Page 1

Operation and

Maintenance

Manual

SEBU8119-02

January 2008

1106D Industrial Engine

(Engine)

PJ

Page 2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

SEBU8119-02 3

Table of Contents

Table of Contents

Foreword ................................................................. 4

Safety Section

Safety Messages .................................................... 5

General Hazard Information ................................... 7

Burn Prevention ...................................................... 9

Fire Prevention and Explosion Prevention .............. 9

Crushing Prevention and Cutting Prevention ......... 11

Mounting and Dismounting .................................... 11

High Pressure Fuel Lines ..................................... 12

Before Starting Engine .......................................... 13

Engine Starting ..................................................... 13

Engine Stopping ................................................... 14

Maintenance In

Warranty S ecti

Warranty Information .......................................... 100

terval Schedule ............................ 65

on

Index Section

Index ................................................................... 101

Electrical System .................................................. 14

Engine Electronics ................................................ 15

Product Information Section

General Information .............................................. 17

Model Views ......................................................... 18

Product Identification Information ........................ 22

Operation Section

Lifting and Storage ................................................ 24

Gauges and Indicators .............................. ............ 26

Features and Controls .......................................... 28

Engine Diagnostics ............................................... 35

Engine Starting ..................................................... 39

Engine Operation .................................................. 42

Engine Stopping ................................................... 43

Cold Weather Operation ....................................... 45

Maintenance Section

Refill Capacities .................................................... 49

Page 4

4 SEBU8119-02

Foreword

Foreword

Literature Information

This manual con

lubrication and maintenance information. This

manual should be stored in or near the engine area

in a literatur

study and keep it with the literature and engine

information.

English is the primary language for all Perkins

publications. The English used facilitates translation

and consiste

Some photographs or illustrations in this manual

show details

from your engine. Guards and covers may have

been removed for illustrative purposes. Continuing

improvemen

may have caused changes to your engine which are

not included in this manual. Whenever a question

arises reg

consult with your Perkins dealer or your Perkins

distributor for the latest available information.

Safety

This safety section lists basic safety precautions.

In addition, this section identifies hazardous,

warning si

precautions listed in the safety section before

operating or performing lubrication, maintenance and

repair on

this product.

tains safety, operation instructions,

e holder or literature storage area. Read,

ncy.

or attachments that may be different

t and advancement of product design

arding your engine, or this manual, please

tuations. Read and understand the basic

Recommended se

appropriate intervals as indicated in the Maintenance

Interval Schedule. The actual operating environment

of the engine a

Schedule. Therefore, under extremely severe,

dusty, wet or freezing cold operating conditions,

more frequen

specified in the Maintenance Interval Schedule may

be necessary.

The maintenance schedule items are organized for

a preventive maintenance management program. If

the prevent

periodic tune-up is not required. The implementation

of a preventive maintenance management program

should mini

avoidances resulting from reductions in unscheduled

downtime and failures.

ive maintenance program is followed, a

mize operating costs through cost

rvice should be performed at the

lso governs the Maintenance Interval

t lubrication and maintenance than is

Maintenance Intervals

Perform maintenance on items at multiples of

the original requirement. We recommend that the

maintenan

near the engine as a convenient reminder. We also

recommend that a maintenance record be maintained

as part of

Your authorized Perkins dealer or your Perkins

distribu

maintenance schedule to meet the needs of your

operating environment.

ce schedules be reproduced and displayed

the engine’s permanent record.

tor can assist you in adjusting your

Overhaul

Operatio

Operating techniques outlined in this manual are

basic. Th

techniques required to operate the engine more

efficiently and economically. Skill and techniques

develop

engine and its capabilities.

The oper

Photographs and illustrations guide the operator

through procedures of inspecting, starting, operating

and sto

discussion of electronic diagnostic information.

n

ey assist with developing the skills and

as the operator gains knowledge of the

ation section is a reference for operators.

pping the engine. This section also includes a

Maintenance

The mai

The illustrated, step-by-step instructions are grouped

by service hours and/or calendar time maintenance

interv

referenced to detailed instructions that follow.

ntenance section is a guide to engine care.

als. Items in the maintenance schedule are

Major engine overhaul details are not covered in

the Operation and Maintenance Manual except

for the i

interval. Major repairs should only be carried out by

Perkins authorized personnel. Your Perkins dealer

or your P

regarding overhaul programs. If you experience

a major engine failure, there are also numerous

after f

your Perkins dealer or your Perkins distributor for

information regarding these options.

nterval and the maintenance items in that

erkins distributor offers a variety of options

ailure overhaul options available. Consult with

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

defects, and other reproductive harm. Battery

birth

posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

Page 5

SEBU8119-02 5

Safety Section

Safety Messages

Safety Section

i02788195

Safety Messages

There may be s

engine. The exact location and a description of the

warning signs are reviewed in this section. Please

become famil

Ensure that all of the warning signs are legible. Clean

the warning s

the words cannot be read or if the illustrations are

not visible. Use a cloth, water, and soap to clean

the warning

other harsh chemicals. Solvents, gasoline, or harsh

chemicals could loosen the adhesive that secures the

warning si

could drop off of the engine.

Replace an

missing.Ifawarningsignisattachedtoapartofthe

engine that is replaced, install a new warning sign on

the replac

provide new warning signs.

everal specific warning signs on your

iar with all warning signs.

igns or replace the warning signs if

signs. Do not use solvents, gasoline, or

gns. The warning signs that are loosened

y warning sign that is damaged or

ement part. Your Perkins distributor can

(1) Un iversal Warning

Do not operate or work on this equipment unless

you have r

and warnings in the Operation and Maintenance

Manuals. Failure to follow the instructions or

heed the

or death.

ead and understand the instructions

warnings could result in serious injury

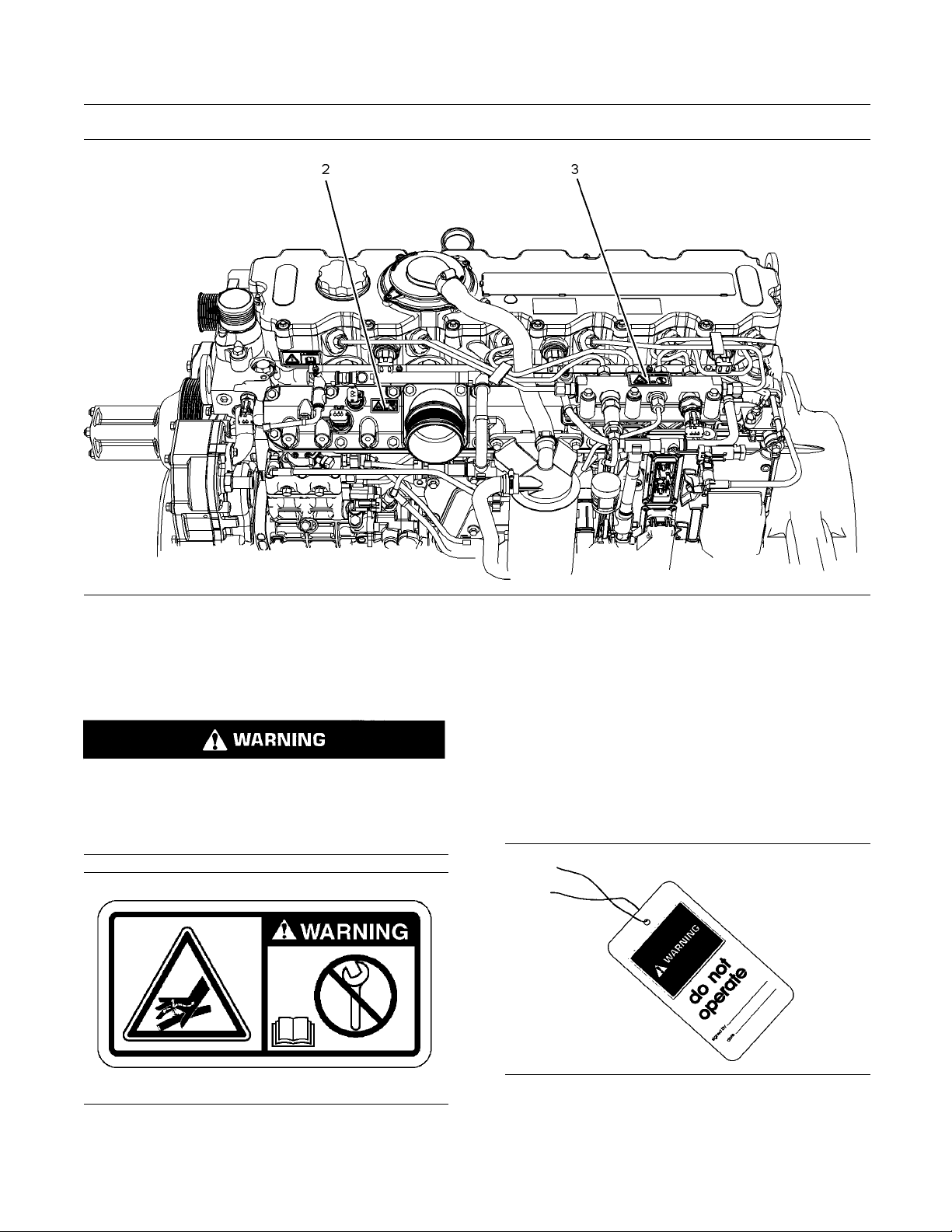

Illustration 1

lexample

Typica

The Universal Warning label (1) is located on both

sides o

f the valve mechanism cover base.

g01154807

Page 6

6 SEBU8119-02

Safety Section

Safety Messages

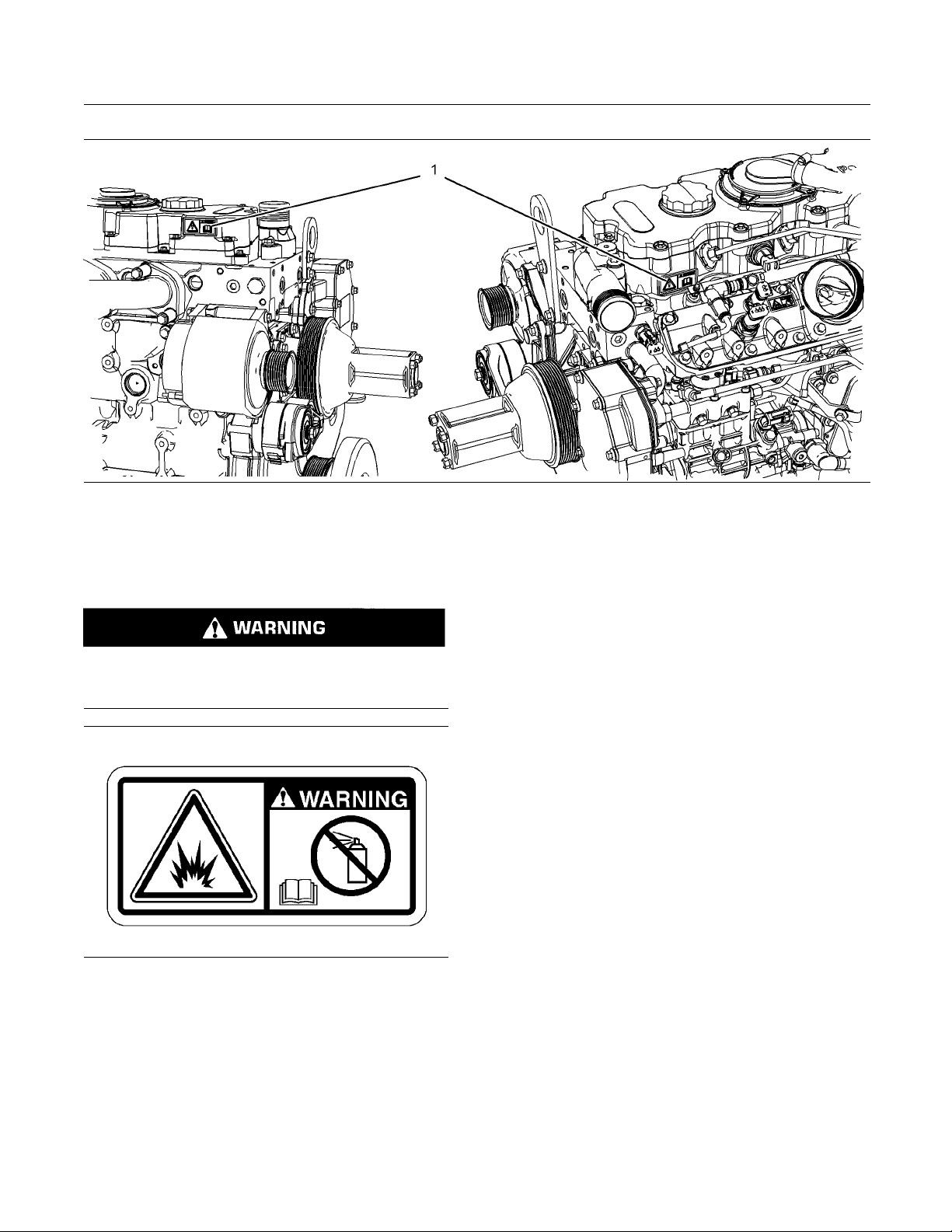

Illustration 2

Location of label

(1) Universal warning

(2) Ether Warning

Do not use aerosol types of starting aids such as

ether. Such use could result in an explosion and

personal injury.

g01392790

Illustration 3

Typical examp le

g01154809

The ether warning label (2) is located on the cover

of the inlet manifold.

