Page 1

MODEL 270

OPERATOR’S MANUAL

Page 2

California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Other chemicals in this vehicle are also known to the State of

California to cause cancer, birth defects, or other reproductive

harm.

Battery posts, terminals, and related accessories contain lead

and lead compounds, chemicals kno wn to the State of Calif ornia

to cause cancer and reproductive harm. Wash hands after

handling.

Page 3

Foreword

– i –

FOREWORD

How to use this handbook

This handbook contains information for

you, the driver , to enable y ou to operate

the vehicle a s effici ent ly and sa fely as

possible and genera lly to ma ke your

driving ea sier and more sat isfying.

Besides subjects such as operating

instr ucti ons, at tent ion also focuses on

maintenance and minor repairs which

you may be able to carry out yourself.

NOTE: This handbook is

based on the chassis and

components as it origin ally left the factory . Depending upon the requi red body

and equ ipmen t, the bodybui lder may

have made fundamental changes to

various parts or systems, such as the

instru ment pan el, the ligh ting , or the

electrical wiring.

The vehicles covered by this handbook

consist of various types and models.

Individual vehicles are constructed in

accordance with all Federal Motor Vehicle Safety Standards and in accordance

with the expected operating conditions.

Certain descriptions or illustrations in

this handbook may therefore not correspond entirely to the situation on your

own vehicle. However, this has no influence on its operation or maintenance.

IMPORTANT: Ensure that this

handbook is in the vehicle at

all times and read it carefully

before making your first journey, especially the “Safety precautions”,

“Technical it ems of s pecia l impor -

tance”, “Instruments and controls”

and “Drivi ng” sectio ns of th is han dbook.

In addition to this handbook (available

from your dealer) the following publications have also been produced:

Bodybuilders’ guidelines

Maintenance manual

For information on how to order the

above publications, please contact your

dealer.

Safety Signals

A number of alerting messages are in

this manual. Please read and follow

them. They are there for your protection

and in forma tio n. T he se me ssages ca n

PB1340A .book Page i F r iday, September 1, 200 0 7:40 AM

Page 4

Foreword

– ii –

help you avoid injury to yourself, your

passengers, and help prevent costly

damage to the vehicle.

Key symbols and “signal words” are

used to in dicate wh at kin d o f m essage

is going to follow. Pay special at tent ion

to instructions preceded by symbols

and signal words “WARNING”, “CAUTION”, or “NOTE”. Please do not ignore

any of these alerts.

©

PACCAR Inc. 9/00

All rights reser ved. No p ar t of this pu blicati on may be

reproduce d, s t ored in a r e tri eval s yste m, or tran sm itted, in any form, whether electronic, or mechanical, or

by photocopying, recording, or other means without

prior permission of PACCAR Inc.

PB1340A .book Page ii Friday, Sept e mber 1, 2000 7:40 AM

Page 5

Foreword

– iii –

W ARNING

When you see this word, the

message that follows is especially vital. It signals a poten-

tially hazardous situation

which , if not avoide d, could

result in death or serious injury.

This message will tell you what

the hazard is, what can happen

if you don’t heed the warning,

and how to avoid it.

Example:

WARNING! Never c arr y a ddi tional fuel contain ers in the

vehicle. Such containers, fu ll

or empty, may leak, explode

or cause a fire in the event of

a collision.

CAUTION

Signals a potentially hazardous situation which, if not

avoided, could result in minor

or moderate injury or damage

to the vehicle.

Example:

CAUTION: Continuing to

operate your vehicle with

insufficient oil pressure will

cause serious engine damage.

NOTE

Provides general information: for example, the note

could warn you on how to

avoid damaging your vehicle or how to

drive the vehicle more efficiently.

Example:

NOTE: Pu mp ing t he ac cel er-

ator wi ll n ot a ssi st in st ar t in g

the engine.

Please take the time to read these messages when you see them, and

remember:

WARNING!

Something that could injure you seriously.

CAUTION:

Something that could cause injury to you or your vehicle.

NOTE:

Useful information.

