Page 1

4555-4558

5G & 10L Pressure Reactors

Operating Instruction Manual

403M

Page 2

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS............................ 2

Related Instructions...........................3

Customer Service.............................. 3

PREFACE ................................................. 4

Scope ................................................ 4

Safety Information ............................. 4

Provisions for Lifting and Carrying.....4

General Specifications....................... 5

Explanation of Symbols..................... 6

Environmental Conditions .................. 6

Intended Usage.................................7

User’s Responsibility.........................7

Unpack Carefully...............................7

INSTALLATION ........................................ 8

Pressure, Temperature Limits ........... 8

Slave Box Control A1761HC3 ........... 8

ASSEMBLE THE REACTOR....................9

Removable Head Vessel................... 9

Fixed Head Vessel .......................... 10

Cylinder Slide Adjustment................ 12

IDENTIFY THE VALVES......................... 13

Gas Inlet Valve................................ 13

Gas Release Valve.......................... 13

Liquid Sampling Valve..................... 13

OTHER VESSEL HEAD FITTINGS ........ 14

Safety Rupture Disc......................... 14

Type J Thermocouple...................... 14

Pressure Gage ................................ 14

Gage and Valve Adapters................14

HOW TO USE THE VESSEL..................15

Flat Gasket or O-ring Seal............... 15

To Open the Vessel......................... 15

Before Closing the Vessel ............... 15

Close the Vessel.............................. 16

Gas Connections............................. 16

Pressurizing the Vessel................... 16

Do Not Overfill.................................17

Releasing Pressure......................... 17

- 2 -

4555 - 58 Series

5G & 10L Pressure Reactors

Withdrawing Liquid Samples............17

The Shaft Seal.................................17

REACTORS WITH SLAVE BOX CONTROLS 18

3-Zone Slave Box A1761HCEE........ 18

3-Zone Slave Box A1761HC3........... 18

Initial Operating Test......................... 18

ACCESSORIES........................................ 19

Internal Cooling Coils........................ 19

Stirrer Drive Systems........................ 19

Quick Disconnect Drive Coupler....... 19

Air Motor...........................................20

Variable Speed Electric Motor ..........20

Spare Parts Kit .................................. 20

EXPLOSION PROOF OPERATION......... 21

The Motor ......................................... 21

The Temperature Controller.............. 21

Slave Box Control............................. 21

The Heater........................................ 21

The Wiring ........................................21

PERIODIC PRESSURE TESTS ............... 22

GENERAL MAINTENANCE NOTES........ 23

Fuses................................................ 24

PARTS LISTS........................................... 25

Vessel Parts List............................... 25

Internal Fittings ................................. 25

External Fittings................................ 26

Internal Parts Identification ............... 27

External Parts Identification..............28

Cooling Coils & Fittings..................... 29

Drive Parts List.................................. 30

Stands............................................... 31

Slave Boxes...................................... 31

Heaters.............................................32

APPENDIX A – REMOVABLE VESSEL

REACTOR DRAWINGS ........................... 33

APPENDIX B – FIXED HEAD VESSEL

REACTOR DRAWINGS ........................... 36

Page 4

4555 - 58 Series

5G & 10L Pressure Reactors

_________________________________

Related Instructions

The following Parr publications are also available to further your understanding of this

instrument and its component parts:

No. Description

201M Limited Warranty

230M Safety Precautions to be observed when operating Pressure Reaction Equipment

231M Operating Instructions for Parr Safety Discs

548M Operating Instructions for 4848 Reactor Controllers

234M Operating and Maintenance Instructions for Parr Magnetic Drives

323M Operating Instructions for Parr Pressure Relief Valves

F0042 Health & Safety Assurance Certification

_________________________________

Customer Service

Questions concerning the installation or operation of this instrument can be answered by the

Parr Customer Service Department:

309-762-7716

800-872-7720

Fax: 309-762-9453

www.parrinst.com

parr@parrinst.com

- 3 -

Page 5

5G & 10L Pressure Reactors

4555 - 58 Series

PREFACE

Scope

These instructions include information for the installation and operation of standard Parr

Models 4555, 4556, 4557, 4558, 4667, and 4668 (5G and 10L volume) Reactors. It should be

noted that these reactors can be custom designed to accommodate a customer’s specific

operating parameters. This may impact certain areas of these instructions or related instructions

mentioned within this manual.

These instructions cover the basic steps to be followed in installing these reactors and

describe the function of all principal components. They are intended to be used in conjunction

with several related instruction sheets listed on the previous page which provide information

describing several components which are common to most Parr pressure reaction apparatus.

These instructions also include safety precautions and other information applicable to all

pressure equipment.

The user should study all of these instructions carefully before starting to use these reactors

to fully understand the capabilities and limitations of the equipment, and to be well aware of the

precautions to be observed in the operation.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current handling capacity.

2. Ensure that the equipment is connected to electrical service according to local national

electrical codes. Failure to properly connect may create a fire or shock hazard.

3. For continued protection against possible hazard, replace fuses with same type and rating of

fuse.

4. Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or combustible materials; fire or explosion may

result. This device contains components which may ignite such material.

2. Refer servicing to qualified personnel.

Provisions for Lifting and Carrying

The 4555, 4556, 4557, 4559, 4667 and 4668 (five gallon and ten liter volume) reactors and

their components are very heavy. Before moving ensure all cables are disconnected. Use

proper and safe lifting techniques when installing or moving the reactor and/or its components.

Caution

Do not use in hazardous atmospheres.

- 4 -

Page 6

5G & 10L Pressure Reactors

4555 - 58 Series

General Specifications

Electrical Ratings

Controller ratings are found in the Operating Instructions for the controller supplied with your

reactor.

Before connecting any Series A1761HC Slave Control Box to an electrical outlet, the user

must be certain that the electrical outlet has an earth ground connection and that the line, load

and other characteristics of the installation do not exceed the following limits:

Voltage: Fluctuations in the line voltage should not exceed 10% of the rated nominal voltage

shown on the data plate.

Slave Boxes

A1761HCEE rated 230VAC, 50/60 Hz, 50.0 Amp

A1761HC3 rated 400/415V 3-P “Y”, 50/60 Hz, 20.0/ Leg Amp

Frequency: Controllers can be operated from either a 50 or 60 Hertz power supply without

affecting their operation or calibration.

Current: The total current drawn should not exceed the rating shown on the data plate on the

slave control box by more than 10 percent.

Thermocouple: Unless otherwise specified, all Parr controllers operate with a Type J (ironconstantan) thermocouple. The total resistance of the thermocouple and the lead wires should

not exceed 20 ohms. If the resistance of the thermocouple circuit is higher, it will reduce the

sensitivity of the control system.

- 5 -

Page 7

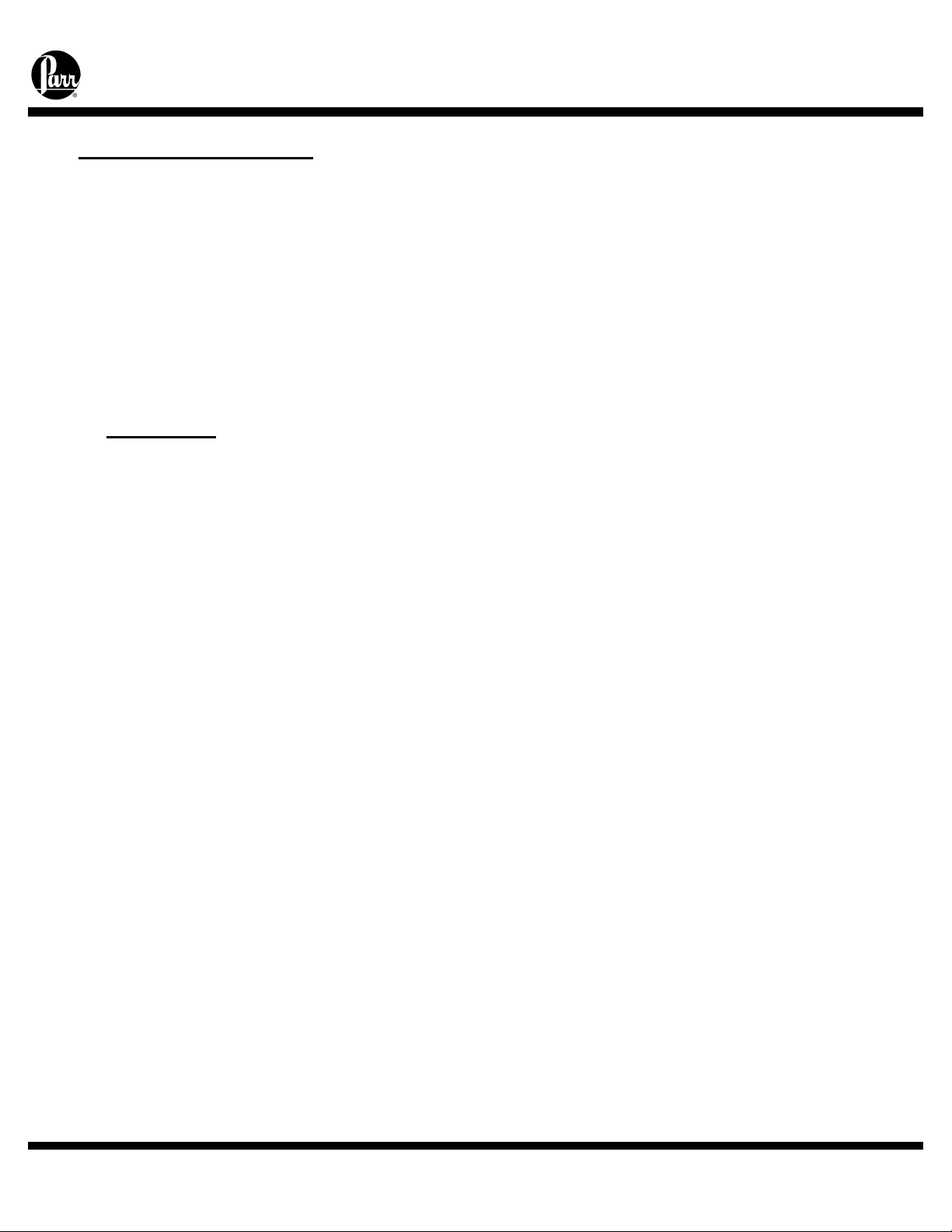

Explanation of Symbols

4555 - 58 Series

5G & 10L Pressure Reactors

I

O

~

3 ~

On position

Off position

Alternating current (AC)

Three–phase alternating current

This CAUTION symbol may be present on the Product

Instrumentation and literature. If present on the product, the

user must consult the appropriate part of the accompanying

product literature for more information.

