Page 1

No. 519M

r

Parr Instrument Company

4857

Process Controlle

Operating Instruction Manual

Page 2

4857 Reactor Controllers

TABLE OF CONTENTS

Related Instructions .............................2

Customer Service.................................2

Preface 3

Scope...................................................3

Applications..........................................3

Explanation of Symbols........................4

Safety Information................................4

Intended Usage....................................4

General Specifications.........................5

Environmental Conditions....................5

User’s Responsibility............................6

Unpack Carefully..................................6

Installation 7

General Instructions.............................7

Connections.........................................7

Switches and Indicators 8

4857 Switches and Indicators..............8

Protective Fuses 8

4857 Fuses ..........................................8

Model 4857 Process Controller

Specifications 9

Temperature Control Parameters.......9

Software Installation 10

Before Software Installation.................10

Minimum PC Requirements.................10

CalGrafix Installation Instructions.........10

Install USB Drivers...............................10

Single Reactor......................................11

Two Reactors.......................................12

Operation of the 4857 Controller 13

Running CalGrafix................................13

Restoring Factory Defaults...................15

Finding the Active COM Port................16

Setting the Active COM Port................16

Changing the Name of a Module .........17

Autotuning............................................18

Module 1: Temperature Control Module

Setpoint Adjustment.............................19

High Temperature Alarm Adjustment...20

Changing PID Settings.........................21

Temperature Programmer....................22

Module 2: Pressure Display and

High Pressure Alarm

Alarm Adjustment.................................25

Module 3: Tachometer

Stirring Speed Adjustment...................26

Module 4: Optional Module

Optional Module...................................27

Data Logging 28

Creating a Chart ..................................28

Exporting Data from a Chart................30

Solenoid Valve Module 30

Cleaning and Maintenance 31

Fuses...................................................31

Access to Controller Cabinet...............31

Controller and Circuit Diagrams 32

Parts for the 4857 Controller 35

Related Instructions

The following Parr publications are also

included to further your understanding of this

instrument and its component parts:

No. Description

201M Limited Warranty

521M 4857 Process Controller CD

547M 4857 CalGrafix CD

567M 4875 Power Controller Operating

Instructions

Customer Service

Questions concerning the installation or

operation of this instrument can be answered

by the Parr Customer Service Department:

309-762-7716

800-872-7720

Fax: 309-762-9453

www.parrinst.com

parr@parrinst.com

- 2 -

Page 3

4857 Reactor Controllers

PREFACE

Scope

These instructions cover the installation and

operation of Parr Model 4857 Process Controller

as used with Parr Laboratory Reactors and

Pressure Vessels. They cover the basic

functions provided in each of these controllers.

The users should study the instructions carefully

before using any of these controllers so that they

will fully understand the capabilities of this

equipment and the safety precautions to be

observed in its operation.

Applications

Each Series 4857 Process Controller consists of

a packaged temperature control unit completely

wired and assembled with appropriate power

and safety relays, switches and pilot lights.

These units are designed specifically for use

with Parr reactors and pressure vessels and are

to be used only with Parr equipment.

Controllers furnished with Parr reactors

equipped with variable speed DC motors have a

motor switch and a speed control knob on the

front panel of the power controller. Controllers to

be used with AC equipment or an air motor do

not have a speed control knob.

- 3 -

Page 4

Explanation of Symbols

4857 Reactor Controllers

I

O

This CAUTION symbol may be present on the Product Instrumentation

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capacity.

2. Ensure that the equipment is connected to

electrical service according to local national

electrical codes. Failure to properly connect may

create a fire or shock hazard.

3. For continued protection against possible

hazard, replace fuses with same type and rating

of fuse.

4. Disconnect from the power supply before

maintenance or servicing. The power supply

cord of the equipment is the main disconnect

device.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials where fire or explosion

may result. This device contains components

which may ignite such materials.

2. Refer servicing to qualified personnel.

On position

Off position

and literature. If present on the product, the user must consult the

appropriate part of the accompanying product literature for more

information.

Protective Earth (PE) terminal. Provided for connection of the

Protective Earth (green or green/yellow) supply system conductor.

Intended Usage

This controller has been designed for use with

Parr Pressure Vessels, Reactors and Power

Controllers. It has been designed, built, and

tested to strict physical and electrical standards.

However, it is the user's responsibility to install

and operate it in conformance with local

pressure and electrical codes.

If the instrument is used in a manner not

specified by Parr Instrument Company, the

protection provided by the equipment may be

impaired.

- 4 -

Page 5

4857 Reactor Controllers

General Specifications

Electrical Ratings:

115VAC 50/60 Hz 3.0 Amps

230VAC 50/60 Hz 3.0 Amps

Before connecting to a reactor or heating device,

the user must be sure that the line, load and

other characteristics of the installation do not

exceed the following limits:

Voltage: Fluctuations in the line voltage should

not exceed 10% of the rated nominal supply

voltage shown on the data plate.

Frequency: Controllers can be operated from

either a 50 or 60 Hertz power supply without

affecting their operation or calibration.

Current: The total current drawn should not

exceed the rating shown on the data plate on

the controller by more than 10 percent.

Thermocouple. Unless otherwise specified, all

Series 4857 Process Controllers operate with a

Type J (iron-constantan) thermocouple. The

total resistance of the thermocouple and the

lead wires should not exceed 100 ohms. If the

resistance of the thermocouple circuit is higher,

it will not function properly.

Environmental Conditions

This instrument is to be used indoors and

requires 3 square feet of space below the

controller in a well-ventilated area with

convenient access to an electric outlet.

Operating: 15°C to 30°C; maximum relative

humidity of 80% non-condensing.

Installation Category II

(overvoltage) in accordance with

IEC 664. Pollution degree 2 in

accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25°C and 65°C; 10% to 85%

relative humidity.

Provisions for Lifting and Carrying

Before moving the instrument, disconnect all

connections from the rear of the apparatus. Lift

the instrument by grabbing underneath each

corner.

Caution

Do not use in hazardous

atmospheres.

- 5 -

Page 6

4857 Reactor Controllers

User’s Responsibility

All Parr Reactors and Pressure Vessels are

designed and manufactured with great care to

assure safe operation when used within their

prescribed temperature and pressure limits.

But…the basic responsibility for safety when

using this equipment rests entirely with the user;

who must:

1. Select a reactor or pressure vessel that has

the capability, pressure rating, corrosion

resistance, and design features that are

suitable for its intended use. Parr engineers

will be glad to discuss available equipment

and material options with prospective users,

but the final responsibility for selecting a

reactor or pressure vessel that will perform to

the user's satisfaction in any particular

reaction or test must rest with the user - not

with Parr.

