Page 1

Perkins 2300 Series

This document has been printed from SPI². Not for Resale

Model 2306C-E14

WORKSHOP MANUAL

6 cylinder turbocharged diesel engines for industrial applications

Publication TSD3455E, Issue 1

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in September 2002 by Technical Publications,

Perkins Engines Company Limited, Shrewsbury SY1 3NX, England

i

Page 2

This document has been printed from SPI². Not for Resale

Chapters

1 General information

2 Specifications

3 Cylinder head assembly

4 Piston and connecting rod assemblies

5 Crankshaft assembly

6 Gear case and drive assembly

7 Crankcase and cylinder liners

8 Engine timing and electronic controls

9 Aspiration system

10 Lubrication system

11 Fuel system

12 Cooling system

13 Flywheel and housing

14 Electrical equipment

15 Auxiliary equipment

16 Special tools

The pages which follow contain a detailed table of contents

ii

Page 3

2300

This document has been printed from SPI². Not for Resale

Contents

1 General information

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...1

Safety precautions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...2

Viton seals . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...4

Welding .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...4

Environmental protection ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...4

Engine views . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...5

Engine identification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6

Engine lift equipment ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6

2 Specifications

Basic engine data - 2306 engine .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...7

Basic engine data - 2806 engine .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...7

Rocker assemblies ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...8

Valves . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...9

Valve guides .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .10

Valve springs . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .10

Valve seat inserts .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .11

Workshop Manual, TSD3455E, Issue 1 iii

Page 4

2300

This document has been printed from SPI². Not for Resale

Cylinder head . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 12

Camshaft and bearings . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 12

Pistons and connecting rods - 2306 engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 13

Pistons and connecting rods - 2806 engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 14

Crankshaft, main bearings and flywheel . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

Crankshaft damper ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

Crankcase and cylinder liners .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

Lubricating oil pump . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18

Coolant pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Recommended torque figures .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20

3 Cylinder head assembly

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 27

Rocker cover

Operation 3-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

Rocker leve r and rocker shaft assemblies

Operation 3-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

Operation 3-3 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30

Operation 3-4 How to check/adjust the tappet clearances ... ... ... ... ... ... ... ... ... ... ... 32

Cylinder head assembly

Operation 3-5 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 35

Valve springs

Operation 3-6 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 39

Valves

Operation 3-7 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 41

Valve seals

Operation 3-8 To renew . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 42

Valve guides

Operation 3-9 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 43

Camshaft

iv Workshop Manual, TSD3455E, Issue 1

Page 5

2300

This document has been printed from SPI². Not for Resale

Operation 3-10 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .45

Operation 3-11 How to set the backlash for the camshaft gear ... ... ... ... ... ... ... ... ... .50

Electronic injector units

Operation 3-12 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .51

Operation 3-13 To check and to adjust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .53

Injector sleeves

Operation 3-14 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .54

4 Pistons and connecting rod assemblies

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .57

Pistons and connecting rod assemblies

Operation 4-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .58

Operation 4-2 To dismantle and assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .60

Piston cooling jets

Operation 4-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .62

5 Crankshaft assembly

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .63

Crankshaft

Operation 5-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .64

Crankshaft front seal and wear sleeve

Operation 5-2 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .66

Crankshaft rear seal and wear sleeve

Operation 5-3 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .68

Crankshaft vibration d amp er

Operation 5-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .70

6 Gear case and drive assembly

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .73

Gear case cover

Operation 6-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .74

Workshop Manual, TSD3455E, Issue 1 v

Page 6

2300

This document has been printed from SPI². Not for Resale

Timing gears

Operation 6-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 75

Operation 6-3 How to check the position of the timing gears ... ... ... ... ... ... ... ... ... ... 78

Gear case

Operation 6-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 79

7 Crankcase and cylinder liners

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 81

Front engine support

Operation 7-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 82

Cylinder liners

Operation 7-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 83

Operation 7-3 To check and to adjust the protrusion of the cylinder liners ... ... ... ... ... 84

8 Engine timing and electronic controls

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 87

Electronic control module

Operation 8-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

Engine timing

Operation 8-2 To check . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 89

9 Aspiration system

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 91

Exhaust manifold

Operation 9-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 92

Turbocharger

Operation 9-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 93

Operation 9-3 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 94

vi Workshop Manual, TSD3455E, Issue 1

Page 7

2300

This document has been printed from SPI². Not for Resale

10 Lubrication system

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .95

Oil filter and oil filter header

Operation 10-1 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .96

Oil filter header

Operation 10-2 To dismantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .98

Sump

Operation 10-3 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .99

Oil pump

Operation 10-4 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...101

Operation 10-5 To dismantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...102

11 Fuel system

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...103

Fuel priming pump

Operation 11-1 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...104

Fuel transfer pump

Operation 11-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...105

Operation 11-3 To test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...106

Drive for the fuel transfe r pump

Operation 11-4 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...107

Fuel filter header

Operation 11-5 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...108

Low pressure fuel system

Operation 11-6 How to eliminate air from the fuel system ... ... ... ... ... ... ... ... ... ... ...109

12 Cooling system

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...111

Cooling system

Operation 12-1 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...112

Operation 12-2 Leakage test . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...113

Workshop Manual, TSD3455E, Issue 1 vii

Page 8

2300

This document has been printed from SPI². Not for Resale

Coolant filler cap

Operation 12-3 To test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 114

Radiator

Operation 12-4 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 115

Fan

Operation 12-5 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 116

Fan drive assembly

Operation 12-6 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 117

Fan drive belts

Operation 12-7 To check and to adjust the tension ... ... ... ... ... ... ... ... ... ... ... ... ... .. 118

Operation 12-8 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 119

Engine oil cooler

Operation 12-9 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 120

Thermostats and thermostat housing

Operation 12-10 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 121

Operation 12-11 To test the thermostats ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 123

Coolant temperature sensor

Operation 12-12 To test . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 124

Coolant pump

Operation 12-13 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 125

Operation 12-14 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 126

Operation 12-15 To test the pressure of the coolant pump ... ... ... ... ... ... ... ... ... ... .. 128

13 Flywheel and housing

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 129

Flywheel

Operation 13-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 130

Flywheel housing

Operation 13-2 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 131

viii Workshop Manual, TSD3455E, Issue 1

Page 9

2300

This document has been printed from SPI². Not for Resale

14 Electrical equipment

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...133

Starter motor

Operation 14-1 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...134

Alternator

Operation 14-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...135

Operation 14-3 To check and to adjust the tension of the alternator belt .. ... ... ... ... ...136

Operation 14-4 To renew the alternator belt . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...137

15 Auxiliary equipment

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...139

Oil sample valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...139

16 Special tools

List of special tools .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...141

Workshop Manual, TSD3455E, Issue 1 ix

Page 10

2300

This document has been printed from SPI². Not for Resale

x Workshop Manual, TSD3455E, Issue 1

Page 11

2300

This document has been printed from SPI². Not for Resale

1

General information 1

Introduction

The 2300 and 2800 Series engines are from Perkins Engines Company Limited, a world leader in the design

and manufacture of high-performance diesel engines.

Perkins approved assembly and quality standards, together with the latest technology, have been applied to

the manufacture of your engine to give you reliable and economic power.

This Workshop Manual has been designed to provide assistance in the service and the overhaul of Perkins

2300 and 2800 Series engines. Most of the general information, which is included in the User’s Handbook

(Chapters 1 to 6), has not been repeated in this Workshop Manual and the two publications should be used

together.

To ensure that you use the relevant information for your specific engine type, refer to "Engine identification"

on page 6.

When reference is made to the "left" or "right" side of the engine, this is as seen from the flywheel end of the

engine.

Special tools have been made available and a list of these is given in Chapter 16, Special tools. Reference to

the relevant special tools is also made at the beginning of each operation.

Data and dimensions are included in Chapter 2, Specifications.

Read the "Safety precautions" on page 2 and remember them. They are given for your protection and must be

applied at all times.

In addition to the general safety precautions, danger to both operator and engine are highlighted by the

following conventions:

Warning! This indicates that there is a possible danger to the person (or the person and engine).

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Workshop Manual, TSD3455E, Issue 1 1

Page 12

1

This document has been printed from SPI². Not for Resale

2300

Safety precautions

These safety precautions are important. You must refer also to the local regulations in the country of use.

Some items only apply to specific applications.

l Always refer to the text of this handbook for specific warnings and cautions.

l Only use these engines in the type of application for which they have been designed.

l Do not change the specification of the engine.

l Do not make adjustments that you do not understand.

l Do not allow the engine to stand on its sump.

l Do not smoke when you put fuel in the tank.

l Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a

safe place.

l Do not put fuel in the tank while the engine runs (unless it is absolutely necessary).

l Do not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training;

even then extreme caution must be used to prevent injury).

l Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions.

l Other persons must be kept at a safe distance while the engine or auxiliary equipment is in operation.

l Do not permit loose clothing or long hair near moving parts.

Warning! Keep away from moving parts during engine operation. Some moving parts cannot be seen clearly

while the engine runs.

l Do not operate the engine if a safety guard has been removed.

l Do not remove the filler cap or any component of the coolant system while the engine is hot and while the

coolant is under pressure, because dangerous hot coolant can be discharged.

l Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the

gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially

to the eyes.

l Disconnect the battery terminals before a repair is made to the electrical system. Always disconnect the

negative terminal first.

l Only one person must control the engine.

l Ensure that the engine is operated only from the control panel or from the operator’s position.

l If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

l Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons.

Protect your hands with gloves or a special solution to protect the skin.

l Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated

with oil into the pockets.

l Discard used lubricating oil and coolant in accordance with local regulations to prevent contamination.

l The combustible material of some components of the engine (for example certain seals) can become

extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with

the eyes.

Continued

2 Workshop Manual, TSD3455E, Issue 1

Page 13

2300

This document has been printed from SPI². Not for Resale

l Always use a safety cage to protect the operator when a component is to be pressure tested in a container

of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to

be pressure tested.

l Do not allow compressed air to contact your skin. If compressed air enters your skin, obtain medical help

immediately.

l Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from

the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces.

l Some components are not waterproof and should not be washed with a high-pressure water jet or steam.

l Fit only genuine Perkins parts.

1

Workshop Manual, TSD3455E, Issue 1 3

Page 14

1

C

This document has been printed from SPI². Not for Resale

2300

Viton seals

Some seals used in engines and in components fitted to engines are made from Viton (fluorocarbon).

Viton is used by many manufacturers and is a safe material under normal conditions of operation.

If Viton is burned, a product of this burnt material is an acid which is extremely dangerous. Never allow this

burnt material to come into contact with the skin or with the eyes.

If it is necessary to come into contact with components which have been burnt, ensure that the precautions

which follow are used:

l Ensure that the components have cooled.

l Use Neoprene gloves and discard the gloves safely after use.

l Wash the area with a calcium hydroxide solution and then with clean water.

l Disposal of gloves and components which are contaminated, must be in accordance with local regulations.

If there is contamination of the skin or eyes, wash the affected area with a continuous supply of clean water or

with a calcium hydroxide solution for 15-60 minutes. Obtain immediate medical attention.

Welding

Welding can cause damage to the electronic components fitted to the engine. If welding is necessary, the

precautions which follow must be undertaken before and during the welding operation.

autions:

l Switch off the engine.

l Disconnect the cable from the negative terminal of the battery. If the machine is fitted with a battery

disconnect the switch then open the switch.

l If welding to the engine, remove the ECM (electronic control module).

l If welding onto the machine chassis, ensure that the earth clamp is attached as close to the welding point

as possible and NOT near to the ECM.

l If it is necessary to weld near to the ECM, remove the ECM from the engine.

Environmental protection

There is legislation to protect the environment from the incorrect disposal of used lubricating oil. To ensure that

the environment is protected, consult your Local Authority who can give advice.

