Page 1

Perkins2800Series

Model 2806C-E16

DIAGNOSTIC MANUAL

6 cylinder turbocharged diesel engine

Publication TSL4247, Preliminary.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in May 2001 by Technical Publications,

Perkins Engines Company Limited, Tixall Road, Stafford, ST16 3UB, England

i

Page 2

Page 3

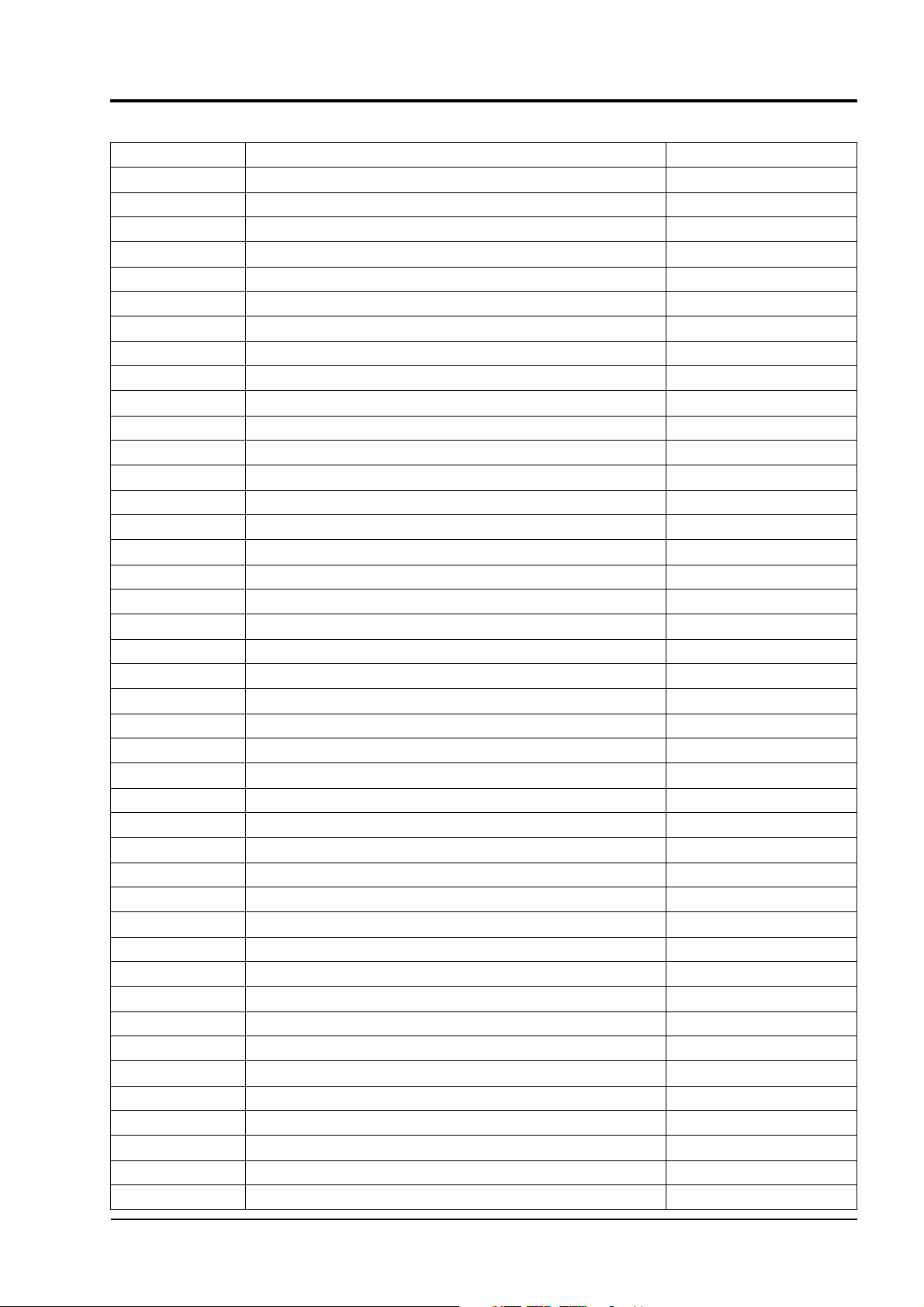

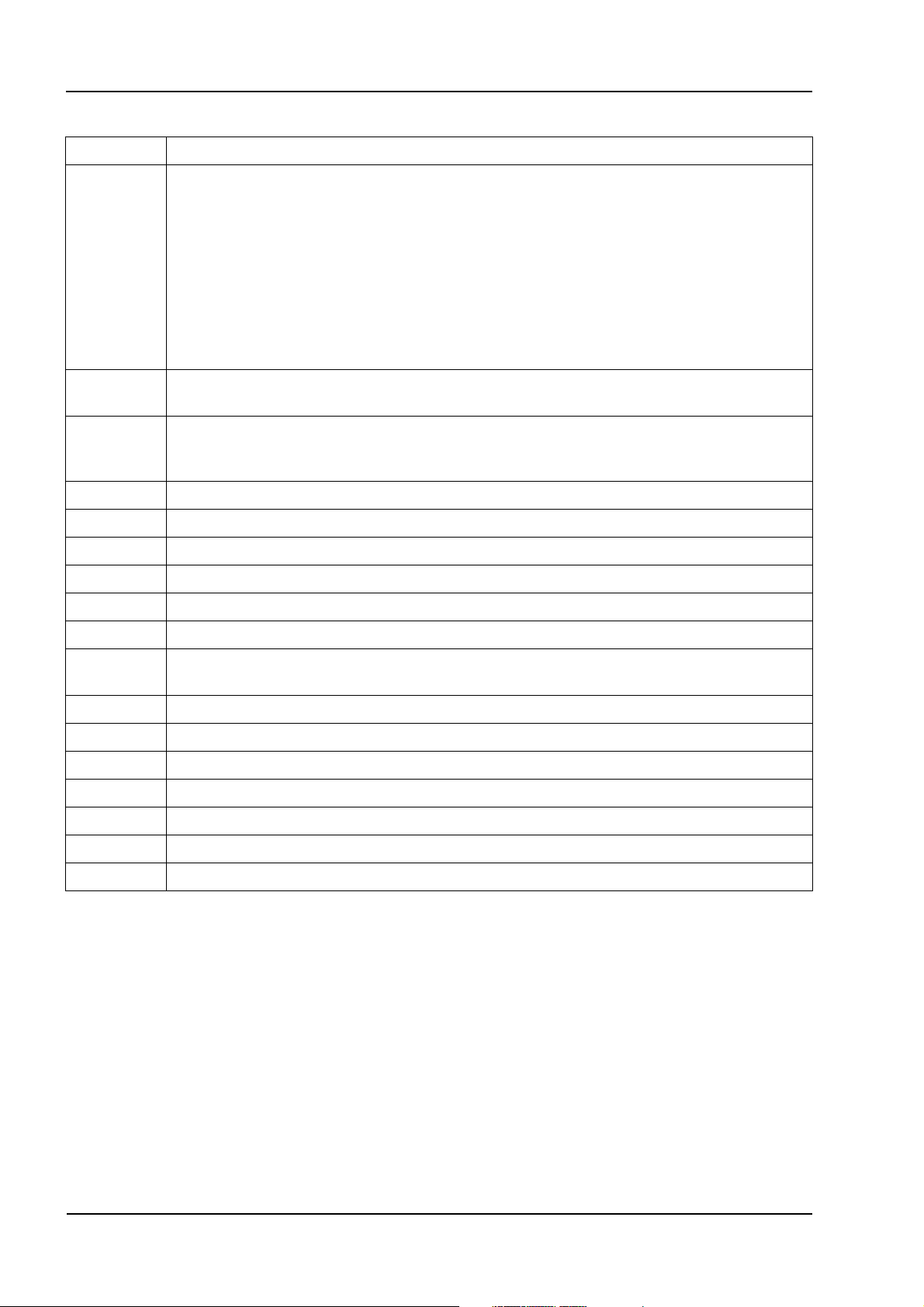

Diagnostic code quick reference

CID-FMI Diagnostic code description Troubleshooting

1-11 Injector Cylinder #1 Fault See Test 10 on page 133

2-11 Injector Cylinder #2 Fault See Test 10 on page 133

3-11 Injector Cylinder #3 Fault See Test 10 on page 133

4-11 Injector Cylinder #4 Fault See Test 10 on page 133

5-11 Injector Cylinder #5 Fault See Test 10 on page 133

6-11 Injector Cylinder #6 Fault See Test 10 on page 133

41-03 ECM 8 Volt DC Supply Open/Short to B+ See Test 6 on page 107

41-04 ECM 8 Volt DC Supply Short to ground See Test 6 on page 107

91-08 PWM Speed Control Abnormal See Test 6 on page 107

100-03 Engine Oil Pressure Sensor Open/Short to B+ See Test 3 on page 88

100-04 Engine Oil Pressure Sensor Short to ground See Test 3 on page 88

110-03 Engine Coolant Temperature Sensor Open/Short to B+ See Test 3 on page 88

110-04 Engine Coolant Temperature Sensor Short to ground See Test 3 on page 88

168-02 Intermittent Battery Power to the ECM See Test 2 on page 85

172-03 Inlet Air Temperature Sensor Open/Short to B+ See Test 3 on page 88

172-04 Inlet Air Temperature Sensor Short to ground See Test 3 on page 88

174-03 Fuel Temperature Sensor Open/Short to B+ See Test 3 on page 88

174-04 Fuel Temperature Sensor Short to ground See Test 3 on page 88

190-02 Engine Speed Sensor Data Intermittent See Test 8 on page 121

190-09 Engine Speed Sensor Abnormal Update See Test 8 on page 121

190-11,190-12 Engine Speed Sensor Mechanical Fault See Test 8 on page 121

252-11 Incorrect Engine Software See page 23

253-02 Check Customer or System Parameters See page 26

261-13 Engine Timing Calibration Required See Test 9 on page 129

262-03 5 Volt Sensor Power Supply Open/Short to B+ See Test 5 on page 102

262-04 5 Volt Sensor Power Supply Short to ground See Test 5 on page 102

268-02 Check Programmable Parameters See page 26

273-03 Turbo Outlet Pressure Sensor Open/Short to B+ See Test 3 on page 88

273-04 Turbo Outlet Pressure Sensor Short to ground See Test 3 on page 88

274-03 Atmospheric Pressure Sensor Open/Short to B+ See Test 3 on page 88

274-04 Atmospheric Pressure Sensor Short to ground See Test 3 on page 88

281-03 Action Alert lamp Open/Short to B+ See Test 4 on page 97

281-04 Action Alert lamp Short to ground See Test 4 on page 97

281-05 Action Alert Lamp Open Circuit See Test 4 on page 97

282-03 Overspeed lamp Open/Short to B+ See Test 4 on page 97

282-04 Overspeed lamp Short to ground See Test 4 on page 97

285-03 Coolant temperature lamp Open/Short to B+ See Test 4 on page 97

285-04 Coolant temperature lamp Short to ground See Test 4 on page 97

286-03 Lub oil pressure lamp Open/Short to B+ See Test 4 on page 97

286-04 Lub oil pressure lamp Short to ground See Test 4 on page 97

286-05 Lub Oil Pressure Lamp Open Circuit See Test 4 on page 97

323-03 Shutdown lamp Open/Short to B+ See Test 4 on page 97

iii

Page 4

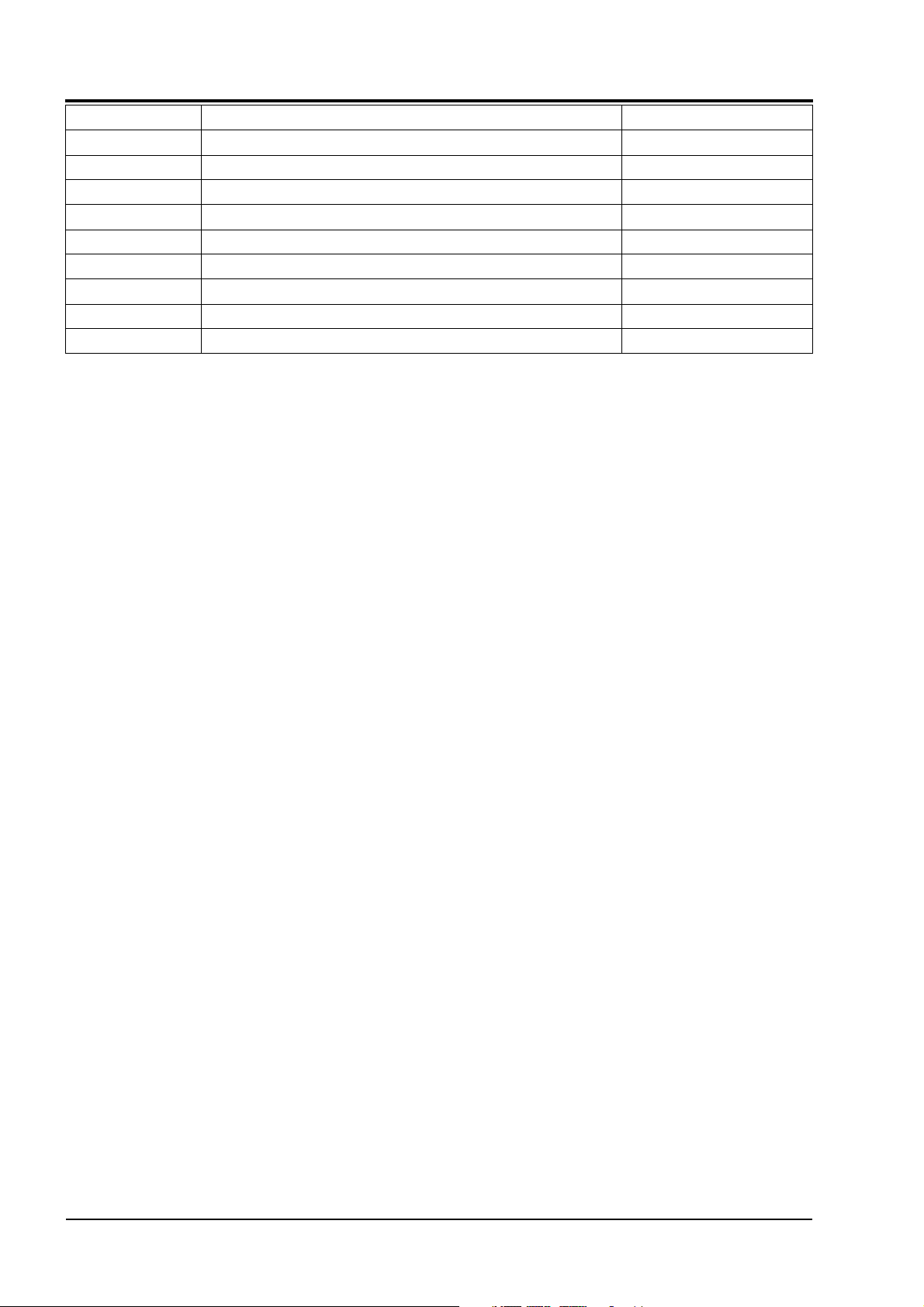

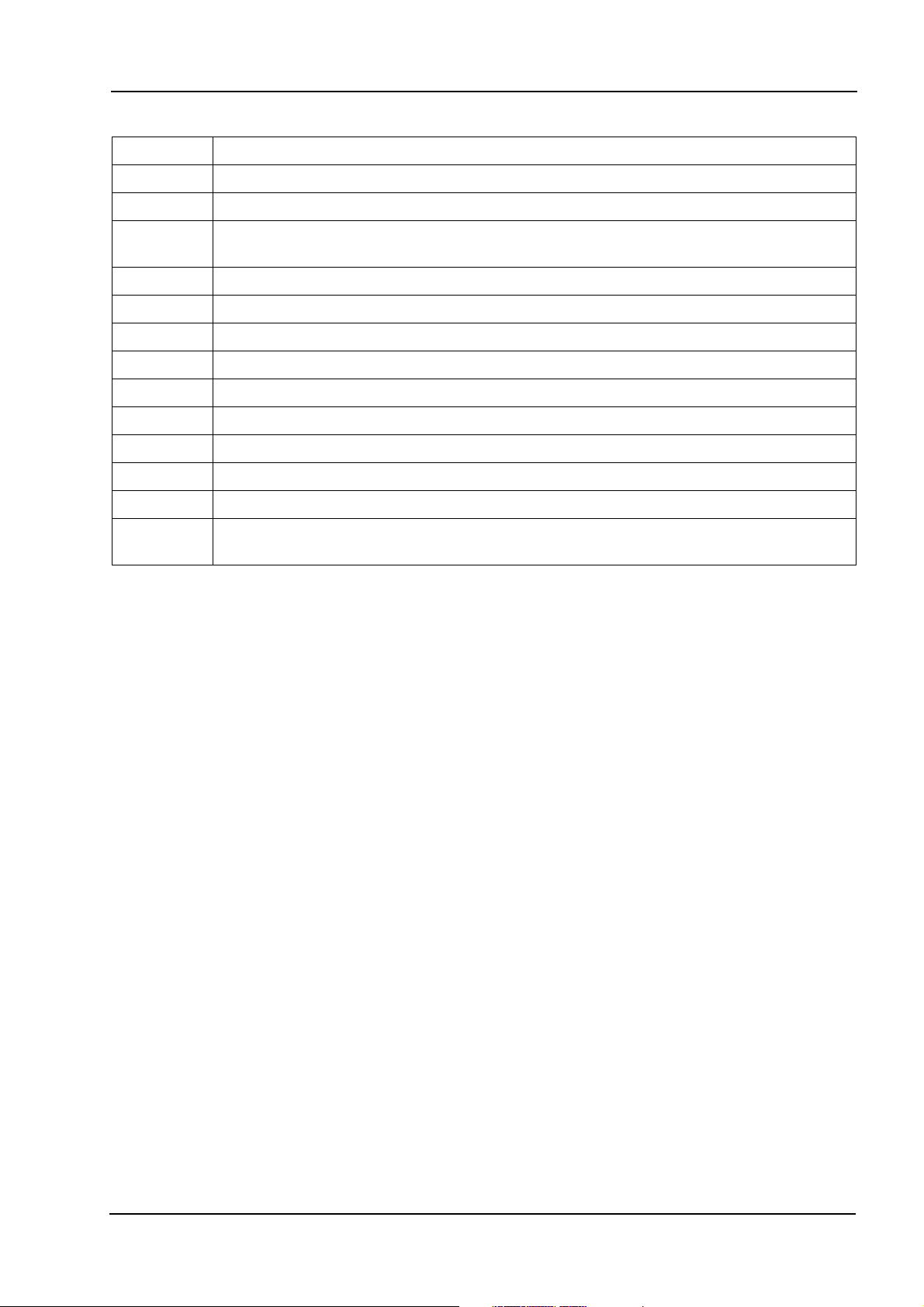

CID-FMI Diagnostic code description Troubleshooting

323-04 Shutdown lamp Short to ground See Test 4 on page 97

323-05 Shutdown Lamp Open Circuit See Test 4 on page 97

324-03 Warning lamp Open/Short to B+ See Test 4 on page 97

324-04 Warning lamp Short to ground See Test 4 on page 97

324-05 Warning Lamp Open Circuit See Test 4 on page 97

342-02 Secondary Engine Speed Sensor Data Intermittent See Test 8 on page 121

342-11, 342-12 Secondary Engine Speed Sensor Mechanical Fault See Test 8 on page 121

861-03 Diagnostic lamp Open/Short to B+ See Test 4 on page 97

861-04 Diagnostic lamp Short to ground See Test 4 on page 97

iv

Page 5

Contents

1 General information

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1

Safety precautions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2

2 Electronic system overview

System operation .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...3

Electronic controls ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3

Engine governor ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...3

Timing considerations .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...3

Fuel injection . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3

Engine monitoring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4

Fuel temperature monitoring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 5

Self diagnostics ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 5

Effect of diagnostic codes on engine performance .. ... ... ... ... ... ... ... ... ... ... ... ... ... 5

Current totals stored in the ECM . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6

Programmable parameters .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6

Passwords . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6

Engine component diagram . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7

v

Page 6

OEM connection diagram . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 8

Sensor and connector location diagram . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 9

Engine wiring diagram .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 10

Machine wiring diagram (all options) .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 11

Electrical connectors and functions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 12

Service tools and diagnostics .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 13

Required service tools .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 14

Optional service tools ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

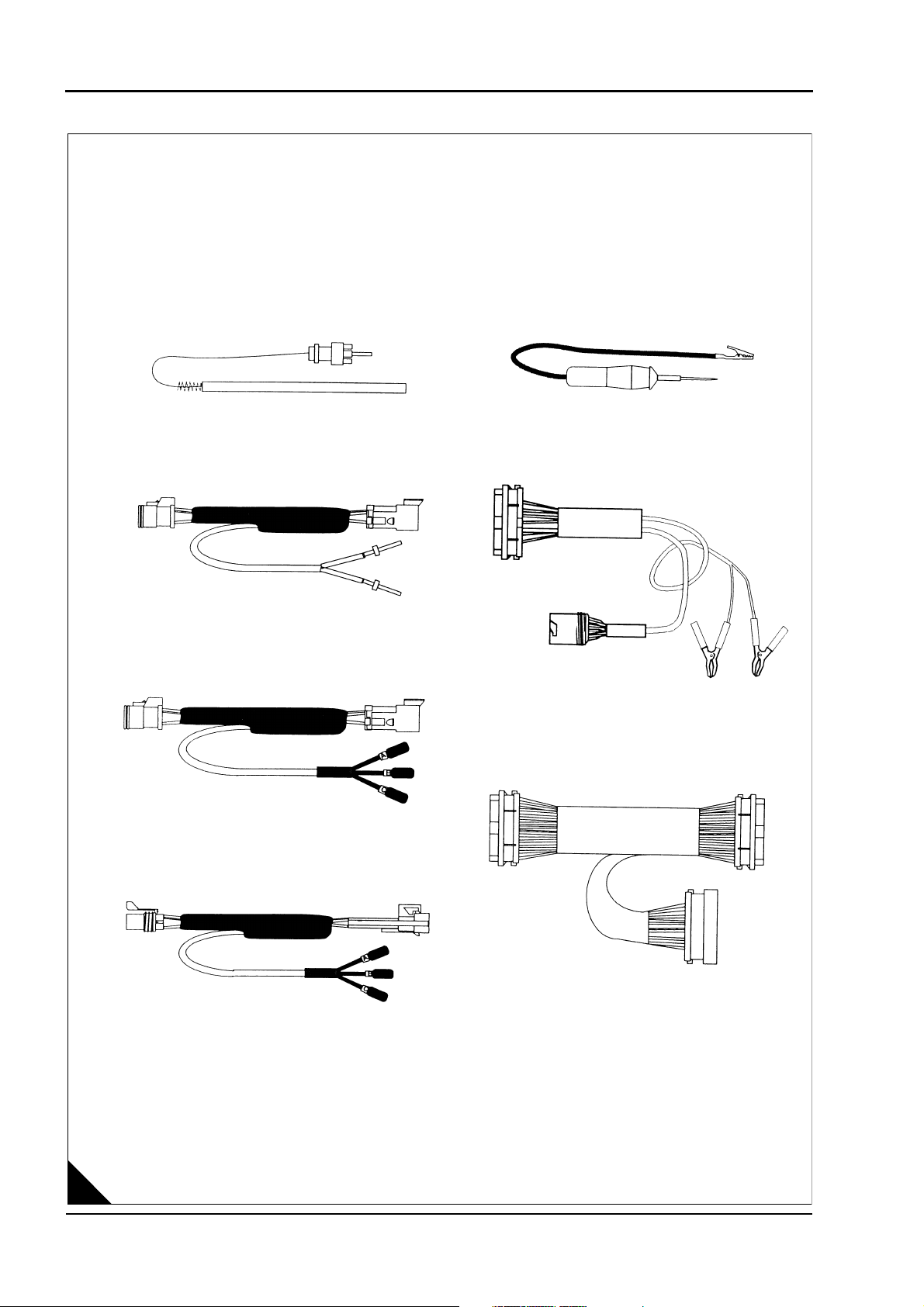

Service tool illustrations ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

3 Programming parameters

Connecting the TIPSS-EST ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 17

Passwords .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Programming a new ECM . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20

Programming a Personality Module using flash programming ... ... ... ... ... ... ... ... 23

ECM date/time clock .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24

ECM diagnostic clock ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24

Injector codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25

TIPSS-EST manual cylinder cutout test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25

