Page 1

User’s

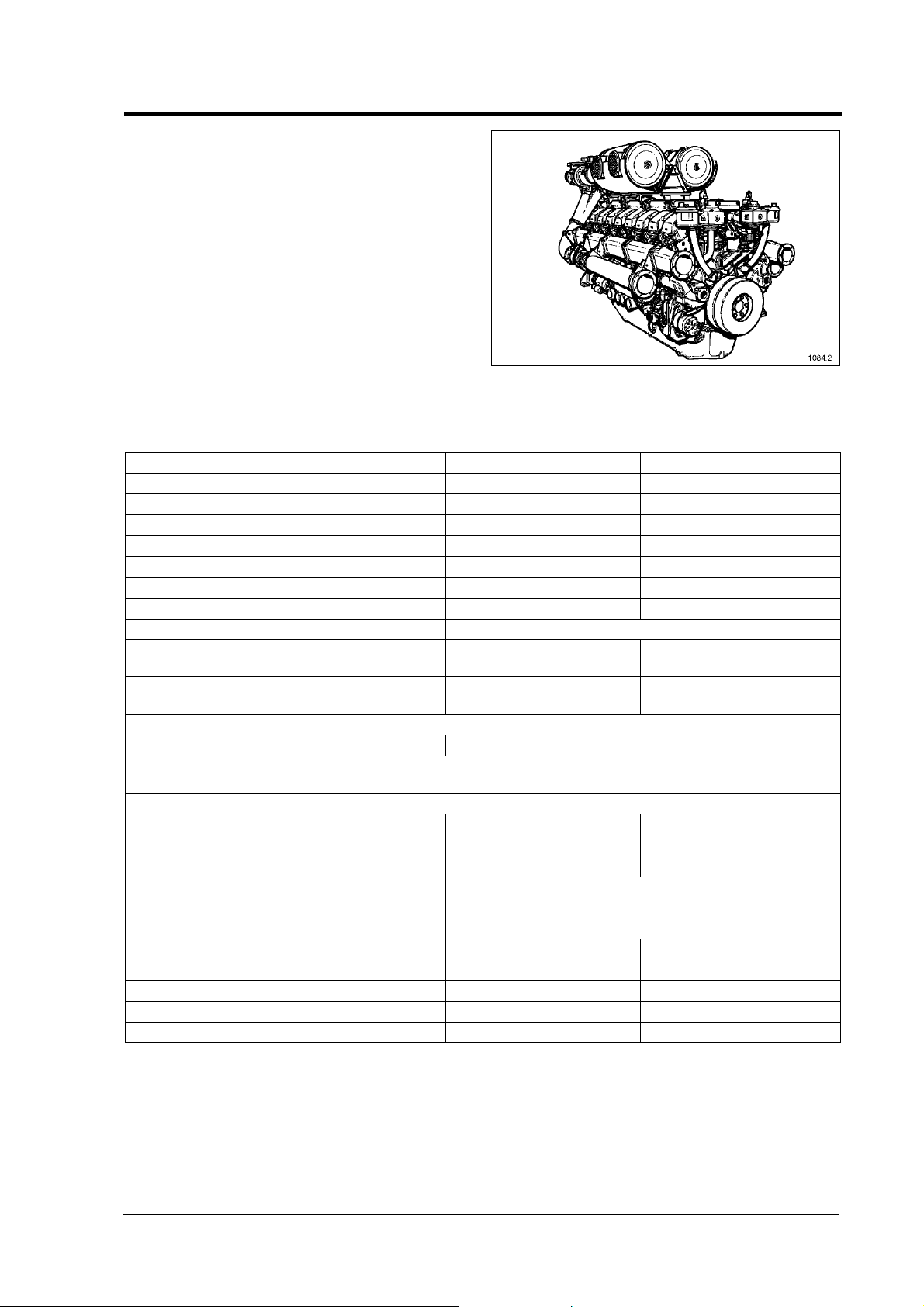

4016 TAG1

4016 TAG2

TSL4186E, Issue 1

February 1998

H

4000 Series

andbook

Diesel

Page 2

4012/16 Diesel, February 1997

WARNING

READ AND UNDERSTAND ALL SAFETY PRECAUTIONS AND

WARNINGS MENTIONED IN THIS MANUAL.

IMPROPER OPERATION OR MAINTENANCE PROCEDURES COULD

RESULT IN A SERIOUS ACCIDENT OR DAMAGE TO THE EQUIPMENT

CAUSING INJURY OR DEATH.

NON-COMPLIANCE WITH THESE INSTRUCTIONS AND THOSE

INCLUDED IN THE INSTALLATION MANUAL TSL4068 MAY

INVALIDATE THE WARRANTY OFFERED WITH THE ENGINE.

MAKE QUITE CERTAIN THAT THE ENGINE CANNOT BE STARTED IN

ANY WAY BEFORE UNDERTAKING ANY MAINTENANCE,

PARTICULARLY IN THE CASE OF AUTOMATICALLY STARTING

GENERATING SETS.

Page 3

INTRODUCTION

4012/16 Diesel, February 1997 1

The purpose of this Operators Handbook is to enable the operator to carry out routine servicing of the engine.

Before undertaking any work on the engine the appropriate section in the

Workshop Manual should be read

fully and completely understood prior to starting work.

The information contained within this Operators Handbook is based on such information as was available at

the time of going to print. In line with Perkins Engines (Stafford) Limited policy of continual development and

improvement that information may change at any time without notice. The engine user should therefore ensure

that he has the latest information before starting work.

The instructions contained in this Operators Handbook will, provided that they are correctly carried out, ensure

the safe operation of the equipment.

Users are respectfully advised that it is their responsibility to employ competent persons to operate, maintain

and service the equipment in the interest of safety.

Certain overhaul operations are impracticable without the use of special tools, and those operators who are

not equipped to undertake major repairs are urged to consult their Perkins distributor.

When not working on the engine, ensure that all covers, blank flanges, doors, etc., are refitted to openings to

prevent the ingress of dirt, etc.

Please quote the engine type and serial number with all your enquiries. This will help us to help you. The type

and serial number are on a plate fitted to the crankcase.

If any doubt exists regarding the installation, use or application of the engine, the Installation Manual should

be consulted for further advice contact Applications Department at Perkins Engines (Stafford) Ltd.

Oil change intervals may be changed according to operating experience by agreement with Perkins Engines

(Stafford) Limited and subject to oil analysis being carried out at regular intervals.

Please note that this 4000 Series manual also covers SE engines dispatched from the factory from 1 March

1996. A table of equivalent engine designations is given on page 2.

PERKINS COMPANIES

P

erkins Group of Companies

Perkins Engines (Peterborough) Ltd.

Frank Perkins Way, Eastfield,

Peterborough, PE1 5NA, England.

Tel: (01733) 67474

Telex: 32501 PERKEN G

Fax: (01733) 582240

Perkins Engines (Shrewsbury) Ltd.

Lancaster Road, Shrewsbury,

SY1 3NX, England.

Tel: (01743) 212000

Telex: 35171/2 PESL G

Fax: (01743) 212700

Perkins Engines (Stafford) Ltd.

Tixall Road, Stafford, ST16 3UB, England.

Tel: (01785) 223141

Telex: 36156 PERKEN G

Fax: (01785) 215110

Perkins Powerpart Distribution Centre

Frank Perkins Way,

Northbank Industrial Park, Irlam,

Manchester, M44 5PP, England.

Tel: (0161) 776 5000

Specifications Help Desk

Tel: (0161) 776 5151

Fax: (0161) 776 5200

Specifications Help Desk

Tel: (0161) 776 5100

Telex: 32501 PERKEN G

Perkins International - North America

12025 Tech Center Drive,

Livonia, Michigan 48150,

U.S.A.

Tel: 313 266 5427

Fax: 313 266 2700

Perkins Engines Latin America Inc

999 Ponce de Leon Boulevard,

Suite 710, Coral Gables,

Florida 33134, U.S.A.

Tel: (305) 442 7413

Telex: 32501 PERKEN G

Fax: (305) 442 7419

Perkins Engines Australia Pty Ltd

Suite 2, 364 Main Street, Mornington

3391, Victoria, Australia.

Tel: (059) 75 1877

Telex: 30816

Fax: (059) 75 1305

Motori Perkins SpA

Via Socrate. 8,22070 Casnate

Con Bernate (Como), Italy.

Tel: 031 56 46 25 / 031 56 46 33

Telex: 380658 PERKIT I

Fax: 031 24 90 92 / 031 56 41 45

Perkins Motoren GmbH

D-63801 Kleinostheim,

Saalackerstrasse 4, Germany.

Tel: (49) (6027) 5010

Fax: (49) (6027) 501130

Moteurs Perkins SA

9 Avenue Michelet, 93583 Saint Quen,

Cedex, France.

Tel: (1) 40 10 71 / (1) 40 10 42 49

Telex: 234 924

Fax: (1) 40 10 42 45

A/S Perkins Engines (Denmark) Ltd

Industrihaven 1, DK-3300

Frederiksvaerk, Denmark.

Tel: (45) 47 771055

Fax: (45) 47 771981

Perkins International Ltd.

Varity Asia/Pacific

Suite 3301, Convention Plaza,

1 Harbour Road, Wanchai,

Hong Kong.

Tel: 852 2588 1883

Fax: 852 2827 2311

Varity (Japan) K.K.

5th Floor, Reinanzaka Building,

14-2 Akasaka 1 - Chome,

Minato-Ku Tokyo 107, Japan.

Tel: (03) 3586 7377

Telex: PERKOIL 12424823

Fax: (03) 3582 1596

Perkins Engines (Far East) Pte Ltd.

39 Tuas Avenue 13,

Singapore 638999.

Tel: (65) 861 1318

Fax: (65) 861 6252

In addition to the above companies, there are Perkins distrib

utors in most countries. Perkins Engines

(Peterborough) Limited or one of the above companies can provide details.

Publication TSL4186

Published by the Technical Publications Department, Stafford.

© 1997 Perkins Engines (Stafford) Limited.

Page 4

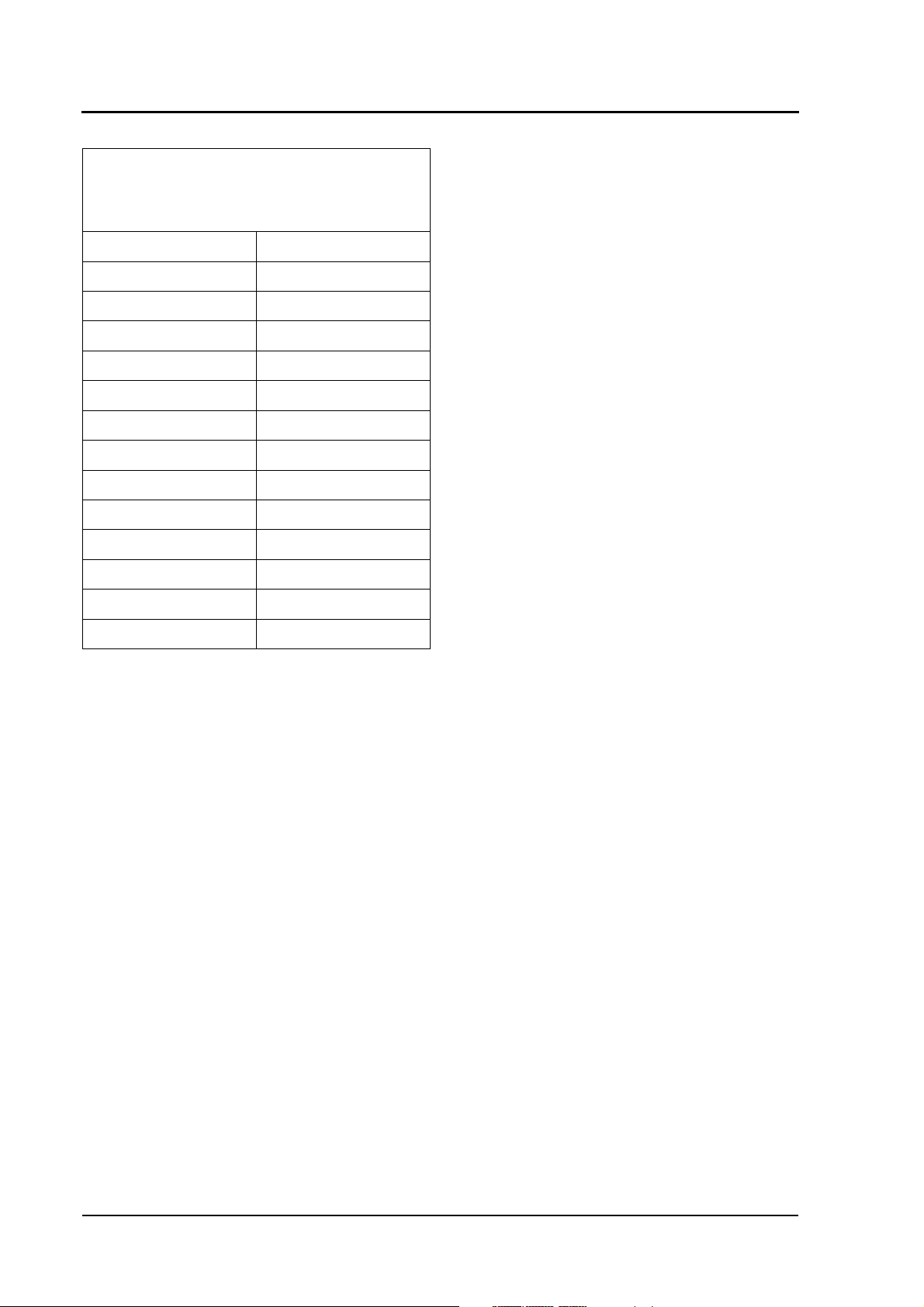

ENGINE DESIGNATIONS

2 4

012/16 Diesel, February 1997

PERKINS ENGINES (STAFFORD)

