Page 1

4550

Floor Stand Reactors

Operating Instruction Manual

395M

Page 2

Floor Stand Reactors

PREFACE 3

Scope 3

Related Instructions 3

Intended Usage 3

Safety Information 3

General Specifications 3

Explanation of Symbols 4

Environmental Conditions 4

Unpack Carefully 4

Provisions for Lifting and Carrying 4

Cleaning & Maintenance 4

User’s Responsibility 5

Fixed Head or Removable Head Design 6

Fixed Head or Removable Head Vessel Design 6

Flat PTFE Gasket or Self Sealing O-ring Closure 6

INSTALLATION 7

Pressure and Temperature Limits 7

Assemble the Reactor 8

HOW TO USE THE VESSEL 14

Fixed Head Vessels 14

To open the Vessel 14

Before Closing the Vessel 14

To Close the Vessel 14

Removable Head Vessels 14

To Open the Vessel 14

Before Closing the Vessel 14

To Close the Vessel 14

Sealing Vessels with PTFE Gaskets 14

Gas Connections 14

Pressurizing the Vessel 15

Do Not Overfill the Vessel 15

Releasing Pressure 15

Withdrawing Liquid Samples 15

Initial Operating Test 15

MAINTENANCE 16

General Maintenance Notes 16

Periodic Pressure Tests 17

IDENTIFY THE VALVES 10

Gas Inlet Valve 10

Gas Release Valve 10

Liquid Sampling Valve 10

OTHER VESSEL HEAD FITTINGS 11

Safety Rupture Disc 11

Type J Thermocouple 11

Pressure Gage 11

Gage and Valve Adapters 11

ACCESSORIES 12

Internal Cooling Coils 12

Variable Speed Electric Motor 12

Air Motor 12

Liners 12

Spare Parts Kit 12

Pneumatic Lift for Fixed Head Vessels 13

PARTS LISTS 18

Reaction Vessel Parts List 18

Overarm Parts List 21

Cooling Coil Parts List 22

Heaters Parts List 23

DRAWINGS 24

4553 - 1 Gallon Fixed Head Stand Assembly 24

4554 - 2 Gallon Fixed Head Stand Assembly 26

Customer Service

Questions concerning the installation or operation

of this instrument can be answered by the Parr

Customer Service Department:

1-309-762-7716 • 1-800-872-7720

Fax: 1-309-762-9453

E-mail: parr@parrinst.com

http://www.parrinst.com

2

Parr Instrument Company

Page 3

4550 Floor Stand Reactors

PREFACE

Scope

These instructions describe the installation, operation and maintenance of Parr Series 4550 Floor

Stand Reactors offered in two sizes, 1 and 2 Gallon

(3.75 and 7.5 liter). They cover the basic steps to

be followed when installing these reactors and

describe the function of all standard components.

They are intended to be used in conjunction with

several related instruction sheets listed on the

previous page. This information describes several

components that are common to most Parr pressure

reaction equipment, and includes safety precautions and other related information applicable to all

reaction laboratories. The users should study all of

these instructions carefully before starting to use

these vessels so that they will fully understand the

capabilities and limitations of the equipment.

Related Instructions

The following Parr publications are also included to

further your understanding of this instrument and

its component parts:

No. Description

201M Limited Warranty

230M Safety Precautions to be observed when

operating Pressure Reaction Equipment

231M Operating Instructions for Parr Safety

Rupture Discs

234M Operating and Maintenance Instructions

for Parr Magnetic Drives

323M Operating Instructions for Parr Pressure

Relief Valves

548M Operating Instructions for 4848 Reactor

Controllers

FX004 Health & Safety Assurance Certification

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capability.

2. Ensure that the equipment is connected to

electrical service according to local national

electrical codes. Failure to properly connect may

create a fire or shock hazard.

3. For continued protection against possible

hazard, replace fuses with same type and rating

of fuse.

4. Disconnect from the power supply before

maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components which

may ignite such material.

2. Refer servicing to qualified personnel.

General Specifications

Electrical Ratings

Controller ratings are found in the Operating

Instructions for the controller supplied with your

reactor and on the controller data plate.

Before connecting a controller to an electrical outlet,

the user must be certain that the electrical outlet has

an earth ground connection and that the line, load

and other characteristics of the installation do not

exceed the following limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: Controllers can be operated from either

a 50 or 60 Hertz power supply without affecting their

operation or calibration.

Intended Usage

This system has been designed for use as a high

pressure reactor system. It has been designed, built,

and tested to strict physical and electrical standards.

However, it is the user’s responsibility to install and

operate it in conformance with local pressure and

electrical codes.

If this equipment is used in a manner beyond its

intended usage, the protection provided by the

equipment may be impaired.

Current: The total current drawn should not exceed

the rating shown on the data plate on the controller

by more than 10 percent.

Thermocouple: Unless otherwise specified, all

Series 4848 Reactor Controllers operate with a

Type J (iron-constantan) thermocouple. The total

resistance of the thermocouple and the lead wires

should not exceed 100 ohms. If the resistance of

the thermocouple circuit is higher, it will reduce the

sensitivity of the control system.

www.parrinst.com

3

Page 4

4550 Floor Stand Reactors

Explanation of Symbols

II On position, full power heater switch

I On position, half power heater switch

O Off Position

~ Alternating Current (AC)

This CAUTION symbol may be present on the Product Instrumentation

and literature. If present on the product, the user must consult the appropriate part of the accompanying product literature for more information.

This CAUTION symbol indicates that the surface may be hot.

Protective Earth (PE) terminal. Provided for connection of the Protective Earth (green or green/yellow) supply system conductor.

Environmental Conditions

This instrument is intended to be used indoors.

Caution!

Do not use in hazardous atmospheres.

Operating: 15 ºC to 35 ºC; maximum relative humidity of 80% non-condensing. Installation Category II

(over voltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 0 to 2000 meters above sea level.

Storage: -25 °C and 65 °C; 10% to 85% relative

humidity.

Unpack Carefully

Unpack the equipment carefully and check all the

parts against the packing list. If shipping damage is

discovered, report it immediately to the delivering

carriers. The vessel, motor, heater, and temperature

controller may be packed separately for convenience

in shipping, but these parts are easily reassembled.

Examine the components closely for any loose parts

or shipping damage and be sure to check all layers of

packing materials thoroughly so as not to overlook

any parts which might otherwise be discarded.

Provisions for Lifting and Carrying

The 4550 Floor Stand Reactor and its components

are very heavy. Before moving ensure all cables are

disconnected. Use proper and safe lifting techniques

when installing or moving the 4550 Reactor and/ or

its components.

Cleaning & Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the instrument with a lightly dampened

cloth containing mild soap solution. All power should

be disconnected when cleaning the instrument.

There are no user serviceable parts inside the product other than what is specifically called out and

discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can

be obtained by calling Parr Instrument Company in

order to determine which part(s) may be replaced or

serviced.

Ensure that any hot surfaces have had

adequate time to cool before cleaning

or maintaining the reactor and/or its

components.

4

Parr Instrument Company

Page 5

4550 Floor Stand Reactors

User’s Responsibility

All Parr Reactors and pressure vessels are designed and manufactured with great care to assure safe operation when used within their prescribed temperature and pressure limits. But . . . the basic responsibility for

safety when using this equipment rests entirely with the user; who must:

1. Select a reactor or pressure vessel which has the

capability, pressure rating, corrosion resistance

and design features that are suitable for its intended use. Parr engineers will be glad to discuss available equipment and material options

with prospective users, but the final responsibility for selecting a reactor or pressure vessel

that will perform to the user’s satisfaction in any

particular reaction or test must rest with the user

– not with Parr.

In exercising the responsibility for the selection

of pressure equipment, the prospective user

is often faced with a choice between over- or

under-designed equipment. The hazards introduced by under-designed pressure vessels are

readily apparent, but the penalties that must

be paid for over-designed apparatus are often

overlooked.

