Page 1

Operating Instruction Manual 592M

6725

Semi-micro Oxygen Bomb Calorimeter

Operating Instruction Manual

For models produced after November 2010

Page 2

6725 Semi-micro Calorimeter Instruction Manual

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................................................................ 1-1

PREFACE......................................................................................................................1-1

Scope.........................................................................................................................1-1

Explanation of Symbols..............................................................................................1-2

Safety Information......................................................................................................1-2

Intended Usage..........................................................................................................1-3

General Specifications...............................................................................................1-3

Environmental Conditions..........................................................................................1-3

Provisions for Lifting and Carrying.............................................................................1-3

INSTALLATION.............................................................................................................2-1

Power Connection......................................................................................................2-1

Oxygen Tank Installation............................................................................................2-2

Motor Installation........................................................................................................2-2

Thermistor Probe Installation.....................................................................................2-2

Communication Connections.....................................................................................2-3

Printer Connections....................................................................................................2-3

Balance Connections.................................................................................................2-3

Mettler 011/012 Interface...................................................................................................2-4

Sartorious Interface...........................................................................................................2-4

Generic Interface................................................................................................................2-4

Bar Code Port ............................................................................................................2-5

Computer Connections ..............................................................................................2-5

QUICK START...............................................................................................................3-1

OPERATION..................................................................................................................4-1

Menu System.............................................................................................................4-1

Menu Keys.................................................................................................................4-1

Control Keys...............................................................................................................4-1

Programming..............................................................................................................4-2

Default Settings..........................................................................................................4-2

Performing an analysis...............................................................................................4-3

Manual Test Sequencing.....................................................................................................4-4

Automatic Test Sequencing.................................................................................................4-6

MENU DESCRIPTIONS.................................................................................................5-1

Main Menu .................................................................................................................5-1

Calorimeter Operation Menu......................................................................................5-1

Temperature vs. Time Plot.........................................................................................5-2

Temperature Plot Setup Menu...................................................................................5-2

Operating Controls Menu...........................................................................................5-3

Spike Controls............................................................................................................5-4

Program Information and Control Menu.....................................................................5-5

Calibration Data and Controls Menu..........................................................................5-7

Thermochemical Corrections Menu.........................................................................5-10

Standardization Correction.......................................................................................5-10

Determination Correction.........................................................................................5-11

Calculation Factors Menu ........................................................................................5-12

Net Heat/Dry Heat Factors.......................................................................................5-13

Data Entry Controls Menu........................................................................................5-13

Reporting Controls Menu.........................................................................................5-15

Communication Controls Menu................................................................................5-16

Page 3

6725 Semi-micro Calorimeter Instruction Manual

File Management Menu ...........................................................................................5-17

Run Data File Manager............................................................................................5-18

Diagnostics Menu.....................................................................................................5-19

CALCULATIONS...........................................................................................................6-1

Corrections.................................................................................................................6-1

Manual vs. Fixed Corrections.....................................................................................6-2

Definitions .................................................................................................................. 6-3

Sulfur Correction........................................................................................................6-4

Acid Correction...........................................................................................................6-4

ASTM, ISO and Other Methods.................................................................................6-7

Conversion to Other Moisture Bases.........................................................................6-8

Conversion to Net Heat of Combustion......................................................................6-8

REPORTS......................................................................................................................7-1

MEMORY MANAGEMENT ............................................................................................8-1

MAINTENANCE.............................................................................................................9-1

TROUBLESHOOTING.................................................................................................10-1

Error List...................................................................................................................10-1

TECHNICAL SERVICE................................................................................................11-1

Contact Us ...............................................................................................................11-1

Return for Repair......................................................................................................11-1

PARTS LISTS..............................................................................................................12-1

Principal Assemblies in 6772 Calorimetric Thermometer ........................................12-1

Parts for the 6725 Semi-micro Calorimeter..............................................................12-2

Parts for the 1824 Oxygen Fill Connection ..............................................................12-2

DRAWINGS.................................................................................................................13-1

6772 Schematic .......................................................................................................13-1

Internal Parts View of 6772 Calorimetric Thermometer ...........................................13-2

Internal Parts View of 6772 Calorimetric Thermometer ...........................................13-3

Back Panel of 6772 Calorimetric Thermometer.......................................................13-4

External Parts View of the 6725 Semi-micro Calorimeter........................................13-5

Internal Parts Views of 6725 Semi-micro Calorimeter .............................................13-6

1824 Oxygen Filling Connection..............................................................................13-7

TABLES.......................................................................................................................14-8

Table 1 – Default Settings........................................................................................14-8

Table 2 – ISO & BSI Method Settings......................................................................14-3

TABLES.......................................................................................................................14-1

Table 1 – Default Settings.........................................................................................14-1

Table 2 – ISO & BSI Method Settings.......................................................................14-2

Page 4

6725 Semi-micro Calorimeter Instruction Manual

PREFACE

Scope

This manual contains instructions for installing and operating the Parr 6725 Semi-micro

Calorimeter. For ease of use, the manual is divided into 13 chapters.

Installation

Quick Start

Operation

Menu Descriptions

Calculations

Reports

Memory Management

Maintenance

Troubleshooting

Technical Service

Parts Lists

Drawings

Tables

Subsections of these chapters are identified in the Table of Contents.

To assure successful installation and operation, the user must study all instructions

carefully before starting to use the 6725 Semi-micro Calorimeter to obtain an

understanding of the capabilities of the equipment and the safety precautions to be

observed in the operation.

Additional instructions concerning the installation and operation of various component

parts and peripheral items used with the 6725 Semi-micro Calorimeter should be made a

part of these instructions. Additional instructions for the optional printer are found in the

respective printer package and should be made a part of this book.

No. Description

201M Limited Warranty

492M Operating Instructions for the 1109A Semi-micro Oxygen Bombs

207M Analytical Methods for Oxygen Bombs

230M Safety in the Operation of Laboratory and Pressure Vessels

483M Introduction to Bomb Calorimetry

This manual contains detailed instructions related to oxygen bomb calorimetry,

standardization of the calorimeter, combustion techniques, and thermochemical

corrections.

Note:

The unit of heat used in this manual is the International Table

(IT) calorie, which is equal to 4.1868 absolute joules.