ENGINE DESIGNATIONS

4000 SERIES AND SE SERIES

EQUIVALENT TERMS

4000 SERIES SE SERIES

4012TWG 12SETCR

4012TAG 12SETCR2

4012TAG1 12SETCA

4012TA2 12SETCA1

4012TEG 12SETCA2

4012TEG2 12SETCW

4016TWG 12SETCW2

4016TWG2 16SETCR

4016TAG 16SETCR2

4016TAG1 16SETCA

4016TAG2 16SETCA2

4016TEG 16SETCW

4016TEG2 16SETCW2

Page 5

CONTENTS

4012/16 Diesel, February 1997 3

PAGE

INTRODUCTION 1-2

CONTENTS 3

SAFETY PRECAUTIONS INSERT

PHOTOGRAPHS 6-7

BRIEF DESCRIPTION OF THE 4012 & 4016 ENGINES 8

GENERAL INFORMATION 9-10

ENGINE DATA 11-15

TORQUE SETTINGS 16-18

LUBRICATING OIL 19-20

COOLANT CORROSION INHIBITORS AND ANTI-FREEZE 21

FUEL SPECIFICATION 22

OPERATING INSTRUCTIONS 23-32

PREPARATION FOR INITIAL START 23

PRIMING THE TURBOCHARGERS 23-24

BATTERIES 25

PRIMING THE FUEL SYSTEM 26-27

FILLING THE COOLING SYSTEM 27

INITIAL STARTING OF THE ENGINE 28

NORMAL STARTING PROCEDURE 30

ENGINE SHUTDOWN 31

LIGHT LOAD OPERATION AND STANDBY GENERATOR SETS 32

INSTRUMENT PANEL 33-35

EXHAUST TEMPERATURE GAUGE 36-38

MAINTENANCE SCHEDULE AND CHECKLIST 39-60

PREVENTIVE MAINTENANCE 61-62

STANDBY DUTY CHECKLIST 61

CONTINUOUS DUTY CHECKLIST 62

FAULT TRACING 63

4012 STARTING CIRCUIT, SINGLE STARTER (EARLY ENGINES) 64

4012/16 STARTING CIRCUIT, STARTERS AND START RELAYS (EARLY ENGINES) 65

4012/16 WIRING DIAGRAM, STARTER, GOVERNOR (EARLY ENGINES) 66

4012/16 WIRING DIAGRAM, STARTERS & RELAYS, GOVERNOR (EARLY ENGINES) 67

4012/16 WIRING DIAGRAM, SINGLE STARTER, GOVERNOR (EARLY ENGINES) 68

4012/16 WIRING DIAGRAM, TWIN STARTERS, SINGLE START RELAY,

ORIGINAL AIR SHUT OFF VALVES 69

4012/16 WIRING DIAGRAM, TWIN STARTERS, SINGLE START RELAY,

ELECTRONIC GOVERNOR (LATER ENGINES) 70

4012/16 WIRING DIAGRAM, TWIN STARTERS, ELECTRONIC GOVENOR,

(INTERMEDIATE ENGINES) 71

4016 WIRING DIAGRAM, TWIN STARTERS, ELECTRONIC GOVENOR

(INTERMEDIATE ENGINES) 72

4012 WIRING DIAGRAM, TWIN STARTERS, ELECTRONIC GOVENOR

(CURRENT ENGINES) 73

4016 WIRING DIAGRAM, TWIN STARTERS, ELECTRONIC GOVENOR

(CURRENT ENGINES) 74

4012/16 SERIES LUBRICATION OIL DIAGRAM TP315

4012/16TAG WATER CIRCULATION DIAGRAM TP372

4012/16TWG WATER CIRCULATION DIAGRAM TP373

4012/16TEG WATER CIRCULATION DIAGRAM TP374

4012 SERIES FUEL SYSTEM DIAGRAM TP321

4016 SERIES FUEL SYSTEM DIAGRAM TP375

Page 6

PHOTOGRAPHS

6 4

012/16 Diesel, February 1997

4012 TAG

4012 TAG

Page 7

PHOTOGRAPHS

4012/16 Diesel, February 1997 7

4016 TAG

4016 TAG

Page 8

BRIEF DESCRIPTION OF THE 4012/16 SERIES DIESEL ENGINES

8 4

012/16 Diesel, February 1997

4012TWG 12 cylinder "V" form diesel engine, water cooled, turbocharged (twin

turbochargers), jacket water cooled charge air coolers and oil coolers in

engine cooling circuit. Earlier engines with vertical air cleaners, later engines

with horizontal air cleaners.

4012TWG2 Up rated version of the 4012TWG 12 cylinder "V" form diesel engine, water

cooled, turbocharged (twin turbochargers) jacket water cooled charge air

coolers in engine cooling circuit. Horizontal air cleaners.

4012TAG 12 cylinder "V" form diesel engine, water cooled, turbocharged (twin

turbochargers), air cooled charge air intercooler in radiator. Oil coolers in

engine cooling circuit. Earlier engines with vertical air cleaners, later engines

with horizontal air cleaners.

4012TAG1 Up rated version of the 4012TAG 12 cylinder "V" form diesel engine, water

cooled, turbocharged (twin turbochargers) air cooled charge air intercooler in

radiator. Oil coolers in engine cooling circuit. Horizontal air cleaners.

4012TAG2 Up rated version of the 4012TAG1 12 cylinder "V" form diesel engine, water

cooled, turbocharged (twin turbochargers), air cooled charge air intercooler in

radiator. Oil coolers in engine cooling circuit. Horizontal air cleaners.

4012TEG 12 cylinder "V" form diesel engine, water cooled, turbocharged (twin

turbochargers), raw water cooled charge air coolers with raw water pump and

separate cooling circuit. Oil coolers in engine cooling circuit. Earlier engines

with vertical air cleaners, later engines with horizontal air cleaners.

4012TEG2 12 cylinder "V" form diesel engine, water cooled, turbocharged (twin

turbochargers), raw water cooled charge air coolers with raw water pump and

separate cooling circuit. Oil coolers in engine cooling circuit. Horizontal air

cleaners.

4016TWG 16 cylinder "V" form diesel engine, water cooled, turbocharged (twin

turbochargers), jacket water cooled air coolers and oil coolers in engine

cooling circuit. Horizontal air cleaners.

4016TWG2 Up rated version of the 4016TWG 16 cylinder "V" form diesel engine, water

cooled, turbocharged (four turbochargers), jacket water cooled charge air

coolers and oil coolers in engine cooling circuit. Horizontal air cleaners.

4016TAG 16 cylinder "V" form diesel engine, water cooled, turbocharged (twin

turbochargers), air cooled charge air intercooler in radiator. Oil coolers in

engine cooling circuit. Earlier engines with vertical air cleaners, later engines

with horizontal air cleaners.

4016TAG1 Up rated version of the 4016TAG 16 cylinder "V" form diesel engine, water

cooled, turbocharged (four turbochargers) air cooled charge air intercooler in

radiator. Oil coolers in engine cooling circuit. Horizontal air cleaners.

4016TAG2 Up rated version of the 4016TAG1 16 cylinder "V" form diesel engine, water

cooled, turbocharged (four turbochargers) air cooled charge air intercooler in

radiator. Oil coolers in engine cooling circuit. Horizontal air cleaners.

4016TEG 16 cylinder "V" form diesel engine, water cooled turbocharged (twin

turbochargers) raw water cooled charge air coolers with raw water pump and

separate cooling circuit. Oil coolers in engine cooling circuit. Earlier engines

with vertical air cleaners, later engines with horizontal air cleaners.

4016TEG1

AND

4016TEG2

Uprated versions of the 4016TEG 16 cylinder "V" form diesel engine, water

cooled, turbocharged (four turbochargers), raw water cooled charge air

coolers with raw water pump and separate cooling circuit. Oil coolers in

engine cooling circuit. Horizontal air cleaners.

Page 9

GENERAL INFORMATION

4012/16 Diesel, February 1997 9

SAFETY

Engine lift equipment

Use only the lift equipment which is designed

for the engine.

Use lift equipment or obtain assistance to lift

heavy engine components such as the

cylinder block, cylinder head, flywheel

housing, crankshaft and flywheel.

Check the engine lift brackets for security

before the engine is lifted.

Asbestos joints

Some joints and gaskets contain

compressed asbestos fibres see Warning

label Fig. A in a rubber compound or in a

metal outer cover. The 'white' asbestos

(Chrysotile) which is used is a safer type of

asbestos and the danger of damage to

health is extremely small.

Contact with asbestos particles normally

occurs at joint edges or where a joint is

damaged during removal, or where a joint is

removed by an abrasive method.

To ensure that the risk is kept to a minimum,

the procedures given below must be

followed when an engine which has

asbestos joints is dismantled or assembled.

● Work in an area with good ventilation.

● Do NOT smoke.

● Use a hand scraper to remove the joints

-

do NOT use a rotary wire brush.

● Ensure that the joint to be removed is

w

et with oil or water to contain any loose

particles.

● Spray all asbestos debris with water and

place it in a closed container which can

be sealed for safe disposal.

Dangers from used engine oils

Prolonged and repeated contact with mineral

oil will result in the removal of natural oils

from the skin, leading to dryness, irritation

and dermatitis. The oil also contains

potentially harmful contaminants which may

result in skin cancer.

Adequate means of skin protection and

washing facilities should be readily available.

The following is a list of 'Health Protection

Precautions', suggested to minimise the risk

of contamination.

1 Avoid prolonged and repeated contact

with used engine oils.

2 Wear protective clothing, including

impervious gloves where applicable.

3 Do not put oily rags into pockets.

4 Avoid contaminating clothes,

particularly underwear, with oil.

5 Overalls must be cleaned regularly.

Discard unwashable clothing and oil

impregnated footwear.

6 First aid treatment should be obtained

immediately for open cuts and wounds.

7 Apply barrier creams before each period

of work to aid the removal of mineral oil

from the skin.

8 Wash with soap and hot water, or

alternatively use a skin cleanser and a

nail brush, to ensure that all oil is

removed from the skin. Preparations

containing lanolin will help replace the

natural skin oils which have been

removed.

9 Do NOT use petrol, kerosene, diesel

fuel, gas oil, thinners or solvents for

washing the skin.

10 If skin disorder appears, medical advice

must be taken.

11 Degrease components before handling

if practicable.

12 Where there is the possibility of a risk to

the eyes, goggles or a face shield

should be worn. An eye wash facility

should be readily available.

Fig. A

Page 10

GENERAL INFORMATION

4012/16 Diesel, February 1997 1

0

Environmental protection

There is legislation to protect the

environment from the incorrect disposal of

used lubricating oil. To ensure that the

environment is protected, consult your Local

Authority who can give advice.

Viton seals

Some seals used in engines and in

components fitted to engines are made from

Viton.

Viton is used by many manufacturers and is

a safe material under normal conditions of

operation.

If Viton is burned, a product of this burnt

material is an acid which is extremely

dangerous. Never allow this burnt material

to come into contact with the skin or with the

eyes.

