Page 1

This document is printed from SPI². Not for RESALE

Troubleshooting

KENR6201-01

February 2010

1106D El

(EPG)

PJ (Engine)

ectric Power Generation

Page 2

This document is printed from SPI². Not for RESALE

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

This document is printed from SPI². Not for RESALE

KENR6201-01 3

Table of Contents

Table of Contents

Troubleshooting Section

Electronic Troubleshooting

System Overview .................................................... 5

Glossary .................................................................. 7

Electronic Service Tools ......................................... 11

Indicator Lamps .................................................... 13

Replacing the ECM ............................................... 16

Self-Diagnostics .................................................... 17

Sensors and Electrical Connectors ....................... 17

Engine Wiring Information .................................... 21

ECM Harness Connector Terminals ..................... 24

Programming Parameters

Programming Parameters ..................................... 26

Test ECM Mode .................................................... 26

Factory Passwords ............................................... 26

Flash Programming .............................................. 27

Injector Trim File ................................................... 27

Speed Demand Input Setup ................................. 28

Customer Specified Parameters

Customer Specified Parameters ........................... 31

Customer Specified Parameters Table ................. 34

Customer Specified Parameters Worksheet ......... 35

System Configuration Parameters

System Configuration P arameters ........................ 36

Troubleshooting without a Diagnostic Code

Alternator Noise .................................................... 37

Alternator Will Not Charge .................................... 37

Battery .................................................................. 38

Can Not Reach Top Engine RPM ......................... 38

Coolant in Engine Oil ............................................ 40

Coolant Temperature Is Too High ......................... 41

ECM Will Not Accept Factory Passwords ............. 42

ECM Will Not Communicate with Other Systems or

Display Modules .................................................. 43

Electronic Service Tool Will Not Communicate with

ECM ................................ .................................... 43

Engine Cranks but Will Not Start .......................... 44

Engine Has Early Wear ........................................ 48

Engine Misfires, Runs Rough or Is Unstable ........ 49

Engine Oil in Cooling System ............................... 50

Engine Vibration ................................................... 51

Engine Will Not Crank ........................................... 52

Excessive Black Smoke ........................................ 53

Excessive Engine Oil Consumption ...................... 55

Excessive Fuel Consumption ............................... 56

Excessive Valve Lash ........................................... 58

Excessive White Smoke ....................................... 58

Intake Air Temperature Is Too High ...................... 59

Intermittent Engine Shutdown ............................... 61

Intermittent Low Power or Power Cutout .............. 62

Low Engine Oil Pressure ...................................... 63

Low Power ............................................................ 64

Mechanical Noise (Knock) in Engine .................... 66

Noise Coming from Cylinder ................................. 67

Troubleshooting with a Diagnostic Code

Diagnostic Cod

CID 0001 FMI 02 .................................................. 70

CID 0001 FMI 05 .................................................. 70

CID 0001 FMI 06

CID 0001 FMI 07 .................................................. 71

CID 0002 FMI 02 .................................................. 71

CID 0002 FMI 0

CID 0002 FMI 06 .................................................. 72

CID 0002 FMI 07 .................................................. 73

CID 0003 FMI

CID 0003 FMI 05 .................................................. 73

CID 0003 FMI 06 .................................................. 74

CID 0003 FMI

CID 0004 FMI 02 .................................................. 75

CID 0004 FMI 05 .................................................. 75

CID 0004 FM

CID 0004 FMI 07 .................................................. 76

CID 0005 FMI 02 .................................................. 76

CID 0005 FM

CID 0005 FMI 06 .................................................. 77

CID 0005 FMI 07 .................................................. 78

CID 0006 F

CID 0006 FMI 05 .................................................. 78

CID 0006 FMI 06 .................................................. 79

CID 0006 F

CID 0041 FMI 03 .................................................. 80

CID 0041 FMI 04 .................................................. 80

CID 0091

CID 0100 FMI 03 .................................................. 81

CID 0100 FMI 04 .................................................. 81

CID 0100

CID 0110 FMI 03 ................................................... 82

CID 0110 FMI 04 ................................................... 82

CID 016

CID 0168 FMI 01 .................................................. 83

CID 0168 FMI 02 .................................................. 84

CID 01

CID 0172 FMI 04 .................................................. 85

CID 0190 FMI 08 .................................................. 85

CID 02

CID 0253 FMI 02 .................................................. 86

CID 0261 FMI 11 ................................................... 86

CID 0

CID 0262 FMI 04 .................................................. 87

CID 0268 FMI 02 .................................................. 87

CID 0

CID 0526 FMI 05 .................................................. 88

CID 0526 FMI 06 .................................................. 88

CID

CID 1779 FMI 05 .................................................. 89

CID 1779 FMI 06 .................................................. 89

CID

CID 1785 FMI 03 .................................................. 90

CID 1785 FMI 04 .................................................. 90

CI

CID 1797 FMI 03 .................................................. 91

CID 1797 FMI 04 .................................................. 92

CI

CID 2246 FMI 06 .................................................. 92

roubleshooting with an Event Code

T

Event Codes ........................................................ 94

8 FMI 00 .................................................. 83

72 FMI 03 .................................................. 84

47 FMI 09 .................................................. 85

262 FMI 03 .................................................. 86

342 FMI 08 .................................................. 88

1690 FMI 08 .................................................. 89

1779 FMI 08 .................................................. 90

D 1785 FMI 10 .................................................. 91

D 1834 FMI 02 .................................................. 92

e Cross Reference ....................... 68

.................................................. 71

5 .................................................. 72

02 .................................................. 73

07 .................................................. 74

I 06 .................................................. 76

I 05 .................................................. 77

MI 02 .................................................. 78

MI 07 .................................................. 79

FMI 08 .................................................. 80

FMI 10 .................................................. 81

Page 4

This document is printed from SPI². Not for RESALE

4 KENR6201-01

Table of Contents

E085 Engine Shutdown Overridden ..................... 94

E255 Diagnosti

E264 Emergency Stop Activated .......................... 94

E360 Low Engine Oil Pressure ............................. 95

E361 High Engi

E362 Engine Overspeed ....................................... 97

E396 High Fuel Rail Pressure .............................. 98

E398 Low Fuel

E539 High Intake Manifold Air Temperature ......... 99

