Page 1

239M

4600 & 4700

General Purpose Pressure Vessels

Operating Instruction Manual

Page 2

Table of Contents

PREFACE 3

Scope 3

Related Instructions 3

Intended Usage 3

Safety Information 3

Explanation of Symbols 4

Environmental Conditions 4

Unpack Carefully 4

Provisions for Lifting and Carrying 4

Cleaning and Maintenance 4

User’s Responsibility 5

Pressure and Temperature Limits 5

CLOSURES 6

Split Ring Closures 6

Split Ring Closure Operations 6

Screw Cap Closures 6

Operating 4700 Screw Cap Vessels 6

PARR PRESSURE VESSEL SEALS 7

Flat Gasket or Self Sealing O-ring Closure 7

Seals for Operating Temperatures up to 350 °C 7

Gaskets for Operating Temperature above 350 °C 7

Sealing the Vessel 7

Vessels with a Flat PTFE Gasket 7

Vessels with an O-ring seal 8

Vessels with a Flexible Graphite Gasket 8

Vessels with a Metal Gasket 8

Sealing 4740 High Pressure Vessels 9

HEAD ASSEMBLY GUIDE 12

MATERIAL DESIGNATIONS 12

Material Designations for Alloys other than T316SS 12

Gasket Material Designations 12

SERIES 4700 WORKING LIMITS AND PARTS LISTS 13

Series 4703-4714 13

Series 4740 14

Series 4750 15

Series 4760-4777 16

Series 4760Q-4777Q 18

Series 4790 20

SERIES 4600 WORKING LIMITS AND PARTS LISTS 22

Series 4600-4620 22

Series 4600Q-4620Q 23

Series 4605-4626 24

Series 4650 25

Series 4660 26

Series 4660Q 27

Series 4670-4674 28

Series 4676-4677 29

Series 4678-4679 30

Series 4680 31

4316 & 4317 GAGE BLOCK ASSEMBLIES 32

Gage Block Parts List 32

Gage Block Assembly Drawing 34

OTHER VESSEL HEAD FITTINGS 9

Gage Block Assemblies 9

Pressure Gages 9

Safety Rupture Discs 9

Coned Pressure Fittings 9

Tapered Pipe Threads 10

MAINTENANCE 10

General Maintenance Notes 10

Periodic Pressure Tests 11

2

Parr Instrument Company

Customer Service

Questions concerning the installation or operation

of this instrument can be answered by the Parr

Customer Service Department:

1-309-762-7716 • 1-800-872-7720

Fax: 1-309-762-9453

E-mail: parr@parrinst.com

http://www.parrinst.com

Page 3

General Purpose Pressure Vessels

PREFACE

Scope

These instructions cover the basic operating steps

to be followed when using a variety of pressure vessels manufactured by the Parr Instrument Company.

They include temperature and pressure ratings for

Series 4600 and 4700 General Purpose Pressure Vessels, also instructions for the gage block assemblies

commonly used with these vessels. This material

is intended to be used in conjunction with several

related instruction sheets listed on page 2 covering

safety precautions and other information applicable

to Parr pressure equipment. The user should study

all of these instructions carefully before starting

to use any Parr pressure vessels in order to obtain

a complete understanding of the capabilities and

limitations of these vessels, and to be well aware of

the precautions to be observed in their operation.

Related Instructions

The following Parr publications are also included to

further your understanding of this instrument and

its component parts:

Intended Usage

This system has been designed for use as a high

pressure reactor system. It has been designed, built,

and tested to strict physical and electrical standards.

However, it is the user’s responsibility to install and

operate it in conformance with local pressure and

electrical codes.

If this equipment is used in a manner beyond its

intended usage, the protection provided by the

equipment may be impaired.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capability.

2. Ensure that the equipment is connected to

electrical service according to local national

electrical codes. Failure to properly connect may

create a fire or shock hazard.

3. For continued protection against possible

hazard, replace fuses with same type and rating

of fuse.

No. Description

201M Limited Warranty

230M Safety Precautions to be observed when

operating Pressure Reaction Equipment

231M Operating Instructions for Parr Safety

Rupture Discs

285M Sealing Instructions for Flexible

Graphite Gaskets

323M Operating Instructions for Pressure

Relief Valves

551M Operating Instructions for 4838

Temperature Controllers

FX004 Health & Safety Assurance Certification

4. Disconnect from the power supply before

maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components which

may ignite such material.

2. Refer servicing to qualified personnel.

www.parrinst.com

3

Page 4

General Purpose Pressure Vessels

Explanation of Symbols

II On position, full power heater switch

I On position, half power heater switch

O Off Position

~ Alternating Current (AC)

This CAUTION symbol may be present on the Product Instrumentation and

literature. If present on the product, the user must consult the appropriate

part of the accompanying product literature for more information.

This CAUTION symbol indicates that the surface may be hot.

Protective Earth (PE) terminal. Provided for connection of the Protective

Earth (green or green/yellow) supply system conductor.

Environmental Conditions

This instrument is intended to be used indoors.

Caution!

Do not use in hazardous atmospheres.

Operating: 15 ºC to 40 ºC; maximum relative humidity of 80% non-condensing. Installation Category II

(over voltage) in accordance with IEC 664. Pollution

degree 2 in accordance with IEC 664.

Altitude Limit: 0 to 6000 feet above sea level.

Storage: -25 °C to 65 °C; 10% to 85% relative humidity.

Unpack Carefully

Unpack the equipment carefully and check all the

parts against the packing list. If shipping damage

is discovered, report it immediately to the delivering carriers. The vessel, motor, heater, and temperature controller may be packed separately for

convenience in shipping, but these parts are easily

reassembled. Examine the components closely for

any loose parts or shipping damage and be sure to

check all layers of packing materials thoroughly so

as not to overlook any parts which might otherwise

be discarded.

Provisions for Lifting and Carrying

The Series 4600 and 4700 General Purpose Vessels

and their components are very heavy. Before

moving ensure all cables are disconnected. Use

proper and safe lifting techniques when installing or

moving the Series 4600 and 4700 General Purpose

Vessels and/ or its components.

Cleaning and Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the instrument with a lightly dampened

cloth containing mild soap solution. All power should

be disconnected when cleaning the instrument.

There are no user serviceable parts inside the product other than what is specifically called out and

discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can

be obtained by calling Parr Instrument Company in

order to determine which part(s) may be replaced or

serviced.

Ensure that any hot surfaces have had adequate

time to cool before cleaning or maintaining the

reactor and/or its components.

4

Parr Instrument Company

Page 5

General Purpose Pressure Vessels

User’s Responsibility

All Parr Reactors and pressure vessels are designed

and manufactured with great care to assure safe

operation when used within their prescribed temperature and pressure limits. But . . . the basic

responsibility for safety when using this equipment

rests entirely with the user; who must:

1. Select a reactor or pressure vessel which has the

capability, pressure rating, corrosion resistance

and design features that are suitable for its intended use. Parr engineers will be glad to discuss available equipment and material options

with prospective users, but the final responsibility for selecting a reactor or pressure vessel

that will perform to the user’s satisfaction in any

particular reaction or test must rest with the user

– not with Parr.

In exercising the responsibility for the selection

of pressure equipment, the prospective user

is often faced with a choice between over- or

under-designed equipment. The hazards introduced by under-designed pressure vessels are

readily apparent, but the penalties that must

be paid for over-designed apparatus are often

overlooked.

Recognizing these criteria, Parr reactors and

pressure vessels are offered in several different

styles, each designed for convenient use in daily

operation within certain temperature and pressure limits, using gaskets, closures and other

elements carefully selected for safe operation

within the limits specified for that design. But in

order to preserve the validity of these designs,

all temperature and pressure limits must be

observed, and no attempt should be made to

increase these limits by making alterations or by

substituting components which are not recommended by Parr Instrument Company.

2. Install and operate the equipment within a

suitable barricade, if required, with appropriate

safety accessories and in full compliance with

local safety codes and rules.

All standard Parr pressure vessels are provided

with either a suitable relief device or a means

to attach one (typically in the form of a plugged

opening). When a pressure vessel is delivered

without a pressure venting device, it is the customer’s responsibility to provide pressure relief

in order to protect the operator and the equipment from destructive high pressures. If you

need more information or need help in selecting

a proper relief device, please contact Parr Instrument Company.

3. Establish training procedures to ensure that any

person handling the equipment knows how to

use it properly.

4. Maintain the equipment in good condition and

establish procedures for periodic testing to be

sure the vessel remains structurally sound.

Pressure and Temperature Limits

The working pressure and temperature at which any

reactor or pressure vessel can be used will depend

upon the design of the vessel and the materials

used in its construction. Since all materials lose

strength at elevated temperatures, any pressure

rating must be stated in terms of the temperature at

which it applies. The standard material of construction for Parr Instrument Company is Type 316 Stainless Steel.

Limits for vessels made of other materials and for

other operating temperatures can be obtained from

Parr Customer Service. No attempt should be made

to increase these limits by making alterations or by

substituting components that are not recommended

by the Parr Instrument Company. It must also be

understood that lower pressure and temperature

limits may be required for modified reactors and for

vessels made of special alloys.

Limits for vessels will be determined by the physical characteristics of the vessel material and will be

prescribed on an individual basis.

The maximum working pressure and temperature

for any vessel is governed by the design of the

vessel and the strength of the material from which

it is constructed. There is also a close relationship

between working pressure and temperature since

the strength of any material will normally fall off

as the temperature is increased. Temperature and

pressure limits are also affected by the physical

properties and temperature limits of the gaskets and

seals used in the vessel, and by any valves, gages

or other fittings attached to the vessel. Obviously,

the safe operating pressure of any system can be no

higher than that of its lowest rated component.

All Parr reactors show the maximum safe operating

pressure and temperature imprinted on the cylinder.

www.parrinst.com

5

Page 6

General Purpose Pressure Vessels

CLOSURES

Split Ring Closures

Most Parr pressure vessels are equipped with

a unique split ring cover

clamp in which the head

of the vessel is clamped to

the cylinder by a hardened

steel ring which has been

split into two sections.

These sections slide into

place from the sides

without interfering with

any fittings attached to the

head.