If it is necessary to come into contact with

components which have been burnt, ensure

that the precautions which follow are used:

● Ensure that the components have

c

ooled.

● Use Neoprene gloves and discard the

gloves safely after use.

● Wash the area with a calcium hydroxide

solution and then with clean water.

● Disposal of gloves and components

which are contaminated, must be in

accordance with local regulations.

If there is contamination of the skin or eyes,

wash the affected area with a continuous

supply of clean water or with a calcium

hydroxide solution for 15-60 minutes. Obtain

immediate medical attention.

Page 11

DIESEL ENGINE DATA

4012/16 Diesel, February 1997 1

1

For full technical data please refer to the Product Information Manual.

Type: Water-cooled, turbocharged, charge cooled, industrial diesel engine.

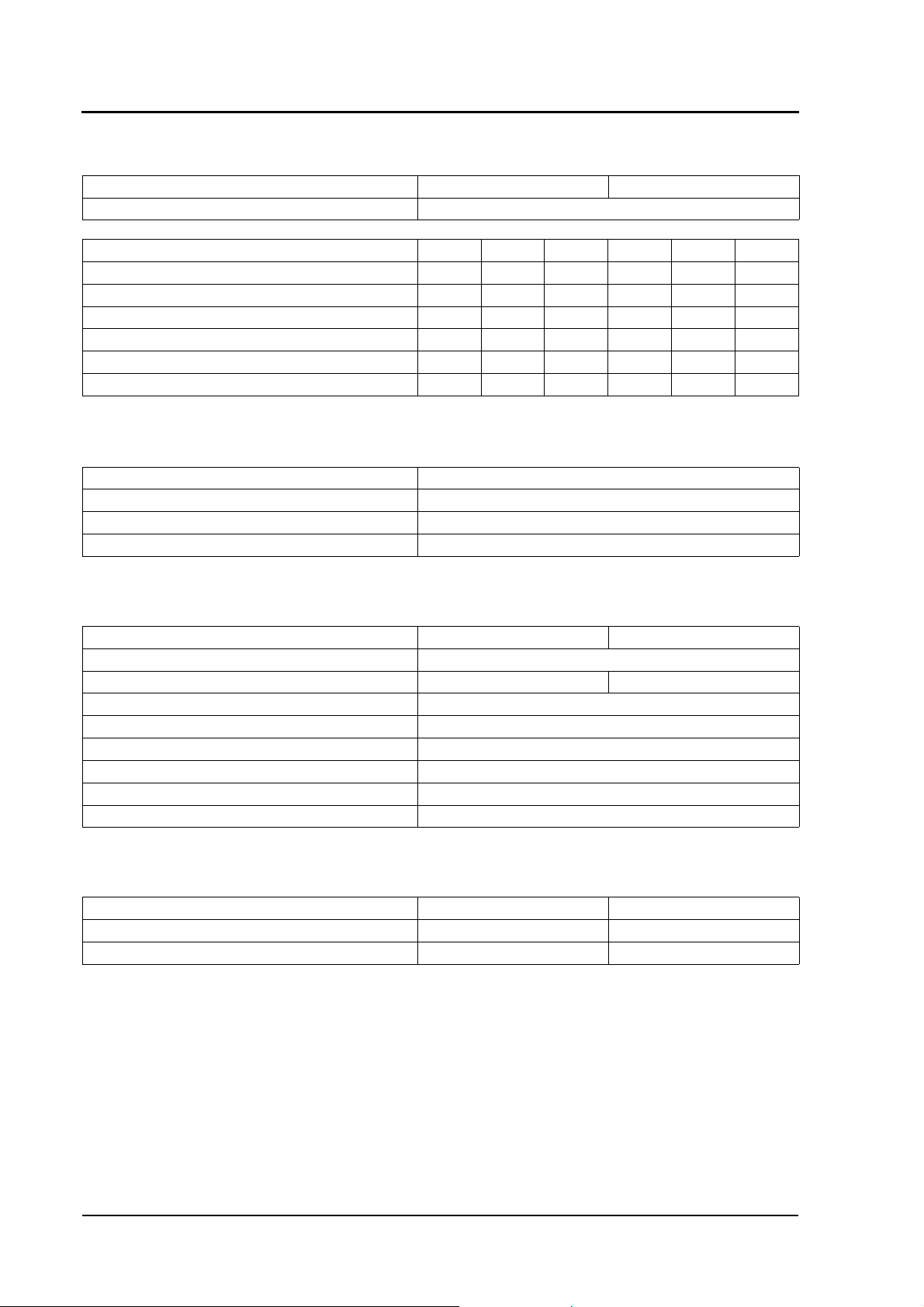

RANGE 4

012 4016

Cycle 4 stroke 4 stroke

No. of cylinders 12 16

Configuration V-form V-form

Bore 160 mm 160 mm

Stroke 190 mm 190 mm

Total swept volume 45,84 litres 61,123 litres

Compression ratio 13,6:1 13,6:1

Rotation Anti-clockwise looking on flywheel end

Firing order

1A-6B-5A-2B-3A-4B-

6A-1B-2A-5B-4A-3B

1A-1B-3A-3B-7A-7B-5A-5B-

8A-8B-6A-6B-2A-2B-4A-4B

Valve Timing

inlet valve opens 60° BTDC

inlet valve closes 46° ABDC

exh valve opens 46° BBDC

exh valve closes 60° ATDC

Cylinder numbering Cylinder 1 furthest from flywheel

Cylinders designated A are on the right hand side of the engine, when viewed from the fly-wheel end and cylinders

designated B are on the left hand side of the engine.

Valve Clearances exhaust 0,40 mm (0,016”)

(Engine cold) inlet 0,40 mm (0,016”)

Valve dia. (mm) inlet and exhaust 48 48

(52 on 4012TAG1/2 AND 4016TAG1/2)

Valve Timing See Workshop Manual Sections U4 and U5

Injection Timing S

ee engine nameplate

Piston Speeds Engine r/min m/s (ft/min)

1000 6,33 (1247)

1200 7,60 (1496)

1500 9,50 (1870)

1800 11,40 (2244)

Fig. B

‘A’ BANK

‘B’ BANK

Page 12

DIESEL ENGINE DATA

12 4

012/16 Diesel, February 1997

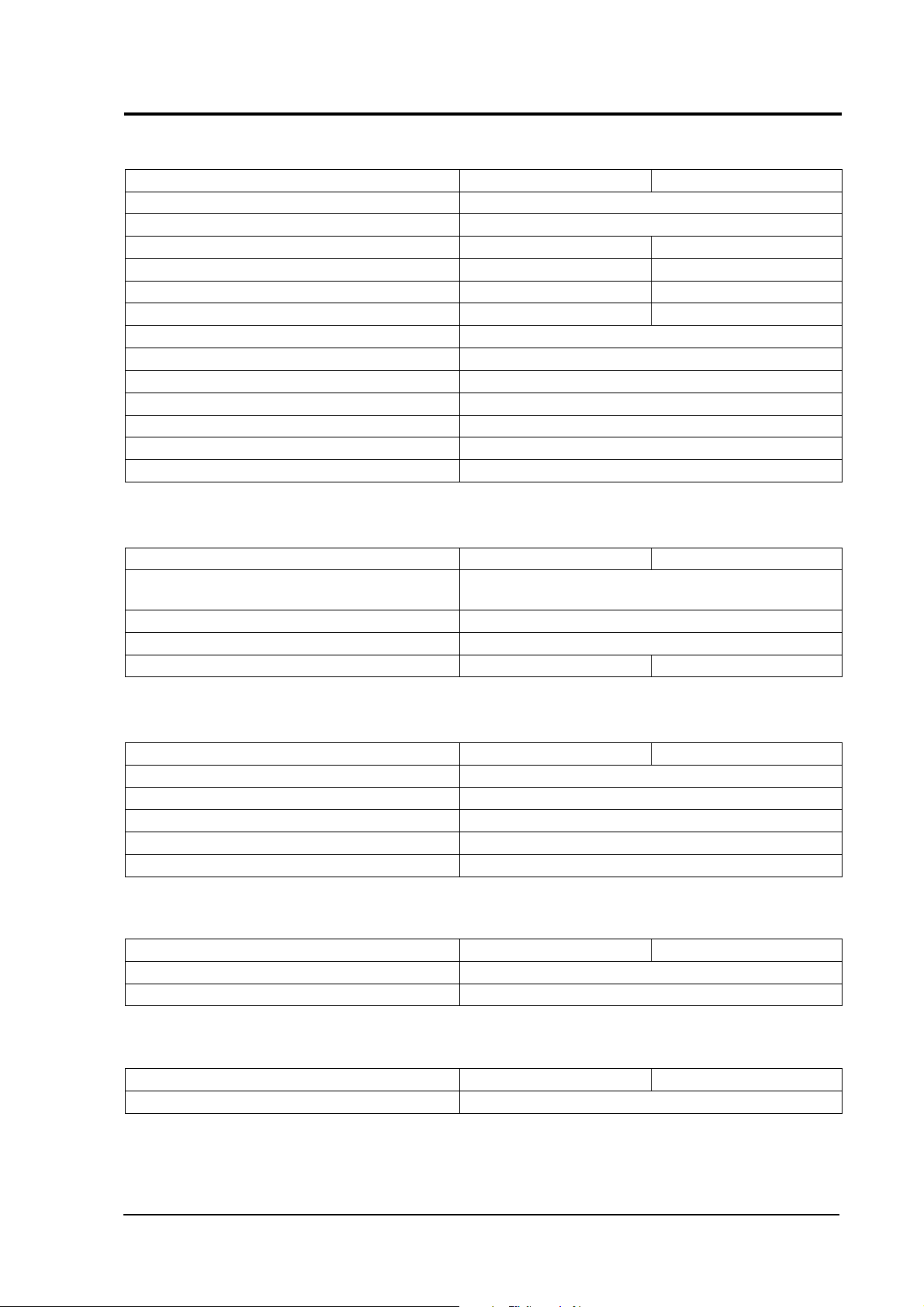

TYPICAL COOLING SYSTEM

* Engine only

*

* Engine with heat exchanger

FUEL SYSTEM

G

OVERNORS

4006 4008

Approved Coolants) See page 21

Total water capacity L

trs Gals Spec Ltrs Gals Spec

200 44 TAG 255 56.1 TAG

232 51 TAG1 316 70 TAG1

232 51 TAG2 316 70 TAG2

185 40 TWG 95 21 TWG*

205 45 TWG2 95 21 TWG2*

82 18 TEG** 108 23.7 TEG**

Max radiator top tank temperature 93°C

Max water temperature into engine 80°C

Thermostat opening temperature 71°C

System pressure 0.5 to 0.7 bar

4012 4016

Approved fuels See

page 20

Minimum size fuel tank 14000 litres (3000 gal.) 18000 litres (

4000 gal.)

