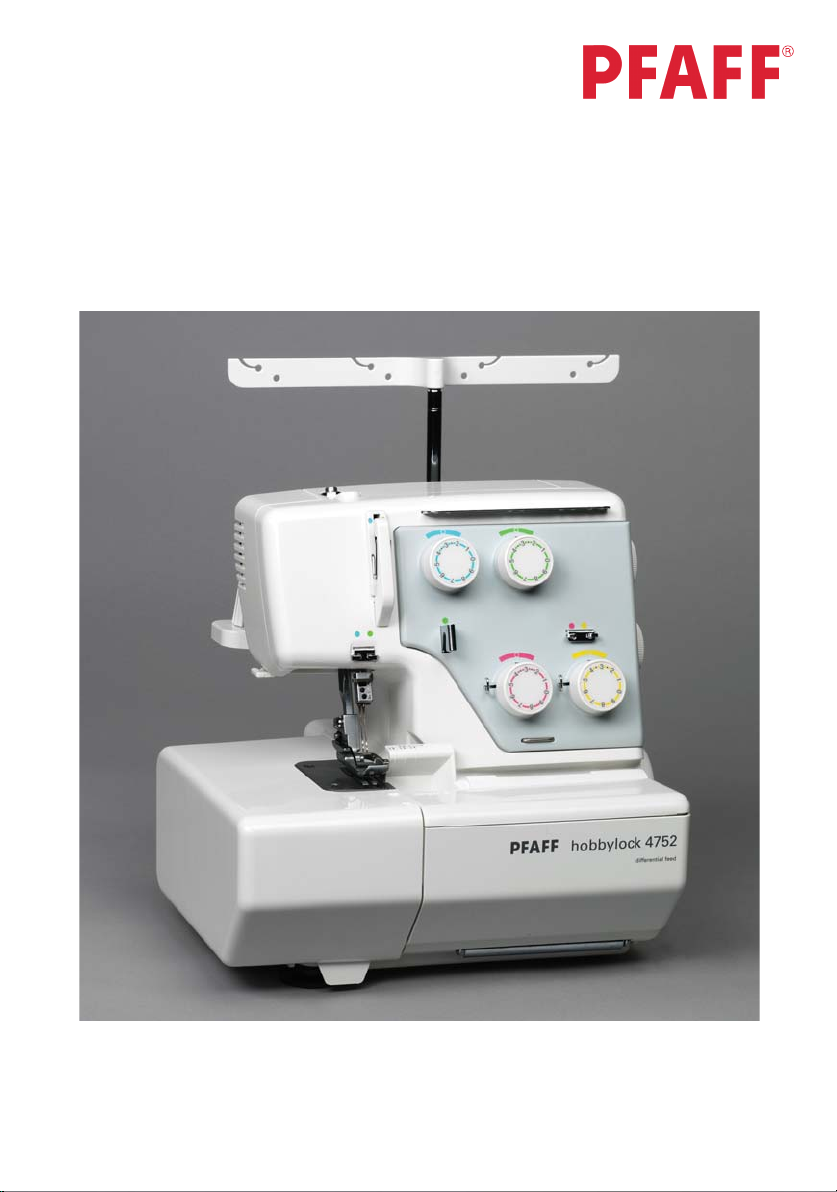

Page 1

hobbylock

4752

Instruction Manual

Page 2

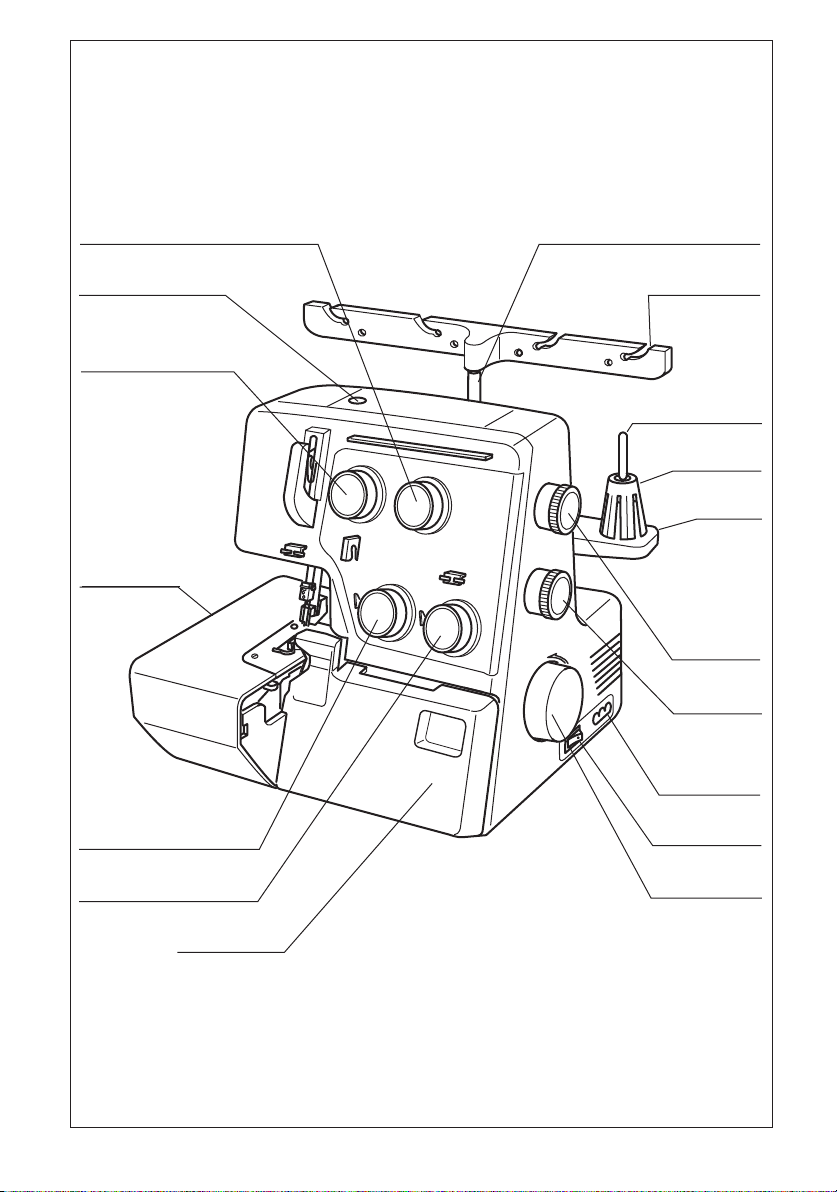

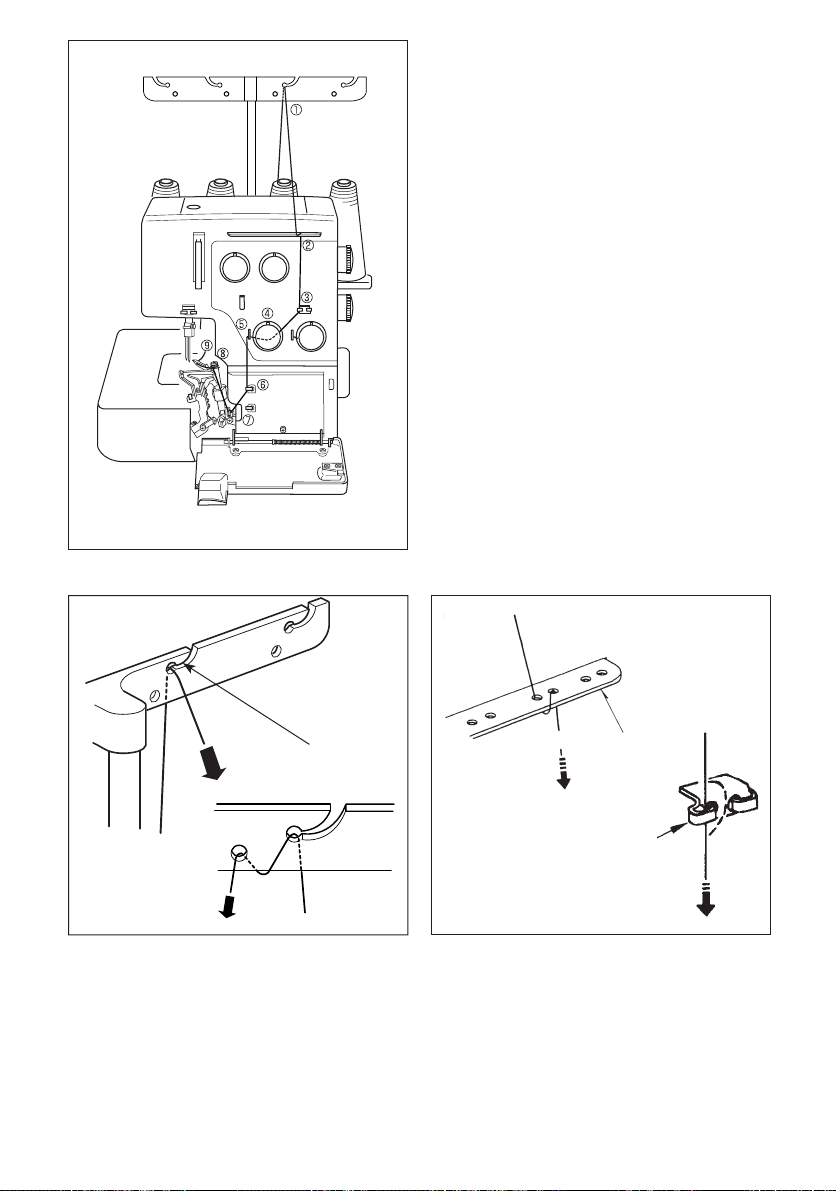

Parts of the hobbylock 4752

Right needle thread tension

(green)

Telescoping thread guide

Setting screw for presser

foot pressure

Left needle thread tension

(blue)

Swivel plate

Upper looper

thread tension (red)

Thread guides

Thread spool pin

Cone thread

adapter

Thread spool stand

Setting knob for

stitch length

Foot control plug

with power

cord

Foot control plug

with power

cord

Electrical power

master switch

Lower looper

thread tension (yellow)

Looper cover

Handwheel

Page 3

Page 4

2

Page 5

Simple, up-to-date sewing

Congratulations! You have bought a high-quality

product that provides unique advantages. Your new

hobbylock 4752 can take any material in its stride

and will sew through thick and thin for you.

