Page 1

Disassembly and

Assembly

SENR9983

October 2005

1106D Ind

PJ (Engine )

ustrial Engine

Page 2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

SENR9983 3

Table of Contents

Table of Contents

Disassembly and Assembly Section

Fuel Priming Pump - Remove and Install .............. 4

Fuel Filter Base - Remove and Install (Secondary

Fuel Filter) ............................................................. 7

Fuel Transfer Pump - Remove ................................ 8

Fuel Transfer Pump - Install .................................. 10

Fuel Injection Lines - Remove .............................. 11

Fuel Injection Lines - Install ................................. 12

Fuel Manifold (Rail) - Remove and Install ............. 14

Fuel Injection Pump - Remove ............................ 16

Fuel Injection Pump - Install ................................ 18

Fuel Injection Pump Gear - Remove .................... 22

Fuel Injection Pump Gear - Install ........................ 23

Electronic Unit Injector - Remove ......................... 25

Electronic Unit Injector - Install ............................. 28

Turbocharger - Remove ........................................ 32

Turbocharger - Disassemble ................................ 35

Turbocharger - Assemble .................................... 35

Turbocharger - Install ............................................ 36

Wastegate Solenoid - Remove and Install ............ 40

Exhaust Manifold - Remove and Install ............... 41

Exhaust Elbow - Remove and Install ................... 45

Inlet Manifold - Remove and Install ..................... 46

Inlet and Exhaust Valve Springs - Remove and

Install ................................................................... 48

Inlet and Exhaust Valves - Remove and Install .... 52

Engine Oil Filter Base - Remove and Install ........ 55

Engine Oil Cooler - Remove ................................. 56

Engine Oil Cooler - Install ..................................... 58

Engine Oil Relief Valve - Remove and Install ....... 61

Engine Oil Pump - Remove .................................. 63

Engine Oil Pump - Install ...................................... 64

Water Pump - Remove ......................................... 65

Water Pump - Install ............................................. 66

Water Temperature Regulator - Remove and Install

............................................................................. 67

Flywheel - Remove ............................................... 69

Flywheel - Install ................................................... 70

Crankshaft Rear Seal - Remove ........................... 71

Crankshaft Rear Seal - Install ............................... 72

Crankshaft Wear Sleeve (Rear) - Remove and

Install ................................................................... 75

Flywheel Housing - Remove and Install .............. 76

Vibration Damper and Pulley - Remove .............. 81

Vibration Damper and Pulley - Install .................. 82

Crankshaft Front Seal - Remove and Install ......... 84

Crankshaft Wear Sleeve (Front) - Remove and

Install ................................................................... 85

Front Cover - Remove and Install ......................... 86

Gear Group (Front) - Remove and Install ............. 88

Idler Gear - Remove ............................................. 91

Idler Gear - Install ................................................. 93

Housing (Front) - Remove .................................... 96

Housing (Front) - Install ........................................ 98

Accessory Drive - Remove and Install ............... 100

Crankcase Breather - Remove ........................... 101

Crankcase Breather - Install ............................... 104

Valve Mechanism Cover - Remove and Install ... 108

Valve Mechanism Cover Base - Remove and

Install ................................................................. 109

Rocker Shaft and Pushrod - Remove .................. 111

Rocker Shaft - Disassemble ............................... 112

RockerShaft-A

Rocker Shaft and Pushrod - Install ...................... 114

Cylinder Head - Remove ..................................... 116

Cylinder Head -

Lifter Group - Remove and Install ....................... 122

Camshaft - Remove and Install ......................... 123

Camshaft Gear - R

Camshaft Bearings - Remove and Install .......... 127

Engine Oil Pan - Remove .................................. 129

Engine Oil Pan - In

Piston Cooling Jets - Remove and Install ........... 138

Pistons and Connecting Rods - Remove ............ 139

Pistons and Conne

Pistons and Connecting Rods - Assemble ......... 142

Pistons and Connecting Rods - Install ................ 144

Connecting Rod Bea

rods in position) ................................................. 145

Connecting Rod Bearings - Install (Connecting rods

in position) ......................................................... 146

Crankshaft Main Bearings - Remove and Install

(Crankshaft in position) ..................................... 148

Crankshaft - Remo

Crankshaft - Install .............................................. 152

Crankshaft Timing Ring - Remove and Install .... 155

Crankshaft Gear - R

Bearing Clearance - Check ................................. 158

Crankshaft Position Sensor - Remove and

Install ................................................................. 159

Coolant Temperature Sensor - Remove and

Install ................................................................. 159

Engine Oil Pressur

........................................................................... 161

Position Sensor (Fuel Injection Pump) - Remove and

Install ................................................................. 162

Fuel Pressure Sensor - Remove and Install ....... 163

Boost Pressure Sensor - Remove and Install ..... 164

Inlet Air Temperat

Install ................................................................. 165

Glow Plugs - Remove and Install ....................... 166

Alternator Belt - R

Fan - Remove and Install ................................... 168

Fan Drive - Remove and Install ......................... 169

Electronic Control

ECM Mounting Bracket - Remove and Install ..... 172

Alternator - Remove ............................................ 175

Alternator - Instal

Electric Starting Motor - Remove and Install ..... 177

ssemble .................................... 113

Install ......................................... 118

emove and Install ................ 125

stall ...................................... 131

cting Rods - Disassemble ..... 140

rings - Remove (Connecting

ve .......................................... 151

emove and Install .............. 156

e Sensor - Remove and Install

ure Sensor - Remove and

emove and Install .................. 167

Module - Remove and Install .. 170

l ................................................ 176

Index Section

Index ................................................................... 178

Page 4

4 SENR9983

Disassembly and Assembly Section

Disassembly an

d Assembly

Section

i02295884

FuelPrimingPump-Remove

and Install

Removal Procedure (Manual

Priming Pump

Ensure that all adjustments and repairs that are

carried out t

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard

Lines” for safety information.

Refer to Tes

liness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obs

system.

o the fuel system a re performed by

Information and High Pressure Fuel

ting and Adjusting Manual, “Clean-

erved during ALL work on the fuel

)

NOTICE

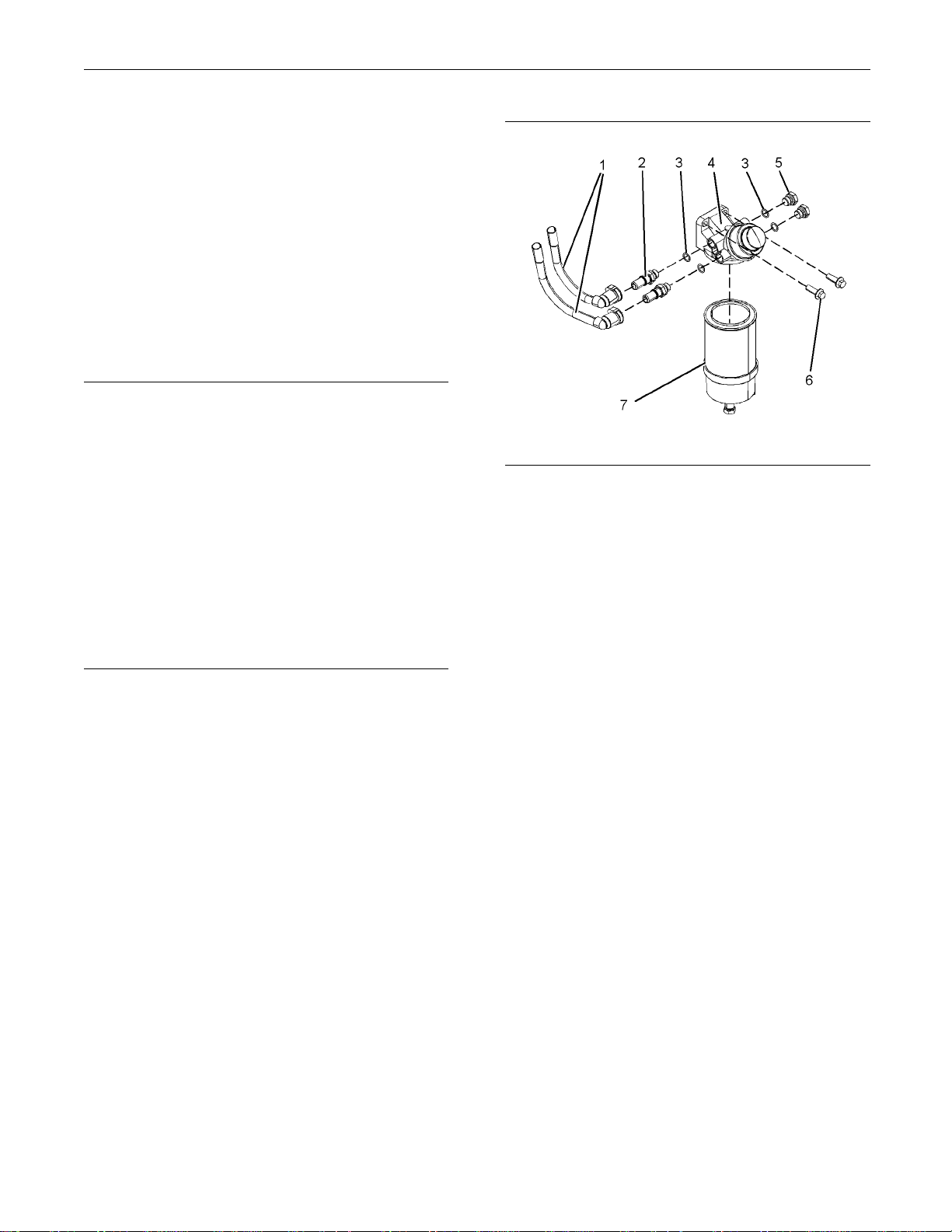

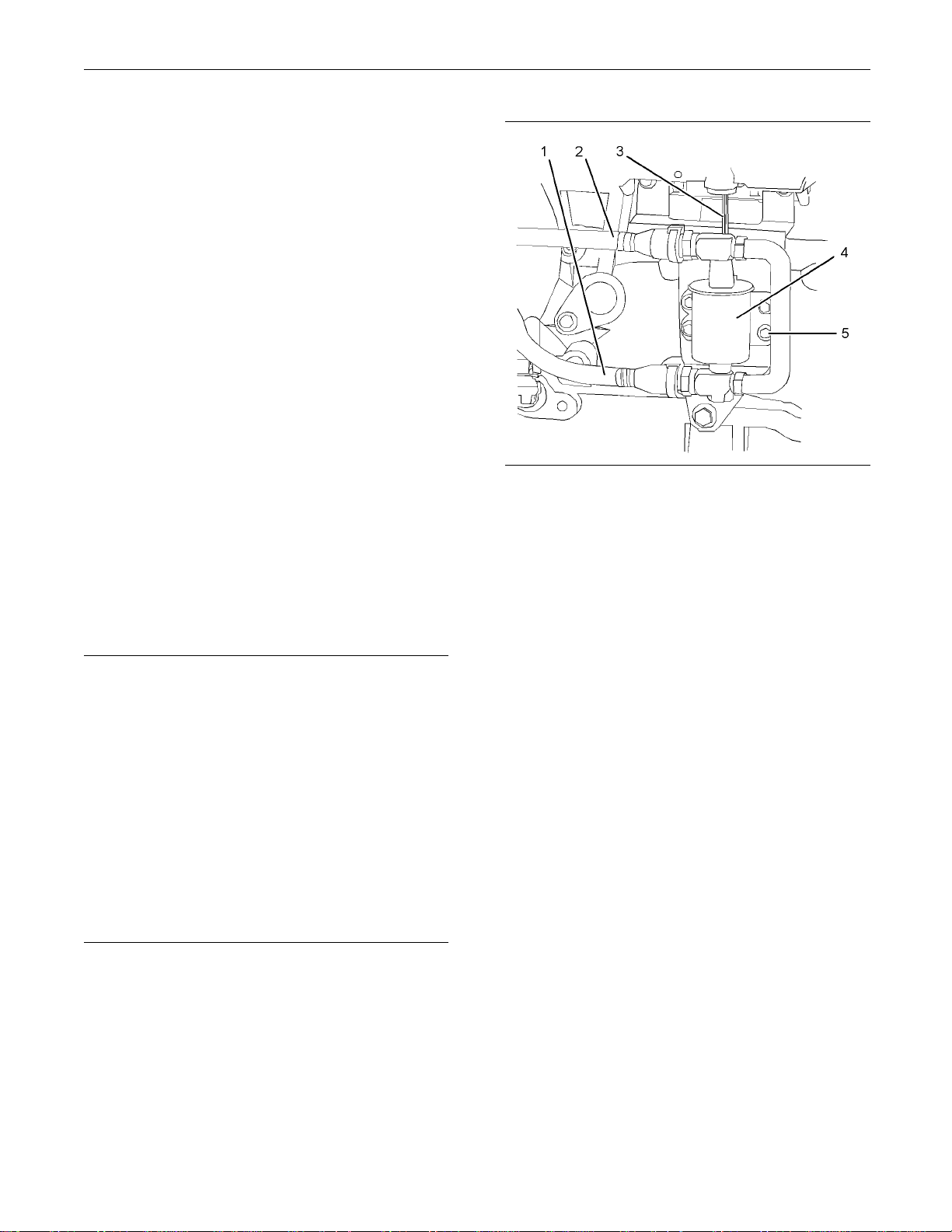

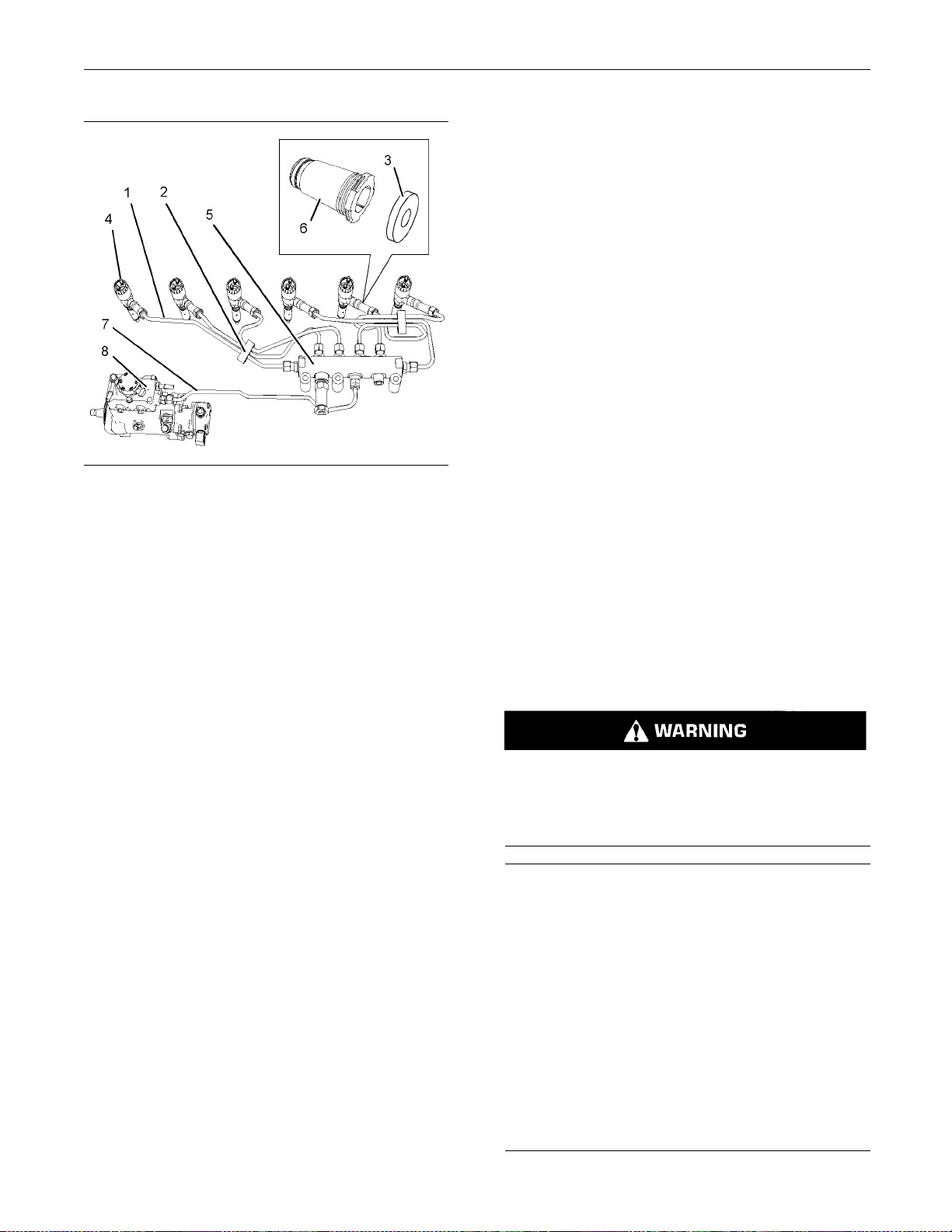

Illustration 1

Typical example

4. Disconnect the plastic tube assemblies (1). Plug

the tube assemblies with new plugs. Cap the open

connectors (2) on the fuel priming pump with new

caps.

5. Remove the primary filter (7) from the fuel priming

pump (4). Refer to Operation and Maintenance

Manual, “Fuel System Primary Filter (Water

Seperator) Element - Replace”.

g01181971

1. Isolate th

2. Makeatemporaryidentificationmarkonthe

plastic tu

correct position of the tube assemblies.

3. Place a sui

pump in order to catch any fuel that might

be spilled. Drain the primary filter (7). Refer

to Operat

System Primary Filter (Water Seperator) Element

-Replace”.

Note: Clean up any spillage of fuel immediately.

e fuel supply.

be assemblies (1) in order to show the

table container below the fuel priming

ion and Maintenance Manual, “Fuel

6. Remove the two setscrews (6) from the fuel

priming pump (4). Remove the fuel priming pump

(4) from the mounting bracket.

7. If necessary, follow Steps 7.a through 7.c in order

to disassemble the fuel priming pump (4).

a. Remove the connectors (2) from the fuel

priming pump (4).

b. Remove the plugs (5) from the fuel priming

pump (4).

c. Remove the O-ring seals (3) from the

connectors (2) and the plugs (5). Discard the

O-ring seals.

Page 5

SENR9983 5

Disassembly and Assembly Section

Removal Procedure (Electric Fuel

Priming Pump)

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be observed during ALL work on the fuel

system.

1. Isolate the fuel supply.

7. Remove the e lectric priming pump (4) from the

mounting brack

Installation P

et.

rocedure (Manual

Priming Pump)

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised pe

ing.

Before begin

fer to Operation and Maintenance Manual, “General Hazard Information and High Pressure Fuel

Lines” for sa

Refer to Testing and Adjusting Manual, “Cleanliness of Fue

information on the standards of cleanline ss that

must be observed during ALL work on the fuel

system.