Relief valve setting 310 kPA (45 psi)

Inferior nozzle pressure 225-235 atm

Injection equipment Lucas-Bryce unit injector

Filter/water separator Spin-on expandable canister(s)

Fuel lift pump Maximum suction lift 1 metre

Fuel flow 20.457 litre/min. (4.5 gpm) @ 1800 r/min

4012 4016

Type Electronic Electronic

Type Hydraulic Hydraulic

Page 13

DIESEL ENGINE DATA

4012/16 Diesel, February 1997 1

3

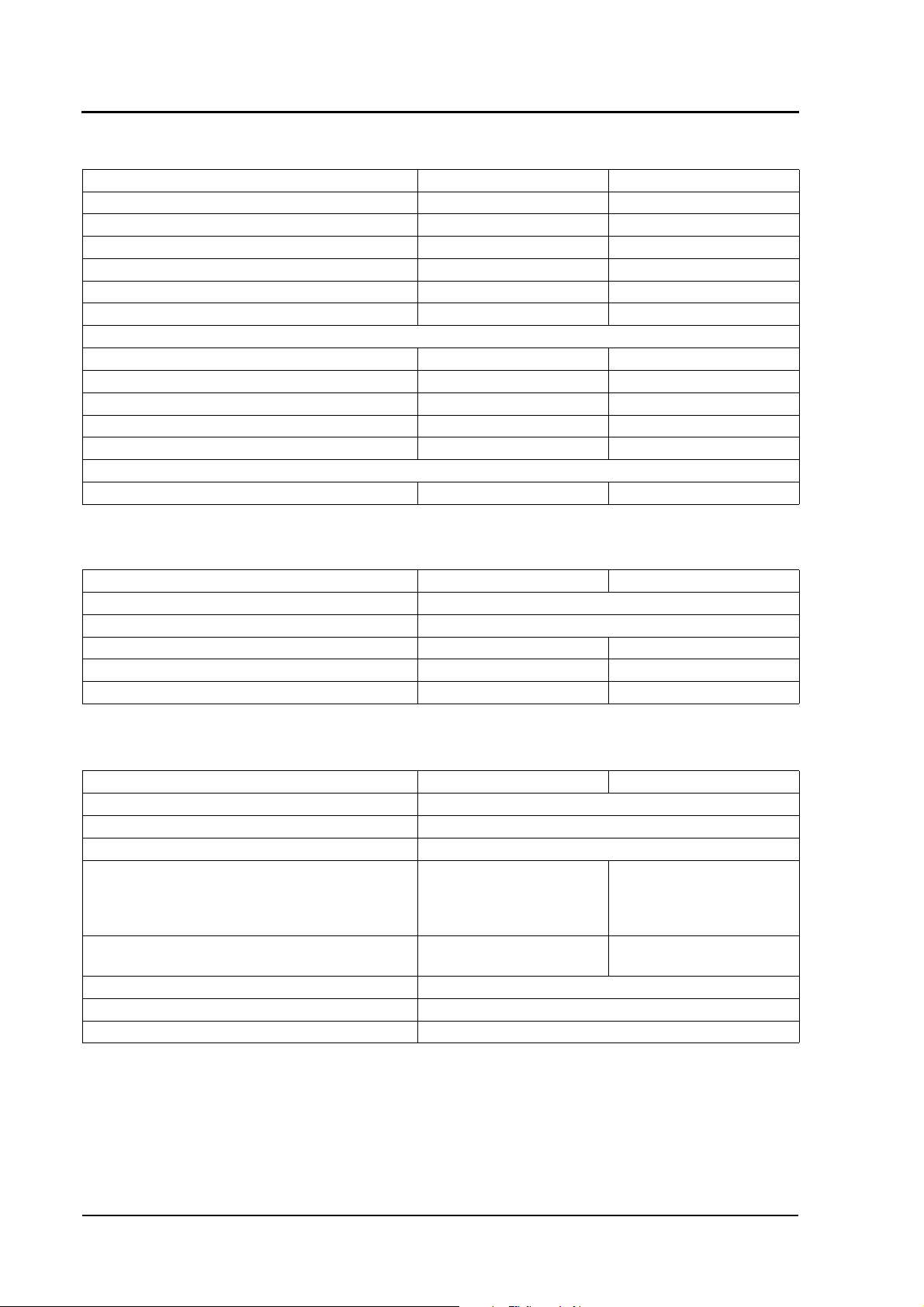

LUBRICATION SYSTEM

INDUCTION SYSTEM

EXHAUST SYSTEM

FLYWHEEL

FLYWHEEL HOUSING

4012 4016

Recommended oil See

pages 19 and 20

Type of system Wet sump, external engine mounted oil pump

Total oil capacity (including cooler and filter) 178 litre (39.2 gal) 238 litre (53 gal)

Sump capacity (dipstick)

Min. 136 litre (30 gal) 147 litre (33 gal)

Max. 159 litre (35 gal) 214 litre (47 gal)

Crankcase pressure (max) 25 mm (1”) water gauge

Lubricating oil temperature max. to bearings 105°C

Lubricating oil pressure at 80°C temp. to bearings 0.34 mPa

Max. oil temperature in sump 115°C

Min. oil pressure (1500 rpm)(at filter head) 200 kPa (30 lb/in²)

Oil filter Disposable canister type

Oil pump location ‘A’ Bank

4012 4016

Air cleaners (earlier)

(current)

Twin vertical air cleaners

Twin horizontal air cleaners

Type Paper element

Air restriction indicator setting 380 mm H

2

0

T

urbochargers x2 off x4 off

4012 4016

Manifold Type Dry or water cooled

Exhaust outlet flange Vertical (Twin)

Mating flange See Installation Manual

Max. exhaust back pressure See Product Information Manual

Max. exhaust temperature

4

012 4016

Drive size SAE 18”

SAE 21” Optional

4012 4016

SAE size 00

Page 14

DIESEL ENGINE DATA

14 4

012/16 Diesel, February 1997

TYPICAL DRY WEIGHT

HOLDING DOWN BOLT HOLES

ELECTRICAL SYSTEM

4012 4016

Dry weight (engine) 4360 kg 4012TAG 5500 kg 4016TAG

4360 kg 4012TAG1 5750 kg 4016TAG1

4400 kg 4012TAG2 5750 kg 4016TAG2

4975 kg 4012TWG 5940 kg 4016TWG/2

5315 kg 4012TWG2 5820 kg 4016TEG

4680 kg 4012TEG2

Dry weight engine & tropical radiator 5280 kg 4012TAG 6900 kg 4016TAG

5760 kg 4012TAG1 8010 kg 4016TAG1

5800 kg 4012TAG2 8010 kg 4016TAG2

4995 kg 4012TWG

5315 kg 4012TWG/2

Dry weight engine & heat exchanger 4860 kg 4012TEG 6000 kg 4016TEG

4012 4016

Hole dia. (Engine feet) 22 mm

No. off 8

Hole dia. (Radiator feet) 18 mm x 6 4012TAG 22 mm x 6 4016TAG/2

Turbochargers 22 mm x 6 4012TAG2

22 mm x 6 4012TWG/1

4012 4016

Voltage 24V

Alternator Belt Driven

Alternator output 30A

Starter motor

Single CAV

(Earlier Engines)

Twin Prestolite

(Current Engines)

Twin Prestolite

No. of teeth (gear ring)

144 (Early Engines)

156 (Current Engines)

156

No. of teeth (starter pinion) 12

Battery (lead acid) 24V DC (2 x 12V)

Capacity down to 0°C (32°F) 286 Ah

Page 15

DIESEL ENGINE DATA

4012/16 Diesel, February 1997 1

5

PROTECTION EQUIPMENT

Before resetting protection equipment, it must be established whether special settings (for

that individual engine) have been specified in the engine sales contract. This is particularly

important with ALL

high water temperature settings, and ALL Cogen applications.

Standard settings for protection equipment are as follows:-

Caution: The above standard settings do not supersede any settings specified in the engine

sales contract.

AIR STARTING

INSTRUMENT PANEL (ENGINE MOUNTED)

COOLANT JACKET HEATING

Alarm Shutdown

High Oil temperature (in sump) 110°C 115°C

Low oil pressure 2.06 bar (30 lb/in²) 1.93 bar (28 lb/in²)

High water temperature

71°C Thermostat 91°C 96°C

85°C Thermostat 96°C 101°C

96°C Thermostat 100°C 105°C

Overspeed

15% above max. running speed

(Except 1800 r/min which is 7%)

4012 4016

Air starter See I

nstallation Manual

Air starter pressure 150 lb/in2(10.34 bar)

Compressed air supply 170 lb/in2(11.72 bar)

Normal Operation

Oil pressure Between 276-413 kPa (40-60 lb/in²)

Oil temperature Between 80-90°C (176-194°F)

Water temperature Between 65-85°C (149-185°F)

Exhaust temperature See Product Information Manual

4012 4016

H

eater 2 x 4 kW

Voltage 210-250V ac

Page 16

TORQUE SETTINGS

16 4

012/4016 Diesel, February 1997

NOTE: * Bolt heads and threads must be lubricated with clean engine oil.

** Cylinder head bolts to be lubricated under the heads, under the washers and on

the threads with PBC (Poly-Butyl-Cuprysil) grease. Important: See Workshop Manual

S

ection R11

before fitting. However, d

ry threads are required for connecting rod bolts and

the raw water pump shaft nut, but all other threads only to be lubricated with clean engine

oil and care must be taken NOT to oil the heads or faces.

TORQUE SETTINGS

CYLINDER HEAD GROUP lbf.ft Nm

Cylinder head bolt ** (early type) M24 550 750

Cylinder head bolt ** (later waisted type) M24 530 720

Rocker shaft capscrew/nut M16 90 120

Rocker adjuster nuts inlet/exhaust M12 35 50

Rocker adjuster nuts pump injectors M14 50 70

Injector clamp capscrews M12 70 95

Bridge piece adjuster nuts M10 25 35

Injector clamp to cylinder head capscrews M12 70 95

Rocker box bolts M10 35 50

Air manifold bolt M10 35 50

Exhaust manifold bolts M10 50 70

Exhaust bellows to exhaust manifold (16 cyl only)

prevailing torque bolts / nuts M10 45 60

Exhaust Y piece (16 cyl only) prevailing torque bolts M10 38 50

Schwitzer turbocharger 'V'-band clamp nuts M8 8 11

Sandwich plate retaining capscrews M10 35 50

CRANKCASE AND CRANKSHAFT GROUPS

Main bearing bolts * See Section W4 M24 580 786

L

ateral capscrews, main bearing caps for sequence M16 124 168

Bolts sump to crankcase M10 40 54

New connecting rod bolts (must be fitted with dry threads) M16 210 285

Inspection covers M10 35 50

Viscous damper bolts M16 250 340

Flywheel bolts See

Section X3 for sequence M16 250 340

F

ront drive adaptor bolts (12 cylinder engines only) M16 250 340

Front drive adaptor bolts (16 cylinder engines only) M20 380 520

Balance weight bolts M16 250 340

Crankshaft pulley bolts M16 250 340

Piston cooling jet screws M10 20 27

Flywheel housing bolts M10 35 50

Lifting bracket Durlock screws M10 50 70

WARNING

IT IS ESSENTIAL THAT THE CORRECT LENGTH OF SCREW OR

BOLT IS USED. INSUFFICIENT LENGTH MAY RESULT IN THE

THREAD BEING STRIPPED, WHEREAS TOO LONG A THREAD MAY RESULT IN

BOTTOMING IN A BLIND HOLE, OR CATCHING ON ADJACENT COMPONENTS.

Page 17

TORQUE SETTINGS

4012/4016 Diesel, February 1997 1

7

LUBRICATING OIL PUMP lbf.ft Nm

Bolts, pump housing to gearcase plate M10 35 50

Thin nut, gear to drive shaft M30 175 237

CAMSHAFT GROUP

Camshaft gear bolt M12 110 150

Camshaft thrust plate bolt M10 35 50

Camshaft follower housing bolt M10 35 50

Idler gear hub bolts M10 35 50

WATER PUMP

Water pump gear nut M24 170 230

Water header to oil cooler bolts M10 35 50

Water pump to gearcase bolts M10 35 50

Raw water pump gear securing nut, dry thread M35 180 244

ENGINE FEET

Engine feet to base frame bolts M20 350 475

Engine feet to cushion feet bolts M16 160 215

Engine feet to gearcase and suspension plate bolt M12 70 95

GOVERNOR

Control shaft mounting plate bolt M10 35 50

FAN

Fan driven pulley taper lock bush screws 1/2" BSW 35 50

Fan driven pulley taper lock bush screws 5/8" BSW 65 90

ALTERNATOR

Drive pulley taper lock bush screw 3/8" BSW 15 20

FUEL PUMP/INJECTORS

Injector capscrew clamp to cylinder head, early engines M10 50 70

Injector capscrew clamp to cylinder head, later engines M12 70 95

Injector nozzle nut to holder M27 150 203

Fuel pump control linkage screw 2BA 6 8

Unit injector control lever capscrews M5 6 8

FLEXIBLE COUPLING

Flexible coupling cover screw M12 or 1/2" UNC 47 64

Coupling driving flange screws (coupling size 2.15) M12 or 1/2" UNC 47 64

Coupling driving flange screws (coupling size 3.86) M16 or 5/8" UNC 114 155

Page 18

TORQUE SETTINGS

18 4

012/4016 Diesel, February 1997

GENERAL TORQUE LOADINGS

The following torque loadings are general for metric coarse threads and for grade 8.8 steel,

but do not supersede the figures quoted above.