This CAUTION symbol indicates that the surface may be hot.

Protective Earth (PE) terminal. Provided for connection of

the Protective Earth (green or green/yellow) supply system

conductor.

Environmental Conditions

This apparatus is to be used indoors. It should be secured to the floor in a well-ventilated

area with convenient access to an electric outlet, running water and a drain.

Operating: 15 °C to 35 °C; maximum relative humidity of 80% non-condensing.

Installation Category II (overvoltage) in accordance with IEC 664. Pollution

degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 °C and 65 °C; 10% to 85%

relative humidity.

- 6 -

Page 8

5G & 10L Pressure Reactors

4555 - 58 Series

Intended Usage

This system has been designed for use as a high pressure reactor system. It has been

designed, built, and tested to strict physical and electrical standards. Ho wever, it is the user's

responsibility to install and operate it in conformance with local pr essure and electrical codes.

If this equipment is used in a manner beyond its intended usage, the protection provided by

the equipment may be impaired.

User’s Responsibility

All Parr reactors and pressure vessels are designed and manufactured with great care to

assure safe operation when used within their prescribed temperature and pressure limits.

But . . . the basic responsibility for safety when using this equipment rests entirely with the user;

who must:

1. Select a reactor or pressure vessel which has the capability, pressure rating, corrosion

resistance and design features that are suitable for its intended use. Parr engineers will be

glad to discuss available equipment and material options with prospective users, but the final

responsibility for selecting a reactor or pressure vessel that will perform to the user’s

satisfaction in any particular reaction or test must rest with the user – not with Parr.

In exercising the responsibility for the selection of pressure equipment, the prospective

user is often faced with a choice between over - or under-designed equipme nt. The ha zards

introduced by under-designed pressure vessels are readily app arent, but the penalties that

must be paid for over-designed apparatus are often overlooked. Recognizing these criteria,

Parr reactors and pressure vessels are offered in several different styles, each designed for

convenient use in daily operation within certain temperature and pressure limits, using

gaskets, closures and other elements carefully selected for safe operation within the limits

specified for that design. But in order to preserve the validity of these designs, all

temperature and pressure limits must be observed, and no attempt should be m ade to

increase these limits by making alterations or by substituting components which are not

recommended by Parr Instrument Company.

2. Install and operate the equipment within a suitable barricade, if required, with appropriate

safety accessories and in full compliance with local safety codes and rules.

All standard Parr pressure vessels are provided with either a suitable relief device or a

means to attach one (typically in the form of a plugged opening). When a pressure vessel is

delivered without a pressure venting device, it is the customer’s responsibility to provide

pressure relief in order to protect the operator and the equipment from destructiv e high

pressures. If you need more information or need help in selecting a proper re lief device,

please contact Parr Instrument Company.

3. Establish training procedures to ensure that any person handling the equipment knows

how to use it properly.

4. Maintain the equipment in good condition and establish procedu res for periodic testing to

be sure the vessel remains structurally sound.

Unpack Carefully

Unpack the equipment carefully and check all the parts against the, packing list. If shipping

damage is discovered, report it immediately to the delivering c arriers. The vessel, motor, heater,

and temperature controller may be packed separately for convenience in shipping, but these

parts are easily reassembled. Examine the components closely for any lo ose parts or shipping

damage and be sure to check all layers of packing materials thoroughly so as not to overlook

any parts which might otherwise be discarded.

- 7 -

Page 9

5G & 10L Pressure Reactors

4555 - 58 Series

INSTALLATION

Pressure and Temperature Limits

The working pressure and temperature at which any reactor or pressure vessel can be

used will depend upon the design of the vessel and the materials used in its construction.

Since all materials lose strength at elevated temperatures, any pressure rating must be

stated in terms of the temperature at which it applies. The standard material of construction

for Parr Instrument Company is Type 316 Stainless Steel.

Limits for vessels made of other materials and for other operating temperatures can be

obtained from Customer Service. No attempt should be made to increase these limits by

making alterations or by substituting components which are not recommended by the Parr

Instrument Company. It must also be understood that lower pressure and temperature limits

may be required for modified reactors and for vessels made of special alloys.

Limits for vessels will be determined by the physical characteristics of the vessel material

and will be prescribed on an individual basis.

Temperature and pressure limits are also affected by the physical properties and

temperature limits of the gaskets and seals used in the vessel, and by any valves, gages or

other fittings attached to the vessel. Obviously, the safe operating pressure of any system

can be no higher than that of its lowest rated component.

All Parr reactors show the maximum safe operating pressure and temperature imprinted

on the cylinder.

The working pressure and temperature in these five gallon and ten liter reactors must not

exceed the following maximum limits:

Pressure and Temperature Limits

Vessel Material Maximum Pressure Maximum Temperature

T316SS 1900 psig 350° C PTFE Flat Gasket

T316SS 1900 psig 225° C FKM O-ring

T316SS 1900 psig 275° C FFKM O-ring

A1761HC3 400/415V 3-Phase "Y" Slave Box Control

Installation of a 3-phase slave box requires a switch or circuit breaker installed in the

building.

1. It shall be in close proximity to equipment and within easy reach of the operator.

2. It shall be marked as disconnecting device for the equipment.

- 8 -

Page 10

5G & 10L Pressure Reactors

4555 - 58 Series

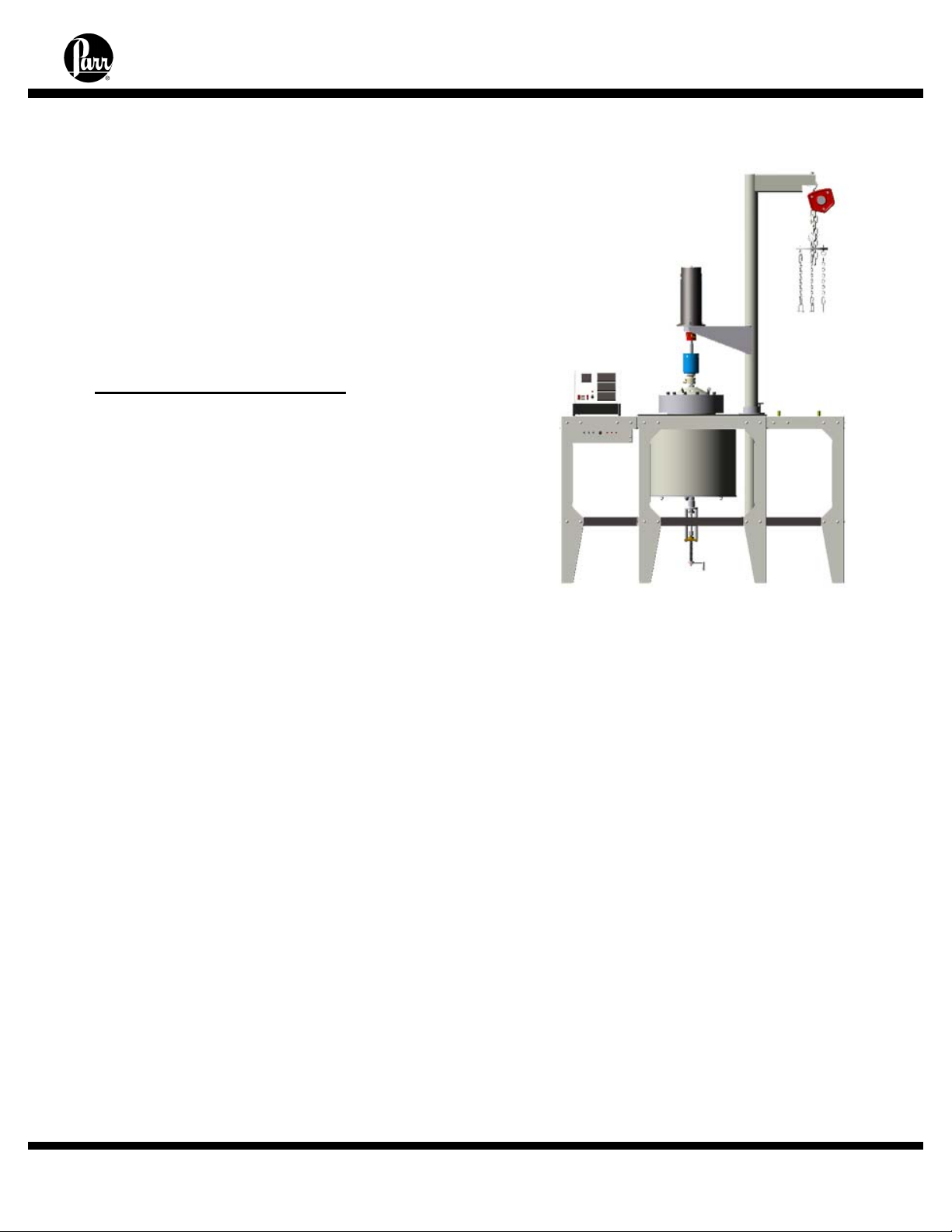

ASSEMBLE THE REACTOR

These reactors require a work area in a well

ventilated area with convenient access to an electric

outlet, running water and a drain. This unit needs to

be placed at least 10 inches away from walls or

flammable materials.

Use the associated assembly reference drawings

included in this manual to help identify parts to

assemble the reactor.

Removable Head Vessel

1. Take the lift tube assembly with the top

bushings/housings on it and lower the tube through

the work surface and center stand section. Place

the end of the tube over the bottom bushing.

2. If applicable, mount the hoist by hooking it to

the lift tube assembly. If it is an electric hoist, plug it

into receptacle provided in the arm of lift tube

assembly.

