Page 1

No. 402M

r

Parr Instrument Company

Operating Instruction Manual fo

5000

Multiple Reactor System

For Models Produced Prior to July 2013

Page 2

5000 Series Multiple Reactor System

TABLE OF CONTENTS

Customer Service.............................2

Related Instruction ........................... 2

Preface............................................3

Scope...........................................3

Safety Information........................ 3

General Specifications ................. 3

Explanation of Symbols................4

Environmental Conditions ............ 4

Provisions for Lifting and

Carrying........................................ 4

Intended Usage............................ 5

Unpack Carefully.......................... 5

User’s Responsibility.................... 5

Pressure and Temperature Limits 6

Installation......................................7

General Setup Guidelines............7

Installation.................................... 7

Software Installation

and Operation................................. 9

Maintenance ................................... 9

Cleaning.......................................9

Fuses ........................................... 9

Head gaskets...............................9

Rupture Discs............................... 9

Parts List....................................... 10

Diagrams....................................... 12

Related Instructions

The following Parr publications are

also available to further your

understanding of this instrument and

its component parts:

No. Description

201M Limited Warranty

230M General Safety

231M Rupture Disc Instructions

323M Relief Valves

477M CD for 5000 Series MRS

Customer Service

Questions concerning the installation

or operation of this instrument can be

answered by the Parr Customer

Service Department:

309-762-7716

800-872-7720

Fax: 309-762-9453

http://www.parrinst.com

E-mail: parr@parrinst.com

- 2 -

Page 3

5000 Series Multiple Reactor System

PREFACE

Scope

These instructions describe the installation,

operation, and maintenance of the Parr

Series 5000 Multiple Reactor System. They

cover the basic steps to be followed for

installing this system and describe the

function of all standard components. They

are intended to be used in conjunction with

several related instruction sheets listed in

the Table of Contents. This information

describes several components that are

common to most Parr pressure reaction

equipment, and includes safety precautions

and other related information applicable to

all reaction laboratories. The users should

study all of these instructions carefully

before starting to use these vessels so that

they will fully understand the capabilities

and limitations of the equipment.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical

outlet of correct voltage and current

handling capability.

2. Ensure that the equipment is

connected to electrical service

according to local national electrical

codes. Failure to properly connect

may create a fire or shock hazard.

3. For continued protection against

possible hazard, replace fuses with

same type and rating of fuse.

4. Disconnect from the power supply

before maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of

flammable or combustible materials;

fire or explosion may result. This

device contains components which

may ignite such material.

2. Refer servicing to qualified

personnel.

General Specifications

Electrical Ratings

Marked Voltages:

230VAC 50/60 Hz 6.5 Amps

115VAC 50/60 Hz 12.5 Amps

Controller ratings are found in the

Operating Instructions for the controller

supplied with your reactor and on the

controller data plate.

Before connecting a controller to an

electrical outlet, the user must be certain

that the electrical outlet has an earth ground

connection and that the line, load and other

characteristics of the installation do not

exceed the following limits:

Voltage: Fluctuations in the line voltage

should not exceed 10% of the rated nominal

voltage shown on the data plate.

Frequency: Controllers can be operated

from either a 50 or 60 Hertz power supply

without affecting their operation or

calibration.

Current: The total current drawn should not

exceed the rating shown on the data plate

on the controller by more than 10 percent.

Thermocouple: Unless otherwise

specified, all Series 5000 Multiple Reactor

Systems operate with a Type-J (IronConstantan) thermocouple. The total

resistance of the thermocouple and the lead

wires should not exceed 100 ohms. If the

resistance of the thermocouple circuit is

higher, it will not function properly.

