Page 1

4560

Mini Bench Top Reactors

Operating Instruction Manual

396M

Page 2

Mini Bench Top Reactors

Table of Contents

Preface

Scope — 3

Related Instructions — 3

Safety Information — 3

General Specifi cations — 3

Electrical Ratings— 3

Explanation of Symbols — 4

Environmental Conditions — 4

Provisions for Lifting and Carrying — 4

Intended Usage — 4

Cleaning & Maintenance — 4

User’s Responsibility — 5

Unpack Carefully — 5

Fixed Head or Removable Head Vessel Design — 6

Flat PTFE Gasket or Self Sealing O-ring Closure — 6

Installation

Pressure and Temperature Limits — 7

Assemble the Reactor — 8

Identify the Valves

Gas Inlet Valve — 9

Gas Release Valve — 9

Liquid Sampling Valve — 9

Other Vessel Head Fittings

Safety Rupture Disc — 10

Type J Thermocouple — 10

Pressure Gage — 10

Heaters — 10

How to Use the Vessel

Removable Vessels — 11

Fixed Head Vessels — 11

Air Motor — 13

Explosion Proof Operation — 14

Periodic Pressure Tests — 15

Accessories

Liners — 15

Spare Parts Kit — 15

General Maintenance Notes — 16

4560 Series Reaction Vessel Parts List

Standard Vessel Fittings — 17

High Temperature Vessel Fittings — 22

Overarm Parts List — 25

Figures

Fixed Head with O-ring — 6

Moveable Head with Flat Gasket — 6

Removable Head Vessel (Standard Temperature) — 19

Air Motor Option — 13

Vessel Closure and Standard Internal Parts — 17

4561 Gas Entrainment Assembly — 20

4563 Gas Entrainment Assembly — 20

Mini Head External Fittings & Parts List — 21

Vessel Closure and Standard Internal Parts — 22

Overarm Diagram — 25

Bomb Support Stand with Fixed Head and 1/8 hp

Stirrer Drive Motor — 26

Bomb Support Stand with Moveable Vessel and 1/4

hp Stirrer Drive Motor — 27

Customer Service

Questions concerning the installation or operation of this instrument

can be answered by the Parr Customer Service Department:

1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail: parr@parrinst.com • http://www.parrinst.com

2

Parr Instrument Company

Page 3

Mini Bench Top Reactors

Preface

Scope

These instructions describe the installation, operation and maintenance of Parr Series 4560 Mini

Bench Top Reactors offered in sizes from 100 mL to

600 mL. They cover the basic steps to be followed

for installing these reactors and describe the function of all standard components. They cover the

basic steps to be followed when installing these

reactors and describe the function of all standard

components. They are intended to be used in conjunction with several related instruction sheets listed

on the previous page. This information describes

several components that are common to most Parr

pressure reaction equipment, and includes safety

precautions and other related information applicable

to all reaction laboratories. The users should study

all of these instructions carefully before starting to

use these vessels so that they will fully understand

the capabilities and limitations of the equipment.

Related Instructions

The following Parr publications are also included to

further your understanding of this instrument and

its component parts:

No. Description

201M Limited Warranty

230M Safety Precautions to be observed when

operating Pressure Reaction Equipment

231M Operating Instructions for Parr Safety

Rupture Discs

234M Operating and Maintenance Instructions

for Parr Magnetic Drives

323M Operating Instructions for Parr Pressure

Relief Valves

548M Operating Instructions for 4848 Reactor

Controllers

F0042 Health & Safety Assurance Certifi cation

Safety Information

To avoid electrical shock, always:

Use a properly grounded electrical outlet of correct

voltage and current handling capacity.

Disconnect from power supply before servicing. The

power supply cord of the equipment is the main

disconnect device.

To avoid personal injury:

Do not use in the presence of fl ammable or combustible materials; fi re or explosion may result. This

device contains components which may ignite such

materials. Refer servicing to qualifi ed personnel.

General Specifi cations

Electrical Ratings

Controller ratings are found in the Operating Instruc-

tions for the controller supplied with your reactor.

Before connecting a controller to an electrical outlet,

the user must be certain that the electrical outlet has

an earth ground connection and that the line, load

and other characteristics of the installation do not

exceed the following limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: Controllers can be operated from either

a 50 or 60 Hertz power supply without affecting their

operation or calibration.

Current: The total current drawn should not exceed

the rating shown on the data plate on the controller

by more than 10 percent.

Inductive Loads: Inductive loads must be limited to

750 watts (1 hp) at 115 volts, or to 1100 watts (1-1/2

hp) at 230 volts. Do not connect these controllers

to the primary (input) side of an auto-transformer

(Variac, Powerstat or the like). The heavy inductive

load on the primary side of such transformers will

destroy the relay. The secondary (output) side of an

auto-transformer can be carried through the relay if

this circuit is isolated from the controller. A separate, full-voltage connection must then be made to

operate the temperature controller and to actuate

the relay.

Thermocouple: Unless otherwise specifi ed, all

Series 4848 Controllers operate with a Type J (ironconstantan) thermocouple. The total resistance of

the thermocouple and the lead wires should not exceed 20 ohms. If the resistance of the thermocouple

circuit is higher, it will reduce the sensitivity of the

control system.

www.parrinst.com

3

Page 4

Mini Bench Top Reactors

Explanation of Symbols

II On position, full power heater switch

I On position, half power heater switch

O Off Position

~ Alternating Current (AC)

This CAUTION symbol may be present on the Product Instrumentation

and literature. If present on the product, the user must consult the appropriate part of the accompanying product literature for more information.

This CAUTION symbol indicates that the surface may be hot.

Protective Earth (PE) terminal. Provided for connection of the Protective Earth (green or green/yellow) supply system conductor.

Environmental Conditions

This instrument is intended to be used indoors.

Caution!

Do not use in hazardous atmospheres.

Operating: 15 ºC to 40 ºC; maximum relative humid-

ity of 80% non-condensing. Installation Category II

(over voltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 °C and 65 °C; 10% to 85% relative hu-

midity.

Provisions for Lifting and Carrying

Before moving ensure all cables are disconnected.

Use proper and safe lifting techniques when install-

ing or moving the 4560 Reactor and/or its compo-

nents.

Intended Usage

This system has been designed for use as a high

pressure reactor system. It has been designed, built,

and tested to strict physical and electrical standards.

However, it is the user’s responsibility to install and

operate it in conformance with local pressure and

electrical codes.

If this equipment is used in a manner beyond its intended usage, the protection provided by the equipment may be impaired.

Cleaning & Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the controller with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected and the power cord should

be unplugged when cleaning the instrument.

There are no user serviceable parts inside the product other than what is specifi cally called out and

discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can

be obtained by calling Parr Instrument Company

in order to determine which part(s) may need to be

replaced or serviced.

Ensure that any hot surfaces have had

adequate time to cool before cleaning

or maintaining the reactor and/or its

components.

4

Parr Instrument Company

Page 5

Mini Bench Top Reactors

User’s Responsibility

All Parr reactors and pressure vessels are designed

and manufactured with great care to assure safe

operation when used within their prescribed temperature and pressure limits.

But . . . the basic responsibility for safety when using this equipment rests entirely with the user; who

must:

1. Select a reactor or pressure vessel that has the

capability, pressure rating, corrosion resistance

and design features that are suitable for its

intended use. Parr engineers will be glad to discuss available equipment and material options

with prospective users, but the fi nal responsibility for selecting a reactor or pressure vessel

that will perform to the user’s satisfaction in any

particular reaction or test must rest with the user

– not with Parr.

In exercising the responsibility for the selection

of pressure equipment, the prospective user is

often faced with a choice between over-or underdesigned equipment. The hazards introduced

by under-designed pressure vessels are readily

apparent, but the penalties that must be paid for

over-designed apparatus are often overlooked.

Recognizing these criteria, Parr reactors and

pressure vessels are offered in several different

styles, each designed for convenient use in daily

operation within certain temperature and pressure limits, using gaskets, closures and other

elements carefully selected for safe operation

within the limits specifi ed for that design. But in

order to preserve the validity of these designs,

all temperature and pressure limits must be

observed, and no attempt should be made to

increase these limits by making alterations or by

substituting components which are not recommended by Parr Instrument Company.

2. Install and operate the equipment within a

suitable barricade, if required, with appropriate

safety accessories and in full compliance with

local safety codes and rules.

All standard Parr pressure vessels are provided

with either suitable relief device or a means to

attach one (typically in the form of a plugged

opening). When a pressure vessel is delivered

without a pressure venting device, it is the customer’s responsibility to provide pressure relief

in order to protect the operator and the equipment from destructive high pressures. If you

need more information or need help in selecting

a proper relief device, please contact Parr Instrument Company.

3. Establish training procedures to ensure that any

person handling the equipment knows how to

use it properly.

4. Maintain the equipment in good condition and

establish procedures for periodic testing to be

sure the vessel remains structurally sound.

