Page 1

4848

Reactor Controller

Operating Instruction Manual

548M

Page 2

Table of Contents

Preface

Related Instructions — 2

Scope — 2

Applications — 2

Explanation of Symbols — 3

Safety Information — 3

Intended Usage — 3

Cleaning & Maintenance — 3

Provisions for Lifting and Carrying — 3

General Specifications — 4

Environmental Conditions — 4

4848 Reactor Controller Specifications — 4

User’s Responsibility — 5

Unpack Carefully — 5

Installation

General Instructions — 6

Connections — 6

Component Summary

Switches and Indicators — 7

Protective Fuses and Relays — 8

High Limit Reset— 9

Access to the Controller Cabinet— 9

Fuses— 9

4848 Factory Defaults

Navigating the Menu System/Factory Default Settings

— 20

Primary Temperature Module — 20

TDM / MCM Module — 21

Pressure Module — 21

HTM/ETLM Module — 22

MTM Module — 23

Appendix A: Controller Parameters

Initial Setting Mode — 24

Operation Mode — 25

Regulation Mode — 26

Parts List

Fuses — 27

Communication — 27

Cooling Solenoids — 27

Primary Temperature Module — 28

Pressure Display Module (PDM) — 28

Tachometer Module (TDM) — 29

or Motor Control Module (MCM) — 29

Hi-Temp Cut-Off Module (HTM) — 29

or External Temperature Limit Module (ETLM) — 29

Instructions for the 4848 Reactor

Controller

Temperature Control Module — 10

Temperature Control— 10

High Temperature Alarm Setpoint— 10

PID groups— 10

Autotuning— 11

Temperature Profiles - Ramp and Soak— 11

Engaging a Program— 12

Adjustments To Speed Control Board— 17

Solenoid Valve Module — 17

Communication with PC — 18

Quick Start Instructions for Connecting with PC— 18

Datalogging and Charting— 19

Converting a Chart File to TXT— 19

Visit our website to find our Controller FAQ

http://www.parrinst.com/support/48484838-controller-support/controller-faq/

2

Parr Instrument Company

Page 3

4848 Reactor Controller

Preface

Related Instructions

The following Parr publications are also included to

further your understanding of this instrument and

its component parts:

No. Description

201M Limited Warranty

576M 4848 Controller CD

Scope

These instructions cover the installation, operation and maintenance of Parr Model 4848 Reactor

Controller as used with Parr laboratory reactors and

pressure vessels. They cover the basic functions

provided in each of these controllers and describe

the several optional control modules which can be

added to these expandable units. The users should

study the instructions carefully before using any of

these controllers so that they will fully understand

the capabilities and limitations of this equipment

and the safety precautions to be observed in its

operation.

Applications

Each 4848 Reactor Controller consists of a packaged

temperature control unit completely wired and assembled with appropriate power and safety relays,

switches and pilot lights.

These units are designed specifically for use with

Parr reactors and pressure vessels and are to be

used only with Parr equipment.

Controllers furnished with Parr reactors equipped

with variable speed, DC motors have a motor switch

and a speed control knob on the front panel. Controllers to be used with AC equipment or an air motor do not have a speed control knob.

Customer Service

Questions concerning the installation or operation of this instrument

can be answered by the Parr Customer Service Department:

1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail: parr@parrinst.com • http://www.parrinst.com

www.parrinst.com

3

Page 4

4848 Reactor Controller

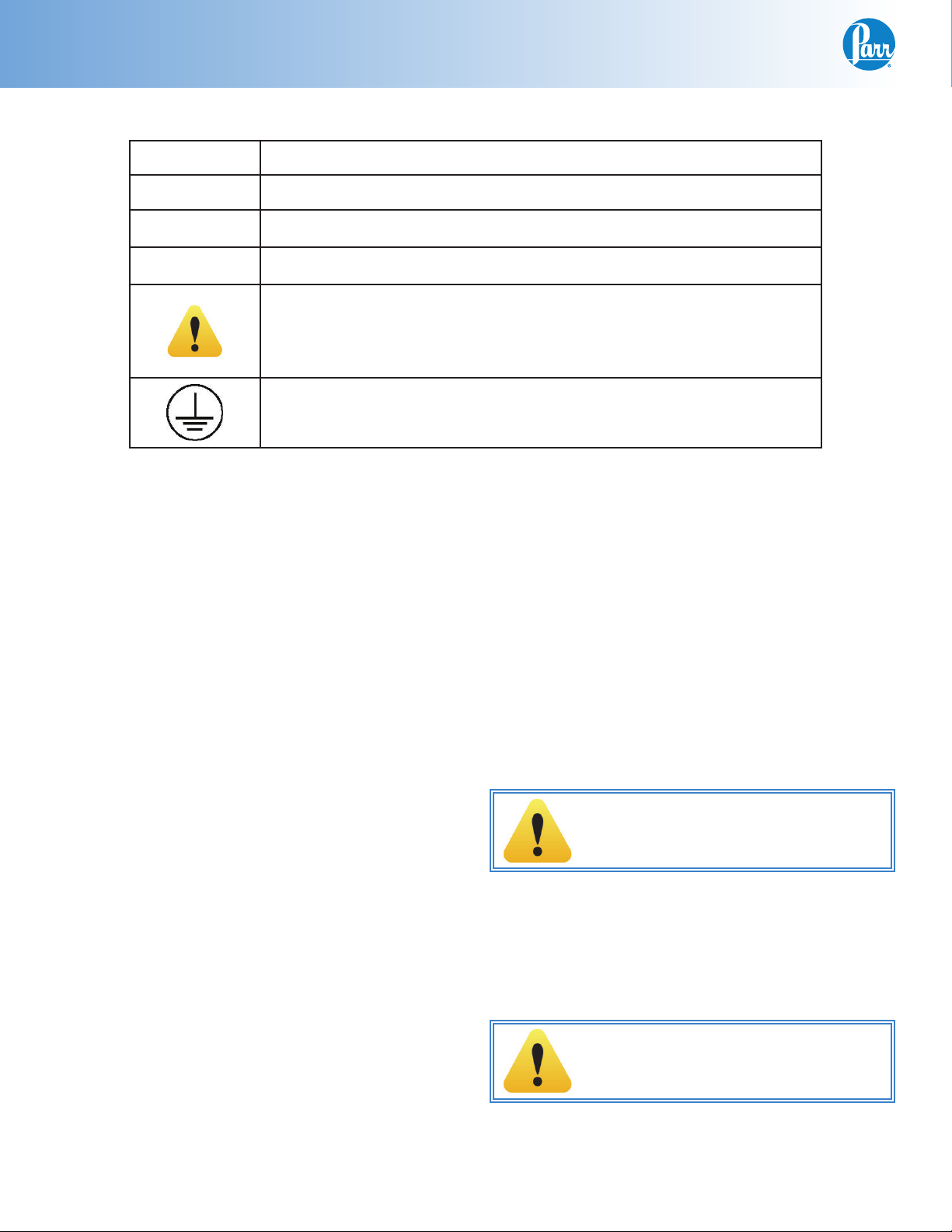

Explanation of Symbols

II On position, full power heater switch

I On position, half power heater switch

O Off Position

~ Alternating Current (AC)

This CAUTION symbol may be present on the Product Instrumentation

and literature. If present on the product, the user must consult the appropriate part of the accompanying product literature for more information.

Protective Earth (PE) terminal. Provided for connection of the protective earth (green or green/yellow) supply system conductor.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current handling capability.

2. Ensure that the equipment is connected to electrical service according to local national electrical codes. Failure to properly connect may create

a fire or shock hazard.

3. For continued protection against possible hazard, replace fuses with same type and rating of

fuse.

4. Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

5. Do not use in the presence of flammable or combustible materials; fire or explosion may result.

This device contains components which may

ignite such material.

6. Refer servicing to qualified personnel.

Intended Usage

This controller has been designed for use with Parr

pressure vessels and reactors. It has been designed, built, and tested to strict physical and electrical standards. However, it is the user’s responsibility to install and operate it in conformance with local

pressure and electrical codes.

Cleaning & Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the controller with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected and the power cord should

be unplugged when cleaning the 4848 Controller.

There are no user serviceable parts inside the product other than what is specifically called out and

discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can

be obtained by calling Parr Instrument Company in

order to determine which part(s) may be replaced or

serviced.

Ensure that any hot surfaces have had adequate time to cool before cleaning or maintaining the reactor and/or its components.

Provisions for Lifting and Carrying

Before moving the instrument, disconnect all connections from the rear of the apparatus. Lift the

instrument by grabbing underneath each corner.

Caution!

Do not use in hazardous atmospheres.

If the instrument is used in a manner not specified

by Parr Instrument Company, the protection provided by the equipment may be impaired.

4

Parr Instrument Company

Page 5

4848 Reactor Controller

General Specifications

Electrical Ratings

115VAC, 15.0 Amps, 50/60 Hz

230VAC, 15.0 Amps, 50/60 Hz

Before connecting a controller to an electrical outlet,

the user must be certain that the electrical outlet has

an earth ground connection and that the line, load

and other characteristics of the installation do not

exceed the following limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: Controllers can be operated from either

a 50 or 60 Hertz power supply without affecting their

operation or calibration.

Current: The total current drawn should not exceed

the rating shown on the data plate on the controller

by more than 10 percent.

Thermocouple: Unless otherwise specified, all 4848

Controllers operate with a Type-J (Iron-Constantan)

thermocouple. The total resistance of the thermocouple and the lead wires should not exceed 100

ohms. If the resistance of the thermocouple circuit

is higher, it will not function properly.

Environmental Conditions

This instrument is intended to be used indoors.

Operating: 15 ºC to 35 ºC; maximum relative humidity of 80% non-condensing. Installation Category II

(over voltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 ºC and 65 ºC; 10% to 85% relative hu-

midity.