Your PFAFF hobbylock features the very latest in design and technology, and it is just as simple to operate as this instruction manual is to follow.

Before you start sewing, please take the time to read

these instructions carefully. It is certainly time well

spent, and is the best way to find out just what your

machine can do and make full use of all its features.

If you have any further questions, just ask your authorized PFAFF dealer. Your dealer is happy to be of

service with any help or advice.

Let’s get started! We wish you many enjoyable hours

creating your very own fashions and projects!

3

Page 6

Contents

Page

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories, optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Accessory box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changing a spool on a threaded machine . . . . . . . . . . . . . . . . 11

Cleaning the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cone thread adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Differential feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Electrical power master switch . . . . . . . . . . . . . . . . . . . . . . . . . 7

Foot control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 8

Handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Light bulb (sewing lamp), changing . . . . . . . . . . . . . . . . . . . . . 41

Looper cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lubricating the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 - 41

Needle holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Needle plate, removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Needle position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Needle, changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Oiling the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Presser foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 21

Presser foot lifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Presser foot pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Presser foot, changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Program overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30, 31

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 7

Seam guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Seam width setting knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4

Page 7

Seam width, setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Securing the seam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27, 28

Sewing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Sewing light cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Sewing problems and their solutions. . . . . . . . . . . . . . . . . . . . 42, 43

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Stitch formation correction measures . . . . . . . . . . . . . . . . . . . 32 - 36

Stitch length setting knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stitch length, setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stitch width latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Swivel plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Telescoping thread guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Thread chain cutter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Thread net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Thread tensions, setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Thread unreeling disc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Threading aid for looper thread . . . . . . . . . . . . . . . . . . . . . . . . 13, 15

Threading aid for needle thread . . . . . . . . . . . . . . . . . . . . . . . . 16, 18

Threading paths/overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

Threading the lower overedge looper (yellow) . . . . . . . . . . . . 14, 15

Threading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Threading the needle(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16, 17, 18

Threading the upper overedge looper (red). . . . . . . . . . . . . . . 12, 13

Threading, important note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Threads and needles chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Upper blade, changing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Upper blade, disengaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Waste container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5

Page 8

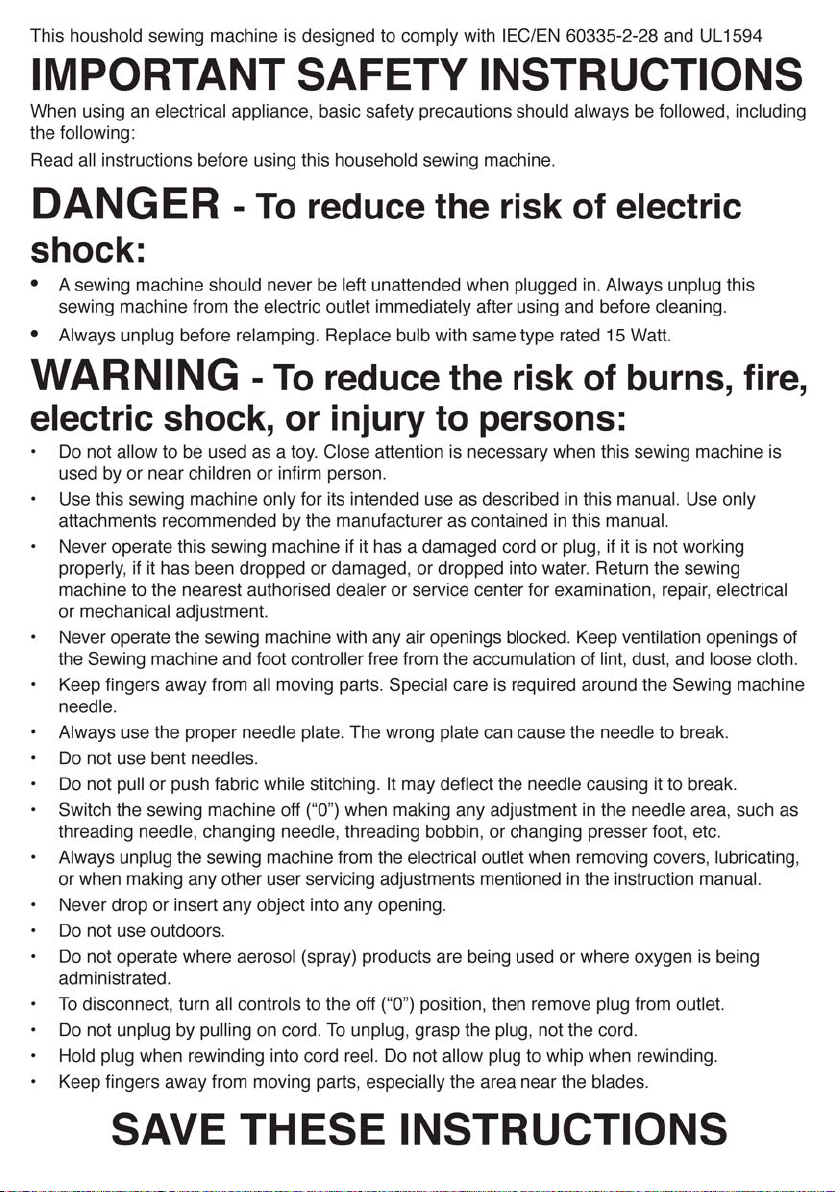

lug

groove

waste

container

looper cover

Attaching the waste container

Guide the lug into the groove on the looper

cover.

Accessories

screw driver tweezers

thread nets

thread unreeling discs

waste

container

accessory box

Storing the accessory box

Place the accessory box in the waste container.