Page 7

SEBU8119-02 7

Safety Section

General Hazard Information

Illustration 4

Location o

(2) Ether (3) Hand (High Pressure)

f labels

(3) Hand (High Pressure)

Contact

penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow thes

structions may cause personal injury or death.

with high pressure fuel may cause fluid

e inspection, maintenance and service in-

g01392789

The warning label for the Hand (High Pressure) (3) is

located o

n the top of the fuel manifold.

i023284

General Hazard Information

35

Illustration 5

lexample

Typica

g01154858

Illustration 6

g0010

Attach a “Do Not Operate” warning tag or a similar

warning tag to the start switch or to the controls

e you service the equipment or before you

befor

repair the equipment.

4545

Page 8

8 SEBU8119-02

Safety Section

General Hazard Information

Illustration 7

Wear a hard hat, protective glasses, and other

protective equipment, as required.

Do not wear loose clothing or jewelry that can snag

on controls or on other parts of the engine.

Make sure that all protective guards and all covers

are secured in place on the engine.

Keep the engine free from foreign material. Remove

debris, oil, tools, and other items from the deck, from

walkways, and from steps.

g00702020

When pressuriz

cleaning, wear protective clothing, protective shoes,

and eye protection. Eye protection includes goggles

or a protectiv

The maximum air pressure for cleaning purposes

must be below

water pressure for cleaning purposes must be below

275 kPa (40 psi).

ed air and/or water is used for

efaceshield.

205 kPa (30 psi). The maximum

Fluid Penetration

Pressure can be trapped in the hydraulic circuit long

after the engine has been stopped. The pressure can

cause hydrau

escape rapidly if the pressure is not relieved correctly.

Do not remove

until pressure has been relieved or personal injury

may occur. Do not disassemble any hydraulic

components

or personal injury may occur. Refer to the OEM

information for any procedures that are required to

relieve th

lic fluid or items such as pipe plugs to

any hydraulic components or parts

or parts until pressure has been relieved

e hydraulic pressure.

Never put maintenance fluids into glass containers.

Drain all liquids into a suitable container.

Obey all local regulations for the disposal of liquids.

Use all cleaning solutions with care.

Report all necessary repairs.

Do not allow unauthorized personnel on the

equipment.

Ensure that the power supply is disconnected before

you work on the bus bar or the glow plugs.

Perform maintenance on the engine with the

equipment in the servicing position. Refer to the

OEM information for the procedure for placing the

equipment in the servicing position.

Pressure Air and Water

Pressurized air and/or water can cause debris

and/or hot water to be blown out. This could result in

personal injury.

The direct application of pressurized air or

pressurized water to the body could result in personal

injury.

Illustration 8

Always use a board or cardboard when you check

for a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

g00687600

Containing Fluid Spillage

Care must be taken in order to ensure that fluids

are contained during performance of inspection,

maintenance, testing, adjusting and repair of the

engine. Make provision to collect the fluid with a

suitable container before any compartment is opened

or before any component is disassembled.

Only use the tools that are suitable for collecting

•

fluids and equipment that is suitable for collecting

fluids.

Page 9

SEBU8119-02 9

Safety Section

Burn Prevention

Only use the too

•

fluids and equipment that is suitable for containing

fluids.

Obey all local regulations for the disposal of liquids.

ls that are suitable for containing

i02334785

Burn Prevention

Do not touch any part of an operating engine.

Allow the engine to cool before any maintenance is

performed on the engine.

Contact with h igh pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

After the engine has stopped, you must wait for 60

seconds in order to allow the fuel pressure to be

purged from the high pressure fuel lines before any

service or repair is performed on the engine fuel lines.

Oils

Hot oil and hot lubricating components can cause

personal injury. Do not allow hot oil to contact the

skin. Also, do not allow hot components to contact

the skin.

Batteries

Electrolyte is an acid. Electrolyte can cause personal

injury. Do not allow electrolyte to contact the skin or

the eyes. Always wear protective glasses for servicing

batteries. Wash hands after touching the batteries

and connectors. Use of gloves is recommended.

i02320721

Fire Prevention and Explosion

Prevention

Allow the pressure to be purged in the air system, in

the hydraulic system, in the lubrication system, or in

the cooling system before any lines, fittings or related

items are disconnected.

Coolant

When the engine is at operating temperature, the

engine coolant is hot. The coolant is also under

pressure. The radiator and all lines to the heaters or

to the engine contain hot coolant.

Any contact with hot coolant or with steam can cause

severe burns. Allow cooling system components to

cool before the cooling system is drained.

Check the coolant level after the engine has stopped

and the engine has been allowed to cool.

Ensure that the filler cap is cool before removing the

filler cap. The filler cap must be cool enough to touch

withabarehand.Removethefiller cap slowly in

order to relieve pressure.

Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

the skin, the eyes, or the mouth.

tion 9

Illustra

All fuels, most lubricants, and some coolant mixtures

are flamma

Flammable fluids that are leaking or spilled onto hot

surfaces

a fire. Fire may cause personal injury and property

damage.

After the emergency stop button is operated ensure

that you allow 15 minutes, before the engine covers

are remo

Determinewhethertheenginewillbeoperatedinan

environ

drawn into the air inlet system. These gases could

cause the engine to overspeed. Personal injury,

proper

If the application involves the presence of combustible

gases,

Perkins distributor for additional information about

suitable protection devices.

ble.

or onto electrical components can cause

ved.

ment that allows combustible gases to be

ty damage, or engine damage could result.

consult your Perkins dealer and/or your

g00704000

Page 10

10 SEBU8119-02

Safety Section

Fire Prevention and Explosion Prevention

Remove all flamm

able combustible materials or

conductive materials such as fuel, oil, and debris from

the engine. Do not allow any flammable combustible

materials or c

onductive materials to accumulate on

the engine.

Store fuels a

nd lubricants in correctly marked

containers away from unauthorized persons. Store

oily rags and any flammable materials in protective

containers.

Do not smoke in areas that are used for

storing flammable materials.

Do not expose

theenginetoanyflame.

Exhaust shields (if equipped) protect hot exhaust

components f

rom oil or fuel spray in case of a line,

a tube, or a seal failure. Exhaust shields must be

installed correctly.

Do not weld on lines or tanks that contain flammable

fluids. Do not flame cut lines or tanks that contain

flammable fl

uid. Clean any such lines or tanks

thoroughly with a nonflammable solvent prior to

welding or fl ame cutting.

Wiring must be kept in good condition. All electrical

wires must be correctly routed and securely attached.

Check all e

lectrical wires daily. Repair any wires

that are loose or frayed before you operate the

engine. Clean all electrical connections and tighten

all elect

rical connections.

Oil filters and f

uel filters must be correctly installed.

The filter housings must be tightened to the correct

torque. Refer to the Disassembly and Assembly

manual for mor

Illustration 10

e information.

g00704059

Use caution when you are refueling an engine. Do

not smoke while you are refueling an engine. Do not

refuel an engine near open flames or sparks. Always

stop the engine before refueling.

Eliminate all wiring that is unattached or unnecessary.

Do not use

any wires or cables that are smaller than

the recommended gauge. Do not bypass any fuses

and/or circuit breakers.

Arcing or sparking could cause a fire. Secure

connections, recommended wiring, and correctly

maintai

ned battery cables will help to prevent arcing

or sparking.

Contact with h igh pressure fuel may cause fluid

penetra

tion and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service in-

ions may cause personal injury or death.

struct

After the engine has stopped, you must wait for 60

second

s in order to allow the fuel pressure to be

purged from the high pressure fuel lines before any

service or repair is performed on the engine fuel lines.

Ensure that the engine is stopped. Inspect all lines

and hoses for wear or for deterioration. The hoses

must be

correctly routed. The lines and hoses must

have adequate support and secure clamps.

Illustration 11

g00704135

Gases from a battery can explode. Keep any open

flames or sparks away from the top of a battery. Do

not smoke in battery charging areas.

Never check the battery charge by placing a metal

object across the terminal posts. Use a voltmeter or

ahydrometer.

Page 11

SEBU8119-02 11

Safety Section

Crushing Prevention and Cutting Prevention

Incorrect jump

an explosion that can result in injury. Refer to

the Operation Section of this manual for specific

instructions

Do not charge a frozen battery. This may cause an

explosion.

The batteries must be kept clean. The covers

(if equipped

recommended cables, connections, and battery box

covers when the engine is operated.

er cable connections can cause

.

)mustbekeptonthecells.Usethe

Fire Extinguisher

Make sure that a fire extinguisher is available. Be

familiar with the operation of the fire extinguisher.

Inspect the fi

extinguisher regularly. Obey the recommendations

on the instruction plate.

re extinguisher and service the fire

Lines, Tubes and Hoses

Do not bend high pressure lines. Do not strike high

pressure lines. Do not install any lines that are

damaged.

Leaks can cause fires. Consult your Perkins dealer

or your Per

Replace the parts if any of the following conditions

are presen

kins distributor for replacement parts.

t:

i02143194

Crushing Prevention and

Cutting Preve

Support the component correctly when work beneath

the component is performed.

Unless other maintenance instructions are provided,

never attempt adjustments while the engine is

running.

Stay clear of all rotating parts and of all moving

parts. Leave

is performed. After the maintenance is performed,

reinstall the guards.

Keep objects away from moving fan blades. The fan

blades will throw objects or cut objects.

When objects are struck, wear protective glasses in

order to avoid injury to the eyes.

Chips or other debris may fly off objects when objects

are struck. Before objects are struck, ensure that no

one will be i

the guards in place until maintenance

njured by flying debris.

ntion

i02235492

Mounting and Dismounting

High pressure fuel line or lines are removed.

•

End fittings are damaged or leaking.

•

Outer cove

•

Wires are exposed.

•

Outer coverings are ballooning.

•

Flexible p

•

Outer covers have embedded armoring.

•

End fittings are displaced.

•

Make sure t

are installed correctly. During engine operation, this

will help to prevent vibration, rubbing against other

parts, an

rings are chafed or cut.

art of the hoses are kinked.

hat all clamps, guards, and heat shields

d excessive heat.

Inspect the steps, the handholds, and the work area

before mounting the engine. Keep these items clean

and keep these items in good repair.

Mount the engine and dismount the engine only at

locations that have steps and/or handholds. Do not

climb on the engine, and do not jump off the engine.

Face the engine in order to mount the engine or

dismount the engine. Maintain a three-point contact

with the steps and handholds. Use two feet and one

hand or use one foot and two hands. Do not use any

controls as handholds.

Do not stand on components which cannot support

your weight. Use an adequate ladder or use a work

platform. Secure the climbing equipment so that the

equipment will not move.

Do not carry tools or supplies when you mount the

engine or when you dismount the engine. Use a hand

line to raise and lower tools or supplies.

Page 12

12 SEBU8119-02

Safety Section

High Pressure Fuel Lines

i02668808

High Pressure Fuel Lines

Contact with h igh pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel spray may ca

low these inspection, maintenance and service instructions may cause personal injury or death.

use a fire haz ard. Failure to fol-

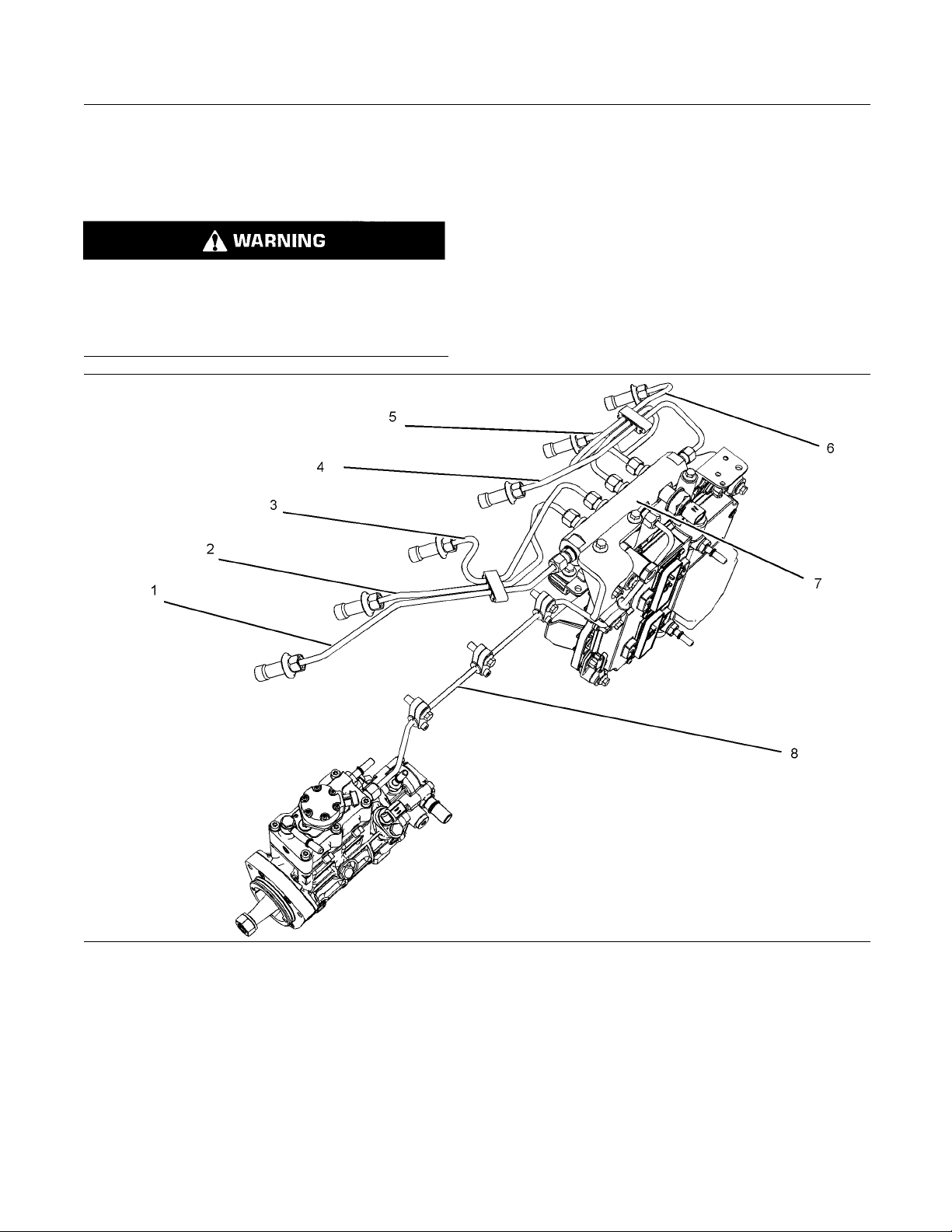

Illustration 1 2

(1)Highpressureline

(2)Highpressureline

(3)Highpressureline

(4) High pressure line

(5) High pressure line

(6) High pressure line

The high pressure fuel lines are the fuel lines that

are between the high pressure fuel pump and the

high pressure fuel manifold and the fuel lines that are

between the fuel manifold and cylinder head. These

fuel lines are different from fuel lines on other fuel

systems.