c Reset ......................................... 94

ne Coolant Temperature .............. 96

Rail Pressure ............................... 99

Diagnostic

5 Volt Sensor Supply Circuit - Test ..................... 101

CAN Data Link Circuit - Test ............................... 107

Data Link Ci

ECM Memory - Test ............................................. 116

Electrical Connectors - Inspect ............................ 117

Engine Pre

Test ................................................................... 121

Engine Speed/Timing Sensor Circuit - Test ........ 128

Engine Tem

Test ................................................................... 135

Fuel Rail Pump Solenoid - Test .......................... 140

Ignition

Test ................................................................... 144

Indicator Lamp Circuit - Test ............................... 150

Injector

Injector Solenoid Circuit - Test ............................ 156

Speed Control (Analog) - Test ............................ 163

Speed Co

Starting Aid (Glow Plug) Relay Circuit - Test ...... 168

Wastegate Solenoid - Test .................................. 172

Functional Tests

rcuit - Test ......................................... 110

ssure Sensor Open or Short Circuit -

perature Sensor Open or Short Circuit -

Keyswitch Circuit and Battery Supply Circuit -

Data Incorrect - Test ............................... 154

ntrol (PWM) - Test ............................... 166

Index Section

Index ................................................................... 177

Page 5

This document is printed from SPI². Not for RESALE

KENR6201-01 5

Troubleshooting Section

Troubleshooting Section

Electronic Troubleshooting

i03805210

System O verview

System Ope

ration

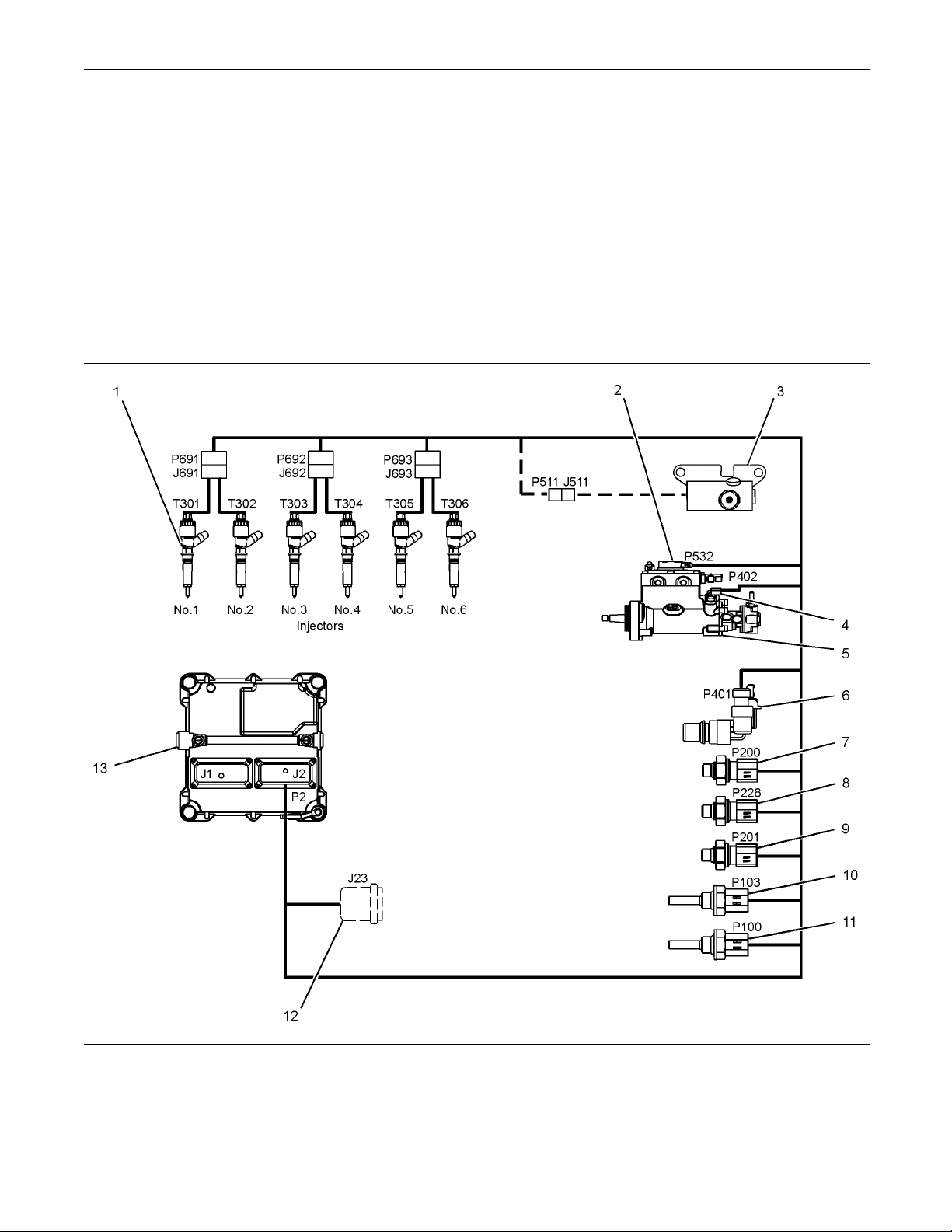

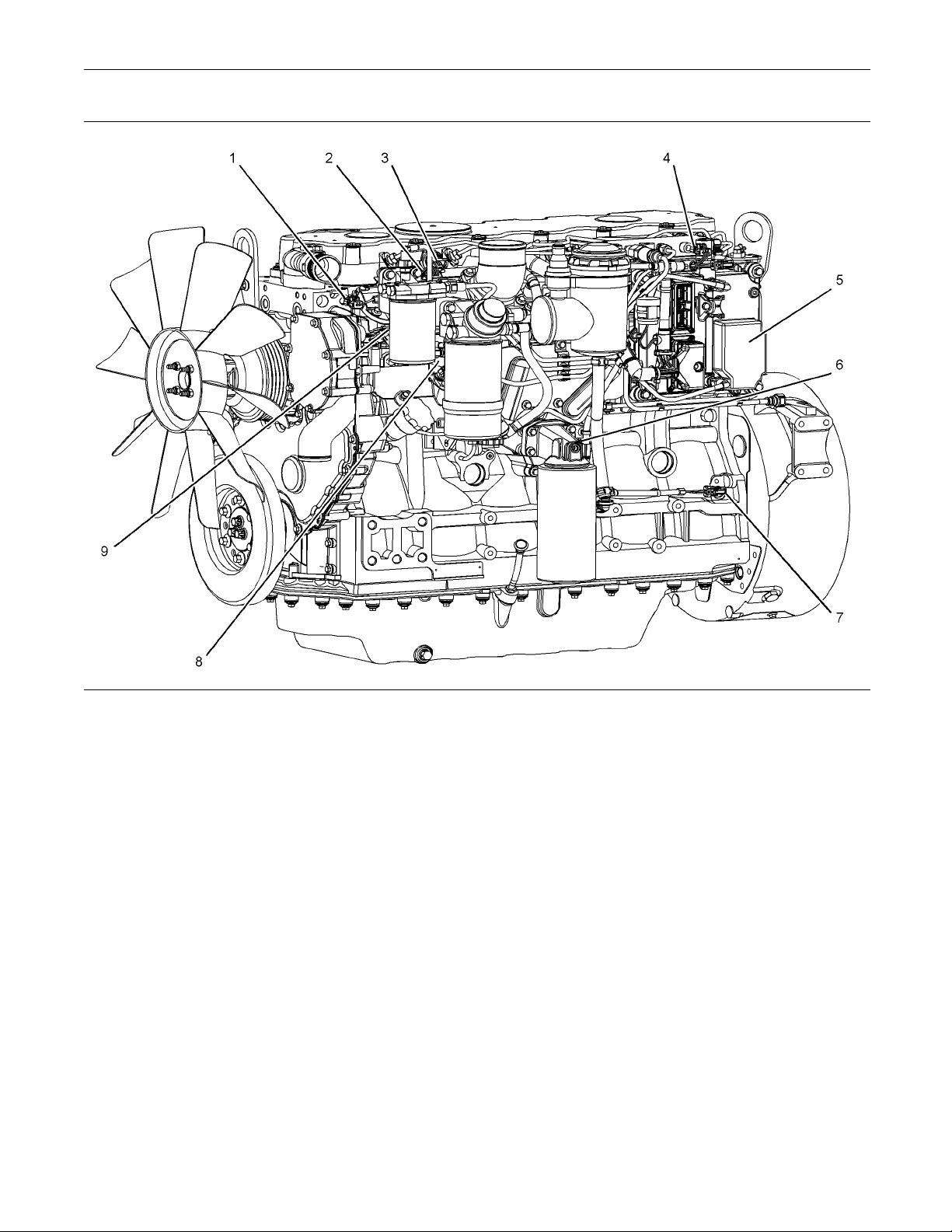

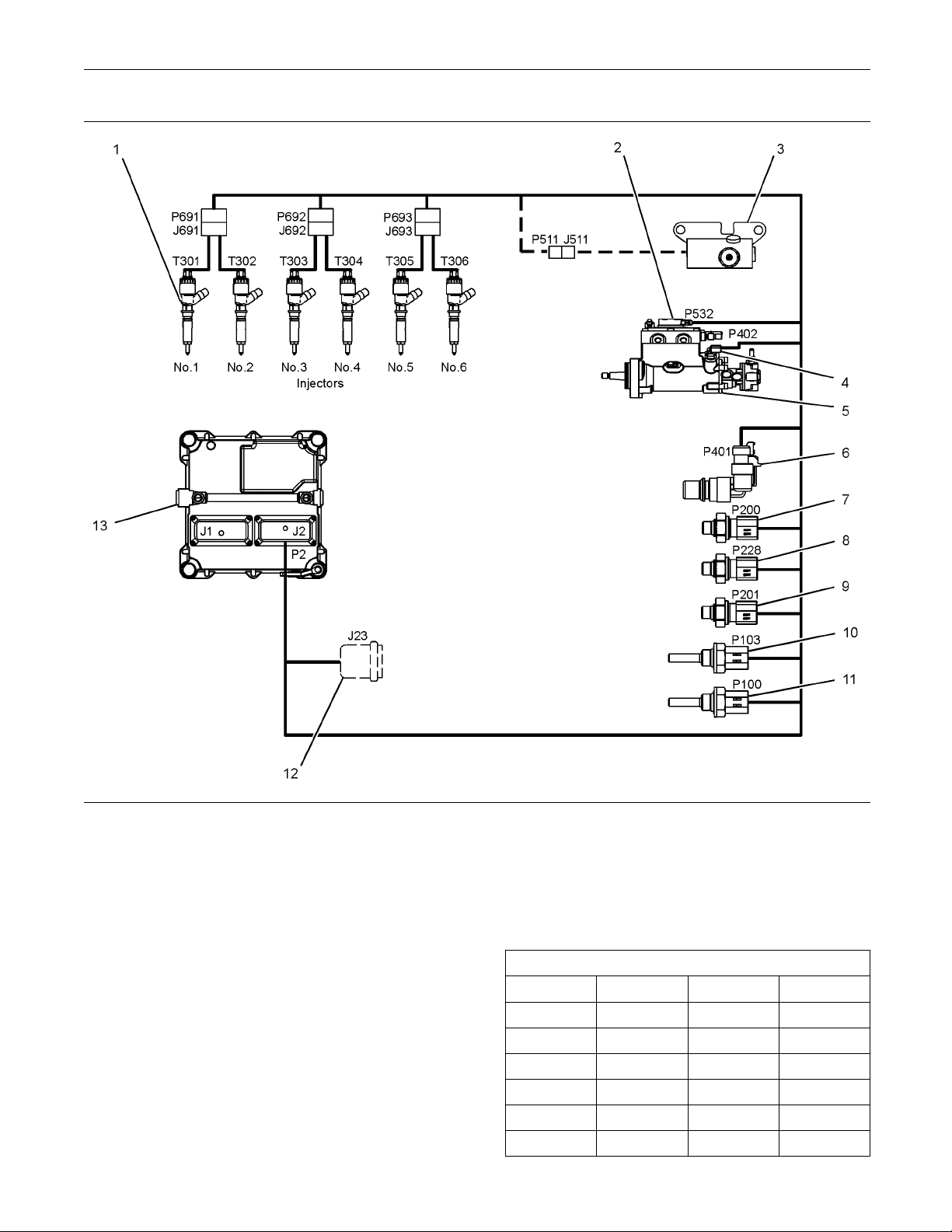

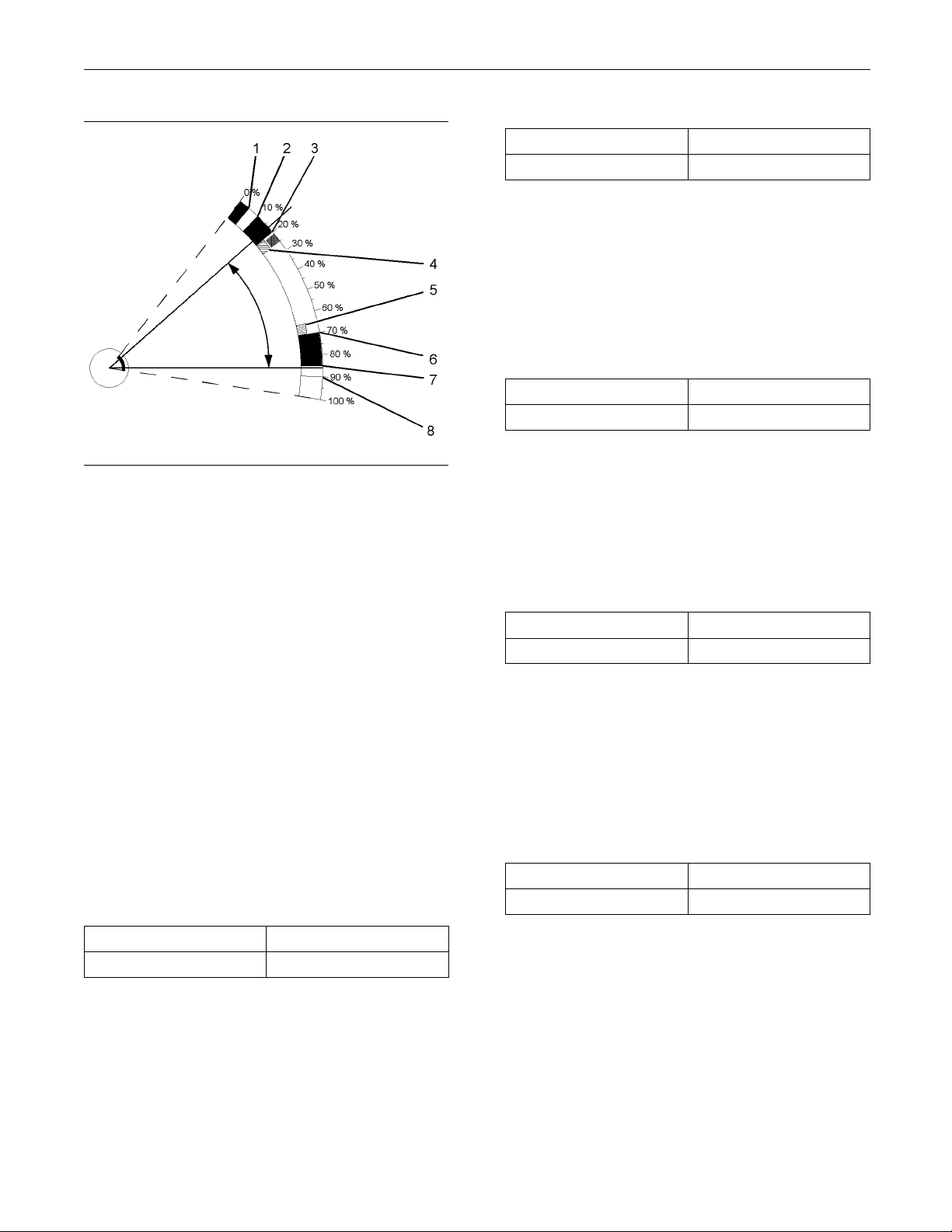

lustration 1

Il

(1) Electronic Unit Injector

(2) Solenoid for the Fuel Rail Pump

(3) Wastegate Regulator (if equipped)

(4) Secondary S peed/Timing Sensor

(5) Fuel Rail Pump

(6) Primary Spee d/Timing Sensor

(7) Intake Manifold Pressure Sensor

(8) Fuel Rail Pressure S ensor

(9) Engine O il Pressure Sensor

(10) Intake Manifold Temperature Sensor

(11) Coolant Temperature Sensor

(12) Diagnostic Connector (if equipped)

(13) Electronic Control M odule (ECM)

g01808033

Page 6

This document is printed from SPI². Not for RESALE

6 KENR6201-01

Troubleshooting Section

The 1 106D engine was designed for electronic

control. The en

(ECM), a fuel rail pump and electronic unit injectors.

All of these items are electronically controlled. There

arealsoanumb

engines can be equipped with an electronically

controlled wastegate for the turbocharger. The ECM

controls the

the software within the ECM and the inputs from the

various sensors. The software contains parameters

that contro

include all of the operating maps and customer

selected parameters.

The electronic system consists of the ECM, the

engine sensors and inputs from the parent machine.

The ECM is t

is the software for the computer. The personality

module defines the following characteristics of the

engine:

Engine power

•

Torque curves

•

Engine sp

•

Engine Noise

•

gine has an Electronic Control Module

er of engine sensors. Turbocharged

engine operating parameters through

l the engine operation. The parameters

he computer. The personality module

eed (rpm)

At start-up, the ECM determines the top center

position of the

speed/timing sensor in the fuel rail pump. The ECM

decides when fuel injection should occur relative to

the top center

performance by control of each of the electronic

unit injectors so that the required amount of fuel is

injected at t

electronic unit injectors are supplied high pressure

fuel from the fuel rail. The ECM also provides the

signal to th

solenoid in the fuel rail pump controls a valve in the

fuel rail pump. This valve controls the pressure in

the fuel rai

is diverted away from the fuel rail pump back to the

fuel tank.

The ECM adjusts injection timing and fuel pressure

for the best engine performance, the best fuel

economy an

Theactualtimingcanbeviewedwithanelectronic

service tool. Also, the desired timing can be viewed

with an el

number 1 cylinder from the secondary

position. The ECM optimizes engine

he precise point of the engine's cycle. The

e solenoid in the fuel rail pump. The

l. Fuel that is not required for the engine

d the best control of exhaust emissions.

ectronic service tool.

Fuel Injection

The personality module inside the ECM sets certain

limits on the amount of fuel that can be injected.

Smoke and Emissions

•

Engine

The ECM determines the injection timing, the amount

of fuel

manifold pressure if an electronically controlled

wastegate is installed on the turbocharger. These

decis

desired conditions at any given time.

The go

engine speed to the actual engine speed. The actual

engine speed is determined through the primary

spee

sensor. If the desired engine speed is greater than

the actual engine speed, the governor injects more

fuel

Speed Governor

that is delivered to the cylinders and the intake

ions are based on the actual conditions and the

vernor has software that compares the desired

d/timing sensor and the secondary speed/timing

in order to increase engine speed.

Timing Considerations

Fuel injection timing is determined by the ECM after

considering input from the following components:

Engine coolant temperature sensor

•

e sensor for the intake manifold air temperature

Th

•

The sensor for the intake manifold pressure

•

Speed/timing sensors

•

The Fuel Ratio Control Limit is a limit that is based

on intake manifold air pressure and engine rpm. The

FRC Lim

to control the engine's exhaust emissions. When the

ECM senses a higher intake manifold air pressure,

the ECM

manifold air pressure indicates that there is more air

in the cylinder. When the ECM increases the FRC

Limit

The Rated Fuel Limit is a limit that is based on the

power

The Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curv

These limits are in the personality module and these

limi

Dia

When the ECM detects an electronic system problem,

the

logs the diagnostic code in order to indicate the time

of the problem's occurrence. The ECM also logs the

nu

codes are provided in order to indicate that the ECM

has detected an electrical problem or an electronic

oblem with the engine control system. In some

pr

cases, the engine performance can be affected when

the condition that is causing the code exists.

it is used to control the air/fuel ratio in order

increases the FRC Limit. A higher intake

, the ECM allows more fuel into the cylinder.

rating of the engine and on the engine rpm.

es of a specific engine model.

ts cannot be changedby the operator.

gnostic Codes

ECM generates a diagnostic code. Also, the ECM

mber of occurrences of the problem. Diagnostic

peed control device

S

•

Page 7

This document is printed from SPI². Not for RESALE

KENR6201-01 7

Troubleshooting Section

If the operator indicates that a performance problem

occurs, the dia

of the problem. Use the electronic service tool to

access the diagnostic codes. The problem should

then be correc

gnostic code may indicate the cause

ted.

Event Codes

Event Codes are used to indicate that the ECM has

detected an abnormal engine operating condition.

The ECM will

This does not indicate an electrical malfunction

or an electronic malfunction. For example, if the

temperatur

than the permitted limit, then the ECM will detect the

condition. The ECM will then log an event code for

the condit

Programma

Certain parameters that affect the engine operation

may be cha

The parameters are stored in the ECM, and the

parameters are protected from unauthorized changes

by passwo

Configuration Parameters.

System C

factory. System Configuration Parameters affect

emissions or power ratings within the engine. Factory

passwor

must be used to change the System Configuration

Parameters.

log the occurrence of the event code.

e of the coolant in the engine is higher

ion.

ble Parameters

nged with electronic service tools.

rds. These parameters are System

onfiguration Parameters are set at the

ds must be obtained and factory passwords

Adaptive Trim – This is a software process that is

performed in th

that optimizes engine performance.

