Page 1

6750

Proximate Interface

Operating Instruction Manual

For models produced after January 2012

650M

Page 2

Page 3

Proximate Interface

Table of Contents

Preface

Related Instructions — 3

Scope — 3

Concept of Operations — 3

Customer Service — 3

Safety Information — 4

Intended Usage — 4

Explanation of Symbols — 5

General Specifi cations — 5

Environmental Conditions — 5

Cleaning & Maintenance — 5

Installation

Balance Port Connections — 6

Printer Port Connections — 6

Ethernet Network Port — 6

Start Up — 6

Instrument Description

Types of Controls — 6

Menu Keys — 7

Control Keys — 7

Program Installation and Control

Software Installation — 7

Factory Default Settings — 7

User Default Settings — 7

Factory Default Settings — 8

Menu Operating Pages

Process Timers — 9

Operating Controls — 9

Program Information and Controls — 10

Data Entry Controls — 11

Reporting Controls — 12

Communication Controls Menu — 13

File Management Menu — 21

Run Data File Manager — 21

Diagnostics — 22

Operating Instructions

Data Entry & Operation — 22

Basic Data Entry Procedures — 23

BTU Weight Entry — 23

BTU & Sulfur Value Entry — 23

Air Dried Loss or Total Moisture Entry — 24

Ash Fusion Entry — 24

FSI Entry — 24

Automatic Sample ID Increment Option — 24

Batch Input Mode — 25

Reporting Instructions

Report Generation — 26

Editing Reports — 26

Memory Management

— 27

Data & Communication Specifi cations

6750 Run Data Template — 28

Filename Convention — 29

Balance Input Driver Specifi cations — 29

Mettler 011/012 Interface — 29

Mettler MT-SICS — 29

Sartorius Balance Interface — 29

A&D Standard Format (type 0) — 30

Generic Interface — 30

Parr Balance Interface Cables — 30

Technical Service

Return for Repair — 30

References

— 31

Figures

Figure 1

6750 Proximate Interface - Internal Parts

View — 32

Figure 2

6750 Proximate Interface - Back View — 33

Figure 3

6750 Proximate Cover Panel - Internal

View — 33

Figure 4

6750 Proximate Interface Schematic — 34

2

Parr Instrument Company

Page 4

Proximate Interface

Preface

Related Instructions

The following Parr publications are also included

to further your understanding of this instrument and

its component parts:

No. Description

201M Limited Warranty

Scope

This manual contains instructions for installing

and operating the 6750 Proximate Interface.

The 6750 Proximate Interface can be installed in

a variety of confi gurations and the user will want to

choose the proper installation procedures for his or

her planned setup. Each 6750 Proximate Interface

is equipped with two USB ports and an Ethernet network connection.

Normally, the USB printer connection will be

used in conjunction with a standalone printer. The

1758 Printer can be used with the 6750 Proximate

Interface. A cable to connect the 6750 Proximate

Interface to the 1758 Printer is supplied

with the printer.

The USB port is also used to accept sample

weights directly from an analytical or top-loader

balance. The Interface software has been confi gured

to operate with a wide variety of balances. Parr can

supply cables for common balance connections.

An Ethernet network connection is used when

the 6750 Proximate Interface will be installed in

conjunction with a calorimeter and / or ADL or total

moisture interface devices. It may also be chosen

when longer distance communications are required.

Separate sections of this manual deal with each of

these communication ports.

Concept of Operations

The 6750 Proximate Interface is an advanced

microprocessor system designed to:

t Collect and store all individual weights obtained

during the series of steps required to determine

moisture, volatile matter, ash, Btu’s and Sulfur

for up to 1000 coal samples, with all data identifi ed by a user assigned alphanumeric sample ID

string (16 characters).

t Collect and store sample weights for Btu deter-

minations.

t Coordinate and organize all data as it becomes

available, and store it in correct order without

regard to entry sequence.

t Calculate the resulting proximate analysis for

each sample on any of four reference bases:

As-determined (AD)

As-received (AR)

Dry (DRY)

Dry, ash-free (DAF)

t Convert and report Btu and sulfur values to se-

lected moisture reference bases.

t Act as a remote Air Dry Loss or Total Moisture

Interface.

t Support data entry, storage and reporting for

two additional types of coal tests commonly

done in the same laboratory along with the

more traditional mass loss or calorimetric based

measurements.

t Free swelling index (FSI)

t Ash Fusion

t Transmit all results to a network printer, and/or

to a 40 or 80-column printer, and/or to a central

computer to obtain a consolidated printout or

report of the proximate analysis, Btu and sulfur

values for each sample.

t Produce fi nal or preliminary reports at any time

for any valid sample ID.

Customer Service

Questions concerning the installation or operation of this instrument

can be answered by the Parr Customer Service Department:

tt'BY

&NBJMQBSS!QBSSJOTUDPNtIUUQXXXQBSSJOTUDPN

www.parrinst.com

3

Page 5

Proximate Interface

Preface (Continued)

The 6750 Proximate Interface does not require

a special oven, furnace or analytical balance. All

drying and ashing operations are performed in the

same oven and furnace normally used for standard

ASTM proximate analyses. The 6750 Proximate

Interface is designed to communicate with a Mettler,

Sartorius, Ohaus or most digital analytical balances

for automatic data entry. Sample weights can also

be entered manually using the touch screen keyboard on the console.

Existing laboratory procedures do not have to

be changed. Samples can be weighed and treated in

any order, with the 6750 Proximate Interface accepting data from a digital balance as generated, organizing and storing it in the correct order, under operator assigned sample IDs. The operator can override

the automatic data entry system at any time to enter

weights as percentage values, manually if necessary. Weights used to determine air-dry loss (ADL)

or total moisture can be entered manually, or the

ADL or total moisture value can be calculated and

entered separately as a percent.

Usually the 6750 Proximate Interface will be

installed adjacent to an electronic analytical balance

and connected to the Interface with a serial communications cable. After each weighing, the entry will

be shown on a LCD display of the 6750 Proximate

Interface for confi rmation before it is entered into

memory. The operator will then use the touch screen

keyboard to identify each entry test (moisture, ash,

volatile matter, Btu or air dry loss) or function (tare,

gross or fi nal weight) to which the data applies.

The 6750 Proximate Interface will also prompt the

operator to identify each entry with a valid sample

ID. Several selectable options are available to speed

data entry procedures by allowing the operator to

enter consecutive tare and gross weights automatically with a minimum number of keystrokes. Data

for up to 1000 samples can be entered before results

must be withdrawn to make room for additional

data. All data is stored in non-volatile Flash ROM

based memory.

Additional 6750 Proximate Interfaces may be

connected to the network confi gured as ADL or total

moisture interface devices at some remote location.

In this system, the primary 6750 Proximate Interface

can then be confi gured to get ADL or total moisture

data (weights) from the remote 6750 Proximate

Interface, confi gured as an ADL or total moisture

device.

If the 6750 Proximate Interface is connected to

a Parr Calorimeter via an Ethernet communications

network, sample weights for heats of combustion

determinations will be transferred automatically to

the calorimeter. Determined Btu and Sulfur values

can then be transferred back to the 6750 Proximate Interface for incorporation in fi nal reports. If

the 6750 Proximate Interface is not connected to a

calorimeter controller, Btu and Sulfur values can be

entered directly through the touch screen.

The user can select from a variety of pre-programmed options to obtain either complete or partial reports for individual samples or for a full range

of tests. A memory management system will clear

the test report memory when desired.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current handling capability.

2. Ensure that the equipment is connected to electrical service according to local national electrical codes. Failure to properly connect may create

a fi re or shock hazard.

3. For continued protection against possible hazard, replace fuses with same type and rating of

fuse.

4. Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of fl ammable or combustible materials; fi re or explosion may result.

This device contains components which may

ignite such material.

2. Refer servicing to qualifi ed personnel.

Intended Usage

If the instrument is used in a manner not specifi ed

by Parr Instrument Company, the protection provided by the equipment may be impaired.

Provisions for Lifting and Carrying

Before moving the instrument, disconnect all

connections from the rear of the apparatus. Lift the

instrument by grabbing underneath each corner.