This is because of the following differences:

g01341328

(7) High pressure fuel manifold (rail)

(8) High pressure line

The high pressure fuel lines are constantly charged

•

with high pressure.

The internal pressures of the high pressure fuel

•

lines are higher than other types of fuel system.

The high pressure fuel lines are formed to shape

•

and then strengthened by a special process.

Page 13

SEBU8119-02 13

Safety Section

Before Starting Engine

Donotsteponth

deflect the high pressure fuel lines. Do not bend or

strike the high pressure fuel lines. Deformation or

damage of the h

point of weakness and potential failure.

Do not check t

engine or the starting motor in operation. After the

engine has stopped allow 60 seconds to pass in order

to allow the p

or repair is performed on the engine fuel lines.

Do not loosen

to remove air from the fuel system. This procedure

is not required.

Visually inspect the high pressure fuel lines before

the engine is started. This inspection should be each

day.

If you inspect the engine in operation, always use

the proper

a fluid penetration hazard. Refer to Operation and

Maintenance Manual, “General hazard Information”.

Inspect the high pressure fuel lines for damage,

•

deformation, a nick, a cut, a crease, or a dent.

Do not operate the engine with a fuel leak. If there

•

isaleakdonottightentheconnectioninorder

to stop the

tightened to the recommended torque. Refer to

Disassembly and Assembly, “Fuel injection lines Remove an

If the high pressure fuel lines are torqued correctly

•

and the hi

high pressure fuel lines must be replaced.

e high pressure fuel lines. Do not

igh pressure fuel lines may cause a

he high pressure fuel lines with the

ressure to be purged before any service

thehighpressurefuellinesinorder

inspection procedure in order to avoid

leak. The connection must only be

d Fuel injection lines - Install”.

gh pressure fuel lines are leaking the

i02813489

Before Starting Engine

Before the init

serviced or repaired, make provision to shut the

engine off, in order to stop an overspeed. This may

be accomplish

supply to the engine.

Overspeed shu

engines that are controlled electronically. If automatic

shutdown does not occur, press the emergency stop

button in ord

Inspect the engine for potential hazards.

Before starting the engine, ensure that no one is on,

underneath, or close to the engine. Ensure that the

area is free

If equipped, ensure that the lighting system for the

engine is su

lights work correctly, if equipped.

All protect

be installed if the engine must be started in order

to perform service procedures. To help prevent an

accident t

around the parts carefully.

Do not bypa

disable the automatic shutoff circuits. The circuits are

provided in order to help prevent personal injury. The

circuits

engine damage.

ialstart-upofanenginethatisnew,

ed by shutting off the air and/or fuel

tdown should occur automatically for

er to cut the fuel and/or air to the engine.

of personnel.

itable for the conditions. Ensure that all

ive guards and all protective covers must

hat is caused by parts in rotation, work

ss the automatic shutoff circuits. Do not

are also provided in order to help prevent

Ensure th

•

are in place. Do not operate the engine with clips

that are damaged, missing or loose.

Do not attach any other item to the high pressure

•

fuel lines.

Loosened high pressure fuel lines must be

•

replaced. Also removed high pressure fuel lines

must be r

assembly manual, “ Fuel Injection Lines - Install”.

at all clips on the high pressure fuel lines

eplaced. Refer to Disassembly and

See the Se

adjustments.

rvice Manual for repairs and for

i02251260

Engine Starting

Do not use aerosol types of starting aids such as

ether. Such use could result in an explosion and

personal injury.

If a warning tag is attached to the engine start switch

or to the controls DO NOT start the engine or move

the controls. Consult with the person that attached

the warning tag before the engine is started.

Page 14

14 SEBU8119-02

Safety Section

Engine Stopping

All protective

be installed if the engine must be started in order

to perform service procedures. To help prevent an

accident that

around the parts carefully.

Start the eng

from the engine start switch.

Always start

that is described in the Operation and Maintenance

Manual, “Engine Starting” topic in the Operation

Section. Kno

prevent major damage to the engine components.

Knowing the procedure will also help to prevent

personal in

To ensure that the jacket water heater (if equipped)

and/or the l

correctly, check the water temperature gauge

and/or the oil temperature gauge during the heater

operation

Engine exhaust contains products of combustion

which can b

engine and operate the engine in a well ventilated

area. If the engine is started in an enclosed area,

vent t he e

Note: The engine is equipped with a device for cold

starting

conditions, then an extra cold starting aid may be

required. Normally, the engine will be equipped with

the corre

operation.

guards and all protective covers must

is caused by parts in rotation, work

ine from the operator’s compartment or

the engine according to the procedure

wing the correct procedure will help to

jury.

ube oil heater (if equipped) is working

.

e harmful to your health. Always start the

ngine exhaust to the outside.

. If the engine will be operated in very cold

ct type of starting aid for your region of

Stop the engine

during the initial start-up of a new engine or an engine

that has been overhauled.

To stop an electronically controlled engine, cut the

power to the engine and/or shutting off the air supply

to the engine

if an overspeed condition occurs

.

i02234878

Electrical System

Never disconnect any charging unit circuit or battery

circuit cable from the battery when the charging unit

is operating. A spark can cause the combustible

gases that are produced by some batteries to ignite.

To help prevent sparks from igniting combustible

gases that are produced by some batteries, the

negative “−” cable should be connected last from the

external power source to the negative “−” terminal

of the starting motor. If the starting motor is not

equipped with a negative “−” terminal, connect the

cabletotheengineblock.

Check the electrical wires daily for wires that

are loose or frayed. Tighten all loose electrical

connections before the engine is started. Repair all

frayed electrical wires before the engine is started.

See the Operation and Maintenance Manual for

specific starting instructions.

These en

aid in each individual cylinder that heats the intake

air in order to improve starting.

ginesareequippedwithaglowplugstarting

i02234873

Engine Stopping

Stop the engine according to the procedure in

the Operation and Maintenance Manual, “Engine

Stopping (Operation Section)” in order to avoid

overheating of the engine and accelerated wear of

the engine components.

Use the Emergency Stop Button (if equipped) ONLY

in an emergency situation. Do not use the Emergency

Stop Button for normal engine stopping. After an

emergency stop, DO NOT start the engine until the

problem that caused the emergency stop has been

corrected.

Page 15

SEBU8119-02 15

Safety Section

Engine Electronics

Grounding Practices

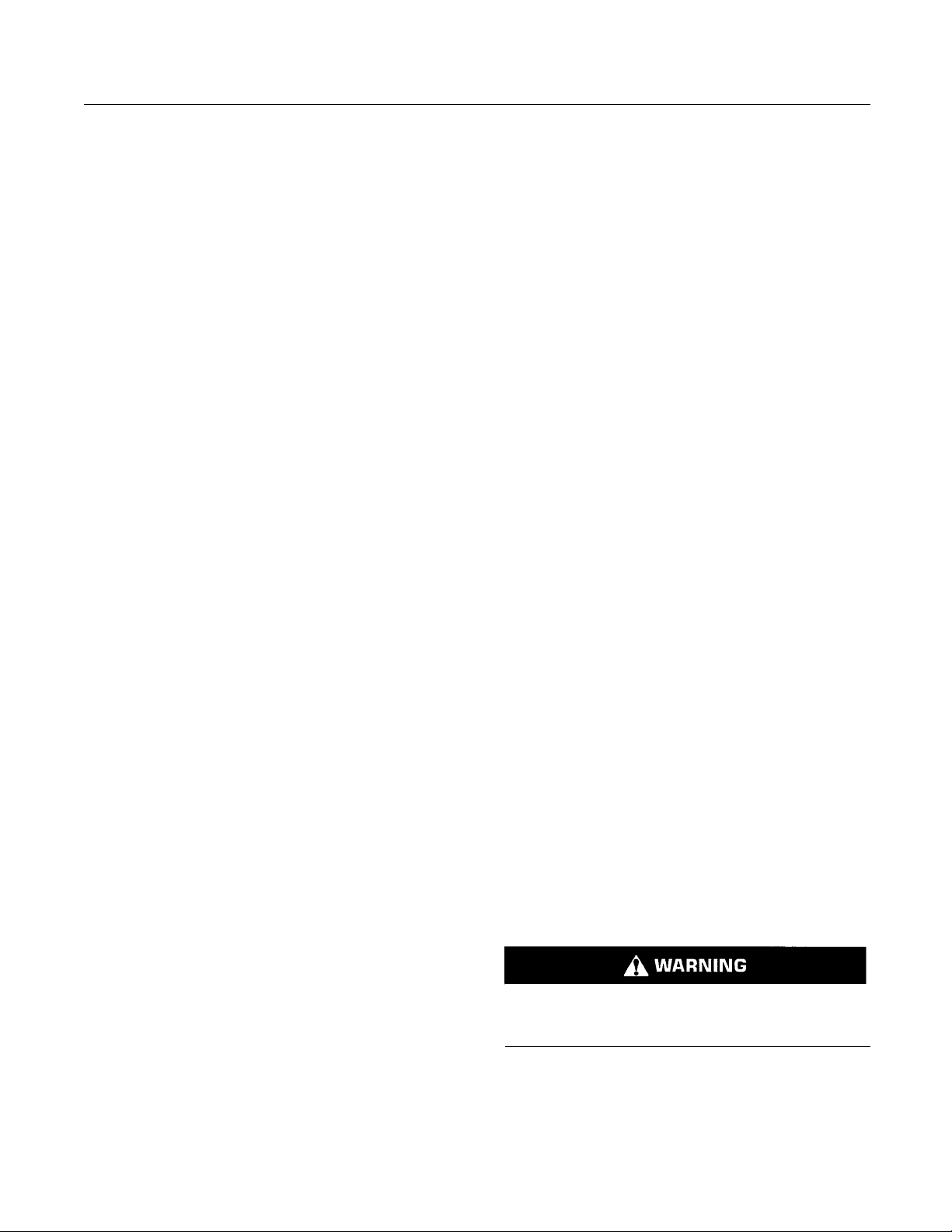

Illustration 13

Typical examp le

(1) Starting motor to engine block

(2) Ground to starting motor

(3) Ground to battery

g01162916

Uncontrolled e

lectrical circuit paths can result in

damage to the crankshaft bearing journal surfaces

and to aluminum components.

Engines that are installed without engine-to-frame

ground straps can be damaged by electrical

discharge.

To ensure that the engine and the engine electrical

systems func

tion correctly, an engine-to-frame

ground strap with a direct path to the battery must be

used. This path may be provided by way of a direct

engine groun

d to the frame.

The connections for the grounds should be tight and

free of corro

sion. The engine alternator must be

grounded to the negative “-” battery terminal with

a wire that is adequate to handle the full charging

current of t

he alternator.