Recognizing these criteria, Parr reactors and

pressure vessels are offered in several different

styles, each designed for convenient use in daily

operation within certain temperature and pressure limits, using gaskets, closures and other

elements carefully selected for safe operation

within the limits specified for that design. But in

order to preserve the validity of these designs,

all temperature and pressure limits must be

observed, and no attempt should be made to

increase these limits by making alterations or by

substituting components which are not recommended by Parr Instrument Company.

2. Install and operate the equipment within a

suitable barricade, if required, with appropriate

safety accessories and in full compliance with

local safety codes and rules.

All standard Parr pressure vessels are provided

with either a suitable relief device or a means

to attach one (typically in the form of a plugged

opening). When a pressure vessel is delivered

without a pressure venting device, it is the customer’s responsibility to provide pressure relief

in order to protect the operator and the equipment from destructive high pressures. If you

need more information or need help in selecting

a proper relief device, please contact Parr Instrument Company.

3. Establish training procedures to ensure that any

person handling the equipment knows how to

use it properly.

4. Maintain the equipment in good condition and

establish procedures for periodic testing to be

sure the vessel remains structurally sound.

www.parrinst.com

5

Page 6

4550 Floor Stand Reactors

Fixed Head or Removable Head Design

Parr Series 4550 Series Reactors are furnished with two structural options in addition to the size, pressure

range, stirrer motor, controller and similar options. These are:

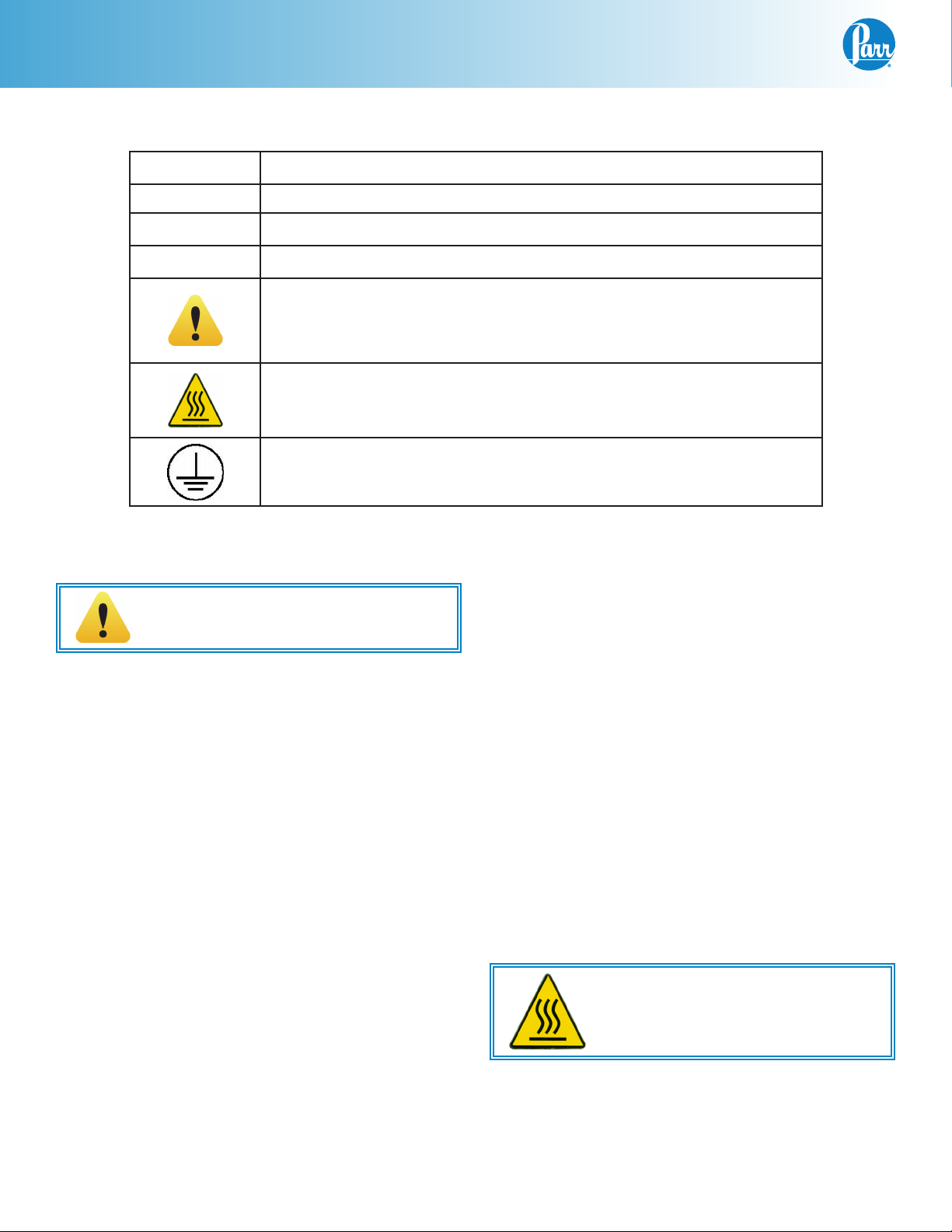

Fixed Head or Removable Head Vessel Design

In the fixed head design, the head of the vessel

may remain fixed in the reactor support stand. All

attachments to the head, gas and liquid feed and

discharge lines, cooling water, vapor take-off and

condenser, thermocouple, and any electrical leads

can remain permanently in place. The reactor is

opened by removing the cover clamp sections and

lowering the cylinder away from the head.

In the removable vessel design, the entire vessel

must be removed from the support stand for charging, product recovery, and cleaning.

There is no difference in the pressure or temperature

limits or basic operating instructions based upon the

fixed head or movable vessel options. There are differences in the design of the stand components which

adapt the vessels to the support system.

Flat PTFE Gasket or Self Sealing O-ring Closure

The flat gasket is held in a recess in the vessel head

and a machine pilot on the cylinder closes the recess

to completely contain the gasket. The split ring closure

used with this gasket has six cap screws which must be

tightened to develop the loading on the gasket.

The self sealing design features an O-ring retained in

a groove on the vessel head. This design is self sealing and the split ring used with this sealing system

does not require nor have the cap screws used with

the flat gasket.

Maximum temperatures of a given system are dependant upon the material of construction and type

of seal. Other accessories may limit operating temperature. The flat PTFE gasket can be used to operating temperatures as high as 350 °C. The flat flexible

graphite gasket can be used to operating temperatures

as high as 500 °C. The maximum temperature of the

vessels equipped with O-ring seals depends upon

the material used for the O-ring. The most common

material is a fluoroelastomer (FKM) which has a 225 °C

maximum operating temperature limit.

Fixed Head with O-ring

6

Parr Instrument Company

Moveable Head with Flat Gasket

Page 7

INSTALLATION

Pressure and Temperature Limits

4550 Floor Stand Reactors

The working pressure and temperature at which any

reactor or pressure vessel can be used will depend

upon the design of the vessel and the materials

used in its construction. Since all materials lose

strength at elevated temperatures, any pressure

rating must be stated in terms of the temperature at

which it applies. The standard material of construction for Parr Instrument Company is Type 316 Stainless Steel.

Limits for vessels made of other materials and for

other operating temperatures can be obtained from

Parr Customer Service. No attempt should be made

to increase these limits by making alterations or by

substituting components that are not recommended

by the Parr Instrument Company. It must also be

understood that lower pressure and temperature

limits may be required for modified reactors and for

vessels made of special alloys.

Limits for vessels will be determined by the physical characteristics of the vessel material and will be

prescribed on an individual basis.

The maximum working pressure and temperature

for any vessel is governed by the design of the

vessel and the strength of the material from which

it is constructed. There is also a close relationship

between working pressure and temperature since

the strength of any material will normally fall off

as the temperature is increased. Temperature and

pressure limits are also affected by the physical

properties and temperature limits of the gaskets and

seals used in the vessel, and by any valves, gages

or other fittings attached to the vessel. Obviously,

the safe operating pressure of any system can be no

higher than that of its lowest rated component.