- 3 -

Page 4

5000 Series Multiple Reactor System

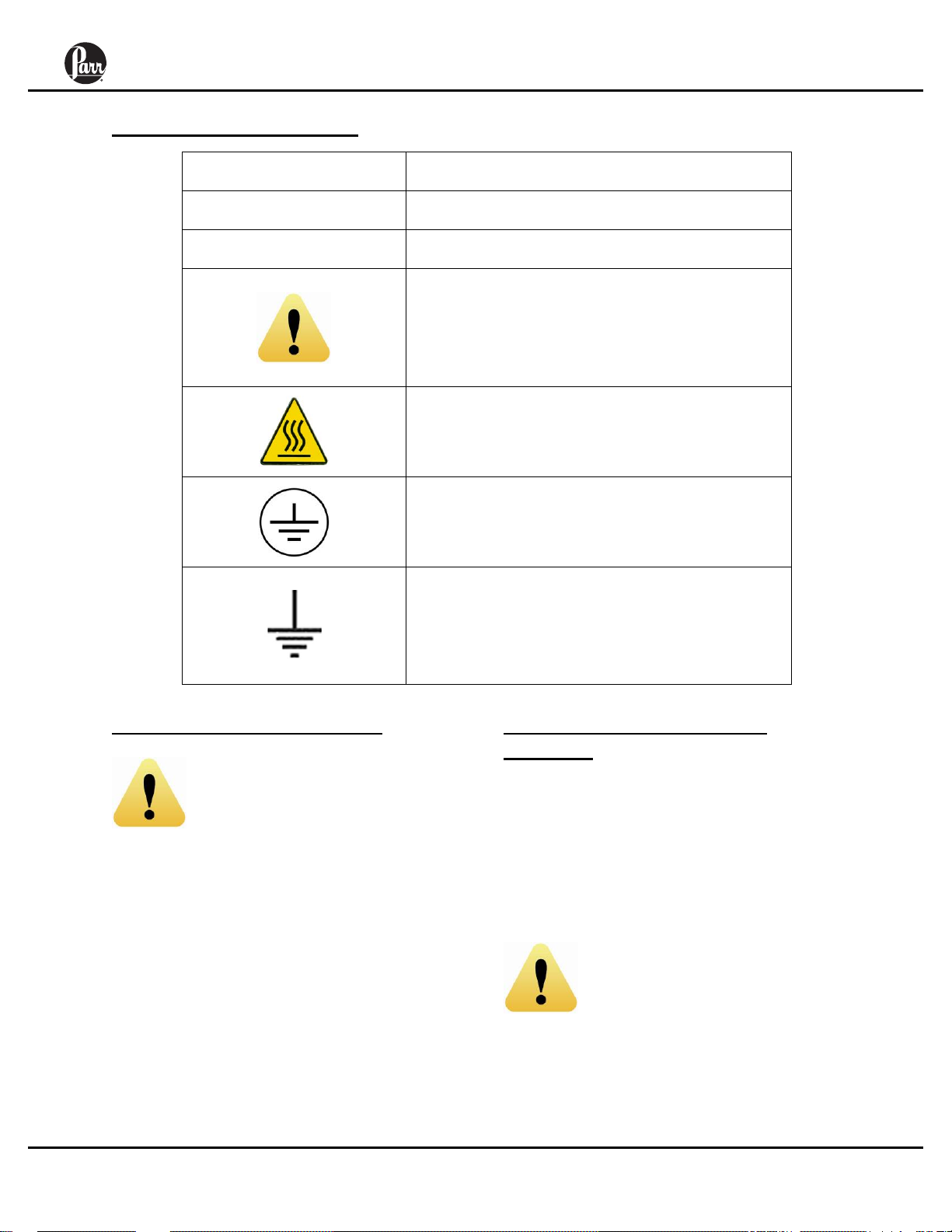

Explanation of Symbols

I

O

~

On position, half power heater switch

Off position

Alternating Current (AC)

This CAUTION symbol may be present on the

Product Instrumentation and literature. If present

on the product, the user must consult the

appropriate part of the accompanying product

literature for more information.

This CAUTION symbol indicates that the surface

may be hot.

Protective Earth (PE) terminal. Provided for

connection of the Protective Earth (green or

green/yellow) supply system conductor.

Earth Ground. Functional earth connection.

NOTE: This connection shall be bonded to

Protective Earth at the source of supply in

accordance with national and local electrical

code requirements.