The closing force is developed by simply tightening

a set of compression bolts

in the ring sections with a

hand wrench. As a further

convenience, larger Parr

vessels in one and two

gallon sizes, and certain

high temperature and

high pressure vessels, are

equipped with split ring

closures which do not

4751 125 mL Vessel with

Split Ring Closure and

4316 Gage Block Assembly

simply sliding the split ring section into place from

the sides and tightening the compression bolts

while the cylinder remains in place in its heater or

other fixed support.

Split Ring Closure Operations

All vessels with split ring closures, except the larger

Series 4660, 4670 and 4680 sizes, must be removed

from the heater and set on a bench or table top

before attempting to remove the split rings and

head.

1. To Open the Vessel: open the gas release valve

to discharge any internal pressure; then loosen

the compression bolts in the split ring sections.

Loosen the cone pointed screw in the outer band

and lower the band to rest on the table. The ring

sections can now be removed, and the head with

all attached fittings is free to be lifted from the

cylinder.

require an outer retaining

ring or drop band. This

allows the vessel to be

opened and closed by

2. Before Closing the Vessel: examine the head seal

carefully to be sure that it is in good condition.

The seal should not have any nicks or be hardened, discolored, or deformed. Examine the

mating surfaces on the cylinder and head to be

sure they are clean and free from burrs; then set

the head on the cylinder.

3. To Close the Vessel: put the two split ring halves

around the head and cylinder flanges, fasten the

latches or tighten the bolts as assembled before.

4. Routinely inspect the bolts on split ring closures for lubrication and cleanliness. These

screws should not be allowed to dry because

the threads will seize. Regularly apply Parr High

Temperature Anti-Seize Lubricant before this

happens.

Screw Cap Closures

On the smallest Parr vessels a

threaded sleeve and screw cap

are used to clamp the head to a

cylinder. This is a union type coupling in which proper alignment

between the head and cylinder

is always assured since neither

of these parts rotates when the

screw cap is tightened. The flat

gasket is held in a recess in the

head. The seal is made as the

lip of the cylinder is compressed

against the gasket through tightening the screw cap and sleeve.

All components must be kept

clean. The gasket must be replaced whenever it becomes worn

4703 22 mL Screw

Cap Vessel

or damaged. Any nicks in gasket

recess area or to the sealing face

of the cylinder must be avoided.

Operating 4700 Screw Cap Vessels

To close the Series 4700 Screw Cap Vessels: raise

the sleeve against the top rim of the cylinder; set

the head on the cylinder and attach the screw cap.

Turn the screw cap down until it is finger tight; then

set the vessel in a Parr A22AC3 bench socket and

tighten the cap firmly with a 21AC4 box wrench.

6

Parr Instrument Company

Page 7

General Purpose Pressure Vessels

PARR PRESSURE VESSEL SEALS

Several different head sealing arrangements are

used in Parr Pressure Vessels, each selected for easy

access to the interior of the vessel as well as for

safe operation within the pressure and temperature

limits for which the vessel is designed. Both flat

compression type gaskets and O-rings are used in

these designs.

The various gasket materials used in Parr pressure

vessels are listed in Table I. Since several of these

materials are produced by different suppliers under

different trade names, the ASTM generic designation is used in these instructions to identify the type

of sealing material (or materials) recommended for

each Parr vessel.

Flat Gasket or Self Sealing O-ring Closure

The flat gasket is held in a recess in the vessel head

and a machine pilot on the cylinder closes the recess

to completely contain the gasket. The split ring closure used with this gasket has cap screws which must

be tightened to develop the loading on the gasket.

The self sealing design features an O-ring retained

in a groove on the vessel head. This design is self

sealing and the split ring used with this sealing

system does not require nor have the cap screws

used with the flat gasket.

The flat PTFE gasket can be used to operating temperatures as high as 350 °C. The flat flexible graphite

(FG) gasket can be used to operating temperatures

as high as 600 °C.

O-rings are available in several different materials

for use within the temperature limit listed in the

following table.

Pressure and Temperature Limits

O-Ring Material Maximum Temperature

NBR 150 °C

FKM 225 °C

FFKM 300 °C

PTFE 350 °C

Gaskets for Operating Temperature above 350 °C

Parr uses a flexible form of graphite which has

proven to be an excellent high temperature sealing

material. It has almost unlimited temperature range,

retaining its structure at temperatures well above the

maximum at which a metal gasket can operate, and

offering broad corrosion resistance as well.

Metal Gaskets can be furnished if required for special

applications. These are usually made of stainless

steel machined to a unique diamond shape with

edges which fit into supporting grooves in the head

and cylinder of the vessel. This type of gasket requires careful maintenance and a uniform loading applied by tightening a ring of compression bolts with a

torque wrench. For easier handling, Parr has replaced

its diamond shaped metal gaskets with flat, flexible

graphite gaskets (FG) described above. But it will

continue to furnish metal gaskets in custom vessels

for applications in which a metal gasket appears to

offer the best solution to a difficult sealing problem.

Sealing the Vessel

The maximum temperature of the vessels equipped

with O-ring seals depends upon the material used

for the O-ring. The most common material is a fluoroelastomer (FKM) which has a 225 °C maximum

operating temperature limit.

Seals for Operating Temperatures up to 350 °C

Parr uses both flat contained gaskets and O-rings

made of different materials, each with a different

maximum working temperature. Flat gaskets made

of PTFE fluoropolymer resins are the recommended

choice for many applications since PTFE materials are inert to most chemicals. PTFE gaskets will

provide good seals under repeated opening and

closing of the vessel if the gasket temperature does

not exceed 350 °C.

Vessels with split ring closures are sealed by tightening the compression bolts in the split ring sections with a wrench furnished with the apparatus. To

ensure uniform loading, turn down each bolt finger

tight, then tighten to the limit described below for

the type of gasket being used. Do not over-tighten

the compression bolts as this can generate excessive strain on the closure.

Vessels with a Flat PTFE Gasket

Tighten the compression bolts using a criss-cross

pattern, applying a firm but hard pull to each

screw. Use a torque wrench to apply 25 ft-lbs to

each compression bolt. Let the vessel stand for

about five minutes after the initial tightening, then

tighten again to 25-ft lbs. This will compensate for

any tendency of the PTFE gasket to flow under the

loading pressure.

www.parrinst.com

7

Page 8

General Purpose Pressure Vessels

Vessels with an O-ring seal

The self-sealing design features an O-ring retained

in a groove on the vessel head. This design is self

sealing and the split ring does not require or have

the compression bolts used with the flat gasket.

Vessels with a Flexible Graphite Gasket

The closure bolts may be tightened using either an

open-end wrench for smaller vessels where the bolt

torque requirement is less or with a torque wrench

where additional loading is required for the higher

operating pressures.

Some of the gasket numbers shown in the attached

table are furnished with vessels that have different

maximum working pressures. We have shown the

maximum torque value to correlate to the maximum

working pressure of the vessel.

It is important to make sure that the bolts are

periodically lubricated with a high-temp anti-seize

compound to insure that they move freely so that

the desired torque value is obtained in the tightening procedure.

It is also important to insure that there is uniform

loading on all of the bolts. Make sure that the head

sits levelly on the cylinder. Install the split ring and

tighten all bolts finger tight.

Pick a starting position and tighten the bolt to 5 or 10

ft-lbs depending on the maximum amount of torque

to be applied. For those vessels with a maximum

torque requirement of 15 ft-lbs, a 5 ft-lb increment

is appropriate. For vessels with a maximum of 135

ft-lbs, 20 ft-lb increments may be used.

Bolt tightening should continue in a criss-cross

pattern from the initial bolt with the second bolt 180

degrees from the first and continuing until all bolts

are tightened. Repeat this procedure increasing the

torque to the required level as shown in the table

below.

Torque Required For Sealing Vessels

with Flexible Graphite Gaskets

Vessel

Series

No.

4600 1900 315HC4KL 35

4790 3000 to 5000 429HC2KL 15

4760 3000 457HC3KL 35

4650 5000 to 6000 457HC3KL 40

4660 190 0 655HC3KL 35

4680 5000 1808HCKL 40

4670 3000 1812HCKL 35

4740 8500 1829HCKL 15

4676 190 0 1559HC2KL 135

Note: It may be possible to extend the life of

the Flexible Graphite gasket by coating both

sealing surfaces of the head and cylinder as

well as the gasket itself with a silicone base

lubricant. Additionally, it helps to rough up

the cylinder lip with 120 grit sandpaper to

insure that the gasket remains in the head

recess and does not stick to the cylinder.

Vessels with a Metal Gasket

Pressure vessels with a metal gasket require a

uniform loading on the gasket carefully applied by

tightening a ring of compression bolts with a torque

wrench. The amount of torque to be applied will

vary with different vessels and with the intended

maximum working pressure. Specific sealing

instructions will be provided for any Parr pressure

vessels with a metal gasket furnished on special

order.

Maximum

Working

Pressure, PSI

Graphite

Gasket

No.

Torque

Required

ft-lb

8

Parr Instrument Company

Page 9

General Purpose Pressure Vessels

G

y

Sealing 4740 High Pressure Vessels

Closing operations for the 1.0 inch I.D., Series 4740

high pressure vessels are similar to those described

for larger vessels with flexible graphite gaskets,

except on the 4740 Series the compression screws

are carried in a screw cap instead of in a split ring.

When closing a 4740, clamp the cylinder in a vise;

check the graphite gasket to be sure that it fits properly in the head groove; set the head on the cylinder

and add the compression ring. Check the screw cap

to be sure that the six screws have been turned back

so that they do not project through the cap, and then

screw the cap onto the cylinder. Turn it down as far

as it will go, then back it off about 1/8 turn. Now,

tighten the screws with a torque wrench with an

initial 10 ft-lbs using the criss-cross pattern described

for larger vessels. After all have been tightened to

10 ft-lbs, repeat the procedure, increasing the torque

until all have been tightened to the recommended 15

ft-lb limit.

OTHER VESSEL HEAD FITTINGS

Gage Block Assemblies

age

mbl

age

The valve in this assembly controls the flow of gas

into the vessel and the gage shows the internal

pressure when the valve is closed. Two styles are

offered: The 4316 gage block assembly has a 3-1/2”

dia. pressure gage and a Type A socket connector.