6

needle

system

machine

oil

looper threading aid

replacement

upper

blade

wrench

cleaning

brush

needle threading

aid

Page 9

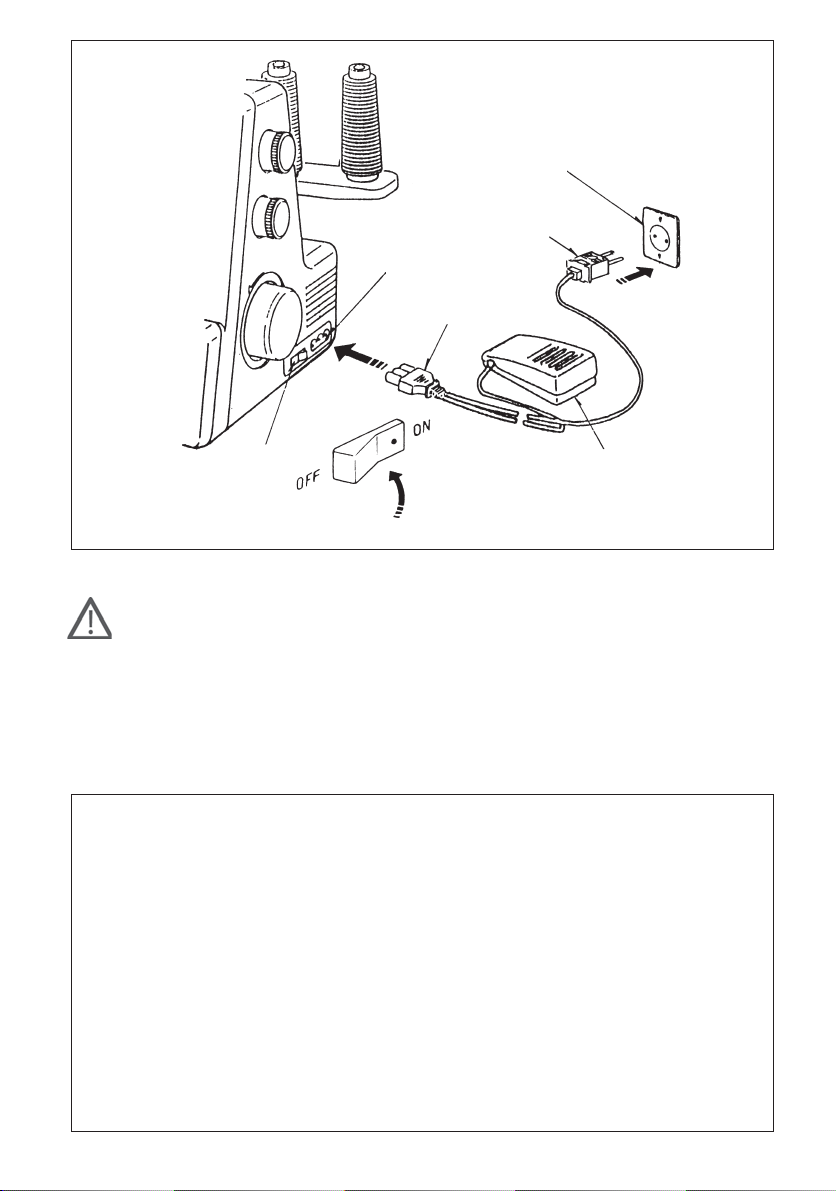

lead cord/plug

connection socket

foot control plug

wall socket

main switch

main switch

foot control

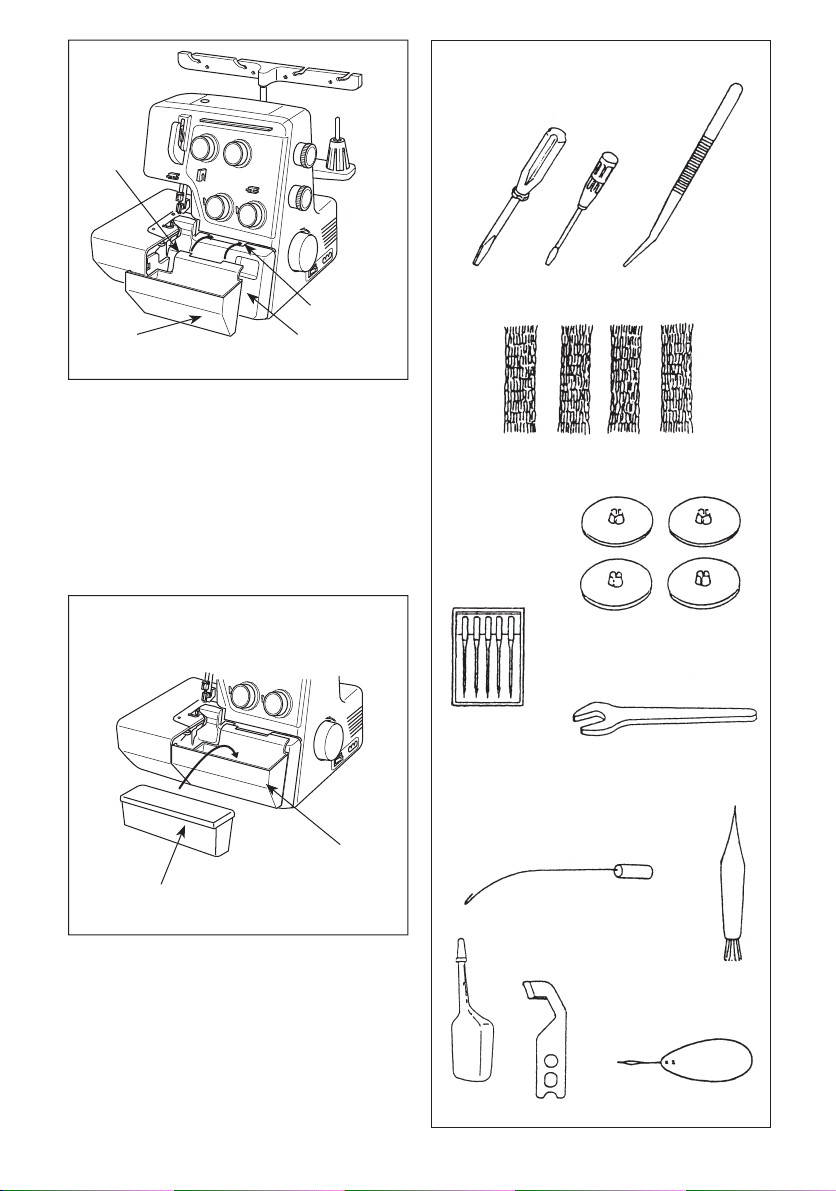

Connecting the machine to the mains power supply

Switch the main switch to OFF.

Plug the foot control plug into the connection socket on the machine.

Plug the lead cord/plug into the wall socket.

Switch the main switch to ON.

Notes on safety

This appliance has a polarized plug (one blade wider than the other).

To reduce the risk of electric shock, it is designed to fit into a polarized outlet only one

way. If the plug does not fit correctly into the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

Foot controller type YC-482J (120 V)/YC-550 (230 V)/YC-551 (240 V) has to be used with

this overlock machine.

For the USA and Canada

This sewing machine has a polarized plug (one blade wider than the other). To reduce

the risk of electric shock, this plug is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper outlet. Do not modify the plug in any way.

7

Page 10

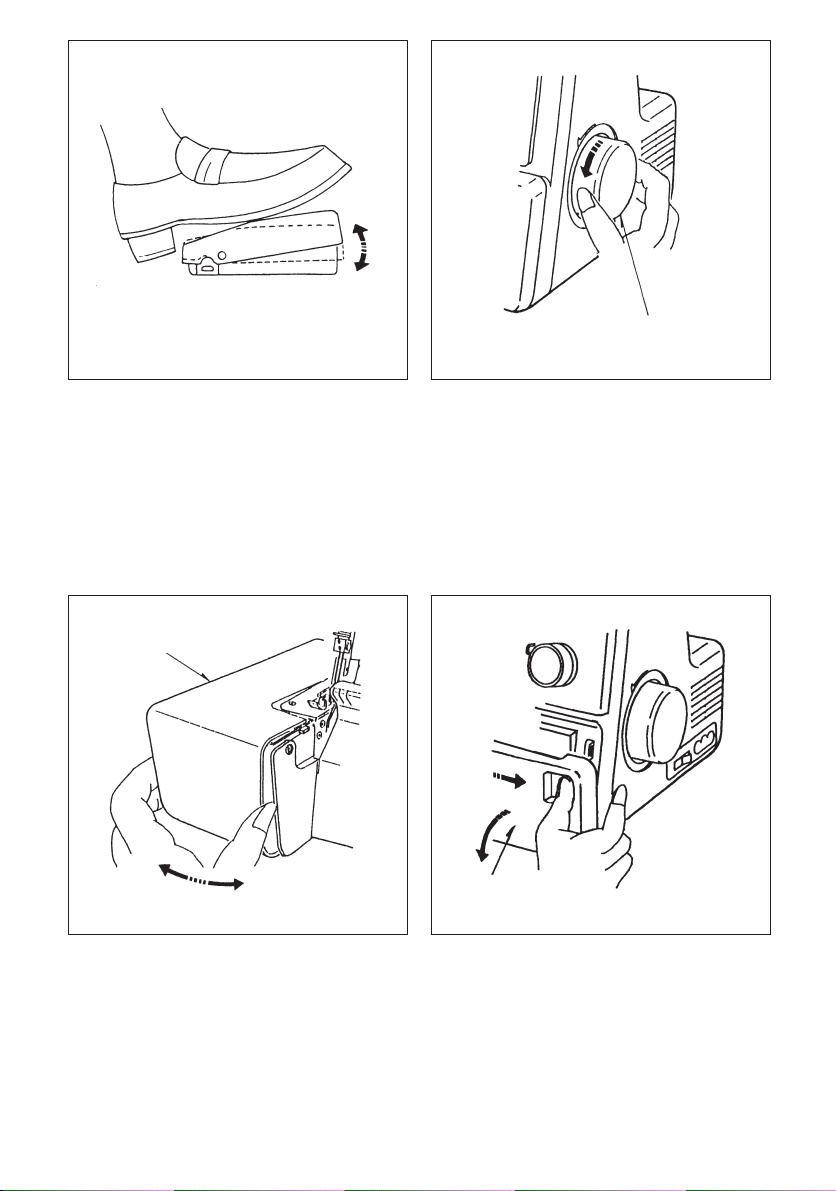

foot control

handwheel

Sewing speed

The sewing speed is regulated by activating

the foot control. The further you press the

foot control down, the faster the machine

will sew.

swivel plate

Opening and closing the swivel plate

Opening: press the swivel plate towards the

left.

Closing: press the swivel plate towards the

right and slightly towards the machine.

Safety note: the swivel plate and the looper cover must always be closed when the

machine is used.

Direction of rotation of the handwheel

Always turn the handwheel towards you, as

shown in the illustration (i.e. counterclockwise).

looper cover

Opening and closing the looper cover

Opening: Push the looper cover fully to the

right and then swivel it down.

Closing: raise the looper cover and press

it towards the machine. The looper cover

snaps into place automatically.