The power supply connections and the ground

connectio

ns for the engine electronics should always

be from the isolator to the battery.

i02650954

Engine Electronics

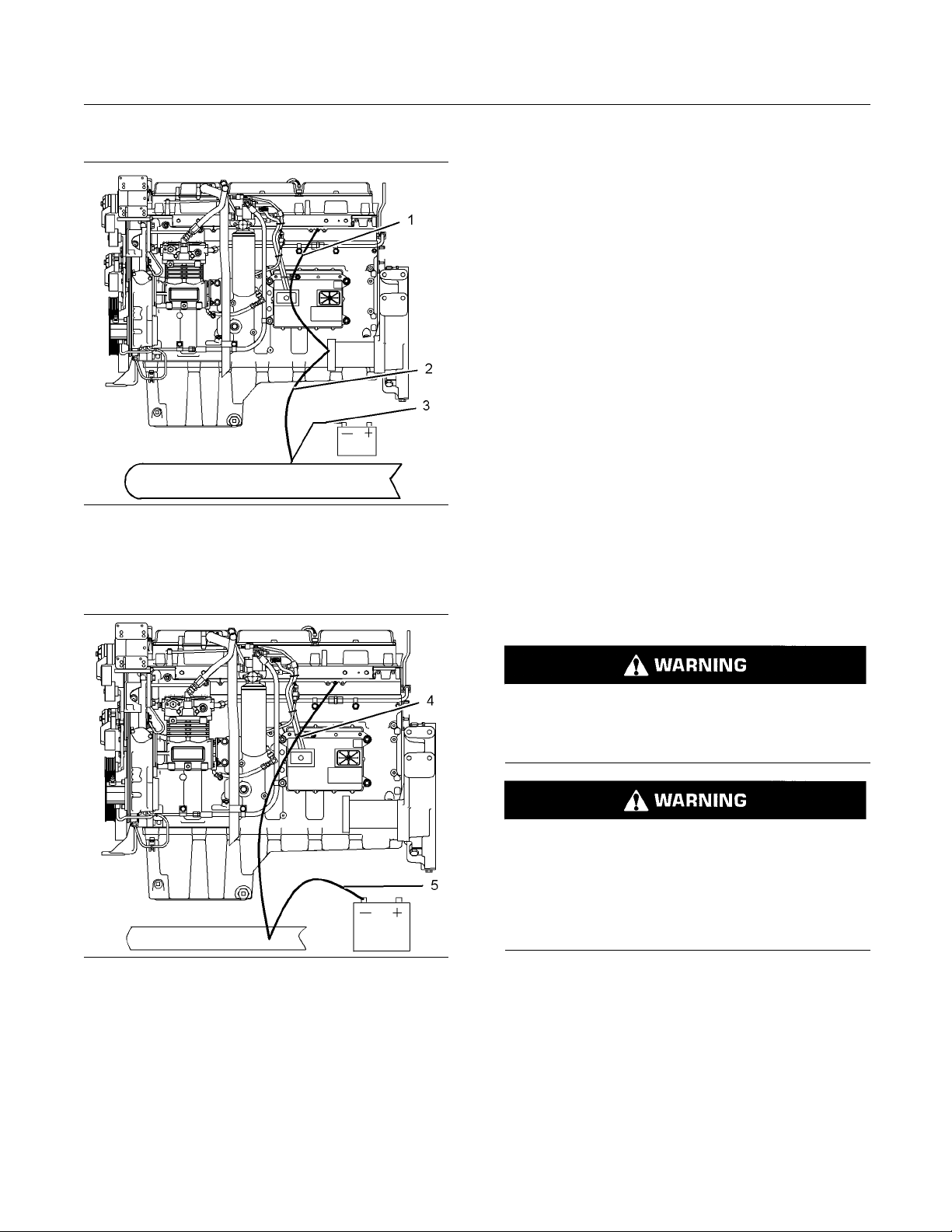

Illustration 14

Typical examp le

(4) Ground to engine

(5) Ground to battery

g01162918

Correct grounding for the engine electrical system

is necessary for optimum engine performance

and reliability. Incorrect grounding will result in

uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

Tampering

with the electronic system ins tallation

or the OEM wiring installation can be dangerous

and could result in personal injury or death and/or

engine da

mage.

Electrical Shock Hazard. The electronic unit injectors use DC voltage. The ECM sends this voltage

to the electronic unit injectors. Do not come in

contact with the harness connector for the electronic unit injectors while the engine is operating.

Failure to follow this instruction could result in

personal injury or death.

This engine has a comprehensive, programmable

Engine Monitoring System. The Electronic Control

Module (ECM) has the ability to monitor the engine

operating conditions. If any of the engine parameters

extend outside an allowable range, the ECM will

initiate an immediate action.

The following actions are available for engine

monitoring control:

Warning

•

Page 16

16 SEBU8119-02

Safety Section

Engine Electronics

Derate

•

Shutdown

•

The following monitored engine operating conditions

have the ability to limit engine speed and/or the

engine power:

Engine Coolant Temperature

•

Engine Oil Pressure

•

Engine Speed/

•

Intake Manifold Air Temperature

•

The Engine Monitoring package can vary for different

engine models and different engine applications.

However, the m

monitoring control will be similar for all engines.

Note: Many of

modules that are available for Perkins Engines will

work in unison with the Engine Monitoring System.

Tog et he r, t

monitoring function for the specific engine application.

Refer to Troubleshooting for more information on the

Engine Moni

Timing

onitoring system and the engine

the engine control systems and display

he two controls will provide the engine

toring System.

Page 17

SEBU8119-02 17

Product Information Section

General Information

Product Information

Section

General Infor mation

i01889424

Welding on Engines with

Electronic Controls

NOTICE

Proper welding procedures are necessary in order

to avoid damage to the engine’s ECM, sensors, and

associated components. When possible, remove the

component from the unit and then weld the component. If removal of the component is not possible,

the following procedure must be followed when you

weld with a unit that is equipped with an Electronic

Engine. The following procedure is considered to be

the safest procedure to weld a component. This procedure should provide a m inimum risk of damage to

electronic components.

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding can

cause damage to the drive train bearings, hydraulic

components, electrical components, and other components.

Clamp the ground cable from the welder to the component that will be welded. Place the clamp as close

as possible to the weld. This will help reduce the possibility of damage.

1. Stop the engine. Turn the switched power to the

OFF position.

2. Disconnect the negative battery cable from the

battery. If a battery disconnect switch is provided,

open the switch.

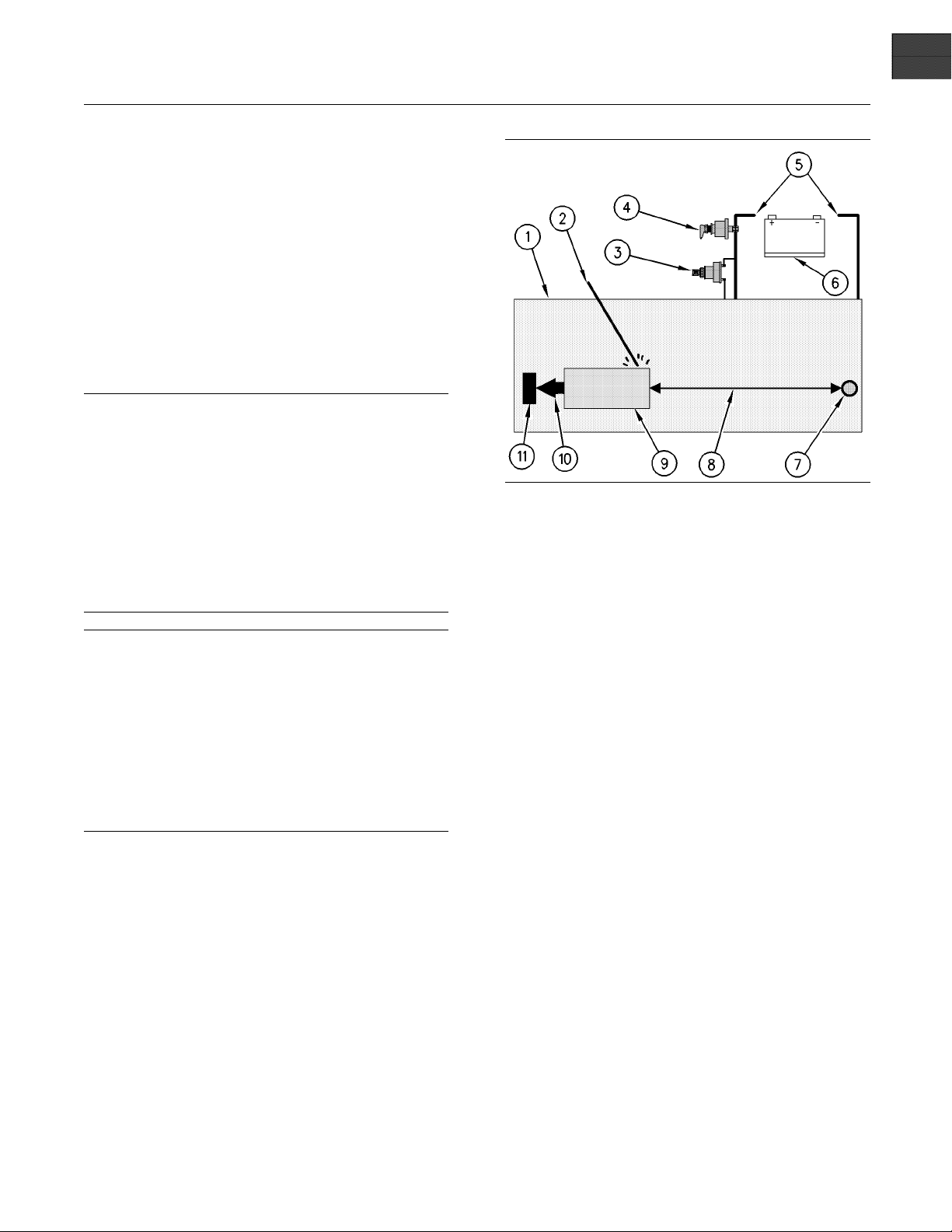

Illustration 15

Use the example above. T he current flow from the welder to

the ground clamp of the welder will not c ause damage to any

associated components.

(1) Engine

(2) Welding rod

(3) Keyswit ch in the OFF position

(4) Battery disconnect switch in the open position

(5) Disconnected battery cables

(6) Battery

(7) Electrical/Electronic component

(8) Maximum distance between the c ompo nent that is being

welded and any electrical/electronic component

(9) The component that is being welded

(10) Current path of the welder

(11) Ground clamp for the welder

4. Connect the welding ground cable directly to the

part that will be welded. Place the ground cable as

close as possible to the weld in order to reduce the

possibility of welding current damage to bearings,

hydraulic components, electrical components, and

ground straps.

Note: If electrical/electronic components are used

as a ground for the welder, or electrical/electronic

components are located between the welder ground

and the weld, current flow from the welder could

severely damage the component.

g00765012

3. Disconnect the J1/P1 connectors from the ECM.

Move the harness to a position that will not allow

the harness to accidentally move back and make

contact with any of the ECM pins.

5. Protect the wiring harness from welding debris

and spatter.

6. Use standard welding practices to weld the

materials.

Page 18

18 SEBU8119-02

Product Information Section

Model Views

Model Views

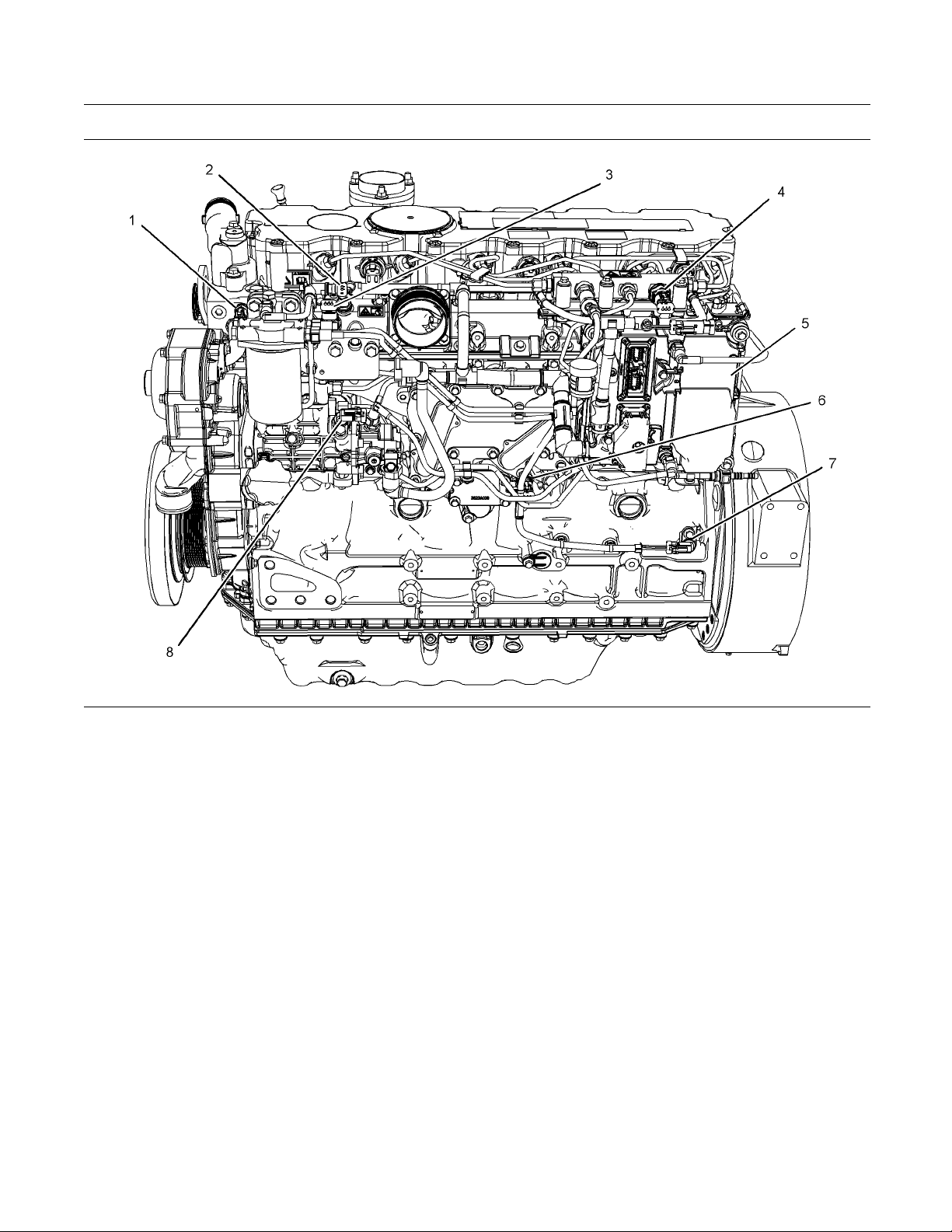

i02786384

Model View Illustrations

The following model views show typical features

of the engine.

engine may appear different from the illustrations.

