Page 1

3900

Hydrogenation Apparatus

Operating Instruction Manual

271M

3910 Hydrogenation Apparatus

3920 Hydrogenation Apparatus

Page 2

Table of Contents

Table of Contents

Preface

Scope — 3

Related Instructions — 3

Safety Information — 3

Explanation of Symbols — 4

General Specifi cations — 4

Environmental Conditions — 4

Provisions for Lifting and Carrying — 4

Intended Usage — 5

The User’s Responsibility — 5

Unpack Carefully — 5

Cleaning & Maintenance — 5

Assembly Instructions — 6

Operating Procedure — 7

Standardization — 7

Pressure Limits — 8

Safety Barricades — 8

General Precautions — 8

Catalysts — 9

Bottle Heater — 9

Water Jacket — 9

Temperature Measurement and

Control — 10

Semi-micro Operations — 11

Alternate Parts — 11

Maintenance Instructions

Fuse Ratings — 11

Special Instructions for the 3921

Hydrogenator

Motor and Gear Box — 12

Bottle Connectors — 12

Glass Reaction Bottles — 12

Stainless Steel Bottle — 13

Bottle Heater — 14

Temperature Measurement — 14

References — 14

Parts Lists

3910 Hydrogenation Apparatus — 16

3920 Hydrogenation Apparatus — 18

Bottle Clamp Assembly - Series 3910 — 20

Shaker Column Assembly - Series 3910 — 21

Flywheel Assembly - Series 3910 — 22

Connecting Rod Assembly - Series 3920 — 23

AA92CA Single Valve Assembly — 24

3A93CA Double Valve Assembly — 25

3910 Wiring Schematic — 26

3920 Wiring Schematic — 27

Explosion Proof Switch Assembly for 1765EEG 115V Series 3910 — 28

Explosion Proof Switch Assembly for 1765EEK 220V -

Series 3910 — 29

Explosion Proof Switch Assembly for A388EEG 115V

& 220V - Series 3920 — 30

Explosion Proof Switch Assembly for A388EEK 220V -

Series 3920 — 31

Thermocouple Assemblies — 32

Reaction Bottles for Parr Hydrogenators — 33

Heating Mantles — 33

Air Motor Assembly — 34

Switch Box Assembly 115V — 35

Switch Box Assembly 230V — 35

Customer Service:

Questions concerning the installation or operation of this instrument

can be answered by the Parr Customer Service Department:

1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail: parr@parrinst.com • http://www.parrinst.com

2

Parr Instrument Company

Page 3

Product Line

Preface

Scope

These instructions describe the installation, operation and maintenance of Parr 3911 or 3921 Hydro-

genators offered with bottle sizes of 250, 500, 1000,

1700, 2000 or 2250 mL. They cover the basic steps

to be followed when installing these reactors and

describe the function of all standard components.

They are intended to be used in conjunction with

several related instruction sheets listed below. This

information describes several components that are

common to most Parr pressure reaction equipment,

and includes safety precautions and other related

information applicable to all reaction laboratories.

The users should study all of these instructions

carefully before starting to use these hydrogenators

so that they will fully understand the capabilities

and limitations of the equipment.

Related Instructions

The following Parr publication is also included to

further your understanding of this instrument and

its component parts:

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current handling capability.

2. Ensure that the equipment is connected to electrical service according to local national electri-

cal codes. Failure to properly connect may create

a fi re or shock hazard.

3. For continued protection against possible haz-

ard, replace fuses with same type and rating of

fuse.

4. Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of fl ammable or com-

bustible materials; fi re or explosion may result.

This device contains components which may

ignite such material.

2. Refer servicing to qualifi ed personnel.

No. Description

201M Limited Warranty

311M Supplemental Instructions for the Parr

4833 Controller

448M CAL 9500P Manual

www.parrinst.com

3

Page 4

Hydrogenation Apparatus

Explanation of Symbols

I On Position

O Off Position

This CAUTION symbol may be present on the Product Instrumentation

and literature. If present on the product, the user must consult the appropriate part of the accompanying product literature for more information.

This CAUTION symbol indicates that the surface may be hot.

Protective Earth (PE) terminal. Provided for connection of the protec-

tive earth (green or green/yellow) supply system conductor.

General Specifi cations

Electrical Ratings

3911 & 3921 Rated:

115 Vac, 60 Hz, 8.0 Amps or

115 Vac, 60 Hz, 3.6 Amps or

115 Vac, 60 Hz, 3.3 Amps or

230 Vac, 50 Hz, 2.1 Amps or

230 Vac, 50 Hz, 8.0 Amps

The electrical ratings are identifi ed on the data plate

of the instrument.

Before connecting any Parr Hydrogenation Apparatus to an electrical outlet, the user must be certain

that the electrical outlet has an earth ground connection and that the line, load and other character-

istics of the installation do not exceed the following

limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: Hydrogenation apparatus can be oper-

ated from a 50 or 60 Hertz power supply without

affecting the apparatus. The frequency ratings are

identifi ed on the data plate of the instrument.

Environmental Conditions

This apparatus is to be used indoors.

Operating: 10 ºC to 35 ºC; maximum relative humidity of 80% non-condensing. Installation Category II

(over voltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 ºC to 65 ºC; 10% to 85% relative humidity.

Electromagnetic Compatibility In accordance with

2004/108/EC.

Provisions for Lifting and Carrying

The 3900 Series Hydrogenation Apparatus and its

components are very heavy. Before moving ensure

all cables are disconnected. Use proper and safe

lifting techniques when installing or moving the ap-

paratus and/or its components.

CAUTION!

Do not use in hazardous atmospheres.

Current: The total current drawn should not exceed

the rating shown on the data plate by more than 10

percent.

4

Parr Instrument Company

Page 5

Hydrogenation Apparatus

Intended Usage

This apparatus has been designed, built, and tested

to strict physical and electrical standards. However,

it is the user’s responsibility to install and operate

it in conformance with local pressure and electrical

codes. If this equipment is used in a manner beyond its intended usage, the protection provided by

the equipment may be impaired.

The User’s Responsibility

The user must realize that it is their responsibility

to keep their equipment in good condition and to

use it only within the prescribed temperature and

pressure limits. They must be constantly aware of

the serious consequences that can result from such

things as: opening the wrong valve, mixing combustible vapors with air or oxidizing gases, adding

reactants too fast or failing to observe and prevent

sudden increases in temperature or pressure. Qualifi ed personnel should make frequent checks to be

sure that all safety rules are being observed. In the

absence of a supervised safety program the user

must take time to become completely familiar with

their equipment and to consider any hazards inherent in the reactions they intend to perform.

Unpack Carefully

Unpack the equipment carefully and check all the

parts against the packing list. If shipping damage

is discovered, report it immediately to the deliver-

ing carriers. Examine the components closely for

any loose parts or shipping damage and be sure to

check all layers of packing materials thoroughly so

as not to overlook any parts which might otherwise

be discarded.

Cleaning & Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the instrument with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected when cleaning the instrument.

There are no user serviceable parts inside the product other than what is specifi cally called out and

discussed in this manual. Advanced troubleshooting

instructions beyond the scope of this manual can

be obtained by calling Parr Instrument Company in

order to determine which part(s) may be replaced or

serviced.

CAUTION!

Ensure that any hot surfaces have had

adequate time to cool before cleaning or

maintaining the hydrogenation apparatus

and/or its components.

www.parrinst.com

5

Page 6

Hydrogenation Apparatus

Assembly Instructions

Rinse or blow air through the hydrogen tank to

remove any dust or foreign material. Likewise, blow

out the gas hose and valves to be sure that they are

dust-free and clean.

