Page 1

Operating Instruction Manual 451M

1564

Water Recirculation System

Page 2

Page 3

1564 Water Recirculation System Operating Instruction Manual

Operating Instructions

For the 1564 Water Recirculation System

Purpose

The 1564 Water Recirculation System provides a convenient means to operate a Parr

6300 Calorimeter when a constant supply of good quality tap water is not available.

This unit works in conjunction with a water cooler such as the Parr 1552 to provide a

“closed loop” and therefore a well-controlled, enclosed system.

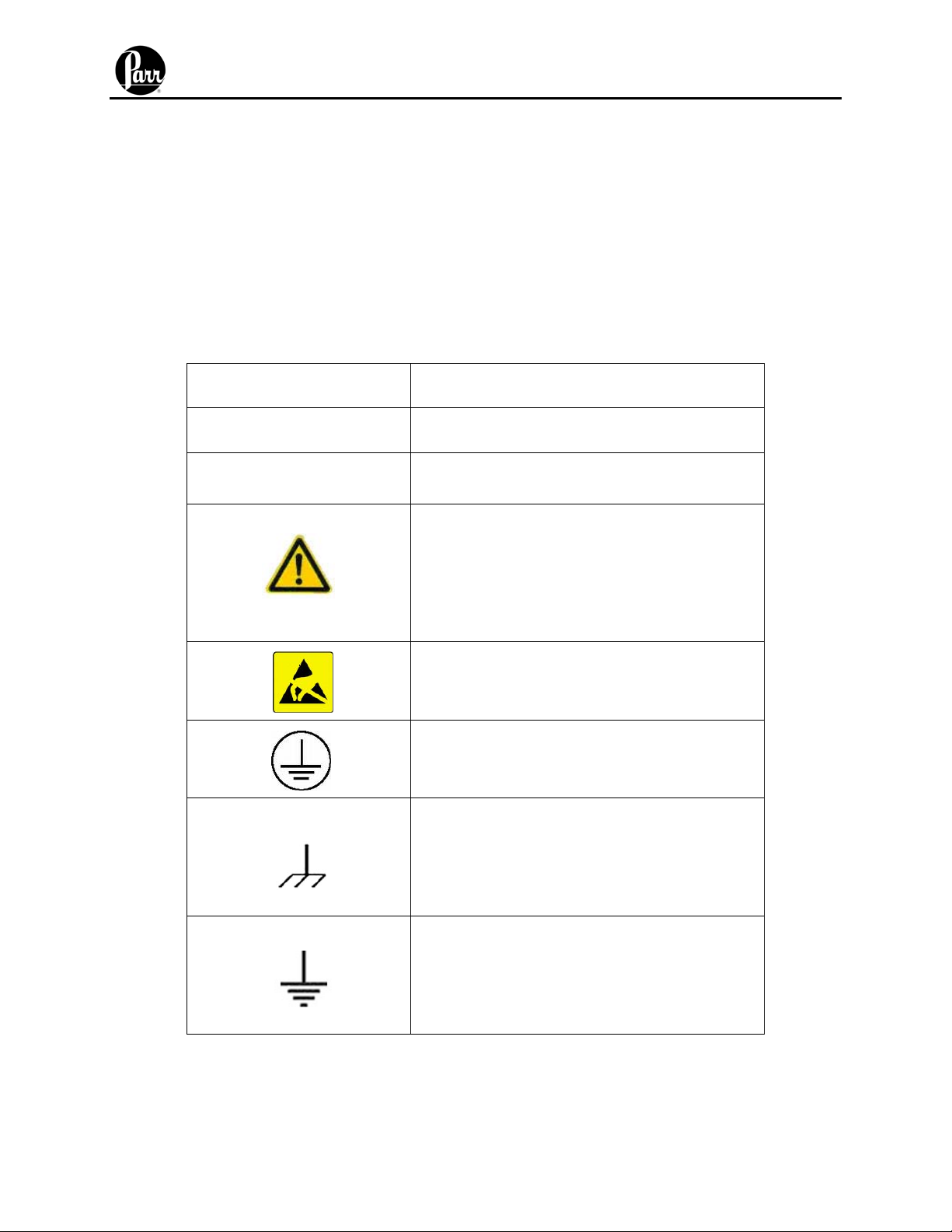

Explanation of Symbols

I

O

~

On position

Off position

Alternating Current (AC)

This CAUTION symbol may be present on

the Product Instrumentation and literature. If

present on the product, the user must

consult the appropriate part of the

accompanying product literature for more

information.