In exercising the responsibility for the

selection of pressure equipment, the

prospective user is often faced with the

choice between over- or under-designed

equipment. The hazards introduced by

under-designed pressure vessels are readily

apparent, but the penalties that must be paid

for over-designed apparatus are often

overlooked. Recognizing these criteria, Parr

reactors and pressure vessels are offered in

several different styles, each designed for

convenient use in daily operation within

certain temperature and pressure limits, using

gaskets, closures, and other elements

carefully selected for safe operation within the

limits specified for that design. But in order to

preserve the validity of these designs, all

temperature and pressure limits must be

observed, and no attempt should be made to

increase these limits by making alterations or

by substituting components which are not

recommended by Parr Instrument Company.

2. Install and operate the equipment within a

suitable barricade, if required, with

appropriate safety accessories and in full

compliance with local safety codes and rules.

All standard Parr pressure vessels are provided

with either a suitable relief device or a means to

attach one (typically in the form of a plugged

opening). When a pressure vessel is delivered

without a pressure venting device, it is the

customer’s responsibility to provide pressure

relief in order to protect the operator and the

equipment from destructive high pressures. If

you need more information or need help in

selecting a proper relief device, please contact

Parr Instrument Company.

3. Establish training procedures to ensure that

any person handling the equipment knows

how to use it properly.

4. Maintain the equipment in good condition and

establish procedures for periodic testing to be

sure the vessel remains structurally sound.

Unpack Carefully

Unpack the equipment carefully and check all

the parts against the packing list. If shipping

damage is discovered, report it immediately to

the delivering carriers. Examine the

components closely for any loose parts or

shipping damage and be sure to check all layers

of packing materials thoroughly so as not to

overlook any parts which might otherwise be

discarded.

- 6 -

Page 7

4857 Reactor Controllers

INSTALLATION

General Instructions

Set the controller near the reactor on a sturdy

bench or table where there is convenient access

to an electrical outlet capable of carrying up to

20 amperes. Leave a space of at least twelve

inches between the controller and the heater of

the reactor so that the controller will not be

affected by radiant heat.

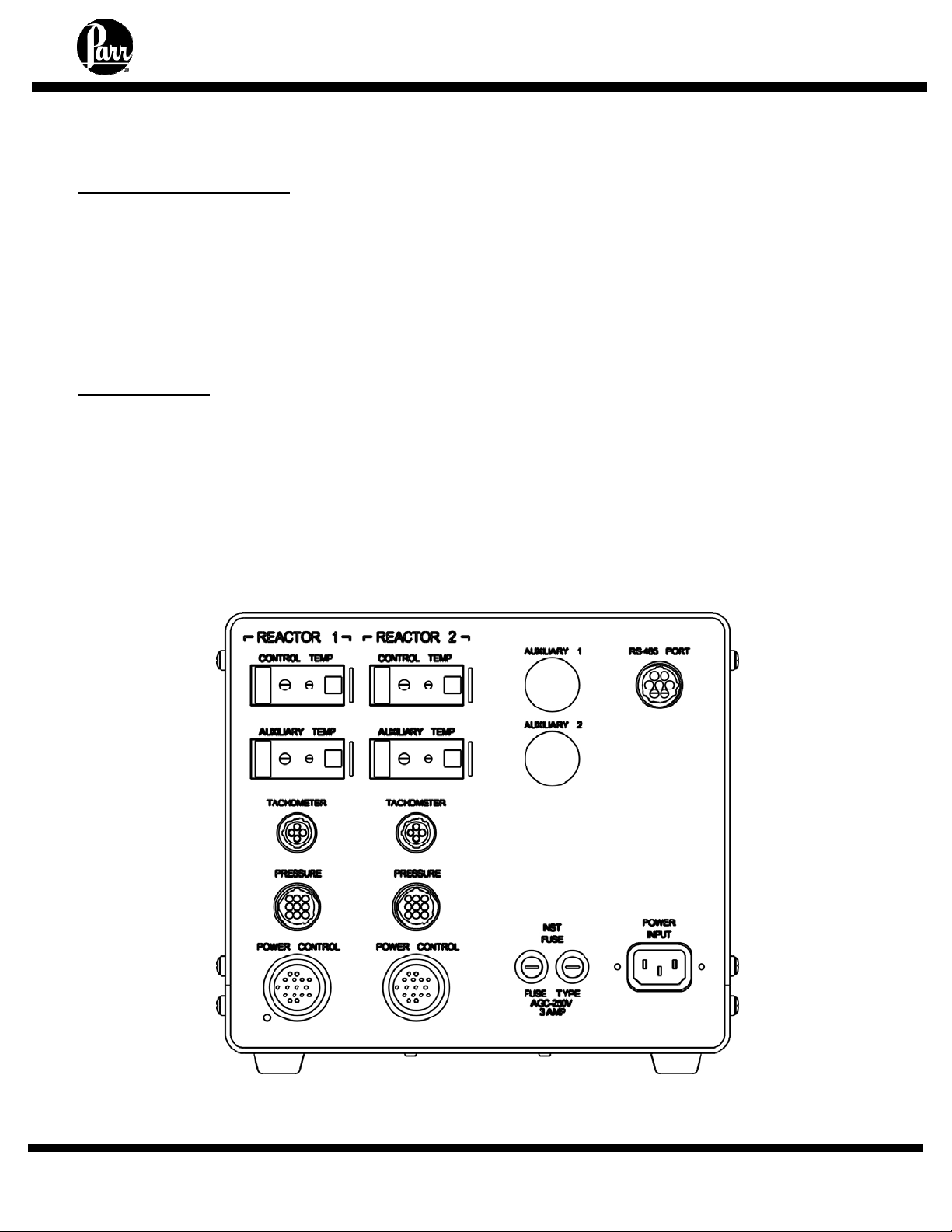

Connections

Labeled connections are provided on the rear

panel of each controller.

The Control Temp connection is for the internal

reactor thermocouple or RTD harness.

The Auxiliary Temp connection is for a

secondary thermocouple or RTD harness.

The Tachometer connection is for the optical

sensor harness.

The Pressure connection is for the reactor

pressure sensor harness.

The Auxiliary connection is for an optional

input.

The Power Control connection is for connection

to the 4875 Power Controller.

The RS-485 PORT connection is for

communication to PC.

- 7 -

Page 8

4857 Reactor Controllers

SWITCHES AND INDICATORS

4857 Switches and Indicators

The Main Switch is a manual, two-position,

illuminated switch which will cut off power to the

controller. The light indicates power the power is

on. Take care to position the controller such that

the main power switch may be accessed easily

when the controller needs to be disconnected.

PROTECTIVE FUSES

4857 Fuses

Two instrument fuses are mounted on the

back panel. These are Fast-acting, 250VAC, 3.0

amp fuses, intended to protect the internal

circuitry of the controller.