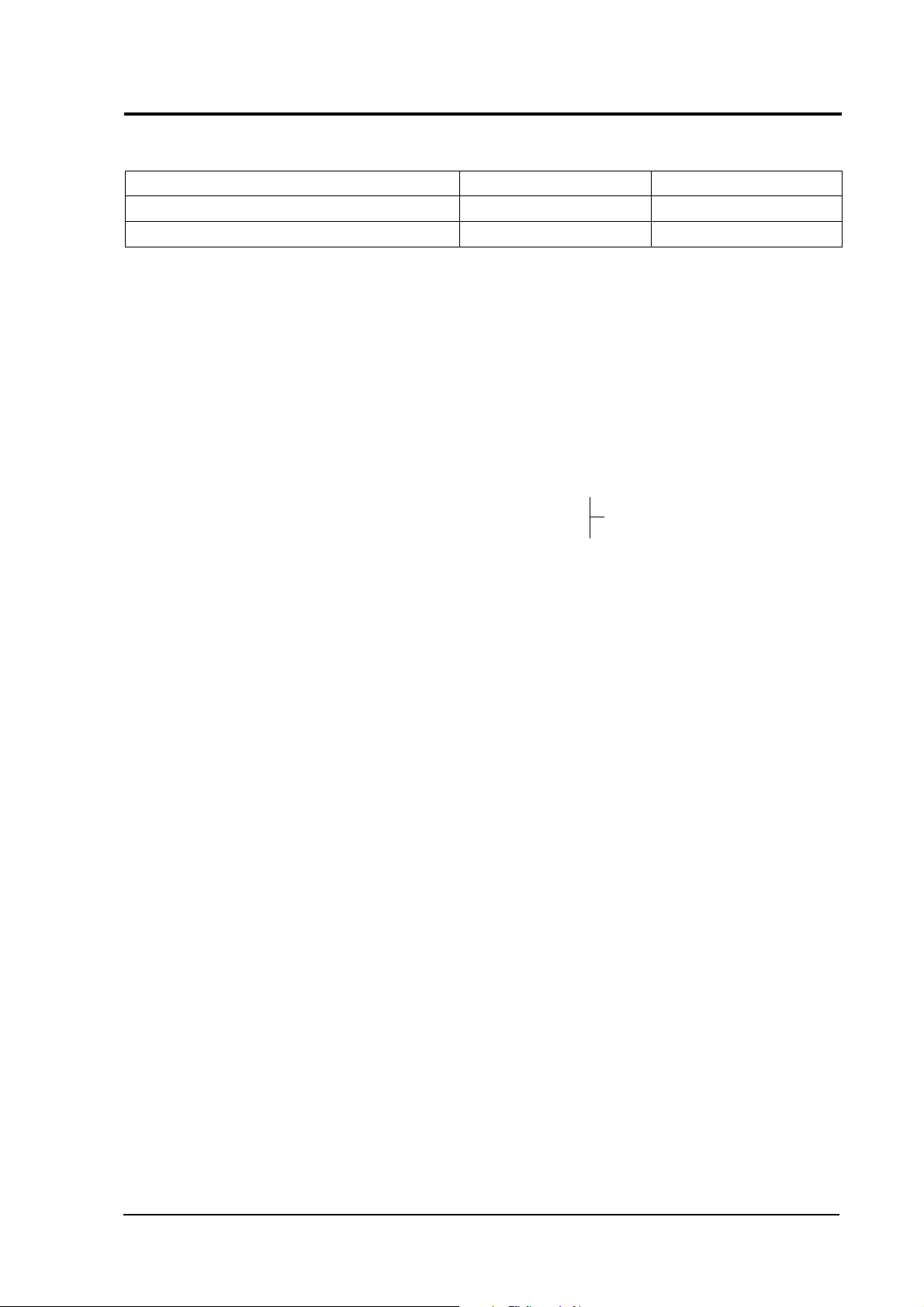

THREAD lbf ft Nm

M5 5 7

M6 9 12

M8 21 28

M10 41 56

M12 72 98

M16 180 244

M20 351 476

M24 606 822

GENERAL NOTE:

M10 - 12.9 Steel 50 70

TIGHTENING TORQUES

These are based on 85% of the proof loads designated in BS3692.

Page 19

LUBRICATING OIL RECOMMENDATIONS

4012/16 Diesel, February 1997 1

9

QUANTITY OF OIL

TYPE OF OIL

The industrial diesel engine should be lubricated with a good quality oil conforming to API

CD or CCMC D4 specifications. All the major oil companies formulate oils to the above

specifications.

VISCOSITY OF OIL

Use oil of:

SAE10W/30 in starting temperatures below -15°C (without sump heater)

SAE10W/40 in starting temperatures from -15°C to 0°C

SAE30 in starting temperatures from 0°C to 32°C or Mobil Devlac Super

SAE40 in starting temperatures above 32°C 1300 SAE 15W/40

OIL CHANGE PERIODS

For normal operation of the engine the oil should be changed every 250 hours or annually

whichever is the sooner.

Under certain circumstances where a centrifugal oil filter is fitted to the engine and an oil

analysis programme has been carried out with the oil supplier over a period of 1000 hours

of engine operation, it may be possible to extend the oil change period up to maximum of

350 hours.

To achieve this extended oil change period, a centrifugal oil filter must be fitted and cleaned

every 250 hours between routine oil changes, and at every oil change point i.e. 350 hours

maximum.

As the oil deteriorates it is essential that the following parameters must not be exceeded at

the oil change point:

1 The viscosity of the oil must not increase by more than 10cSt at 100°C.

2 The total base number of the oil should not reduce to less than 50% of the value of new

oil.

3 The flash point of the oil should exceed 180°C.

4 The water content of the oil must not exceed 1%.

5 The fuel content of the oil must not exceed 1%.

6 Oil samples should be taken from the mean sump oil level of the engine.

Sump Capacity Dipstick 4012 4016

Minimum 136 litre(30 gal) 147 litre (33 gal)

Maximum 159 litre (35 gal) 214 litre (47 gal)

Page 20

LUBRICATING OIL RECOMMENDATIONS

20 4

012/16 Diesel, February 1997

ENGINE OPERATION

Excessive periods of idling or repeated cold starts should be avoided, as they will cause

excessive dilution of the oil by fuel, requiring more frequent oil changes and dangerously

lowering the flash point of the oil.

Should there be a lubricating oil supply problem, or if the fuel being used contains more than

0.5% sulphur, Perkins Engines (Stafford) Limited must be consulted to give advice in

selecting a suitable grade.

The following list gives details of some of the oils that meet the required specifications. Note

that the brand names may change as oils are upgraded or reformulated.

An up-to-date list is maintained by Perkins Engines (Stafford) Limited of major oil companies

products and information, which can be obtained from Perkins Engines (Stafford) Service

Department.

APPROVED INDUSTRIAL OIL A1 SPECIFICATIONS BSEN 590

(Suitable for fuel to Class A2 specifications BS2869 Part 2).

Oil Company Type

CASTROL CRH/RX Super

ELF Multiperfo XC

KUWAIT OIL Co Q8 T400

MOBIL Delvac 13

Delvac Super 1300 (15W/40)

SHELL Rimula X

ESSO Essolube XD 3+

TEXACO Ursa Super LA

WARNING

FAILURE TO COMPLY WITH THESE INSTRUCTIONS WILL

INVALIDATE THE WARRANTY OFFERED WITH THE ENGINE, AS

IT MAY RESULT IN ENGINE DAMAGE.

Page 21

COOLANT

4012/16 Diesel, February 1997 2

1

ENGINE COOLING SYSTEM

The cooling system of an engine contains

many different materials e.g. cast iron,

aluminium, copper, solder, rubber (various

types). To prevent deterioration of these

materials, it is essential to use a very good

quality coolant. Untreated water is not

suitable. It is essential that the water is

treated with an additive that gives the

necessary protection.

WATER QUALITY

The water to be mixed with the additive must

have the following characteristics:

Chlorides less than 80 PPMV

(PPMV = parts per million by volume)

Sulphates less than 80 PPMV

Total hardness less than 200 PPMV

pH of water between 7 to 7.5

(neutral to slightly alkaline)

ADDITIVES TO WATER

Due to the complexity of the cooling system

it is necessary to use an additive that

contains a balanced package of corrosion

inhibitors.

To achieve the required solution a 50/50 mix

of Shell Safe Premium antifreeze with water

should be used at all times, even in areas

where frost is unlikely.**

The 50/50 mixture will give frost protection

down to -35°C. In areas where Shell Safe

Premium is not available contact Perkins

Engines (Stafford) Limited for advice on a

recommended alternative.

Under no circumstances should an additive

containing nitrites, borates, phosphates,

chromates, nitrates, or silicates be used, as

they are not compatible with the materials

used in the cooling system.

When mixing the antifreeze with the water

always follow the manufacturer's

recommendation to add the antifreeze in the

correct proportion before introducing it into

the engine cooling system. Adding water to

antifreeze can lead to the formation of a gel

in the mixture, which can cause blockage of

the water passages and subsequent local

overheating.

MAINTENANCE OF COOLANT

The water/antifreeze mixture should be

regularly replaced in operating engines at

least once a year.

In engines used for standby duty it is

essential to maintain the water/antifreeze

mixture at the correct alkalinity level i.e. the

pH should not increase above 7.5. A

hydrometer only shows the proportion of

ethylene glycol, not the degree of corrosion

protection.

4012TWG2 only to this rule is when two

section radiators are used in conjunction

with charge air coolers under tropical

conditions. It may be necessary to reduce

the antifreeze content of the coolant from

50% to 10% to achieve an adequate heat

transfer coefficient.

WARNING

ALWAYS STOP THE

ENGINE AND ALLOW

THE PRESSURISED SYSTEM TO COOL

BEFORE REMOVING FILLER CAP.

AVOID SKIN CONTACT WITH

ANTIFREEZE BY WEARING HAND, ETC.

WARNING

FAILURE TO FOLLOW

THE ABOVE

RECOMMENDATIONS MAY RESULT IN

DAMAGE TO THE ENGINE, AND WILL

INVALIDATE THE ENGINE WARRANTY.

Page 22

FUEL SPECIFICATION

22 4

012/16 Diesel, February 1997

Fuel should be wholly hydrocarbon oil derived from petroleum, with which small quantities

of additives may be incorporated for the improvement of ignition or other characteristics and

should conform to British Standard Specification 2869. Class A1 or A2.

If fuels other than the above classes are considered, the operator must consult Perkins

Engines (Stafford) Limited, and ensure that a suitable grade of lubricating oil is used.

BS2869 REQUIREMENTS FOR ENGINE FUEL

Property Class A1 Class A2

Viscosity, Kinematic at 40°C, cSt *

Min. 1.5 1.5

Max. 5.0 5.5

Cetane number, min. 50 45

Carbon residue, Ramsbottom on 10% residue, % (m/m), max. 0.20 0.20

Distillation, recovery at 350°C, % (V/V), min. 56°C 56°C

Sulphur content, % (V/V), max. 0.05 0.05

Sediment, % (m/m), max. 0.01 0.01

Ash, %(m/m), max. 0.01 0.01

Sulphur content, % (m/m), max. 0.30++ 0.50++

Copper corrosion test, max. 1 1

Cold filter plugging point C, max.

Summer (March/September inclusive) -4 -4

Winter (October/February inclusive) -15 -12

* cSt = 1 mm²/s.

++ This limit is set in accordance with the legislative requirements for gas oil of the 'Council

Directive (75/716/EEC of the European Economic Community) on the approximation of the

laws of Member States relating to the sulphur content of certain liquid fuels'.

In countries where this legislation does not apply, it is permissible to run 4000 Series

engines on fuels with up to 1.0% sulphur. (See

page 20 "Engine Operation").

E

NGINE FUELS

1 The two classes of fuel specified in the table are marketed specifically as oil engine

fuels. Class A1 is of higher quality and is intended primarily as an automotive diesel

fuel, whilst Class A2 is intended as a general purpose diesel fuel. Classes A1 and A2

are distillate grades and are so specified as to prevent the inclusion of residuum.

2 The specifications for Classes A1 and A2 include limits for cold filter plugging point

chosen to cover seasonal requirements in the United Kingdom.

3 Ignition quality is specified in terms of cetane number, but the calculated cetane index

is referred to as an alternative for routine purposes with fuels not containing ignition

improver additives.

NOTE: If local supply problems dictate that fuels which fall outside the above specification

are to be used, our Service Department must be consulted prior to use.

Page 23

OPERATING INSTRUCTIONS

4012/16 Diesel, February 1997 2

3

PREPARING FOR INITIAL START

FILLING THE ENGINE WITH OIL

Remove the drain plug to ensure that the

sump is clean and empty. Refit and tighten

the plug. Remove the oil filler situated on the

left hand side of the crankcase, by rotating

the T-bar anti-clockwise and pulling up (Fig.

1). Fill the sump to the maximum mark on

the dipstick with the appropriate grade and

quantity of oil (see page 19 & 20).

NOT

E: If the engine has been overhauled

ensure that, with the governor in the stop

position, the pump injectors are set in the

'NO FUEL' position.