4

Parr Instrument Company

Page 6

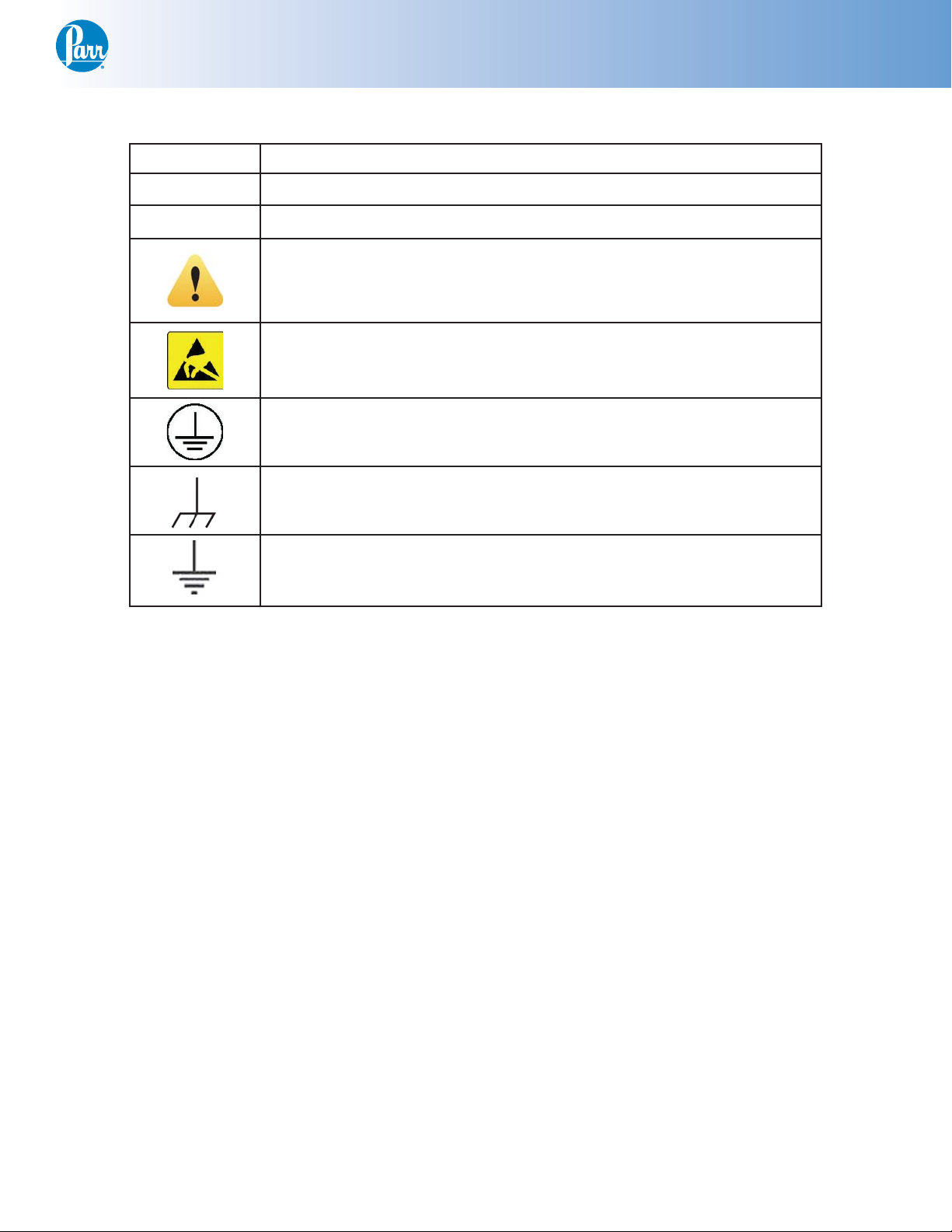

Explanation of Symbols

I On position

O Off Position

~ Alternating Current (AC)

Proximate Interface

This CAUTION symbol may be present on the Product Instrumentation and literature. If present on the product, the user must consult

the appropriate part of the accompanying product literature for more

information.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precau-

tions for handling electrostatic sensitive devices.

Protective Earth (PE) terminal. Provided for connection of the Protec-

tive Earth (green or green/yellow) supply system conductor.

Chassis Ground. Identifi es a connection to the chassis or frame of the

equipment shall be bonded to Protective Earth at the source of supply

in accordance with national and local electrical code requirements.

Earth Ground. Functional earth connection. Note: This connection shall

be bonded to Protective earth at the source of supply in accordance

with national and local electrical code requirements.

General Specifi cations

Electrical Ratings

115VAC, 2.0 Amps. 50/60 Hz

230VAC, 2.0 Amps, 50/60 Hz

Before connecting the 6750 Proximate Interface

to an electrical outlet, the user must be certain that

the electrical outlet has an earth ground connection

and that the line, load and other characteristics of

the installation do not exceed the following limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: 6750 Proximate Interface units can be

operated from either a 50 or 60 Hertz power supply

without affecting their operation or calibration.

Current: The total current drawn should not exceed

the rating shown on the data plate on the unit by

more than 10 percent.

Environmental Conditions

Operating:

15 ºC to 40 ºC; maximum relative humidity of

80% non-condensing.

Installation Category II (overvoltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage:

-25 ºC and 65 ºC; 10% to 85% relative humidity.

Cleaning & Maintenance

Periodic cleaning may be performed on the

exterior surfaces of the instrument with a lightly

dampened cloth containing mild soap solution. All

power should be disconnected when cleaning the

instrument. There are no user serviceable parts

inside the product other than what is specifi cally

called out and discussed in this manual. Advanced

troubleshooting instructions beyond the scope of

this manual can be obtained by calling Parr Instrument Company in order to determine which part(s)

may be replaced or serviced.

Fuses

Lines protective fuses rated: Fast-Act 15 Amp,

250VAC (Parr number 139E23).

The replacement of protective fuses for the 6750

Proximate Interface should be performed by qualifi ed personnel.

www.parrinst.com

5

Page 7

Proximate Interface

Installation

This apparatus is to be used indoors. It requires

at least 2 square feet of workspace on a sturdy

bench or table in a well-ventilated area with convenient access to an electric outlet. The supply voltage

must be within ± 10% of marked nominal voltage on

the apparatus. The supply voltage receptacle must

have an earth ground connection.

Balance Port Connections

The balance driver software in the 6750 Proximate Interface has been confi gured to operate with

a wide variety of balances. The following three balance protocols are supported:

1. Mettler

2. Sartorius

3. A & D

A fourth “generic” protocol is provided which

may, in many cases work with other balances that

are not directly supported. The user should fi rst

study the input specifi cation of the generic format

for compatibility with the intended balance if it is

not one of the fi rst three protocols listed above.

Other balances may be supported if their output

formats are compatible with the above four balances or a generic format which is supported by the

6750 Proximate Interface. Parr can supply the cables

for the balance port to balance connection. The

cables are listed in the

chapter of this manual.

Balances with an RS232C output will need to use

the 2203E RS232 to USB converter.

Data and Communications

be transferred to an Ethernet network connected

computer using the FTP File Transfer Protocol. By

default, the network interface is turned off. The

Interface can be confi gured to use DHCP (Dynamic

Host Confi guration Proticol) or have a static or fi xed

IP address. It is recommended, that any network

confi guration parameters only be set or altered after

consulting with your network administrator. Further

details related to the Ethernet port can be found in

the chapter that specifi cally addresses the data and

communication specifi cations.

Start Up

Once the appropriate cable connections have

been made, the unit is ready to be turned on by

moving the main power switch on the back of the

instrument to the on (I) position. The unit will display the Parr logo in the upper left hand corner of

the LCD, followed by a running description of the

instrument boot sequence. This boot sequence ends

when the instrument Main Menu is displayed.