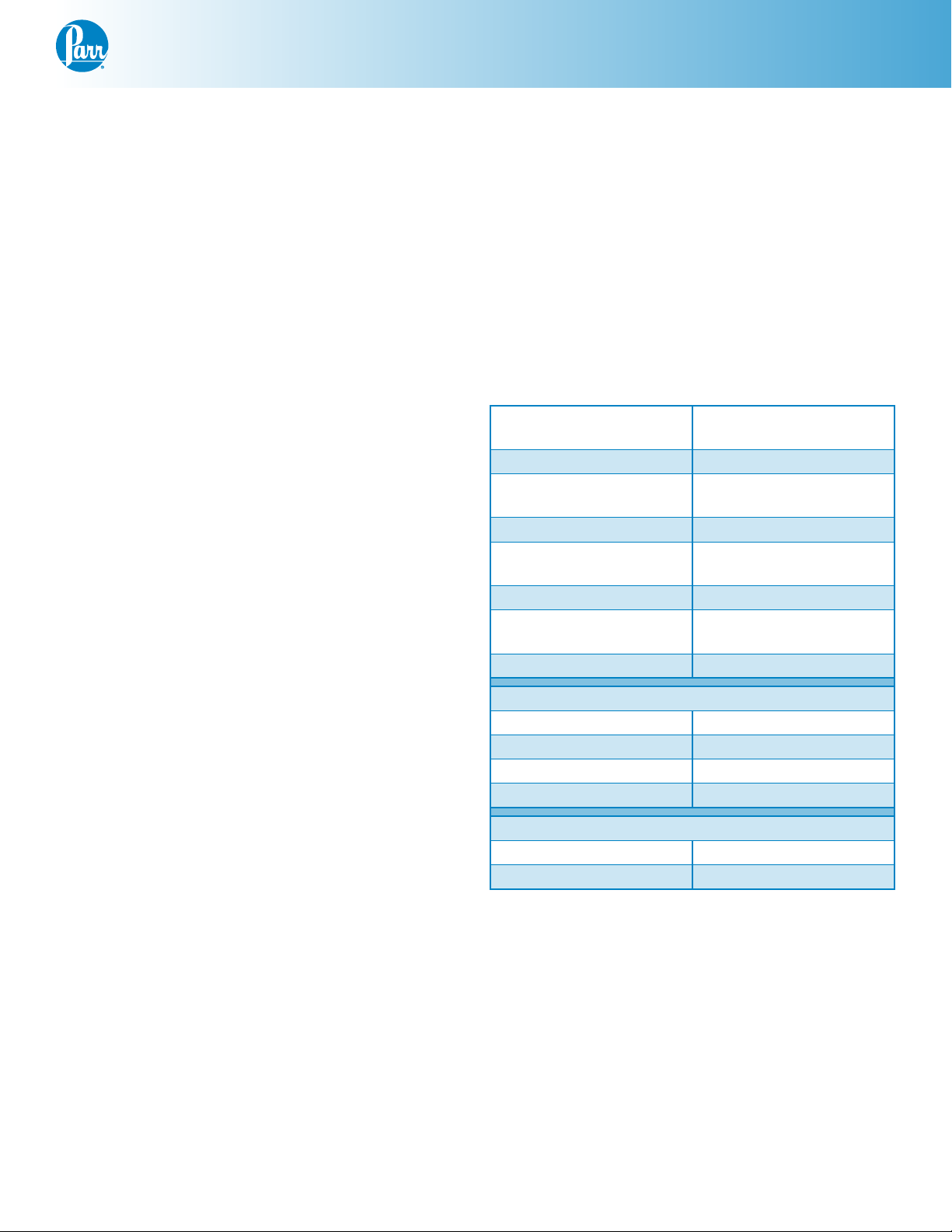

4848 Reactor Controller Specifications

Input Thermocouple

type

Operating Range 0-800 °C

Readout and Setpoint

Resolution

System Accuracy +/-2 °C

Control action three-term PID plus limit

Control output 1 115VAC or 230VAC

Control output 2 .2 amp max

Operating voltages 115VAC or 230 VAC

Heater Loop

Proportional Band: 12 C

Integral time: 375 sec

Derivative: 93 C/sec

Cycle time: 20 sec

Type-J

1 °C

control

115VAC or 230VAC

Cooling Loop

Proportional Band: 5 C

Cycle time: 5 sec

www.parrinst.com

5

Page 6

4848 Reactor Controller

User’s Responsibility

All Parr Reactors and Pressure Vessels are designed

and manufactured with great care to assure safe

operation when used within their prescribed temperature and pressure limits.

But… the basic responsibility for safety when using this equipment rests entirely with the user; who

must:

1. Select a reactor or pressure vessel that has the

capability, pressure rating, corrosion resistance,

and design features that are suitable for its

intended use. Parr engineers will be glad to discuss available equipment and material options

with prospective users, but the final responsibility for selecting a reactor or pressure vessel

that will perform to the user’s satisfaction in any

particular reaction or test must rest with the user

- not with Parr.

In exercising the responsibility for the selection

of pressure equipment, the prospective user

is often faced with the choice between over or

under-designed equipment. The hazards introduced by under-designed pressure vessels are

readily apparent, but the penalties that must be

paid for over-designed apparatus are often overlooked. Recognizing these criteria, Parr reactors and pressure vessels are offered in several

different styles, each designed for convenient

use in daily operation within certain temperature

and pressure limits, using gaskets, closures, and

other elements carefully selected for safe operation within the limits specified for that design.

But in order to preserve the validity of these designs, all temperature and pressure limits must

be observed, and no attempt should be made to

increase these limits by making alterations or by

substituting components which are not recommended by Parr Instrument Company.

2. Install and operate the equipment within a

suitable barricade, if required, with appropriate

safety accessories and in full compliance with

local safety codes and rules.

All standard Parr pressure vessels are provided

with either suitable relief device or a means to

attach one (typically in the form of a plugged

opening). When a pressure vessel is delivered

without a pressure venting device, it is the customer’s responsibility to provide pressure relief

in order to protect the operator and the equipment from destructive high pressures. If you

need more information or need help in selecting

a proper relief device, please contact Parr Instrument Company.

3. Establish training procedures to ensure that any

person handling the equipment knows how to

use it properly.

4. Maintain the equipment in good condition and

establish procedures for periodic testing to be

sure the vessel remains structurally sound.

Unpack Carefully

Unpack the equipment carefully and check all the

parts against the packing list. If shipping damage

is discovered, report it immediately to the delivering carriers. Examine the components closely for

any loose parts or shipping damage and be sure to

check all layers of packing materials thoroughly so

as not to overlook any parts which might otherwise

be discarded.

6

Parr Instrument Company

Page 7

4848 Reactor Controller

Installation

General Instructions

Set the controller on a sturdy bench or table where

there is convenient access to an electrical outlet

with the appropriate supply voltage and current ratings in accordance with national and local electrical

code requirements. Leave a space of at least twelve

inches between the controller and the heater of the

reactor so that the controller will not be affected by

radiant heat.

Connections

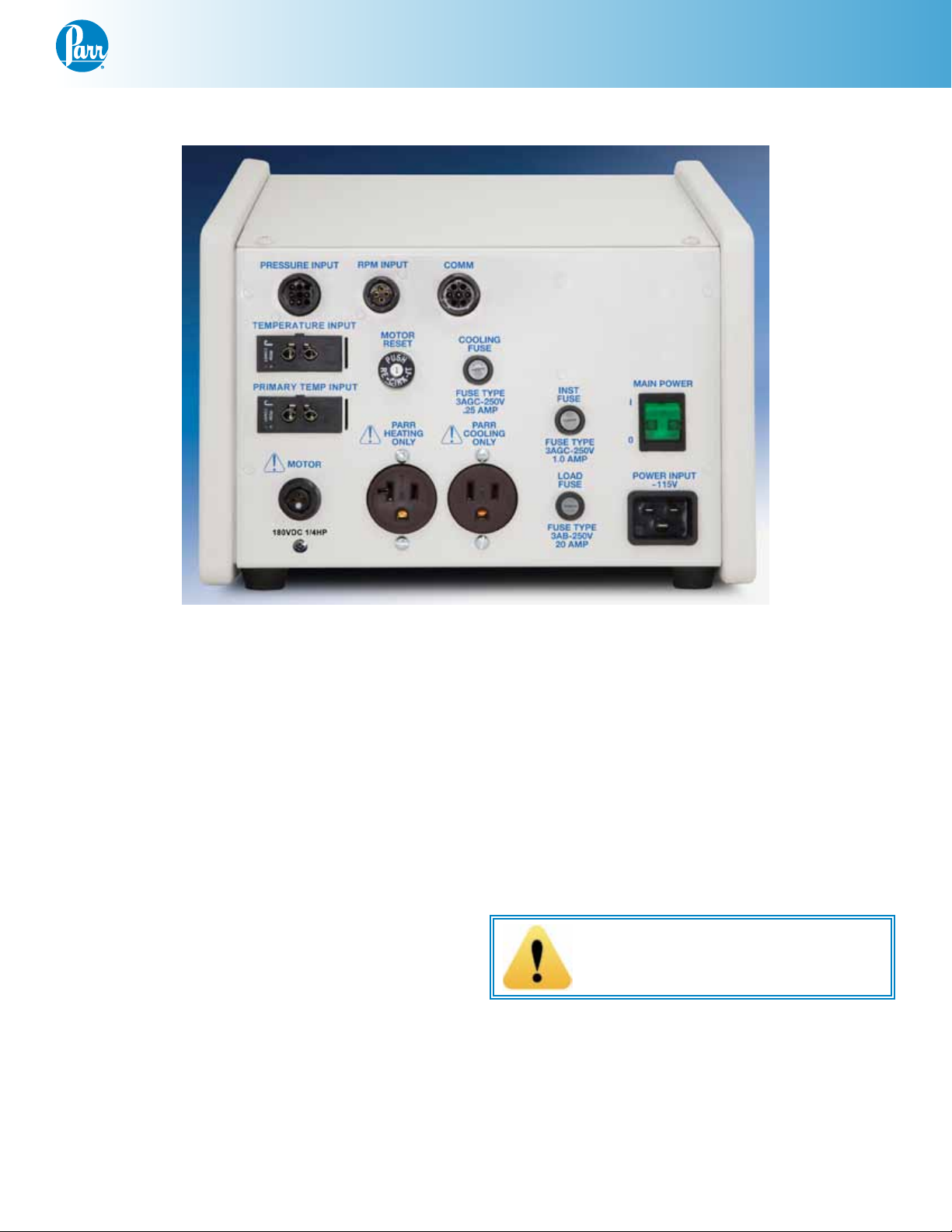

Labeled connections are provided on the rear panel

of the controller.