4 Workshop Manual, TSD3455E, Issue 1

Page 15

2300

This document has been printed from SPI². Not for Resale

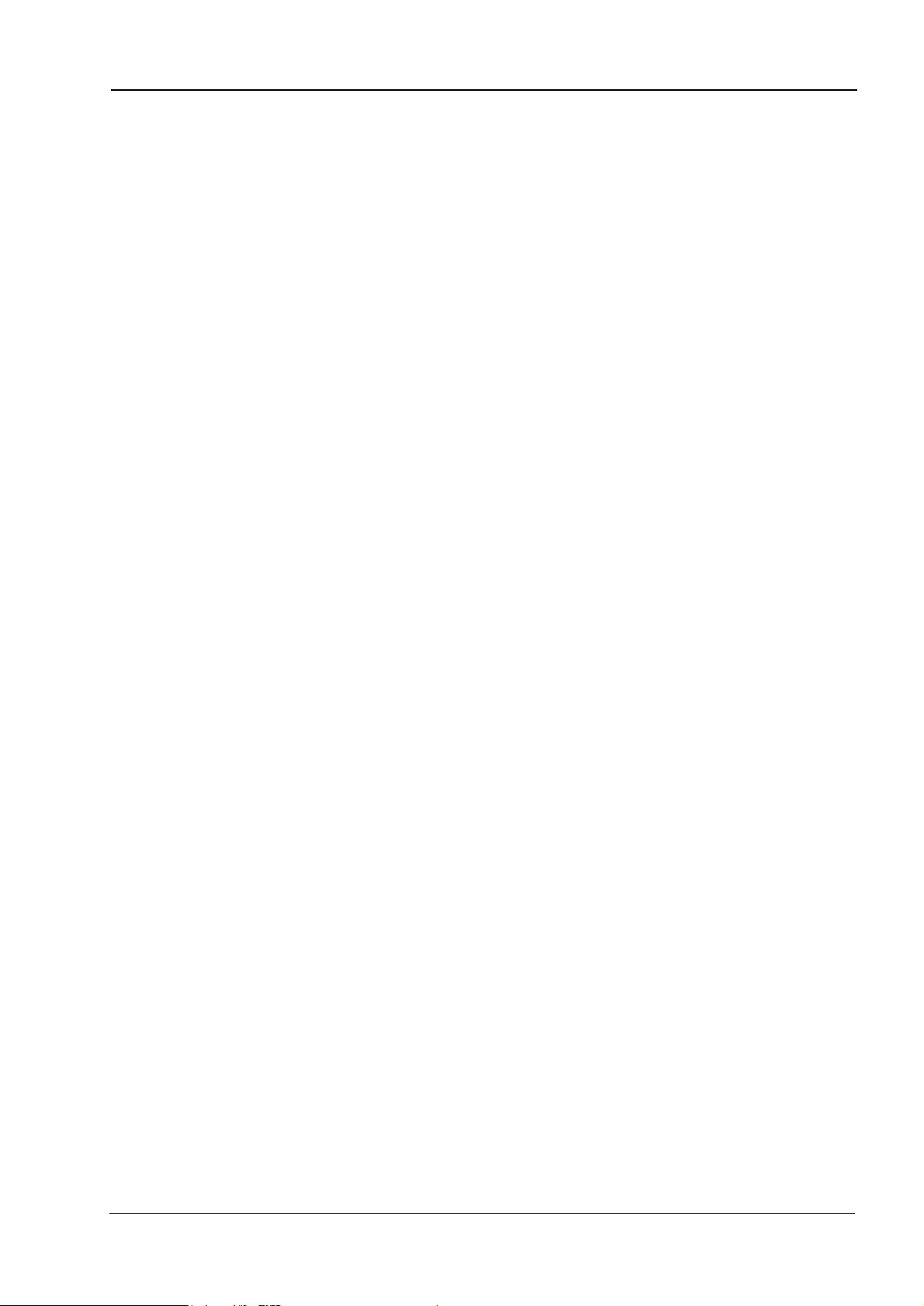

Engine views

1

Workshop Manual, TSD3455E, Issue 1 5

Page 16

1

This document has been printed from SPI². Not for Resale

2300

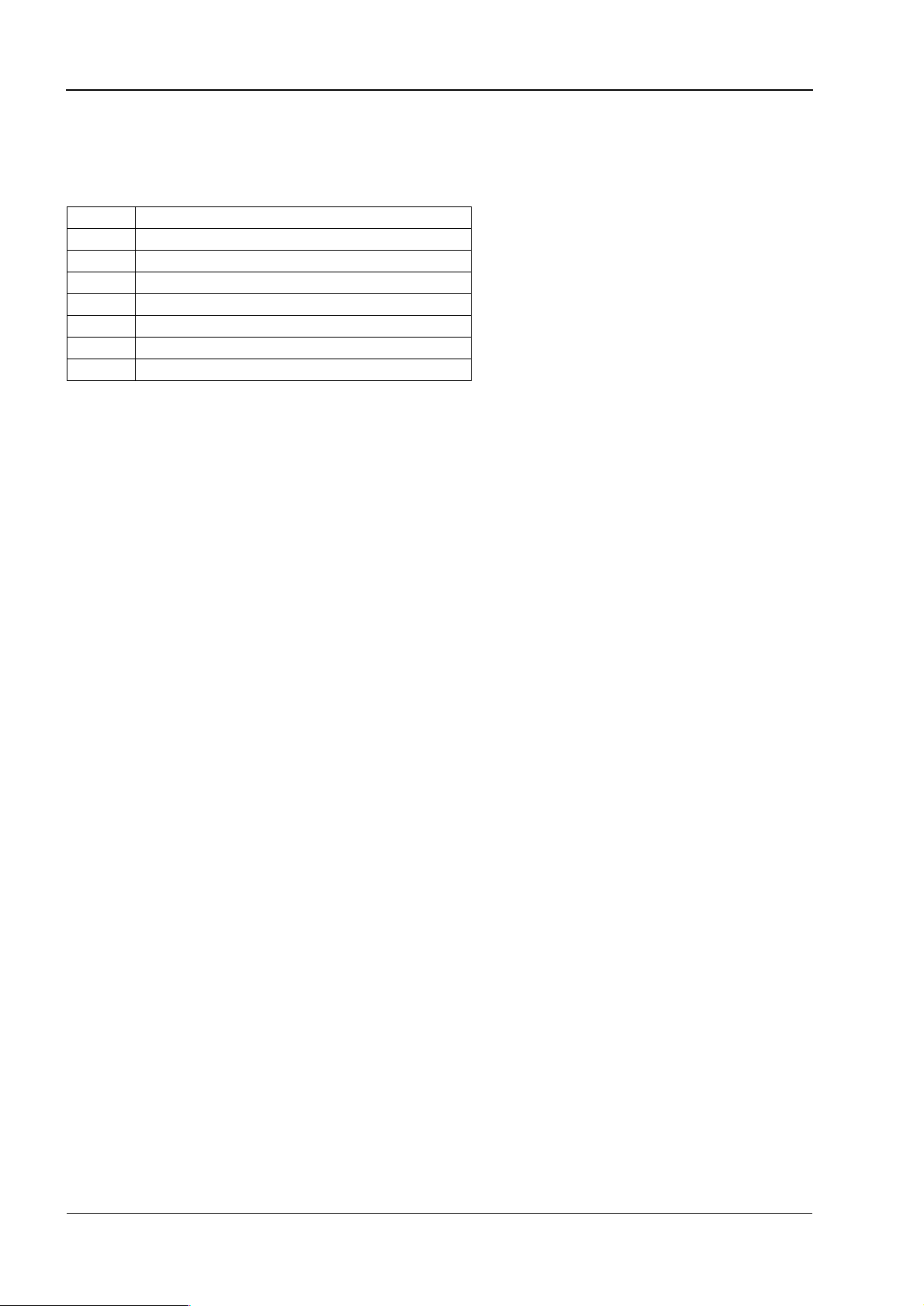

Engine identification

If you need parts, service or information for your engine, you must give the complete engine number. The

engine number is stamped on a data plate which is fastened to the right side of the engine.

A typical engine number is: HGA060125U 1103H, which consists of these codes:

H Code for engine capacity

G Engine application

A Engine type

06 Number of engine cylinders

0125 Engine specification number

U The country of manufacture

1103 Build line number

H Year of manufacture

Engine lift equipment

A dry engine weighs approximately 1551 kg (3,419 lb). Ensure that the lift equipment used is suitable. An

adjustable lifting beam should be used and the chains or cables must be parallel to each other during use.

Before the engine is lifted:

l Always use lift equipment of the approved type and of the correct capacity to lift the engine. Never use a

single lift bracket to raise an engine.

l Check the engine lift brackets for damage and security before the engine is lifted.

Use suitable lift equipment or obtain assistance to lift heavy engine components such as the cylinder block,

cylinder head, damper unit, flywheel housing, crankshaft and flywheel.

Warning! The lifting eyes which are fitted to the engine must be used for lifting only the engine. Do NOT use

them to lift the engine if it is still attached to its driven unit.

6 Workshop Manual, TSD3455E, Issue 1

Page 17

2300

This document has been printed from SPI². Not for Resale

2

Specifications 2

Basic engine data - 2306 engine

Number of cylinders. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

Cylinder arrangement.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .In line

Cycle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Four stroke

Induction system.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Turbocharged

Combustion system. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Direct injection

Nominal bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .137 mm (5.394 in)

Nominal stroke. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .165 mm (6.496 in)

Compression ratio ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15.9:1

Cubic capacity . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 14,6 litres (893 in

Firing order .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1, 5, 3, 6, 2, 4

Direction of rotation . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Anti-clockwise viewed on flywheel

Lubricating oil capacity:

Total system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..68 litres (1 20 UK pints)

Sump maximum... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..60 litres (106 UK pints)

Sump minimum ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45 litres (79 UK pints)

Lubricating oil pressure:

3

)

At rated speed . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...4,5 bar

Typical coolant capacity of engine... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20,8 litres (4.6 UK gallons)

Typical coolant capacity of engine and radiator .. ... ... ... ... ... ... ... ... ... ... ... ... ... .47 litres (10.3 UK gallons)

Basic engine data - 2806 engine

Number of cylinders. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

Cylinder arrangement.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .In line

Cycle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Four stroke

Induction system.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Turbocharged

Combustion system. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Direct injection

Nominal bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .140 mm (5.512 in)

Nominal stroke. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .171 mm (6.732 in)

Compression ratio ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15.9:1

Cubic capacity . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...15,8 litres (964.18 in

Firing order .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1, 5, 3, 6, 2, 4

Direction of rotation . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Anti-clockwise viewed on flywheel

Lubricating oil capacity:

Total system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..68 litres (1 20 UK pint s)

Sump maximum... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..60 litres (106 UK pints)

Sump minimum ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45 litres (79 UK pints)

Lubricating oil pressure:

3

)

At rated speed . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...4,5 bar

Typical coolant capacity of engine... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20,8 litres (4.6 UK gallons)

Typical coolant capacity of engine and radiator .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50 litres (11 UK gallons)

Workshop Manual, TSD3455E, Issue 1 7

Page 18

2

This document has been printed from SPI². Not for Resale

2300

Rocker ass emblies

Rocker shaft diameter (A2) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...40,000 +/- 0,010 mm (1.5748 +/- 0.0004 in)

Valve rocker lever bore (A1).. ... ... ... ... ... ... ... ... ... ... ... ... ... ...40,065 +/- 0,015 mm (1.5774 +/- 0.0006 in)

Bearing clearance between valve rocker lever and shaft .. ... ... ... ... 0,040 to 0,090 mm (0.0016 to 0.0035 in)

Unit injector rocker lever bore (A3) ... ... ... ... ... ... ... ... ... ... ... ...43,000 +/- 0,020 mm (1.6929 +/- 0.0008 in)

If a new bearing is fitted to the unit injector rocker lever, the oil hole in the bearing must be aligned with the oil

passage in the rocker lever within 2,4 mm (0.09 in). The bearing must not extend beyond either face of the

rocker lever.

Bore in the rocker lever bearing (A4). ... ... ... ... ... ... ... ... ... ... ... . 40,065 +/- 0,15 mm (1.5774 +/- 0.0006 in)

Maximum permissible worn dimension.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...40,193 (1.5824 in)

8 Workshop Manual, TSD3455E, Issue 1

Page 19

2300

This document has been printed from SPI². Not for Resale

2

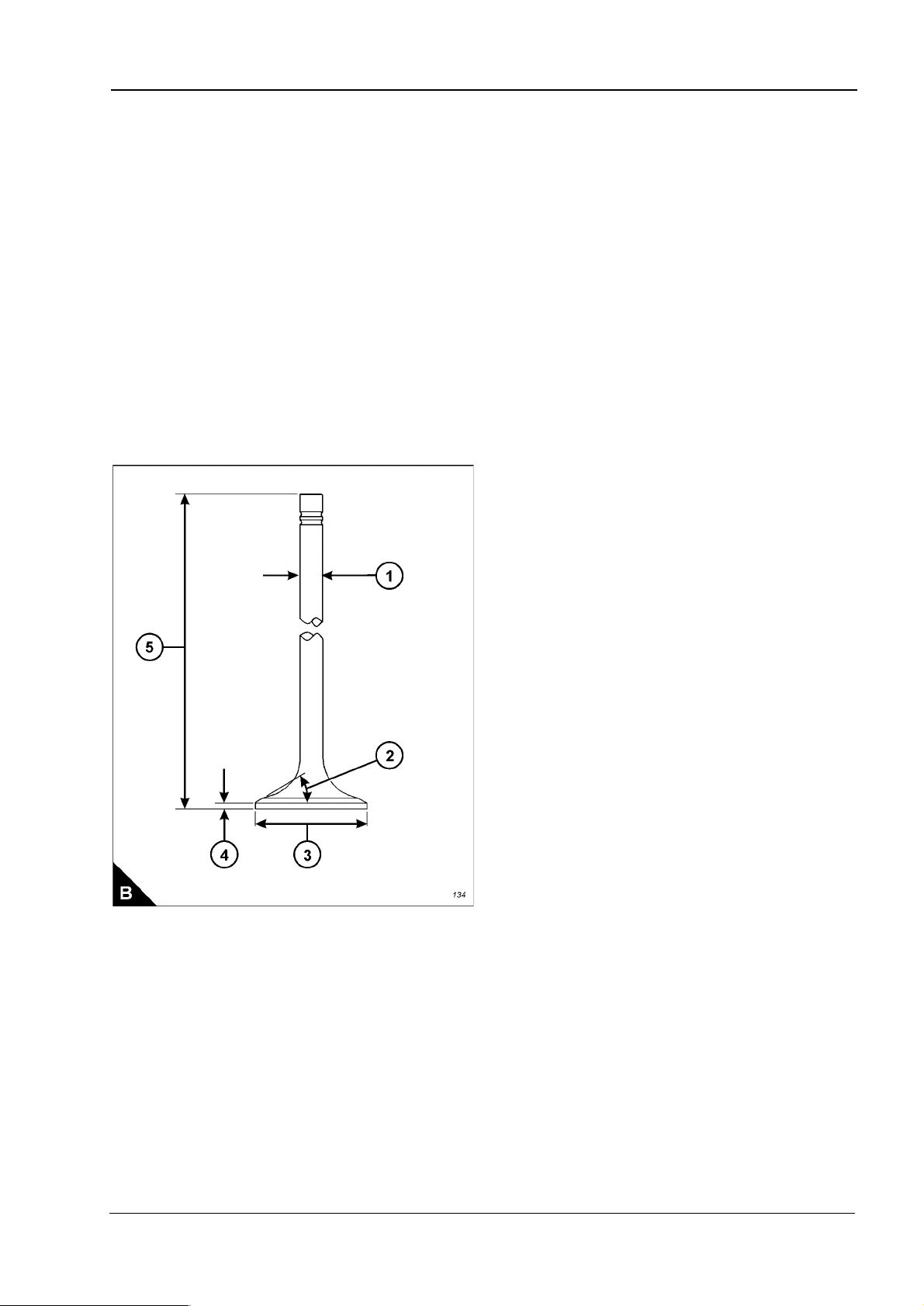

Valves

Diameter of valve stem (B1) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 9,441 +/- 0,010 mm (0.3717 +/- 0.0004 in)

Permissible worn dimension ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 9,408 mm (0.3704 in)

Diameter of valve head (B3):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 47,00 +/- 0,13 mm (1.850 +/- 0.005 in)

Exhaust valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 41,81 +/- 0,13 mm (1.646 +/- 0.005 in)

Angle of face of valve (B2):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...29 1/4 +/- 1/4 degrees

Exhaust valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...44 1/4 +/- 1/4 degrees

Minimum thickness of valve lip (B4):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,75 mm (0.108 in)

Exhaust valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,05 mm (0.081 in)

Length of valve:

Inlet.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 202,00 +/- 0,45 mm (7.953 +/- 0.018 in)

Exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 202,06 +/- 0,45 mm (7.955 +/- 0.018 in)

Workshop Manual, TSD3455E, Issue 1 9

Page 20

2

This document has been printed from SPI². Not for Resale

2300

Valve guides

Bore of valve guide when installed ... ... ... ... ... ... ... ... ... ... ... ... ...9,487 +/- 0,025 mm (0.3735 +/- 0.010 in)

Maximum permissible dimension... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..9,538 mm (0.3755 in)

Do not use a combination of a valve and valve guide which have a difference of 0,13 mm (0.005 in) or more.