All Parr reactors show the maximum safe operating

pressure and temperature imprinted on the cylinder.

The working pressure and temperature in these one and two gallon reactors must not exceed the

following maximum limits:

Pressure Vessel and Temperature Limits

Vessel Material Maximum Pressure Maximum Temperature

T316SS 1900 psig 350 °C PTFE Flat Gasket

T316SS 1900 psig 300 °C FFKM O-ring

T316SS 1900 psig 225 °C FKM O-ring

www.parrinst.com

7

Page 8

4550 Floor Stand Reactors

Assemble the Reactor

These reactors require at least 10 sq. ft. of workspace in a well-ventilated area with convenient

access to an electric outlet, running water, air and a

drain. This unit needs to be placed at least 10 inches

away from walls or flammable materials.

1. Set the stand in the workspace.

2A. Removable Vessels.

First pivot the overarm assembly to the back of

the support stand.

The pressure vessel has been shipped as a

complete assembly; it may be easiest on the

initial setup to place the entire pressure vessel

assembly into the heater. Note: The complete

assembly does not need to be removed from the

heater during opening and closing operations.

It is designed so that the cylinder can remain

in the heater while the head and split rings are

attached or removed.

Once the vessel assembly is in place rotate the

magnetic stirrer by hand to make sure that it

turns freely. Then move the overarm back into

position above the vessel. The knob on the top

of the overarm will raise the upper shaft with

coupling for attachment to the adapter on the

top of the magnetic stirrer. Push down and

rotate the upper shaft to bring these components into alignment.

Occasionally the motor housing and overarm assembly may vibrate out of the standard position.

If the upper shaft is not in alignment with the

center of the top of the magnetic stirrer it will be

necessary to loosen the bolt which attaches the

motor housing to the support stand. Remove

the motor housing panel; there is a single bolt

that runs through the lower housing support

and the top shelf of the floor stand. Once the

bolt is loosened, rotate the housing the required

amount, connect the upper shaft to the magnetic

stirrer and then tighten the motor housing bolt.

2B. Fixed Head Reactor.

Bolt the stand to the floor using the

holes in the base plate.

Loosen the panel screw of the vessel retainer

mounted on the midplate of the support stand

and open the retainer bracket.

The pressure vessel has been shipped as a

complete assembly. It is necessary to loosen the

split ring bolts and remove the split ring. Lift the

head assembly out of the cylinder and slide it

into the midplate of the stand. Close the retainer

bracket. The cylinder should be placed in the

cylinder lift bracket.

Rotate the magnetic stirrer by hand to make sure

that it turns freely.

Connect an air line to the 1/4” quick disconnect

fitting at the base of the support stand. This

pneumatic lift package will raise or lower the

cylinder. It may also be used for the heater. The

lever on the side panel of the support frame

controls the lift motion.

The pneumatic package includes a pressure

regulator with gage located inside of the support

stand housing. It can be accessed by removing

the back panel of the support stand. The regulator has been preset to 50 psi. The regulator can

be adjusted by lifting up on the cap. Rotate

clockwise to increase pressure, counter-clockwise to decrease the amount of pressure sent to

the pneumatic lift cylinder. Press the cap back

down after setting the pressure.

The flow control valves have been preset for

optimum performance. Both the speed and

lifting capacity of the pneumatic lift package can

be adjusted with the flow control valves located

on the input and output ports of the pneumatic

cylinder.

8

Parr Instrument Company

Page 9

4550 Floor Stand Reactors

3. Set the Reactor Controller near the reactor, leaving a space of at least six inches between the

controller and the base of the reactor so that the

controller will not be unduly affected by radiant

heat. Connect the reactor to the controller using

information contained in its Instruction Manual

548M or follow the steps below.

Labeled connections are provided on the rear

panel of the controller.

Parr Cooling Only:

The Parr Cooling output connector is to be used

only with Parr Instrument Company cooling solenoid valve assemblies supplied with the appropriate cooling power cord.

Parr Heating Only:

5. Plug the motor cord into the motor socket on the

rear of the controller.

Secure the clamp on the motor cord

with the provided screw next to the

motor socket for safety purposes.

6. Connect the thermocouple and extension wire

to both the thermocouple and to the controller

in the “Primary Temp Input” position on the rear

panel. Insert the thermocouple in the thermowell.

7. Connect leads from accessory packages such as

tachometer, pressure transducer and high temp

cut-off to the designated positions on the back

panel of the 4848 Controller.

8. Connect cooling water to the magnetic drive.

See Instruction Manual No. 234M.

9. Connect tubing to the rupture disc outlet and run

to a safely vented area. See Instruction Manual

231M.

The Parr Heating output connector is to be used

only with Parr Instrument Company heater assemblies supplied with the appropriate heater

power cord.

Note: Do not make connections to a Variac,

Powerstat or the like to attempt to control the

heating output. The heavy inductive load on

the primary side of such devices can destroy

the internal solid state relay located in the

4848 Controller.

Parr Motor Only:

The Motor output connector is to be used only

with Parr Instrument Company motor assemblies

supplied with the appropriate motor power cord.

4. Connect the heater cord from the heater into

the heater socket on the rear panel of the Series

4848 Reactor Controller.

10. Note the voltage and amperage requirement

stamped on the controller data plate, and then

plug the power cord into an appropriate outlet.

Power for these reactors should be drawn from

a grounded outlet capable of carrying up to the

full current rating of the reactor.

11. If an electric stirrer motor is supplied, turn the

speed control knob fully counterclockwise on

the Reactor Controller, turn on the motor switch

and slightly increase the speed for a short run

to check the stirrer drive system but do not turn

on the heater, put heater toggle switch in center

position (OFF). There must always be a vessel in

the heater when it is turned on, and the vessel

and heater sizes must match. If the heater is operated without proper size vessel in contact with

the mantle, the mantle may overheat and fail.