4857 Process Controller Front Panel

- 8 -

Page 9

4857 Reactor Controllers

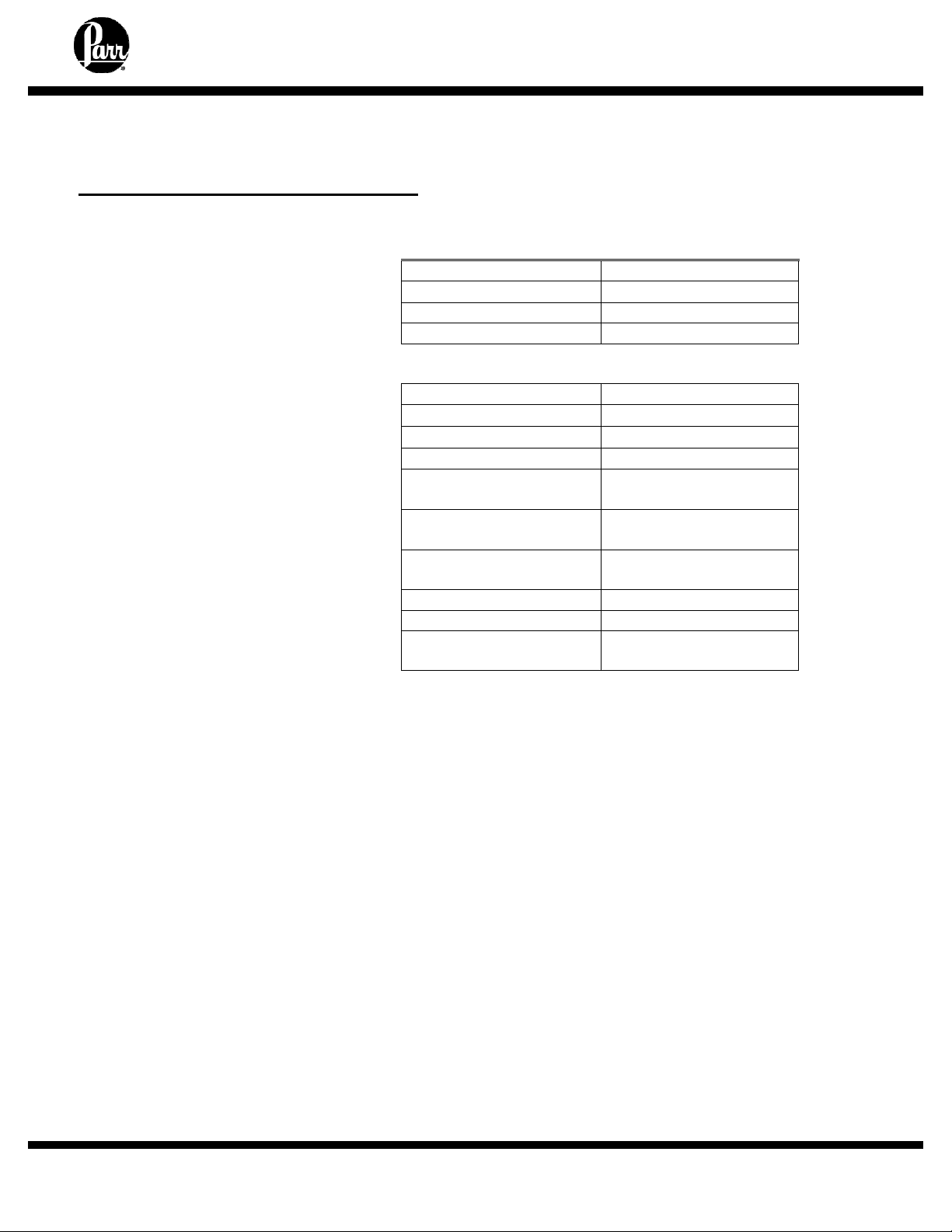

MODEL 4857 PROCESS CONTROLLER SPECIFICATIONS

Temperature Control Parameters

To facilitate start up with reasonably

good PID control parameters for heating

and cooling, all 4857 Process

Controllers are programmed at the

factory with the temperature control

settings shown on the right.

Output 1 on these controllers drives the

heater. Output 2 can be used to

activate a cooling system. Control

parameters can be set independently for

each of these outputs.