PB1340A.book Page iii Friday, September 1, 2000 7:40 AM

Page 6

Foreword

– iv –

PB1340A .book Page iv Friday, Sep tember 1, 2000 7:40 AM

Page 7

– v –

Foreword

How to use this handbook..... .. .. ........ i

Safety Signals......................... .. ........ i

Contents

General

Safety Precautions..............................1

General ....... ... ......... ... ......... ... .. ........ 1

Engine.. .. ... ......... ... .......... .. .......... .. ... 1

Cooling System................................ 1

Components..................................... 2

Electr ic a l ..... ... ......... ... ......... ... .. ........ 2

Oils and Lubricants.......................... 3

Maintenance Acti vities................. .. .. 3

Chassis Frame................................. 3

Vehicle Load .... .. .......... ... ......... ... ..... 4

First Aid Kit....................................... 4

Winter Driving Conditions ................ 4

Items of Special Importance...............5

Break-i n....... ... ......... ... ......... ... .......... 5

Cooling System................................ 6

Air Leaka g e........... .. .......... .. .......... ... 6

System Voltage................................ 6

Batte r ie s ........ .. .. .......... ... ......... ... ..... 6

Batte r y C ha r g in g .... ... .. .......... .. ........ 7

Protecting the Environment............. 10

Cleaning the Vehicle......................... 11

Cleaning the Cab........................... 12

Waxing the Cab............................. 12

Cleaning the Cab Interior.......... .. .. 12

Getting to Know Your Vehicle

Cab.....................................................13

Entry and Exit................................ 13

Door s... .......... .. .......... .. .......... .. ... ... 1 4

Tilting the Cab............................... 14

Door Mirrors................................... 16

Windshield Wiper Blades............... 17

Seats ........ ......... ... .......... .. .......... .. . 17

Seat Be lts ........ .. .......... ... .. .......... .. . 18

Storage Tray.. .. .......... .. .......... .. ...... 21

Glove Box ...................................... 21

Sun Visors..................................... 22

Roof Vent (option).......................... 23

Courtesy Lights ............................. 23

Interior Light Unit........................... 24

Ashtray ..... .. .......... .. .......... .. .......... . 24

Cigarette Lighter ........................... 24

Instru ments and C o n tr ol s....... ......... 2 5

Instrument Panel........... .. .............. 26

Switches, Gauges , an d W arning Li ghts

on the Instrument Panel ................ 28

Chassis.............................................. 46

Towing Pin..................................... 46

Daily and Weekly

Maintenance

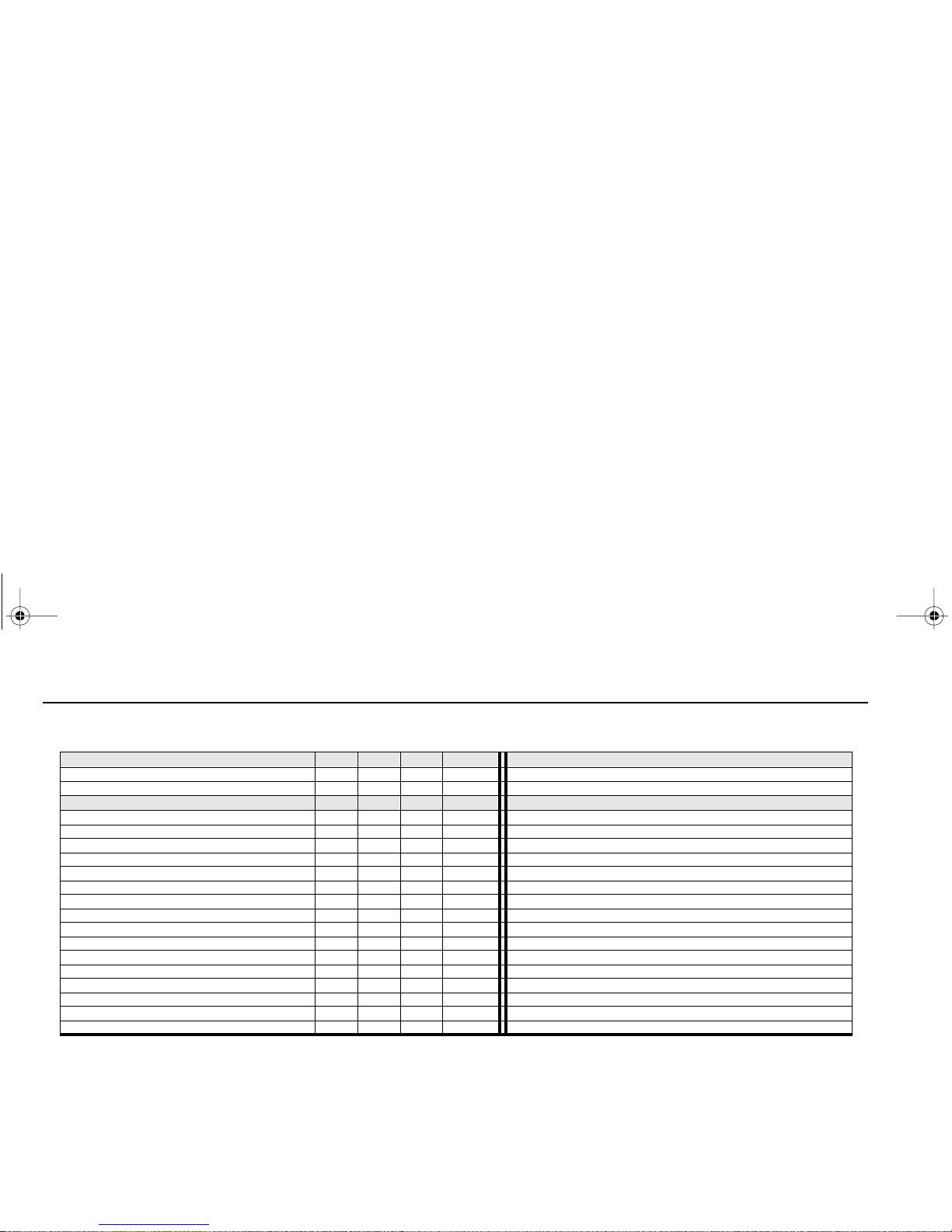

Driver’s Check List ........................ 47

Daily Maintenance............................ 50

Front Access Panel ....................... 50

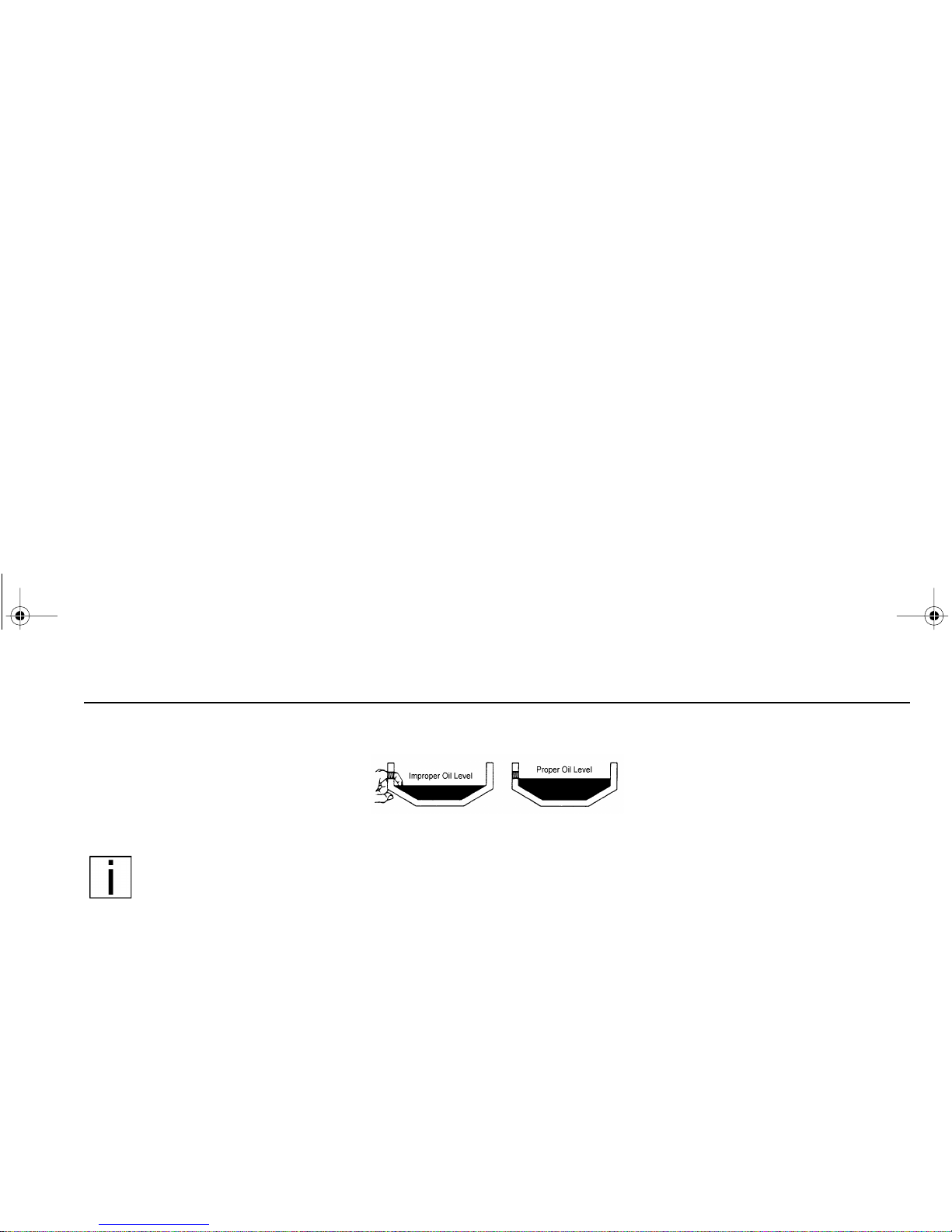

Engine Oil Level ............................ 50

Coolant Level ................................ 51

Wheels And Tires............ .. ............ 52

Lighting And Instruments .............. 52

Driver’s Seat And Mirrors .............. 52

Weekly maintenance........................ 53

Power Steering Fluid Level ........... 53

Air Filter Restrict ion Indicator...... .. 53

Brake System Air Dryer (opt ional

equipment)...................... .............. 54

Clutch Fluid Level.......................... 55

CONTENTS

PB1340A .book Page v Friday, Sept ember 1, 2000 7:40 AM

Page 8

Contents

– vi –

Windshield Washer Fluid Le vel ..... 56

Tires .............................................. 56

Driving

General .............................................. 57

Ignition Switch.................................. 57

Startin g Pro c e d ur e .............. ... ......... . 5 8

Operating the Transmission............58

Introduction.................................... 58

Operating Manual Transmissions.. 59

Putting the Vehicle in Motion......... 59

More Transmission Tips ................ 61

Operating Automatic Transmissions 62

Operating Automated Manual

Transmissions................................ 63

Cruise Control ............................... 64

Steering ............................................. 65

Brakes................................................65

Service brakes............................... 66

Parking brake / emergency br ake.. 66

Engine Retarder (option)............... 67

Stopping............................................69

Parking .......................................... 69

Turning off the engine.................... 69

Diesel Fuel.........................................70

Cold Weather Recommendations . 70

Periodical maintenance

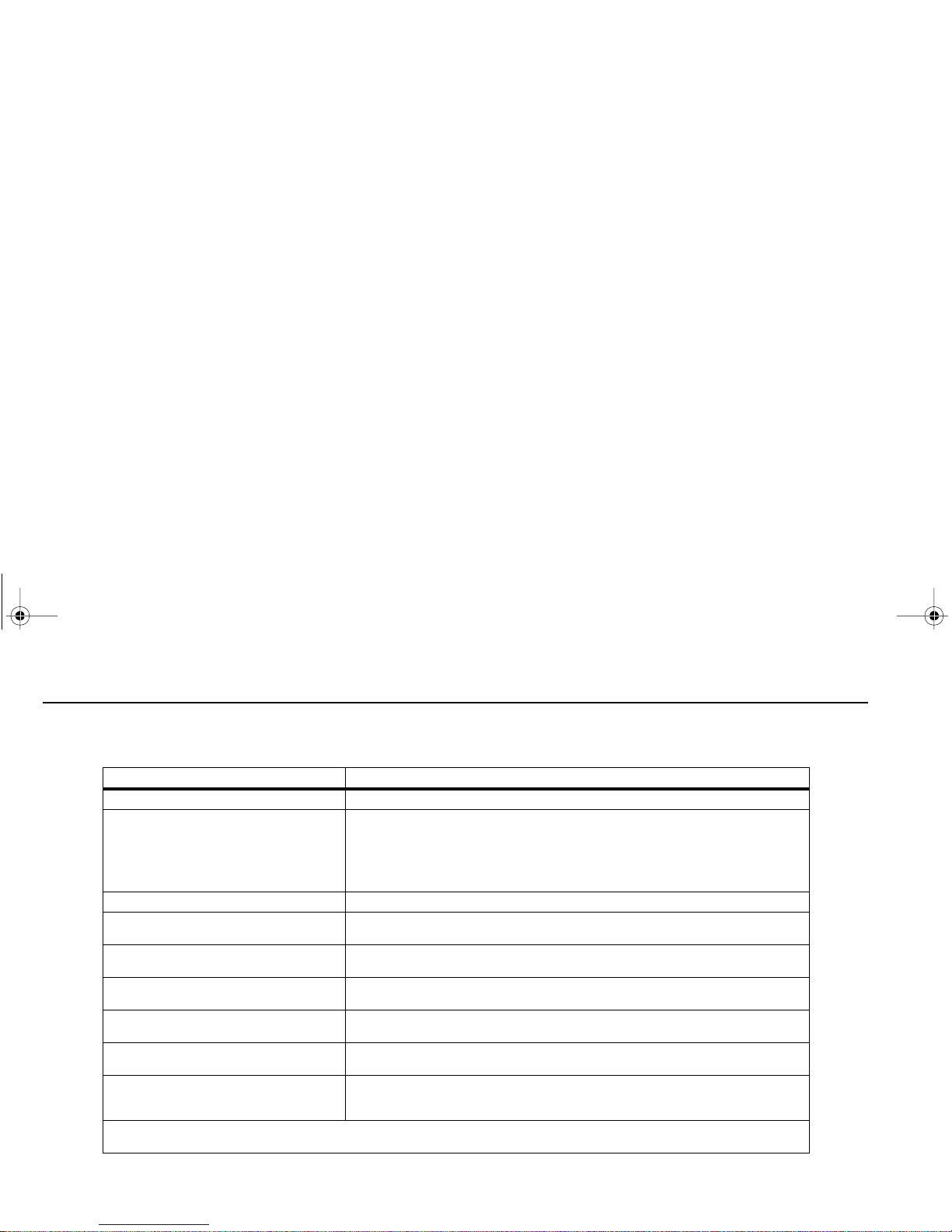

General......... ........................... ...........71

Maintenance and

Lubrication Intervals....................... 72

Lubrication Specifications .............. 83

Oil Rese rvoirs .......... .. .. .......... ... ..... 8 5

Lubrication Chart........................... 85

Maintenance in Speci al and

Exceptional Operating Conditions.. 88

Cab Maintenance........................... 88

Preventive Maintenance Before the

Winter Season ............................... 88

Emergency repairs

Vehicle Tool Kit............................... 93

Replacing The Drive Belt........ ....... 93

Replacing The Compressor Belt.... 93

Replacing The Fuel Filt er............... 94

Adjus ti n g T h e Bra kes... ... .......... .. ... 94

Spring Brakes — Manual Rel ease. 94

Jacking The Vehicle....................... 96

Wheels........ ... .......... .. .......... .. ... ..... 9 7

Towing Pin...................................... 99

Towing.............. ... ......... ... .. .......... .. . 99

Replacing Bulbs........................... 100

Fuses... ... ......... ... ......... ... .. .......... . 103

Radio (optional)...... .. ................... 103

Electrical Connections................. 104

Speakers..................................... 104

Noise and Emission Control..........105

Noise Emission Warranty ............ 105

Inspection and Mai ntenance

Instr uc tions......... .. ... ......... ... ........ 106

Consumer Information

and Vehi cle Identification

Reporting Safety Defects...............109

Vehicle Id e n tificatio n. ......... ... ......... 109

Complete Vehicle Certification

Label............................................ 111

Incomp le te Vehicle Certifica tio n

Label............................................ 111

Tire and Rim Information Label... 111

Noise Emission Label .................. 112

Paint Data Label .......................... 112

Federal Safety Standard

Cer tification L abe l ....... ... .......... .. . 112

Component Identification............. 113

General Alphabetical Index

PB1340A .book Page vi Friday, Sep tember 1, 2000 7:40 AM

Page 9

Safety Precautions

– 1 –

GENERAL

Safety Precautions

The following list of safety

precau tions agai nst possi ble safety hazards is not

exhaustive and, therefore all

safety related workshop

practices and precautions

must be exercised.

General

Ensure all Warnings and Cautions

listed in this publication are strictly

adhered to. Always read carefully the

instructions printed on labels or

stamped on components and obey

them completely. Such instructions are

included for your health and safety; do

not disregard them.

Wear clean protective clothing or apparatus when necessary.

Engine

Do not r un engine in a confined space

or unventilated area or with a leaky

exhaust sys te m. If t he e ng ine must be

run in a con fined space ensu re that an

exhaust extractor is used.

To prevent a possible fire risk, ensure

that the eng ine and its surround ing

areas are clean and free from leakages/

spillages of any inflammable liquids

(e.g. fuel oil, engine oil, etc.).

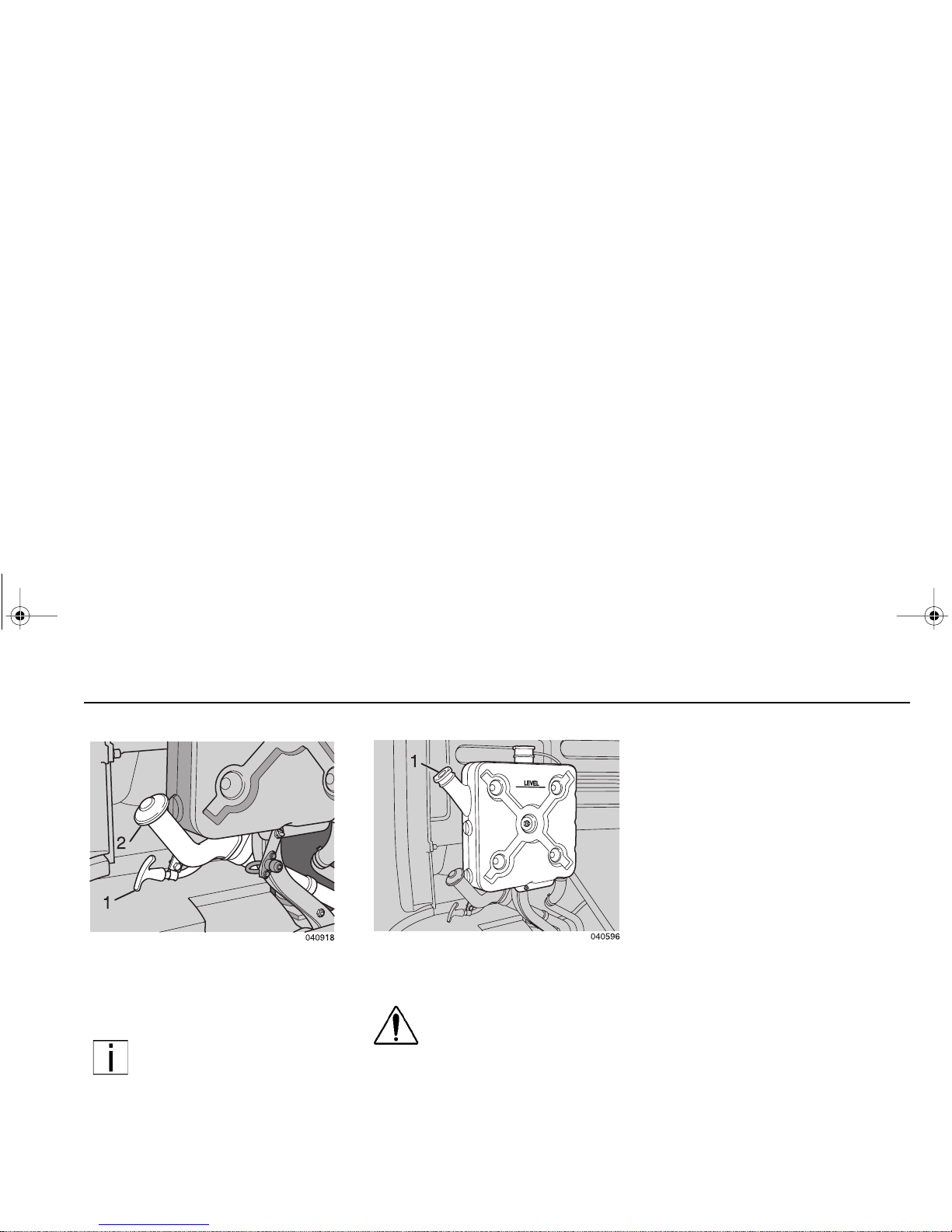

Cooling System

Do not a ttem pt to r emove th e surg e

tank fill er c ap w hil e th e en gi ne i s ru nning or still hot.

Do not att empt to f ill a hot e ngin e w ith

cold coolant.

Do not fill the cooling system through

the pressure cap aperture.

PB1340A .book Page 1 Friday, Sept ember 1, 2000 7:40 AM

Page 10

Safety Preca u tions General

– 2 –

Components

Ensure that all personnel are clear of

any rotating parts or moving components.

Synthetic rubber seals, O-rings and

gaskets which have been dama ged by

fire or come into contact with direct

heat, may produce hazardous fumes

and highly corrosive chemicals.

Allow burnt or decomposed seals etc.

to completely cool. Use impervious protective clothing and gloves. Work in a

well ventilated area when handling

these components. In the even t of

skin contact seek medical attention

immediately.

Electrical

Batteries contain electr olyte (s ulfuric

acid) wh ich is a hig hly co rrosive an d

toxic subst ance. Accide ntal sk in/eye

contact with battery electr olyte can

cause serious personal injury.

Always wear protective clothing and

suitable eye protection when handling

batteries and wash hands after use.

WARNING! Battery posts,

terminals and relat ed acce ssories contain lea d an d lea d

compounds, chemicals

known t o the St ate of Cal ifornia to cause cance r and

reproductive harm. Wash

hands after handling.

Always disconnect the ba tter ies before

commenc ing work on the vehicle. To

minimize the risk of accidental short circuits when disconnecting the batter ies,

ensure that the negative (–) lead is disconnected first and the positive (+)

lead last ; reverse this pro cedu re w hen

re-connecting the batteries.

To prevent acci dent al short cir cuit s do

not place tools/metal objects on or near

the battery terminals.

Batteries produce a highly flammable

and explosive gas while being charged.

It is essen tial th at th e area ar ound the

battery is we ll ventila ted and prote cted

against any flame, spark or intense

heat sourc e. The u se o f

“boost”

charg-

ers is not recommended.

The ignition switch, steering lock, and

its electrical circuits are designed to

prevent the auxiliary circuits and starter

motor from being energized while the

steering lock is engage d. Serio us consequences could result from alteration

or substitution of the ignition switch and

PB1340A .book Page 2 Friday, Sept ember 1, 2000 7:40 AM

Page 11

Safety Precautions General

– 3 –

steering lock or its wiring. Under no circumstances must the ignition switch be

separated from the steering lock.

Oils and Lubricants

Many liquid s and othe r substa nces

used in commercia l vehicles are high ly

toxic. These must not be consumed or

inhaled and, as far as possible , must be

kept from skin contact. These substances, amongst others, include battery acid , anti-freeze, hydraulic flu id,

lubricants, fuel, windshield w asher flui d,

refrigerant, and various adhesives.

Avoid unnecessary contact with used

engine oil. Prolonged and repeated

contact with used engine oil may cause

serious skin disorders.

Extre me car e must be taken w hen

draining engine oil; hot engine oil can

cause severe personal injury.

Maintenance Activities

Do not use the jack as the sole means

of support; position suitable supports

beneath the chassis frame.

Do not attempt to work on the vehicle

with the cab partially tilted.

Do not attempt to stand on the cab roof.

Chassis Frame

Do not weld or subject the chassis

frame to a severe localized heat source.

Failure to obs erve th is precau tion m ay

result in irreparable damage to the

mater ial structur e of the chassis frame

with consequent loss in chassis frame

strength.

Welding or drilling on the chassis frame

must not be undertaken without the

prior written consent of PACCAR Inc.

Unauthorized, indiscriminate welding or

drilling may adve rsely affect the sa fe

load-carr ying charact eristics of the

chassis frame.

Welding

• Observe these recommended procedures to protect electronic systems during welding operations.

All Electronic Engines

Before welding on vehicle s equippe d

with electronic engines, the following

precautions should be observed:

NOTE: Weldin g to fram e rail

may void frame rail warranty.

• Turn engine OFF.

• Disconnect all electronic connections to the vehicle batteries.

• Remove battery power cable and

insulate it from the vehicle.

PB1340A .book Page 3 Friday, Sept ember 1, 2000 7:40 AM

Page 12

Safety Preca u tions General

– 4 –

• Disconnect all Electronic Control

Module (ECM ) connectors (on

electronic engines).

• Do not use the ECM or engine

ground stud for the ground of the

welding probe.

• Ensure that the ground connection

for the welder is as close to the

weld point as possible. This

ensures maximu m weld current

and minimum risk to damage of

electrical comp onents on th e vehicle.

All Anti–Lock Braking Systems

(ABS)

Before welding anywhere on the vehicle, detach the ABS Electronic Control

Unit (E CU) conn ector and all othe r

electronic control units.

Veh i c le Lo ad

The load must always be properly

secured so tha t it cannot move while

the vehicle is in motion, even during an

emergency stop. Side walls, pa rtitions,

headboards, etc., are not designed to

withstand high forces. Loads must not

project mo re than is per mitte d by local

or nationa l regu lation s. The sta bility of

the vehicle may be impaired by the load

and an increased turning circle may be

required.

