down,

off:

light

of

follows:

you

faster

the

Machine

again.

switched

are

Hobbylockisregula

the

the

press

the

foot

machine

off.

and

control

will

sew.

Notes

This

reduce

outlet

zed

reverse

install

For

this

safety

on

appliance

the

the

the

sewing

risk

only

plug.

proper

has

a

electric

of

one

It

outlet.

machine

polarized

way.

it

still

shock,

If

does

Do

has

the

not

to

plug

plug

not

motify

be

this

(one

does

fit,

used

blade

plug

contact

the

foot

wider

is

intended

fully

fit

not

a

pluginany

controller

than

in

qualified

to

fit

the

way.

modell

other).

the

in

a

outlet,

electrican

AE

To

polari

to

013.

7

Page 12

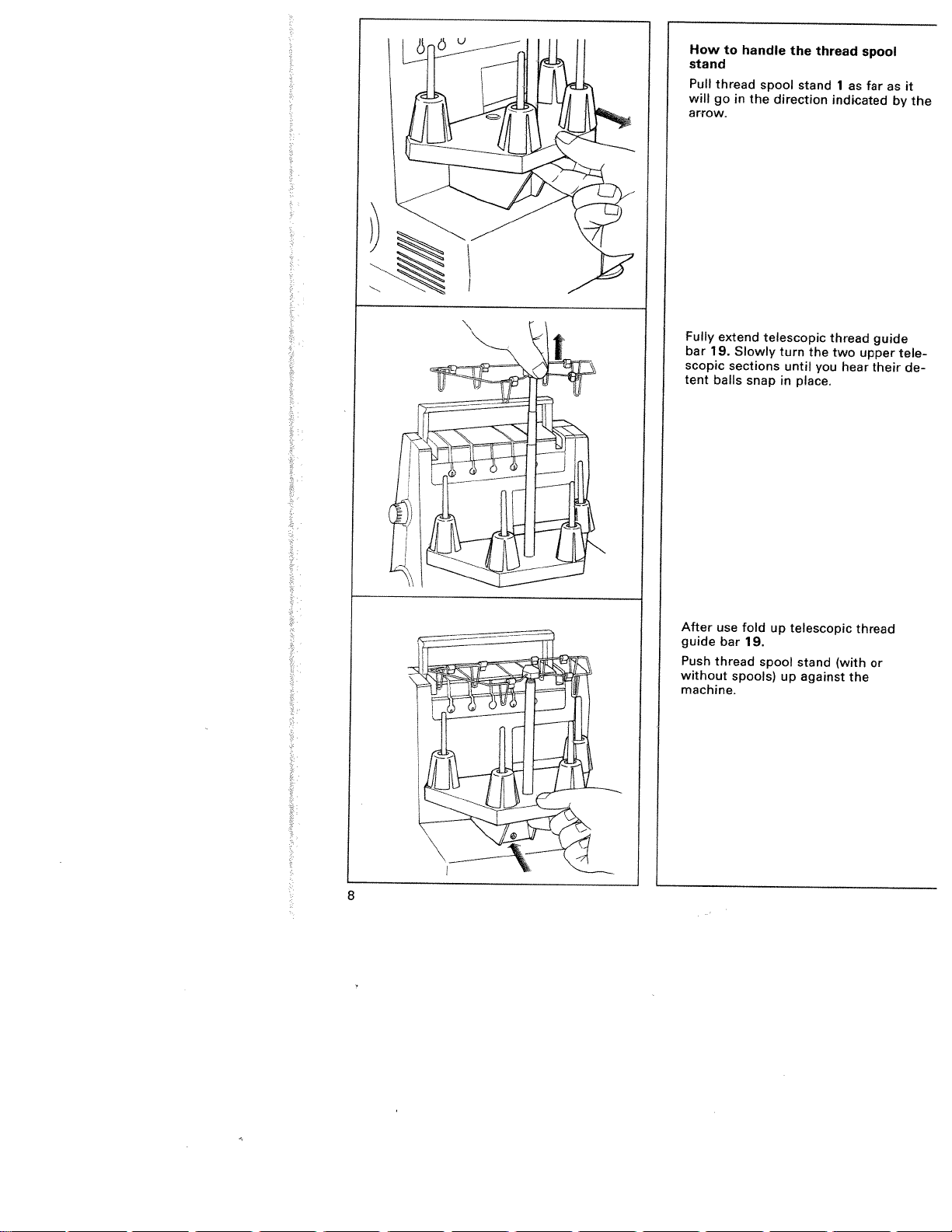

How

stand

Pull

will

arrow.

Fully

bar

scopic

tent

to

thread

go

extend

19.

balls

handle

spool

in

the

Slowly

sections

snap

the

stand

direction

telescopic

turn

until

place.

in

thread

the

you

1

as

indkated

thread

two

upper

hear

spool

farasit

guide

their

by

the

tele

de

After

use

fold

up

guide

bar

Push

thread

without

machine.

8

spools)

19.

spool

telescopic

stand

against

up

(with

the

thread

or

Page 13

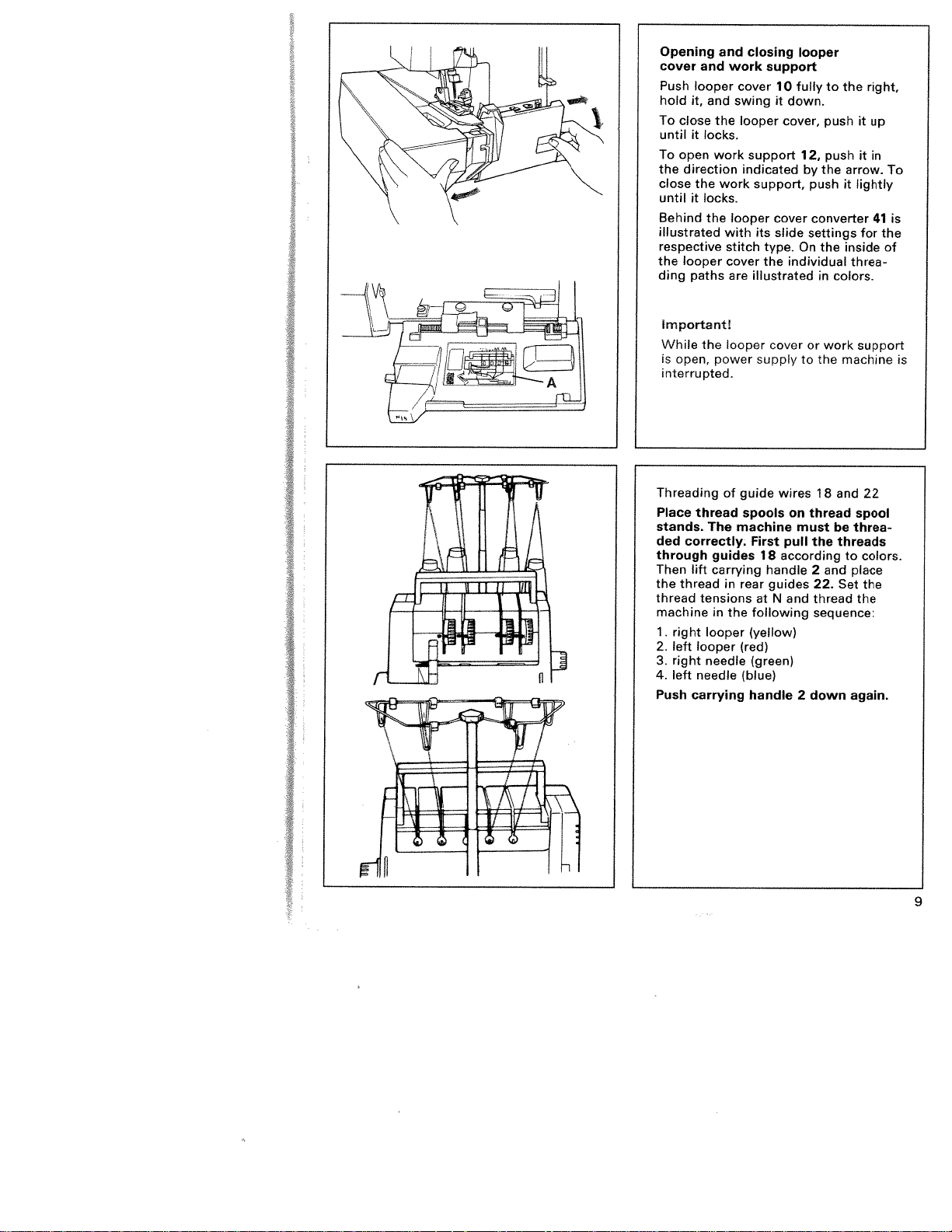

Opening

cover

and

Push

looper

hold

it,

To

close

until

it

To

open

the

direction

close

the

until

it

Behind

illustrated

respective

the

looper

ding

paths

Important!

While

the

is

open,

interrupted.

and closing

work

cover

and

swing

the

looper

locks.

work

work

locks.

the

looper

with

stitch

cover

are

looper

power

support

10

it

support

indicated

support,

cover

its

slide

type.

the

illustrated

cover

supply

looper

fully

down.

cover,

12,

by

push

converter

settings

On

individual

or

to

to

push

push

the

the

in

work

the

the

arrow.

it

inside

threa

colors.

machine

right.

it

up

it

in

lightly

41

for

support

To

is

the

of

is

Threading

Place

thread

stands.

correctly.

ded

through

Then

lift

the thread

thread

machine

1.

right

left

2.

looper

right

3.

4.

left

needle

Push

carrying

of

The

guides

carrying

in

tensions

in

the

looper

needle

guide

spools

machine

First

18

handle

rear

guides

at

following

(yellow)

(red)

(green)

(blue)

handle

wires

on

must

pull

according

N

and

2

18

and

thread

be

the

threads

2

and

22.

Set

thread

sequence:

down

spool

threa

to

place

the

again.

22

colors.

the

9

Page 14

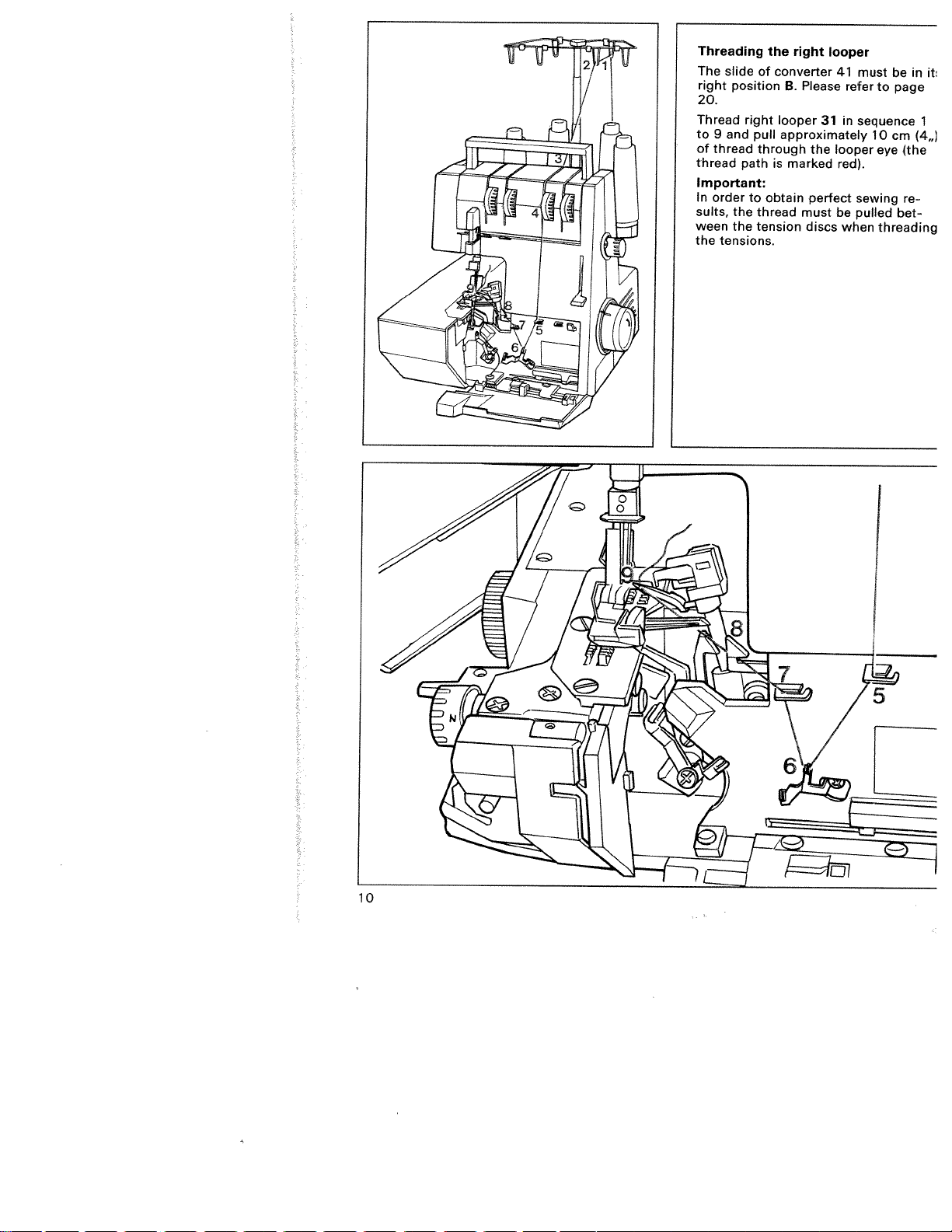

Threading

The

slideofconverter

right

position

20.