8

Page 11

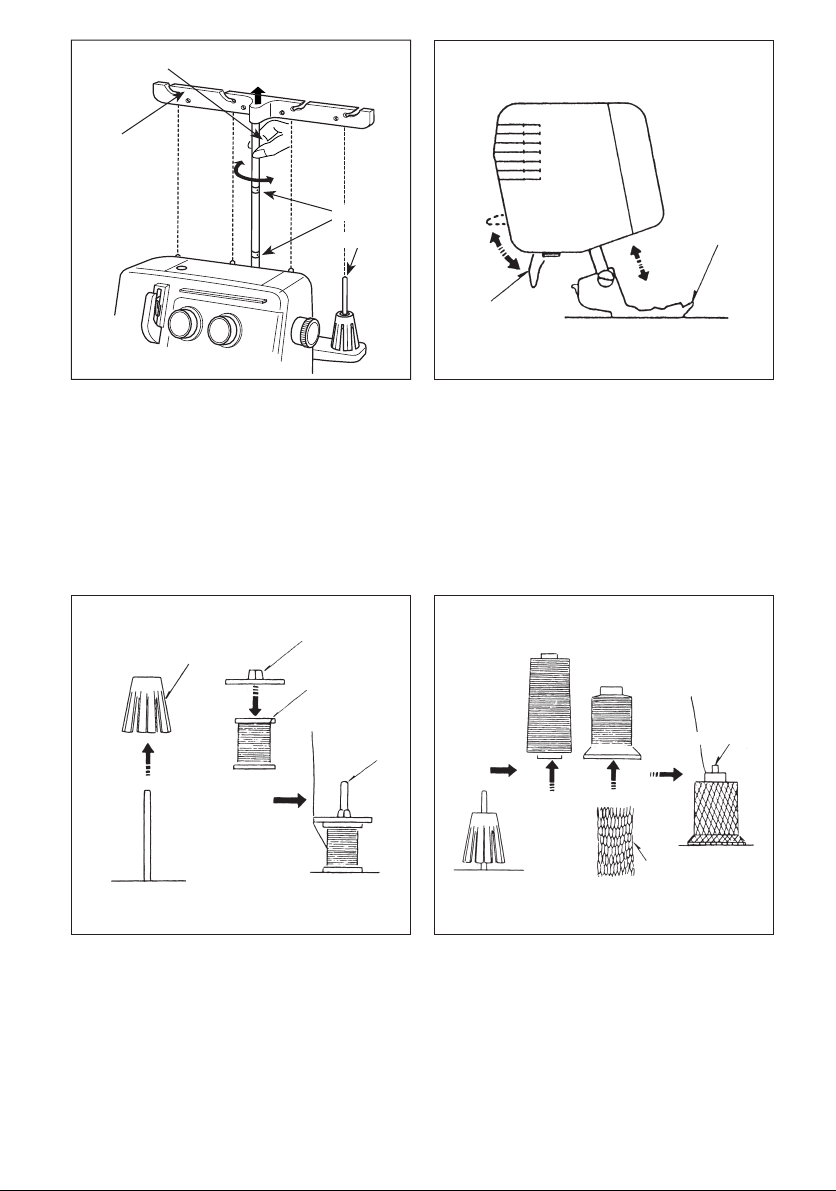

telescoping

thread guide

thread

guides

stops

spool pin

Telescoping thread guide

Pull the telescoping thread guide upward to

its highest position.

The two upper telescopes must be rotated

slowly until their locking balls are heard to

lock into place.

cone thread

adapter

thread unreeling discs

slit

spool

pin

standard

presser foot

presser foot

lifter

Presser foot lifter

The presser foot can be raised and lowered

using the presser foot lifter.

The presser foot must always be lowered

when the machine is used.

spool

pin

Attaching the thread unreeling discs and the

thread nets

Pull the cone thread adapter off the spool

pin when using a small spool. Place the

spool on the spool pin in such a way that the

slit is at the top and place the thread unreeling disc on top of the spool.

thread net

If the thread jumps off the spool during

threading or sewing or if it slips out of the

thread tensioners when sewing rolled hems,

pull the enclosed net over the spool, as

shown in the illustration. In this way, you

can prevent the thread from jamming.