1-1

Page 5

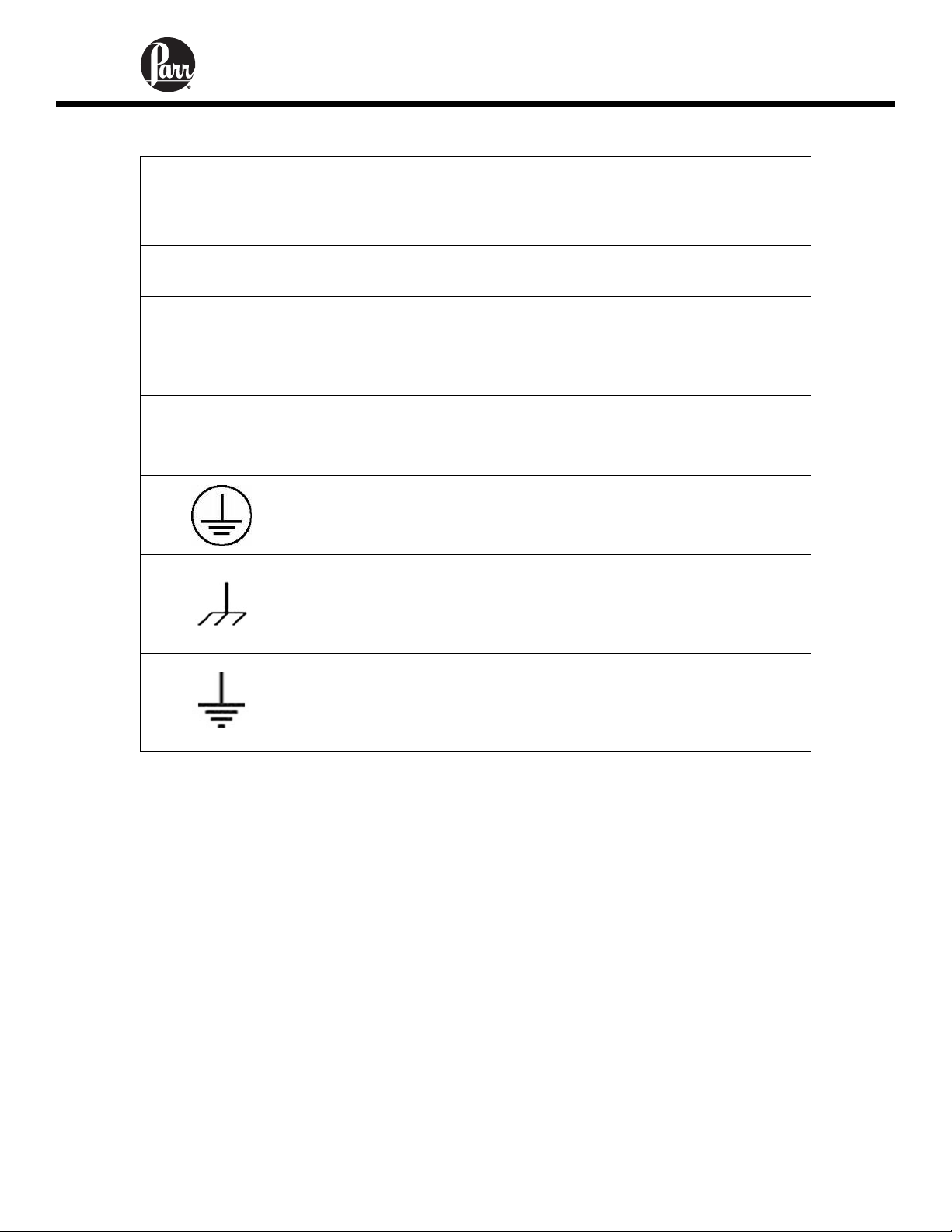

Explanation of Symbols

6725 Semi-micro Calorimeter Instruction Manual

I

O

~

On position

Off position

Alternating Current (AC)

This CAUTION symbol may be present on the Product

Instrumentation and literature. If present on the product, the user

must consult the appropriate part of the accompanying product

literature for more information.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe

precautions for handling electrostatic sensitive devices.

Protective Earth (PE) terminal. Provided for connection of the

Protective Earth (green or green/yellow) supply system

conductor.

Chassis Ground. Identifies a connection to the chassis or frame

of the equipment shall be bonded to Protective Earth at the

source of supply in accordance with national and local electrical

code requirements.

Earth Ground. Functional earth connection. NOTE: This

connection shall be bonded to Protective earth at the source of

supply in accordance with national and local electrical code

requirements.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current handling

capability.

2. Ensure that the equipment is connected to electrical service according to local

national electrical codes. Failure to properly connect may create a fire or shock

hazard.

3. For continued protection against possible hazard, replace fuses with same type

and rating of fuse.

4. Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or combustible materials; fire or

explosion may result. This device contains components which may ignite such

material.

2. Refer servicing to qualified personnel.

1-2

Page 6

6725 Semi-micro Calorimeter Instruction Manual

Intended Usage

If the instrument is used in a manner not specified by Parr Instrument Company, the

protection provided by the equipment may be impaired.

General Specifications

Electrical Ratings

115VAC, 2.0 Amps. 50/60 Hz

230VAC, 2.0 Amps, 50/60 Hz

Before connecting the calorimeter to an electrical outlet, the user must be certain that the

electrical outlet has an earth ground connection and that the line, load and other

characteristics of the installation do not exceed the following limits:

Voltage: Fluctuations in the line voltage should not exceed 10% of the rated nominal voltage

shown on the data plate.

Frequency: Calorimeters can be operated from either a 50 or 60 Hertz power supply without

affecting their operation or calibration.

Current: The total current drawn should not exceed the rating shown on the data plate on

the calorimeter by more than 10 percent.

Environmental Conditions

This apparatus is to be used indoors.

Operating: 15 °C to 30 °C; maximum relative humidity of 80% non-condensing.

Installation Category II (overvoltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 °C and 65 °C; 10% to 85% relative humidity.

Provisions for Lifting and Carrying

Before moving the instrument, disconnect all connections from the rear of the

apparatus. Lift the instrument by grabbing underneath each corner.

Periodic cleaning may be performed on the exterior surfaces of the instrument with a lightly

dampened cloth containing mild soap solution. All power should be disconnected when

cleaning the instrument. There are no user serviceable parts inside the product other than

what is specifically called out and discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can be obtained by calling Parr Instrument

Company in order to determine which part(s) may be replaced or serviced.

Specifications

Probe type Thermistor

Thermometer range 10-50 °C

Resolution 0.0001 °C

Absolute accuracy

without calibration

with calibration

Repeatability,

single point

Linearity, 10 °C span +/- 0.002 °C

Communications port Ethernet

Data logging capacity 1MB (~10000 points)

+/- 0.100 °C

+/- 0.0500 °C

+/- 0.002 °C

1-3

Page 7

6725 Semi-micro Calorimeter Instruction Manual

INSTALLATION

The 6725 Semi-micro Oxygen Bomb Calorimeter is to be used indoors. It requires at

least 4 square feet of workspace on a sturdy bench or table free from room drafts or

radiant heat sources, (preferably in an air conditioned room providing minimal

temperature change), an electrical outlet, a supply of water which is at least 1 °C cooler

then room temperature and a waste drain will be required. The supply voltage must be

within ± 10% of marked nominal voltage on the apparatus. The supply voltage

receptacle must have an earth ground connection.

Other necessary accessories include:

• Oxygen tank of 99.5% minimum purity

• Chemical balance sensitive to 0.1 mg

• Top loading balance capable of weighing up to 1.5 kg with a sensitivity of 0.1g

Unpack the calorimeter carefully and check the individual parts against the packing list.

If shipping damage is discovered, report it immediately to the delivery carrier. Handle

the Dewar flask and the thermistor probe with care as these parts are fragile and easily

broken.

Set the calorimeter on a bench or table in a location that is free from drafts and protected

from sources of radiant heat. Temperature changes in the room should be minimal.

Power Connection

Plug the power line into any grounded outlet providing proper voltage that matches the

specification on the nameplate of the Calorimetric Thermometer. The calorimeter will

draw approximately 100 watts of power. Grounding is very important not only as a

safety measure, but also to ensure satisfactory controller performance. If there is any

question about the reliability of the ground connection through the power cord, run a

separate earth ground wire to the controller chassis.

Turn the power switch to the on position. After a short time, the Parr logo will appear on

the LCD display followed by a running description of the instrument boot sequence.

When the boot sequence is complete, the 6772 Calorimetric Thermometer Main Menu is

displayed.

2-1

Page 8

6725 Semi-micro Calorimeter Instruction Manual

Figure 1

6772 Calorimetric Thermometer Back Panel

493E Plug

with 3280HC

Retainer installed to

insulate from live

circuits when no

motor is attached.

Oxygen Tank Installation

Install the oxygen tank according to the manufacturer’s recommendations. Unscrew the

protecting cap and inspect the threads on the outlet nipple to be sure they are clean and

in good condition; attach the 1824 Oxygen Filling Connection to the outlet nipple and

tighten the union nut with a wrench.

Motor Installation

Attach the motor cord to the rear of the calorimeter case using the mounting screws

provided for safety purposes. Set the cover with its attached stirring shaft onto the

stainless steel air can; drop the geared drive belt over the motor and stirrer pulleys. The

drive system should run freely. Although the belt may appear to be unusually loose, it is

intended to operate under light tension to minimize friction in the stirrer bearing. The

gearing on the belt and pulleys will prevent slippage.

Thermistor Probe Installation

Connections for two thermistor probes are located on the back of the 6772 Calorimetric

Thermometer. If only one probe is to be used, connect it to the “bucket” connection. If

the second probe is used, it should be inserted in the hole on the left, rear of the

2-2

Page 9

6725 Semi-micro Calorimeter Instruction Manual

instrument. Install the thermistor in the cover opening and press the bushing firmly into

place to anchor the probe in its proper position. Place the cover on the calorimeter with

the orienting pin in the alignment hole. The 6772 Calorimetric Thermometer acts an

ignition unit for automatically firing the bomb in the 6725 calorimeter. The ignition leads

to the thermometer need to be connected to the red and black terminals marked

“Ignition” on the back of the thermometer to take advantage of this feature.

Communication Connections

There is a USB connection on the rear of the 6772 to facilitate printer and balance

connections.

The 6772 will also allow the user to specify the IP addresses of one or more Balance

Interface devices on the network by selecting the Network Data Device menu in the

Communications Controls menu. Balance Interface devices are polled from device 1 to

15 for sample and / or spike weights when the weight entry mode is set to Network.

The 6772 will also allow the user to specify the IP addresses of one or more Balance

Interface devices on the network by selecting the Network Data Device menu in the

Communications Controls menu. Balance Interface devices are polled from device 1 to

15 for sample and / or spike weights when the weight entry mode is set to Network.