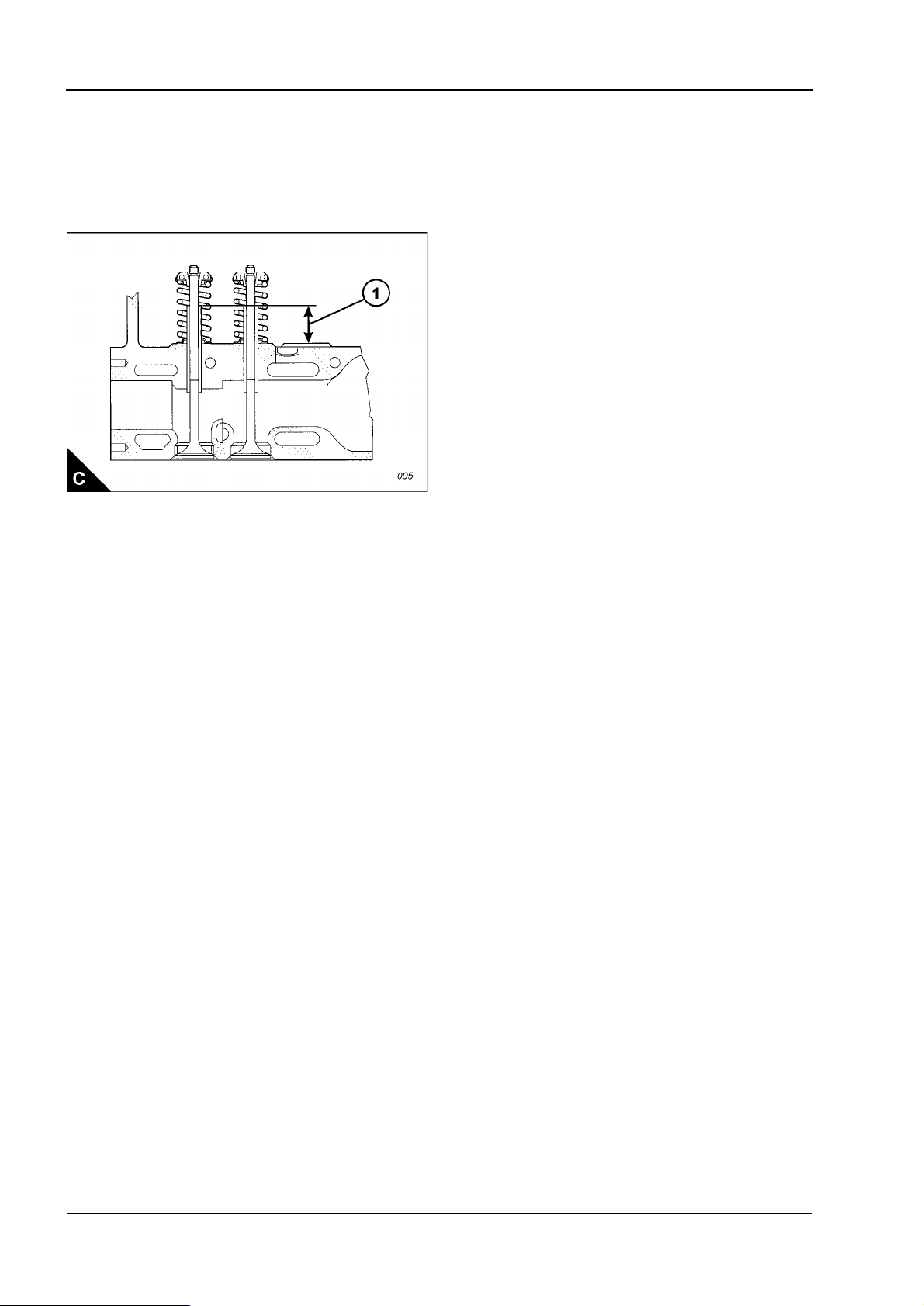

Height from cylinder head to top of valve guide (C1). ... ... ... ... ... ... ...35,00 +/- 0,50 mm (1.378 +/- 0.020 in)

Valve springs

Inner

Assembled length .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 60,14 mm (2.368 in)

Load at assembled length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..118

Minimum operating length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 44,02 mm (1.733 in)

Load at minimum operating length. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..356

Free length after test.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 71,03 mm (2.797 in)

Outside diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25,20 mm (0.992 in)

Outer

Assembled length .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 67,12 mm (2.643 in)

Load at assembled length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..248

Minimum operating length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 51,00 mm (2.008 in)

Load at minimum operating length. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 756

Free length after test.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 77,88 mm (3.066 in)

Outside diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 36,30 mm (1.429 in)

+/- 12 N (27 +/- 3 lb)

+/- 18 N (80 +/- 4 lb)

+/- 25 N (56 +/- 6 lb)

+/- 35 N (165 +/- 8 lb)

10 Workshop Manual, TSD3455E, Issue 1

Page 21

2300

This document has been printed from SPI². Not for Resale

2

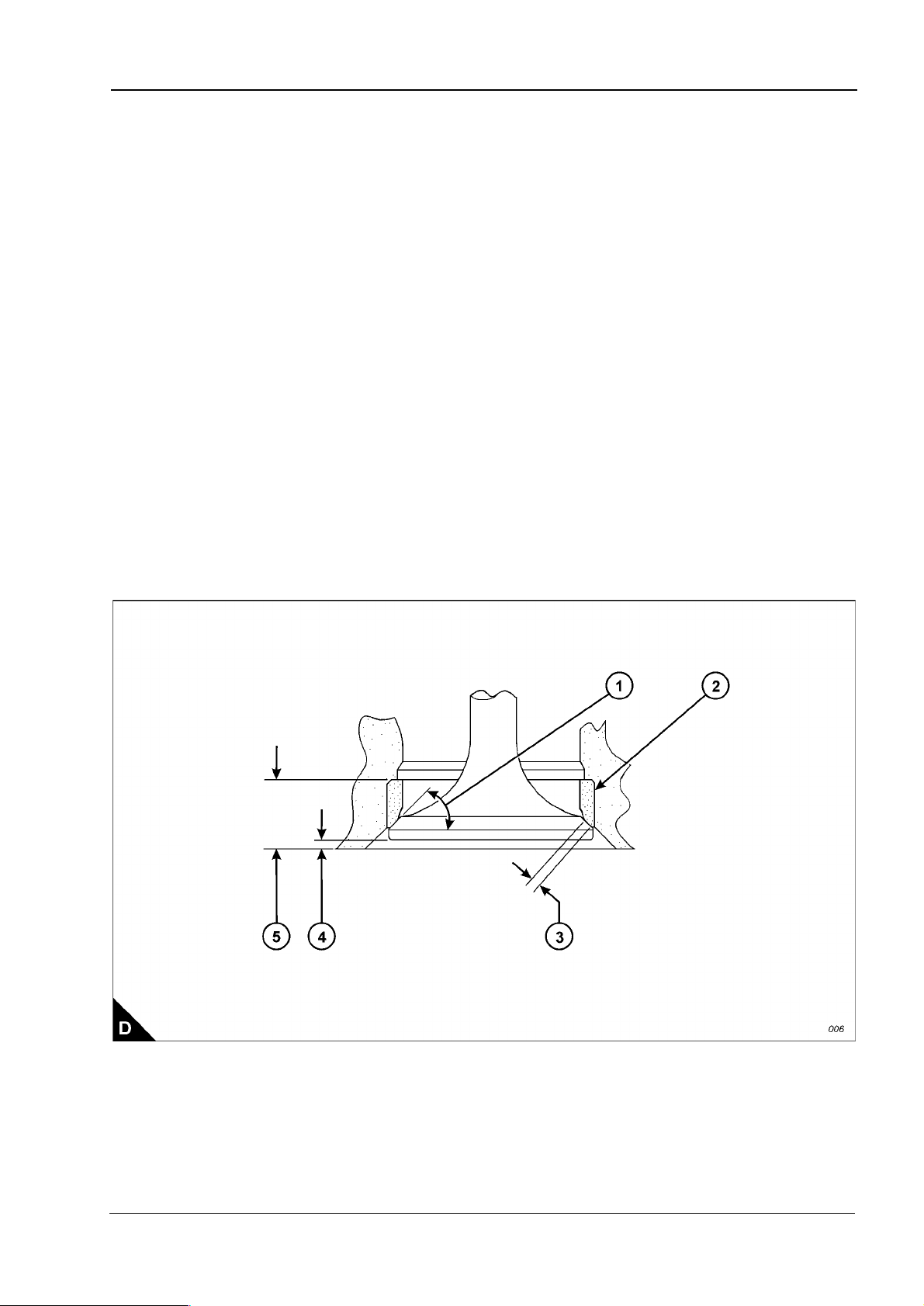

Valve seat inserts

Depth of bore in cylinder head for valve seat insert (D5):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 14,00 +/- 0,10 mm (0.551 +/- 0.004 in)

Exhaust valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 13,90 +/- 0,10 mm (0.547 +/- 0.004 in)

Diameter of valve seat insert (D2):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 48,025 +/- 0,13 mm (1.8907 +/- 0.0005 in)

Exhaust valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 42,840 +/- 0,13 mm (1.6866 +/- 0.0005 in)

Bore in cylinder head for valve seat insert (D2):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 47,950 +/- 0,025 mm (1.8878 +/- 0.0010 in)

Exhaust valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 42,774 +/- 0,025 mm (1.6840 +/- 0.0010 in)

Angle of face of valve seat insert (D1):

Inlet valve insert... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...30 1/4 +/- 1/2 degrees

Exhaust valve insert ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...45 1/4 +/- 1/2 degrees

Valve recess (D4):

Inlet valve (new parts) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..2,20 to 2,80 mm (0.087 to 0.110 in)

Exhaust valve (new parts)... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,20 to 1,80 mm (0.047 to 0.071 in)

Inlet valve (reconditioned parts) .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..2,20 to 3,29 mm (0.087 to 0.129 in)

Exhaust valve (reconditioned parts) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,20 to 2,29 mm (0.047 to 0.090 in)

Minimum recommended width of valve seat (D3):

Inlet.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,00 mm (0.079 in)

Exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1,25 mm (0.049 in)

Workshop Manual, TSD3455E, Issue 1 11

Page 22

2

This document has been printed from SPI². Not for Resale

2300

Cylinder head

Thickness of cylinder head (new) .. ... ... ... ... ... ... ... ... ... ... ... ... ... .120,00 +/- 0,15 mm (4.724 +/- 0.006 in)

Minimum thickness for a used cylinder head. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..119,50 mm (4.705 in)

Flatness of cylinder head: The cylinder head must be flat to within a total of 0,13 mm (0.005 in). Additionally,

the cylinder head must be flat within a maximum of 0,03 mm (0.001 in) across any 76,2 mm (3.00 in) span.

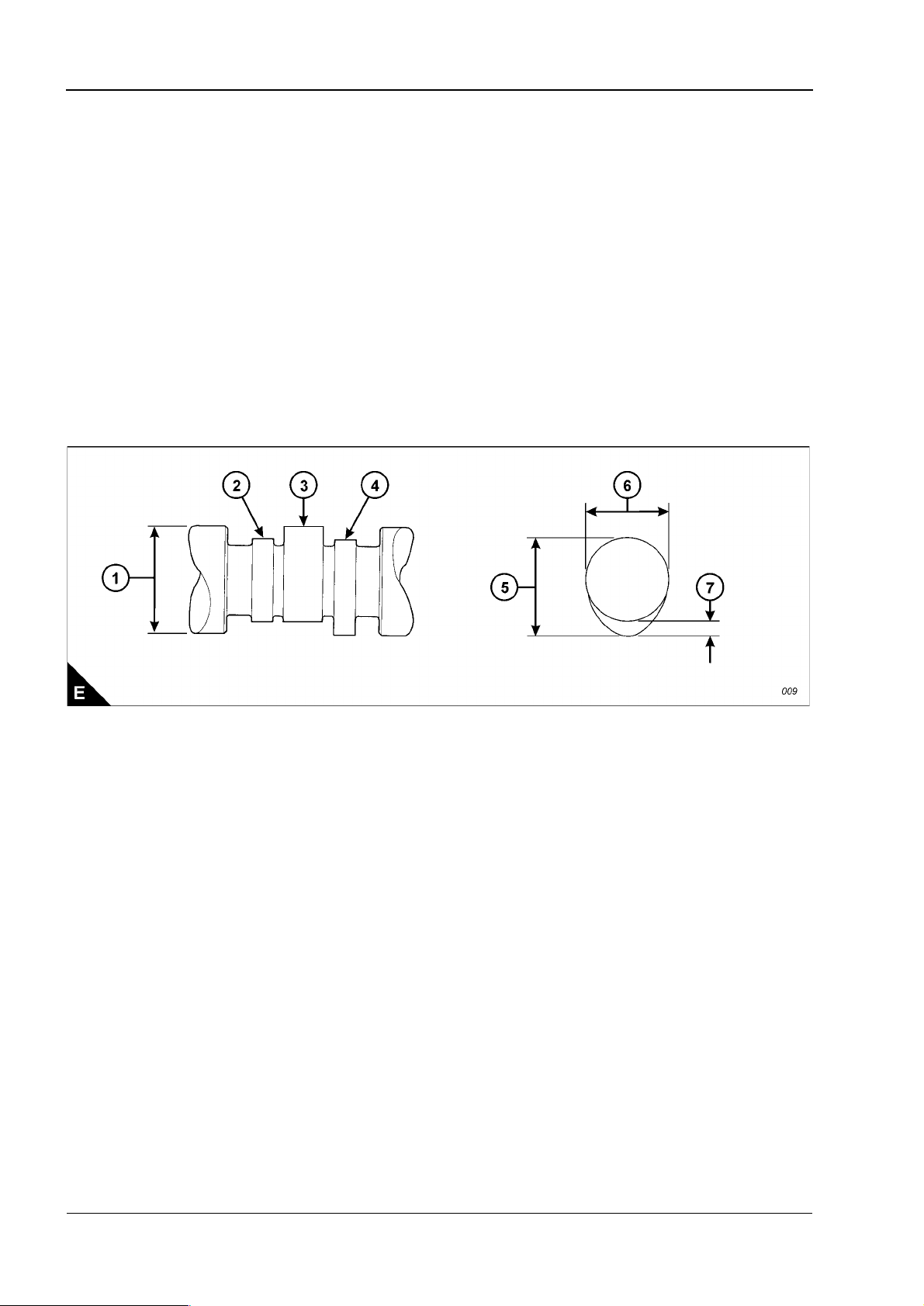

Camshaft and bearings

Diameter of camshaft journal (E3) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... 84,85 +/- 0,02 mm (3.341+/- 0.001 in)

Exhaust lobe lift.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..8,515 mm (0.3352 in)

Inlet lobe lift ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..9,431 mm (0.3713 in)

Injector lobe lift... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 10,451 mm (0.4114 in)

Maximum permissible difference between the actual lobe lift (E7)

and the specified dimension .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,0 mm (0.0394 in)

To obtain the lobe lift (E7) proceed as follows: Measure the lobe height (E5) and measure the base circle (E6).