Thread

to9and

of

thread

Important:

In

suits,

ween

the

thread

order

the

the

tensions.

right

path

to

the

B.

looper

pull

approximately

through

is

marked

obtain

thread

tension

right

Please

must

discs

looper

31

the

perfect

41

refer

in

looper

red).

be

when

must

to

sequence

10cm

eye

sewing

pulled

threading

be

page

(the

re

bet

it:

in

1

(4

10

Page 15

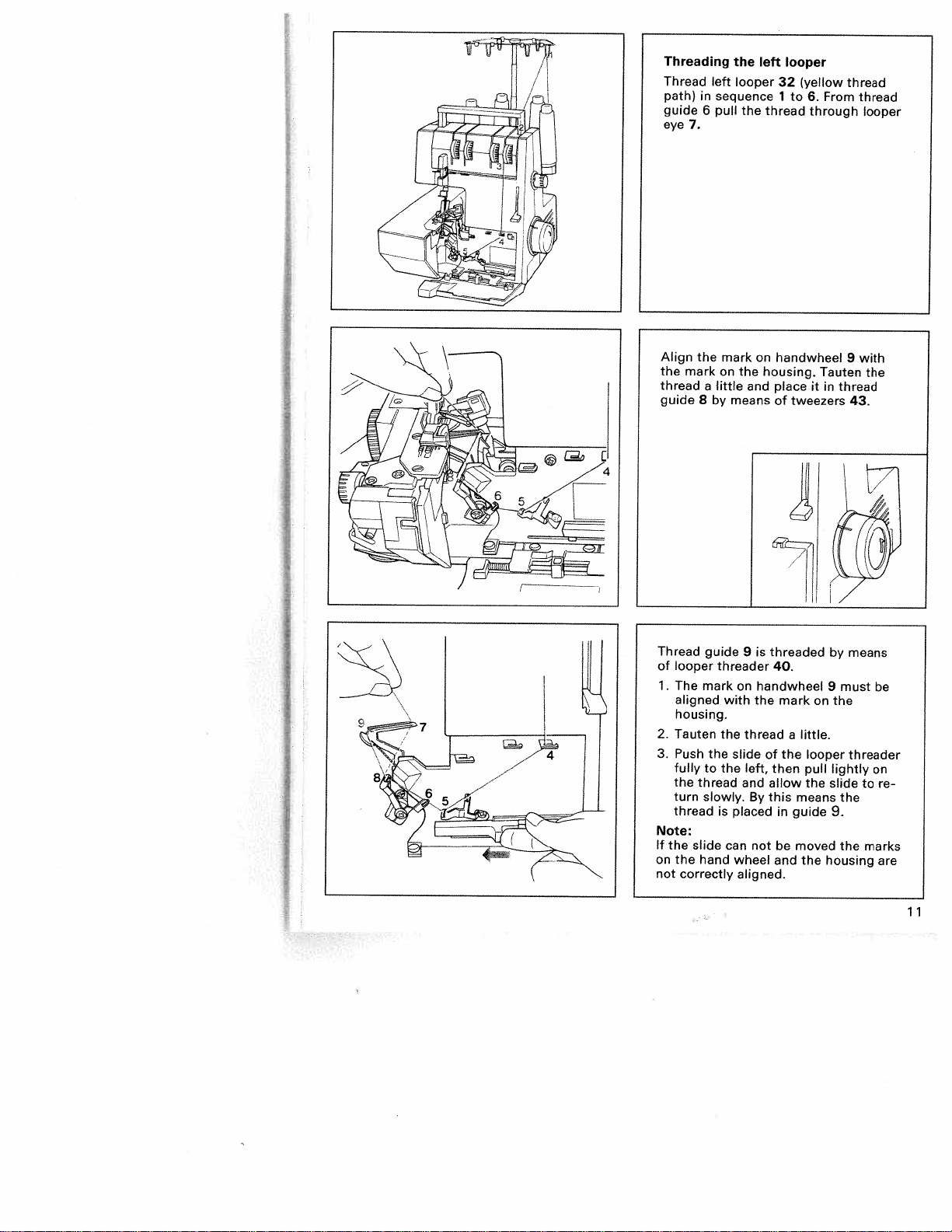

Threading

Thread

left

the

looper

path)insequence

guide6pull

eye

7.

Align

mark

the

thread

guide

the

8

a

little

by

mark

on

means

the

the

left

thread

on

housing.

and

looper

(yellow

32

to

6.

1

through

handwheel

place

it

of

tweezers

From

Tauten

thread

in

thread

thread

looper

9

with

the

43.

Thread

of

looper

The

1.

aligned

housing.

Tauten

2.

Push

3.

fully

the

turn

thread

Note:

If

the

on

the

not

guide

mark

the

to

thread

slowly.

slide

hand

correctly

9

threader

on

with

thread

the

slide

left,

the

and

is

placed

can

wheel

aligned.

threaded

is

40.

handwheel

mark

the

of

the

then

allow

By

this

in

not

be

and

a

little.

pull

means

guide

moved

the

9

on

looper

the

housing

means

by

must

the

threader

lightly

slide

the

9.

the

be

on

to

re

marks

are

11

Page 16

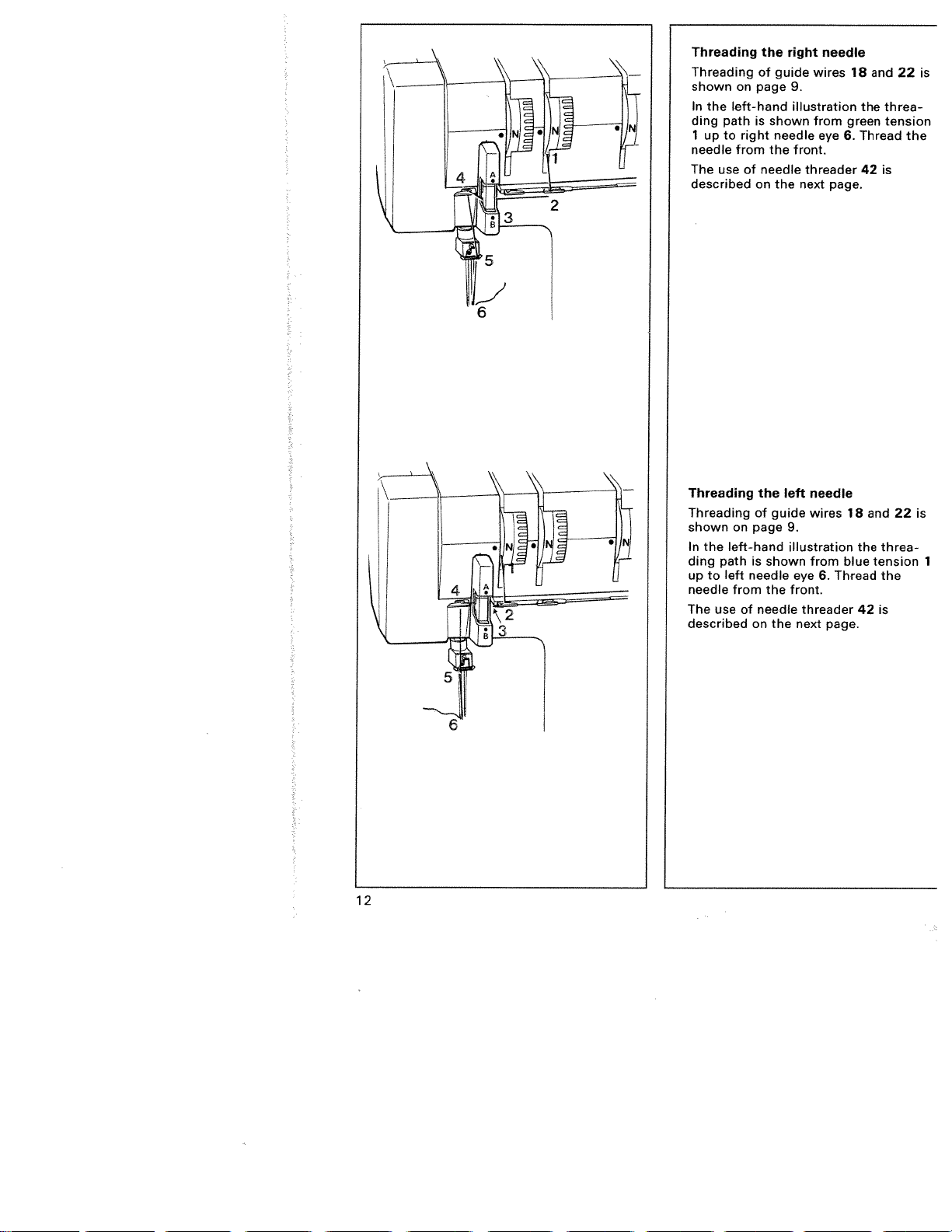

Threading

Threading

shown

In

the

ding

path

1

up

to right

needle

The

use

described

the

of

on

page

left-hand

is

from

needle

of

on

right

guide

shown

needle

the

the

needle

wires

9.

illustration

from

eye 6.

front.

threader

next

page.

18

the

green

Thread

42

and

22

threa

tension

is

is

the

12

Threading

Threading

shown

In

the

ding

path

to

left

up

needle

The

use

described

the

of

on

page

left-hand

is

needle

from

needle

of

on

left

guide

shown

the

the

needle

wires

9,

illustration

from

eye

6.

front.

threader

next

page.