Alternating C

electric current that reverses direction at a regular

interval that is reoccurring.

Before Top Center (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top dead cen

rotation.

Breakout Ha

test harness that is designed to connect into the

engine harness. This connection allows a normal

circuit op

provides a Breakout T in order to measure the

signals.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass ci

CAN Data Link (see also J1939 CAN Data Link) –

The CAN Da

port that is used for communication with other

microprocessor based devices.

Code – Refer to “Diagnostic Code” or “Event Code”.

Communi

communication adapter provides a communication

link between the ECM and the electronic service tool.

e Electronic Control Module (ECM)

urrent (AC) – Alternating current is an

ter position in the normal direction of

rness – A breakout harness is a

eration and the connection simultaneously

rcuit is typically used as a test circuit.

ta Link is a serial communications

cation Adapter Tool – The

Passwords

System Configuration Parameters are protected by

factory passwords. Factory passwords are calculated

onaco

Perkins distributors. Since factory passwords contain

alphabetic characters, only an electronic service

tool

System C onfiguration Parameters affect the power

rating or the emissions.

Refer to Troubleshooting, “Programming Parameters”

and Troubleshooting, “Factory Passwords”.

mputer system that is available only to

may change System Configuration Parameters.

i03805350

Glossary

Active Diagnostic Code – An active diagnostic

code alerts the operator or the service technician that

an electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Component Identifier (CID) – TheCIDisanumber

that identifies the specific component of the electronic

ol system that has experienced a diagnostic

contr

code.

nt Temperature Sensor – The coolant

Coola

temperature sensor detects the engine coolant

temperature for all normal operating conditions and

ngine monitoring.

for e

Data Link – The Data Link is a serial communication

that is used for communication with other devices

port

such as the electronic service tool.

ate – Certain engine conditions will generate

Der

event codes. Also, engine derates may be applied.

The map for the engine derate is programmed into

ECM software. The derate can be one or more of

the

3 types: reduction of rated power, reduction of rated

engine speed, and reduction of rated machine speed

r OEM products.

fo

Desired Engine Speed – The desired engine speed

input to the electronic governor within the ECM.

is

The electronic governor uses the signal from the

throttle position sensor, the engine speed/timing

ensor, and other sensors in order to determine the

s

desired engine speed.

Page 8

This document is printed from SPI². Not for RESALE

8 KENR6201-01

Troubleshooting Section

Diagnostic Code – A diagnostic code is sometimes

referred to as a

electronic system malfunction.

Digital Senso

from the ECM is used as ground for the digital

sensors.

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with power f

Digital Sensor Supply – The power supply for the

digital sen

Direct Current (DC) – Direct current is the type of

current th

DT, DT Connector, or Deutsch DT – This is a

type of con

connectors are manufactured by Deutsch.

Duty Cycl

Electronic Engine Control – The electronic

engine co

The electronic engine control monitors the engine

operation under all conditions. The electronic engine

control

conditions.

Electro

is the control computer of the engine. The ECM

provides power to the electronics. The ECM monitors

data th

ECM acts as a governor in order to control the speed

and the power of the engine.

also controls the engine operation under all

nic Control Module (ECM) – The ECM

at is input from the sensors of the engine. The

fault code. These codes indicate an

rReturn –The common line (ground)

rom the ECM.

sors is provided by the ECM.

at flows consistently in only one direction.

nector that is used on the engine. The

e–Refer to “Pulse Width Modulation”.

ntrol is a complete electronic system.

Event Code – An event code may be activated

in order to indi

condition. These codes usually indicate a mechanical

problem instead of an electrical system problem.

Failure Mode Identifier (FMI) – This identifier

indicates the type of failure that is associated with

the componen

SAE practice of J1587 diagnostics. The FMI follows

the parameter identifier (PID) in the descriptions of

the fault co

the following list.

0–The data i

operational range.

1–The data

operational range.

2–The data

3–The voltage is above normal or the voltage is

shorted h

4–The voltage is below normal or the voltage is

shorted l

5–The current is below normal or the circuit is open.

6–The current is above normal or the circuit is

grounded.

7–The mechanical system is not responding

properly.

8–There is an abnormal frequency, an abnormal

pulse width, or an abnormal time period.

cate an abnormal engine operating

t. The FMI has been adopted from the

de. The descriptions of the FMIs are in

s valid but the data is above the normal

isvalidbutthedataisbelowthenormal

is erratic, intermitte nt, or incorrect.

igh.

ow.

Electronic Service Tool – The electronic service

tool allows a computer (PC) to communicate with the

ECM.

Engine Monitoring – Engine Monitoring is the part

e electronic engine control that monitors the

of th

sensors. This also warns the operator of detected

problems.

Engine Oil Pressure Sensor – The engine oil

pressure sensor measures engine oil pressure. The

sor sends an electronic signal to the ECM that is

sen

dependent on the engine oil pressure.

ine Speed/Timing Sensor – An engine

Eng

speed/timing sensor is a hall effect switch that

provides a signal to the ECM. The ECM interprets

is signal as the crankshaft position and the engine

th

speed. Two sensors are used to provide the speed

and timing signals to the ECM. The primary sensor

associated with the crankshaft and the secondary

is

sensor is associated with the camshaft.

ther Relay – Theetherrelayisusedtoactuatethe

E

ether injection system. The ECM controls the relay.

9–There has been an abnormal update.

10 – Th

11 – The failure mode is not identifiable.

12 – The device or the component is damaged.

13 – T

14 and 15 – These locations are reserved for a

fut

Flash Programming – Flash programming is the

met

an electronic service tool over the data link instead

of replacing components.

Fuel Injector E-Trim – Fuel injector E-trim is a

software process that allows precise control of fuel

in

the ECM for each fuel injector. With the use of the

electronic service tool, the service technician can

ead status information for the E-Trim. Data for

r

E-Trimcanalsobeprogrammed.

ere is an abnormal rate of change.

he device or the component is not calibrated.

ure assignment.

hod of programming or updating an ECM with

jectors by parameters that are programmed into

Page 9

This document is printed from SPI². Not for RESALE

KENR6201-01 9

Troubleshooting Section

FRC – See “Fuel Ratio Control”.

Fuel Pump – See “Fuel Rail Pump”.

Fuel Rail – Thi

the High Pressure Fuel Rail. The fuel rail supplies

fuel to the electronic unit injectors. The fuel rail pump

and the fuel r

in order to maintain the desired fuel pressure in the

fuel rail. This pressure is determined by calibration

of the engin

emissions and performance requirements.

FuelRailPr

sensor sends an electronic signal to the ECM that is

dependent on the pressure of the fuel in the fuel rail.

Fuel Rail Pump – This item is sometimes referred

toastheHighPressureFuelRailPump.Thisisa

device tha

rail (high pressure fuel rail).

Fuel Rail

referred to as the High Pressure Fuel Rail Pump

Solenoid Valve. This is a control device in the high

pressure

pressure in the fuel rail by using this valve to divert

excess fuel from the pump to the fuel tank.

Fuel Ratio Control (FRC) – The FRC is a limit that

is based on the control of the ratio of the fuel to air.

The FRC i

When the ECM senses a higher intake manifold

air pressure (more air into the cylinder), the FRC

ses the FRC Limit (more fuel into the cylinder).

increa

Full Load Setting (FLS) – The FLS is the number

epresents the fuel system adjustment. This

that r

adjustment is made at the factory in order to fine tune

thefuelsystem.Thecorrectvalueforthisparameter

mped on the engine information ratings plate.

is sta

This parameter must be programmed.

Plug – The glow plug is an optional starting aid

Glow

for cold conditions. One glow plug is installed in each

combustion chamber in order to improve the ability of

ngine to start. The ECM uses information from

the e

the engine sensors such as the engine temperature

to determine when the glow plug relay must provide

er to each glow plug. Each of the glow plugs

pow

then provides a very hot surface in the combustion

chamber in order to vaporize the mixture of air and

l. This improves ignition during the compression

fue

stroke of the cylinder.

ow Plug Relay – The glow plug relay is controlled

Gl

by the ECM in order to provide high current to the

glow plugs that are used in the starting aid system.

Harness – The harness is the bundle of wiring

(loom) that connects all components of the electronic

ystem.

s

s item is sometimes referred to as

ail pressure sensor work with the ECM

e in order to enable the engine to meet

essure Sensor – Thefuelrailpressure

t supplies fuel under pressure to the fuel

Pump Solenoid Valve – This is sometimes

fuel rail pump. The ECM controls the

s used for purposes of emission control.

Hertz (Hz) – Hertz is the measure of electrical

frequency in cy

High Pressure Fuel Rail Pump – See “Fuel Rail

Pump”.

High Pressure Fuel Rail Pump Solenoid Valve –

See “Fuel Rai

High Pressure Fuel Rail – See “Fuel Rail”.

Injector Codes – The injector codes or injector trim

codes are numeric codes or alphanumeric codes

that are etc

unit injectors. These codes are used to fine tune the

fuel delivery.

Injector Trim Files – Injector trim files are

downloaded from a disk to the ECM. The injector trim

files compe

the electronic unit injector. The serial number for the

electronic unit injector must be obtained in order to

retrieve

Intake Manifold Air Temperature Sensor – The

intake ma

air temperature in the intake manifold. The ECM

monitors the air temperature and other data in the

intake m

other performance functions.

Intake M

Manifold Pressure Sensor measures the pressure

in the intake manifold. The pressure in the intake

manifo

the engine (atmospheric pressure). The difference

in pressure may be caused by an increase in air

press

Integrated Electronic Controls – The engine is

desig

part of the system. The engine will not operate

without the electronic controls.

J1939 CAN Data Link – This data link is a SAE

standard diagnostic communications data link that

is us

electronic devices.

Log

codes are codes which are stored in the memory.

These codes are meant to be an indicator of possible

cau

term “Diagnostic Code” in this glossary for more

information.

OEM – OEM is an abbreviation for the Original

Equipment Manufacturer. This is the manufacturer of

th

the correct injector trim file.

ld may be different to the pressure outside

ure by a turbocharger (if equipped).

ned with the electronic controls as a necessary

ed to communicate between the ECM and the

ged Diagnostic Codes – Logged diagnostic

ses for intermittent problems. Refer to the

e machine or the vehicle that uses the engine.

cles per second.

l Pump Solenoid Valve”.

hed or stamped on individual electronic

nsate for variances in manufacturing of

nifold air temperature sensor detects the

anifold in order to adjust injection timing and

anifold Pressure Sensor –

The Intake

Page 10

This document is printed from SPI². Not for RESALE

10 KENR6201-01

Troubleshooting Section

Open Circuit – An open circuit is a condition that is

caused by an ope

or a connection that is broken. When this condition

exists, the signal or the supply voltage can no longer

reach the inte

Parameter – A parameter is a value or a limit that

is programma

characteristics or behaviors of the engine.

Password – A

characters or a group of alphanumeric characters

that is designed to restrict access to parameters. The

electronic

to change some parameters (Factory Passwords).

Refer to Troubleshooting, “Factory Passwords” for

more infor

Personality Module – This module is software

that is ins

instructions (software) for the ECM and the module

contains the performance maps for a specific engine.

The perso

through flash programming.

Power Cyc

of cycling the keyswitch from any position to the OFF

position, and to the START/RUN position.

Primary Speed/Timing Sensor – This sensor

determines the position of the crankshaft during

engine o

sensor fails during engine operation, the secondary

speed/timing sensor is used to provide the signal.

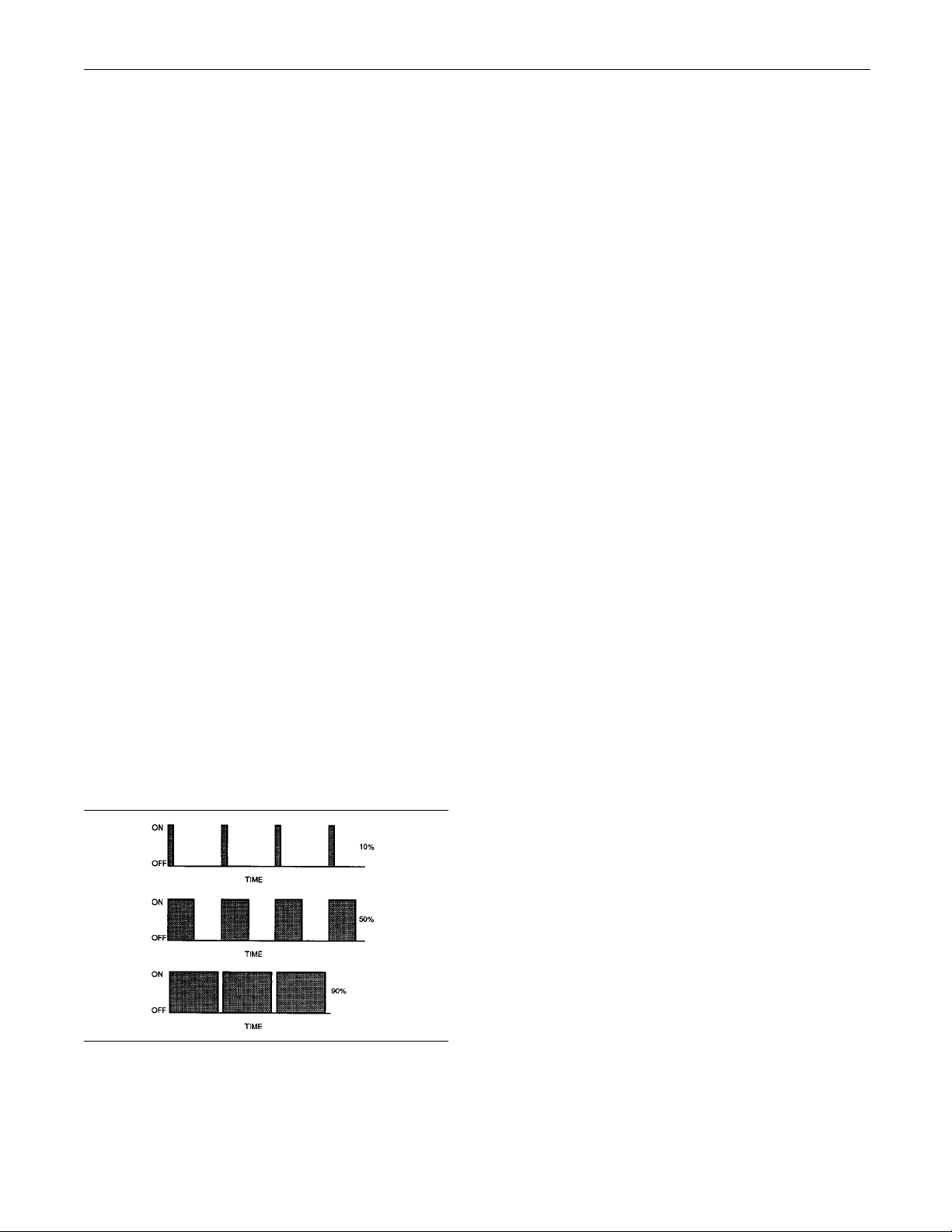

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width

of “TIME ON” versus total “TIME OFF” can be varied.