Printer Connections

The printer type setting is on the Communication Controls Menu. The default

parameters for the 6772 Calorimetric Thermometer are set up for use with the Parr 1758

Printer.

Balance Connections

The 6772 Calorimetric Thermometer supports input from the multiple balance types.

Additionally, a generic input driver is provided for communications with balances that do not

conform to the eight supported protocols. A new feature supported by all four balance input

drivers is the ability to change the expected number of characters in the data field. The

number of data characters indicated for each of the drivers, below, are default values. This

feature virtually eliminates the need for balance input drivers to be re-written in the event

the balance manufacturer elects to alter the output string of a balance when new models

are introduced.

2-3

Page 10

6725 Semi-micro Calorimeter Instruction Manual

The format of an unknown balance can be determined by logging the balance output to

the printer attached to the Calorimetric Thermometer. Those protocols which send a

command string to the balance will do so while logging is active. In order for the logging

to produce meaningful results, the cable connecting the balance to the balance input

port of the Calorimetric Thermometer must be correctly wired or configured. In addition,

the specifics of the data frame, such as the baud rate, # of data bits, parity, # of stop bits

and handshaking (if used) must be the same for both the balance and the Calorimetric

Thermometer.

Mettler 011/012 Interface

The ID field must contain “S_” to

indicate a stable mass. The data field

contains the current mass, right

justified, with a decimal point. The

balance should be configured to send

continuously.

Sartorious Interface

The polarity field must contain either a

“+” or a space. Leading zeros in the

data field are blanked, except for the

one to the left of the decimal point.

The stability field must contain “g_” for

the Calorimetric Thermometer to

accept a mass. The balance should be

configured to transmit data upon

receipt of the following command

string:

[ESC] P [CR] [LF]

Note:

The automatic data output option should not be used.

The Calorimetric Thermometer will send this command string once every few

seconds after the ENTER key has been pressed during a mass entry

sequence. The ENTER key should only be pressed when the mass reading

is stable. However, unstable readings will be rejected and a warning will be

issued. Acknowledging the warning by pressing the CLEAR ENTRY key will

re-issue the command string to the balance on a periodic basis.

Generic Interface

The data field should consist of 9

numeric characters (0 through 9, +, and space) terminated with a carriage

return (CR). Leading zeros may be

blanked as spaces and are counted. Non-numeric characters are ignored

and will reset the input buffer if the data field has not been filled. Any

characters received after filling the data field and before the carriage return

are ignored.

Field Length

ID 2

space 1

data 9

space 1

g 1

CR 1

LF 1

Field Length

polarity 1

space 1

data 8

space 1

stability 2

CR 1

LF 1

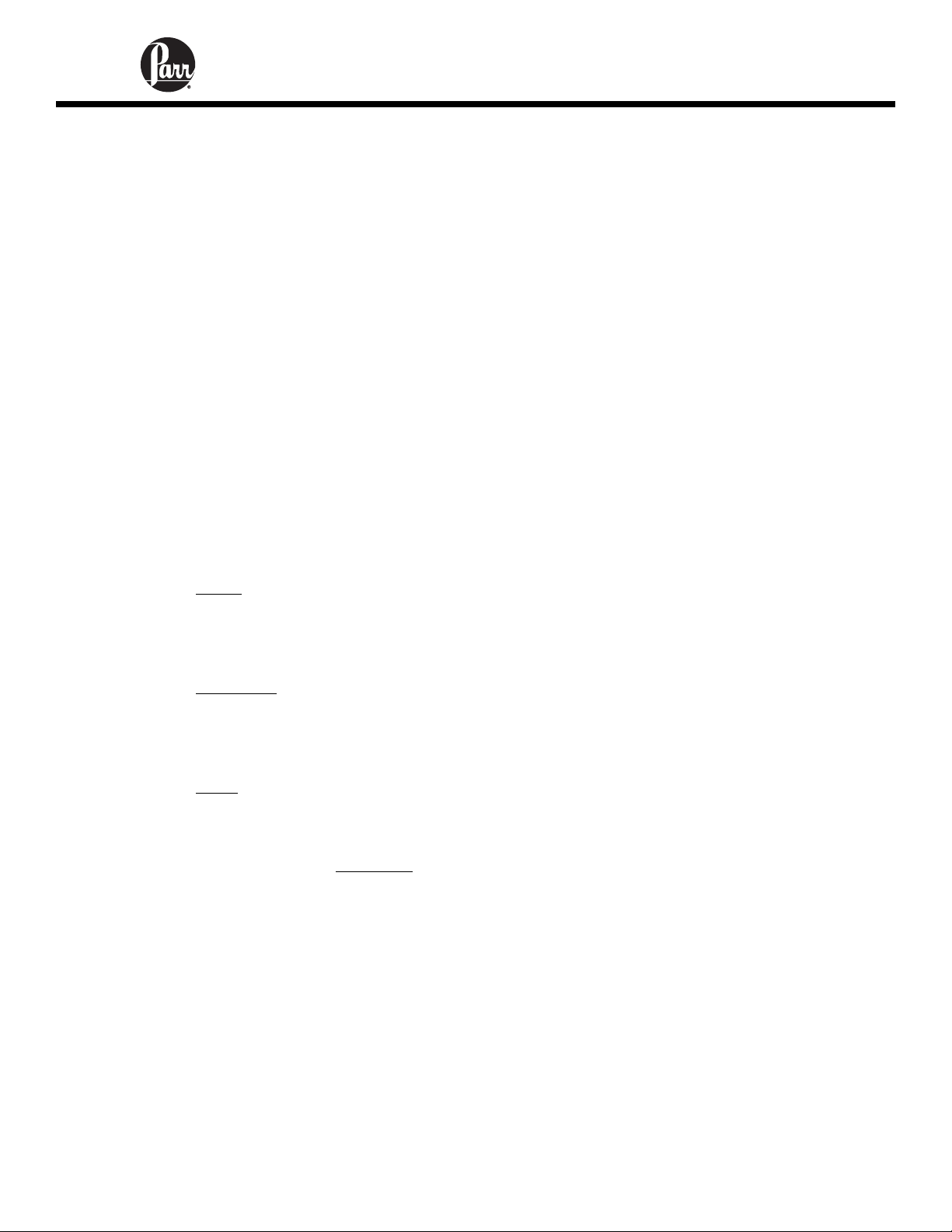

Field Length

data 8

CR 1

2-4

Page 11

6725 Semi-micro Calorimeter Instruction Manual

Bar Code Port

The use of barcodes in the laboratory has become a highly accurate, rapid and

inexpensive way to identify samples. When purchasing this feature, the user must

supply Parr with the MAC address of the calorimeter (found in the Software & Hardware

Info menu screen). This allows Parr to activate the feature key. In order to enable the

calorimeter to use the bar code feature, the feature key needs to be entered into the

instrument. Select the “Program Information and Control” key from the Main Menu.

Next, select “Feature Key” and enter the feature key purchased from Parr Instrument

Company into the instrument by using the touchpad. Pressing the key labeled “ABC”

allows the user to switch from upper case letters, to lower case letters and finally to

numerals. A CD containing all the necessary documentation and setup information for

using both the scanner and the printer is provided at the time of purchase. A PC based

program used for printing bar coded labels is also provided on this CD.

Computer Connections

If the 6772 Calorimetric Thermometer is

to be connected to a computer, the

Ethernet connection should be used.

Calorimetric Thermometer test data can

be transferred to an Ethernet network

connected computer using the FTP File

Transfer Protocol. First, you must know

the IP address of the networkconnected Calorimetric Thermometer.

The network DHCP (Dynamic Host

Configuration Protocol) server provides

this address shortly after the

Calorimetric Thermometer is turned on.

The address can be seen on the

Software & Hardware Info” screen, under Program Info and Control Menu; see the

example screenshot. Users who don’t have a network infrastructure can create a simple

network by connecting a router with DHCP server capability to the Calorimetric

Thermometer using an ordinary CAT 5 network cable. The Calorimetric Thermometer

should be connected to LAN side of the router. The PC in turn is also connected to the

LAN side of the router using a similar CAT 5 cable. A D-Link 614+ router is

recommended for this purpose. For this router, operated without a WAN connection, the

primary DNS address of the router (WAN setup) must be set to the IP address of the

router found on the LAN setup page. Other routers behave differently in the absence of

a WAN connection. Providing an active upstream connection to the WAN port of most

routers generally minimizes the use of any obscure setup configurations. An FTP

enabled web browser can be used to access stored test data. The URL is of the

following form:

ftp://root:rootroot@192.168.0.125/../flash/data/

In this case, 192.168.0.125 is the IP address of the Calorimetric Thermometer.