This unit is normally used on smaller vessels where

space is limited.

The 4317 gage block assembly has a 4-1/2” dia. gage

and a Type B connector. It is typically furnished on

vessels one liter and larger.

Pressure Gages

Pressure gages display in both psi and bar in various ranges for use on Parr gage block assemblies.

The available ranges are shown in the gage block

parts list. All of these gages have stainless steel

cases with T316SS Bourdon tubes and ¼” NPT male

connections. Gages constructed of Alloy 400 are

available on special order.

Safety Rupture Discs

Detailed instructions for the safety rupture disc

installed in Parr gage blocks and heads are provided

in a separate Instruction Sheet No. 231M. The user

should review these instructions carefully. Please

note that the operating pressures in the vessel

should not exceed 90% of the range of the pressure

gage and rupture disc. Also note the warning that

the discharge port from the rupture disc must always

be directed away from all operating personnel. A

compression fitting for use with 3/8” O.D. tubing is

attached to the rupture disc body. It is recommended that tubing be attached to this connector to carry

any discharge to a fume hood or safe area in the

event of an over-pressure. The free or discharge end

of any attached tubing must be anchored securely.

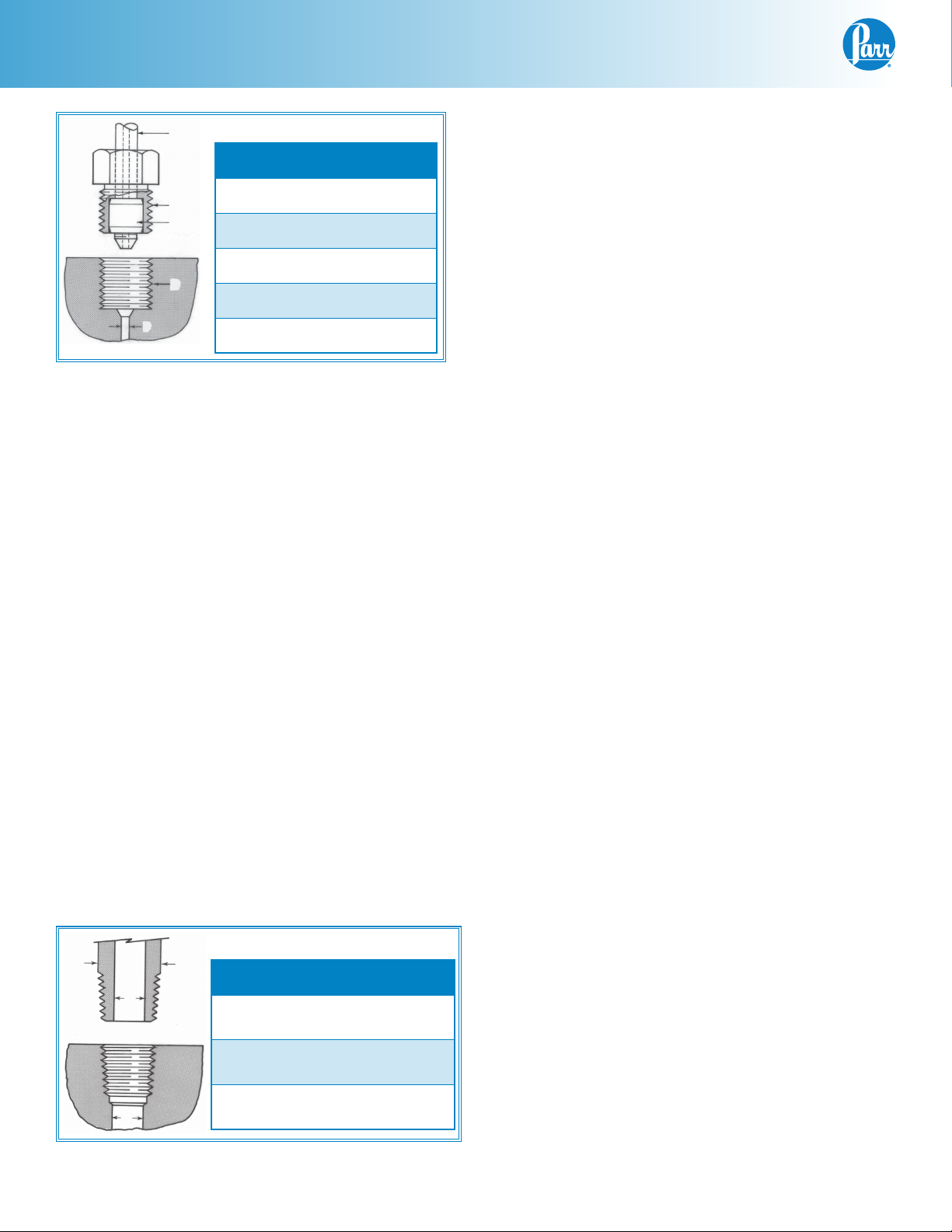

Coned Pressure Fittings

The coned pressure fittings used to connect gage

blocks, pressure hoses and other detachable parts

Parr gage block assemblies combine the function of

an inlet valve, a pressure gage and a safety rupture

disc in a compact assembly on a block which can

be attached to the head of a pressure vessel with a

single connecting tube. There is a threaded socket

in the block for a gas connection with a pressure

hose or tubing using a Type A coned pressure fitting.

Coned pressure fittings are also used on the tube

which connects the block to the pressure vessel.

to Parr pressure vessels are illustrated below. These

fittings have a sleeve with a left-handed thread

which screws onto the end of a thick-walled tube

plus a compression nut to complete the assembly.

When screwed into a matching socket, these parts

form a rigid joint which will remain tight over a wide

temperature and pressure range, yet the joint can be

made and broken repeatedly without destroying the

sealing faces. No gasket is required.

www.parrinst.com

9

Page 10

General Purpose Pressure Vessels

TUBING

Coned Pressure Fittings

Type A B

NUT

BUSHING

D

E

Tube Size 1/4” 3/8”

Thread (D) 9/16-18 3/4-16

Bore (E) 3/32” 1/8”

Nut No. 35HC 326HC

Bushing No.

40HC 366HC

When using these coned connectors, screw the

bushing onto the tube as far as it will go; then insert

the end of the tube into the head or gage block and

tighten the compression nut firmly while holding the

block stationary with the gage facing in the desired

direction. Note that this assembly behaves like a

pipe union, allowing the connecting tube or hose to

remain stationary while the joint is tightened.

Note: PTFE tape is not required on these connectors.

MAINTENANCE

General Maintenance Notes

1. Periodically inspect all electrical wiring and pressure connections for excessive corrosion. Suspect parts should be replaced by components

only supplied by Parr Instrument Company.

2. Always use appropriate wrenches on all fittings

and valves. Never use pliers or pipe wrenches.

3. Head and cylinder service fixtures are available

for convenience and protection of components

during maintenance of your reactor.

Note: For more information about available

service fixtures, reference TechNote 307.

4. A light coating of thread lubricant, such as Parr

High Temperature Anti-Seize Lubricant, (424HC2)

should be applied to the straight threads of

coned pressure connections as well as to the

nose of the mating piece this will help to obtain

a tight joint.

Tapered Pipe Threads

The pressure gage, needle valves and other fixed

attachments on Parr vessel heads have tapered pipe

threads which are not to be disturbed after they

have been screwed into place. If it becomes necessary to remove any of these fittings, the pipe threads

must be coated with PTFE tape, flexible graphite

tape, or similar luting material on reassembly.

The ID of a pipe or pipe fitting can be enlarged to

accommodate a tubing feed-thru. Note that, in some

cases, this may cause a reduction of the pressure

rating. The port below a female pipe connection can

also be opened up to a larger size.

The maximum openings are shown in the table below.

Tapered Pipe Threads

A

Nominal Size

B

Pipe OD (A) 0.405” 0.540”

Maximum

Feed-thru (B)

Maximum Exit

C

Port (C)

1/8” 1/4”

1/4” 3/8”

0.339” 0.458”

Note: PTFE tape should be used only on

all tapered (NPT) threads not NPS straight

threads.

5. NPT (National Pipe Taper) threads should not be

disassembled any more than necessary. It will

become increasingly difficult to maintain a tight

seal with these tapered threads if the joint is

made and broken repeatedly.

6. Do not use oil or anti-seize lubricant on threads

or fittings if the vessel is to be used with oxygen.

7. If your vessel is equipped with a loose compression ring be sure that it is in place on the head

before attaching any head fittings. The compression ring cannot be installed after fittings have

been screwed into the head.

10

Parr Instrument Company

Page 11

General Purpose Pressure Vessels

8. Clean all threads and gas passages thoroughly

and remove all tape fragments when overhauling a vessel. An ultrasonic bath is excellent for

cleaning metal parts, but do not place a thermocouple probe, pressure gage, face seals or ball

bearings in an ultrasonic bath. Periodic cleaning

may be performed on the exterior surfaces of

the reactor stand with a damp cloth. All power

should be disconnected when cleaning.

9. Routinely inspect the bolts on split ring closures for lubrication and cleanliness. These

screws should not be allowed to dry because

the threads will seize. Regularly apply Parr High

Temperature Anti-Seize Lubricant before this

happens. It is important to keep the bolts lubricated so they will not seize and also to achieve

the intended torque value.

10. Routinely inspect screw cap threads for wear

and cleanliness.

11. If servicing assistance is needed, contact Parr Instrument Company direct at the address shown

on the back of these instructions.

Periodic Pressure Tests

Each cylinder used in a Parr pressure vessel is tested

under hydrostatic pressure at room temperature to

the higher of 1.43 times the rated working pressure

or 1.30 times the rated working pressure corrected

for room temperature before it is released from

the factory. Micrometer caliper measurements are

taken during this test to check the deflection of the

walls under pressure. Excessive deflection or failure

of the metal to resume its original dimensions after

pressure is released indicates that a cylinder is potentially unsafe and it will be rejected. Similar tests

should be made at regular intervals during the life

of each cylinder, and particularly whenever the user

suspects that the equipment has been over-stressed

or damaged.