Set the apparatus on a sturdy bench or table where

there is convenient access to an electrical outlet with

the appropriate supply voltage and current ratings

in accordance with national and local electrical code

requirements. The supply voltage must not exceed

the marked nominal voltage shown on the instru-

ment by more than 10%. The supply voltage recep-

tacle must have an earth ground connection.

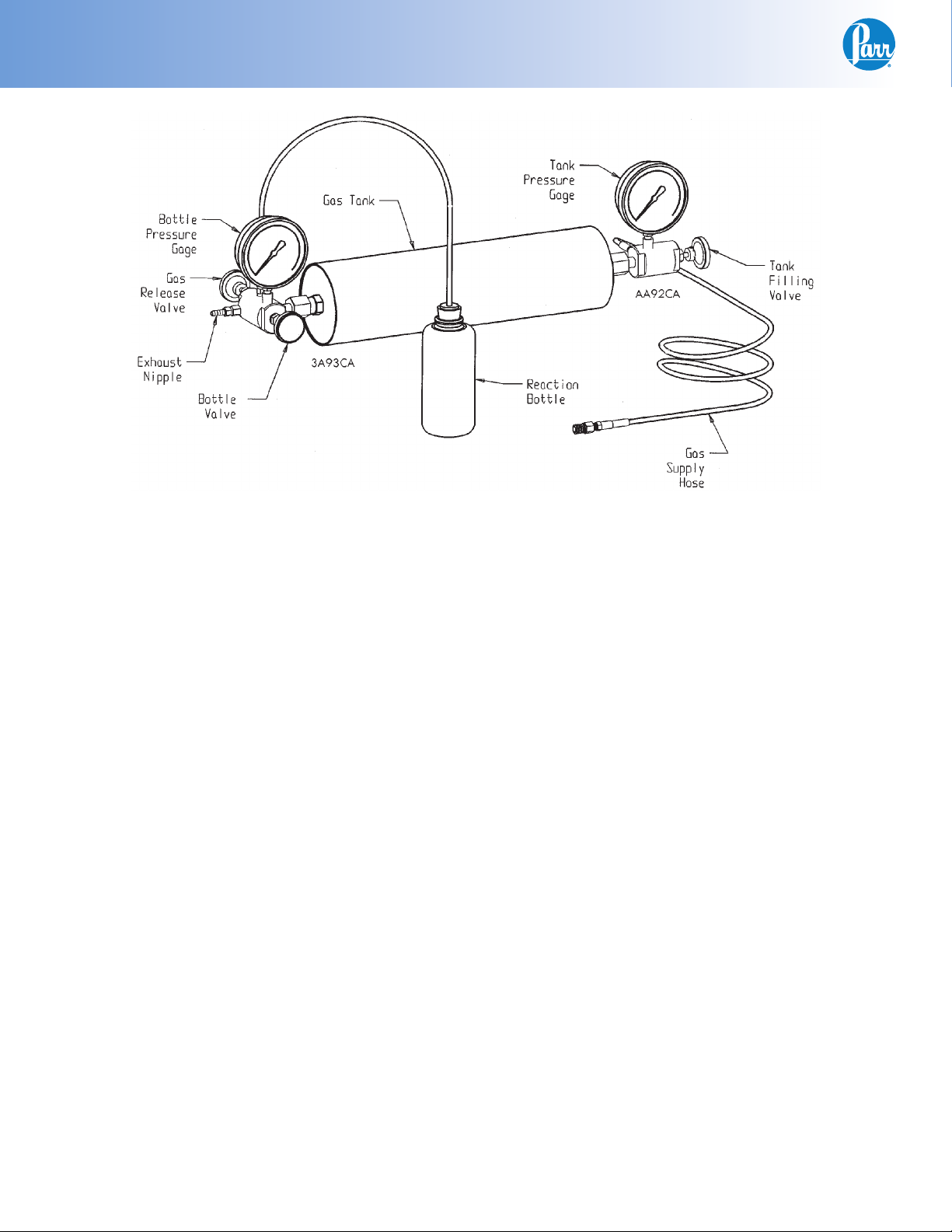

Attach the valves to the hydrogen tank and tighten

the couplings fi rmly with a wrench. This tank is fi lled

through the AA92CA valve which is attached to the

right end. The gage on this valve shows the tank

pressure when the valve is closed. The gage on the

3A93CA valve at the left end of the tank shows the

pressure in the reaction bottle and connecting tube.

The front knob on the 3A93CA valve controls the

fl ow of gas from the tank to the bottle. The rear knob

at the opposite end of the block is used when discharging gas from the bottle or when evacuating the

bottle through the hose nipple.

A 6-ft hose (A118CA) is furnished for connecting the

apparatus to the pressure regulator or needle valve

on a commercial hydrogen tank. Screw one end of

the hose into the socket in the AA92CA valve and

connect the other end to the pressure regulator or

tank valve. The 1/8” NPT pipe threads on the ends of

the pressure hose should be coated with Tefl on tape,

plastic lead or other thread dope to ensure tight

seals. The 1/8” to 1/4” bushing can be removed from

the hose if it is not required but do not unscrew the

fi ttings which anchor the end nipples to the hose

itself.

Before using a new apparatus for the fi rst time,

assemble it with an empty bottle and test for gas

leaks, as follows: Fill the tank with hydrogen to

40 psig; then close the tank fi lling valve. Open the

bottle valve and allow the full tank pressure into

the bottle; then close the bottle valve. The tank and

bottle gages should now read the same. Record

these pressures and continue to observe them over

a period of four to six hours. The pressures should

remain constant throughout this period unless there

is a signifi cant change in room temperature. If a

noticeable drop is observed in either gage, fi nd and

correct the leak before starting to use the apparatus.

Any leaks can usually be detected by brushing the

joints with a soap solution.

The 25-inch length of polypropylene tubing leading

to the reaction bottle must be fi rmly connected to

the outlet fi tting on the 3A93CA valve. No special

clamps or fi ttings are required to fasten this tube

into the bottle stopper. Simply slide the end of the

tube through the 61CA4 washer and through the

166CA retaining ring, then push the tube through

the one-hole Neoprene stopper leaving a projection

of about one inch below the bottom of the stopper.

Slide the safety screen over the bottle; place the

bottle into the holder and tighten the thumb nuts on

the ends of the two tie rods. The clamping pressure

developed by the thumb nuts will hold the bottle in

the shaker mechanism and it will also anchor the

connecting tube in the stopper.

6

Parr Instrument Company

Page 7

Hydrogenation Apparatus

Operating Procedure

Samples to be treated in a Parr hydrogenator are

placed in a reaction bottle with a catalyst and

clamped in a shaking mechanism. A gas connection

is made to the bottle from a multiple valve and all

air is removed either by evacuation or by fl ushing

with hydrogen. Hydrogen is then introduced from

a 4-liter reservoir while the bottle is shaken vigor-

ously to initiate the reaction. Heating or cooling can

be applied, if necessary. After the reaction reaches

the desired point the shaker is stopped, the bottle

vented and the product and catalyst are recovered.

The individual steps in this operating procedure are

listed below. These can be varied to suit each individual application.

1. Place the catalyst, solvent and sample in the

reaction bottle, adding the catalyst fi rst to avoid

possible vapor ignition by the dry catalyst. The

total volume of solution should not exceed two-

thirds the capacity of the bottle.