18

the

blue

Thread

42

and

threa

tension

the

is

22

is

1

Page 17

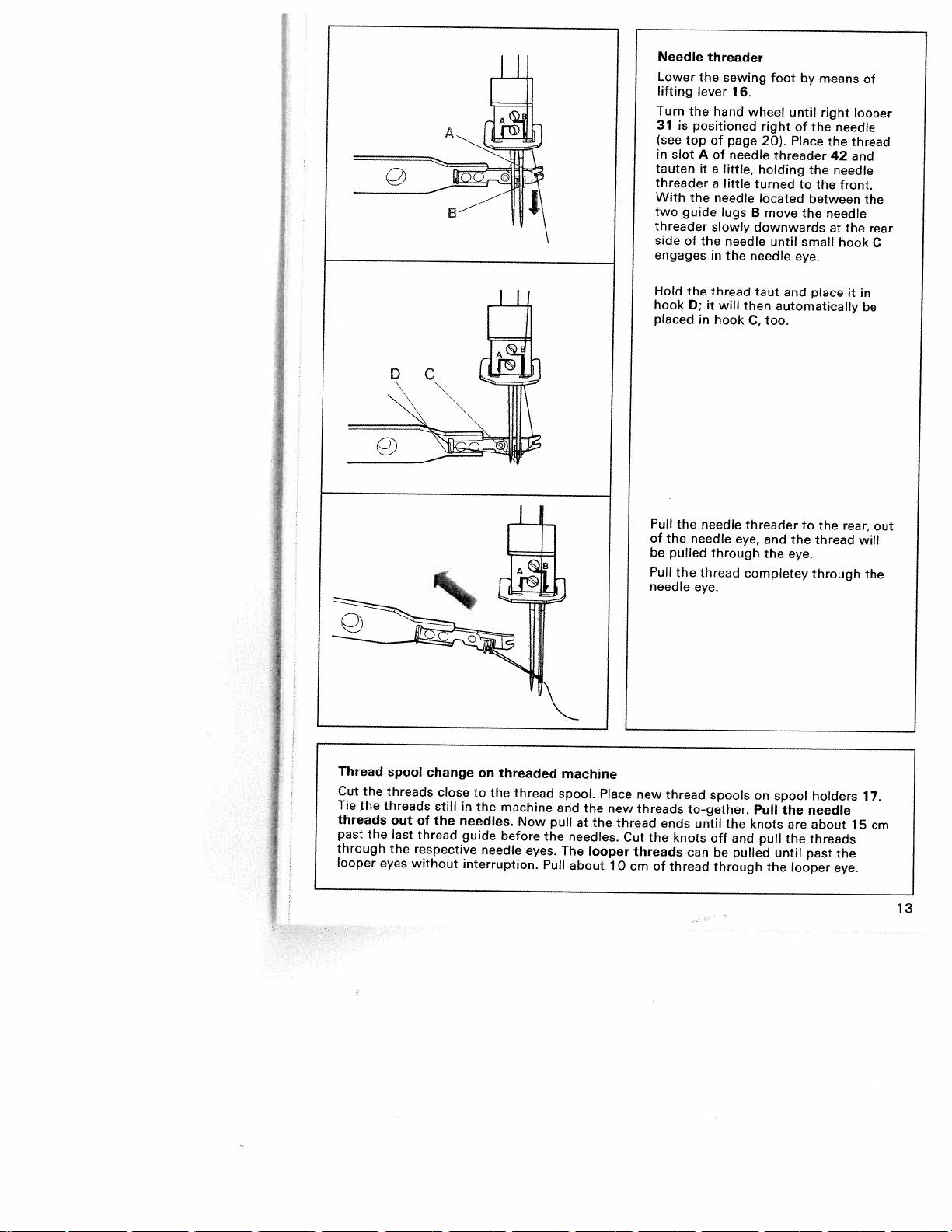

Needle

Lower

lifting

Turn

31

is

(see

in

slot

tauten

threader

With

two

guide

threader

side

engages

Hold

hook

placed

threader

the

lever

the

hand

positioned

top

of

A

of

it

a

a

the

needle

slowly

of

the

in

the

thread

it

D;

in

hook

sewing

16.

page

needle

little,

little

lugs

needle

the

will

foot

wheel

right

20).

threader

holding

turned

located

move

B

downwards

until

needle

taut

then

automatically

too.

C,

and

by

until

of

Place

to

the

small

eye.

means

right

the

needle

the

42

the

needle

the

between

needle

at

hook

place

looper

thread

and

front.

the

it

of

the

rear

C

in

be

Thread

the

Cut

Tie

the

threads

past

through

looper

the

spool

threads

threads

out

last

the

eyes

change

close

still

of

the

thread

respective

without

on

threaded

the

to

in

the

machine

needles.

guide

before

needle

interruption.

thread

Now

eyes.

and

pull

the

Pull

machine

spool.

the

at

needles.

The

looper

about

the

Place

new

10

thread

Cut

threads

cm

Pull

of

be

Pull

needle

new

threads

ends

the

of

the

the

pulled

the

thread

knots

thread

needle

needle

through

thread

eye.

spools

to-gether.

until

off

can

be

through

threader

eye,

completey

the

and

pulled

and

the

on

Pull

knots

pull

the

eye.

spool

the

are

the

until

to

the

through

needle

about

threads

past

looper

the

thread

holders

the

eye.

rear,

15

out

will

the

17.

cm

Page 18

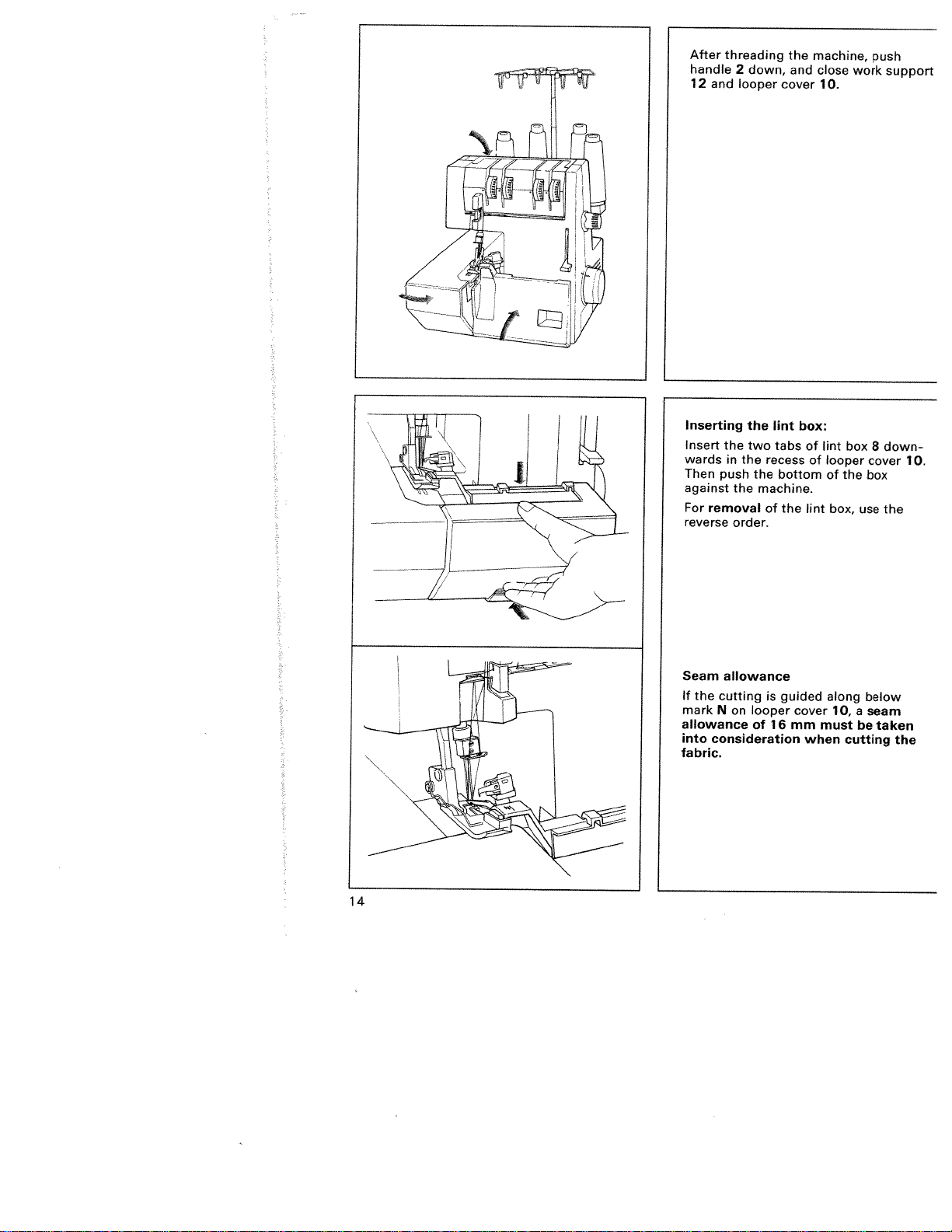

After

handle

12

and

threading

2

down,

looper

the

and

cover

machine,

close

10.

work

push

support

Inserting

Insert

the

wards

in

Then

push

against

For

removal

reverse

Seam

allowance

If

the

cuttingisguided

mark

N

allowance

into

consideration

fabric.

the

two

the

the

order.

on

lint

tabs

recess

the

machine.

of

looper

16

of

box:

bottom

the

cover

mm

of

of

lint

when

lint

looper

of

box,

along

10,

must

box

the

use

a

be

cutting

8

cover

box

below

seam

taken

down

10.

the

the

14

Page 19

Sewing

After

be

Raise

the

Hold

hand

your

ted

Hold

back

sure

during

test

threading,

made.

sewing

illustration.

the

thread

while

right

by

the

the

threads

under

the

threads

sewing

turning

hand

arrow

sewing

a

foot

ends

in

on

interlock

(thread

sewing

lever

the

the

the

taut

foot

16,

with

hand

direction

wheel.

and

14.

chain).

test

as

your

wheel

lay

Make

correctly

should

shown

left

indica

them

in

with

Insert

11

and

the

test

lower

fabric

sewing

up

foot

to

upper

knife

lever

16.

15

Page 20

Points

Sew

chine

fabric

up

to

Since

not

hands

the

pull

to

has

under

the

the

for

observe

first

been

needle

fabric

or

guiding

stitches

sewing

push

during

slowly.

rethreaded,

foot

before

is

automatically,

fed

fabric.

the

only.

sewing

place

14

and

starting

Use

If

the

ma

the

push

it

to

sew.

do

your

Thread

In

order

39

it

end

of

thread

from

left).

Securing

Knot

the

crochet

a

thread

the

Or:

Sew

about

seam.

sew

a

sewn

cutter

tobeable

is

necessary

the

chain

the

rear

the

thread

needle

Turn

few

without

seam.

through

(see

seam:

chain

5

cm

the

stitches

cutting

to

to

sew

Draw

the

illustration

chain.

can

be

into

the

beyond

(2”)

workpiece

over

the

use

For

the

used

seam.

the

thread

thread

beyond

resulting

thread

below

knit

to

the

around

seam

cutter

the

cutter

fabrics,

pull

end

and

just

chain.