Due to individual applications, your

Note: Only maj

or components are identified on the

following illustrations.

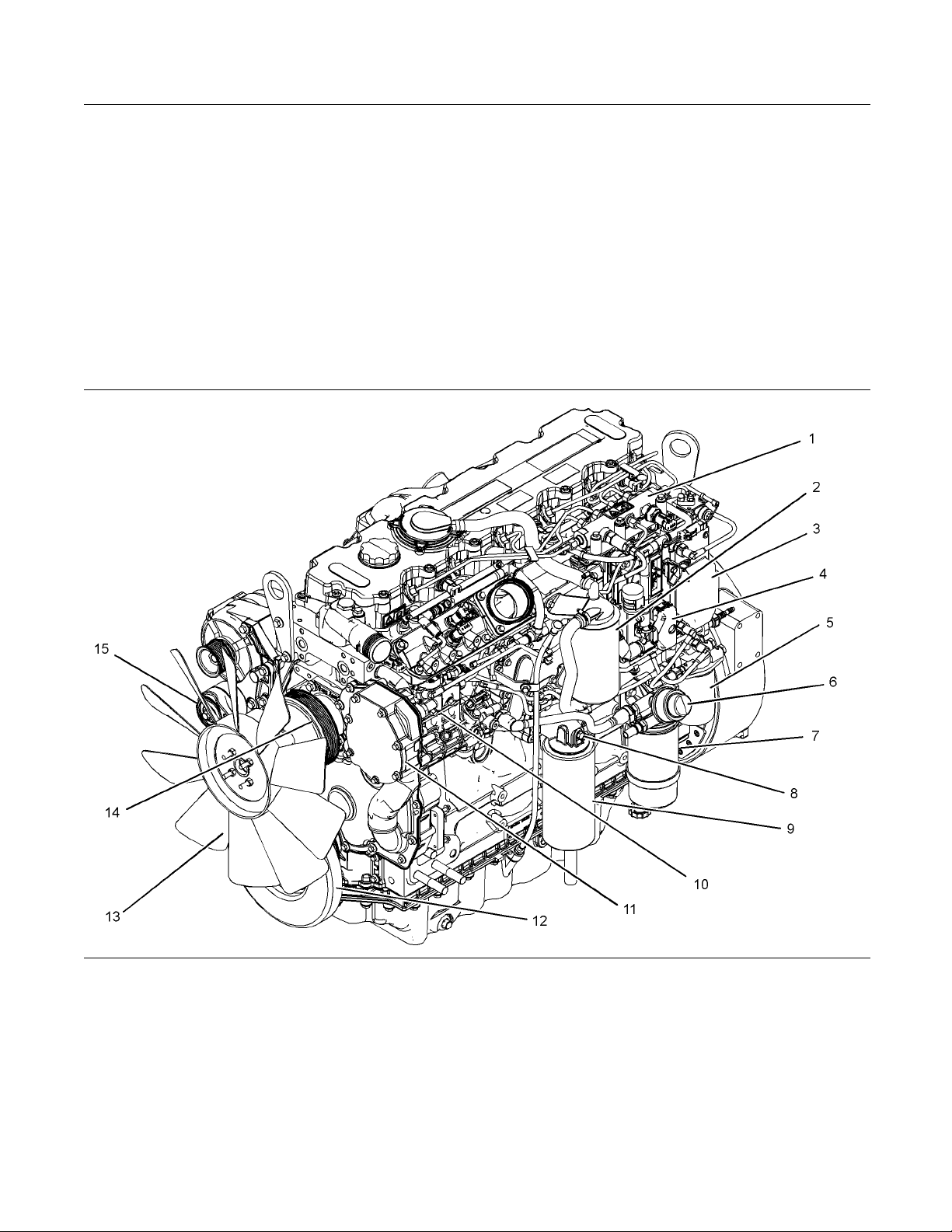

Illustration 1 6

Front left engine view

(1) Fuel manifold (Rail)

(2) Canister for the crankcase breather

(3) Electronic control module

(4) P2 connector

(5) Secondary fuel filter

(6) Hand primer

(7) Pr im ary fue l filter

(8) Oil sampling valve

(9) Oil filter

(10) Fuel pump

g01391892

(11) Water pump

(12) Damper

(13) Fan

(14) Fan pulley

(15) Belt tensioner

Page 19

SEBU8119-02 19

Product Information Section

Model Views

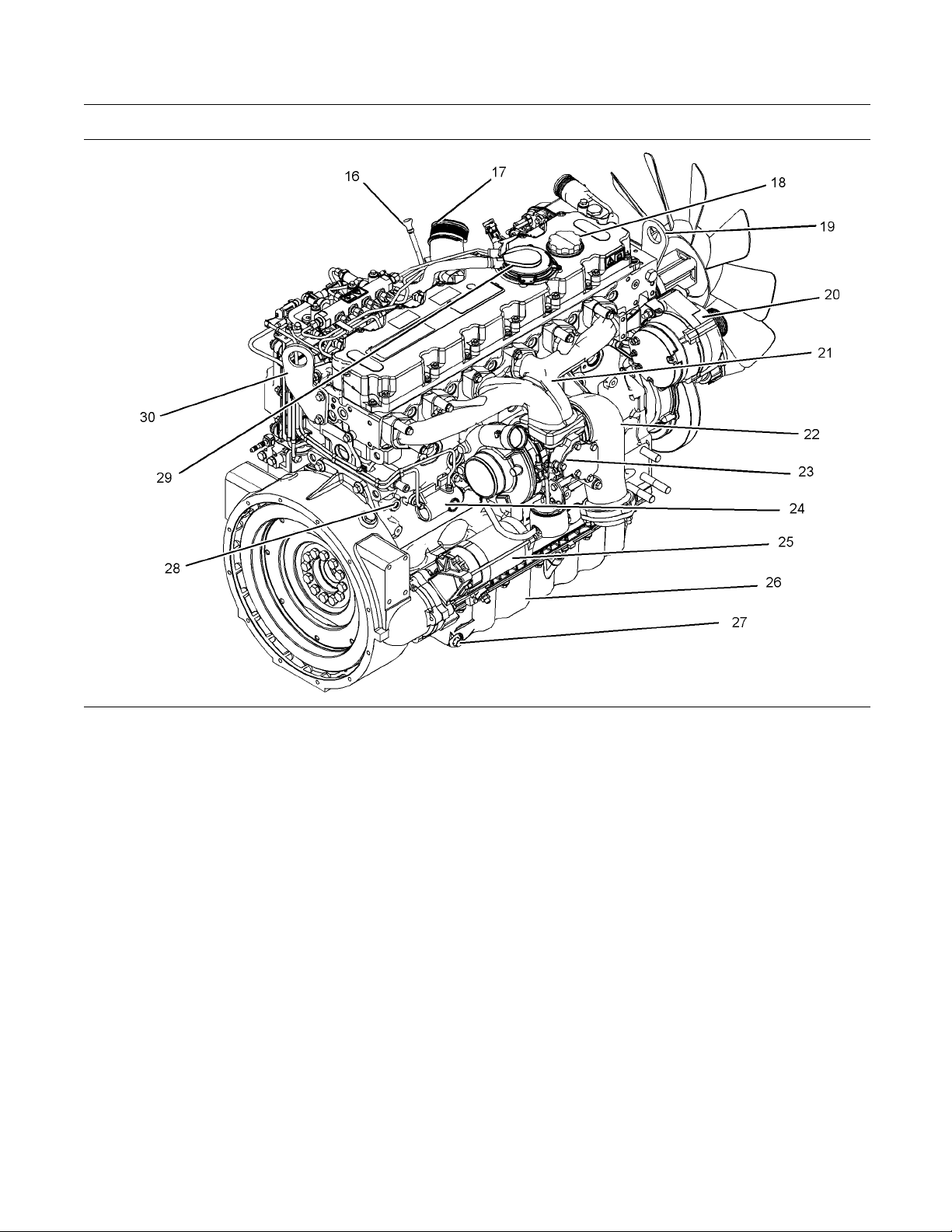

Illustration 1 7

Rear right engine view

(16) Oil gauge

(17) Air intake

(18) Oil filler

(19) Front lifting eye

(20) Alternator

(21) Exhaust manifold

(22) Exhaust elbow

(23) Turbocharger

(24) Wastegate solenoid

(25) Starting motor

i02715685

Engine Description

The 1106 Electronic Engine model PJ is designed

for the following applications: machine and industrial

mobile equipment. The engine is available in the

following type of aspiration:

Turbocharged aftercooled

•

Four stroke cycle

•

In-line 6 cylinder

•

g01391893

(26) Oil pan

(27) Drain plug (oil)

(28) Drain plug or coolant sampling valve

(29) Breather

(30) Rear lifting eye

Engine Specifications

Note: The front end of the engine is opposite the

flywheel end of the engine. The left and the right

sides of the engine are determined from the flywheel

end. The number 1 cylinder is the front cylinder.

Page 20

20 SEBU8119-02

Product Information Section

Model Views

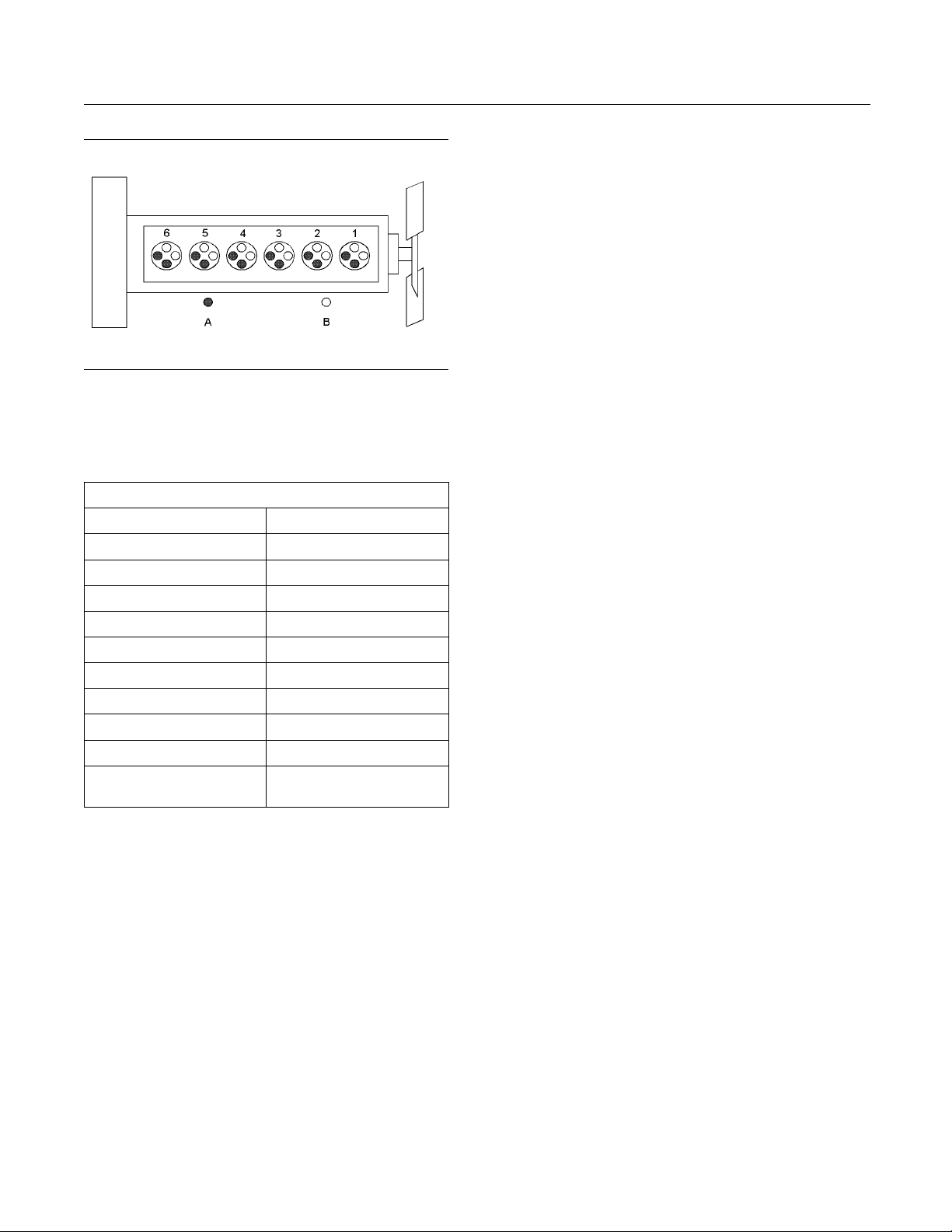

Illustration 18

1106 Electronic Engine model PJ

(A) Exhaust valves

(B) Inlet valves

Table 1

1106 Electronic Engine Model PJ Specifications

Operating Range (rpm)

Number of Cylinders 6 In-Line

Bore

Stroke 127 mm (5.0 inch)

Aspiration

Compression Ratio 16.2:1

Displacement 6.6 L (403 in3)

Firing Order 1-5-3-6-2-4

Rotation (fl

Valve Lash Setting (Inlet) 0.35 mm (0.013 inch)

Valve Lash Setting

(Exhaust)

(1)

The operating rpm is dependent on the engine rating, the

application and the configuration of the throttle.

ywheel end)

900 to 2800

105 mm (4.13 inch)

Turbocharged aftercooled

Counterclo

0.35 mm (0.013 inch)

g01127295

(1)

ckwise

Electronic Engine Features

Automatic air/

•

Torque rise shaping

•

Injection timing control

•

System diagno

•

fuel ratio control

stics

For more information on electronic engine features,

refer to the Op

eration and Maintenance Manual,

“Features and Controls” topic (Operation Section).