Thisratioisalsoreferredtoasadutycycle.

system requires correct passwords in order

mation.

ide the ECM. The module contains all the

nality module may be reprogrammed

peration. If the primary speed/timing

. These pulses occur at fixed intervals. The ratio

n switch, or by an electrical wire

nded destination.

ble. This helps determine specific

password is a group of numeric

ling – Power cycling refers to the action

Rated Fuel Limit – This is a limit that is based on

the power ratin

The Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curves of a spe

in the personality module and these limits cannot be

changed.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by

voltage is used by the sensor to generate a signal

voltage.

Relay – A relay is an electromechanical switch. A

flow of electricity in one circuit is used to control the

flow of elec

voltage is applied to a relay in order to switch a much

larger current or voltage.

Secondary Speed/Timing Sensor – This sensor

determines the position of the camshaft during engine

operatio

during engine operation, the secondary speed/timing

sensor is used to provide the signal.

Sensor – A sensor is a device that is used to

detect the current value of pressure or temperature,

or mecha

detected is converted into an electrical signal.

Short Ci

an electrical circuit that is inadvertently connected to

an undesirable point. An example of a short circuit

is a wir

this rubbing eventually wears off the wire insulation.

Electrical contact with the frame is made and a short

circu

Signal – The signal is a voltage or a waveform that

is use

asensortotheECM.

e which rubs against a vehicle frame and

it results.

d in order to transmit information typically from

g of the engine and on the engine rpm.

cific engine model. These limits are

the ECM to a sensor. The reference

tricity in another circuit. A small current or

n. If the primary speed/timing sensor fails

nical movement. The information that is

rcuit – A short circuit is a condition that has

dDemandInput –The speed demand input is

Spee

a signal that is sent to the ECM in order to calculate

desired engine speed.

Supply Voltage – The supply voltage is a continuous

voltage that is supplied to a component in order to

vide the electrical power that is required for the

pro

component to operate. The power may be generated

by the ECM or the power may be battery voltage that

upplied by the engine wiring.

is s

System Configuration Parameters – System

nfiguration parameters are parameters that affect

co

emissions and/or operating characteristics of the

engine.

Illustration 2

g00284479

Page 11

This document is printed from SPI². Not for RESALE

KENR6201-01 11

Troubleshooting Section

Tattletale – Certain parameters that affect the

operation of th

These parameters can be changed by use of the

electronic service tool. The tattletale logs the number

of changes tha

ThetattletaleisstoredintheECM.

Throttle Pos

interpretation by the ECM of the signal from the

speed controller.

Timing Calibration – The timing calibration is the

adjustment of an electrical signal. This adjustment is

made in orde

camshaft and the engine speed/timing sensors or

between the crankshaft and the engine speed/timing

sensors.

Top Center Position – The top center position refers

to the cran

position is at the highest point of travel. The engine

must be turned in the normal direction of rotation in

order to r

T otal Tattletale – The total tattletale is the total

number of

stored in the ECM.

Wastega

engine that controls the maximum boost pressure

that is provided to the inlet manifold.

Wastegate Regulator (if equipped) – The

wastegate regulator controls the pressure in the

manifold to a value that is determined by the

intake

ECM. The wastegate regulator provides the interface

between the ECM and the mechanical system that

ates intake manifold pressure to the desired

regul

value that is determined by the software.

e engine are stored in the ECM.

t have been made to the parameter.

ition – The throttle position is the

r to correct the timing error between the

kshaft position when the engine piston

each this point.

changes to all the parameters that are

te – This is a device in a turbocharged

Required Service Tools

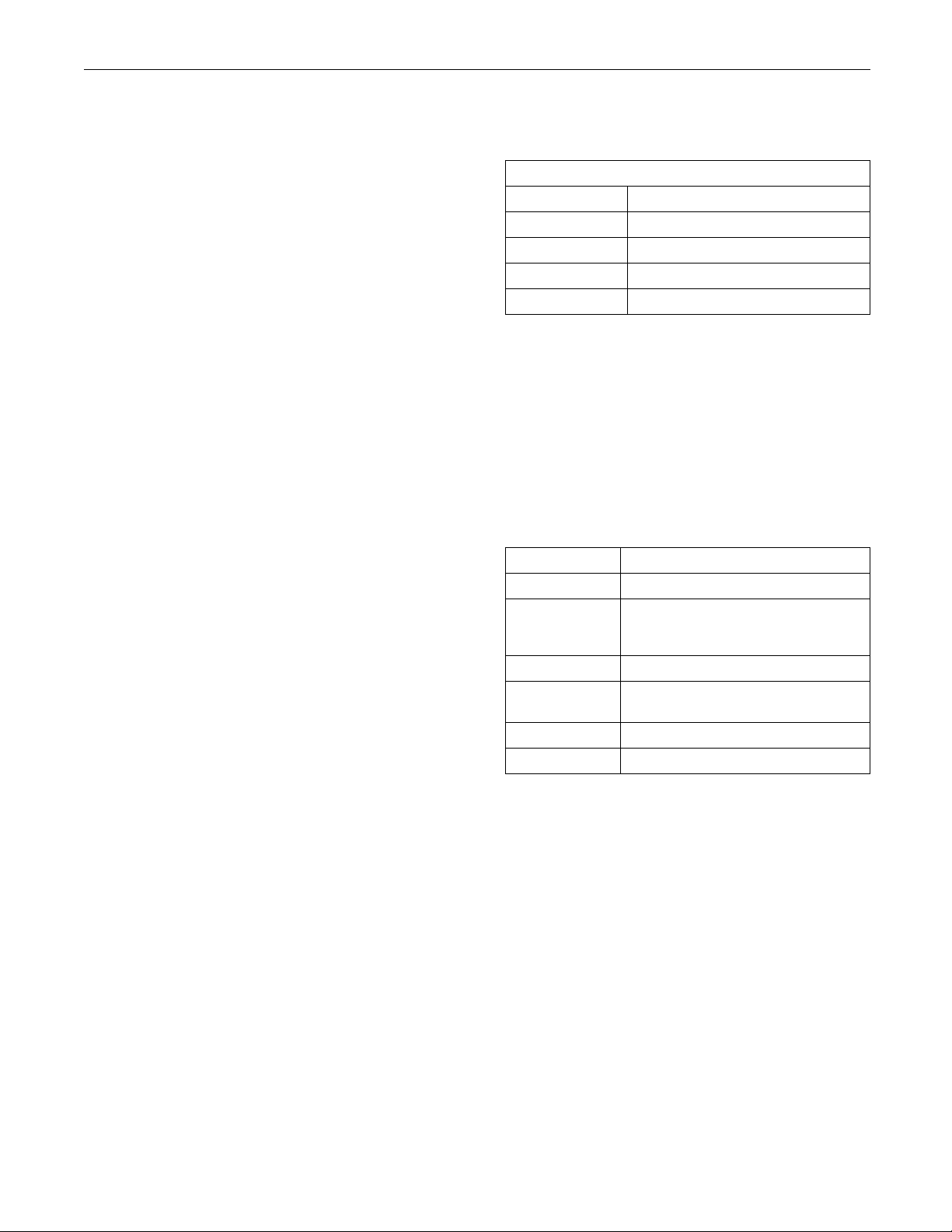

Table 1

Required Service Tools

Part Number Description

CH11155

2900A019

27610285

-

Two short jumper wires are needed to check the

continuity of some wiring harness circuits by shorting

two adjacent terminals together in a connector. A

long extension wire may also be needed to check the

continuity of some wiring harness circuits.

Crimp Tool (1

Wire Removal Tool

Removal To ol

Suitable Digital Multimeter

2−AWG TO 18−AWG)

Optional Service Tools

Table 2 lists the optional service tools that can be

used when the engine is serviced.

Table 2

Part Number Description

U5MK1092

-

or

-

-

-

28170107

2900A038

Spoon Probe Kit(MULTIMETER)

Suitable Digital Pressure Indicator

or

Engine Pressure Group

ble Battery Load Tester

Suita

Suitable Temperature Adapter

(MULTIMETER)

Bypass Harness As

Harness As

i02517580

Electronic Service Tools

Perkins electronic service tools are designed to help

the service technician:

Retrieve diagnostic codes.

•

Diagnose electrical problems.

•

Read parameters.

•

Program parameters.

•

Install trim files.

•

Perkins Electronic Service Tool

The Perkins Electronic Service Tool can display the

following information:

Status of all pressure sensors and temperature

•

sensors

Programmable parameter settings

•

Active diagnostic codes and logged diagnostic

•

codes

Logged events

•

Histograms

•

The Electronic Service Tool can also be used to

perform the following functions:

Diagnostic tests

•

Page 12

This document is printed from SPI². Not for RESALE

12 KENR6201-01

Troubleshooting Section

Sensor calibrations

•

Programming of flash files

•

Parameter pro

•

Copy configuration function for ECM replacement

•

Data logging

•

Graphs (rea

•

gramming

ltime)

Table 3 lists the service tools that are required in

order to use

Table 3

Service Tools for the Use of the Electronic

Part

Number

-

-

27610251

27610164

(1)

Refer to Perkins Engine Company Limited.

the Electronic Service Tool.

Service Tool

(1)

(1)

Single Use Program License

Data Subscription for All Engines

Communication Adapter (Electronic

Service

Adapter Cable As

Tool to ECM interface)

Description

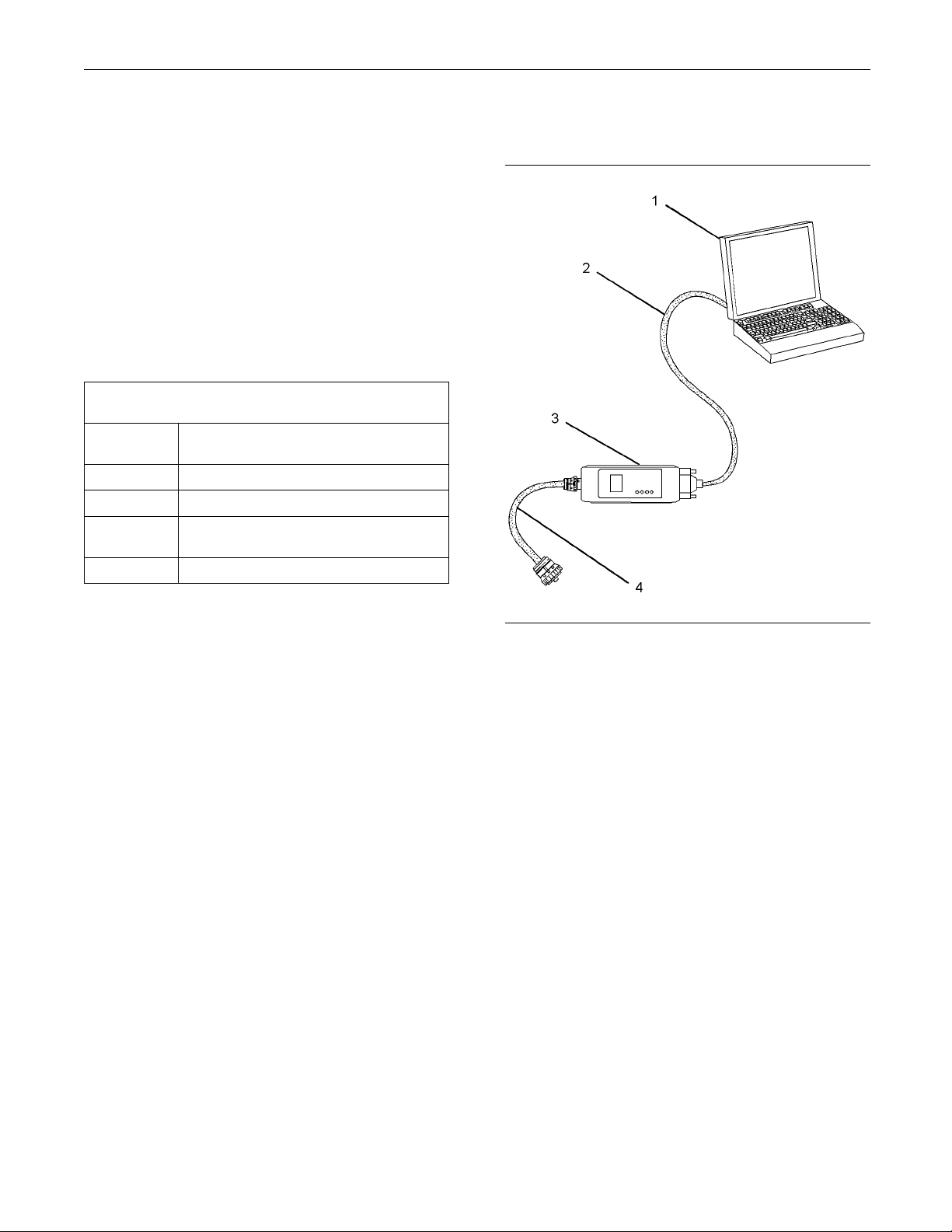

Connecting the Electronic Service Tool

and the Communi

cation Adapter II

Note: For more information regarding the use of the

Electronic Service Tool and the PC requirements

for the Electronic Service Tool, refer to the

documentation that accompanies your Perkins

Electronic Service Tool software.