2. Attach the stopper with connecting tube and

slide the bottle into the guard screen, then set

the assembly in the bottle holder and tighten the

knurled clamping nuts.

3. If air is removed from the bottle by evacuation, attach a vacuum hose to the nipple on the

3A93CA valve; close the bottle valve: open the

gas release valve and evacuate until the solvent

starts to boil. If a low boiling solvent is not used,

evacuate to a negative pressure suffi cient to

remove most of the air. Air can also be removed

by alternately fi lling the bottle with hydrogen to

20 or 30 psig. and venting it at least three times.

After purging the bottle, close the gas release

valve and leave it closed throughout the run.

4. Starting with the hydrogen tank fi lled to 30

psig. open the bottle valve and read the bottle

pressure gage after equilibrium has been established.

5. Start the shaker and follow the progress of the

reaction by observing the bottle pressure gage.

If complete hydrogenation is desired, continue

shaking until there is no further pressure drop.

For partial or quantitative hydrogenation, contin-

ue shaking until the pressure drops to a calculated value as determined by prior standardization

runs.

6. At the end of the run, stop the shaker; close

the bottle valve and allow the catalyst to settle.

Any residual pressure in the bottle and connecting tube can be discharged by opening the gas

release valve.

7. Open the bottle clamp and remove the bottle.

Decant the solution leaving the catalyst in the

bottle for a second reduction, or remove the

catalyst on a fi lter.

Standardization

The apparatus can be standardized by making a

preliminary run with a known amount of any compound that can be completely and quantitatively

reduced. The pressure drop per mole of hydrogen

consumed in such tests is then used as a basis for

estimating the progress of a reaction with unfamiliar materials. A procedure is described in reference

(3) for standardizing the apparatus by reducing 11.6

grams (0. 1 mole) of pure maleic acid dissolved in

150 mL of 95% ethanol using 0.1 gram of catalyst.

The reaction is carried out as previously described

with shaking continued until no more hydrogen is

consumed. This usually takes twenty to thirty minutes, after which the pressure drop in the tank is

recorded. Since exactly 0.1 mole of hydrogen has

been consumed in this run, this decrease in tank

pressure can be used as a basis for measuring or

regulating the amount of hydrogen consumed when

treating other compounds.

Standardization tests are not limited to runs with

maleic acid. Fumaric acid is equally suitable for

this purpose, or any other pure compound can be

used provided that it is completely or quantitatively

reduced. If the intended usage for the apparatus

involves the consumption of only a small amount

of hydrogen, the apparatus can be standardized

with the tank valve closed. The gage will then give a

more signifi cant reading as gas is consumed from

the connecting tube and bottle alone while these

parts are isolated from the tank.

www.parrinst.com

7

Page 8

Hydrogenation Apparatus

Gas Tank and Valve System

Pressure Limits

The use of glass bottles in these reactors introduces

certain pressure limitations and a potential hazard

which the user must understand. Although each

bottle is pressure tested before it is sold, the physical characteristics of glass are such that it is impossible to guarantee these bottles against breakage

or to predict their service life. For this reason, each

apparatus is equipped with a bottle shield to restrain

fl ying glass in case of breakage. The user must take

whatever additional precautions he considers necessary to protect himself from injury in case a bottle

should unexpectedly fail. Working pressures should

never exceed 60 psig when using either 250 or 500

mL bottles in the 3911 apparatus, and never more

than 40 psi for one liter bottle and 30 psi for two liter

bottle in the 3921 apparatus.

Safety Barricades

If a barricade is used it should be built of concrete,

brick or steel in whatever thickness or form is considered necessary to protect the operator from fl y-

ing fragments if the reaction bottle should explode.

Glass shields, either plain or reinforced with wire

mesh, are not recommended. The requirements

for barricades differ so widely that each should be

designed and built in order to protect against the

potential hazards inherent in each installation. This

subject is well covered in the references listed on

page 15.

General Precautions

Pressure reactions with hydrogen are not unduly

hazardous if the user maintains his hydrogenator in

good condition and operates it with the realization

that hydrogen is highly fl ammable and that pressures and reaction rates must be carefully controlled

at all times.

Parr shaker type hydrogenators are usually operated

in an open laboratory without additional barricades

or protective screens, but the operator must realize

that additional protection may be necessary if there

is any possibility that a reaction might run out of

control, or if unexpected bottle breakage would produce a hazardous spill of toxic or fl ammable materials. Potentially explosive reactions are best handled

with the apparatus located behind a suitable barricade or in a pressure test cell.

8

Parr Instrument Company

All catalysts must be handled cautiously because of

their highly reactive nature. Do not add dry catalyst

to a bottle containing a fl ammable solution or vapor.

The vapor might ignite. Instead, add the catalyst

fi rst and cover it immediately with the sample in

solution. Precautions must also be taken to wash the

catalyst from the thermocouple, the inlet tube and

the stopper when opening the bottle. Any catalyst

left on these parts may ignite when exposed to the

Page 9

Hydrogenation Apparatus

air. If breakage or spills occur, fl ush the contaminated area immediately with large volumes of water

and keep the area wet until all traces of catalyst

have been removed.

Vacuum fi ltration through a paper fi lter can be

dangerous if air is drawn through the fi lter in the

presence of a catalyst. To reduce this hazard, keep

the paper covered with solution while it is under

suction, or use a fi lter made of a non-fl ammable

material.

Care must be taken to keep the apparatus free of impurities which might poison the catalyst. Although

a small amount of air trapped in the bottle will not

interfere with most hydrogenations, the reaction

rate can sometimes be improved by evacuating the

bottle before adding hydrogen. Or the air can be

removed by fi lling the bottle with hydrogen to 20

or 30 psig and venting it at least three times before

starting the shaker.

If the reaction proceeds too rapidly it can usually

be checked by stopping the shaker. If overheating

becomes a dangerous problem, the bottle can be

cooled by using the A103CA water jacket described

below.

There should be no gas burners or open fl ames near

a hydrogenation apparatus. The room must be well

ventilated and any gas released from the apparatus

should be discharged into an explosion proof hood

or ventilating duct. Care must be taken to prevent

ignition by a static charge from an insulated object.

For this reason, a good ground connection through

the power cord or directly to the base of the apparatus must be maintained at all times.

Loss of gas is an annoying factor which can be

avoided by careful maintenance and frequent test-

ing. It should not be necessary to use extreme force

to close any of the valves on this apparatus. If a

tight seal cannot be secured without a hard turn on

the valve handle, dismantle the valve and replace

the 20VB valve seat and any other worn or damaged

parts. If the valve leaks through the packing, back

the needle away from its seat and tighten the 8VB2

packing nut. If this does not stop the leak replace the

4VB3 packing rings.

Catalysts

The most active catalysts for hydrogenation reactions in this apparatus are made of platinum and

palladium. A hydrated platinum oxide, often called

Adams catalyst, is used in many procedures. This

is prepared by drying and heating chloroplatinic

acid in air to form a brown oxide which can then be

reduced to the more active black form by shaking

with hydrogen either before or after mixing with the

sample. Instructions for preparing this and other

catalysts are given in the references on page 15.

Raney nickel is used in certain procedures but other

less active nickel catalysts require pressures outside

the range of this apparatus. Platinum oxide and

other catalytic chemicals can be obtained from most

laboratory supply houses.

Bottle Heater

Bottle temperatures up to 80 ° C can be developed

in the 3911 Hydrogenator by wrapping a glass fabric

heating mantle (A450E) around the 500 mL bottle.