Programming parameters . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 26

System configuration parameters ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 26

Customer specified parameters ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

vi

Page 7

4 Troubleshooting without a diagnostic code

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 31

P-401 Engine will not crank ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 32

P-402 Engine cranks but will not start ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 33

P-403 Engine misfires, runs rough or is unstable .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 34

P-404 Low power/poor or no response to throttle . ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 35

P-405 Intermittent engine shutdowns ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 36

P-406 Intermittent low power or power cutouts . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .37

P-407 Electronic service tool will not communicate with the ECM ... ... ... ... ... ... ... ... .38

P-408 ECM will not accept factory passwords .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .39

P-409 Excessive black smoke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 40

P-410 Excessive white smoke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .41

P-411 Engine cannot reach correct rev/min .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 42

P-412 Poor acceleration or response ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 43

P-413 Poor fuel consumption ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 44

P-414 Too much vibration . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 45

P-415 Noise coming from cylinder ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .46

P-416 Excessive valve clearance .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 47

P-417 Valve rotocoil or spring lock is free . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .48

P-418 Mechanical noise (knock) in engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .49

P-419 Oil in cooling system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .50

P-420 Fuel in cooling system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .51

P-421 Coolant in lubricating oil .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 52

P-422 Fuel dilution of lubricating oil .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 53

P-423 Engine has early wear ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .54

P-424 Engine has low oil pressure ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .55

P-425 Engine uses too much lubricating oil .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 56

P-426 Engine coolant is too hot ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 57

P-427 Oil at the exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .58

P-428 Engine has a fuel supply problem ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .59

P-429 Indicator lamp not functioning correctly .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .60

P-430 Inlet air manifold temperature is too high ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .61

P-431 Engine has a high fuel temperature ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 62

5 Troubleshooting with an event code

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 63

Event codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .64

E36-2 Low coolant temperature Action Alert . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 65

E162-1 High boost pressure Warning ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 66

E162-2 High boost pressure Action Alert .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 66

E360-1 Low oil pressure Warning . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .67

E360-2 Low oil pressure Action Alert ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 67

E360-3 Low oil pressure Shutdown ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .67

E361-1 High coolant temperature Warning ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 68

E361-2 High coolant temperature Action Alert .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .68

vii

Page 8

E361-3 High coolant temperature Shutdown . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 68

E362-1 Engine overspeed Warning ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 69

E362-2 Engine overspeed Action Alert .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 69

E362-3 Engine overspeed Shutdown ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 69

E363-1 High fuel temperature Warning . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 70

E363-1 High fuel temperature Action Alert ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 70

E368-1 High inlet air temperature Warning ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 71

E368-2 High inlet air temperature Action Alert ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 71

6 Troubleshooting with a diagnostic code

Diagnostic codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 73

Diagnostic terminology . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 75

Quick reference for ECM diagnostic codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 76

7 Functional tests

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 77

Connectors . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 77

Test 1 Inspecting electrical connectors .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 78

Test 2 Electrical power supply to the ECM ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 83

Test 3 Analogue sensor open or short circuit test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 86

Test 4 ECM Status indicator output circuit test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 95

Test 5 +5 V Sensor voltage supply circuit test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 100

Test 6 PWM desired speed setting circuit test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 105

Test 7 Perkins Data Link circuit test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 112

Test 8 Engine speed/timing circuit test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 119

Test 9 Engine speed/timing calibration .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 127

Test 10 Injector solenoids circuit test . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 131

8Glossary

Glossary of terms .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 141

viii

Page 9

2800 Series

1

General information 1

Introduction

The 2800 Series industrial diesel engines are the latest development from Perkins Engines Company Limited,

a world leader in the design and manufacture of high performance diesel engines.

