Page 1

5100

Low Pressure Reactors

Operating Instruction Manual

378M

Page 2

5100 Low Pressure Reactors

Preface 3

Scope 3

Related Instructions 3

Intended Usage 3

Safety Information 3

General Specifications 3

Explanation of Symbols 4

Unpack Carefully 4

Provisions for Lifting and Carrying 4

Cleaning & Maintenance 4

Users Responsibility 5

Installation 6

Pressure and Temperature Limits 6

Assemble the Reactor 6

Assembling and Connecting the Circulator Jacket Hoses 8

Draining the Jacket 8

Do Not Overfill the Vessel 11

Releasing Pressure 11

Withdrawing Liquid Samples 11

Initial Operating Test 11

Maintenance 12

General Maintenance Notes 12

Periodic Pressure Tests 13

Technical Support 13

Parts List 14

Cylinders 14

Heads 14

Internal Fittings 14

External Fittings 17

Accessories 18

Heaters 18

Identify the Valves 9

Gas Inlet Valve 9

Gas Release Valve 9

Liquid Sampling Valve 9

Relief Valve 9

Other Vessel Head Fittings 9

Safety Rupture Disc 9

Pressure Gage 9

Type J Thermocouple 9

Accessories 10

Air Motor 10

Spare Parts Kit 10

Mantle Heaters 10

Variable Speed Electric Motor 10

Cooling Loop 10

Product Features and Part Identification 19

5100 Stand 19

Stand for 5100 20

Stand for 5110 21

5100 Overarm 22

5100 Internals 23

5111 & 5112 Internals 26

5100 Metal Vessels Internals 27

5100 Head Assembly 28

5110 Head Assembly 29

5100 Head Fittings and Valves 30

5110 Head Fittings and Valves 30

Customer Service

Questions concerning the installation or operation

of this instrument can be answered by the Parr

Customer Service Department:

How to use the Vessel 11

Gas Connections 11

Pressurizing the Vessel 11

2

Parr Instrument Company

1-309-762-7716 • 1-800-872-7720

Fax: 1-309-762-9453

E-mail: parr@parrinst.com

www.parrinst.com

Page 3

5100 Low Pressure Reactors

Preface

Scope

These instructions describe the installation, operation and maintenance of Parr Series 5100 Fixed Head

Bench Top Reactors offered in six sizes from 160 mL

to 1.5 L with glass and/or metal cylinders. They cover

the basic steps to be followed for installing these

reactors and describe the function of all standard

components. They are intended to be used in conjunction with several related instruction sheets listed

on the previous page. This information describes

several components which are common to most Parr

pressure reaction equipment, and includes safety

precautions and other related information applicable

to all reaction laboratories. The users should study all

of these instructions carefully before starting to use

these vessels so that they will fully understand the

capabilities and limitations of the equipment.

Related Instructions

The following Parr publications are also available to

further your understanding of this instrument and

its component parts:

No. Description of Instructions

230M Safety Precautions to be observed when

operating Pressure Reaction Equipment

231M Parr Safety Rupture Discs

548M 4848 Reactor Controllers

549M 4848 Controller CD-ROM

553M A2110E Motor Controller

234M Parr Magnetic Drives

323M Parr Pressure Relief Valves

201M Limited Warranty

FX004 Health & Safety Assurance Certification

Intended Usage

This system has been designed for use as a low

pressure reactor system. It has been designed,

built, and tested to strict physical and electrical

standards. However, it is the user's responsibility

to install and operate it in conformance with local

pressure and electrical codes.

If the instrument is used in a manner not specified

by Parr Instrument Company, the protection provided by the equipment may be impaired.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capability.

2. Ensure that the equipment is connected to

electrical service according to local national

electrical codes. Failure to properly connect may

create a fire or shock hazard.

3. For continued protection against possible

hazard, replace fuses with same type and rating

of fuse.

4. Disconnect from the power supply before

maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components which

may ignite such material.

2. Refer servicing to qualified personnel.

General Specifications

Electrical Ratings

Controller ratings are found in the Operating Instructions for the controller supplied with your reactor

and on the controller data plate.

Before connecting a controller to an electrical outlet,

the user must be certain that the electrical outlet has

an earth ground connection and that the line, load

and other characteristics of the installation do not

exceed the following limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: Controllers can be operated from either

a 50 or 60 Hertz power supply without affecting their

operation or calibration.

Current: The total current drawn should not exceed

the rating shown on the data plate on the controller

by more than 10 percent.

Thermocouple: Unless otherwise specified, all

Series 4848 Controllers operate with a Type J (ironconstantan) thermocouple. The total resistance of

the thermocouple and the lead wires should not

exceed 100 ohms. If the resistance of the thermocouple circuit is higher, it will reduce the sensitivity

of the control system.

www.parrinst.com

3

Page 4

5100 Low Pressure Reactors

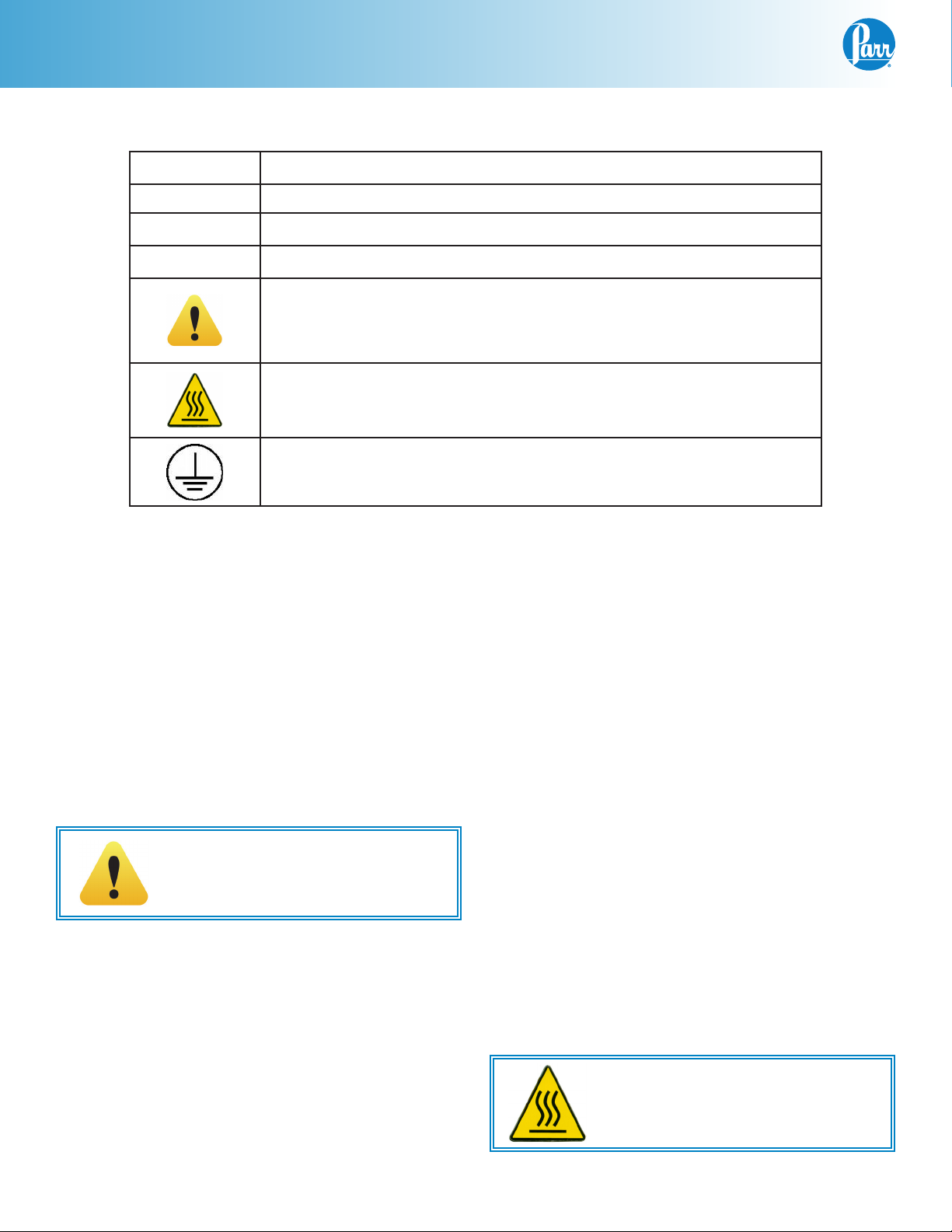

Explanation of Symbols

II On position, full power heater switch

I On position, half power heater switch

O Off Position

~ Alternating Current (AC)

This CAUTION symbol may be present on the Product Instrumentation and literature. If present on the product, the user must consult

the appropriate part of the accompanying product literature for more

information.

This CAUTION symbol indicates that the surface may be hot.

Protective Earth (PE) terminal. Provided for connection of the Protective Earth (green or green/yellow) supply system conductor.

Environmental Conditions

This instrument is intended to be used indoors.

Operating: 15 ºC to 35 ºC; maximum relative humidity

of 80% non-condensing.