2-5

Page 12

6725 Semi-micro Calorimeter Instruction Manual

The following screenshot illustrates the contents of the Calorimetric Thermometer data

directory as presented by a web browser.

You can drag and drop or copy and paste test data files (with the csv suffix) from the

web browser window to any convenient folder or directory on the PC.

2-6

Page 13

6725 Semi-micro Calorimeter Instruction Manual

The Calorimetric Thermometer offers a web server service. Test reports can be viewed

with a web browser using a URL of the following form.

http://192.168.0.125

Where 192.168.0.125 is the IP address of the Calorimetric Thermometer. The following

screenshot illustrates the Calorimetric Thermometer status page.

2-7

Page 14

6725 Semi-micro Calorimeter Instruction Manual

Clicking on the Config tab displays some of the configuration options available in the

6772. Changes made on this page will change the settings in the 6772.

2-8

Page 15

6725 Semi-micro Calorimeter Instruction Manual

Clicking on the Run Data tab displays a list of reports currently in the instrument

memory. Clicking on any given report will provide a display similar to the following:

2-9

Page 16

6725 Semi-micro Calorimeter Instruction Manual

Clicking on System Info will bring up the Software and Hardware Info screen from the

6772.

2-10

Page 17

6725 Semi-micro Calorimeter Instruction Manual

Clicking on the LCD Snapshot Page will bring up an image of the current display on the

6772. Note that this is a picture only. To operate the 6772 from a PC a Remote Feature

Key must be installed. Please contact Parr Instrument Company for more details.

2-11

Page 18

6725 Semi-micro Calorimeter Instruction Manual

Clicking on Documentation will provide links to the manual and other helpful documents.

Note: a connection to the Internet is required to access the documentation.

2-12

Page 19

6725 Semi-micro Calorimeter Instruction Manual

QUICK START

Detailed Instructions for preparing the sample and charging the 1109A Oxygen Bomb

are given in Operating Instructions Manual No. 492M. Follow these instructions

carefully, giving particular attention to the precautions to be observed in charging and

handling the bomb. The default values of the 6772 are designed to operate with the

1341 Plain Jacket calorimeter. Note the parameter changes in the Operation section

of this manual.

1. Allow at least 20 minutes for the calorimeter to warm up. The bomb parts should be

wetted and then dried in the manner used at the conclusion of a test. This serves to

wet all sealing parts as well as leaving the bomb with the same amount of residual

water which will exist in all subsequent testing.

2. Turn on the stirrer motor switch on the 6725 calorimeter.

3. Prepare and weigh the sample to 0.0001g. Charge the oxygen bomb as described in

manual 492M. Each bomb and bucket combination will have to be standardized

separately and the proper energy equivalent for each set must be used when

calculating the heat of combustion.

4. Fill the Dewar with water to the nearest multiple of 50 milliliters (grams) which just

covers the small hole (gas inlet/outlet) on the bomb head inlet valve. This will be

either 400 or 450 mL of water.

5. Attach one of the ignition wires to the central terminal on the bomb head and push it

down as far as it will go. Attach the second wire to the socket provided on the bomb

hanger. Set the bomb in the loop of the A67C2 bomb support and carefully lower it

into the Dewar to hang from the top rim of the flask. Position the bomb so that the

stirrer can operate freely without striking the bomb. Check for gas bubbles.

6. Close the calorimeter cover and turn on the stirrer motor in the Calorimeter Operation

menu.

7. Select determination or standardization as appropriate on the Calorimeter Operation

page, by toggling the operating mode key. The calorimeter will now prompt the operator

for Bomb ID number, sample ID number, sample weight and spike weight in accordance

with the instructions set into the operating controls page.

8. The thermometer will now take over and conduct the test. During the time it is

establishing the initial equilibrium, it will display PREPERIOD on the status bar. Just

before it fires the bomb, it will sound a series of short beeps to warn the user to move

away from the calorimeter. Once the bomb has been fired, the status bar will display

POSTPERIOD. The calorimeter will check to make certain that a temperature rise

occurs and will then look for the final equilibrium conditions to be met. If it fails to

meet either the initial or final equilibrium conditions, or if it fails to detect a

temperature rise within the allotted time, the calorimeter will terminate the test and

advise the user of the error.

3-1

Page 20

6725 Semi-micro Calorimeter Instruction Manual

9. At the conclusion of the test, the calorimeter will signal the user.

10. Open the cover and remove the bomb and Dewar flask. Remove the bomb from the

flask and release the residual gas pressure before attempting to remove the cap.

This release should proceed slowly over a period of not less than one minute to

avoid entrainment losses. After all pressure has been released, unscrew the cap; lift

the head out of the cylinder and examine the interior of the bomb for soot or other

evidence of incomplete combustion. If such evidence is found, the test will have to

be discarded. Otherwise, wash all interior surfaces of the bomb, including the head,

with a jet of distilled water and collect the washings in a beaker.

11. Remove all unburned pieces of fuse wire from the bomb electrodes; straighten and

measure the combined length in centimeters. Subtract this length from the initial

length of 10 centimeters. Multiply the burned length by 2.3 calories per cm (for Parr

45C10 Fuse Wire) to obtain the fuse correction. The scale on the fuse wire card can

be used to obtain this value in calories by laying the unburned pieces from right to

left on the card. (Alternatively a fixed correction of 1.5 calories may be entered into

the calorimeter in the Thermochemical Corrections menu.)

12. Titrate the bomb washings with a standard sodium carbonate solution using methyl

orange, red or purple indicator. A 0.0709N sodium carbonate solution is

recommended for this titration to simplify the calculation. This is prepared by

dissolving 3.76 grams of Na

solutions of the same normality may be used.

13. Analyze the bomb washings to determine the sulfur content of the sample if it

exceeds 0.1%. Methods for determining sulfur are discussed in Operating

Instructions No. 207M.

14. At the end of the testing period, turn OFF the stirrer motor and the thermometer at

the power switch.

in the water and diluting to one liter. NaOH or KOH

2CO3

3-2

Page 21

6725 Semi-micro Calorimeter Instruction Manual

OPERATION

Menu System

All configurations and operations are

handled by a menu-driven system

operated from the bright touch screen

display. The settings and controls are

organized into ten main sections as

displayed on the MAIN MENU.

Note:

Keys with a “double box” in the upper left

hand corner lead to sub-menus.

Menu Keys

The controls that change the data field information in the menus will be one of the

following:

1. Toggles. These data fields contain ON/OFF or YES/NO choices. Simply touching

the key on the screen toggles the choice to the other option. The current setting is

displayed in the lower right corner of the key.

2. Option Selection. These data fields contain a list of options. Touching the key on

the screen steps the user through the available choices. The current setting is

displayed in the lower right corner of the key.

3. Value Entry Fields. These data fields are used to enter data into the Calorimetric

Thermometer. Touching the key on the screen brings up a sub-menu with a key pad

or similar screen for entering the required value.

choices. Always clear the current value before entering a new value. Once entered

the screen will return to the previous menu and the new value will be displayed in the

lower right corner of the key.

4. Data Displays. Most of these keys display values that have been calculated by the

Calorimetric Thermometer and are informational only. Certain ones can be

overridden by the user entering a desired value through a sub-menu. The value is

displayed in the lower right corner of the key.

Note:

Some keys will respond with an opportunity for the user to confirm the specified

action to minimize accidental disruptions to the program and/or stored data.

Control Keys

There are five control keys which always appear in the right column of the primary

displays. These keys are unavailable when they are gray instead of white.

1. Escape. This key is used to go up one level in the menu structure.

2. Main Menu. This key is used to return to the main menu touch screen from

anywhere in the menu structure.

3. Start. This key is used to start a Calorimetric Thermometer test.

4. Report. This key is used to access the test results stored in the Calorimetric

Thermometer, to enter thermochemical corrections, and to initiate a report on the

display, printer or attached computer.

Some keys lead to multiple

4-1

Page 22

6725 Semi-micro Calorimeter Instruction Manual

5. Help. This key is used to access help screens related to the menu currently

displayed on the touch screen.

This key appears in the Escape key location when the main menu is displayed.

6.

This key is used to shut down the calorimeter program before turning off the power.

Programming

The program in the 6772 Calorimetric Thermometer can be extensively modified to tailor

the unit to a wide variety of operating conditions, reporting units, laboratory techniques,

available accessories and communication modes. In addition, the calculations,

thermochemical corrections and reporting modes can be modified to conform to a

number of standard test methods and procedures. Numerous provisions are included to

permit the use of other reagent concentrations, techniques, combustion aids and short

cuts appropriate for the user’s work.