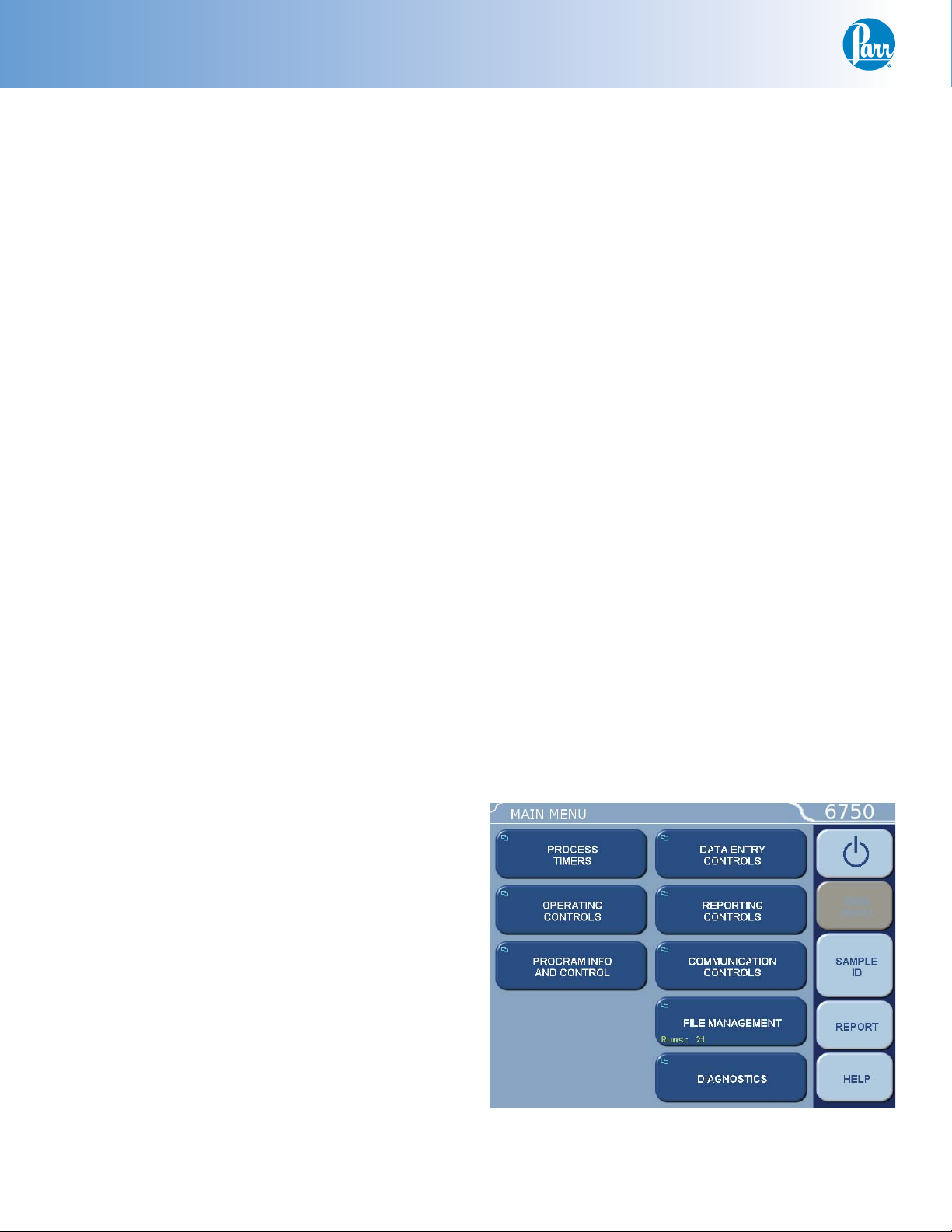

Instrument Description

Types of Controls

All confi gurations and operations are handled

by a menu-driven system operated from the bright

touch screen display. The settings and controls are

organized into ten main sections as displayed on the

MAIN MENU.

Note: Keys with a “double box” in the upper left

hand corner lead to sub-menus.

Printer Port Connections

The USB Ports on the 6750 Proximate Interface

may be used for connection to either a 40 or 80-column printer. Before making either of these connections, the data transmission rate of the 6750 Proximate Interface and the printer must be matched.

Parr offers the 1758 Printer for use with the 6750

Proximate Interface. An A2170E cable (supplied with

the printer) is used to connect the 6750 Proximate

Interface to the 1758 Printer. The Ethernet network

port can be used for long distance communications.

Ethernet Network Port

The Interface uses the TCP/IP protocol to communicate with other devices, such as PC, on a

standard Ethernet network. Interface test data can

6

Parr Instrument Company

Page 8

Proximate Interface

Menu Keys

The controls that change the data fi eld information in the menus will be one of the following:

Toggles. These data fi elds contain ON/OFF or

t

YES/NO choices. Simply touching the key on the

screen toggles the choice to the other option.

The current setting is displayed in the lower

right corner of the key.

Option Selection. These data fi elds contain a list

t

of options. Touching the key on the screen steps

the user through the available choices. The current setting is displayed in the lower right corner

of the key.

Value Entry Fields. These data fi elds are used to

t

enter data into the Interface. Touching the key on

the screen brings up a sub-menu with a keypad

or similar screen for entering the required value.

Some keys lead to multiple choices. Always

clear the current value before entering a new

value. Once entered, the screen will return to

the previous menu and the new value will be

displayed in the lower right corner of the key.

Data Displays. Most of these keys display val-

t

ues that have been calculated by the Interface

and are informational only. The user, entering

a desired value through a sub-menu, can override certain values. The value is displayed in the

lower right corner of the key.

Note: Some keys will respond with an opportunity

for the user to confi rm the specifi ed action to minimize accidental disruptions to the program and/or

stored data.

Control Keys

There are fi ve control keys that always appear

in the right column of the primary displays. These

keys are unavailable when they are gray instead of

white.

Escape. This key is used to go up one level in

1.

the menu structure.

Main Menu. This key is used to return to the

2.

main menu touch screen from anywhere in the

menu structure.

Sample ID. This key is used to start the data

3.

entry sequence for a given analysis.

Report. This key is used to access the test

4.

results stored in the Interface and to initiate a

report on the display or printer.

Help. This key is used to access help screens

5.

related to the menu currently displayed on the

touch screen.

System Shutdown. This key appears in the

ESCAPE key location when the Main Menu is

displayed. Pressing this button will prompt the

user to confi rm a system shutdown.

Program Installation and Control

Software Installation

The program in the Interface can be extensively

modifi ed to tailor the unit to a wide variety of standard test methods, laboratory techniques, and communication modes.

Note: Changes to the program are made by use of

the menu structure described later in this manual.

Any of these items can be individually entered at

any time to revise the operating program.

Factory Default Settings

Units are preprogrammed with DEFAULT SETTINGS. These default settings remain in effect until

changed by the user. Should the user ever wish to

return to the factory default settings, go to the Program Information and Control Menu, touch Reload

Factory Default Settings and YES.

Flash ROM based memory is provided to retain

any and all operator initiated program changes;

even if power is interrupted or the unit is turned off.

User Default Settings

The user default parameters of the Interface can

be changed to guarantee that the instrument will

always be in the desired confi guration before beginning a series of tests.

Users who wish to permanently revise their default settings may do so using the following procedure:

1. Establish the operating parameters to be stored

as the user default settings.

2. Go to the Program Information and Control

Menu, User/Factory Settings, User Setup ID,

and enter the desired User Setup ID (up to eight

characters).

3. Go to the Program Information and Control

Menu, Save User Default Settings, and YES.

4. To re-load the user default settings, go to the

Program Information and Control Menu, Re-load

User Default Settings, and YES.

Note: It is a good idea to enable “protect settings”

on the Interface to prevent them from being inadvertently changed.