Module 1: Temperature Control

Cycle time 2 seconds

Proportional Band

Integral Time 5 min

Derivative Time 25 sec

Input thermocouple

Operating range

Display resolution

Setpoint resolution

System accuracy

Control action

Control output 1

Control output 2

Operating voltages

Maximum switching

load

25 °C

Type J

0 to 800 °C

.1 °C

.1 °C

+/- 0.1% FS

+/- 1°C typical

Three term PID control

plus limit control

15 amp @ 115V,

15 amp @ 230V

0.25 amp

115 and 230 VAC

15 amp @ 115 VAC

15 amp @ 230 VAC

- 9 -

Page 10

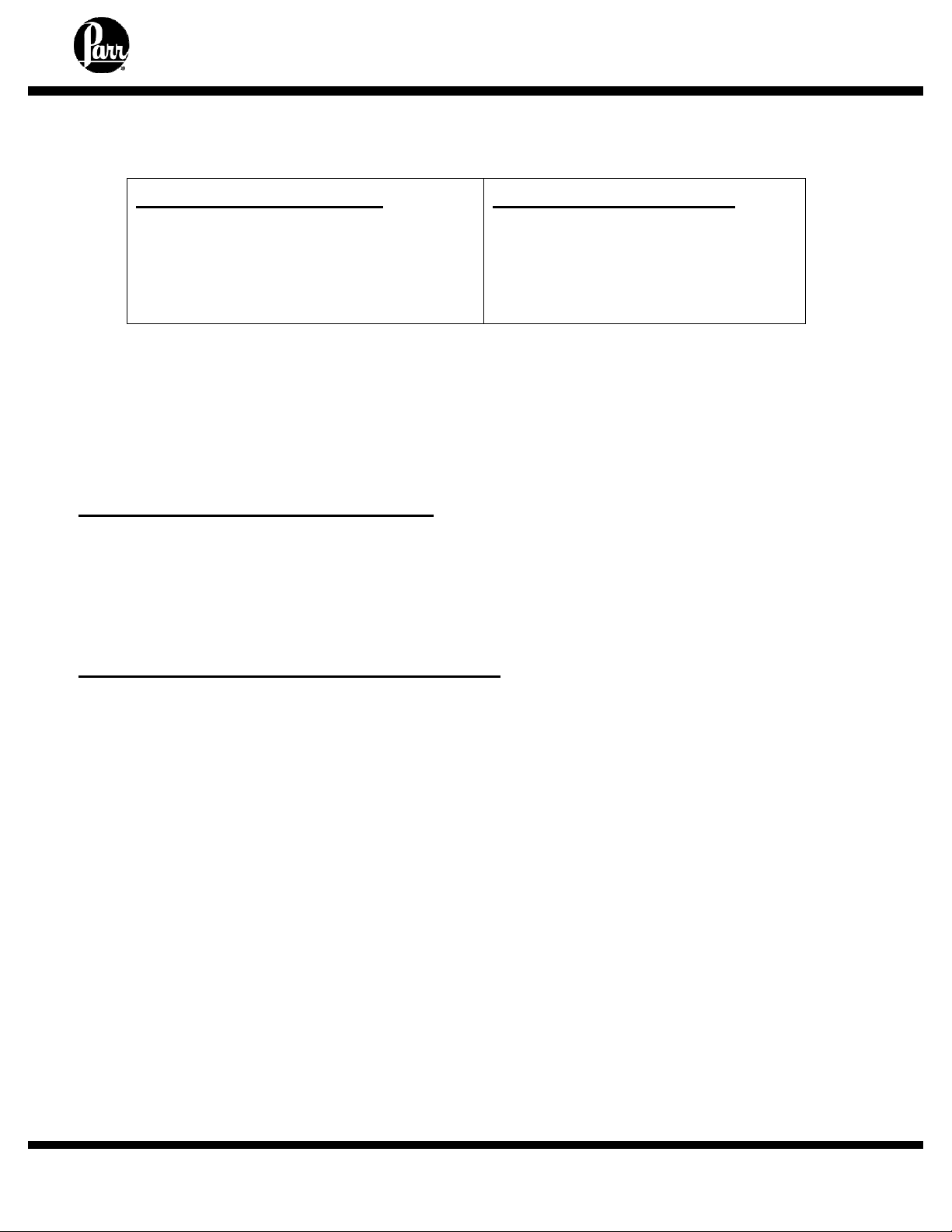

4857 Reactor Controllers

SOFTWARE INSTALLATION OF THE 4857 PROCESS CONTROLLER

Before Software Installation

The CalGrafix software should be installed on a

PC which has not previously been used to run

software for Cal applications. The PC should

meet at least the minimum system requirements.

Minimum PC Requirements

As a general requirement, we would

recommend a minimum of Pentium 450MHz

with 256MB RAM, Windows

screen resolution, 1024 x 768. 100MB of

free hard drive space is more than

sufficient.

TM

2000/XP and

Installation Instructions:

Note: Temperature control modules have been set to park mode as a precaution against

heating before connection to a PC. Following these installation instructions will reset the

parameters for these modules to allow heating and stirring.

Do not connect the 4857 to the PC until the following installation has been completed.

CalGrafix Installation Instructions:

1. Locate the 547M CalGrafix CD and insert it into the CD drive.

2. From the CD, open the setup.exe file to run the installation program.

3. Follow on screen instructions to complete installation.

Install USB Drivers (for USB cables only)

Note: If using serial port communication, no driver installation is required.

1. Insert the 521M CD.

2. Attach USB Cable to PC. Do not connect cable to 4857 Process Controller yet.

3. The "Add new hardware" wizard should appear. Click "Next."

4. Select "Search for the best driver for your device." Click "Next."

5. The wizard will then ask the location of the driver. With the Parr 521M CD in the CD-

drive, select "CD-ROM drive" and click "Next."

6. The wizard should find the "\FTDIBUS.INF" file. If it does not find the driver, select

“specify driver location” and find the driver at: ”/installation/USB-SerialPortAdapter/BBElec/USOTL4/VISTA_XP or WIN98_ME”. Click "Next."

7. The wizard should install the driver. Click "Next."

8. The wizard will also find the USB Serial Port. This should be installed in the same

manner as the previous driver. When it is finished, click "Finish."