Some laboratories maintain hydraulic test facilities

and make it a rule that all pressure vessels must

be tested at regular intervals. Records are kept of

deflections at specific test pressures so that any

increase in deflection becomes a warning that the

metal has lost strength. Any cylinder that fails to

return to its original dimensions after application of

the prescribed hydrostatic test should be discarded

as unsafe for further use.

Users who do not have pressure test facilities can

return any Parr pressure vessel to the factory for hydrostatic testing and overhaul. This should be done

whenever the metal shows excessive damage from

corrosion or whenever an over-pressure or other

unusual occurrence raises any safety questions.

To return a vessel for repair, contact Parr Instrument

Company for a return authorization number (RMA).

Apparatus returned for testing and overhaul should

be shipped prepaid to the following address:

Ship repair to:

Parr Instrument Company

Attn: Service Department

RMA # XXXXXX

211 53rd Street

Moline, Illinois 61265

USA

An order or letter of instructions should be mailed to

the same address, as no repair work will be started

without specific instructions and a Health & Safety

Assurance Certification form (FX004) signed by a

responsible user.

www.parrinst.com

11

Page 12

General Purpose Pressure Vessels

HEAD ASSEMBLY GUIDE

Refer to this table for more information about Head Styles Listed in Series Working Limits and Parts List section.

Head Style Description

One opening, TBD

“A” Socket One Type “A” Socket opening, to be used with 4316 Gage Block Assembly

“B” Socket One Type “B” Socket opening, to be used with 4317 Gage Block Assembly

VGR Valve, gage, rupture disc, and thermocouple

Notes:

1) Reference pages 32-35 for more information about Gage Block Assemblies.

2) Number of valves varies amongst series. See individual heads for number of valves.

3) A thermowell with thermocouple is offered for most series if needed.

One opening, size to be determined by user

1

1

2 3

MATERIAL DESIGNATIONS

Material Designations for Alloys other than T316SS

For parts made from alternate materials use the codes shown below as a suffix to the standard part number.

CM - Alloy 400 CC - Alloy 20Cb3 CH - Alloy C-276

CT - Alloy 600 CAD - Titanium G2 CXA - Zirconium G702

CG - Alloy B-2 CAA - Titanium G4 CXB - Zirconium G705

Gasket Material Designations

Common Trade Name Type of Material ASTM Designations Parr Suffix

Nitrile, buna-N Butadiene / acryloelastomer NBR JB

Viton®

Kalrez®

Chemraz®

Parofluor®

Ethylene/ Propylene Ethylene propylene Copolymer elastomer EP JE

Teflon ®

Grafoil®

1

2

3

4

5

6

Fluoroelastomer FKM JV

Perfluoroelastomer FFKM JK

Tetrafluoroethylene polymer PTFE HA

Flexible graphite FG KL

1) Viton® is a registered trademark of DuPont

2) Kalrez® is a registered trademark of DuPont

3) Chemraz® is a registered trademark of Green, Tweede & Co. Ltd.

4) Parofluor® is a registered trademark of Parker Hannifin Corporation

5) Teflon® is a registered trademark of DuPont

6) Grafoil® is a registered trademark of UCAR Carbon, Inc.

12

Parr Instrument Company

Page 13

General Purpose Pressure Vessels

SERIES 4700 WORKING LIMITS AND PARTS LISTS

Series 4703-4714

Model Size Head Style

4703 22 mL

4704 22 mL “A" Socket Steel

4713 45 mL

4714 45 mL “A” Socket Steel

Working Limits

Maximum Working Pressure

(T316SS) 1700 psi (117 bar)

Maximum Working Temperature

with Steel Closure 300 °C

One opening, TBD

One opening, TBD

Closure

Material

Steel

Steel

7AC27, HEAD, 1/8 NPT

W/PLUG (4703/4713)

7AC7 HEAD, A SKT (4704/4714)

Recommended Bolt Torque:

PTFE Gasket

500 PSI 15 ft - lbs

1000 PSI 20 ft - lbs

1500 PSI 30 ft - lbs

1700 PSI 40 ft - lbs

Part No. Description Flat Gasket Seal

7AC7 Head, "A" socket

7AC8 Head, one 1/4" NPT opening

7AC27 Head, one 1/8” NPT opening

2AC Cylinder, 22 mL, 1.62" deep

2AC4 Cylinder, 45 mL, 3.81" deep

170AC Screw cap, alloy steel

6ACDB Body Sleeve, alloy steel

27ACHA Gasket, PTFE

21AC4 Wrench, 1-5/8" octagon

A22AC3 Holder Socket with screws

170AC SCREW CAP

27ACHA GASKET

6ACDB BODY SLEEVE

2AC CYLINDER, 22mL

2AC4 CYLINDER, 45mL

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

www.parrinst.com

13

Page 14

General Purpose Pressure Vessels

Series 4740

Model Size Head Style

4740 75 mL “A” Socket

4742 22 mL “A” Socket

Working Limits***

Maximum Working Pressure** (T316SS)

8500 psi (586 bar) @ 350 °C

1850 psi (124 bar) @ 600 °C

Maximum Working Temperature 600 °C

***See Manual No. 294M for more information.

Recommended Bolt Torque:

PTFE or Flexible Graphite

8500 PSI 15 ft - lbs

1827HC HEAD

(6) 33HDF2

COMPRESSION BOLTS

Part No. Description Flat Gasket Seal

1827HC Head , "A" Socket opening

A1828HC Cylinder, 75 mL, w/ A33HD2 screw cap

A1828HC2 Cylinder, 22 mL, w/ A33HD2 screw cap

1829HCKL Gasket, Flexible Graphite

1826HC Compression Ring

A33HD2 Screw cap with cap screws, alloy steel

33HDF2 Cap screw for above (6 required)

A33HD2CH**Screw Cap, Hastelloy C

40HD Pyrex Liner, 75 mL

1826HC

COMPRESSION RING

1829HCKL

GASKET, GRAFOIL

A33HD2

SCREW CAP

A1828HC (4740)

CYLINDER, 75mL

A1828HC2 (4742)

CYLINDER, 25mL

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

**Required for max work pressure 5700 psi at 600 °C temp. for vessel of T316SS

14

Parr Instrument Company

Page 15

Series 4750

Model Size Head Style

4750 125 mL One opening, TBD

4751 125 mL “A” Socket

4752 200 mL One opening, TBD

4753 200 mL “A” Socket

4754 125 mL “A” Socket & 1/8” NPT

with thermocouple

4755 200 mL “A” Socket & 1/8” NPT

with thermocouple

Working Limits

Maximum Working Pressure (T316SS)

3000 psi (207 bar)@ 350 °C

Maximum Working Temperature 350 °C

Recommended Bolt Torque:

PTFE or Flexible Graphite

15 ft - lbs max

General Purpose Pressure Vessels

Part No. Description Flat Gasket Seal

428HC3 Head, "A" socket opening

428HC9 Head, two 1/8" NPT

428HC11 Head, "A" socket & 1/8" NPT

428HC22 Head, "A" socket & 1/8" NPT

for thermowell

425HC Cylinder, 125 mL, 4.44" deep

425HC3 Cylinder, 200 mL, 6.94" deep

429HC2 Gasket, PTFE

429HC2KL Gasket, Flexible Graphite

430HC Compression Ring

A431HC Split ring, pair, with cap screws

232HCFDE Cap Screw for above (6 required)

A432HC Drop band with set screw

456HCF2 Set screw for above

A833HC Male Connector for thermocouple

A472E Thermocouple, 7-1/2”, SS

A472E2 Thermocouple, 9-1/2”, SS

A138CA Male Connector for thermowell

A1453HC Thermowell

2920HC4HA PTFE liner, 125 mL

2920HC2 Pyrex liner, 125 mL

A472E THERMOCOUPLE, 125mL

A472E2 THERMOCOUPLE, 200mL

A833HC MALE CONNECTOR

428HC SERIES HEAD

A431HC SPLIT RING ASSY

430HC COMPRESSION RING

429HC2 GASKET

A432HC DROP BAND W/SCREW

425HC CYLINDER, 125mL

425HC3 CYLINDER, 200mL

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

www.parrinst.com

15

Page 16

General Purpose Pressure Vessels

Series 4760-4777

Model Size Head Style

4760 300 mL One opening, TBD

4761 300 mL “A” Socket

4762 450 mL One opening, TBD

4763 450 mL

4764 600 mL One opening, TBD

4765 600 mL “A” Socket

4766 300 mL VGR

4767 450 mL VGR

4768 600 mL VGR

4772 160 mL One opening, TBD

4773 160 mL

4774 160 mL VGR

4775 100 mL One opening, TBD

4776 100 mL

4777 100 mL VGR

Working Limits

Maximum Working Pressure

Maximum Working Temperature

with PTFE confined flat gasket

Recommended Bolt Torque:

PTFE Gasket

Flexible Graphite

“A” Socket

“A” Socket

“A” Socket

3000 psi (207 bar) @ 350 °C

25 ft - lbs

35 ft - lbs

350 °C

Part No. Description Flat Gasket Seal

453HC Head, "A" Socket opening

453HC5 Head, "A" Socket & 1/8” NPT

453HC79*

818HC45 Head, VGR

452HC Cylinder, 300 mL, 3.94" deep

452HC2 Cylinder, 450 mL, 5.94" deep

452HC3 Cylinder, 600 mL, 7.94" deep

452HC9 Cylinder, 160 mL, 2.00" deep

452HC8 Cylinder, 100 mL, 2.00" deep, 2” ID

457HC2 Gasket, PTFE

457HC3KL Gasket, Flexible Graphite

454HC Compression Ring

A455HC Split ring, pair, with cap screws

232HCFDE Cap screw for above (6 required)