www.parrinst.com

7

Page 9

Proximate Interface

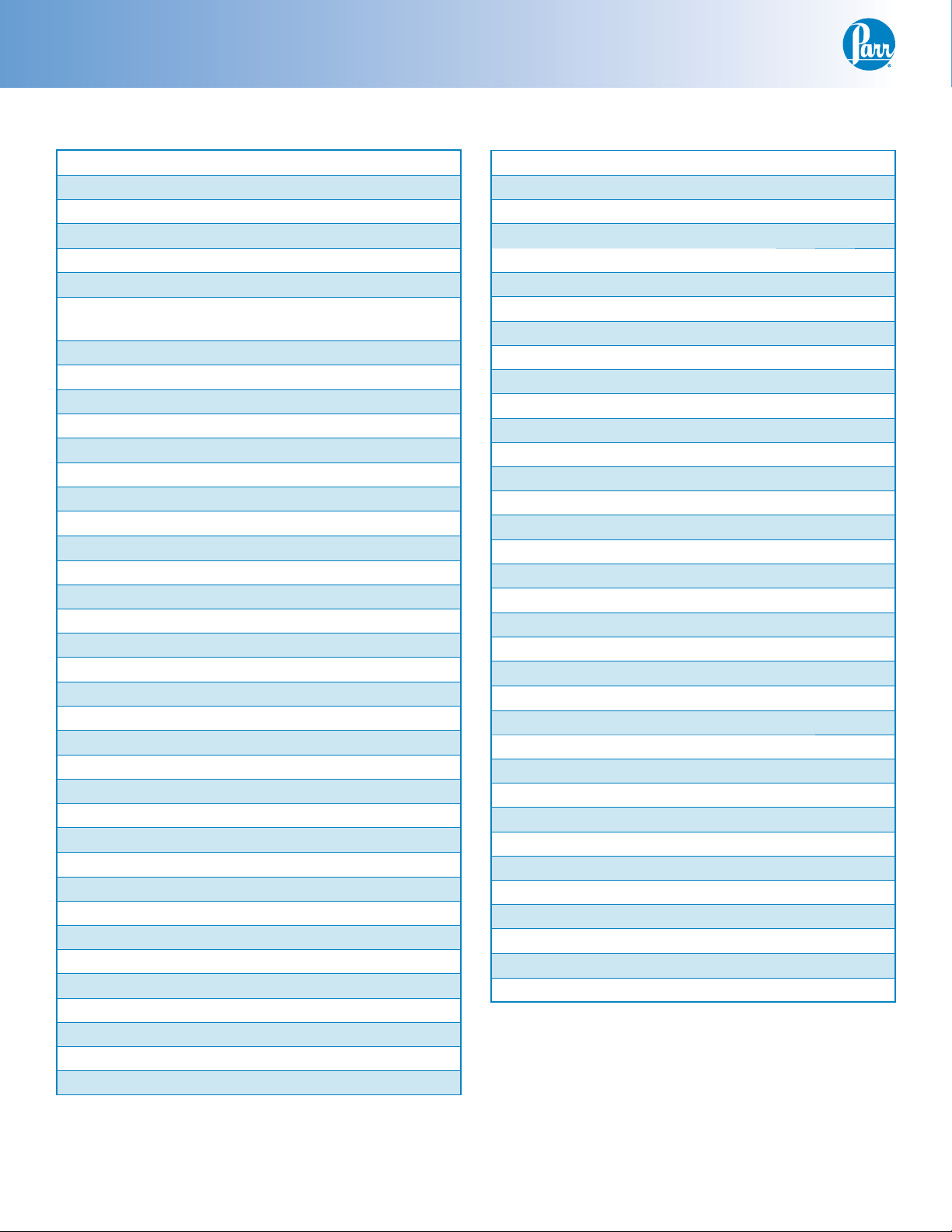

Factory Default Settings

Process Timers

Moisture 01:00:00

Ash 04:00:00

VM 00:07:00

Operating Controls

Device Type Proximate Inter-

face

LCD Backlight Timeout 1200

LCD Backlight Intensity 90%

Language English

Program Information & Control

User Setup ID 00000001

Settings Protect Off

Data Entry Controls

Auto Sample ID Controls On

Verify Data On

BTU/Spike Tare Zero

Moisture and Ash Separate

ADL Prompt Order Tare-Gross-Final

FSI Units Fahrenheit

Auto Sample ID Controls

Automatic Sample ID On

Next Auto Sample ID Number 1

Auto Sample ID Increment 1

Data Source Controls

ADL/Total Moisture Source Touchscreen

Moisture Source Touchscreen

Ash Source Touchscreen

Volatile Matter Source Touchscreen

Spike Weight Source Touchscreen

Sulfur Source Touchscreen

BTU Source Touchscreen

BTU Weights Source Touchscreen

Reporting Controls

Report Width 40

Report Format Text

Individual Printed Reports Off

Edit Final Reports Off

Report Inclusions

BTU On

BTU Weights On

Sulfur On

Moisture On

Ash On

Volatile Matter On

ADL/Total Moisture On

FSI On

Ash Fusion On

Spike Weight On

Balance Port Communications

Balance Type Generic

Balance Port Device /dev/ttyUSB0

Balance Port Settings

Number of Data Bits 8

Parity None

Number of Stop Bits 1

Handshaking None

Baud Rate 9600

Characters from Balance 8

Data Precision 4

Transfer T imeout (seconds) 10

Network Communications

DHCP (Automatic Setup) Off

Network Driver Off

8

Parr Instrument Company

Page 10

Proximate Interface

Menu Operating Pages

The 6750 Proximate Interface contains the following keys that lead to sub-menus.

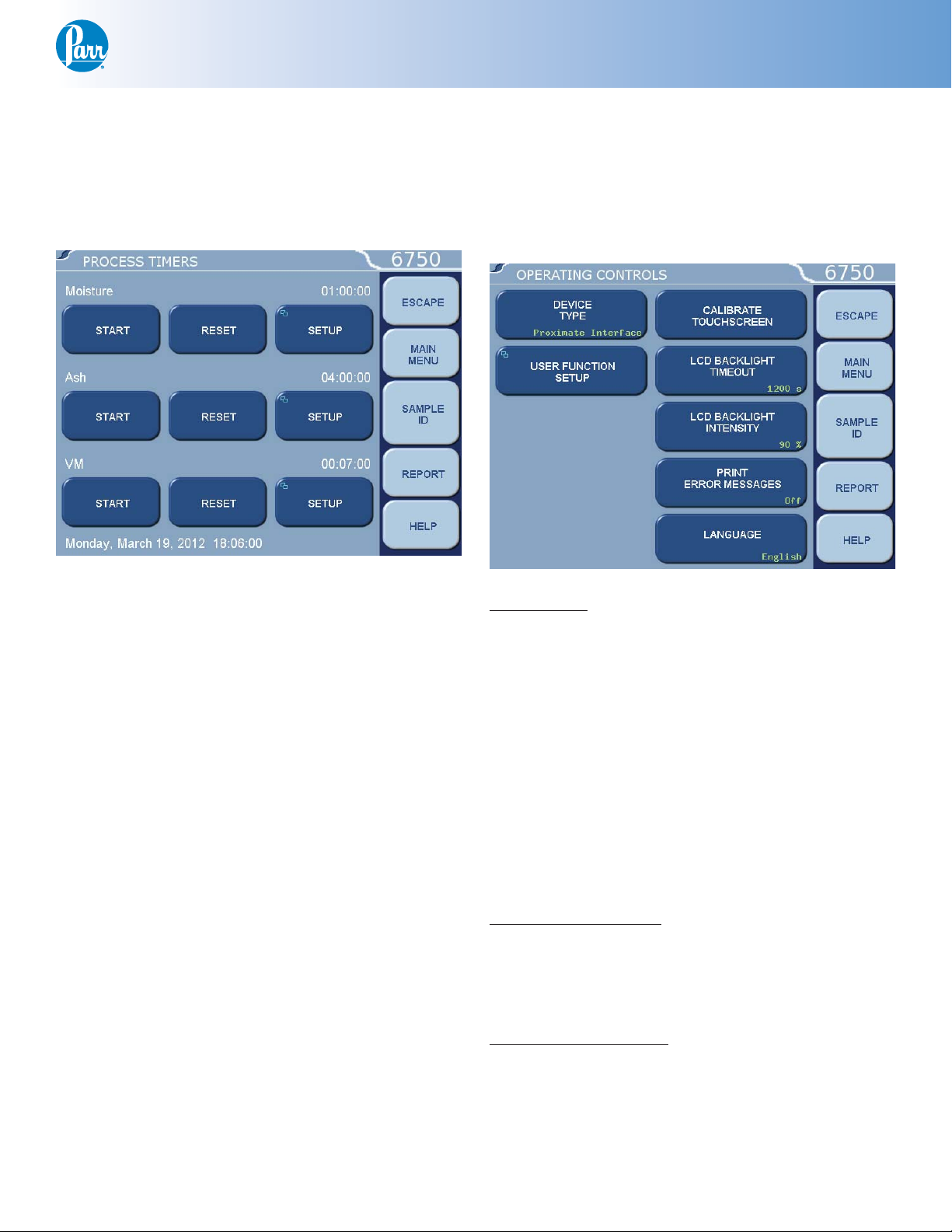

Process Timers

popup is displayed and the prior alarm is queued

underneath it.

The lower portion of the Timers page displays

the current date and time.

Operating Controls

Many of the tests involving proximate analysis

require holding the sample at a set temperature for

a pre-set time. As a result, a series of three independent countdown timers are provided. By default

these timers are labeled Moisture, Ash, and VM after

the most popular items to time. Each timer has three

buttons associated with it. The fi rst button starts and

stops the timer (toggle). The timer value is displayed

to the right of the label in a HH:MM:SS format.

The next button is a reset button that will reload

the timer preset value when the timer is not running. When the timer is running the reset button is

not active.

The third button associated with each timer is a

setup button that leads to a submenu. The submenu

allows the user to change the label and duration

for a timer. Each timer has a series of tones that are

sounded when the timer reaches zero. This alarm is

repeated indefi nitely until it is acknowledged.

When the timer reaches zero, the backlighting is

turned on, if required, and a popup box is displayed

in order to allow acknowledgment of the alarm.

The popup box displays the timer tag. Pressing the

continue button inside the large popup box provides

alarm acknowledgment. If an alarm occurs before an

active one is acknowledged, the most recent alarm

Device Type:

This key allows the user to customize the operation

of the device. Various screens and related prompts

will change depending on what type of device is selected. This setting also determines how the device

is confi gured in a networked environment.

The device options available are:

t Proximate Interface

t ADL Interface

t Total Moisture Interface

t Balance Interface

t Moisture Interface

t Ash Interface

t Volatile Interface

User Function Setup:

This key leads to sub-menus that support the confi guration of fi ve factory/user defi nable function keys.

The function keys are accessible from the Diagnostics page.

Calibrate Touchscreen:

This key prompts the user to touch the screen

at predefi ned points in order to facilitate touch

screen calibration. It’s important that a touch screen

stylus, rather than a fi nger, be used in order to realize an accurate calibration.

www.parrinst.com

9

Page 11

Proximate Interface

Operating Controls (Continued)

LCD Backlight Timeout:

The unit is equipped with an automatic circuit to

shut-off the backlight when it is not being used. The

back light will shut-off if there is no keyboard activity for the number of seconds entered. Touching the

screen will automatically turn the back lighting ON.

A setting of 0 will keep the backlight ON at all times.