Engine Diagnostics

The engine has

that the engine systems are functioning correctly. The

operator will be alerted to the condition by a “Stop or

Warning” lam

horsepower and the vehicle speed may be limited.

Theelectronicservicetoolmaybeusedtodisplay

the diagnos

There are three types of diagnostic codes: active,

logged, and

Most of the diagnostic codes are logged and stored

in the ECM. F

the Operation and Maintenance Manual, “Engine

Diagnostics” topic (Operation Section).

The ECM provides an electronic governor that

controls the injector output in order to maintain the

desired en

Engine Coo

The cooling system consists of the following

component

Gear-driven centrifugal water pump

•

Water temperature regulator which regulates the

•

engine coolant temperature

built-in diagnostics in order to ensure

p. Under certain conditions, the engine

tic codes.

event.

or additional information, refer to

gine rpm.

ling and Lubrication

s:

The engine operating conditions are monitored.

The Electronic Control Module (ECM) controls the

response of the engine to these conditions and to

the demands of the operator. These conditions and

operator demands determine the precise control of

fuel injection by the ECM. The electronic engine

control system provides the following features:

Engine monitoring

•

Engine speed governing

•

Control of the injection pressure

•

Cold start strategy

•

Gear-driven rotor type oil pump

•

Oil cooler

•

The engine lubricating oil is supplied by a rotor type

oil pump.

The engine lubricating oil is cooled and the

engine lubricating oil is filtered. The bypass valve

can provide unrestricted flow of lubrication oil to

the engin

e if the oil filter element should become

plugged.

Page 21

SEBU8119-02 21

Product Information Section

Model Views

Engine efficien

engine performance depend on adherence to proper

operation and maintenance recommendations.

Engine perfor

the use of recommended fuels, lubrication oils, and

coolants. Refer to this Operation and Maintenance

Manual, “Mai

information on maintenance items.

cy, efficiency of emission controls, and

mance and efficiency also depend on

ntenance Interval Schedule” for more

Page 22

22 SEBU8119-02

Product Information Section

Product Identification Information

Product Identification

Information

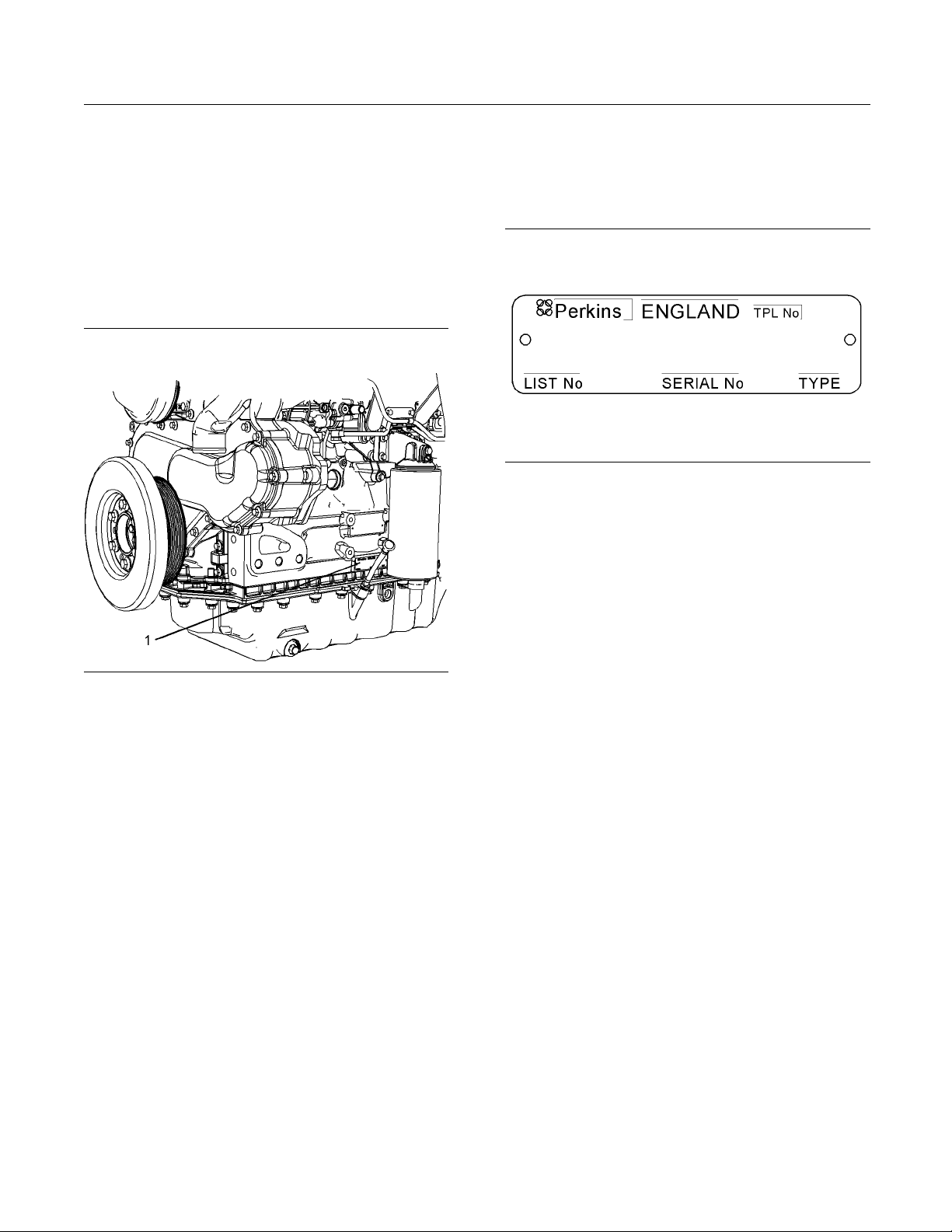

Plate Locations and Film

Locations

i02650956

Serial Number Plate (1)

Theengineserialnumberplateislocatedonthe

left side of the cylinder block to the rear of the front

engine mounting.

on 20

Illustrati

Serial number plate

g01094203

i02164876

Reference Numbers

Illustration 19

Location of the serial number plate

g01331472

Perkins engines are identified by an engine serial

number.

An example of an engine number is PJ*****U000001J.

*****

____________________ The list number for the engine

__________________________________________ Type of engine

PJ

____________________________ Built in the United Kingdom

U

000001

J

___________________________ Engine Serial Number

_____________________________________ Year of Manufacture

Perkins dealers or Perkins distributors need all of

these numbers in order to determine the components

that were included with the engine. This permits

accurate identification of replacement part numbers.

The numbers for fuel setting information for electronic

engines are stored within the flash file. These

numbers can be read by using the electronic service

tool.

Informatio

n for the following items may be needed to

order parts. Locate the information for your engine.

Record the information in the appropriate space.

Makeacopyo

f this list for a record. Keep the

information for future reference.

Record for Reference

_______________________________________________

Engine Mod

Engine Serial number _____________________________________

Engine Low Idle rpm ______________________________________

Engine Ful

Primary Fuel Filter _________________________________________

Water Separator Element ________________________________

Secondary

Lubrication Oil Filter Element ___________________________

Auxiliary Oil Filter Element ________ _______________________

Tot al Lu br

Total Cooling System Capacity _________________________

el

l Load rpm

Fuel Filter Element

_____________________________________

__________________________

ication System Capacity

_____________________

Air Cleaner Element _______________________________________

Page 23

SEBU8119-02 23

Product Information Section

Product Identification Information

Fan Drive Belt _

_____________________________________________

Alternator Belt ______________________________________________

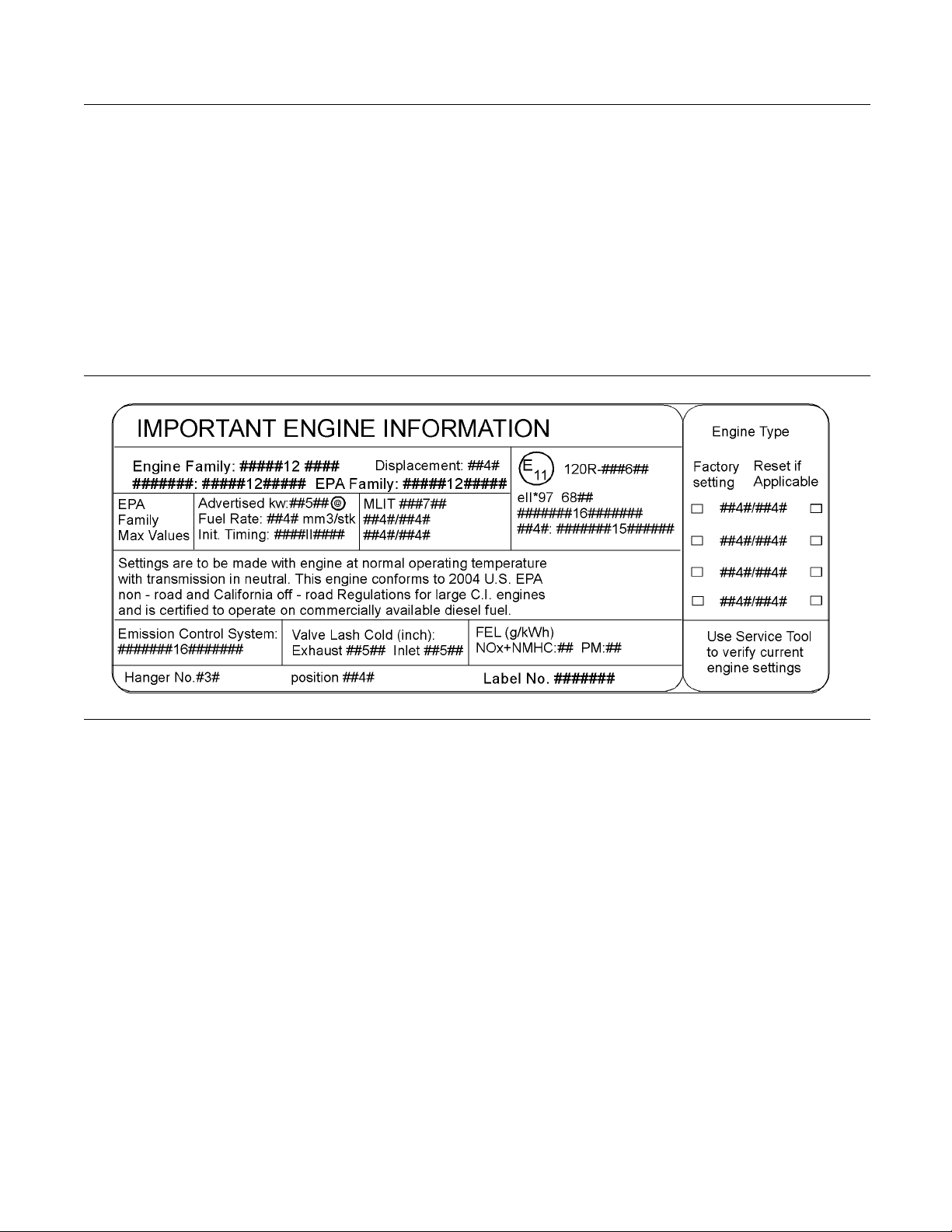

i02894856

Emissions Certification Film

Label for compliant engines

Typical examp

les of emissions labels

Illustration 2 1

g01440937

Page 24

24 SEBU8119-02

Operation Section

Lifting and Storage

Operation Section

Lifting and Storage

Engine Lifting

i02164186

Some removals r

obtain correct balance and safety.

To r e m ov e t h e e

are on the engine.

Lifting eyes a

engine arrangements. Alterations to the lifting eyes

and/or the engine make the lifting eyes and the lifting

fixtures obso

that correct lifting devices are provided. Consult

your Perkins dealer or your Perkins distributor for

information

lifting.

equire lifting the fixtures in order to

ngine ONLY, use the lifting eyes that

re designed and installed for specific

lete. If alterations are made, ensure

regarding fixtures for correct engine

i02308881

Engine Storage

If the engine is not started for a month or longer the

lubricating oil will drain from the cylinder walls and

from the piston rings. Rust can form on the cylinder

walls. Rust on the cylinder walls will cause increased

engine wear and a reduction in engine service life.