Installation Category II (over voltage) in accordance

with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

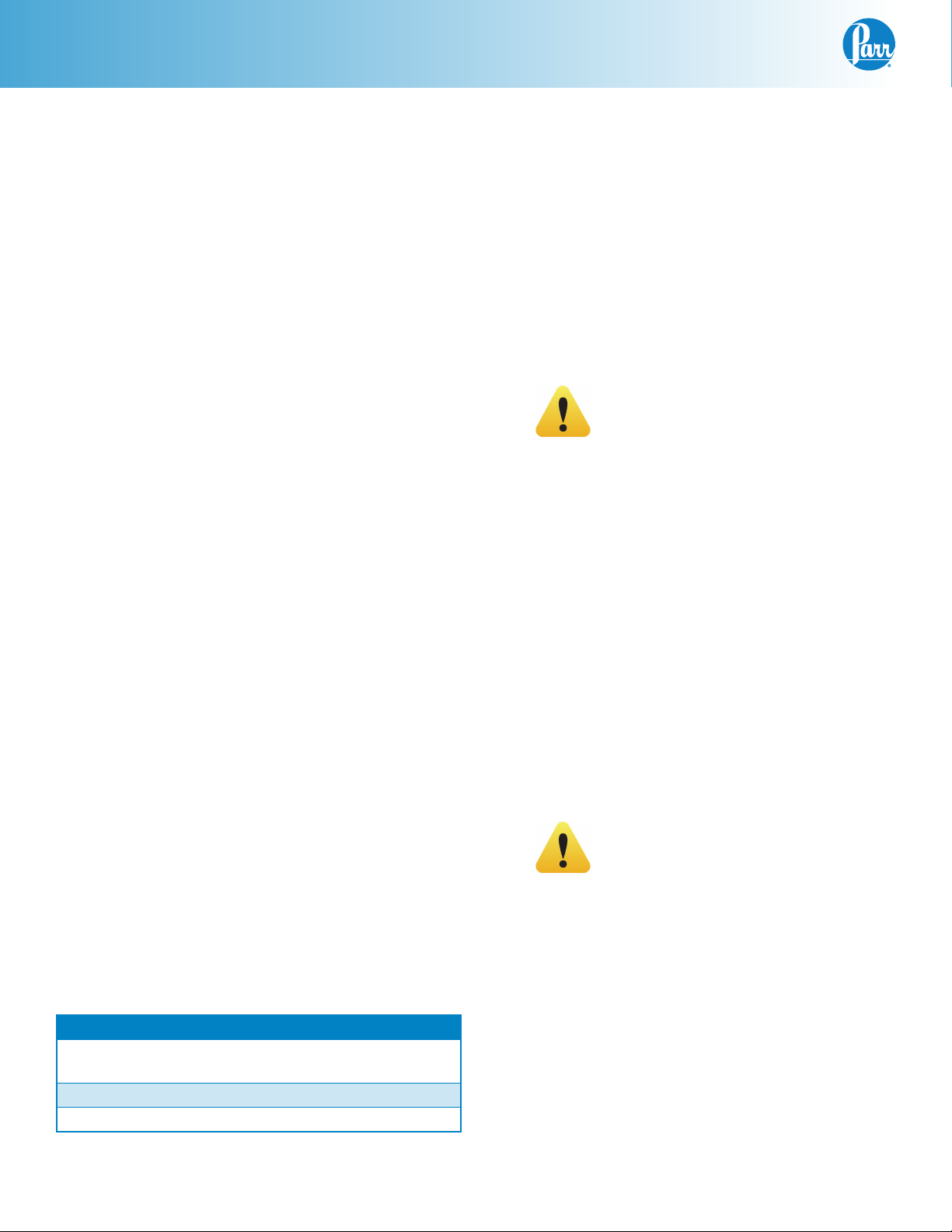

Caution!

Do not use in hazardous atmospheres.

Unpack Carefully

Unpack the equipment carefully and check all the

parts against the packing list. If shipping damage

is discovered, report it immediately to the delivering carriers. Examine the components closely for

any loose parts or shipping damage and be sure to

check all layers of packing materials thoroughly so

as not to overlook any parts which might otherwise

be discarded.

Provisions for Lifting and Carrying

The Parr Series 5100 Fixed Head Bench Top Reactors

and its components are very heavy. Before moving

ensure all cables are disconnected. Use proper and

safe lifting techniques when installing or moving the

Parr Series 5100 Fixed Head Bench Top Reactors and/

or its components.

Cleaning & Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the controller with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected and the power cord should

be unplugged when cleaning the instrument.

There are no user serviceable parts inside the product other than what is specifically called out and

discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can

be obtained by calling Parr Instrument Company

in order to determine which part(s) may need to be

replaced or serviced.

Ensure that any hot surfaces have had

adequate time to cool before cleaning

or maintaining the reactor and/or its

components.

4

Parr Instrument Company

Page 5

5100 Low Pressure Reactors

Users Responsibility

All Parr reactors and pressure vessels are designed and manufactured with great care to assure safe

operation when used within their prescribed temperature and pressure limits.

But… the basic responsibility for safety when using this equipment rests entirely with the user; who must:

1. Select a reactor or pressure vessel that has the

capability, pressure rating, corrosion resistance,

and design features that are suitable for its

intended use. Parr engineers will be glad to

discuss available equipment and material

options with prospective users, but the final

responsibility for selecting a reactor or pressure

vessel that will perform to the user's satisfaction

in any particular reaction or test must rest with

the user - not with Parr.

In exercising the responsibility for the selection

of pressure equipment, the prospective user

is often faced with the choice between overor under-designed equipment. The hazards

introduced by under-designed pressure vessels

are readily apparent, but the penalties that

must be paid for over-designed apparatus are

often overlooked. Recognizing these criteria,

Parr reactors and pressure vessels are offered

in several different styles, each designed for

convenient use in daily operation within certain

temperature and pressure limits, using gaskets,

closures, and other elements carefully selected

for safe operation within the limits specified for

that design. But in order to preserve the validity

of these designs, all temperature and pressure

limits must be observed, and no attempt should

be made to increase these limits by making

alterations or by substituting components

which are not recommended by Parr Instrument

Company.

2. Install and operate the equipment within a

suitable barricade, if required, with appropriate

safety accessories and in full compliance with

local safety codes and rules.

All standard Parr pressure vessels are provided

with either a suitable relief device or a means

to attach one (typically in the form of a plugged

opening). When a pressure vessel is delivered

without a pressure venting device, it is the customer’s responsibility to provide pressure relief

in order to protect the operator and the equipment from destructive high pressures. If you

need more information or need help in selecting

a proper relief device, please contact Parr Instrument Company.

3. Establish training procedures to ensure that any

person handling the equipment knows how to

use it properly.

4. Maintain the equipment in good condition and

establish procedures for periodic testing to be

sure the vessel remains structurally sound.

www.parrinst.com

5

Page 6

5100 Low Pressure Reactors

Installation

Pressure and Temperature Limits

The maximum working conditions for Parr vessels

are stamped on the cylinder. No attempt should

be made to increase these limits by making alterations or by substituting components which are not

recommended by the Parr Instrument Company. It

must also be understood that lower pressure and

temperature limits may be required for modified

reactors and for vessels made of special alloys.

Limits for such vessels will be determined by the

physical characteristics of the vessel material and

will be prescribed on an individual basis.

Working temperatures up to 225 °C are permissible

in reactors equipped with fluoroelastomer (FKM)

O-ring seals, such as Viton®. The higher the operating temperature above 200 °C, the shorter the life of

the O-ring will be. Perfluoroelastomer (FFKM) O-ring

seals such as Kalrez® have a broad chemical resistance. Unfortunately, they are very expensive and

will generally be reserved for unique applications.

Ethylene propylene (EP) O-rings can be used to 170

°C and are recommended for applications where

solvents such as ammonia and amines which will

rapidly destroy fluoroelastomer O-rings.

The maximum working pressure and temperature

for any vessel is governed by the design of the

vessel and the strength of the material from which

it is constructed. There is also a close relationship

between working pressure and temperature since

the strength of any material will normally fall off

as the temperature is increased. Temperature and

pressure limits are also affected by the physical

properties and temperature limits of the gaskets and

seals used in the vessel, and by any valves, gages

or other fittings attached to the vessel. Obviously,

the safe operating pressure of any system can be no

higher than that of its lowest rated component.

All Parr reactors show the maximum safe operating

pressure and temperature imprinted on the cylinder.

The working pressure and temperature in these 160

mL to 1.5 L reactors must not exceed the following

maximum limits:

Pressure and Temperature Limits

Vessel

Material

Glass 150 psi 225 °C

T316 SS 1000 psi 225 °C

Maximum

Pressure

Maximum

Temperature

Assemble the Reactor

These reactors require at least 10 inches of workspace from walls or flammable materials on a

sturdy bench, table, or floor in a well ventilated area

with convenient access to an electric outlet, running

water, and a drain. If the tabletop is not heat resistant it would be ideal to provide an insulated pad on

which to set the vessel when it is hot.

Review the following instructions first, prior to assembling the reactor.

1. Set the stand in the workspace.

Bolt the stand to a workbench or to the

floor using the holes in the base plate.

Place the head assembly in the stand. Make sure

the O-ring that seals the head and the cylinder

together is installed in the head groove.