3. The wiring for the electric hoist, motor, and tachometer is routed through the lift tube and

out through the bottom bearing support. Route this wiring through the conduit ducts

underneath the center stand bottom shelf and up through the conduit duct on the left rear

leg of the center stand. Connect these wires to the appropriate connectors.

4. Install two Lift Rings (1593HC) in cylinder flange. Attach one Lift Ring (1593HC) into the

Lift Plate (1594HC). Attach two Lift Cables (A1595HC) to the lift plate in the holes that are

180° apart. Attach Lift Cables to the Lift Rings in cylinder. Attach this assembly to the lift

hoist hook. Lift the cylinder and carefully lower into the heater. Remove the two Lift

Rings from the cylinder flange after it is in the heater.

5. If applicable, install the Bottom Drain Valve into bottom of cylinder, through the bottom

of the heater.

6. Lift the head with three Lift Cables (A1595HC) attached to the lift plate in the holes that

are 120° apart. Attach the cables to the three 1571HC Lift Eyes on the head. Lift the head

and place carefully on the cylinder to avoid damage to the sealing surfaces.

7. Install the Split Rings per instructions in section, "How to Use the Vessel".

8. If the drive coupler needs to be adjusted to center the coupler halves, loosen the

mounting bolts of the motor and move the motor assembly as required to center the drive

couplers. Tighten the bolts while holding the motor assembly in position.

- 9 -

Page 11

5G & 10L Pressure Reactors

4555 - 58 Series

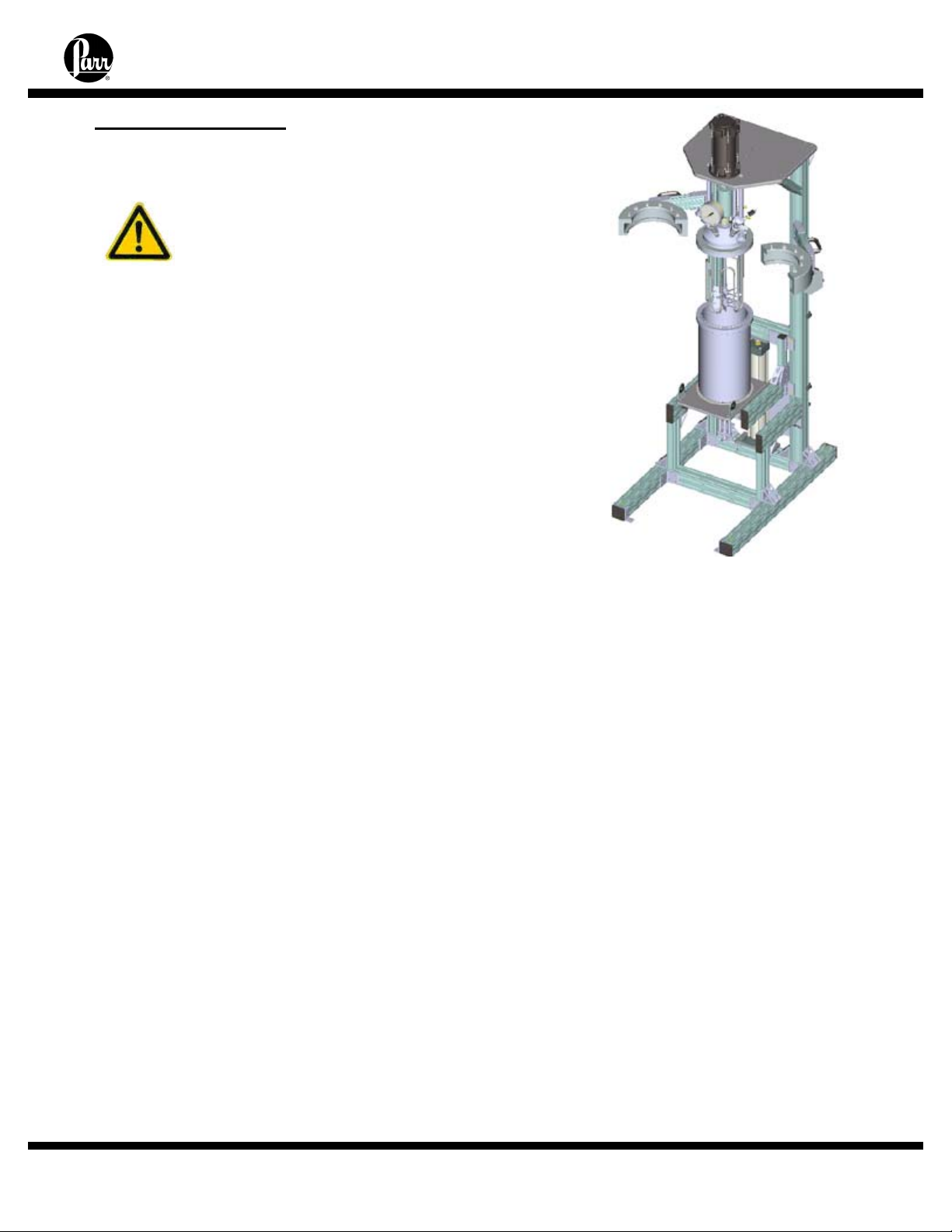

Fixed Head Vessel

Caution Symbols:

1. For the apparatus to be fully stable in all

configurations, the base of this unit must be securely

fastened to the floor before operation. Four 3-hole inside

corner brackets are provided (3159HC). Brackets will

accommodate 5/16” diameter anchoring hardware (not

provided). See drawing A3130HC Basic Main Support

Frame Pkg. shown in Appendix B.

2. See drawing A3140HC Pneumatic Vertical Lift Pkg in

the appendix. Moving parts, potential pinch-point. Keep

hands clear.

3. See drawing A3170HC 2 Hinged Split Ring Pkg in the appendix. Moving parts, potential

pinch-point. Keep hands clear.

Setting up the stand.

1. If the motor has been removed for shipping purposes, reinstall the motor. Refer to

drawings A3160HC and A3160HC2 (pages 43-45).

2. Unpack vessel assembly, remove the split rings, and lift the head assembly from the

cylinder.

3. If furnished with band heaters, install prior to mounting the cylinder.

4. Set cylinder mounting pad on the cylinder support plate. Refer to drawing A3150HC in

the appendix.

5. Handles are provided to assist in lifting the cylinder. Lift the cylinder and place it on the

cylinder support plate, lining up the holes for the retaining bolts. Install retaining bolts. Refer

to drawing A3150HC in the appendix.

6. Set the head assembly on the cylinder carefully to avoid damage to the sealing

surfaces.

7. Push in the cylinder support plate. Install 3 fixed head support rods (3156HC). Refer

to drawing 4557 Sheet 2 in the appendix.

- 10 -

Page 12

8. Remove the front drive guard shield if applicable. Refer to drawing 4557 Sheet 2 in

the appendix.

9. Connect pneumatics. A quick disconnect fitting has been provided on the back of the

unit for airline connection. User is responsible for providing air source.

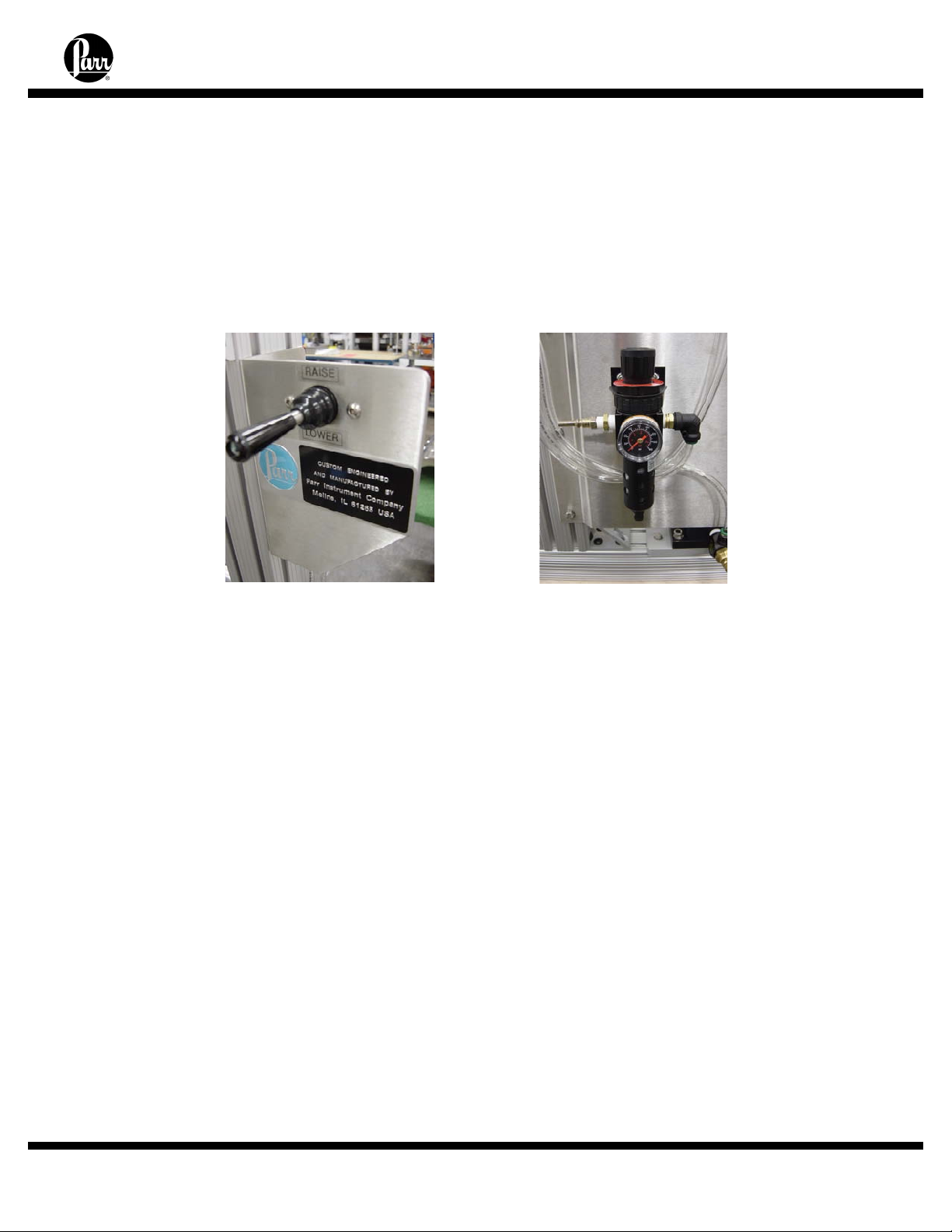

10. Lift “up” on joystick to raise cylinder, push “down” to lower. The joystick can provide

speed control up to the maximum preset speed. Lift up slowly to raise the head and

cylinder into position for attaching the fixed head support rods to the upper motor

platform. Refer to drawing 4557 Sheet 2 in the appendix.