1. Ensure that the fuel priming pump (4) is clean and

free from we

the fuel priming pump.

rsonnel that have the correct train-

ing ANY work on the fuel system, re-

fety information.

l System Components” for detailed

ar or damage. If necessary, replace

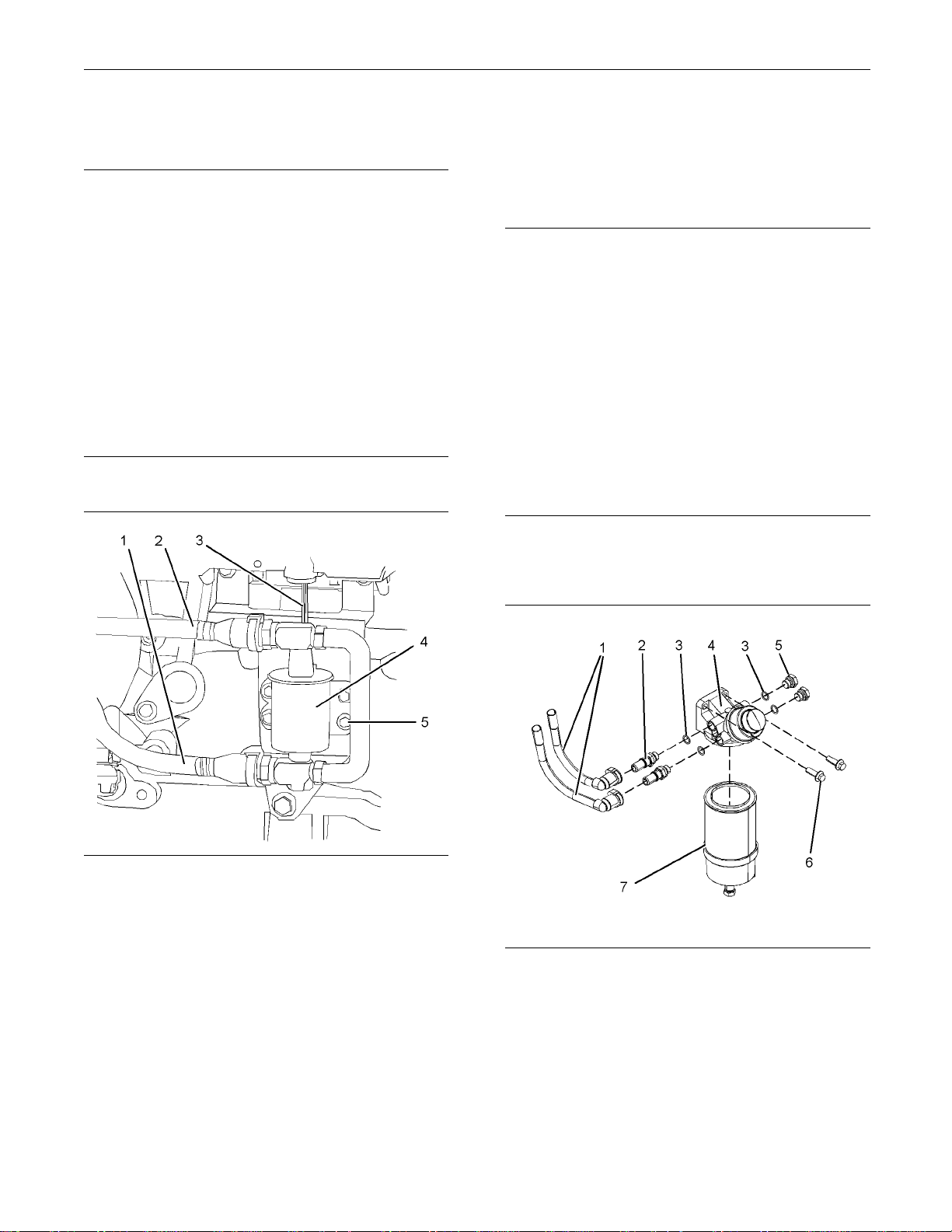

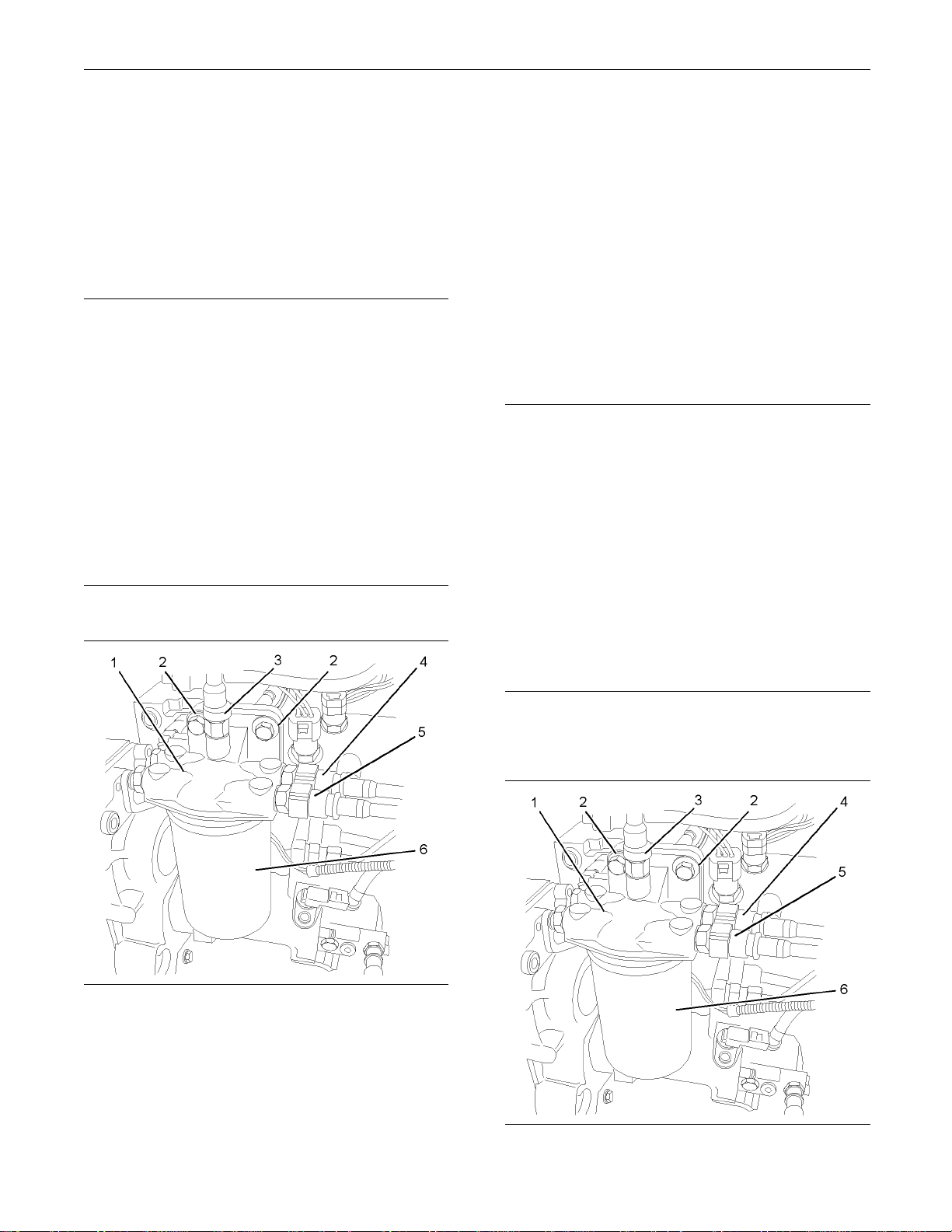

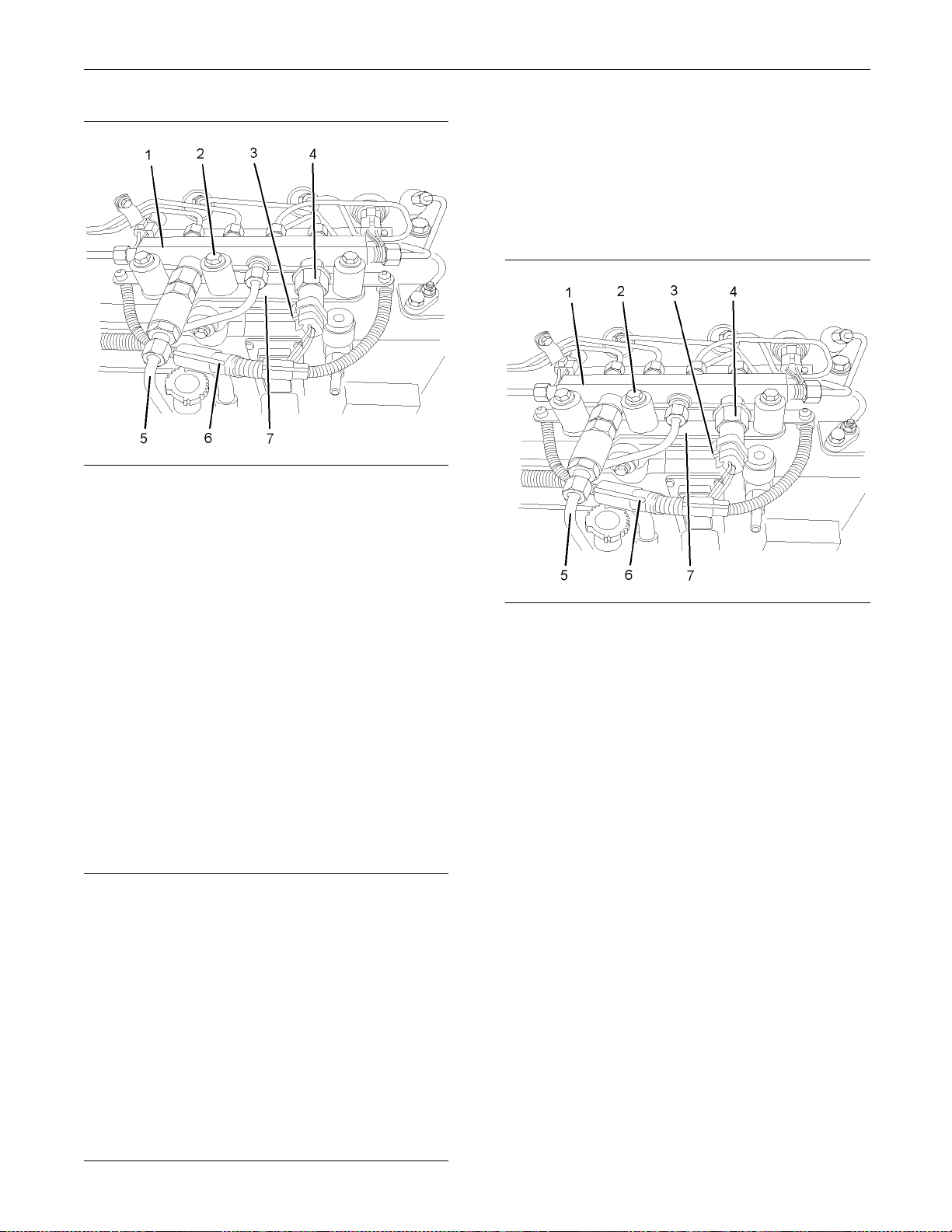

Illustration 2

Typical exam p le

2. Isolate the electrical supply.

3. Disconnect the electrical lead (3) for the electric

priming pump (4).

4. Makeatemporaryidentificationmarkonthe

plastic tube assemblies (1) and (2) in order to

show the correct position of the tube assemblies.

5. Disconnect the plastic tube assemblies (1) and (2).

Plug the tube assemblies with new plugs. Cap the

ports in the fuel priming pump (4) with new caps.

6. Remove the four setscrews (5) from the electric

priming pump (4).

g01186418

Illustration 3

Typical example

2. If necessary, follow Steps 2.a through 2.d in order

to assemble the fuel priming pump (4).

a. Install new O-ring seals (3) to the connectors

(2) and to the plugs (5).

b. Install the connectors (2) to the fuel priming

pump (4).

c. Install the plugs (5) to the fuel priming pump (4).

g01181971

Page 6

6 SENR9983

Disassembly and Assembly Section

d. Tighten the plugs and the connectors to a

torque of 20 N·m

3. Position the fuel priming pump (4) on the mounting

bracket. Inst

primingpump.Tightenthesetscrewstoatorque

of 44 N·m (32 lb ft).

4. Remove the plugs from the plastic tube

assemblies. Remove the caps from the

connectors.

5. Connect the plastic tube assemblies (1) to the

connectors (

Note: Ensure that the plastic tube assemblies are

installed in

6. Install a new primary filter (7) to the fuel priming

pump (4). Ref

Manual, “Fuel System Primary Filter (Water

Seperator) Element - Replace”.

7. Restore the fuel supply.

8. Prime the fu

Maintenance Manual, “Fuel System - Prime”.

all the two setscrews (6) to the fuel

2).

the original positions.

el system. Refer to Operation and

(14 lb ft).

er to Operation and Maintenance

Illustration 4

Typical example

2. Position the electric priming pump (4) on the

mounting bracket. Install the four setscrews (5) to

the electric priming pump (4).

g01186418

Installation Procedure (Electric

Fuel Primin

Ensure that all adjustments and repairs that are

carried out

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazar

Lines” for safety information.

Refer to T

liness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be ob

system.

1. Ensure th

and free from wear or damage. If necessary,

replace the electric priming pump.

g Pump)

NOTICE

to the fuel system a re performed by

d Information and High Pressure Fuel

esting and Adjusting Manual, “Clean-

served during ALL work on the fuel

at the electric priming pump (4) is clean

3. Tighten the setscrews (5) to a torque of 9 N·m

(79 lb in).

4. Remove the plugs from the plastic tube

assemblies. Remove the caps from the electric

priming pump.

5. Connect the plastic tube assemblies (1) and (2) to

the electric priming pump (4).

Note: Ensure that the plastic tube assemblies are

installed in the original positions.

6. Connect the electrical lead (3) for the electric

priming pump (4).

7. Restore the electrical supply.

8. Restore the fuel supply.

9. Prime the fuel system. Refer to Operation and

Maintenance Manual, “Fuel System - Prime”.

Page 7

SENR9983 7

Disassembly and Assembly Section

i02295889

Fuel Filter Base - Remove and

Install

(Secondary Fue

Removal Procedure

Ensure that all adjustments and repairs that are

carried out to t

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

Lines” for safety information.

Refer to Test

liness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obser

system.

he fuel system are performed by

formation and High Pressure Fuel

ing and Adjusting Manual, “Clean-

ved during ALL work on the fuel

l Filter)

NOTICE

4. Disconnect the plastic tube assemblies (3), (4)

and (5) from the

tube assemblies with new plugs. Cap the ports in

the fuel filter base with new caps.

5. Remove the fuel filter (6). Refer to Operation and

Maintenance Manual, “Fuel System Secondary

Filter - Repl

6. Remove the two setscrews (2) from the fuel filter

base (1). Rem

mounting bracket.

Note: Do not d

Installatio

Ensure that al

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Opera

eral Hazard Information and High Pressure Fuel

Lines” for s afety information.

fuel filter base (1). Plug the plastic

ace”.

ove the fuel filter base from the

isassemble the fuel filter base.

n Procedure

NOTICE

l adjustments and repairs that are

tion and Maintenance Manual, “Gen-

1. Isolate the f

Illustration 5

Typical exam p le

2. Make temporary identification marks on the plastic

tube assemblies (3), (4) and (5) in order to show

the correct position of the tube assemblies.

uel supply.

g01165584

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

informatio

must be observed during ALL work on the fuel

system.

1. Ensure that the fuel filter base (1) is clean and free

from damage. If necessary, replace the complete

fuel filte

n on the standards of cleanliness that

r base and filter assembly.

3. Place a suitable container below the fuel filter base

in order to catch any fuel that might be spilled.

Note: Clean up any spillage of fuel immediately.

Illustration 6

Typical example

g01165584

Page 8

8 SENR9983

Disassembly and Assembly Section

2. Position the fuel filter base (1) on the mounting

bracket. Insta

setscrews to a torque of 44 N·m (32 lb ft).

3. Remove the plu

assemblies. Remove the caps from the ports in

the fuel filter base.

Ensure that th

in the original positions. Failure to connect the plastic

tube assemblies to the correct ports will allow contamination to en

cause serious damage to the engine.

4. Connect the p

(5) to the fuel filter base (1).

Note: Ensure

installed in the original positions. Failure to connect

the plastic tube assemblies to the correct ports

will allow c

Contaminated fuel will cause serious damage to the

engine.

5. If necessary, install a new fuel filter (6) to the

fuel filter base (1). Refer to Operation and

Maintenanc

Filter - Replace” for the correct procedure.

6. Restore th

End By:

ll the setscrews (2). Tighten the

gs from the plastic tube

NOTICE

e plastic tube assemblies are installed

ter the fuel system. Contaminated fuel will

lastic tube assemblies (3), (4) and

that the plastic tube assemblies are

ontamination to enter the fuel system.

e Manual, “Fuel System Secondary

e fuel supply.

i02296828

Fuel Transfer Pump - Remove

Removal Proced

Ensure that all

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operati

eral Hazard Information and High Pressure Fuel

Lines” for s afety information.

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information

must be observed during ALL work on the fuel

system.

1. Isolate the fuel supply.

2. Place a suita

pump (1) in order to catch any fuel that might be

spilled.

Note: Clean up any spillage of fuel immediately.

adjustments and repairs that are

on and Maintenance Manual, “Gen-

on the standards of cleanliness that

ble container below the fuel transfer

ure

NOTICE

a. Remove the air from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

- Prime”.

Page 9

SENR9983 9

Disassembly and Assembly Section

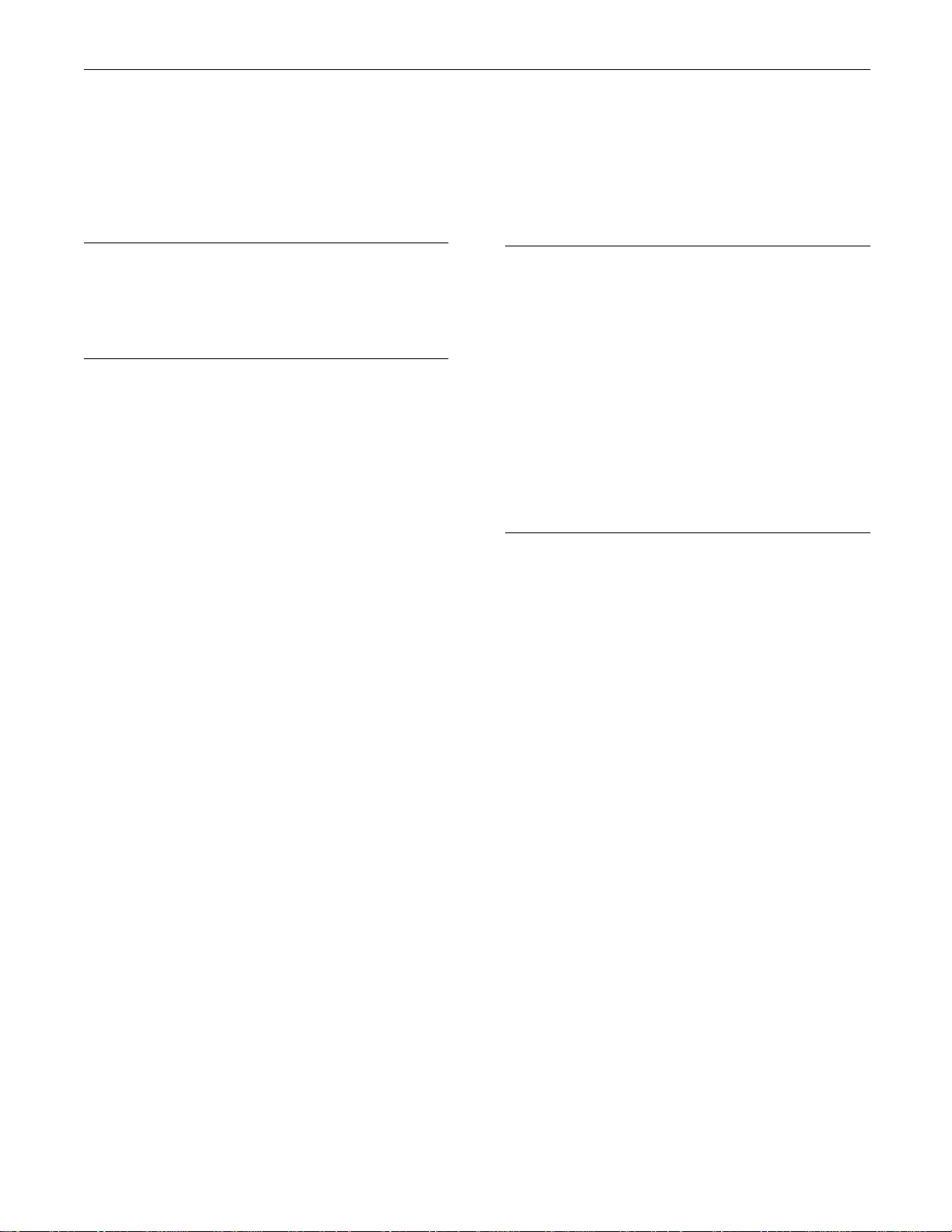

ion 7

Illustrat

Typical exam p le

g01162545

3. Remove the plastic tube assembly (2) from the

fuel transfer pump (1).