Parr Cooling Only:

The Temperature Input connection is for the Tem-

perature Module or ETLM sensor input.

The Pressure Input connection is for the Pressure

Module sensor input.

The RPM Input connection is for the RPM Module

sensor input.

The Comm connector is for Communication output.

The Auxiliary 1 and Auxiliary 2 input connections

are for additional connections and may be used on a

number of devices. The 4848 Reactor Controller can

be purchased with Auxiliary 1 and/or 2 configured as

a Temperature Module Input or a Pressure Module

Input.

The cooling output connector is to be used only

with Parr Instrument Company cooling solenoid

valve assemblies supplied with the appropriate

cooling power cord.

Parr Heating Only:

The heating output connector is to be used only

with Parr Instrument Company heater assemblies

supplied with the appropriate heater power cord.

Motor:

Secure the clamp on motor cord to the controller with the provided screw next to the

motor socket for safety purposes.

The motor output connector is to be used only with

Parr Instrument Company motor assemblies supplied with the appropriate motor power cord.

Other appropriate connectors are provided on the

rear panel of the controller.

4848 Rear Panel 115V

The Primary Temp Input connection is for the Pri-

mary Temperature Module sensor input.

4848 Rear Panel 230V

www.parrinst.com

7

Page 8

4848 Reactor Controller

Component Summary

Switches and Indicators

Front Side

4848 Reactor Controller

The Heater Switch is a manual, three-position, illu-

minated switch which controls the amount of power

sent to the heater. In the HIGH (II) position, full

power is developed by the heater. In the middle (0)

position the heater is off. In the LOW (I) position, a

diode is switched into the system to allow only onehalf of the rated voltage to be supplied to the heater.

This low setting will be most useful when operating

the reactor at temperatures below 175 °C. Power

for the heater is supplied through a solid state relay

controlled by the temperature control module. The

light in the heater switch will glow only when current is flowing to the heater.

The high limit indicator light will glow if the controller receives an indication from any of its sensors

that a high temperature or high pressure limit has

been reached and the High Limit Reset has opened.

When the light comes on, the user must find the

source of the problem, correct it, and then manually

reset the system using the high limit reset button on

the front of the controller.

The Motor Controls consist of an on-off switch

and a speed control knob. The speed control knob

should be turned down to a minimum setting before

turning on the motor switch to minimize electrical surges within the speed control unit. A speed

control know is not included when the reactor is

equipped with an air motor for stirring or when the

controller is created for use with a non-stirred vessel.

If equipped with a motor control module, there will

also be a remote/local switch. When the remote/

local switch is in local mode, the speed control

knob will adjust the motor stirring speed. When the

remote/local switch is in remote mode, the RPM

module will adjust the motor stirring speed. If there

is no motor control module installed, the remote/local port will be plugged and the speed control knob

is the sole control for the stirring speed.

The Main Power Switch will cut off power to the

controller. Take care to position the controller such

that the main power switch may be accessed easily

when the controller needs to be disconnected.

8

Parr Instrument Company

Page 9

Back Side

4848 Reactor Controller

4848 Reactor Controller

Protective Fuses and Relays

An instrument fuse is mounted on the back panel.

This is a Fast-acting, 250VAC, 1.0 amp fuse, intended

to protect the temperature control module and any

installed display modules.

The motor reset/motor fuse provides overload

protection for 0-90VDC motors. This is a re-settable

breaker designed to protect the motor if it becomes

overloaded. The breaker will have a rating selected

to match the motor on the apparatus.

A lighted fuse holder provides protection for 0-180

VDC motors. A light will come on if the motor becomes overloaded and the fuse burns out. The fuse

rating will be selected to match the motor on the

apparatus.

A load fuse is mounted on the back panel on 115V

systems. This fast-acting, 250VAC, 20 amp fuse is intended to protect the controller and prevent electric

shock hazard from fault from occurring.

Two load fuses are mounted on the back panel

on 230V systems. These are fast-acting, 20 Amps,

250VAC and are intended to protect the controller

and to prevent electric shock hazard from fault from

occurring.

Caution!

Unplug unit before servicing. For continued

protection against possible hazard, replace

fuses with same type and rating of fuse.

www.parrinst.com

9

Page 10

4848 Reactor Controller

Thermocouple burnout protection is included in

each of these controllers. If the thermocouple

should burn out, or if there is a break in the thermocouple circuit, power to the heater will be shut off.

In most cases this will cause the controller to show

a “NO CONT” reading. A similar high reading will

be displayed if the controller is turned on without an

attached thermocouple. In either of these situations,

the high limit reset will activate. The thermocouple

break must then be corrected and the High Limit Reset must be reset in order to activate the system.

High Limit Reset

Each Series 4848 Controller has a high temperature

limit control which will trip the High Limit Relay

and shut off the heater if the temperature reaches

a preset level. If tripped, the lockout relay will pop

out, thereby preventing the system from heating

the reaction when the temperature falls back below

the limit setting. This must be manually reset before

heating can occur again.

On Model 4848 Controllers the high temperature

limit is preset at the factory to 375 °C for most

systems. On these controllers an alarm condition

is indicated by an illuminated red indicator labeled

as "ALM". If the temperature exceeds the limit, the

controller alarm condition will appear, the High

Limit Reset will be tripped, and power to the heater

will be shut off.

Access to the Controller Cabinet

To open the controller cabinet, unplug the power

cord and remove the two screws in the upper

corners of the back panel. Then lift the top plate

upwards, allowing the hinged top and front panel to

swing forward, providing full access to all internal

components.

Caution!

Inside of controller cabinet should be accessed by qualified personnel only.

Fuses

The 4848 Controller has a number of fuses which

are intended to be field serviceable.

Fuse Rating Part No.

Instrument

Fuse

Cooling Fuse Fast acting, .25 Amp,

Line Fuse(s) Fast acting, 20 Amp,

Motor Board

Fuse (A+)

Motor Board

Fuse (L)

Motor fuse/

reset

Fast acting, 1 Amp,

250VAC

250VAC

250VAC

Very Fast acting, 8

Amp, 250VAC

Fast acting, 10 Amp,

250VAC

Check back panel for

specifications

139E6

139E10

2074E

959E5

185E2

Check part

list

10

Caution!

Unplug unit before servicing. For continued

protection against possible hazard, replace

fuses with same type and rating of fuse.

Parr Instrument Company

Page 11

4848 Reactor Controller

Instructions for the 4848 Reactor

Controller

Caution!

Check that controller settings are set to

factory defaults before operating for the first

time. The default settings are listed at the

back of this manual.

Note: Controller parameters can be found in

Appendix A on page 24 of this manual.

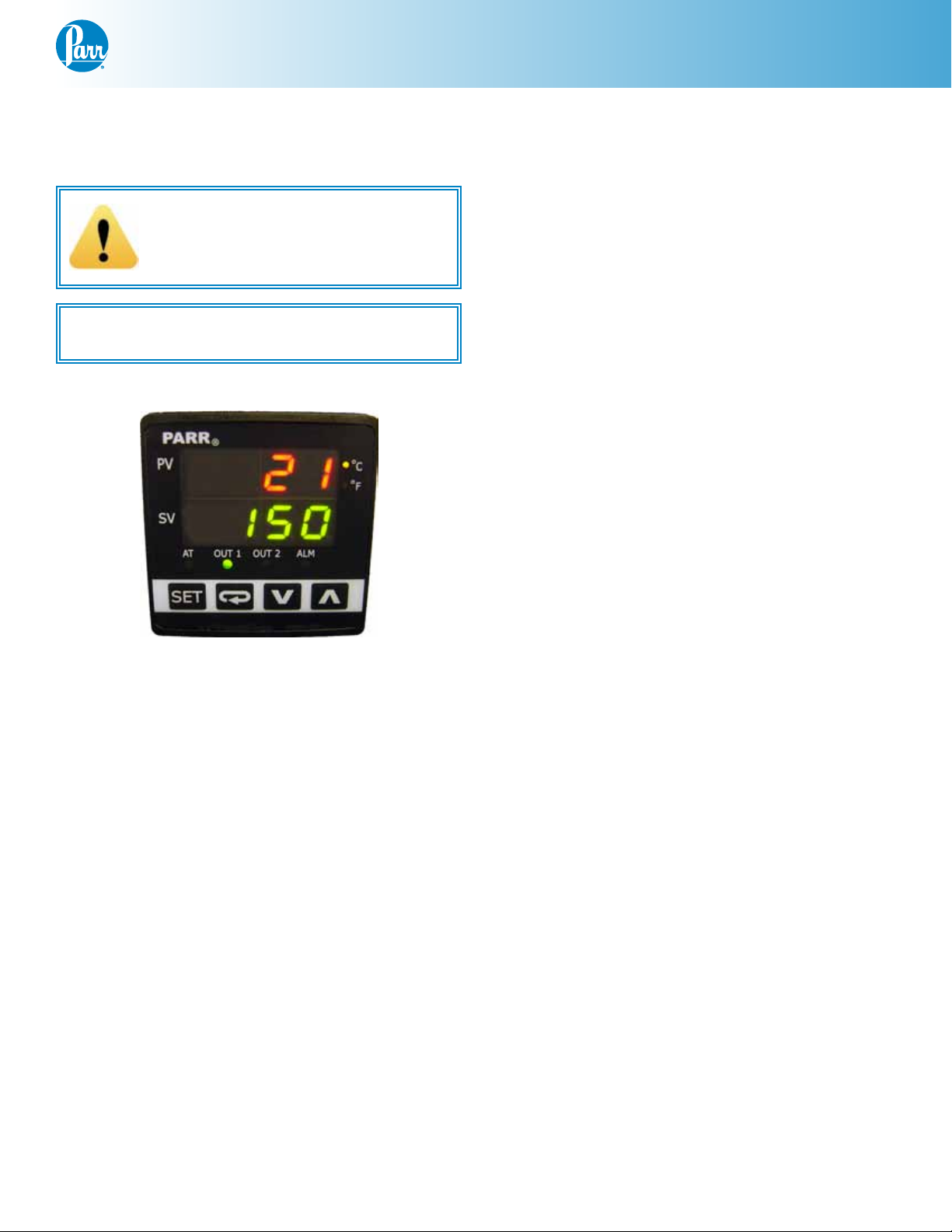

Temperature Control Module

power to the heater, and the ALM light will illuminate indicating a High Limit was activated.