of

16

Page 21

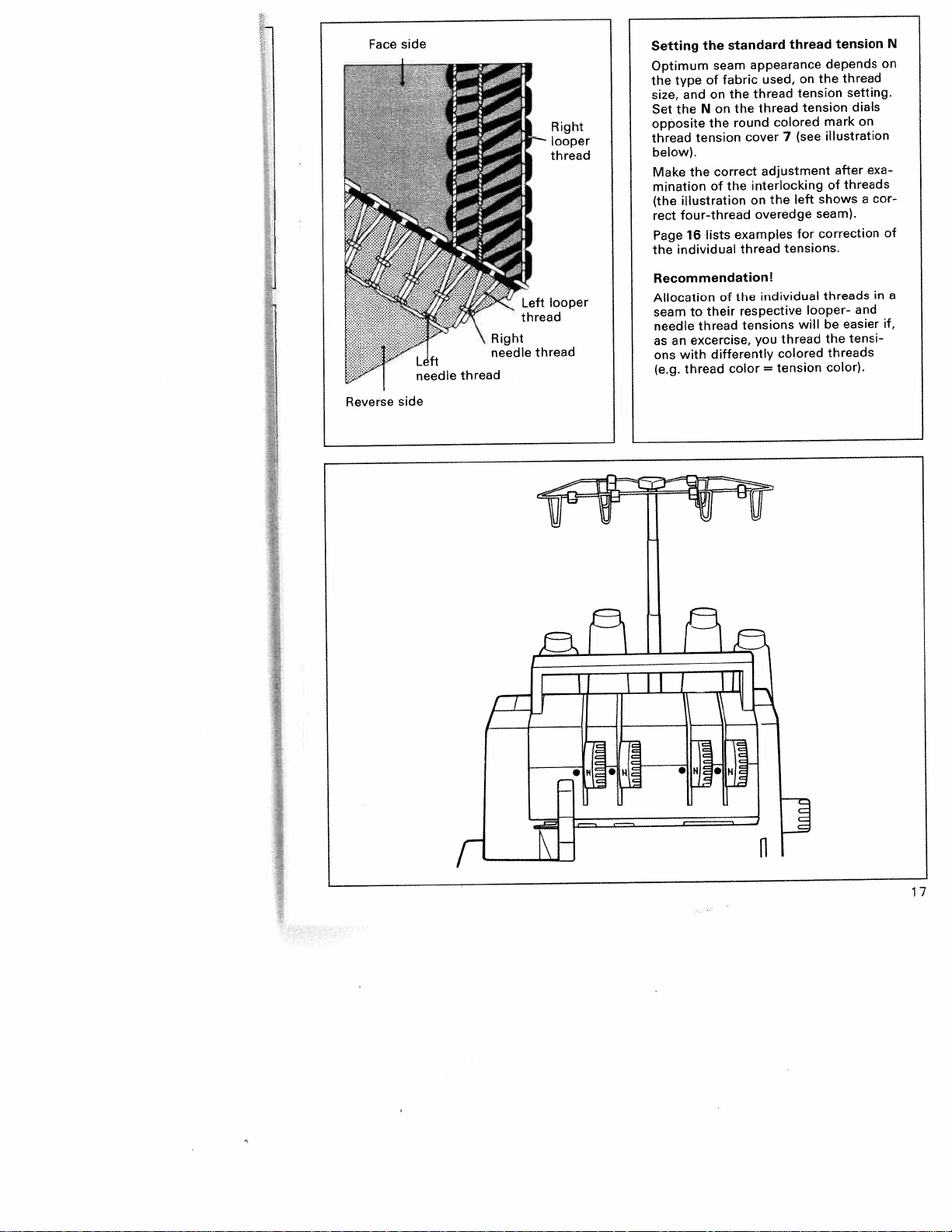

Face

side

Right

looper

thread

standard

Setting

Optimum

the

size,

Set

opposite

thread

below).

Make

mination

(the

rect

Page

the

Recommendation!

Allocation

seam

needle

as

ons

(e.g.

the

type

of

on

and

the

N

the

tension

the

illustration

four-thread

lists

16

individual

their

to

thread

an

excercise,

with

thread

seam

fabric

the

on

round

correct

the

of

of

differently

color

appearance

used,

thread

thread

the

colored

cover7(see

adjustment

interlocking

the

on

overedge

examples

thread

individual

the

respective

tensions

thread

you

colored

tension

=

thread

on

tension

tension

left

seam).

for

tensions.

looper-

will

tension

depends

thread

the

setting.

dials

on

mark

illustration

after

threads

of

shows

correction

threads

and

easier

be

tensi

the

threads

color).

a

exa

cor

in

N

on

of

a

if,

Ft

17

Page 22

Face

side

Reverse

side

decreased.

The

(blue

The

(green

1.

The

(red

2.

The

(yellow

3.

Both

When

(+)

When

Possibihties

corrections

the

direction,

turned

left

needle

thread

right

thread

right

thread

left

looper

thread

tensions

thread

needle

looper

tension>.

requiring

the

in

(—)

thread

tension).

thread

tension>.

thread

thread

tension).

must

tension

tension

direction

be

thread

is

is

A

is

too

B

is

too

C

is

0

is

too

corrected.

tension

turned

increased.

it

is

loose

loose

too

tight

loose

in

18

1.

2.

3.

The

(yellow

The

loose

Both

left

looper

thread

right

(red

tensions

looper

thread

thread

tension).

thread

tension).

must

D

be

corrected.

is

too

tight

C

is

too

Page 23

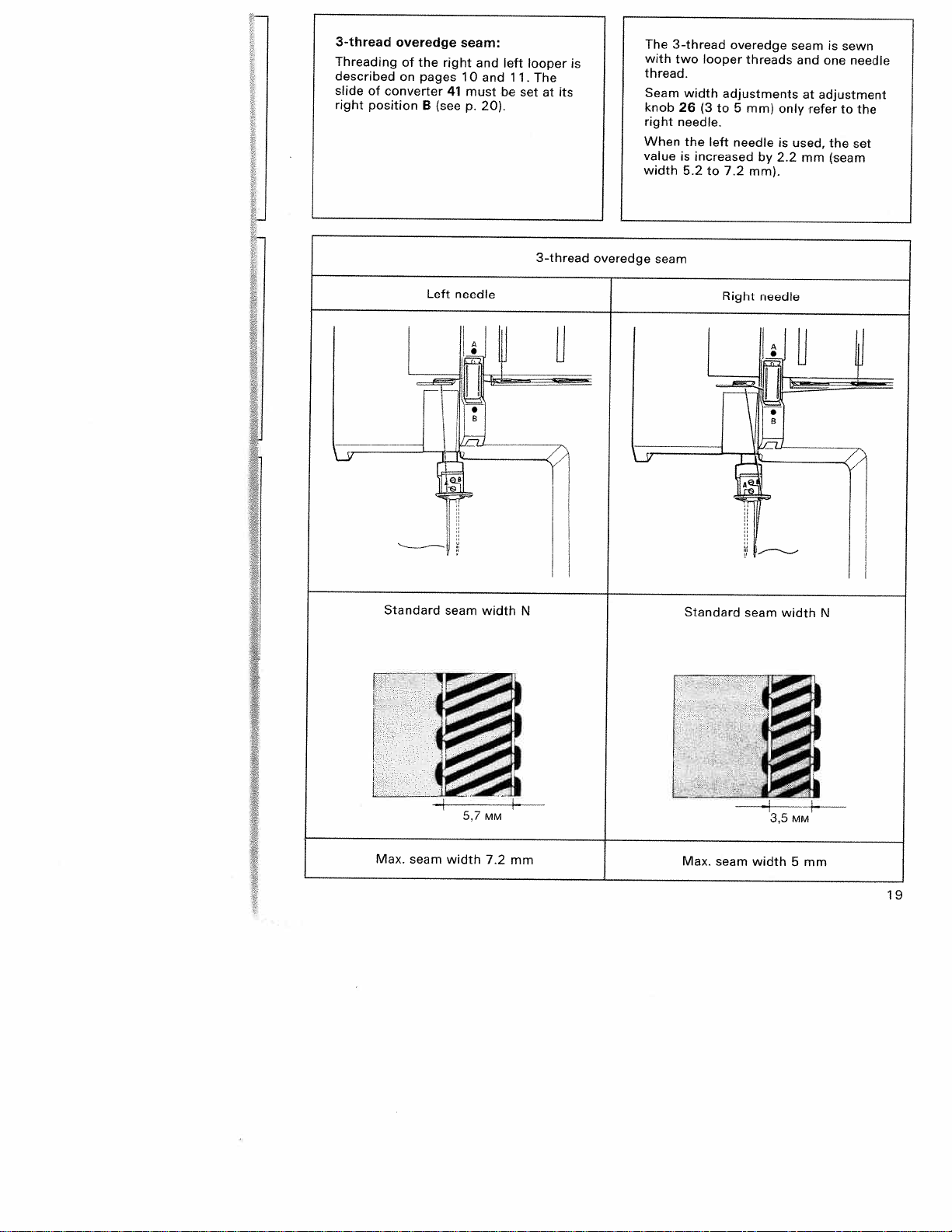

3-thread

Threading

described

slide

of

position

right

overedge

of

the

on

converter

pages

B

right

(see

41

seam:

and

10

must

p.

and

20).

left

11.

be

looper

The

setatits

The

3-thread

with

is

thread.

Seam

knob

right

When

value

width

two

26

needle.

is

5.2

looper

width

(3

the

increased

to

overedge

adjustments

to

5

left

needle

7.2

threads

mm)

by

mm).

only

is

2.2

seam

and

at

refer

used,

mm

is

sewn

one

needle

adjustment

to

the

the

set

(seam

Standard

Left

needle

seam

width

3-thread

N

overedge

seam

Standard

Right

seam

needle

width

N

Max.

seam

-1

width

5.7

MM

7.2

I

mm

El

MM

3,5

Max.

seam

width

5

mm

19

Page 24

Engaging

Turn

the

31

positioned

is

For

sewing

looper

pulled

All

seams

only

sewn

with

one

The

left

looper

31

of

point

of

the

arrow,

illustration.

hand

thread

out

or

looper

the

the

with

of

sewn

with

two

must

right

converter

wheel

converter

must

the

with

left

needle

thread

be

shown

as

right

looper

pulled

looper

until

the

of

be

cut

eye.

converter

looper

threads.

placed

over

in

in

the

right

needle.

41

off

32

over

the

looper

the

right

and

41

are

and

right

the

direction

left-hand

20

Push

the

left

until

aligned

the

point

the

eye

Converter

Converter

Disengaging

Turn

hand

looper

thread

right

looper

ter

in

this

threading

slide

the

with

the

of

of

the

engaged

disengages

wheel

31.

position

the

converter

of

triangular

each

other.

slide

looper,

the

converter

9

drops

Disengage

right

symbols

must

see

=

position

=

position

slowly

from

(position

looper,

41

As

you

engage

Fig.

A

until

point

the

the

B).

seep.10.

to

the

are

do

A.

B

the

conver

For

so

in

left

of

Page 25

Left

needle

2-thread

overedge seam

Right

needle

Adjustable

ceside•Heve

Standard

r

L__

range

seam

5,7

5.2

width

MM

to

7.2

N

mm

The

2-thread

set

Standard

Adjustable range3to5mm

left-hand

overedge

thread tensions.

seam

illustration

seam

width

shows

with

N

the

correctly

I

Possible

1.

Looper

thread

2.

Needle

green

3.

Both

Looper

1.

thread

2.

Needle

green

3.

Both

correction

thread

tension>.

threadBis

thread

tensions

thread

tension>.

threadBis

thread

tensions

requirements:

Aistoo

too

tension).

havetobe

is

too

A

too

tension).

havetobe

loose

tight

corrected.

tight

loose

corrected.

(yellow

(blue or

(yellow

(blue

or

21

Page 26

!

Light

materials:

Organdy,

fabric,

lining

materials

Medium-heavy

materials:

Cotton,

linen,

dress

Heavy

materials:

Tweed,

denim,

Knit

fabrics:

Rolled

hem

or

2

threads

3

thread)

(bulk

Material

light-knit

Taffeta,

tricot

suit

heavy

with

silk

materials

materials,

cloth

Thread

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Cotton

Silk

Synthetic

Polyester

Mercerized

chart

Cotton

Silk

Synthetic

for

thread

thread

thread

thread

thread

thread

2-,

3-,

Thread

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

4-thread-

80

—

80

—

70

—

60—

50

—

70

—

40

—

40

—

70

—

40

—

40

—

70

—

1

20

—

100

100

140

100

100

140

60

60

140

60

60

140

140

overedge

seam

2,0

1,0

2,0

2,0

2.0

to

to

to

to

to

Stitch

4,0

4,0

4,0

4,0

2.0

length

mm

mm

mm

mm

mm

22

Setting

Open

Hold

length

length

Standard

the

work

hand

wheel

adjustment

desired

setting

stitch

support

between

9

N

length

12.

fast

knob

is

and

set

stitch

25

at

the

1

and

3

mm.

stitch

4

mm.