11. The lift pressure regulator pressure may need to be increased to raise the additional

weight of the head assembly and cylinder. After the head has been fixed, readjust the

pressure for cylinder weight. The maximum lifting capacity can be adjusted using the

pressure regulator pressure setting. Adjust by lifting up on the top cap and turning clockwise

to increase the amount of pressure being sent to the pneumatic cylinder. Turn

counterclockwise to decrease the amount of pressure. After adjusting, press the cap down

to lock. Depending on vessel size, type, and weight, regulator will be preset at factory for 60

to 80 psi.

12. Ensure the motor coupling and the drive coupler are aligned. If adjustment is

required, loosen the motor bolts to realign and then retighten bolts.

13. Install the front drive guard shield if applicable.

14. Lower the cylinder.

15. If furnished with a flexible mantle heater and/or a bottom drain valve, install at this

time.

5G & 10L Pressure Reactors

4555 - 58 Series

- 11 -

Page 13

5G & 10L Pressure Reactors

4555 - 58 Series

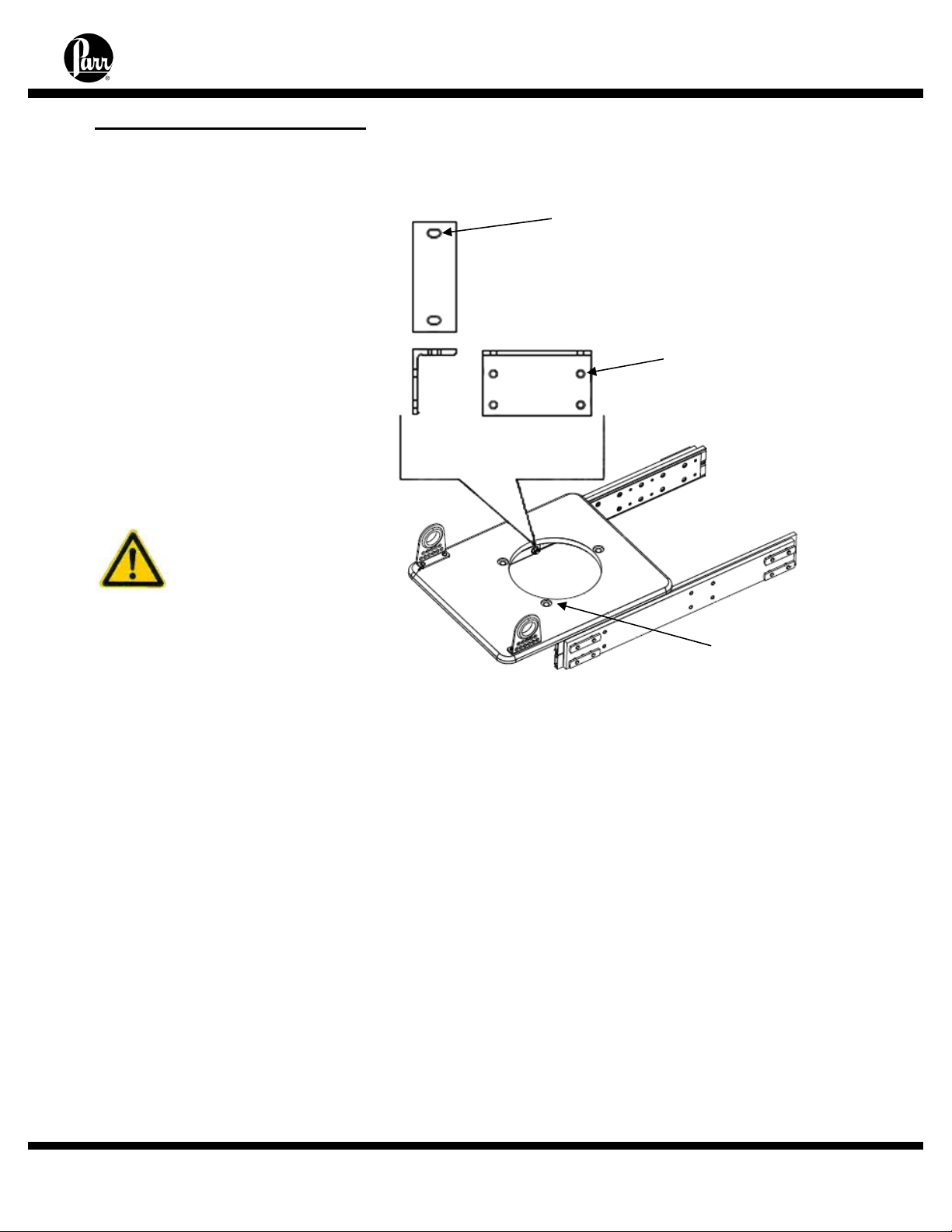

Cylinder Slide Adjustment

Minimal, if any, adjustments

are required for binding or sagging

of the cylinder slide support.

Note: To adjust for sagging, the

cylinder must be removed from the

Slide Support. This can be done

by leaving the closure intact with

the head and cylinder and

removing the (3) 3/8” nuts from the

bottom of the cylinder standoffs.

Lower the support stand

accordingly. This may require

removal of any plumbing devices

or accessories located on the

bottom of the cylinder.

Caution: The

cylinder is very

heavy and caution

should be

observed when the

cylinder is

disconnected from

the Slide Support.

1. Any adjustments to the Slide Support must be made with the Slider Support in the “IN”

position. Adjustments in the “OUT” position can cause unwanted binding to occur.

2. Once the (3) nuts have been removed from the bottom of the Slide Support, the Slide

Support can be lowered. It can then be leveled by loosening the Angle Support Brackets

detailed in the figure F1. Gently loosen the (8) horizontally mounted 5/16 x ¾” fasteners on

the Angle Support Brackets and adjust the Cylinder Support until it is level. Then tighten the

(8) 5/16 x ¾” fasteners accordingly.

3. Loosen the (4) 5/16 x ½” vertically mounted fasteners on the Angle Support brackets

until the support bracket moves freely. Center (left to right) the Slide Support and ensure

that there is no excessive force being applied against or away from the slide rails. Then

tighten the (4) fasteners accordingly.

4. Raise the Slide Support to the bottom of the cylinder until the standoffs are inserted into

the holes provided on the Slide Support. Attach the Slide Support to the cylinder using the

3/8” nuts previously removed.

Slotted holes for

center adjustment

(Left/Right)

(4) 5/16 x 1/2”

Oversized holes for

level adjustment

(Sagging)

(4) 5/16 x 3/4” Bolts

Holes for

cylinder

mounting

(3) 3/8” Nuts and

Flat Washers

- 12 -

Page 14

5G & 10L Pressure Reactors

4555 - 58 Series

IDENTIFY THE VALVES

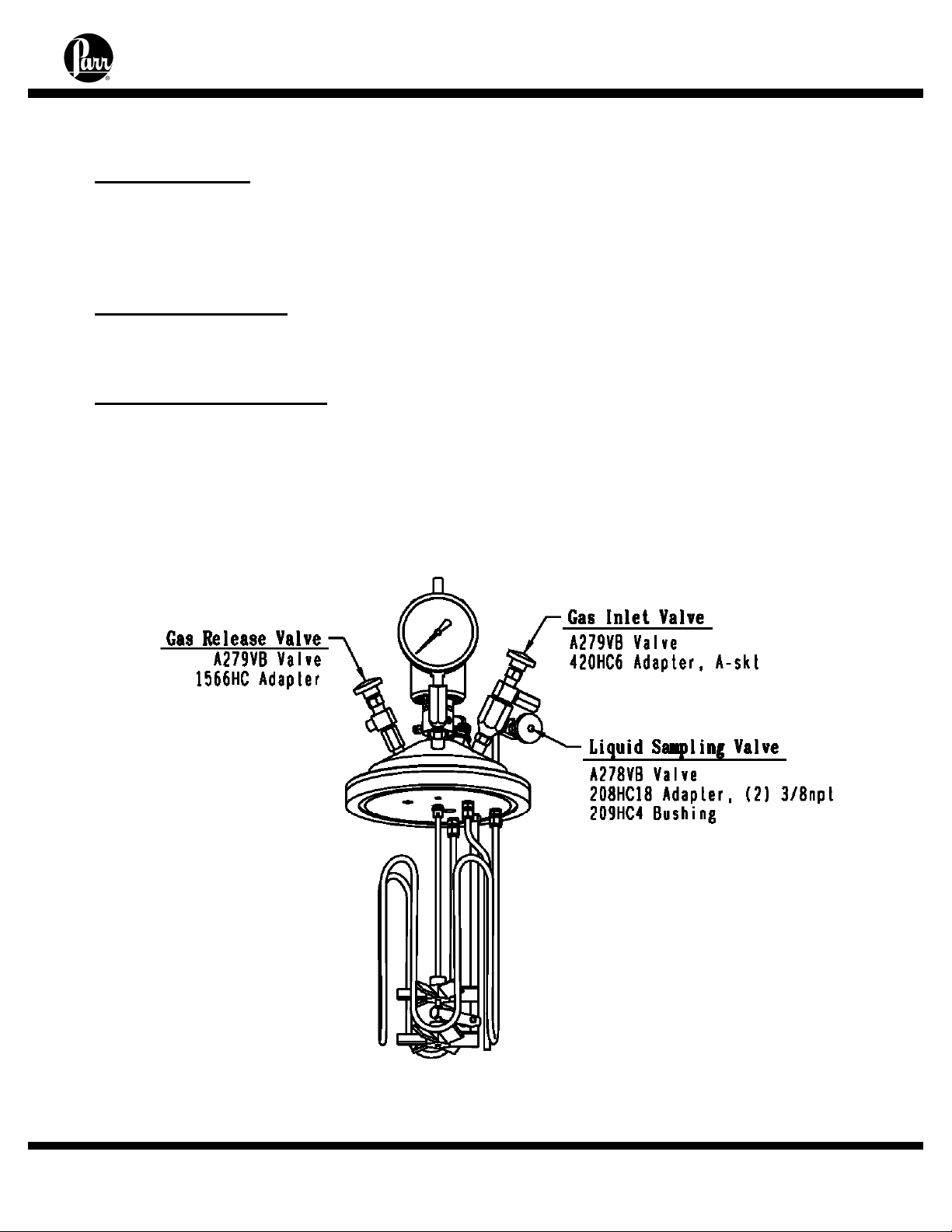

Gas Inlet Valve

The gas inlet valve is easily identified when the vessel is open by noting that it is

connected to a dip tube which extends to a point near the bottom of the cylinder. Typically,

this is an angle valve with an attached fitting which provides a socket for attaching the

A495HC pressure hose furnished with the reactor.