PRIMING THE TURBOCHARGERS ON

ENGINES FITTED WITH THE

ELECTRONIC GOVERNOR

Before starting the engine for the first time, or

if it has stood idle for more than three

months, the turbocharger bearings should

be primed. To prime the turbocharger, the

engine needs to be motored over on the

starter. In order that the engine does not run

up to speed when operating the key switch

(i.e. energising the stop solenoids) it will be

necessary to hold the governor lever in the

stop position (see Fig. 13) but ensure that

t

he air shut-off valves have been manually

set to the run position (see Fig. 12).

K

ey

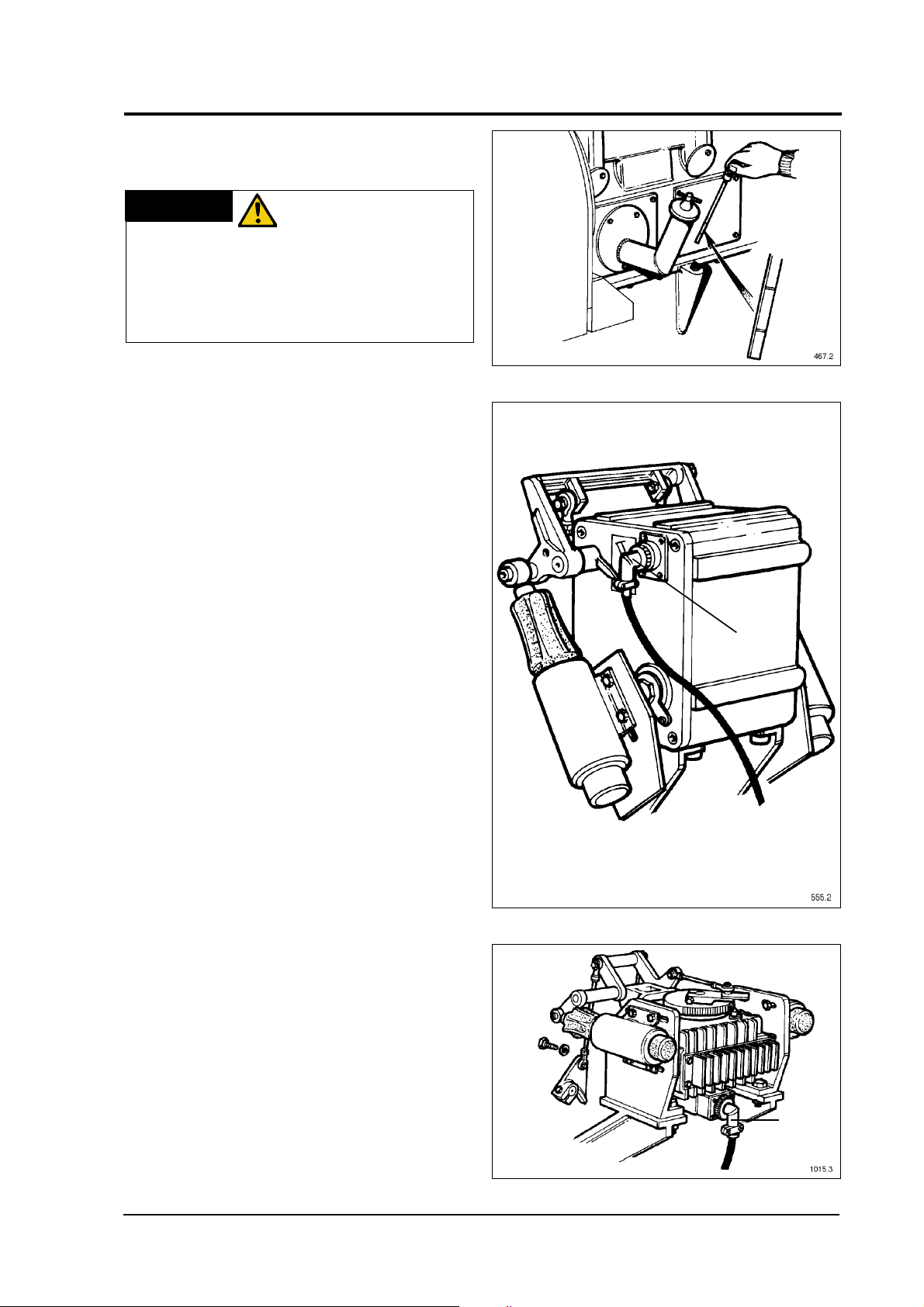

(Fig. 2 & Fig. 3)

1. Electronic plug

WARNING

NEVER OPERATE

THE ENGINE WHEN

THE OIL LEVEL IS BELOW THE

MINIMUM MARK OR ABOVE THE

MAXIMUM. ALWAYS WEAR

PROTECTIVE GLOVES WHEN

HANDLING ENGINE OIL.

Fig. 1

Fig. 2

1

Fig. 3

1

Page 24

OPERATING INSTRUCTIONS

24 4

012/16 Diesel, February 1997

For earlier engines not fitted with a stop

lever, disconnect the battery leads and

remove the electric plug from the governor

by unscrewing the locking collar and pulling

the plug out of its socket. (See Fig. 2 & Fig.

3

).

O

perate the starting control or key switch

and motor the engine over on the starter until

an oil pressure of approximately 40 kPa (5 lb/

in²) is indicated on the pressure gauge.

Continue for a further 10 seconds to ensure

that the oil has reached the turbochargers,

and stop the engine by releasing the start

control. Disconnect the battery leads and

reconnect the electric plug in the actuator.

Reconnect the battery leads.

PRIMING THE TURBOCHARGERS ON

ENGINES FITTED WITH REGULATEURS

EUROPA OR HYDRAULIC GOVERNORS

Let the engine run without load for about 5

minutes ensuring the lubricating oil has

reached the turbochargers.

PRIMING THE TURBOCHARGERS ON

ENGINES FITTED WITH A WOODWARD

TYPE UG10 OR 3161 HYDRAULIC

GOVERNOR

NOTE: It is recommended that for initial

starting of new or overhauled engines, that

the load is disengaged, with the governor

speed control lever in the minimum speed

position, the shutdown solenoid in the STOP

position and the air shut-off valves manually

set to the run position (see Fig. 4 and

Fig.

1

1

).

Check the oil level by means of the sight

gauge. If necessary, add new SAE 30 or

SAE15W/40 engine oil (after lifting the filler

cap) to bring the oil up to the correct level

(see Fig. 2). Ensure that the fuel supply to

t

he engine is turned off.

Key

(Fig. 4)

1 Low speed stop

2 Oil filler

3 Compensation adjustment

4 Oil drain plug

5 Compensating needle valve

6 High speed stop

7 Oil level gauge

With the speed control unit set in the idling

position, (for generator duty the governor

minimum and maximum speed stops are

factory set) ensure that the governor speed

lever is in the minimum speed position. Turn

the key in the instrument panel from the stop

position to the start position and motor the

engine over on the starter until the oil

pressure gauge registers approximately 40

kPa (5 lb/in²). Continue cranking for a further

10 seconds to ensure that the oil has

reached the turbochargers.

WARNING

THE OPERATOR

MUST BE IN A TO

PRESS THE EMERGENCY STOP

BUTTON IN THE EVENT OF A

PROTECTION EQUIPMENT FAILURE.

Fig. 4

1

2

3

4

5

6

7

Page 25

OPERATING INSTRUCTIONS

4012/16 Diesel, February 1997 2

5

BATTERIES (SUPPLIED DRY CHARGED)

See Installation Manual

Check the level of electrolyte in each battery

cell which should be approximately 8 mm

above the plates. Using a hydrometer, check

that the batteries are fully charged. A fully

charged battery will have a specific gravity of

1.27 to 1.285, assuming the air temperature

is below 32°C. For higher temperatures the

specific gravity will be 1.24 to 1.255. When

topping up the batteries always use pure

distilled water and always replace the plugs

after filling.

WARNING

HAND PROTECTION

MUST BE WORN

WHEN CHECKING THE BATTERY

ELECTROLYTE. NEVER CHECK WITH A

NAKED FLAME.

WARNING

NEVER CONNECT A

BATTERY INTO THE

SYSTEM WITHOUT FIRST CHECKING

THE POLARITY AND VOLTAGE. NEVER

DISCONNECT THE BATTERY WHILST

THE ENGINE IS RUNNING. NEVER

FLASH CONNECTIONS TO CHECK FOR

CURRENT FLOW.

Page 26

OPERATING INSTRUCTIONS

26 4

012/16 Diesel, February 1997

PRIMING AND VENTING THE FUEL

SYSTEM AS FITTED ON THE EARLIER 12

& 16 CYLINDER ENGINES.

Loosen the union nut on the fuel feed pipe

from the fuel filter, Fig. 5.

Operate the priming pump by pressing the

rubber button Fig. 6. Continue priming until

air free fuel flows from the union. Re-tighten

the union nut.

Then slacken off the vent plugs located at

the opposite to flywheel end of 'A' and 'B'

bank fuel return rails, Fig. 7 and continue

priming until air free fuel flows. Tighten the

vent plugs.

When priming a fuel system fitted with

changeover fuel filters, undo the left hand

bleed screws 'L' (see Fig. 8). Operate the

priming pump by pressing the rubber button

(see Fig. 6), until air free fuel flows from the

bleed screws. Retighten the left bleed

screws 'L'. Repeat the above operation with

the right hand bleed screws 'R' until all four

filters have been primed with fuel.

Slacken off the vent plugs located at the front

end of both fuel return rails (see Fig. 7) and

continue priming until air free fuel flows.

Retighten the vent plugs.

Key

(Fig. 6 & Fig. 7)

1 Priming pump

2 Strainer

3 Vent plug

Fig. 5

Fig. 6

1

2

Fig. 7

3

Fig. 8

L

L

R

R

Page 27

OPERATING INSTRUCTIONS

4012/16 Diesel, February 1997 2

7

PRIMING AND VENTING THE FUEL

SYSTEM AS FITTED ON LATER 12 & 16

CYLINDER ENGINES

Loosen the union nut on the fuel feed pipe to

the front cylinder head on the fuel rail Fig. 9.

NOTE: The fuel system should not be bled

from the water trap/sedimenter filter (if

fitted), since this is on the suction side of the

lift pump. Fig. 10. However, it is important to

drain the water from this unit periodically. Do

not operate the priming pump but unscrew

the valve at the bottom of the filter about 4

turns until it drops down about 25 mm (1

inch). Allow the water to drain out and then

screw the valve back in until it is hand tight.

Operate the priming pump by pressing the

rubber button Fig. 10. Continue priming until

air free fuel flows from the union. Re-tighten

the union nut.

FILLING THE COOLING SYSTEMS

The use of non-inhibited water is not

recommended owing to chemical reactions

which can result in corrosion and furring-up

of the cooling system. A solution of either

universal anti-freeze or corrosion

preventative and water must be used. Refer

to page 21.

A

fter installation and before the first start

remove the radiator cap, see Fig. 11. Fill the

cooling system and run the engine off-load

for one minute to ensure that the system is

completely filled. Stop the engine and top up

the system to within 25 mm (1") of the top of

the filler neck then replace the cap. Should

the engine be fitted with water cooled

exhaust manifolds, these will need bleeding.

(Older engines without vent pipes only).

(See Workshop Manual Section Q3).

K

ey

(Fig. 10 & Fig. 11)

1 Normal fuel flow

2 Priming circuit

3 Water trap/sedimenter

4 Drain valve - DO NOT open when

engine running

5 Radiator cap

WARNING

THE COOLING

SYSTEM IS

PRESSURISED - DO NOT REMOVE THE

FILLER CAP FROM THE RADIATOR

WHILE THE ENGINE IS HOT. HAND

PROTECTION MUST BE WORN.

Fig. 9

Fig. 10

1

2

3

4

Fig. 11

5

Page 28

OPERATING INSTRUCTIONS

28 4

012/16 Diesel, February 1997

INITIAL STARTING OF THE ENGINE

WHEN FITTED WITH THE ELECTRONIC

GOVERNOR

With the load disengaged, ensure that the

stop control on engine/panel is in the 'stop'

position, and that the air shut-off valves have

been manually set to the 'run' position (see

Fig. 12) typical installation.

EARLIER ENGINES NOT FITTED WITH

AN ENGINE STOP LEVER

Disconnect the battery leads and remove the

electric plug from the Heinzmann actuator by

unscrewing the locking collar and pulling the

plug out of its socket.

Press the emergency stop button to deenergise the stop solenoids, to prevent the

governor levers moving into the 'run'

position.