9

Page 12

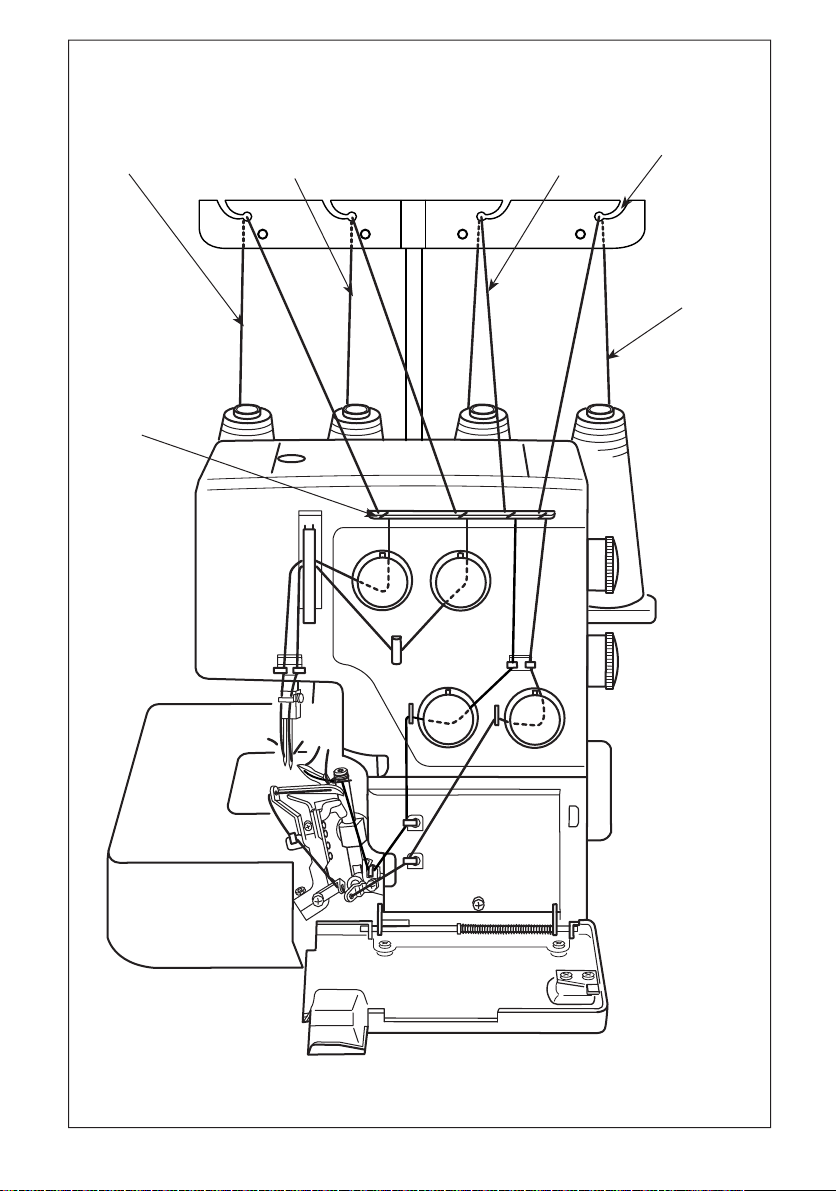

Threading the machine

left needle

thread

thread

guide

plate

right needle

thread

upper looper

thread

thread

guides

lower looper

thread

10

Page 13

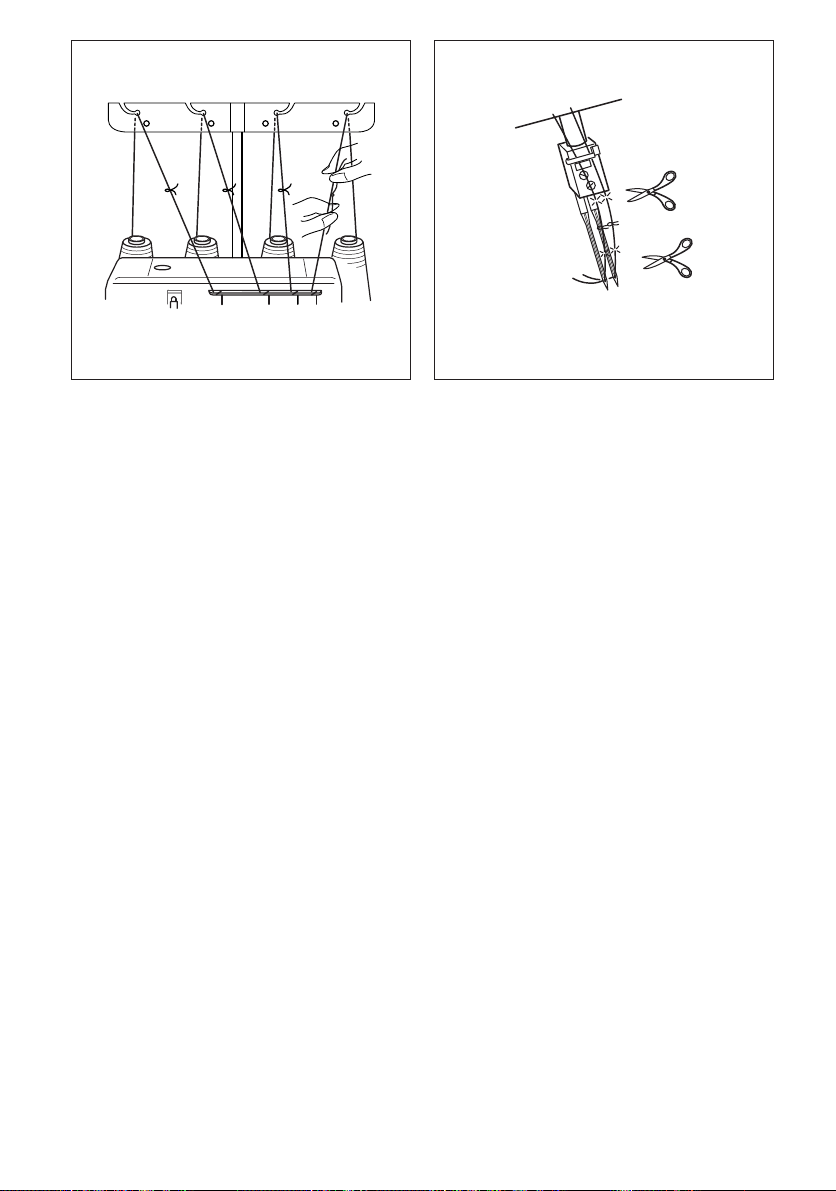

Before the machine leaves the factory,

threads are already threaded and their ends

are cut off. Tie one of these thread ends to

the thread from a spool with an overhand

knot, raise the presser foot and pull the new

threads through the loopers. In order to

thread the needle threads, pull the thread

ends through until the knots reach the

needle eye. Cut the threads on both sides

of the knots. Rethread the eye of the needle

with the needle threading aid (see Pages 16,

18). With this procedure, you can save a

great deal of time when threading.

If the threads are not threaded in the machine, thread the upper looper thread (red) first,

then the lower looper thread (yellow), the

left needle thread (blue) and finally the right

needle thread (green). Two threading diagrams are located behind the looper cover

to help you correctly thread the machine.

Threads that are threaded incorrectly will

lead to irregular (skipped) stitches, broken

needles and uneven thread tension. Therefore always make sure that all the threads

are perfectly threaded before beginning to

sew.

In order to replace spools, cut the threads

between the thread guides and the thread

guide plate. Thread the new threads in the

manner described opposite.

In order to make threading easier, set the

thread tension to “0”. After threading, reset

the thread tension to the desired number

(see Pages 30, 31).

11

Page 14

Threading the upper looper (red)

Open the looper cover and the swivel plate.

Place the spool on the second spool pin

from the right. The guide points for the upper looper thread are marked in red. Two

threading diagrams are located behind the

looper cover to help you with the threading.

thread guides

Guide the thread from the rear through the

second thread guide from the right.

12

guide (3) for

the upper

looper

guide plate

thread

Guide the thread through the fourth and the

third hole from the right on the thread guide

plate, as shown in the illustration.

Guide the thread from the right to the left

into the left guide (3).

Page 15

guide (5) for

the upper

looper thread

take-up lever

(7) of the

upper looper

thread

thread tensioner of

the upper looper

thread

guide (6) for

the upper

looper thread

Guide the thread through from the right between the tension discs and pull the thread

tight from both sides.

Feed the thread into the guide (5) for the upper looper thread.

Feed the thread into the guide (6) for the upper looper thread. Guide the thread into the

take-up lever (7) of the upper looper thread.

looper

threading

aid

upper

looper

guide (8) for

the upper

looper

Feed the thread into the guide (8) of the upper looper. Feed the looper threading aid

through the eye in the upper looper. Then

hook the thread end into the looper threading aid and pull the latter with the thread

through the eye. Remove the thread from

the looper threading aid and pull on the free

thread end until at least 10 cm (4”) is

showing beyond the eye. Lay the thread to

the left under the presser foot. Close the

swivel plate and the looper cover.

13

Page 16

thread guide (1)

Threading the lower looper (yellow)

Open the looper cover and the swivel plate.

Place the spool on the second spool pin. The

guide points for the lower looper thread are

marked in yellow. Two threading diagrams

are located behind the looper cover to help

you with the threading.

Guide the thread from the rear through the

right thread guide (1).

14

guide (3) for

the lower

looper

thread

guide plate (2)

Guide the thread through both the right

holes on the thread guide plate (2), as shown

in the illustration.

Guide the thread from the left to the right

into the right guide (3).

Page 17

guide (5) for

the lower

looper thread

thread tensioner of

the lower looper

thread

guide (9) for

the lower

looper thread

guide (8) for the lower

looper thread

guide (6) for the

lower looper thread

take-up lever (7) of the

lower looper thread

Guide the thread through from the right between the tension discs and pull the thread

tight from both sides.

Feed the thread into the guide (5) for the

lower looper thread.

guide (10)

for the lower

looper thread

thread

looper threading

aid

looper

threading

aid

Turn the handwheel towards you (counterclockwise), until the looper is on the extreme

right. Feed the looper threading aid through

the eye of the guide (10) for the lower

looper. Then hook the thread end into the

looper threading aid and pull the latter with

the thread through the eye of the guide (10).

Feed the thread into the guide (6) for the lower looper thread.

Guide the thread into the take-up lever (7) of

the lower looper thread.

Feed the thread into the guide (8) for the

lower looper thread.

Feed the thread into the guide (9) for the

lower looper thread.

looper threading

lower looper

aid

tweezers

Remove the thread from the looper threading aid and using the tweezers pull on the

free thread end until at least 10 cm (4”) is

showing beyond the eye of the lower looper.

Lay the thread to the left under the presser

foot. Close the swivel plate and the looper

cover.

15

Page 18

Threading the left needle (blue)

Place the spool on the left spool pin. The

guide points for the left needle thread are

marked in blue. Two threading diagrams are

located behind the looper cover to help you

with the threading.

Guide the thread from the rear through the

left thread guide (1) and both the left holes

on the thread guide plate (2).

thread tension (3) of

the left

cover of the

take-up lever

(4)

needle

thread

Guide the thread from the right between

the tension discs and pull the thread tight

from both sides. Raise the needle(s) to the

high-est position by turning the handwheel

towards you. Guide the thread into the takeup lever (4). Feed the thread from the right

to the left into the left guide (5) for the

needle thread.

16

Führung

des Nadel-

fadens

Faden-

führung

der

Nadel-

stange

guide (5) for the

needle thread

thread guid

(6) on the

needle bar

Feed the thread from the left to the right

into the thread guide (6). Feed the needle

threading aid through the needle eye from

the rear. Then hook the thread end into the

needle threading aid and pull the needle

threading aid with the thread through the

needle eye. Pull on the free thread end until

at least 10 cm (4”) is showing beyond the

needle eye. Lay the thread to the left under

the presser foot.

Page 19

Threading the right needle (green)

Place the spool on the second spool pin

from the left. The guide points for the right

needle thread are marked in green. Two

threading diagrams are located behind the

looper cover to help you with the threading.

Guide the thread from the rear through the

second thread guide (1) from the left. Guide

the thread through the fourth and the third

hole from the left on the thread guide plate

(2).

cover of the take-up

lever (5)

thread tension

(3) of the right

needle thread

Guide the thread from the right between the

tension discs and pull the thread tight from

both sides.

guide for the

right needle

thread (4)

Raise the needle(s) to the highest position

by turning the handwheel towards you.

Guide the thread through the guide (4) for

the right needle thread and through the

take-up lever (5)

17

Page 20

guide (6 for the

needle thread

thread guide (7)

Feed the thread from the left to the right into

the right guide (6) for the needle thread.

Feed the thread from the left to the right into

the thread guide (7).

Feed the needle threading aid through the

needle eye from the rear. Then hook the thread end into the needle threading aid and

pull the needle threading aid with the thread

through the needle eye. Pull on the free

thread end until at least 10 cm (4”) is

showing beyond the needle eye. Lay the thread to the left under the presser foot.

Important note on threading

The needle(s) must always be threaded last

so that the needle threads do not run under

the looper thread as seen in drawing 1, but

instead over the looper thread as depicted

in drawing 2. Should this sequence not be

followed, thread breakage or skipped

stitches can occur.

18

If the looper threads break, you must pull

the needle threads out of the needle eye,

rethread the looper thread and then

rethread the needle threads.

Page 21

(A)

the right seam

width

Setting the seam width

Set the seam width as follows:

1. Switch the main switch to OFF and pull out the lead cord/plug.

2. Open the looper cover and the swivel plate.

3. Move the upper blade to its lower position (see Page 24).

4. Adjust the setting knob until the lower blade is in the desired position.

(A) The seam width is too small - there are extra loops.

Turn the setting knob clockwise. The lower blade moves to the right.

(B) The seam width is too large - the edge is rolling up.

Turn the setting knob counterclockwise. The lower blade moves to the left.

5. Move the upper blade to its upper position.

6. Close the looper cover and the swivel plate.

(B)

Setting the seam width for rolled hems (Programs 05, 06)

Turn the setting knob counterclockwise to an extremely narrow setting.