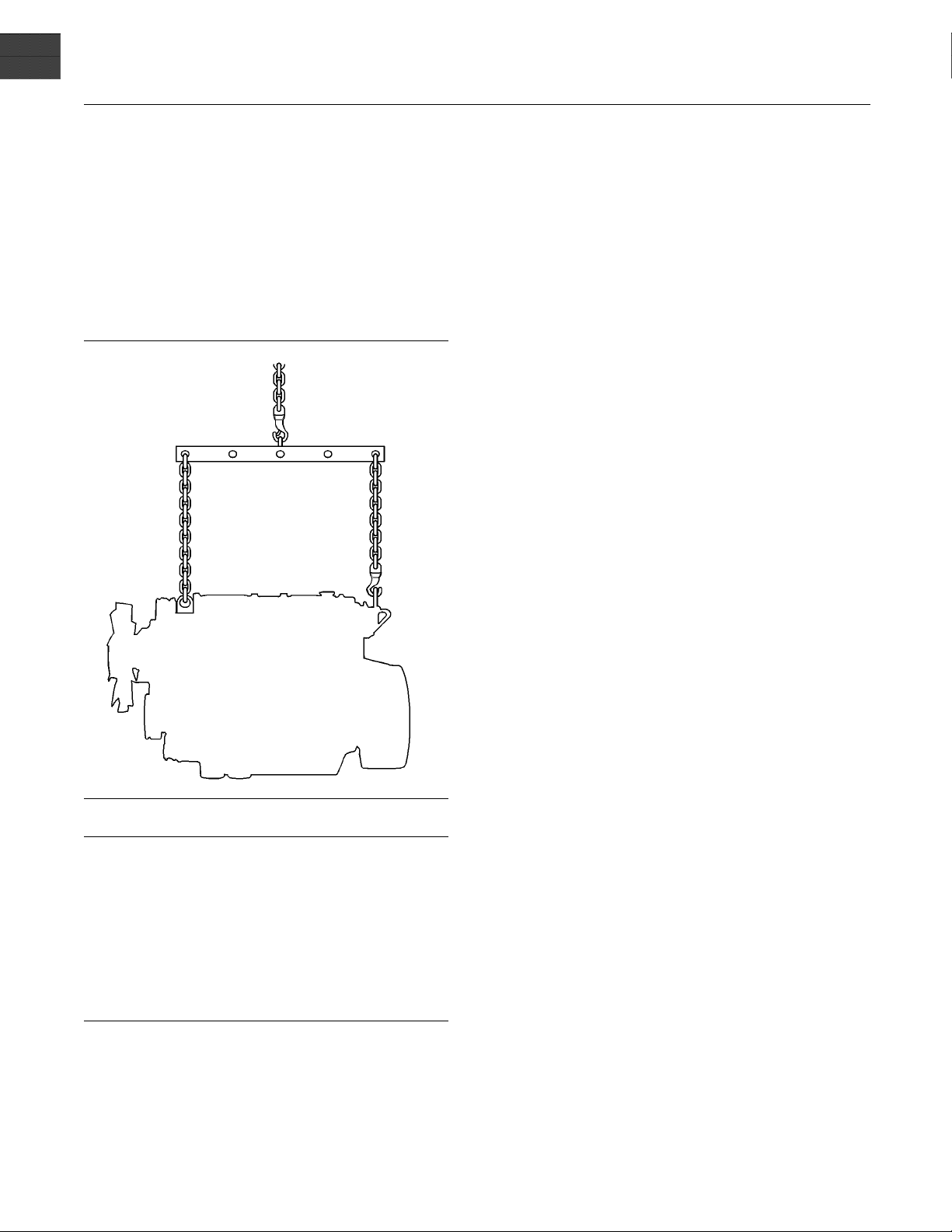

Illustration 22

NOTICE

Never bend the eyebolts and the brackets. Only load

the eyeb

ber that the capacity of an eyebolt is less as the angle

between the supporting members and the object becomes le

When it is necessary to remove a component at an

angle, o

the weight.

Use a ho

an adjustable lifting beam to lift the engine. All

supporting members (chains and cables) should be

parall

be perpendicular to the top of the object that is being

lifted.

olts and the brackets under tension. Remem-

ss than 90 degrees.

nly use a link bracket that is properly rated for

ist to remove heavy components. Use

el to each other. The chains and cables should

g01097527

Perkins are not responsible for damage which may

occur when an engine is in storage after a period in

service.

Your Perkins dealer or your Perkins distributor can

assist in preparing the engine for extended storage

periods.

If an engine is out of operation and if use of the

engine is not planned for more than one month, a

complete protection procedure is recommended.

To help prevent excessive engine wear and corrosion

to the engine, use the following guidelines:

1. Completely clean the outside of the engine.

2. Ensure that the vehicle is on level ground.

3. Drain the fuel system completely and refill

thesystemwithpreservativefuel.1772204

POWERPARTLay-Up1canbemixedwith

the normal fuel in order to change the fuel into

preservative fuel.

If preservative fuel is not available, the fuel system

can be filled with normal fuel. This fuel must be

discarded at the end of the storage period together

with the fuel filter elements.

Page 25

SEBU8119-02 25

Operation Section

Lifting and Storage

Personal injury can result from hot coolant. Any

contact with hot coolant or with steam can cause

severe burns. Allow cooling system components

to cool before the cooling system is drained.

4. Drain and refill the cooling system. Refer to this

Operation and Maintenance Manual, “Cooling

System coolant (Commercial Heavy Duty Change or Cooling System coolant (ELC) Change” for information on draining, flushing and

refilling the cooling system.

Contact with h igh pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

5. Operate the engine until the engine reaches

normal operating temperature. Stop the engine.

After the engine has stopped, you must wait for 60

seconds in order to allow the fuel pressure to be

purged from the high pressure fuel lines before any

service or repair is performed on the engine fuel

lines. If necessary, perform minor adjustments.

Repair any leaks from the low pressure fuel

system and from the cooling, lubrication or air

systems. Replace any high pressure fuel line that

has leaked. Refer to Disassembly and assembly

Manual, “Fuel Injection Lines - Install”.

6. Drain the lubricating oil from the oil pan.

Renew the canister(s) of the lubricating oil filter.

9. If equipped, re

element. Seal the end of the breather pipe.

10. Remove the val

1762811 POWERPART Lay-Up 2 around the

rocker shaft assembly.

11. Remove the glow plugs. Slowly rotate the

crankshaft. By checking the valves, position the

piston at BDC

Lay-Up 2 for two seconds into the cylinder bore.

This procedure must be carried out on each

cylinder.

12. Install the glow plugs. Install the valve mechanism

cover.

13. Remove the pipes that are installed between

the air filte

Spray 1762811 POWERPART Lay-Up 2 into

the turbocharger. The duration of the spray is

printed on

with waterproof tape.

14. Remove the

the turbocharger. Spray 1762811 POWERPART

Lay-Up 2 into the turbocharger. The duration of

the spray i

turbocharger with waterproof tape.

15. Seal the ve

with waterproof tape.

16. Remove the

belt into storage.

17. In order t

of the engine, spray the engine with 1734115

POWERPART Lay-Up 3. Do not spray the area

inside th

e alternator.

place the crankcase breather

ve mechanism cover. Spray

.Spray1762811 POWERPART

r assembly and the turbocharger.

the container. Seal the turbocharger

exhaust pipe from the output side of

s printed on the container. Seal the

nt of the fuel tank or the fuel filler cap

alternator drive belt and put the drive

o prevent corrosion to the outside

Fill the oil pan to the Full Mark on the engine oil

level gauge with new, clean lubricating oil. Add

1762811 POWERPARTLay-Up2totheoilin

order to protect the engine against corrosion. If

1762811 POWERPART Lay-Up 2 is not available,

use a preservative of the correct specification

instead of the lubricating oil. If a preservative is

used, this must be drained completely at the end

of the storage period and the oil pan must be

refilled to the correct level with normal lubricating

oil.

7. Operate the engine in order to circulate engine oil.

8. Disconnect the battery. Ensure that the battery is

in a fully charged condition. Protect the terminals

against corrosion. 1734115 POWERPART

Lay-Up 3 can be used on the terminals. Put the

battery into safe storage.

Page 26

26 SEBU8119-02

Operation Section

Gauges and Indicators

Gauges and Ind icators

i02717240

Gauges and Indicators

Your engine m

the gauges that are described. For more information

about the gauge package, see the OEM information.

Gauges provide indications of engine performance.

Ensure that the gauges are in good working order.

Determine th

the gauges over a period of time.

Noticeable c

potential gauge or engine problems. Problems may

also be indicated by gauge readings that change

even if the r

Determine and correct the cause of any significant

change in the readings. Consult your Perkins dealer

or your Per

Some engine applications are equipped with Indicator

Lamps. Ind

aid. There are two lamps. One lamp has an orange

lens and the other lamp has a red lens.

These indicator lamps can be used in two ways:

The indica

•

current operational status of the engine. The

indicator lamps can also indicate that the engine

has a faul

via the ignition switch.

The indic

•

diagnostic codes. This system is activated by

pressing the Flash Code button.

Refer to the Troubleshooting Guide, “Indicator

Lamps” for further information.

If no oil pressure is indicated, STOP the engine. If

maximum coolant temperature is exceeded, STOP

the engine. Engine damage can result.

SAE10W40is350to450kPa(50to65psi)atrated

rpm.

A lower oil pressure is normal at low idle. If the load

is stable and the gauge reading changes, perform

the following procedure:

ay not have the same gauges or all of

e normal operating range by observing

hanges in gauge readings indicate

eadings are within specifications.

kins distributor for assistance.

icator lamps can be used as a diagnostic

torlampscanbeusedtoidentifythe

t. This system is automatically operated

ator lamps can be used to identify active

NOTICE

Engine Oil Pressure – The oil pressure

should be greatest after a cold engine is

started. The typical engine oil pressure with

1. Remove the load

2. Stop the engine.

3. Check and maintain the oil level.

Jacket Water C

Typical temperature range is 83° to 95°C

(181.4° to 171°F). The maximum allowable

temperature a

system at 48 kPa (7 psi) is 103 °C (217.4 °F). Higher

temperatures may occur under certain conditions.

The water tem

to load. The temperature reading should never

exceed 7 °C (44.6 °F) below the boiling point for the

pressurized

A 100 kPa (14.5 psi) radiator cap may be installed on

the cooling system. The temperature of this cooling

system must n

If the engine is operating above the normal range

and steam be

procedure:

1. Reduce the l

2. Determine if the engine must be shut down

immediatel

reducing the load.

3. Inspect the

load, the engine is running at high idle. The engine is

running at

lever is at the full throttle position with maximum

rated load.

To help prevent engine damage, never exceed the

high idle rpm. Overspeeding can result in serious

damage to the engine. Operation at speeds exceeding high idle rpm should be kept to a minimum.

indicator should be to the “+” side of “0” (zero).

is in the “on” position.

system that is being used.

Tachometer – This gauge indicates engine

speed (rpm

ismovedtothefullthrottlepositionwithout

thefullloadrpmwhenthethrottlecontrol

Ammeter – This gauge indicates the

amount of charge or discharge in the

battery charging circuit. Operation of the

Fuel Level – This gauge indicates the fuel

level in the fuel tank. The fuel level gauge

operates when the “START/STOP” switch

.

oolant Temperature –

t sea level with the pressurized cooling

perature reading may vary according

ot exceed 112 °C (233.6 °F).

comes apparent, perform the following

oad and the engine rpm.

y or if the engine can be cooled by

cooling system for leaks.

). When the throttle control lever

NOTICE

Page 27

SEBU8119-02 27

Operation Section

Gauges and Indicators

Service Hour Meter – The gauge indicates

total operating hours of the engine.

Page 28

28 SEBU8119-02

Operation Section

Features and Controls

Features and Controls

i02651062

Monitoring System

If the Shutdown mode has been selected and the

warning indi

take as little as 20 seconds from the time the warning indic ator is activated. Depending on the application, s

avoid personal injury. The engine can be restarted

following shutdown for emergency maneuvers, if

necessary.

The Engine Monitoring System is not a guarantee

against catastrophic failures. Programmed delays

and derate schedules are designed to minimize false

alarms and provide time for the operator to stop the

engine.

The following parameters are monitored:

Coolant temperature

•

Intake air temperature

•

Engine intake manifold pressure

•

Engine Oil pressure

•

Pressure in the fuel rail

•

cator activates, engine shutdown may

pecial precautions should be taken to

NOTICE

“Warning”

The “Warning” lamp and the warning signal (orange

lamp) turn “ON

continuously in order to alert the operator that one or

more of the engine parameters is not within normal

operating ra

” and the warning signal is activated

nge.

“Warning/Derate”

The “Diagnostic” lamp turns “ON” and the warning

signal (red lamp) is activated. After the warning, the

engine power

begin to flash when the derating occurs.

Theenginewi

preset operational limits. The engine derate is

achieved by restricting the amount of fuel that is

available f

reduction of fuel is dependent on the severity of the

fault that has caused the engine derate, typically up

to a limit o

predetermined reduction in engine power.

“Warning/

The “Diagnostic” lamp turns “ON” and the warning

signal (re

the engine power will be derated. The engine will

continue at the rpm of the set derate until a shutdown

of the engi

after a shutdown for use in an emergency.

A shutdow

as 20 seconds. The engine can be restarted after

a shutdown for use in an emergency. However,

the cause

Theenginemayshutdownagaininaslittleas20

seconds.

will be derated. The warning lamp will

ll be derated if the engine exceeds

or each injection. The amount of this

f 50%. This reduction in fuel results in a

Derate/Shutdown”

d lamp) is activated. After the warning,

ne occurs. The engine can be restarted

n of the engine may occur in as little

of the initial shutdown may still exist.