4. Disconnect the plastic tube assembly (3) from the

outlet of the fuel transfer pump (1).

5. Remove the connector (4) from the fuel transfer

pump (1). Remove the O-ring seal (not shown)

from the c

onnector (4). Discard the O-ring seal.

If necessary, remove the connector (7) from the

fuel tran

sfer pump (1). Remove the O-ring seal

(not shown) from the connector (7). Discard the

O-ring seal.

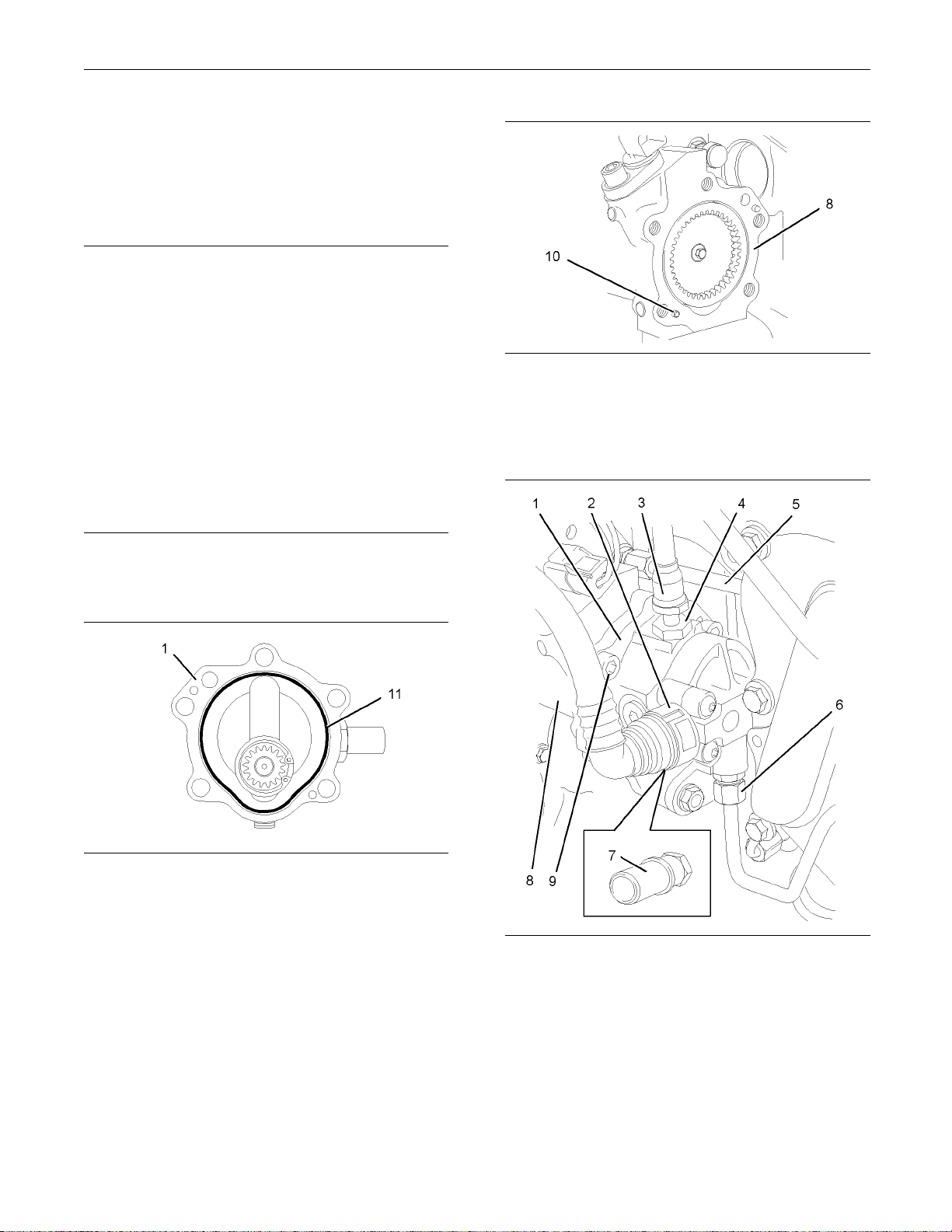

Illustration 8

g01162543

10. Remove fuel transfer pump (1) from the fuel

injection pump (8).

Note: Do not remove the dowels (10) from the fuel

injection pump.

Illustrat

ion 9

g01162544

11. Remove the O-ring seal (11) from the fuel transfer

pump (1). D

iscard the O-ring seal.

6. Remove the tube assembly (6) for the fuel return

from the fuel transfer pump and the cylinder head.

Note: Disconnect the tube assembly at the fuel

transfer pump first in order to drain the fuel from the

cylinde

r head.

7. Remove the tube assembly (5) for the engine oil

supply f

rom the fuel injection pump (8).

8. Plug or cap all open ports and tube assemblies

immedi

ately with new plugs or caps.

9. Use an allen wrench with a ball end in order to

remove

the five allen head screws (9) that secure

the fuel transfer pump to the fuel injection pump

(8).

Page 10

10 SENR9983

Disassembly and Assembly Section

i02296829

Fuel Transfer Pump - Install

Installation P

rocedure

NOTICE

Ensure that all

adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operati

on and Maintenance Manual, “General Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information

on the standards of cleanliness that

must be observed during ALL work on the fuel

system.

1. Ensure that the mating faces of the fuel injection

pump (8) and the fuel transfer pump (1) are clean

and free fro

m damage.

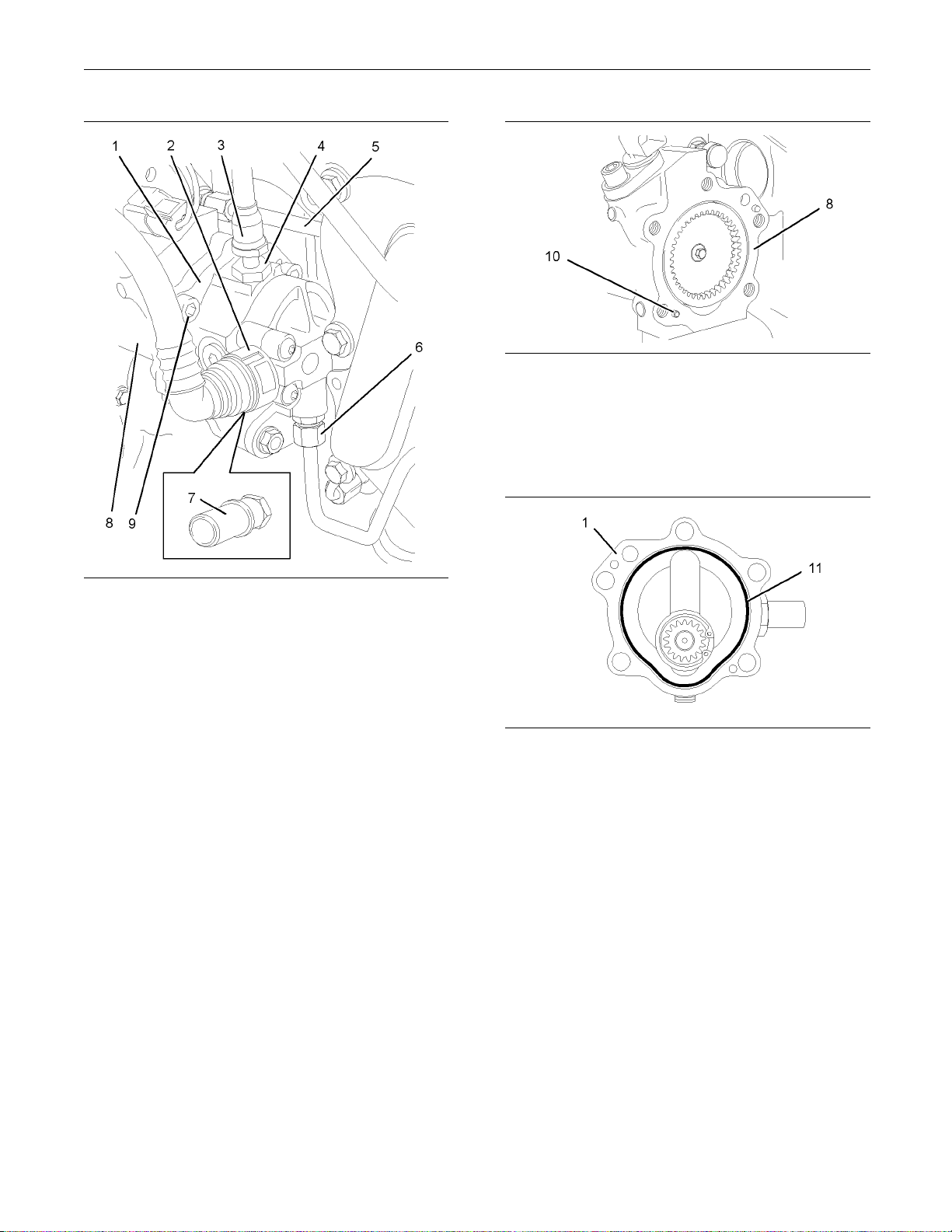

Illustration 11

g01162543

3. Align the holes in the fuel transfer pump (1) with

thedowels(10)inthefuelinjectionpump(8).

Install the fuel transfer pump to the fuel injection

pump.

Illustration 10

g01162544

2. Install a new O-ring seal (11) to fuel transfer pump

(1). Lubricate the O-ring seal with clean engine oil.

ration 12

Illust

Typical example

g01162545

4. Use an allen wrench with a ball end to install the

five allen head screws (9). Tighten the allen head

screws

toatorqueof30N·m(22lbft).

5. Remove the plugs and the caps from the ports

and tub

e assemblies.

Page 11

SENR9983 11

Disassembly and Assembly Section

6. Install the tube assembly (5) for the engine oil

supply to the fu

cylinder block.

7. Install the tu

the fuel transfer pump (1) and to the cylinder head.

el injection pump (8) and to the

be assembly (6) for the fuel return to

NOTICE

Ensure that all adjustments and repairs that are

carried out to t

he fuel system are performed by

authorised personnel that have the correct training.

8. Install a new O

-ring seal (not shown) to the

connector (4). Install the connector (4) to the fuel

transfer pump (1). Tighten the connector to torque

of 15 N·m (11 l

b ft).

9. If necessary, install a new O-ring seal (not shown)

to the connec

tor (7) and install the connector (7) to

the fuel transfer pump (1). Tighten the connector

to torque of 15 N·m (11 lb ft).

10. Connect the plastic tube assembly (3) to the

outlet of the fuel transfer pump (1).

11. Install the plastic tube assembly (2) to the fuel

transfer pump (1).

12. Restore the fuel supply.

13. Remove the a

ir from the fuel system. Refer to

Testing and Adjusting Manual, “Fuel System Prime”.

i02295890

Fuel Injection Lines - Remov e

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

formation and High Pressure Fuel

Lines” for s afety information.

Refer to Testi

ng and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obser

ved during ALL work on the fuel

system.

1. Isolate the f

uel supply.