Subtract the base circle from the lobe height to give the lobe lift.

12 Workshop Manual, TSD3455E, Issue 1

Page 23

2300

This document has been printed from SPI². Not for Resale

2

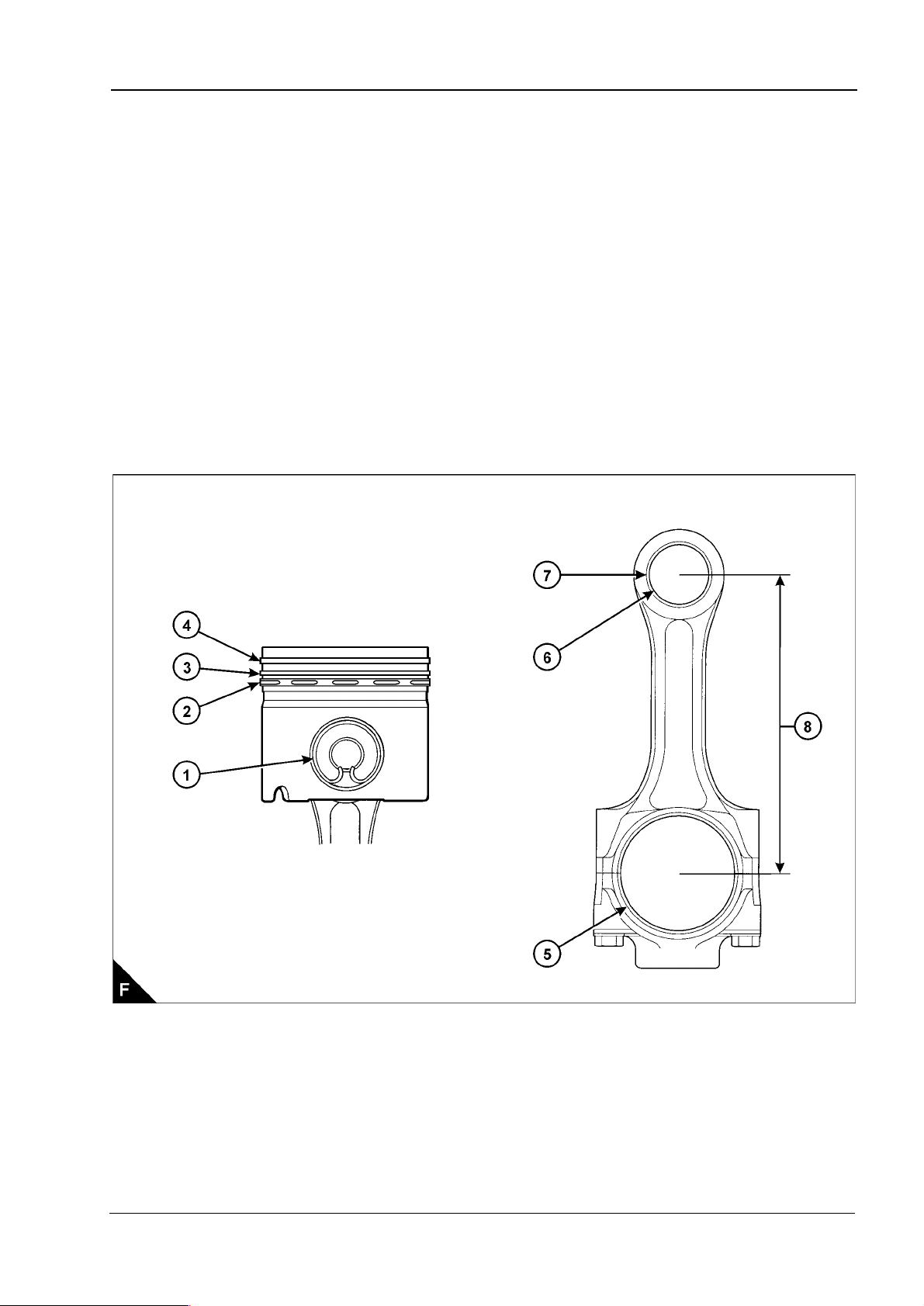

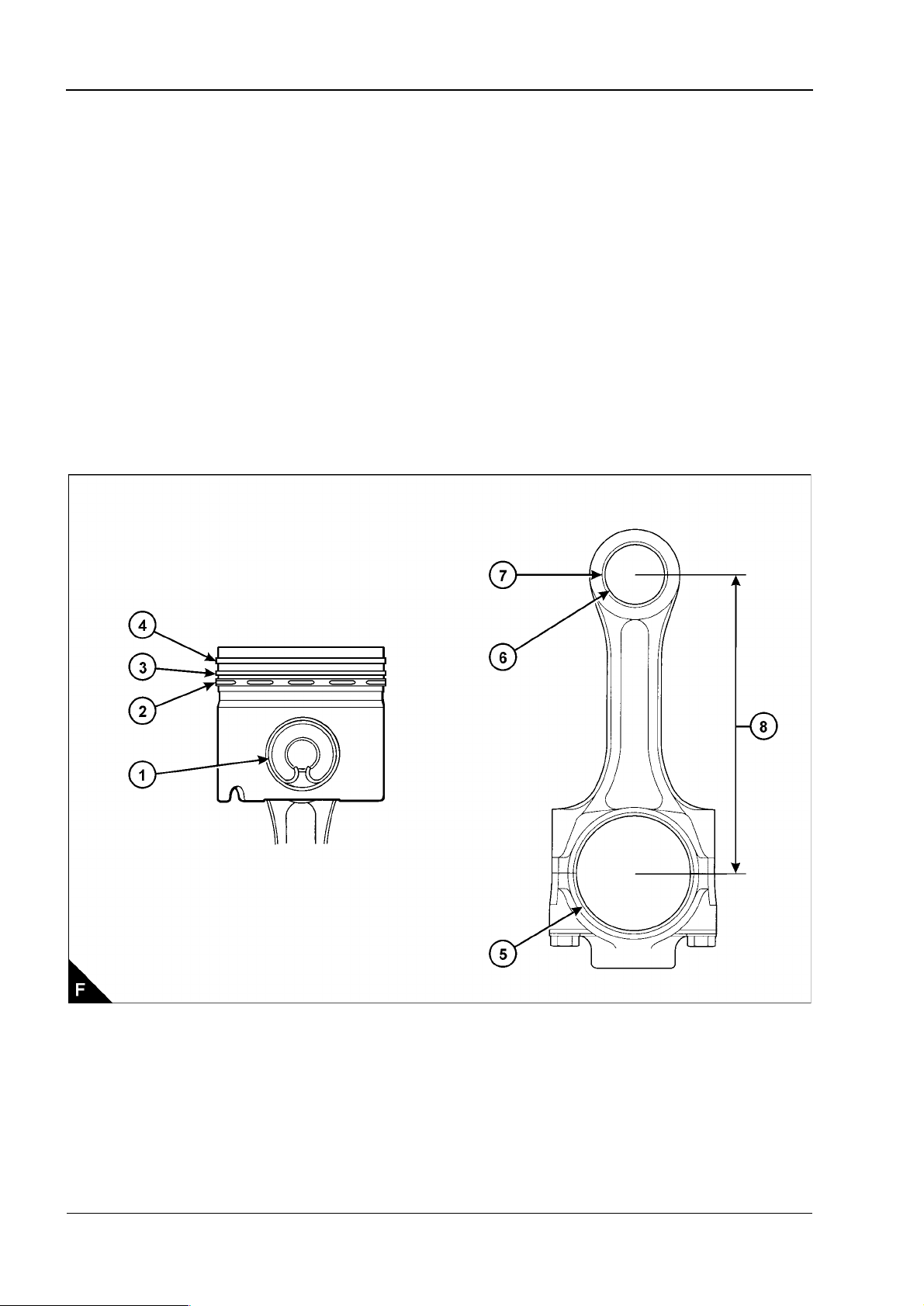

Pistons and connecting rods - 2306 engine

Piston ring gaps measured with the ring fitted in a new liner with a bore size 137.16 mm (5.400 in):

Top piston ring (F4) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,55 +/- 0,15 mm (0.022 +/- 0.006 in)

Intermediate ring (F3).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,83 +/- 0,15 mm (0.033 +/- 0.006 in)

Oil control ring (F2).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,550 +/- 0,15 mm (0.022 +/- 0.00 59 in)

Width of groove for oil control ring in new piston. ... ... ... ... ... ... ... ... . 4,03 +/- 0,01 mm (0.159 +/- 0.0004 in)

Thickness of a new oil control ring .. ... ... ... ... ... ... ... ... ... ... ... ... ... 3,98 +/- 0,01 mm (0.1567 +/- 0.0004 in)

Clearance between piston ring groove and new oil control ring.. ... ... . 0,05 +/- 0,02 mm (0.002 +/- 0.0008 in)

Maximum permissible clearance between piston

ring groove and a used oil control ring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,15 mm (0.006 in)

Bore of piston crown bearing (F1) ... ... ... ... ... ... ... ... ... ... ... . 55,0355 +/- 0,0055 mm (2.1667 +/- 0.0002 in)

Bore of piston skirt bearing (F1) .. ... ... ... ... ... ... ... ... ... ... ... ... . 55,020 +/- 0,005 mm (2.1661 +/- 0.0002 in)

Gudgeon pin diameter (F1) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 55,000 +/- 0,005 mm (2.1654 +/- 0.0002 in)

Length of gudgeon pin. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 113,20 +/- 0,15 mm (4.457 +/- 0.006 in)

Bore in connecting rod for small end bearing (F7) .. ... ... ... ... ... . 59,640 +/- 0,013 mm (2.3480 +/- 0.0005 in)

Bore of connecting rod small end bearing (F6) ... ... ... ... ... ... ... . 55,035 +/- 0,008 mm (2.1667 +/- 0.0003 in)

Bore in connecting rod for big end bearing shells (F5) ... ... ... ... . 96,200 +/- 0,013 mm (3.7874 +/- 0.0005 in)

Distance between centres of big and small end bearings (F8) ... ... . 261,62 +/- 0,05 mm (10.300 +/- 0.002 in)

Workshop Manual, TSD3455E, Issue 1 13

Page 24

2

This document has been printed from SPI². Not for Resale

2300

Pistons and connecting rods - 2806 engine

Piston ring gaps measured with the ring fitted in a new liner with a bore size 139,66 mm (5.498 in):

Top piston ring (F4) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .0,50 +/- 0,10 mm (0.020 +/- 0.004 in)

Intermediate ring (F3) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .0,83 +/- 0,15 mm (0.033 +/- 0.006 in)

Oil control ring (F2) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .0,450 +/- 0,150 mm (0.0177 +/- 0.0059 in)

Width of groove for oil control ring in new piston... ... ... ... ... ... ... .4,033 +/- 0,013 mm (0.1588 +/- 0.0005 in)

Thickness of a new oil control ring. ... ... ... ... ... ... ... ... ... ... ... ... .3,980 +/- 0,010 mm (0.1567 +/- 0.0004 in)

Clearance between piston ring groove and new oil control ring ... .0,053 +/- 0,023 mm (0.0021 +/- 0.0009 in)

Maximum permissible clearance between piston

ring groove and a used oil control ring... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,15 mm (0.006 in)

Bore of piston crown bearing (F1).. ... ... ... ... ... ... ... ... ... ... ...55,0355 +/- 0,0055 mm (2.1667 +/- 0.0002 in)

Bore of piston skirt bearing (F1). ... ... ... ... ... ... ... ... ... ... ... ... ...55,020 +/- 0,005 mm (2.1661 +/- 0.0002 in)

Gudgeon pin diameter (F1) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...55,000 +/- 0,005 mm (2.1654 +/- 0.0002 in)

Length of gudgeon pin... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .113,20 +/- 0,15 mm (4.457 +/- 0.006 in)

Bore in connecting rod for small end bearing (F7). ... ... ... ... ... ... 59,640 +/- 0,013 mm (2.3480 +/- 0.0005 in)

Bore of connecting rod small end bearing (F6).. ... ... ... ... ... ... ...55,035 +/- 0,008 mm (2.1667 +/- 0.0003 in)

Bore in connecting rod for big end bearing shells (F5).. ... ... ... ...96,200 +/- 0,013 mm (3.7874 +/- 0.0005 in)