Read and remember the "Safety precautions" on page 2. They are given for your protection and must be

applied at all times.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person.

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Ensure that all adjustments and repairs are done by personnel who have had the correct training.

Diagnostic Manual, TSL4247, Preliminary 1

Page 10

1

2800 Series

Safety precautions

These safety precautions are important.

Reference must also be made to the local regulations in the country of operation.

l

Only use these engines in the type of application for which they have been designed.

l

Do not change the specification of the engine.

l

Do not smoke when you put fuel in the tank.

l

Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a

safe place.

l

Do not put fuel in the tank while the engine runs (unless it is absolutely necessary).

l

Do not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training;

even then extreme caution must be used to prevent injury).

l

Do not make adjustments that you do not understand.

l

Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions.

l

Other persons must be kept at a safe distance while the engine or equipment is in operation.

l

Do not permit loose clothing or long hair near moving parts.

l

Keep away from moving parts during engine operation. Warning! Some moving parts cannot be seen

clearly while the engine runs.

l

Do not operate the engine if a safety guard has been removed.

l

Do not remove the filler cap of the cooling system while the engine is hot and while the coolant is under

pressure, because dangerous hot coolant can be discharged.

l

Do not use salt water or any other coolant which can cause corrosion in the closed coolant circuit.

l

Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the

gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially

to the eyes.

l

Disconnect the battery terminals before a repair is made to the electrical system.

l

Only one person must control the engine.

l

Ensure that the engine is operated only from the control panel or from the operator’s position.

l

If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

l

Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons.

Protect your hands with gloves or a special solution to protect the skin.

l

Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated

with oil into the pockets.

l

Discard used lubricating oil in a safe place to prevent contamination.

l

The combustible material of some components of the engine (for example certain seals) can become

extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with

the eyes.

l

Fuel and oil pipes MUST be inspected for cracks or damage before they are fitted to the engine.

l

Fit only genuine Perkins parts.

2 Diagnostic Manual, TSL4247, Preliminary

Page 11

2800 Series

2

Electronic system overview 2

System operation

The 2800 Series industrial diesel engines are designed for electronic control. The injection pump, fuel lines

and nozzles used in mechanical engines have been replaced with an electronic unit injector in each cylinder.

A solenoid on each injector controls the amount of fuel that is delivered by the injector. An Engine Control

Module (ECM) sends a signal to each injector solenoid in order to provide complete control of the engine.

Electronic controls

The electronic system consists of the Engine Control Module (ECM), the engine sensors and the OEM

interface. The ECM is the computer which controls the engine. The Personality Module in the ECM contains

the software which controls how the ECM behaves (the Personality Module stores the operating maps that

define power, rev/min, etc).

Engine governor

The electronic controls on the engine serve as the engine governor, determining when and how much fuel to

deliver to the cylinders based on the actual and desired conditions at any given time.

The ECM uses one of three possible speed control inputs to determine the desired engine speed and

compares this to the actual engine speed determined through the crankshaft position sensor. If the desired

engine speed is greater than the actual engine speed, more fuel is injected in order to increase engine speed.

Timing considerations

Once the ECM has determined how much fuel is required, it must next determine when to inject the fuel.

Injection timing is determined by the ECM after considering input from the following components:

l

Coolant temperature sensor

l

Intake manifold air temperature sensor

l

Atmospheric pressure sensor

l

Boost pressure sensor

The ECM determines where top centre on cylinder number one is located from the engine camshaft position

sensor signal. The ECM decides when injection should occur relative to top centre and provides the signal to

the injector at the desired time. The ECM adjusts timing for the best engine performance, fuel economy and

white smoke control.

Note: Actual or desired timing cannot be viewed with an electronic service tool.

Fuel injection

The ECM controls the amount of fuel injected by varying the signals to the injectors. The injectors will pump

fuel only if the injector solenoid is energized. The ECM sends a high voltage signal to energize the solenoid.

By controlling the timing and duration of the high voltage signal, the ECM can control injection timing and the

amount of fuel that is injected.

The Personality Module inside the ECM sets certain limits on the amount of fuel that can be injected. The FRC

Fuel Limit is a limit based on boost pressure to control the air/fuel ratio for control of emissions. When the

ECM senses a higher boost pressure (more air into cylinder) it increases the FRC Fuel Limit (allows more fuel

into cylinder).

Diagnostic Manual, TSL4247, Preliminary 3

Page 12

2

The Rated Fuel Limit is a limit that is based on the power rating of the engine and engine rev/min. It is similar

to the rack stops and torque spring on a mechanically governed engine. It provides power and torque curves

for a specific engine family and rating.

Note: All of these limits are determined at the factory in the Personality Module and cannot be changed.

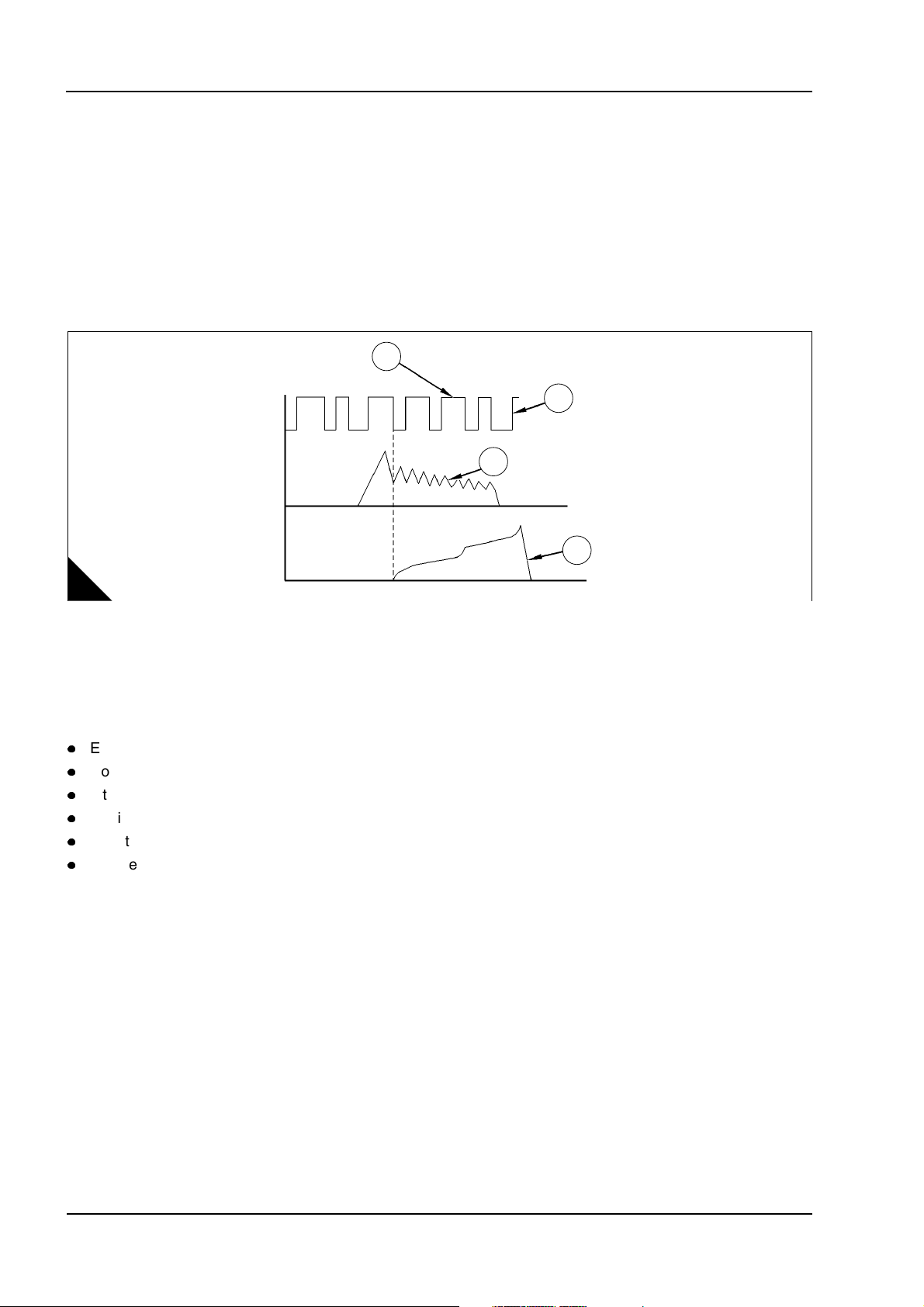

Example of EUI system

1 TC reference

2 Speed/timing signal

3 Electrical current to the injector solenoid

4 Injection pressure curve

2800 Series

1

2

3

4

A

Note: Signals and timing are not to scale.

Engine monitoring

Perkins provides a factory installed engine monitoring system. The Perkins engine monitoring system monitors

the following parameters:

l

Engine oil pressure

l

Coolant temperature

l

Intake manifold air temperature

l

Engine speed

l

Boost pressure

l

Fuel temperature

The Perkins engine monitoring system has three levels of operation, WARNING, ACTION ALERT and

SHUTDOWN as described below.

Perkins engine monitoring WARNING operation

In the WARNING condition the ECM causes the Warning lamp to turn ON to indicate a problem has been

detected by the Engine Monitoring System. No further ECM or engine action occurs.

Perkins engine monitoring ACTION ALERT operation

In the ACTION ALERT condition the ECM begins by activating the Action Alert lamp ON to indicate a problem

has been detected by the Engine Monitoring System. This is also normally wired to cause a shutdown via the

OEM control panel.

Perkins engine monitoring SHUTDOWN operation

If the fault reaches the SHUTDOWN condition the ECM activates the shutdown lamp and unless the engine is

in CRITICAL OVERRIDE condition, the engine will shutdown.

4 Diagnostic Manual, TSL4247, Preliminary

Page 13

2800 Series

2

Fuel temperature monitoring

The fuel temperature sensor monitors the fuel temperature, adjusting the ECM calculated fuel rate to

compensate for fuel temperature changes and to adjust the fuel rate for constant power. The sensor is also

used to warn the operator of excessive fuel temperature with a diagnostic event code because excessive fuel

temperatures can adversely affect engine performance.

Self diagnostics

The electronic system has the ability to diagnose problems. When a problem is detected, a diagnostic code is

generated and stored in permanent memory (logged) in the ECM. The diagnostic lamp is also activated.

When diagnostic codes occur, the diagnostic codes are referred to as Active diagnostic codes. They indicate

that a problem of some kind currently exists.

Diagnostic codes that are stored in memory are called Logged diagnostic codes. Since the problem may have

been temporary, or may have been repaired since the problem was logged, logged codes do not necessarily

mean that something needs to be repaired. They are instead meant to be an indication of probable causes for

intermittent problems.

Diagnostic codes that identify operating conditions outside the normal operating range are called Events.

Event codes are not typically an indication of an electronic system problem.

Note: Some of the diagnostic codes require passwords to clear.

Effect of diagnostic codes on engine performance

The discussion on engine monitoring mentions that the diagnostic lamp activates when a specific condition

exists. When the ECM detects an engine problem, it generates an active diagnostic code and also logs the

diagnostic code in order to indicate when, and if appropriate, how many times the problem occurred. There are

two types of diagnostic codes, Fault codes and Event codes.

Diagnostic fault codes

These are provided in order to indicate that an electrical or electronic problem has been detected by the ECM.

In some cases the engine performance can be affected when the condition causing the code exists. More

frequently, however, no difference in the engine performance can be detected.

Diagnostic event codes

Diagnostic event codes are used to indicate that some operational problem has been detected in the engine

by the ECM. This usually does not indicate an electronic malfunction.

The ECM also provides an ECM clock with date/time to date and time stamp the following critical event codes:

l

362-3 Engine overspeed Shutdown

l

360-3 Low oil pressure Shutdown

l

361-3 High coolant temperature Shutdown

For a listing all of the CID-FMI Diagnostic codes, along with the page number where details regarding the

cause, performance effect, and troubleshooting of the code can be located, refer to "Quick reference for ECM

diagnostic codes" on page 76.

Diagnostic Manual, TSL4247, Preliminary 5

Page 14

2

2800 Series

Current totals stored in the ECM

The ECM maintains engine total data for the following parameters:

Total time

The total time is the engine's operating hours. This does not include operating time when the ECM is powered

ON but the engine is not running.

Programmable parameters

Certain parameters affecting engine operation may be changed with electronic service tools. The parameters

are stored in the ECM, and are protected from unauthorized changes by passwords. These parameters are

either System Configuration Parameters or Customer Parameters.

System configuration parameters

These are set at the factory and affect emissions or power ratings within an engine family. Factory passwords

must be obtained and used to change the system configuration parameters.