Environmental Conditions

This instrument is to be used

indoors and requires 3 square

feet of space below the

controller in a well-ventilated

area with convenient access to an electric

outlet.

Operating: 15 °C to 40 °C; maximum

relative humidity of 80% non-condensing.

Installation Category II (overvoltage) in

accordance with IEC 664. Pollution degree

2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 °C and 65 °C; 10% to 85%

relative humidity.

Provisions for Lifting and

Carrying

Before moving the instrument, disconnect

all connections from the rear of the

apparatus. Disconnect the grounding strap

between the Heater assembly and Stirrer

assembly. Lift the instrument by grabbing

underneath each corner.

Caution

Do not use in hazardous

atmospheres.

- 4 -

Page 5

5000 Series Multiple Reactor System

Intended Usage

This system has been designed for use as a

high pressure multiple reactor system. It

has been designed, built, and tested to strict

physical and electrical standards. However,

it is the user's responsibility to install and

operate it in conformance with local

pressure and electrical codes.

If this equipment is used in a manner

beyond its intended usage, the protection

provided by the equipment may be

impaired.

Unpack Carefully

Unpack the equipment carefully and check

all the parts against the packing list. If

shipping damage is discovered, report it

immediately to the delivering carriers. The

vessels, heater block, stirrer and controller

may be packed separately for convenience

in shipping, but these parts are easily

reassembled. Examine the components

closely for any loose parts or shipping

damage and be sure to check all layers of

packing materials thoroughly so as not to

overlook any parts which might otherwise

be discarded.

User’s Responsibility

All Parr Reactors and Pressure Vessels are

designed and manufactured with great care

to assure safe operation when used within

their prescribed temperature and pressure

limits. But…the basic responsibility for

safety when using this equipment rests

entirely with the user; who must:

1. Select a reactor or pres sure vessel

that has the capability, pressure rating,

corrosion resistance, and design features

that are suitable for its intended use. Our

engineers will be glad to discuss available

equipment and material options with

prospective users, but the final responsibility

for selecting a reactor or pressure vessel

that will perform to the user's satisfaction in

any particular reaction or test must rest with

the user - not with Parr Instrument

Company.

In exercising the responsibility for the

selection of pressure equipment, the

prospective user is often faced with the

choice between over or under-designed

equipment. The hazards introduced by

under-designed pressure vessels are

readily apparent, but the penalties that must

be paid for over-designed apparatus are

often overlooked. Recognizing these

criteria, our reactors and pressure vessels

are offered in several different styles, each

designed for convenient use in daily

operation within certain temperature and

pressure limits, using gaskets, closures, and

other elements carefully selected for safe

operation within the limits specified for that

design. But in order to preserve the validity

of these designs, all temperature and

pressure limits must be observed, and no

attempt should be made to increase these

limits by making alterations or by

substituting components which are not

recommended by Parr Instrument

Company.

2. Install and operate the equipment

within a suitable barricade, if required, with

appropriate safety accessories and in full

compliance with local safety codes and

rules.

All standard Parr pressure vessels

are provided with either a suitable

relief device or a means to attach one

(typically in the form of a plugged

opening). When a pressure vessel is

delivered without a pressure venting

device, it is the customer’s responsibility

to provide pressure relief in order to

protect the operator and the equipment

from destructive high pressures. If you

need more information or need help

in selecting a proper relief device,

please contact Parr Instrument Company.

3. Establish training procedures to

ensure that any person handling the

equipment knows how to use it properly.

4. Maintain the equipment in good

condition and establish procedures for

periodic testing to be sure the vessel

remains structurally sound.

- 5 -

Page 6

5000 Series Multiple Reactor System

PRESSURE AND

TEMPERATURE LIMITS

Working pressures up to 3000 psi (207

bar) maximum are permissible in these

reactors when constructed of Type 316

Stainless Steel. Contact Parr Customer

Service if your vessel is not constructed

of T316 Stainless Steel and you are

unsure of the pressure and temperature

limit. No attempt should be made to

increase these limits by making

alterations or by substituting

components which are not

recommended by Parr Instrument

Company. It must also be understood

that lower pressure and temperature

limits may be required for modified

reactors and for vessels made of

materials other than T316 Stainless

Steel. Limits for such vessels will be

determined by the physical

characteristics of the material of

construction and will be prescribed on

an individual basis.