LCD Backlight Intensity:

This button provides a slider control that allows

the user to adjust the display backlight intensity for

optimum viewing.

Print Error Messages:

When turned ON, all error messages are printed on

the printer as well as displayed on the screen.

Language:

This button steps the calorimeter through the installed operating languages.

t Time Zone. Displays the selected time zone

in relation to Greenwich Mean Time. Pressing this key will step through the time

zones and automatically adjust the time

setting.

Volume Level Adjust:

Opens a window with a slide adjustment to set the

volume of the key clicks and alarms of the calorimeter. Default is 85%.

Program Information and Controls

Date & Time:

Accesses a sub-menu to set the current date and

time.

t Date. Displays current date and accesses

sub-menu on which date is set in (YY/MM/

DD) format.

Software and Hardware Info:

This screen displays important information such as

the main software version, I/O board information,

CPU information, and IP address assigned.

Settings Protect:

Provides protection for the program options and

settings on the menus. If this is turned ON, the user

will be warned that enumeration keys are locked

when a key is pressed. Enumeration Keys either

toggle a value (ON/OFF) or select from a predefi ned

list. This feature is used primarily to protect the

instrument settings from accidental changes if one

were to inadvertently touch or bump up against the

touchscreen.

t Time. Displays current time and accesses

sub-menu on which time is set in (HH:MM)

format.

10

Parr Instrument Company

Page 12

User/Factory Settings:

This key leads to a sub-menu that allows the user to

save or recall user defi ned instrument settings. Additionally, factory pre installed settings supporting

different bombs or special operating modes can also

be recalled.

Proximate Interface

Cold Restart:

This is essentially the same as cycling power on the

unit. All valid test data will be retained during this

cold restart procedure.

Data Entry Controls

t User Setup ID. Used to enter a unique identi-

fi er for recalling or saving user settings.

t Reload Factory Default Settings. Used to erase

all of the settings and restore the factory

default settings.

t Reload User Default Settings. Used to restore

the user setup ID settings should the program in the instrument be corrupted for

any reason.

t Save User Default Settings. Used to record the

setup to the memory once the user has

confi gured the instrument to their operating requirements.

t Compare Settings With Factory Defaults.

button will bring up a screen that will show

the differences in the current settings of the

calorimeter with the factory defaults.

This

Feature Key:

This key displays a screen which allows the user to

input a code to access special calorimeter features

such as the bar code capabilities, remote operation

by PC or Samba server feature.

Auto Sample ID Controls:

This key accesses the sub-menu for controlling the

automatic assignment of sample identifi cation numbers.

Verify Data:

When this setting is set to ON, the user must press

the <ENTER> key to store incoming data. The value

may be edited prior to storage. The user may turn

this option ON or OFF.

Btu/Spike Tare:

When this setting is set to Zero, the Btu tare weight

is always equal to zero. The Btu net weight is then

entered as the Btu gross weight. The user may set

this key to Zero or Tare.

Moisture and Ash:

When this setting is set to Combined, it specifi es

that the weights entered for moisture tare, gross

shall be used for ash tare and gross. The user may

set this key to Combined or Separate.

ADL Prompt Order:

This key establishes the ADL or TM weight prompting order: Tare-Gross-Final or Gross-Final-Tare.

FSI Units:

The user may set either degrees Celsius or Fahrenheit.

www.parrinst.com

11

Page 13

Proximate Interface

Data Entry Controls (Continued)

Data Sources:

This key accesses a sub-menu where the user can

select input devices for each of the following types

of data:

Note: Ash fusion and FSI only come from the keyboard.

t ADL/Total Moisture – Touchscreen / Balance Port

/ Network

t Moisture Source – Touchscreen / Balance Port /

Network

t Ash Source – Touchscreen / Balance Port / Net-

work

t Volatile Matter Source – Touchscreen / Balance

Port / Network

t Spike Weight Source - Touchscreen / Balance Port

/ Network

t Sulfur Source – Touchscreen / Balance Port /

Network

t Btu Source – Touchscreen / Balance Port / Net-

work

t Btu Weights Source – Touchscreen / Balance Port

Network Device IP Addresses

This key accesses a sub menu where the user can

input the IP addresses of equipment attached to the

network.

Reporting Controls

Report Width

This key allows the user to select either 40 or 80 column report width. Select 40 when the 1758 Printer

is used.

Report Format

This setting allows the user to select the type of

report format for the printer or device attached to

the local printer port, either Data or Text. When Data

is selected, only numerical items are reported with a

comma delimiter.

Individual Printed Reports

When set to ON, will generate header information

for each report printed. In the OFF position, only one

header will be printed for a series of tests.

Edit Final Reports

When set to ON, this enables the user to revise

sample weights and related values contained in fi nal

reports.

Report Inclusions

This key leads to a submenu that allows the user to

select which analyses (and associated bases) are reported. Proper selection of the tests that correspond

to the types of analyses actually done will determine

when a report becomes fi nal. This selection will also

determine which kinds of test choice keys are displayed during a data entry session.

This key accesses a sub-menu where the user

can establish the report format for the local printer

port.

t Btu

t Btu Weights

t Sulfur

t Moisture

t Ash

t Volatile Matter

t ADL / Total Moisture

t FSI

t Ash Fusion (oxidizing and reducing)

t Spike Weight

12

Parr Instrument Company

Page 14

Proximate Interface

Communication Controls Menu

Accesses sub-menus which set the communications protocols for the printer and balances.

Printer Type:

Toggles between Parr 1758 and Generic.

Balance Port:

Accesses sub-menu, Balance Port Communications.

t Customize Balance Setting. Sets the com-

munication parameters for the balance

port. Standard options for data bits, parity, stop bits, handshaking, baud rate and

balance type are provided to match any

devices that might be connected to these

ports.

» Number of Data Bits. Standard options

for data bits. Toggles between 7 and 8.

» Parity. Standard options for parity.

Choose from None, Even or Odd.

» Number of Stop Bits. Standard options

for stop bits. Toggles between 1 and 2.

» Handshaking. Standard options for hand-

shaking. Choose from None, Xon/Xoff,

and RTS/CTS.

» Baud Rate. Standard options for baud

rate. Choose from 19.2K , 9600, 4800,

2400, 1800, 1200, 600, 300, 150, 134.5,

110, and 75.

» Data Characters from Balance. This

setting is only used when the generic

balance format is selected. This value

determines the number of numeric data

characters (0-9 . + -) to accept. Any additional characters after this value and

before the string terminating <CR> are

discarded.

t Balance Type. Toggles through the available

balance templates.

t Balance Port Device.

screen which allows the user to specify the

balance port device. The default

(dev/ttyUSB0) is the designation for the fi rst

USB to serial converter cable assigned by the

calorimeter upon power up.

This key displays a

» Data Precision. This key allows the user to

establish the number of digits to the right

of the decimal point that are passed from

the balance handler.

» Transfer T imeout (seconds). This value

determines how long the interface will

wait before giving up on a weight transfer. The value is entered in seconds.

www.parrinst.com

13

Page 15

Proximate Interface

Communication Controls Menu (Continued)

» Balance Handler Strings. This key leads to

a submenu that allows balance template

to be customized for unique balances or

needs.

t Log Balance to Display. Directs the incom-

ing data stream from the balance to a display

buffer. This function can be used to deter-

mine the data format from an unknown bal-

ance type. The display buffer is 40 characters

in length. The balance must be forced to is-

sue at least 40 characters before the contents

of the buffer are displayed.

t Balance Port LoopBack Test. Initiates a

loopback test on the port. A special loopback

plug is required in order to perform this test.

Further information on establishing

communications for the Printer, Balance, Network

Interface, Bar Code and other Network Data Devices

can be found in the

and Communication Specifi cations section of this

manual.

Installation section and Data

Users who don’t have a network infrastructure

can create a simple network by connecting a router

with DHCP server capability to the calorimeter using

an ordinary CAT 5 network cable. The unit should be

connected to the LAN side of the router. The PC in

turn is also connected to the LAN side of the router

using a similar CAT 5 cable. A D-link 614+ router is

recommended for this purpose.

For this router, operated without a WAN connection, the primary DNS address of the router (WAN

setup) must be set to the IP address of the router

found on the LAN setup page. Other routers behave

differently in the absence of a WAN connection. Providing an active upstream connection to the WAN

port of most routers generally minimizes the use of

any obscure setup confi gurations.

The Proximate Interface also supports the use of

a static IP address. A static IP address can be assigned from the Network Interface page under Communication Controls.

An FTP enabled web browser can be used to

access stored test data. The URL is of the following

form:

Network Interface

The test data can be transferred to an Ethernet

network connected computer using the FTP File

Transfer Protocol. First you must know the IP address of the network-connected Proximate Interface.