Reconnect the battery leads.

LATER ENGINES FITTED WITH AN

ENGINE STOP LEVER

In order to prevent the engine running up to

its rated speed when operating the key

switch, it will be necessary to hold the stop

lever in the 'stop' position. Fig. 13.

Key

(Fig. 12 & Fig. 13)

1 Closed (stop)

2 Latched in (run)

3 Governor lever

4 Stop position

5 Run position

6 Solenoid energised

7 Solenoid de-energised

WARNING

ALWAYS BE IN A

POSITION TO

MANUALLY STOP THE ENGINE IN THE

EVENT OF A MALFUNCTION BY

OPERATING THE EMERGENCY STOP

BUTTON.

Fig. 12

1

2

Fig. 13

3

4

6

7

5

Page 29

OPERATING INSTRUCTIONS

4012/16 Diesel, February 1997 2

9

INITIAL STARTING OF THE ENGINE

WHEN FITTED WITH THE

REGULATEURS EUROPA 2100

HYDRAULIC GOVERNOR

NOTE: It is recommended that for initial

starting of new or overhauled engines, any

automatic starting or control systems are bypassed and the engine is controlled

manually with the load disengaged, but with

the air shut-off valves manually set to the

'run' position (see Fig. 12).

R

emove the filler plug from the top face of

the governor and fill with oil to the line in the

sight glass (see Fig. 14). Refer to

Workshop Manual, Section AA41 for the

c

orrect grade of oil. Replace the plug.

Ensure that the fuel supply to the engine is

turned off.

Rotate the engine using the cranking device,

as described on page 55, in the correct

d

irection of rotation for two revolutions to

ensure that all working parts are free.

Disengage or remove the cranking device

immediately after use.

NOTE: When the engine is fitted with three

starter motors i.e. two electric and maybe

one air starter then on early engines one of

the starters may need to be removed to

enable the cranking device to be fitted.

The minimum and maximum speed stops

are factory set. Reduce the governor speed

setting by turning the hand wheel clockwise

until there is no further movement of the

output levers.

Key

(Fig. 14)

1 Locknut

2 Solenoid energised to stop

3 Minimum speed stop screw

4 Maximum speed stop screw

5 Oil filler plug

6 Hand control wheel

7 Oil level sight glass

Ensure the starting batteries are fully

charged. Energise the shutdown solenoid

('stop' position) and motor the engine over

on the starter until the oil pressure gauge

registers approximately 40 kPa (5 lb/in²).

Continue cranking for a further 10 seconds,

to ensure that the oil has reached the

turbochargers. Stop the engine by releasing

the start control and visually check the

engine for fuel or oil leaks, rectifying where

necessary. Turn on the fuel supply and bleed

the fuel system. Ensuring that the shutdown

solenoid is de-energised ('run' position)

crank the engine on the starter. The engine

should start and run up to the minimum

speed setting. Increase the engine speed by

turning the hand wheel anti-clockwise until

there is no further movement of the output

levers. With the engine running up to the

maximum speed setting, adjust the hand

wheel to obtain the desired operating speed.

Check the engine for fuel and oil leaks. Apply

load.

WARNING

UNDER NORMAL

CONDITIONS

GENERATING SETS MUST NOT BE RUN

AT LESS THAN THEIR NORMAL

OPERATING SPEED. OPERATION

BELOW THIS SPEED WILL DAMAGE

THE AUTOMATIC VOLTAGE

REGULATOR (AVR) THEREFORE

ISOLATE THE AVR BEFORE REDUCING

THE ENGINE SPEED.

Fig. 14

2

3

4

5

6

7

1

Page 30

OPERATING INSTRUCTIONS

30 4

012/16 Diesel, February 1997

NORMAL STARTING PROCEDURE

WHEN FITTED WITH THE

REGULATEURS EUROPA 2100

GOVERNOR AND A WOODWARD TYPE

UG10 OR 3161

Ensure that where possible the load is off.

Set the engine switch to the 'run' position and

press the starter button, the engine should

start immediately and run up to full speed.

If the engine does not start within a few

seconds, do not keep the starter engaged,

let the engine come to rest and begin again.

Allow 15 seconds between start attempts. If

the engine fails to start after several

attempts, do not persist in motoring the

engine but investigate the cause. Check oil

pressure, for fuel and oil leaks and that the

ammeter in the instrument panel is showing

charge to the engine batteries. Allow the

engine to run for 5 minutes. Check

instruments are reading correctly. Apply

load.

NORMAL STARTING PROCEDURE

WHEN FITTED WITH THE HEINZMANN

E16 AND WOODWARD PROACT II

ELECTRONIC GOVERNOR

Operate the start control, which will energise

the solenoid and allow the governor lever to

move to the 'run' position Fig. 11, the engine

should then start immediately. Again check

the oil pressure, for any fuel or oil leaks, and

that the ammeter in the instrument panel is

showing charge to the engine batteries.

Allow the engine to run for five minutes,

checking that instruments are reading

correctly. Apply load.

Page 31

OPERATING INSTRUCTIONS

4012/16 Diesel, February 1997 3

1

ENGINE SHUTDOWN

The engine is normally stopped by operating

an electric stop control via a key switch. In

this case it is only necessary to turn the key

in an anti-clockwise direction which deenergises the stop solenoids to stop the

engine. The solenoids remain de-energised

until the engine is started up again.

NOTE: For engines fitted with Regulateurs

Europa 2100, Woodward UG 10 or 3161

hydraulic governors, the 'stop' solenoids are

built into the governors and they are

energised to stop (ETS) the engine and deenergised shortly after the engine stops.

Should the engine stop due to the air shut-off

valves being operated, it is imperative that

the cause of the fault be investigated

immediately.

It is essential to allow the engine to run at no

load for 3 - 5 minutes before stopping to

allow the circulating lubricating oil to take the

heat away from the bearings and shafts, etc.

This is especially important with

turbocharged engines where extremely high

temperatures are experienced within the

turbocharger. Heat rise by suddenly

stopping an engine on load can cause

seizure of bearings and damage to oil seals.

NOTE: Excessive idling of the engine will

result in only partial burning of the fuel,

causing high carbon build-up on injector

nozzles, valves, piston rings, etc. Also

unburnt fuel will tend to wash the

lubricating oil from cylinder bores and

dilute the oil in the sump. This can

eventually cause inefficient lubrication of

bearings and result in seizure.

WARNING

DO NOT RUN THE

ENGINE AT LOW

SPEEDS OR LOADS. IF THE ENGINE IS

NOT BEING USED SHUT IT DOWN.

Page 32

LIGHT LOAD OPERATION & STANDBY GENERATING SETS

32 4

012/16 Diesel, February 1997

If an engine is operated on a load less than

25-30% of its rated output, certain symptoms

will be observed which may give cause for

concern.

The usual results of this operation are

heavier than normal lubricating oil

consumption, and oil leaks from the air and

exhaust manifolds. This condition is

particularly evident on stand-by generator

set applications where a weekly exercise on

no load is the usual practice.

These phenomena are due to the fact that:

1 Turbocharger oil seals are not fully

effective on light load which results in oil

being delivered together with the air into

the engine air manifolds.

2 The cylinder temperatures are too low to

ensure complete burning of all the fuel

delivered. This results in an unsightly

drip from the exhaust manifold

junctions. A further result is that of

abnormal carbon build-up on the valves,

piston crowns and exhaust ports, thus

the normal service interval of 2500

hours between top overhauls may have

to be reduced. Fuel dilution of the

lubricating oil will also occur.

To alleviate this condition the following

recommendations are made:-

1 Running on light load should be avoided

or reduced to the minimum period. If

weekly exercising on no load is carried

out, the running period should be kept

down to say, 10 minutes, or until the

battery charging rate returns to normal.

Periodically site load should be applied

(min 25%) through the year.

2 Every year the engine or generator set

should be run for four hours, to burn off

accumulations of carbon in the engine

and exhaust system. This will require

the use of a 'dummy load', which

should be built up gradually from zero to

the maximum over a four hour run.

On standby sets, air cleaner elements

should be changed annually.

Lubricating oil and fuel filter elements

should be changed every six months.

The fuel pump injectors should be

checked every 2 years.

Page 33

INSTRUMENT PANEL (ENGINE MOUNTED)

4012/16 Diesel, February 1997 3

3

DESCRIPTION

The instrument panel is flexibly mounted on the engine (see Fig. 15). The basic engine

mounted panel includes the instruments associated with the engine only, which show the

readings for the following conditions:

1 Cooling water temperature 4 Battery charging rate 7 Fuse holder

2 Lubricating oil temperature 5 Speed and hours run 8 Exhaust temperature

3 Lubricating oil pressure 6 Keyswitch gauge (when fitted)

Fig.15

1

2

34

8

6

7

1

2 3

5

Page 34

INSTRUMENT PANEL

34 4

012/16 Diesel, February 1997

1 Engine water temperature gauge

(Fahrenheit/Centigrade) Fig. 16

The coolant temperature during normal

operation should be between 65°C 85°C (149°F - 185°F). If the temperature

should rise above 93°C (200°F) for a

prolonged period of time, stop the

engine and investigate the cause. The

engine should, on the other hand, not be

run at too low a temperature for long

periods either.

2 Engine oil temperature gauge

(Fahrenheit/Centigrade) Fig. 17

The lubricating oil temperature should

be between 80°C - 90°C (176°F 194°F) when the engine is hot. If the

temperature should rise above 115°C

(240°F), stop the engine immediately

and investigate the cause.

3 Engine oil pressure gauge Fig. 18

(pounds per square inch/kiloPascal x

100)

The lubricating oil pressure should be

between 276 - 413 kPa (40 - 60 lb/in2)

when the engine is hot. If the pressure

should drop below 200 kPa (30 lb/in2) at

higher engine speeds than idling, stop

the engine immediately and investigate

the cause.

4 Ammeter (Ampere) Fig. 19

The ammeter indicates at what charging

current the battery is being charged by

the alternator, or to what extent current

is taken from the battery without the

battery being recharged.

Fig. 16

Fig. 17

Fig.18

Fig. 19

Page 35

INSTRUMENT PANEL

4012/16 Diesel, February 1997 3

5

5 Engine tachometer and hour counter

(revolutions per minute x 1000 and

hours) Fig. 20

The electrically operated tachometer/

hour counter shows the speed of the

engine in r/min. and the actual operating

hours the engine has run. The

tachometer/hour counter starts

operating from an alternator voltage of

12 V onwards, which has already been

reached at engine idling speed.

6 Key switch (3 position) (Off/run/start)

The hand operated keyswitch with

switch lock is moved by a separate key

to the positions shown, (see Fig. 21)

viewed from front of switch.

7 Fuse holder

To protect the instrument panel a 2 amp

fuse is fitted to remove the fuse (1)

unscrew its holder (2) (see Fig. 21.1).

Key

(Fig. 21)

1 Off

2 Run

3 Start

Fig. 20

Fig. 21

1

2

3

Fig. 21.1

1

2

Page 36

EXHAUST TEMPERATURE GAUGE (OPTIONAL)

36 4

012/16 Diesel, February 1997

DESCRIPTION

All exhaust temperature gauges are of the

high accuracy type with digital LCD display,

and are powered by the engine 24 volt

system.

A two-point gauge may be fitted to these

engines, measuring the exhaust

temperature of both banks after the

turbocharger (see Fig. 22, Fig. 23 and Fig

2

4).

NOTE: These gauges are wired with 'A' bank

defined as 'the left hand bank as viewed from

the FRONT (free end) of the engine'.

Key

(Fig. 22)

1 Red terminal

2 Compensating cables

3 Red terminal

4 Locknuts

5 Mounting bracket

6 Exhaust temperature gauge

7 Mounting bracket

8 Nylon connector

9 Armour braided cable

10 Exhaust bend

11 Thermocouple

12 Probe

Fig. 22

1

2

5

6

3

4

7

8

11

12

9

10

Page 37

EXHAUST TEMPERATURE GAUGE (OPTIONAL)

4012/16 Diesel, February 1997 3

7

SPECIFICATION

Temperature range -20/+800°C

Resolution 1°C

Accuracy + 0.5% F.S.D.

Probe fitting 3/8" BSP

Terminal size to suit 4BA eyelet connector

Cable size 2 core 7 strand 0.1 mm dia.