2. Isolate the electrical supply.

Removal Procedure

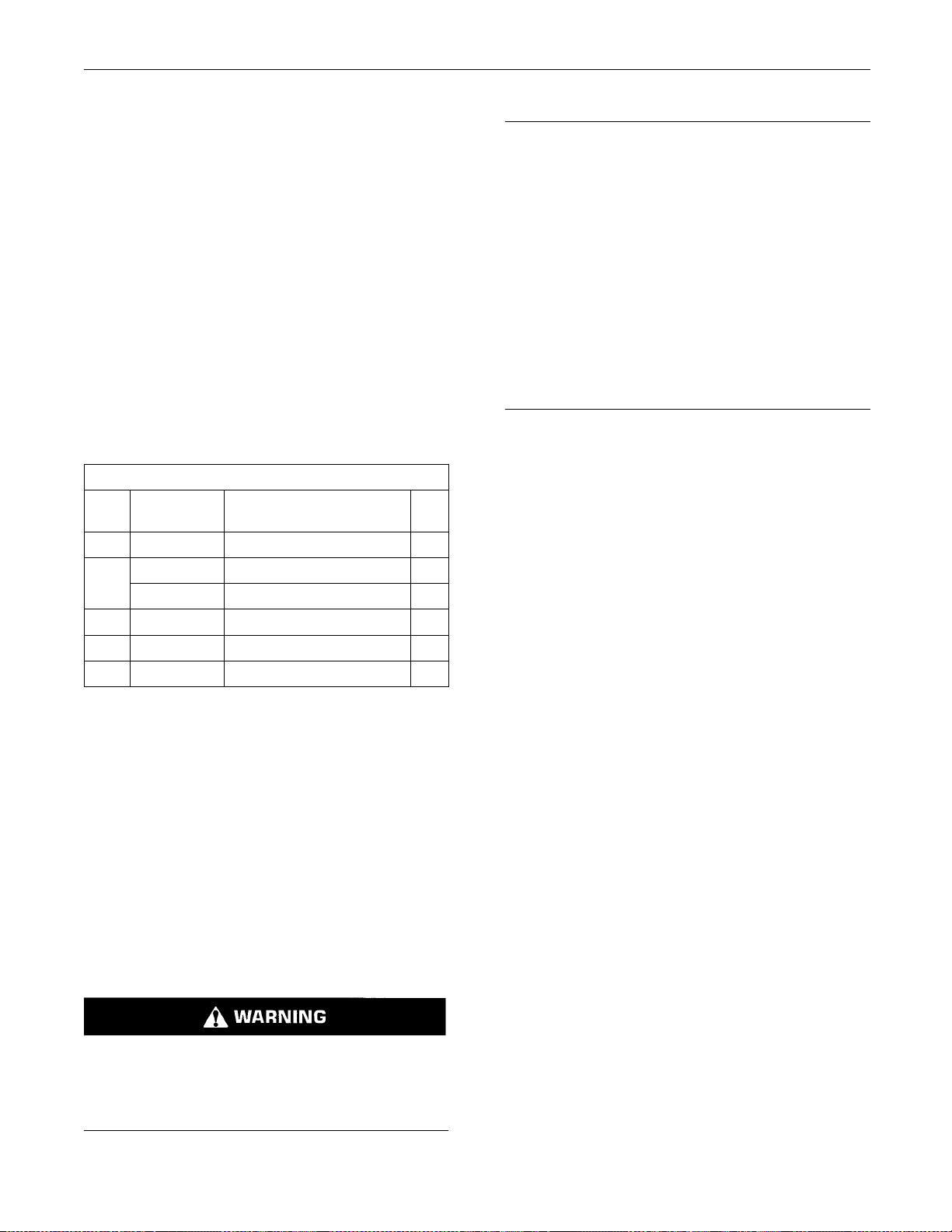

Table 1

Required Tools

Too l

A

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Part

Number

U5MK1124

Part Name Qty

Cap Kit 1

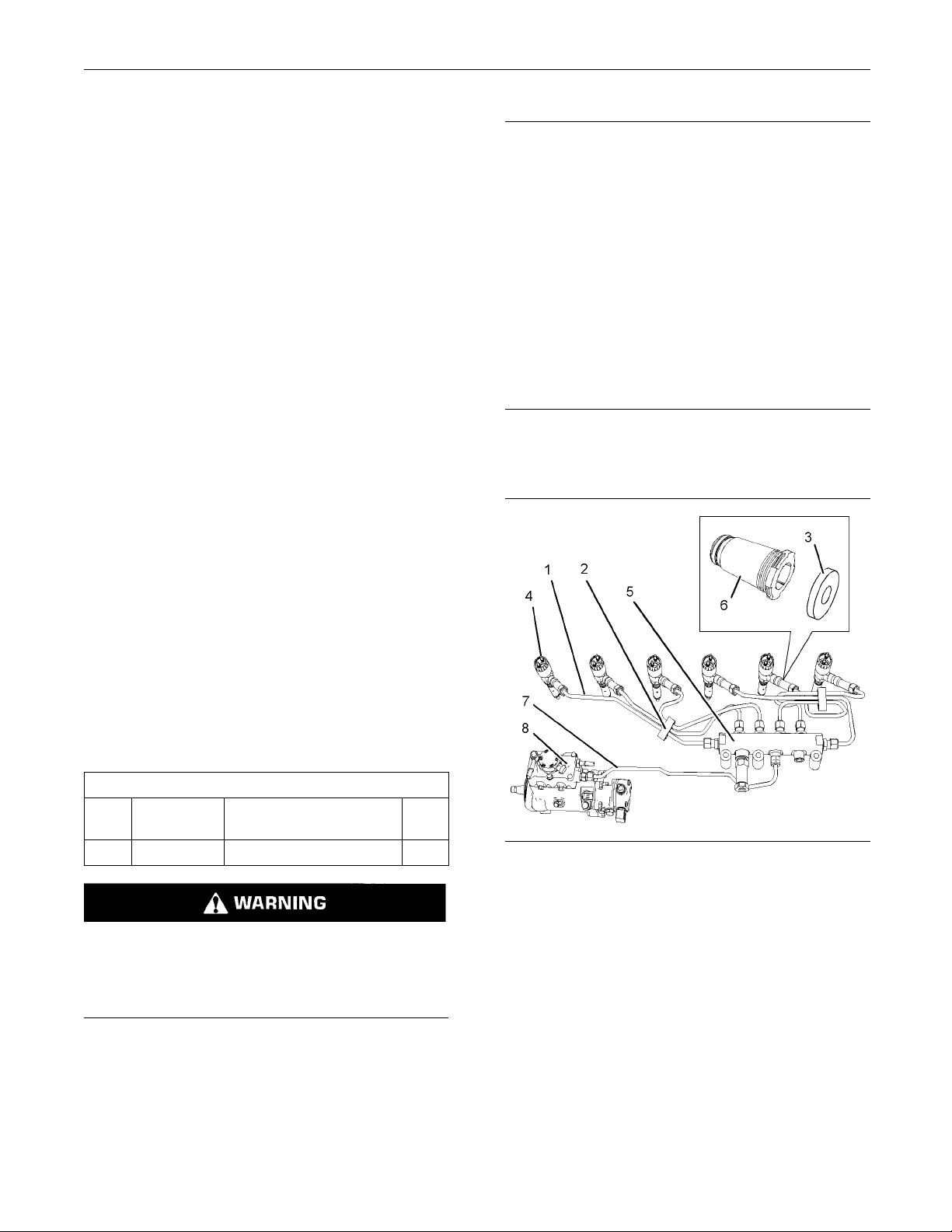

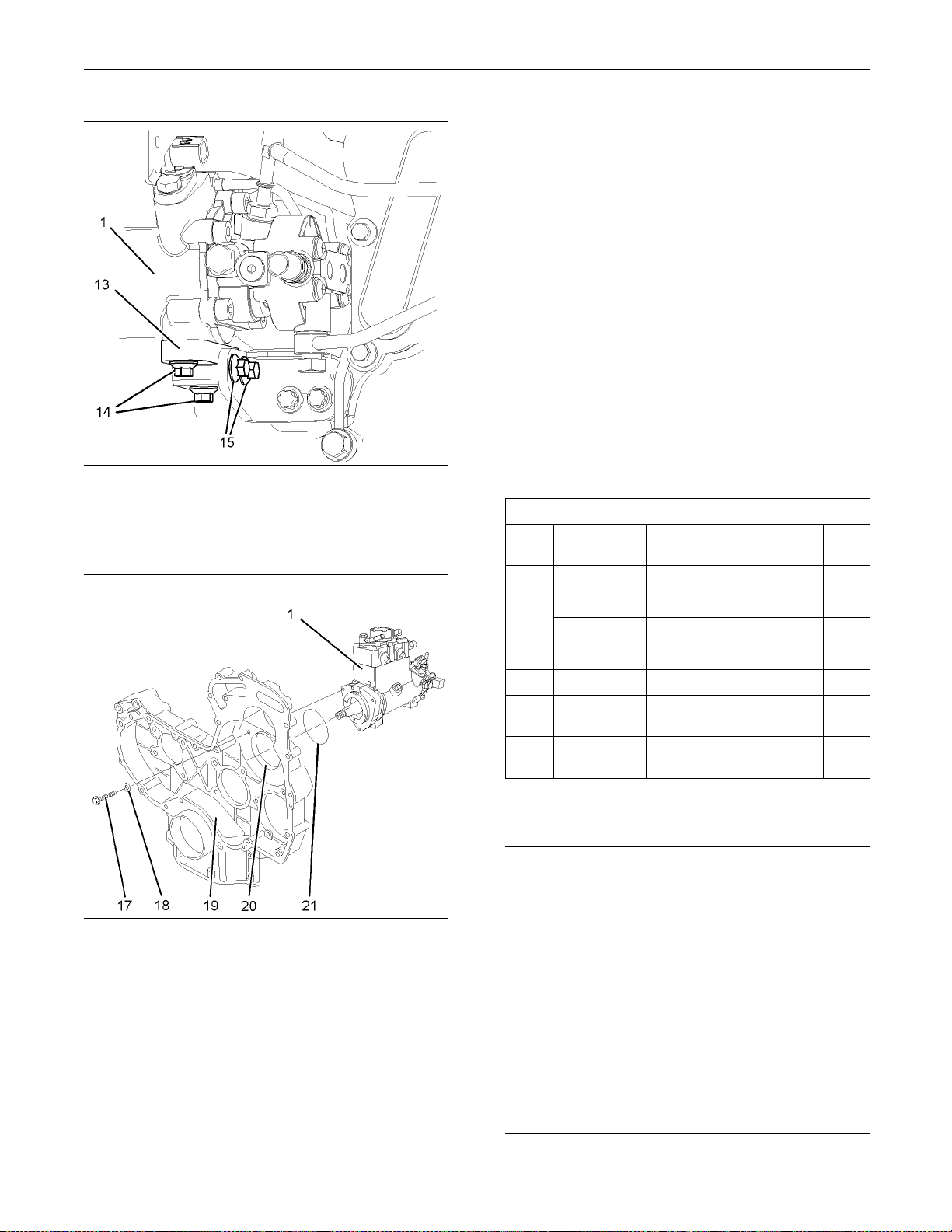

Illustration 13

Typical example

g01178882

3. Remove the two plastic clamps (2) from the fuel

injection lines (1). Discard the plastic clamps.

4. Slide the dust seal (3) from the nut on the fuel

injection line (1).

5. Disconnect the fuel injection line (1) at the

electronic unit injector (4).

6. Disconnect the fuel injection line (1) at the fuel

manifold (5).

7. Remove the fuel injection line (1). Discard the fuel

injection line.

Note: Clean up any spillage of fuel immediately.

Page 12

12 SENR9983

Disassembly and Assembly Section

8. Plug the open port in the fuel manifold (5)

immediately. U

se Tooling (A) in order to plug the

open port in the fuel manifold.

9. Remove the sea

l (6) from the electronic unit

injector (4) and the base of the valve mechanism

cover (not shown).

Note: The seal can be damaged by contact with fuel.

10. Plug the open p

ort in electronic unit injector (4)

immediately. Use Tooling (A) in order to plug the

open port in the electronic unit injector.

11. Repeat Steps 4 through 11 in order to remove

the remaining fuel injection lines from the fuel

manifold to t

Illustration 14

Typical Exam ple

he electronic unit injectors.

g01198424

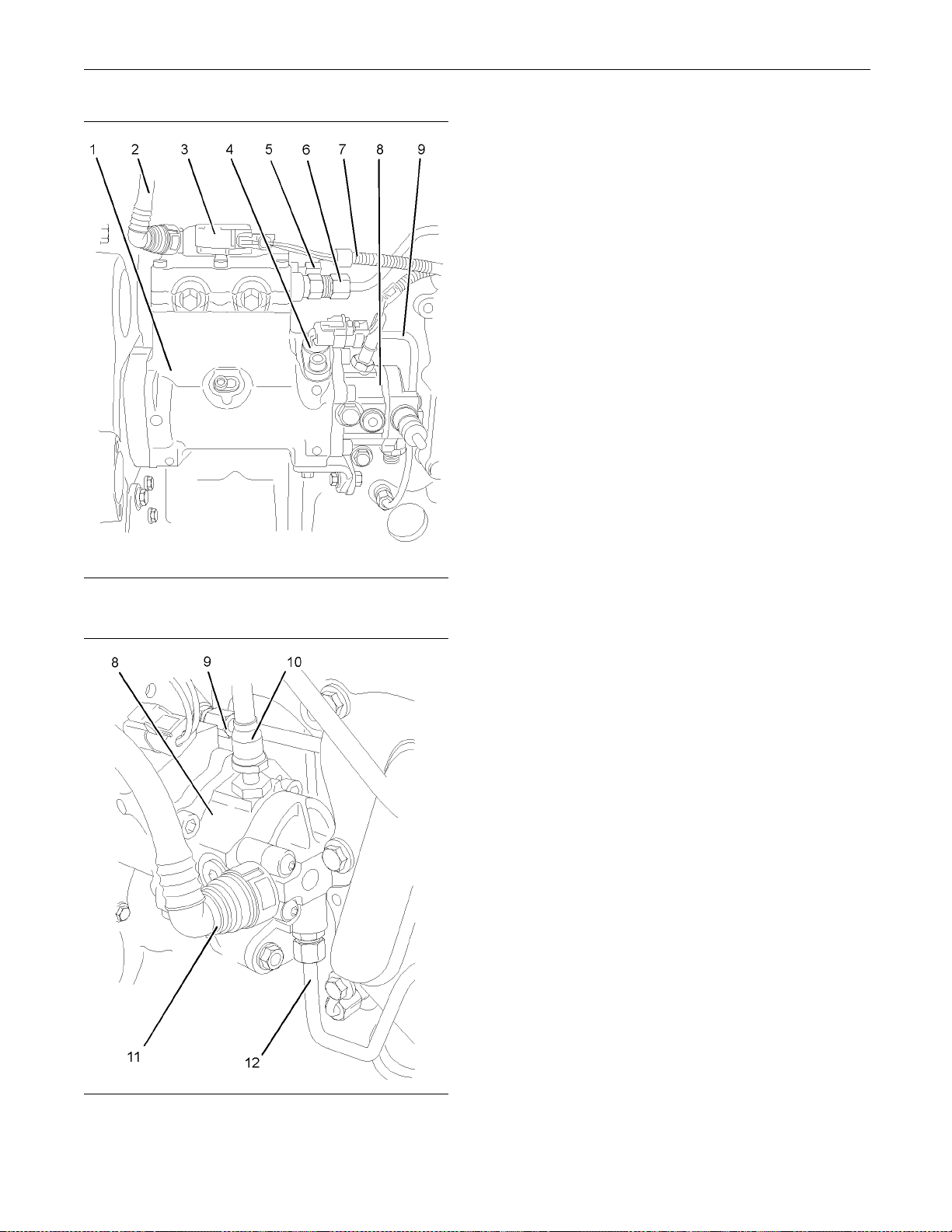

12. Disconnect the harness assembly (9) from the

fuel injection pump (8). Slide the locking tab

(10) into the unlocked position. Disconnect the

harness assembly (9) from the position sensor

(11). Position the harness assembly (9) so that

the harness assembly is clear of the fuel injection

line (7).

Illustration 16

Assembly of the tube clip

g01208399

13. Remove the fasteners (12) from the three tube

clips (13) that secure the fuel injection line (7).

Loosen the three allen head screws (14). Position

the tube clips in order to allow removal of the fuel

injection line.

14. Disconnect the fuel injection line (7) at the fuel

injection pump (8).

15. Disconnect the fuel injection line (7) at the fuel

manifold (5).

16. Plug all open ports immediately. Use Tooling (A)

in order to plug the open ports in the fuel manifold

(5) and in the fuel injection pump (8).

17. Remove the fuel injection line (7).

Note: Clean up any spillage of fuel immediately.

18. Remove the allen head screws (14) and the

assemblies of the three tube clips (13) from fuel

injection line (7). Discard the fuel injection line.

i02295912

Illustration 15

g01208398

Fuel Inje

ction Lines - Install

Installation Procedure

Table 2

Tools

Part Name

Tool

A

Part

Number

27610294

Required

Injector Pipe Nut Tool 1

Qty

Page 13

SENR9983 13

Disassembly and Assembly Section

1. Loosely install the assemblies of the three tube

NOTICE

Ensure that all adjustments and repairs that are

carried out to t

he fuel system are performed by

authorised personnel that have the correct train-

clips (13) and t

fuel injection line (7).

2. Place the fuel

he allen head screws (14) to the

injection line (7) in position.

ing.

3. Remove the caps from the port in the fuel injection

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

formation and High Pressure Fuel

pump (8) and fr

manifold (5). Remove the caps from the new fuel

injection line (7).

om the appropriate port in the fuel

Lines” for safety information.

4. Loosely connect the nuts at both ends of the fuel

Refer to Testi

ng and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obser

ved during ALL work on the fuel

injection line (7), to the fuel manifold (5) and to

the fuel inje

ction pump (8). Ensure that the ends

of the fuel injection line are correctly seated in the

fuel injection pump and in the fuel manifold.

system.

5. Use Tooling (A) to tighten the nuts on the fuel

injectionline(7)toatorqueof30N·m(22lbft).

Note: The fol

in order to install the fuel injection lines when the

electronic unit injectors or the fuel manifold have

not been rem

or the fuel manifold have been removed, refer to

Disassembly and Assembly Manual, “Electronic Unit

Injector-I

lowing procedure should be adopted

oved. If the electronic unit injectors

nstall” and Disassembly and Assembly

6. Install the setscrews (12) for the three tube clips

(13) that secure the fuel injection line (7). Tighten

the setscre

ws (12) to a torque of 22 N·m (16 lb ft).

Tighten the M5 allen head screws (14) to a torque

of 10 N·m (89 lb in). Ensure that fuel injection line

does not co

ntact any other engine component.

Manual, “Fuel Manifold - Install” for more information.

Illustration 17

Assembly o f the tube clip

Illustration 18

g0120839

g01208398

9

Illustration 19

Typical example

g01198424

7. Connect the harness assembly (9) to the position

sensor (11). Slide the locking tab (10) into the

locked position. Connect the harness assembly

(9) to the fuel injection pump (8).

Page 14

14 SENR9983

Disassembly and Assembly Section

15. Install two new clamps (2) to the fuel injection

lines. Ensure t

order to retain the fuel injection lines.

hat the clamps are fully closed in

Illustration 20

Typical exam p le

8. Thoroughly clean the seal (6). Inspect the seal for

damage. If necessary, replace the seal.

Note: The seal can be damaged by contact with

fuel. If the seal has been in contact with fuel for a

prolonged period, the seal should be replaced.

g01178882

Note: Ensure t

any other engine component.

16. Restore the fu

17. Restore the electrical supply.

18. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prim

hat fuel injection lines do not contact

el supply.

e”.

i02403286

Fuel Ma nifold ( R ail) - Remove

and Install

Removal Procedure

Start By:

a. Remove the fuel injection lines. Refer to

Disassembly and Assembly Manual, “Fuel

Injection Lines - Remove”.

9. Install the seal (6) to the electronic unit injector

(4). Ensure that the flange on the seal is flush with

the valve mechanism cover base.

10. Remove the caps from the new fuel injection line

(1). Ensure that a new dust seal (3) is installed

to the fuel injection line.

11. Remove the caps from the electronic unit injector

(4) and from the appropriate port in the fuel

manifold (5).

12. Loosely connect the nuts at both ends of the fuel

injection line (1), to the electronic unit injector (4)

and to the appropriate port in the fuel manifold

(5). Ensure that the ends of the fuel injection line

are correctly seated in the electronic unit injector

andinthefuelmanifold.

13. Use Tooling (A) to tighten the nuts on the fuel

injectionline(1)toatorqueof30N·m(22lbft).

Slide the dust seal (3) into position over the nut on

the fuel injection line. Ensure that the dust seal (3)

is in contact with the seal (6).

14. Follow Steps 8 through 13 in order to install the

remaining fuel injection lines.

b. If necessary, remove the fuel pressure sensor.

Refer to Disassembly and Assembly Manual,

“Fuel Pressure Sensor - Remove and Install”.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuelspraymaycauseafirehazard.Failuretofollow these inspection, maintenance and service instructions ma y cause personal injury or death.

NOTICE

Ensure that all adjustments and repairs that are

carried ou

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Haza

Lines” for s afety information.

Refer to T

liness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be ob

system.

t to the fuel system are performed by

rd Information and High Pressure Fuel

esting and Adjusting Manual, “Clean-

served during ALL work on the fuel

Page 15

SENR9983 15

Disassembly and Assembly Section

1. Ensure that all ports on the fuel manifold are

capped. Ensure

that the fuel manifold is externally

clean and free from damage.

Illustration 21

The fuel m anifold is shown with fuel injection lines in position.

g01190733

1. If the fuel sensor (4) has not been removed from

the fuel manifold (1), slide the locking tab (3) into

the unlocked position. Disconnect the plug on

the harness assembly (6) from the fuel pressure

sensor (4).

2. Disconnect the tube assembly (5) from the fuel

pressure relief valve on the fuel manifold (1).

Immediately cap the open port in the fuel manifold

(1) with a new cap. Immediately plug the open end

of the tube assembly (5) with a new plug.

3. Remove the three setscrews (2) from the fuel

manifold (1).

4. Remove the fuel manifold (1) from the mounting

bracket (7).

Note: Do not in

stall a fuel manifold that has not

been capped. All caps must be left in place until the

fuel injection lines or the fuel pressure sensor are

installed.

Illustration 22

The fuel manifold is shown with fuel injection lines in position.

g01190733

2. Position the fuel manifold (1) on the mounting

bracket (7).

3. Install the three setscrews (2) to the fuel manifold

(1)fingertight.

4. Install a new set of fuel injection lines and seals.

Refer to Disassembly and Assembly Manual,

“Fuel Injection Lines - Install” for more information.

Installation Procedure

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be observed during ALL work on the fuel

system.

5. Tighten the setscrews (2) to a torque of 22 N·m

(16 lb ft).

6. Removetheplugfromthetubeassembly(5).

Remove the cap from the appropriate port in the

fuel manifold (1). Connect the tube assembly

(5) to the fuel pressure relief valve on the fuel

manifold (1).

7. If the fuel pressure sensor (4) was not removed

from the fuel manifold (1), connect the plug on

the harness assembly (6) to the fuel pressure

sensor (4). slide the locking tab (3) into the locked

position.

Page 16

16 SENR9983

Disassembly and Assembly Section

If the fuel pressure sensor (4) was removed from

the fuel manifo

sensor (4) and a new sealing washer. Refer

to Disassembly and Assembly Manual, “Fuel

Pressure Sens

information.

ld (1), install the fuel pressure

or - Revove and Install” for more

NOTICE

Ensure that all adjustments and repairs that are

carried out to t

he fuel system are performed by

authorised personnel that have the correct training.

8. Remove the ai

r from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

-Prime”formoreinformation.

i02295929

Fuel Injection Pump - Remove

Removal Procedure

Table 3

Required Tools

Tool

A

A

B

C

D

Part

Number

21825576

27610289

27610290

27610212

27610286

-

Part Name Qty

Crankshaft Turning Tool 1

Crankshaft Turning Tool 1

Gear 1

Camshaft Timing Pin 1

Crankshaft Timing Pin 1

Cap

2

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

formation and High Pressure Fuel

Lines” for s afety information.

Refer to Testi

ng and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obser

ved during ALL work on the fuel

system.

1. Isolate the f

uel supply.

2. Isolate the electrical supply.

3. Use Tooling (A) in order to rotate the crankshaft

so that number one piston is at top dead center

on the compr

ession stroke. Refer to Testing and

Adjusting Manual, “Finding Top Centre Position for

No.1 Piston”.

4. Use Tooling (B) in order to lock the camshaft in

the correct position. Use Tooling (C) in order to

lock the cra

nkshaft in the correct position. Refer to

Disassembly and Assembly, “Gear Group (Front)

- Remove” for the correct procedure.

Start By:

a. If necessary, remove the fuel filter base. Refer to

Disassembly and Assembly Manual, “Fuel Filter

Base - Remove and Install”.

b. If necessary, remove the fuel priming pump. Refer

to Disassembly and Assembly Manual, “Fuel

PrimingPump-Remove”.

c. Remove the front cover. Refer to Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

Note: Either Tooling (A) can be used. Use the Tooling

that is most suitable.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

5. Remove the backlash from the fuel pump gear.

Lock the fuel injection pump in the correct

position a

nd remove the fuel pump gear. Refer to

Disassembly and Assembly, “Fuel Pump Gear Remove and Install” for the correct procedure.

Page 17

SENR9983 17

Disassembly and Assembly Section

6. Place a suitable container below the fuel injection

pump (1) in orde

r to catch any fuel that might be

spilled.