The mantle then takes the place of the perforated

metal guard screen. No special fi ttings are needed

for attaching this heater. Simply wrap the mantle

tightly around the bottle and run the connecting

cord through the slot in the bottle clamp. Use the

plastic cable clip (453E) furnished with the heater

to anchor the heater cord to the top of the bottle

clamp, then run the cord out from the shaker pivot,

arranging it for minimum fl exing when the shaker is

operating.

Water Jacket

The 500 mL reaction bottle can be

cooled while it is clamped in the

shaker mechanism by installing an

A103CA water jacket. This jacket fi ts

into the bottle clamp in place of the

65CA perforated steel guard. A soft

rubber ring seals the neck of the

bottle into the jacket. The only change

required when adding a water jacket

is to use the special cut-down stop-

per which is furnished, or cut 1/4 inch

from the top of the regular 62CA stopper to shorten

the overall height of the combined assembly. Always install the soft rubber sealing ring with the

large diameter downward and the smaller diameter

at the top: otherwise it will be very diffi cult to remove the bottle from the cooling jacket.

A103CA

Water Jacket

www.parrinst.com

9

Page 10

Hydrogenation Apparatus

Temperature Measurement and Control

4833 Temperature Controller

Reaction temperatures can be measured and con-

trolled with a Parr 4833 Temperature Controller

which operates with an A295E, Type J (iron-constan-

tan) thermocouple installed in the reaction bottle.

The thermocouple is sealed in an 1/8” diameter

stainless steel sheath and held in an A159CA bottle

connector assembly which carries both the probe

and the gas passage through a single opening in

the bottle stopper. A295E thermocouples are made

in two lengths to fi t different bottle sizes as listed on

page 30.

To install the A159CA bottle connector, remove the

existing gas inlet tube and fi ttings and install the

new fi ttings which are provided. Clamp the bottle in

the shaker with the thermocouple positioned so that

the tip of the probe reaches a point three-fourths of

the distance from the neck of the bottle. This distance can be changed by loosening the cap nut at

the top of the connector and sliding the probe up or

down in the tee fi tting.

Loop the thermocouple wire downward and fasten it

above the tee fi tting using one of the cable ties furnished with the bottle connector; then run the wire

along the polypropylene tube, fastening it fi rmly

to the tube at several points to prevent excessive

fl exing and breakage. Bring the bottle heater cord

upward and fasten it under the clip at the top of the

shaker; then run the cord parallel to the shaker pivots and plug it into the heater socket on the controller.

To activate the heater, plug the thermocouple and

the heating mantle into sockets on the rear panel

of the controller, and connect the controller to an

electric supply that corresponds to the voltage of

the heater. Turn the DISPLAY and HEATER switches

ON, and set the controller to the desired operating

temperature using the UP and DOWN arrow keys

on the front of the controller module. The indicator

light in the heater switch will illuminate when the

switch is ON and current is being supplied to the

heater. The set point can be changed at any time

regardless of whether the heater is on or off. Copies

of Parr Bulletin 311M, Supplemental Instructions for

the 4833 Controller, and the CAL-9500 User’s Manual

furnished with the 4833 Controller provides instruc-

tions for tuning the Controller and using the alarm

features.

The 4833 Temperature Controller has dual displays:

one for the process temperature and the other for

the set point. The operating range of the Controller

covers the span from 0 ° to 100 ° C with the high

limit extending somewhat beyond the temperature

limit for the 3911 and 3921 Hydrogenators. These hydrogenators should not be operated at temperatures

above 80 ° C.

The 4833 Controller is sensitive to temperature

changes of less than 0.5 ° C but temperature varia-

tions in the reaction bottle may be larger than this

due to lag in the heating system and turbulence in

the bottle. In most cases temperatures in a 500 mL

bottle will not vary by more than one degree above

or below the set point. Variations in larger bottles

may run as much as two degrees, but this is still

within permissible limits for most reactions. Bottle

temperatures will tend to overshoot at low tempera-

tures in the 30° to 40° range. There will be less over-

shoot at higher settings. Overshoot can be avoided

by setting the controller several degrees low during

the initial period, then raising the temperature in

one or two steps after cycling has been established

slightly below the working level.

Fail-safe protection against a thermocouple break

is provided in the controller. This can be tested by

disconnecting the thermocouple from the controller,

which should turn off the heater.

10

Parr Instrument Company

Page 11

Hydrogenation Apparatus

Semi-micro Operations

Small samples can be treated in a 3911 Hydrogena-

tor by replacing the standard 500 mL bottle with

a smaller 250 mL bottle (66CA2). This requires a

101CA2 spacer to compensate for the difference in

bottle heights. To install the 250 mL bottle, remove

the stopper and the 61CA4 washer from the gas

inlet tube and slide the 101CA2 spacer onto the tube,

then clamp the bottle and spacer in the holder in

the usual manner. Since small samples may require

only small amounts of hydrogen, it may be advantageous to replace the standard four liter hydrogen

tank with an alternate one liter tank (A16CA2) for

semi-micro operations. The same tank valves are

used on both sizes and are easily transferred to the

small tank.

Augustine (reference 1 on page 15) describes an

interesting holder for handling small samples in a

3911 Hydrogenator which he prepares by sealing a

50 mL or smaller heavy walled fl ask inside a larger

bottle.

Alternate Parts

If bottle pressure measurements are not required,

the gage can be removed from the 3A93CA valve

assembly and replaced with a 94CA plug.

Tefl on tubing can be furnished in place of the standard 119CA polypropylene tube for use with chemicals which might attack polypropylene. The same

fi ttings are used to attach either Tefl on or polypropylene tubing to the 3A93CA valve.

about once a month. Lubricate the fl ywheel shaft

by placing a few drops of light oil in the oil cup at

regular intervals. A light application of a lithium

grease such as “Lubriplate” on the shaker pivots is

also advisable. The spacing of these pivots should

be adjusted so that the bottle clamp swings freely

without excessive friction.

To inspect and replace the valves, unscrew the 8VB2

packing nut and remove the needle and knob. The

internal parts can then be removed with a small

wire hook. These will come out in the following se-

quence: 6VB packing cover, two 4VB3 packing rings,

21VB lantern ring, and 20VB valve seat. If the plastic

valve seat will not slide out of its socket, use a 1

1/2” wood screw as a removal tool. Replace these

parts in the same order; insert the valve needle and

tighten the 8VB2 packing nut fi rmly with a wrench.

Caution: Always back the valve needle away from its

seat before tightening the packing nut.

It will be necessary to use a new plastic ferrule in

the A102CA connector whenever a new polypropylene tube is installed. A new A102CA connector is

furnished with each replacement A154CA polypro-

pylene tube so that a complete set of parts will be

available when changing tubes. If the body and cap

nut in the old connection are in good condition they

can be used with the ferrule from the new connector. But if there is any question about the old parts,

discard them and install a new connector. The steps

required to attach the tube to the connector are as

follows: Be sure that the end of the tube has been

cut squarely; then disassemble the connector and

slide the cap nut and ferrule onto the tube. Insert the

tube into the connector body and tighten the cap

nut fi rmly.

Maintenance Instructions

Periodic cleaning may be performed on the exterior

surfaces of the instrument with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected when cleaning the instrument. There are no user serviceable parts inside the

product other than what is specifi cally called out

and discussed in this manual. Advanced troubleshooting instructions beyond the scope of this

manual can be obtained by calling Parr Instrument

Company in order to determine which part(s) may

be replaced or serviced.