Fire Extinguisher

Ensure t hat you always have a fire

extinguisher with you. It shou ld be w ell

secured within hand ’s reach of th e

driver and easi ly accessible for rescue

workers and others providing assistance. Have the fire extinguisher

checked for operational readiness as

recommended by the manufacturer.

When it has been use d, have it refilled

at the earliest opportunity.

First Aid Kit

Make sure that you always have a first

aid kit with you. Replenish the contents

as soon as possible after use.

Winter Driving Conditions

When winter driving conditions are

expected, ensure that your vehicle is

prepared in accordance w ith the recommendations in “

Preventive Maintenance

Before the Winter Season” on page 88 .

When severe winter driving conditions

are anticipated, ensure that your vehicle is fitte d wit h win ter ti res or th at you

have snow equipment, as allowed by

state law.

PB1340A .book Page 4 Friday, Sept ember 1, 2000 7:40 AM

Page 13

Items of Special Importance General

– 5 –

Items of Special

Importance

To prevent damage to the vehicle,

the following instru ction s must be

strictly observed.

Break-in

The following “break-in” recommendations should be applied dur ing the first

1,000 miles (1,600 km) of a new vehicle:

•Do not operate at full engine power

in any gear.

•Do not allow the engine to labor in

any gear.

•Do not allow the engine to run at

idling speeds for ex cessi ve periods.

During the “break-in” p eriod do not

subject the n ew vehicle to excess ive

loads; this also applies when an overhauled engine, transmission, or differential has been installed.

After a cold start continue to drive in a

low gear and at a mode rate engine

speed until the engine coolant temperature has reached 140°F (60°C).

Check the instrument panel regularly

when driving and take immediate steps

to rect ify po ssi ble pr o blem s at t he f ir st

sign of trouble.

Do not let the engine idle for longer

than necessary. This is har mful for the

engine and also causes unnecessary

pollution of the environment.

CAUTION: In the event of the

engine st alling while th e

vehicle is in motio n, power

assistance to the steering will be lost

and, consequently, greater effort will

be required to steer the vehicle.

The engine turbocharger is a preci-

sion instrument. For this reason the following operating procedures should be

observed:

• When starting the engine, do not

allow it to exceed its idling speed

for 10 seconds; this proce dure will

ensure that adequate oil pressure

is available at the turbocharge r

bearings thus preventing initial oil

starvation.

PB1340A .book Page 5 Friday, Sept ember 1, 2000 7:40 AM

Page 14

Items of Special Import ance General

– 6 –

• Before stopping the engine, allow it

to idle for one t o tw o m inutes (pa rticularly if the engine has been subjected to a high speed journey or

high engine loadings). This procedure will ensure an adequate oil

supply to the turbocharger bearings while the rotor assembly is

cooling, thus improving the life

span of the turbocharger bearings.

• Any abnormal noises or vibrations

from the turbocharger must be

reported immediately.

Cooling System

CAUTION: Damage to the

engine and cooling system,

such as c orrosion and cav itation erosion, will occur unless antifreeze ZEREX PENRAY 2792 is used

and ma intained with suppl ement al

coolant additive Pencool 3000 with

Stabil-A id . As n eed ed , f ill or to p off

the cooling system only with a

ready-mixe d clean water/ approved

antifreeze solution using these products. The use of other antifreeze

products will void your engine , radiator, and cooling system warranties.

The engine cooling system is thermostatically controlled, so the use of a

radiator cover in cold weather is

unnecessary.

Air Leakage

If the pressure in the air rese rvoirs

drops rapid ly with th e engin e switched

off, this indicates a leak in the compressed air system. Since this affects

the safety of the brake system, the leak

must be traced and repaired a s quickly

as possible.

System Voltage

The vehicle is equipped with a 12 volt

negative ground electrical system.

When replacing or fitting electrical or

electronic compon ents, always verify

that th ey are suita ble for t his s ystem

voltage, polarity, and capacity.

Batteries

Do not disconnect the battery terminals

while the engine is running; failure to

observe this precaution may result in

major damage to the alternator.

Serious battery damage and vehicle

starti ng dif fi cult ies will o ccur if the b at teries are discharged (“drained”) below

12 volt s. To prevent th e b a tte r i es fr om

being inadvertently discharged, it is

essential the followin g preca ut ion s a re

observed:

PB1340A .book Page 6 Friday, Sept ember 1, 2000 7:40 AM

Page 15

Items of Special Importance General

– 7 –

• Ensure that all lights are switched

off when not required.

•

Vehicles fitted with a liftgate:

Avoid

excessive and severe battery drain

when operating the liftgate.

Battery Charging

WARNING! Battery posts,

terminals and r elated accessories contain lead and lead

compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash

hands after handling.

WARNING! Do not try to

charge a frozen battery.

(Even a ba tte ry w i th ice par ticles on the ele ctrolyte surface is dangerous.) Allow it

to thaw out first. And always

allow the batter y to thaw

gradually—do not apply

direct heat . Gas trapped in

the ice m ay c au se an expl osion.

First connect the positive (+) terminal of

the battery charger to the positive (+)

term inal po st of the batte ry and th en

the negative (–) terminal to the negative

(–) terminal post. After charging, switch

off the battery charger and then disconnect th e negat ive (–) ter min al followed

by the positive (+) terminal. For norm al

charging, the battery cables may

remain in place. For fast-charging, both

battery cables must be disconnected.

Jump Starting Vehicles

It is not recommended that you attempt

to jump start your vehicle. If you have a

battery problem, it is best to contact a

dealer or a reputable towing service.

However, if your battery is discharged

(dead), you may be able to start it by

using energy from a good battery in

another vehicle. This is termed “jump

start ing.” Be sur e to follow the preca utions and instructions below.

WARNING! Batteries can

injure you severely. They

contain acid, produce poisonous and explosive

gases, and supply levels of

electric current high enoug h

to cause bur ns. A spark or

flame near a battery on

charge may cause it to

explode with great force.

PB1340A .book Page 7 Friday, Sept ember 1, 2000 7:40 AM

Page 16

Items of Special Import ance General

– 8 –

WARNING! Do not allow b attery fluid to contact eyes,

skin, fabrics, or p ainted sur faces. A lw ays wea r eye protection. Battery acid that

may spill during cha rging

should b e wash ed o ff with a

solution of warm water and

baking soda to neutralize

the acid. If you accidentally

get acid in your eyes or on

your skin, immediat ely ri nse

with cold water for several

minutes and call a doctor.

• Be careful that metal tools (or

any meta l in contact with the

positive terminal) do not contact

the positive battery terminal and

any other metal on th e vehicle at

the same time . Remove metal

jewelry and avoid leaning over

the battery.

• If metal jewelry or other metal

comes in contact with electrical

circuits, a short circuit may

occur causing you to be injure d,

as well a s ele ctr ica l syst em f ailure and damage to the vehicle.

• If the level of electrolyte is low, add

distilled water and repla ce th e ba ttery c ap s b efor e p roc ee di ng . If n o

water is avail able, rem ove the ba ttery caps and cover the filler openings with a cloth before proceeding.

After jump starting the vehicle, dispose of the cloth.

To Jump Start Your Vehicle

WARNING! The voltage of

the booster battery must

have a 12–volt rating. And

the capacity of the booster

battery should not be lower

than that of the discharged

battery. Use of bat teries of

different voltage or substan tially different capacity rating may cause an explos ion

and personal injury.

CAUTION: Applying a higher

voltage booster battery will

caus e expensi ve da mage to

sensitive electronic components, such as relays, and

the radio.

• Improper hook-up of jumper

cables o r not follow ing these

procedures can damage the

alternator or cause serious damage to both vehicles.

WARNING! To avoid serious

personal injury and damage

to the vehicle, heed all warnings and instructions of the

jumper cable manufacturer.

• The jum per cables must be long

enough so that the veh icles do

not touch.

If either ba tte r y has vent caps, r em ove

them and check th e fluid level. If it is

OK, replace the caps before proceeding. If no water is available, remove the

PB1340A .book Page 8 Friday, Sept ember 1, 2000 7:40 AM

Page 17

Items of Special Importance General

– 9 –

caps and cover the filler openi ngs with

a cloth before proceeding. After jump

starti ng the vehicle, di spose of the

cloth.

WARNING! If you do not

cover the filler openings on

the battery, electrolyte could

boil out of the openings and

hurt someone or damage the

vehicle. Replace caps

securely if the battery has

the full level of electrolyte. If

the electrolyte is low and no

water is available, cover with

a cloth.

Preparing the vehicles:

1. Position the two vehicles together,

but do not let them touch.

2. Turn OFF all lights, heater, radio,

and any other accessories.

3. Set the parking brakes

.

4. Ensure that the transmission is in

neutral position or, if auto shift, that

it is in park position.

5. Turn engine OF F (booster vehicle).

6. Disconnect ground cable on

booster battery.

Connect the batteries:

1. Attach one end of a jumper c abl e to

the po sitive terminal of the discharged (dead) battery. This will

have a large red “+” or “P” on the

battery case, post, or clamp.

• Attach the other end of the

same cable to the positive (+)

term inal of the go od (boo ster )

battery.

• Attach the remaining jumper

cable FIRST to the negative

terminal (black “–” or “N”) of

the good battery.

• Attach the other end of the

negative cable to a bar e me tal

part bolted t o the engine block

(of the vehicle with the dead

battery) or, if possible, clamp

directly to the engine block.

IMPORTANT: Alw a ys c onnect positive (+) to positive (+) and negative

(–) to negative (–).

2. Start the engine:

• Start the vehicle that has the

good batter y firs t. Let it run for

a few minutes.

• Then start the vehicle that has

the discharged (dead) battery.

If the engine fail s to sta rt, do not

continue to crank the starter.

Contact the nearest Authorized

Service Center.

PB1340A .book Page 9 Friday, Sept ember 1, 2000 7:40 AM

Page 18

Protecting the Environment General

– 10 –

Remove jumper cables:

WARNING! When disconnecting jumper cables, make

sure they do not get caught

in any moving parts in the

engine co mpartmen t. You

could be seriously injured.

• Reverse the above procedure

exactly when removin g the ju mpe r

cables. With engine ru nning, disconnect jumper cables from both

vehicles in th e exact reverse ord er

(Steps 4 – 1), making sure to first

remove the negative cable from the

vehicle with the discharged battery.

Protecting the

Environment

The growing scarcity of the world's natural resources and the escalating problem of pollution pose serious t hreats to

the environment. In order to conserve

resources and to minimize pollution it is

recommended that the following practices are adopted:

• Do not dispose of used oils,

hydraulic fluids, or engine coolant

in drains, sewers, water courses, or

land-fill sites. These fluids are

harmful to the environment and

must be disposed of properly.

• Used oils, coolant, and hydraulic

fluids should be returned to the

appropria te au th orit y for recycli ng.

Ensure that all waste fluid products

are segregated and are not intermixed; this practice will in crease

the efficiency and viability of the recycling process.

• Ensure that the vehicle is regularly

serviced to maintain peak efficiency. A correctly maintained vehicle will contribute t o maximum fuel

economy and a reduction in

exhaust gas pollutants.

PB1340A .book Page 10 Friday, Sept ember 1, 2000 7:40 AM

Page 19

Cleaning the Vehicle General

– 11 –

Cleaning the Vehicle

Before cleaning the vehicle, check for

evidence of leakage around the engine,

axles, transmission, etc., because this

will not be possible when carrying out

service operations after the vehicle has

been cleaned.

When a high-pressur e cleaner is used,

take special note of the f ol low ing points:

• Ensure that all doors, w indo ws, and

cab grille are correctly closed.

• Do not spray directly on seals.

There is a danger of the seals

being forced open by the high-pressure jet of water so that the grease

packed behind them is flushed

away.

• The hydraulic fluid reservoir for the

steering gear is provided with a

ventilation opening. Water may

enter the reser voir through this

opening and damage the steering

gear.

• When cleaning the radiator/intercooler, tak e care not to damage the

ribs or fins of the cores.

• Make sure that no water can enter

the differential or transmission via

the ventilation openings.

• Ensure that no water is allowed to

enter the clutch fluid reservoir via

the ventilation opening.

• The engine and engine compartment may be clea ned with a hi ghpressure cleaner. However, do not

aim the jet of water directly at electrical components such as the

starter motor, alternator, etc.

• Do not aim the jet of water directly

at electrical connections such as

connecto rs, cable feed-through for

the vehicle lighting, etc.

• When cleaning the vehicle, make

sure that no water enters the air

intake system via the air inlet or its

flexible joints.

CAUTION: After steam

cleaning the vehicle, it is

essential that all grease

points are lubricated with a

grease gun or with the automatic ch assis l ubricat ion

system to prevent moisture

and dirt from entering the

various pivot points.

PB1340A .book Page 11 Friday, Sept ember 1, 2000 7:40 AM

Page 20

Cleaning the Vehicle General

– 12 –

Cleaning the Cab

The external paintwork of the cab is

subject to attack by aggressive substances, the severity of which de pends

upon the specific transport role and

operating conditions of the vehicle, for

example salt scattered on icy roads,

and air pollution. The paintwork must

therefore be cleaned regularly.

When cleaning the cab, make sure that:

• no aggressive cleaners are used;

• no stiff brushes are used;

• all seams, gaps, and door frames

are thoroughly cleaned.

Waxing the Cab

To maintain and protect the cab paintwork, it is recommende d that a coat ing

of wax is applied at least twice a year.

Your dealer can advise you about additional anti-rust treatment and maintenance of the paintwork when the

vehicle is in service.

Cleaning the Cab Interior

Clean the car pets and se ats with a

brush or vacuum cleaner and occasionally with dil ute d u pho lste ry cle ane r ; do

not attempt to “dry clean” the carpets

or seats.

Clean vinyl faced upholstery and paintwork with a mild household detergent;

do not use harsh abrasives or solventbased cleaning solutions.

NOTE: The appeara nce of

your vehicle is the calling card

of your company!

PB1340A .book Page 12 Friday, Sept ember 1, 2000 7:40 AM

Page 21

Cab Getting to Know Your Vehicle

– 13 –

GETTING TO KNOW YOUR VEHICLE

Cab

The equip men t, contro ls, an d switches

within the cab may vary depending on

the vehicle specification.

Entry and Exit

When entering or exiting th e cab

observe the following procedures:

• Always face the cab when entering

or exiting the cab.

• Always use the grab handles fitted

to the driver`s and passengers

door pillars when entering or exiting the cab.

•Do not use the steering wheel or

instrument panel as a grab handle.

• Always use all cab steps when

entering or exiting the cab.

•Do not use the fender as a step.

WARNING! Do not jump out

of the cab or get into the cab

without proper caution. You

could slip or fall, possibly

suffering a serious injur y.

You coul d sli p and fall if the step s

are wet or icy, or if you step in fuel,

oil, or grease.

To help avoid personal injury due to

a slip or fall:

• Use three points of contact (two

feet-one hand or one foot- two

hands) to grip the steps or han dholds whenever possible and look

where you are going.

• Use even more care when steps

and handholds (or footwear) are

wet, coat ed w ith ice, snow, mud,

oil, fuel, or grease.

PB1340A .book Page 13 Friday, Sept ember 1, 2000 7:40 AM

Page 22

Cab Getting to Know Your V ehi cle

– 14 –

Doors

Do not drive the vehicle if the doors are

not closed.