Customer parameters

These are variable and can be used to tailor the engine to customer requirements within the limits set by the

factory and Perkins engine monitoring operation. Customer passwords may be required to change customer

parameters.

Caution: Some of the parameters may affect engine operation. Without adequate training, these parameters

may lead to power or performance complaints even when the engine is performing to specification.

Refer to "Programming parameters" on page 26 for further information.

Passwords

System configuration parameters are protected by Factory passwords. Factory passwords are calculated on

a computer system that is available only to Perkins dealers.

Customer parameters can be protected by Customer passwords. The customer passwords are programmed

by the customer. Factory passwords can be used to change customer passwords if they are lost.

Refer to "System configuration parameters" on page 26 for further information when passwords are needed

and how to obtain them.

6 Diagnostic Manual, TSL4247, Preliminary

Page 15

2800 Series

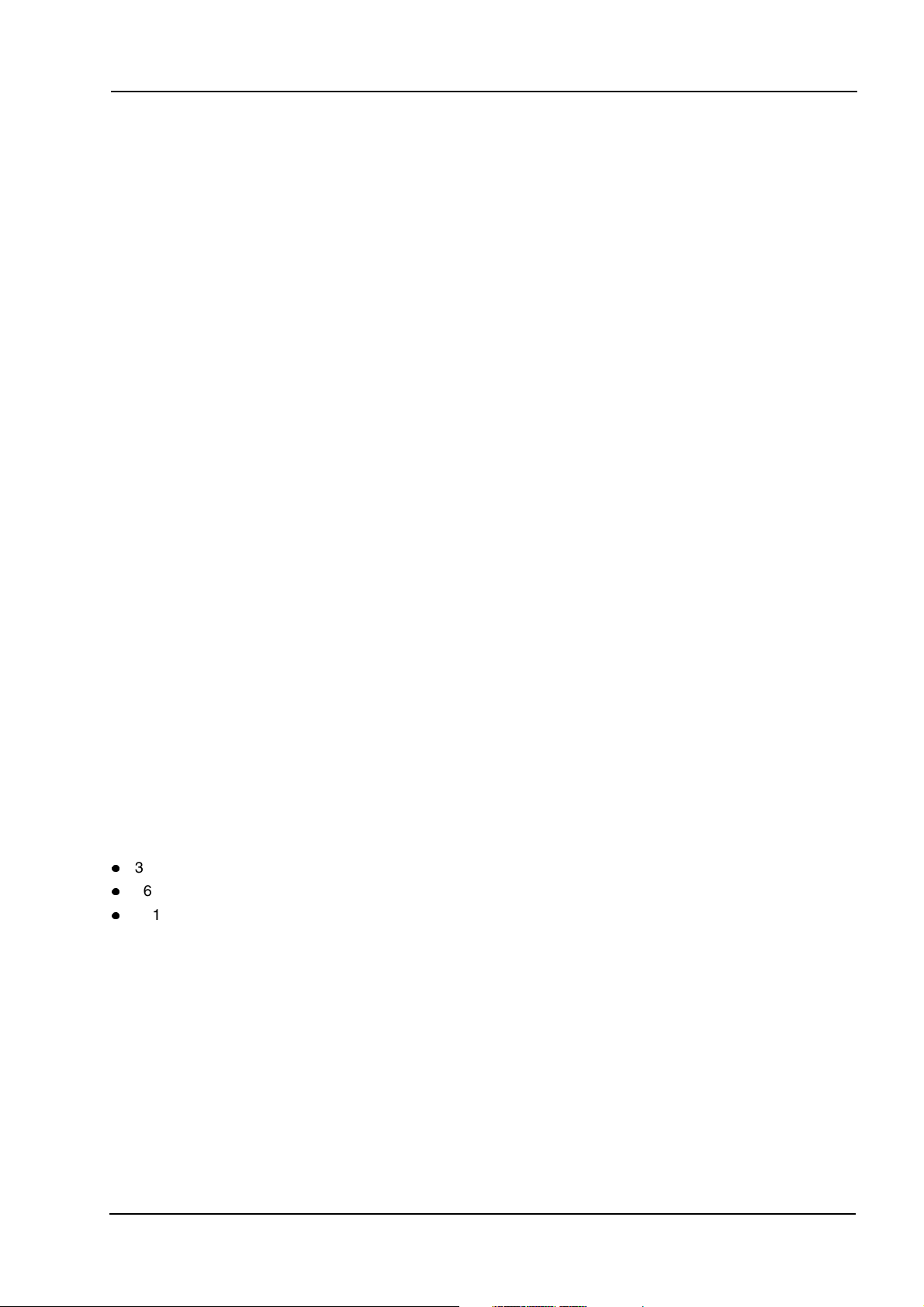

Engine component diagram

Internal Injector Harness

2

36+1 TOOTH

CRANK

GEAR

Main Engine Harness

Crank Speed/Timing

12PIN Connector

Service

Tool

Connector

Interface

Connector

OEM Interface Connectors

A3 ECM

Inlet Air Manifold Temperature

Cam Speed/Timing

Fuel Temperature

36+1 TOOTH

CAM GEAR

Coolant Temperature

Boost

Pres Sensor

Lub Oil Pressure

Sensor

Atmospheric Pressure Sensor

Calibration

Probe

A

Diagnostic Manual, TSL4247, Preliminary 7

Page 16

2

OEM connection diagram

To ECM J1 Connector

2800 Series

Service

Tool

Connector

Lamp Box

1: Diagnostics

2: Caution

3: Warning

4: Shutdown

5: Overspeed

6: High Coolant Temp

7: Low Pressure

Customer connecter (If fitted)