Page 27

Adjusting

The

the

differential

shift.Itconsists

ranged

both

at

The

be

the

feed

versa.

results

rential

you

24).

at

Setting

Setting

Setting

to

The

tely from

one

behind

pickupand move

the

same

time.

feed

amountofeither

set separately,Itis

workpiece

thanbythe

dog

Owing

are

accomplished.

feed accordingtothe

wish to

The

button

process

following

23:

=

0.5

=

N

1.5

=

2

differential

0.5to2,

Note

The

following

obtain

fashionable

to

garments:

The

gather

differential

when

wave

The

differential

medium to

effectisobtainedata

feed

light

fabrics

effectisobtained

feed

heavy

processed.

differentia’

feed

of

two

the

prevents

feed

other,

the

feed

dogs,

workpiece

feed

possibletohave

moved

morebythe

rear

very

one

good

to

that

Set

material

table

(see

settings

are

Short strokeoffront

feed

dog,

rear feed

Same

feed

Long

feed

of

feed

variants

settingof1

setting

elastic

long

dog

strokeofboth

dogs

strokeoffront

dog,

short

rear feed

can be

also

during sewing.

can

be

effects

are

processed.

of

0.5

fabrics

dog

set

on

.5—2

at

inter-ply

ar

which

dog

front

and

vice

sewing

diffe

the

on

page

possible

stroke

stroke

infini

employed

a

when

are

can

of

23

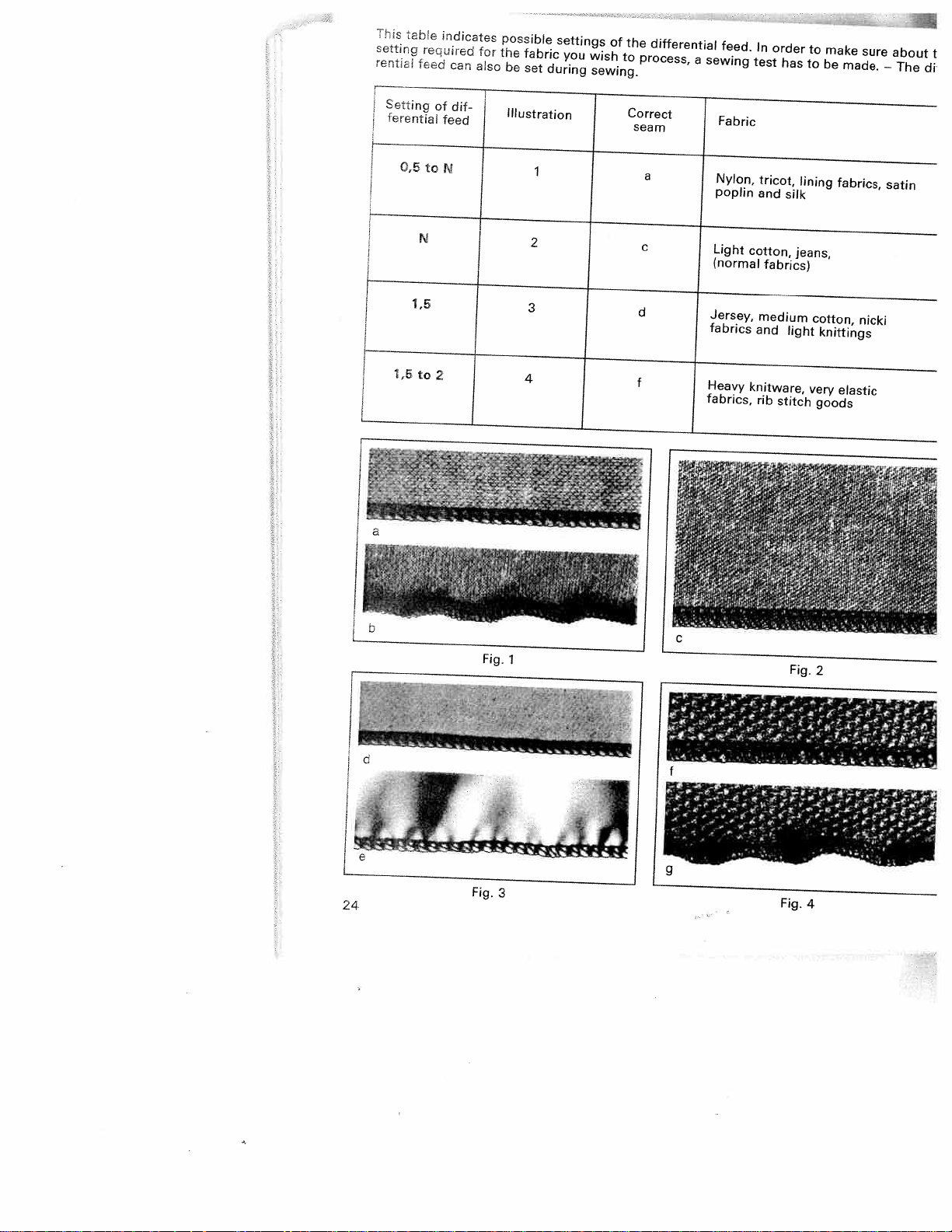

Page 28

;s

settino

renusi

table

tead

indicates

recuired

can

for

also

possible

the

fabric

be

set

settings

you

during

of

wish

sewing.

the

to

process,

differential

a

feed.

sewing

In

test

order

has

to

make

sure

about

to

be

made.

—

The

t

di

Setting

rerential

6,5

1,5

1,5

of

dif-

feed

to

N

N

to

2

Illustration

1

2

3

4

Correct

seam

a

c

d

f

Fabric

Nylon,

poplin

Light

(normal

Jersey,

fabrics

Heavy

fabrics,

tricot,

and

cotton,

fabrics)

medium

and

knitware,

rib

stitch

silk

light

lining

jeans,

very

fabrics,

cotton,

knittings

elastic

goods

satin

nicki

24

b

Fig.

1

r

C

C

NI

Fig.

2

J

g

Fig.

3

Fig.

4

Page 29

Disengaging

Remove

12

and

loosen

upper

Push

rotary

knife

guide

and

turn

ges

in

the

upper

knife

lint

looper

it

forwards

hole

the

box

8.

cover

knife

lever

fully

to

of

is

disengaged.

upper

Open

arresting

27

the

until

the

10.

of

knife.

knife

work

If

the

right,

the

support

necessary,

screw

axial

upper

hold

pin

enga

Now

the

37.

it,

I

I

i

I

I

Adjusting

The

standard

marked

Disengage

above

the

The

desired

justing

seam-width

from

3

Set

the

again

and

When

sewing

screw

37

system

Sew

test

a

Note

The

seam

adjustment

refer

to

needle

sed

by

7.2

mm).

with

description.

knob

to

5

upper

close

of

securely

width

the

is

used

2.2

mm

seam

the

seam

N

(3.5

upper

seam

26.

adjustment

mm,

knife

the

thick

the

upper

(see

seam.

adjustments

knob

right

the

(seam

width

width

mm).

knife

width

The

scale

its

at

looper

materials,

p.

26(3to

needle.

value

width

setting

11

according

is

set

tne

on

knob

ranges

basic

cover.

tighten

knife

arresting

34).

made

5

mm)

When

setisincrea

5.2

is

with

position

only

the

to

to

ad

at

left

25

Page 30

Changing

Raise

sewing

Disengage

lever

F.

the

the

sewing

foot

sewing

lifting

foot

foot

lever

by

16.

pressinc

G

Engaging

Place

foot

sewing

of

the

sewing

Changing

Pull

out

Loosen

Open

Behind

light

is

Removing

Push

the

fully

to

the

holder

foot

foot

foot

the

lamp

the

it.

situated.

light

the

the

sewing

engages

the

lamp

the

the

left.

sewing

so

that

lifting

holder.

light

mains

cover

cover.

light

light

bulb

foot

when

lever,

in

bulb:

plug.

retaining

bulb

bulb:

upwards

foot:

under

you

crosspiece

groove

of

the

the

screw

and

sewing

lower

H

of

sewing

turn

the

G

the

38.

it

2E

Inserting

Insert

the

/

/

-

turn

Close

pins

it

the

fully

and

the

in

new

the

to

fasten

light

bulb

slots,

the

right.

lamp

bulb:

(15

push

watt

cover.

it

max.)

up,

with

and

Page 31

Cleaning

the

At

tension

arrows.

remove

the

Set

the

Use

remove

tension

Reset

values

Press

tension

the

by

snap

points

cover

thus

it

4

dust

discs

all

set

the

cover

arrows,

in

place.

the

loosening

towards

thread

cleaning

and

thread

before

individual

thread

indicated,

the

in

7

the

tensions

brush

lint

the

of

tensions

cleaning.

the

in

until

tensions:

press

direction

the

front.

(accessories)

from

tensions.

4

tabs

direction

tabs

the

cover,

—

at

between

N,

to

the

of

thread

of

5.

or

thread

indicated

audibly

the

then

to

to

the

the

Then

corners

indicated

ensure

cover.

sion

press

proper

of

against

the

by

the

the

in

cover

arrows

engagement

two

the

in

bottom

direction

order

of

the

to

ten

27

Page 32

Reverse

side

Fold-over

sewn

A

rolled

fabrics

open

sew

professional

scarves,

This

rolled

threads

with

hem

and

edges.

shawls

(see

3-thread

polyester

is

is

an

Without

hem

page

rolled

used

attractive

rolled

and

valances.

is

sewn

29).

thread

for

any

light,

effort

hems

with

hem

finish

on

three

120

-140

delicate

for

you

neck

ca

I

Face

side

Reverse

side

3-thread

rolled

hem

28

2

Page 33

Rolled

hem

with

polyester

thread

Preparation

Needle:

Sewing

Seam

width:

Stitch

Thread:

Threading

right

1.

left

looper,

2.

3.

needle

For

threading

Tension

Red

thread

Yellow

Green

thread

Depending

or

lower.

Rolled

This

hem

Preparation

Thread:

polyester

foot:

length:

looper,

thread,

setting:

thread

hem,

requires

thread

the

sewing

of

remove

engage

3.0

from

1.0

from

polyester

path:

red

path

yellow

path

green

of

needle

tension,

right

tension,

tension,

on

sewn

material

needle

with

three

of

the

machine,asdescribed

thread

bulk

120-140

machine:

left

needle

rolled-hem

to

4.0

to

2.0

thread

path

and

loopers,

looper

left

looper

and

thread,

bulk

threads,

—

for

mm

mm

thread

thread:

red

green

/

foot

(depending

(short

1

20-140

approx.

the

one

tension

and

insert

,,R”

polyester

polyester

polyester

see

fold-over

hem,

approx.,,

+5

respective

bulk

yellow

right

stitch

for

pages

thread

above.

green,

Fig.

,,N”

needle

on

material)

length)

thread

thread

thread

9

to

3-thread

I

N”

thread

and

tensions

1

red

two

3.

and

tension

polyester

yellow

3-thread

Fig.

approx.

approx.

approx.

must

thread

2

be

threads

+

,,N”

,,N”

tensions

hem,

5

to

to

set

120

—

1

+

higher

—140.

1

Threading

right

1.

left

2.

needle

3.

For

threading

Tension

Red

thread

Yellow

Green

thread

Note:

Rolled

threads

Depending

lower.

or

looper,

looper,

thread,

setting:

thread

hems

must

path:

yellow

of

tension,

tension,

tension,,

can

then

on

material

red

path

path

green

path

needle

and

looper

right

left

needle

alsobesewn

be

threaded

and

loopers,

looper

thread

thread,

with

in

the

see

two

the

pages

fold-over

hem,

approx.

approx.

approx.

bulk

and

left

respective

9

Fig.

,,N”

±

,,N”

threads

right

bulk

polyester

polyester

to

1

3-thread

1

to

5

and

looper.

thread

thread

3.

—3

one

thread

thread

polyester

tension

120—

120—140

3-thread

Fig.