Unpack Carefully

Unpack the equipment carefully and check all the

parts against the, packing list. If shipping damage

is discovered, report it immediately to the delivering carriers. The vessel, motor, heater, and temperature controller may be packed separately for

convenience in shipping, but these parts are easily

reassembled. Examine the components closely for

any loose parts or shipping damage and be sure to

check all layers of packing materials thoroughly so

as not to overlook any parts which might otherwise

be discarded.

www.parrinst.com

5

Page 6

Mini Bench Top Reactors

Parr Series 4560 Mini Reactors are furnished with two structural options in addition to the size, pressure

range, stirrer motor, controller and similar options. These are:

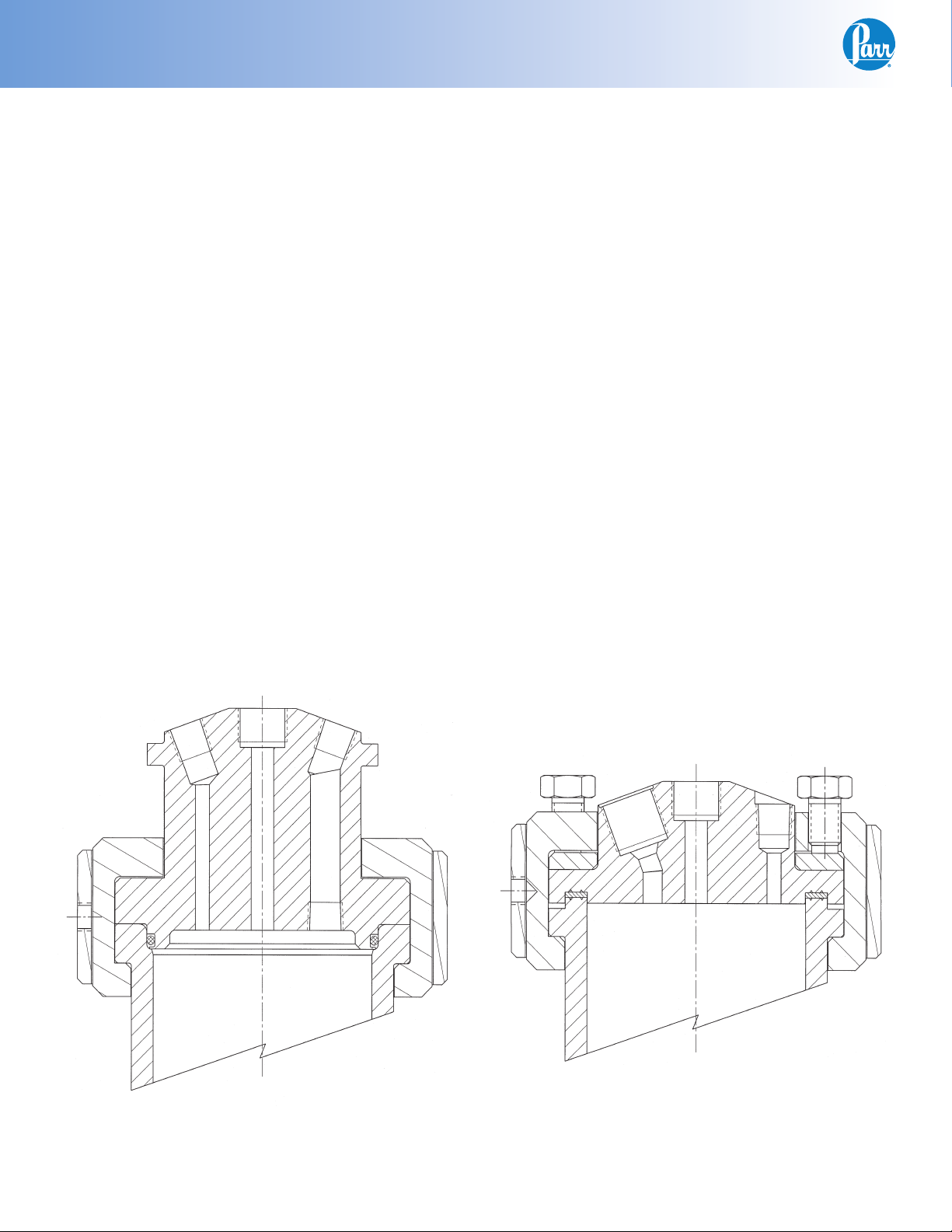

Fixed Head or Removable Head

Vessel Design

In the fi xed head design, the head of the vessel

may remain fi xed in the reactor support stand. All

attachments to the head, gas and liquid feed and

discharge lines, cooling water, vapor take-off and

condenser, thermocouple, and any electrical leads

can remain permanently in place. The reactor is

opened by removing the cover clamp sections and

lowering the cylinder away from the head.

In the removable vessel design, the entire vessel

must be removed from the support stand for charging, product recovery, and cleaning.

There is no difference in the pressure or temperature limits or basic operating instructions based

upon the fi xed head or movable vessel options.

There are differences in the design of the stand

components which adapt the vessels to the support

system.

Flat PTFE Gasket or Self Sealing

O-ring Closure

The fl at gasket is held in a recess in the vessel head

and a machine pilot on the cylinder closes the recess to completely contain the gasket. The split ring

closure used with this gasket has six cap screws

which must be tightened to develop the loading on

the gasket.

The self sealing design features an O-ring retained

in a groove on the vessel head. This design is self

sealing and the split ring used with this sealing system does not require nor have the cap screws used

with the fl at gasket.

Maximum temperatures of a given system are dependant upon the material of construction and type

of seal. Other accessories may limit operating temperature. The fl at PTFE gasket can be used to operat-

ing temperatures as high as 350 °C. The fl at fl exible

graphite gasket can be used to operating temperatures as high as 500 °C. The maximum temperature

of the vessels equipped with O-ring seals depends

upon the material used for the O-ring. The most

common material is a fl uoroelastomer (FKM) which

has a 225 °C maximum operating temperature limit.

Fixed Head with O-ring

6

Parr Instrument Company

Moveable Head with Flat Gasket

Page 7

Mini Bench Top Reactors

Installation

Pressure and Temperature Limits

The working pressure and temperature at which any

reactor or pressure vessel can be used will depend

upon the design of the vessel and the materials

used in its construction. Since all materials lose

strength at elevated temperatures, any pressure

rating must be stated in terms of the temperature at

which it applies. The standard material of construction for Parr Instrument Company is Type 316 Stainless Steel.

Limits for vessels made of other materials and for

other operating temperatures can be obtained from

Parr Customer Service. No attempt should be made

to increase these limits by making alterations or by

substituting components that are not recommended

by the Parr Instrument Company. It must also be

understood that lower pressure and temperature

limits may be required for modifi ed reactors and for

vessels made of special alloys.

Limits for vessels will be determined by the physical characteristics of the vessel material and will be

prescribed on an individual basis.

The maximum working pressure and temperature

for any vessel is governed by the design of the

vessel and the strength of the material from which

it is constructed. There is also a close relationship

between working pressure and temperature since

the strength of any material will normally fall off

as the temperature is increased. Temperature and

pressure limits are also affected by the physical

properties and temperature limits of the gaskets and

seals used in the vessel, and by any valves, gages or

other fi ttings attached to the vessel. The safe operating pressure of any system can be no higher than

that of its lowest rated component.

Working temperatures up to 225 °C are permissible

in Mini Reactors equipped with fl uoroelastomer

(FKM) O-ring seals. The higher the operating temperature above 200 °C, the shorter the life of the Oring will be. Perfl uoroelastomer (FFKM) O-ring seals

have a broad chemical resistance and can be used

to temperatures up to 300 °C. Unfortunately they

are very expensive and will generally be reserved

for unique applications. Ethylene-propylene (EP)

O-rings can be used to 170 °C and are recommend-

ed for applications such as ethers, ammonia and

amines which will rapidly destroy fl uoroelastomer

O-rings.