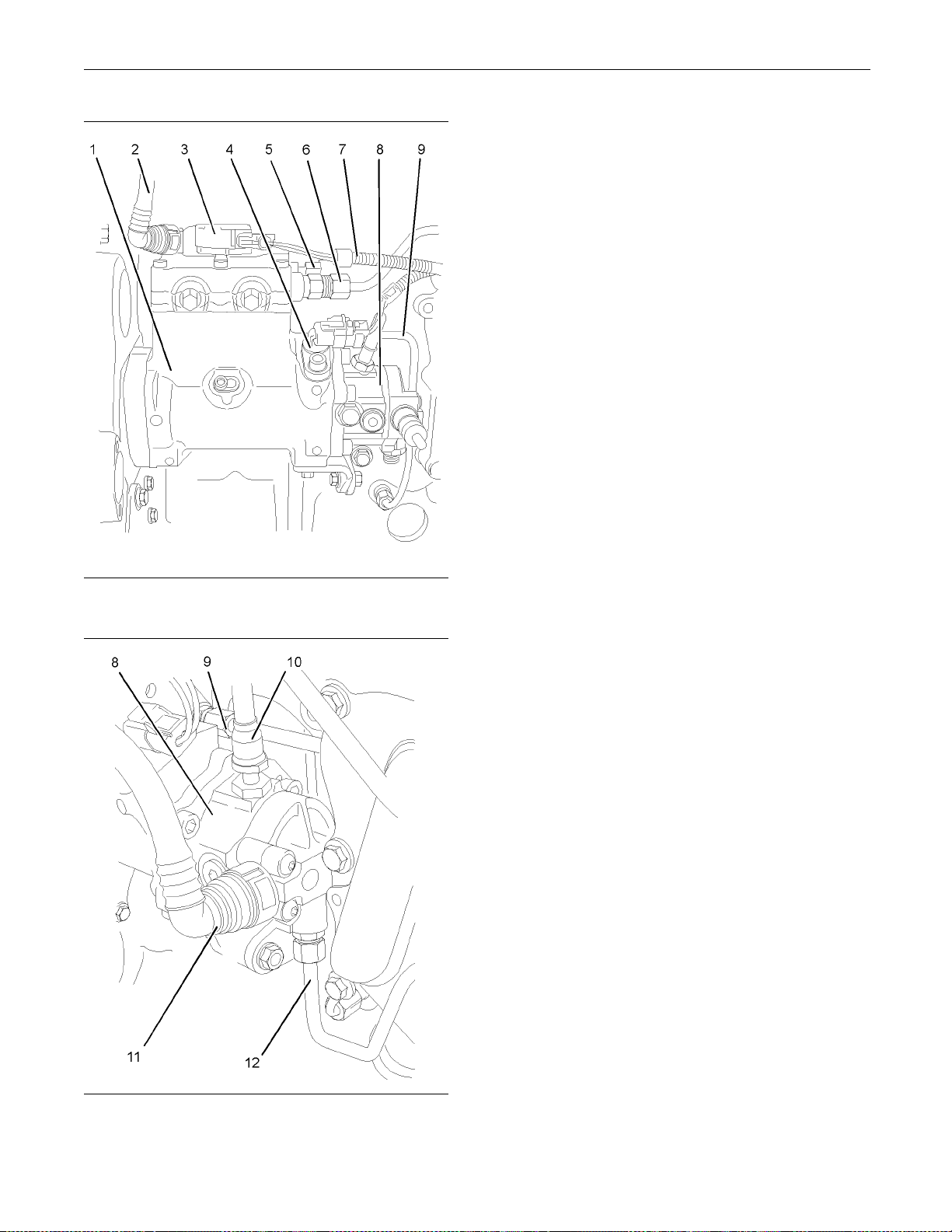

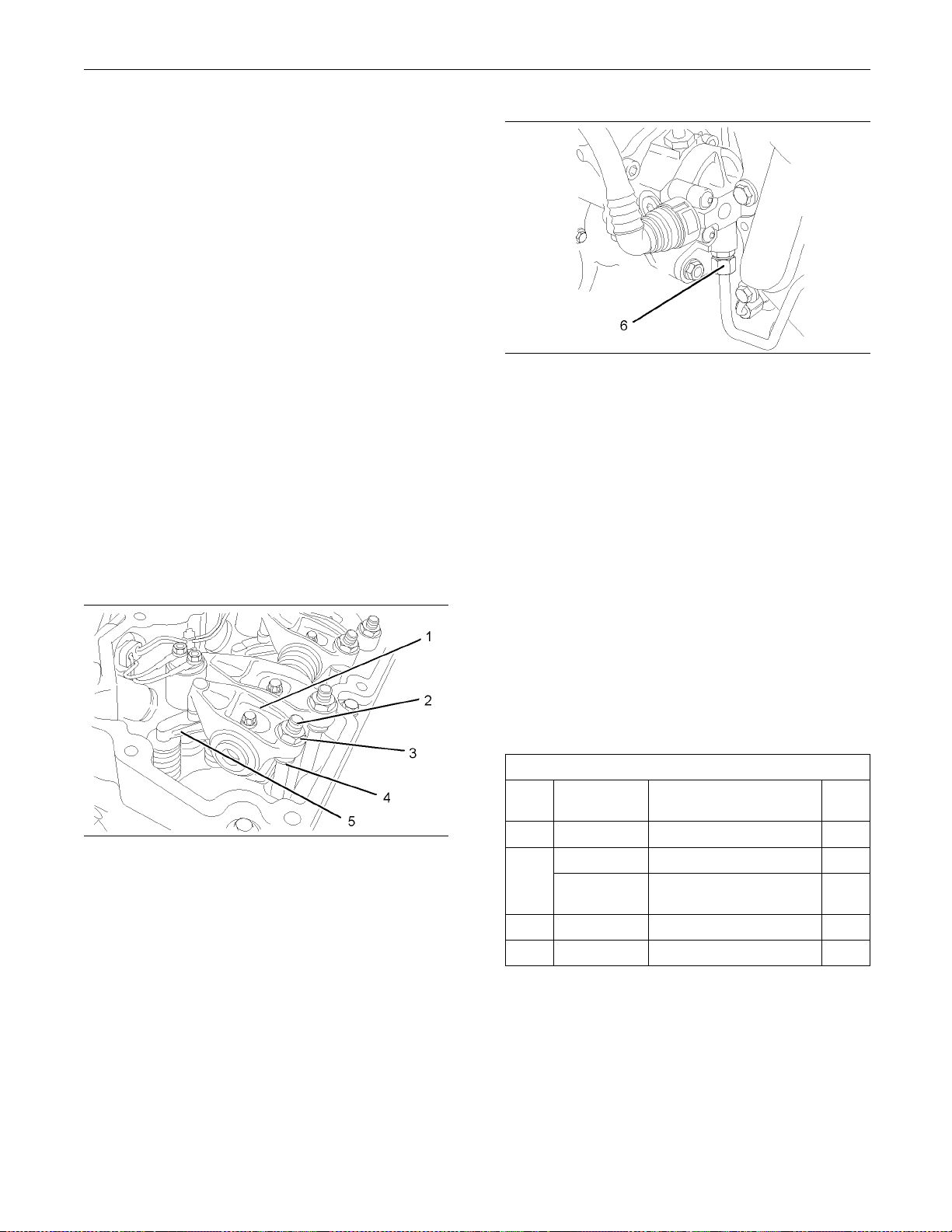

ion 2 3

Illustrat

Typical exam p le

g01173307

Note: Clean up

any spillage of fuel immediately.

7. Disconnect the plastic tube assembly (2) from the

fuel injectio

n pump (1).

8. Disconnect the engine wiring harness (7) from the

solenoid (3) o

f the fuel injection pump. Disconnect

the engine wiring harness (7) from the position

sensor (4) for the fuel injection pump.

Note: The engine wiring harness should be

positioned in order to avoid an obstruction to the fuel

injection pu

mp.

9. Remove the plastic tube assembly (11) from the

fuel transfe

r pump (8).

10. Disconnect the plastic tube assembly (10) from

the outlet o

f the fuel transfer pump (8).

11. Disconnect the plastic tube assembly (5) from the

fuel inject

ion pump (1).

12. Remove the tube assembly (12) for the fuel return

from the fue

l transfer pump and the cylinder head.

Note: Disconnect the tube assembly at the fuel

transfer pu

mp first in order to drain the fuel from the

cylinder head.

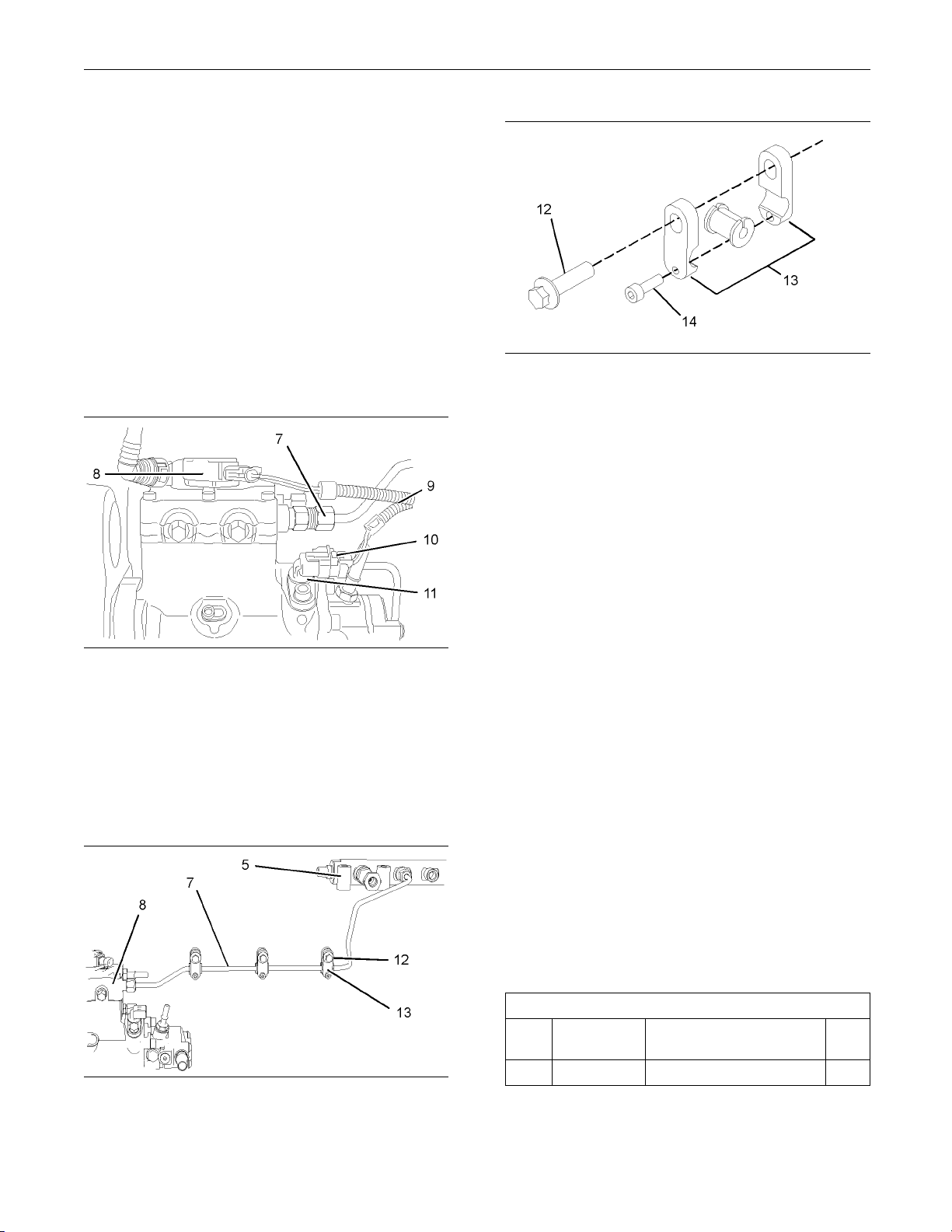

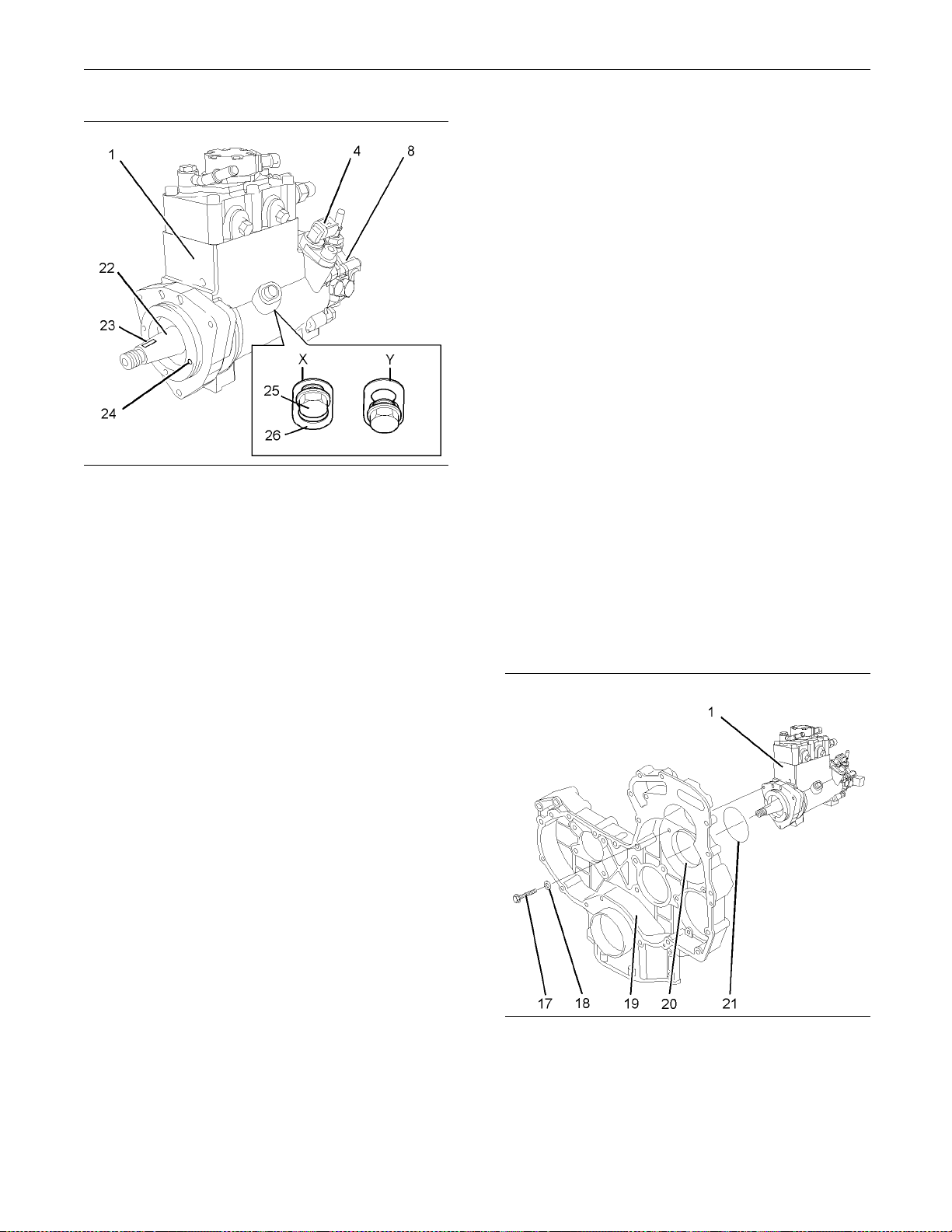

Illustration 24

Typical exam p le

g01173310

13. Remove the t

ube assembly (9) for the engine oil

supply to the fuel injection pump (1).

14. Plug or cap

all open ports and tube assemblies

immediately with new plugs or caps.

15. Remove the

fuel injection line (6) that connects

the fuel injection pump to the fuel manifold. Refer

to Disassembly and Assembly Manual, “Fuel

Injection

Lines - Remove”. Use Tooling (D) in

order to plug the open ports in the fuel injection

pump and in the fuel manifold. Discard the fuel

injectio

nline.

Page 18

18 SENR9983

Disassembly and Assembly Section

19. Remove the O-ring seal (21) from the fuel

injection pump

(1). Discard the O-ring seal.

20. If necessary, remove the position sensor (4) from

the fuel injec

tion pump (1). Refer to Disassembly

and Assembly Manual, “Position Sensor (Fuel

Injection Pump) - Remove and Install”.

21. If necessary, remove the fuel transfer pump

(8) from the fuel injection pump (1). Refer to

Disassembly

and Assembly Manual, “Fuel

Transfer Pump - Remove”.

i02295933

Illustration 25

g01208416

16. Remove the two setscrews (15). Remove the two

setscrews (14) and remove the support bracket

(13) from the fuel injection pump (1).

Fuel Inject

ionPump-Install

Installation Procedure

Table 4

Required To

Too l

A

A

B 27610212

C

E 27610302

F 21820221

Part

Number

21825576

27610289

27610290

27610286

Crankshaft Turning Tool

Crankshaft Turning Tool

Gear

Camshaft Timing Pin

Crankshaft Timing Pin

Fuel Injection Pump

Timing Tool

POWERPART

Rubber Grease

Note: EitherTooling(A)canbeused.UsetheTooling

that is most suitable.

ols

Part Description Qty

1

1

1

1

1

1

-

Illustration 26

Typical exam p le

g01173314

17. Remove the three setscrews (17) and sealing

washers (18). Discard the sealing washers.

Note: The fuel injection pump should be supported

by hand as the setscrews are removed.

18. Carefully remove the fuel injection pump (1) from

the front housing (19). Ensure that the bore (20)

in the front housing is not damaged as the fuel

injection pump is removed.

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard Information and High Pressure Fuel

Lines” for s afety information.

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be observed during ALL work on the fuel

system.

Page 19

SENR9983 19

Disassembly and Assembly Section

3. If the fuel injection pump timing has been lost

follow Steps 3.

a through 3.e in order to reset the

fuel injection pump timing.

Illustration 27

1. If the fuel injection pump was previously

disassembled, follow Steps 1.a and 1.b in order to

assemble the fuel injection pump.

a. Install the fuel transfer pump (8) to the fuel

injection pump (1). Refer to Disassembly and

Assembly Manual, “Fuel Transfer Pump Install”.

b. Install the position sensor (4) to the fuel

injection pump (1). Refer to Disassembly and

Assembly Manual, “Position Sensor (Fuel

Injection Pump) - Remove and Install”.

g01174932

a. If necessary,

loosen the locking screw (25) on

the fuel injection pump. Slide the spacer (26)

into position (X). Tighten the locking screw (25)

toatorqueof

9N·m(80lbin).Thiswillprevent

the locking screw from tightening against the

shaft (22).

The fuel injection pump is now unlocked.

b. Position Too

ling (E) onto the shaft (22) of the

fuel injection pump. Align the lever of Tooling

(E) with the key slot (23) in the fuel injection

pump. Engage

the lever into the key slot.

c. Use the lever of Tooling (E) to rotate the shaft

(22) until t

he pin of Tooling (E) can be engaged

into the hole (24). Engage the pin of Tooling

(E) into the hole.

d. Loosen the locking screw (25) in the fuel

injection pump. Slide the spacer (26) into

position (

Y). Tighten the locking screw (25)

against the shaft of the fuel injection pump to a

torqueof9N·m(80lbin).

The fuel injection pump is now locked.

e. Remove too

ling (E).

Note: A new fuel injection pump assembly includes

the fuel transfer pump and the position sensor.

2. To check the fuel injection pump timing, follow

Steps 2.a and 2.b.

a. Position Tooling (E) onto the shaft (22) of the

fuel injection pump. Align the lever of Tooling

(E) with the key slot (23). Engage the lever into

the key slot.

b. Insert the locking pin of Tooling (E) into the

hole (24) in fuel injection pump.

If the locking pin can be inserted into the hole,

the fuel injection pump timing is correct.