Temperature Control

The easiest way to control temperature with the

4848 Controller is to use setpoint control. With setpoint control, the controller will attempt to bring the

temperature to the value of the setpoint by adjusting the heater output.

The setpoint may be adjusted by doing the following:

1. Press the up or down arrow until the lower

display shows the desired setpoint. The lower

display will blink, showing the value has not

been set yet.

2. Press the set button. The lower display will stop

blinking, showing the new value has been set.

High Temperature Alarm Setpoint

The 4848 Reactor Controller also has a High Temperature Alarm built into it. When the temperature

exceeds this limit, it will pop the High Limit Reset,

preventing power from going to the heater. The

High Temperature Alarm setpoint may be adjusted

by doing the following:

PRIMARY

TEMPERATURE

The 4848 Reactor Controllers are available with a

microprocessor based control module that provides

full three-term PID control with adjustable tuning

parameters. The temperature control interface is

labeled as Primary Temperature on front panel.

To facilitate start up with reasonably good PID control, parameters for both heating and cooling are

pre programmed at the factory.

Output 1 on these controllers drives the heater.

Output 2 can be used to activate a cooling system.

The control parameters can be set independently for

each of these outputs.

Two lines of information, labeled PV and SV, are

shown on the display during normal operations.

The upper line (PV) shows the actual temperature

as read by the control thermocouple. The lower

line (SV) shows the set point. When the controller

is heating, the Out1 light will illuminate or blink.

When the controller is cooling, the Out2 light will

illuminate or blink. When an alarm condition has

been reached, the High Limit Reset will trip, cutting

1. Press the circular arrow key three times. The upper display will read AL1H and the lower display

will read the High Temperature Alarm setpoint

(usually 375C).

2. Use the up or down arrow to adjust this to the

desired setpoint.

3. Press the up or down arrow until the lower

display shows the desired setpoint. The lower

display will blink, showing the value has not

been set yet.

4. Press the set button. The lower display will stop

blinking, showing the new value has been set.

5. Pressing the set button again will return the display to the main screen.

PID groups

a. The primary temperature controller contains

4 groups of PID parameters (PID0, PID1, PID2

and PID3), which can be used to store up to four

different sets of PID parameters. Each group is

identified by the SV used during the autotuning

cycle.

www.parrinst.com

11

Page 12

4848 Reactor Controller

b. The parameter displayed is the group in use

with exception of PID4. When PID4 is set, the PID

parameters will automatically switch between

PID groups 0, 1, 2 and PID group 3, depending

on which group’s SV best matches the current

temperature (PV).

c. All of PID parameters in the group can be ob-

tained from auto-tuning or they can be set

manually. When manually entering PID values

into a particular group, the SV for that group can

be manually entered as well.

Autotuning

1. Fill the vessel with an amount of liquid which

well represents the intended process.

Caution!

Refer to Manual 230M for safety information

on the heating of liquids in Parr Reactors

and Pressure Vessels.

2. If you wish to autotune at different temperatures

using the four available PID groups proceed with

step 3, otherwise skip to step 4.

3. Press the set key once followed by the return key

PID0

(circular arrow) twice. [

] will be displayed

on the screen in the top display. Use the up and

down arrow keys to change between PID groups

0, 1, 2 and 3. Press the set key to solidify the

change. Press the set key again to return to the

main screen.

4. Heat the system to the desired temperature using set point control on the primary temperature

controller. Let the temperature come to steady

state which will typically occur 15 to 30 minutes

after reaching the desired set point depending

on the size of the reactor.

5. On the main screen of the controller, press the

set key. The screen will show [AT] on the top

display and [

OFF

] on the bottom display. Press

the up arrow to change the lower display to

[ON]. The display will blink, press set to solidify

the change. Press set again to return to the main

screen.

6. As the Autotune starts, the LED indicator under

AT will blink, and Out 1 will fully engage attempting to heat the reactor 100% power. This

will continue for a while, and the controller

will go through a few cycles where it turns the

power on at 100% and turns it off to see how the

temperature responds.

7. A typical Autotune time is half an hour for liquid

water systems, but it may take longer depending

on the process. When the process is complete,

the AT light will stop flashing, and the temperature will settle on the set point.

Temperature Profiles - Ramp and Soak

The 4848 Controller has a programming feature

which allows more flexibility when compared to set

point control. Rather than controlling temperature

to a single set point, a ramp and soak program may

be entered to control various soak times, ramp rates

and set points. Within the programming mode there

are eight patterns available with each pattern having up to eight steps which can be programmed.

Patterns can be set to repeat and they can be linked

to other patterns (or the same pattern which allows

for infinite program cycles). This allows for up to 64

unique steps and thousands of possible program

configurations.

To input a ramp and soak:

1. First set the controller’s Run/Stop [

rameter to Stop [

STOP

]. This will prevent the

R-S

] pa-

program from automatically starting after the

program has been entered. You can do this by

pressing the return key once and use the arrow

keys to change the setting to “stop” and press

the set key to solidify the change.

2. To enable the ramp and soak control mode, hold

the set key for approximately three seconds. The

upper display will change to indicate the Input

INPT

[

] parameter, and the lower display will

indicate the temperature sensor type.

3. Press the return key until the upper display

indicates the control mode parameter [

CRTL

]

and the lower display indicates the control

method (default is PID [

to change this value to the program [

PID

]). Use the arrows

PROG

]

setting. The display will blink, and pressing the

set key will solidify the change.

4. Press the return key once. The upper display will

indicate the pattern [

PAT N

] parameter and the

lower display will show the pattern number. The

pattern parameter defines which pattern parameters are being viewed in steps 5 - 10. Setting the

pattern parameter to off [

OFF

] allows you to

skip the proceeding ramp/soak parameters. Use

12

Parr Instrument Company

Page 13

4848 Reactor Controller

the arrow keys to change the pattern number

and press the set key to solidify the change.

5. Press the return key once. The upper display will

SP00

read [

], where the “00” represents the

pattern and step number, respectively. The lower

display will indicate the set point for indicated

step. The set point can be adjusted using the

arrow keys then press the set key to solidify the

change.

Note: The first SP_O used must be a higher

temperature than the current temperature

(PV) or the program will not execute properly.

6. Press the return key once. The upper display will

TI00

read [

], where the “00” represents the

pattern number and the step number, respectively. The lower display will show the time to

execute the current set point in “hh:mm” format.

The time setting can be changed by using the

arrow keys then press the set key to solidify the

change.

7. Repeat steps 4 and 5 for “SP01” through “SP07”

and “tI01” through “tI07” as required. Once you

have entered all the steps you want, you can

leave the remaining “SP” and “tI” variables at

zero and press the return key to advance.

8. Press the return key to display [

PSY0

] on the

upper display, where “0” represents the current

pattern number. This parameter determines the

last step to execute in the pattern. For example,

if PSy0 has a value of 3, Steps SP00 through

SP03 will execute. Use the arrow keys to change

the setting and press the set key to solidify the

change.

9. Press the return key to display [

CYC0

], where

“0” represents the pattern number. This parameter defines how many times you want the

indicated pattern to repeat. If you would like the

pattern to only execute once, set this value to

zero. Use the arrow keys to change the setting

and press the set key to solidify the change.

10. Press the return key to display [

LIN0

], where

“0” represents the pattern number. This parameter allows you to link the indicated pattern another. If you would like more than seven

separate steps in the process, set this to the next

pattern number you wish to link to. Use the ar-

row keys to change the setting and press the set

key to solidify the change.

11. Press set to return to the main screen. Note

that the lower display of the main screen has

changed to show the program step.

Note: The program will attempt to hold the

temperature at the set point determined by

the last step executed. So, if you wish for the

reactor cool to room temperature once the

program has finished, the last executed step

must have a set point consistent with room

temperature and the time for the last step

can be set to 00:00.

Engaging a Program

1. From the main screen, press the return key two

times to display [

PTRN

] on the upper display. The

lower display will indicate the pattern at which you

wish to execute.

2. Press the return key until the run/stop parameter

R-S

[

] is on the upper display. The lower display

will indicate the setting of the run/stop parameter.

Change this value to [

RUN

] in order to start the

program determined in step 1. Press set to return to

the main screen.

If you wish to stop the program completely, you

may change this value to [

STOP

]. Changing the

run/stop mode back to stop will restart the program

from the beginning.

If you wish to stop the program and continue controlling the temperature at the current set point, you

may change this value to program stop [

PSTP

].

Changing back to run mode from a program stop

will restart the program from the beginning.

If you wish to hold the program at the current

temperature, you may change this to program hold

PHOD

[

]. Changing back to run mode from a program hold will continue the program from its current step.