- 10 -

Page 11

4857 Reactor Controllers

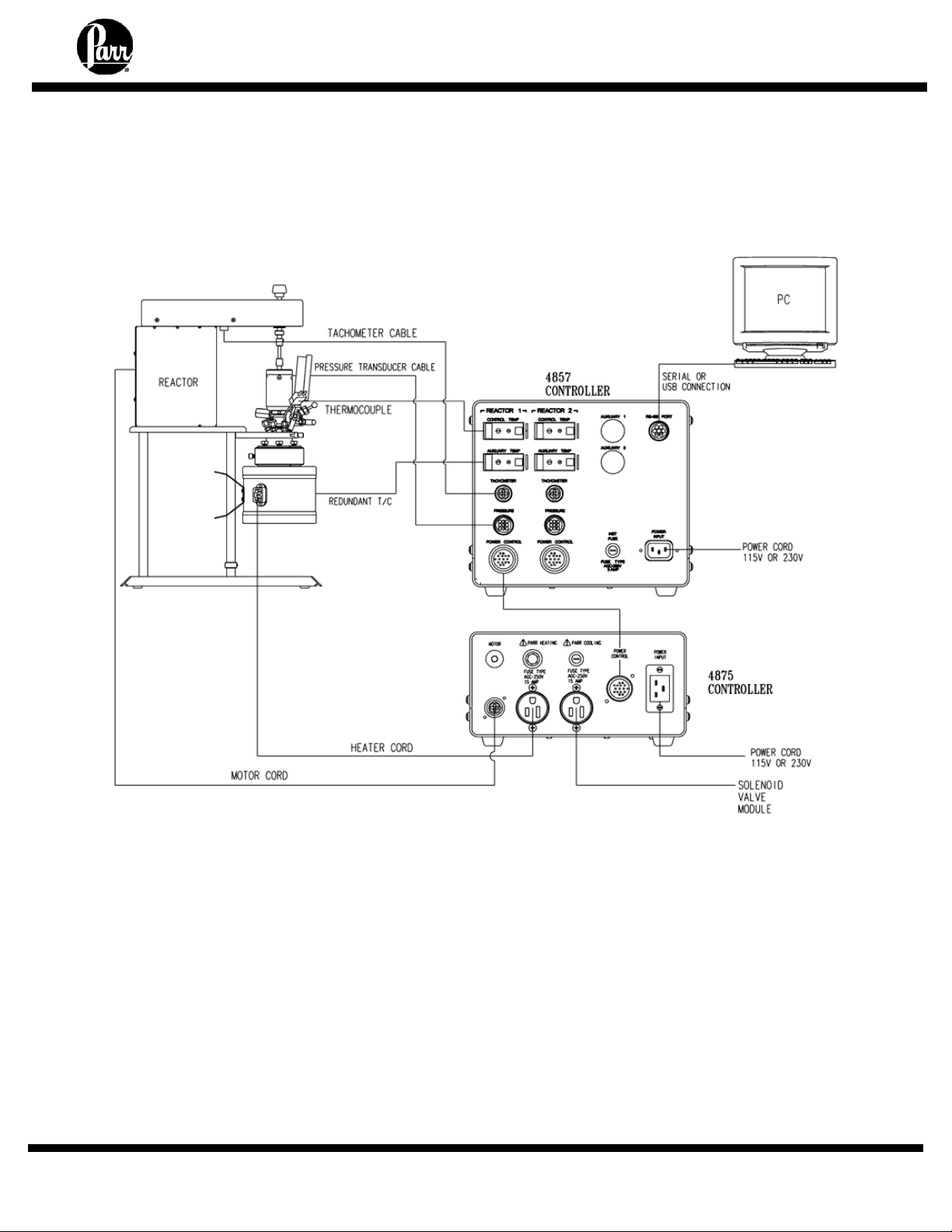

Connections between single Reactor,

4857 Process Controller, and single 4875 Power Controller

Diagram 1: Schematic Diagram of Connections to

4857 Process Controller for control of

a single reactor with 4875 Power Controller

- 11 -

Page 12

4857 Reactor Controllers

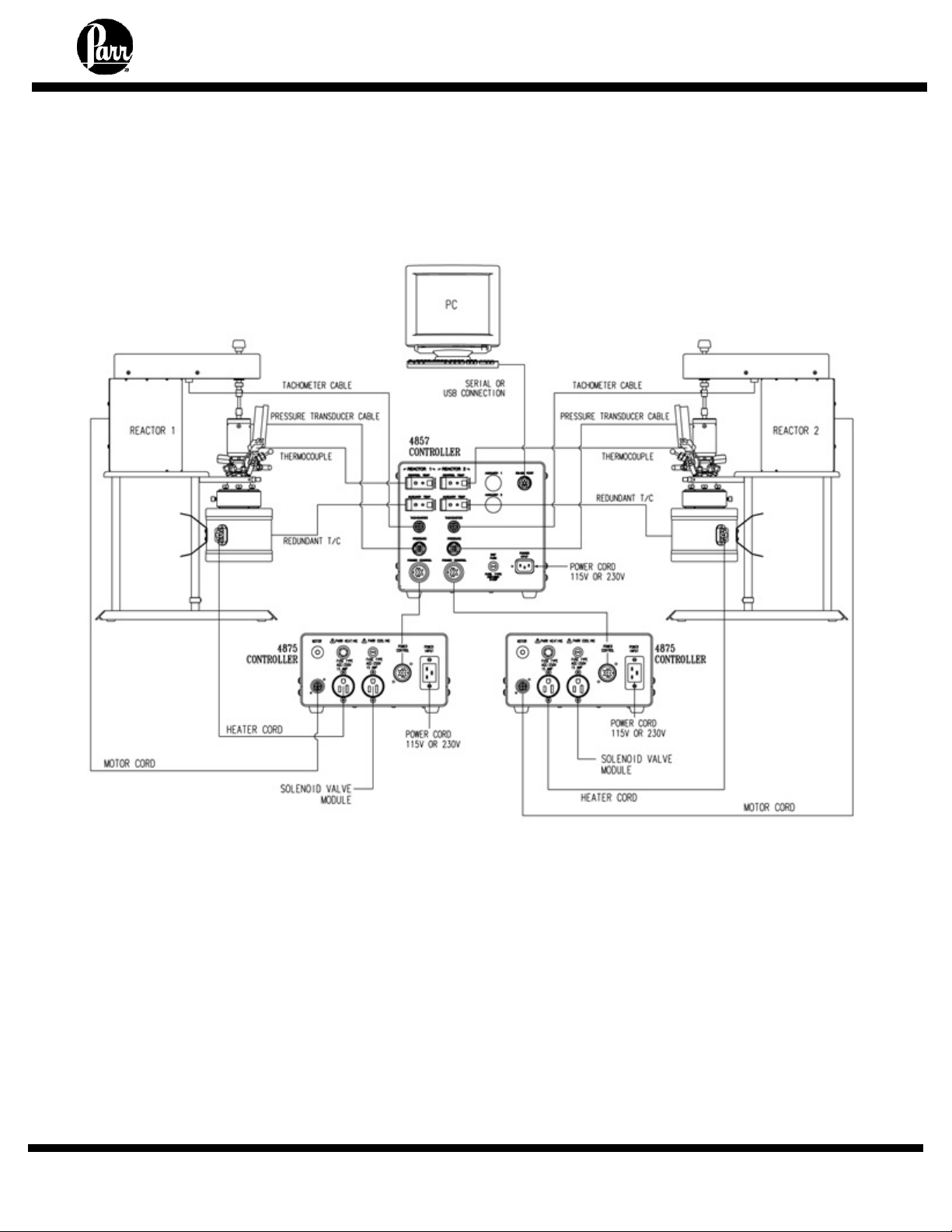

Connections between two Reactors,

4857 Process Controller, and dual 4875 Power Controllers

Diagram 2: Schematic Diagram of Connections to

4857 Process Controller for control of

two reactors with two 4875 Power Controllers

- 12 -

Page 13

4857 Reactor Controllers

OPERATION OF THE 4857 PROCESS CONTROLLER

Before operation

Be certain to set the power settings on the PC such that it will not hibernate or time out after a period of time.

After CalGrafix and the USB Drivers are installed on the PC, it is OK to attach the 4857 to the

PC according to diagram 1 or diagram 2 and turn it on.

Run the CalGrafix Program

1. The CalGrafix Program has been added to the program list. Access it at:

"Start >> Programs >> CalGrafix >> CalGrafix"

Accessing the CalGrafix program

through the Start menu

2. Click on the small controller faceplate icon on the menu bar, or select "File >> New

Instrument".

3. CalGrafix will attempt to locate the 4857 Process Controller.

a. If the 4857 is not shown in the device box, click "browse" and

select the COM port being used by the 4857. Then click the

"browse" button again. Repeat this step until the device appears

in the device box. Click OK.

b. The 4857B will find two devices when the proper COM port is

selected. Using the Shift key, select both devices and click OK.

c. If there is uncertainty for which COM port is being used, see the

section on "Finding the active COM port" in this manual.

Locating the 4857 with the Device Box

- 13 -

Page 14

4857 Reactor Controllers

OPERATION OF THE 4857 PROCESS CONTROLLER (CONTINUED)

Run the CalGrafix Program (continued)

4. A graphic of the 4857 Control Module will be displayed. The base module is illustrated in the

center with modules 1-4 on either side. The 4857B will have two graphics displayed instead

of one.

4857 Main Control Screen

5. The process may be controlled according to the instructions regarding operation of

the individual modules.

During initial installation, Modules 1 and 3 are set to Park for safety. See instructions on

Modules 1 and 3 to reset mode from Park to the PID (for Module 1) and PI (for Module 3).

6. Save the application file to the PC. Select “File” >> “Save As”, and save the file in an

appropriate place. One convenient place for this would be located at "C:\Program Files\CAL

Controls\CALGrafix". This file may be used later to restore the controller to its current

defaults.

7. CalGrafix may be exited by selecting "File >> Quit".

- 14 -

Page 15

4857 Reactor Controllers

OPERATION OF THE 4857 PROCESS CONTROLLER (CONTINUED)

Factory Defaults

Restoring the 4857 to it factory defaults is relatively simple. There are is a file on the 521M CD

which may be copied to the PC at "\Factory Defaults\factorydefaults.dev".

Opening the .dev file with CalGrafix will restore the controller settings in the 4857 Process

Controller.

Restoring Factory Default Values

1. Set the active COM port to COM7. If you are unsure of how to do this, see the section on

"Setting the active COM port" in this manual.

2. Open the CalGrafix program in the usual manner. Connect to the 4857 Controller by

clicking on the small controller faceplate icon on the menu bar, or selecting "File >>

New Instrument".