Two types of glass cylinders can be used with

this apparatus (jacketed and non-jacketed) If

a jacketed cylinder is being used, remove the

jacket connection hoses, if present. A pair of

split rings, with thumbscrews, is used to join the

head and the cylinder flanges. The split rings are

lined at the bottom with plastic cushions that

eliminate metal against glass contact that could

result in dangerous point loading on the glass.

Examine the plastic cushions carefully. If they

are cracked or otherwise appear damaged, they

should be replaced.

CAUTION! Take care when handling the

glass cylinder. If any of the pressure or

load bearing surfaces become chipped

or scratched, the pressure rating of the

cylinder will be compromised.

If a metal cylinder is also being used with this

apparatus, note that the split rings differ from

those provided for a glass cylinder. Split rings

intended for sealing a metal cylinder to a metal

head should not be used with glass cylinders.

A clasp system on both ends of the split rings

is used to ensure proper alignment when assembled. Before using the split rings to mate

the head and the cylinder, make sure the three

thumbscrews on each half ring are backed off so

that the end of the screw is flush with the inside

of the split ring. Both sets of split rings feature

thumb screws to be installed finger-tight.

6

Parr Instrument Company

Page 7

5100 Low Pressure Reactors

Carefully bring the flange of the glass cylinder

in contact with underside of the reactor head.

A lab jack / cork support is provided for 1.0 and

1.5 liter glass reactors. When using the lab jack,

bring the cylinder flush with the O-ring in the

head, ensuring no stress is put on the glass.

Align the major OD of the head with the OD

of the cylinder flange. If a jacketed cylinder is

being used, orient the cylinder so that the jacket

connections are oriented to either side. Hold the

cylinder carefully at the bottom with one hand,

slide one of the half split rings onto the head/cylinder flanges, and rotate/slide around the head/

cylinder flanges until the latches are facing you.

Use one hand to steady this half split ring to the

head/cylinder flanges as you attach the other

half split ring from the front. Secure the latches.

If using a lab jack, now lower it so that cylinder

hangs freely.

At this point, the glass cylinder will be held in

place loosely and can be rotated for proper orientation if needed. Tighten the six thumb screws

two at a time, 180 degrees apart in a criss-cross

pattern rather than progressively around the

circle until finger-tight and the head flange is

flush with the top of the cylinder flange. Do not

over-tighten.

Labeled connections are provided on the rear

panel of the controller.

Parr Cooling Only:

The Parr Cooling output connector is to be used

only with Parr Instrument Company cooling

solenoid valve assemblies supplied with the

appropriate cooling power cord.

Parr Heating Only:

The Parr Heating output connector is to be used

only with Parr Instrument Company heater

assemblies supplied with the appropriate heater

power cord.

Note: Do not make connections to a

Variac, Powerstat or the like to attempt

to control the heating output. The heavy

inductive load on the primary side of such

devices can destroy the internal sold state

relay located in the 4848 Controller.

CAUTION! Never use tools, such as pliers, to

tighten the thumbscrews. Excessive loading

on the cylinder flange can compromise the

pressure rating of the cylinder.

CAUTION! Before applying pressure to the

reactor, install the transparent Lexan safety

shield onto the front of the reactor stand.

Failure to do so can result in serious injury if

the cylinder should break under pressure.

To remove the cylinder from the head, follow the

above procedure in the reverse order. If a jacketed cylinder is being used, drain and disconnect

the jacket hoses first.

2. Set the Controller near the reactor, leaving

a space of at least six inches between the

controller and the base of the reactor so that the

controller will not be unduly affected by radiant

heat. Connect the reactor to the controller using

information contained in its Instruction Manual

548M or follow the steps below.

Parr Motor Only:

3. The support and heater are shipped fully

assembled. The heater raises and lowers on its

support rod to permit the vessel or cylinder to

be removed. Lower the heater, open the hinged

retainer on the front of the support and slide the

vessel into its support. Fixed head vessels have

a square lip which fits into a matching groove

in the support plate. Removable vessels are

supported by the split rings which rest on top

of the support plate. The stirrer drive connector

lifts by rotating and lifting the knob above the

belt guard. The universal joint contains a cross

pin that slips into the groove on top of the

magnetic drive.

4. Connect the heater cord from the heater into

the heater socket on the rear panel of the Series

4848 Reactor Controller.

5. Plug the motor cord into the motor socket on the

rear of the controller.

www.parrinst.com

7

Page 8

5100 Low Pressure Reactors

Secure the clamp on the motor cord with

the provided screw next to the motor

socket for safety purposes.

6. Connect the thermocouple extension wire to

both the thermocouple and to the controller in

the “Primary Temp Input” position on the rear

panel. Insert the thermocouple into thermowell.

7. Connect leads from accessory packages such as

tachometer, pressure transducer and high temp

cut-off to the designated positions on the back

panel of the 4848 Controller.

8. Connect cooling water to internal cooling coil if

installed.

9. Connect cooling water to the magnetic stirrer.

See Instruction Manual 234M.

10. Connect tubing to the rupture disc outlet and run

to a safely vented area. See Instruction Manual

231M.

11. Note the voltage requirement on the controller

identification label on the back panel, and then

plug the power cord into an appropriate outlet.

Power for these reactors should be drawn from

a 3-slot, grounded outlet capable of carrying up

to the full current rating of the system.

12. Using the switch on the Reactor Controller, turn

on the motor for a short run to check the stirrer

drive system.

This apparatus includes a safety shield

which should be used at all times. A relief

valve pre-set to either 145 psi (CE certified)

or 150 psi is also provided as a safety

precaution to prevent over-pressurizing

the glass cylinder - this also should be

used at all times. Should this relief valve

be inadvertently removed, the glass vessel

could be over-pressurized, resulting in

an explosion. The safety shield has been

designed to withstand the force of this

explosion. However, in the event of an

explosion, some glass fragments will

exhaust through the vertical slots provided in

the back of the shield for the hoses.

Assembling and Connecting the Circulator Jacket Hoses

CAUTION! If a jacketed vessel is being used,

the compression fittings should be preassembled onto the insulated hoses before

attaching them to the cylinder. Failure to

do so or tightening any of the compression

fittings while the hoses are attached to the

cylinder will likely cause the jacket nipple

to break off.

Once the hoses are fixed at one end, they tend to

have a preferred orientation. The following hose

assembly procedure will minimize any side loading

by the hoses against the jacket connection nipples.

Attach the hoses to the circulating bath first and

route them through the openings at the rear of

the reactor stand. Note that lower left connection

is the jacket inlet. This should be connected to the

circulator pump discharge. Elbows are used on the

cylinder end to route the insulated hoses down and

then out the rear of the stand. With the hose in its

free state and not being twisted or rotated, tighten

the elbows to the hoses in a manner that orients the

open end of the elbow in line with the jacket nipple.

This minimizes any side loading of the hose against

the nipple.

Slide the brown plastic nut onto the nipple adapter

so that the flange with the O-ring groove is recessed

inside the nut. Tighten the tube stub onto the elbow.

Place the O-ring in the groove of each of the assembled adapters and then screw the hose adapter

onto the jacket nipple. Tighten firmly, by hand only!

No pliers!

Draining the Jacket

To drain the jacket, first lower the temperature of the

jacket circulating fluid to 60 °C or less.

Note: Oil, used as the circulating fluid,

drains much faster when it is hot.

Turn off the circulator and loosen the hose connection at the top of the jacket. This will allow air to

enter the jacket and cause to fluid to drain back into

the circulator. When the draining is complete, both

hoses can be disconnected from the jacket. The ends

of the hoses should be supported at a level higher

than that of the circulator bath to prevent siphoning

and fluid loss.

8

Parr Instrument Company

Page 9

5100 Low Pressure Reactors

Identify the Valves

Gas Inlet Valve

The gas inlet valve is easily identified when the

vessel is open by noting that it is connected to a

dip tube which extends to a point near the bottom

of the vessel cylinder. This is an angle valve with an

attached fitting which provides a socket for attaching

the A495HC pressure hose furnished with the reactor.

Gas Release Valve

The gas release valve is connected to the gage

adapter on vessels with volumes of 160 – 600 mL.

The gas release valve is installed in a port by itself

on 1 L & 1.5 L vessels. These ports do not have a

threaded connection on the underside of the head;

they are always open to the gas phase of the reactor.

Liquid Sampling Valve

The liquid sampling valve is attached to the same

fitting as the gas inlet valve and connected to a

common dip tube. With this arrangement, incoming

gas is always introduced below the surface of the

liquid and the operator is provided with a means for

clearing the dip tube to be sure that any sample taken

during a run will be representative of the charge. This

can be done by opening the upper gas inlet valve

momentarily to allow the inlet gas to force any liquid

in the dip tube back into the reactor before withdrawing a sample from the sampling valve.

Relief Valve

The relief valve is connected to the gage adapter

and is pre-set to either 145 psi (CE certified) or 150

psi to ensure that the glass cylinder is not overcharged. When using a metal cylinder, a plug is

provided so that the relief valve can be removed

(due to higher pressure rating of metal cylinder).

Other Vessel Head Fittings

Safety Rupture Disc

There is a safety rupture disc attached to the head

which is intended to rupture and release the pressure before it reaches a dangerous level. A metal tag

wired to the safety head identifies the burst pressure at room temperature for that particular disc.