Gas Release Valve

The gas release valve is connected to a plain opening on the underside of the head. Gas

released from this valve will be drawn from the top of the reactor.

Liquid Sampling Valve

The liquid sampling valve is attached to the same fitting as the gas inlet valve and

connected to the same dip tube. With this arrangement, incoming gas is always introduced

below the surface of the liquid and the operator is provided with a means for clearing the dip

tube to be sure that any sample taken during a run will be representative of the charge. This

can be done by opening the gas valve momentarily to force any liquid in the dip tube back

into the reactor before withdrawing a sample from the sampling valve.

- 13 -

Page 15

5G & 10L Pressure Reactors

4555 - 58 Series

OTHER VESSEL HEAD FITTINGS

Safety Rupture Disc

There is a safety rupture disc attached to the head which is intended to rupture and

release the pressure before it reaches a dangerous level. A metal tag wired to the safety

head identifies the burst pressure at room temperature for that particular disc. A similar tag

is furnished with each replacement disc. This tag must remain with the apparatus at all

times so that both present and future operators will be aware of the disc rating. Users

should read the discussion of rupture discs given in the Instruction Sheet No. 231M for a

complete description of the characteristics of rupture discs and the precautions to be

observed when operating pressure equipment protected by this type of safety device.

Type J Thermocouple

A Type J thermocouple in a 1/8" dia. stainless steel sheath is furnished with the reactor.

Insert this thermocouple into the head thermowell and connect it to the thermocouple socket

on the rear panel of the temperature controller using the A470E2 extension wire furnished

with the reactor.

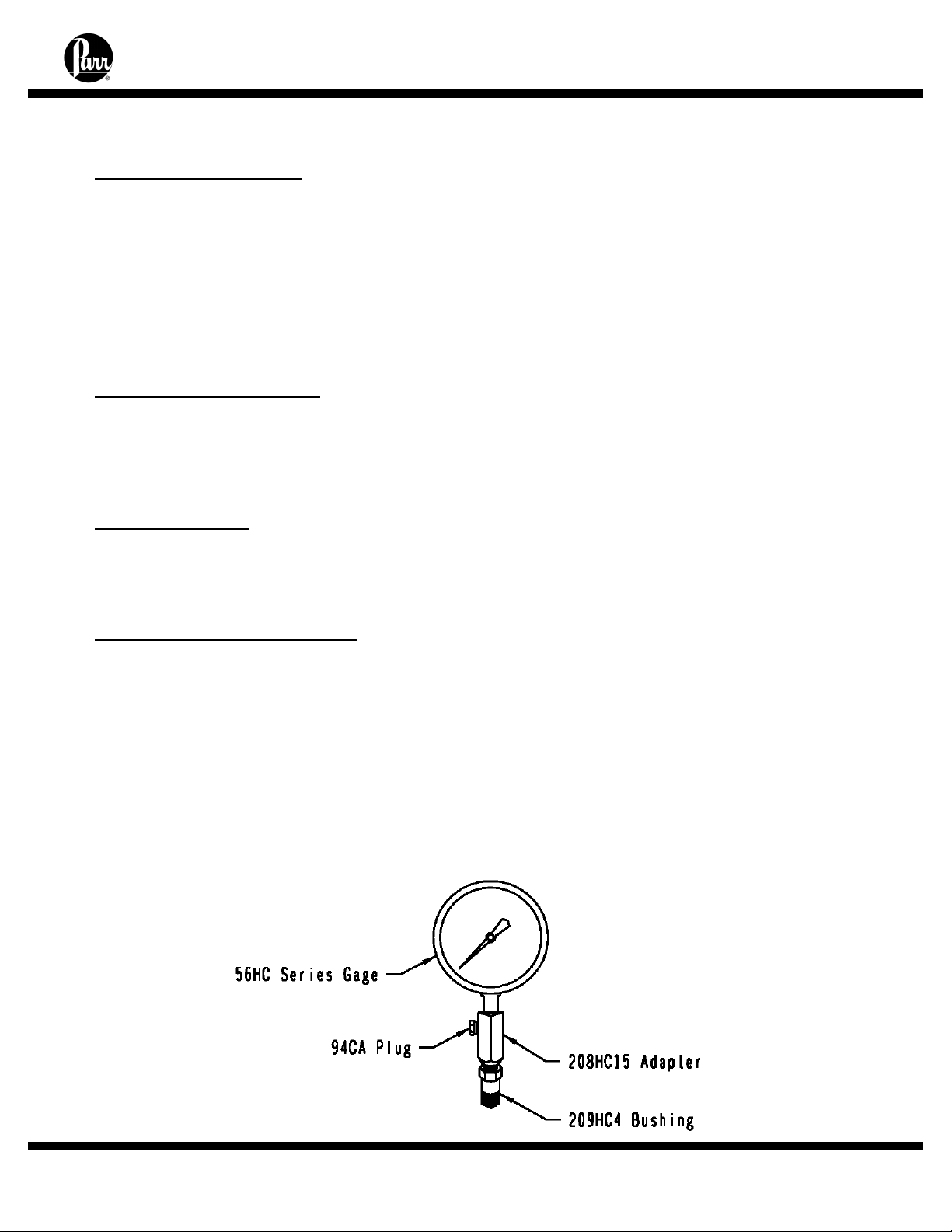

Pressure Gage

A pressure gage, typically a 0-2000 psi with a T316 Stainless Steel Bourdon tube, is

mounted on the head using attachment fittings similar to those used for the inlet/sampling

valve assembly

Gage and Valve Adapters

The pressure gage and the combined gas inlet and sampling valves are attached to the

head with an adapter which allows these fittings to be drawn up tightly when facing in any

direction. To attach these fittings to the head, screw the gage or valves firmly into the

adapter, and then run the 209HC4 bushing onto the threaded stem as far as it will go.

Screw this assembly into the head until the nose of the adapter is seated; then back it off

until the valve or gage is facing in the desired direction. Now hold the fitting firmly in place

and close the joint by tightening the 209HC4 bushing. This connection can be made and

broken repeatedly without destroying the sealing faces. A light coating of thread lubricant,

such as Parr No. 424HC2 High Temperature Anti-Seize Lube, applied to the threads and to

the nose of the adapter will help to obtain a tight joint.

- 14 -

Page 16

5G & 10L Pressure Reactors

4555 - 58 Series

HOW TO USE THE VESSEL

The vessels used in Model 4555, 4556, 4557, 4558, 4667 and 4668 Reactors have two

types of closures: fixed head and removable head. They are designed so that the vessel

cylinder and heater can remain together while the head and split rings are attached or

removed.

Flat Gasket or Self Sealing O-ring Closure

The flat gasket is held in a recess in the vessel head and a machine pilot on the cylinder

closes the recess to completely contain the gasket. The split ring closure used with this

gasket has compression bolts which must be tightened to develop loading on the gasket.

The closure is designed so that the compression bolts in the split ring sections must make

contact within a lip on the compression ring which will bring the split sections into their

proper position. When opening these vessels, the compression bolts must be loosened

enough to clear the retaining lip on the compression ring before the split ring sections can

be removed.

The self sealing design features an O-ring retained in a groove on the vessel head. This

design is self sealing and the split ring used with this sealing system does not require nor

have the compression bolts as with the flat gasket.

To Open the Vessel

Open the gas release valve to discharge any internal pressure; then loosen the

compression bolts in the split ring sections (flat gasket design). The split ring sections can

now be removed, and the head with all attached fittings is free to be separated from the

cylinder.

For removable heads, Disconnect the drive by pulling down on the bottom 1743HC

Coupler Halve to disengage the 1746HC Spider from it and swing the lift tube assembly

positioning the lift plate/lift cables over the head and attach the three cables to the lift eyes

in the head until all internal appendages clear the cylinder lip. Rotate the head assembly

around and lower it into the rear service position of the right hand stand assembly. Handle

the head carefully so as not to damage the stirring shaft and other appendages when they

are outside of the cylinder. The cylinder may also be removed from the heater and lowered

into the front service position of the right hand stand assembly.

For fixed heads, slowly and carefully lower the cylinder using the joystick on the

pneumatic lift.

Before Closing the Vessel

Examine the head gasket carefully to be sure that it is in good condition. In flat gasket

designs, after considerable use, some of the PTFE gasket may extrude into a thin, ragged

edge around the inside diameters. This does not necessarily mean that the gasket must be

replaced, but the extruded portion should be removed with a sharp knife. Examine the

mating surfaces on the cylinder and head to be sure they are clean and free from burrs.

- 15 -

Page 17

5G & 10L Pressure Reactors

4555 - 58 Series

Close the Vessel

For removable heads, lift the head carefully from its service position and lower into the

cylinder. Slide the two split ring sections into place. Tighten each of the compression bolts

with the wrench furnished with the apparatus or with a torque wrench. Tightening should

proceed in a crisscross pattern rather than progressively around the circle. Let the vessel

stand for about five minutes after initial tightening; then tighten the cap screws again. This

will compensate for any tendency of the PTFE gasket to flow under the loading pressure.