Keyswitch

Digital Speed Control

Optional

Optional

Speed

Raise/Lower

Critical Override

Optional

Shutdown Reset

Optional

Injector Disable

Optional

16A Breaker

E-Stop

Throttle Adjust

1

23

-B S D +B

Pot

droop

adjust

+

24V

-

Optional

Speed

Control

Switched

0.5-4.5V

Battery +ve

Optional

Screen tied to

ECM -VE

Optional

Droop/Isoch

Speed Selection

Optional

Potentiometer

A

8 Diagnostic Manual, TSL4247, Preliminary

Page 17

2800 Series

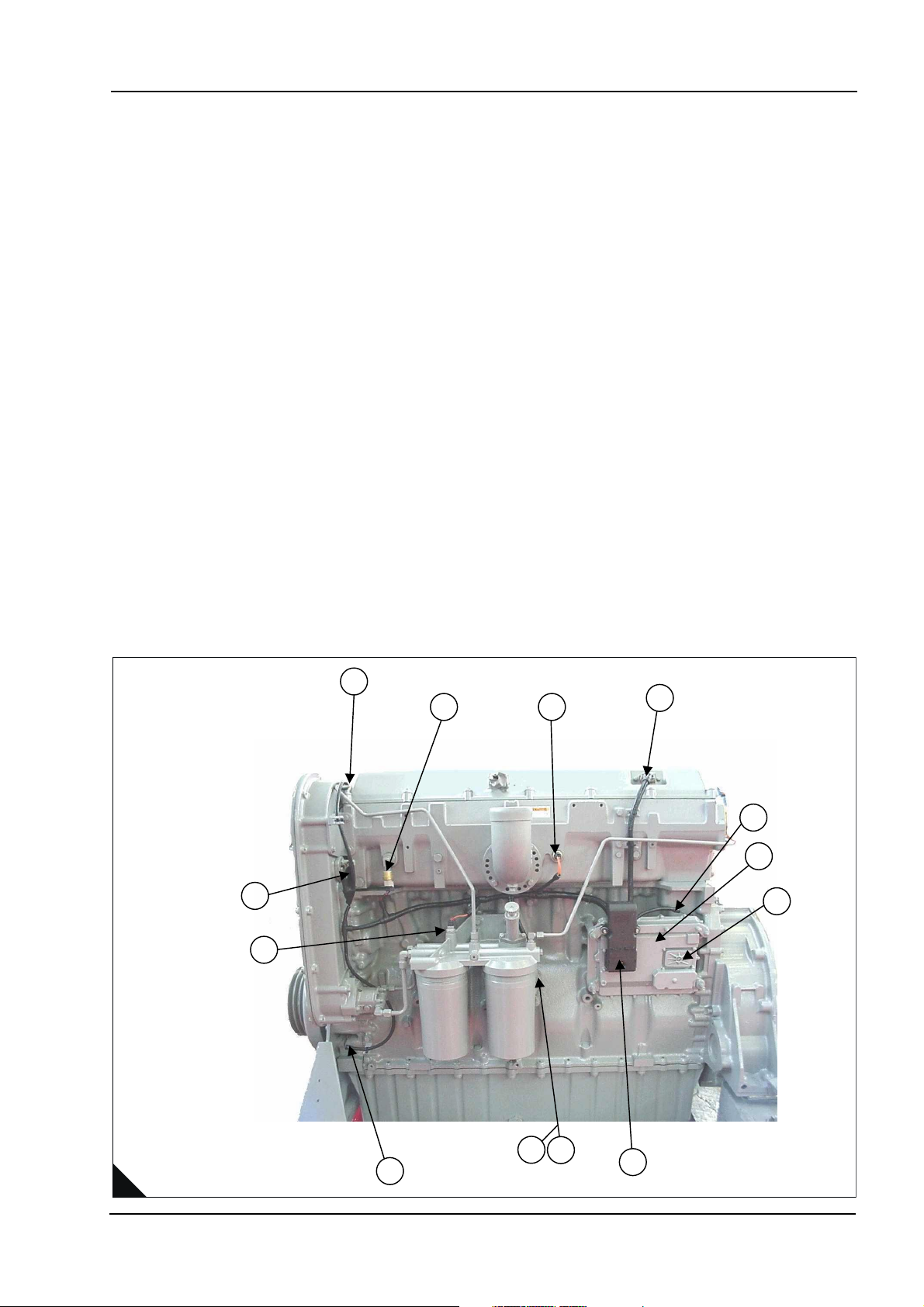

Sensor and connector location diagram

Key

1 Electronic Control Module (ECM)

2 J1/P1 Machine connector

3 J2/P2 Engine connector

4 Atmospheric pressure sensor

5 Oil pressure sensor

6 Crankshaft position sensor

7 Fuel temperature sensor

8 Camshaft position sensor

9 Coolant temperature sensor

10 Boost pressure sensor

11 Intake manifold air temperature sensor

12 Electronic unit injector connector

13 Timing calibration pickup connector

2

9

10

8

7

11

12

13

1

2

5

4

6

3

A

Diagnostic Manual, TSL4247, Preliminary 9

Page 18

2

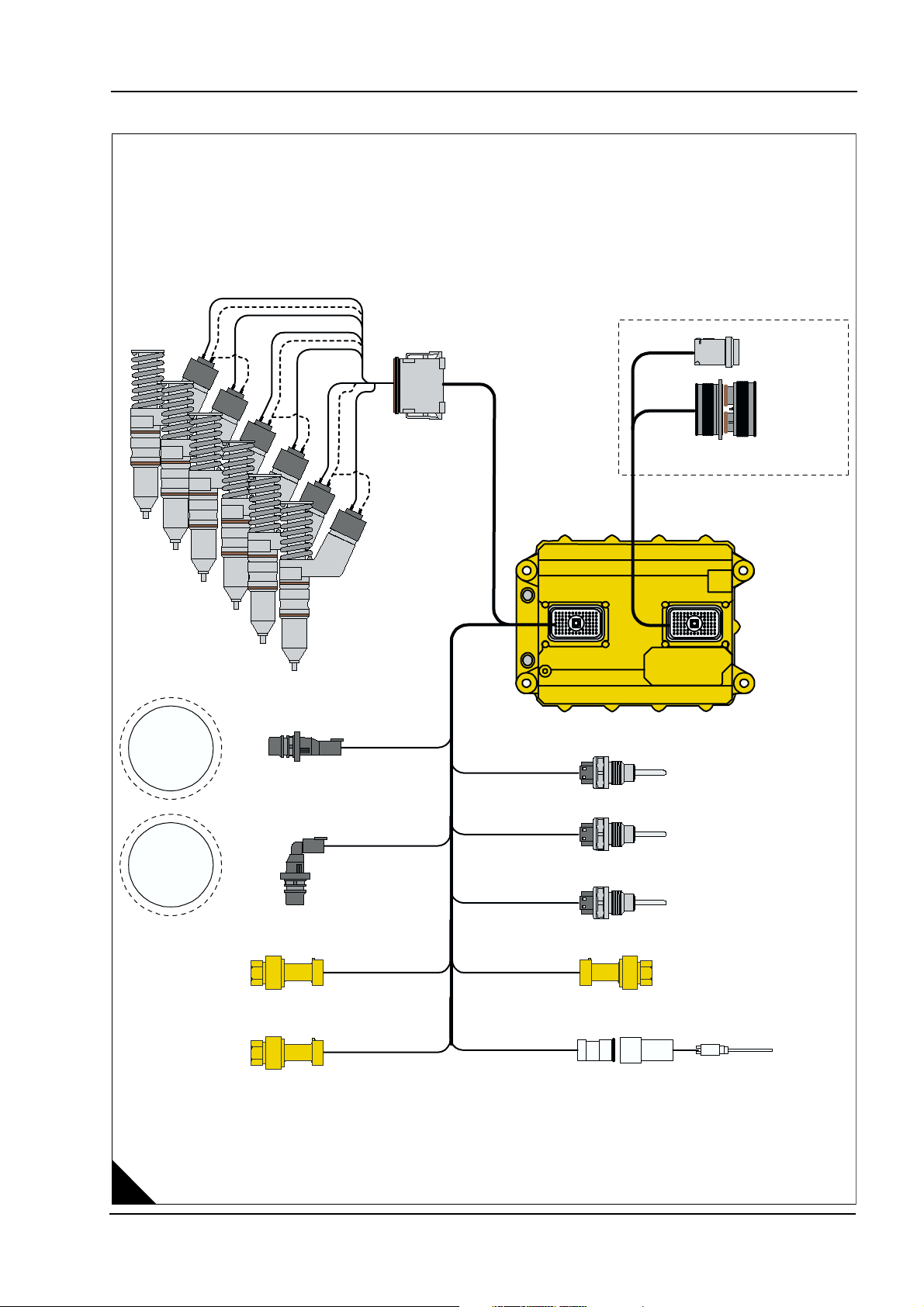

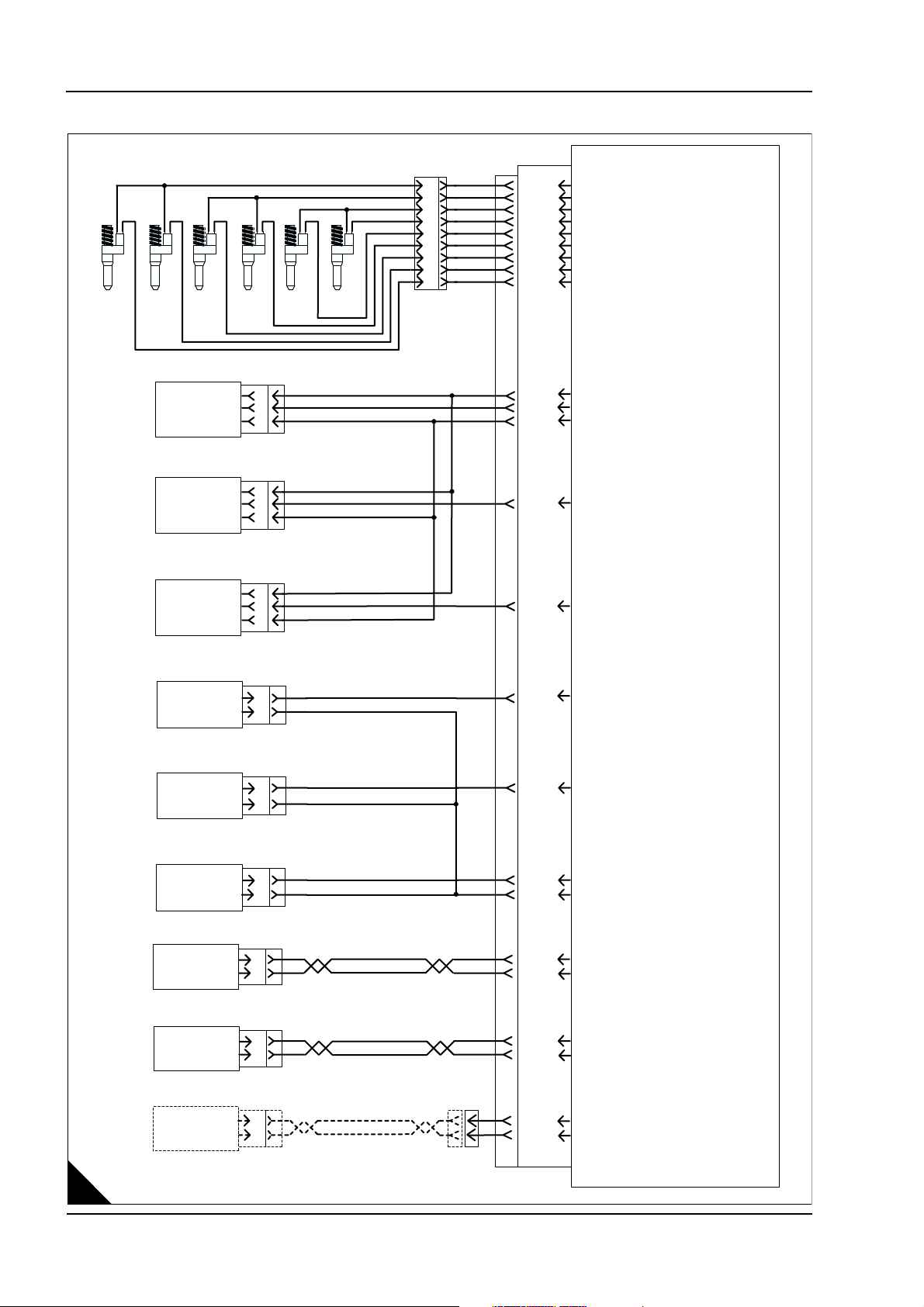

Engine wiring diagram

Injector

Injector

Cyl 2

Cyl 1

Atmospheric Pressure Sensor

Turbo Outlet Pressure Sensor

Injector

Cyl 3

+5V

Signal

+5V

Signal

Injector

Cyl 4

P203 J203

P200 J200

2800 Series

ECM

5

7

6

10

3

11

2

12

1

Injector

A

C

BReturn

A

C

BReturn

Cyl 5

Injector

Cyl 6

J300 P300

J2/44

J2/45

J2/46

J2/55

J2/54

J2/39

J2/38

J2/37

J2/36

J2/2

J2/14

J2/3

J2/40

Injector Common Cylinders 1 & 2

Injector Common Cylinders 3 & 4

Injector Common Cylinders 5 & 6

Injector Cylinder 6

Injector Cylinder 5

Injector Cylinder 4

Injector Cylinder 3

Injector Cylinder 2

Injector Cylinder 1

+5VDC Supply

Atmospheric Pressure

Analogue Return

Turbo Outlet Pressure

A

Oil Pressure Sensor

A

+5V

Signal

Return

Coolant Temperature Sensor

Signal

Fuel Temperature Sensor

Signal

Return

Inlet Air Temperature Sensor

Signal

Return

Crankshaft Position Sensor

Signal

Return

Camshaft Position Sensor

Signal

Calibration Probe

Signal

Return

C

B

P201 J201

C

BReturn

J100 P100

C

B

J105 P105

C

B

J103 P103

2

1

J401 P401

2

1Return

J402 P402

1

2

J400 P400

J2/24

J2/32

J2/33

J2/35

J2/18

J2/48

J2/49

J2/58

J2/59

J2/22

J2/23

P2 J2

Oil Pressure

Coolant Temperature

Fuel Temperature

Inlet Air Temperature

Return

Crank Speed Timing +

Crank Speed Timing -

Cam Speed timing +

Cam speed timing -

Calibration Probe +

Calibration Probe -

10 Diagnostic Manual, TSL4247, Preliminary

Page 19

2800 Series

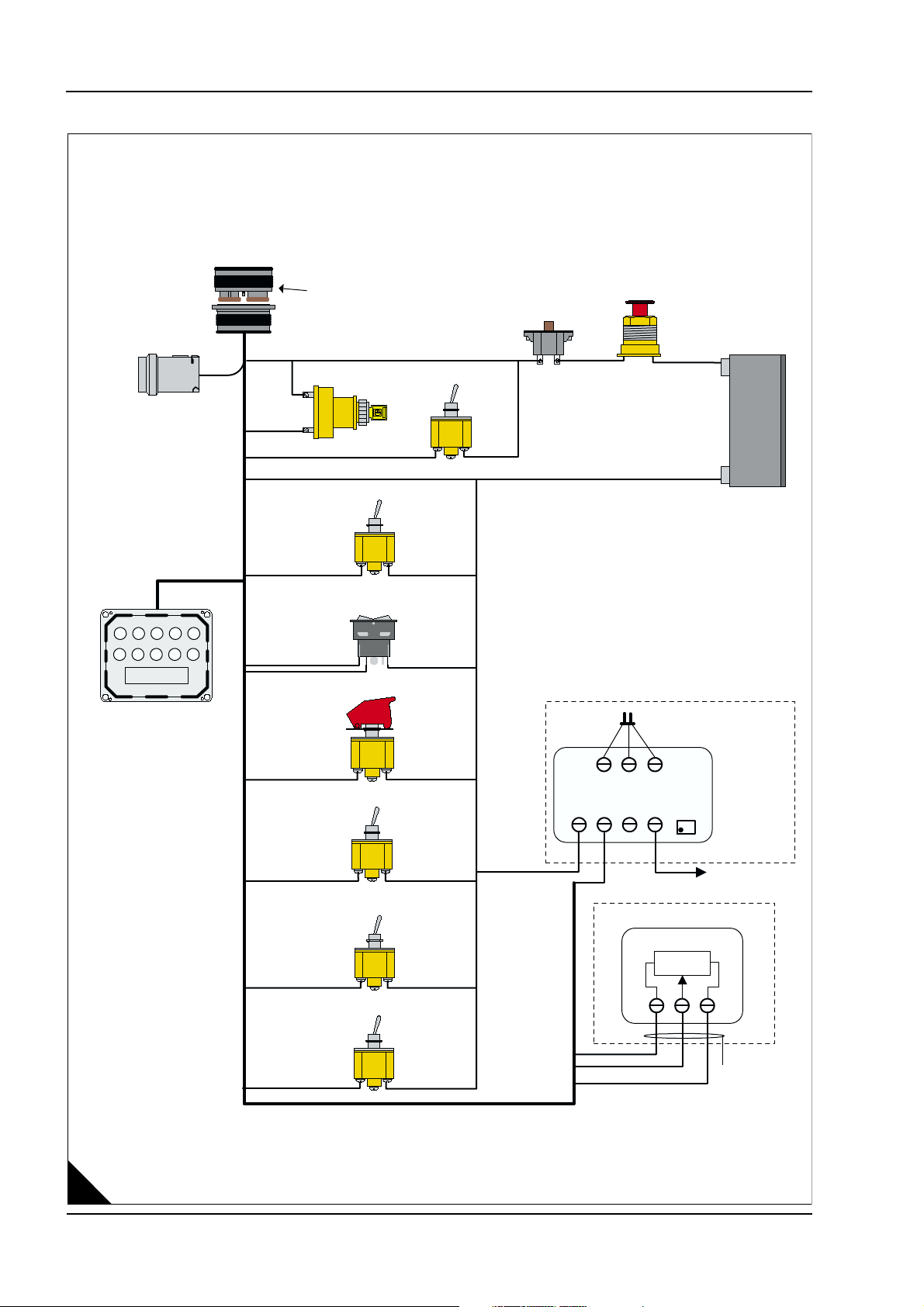

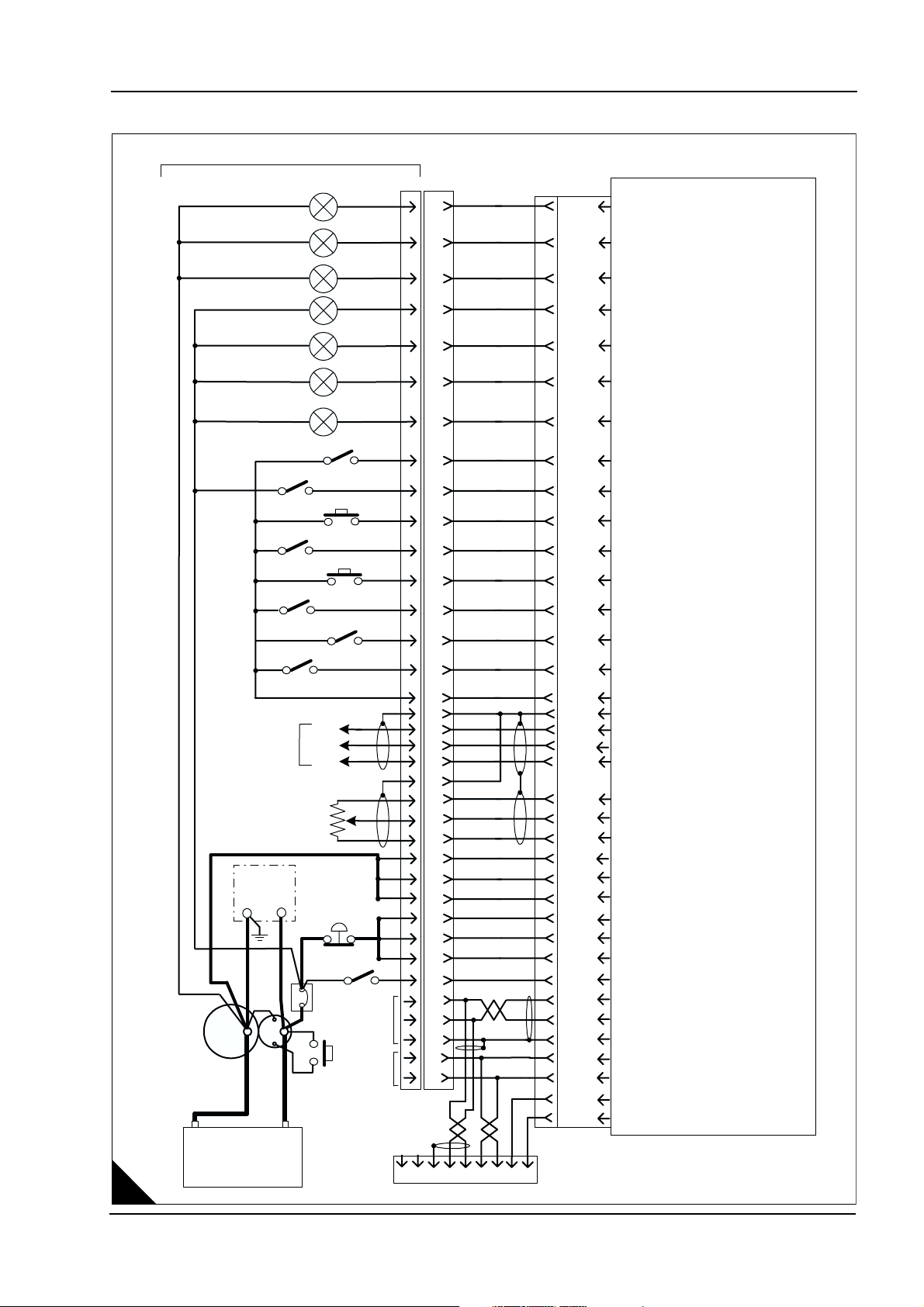

Machine wiring diagram (all options)