3. The main screen will now show the current set

point on the lower display. Pressing the arrows will

allow you to change between: [

the current pattern and step, [

P-ST

] to display

R-TC

] to display the

remaining time in the current pattern step, or [SP]

to display the set point for the current pattern step.

Press set will solidify this display change.

www.parrinst.com

13

Page 14

4848 Reactor Controller

Appendix: sample programs

A sample program to ramp from 25 °C to 250 °C in

2-hrs:

Variable Value Meaning

ptrn 00 Pattern 0

SP00 25 Setpoint of 25 ºC (first step is a

soak by default)

tI00 00:01 Hold for 1-min

SP01 250 Setpoint of 250 °C

tI01 02:00 Ramp to setpoint in 2 hrs

SP02 250 Setpoint of 250 °C

tI02 00:40 Ramp to setpoint in 40-min*

SP03 25 Setpoint of 250 °C

tI03 00:00 Ramp to setpoint immediately**

SP04 25 Setpoint of 25 °C

tI04 00:00

SP05 25 Setpoint of 25 °C

tI05 00:00

SP06 25 Setpoint of 25 °C

tI06 00:00

SP07 25 Setpoint of 25 °C

tI07 00:00

PSy0 3 Execute steps 0-3 only***

CyC0 0 Do not re-cycle program

Lin0 off Do not execute another program

upon completion

* The beginning and final setpoint are equal, making

this a soak step.

** The time is zero, making this a step function instead of a ramp.

*** Steps 4-7 are not executed here.

**** The SP_0 vaue must be higher than the initial

temperature (PV) of the reactor or the program will

not initiate correctly.

A sample program to heat to 200 °C as fast a possible, hold for 2-hrs, and come back down as quickly

as possible:

Variable Value Meaning

ptrn 00 Pattern 0

SP00 200 Setpoint of 200 °C (first step is

a soak by default)

tI00 00:00 Move setpoint to 200 °C im-

mediately

SP01 200 Setpoint of 200 °C

tI01 01:00 Ramp from 200°C to 200 °C

over 1-hrs *

SP02 200 Setpoint of 200 °C

tI02 02:00 Ramp from 200C to 200 °C over

2-hrs **

SP03 25 Setpoint of 25 °C

tI03 00:00 Ramp to setpoint immediate-

ly***

SP04 25 Setpoint of 25 °C

tI04 00:00

SP05 25 Setpoint of 25 °C

tI05 00:00

SP06 25 Setpoint of 25 °C

tI06 00:00

SP07 25 Setpoint of 25 °C

tI07 00:00

PSy0 3 Execute steps 0-3 only****

CyC0 0 Do not re-cycle program

Lin0 off Do not execute another pro-

gram upon completion of this

program

* The physical system will take some time to go from

room temp to 200 °C. Step 01 is presented as a “heat

up” step. The time value in this step should be adjusted after the first run is complete and the operator

knows the expected heat up time.

** It is useful to keep this step 02 separate from step

01 so you can adjust step 01 to match the heat up

time.

14

*** The time is zero, making this a step function instead of a ramp.

**** Steps 4-7 are not executed here.

Parr Instrument Company

Page 15

4848 Reactor Controller

Pressure Display Module (PDM)

PRESSURE

When this optional module is present, the left display in red shows the pressure, and the right hand

display in green shows the Pressure Alarm setpoint.

If the reactor pressure exceeds this setpoint, the

pressure module will trip the High Limit Alarm, cutting power to the heater.

This module provides a digital read out for continuously monitoring the pressure within the reactor,

plus a backup safety feature which will terminate

power to the heater if a preset maximum is reached.

Pressure is displayed with a 1 psi resolution and a

1% FS accuracy. The safety cut-out feature offers

excellent protection against accidental over-pressure

by allowing the user to set a maximum pressure

which, if reached, will activate the high limit relay

and turn off the heater immediately.

The signal for the pressure display is generated by

a transducer in a stainless steel housing mounted

on the reactor. The transducer must not be heated

above 120 °C; an elevated temperature can caused

the accuracy of the transducer to suffer. A water

cooling sleeve attached to the transducer mounting

body can be used to keep the transducer below this

limit when operating the reactor at higher temperatures.

For applications involving reactants corrosive to

stainless steel, the transducer body can be replaced

with an isolator of special alloys which will keep the

reactants away from the transducer. Users should

consult with the Parr Technical Support before purchasing one of these.

The Pressure Alarm setpoint may be adjusted by doing the following:

2. Press the set button. The lower display will stop

blinking, showing the new value has been set.

When ordering a pressure display module separately or installed in any Parr controller, always

specify the reactor on which the transducer will be

installed so that the proper mounting hardware can

be furnished.

Note: if the pressure transducer is not attached

to the 4848 Controller, the High Limit Reset

may trip or show a fixed but incorrect value.

We recommend always operating with the

transducer attached.

Tachometer Display Module (TDM)

RPM

This optional feature can be included in any 4848

Controller to provide a means for continuously

monitoring the stirring speed in a Parr reactor. It

consists of an optical sensor installed in the overarm drive on the reactor which is then connected to

the 4848 Controller.

The connecting cable has a plug which fits the

marked socket on the back panel of the controller.

The digital display will show the stirring speed over

a range of 0-2200 rpm with a 1 rpm resolution and

+/- 10 rpm accuracy.

Note: The SV display serves no function on a

TDM

Users wishing to control the stirring speed remotely

with setpoint control ought to consider the Motor

Control Module (MCM) in lieu of the TDM.

1. Press the up or down arrow until the lower

display shows the desired setpoint. The lower

display will blink, showing the value has not

been set yet.

www.parrinst.com

15

Page 16

4848 Reactor Controller

Motor Control Module (MCM)

RPM

When this optional module is present, the left display in red shows the stirring speed, and the right

hand display in green shows the rpm setpoint. The

4848 Controller is designed to run in either Local

or Remote stirring mode. The local/remote switch

on the front panel will toggle between these two

modes.

In Local mode, the stirring speed is controlled by

turning the speed control knob on the front panel.

The rpm setpoint has no bearing on the stirring

speed.

In Remote mode, the motor will stir at the rpm setpoint using closed loop PI control. The speed control knob has no bearing on the stirring speed.

The RPM setpoint may be adjusted by doing the following:

1. Press the up or down arrow until the lower

display shows the desired setpoint. The lower

display will blink, showing the value has not

been set yet

2. Press the set button. The lower display will stop

blinking, showing the new value has been set.

Motor Torque Module (MTM)

This module provides a means for continuously

monitoring the motor output percent to the stirrer

motor. When used with a Motor Control Module

(MCM), the motor speed control will provide a constant stirring speed at a given setting. Changes in

the power required by the motor will correspond to

changes in the viscosity of the fluids in the vessel.

This will be a useful option for users who want to

monitor the progress of a polymerization reaction

in which there are viscosity changes as the reaction

proceeds.

High-Temp Cut-Off Module (HTM)

TEMPERATURE

This module provides a redundant high temperature safety cut-off which will shut down the reactor

heater if an unusual malfunction should develop in

the primary control system. It is a completely independent safety backup system, operating in addition

to the high-limit control built into each Parr temperature controller. It has its own thermocouple, digital

display and wiring, and can be preset to shut down

the heater at any desired temperature.

If the secondary temperature (PV) exceeds the alarm

setpoint (SV), the alarm indicator on this display will

illuminate and the High Limit breaker will trip, interrupting power to the heater.

The High Temp Cut-Off Alarm setpoint may be adjusted by doing the following:

1. Press the up or down arrow until the lower

display shows the desired setpoint. The lower

display will blink, showing the value has not

been set yet.

2. Press the set button. The lower display will stop

blinking, showing the new value has been set.

This secondary temperature module does not control the heater. It is used as an alarm only.

When ordering this option separately or installed in

the 4848 Parr Controller, always specify the reactor

with which it will be used so that a thermocouple of

the proper style and length can be furnished.

16

Parr Instrument Company

Page 17

4848 Reactor Controller

External Heater Temperature Limit Control

Module (ETLM)

TEMPERATURE

ETLM

This module should be considered in systems with

large thermal lags or long dead times such as gas

phase reactions or other systems where temperature control is difficult.

This configuration is similar to the High Temperature Cut Off Module (HTM), but the display will now

turn off the heater if it exceeds a pre-set adjustable

setpoint. This non-latching setpoint will establish a

maximum wall temperature, and combined with the

main temperature control module will help suppress

overshoot in difficult to control processes.

As an added safety feature, there is also a secondary alarm which will trip the High Limit Reset when

breached. This secondary alarm provides a redundant high temperature safety cut-off which will shut

down the reactor heater if an unusual malfunction

should develop in the primary control system. It is

a completely independent safety backup system,

operating in addition to the high limit control built

into each Parr temperature controller. It has its own

thermocouple, digital display and wiring, and can be

preset to shut down the heater at any desired temperature.

To set the primary (non-latching) temperature limit,

press the up or down arrow on the display. The setpoint value on the right will flash. Press the set button to solidify this display and complete the change.

To set the secondary (latching) temperature limit,

press the circular arrow key three times. The lefthand display will read ALIH and the right-hand

display will read the secondary temperature limit

setpoint (usually 375 °C). Press the up or down arrow on the display. The setpoint value on the right

will flash. Press the set button to solidify this display and complete the change.

When ordering this option separately or installed in

the 4848 Parr Controller, always specify the reactor

with which it will be used so that a thermocouple of

the proper style and length can be furnished.

Motor Speed Control

Parr 4848 Controllers are equipped with a solid

state speed control module for use with the variable

speed, DC motors installed on Parr stirred reactors.