The recommended bolt torque for sealing a vessel with a PTFE flat gasket is shown in

the chart below. Rotate the drive into position. Connect the drive by pushing up on the lower

coupler halve to engage it into the spider. Make sure the ball detent of the lower coupler

snaps into position.

For fixed heads, raise the cylinder slowly and carefully in to position. Slide the two split

ring halves into place and secure the latches. Tighten the compression bolts in the same

manner as noted above.

Recommended Bolt Torque

10 Liter

Pressure

(psi)

500 psi

1000 psi

1500 psi

1900 psi

Torque

(ft-lb)

25

50

75

100

Recommended Bolt Torque

5 Gallon

Pressure

(psi)

500 psi

1000 psi

1500 psi

1900 psi

Torque

(ft-lb)

35

70

100

135

Gas Connections

Gas connections are dependent on applications. For general usage, use the pressure

hose furnished with the reactor. Screw the Type "A" coned pressure fitting into the adapter

attached to the gas inlet valve and tighten the compression nut firmly. Do not use any

thread dope on the coned fitting. The A495HC pressure hose is made of reinforced Nylon

which can be used for all non-corrosive gases at pressures up to 2500 psig. For operations

involving corrosive gases, this hose should be replaced with an A490HC hose which has a

PTFE lining and a braided stainless steel outer covering. An A506HC all metal hose is also

available in stainless steel and other corrosion resistant materials. All of these hoses have

the same fittings.

Pressurizing the Vessel

Check all valves carefully before admitting gas into the system. The liquid sampling

valve must remain closed throughout the charging procedure. The gas release valve must

also be closed unless the vessel is to be purged, or unless there is to be a continuous flow

through the reactor during a run. Always make certain that the pressure in the gas tank is

greater than the pressure in the vessel; otherwise liquid will be forced out of the vessel and

into the gas tank when the inlet valve is opened. If there is any possibility that the tank

pressure might not be high enough to force gas into the reactor, install a one way check

valve (optional) in the gas line to prevent any reverse flow. With the inlet valve open and the

- 16 -

Page 18

flow control valve on the gas tank closed, open the main valve on the gas tank only about

one-quarter turn; then use the flow control valve or the valve on a pressure regulator to

control the flow of gas into the vessel. After the desired pressure has been reached, close

the tank valves and the vessel inlet valve and disconnect the hose at the vessel end.

5G & 10L Pressure Reactors

4555 - 58 Series

Do Not Overfill the Vessel

Always watch the pressure gage closely when admitting gas so as not to exceed the

maximum working limit. Remember that any subsequent increase in temperature will raise

the pressure. Also, be sure that the amount of liquid placed in the vessel is carefully

controlled. As a general rule, the liquid charge should not exceed two-thirds of the capacity

of the cylinder. Too much liquid in the vessel can lead to development of dangerous

pressures if sufficient space is not provided for expansion when the liquid is heated. This

hazard is explained in greater detail in a warning statement included in the Safety

Instruction Manual No. 230M.

Releasing Pressure

Use the gas release valve to reduce the pressure in the vessel if the reactor is

accidentally overcharged when filling. Use this valve also to release any excess pressure

during a run and to exhaust the vessel at the end of a run. If the discharge gases are

flammable or toxic, discharge to an exhaust hood or to any other safe release point.

Withdrawing Liquid Samples

Liquid samples may be withdrawn from the sampling valve attached to the same adapter

as the gas inlet valve whenever the vessel is pressurized. Always close the inlet valve

before withdrawing a liquid sample and open the sampling valve cautiously because liquid

will be discharged with considerable force. Be particularly careful if the temperature of the

sample is above its boiling point at atmospheric pressure. If so, it will “flash” and be lost as

soon as it is released from the vessel. This problem can be avoided by connecting an

optional 4351 Sample Collection Vessel to the sampling valve to collect the liquid into an

appropriate receiver. The addition of a small amount of gas can be used to clear the dip

tube between liquid samples so that the next sample drawn through the tube will truly be

representative of the mixture.

The Shaft Seal

The stirrer shafts on these reactors are sealed with a magnetically coupled gland.

Operating and Maintenance instructions for these are provided in Instruction Manual No.

234M.

- 17 -

Page 19

5G & 10L Pressure Reactors

4555 - 58 Series

REACTORS WITH SLAVE BOX CONTROLS

Reactors can be set up with a wide variety of heaters. Single zone flexible mantle type

heaters or 3-zone ceramic fiber, band or aluminum block type heaters can be used

depending on the customer’s requirements. For the high powered 3-zone type heaters, Parr

Instrument Company offers a series of slave box controls. Having zone control allows a

wide range of heating power to be selectable by the operator. These slave controls are used

in conjunction with the 4848M Master Controllers.

Note- 3-Zone Heater locations are traditionally:

Zone 1 = Bottom Heater

Zone 2 = Middle Heater

Zone 3 = Top Heater

A1761HCEE 3-Zone Slave Control Box

The A1761HCEE slave control box is supplied with a 250 volt, 50 amp (NEMA 6-50P)

power plug. A 230 volt, 50 or 60 Hz, single phase power supply capable of a maximum

current draw of 40 amperes is required.

The A1761HCEE slave control box has 3 heater outputs each corresponding with a

respective heated zone. There is a 4 position selectable switch, on the front panel, which

can switch the heaters off or turn on zone 1, zones 1 and 2, or zones 1, 2 and 3.

Also located on the front panel are 3 manual reset, high limit switches. These switches

will trip if an alarm condition is present on the master controller. Once the alarm condition

has been resolved, ensure the selector switch is in the “off” position, and reset each switch

by pushing in each button until it latches. These switches may have to be set when the unit

is first powered on.

A1761HC3 3-Zone Slave Box Control

The A1761HC3 slave control box is supplied with an IEC 60309, 5 pin, 32 amp power

plug. A 400 to 415 volt, 3-phase power supply wired in a 5-wire WYE configuration capable

of supplying a maximum of 20 amperes is required.

The A1761HC3 slave control box has 3 heater outputs each corresponding with a

respective heated zone. There is a 4 position selectable switch, on the front panel, which

can switch the heaters off or turn on zone 1, zones 1 and 2, or zones 1, 2 and 3.

Also located on the front panel is a manual reset, high limit switch. This switch will trip if

an alarm condition is present on the master controller. Once the alarm condition has been

resolved, ensure the selector switch is in the “off” position, and reset the switch by pushing it

upwards until it latches. This switch may have to be set when the unit is first powered on.

Initial Operating Test

Read all operating instructions carefully so as to be well acquainted with the correct

procedures for handling the vessel and for operating the controller and other accessories.

An initial operating test should be made, with only water, to check the apparatus before

starting the first experimental runs. For this initial test, fill the cylinder not more than half-full

of water and run the temperature up to 150 °C while checking the apparatus for leaks and

observing the performance of the temperature controller.

- 18 -

Page 20

5G & 10L Pressure Reactors

4555 - 58 Series

ACCESSORIES

Internal Cooling Coils

Cooling coils can be installed in any of these reactors. Reactors purchased without a coil

can have this feature added by ordering the appropriate parts from Parr Instrument

Company.

Cooling coils are made in serpentine configurations. A serpentine coil does not interfere

with the use of a liner. Plugs are available to seal the cooling coil opening when the coil is

not used.

Replacement coils are furnished with excess tubing at the ends to allow for any

adjustments that might be required when installing a new coil. Align the replacement coil

with the internals before retightening the connections. Remove any sharp burrs and attach

the elbow connectors. Use only moderate force when tightening these elbows so that the

ferrules will not be crimped too deeply into the tube. If tightened too hard it will be difficult to

remove the brass ferrules without damaging the tube, making it impossible to reuse the coil

after it has been removed from the vessel head.

Stirrer Drive Systems

Two types of drive systems are available on the 4555 Series Reactors. They are the

direct drive and the gearbox drives. The direct drive has the motor mounted vertically above

the reactor with the drive coupler connected to the motor shaft. This will produce speeds

from 0 to 1700 RPM. The gearbox drive is offered with three different speed ranges. They

are 3:1 ratio, 5:1 ratio, and 10:1 ratio. These are usually used in low RPM, high stirring load

applications.

Quick Disconnect Drive Coupler

The top coupler half is stationary mounted with a set screw to the drive motor shaft. The

bottom coupler half provides vertical movement for quick disconnect of the couplers. The

bottom coupler is held in the up or engaged position by a spring loaded ball that rests in a

detent in the square drive key. The spring loaded ball inside the threaded hole in the bottom

coupler half and is adjustable to obtain the necessary force to hold coupler in drive or

engaged position.

Removable vessel only: If the coupler needs to be adjusted to align the coupler halves

over each, either relocate the drive motor or the overarm plate or, on moveable vessel

designs, loosen the mounting bolts of the 1578HC Top Bearing Housing and move the

A1575HC Series Welded Overarm Assembly as required to align the drive couplers. Tighten

the mounting flange bolts while holding the welded overarm assembly in position.

- 19 -

Page 21

5G & 10L Pressure Reactors

4555 - 58 Series

Air Motor

Variable stirring speeds from 100 to 2000 rpm can be obtained by replacing the standard

motor with a 1678HC air motor. This motor operates on compressed air which must be

supplied at 20 psig minimum pressure with at least 10CFM available at that pressure. It is

furnished with a speed control valve and oiler, all assembled on a mounting bracket.

To operate reactors equipped with an air motor, mount the drive system firmly on the

heater and connect the air hose to a compressed air line. Fill the oiler with SAE 10 oil and

adjust the oiler to feed one drop per minute into the air stream. For long continuous runs at

high speeds the oiling rate should be increased to three drops per minute.

If the motor becomes sluggish, flush it with a non-flammable solvent in a well ventilated

area. Disconnect the airline and muffler and pour a small amount of solvent into the inlet

port. Rotate the shaft by hand in both directions for a few minutes; then connect the air line

and run the motor until there is not further trace of solvent in the exhaust. If the muffler felts

are dirty, wash them in solvent or replace them. Re-lubricate the motor with a squirt of oil

into the chamber and reassemble. If it becomes necessary to disassemble the motor to

replace the vanes, follow directions given in the instruction sheet published by the Gast

Manufacturing Corp., Benton Harbor, Michigan.