Distance between centres of big and small end bearings (F8).. ... ...261,62 +/- 0,05 mm (10.300 +/- 0.002 in)

14 Workshop Manual, TSD3455E, Issue 1

Page 25

2300

This document has been printed from SPI². Not for Resale

2

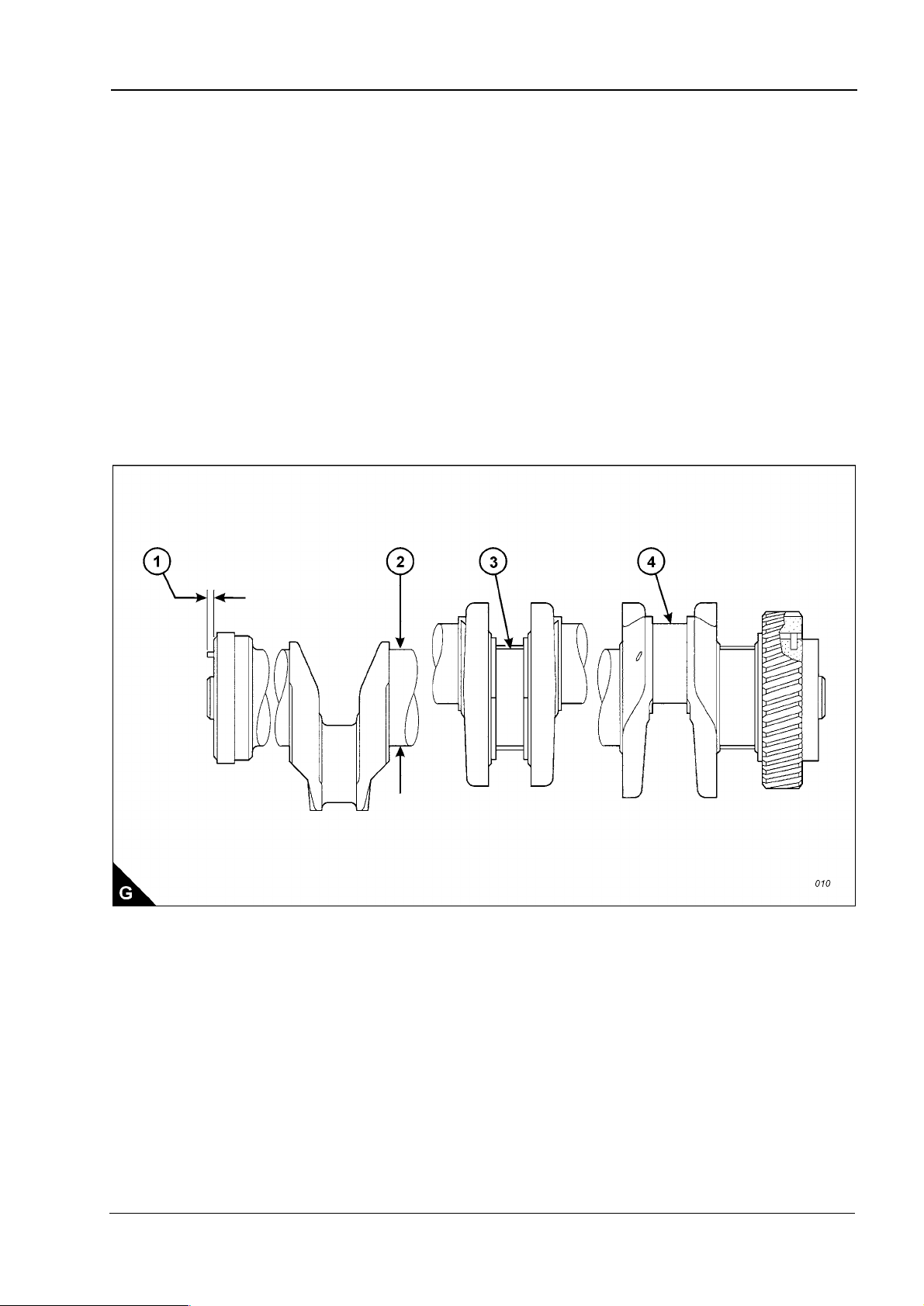

Crankshaft, main bearings and flywheel

Diameter of main bearing journal (G2) ... ... ... ... ... ... ... ... ... ... 120,650 +/- 0,020 mm (4.7500 +/- 0.0008 in)

Journal undersize by 0,63 mm (0.025 in) ... ... ... ... ... ... ... ... ... ... .. 120,015 +/- 0,020 (4.7250 +/- 0.0008 in)

Journal undersize by 1,27 mm (0.050 in) ... ... ... ... ... ... ... ... ... 119,380 +/- 0,020 mm (4.7000 +/- 0.0008 in)

Clearance between a new bearing and the journal (G3). ... ... ... ... ..0,091 to 0,186 mm (0.0036 to 0.0073 in)

Maximum permissible clearance between the

bearing and journal.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,25 mm (0.010 in)

Diameter of main bearing bore ... ... ... ... ... ... ... ... ... ... ... ... ... 129,891 +/- 0,013 mm (5.1138 +/- 0.0005 in)

Diameter of main bearing bore, oversize by 0,63 mm (0.025 in). 130,526 +/- 0,013 mm (5.1388 +/- 0.0005 in)

Diameter of connecting rod journal (G4) . ... ... ... ... ... ... ... ... ... . 90,000 +/- 0,020 mm (3.5433 +/- 0.0008 in)

Journal undersize by 0,63 mm (0.025 in) ... ... ... ... ... ... ... ... ... ... ... 89,370 +/- 0,020 (3.5185 +/- 0.0008 in)

Journal undersize by 1,27 mm (0.050 in) ... ... ... ... ... ... ... ... ... . 88,730 +/- 0,020 mm (3.4933 +/- 0.0008 in)

Clearance between a new bearing and the journal. ... ... ... ... ... ... ..0,062 to 0,160 mm (0.0024 to 0.0063 in)

Maximum permissible clearance between the

bearing and journal.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,20 mm (0.008 in)

End-float of crankshaft. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,15 to 0,55 mm (0.006 to 0.022 in)

Maximum permissible end-float (with used bearings) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,89 mm (0.035 in)

Maximum protrusion of dowel (G1) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6,4 mm (0.25 in)

Crankshaft damper

Maximum permissible run-out of face of damper ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,03 mm (0.080 in)

Workshop Manual, TSD3455E, Issue 1 15

Page 26

2

This document has been printed from SPI². Not for Resale

2300

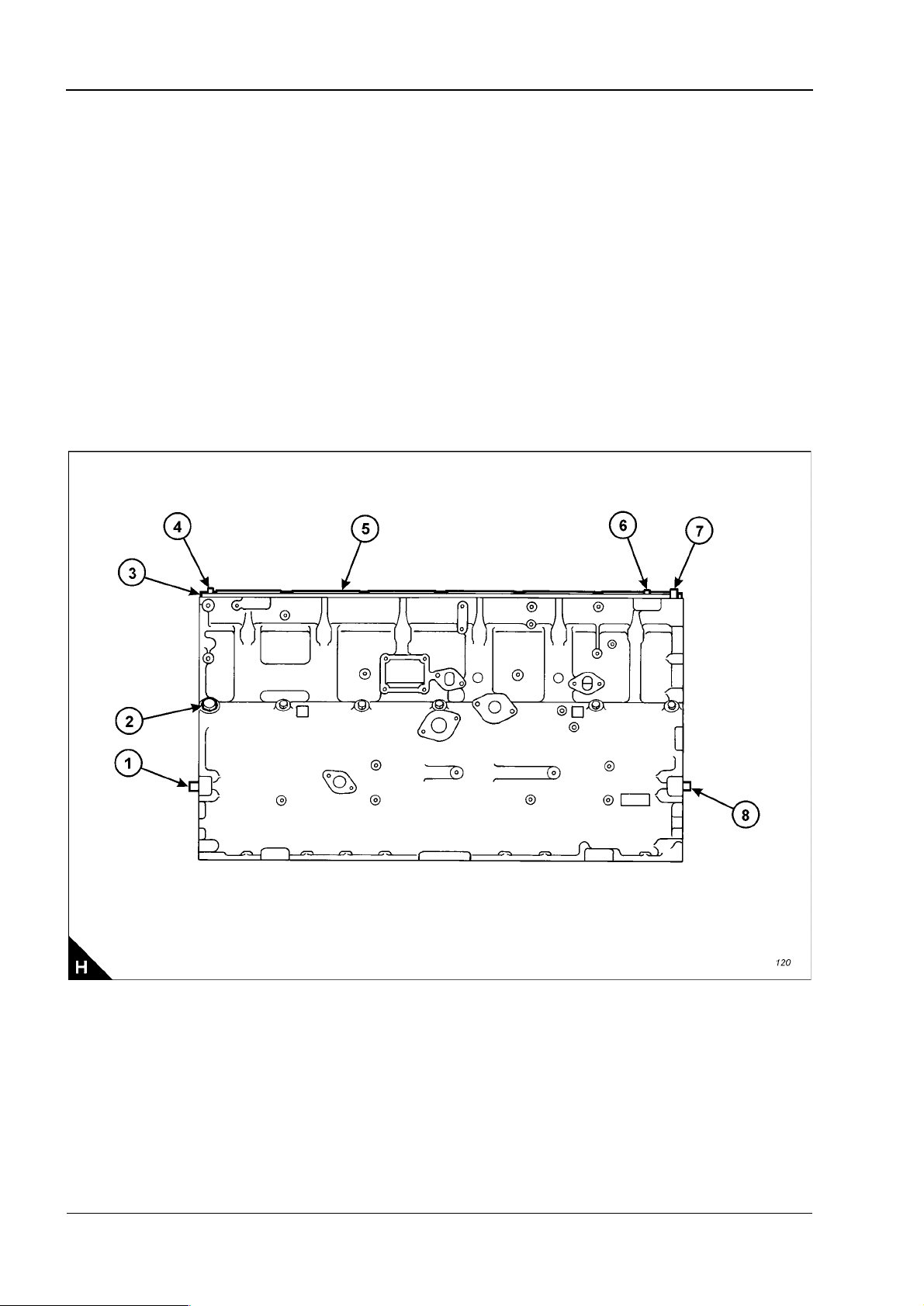

Crankcase and cylinder liners

Thickness of spacer plate (H3).. ... ... ... ... ... ... ... ... ... ... ... ... ... .8,585 +/- 0,025 mm (0.3380 +/- 0.0010 in)

Thickness of gasket fitted between spacer plate and crankcase... .0,238 +/- 0,032 mm (0.0094 +/- 0.0013 in)

Cylinder liner protrusion (H5) above the spacer plate ... ... ... ... ... ... 0,025 to 0,152 mm (0.0010 to 0.0060 in)

Maximum variation in each cylinder liner... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,051 mm (0.0020 in)

Maximum average variation between adjacent cylinder liners... ... ... ... ... ... ... ... ... ... ..0,051 mm (0.0020 in)

Maximum variation between all cylinder liners... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,102 mm (0.0040 in)

Refer to Operation 7-3 for further cylinder liner information.

Protrusion of front cylinder head dowel (H6) above top face of crankcase ...16,0 +/- 0,5 mm (0.63 +/- 0.02 in)

Protrusion of rear cylinder head dowel (H4) above top face of crankcase ...18,5 +/- 0,5 mm (0.73 +/- 0.02 in)

Protrusion of oil transfer tube (H7) above top face of crankcase... ... ... ... ...20,0 +/- 0,5 mm (0.79 +/- 0.02 in)

Protrusion of flywheel housing dowels (H1) from rear face of crankcase.. ...19,1 +/- 0,5 mm (0.75 +/- 0.02 in)

Protrusion of gear case dowels (H8) from front face of crankcase ... ... ... ...19,1 +/- 0,5 mm (0.75 +/- 0.02 in)

Plug (H2) must be tightened to a torque of ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 70 +/- 10 Nm (52 +/- 7 lbf ft)

The total flatness of the top face of the crankcase must be within 0,10 mm (0.004 in). The flatness must also

be within 0,05 mm (0.002 in) for any 177,5 mm (6.99 in) section of the surface.