ATTENTION, Electrostatic Discharge (ESD)

hazards. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth (PE) terminal. Provided

for connection of the protective earth (green

or green/yellow) supply system conductor.

Chassis Ground. Identifies a connection to

the chassis or frame of the equipment shall

be bonded to Protective Earth at the source

of supply in accordance with national and

local electrical code requirements.

Earth Ground. Functional earth connection.

NOTE: This connection shall be bonded to

Protective earth at the source of supply in

accordance with national and local electrical

code requirements.

- 2 -

Page 4

1564 Water Recirculation System Operating Instruction Manual

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current handling

capability.

2. Ensure that the equipment is connected to electrical service according to local

national electrical codes. Failure to properly connect may create a fire or shock

hazard.

3. For continued protection against possible hazard, replace fuses with same type

and rating of fuse.

4. Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or combustible materials; fire or

explosion may result. This device contains components which may ignite such

material.

2. Refer servicing to qualified personnel.

Intended Usage

If the instrument is used in a manner not specified by Parr Instrument Company, the

protection provided by the equipment may be impaired.

General Specifications

Electrical Ratings

115VAC, 2.0 Amps. 50/60 Hz

230VAC, 2.0 Amps, 50/60 Hz

Before connecting the water recirculation system to an electrical outlet, the user must

be certain that the electrical outlet has an earth ground connection and that the line,

load and other characteristics of the installation do not exceed the following limits:

Voltage: Fluctuations in the line voltage should not exceed 10% of the rated nominal

voltage shown on the data plate.

Frequency: Water recirculation systems can be operated from either a 50 or 60 Hertz

power supply without affecting their operation or calibration.

Current: The total current drawn should not exceed the rating shown on the data plate

on the water recirculation system by more than 10 percent.

Environmental Conditions

Operating: 15ºC to 30ºC; maximum relative humidity of 80% non-condensing.

Installation Category II (overvoltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25ºC and 65ºC; 10% to 85% relative humidity.

- 3 -

Page 5

1564 Water Recirculation System Operating Instruction Manual

Description

The system consists of a 1.5 gallon reservoir to receive the overflow from the 6300

Calorimeter, a recirculation pump, and a power supply. As the calorimeter flushes and

cools the bomb, the overflow water drains freely into the reservoir. The recirculation

pump then pumps water back to the calorimeter on demand.

Required Accessories and Utilities

A separate water cooler must be used with the 1564 system to remove the heat

introduced by each calorimeter test. A Parr 1552 Water Cooler is recommended for this

purpose. The cooler must be placed between the 1564 system and the 6300

Calorimeter. The circulating pump in the 1564 system provides enough pressure for

both the cooler and the calorimeter.

Approximately 4 L of water with a total hardness of less than 85 ppm is required for

filling the tank of the system.

Installation

Install the 1564 system below and near the calorimeter so that the cooling and overflow

water can drain freely from the calorimeter. This instrument is to be used indoors and

requires 3 square feet of space below the calorimeter in a well-ventilated area with

convenient access to an electric outlet. The supply voltage must be within ± 10% of

marked nominal voltage on the instrument. The supply voltage receptacle must have an

earth ground connection.

The water cooler can be installed in any convenient location however care should be

taken that heat from the compressor not reach the calorimeter. Additionally, air must be

allowed to move freely from the cooling fan into the cooler.

Make the tubing connections as illustrated in Figure-1.

Note: It is critical to keep the tubing between the calorimeter and the water

system as short as possible and eliminate any uphill runs or kinks. This

will impede the free flow of water from the calorimeter.

Connect the A1336DD drain tube assembly from the 412VB union bulkhead, labeled

Drain, on the back panel of the calorimeter to the 271HWHJ hose barb on the top of the

1564 Water Recirculation System. The A1336DD drain tube assembly is supplied in the

A1267DD accessory and installation kit of the 6300.

Connect the supplied ¼” tubing from the female connector (P/N 526VBAD) labeled

“Water Outlet” on the back panel of the Water Recirculation System to the union elbow

(P/N 496VB) labeled “Water In” on the top of the water cooler.

Connect the supplied ¼” tubing from the union elbow (P/N 496VB) labeled “Water Out”

on the top of the water cooler to the female connector (P/N 477VB) labeled “Water” on

the back panel of the calorimeter.