To open the vent window:

depress the sliding collar and push

handle A downwards.

To open the door:

pull handle B upwards.

To lock the door from the inside:

depress button C.

To open the door window:

turn the window crank D.

Both doors can be locked and unlocked

from the outside with the key.

Tilting the Cab

The cab is tilted and lowered hydraulically. The c ab should only be t ilted

while the vehicle is parked on level

ground.

WARNING! You can be seriously injured by the cab if

you do not follow safety precautions. Whenever you

raise or lower the cab, or

when you work under the

cab, please remember the

following safety rules:

– Ensure that the area in front

of the cab is clear.

– Ensure that the vehicle tool

kit an d hydr aulic jack ar e

secured in their stowed

positions.

– Ensure that there are no

loose objects in the cab.

– Ensure that the engine is

switched off, the parking

brake is applied, and the

shift lev er is in n eu tral po si tion.

– Ensure that the cab tilt cylin-

der is fully extended before

attempting to work on the

vehicle.

PB1340A .book Page 14 Friday, Sept ember 1, 2000 7:40 AM

Page 23

Cab Getting to Know Your Vehicle

– 15 –

Tilting

• Ensure that all cab doors and cab

grille are closed and secure.

• Rotate the tilt pump spool valve pin

(A) to the up position.

• Using the pump handle from the

tool kit, operate the hydraulic tilt

pump until the cab attains its fully

tilted position.

NOTE: The cab is secured in

the d own p os iti on by hydraulically operated mounting locks;

operation of the tilt pump will

automatically disengage the

mounting locks.

Lowering

• Ensure that all personnel are

standing clear and that there are no

obstructions that would impede the

lowering of the cab.

• Ensure that the shift lever is in the

neutral position.

• Rotate the tilt pump spool valve pin

(A) to the down position.

• Operate the hydraul ic til t pump until

the cab is fully lowered and the cab

mounting locks have automatically

engaged. Ensure that the spool

valve pin remains in the down position while the vehicle is in service.

• Check that the cab is correctly

secured by both cab mounting

locks. This condition is shown by

the lock-d own wa r n ing lig ht on th e

PB1340A .book Page 15 Friday, Sept ember 1, 2000 7:40 AM

Page 24

Cab Getting to Know Your V ehi cle

– 16 –

instru ment pa nel. This warni ng

light must remain extinguished

when the ignition is switched on.

Door Mirrors

This vehi cle is equippe d w ith elect rically heated door mirrors, a passengerside m ir ror a nd, dep en de nt upo n vehicle specification, an auxiliary wide

angle mirror (electrically heated).

Mirror head attachment

When required, the attachment of the

door mirror he ad to t he mirror arm can

be loosened (to aid adjustment) or tightened (to secure in position) using the

following procedure:

• Using a suitable implement

inserted into the slot provided,

release the trim cover (1) and then

extract it from its slotted location in

the mirror head.

• As applicable, release/tighten the

mirror head retainin g b olt (2) to 11

lb. ft. (15 Nm).

• When replacing the mirror head

trim cover, ensure that it is correctly

located with in its s lotted location

and then pushed firmly in to its

engaged position; no gaps must

exist between the trim cover (slotted end) and mirror head.

Mirror arm fold position s

The mirror arms ar e held in position by

a detent located under the mirror arm

shroud. The detent is equipped with a

spring-loade d c lutch to en able the mir -

PB1340A .book Page 16 Friday, Sept ember 1, 2000 7:40 AM

Page 25

Cab Getting to Know Your Vehicle

– 17 –

ror arm s to rem ain in position dur ing

normal conditions; this enables the mirror arms to be folded forward or rearward against the cab when

maneuvering the vehicle in a confined

space.

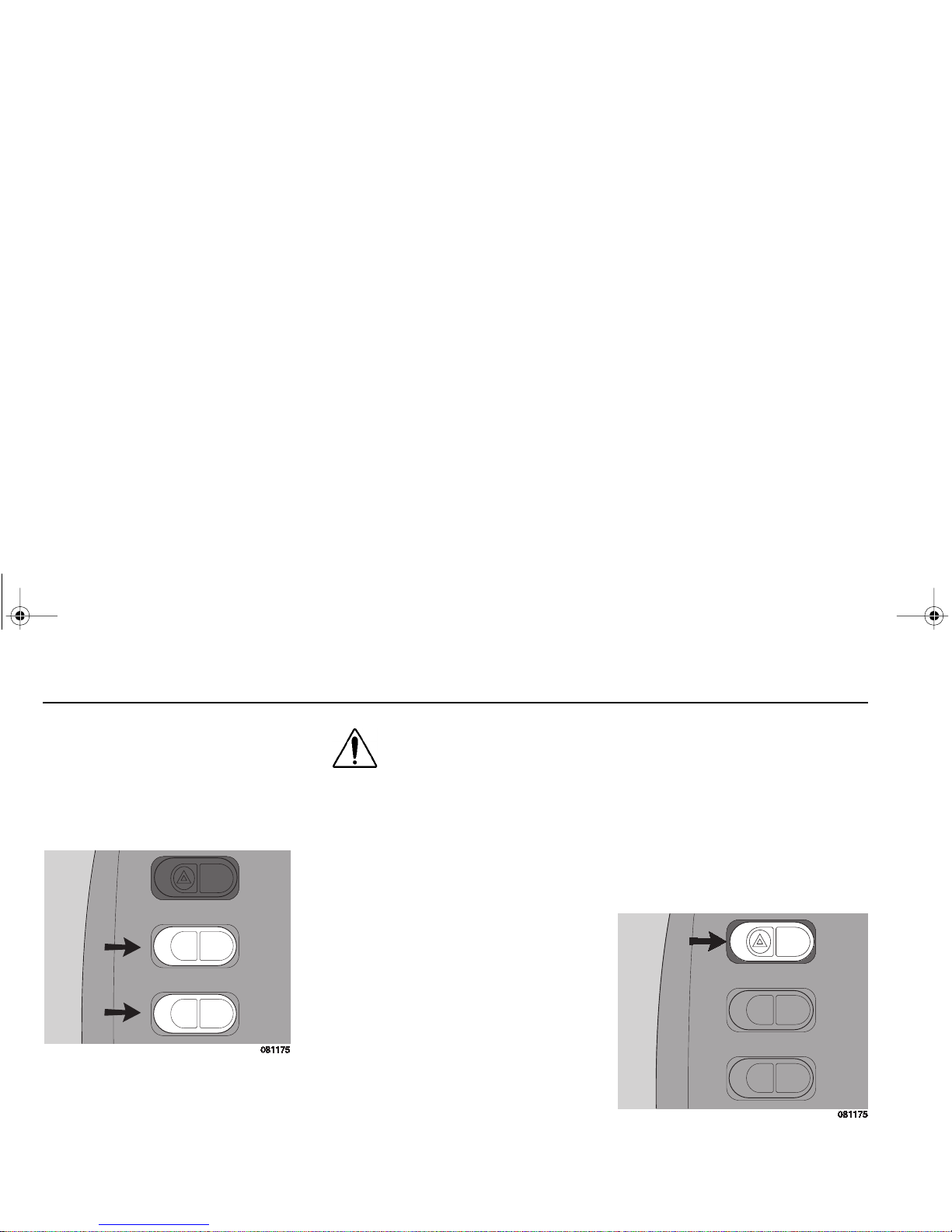

WARNIN G! It is u nsafe t o

drive without full visibility to

the rear. Do not attempt to

drive the vehicle wi th the

mirror arms in the folded

position.

Windshield Wiper Blades

To prevent damage to the wiper blades

during operation in winter conditions,

always check that the blades are not

frozen to the windshield. Th is can be

prevented by placing something under

the wiper blades. Clean the wiper

blades regularly with water and dr y

them with a soft cloth.

Seats

WARNING! Do not adjust the

driver’s seat while the vehicle is moving. The seat

could move sudd enly and

unexpectedly and can cause

the driver to lose control of

the vehicle. Make all adjustments to the seat while the

vehicle is stopped.

• After adjusting the seat and

before dri vin g o ff, always ch eck

to ensure that the seat is firmly

latched in position.

The driver’s seat must be adjusted only

when the vehicle is stationary. Do not

attempt to adjust the seat while the

vehicle is in motion.

PB1340A .book Page 17 Friday, Sept ember 1, 2000 7:40 AM

Page 26

Cab Getting to Know Your V ehi cle

– 18 –

Driver’s Seat (adjustable)

The driver’s seat has the following adjustment modes:

Fore/aft adjustment

Pull up bar 1 and slide the seat to the

required position.

Seat cushion height adjustmentfront

Pull up handle 2 and adjust the front

end of the seat cush ion to the requ ired

height.

Seat cushion height adjustment-rear

Pull up handle 3 and adju st the rear

end of the seat cush ion to the requ ired

height.

Backrest adjustment

Pull up handle 4 and adjust the back-

rest to the required position.

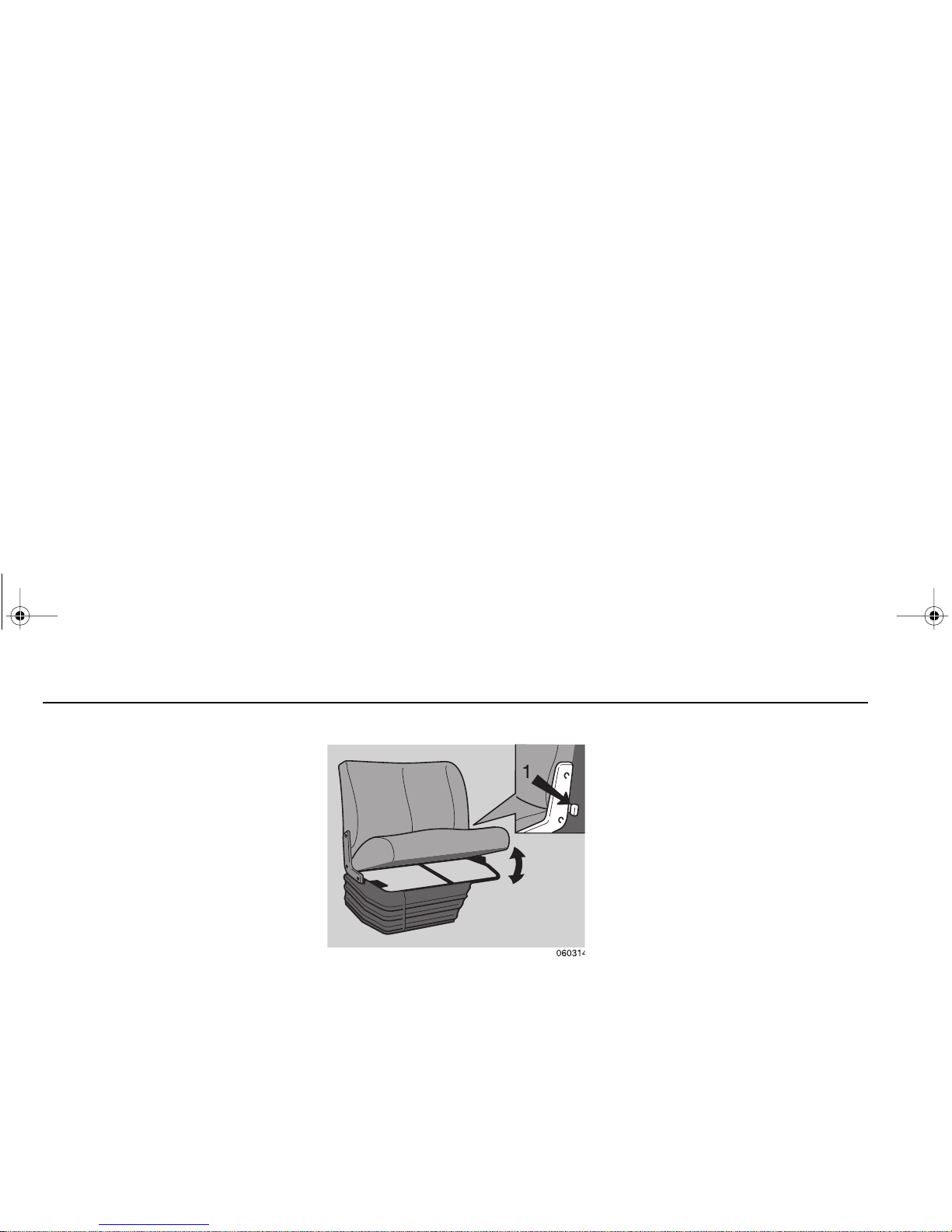

Passenger’s Seat (2-man)

The 2-man passenger seat is fixed and

non-adjustable. A storage compar tment, con taini ng the vehicl e tool kit, is

located beneath the seat cushion. To

gain access to the storage compartment depress the lock cont rol lever 1

and lift the seat cushion. When the seat

cushion is fully upr ight, it will aut omatically lock in position; depress the lock

control lever to release the seat cushion.

Passenger’s Seat (single-adjustable)

The single passenger’s seat can be

adjusted for fore/aft position, seat cushion height, and backrest rake. Refer to

“Driver's Seat (adjustable)”

for the

adjustment procedures.

Seat Belts

The driver’s seat and pa ssenge rs seat

are equipped with seat belts, these

should be w or n by t he se at u ser w hen

the vehicle is in motion.

PB1340A .book Page 18 Friday, Sept ember 1, 2000 7:40 AM

Page 27

Cab Getting to Know Your Vehicle

– 19 –

WARNING! Do not drive

vehicle without your seat

belt and your riders’ belt fastened. Riding without a

safety belt properly fastened

can lead to increased injury

or death in an emergency.

Unbelted riders could be

thrown into the wind shie ld

or other parts of the cab or

coul d be thrown out of t he

cab. They could strike

another p erson . In juries can

be much worse when riders

are unbelted. Always fasten

your seat belt and be sure

anyone riding with you does

the same.

WARNING! Always wear

your seat b el t low over you r

pelvic bones.

• You can be seriously injured if

your belt is buckled too high. In a

crash, it would apply force to

your abdomen, not your pelvic

bones. This can result in serious

internal injuries.

• Do not drive with your seat belt

loose. A too-loose seat belt can

allow you to fall too far forward,

possibly causing head an d ne ck

injuries. You could strike the

whee l or the win dsh iel d. Ad jus t

your belt so that there is no more

than 1 in. (25mm) of slack.

WARNING! Do not wear the

shoulder part of belt und er

your arm or otherwise out of

position. In a crash your

body would move too far forward, increasin g the chan ce

of head and neck injury.

Also, the belt would apply

too much force to the ribs,

which are not as strong as

your shoulde r bones , and

could cause you to suffer

internal injuries. Wear the

shoulder belt over your

shoulder.

WARNING! Do not twist the

belt in the process of putting

it on. A twisted belt will not

work as well to protect you.

In a crash, the full w idth of

the belt would not be protecting you. A twisted belt

could cut into your body and

cause serious injuries.

Straighten t he belt b efore

buckling it. If you are unable

to wear it withou t tw isting it,

have your dealer or service

person replace it as soon as

possible.

Observe the following recommendations:

•Do not use any seat belt for more

than one person.