Note:

Changes to the program are made by use of the menu structure. Any of these items can

be individually entered at any time to revise the operating program.

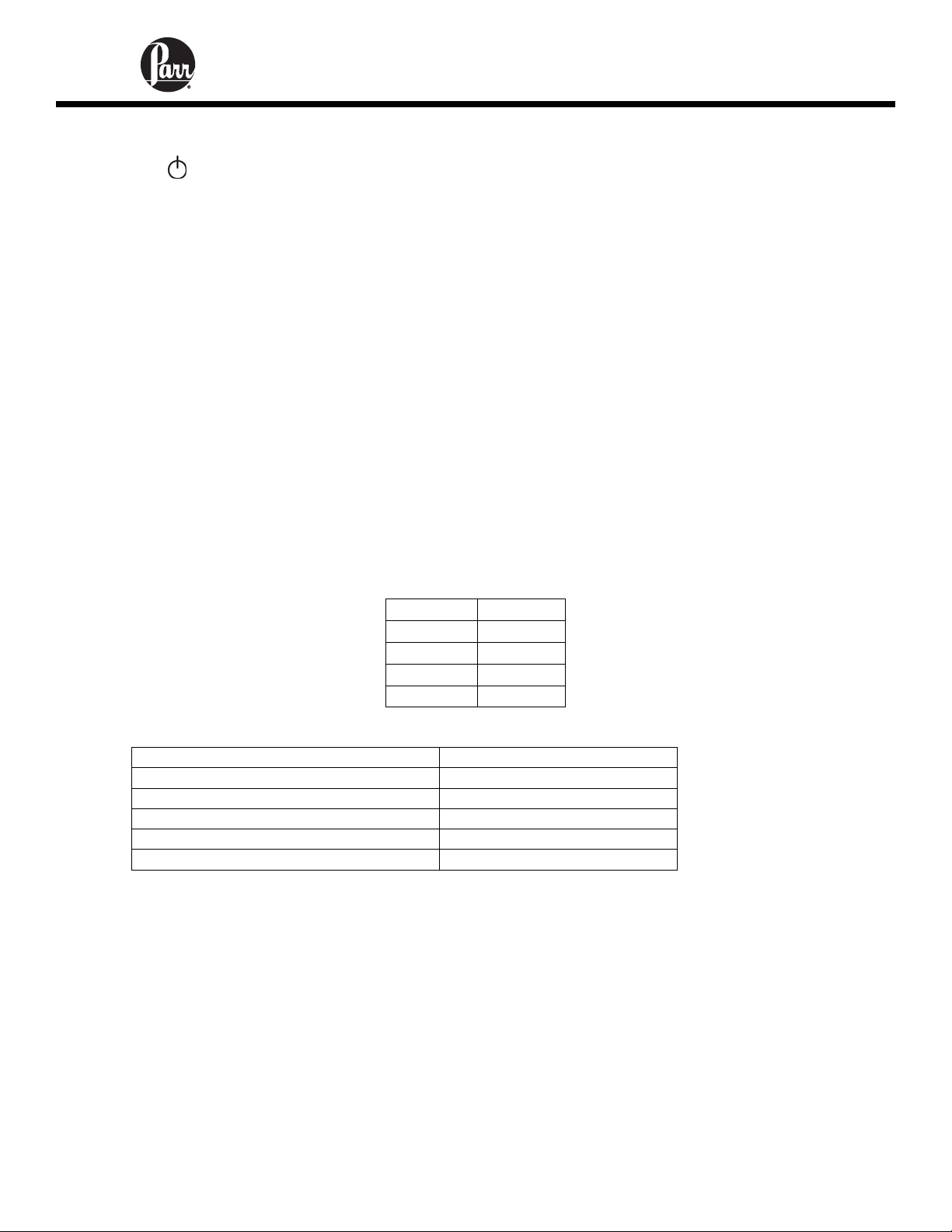

Default Settings

The 6772 Calorimetric Thermometer is preprogrammed with default settings for use with

the 1341 Plain Jacket Calorimeter. Therefore, the following parameters must be

changed in the Calorimetry Parameters menu found in the Diagnostics Menu.

Correction (K) Parameters:

K1 0.5

K2 0.00040

K3 1.0

K4 0.0

K5 0.0

Blackout (B) Parameters:

Mis-Fire Blackout (B2) 6

Derivative Blackout (B3) 0.5

Dynamic Blackout (B4) 6

Equilibrium Blackout (B5) 36

Dynamic Derivative Blackout (B6) 0.02

Dynamic Time Blackout (B7) 20

It is recommended that a Fixed Acid value of 1.5 be set on the Thermochemical

Corrections menu.

A more in-depth explanation of these parameters is found on the corresponding

parameter group help pages. These default settings remain in effect until changed by

the user. Should the user ever wish to return to the factory default settings, go to the

Program Info and Control Menu, User/Factory Settings, touch Reload Factory Default

Settings and YES. Non-volatile memory is provided to retain any and all operator

initiated program changes; even if power is interrupted or the unit is turned off. If the unit

experiences an intentional or unintentional “Cold Restart”, the controller will return to the

last known settings.

4-2

Page 23

6725 Semi-micro Calorimeter Instruction Manual

The default parameters of the 6772 Calorimetric Thermometer can be changed to

guarantee that the thermometer, when cold restarted, will always be in the desired

configuration before beginning a series of tests. Users who wish to permanently revise

their default settings may do so using the following procedure:

• Establish the operating parameters to be stored as the user default settings.

• Go to the Program Info and Control Menu, User/Factory Settings, User Setup ID, and

enter the desired User Setup ID.

• Select Save User Default Settings

To re-load the user default setting, go to the Program Info and Control Page,

User/Factory Settings, Re-load User Default Settings, and YES.

Performing an analysis

Tests can be run in a strictly manual fashion or automatically where the thermometer

sequences the calorimeter through the pre and post periods. The manual sequencing

approach is useful for applications where raw data is logged and subsequently analyzed,

off-line. In the automatic mode, the thermometer fully sequences the test and applies

real time corrections to the calorimeter temperature rise in order to correct for all

systemic heat leak effects. In either case the operator must determine the appropriate

temperature source for the jacket.

• Probe

• Calculated

• Fixed

For most applications the calculated

Detailed instructions for preparing the sample and charging the 1109 oxygen bomb are

given in the Operating Instructions for the 1109/1109A Semi-micro Oxygen Combustion

Bomb, manual 492M. Follow these instructions carefully, giving particular attention to

the precautions to be observed in charging and handling the bomb.

The bomb parts should be wetted and then dried in the manner used at the conclusion of

a test. This serves to wet all sealing parts as well as leaving the bomb with the same

amount of residual water which will exist in all subsequent testing.

The two operating modes, (manual or automatic) are outlined below:

– This method uses an additional 1168E2 thermistor probe attached to the

jacket wall to measure the actual temperature of the surroundings (at the chosen

point) and the heat leak correction are based upon the actual differences

between the bucket and this external jacket temperature.

– During the initial equilibrium period this method analyzes the actual

heat leak rate and calculates the apparent temperature of the surroundings which

would generate this rate and applies this calculated jacket temperature for the

determination.

– In this method the operator determines what his jacket temperature will

be and enters it into the thermometer. All heat leak corrections are then based

upon this fixed jacket temperature.

method is recommended.

4-3

Page 24

6725 Semi-micro Calorimeter Instruction Manual

Manual Test Sequencing

Some users may wish to construct their own thermogram and apply the classic graphical

corrections developed by Dickenson and others. In this case the actual temperatures

can be logged to the thermometer memory of the thermometer and then analyzed at the

end of the test. These logged temperatures can be recalled to display on the

thermometer, printed on an attached printer or transferred to a computer using either the

Ethernet Connection or a Compact Flash Card. The Ethernet Connection can also be

used to transfer temperatures to a computer for plotting and analysis in real time.

First, select the appropriate jacket temperature source as described previously. Then

prepare the sample and charge the oxygen bomb as described in Operating Instructions

No. 492M. Each bomb and bucket combination will have to be standardized separately

and the proper energy equivalent for each set must be used when calculating the heat of

combustion.