2

approx.

approx.

approx.

must

140

hem,

,,N”

,,N”

,,N”

thread.

be

+5

to

The

bulk

set

higher

29

Page 34

0

CD

CD

c1)c)z

C

0

CD

CD

Cd)

a

CT)

3

C

D

DCDCL

‘J

033

0)

CD

D

0

C),

0

D

C),

CD

-o

CD

0

9:

ø

3

0

0

CD

3

_

CD

—

CD

0)

DO)

CD

3

D-

D3

CDØ

—CD

0

9:

3

CD

=

CD

Z

0—

0

0

CD

rs

-4

CD

0)

0

CD

CD

3

0

Page 35

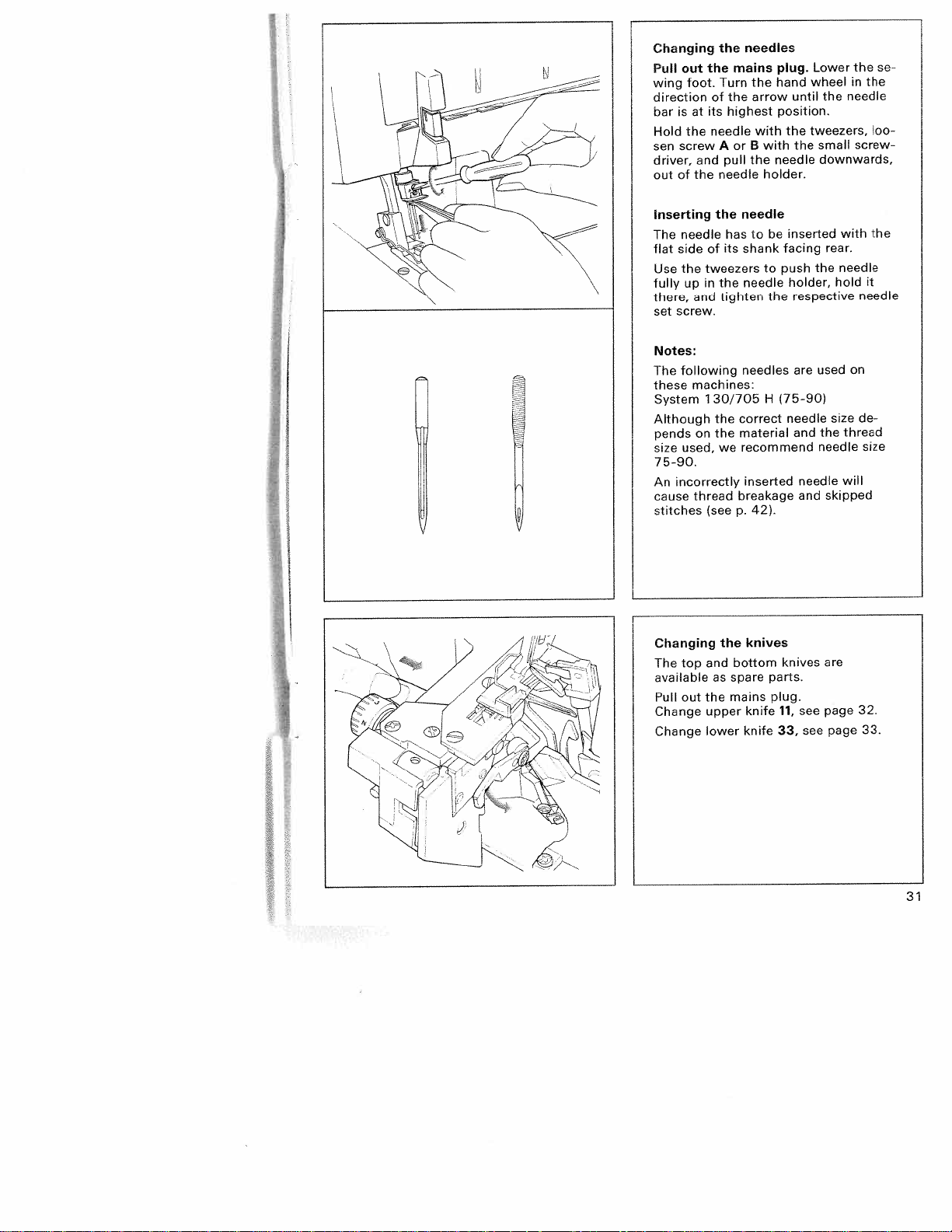

Changing

out

Pull

foot.

wing

direction

is

at

bar

Hold

the

screw

sen

driver,

of

out

Inserting

needle

The

flat

side

the

Use

fully

up

there,

screw.

set

Notes:

following

The

machines:

these

System

Although

pends

size

used,

75-90.

incorrectly

An

cause

stitches

the

of

its

needle

and

the

of

tweezers

in

and

130/705

on

thread

(see

the

Turn

the

highest

A

pull

needle

the

has

its

the

tighten

the

the

we

mains

or

p.

needles

plug.

hand

the

arrow

position.

with

with

B

needle

the

holder.

needle

to

be

shank

push

to

needle

the

needles

H

(75-90)

correct

material

recommend

inserted

breakage

42).

wheel

until

tweezers,

the

the

inserted

facing

holder,

respective

are

needle

and

needle

and

the

Lower

in

needle

the

small

screw

downwards,

with

rear.

needle

the

hold

on

used

size

thread

the

needle

will

skipped

se

the

loo

the

it

needle

de

size

Changing

top

The

available

out

Pull

Change

Change

the

and

as

the

upper

lower

knives

bottom

spare

mains

knife

knife

knives

parts.

plug.

11,

33,

see

see

are

page

page

32.

33.

Page 36

Changing

out

Pull

Unscrew

remove

Disengage

page

see

Insert

its

retaining

upper

the

upper

the

knife

the

knife

the

25.

new

upper

mains

retaining

knife

upper

upper

screw

its

to

knife:

plug!

11.

knife,

knife

securely.

cutting

screw

and

position.

35

Reset

and

tighten

L

32

Set

(cutting

El

It)

until

position.

In

upper

below

knife.

this

the

position,

knife

the

position).

upper

must

cutting

Turn

knife

the

be

edge

is

front

O5

the

at

its

edge

to

of

handwheel

lowest

of

mm

1

lower

the

the

up

27

guide

knife

with

knife

upper

Page 37

Changing

Pull

out

Disengage

Remove

33.

knife

seam

Turn

position

at

the

Hold

that

the

lower

of

the

taining

pressure

the

the

the

retaining

width

3

new

pin

screw

tab.

lower

mains

upper

(smallest

lower

extends

knife.

34

knife

plugl

knife

screw

adjustment

seam

knife

into

Then

together

(see

34

in

the

screw

with

lower

of

knob

width).

such

front

down

p.

the

a

25).

26

way

hole

re

Align

knife

plate

Before

align

knife

Set

ment

the

so

surface.

tightening

the

to

the

knob

cutting

that

pressure

cutting

required

26.

is

it

edge

flush

the

tab.

position.

seam

the

of

with

retaining

Reset

width

the

lower

the

at

needle

screw,

upper

adjust

33

Page 38

Upper

Sewing

with

ces

this

On

from

be

can

mely

different

upper

shown

tightening

By

knife

knife

very

different

machine,

extremely

processed.

fabrics

thick

thicknesses,

knife

the

in

arrested

is

arresting

thick

ply

all

thin

be

must

illustration.

screw

axially.

fabrics

thicknesses:

kinds

extremely

to

When

workpieces

or

the

tightened,

37,

and

fabric

of

sewing

screw

the

workpie

thick

extre

with

of

as

upper

the

L

Note:

When

screw

system

turns,

axially.

Cleaning

Disengage

p.

25).

the

Use

move

sewing

of

37

must

that

so

lint

lint

the

the

from

thin

the

be

the

brush

upper

loosened

upper

knives

upper

upper

medium

or

knife

by

knife

knife

(accessories)

and

fabrics,

arresting

about

can

(see

lower

mo

top

to

knifE

2

o

re

34

Page 39

Oiling

the

machine:

Every

into

oil

to

hings

parts

need

month.

sewing

time

operation,

places

the

other

and

made

are

be

to

One

machine

before

oiled

to

you

should

you

indicated.

important

special

of

only

drops

two

oil

take

once

are

the

apply

The

moving

material

twice

or

PFAFF

of

sufficient.

machine

little

a

bus

and

a

35

Page 40

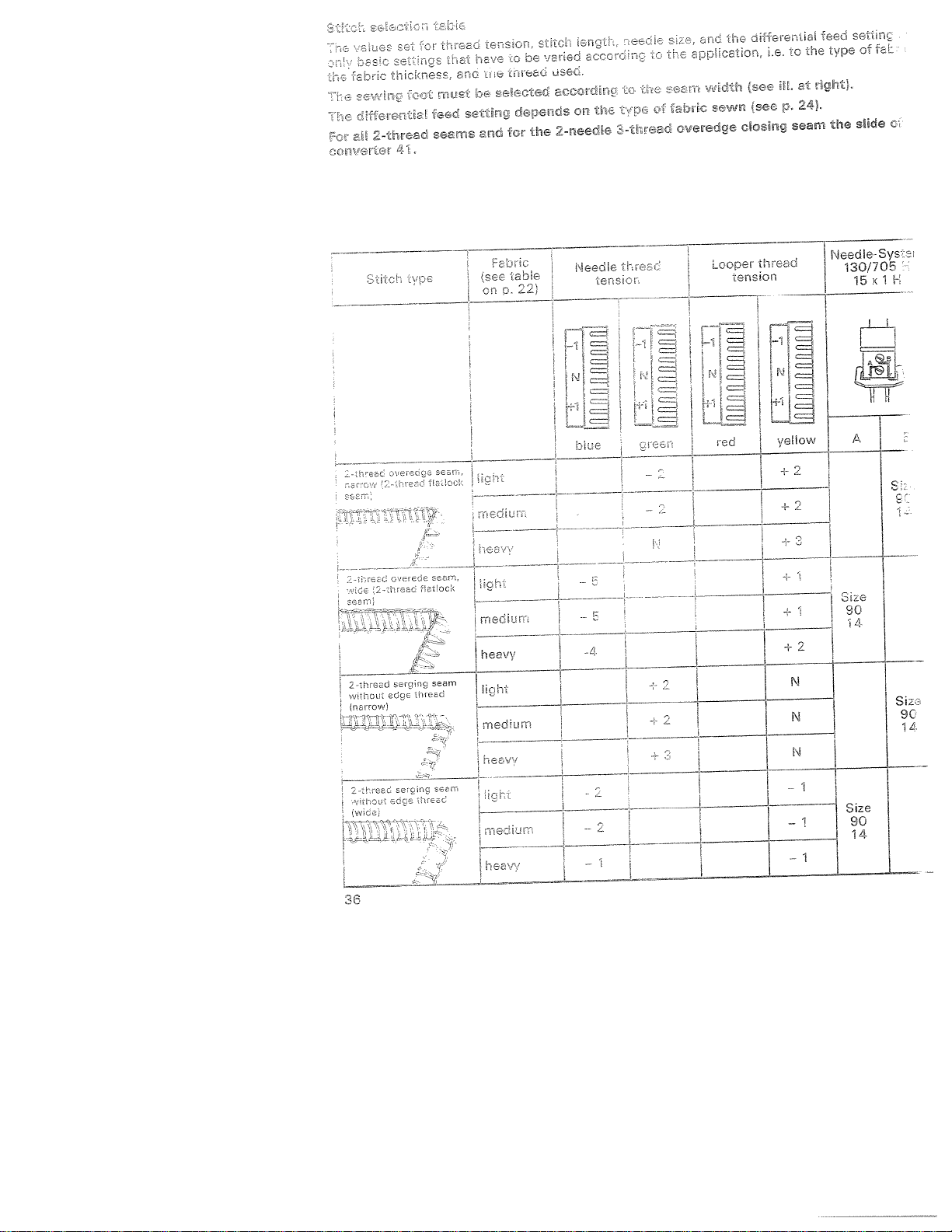

thDc:

.e

-

1k

0Cfl”et&

:csc

c-a:

81!

ers

thioicress,

ferenta[

2-chreed

/2!,

c

rb:ee

cc’

ieec

seams

he

EflG

see1o

ne’e

hr

anc

re-scr.

i:s,

:o

eeorea

depends

for

feco

ddIerea1ei

the

ccc

ae.

a

idea-

cr:cc

::

c-:dieco

ee

appcat!oc,

c

c

ee&

coth

cea.

see

CewS

labnc

c

e

oeedue

ccshic

Le.

.

0

2

seam

he

ci

24).

enor:

scc

‘crIed

be

u6C.

C0

acccrdcc

on

2-neeche

the

type

1oht!.

the

sethr

of

slide

fe

sc

I

2-thrcd

harrow)

N

N

ow

NeedIe-Sy

130/705

15

A

a

1

C

C

Sic

9C

14

Fe!:!c

[able

sec

22’

:

cc-

scac

cc

=ecL

serene

Eitt

scSSffi

oc:

ct”

:

sean

SeC.