The connecting rod has oil-impregnated bronze

bearings which do not require heavy lubrication.

Place a drop or two of light oil on each bearing

Fuse Ratings

The replacement of protective fuses should be performed by qualifi ed personnel.

Parr No. Type Ratings

139E21 Slo-blo 5 Amps, 250 Vac

139E20 Slo-blo 4 Amps, 250 Vac

139E8 Slo-blo 2.5 Amps, 250 Vac

139E25 Slo-blo 10 Amps, 250 Vac

139E26 Slo-blo 6 Amps, 250 Vac

Note: Check the labels on Switch Box for correct fuse rating.

www.parrinst.com

11

Page 12

Hydrogenation Apparatus

Special Instructions for the 3921 Hydrogenator

Customer installed location of

Blue Plastic Vent Plug

All instructions given in the preceding sections of

this Manual apply equally to both the 3911 and 3921

Hydrogenators. Both models use the same hydrogen tank and valves, but the 3921 apparatus has a

larger and heavier bottle clamp and shaker mechanism to accommodate larger reaction bottles.

Motor and Gear Box

Before starting the motor, replace the uppermost

pipe plug on the gearbox with the blue plastic vent

plug which is furnished. The hole in the vent plug

must point up. See Boston gear instruction sheets

for lubricating instructions.

Bottle Connectors

Attach the valves to the gas tank and connect the

polypropylene tube to the reaction bottle by slid-

ing the tube through the 82CA2 washer and 166CA

retaining ring, then push the tube through the bottle

stopper leaving a projection of about one inch below the stopper. To complete the assembly, set the

bottle on top of the rubber pad in the holder: slide

the tube through the slot in the clamping screw and

tighten the screw fi rmly. Always attach the steel

guard screen to the front of the bottle holder before

pressurizing the bottle.

An 80CA2 spacer must be placed between the

clamping screw and the stopper to compensate for

the difference in bottle heights when using a 1000

mL bottle, Assemble the inlet tube with the 80CA2

spacer and 166CA retaining ring above the stopper

and clamp the bottle in the shaker in the usual man-

ner. The 82CA2 washer is not required when using a

spacer.

Glass Reaction Bottles

The 1000 and 2000 mL reaction bottles (71CA and

72CA) supplied with this apparatus have been

individually pressure tested to 80 psig and 60 psig

respectively. In spite of these tests, the Parr Instrument Company cannot guarantee that these bottles

will not break at lower pressures. The user must

therefore be constantly aware of the hazards involved in handling large volumes of liquids in glass

bottles under pressure, and he must take whatever

precautions he considers necessary to protect him-

self from injury in case a bottle should unexpect-

edly fail. It is recommended that working pressures

in these 1000 and 2000 mL bottles should never

exceed 40 psi and 30 psi respectively. Pressures

should be held below this maximum whenever pos-

sible.

12

Parr Instrument Company

Page 13

Alternate 1000 and 2000 mL reaction bottles with

a fi berglass covering (71CA2 and 72CA3) can be

furnished for the 3921 Hydrogenator. These coated

bottles are no stronger than the plain bottles, but

the fi berglass envelope will usually retain any

broken glass and prevent the loss of valuable reac-

tants in case of accidental breakage. The maximum

working pressures mentioned above applies to both

plain and coated bottles alike. Both styles use the

same connecting tube and fi ttings.

If higher pressures up to 60 psig are required for

treating large amounts of reactants, users are urged

to purchase the special 2500 mL heavy duty bottle

(72CA4) which is made specifi cally for this purpose.

This is a hand blown, borosilicate glass bottle with

an extra heavy wall which is much stronger than the

standard machine-made bottles.

Stainless Steel Bottle

Hydrogenation Apparatus

The breakage hazard which is always present when

using glass bottles can be eliminated by substituting

a 1700 mL stainless steel reaction bottle which can

be used at working pressures up to 60 psig maxi-

mum. The complete stainless steel bottle assembly

with cover, spacer spool, connecting tube and fi ttings can be ordered under Cat. No. A129CA3.

To install the stainless bottle, slide the 133CA2

spacer spool onto the polypropylene tube with the

parts arranged so that the plain end of the spool will

rest on the cover, leaving the shallow depression in

the other end of the spool to engage the clamping

screw. Attach the O-ring to the cover, close the bottle

and slide the assembly into the holder. Tighten the

clamping screw and attach the guard screen before

pressurizing the bottle.

A129CA3 Stainless Steel Bottle Assembly

www.parrinst.com

13

Page 14

Hydrogenation Apparatus

Bottle Heater

The 71CA one liter bottle, 72CA two liter bottle

and the A129CA3 stainless bottle assembly may

be heated in the 3921 Hydrogenator by wrapping

a glass fabric heating mantle (A451E) around the

bottle. No special fi ttings are needed for attaching

this heater. Simply wrap the mantle tightly around

the bottle and run the connecting cord through the

slot in the top housing. Use the plastic clip furnished

with the heater to anchor the cord to the top edge of

the bottle clamp: then run the cord out laterally on

the axis of the shaker, arranging it to avoid excessive fl exing when the shaker is operating.

Note: Connect cord to temperature controller

to control operations of heater. See page 10 for

instructions on Parr’s temperature controller and

thermocouple.

The 72CA4 heavy wall bottle should not be used

with the heating mantle because the heat will destroy the protective polyvinyl coating on the bottle.

Temperature Measurement

Temperatures in the reaction bottle can be measured by installing a stainless sheathed thermocouple using the same fi ttings described for the 3911

Hydrogenator on page 10, but with a longer sheath

on the thermocouple to match the larger bottles. The

various assemblies are identifi ed in the Parts List on

page 30.

References

No attempt is made here to list the hundreds of

references to the Parr hydrogenator which have appeared in chemical literature since Dr. Roger Adams

published his fi rst paper describing an apparatus of

this kind in 1923. More than fi ve hundred literature

references are cited in Augustine’s book on Catalytic

Hydrogenation which is listed below. Additional

references can be obtained from other books in

this list. Among these, the books by Augustine,

Freifelder and Rylander will be particularly help-

ful to those users who want additional information

regarding hydrogenation techniques, catalysts and

procedures for treating specifi c functional groups.

The following references are therefore highly recommended:

R.L. Augustine, Catalytic Hydrogenation, Marcel

Dekker, Inc.: New York , 1965.

Morris Freifelder, Practical Catalytic Hydrogenation,

Wiley-Interscience Div. of John Wiley & Sons, Inc.:

New York, 1971.

Gilman-Blatt, Organic Synthesis, Collective Volume I,

p. 65, John Wiley & Sons, Inc.: New York, 1948.

H.W. Lohse, Catalytic Chemistry, Chemical Publish-

ing Co., Inc.: New York, l945.

Paul N. Rylander, Catalytic Hydrogenation Over

Platinum Metals, Academic Press: New York, 1967.

14

Paul N. Rylander, Catalytic Hydrogenation in Organic

Synthesis, Academic Press: New York, 1979.

Paul N. Rylander, Hydrogenation Methods, Academ-

ic Press: New York, 1985.

Biennial conferences originally held at the New York

Academy of Sciences and now in a variety of locations by ORCS (Organic Reaction Catalysis Society)

in even-numbered years starting in 1966 have pro-

duced excellent collections of papers under the gen-

eral title, Catalytic Hydrogenation and Analogous

Pressure Reactions. The initial set is published in the

Annals of The New York Academy of Sciences, Vol.