The module itself (approximately 4 inches square) is

mounted inside the chassis on the bottom plate. A

motor switch and a speed adjustment potentiometer

are mounted on the front panel. Each module also

requires a resistor matched to the horsepower of

the motor with which it will be used, as listed in the

following table:

Motor

Rating

1/17 HP 90 VDC 0.25 ohm 876E6

1/8 HP 90 VDC 0.10 ohm 876E3

1/4 HP 90 VDC 0.05 ohm 876E

1/4 HP 180 VDC 0.10 ohm 876E3

1/2 HP 90 VDC 0.025 ohm 876E2

1/2 HP 180 VDC 0.05 ohm 876E

3/4 HP 180 VDC 0.035 ohm 876E5

Motor

Voltage

Resistor

Required

Parr Part

Number

If the heater temperature exceeds the ETLM setpoint

(non-latching), the output to the heater will be interrupted. This will not trip the High Limit Reset, and

when the heater temperature falls back below the

primary setpoint, it will allow power to flow to the

heater again.

www.parrinst.com

17

Page 18

4848 Reactor Controller

4848 Controllers furnished as a part of a complete

Parr stirred reactor system will have the proper

resistor installed at the factory. Any controller sold

separately will require a motor specification so that

the proper resistor may be provided.

Always turn the speed control knob fully counterclockwise to the off position before turning on the

motor switch, then advance the knob clockwise

slowly to develop the desired speed. Do not overload the motor. Any high speed or high viscosity

load which trips the circuit breaker (90 VDC motors)

is too heavy. Reduce the speed to avoid overloading and use the reset button on the rear panel to

restart the motor.

Adjustments To Speed Control Board

There are five trimpots in the speed control module

that can be used to adjust the performance of the

motor. These are set at the factory for optimum

performance and should not be disturbed unless

customized settings are required to match a particular set of operating conditions. The instructions

below should be followed carefully if these controls

are to be readjusted.

The CL, current limiting/torque adjustment is set at

the factory to 1.5 times the motor rating. It is intended to protect both the module and the motor against

overloads and heavy surge currents during startup.

It can also serve as a torque limiting device by reducing the maximum power output of the system.

The IR, compensation adjustment is used to improve motor control under varying load conditions.

If the loads do not fluctuate, this control can remain

at approximately one-fourth of full setting. But if the

motor speed drops more than 2% under load, this

adjustment should be increased. If it is set too high,

the motor speed will fluctuate in a cyclical manner.

The MAX, maximum speed adjustment controls the

maximum speed of the motor. To increase the motor speed, turn the control knob on the front panel

to its maximum setting, then use the MAX trimpot

to raise the speed to the desired level. Note, however, that the motor may become dangerous if the

speed is raised above the motor's rated rpm.

The MIN, minimum speed adjustment can be used

to raise the minimum motor speed. To change this

setting, turn the control knob on the front panel to

its minimum setting, then adjust the MIN trimpot

to obtain the desired minimum speed, this adjustment will also affect the maximum setting, making it

necessary to adjust both MAX and MIN trimpots to

obtain the desired spread.

The ACCEL, acceleration adjustment is normally set

to provide controlled acceleration from zero to full

speed in 2 seconds. It can be adjusted to higher or

lower acceleration times anywhere between 0.5 and

4 seconds, but changing this setting will affect the

MAX speed and IR compensation which will have to

be readjusted. If the acceleration time is reduced to

0.5 seconds (6 o'clock trimpot position), increase the

IR trimpot one quarter turn clockwise and decrease

the MAX trimpot one fifth turn counterclockwise. If

the acceleration time is increased to the maximum

time of 4 seconds (full rotation), the IR trimpot must

be decreased and the MAX increased in the same

rotation amounts mentioned above.

Solenoid Valve Module

This module provides a solenoid valve, a metering

valve and all parts needed to assemble an automatic

cooling system for any reactor. It usually is installed

in a cold water line with a flow connection to the

cooling coil and an electrical connection to the

cooling socket on the back of the 4848 Controller.

Coolant will then be admitted to the coil whenever

cooling is called for by the controller, thereby minimizing any temperature overshoot. This system is

particularly advantageous when holding fixed temperatures below 150 °C or for controlling exothermic

reactions. Compressed air can be used as a coolant

if the amount of heat to be removed is not large.

18

Parr Instrument Company

Page 19

Communication with PC

The 4848 Controller is provided with RS-485 port

(labeled comm) and may be connected to a USB

port on a PC with optional A1925E4 communication

cable.

Quick Start Instructions for Connecting with PC

1. Put the 576M CD into the CD-ROM.

2. Connect the A1925E4 communication cable

between the comm port on the back of the 4848

Controller and an open USB slot on the PC.

3. The PC should open an "Install Hardware" wizard

automatically when the cable is connected to the

USB slot. If it does not, go to the Control Panel

and select "Add Hardware" to start the wizard.

4. When prompted, check the box to search removable media for the proper driver. The wizard

should find the driver on the 576M CD and install

the USB driver. It may prompt that the driver

has not been validated; select "continue anyway"

to continue the installation. After this it may

repeat the installation process for the RS-485

converter.

5. Copy the controller software to the PC. The software is located on the CD at: "software\ParrCom.

exe”.

6. Once copied to the PC, open the ParrCom.exe

file. No installation is necessary.

7. At the main ParrCom program screen, select

"protocol >> set PC". Ensure that the following

values are set:

Baud: 9600

Data length: 8

Parity: even

Stop bit: 1

ASCII: RTU

4848 Reactor Controller

Click OK to return to the main screen.

8. At the main screen, select "Program >> Monitor".

The Monitor screen will come up. There will be

a generic icon on the left, and four mini screens

on the right. Each mini screen can be used to

connect to a different module on the 4848 Controller.

9. In the first mini screen, select 1 for the Address,

and click Connect. It should connect to the

Primary Temperature module on the 4848 Controller, and the bottom half of the screen should

show parameters for the controller. These may

be modified here. Of most interest will be the

"Input >> SV" value, which is the setpoint for

temperature. Also, the "Alarm >> Alarm 3" value

will show the High Limit alarm for this module.

10. Any other modules on the 4848 Controller may

be accessed through the remaining available

mini screens. The modules have addresses

numbered 1-4 starting from the left most module

on the 4848 Controller.

www.parrinst.com

19

Page 20

4848 Reactor Controller

Datalogging and Charting

The 4848 Controller comes equipped with a charting

and datalogging program. This program cannot be

run simultaneously with the control program, but

once the user is satisfied that the controller is set,

the control program may be closed, allowing the

charting and datalogging program to run. The modules on the 4848 may still be modified manually at

the physical panel during datalogging and charting.

1. Open the ParrCom.exe file. No installation is

necessary.

2. At the main program screen, select "protocol >>

set PC" (if you have already done previously, you

may skip this step). Ensure that the following

values are set:

Baud: 9600

Data length: 8

Parity: even

Stop bit: 1

ASCII: RTU

Click OK to return to the main screen.

3. At the main screen, select "Program >> Recorder". The Recorder screen will come up.

4. Select the proper address for the Devices you

wish to chart. The primary temperature has address 1, and each additional module would have

an address numbered 2-4 going from left to right

on the physical 4848 Controller.

7. The chart will show the process values of each

module represented. As the values change, the

chart will automatically scale to show the values.

8. When you wish to stop recording, click the stop

button. The chart has already been

saved in the REC file created in step 5.

You may view the chart by clicking the

recorder button.

9. You can convert the file to a TXT file for export to

a spreadsheet as well.

Converting a Chart File to TXT

Once a chart REC file has been created, you can convert it to a TXT file for export into a spreadsheet.

1. Insert the 576M CD into the CD-ROM. Locate the

conversion file at “ \software\convert.exe”. Copy

it to the PC.

2. Open the convert.exe file. No installation is

necessary.

3. Click the "CONVERT" button. Locate the REC file

to be converted, and click "Open".

4. The conversion program will create a new TXT

file in the same location as the REC file with the

name "CONVFILE.TXT".

5. Click the Save button and save a REC

file to an appropriate place on the PC.

When the chart is generated, it will write

to this file.

6. When you return to the main Recorder screen, notice that the Save button

is depressed. Hit the Start button to

begin recording.

20

Parr Instrument Company

Page 21

4848 Reactor Controller

4848 Factory Defaults

Navigating the Menu System/Factory

Default Settings

There are three broad categories of functions in the

4848 Controller modules. They are Regulation, Operation, and Initial Settings. From the main screen,

Regulation mode is accessed by pressing the set

button. The Initial Setting mode is accessed by

holding the set button for three seconds. Operation

mode is accessed by pressing the circular arrow.

In each mode, you can cycle through the variables

by pressing the circular arrow. To change a value,

use the up or down arrow, which causes the value

to flash. Then press the set button to solidify the

choice. Return to the main screen by pressing set

again.

Keys command:

1. Press “SET” to select

2. Press return key move to next operation mode

3. Up/Down arrow keys to adjust value or select

type

Primary Temperature Module

Press and hold down “SET” for 5-sec

Operation

Mode

InPt J** Input type

tPUn C Temperature unit

tP-H 800** Upper-limit range

tP-L 0 Lower-limit temperature range

CTRL PID Control mode (ON/OFF, MANU-

S-HC H1C2 Output 1 is Heating and output

ALA1 6 Absolute upper limit alarm op-

ALA2 0 Alarm 2 is disabled

SALA OFF System alarm

CoSH ON Communication write function

C-Sl RTU Format type

C-no 1 Communication address

bPS 9600 Communication baud rate

Len 8 Data length setting

PrtY Even Parity bit setting

StoP 1 Stop bit setting

Select

type/value

Comment

AL, PID and PID PROG)

2 is Cooling

erates when PV value is higher

than AL1H setting

that able to use set point from

software

Press return key and release

Operation

Mode

r-S Run Run/Stop

SP 0** Decimal point position

AL1H 375 Upper alarm setting

LoC OFF Lock mode (lock all keys or

Out1 - (read-only) Heater output %

Out2 - (read-only) Cooling output %

Select

type/value

Comment

only up/down arrow able to

use)