www.parrinst.com

9

Page 10

4550 Floor Stand Reactors

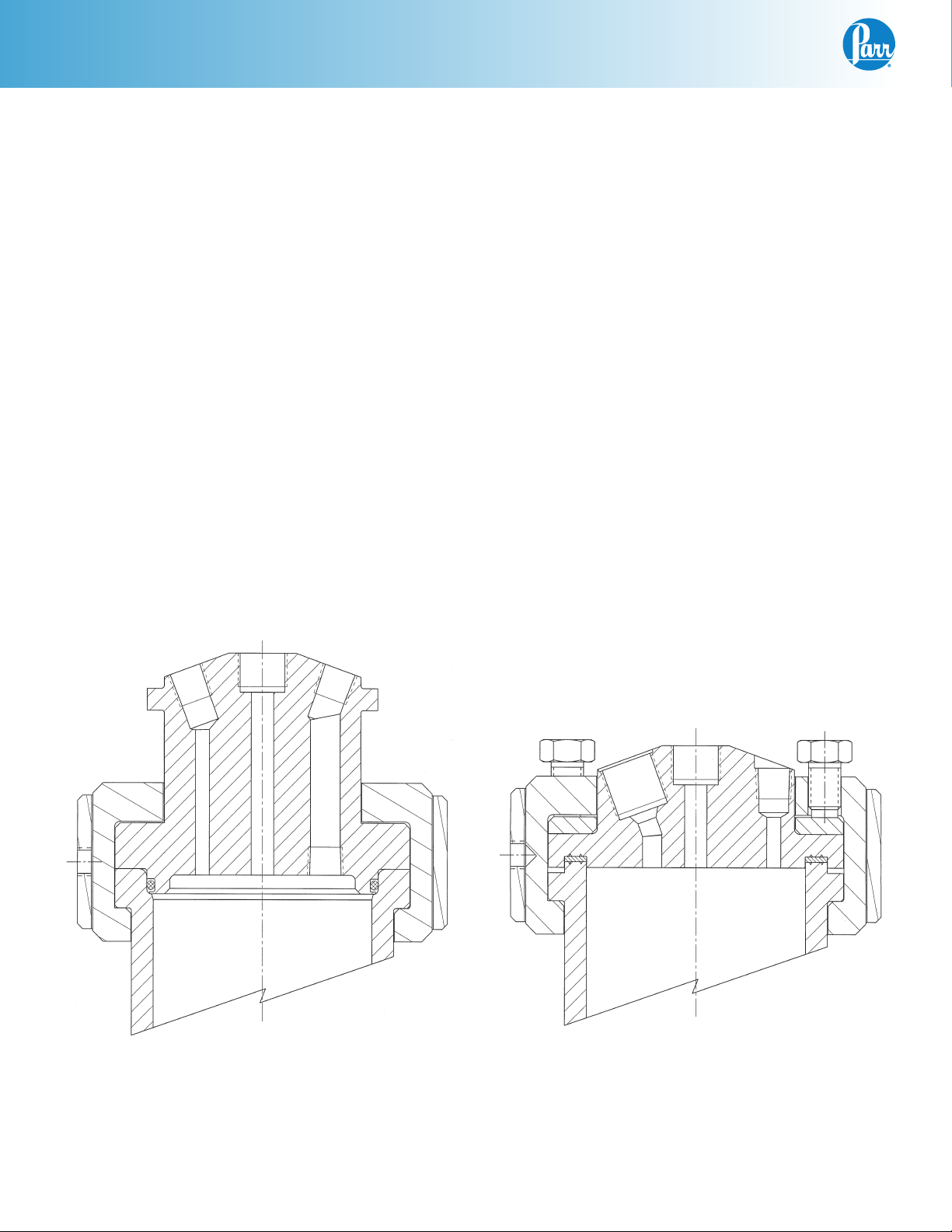

IDENTIFY THE VALVES

Gas Inlet Valve

The gas inlet valve is easily identified when the bomb

is open by noting that it is connected to a dip tube

that extends to a point near the bottom of the bomb

cylinder. This is an angle valve with an attached fitting

which provides a socket for attaching the A495HC

pressure hose furnished with the reactor.

Gas Release Valve

The gas release valve is connected to an opening

that will not have any fitting installed on the underside of the head. Gas released from this valve

will be drawn from the top of the reactor. The gas

release port does include a 1/8th NPT thread on the

PRESSURE GAGE

underside of the head where an additional dip tube

or catalyst addition device may be added. If one of

these additions is made to this port then an additional valve must be added to the gage adapter to

be used as a gas release valve.

Liquid Sampling Valve

The liquid sampling valve is attached to the same

fitting as the gas inlet valve and connected to the

same dip tube. With this arrangement, incoming gas

is always introduced below the surface of the liquid

and the operator is provided with a means for clearing

the dip tube to be sure that any sample taken during

a run will be representative of the charge. This can be

done by opening the gas valve momentarily to force

any liquid in the dip tube back into the reactor before

withdrawing a sample from the sampling valve.

MAGNETIC DRIVE ASSY

HEX PLUG (EXTRA PORT)

(2) ELBOW,COOLING COIL

(INLET/OUTLET)

GAS RELEASE VALVE

RUPTURE DISC ASSY

VALVE ADAPTER

COMPRESSION RING

ADAPTER BUSHING

HEAD, REMOVABLE

(2) MALE CONNECTOR

(COOLING COIL)

STIRRER SHAFT ASSY

THERMOWELL

SERPENTINE COOLING COIL

THERMOCOUPLE

GAS INLET VALVE

ADAPTER, GAS CONNECTION

VALVE ADAPTER

VALVE, LIQUID SAMPLING

GAGE ADAPTER

ADAPTER BUSHING

GLAND NUT, MAG DRIVE

MALE CONNECTOR, DIP TUBE

DIP TUBE

10

(2) IMPELLER ASSY

STIRRER BRACKET ASSY

Parr Instrument Company

Page 11

4550 Floor Stand Reactors

INLET SAMPLING VALVE

OTHER VESSEL HEAD FITTINGS

Safety Rupture Disc

There is a safety rupture disc attached to the head that

is intended to rupture and release the pressure before

it reaches a dangerous level. A metal tag wired to

the safety head identifies the burst pressure at room

temperature for that particular disc. A similar tag is

furnished with each replacement disc. This tag must

remain with the apparatus at all times so that both present and future operators will be aware of the disc rating.

Users should read the discussion of rupture discs given

in the Instruction Sheet No. 231M for a complete description of the characteristics of rupture discs and the

precautions to be observed when operating pressure

equipment protected by this type of safety device.

A typical pre-bulged disc can be used to 90% of the

rating on the tag. For additional protection, the user

should install an adequate and safe venting system for

removing any toxic, flammable or volatile material which

would be released if the rupture disc should burst. A

connector for attaching 3/8” OD tubing to the discharge

port of the rupture disc is provided for this purpose.

Type J Thermocouple

A Type J thermocouple in a 1/8” dia. stainless steel

sheath is furnished with the reactor. Insert this thermocouple into the head thermowell and connect

it to the thermocouple socket on the rear panel of

the temperature controller using the extension wire

furnished with the reactor.

Pressure Gage

The pressure gage furnished with this reactor has a T316

Stainless Steel Bourdon tube. Gages are furnished in

a variety of ranges to meet individual needs. Typically,

the gage and the rupture disc are furnished as matched

ranges. For applications where a gage is selected with

a range under 1000 psi, a relief valve is added and set

to protect the gage. A 1000 psi rupture disc is installed

as the fail-safe vessel protection.

For highly corrosive applications where the vapor

phase might corrode the stainless Bourdon tube, Parr

offers isolator assemblies in a variety of materials.

These isolators with their internal piston isolate the

vapors from the gage.

The gage adapter includes a ¼” NPT side port with a

plug installed. This position may be used for a variety

of fittings such as a needle valve, pressure transducer

or relief valve.

Gage and Valve Adapters

The pressure gage and the combined gas inlet and

sampling valves are attached to the head with an

adapter which allows these fittings to be drawn up

tightly when facing in any direction. To attach these

fittings to the head, screw the gage or valves firmly

into the adapter, then run the 209HC4 bushing onto the

threaded stem as far as it will go. Screw this assembly

into the head until the nose of the adapter is seated;

then back it off until the valve or gage is facing in the

desired direction. Now hold the fitting firmly in place

and close the joint by tightening the 209HC4 bushing.

This connection can be made and broken repeatedly

without destroying the sealing faces. A light coating of

thread lubricant, such as Parr No. 424HC2 High Temperature Anti-Seize Lube, applied to the threads and to

the nose of the adapter will help to obtain a tight joint.

Note: Do not use PTFE tape on the straight thread

connections of the coned adapters and mating

bushings. PTFE tape should only be used on the (NPT)

threads such as the needle valves or gage connection.

56HC

208HC15

209HC4

PRESSURE GAGE

420HC2

A129VB

A131VB

208HC6

209HC4

GAS RELEASE VALVE

www.parrinst.com

A130VB

658HC

11

Page 12

4550 Floor Stand Reactors

ACCESSORIES

Internal Cooling Coils

Cooling coils can be installed in any of these reactors. Reactors purchased without a coil can have this

feature added.

Standard cooling coils are made in serpentine

configurations. A serpentine coil offers a smaller

but effective cooling area and it does not interfere

with the use of a liner. An optional spiral coil can

be provided, which offers more surface area than a

serpentine coil but it is more difficult to clean and,

when installed, it prevents the use of some internals

and liners. Plugs are available to seal the cooling

coil opening when the coil is not used.