- 4 -

Page 6

1564 Water Recirculation System Operating Instruction Manual

Provisions for Lifting and Carrying – Before moving the instrument, disconnect all

connections from the rear of the apparatus. Lift the instrument by grabbing

underneath each corner.

Operation

Using water with less than 85 ppm total hardness, fill the water tank (P/N A262HW) to

within 10 cm (4 inches) of the top. Take care not to fill the tank with water higher than

the tube that enters through the side of the tank. Approximately 4L (1 gal) will be

required.

Do not apply power to the cooler at this time.

Check the voltage requirements of the system by examining the data label found on the

back of the unit. Plug the power cord into a suitable electrical outlet. Turn on the water

recirculation system by flipping the switch to the “ON” position. This will start the pump

that delivers water through the cooler and on into the calorimeter. Monitor the amount

of water in the water tank. Add water as required to maintain the water level in the

reservoir. Check for water leaks in the external lines and fix as required.

Check the voltage requirements of the calorimeter by examining the data label found on

the back of the unit. Plug in the power cord to a suitable electric outlet. Turn on the

calorimeter by flipping the switch to the “ON” position. This will open a water solenoid

inside the calorimeter that allows the calorimeter jacket to begin filling.

Note: Do not turn on the calorimeter heater and pump until the calorimeter

jacket is full otherwise damage can occur to the unit.

This initial filling process can take upwards of fifteen minutes to complete. During this

time, the pump in the 1564 Water Handling System will cycle on and off as required in

order to maintain pressure in the water lines. As the calorimeter jacket is filled, continue

to add water as required in order to maintain the water level in the reservoir of the water

handling system.

Make sure that the voltage requirements of the water cooler correspond to the rating on

the data plate. After the calorimeter jacket is filled and the water level in the water tank

of the 1564 Water Handling System tank has reached equilibrium, apply power to the

water cooler. Activate the calorimeter heater and pump.

Note: Allow one-half hour for these units to reach their normal operating

temperature.

- 5 -

Page 7

1564 Water Recirculation System Operating Instruction Manual

Preventative Maintenance

The following preventative maintenance for the 1564 Water Handling System is

recommended:

Change the water in the tank monthly.

Change the in-line filter, 149C, every 3 months

Replace the

3

/8OD tubing, HX0038TB062, annually

Wipe exterior surfaces with lightly dampened cloth containing mild soap solution.

Add an anti-microbial solution, such as VWR Clear Bath Algicide (13272-031), per the

manufacturer’s instructions.

There are no user serviceable parts inside the product other than what is specifically

called out and discussed in this manual. Advanced troubleshooting instructions beyond

the scope of this manual can be obtained by calling Parr Instrument Company in order

to determine which part(s) may be replaced or serviced.

Fuses

Lines protective fuses rated: Fast-Act 15 Amp, 250VAC (Parr number 139E23)

The replacement of protective fuses for the 1564 Water Recirculation System should be

performed by qualified personnel.

- 6 -

Page 8

1564 Water Recirculation System Operating Instruction Manual

Parts List

Part No. Description

451M Operating Instructions for the 1564

Water Recirculation System

139E23 Fuse Fast/ Act 15 Amp 250V

149C In-line Filter

HX0038TB062 Tubing, Bev-A-Line, 3/8” OD

271HWHJ Hose Barb, Male 1/2M-Barb

526VBAD Female Connector,

496VB Elbow, Union

1

1

/4T X ½ NPTF

/4T Brass

A262HW Water Tank

A1418DD Cooling Pump Assembly

230HW Tube Elbow Union 3/8T-T stem

261HW Female Connector,

3

/8T-1/2NPTF

258HW End Cap, Water Tank

1795E Power Supply, 24V

WARNING: For continued protection against possible hazard,

replace fuses with same type and rating of fuse.

- 7 -

Page 9

1564 Water Recirculation System Operating Instruction Manual

Figure 1

- 8 -

Page 10

1564 Water Recirculation System Operating Instruction Manual

Figure 2

WARNING: For continued protection against possible hazard,

replace fuses with same type and rating of fuse.

- 9 -

Page 11

1564 Water Recirculation System Operating Instruction Manual

Figure 3

- 10 -

Page 12

Revision 04/11/08

PARR INSTRUMENT COMPANY

211 Fifty-Third Street

Moline, Illinois 61265 USA

309/762-7716 800/872-7720

Fax 309/762-9453

http://www.parrinst.com

• E-Mail: parr@parrinst.com

Loading...

Loading...