145, Art. 1, pp. 1-206, 1967. Currently titled Catalysis

of Organic Reactions published by Marcel Dekker,

Inc.: New York.

Parr Instrument Company

Page 15

Notes

www.parrinst.com

15

Page 16

Hydrogenation Apparatus

Parts Lists

15

6

7

5

8

14

8

4

12

9

13

11

21

10

17

(4 PL)

16

3

(4 PL)

2

31

19

20

22

(2 PL)

45

(2 PL)

44

(4 PL)

24

(4 PL)

26

54

(4 PL)1852

3910 Hydrogenation Apparatus

39 38

51

16 35

43

48

49

32

30

41

33

42

28

34

27

(2 PL)

17

29

17

40

37

37

(2 PL)

24

(2 PL)

26

36

23

16

25B 25E

25A

25C

25D 25

Parr Instrument Company

53

56

531

Page 17

Hydrogenation Apparatus

ITEM

NO.

1 221CA BASE PLATE 1

2 2CA2 SHAKER COLUMN 1

3 SB3118HX14 5/16-18 X 7/8 HHCS 8-18 SS 4

4 54CA BOTTLE CLAMP TOP 1

5 453E CLIP, 3/8 DIA TENSION CLEAR 1

6 SA1332RD04 6-32 X 1/4 RHMS SLOTTED 1

7 SW13FT #6 BOLT WASHER 18-8 SS 1

8 59CA KNURLED NUT, TIE ROD 2

9 A55CA TIE ROD SHORT ASSEMBLY 1

10 66CA REACTION BOTTLE 500ML 1

11 62CA

12 61CA4 WASHER, 1" ALUMINUM 1

13 166CA

14 101CA2 SPACER FOR 250ML BOTTLE 1

15 HL0025TB040 POLYPROPYLENE TUBE 2.08 FT

16 5CA3 PIVOT PIN 2

17 SC2520SC04 1/4-20 X 1/4 SHSS 18-8 SS 7

18 65CA BOTTLE GUARD T304, 500 mL 1

19 53CA2 BOTTLE CLAMP BASE 1

20 TD3118SC12 5/16 X 3/4 SH SHLD BOLT STEEL 1

21 56CA TIE ROD, LONG 1

22 SN3124HX 5/16-24 HEX JAM NUT 18-8 SS 1

23 1765EEF MOTOR 230/50 1/4HP 1425 RPM 1

24 SB3118HX10 5/16-18 X 5/8 HHCS 18-8 SS 6

25 X2291EB

25A 909E SWITCH, POWER 16AMP 1

25B 1471E

25C 911E FILTER, INTERFERENCE; 10AMP 1

25D 139E8

PART

NUMBER

221CA2 BASE PLATE (AIR) 1

221CA3 BASE PLATE (EXP) 1

66CATC REACTION BOTTLE 500ML PED 1

66CA2 REACTION BOTTLE 250ML 1

66CA2TC REACTION BOTTLE 250ML PED

65CA2 BOTTLE GUARD T304, 250 mL

1765EEA MOTOR 115/60 1/6 HP 1725 RPM 1

1765EEG

1765EEK

X2353 AIR MOTOR PACKAGE 3910 1

DESCRIPTION QTY

STOPPER, #6 NEOPRENE

1-HOLE

RETAINING RING; TRIANGLE

PUSH

MOTOR 115/60 EP 1/6HP

1725 RPM

MOTOR 230/50 EP 1/6HP

1425 RPM

SWITCH BOX PKG

115V(3910/3920)

CARRIER, FUSE 3AG 1/4 X

1-1/4

FUSE 3AG SLO-BLO 250V 2.5

AMP

1

1

1

1

1

1

2

ITEM

NO.

25E 139E26 FUSE SLO-BLO 6 AMP 250V 1

26 SW31FT 5/16 BOLT WASHER 18-8 SS 6

27 4CA BASE, ALUM FLYWHEEL 1

28 8CA3 FLYWHEEL W/SHAFT 1

29 18CA2 COLLAR W/SET SCREWS 1

30 A58CA

31 SR3118

32 19CA3 CRANK PIN W/NUT 1

33 SN2520HX 1/4-20 HEX JAM NUT 1

34 50CA OIL HOLE COVER 1

35 A16CA HYDROGEN TANK 4L T304SS 1

36 49CA TANK SUPPORT 1

37 XC0210 TRIM, PROTECTIVE BLACK 2

38 11CA TANK CLAMP 1

39 SB3118HX24 5/16-18 X 1-1/2 HHCS 18-8 SS 1

40 34CA3

41 37CA3 VEE BELT, NOTCHED 25" 1

42 SA3118FT14 5/16-18 X 7/8FHMS 18-8 SS 3

43 A150CA BELT GUARD 1

44 SA2520RD10 1/4-20 X 5/8 RHMS 18-8 SS 2

45 SW25NL

46 SW16NL

47 SA1632RD08 8-32 X 1/2 RHMS 18-8 SS 2

48 AA92CA SINGLE VALVE ASSY W/GAGE 1

49 A118CA GAS HOSE ASSY, NYLON, 6FT 1

51 3A93CA DOUBLE VALVE W/GAGE 1

52 64PR FOOT, RUBBER; W/ 1/4-20 THRD 4

53 328E7 HOLE PLUG 1/2 2

57 504HCAA

PART

NUMBER

139E21

139E20

X2291EE

A16CATC

A16CATD

DESCRIPTION QTY

FUSE 3AG SLO-BLO 250V 5.0

AMP

FUSE 3AG SLO-BLO 250V 4.0

AMP

SWITCH BOX PKG 230V

(3910/3920)

CONNECTING ROD ASSY W/

BUSHINGS

5/16 DIA X 1-1/8 ROLLPIN

420SS

HYDROGEN TANK 4L T304SS

PED

HYDROGEN TANK 4L T304

(CHINESE)

MOTOR PULLEY W/SET

SCREW

1/4 LOCK WASHER, INT TOOTH

410S

#8 LOCK WASHER INT TOOTH

410SS

REDUCING BUSHING,

1/8NPTF-1/4NPTM

1

2

1

1

1

1

1

1

2

2

1

www.parrinst.com

17

Page 18

Hydrogenation Apparatus

(2 PL)

58

60

38

37

54

40

53

52

51

41

(4 PL)

39

(10 PL)

30

31

32

26

(4 PL)

33

34

25

35

23

(4 PL)

6

5

8

22

42

46

42

43

45

(2 PL)

48

44

47

24

(4 PL)

5

19

20

21

(4 PL)

17

3920 Hydrogenation Apparatus

26

34

33

32

31

30

25

29

36

18

10

15

14

11

7

5

16

9

59

9

4

12

13

1

2

18

52 86550 49

(4 PL)

Parr Instrument Company

(2 PL) (2 PL)

6 8

5027 28

(4 PL)

49B

49C

49D49A

Page 19

Hydrogenation Apparatus

ITEM

NO.