Continued

16 Workshop Manual, TSD3455E, Issue 1

Page 27

2300

This document has been printed from SPI². Not for Resale

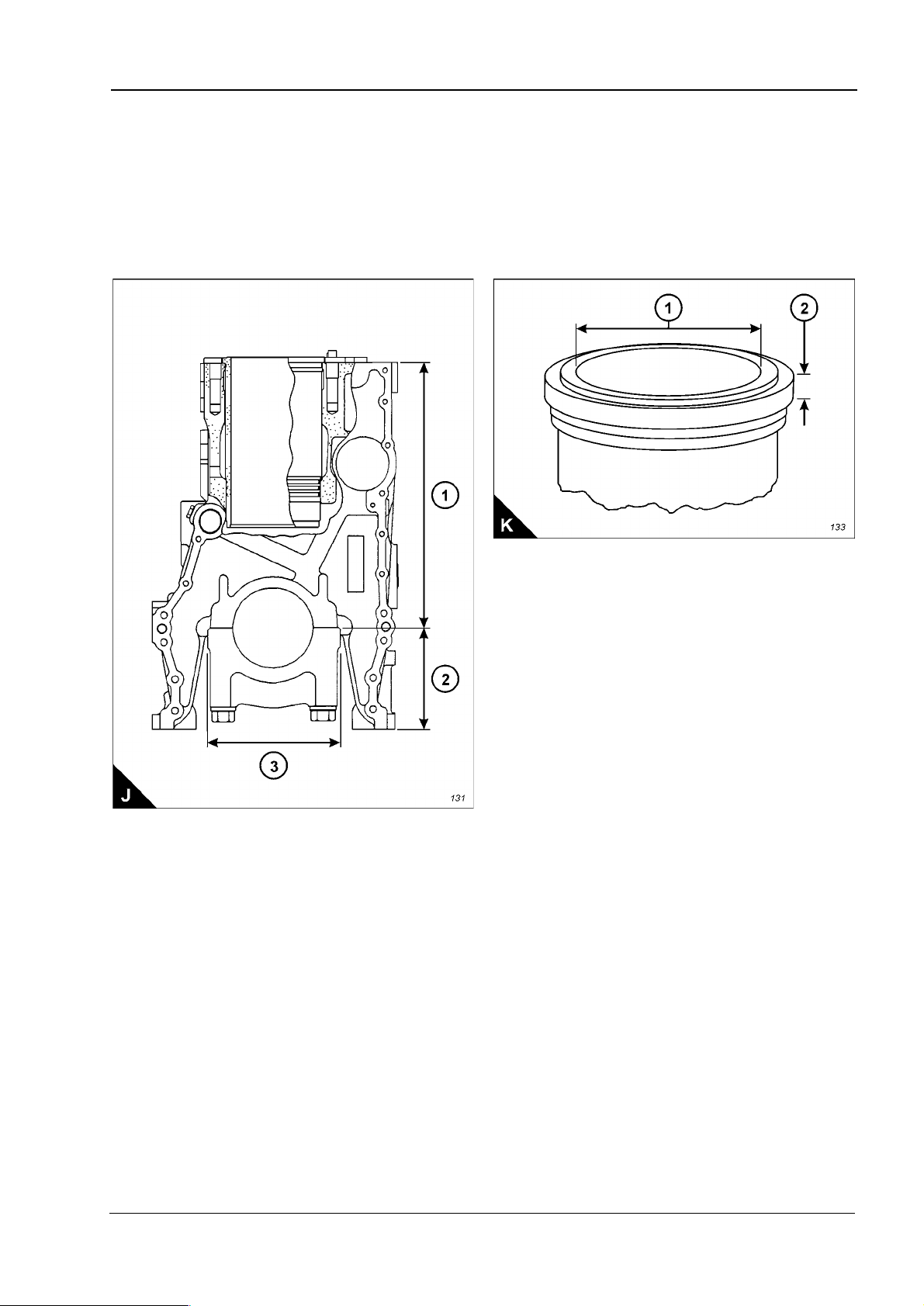

Distance from top of crankcase to centre of main

bearing bore (J1) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 425,45 +/- 0,15 mm (16.750 +/- 0.006 in)

Minimum permissible (J1) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..425,02 mm (16.733 in)

Distance f rom bottom of crankcase to centre of main

bearing bore (J2) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 165,10 +/- 0,10 mm (6.500 +/- 0.004 in)

Bore in new cylinder liner - 2306 engine (K1).. ... ... ... ... ... ... ... 137,185 +/- 0,025 mm (5.4010 +/- 0.0010 in)

Bore in new cylinder liner - 2806 engine (K1).. ... ... ... ... ... ... ... 139,685 +/- 0,025 mm (5.4994 +/- 0.0010 in)

Thickness of liner flange (K2).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8,890 +/- 0,020 mm (0.3500 +/- 0.0008 in)

Minimum thickness permissible (K2)... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8,870 mm (0.3492 in)

2

Workshop Manual, TSD3455E, Issue 1 17

Page 28

2

This document has been printed from SPI². Not for Resale

2300

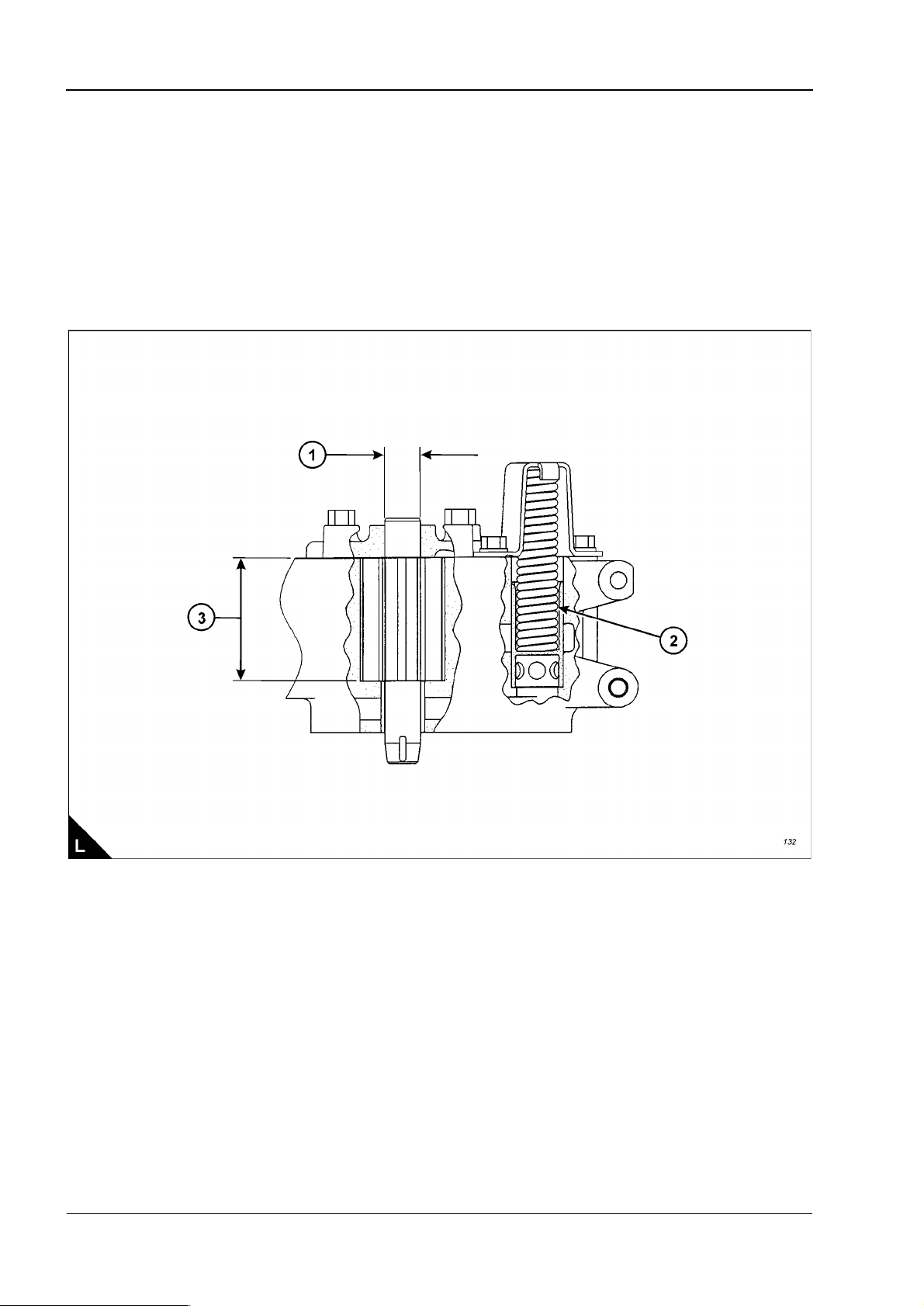

Lubricating oil pump

Diameter of shafts (L1) .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...22,217 +/- 0,005 mm (0.8747 +/- 0.0002 in)

Diameter of bores in cover for shafts. ... ... ... ... ... ... ... ... ... ... ...22,258 +/- 0,008 mm (0.8763 +/- 0.0003 in)

Length of gears (L3)... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 79,375 +/- 0,025 mm (3.1250 +/- 0.0010 in)

Depth of bores for gears (L3). ... ... ... ... ... ... ... ... ... ... ... ... ... ...79,502 +/- 0,020 mm (3.1300 +/- 0.0008 in)

Spring (L2):

Test force... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 150 +/- 8 Nm (110 +/- 6 lbf ft)

Length under test force.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..117,9 mm (4.64 in)

Free length after test.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..152,9 mm (6.02 in)

Outside diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .27 mm (1.063 in)

18 Workshop Manual, TSD3455E, Issue 1

Page 29

2300

This document has been printed from SPI². Not for Resale

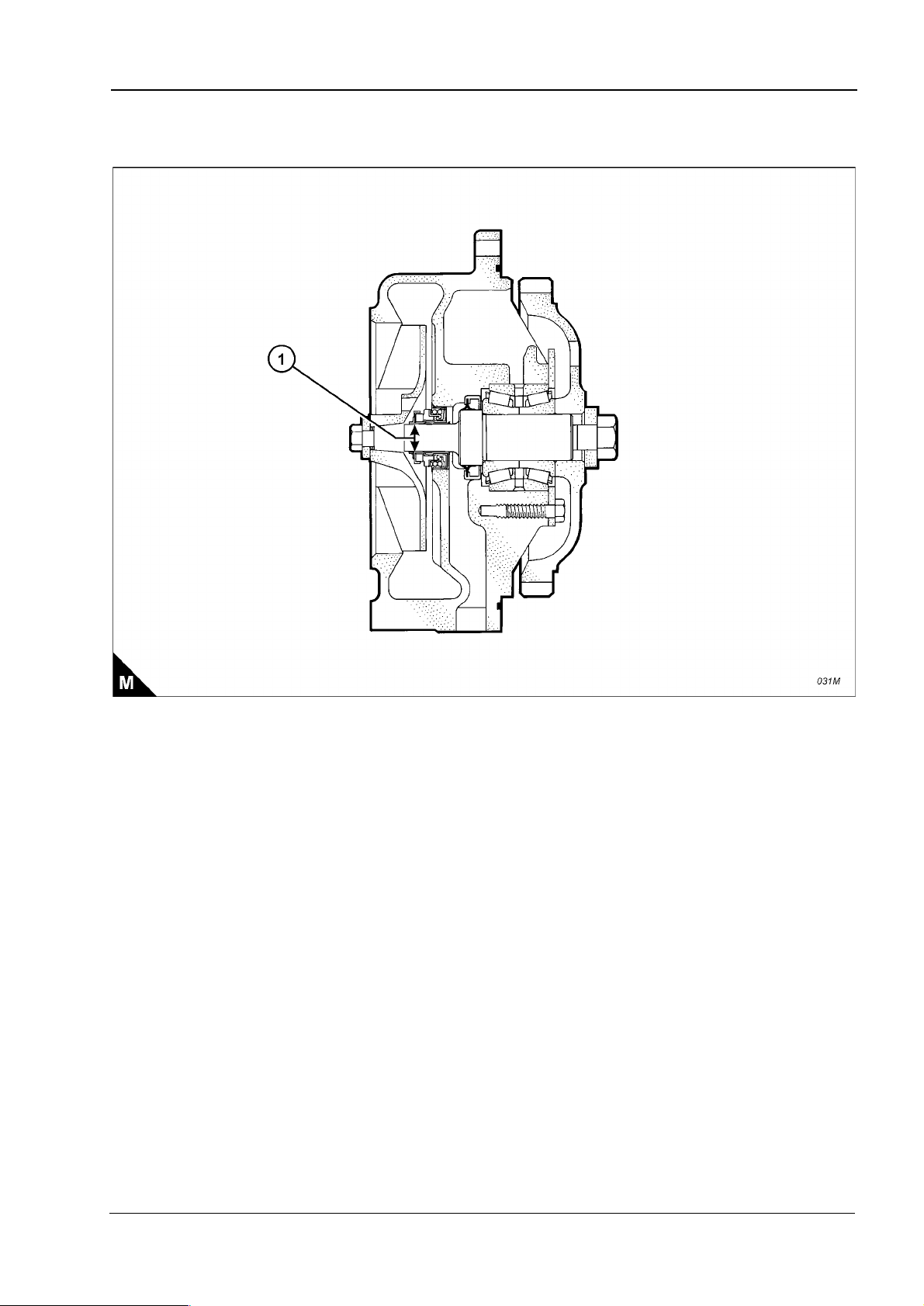

Coolant pump

Shaft diameter at the position of the coolant seal (M1) ... ... ... ... ... . 19,10 +/- 0,01 mm (0.7520 +/- 0.0004 in)

2

Workshop Manual, TSD3455E, Issue 1 19

Page 30

2

This document has been printed from SPI². Not for Resale

2300

Recommended torque figures

Exceptions to these torque figures are given in the Workshop Manual where necessary.

Before any components are fitted to the engine, ensure that they are in a new or close to new condition. Bolts

or threads must not be worn or damaged. Components must be free from rust or other corrosion. Clean with

a non-corrosive cleaner if necessary. Do not lubricate the threads of fasteners. Rust preventative which has

been applied by the component supplier for shipping and storage is acceptable. Certain components may

require an application of a particular lubricant, details are given in the Workshop Manual where relevant.