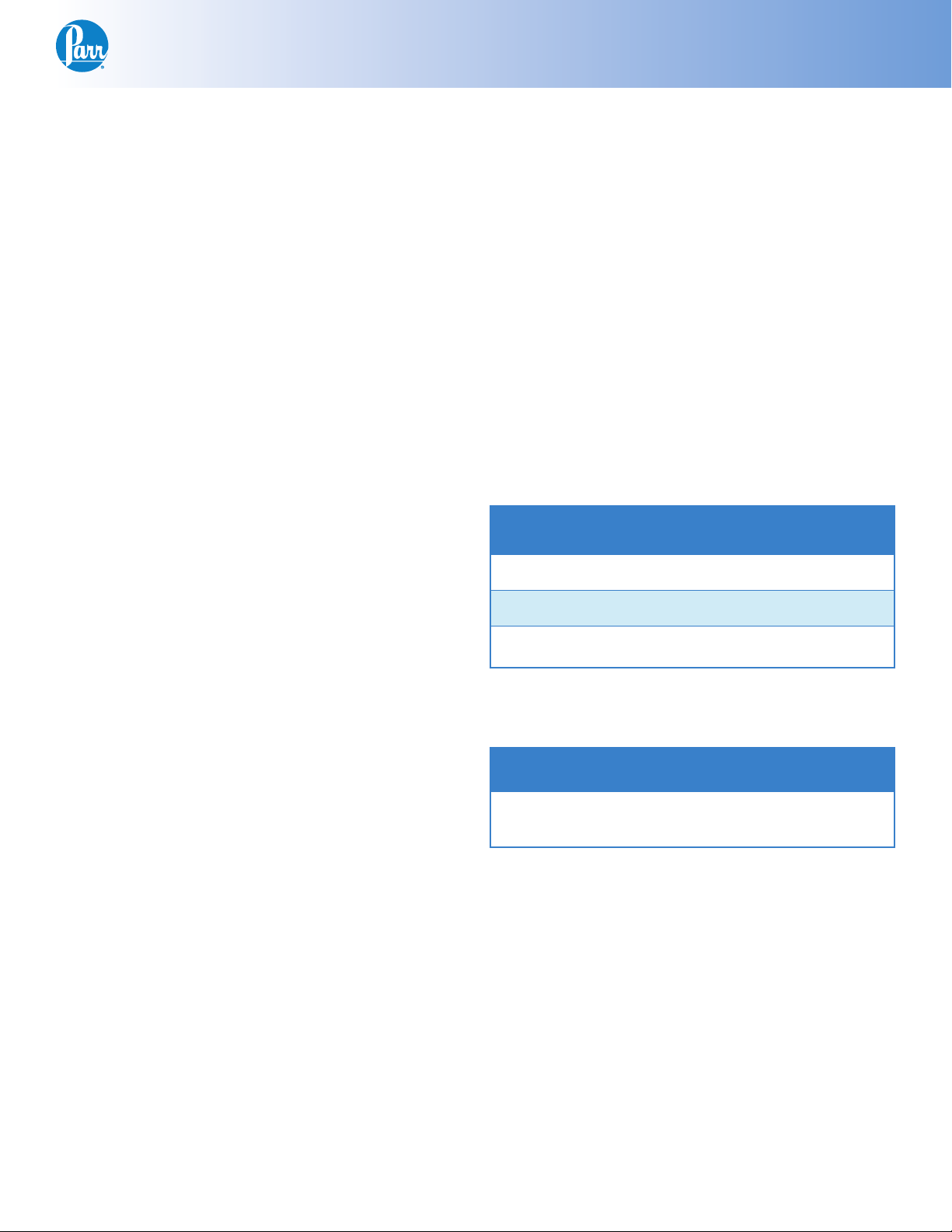

Pressure Vessel and Temperature Limits

In the standard pressure and temperature setup, the

system must not exceed the following:

Vessel

Material

T316SS 3000 psig (200 bar)

T316SS 3000 psig (200 bar)

T316SS 3000 psig (200 bar)

Maximum

Pressure

Maximum

Temperature

350 °C PTFE

Flat Gasket

225 °C FKM

O-Ring

300 °C FFKM

O-Ring

In the high pressure/high temperature setup, the

system must not exceed the following:

Vessel

Material

T316SS (HT) 2000 psig (138 bar) 500 °C Flexible

Maximum

Pressure

Maximum

Temperature

Graphite Flat

Gasket

All Parr reactors show the maximum safe operating

pressure and temperature imprinted on the cylinder.

An accompanied restricted operating limit tag and/

or supplemental manual is given when a component of the system limits the operation below the

imprinted valves.

www.parrinst.com

7

Page 8

Mini Bench Top Reactors

Assemble the Reactor

These reactors require at least 10 sq. ft. of workspace in a well-ventilated area with convenient

access to an electric outlet, running water, air and a

drain.

1. Set the stand in the workspace.

Bolt the stand to the bench top using the

holes in the base plate.

2. The support and heater are shipped fully assembled. The heater raises and lowers on its

support rod to permit the vessel or cylinder to

be removed. Lower the heater, open the hinged

retainer on the front of the support and slide the

vessel into its support. Fixed head vessels have

a square lip which fi ts into a matching groove in

the support plate. Removable vessels are supported by the split rings which rest on the support plate adapter. The stirrer drive connector

lifts by rotating and lifting the knob above the

belt guard. The universal joint contains a cross

pin that slips into the groove on top of the magnetic drive. There is a bracket at the back of the

area where the split ring rests. The thumb screw

on the drop band which encircles the split ring

closure should fi t into the slot on this bracket.

This will keep the vessel from rotating when

stirring viscous reactions. It may be necessary

to reposition the drop band if the gage does not

face forward when the thumb screw is in the

slot.

3. Set the Temperature Controller near the reactor,

leaving a space of at least six inches between

the controller and the base of the reactor so

that the controller will not be unduly affected by

radiant heat. Connect the reactor to the controller using information contained in its Instruction

Manual 548M or follow the steps below.

Parr Heating Only:

The Parr Heating output connector is to be used

only with Parr Instrument Company heater assemblies supplied with the appropriate heater

power cord.

Note: Do not make connections to a Variac,

Powerstat or the like to attempt to control the

heating output. The heavy inductive load on

the primary side of such devices can destroy

the internal sold state relay located in the 4848

controller.

Motor:

Secure the clamp on motor cord to the

controller with the provided screw next

to the motor socket for safety purposes.

The Motor output connector is to be used only with

Parr Instrument Company motor assemblies supplied with the appropriate motor power cord.

4. Connect the heater cord from the heater into

the heater socket on the rear panel of the Series

4848 Reactor Controller.

5. Plug the motor cord into the motor socket on the

rear of the controller.

Secure the clamp on the motor cord with

the provided screw next to the motor

socket for safety purposes.

6. Connect the thermocouple and extension wire

to both the thermocouple and to the controller

in the “Primary Temp Input” position on the rear

panel. Insert the thermocouple in the thermowell.

Labeled connections are provided on the rear

panel of the controller.

Parr Cooling Only:

The Parr Cooling output connector is to be used

only with Parr Instrument Company cooling solenoid valve assemblies supplied with the appropriate cooling power cord.

8

Parr Instrument Company

7. Connect leads from accessory packages such as

tachometer, pressure transducer and high temp

cut-off to the designated positions on the back

panel of the 4848 Controller.

8. Connect cooling water to the magnetic drive.

See Instruction Manual No. 234M.

9. Connect tubing to the rupture disc outlet and run

to a safely vented area. See Instruction Manual

231M.

Page 9

Mini Bench Top Reactors

10. Note the voltage and amperage requirement

stamped on the controller data plate, and then

plug the power cord into an appropriate outlet.

Power for these reactors should be drawn from

a grounded outlet capable of carrying up to the

full current rating of the reactor.

11. If an electric stirrer motor is supplied, turn the

speed control knob fully counterclockwise on

the Reactor Controller, turn on the motor switch

and slightly increase the speed for a short run

to check the stirrer drive system but do not turn

on the heater, put heater toggle switch in center

position (OFF). There must always be a vessel in

the heater when it is turned on, and the vessel

and heater sizes must match. If the heater is operated without proper size vessel in contact with

the heater, the heater may overheat and fail.

Identify the Valves

Gas Inlet Valve

The gas inlet valve is easily identifi ed when the

vessel is open by noting that it is connected to a dip

tube which extends to a point near the bottom of

the cylinder. With this arrangement, incoming gas is

always introduced below the surface of the liquid.

This valve includes a coupling with an “A” socket

connection for attachment of the pressure hose.

Gas Release Valve

The gas release valve is typically connected to a side

opening on the gage adapter. Gas released from

this valve will be drawn from the top of the reactor.

Liquid Sampling Valve

The liquid sampling valve is attached to the same

fi tting as the gas inlet valve and connected to the

same dip tube. This provides the operator with a

means for clearing the dip tube to be sure that any

sample taken during a run will be representative of

the charge. This can be done by opening the upper

gas inlet valve momentarily to allow the inlet gas to

force any liquid in the dip tube back into the reactor before withdrawing a sample from the sampling

valve.

