Page 1

Sealing Instructions for 44HC5 and

44HC6 Metal Gaskets

273M

A torque-wrench should be used to tighten the cap screws and seal the reactor.

The torque required to pre-load the metal

gasket is a function of the operating pressure of the bomb.

Table 1 provides recommended torque

levels.

To insure uniform loading, level the head

of the vessel and turn each of the cap

screws fi nger tight. Then use the following procedure when tightening with a

torque wrench.

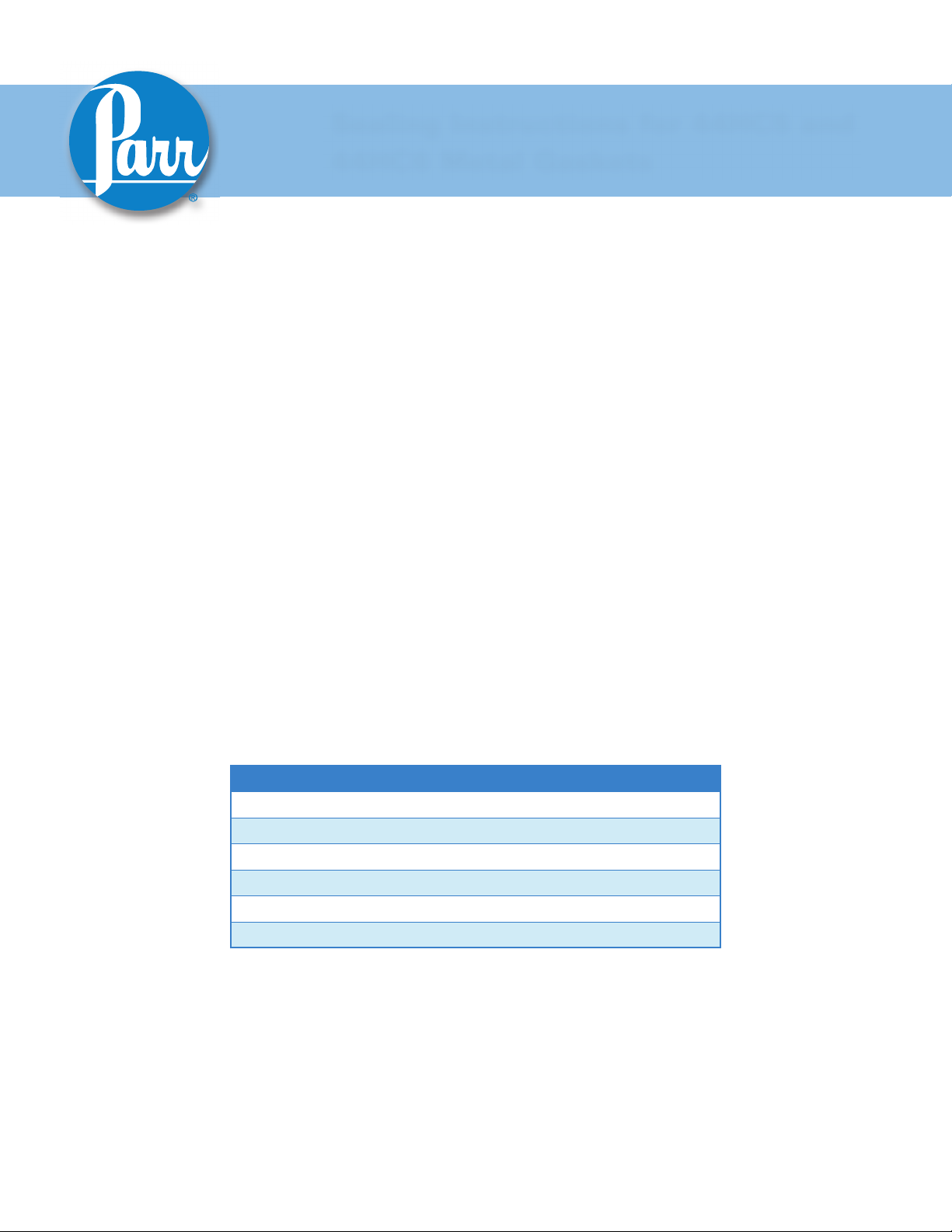

Table 1

Recommended Bolt-Torque for 44HC5 and 44HC6 Metal Gaskets

Pick a starting screw and tighten it to

approximately 5 ft-lb. Then by-pass the

adjacent screw and move around the

closure to a screw approximately 180 degrees from the start. Torque the second

screw and continue in the same pattern

until all screws are snug at 5 ft-lb. Repeat

this procedure increasing the torque in

5 ft-lb increments until the torque level

shown in Table 1 is reached.

Repeated use of the metal gasket may require increased bolt torque up to a maximum of 50 ft-lb. When the gasket does

not seal with 50 ft-lb torque it should be

replaced.

Revision 09/26/12

Pressure (psi) Torque (ft-lb)

2000 10

3000 10

4000 15

5000 25

6000 35

Maximum Torque 50 ft-lb

P

arr Instrument Company

211 53rd Street • Moline, Illinois 61265 USA 1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail: parr@parrinst.com • http://www.parrinst.com

Loading...

Loading...