1

1

g

meci:’:

heavy

C’Et5c

1+0.

meourc

“eeole

:ensc

—

-4

three:

--

-

cit

—

2

-

Loc’per

€enS!ofl

red

rh:eao

ye!

+

N

-—5V-

sec.

ore

as

rccc

it-

Size

90

14

-1

Page 41

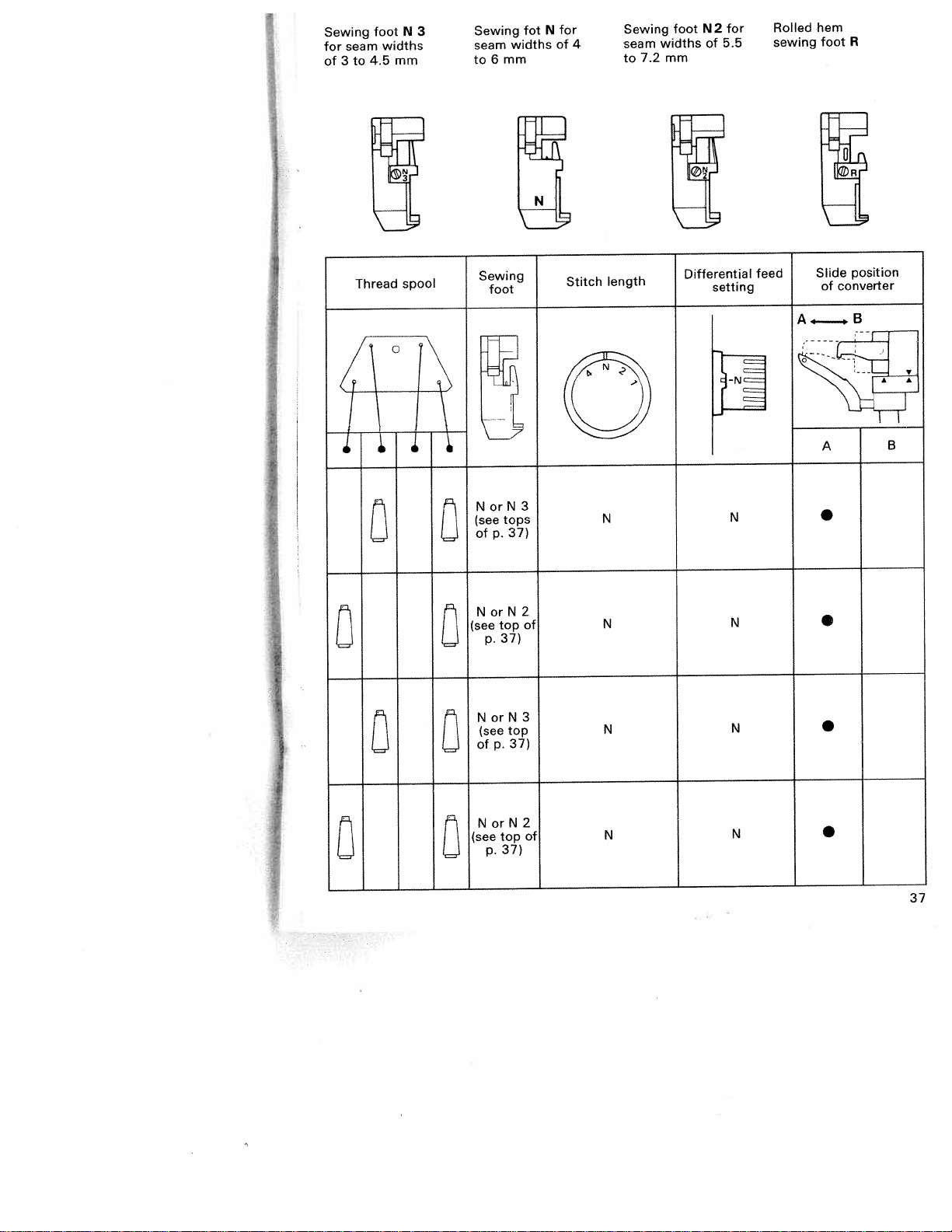

Sewing

seam

for

3

of

hem

N2

for

5.5

of

7.2

foot

widths

mm

for

N

6

widths

mm

fot

4

of

3

foot

N

widths

4.5

mm

to

Sewing

seam

to

Sewing

seam

to

Rolled

sewing

foot

R

I

I

37

Page 42

Stitch

type

(see

on

Fabric

table

p.

22)

Neeae

tension

thread

Looper

tension

thread-

Needle-Syst

2-thread

hem

Folded

rolled

3-thread

seam

[

-‘

rears

3-thread

without

(narrow)

(narrow)

(narrow)

hre

roiled

2-thread

hem

—-

.c

.wio.:

edge

A,

overedge

eseredge

se-awn

An

thread

7’

-

w:.m

-

light

medium

light

[medium

medium

heavy

..

light

medium

heavy

-

light

blue

-_________

green

—

2

red

-2

N

yellow

1

—

-1

—

1

to

toN

to

A

N

—

7

N

—

N

1

—

N

I

+1

N

N

N

j

2

—

4

-3

—

-2

N

N

c

N

1

—

-1

—

Size

14

+

+2

N

2

—

N

N

N

N

3

-

-3

.

H--

38

heavy

flL

light

medium

-

•

heavy

3

-2

N

N

-3

4

-

-4

-4

+2

+

+2

+4

3

—

14

Page 43

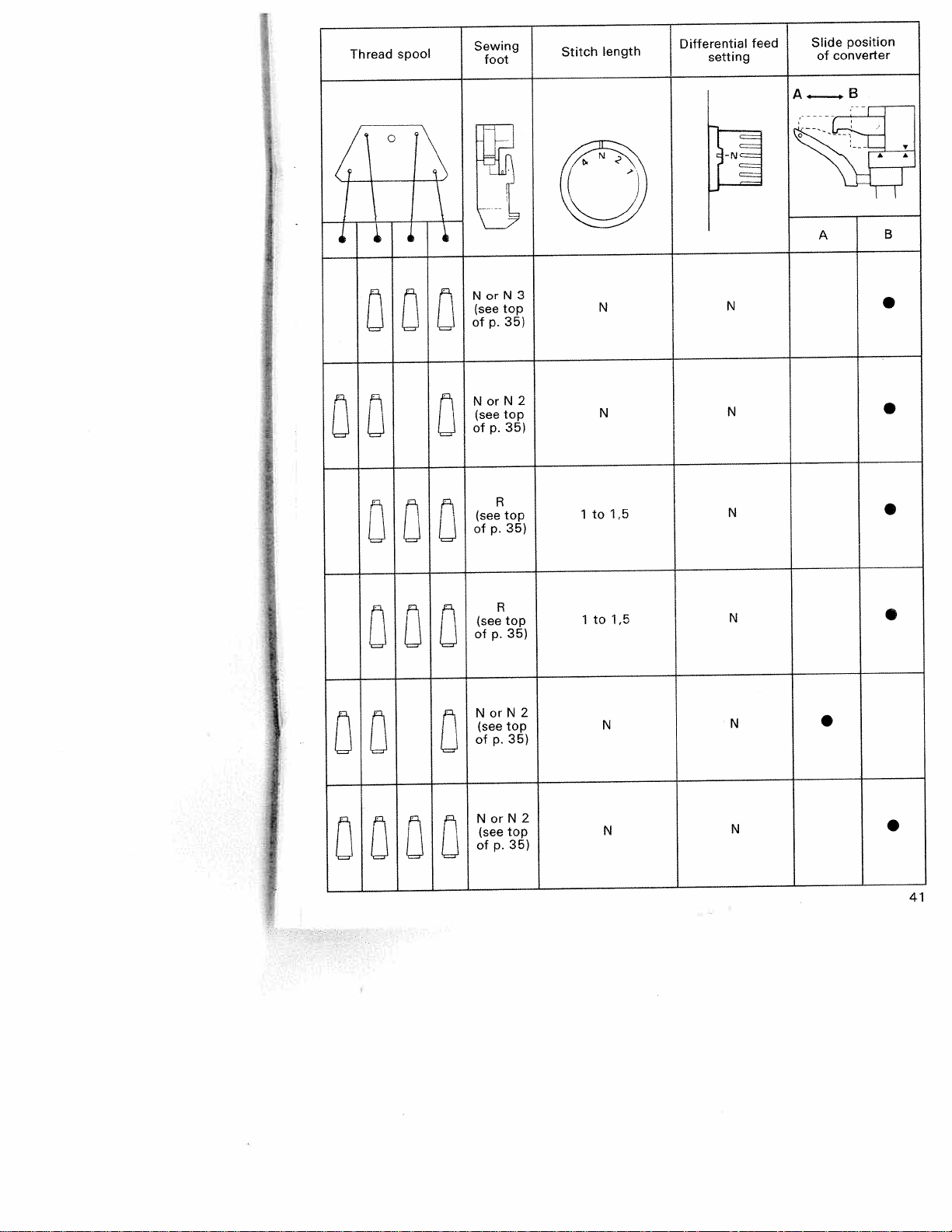

N

(see

of

N

(see

of

N

(see

of

N

(see

of

3

or

N

top

p.

37)

2

or

N

top

37)

p.

N

3

or

top

p.

37)

N

2

or

top

37)

p.

39

Page 44

Oh

Page 45

4

I

I

I

I

I

I

N

(see

of

3

N

or

top

35)

p.

N

(see

of

or

2

N

top

35)

p.

Page 46

Sewing

These

be

to

and

problems

machines

made.

operation

Sewing

errors.

have

and

been

problems

They

solutions

developed

can

of

easily

the

for

kind

be

easy

described

corrected

operation,

below

by

and

may

following

there

occur

the

difficult

no

are

to

due

instructions

minor

adjustmen

adjustmer

below.