The calorimeter bucket consists of the Dewar flask with its attached spacer ring. The

bucket may be filled either gravimetrically or volumetrically, as long as it can be done

with a precision of 0.03% or better. The bucket should be filled with water to the nearest

multiple of 50 milliliters (grams) which just covers the small hole (gas inlet/outlet) on the

bomb head inlet valve. Due to differences in construction and manufacturing tolerance

on both the Dewar flask and the bomb hanger, the amount of water will be 400 or 450

mL (grams). Distilled water is preferred, but demineralized or tap water containing less

than 250 ppm of dissolved solids will suffice. The temperature of the water should be

within ± 1 °C of room temperature and be consistent from test to test. After filling the

Dewar, set it in the stainless steel air can and gently push the spacer ring down as far as

it will go.

Attach one of the ignition wires to the socket in the center terminal on the bomb head

and push it down as far as it will go. Attach the second wire to the socket provided on

the bomb hanger. Set the bomb in the loop of the A67C2 bomb support and carefully

lower it into the Dewar to hang from the top rim of the flask. Position the bomb as shown

in Figure 2 so that the stirrer can operate freely without striking the bomb.

4-4

Page 25

6725 Semi-micro Calorimeter Instruction Manual

Figure 2

Cross-Section of the 6725 Semi-micro Calorimeter

Install the thermistor in the cover opening and press the bushing firmly into place to

anchor the probe in its proper position. Place the cover on the calorimeter with the

orienting pin in the alignment hole. Turn the stirrer drive by hand to be sure that it runs

freely, then slip the drive belt first onto the motor pulley and then onto the stirrer pulley.

After the calorimeter is fully assembled with a charged bomb, turn on the motor switch,

and then turn on the stirrer by pressing the stirrer key on the calorimeter operation menu

screen. This will begin gently circulating the water that surrounds the combustion bomb.

Turn on the data logger (accessed via the Diagnostics page) in order to periodically

record the bucket or calorimeter temperature. This begins the calorimetric pre-period.

The bucket temperature is updated every 12 seconds. The pre-period should last for 6-7

minutes. After the 6-7 minute pre-period test phase, activate the calorimeter ignition

circuit by pressing the activate ignition button. This will charge the ignition circuit and

ignite the sample. This begins the calorimetric post-period. The calorimeter temperature

4-5

Page 26

6725 Semi-micro Calorimeter Instruction Manual

should begin to significantly rise at this point, indicating sample combustion. The

calorimetric post-period should last for an additional 6-7 minutes. At the conclusion of

the post-period, turn the stirrer off by pressing the stirrer key once again. The motor

switch may be left in the “on” position for subsequent tests.

If the data log destination is a log file, the log file is located at /flash/datalog.csv and may

be retrieved via FTP. The log file is easily imported into a spreadsheet program where

the calorimeter temperature can be plotted in order to realize a thermal curve.

Instructions for working with or analyzing thermal curves are found in the calculations

section.

At the conclusion of the test, open the cover, remove the bomb and Dewar. Remove the

bomb from the flask and open the valve to release the residual gas pressure before

attempting to remove the cap. This release should proceed slowly over a period of not

less than one minute to avoid entrainment losses.

After all pressure has been released, unscrew the cap; lift the head out of the cylinder

and place it on the support stand. Examine the interior of the bomb and the capsules for

soot or other evidence of incomplete combustion. If such evidence is found, the test will

have to be discarded. Wash all interior surfaces of the bomb with a jet of distilled water

and collect the washings in a beaker. Remove all unburned pieces of fuse wire from the

bomb electrodes; straighten them and measure their combined length in centimeters.

Subtract this length from the initial length of 10 centimeters and multiply this burned

length by 2.3 calories per cm (for Parr 45C10 Fuse Wire) to obtain the fuse correction.

The scale on the fuse wire card can be used to obtain this value directly.

Titrate the bomb washings with a standard sodium carbonate solution using methyl

orange, red or purple indicator. A 0.0709N sodium carbonate solution is recommended

for this titration to simplify the calculation. This is prepared by dissolving 3.76 grams of

Na

normality may be used.

Analyze the bomb washings to determine the sulfur content of the sample if it

exceeds 0.1%. Methods for determining sulfur are discussed in Operating

Instructions No. 207M.

in the water and diluting to one liter. NaOH or KOH solutions of the same

2CO3

Automatic Test Sequencing

First, select the appropriate jacket temperature source. For most applications, the

calculated jacket approach works well. Next, select the desired test mode

(standardization or determination) by toggling the Operating Mode key on the

Calorimeter Operation screen. After the calorimeter is fully assembled with a charged

bomb, press the START key located on the right hand side of the screen. This will

activate the stirrer that gently circulates the water that surrounds the combustion bomb.

The thermometer will prompt for sample ID number, a bomb ID number (1-4) and the

mass of the sample in grams. This begins the calorimetric pre-period. After the

thermometer determines that adequate temperature equilibrium is realized, the sample

is ignited. This starts the calorimetric post-period.

4-6

Page 27

6725 Semi-micro Calorimeter Instruction Manual

The calorimeter temperature should begin to significantly rise at this point, indicating

sample combustion. The calorimetric post-period will last for an additional 9-10 minutes

until the calorimeter temperature drift rate sufficiently stabilizes. At the conclusion of the

post-period the thermometer will turn off the stirrer and prepare a calorimetric test report

indicating the calorimeter temperature rise, fully corrected for all systemic heat leaks,

and whether a heat of combustion value or an energy equivalent (instrument calibration)

factor. Pressing the REPORT key, on the right hand side of the screen, and following

the indicated prompts, allows the user to view the test report.

At the conclusion of the test, open the cover, remove the bomb and Dewar. Remove the

bomb from the flask and open the valve to release the residual gas pressure before

attempting to remove the cap. This release should proceed slowly over a period of not

less than one minute to avoid entrainment losses.

After all pressure has been released, unscrew the cap; lift the head out of the cylinder

and place it on the support stand. Examine the interior of the bomb for soot or other

evidence of incomplete combustion. If such evidence is found, the test will have to be

discarded. Wash all interior surfaces of the bomb with a jet of distilled water and collect

the washings in a beaker.

Remove all unburned pieces of fuse wire from the bomb electrodes; straighten them and

measure their combined length in centimeters. Subtract this length from the initial length

of 10 centimeters and multiply this burned length by 2.3 calories per cm (for Parr 45C10

Fuse Wire) to obtain the fuse correction. The scale on the fuse wire card can be used to

obtain this value directly.

Titrate the bomb washings with a standard sodium carbonate solution using methyl

orange, red or purple indicator. A 0.0709N sodium carbonate solution is recommended

for this titration to simplify the calculation. This is prepared by dissolving 3.76 grams of

Na

normality may be used.

Analyze the bomb washings to determine the sulfur content of the sample if it

exceeds 0.1%. Methods for determining sulfur are discussed in Operating

Instructions No. 207M.

in the water and diluting to one liter. NaOH or KOH solutions of the same

2CO3

4-7

Page 28

6725 Semi-micro Calorimeter Instruction Manual

MENU DESCRIPTIONS

Note:

Keys which make global changes to the setup of the calorimeter contain a

YES or NO response to make certain that the user wishes to proceed.

This two step entry is intended to prevent inadvertent global program

changes.

Main Menu

Selecting the Main Menu key on any menu

will return you to the screen pictured on

the right of this page.

:

This key appears in the Escape key

location when the main menu is displayed.

This key is used to shut down the

calorimeter program before turning off the

power.

Start Key:

Press the Start key to begin any

Determination or Standardization run.

Report:

Press the Report key to begin the reporting process.

Help:

Press the Help key on any screen to display the explanation text for that screen.

Calorimeter Operation Menu

The Calorimetric Thermometer will normally be operated from the Calorimeter Operation

Menu, although tests can always be started from any menu screen.

Operating Mode:

Sets the operating mode by toggling

between standardization (for instrument

calibration) and determination (for test

runs).

Temperature Graph:

Press this key to display a real-time plot

of the bucket and / or jacket temperature

on the Temperature vs. Time Plot screen.

Bomb / EE:

Used to identify the bomb presently

installed in the Calorimetric Thermometer

and its EE value.

5-1

Page 29

6725 Semi-micro Calorimeter Instruction Manual

Start Preweigh:

This key is used to start the sample pre-weigh process. The user is presented with or

prompted for a sample ID. Next, the user is asked to key in the associated sample mass

or alternatively the mass is retrieved from a connected balance.

Stirrer:

On / Off This key provides a convenient way to manually start and stop the calorimeter

stirrer motor. The motor must be physically turned on for this function to be active.

Ignite Sample:

This key is used to manually start an ignition

charge and fire sequence.

Temperature vs. Time Plot

Press the Setup key to access the Temperature

Plot Setup Menu, which has many keys that

permit the user to fully customize both the x

(time) axis and the scaling of the y axis.