1 73CA6 BASE PLATE 1

4 49CA TANK SUPPORT 1

5 SW31FT 5/16 BOLT WASHER 18-8 SS 12

6 TW31SL 5/16 LOCK WASHER STEEL PLATED 14

7 SB3118HX14 5/16-18 X 7/8 HHCS 18-8 SS 2

8 SN3118HX JAM NUT, 5/16-18 THD 7

9 XC0210 TRIM, PROTECTIVE BLACK 2

10 11CA TANK CLAMP 1

11 A16CA HYDROGEN TANK 4L T304SS 1

12 SA2520RD28 1/4-20 X 1-3/4 RHMS 18-8 SS 1

13 SN2520HX 1/4-20 HEX JAM NUT 18-8 SS 1

14 SW25FT 1/4 BOLT WASHER (FLAT) 18-8 SS 1

15 SN2520WG 1/4-20 WING NUT 18-8 SS 1

16 AA92CA SINGLE VALVE W/GAGE 1

17 180HC MOTOR SUPPORT 4

18 3A93CA DOUBLE VALVE W/GAGE 1

19 A387E2 GEAR BOX W/BASE 10-1 RATIO 1

20 1748HC DRIVE KEY MACH. .185 SQ X 1” LG 1

21 A388EEL MOTOR 110/220V 60 HZ 1/4 HP 1

22 220CA FLYWHEEL GUARD 1

23 SB3118HX10 5/16-18 X 5/8 HHCS 18-8 SS 8

24 SB3118HX36 5/16-18 X 2-1/4 HHCS 18-8 SS 4

25 92HC5 ROCKER COLUMN 2

26 TC2520SC04 1/4-20 X 1/4 SHSS ALLOY STEEL 4

27 TW75FT 3/4 BOLT WASHER STEEL PLATED 2

28 TB7516HX16

29 A76CA2 REAR GUARD ASSEMBLY 1

30 TB5020HX36 1/2-20 X 2-1/4 HHCS STEEL 2

PART

NUMBER

X2290EA MOTOR GROUP 115/60

X2290EF MOTOR GROUP 230/50

X2290EG MOTOR GROUP 115/60EP

159X40EGX MOTOR GROUP 115/60 EPX

X2290EK MOTOR GROUP 230/50 EP

159X40EKX MOTOR GROUP 230/50 EPX

159X40EY MOTOR GROUP AIR

DESCRIPTION

3/4-16 X 1 HHCS STEEL GRD5

PLATED

QTY

2

ITEM

NO.

31 427E4 BUSHING, INNER 2

32 1055HC SPHERICAL BEARING PTFE LINED 2

33 427E3 BUSHING, OUTER 2

34 SN5020HC 1/2-20 HEX CAP NUT 18-8 SS 2

35 74CA2 BOTTLE HOLDER BASE 1

36 172CA BOTTLE PAD NEOPRENE 1

37 75CA BOTTLE HOLDER TOP 1

38 79CA2 BOTTLE CLAMP SCREW 1

39 SB2520BT08 1/4-20 X 1/2” BHSCS 18-8 SS 10

40 A77CA2 FRONT GUARD ASSEMBLY 1

41 A83CA THUMB SCREW 1/4-20 X 1/2L 4

42 109CA2 SPACER 2

43 89CA2 CRANK PIN W/NUT 1

44 1065HC FLYWHEEL 1

45 SC3118SC06 5/16-18 X 3/8 SHSS CUP PT 18-8 2

46 SB3716SC16 3/8-16 X 1 SHCS 18-8 SS 1

47 SW39FT .625 X .390 X .063 WASHER 18-8 1

48 A87CA4 CONNECTING ROD ASSEMBLY 1

49 X2291 SWITCH BOX PACKAGE 1

49A 909E SWITCH, POWER 16 AMP 1

49B 1470E

49C 1471E CARRIER, FUSE 3AG 1/4 X 1-1/4 1

49D 911E FILTER, INTERFERENCE, 10AMP

50 328E7 HOLE PLUG 1/2 2

51 72CA REACTION BOTTLE 2000ML 1

52 62CA STOPPER, #6 NEOPRENE 1 HOLE 5

53 166CA

54 82CA2 WASHER 9/32” 1

58 HL0025TB040 POLYPROPYLENE TUBE 1

59 A118CA GAS HOSE ASSY NYLON 6FT 1

60 A102CA

PART

NUMBER

71CA REACTION BOTTLE 1000ML

71CATC REACTION BOTTLE 1000ML PED

72CATC REACTION BOTTLE 2000ML PED

DESCRIPTION

FUSEHOLDER, INTERNATIONAL

1/4”

RETAINING RING, TRIANGLE

PUSH

MALE CONN: 1/4T-1/8 NPT

BRASS

QTY

1

1

1

www.parrinst.com

19

Page 20

Hydrogenation Apparatus

Bottle Clamp Assembly - Series 3910

20

Parr Instrument Company

Page 21

Shaker Column Assembly - Series 3910

R1

DATE

SHAKER COLUMN ASSEMBLY

R1 WAS CK, REDRAWN; [EC10291] 07-02-09 JPR

APPROVED

BY

BY

SCALE

DWG NO.

DATE

DRAWN

DESCRIPTION

REVISIONS

FOR

SHEET 2

REVISED AND REDRAWN; 01-15-02 RPE

08-23-94

1:2

3910 HYDROGENATION APPARATUS

RPE

SIZE

C

3910

ANGULAR ... ±1/2°

PARR INSTRUMENT CO.

211 53rd STREET

MOLINE, ILLINOIS 61265

DO NOT SCALE DRAWING

TOLERANCES

IN INCHES

UNLESS OTHERWISE SPECIFIED

1/X .... ±1/64

.00 .... ±.010

.000 .... ±.003

08-24-94

VGM

COMPANY.

DRAWN IN 3rd ANGLE PROJECTION

OR BETTER

64

MACHINED SURFACES:

UNMARKED RADII .03"

PROPRIETARY

NEITHER THE DRAWING

NOR INFORMATION

CONTAINED HEREIN

MAY BE COPIED,

REPRODUCED, OR

OTHERWISE USED

WITHOUT WRITTEN

PERMISSION FROM

PARR INSTRUMENT

R2 REVISED 65CA [EC10603];09-14-10 JPR

Hydrogenation Apparatus

WHITE LUBE

TYP (2) PLACES

3910 SHEET 1

CRANK PIN W/NUT

19CA3

FLYWHEEL W/SHAFT

8CA3

34CA3

SC2520SC04

MOTOR PULLEY

1/4-20 X 1/4 SHSS

37CA3

W/SET SCREW

VEE BELT, NOTCHED 25"

SN2520HX

1/4-20 HEX JAM NUT

2CA2

SC2550SC04

TYP (4) PLACES

1/4-20 X 1/4 SCSS

SHAKER COLUMN

5CA3

PIVOT PIN

TYP (2) PLACES

www.parrinst.com

21

Page 22

Hydrogenation Apparatus

Flywheel Assembly - Series 3910

22

Parr Instrument Company

Page 23

Connecting Rod Assembly - Series 3920

Hydrogenation Apparatus

www.parrinst.com

23

Page 24

Hydrogenation Apparatus

AA92CA Single Valve Assembly

A150VB

KNOB

6VBBB

PACKING

CONE

8VB2

PACKING

NUT

112VB4AK

VALVE

NEEDLE

12CA GAGE

70

60

50

40

30

80

20

90

LBS. PER SQ. INCH

10

100

0

arr

P

21VBBB

LANTERN

RING

PARR

INSTRUMENT

COMPANY

4VB3

PTFE

20VB

VALVE

PACKING

SEAT

NOTE:

ALL PIPE THREADS TO BE

SEALED WITH TEFLON TAPE

24

92CA VALVE BODY

124VB NIPPLE

9VB1 NUT

Parr Instrument Company

Page 25

12CA

70

60

3A93CA Double Valve Assembly

80

90

100

Hydrogenation Apparatus

50

40

30

20

LBS. PER SQ. INCH

10

60HW Nipple

0

arr

P

A102CA

GAGE FACES

21VBBB

(2) PLACES

PARR

COMPANY

INSTRUMENT

4VB3

20VB

93CA

(2) PLACES

(4) PLACES

9VB1

A150VB

124VB

Note: AA93CA Valve Assembly as show except without gage.