Working temperatures up to 300 °C are

permissible in reactors with a standard

2895HCHA flat PTFE gasket. A PTFE

gasket is the recommended choice for

most applications since the PTFE is

inert to most chemicals and it will

provide good seals under repeated

opening and closing if the gasket

temperature does not exceed 300 °C.

The service life of a PTFE gasket will,

however, be reduced considerably if

used at temperatures close to the

300 °C limit.

The maximum working pressure and

temperature for any vessel is governed

by the design of the vessel and the

strength of the material from which it is

constructed. There is also a close

relationship between working pressure

and temperature since the strength of

any material will normally fall off as the

temperature is increased.

Temperature and pressure limits are

also affected by the physical properties

and temperature limits of the gaskets

and seals used in the vessel, and by

any valves, gages, or other fittings

attached to the vessel. Obviously, the

maximum safe operating pressure of

any system can be no higher than that

of its lowest rated component.

Working temperatures up to 220 °C are

permissible in reactors equipped with

fluoroelastomer (FKM) O-ring seals.

The higher the operating temperature

above 200 °C, the shorter the life of the

O-ring will be. Perfluoroeleastomer

(FFKM) O-ring seals have a broad

chemical resistance and be used to

temperatures up to 275 °C.

Unfortunately they are very expensive

and will generally be reserved for unique

applications. Ethylene-propylene (EP)

O-rings can be used to 150 °C and are

recommended for applications such as

ethers, ammonia, and amines which will

rapidly destroy fluoroelastomer O-rings.

The working pressure and temperatures

in these reactors must not exceed the

following maximum limits:

Pressure and Temperature Limits

Vessel

Material

T316SS 3000 psi

T316SS 3000 psi

T316SS 3000 psi

T316SS 3000 psi

Maximum

Pressure

Maximum

Temperature

300 °C PTFE

Flat Gasket

220 °C FKM

O-ring

275 °C FFKM

O-ring

150 °C EP

O-ring

- 6 -

Page 7

5000 Series Multiple Reactor System

INSTALLATION

General Setup Guidelines

The Series 5000 Multiple Reactor

System requires at least 10 square feet

of work space on a sturdy bench or

table in a well ventilated area with

convenient access to an electric outlet.

If the tabletop is not heat resistant it

would be ideal to provide an insulated

pad on which to set the vessels when

hot.

Set the controller near the reactor on a

sturdy bench or table where there is

convenient access to an electrical outlet

capable of carrying up to 20 amperes.

Leave a space of at least twelve inches

between the controller and the heater

block so that the controller will not be

affected by radiant heat.