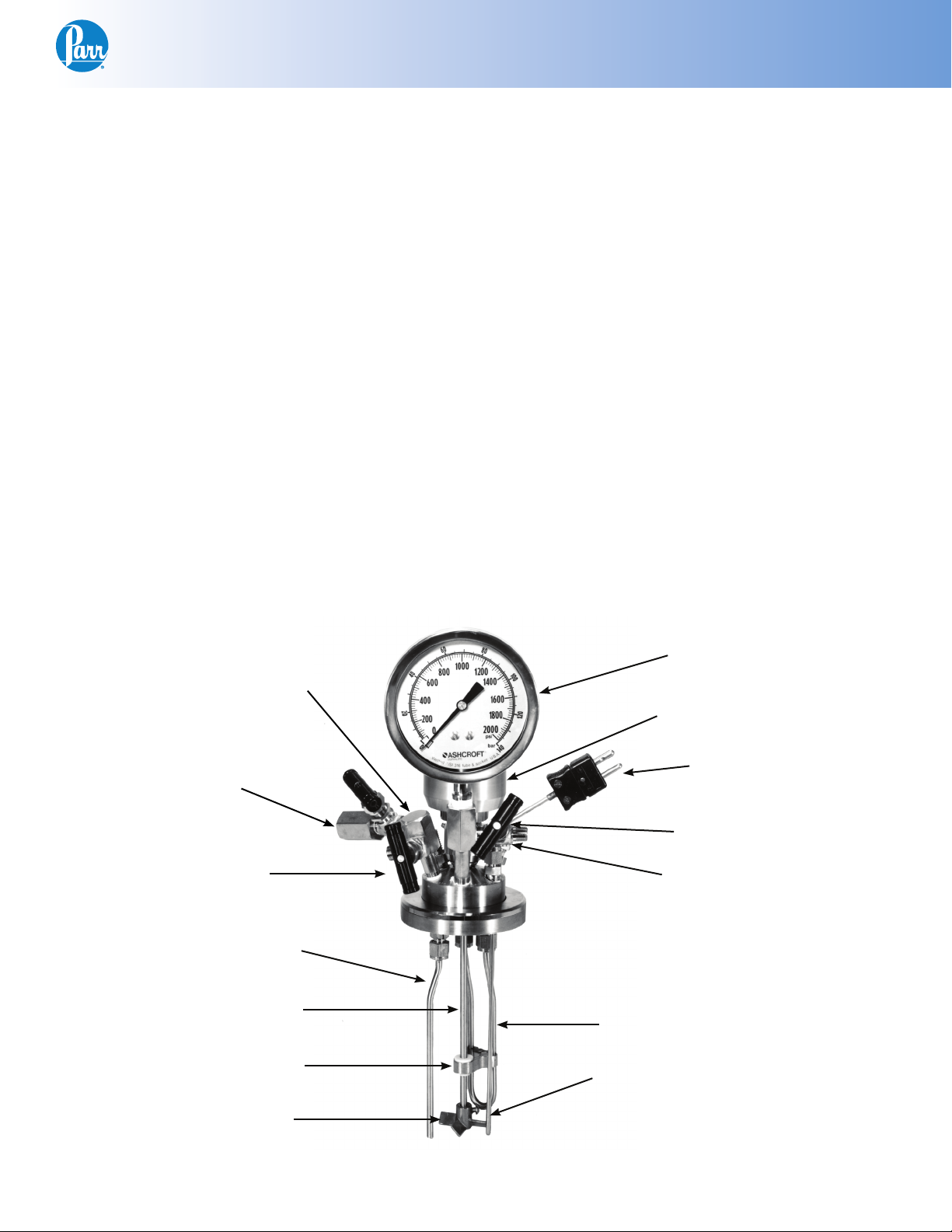

Safety Rupture Disc

Gas Inlet Valve

Liquid Sampling Valve

Dip Tube

Stirring Shaft

Lower Guide

Bearing

Pressure Gage

Magnetic Drive

Thermocouple

Gas Release Valve

Vessel Water Cooling

Channel

Cooling Loop

Thermocouple / Thermowell

Adjustable

Impeller(s)

Removable Head Shown (Standard Temperature, T316)

www.parrinst.com

9

Page 10

Mini Bench Top Reactors

Other Vessel Head Fittings

Safety Rupture Disc

There is a safety rupture disc attached to the head

which is intended to rupture and release the pressure before it reaches a dangerous level. A metal

tag wired to the safety head identifi es the burst

pressure at room temperature for that particular

disc. A similar tag is furnished with each replacement disc. This tag must remain with the apparatus

at all times so that both present and future operators will be aware of the disc rating. Users should

read the discussion of rupture discs given in the

Operating Instruction No. 231M for a complete

description of the characteristics of rupture discs

and the precautions to be observed when operating

pressure equipment protected by this type of safety

device.

A typical pre-bulged disc can be used to 90% of the

rating on the tag. For additional protection, the

user should install an adequate and safe venting

system for removing any toxic, fl ammable or volatile materials which would be released if the rupture

disc should burst. A connector for attaching 3/8” OD

tubing to the discharge port of the rupture disc is

provided for this purpose.

Heaters

The Mini Reactor Systems offer an array of heating

choices to suit the needs of the operator.

The 100 and 160 mL models are offered with a high

watt density band heater, which is to be clamped

directly onto the cylinder. After the vessel has been

placed in its holder, slide the heater onto the cylinder and tighten the clamping screw which projects

from the aluminum housing.

The 300, 450 and 600 mL Mini Reactors are standard

equipped with heating mantles housed in sturdy

aluminum shells. These mantles are made in three

sizes, designed to provide uniform heat distribution

to the walls and bottoms of these vessels. They are

attached to the support rod with a clamp, arranged

so that they can be raised or lowered on the rod as

desired.

Alternately the 300, 450 and 600 mL Reactor systems can be heated with an aluminum block heater

which features integrated cooling.

The high temperature Mini Reactor systems utilize a

higher wattage ceramic fi ber heater.

Type J Thermocouple

A Type J Thermocouple in a 1/8” diameter stainless

steel sheath is installed in each reactor. In reactors made of alloys other than stainless steel, the

stainless thermocouple is installed in a thermowell

made of the same alloy as the vessel. Connect the

thermocouple to the socket on the rear panel of the

temperature controller using the A470E2 extension

wire furnished with the reactor.

Pressure Gage

The pressure gage furnished with this reactor has

a T316 stainless steel Bourdon tube. Gages are

furnished in a variety of ranges to meet individual

needs. Typically, the gage and the rupture disc are

furnished as matched ranges. For applications

where a gage is selected with a range under 1000

psi, a relief valve is added and set to protect the

gage. A 1000 psi rupture disc is installed as the failsafe vessel protection.

For highly corrosive applications where the vapor

phase might corrode the stainless Bourdon tube,

Parr offers isolator assemblies in a variety of materials. These isolators with their internal piston isolate

the vapors from the gage.

Parr heaters are offered with optional thermowell

port to accommodate the Parr A511E bayonet style

thermocouple, an open bottom to accommodate a

cylinder bottom drain valve, and/or the quick con-

nect mounting style for conveniently changing

heater size. Please consult the experienced customer service staff at Parr Instrument Company for

assistance in determining the correct heater for your

reactor system.

Each heater must always be used with a vessel

of the size for which it was designed, and it must

always be fully attached to the vessel before heat is

turned on. Similarly, a short vessel must never be

heated in a deep heater. Without full contact with a

metal wall, a heater may overheat and burn out.

10

Parr Instrument Company

Page 11

Mini Bench Top Reactors

How to Use the Vessel

Removable Vessels

Always remove removable vessels from the support

stand before attempting to open or close them.

To open the Vessel

Open the gas release valve to discharge any internal

pressure. For the bolted closure, loosen the six cap

screws in the split ring sections. Loosen the cone

pointed screw in the outer band and lower the band

to rest on the table. The ring sections can now be

removed, and the head with all attached fi ttings is

free to be lifted from the cylinder. Handle the head

carefully so as not to damage the stirring shaft and

other internals when they are outside of the cylinder.

Before Closing the Vessel

Examine the head gasket or o-ring carefully to be

sure that it is in good condition. After considerable

use, some of the PTFE gasket may extrude into a

thin, ragged edge around the inside and outside

diameters. This does not necessarily mean that the

gasket must be replaced, but the extruded portion

should be removed with a sharp knife. Examine the

mating surfaces on the cylinder and head to be sure

they are clean and free from burrs; then set the head

on the cylinder.

Sealing Vessels with PTFE Gaskets

Initially tighten the cap screws to 15 ft-lbs then

increase to 20-25 ft-lbs. Tightening should proceed

in a criss-cross pattern rather than progressively

around the circle. Let the vessel stand for about fi ve

minutes after the initial tightening; then tighten the

cap screws again. This will compensate for any ten-

dency of the PTFE gasket to fl ow under the loading

pressure.

Sealing with Flexible Graphite Gaskets

Initially tighten the cap screws to 15 ft-lbs then increase to 20-25 ft-lbs. Tightening should proceed in a

criss-cross pattern rather than progressively around

the circle.

Flexible graphite gaskets tend to be somewhat

fl akey. To extend the useful life of these gaskets, fi rst

rough up the sealing surface of the cylinder with

120 grit sand paper to ensure the gasket remains in

the head groove and does not stick to the cylinder.

Secondly, coat both sealing surfaces with a silicone

lubricant. This process will aid in compressing the

gasket so it does not break apart after one use.

Recommended Bolt Torque

PTFE or

Flexible Graphite

O-ring Closures

The split rings used with an o-ring seal do not include any compression bolts.

With the easy close split ring, the o-ring is attached

to the pilot on the underside of the head. When

closing the vessel, set the head on the cylinder and

press down on the head until the bottom of the head

meets with the cylinder fl ange. Then install the two

split ring halves and attach the outer drop band.

Note: The following steps are common to both

head confi gurations.

0-3000 psig

(0-200 bar)

20-25 ft-lbs

Fixed Head Vessels

Fixed head vessels are opened and closed with the

same procedure used for removable vessels except

that they are opened and closed with the head in

place. Before opening the vessel lower the heater

and swing it well to the side so that it will not be

damaged by any materials that drip from the ves-

sel as it is opened. When closing the vessel always

hold the cylinder until both split ring sections are in

place to lock the cylinder to the head.

Gas Connections

For a gas connection to the vessel, use the A495HC

pressure hose furnished with the reactor. Attach the

hose to a pressure regulator or fl ow control valve on

a commercial gas cylinder using PTFE tape or other

thread sealant on the 1/8” NPT male nipple and on

the 1/4” NPT bushing, if used. Then screw the Type

A coned pressure fi tting into the adapter attached

to the gas inlet valve and tighten the compression nut fi rmly. Do not use any thread dope or tape

on the coned fi tting. The A495HC pressure hose is

made of reinforced Nylon which can be used for all

non-corrosive gases at pressures up to 2500 psig.