Variable Speed Electric Motor

Reactors are normally equipped with a DC variable

speed motor supplied and controlled through the

Series 4848 Reactor Controller. Instructions for connecting and operating these motors are included in

the controller instruction sheet No. 548M. This motor

is usually installed in a drive system designed to

produce stirring speeds from 0 to 600 rpm. Higher

speeds (1000 or 1700 rpm) can be obtained by

substituting larger diameter motor drive pulleys.

Air Motor

directions for a few minutes; then connect the air

line and run the motor until there is no further

trace of solvent in the exhaust. If the muffler felts

are dirty, wash them in solvent or replace them.

Re-lubricate the motor with a squirt of oil into the

chamber and reassemble. If it becomes necessary to

disassemble the motor to replace the vanes, follow

directions given in the instruction sheet published

by the Gast Manufacturing Corp., Benton Harbor,

Michigan.

Liners

Glass or PTFE liners can be furnished to fit most

Parr reactors. These liners slide into the cylinder.

Although they will not keep corrosive vapors from

reaching the surfaces of the cylinder and head, they

make it much easier to add and remove liquid reactants, and they give some protection to the cylinder

when working with corrosive solutions. It must be

noted, however, that adding a liner will slow the

heat transfer rate into the vessel, and it may be

necessary to adjust the temperature control method

to prevent overheating.

Liner Part Numbers

Fits

ID

6 inches 1 Gallon 894HC 894HC4HA

6 inches 2 Gallon 894HC2 894HC5HA

Cylinder

Size

Glass

Liner

PTFE

Liner

Variable stirring speeds from 100 to 2000 rpm can

be obtained by replacing the standard motor with

an A1393HC air motor. This motor operates on

compressed air, which must be supplied at 40 psig

minimum pressure with at least 10CFM available at

that pressure. It is furnished with a speed control

valve and oiler.

To operate reactors equipped with an air motor, connect the air hose to a compressed air line. Fill the

oiler with SAE 10 oil and adjust the oiler to feed one

drop per minute into the air stream. For long continuous runs at high speeds, the oiling rate should

be increased to three drops per minute. If the motor

becomes sluggish, flush it with a non-flammable

solvent in a well-ventilated area. Disconnect the air

line and muffler and pour a small amount of solvent

into the inlet port. Rotate the shaft by hand in both

Spare Parts Kit

Parr can furnish spare parts kits for these reactors

which will provide a reserve supply of parts and

tools sufficient to handle most normal replacements

and emergency repairs during a year of heavy

usage.

These kits contain replacement gaskets, packing,

O-rings, shafts, bearings, and rupture discs. They

can be ordered from any Parr Dealer or direct from

the Parr Instrument Company. The order must

specify the reactor size and indicate type of rupture

disc, stirrer drive and whether it has a flat-gasket

or O-ring seal. Always provide the reactor serial

number (stamped on head and cylinder) to assure

receipt of proper replacement parts.

12

Parr Instrument Company

Page 13

Pneumatic Lift for Fixed Head Vessels

For those models equipped with a

pneumatic lift package, the following

instructions apply:

This pressure reactor assembly uses

an A2760HC Pneumatic Lift Package

to raise and lower the Cylinder. If

needed, It can also be used to raise

and lower the Heater assembly.

4550 Floor Stand Reactors

Technical Support

Contact our customer service

department with questions

concerning the Pneumatic Lift

Package.

Toll Free: 1(800) 872-7720

E-mail: parr@parrinst.com

Hand Lever Valve Assembly “Joystick”

Lift up on joystick to go “UP” or

Push down on joystick to go “DOWN”.

Cylinder Lift Assembly

Pneumatic Lift Cylinder

Pressure Regulator Cap

Pressure Regulator with Gage

The air pressure has been preset

to 50 psi. The regulator can be

adjusted by lifting up on this cap

and then turning “clockwise” to

increase or “counterclockwise”

to decrease the amount of

pressure being sent to the

pneumatic cylinder.

Press cap back down after setting

pressure, this will prevent the

cap from being unintentionally

turned.

Heater Assembly

Hose Bulkhead Flow Control Connector

A (1/4”) quick disconnect fitting has been

provided for the air line connection.

User is responsible for connecting to their

air supply.

Hose Coupler

Flow Control Valves

The flow control valves have been preset for optimum

performance. Both the speed and lifting capacity of the

Pneumatic lift package can be adjusted with the flow

control valves located on the input and output ports of

the pneumatic cylinder.

www.parrinst.com

13

Page 14

4550 Floor Stand Reactors

HOW TO USE THE VESSEL

Fixed Head Vessels

First, lower the heater and push it aside before

attempting to remove the split ring and cylinder.

Raise the cylinder support holder to the bottom of

the cylinder. Open the gas release valve to discharge

any internal pressure.

To open the Vessel

Remove the split rings. For vessels with a confined,

flat PTFE gasket, loosen the six bolts. For vessels

with an O-ring closure, loosen the latches on each

side of the split rings. The split ring halves can now

be removed. The head with all attached fittings will

remain in place. The cylinder can now be lowered

away. Handle the cylinder carefully so as not to

damage the stirring shaft and other internals.

Before Closing the Vessel

Examine the head seal carefully to be sure that

it is in good condition. The seal should not have

any nicks or be hardened, discolored or deformed.

Examine the mating surfaces on the cylinder and

head to be sure they are clean and free from burrs;

then raise the cylinder up to the head.

To Close the Vessel

Put the two split ring halves around the head and

cylinder flanges and fasten the latches or tighten the

bolts as assembled before.

Removable Head Vessels

First, open the gas release valve to discharge any

internal pressure. For vessels on a movable floor

cart, lift the vessel out of the heater before attempting to remove the split ring and head. For vessels

on a stationary stand, loosen the panel screw holding the vessel retainer, remove the vessel from the

stand and set it on a table.

To Open the Vessel

Remove the split rings. For vessels with a confined,

flat PTFE gasket, loosen the six bolts. For vessels

with an O-ring closure, loosen the latches on each

side of the split rings. The split ring halves can now

be removed. The head with all attached fittings is

free to be lifted from the cylinder. Handle the head

carefully so as not to damage the stirring shaft and

other internals.

Before Closing the Vessel

Examine the head seal carefully to be sure that

it is in good condition. The seal should not have

any nicks or be hardened, discolored or deformed.

Examine the mating surfaces on the cylinder and

head to be sure they are clean and free from burrs.

Then carefully set head on cylinder.

To Close the Vessel

Slide the two split ring halves around the cylinder

and head flanges. If equipped with a drop band,

position the split ring halves such that the indentation for one of the halves is located 180 degrees

away from the pressure gage. Slide the drop band

over the split ring halves and tighten the set screw

lightly to hold the band in place.

For vessels on a movable floor cart, place the vessel

into the heater with the gage facing forward and

swing the drive arm into position, connecting the

rubber sleeve onto the spline coupling on the stirrer.

For vessels on a stationary stand, place the vessel

onto the midplate such that the drop band set screw

fits into the slot on the back of the midplate.

Note: The following steps are common

to both head configurations

Sealing Vessels with PTFE Gaskets

If your split ring has compression bolts, tighten each

of the bolts with the wrench furnished. Apply a firm

but hard pull to each bolt. Or, if a torque wrench

is available, apply 25ft-lbs to each bolt. Tightening

should proceed in a criss-cross pattern rather than

progressively around the circle. Let the vessel stand

for about five minutes after the initial tightening;

then tighten the bolts again. This will compensate

for any tendency of the PTFE gasket to flow under

the loading pressure.

Gas Connections

Gas connections are dependent on applications.

For general usage, use the pressure hose furnished

with the reactor. Screw the Type “A” coned pressure

fitting into the adapter attached to the gas inlet valve

and tighten the compression nut firmly. Do not use

any thread dope on the coned fitting. The A495HC

pressure hose is made of reinforced Nylon that can

be used at ambient temperature for all non-corrosive gases at pressures up to 2500 psig. For operations involving corrosive gases, this hose should

14

Parr Instrument Company

Page 15

4550 Floor Stand Reactors

be replaced with an A490HC hose which has a PTFE

lining and a braided stainless steel outer covering.