A similar tag is furnished with each replacement

disc. This tag must remain with the apparatus at all

times so that both present and future operators will

be aware of the disc rating. Users should read the

discussion of rupture discs given in the Instruction

Sheet No. 231M for a complete description of the

characteristics of rupture discs and the precautions

to be observed when operating pressure equipment

protected by this type of safety device. The disc is

rated for 1000 psi and should remain installed for

both glass and metal cylinders.

Pressure Gage

A pressure gage, typically 200 psi gage for glass

cylinders and 1000 psi gage for metal cylinders

includes a T316 Stainless Steel Bourdon tube. It

is mounted on the head using attachment fittings

similar to those used for the inlet/sampling valve

assembly.

Type J Thermocouple

A Type J thermocouple in a 1/8” diameter stainless

steel sheath is furnished with the reactor. Insert this

thermocouple into the head thermowell and connect it to the thermocouple socket on the rear panel

of the reactor controller using the extension wire

furnished with the reactor.

*See Page 30 for drawing of head fittings and valves.

www.parrinst.com

9

Page 10

5100 Low Pressure Reactors

Accessories

Air Motor

Variable stirring speeds from 100 to 2000 rpm with

no spark hazard can be obtained by replacing the

standard motor with an air motor. This motor operates on compressed air which must be supplied

at 40 psig minimum pressure with at least 10CFM

available at that pressure. It is furnished with a

speed control valve and oiler, all assembled on a

mounting bracket.

To operate reactors equipped with an air motor,

mount the drive system firmly on the support stand

and connect the air hose to a compressed air line.

Fill the oiler with SAE 10 oil and adjust the oiler to

feed one drop per minute into the air stream. For

long continuous runs at high speeds, the oiling rate

should be increased to three drops per minute. If the

motor becomes sluggish, flush it with a non-flammable solvent in a well-ventilated area. Disconnect

the air line and muffler and pour a small amount of

solvent into the inlet port. Rotate the shaft by hand

in both directions for a few minutes; then connect

the air line and run the motor until there is no

further trace of solvent in the exhaust. If the muffler

felts are dirty, wash them in solvent or replace them.

Relubricate the motor with a squirt of oil into the

chamber and reassemble. If it becomes necessary to

disassemble the motor to replace the vanes, follow

directions given in the instruction sheet published

by the Gast Manufacturing Corp., Benton Harbor,

Michigan.

Spare Parts Kit

Parr can furnish spare parts kits for these reactors

which will provide a reserve supply of parts and

tools sufficient to handle most normal replacements

and emergency repairs during a year of heavy

usage.

These kits contain replacement gaskets, packing,

O-rings, shafts, bearings, and rupture discs. They

can be ordered from any Parr Dealer or direct from

the Parr Instrument Company. The order must

specify the reactor size and indicate type of rupture

disc, stirrer drive and whether it has a flat-gasket or

O-ring closure.

Mantle Heaters

Mantle heaters with high temperature fabric heating

mantles housed in sturdy aluminum shells can be

provided for any plain (non-jacketed) cylinder. These

heaters are designed to provide uniform heat distribution to the walls and bottoms of these vessels.

They are attached to a support rod with a spring

steel clamp and arranged so that they can be raised

or lowered on the rod as desired. Each mantle must

always be used with the vessel of the size for which

it was designed, and must always be fully attached

to the vessel before heat is turned on. Similarly, a

short vessel must never be heated in a deep mantle.

Without full contact with a vessel wall, a mantle will

overheat and burn out.

Variable Speed Electric Motor

Reactors are normally equipped with a DC variable

speed motor supplied and controlled through the

Series A2110E or 4848 Controllers. Instructions for

connecting and operating these motors are included

in the controller’s instruction manual No. 553M

or 548M. This motor is installed in a drive system

designed to produce stirring speeds from 0 to 1700

rpm.

Cooling Loop

Each 5100 Reactor has a single loop cooling coil

installed in the vessel (except the 160 & 215 mL

units). A slow, continuous flow of cold water

through a cooling loop proves a very effective

means for controlling temperature overshoot in

these reactors, particularly when operating at temperatures below 150 °C. Water flow through the loop

can be controlled automatically using a solenoid

valve in the cold water line, with the solenoid connected to the cooling socket on the rear panel of the

4848 Reactor Controller. With this arrangement, cold

water will be admitted to the cooling loop whenever

the controller calls for cooling.

10

Parr Instrument Company

Page 11

5100 Low Pressure Reactors

How to use the Vessel

Gas Connections

Gas connections are dependent on applications.

For general usage, use the pressure hose furnished

with the reactor. Screw the Type “A” coned pressure

fitting into the adapter attached to the gas inlet valve

and tighten the compression nut firmly. Do not use

any thread dope on the coned fining. The A495HC

pressure hose is made of reinforced Nylon which

can be used for all noncorrosive gases at pressures

up to 2500 psig. For operations involving corrosive

gases, this hose should be replaced with an A490HC

hose which has a PTFE lining and a braided stainless steel outer covering. Both of these hoses have

the same fittings. An A506HC all metal hose is also

available in stainless steel and other corrosion

resistant materials.

Pressurizing the Vessel

Check all valves carefully before admitting gas into

the system. The liquid sampling valve must remain

closed throughout the charging procedure. The gas

release valve must also be closed unless the vessel

is to be purged, or unless there is to be a continuous

flow through the reactor during a run. Always make

certain that the pressure in the gas tank is greater

than the pressure in the vessel; otherwise, liquid

will be forced out of the vessel and into the gas

tank when the inlet valve is opened. If there is any

possibility that the tank pressure might not be high

enough to force gas into the reactor, install a oneway check valve (optional) in the gas line to prevent

any reverse flow. With the inlet valve open and the

flow control valve on the gas tank closed, open the

main valve on the gas tank only about one-quarter

turn; then use the flow control valve or the valve

on a pressure regulator to control the flow of gas

into the vessel. After the desired pressure has been

reached, close the tank valves and the vessel inlet

valve and disconnect the hose at the vessel end.

Do Not Overfill the Vessel

Always watch the pressure gage closely when

admitting gas so as not to exceed the maximum

working limit. Remember that any subsequent

increase in temperature will raise the pressure.

Also, be sure that the amount of liquid placed in the

vessel is carefully controlled.

As a general rule, the liquid charge should not

exceed two-thirds of the capacity of the cylinder. Too

much liquid in the vessel can lead to development

of dangerous pressures if sufficient space is not

provided for expansion when the liquid is heated.

This hazard is explained in greater detail in a warning statement included in the Instruction Manual

No. 230M.

Releasing Pressure

Use the gas release valve to reduce the pressure in

the vessel if the reactor is accidentally overcharged

when filling. Use this valve also to release any

excess pressure during a run and to exhaust the

vessel at the end of a run. If the discharge gases are

flammable or toxic, discharge to an exhaust hood or

to any other safe release point.

Withdrawing Liquid Samples

Liquid samples may be withdrawn from the sampling valve attached to the same adapter as the gas

inlet valve whenever the vessel is pressurized. Always close the inlet valve before withdrawing a liquid sample and open the sampling valve cautiously

because liquid will be discharged with considerable

force. Be particularly careful if the temperature of

the sample is above its boiling point at atmospheric

pressure. If so, it will “flash” and be lost as soon

as it is released from the vessel. This problem can

be avoided by connecting an optional 4351 Sample

Collection Vessel to the sampling valve to collect the

liquid into an appropriate receiver. The addition of

a small amount of gas can be used to clear the dip

tube between liquid samples so that the next sample drawn through the tube will truly be representative of the mixture.

Initial Operating Test

Read all operating instructions carefully so as to be

well acquainted with the correct procedures for handling the vessel and for operating the controller and

other accessories. An initial operating test should

be made, with only water, to check the apparatus

before starting the first experimental runs. For this

initial test, fill the cylinder not more than half full of

water and run the temperature up to 150 ° C while

checking the apparatus for leaks and observing the

performance of the reactor controller.

www.parrinst.com

11

Page 12

5100 Low Pressure Reactors

Maintenance

General Maintenance Notes

1. Periodically inspect all electrical wiring and pressure connections for excessive corrosion. Suspect parts should be replaced by components

only supplied by Parr Instrument Company.

2. Always use appropriate wrenches on all fittings

and valves. Never use pliers or pipe wrenches.

3. Head and cylinder service fixtures are available

for convenience and protection of components

during maintenance of your reactor.

4. To reinstall straight thread (NPS) fittings to the

head, screw the gage or valves firmly into the

adapter. Run the bushing onto the threaded

stem as far as it will go. Screw this assembly

into the head until the nose of the adapter is

seated; then back it off until the valve or gage

is facing in the desired direction (no more than

one full turn). Hold the fitting firmly in place and

close the joint by tightening the bushing. This

connection can be made and broken repeatedly

without destroying the sealing surfaces. A light

coating of thread lubricant, such as Parr High

Temperature Anti-Seize Lubricant, applied to the

straight threads and to the nose of the adapter

will help to obtain a tight joint.

Note: PTFE tape should not be used on this

joint.

5. NPT (National Pipe Taper) threads should not

be disassembled any more than necessary. It

will become increasingly difficult to maintain a

tight seal with these tapered threads if the joint

is made and broken repeatedly. Grafoil tape or

PTFE tape (if temp allows) should be used on all

NPT threads.