3. If the 4857 is not shown in the device box, click "browse" and select COM7.

4. When the CalGrafix program finds the 4857, select “File” >> “Open.”

5. Locate the factorydefaults.dev file on the 521M CD at "\Factory

Defaults\factorydefaults.dev". Select open.

6. CalGrafix will ask which values to write. Check the boxes of "Modules 1-3". Click OK. If you

have a 4th module which needs to be reset, contact Parr Technical Support .

7. CalGrafix will write the application data from the default file to the 4857.

- 15 -

Page 16

4857 Reactor Controllers

OPERATION OF THE 4857 PROCESS CONTROLLER (CONTINUED)

Finding the Active COM Port

When using CalGrafix to connect to the 4857 Process Controller, it is advantageous to know

which COM port the PC is using to connect to the controller. The following instructions detail

how to find the active COM port with Windows 2000 as the operating system.

1. Connect the 4857 to the PC using the provided cable and turn the 4857 on.

2. On the Desktop, right click on "My Computer" and select "Properties."

3. Switch to the "Hardware" tab and click on "Device Manager."

4. The Device Manager should come up. Expand the "Ports (COM & LPT)" box.

5. The COM ports which are in use should be listed here. Make a note of the ones listed; one

of these should be the one to instruct CalGrafix to use to connect to the 4857.

Setting the Active COM Port

In some instances (such as restoring Factory Defaults) it is necessary to instruct the PC which

COM port to use for connection to the 4857. You will need Administrator privileges in order to

set the active COM port.

1. Connect the 4857 to the PC using the provided cable and turn the 4857 on.

2. On the Desktop, right click on "My Computer" and select "Properties."

3. Switch to the "Hardware" tab and click on "Device Manager."

4. The Device Manager should come up. Expand the "Ports (COM & LPT)" box.

5. Right click on the active COM port and select "Properties." Tab to "Port Settings" and click

on "Advanced."

6. Set the COM port using the "COM port number" box. Click OK and exit the device manager.

- 16 -

Page 17

4857 Reactor Controllers

OPERATION OF THE 4857 PROCESS CONTROLLER (CONTINUED)

Changing the Name of a Module

1. Right click on controller image.

2. Select properties and select "Properties >> Module 1", or whichever module you would like

to change.

3. Expand "Module Settings".

4. Change the name from "Module 1" to another name such as "Temperature" and

click OK.

- 17 -

Page 18

4857 Reactor Controllers

OPERATION OF THE 4857 PROCESS CONTROLLER (CONTINUED)

Autotuning

The 4857 Process Controller is equipped with default PID values from the factory designed to

give reasonable temperature control across a wide temperature range. Autotuning is not

recommended unless the system has exhibited poor control using the default PID values.

The 4857 Process Controller may be auto tuned at setpoint. Using the other types of auto tune

(not the tune at setpoint) will likely result in an error.

1. Bring the system to the desired setpoint for the process by adjusting the setpoint of the

controller. Let the system come to equilibrium and hold steady at the setpoint for at least ten

minutes. This step may require that the temperature overshoot or undershoot significantly

with existing PID values.

2. Right click on the main screen, select "Properties >> Module 1", and then change the mode

on "Autotune Setting" to "ATSP".

3. On the main screen, Module 1 should flash “ATSP" at the bottom. This indicates that the

controller is tuning.

4. During the auto tune, the temperature may rise or fall by a few degrees. This is normal.

When the auto tune is complete, the “ATSP" will stop flashing. The temperature should

remain at the setpoint upon completion of the auto tune.

5. Check the PID settings in Module 1 after the autotune. Values which were changed by the

auto tune will have an “A” before the value.

6. If the auto tune selected a value of less than 5 for either the CyC.t or CyC.2, change this

value back to 5. If it selected a value larger than 5, this is OK.

- 18 -

Page 19

4857 Reactor Controllers

MODULE 1: TEMPERATURE CONTROL MODULE

Setpoint Adjustment

Before carrying out an autotune or run with the default settings to ensure the system is safe to

operate at the setpoint value.

1. Right click on controller image.

2. Select properties and select programmer and set-points.

3. Expand (+) setpoints menu.

4. Enter Module 1 - Setpoint 1 value for the required module (click out of value box once

setting entered to ensure value is accepted)

5. Apply setting and click OK

6. New setpoint is now written to the controller and should be visible on controller image.

- 19 -

Page 20

MODULE 1: TEMPERATURE CONTROL MODULE (CONTINUED)

High Temperature Alarm Adjustment

The high temperature alarm on Module 1 may also be adjusted.

1. Right click on controller image.

2. Select properties and select "Properties >> Module 1".

4857 Reactor Controllers

3. Expand "Module 1 - Setpoint 3 control".

4. Enter Module 1 - Setpoint 3 value for the required module (click out of value box once

setting entered to ensure value is accepted)

5. Apply setting and click OK.

6. New setpoint is now written to the controller. The high temperature alarm setpoint will not be

visible on the main controller screen.

- 20 -

Page 21

MODULE 1: TEMPERATURE CONTROL MODULE (CONTINUED)

Changing PID Settings, Changing from PARK to PID Mode

Installation Note:

During initial installation, the mode on Module 1 will need to be changed.

Right click on the controller image and select “Properties >> Module 1.”

Expand (+) Module1 – Setpoint1 Control, and change mode from Park to PID.

1. Right click on controller image.

2. Select properties and select "Properties >> Module 1".

4857 Reactor Controllers

3. Expand "Module 1 - Setpoint1 control".

4. The "Mode" value may be changed to PID. Also, the values for Band, Integral Time, and

Derivative Time may be adjusted here as well to suit the process.

5. Apply setting and click OK.

- 21 -

Page 22

4857 Reactor Controllers

MODULE 1: TEMPERATURE CONTROL MODULE (CONTINUED)

Temperature Programmer

The temperature programmer may be used as an alternative to set point control. This feature is

particularly useful when more complex temperature profiles are required.

Creating a Program:

1. From the main screen, click on the "Edit Programs button."

2. The Program window will appear. Click on "Programmer >> New Program."

3. You may add your first step to the program by right clicking on the Program window and

selecting "Add Segment >> Ramp / Soak / Step."

4. The program will ask the number of segments to add. Add the number of segments

necessary for the process and click OK.

- 22 -

Page 23

4857 Reactor Controllers

MODULE 1: TEMPERATURE CONTROL MODULE (CONTINUED)

Temperature Programmer (continued)

5. You may select the segment type by clicking on the box next to "Segment Type." Most

temperature programs will make use only of the Ramp and the Soak types. A Soak step will

hold the temperature at its programmed level for the specified period of time. A Ramp step

will increase the setpoint from its current value to another value over a specified period of

time.

6. When all the desired steps are entered, write the program to the controller by selecting

"Programmer >> Write Program Data." Then close the program window.