2

A

This Wiring Supplied By OEM

Outputs may be used to

drive lamps or relays

Injection

Disable

Shutdown

Emergency Override

1500/1800

rpm Select

Fault Reset

To P WM

Speed Control

(If Required)

Analogue Speed

Setting

Potentiometer or

Input from Load

Sharer/Synchroniser

Charging

Alternator

GRD POS

Starter

Motor

-

Battery

24V DC

Button

+

Ground

PWM

Emergency

Stop Button

Circuit

Breaker

Start

Shutdown

Action Alert

Warn ing

Diagnostics

Oil Pressure

Coolant Temp

Overspeed

Digital Speed

Control Enable

Lower

Speed

Raise

Speed

Droop/

Isochronous

+8V

Key

Switch

Perk ins

J1939

Data

Link

Data

Link

J3 P3

16

17

34

29

35

28

25

26

18

23

27

22

36

21

23

20

24

19

38

39

40

15

33

1

10

31

32

11

HJ

5

4

3

8

9

2

7

6

GFC

Customer

Interface

Connector

DE

P1 J1

B

A

J1/10

J1/19

J1/20

J1/31

J1/28

J1/29

J1/30

J1/49

J1/62

J1/59

J1/58

J1/7

J1/56

J1/46

J1/41

J1/18

J1/67

J1/5

J1/66

J1/4

J1/3

J1/15

J1/2

J1/61

J1/63

J1/65

J1/48

J1/52

J1/53

J1/70

J1/50

J1/34

J1/42

J1/8

J1/9

J1/55

J1/69

Shutdown lamp Output

Action Alert Lamp Output

Warning Lamp Output

System Fault Lamp Output

Oil Pressure Lamp Output

Coolant Temperature Lamp Output

Overspeed Lamp Output

Digital Speed Control Enable

Injection Disable

Lower Speed

Shutdown Emergency Override

Raise Speed

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

Digital Ground

- Battery

Ground

PWM Input

+8V

Analogue Ground

Analogue Speed Input

+5V

- Battery

- Battery

- Battery

Unswitched + Battery

Unswitched + Battery

Unswitched + Battery

Switched + Battery

J1939 Data Link +

J1939 Data Link -

J1939 Screen

Perkins Data Link +

Perkins Data Link -

Unswitched + Battery

- Battery

9 Pin Perkins Data

Link Connector

ECM

Diagnostic Manual, TSL4247, Preliminary 11

Page 20

2

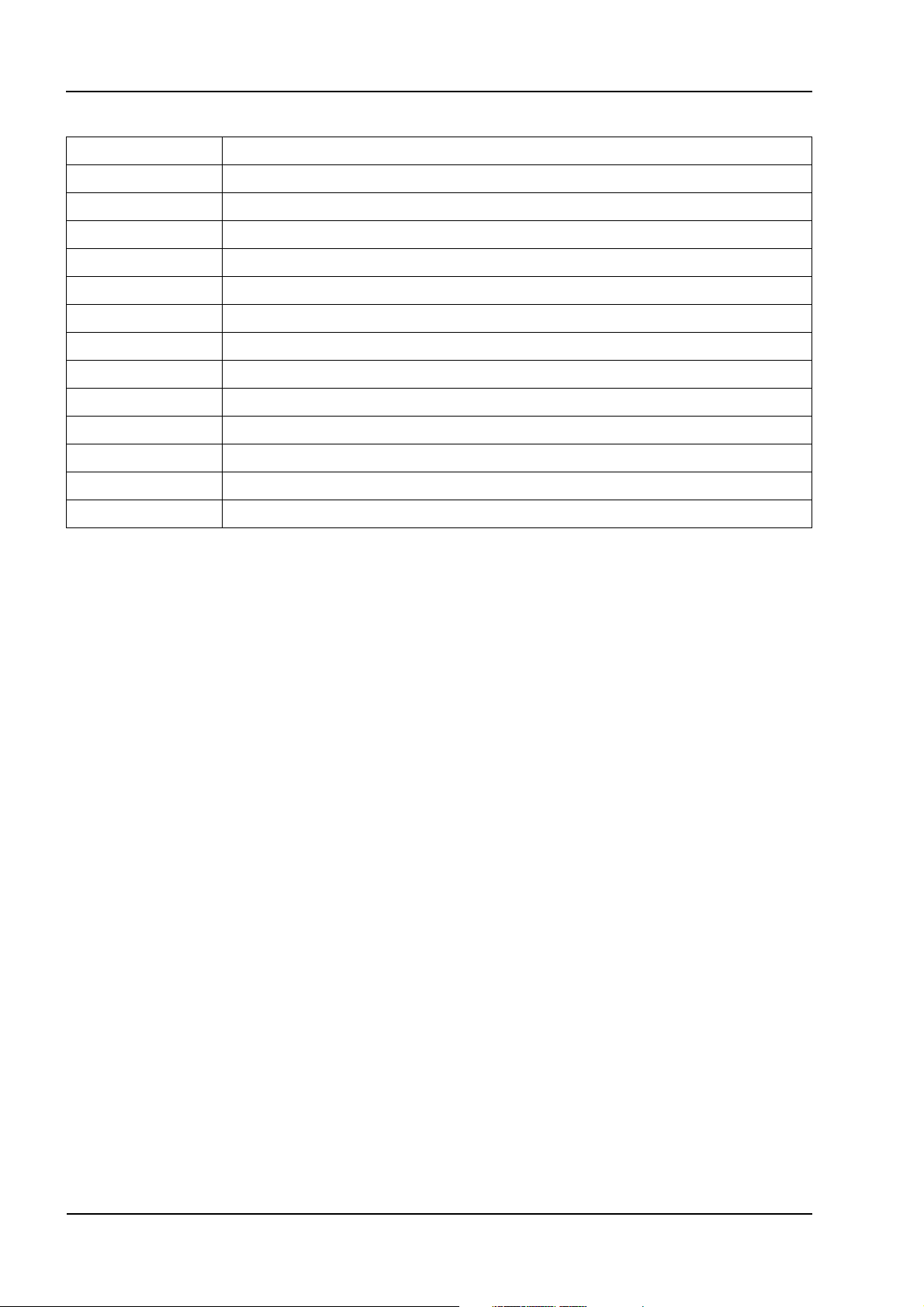

Electrical connectors and functions

Connector Function

J1/P1 ECM connector (70-Pin OEM harness)

J2/P2 ECM connector (70-Pin Engine harness)

J3/P3 Machine wiring connector (40-Pin connector) - optional

J100/P100 Engine coolant temperature sensor (2-pin connector)

J103/P103 Engine inlet air temperature sensor (2-pin connector)

J105/P105 Engine fuel temperature sensor (2-pin connector)

J200/P200 Engine turbo outlet pressure sensor (3-pin connector)

J201/P201 Engine oil pressure sensor (3-pin connector)

J203/P203 Engine atmospheric pressure sensor connector (3-pin connector)

J300/P300 Injector solenoid harness (12-pin connector)

J400/P400 Engine timing calibration probe (2-pin connector)

J401/P401 Crankshaft position sensor (2-pin connector)

J402/P402 Camshaft position sensor (2-pin connector)

2800 Series

12 Diagnostic Manual, TSL4247, Preliminary

Page 21

2800 Series

2

Service tools and diagnostics

The Perkins TIPSS-EST service tools are designed to help the service technician analyze and locate faults or

problems within the system. They are required to perform calibrations and to read or change engine

parameters.

Perkins TIPSS-EST is a software program that runs on a personal computer and requires a communication

adapter to translate information from the Perkins Data Link to the computer RS232 port.

Perkins TIPSS-EST can be used to display the following information:

l

Programmable parameter settings

l

Active and logged diagnostic codes

l

Logged events

l

Engine rating history

l

Histograms

l

Custom data

l

ECM date/time clock

Perkins TIPSS-EST can also be used to perform the following functions:

l

Diagnostic tests

l

Sensor calibrations

l

Flash programming

l

Parameter programming

l

Copy configuration (ECM replacement)

l

Data logging

l

Real time graphing

There are several adapter cables, breakout T cables, etc that are used in order to access measurements of

signals. A heavy duty multimeter is suitable in order to make the necessary measurements. A multimeter that

has the ability to measure duty cycle may also be required. Other special tools include those needed to

measure pressure and temperature.

Diagnostic Manual, TSL4247, Preliminary 13

Page 22

2

Required service tools

Part No. Description

IBM PC Compatible:

Minimum - Pentium 100 MHz processor or greater, 32 Mb RAM, 200 Mb of available hard disk

space, VGA monitor or display, CD-ROM, 3.5 in 1.44 Mb diskette drive, Windows 95 or greater,

Windows NT, Windows 2000, RS232 port with 16550AF UART, Built in pointing device or

-

mouse.

Recommended - Pentium 200 MHz processor, 64 Mb RAM, 1Gb of available hard disk space,

Super VGA monitor or display, 12X CD-ROM, 3.5 in 1.44 Mb diskette drive, Windows 95 or

greater, Windows NT, Windows 2000, RS232 port with 16550AF UART, Built in pointing

device or mouse

2800 Series

-

27610164

27610165 Communication adapter

27610167 Communication adapter software

27610169 RS232 cable (connects communication adapter to PC)

27610168 Connector cable (connects communication adapter to diagnostic connector)

- Terminal removal tool (14 AWG wire) used for removing pin and socket terminals

- Terminal removal tool (16 and 18 AWG wire) used for removing pin and socket terminals

-

- Service tool bypass harness

- 70-terminal “AMP” breakout T

- Engine timing probe

- Timing probe adapter

- Deutsch “DT” timing probe cable

Single user license for TIPSS

All engine data subscription

Communication adapter II group

(Communication adapter II, harness cables, software program, users manual and storage

case)

Heavy duty digital multimeter

Digital multimeter capable of reading duty cycle

- Slotted socket for removing coolant temperature sensor

- Voltage test lamp

14 Diagnostic Manual, TSL4247, Preliminary

Page 23

2800 Series

Optional service tools

Part No. Description

27610181 Harness repair tool kit (includes crimping tool)

27610182 Harness repair tool kit top-up

2

-

- 3-Pin "HD" breakout T (for remote mounted throttle sensor only)

- Signal reading probes

- Extraction pump used to pull a vacuum for atmospheric pressure test

- Suction tube attachment to 1U-5718

- Bottle assembly attachment to 1U-5718

- Turning tool permits turning engine by hand

- Pressure group used to measure oil pressure

- Temperature adapter group

- 3-terminal Packard breakout T

-

3-Pin "DT" breakout T (breakout T harness is inserted in series between a harness jack and

plug to permit voltage measurement on an operating system)

3-Pin "DT" harness bypass T (used to bypass the harness signal lines for engine pressure

sensors)

Diagnostic Manual, TSL4247, Preliminary 15

Page 24

Service tool illustrations

Engine Timing Probe

125-3662 Engine Sensor Harness Bypass

This page is intentionally blank

7X-6370 3-Pin DT Breakout T

Voltage Test Lamp 5P-7277

167-9225 Service Tool Bypass Harness

A

140-2266 70-Terminal Breakout T

124-5643 3-Terminal Packard Breakout T

16

Page 25

2800 Series

3

Programming parameters 3

Connecting the TIPSS-EST

The communications adapter is powered by 24 volts DC from the engine battery. This permits operation beside

the engine to allow use during engine operation.

Use the following procedures to connect the service tool to the engine.

1 Turn the key switch to the OFF position

2 The PC (with the TIPSS-EST software installed) should be connected to the engine system through the

diagnostics connector.

3 Connect the opposite end of the service tool harness cable to the communication adapter. Refer

"Connecting TIPSS-EST using a TIPSS communication adapter" on page 18.

4 Connect the communication adapter to the PC using the appropriate cable.

5 Turn the key switch to the ON position in order to begin testing. The service tool will operate while the engine

is running or with the engine OFF and the key switch ON. If the tool does not communicate with the ECM

disconnect and reconnect the diagnostics connector cable. Check the communication. If the problem is still

present refer to Test 7: Perkins Data Link circuit test on page 114.

Notes:

l

The service tool may restart during engine cranking due to a voltage dip on the battery line.

l

The TIPSS-EST must be configured to communicate with the specific type of communication adapter used.

Go to the ‘Preferences’ menu that is located under ‘Settings’ in order to select the appropriate

communication adapter.