Illustration 3

(1) Personal Computer (PC)

(2) Adapter Cable (Computer Serial Port)

(3) Communication Adapter II

(4) Adapter Cable Assembly

g01121866

Note: Items (2), (3) and (4) are part of the

Communication Adapter II kit.

Use the following procedure in order to connect

the Electronic Service Tool and the Communication

Adapter II.

1. Turn the keyswitch to the OFF position.

2. Connect cable (2) between the “COMPUTER”

end of communication adapter (3) and the RS232

serial port of PC (1).

Note: The Adapter Cable Assembly (4) is required to

connect to the USB port on computers that are not

equipped with a RS232 serial port.

3. Connect cable (4) between the “DATA LINK” end

of communication adapter (3) and the service tool

connector.

4. Place the keyswitch in the ON position. If the

Electronic Service Tool and the communication

adapter do not communicate with the Electronic

Control Module (ECM), refer to the diagnostic

procedure Troubleshooting, “Electronic Service

Tool Will Not Communicate With ECM”.

Page 13

This document is printed from SPI². Not for RESALE

KENR6201-01 13

Troubleshooting Section

i03787449

Indicator Lamps

Indicator Lam

The functions of the indicator lamps are designed to

display the m

minimum number of lamps.

Eight lamps

lamp and the “Warning” lamp will normally be

installed in the application. Dedicated optional lamps

for other it

optional lamps are “Low oil pressure”, “Overspeed”,

“High Coolant Temperature”, “Diagnostic”, “Derate”

and “Maint

The “Shutdown” lamp and the “Warning” lamp can

also be us

the “Flash Code” feature. The “Flash Code” feature

can be used to indicate all active diagnostic codes

and logge

Functio

aximum amount of information on the

are available as options. The “Shutdown”

ems may also be installed. The remaining

enance”.

ed to indicate a diagnostic code by use of

d diagnostic codes.

ns of the Lamps

ps

On – Thelampwillcomeonwhena“highcoolant

temperature” e

and the “Shutdown” lamp may also come on.

Overspeed Lam

Lamp check – When the keyswitch is turned to

the ON positi

seconds. The lamp will then go off unless the engine

overspeeds.

On – Thelampwillcomeonwhenan“engine

overspeed” event is detected. The “Warning” lamp

and the “Shu

vent is detected. The “Warning” lamp

p

on,thelampwillcomeonfortwo

tdown” lamp may also come on.

Derate Lamp

Lamp check – When the keyswitch is turned to the

ON position, the lamp will come on for two seconds.

On – Thelampwillcomeonwhentheengineis

derated.

Diagnostic Lamp

Lamp che

ON position, the lamp will come on for two seconds.

ck – When the keyswitch is turned to the

Shutdown Lamp

Lamp check – When the keyswitch is turned to the

ON position, the lamp will come on for two seconds.

The lam

warning.

On – Th

the engine protection strategy has been reached.

Warni

Lamp check – When the keyswitch is turned to the

ON po

Thelampwillthengooffunlessthereisanactive

warning.

On – Thelampwillbeonwhenthewarninglevel

has been reached.

pwillthengooffunlessthereisanactive

elampwillbeonwhentheshutdownlevelin

ng Lamp

sition, the lamp will come on for two seconds.

Low Oil Pressure

pcheck –When the keyswitch is turned to the

Lam

ON position, the lamp will come on for two seconds.

– Thelampwillcomeonwhenalowoilpressure

On

event is detected. The “Warning” lamp and the

“Shutdown” lamp may also come on.

Flashin

code or an event code is active. Refer to “Flash

Codes”.

g–Thelampwillflashwhenadiagnostic

Maintenance Lamp

Lamp ch

ON position, the lamp will come on for two seconds.

The lamp will then go off unless maintenance is due.

On – The lamp will come on when maintenance is

due.

eck – When the keyswitch is turned to the

Color of Lamps

Typically, the “Shutdown” lamp is colored red and the

“Warning” lamp is colored amber. The other lamps

ptional.

are o

High Coolant Temperature Lamp

amp check – When the keyswitch is turned to the

L

ON position, the lamp will come on for two seconds.

Page 14

This document is printed from SPI². Not for RESALE

14 KENR6201-01

Troubleshooting Section

Operation of the I ndi cator Lamps

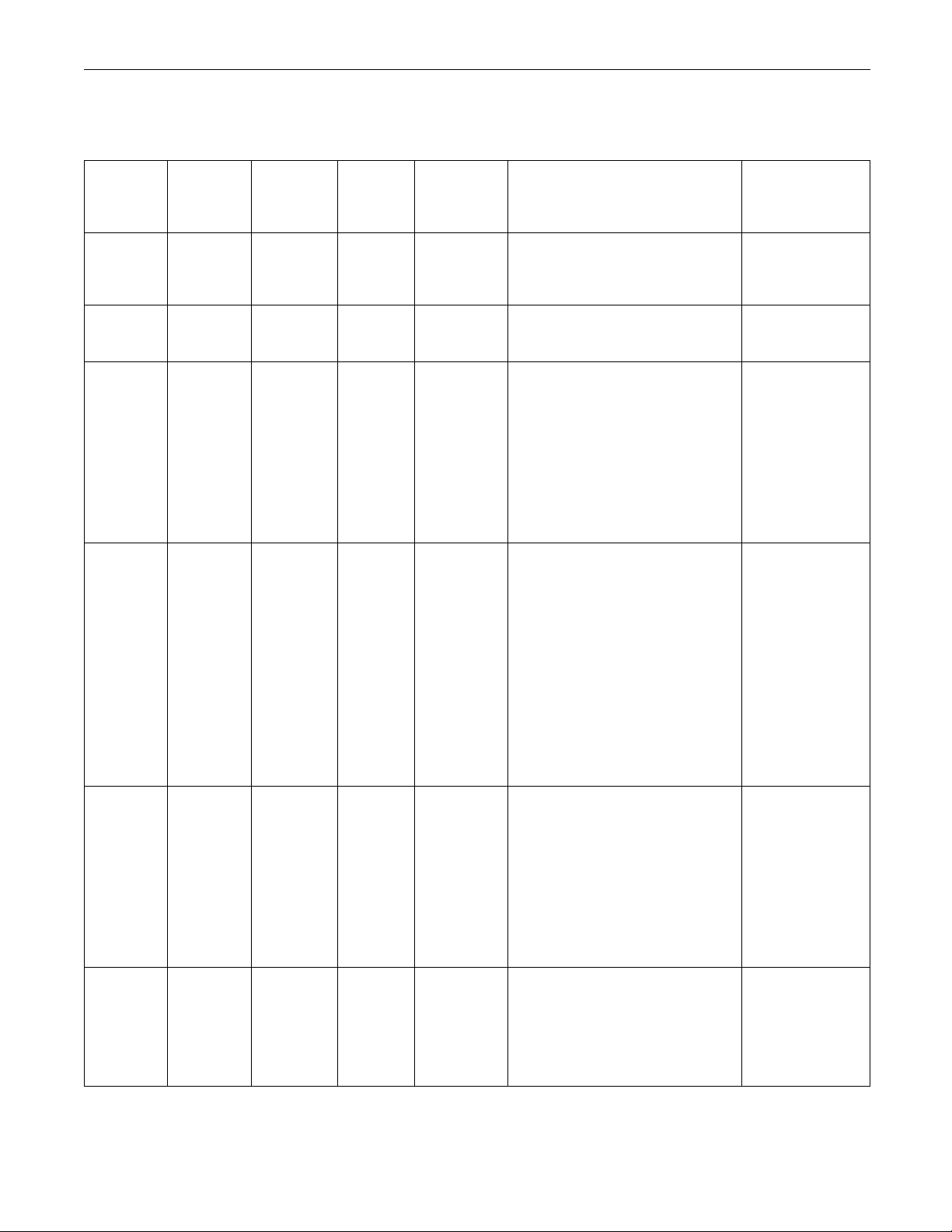

Table 4

Warning

Lamp

(Alert

Lamp)

On On On On

Off Off Off Off

On Off Flashing Off

On Off Flashi

On On Flashing Off

Off Off

Shutdown

Lamp

(Action

Lamp)

Diagnostic

Lamp

ng

Flashing

Derate

Lamp

On

Off

Lamp State Description of the Indication Engine State

Lamp Check

No Faults With the engine in operation, there

Warning

(Warning

only)

Derate

ng

(Warni

and Derate)

Engine

down

shut

(Warning

and

tdown)

shu

Diagnostic

(Diagnostic

ly)

on

When the keyswitch is switched on,

the lamps come on for a period of

2 seconds and the lamps will then

go off.

are no active warnings, diagnostic

codes or event codes.

If the warn

during engine operation, and the

diagnostic lamp is flashing , the

lamps ind

the warning values for the engine

protection strategy have been

exceeded

active event code. However, the

value has not been exceeded to a

level th

shutdown.

If both the warning lamp and the

derate lamp come on during engine

operation, and the diagnostic lamp

is flashing, the lamps indicate that

one or more of the values for the

engine protection strategy have

been exceeded beyond the level

that will cause an engine derate.

If both the warning lamp and

the shutdown lamp come on

during engine operation, and the

diagnostic lamp is flashing, the

lamps indicate that one or more

of the shutdown values for the

engine protection strategy has

been exceeded and there is an

active event code.

When the diagnostic lamp flashes

during operation of the engine,

the lamp indicates that an active

diagnostic code (an electrical fault)

is present. However, the diagnostic

code is not serious enough to

cause a derate or a shutdown.

ing lamp comes on

icate that one or more of

and that there is an

at will cause a derate or a

The keyswitch is

on but the engine

has not yet been

cranked.

The engine is

operating with no

detected faults.

The engine

is operating

normally.

However, there is

oneormoreofthe

monitored engine

parameters that

are outside of

the range that is

acceptable.

The engine

ating.

is oper

However, one

or more of the

red engine

monito

parameters is

outside of the

table range.

accep

The acceptable

range has been

ded to

excee

alevelwhich

requires a warning

nengine

and a

derate.

The engine is

er shutdown

eith

or an engine

shutdown is

inent.

imm

One or more

monitored engine

ameters have

par

exceeded the

limit for an engine

utdown.

sh

The engine is

operating but

ere is one or

th

more faults with

the electronic

ystem for the

s

engine.

(continued)

Page 15

This document is printed from SPI². Not for RESALE

KENR6201-01 15

Troubleshooting Section

(Table 4, contd

Off Off Flashing On

Off On Flashing Off

)

Derate

(Diagnostic

and Derate)

Engine

Shutdown

Flash Codes

The “Flash Code” feature is used to flash the two digit

code of all active diagnostic and event codes. Refer

to the Troubleshooting Guide, “Diagnostic Codes” for

the flash code that is related to the diagnostic code

or an event.

If the derate lamp comes on

during engine operation, and

the diagnostic lamp is flashing,

the lamps indicate that an active

diagnostic code (an electrical fault)

is present. The diagnostic code is

serious enough to cause an engine

derate.

If the shutdown lamp comes on

during engine operation, and the

diagnostic lamp is flashing, this

indicates that an active diagnostic

code (an electrical fault) is present.

The diagnostic code is serious

enough to cause the engine to

shutdown.

The engine

is operating.

However, an

active diagno

code is causing

an engine derate.

The engine is

either shutdown

or an engine

shutdown is

imminent. A

serious diagnostic

code is active.

stic

When a diagnostic code or an event code is active

or logged, the diagnostic lamp will flash repeatedly in

order to indicate the codes.