A456HC Drop band with set screw

456HCF Set screw for above

A833HC Connector for thermocouple

A472E Thermocouple, 7-1/2”, SS

A472E2 Thermocouple, 9-1/2”, SS

A472E3 Thermocouple, 11-1/2, SS

A1453HC Thermowell

A138CA Connector for thermowell

2583HC Head/Cylinder Service Fixture

Head, “A” Socket & 1/8” NPT for

thermowell

Liners

Volume Pyrex PTFE

100 mL 762HC7 762HC7HA

160 mL 762HC8 762HC8HA

300 ML 762HC 762HC4HA

450 mL 762HC2 762HC5HA

600 mL 762HC3 762HC6HA

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

16

Parr Instrument Company

Page 17

General Purpose Pressure Vessels

526HC SERIES R/D

832HC4 DIP TUBE W/NUT

836HC GAGE ADAPTER

818HC45 HEAD

452HC CYLINDER, 300mL

288VBAD MALE CONNECTOR

366VBAA HEX COUPLING

A455HC SPLIT RING ASSY

457HC2 GASKET

454HC COMPRESSION RING

A456HC DROP BAND W/SCREW

A472E THERMOCOUPLE

A888HC2 R/D HOLDER ASSY

593HC SERIES PRESSURE GAGE

A833HC MALE CONNECTOR

A122VB STRAIGHT VALVE

420HC ADAPTER

835HC ADAPTER TEE

A146VB ANGLE VALVE

A122VB STRAIGHT VALVE

www.parrinst.com

17

Page 18

General Purpose Pressure Vessels

Series 4760Q-4777Q

Model Size Head Style

4760Q 300 mL One opening, TBD

4761Q 300 mL “A” Socket

4762Q 450 mL One opening, TBD

4763Q 450 mL

4764Q 600 mL One opening, TBD

4765Q 600 mL “A” Socket

4766Q 300 mL VGR

4767Q 450 mL VGR

4768Q 600 mL VGR

4772Q 160 mL One opening, TBD

4773Q 160 mL

4774Q 160 mL VGR

4775Q 100 mL One opening, TBD

4776Q 100 mL

4777Q 100 mL VGR

Working Limits

Maximum Working Pressure (T316SS)

Maximum Working Temperature

with FKM O-ring

with FFKM O-ring

“A” Socket

“A” Socket

“A” Socket

3000 psi (207 bar)

225 °C

300 °C

Part No. Description O-ring Seal

2321HC2 Head, “A" socket opening

2321HC3

2340HC11 Head, VGR

2342HC Cylinder, 300 mL, 3.94" deep

2342HC2 Cylinder, 450 mL, 5.94" deep

2342HC3 Cylinder, 600 mL, 7.94" deep

2342HC4 Cylinder, 100 mL, 2.00” deep, 2” ID

2342HC5 Cylinder, 160 mL, 2.00" deep

2341HCJV O-ring, FKM

2341HCJK O-Ring, FFKM

2195HC Split ring, pair

A456HC Drop band with set screw

456HCF Set screw for above

A833HC Connector for thermocouple

A472E Thermocouple, 7-1/2”, SS

A472E2 Thermocouple, 9-1/2”, SS

A472E3 Thermocouple, 11-1/2, SS

A1453HC Thermowell

A138CA Connector for thermowell

2587HC Head/Cylinder Service Fixture

Head, "A" socket & 1/8” NPT

Liners

Volume Pyrex PTFE

100 mL 762HC7 762HC7HA

160 mL 762HC8 762HC8HA

300 ML 762HC 762HC4HA

450 mL 762HC2 762HC5HA

600 mL 762HC3 762HC6HA

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

18

Parr Instrument Company

Page 19

General Purpose Pressure Vessels

288VBAD MALE CONNECTOR

A472E THERMOCOUPLE

366VBAA HEX COUPLING

A833HC MALE CONNECTOR

A888HC2 R/D HOLDER ASSY

562HC SERIES R/D

2340HC11 HEAD

2195HC SPLIT RING ASSY

A456HC DROP BAND W/SCREW

2341HCJV O-RING

832HC4 DIP TUBE W/NUT

2342HC CYLINDER, 300mL

593HC SERIES PRESSURE GAGE

836HC GAGE ADAPTER

A122VB STRAIGHT VALVE

835HC ADAPTER TEE

A146VB ANGLE VALVE

A122VB STRAIGHT VALVE

420HC ADAPTER

www.parrinst.com

19

Page 20

General Purpose Pressure Vessels

Series 4790

Model Size Head Style

4791 25 mL VGR

4792 50 mL VGR

4793 100 mL VGR

Working Limits (Standard Ratings)

Maximum Working Pressure

(T316SS) 3000 psi (200 bar)

With PTFE Flat Gasket

With FKM O-ring

With FFKM O-ring

350 °C

225 °C

300 °C

Working Limits (High Pressure/High Temp.)

Maximum Working Pressure

(T316SS) 5000 psi (345 bar)

With PTFE Flat Gasket

With Flexible Graphite Gasket*

*A vessel with a Fixed Head is required for effective heating to 500 °C.

350 °C

500 °C

4790 with Flat Gasket & Split Ring

Part No. Description

2432HC3

3665HC

Head, VGR (three valves) & 1/8” NPT

(General Purpose & HP vessels)

Fixed Head, VGR (two valves) &

1/8” NPT

(HP/HT vessels)

&

2430HC Cylinder, 25 mL

2430HC18 Cylinder, 25 mL, 100 mL Profile (HP/HT)

2430HC2 Cylinder, 50 mL

2430HC19 Cylinder, 50 mL, 100 mL Profile (HP/HT)

2430HC3 Cylinder, 100 mL

429HC2 Gasket, PTFE

429HC2KL Gasket, Flexible Graphite

454HC Compression Ring

A455HC Split Ring

A456HC Drop Band

232HCFDE Bolt for Split Ring

4790 with O-ring Seal and Screw Cap

Part No. Description

1432HC Head, VGR (three valves) & 1/8” NPT

1430HC Cylinder, 25 mL, 2" deep

1430HC2 Cylinder, 50 mL, 2.25" deep

1430HC3 Cylinder, 100 mL, 4.5" deep

1433HCJE O-Ring Gasket, EP

1433HCJK O-Ring Gasket, FFKM

1433HCJV O-Ring Gasket, FKM

1379HC Screw Cap

4790 with O-ring Seal & Easy Close Split Ring

Part No. Description

2902HC3 Head, VGR (three valves) & 1/8” NPT

2520HC Cylinder, 25 mL

2520HC2 Cylinder, 50 mL

2520HC3 Cylinder, 100 mL

2521HCJV O-Ring, FKM

2521HCJK O-Ring, FFKM

2195HC Split Ring

A456HC Drop Band

195VBAD Tee, 1/8” NPT

836HC Gage Adapter

420HC Adapter, A socket x 1/8” NPT

593HC SERIES PRESSURE GAGE

836HC GAGE ADAPTER

288VBAD MALE CONNECTOR

366VBAD MALE CONNECTOR

1432HC SERIES HEAD

A888HC2 R/D HOLDER ASSY

526HC SERIES R/D

1379HC SCREW CAP

1433HC SERIES O-RING

1443HC DIP TUBE, 25mL

1443HC2 DIP TUBE, 50mL

1443HC3 DIP TUBE, 100mL

1430HC CYLINDER, 25mL

1430HC2 CYLINDER, 50mL

1430HC3 CYLINDER, 100mL

4790Q General Purpose Vessel

O-ring Seal and Screw Cap

20

Parr Instrument Company

Page 21

A833HC MALE CONNECTOR

A472E4 THERMOCOUPLE

A122VB STRAIGHT VALVE

420HC ADAPTER

593HC SERIES PRESSURE GAGE

A146VB ANGLE VALVE

836HC GAGE ADAPTER

154VB 45 DEGREE ELBOW

260HC2 ADAPTER

288VBAD MALE CONNECTOR

2432HC3 HEAD

366VBAA MALE CONNECTOR

A888HC2 R/D HOLDER ASSY

526HC SERIES R/D

429HC2 GASKET

A455HC SPLIT RING ASSY

454HC COMPRESSION RING

A456HC DROP BAND W/SCREW

General Purpose Pressure Vessels

Recommended Bolt Torque

PTFE or Flexible Graphite

15 ft - lbs max

1443HC DIP TUBE, 25mL

2430HC CYLINDER, 25mL

4790 General Purpose Vessel

Flat Gasket Seal and Split Ring

Common Parts List for Series 4790

Part No. Description

195VBAD Tee, 1/8” NPT

836HC Gage Adapter

420HC Adapter, A socket x 1/8” NPT

A888HC2

Rupture Disc Assembly

(See Manual No. 231M)

526HCPD Rupture Disc, 1000 psi

526HCPF Rupture Disc, 2000 psi

526HCPG Rupture disc, 3000 psi

526HCPH Rupture disc, 5000 psi

593HCPD Pressure Gage, 0-1000 psi

593HCPF Pressure Gage, 0-2000 psi

593HCPG Pressure Gage, 0-3000 psi

593HCP50AD Pressure Gage, 0-5000 psi

A122VB Valve, Straight, 1/8” NPT (M)

Part No. Description

A146VB Valve, Angle, 1/8” NPT (M)

A472E4 Thermocouple, 5-1/2”

A472E Thermocouple, 7-1/2”

A833HC Connector for Thermocouple

1467HC Thermowell

A138CA Thermowell Connector

1443HC Dip Tube, 25 mL

1443HC2 Dip Tube, 50 mL

1443HC3 Dip Tube, 100 mL

2589HC Head/Cylinder Service Fixture

1431HC Pyrex Liner, 50 mL

1431HC2 Pyrex Liner, 100 mL

1431HCHA PTFE Liner, 50 mL

1431HC2HA PTFE Liner, 100 mL

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

www.parrinst.com

21

Page 22

General Purpose Pressure Vessels

A146VB ANGLE VALVE

179VBAD STREET TEE

236HC20 CYLINDER, 2L

260HC2 EXTENSION

257HC27 DIP TUBE, 2L

A232HC SPLIT RING ASSY

315HC2 SERIES GASKET

(OPTIONAL)

A233HC DROP BAND ASSY

265HC7 THERMOWELL, 1L

48HC GASKET

A122VB STRAIGHT VALVE

1370HC30 HEAD

265HC12 THERMOWELL, 2L

914HC LOCK NUT

257HC26 DIP TUBE, 1L

(OPTIONAL)