The network DHCP (Dynamic Host Confi guration

Protocol) server provides this address shortly after

the unit is turned on. The address can be seen on

the “Software and Hardware Info” page within the

“Program Information & Control” menu.

ftp://root.rootroot@10.1.5.32/../fl ash/data/

In this case, 10.1.5.32 is the IP address of the

Proximate Interface.

14

Parr Instrument Company

Page 16

Proximate Interface

The following screen shot illustrates the contents of the Proximate Interface data directory as presented

be a web browser.

The user can drag and drop or copy and paste test data fi les (with the csv suffi x) from the web browser

window to any convenient folder or directory on the PC.

The four folders or directories correspond to the device confi guration. For example, if the device is confi gured as a proximate interface device, all entered data is placed in the prox folder or directory. The three

other folders correspond to ADL, total moisture and balance interface devices.

The following screen shot illustrates the typical contents of the prox directory.

www.parrinst.com

15

Page 17

Proximate Interface

You can drag and drop or copy and paste test data fi les (with csv suffi x) from the web browser window

to any convenient folder or directory on the PC.

The Proximate Interface offers a web server service. Test reports can be viewed with a web browser using a URL of the following form:

http://10.1.5.32

16

Parr Instrument Company

Page 18

Proximate Interface

Where 10.1.5.32 is the IP address of the Proximate Interface. The following screen shot illustrates the

Proximate Interface home page.

From this page the Process Timers can be remotely monitored.

Clicking on the Sample Data tab displays a list of reports currently in the instrument memory.

www.parrinst.com

17

Page 19

Proximate Interface

From the Confi guration Page the Error Reporting and Sample ID & Bomb ID options can be set. Changes

made to this screen will change the settings in the 6750.

18

Parr Instrument Company

Page 20

Proximate Interface

On the Run Data screen test data can be reviewed and fi ltered by status and type.

www.parrinst.com

19

Page 21

Proximate Interface

The System Info page displays the Software and Hardware Information page of the 6750.

20

Parr Instrument Company

Page 22

Proximate Interface

File Management Menu

Run Data File Manager:

This key activates the File Manager. The File Manager is used to delete or rename test report fi les. It

is also used to convert fi le types.

Format the SD Card:

This key allows the user to format an installed SD

card in a manner that is compatible with the calorimeter.

Run Data File Manager

The white upper portion of the Run Data File

Manager screen presents all tests in memory in a

scrollable window. Test attributes include fi lename

(sample ID), test type, status, and date. Touching

anywhere in the column related to a given test attribute will sort the fi le list by that attribute. Successive touches will toggle between an ascending and

descending sort.

Note: Formatting will erase all fi les on the card!

Copy Run Data to SD Card:

This key copies all test data to an SD card inserted

into the rear of the calorimeter controller. This feature is used as a means of either archiving data or

transferring it to a PC.

Note: Subsequent use of the same SD card will

overwrite the data currently on the card.

Copy User Settings to SD Card:

This key copies all previously saved user setups to

SD.

Copy User Settings From SD Card:

This key copies all user setups previously saved to

SD back to the calorimeter controller memory. This

feature can be used to confi gure multiple calorimeters in an identical manner.

Select:

This key is used to begin the fi le selection process.

The up/down (single arrow) and page up/page down

(double arrow) keys are used to scroll up and down

the fi le list. Pressing the select key when a fi le is

highlighted blue will highlight the fi le with a cyan

color. This indicates that it is selected. Multiple fi les

throughout the list can be selected in this fashion.

Extend Sel:

This key selects all fi les between the last fi le selected and the fi le that is highlighted in blue.

Desel All:

This key deselects all fi les previously selected.

Rename:

This key allows the user to rename the blue highlighted fi lename.

Delete:

This key deletes all selected fi les.

Edit:

This key allows one or more selected tests to be

edited from determinations to standardizations and

vice versa.

www.parrinst.com

21

Page 23

Proximate Interface

Diagnostics

View System Log :

This key is used to display the contents of /fl ash/log/

messages. This fi le is used primarily to log application program debug messages.

View System Information:

This screen illustrates current operating system

information / statistics such as:

t Processes and their associated PIDs

t Memory

t Mass storage

t Network

View Instrument Log :

This screen displays the contents of /tmp/instlog.

Operating Instructions

Data Entry & Operation

There is a basic method for identifying and entering sample weight data into the 6750 Proximate

Interface. Settings are available through the Data

Entry Controls page to speed this process in the following situations.

t When consecutive Sample IDs are used.

t When gross and tare weights are entered con-

secutively.

t When only net weights are entered for Btu deter-

minations.

t When results are entered as percentages.

t When the same sample is used for both mois-

ture and ash determinations.

22

For dealing with these unique situations, the operator should be familiar with the data entry procedure, which is identical for air dry loss, total moisture, residual moisture, ash, volatile matter, sulfur,

Btu weights and/or values.

Parr Instrument Company

Page 24

Proximate Interface

Basic Data Entry Procedures

Pressing the SAMP ID key starts the data entry

sequence. This will prompt the operator to enter

the sample identifi cation string through the touch

screen (up to sixteen characters permitted). Next,

the operator presses the test identifi cation key,

MOIST, ASH, VM to identify the test followed by the

weight identifi cation key, TARE, GROSS, FINAL that

identifi es the weight. More than one weight identifi cation key can be selected. Most procedures call for

pressing both the tare and gross key initially.

The Interface will prompt for the tare weight of

the crucible followed by the gross weight. All this

time the Sample ID number and the selected test

and weight type(s) will be displayed. Once these

are verifi ed, the operator presses the ENTER key to

enter this identifi cation information. The display will

prompt the operator for weight information with a

prompt.

BTU Weight Entry

The 6750 Proximate Interface can be used as a

balance interface device to enter and store sample

weights for calorimetric tests. The weight entry process uses the BTU test identifi cation key followed

by pressing the gross key. Alternately the Date Entry

Controls page can be set to prompt for the tare

weight for those balances that do not have an automatic tare function.

BTU & Sulfur Value Entry

Btu and Sulfur values may be retrieved from

calorimeters or manually entered through the touch

screen. Entries on the Data Sources page controls

this choice. To enter these values, press the SAMP

ID and enter the sample identifi cation number.

Press the BTU or Sulfur key followed by ENTER. In

the retrieval mode, the appropriate value will be

transferred from a calorimeter to the display of the

Interface.

Weights are automatically transferred from the

balance when confi gured by pressing the <TRANSFER> key or they can be entered manually through

the keypad. The value can be verifi ed by the operator and entered into the 6750 Proximate Interface by

pressing the ENTER key, unless the automatic store

feature has been enabled. The basic weight entry

process is complete and can be repeated for the

next sample or weight. Moisture, ash, and volatile

matter can also be entered as percentages from the

keyboard by pressing the SAMP ID key, entering the

sample number, followed directly by ENTER which

causes a prompt for the percent value to be entered.

Once verifi ed, this value can be entered into the

Interface by pressing ENTER. If Btu values in the calorimeter or controller are preliminary values, then

any Btu or Sulfur values found by the Interface will

not be accepted. In the manual mode the operator

simply keys in the value in response to the prompt.

Btu and Sulfur values should be entered into the

Interface as “as determined values”.

www.parrinst.com

23

Page 25

Proximate Interface

Air Dried Loss or Total Moisture Entry

Air Dried Loss (ADL) or Total Moisture (TM)

weights are identifi ed with the corresponding key. A

report fi le can contain ADL or TM data but not both.

Entering one kind of data excludes the other from

being entered unless the other is cleared by editing

the report. The total moisture value is numerically

equal to moisture as received.

Settings on the Data Entry and Controls page

determine the ADL and TM prompting order for

data entry. Users having a second 6750 Proximate

Interface confi gured as an ADL or TM Interface may

obtain these data from the remote interface via the

Ethernet port. Settings on the Data Entry and Controls page control the source of the ADL or TM data.

The procedure for obtaining the ADL or Total

Moisture Weights from a remote interface is the

same as a manual entry procedure. To expedite

ADL or TM weights from a remote device, the recommended procedure is to press all three weight

identifi cation keys (TARE, GROSS and FINAL) before

the enter key when obtaining weights from a remote

6750 ADL or TM Interface. No information will be

sent, even if only one datum is requested, unless

all three weights have been entered into the remote

interface.

Ash Fusion Entry

Ash Fusion values are identifi ed with the corresponding keys. The user can choose either Ash

Fusion Oxidizing or Ash Fusion Reducing. Once this

choice is made the following four critical point temperature keys are displayed.

t IT, Initial deformation temperature

t ST, Softening temperature

t HT, Hemispherical temperature

t FT, Fluid temperature

Any number of these keys can be pressed. The

Interface will then prompt for the corresponding

value(s). Typical values for this test range from 1470

F (800 C) to 2900 F (1600 C). Values are reported to

the nearest unit. The reporting units, degrees C or F,

for the critical point temperatures is set on the Data

Entry and Controls page.