- 23 -

Page 24

4857 Reactor Controllers

MODULE 1: TEMPERATURE CONTROL MODULE (CONTINUED)

Temperature Programmer (continued)

Running a Program:

1. From the main instrument screen, right click and select "Properties >> Module 1."

2. Then double click on "Module 1 - Programmer" and select your desired program number.

Click Apply, and then change the value of "run mode" to "on." Hit OK. If you need to

interrupt the program, returning to this screen and changing the value of "run mode" to "off"

will halt the program.

- 24 -

Page 25

4857 Reactor Controllers

MODULE 2: PRESSURE DISPLAY AND HIGH PRESSURE ALARM

Alarm Adjustment

The high pressure alarm will trip the High Limit Alarm if the pressure exceeds the setpoint

specified on Module 2. If the High Limit Alarm is tripped, the power to the heater will be

interrupted, and the operator will need to manually reset the switch. The pressure will be shown

in the upper display, with the high pressure alarm underneath.

1. Right click on controller image.

2. Select properties and select programmer and set-points.

3. Expand (+) setpoints menu.

4. Enter Module 2 -Setpoint 1 value for the required module (click out of value box once

setting entered to ensure value is accepted)

5. Apply setting and click OK

6. New setpoint is now written to the controller and should be visible on controller image.

- 25 -

Page 26

4857 Reactor Controllers

MODULE 3: TACHOMETER

Stirring Speed Adjustment

When the local/remote switch on the front panel of the 4875 Power Controller is set to remote,

the desired stirring speed will be set by Setpoint 1 on Module 3. The stirring speed should be

shown in the upper display, with the setpoint just underneath. The stirring speed may be

adjusted manually when the switch is in the "local" position.

Installation Note:

During initial installation, the mode on Module 3 will need to be changed.

Right click on the controller image and select “Properties >> Module 3.”

Expand (+) Module3 – Setpoint1 Control, and change mode from Park to PI.

1. Right click on controller image.

2. Select properties and select programmer and set-points.

3. Expand (+) setpoints menu.

4. Enter Module 3 - Setpoint 1 value for the required module (click out of value box once

setting entered to ensure value is accepted)

5. Apply setting and click OK

6. New setpoint is now written to the controller and should be visible on controller image.

- 26 -

Page 27

4857 Reactor Controllers

MODULE 4: OPTIONAL MODULE

Optional Module

Module 4 may be specified as a temperature, pressure, control logic module, or not present at

all. Control will be similar to modules 1 and 2.

- 27 -

Page 28

4857 Reactor Controllers

DATA LOGGING

Creating a Chart

Data logging is most easily accomplished by creating a chart to plot the values you wish to log,

and then exporting the chart data as a .CSV file. CSV files can be opened directly by most data

analysis type programs, including Microsoft Excel.

1. Select the <new> option from the File menu, and then click the “New Chart” button and click

OK. Alternatively, you may press the [New Chart] button on the toolbar.

2. This opens the Chart Properties dialog. First, enter the required title for the new chart. Then

select any changed chart options and press Next.

3. This opens the Chart Trace Selection dialog. Press the Add button to add a new trace to the

chart.

- 28 -

Page 29

4857 Reactor Controllers

DATA LOGGING (CONTINUED)

Creating a Chart (continued)

4. This opens the Select Data Source dialog. First select “CalControls.CALogixServer” from

the Server pull down list. Then select a data source tag from the tree in the instrument list to

add to the chart. The default name for the temperature read from the control thermocouple

is:

“Module 1 >> tag-Input1FormattedProcessValue”

The pressure tag would be located under

"Module 2 >> tag-Input1FormattedProcessValue"

and the RPM tag would be

"Module 3 >> tag-Input1FormattedProcessValue."

5. This should bring you to the Trace Properties dialog. Enter the required name and scales for

this trace (or use default values) and press Finish.

- 29 -

Page 30

4857 Reactor Controllers

DATA LOGGING (CONTINUED)

Creating a Chart (continued)

6. Repeat to add more traces as required and then press Next. This brings you back to the

Chart properties dialog. Change chart properties as required, and press Finish.

7. A new chart window will now appear in the application. This chart automatically scrolls to the

end of the selected timescale. Hit Next to format properties, then hit Finish.

Exporting Data from a Chart

Select the File, Export => Chart menu option. This exports the chart data into the specified

Comma Separated Value (CSV) file. CSV files can be opened directly by most data analysis

type programs, including Microsoft Excel.

SOLENOID VALVE MODULE

The Solenoid Valve Module provides a solenoid valve, a metering valve and all parts needed to

assemble an automatic cooling system for any reactor fitted with a cooling coil. It usually is

installed in a cold water line with a flow connection through the solenoid valve, to the cooling

coil, and to the drain. The solenoid valve has an electrical connection to the cooling socket on

the back of the 4875 Power Controller. Coolant will then be admitted to the coil whenever

cooling is called for by the controller, thereby minimizing any temperature overshoot. This

system is particularly advantageous when holding fixed temperatures below 150°C or for

controlling exothermic reactions. Compressed air can be used as a coolant if the amount of

heat to be removed is not large.

- 30 -

Page 31

4857 Reactor Controllers

CLEANING AND MAINTENANCE

Periodic cleaning may be performed on the exterior surfaces of the controller with a lightly dampened

cloth containing mild soap solution. All power should be disconnected and the power cord should be

unplugged when cleaning the controller.

There are no user serviceable parts inside the product other than what is specifically called out in this

manual. Advanced troubleshooting instructions beyond the scope of this manual can be obtained by

calling Parr Instrument Company in order to determine which part(s) may be replaced or serviced.

Fuses

Description Parr No. Type Ratings

For 4857

Instruments fuse 139E24 Fast-Acting 3 Amp, 250VAC

For 4875

Heater fuse 139E23 Fast-Acting 15 Amp, 250 VAC

Cooling fuse 139E10 Fast-Acting .25 Amp, 250 VAC

For 230 VAC model:

Fuse (A+) on motor control circuit board 959E5 Very Fast-Acting 8 Amp, 250VAC

Fuse (L) on motor control circuit board 185E2 Fast-Acting 10 Amp, 250VAC

Access to the Controller Cabinet

To open the controller cabinet, turn off the power switch, unplug the power cord and locate the four

screws on the upper half of the chassis, and the eight screws on the lower half of the chassis. The

four screws on the upper half should be removed first, and then the four screws o n the up per row on

the lower half of the chassis should be removed. Then lift the top panel away.

WARNING:

The inside of the controller cabinet should be accessed by qualified personnel only

.