PB1340A .book Page 19 Friday, Sept ember 1, 2000 7:40 AM

Page 28

Cab Getting to Know Your V ehi cle

– 20 –

• Before securing a seat belt, ensure

that the webbing is not twisted,

looped or obstructed in any way

that co uld impair the operat ing

mechanism.

• Optimal safety can be offered by a

seat be lt only when i t is prop erly

tightened.

• Never have repair s or modifica tions

made to the seat belts.

• Replace the seat belt when the

webbing is worn or damaged.

• If the seat belts have been subjected to high loading during a collision, then the complete assembly

must be replaced, even if there is

no visible evidence of damage.

Seat belt upper anchorage adjustment

The seat belt upper anchorage point

should be adjusted so that the belt webbing crosses m idway betw een th e

user’s neck and the edge of the

shoulder.

To adjust the position of the upper

anchorage point, depress the locking

button a nd, simult aneou sly, slide the

anchorage point to the desired position;

release the locking button when the

required position is obtained.

Seat belt care

• Regularly inspect all seat belt webbing, anchorage points, and locking

mechanisms for correct operation

and for evidence of excessive wear

or damage.

• Check the seat belt locking action

by rapidly pu lli ng t he b el t webb ing

out o f its re trac ting un it; t he belt

webbing must lock, i.e. i t must not

be pulled out of the retracting unit.

•Do not clean the belts with aggres-

sive cleaning agents; if ne cessary,

use an all-purpose cleaner.

PB1340A .book Page 20 Friday, Sept ember 1, 2000 7:40 AM

Page 29

Cab Getting to Know Your Vehicle

– 21 –

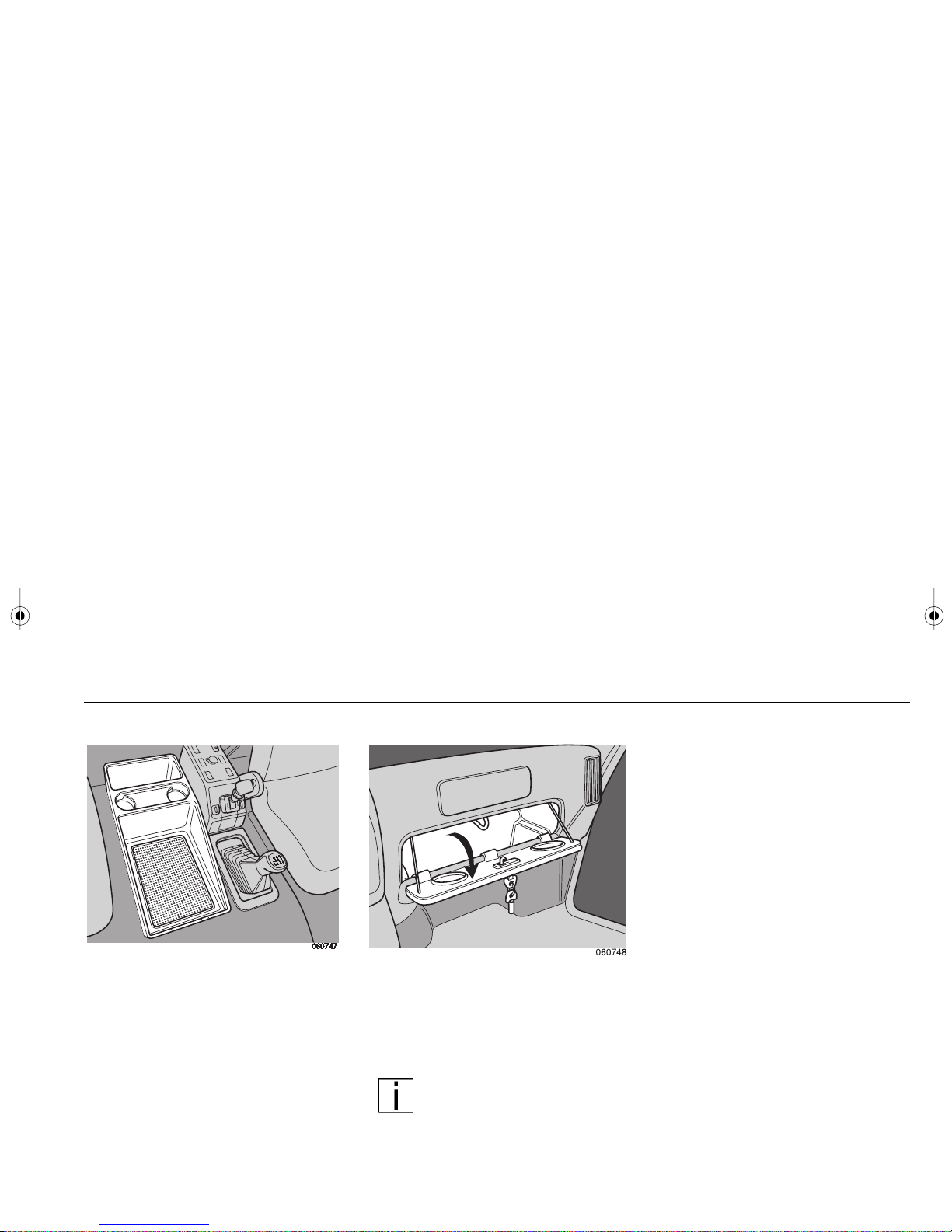

Storage Tray

Your truck ma y be equipped with a fixed

storage tray. The storage tray is of a

pre-formed construction incorporating

storage bins and cup holders.

Glove Box

All vehicles are equipped with a lockable glove box.

NOTE: The “ Operator’s Man-

ual” is stored in the glove box.

Keep this book in the cab at all

times.

PB1340A .book Page 21 Friday, Sept ember 1, 2000 7:40 AM

Page 30

Cab Getting to Know Your V ehi cle

– 22 –

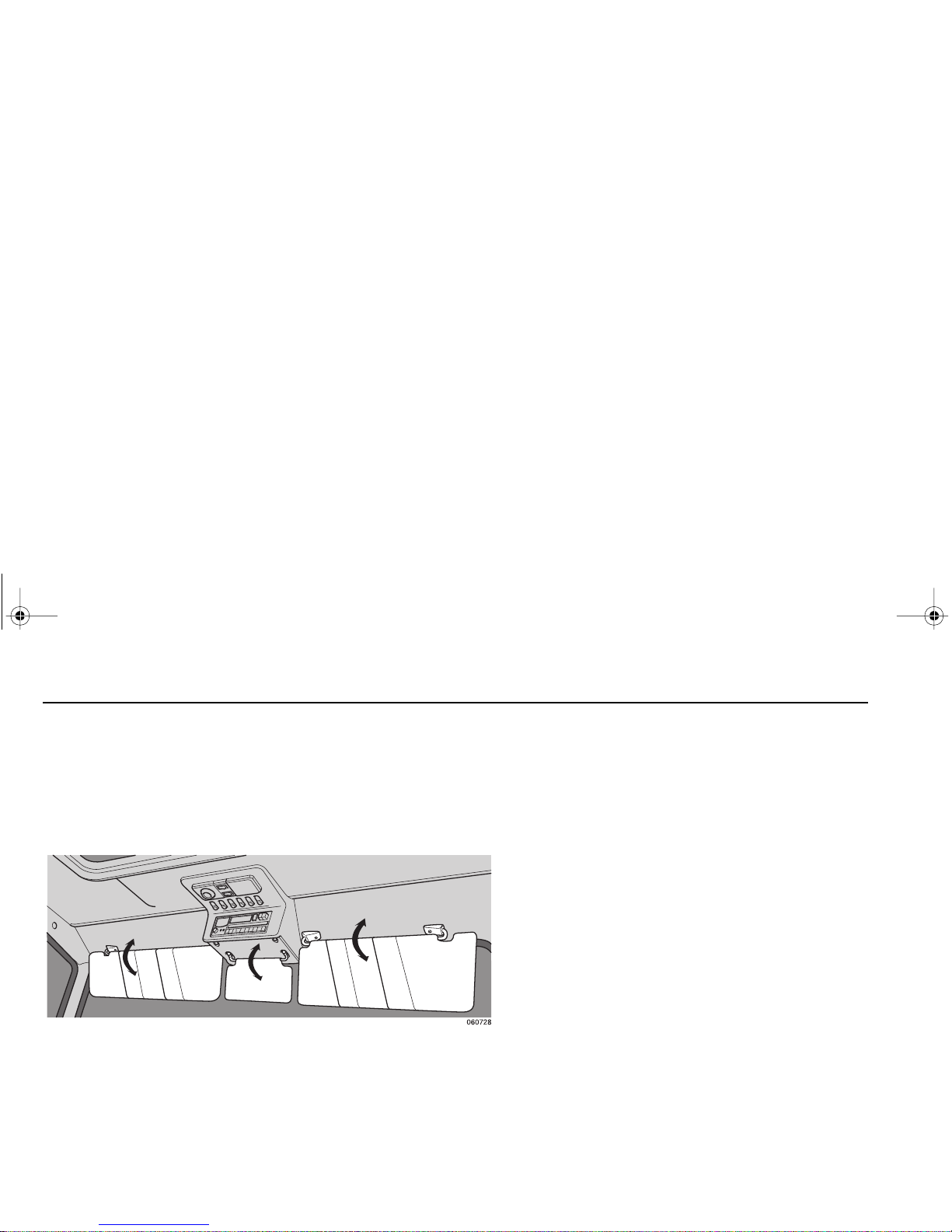

Sun Visors

The cab is fitted with 3 sun visors

which are provided for the driver and

passenger. The sun visors can be

swung down to block the sun.

PB1340A .book Page 22 Friday, Sept ember 1, 2000 7:40 AM

Page 31

Cab Getting to Know Your Vehicle

– 23 –

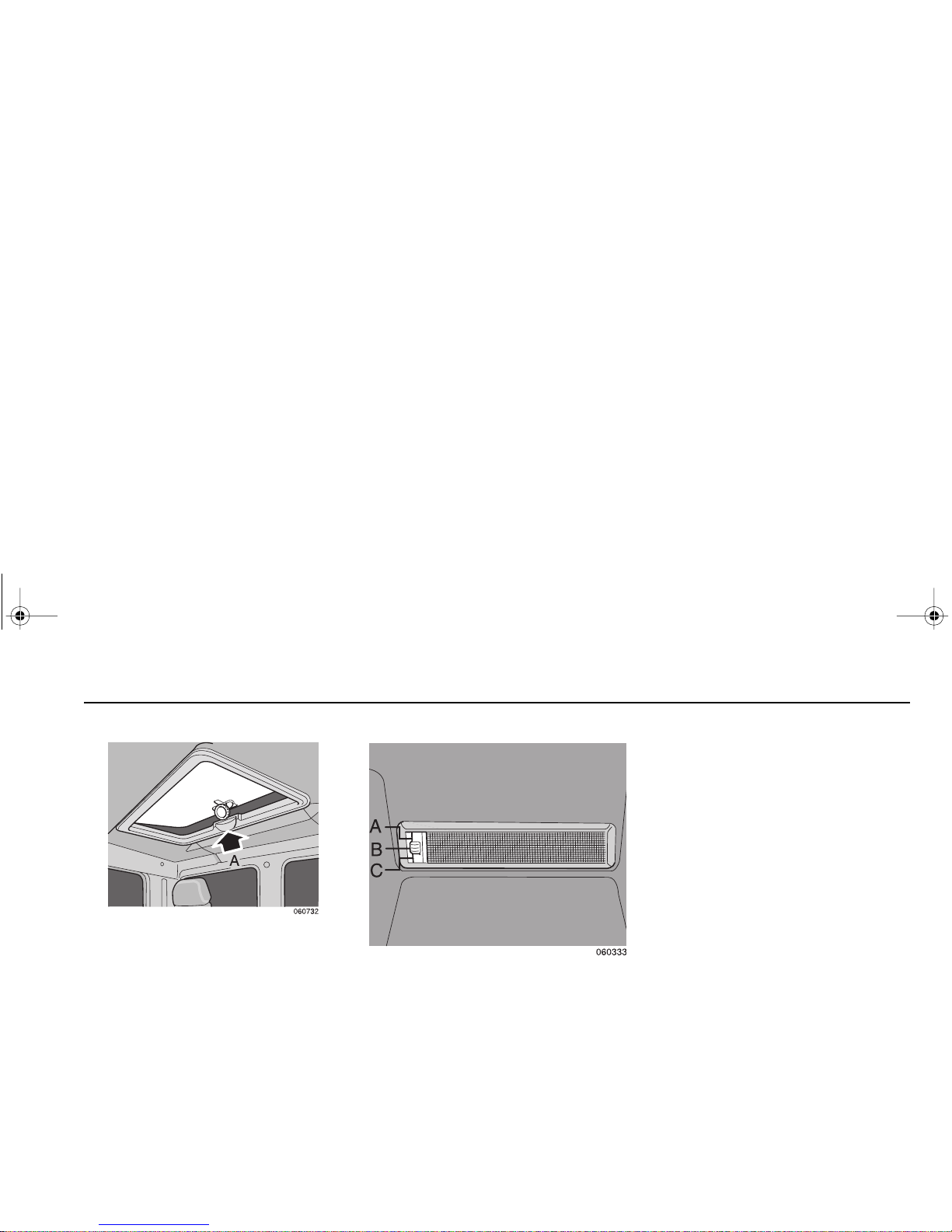

Roof Vent (option)

Rotate the control knob (A) to open and

raise the roof vent to the required position.

Courtesy Lights

All cabs are equipped with two courtesy

lights which are fitted in the cab roof lining above each door.

The court esy light switch has three

positions:

Position A: the lig ht will onl y illumin ate

when the door is opened.

Position B: light is switched off.

Position C: light is on permanently.

PB1340A .book Page 23 Friday, Sept ember 1, 2000 7:40 AM

Page 32

Cab Getting to Know Your V ehi cle

– 24 –

Interior Light Unit

All cabs are equipped with an interior

light unit which is fitted in the c ab center

roof pan el. T he in ter ior l igh t uni t i nco rporates a directable reading light and a

courtesy inter ior light; both lights are

indepen dently ope rated using the interior light mounted switches.