FSI Entry

Pressing the FSI key will simply initiate a prompt

for a numerical value for the free swelling index of

the sample, displayed to the nearest tenth of a unit.

The typical range of values is zero to 12.

Automatic Sample ID Increment Option

The basic data entry procedure can be modifi ed

to streamline the entry of data, and to adapt it to the

individual user’s operation procedures. One method

of modifying these procedures is through the use

of the Auto Sample ID Controls. When this option is

turned on, the Interface will automatically increment

the Sample ID by the value indicated on the Auto

Sample ID Controls page and prompt for a new set

of values each time a data entry sequence is completed.

24

Parr Instrument Company

Page 26

Proximate Interface

Batch Input Mode

The block input mode consists of allowing the

6750 Proximate Interface to automatically prompt

for and/or acquire data for ID’s that already exist in

the memory of the Interface. This type of transfer

is especially useful, but not limited to, transfers of

BTU, Sulfur, ADL and Total Moisture data from remote devices.

Batch Mode:

A patch list is a set of sample ID’s. This list is created

by recording or played back by playing one of 8 possible Batch Lists:

[1-5], [2-6], [3-7], [4-8]

The batch lists are selected by pressing the desired batch number. To toggle to the upper or lower

4 batch ID’s press the batch ID button a second time.

Delete:

This button deletes the sample ID at the current position in the batch list.

Rewind, Back, Forward, Fast Forward:

These buttons are used to skip over or repeat sample ID’s when playing back a batch list. This is useful if your batch becomes out of sequence or if you

wish to edit a batch list.

Play, Stop:

When batch list Play is selected and the batch list is

empty, a warning dialog is displayed and the batch

mode stays in the prior state. When a Sample ID

would normally be prompted for the next ID in the

batch list is displayed. When the end of the batch

list is encountered the batch mode is returned to the

Idle state.

Record, Stop:

When Record is selected all subsequent sample ID

entries are appended tot he end of the currently

selected list. Recording continues until the user

presses the stop button.

Mode:

This button toggles between Bock Mode and Single

Mode of sample ID entry. In Block Mode the ending

sample ID entry. In Block Mode the ending sample

ID is enabled and may be edited.

Accept:

Accepts the currently displayed sample ID and begins data prompts.

Each batch list contains 0 or more sample ID’s.

Upload:

The Upload button is used to upload copies of the

currently selected batch list to all devices specifi ed

in the network data device lists. The Upload button

is disabled when the batch list is on record mode.

Erase:

To completely erase a batch list press Erase with

batch list selected. You will be prompted to confi rm

this operation.

Play, Record, Idle:

Batch lists are in one of 3 states. All non-selected

batch lists are in the Idle state. A selected batch list

can be Idle, Playing, or Recording.

www.parrinst.com

25

Page 27

Proximate Interface

Reporting Instructions

The 6750 Proximate Interface can transmit formatted data over the USB port to a 40 or 80 column

printer to provide a printed report. Alternatively, test

reports can be transferred over the Ethernet network

to a specifi ed network printer. In addition to the

cabling and communication requirements contained

in the

Proximate Interface must be correctly programmed

to format and direct the report to the desired printing device. These options are set up Reporting

Controls page. In addition to the options available

for printing the report, the 6750 Proximate Interface

offers a wide selection of data and information that

can be included in the reports. The user can choose

to eliminate any tests not appropriate to his or her

work. All calculations and reporting by the 6750

Proximate Interface are performed in accordance

with the ASTM Methods listed in

in this manual.

Report Generation

Reports can be broadly classifi ed into one of two

categories: Preliminary and Final.

Installation chapter of this manual, the 6750

References section

the cursor. Press the SELECT key to actually enter

the selection. Once selected the highlight will turn

from dark blue to light blue. Scrolling through the

list and selecting individual fi les can select a series

of tests.

The double up and down keys will jump the cursor to the top or bottom of the current display.

If a range of tests is to be selected, select the

fi rst test in the series, scroll the selection bar to the

last test in the series and press EXTEND SELECT to

select the series. The DESELECT ALL key is used to

cancel the current selection of fi les.

To bring the selected report or series of report

to the display, press the DISPLAY key. To send the

reports to the printer press the PRINT key.

Editing Reports

t 1SFMJNJOBSZ3FQPSUTBSFHFOFSBUFEXIFOBMM

operator specifi ed data have not been completely

entered. When a report is fl agged as preliminary,

the operator or supervisor can quickly identify the

sample(s) requiring attention.

t 'JOBMSFQPSUTBSFHFOFSBUFEPODFBMMPGUIFPQFSB

tor specifi ed items have been entered into the fi le.

Test results are stored as fi les using the sample

ID number as the fi le name. Pressing the REPORT

command key accesses a listing of the stored results. The REPORT command key brings up a submenu on which the operator specifi es.

Select From List:

This key displays the stored results specifi ed with

the following key.

Run Data State

This key enables the operator to display only preliminary reports, only fi nal reports, or all stored reports.

The displayed fi les can be sorted by sample

ID number, by status or by date of test by simply

touching the appropriate column.

The EDIT key on this fi le selection screen brings

up a dialog box that enables the operator to edit any

of the data in the report or add additional data in

order to convert preliminary reports to fi nal reports.

Pressing the <CLEAR> key immediately followed by

the <ENTER> key will reset the entered bit associated with the given datum. Final reports can only be

edited if Edit Final Reports on the Reporting Controls

Menu is turned on.

Individual fi les can be chosen by highlighting

them using the up and down arrow keys to move

26

Parr Instrument Company

Page 28

Proximate Interface

Memory Management

The 6750 Calorimeter will hold data for 1000

tests in its memory. These tests may be pre weights,

preliminary or fi nal reports for either standardization or determination runs. Once the memory of the

controller is fi lled, the controller will not start a new

analysis until the user clears some of the memory.

The FILE MANAGEMENT key on the main menu

leads to the fi le management sub-menu. The RUN

DATA FILE MANAGER key leads to a listing of the

fi les. Single fi les can be deleted by highlighting the

fi le and pressing the DELETE key. The controller will

then ask the user to confi rm that this fi le is to be

deleted. A series of fi les can be deleted by selecting

the fi rst fi le in the series and then the last fi le in the

series using the EXTEND SEL key and then pressing

the DELETE key.

The controller of the 6750 Calorimeter can accept SD memory cards, Parr part number 2201E.

These cards can be used to:

Copy test fi le data for transfer to a computer

Copy user settings for back up

Reload user settings to the controller

Restore or update the controller’s operating

system.

Copy the log fi le

SD memory cards are inserted into either slot on

the back of the control section of the Calorimeter.

Keys are provided on the FILE MANAGEMENT submenu to initiate each of the above actions except

restoring or updating the controller’s operating

system and copying the log fi le.

www.parrinst.com

27

Page 29

Proximate Interface

Data & Communication Specifi cations

6750 Run Data Template

The following list illustrates the order in which the data is presented in a proximate analysis data fi le. A

comma separates each datum.

1 A Sample ID (char[16])

2 B Timestamp (MM/DD/YY HH:MM:SS

3 C State (1=preliminary, 2=fi nal)

4 D Status 1 (0 – 65535)

5 E Status 2 (0 – 65535)

6 F Moisture Tare Wt.

7 G Moisture Gross Wt.

8 H Moisture Final Wt.

9 I Ash Tare Wt.

10 J Ash Gross Wt.

11 K Ash Final Wt.

12 L Volatile Tare Wt.

13 M Volatile Gross Wt.

14 N Volatile Final Wt.

15 O ADL Tare Wt.

16 P ADL Gross Wt.

17 Q ADL Final Wt.

18 R TMoist Tare Wt.

19 S TMoist Gross Wt.

20 T TMoist Final Wt.

21 U Btu Tare Wt.

22 V Btu Gross Wt.

23 W Btu Net Wt.

24 X ADL

25 Y Moisture as determined

26 Z Ash as determined

27 AA Volatile as determined

28 AB Fixed Carbon as determined

29 AC Sulfur as determined

30 AD Btu as determined

31 AE Moisture as received

32 AF Ash as received

33 AG Volatile as received

34 AH Fixed Carbon as received

35 AI Sulfur as received

36 AJ Btu as received

37 AK Ash Dry

38 AL Volatile Dry

39 AM Fixed Carbon Dry

40 AN Sulfur Dry

41 AO Btu Dry

42 AP Sulfur Dry Ash Free

43 AQ Btu Dry Ash Free

44 AR Volatile Dry Ash Free

45 AS Fixed Carbon Dry Ash Free

46 AT FSI

47 AU Ash Fusion temperature units 0=F, 1=C

48 AV Ash Fusion-reducing-IT

49 AW Ash Fusion-reducing-ST

50 AX Ash Fusion-reducing-HT

51 AY Ash Fusion-reducing-FT

52 AZ Ash Fusion-oxidizing-IT

53 BA Ash Fusion- oxidizing -ST

54 BB Ash Fusion- oxidizing -HT

55 BC Ash Fusion- oxidizing –FT

56 BD Btu Spike Tare Wt.

57 BE Btu Spike Net Wt.

58 BF Btu Spike Gross Wt.

28

Parr Instrument Company

Page 30

Proximate Interface

Filename Convention

Test data fi les are named with the following convention.