If the locking pin cannot be inserted into the

hole, the fuel injection pump timing is not

correct.

Note: There should be no resistance when the

locking pin is inserted.

Illustration 28

Typical example

g01173314

4. Inspect the bore (20) in the front housing (19)

for damage. If the bore is damaged, replace

the front housing. Refer to Disassembly and

Assembly Manual, “Housing (Front) - Remove”

and Disassembly and Assembly Manual, “Housing

(Front) - Install”.

Page 20

20 SENR9983

Disassembly and Assembly Section

5. Use Tooling (F) to lubricate a new O-ring seal

(21). Install t

he O-ring seal onto the fuel injection

pump (1).

6. Align the hole

s in the fuel injection pump (1) with

the holes in the front housing (19). Carefully install

the fuel injection pump to the front housing.

Note: The fuel injection pump should be supported

by hand until the setscrews are installed.

7. Install the three setscrews (17) and three new

sealing washers (18). Tighten the setscrews to a

torque of 25 N

·m(18lbft).

8. If necessary, use Tooling (A) in order to rotate the

crankshaft s

o that number one piston is at top

dead center on the compression stroke. Refer

to Testing and Adjusting Manual, “Finding Top

Centre Posi

tion for No.1 Piston”.

9. Use Tooling (B) in order to lock the camshaft in

the correct

position. Use Tooling (C) in order to

lock the crankshaft in the correct position. Refer to

Disassembly and Assembly, “Gear Group (Front)

- Remove” f

or the correct procedure.

10. Install the fuel injection pump gear to the fuel

injection

pump. Refer to Disassembly and

Assembly Manual, “Fuel Injection Pump Gear Install” and refer to Disassembly and Assembly

Manual, “G

ear Group (Front) - Install”.

Note: Ensure that the spacer (26) on the fuel

injection

pump is in the unlocked position (X) after the

installation of fuel injection pump gear is completed.

Refer to Illustration 27.

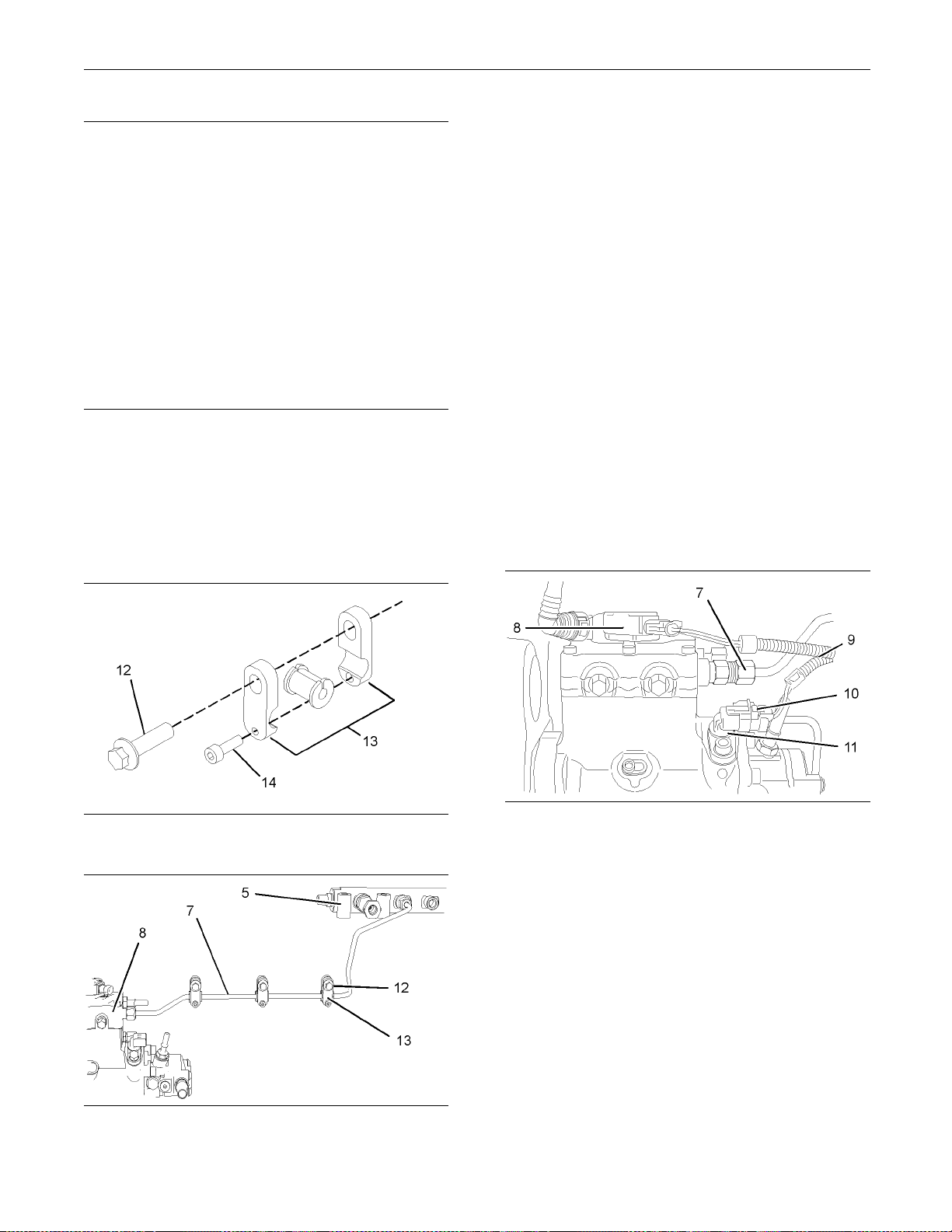

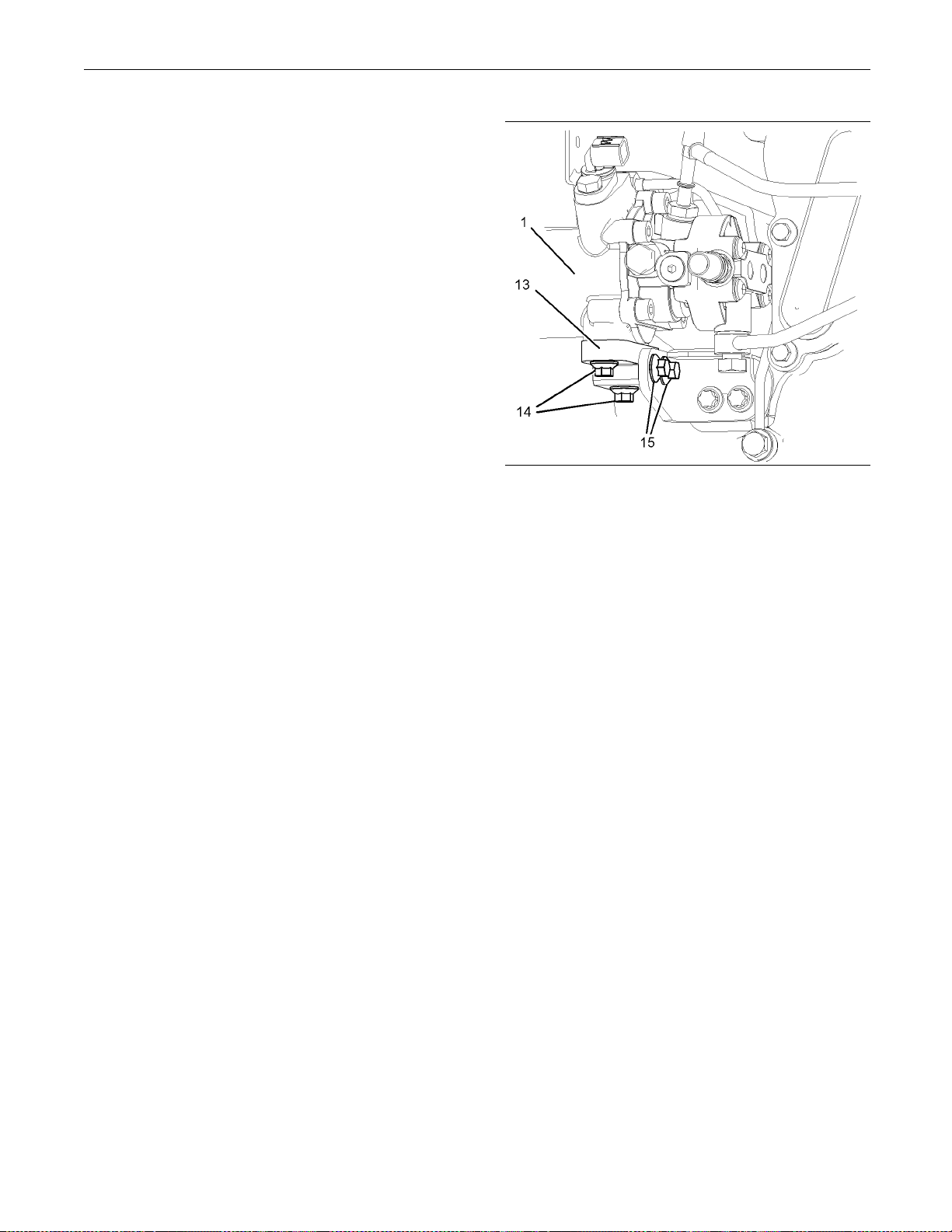

Illustration 29

Typical example

g01208416

12. Position the support bracket (13) onto the fuel

injection pump (1). Install the two setscrews (14)

finger tight.

13. Install the two setscrews (15) finger tight.

14. Tighten the setscrews (15) to a torque of 22 N·m

(16 lb ft). the setscrews (14) to a torque of 22 N·m

(16 lb ft).

Some engines have a single M10 nut and a bolt in

place of the two setscrews (15). Tighten the nut

and bolt to a torque of 44 N·m (32.5 lb ft).

11. Install the front cover. Refer to Disassembly and

Assembly Manual, “Front Cover - Remove and

.

Install”

Note: Ensure that the fuel injection pump is not

stressed as the fasteners for the bracket are

tightened.

Page 21

SENR9983 21

Disassembly and Assembly Section

15. Remove the appropriate plugs and caps in order

to install tube

assembly (9) for the engine oil

supply to the fuel injection pump. Install the tube

assembly (9). Tighten the nuts at both ends of the

tube assembly

.

16. Remove the appropriate caps in order to install

the fuel inje

ction line (6). Install a new fuel injection

line (6) to the fuel injection pump and to the fuel

manifold. Refer to Disassembly and Assembly

Manual, “Fue

l Injection Lines - Install”.

17. Remove the plugs and caps from the remaining

ports and tub

eassemblies.

18. Install the tube assembly (12) for the fuel return

to the fuel tr

ansfer pump and to the cylinder

head. Tighten the nuts at both ends of the tube

assembly.

19. Install the plastic tube assembly (5) to the fuel

injection pump (1).

ion 3 0

Illustrat

Typical exam p le

g01173307

20. Install the plastic tube assembly (10) for the fuel

outlet to the fuel transfer pump (8).

21. Install the plastic tube assembly (11) to the fuel

transfer pump (8).

22. Connect the harness assembly (7) to the solenoid

(3) on the fuel injection pump. Connect the

harness as

sembly (7) to the position sensor (4) on

the fuel injection pump. Slide the locking tab (not

shown) into the locked position.

23. If necessary, install the fuel priming pump. Refer

to Disassembly and Assembly Manual, “Fuel

Priming P

ump - Remove and Install”.

24. If necessary, install the fuel filter base. Refer to

Disassem

bly and Assembly Manual, “Fuel Filter

Base - Remove and Install”.

25. Restore t

he fuel supply.

26. Restore the electrical supply.

27. Remove the air from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

-Prime”f

or more information.

Illustration 31

Typical exam p le

g01173310

Page 22

22 SENR9983

Disassembly and Assembly Section

i02296762

Fuel Injection Pump Gear Remove

Removal Procedure

Table 5

Required Tools

Too l

A

A

B

C

D

Start By:

a. Remove the front cover. Refer to Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

Note: Either Tooling (A) can be used. Use the Tooling

that is most suitable.

Part

Number

21825576

27610289

27610290

27610212

27610286

-

Part Name Qty

Crankshaft Turning Tool 1

Crankshaft Turning Tool 1

Gear 1

Camshaft Timing Pin 1

Crankshaft Timing Pin 1

Puller (Two Leg)

1

1. Use Tooling (A) in order to rotate the crankshaft

so that number o

ne piston is at top dead center

on the compression stroke. Refer to Testing and

Adjusting Manual, “Finding Top Centre Position for

No.1 Piston”.

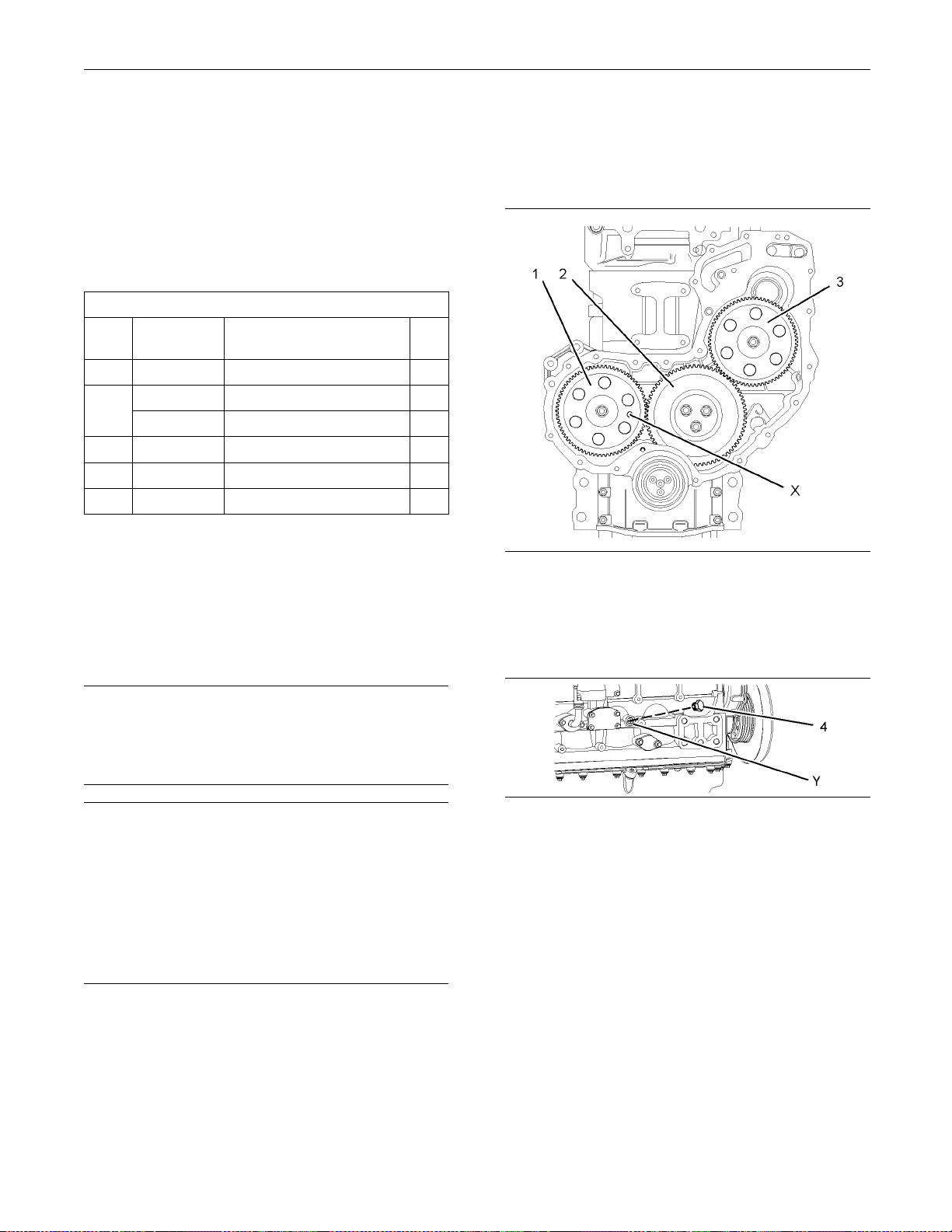

Illustration 32

g01194629

2. Install Tooling (B) through the hole (X) in the

camshaft gear (1) into the front housing. Use

Tooling (B) in order to lock the camshaft in the

correct position.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: Care must be taken in order to ensure that

the fuel injection pump timing is not lost during the

removal of the fuel pump gear. Carefully follow the

procedure in order to remove the fuel pump gear.

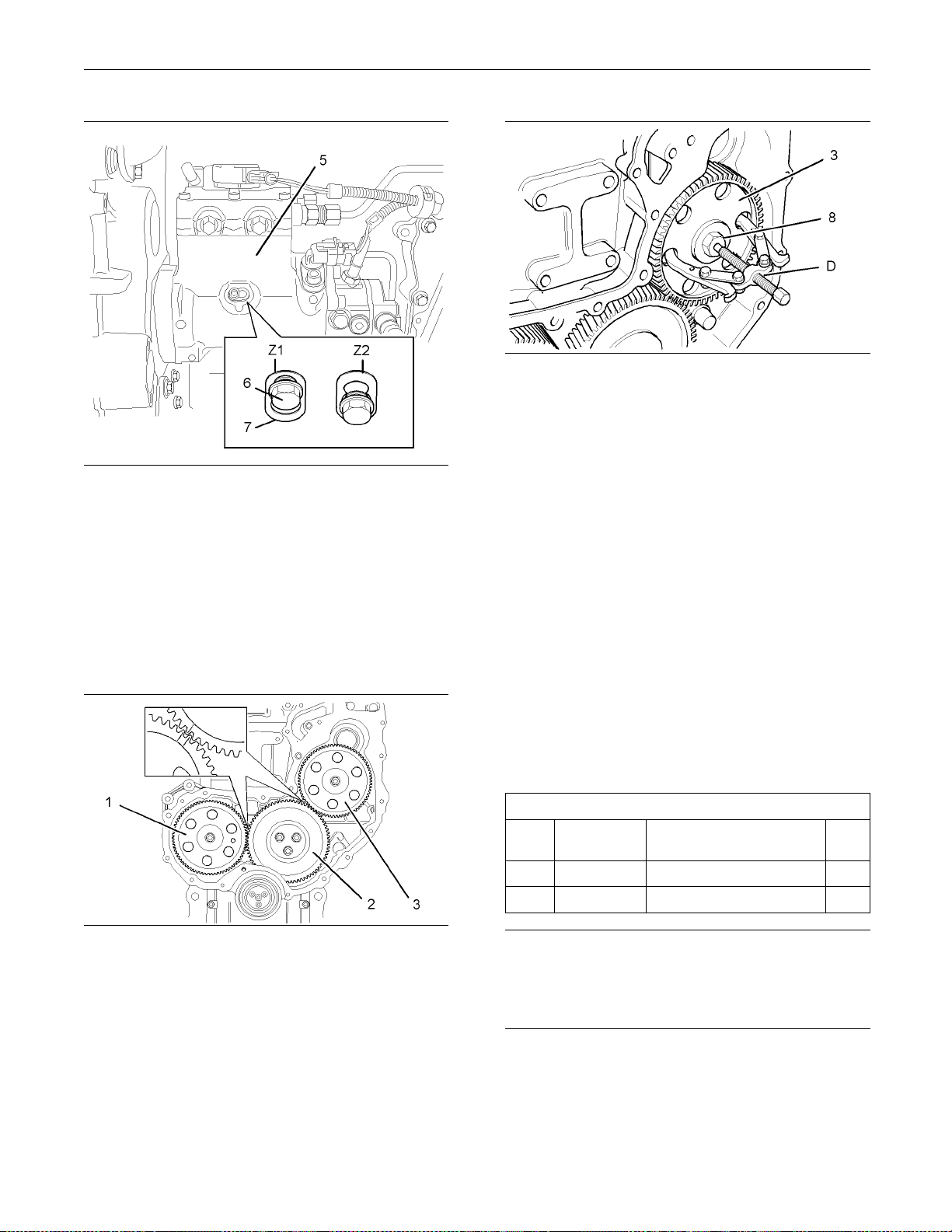

Illustration 33

g01195325

3. Remove the plug (4) from the cylinder block. Install

Tooling (C) into the hole (Y) in the cylinder block.