Standard torque figures for metric fasteners

Metric nuts and bolts

Thread size

metric

M6 12 +/- 3 Nm (9 +/- 2 lbf ft)

M8 28 +/- 7 Nm (21 +/- 5 lbf ft)

M10 55 +/- 10 Nm (41 +/- 7 lbf ft)

M12 100 +/- 20 Nm (75 +/- 15 lbf ft)

M14 160 +/- 30 Nm (120 +/- 22 lbf ft)

M16 240 +/- 40 Nm (175 +/- 30 lbf ft)

M20 460 +/- 60 Nm (340 +/- 44 lbf ft)

M24 800 +/- 100 Nm (590 +/- 75 lbf ft)

M30 1600 +/- 200 Nm (1180 +/- 150 lbf ft)

M36 2700 +/- 300 Nm (2000 +/- 220 lbf ft)

Standard torque

Metric taperlock studs

Thread size

metric

M6 8 +/- 3 Nm (6 +/- 2 lbf ft)

M8 17 +/- 5 Nm (13 +/- 4 lbf ft)

M10 35 +/- 5 Nm (26 +/- 4 lbf ft)

M12 65 +/- 10 Nm (48 +/- 7 lbf ft)

M16 110 +/- 20 Nm (80 +/- 15 lbf ft)

M20 170 +/- 30 Nm (125 +/- 22 lbf ft)

M24 400 +/- 60 Nm (300 +/- 44 lbf ft)

M30 750 +/- 80 Nm (550 +/- 60 lbf ft)

M36 1200 +/- 150 Nm (880 +/- 110 lbf ft)

Standard torque

20 Workshop Manual, TSD3455E, Issue 1

Page 31

2300

This document has been printed from SPI². Not for Resale

Standard torque figures for imperial fasteners

Imperial nuts and bolts

Thread size

inches

1/4 12 +/- 3 Nm (9 +/- 2 lbf ft)

5/16 25 +/- 6 Nm (18 +/- 4 lbf ft)

3/8 47 +/- 9 Nm (35 +/- 7 lbf ft)

7/16 70 +/- 15 Nm (50 +/- 11 lbf ft)

1/2 105 +/- 20 Nm (75 +/- 15 lbf ft)

9/16 160 +/- 30 Nm (120 +/- 22 lbf ft)

5/8 215 +/- 40 Nm (160 +/- 30 lbf ft)

3/4 370 +/- 50 Nm (275 +/- 37 lbf ft)

7/8 620 +/- 80 Nm (460 +/- 60 lbf ft)

1 900 +/- 100 Nm (660 +/- 75 lbf ft)

1 1/8 1300 +/- 150 Nm (960 +/- 110 lbf ft)

1 1/4 1800 +/- 200 Nm (1320 +/- 150 lbf ft)

1 3/8 2400 +/- 300 Nm (1780 +/- 220 lbf ft)

1 1/2 3100 +/- 350 Nm (2280 +/- 260 lbf ft)

Imperial taperlock studs

Thread size

inches

1/4 8 +/- 3 Nm (6 +/- 2 lbf ft)

5/16 17 +/- 5 Nm (13 +/- 4 lbf ft)

3/8 35 +/- 5 Nm (26 +/- 4 lbf ft)

7/16 45 +/- 10 Nm (33 +/- 7 lbf ft)

1/2 65 +/- 10 Nm (48 +/- 7 lbf ft)

5/8 110 +/- 20 Nm (80 +/- 15 lbf ft)

3/4 170 +/- 30 Nm (125 +/- 22 lbf ft)

7/8 260 +/- 40 Nm (190 +/- 30 lbf ft)

1 400 +/- 60 Nm (300 +/- 44 lbf ft)

1 1/8 525 +/- 60 Nm (390 +/- 44 lbf ft)

1 1/4 750 +/- 80 Nm (550 +/- 60 lbf ft)

1 3/8 950 +/- 125 Nm (700 +/- 90 lbf ft)

1 1/2 1200 +/- 150 Nm (880 +/- 110 lbf ft)

2

Standard torque

Standard torque

Workshop Manual, TSD3455E, Issue 1 21

Page 32

2

This document has been printed from SPI². Not for Resale

Standard torque figures for ‘O’ ring face seal fittings and 37 degree flared fittings

Torque figures for ferrous straight thread ‘O’ ring fittings when connected to ferrous materials

Outside diameter of nominal tube

3,18 mm

(0.125 in)

4,76 mm

(0.188 in)

6,35 mm

(0.250 in)

7,94 mm

(0.312 in)

9,52 mm

(0.375 in)

12,70 mm

(0.500 in)

15,88 mm

(0.625 in)

19,05 mm

(0.750 in)

22,22 mm

(0.875 in)

25,40 mm

(1.000 in)

31,75 mm

(1.250 in)

38,10 mm

(1.500 in)

50,80 mm

(2.000 in)

Thread size

Inches

5/16 - 24

3/8 - 24

7/16 - 20

1/2 - 20

9/16 - 18

3/4 - 16

7/8 - 14

1 1/16 - 12

1 3/16 - 12

1 5/16 - 12

1 5/8 - 12

1 7/8 - 12

2 1/2 - 12

Standard

torque

5,0 +/- 1,5 Nm

(4 +/- 1 lbf ft)

12 +/- 2 Nm

(9 +/- 1 lbf ft)

22 +/- 2 Nm

(16 +/- 1 lbf ft)

30 +/- 3 Nm

(22 +/- 2 lbf ft)

48 +/- 5 Nm

(35 +/- 4 lbf ft)

82 +/- 8 Nm

(60 +/- 6 lbf ft)

143 +/- 15 Nm

(105 +/- 11 lbf ft)

190 +/- 20 Nm

(140 +/- 15 lbf ft)

250 +/- 25 Nm

(185 +/- 18 lbf ft)

300 +/- 30 Nm

(220 +/- 22 lbf ft)

350 +/- 30 Nm

(260 +/- 22 lbf ft)

430 +/- 40 Nm

(320 +/- 30 lbf ft)

450 +/- 45 Nm

(330 +/- 33 lbf ft)

2300

Note: For the table above, use 50 percent of the torque figure when the fitting, the plug or the port material is

nonferrous.

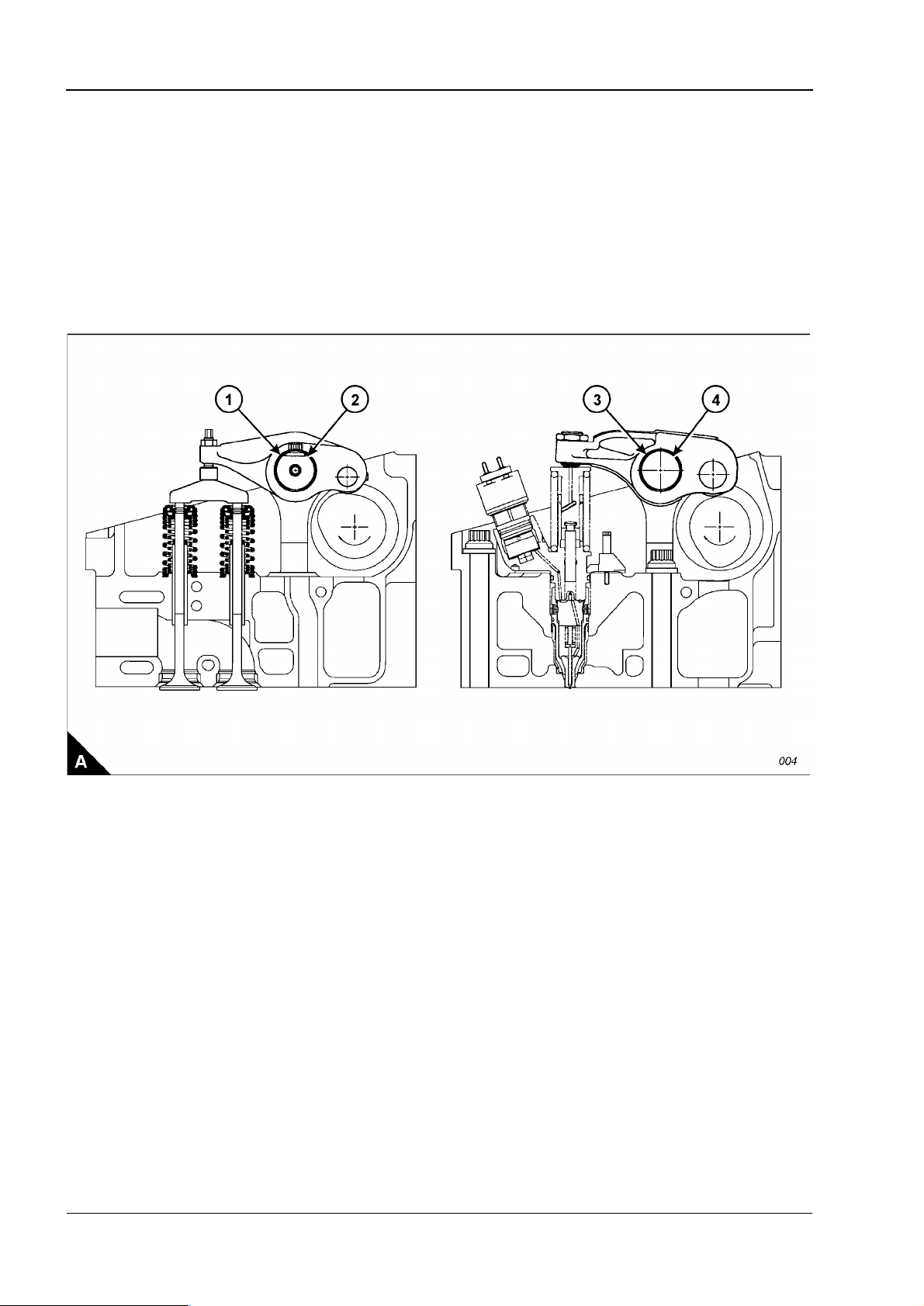

Examples of relevant fittings are shown (A): ‘O’ ring face seal (A1), 37 degree flare (A2) and plug with a

hexagon or socket-type head (A3).

22 Workshop Manual, TSD3455E, Issue 1

Page 33

2300

This document has been printed from SPI². Not for Resale

‘O’ ring face seal fittings

Torque figures for ferrous straight thread ‘O’ ring fittings (B)

Thread size

inches

1/4 8 +/- 3 Nm (6 +/- 2 lbf ft)

5/16 17 +/- 5 Nm (13 +/- 4 lbf ft)

3/8 35 +/- 5 Nm (26 +/- 4 lbf ft)

7/16 45 +/- 10 Nm (33 +/- 7 lbf ft)

1/2 65 +/- 10 Nm (48 +/- 7 lbf ft)

5/8 110 +/- 20 Nm (80 +/- 15 lbf ft)

3/4 170 +/- 30 Nm (125 +/- 22 lbf ft)

7/8 260 +/- 40 Nm (190 +/- 30 lbf ft)

1 400 +/- 60 Nm (300 +/- 44 lbf ft)

1 1/8 525 +/- 60 Nm (390 +/- 44 lbf ft)

1 1/4 750 +/- 80 Nm (550 +/- 60 lbf ft)

1 3/8 950 +/- 125 Nm (700 +/- 90 lbf ft)

1 1/2 1200 +/- 150 Nm (880 +/- 110 lbf ft)

2

Standards torque

Workshop Manual, TSD3455E, Issue 1 23

Page 34

2

This document has been printed from SPI². Not for Resale

2300

Torque figures for flared and ‘O’ ring fittings

The torque figures given in the table below and the table given on page 17 should be applied to the nut of the

fittings which follow: 37 degree flared fittings (C1), 45 degree flared fittings (C3), inverted flared fittings (C2),

‘O’ ring fittings for a recessed drive, ‘O’ ring fittings for air conditioning and swivel nuts (C2). The figures should

be used for applications which allow these working pressures: 7750 to 34450 kPa (1125 to 5000 lb/in²). The

torque figure depends on the size and type of fitting.

Nuts for 37 degree flared fittings

Outside diameter of nominal tube

3,18 mm

(0.125 in)

4,76 mm

(0.188 in)

6,35 mm

(0.250 in)

7,94 mm

(0.312 in)

9,52 mm

(0.375 in)

9,52 mm

(0.375 in)

12,70 mm

(0.500 in)

15,88 mm

(0.625 in)

19,05 mm

(0.750 in)

22,22 mm

(0.875 in)

25,40 mm

(1.000 in)

31,75 mm

(1.250 in)

38,10 mm

(1.500 in)

50,80 mm

(2.000 in)

Thread size

Inches

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1 1/16

1 3/16

1 5/16

1 5/8

1 7/8

2 1/2

Standard

torque

5,0 +/- 1,5 Nm

(4 +/- 1 lbf ft)

11 +/- 2 Nm

(8 +/- 1 lbf ft)

16 +/- 4 Nm

(12 +/- 3 lbf ft)

20 +/- 5 Nm

(15 +/- 4 lbf ft)

25 +/- 5 Nm

(18 +/- 4 lbf ft)

35 +/- 5 Nm

(26 +/- 4 lbf ft)

50 +/- 7 Nm

(37 +/- 5 lbf ft)

65 +/- 7 Nm

(48 +/- 5 lbf ft)

100 +/- 10 Nm

(75 +/- 7 lbf ft)

120 +/- 10 Nm

(90 +/- 7 lbf ft)

135 +/- 15 Nm

(100 +/- 11 lbf ft)

180 +/- 15 Nm

(135 +/- 11 lbf ft)

225 +/- 15 Nm

(165 +/- 11 lbf ft)

320 +/- 30 Nm

(240 +/- 22 lbf ft)

Note: For the table above, use 50 percent of the torque figure when the fitting, the plug or the port material is

nonferrous.

24 Workshop Manual, TSD3455E, Issue 1

Page 35

2300

This document has been printed from SPI². Not for Resale

45 degree flared and 45 degree inverted flare fittings

45 degree flared and 45 degree inverted flare fittings

Outside diameter of nominal tube

3,18 mm

(0.125 in)

4,76 mm

(0.188 in)

6,35 mm

(0.250 in)

7,94 mm

(0.312 in)

9,52 mm

(0.375 in)

11,11 mm

(0.438 in)

12,70 mm

(0.500 in)

15,88 mm

(0.625 in)

19,05 mm

(0.750 in)

22,22 mm

(0.875 in)

Thread size

Inches

5/16

3/8

7/16

1/2

5/8

11/16

3/4

7/8

1 1/16

1 1/4

2

Standard

torque

5,0 +/- 1,5 N m

(4 +/- 1 lbf ft)

8 +/- 1,5 Nm

(6 +/- 1 lbf ft)

11 +/- 2 Nm

(8 +/- 1 lbf ft)

17 +/- 3 Nm

(13 +/- 2 lbf ft)

30 +/- 3 Nm

(22 +/- 2 lbf ft)

30 +/- 3 Nm

(22 +/- 2 lbf ft)

38 +/- 4 Nm

(28 +/- 3 lbf ft)

50 +/- 5 Nm

(37 +/- 4 lbf ft)

90 +/- 8 Nm

(65 +/- 6 lbf ft)

100 +/- 10 Nm

(75 +/- 7 lbf ft)

Tapered pipe thread fittings

Tapered pipe thread fittings

Thread size

Inches

1/16 - 27 10 Nm (7 lbf ft) 10 Nm (7 lbf ft)

1/8 - 27 16 Nm (12 lbf ft) 16 Nm (12 lbf ft)

1/4 - 18 20 Nm (15 lbf ft) 25 Nm (18 lbf ft)

3/8 - 18 35 Nm (26 lbf ft) 45 Nm (33 lbf ft)

1/2 - 14 45 Nm (33 lbf ft) 60 Nm (44 lbf ft)

3/4 - 14 60 Nm (44 lbf ft) 75 Nm (55 lbf ft)

1 - 11 1/2 75 Nm (55 lbf ft) 90 Nm (65 lbf ft)

1 1/4 - 11 1/2 90 Nm (65 lbf ft) 110 Nm (80 lbf ft)

1 1/2 - 11 1/2 110 Nm (80 lbf ft) 130 Nm (95 lbf ft)

2 - 11 1/2 130 Nm (95 lbf ft) 160 Nm (120 lbf ft)

Threads with pipe sealant

(CV60891)

Note: For t he t a bl e ab o ve , us e 5 0 p er ce nt o f t he t or q ue f i gu re w h en t he f itting, th e pl ug o r t he po r t m ate r i al i s

nonferrous.