Test type Filename

Preliminary <ID>.plim.csv

Final <ID>.fi nl.csv

Balance Input Driver Specifi cations

Overview

The 6750 Proximate Interface supports input

from the three balance types indicated below. Additionally, a generic input driver is provided for

communications with balances that do not conform

to the directly supported protocols. A feature supported by all balance input drivers is the ability to

change the expected number of characters in the

data fi eld. The number of data characters indicated

for each of the drivers, below, are default values.

This feature virtually eliminates the need for balance

input drivers to be re-written in the event the balance manufacturer elects to alter the output string

of a balance when new models are introduced.

The format of an unknown balance can be determined by logging the balance output to display. In

order for the logging to produce meaningful results,

the cable connecting the balance to the balance

input port of the Interface must be correctly wired

or confi gured. In addition, the specifi cs of the data

frame, such as the baud rate, # of data bits, parity, #

of stop bits and handshaking (if used) must be the

same for both the balance and the Interface.

Mettler 011/012 Interface

Field Length

ID 2

space 1

data 9

space 1

g1

CR 1

LF 1

The ID fi eld must contain “S_” to indicate a

stable mass. The data fi eld contains the current

mass, right justifi ed, with a decimal point. The balance should be confi gured to send continuously.

Mettler MT-SICS

Field Length

ID 2

stability 1

space 1

data 10

space 1

g1

CR 1

LF 1

The ID fi eld must contain “S_” to indicate a stable mass. The data fi eld contains the current mass,

right justifi ed, with a decimal point. The balance

should be confi gured to transmit data upon receipt

of the following command string:

S [CR] [LF]

Note: The automatic data output option should not

be used.

The interface will send this command string

once after the PROCEED key has been pressed

during a mass entry sequence. The PROCEED key

should only be pressed when the mass reading is

stable. However, unstable readings will be rejected

and a warning will be issued. Acknowledging the

warning by pressing the CLEAR ENTRY key will restart the mass entry process all over again.

Sartorius Balance Interface

Field Length

polarity 1

space 1

data 8

space 1

stability 2

CR 1

LF 1

The polarity fi eld must contain either a “+” or a

space. Leading zeros in the data fi eld are blanked,

except for the one to the left of the decimal point

The balance should be confi gured to transmit data

upon receipt of the following command string:

[ESC] P [CR] [LF]

Note: The automatic data output option should not

be used.

www.parrinst.com

29

Page 31

Proximate Interface

Sartorius Balance Interface (Continued)

The interface will send this command string

once after the PROCEED key has been pressed

during a mass entry sequence. The PROCEED key

should only be pressed when the mass reading is

stable. However, unstable readings will be rejected

and a warning will be issued. Acknowledging the

warning by pressing the CLEAR ENTRY key will restart the mass entry process all over again.

A&D Standard Format (type 0)

Field Length

header 2

comma 1

data 9

units 3

CR 1

LF 1

The header fi eld must contain “ST” to indicate

stable mass. The data fi eld contains the current

mass, with leading zeros, and a decimal point.

Technical Service

Should you need assistance in the operation or

service of your instrument, please contact the Technical Service Department.

Telephone: (309) 762-7716

Toll Free: 1-800-872-7720

Fax: (309) 762-9453

Email: parr@parrinst.com

Any correspondence must include the following

basic information:

1. The model and serial # of the instrument.

2. Date purchased.

3. Software version(s) shown on the “Software and

Hardware Information” page.

Generic Interface

Field Length

data 2

CR 1

The data fi eld should consist of 8 numeric characters (0 through 9,+,- and space) terminated with a

carriage return (CR).

Leading zeros may be blanked as spaces and are

counted. Non-numeric characters are ignored and

will reset the input buffer if the data fi eld has not

been fi lled. Any characters received after fi lling the

data fi eld and before the carriage return are ignored.

Parr Balance Interface Cables

Part # Description

A1880E 9 pin DS to 25 pin DP S-T

A1881E 9 pin DS to 25 pin DP Null

A1882E 9 pin DS to 25 pin DS S-T

A1883E 9 pin DS to 25 pin DS Null

A1884E 9 pin DS to 9 pin DP S-T

A1885E 9 pin DS to 9 pin DP Null

A1886E 9 pin DS to 9 pin DS S-T

A1887E 9 pin DS to 9 pin DS Null

2203E USB to Serial Adapter

4. Help system revision. This is displayed by press-

ing the <MAIN MENU> key and then the <HELP>

key.

When calling by phone, it is helpful if the person

is close to the instrument in order to implement

any changes recommended by the Technical Service

Department.

Return for Repair

To return the instrument for repair, please call

the Technical Service Department for shipping

instructions and a RETURN AUTHORIZATION NUMBER. This number must be clearly shown on the

outside of the shipping carton in order to expedite

the repair process.

Ship repair to:

Parr Instrument Company

Attn: Service Department

211- 53rd Street

Moline, Illinois 61265

30

Parr Instrument Company

Page 32

Proximate Interface

References

1. ASTM D2013 Standard Method of preparing Coal Samples for Analysis.

2. ASTM D3172 Standard Practice for Proximate Analysis for Coal and Coke.

3. ASTM D3173 Standard Test Method for Moisture in the Analysis Sample of Coal and Coke.

4. ASTM D3174 Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal.

5. ASTM D3175 Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke.

6. ASTM D3180 Standard Method for Calculating Coal and Coke Analyses as Determined to Different Bases.

7. ASTM D2961 Standard Test Method for Total Moisture in Coal Reduced to #8 Top Sieve Size.

8. ASTM D3302 Standard Test Method for Total Moisture in Coal.

9. ASTM D720 Standard Test Method for Free-Swelling Index of Coal.

10. ASTM D1857 Standard Test Method for Fusibility of Coal and Coke Ash

11. ASTM D5865 Standard Test Method for Gross Calorifi c Value of Coal and Coke

www.parrinst.com

31

Page 33

Proximate Interface

Figures

Figure 1

6750 Proximate Interface - Internal Parts View

(2) 1157E FUSE HOLDER

139E14 FUSE

TN1140HL

(2) 200F2

FUSE LABELS

353C2

BACK PANEL

911E FILTER

W/(2) TN1140HL

909E

POWER SWITCH

A1821E

SPEAKER ASSEMBLY

W/(2) SN1140HLHJ

A2167E

USB CABLE ASSY

W/(2) SA1140RP06

TYP (2) PLACES

(4) TA1332PP06X

351C2

BASE

1796E POWER SUPPLY

W/(4) SA1140RP06

325C HINGE

W/(4) TN1332HL

MF2154E

CPU BOARD

W/(4) SA1140RP06

WARNING:

For continued protection against possible hazard, replace

fuses with same type and rating of fuse.

32

Parr Instrument Company

Page 34

Figure 2

3

6750 Proximate Interface - Back View

Proximate Interface

1472DD

DISPLAY

ENCASEMENT

(4) TN1140HL

Figure 3

6750 Proximate Cover Panel - Internal View

352C2

COVER

F

1477DD

DISPLAY

(4) TN13

www.parrinst.com

33

Page 35

Proximate Interface

TRANSITION

BOARD TO

W/A2141E)

A2165E

(REF SUPPLIED

Figure 4

6750 Proximate Interface Schematic

REF

A2165E

DISPLAY

CABLE

IN THIS VIEW

CONTACTS ARE

EXPOSED

DETAIL "A"

A2141E

BOARD

LCD TRANSISTION

1472DD

LCD ENCASEMENT

A

J1

J10

J6

J9

J2

J8

2147E

LCD DISPLAY

CABLE

ASSEMBLY

SPEAKER

A1821E

A2164E BACKLIGHT CONTROL CABLE ASSY

J1

A1823E2 TOUCH

SCREEN CABLE ASSY

A2163E LCD CABLE ASSY

J5

J17J19

J100

J4

J8

J1

BACK PANEL

USB PORT 1

A2167E USB PERIPHERAL

OF J4 OF CPU

CABLE ASSY

CONNECTS IN UPPER PORT

J6

R1

BACK PANEL

USB PORT 2

CABLE ASSY

A2167E USB PERIPHERAL

CONNECTS IN LOWER PORT

OF J4 OF CPU

A1822E POWER CABLE ASSY

CN2

POWER

1796E

CN1

J10 J9

A2154E

CPU BOARD

SUPPLY

34

Parr Instrument Company

Page 36

Revision 05/18/12

Loading...

Loading...