For operations involving corrosive gases, this hose

should be replaced with an A490HC hose (optional)

which has a PTFE lining and a braided stainless steel

outer covering. These hoses have the same fi ttings

as in the A495HC.

www.parrinst.com

11

Page 12

Mini Bench Top Reactors

Pressurizing the Vessel

Check all valves carefully before admitting gas into

the system. The liquid sampling valve must remain

closed throughout the charging procedure. The gas

release valve must also be closed unless the vessel

is to be purged, or unless there is to be a continuous

fl ow through the reactor during a run. Always make

certain that the pressure in the gas tank is greater

than the pressure in the vessel; otherwise liquid

will be forced out of the vessel and into the gas

tank when the inlet valve is opened. If there is any

possibility that the tank pressure might not be high

enough to force gas into the reactor, install a one

way check valve (optional) in the gas line to prevent

any reverse fl ow.

With the inlet valve open and the fl ow control valve

on the gas tank closed, open the main valve on the

gas tank only about one-quarter turn; then use the

fl ow control valve or the valve on a pressure regulator to control the fl ow of gas into the vessel. After

the desired pressure has been reached, close the

tank valves and the vessel inlet valve and disconnect the hose at the vessel end.

Do Not Overfi ll the Vessel

Always watch the pressure gage closely when admitting gas so as not to exceed the maximum working limit. Remember that any subsequent increase

in temperature will raise the pressure. Also, be

sure that the amount of liquid placed in the vessel

is carefully controlled. As a general rule, the liquid

charge should not exceed two-thirds of the capacity of the cylinder. Too much liquid in the vessel can

lead to development of dangerous pressures if suffi cient space is not provided for expansion when the

liquid is heated. This hazard is explained in greater

detail in a warning statement included in the Instruc-

tion Manual No. 230M.

Releasing Pressure

Use the gas release valve to reduce the pressure in

the vessel if the reactor is accidentally overcharged

when fi lling. Use this valve also to release any

excess pressure during a run and to exhaust the

vessel at the end of a run. If the discharge gases are

fl ammable or toxic, discharge to an exhaust hood or

to any other safe release point.

Withdrawing Liquid Samples

Liquid samples may be withdrawn from the sampling valve attached to the same adapter as the gas

inlet valve whenever the vessel is pressurized. Al-

ways close the inlet valve before withdrawing a liquid sample and open the sampling valve cautiously

because liquid will be discharged with considerable

force. Be particularly careful if the temperature of

the sample is above its boiling point at atmospheric

pressure. If so, it will “fl ash” and be lost as soon

as it is released from the vessel. This problem can

be avoided by connecting an optional 4351 Sample

Collection Vessel to the sampling valve to collect the

liquid into an appropriate receiver. The addition of

a small amount of gas can be used to clear the dip

tube between liquid samples so that the next sample drawn through the tube will truly be representative of the mixture.

Initial Operating Test

Read all operating instructions carefully so as to be

well acquainted with the correct procedures for handling the vessel and for operating the controller and

other accessories. An initial operating test should

be made, with only water, to check the apparatus

before starting the fi rst experimental runs. For this

initial test, fi ll the cylinder not more than half full of

water and run the temperature up to 150 ºC while

checking the apparatus for leaks and observing the

performance of the temperature controller.

Internal Cooling Loop

Each Mini Reactor (except the 100 and 160 mL sizes)

has a single loop cooling coil installed in the vessel with compression fi ttings on the head for con-

necting 1/4” copper or plastic tubing to the loop.

(Special 1/8” OD spiral coils can be furnished for

100 mL & 160 mL if required. Due to internal space

limitations these coils are attached with male connectors on the top side of the head thereby making

the coil captive.) A slow, continuous fl ow of cold

water through a cooling loop proves a very effective means for controlling temperature overshoot

in these reactors, particularly when operating at

temperatures below 150 °C. Water fl ow through the

loop can be controlled automatically using a solenoid valve in the cold water line, and connected to

the cooling socket on the rear panel of the Tempera-

ture Controller. With this arrangement, cold water

will be admitted to the cooling loop whenever the

controller calls for cooling.

If internal cooling is not desired, the cooling loop

can be removed and the opening in the head can

be closed with No. 79HW, 1/8” NPT plugs. Optionally, other 1/8” NPT threaded fi ttings can also be

installed in the coil openings.

12

Parr Instrument Company

Page 13

Air Motor

Mini Bench Top Reactors

Variable speeds from 100 to 2000 rpm with no spark

hazard can be obtained by replacing the standard

motor with an A1393HC air motor assembly. This

motor operates on compressed air which must be

supplied at 40 psig minimum pressure with at least

10 CFM available at that pressure. It is furnished

with a speed control valve and oiler, all assembled

on a mounting bracket.

To operate reactors equipped with an air motor,

mount the assembly fi rmly on the stand and con-

nect the air hose to a compressed air line. For best

torque and speed control the piping to the motor

should be at least 1/4" IPS or larger. Fill the oiler

with SAE 10 oil and adjust the oiler to feed one drop

per minute into the air stream. For long continu-

ous runs at high speeds the oiling rate should be

increased to three drops per minute.

Air Motor Option

If the motor becomes sluggish, fl ush it with a nonfl ammable solvent in a well ventilated area. Disconnect the air line and muffl er and pour a small

amount of solvent into the inlet port. Rotate the

shaft by hand in both directions for a few minutes;

then connect the air line and run the motor until

there is no further trace of solvent in the exhaust.

If the muffl er felts are dirty, wash them in solvent or

replace them.

Re-lubricate the motor with a squirt of oil into the

chamber and reassemble.

If it becomes necessary to disassemble the motor to

replace the vanes, follow the directions given in the

instruction sheet published by the Gast Manufactur-

ing Corporation, Benton Harbor, Michigan.

www.parrinst.com

13

Page 14

Mini Bench Top Reactors

Explosion Proof Operation

If the local safety code requires that equipment installed in the user’s laboratory must be explosion proof

there are four possible ignition hazards to be considered:

1. The Motor

The standard variable speed motor is not explosion proof, yet these motors are not unduly hazardous if operated in a well ventilated location

where care is taken to prevent the accumulation

of explosive gases or vapors. To eliminate any

possible spark hazard originating at the motor, Parr can furnish an air motor as described

previously, or the reactor can be equipped with

a variable speed, explosion proof motor which

is approved for use in Class 1, Div. 1, Groups C

& D, and Class 2, Groups E, F, & G atmospheres.

Explosion proof motors are furnished with a

temporary power cord and plug which are not

explosion proof. The user should remove this

temporary wiring and replace it with an explosion proof switch and wiring which will comply

with the local electrical code.

2. The Temperature Controller

The Temperature Controllers furnished with

these reactors contain switches and other elements which are not explosion proof. The minimal spark hazard associated with these units

can be resolved by installing the controller in a

remote location outside of the hazardous area or

by enclosing it in an approved explosion proof

housing. If enclosed within a positive pressure,

clean air housing, the discharge from the housing must be directed into a safe area. If requested, Parr will furnish the long lead wires needed

to mount the controller in a remote location. If

the controller is to be installed in an explosion

proof housing, the user must provide the necessary housing and installation.

3. The Heater

The elements in the heater could be dangerous

in an explosive atmosphere if the surface temperature of the element becomes high enough

to ignite fl ammable vapors. This hazard must be

evaluated for each individual installation since

major modifi cations are required if the heater

must be isolated from the surrounding atmosphere. Users who consider this a signifi cant

hazard are urged to contact the Parr Instrument

Company for further discussion and suggestions

which might be helpful. Parr is currently offering

aluminum block heaters and circulating jacketed

cylinders which can be used in hazardous environments.

4. The Wiring

Unless specifi cally designed for use in hazardous atmospheres, the wiring in these reactors

will not meet the standards prescribed for explo-

sion proof equipment. Optional intrinsically safe

barriers are also available.

14

Parr Instrument Company

Page 15

Mini Bench Top Reactors

Periodic Pressure Tests

Each cylinder used in a Parr stirred reactor is tested

under hydrostatic pressure to 1.3 times its maximum rating before it is released from the factory.

Micrometer caliper measurements are taken during this test to check the defl ection of the walls of

the cylinder under pressure. Excessive defl ection

or failure of the metal to resume its original dimensions after pressure is released indicates that a

cylinder is potentially unsafe and it will be rejected.

Similar tests should be made at regular intervals

during the life of each cylinder, and particularly

whenever the user suspects that the equipment has

been over-stressed or damaged.

Some laboratories maintain hydraulic test facilities

and make it a rule that all pressure vessels must

be tested at regular intervals. Records are kept of

defl ections at specifi c test pressures so that any

increase in defl ection becomes a warning that the

metal has lost strength. Any cylinder which fails to

return to its original dimensions after application of

the prescribed hydrostatic test should be discarded

as unsafe for further use.