19

Page 22

setting

mark

setting

mark

stitch length

setting knob

setting knob

for differential feed

Setting the stitch length

Turn the stitch length setting knob in such a

way that the desired stitch length is indicated at the setting mark. The higher the number, the longer the stitch. The stitch length

can be adjusted between 1 and 5 mm.

The setting R is used for sewing rolled hems.

stretched

Setting the differential feed ratio

The differential feed ratio can be altered by

turning the setting knob. The number at the

setting mark shows the ratio between the

two feed dogs arranged behind each other.

The normal setting is 1.0.

The maximum differential feed ratio (2.0) is

only fully effective within the setting range

from 1 to 3.3 on the stitch length setting

knob. If the stitch length setting knob is set

to a value between 3.3 and 5.0, the differential feed ratio is automatically adjusted to a

value between 2.0 and 1.3.

20

contracted

Setting:

– Turn the setting knob counterclockwise

(towards 2.0) to achieve gathering effects

on lightweight fabric or to smooth fabric

that is being overly stretched out of

shape.

– Turn the setting knob clockwise (towards

0.7) to achieve a ruffled (lettuce) effect on

knit or bias-cut fabrics or to smooth fabric

that is being contracted while sewing.

Page 23

Standard setting

Top side of

the machine

adjusting screw

presser

foot lifter

2 mm

to reduce

needle

to increase

Presser foot pressure

The presser foot pressure does not need to

be adjusted for most fabrics. If you are

working with light or heavy fabrics then

you may need to adjust the pressure. In this

case set the adjusting screw as follow:

– for heavyweight fabrics increase pres-

sure by turning the adjusting screw to

the right

– for lightweight fabrics reduce pressure

by turning the adjusting screw to the left

Adjust the adjusting screw for normal

sewing work in such a way that its upper

edge protrudes 2 mm out from the top side

of the machine (see illustration).

lever

presser foot

holder

Removing the presser foot

Turn the machine off.

Raise the needle(s) to the highest position.

Raise the presser foot and press the lever

at the rear of the presser foot holder. The

presser foot will be released automatically

from the holder.

lever

clamp

pin

Attaching the presser foot

Place the presser foot beneath the presser

foot holder, until the pin of the foot is directly under the presser foot holder clamp.

Lower the presser foot holder and press

lever until the foot then clicks into place. Lift

the presser foot lever to check that the pressser foot is properly locked into place.

21

Page 24

fastening screw

for the left needle

fastening

screw for

the right

needle

Changing the needle

Switch the main switch to OFF.

Move the needle(s) to the highest position.

Loosen the fastening screw of the needle

that is to be changed.

Needle system HA X 1SP (130/705 H-PS) is

required for this machine.

edge of the

needle bar

needle

fastening

screw

the flat

side

points

towards

the rear

edge of the

needle bar

stop

pin

needle

holder

Do not use bent or blunt needles.

Inserting the right needle

Insert the new needle in such a way that

the flat side points towards the rear. Push

the needle upward until it touches the stop

pin. Tighten the fastening screw of the right

needle.

Inserting the left needle

Insert the new needle into the needle holder in such a way that the flat side points

towards the rear. Push the needle upward

until it touches the edge of the needle bar.

Tighten the fastening screw of the left

needle.

– If the needles are inserted correctly,

the position of the left needle should

be slightly higher than that of the right

needle.

22

Page 25

Use of the right needle only

(for 3-thread seams with a narrow seam

width)

Turn the machine off.

Remove the left needle and the left needle

thread. Tighten the left needle fastening

screw again slightly so it does not fall out.

Use of the left needle only

(for 3-thread seams with a wide seam

width)

Turn the machine off.

Remove the right needle and the right

needle thread. Tighten the right needle

fastening screw again slightly so it does

not fall out.

Changing the needle when sewing with three threads

Undo both needle fastening screws and remove the old needle. Insert the new needle

as far as it will go and tighten the relevant

fastening screw. Also tighten the other

fastening screw slightly so it does not fall

out.

23

Page 26

ridged knob for lowering the upper blade

upper blade

blocking

pin

Disengaging the upper blade

Turn the machine off.

– Open the looper cover and the swivel

plate.

– Push the ridged knob for lowering the

upper blade to the right and turn it

towards you. Guide the upper blade over

the blocking pin so that the upper blade

engages in its lower position.

– Close the looper cover and the swivel

plate.

Engaging the upper blade

Turn the machine off.

24

ridged knob for lowering

the upper blade

blocking

pin

– Open the looper cover and the swivel

plate.

– Push the ridged knob for lowering the

upper blade to the right and turn it away

from you. Guide the upper blade over

the blocking pin so that the upper blade

engages in its upper position again.

– Close the looper cover and the swivel

plate.

Page 27

setting

knob

setting

marks

stitch width

latch

Setting the stitch width latch

(for standard overlock seams or rolled

hems)

Switch the main switch to OFF.

– Open the looper cover and the swivel

plate.

– Disengage the upper blade (see Page 24).

– Press the stitch width setting knob

towards the right and push the bed slide

of the stitch width latch to the setting

mark S (standard) or R (rolled hem). Then

release the setting knob again slowly.

– Move the upper blade to its upper posi-

tion.

– Close the looper cover and the swivel

plate.

standard

seams

stitch

width

latch

bed slide

Set the bed slide for the stitch width latch to

position S. The stitch width latch will be

pushed forward. This setting allows you to

sew all types of standard overlock seams.

rolled

hems

stitch

width

latch

bed slide

Set the bed slide for the stitch width latch to

position R. The stitch width latch will be

pushed backward. This setting allows you to

sew all types of rolled hems.

25

Page 28

Starting sewing

Lay the sewing material under the front of

the presser foot (it is not necessary to raise

the presser foot). Turn the handwheel carefully a few revolutions towards you and

check the thread chain. Start sewing slowly.

The sewing material is fed automatically.

Guide the sewing material in the desired

direction.

Using the seam guidelines

On the top side of the looper cover, you will

find seam guidelines which indicate the

distance from the needles. These guidelines

should help you to properly position your

fabric when sewing.

Finishing sewing

When you have completed your seam, allow

the machine to continue to sew slowly until

the thread chain has attained a length of approx. 12 cm (4 3/4”). At the same time, pull

the thread chain gently towards the rear.

26

Cut the threads off using the thread cutter,

as shown in the illustration. Leave a thread

chain approx. 5 cm (2”) long beyond the end

of the fabric.

Page 29

A B

Securing the seam ends

Leave a thread chain of approx. 5 cm (2”) in

length extending at the beginning and the

end of the seam to prevent the seam from

coming undone. Secure the thread chain at

the beginning and end of the seam using

one of the following methods.

Separate the individual thread ends and knot

them together.

C C

Stitching the beginning of the seam

1. Before inserting fabric under the presser

foot, serge a thread chain of approx. 5 cm

(2”) in length.

2. Insert the sewing fabric into the machine

and sew 2-3 stitches into the fabric.

3. Raise the presser foot, guide the thread

chain to the left around the presser foot

towards the front and lay the thread chain

under the presser foot.

Thread the thread chain into a needle with a

large eye and pull the thread chain into the

overlock stitches of the sewing fabric.

4. Pull the thread chain slightly taught

towards the upper blade. Lay the thread

chain under the upper blade. Hold the

thread chain firmly in this position, lower

the presser foot and begin to sew.

5. The upper blade will cut off the excess thread chain, leaving an overstitched seam

of approx. 2.5 cm (1”).

27

Page 30

Stitching the end of the seam

1. Sew 2-3 stitches off the end of your fabric.

2. Turn the needles to their highest position

and raise the presser foot.

3. Flip the fabric over so the bottom side is

now on the top. Pull the fabric around so

it is positioned under the presser foot and

in front of the needles. Make sure the

fabric is not positioned in the path of the

upper blade.

28

5. Lower the presser foot, sew approx. 2.5

cm (1”) over the seam and pull the fabric

away to the side at an angle, sewing off

the fabric.

Page 31

Threads and needles chart

Light Medium-heavy heavy Knitwear

fabrics fabrics fabrics

organdy, cotton, tweed, knitwear

georgette, linen, satin, upholstery

Fabric

batiste, standard fabric, denim,

crepe-de-Chine, fabrics heavy cloth

lining fabrics

Thread

Needle

Thread tension

cotton: cotton: cotton: cotton:

no. 80 - 100 no. 50 - 100 no. 50 - 60 no. 50 - 60

silk: silk: silk: synthetic thread:

no. 80 - 100 no. 50 - 100 no. 50 - 60 no. 50 - 60

synthetic thread: synthetic thread: synthetic thread:

No. 80 - 100 No. 50 - 100 No. 50 - 60

cotton nylon +

polyester thread

(looper thread)

130/705 H-PS 130/705 H-PS 130/705 H-PS 130/705 H-PS

70/80 80/90 80/90 90

Setting thread tension

setting

mark

The following pages contain directions for

setting thread tensions for all programs.

Adjust the tension by turning the tensioning

wheel until the dot marker is at the desired

setting.