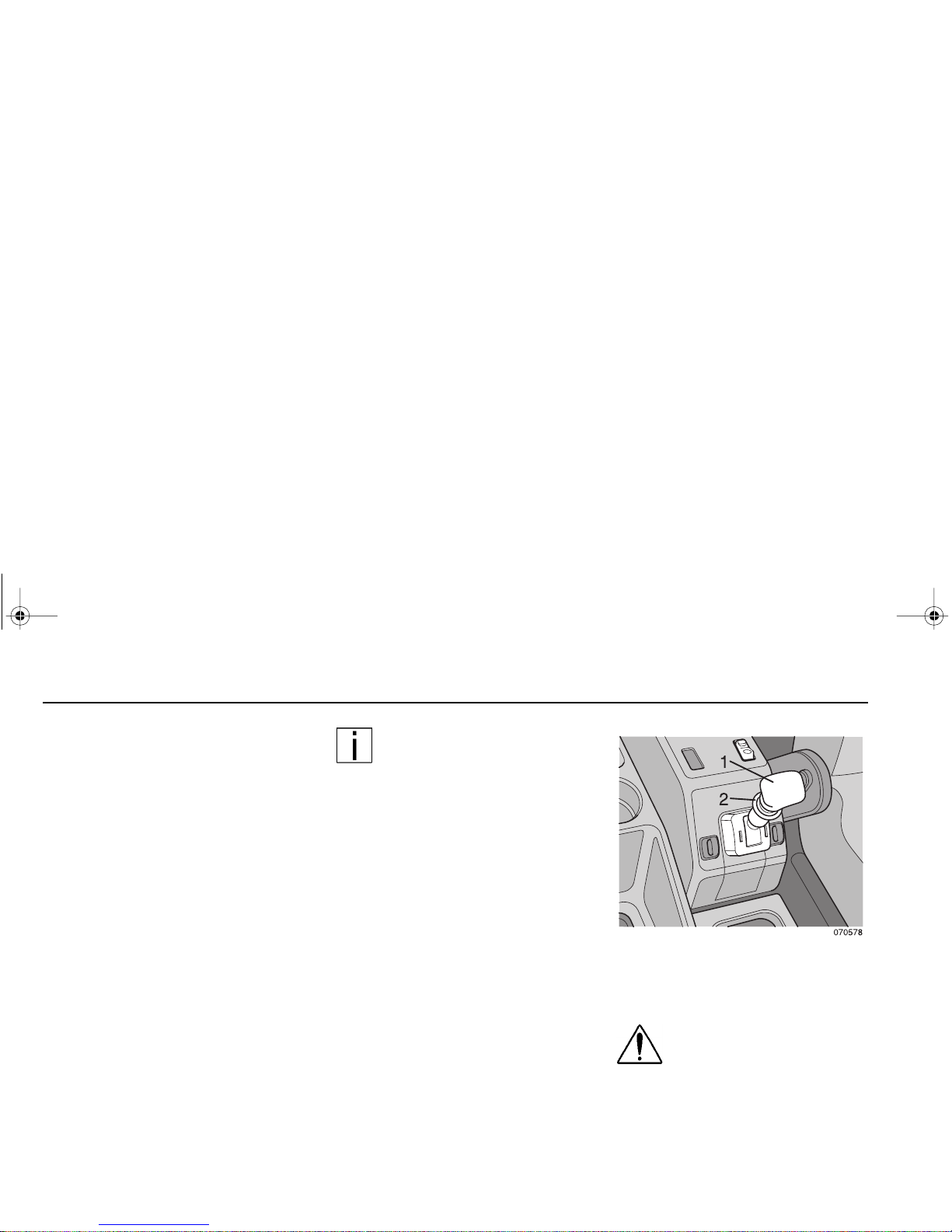

Courtesy interior light

The cour tesy i nterio r light swit ch (1)

has three positions:

Position A: li ght is switched off.

Position B: li ght is switched off.

Position C: li ght is switched on.

Reading light

The reading light is operated by the on/

off swit ch (2); the lig ht beam can be

directed to the required position by

moving the swivel lens.

Ashtray

An ashtray is provided in the center

panel. Raise the cover to open the ashtray. To empty the ashtray, close the

cover and extract the complete a shtray

unit from its holder . Replace the ashtray

by reversing the removal procedure.

Cigarette Lighter

A cigarette lighter is provided in the

center panel adj acent to the asht ray.

Depress the cigarette lighter in its

socket; the cigarette lighter will partially

eject when ready for use.

The cigarette lighter can be used as a

12 volt accessory power supply. Before

connecting electrical equipment to the

A

PB1340A .book Page 24 Friday, Sept ember 1, 2000 7:40 AM

Page 33

Instruments and Controls Getting to Know Your Vehicle

– 25 –

cigarette lighter socket it is essential to

ensure that:

• only 12 volt (negative ground) electrical equipment is connected to the

cigarette lighter power socket.

• the power consumption of any electrical com ponen t does no t exceed

10 amps.

Instrume n ts an d

Controls

General

The instru ments and control s are

located on the instrument panel, center

console, center roof console, and steering column.

Warning Light s

All warning lights are color coded to

indicate the level of their importance.

The color codes and th e required

driver's response are as follows:

Red

Illumination of any red warning light

during normal dr iving conditions indicates a major system or equipment

malfunction. In the event of any red

warning light illuminat ing, the vehicle

must be stopped and the engine

switched off. Do not attempt to drive the

vehicle until the fault has been fixed.

Amber

Illumination of any amber warn ing light

during normal dr iving conditions indicates an eq uipment /system malfu nction. In the event of an amber warning

light i llu min a ting, th e vehic le m ay con-

tinue on its jo urney but ad dition al driving caution must be observed. The fault

should be fixed at the earl iest o ppor t unity.

Green Or Blue

Illumination of any green or blue warning lig ht i nd ica tes t hat a un it/sys te m is

operational.

WARNING! Do not ignore a

warning light or buzz er.

These signa ls may tell you

somethin g is wrong wit h

your vehicle. It could be a

failure in an impor tant system, such as t he brakes,

which coul d lead to an acc ident. Have the appropriate

system checked imm ediately.

PB1340A .book Page 25 Friday, Sept ember 1, 2000 7:40 AM

Page 34

Instruments and Controls Getting to Know Your Vehicle

– 26 –

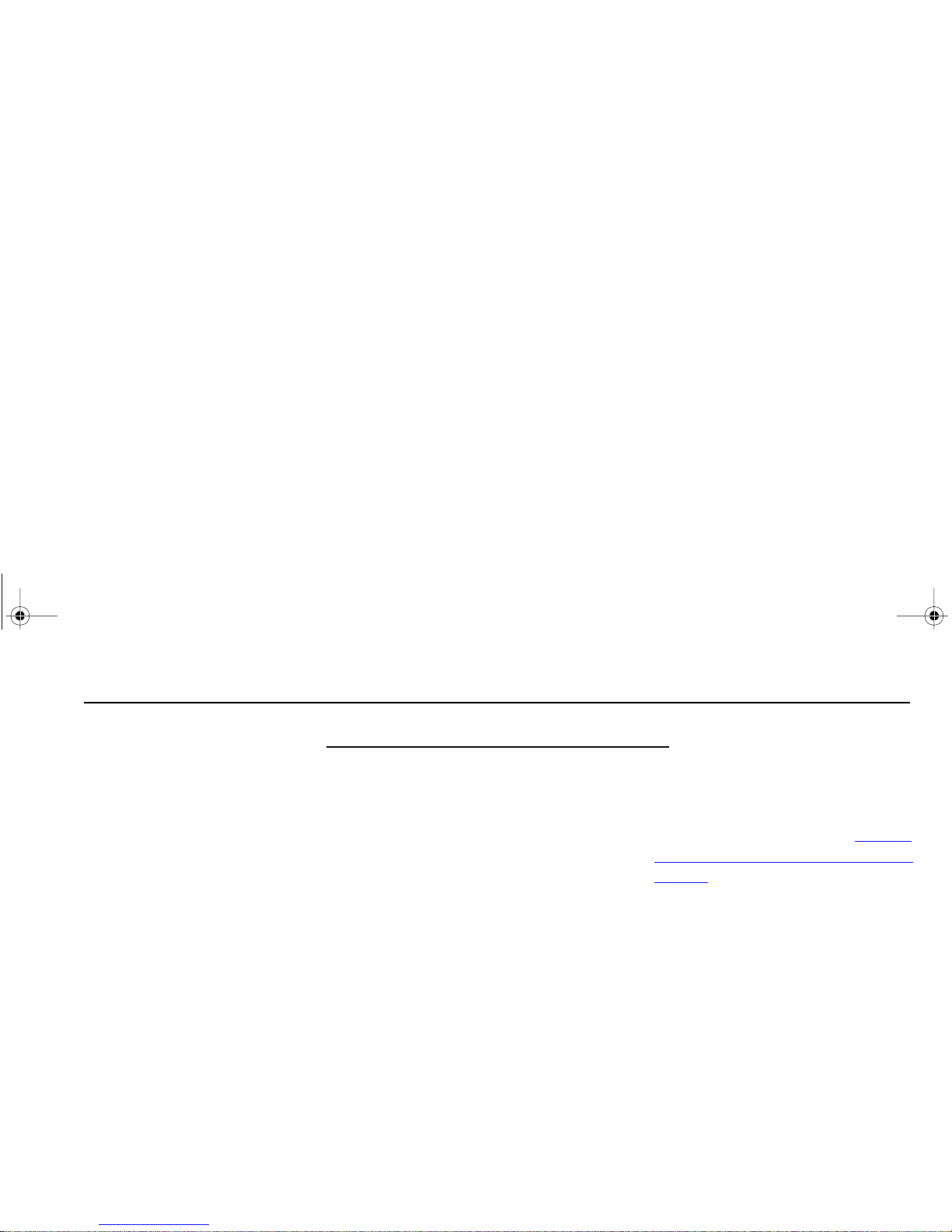

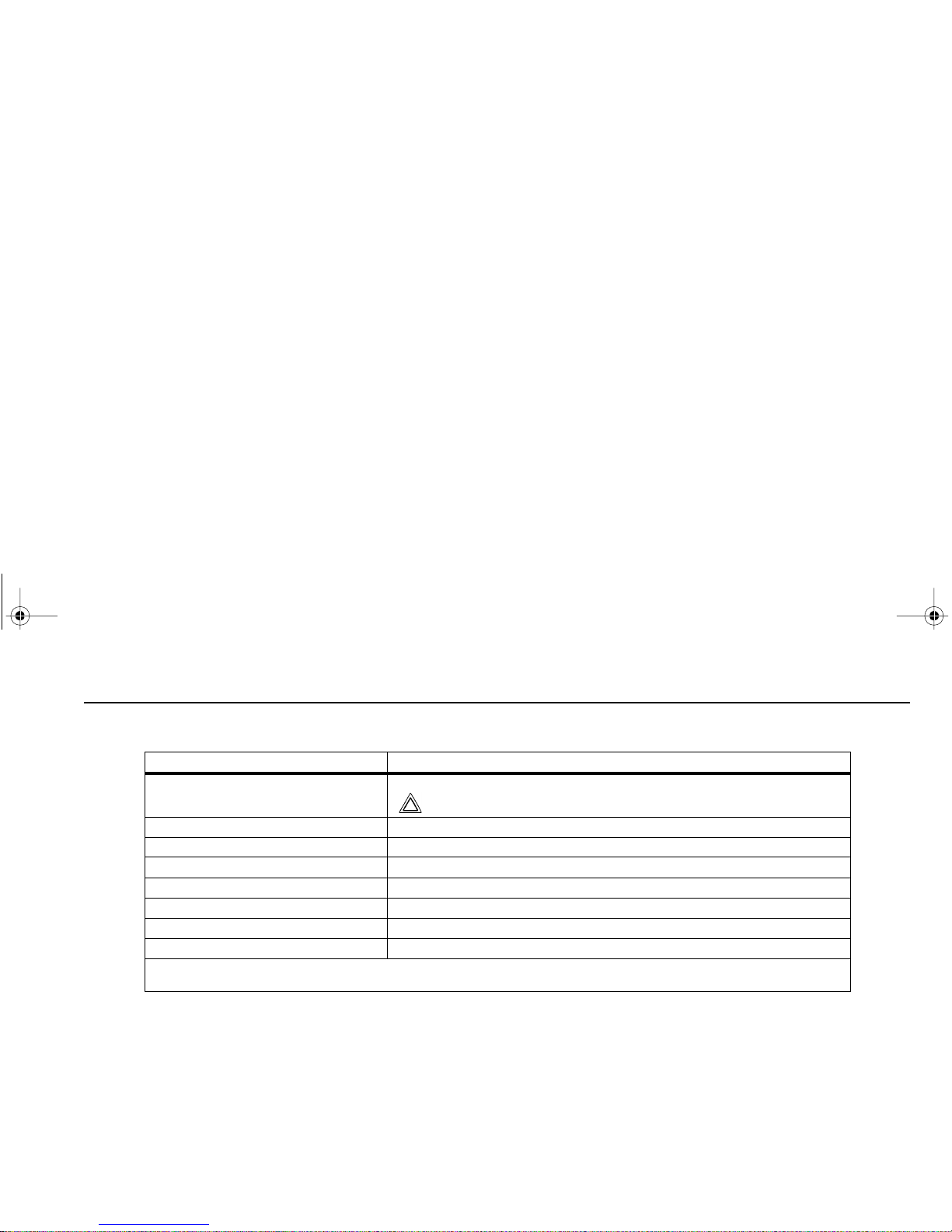

Instru me nt Panel

A/C

RECIRC

0

75

130

175

250

100

200

0

75

130

175

CRUISE ON/OFF

SET/RESUME

35

34

33

32

31

30

29

28

27

26

25

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

BRAKE

AIR

PTO

TRANS

TEMP

CHECK

TRANS

CRUISE

CONTROL

DIFF

LOCK

BRAKE

AIR

PTO

TRANS

TEMP

CHECK

TRANS

CRUISE

CONTROL

DIFF

LOCK

PB1340A .book Page 26 Friday, Sept ember 1, 2000 7:40 AM

Page 35

Instruments and Controls Getting to Know Your Vehicle

– 27 –

1. Tachometer

2. PTO warning light

3. High beam warning light

4. Hazard switch warning light

5. Turn signal warning light - vehicle

6. Cruise control warning light

7. Cab-lock warning light

8. Oil pressure warning light

9. Low air pressure warning light

10. Battery charge warning light

11. Parking brake warning light

12. Not used

13. Differential lock warning light

14. ABS warning light

15. Maintenance - Water in Fuel

16. Check engine warning light

17. Stop engine warning light

18. Coolant temperature warning light

19. Wait to Start engine warning light

20. Transmission oil temperature

warning light

21. Check transmission warning light

22. Fuel gauge

23. Coolant temperature gauge

24. A/C On-Off switch

25. Heating and ventilation controls

26. Ventilation fan indicator light

27. Air pressure gauge - (secondary)

28. Fuse box - right

29. Air pressure gauge - (primary)

30. Speedometer/odometer

31. Fuse box - left

32. Vehicle lighting switch

33. Cruise control Set/Resume switch

34. Cruise control On-Off switch

35. Hazard warning light switch

PB1340A .book Page 27 Friday, Sept ember 1, 2000 7:40 AM

Page 36

Instruments and Controls Getting to Know Your Vehicle

– 28 –

Switches, Gauges, and

Warning Lights on the

Instru me nt Panel

1. Tachometer

White field: low-idling speed

Green Field: economical speed range

Yellow field: maximum power range

Red field: excessive/overspeed range

(not permitted)

2. PTO Warning Light

(A PTO is not available from the factory.) This warning light will illuminate

whenever the PTO is engaged.

Do not drive vehicle at highway speeds

if PTO is engaged (light is ON).

3. High Beam Warning Light

This war nin g light w ill illu mina te whe never the headlights are in the high

beam p ositio n or w hen the he adligh t

flash is operated.

4. Hazard Switch Warning Light

This warning light will flash simultaneously in conju nction with both dire ction indicators whenever the hazard

warning light switch is activated.

5. Turn Signal Warning Light - Vehicle

This warning light flashes in conjunction

with the vehicle turn signals.

6. Cruise Control Warning Light

This war nin g light w ill illu mina te whe never the cruise control is switched ON.