** If using a type-J or type-K thermocouple, SP = 0

If using an RTD, SP = 1

** If using a type-J thermocouple, InPt = J, tP-H = 800

If using a type-K thermocouple, InPt = K, tP-H = 800

If using an RTD, InPt = Pt, tP-H = 600

Press “SET” and release

Operation

Mode

At OFF Auto Tuning ON/OFF

PID0 0 The 0th PID Parameter

SV 0 The 0th SV

P0 11.8 Proportional control

I0 375 Integral control

D0 93 Derivative control

IoF0 0 Integral value offset

HtPd 5 Heat cycle control

HcPd 5 Cool cycle control

CoEF 1 1 & 2 value output group dur-

dEAd 0 Dead band

tPoF * PV Offset

Select

type/value

Comment

ing dual loop output control

* Set at factory

www.parrinst.com

21

Page 22

4848 Reactor Controller

TDM / MCM Module

Press return key and release

Operation

Mode

r-S Run Run/Stop

SP 0 Decimal point position

LoC OFF Lock mode (lock all keys or

Out1 - (read-only) Motor output %

Select

type/value

Comment

only up/down arrow able to

use)

Press and hold down “SET” for 5-sec

Operation

Mode

InPt v5 Input type (v5 = 0-5V, v10 =

tP-H 2206 Upper-limit range

tP-L 0 Lower-limit temperature range

CTRL PID Control mode (ON/OFF, MAN-

S-HC Heat Heat/Cool control

ALA1 0 Alarm 1 is disabled

SALA OFF System alarm

CoSH ON Communication write func-

C-Sl RTU Format type

C-no 2 Communication address

bPS 9600 Communication baud rate

Len 8 Data length setting

PrtY Even Parity bit setting

StoP 1 Stop bit setting

Select

type/value

Comment

0-10V, nA0 = 0-20mA, nA4 =

4-20mA, nV =0-50mV)

UAL, PID and PID PROG)

tion that able to use set point

from software

Press “SET” and release

Operation

Mode

At OFF Auto Tuning ON/OFF

PID0 0 The 0th PID Parameter

SV 0 The 0th SV

P0 170 Proportional control

C0 1 Integral control

D0 0 Derivative control

CoF0 0 Integral value

HtPd .5 Heat/Cool cycle control

tPoF * PV Offset

CrHI 0 Analog output high

CrLo 0 Analog output low

Select

type/value

Comment

Pressure Module

Press return key and release

Operation

Mode

r-S Run Run/Stop

SP To be deter-

AL1H 0 Upper-limit alarm 1

LoC OFF Lock mode (lock all keys or

Select

type/value

mined**

Comment

Decimal point position

only up/down arrow able to

use)

** If units are psi, SP = 0

If units are Bar, SP = 1

If units are MPa, SP = 2

Press and hold down “SET” for 5-sec

Operation

Mode

InPt V5 Input type (V5 = 0-5V, V10 =

tP-H Determined

tP-L 0

CTRL ON/OFF Control mode (ON/OFF,

S-HC Heat Heat/Cool control

ALA1 2 Alarm operates when PV

SALA OFF System alarm

CoSH ON Communication write func-

C-Sl RTU Format type

C-no 3 Communication address

bPS 9600 Communication baud rate

Len 8 Data length setting

PrtY Even Parity bit setting

StoP 1 Stop bit setting

Select

type/value

by transducer**

[-14.7 if compound psi]

[-1.0 if compound bar]

[-0.1 if compound mPa]

Comment

0-10V, nA0 = 0-20mA, nA4 =

4-20mA, nV =0-50mV)

Upper-limit pressure range

Lower-limit pressure range

MANUAL, PID and PIDPROG)

value is higher than SV

Value + ALH setting

tion that able to use set

point from software

* Set at factory

22

Parr Instrument Company

Page 23

4848 Reactor Controller

** Set according to the following:

Transducer

range - psi

200 200 13.79 1.38

500 500 34.47 3.45

300

(compound)

1000 1000 68.95 6.89

2000 2000 137.9 13.79

3000 3000 206.8 20.68

5000 5000 344.7 34.47

7500 7500 517.1 51.71

tP-H for

psi

300 20.68 2.07

tP-H for

Bar

tP-H for

MPa

Press “SET” and release

Operation

Mode

HtS 0 Heating hysteresis setting

tPoF * PV Offset

Select

type/value

Comment

* Set at factory

HTM/ETLM Module

Press return key and release

Operation

Mode

r-S Run Run/Stop

SP 0** Decimal point position

AL1H 375*** Upper-limit alarm 1

LoC OFF Lock mode (lock all keys or

Out1 - (read-only) Heater Output %

Select

type/value

Comment

only up/down arrow able to

use)

** If using a type-J or type-K thermocouple, SP = 0

If using an RTD, SP = 1

*** If using an HTM, AL1H = 0

If using an ETLM, AL1H = 375

Press and hold down “SET” for 5-sec

Operation

Mode

InPt J** Input type

tPUn C Temperature unit

tP-H 800** Upper-limit temperature

tP-L 0 Lower-limit temperature

CTRL ON/OFF Control mode (ON/OFF,

S-HC Heat Heat/Cool control

ALA1 6*** Alarm operates when PV

SALA OFF System alarm

CoSH ON Communication write func-

C-Sl RTU Format type

C-no 4 Communication address

bPS 9600 Communication baud rate

LEn 8 Data length setting

PrtY Even Parity bit setting

StoP 1 Stop bit setting

Select

type/value

Comment

range

range

MANUAL, PID and PID

PROG)

value is higher than AL1H

value

tion that able to use set

point from software

** If using a type-J thermocouple, InPt = J, tP-H = 800

If using a type-K thermocouple, InPt = K, tP-H = 800

If using an RTD, InPt = Pt, tP-H = 600

*** If using an HTM, ALA1 = 2

If using an ETLM, ALA1 = 6

Press “SET” and release

Operation

Mode

HtS 0 Heating hysteresis setting

tPoF * PV Offset

Select

type/value

Comment

* Set at factory

www.parrinst.com

23

Page 24

4848 Reactor Controller

MTM Module

Press return key and release

Operation

Mode

r-S Run Run/Stop

SP 1 Decimal point position

LoC OFF Lock mode (lock all keys or

Select

type/value

Comment

only up/down arrow able to

use)

Press and hold down “SET” for 5-sec

Operation

Mode

InPt v10 Input type (v5 = 0-5V, v10 =

tP-H To be deter-

tP-L 0 Lower-limit temperature

CTRL ON/OFF Control mode (ON/OFF,

S-HC Heat Heat/Cool control

ALA1 0 Alarm mode

SALA OFF System alarm

CoSH ON Communication write func-

C-Sl RTU Format type

C-no 4 Communication address

bPS 9600 Communication baud rate

Len 8 Data length setting

PrtY Even Parity bit setting

StoP 1 Stop bit setting

Select

type/value

mined**

Comment

0-10V, nA0 = 0-20mA, nA4 =

4-20mA, nV =0-50mV)

Upper-limit range

range

MANUAL, PID and PID

PROG)

tion that able to use set

point from software

Press “SET” and release

Operation

Mode

HtS 0 Hysteresis

TPoF 0 PV Offset

CrHI 0 Analog output high

CrLo 0 Analog output low

Select

type/value

Comment

** For 90VDC motor, 115VAC, tP-H = 142.9

For 180VDC motor, 230VAC, tP-H = 120.4

For 90VDC motor, 230VAC, tP-H = 153.2

24

Parr Instrument Company

Page 25

Appendix A: Controller Parameters

Initial Setting Mode

Press to advance

Set input type

Set temperature unit

(Does not display when analog input)

Set upper-limit of temperature range

Set lower-limit of temperature range

Select control mode

Select heating/cooling control or dual loop output control

Alarm 1 mode setting

Alarm 2 mode setting

(Only available on Primary Temperature Controller)

Alarm 3 mode setting

(Only available on Primary Temperature Controller)

4848 Reactor Controller

Set system alarm

Communication write function enable/disable

ASCII, RTU communication format selection

Communication address setting

Communication baud rate setting

Data length setting

Parity bit setting

Stop bit setting

www.parrinst.com

25

Page 26

4848 Reactor Controller

Operation Mode

Press to advance

Use key to set temperature set point

Control setting RUN or STOP

Start pattern setting

(PID program control and

Decimal point position selection

(except for B, S, R type inputs, all the other types can be set)

Upper-limit alarm 1

(This parameter is available only when ALA1 function is enabled)

Lower-limit alarm 1

(This parameter is available only when ALA1 function is enabled)

Upper-limit alarm 2

(This parameter is available only when ALA2 function is enabled)

Lower-limit alarm 2

(This parameter is available only when ALA2 function is enabled)

Upper-limit alarm 3

(This parameter is available only when ALA3 function is enabled)

Lower-limit alarm 3

(This parameter is available only when ALA3 function is enabled)

Time setting)

Setting lock mode

Display output value of 1st output group

Display output value of 2nd output group

26

Parr Instrument Company

Page 27

Regulation Mode

Press to advance

Auto-tuning

(Available in PID control and RUN mode)

4 groups PID modes (n=0~3). When n=4, PID control is auto regulated.