236HC10 CYLINDER, 1L

2X 420HC ADAPTER

234HC COMPRESSION RING

SERIES 4600 WORKING LIMITS AND PARTS LISTS

Series 4600-4620

Model Size Head Style

4601 1000 mL One opening, TBD

4602 2000 mL One opening, TBD

4611 1000 mL “B” Socket

4612 2000 mL “B” Socket

4621 1000 mL VGR, thermowell

4622 2000 mL VGR, thermowell

Working Limits

Maximum Working Pressure

(T316SS) 1900 psi (131 bar)

Maximum Working Temperature

with PTFE confined flat gasket 350 °C

Recommended Bolt Torque:

PTFE Gasket 25 ft - lbs

Flexible Graphite 35 ft - lbs

56HC SERIES

PRESSURE GAGE

A472E2

THERMOCOUPLE, 1L

A472E6

THERMOCOUPLE, 2L

A888HC2 R/D HOLDER ASSY

526HC /581HC STYLE R/D

366VBAA HEX COUPLING

288VBAD MALE CONNECTOR

Part No. Description Flat Gasket Seal

229HC3 Head, "B" Socket

229HC6 Head, "B" Socket, thermowell

942HC59 Head, one Rupture Disc Opening

1370HC30 Head, VGR, thermowell

236HC10 Cylinder, 1000 mL, 5.32" deep

236HC20 Cylinder, 2000 mL, 10.44" deep

315HC2 Gasket, PTFE

315HC4KL Gasket, Flexible Graphite

A232HC Split Ring pair, with cap screws

232HCFDE Cap Screw for above (6 required)

A233HC Drop Band with Screw

233HCF Drop Band Screw

234HC Compression Ring

A256HC Thermowell, 2000 mL w/ nut & gasket

A256HC2 Thermowell, 1000 mL w/ nut & gasket

SN4320HX Thermowell Nut

319HCFH Thermowell Gasket, Silver

319HCFG Thermowell Gasket, Gold

A472E2 Thermocouple, 9-1/2”, 1000mL

A472E6 Thermocouple, 15-1/2”, 2000mL

2584HC Head/Cylinder Service Fixture

398HC Pyrex Liner, 1000 mL

398HCHA PTFE Liner, 1000 mL

399HC PTFE liner, 2000 mL

399HCHA Pyrex Liner, 2000 mL

A122VB

*For special material vessels add material code

for head, cylinder or internal fittings per page 12.

22

Parr Instrument Company

STRAIGHT VALVE

208HC20

GAGE ADAPTER

209HC4

ADAPTER BUSHING

Page 23

General Purpose Pressure Vessels

A146VB ANGLE VALVE

260HC2 EXTENSION

2245HC SPLIT RING, QC

2740HC30 HEAD

179VBAD STREET TEE

A122VB STRAIGHT VALVE

2X 420HC ADAPTER

(OPTIONAL)

914HC LOCK NUT

A146VB ANGLE VALVE

265HC7 THERMOWELL, 1L

260HC2 EXTENSION

2245HC SPLIT RING, QC

48HC GASKET

A233HC DROP BAND ASSY

2741HCJV O-RING

2740HC30 HEAD

257HC27 DIP TUBE, 2L

179VBAD STREET TEE

265HC12 THERMOWELL, 2L

A122VB STRAIGHT VALVE

2X 420HC ADAPTER

257HC26 DIP TUBE, 1L

(OPTIONAL)

2742HC10 CYLINDER, 1L

2742HC20 CYLINDER, 2L

Series 4600Q-4620Q

Model Size Head Style

4601Q 1000 mL One opening, TBD

4602Q 2000 mL One opening, TBD

4611Q 1000 mL “B” Socket

4612Q 2000 mL “B” Socket

4621Q 1000 mL VGR, thermowell

4622Q 2000 mL VGR, thermowell

Working Limits

Maximum Working Pressure

(T316SS) 1900 psi (131 bar)

Maximum Working Temperature

with FKM O-ring 225 °C

Maximum Working Temperature

with FFKM O-ring 300 °C

Part No. Description O-ring Seal

2326HC2 Head, “B” Socket

2326HC3 Head, "B" Socket & thermowell

2740HC30 Head, VGR, thermowell

2742HC10 Cylinder, 1000 mL, 5.32" deep

2742HC20 Cylinder, 2000 mL, 10.44" deep

2245HC Split Ring, pair

A233HC Drop Band with Screw

233HCF Drop Band Screw

2741HCJV O-Ring FKM

2741HCJK O-Ring FFKM

265HC12 Thermowell for 2000 mL vessel

265HC7 Thermowell for 1000 mL vessel

48HC Thermowell Gasket, Silver

48HCFG Thermowell Gasket, Gold Plated

A472E2 Thermocouple, 9-1/2”, 1000mL

A472E6 Thermocouple, 15-1/2”, 2000mL

2584HC Head/Cylinder Service Fixture

56HC SERIES

PRESSURE GAGE

A472E2

THERMOCOUPLE, 1L

A472E6

THERMOCOUPLE, 2L

A888HC2 R/D HOLDER ASSY

526HC/581HC STYLE R/D

366VBAA HEX COUPLING

288VBAD MALE CONNECTOR

398HC Pyrex Liner, 1000 mL

398HCHA PTFE Liner, 1000 mL

399HC Pyrex Liner, 2000 mL

399HCHA PTFE Liner, 2000 mL

A122VB

STRAIGHT VALVE

208HC20

GAGE ADAPTER

*For special material vessels add material code

for head, cylinder or internal fittings per page 12.

209HC4

ADAPTER BUSHING

www.parrinst.com

23

Page 24

General Purpose Pressure Vessels

2304HC

COMPRESSION RING

2303HC GASKET

265HC21

THERMOWELL, 1200mL

48HC GASKET

257HC40 DIP TUBE,

A451VB2 ANGLE VALVE

1200mL (OPTIONAL)

914HC LOCK NUT

A451VB STRAIGHT VALVE

208HC6ADAPTER

420HC2 ADAPTER

209HC4 BUSHING

2300HC9 HEAD

265HC20

THERMOWELL, 600mL

A2305HC

SPLIT RING ASSY

257HC39 DIP TUBE,

600mL (OPTIONAL)

2302HC

CYLINDER, 600mL

2302HC10

CYLINDER, 1200mL

Series 4605-4626

Model Size Head Style

4605 600 mL One opening, TBD

4606 1200 mL One opening, TBD

4615 600 mL “B” Socket

4616 1200 mL “B” Socket

4625 600 mL

VGR, thermowell

4626 1200 mL VGR, thermowell

56HC SERIES

PRESSURE GAGE

A472E2 THERMOCOUPLE, 600mL

A472E6 THERMOCOUPLE, 1200mL

288VBAD

MALE CONNECTOR

366VBAD

HEX COUPLING

A888HC2 R/D HOLDER ASSY

526HC/581HC R/D

208HC15 ADAPTER, ANGLED

A451VB STRAIGHT VALVE

209HC4

BUSHING

Part No. Description Flat Gasket Seal

2330HC2 Head, "B" socket

2330HC3

Head, "B" socket, thermowell

2300HC9 Head, VGR, thermowell

2302HC Cylinder, 600 mL

2302HC10 Cylinder, 1200 mL

2304HC Compression Ring

A2305HC Split Ring

1278HC6F

Compression Bolts 5/8–18 (8 req.)

A2313HC Drop Band

233HCF Bolt for Drop Band

2303HC Gasket, PTFE

2303HC2KL Gasket, Flexible Graphite

265HC20 Thermowell, 600 mL

265HC21 Thermowell, 1200 mL

48HC Thermowell Gasket, Silver

48HCFG Thermowell Gasket, Gold Plated

A472E2 Thermocouple, 9-1/2”, 1000 mL

A472E6 Thermocouple, 15-1/2”, 2000 mL

2585HC Head/Cylinder Service Fixture

2312HC Pyrex Liner, 600 mL

2312HC2 Pyrex Liner, 1200 mL

2312HC3 PTFE Liner, 600 mL

2312HC4 PTFE Liner, 1200 mL

Working Limits

Maximum Working Pressure

(T316SS) 5000 psi (345 bar)

Maximum Working Temperature

with PTFE confined flat gasket 350 °C

Recommended Bolt Torque:

PTFE or Flexible Graphite

2100 psi

5000 psi

*For special material vessels add material code

for head, cylinder or internal fittings per page 12.

24

Parr Instrument Company

25 ft - lbs

45 ft - lbs

Page 25

Series 4650

Model Size Head Style

4651 250 mL VGR, thermowell

4652 500 mL VGR, thermowell

4653 1000 mL VGR, thermowell

Working Limits

Maximum Working Pressure** (T316SS)

6000 psi (414 bar) @ 350 °C

5900 psi (407 bar) @ 500 °C

Maximum Working Temperature** 500 °C

Recommended Bolt Torque:

PTFE or Flexible Graphite

3000 psi

5000-6000 psi

35 ft - lbs

40 ft - lbs

General Purpose Pressure Vessels

56HC SERIES PRESSURE GAGE

A888HC2 R/D HOLDER ASSY

526HC/581HC R/D

288VBAD MALE CONNECTOR

366VBAA HEX COUPLING

A176VB STRAIGHT VALVE

491HCAD NIPPLE

154VB2 ELBOW

1452HC ADAPTER, GAGE

326HC COMPRESSION NUT

366HC BUSHING

Part No. Description Flat Gasket Seal

1836HC7 Head, VGR, thermowell

1835HC Head, “B" Socket, thermowell

1834HC Cylinder, 250 mL, 3.25" deep

1834HC2 Cylinder, 500 mL, 6.63" deep

1834HC3 Cylinder, 1000 mL, 13.13" deep

457HC3KL Gasket, Flexible Graphite

457HC2 Gasket, PTFE

A3565HC Split ring, pair, w/ compression bolts

1278HC6F Compression bolts for above (8 req.)

A247HC2 Drop Band with set screws

SC3118SC04 Set screw for above

TX15SK 5/32 Socket screw key

248HC Compression Ring

48HC Thermowell gasket, silver

48HCFG Thermowell gasket, gold plated

263HC Thermowell, 1" deep

265HC Thermowell, 3-1/4" deep

265HC2 Thermowell, 6-1/2" deep

265HC4 Thermowell, 8" deep

424HC2 High Temp. Anti-seize lube, 1 oz.