7. Cab-lock Warning Light

This warning lig ht wi ll il lu min ate a nd a

warnin g buzzer will so un d if t he c ab is

not correctly locked in the down position; this warning ligh t is on ly operative

while the ignition is switched on. Also

see the

“Cab”

section of this handbook.

Do not attempt to dr ive the vehicle

while this warning light is illuminated.

8. Oil Pressure Warning Light

This warning lig ht wi ll il lu min ate a nd a

warning buzzer will sound when the

engine oil pressure is too low. In the

event of the oil pressure warning light

illuminatin g dur ing nor mal dr ivin g conditions, the vehicle mu st be stopped

and the engine switched off. Do not

attempt to re-start the engine until the

fault has been rectified.

PB1340A .book Page 28 Friday, Sept ember 1, 2000 7:40 AM

Page 37

Instruments and Controls Getting to Know Your Vehicle

– 29 –

WARNING! The air pressure

warning light and the au dible alarm in dica te a dange rous situation: there is not

enough air pressure in the

reservoirs for repeated braking and, except when the

engine is started, indicates

the brake system has failed.

Without the use of your service brakes your spring

brakes could suddenly apply

causing a wheel lock-up,

loss o f c o nt rol, or ove r- take

by following vehicles. You

coul d be in an acci den t and

severely injured.

• Bring the vehicle to a safe stop

right away, while you still have

control of the vehicle. Follow the

procedure below:

Air Loss Emergency Procedure

1. Slow down carefully.

2. Move a safe distance off the road

and stop.

3. Place the transmission in park and

set the parking brake. (See pages

58

and 66 for transmission shifting

and parking brake information.)

4. Tur n OFF the engine.

5. Turn ON the emergency flasher

and use other warning devices to

alert other motorists.

If the li ght an d alar m do no t tur n off at

startup, do not try to drive the vehicle

until the problem is found and fixed.

9. Low Air Pressure Warning Light

This war nin g light w ill ill umin ate an d a

warning buzzer will sound whenever

there is insufficient air pressure (less

than 80 ps i or 5.5 ba r) available in a ny

air reservoir.

Do not attemp t to drive th e vehicle

while this warning light is illuminated.

10. Battery Charge Warning Light

This warning light will illuminate if the

battery cha rg ing voltage falls below 1 1

volts.

11. Parking Brake Warning Light

This war nin g light w ill illu mina te whe never the parking brake is applied or

when there is insufficient air pressure

available to release the parking brake.

12. Blank

This warning light is not used.

13. Differential Lock Warning Light

(A locking differential is not available

from the factory.) This warning light will

illuminate whenever the differential is

locked.

PB1340A .book Page 29 Friday, Sept ember 1, 2000 7:40 AM

Page 38

Instruments and Controls Getting to Know Your Vehicle

– 30 –

14. ABS Warning Light

This war n ing light mo nit ors the vehicle

anti-lock braking syste m (ABS). This

warning light will illuminate when:

• the ignition is switched on; the light

should extinguish as soon as the

vehicle road speed exceeds 5 mph

(7 km/h);

• the vehicle ABS is defective; the

conventional braking will remain

operative but the vehicle must be

driven with care and the ABS must

be rectified at the ear lie st opp or tunity.

Also see

“Driving”

and

“Emergency

repairs”

sections of this handbook.

15. Maintenance - Water in Fuel

This warning light will illuminate if the

water/fuel separator needs to be

drained.

16. Check Engine Light

This warning light will illuminate when

an engine problem exists, but the vehicle can still be sa fely driven. Th e vehicle should b e ser viced to correct the

problem but the situation should not be

considered an emergency.

17. Stop En gi ne Li ght

This warning light will illuminate when a

major eng ine pr oblem exi st s. It me an s

you should stop and shut down your

vehicle as soon as it is safely possible.

NOTE: If you need to determine

the exact engine problem that

turns on warning light 16 or 17,

you must access the on-board diagnostic system. With the key switch ON but

the engin e NOT running, pre ss the

throttle pedal to full throttle and release

to idle th ree times. The active fault

codes will flash out as descr ibed in the

Cummins ISB Engine Operation and

Maintena nce Manual. Contact your

dealer or th e Cumm ins engi ne ser vice

center for t he explana tion of th e code.

Turn the key switch OFF to exit the

diagnostic mode.

18. Coolant Temperature Warning

Light

This warning lig ht wi ll il lu min ate a nd a

warning buzzer will sound whenever

the engine coolant temperature

exceeds the maximum permissible

level.

PB1340A .book Page 30 Friday, Sept ember 1, 2000 7:40 AM

Page 39

Instruments and Controls Getting to Know Your Vehicle

– 31 –

19. Wait to Start Light

This warning light will illuminate when

the air intake h eater is ON. Do not

attempt to start the engine until the light

goes out.

20. T ransmission Oil Temperature

Warning Light

(Functional only if optional Allison automatic transmissi on is installed.) Thi s

warning light will illuminate whenever

the transmission oil temperature

exceeds the maximum permissible

level.

21. Check Transmission Warning

Light

(Functional only if optional Allison automatic transmissi on is installed.) Thi s

warning light will illuminate w hen a

problem exists with the transmission,

but the vehicle can still be safely driven.

The vehicle should be serviced to correct the problem, but the situation

should n ot be consid ered an eme rgency.

22. Fuel Ga ug e

The fuel gauge gives an approximate

indication of the fuel t ank con tents and

only operates with the ignition switched

on.

PB1340A .book Page 31 Friday, Sept ember 1, 2000 7:40 AM

Page 40

Instruments and Controls Getting to Know Your Vehicle

– 32 –

23. Coolant Temperature Gauge

The coolant operating temperature

should be between 165°F (74°C) and

198°F (92°C ). A t a tem perat ure of less

than 140°F (60 °C) the eng ine should

not be fully loaded by the driver. If the

coolant temperature suddenly r ises

and/or the gauge pointer enters the red

field, then the following items should be

checked:

• The coolant level. See “Coolant

Level” on page 51.

• The drive belt and water hoses.

• The operation of the viscous fan

drive.

24. A/C On/Off Switch

(With optional air conditioning only)

This switch turns the air conditioner

compressor and t he rem otely m ounte d

condenser on and off.

25. Heater And Air Conditioner

Controls

WARNING! Do not drive with

your visi bility reduced by

fog, co nden sation, or frost

on the windshield. Your view

may be obscured, which

could result in an injury

250

100

200

A/C

A/C

RECIRC

0

75

130

175

250

100

200

1

2

3

4

PB1340A .book Page 32 Friday, Sept ember 1, 2000 7:40 AM

Page 41

Instruments and Controls Getting to Know Your Vehicle

– 33 –

accident. For clear visibility and safe

driving it is extremely important for

you to follow the ins tru ction s on the

use of the ventilation/heating and

defogging/defrosting system. If in

doubt, consult your dealer. Maximum heating output and fast

defrosting can be obtained only after

the engine has reached operating

temperature.

WARNING! Excessive heat

may cause the pressurized

components of the air conditionin g system to explode.

Never weld, sold er, steam

clean, or use a blow torch

near any par t of the air conditioning system.

• If a refrigerant leak develops in

the presence of excessive heat

or an open flame, hazardous

gases may be generated. These

gases may cause unconsciousness or deat h. If you become

aware of a refrigerant leak on

your vehicle, have your system

serviced immediately and

observe the following precautions:

– Stay away from the hot

engine until the exhaust

manifold has cooled.

– Do not permit any open

flame in the area. Even a

match or a cigarette lighter

may generate a hazardous

quantity of poisonous gas.

– Do not smoke in the area.

Inhaling gas eous refr ig erant

through a cigarette may

cause violent illness.

The heating and air conditioner controls

are located on the instrument panel.

The heater and air co nditione r controls

consist of a rot ary switch for regula ting

the bl ower spe ed, a slide c ontrol for

selecting air distribution, a slide control

for selecting air temperature, and with

optional air conditionin g, a push button

switch for turning the ai r conditioning on

or off.

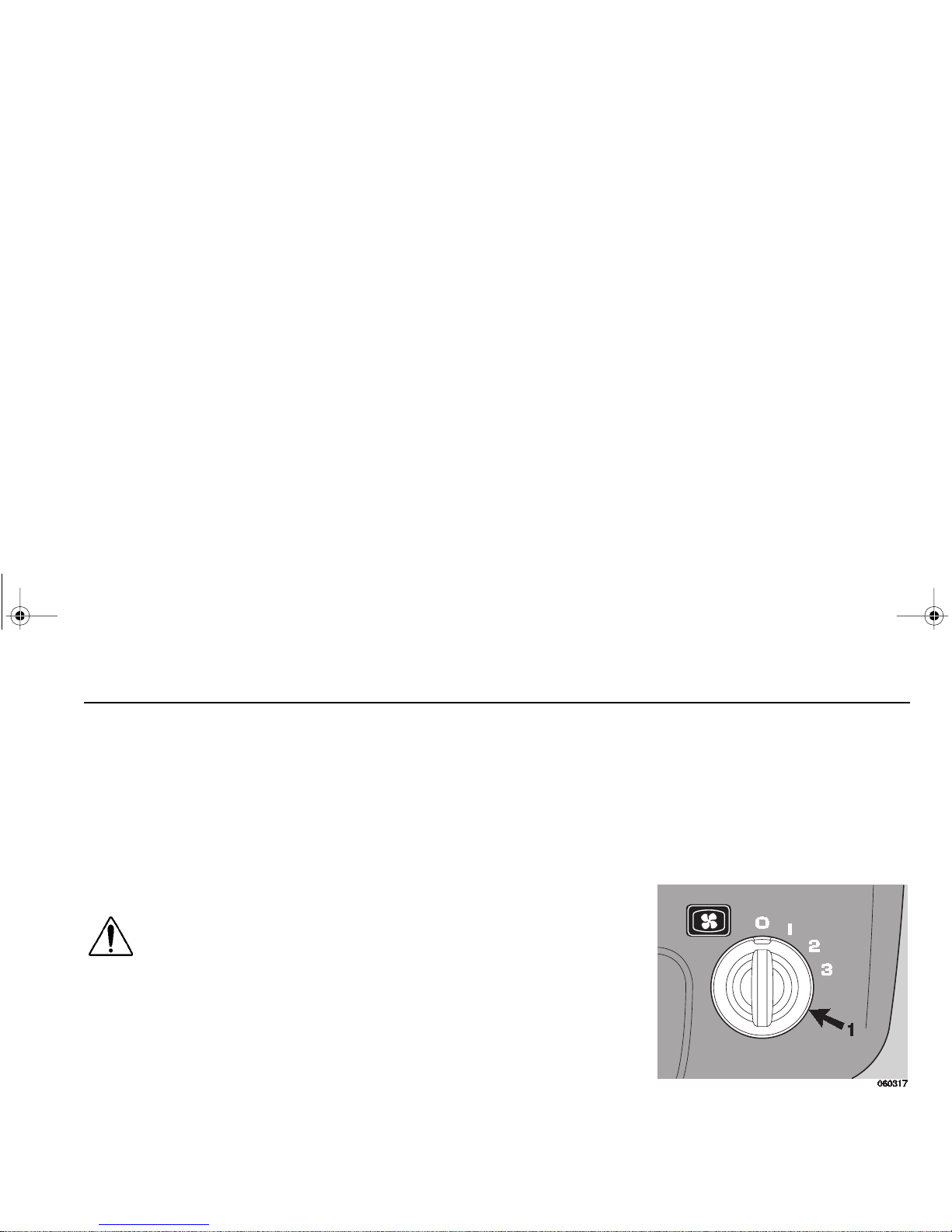

22. Ventilation Fan Indicator Light

When illu minated , indica tes th e blower

switch is on (Positions 1-3).

Rotar y switch (1) Contro ls the blower

speed (3 speeds and an off position).

PB1340A .book Page 33 Friday, Sept ember 1, 2000 7:40 AM

Page 42

Instruments and Controls Getting to Know Your Vehicle

– 34 –

Slide control (2) Controls the air distribution within the cab.

A bi-level mode exists when the slide

control is placed between Windshield

and Floor position s or between Floor

and Panel (Fresh) positions.

The optional air conditioner compressor

is engaged when the control is placed

in Windshield mode (top-most position).

Slide control 3. Controls progressive

adjustment of the heater from 0 to

100% output.

Air vents and defoggers

The heater and air conditioner system

has fixed and adjustable air vents for

windshield defogging, heating or cooling the interior of the cab, defogging the

door glass, and heating or cooling the

footwell area.

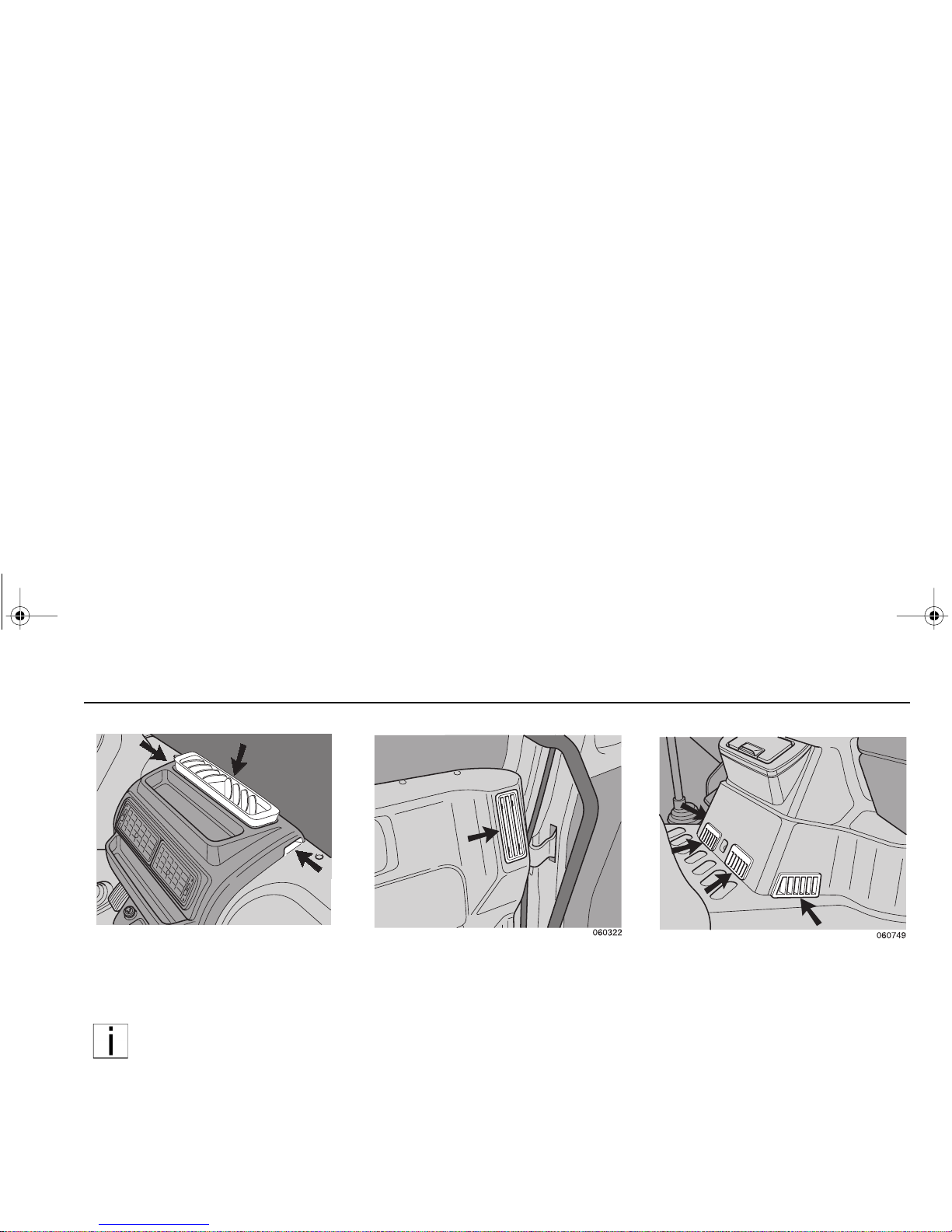

The center panel has two air vents,

adjustable for direction and volume of

air flow.