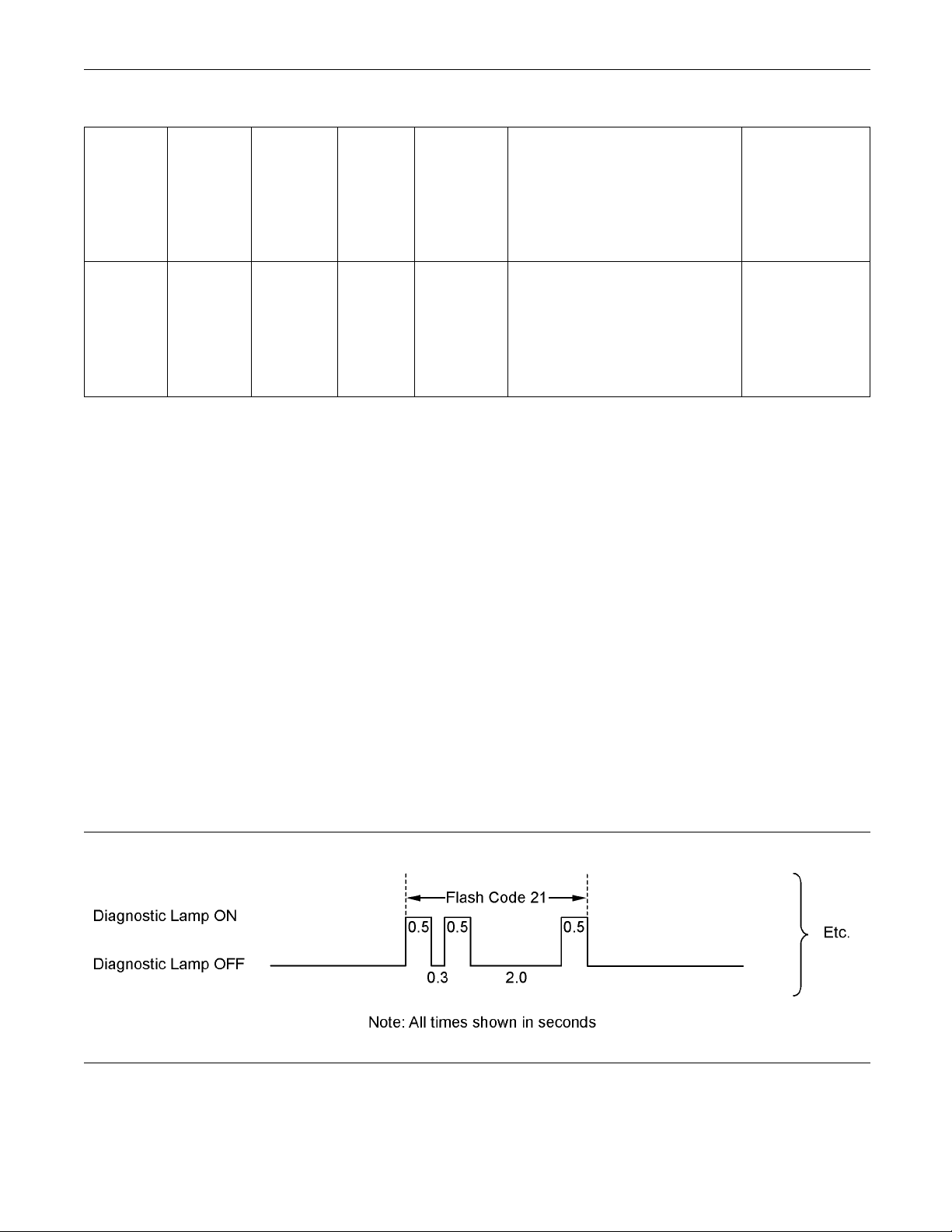

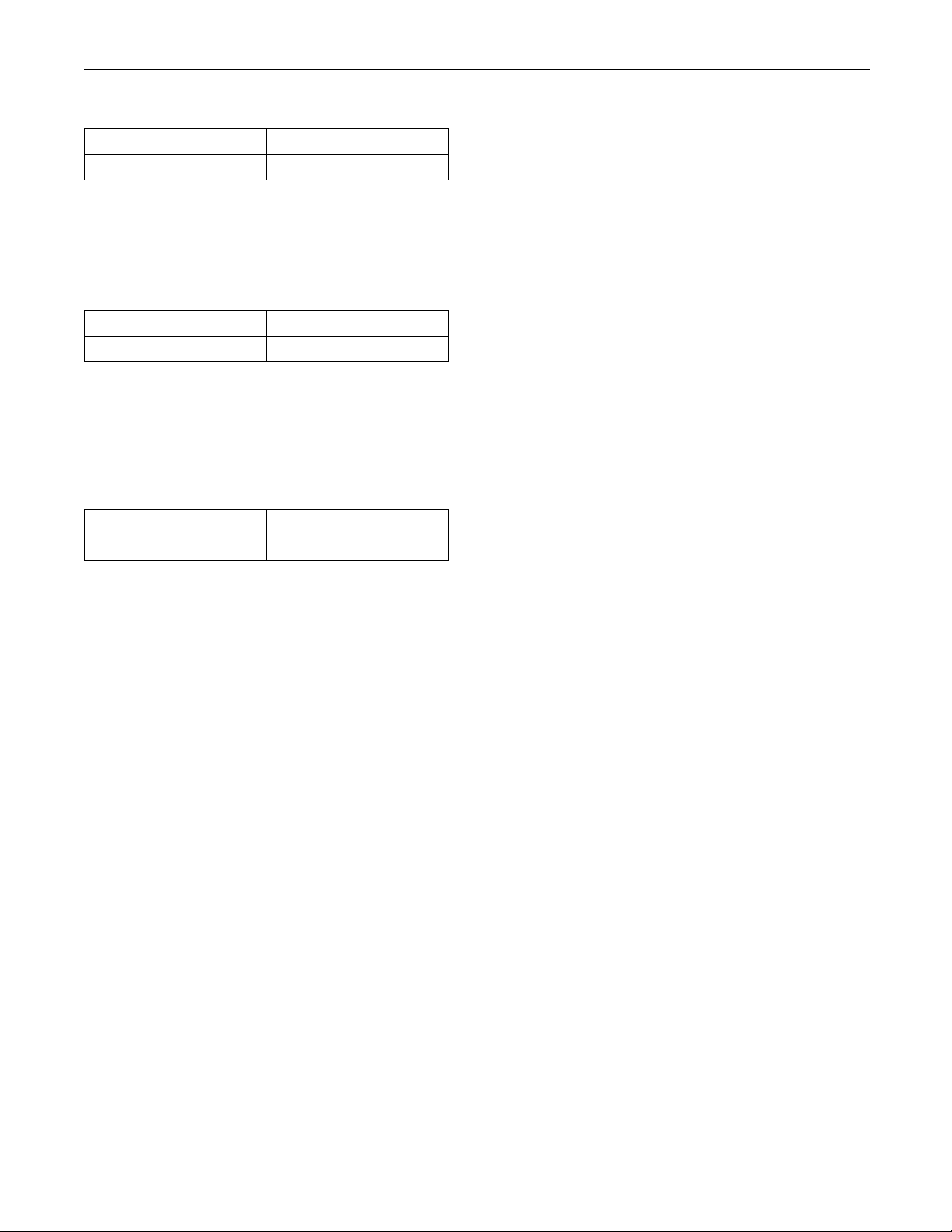

Each flash will be on for half a second and off for 300

milliseconds. The “Diagnostic” lamp will remain off for

two seconds between each digit of a code. If there

is more than one diagnostic code, the “Diagnostic”

lamp will go off for five seconds. The lamp will then

flash in order to indicate the next code.

As an example, an active diagnostic code of “21” is

indicated by the “Diagnostic” lamp coming on for 500

ms, then off for 300 ms, then on for 500 ms, then off

for 2000 ms, then on for 500 ms and then off.

Illustration 4

Once all codes have been flashed, the “Diagnostic”

lamp will go off for a period of 15 seconds before

Note: Flash codes are always sent in ascending

numerical order.

g02048816

starting the sequence again.

Page 16

This document is printed from SPI². Not for RESALE

16 KENR6201-01

Troubleshooting Section

i03805671

Replacing the ECM

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjust

collect the fluid with suitable containers before opening any compartment or disassembling any component contai

Dispose of all fluids according to local regulations and

mandates.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

The engine is equipped with an Electronic Control

Module (ECM). The ECM contains no moving parts.

Follow

in order to be sure that replacing the ECM will correct

the problem. Verify that the suspect ECM is the

cause o

ing and repair of the product. Be prepared to

ning fluids.

NOTICE

the troubleshooting procedures in this manual

f the problem.

Note: When a new ECM is not available, an ECM

canbeusedfrom

The ECM must have the same serial number

suffix. Ensure that the replacement ECM and the

part number fo

ECM. Be sure to record the parameters from the

replacement ECM. Use the “Copy Configuration ECM

Replacement

If the flash file and engine application are not matched,

engine damage may result.

Perform the following procedure in order to replace

the ECM.

1. Connect the electronic service tool to the

diagnostic connector.

2. Use the “Copy Configuration ECM Replacement”

function from the electronic service tool. If the

“Copy Configuration” is successful, proceed to

Step 4. If the “Copy Configuration” failed, proceed

to Step 3.

Note: Record any Logged Faults and Events for your

records.

3. Record the following parameters:

an engine that is not in service.

rtheflash file match the suspect

” function in the electronic service tool.

NOTICE

Note: Ensure that the ECM is receiving power

at the ECM is properly grounded before

and th

replacement of the ECM is attempted. Refer to the

schematic diagram.

A test ECM can be used in order to determine if the

ECM on the engine is faulty. Install a test ECM in

e of the suspect ECM. Install the flash file with

plac

the correct part number into the test ECM. Program

the parameters for the test ECM. The parameters

match the parameters in the suspect ECM.

must

Refer to the following test steps for details. If the test

ECM resolves the problem, reconnect the suspect

. Verify that the problem returns. If the problem

ECM

returns, replace the ECM.

e: If an ECM is intended to be used as a test

Not

ECM, “Test ECM Mode” must be selected on the

electronic service tool before the engine serial

mber is entered.

nu

Use the electronic service tool to read the parameters

the suspect ECM. Record the parameters in

in

the suspect ECM. Install the flash file into the new

ECM. After the ECM is installed on the engine, the

arameters must be programmed into the new ECM.

p

Record all of th e parameters on the

•

“Configuration” screen.

Record all of the parameters on the “Throttle

•

Configuration” screen.

Record all of the p arameters on the “Mode

•

Configuration” screen.

Record the serial numbers of the electronic unit

•

injectors. The injector serial numbers are shown

on the “Injector Trim Calibration” screen.

Note: If the parameters cannot be read, the

parameters must be obtained elsewhere. Some

parameters are stamped on the engine information

plate, but most parameters must be obtained from

thePTMIdataonthePerkinsintranet.

4. Remove power from the ECM.

5. Remove the ECM. Refer to Disassembly and

Assembly, “Electronic Control Module - Remove

and Install”.

6. Install the replacement ECM. Refer to Disassembly

and Assembly, “Electronic Control Module Remove and Install”.

7. If the replacement ECM is intended to be used

as a test ECM, select “Test ECM Mode” on the

electronic service tool.

Page 17

This document is printed from SPI². Not for RESALE

KENR6201-01 17

Troubleshooting Section

8. Download the flash file.

a. Connect the electronic service tool to the

diagnostic connector.

b. Select “WinFlash” from the “Utilities” menu of

the electronic service tool.

c. Select the downloaded flash file.

9. If necessar

the rating interlock. To clear the rating interlock,

enter the factory password when the electronic

service too

ECM mode will also clear the rating interlock.

10. Use the ele

parameters. Perform the following procedure.

a. If the “Cop

successful, use the “Copy Configuration, ECM

Replacement” function to load the configuration

file into t

Note: During the following procedure, factory

password

b. If the “Copy Configuration” procedure failed,

configur

parameters should match the parameters from

step 3.

Perform the “Fuel System Verification Test”.

11. Check f

passwords are required to clear logged events.

y, use the electronic service tool to clear

lisfirst connected. Activating the Test

ctronic service tool to program the

yConfiguration” procedure was

he ECM.

s may be required.

e the parameters individually. The

or logged diagnostic codes. Factory

Self-Diagnostics

i03538621

Logged

•

Active Code – An active diagnostic code indicates

that an active fault has been detected by the control

system. Activ

Always service active codes prior to servicing logged

codes.

Logged Code – Every generated code is stored

in the permanent memory of the ECM. The codes

are logged f

cleared by use of the electronic service tool.

Event Code –

detection of an abnormal engine operating condition.

For example, an event code will be generated if the

oil pressu

indicates the symptom of a fault.

Logged cod

needed. The fault may have been temporary. The

fault may have been resolved since the logging of

the code.

to generate an active diagnostic code whenever a

component is disconnected. When the component is

reconnec

codes may be useful to help troubleshoot intermittent

faults. Logged codes can also be used to review the

perform

e codes require immediate attention.

or 100 operating hours unless a code is

An event code is generated by the

re is too low. In this case, the event code

es may not indicate that a repair is

If the system is powered, it is possible

ted, the code is no longer active. Logged

ance of the engine and the electronic system.

i03473503

Sensors and Electrical

Connectors

The Electronic Control Module (ECM) and the

sensors are located on the left side of the engine.

RefertoFigure5.

The Electronic Control Module (ECM) has the ability

to detect faults in the electronic system and with

engine operation. A self-diagnostic check is also

performed whenever power is applied to the ECM.

When a fault is detected, a code is generated. An

alarm may also be generated. There are two types

of codes:

Diagnostic codes

•

Event codes

•

Diagnostic Code – When a fault in the electronic

system is detected, the ECM generates a diagnostic

code. This indicates the specific fault in the circuitry.

Diagnostic codes can have two different states:

Active

•

Page 18

This document is printed from SPI². Not for RESALE

18 KENR6201-01

Troubleshooting Section

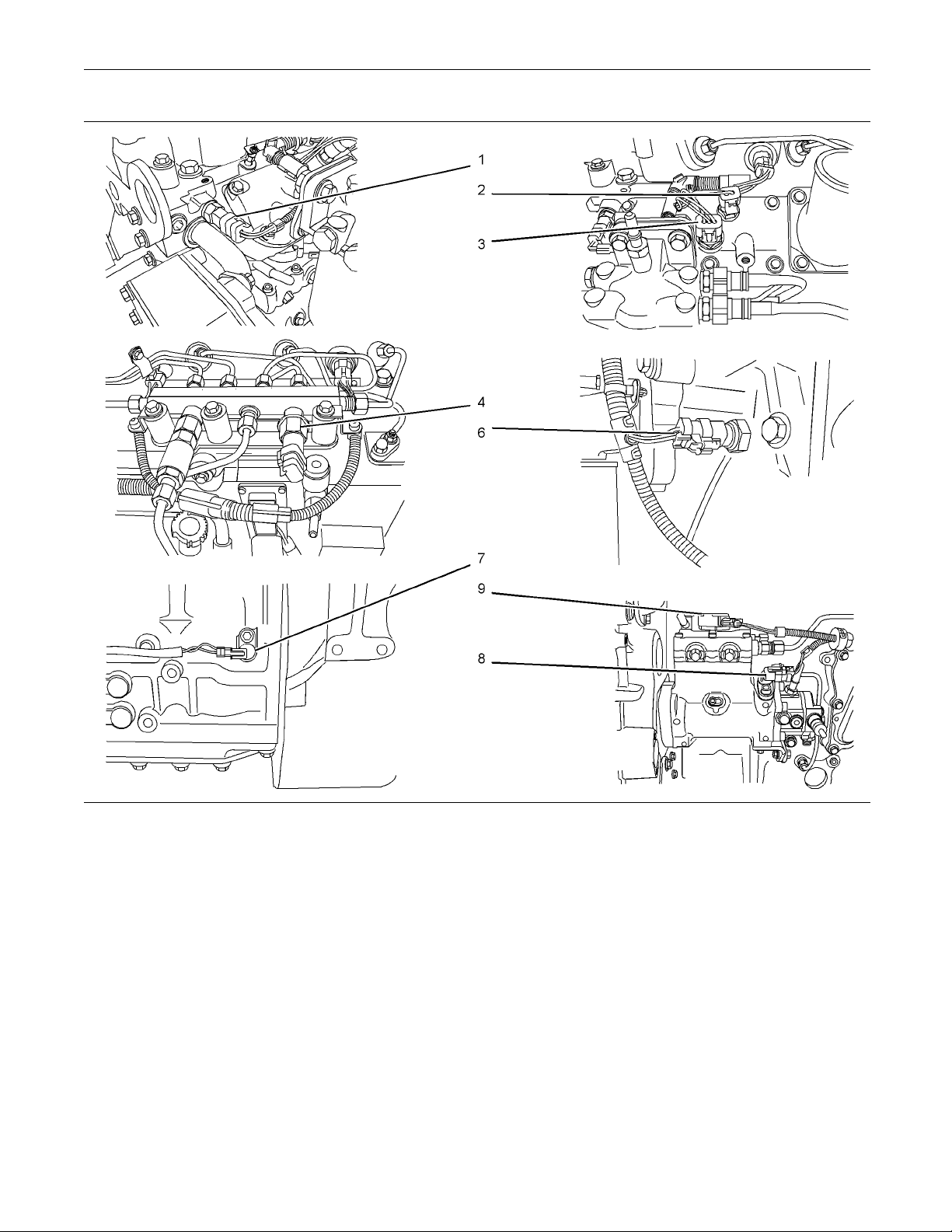

Illustration 5

Sensor locations

(1) Coolant Te mperature Sensor

(2) Intake Manifold Temperature Sensor

(3) Intake M anifold Pressure Sensor

(4) Fuel Rail Pressure S ensor

(5) Electronic Control Module (ECM)