The settings for adjusting thread tension are

recommendations. Fabric type, thread quality and needle gauge will influence seam

results. Always sew off a test seam onto a

piece of scrap fabric and check the thread

loops. Adjust the thread tension if necessary.

to increaseto reduce

Tip: as practice, use threads that match the

tension dials, e.g. thread the upper looper

with red thread, the lower looper with yellow thread, etc.

Note: in the program overview on Pages 30

and 31, you will find the appropriate settings

for each individual program.

29

Page 32

Program overview

Program Application Needle

Program 01

Program 02

Program 03

Program 04

3-thread

overedge,

narrow

3-thread

overedge,

wide

3-thread

flatlock,

narrow

3-thread

flatlock,

wide

Serging light (easily frayed)

fabrics.

Serging tightly woven

(easily frayed) fabrics.

Serging medium-heavy

fabrics. As a flatlock seam,

for joining stretch fabrics and

decorative finished edges.

Serging medium-heavy

fabrics. As a flatlock seam,

for joining stretch fabrics and

decorative finished edges.

position

L = left

R = right

R

L

R

L

Program 05

Program 06

Program 07

30

3-thread

rolled hem

Folded

3-thread

rolled hem

4-thread

overedge

Serging light to mediumheavy fabrics. Decorative

edges.

Serging light to mediumheavy fabrics. Decorative

edges.

Joining and simultaneous

serging of all fabrics, in particular stretchy fabrics.

R

R

LR

Page 33

Thread tension: The values refer to medium-heavy

fabrics and normal polyester thread

blue green red yellow

Stitch

length

Position of

stitch width

latch

3 3 3 3 S

3 3 3 3 S

0 2 3 3 S

0 2 3 3 S

4 3 3 R R

4 3 8 – 9 R R

3 3 3 3 3 S

31

Page 34

Seam pattern

Top side

Underside

Stitch formation correction measures

4-thread overedge seam (program 07)

blue green red yellow

3 3 3 3

When all tensions are correctly set, the loops

of both looper threads are directly on the

edge of the fabric.

Top side

Top side

Underside

The left needle thread (blue) is too loose.

Set the blue thread tension to a higher

value.

Top side

Underside

The upper looper thread (red) appears on

the underside of the fabric.

Set the red thread tension to a higher value

and/or the yellow thread tension to a lower

value.

32

Underside

The lower looper thread (yellow) appears on

the top side of the fabric.

Set the yellow thread tension to a higher

value and/or the red thread tension to a

lower value.

Page 35

Seam pattern

Top side Top side

Underside

3-thread overedge seam (progr. 01, 02)

blue green red yellow

wide

3 3 3

narrow

blue green red yellow

3 3 3

Top side

Underside

Underside

The needle thread is too loose.

Set the relevant needle thread tension to a

higher value.

Top side

Underside

The upper looper thread (red) appears on

the underside of the fabric.

Set the red thread tension to a higher value

and/or the yellow thread tension to a lower

value.

The lower looper thread (yellow) appears on

the top side of the fabric.

Set the yellow thread tension to a higher

value and/or the red thread tension to a

lower value.

33

Page 36

Seam pattern

Top side

Underside

3-thread flatlock seam (progr. 03, 04)

blue green red yellow

wide

0 2 3

narrow

blue green red yellow

0 2 3

Top side

Top side

Underside

The needle thread is too tight.

Set the relevant needle thread tension to a

lower value.

Top side

Underside

The upper looper thread (red) appears on

the underside of the fabric.

Set the red thread tension to a higher value.

34

Underside

The lower looper thread (yellow) is too

loose.

Set the yellow thread tension to a higher

value.

Page 37

Seam pattern

Top side

Underside

3-thread rolled hem (progr. 05)

blue green red yellow

4 3 3

Top side

Top side

Underside

The right needle thread (green) is too loose.

Set the green thread tension to a higher

value.

Top side

Underside

The upper looper thread (red) appears on

the underside of the fabric.

Set the red thread tension to a higher value

and/or the yellow thread tension to a lower

value.

Underside

The lower looper thread (yellow) appears on

the top side of the fabric.

Set the yellow thread tension to a higher

value and/or the red thread tension to a lower value.

35

Page 38

Seam pattern

Top side Top side

Underside

Folded 3-thread rolled hem (progr. 06)

blue green red yellow

4 3 8 – 9

Top side

Underside

Underside

The right needle thread (green) is too loose.

Set the green thread tension to a higher

value.

Top side

Underside

The upper looper thread (red) only partly

loops around the fabric edge.

Set the red thread tension to a lower value

and/or the yellow thread tension to a higher

value.

36

The lower looper thread (yellow) appears on

the top side of the fabric.

Set the yellow thread tension to a higher

value and/or the red one to a lower value.

Page 39

Optional accessories Order No.

98-200 277-10/900

98-200 278-10

98-200 278-10

98-200 279-10/100

98-200 280-10/500

98-200 281-10/600

98-200 282-10/700

1 Blindstitch foot

For serging blind hems on mediumheavy and thick fabrics.

2/3 Taping attachment with tape guide

Use to protect knit and other stretchy

fabric from stretching out of shape

when you sew a shoulder.

4 Cording foot type A

For sewing on cords, elastic thread and

fishing line on the top side of the fabric

and for decorative cording.

5 Cording foot type B

For sewing on cords and yarn on the

top or on the underside of the fabric

and for decorative cording.

6 Piping foot

For sewing together two pieces of fabric with a piping tape between them,

in one operation.

7 Beading attachment with beading

guide

For serging on beading and sequins.

98-200 283-10/800

98-200 284-10/900

98-200 285-10

98-200 286-10/100

8 Shirring/Gathering attachment

For shirring/gathering and joining two

pieces of fabric simultaneously.

9 Elastic tape attachment

For sewing on elastic.

10 Edge guide

For guiding the fabric edge and

measuring cut widths and seam widths

simultaneously.

11 Needle threader

For easy threading of the needle.

37

Page 40

Machine maintenance

Cleaning the machine

Switch the main switch to OFF.

Open the looper cover and swivel plate. Use

the cleaning brush provided to remove any

waste thread.

In order to clean the upper blade and the

feed dog, you may also use a vacuum

cleaner.

fastening screw

of the needle

plate

Cleaning the feed dog

Switch the main switch to OFF.

Open the looper cover and the swivel plate.

Remove the needles and the presser foot.

Loosen the fastening screw of the needle

plate and remove the needle plate.

38

Remove any waste thread from the feed dog

towards the front using the cleaning brush.

Fasten the needle plate, attach the presser

foot, insert the needles and close the looper

cover and the swivel plate.

Page 41

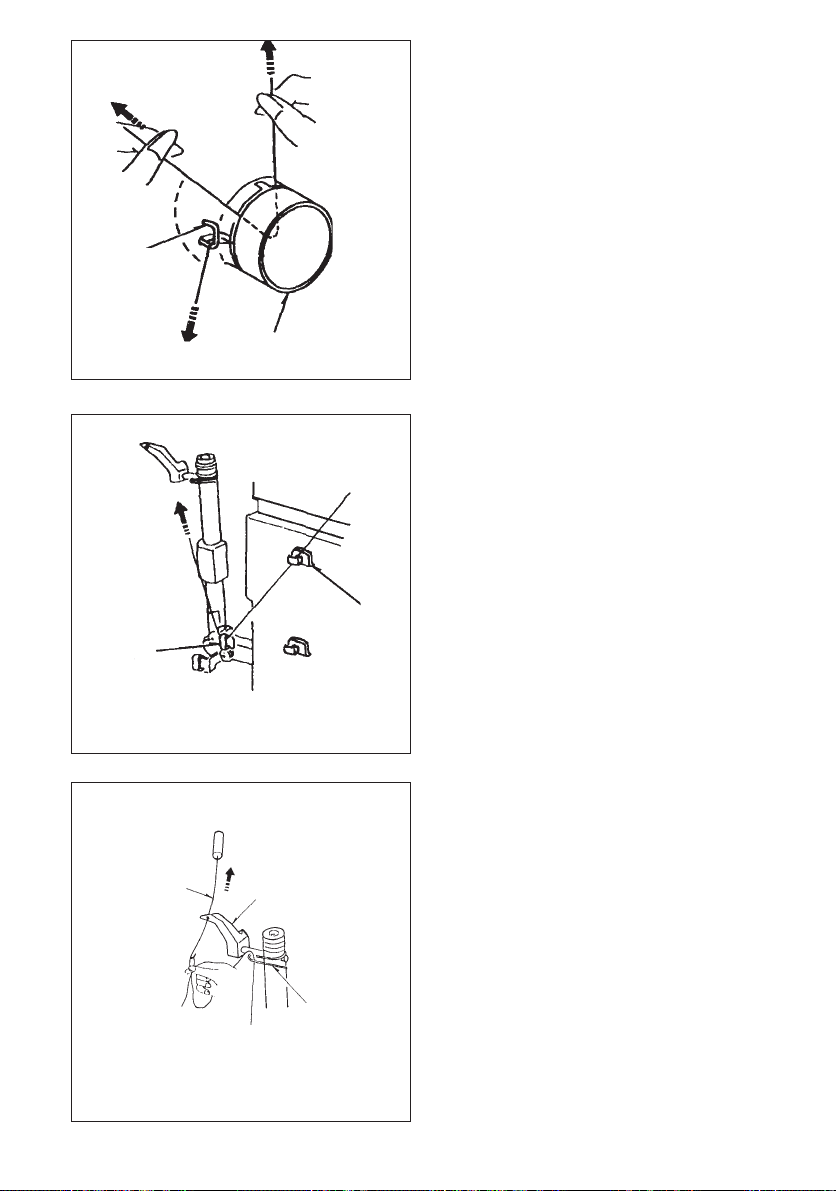

Lubricating the machine

Switch the main switch to OFF.