= Windshield

= Floor

= Panel (Fresh)

= Panel (Recirc)

RECIRC

RECIRC

RECIRCRECIRC

PB1340A .book Page 34 Friday, Sept ember 1, 2000 7:40 AM

Page 43

Instruments and Controls Getting to Know Your Vehicle

– 35 –

The center panel incorp orate s a cen -

tral defogger with two integral side

vents for defogging the entire width of

the windshield.

NOTE: The ce ntral defogg er

outlet is fitted with a prote ctive

mesh to prevent the entry of

foreign objects. To maintain

maximum air flow efficiency, do

not place objects on the protective mesh or obstruct the

central defogger in any way.

Two fixed air outlets at the left and right

of the cab fascia are directed at the

door glass. These vents and outlets

admit heated or cooled air into the cab.

In the footwell area there are four outlets which are no t adjus table for dire ction of the air flow. These vents and

outlet s admi t hea ted or cool ed ai r into

the cab.

PB1340A .book Page 35 Friday, Sept ember 1, 2000 7:40 AM

Page 44

Getting to Know Your Vehicle Instruments and Controls

– 36 –

NOTE: Fo r the r em aind er of

the Heating section, numbers

in parentheses ( ) refer to

items shown in this figure .

A/C

RECIRC

0

75

130

175

250

100

200

060752

1

2

3

4

Heating

To heat the cab: select the desired air distribution (2) and temperature (3) to hot (red

position on the control). Adjust the fan speed (1) as desired.

CAUTION: During extreme cold weather, do not blow hot air onto cold

windshields. This could crack the glass. Turn the air direction lever to

Defrost and adjust the fan speed accordingly while the engine warms.

If the engine is already war m, m ove the temperatur e selector to Coo l,

then gradua lly in crease the tem perat ure w hen you see th at the wind shield is starting to warm up.

HEATING A/C CONTROL

CONTROL S

HEATING COOLING DEFOGGING

MAX NML MAX NML MAX NML

Fan Speed (1) High Adjust High Adjust High Adjust

Air Dist ribution

(2) Panel

Panel

or Bi-

Level

Recirc Adjust

Windshield

Wind-

shield or

Bi-Level

Temperature (3) Warm Adjust Cool Adjust W arm Adjust

Air Conditioner -

AC (4)

OFF OFF ON ON ——

PB1340A .book Page 36 Friday, Sept ember 1, 2000 7:40 AM

Page 45

Instruments and Controls Getting to Know Your Vehicle

– 37 –

Defogging

NOTE: If equipped with

optional air conditioning, the

air conditioning system is

active when the Defrost mode

is selected.

To defog the windshi eld: sele ct air dis tribution to Windshield or between

Windshield/Floor and turn the fan

speed switch (1) to high. Set the temperature control (3 ) to ho t (red position

on the control). The air conditioner (if

equipped ) is automat ically acti vated to

remove moisture from the cab. After the

windshi eld is cl ear, adjust the co ntrol s

as desired.

Cooling

To cool the cab: turn on the air conditioner (if equipped) (switch 4), set the

temperature control (3) to cool (blue

side), and the fan (1) to high until the

cab becomes cool—adjust as desired.

When set to Recirc mode, the air condi-

tioning system will automatically shut

off fresh air intake and will recirculate

cab air.

For Efficient Cooling:

1. Ensure all heater/air conditioner

controls are off.

2. Start the engine. Allow time for

warm–up.

NOTE: A cold compressor can

cause refrigerant to liquefy and

warp the valve plates or cause

a hydraulic lock. Warm the

engine before starting the air

conditioner.

3. Set the ai r condi tioner for maximum

cooling.

4. Close all windows.

5. Idle the engine between 1,000 and

1,500 rpm and turn the fan switch

to High.

6. After the cab temperature cools to

a comfortable level, adjust the fan

speed and other controls to keep

the desired condition.

7. For efficient air flow in fresh air

mode, regularly clean the HVAC filter located on the bottom of the

cab. First, place the system in

“recirc” mode and then clean the filter with a low pressure air hose.

• If the air conditioner does not cool

the air, have the unit checked at an

Authorized Service Center.

NOTE: When the air conditioner isn’t i n regular use, operate it for at least 15 minutes at

least once a month or every

5,000 miles (8,000 km), whichever

comes first. This will lubricate the seals

in the air conditioning system.

PB1340A .book Page 37 Friday, Sept ember 1, 2000 7:40 AM

Page 46

Instruments and Controls Getting to Know Your Vehicle

– 38 –

27. Air Pressure Gauge “Sec ondary”

Air gauge “2” constantly monitors the

air pressure in the rear brake reservoir.

At reservoir air pressures below 80 psi

(5.5 bar) a warning buzzer will sound

and a warning light, mounted in the

instr ume nt panel , will il lumin ate; th e

warning buzzer and warning light are

only operative while the ignition is

switched on. Do not attempt to drive

the vehicle with less tha n 80 ps i (5.5

bar) of air pressure.

28. Fuse Box - Right

To gain access to th e circ uit and spar e

fuses, rotate the quick release fastener

(1) using a coin and then slide the fuse

cover downward. To enable the fuses to

be easily removed, a fuse extraction

tool (2) is attached to the inside of the

fuse cover. Also see the

“Emerg ency

repairs”

section of this handbook.

29. Air Pressure Gauge “Primary”

Air gauge “1” constantly monitors the

air pressure in the front brake reservoir.

At reservoir air pressu res below 8 0 ps i

(5.5 bar) a warning buzzer will sound

and a warning light, mounted in the

instrument panel, will illuminate; the

warning buzzer and warning light are

only operative when the ignition is

switched on. Do not attempt to dr ive

the vehicle with le ss than 80 psi ( 5.5

bar) air pressure.

060751

0

75

130

175

060751

0

75

130

175

PB1340A .book Page 38 Friday, Sept ember 1, 2000 7:40 AM

Page 47

Instruments and Controls Getting to Know Your Vehicle

– 39 –

30. Speedometer/Odometer

The speedome ter indic ates the vehicle

speed in miles per hour (MPH) and in

kilometers per hour (kph)

The odomete r records the d istance

trav eled by the vehicl e, either in miles or

kilometer s, depen di ng on wh ich u nit i s

installed in the vehicle.

31. Fuse Box - Left

To gain access to the circuit and spare

fuses, rotate the quick release fastener

(1) using a coin and then slide the fuse

cover downward. To enable the fuses to

be easi ly removed, a fu se extracti on

tool (2) is attached to the inside of the

fuse cover. Also see the

“Emergency

repairs”

section of this handbook.

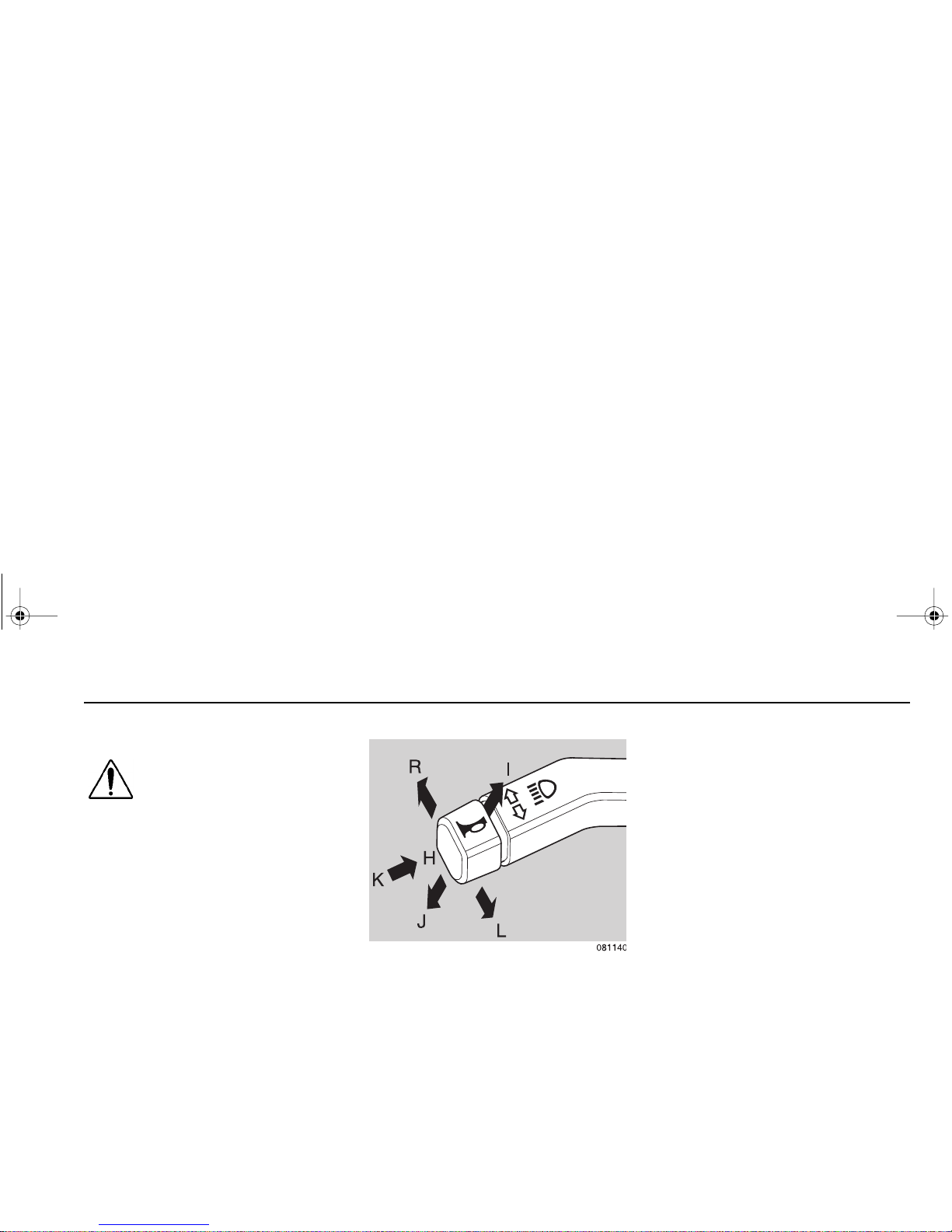

32. Vehicle Lighting Switch

The vehicle lig hting is op erated by a

rotary type switch with three positions:

km/hkm/h

mphmph

milesmiles

1010

2020

3030

4040

5050

5555

6060

7070

8080

2020

4040

6060

8080

100100

120120

lighting switched off

side lights, instrument

panel, and cab marker

lights

headlights, side lights,

instrument panel, and

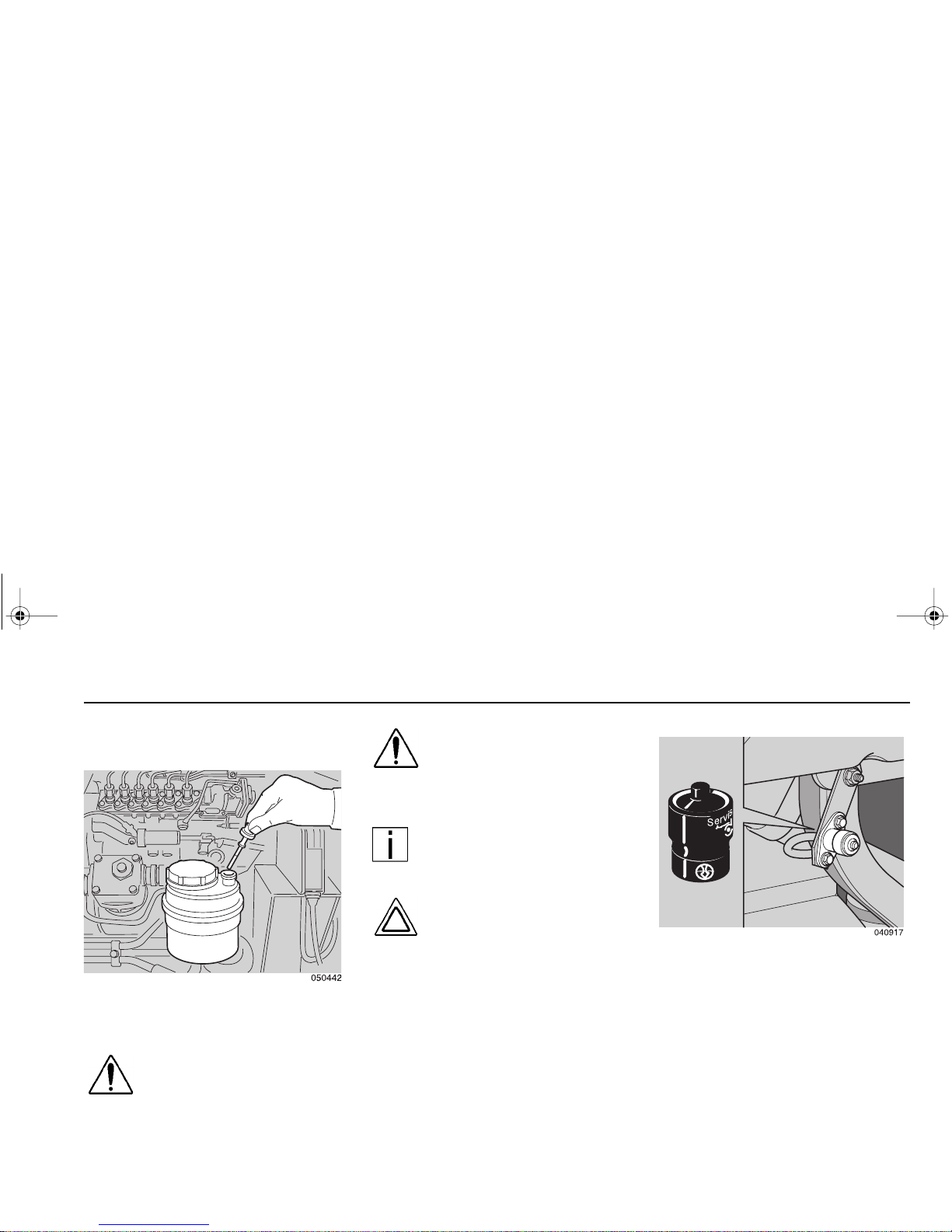

cab marker lights