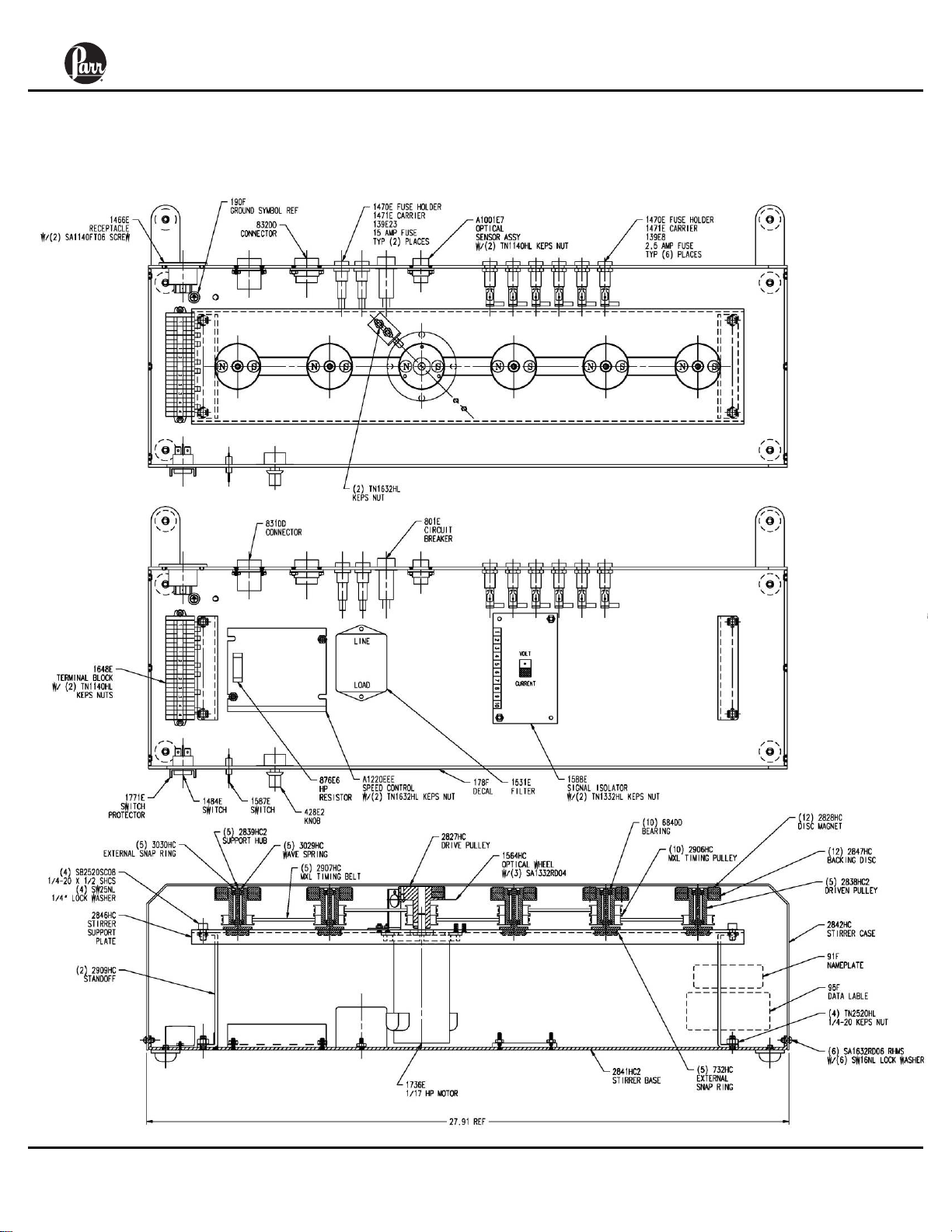

Installation

The system should be assembled

according to Diagram 1. Please note

that this figure illustrates the rear

view of all components in order to

clearly show the external wiring

details. From the front, the stations are

numbered 1 through 6, from left to right.

- 7 -

Page 8

5000 Series Multiple Reactor System

INSTALLATION (continued)

Diagram 1: Layout Diagram of Multiple Reactor System

Connect the external grounding

strap between the heater and

stirrer assembly.

The A1330E2 Heater Cable

assembly is to be fixed with

screws to prevent access to

live electrical components.

There will be a metal bracket on each

end of the cable with a screw on it.

Unthread the screw and line it up with

the port on the chassis. Then tighten

the screw to fix the cable in place.

Turn on the power switches located on

the front of the controller and the stirrer

assembly. If present, make sure the

stirrer local/remote switch is in the

remote position. If there is no stirrer

local/remote switch present on this unit,

no adjustment is necessary.

- 8 -

Page 9

5000 Series Multiple Reactor System

SOFTWARE INSTALLATION

AND OPERATION

Installation instructions are listed on the

477M CD which accompanied the 5000

MRS System as "MRS_ReadMe.htm".

Operation of the graphical user interface

is listed on the 477M CD which

accompanied the 5000 MRS System as

"Instructions_index.htm".

MAINTENANCE

Cleaning

The chassis, manifold, and valves and

fittings may be cleaned with a damp

cloth. The top and front of the 4871 and

MRS may be cleaned with a lightly

dampened cloth containing mild soap

solution. The heater, the back of the

4871, and the back of the MRS should

not be directly exposed to any liquid

cleaning agent.