Temperature Plot Setup Menu

Enable Bucket: Toggles ON/OFF.

Bucket Autoscale: Toggles ON/OFF.

Enable Jacket: Toggles ON/OFF.

Jacket Autoscale: Toggles ON/OFF.

Time Mode: Toggles between Autoscale, Window, and Range.

Bucket Plot Symbol: Toggles between:

• No Point

• Small Dot

• Round

• Square

• Up Triangle

• Down Triangle

• Diamond

Press this key to access its numeric dialog box

to set a minimum bucket value.

Bucket Min Value: Press this key to access its

numeric dialog box to set a minimum bucket

value.

Jacket Plot Symbol: Toggles between (same as Bucket Plot Symbol, above).

Jacket Min Value: Press this key to access its numeric dialog box to set a minimum jacket

value.

Time Window: Sets the time scale for the X-axis

Time Units: Toggles between minutes and seconds.

5-2

Page 30

6725 Semi-micro Calorimeter Instruction Manual

Bucket Plot Color: Toggles between:

• Red

• Green

• Yellow

• Blue

• Magenta

• Cyan

• White

• Black

Bucket Max Value: Press this key to access its numeric dialog box to set a maximum

bucket value.

Jacket Plot Color: Toggles between:(same as Bucket Plot Color, above).

Jacket Max Value: Press this key to access its numeric dialog box to set a

maximum jacket value.

Time Minimum: Press this key to access its numeric dialog box to set the least

amount of time for the run.

Time Maximum: Press this key to access its numeric dialog box to set the greatest

amount of time for the run.

Operating Controls Menu

Method of Operation:

Offers an operating mode of either

combustion or solution. In the combustion

calorimetry mode, the instrument menu

structure is streamlined in order to remove

items that are only relevant to solution

calorimetry. The text on the key displays

the current instrument operating mode.

Pressing the key toggles the mode and

prompts that the unit will be restarted after

the operating mode has been reset. Help

screens are context sensitive with respect

to the operating mode.

Reporting Units:

Offers a choice of Btu/lb, cal/g, J/kg, MJ/kg, or Other. When “Other” is chosen, the user

can enter the desired multiplier by using the Other Multiplier key.

Spiking Correction:

Accesses the Spike Controls sub-menu:

Spiking is the material addition, such as benzoic acid or mineral oil, to samples which

are difficult to burn in order to drive the combustion to completion.

5-3

Page 31

6725 Semi-micro Calorimeter Instruction Manual

Jacket Temp. Source:

Press this key to display a menu that allows the user to select the source for the jacket

temperature used for tests.

“Other” Multiplier:

Press this key to display the Other Multiplier dialog box, where the user can enter a final

multiplier to be used when the reporting units are set to “Other”.

Calibrate Touchscreen:

This key prompts the user to touch the screen at predefined points in order to facilitate

touch screen calibration. It is important that a touch screen stylus, rather than a finger,

be used in order to realize an accurate calibration.

LCD Backlight Timeout:

The unit is equipped with an automatic circuit to shut off the backlight when it is not

being used. The back light will shut off if there is no keyboard activity for the number of

seconds entered. Pressing any key will automatically turn the back lighting ON. A

setting of 0 will keep the backlight ON at all times.

LCD Backlight Intensity:

This key accesses a sub-menu with a slide control which adjusts the brightness on the

LCD display for optimum viewing.

Print Error Messages:

When turned ON, all error messages will be printed on the printer as well as displayed

on the screen. When turned OFF, messages will only display on the screen.

Language:

Steps the Calorimetric Thermometer through the installed operating languages.

Spike Controls

Use Spiking:

When set to ON, the Calorimetric

Thermometer will prompt for the weight of

the spike added and will compensate for

the heat of combustion in the calculations.

Heat of Combustion of Spike:

The heat of combustion of spike is

entered on sub-menu keyboard in cal/g.

Use Fixed Spike:

When set to ON, a constant amount of

spike is to be added to each test.

Note:

The precision of tests with fixed spikes can be no better than the repeatability of the

spike weight.

5-4

Page 32

6725 Semi-micro Calorimeter Instruction Manual

Weight of Fixed Spike:

The weight of the fixed spike is entered on sub-menu keyboard. Normally the

Calorimetric Thermometer will prompt the user for the weight of the sample and then the

weight of the spike.

Prompt for Spike Before Weight:

When set to ON, the Calorimetric Thermometer will prompt the user for the weight of the

sample and the weight of the spike.

Program Information and Control Menu

Date & Time Settings:

Access the sub-menu on which Date &

Time are set.

Date:

Displays current date and accesses the

sub-menu on which the date is set

(YY/MM/DD) format.

Time:

Display current time and accesses the

sub-menu on which time is set in

(HH:MM) format.

Time zone:

Allows the user to select the local time zone. Pressing the button will toggle through the

time zones.

Software and Hardware Info:

This screen displays important information such as the main software version, I/O board

hardware information, CPU type, I/O firmware revision, and Controller IP address.

5-5

Page 33

6725 Semi-micro Calorimeter Instruction Manual

Settings Protect:

Provides protection for the program options and settings on the menus. If this is turned

ON, the user will be warned that enumeration keys are locked when a key is pressed.

Enumeration Keys either toggle a value (ON/OFF) or select from a predefined list. This

feature is used primarily to protect the instrument settings from accidental changes if one

were to inadvertently touch or bump up against the touch screen.

User/Factory Settings:

This key leads to a sub-menu that

allows the user to save or recall

user defined instrument settings.

Additionally, factory pre installed

settings supporting different bombs

or special operating modes can also

be recalled.

Reload Factory Default Settings:

Used to erase all of the settings and

restore the factory default settings.

Reload User Default Settings:

Used to restore the last saved user’s setup should the program in the instrument be

corrupted for any reason.

Save User Default Settings:

Used to record the setup to the memory once the user has configured the instrument to

their operating requirements.

Note:

Keys which make global changes to the setup of the calorimeter

contain a YES or NO response to make certain that the user

wishes to proceed. This two step entry is intended to prevent

inadvertent global program changes.

Compare Settings With Factory Defaults:

This button will bring up a screen that will show the differences in the current settings of

the calorimeter with the factory defaults.

Feature Key:

Unique Feature Keys obtained from Parr allow the user to access capabilities on the

instrument such as bar code interfacing or remote operation of the calorimeter.

Bomb Type Select:

Not currently configured for the 6772 changes for different bomb types are loaded by

changing the User Setup ID and Reload User Default Settings.

5-6

Page 34

6725 Semi-micro Calorimeter Instruction Manual

User Function Setup:

This key leads to sub menus that support the configuration of five factory/user definable

function keys. The function keys are accessible from the Diagnostics page.

Cold Restart:

This is essentially the same as cycling power on the unit. All valid test data will be

retained during this cold restart procedure.

Calibration Data and Controls Menu

Calibration Run Limit:

Displays the maximum number of runs that

will be included in determining the EE value

of a bomb and bucket combination and

accesses the sub-menu on which this limit is

set. Most test methods suggest 10 tests.

Tests in excess of the most recent ones

used are still available but are not used in

the calculation of the EE value. For example

if 11 standardization tests have been run, the

calorimeter will only use the most recent 10.

The 11

available for view or printing. Only runs that

are at final status will be used in this calculation.

EE Max Std Deviation:

Displays the maximum relative standard deviation in percent that will be

permitted for any EE value calculated by the Calorimetric Thermometer and

accesses the sub-menu on which this limit is set. If this value is exceeded, the

user will be warned to take corrective action before proceeding with testing. A

setting of zero disables this check.

Heat of Combustion of Standard:

Displays the heat of combustion in calories per gram for the material used to standardize

the Calorimetric Thermometer and accesses the sub-menu on which this value is set.

For benzoic acid, this value is 6318.4 calories per gram.

Bomb Service Interval:

Displays the maximum number of times a bomb may be fired before it is flagged as due

for service and accesses the sub-menu on which this limit is set. Parr recommends 500

firings for this service interval. (Parts may need to be replaced on a more frequent basis

depending upon the nature of the sample).

Control Chart Parameters

A control chart is a graphical tool which can assist the user in determining whether or not

their process is in control. Many standard methods will dictate that a reference sample

be measured periodically and the results plotted on a graph. Limits for acceptable values

are defined and the process is assumed to be in control as long as the results stay within

these limits. Since results are expected to scatter with a normal distribution within

established limits, systematic trends or patterns in the data plots may also be an early

warning of problems.

th

is still stored in the memory and is

:

5-7

Page 35

6725 Semi-micro Calorimeter Instruction Manual

• Charted Value:

Toggles the charted value between the HOC Standard (Heat Of Combustion of

Standard) and Energy Equivalent.