8. Clean all threads and gas passages thoroughly

and remove all tape fragments when overhauling a vessel. An ultrasonic bath is excellent for

cleaning metal parts, but do not place a thermocouple probe, pressure gage, face seals or ball

bearings in an ultrasonic bath. Periodic cleaning

may be performed on the exterior surfaces of

the reactor stand with a lightly dampened cloth

containing mild soap solution. All power should

be disconnected when cleaning.

9. Routinely inspect cap screws on split ring closure for lubrication and cleanliness. These

screws should not be allowed to dry because

the threads will seize. Regularly apply Parr

High Temperature Anti-Seize Lubricant (Parr No.

424HC2) before this happens.

10. To operate reactors equipped with an air motor,

connect air hose to a compressed air line. For

best torque and speed control the piping to the

motor should be at least 3/8” IPS or larger. Fill

the oiler with SAE 10 oil and adjust the oiler feed

one drop per minute into the air stream. For long

continuous runs at high speeds the oiling rate

should be increased to three drops per minute. If

the motor becomes sluggish, flush it with a nonflammable solvent in a well ventilated area.

Disconnect the air line and muffler and pour

a small amount of solvent into the inlet port.

Rotate the shaft by hand in both directions for

a few minutes; then connect the air line and

run the motor until there is not further trace of

solvent in the exhaust. If the muffler is dirty,

replace it. Re-lubricate the motor with a squirt of

oil into the chamber and reassemble.

6. Do not use oil or anti-seize lubricant on threads

or fittings if the vessel is to be used with oxygen.

7. If your vessel is equipped with a loose compression ring be sure that it is in place on the head

before attaching any head fittings. The compression ring cannot be installed after fittings have

been screwed into the head.

12

Parr Instrument Company

Page 13

5100 Low Pressure Reactors

Periodic Pressure Tests

Each cylinder used in a Parr stirred reactor is tested

under hydrostatic pressure to the higher of 1.43

times the rated working pressure at room temperature or 1.30 times the rated working pressure

corrected for temperature before it is released from

the factory. Micrometer caliper measurements are

taken during this test to check the deflection of the

walls under pressure. Excessive deflection or failure

of the metal to resume its original dimensions after

pressure is released indicates that a cylinder is potentially unsafe and it will be rejected. Similar tests

should be made at regular intervals during the life

of each cylinder, and particularly whenever the user

suspects that the equipment has been over-stressed

or damaged.

Some laboratories maintain hydraulic test facilities

and make it a rule that all pressure vessels must

be tested at regular intervals. Records are kept of

deflections at specific test pressures so that any

increase in deflection becomes a warning that the

metal has lost strength. Any cylinder that fails to

return to its original dimensions after application of

the prescribed hydrostatic test should be discarded

as unsafe for further use.

Users who do not have pressure test facilities can

return any Parr pressure vessel to the factory for hydrostatic testing and overhaul. This should be done

whenever the metal shows excessive damage from

corrosion or whenever an over-pressure or other

unusual occurrence raises any safety questions.

To return a vessel for repair, contact Parr Instrument

Company for a return authorization number (RMA).

Technical Support

Parr Instrument Company strives to provide our

customers with world class support. When contacting Parr for technical support, please provide the

complete serial number etched on the side of the

cylinder. Serial numbers are a long string of letters

and numbers. See highlighted text in figure below

for an example of a complete serial number.

PARR INSTRUMENT COMPANY

MOLINE, IL. USA

2430HC3 222315 T316 112409 4600-1003-14106

MAWP 1900 PSI AT 350C 2010

Each Parr operating instruction manual binder

comes with a customized Parts Lists that contains

a list of the parts in each major component of your

Parr Reactor. Do not discard this Parts List. You

should use this parts list for reordering consumable

and replacement parts to ensure that you order the

correct parts for your reactor system.

Apparatus returned for testing and overhaul should

be shipped prepaid to the following address:

Ship repair to:

Parr Instrument Company

Attn: Service Department

RMA # XXXXXX

211 53rd Street

Moline, Illinois 61265

An order or letter of instructions should be mailed to

the same address, as no repair work will be started

without specific instructions and a Health & Safety

Assurance Certification form (FX004) signed by a

responsible user.

Customer Service

Questions concerning the installation or operation

of this instrument can be answered by the Parr

Customer Service Department:

1-309-762-7716 • 1-800-872-7720

Fax: 1-309-762-9453

E-mail: parr@parrinst.com

www.parrinst.com

www.parrinst.com

13

Page 14

5100 Low Pressure Reactors

Parts List

*Note: Special material internal parts (not T316) will have a suffix designating the material:

CH - Alloy C-276 CA - Titanium CB - Alloy Cb-20

CG - Alloy B-2 CX - Zirconium HZ - PTFE coated T316

(I.e.- a 300 mL Alloy C-276 dip tube would be 832HC31CH)

Cylinders*

Model No. Size Material Plain Jacketed

5101

5102

5103

5104

5111

5112

300 mL Glass 2525HC 2525HC11

300 mL Metal 2630HC 2630HC11

450 mL Glass 2525HC2 2525HC12

450 mL Metal 2630HC2 2630HC12

600 mL Glass 2525HC3 2525HC13

600 mL Metal 2630HC3 2630HC13

160 mL / 215 mL Glass 2525HC4 (160 mL) 2525HC14 (215 mL)

160 mL / 215 mL Metal 2630HC4 (160 mL) 2630HC14 (215 mL)

1000 mL Glass 2825HC 2825HC11

1000 mL Metal 2910HC3 2910HC13

1500 mL Glass 2825HC2 2825HC12

1500 mL Metal 2910HC4 2910HC14

Heads*

Part No. Description

2635HC3 Head for 160 mL - 600 mL

2635HC4 Head for 160 mL - 600 mL,

footless mag drive

2915HC2 Head for 1000 mL - 1500 mL

2915HC3 Head for 1000 mL - 1500 mL,

footless mag drive

Internal Fittings*

Thermowell and Thermocouple*

Part No. Description

For 160 mL - 600 mL:

217VBAD Replacement nut for thermowell

218VBAD Replacement ferrule set for thermowell

A1453HC Thermowell, 1/4" OD, T316, 12" L

(cut to length)

Thermowell and Thermocouple (Continued)

Part No. Description

2943HCHZ Thermowell, 300 mL, PTFE coated

T316, 6.86" length

2943HC2HZ Thermowell, 450 mL, PTFE coated

T316, 8.86" length

2943HC3HZ Thermowell, 600 mL, PTFE coated

T316, 10.86" length

2943HC4HZ Thermowell, 160 mL, PTFE coated

T316, 4.73" length

2943HC5HZ Thermowell, 215 mL, PTFE coated

T316, 5.43" length

A472E Thermocouple, type-J, 7 ½”, grounded

A472E2 Thermocouple, type-J, 9 ½”, grounded

A472E3 Thermocouple, type-J, 11 ½”, grounded

A472E4 Thermocouple, type-J, 5 ½”, grounded

A490E Dual thermocouple, type-J, 7 ½”

A490E2 Dual thermocouple, type-J, 9 ½”

A490E3 Dual thermocouple, type-J, 11 ½”

14

Parr Instrument Company

Page 15

5100 Low Pressure Reactors

Thermowell and Thermocouple (Continued)

Part No. Description

For 1000 mL - 1500 mL:

48HC Gasket for thermowell, Silver

48HCFG Gasket for thermowell,

Gold plated Silver

265HC7 Thermowell, 1000 mL, T316

265HC7HZ Thermowell, 1000 mL,

PTFE coated T316

265HC27 Thermowell, 1500 mL, T316

265HC27HZ Thermowell, 1500 mL,

PTFE coated T316

A472E2 Thermocouple, type-J, 1000 mL,

grounded

A472E3 Thermocouple, type-J, 1500 mL,

grounded

Male Connectors

Part No. Description

A92HWAD Male connector, 1/4T x 1/8"NPT for

dip tube and cooling loop

A138CA Male connector, 1/4T x 1/8"NPT for

thermowell

Dip Tubes

Part No. Description

832HC35 Dip tube, 160 mL, T316, .75” length

832HC35HZ Dip tube, 160 mL, PTFE coated, T316

832HC36 Dip tube, 215 mL, 1.46” length

832HC36HZ Dip tube, 215 mL, 1.46” length,

PTFE coated, T316

832HC31 Dip tube, 300 mL, T316

832HC31HZ Dip tube, 300 mL, PTFE coated, T316

832HC32 Dip tube, 450 mL, T316

832HC32HZ Dip tube, 450 mL, PTFE coated, T316

832HC33 Dip tube, 600 mL, T316

832HC33HZ Dip tube, 600 mL, PTFE coated, T316

686HC19 Dip tube, 1000 mL, T316

686HC19HZ Dip tube, 1000 mL, PTFE coated, T316

686HC20 Dip tube, 1500 mL, T316

686HC20HZ Dip tube, 1500 mL, PTFE coated, T316

Cooling Loop

Part No. Description

831HC6 Cooling loop, 300 mL, T316

831HC6HZ Cooling loop, 300 mL,

PTFE coated T316

831HC7 Cooling loop, 450 mL, T316

831HC7HZ Cooling loop, 450 mL,

PTFE coated T316

831HC8 Cooling loop, 600 mL, T316

831HC8HZ Cooling loop, 600 mL,

PTFE coated T316

2930HC3 Cooling loop, 1000 mL, T316

2930HC3HZ Cooling loop, 1000 mL,

PTFE coated T316

2930HC4 Cooling loop, 1500 mL, T316

2930HC4HZ Cooling loop, 1500 mL,

PTFE coated T316

Gaskets and Seals

Part No. Description

For 160 mL - 1500 mL:

48HC Gasket for mag drive, Silver

48HCFG Gasket for mag drive,

Gold plated Silver

48HCKL Gasket for mag drive, Graphite

2142HC Gasket, Silver for footless mag drive

2142HC2KL Gasket, Graphite for footless mag drive

For 160 mL - 600 mL:

2632HCJV Head seal O-ring, FKM

2632HCJK Head seal O-ring, FFKM

2632HCJE Head seal O-ring, EP

2632HCJB Head seal O-ring, NBR

For 1000 mL - 1500 mL:

2913HCJV Head seal O-ring, FKM

2913HCJK Head seal O-ring, FFKM

2913HCJE Head seal O-ring, EP

www.parrinst.com

15

Page 16

5100 Low Pressure Reactors

Stirrer Shaft and Impellers

Part No. Description

For 160 mL - 600 mL:

A837HC Propeller, turbine, T316

A837HC5HZ Propeller, turbine, PTFE coated T316

822HC33 Stirrer shaft, 160 mL, T316, 4.99” length

822HC33HZ Stirrer shaft, 160 mL, PTFE coated

T316, 4.99” length

822HC44 Stirrer shaft, 215 mL, T316, 5.69” length

822HC44HZ Stirrer shaft, 215 mL, PTFE coated

T316, 5.69” length

822HC30 Stirrer shaft, 300 mL, T316, 6.92" length

822HC30HZ Stirrer shaft, 300 mL, PTFE coated

T316, 6.92" length

822HC31 Stirrer shaft, 450 mL, T316, 8.92” length

822HC31HZ Stirrer shaft, 450 mL, PTFE coated

T316, 8.92” length

822HC32 Stirrer shaft, 600 mL, T316, 10.92” length

822HC32HZ Stirrer shaft, 600 mL, PTFE coated

T316, 10.92” length

2070HC Gas Entrainment impeller, 300 mL -

600 mL, T316

2070HCHZ Gas Entrainment impeller, 300 mL -

600 mL, PTFE coated

2070HC2 Gas Entrainment impeller, 160 mL, T316

2070HC2HZ Gas Entrainment impeller, 160 mL,

PTFE coated T316

2027HC3 Gas Entrainment upper shaft, T316

2028HC5 Gas Entrainment shaft, 300 mL, T316

2028HC5HZ Gas Entrainment shaft, 300 mL,

PTFE coated T316

2028HC6 Gas Entrainment shaft, 450 mL, T316

2028HC6HZ Gas Entrainment shaft, 450 mL,

PTFE coated T316

2028HC7 Gas Entrainment shaft, 600 mL, T316

2028HC7HZ Gas Entrainment shaft, 600 mL,

PTFE coated T316

2028HC8 Gas Entrainment shaft, 160 mL, T316

Stirrer Shaft and Impellers (Continued)

Part No. Description

For 1000 mL - 1500 mL:

352HC9 Upper shaft, 1000 mL - 1500 mL, T316

A358HC5 Propeller, turbine, 1000 mL - 1500 mL,

T316

A358HC8 Propeller, turbine, 1000 mL - 1500 mL,

PTFE coated T316

A2044HC Gas Entrainment shaft/impeller, 1000

mL, T316

A2044HCHZ Gas Entrainment shaft/impeller, 1000

mL, PTFE coated T316

A2044HC3 Gas Entrainment shaft/impeller, 1500

mL, T316

A2044HC3HZ

A449HC Lower shaft with coupling, 1000 mL,

A449HCHZ Lower shaft with coupling, 1000 mL,

A449HC22 Lower shaft with coupling, 1500 mL,

A449HC22HZ

Gas Entrainment shaft/impeller, 1500

mL, PTFE coated T316

T316

PTFE coated T316

T316

Lower shaft with coupling, 1500 mL,

PTFE coated T316

Stirrer Support Bracket

Part No. Description

For 450 mL - 600 mL:

A1260HC2 Stirrer bracket, for cooling loop,

T316

A1260HC5HZ Stirrer bracket, PTFE coated T316

A1872HC Stirrer bracket, for 265HC style

thermowell

1261HC Bushing for stirrer bracket, PTFE

For 1000 mL - 1500 mL:

A1404HC2 Stirrer bracket, for thermowell, T316

A1404HC3HZ Stirrer bracket, PTFE coated T316

299HC Bushing for stirrer bracket, PTFE

16

Parr Instrument Company

Page 17

5100 Low Pressure Reactors

External Fittings

Part No. Description

A888HC2 Rupture disc assembly

49HC2 Orifice cone

527HC Orifice ring

433HC4 Safety head outlet

366VBD Hex Coupling, 1/4 NPTF

288VBAD Male Connector, 3/8” T-1/4” NPTM

A92HWAD Male Connector 1/8 NPTMx1/4T

(T316SS for top of cooling loop)

79HW* Plug, Hex Head 1/8” NPTM

835HC Adapter, two 1/8” NPT(F) side ports

A122VB Needle Valve T316 1/8 NPTM

A146VB Angle Valve T316 1/8 NPTM-M

420HC Adapter, T303 A Skt × 1/8 NPTF

208HC10 Adapter, T316 2-1/8 NPTF Valve

260HC2 Valve extension

Rupture Disc Assembly

See manual 231M for a full list of safety rupture disks.

Magnetic Drive Parts

See manual 234M for a full list of Magnetic Drives.

Part No. Description

Parts For A1120HC9 Drive

264AC4 Pin spanner wrench

264AC5 Face spanner wrench

1132HC Thrust washer, pk of 2

1133HC Bushings, pk of 3

1137HCHA PTFE O-ring

48HC Silver gasket

1138HC Upper snap ring

1138HC2 Lower snap ring

1139HC Ball bearings, pk of 2

2714HC Nipples for cooling sleeve

827HC Cooling sleeve O-rings

1144HC Wave spring

Split Rings

Part No. Description

For 160 mL - 600 mL:

A2526HC Split ring, glass and glass jacketed

cylinder

A2735HC Split ring, metal cylinder

2524HC Spacer, Ultem, for A2526HC split ring

2524HCHA Spacer, PTFE, for A2526HC split ring

For 1000 mL - 1500 mL:

A2916HC Split ring, glass cylinder

A2912HC2 Split ring, metal cylinder

2914HC Spacer, Ultem, for A2916HC split ring

2914HCHA Spacer, PTFE, for A2916HC split ring

Gage Assembly

Part No. Description

836HC Gage adapter, 1/4” NPT(F) top x 1/8”

NPT(F) side port

836HC6 Gage adapter, 1/4” NPT(F) top x 1/8”

NPT(F) + two 1/4” NPT(F) side ports

836HC7 Gage adapter, 1/4” NPT(F) top, one

1/8” + 1/4” NPT(F) side ports (std)

208HC15 Gage adapter, angled 2 1/4" NPTF

209HC4 Adapter bushing, 1/2" NPS T303

A122VB Needle Valve T316 1/8 NPTM

414VBAD Elbow, 1/4" NPT(M) x 1/4" NPT(F)

Pressure Gages

Part No. Description

2633HCP10AD Gage, 3-1/2”, 1000 psi, back MT

2633HCP20AD Gage, 3-1/2”, 2000 psi, back MT

2633HCP30AD Gage, 3-1/2”, 3000 psi, back MT

2633HCP50AD Gage, 3-1/2”, 5000 psi, back MT

2633HCP75AD Gage, 3-1/2”, 7500 psi, back MT

2633HCP3YB Gage, 30"/300 psi back MT

2633HCP1AD Gage, 3-1/2”, 100 psi, back MTG

2633HCP2AD Gage, 3-1/2”, 200 psi, back MTG

2633HCP6AD Gage, 3-1/2”, 600 psi, back MTG

www.parrinst.com

17

Page 18

5100 Low Pressure Reactors

Part No. Description

424HC2 High temperature thread lubricant, 1oz tube

A495HC Gas inlet hose assembly, 6-ft, 2500 psi, Nylon

JP0025TB06 Neoprene tubing, 1/4"OD, for cooling water

TX31SK 5/16 socket screw key

2925HC Lab Jack (for 1000 mL - 1500 mL glass cylinders)

A2995HC Hose assembly for circulator consists of the following parts:

221VBAD Nut

222VBAD Ferrule

277VBAD Union fitting

275VBAD Male connector, 3/8T x 3/8 NPTM

2648HC2 Cap for hose end

2649HC Tube adapter

Accessories

Heaters

Part No. Description

For 160 mL - 600 mL:

A2230HCEB Electric heater, 300 mL metal or glass cylinder, 115V

A2230HCEE Electric heater, 300 mL metal or glass cylinder, 230V

A2230HC2EB Electric heater, 450 mL metal or glass cylinder, 115V

A2230HC2EE Electric heater, 450 mL metal or glass cylinder, 230V

A2230HC3EB Electric heater, 600 mL metal or glass cylinder, 115V

A2230HC3EE Electric heater, 600 mL metal or glass cylinder, 230V

A2230HC4EB Electric heater, 160 mL metal cylinder, 115V

A2230HC4EE Electric heater, 160 mL metal cylinder, 230V

A2230HC16EB Electric heater, 160 mL glass cylinder, 115V

A2230HC16EE Electric heater, 160 mL glass cylinder, 230V

For 1000 mL - 1500 mL:

A2945HCEB Electric heater, 1000 mL metal cylinder, 115V

A2945HCEE Electric heater, 1000 mL metal cylinder, 230V

A2945HC2EB Electric heater, 1500 mL metal cylinder, 115V

A2945HC2EE Electric heater, 1500 mL metal cylinder, 230V

A2944HCEB Electric heater, 1000 mL glass cylinder, 115V

A2944HCEE Electric heater, 1000 mL glass cylinder, 230V

A2944HC2EB Electric heater, 1500 mL glass cylinder, 115V

A2944HC2EE Electric heater, 1500 mL glass cylinder, 230V

18

Parr Instrument Company

Page 19

Product Features and Part Identification

5100 Stand

Mini Stand (160 mL - 600 mL)

5100 Low Pressure Reactors

2221HC BEARING HSG

2187HC BEARING

2226HC SNAP RING

4X SB1932BT06

4X TW19NL

4X TA1632PP06

2657HC4

ENCASEMENT

4X SB2528SC06

4X SW25NL

2658HC3 BACKPLATE

4X SA1632RP06

2222HC5

DRIVE SHAFT

FRONT GUARD PARTS

NOT SHOWN

2209HC3

FLEX COUPLING

3452HC3

MIDPLATE

2064EKX

.18KW ATEX MOTOR

4X SB3716HX16

4X SW37FT

4X SN3716HX

3X 2198HC10 SUPT ROD

3X TW50FT

3X SN5013HX

AA

A2651HC3

BASEPLATE ASS'Y

ADD 2X SN3118HL 5/16-18 KEPS

NUT AND SW31FT FLAT WASHER

TO SH3118XX12 GROUND STUD

DURING ASSEMBLY

A-ASECTION

Note: Liter Stands (larger) can be converted to accept Mini Vessel Assemblies. Mini Stands are for

Mini Vessel Assemblies only.

www.parrinst.com

19

Page 20

5100 Low Pressure Reactors

Stand for 5100

160 - 600 mL Vessels

1355EES MOTOR 1/8 HP

(4) SB1932BT06

(8) SW19FT

(4) TW19NL

(4) 2186HC

1564HC OPTICAL WHEEL 1:1

1564HC2 OPTICAL WHEEL 2:1

(3) SA1332RP04

A1001E6 SENSOR ASSY

SN1632WG

(2) TN1140HL

847HC10 DRIVE BELT 1:1 DRIVE

847HC9 DRIVE BELT 2:1 DRIVE

857HC4 DRIVEN PULLEY

X2170A MAG DRIVE SHIELD

2206HC RETAINER

2207HC PANEL SCREW

1374HCJV O-RING

2208HC WASHER, SPLIT

SC1932SC08 SET SCREW

2666HC2 PLATE SHIELD TOP

(9) TN1632HC

300mL GLASS

SHOWN (REF)

2656HC BELT GUARD

2663HC HINGE, BELT GUARD

(3) SA1632RP06

(3) SA1332RP04

(3) SW16FT

2661HC PULLEY

2-STAGE, LD DRIVE

2662HC PULLEY

2-STAGE, HD DRIVE

2655HC OVERARM PLATE

(2) 2446HC THUMB SCREWS

(5) SB1932SC08

(5) SW19FT

(5) TW19NL

2667HC SUPPORT, VESSEL

(REAR OF STAND ASSEMBLY)

2658HC BACKPLATE, UPPER

2659HC BACKPLATE, LOWER

(10) SA1632RP06

799DD BUSHING

2657HC2 ENCASEMENT

(5) TN1332HL

(6) 2246HC STRIKERS

(12) SB1332BT06

(12) TN1332HL

2652HC2 GUARD, REAR

XC0240 STRIPPING

(8) TA1632PP06

20

A2651HC BASE ASSY W/FEET

2668HC STIFFENER

(10) TN1932HL

(3) 2660HC SUPPORT RODS

(3) TW50FT

(3) SN5013HX

A2230HC SERIES

(2) 2654HC3 SIDE GUARDS

(24) TN1632HL

(6) 2244HC LATCHES

(12) SB1332BT06

(12) TN1332HL

2654HC2 FRONT GUARD

(12) TN1632HL

2653HC2 FRAME, FRONT

XC0240 STRIPPING

HEATER ASSY (REF)

(2) 2202HC COLLAR

2664HC SUPPORT ROD

TW50FT

SN5013HX

5100 OVERALL DIMENSIONS OF APPARATUS: 16.50" WIDE X 23.50" DEEP X 29.57" TALL

Parr Instrument Company

Page 21

Stand for 5110

1 L and 1.5 L Vessels

5100 Low Pressure Reactors

SC1932SC08 SET SCREW

2923HC PLATE SHIELD TOP

(11) TN1632HC

2660HC3 SUPPORT ROD NOTCHED

1355EES MOTOR 1/8 HP

1564HC OPTICAL WHEEL 1:1

1564HC2 OPTICAL WHEEL 2:1

847HC10 DRIVE BELT 1:1 DRIVE

847HC9 DRIVE BELT 2:1 DRIVE

X2170A MAG DRIVE SHIELD

2359HC RETAINER

2207HC PANEL SCREW

1374HCJV O-RING

2208HC WASHER, SPLIT

1.0 LITER GLASS

SHOWN (REF)

(4) SB1932BT06

(3) SA1332RP04

A1001E6 SENSOR ASSY

(2) TN1140HL

857HC4 DRIVEN PULLEY

TW50FT

SN5013HX

(8) SW19FT

(4) TW19NL

(4) 2186HC

SN1632WG

2656HC BELT GUARD

2663HC HINGE, BELT GUARD

(3) SA1632RP06

(3) SA1332RP04

(3) SW16FT

2661HC PULLEY

2-STAGE, LD DRIVE

2662HC PULLEY

2-STAGE, HD DRIVE

2655HC OVERARM PLATE

(2) 2446HC THUMB SCREWS

(5) SB1932SC08

(5) SW19FT

(5) TW19NL

2918HC SUPPORT, VESSEL

(REAR OF STAND ASSEMBLY)

2658HC BACKPLATE, UPPER

2921HC BACKPLATE, LOWER

(10) SA1632RP06

799DD BUSHING

2919HC ENCASEMENT

(5) TN1932HL

(6) 2246HC STRIKERS

(12) SB1332BT06

(12) TN1332HL

2926HC GUARD, REAR

XC0240 STRIPPING

(8) TA1632PP06

(3) 2660HC2 SUPPORT RODS

(3) TW50FT

(3) SN5013HX

(2) 2922HC SIDE GUARDS

(24) TN1632HL

(6) 2244HC LATCHES

(12) SB1332BT06

(12) TN1332HL

2932HC FRONT GUARD

(12) TN1632HL

2924HC FRAME, FRONT

XC0240 STRIPPING

A2651HC2 BASE ASSY W/FEET

2668HC2 STIFFENER

(10) TN1932HL

A2944HC/A2945HC SERIES

HEATER ASSY (REF)

(2) 2202HC COLLAR ASSY

2664HC SUPPORT ROD

TW50FT

SN5013HX

2928HC JACK LIFT

(4) TN1932HL

2931HC JACK PLATE (1.0L)

2927HC CORK RING

5110 OVERALL DIMENSIONS OF APPARATUS: 20.38" WIDE X 26.00" DEEP X 32.57" TALL

www.parrinst.com

21

Page 22

5100 Low Pressure Reactors

Overarm Components, Common For All 5100 Series Reactors

2656HC BELT GUARD

2663HC HINGE

1564HC OPTICAL WHEEL 1700 RPM

1564HC2 OPTICAL WHEEL 850 RPM

2661HC PULLEY, 2 STAGE (1/8 HP MOTOR)

2662HC PULLEY, 2 STAGE (1/4 HP MOTOR)

857HC7 PULLEY (AIR MOTOR)

A1001E6 TACH SENSOR ASSY

2655HC OVERARM PLATE

(2) 2446HC THUMB SCREWS

5100 Overarm

847HC10 DRIVE BELT 1700 RPM

847HC9 DRIVE BELT 850 RPM

857HC PULLEY, DRIVEN

(FLIP OVER WHEN USING

2634HC DRIVE ADAPTER

A1120HC9 MAG DRIVE ASSY

X2170A SHIELD, MAG DRIVE

850 MAX RPM)

22

Parr Instrument Company

Page 23

5100 Internals

300 mL - 450 mL Glass Vessels

5100 Low Pressure Reactors

5101 300mL

A138CA

MALE CONNECTOR

(REF)

2635HC3

HEAD

(3) A92HW

MALE CONNECTOR

A1453HC

THERMOWELL

2943HCHZ

THERMOWELL,

PTFE COATED

A472E

THERMOCOUPLE

(NOT SHOWN)

832HC31

DIP TUBE

822HC30

SHAFT, STIRRER

831HC6

COOLING LOOP

A837HC

IMPELLER

A138CA

MALE CONNECTOR (REF)