Both of these hoses have the same fittings. The

A506HC all metal hose is also available in stainless

steel and other corrosion resistant materials.

Pressurizing the Vessel

Check all valves carefully before admitting gas into

the system. The liquid sampling valve must remain

closed throughout the charging procedure. The gas

release valve must also be closed unless the vessel

is to be purged, or unless there is to be a continuous

flow through the reactor during a run. Always make

certain that the pressure in the gas tank is greater

than the pressure in the vessel; otherwise liquid

will be forced out of the vessel and into the gas

tank when the inlet valve is opened. If there is any

possibility that the tank pressure might not be high

enough to force gas into the reactor, install a oneway check valve (optional) in the gas line to prevent

any reverse flow. After the desired pressure has

been reached, close the valves and disconnect the

hose at the vessel end.

Alternate gas hoses with check valves are available

from Parr upon request.

Do Not Overfill the Vessel

Always watch the pressure gage closely when admitting gas so as not to exceed the maximum working limit. Remember that any subsequent increase

in temperature will raise the pressure. Also, be

sure that the amount of liquid placed in the vessel

is carefully controlled. As a general rule, the liquid

charge should not exceed two-thirds of the capacity

of the cylinder. Too much liquid in the vessel can

lead to development of dangerous pressures if sufficient space is not provided for expansion when the

liquid is heated. This hazard is explained in greater

detail in a warning statement included in the Safety

Instruction Manual No. 230M.

Withdrawing Liquid Samples

Liquid samples may be withdrawn from the sampling valve attached to the same adapter as the

gas inlet valve whenever the vessel is pressurized.

Always close the inlet valve before withdrawing a liquid sample and open the sampling valve

cautiously because liquid will be discharged with

considerable force. Be particularly careful if the

temperature of the sample is above its boiling point

at atmospheric pressure. If so, it will “flash” and be

lost as soon as it is released from the vessel. This

problem can be avoided by connecting an optional

4352 Sample Collection Vessel to the sampling valve

to collect the liquid into an appropriate receiver. The

addition of a small amount of gas can be used to

clear the dip tube between liquid samples so that

the next sample drawn through the tube will truly

be representative of the mixture..

Initial Operating Test

Read all operating instructions carefully so as to be

well acquainted with the correct procedures for handling the vessel and for operating the controller and

other accessories. An initial operating test should

be made, with only water, to check the apparatus

before starting the first experimental runs. For this

initial test, fill the cylinder not more than half full of

water and run the temperature up to 150 ºC while

checking the apparatus for leaks and observing the

performance of the temperature controller.

Releasing Pressure

Use the gas release valve to reduce the pressure in

the vessel if the reactor is accidentally overcharged

when filling. Use this valve also to release any

excess pressure during a run and to exhaust the

vessel at the end of a run. If the discharge gases are

flammable or toxic, discharge to an exhaust hood or

to any other safe release point.

www.parrinst.com

15

Page 16

4550 Floor Stand Reactors

MAINTENANCE

General Maintenance Notes

1. Periodically inspect all electrical wiring and pressure connections for excessive corrosion. Suspect parts should be replaced by components

only supplied by Parr Instrument Company.

2. Always use appropriate wrenches on all fittings

and valves. Never use pliers or pipe wrenches.

3. Head and cylinder service fixtures are available

for convenience and protection of components

during maintenance of your reactor.

4. To reinstall straight thread (NPS) fittings to the

head, screw the gage or valves firmly into the

adapter.

Run the bushing onto the threaded stem as far

as it will go. Screw this assembly into the head

until the nose of the adapter is seated; then

back it off until the valve or gage is facing in the

desired direction (no more than one full turn).

Hold the fitting firmly in place and close the

joint by tightening the bushing. This connection

can be made and broken repeatedly without

destroying the sealing surfaces. A light coating

of thread lubricant, such as Parr High Temperature Anti-Seize Lubricant, applied to the straight

threads and to the nose of the adapter will help

to obtain a tight joint.

Note: PTFE tape should not be used on this

joint.

5. NPT (National Pipe Taper) threads should not

be disassembled any more than necessary. It

will become increasingly difficult to maintain a

tight seal with these tapered threads if the joint

is made and broken repeatedly. Grafoil tape or

PTFE tape (if temp allows) should be used on all

NPT threads.

7. If your vessel is equipped with a loose compression ring be sure that it is in place on the head

before attaching any head fittings. The compression ring cannot be installed after fittings have

been screwed into the head.

8. Clean all threads and gas passages thoroughly

and remove all tape fragments when overhauling a vessel. An ultrasonic bath is excellent for

cleaning metal parts, but do not place a thermocouple probe, pressure gage, face seals or ball

bearings in an ultrasonic bath. Periodic cleaning

may be performed on the exterior surfaces of

the reactor stand with a lightly dampened cloth

containing mild soap solution. All power should

be disconnected when cleaning.

9. Routinely inspect compression bolts on split ring

closure for lubrication and cleanliness. These

screws should not be allowed to dry because

the threads will seize. Regularly apply Parr

High Temperature Anti-Seize Lubricant (Parr No.

424HC2) before this happens.

10. To operate reactors equipped with an air motor,

connect the air hose to a compressed air line.

For best torque and speed control the piping to

the motor should be at least 3/8” IPS or larger.

Fill the oiler with SAE 10 oil and adjust the oiler

feed one drop per minute into the air stream.

For long continuous runs at high speeds, the oiling rate should be increased to three drops per

minute. If the motor becomes sluggish, flush

it with a non-flammable solvent in a well ventilated area.

Disconnect the air line and muffler and pour

a small amount of solvent into the inlet port.

Rotate the shaft by hand in both directions for

a few minutes; then connect the air line and

run the motor until there is not further trace of

solvent in the exhaust. If the muffler is dirty,

replace it. Relubricate the motor with a squirt of

oil into the chamber and reassemble.

6. Do not use oil or anti-seize lubricant on threads

or fittings if the vessel is to be used with oxygen.

16

Parr Instrument Company

11. If servicing assistance is needed, contact Parr

Instrument Company directly at the address

shown on the back of these instructions.

Page 17

Periodic Pressure Tests

Each cylinder used in a Parr stirred reactor is tested

under hydrostatic pressure to the higher of 1.43

times the rated working pressure at room temperature or 1.30 times the rated working pressure

corrected for temperature before it is released from

the factory. Micrometer caliper measurements are

taken during this test to check the deflection of the

walls under pressure. Excessive deflection or failure

of the metal to resume its original dimensions after

pressure is released indicates that a cylinder is potentially unsafe and it will be rejected. Similar tests

should be made at regular intervals during the life

of each cylinder, and particularly whenever the user

suspects that the equipment has been over-stressed

or damaged.

Some laboratories maintain hydraulic test facilities

and make it a rule that all pressure vessels must

be tested at regular intervals. Records are kept of

deflections at specific test pressures so that any

increase in deflection becomes a warning that the

metal has lost strength. Any cylinder that fails to

return to its original dimensions after application of

the prescribed hydrostatic test should be discarded

as unsafe for further use.

Users who do not have pressure test facilities can

return any Parr pressure vessel to the factory for

hydrostatic testing and overhaul. This should be

done whenever the metal shows excessive damage

from corrosion or whenever an over-pressure or

other unusual occurrence raises any safety questions. To return a vessel for repair, contact Parr

Instrument Company for a return authorization

number. Apparatus returned for testing and over-

haul should be shipped prepaid to Parr Instrument

Company, 211-53rd Street, Moline, Illinois 61265. An

order or letter of instructions should be mailed to

the same address, as no repair work will be started

without specific instructions and a Health & Safety

Assurance Certification form (FX004) signed by a

responsible user.