(6) Oil Pressure S ensor

Note: If equipped, the wastegate regulator is installed

on the right side of the engine.

g01811780

(7) Primary S peed/Timing Senso r

(8) Secondary Speed/Timing Sens or

(9) Solenoid for the Fuel Rail Pump

Page 19

This document is printed from SPI². Not for RESALE

KENR6201-01 19

Troubleshooting Section

Illustration 6

Detailed views of the sensor locations

g01811835

Page 20

This document is printed from SPI². Not for RESALE

20 KENR6201-01

Troubleshooting Section

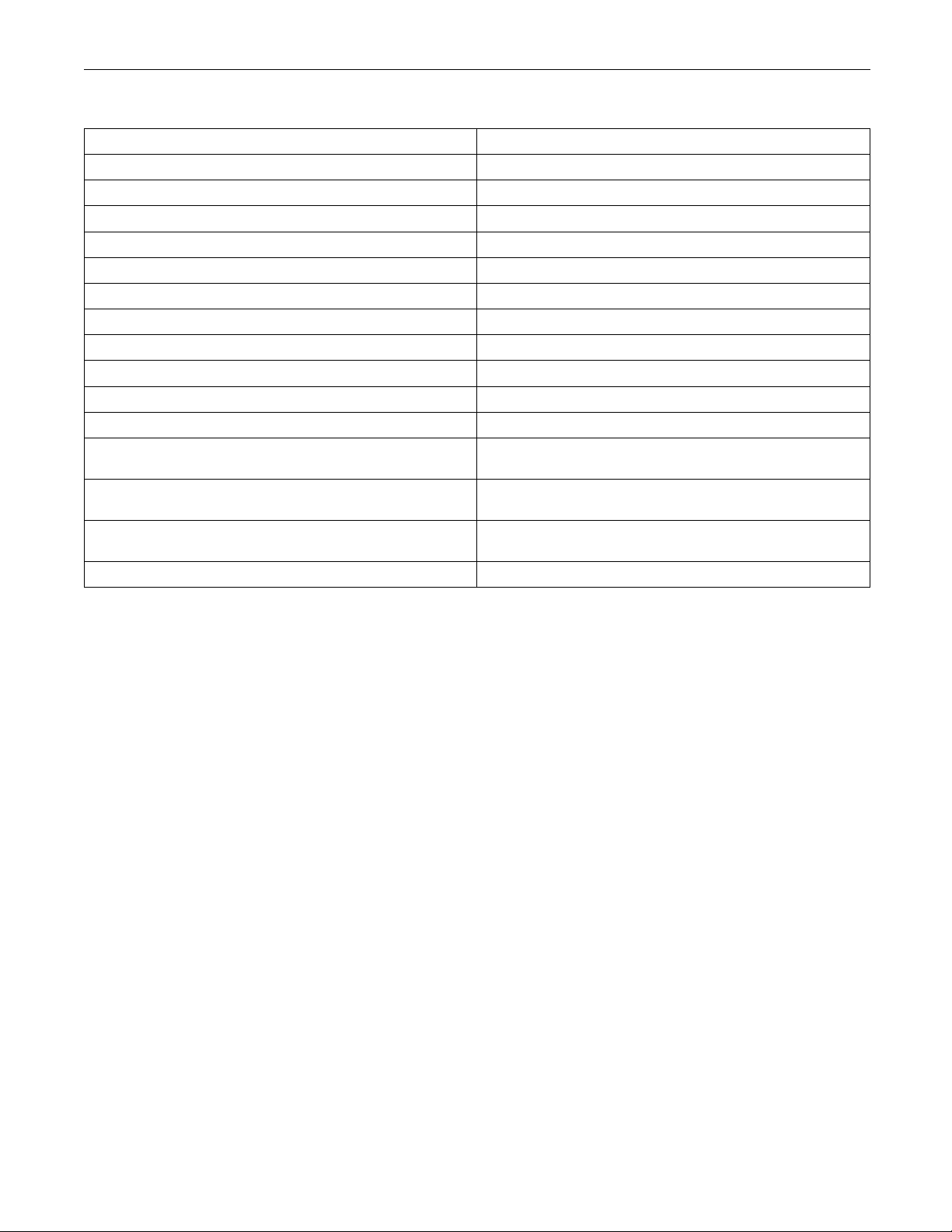

Table 5

Connector

P1

P2

P532

P402

P401

P201

P228

P200 Intake Manifold Pressure Sensor (3 Pin Connector)

P103 Intake Manifold Temperature Sensor (2 Pin Connector)

P100 Coolant Temperature Sensor (2 Pin Connector)

J23

P691/J691 Electronic Unit Injectors for No. 1 and No. 2 Cylinders (4 Pin

P692/J692 Electronic Unit Injectors for No. 3 and No. 4 Cylinders (4 Pin

P693/J693 Electronic Unit Injectors for No. 5 and No. 6 Cylinders (4 Pin

P511

Machine Harness to ECM Connector (64 Pin Connector)

Engine Harness to ECM Connector (64 Pin Connector)

Fuel Rail Pump Solenoid Connector (2 Pin Connector)

Secondary Speed/Timing Sensor (2 Pin Connector)

Primary Speed/Timing Sensor (2 Pin Connector)

Engine Oil Pressure Sensor (3 Pin Connector)

Fuel Rail Pressure Sensor (3 Pin Connector)

Diagnos

Connector)

Connector)

Connector)

Wastegate regulator (if equipped) (2 Pin Connector)

tic Connector (if equipped)

Function

Page 21

This document is printed from SPI². Not for RESALE

KENR6201-01 21

Troubleshooting Section

Illustration 7

(1) Electronic Unit Injector

(2) Solenoid for the Fuel Rail Pump

(3) Wastegate Regulator (if equipped)

(4) Secondary S peed/Timing Sensor

(5) Fuel Rail Pump

(6) Primary Spee d/Timing Sensor

(7) Intake Manifold Pressure Sensor

(8) Fuel Rail Pressure S ensor

(9) Engine O il Pressure Sensor

(10) Intake Manifold Temperature Sensor

Engine Wiring Information

Harness Wire Identification

i03805830

(11) Coolant Temperature Sensor

(12) Diagnostic Connector (if equipped)

(13) Electronic Control M odule (ECM)

Table 6

Color Codes for the Harness Wire

Color Code Color Color Code Color

BK Black BU Blue

BR Br

RD Red

own

PU Pu

GY Gray

g01808033

rple

Perkins identifies all wires with eleven solid colors.

The circuit number is stamped on the wire at a 25 mm

(1 inch) spacing. Table 6 lists the wire colors and the

OR Orange

YL Yellow PK Pink

WH White

color codes.

GN Green

Page 22

This document is printed from SPI². Not for RESALE

22 KENR6201-01

Troubleshooting Section

For example, a wire identification of F730-OR on

the schematic w

circuit number F730. F730-OR identifies the power

supply for the oil pressure sensor.

Note: Always replace a harness wire with the same

gauge of wire and with the same color code.