Engine speed/timing

•

Programmable O ptions and

Systems Operation

If the Warning/Derate/Shutdown mode has been

selected and the warning indicator activates,

bring the engine to a stop whenever possible. Depending on the application, special precautions

should be taken to avoid personal injury.

The engine can be programmed to the following

modes:

If there is a signal for low oil pressure or for coolant

temperature, there will be a two second delay in

order to

For each of the programmed modes, refer to

Trouble

information on Indicator Lamps.

For m ore

your Perkins dealer or your Perkins distributor.

verify the condition.

shooting , “Indicator Lamps” for more

information or assistance for repairs, consult

Page 29

SEBU8119-02 29

Operation Section

Features and Controls

i02296746

Monitoring System

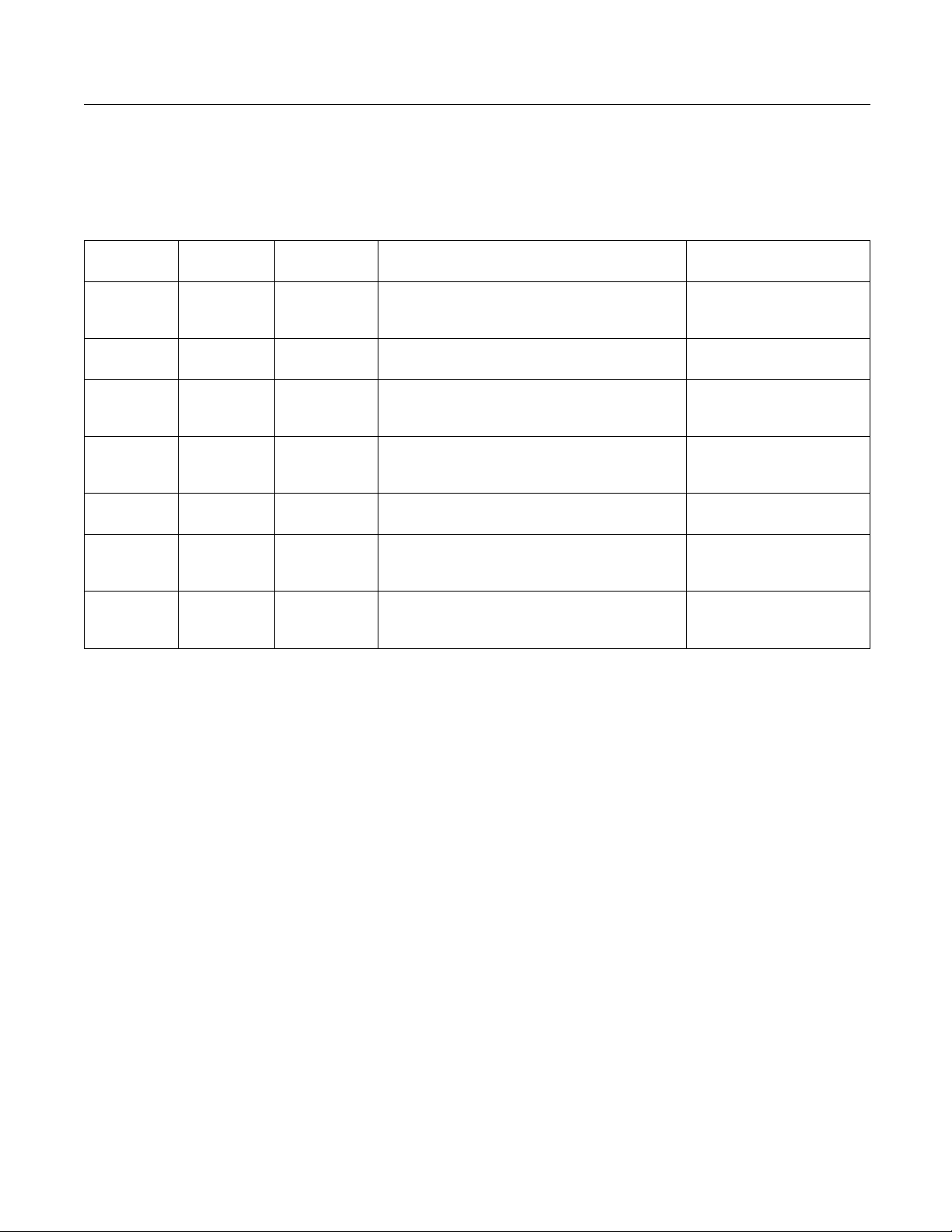

Table 2

Warning

Lamp

ON ON

OFF OFF

ON OFF

ON FLASHING

FLASHING OFF

FLASHING FLASHING

ON ON

Shutdown

Lamp

Lamp Status Description of lamp status Engine Status

Lamp check When the engine start switch is turned to the

“ON” position both lamps w ill illuminate for 2

seconds only.

No faults There are no active diagnostic faults.

Active

diagnostic

fault

Active

diagnostic

fault

Warning One or more of the engine protection values

Derate and

warning

Engine

shutdown

An active diagnostic fault has been detected.

A serious active diagnostic fault has been

detected and an engine derate has been

invoked.

has been exceeded.

One or more of the engine protection values

has been exceeded.

One or more of the engine protection values has

been exceeded or a serious active diagnostic

fault has b

een detected.

The engine has not been

started.

Theengineisrunning

normally.

Theengineisrunning

normally.

Theengineisrunning

but the engine has been

derated.

Theengineisrunning

normally.

Theengineisrunning

but the engine has been

derated.

The engine is shutdown or

shutdown is imminent.

i02788240

Sensors and Electrical

Components

Sensor Locations

tion 23 shows the typical locations of the

Illustra

sensors on the engine. Specific engines may appear

different from the illustration due to differences in

applicat

Module (ECM) is illustrated.

ions. The location of the Electronic Control

Page 30

30 SEBU8119-02

Operation Section

Features and Controls

Illustration 2 3

(1) Coolant tempe rature sensor

(2) Intake manifold air tem perature sensor

(3) Intake manifold pressure sensor

(4) Fuel pressure sensor

(5) Electronic control mod ule (ECM)

(6) Oil pressure sensor

g01392818

(7) Primary pos ition sensor

(8) Secondary position sensor

Page 31

SEBU8119-02 31

Operation Section

Features and Controls

Illustration 2 4

(1) Coola

(2) Intak

nt temperature sensor

e manifold air temperature sensor

e manifold pressure sensor

(3) Intak

(4) Fuel p

ressure sensor

ronic control module (ECM)

(5) Elect

g01330220

Illustration 2 5

(6) Engine oil pressure sensor (7) Primary speed/timing sensor (8) Secondary speed/timing sensor

g01330325

Page 32

32 SEBU8119-02

Operation Section

Features and Controls

Illustration 2

andtheECMinpositionontheengine.

4 and illustration 25 shows the sensors

Failure of Sensors

All Sensors

A failure of any of the sensors may be caused by one

of the followi

Sensor output is open.

•

Sensor output is shorted to “- battery” or “+ battery”.

•

Measured read

•

specification.

ng malfunctions:

ing of the sensor is out of the

Programmable Monitoring System

(PMS)

The Programmable Monitoring System determines

the level of a

Module (ECM) (5) in response to a condition that can

damage the engine. These conditions are identified

by the ECM fr

the following sensors.

ction that is taken by the Engine Control

om the signals that are produced from

Failure of the C

oolant Temperature

Sensor

The ECM (5) wil

temperature sensor. The diagnostic lamp will warn the

operator about the status of the coolant temperature

sensor. A fai

will not cause a shutdown of the engine or any

horsepower change. In order to check the correct

operation of

“Engine Temperature Sensor Circuit - Test”.

l detect a failure of the coolant

lure of the coolant temperature sensor

the sensor, refer to Troubleshooting,

Intake Manifold Air Temperature

Sensor 2

The intake manifold air temperature sensor measures

the intake a

ECM (5). The intake manifold air temperature sensor

is also used by the ECM to determine initiation of the

Cold Start

In order to check the correct operation of the sensor,

refer to Tr

Circuit - Test”.

ir temperature. A signal is sent to the

Strategy.

oubleshooting, “EngineTemperature Sensor

Intake Manifold Pressure Sensor 3

Coolant Tem

•

Intake manifold Air Temperature Sensor

•

Intake manifold Pressure Sensor

•

Fuel Pressu

•

Engine Oil Pressure Sensor

•

Primary Speed/Timing Sensor

•

Secondary S

•

Coolant Tem

The coolant temperature sensor monitors engine

coolant tem

indicate a high coolant temperature through a relay

or a lamp. The coolant temperature sensor is used

by the ECM t

Condition.

perature Sensor

re Sensor

peed/Timing Sensor

perature Sensor 1

perature. The output of the ECM (5) can

o determine initiation of the Cold Start

The intake

pressure in the manifold. A signal is sent to the ECM

(5).

manifold pressure sensor measures

Fuel Pressure Sensor 4

The fuel pressure sensor measures the fuel pressure

in the fuel manifold. A signal is sent to the ECM (5).

Electronic Control Module 5

The ECM is the control computer of the engine. The

ECM provides power to the electronics. The ECM

monitors

engine. The ECM acts as a governor in order to

control the speed and the power of the engine.

The ECM adjusts injection timing and fuel pressure

for the best engine performance, the best fuel

economy

Engine O

The engine oil pressure sensor is an absolute

pressur

pressure in the main oil gallery. The engine oil

pressure sensor detects engine oil pressure for

diagno

sends a signal to the ECM (5).

data that is input from the sensors of the

and the best control of exhaust emissions.

il Pressure Sensor 6

e sensor that measures the engine oil

stic purposes. The engine oil pressure sensor

Page 33

SEBU8119-02 33

Operation Section

Features and Controls

Low Oil Pressur

The setpoint for the low pressure warning is

dependent upo

active and logged only if the engine has been running

for more than 8 seconds.

e Warning

n the engine speed. The fault will be

Very Low Oil Pressure Warning

The very low oi

upon the engine speed. If the DERATE mode of the

engine monitoring system is selected, the ECM (5)

will derate t

will be limited.

Failure of th

The ECM (5) will detect failure of the engine oil

pressure sen

about the status of the engine oil pressure sensor.

The engine oil pressure related strategies will be

disabled in

pressure sensor. A failure of the engine oil pressure

sensor will not cause a shutdown of the engine or

any horsep

operation of the sensor, refer to Troubleshooting, “5

Volt Sensor Supply Circuit - Test”.

l pressure setpoint is dependent

he engine power. The engine horsepower

e Engine Oil Pressure Sensor

sor. The diagnostic lamp warns the user

the event of a failure of the engine oil

ower change. In order to check the correct

Primary Speed/Timing Sensor 7

If the ECM (5) does not receive a signal from the

primary speed/timing sensor , the “DIAGNOSTIC”

lamp will i

logged in the ECM memory.

If the ECM

speed/timing sensor (7), the ECM will read the signal

from the secondary speed/timing sensor (8). The

ECM conti

is a signal from both sensors.

ndicate a diagnostic fault code which will be

does not receive a signal from the primary

nually checks in order to determine if there

Secondary Speed/Timing Sensor 8

The signal from the secondary speed/timing sensor

is used by the ECM (5) on engine start-up in order

to check the stroke of the pistons. The secondary

speed/timing sensor may be used by the ECM

in order to operate the engine if the primary

speed/timing sensor is faulty.

In order to check the correct operation of the sensor,

refer to Troubleshooting, “Engine speed/Timing

sensor-Test”.

i02858345

Engine Shutoffs and E ngine

Alarms

Shutoffs

The shutoffs are electrically operated or mechanically

operated. The electrically operated shutoffs are

controlled by the ECM.

Shutoffs are set at critical levels for the following

items:

Operating temperature

•

Operating pressure

•

Operating level

•

Operating rpm

•

The particular shutoff may need to be reset before

theenginewillstart.

Intermi

engine control.

Failure

ttent failure of the sensors will cause erratic

of the Primary Speed/Timing

Sensor

Correct

sensor is essential. Software in the ECM protects

against reverse running of the engine. If the primary

speed/

protection against reverse running. In some

applications, it is possible for the transmission to

run the

engine immediately. Turn the keyswitch to the “OFF”

position.

In order to check the correct operation of the sensor,

refer to Troubleshooting, “Engine speed/Timing

senso

operation of the primary speed/timing

timing sensor fails there is no automatic

engine in reverse. In this event, Stop the

r-Test”.

NOTICE

Always determine the cause of the engine shutdown.

Make necessary repairs before attempting to restart

the engine.

Be familiar with the following items:

Types and locations of shutoff

•

Conditions which cause each shutoff to function

•

The resetting procedure that is required to restart

•

the engine

Alarms

The alarms are electrically operated. The operation

of the alarms are controlled by the ECM.

Page 34

34 SEBU8119-02

Operation Section

Features and Controls

The alarm is ope

When the sensor or the switch is activated a signal

is sent to the ECM. An event code is created by

the ECM. The EC

illuminate the lamp.

Your engine m

sensors or switches:

Coolant leve

indicates when the coolant level is low.

Coolant temp

sensor indicates high jacket water coolant

temperature.

Intake manifold air temperature – The intake

manifold air temperature sensor indicates high intake