Remove these screws

(total of 8)

Diagram 3: 4857 Process Controller

Side View showing screws

- 31 -

Page 32

CONTROLLER AND CIRCUIT DIAGRAMS

Diagram 4: Schematic of 4857 top plate components

Diagram 5: Schematic of 4857 back panel

Diagram 6: Schematic of 4875 components

4857 Reactor Controllers

Diagram 4: Schematic of top plate of 4857

- 32 -

Page 33

CONTROLLER AND CIRCUIT DIAGRAMS (CONTINUED)

4857 Reactor Controllers

Diagram 5: Schematic of back plate of 4857 Process Controller

- 33 -

Page 34

CONTROLLER AND CIRCUIT DIAGRAMS (CONTINUED)

4857 Reactor Controllers

Diagram 6: Schematic of 4875 Power Controller

- 34 -

Page 35

PARTS FOR THE 4857 PROCESS CONTROLLER

Part #: Description:

Controller Electrical part

139E23 Heater fuse, fast-act, 15A, 250V

139E24 Main instrument fuse for 4857, fast-act 3A, 250V

139E10 Cooling fuse, fast-act, 0.25A, 250V

328E5 Hole plug for secondary tachometer port

416E Hole plug for Auxilary ports

494E Connector, motor, back panel of 4875

542E High limit reset breaker

585E2EE Motor switch

828EEE Light, red, 250 V, high limit indicator

828E2EE Light, green, 250 V, heating/cooling indicator

831DD Connector, Power Control

909E Power, 16 amp, main power switch

911E Filter

1111E Solid State Relay, cooling

1119E Solid State Relay, heating, 25 A, 3-32 VDC input

1259E Fuse holder, lighted

1375E Terminal Block in 4857

1451HC Solid State Relay pad

1466E Receptacle, main power cord

1468E Receptacle, Heating/cooling output

1470E Fuse holder

1471E Carrier

1484E Main power switch on front panel

1531E RFI Power Line Filter 3A/2A

1532E RFI Power Line Filter 6A/5A

1587E Local / Remote Switch

1588E Signal Isolator

1879E Power Supply, 24 VDC, converts 115 V to 24 VDC

1901E Calogix module, base unit

1902E PID Module, pressure, rpm

1903E PID Module, thermocouple

1973E Hole plug for secondary Power Harness port

3109HC DIN Rail for Control Base and Modules

A1695E 2 Tachometer / 8 Pressure Excitation Board

A1710E Trip relay for 1119E Solid State Relay

A1929E RS-485 harness receptacle

A1966E Power Supply Filter

A1967E Internal Power Harness

A1969E Internal Pressure Harness

A1970E Internal Tachometer Harness

WARNING: For continued protection against possible

hazard, replace fuses with same type and rating of fuse.

4857 Reactor Controllers

- 35 -

Page 36

PARTS FOR THE 4857 PROCESS CONTROLLER (CONTINUED)

Part #: Description:

Communication cables:

A1725E Communication cordset, RS-485 to Serial

A1925E Communication cordset, RS-485 to USB

Cordsets:

A1478EEB 115 V N.A. Plug to IEC

A1478E 230 V N.A. Plug to IEC

A1477E European Plug to IEC

A1482E British 13 A Plug to IEC

1859EEE 16 A / 220 V China Plug to IEC

Motor parts:

139E8 Fuse for 1/2 hp motor, 180 VDC. 2.5A, 3AG, slo-blo

139E19 Fuse for 1/4 hp motor, 180 VDC. 1.5A, 3AG, slo-blo

139E20 Fuse for 3/4 hp motor, 180 VDC, 4.0A, 3AG, slo-blo

185E2 Speed control fuse, 250V, 10A

428E2 Speed control knob, with screw

801E2 Breaker for 1/4 hp motor, 90 VDC. 2.5 amp.

801E3 Breaker for 1/8 hp motor, 130 VDC. 1.5 amp.

801E4 Breaker for 1/2 hp motor, 90 VDC. 5 amp.

876E Resistor for 1/4 hp motor, 90 VDC. .05 ohm.

Also for 1/2 hp motor, 180 VDC.

876E2 Resistor for 1/2 hp motor, 90 VDC. .025 ohm.

876E3 Resistor for 1/8 hp motor, 130 VDC. .10 ohm.

876E5 Resistor for 3/4 hp motor, 180 VDC. .035 ohm.

Also for 1/4 hp motor, 180 VDC.

959E5 Speed control fuse, 8A, fast-acting

A410E8EB Speed control board, 1/4 hp, 90 VDC, 115 V

A410E8EE Speed control board, 1/4 hp, 90 VDC, 230 V

A410E9EB Speed control board, 1/2 hp, 90 VDC, 115 V

A410E9EE Speed control board, 1/2 hp, 90 VDC, 230 V

A410E10EB Speed control board, 1/8 hp, 130 VDC, 115 V

A410E10EE Speed control board, 1/8 hp, 130 VDC, 230 V

A1250EEE Speed control, 240VAC/180VDC

A1252EEE Speed control board, 1/2 hp, 180 VDC, 230 V

A1252E2EE Speed control board, 1/4 hp, 180 VDC, 230 V

A1252E3EE Speed control board, 3/4 hp, 180 VDC, 230 V

WARNING: For continued protection against possible

hazard, replace fuses with same type and rating of fuse.

- 36 -

Page 37

PARTS FOR THE 4857 PROCESS CONTROLLER (CONTINUED)

Part #:

Pressure module parts:

A1906EP02 Pressure transducer, 0-200 psi

A1906EP05 Pressure transducer, 0-500 psi

A1906EP10 Pressure transducer, 0-1000 psi

A1906EP20 Pressure transducer, 0-2000 psi

A1906EP30 Pressure transducer, 0-3000 psi

A1906EP50 Pressure transducer, 0-5000 psi

A2599HC2 Transducer mounting body with cooling sleeve, 1/8”NPTF

A1905E Harness, pressure tranducer, 10-ft

A1905E3 Harness, pressure tranducer, 20-ft

A1905E5 Harness, pressure tranducer, 5-ft

Temperature module parts:

A472E Thermocouple, type-J, 7-½“, grounded

A472E2 Thermocouple, type-J, 9-½“, grounded

A472E3 Thermocouple, type-J, 11-½“, grounded

A472E4 Thermocouple, type-J, 5-½“, grounded

A472E5 Thermocouple, type-J, 21-½“, grounded

A472E6 Thermocouple, type-J, 15-½“, grounded

1129E Thermocouple socket, snap-in type-J panel

A470E2 Thermocouple extension wire, type-J, 5-ft

A470E4 Thermocouple extension wire, type-J , 10-ft

A470E5 Thermocouple extension wire, type-J , 20-ft

Tachometer module parts:

A1001E Tachometer sensor for benchtop reactor

A1001E2 Tachometer sensor for floor stand reactor

A1177E Tachometer harness, 10-ft

Cooling module parts:

A160HW3EB Solenoid valve package, 115 V

A160HW3EE Solenoid valve package, 230 V

Description:

WARNING: For continued protection against possible

hazard, replace fuses with same type and rating of fuse.

- 37 -

Page 38

Revision 02/15/11

PARR INSTRUMENT COMPANY

211 Fifty -Third Street

Moline, Illinois 61265 USA

309/762-7716 800/872-7720

Fax 309/762-9453

http://www.parrinst.com • E-Mail: parr@parrinst.com

Loading...

Loading...