ould signify an orange wire with the

Page 23

This document is printed from SPI². Not for RESALE

KENR6201-01 23

Troubleshooting Section

Schematic Diagrams

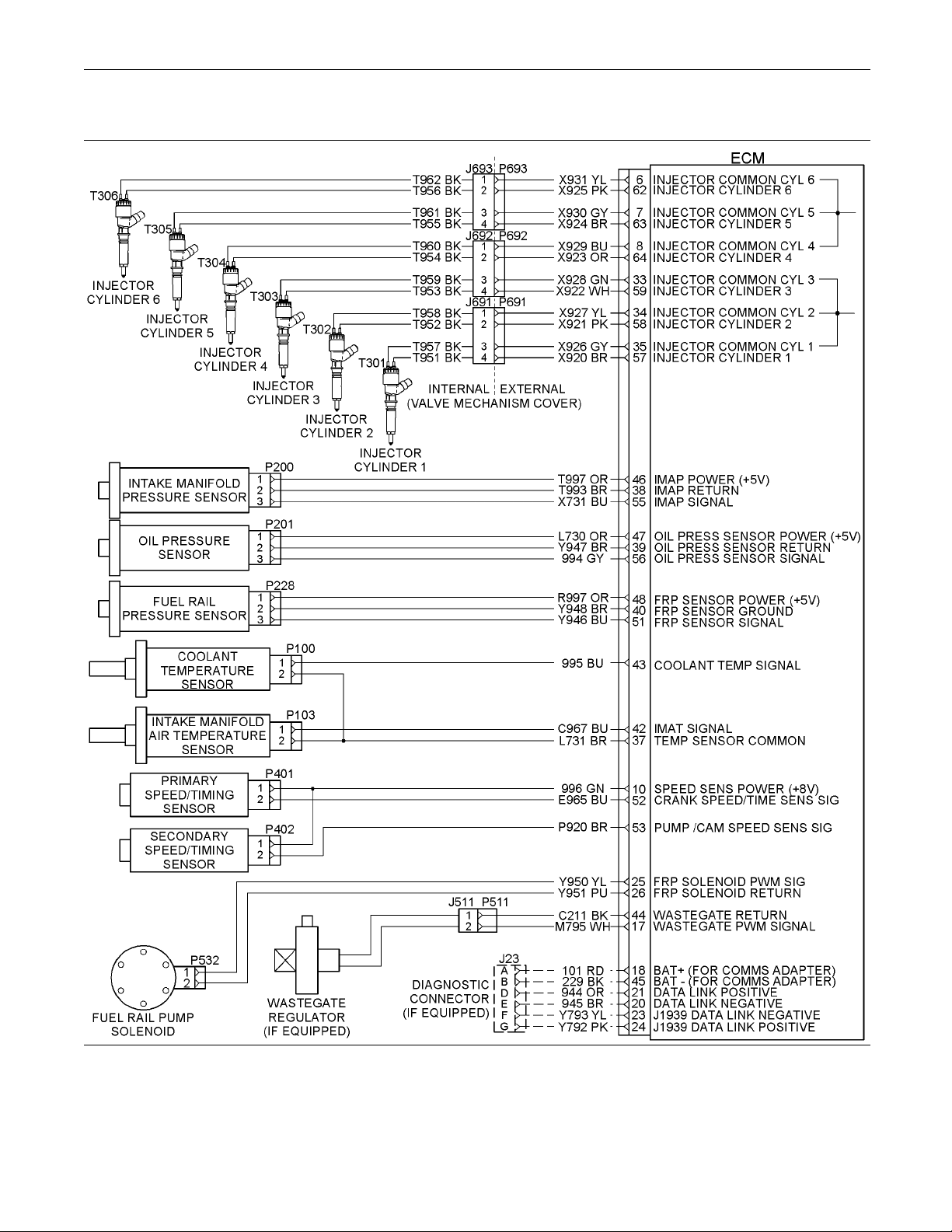

Illustration 8

hematic Diagram for the Engine Harness

Sc

g01782875

Page 24

This document is printed from SPI². Not for RESALE

24 KENR6201-01

Troubleshooting Section

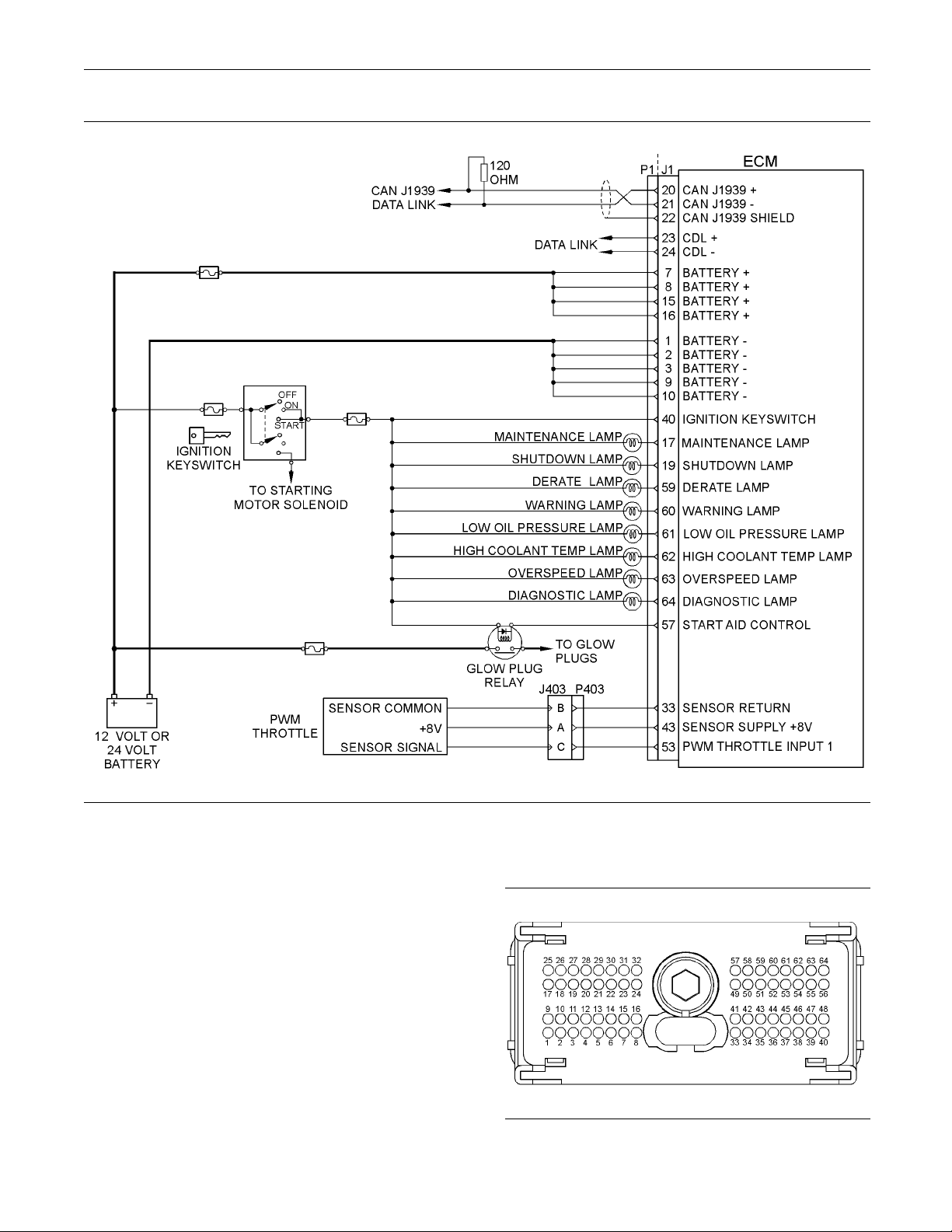

Illustration 9

Schematic Diagram for a Typical Application

i03434106

g02047353

ECM Harness Connector

Terminals

The Electronic Control Module (ECM) uses

connectors that have 64 terminals to interface to the

wiring harness.

Illustration 10

ayout of the Connector Pins (view from the rear)

L

g01784773

Page 25

This document is printed from SPI². Not for RESALE

KENR6201-01 25

Troubleshooting Section

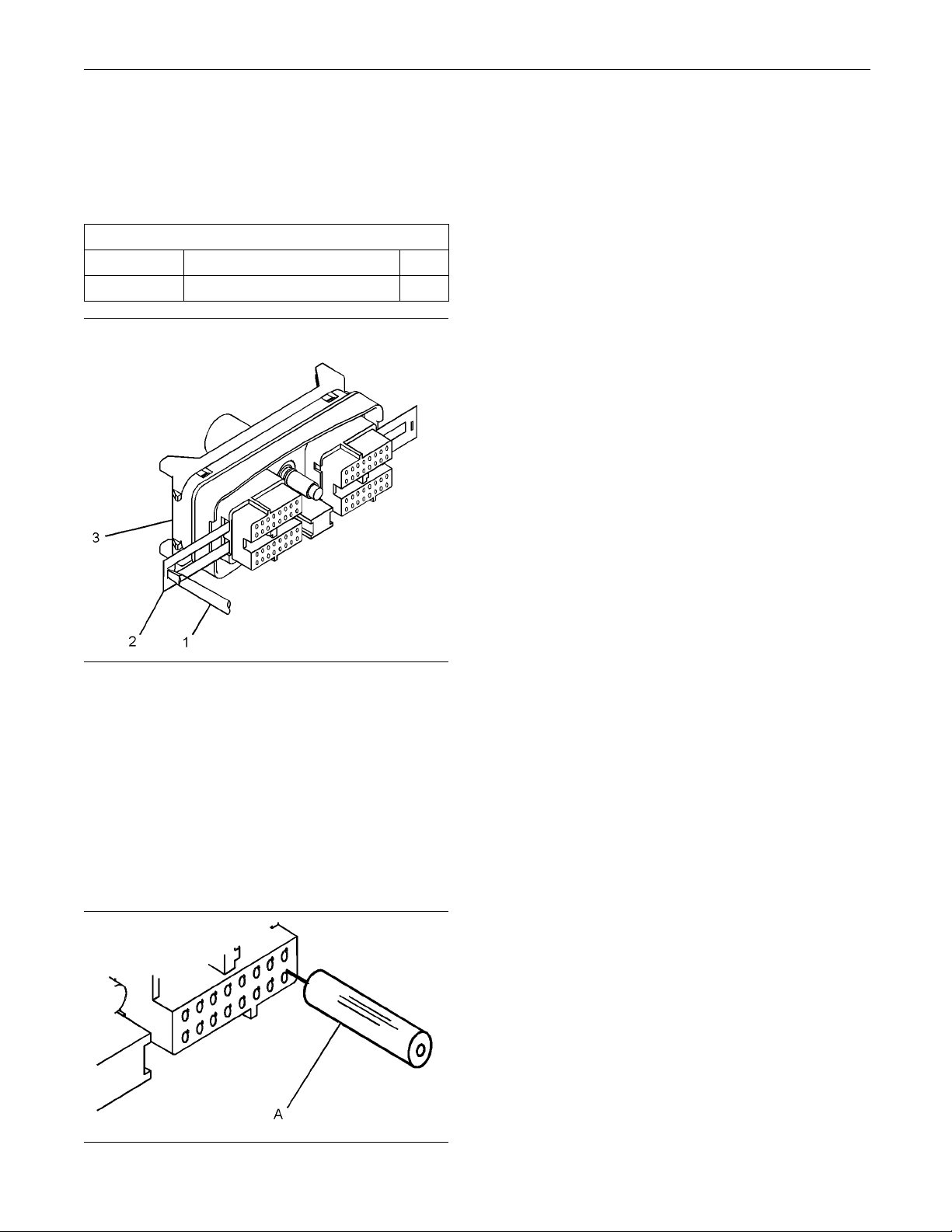

Removal and Installation of the

Harness Connector Terminals

Terminal Removal

Table 7

Required Tools

Part Number Part Description Qty

27610285 Removal Tool 1

3. Insert the removal tool into the hole that is

adjacent to the

locking device.

Note: Make sur

the face of the connector.

4. Hold the tool

order to remove the terminal from the rear of the

connector (3).

5. Remove the removal tool from the face of the

connector (3).

Note: If a terminal must be replaced, part number

28170085 must be used.

terminal in order to release the

e that the tool stays perpendicular to

in position and gently pull the wire in

Terminal Insertion

1. Push the te

until the terminal engages with the locking device.

2. Gently pu

the terminal is retained by the locking device.

3. Install

components (2) into the sides of the connector (3).

rminal into the rear of the connector (3)

llonthewireinordertomakesurethat

the two terminal position assurance

Illustration 11

Removal of Terminal Position Assurance Components

1. Remove the connector from the ECM. Refer to

Disassembly and Assembly, “Electronic Control

Module - Remove and Install”.

2. Use a screwdriver that has a flat blade (1) to

remove the two terminal position assurance

components (2) from the connector (3).

Note: Do not use the removal tool to remove the

terminal position assurance components.

g01784793

4. Connect

Disassembly and Assembly, “Electronic Control

Module - Remove and Install”.

the connector to the ECM. Refer to

Illustration 12

Removal Tool

g01784822

Page 26

This document is printed from SPI². Not for RESALE

26 KENR6201-01

Troubleshooting Section

Programming Pa

rameters

i02415216

Programming Parameters

Theelectronicservicetoolcanbeusedtoview

certain parameters that can affect the operation of the

engine. The electronic service tool can also be used

to change certain parameters. The parameters are

stored in the Electronic Control Module (ECM). Some

of the parameters are protected from unauthorized

changes by passwords. Parameters that can be

changed have a tattletale number. The tattletale

number shows if a parameter has been changed.

i0343420

Test ECM Mode

“Test EC

can be used to help troubleshoot an engine that may

have a fault in the Electronic Control Module (ECM).

This fe

test ECM. This feature eliminates the need to stock

atestECM.

M Mode” is a feature in the software that

ature allows a standard ECM to be used as a

Note: “Test ECM Mode” can only be activated if

the engine seri

programmed during normal operation of the ECM.

If the engine serial number is programmed and the

ECM is not in “T

be used as a test ECM.

6. Use the “Copy

electronic service tool to program the test ECM.

Note: If the

used, program the test ECM with the values from the

“Customer Specified Parameters Worksheet” and the

values from

7. Program the engine serial number into the test

ECM.

Note: The “Test ECM Mode” must be activated

4

before the

the ECM.

8. Verify th

When the “Test ECM Mode” is activated, an internal

timer set

only while the ECM is powered and the keyswitch

is in the ON position. After the ECM has counted

down the

ECM Mode”. The parameters and the engine serial

number will be set.

al number has not already been

est ECM Mode”, the ECM can never

Configuration” feature on the

“ECM Replacement” feature can not be

the System Configuration Parameters.

engine serial number is programmed into

at the test ECM rectifies the fault.

s a 24 hour clock. This clock will count down

24 hour period, the ECM will exit the “Test

1. Search for the latest flash file for the engine.

If a newer software version is available for the

Note:

engine, install the newest software on the suspect

ECM. If the new software does not rectify the fault,

inue with this procedure.

cont

2. Use the “Copy Configuration” feature on the

tronic service tool to copy the parameters

elec

from the suspect ECM.

e: If the “ECM Replacement” feature cannot

Not

be used, record the programmed values into the

“Customer Specified Parameters Worksheet”. Also

ord the system configuration parameters.

rec

3. Disconnect the suspect ECM. Temporarily connect

e test ECM to the engine. Do not mount the test

th

ECM on the engine.

ash program the test ECM with the newest

4. Fl

software that is available.

art the “Test ECM Mode” on the electronic

5. St

service tool. Access the feature through the

“Service” menu. The electronic service tool will

isplay the status of the test ECM and the hours

d

that are remaining for the “Test ECM Mode”.

If the test ECM rectifies the fault, the engine can be

released while the “Test ECM Mode” is still active.

Once an ECM has been activated in the “Test ECM

Mode”, the ECM will stay in the “Test ECM Mode”

the timer times out. If the ECM is used as a test

until

ECM for more than one engine, the “Test ECM Mode”

must be reactivated. Anytime prior to the “Test ECM

Mode”

timing out, the ECM can be reset to 24 hours.

i03434261

Factory Passwords

NOTICE

Operating the engine with a flash file not designed for

that engine will damage the engine. Be sure the flash

file is correct for your engine.

Note: Factory passwords are provided only to

Perkins dealers.

Factory passwords are required to perform each of

the following functions:

Page 27

This document is printed from SPI². Not for RESALE

KENR6201-01 27

Troubleshooting Section

Program a new Electronic Control Module (ECM).

•

When an ECM is replaced, the system configuration

parameters must be programmed into the new

ECM. A new ECM w

be programmed once without factory passwords.

After the initial programming, some parameters are

protected by

Rerate the engine.

•

This may require changing the interlock code,

which is protected by factory passwords.

Clear engine events and certain diagnostic codes.

•

Most engin

order to clear the code from ECM memory. Clear

these codes only when you are certain that a fault

has been re

Overspeed requires the use of factory passwords

in order to clear the code from ECM memory.

Since factory passwords contain alphabetic

characters, the electronic service tool must be

used to pe

factory passwords, proceed as if you already have

the password. If factory passwords are needed,

the elec

passwords and the electronic service tool will

display the information that is required to obtain the

passwor

tronic service tool will request the factory

ds.

factory passwords.

e events require factory passwords in

ctified. For example, the E362-1 Engine

rform these functions. In order to obtain

ill allow these parameters to

i03807

Flash Programming

230

4. Select “WinFlash” from the “Utilities” menu on the

electronic ser

Note: If “WinFlash” will not communicate with the

ECM, refer to T

Tool Will Not Communicate with ECM”.

5. Program the fl

a. Select the engine ECM under the “Detected

ECMs”.

b. Press the “Browse” button in order to select

the part num

programmed into the ECM.

c. When the co

the “Open” button.

d. Verify tha

application. If the “File Values” do not match

the application, search for the correct flash file.

e. When the correct flash file is selected, press

the “Begin Flash” button.

f. The electronic service tool will indicate

when programming has been successfully

complet

6. Start the engine and check for proper operation.

7. Access the “Configuration” screen under the

“Service” menu in order to determine the

parame

the “Tattletale” column. All of the parameters

should have a tattletale of 1 or more. If a parameter

has a t

vice tool.

roubleshooting, “Electronic Service

ash file into the ECM.

ber of the flash file that will be

rrect flash file is selected, press

t the “File Values” match the

ed.

ters that require programming. Look under

attletale of 0, program that parameter.

h Programming – A method of loading a flash

Flas

file into the Electronic Control Module (ECM)

lectronic service tool can be utilized to program

The e

a flash file into the ECM. The programming transfers

the flash file from the PC to the ECM.

Flash Programming a Flash File

1. Obtain the part number for the new flash file.

te: If you do not have the part number for the flash

No

file, use “PTMI” on the Perkins Intranet.

te: You must have the engine serial number in

No

order to search for the part number for the flash file.

nnect the electronic service tool to the service

2. Co

tool connector.

urn the keyswitch to the ON position. Do not start

3.T

the engine.

“WinFlash” Error Messages

If you receive any error messages during

programming, click on the “Cancel” button in order

op the process. Access the information about

to st

the “ECM Summary” under the “Information” menu.

Ensure that you are programming the correct flash