Users who do not have pressure test facilities can

return any Parr pressure vessel to the factory for hydrostatic testing and overhaul. This should be done

whenever the metal shows excessive damage from

corrosion or whenever an over-pressure or other

unusual occurrence raises any safety questions. To

return a vessel for repair contact Parr Instrument

Company for a return authorization number. Apparatus returned for testing and overhaul should be

shipped prepaid to the Parr Instrument Company,

211-53rd Street, Moline, Illinois 61265. An order or

letter of instructions should be mailed to the same

address, as no repair work will be started without

specifi c instructions and a Health & Safety Assurance Certifi cation form (F0042) signed by a respon-

sible user.

Accessories

Liners

Glass or PTFE liners can be furnished to fi t most

Parr reactors. These liners slide into the cylinder.

Although they will not keep corrosive vapors from

reaching the surfaces of the cylinder and head, they

make it much easier to add and remove liquid reactants, and they give some protection to the cylinder

when working with corrosive solutions. It must be

noted, however, that adding a PTFE liner will slow

the heat transfer rate into the vessel, and it may be

necessary to adjust the temperature control method

to prevent overheating.

Liner Part Numbers

Fits ID

2.06” 100 mL 762HC7 762HC7HA

2.5” 160 mL 762HC8 762HC8HA

2.5” 300 mL 762HC 762HC4HA

2.5” 450 mL 762HC2 762HC5HA

2.5” 600 mL 762HC3 762HC6HA

Cylinder

Size

Spare Parts Kit

Spare parts kits are available for these reactors. The

kits will provide a reserve supply of parts and tools

suffi cient to handle most normal replacements and

emergency repairs during a year of heavy usage.

The kits contain small perishable items required for

continuous operation including gaskets, bushings,

rupture discs and seals. They can be ordered from

any Parr Dealer or direct from the Parr Instrument

Company. The order must specify the reactor size

and indicate type of rupture disc, stirrer drive and

whether it has a fl at-gasket or O-ring closure. It is

most advantageous to provide the complete vessel

number from the head or cylinder.

Glass

Liner

PTFE

Liner

www.parrinst.com

15

Page 16

Mini Bench Top Reactors

General Maintenance Notes

1. Periodically inspect all electrical wiring and pressure connections for excessive corrosion. Suspect parts should be replaced by components

only supplied by Parr Instrument Company.

2. Always use appropriate wrenches on all fi ttings

and valves. Never use pliers or pipe wrenches.

3. Head and cylinder service fi xtures are available

for convenience and protection of components

during maintenance of your reactor.

4. A light coating of thread lubricant, such as Parr

High Temperature Anti-Seize Lubricant (424HC2),

applied to the straight threads and to the nose

of coned adapter will help to obtain a tight joint.

PTFE tape should be used only on all tapered

(NPT) threads not NPS straight threads.

5. NPT (National Pipe Taper) threads should not be

disassembled any more than necessary. It will

become increasingly diffi cult to maintain a tight

seal with these tapered threads if the joint is

made and broken repeatedly.

9. Routinely inspect cap screws on split ring closure for lubrication and cleanliness. It is important to clean and lubricate periodically so that

the required torque is achieved when tightening

the bolts.

10. To operate reactors equipped with an air motor,

connect air hose to a compressed air line. For

best torque and speed control the piping to the

motor should be at least 1/4” IPS or larger. Fill

the oiler with SAE 10 oil and adjust the oiler feed

to one drop per minute into the air stream. For

long continuous runs at high speeds the oiling rate should be increased to three drops per

minute. If the motor becomes sluggish, fl ush

it with a non-fl ammable solvent in a well ventilated area. Disconnect the air line and muffl er

and pour a small amount of solvent into the inlet

port. Rotate the shaft by hand in both directions

for a few minutes; then connect the air line and

run the motor until there is no further trace of

solvent in the exhaust. If the muffl er is dirty,

replace it. Re-lubricate the motor with a squirt of

oil into the chamber and reassemble.

6. Do not use oil or anti-seize lubricant on threads

or fi ttings if the vessel is to be used with oxygen.

7. If your vessel is equipped with a loose compression ring be sure that it is in place on the head

before attaching any head fi ttings. The compression ring cannot be installed after fi ttings have

been screwed into the head.

8. Clean all threads and gas passages thoroughly

and remove all tape fragments when overhauling a vessel. An ultrasonic bath is excellent for

cleaning metal parts, but do not place a thermocouple probe, pressure gage, face seals or ball

bearings in an ultrasonic bath. Periodic cleaning

may be performed on the exterior surfaces of

the reactor stand with a lightly dampened cloth

containing a mild soap solution. All electrical

power should be disconnected when cleaning.

11. If servicing assistance is needed, contact Parr

Instrument Company directly at the address

shown on the back of these instructions.

16

Parr Instrument Company

Page 17

4560 Series Reaction Vessel Parts List

Standard Vessel Fittings

(3000 psig/ 350°C)

Vessel Closure and Standard Internal Parts

SAFETY HEAD ASSY

A1120HC6

593HC

SERIES

GAGE

MAG DRIVE ASSY

COUPLING

CONNECTOR

A888HC2

(BELOW 366VB)

366VB

288VB

A92HWAD

CONNECTOR

Mini Bench Top Reactors

A472E THERMOCOUPLE

W/ A833HC CONNECTOR

818HC

HEAD

457HC2 GASKET REF

832HC

DIP TUBE

822HC15

SHAFT

A834HC

MALE CONNECTOR

TYP (3) PLACES

831HC

COOLING LOOP

A837HC

PROPELLER

Consult the itemized list for your reactor, provided

along with this manual. For purpose of reactor iden-

tifi cation the following abbreviation codes are used:

RV - Removable Vessel FH - Fixed Head

FG - Flat Gasket Seal OR - O-ring Seal

SS - T316 only SP - Special Alloy

MD - Magnetic Drive

FMD - Footless Magnetic Drive

* For parts made from alternate materials use the

codes shown below as a suffi x to the standard part

number.

CM - Alloy 400 CC - Alloy 20Cb3

CT - Alloy 600 CA - Titanium G2 or G4

CG - Alloy b-2 CH - Alloy C-276

CX - Zirconium

A122VB

STRAIGHT

VALVE

420HC

ADAPTER

835HC

ADAPTER TEE

A146VB

ANGLE VALVE

(GAGE HIDDEN FOR CLARITY)

GAGE ADAPTER

Cylinders*

Part No. Description Code

452HC8 Cylinder, 100 mL FG

2342HC4 Cylinder, 100 mL OR

452HC9 Cylinder, 160 mL FG

2342HC5 Cylinder, 160 mL OR

452HC Cylinder, 300 mL FG

2342HC Cylinder, 300 mL OR

452HC2 Cylinder, 450 mL FG

2342HC2 Cylinder, 450 mL OR

452HC3 Cylinder, 600 mL FG

2342HC3 Cylinder, 600 mL OR

* For Special Fittings

836HC

A455HC SPLIT

RING ASSY W/

A456HC DROP

BAND

REF

A122VB

STRAIGHT

VALVE

www.parrinst.com

17

Page 18

Mini Bench Top Reactors

Magnetic Stirrer

Part No. Description

A1120HC6 Magnetic Stirrer, 16in-lb

A2140HC2 Footless Magnetic Stirrer, 16 in-lb

A2685HC Cooling Sleeve

827HC O-ring

2714HC Hose connector

See manual 234M for a full list of magnetic stirrers

and parts.

Heads for A1120HC6 Magnetic Stirrer*

Part No. Description Code

818HC Head, for thermocouple RV FG

818HC2* Head, for thermowell RV FG

2201HC Head, for thermocouple FH FG

2201HC2* Head, for thermowell FH FG

2340HC Head, for thermocouple RV OR

2340HC* Head, for thermowell RV OR

2343HC Head, for thermocouple FH OR

2343HC2* Head, for thermowell FH OR

Heads for A2140HC2 Footless Magnetic Stirrer*

Part No. Description Code

818HC39 Head, for thermocouple RV FG

818HC40* Head, for thermowell RV FG

2201HC5 Head, for thermocouple FH FG

2201HC6* Head, for thermowell FH FG

2340HC5 Head, for thermocouple RV OR

2340HC6* Head, for thermowell RV OR

2343HC5 Head, for thermocouple FH OR

2343HC6* Head, for thermowell FH OR

Gaskets & Seals

Part No. Description Code

457HC2 Head Gasket, PTFE FG

457HC3KL Head Gasket, Flexible

Graphite

2341HCJV O-ring FKM OR

2341HCJK O-ring FFKM OR

48HC Gasket, silver; A1120HC

48HCFG Gasket, gold plated; A1120HC

2142HC Gasket, silver; A2140HC

2142HCFG Gasket, gold plated; A2140HC

2142HC2KL Gasket, graphite; A2140HC

FG

Split Rings and Accessories

Part No. Description Code

A455HC Split Ring Assembly w/ bolts RV FG

454HC Compression Ring, Head Drop

Band

A456HC Drop Band w/ screw RV FG

A2205HC S/R, 6 bolt, Captive Compres-

sion Ring

232HCFDE Compression bolt, GR-B7 FG

2195HC Split ring, quick close OR

372HC2 Wrench, 9/16”