Use Tooling (C) in order to lock the crankshaft in

the correct position.

Note: Do not use excessive force to install Tooling

(C). Do not use Tooling (C) to hold the crankshaft

during repairs.

Page 23

SENR9983 23

Disassembly and Assembly Section

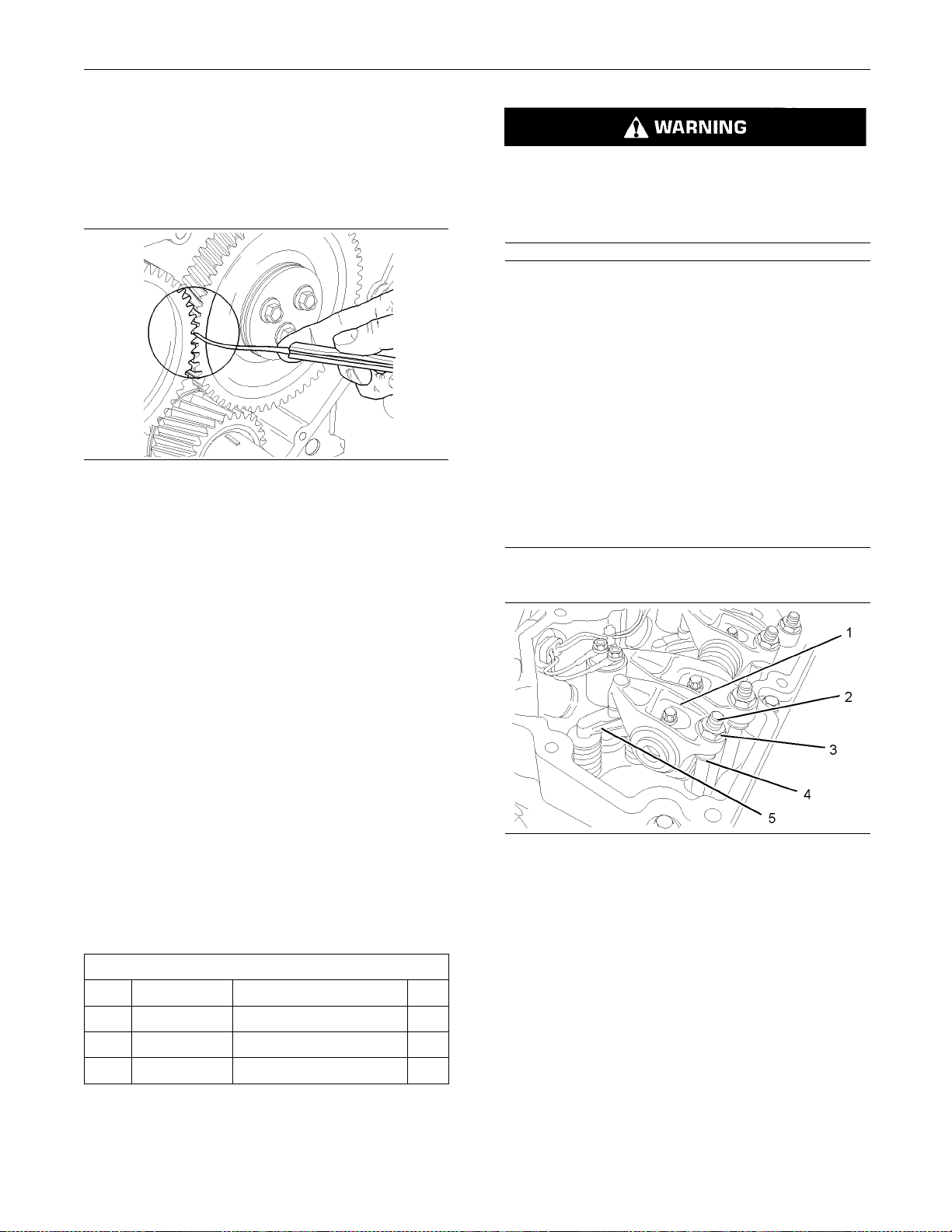

Illustration 34

g01196435

4. Apply sufficient pressure to the fuel injection pump

gear (3) in a counterclockwise direction in order

to remove the backlash. Lock the fuel injection

pump (5) in this position.

In order to lock the fuel injection pump (5), loosen

the locking screw (6) in the fuel injection pump.

Slide the spacer (7) into position (Z). Tighten the

locking screw (6) against the shaft of the fuel

injection pump to a torque of 9 N·m (80 lb in).

Illustration 36

g01196132

6. Loosen the nut (8) for the fuel pump gear (3).

7. Install Tooling (D) through two opposite holes in

the fuel pump gear (3). Tighten Tooling (D) until

the fuel pump gear (3) is released.

8. Remove Tooling (D) from the fuel pump gear (3).

9. Remove the nut (8) and washer (not shown) from

the fuel pump gear (3). Remove the fuel pump

gear.

i02296767

Fuel Inje ctio n Pump Gear Install

Installation Procedure

Table 6

Required Tools

Too l

B

C

Part

Number

27610212

27610286

Part Name Qty

Camshaft Timing Pin 1

Crankshaft Timing Pin 1

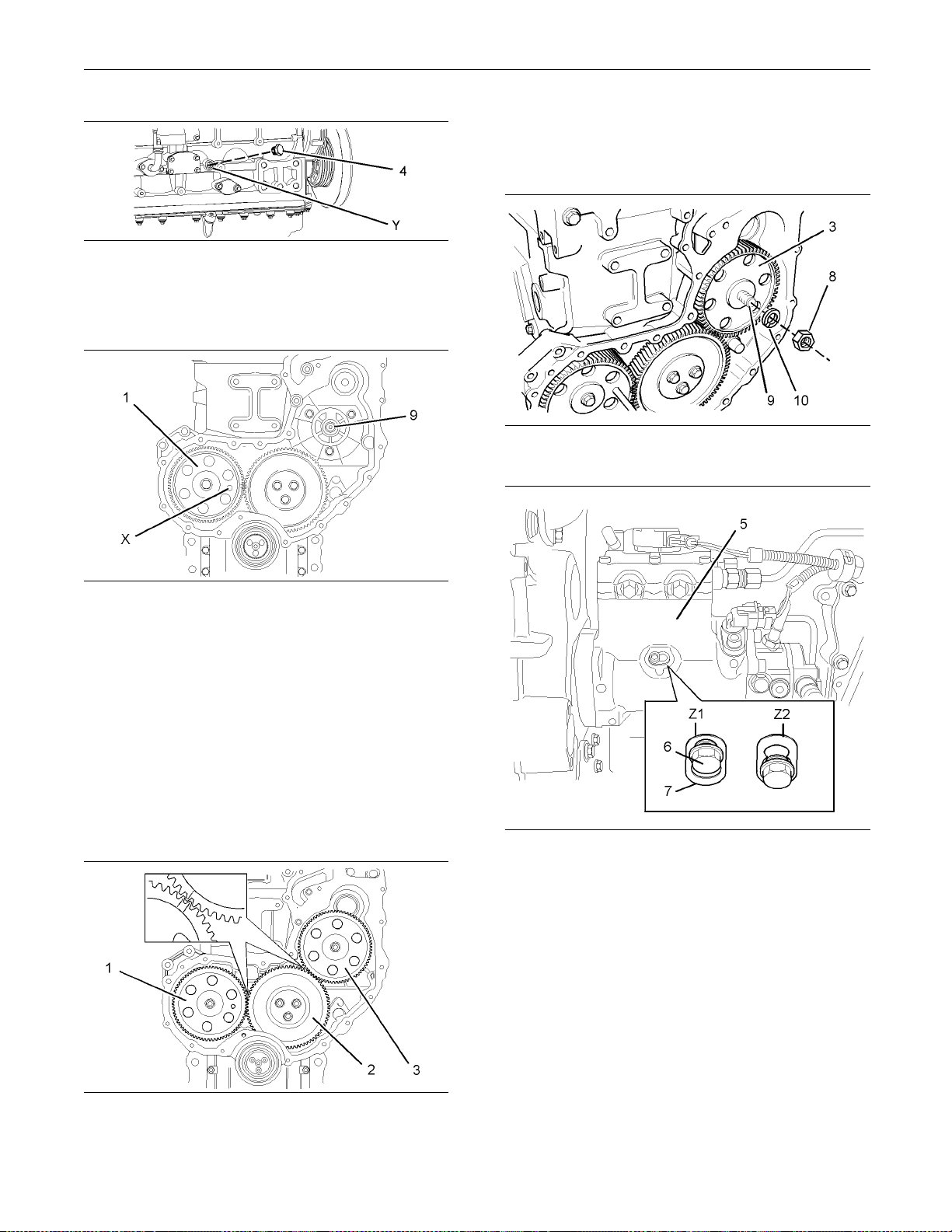

Illustration 35

Alignment of timing marks

g01196142

5. Mark the gears (1), (2) and (3) in order to show

alignment. Refer to Illustration 35.

Note: Identification will ensure that the gears can be

installed in the original alignment.

NOTICE

Keep all p

arts clean from contaminants.

Contaminants may cause rapid wear and shortened

componen

tlife.

Note: The fuel injection pump must remain locked

until the procedure instructs you to unlock the fuel

injection pump.

1. Ensure that number one piston is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Finding Top Center

for No. 1 Piston”.

Page 24

24 SENR9983

Disassembly and Assembly Section

7. Install the fuel pump gear (3) to the shaft (9) of the

fuel injection

pump. Ensure that the timing marks

on the gears (2) and (3) are in alignment and that

the mesh of the gears is correct.

Illustration 37

g01195325

2. Ensure that Tooling (C) is installed in hole (Y) in

the cylinder block. Use Tooling (C) in order to lock

the crankshaft in the correct position.

Illustration 38

g01196475

3. Ensure that Tooling (B) is installed into the hole

(X) in the camshaft gear (1).

4. Ensure that the shaft (9) of the fuel injection pump

is clean and free from damage.

Illustration 40

Typical example

g01196488

5. Ensure that the fuel injection pump is locked in

the correct position. Refer to Disassembly and

Assembly Manual, “Fuel Injection Pump - Install”.

6. Ensure that the fuel pump gear is clean and free

from wear of damage. If necessary, replace the

fuel pump gear.

Illustration 39

Alignment of timing marks

g01194949

Illustration 41

g01196435

8. Install a new spring washer (10) and install the

nut (8) to the shaft (9) of the fuel injection pump.

Apply sufficient pressure to the fuel injection

pump gear (3) in a counterclockwise direction in

order to remove the backlash. Tighten the nut (8)

toatorqueof25N·m(18lbft).Unlockthefuel

injection pump (5).

In order to unlock the fuel injection pump (5),

loosen the locking screw (5) in the fuel injection

pump. Slide the spacer (7) into position (Z1).

Tighten the locking screw (6) against the spacer to

a torque of 9 N·m (80 lb in). This will prevent the

locking screw from tightening against the shaft of

the fuel injection pump.

Page 25

SENR9983 25

Disassembly and Assembly Section

9. RemoveTooling(B)and(C).Installtheplug

(4) into hole (Y

Illustration 37.

10. Tighten the nu

(66.4lbft).

) in the cylinder block. Refer to

t(8)toatorqueof90N·m

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuelspraymaycauseafirehazard.Failuretofollow these inspection, maintenance and service instructions ma y cause personal injury or death.

NOTICE

Ensure that al

l adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operati

on and Maintenance Manual, “General Hazard Information and High Pressure Fuel

Lines” for s afety information.

Illustration 42

Checking backlash

g00944084

11. Ensure that the backlash for the gears (2)

and (3) is within specified values. Refer to the

Specifications Manual, “Gear Group (Front)” for

further information.

12. Lubricate the teeth of the gears with clean engine

oil.

End By:

a. Install the front cover. Refer to Disassembly and

Assembly Manual, “Front Cover - Remove and

Install”.

i02295935

Electronic Unit Injec tor Remove

Removal Procedure (One Injector)

Table 7

Required Tools

Tool Part Number Part Description Qty

21825576

A

B

C

-

27610288

Start By:

a. Remove the valve mechanism cover. Refer

to Disassembly and Assembly Manual, “Valve

Mechanism Cover - Remove and Install”.

Engine Turning Tool 1

T40 T orx Socket

Pry Bar 1

1

Refer to Testing and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

informatio

n on the standards of cleanliness that

must be observed during ALL work on the fuel

system.

1. Isolate the fuel supply to the engine.

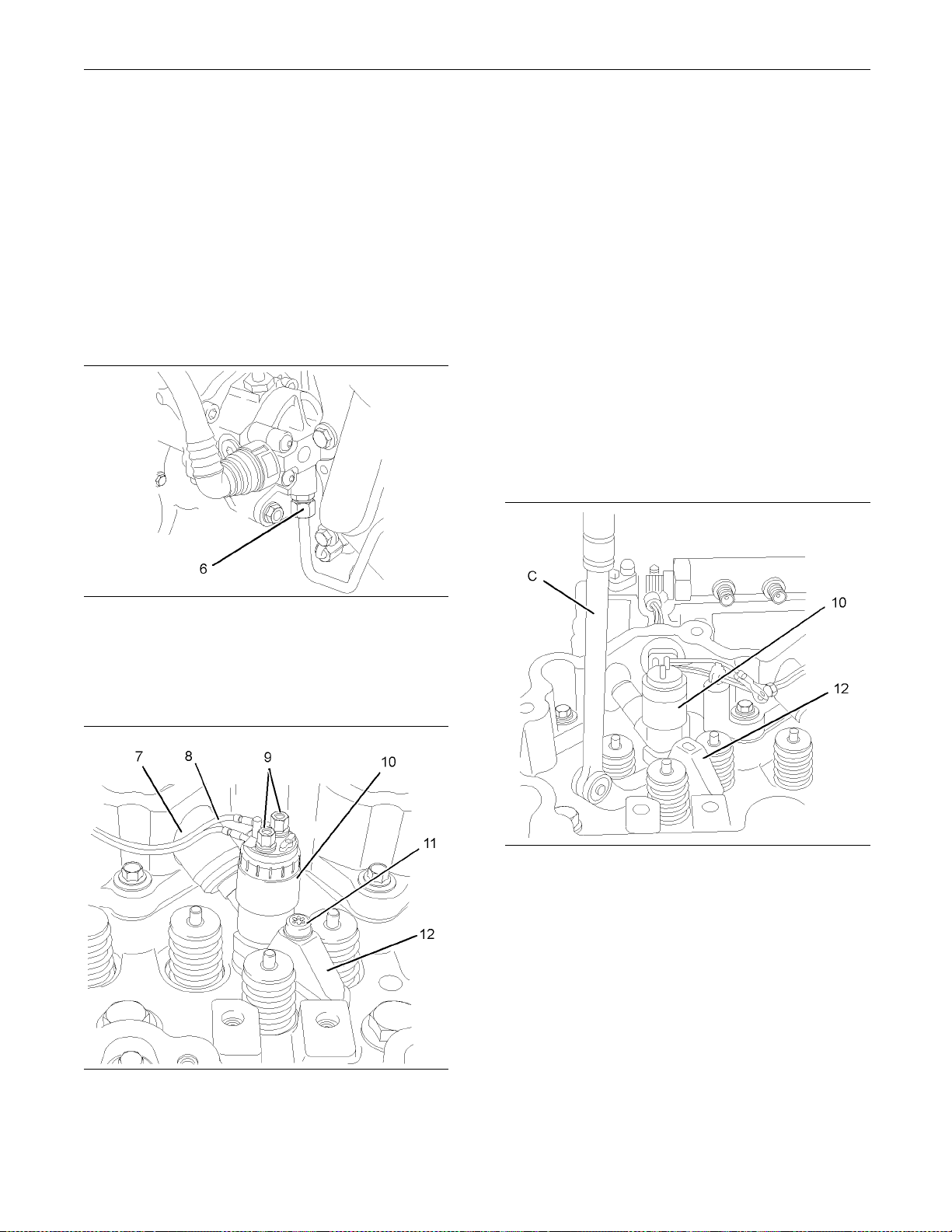

Illustration 43

Typical example

g01193285

2. Use Tooling (A) in order to rotate the crankshaft

until the rocker arms (1) for the appropriate

cylinder are in the correct position in order to adjust

the valve lash. Refer to Testing and Adjusting

Manual, “Engine Valve Lash - Inspect/Adjust”.

3. Follow Steps 3.a through 3.c in order to gain

access to the assembly of the electronic unit

injector.

a. Loosen the nuts (3) on the appropriate cylinder.

Unscrew the adjusters (2) on the appropriate

cylinder until the pushrods (4) can be withdrawn

from the balls of the adjusters.

b. Withdraw the cups of the pushrods (4) from the

balls of the adjusters (2).

Page 26

26 SENR9983

Disassembly and Assembly Section

c. Make a temporary mark on the valve bridges

(5) in order to s

how the location and orientation.

Remove valve bridges from the cylinder head.

Note: Identif

ication will ensure that the valve bridges

can be reinstalled in the original location and the

original orientation. Do not interchange the location

or the orient

ation of used valve bridges.

4. Place a suitable container below the fuel transfer

pump in order

to catch any fuel that might be

spilled.

Note: Clean u

p any spillage of fuel immediately.

6. Remove the fuel injection line (not shown) and

the seal (7) fro

m the appropriate electronic unit

injector (10). Refer to Disassembly and Assembly

Manual, “Fuel Injecton Lines - Remove”.

Note: Cap all open ports immediately with new caps.

7. Place a tempor

ary identification mark on the

connections (9) for the harness assembly (8).

8. Use a deep sock

et to remove the connections (9)

from the electronic unit injectors (10).

9. Slide the roc

ker arms (1) to one side in order to

gain access to the torx screw (11). Use Tooling (B)

in order to remove the torx screw from the clamp

(12). Discar

d the t orx screw.

10. Place a temporary identification mark on the

electronic u

nit injector (10). The electronic unit

injector must be reinstalled in the original location

in the cylinder head.

Illustration 44

Typical exam p le

g01193839

5. Disconnect the tube assembly (6) for the injector

leak-off from the fuel transfer pump. Allow the fuel

to drain from the tube assembly.

Illustration 46

The rocker shaft is not shown for clarity.

g01193295

11. Use Tooling (C) to pry beneath the clamp (12)

and free the electronic unit injector (10) from the

cylinder head.

12. Remove the electronic unit injector (10) and the

clamp (12) from the cylinder head.

Illustration 45

The rocker shaft is not shown for clarity.

g01193293

Page 27

SENR9983 27

Disassembly and Assembly Section

NOTICE

Ensure that all adjustments and repairs that are

carried out to t

he fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

formation and High Pressure Fuel

Lines” for s afety information.