Diagnostic Manual, TSL4247, Preliminary 17

Page 26

3

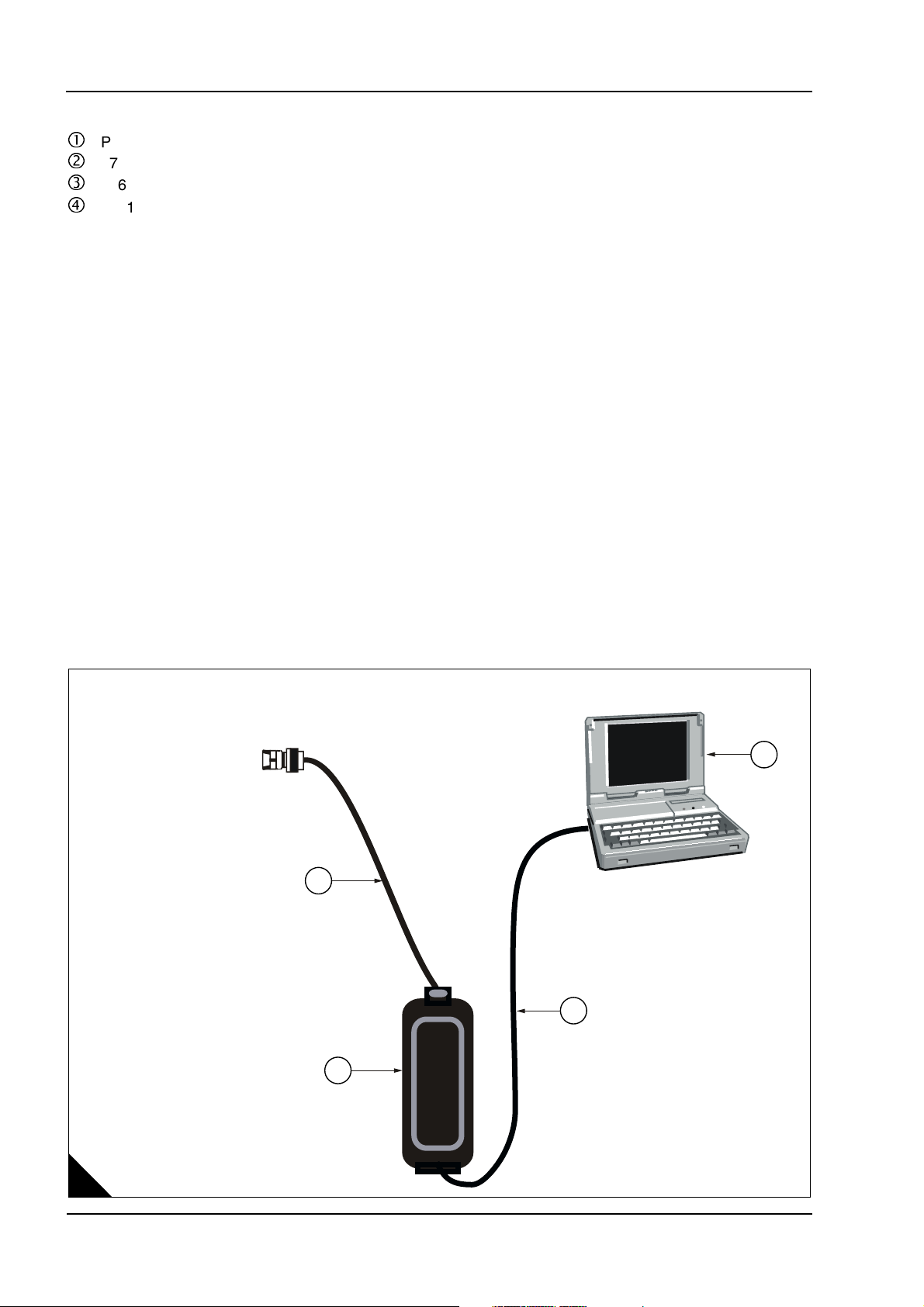

Connecting TIPSS-EST using a TIPSS communication adapter

Q

PC with TIPSS-EST installed

R

27610169 PC to communication adapter cable

S

27610165 communication adapter

T

27610168 service tool harness cable

2800 Series

A

1

4

2

3

18 Diagnostic Manual, TSL4247, Preliminary

Page 27

2800 Series

3

Passwords

Factory passwords

Factory passwords are required to perform each of the following five functions:

1 Program a new ECM

When an ECM is replaced the system configuration parameters must be programmed into the new ECM. A

new ECM will allow these parameters to be programmed once without factory passwords. After the initial

programming these parameters are protected by factory passwords.

2 Rerate to another engine family

This requires changing the Personality Module code, which is protected by factory passwords.

3 Read customer passwords

If the owner loses his customer passwords, he will not be able to program customer parameters. By using

factory passwords, one can read customer passwords, then use those customer passwords to program

customer parameters.

4 Clear certain diagnostic codes

Critical event codes require the use of factory passwords in order to clear the code once it is logged. Diagnostic

code 252-11 (Incorrect Engine Software) also requires factory passwords. This diagnostic code should be

cleared only if you are certain that the Personality Module is for the specific engine.

Caution: Operating the engine with a Personality Module not designed for that engine will result in engine

damage. Be sure the Personality Module is correct for your engine.

Certain other codes require customer passwords. The majority of logged codes do not require passwords to

be cleared. To obtain factory passwords, proceed as if you already have the password. At some point, if the

factory passwords are actually needed, TIPSS-EST will request the factory passwords and display the

information required to obtain the passwords.

Customer passwords

If customer passwords have been entered, they are then required to change ANY customer parameter.

TIPSS-EST can be used to change customer parameters. To obtain customer passwords, contact the supplier

of the equipment. If the owner has lost the passwords, customer passwords may be read by using TIPSS-EST

(factory passwords are required in order to read customer passwords) by using the following procedure.

1 In TIPSS-EST access “View Passwords” under the “Utilities” menu.

2 When the Factory Password screen appears, record the information listed.

3 Obtain the factory passwords. The information recorded above must be provided, and generates a

permanent record at Perkins of the access.

4 From the Factory Password screen, enter the factory passwords.

5 When the View Customer Passwords screen appears, record the customer passwords. The customer

passwords may then be used to change customer parameters.

Diagnostic Manual, TSL4247, Preliminary 19

Page 28

3

2800 Series

Programming a new ECM

The Engine Control Module or ECM is the brain of the system. When a problem occurs, it is easy to assume

that the ECM is responsible. This is usually the wrong conclusion.

Most failures occur at the wiring and connectors or at a sensor input/output. Follow the troubleshooting

procedures, and do not replace an ECM on speculation.

However, when your troubleshooting indicates that a failure has in fact occurred in the ECM, the following

procedure outlines the steps required to replace a faulty ECM.

Note: If an ECM replacement is required, the ECM parameters, injector trim codes, and timing calibration can

be transferred from the suspect ECM to the replacement ECM. Timing calibration will NOT be necessary. This

feature requires TIPSS-EST and is only possible if the suspect ECM can communicate with the TIPSS-EST.

Replacing the ECM using TIPSS-EST ECM replacement feature

1 Ensure that the ECM is the problem by first temporarily connecting a test ECM. Hang the test ECM on the

side of the engine. Flash program the identical Personality Module that was used in the suspect ECM into the

test ECM. Use the TIPSS-EST ECM Replacement feature to copy the parameter configuration of the suspect

ECM into the test ECM. Ensure that the parameters in the test ECM are programmed the same as the

parameters in the suspect one.

2 If the test ECM repairs the problem, reconnect the suspect ECM. Verify that the problem returns when the

suspect ECM is reconnected.

3 Select the ECM Replacement feature under the Service/Copy Configuration menu and load the parameters

from the failed ECM.

4 Temporarily connect the new ECM by connecting both ECM connectors. Do not mount the ECM on the

engine yet.

5 Flash program the Personality Module into the new ECM if the Personality Module is not already installed.

Note: The new ECM may be shipped with a blank Personality Module, or may have been pre-flashed at the

factory.

6 Use the TIPSS-EST ECM Replacement feature to program the new ECM

7 Enter Rating Number parameter into the new ECM

8 Check for active codes. Program any required parameters that have not been programmed.

Note: On initial power-up of a new ECM, the Rating Number parameter must be programmed to avoid a

253-02 Check Customer Or System Parameters diagnostic code.

If a 261-13 Check Timing Sensor Calibration diagnostic code is not active, install the new ECM on the engine,

otherwise perform a timing calibration first.

20 Diagnostic Manual, TSL4247, Preliminary

Page 29

2800 Series

3

Replacing the ECM (if ECM replacement feature cannot be used)

1 Ensure that the ECM is the problem by first temporarily connecting a test ECM. Hang the test ECM on the

side of the engine. Flash program the identical Personality Module that was used in the suspect ECM into the

test ECM. Program any parameters that are necessary to use the ECM for the test. Program the parameters

exactly the same as they are in the suspect ECM.

2 If the test ECM repairs the problem, reconnect the suspect ECM. Verify that the problem returns when the

suspect ECM is reconnected.

3 Obtain customer parameters from the failed ECM

Obtain and record the customer passwords. If the customer has lost or forgotten their passwords, obtain

factory passwords to get them.

Use TIPSS-EST to access customer specified parameters from the ECM that is being replaced. If the ECM

does not communicate with the electronic service tool, obtain the required parameter list from the OEM.

Record the customer parameters

4 Record ECM current totals

5 Temporarily connect the new ECM by connecting both ECM connectors. Do not mount the ECM to the

engine until the timing calibration has been performed.

6 Flash program the Personality Module into the new ECM if the Personality Module is not already installed.

Note: The new ECM may be shipped with a blank Personality Module, or may have been pre-flashed at the

factory.

7 Obtain factory passwords if required.

The following parameters can be programmed on a new ECM without factory passwords:

l

Full Load Setting (FLS)

l

Full Torque Setting (FTS)

l

Engine serial number

System configuration parameters must be entered before the customer specified parameters are entered

If customer parameters are entered before the system configuration parameters, the total tattletale will change.

It will then be necessary to obtain another set of factory passwords in order to access system configuration

parameters.

8 Record the following information from the engine information plate:

l

Full Load Setting (FLS)

l

Full Torque Setting (FTS)

l

Engine serial number

Use TIPSS-EST to access system configuration parameters. When the Factory Specified Passwords screen

appears record the following information:

l

ECM serial number

l

Engine serial number

l

TIPSS-EST serial number

l

Total tattletale

l

Reason code

Leave TIPSS-EST on the Factory Specified Passwords screen and obtain the factory passwords.

9 Program the new ECM

Note: On initial powerup of a new ECM the following five parameters must be programmed to avoid a 253-02

Check Customer Or System Parameters diagnostic code:

l

Full Load Setting (FLS)

l

Full Torque Setting (FTS)

l

Rating number

l

Engine serial number

l

Injector trim codes

Continued

Diagnostic Manual, TSL4247, Preliminary 21

Page 30

3

Use TIPSS-EST to access system configuration parameters. Enter the recorded values for the following

parameters:

l

Full Load Setting (FLS)

l

Full Torque Setting (FTS)

l

Engine serial number

Use TIPSS-EST to access customer specified parameters. Enter the customer specified parameters and the

original customer passwords.

Use TIPSS-EST to access current totals from the Read/Change Current Totals main menu. Using the recorded

factory passwords enter the totals from the original ECM.

Use the Service\Calibrations\Timing Calibration menu to calibrate the timing. Refer to Test 8: Engine

speed/timing circuit test on page 121.

10 Install the new ECM on the engine.

2800 Series

22 Diagnostic Manual, TSL4247, Preliminary

Page 31

2800 Series

3

Programming a Personality Module using flash programming

1 Connect the PC to the appropriate communication adapter and connect the communication adapter to the

ECM. Refer to "Connecting TIPSS-EST using a TIPSS communication adapter" on page 18.

2 Start the WinFlash PC Program.

3 Ensure that the key switch is ON and the engine is OFF.

4 Select the part number of the engine Personality Module that needs to be programmed into the ECM and

proceed with programming the Personality Module. A new ECM is shipped with a blank Personality Module.

Note: The WinFlash PC program provides the ECM, application and software part number of the selected file.

Ensure that this file matches the engine before you begin to Flash the file into the ECM

PC program Personality Module messages and their meaning

A new ECM comes with a blank Personality Module (previously unprogrammed). A blank Personality Module

will prompt you for all three of the following messages. The information that is contained in the ECM Status will

be scrambled and meaningless if the module has not been programmed previously (this is normal).

Message: The engine ID in the flash file does not match the engine ID in the ECM

Meaning: The ECM has a Personality Module for a different engine.

Solution: Stop the transfer and access information about the ECM Status under the Electronic Control Module

menu. Ensure that the file you are about to transfer matches the engine application.

Message: The application ID in the flash file does not match the application ID in the ECM

Meaning: The ECM has a Personality Module for a different application.

Solution: Stop the transfer and access information about the ECM Status under the Electronic Control Module

menu. Ensure that the file you are about to transfer is for the correct Personality Module.

Message: The ID of the ECM in the flash file does not match the ID of the ECM in the ECM

Meaning: The ECM is not for use with this application.

Solution: Stop the transfer and access information about the ECM Status under the Electronic Control Module

menu. Ensure that the ECM on the engine is for the correct application.

Note: If you access the ECM Status under the Engine Control Module menu, but do not program the

Personality Module, complete the following procedure.

Turn the key switch to the OFF position, and then to the ON position before using TIPSS-EST. If the key switch

is not cycled after reading the ECM Status, the ECM will not communicate with your service tool or will not start.

Cycling the key switch is not necessary after the Personality Module has been successfully programmed using

the WinFlash program.

5 Start the engine and check for correct operation.

Program any parameters not previously in the old Personality Module if a 253-02 Check Customer or System

Parameters diagnostic code is active. Read the diagnostic code from service tool Active Diagnostic Code

screen in order to determine the parameter(s) requiring programming.

On initial powerup of a new ECM five parameters must be programmed to avoid a 253-02 Check Customer or

System Parameters diagnostic code:

l

Full Load Setting (FLS)

l

Full Torque Setting (FTS)

l

Rating number

l

Engine serial number

l

Injector trim codes

Refer to "Programming a new ECM" on page 20.

Diagnostic Manual, TSL4247, Preliminary 23

Page 32

3

2800 Series

ECM date/time clock

ECM date/time stamped information

The ECM date and time can be programmed with an electronic service tool. This will display the programmed

date in month/day/year format and the programmed time in hour:minute:second format. The tool has the option

to program any date/time or automatically select the date/time stored in the PC real time clock.