4550 Floor Stand Reactors

www.parrinst.com

17

Page 18

4550 Floor Stand Reactors

PARTS LISTS

Reaction Vessel Parts List

Consult the itemized list for your reactor provided

along with this manual. For purpose of reactor

identification, the following abbreviation/codes are

used:

FH - Fixed Head FG - Flat Gasket

RV - Removable Head OR - O-Ring Seal

MD - Mag Drive LD - Light Duty

FMD - Footless Mag Drive HD - Heavy Duty

PRESSURE GAGE

MAGNETIC DRIVE ASSY

HEX PLUG (EXTRA PORT)

(2) ELBOW,COOLING COIL

(INLET/OUTLET)

GAS RELEASE VALVE

* For parts made from alternate materials use the

codes shown below as a suffix to the standard part

number.

CM - Alloy 400 CC - Alloy 20Cb3

CT - Alloy 600 CAD - Titanium G2

CG - Alloy B-2 CAA - Titanium G4

CXA Zirconium G702 CH - Alloy C-276

CXB Zirconium G705

THERMOCOUPLE

GAS INLET VALVE

ADAPTER, GAS CONNECTION

VALVE ADAPTER

VALVE, LIQUID SAMPLING

RUPTURE DISC ASSY

VALVE ADAPTER

COMPRESSION RING

ADAPTER BUSHING

HEAD, REMOVABLE

(2) MALE CONNECTOR

(COOLING COIL)

STIRRER SHAFT ASSY

THERMOWELL

SERPENTINE COOLING COIL

(2) IMPELLER ASSY

STIRRER BRACKET ASSY

GAGE ADAPTER

ADAPTER BUSHING

GLAND NUT, MAG DRIVE

MALE CONNECTOR, DIP TUBE

DIP TUBE

18

Parr Instrument Company

Page 19

4550 Floor Stand Reactors

Cylinders

Part No. Description Code

660HC Cylinder, 1G FG

660HC6 Cylinder, 2G FG

2692HC10 Cylinder, 1G OR

2692HC20 Cylinder, 2G OR

Heads

Part No. Description Code

657HC Head RV FG

2690HC Head RV OR

2271HC Head FH FG

2700HC Head FH OR

Split Rings and Accessories

Part No. Description Code

A754HC Split Ring Assembly RV FG

659HC Compression Ring, Head RV FG

A2265HC

A2265HC2

A2275HC3

754HCFDE Bolts, Split Ring, 5/8-18” 3/4 hex

1368HC

2701HC

Split Ring Assembly,

quick close, latches

Split Ring Assembly, hinged,

quick close, latches

Split Ring Assembly, hinged

w/bolts, comp. ring & latches

Torque Wrench 3/8” Drive

(optional)

Torque Adapter 3/8” Drive X

3/4” Hex (optional)

RV OS

FH OS

FH FG

Gages

Part No. Description

56HCPC Pressure gage, 4-1/2”, 0-600 psi

56HCPD Pressure gage, 4-1/2”, 0-1000 psi

56HCPF Pressure gage, 4-1/2”, 0-2000 psi

56HCPG Pressure gage, 4-1/2”, 0-3000 psi

Internal Fittings

Thermowell

Part No. Description

265HC4 Thermowell, 8.0”, 1G

A935HC Thermowell, 16.56”, 2G

Dip Tubes

Part No. Description

686HC Dip Tube, 1G

686HC3 Dip Tube, 2G

A92HW Male connector

Shafts

Part No. Description Code

1025HC14 Stub Shaft, Mag Drive RV

1025HC40 Stub Shaft, Mag Drive FH

A1030HC3 Shaft Assy w/coupling, 1G

A1030HC4 Shaft Assy w/coupling, 2G

1028HC Coupling for shaft assy

1029HC Pin for shaft assy

1027HC Bushing PTFE for shaft

1025HC3 Shaft w/bushing, 1G

1025HC4 Shaft w/bushing, 2G

A709HC Impeller w/set screws

709HCF Set screws for impeller

Gaskets & Seals

Part No. Description Code

48HC Gasket, silver, mag drive

48HCFG

655HC Head Gasket, PTFE FG

2691HCJV O-ring, FKM OR

2691HCJK O-ring, FFKM OR

663HC Olive seal for mag drive

Gasket, gold plated, mag

drive

www.parrinst.com

19

Page 20

4550 Floor Stand Reactors

%5$&.(7

External Fittings

Part No. Description

94CAAD Plug, 1/4” NPTM

A129VB

A130VB

A131VB

658HC

208HC6 Valve Adapter, two 1/4” NPTF

208HC15 Gage Adapter, two 1/4” NPTF

209HC4 Bushing, gage & valve adapters

0$*1(7,&67,55(5

Valve, straight 1/4” NPTM x 1/4”

(Liquid Sampling)

Valve, angled 1/4” NPTM x 1/4”T

(Gas Release)

Valve, angled 1/4” NPTM x 1/4” NPTM

(Gas Inlet)

Adapter, 1/4” NPTM x 1/4” NPTF

(Gas Release)

Part No. Description

664HC3 Stirrer Plug (optional-use w/olive)

A472E6

A472E5

A707HC2

A1180HC

A1180HC4

664HC Nut, gland, drive seal

A740HC Cooling sleeve for Mag Drive Assembly

Thermocouple, grounded,

Type J 15-1/2” 1G

Thermocouple, grounded,

Type J 21-1/2” 2G

Safety Rupture Disc assembly w/o disc

(See 231M)

Mag Drive Assembly

(rubber coupling) (See 234M)

Mag Drive Assembly

(universal coupling) (See 234M)

678%6+$)7

*$6.(7

&283/,1*:,7+

67,55(56+$)7

7+(502:(//

*/$1'187

2/,9(

%86+,1*

&2035(66,21%2/7

63/,75,1*

+($'*$6.(7

&</,1'(5

6$03/,1*,1/(778%(

,03(//(5

67,55(56833257

20

Parr Instrument Company

Page 21

Overarm Parts List

RELEASE KNOB

OPTICAL WHEEL

LOWER BACK PLATE

HUB ASSEMBLY

UPPER BACK PLATE

DRIVEN PULLEY

UPPER DRIVE SHAFT

MOTOR

ENCASEMENT

OVERARM PLATE

DRIVE PULLEY

BELT GUARD

BELT TACH SENSOR

ASSEMBLY

UNIVERSAL COUPLING

4550 Floor Stand Reactors

Motor

Part No. Description Code

A388E6 Air Motor HD

A388E2ER Motor, 1/2 HP EXP VS 180 VDC

A388E2ET Motor 1/2 HP VS 180 VDC

A388EER Motor 1/4 HP EXP VS 180 VDC

A388EET Motor 1/4 HP VS 180 VDC

Driven Pulley Assembly

Part No. Description Code

A2519HC Driven Pulley Assembly HD

706HC2 Pulley, Driven HD

725HC Support Hub HD

730HC Ball Bearing HD

731HC Snap Ring Internal 2” HD

732HC Snap Ring External 1” HD

2429HC Bushing PTFE HD

Drive Pulleys (Motor)

Part No. Description Code

695HC5 Pulley 600 RPM .62 HD

695HC3 Pulley 1000 RPM .62 HD

695HC2 Pulley 1700 RPM .62 HD

Pulley Belt Combinations (HD Drive)

HD Pulley Cart-Belt FH-Belt

695HC5 728HC 728HC5

695HC3 728HC 728HC5

695HC2 728HC3 728HC6

Optional Tach Parts

Part No. Description

1564HC Optical Wheel

A1001E Tach Sensor Assembly (9.0”L)

A1001E2 Tach Sensor Assembly (5.5”L)

Upper Drive Shafts

Part No. Description Code

A742HC17

A2564HC2

Upper Drive Shaft 5.88”

Upper Drive Shaft 7.64”