• Process Sigma:

In relation to calorimetry, sigma is used as the classification of the instrument.

The higher the process sigma the higher the limits for acceptable values for

precision control.

The Process Sigma of the 6772 will depend on the application.

• Temp. Rise High Warning:

Sets the high warning limit on the bucket temperature rise. A temperature rise

higher than this value will generate a warning message.

• Temp. Rise Low Warning:

Sets the low warning limit on the bucket temperature rise. A temperature rise

lower than this value will generate a warning message.

Use Bomb:

Displays the bomb number of the bomb currently being used in the Calorimetric

Thermometer and toggles through the four possible bomb numbers.

Bomb 1:

Leads to sub-menu, Bomb 1. Displays

standardization information for bomb and

bucket combinations. While only one

bomb and bucket is installed in the

calorimeter at a time, a spare may be

used for servicing and for more rapid turnaround. The respective EE values for

each bomb can be stored in memory.

Note:

For rapid turn around between tests,

the user may wish to use an extra

bomb. Each bomb can be assigned a

bomb number if the EE Values are significantly different. On the Data Entry

Controls Menu, set the Prompt for Bomb ID to “ON”.

The following four values are displayed for the Bomb # shown in the title on top of the

screen.

• Bomb EE Value. Displays the calculated EE value.

• # Runs, EE Val. Displays how many runs have been used to determine the EE

value.

• Rel. Std. Dev. Displays the relative standard deviation for the series of tests used

to determine the current EE value in percent of the EE value.

• Bomb Fire Count. Displays the current bomb firing count or the number of times

the bomb has been fired since it was last serviced. When this count matches the

5-8

Page 36

6725 Semi-micro Calorimeter Instruction Manual

limit set by Bomb Service Interval (on the Calibration Data and Controls screen),

the user will be informed that the bomb is ready for service.

Name:

Enables the operator to assign a unique alpha-numeric label for the bomb ID. The ID

can be up to 8 characters.

Protect EE Value:

Toggles between OFF and ON. When set to OFF, the 6772 automatically updates

the EE value as new tests are run. When set to ON, it keeps the EE value protected,

whether it has been revised manually via the Manual EE Entry key or calculated by

the instrument.

Update Statistics:

If the Protect EE Value is set to OFF, pressing this key will cause the EE Value

for this Calorimetric Thermometer to be updated using all standardization runs

currently in memory. If the Protect EE value is set to ON, this key is not

functional.

Manual EE Entry:

This key allows the user to manually enter an EE or calibration factor for a given

calorimeter ID or bomb head. If an EE value is manually entered, it is necessary

to turn the Protect EE Value ON in order to prevent this value from being

overwritten by an automatic or manual update.

Print Standardization Runs:

Will print all of the tests that have been incorporated into the calculated EE value.

This will be helpful in evaluating a series of tests which fail to produce a

satisfactory EE value and relative standard deviation.

Reset Bomb Fire Count:

After bomb service, press this key to reset the fire count to zero.

Control Chart Plot:

Displays the current

standardization runs being used to

calculate the Bomb EE Value. The

display will either chart the value

of the Heat of Combustion (HOC)

of the Standard or the Energy

Equivalent (EE) depending on the

selection on the Control Chart

Parameters menu (see Calibration

Data and Controls menu).

You can display the information

used for each test by selecting the

appropriate dot.

5-9

Page 37

6725 Semi-micro Calorimeter Instruction Manual

Thermochemical Corrections Menu

The Thermochemical Corrections Menu

permits three types of fixed corrections for

standardization (instrument calibration) runs,

and the same three types for determination

(test) runs. Pressing the LEFT side of each

key toggles the correction ON or OFF.

Press the RIGHT side of each key to access

the specific numeric dialog box where that

fixed value can be set. Each value entered

for these fixed corrections is used in all

preliminary reports.

When any fixed correction is set to ON, the

specified value will be used in the final reports, and the 6772 will not prompt for actual

corrections to be entered. (If all corrections are fixed, then preliminary and final reports

will be identical).

When any fixed correction is set to OFF, during the data entry reporting steps the user

will be prompted to enter an appropriate desired value which will be used in the final

report.

Standardization Correction

Fixed Fuse Correction:

Press this key on the LEFT side to toggle ON or OFF the fixed fuse correction for

standardization runs. Press it on the RIGHT side to access the Fixed Fuse numeric

dialog box on which the value can be set. An appropriate fixed fuse value is 15 calories.

Acid Correction:

Displays both the ON/OFF of the fixed acid corrections for standardization runs and the

value of the correction. This key toggles the options for treatment of the acid correction

and accesses a submenu on which the value is set. An appropriate fixed HNO3 value is

10 calories when one-gram benzoic acid pellets are used to calibrate the instrument.

Options for the Acid Correction:

Fixed HNO

Calculated HNO

Entered Total

Entered HNO

Fixed Total

These options are discussed further in Section 6 - Calculations.

Fixed Sulfur Correction:

Press this key on the LEFT side to toggle ON or OFF the fixed sulfur correction for

standardization runs. Press it on the RIGHT side to access the Fixed Sulfur

numeric dialog box on which the value can be set. When benzoic acid is used as

the calibrant, a fixed sulfur value of zero should be used.

3

3

3

5-10

Page 38

6725 Semi-micro Calorimeter Instruction Manual

Calculation Factors:

Accesses the Calculation Factors sub-menu, which provides for setting a number

of options for the way the thermochemical corrections are applied.

Determination Correction

Fixed Fuse Correction:

Press this key on the LEFT side to toggle ON or OFF the fixed fuse correction for

determination runs. Press it on the RIGHT side to access the Fixed Fuse numeric dialog box

on which the value can be set

Acid Correction:

Displays both the ON/OFF of the fixed acid corrections for standardization runs and the

value of the correction. This key toggles the options for treatment of the acid correction

and accesses a submenu on which the value is set. An appropriate fixed HNO3 value is

10 calories when one-gram benzoic acid pellets are used to calibrate the instrument.

Options for the Acid Correction:

Fixed HNO

Calculated HNO

Entered Total

Entered HNO

Fixed Total

These options are discussed further in Section 6 - Calculations.

Fixed Sulfur Correction:

Press this key on the LEFT side to toggle ON or OFF the fixed sulfur correction

for determination runs. Press it on the RIGHT side to access the Fixed Sulfur

numeric dialog box on which the value can be set.

Note:

When fixed corrections are turned ON, the value in the specified field will be used in both

the preliminary and final reports. The Calorimetric Thermometer will not prompt for

actual corrections. If all corrections are fixed, only final reports will be generated. If any

correction value is entered and the toggle is set to OFF, then the preliminary report will

use the displayed fixed value, but the final report will use the value entered when

prompted during the reporting process.

Net Heat/Dry Factors:

Accesses the Net Heat/Dry Factors sub-menu, which provides for setting the net

heat of combustion and Dry Factors Thermochemical Corrections.

3

3

3

5-11

Page 39

6725 Semi-micro Calorimeter Instruction Manual

Calculation Factors Menu

Nitric Acid Factor:

Ratio of the nitric acid correction when the

released energy corresponds to 6318 calories.

The default is 1.58 calories per 1000 calories of

released energy.

Acid Multiplier:

This multiplier is the normality of the sodium

carbonate used to titrate for the acid correction.

The default value of 0.0709 allows for direct

entry of the acid correction in calories. If the

bomb rinses are titrated in order to determine

the acid correction, press this key to display the

Acid Multiplier numeric dialog box, where you can change the multiplier to represent the

concentration of the base (equivalents/L) or normality used for titration. In this case, the

acid correction is entered as milliliters of base used to titrate the bomb rinses.

Sulfur Value is Percent:

When set to ON, the sulfur value is being entered as weight percent sulfur. If another

system is to be used, this must be turned OFF and the sulfur multiplier set accordingly.

Sulfur Multiplier:

Values entered by the user to be used for the sulfur correction are multiplied by this value

to get the product into units of milliequivalents. The default number (0.6238) requires that

the sulfur value be entered in weight percent.

Fuse Multiplier:

The fuse corrections represent the number of calories liberated by the burning fuse wire used

to ignite the sample. If another measurement is used, the correction factor must be entered

here. Press this key to access the Fuse Multiplier numeric dialog box and enter this multiplier

value.

Use Offset Correction (ISO):

The thermochemical calculations used for treatment of nitric acid and sulfuric acid corrections

in the ISO and B. S. methods require an offset correction to compensate for the back titration