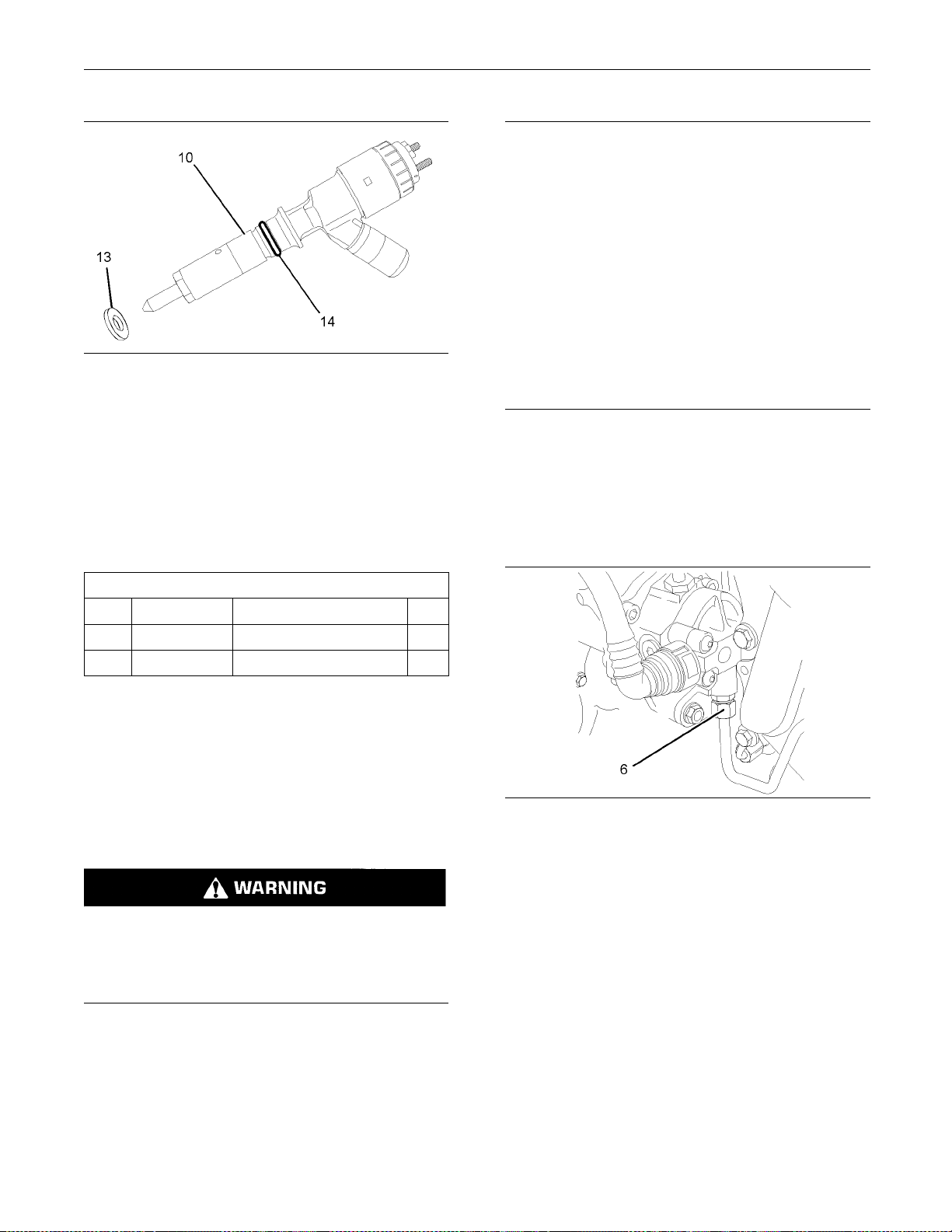

Illustration 47

g01193297

13. Remove the sealing washer (13) from the base of

the electronic unit injector (10) or from the bore in

the cylinder head. Discard the sealing washer.

14. Remove the O-ring seal (14) from the electronic

unit injector (10). Discard the O-ring seal.

Removal Procedure (All Injectors)

Table 8

Required Tools

Tool Part Number Part Description Qty

B

C

-

27610288

T40 T orx Socket

Pry Bar 1

Start By:

a. Remove the rocker shaft assembly. Refer to

Disassembly and Assembly Manual, “Rocker

Shaft - Remove”.

1

Refer to Testi

ng and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanline ss that

must be obser

ved during ALL work on the fuel

system.

1. Isolate the f

uel supply to the engine.

2. Place a suitable container below the fuel transfer

pumpinorde

r to catch any fuel that might be

spilled.

Note: Clean

up any spillage of fuel immediately.

b. Remove the fuel injection lines. Refer to

Disassembly and Assembly Manual, “Fuel

Injecton Lines - Remove”.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Illustration 48

Typical example

g01193839

3. Disconnect the tube assembly (6) for the injector

leak-off from the fuel transfer pump. Allow the fuel

to drain from the tube assembly.

Page 28

28 SENR9983

Disassembly and Assembly Section

8. Use Tooling (C) to pry beneath the clamp (12)

and free the ele

ctronic unit injector (8) from the

cylinder head.

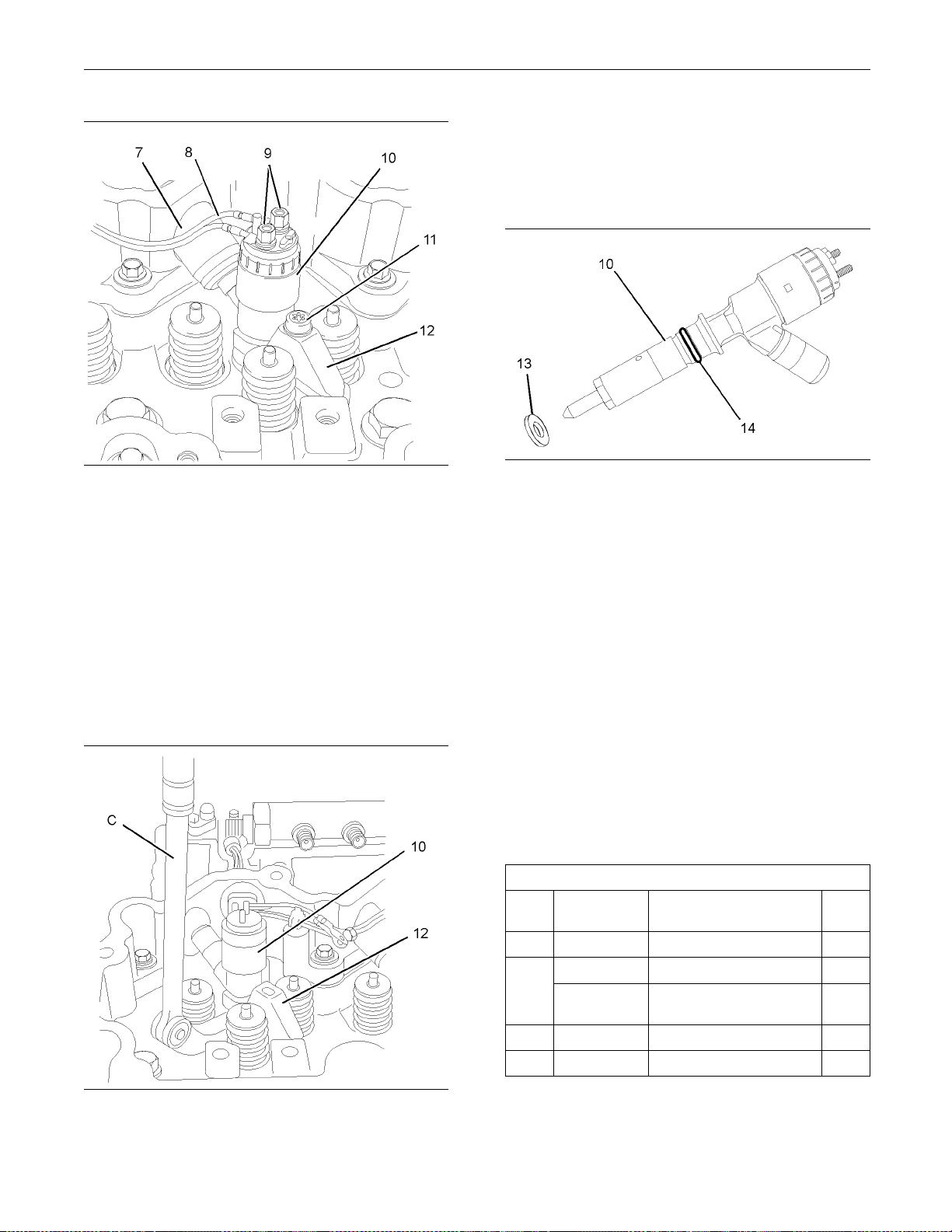

Illustration 49

g01193293

4. Place a temporary identification mark on the

connections (9) for the harness assembly (8).

5. Use a deep socket to remove the connections (9)

from the electronic unit injectors (10).

6. Use Tooling (B) in order to remove the torx screw

(11) from the clamp (12). Discard the torx screw.

7. Place a temporary identification mark on the

electronic unit injector (10). The electronic unit

injector must be reinstalled in the original location

in the cylinder head.

9. Remove the ele

ctronic unit injector (10) and the

clamp (12) from the cylinder head.

Illustration 51

g01193297

10. Remove the sealing washer (13) from the base of

the electronic unit injector (10) or from the bore in

the cylinder head. Discard the sealing washer.

11. Remove the O-ring seal (14) from the electronic

unit injector (8). Discard the O-ring seal.

12. Repeat Steps 4 through 11 in order to remove the

remaining electronic unit injectors.

i02295941

Electroni

c Unit Injector - Install

Illustration 50

g01193295

Installation Procedure (One

Injector)

Table 9

Required Tools

Too l Part

B

D

E

F 2761029

Number

-

-

-

27610294

6

Part Description

T40 Torx Socket 1

Vac u um Pum p 1

Tube

7.9 mm (0.31 inch) OD

Injector Pipe Nut Tool 1

Tor q u e W re n ch 1

Qty

1

Page 29

SENR9983 29

Disassembly and Assembly Section

NOTICE

Ensure that all adjustments and repairs that are

carried out to t

he fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

formation and High Pressure Fuel

Lines” for safety information.

Refer to Testi

ng and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obser

ved during ALL work on the fuel

system.

Illustration 53

g01193297

4. Install a new O-ring seal (14) to the electronic unit

injector (10).

Note: Do not lubricate the O-ring seal.

5. Ensure that the seat for the electronic unit injector

in the cylinder head is clean and free from

damage. Position a new sealing washer (13)

onto the seat for the electronic unit injector in the

cylinder head.

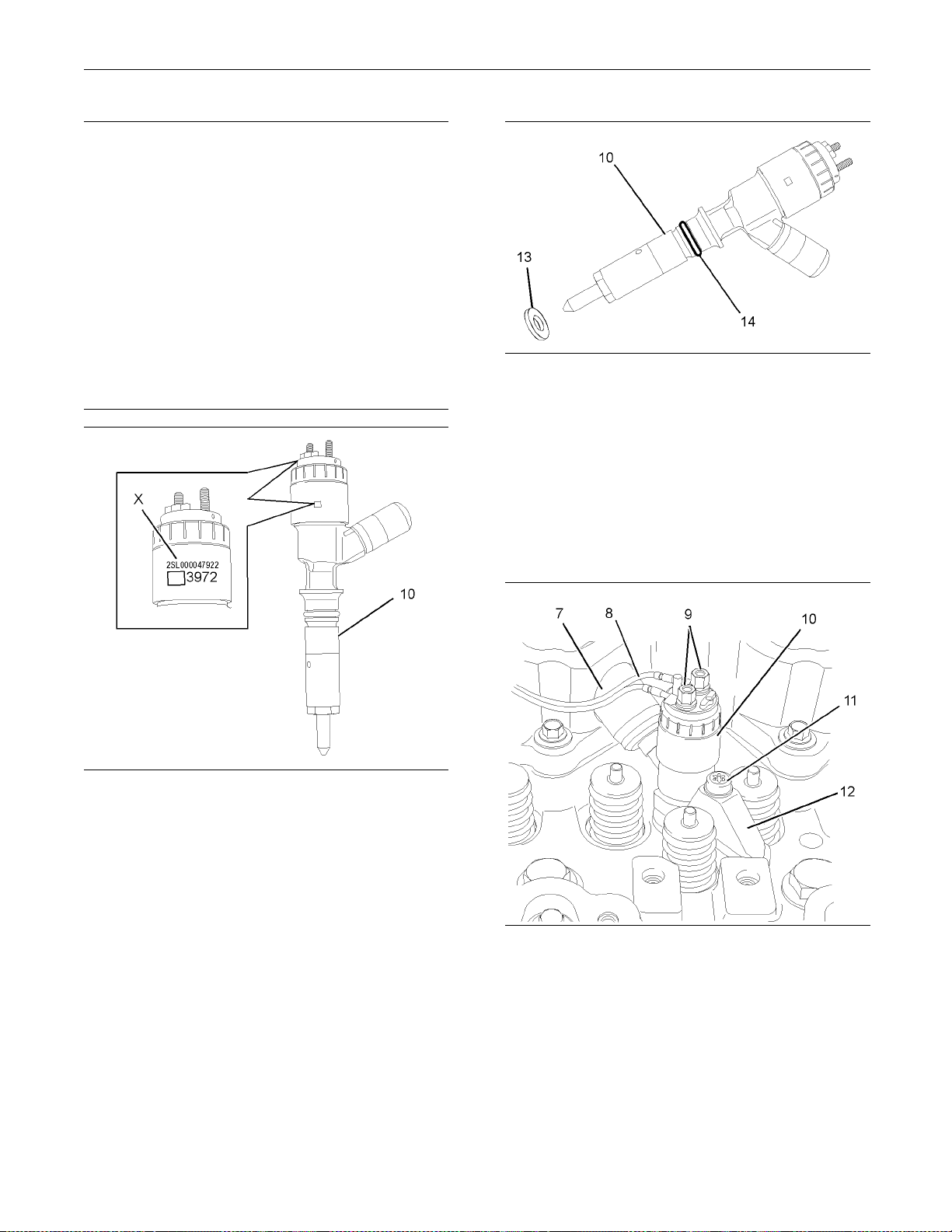

Illustration 52

The location of the calibration code

g01194240

1. If a replacement electronic unit injector is installed,

the calibration code that is located at position (X)

must be programmed into the electronic control

module. Refer to Troubleshooting Guide, “Injector

Trim File” for more information.

2. Use Tooling (D) in order to remove any fuel from

the cylinder.

Note: Evacuate as much fuel as possible from the

cylinder before installing the electronic unit injector.

3. Ensure that the fuel inlet port of the electronic unit

injector is capped. Ensure that the electronic unit

injector is clean.

Illustration 54

The rocker shaft is not shown for clarity.

g01193293

6. Install the clamp (12) to the electronic unit injector

(10). Install the electronic unit injector assembly

into the cylinder head.

Note: Ensure that the electronic unit injector is

pushed firmly against the seat in the cylinder head.

7. Install a new torx screw (11) to the clamp (12).

Tighten the torx screw finger tight.

8. Thoroughly clean the seal (7). Inspect the seal for

damage. If necessary, replace the seal.

Page 30

30 SENR9983

Disassembly and Assembly Section

Note: The seal can be damaged by contact with fuel.

9. Remove the cap from the electronic unit injector

(10). Install the seal (7) to the electronic unit

injector (10)

. Ensure that the flange on the seal is

flush with the valve mechanism cover base.

10. Remove the plu

gs from the new fuel injection line.

Loosely install the fuel injection line (not shown).

Refer to Disassembly and Assembly Manual,

“Fuel Inject

on Lines - Install”.

Note: Ensure that the ends of the fuel injection line

are seated in

the electronic unit injector and the fuel

manifold. Tighten the nuts finger tight.

11. UseTooling(

B) to tighten the torx screw (11) to a

torque of 27 N·m (20 lb ft).

12. Use Tooling (

E) to tighten the fuel injection line

(notshown)toatorqueof30N·m(22lbft).Refer

to Disassembly and Assembly Manual, “Fuel

Injecton Li

nes - Install”.

13. Use a deep socket to install the harness assembly

(8) to the el

ectronic unit injector (10). Use Tooling

(F) to tighten the connections to a torque of

2.4N·m(21lbin).

Illustration 56

Typical example

g01193839

16. Connect the tube assembly (6) for the injector

leak-off to the fuel transfer pump.

17. Restore the fuel supply to the engine.

18. Remove the air from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

- Prime” for more information.

End By:

a. Install the valve mechanism cover. Refer to

Disassembly and Assembly Manual, “Valve

Mechanism Cover - Remove and Install”.

Installation Procedure (All

Injectors)

Illustration 55

Typical exam p le

g01193285

14. Install bridges (5) to the cylinder head.

Note: Ensure that used valve bridges are reinstalled

in the original location and the original orientation.

Do not interchange the location or the orientation of

used valve bridges.

15. Ensure that the bottoms of the pushrod are

seated in the cups of the valve lifters. Locate

the balls of the adjusters (2) into the cups of the

pushrods (4). Adjust the valve lash. Refer to

Testing and Adjusting Manual, “Engine Valve Lash

- Inspect/Adjust”.

Table 10

Too l Part

B

D

E

F

Number

27610294

27610296

Required Tools

-

-

-

Part Descr

T40 Torx Socket

Vac u um Pum p 1

Tube

7.9 mm (0.31 inch) OD

Injector Pipe Nut Tool 1

Tor q ue W r en ch 1

iption

Qty

1

1

Page 31

SENR9983 31

Disassembly and Assembly Section

NOTICE

Ensure that all adjustments and repairs that are

carried out to t

he fuel system are performed by

authorised personnel that have the correct training.

Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, “General Hazard In

formation and High Pressure Fuel

Lines” for safety information.

Refer to Testi

ng and Adjusting Manual, “Cleanliness of Fuel System Components” for detailed

information on the standards of cleanliness that

must be obser

ved during ALL work on the fuel

system.

Illustration 58

g01193297

4. Install a new O-ring seal (14) to the electronic unit

injector (10).

Note: Do not lubricate the O-ring seal.

5. Ensure that the seat for the electronic unit injector

in the cylinder head is clean and free from

damage. Position a new sealing washer (13)

on the seat for the electronic unit injector in the

cylinder head.

Illustration 57

The location of the calibration code

g01194240

1. If a replacement electronic unit injector is installed,

the calibration code that is located at position (X)

must be programmed into the electronic control

module. Refer to Troubleshooting Guide, “Injector

Trim File” for more information.

2. Use Tooling (D) to remove any fuel from the

cylinder.

Note: Evacuate as much fuel as possible from the

cylinder before installing the electronic unit injector.

3. Ensure that the fuel inlet port of the electronic unit

injector is capped. Ensure that the electronic unit

injector is clean.

Illustration 59

g01193293

6. Install the clamp (12) to the electronic unit injector

(10). Install the electronic unit injector assembly

into the original location in the cylinder head.

Note: Ensure that the electronic unit injector is

pushed firmly against the seat in the cylinder head.

7. Install a new torx screw (11) to the clamp (12).

Tighten the torx screw finger tight.

8. Thoroughly clean the seal (7). Inspect the seal for

damage. If necessary, replace the seal.

Page 32

32 SENR9983

Disassembly and Assembly Section

Note: The seal can be damaged by contact with fuel.

9. Remove the cap from the electronic unit injector