Variable Speed Electric Motor

Reactors are normally equipped with a DC variable speed motor supplied and controlled

through the 4848M/A3600HC_Series controller. Instructions for connecting and operating

these motors are included in the controller Instruction Manual No. 548M. This motor is

usually installed in a drive system designed to produce stirring speeds up to 1700 rpm.

Spare Parts Kit

Parr can furnish spare parts kits for these reactors which will provide a reserve supply of

parts and tools sufficient to handle most normal replacements and emergency repairs during

a year of heavy usage. These kits contain replacement gaskets, packing, O-rings, shafts,

bearings, and rupture discs. They can be ordered from any Parr Dealer or direct from Parr

Instrument Company. The order must specify the reactor size and indicate type of rupture

disc, stirrer drive. It is advantageous to provide the serial number stamped on the vessel

head or cylinder.

- 20 -

Page 22

5G & 10L Pressure Reactors

4555 - 58 Series

EXPLOSION PROOF OPERATION

If the local safety code requires that equipment installed in the user’s laborat ory must be

explosion proof, there are five possible ignition hazards to be considered:

1. The Motor

The standard variable speed motor is not explosion proof, yet these motors are not unduly

hazardous if operated in a well ventilated location where care is taken to prevent the

accumulation of explosive gases or vapors. To eliminate any possible spark hazard originating

at the motor, Parr can furnish an air motor as described above, or the reactor can be equipped

with a variable speed, encased electrical explosion proof motor which is approved for use in

Class 1, Groups C & D, and Class 2, Groups E, F, & G atmospheres. Explosion proof m otors

are furnished with a temporary power cord and plug which are not explosion proof. The user

should remove this temporary wiring and replace it with an explosion proof wiring as required to

comply with the local electrical code.

2. The Temperature Controller

The 4848M/A3600HC_Series Temperature Controllers furnished with these reactors contain

switches and other elements which are not explosion proof. The mini mal spark hazard

associated with these units can be resolved by installing the controller in a re mote location

outside of the hazardous area or by enclosing it in an approved explosion proof h ousing. If

enclosed within a positive pressure, clean air housing, the discharge from the housing must be

directed into a safe area. If requested, Parr will furnish the long lead wires needed to mount th e

controller in a remote location. If the controller is to be installed in an explosion proof housing,

the user must provide the necessary housing and installation.

3. Slave Box Control

Reactors furnished with 3-zone high power heaters are supplied with a slave control box.

These slave boxes also contain switches and other elements that are not explo sion proof. The

minimal spark hazard associated with these units can be resolved by installing the controller

and slave box in a remote location outside of the hazardous area or b y enclosing it in an

approved explosion proof housing. If enclosed within a positive pressure, clean air housing, the

discharge from the housing must be directed in to a safe area. If requested, Parr will furnish the

long lead wires needed to mount the controller and slave box in a rem ote location. If the

controller is to be installed in an explosion proof housing, the user must prov ide the necessary

housing and installation.

4. The Heater

The elements in the heater could be dangerous in an explosive atmosphere if the surface

temperature of the element becomes high enough to ignite flammable vapors. This hazard must

be evaluated for each individual installation since major modifications are required if the heater

must be isolated from the surrounding atmosphere. Users who consider this a significant hazard

are urged to contact Parr Instrument Company for further discussion and sugge stions which

might be helpful. Parr is currently offering aluminum block heaters (4555 on ly) and circulating

jacketed cylinders which have been used in explosive environments.

5. The Wiring

Unless specifically designed for use in hazardous atmospheres, the wiring in these reactors

will not meet the standards prescribed for explosion proof equipment. Optional, intrinsically safe

barriers are available.

- 21 -

Page 23

5G & 10L Pressure Reactors

4555 - 58 Series

PERIODIC PRESSURE TESTS

Each cylinder used in a Parr stirred reactor is tested under hydrostatic pressure to 1.3

times its maximum rating before it is released from the factory. Micrometer caliper

measurements are taken during this test to check the deflection of the cylinder walls under

pressure. Excessive deflection or failure of the metal to resume its original dimension after

pressure is released indicates that a cylinder is potentially unsafe and it will be rejected.

Similar tests should be made at regular intervals during the life of each cylinder, and

particularly whenever the user suspects that the equipment has been over-stressed or

damaged.

Some laboratories maintain hydraulic test facilities and make it a rule that all pressure

vessels must be tested at regular intervals. Records are kept of deflections at specific test

pressures so that any increase in deflection becomes a warning that the metal has lost

strength. Any cylinder which fails to return to its original dimensions after application of the

prescribed hydrostatic test should be discarded as unsafe for further use.

Users who do not have pressure test facilities can return any Parr pressure vessel to the

factory for hydrostatic testing and overhaul. This should be done whenever the metal shows

excessive damage from corrosion or whenever an over-pressure or other unusual

occurrence raises any safety questions. To return a vessel for repair, contact Parr

Instrument Company for a return authorization number. Apparatus returned for testing and

overhaul should be shipped prepaid to the Parr Instrument Company, 211-53rd Street,

Moline, Illinois 61265. An order or letter of instructions should be mailed to the same

address, as no repair work will be started without specific instructions and a Health & Safety

Assurance Certification form (F0042) signed by a responsible user.

- 22 -

Page 24

5G & 10L Pressure Reactors

4555 - 58 Series

GENERAL MAINTENANCE NOTES

1. Periodically inspect all electrical wiring and pressure connections for excessive corrosion

or wear. Suspect parts should be replaced by components only supplied by Parr Instrument

Company.

2. Always use appropriate wrenches on all fittings and valves. Never use pliers or pipe

wrenches.

3. Head and cylinder service fixtures are available for convenience and protection of

components during maintenance of your reactor.

4. To reinstall straight thread (NPS) fittings to the head, screw the gage or valves firmly into

the adapter. Run the bushing onto the threaded stem as far as it will go. Screw this

assembly into the head until the nose of the adapter is seated; then back it off until the valve

or gage is facing in the desired direction (no more than one full turn). Hold the fitting firmly in

place and close the joint by tightening the bushing. This connection can be made and

broken repeatedly without destroying the sealing surfaces. A light coating of thread

lubricant, such as Parr High Temperature Anti-Seize Lubricant, applied to the straight

threads and to the nose of the adapter will help to obtain a tight joint. Note: PTFE tape

should be used only on all tapered (NPT) threads, not NPS straight threads.

5. NPT (National Pipe Taper) threads should not be disassembled any more than

necessary. It will become increasingly difficult to maintain a tight seal with these tapered

threads if the joint is made and broken repeatedly.

6. Do not use oil or anti-seize lubricant on threads or fittings if the vessel is to be used with

oxygen.

7. If your vessel is equipped with a loose compression ring, be sure that it is in place on the

head before attaching any head fittings. The compression ring cannot be installed after

fittings have been screwed into the head.

8. Clean all threads and gas passages thoroughly and remove all tape fragments when

overhauling a vessel. An ultrasonic bath is excellent for cleaning metal parts, but do not

place a thermocouple probe, pressure gage, face seals or ball bearings in an ultrasonic

bath. Periodic cleaning may be performed on the exterior surfaces of the reactor stand with

lightly dampened cloth containing mild soap solution. All power should be disconnected

when cleaning.

9. Routinely inspect cap screws on split ring closure for lubrication and cleanliness. It is

important to clean and lubricate periodically with Parr High Temperature Anti-Seize

Lubricant so that the required torque is accurately applied.

- 23 -

Page 25

10. To operate reactors equipped with an air motor, connect air hose to a compressed air

line. For best torque and speed control the piping to the motor should be at least 3/8" IPS or

larger. Fill the oiler with SAE 10 oil and adjust the oiler feed to a rate of one drop per minute

into the air stream. For long continuous runs at high speeds, the oiling rate should be

increased to three drops per minute.

If the motor becomes sluggish, flush it with a non-flammable solvent in a well ventilated

area. Disconnect the air line and muffler and pour a small amount of solvent into the inlet

port. Rotate the shaft by hand in both directions for a few minutes; then connect the air line

and run the motor until there is not further trace of solvent in the exhaust. If the muffler is

dirty, replace it. Re-lubricate the motor with a squirt of oil into the chamber and reassemble.

11. If servicing assistance is needed, contact Parr Instrument Company directly at the

address shown on the back of these instructions

5G & 10L Pressure Reactors

4555 - 58 Series

Fuses

The replacement of protective fuses should be performed by qualified personnel.

Note: Check the labels on the instrument for correct fuse rating.

Parr Part # Description Slave Box Type Ratings

1535E Heater Fuse A1761HC3 KAC 25 Amps, 600VAC

185E

2094E Heater Fuse A1761HCEE Fast-Acting 25 Amps, 250VAC

2093E Main Fuse A1761HCEE Fast-Acting 50 Amps. 250 VAC

139E8 Lift Fuse A1761HCEE Slo-Blo 2.5 Amps, 250VAC

Master

Controller Fuse

A1761HC3 Slo-Blo 5 Amps, 250VAC

- 24 -

Page 26

5G & 10L Pressure Reactors

4555 - 58 Series

PARTS LISTS

Vessel Parts List

Consult the itemized list of part numbers provided with your reactor.