Type of cable Compensating type K

i.e. nickel/chrome or

nickel/alumel to British

Standard 4937 alternatively

copper/constantan

Supply 24V DC or PP3 lithium

battery

(earlier engines)

Key

(Fig. 23)

1 Push button to read (battery powered

only)

2 Switch

(Fig. 24)

1 24V DC Supply

Fig. 23

1

2

Fig. 24

1

Page 38

EXHAUST TEMPERATURE GAUGE (OPTIONAL)

38 4

012/16 Diesel, February 1997

A four point gauge may also be fitted which

measures the exhaust temperature of both

banks before as well as after the

turbocharger (see Fig. 25 and Fig. 26).

NOTE: These gauges are wired with 'A'

bank defined as 'the left hand bank as

viewed from the FRONT (free end) of the

engine'.

With both the above gauges, a thermocouple

is inserted into each exhaust at the point to

be measured, and is connected via armour

braided cable to a nylon terminal connector.

Type K compensating cables are used to

connect the nylon terminal connector to the

gauge. (see Fig. 22).

W

iring is quite straightforward, with the

positive (red) terminal on the nylon terminal

connector, connected to its corresponding

positive (red) terminal at the back of the

gauge (see

Figs. 22, 24 and 26).

Key

(Fig. 26)

1 24V DC Suppy

Fig. 25

Fig. 26

1

Page 39

MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 3

9

Towards the rear of this section are two

check sheets, one for continuous duty sets

and one for standby duty sets, which are to

be used as a guide for operators and

maintenance personnel. The following

schedule details some of the maintenance to

be carried out as in the maintenance check

lists. However, not all are detailed. In these

cases please refer to the Workshop

M

anual

. The Schedule within this section

will be perfectly suitable for an engine

working under average conditions. If your

engine is working under particularly arduous,

dirty or dusty conditions, it will be necessary

to undertake more frequent servicing,

particularly in respect of the lubricating oil,

fuel systems and air cleaners. Correct and

regular maintenance will help prolong the life

of your engine.

The periods referred to throughout this

maintenance section are true engine running

hours as indicated on the hour recorder fitted

in the instrument panel.

DAILY INSPECTION

LUBRICATING OIL LEVEL

With the engine stopped for at least 5

minutes withdraw the dipstick, wipe clean

and re-insert into the sump. After waiting 5 10 seconds for the oil level to stabilise,

withdraw and check the oil level in relation to

the two marks on the dipstick. If the level is

below the top mark, remove the oil filler cap

and add the correct grade of oil to bring the

level up to the top mark. Always replace the

filler cap immediately replenishment is

completed.

COOLANT LEVEL

With the engine stopped, remove radiator

cap; the coolant should be 25 mm (1") below

the top of the filler neck. If the level is low top

up with a solution of water and inhibitor or

water and anti-freeze similar to that already

in the engine. Refer to page 21.

L

EAKS

Visually check the engine for fuel, oil, coolant

and exhaust leaks, repairing where

necessary.

AIR FILTER MAINTENANCE

(See Section A4 Maintenance Manual)

The middle section of the restriction indicator

'A' will remain clear while the air cleaner is in

a serviceable condition. When the filter

reaches its contamination limit the restriction

indicator will sense the change in manifold

pressure and middle section 'A' will change

to red. At this point the air filter must be

changed. When the air filters have been

changed reset the indicator by pressing

button 'B'. (See Fig. 26.1). Check this signal

daily.

WARNING

MAKE QUITE

CERTAIN THE

ENGINE CANNOT BE STARTED

BEFORE UNDERTAKING ANY

MAINTENANCE, PARTICULARLY IN THE

CASE OF AUTOMATICALLY STARTING

GENERATING SETS.

Fig. 26.1

A

B

WARNING

THE COOLING

SYSTEM IS

PRESSURISED - DO NOT REMOVE THE

FILLER CAP WHEN THE ENGINE IS HOT.

HAND PROTECTION MUST BE WORN.

Page 40

MAINTENANCE SCHEDULE & CHECKLISTS

40 4

012/16 Diesel, February 1997

AIR FILTER MAINTENANCE

GENERAL SERVICING INSTRUCTIONS

Servicing procedures include replacing the

filter element, cleaning the filter housing, and

assuring that all piping and hose

connections from the filter outlet to the

turbocharger intake are sealed and airtight.

(See Fig. 27).

Key

(Fig. 27)

1 Mesh guard

2 Element

3 End cover

4 Pre-cleaner (Cyclone unit) (Optional)

WARNING

REPLACE ANY

ELEMENT WHICH IS

DAMAGED. NEVER EXCEED

RECOMMENDED MAXIMUM. NEVER

BLOW DIRT OUT OF THE FILTER

HOUSING. THIS MAY INTROSUCE

DUST INTO THE ENGINE. INSTEAD,

USE A CLEAN, DAMP CLOTH. DO NOT

OIL THE ELEMENT. ALWAYS USE EYE

PROTECTION WHEN USING

COMPRESSED AIR.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING ENGINE.

Fig. 27

1

2

3

4

Page 41

MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 4

1

DAILY INSPECTION

DRAINING THE WATER TRAP/

SEDIMENTER (WHERE FITTED)

There are no moving parts or elements to

service, however daily open the drain plug to

remove collected water and sediment. The

plug is self retaining, unscrew until loose.

Leave open until clean fuel is seen. Screw

back in (see Fig. 28).

AFTER FIRST 50 HOURS ONLY

FENNER TAPER LOCK BUSHES

Maintenance Instructions

Experience has shown that taper lock

bushes, as fitted in the fan and alternator

driven pulleys, can work loose shortly after

being put into service. After a bush has been

run for the first 50 hours, check the tightness

of the screws. Tighten the screws gradually

and alternately until tightened to the required

torque (see

Torque Settings). Replace any

g

uards removed before running the engine

(see Fig. 29).

AFTER FIRST 100 HOURS

NEW OR REBUILT ENGINES

It is essential to carry out the following

maintenance procedure after the initial 100

hours.

Equalise bridge pieces and check valve

clearances (see pages 55-58).

E

VERY 250 HOURS OR EVERY 6

MONTHS

ENGINE OIL AND FILTERS

Change engine oil and filter (see page 48).

E

qualise bridge pieces and check valve

clearances (see pages 55-58).

Key

(Fig. 29)

1 Locating screw

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING. ALWAYS

WEAR PROTECTIVE GLOVES.

Fig. 28

Fig. 29

Page 42

MAINTENANCE SCHEDULE & CHECKLISTS

42 4

012/16 Diesel, February 1997

EVERY 250 HOURS OR 6 MONTHS

CENTRIFUGAL OIL FILTER (IF FITTED)

Stop the engine, and allow time for the oil to

drain back to the sump. Refer to Fig. 30.

1 Slacken safety clamp (1) unscrew cover

nut and lift off cover.

2 Lift off rotor assembly (2) having

allowed oil to drain from nozzles. The

rotor should be removed and replaced

on the spindle with extreme care in

order to ensure that bearings are not

damaged.

3 Secure rotor in dismantling tool T6253/

292. Unscrew rotor cover nut (3) and

separate rotor cover from body.

4 Remove standtube (4) using extraction

tool T6253/293 and clean.

5 Remove sludge from inside the rotor by

means of a spatula and wipe clean.

Ensure that all rotor components are

thoroughly cleaned and free from

deposits of dirt before reassembling the

rotor. Failure to do so could cause an

out-of-balance condition which will

accelerate bearing spindle wear.

6 Clean nozzle with brass wire. Examine

'O'-ring (5) and renew if damaged.

7 Reassemble rotor completely and

tighten top nut.

IMPORTANT: Ensure that rotor cover

and rotor body are always matched by

balance reference number and pin

location.

DO NOT INTERCHANGE ROTOR

COVERS.

8 Examine spindle journals, if damaged or

worn replace with body assembly

complete.

9 Reassemble filter completely, checking

that rotor revolves freely, then replace

filter body cover. Tighten cover nut and

secure safety clamp. The clamp ring

should be securely fitted at all times and

the filter should not be run without the

clamp ring fitted.

10 With engine running check all joints for

leakage. Check for excessive vibration.

See page 19 for oil change periods.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING.

ALWAYS WEAR PROTECTIVE GLOVES.

Fig. 30

2

1

3

4

5

Page 43

MAINTENANCE SCHEDULE & CHECKLISTS

43 4

012/16 Diesel, February 1997

EVERY 250 HOURS OR EVERY 6

MONTHS

ALTERNATOR DRIVE BELT

Remove the small mesh guard around the

alternator. The toothed belt used to drive the

alternator relies on tooth engagement to

transmit load. It does not require pre-loading,

however a slight initial tension to ensure that

the belt fits snugly round the pulleys is

desirable. Using light pressure midway

between the two pulleys a total deflection of

1.5 mm (1/16") is satisfactory (see Fig. 31).

Refit the guard.

Key

(Fig. 31)

1 Pulley guard

2 Tensioning arm

3 Drive guard

4 Pivot bracket and bolt

MAINTENANCE OF COOLANT

COOLING SYSTEM

Check the specific gravity and the pH value

of the coolant (see page 25 of the

W

orkshop Manual). Visually check the

radiator core for debris causing air

restriction.

FAN BELTS

Fan belts should be checked for wear and

condition, particularly the following faults:

a Small cracks on 'V'-belt side and base.

Generally caused by lack of belt tension

but excessive heat and/or chemical

fumes can also give same failure.

b 'V'-belt swelling or softening.

Caused by excessive contamination by

oil, certain cutting fluids or rubber

solvent.

c Whipping during running.

Usually caused by incorrect tensioning,

principally on long centre drives. If a

slightly higher (or lower) tension does

not cure the problem, there may be a

critical vibration frequency in the

system, which requires re-design or the

use of a banded belt.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING THE

ENGINE.

Fig. 31

1

2

3

Page 44

MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 4

4

EVERY 250 HOURS OR EVERY 6 MONTHS

BEARINGS AND BELTS (COVRAD

RADIATOR)

Remove the mesh guard around the fan

belts, grease the fan bearings (2) and jockey

pulley bearings (4) Fig. 32, using high

melting point lithium LM grease at greasing

points (5).

Check the tension and wear of the fan belts.

Using moderate thumb pressure midway

between the crankshaft and fan pulley, a

total deflection of 12.5 mm (1/2") is

satisfactory.

If the fan belts are worn, the complete set

should be replaced and the fan pulley to

crankshaft pulley alignment checked.

If adjustment is found necessary, slacken

the two adjusting screws (3) and using a tube

extension (6) fitted over either the fan or

jockey pulley adjusting tag (1), move

outwards to tension the belts and inwards to

slacken the belts. Having set the tension of

the belts, tighten the adjusting screws (3)

and refit the fan belt guard.

FAN BEARINGS AND BELTS

(BEARWARD RADIATOR)

Remove the mesh guard around the fan

belts. The fan bearings (1) and jockey pulley

bearings (2) do not need greasing as these

are of the pre-packed type.

Check the tension and wear of the fan belts.

Using moderate thumb pressure midway

between the crankshaft and fan pulley (1), a

total deflection of 12.5 mm (1/2") is

satisfactory (see Fig. 33). If one or more fan

belts are faulty, a complete set must

always be fitted, and the fan pulley to

crankshaft pulley alignment checked. If

adjustment is found necessary slacken the

locking bolts (3) and adjust nut (4) either way

retighten locking bolts (3) and adjusting nut

(4).

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING THE

ENGINE.

Fig. 32

1

2

3

4

5

6

Fig. 33

1

2

3

4

Page 45

MAINTENANCE SCHEDULE & CHECKLISTS

45 4

012/16 Diesel, February 1997

EVERY 250 HOURS OR EVERY 6 MONTHS

CRANKCASE BREATHER, EARLIER

ENGINES (RADIATOR COOLED)

An extension pipe runs from both sides of the

engine gearcase to the engine breathers,

which are mounted on each side of the

radiator Fig. 34 and Fig. 35. Unscrew each

breather by turning it anti-clockwise. Wash it

thoroughly. Shake it as dry as possible,

finally blow it dry with compressed air and

screw the breather firmly back into position.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING. ALWAYS

WEAR EYE PROTECTION AND

PROTECTIVE GLOVES WHEN

CLEANING BREATHER.

Fig. 34

Fig. 35

Page 46

MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 4

6

EVERY 250 HOURS OR EVERY 6 MONTHS

CRANKCASE BREATHER (HEAT

EXCHANGER COOLED ENGINES)

The crankcase breathers are mounted on

the side of each thermostat housing and are

connected to the engine via an extension

pipe and bend fitted on each side of the

gearcase (see Fig. 37). To clean a breather,