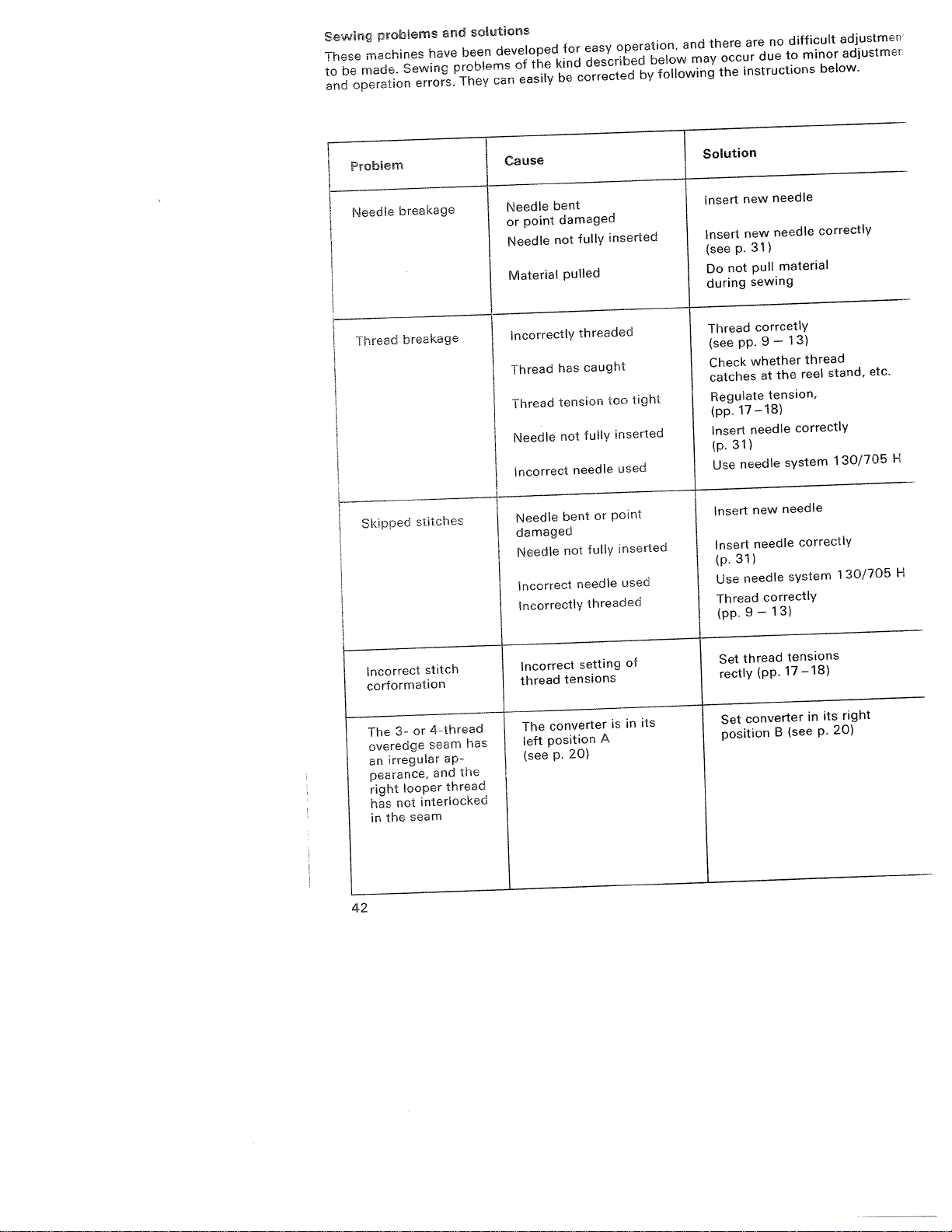

Problem

Needle

Thread

Skipped

breakage

breakage

stitches

Cause

Needle

point

or

Needle

Material

incorrectly

Thread

Thread

Needle

incorrect

Needle

damaged

Needle

Incorrect

Incorrectly

bent

damaged

fully

not

pulled

threaded

caught

has

tension

not

needle

bent

not

needle

inserted

too

fully

point

or

fully

threaded

tight

inserted

used

inserted

used

Solution

new

Insert

new

Insert

(seep.31)

not

Do

during

Thread

(seepp.9—13)

Check

catches

Regulate

17—18)

(pp.

Insert

31)

(p.

needle

Use

Insert

Insert

31)

(p.

needle

I

Use

Thread

9

(pp.

needle

needle

material

pull

sewing

corrcetly

whether

the

at

tension,

needle

new

needle

correctly

13)

—

reel

correctly

system

needle

correctly

system

correctly

thread

stand,

30/705

1

30/705

1

etc.

H

H

Incorrect

corformation

The

overedge

irregular

an

pearance,

right

has

the

in

42

3-

looper

not

or

seam

stitch

4-thread

seam

ap-

the

and

thread

interlocked

has

Incorrect

thread

converter

The

position

left

(see

tensions

p.

setting

20)

of

its

in

is

A

Set

rectly

Set

position

(pp.

converter

B

17—18)

in

see

right

its

20)

p.

tensions

thread

Page 47

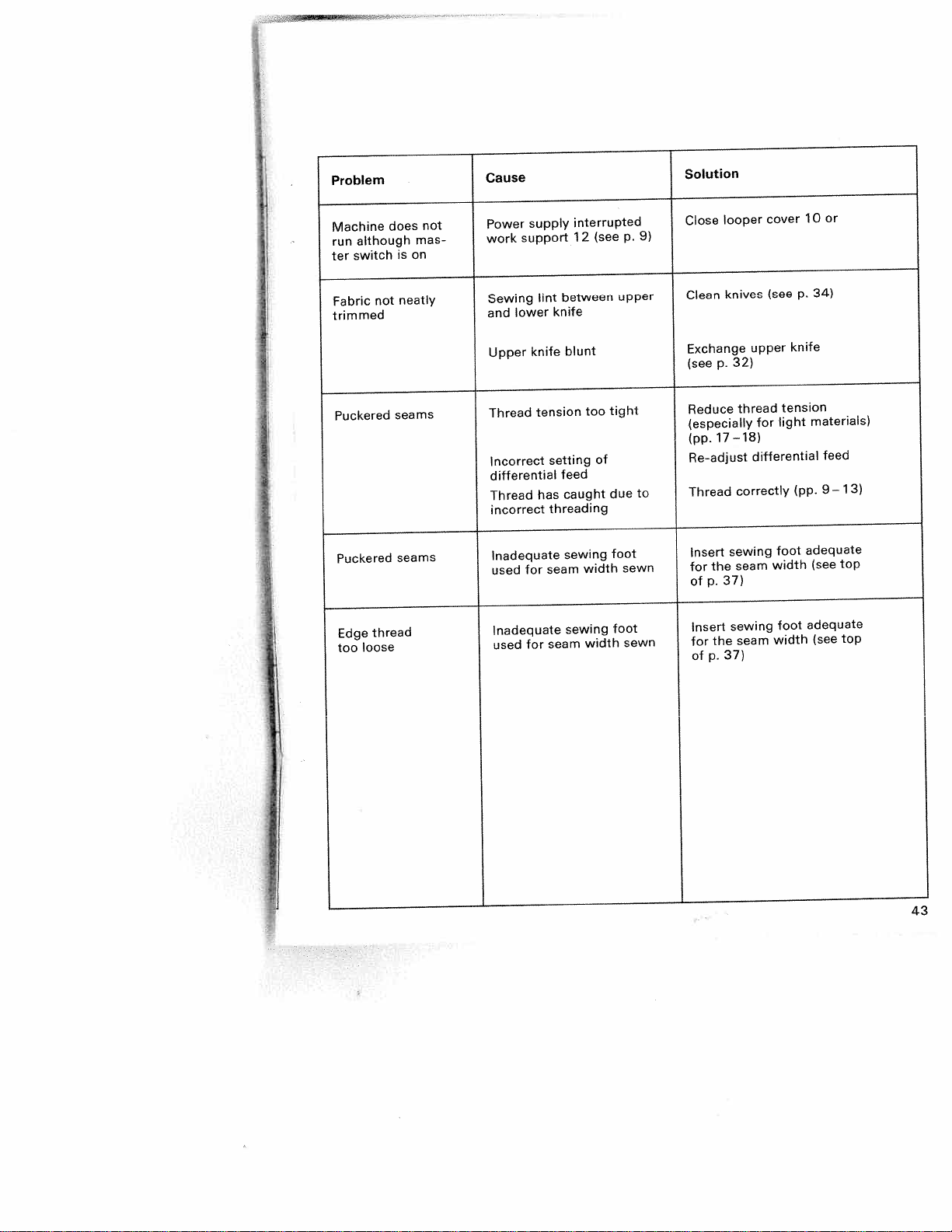

Problem

Machine

although

run

switch

ter

Fabric

trimmed

Puckered

Puckered

Edge

loose

too

does

not

thread

on

is

neatly

seams

seams

not

mas-

Cause

Power

support

work

Sewing

lower

and

Upper

Thread

Incorrect

differential

Thread

incorrect

Inadequate

for

used

Inadequate

used

supply

lint

knife

tension

has

for

interrupted

12

between

knife

blunt

setting

feed

caught

threading

sewing

seam

sewing

seam

(see

too

of

width

width

upper

tight

due

foot

foot

p.

to

sewn

sewn

Solution

or

10

cover

looper

Close

9)

34)

p.

(see

knives

Clean

knife

p.

17—18)

the

37)

p.

the

37)

p.

upper

32)

thread

differential

correctly

sewing

seam

sewing

seam

for

tension

light

foot

width

foot

width

materials)

(pp.

adequate

(see

adequate

(see

feed

9—

1

top

top

3)

Exchange

(see

Reduce

(especially

(pp.

Re-adjust

Thread

Insert

for

of

Insert

for

of

43

Page 48

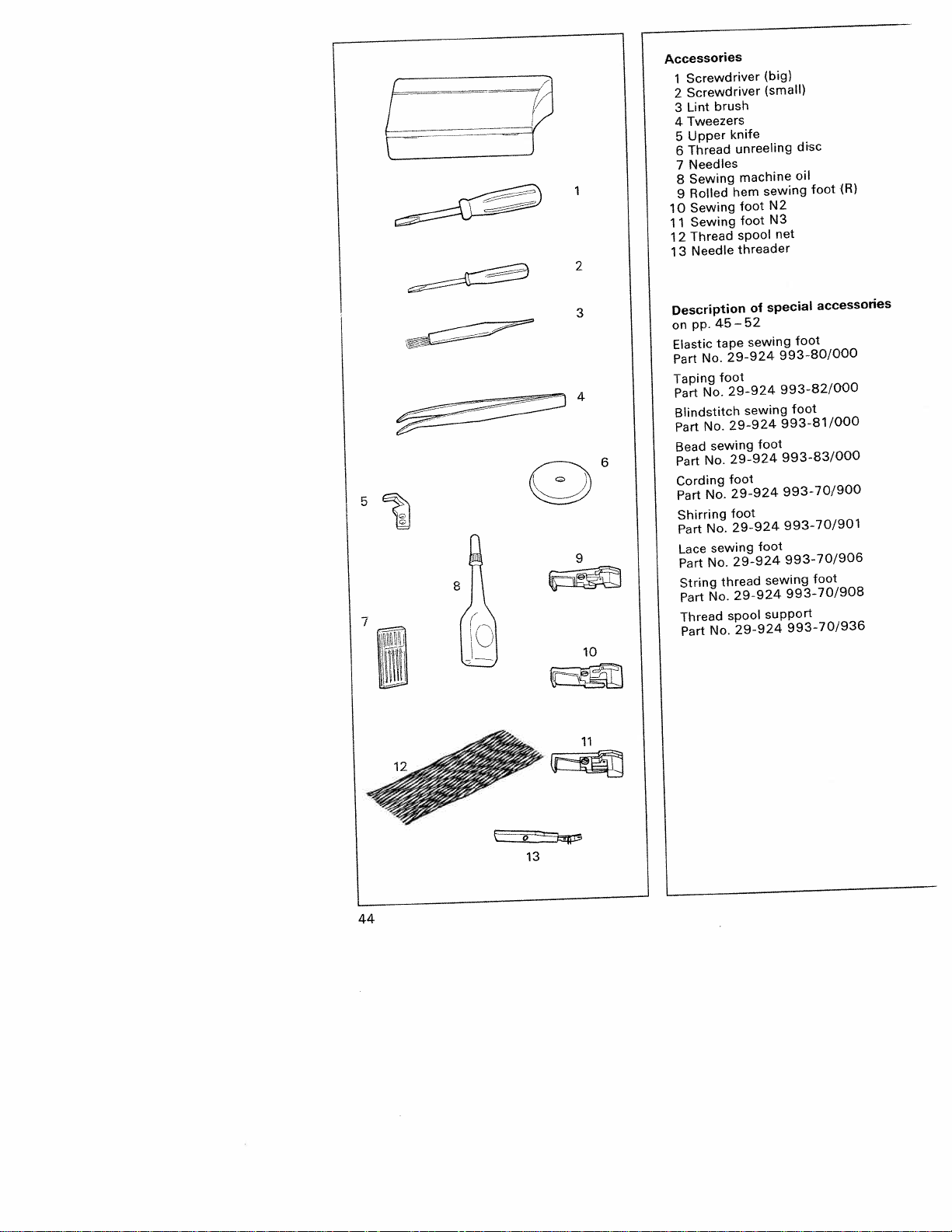

Accessories

knife

unreeling

machine

hem

foot

foot

spool

threader

(big)

(small)

sewing

N2

N3

net

disc

oil

foot

(R)

Screwdriver

1

Screwdriver

2

Lint

3

Tweezers

4

Upper

5

Thread

6

Needles

7

Sewing

8

Rolled

9

Sewing

10

Sewing

1

1

Thread

2

1

Needle

13

brush

2

special

45—52

tape

foot

No.

sewing

No.

No.

No.

sewing

No.

No.

No.

29-9

29-924

29-924

9-924

2

foot

29-924

foot

29-924

29-924

thread

29-924

spool

2

of

sewing

24

sewing

foot

foot

sewing

support

9-924

3

Description

on

pp.

Elastic

No.

Part

Taping

No.

Part

Blindstitch

Part

Bead

Part

Cording

Part

Shirring

Part

9

Lace

Part

String