For parts made from alternate materials the following suffixes are used:

CA - Titanium CH – Alloy C-276 CT - Inconel CC – Alloy 20Cb3

CG – Alloy B-2 CM - Monel CX - Zirconium

1557HC Series 5G Flat Gasket 1559HC 5G Flat Gasket PTFE

3187HC Series 5G O-ring Seal 3184HCJV 5G O-ring Seal FKM

2957HC Series 10L Flat Gasket 2959HC 10L Flat Gasket PTFE

3197HC Series 10L O-ring Seal 3194HCJV 10L O-ring Seal FKM

CYLINDERS SPLIT RINGS-MOVABLE

1555HC Series 5G Flat Gasket A1556HC 5G Flat Gasket

3185HC Series 5G O-ring Seal A3186HC 5G O-ring Seal

2955HC Series 10L Flat Gasket A2956HC 10L Flat Gasket

3195HC Series 10L O-ring Seal A3196HC 10L O-ring Seal

SPLIT RINGS-FIXED HEAD COMPRESSION RINGS

A1556HC2 5G Flat Gasket 1554HC 5G Flat Gasket

A3186HC3 5G O-ring Seal N/A 5G O-ring Seal

A2956HC2 10L Flat Gasket 2954HC 10L Flat Gasket

A3196HC2 10L O-ring Seal N/A 10L O-ring Seal

ACCESSORIES

1556HCF Compression Bolts

1571HC Lift Eye (Head)

1593HC Lift Ring (Cylinder)

891DD 5/8” Comb. Wrench

Internal Fittings

Thermowell

265HC15 Thermowell, 5G 15.94”L

265HC10 Thermowell, 10L 12.12”L

48HC Thermowell, Gasket, Silver

48HCFG Thermowell, Gasket, Gold (for Special Alloy)

Dip Tube

1567HC Series Inlet (Dip) Tube

275VBAD Male Connector to hold tube

HEADS HEAD SEAL

- 25 -

Page 27

5G & 10L Pressure Reactors

Internal Fittings continued

Shafts

1025HC28 Upper Stub Shaft 5G Magnetic Drive

A1030HC27 Lower Shaft Assembly 5G Magnetic Drive

1025HC45 Upper Stub Shaft 10L Magnetic Drive

A1030HC44 Lower Shaft Assembly 10L Magnetic Drive

2135HC9 Shaft, 5G, Footless Magnetic Drive

2135HC21 Shaft, 10L, Footless Magnetic Drive

Impellers

1569HC Impeller, 5G, Magnetic Drive

709HC Impeller, 10L, Magnetic Drive

A2138HC3 Impeller, 5G, Footless Magnetic Drive

A2138HC2 Impeller, 10L, Footless Magnetic Drive

709HCF Impeller Screw, ¼-20 thread (for all the above)

Stirrer Support Brackets

A1570HC Support Bracket, 5G

A380HC3 Support Bracket, 10L

380HCF Bolt, 5/16-18 thread (for all the above)

External Fittings

94CAAD Plug, Hex Head, 1/4NPTM, T316SS

A278VBAD Valve, Straight 3/8" NPTM (Liquid Sampling)

A279VBAD Valve, Angled 3/8" NPTM x 3/8" NPTM (Gas Release)

A279VBAD Valve, Angled 3/8" NPTM x 3/8" NPTM (Gas Inlet)

420HC6 Adapter, 3/8" NPTF x A socket (Inlet Hose)

1566HC Adapter, 3/8" NPTM x 3/8" NPTF (Gas Release)

208HC18 Valve Adapter, two 3/8" NPTF (Gas Inlet/ Liquid Sampling)

208HC15 Gage Adapter, two 1/4" NPTF

209HC4 Bushing for gage and valve adapters

56HC Series Gages, 4-1/2”, psi/bar

664HC3 Magnetic Stirrer Plug (optional – use with 663HC olive)

A472E5 Thermocouple, Grounded Type J, 21-1/2"

A511E2 Thermocouple, Type J, Bayonet

A707HC2 Safety Rupture Disc Assembly without disc (See 231M)

A1750HC* Magnetic Drive (See 234M)

A1750HC2* Double Magnetic Drive Assembly (See 234M)

A2170HC* Footless Magnetic Drive (See 234M)

A2170HC2* Double Footless Magnetic Drive Assembly (See 234M)

664HC Nut, Gland, Magnetic Drive seal

663HC* Olive, Magnetic Drive seal

2136HC Gasket, Footless Magnetic Drive

A740HC Cooling Sleeve for Magnetic Driv e Assemblies

715HC O-ring, NBR (for Cooling Sleeve)

716HC Quick Disconnect (for Cooling Sleeve)

4555 - 58 Series

- 26 -

Page 28

Internal Parts Identification

4555 - 58 Series

5G & 10L Pressure Reactors

4556 / 4558 10 L

4555 / 4557 5 Gallon

- 27 -

Page 29

External Parts Identification

4555 - 58 Series

5G & 10L Pressure Reactors

- 28 -

Page 30

Cooling Coils & Fittings

1568HC Serpentine Cooling Coil, 3/8T, 5G

2968HC Serpentine Cooling Coil, 3/8T, 10L

276VB Male Connector, 3/8T x 3/8NPTM Bored Thru

428VB Female Elbow, 3/8T x 1/8NPTF

A92HWBB Male Connector, 1/8 NPTM x 1/4T, Brass

122HW Ferrule, Brass 1/4T (for A92HWBB)

4555 - 58 Series

5G & 10L Pressure Reactors

- 29 -

Page 31

Drive Parts List

Motor

A388E2ES Motor, 1/2 HP VS 90VDC

A388E2EQ Motor, 1/2 HP EXP VS 90VDC

A388E2ER Motor 1/2 HP EXP VS 180VDC

A388E2ET Motor 1/2 HP VS 180VDC

A388E3ER Motor 3/4 HP EXP VS 180VDC

A388E3ET Motor 3/4 HP VS 180VDC

1678HC Air Motor

Shaft Couplings

1743HC Chamfered Coupling Half

1744HC Machined Coupling Half

1746HC Spider

Optional Tach Parts

1564HC Optical Wheel

A1060E Tach Sensor Assembly 5G/10L Removable Vessel

A1001E9 Tach Sensor Assembly 5G/10L Fixed Head Vessel

A1177E Optical Tach Harness (10 ft)

Lift System (Removable Vessel Only)

A1575HC Lift Tube Assembly , Direct Drive

A1575HC2 Lift Tube Assembly, Gear Box Drive

A1574HC Lift Tube Assembly, Non-Stirred

1578HC Housing, Bearing; Aluminum Top

1579HC Housing, bearing; Aluminum Bottom

1580HC Bushing, Brass; Top

1581HC Bushing, Brass; Bottom

1593HC Lift Ring, Cylinder

A1595HC Plate, Lift (Stirred)

1594HC Plate, Lift (Non-Stirred)

1680HC Spacer

1743HC Chamfered Coupling Half

1746HC Spider, Coupling

1744HC Machined Coupling Half

1766HC Grommet, insulating

4555 - 58 Series

5G & 10L Pressure Reactors

- 30 -

Page 32

5G & 10L Pressure Reactors

Stands

Stand Parts (Fixed Head Vessel)

A2760HC2 Pneumatic Lift Package with Regulator, Hand Lever & Tubing

3174HC Shield, Magnetic Drive

2446HC Thumb Screws for Shield

3154HC Cylinder Mounting Pad

2548HC3 Lift Handle

2759HC Lift Handle Grommet

1743HC Chamfered Coupling Half

1746HC Spider, Coupling

1744HC Machined Coupling Half

Slave Boxes

Parts Used in A1761HCEE Slave Boxes

139E8 Fuse, Slo-blo, 250V 3AG

2094E Fuse, Fast-Acting, 250 vac, 25 amp

2092E Fuse Holder

2093E Fuse, Fast-Acting, 250 vac, 50 amp

2095E Fuse Holder

542E Circuit Breaker, .08 Amp

1119E Relay, 25 Amp

Parts Used in A1761HC3 Slave Box

185E Fuse, Slo-blo, 250V

1119E Relay, 25 Amp

1524E Circuit Breaker

1535E Fuse

1536E Fuse Holder

4555 - 58 Series

- 31 -

Page 33

5G & 10L Pressure Reactors

Heaters

A1590HCEE 3-Zone Ceramic Heater Assembly (Removable Vessel)

83E Locknut

460E3EE Cord Set Hi-Temp

A491E3 Cord Grip

509E Connector, Bayonet

1006EEE Element, Heater

1883HC Guide Tube, Thermocouple

1582HC Tie Bolt

1583HC Header, Top

1585HC2 Header, Bottom

1586HC2 Disc, Bottom

ME1587HC Shell, Outer

1588HC Outlet Box

1589HC Cover, Outlet Box

A1755HC2EE 3-Zone Aluminum Block Heater Assembly (Removable Vessel)

460E3EE Cord Set

A491E2 Cord Grip

A776E2EE Heater, Cast Alum

783E Plug, ½ NPT

787E Seal

791E2 Nipple 1.5”L

791E4 Nipple 2.5”L

791E6 Nipple 3.5”L

795E Elbow, Capped

797E Packing Fiber

798E Sealing Compound

1582HC Tie Bolt

1665E Coupler

1749HC Top Header

1783HC Insulating Jacket

1777HC Tee Hub

1778HC Cross Hub

1780HC Nipple, 8”L

1813HC Ceramic Wire Nut

1914HC Ceramic Wire Nut

Band Heaters (Fixed Head Vessel)

A1930EEE Band Heater 5G (Standard), 2000W

A1930E2EE Band Heater 5G (Hi-Temp), 2000W

A1932EEE Band Heater 10L (Standard), 1200W

A1932E2EE Band Heater 10L (Hi-Temp), 1200W

4555 - 58 Series

- 32 -

Page 34

5G & 10L Pressure Reactors

4555 - 58 Series

APPENDIX A – REMOVABLE VESSEL REACTOR DRAWINGS

- 33 -

Page 35

5G & 10L Pressure Reactors

4555 - 58 Series

APPENDIX A – REMOVABLE VESSEL REACTOR DRAWINGS

- 34 -

Page 36

5G & 10L Pressure Reactors

4555 - 58 Series

APPENDIX A – REMOVABLE VESSEL REACTOR DRAWINGS

- 35 -

Page 37

5G & 10L Pressure Reactors

4555 - 58 Series

APPENDIX B – 5-GALLON, FIXED HEAD VESSEL REACTOR DRAWINGS

- 36 -

Page 38

5G & 10L Pressure Reactors

4555 - 58 Series

APPENDIX B – 10-LITER FIXED HEAD VESSEL REACTOR DRAWINGS

- 37 -

Page 39

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 38 -

Page 40

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 39 -

Page 41

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 40 -

Page 42

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 41 -

Page 43

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 42 -

Page 44

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 43 -

Page 45

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 44 -

Page 46

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 45 -

Page 47

5G & 10L Pressure Reactors

APPENDIX B – FIXED HEAD VESSEL REACTOR DRAWINGS

4555 - 58 Series

- 46 -

Page 48

Revision 11/16/12

Loading...

Loading...