Open the swivel plate. Apply a few drops

of high-quality machine oil to the points

marked with arrows.

Oil the machine once a week for normal

operation or every ten hours for continuous

operation.

Open the looper cover and oil the marked

points.

Oil the marked point on the top of the

machine.

39

Page 42

blocking pin

0,5 - 1 mm (1/32”)

lower blade

upper blade

lower

blade

hexagonhead screw

upper blade

Changing the upper blade

Switch the main switch to OFF.

Open the looper cover and the swivel plate.

Move the upper blade to its lower position

(see Page 24).

Undo the hexagon-head screw of the upper

blade and remove the upper blade.

Insert the new upper blade into the blade

holder in such a way that the blocking pin

engages in the groove. Tighten the hexagonhead screw slightly.

Move the upper blade to its upper position.

Turn the handwheel towards you until the

upper blade has reached its lowest position.

Undo the hexagon-head screw and adjust

the position of the upper blade so that the

edges of the upper blade and of the lower

blade overlap by about 0.5 to 1 mm (1/32”)

(see illustration). Tighten the hexagon-head

screw.

– Close the looper cover and the swivel

plate.

40

hexagon-

head screw

blocking pin

Page 43

fastening

screw

sewing light

cover

Changing the light bulb

Switch the main switch to OFF.

Loosen the fastening screw to the sewing

light cover until the cover can be removed.

Removing the light bulb

Bayonet holder: press the lamp in and turn

to the left.

to remove

to

insert

light

bulb

Inserting the light bulb

Bayonet holder: press the lamp in and turn

to the right.

Replace the sewing lamp cover and tighten

the fastening screw.

Safety notes

Only use bulbs with a maximum output of

15 Watt.

The bulb becomes very hot. Never touch the

bulb with bare hands.

Transporting the machine

Position your fingers in the cutout on the

rear side of the machine, as shown in the illustration.

41

Page 44

Sewing problems and their solutions

This machine has been developed with ease of operation in mind. No difficult or tricky settings need to be made. Sewing problems of the kind described below may occur as a result

of minor adjustment and operating errors. They can be easily adjusted by following the

instructions.

Problem Cause Solution

Needle breakage The needle was bent or the Insert new needle

point damaged. (see Page 22).

The needle was not fully inserted. Insert needle fully

(see Page 22).

The fabric was pulled too firmly. Do not pull on the fabric

when sewing.

Thread breaks Incorrectly threaded. Thread properly

(see Page 10 - 18).

Thread has caught. Check if the thread is caught

on the spool stand etc.

Thread tension is too tight. Correct the tension

(see Page 32 - 36).

Needle not fully inserted. Insert needle correctly

(see Page 22).

Incorrect needle used. Use needle system HAx1SP

(130/705 PS).

Skipping stitches Needle bent or point damaged. Insert new needle

(see Page 22).

Needle not fully inserted. Insert needle correctly

(see Page 22).

Incorrect needle used. Use needle system

HAx1SP (130/705 H-PS).

Incorrectly threaded. Thread correctly

(see Page 10 - 18).

Stitch Incorrect setting of thread tensions Re-set thread tensions

formation faulty (see Page 32 - 36).

42

Page 45

Problem Cause Solution

Fabric not neatly Waste thread between upper Upper blade is blunt.

trimmed and lower blade.

Clean blades. Replace upper blade

(see Page 40).

Puckered seams Thread tension too tight. Reduce thread tension.

Incorrect setting of differential feed. Re-adjust differential feed

(see Page 20)

Thread has caught due to incorrect Thread correctly

threading. (see Pages 10 - 18).

Fabric not fed Stitches too short. Increase stitch length

through evenly (see Page 20).

Sewing foot pressure too low for Increase sewing foot pressure

heavy fabrics. (see Page 21).

Sewing foot pressure too high for Reduce sewing foot pressure

lightweight fabrics. (see Page 21).

Waste thread in the feed dog. Clean the feed dog.

Machine will The lead cord/plug is not seated (see Page 7).

not operate properly in the socket.

The main switch is not switched on. (see Page 7).

43

Page 46

Specifications

Maximum sewing speed 1200 stitches/min.

Seam width 3.0 mm - 6.7 mm

Stitch length 1.0 mm - 5.0 mm

Presser foot exchangeable

Lubrication manual

Presser foot height 4.5 mm

Overedge stroke 2.0 mm

Needle system HAx1SP (130/705 H-PS)

Needle size 80/12, 90/14

Number of threads 3, 4

Dimensions (width x height x depth) 310 x 280 x 270 mm

Weight 7.1 kg

Packing contents

1 machine

1 foot control

1 instruction manual/guarantee card

1 machine cover

1 accessory box

1 waste container

44

Page 47

Notes

45

Page 48

Notes

46

Page 49

Notes

47

Page 50

Page 51

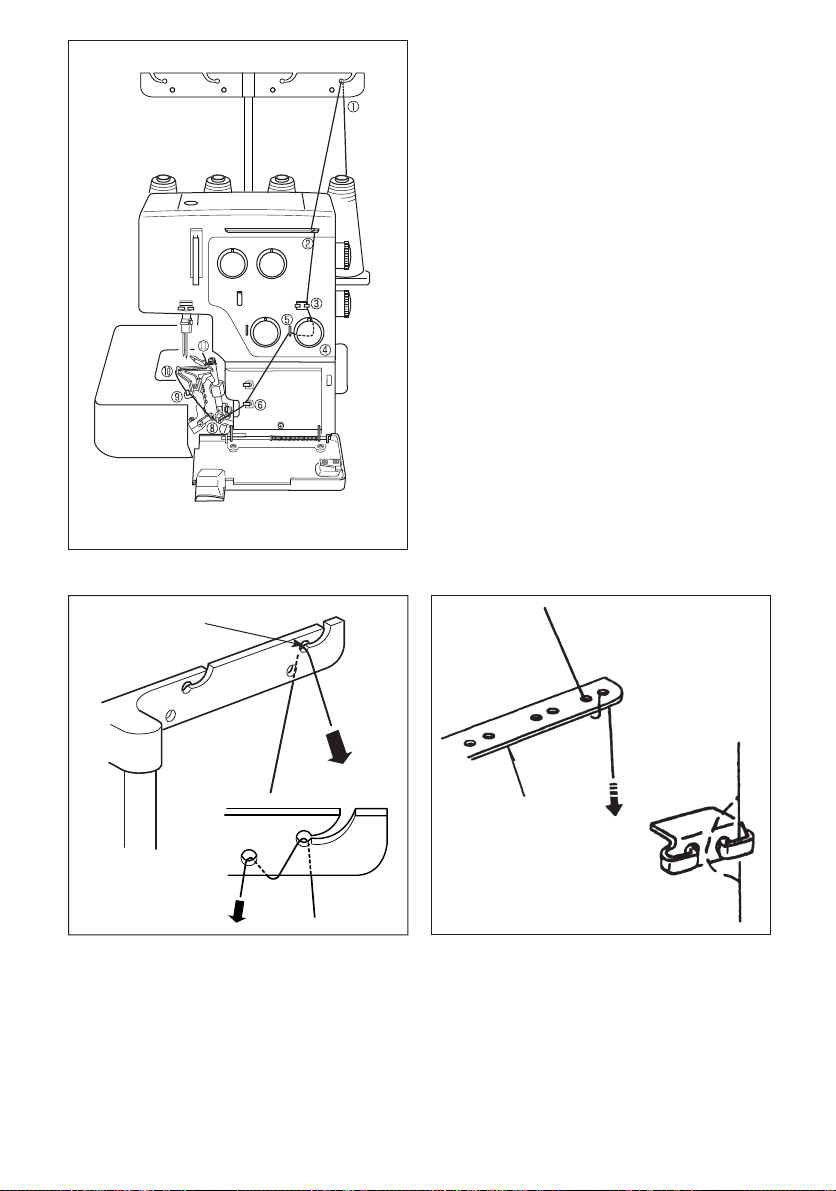

Parts of the hobbylock 4752

Movable upper blade

Fixed lower

blade

Thread chain cutter

Upper overedge

looper (red)

Lower overedge

looper (yellow)

Standard presser foot

Bed slide for stitch

width latch

Presser foot lifter

Needle plate

Ridged knob for lowering

the upper blade

Setting knob for

seam width

Page 52

VSM Group AB • SE-561 84 Huskvarna • SWEDEN

www.pfaff.com

412 86 03-26D • English • Inhouse • © 2004-2008 VSM Group AB • Printed in Sweden on environmental-friendly paper

Loading...

Loading...