The date and time will remain programmed in the ECM even if the Unswitched Battery connections are

removed.

The ECM Date/time clock is used to stamp the following critical event codes:

l

360-3 Low oil pressure Shutdown

l

361-3 High coolant temperature Shutdown

l

362-3 Engine overspeed Shutdown

Before adjusting the ECM date/time clock

Before adjusting the ECM date/time clock, ask the owner/operator if the time stamped information should be

recorded. After the time stamped information is recorded, clear this information before adjusting the ECM

date/time clock. This is a very important step if the adjustment of the clock is a big adjustment. This will prevent

unnecessary confusion if someone else views the information at a later date.

Determining time stamped information occurrence

When viewing time stamped information remember that the time is set to GMT, or that someone may have

incorrectly or never set the clock.

Use the time currently set in the ECM to compare any ECM recorded information to the time the ECM indicates

to determine how long ago the time stamped event occurred.

Caution: Do not replace an ECM because of an incorrect time.

The following example indicates the correct use of the clock.

Example use of ECM date/time stamped information

The electronic service tool indicates an Engine Overspeed occurred on NOV 19 1998 10:30:46. The electronic

service tool also indicates that the current time of day in the ECM is NOV 24 1998 11:20:58.

This indicates that the problem occurred approximately one week and 50 minutes ago.

Caution: Do not compare it to the current time at your location.

If the ECM time is significantly different than your current time, for example the wrong month is programmed,

make sure you have recorded the time stamped information if it is important. After recording the information,

clear the code and then adjust the clock.

ECM diagnostic clock

The diagnostic clock should not be confused with the ECM date/time clock. The diagnostic clock records the

actual hours the ECM has been powered (key switch ON and engine running). This information is maintained

even if the unswitched battery connections are removed. The clock information is used to log diagnostic code

and event code occurrences. Logged diagnostic codes and event codes display the diagnostic clock hour of

the first and last occurrence and the total number of occurrences.

Note: Actual engine running hours (total time) can be obtained from the Current Totals menu of TIPSS-EST.

24 Diagnostic Manual, TSL4247, Preliminary

Page 33

2800 Series

3

Injector codes

Injector codes are etched on each injector. The injector codes can be viewed/changed using TIPSS-EST by

selecting the Calibrations screen under the Service menu. The Injector Codes Calibration is located under the

Calibration menu. The injector code must match the code on the corresponding injector. When an injector is

replaced, reprogram the new code for the new injector.

TIPSS-EST manual cylinder cutout test

The 2800 Series engines use electronic fuel injectors. These injectors are mechanically actuated and

electronically energized. The cylinder cutout tests are used to confirm that the cylinders are functioning

correctly.

The Manual Cylinder Cutout test allows a specific cylinder to be cut out while the fuel position is monitored for

the remaining cylinders.

To perform a cylinder cutout test, connect TIPSS-EST to the diagnostic connector as described in "Connecting

the TIPSS-EST" on page 17. Access the Cylinder Cutout test located under the Diagnostics menu.

The Cylinder Cutout test opens with the Manual test. At the bottom of the TIPSS-EST screen there is a row of

buttons that function as follows:

l

Change toggles the highlighted cylinder between powered and not powered

l

Power All returns all cylinders to the normal operating state

l

Start initiates the automated Cylinder Cutout test.

l

Stop terminates the automated test.

l

Results displays the test results.

l

Print allows the contents of the screen to be previewed or to be sent to a file or printer.

Diagnostic Manual, TSL4247, Preliminary 25

Page 34

3

2800 Series

Programming parameters

Many programmable parameters affect engine operation. These parameters may be changed by using

electronic service tools. The parameters are stored in the ECM not the Personality Module. Whilst any

parameter can be read, passwords can be used to protect parameters from unauthorized changes.

Two categories contain various parameters, System Configuration Parameters and Customer Specified

Parameters.

System configuration parameters can only be altered with factory passwords by using TIPSS-EST.

Customer specified parameters can be changed by using an electronic service tool (this may require customer

passwords if customer passwords have been programmed). Refer to "Passwords" on page 19 for more details

on how to receive and use factory and customer passwords.

System configuration parameters

System configuration parameters affect critical settings for the engine. They are programmed at the factory

and would normally never need to be changed through the life of the engine. A complete list of these

parameters is given in the table on the following page.

Note: System Configuration Parameters must be reprogrammed if an ECM is replaced, but not if the

Personality Module is replaced (unless the engine rating changes). Failure to programme these parameters

will result in a 268-02 Check Programmable Parameters diagnostic code.

Proper values for these parameters are stamped on the engine information ratings plate located on the valve

cover or air inlet manifold. Factory passwords are required to change these parameters. The following

information is a description of the system configuration parameters.

Full Load Setting (FLS)

Number representing fuel system adjustment made at the factory to “fine tune” the fuel system. The correct

value for this parameter is stamped on the engine information ratings plate. A new ECM requires this

parameter to be programmed to avoid generating a 253-02 Check Customer or System Parameters diagnostic

code.

Full Torque Setting (FTS)

Similar to Full Load Setting. This parameter must be programmed to avoid generating a 253-02 Check

Customer or System Parameters diagnostic code.

Personality Module part number

This is the part number of the Personality Module flashed into the ECM.

When a Personality Module is replaced (flash programmed) this code (stored in the ECM) must match the one

in the introduced Personality Module or the engine will only run at low idle and a 253-02 Check Customer or

System Parameters diagnostic code will be generated.

When the engine is being rerated, programming this code to “0” will prompt the ECM to read and match its

stored code to the Personality Module code. This code does not need to be programmed when a Personality

Module is replaced, as long as the new module is of the same family and emission year.

Engine serial number

This should be programmed to match the engine serial number that is stamped on the engine information plate.

A new ECM is delivered without the engine serial number programmed.

ECM serial number

This is a read-only parameter which displays the serial number of the ECM.

Personality Module release date

This parameter is defined by the Personality Module and is not programmable. It is used to provide the version

of the software. Customer parameters software changes can be tracked by this date. The date is provided in

the month and year (NOV99), where NOV is the month (November) and 99 is the year (1999).

26 Diagnostic Manual, TSL4247, Preliminary

Page 35

2800 Series

Critical override switch install

The critical override switch, if fitted and enabled, allows the engine to continue running even if engine oil

pressure or coolant temperature have reached the limits where the engine would normally be shutdown. If the

engine is run in this condition, the engine warranty is void and any events occurring are stored in the ECM with

time and date stamping. Implementation of this facility requires a factory password.

Total tattletail

Displays the total number of times the configuration parameters have been changed.

Configuration parameters

Configuration parameter description R/W Security

Selected engine rating

Rating duty selection Customer

External speed selection switch enable Customer

Currently defined rating Read Only

ECM identification parameters

Equipment ID Customer

Engine serial number Factory

ECM serial number Read Only

Personality module part number Read Only

Personality module release date Read Only

Personality module description Read Only

Security access parameters

Total tattletale Read Only

Engine/gear parameters

Engine startup accel. rate Customer

Droop/isochronous switch enable Customer

Droop/isochronous selection Customer

Engine speed droop Customer

Critical override switch install Factory

Remote throttle control install Customer

Remote throttle control min speed Customer

Remote throttle control max speed Customer

Remote throttle control ramp rate Customer

I/O configuration parameters

Desired speed input configuration Customer

System parameters

FLS Factory

FTS Factory

Governor gain factor None

Governor minimum stability factor None

Governor maximum stability factor None

Passwords

Customer parameter 1 Customer

Customer parameter 2 Customer

3

Diagnostic Manual, TSL4247, Preliminary 27

Page 36

3

2800 Series

Customer specified parameters

Customer specified parameters allow the OEM to modify engine parameters to suit the application.

Customer parameters may be changed repeatedly as a customer changes his requirements. Customer

passwords are required to change these parameters.

The following information is a brief description of the customer specified parameters.

Rating duty selection

This enables selection of the engine rating from a series of maps within the ECM. Changing the rating requires

a customer password. The available ratings within the ECM will vary with engine type and specification.

External speed selection switch enable

For dual speed (1500 rev/min or 1800 rev/min) applications, where an external speed selection switch is

required, this parameter enables the functionality of the speed selection switch within the software. Changing

this parameter requires a customer password.

Currently defined rating

This brings up a screen detailing the rating currently selected.

Engine startup acceleration rate

Enables the acceleration rate of the engine in rev/min/s, from idle speed to rated speed, to be programmed.

Control of this parameter enables any overshoot in speed on start up to be limited. Changing this parameter

requires a customer password.

Droop/isochronous switch enable

Determines whether the external droop/isochronous switch is enabled or disabled. Changing this parameter

requires a customer password.

Droop/isochronous selection

The engine will normally be run in isochronous mode i.e. the engine speed is the same at all loads. For certain

applications where parallel operation with another generating set or with the grid is required, it is necessary for

stability reasons to run in droop condition where engine speed drops with load. This parameter enables

droop/isochronous running selection. Changing this parameter requires a customer password.

Engine speed droop

If droop operation is selected, this parameter allows the setting of percentage droop i.e. the percentage that

the engine speed will drop with load. This parameter has no effect when the engine is running in isochronous

mode. Changing this parameter requires a customer password.

Remote throttle control install

This parameter determines whether raise/lower switch input control of engine speed is installed. If remote

throttle control is not installed, speed control reverts to the analogue or PWM inputs depending on which input

is selected via the desired speed input configuration detailed on the following page. Changing this parameter

requires a customer password.

Remote throttle control min speed

This setting determines the minimum speed range of both the raise/lower button control and the analogue

control i.e. if this is set to 100 rev/min and the nominal engine speed is selected for 1500 rev/min, the minimum

speed setting is 1400 rev/min. It does not affect the PWM speed control range which has fixed min/max limits.

Changing this parameter requires a customer password.

Remote throttle control max speed

This setting determines the maximum speed range of both the raise/lower button control and the analogue

control, i.e. if this is set to 100 rev/min and the nominal engine speed is selected for 1500 rev/min, the

maximum speed setting is 1600 rev/min. It does not affect the PWM speed control range which has fixed

min/max limits. Changing this parameter requires a customer password.

28 Diagnostic Manual, TSL4247, Preliminary

Page 37

2800 Series

3

Remote throttle control ramp rate

This setting determines the rate of change of engine speed in rev/min/s when the raise/lower switch inputs are

closed. Changing this parameter requires a customer password.

Desired speed input configuration

This parameter allows selection of the analogue or PWM external speed control if the remote throttle control

is not installed. The Analogue or PWM speed control inputs are normally used with generating set load sharing

and synchronising controllers. Changing this parameter requires a customer password.

Governor Gain parameters

The adjustable Governor Gain parameters are:

l

Governor Gain Factor

l

Governor Minimum Stability Factor

l

Governor Maximum Stability

Notes:

l

No engineering units associated with these numbers.

l

The programmable range is wide for flexibility. The values are valid from 1- 40000. This wide programmable

range may not be fully used on any system. Do not expect to use the whole range.

Gain Explanations

Governor Gain Factor

The Governor Gain Factor is multiplied to the difference between desired speed and actual speed.

l

If the Governor Gain Factor value is too large, the engine speed can overshoot the desired speed. The

overshoot is caused by an overcorrection or a steady state instability.

l

If the Governor Gain Factor is too small, the response necessary to accelerate the engine to the desired

speed must be obtained by ramping the stability terms to a higher value. This process is time consuming

so, as a result, the engine speed is slow to respond.

Governor Minimum/Maximum Stability Factor

The Stability Factor terms work to eliminate a steady state speed error. There are two gain terms used for

stability. If the error is greater than 20 rev/min and the error is increasing, then the Maximum Stability Gain is

functioning. If the error is less than 20 rev/min, then the Minimum Stability Gain is used. This function allows

the use of a high gain that would otherwise cause the engine to be unstable when the engine is operating near

the desired speed.

l

If either the Minimum Stability Gain or the Maximum Stability Gain is set too high, the governor will provide

more fuel than is necessary to bring the error to zero. The additional fuel will cause the engine speed to

overshoot and ring.

l

If either the Minimum Stability Gain or the Maximum Stability Gain is set too low, the engine will take too

long to arrive at a steady state speed.

Tuning Procedure

1 Turn the ECS to the OFF/RESET position. Connect TIPSS-EST and verify that Engine Overspeed

Protection is enabled before beginning the tuning process. Engine Overspeed is configured on the

Service\Monitoring System screen on TIPSS-EST.

Warning! Performing engine governor tuning without engine overspeed protection could result in serious

engine damage. Ensure that this parameter is ON while performing this procedure.

2 Start the engine. Observe, on the engine mounted genset control panel, that the engine has reached rated

speed. This panel will serve as the speed reference point during this procedure.

3 Enter the Configuration Parameters screen on TIPSS-EST.

4 Determine the desired scenario to tune the engine. For example, is the engine having poor response during

specific load assignments or specific load dumps ?

Continued

Diagnostic Manual, TSL4247, Preliminary 29

Page 38

3

5 Perform the desired load change from step 4. Observe the response of the engine by viewing the engine

speed on the genset mounted control panel, by looking at the system bus frequency response to the load

change, or by listening to the response of the engine.

6 Use the suggestions listed under the bulleted items to determine which gains should be adjusted.

Note: Usually, the Governor Gain Factor should be somewhat lower that the Governor Minimum Stability

Factor for optimum performance. The Maximum Stability Factor is typically a smaller value than the Minimum

Stability Gain and Governor Gain Factor.

7 Repeat steps 5,6, and 7 until a desired engine response can be met. Use large adjustments (10% of original

gain) at first to generally tune the engine in the proper manner. As the response is closer to desired, increase

the gains in smaller increments (1% of total gain).

Customer parameter 1, Customer parameter 2