Note: Disconnect from power source

before cleaning.

Fuses

The replacement of protective fuses and

backup AA size, 3.6 V battery for the

4871 Controller are the only internal

maintenance procedures that should be

performed by qualified personnel.

Proper fuse rating should be discussed

with Parr Instrument Company

Technical Support. Advanced

troubleshooting instructions can be

obtained by calling Parr Instrument

Company to determine which parts may

need to be replaced or serviced.

Head gaskets

Some extrusion of the PTFE gasket will

occur if the vessels are operated in 200

- 300 °C range. Normally this extrusion

doesn’t preclude reuse of the gasket;

the extruded portion should be removed

with a sharp knife. However, when the

gasket thickness is reduced to half of its

original thickness, it should be replaced.

If an FKM O-ring head gasket is used,

the life of the gasket will be shortened if

the operating temperature is above

200 °C. FFKM O-ring seals may be

used up to 275 °C. Unfortunately they

are very expensive and will generally be

reserved for unique applications. EP Orings may be used up to 150 °C.

Rupture discs

With normal use, rupture discs should

be replaced annually. More frequent

replacement may be necessary

depending on the operating conditions.

- 9 -

Page 10

5000 Series Multiple Reactor System

PARTS LIST

Please see Diagrams section for additional parts.

Cables:

A1330E2 Heater cable assembly, 14-in

A1120E Control cable, 10-ft

A1177E Tachometer harness, 10-ft

A1740E Thermocouple extension wire, type-J, 10-ft

A1623E Pressure harness, 10-ft

A1725E Communication cable to PC, RS-485 to Serial

A1725E2 Communication cable to PC, RS-485 to Ethernet

A1715E Configuration cable, RS-232 to RS-232

A1483EEB Main power cord, North American, 115V

A1483E Main power cord, North American, 230V

A1477E Main power cord, European plug, 230V

A1482E Main power cord, British plug, 230V

1859EEE Main power cord, China plug, 220V

A719E 4871 power cord, North American, 115V

A719EEE 4871 power cord, North American, 220V

1200EEE 4871 power cord, European plug, 230V

1465EEE 4871 power cord, British plug, 230V

1858EEE 4871 power cord, China plug, 220V

A1998E Grounding strap

Pressure Transducers:

A1906EP02 Pressure transducer, 0-200 psi

A1906EP05 Pressure transducer, 0-500 psi

A1906EP10 Pressure transducer, 0-1000 psi

A1906EP20 Pressure transducer, 0-2000 psi

A1906EP30 Pressure transducer, 0-3000 psi

1394HC6 Body for mounting transducer

2683HC Cooling sleeve

827HC O-rings for cooling sleeve

2714HC Hose connection for cooling sleeve

825HC Snap ring for cooling sleeve

Gaskets and seals:

2895HCHA PTFE head gasket for flat gasket vessels

2887HCJV FKM O-ring head g asket for O-ring vessels

2887HCJK FFKM O-ring head gasket for O-ring vessels

Gas Hose assemblies:

A2864HC2 Hose assy, PTFE lined, remote mounted valves

A2864HC3 Flexible metal hose assy, remote mounted valves

HD0012TB03 PEEK tubing, 1/8"OD, head mounted valves

A476A3AA Slip connector, head mounted valves

394HCJE EP O-ring for slip connector, head mo unted valves

- 10 -

Page 11

5000 Series Multiple Reactor System

PARTS LIST (continued)

Rupture disc parts:

526HCPD Rupture disc, 1000 psi

526HCPF Rupture disc, 2000 psi

526HCPG Rupture disc, 3000 psi

581HCPD Rupture disc, 1000 psi, gold faced

581HCPF Rupture disc, 2000 psi, gold faced

581HCPG Rupture disc, 3000 psi, gold faced

49HC2* Orifice cone for rupture disc assembly

527HC Orifice ring for rupture disc assembly

433HC4 Rupture disc body

633HC3 Safety body

Manifold parts:

A525VB Needle valve, 1/8"NPT x 1/8"T

A130VB2 Needle valve, angle, brass, 1/4"NPT x 1/4"T

A541VB Relief valve, 1/8"NPT

Vessel parts:

A129VB Needle valve, 1/4"NPT x 1/4"T

A147VB Needle valve, 1/4"NPT x 1/4"NPT

2898HC2 Adapter for head mounted vessels

2896HC Thermowell, flat gasket vessels, 71 mL, T316

2896HCCH Thermowell, flat gasket vessels, 71 mL, Alloy C-276

2896HC2 Thermowell, O-ring vessels, 71 mL, T316

2896HC2CH Thermowell, O-ring vessels, 71 mL, Alloy C-276

A1742E Thermocouple, T316, 4½” L, 1/16” dia

A2888HC Screw cap, flat gasket vessels, with bolts

1932HC3DE Spare screw cap bolts, flat gasket vessels

2886HC Compression ring, flat gasket vessels

2891HC* Bare head, flat gasket vessel, 71 mL, T316

2893HC* Bare head, O-ring vessel, 71 mL, T316

2890HC* Cylind er, flat gasket vessel, 71 mL, T316

2892HC* Cylinder, O-ring vessel, 71 mL, T316

3011HC* Bare head, flat gasket vessel, 45 mL, T316

3013HC* Bare head, O-ring vessel, 45 mL, T316

3010HC* Cylind er, flat gasket vessel, 45 mL, T316

3012HC* Cylinder, O-ring vessel, 45 mL, T316

2920HC Glass liner, open top, 71 mL

3020HC Glass liner, open top, 45 mL

* Special Materials Available

- 11 -

Page 12

5000 Series Multiple Reactor System

DIAGRAMS

Diagram 1: Layout diagram of 5000 Multiple Reactor System

Diagram 2: 5050/5051 Vessel body diagram, PTFE seal and O-ring seal

Diagram 3: 5050 Vessel, head mounted valves, manual inlet

Diagram 4: 5050 Vessel, head mounted valves, check valve inlet

Diagram 5: Manifold panel for head mounted valves

Diagram 6: Manifold panel for remote mounted valves

Diagram 7: Base assembly with heater and stirrer, 115V

Diagram 8: Base assembly with heaters and stirring assembly, 230V

Diagram 1: Layout Diagram of Multiple Reactor System

- 12 -

Page 13

5000 Series Multiple Reactor System

DIAGRAMS (continued)

5050 Flat Gasket vessel, 75 mL 5050 O-ring seal vessel, 75 mL

5051 Flat Gasket vessel, 45 mL 5051 O-ring seal vessel, 45 mL

Diagram 2: 5050/5051 Vessel Flat Gasket and O-ring

- 13 -

Page 14

5000 Series Multiple Reactor System

DIAGRAMS (continued)

Diagram 3: 5050 Vessel, head mounted valves, manual inlet

Diagram 4: 5050 Vessel, head mounted valves, check valve inlet

- 14 -

Page 15

5000 Series Multiple Reactor System

DIAGRAMS (continued)

Diagram 5: Manifold panel for head mounted valves

- 15 -

Page 16

5000 Series Multiple Reactor System

DIAGRAMS (continued)

Diagram 6: Manifold panel for remote mounted valves

- 16 -

Page 17

5000 Series Multiple Reactor System

DIAGRAMS (continued)

Diagram 6 (continued):

Manifold panel for remote mounted valves

- 17 -

Page 18

5000 Series Multiple Reactor System

DIAGRAMS (continued)

Diagram 7: Base assembly with heaters and stirring assembly, 115V

- 18 -

Page 19

5000 Series Multiple Reactor System

DIAGRAMS (continued)

Diagram 8: Base assembly with heaters and stirring assembly, 230V

- 19 -

Page 20

Revision 02/15/11

PARR INSTRUMENT COMPANY

211 Fifty-Third Street

Moline, Illinois 61265 USA

309/762-7716 800/872-7720

Fax 309/762-9453

http://www.parrinst.com E-Mail: parr@parrinst.com

Loading...

Loading...