RV

FH

Shaft Couplings

Part No. Description Code

A722HC

Shaft Coupling .50, Rubber

(cart only)

RH

2352HC Shaft Coupling .50, Universal FH

Release knobs

Part No. Description Code

726HC Release Knob, .50 Shaft HD

www.parrinst.com

21

Page 22

4550 Floor Stand Reactors

Cooling Coil Parts List

Cooling Coils

Part No. Description

689HC9 Cooling Coil, Serpentine 1G RV

689HC11 Cooling Coil, Serpentine 2G RV

689HC Cooling Coil, Spiral 1G RV

689HC3 Cooling Coil, Spiral 2G RV

2267HC10 Cooling Coil, Serpentine 1G FH

2267HC20 Cooling Coil, Serpentine 2G FH

2267HC11 Cooling Coil, Spiral 1G FH

2267HC21 Cooling Coil, Spiral 2G FH

Cooling Coil Fittings

Part No. Description

511HC Elbow, Tube Conn, ¼” T, Brass

122HW Ferrule for 511HC, Brass

123HW Cap Nut for 511HC, Brass

A138CA Male Connector FH

217VB Nut for A138CA ¼T

218VB Ferrule for A138CA ¼” T

885HC2 Plug, ¼” T Cap & Nut, SS only

79HW Plug, Hex Head, 1/8” NPTM

NUT

(4) REF

HEAD

MALE CONNECTOR

1/8" NPT - 1/4" TUBING

22

(2) REF

ELBOW

(2) REF

COOLING COIL

TUBE

REMOVABLE HEAD

Parr Instrument Company

HEAD

COOLING COIL

TUBE

ELBOW

(2) REF

FIXED HEAD

NUT

(4) REF

MALE CONNECTOR

1/8" NPT - 1/4" TUBING

(2) REF

Page 23

Heaters Parts List

Heaters on Moveable Floor Cart

Part No. Description

A693HC2EE Heater Assembly, 2250W 230V 1G

A693HC3EE Heater Assembly, 2750W 230V 2G

4550 Floor Stand Reactors

Heaters on Floor Stand

Part No. Description

A2693HC10EE Heater Assembly 2250W 230V 1G

A2693HC20EE Heater Assembly 2700W 230V 2G

Heating Elements

Part No. Description For Use With

661HCEE

661HC2EE

95EEE

Heating Element

1500W 230V

Heating Element

1000W 230V (Qty 2)

Ring Heater

750W 240V

A693HC2EE

A693HC3EE

A693HC2EE &

A693HC3EE

Heating Elements

Part No. Description For Use With

1689EEE

1689E2EE

Heating Element

2250W 230V

Heating Element

2700W 230V

A2693HC10EE

A2693HC20EE

Moveable Floor Cart

Floor Stand

www.parrinst.com

23

Page 24

4550 Floor Stand Reactors

4553 - 1 Gallon Fixed Head Stand Assembly

15.32

.62

74.50

51.00

A2693HC10 SERIES

HEATER ASSEMBLY

(SHOWN)

A2680HC11 SERIES

ALUM BLK HEATER

(NOT SHOWN)

2401HC

COLLAR CLAMP

2875HC5

BRACKET, HTR LIFT

(SHOWN)

3762HC

BRACKET, HTR LIFT ABH

(NOT SHOWN)

2481HC3

HEATER SUPPORT ROD

24

Parr Instrument Company

Page 25

4553 - 1 Gallon Fixed Head Stand Assembly

4550 Floor Stand Reactors

RELEASE KNOB

726HC

A2564HC2

DRIVE SHAFT ASSY

X2173

MAG DRIVE SHIELD

2352HC

COUPLING

2444HC

RETAINER PLATE

(2) SB2528FT08

1/4-28 X .50 FHSCS

A2275HC3

SPLIT RING ASSY

(SHOWN)

A2265HC2

SPLIT RING ASSY

QUICK CLOSE

(NOT SHOWN)

A3170HC3

HINGED SPLIT

RING PKG

4553

1 GAL FIXED HEAD

VESSEL ASSEMBLY

2407HC2

SLEEVE BEARING

(3) 2408HC

LEVELING SCREWS

2455HC

BELT GUARD

2566HC2

UPPER BACKPLATE

1/2 HP MOTOR

2350HC9

UPPER ENCASEMENT

799DD

BUSHING

2565HC2

LOWER BACKPLATE

2745HC

MIDPLATE

2553HC

CONTROLLER MOUNT

2704HC

REAR PANEL

2703HC

BOTTOM ENCLOSURE

(2) 2482HC2

SUPPORT ROD

(2) 2706HC10 LIFT BRACKET

2705HC LIFT NUT

SN7516HX HEX NUT

(2) 2394HC SPACER

(4) SW25NL WASHER

(4) SB2528SC08 SCREW

UPPER CYLINDER

2757HC

SUPPORT

2709HC

CYLINDER MOUNTING

BRACKET

2756HC

LOWER CYLINDER

SUPPORT

2708HC

LIFT BLOCK

2474HC

THREADED PIVOT

2707HC

LIFT BLOCK

2407HC2

SLEEVE BEARING

2481HC2

SUPPORT ROD

A2760HC4

PNEUMATIC LIFT PKG

A2755HC

BASE ASSEMBLY

(4) 2408HC

LEVELING SCREW

www.parrinst.com

25

Page 26

4550 Floor Stand Reactors

4554 - 2 Gallon Fixed Head Stand Assembly

15.32

.62

74.50

51.00

2481HC4

HEATER SUPPORT ROD

A2693HC20 SERIES

HEATER ASSEMBLY

(SHOWN)

A2680HC12 SERIES

ALUM BLK HEATER

(NOT SHOWN)

2401HC

COLLAR CLAMP

2875HC2

BRACKET, HTR LIFT

(SHOWN)

3762HC2

BRACKET, HTR LIFT ABH

(NOT SHOWN)

26

Parr Instrument Company

Page 27

4554 - 2 Gallon Fixed Head Stand Assembly

4550 Floor Stand Reactors

RELEASE KNOB

726HC

A2564HC2

DRIVE SHAFT ASSY

X2173

MAG DRIVE SHIELD

2352HC

COUPLING

2444HC

RETAINER PLATE

(2) SB2528FT08

1/4-28 X .50 FHSCS

A2275HC3

SPLIT RING ASSY

(SHOWN)

A2265HC2

SPLIT RING ASSY

QUICK CLOSE

(NOT SHOWN)

A3170HC3

HINGED SPLIT

RING PKG

4554

2 GAL FIXED HEAD

VESSEL ASSEMBLY

2455HC

BELT GUARD

2566HC2

UPPER BACKPLATE

1/2 HP MOTOR

2350HC9

UPPER ENCASEMENT

799DD

BUSHING

2565HC2

LOWER BACKPLATE

2745HC

MIDPLATE

2553HC

CONTROLLER MOUNT

2704HC

REAR PANEL

2703HC

BOTTOM ENCLOSURE

(2) 2482HC2

SUPPORT ROD

SLEEVE BEARING

2407HC2

2707HC

LIFT BLOCK

2474HC

THREADED PIVOT

2708HC

LIFT BLOCK

(3) 2408HC

LEVELING SCREWS

2757HC

UPPER CYLINDER

SUPPORT

2709HC

CYLINDER MOUNTING

BRACKET

2756HC

LOWER CYLINDER

SUPPORT

2407HC2

SLEEVE BEARING

2481HC2

SUPPORT ROD

(2) 2706HC11 LIFT BRACKET

2705HC LIFT NUT

SN7516HX HEX NUT

(2) 2394HC SPACER

(4) SW25NL WASHER

(4) SB2528SC08 SCREW

A2760HC4

PNEUMATIC LIFT PKG

A2755HC

BASE ASSEMBLY

(4) 2408HC

LEVELING SCREW

www.parrinst.com

27

Page 28

395M R06 04/24/14

Loading...

Loading...