PD control offset setting

(Available when PID control is ON and Ti=0, set the value of PdoF)

Heating hystereisis setting

(Available in ON/OFF control mode)

Cooling hystereisis setting

(Available in ON/OFF control mode)

or

Heating and Cooling control cycle

(Available in PID control mode)

4848 Reactor Controller

Control cycle setting of 2nd output group

(Available in PID control and Dual Loop output control mode)

P value of 1st & 2nd output group during dual loop output control

P value of 2nd output group = (P value of 1st output group) x

Dead Band (Available in Dual Loop output control mode)

Regulate temperature deviation value

Regulate upper-limit of analog output value

(Display when equipped with an analog output)

Regulate lower-limit of analog output value

(Display when equipped with an analog output)

www.parrinst.com

27

Page 28

4848 Reactor Controller

Parts List

Fuse Rating Part Number

Instrument Fuse Fast acting, 1 Amp, 250VAC 139E6

Cooling Fuse Fast acting, .25 Amp, 250VAC 139E10

Line Fuse(s) Fast acting, 20 Amp, 250VAC 2074E

Motor Board Fuse (A+) Very Fast acting, 8 Amp, 250VAC 959E5

Motor Board Fuse (L) Fast acting, 10 Amp, 250VAC 185E2

1/2 hp, 180VDC Slo-blo, 2.5 Amp, 250VAC 139E8

1/4 hp, 180VDC Slo-blo, 1.5 Amp, 250VAC 139E19

3/4 hp, 180VDC Slo-blo, 4.0 Amp, 250VAC 139E20

1/12 hp, 90VDC Circuit breaker, 1.0 Amp 801E

1/17 hp, 90VDC Circuit breaker, 1.0 Amp 801E

1/8 hp, 90VDC Circuit breaker, 1.5 Amp 801E3

1/4 hp, 90VDC Circuit breaker, 2.5 Amp 801E2

1/2 hp, 90VDC Circuit breaker, 5.0 Amp 801E4

Fuses

Motor breaker / fuse

Caution:

For continued protection against possible hazard, replace fuses with same type and rating of fuse.

Communication

Part Number Description

A1925E4 RS-485 to USB Conversion Cable

Cooling Solenoids

Part Number Description

A160HW3EB Solenoid Valve Pkg 115V

A160HW3EE Solenoid Valve Pkg 230V

A160HW7EB Solenoid Valve Pkg 115V 10FT

A160HW7EE Solenoid Valve Pkg 230V 10FT

A160HW8EB Solenoid Valve Pkg 115V 20FT

A160HW8EE Solenoid Valve Pkg 230V 20FT

A160HW9EB Solenoid Valve Pkg 115V 30FT

A160HW9EE Solenoid Valve Pkg 230V 30FT

28

Parr Instrument Company

Page 29

4848 Reactor Controller

Primary Temperature Module

Part No. Description

A470E2 Thermocouple extension wire,

type-J, 5-ft

A470E4 Thermocouple extension wire,

type-J, 10-ft

A470E7 Thermocouple extension wire,

type-J, 15-ft

A470E5 Thermocouple extension wire,

type-J, 20-ft

A470E8 Thermocouple extension wire,

type-J, 25-ft

A470E6 Thermocouple extension wire,

type-J, 30-ft

A470E9 Thermocouple extension wire,

type-J, 35-ft

A470E10 Thermocouple extension wire,

type-J, 40-ft

A472E4 Thermocouple, type-J, 5-1/2" length

A472E2 Thermocouple, type-J, 9-1/2" length

A472E3 Thermocouple, type-J, 11-1/2" length

A472E Thermocouple, type-J, 7-1/2" length

A472E5 Thermocouple, type-J, 21-1/2" length

A472E6 Thermocouple, type-J, 15-1/2" length

A490E4 Dual T/C, type-J, 5-1/2" length

A490E Dual T/C, type-J, 7-1/2" length

A490E2 Dual T/C, type-J, 9-1/2" length

A490E3 Dual T/C, type-J, 11-1/2" length

A490E6 Dual T/C, type-J, 15-1/2" length

A490E2 Dual T/C, type-J, 21-1/2” length

A511E2 Heater thermocouple, type-J,

bayonet style

A511E4 Heater thermocouple, dual, type-J,

bayonet style

Pressure Display Module (PDM)

Part No. Description

A1905E5 Pressure harness, 5-ft, covered

A1905E Pressure harness, 10-ft, covered

A1905E8 Pressure harness, 15-ft, covered

A1905E3 Pressure harness, 20-ft, covered

A1905E9 Pressure harness, 25-ft, covered

A1905E7 Pressure harness, 30-ft, covered

A1905E10 Pressure harness, 35-ft, covered

A1905E11 Pressure harness, 40-ft, covered

A1906EP02 Transducer, 200 psi

A1906EP05 Transducer, 500 psi

A1906EP10 Transducer, 1000 psi

A1906EP20 Transducer, 2000 psi

A1906EP30 Transducer, 3000 psi

A1906EP50 Transducer, 5000 psi

A2599HC2 Transducer cooling body assembly

A2685HC Cooling sleeve assembly

2083HC Cooling sleeve for A2599HC2

827HC O-rings for cooling sleeve

2714HC Hose nipple

Note: Additional Pressure Ranges are available

upon request.

www.parrinst.com

29

Page 30

4848 Reactor Controller

Tachometer Module (TDM)

or Motor Control Module (MCM)

Part No. Description

A10 01E Optical sensor for cart reactor

A1001E2 Optical sensor for bench reactor

A1001E3 Optical sensor for gear box drives

A1001E4 Optical sensor for 4553/54/77/78

A1001E6 Optical sensor for 5100 reactor

A1001E8 Optical sensor for 3:1 gear box drive

A1001E9 Optical sensor for 4555 reactor

A10 01E10 Optical sensor for 10:1 gear box drive

A1831E Optical sensor for 5500 Compact Lab

Reactor

1564HC Slotted wheel for cart, bench, and low

pressure (1:1) reactors

1564HC2 Slotted wheel for low pressure (2:1)

reactors

3056HC Slotted wheel for 5500 Compact Lab

Reactor

A1177E8 Tachometer harness, 5-ft

A1177E Tachometer harness, 10-ft

A1177E4 Tachometer harness, 15-ft

A1177E2 Tachometer harness, 20-ft

A1177E5 Tachometer harness, 25-ft

A1177E3 Tachometer harness, 30-ft

A1177E6 Tachometer harness, 35-ft

A1177E7 Tachometer harness, 40-ft

Hi-Temp Cut-Off Module (HTM)

or External Temperature Limit Module (ETLM)

Part No. Description

A470E2 Thermocouple extension wire, 5-ft

A470E4 Thermocouple extension wire, 10-ft

A470E7 Thermocouple extension wire, 15-ft

A470E5 Thermocouple extension wire, 20-ft

A470E8 Thermocouple extension wire, 25-ft

A470E6 Thermocouple extension wire, 30-ft

A470E9 Thermocouple extension wire, 35-ft

A470E10 Thermocouple extension wire, 40-ft

A472E Thermocouple, type-J, 7-1/2" length

A472E2 Thermocouple, type-J, 9-1/2" length

A472E3 Thermocouple, type-J, 11-1/2" length

A472E4 Thermocouple, type-J, 5-1/2" length

A472E5 Thermocouple, type-J, 21-1/2" length

A472E6 Thermocouple, type-J, 15-1/2" length

A490E Dual T/C, type-J, 7-1/2" length

A490E2 Dual T/C, type-J, 9-1/2" length

A490E3 Dual T/C, type-J, 11-1/2" length

A490E4 Dual T/C, type-J, 5-1/2" length

A490E5 Dual T/C, type-J, 21-1/2" length

A490E6 Dual T/C, type-J, 15-1/2" length

A511E2 Heater thermocouple, type-J, bayonet

style

A511E4 Heater thermocouple, dual, type-J,

bayonet style

30

Parr Instrument Company

Page 31

115VAC Controllers

4848 Reactor Controller

Controller Diagrams

Parts shown in Diagram 1:

Part No. Description

1532E Filter

2075E Heater switch

2076E Motor switch

2079E High Limit Light

3353HC Front Panel plate

542E High Limit breaker

Diagram 1: Front Panel, 115VAC

www.parrinst.com

31

Page 32

4848 Reactor Controller

115VAC Controllers (continued)

Diagram 2: Chassis, 115VAC

Parts shown in Diagram 2:

Part No. Description Part No. Description Part No. Description

2072E Fuse holder SA1332RD06 Screw A410E series Speed control board

2074E Fuse, 20 amp SA1632RD06 Screw A410E10EB Board, 1/8 hp,

90VDC

2077E Main switch SB1332BT06 Hex nut A410E8EB Board, 1/4 hp,

90VDC

2081E Power receptacle SN2520HX Hex nut A410E9EB 1/2 hp, 90VDC

283E2 Spacer SW25NL Lock washer

3361HC Chassis TN1332HL Chassis screw

412E Diode TN1632HL Hex nut

417E Heat sink

824E Hinge

32

Parr Instrument Company

Page 33

115VAC Controllers (continued)

4848 Reactor Controller

Diagram 3: Chassis, 115VAC

Parts shown in Diagram 3:

Part No. Description Part No. Description Part No. Description

1119E Solid State Relay 2066E Terminal block A1695E Excitation board

132E6EB Receptacle 2067E Terminal block SA1140RD04 Screw

139E6 Fuse, 1 amp 2068E Power supply SA1332RD04 Screw

139E10 Fuse, 1/4 amp 2087E Receptacle SA1632RD06 Screw

1470E Fuse holder 2807HC Spacer TN1140HL Hex nut

1471E Fuse carrier 283E5 Aluminum spacer TN1332HL Hex nut

1664HC2 Rubber foot 3352HC Wire retainer TN1632HL Hex nut

1709E Receptacle 3356HC Mounting bracket

2065E Terminal block 494E Receptacle

www.parrinst.com

33

Page 34

4848 Reactor Controller

230VAC Controller with 90VDC Motor

Diagram 4: Front Panel Inside, 230VAC, 90VDC motor

Parts shown in Diagram 4:

Part No. Description

1532E Filter

2075E Heater switch

2076E Motor switch

2079E High Limit Light

3353HC Front Panel plate

542E High Limit breaker

TN1332HL Hex nut

34

Parr Instrument Company

Page 35

230VAC controller with 90VDC motor (continued)

4848 Reactor Controller

Diagram 5: Chassis, 230VAC, 90VDC motor

Parts shown in Diagram 5:

Part No. Description Part No. Description Part No. Description

1071E Capacitor SA1332RD06 Screw A410E series Speed control board

2072E Fuse holder SA1632RD06 Screw A410E10EE Board, 1/8 hp, 90VDC

2074E Fuse, 20 amp SB1332BT06 Hex nut A410E8EE Board, 1/4 hp, 90VDC