RV FG

FH FG

Dip Tubes

Part No. Description Code

832HC Dip Tube for 300 mL SS

832HC4* Dip Tube with nut, 300 mL SP

832HC2 Dip Tube, 450 mL SS

832HC5* Dip Tube with nut, 450 mL SP

832HC3 Dip Tube, 600 mL SS

832HC6* Dip Tube with nut, 600 mL SP

832HC8* Dip Tube with nut, 160 mL SS / SP

832HC19* Dip Tube with nut, 100 mL SS / SP

Male Connectors

Part No. Description Code

A833HC Male Connector, 1/8NPTM x 1/8T,

(Thermocouple)

A834HC Male Connector, 1/8NPTM x

3/16T, (SS dip tube)

A92HW* Male Connector, 1/8NPTM x 1/4T,

(Special mate diptube)

A138CA Male Connector, 1/8NPTM x 1/4T,

TW, (thermowell)

SS

SS

SS / SP

SP

Cooling Loop

Part No. Description Code

831HC Cooling Loop for 300 mL SS

831HC6* Cooling Loop for 300 mL SP

831HC2 Cooling Loop for 450 mL SS

831HC7* Cooling Loop for 450 mL SP

831HC3 Cooling Loop for 600 mL SS

831HC8* Cooling Loop for 600 mL SP

A92HW* Internal Connector, cooling loop*

217VB* Nut for A92HW* ¼” T

218VB* Ferrule for A92HW* ¼” T

* For Special Fittings

18

Parr Instrument Company

Page 19

Mini Bench Top Reactors

Stirrer Support Bracket

Part No. Description Code

A1260HC Stirrer Bracket w/ bushing SS

A1260HC2* Stirrer Bracket w/ bushing SP

1261HC Stirrer Bracket Bushing, PTFE

graphite

1261HC2KF Stirrer Bracket Bushing, graphite

Note: 450 mL and 600 mL only

Stirrer Shafts for A1120HC6 Magnetic Stirrer*

Part No. Description Code

822HC15 Shaft, 300 mL, 5.81” RV MD

822HC30 Shaft, 300 mL, 6.42” FH MD

822HC16 Shaft, 450 mL, 7.81” RV MD

822HC31 Shaft, 450 mL, 8.92” FH MD

822HC17 Shaft, 600 mL, 9.81” RV MD

822HC32 Shaft, 600 mL, 10.92” FH MD

822HC18 Shaft, 100 mL, 3.88” RV MD

822HC33 Shaft, 100 mL, 4.99” FH MD

822HC18 Shaft, 160 mL, 3.88” RV MD

822HC33 Shaft, 160 mL, 4.99” FH MD

Gage Assembly

Part No. Description

836HC Gage adapter, 1/4” NPT(F) top x 1/8”

NPT(F) side port

836HC6 Gage adapter, 1/4” NPT(F) top x 1/8”

NPT(F) + two 1/4” NPT(F) side ports

836HC7 Gage adapter, 1/4” NPT(F) top, one 1/8” +

1/4” NPT(F) side ports

A122VB Needle Valve T316 1/8 NPTM

Gages

Part No. Description

593HCP1AD Pressure Gage, 3-1/2”, 100 psi/bar

593HCP2AD Pressure Gage, 3-1/2”, 200 psi/bar

593HCP6AD Pressure Gage, 3-1/2”, 600 psi/bar

593HCPD Pressure Gage, 3-1/2”, 1000 psi/bar

593HCPF Pressure Gage, 3-1/2”, 2000 psi/bar

593HCPG Pressure Gage, 3-1/2”, 3000 psi/bar

Heaters

Part No. Description

A2230HCEB Heater, 300 mL, 115V

A2230HCEE Heater, 300 mL, 230V

Stirrer Shafts for A2140HC2 Footless Magnetic Stirrer

Part No. Description Code

2141HC Shaft, 300 mL, 7.93” RV FMD

2141HC7 Shaft, 300 mL, 9.05” FH FMD

2141HC2 Shaft, 450 mL, 9.93” RV FMD

2141HC8 Shaft, 450 mL, 11.05” FH FMD

2141HC3 Shaft, 600 mL, 11.93” RV FMD

2141HC9 Shaft, 600 mL, 13.05” FH FMD

2141HC46 Shaft, 100/160 mL, 5.93” RV FMD

2141HC50 Shaft, 100/160 mL, 7.05” FH FMD

Impellers*

Part No. Description Code

A2148HC Impeller with screw, for 2141HC

series shafts

A837HC Impeller with screw, for 822HC

series shafts

FMD

MD

A2230HC2EB Heater, 450 mL, 115V

A2230HC2EE Heater, 450 mL, 230V

A2230HC3EB Heater, 600 mL, 115V

A2230HC3EE Heater, 600 mL, 230V

A2235HCEB Heater, 100/160 mL, 115V

A2235HCEE Heater, 100/160 mL, 230V

* For Special Fittings

www.parrinst.com

19

Page 20

Mini Bench Top Reactors

Thermocouple/Thermowell

Part No. Description Code

A833HC Male Conn, 1/8” NPT(M) ×

1/8” T for Thermocouple

A138CA Male Conn, 1/8” NPT(M) ×

1/4” T for thermowell

A1453HC Thermowell, 1/4”OD

A472E Thermocouple, Grounded

300mL Type J, 7-1/2

A472E2 Thermocouple, Grounded

450mL Type J, 9-1/2

A472E3 Thermocouple, Grounded

600mL Type J, 11-1/2

A472E4 Thermocouple, Grounded

100/160mL Type J, 5-1/2

A490E Thermocouple, Dual

Grounded, 7-1/2, 1/8”OD

A490E2 Thermocouple, Dual

Grounded 9-1/2

A490E3 Thermocouple, Dual

Grounded 11-1/2

213VBAD Nut 1/8” T TC

214VBAD Ferrule 1/8” T TC

217VBAD Nut 1/4” T TW

218VBAD Ferrule 1/4” T TW

TC

TC

TC

TC

TC

TC

TC

External Fittings

Part No. Description

A888HC2 Rupture disc assembly

49HC2 Orifice cone

527HC Orifice ring

433HC4 Safety head outlet

366VBD Hex Coupling, 1/4 NPTF

288VBAD Male Connector, 3/8” T-1/4” NPTM

A92HWAD Male Connector 1/8 NPTMx1/4T

(T316SS for top of cooling loop)

79HW* Plug, Hex Head 1/8” NPTM

835HC Adapter, two 1/8” NPT(F) side ports

A122VB Needle Valve T316 1/8 NPTM

A146VB Angle Valve T316 1/8 NPTM-M

420HC Adapter, T303 A Skt × 1/8 NPTF

Rupture Disc Assembly

See manual 231M for a full list of safety rupture disks.

Specify volume & head style (fi xed or movable)

* For Special Fittings

20

Parr Instrument Company

Page 21

Mini Bench Top Reactors

Digitally signed

by Vern Moon

Gas Entrainment Upper Shaft

Part No. Description Code

2027HC 2.83” Shaft, upper MV MD

2027HC3 3.94” Shaft, upper FH MD

Gas Entrainment Lower Shaft

Part No. Description Code

2028HC5 3.04” Shaft, 300 mL MD

2141HC1 8.16” Shaft, 300 mL FH FMD

2141HC15 7.11” Shaft, 300 mL MV FMD

4561 Gas Entrainment Assembly

300mL Removable Vessel

REF

818HC HEAD

REF

2027HC SHAFT

Part No. Description Code

2028HC6 4.04” Shaft, 450 mL MD

2141HC12 9.72” Shaft, 450 mL FH FMD

2141HC16 8.61” Shaft, 450 mL MV FMD

2028HC7 5.54” Shaft, 600 mL MD

2141HC13 11.22” Shaft, 600 mL FH FMD

2141HC17 10.11” Shaft, 600 mL MV FMD

2028HC8 1.18” Shaft, 100/160 mL MD

2141HC14 6.85” Shaft, 100/160 mL FH FMD

2141HC18 5.73” Shaft, 100/160 mL MV FMD

832HC DIP TUBEA834HC MALE CONN

REF

A1870HC2 STIRRER BRKT REF

1869HC OR 1869HC2KF

BUSHING NOT FURNISHED

SEE NOTE

452HC CYLINDER

REF

2070HC IMPELLER

A833HC MALE CONN

A472E/A490E THERMOCOUPLE

REF

REF

457HC2 GASKET

2028HC5 SHAFT

REF3.94

4563 Gas Entrainment Assembly

600mL Removable Vessel

A2043HC BAFFLE

REF

.46 REF

NOTE:

FOR 1/4" OD SPECIAL ALLOY AND HIGH

TEMP DIP TUBES USE A1870HC

www.parrinst.com

21

Page 22

Mini Bench Top Reactors

4560 Series Reaction Vessel Parts List

High Temperature Vessel Fittings

(2000 psig/500°C)

Vessel Closure and Standard Internal Parts

593HC SERIES

GAGE

A1120HC6

1446HC2

ADAPTER

35HC

40HC

MAG DRIVE ASSY

A544VBKL

280VB NIPPLE

VALVE

SAFTEY HEAD ASSY

(BELOW 302VBAD)

CONNECTOR

A888HC2

302VBAD

A92HWAD

A92HWAD

CONNECTOR

CONNECTOR

A472E

THERMOCOUPLE

W/ 3366HC, 3367HC

3460HC

HEAD

1359HC NUT

1360HC FERRULE

831HC24

COOLING LOOP

A837HC

PROPELLER

914HC

LOCKNUT

REF

1261HCKL

BUSHING

(OPTIONAL)

832HC37

DIP TUBE

822HC30

SHAFT

35HC

40HC

*Special Materials

Consult the itemized list for your reactor, provided

along with this manual. For purpose of reactor iden-

tifi cation the following abbreviation codes are used:

RV - Removable Vessel FH - Fixed Head

FG - Flat Gasket Seal SP - Special Alloy

SS - T316 only MD - Magnetic Drive

FMD - Footless Magnetic Drive

* For parts made from alternate materials use the

codes shown below as a suffi x to the standard part

number.