6VBBB TYP

(2) PLACES

(2) PLACES

www.parrinst.com

8VB2

(2) PLACES

112VB4AK

(2) PLACES

25

Page 26

Hydrogenation Apparatus

3910 Wiring Schematic

26

Parr Instrument Company

Page 27

3920 Wiring Schematic

Hydrogenation Apparatus

www.parrinst.com

27

Page 28

Hydrogenation Apparatus

Explosion Proof Switch Assembly for 1765EEG 115V - Series 3910

28

Parr Instrument Company

Page 29

Hydrogenation Apparatus

Explosion Proof Switch Assembly for 1765EEK 220V - Series 3910

www.parrinst.com

29

Page 30

Hydrogenation Apparatus

Explosion Proof Switch Assembly for A388EEG 115V & 220V - Series 3920

30

Parr Instrument Company

Page 31

Hydrogenation Apparatus

Explosion Proof Switch Assembly for A388EEK 220V - Series 3920

www.parrinst.com

31

Page 32

Hydrogenation Apparatus

Thermocouple Assemblies

Assembly

No.

A159CAPA A295E 66CA2 250 mL

A159CA2PA A295E 66CA 500

A159CA3PA A295E2 71CA 1000

A159CA4PA A295E2 72CA 2000

A159CA5PA A295E2 129CA3 1700

Equipped with

Thermocouple No.

Fits Bottle

No. Size

72CA4 3000

A159CA2

Thermocouple

Assembly

32

Parr Instrument Company

Page 33

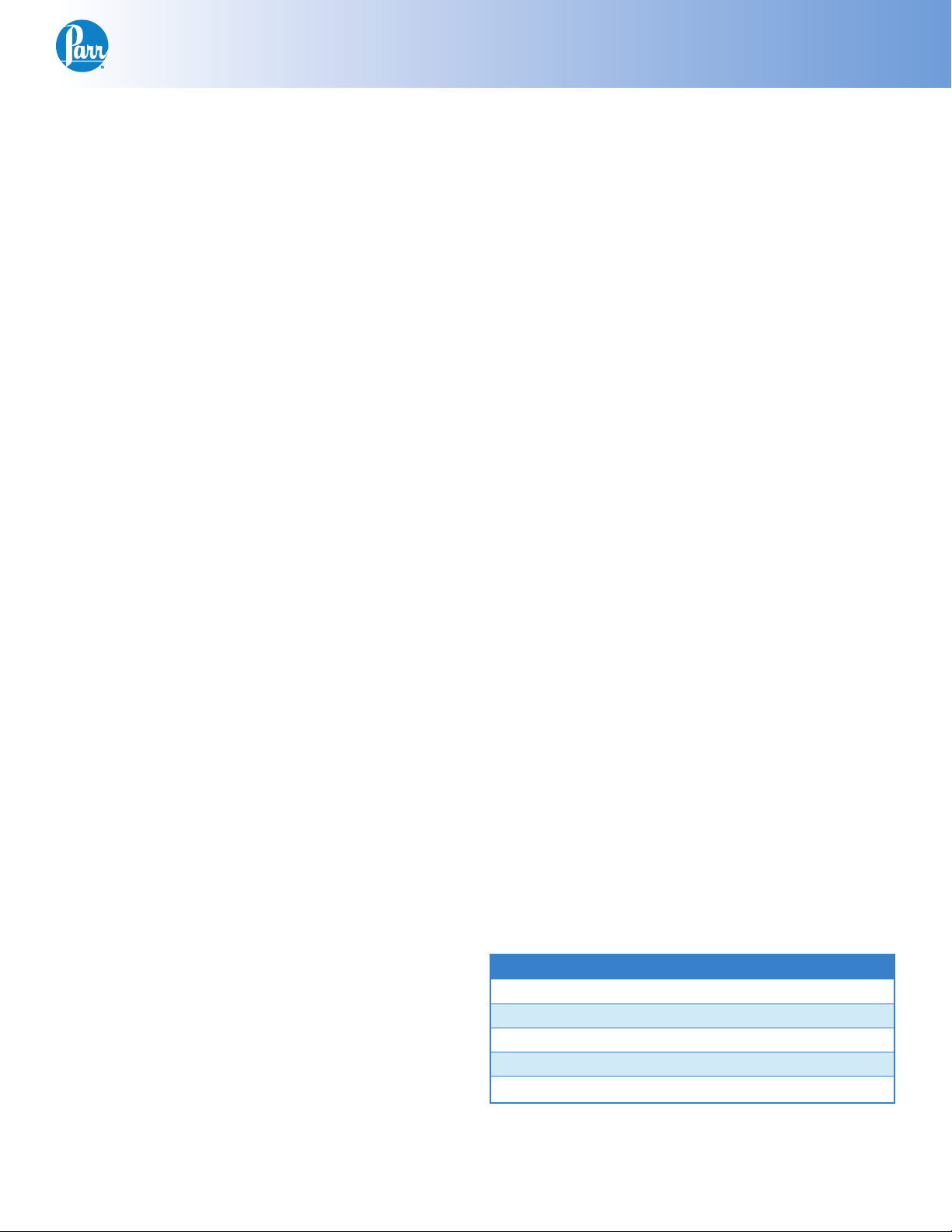

Reaction Bottles for Parr Hydrogenators

Hydrogenation Apparatus

Apparatus

No.

Bottle

No.

Size

mL

Bottle Type

Maximum

Working

Pressure

psig

Requires

Connector

No.

3911 66CA2 250 Borosilicate Glass 60 A122CA2*

3911 66CA 500 Borosilicate Glass 60 A122CA

3911 66CA3 500 Borosilicate Glass Fiberglass Covered 60 A122CA

3921 71CA 1000 Borosilicate Glass 40 A123CA2*

3921 71CA2 1000 Borosilicate Glass Fiberglass Covered 40 A123CA2*

3921 72CA 2000 Borosilicate Glass 30 A123CA

3921 72CA3 2000 Borosilicate Glass Fiberglass Covered 30 A123CA

3921 72CA4 2500 Hand Blown, Heavy Wall Borosilicate Glass 60 A123CA

3921 A129CA3 1700 Stainless Steel Bottle Assembly 60 A155CA

Tube with

133CA2

Spacer

Spool

3921 A226CA Cylinder only, Stainless Steel, 1700 mL

A129CA3

Stainless

Bottle

72CA

2.0 L

Bottle

71CA

1.0 L

Bottle

66CA

500 mL

Bottle

66CA2

250 mL

Bottle

Heating Mantles

Mantle No. Watts Volts Use with Bottle No.

A450EEB 100 11 5 66CA, 66CA2

A450EEE 10 0 230 66CA, 66CA2

A451EEB 200 115 71CA, 72CA, A129CA3

or A226CA

A451EEE 200 230 71CA, 72CA, A129CA3

or A226CA

www.parrinst.com

33

Page 34

Hydrogenation Apparatus

Air Motor Assembly

34

Parr Instrument Company

Page 35

Switch Box Assembly 115V

Hydrogenation Apparatus

Switch Box Assembly 230V

Note: All components are the same

as 115V except as noted.

www.parrinst.com

35

Page 36

Revision 03/14/13

Loading...

Loading...