2635HC3

HEAD

(3) A92HW

MALE CONNECTOR

A1453HC

THERMOWELL

2943HC2HZ

THERMOWELL,

PTFE COATED

A472E2

THERMOCOUPLE

(NOT SHOWN)

832HC32

DIP TUBE

822HC31

SHAFT, STIRRER

831HC7

COOLING LOOP

(2) A837HC

IMPELLER

A1260HC2

STIRRER BRACKET ASSY

PTFE COATED =

1218HC5HZ INNER BRACKET

1219HC5HZ OUTER BRACKET

1260HCFHZ SCREW

5102 450mL

www.parrinst.com

23

Page 24

5100 Low Pressure Reactors

5100 Internals (continued)

600 mL Glass Vessels

A138CA

MALE CONNECTOR (REF)

2635HC3

HEAD

NOT SHOWN / COMMON FOR ALL

A2526HC SPLIT RING ASSY (GLASS)

A2735HC SPLIT RING ASSY (METAL)

2632HC SERIES O-RING

(3) A92HW

MALE CONNECTOR

A1453HC

THERMOWELL

2943HC3HZ

THERMOWELL, PTFE COATED

A472E3

THERMOCOUPLE (NOT SHOWN)

832HC33

DIP TUBE

822HC32

SHAFT, STIRRER

831HC8

COOLING LOOP

5103 600mL

(2) A837HC

IMPELLER

A1260HC2

STIRRER BRACKET ASSY

PTFE COATED =

1218HC5HZ INNER BRACKET

1219HC5HZ OUTER BRACKET

1260HCFHZ SCREW

24

Parr Instrument Company

Page 25

A2526HC SPLIT RING ASSY

2632HC SERIES O-RING

HEAD

A138CA

A92HW

MALE CONNECTOR

A1453HC

NOT SHOWN:

2943HC4HZ

PTFE COATED THERMOWELL

THERMOWELL

A472E THERMOCOUPLE

(ALL OTHER HEAD EXTERNALS)

DIP TUBE

2635HC3

CYLINDER, GLASS, 160mL

2525HC4

SHAFT, STIRRER

822HC33

IMPELLER

A837HC

MALE CONNECTOR (REF)

832HC35

5104 160mL GLASS

CYLINDER, JACKETED

A138CA

MALE CONNECTOR (REF)

A837HC

IMPELLER

2525HC14

DIP TUBE

A92HW

MALE CONNECTOR

GLASS, 215mL

2653HC3

HEAD

SHAFT, STIRRER

822HC44

832HC36

5104 215mL GLASS JACKETED

A1453HC

THERMOWELL

2943HC5HZ

PTFE COATED THERMOWELL

5100 Internals (continued)

CYLINDER, JACKETED

A138CA

MALE CONNECTOR (REF)

A837HC

IMPELLER

2525HC14

DIP TUBE

A92HW

MALE CONNECTOR

GLASS, 215mL

2653HC3

HEAD

SHAFT, STIRRER

822HC44

832HC36

5104 215mL GLASS JACKETED

A1453HC

THERMOWELL

2943HC5HZ

PTFE COATED THERMOWELL

160 mL - 215 mL Glass Vessels

5100 Low Pressure Reactors

www.parrinst.com

25

Page 26

5100 Low Pressure Reactors

686HC19 DIP TUBE (1.0L)

686HC20 DIP TUBE (1.5L)

(2) A358HC5 PROPELLER ASSY

5111 & 5112 Internals

1 L & 1.5 L Glass Vessels

2915HC2 HEAD

NOT SHOWN:

A2916HC SPLIT RING ASSY (FOR GLASS)

A2912HC SPLIT RING ASSY (FOR METAL)

2913HC SERIES O-RING

A472E2 THERMOCOUPLE (1.0L)

A472E3 THERMOCOUPLE (1.5L)

(3) A92HW

MALE CONNECTOR

A449HC STIRRER SHAFT ASSY (1.0L)

A449HC22 STIRRER SHAFT ASSY (1.5L)

265HC7 THERMOWELL (1.0L)

265HC27 THERMOWELL (1.5L)

48HC SERIES GASKET

2930HC3 COOLING LOOP (1.0L)

2930HC4 COOLING LOOP (1.5L)

A1404HC2 STIRRER BRACKET ASSY

A1404HC3HZ = PTFE COATED

2825HC SERIES

GLASS CYLINDER (SHOWN)

2910HC SERIES

METAL CYLINDER (REF)

26

Parr Instrument Company

Page 27

5100 Metal Vessels Internals

160 mL - 215 mL Vessels

A138CA

MALE CONNECTOR (REF)

2635HC3

HEAD

A92HW

MALE CONNECTOR

822HC33

SHAFT, STIRRER

832HC35

DIP TUBE

A1453HC

THERMOWELL

2943HC4HZ = PTFE COATED

A837HC

IMPELLER

5100 Low Pressure Reactors

2630HC4

METAL CYLINDER 160mL

NOT SHOWN:

A2735HC SPLIT RING ASSY

2632HC SERIES O-RING

A472E THERMOCOUPLE

A138CA

MALE CONNECTOR (REF)

2635HC3

HEAD

A92HW

MALE CONNECTOR

822HC44

SHAFT, STIRRER

832HC36

DIP TUBE

A1453HC

THERMOWELL

2943HC5HZ = PTFE COATED

A837HC

IMPELLER

2630HC14

METAL JACKETED

CYLINDER, 215mL

NOT SHOWN:

A2735HC SPLIT RING ASSY

2632HC SERIES O-RING

A472E THERMOCOUPLE

www.parrinst.com

27

Page 28

5100 Low Pressure Reactors

5100 Head Assembly

Head Assembly for 160 mL - 600 mL Vessels

RUPTURE DISC ASSY

MALE CONNECTOR

ELBOW, 45 DEGREE

RELIEF VALVE (CE)

A888HC2

366VBAA

420HC

ADAPTER

NEEDLE VALVE

A122VB

835HC

ADAPTER

A146VB

ANGLE VALVE

154VB2

A140VB2P1

*

RELIEF VALVE

A693VBP145

OR

A92HWAD

MALE CONNECTOR

TYP (2) PLACES

)POOLGNILOOC/W(GNILPUOCXEH

79HWAD288VBAD

PLUG, HEX HEAD

TYP (2) PLACES

(W/O COOLING LOOP)

A122VB

NEEDLE VALVE

2634HC

DRIVE ADAPTER

2633HCP2AD

GAGE

414VB

ELBOW, 90 DEGREE

836HC7

ADAPTER, GAGE

A1120HC9

MAG DRIVE ASSY

A138CA

MALE CONNECTOR

A1453HC

THERMOWELL

(NOT SHOWN)

A472E SERIES

THERMOCOUPLE

(NOT SHOWN)

2635HC3

HEAD

28

Parr Instrument Company

Page 29

RUPTURE DISC ASSY

A888HC2

302VBAD

FEMALE CONNECTOR

260HC2

VALVE EXTENSION

A146VB

ANGLE VALVE

5100 Low Pressure Reactors

5110 Head Assembly

Head Assembly for 1 L & 1.5 Vessels

HOLE FOR A472E_

THERMOCOUPLE

A92HWAD

MALE CONNECTORS

TYP (2) PLACES

ADAPTER BUSHING

ADAPTER, GAGE

ELBOW, 45 DEGREE

RELIEF VALVE (CE)

209HC4

208HC15

154VB2

A140VB2P1

*

RELIEF VALVE

A693VBP145

OR

2633HCP2AD

GAGE

414VB

ELBOW, 90 DEGREE

2634HC

DRIVE ADAPTER

A1120HC9

MAG DRIVE ASSY

A146VB

ANGLE VALVE

420HC

ADAPTER

A122VB

NEEDLE VALVE

208HC10

ADAPTER

209HC4

ADAPTER BUSHING

2915HC2

HEAD

www.parrinst.com

29

Page 30

5100 Low Pressure Reactors

5100 Head Fittings and Valves

2633HCP2AD

GAGE

414VB

ELBOW

A140VB2P1

RELIEF VALVE

154VB2

ELBOW, 45 DEG

836HC7

GAGE ADAPTER

A122VB

NEEDLE VALVE

(GAS RELEASE)

2635HC3

HEAD

A146VB

ANGLE VALVE

A122VB

NEEDLE VALVE

420HC

ADAPTER

835HC

ADAPTER

5100 PRESSURE GAGE

5110 Head Fittings and Valves

2633HCP2AD

GAGE

414VB

ELBOW

A146VB

ANGLE VALVE

260HC2

VALVE EXTENSION

2915HC2

HEAD

5100 GAS INLET/LIQUID SAMPLING VALVES

A140VB2P1

RELIEF VALVE

154VB2

ELBOW 45 DEG

208HC15

GAGE ADAPTER

209HC4

ADAPTER BUSHING

A146VB

ANGLE VALVE

420HC

ADAPTER

208HC10

ADAPTER

A122VB

NEEDLE VALVE

209HC4

ADAPTER BUSHING

30

5110 GAGE ASSY/GAS RELIEF VALVE

Parr Instrument Company

5110 GAS INLET/LIQUID SAMPLING VALVES

Page 31

Notes

www.parrinst.com

31

Page 32

378M R06 10/24/14

Loading...

Loading...