CM - Alloy 400 CC - Alloy 20Cb3

CT - Alloy 600 CA - Titanium G2 or G4

CG - Alloy b-2 CH - Alloy C-276

CX - Zirconium

A544VB2KL

ANGLE VALVE

1452HC6

ADAPTER TEE

1452HC5

GAGE ADAPTER

(GAGE HIDDEN FOR CLARITY)

A544VBKL

VALVE

280VB NIPPLE

Cylinders*

Part No. Description Code

452HC Cylinder, 300 mL FG

452HC2 Cylinder, 450 mL FG

452HC3 Cylinder, 600 mL FG

Heads*

Part No. Description

3619HC Head, for thermocouple RVMD

3619HC* Head, for thermowell RVMD

3460HC* Head, for thermocouple FHMD

3460HC2* Head, for thermowell FHMD

3460HC3 Head, for thermocouple FHFMD

* For Special Fittings

22

Parr Instrument Company

Page 23

Mini Bench Top Reactors

Gaskets*

Part No. Description Code

457HC3KL Head Gasket, Flexible Graphite RV FG

48HC Gasket, silver; A1120HC RV FG

48HCFG Gasket, gold plated; A1120HC FH FG

2142HC Gasket, silver; A2140HC FH FG

Closure*

Part No. Description Code

A455HC7 Split Ring Assembly with bolts RV

454HC Compression Ring, Head RV

A456HC Drop Band RV

A2205HC3 Split Ring Assembly with com-

pression ring & bolts

372HC2 Wrench, 9/16” RV

3646HC Wrench, 7/16” FH

FH

Dip Tubes*

Part No. Description Code

832HC37 Dip Tube for 300 mL

832HC38 Dip Tube, 450 mL

832HC39 Dip Tube, 600 mL

Cooling Loop*

Part No. Description Code

831HC24 Cooling Loop for 300 mL

831HC25 Cooling Loop for 450 mL

831HC26 Cooling Loop for 600 mL

1359HC* Nut, 1/4” Tube Seal

1360HC* Ferrule, 1/4” Tube Seal

Stirrer Support Bracket

Part No. Description Code

A1260HC2* Stirrer Bracket w/ bushing

1261HC2KF Stirrer Bracket Bushing

Magnetic Stirrer

Part No. Description

A1120HC6 Magnetic Stirrer, 16in-lb

A2140HC2 Footless Magnetic Stirrer, 16 in-lb

A2685HC Cooling Sleeve Assembly

827HC O-ring

2714HC Hose connector

See manual 234M for a full list of magnetic stirrers

and parts.

Stirrer Shafts for A1120HC6 Magnetic Stirrer*

Part No. Description Code

822HC15 Shaft, 300 mL, 5.81” RV MD

822HC30 Shaft, 300 mL, 6.42” FH MD

822HC16 Shaft, 450 mL, 7.81” RV MD

822HC31 Shaft, 450 mL, 8.92” FH MD

822HC17 Shaft, 600 mL, 9.81” RV MD

822HC32 Shaft, 600 mL, 10.92” FH MD

Stirrer Shafts for A2140HC2 Footless Magnetic Stirrer*

Part No. Description Code

2141HC Shaft, 300 mL, 7.93” RV FMD

2141HC7 Shaft, 300 mL, 9.05” FH FMD

2141HC2 Shaft, 450 mL, 9.93” RV FMD

2141HC8 Shaft, 450 mL, 11.05” FH FMD

2141HC3 Shaft, 600 mL, 11.93” RV FMD

2141HC9 Shaft, 600 mL, 13.05” FH FMD

Impellers*

Part No. Description Code

A2148HC Impeller with screw, for 2141HC

series shafts

A837HC Impeller with screw, for 822HC

series shafts

FMD

MD

Note: 450 mL and 600 mL only

Thermowell*

Part No. Description Code

A1453HC* Thermowell, specify reactor vol-

ume & head style when ordering

Gages

Part No. Description

593HCP1AD Pressure Gage, 3-1/2”, 100 psi/bar

593HCP2AD Pressure Gage, 3-1/2”, 200 psi/bar

593HCP6AD Pressure Gage, 3-1/2”, 600 psi/bar

593HCPD Pressure Gage, 3-1/2”, 1000 psi/bar

593HCPF Pressure Gage, 3-1/2”, 2000 psi/bar

593HCPG Pressure Gage, 3-1/2”, 3000 psi/bar

* For Special Fittings

www.parrinst.com

23

Page 24

Mini Bench Top Reactors

Thermocouple/Thermowell

Part No. Description Code

A472E Thermocouple, Grounded

300mL Type J, 7-1/2

A472E2 Thermocouple, Grounded

450mL Type J, 9-1/2

A472E3 Thermocouple, Grounded

600mL Type J, 11-1/2

A472E4 Thermocouple, Grounded

100/160mL Type J, 5-1/2

A490E Thermocouple, Dual

Grounded, 7-1/2, 1/8”OD

A490E2 Thermocouple, Dual

Grounded 9-1/2

A490E3 Thermocouple, Dual

Grounded 11-1/2

3366HC Nut, 1/8” Tube Seal TC

3367HC Ferrule, 1/8” Tube Seal TC

1360HC Ferrule SS, 1/4” Tube Seal TW

1359HC Nut, 1/4” T Seal TW

A1453HC Thermowell, 1/4” OD

TC

TC

TC

TC

TC

TC

TC

Specify volume & head style (fi xed or movable)

External Fittings

Part No. Description

A888HC2 Rupture disc assembly

49HC2 Orifice cone

527HC Orifice ring

433HC4 Safety head outlet

A544VBKL Valve, Straight 1/8” NPTF

A544VB2KL Valve, Angled 1/8” NPTF

280VBAD Nipple, 1/8” NPTM

A92HWAD Male Connector 1/8 NPTMx1/4T

(T316SS for top of cooling loop)

35HC Compression Nut

40HC Bushing

1452HC5 Gage Adapter

1452HC6 Valve Adapter

302VBAD Female Conn, 38” Tube – 1/4” NPTF

1446HC2 Adapter, ‘A’ Cone F – 1/8” NPTM

424HC2 Anti-Seize Lubricant

79HW* Plug, Hex Head 1/8” NPTM

94CAAD Plug, Hex Head 1/4” NPTM

Rupture Disc Assembly

See manual 231M for a full list of safety rupture discs.

* For Special Fittings

24

Parr Instrument Company

Page 25

Overarm Parts List

Mini Bench Top Reactors

Motor

Part No. Description

1355EES Motor VS/PM130VDC 1/8 HP

A1554EES Motor VS/PM 130VDC 1/8 HP with EMC

fi lter for CE

A1393HC Air Motor

A388EEQ Motor ¼ HP EXP VS 90 VDC

A388EER Motor ¼ HP EXP VS 180 VDC

A388EES Motor ¼ HP VS 90 VDC

A388EET Motor ¼ HP VS 180 VDC

Driven Pulley Assembly

Part No. Description

A2179HC Driven Pulley Assembly includes:

839HC Ball Bearing

841HC Snap Ring, External .693”

842HC Snap Ring, 1.804”

858HC2 Pulley, Driven

862HC Support Hub

299HC2 Bushing, PTFE

Upper Drive Shafts

Part No. Description

A2223HC Upper Drive Shaft

Shaft Couplings

Part No. Description

2075HC2 Shaft Coupling .38, Universal

Release Knobs

Part No. Description

845HC2 Release Knob, .38 Shaft

Drive Pulleys

Motor

Part No.

857HC Pulley 600 RPM 847HC8

857HC3 Pulley 800 RPM 847HC8

857HC4 Pulley 1000 RPM 847HC8

857HC5 Pulley 1700 RPM 847HC4

857HC7 Pulley, Air Motor only 847HC8

Description

Belt

Part No.

Optional Tach Parts

Part No. Description

A1001E2 Tach Sensor Assembly (5.5”L)

www.parrinst.com

25

Page 26

Mini Bench Top Reactors

Bomb Support Stand with Fixed Head and 1/8 hp Stirrer Drive Motor

A2262E

A2179HC PULLEY ASS’Y:

26

Parr Instrument Company

Page 27

Mini Bench Top Reactors

Bomb Support Stand with Moveable Vessel and 1/4 hp Stirrer Drive Motor

www.parrinst.com

27

Page 28

Revision 05/29/13

Loading...

Loading...