A472E Thermocouple, 7-1/2”, 250mL

A472E2 Thermocouple, 9-1/2”, 500mL

A472E6 Thermocouple, 15-1/2”, 1000mL

1446HC ADAPTER

A176VB STRAIGHT VALVE

A176VB STRAIGHT VALVE

197VB TEE, MALE

1452HC ADAPTER

326HC COMPRESSION NUT

366HC BUSHING

A472E THERMOCOUPLE, 250mL

A472E2 THERMOCOUPLE, 500mL

A472E6 THERMOCOUPLE, 1000mL

1836HC7 HEAD

A3565HC SPLIT RING ASSY

248HC COMPRESSION RING

A247HC2 DROP BAND W/ SCREWS

457HC3 SERIES GASKET

48HC GASKET

265HC THERMOWELL, 250mL

265HC2 THERMOWELL, 500mL

265HC4 THERMOWELL, 1000mL

914HC LOCK NUT

1461HC2 DIP TUBE, 250mL

(OPTIONAL)

1461HC DIP TUBE, 500mL

(OPTIONAL)

1461HC5 DIP TUBE, 1000mL

(OPTIONAL)

1834HC CYLINDER, 250mL

1834HC2 CYLINDER, 500mL

1834HC3 CYLINDER, 1000mL

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

**For alternate ratings please consult Parr Instrument Company.

www.parrinst.com

25

Page 26

General Purpose Pressure Vessels

660HC6

CYLINDER, 2 GAL

56HC SERIES

PRESSURE GAGE

A754HC

SPLIT RING ASSY

658HC

ADAPTER, VALVE

655HC

GASKET

659HC

COMPRESSION RING

A131VB

ANGLE VALVE

658HC

ADAPTER, VALVE

658HC

ADAPTER, VALVE

A131VB

ANGLE VALVE

660HC

CYLINDER, 1 GAL

657HC16 HEAD

420HC2 ADAPTER

Series 4660

Model Size Head Style

4661 3.78 L One opening, TBD

4662 3.78 L VGR, thermowell

4665 7.99 L One opening, TBD

4666 7.99 L VGR, thermowell

Working Limits

Maximum Working Pressure

Maximum Working Temperature

Part No. Description Flat Gasket Seal

657HC16

657HC100

660HC Cylinder, 7.99 L (2 gal), 17.2” deep

660HC6 Cylinder, 3.78 L (1 gal), 8.62" deep

655HC Gasket, Flexible Graphite

655HC3KL Gasket, PTFE

659HC Compression Ring

A754HC Split Ring with compression bolts

754HCFDE Compression Bolts (10 required)

48HC Thermowell gasket, silver

48HCFG Thermowell gasket, gold plated

265HC4 Thermowell, 8" deep

A935HC Thermowell, 16.68" deep

A472E6 Thermocouple, 15-1/2”, 1 G

A472E5 Thermocouple, 21-1/2”, 2 G

56HCPD Pressure gauge, 4-1/2", 0-1000 psi

56HCPF Pressure gauge, 4-1/2", 0-2000 psi

56HCPG Pressure gauge, 4-1/2", 0-3000 psi

A131VB Angle Valve, 1/4" NPT (M)

A129VB Valve, Straight, 1/4” NPT(M) X 1/4”T

A147VB Valve, Straight, 1/4” NPT(M)

658HC Valve Extension

686HC Dip Tube, 1 G

686HC3 Dip Tube, 2 G

A92HWAD Connector for Dip Tube

A707HC2

708HCP10CT Rupture disc, Inconel, 1000 psi

708HCP20CT Rupture disc, Inconel, 2000 psi

708HCP30CT Rupture disc, Inconel, 3000 psi

2587HC Head/Cylinder Service Fixture

894HC Pyrex Liner, 1 G

894HC2 Pyrex Liner, 2 G

894HC4HA PTFE Liner, 1 G

894HC5HA PTFE Liner, 2 G

(T316SS) 1900 psi (131 bar)

with PTFE 350 °C

Head, VGR (two valves) & thermowell

Head, one 1/4” NPT opening

Rupture Disc Assembly (Manual 231M)

Recommended Bolt Torque:

PTFE Gasket

Flexible Graphite

A707HC2

R/D HOLDER ASSY

708HCP

SERIES R/D

A472E6

THERMOCOUPLE, 1 GAL

A472E5

THERMOCOUPLE, 2 GAL

48HC GASKET

265HC4

THERMOWELL, 1 GAL

A935HC

THERMOWELL, 2 GAL

NOT SHOWN:

A92HWAD MALE CONNECTOR

686HC DIP TUBE, 1 GAL

(OPTIONAL)

686HC3 DIP TUBE, 2 GAL

(OPTIONAL)

25 ft - lbs

35 ft - lbs

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

26

Parr Instrument Company

Page 27

Series 4660Q

A131VB

ANGLE VALVE

2691HCJV

O-RING

2690HC3

HEAD

56HC SERIES

PRESSURE GAGE

658HC

ADAPTER, VALVE

A131VB

ANGLE VALVE

658HC

ADAPTER, VALVE

658HC

ADAPTER, VALVE

A2265HC

SPLIT RING ASSY

2692HC10

CYLINDER, 1 GAL

2692HC20

CYLINDER, 2 GAL

420HC

ADAPTER

General Purpose Pressure Vessels

Model Size Head Style

4661Q 3.78 L One opening, TBD

4662Q 3.78 L VGR, thermowell

4665Q 7.99 L One opening, TBD

4666Q 7.99 L VGR, thermowell

Part No. Description O-ring Seal

2690HC3 Head, VGR (two valves) & thermowell

2690HC6

2692HC10 Cylinder, 3.78 L (1 gal), 8.62" deep

2692HC20 Cylinder, 7.99 L (2 gal), 17.25" deep

A2265HC Split Ring with latches

48HC Thermowell gasket, silver

48HCFG Thermowell gasket, gold plated

265HC4 Thermowell, 8" deep

A935HC Thermowell, 16.68" deep

A472E6 Thermocouple, 15-1/2”, 1 G

A472E5 Thermocouple, 21-1/2”, 2 G

56HCPD Pressure gauge, 4-1/2", 0-1000 psi

56HCPF Pressure gauge, 4-1/2", 0-2000 psi

56HCPG Pressure gauge, 4-1/2", 0-3000 psi

2691HCJV O-Ring, FKM

2691HCJE O-Ring, EP

A129VB Valve, Straight, 1/4"NPT (M) x 1/4"T

A130VB Angle Valve, 1/4"NPT (M) x 1/4"T

A131VB Angle Valve, 1/4"NPT (M)

A147VB Valve, Straight, 1/4”NPT (M)

A707HC2

708HCP20CT Rupture disc, Inconel, 2000 psi

708HCP30CT Rupture disc, Inconel, 3000 psi

708HCP10CT Rupture disc, Inconel, 1000psi

658HC Valve Extension

686HC Dip Tube, 1 G

686HC3 Dip Tube, 2 G

A92HWAD Connector for Dip Tube

2587HC Head/Cylinder Service Fixture

894HC Pyrex Liner, 1 G

894HC2 Pyrex Liner, 2 G

894HC4HA PTFE Liner, 1 G

894HC5HA PTFE Liner, 2 G

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

Head, one 1/4” NPT opening

Rupture Disc Assembly

(See Manual 231M)

Working Limits

Maximum Working Pressure

(T316SS) 1900 psi (131 bar)

Maximum Working Temperature

with FKM O-ring 225 °C

Maximum Working Temperature

with FFKM O-ring 300 °C

NOT SHOWN:

A92HWAD MALE CONNECTOR

686HC DIP TUBE, 1 GAL

(OPTIONAL)

686HC3 DIP TUBE, 2 GAL

(OPTIONAL)

A707HC2

R/D HOLDER ASSY

708HC9

SERIES R/D

A472E6

THERMOCOUPLE, 1 GAL

A472E5

THERMOCOUPLE, 2 GAL

48HC GASKET

265HC4

THERMOWELL, 1 GAL

A935HC

THERMOWELL, 2 GAL

www.parrinst.com

27

Page 28

General Purpose Pressure Vessels

1811HC6 HEAD

A472E5 THERMOCOUPLE, 1.5 GAL

659HC COMPRESSION RING

1810HC3 CYLINDER, HP/HT, 1.5 GAL

265HC10 THERMOWELL, 1.5 GAL

1810HC CYLINDER, HP/HT, 1 GAL

A472E6 THERMOCOUPLE, 1 GAL

1415HCP SERIES R/D

A1423HC SPLIT RING ASSY

265HC4 THERMOWELL, 1 GAL

1812HCKL GASKET, GRAPHOIL

A1417HC R/D HOLDER ASSY

48HC GASKET

NOT SHOWN:

2X 36HC5 HANDLE, HP/HT CYL

209HC11 ADAPTER, VALVE

209HC4 BUSHING

A176VB STRAIGHT VALVE

(OPTIONAL)

56HC SERIES PRESSURE GAGE

1446HC ADAPTER

A176VB STRAIGHT VALVE

A176VB STRAIGHT VALVE

94CAAD PLUG, HEX

208HC13 ADAPTER, VALVE

209HC4 BUSHING

208HC15 ADAPTER, ANGLED

209HC4 BUSHING

914HC LOCKNUT

257HC28 DIP TUBE, 1 GAL

(OPTIONAL)

257HC29 DIP TUBE, 1.5 GAL

491HC NIPPLE

Series 4670-4674

Model Size Head Style

4671 3.8 L One opening, TBD

4672 3.8 L VGR, thermowell

4673 5.8 L One opening, TBD

4674 5.8 L VGR, thermowell

Working Limits

Maximum Working Pressure**

(T316SS) 3000 psi (207 bar) @ 500 °C

Maximum Working Temperature**

with PTFE

with Flexible Graphite

Recommended Bolt Torque:

PTFE or Flexible Graphite

8500 PSI 15 ft - lbs

350 °C

500 °C

Part No. Description Flat Gasket Seal

1811HC6

1810HC

1810HC3

1812HCHA

1812HCKL

659HC

A1423HC

1278HC7F

265HC4

265HC10

48HC

48HCFG

A472E6

A472E5

209HC4

208HC11

208HC13

208HC15

A176VB

491HCAD

1446HC

A1417HC

2587HC

Head, VGR (two valves) & thermowell

Cylinder, 3.8 L, 9.95" deep

Cylinder, 5.8 L, 15.19" deep

Gasket, PTFE

Gasket, Flexible Graphite

Compression Ring

Split ring, pair, w/ compression bolts

Compression bolt for above (16 req.)