Standard torque

Threads without pipe sealant

Workshop Manual, TSD3455E, Issue 1 25

Page 36

2

This document has been printed from SPI². Not for Resale

Torque figures for standard hose clamps of the worm drive band type

2300

Width of clamp

7,9 mm (0.31 in) 0,9 +/- 0,2 Nm (8 +/- 2 lbf in)

13,5 mm (0.53 in) 4,5 +/- 0,5 Nm (40 +/- 4 lbf in)

15,9 mm (0.63 in) 7,5 +/- 0,5 Nm (65 +/- 4 lbf in)

Width of clamp Torque figure for used clamp

7,9 mm (0.31 in) 0,7 +/- 0,2 Nm (6 +/- 2 lbf in)

13,5 mm (0.53 in) 3,0 +/- 0,5 Nm (27 +/- 4 lbf in)

15,9 mm (0.63 in) 4,5 +/- 0,5 Nm (40 +/- 4 lbf in)

Torque figure for initial

installation on a new hose

Torque figures for constant torque hose clamps

Use a torque wrench for the correct installation of a constant torque hose clamp. For a constant torque hose

clamp to be installed correctly, these conditions must exist:

The screw tip (D1) must extend by 6,35 mm (0.250 in) beyond the housing (D2).

The belleville washers must be collapsed almost flat after the screw (D3) has been tightened to a torque of

11 +/- 1 Nm (98 +/- 9 lb in).

26 Workshop Manual, TSD3455E, Issue 1

Page 37

2300

This document has been printed from SPI². Not for Resale

3

Cylinder head assembly 3

General information

The cylinder head is a single-piece cast iron component. The camshaft is mounted in the cylinder head and

runs in shell bearings. The bearings are pressed into each journal and are lubricated under pressure. Bridge

piece guides have been eliminated as floating valve bridges have been utilised.

Special thermal sleeves manufactured from stainless steel are fitted to the exhaust ports. These reduce the

amount of heat transferred to the cooling system and direct the thermal energy to the turbocharger.

The electronic unit injectors are mounted in stainless steel sleeves which have been pressed into the injector

bores of the cylinder head.

The operations to remove and to fit valve seat inserts and to remove and to fit camshaft bearings are not

included as specialist equipment is required. It is recommended that operators take advantage of the Perkins

service exchange scheme if these procedures become necessary.

Workshop Manual, TSD3455E, Issue 1 27

Page 38

3

This document has been printed from SPI². Not for Resale

2300

Rocker cover

To remove and to fit Operation 3-1

To remove

Warning! The electrical circuit for the fuel injector units operates on 110 volts. Do NOT work on the fuel injector

units unless the power supply to the ECM has been disconnected.

1 Disconnect the wiring harness at the socket on the rocker cover (A1). 2 Disconnect and remove the engine breather pipe (A2). 3 Loosen fully the bolts which retain the rocker cover, but do not remove the bolts from the assembly; allow

them to be retained by the seal.

4 Remove the rocker cover. To fit 1 Inspect the seal of the rocker cover and renew if worn of damaged.

2 Fit the rocker cover, complete with seal and bolts. Tighten the bolts to a torque of 20 Nm (15 lbf ft); use the

sequence shown (B).

3 Fit the engine breather pipe (A2). 4 Connect the wiring harness. Ensure that the wiring harness is fully engaged with the connector.

28 Workshop Manual, TSD3455E, Issue 1

Page 39

2300

This document has been printed from SPI². Not for Resale

3

Rocker lever and rocker shaft assemblies

To remove and to fit Operation 3-2

To remove 1 Remove the rocker cover, Operation 3-1.

2 The valve rocker levers (A1) and the unit injector rocker levers (A2) can move on the shaft (A6) after the four

bolts (A5) have been removed. The shaft (A6) should be kept level when removed from the cylinder head. To

avoid possible personal injury, keep fingers clear of the rocker levers (A1 and A2) during removal of the

assembly from the cylinder head.

3 Remove the four bolts (A5). 4 Remove the shaft (A6), valve rocker levers (A1) and unit injector rocker levers (A2) as a unit. 5 Repeat steps 1 and 2 for the rocker shaft assemblies which remain.

To fit

1 Loosen the adjustment screws (A3 and A4) of each of the rocker levers which have been removed. Install

the rocker shaft assembly in the reverse order to removal.

2 Set the tappet clearances, Operation 3-4. 3 Check/adjust the unit injectors, Operation 3-13. 4 Fit the rocker cover, Operation 3-1.

Workshop Manual, TSD3455E, Issue 1 29

Page 40

3

This document has been printed from SPI². Not for Resale

To dismantle and to assemble Operation 3-3

To dismantle Note: Check the condition of all components and renew any which are worn or damaged. 1 Slide the valve rocker levers (A3) and the unit injector rocker levers (A4) from the shaft (A7).

Note: Fit a new ‘O’ ring seal to any rocker lever adjuster if its button (A1) has been removed from the

adjustment screw (A2).

2 Remove the button (A1) from the adjustment screw (A2) in the valve rocker lever (A3). 3 Remove the button (A6) from the adjustment screw (A5) in the unit injector rocker lever (A4). 4 Repeat steps 1 to 3 for the rocker lever assemblies which remain.

2300

30 Workshop Manual, TSD3455E, Issue 1

Page 41

2300

This document has been printed from SPI². Not for Resale

To assemble 1 Install new ‘O’ ring seals in the buttons (A1).

2 Install new ‘O’ ring seals in the buttons (A6). 3 To fit the ‘O’ ring seals and buttons to the valve rocker levers, proceed as follows: a. Support the valve rocker lever (A3) in a vice which has soft jaws.

b. Put the ‘O’ ring seal and button (A1) on the round end of the adjustment screw (A2). c. Use a soft hammer to seat the button on the adjustment screw. 4 To fit the ‘O’ ring seals and buttons to the unit injector rocker levers, proceed as follows:

a. Support the unit injector rocker lever (A4) in a vice which has soft jaws. b. Put the ‘O’ ring seal and button (A6) over the end of adjustment screw (A5). c. Use a soft hammer to seat the button on the adjustment screw. 5 Repeat steps 3 and 4 for the rocker levers which remain.

6 Fit the assembled rocker levers to the shafts (A7). Ensure that they are fitted to their original positions.

3

Workshop Manual, TSD3455E, Issue 1 31

Page 42

3

This document has been printed from SPI². Not for Resale

2300

How to check/adjust the tappet clearances Operation 3-4

Special requirements

Special tools Tappet clearances

Description Part number Inlet Exhaust

Engine turning tool CH11148 0,38 mm (0.015 in) 0,76 mm (0.030 in)

The tappet clearance is measured between the rocker levers and the top of the valve bridge pieces. The

operation must be done with the engine cold and stopped. Refer also to Operation 3-13, How to check/adjust

the electronic unit injectors.

1 Remove the rocker cover, Operation 3-1. 2 Remove the cover (A2) from the flywheel housing. The top bolt (A1) is the timing bolt.

Caution: If a customer-fitted speed sensor is fitted to the flywheel housing, it must be removed before the

engine turning tool can be inserted.

3 Remove the plug (A3) from the timing bolt location in the flywheel housing and fit the timing bolt.

Note: There are two locations for the timing bolt, one at each side of the flywheel housing. Use the location

that is the most convenient.

4 Insert the engine turning tool, CH11148, into the flywheel housing through the aperture behind the cover

(A2). Use a

rotation (anti-clockwise when viewed on the flywheel) until the timing bolt engages with the threaded hole in

the flywheel. The piston of number 1 cylinder is now at TDC (top dead centre).

Caution: If the flywheel is turned past the threaded hole, the flywheel must be turned in the opposite direction

for approximately 45 degrees and then back in the normal direction of rotation until the timing bolt engages

with the threaded hole. This is to eliminate backlash.

1

/2 inch drive ratchet with the turning tool to rotate the engine flywheel in the normal direction of

Continued

32 Workshop Manual, TSD3455E, Issue 1

Page 43

2300

This document has been printed from SPI². Not for Resale

5 Check the inlet and exhaust valves of the number 1 cylinder. If they are fully closed the piston is on its

compression stroke and the rocker levers can be moved by hand. If the rocker levers can not be moved

because the valves are slightly open, the piston is on its exhaust stroke. If it is on its exhaust stroke, withdraw

the timing bolt and turn the flywheel a further 360 degrees in the normal direction of rotation so that the number

1 cylinder is set to TDC on its compression stroke, then insert again the timing bolt.

6 Before each set of tappet clearances is adjusted, ensure that the roller of the rocker lever is fully against the

camshaft lobe.

7 Use a set of feeler gauges, inserted at the position shown (B3) between the valve bridge piece and the rocker

lever button, to check the tappet clearances for the inlet valves (C1) on cylinders 1, 2 and 4. Adjust the

clearances if necessary. Check the tappet clearance for the exhaust valves (C2) on cylinders 1, 3 and 5, and

adjust the clearances if necessary.

3

Continued

Workshop Manual, TSD3455E, Issue 1 33

Page 44

3

N

This document has been printed from SPI². Not for Resale

otes:

l Move each valve bridge piece before the feeler gauge is inserted to reduce the effect of the oil film.

l During the procedure, ensure that the feeler gauge is fully inserted

8 After each unit has been adjusted, tighten the lock nut (B2) of the adjustment screw (B1) to a torque of 30 +/

- 4 Nm (22 +/- 3 lbf ft).

9 Withdraw the timing bolt and rotate the flywheel by 360 degrees so that the number 6 piston is at TDC on

its compression stroke. Insert again the timing bolt into the threaded hole.

10 Check the tappet clearances for the inlet valves (C1) on cylinders 3, 5 and 6. Adjust the clearances if

necessary. Check the tappet clearances for the exhaust valves (C2) on cylinders 2, 4 and 6, and adjust the

clearances if necessary.

11 After each unit has been adjusted, tighten the lock nut of the adjustment screw to a torque of 30 +/- 4 Nm

(22 +/- 3 lbf ft).

12 Check again the tappet clearances for all six cylinders. 13 Fit the rocker cover. Remove the engine turning tool and the timing bolt and fit the cover to the flywheel

housing. Fit the plug to the timing bolt location.

2300

34 Workshop Manual, TSD3455E, Issue 1

Page 45

2300

This document has been printed from SPI². Not for Resale

3

Cylinder head assembly

To remove and to fit Operation 3-5

Special requirements

Special tools Consumable products

Description Part number Description Part number

Guide bolt, camshaft gear GE50019 Special lubricant CV60895

Socket, cylinder head bolt GE50020

Lifting bracket VP12712

To remove 1 Remove the thermostat housing, Operation 12-10.

2 Remove the exhaust manifold, Operation 9-1. 3 Remove the rocker lever and rocker shaft assemblies, Operation 3-2. 4 Remove the electronic unit inj ec tor s, Oper at ion 3-12. 5 Remove the gear case cover, Operation 6-1. 6 Disconnect the cable and remove the timing sensor from the cylinder head. 7 Remove the support bracket which is fitted between the gear case and the cylinder head. 8 Remove one bolt from the camshaft gear and install the guide stud, GE50019. Remove the five bolts which

remain and withdraw carefully the camshaft gear. Remove the guide stud.

9 Disconnect the fuel lines from the front and rear of the cylinder head. Fit temporary covers to the fuel lines

and also to the ports on the cylinder head.

10 Remove the cylinder head bolts; use the special socket, GE50020. 11 Fit the lifting bracket (A1), VP12712, to the cylinder head and attach a suitable hoist. Remove the cylinder

head. The cylinder head weighs approximately 148 kg (325 lb).

Retaining compound 21820 638

Continued

Workshop Manual, TSD3455E, Issue 1 35

Page 46

3

This document has been printed from SPI². Not for Resale

12 Remove the cylinder head gasket (B4). 13 Remove the ‘O’ ring seal from the oil transfer tube (B6) and remove the 24 coolant seals (B3). 14 Remove the seal (B2). 15 Remove the spacer plate (B5) and discard the spacer plate gasket. 16 Remove the second ‘O’ ring seal from the oil transfer tube (B6).

2300

36 Workshop Manual, TSD3455E, Issue 1

Page 47

2300

This document has been printed from SPI². Not for Resale

To fit

1 If the oil transfer tube (B6) has been removed, apply retaining compound, 21820 638, and insert it in the

crankcase. It must protrude from the top face of the crankcase by 20,0 +/- 0,5 mm (0.79 +/- 0.02 in). Remove

any excess compound and ensure that the bore of the oil transfer tube is clean.

2 If the rear dowel has been removed, apply retaining compound, 21820 638, and insert it in the crankcase.

It must protrude from the top face of the crankcase by 18,5 +/- 0,5 mm (0.73 +/- 0.02 in).

3 If the front dowel, close to the oil transfer tube, has been removed, it must be fitted in a dry condition. It must

protrude from the top face of the crankcase by 16,0 +/- 0,5 mm (0.63 +/- 0.02 in).

Note: Ensure that the spacer plate and the machined surface of the cylinder block are clean and free from dirt

and gasket material. Both surfaces of the spacer plate gasket and the top of the cylinder block must be clean.

Do NOT use a gasket adhesive on the surfaces.

4 Fit suitable guide studs (B1) to the cylinder block. Fit a new spacer plate gasket over the dowels in the

cylinder block.

Note: Apply a small amount of clean engine oil to the seals and ‘O’ ring seals before installation. 5 Fit a new ‘O’ ring seal to the oil transfer tube (B6).

6 Fit the spacer plate (B5) and fit the second ‘O’ ring seal to the oil transfer tube (B6). Fit the 24 coolant seals