Thermowell, 7.75" deep

Thermowell, 11.87" deep

Thermowell Gasket, Silver

Thermowell Gasket, Gold Plated

Thermocouple, 15-1/2”, 1G

Thermocouple, 21-1/2”, 1.5G

Bushing

Adapter, Valve, ¼ NPTM

Adapter, Valve, ¼ NPTM X ¼ NPTF

Adapter, Angled, two ¼ NPTF

Valve, ¼ NPTF

Nipple, Hex, Brass, ¼ NPTM

Adapter, “A” cone, X ¼ NPTM

Rupture Disc Assembly (See 231M)

Head/Cylinder Service Fixture

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

**For alternate ratings please consult Parr Instrument Company.

28

Parr Instrument Company

Page 29

General Purpose Pressure Vessels

Series 4676-4677

Model Size Head Style

4676 5 gallons One opening, TBD

4677 5 gallons VGR, thermowell

Working Limits

Maximum Working Pressure

(T316SS) 1900 psi (131 bar)

Maximum Working Temperature

with PTFE 350 °C

Recommended Bolt Torque:

PTFE Gasket

500 PSI 15 ft - lbs

1000 PSI 20 ft - lbs

1500 PSI 30 ft - lbs

1700 PSI 40 ft - lbs

Part No. Description Flat Gasket Seal

1557HC3 Head, VGR (two valves) & thermowell

1555HC Cylinder, 5 gal, 16.68" deep

1555HC2

1559HC Gasket, PTFE

1559HC2KL Gasket, Flexible Graphite

1554HC Compression Ring

A1556HC Split ring, pair, with compression bolts

1556HCF

A278VBAD Valve, straight, 3/8" NPT (M), T316SS

A279VBAD Valve, angle, 3/8" NPT (M), T316SS

265HC15 Thermowell, 15.94”

1571HC Head Lift Rings

1593HC Cylinder Lift Rings

1566HC Valve Extension

A472E5 Thermocouple, 21-1/2”, SS

56HCPD Pressure gauge, 4-1/2", 0-1000 psi

56HCPF Pressure gauge, 4-1/2", 0-2000 psi

56HCPG Pressure gauge, 4-1/2", 0-3000 psi

A707HC2

708HCP10CT Rupture disc, Inconel, 1000 psi

708HCP20CT Rupture disc, Inconel, 2000 psi

708HCP30CT Rupture disc, Inconel, 3000 psi

1567HC Dip Tube, 3/8” O.D.

275VBAD Connector, 3/8” NPT (M) x 3/8”T

Cylinder, 5 gal, w/ 3/4" NPT bottom opening

Compression bolt for above (12 required)

Rupture Disc Assembly

(See Manual 231M)

A279VBAD ANGLE VALVE

1566HC ADAPTER

A279VBAD ANGLE VALVE

1566HCADAPTER

420HC6 ADAPTER

A1556HC SPLIT RING ASSY

1554HC COMPRESSION RING

1559HC GASKET

1557HC3 HEAD

275VBAD MALE CONNECTOR

1567HC DIP TUBE, 5 GAL

1555HC CYLINDER, 5 GAL

56HC SERIES PRESSURE GAGE

A707HC2 R/D HOLDER ASSY

708HCP SERIES R/D

A472E5 THERMOCOUPLE

1566HC2 ADAPTER, REDUCER

3X 1571HC EYE LIFT

NOT SHOWN:

2X 1593HC LIFT RING

48HC GASKET

265HC15 THERMOWELL

*For special material vessels add material code for head, cylinder or internal fittings per page 12.

www.parrinst.com

29

Page 30

General Purpose Pressure Vessels

Series 4678-4679

Model Size Head Style

4678 10 L One opening, TBD

4679 10 L VGR, thermowell

Working Limits

Maximum Working Pressure

(T316SS) 1900 psi (131 bar) @ 350 °C

Maximum Working Temperature

with PTFE 350 °C

Recommended Bolt Torque:

PTFE or Flexible Graphite

500 PSI 25 ft - lbs

1000 PSI 50 ft - lbs

1500 PSI 75 ft - lbs

1900 PSI 100 ft - lbs

Part No. Description Flat Gasket Seal

2957HC11

Head, VGR (two valves) & thermowell

2955HC Cylinder, 10 L

2955HC2 Cylinder, 10 L w/ ¾”NPT

A2956HC Split Ring

2956HCF

Compression bolt for above (10 req.)

A278VBAD Valve, straight, 3/8" NPTM, T316SS

A279VBAD Valve angle, 3/8" NPTM, T316SS

265HC10 Thermowell, 12.12”

1571HC Head Lift Rings

1593HC Cylinder Lift Rings

2959HC PTFE Gasket

2954HC Compression Ring

1566HC Valve Extension

A472E6 Thermocouple, 15-1/2”

56HCPD Pressure gauge, 4-1/2", 0-1000 psi

56HCPF Pressure gauge, 4-1/2", 0-2000 psi

56HCPG Pressure gauge, 4-1/2", 0-3000 psi

A707HC2

Rupture Disc Assembly

(See Manual 231M)

708HCP10CT Rupture disc, Inconel, 1000 psi

708HCP20CT Rupture disc, Inconel, 2000 psi

708HCP30CT Rupture disc, Inconel, 3000 psi

1567HC Dip Tube, 3/8” O.D.

275VBAD Connector, 3/8” NPT (M) x 3/8”T

A279VBAD ANGLE VALVE

1566HC ADAPTER

A279VBAD ANGLE VALVE

420HC6 ADAPTER

A2956HC SPLIT RING ASSY

2954HC COMPRESSION RING

2959HC GASKET

2957HC11 HEAD

275VBAD MALE CONNECTOR

1567HC2 DIP TUBE

265HC10 THERMOWELL

2955HC CYLINDER, 10L

48HC GASKET

56HC SERIES PRESSURE GAGE

A472E5 THERMOCOUPLE

A707HC2 R/D HOLDER ASSY

1566HC2 ADAPTER, REDUCER

3X 1571HC EYE, LIFT

NOT SHOWN:

2X 1593HC LIFT RING

*For special material vessels add material code for

head, cylinder or internal fittings per page 12.

30

Parr Instrument Company

Page 31

Series 4680

56HC SERIES PRESSURE GAGE

Model Size Head Style

4680 1000 mL One opening, TBD

4681 1000 mL VGR, thermowell

4682 1800 mL One opening, TBD

4683 1800 mL VGR, thermowell

Working Limits

Maximum Working Pressure (T316SS)

6000 psi (414 bar) @ 350 °C

5000 psi (345 bar) @ 500 °C

4000 psi (276 bar) @ 600 °C

Maximum Working Temperature

with PTFE 350 °C

with Flexible Graphite 600 °C

General Purpose Pressure Vessels

A176VB STRAIGHT VALVE

491HCAD NIPPLE

1446HC ADAPTER

154VB2 ELBOW, 45 DEGREE

A176VB STRAIGHT VALVE

208HC17 ADAPTER, ANGLED

94CA PLUG, HEX HEAD

A176VB STRAIGHT VALVE

491HCAD NIPPLE

208HC13 ADAPTER, VALVE

209HC4 BUSHING

Recommended Bolt Torque:

PTFE or Flexible Graphite

2100 PSI 25 ft - lbs

4000-6000 PSI 40 ft - lbs

Part No. Description Flat Gasket Seal

1807HC11 Head, VGR, thermowell

1807HC4

1806HC

1806HC3

1808HCHA

1808HCKL

1314HC

A1316HC

1278HC6F

48HC

48HCFG

265HC6

265HC8

36HC5

1368HC

1369HC

A472E2

A472E6

2586HC

1441HC

1442HC

1441HCHA

1442HCHA

Head, “B” Socket, thermowell

Cylinder, 1000 mL, 6.24" deep

Cylinder, 1800 mL, 10.62" deep

Gasket, PTFE

Gasket, Flexible Graphite

Compression Ring

Split ring, pair, w/ compression bolts

Compression bolts for above (12 req.)

Thermowell gasket, silver

Thermowell gasket, gold plated

Thermowell, 5.75" deep

Thermowell, 10.19" deep

Handles

Torque Wrench

Torque Adapter

Thermocouple, 9-1/2”, SS

Thermocouple, 15-1/2”, SS

Head/Cylinder Service Fixture

Pyrex Liner, 1000 mL

Pyrex Liner, 1800 mL

PTFE Liner, 1000 mL

PTFE Liner, 1800 mL

291HC2 NUT

257HC24 INLET TUBE, 1L

(OPTIONAL)

257HC5 INLET TUBE, 1.8L

(OPTIONAL)

A472E3 THERMOCOUPLE, 1L

A472E6 THERMOCOUPLE, 1.8L

A888HC2 R/D HOLDER ASSY

562HC/581 SERIES R/D

366VBAD HEX COUPLING

288VBAD MALE CONNECTOR

A1316HC SPLIT RING ASSY

1314HC COMPRESSION RING

1808HCKL GASKET GRAFOIL

1807HC11 HEAD

NOT SHOWN:

2X 36HC5 HANDLE, HP/HT CYL

48HC GASKET

265HC6 THERMOWELL, 1L

265HC8 THERMOWELL, 1.8L

1806HC CYLINDER, 1L

1806HC3 CLYINDER, 1.8L

*For special material vessels add material code

for head, cylinder or internal fittings per page 12.

www.parrinst.com

31

Page 32

General Purpose Pressure Vessels

4316 & 4317 GAGE BLOCK ASSEMBLIES

Gage Block Parts List

Part No. Description

112VB4AK Valve needle

123VB2 Valve handle

126VB Lantern ring for high temp service (Use w/4VB4KL packing w/out 20VB)

20VB Valve seat, Kel-F